Preparation method of iron-copper based composite friction materials

A composite friction material, iron-copper-based technology, applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of poor friction coefficient stability, heavy metal Cu pollution, insufficient wear resistance, etc. No pollution, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

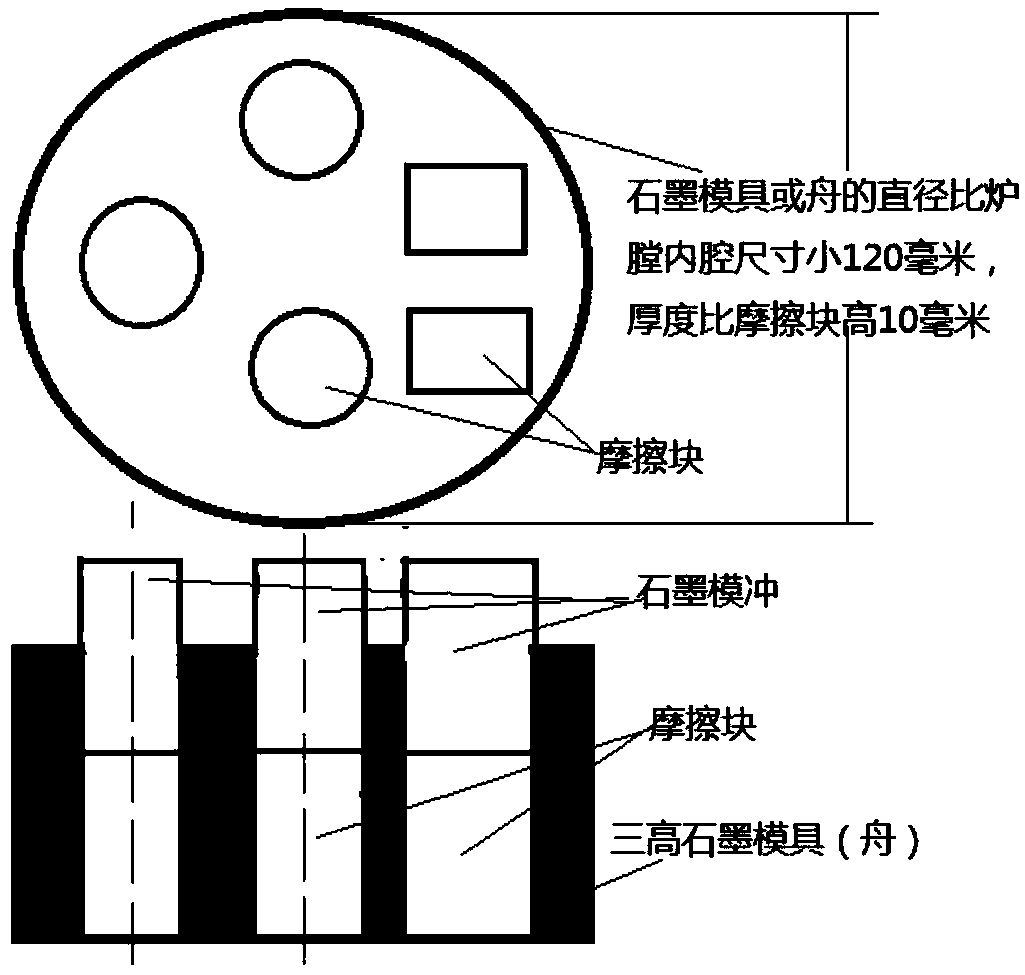

[0031] Prepare a cylindrical friction block with a diameter of about 25 mm and a height of 10 mm, including the following steps:

[0032] Step 1, ingredients. Mix 30% of dendritic electrolytic copper powder of 40 microns, 35% of spherical or nearly spherical atomized iron powder with a particle size of 40 microns, 3% of titanium powder, nickel powder and molybdenum powder of 40 microns and 60 microns of scaly graphite powder 9%, 4% chopped carbon fiber with a diameter of 5 microns and a length of 1 mm, 2% of nearly spherical molybdenum disulfide of 60 microns, plus 3% of kaolin, feldspar powder and mullite of 70 microns, and 2% of 70 microns mixed with vermiculite powder. And according to the formula 1, the theoretical density ρ is calculated to be 4.88 g / cm 3 .

[0033] Step 2, mixing ingredients. Weigh the raw materials in step 1 according to the proportion and put them into a "Y"-shaped mixer, add 120# solvent gasoline at 10 ml / kg, and then mix for 2 hours at a speed of...

Embodiment 2

[0040] Prepare a cuboid friction block with a length of 40 mm, a width of 20 mm, and a height of 10 mm, comprising the following steps:

[0041] Step 1, ingredients. 40% of dendritic electrolytic copper powder of 60 microns, 30% of spherical or nearly spherical atomized iron powder with a particle size of 60 microns, 2.5% of titanium powder, nickel powder and molybdenum powder of 60 microns and flaky graphite powder of 80 microns 8%, 3% chopped carbon fiber with a diameter of 7 microns and a length of 3 mm, 4% of nearly spherical molybdenum disulfide of 80 microns, plus 100 microns of kaolin, feldspar powder and mullite each 2%, and 1.5% of 100 microns mixed with vermiculite powder. And according to formula 1, the theoretical density ρ is calculated to be 5.31 g / cm 3 .

[0042] Step 2, mixing ingredients. Weigh the raw materials in step 1 according to the proportion and put them into a "Y"-shaped mixer, add 120# solvent gasoline at 12 ml / kg, and then mix the materials for ...

Embodiment 3

[0049] Prepare a fan-shaped friction block with an outer arc radius of 80 mm, an inner arc radius of 60 mm, a central angle of 80 degrees, and a thickness of 10 mm, including the following steps:

[0050] Step 1, ingredients. 37% of dendritic electrolytic copper powder of 50 microns, 33% of spherical or nearly spherical atomized iron powder with a particle size of 50 microns, 2% of titanium powder, nickel powder and molybdenum powder of 50 microns and 70 microns of flake graphite powder 10%, 2% chopped carbon fiber with a diameter of 6 microns and a length of 3 mm, 2.7% of nearly spherical molybdenum disulfide of 70 microns, plus 2.7% of kaolin, feldspar powder and mullite of 80 microns, and 1.2% of 80 Micron vermiculite powder is mixed, and according to formula 1, the theoretical density ρ is calculated to be 5.05 g / cm 3 .

[0051] Step 2, mixing ingredients. Weigh the raw materials in step 1 according to the proportion and put them into a "Y"-shaped mixer, add 120# solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com