Drum type four-ungulae pneumatic brake with gap adjusted automatically

An automatic adjustment and brake technology, applied in hydraulic drum brakes, brakes, slack adjusters, etc., can solve problems such as inability to install, and achieve the effects of enhanced heat dissipation capacity, uniform pressure distribution, and slowing down heat recession.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

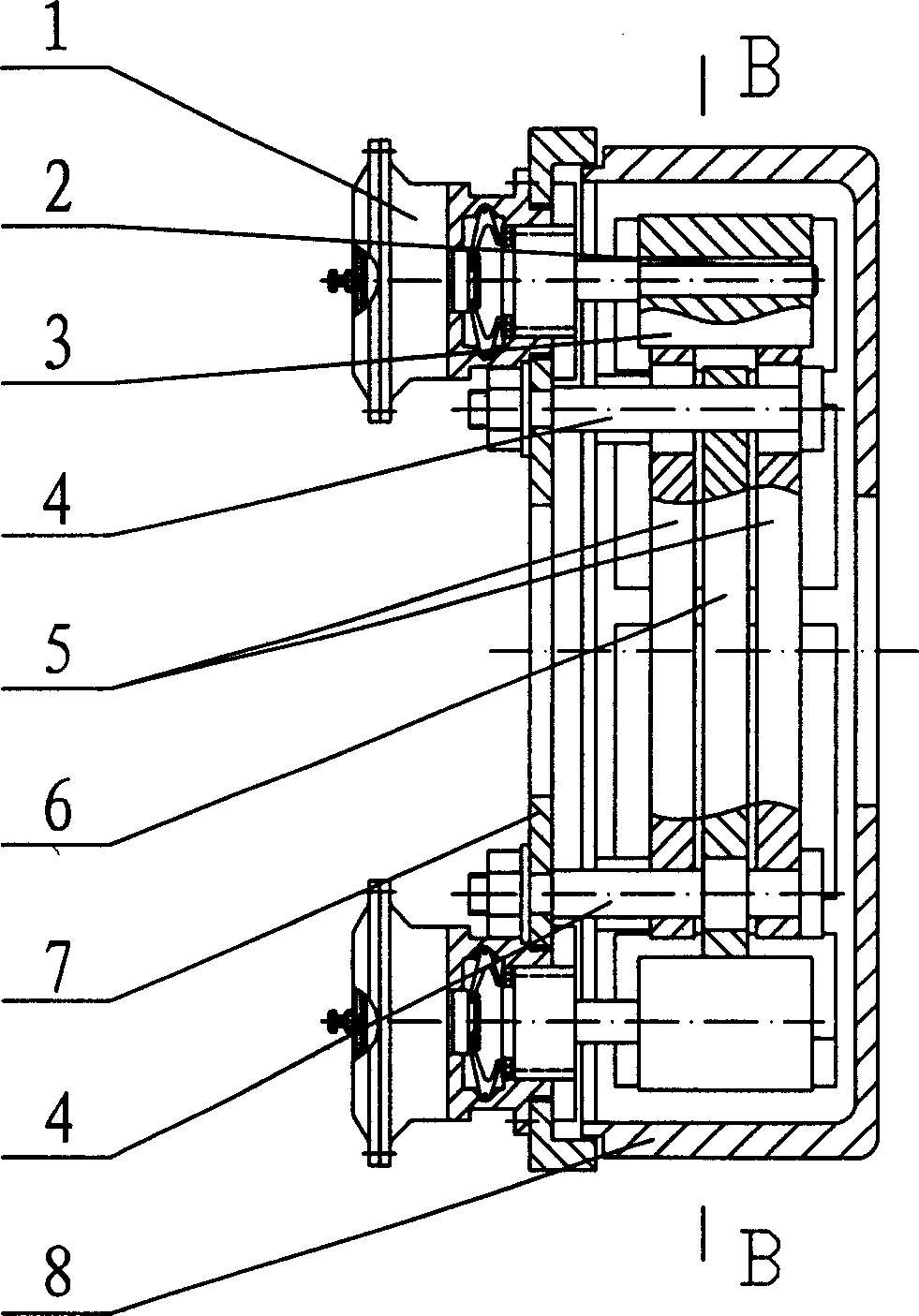

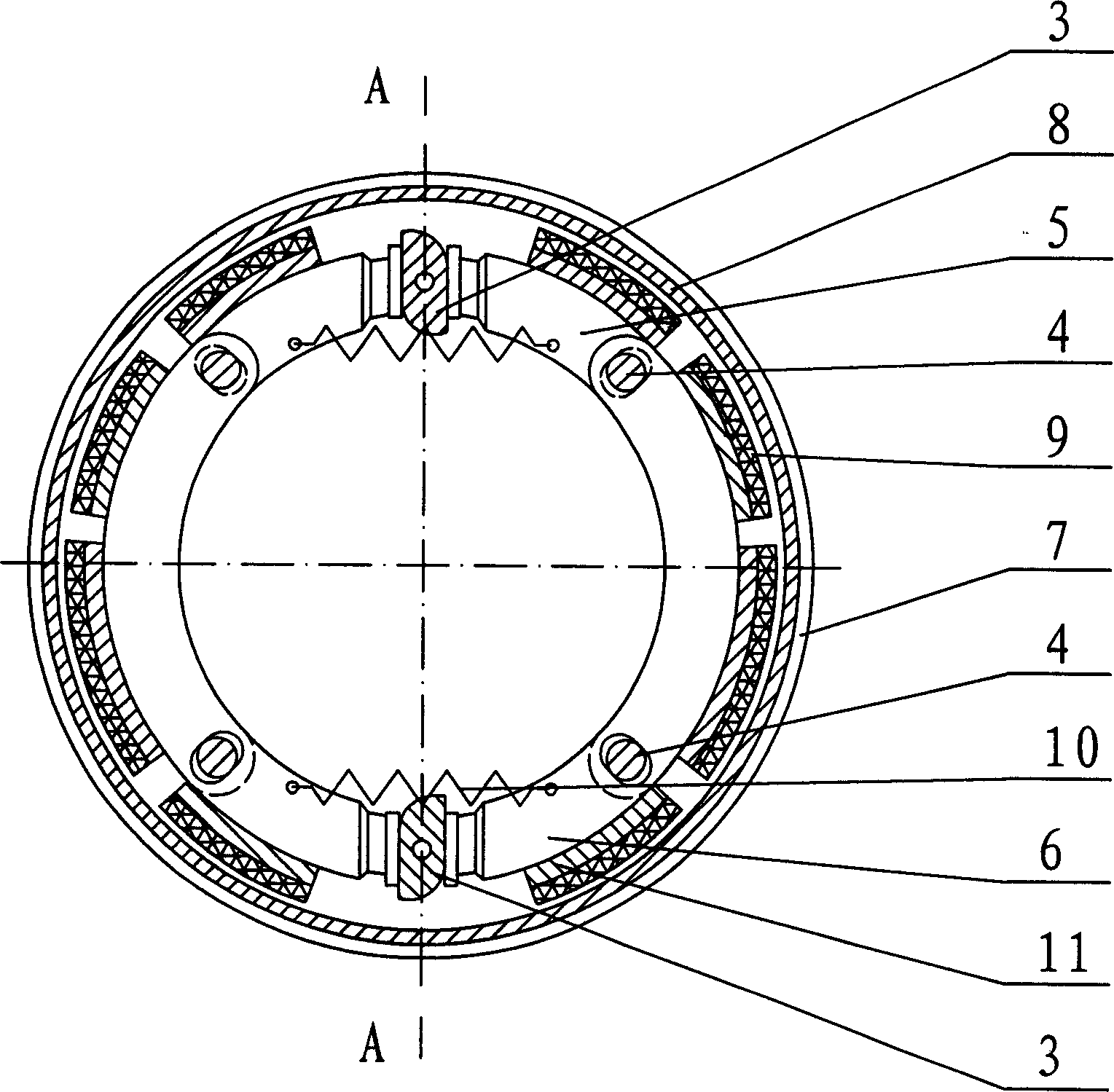

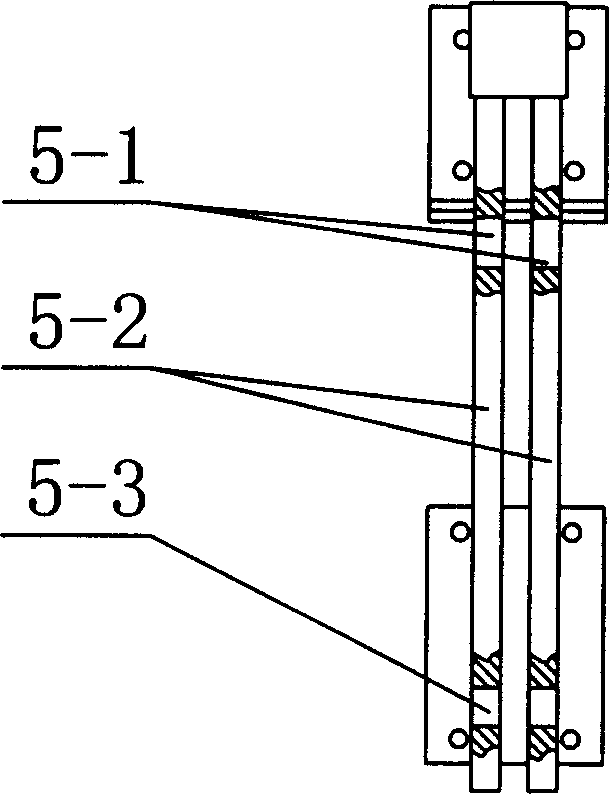

[0037] Figure 1-14 The figure numbers corresponding to the parts shown are as follows:

[0038] 1-brake chamber, 2-key, 3-brake cam, 4-connecting pin, 5-brake split shoe II, 5-1-long hole, 5-2-curved rib, 5-3- Support hole, 6-brake split hoof I, 6-1-support hole, 6-2-arc rib, 6-3-long hole, 7-brake bottom plate, 8-brake drum, 9-brake pad, 10-Tension spring, 11-Brake pad fixing plate, 12-Adjusting screw, 13-Push rod, 14-"V" shaped booster, 15-Hinge, 16-Thrust bearing, 17-Connecting seat, 18-Ring Claw, 19-ratchet, 19-1 ratchet, 19-2 arc groove, 20-screw, 21-groove, 22-column pin, 23-ratchet disc, 23-1 arc groove, 23-2 ratchet Teeth, 24-ratchet seat, 25-jack, 26-connecting shaft.

[0039] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

[0040] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 yes figure 1 The B-B sectional view, Figure 3 to Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com