Water jacket structure of cylinder cover covering exhaust manifold

An exhaust manifold and cylinder head technology, which is applied to cylinder heads, cylinders, engine components, etc., can solve the problems of increased difficulty in the production of water jacket sand cores, difficulty in meeting production and manufacturing requirements, and complex cooling water jacket structures. Excellent manufacturability, guaranteed combustion performance, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

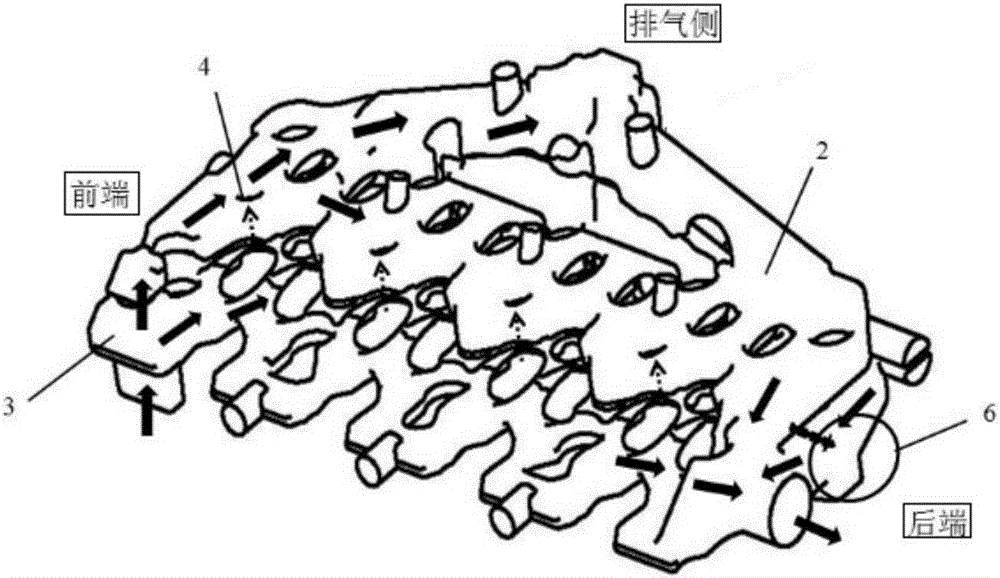

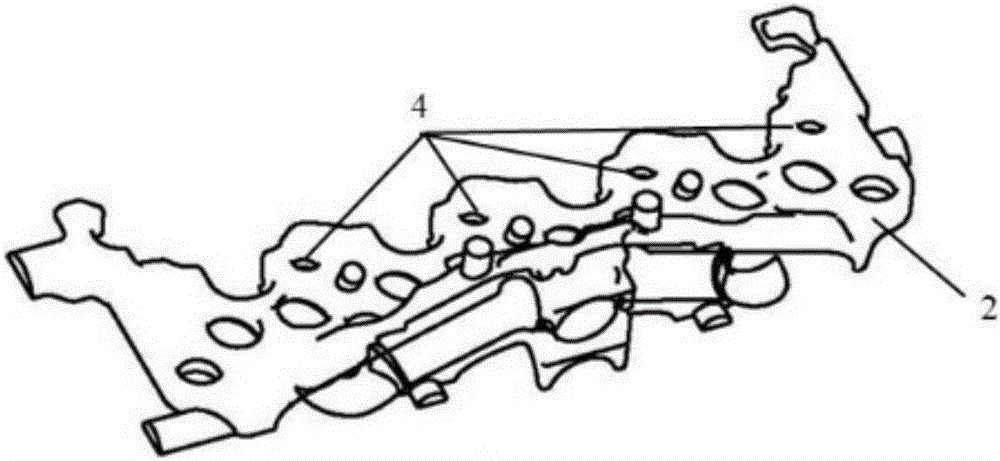

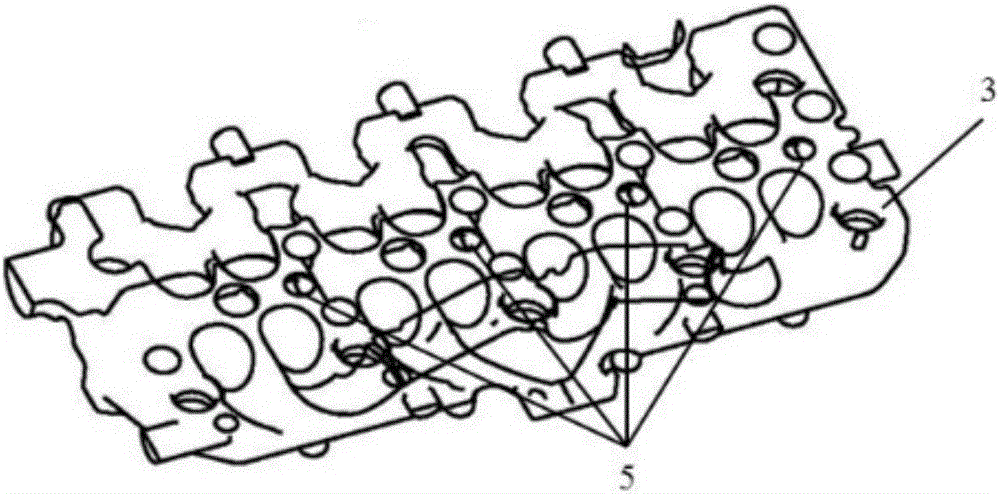

[0024] see Figure 1 to Figure 10 A cylinder head water jacket structure covering the exhaust manifold is shown, including a cylinder head body 1, an upper water jacket 2 and a lower water jacket 3 are arranged in the cylinder head body, and the upper water jacket is used to cool the combustion chamber of the cylinder head The upper and lower water jackets are used to cool the combustion chamber surface of the cylinder head and the nose bridge area between the cylinders, and reduce the thermal load on the combustion chamber surface; its outstanding substantive features are: the upper water jacket 2 is provided with four upper water holes 4, Four water inlet holes 5 are arranged on the lower water jacket 3, and the four upper water holes 4 correspond to the four water inlet holes 5 respectively; the upper water jacket 2 covers the first cylinder and the second cylinder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com