Elastic knocking device for track fastener detection trolley

A technology for track fasteners and detection vehicles, which is used in tracks, track maintenance, roads, etc., can solve the problems of high measurement frequency, inability to collect vibration signals of loose track fasteners, and relatively large friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

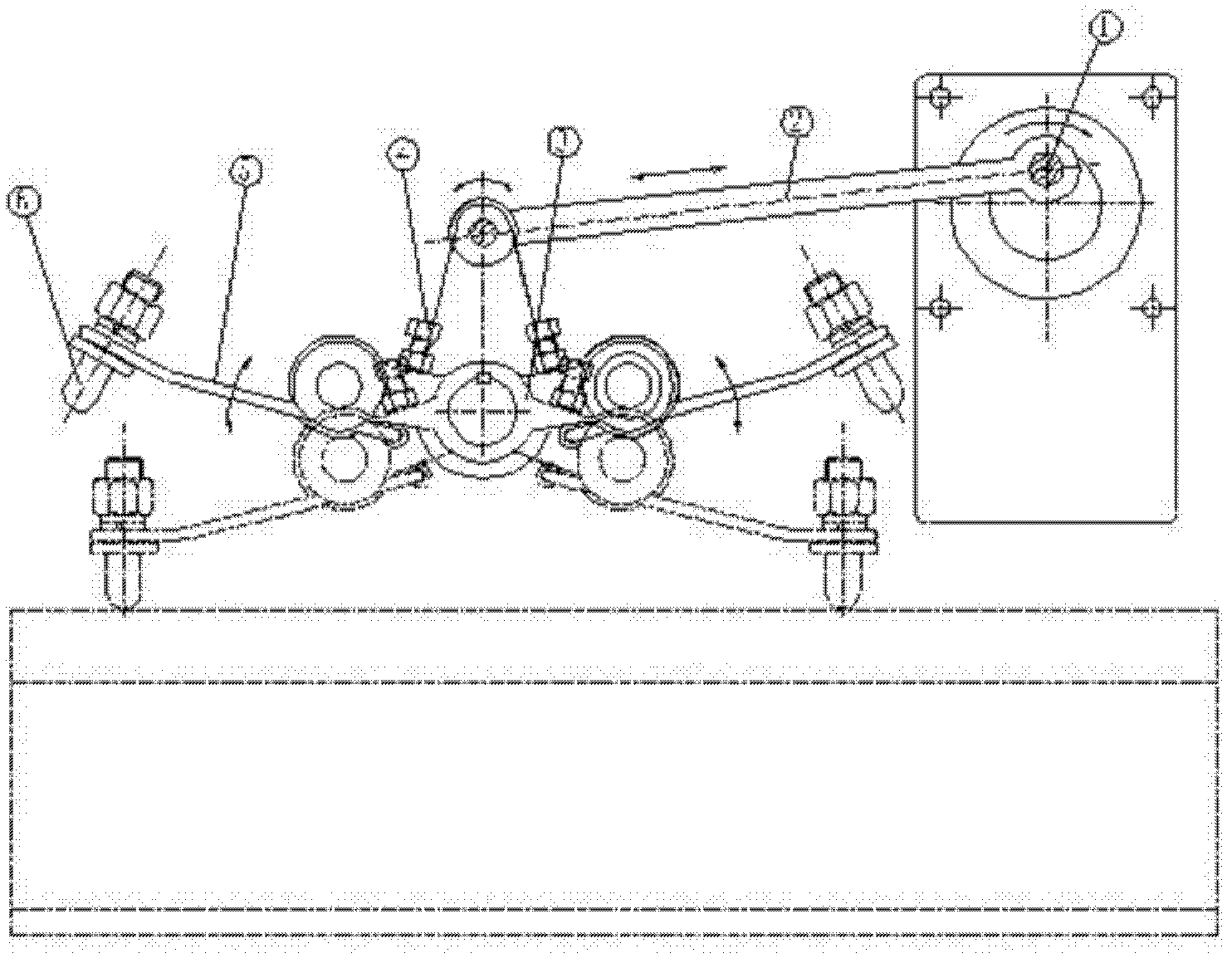

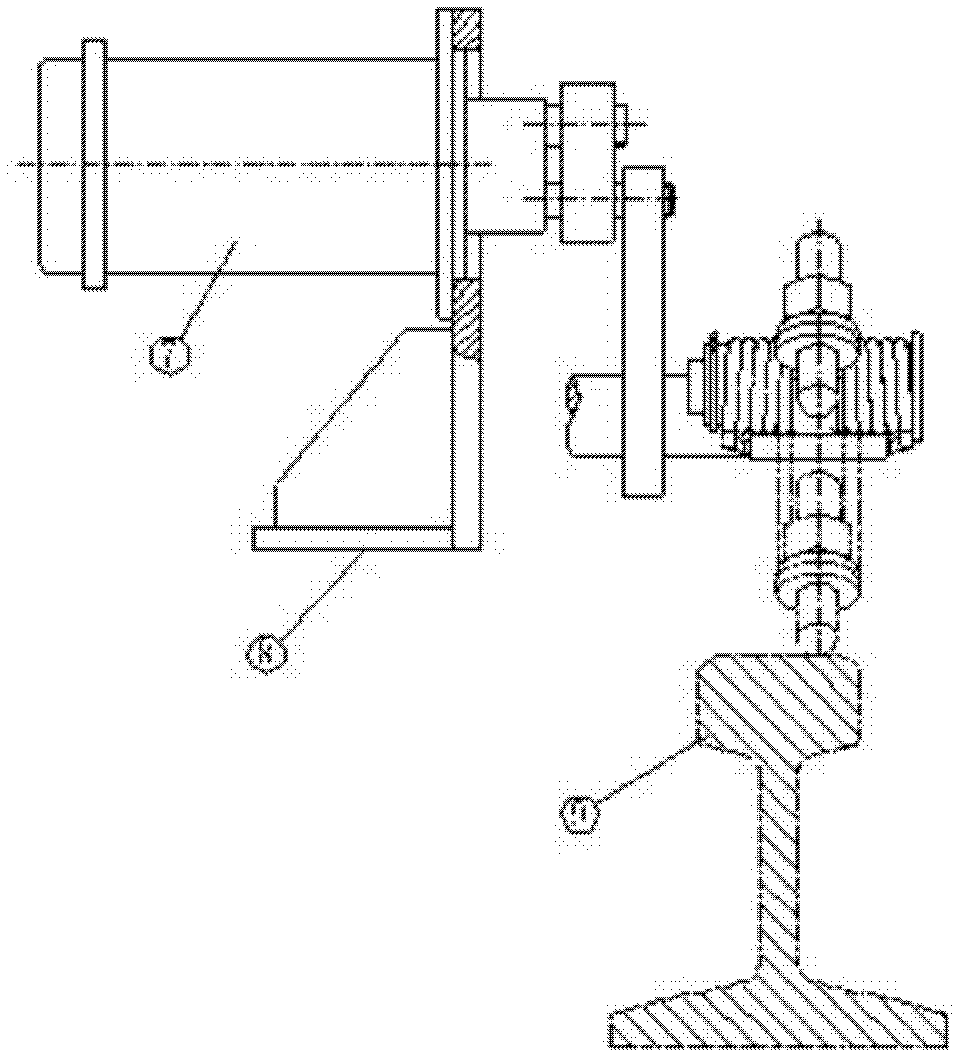

[0012] Such as figure 1 As shown, an elastic percussion device for a rail fastener inspection vehicle has a driving motor 7, and a percussion head 6 reciprocating up and down is installed on the output shaft of the motor 7. The motor 7 is fixed on the mounting base 8, and its output shaft is connected with a drive crank 1 to drive the connecting rod 2 to make the rocking bar 3 swing, and the rocking bar 3 drives the elastic arm 5 connected thereto to do the elastic swing of reciprocating oscillation up and down. The percussion head 6 is installed on the elastic arm 5 composed of an integral double torsion spring structure. The one-piece double torsion spring has two torsion springs, and the two torsion springs are connected as a whole through the elastic arm 5 , and the one-piece double torsion spring is set on the rocker 3 . Rocking bar 3 both sides are equipped with the adjusting bolt 4 that changes the distance between the striking head 6 and the rail surface to be knocked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com