Patents

Literature

363results about "Fluid actuated drum brakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

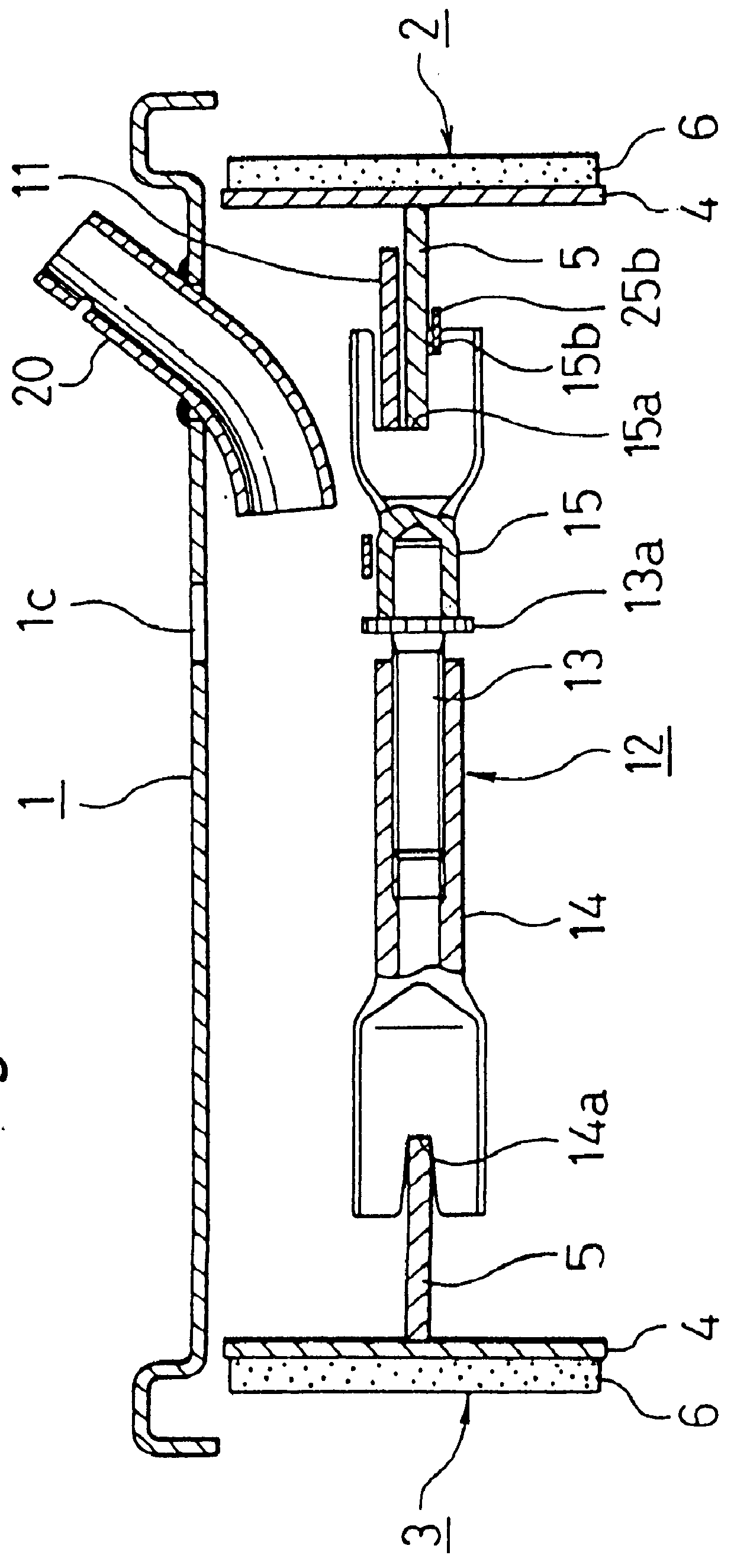

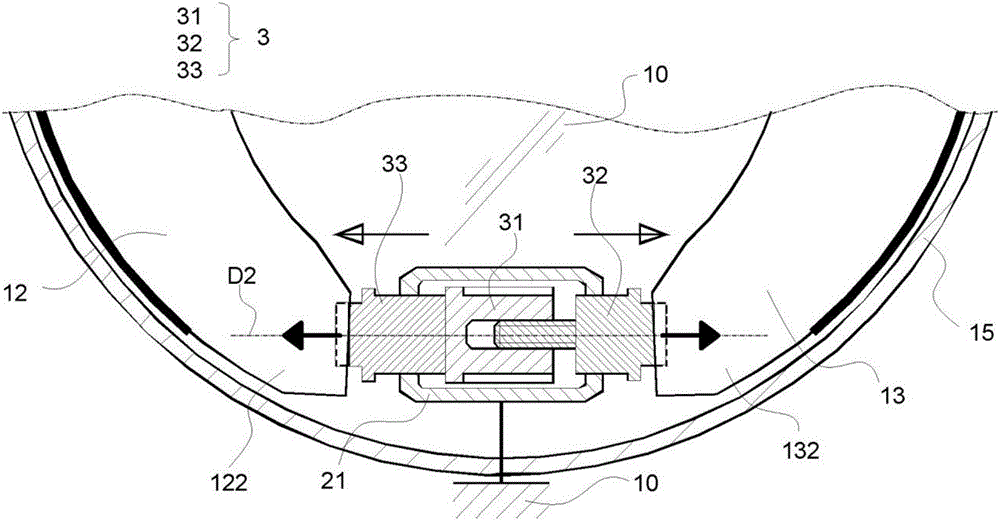

Brake system with integrated car load compensating arrangement

ActiveUS7416262B2Improve efficiencyBraking action transmissionRail brake actuationLoad generationTruck

A railway car brake system comprising a control device engageable with a predetermined portion of such railway car for compensating braking force in response to a load carried by such railway car. The control device includes a sensor mechanism engageable with a truck bolster or a movable car structure for sensing a vertical position thereof corresponding to a load carried by the railway car. There is a control valve engageable with the sensor mechanism which generates a fluid pressure signal responsive to such load. A pneumatic actuator engageable with a predetermined brake beam disposed on such truck assembly and connected to such control valve. This pneumatic actuator generates a predetermined braking force responsive to the fluid pressure signal and further responsive to the load carried by the railway car as sensed by the sensor mechanism. Such predetermined braking force may be proportionally adjusted to variations in the load carried by the railway car.

Owner:WABTEC HLDG CORP

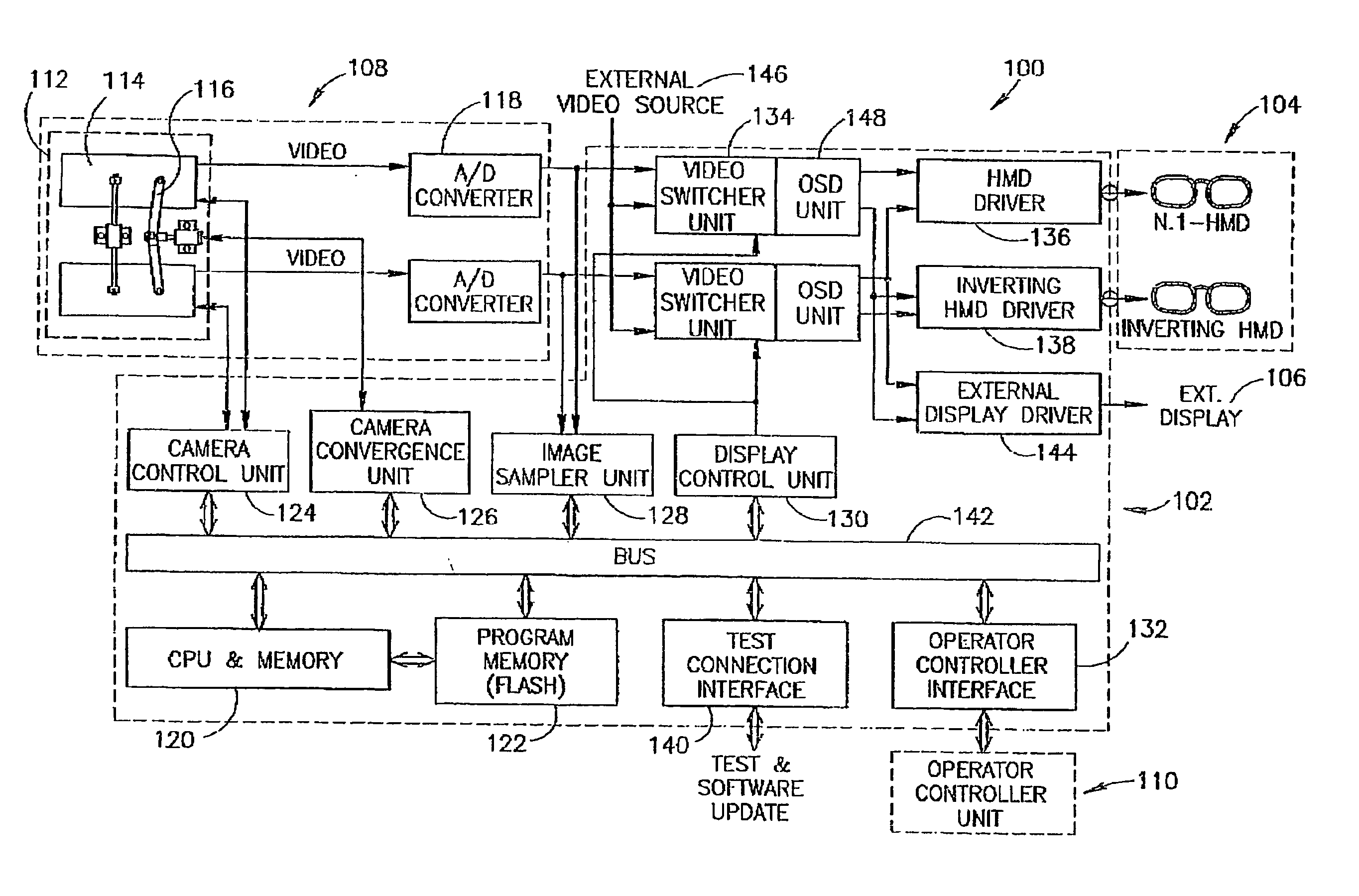

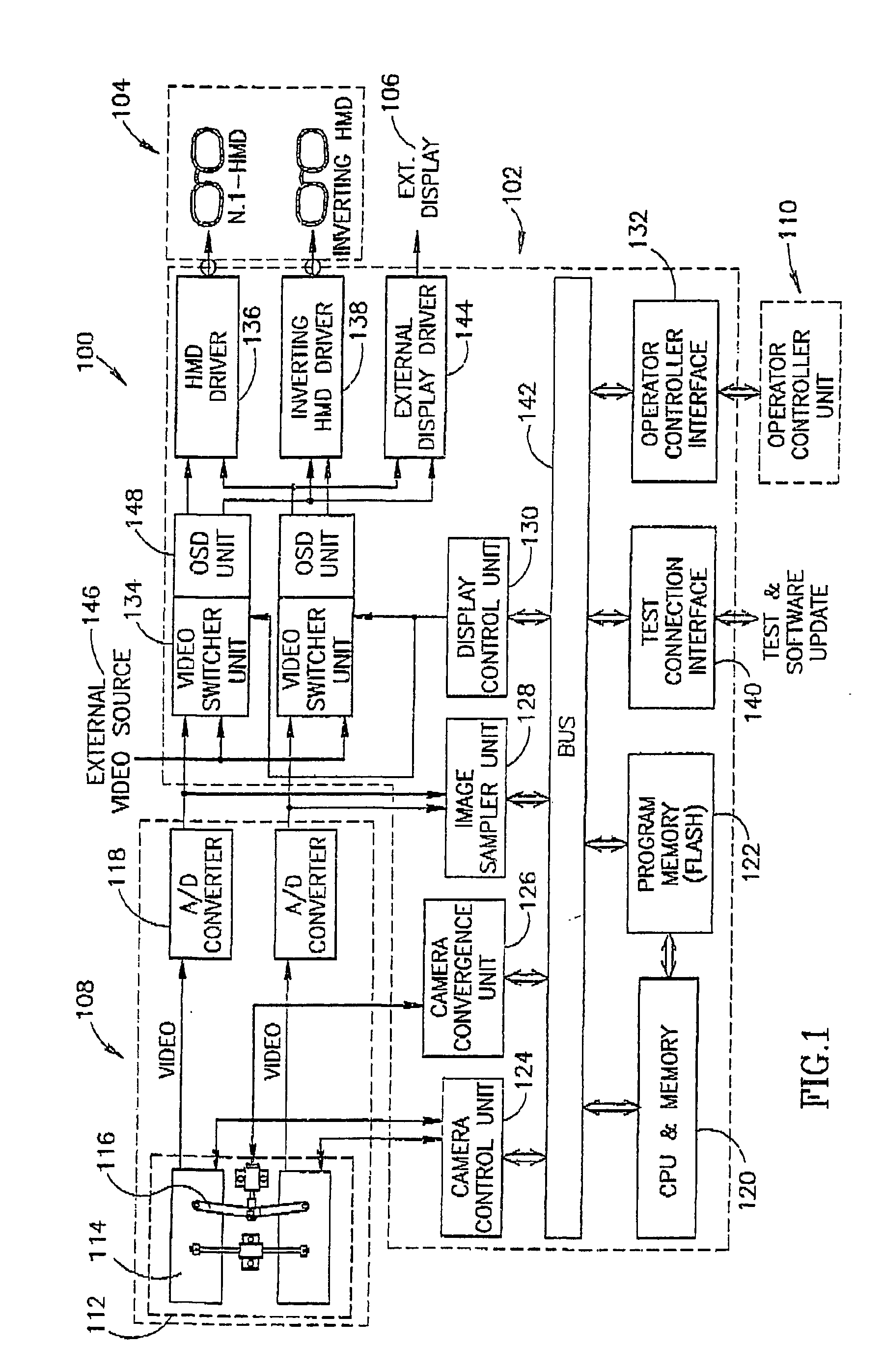

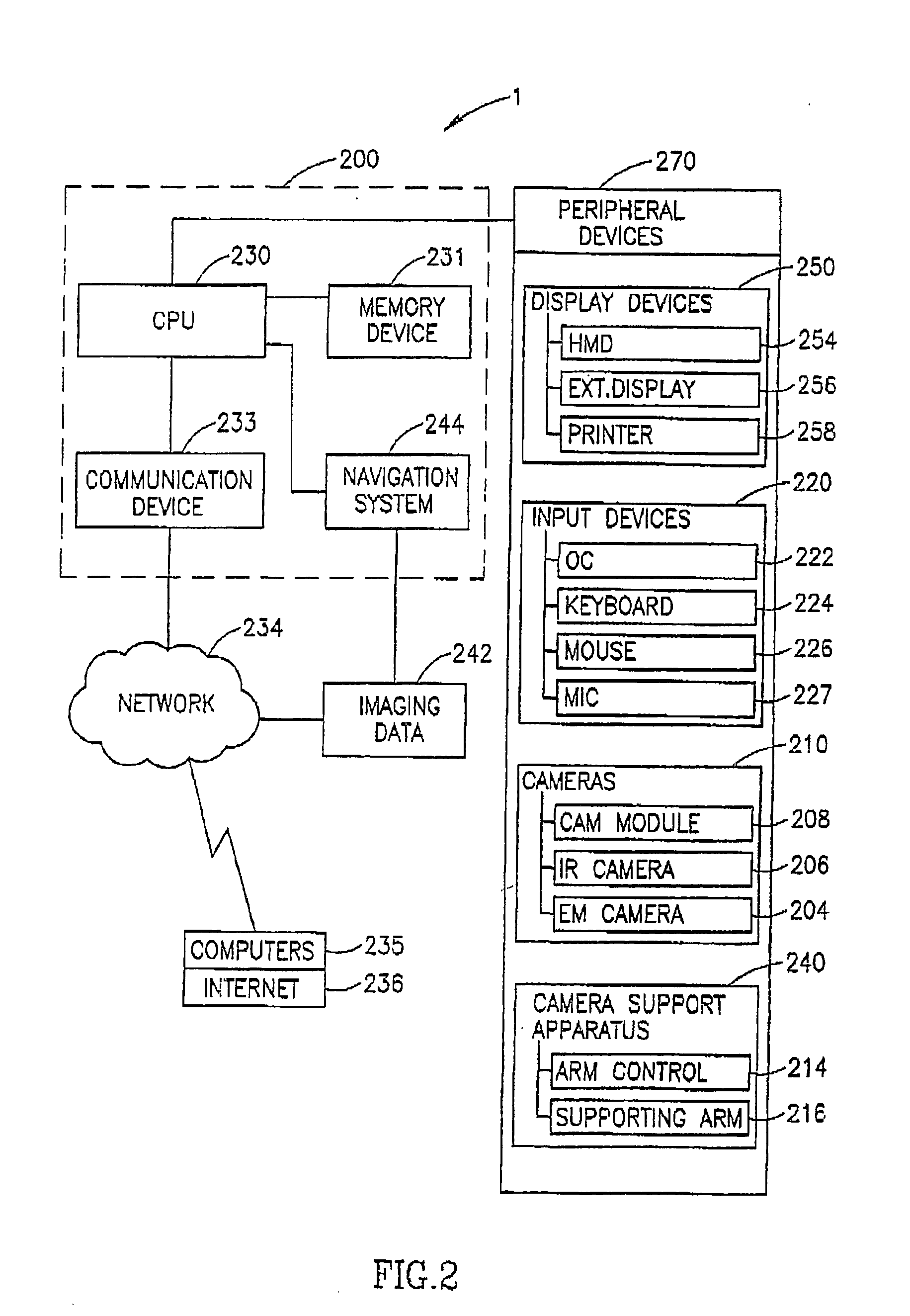

Stereoscopic video magnification and navigation system

InactiveUS20050090730A1Accurate informationImprove ergonomicsDiagnostic recording/measuringSensorsStereoscopic videoDisplay device

An apparatus and method for providing stereoscopic magnified observation enabling an operator to perform surgical procedures without having to remove his eyes from the operating field comprising a head mounted display for provding the operator with stereoscopic magnified images in an operating field, a camera module for providing stereoscopic magnified images, an operator controller unit for enabling an operator to control the operation of the apparatus; and an interface processing unit for processing and dynamically presenting the stereoscopic magnified images in an operating field.

Owner:FRENI BREMBO SPA

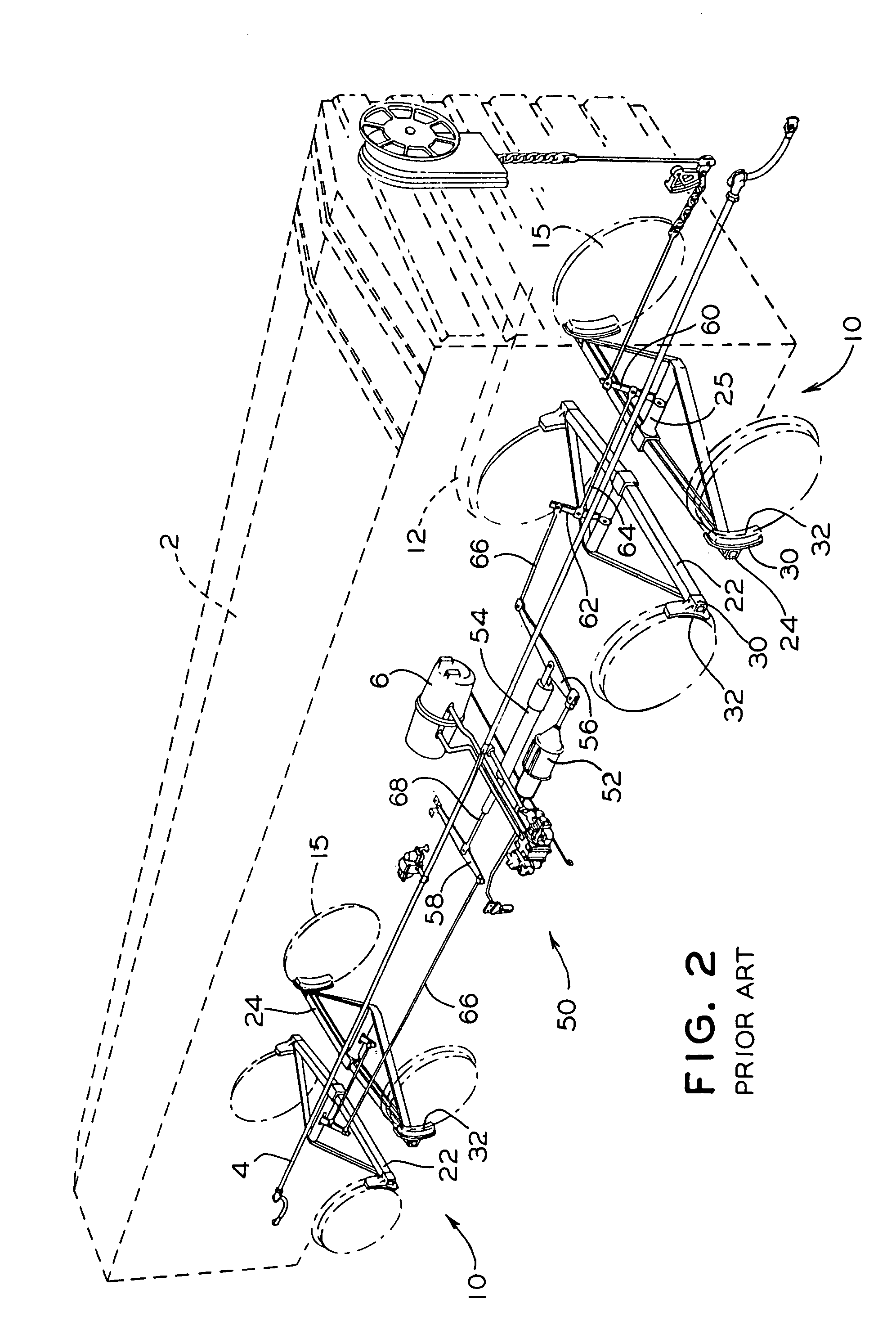

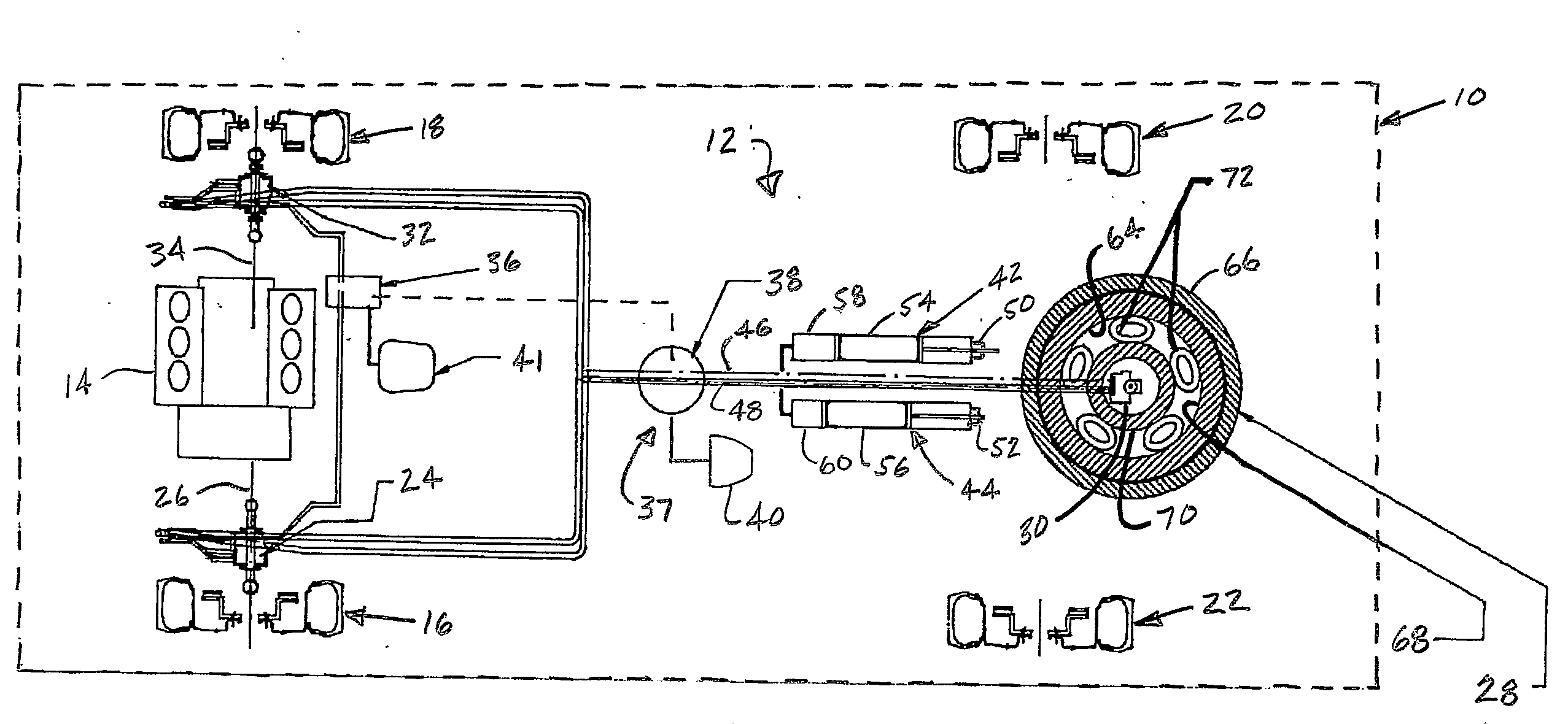

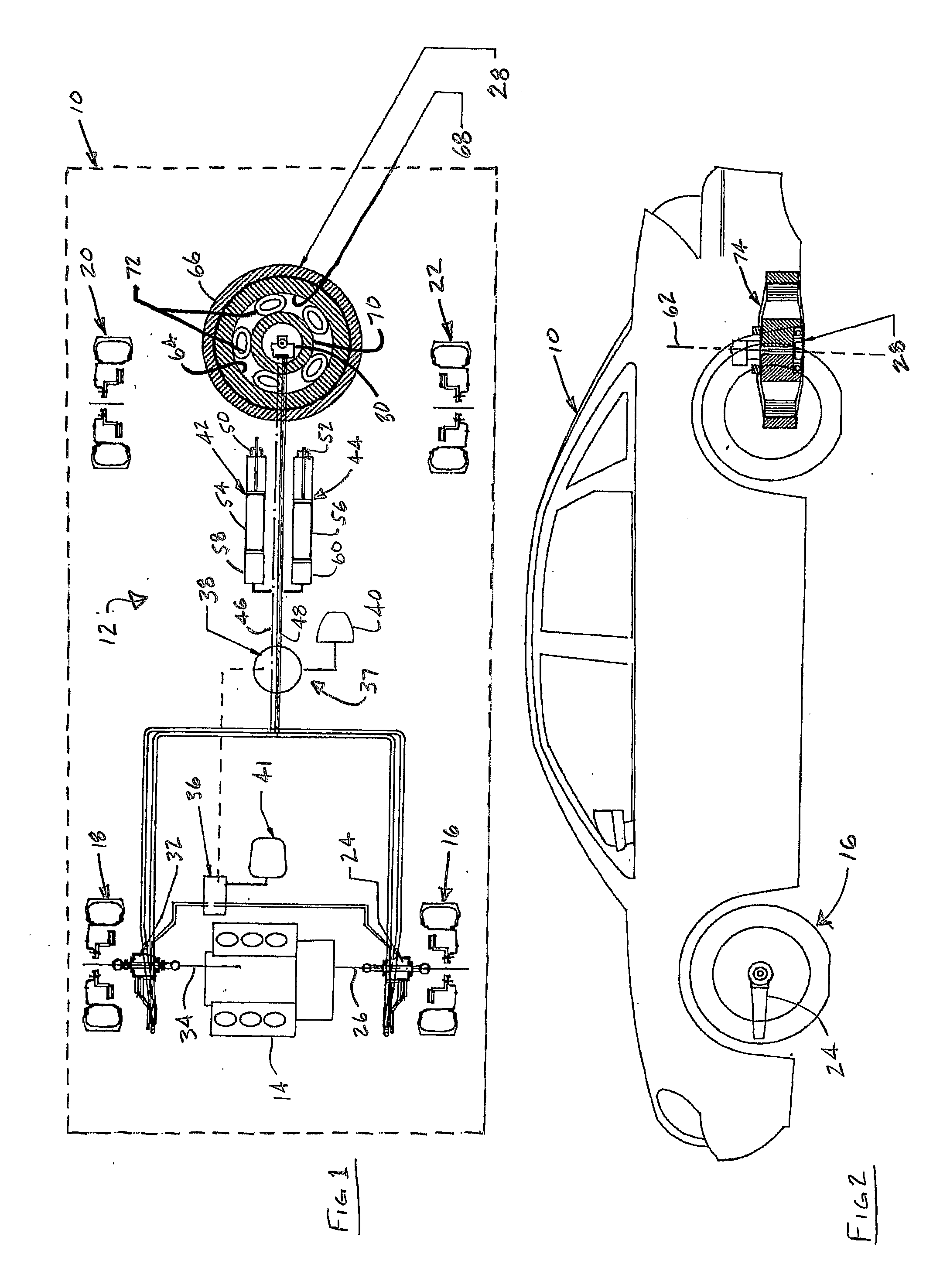

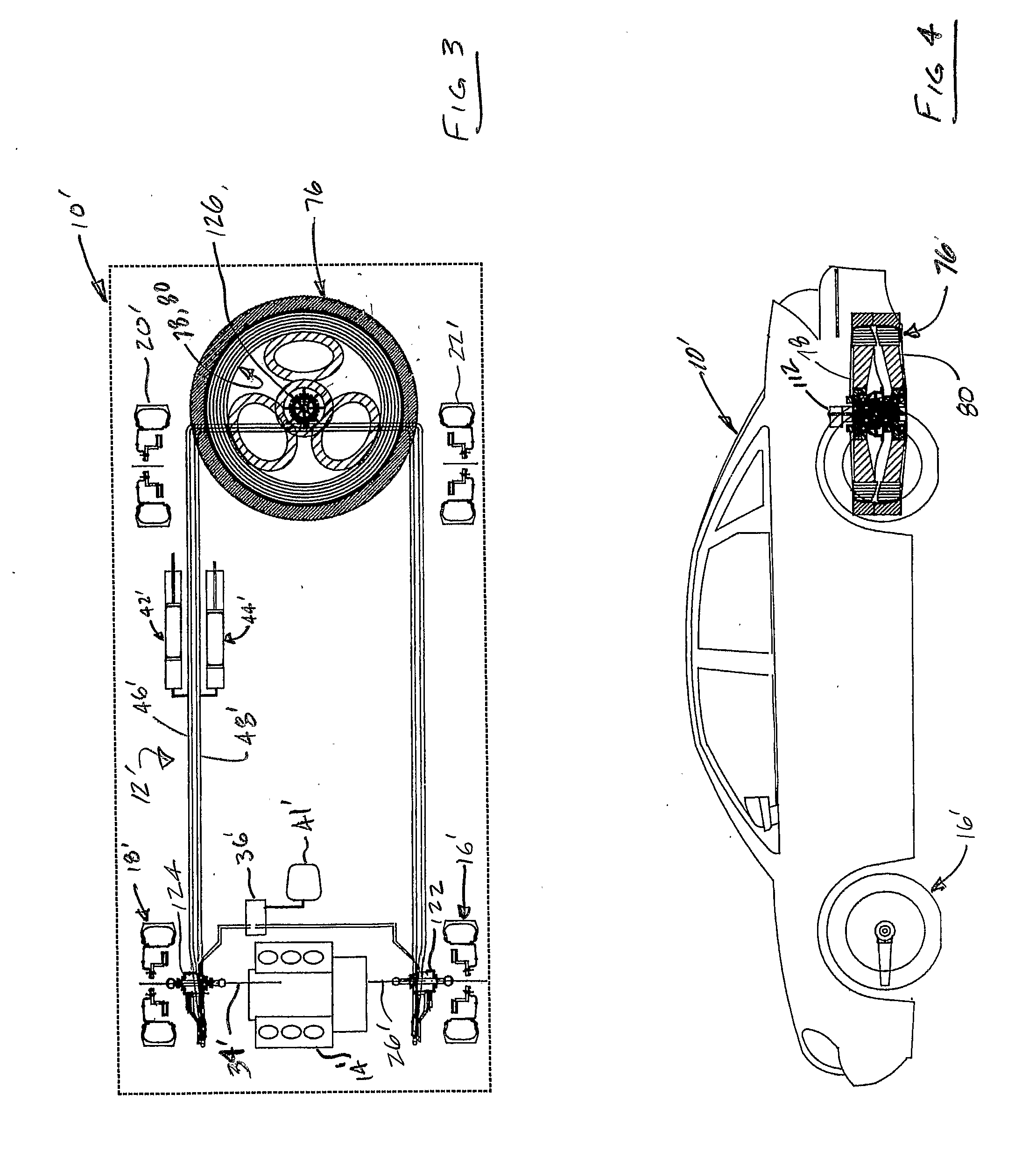

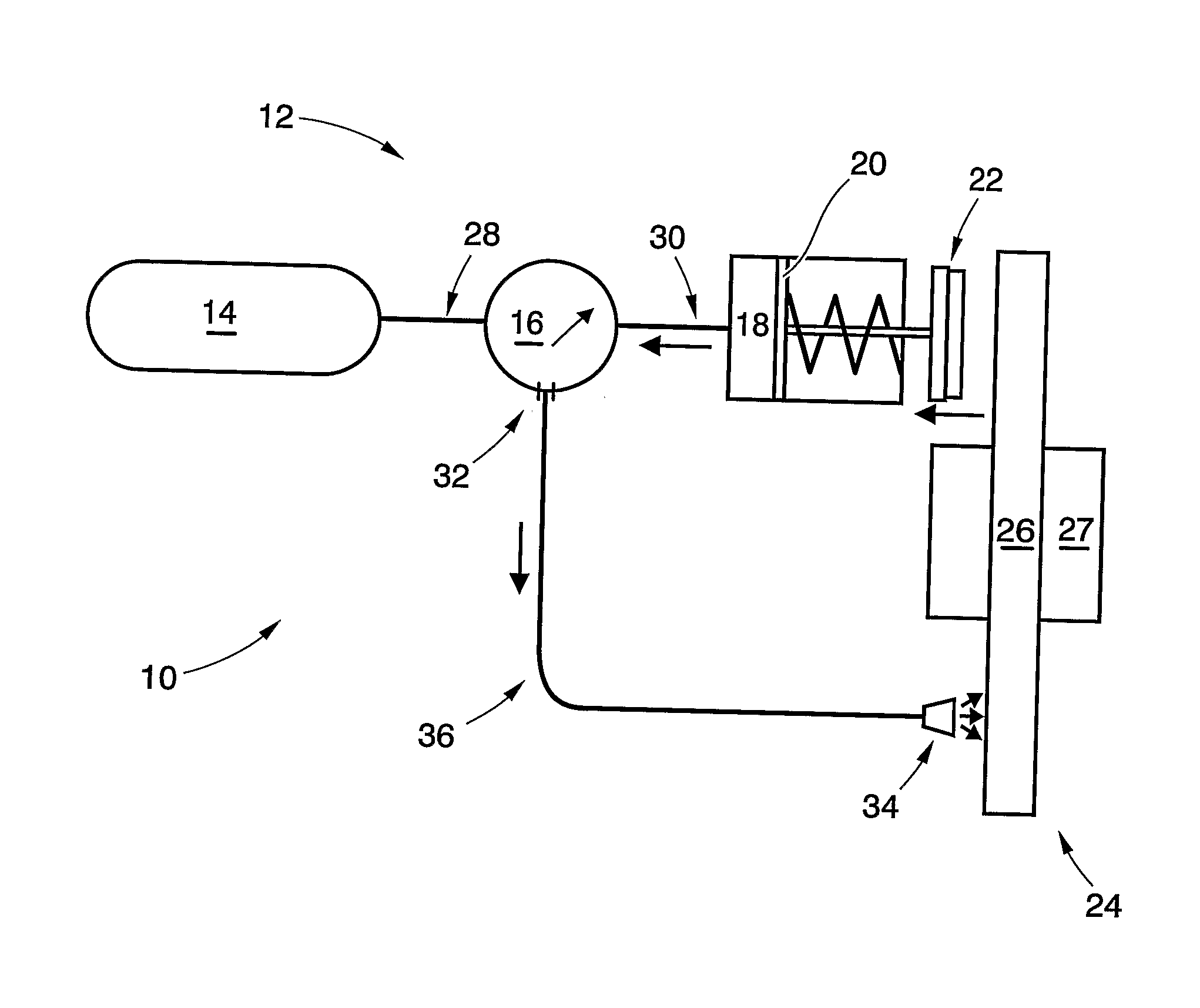

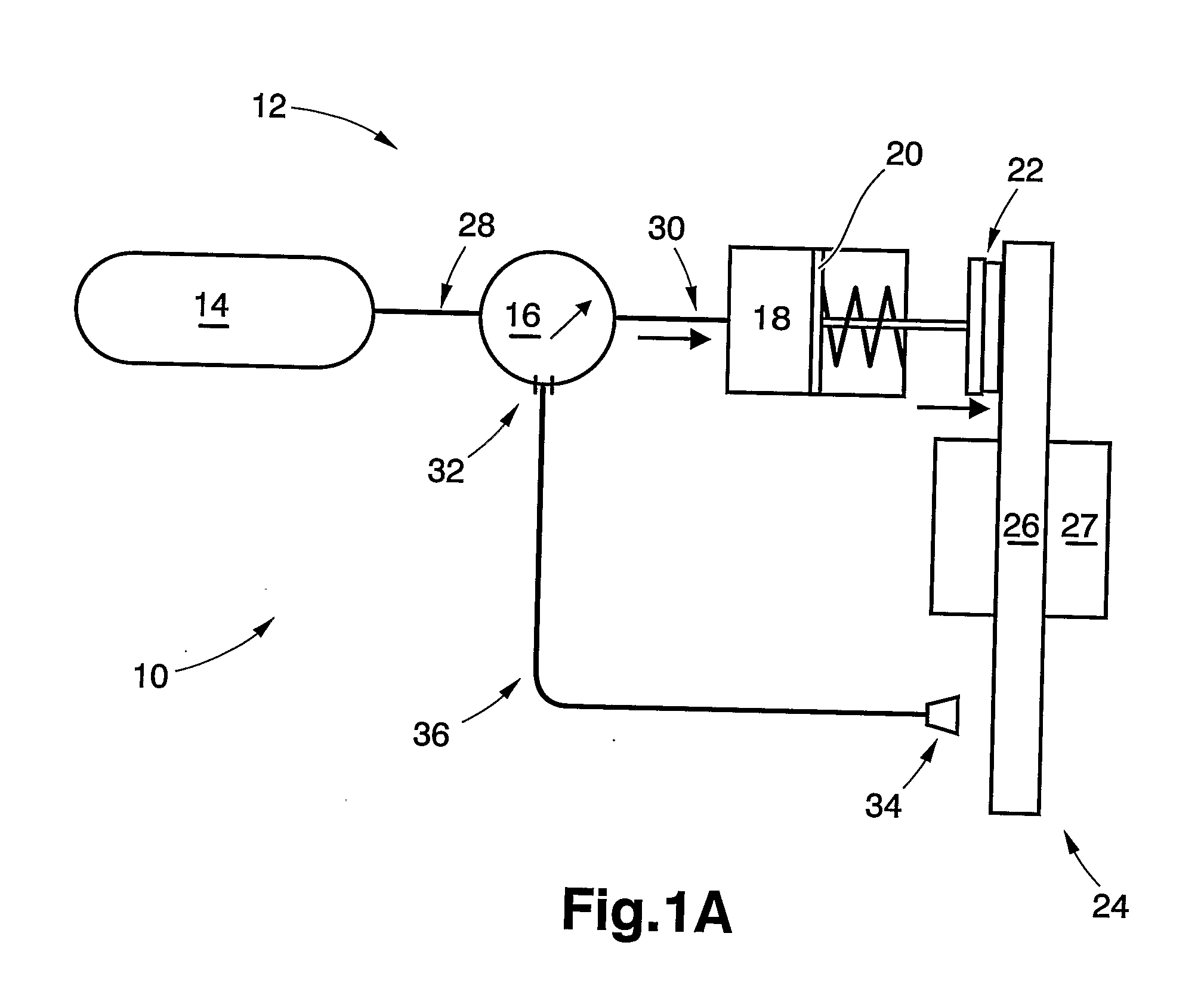

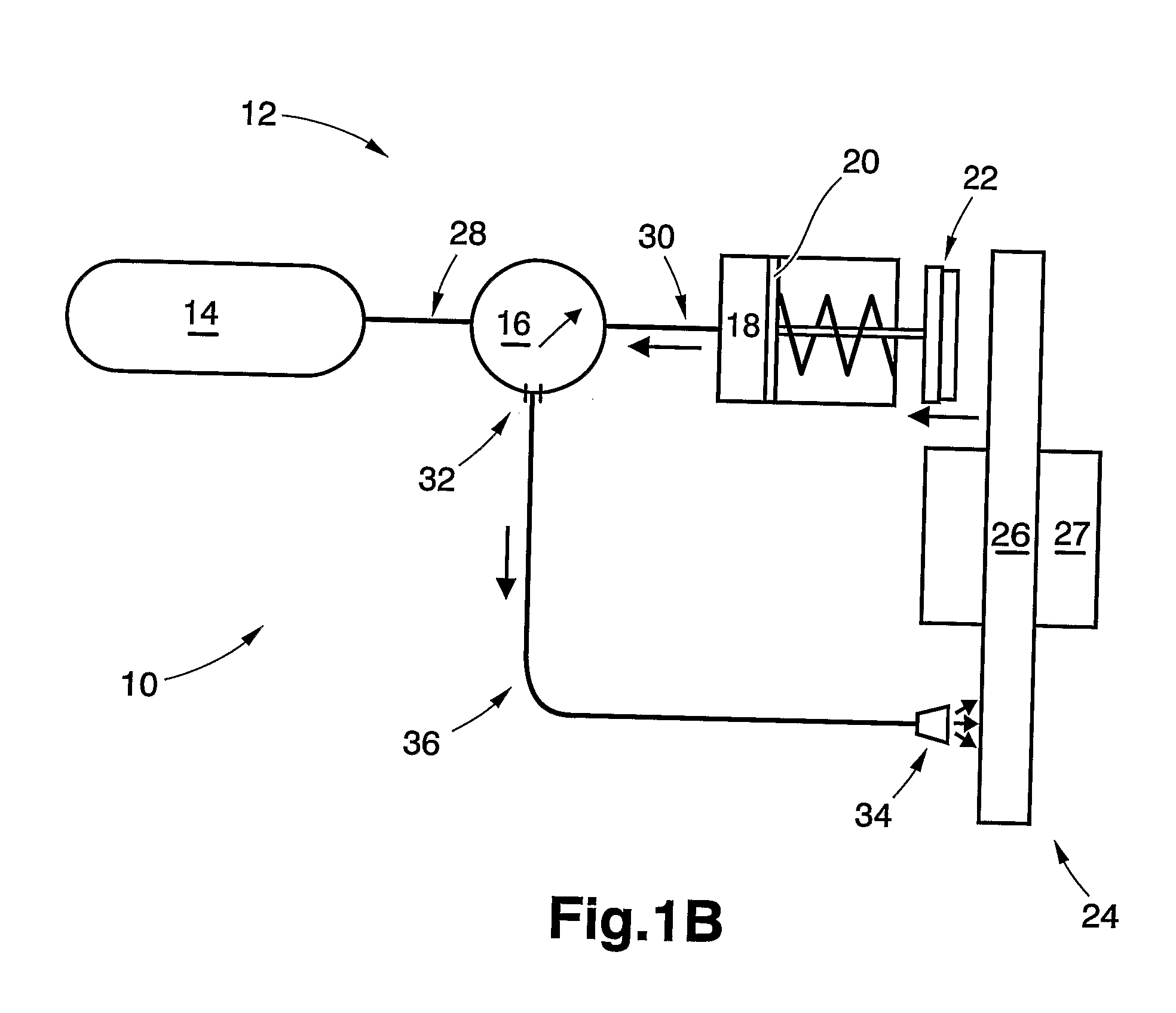

Hydraulic Regenerative Braking System For a Vehicle

InactiveUS20080210500A1Reduce flow interruptionQuick changeBraking element arrangementsAnalogue computers for trafficRegenerative brakeDrive wheel

One embodiment of a hydraulic regenerative braking system for a vehicle having at least one drive wheel includes first (24) and second (32) hydraulic machines operable as pumps or motors. One of the hydraulic machines operates in conjunction with the vehicle drive wheels, while the other hydraulic machine operates in conjunction with a flywheel arrangement (28) to store and receive energy. The hydraulic machines are connected to each other such that when one is operating as a pump, it provides fluid to the other to operate that machine as a motor. A control system is provided to receive inputs related to the operation of the vehicle, and to control the fluid flow through the hydraulic machines.

Owner:WALKER FRANK H

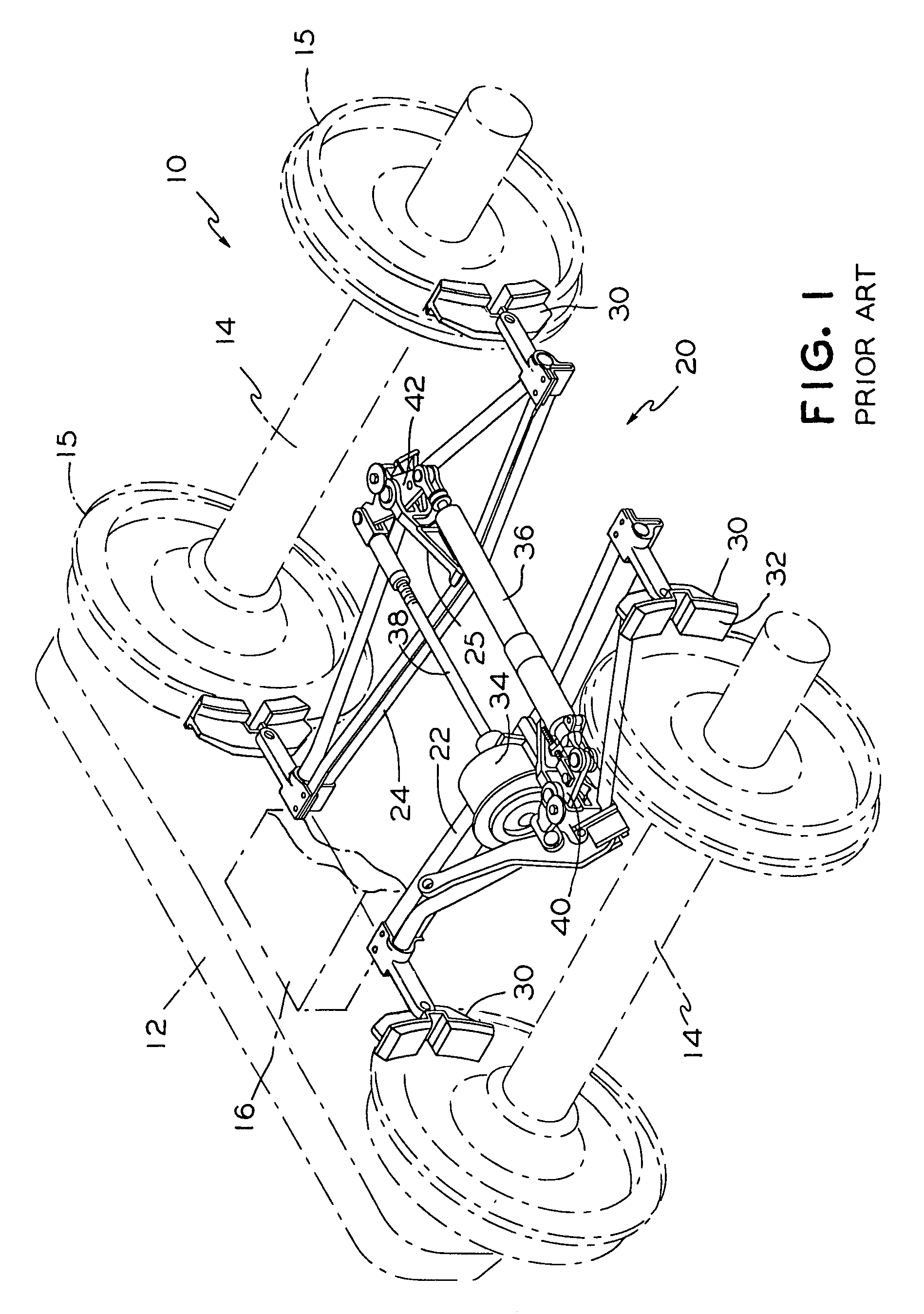

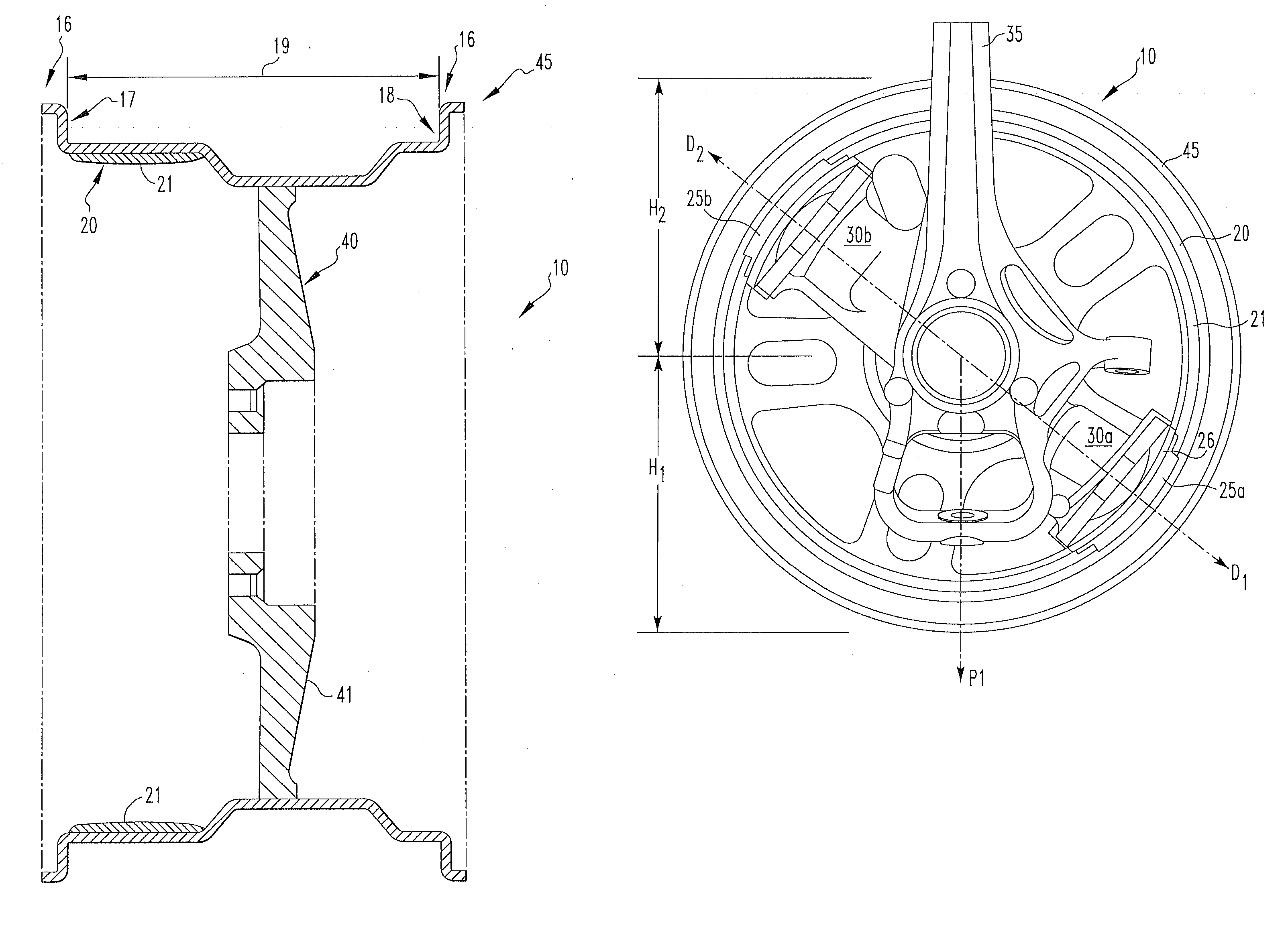

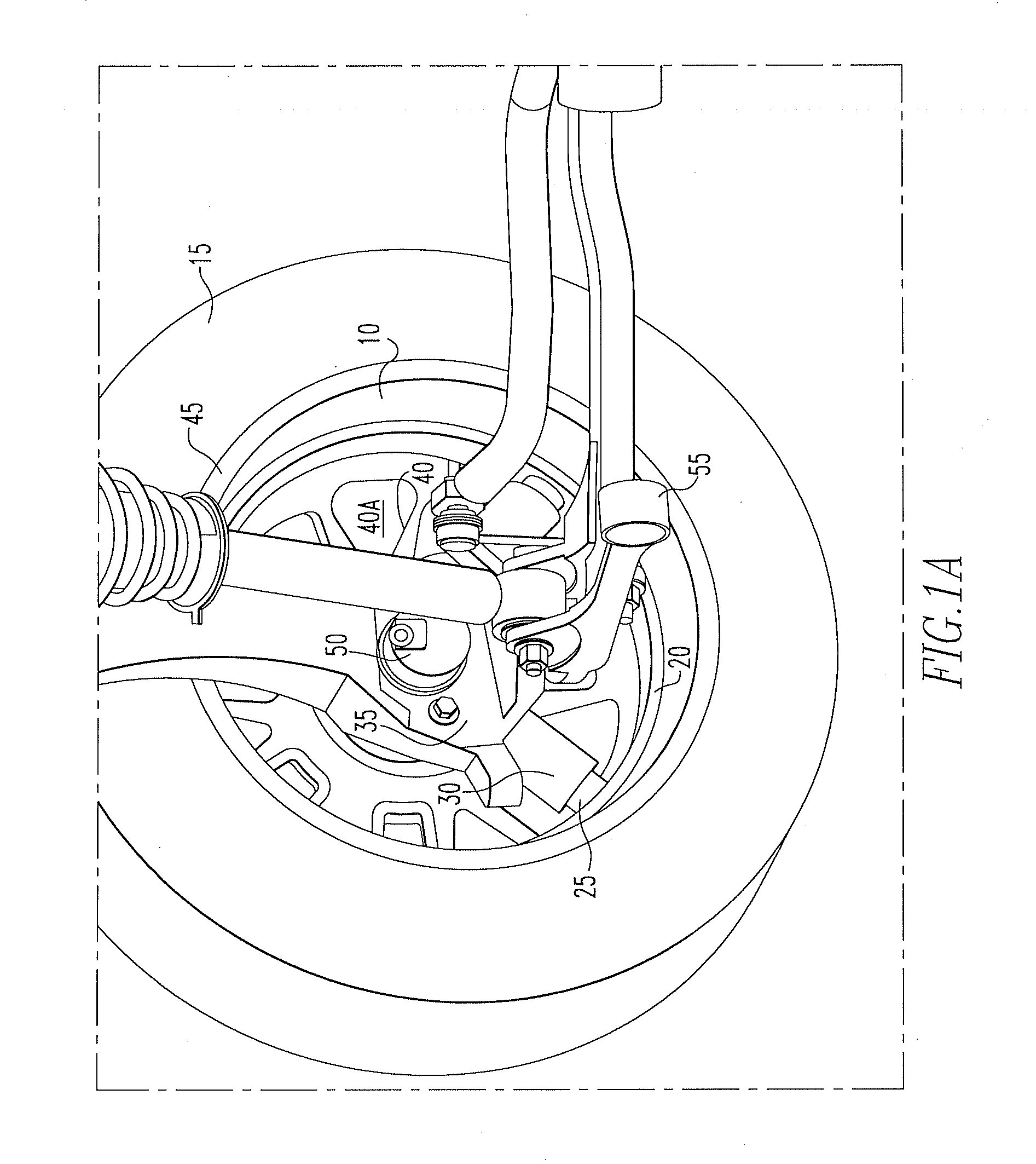

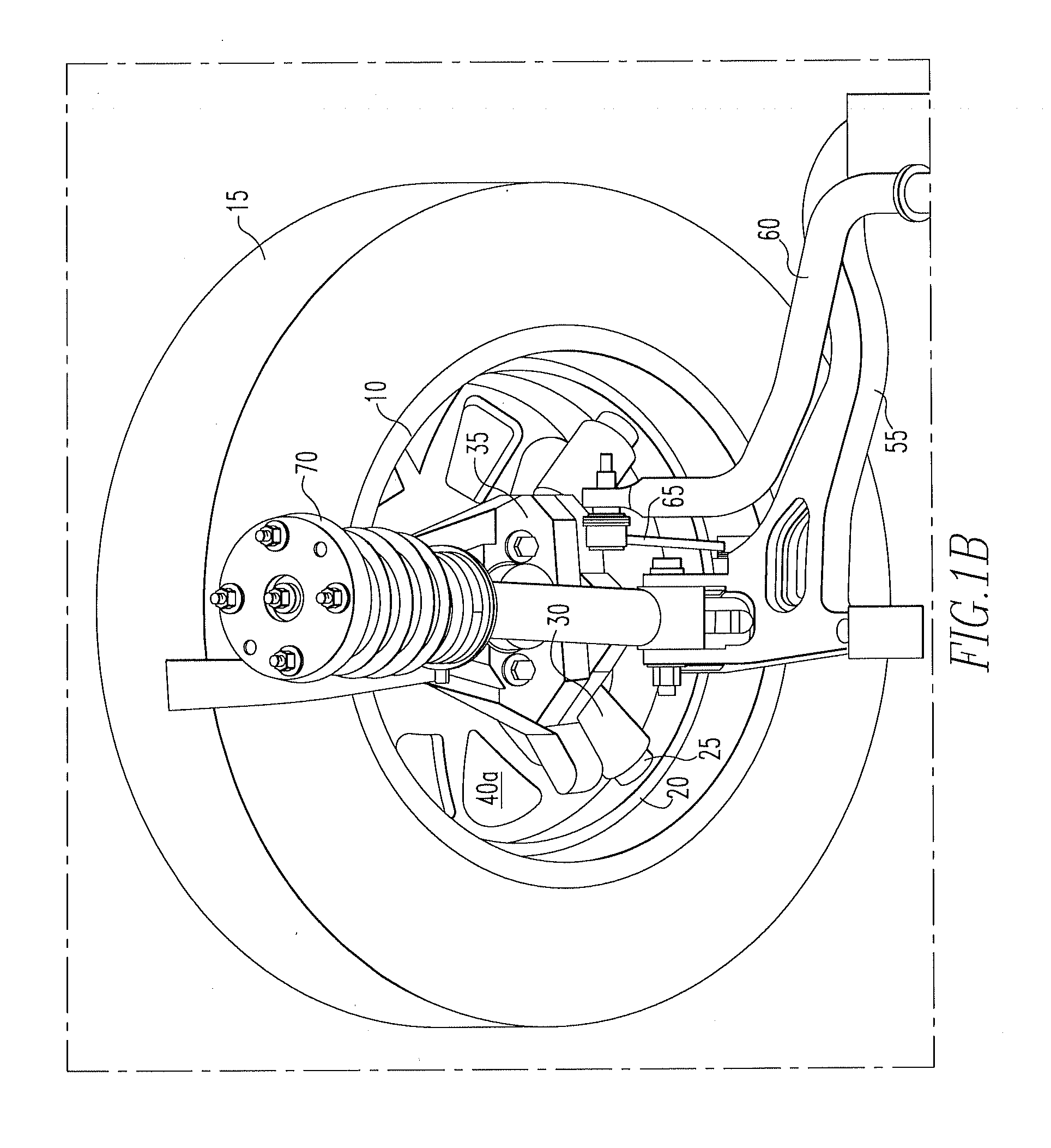

Integrated brake, suspension and wheel system

InactiveUS20070144839A1Reduce weightIncrease heating capacityMolten spray coatingRimsEngineeringMechanical engineering

A brake system including a suspension component housing at least one actuation piston to reversibly extend a brake pad; and a wheel that is in rotational engagement to the suspension component, the wheel having a rim portion with an interior surface that is contacted by the brake pad of at least one actuation piston when in an extended position.

Owner:ARCONIC INC

Method and a vehicle system for ensuring the functionality of a brake assembly and a vehicle comprising such system

InactiveUS20100258385A1Increase temperatureReduce heatAxially engaging brakesBraking action transmissionAutomotive engineeringCompressed air

A vehicle system includes a compressed air system and a brake assembly. The compressed air system includes an actuating means for actuating a pneumatic-controlled vehicle component and an exhaust outlet adapted to discharge exhaust air from the actuating means. The vehicle system includes a discharge device for discharging air to at least a portion of the brake assembly. A method of improving the braking characteristics of a brake assembly is also provided. Furthermore, the use of exhaust air in order to improve the braking characteristics of a brake assembly is also described.

Owner:VOLVO LASTVAGNAR AB

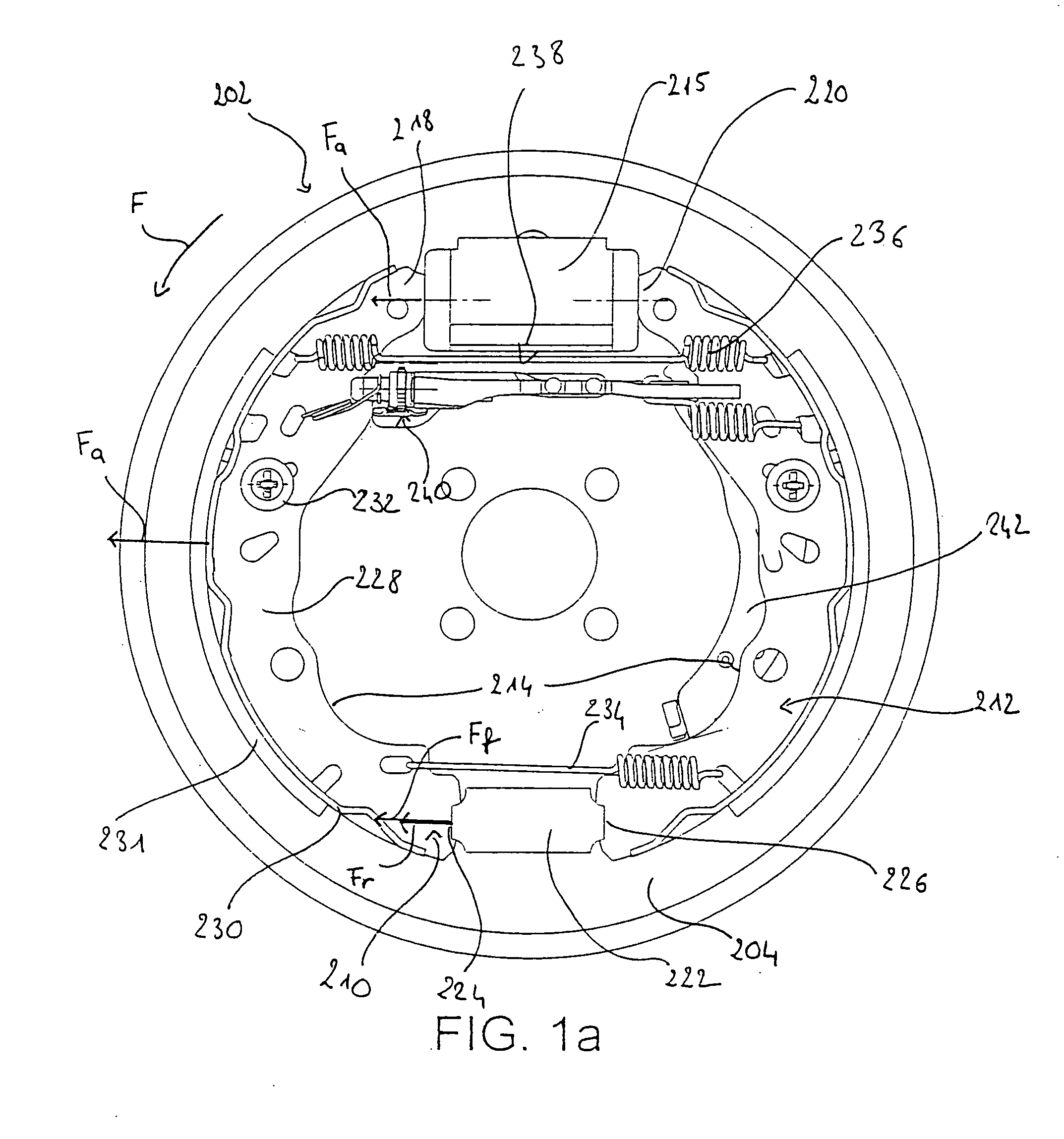

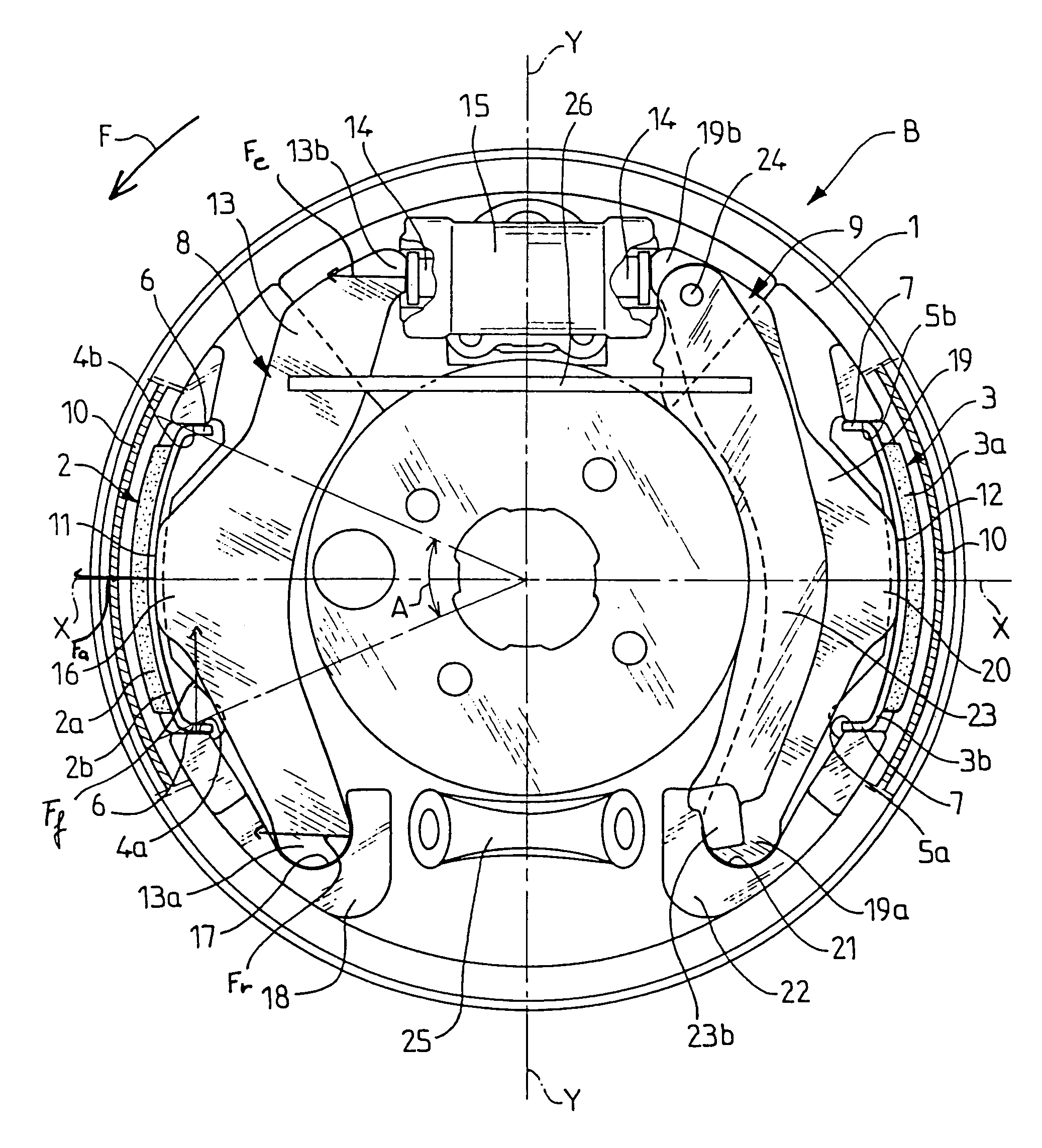

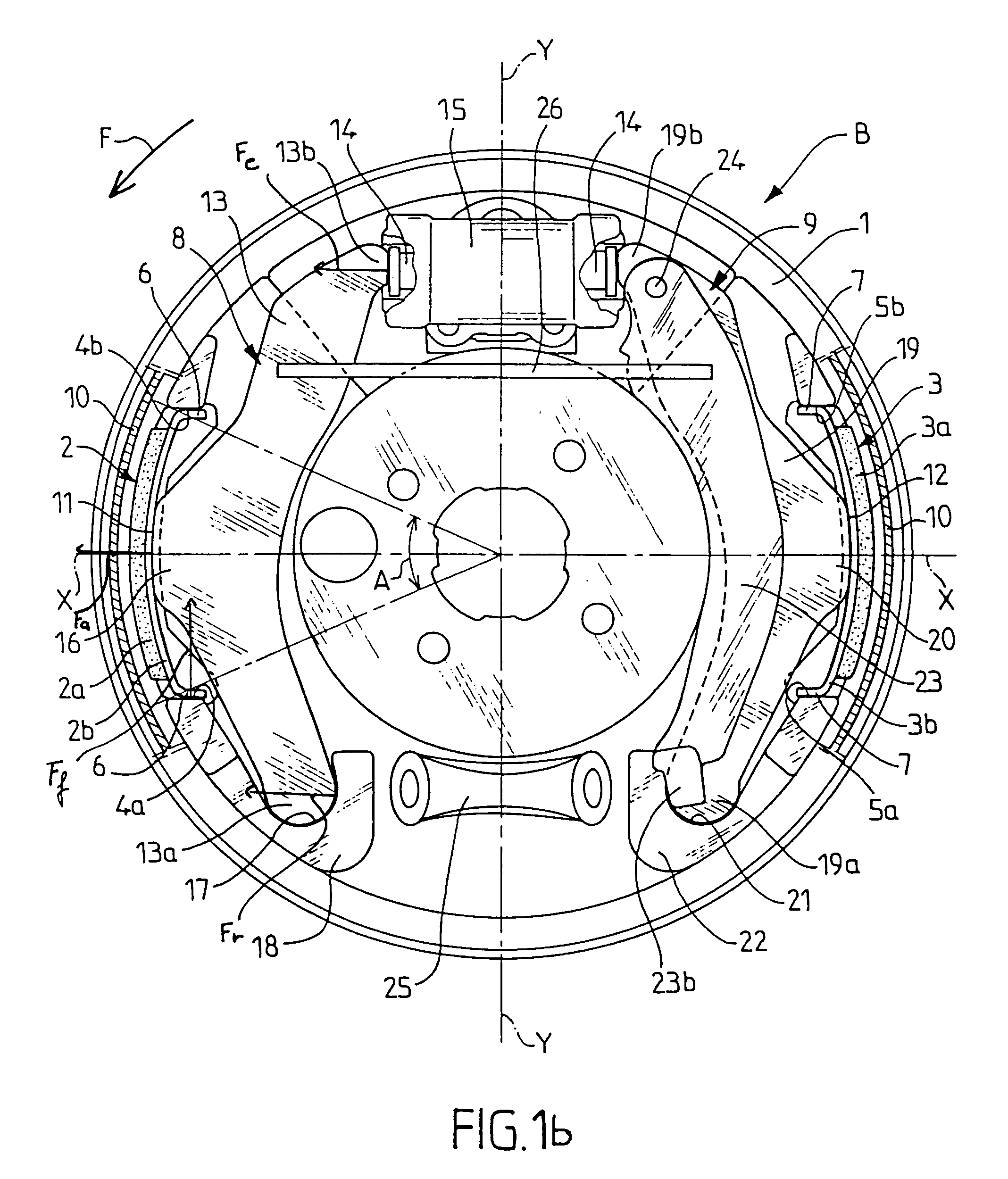

Drum brake and brake shoe for one such brake

ActiveUS20050205367A1Easy to replaceImproved torque stabilityMechanically actuated brakesFluid actuated drum brakesEngineeringMechanical engineering

A drum brake comprising a plate on which at least one shoe having a friction lining is mounted. A lever moves the shoe against a wheel drum in response to a braking command to effect a brake application. A resilient return spaces the shoe apart from the drum when braking ceases. The shoe is mounted to slide along an essentially radial axis between two guide walls secured to the plate The lever for applying the shoe bears against the inside wall of the shoe for exerting a substantially radial force.

Owner:ROBERT BOSCH GMBH

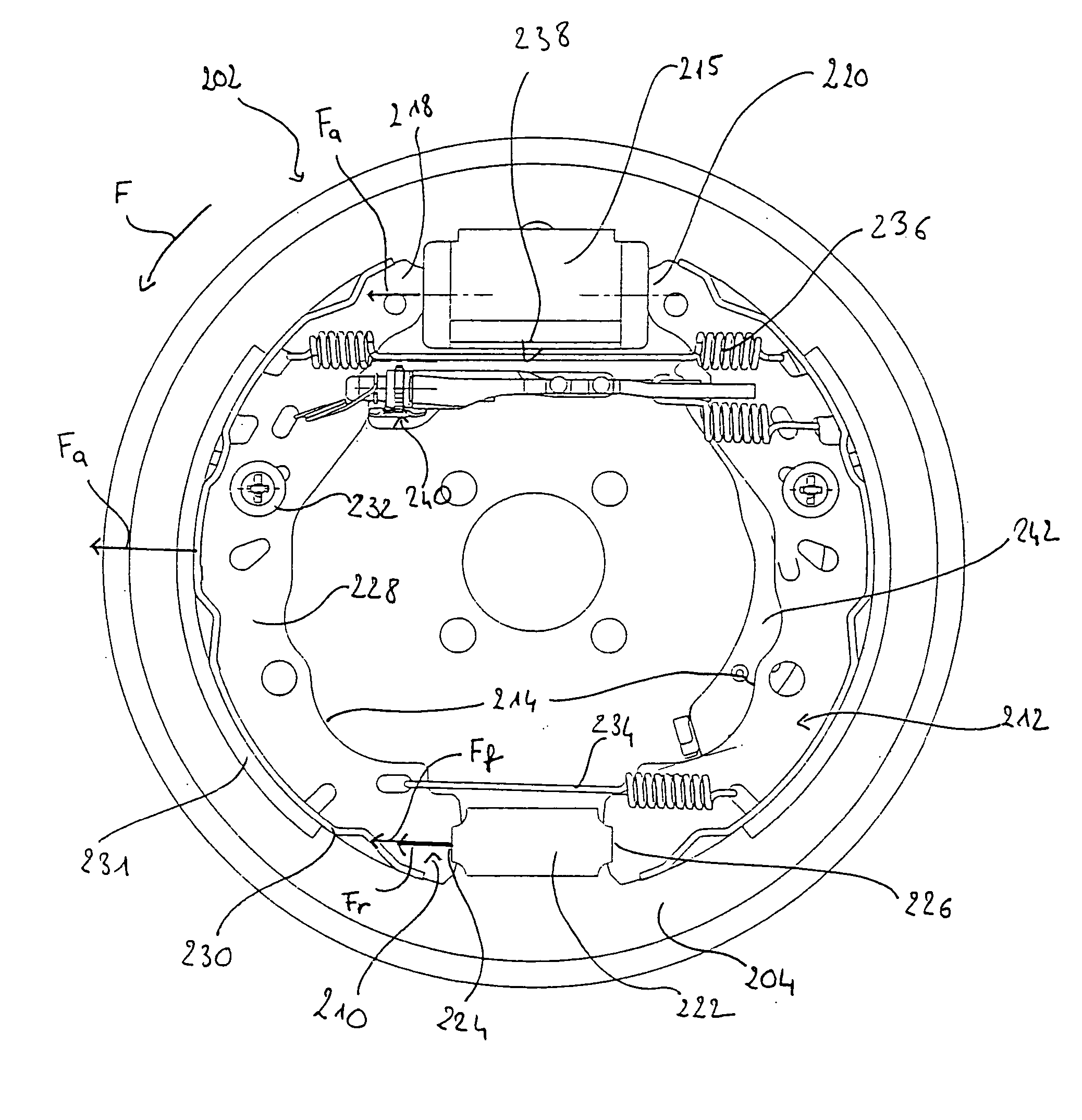

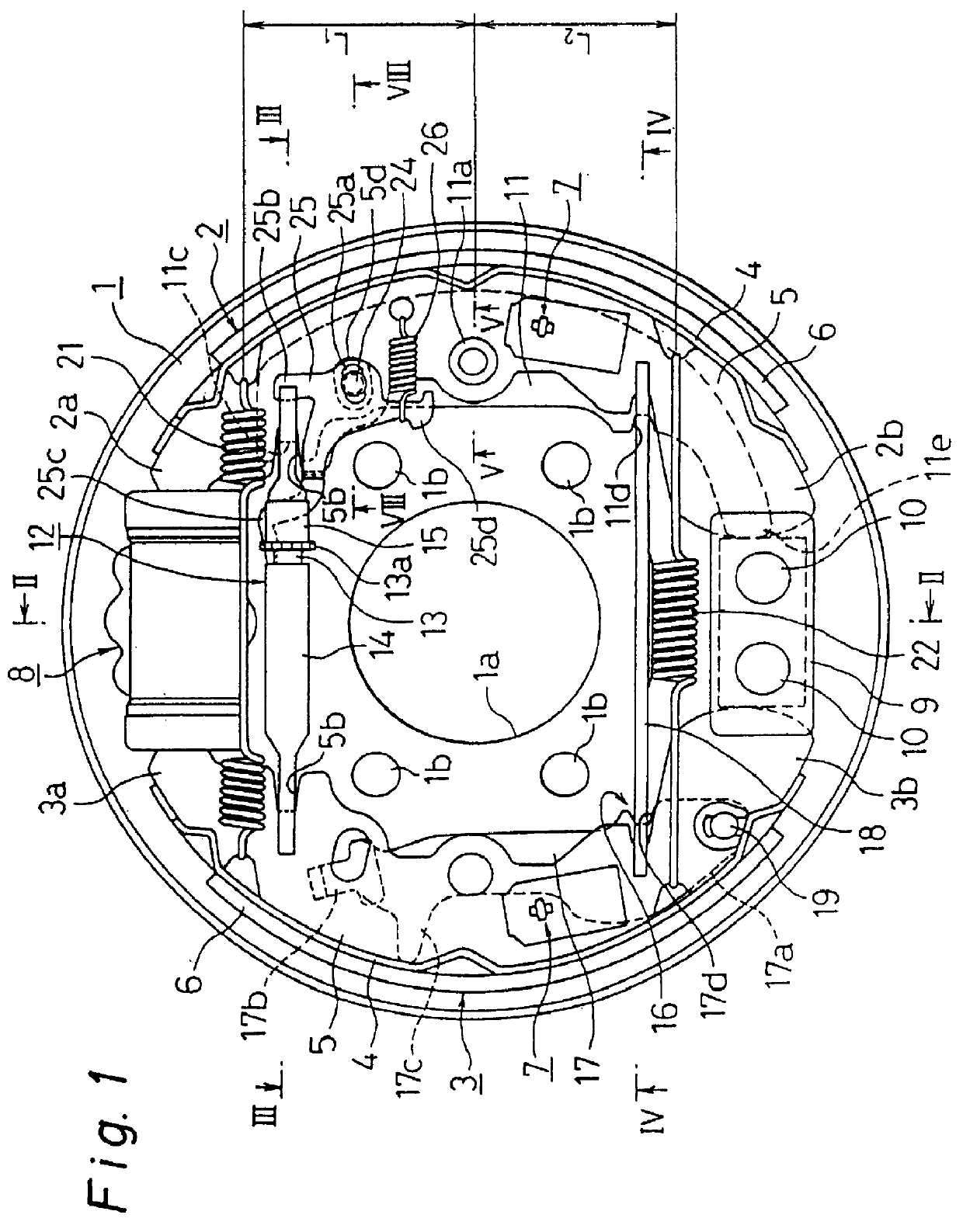

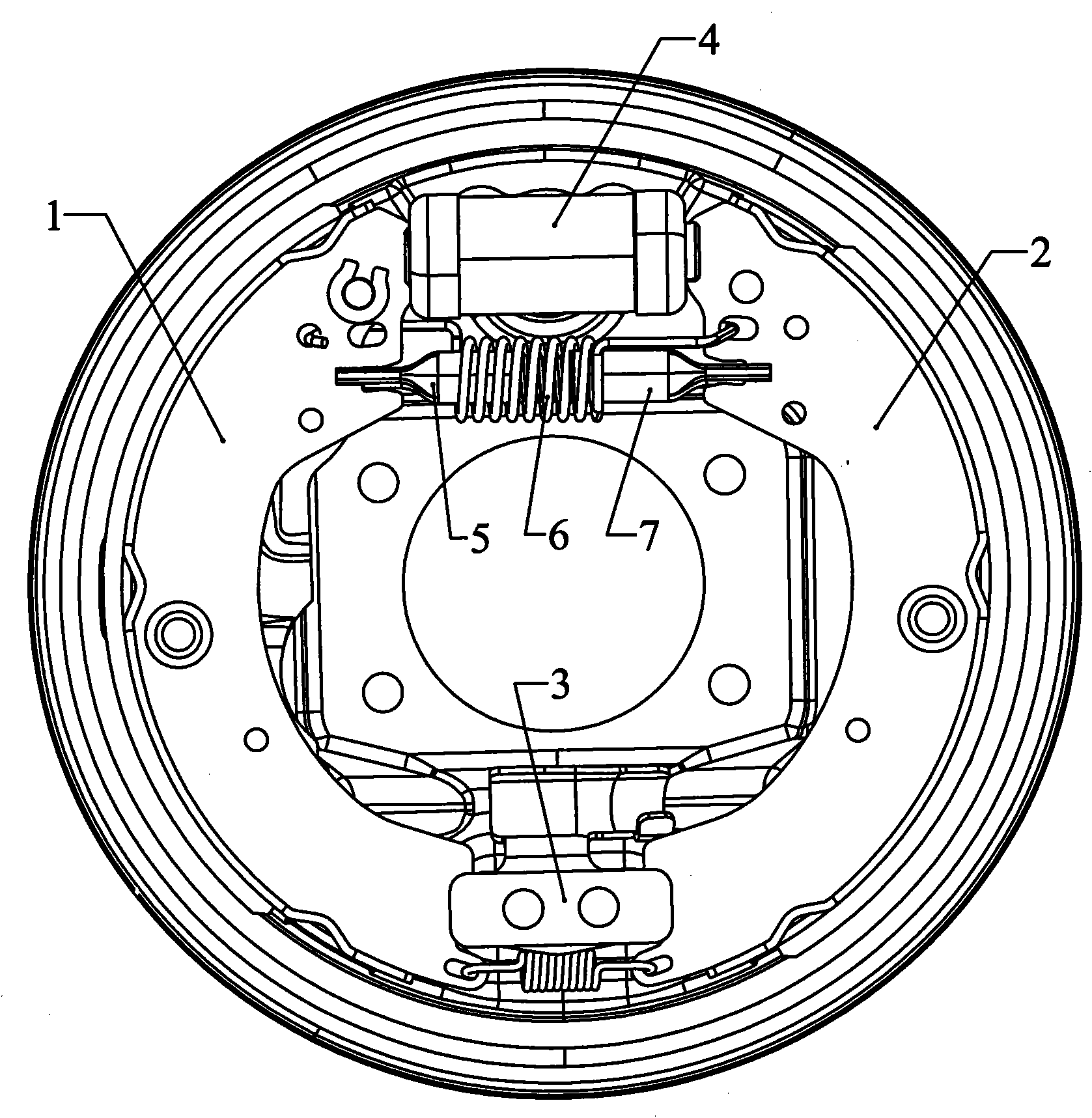

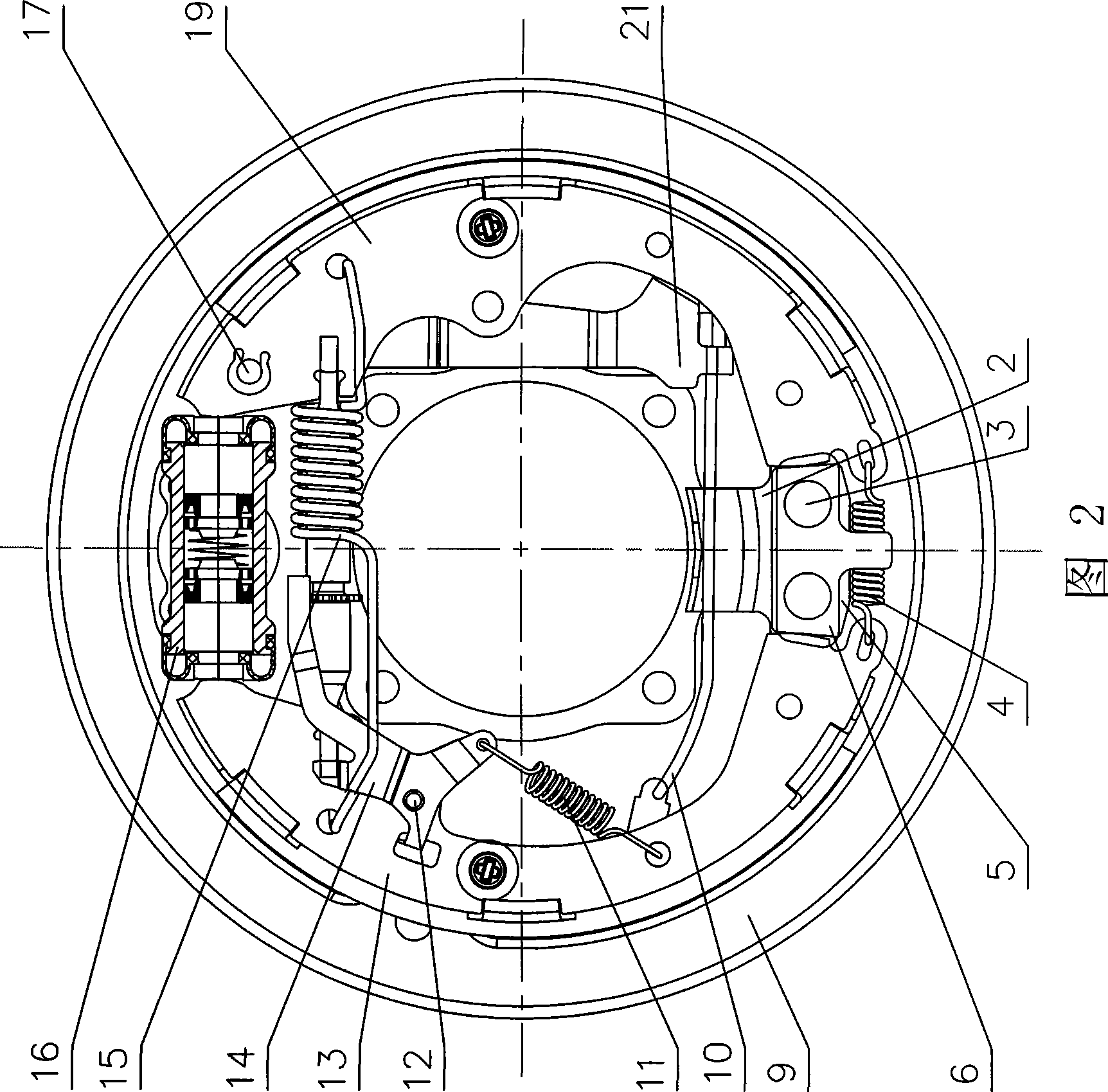

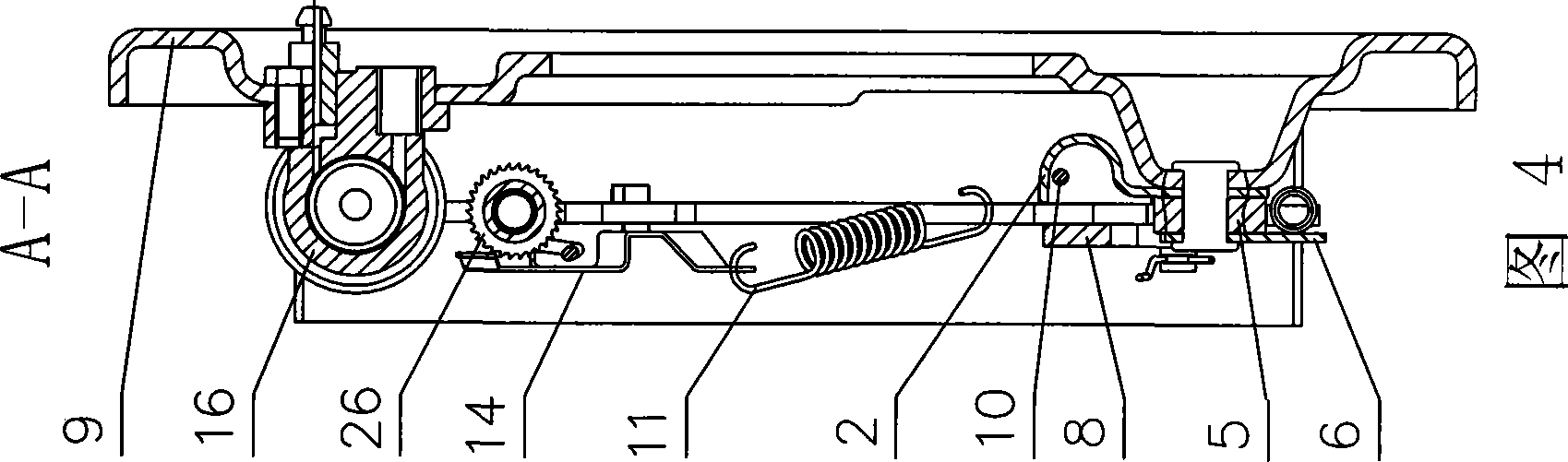

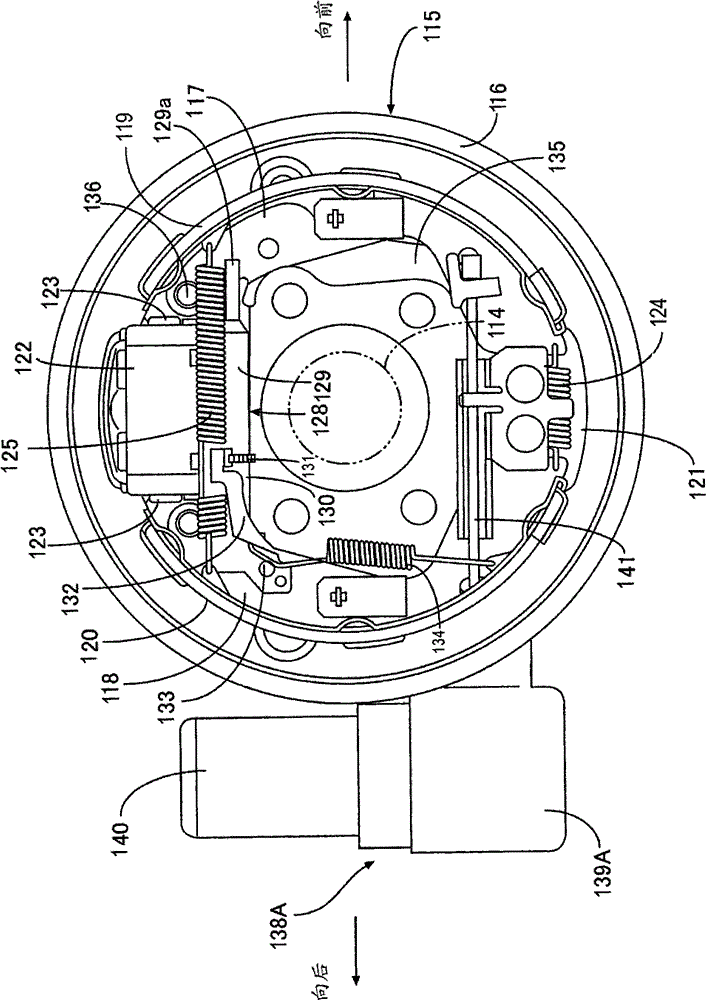

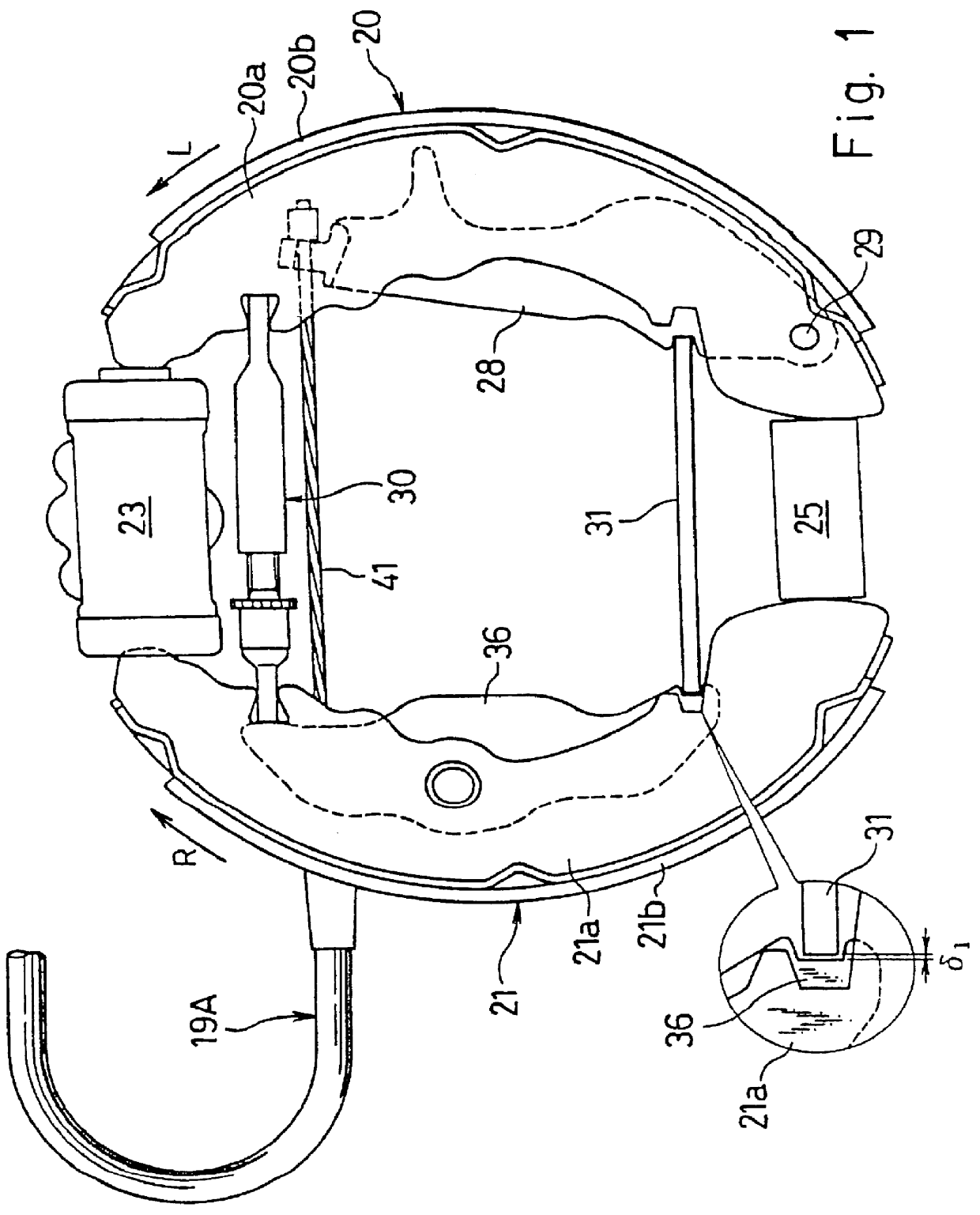

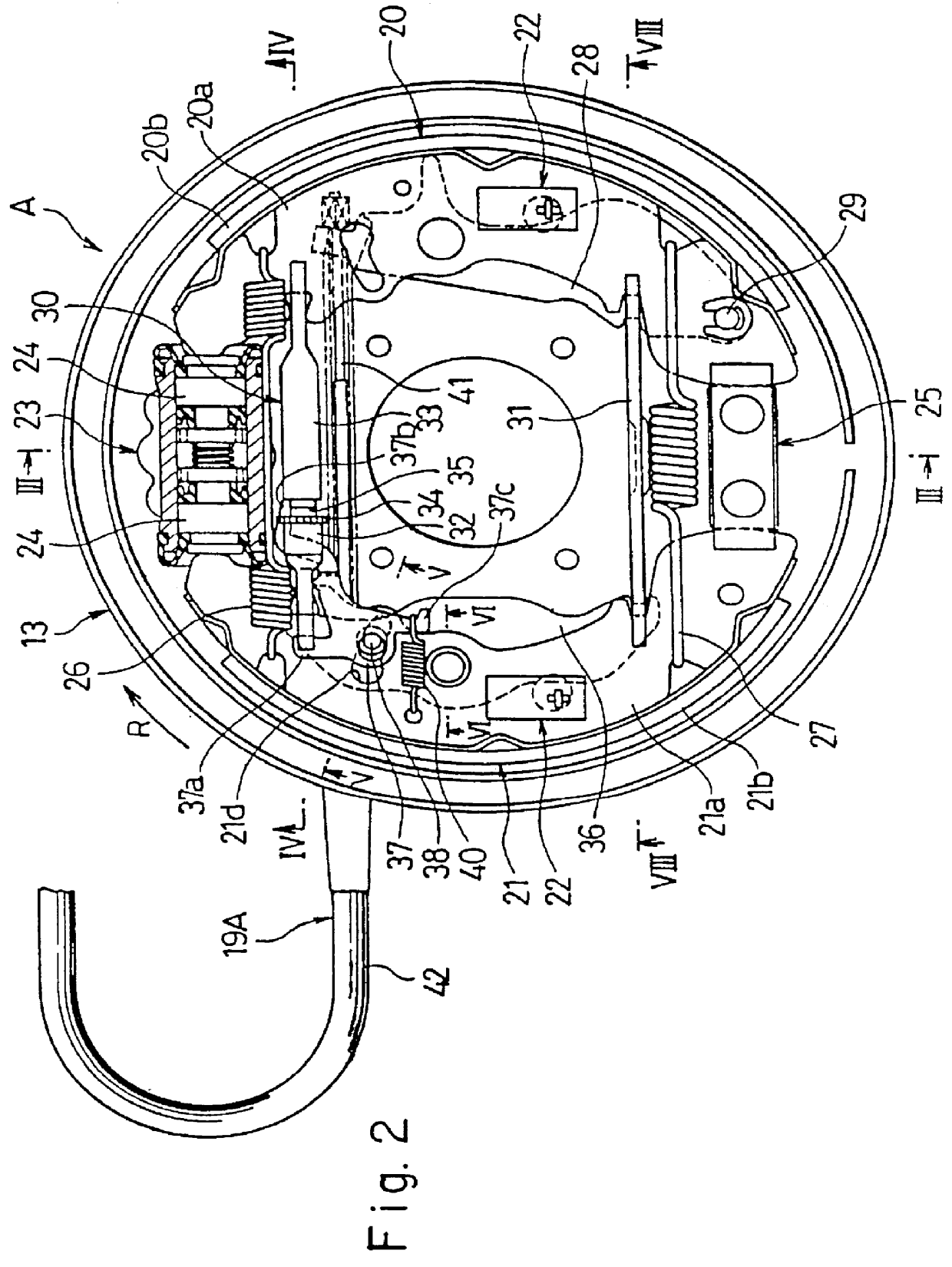

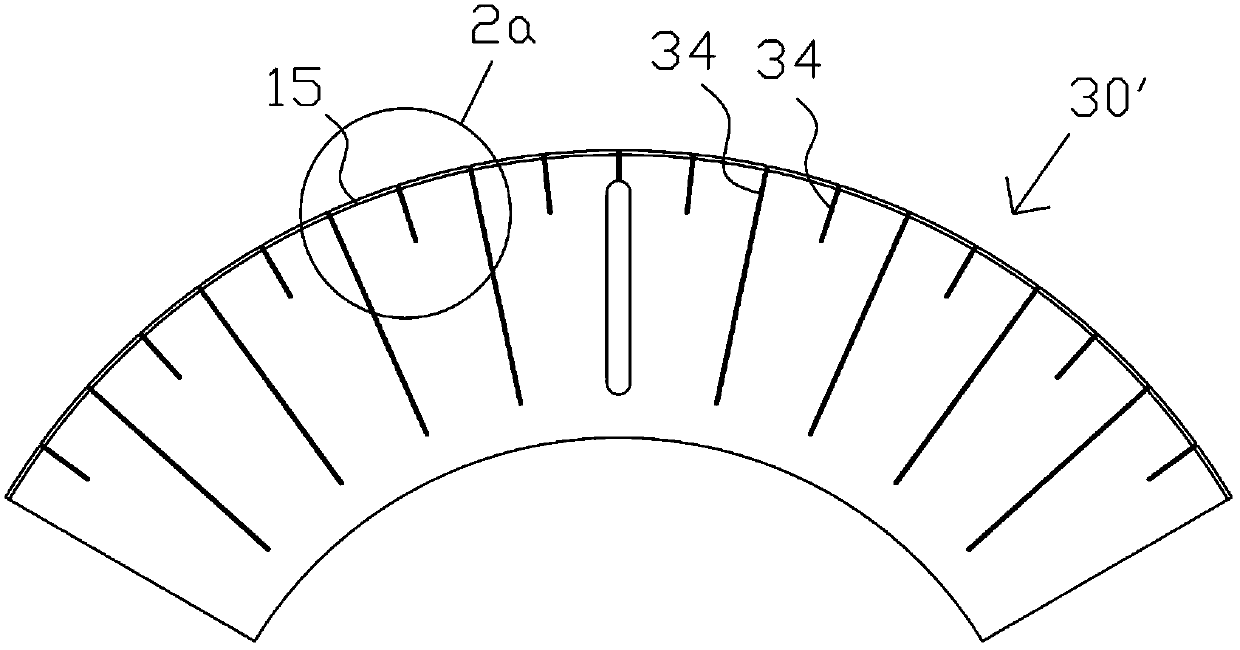

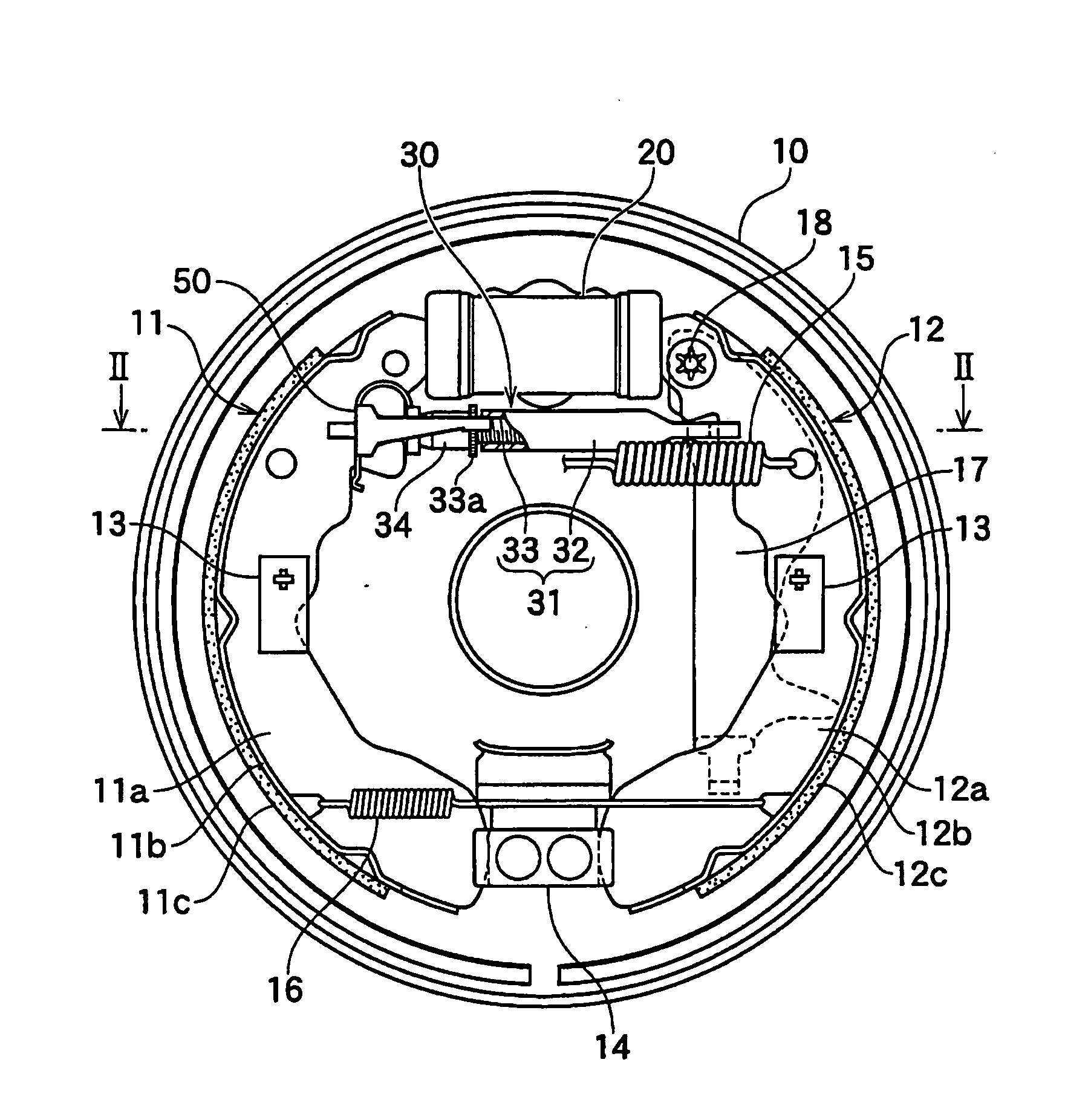

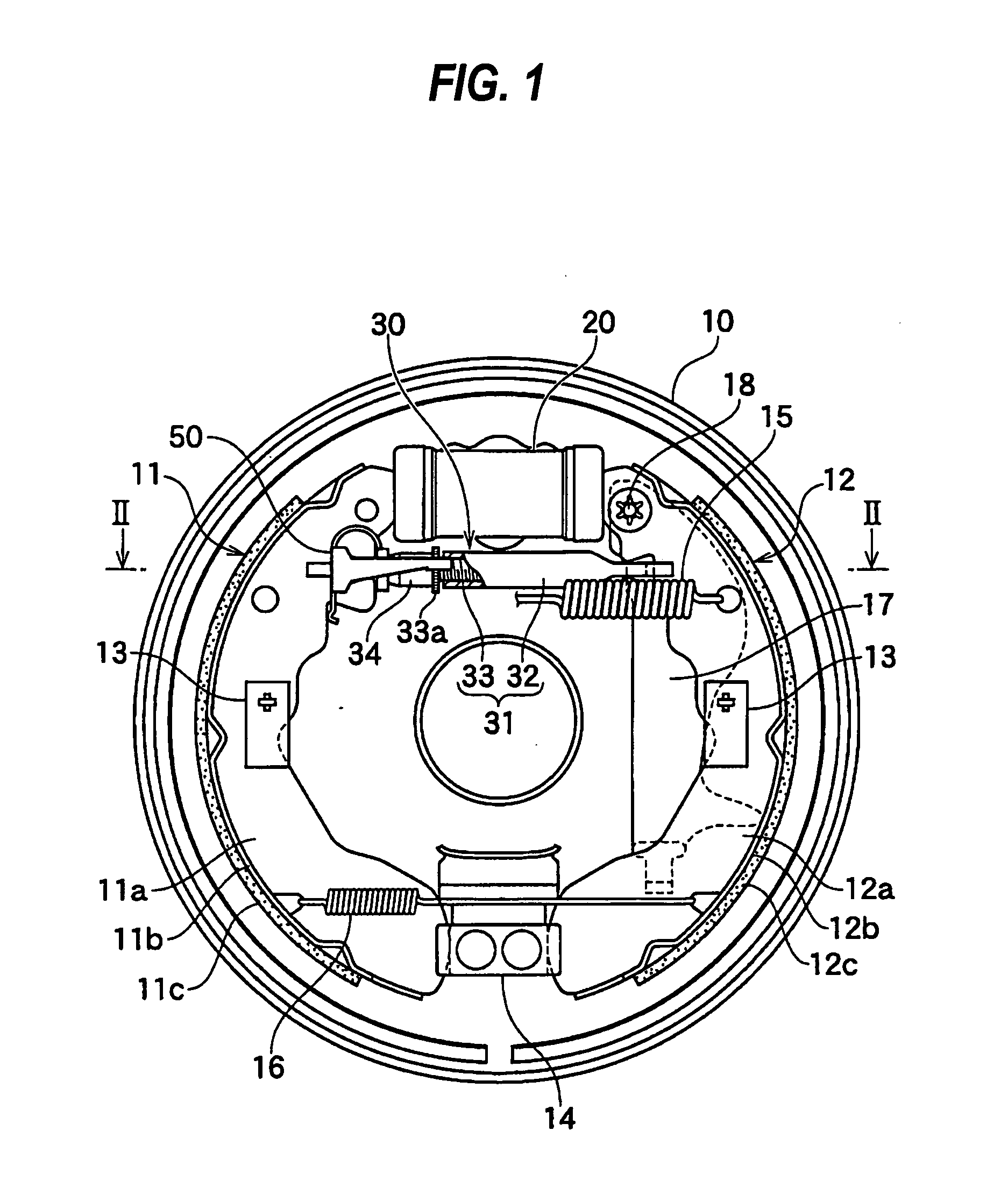

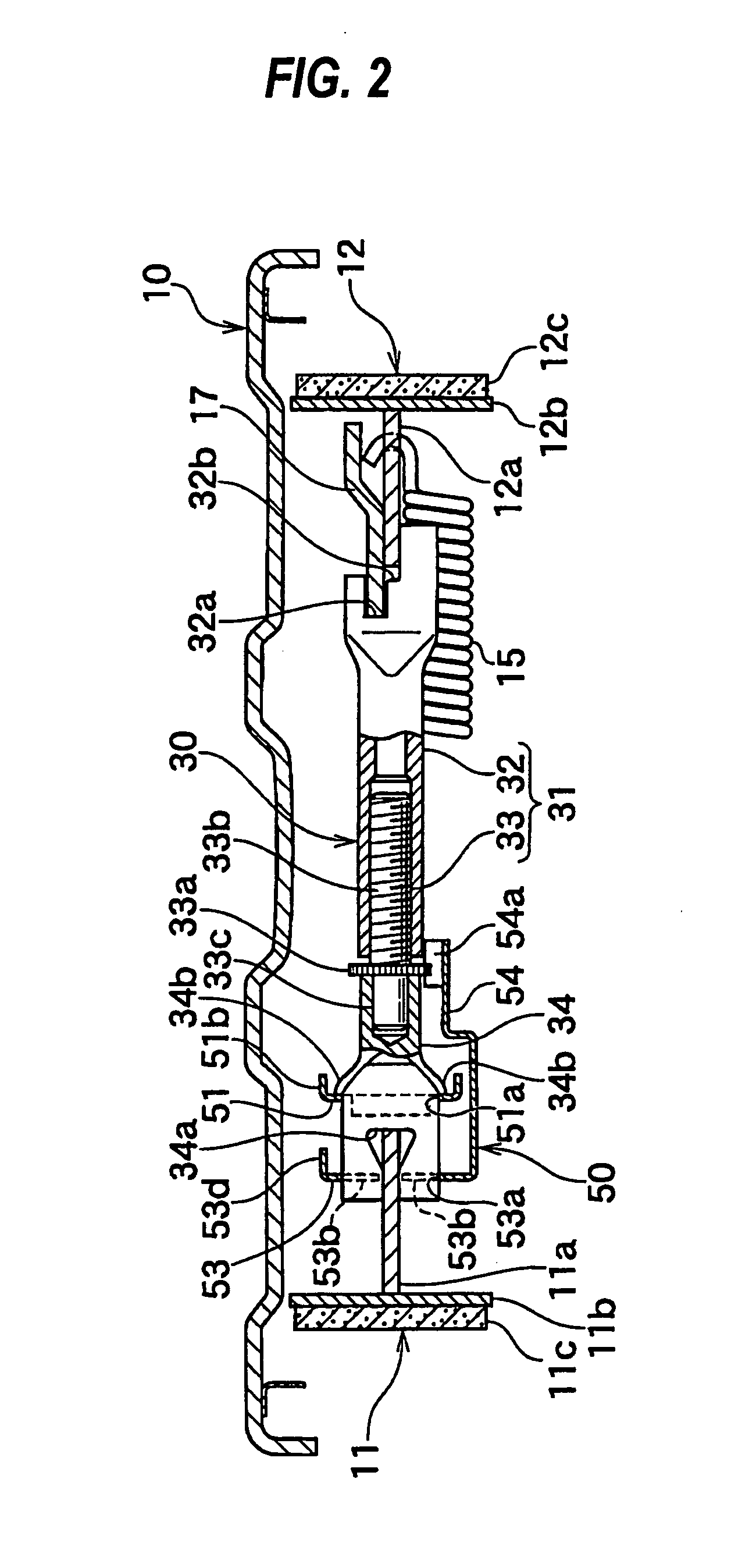

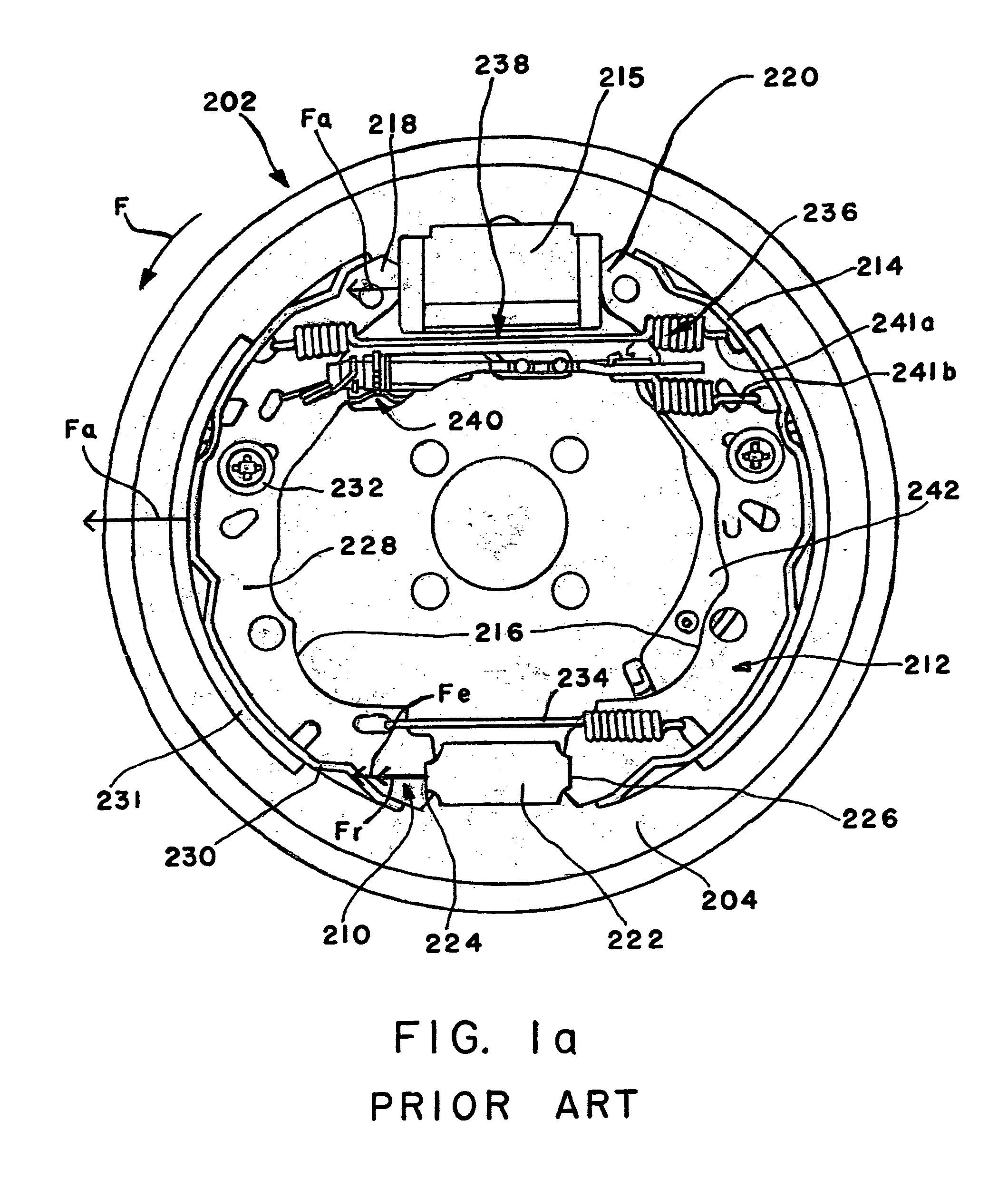

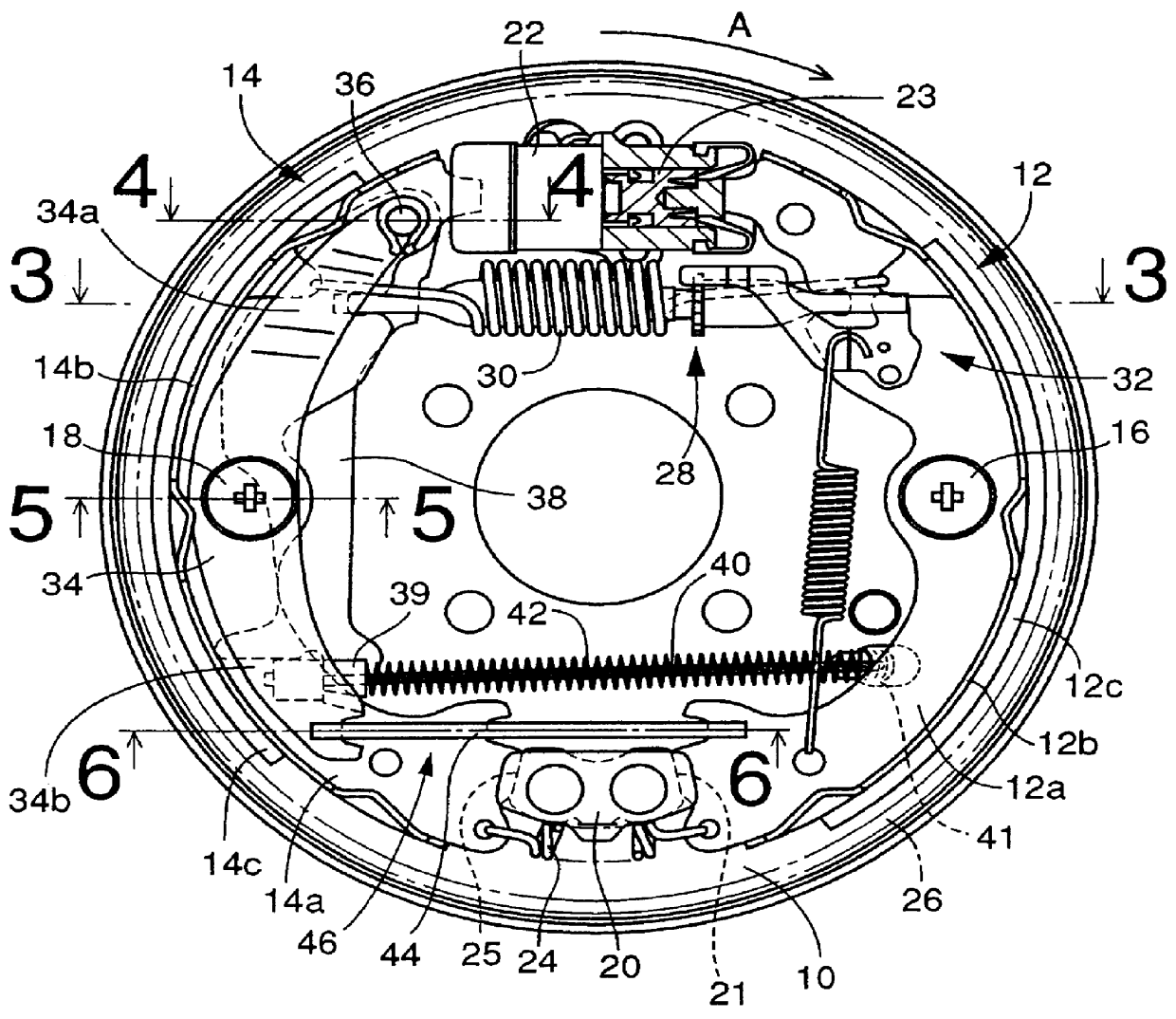

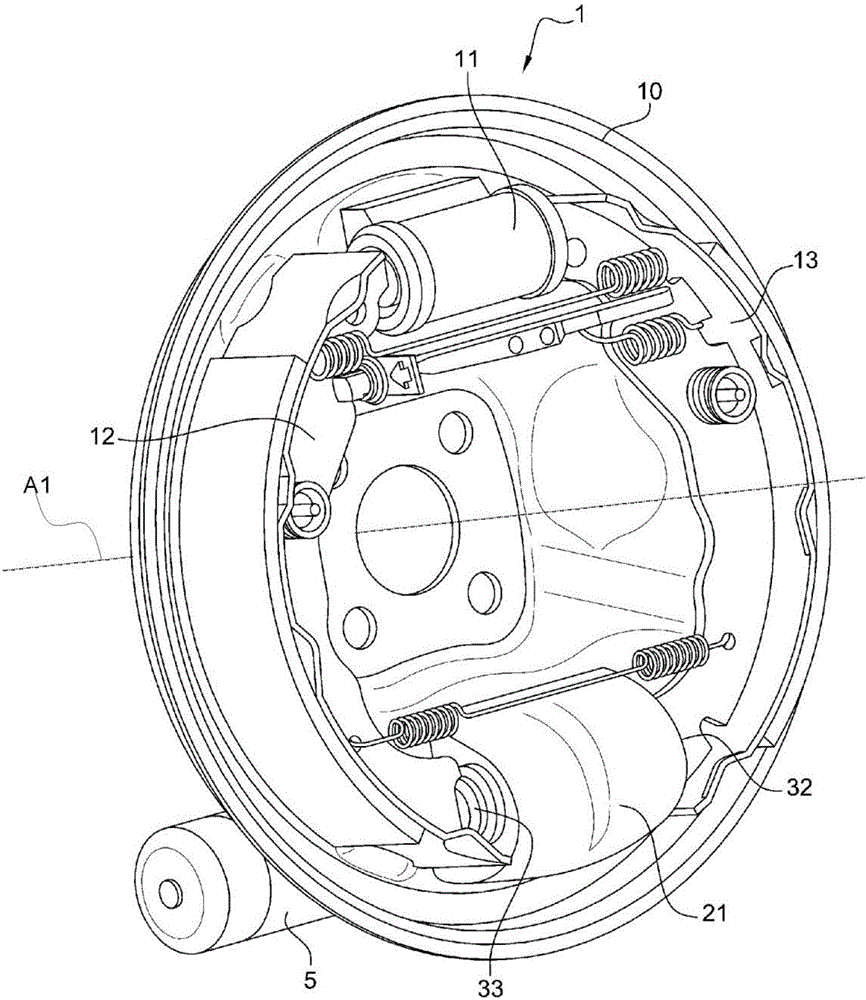

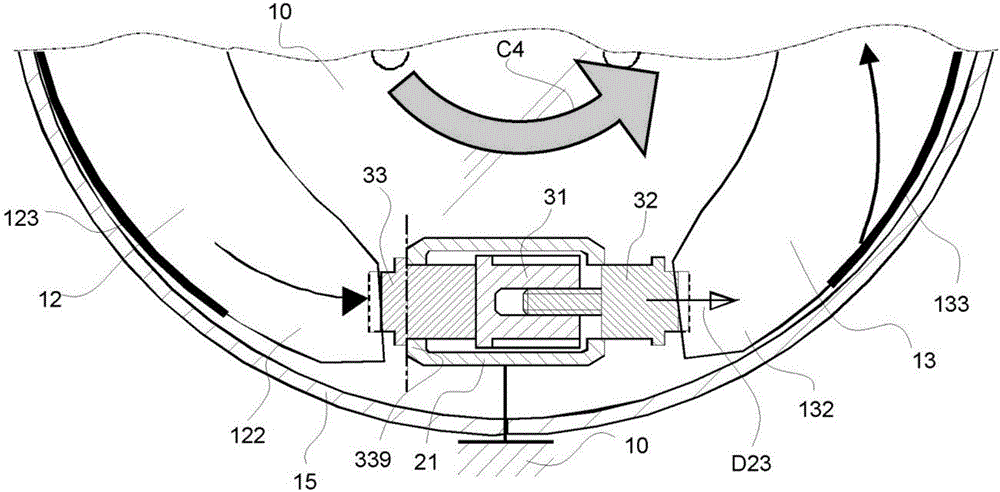

Drum brake device

InactiveUS6125976AEasy to observeEliminate discomfortBraking membersFluid actuated drum brakesEngineeringParking brake

A drum brake device that functions as a leading-trailing (LT) type when the service brake is applied, and as a duo-servo (DS) type when the parking brake is applied, in which the automatic shoe clearance adjustment mechanism functions precisely for a prolonged period, thereby generating no strange noise. This mechanism also eliminate any impact load applied to any of the components, thus enabling a lighter device. The middle segment of a long link 11 is pivotable in the middle of the one brake shoe 2.

Owner:NISSHINBO IND INC

Drum brake

InactiveCN102312944ARealize stepless adjustmentImprove securityFluid actuated drum brakesSlack adjustersSelf adjustmentDrum brake

The invention provides a drum brake, which comprises a brake drum, a first brake shoe, a second brake shoe, a return spring and a gap self-adjustment mechanism, wherein the two ends of the return spring are hooked on the first brake shoe and the second brake shoe respectively; the gap self-adjustment mechanism is connected between the first brake shoe and the second brake shoe and comprises a screw sleeve, a screw and a pivotal carrier; a first section of the screw is provided with external threads; the screw sleeve is provided with internal threads; the external threads and the internal threads form a self-lock thread pair; the internal threads are in clearance fit with the external threads; a second section of the screw is pivotally connected with the pivotal carrier; and the gap self-adjustment mechanism also comprises a pushing component for separating the screw sleeve away from the screw. The drum brake can realize continuous and stepless adjustment of gaps produced by wear; and the reliability of brake and the safety performance of a vehicle are enhanced. Since the number of the parts of the drum brake is much less than that of the parts of the conventional structure, the assembly is easy, the cost can be reduced, and the assembly processes are reduced.

Owner:BYD CO LTD

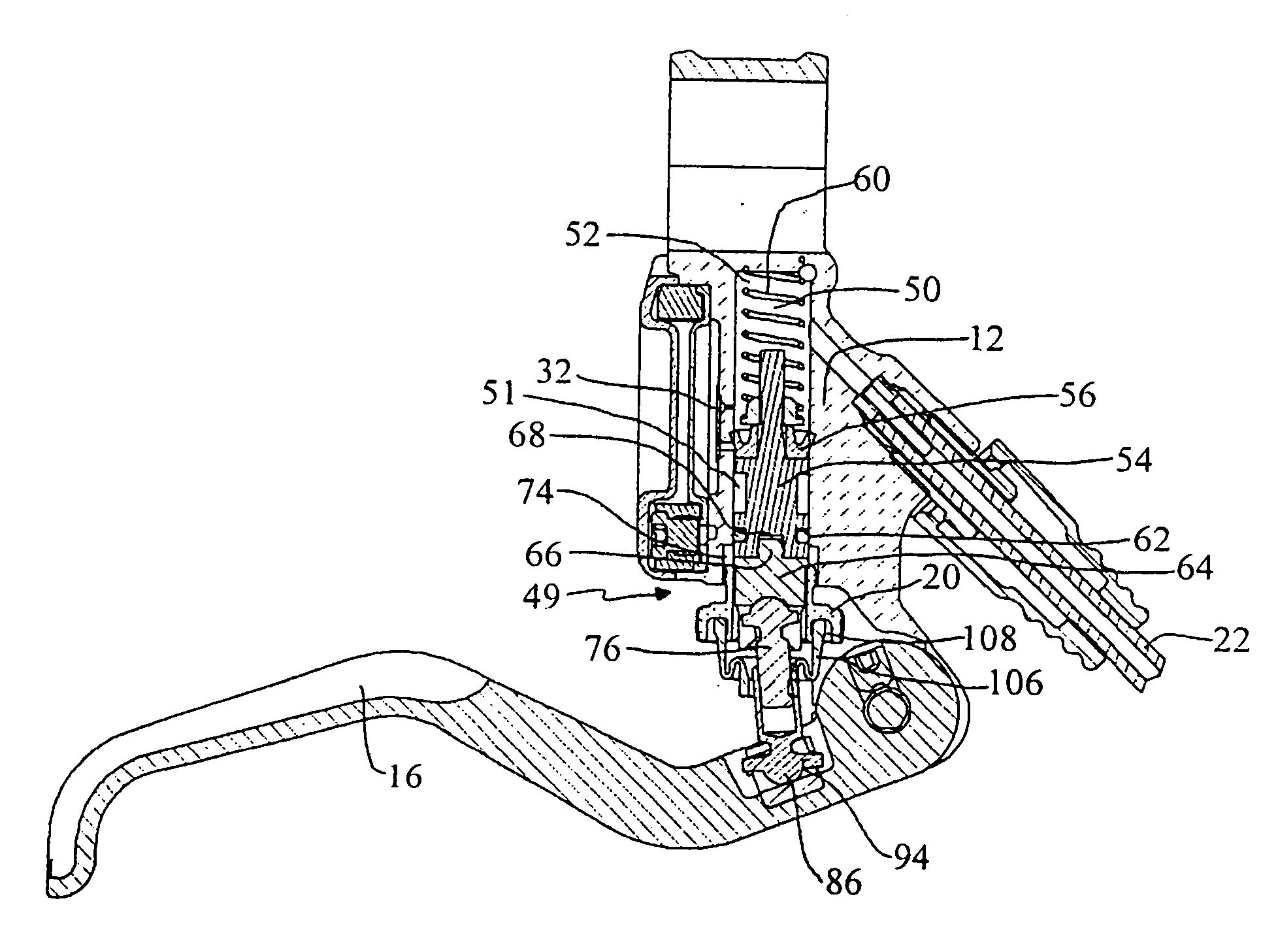

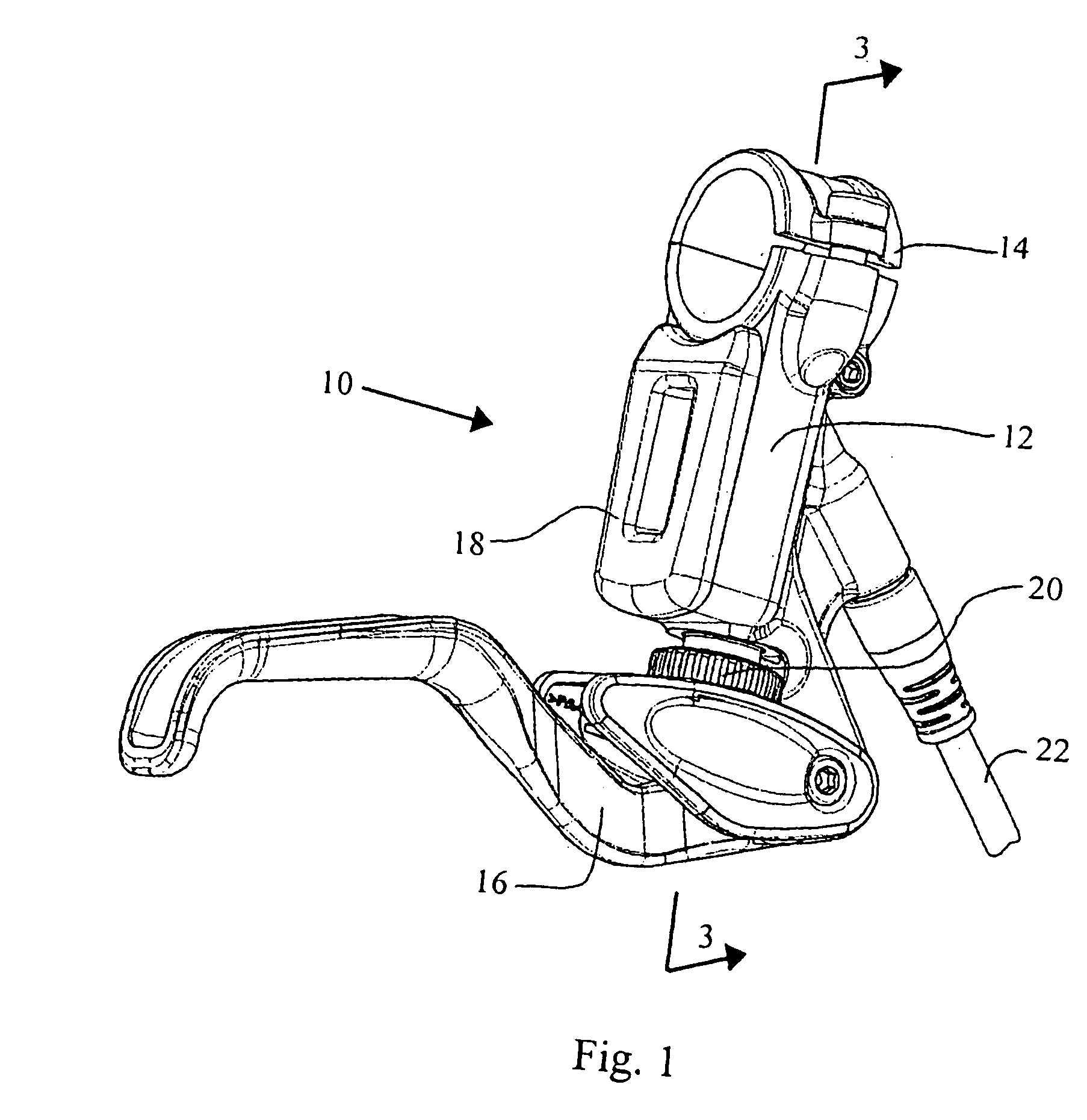

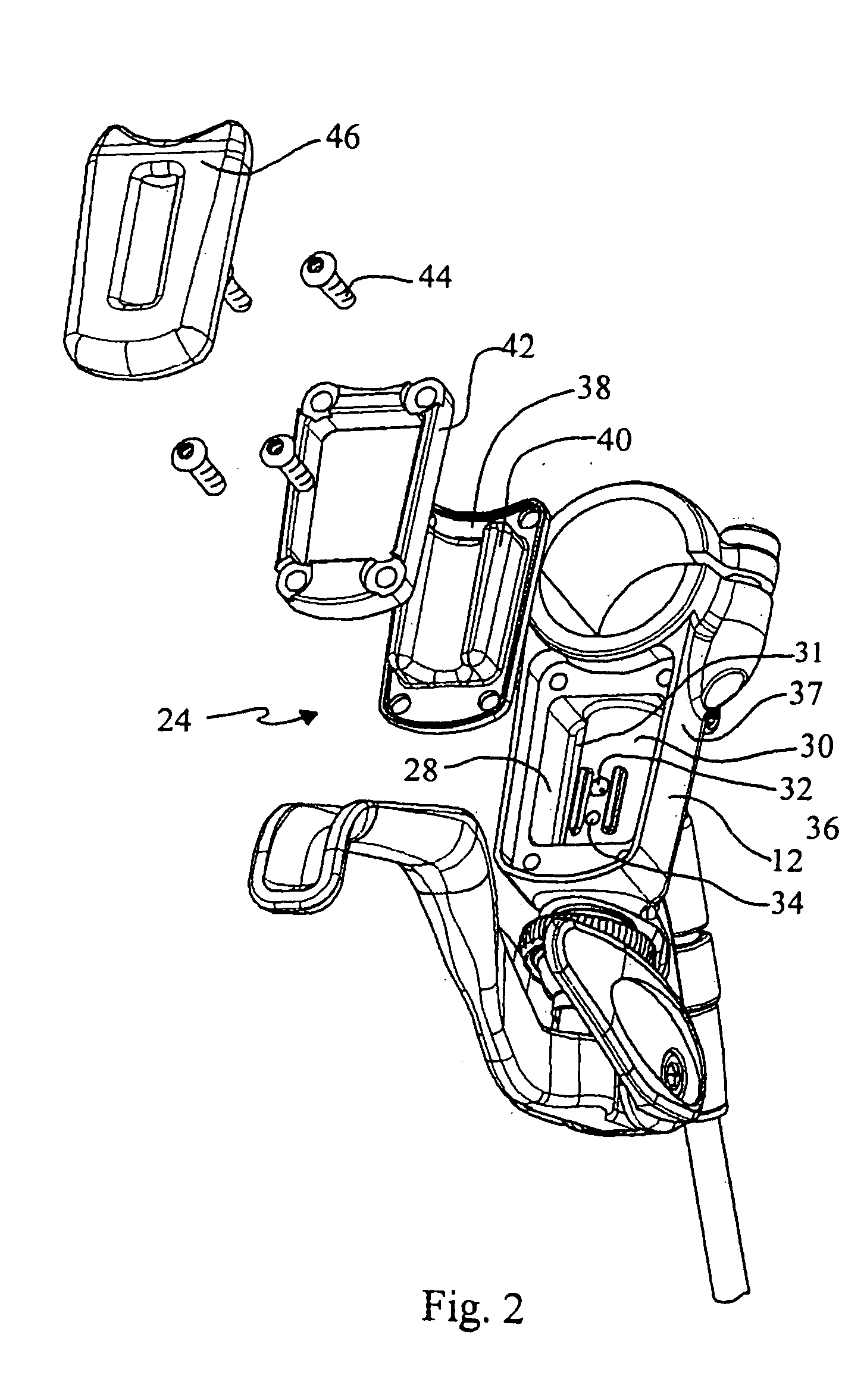

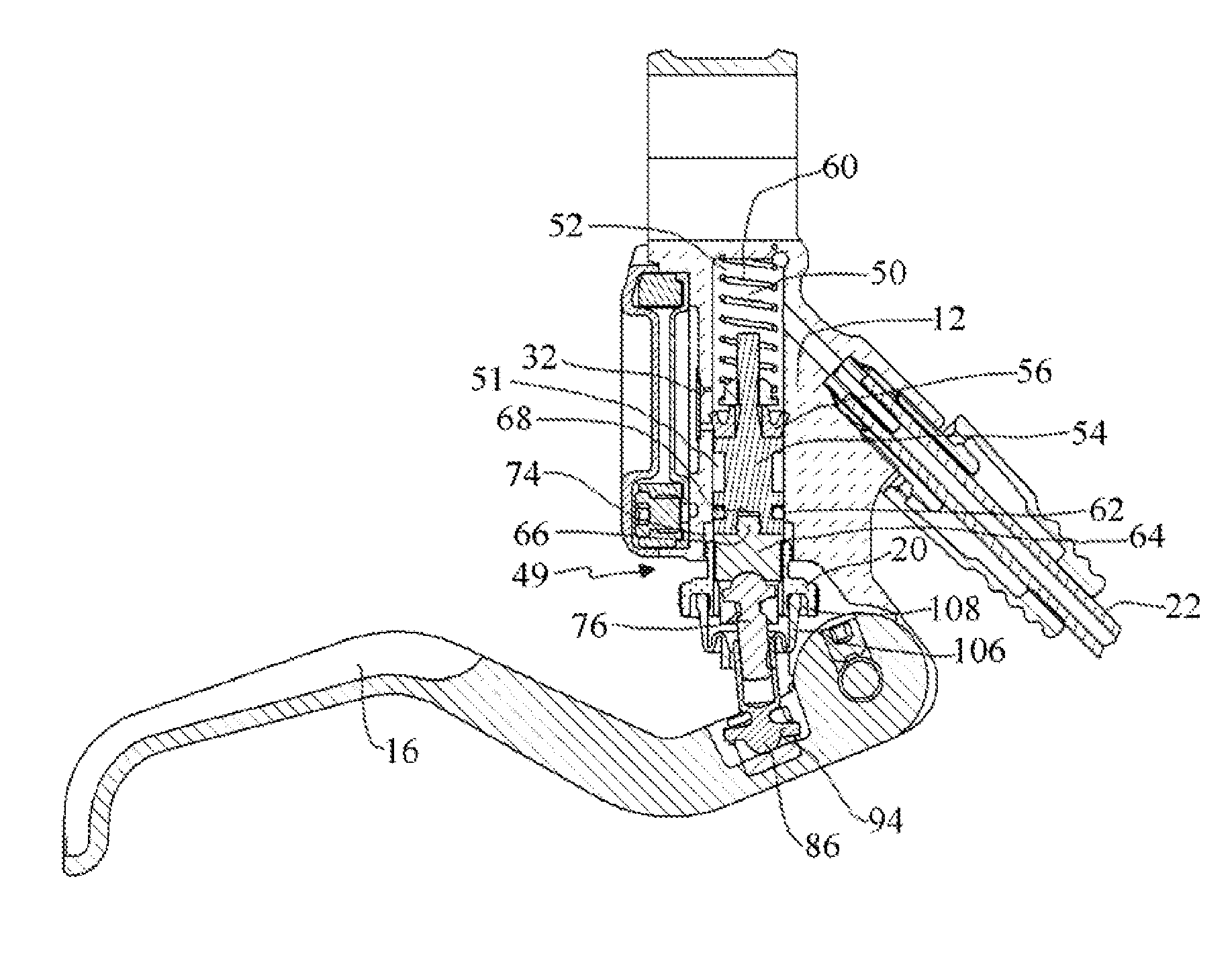

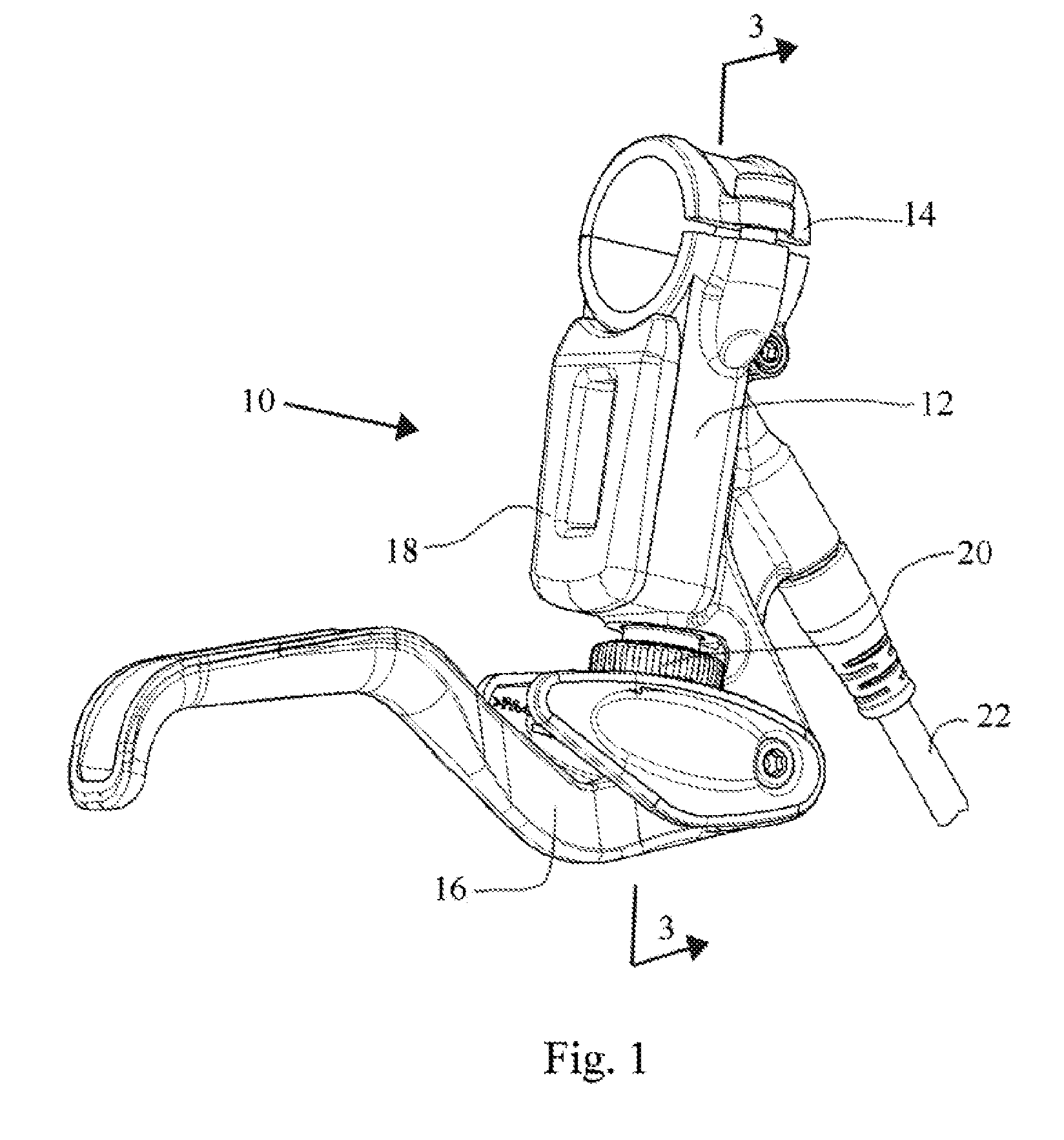

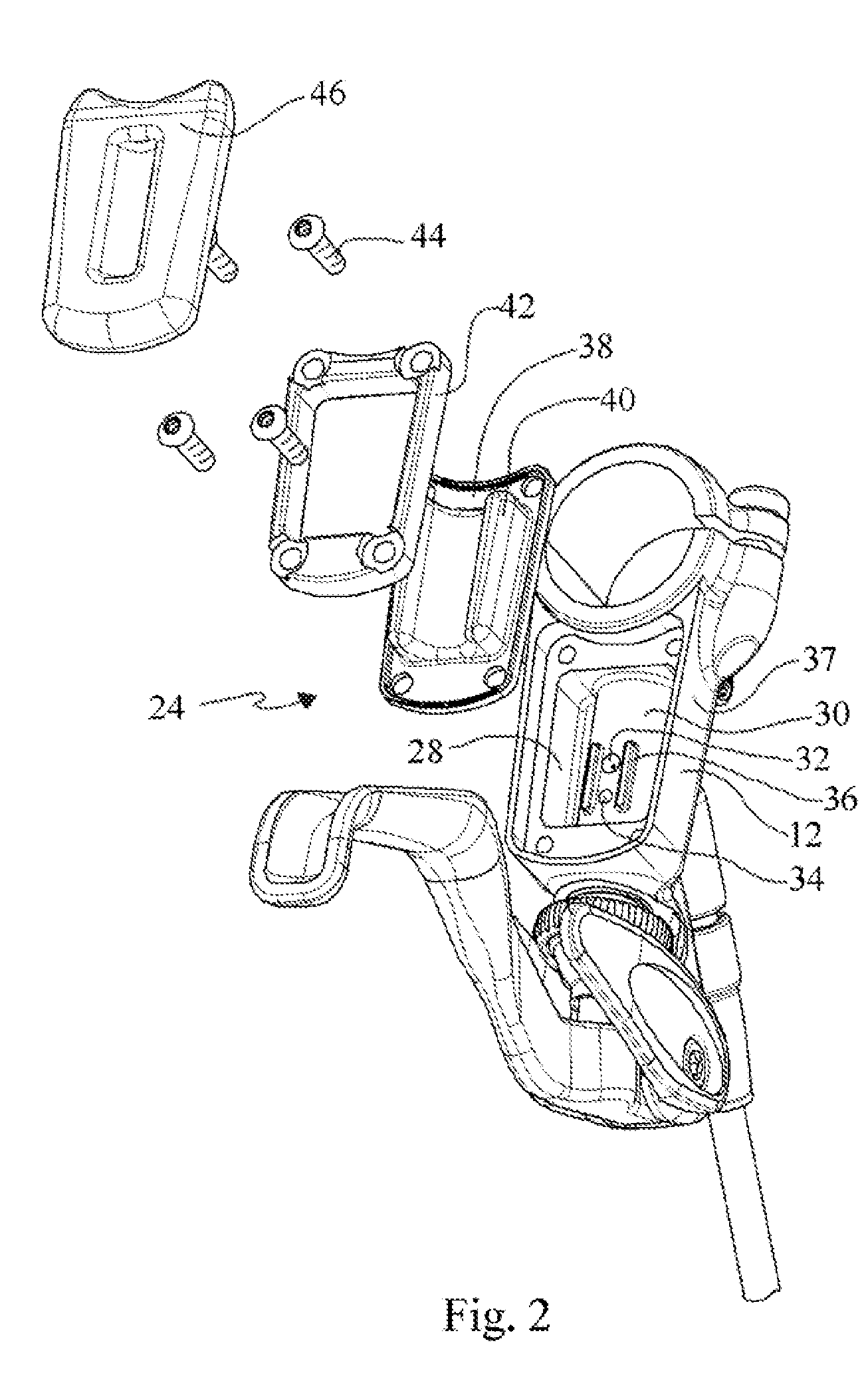

Master cylinder lever for a hydraulic disc brake having a backpack reservoir

InactiveUS20050061590A1Avoid enteringEliminate riskFluid braking transmissionFluid actuated drum brakesMaster cylinderHydraulic fluid

A master cylinder for a bicycle hydraulic disc brake includes a cylinder wall defining a cylinder interior and a cylinder exterior. A piston is received within the cylinder interior. A reservoir for hydraulic fluid is defined in part by a portion of the cylinder exterior, the portion of the cylinder exterior protruding into the reservoir. A port through the portion of the cylinder exterior which protrudes into the reservoir provides fluid communication between the reservoir and the cylinder interior. The port is located on the portion of the cylinder exterior which protrudes into the reservoir at a position which prevents air bubbles within the reservoir from entering the port.

Owner:SRAM CORPORATION

Hydraulic drum brake with upper and lower double pushrods parking mechanism

InactiveCN101412398AEnsure braking reliabilityReasonable structural designBraking element arrangementsFluid actuated drum brakesParking brakeFriction force

The invention provides a hydraulic drum type brake for a parking mechanism with upper and lower push rods. The hydraulic drum type brake solves the problem that the prior drum type brake is insufficient in brake friction force fundamentally, which comprises a brake base plate, a brake cylinder, an automatically adjusting device for brake clearances, a front brake shoe and a rear brake shoe. The technical points of the brake comprise that the push rods comprise a combined upper push rod and a lower push rod, the upper end of a parking draw arm is hinged together with the upper end of a supporting arm at the upper end of the rear brake shoe, and the middle part of the supporting arm is hinged with the rear brake shoe through a pin roll, a fork horn of the upper front push rod is tensioned on the front brake shoe, and a fork horn of the upper rear push rod is tensioned on the parking draw arm and the rear brake shoe; and the front end of the lower push rod is hinged on the front brake shoe, while the rear end is tensioned in an arc-shaped groove at the lower end of the supporting arm. The structural design is reasonable, the brake shoe is contacted fully with the brake surface of the brake drum to increase the brake friction force, so that the automobile needs no auxiliary parking brake when stopping at a ramp way, and the parking is safe and convenient, thereby not only improving the braking reliability of the parking mechanism, but also prolonging the service life of the brake.

Owner:LIAONING SG AUTOMOTIVE GRP CO LTD

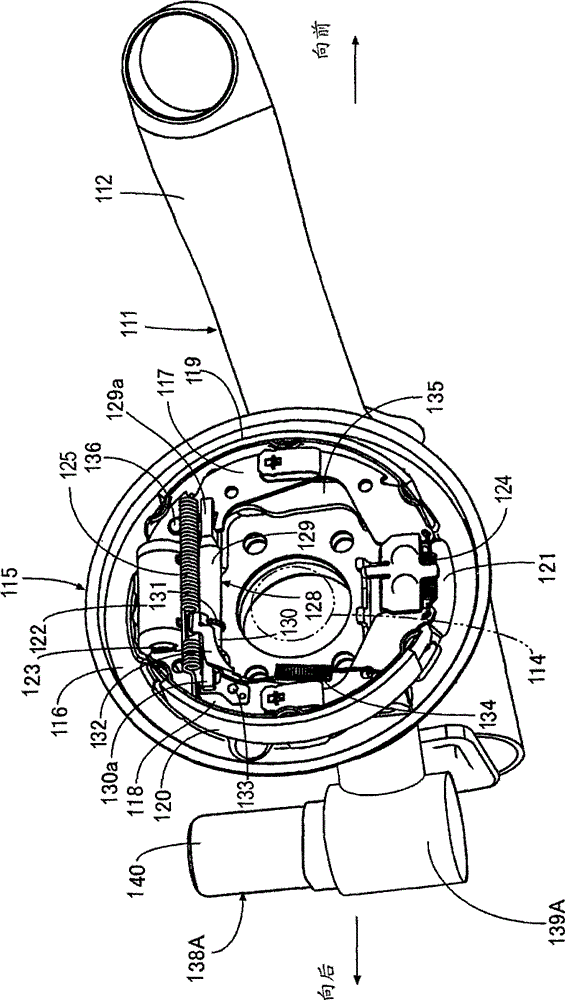

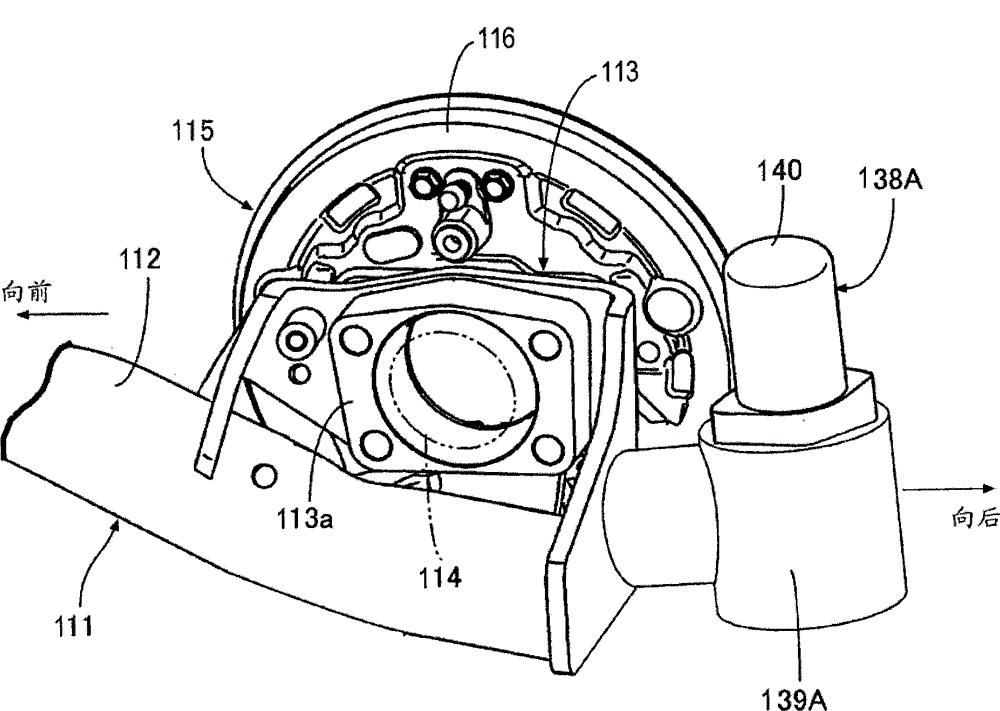

Vehicle brake apparatus

InactiveCN104912974AIncrease freedomImprove layout effectBraking element arrangementsFluid actuated drum brakesActuatorDrum brake

One embodiment provides a vehicle brake apparatus, including: an electric actuator; and a drum brake. The drum brake is attached to a wheel so as to be driven by power exhibited by the electric actuator. In a state of being mounted on a vehicle, the electric actuator is disposed and fixed further rearwards than an axle of the wheel.

Owner:NISSIN KOGYO CO LTD

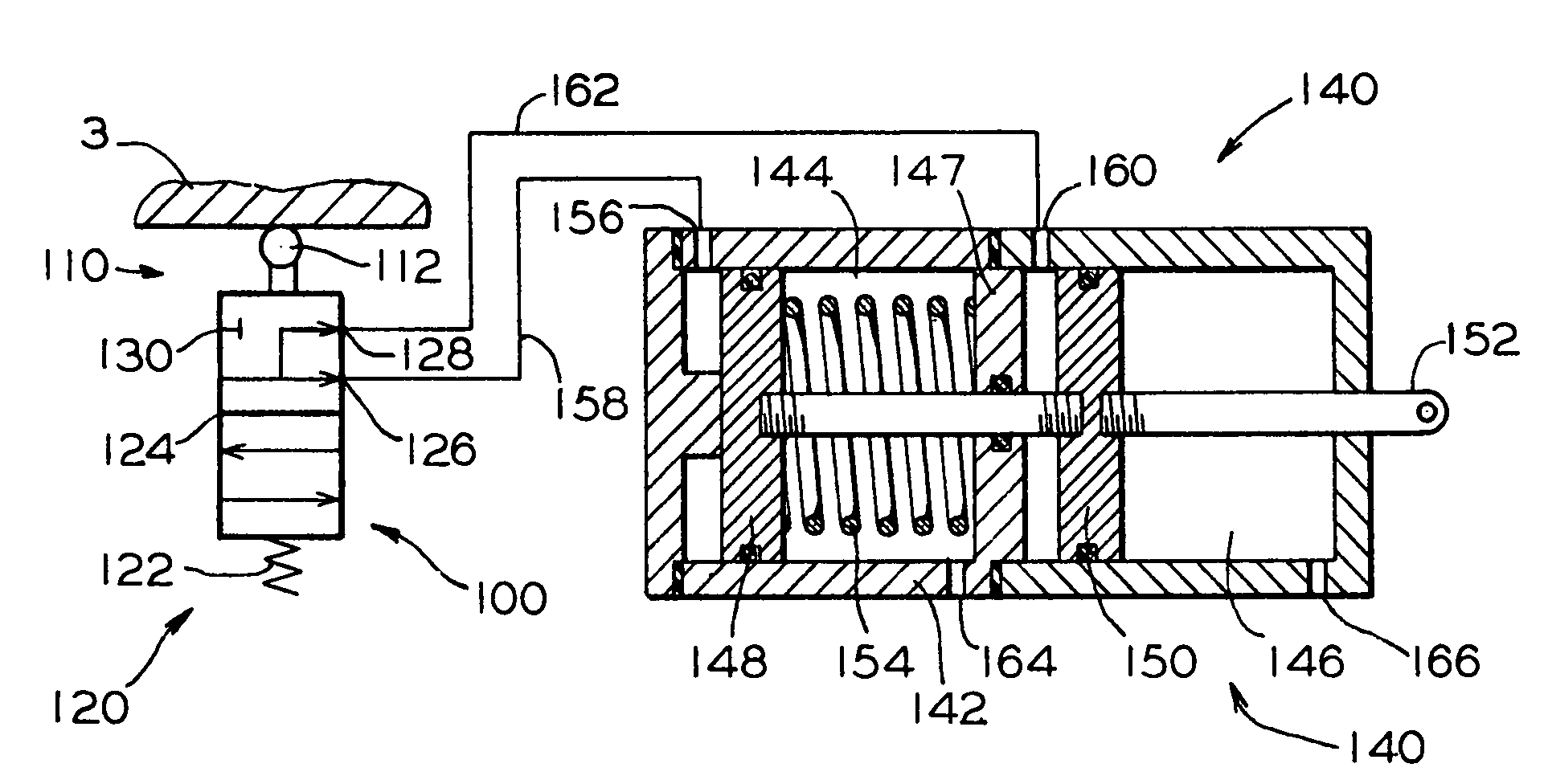

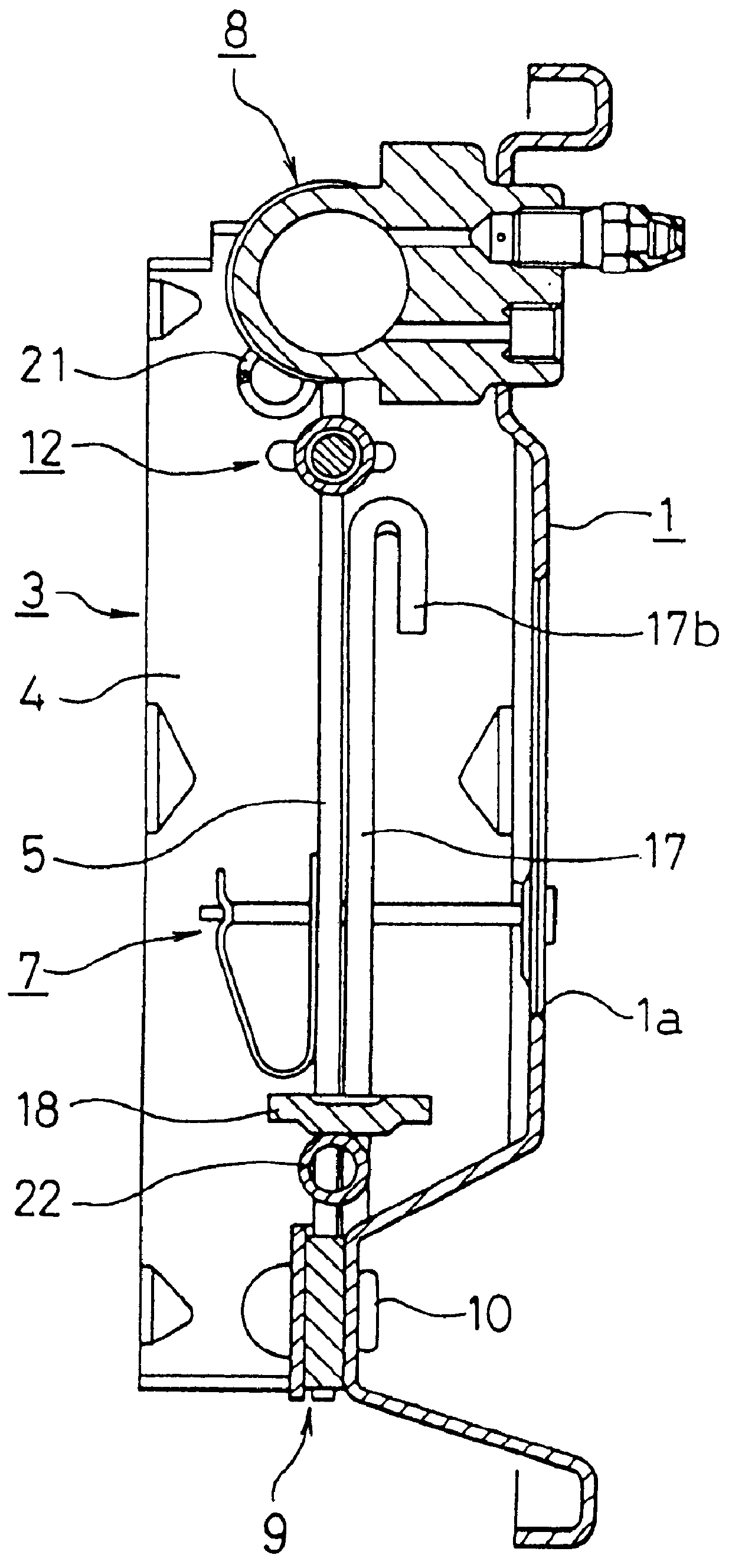

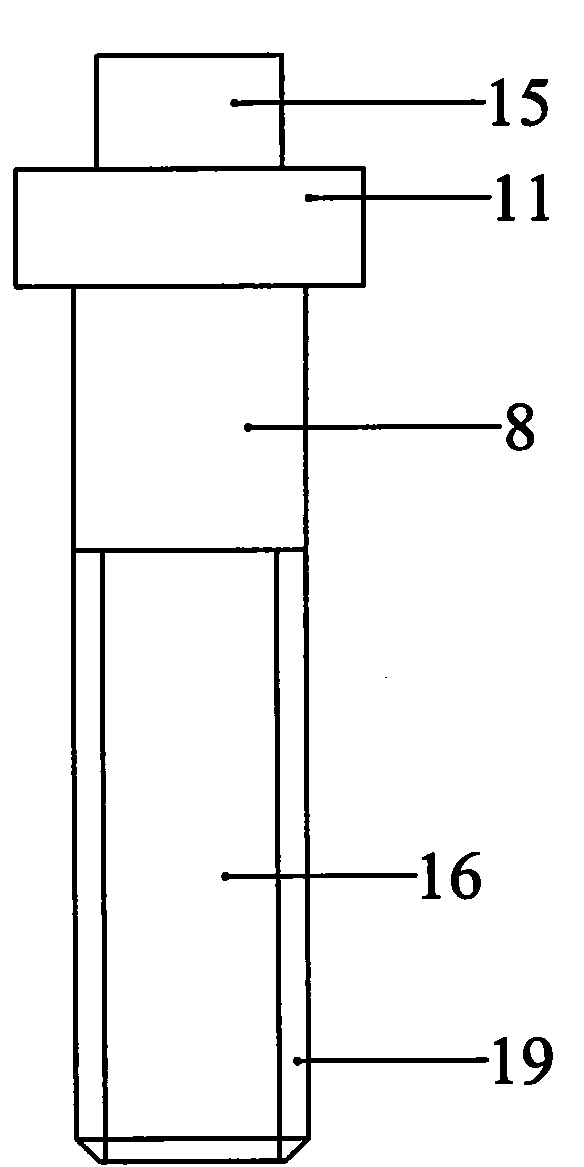

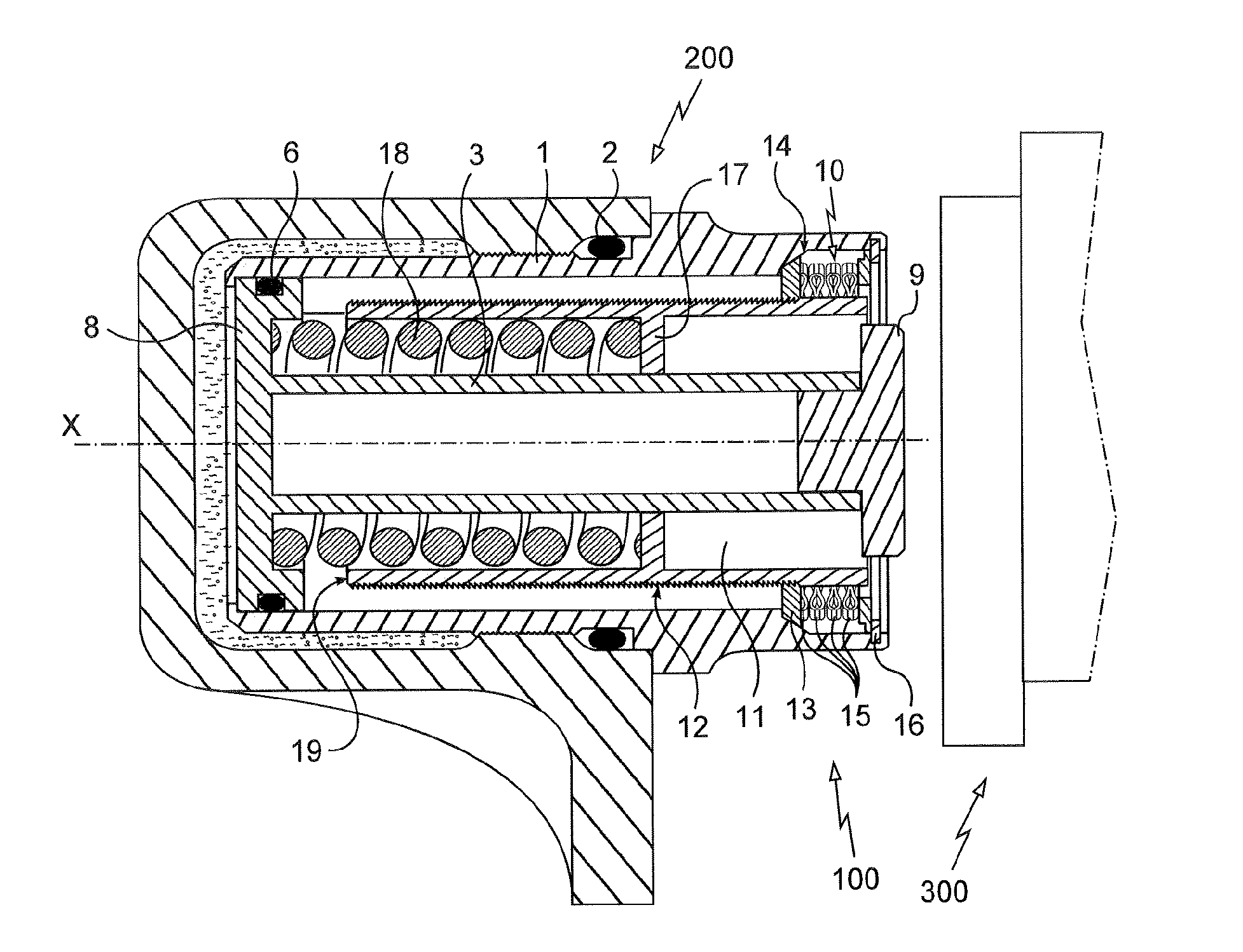

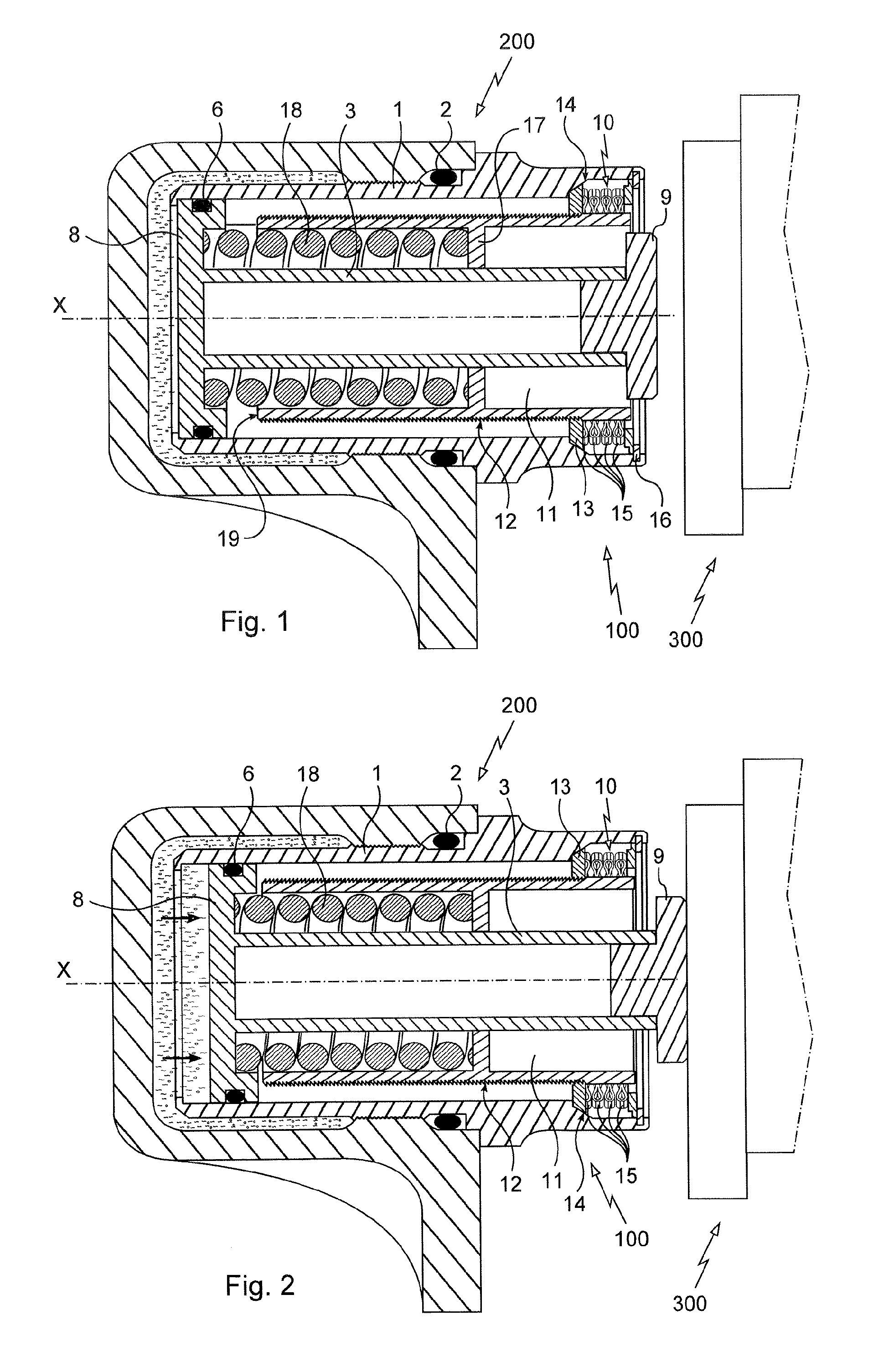

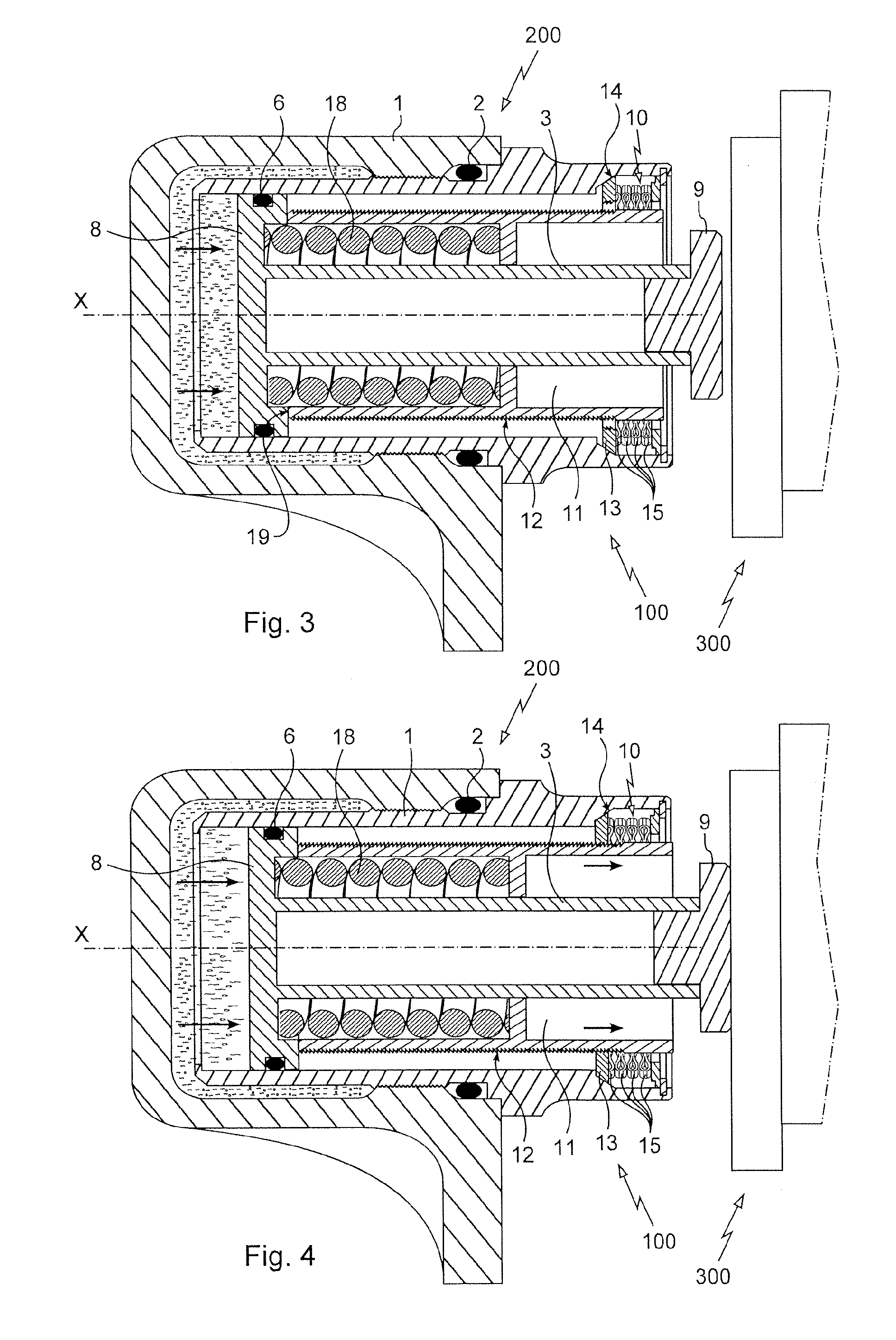

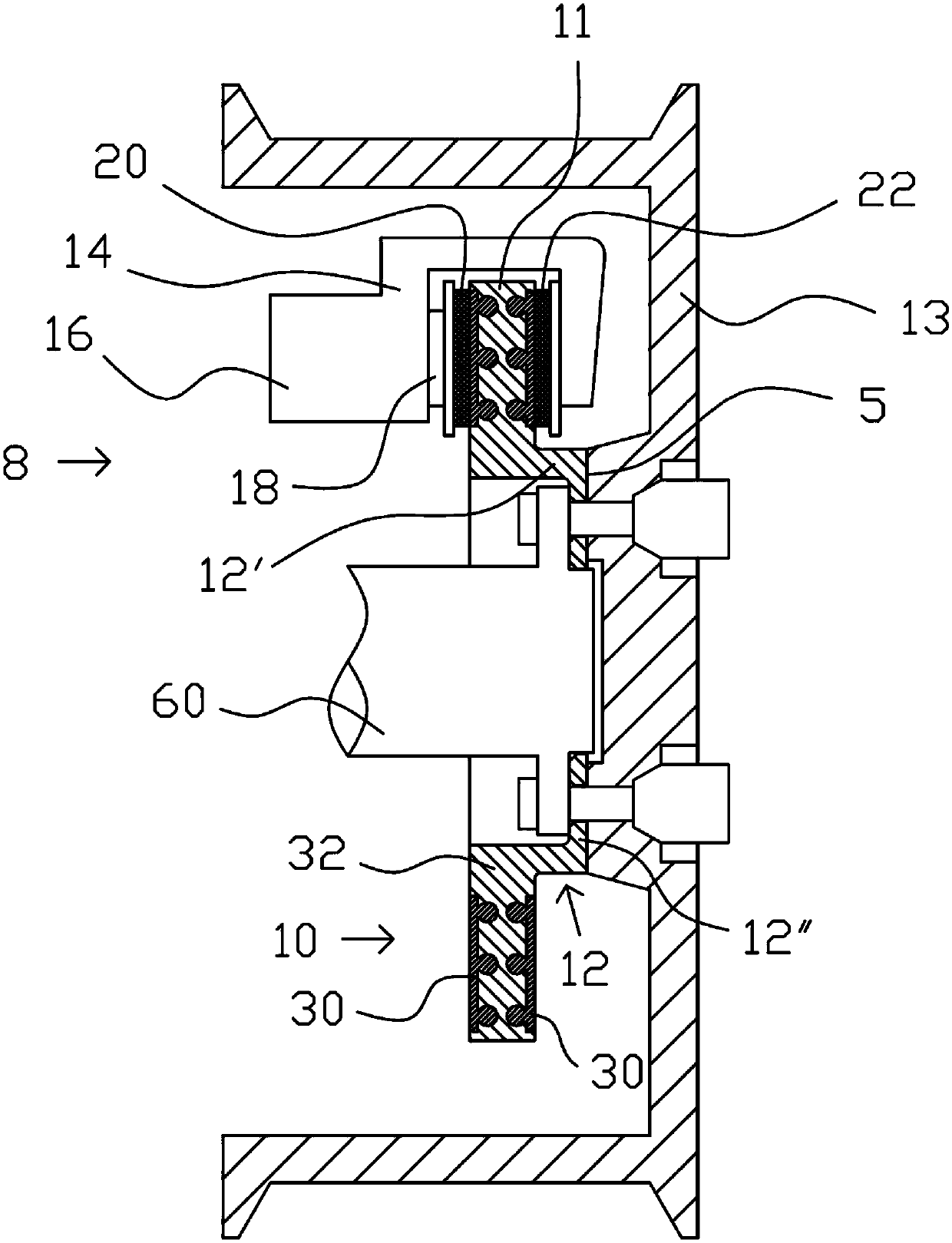

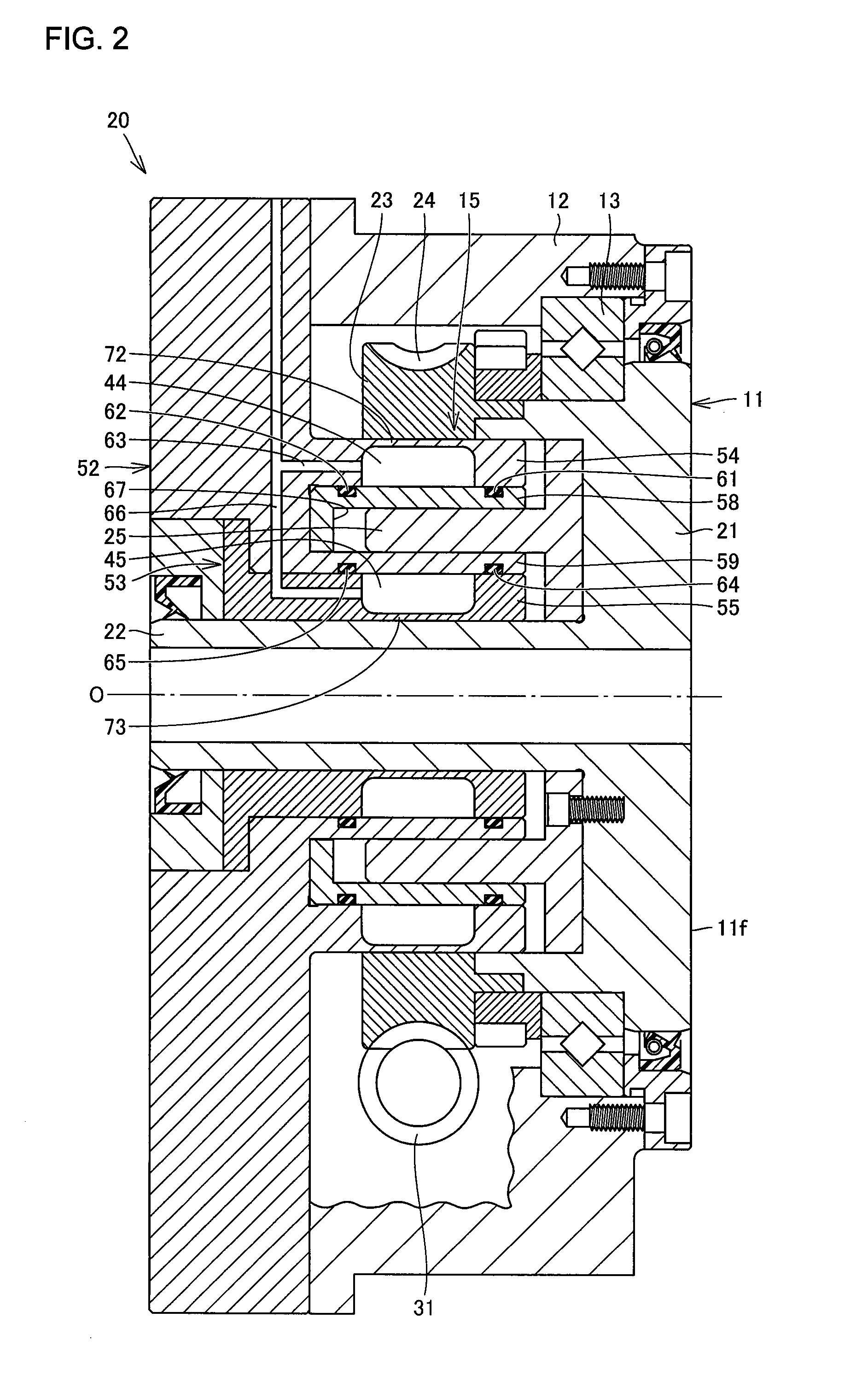

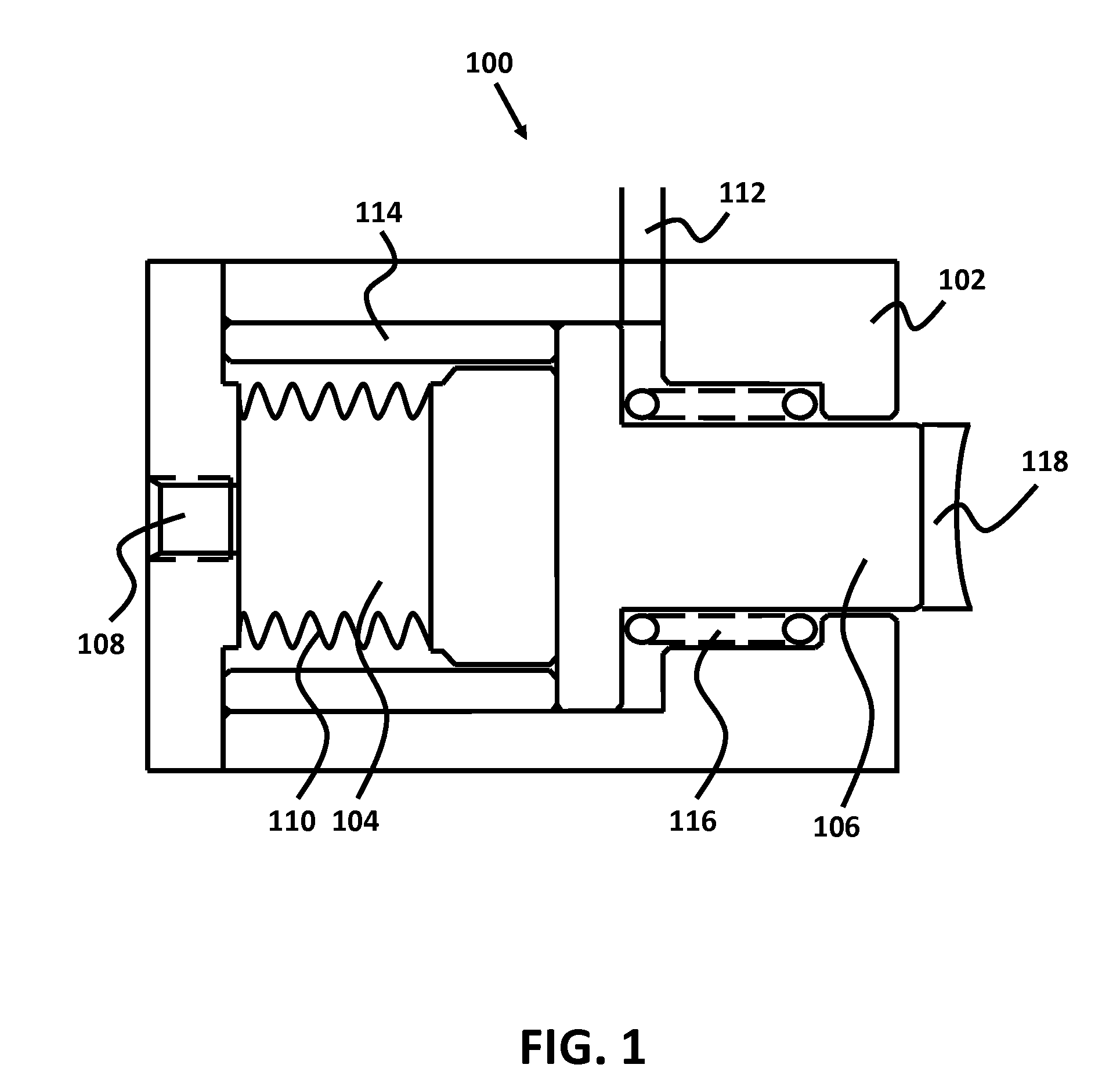

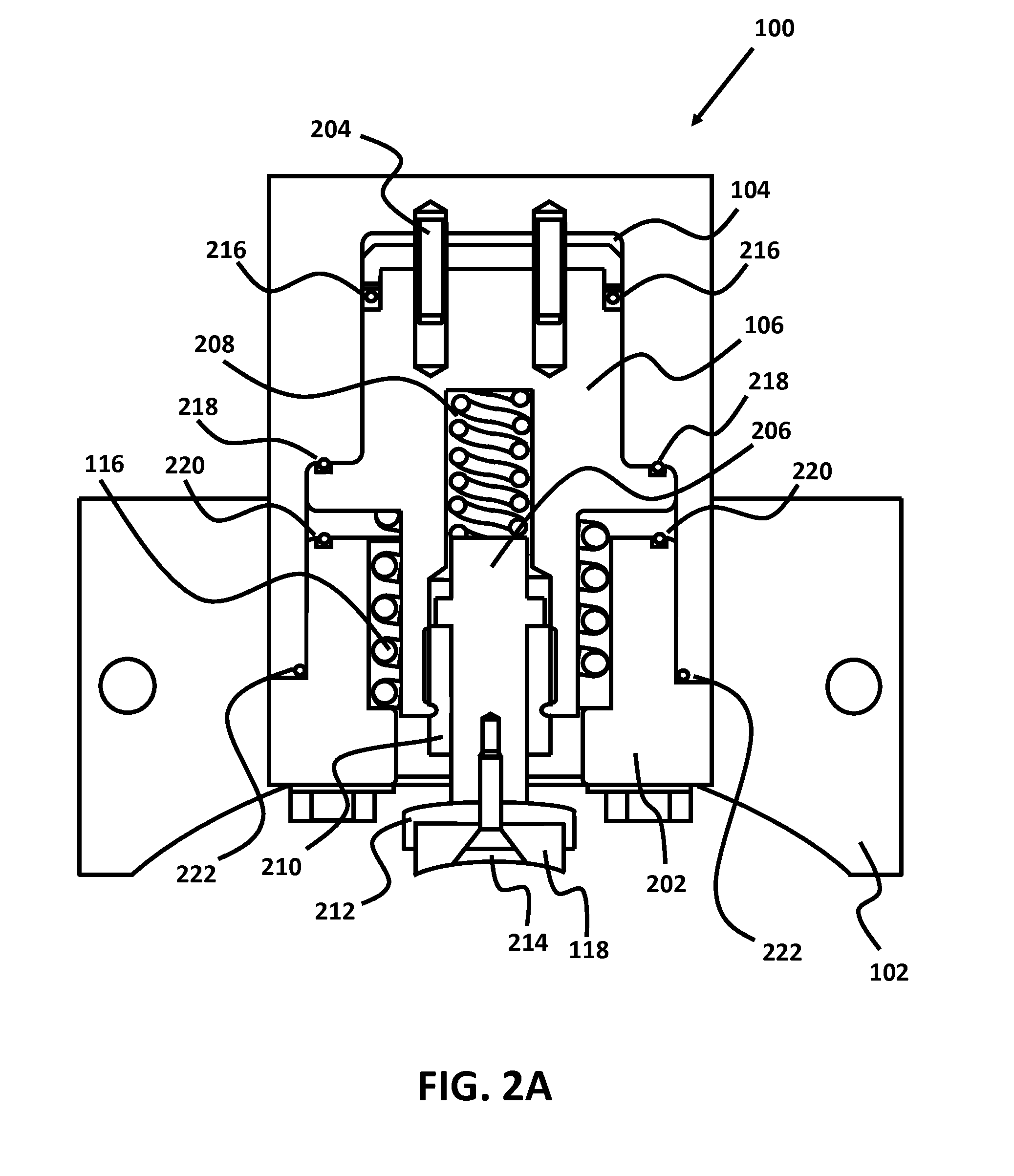

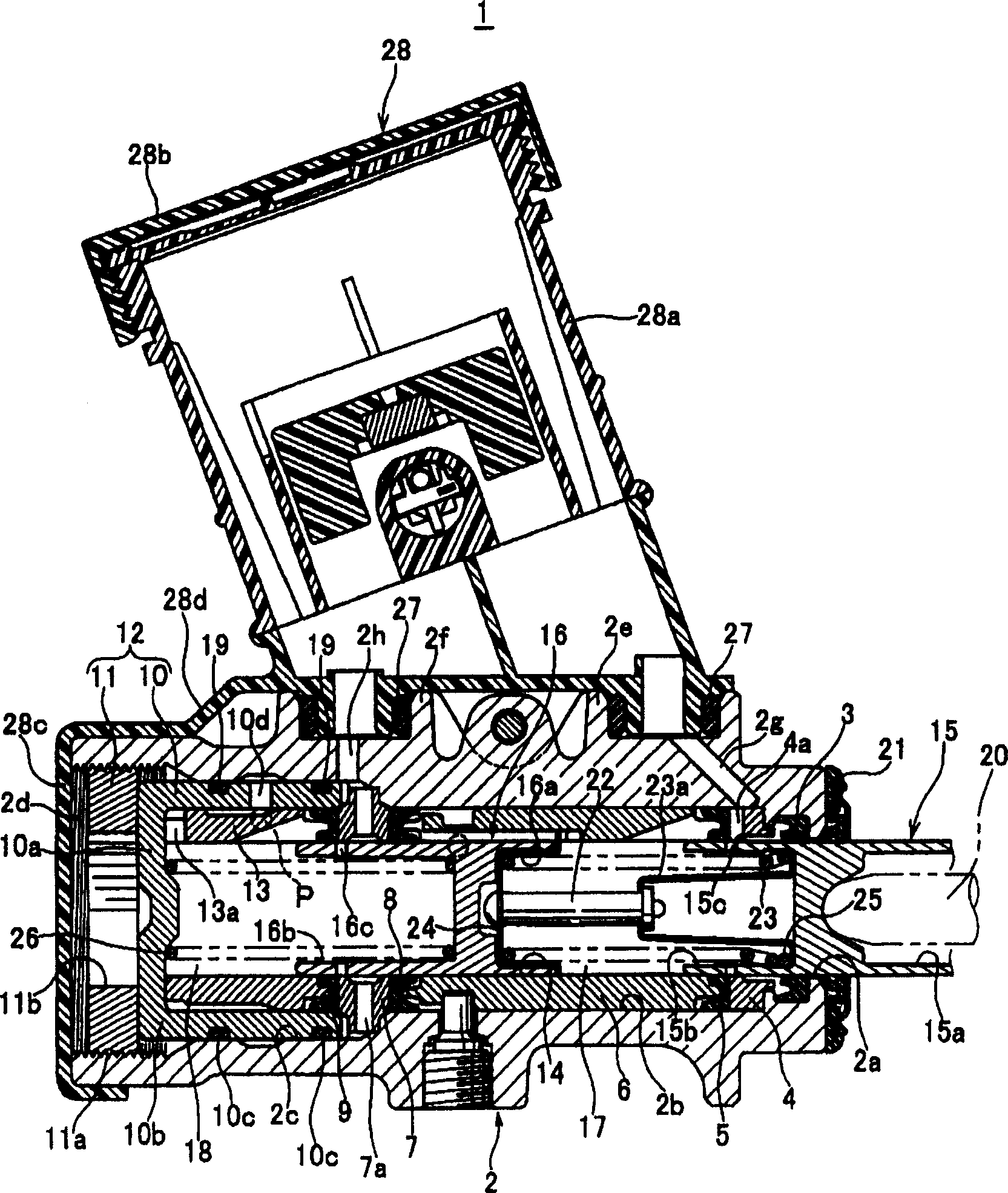

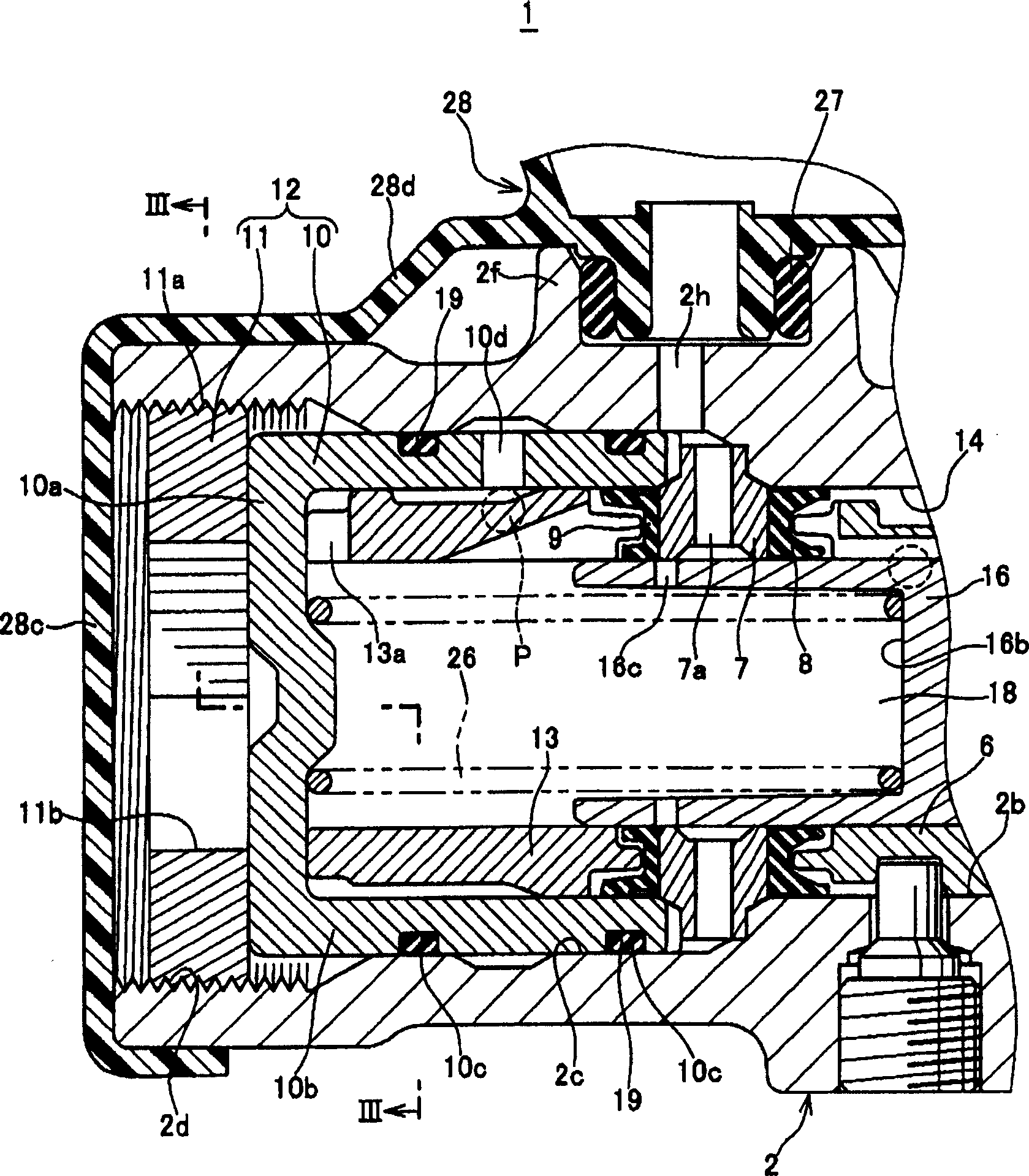

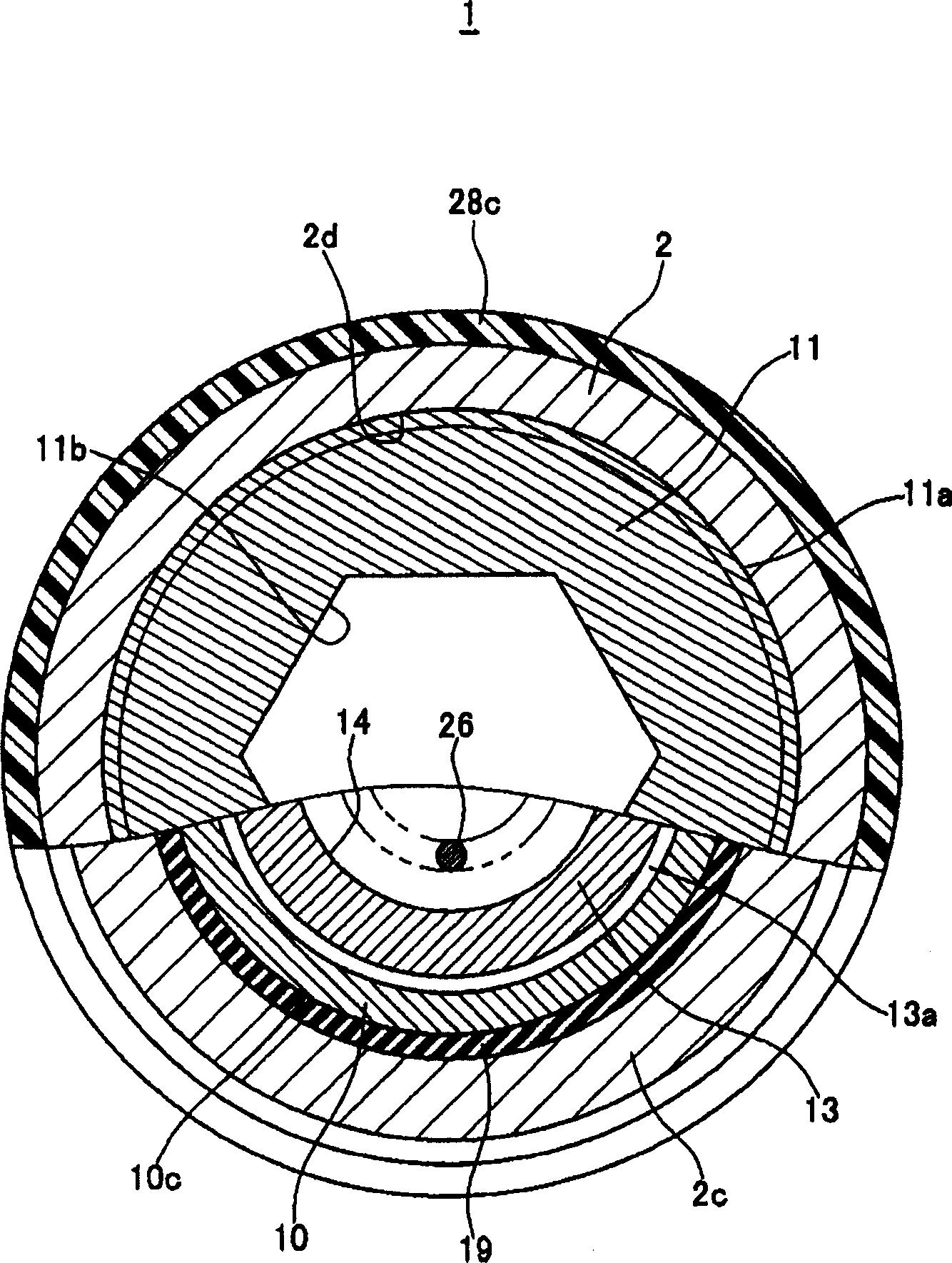

Brake actuator for aircraft wheel hydraulic brake

InactiveUS20160176518A1Fluid actuated brakesAircraft brake actuating mechanismsActuatorHydraulic brake

The invention relates to a brake actuator for an aircraft hydraulic brake, which is intended to be added into one of the cavities of a brake ring, the actuator comprising:a liner (1) designed to be housed sealingly in the cavity of the ring;a piston (3) mounted to slide sealingly in the liner along an axis of sliding so as to apply a braking force when a fluid is introduced under pressure into the cavity;a wear compensation device (10) which defines a position to which the piston retreats into the liner by means of a mobile stop (11; 111) that can be moved forward by the piston as a braking force is applied;an elastic return member (18) returning the piston towards the retracted position bearing against the mobile stop;according to the invention, the mobile stop is associated with a notched indexing member (13) allowing the mobile stop to move under the thrust of the piston, but preventing any return motion of the mobile stop with respect to the liner.

Owner:SAFRAN LANDING SYSTEMS

Drum brake system and device

InactiveUS6065571AFeel discomfortEliminate riskFluid actuated drum brakesBrake actuating mechanismsDriver/operatorSTI Outpatient

A drum brake device is provided in which a stroke before effectuating the parking brake effect of the brake shoes is restricted so that any disconcerting feeling to the driver and any delay in effectuating the parking brake when in an emergency situation are eliminated. The drum brake device includes a pair of the brake shoes 20, 21, a pivot lever 36 pivotally provided at one of the two brake shoes 21, a shoe clearance adjustment device provided between one end of the pivot lever 36 and one end of the brake shoe 20, and a strut provided between the other end of the pivot lever 36 and one end of the brake lever 28, wherein the braking force is transferable between the two brake shoes 20, 21 through the connection with the pivot lever 36. This produces a duo-servo type of brake device. The brake shoe 21 functions as a trailing shoe in which the lining wears slower when the service brake is in operation.

Owner:NISSHINBO IND INC

Disk brake assembly, brake rotor and manufacturing method thereof

Disclosed is an automotive disk brake assembly installed in an automobile having a wheel. The assembly includes a floating caliper supporting inner and outer brake pads and a brake rotor having a disk, a hat, wherein the hat is bolted to the wheel. A hydraulic cylinder pushes the inner brake pads into the disk surface, thereby causing the floating caliper to move so as to bring the outer brake pad into contact with the disk surfaces. Finally, the rotor is made of a material having a thickness and a coefficient of thermal expansion and conductivity, such that a complete 100 kilometer per hour, 0.9 gross vehicle weight braking causes the disk to expand in thickness by at least 0.10 mm and to cool to shrink in thickness, from its expanded thickness, by at least 0.05 mm within 60 seconds of cessation of braking, in an ambient temperature of less than 30 DEG C. The invention further provides a brake rotor and a manufacturing method thereof.

Owner:黄小弟 +1

Symmetric master cylinder lever for a hydraulic disc brake

InactiveUS20070187191A1Avoid enteringEliminate riskSpringsFluid braking transmissionMaster cylinderEngineering

A hydraulic disc brake master cylinder having a bar clamp attached to a master cylinder housing allowing the attachment of the master cylinder to a handle bar along a longitudinal clamp axis. The master cylinder also includes a cylinder wall associated with the master cylinder housing extending axially along the cylinder axis. The cylinder axis is not parallel to the longitudinal clamp axis. This embodiment further includes a reservoir for hydraulic fluid which includes a first wall which first wall includes only a radial portion of the cylinder exterior. The reservoir also includes an elastomeric diaphragm. The cylinder axis and the longitudinal clamp axis lie in a plane substantially bisecting the first wall. Thus, the symmetric master cylinder lever may be disposed on either the right or left portion of a handle bar without effecting operation of the master cylinder lever by a user.

Owner:SRAM CORPORATION

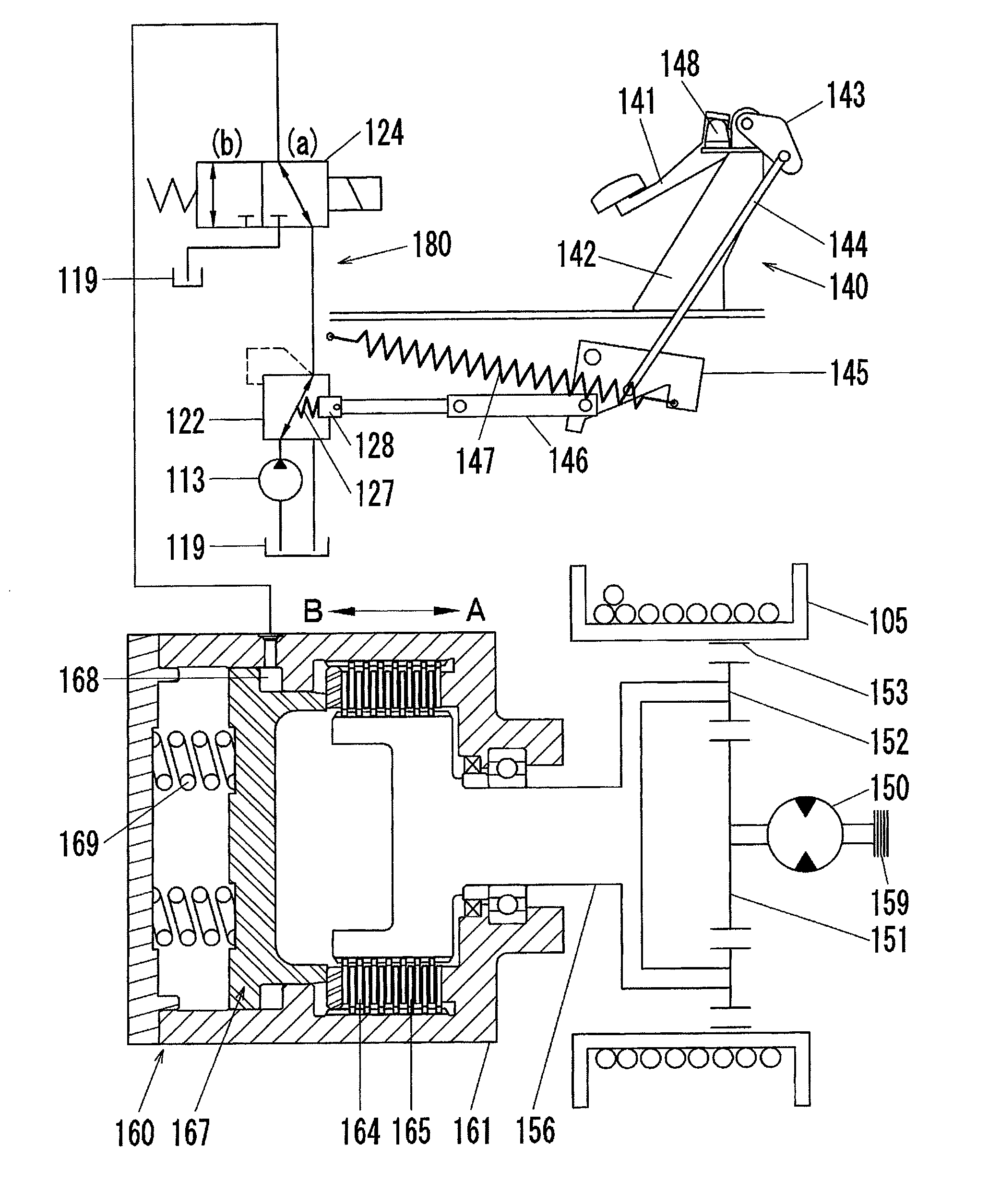

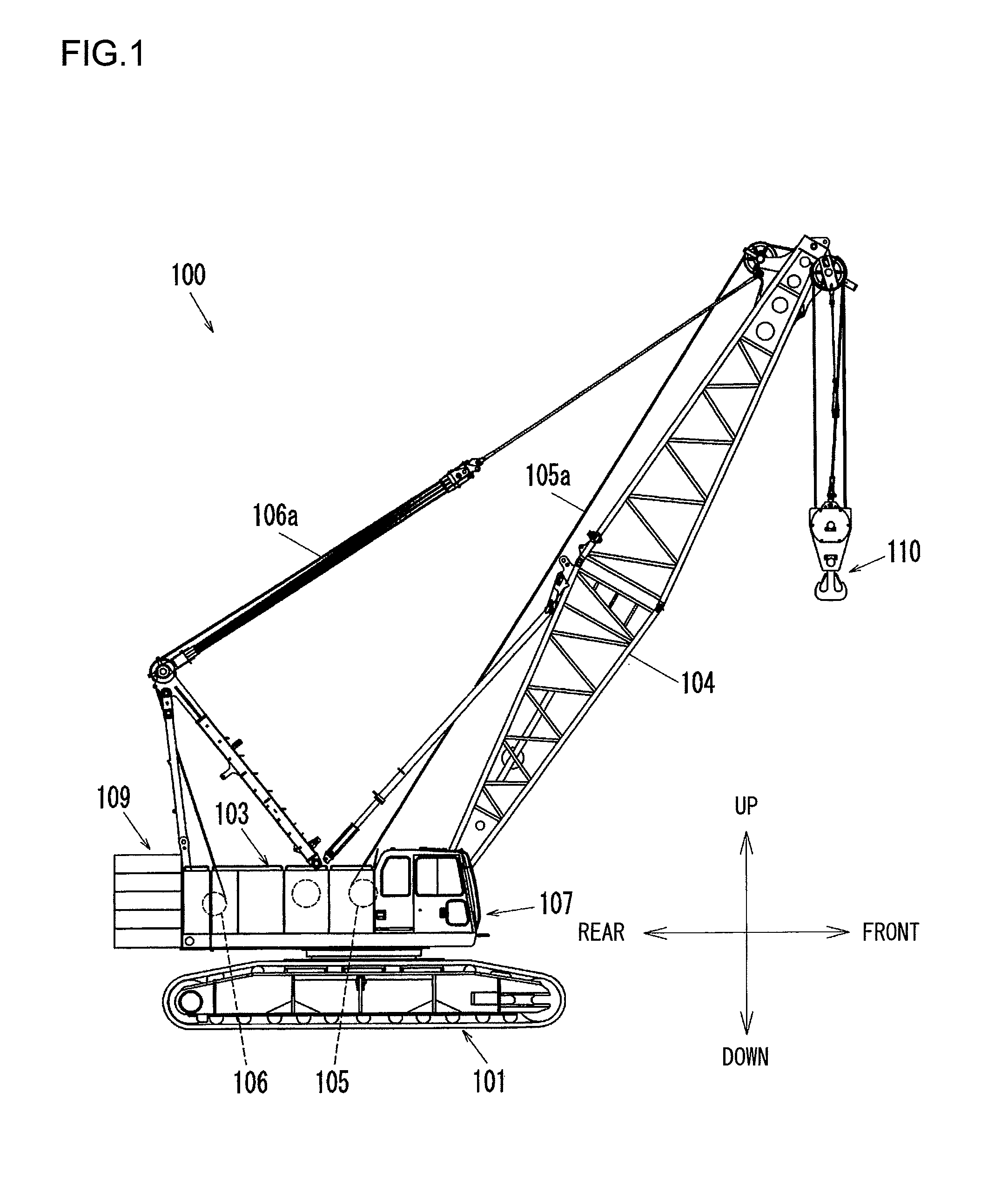

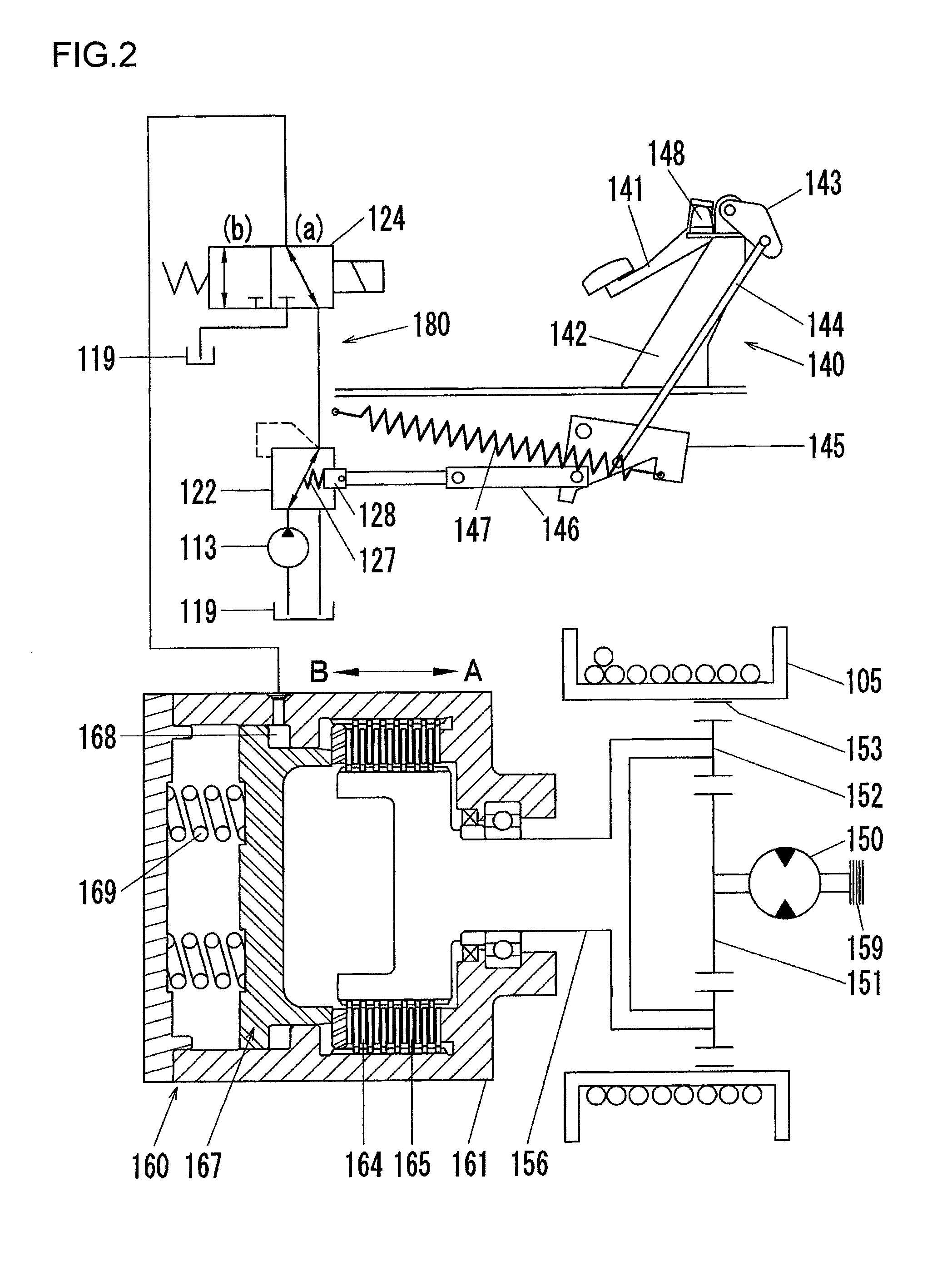

Winch Braking Device

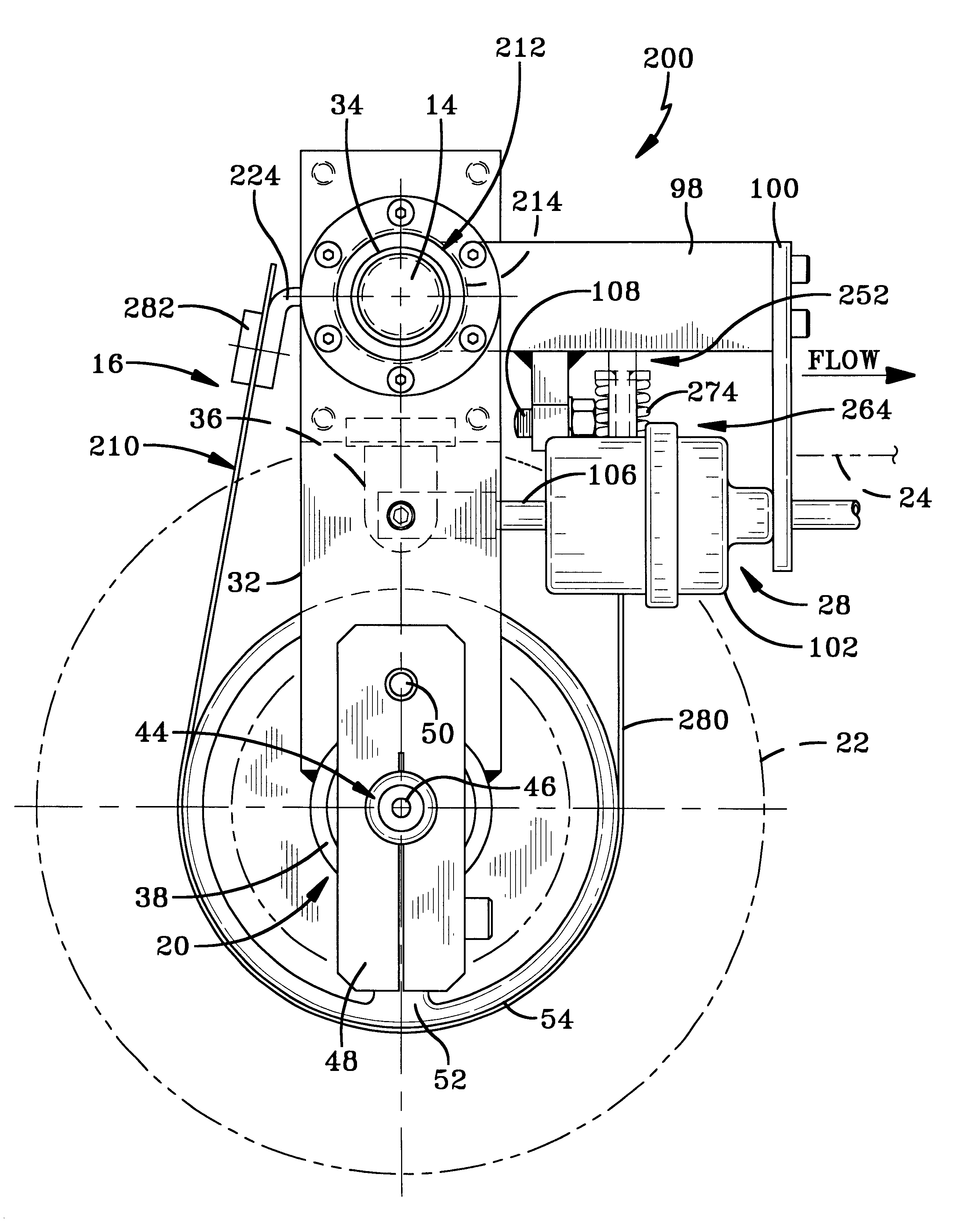

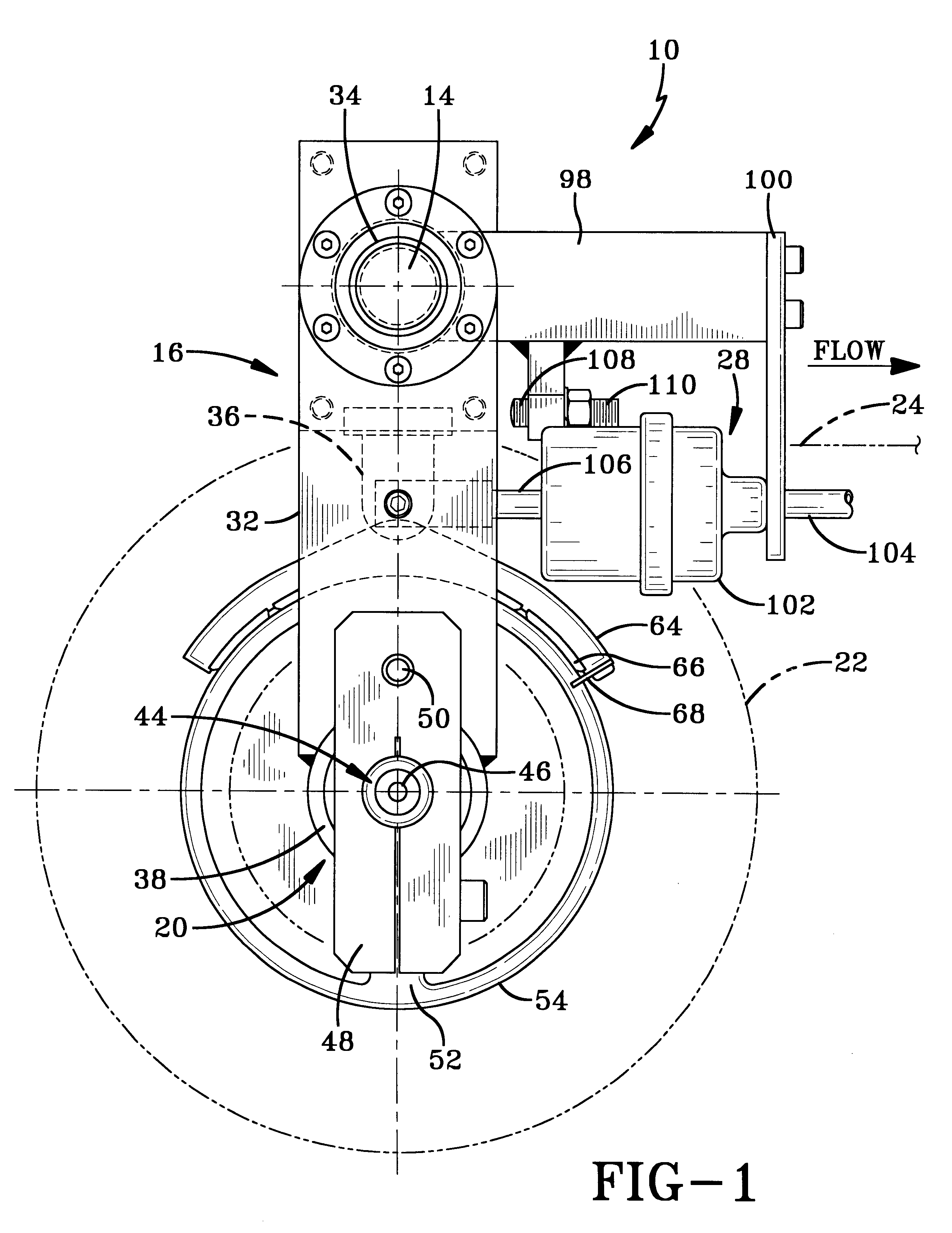

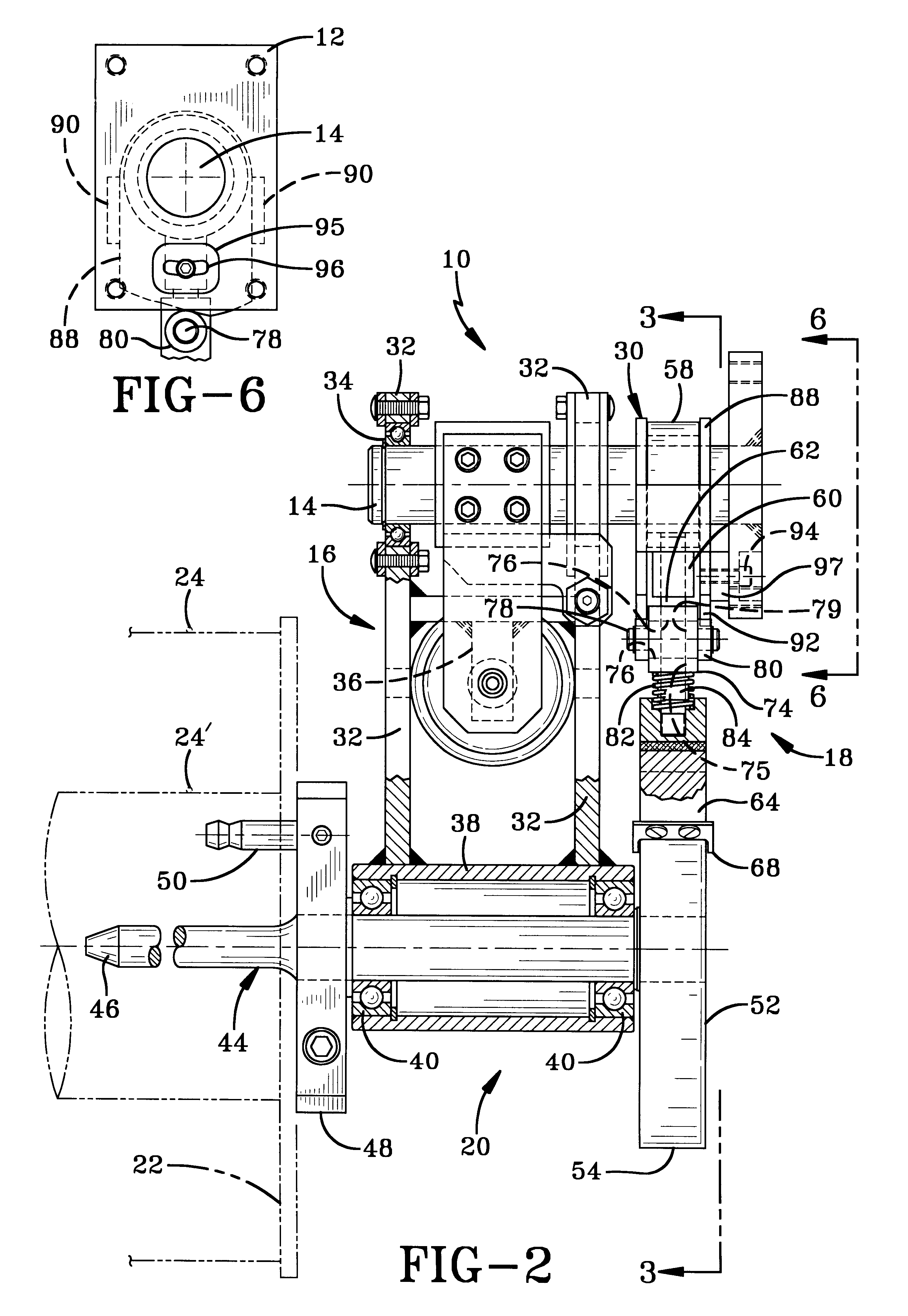

ActiveUS20140083806A1Avoiding characteristicFluid actuated drum brakesHoisting equipmentsCentre of rotationEngineering

A winch braking device includes: a brake; a brake pedal; a reaction force-imparting element that imparts a reaction force to the brake pedal; a rotation link that rotates by interlocking with the foot operation at the brake pedal; a brake valve linked to the rotation link, that applies a secondary pressure to the brake in response to the foot operation at the brake pedal; and a tension spring, with one end thereof attached to the vehicle body at a predetermined position and another end thereof attached to the rotation link, that applies a force to the brake pedal along a direction opposite a direction of the foot operation. As the foot operation is performed at the brake pedal, the tension spring extends and a shortest distance between a rotational center of the rotation link and a central axis of the tension spring becomes smaller.

Owner:SUMITOMO HEAVY INDUSTRIES CONSTRUCTION CRANE CO LTD

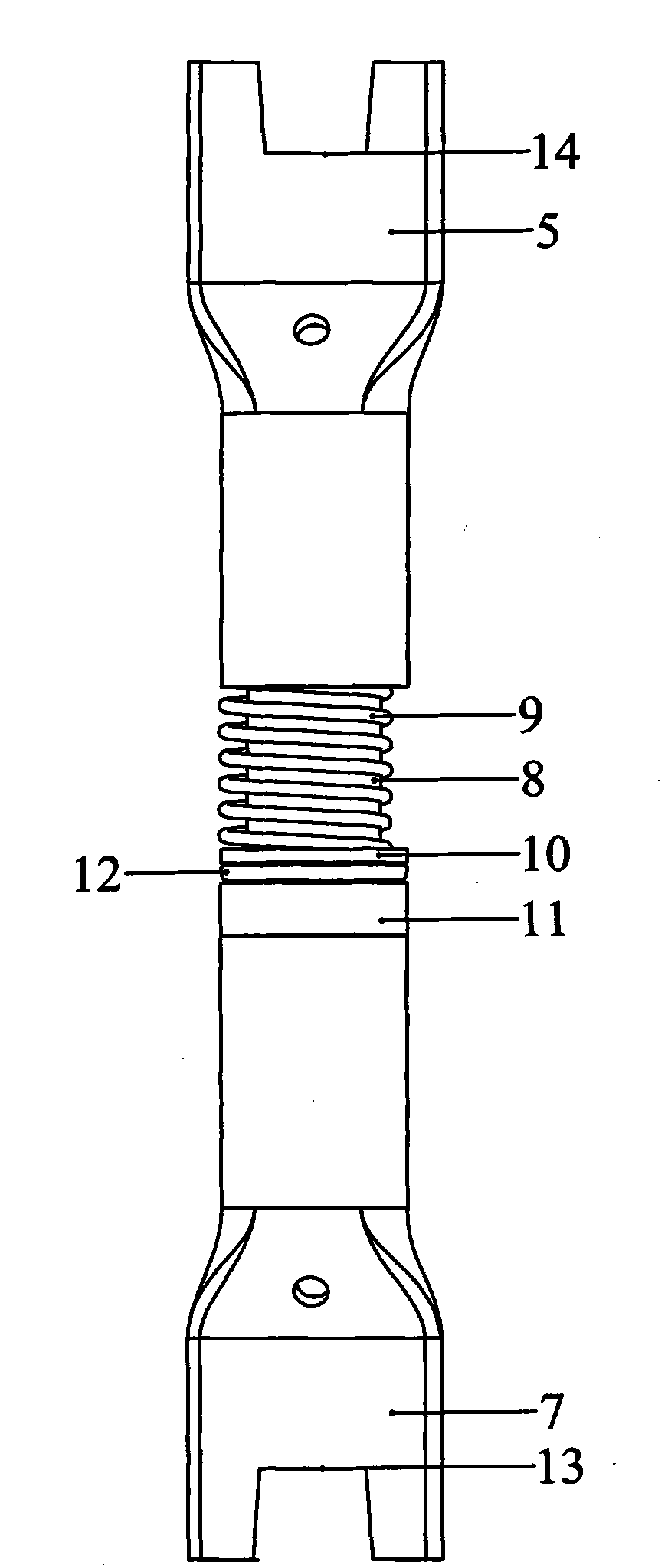

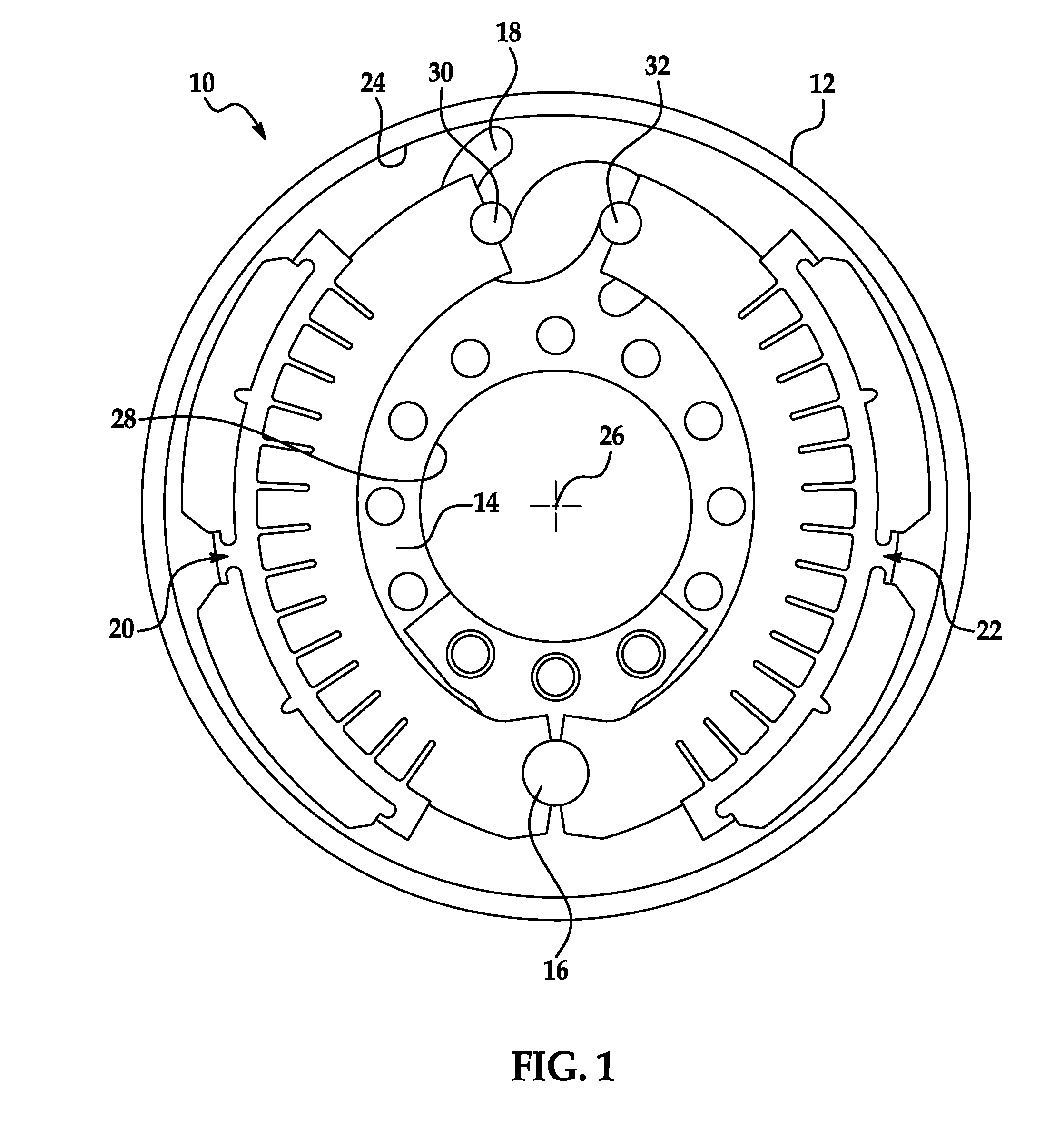

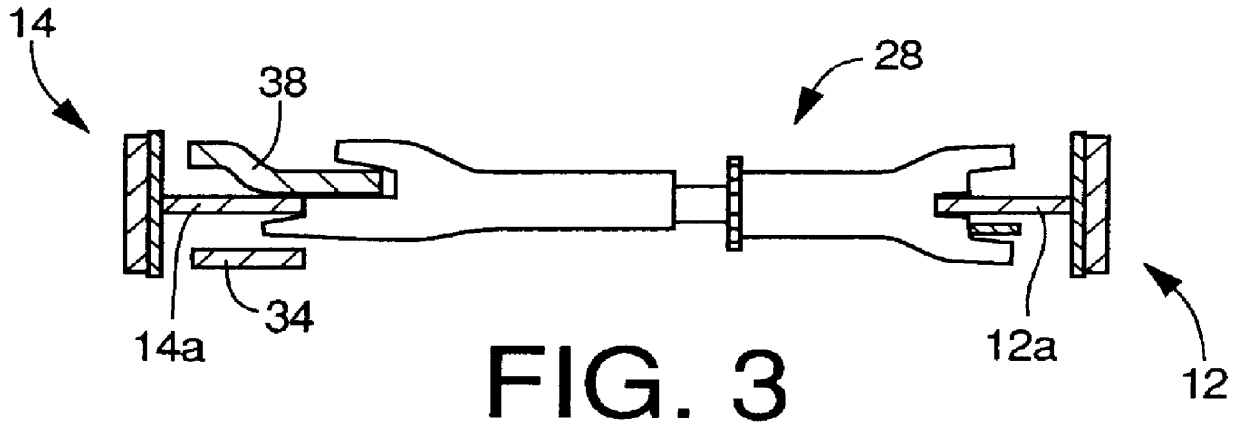

Automatic shoe clearance adjustment apparatus

InactiveUS20060219493A1Reduce component countReduce manufacturing costAxially engaging brakesFluid actuated drum brakesEngineeringBrake shoe

To reduce the number of components of the automatic shoe clearance adjustment apparatus and to improve the ease of assembly of the same, the proximal portion of the driving member is fixed on the strut. The operating portion and the arm of the driving member are integrally formed therewith is placed between the brake shoe and the strut. The operating portion together with the arm of the driving member are moved (rotated) so as to follow the movement of the brake shoe by utilizing the resilient force of the driving member, and the pawl at the end of the arm drives the adjustment teeth of the strut to extend the entire length of the strut.

Owner:NISSHINBO IND INC

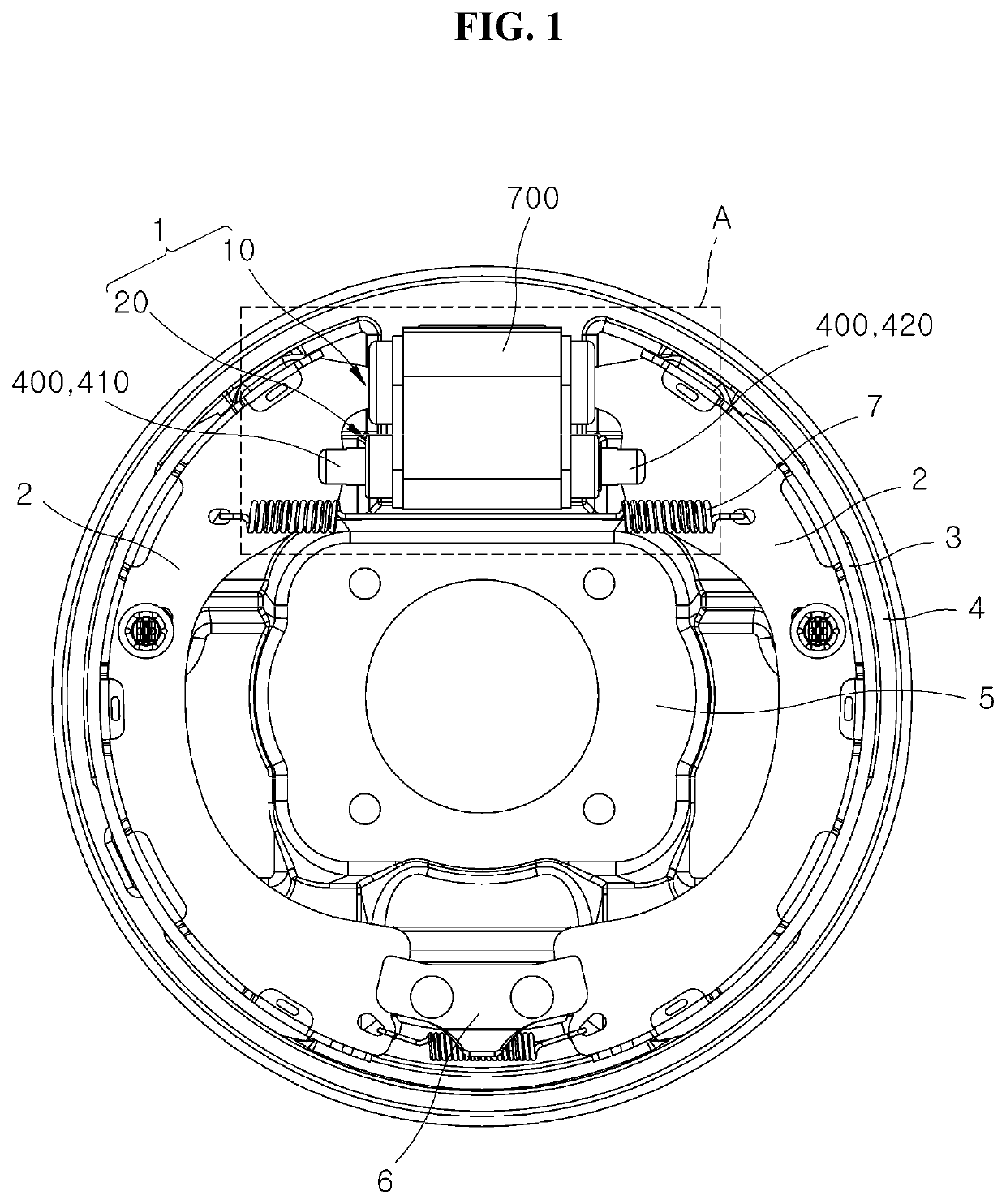

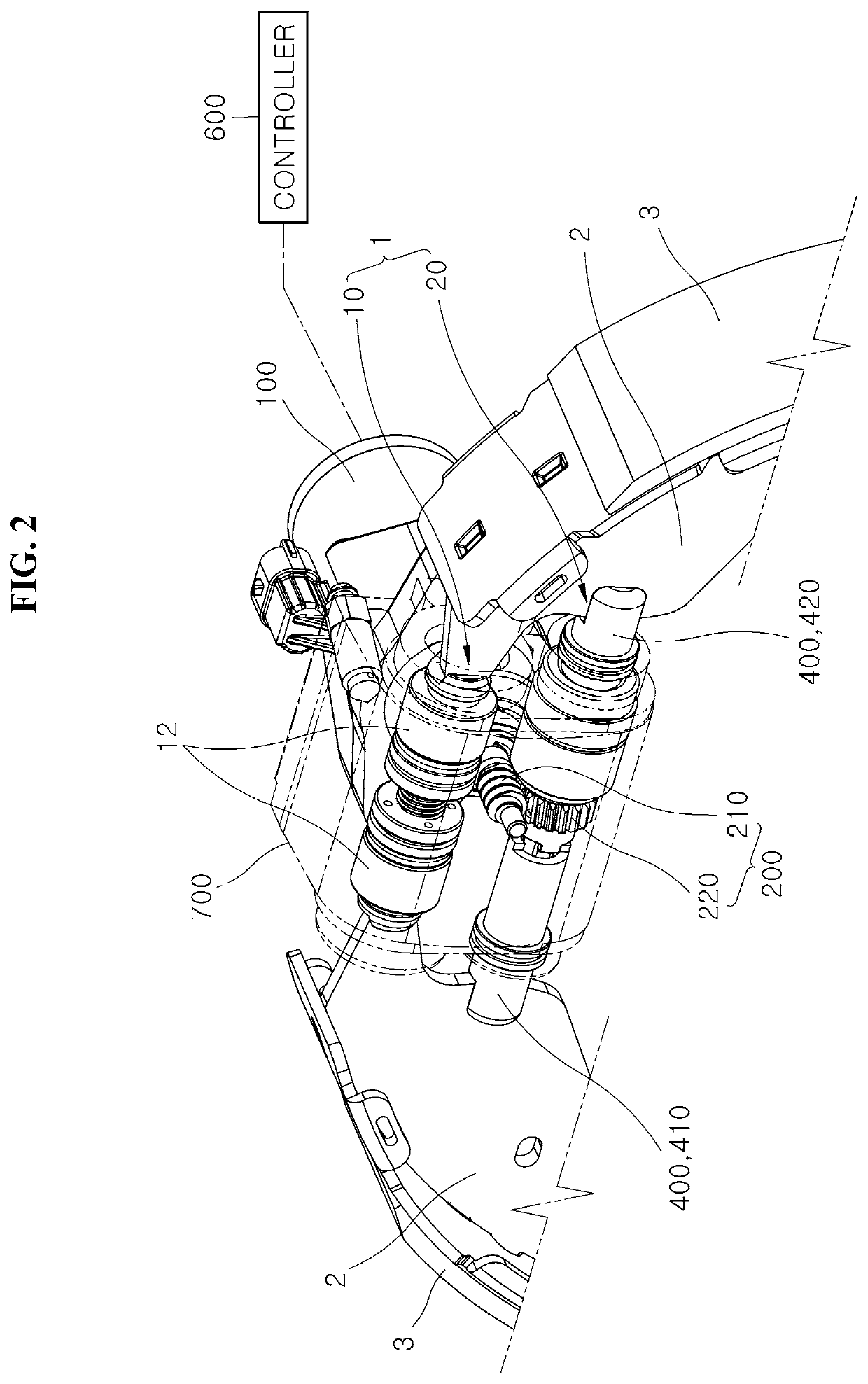

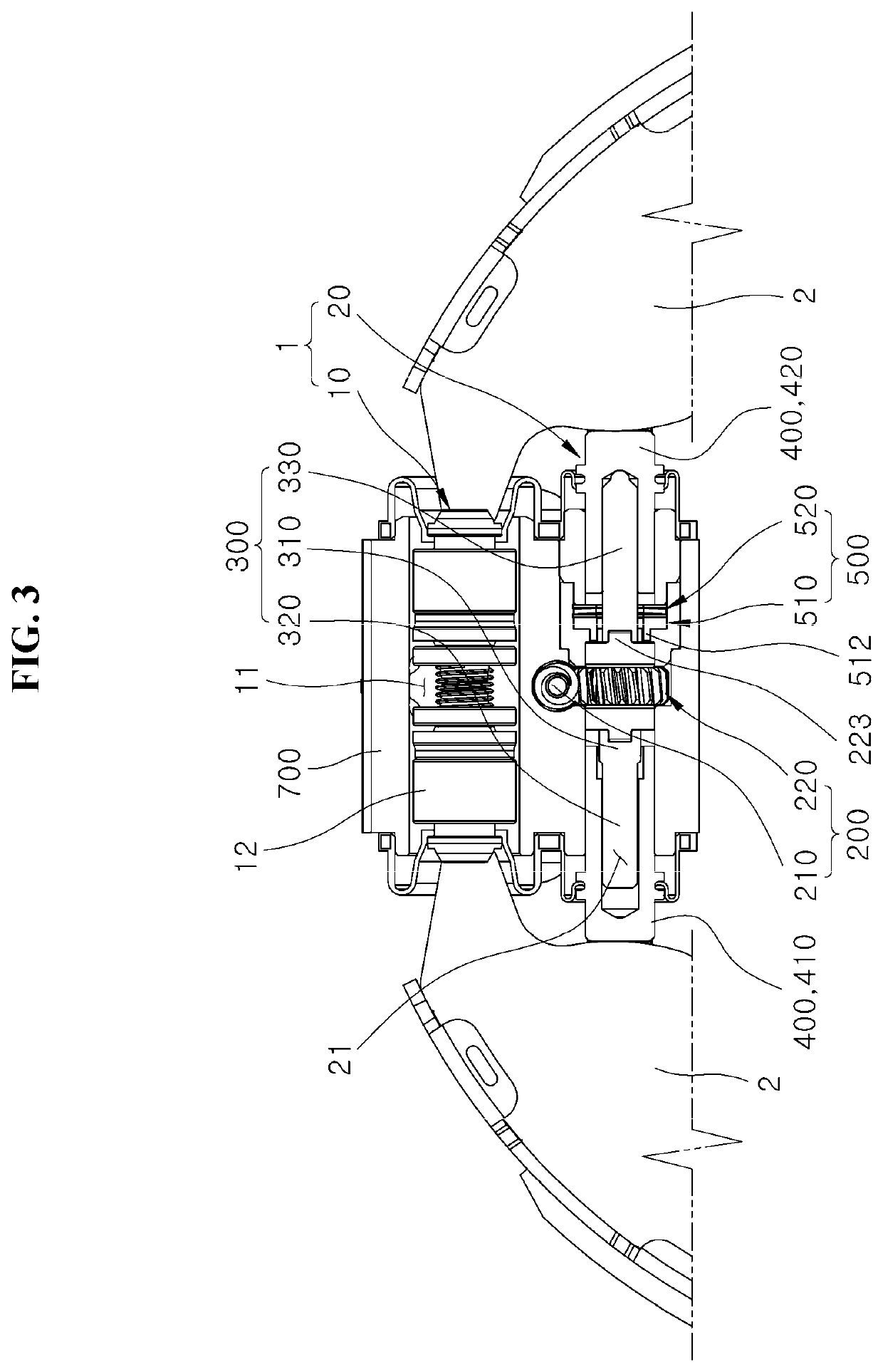

Electric parking brake device

ActiveUS20200055505A1Simple structureRespond effectivelyBraking action transmissionGearing controlElectric parking brakeGear wheel

An electronic parking brake device may include: a gear unit driven by an actuator; a rotating rod connected to the gear unit; a push rod unit configured to pressurize one or more shoes while moved in connection with the rotating rod; a clutch unit disposed to interfere with a moving line of the gear unit, and configured to apply a rotational load to the gear unit while abutting on the gear unit, when the gear unit is rotated at a present angle; and a controller configured to control the operation of the actuator according to the load applied to the actuator.

Owner:HYUNDAI MOBIS CO LTD

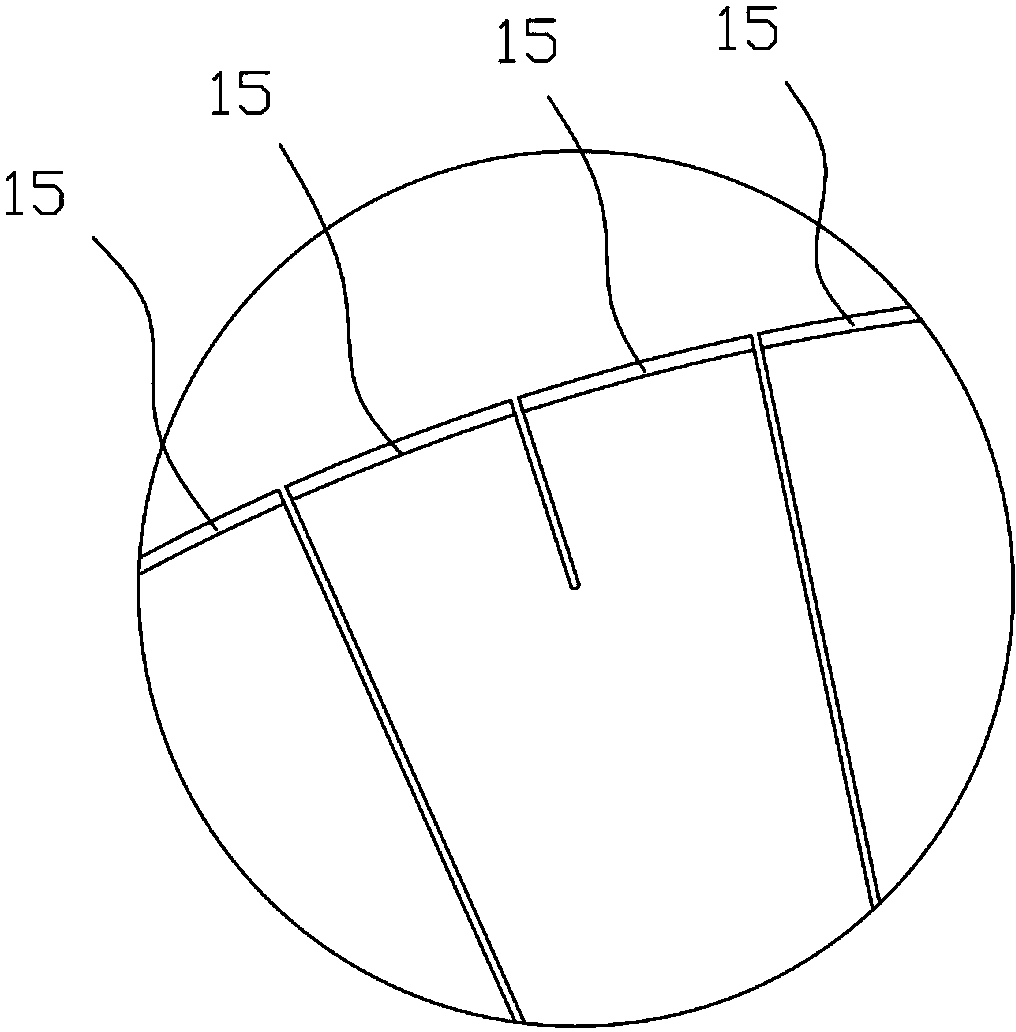

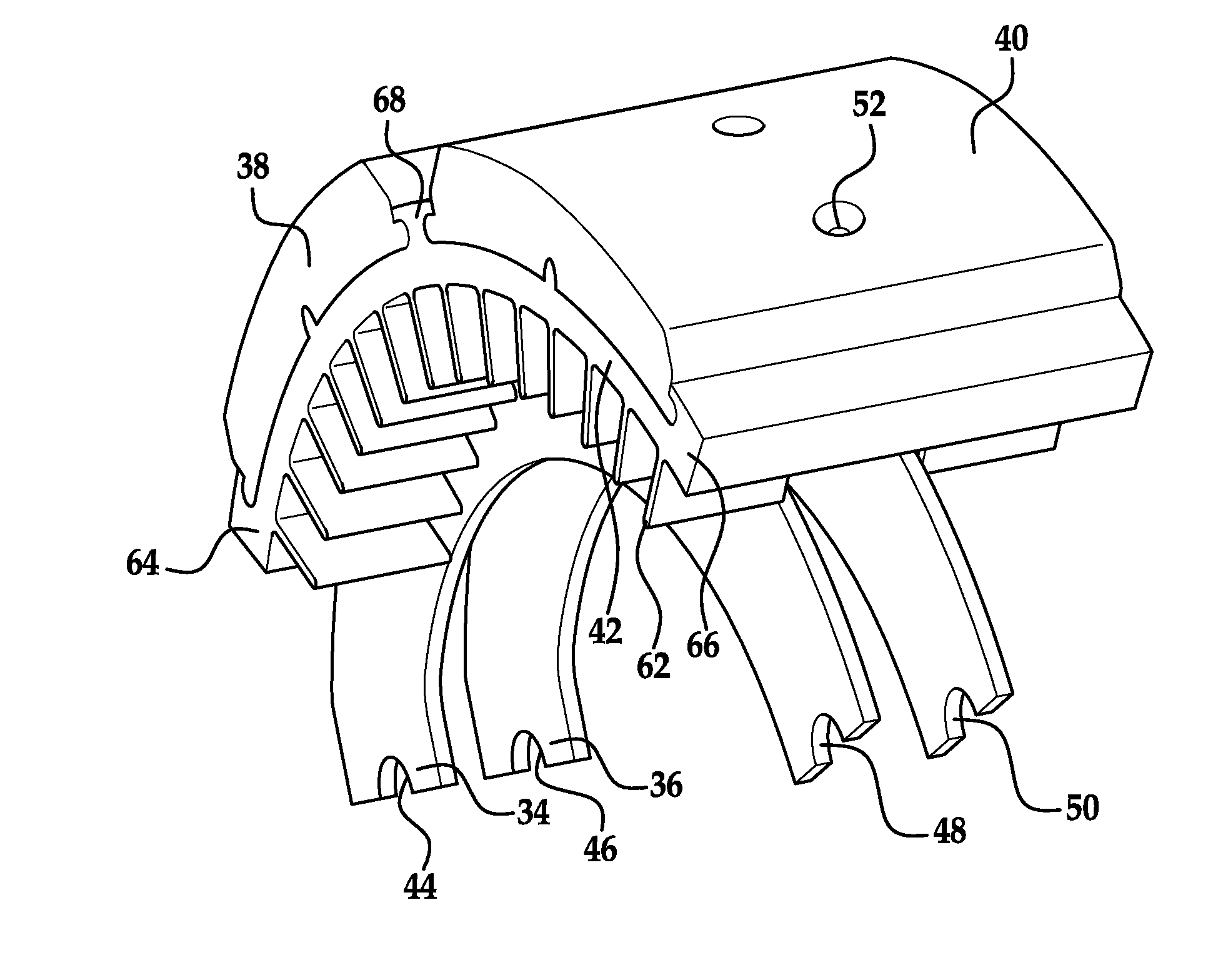

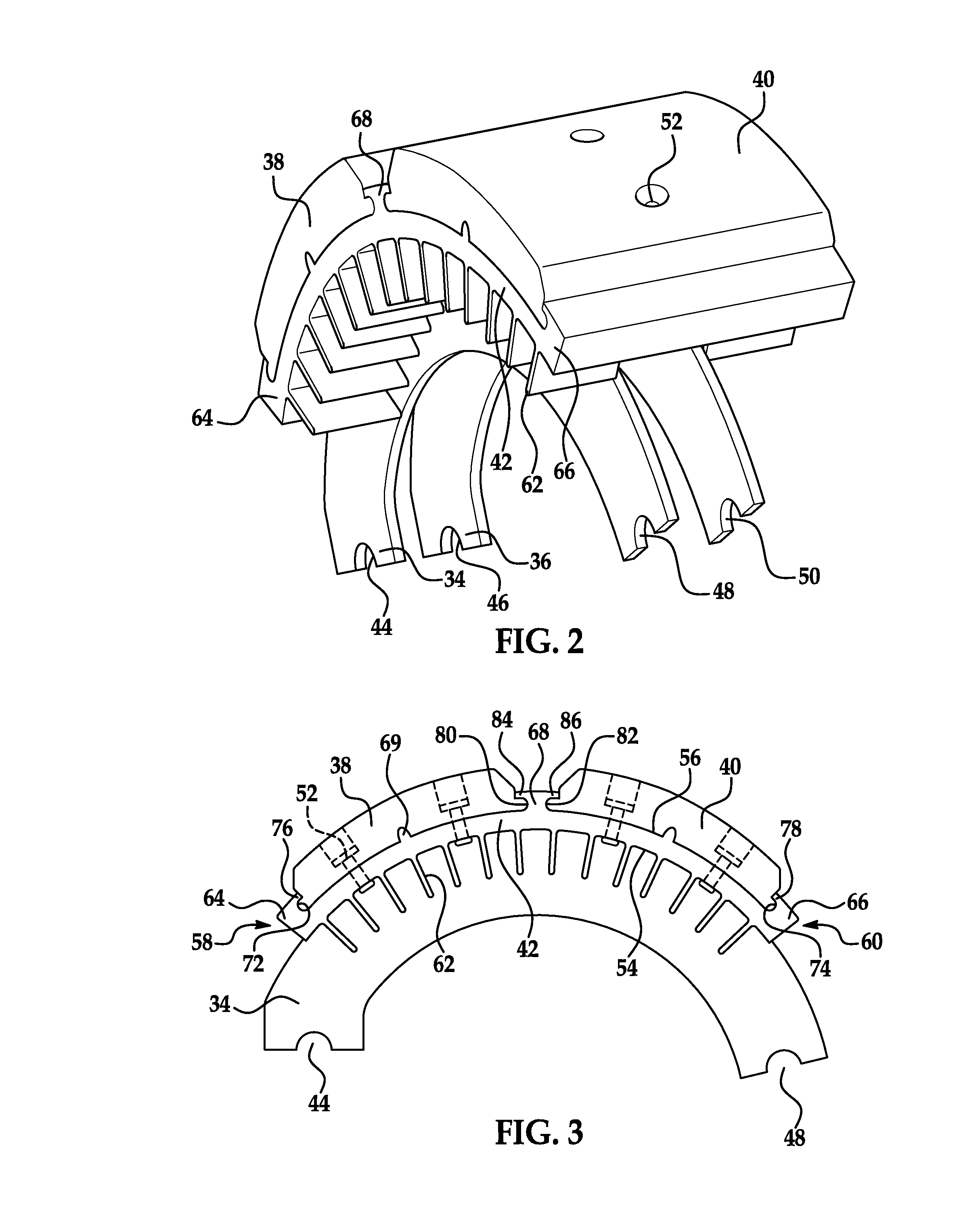

Extruded table for a brake shoe

InactiveUS20140116823A1Easy to replaceReduce stepsBraking membersFluid actuated drum brakesEngineeringBrake lining

A brake shoe for a drum brake includes an arcuate brake table defining radially inner and outer sides. First and second webs are disposed on the radially inner side of the brake table and configured to support the brake table. One or more brake linings are disposed on the radially outer side of the brake table. In one embodiment, the brake table defines a plurality of fins projecting radially inwardly from the radially inner side of the brake table, each of the plurality of fins having a length in a radial direction. In another embodiment, the brake table is a unitary body and is configured at first and second ends and a point intermediate the first and second ends to engage first and second brake linings and prevent circumferential movement of the first and second brake linings relative to the brake table. The brake table may comprise extruded aluminum.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

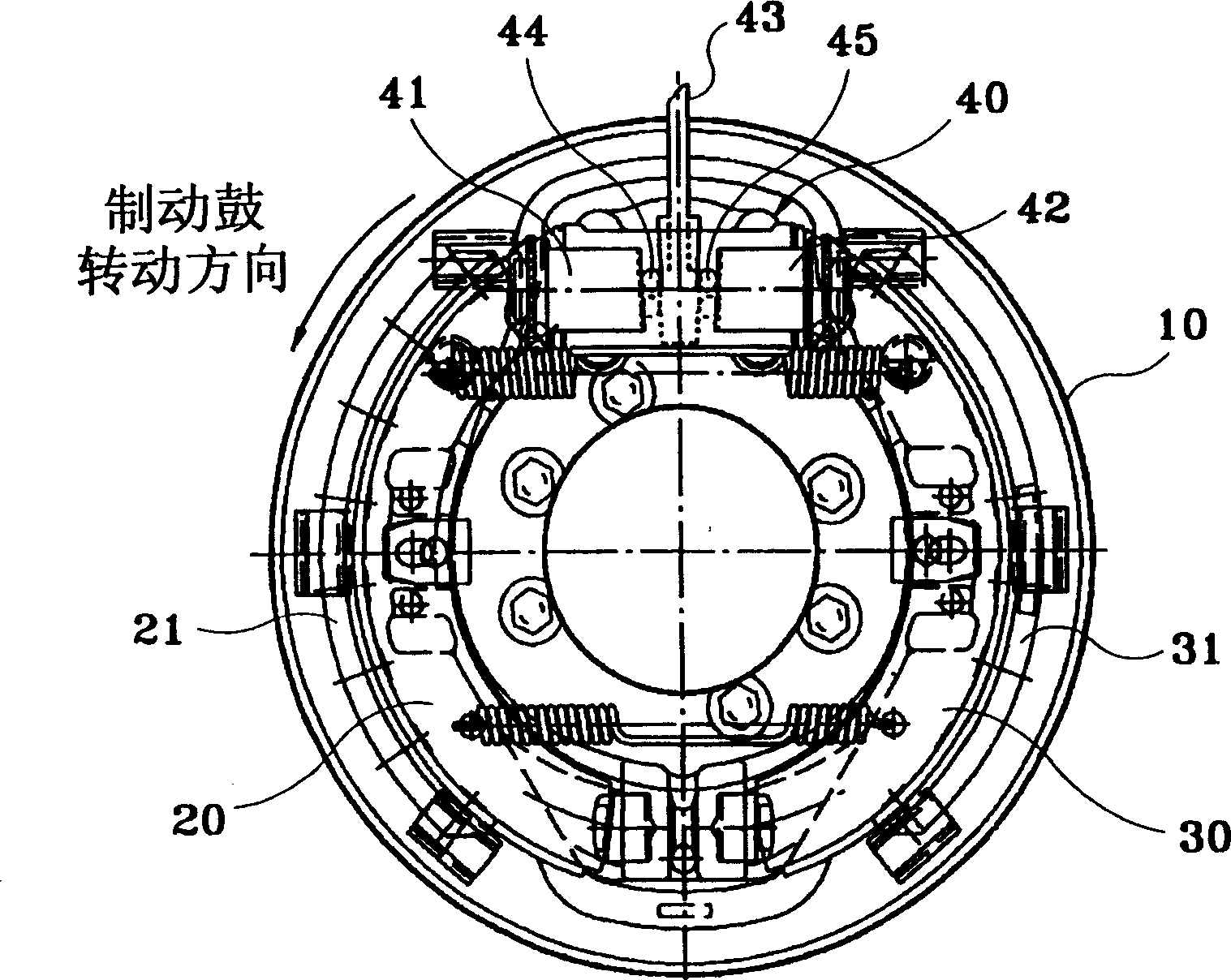

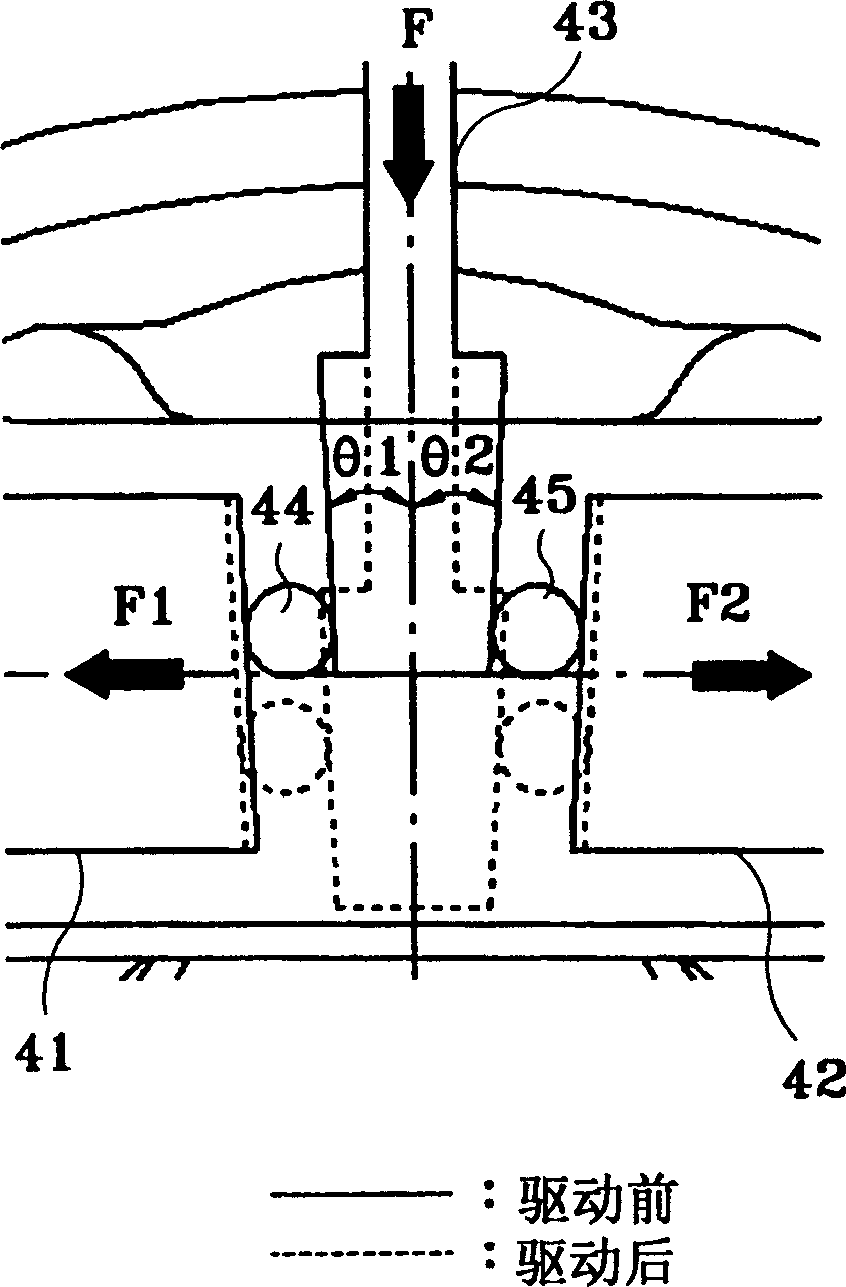

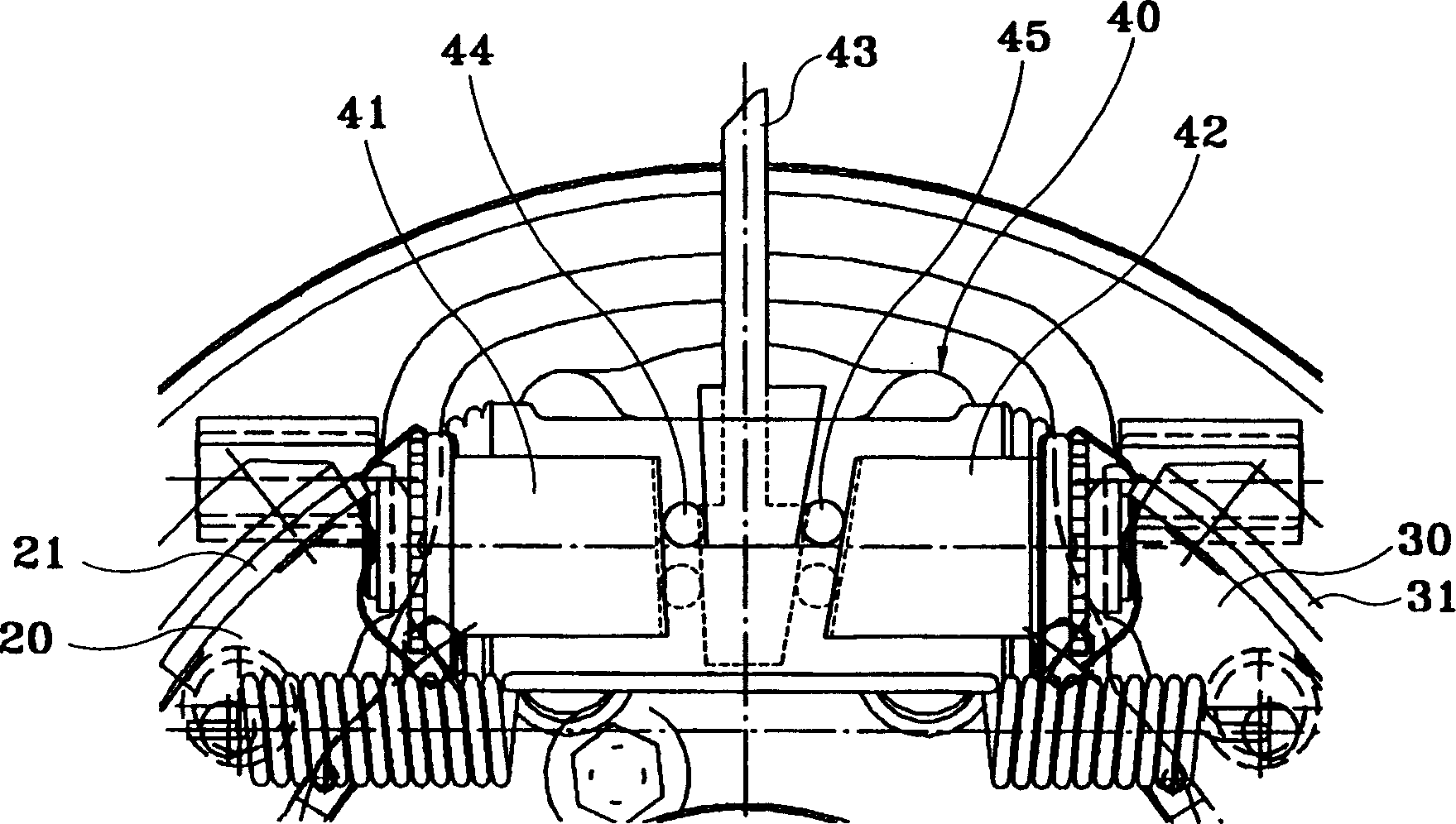

Wedge actuating drum type brake

InactiveCN1442621AIncrease braking powerExpansion force is the sameFluid actuated drum brakesBrake actuating mechanismsPistonDrum brake

The present invention discloses a wedge actuated drum brake for a motor vehicle. A vertically descending support wedge pushes out a pair of pistons of the wheel brake cylinder, so that the leading shoe and the trailing shoe are pressed against the inner periphery of the brake drum 10 . Among them, the inclination angle of the support wedge on the slave hoof side is larger than the inclination angle on the leading hoof side, therefore, the inclination angles of the two piston end surfaces facing the supporting wedge are different, which strengthens the expansion force of the slave hoof. As a result, the leading hoof and the slave hoof The expansion force of the hoof is the same.

Owner:HYUNDAI MOTOR CO LTD

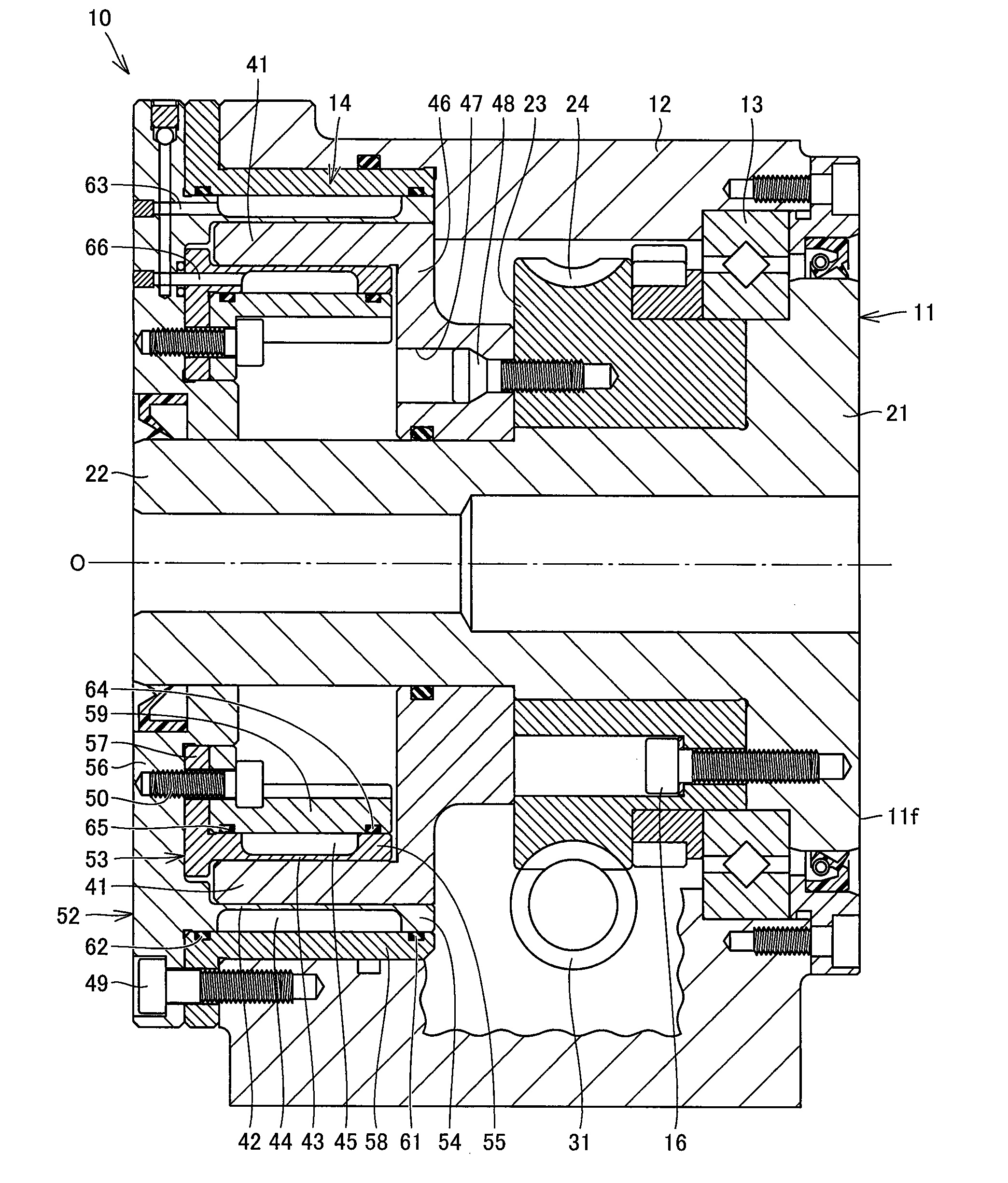

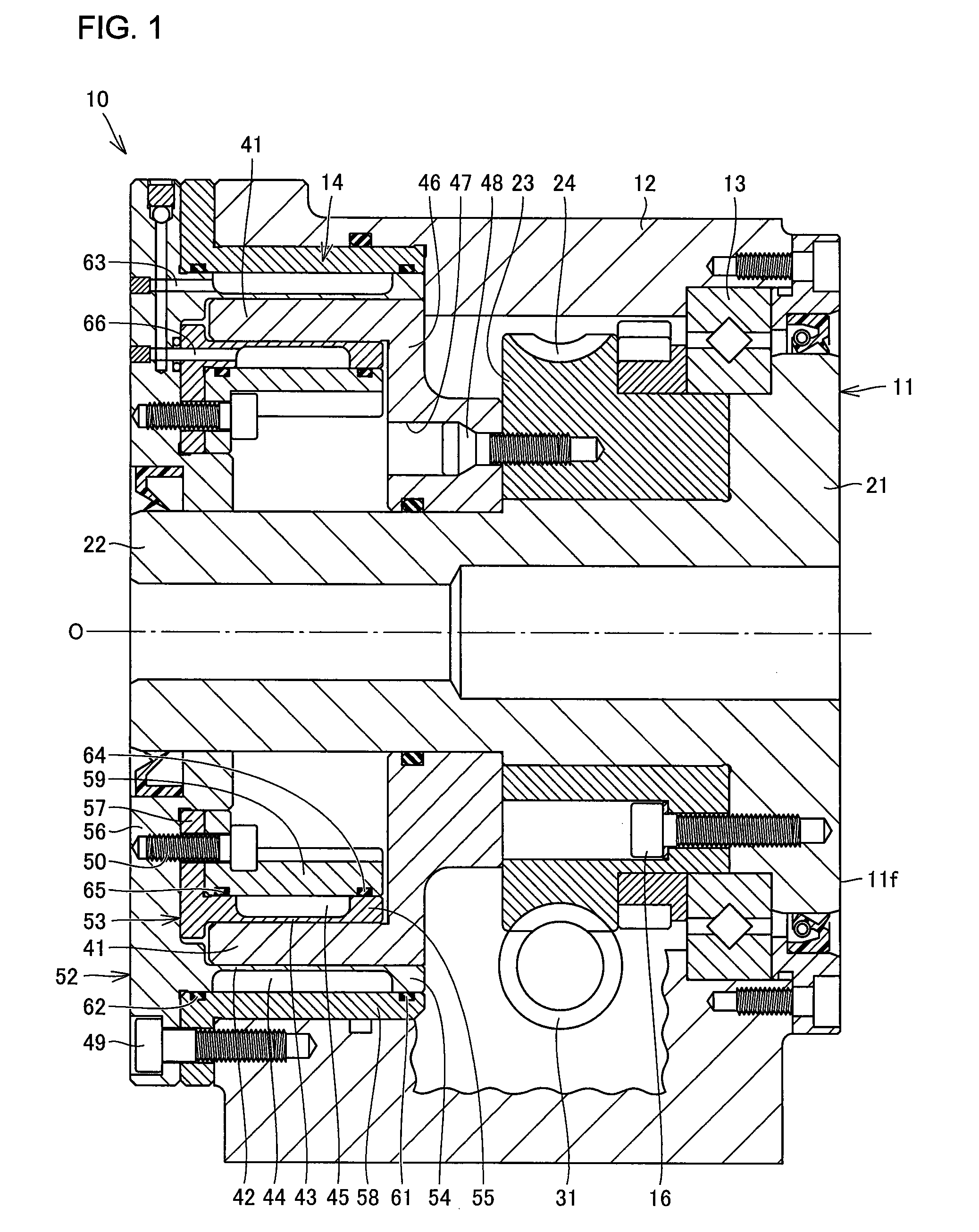

Brake Structure of Rotary Table

ActiveUS20130105255A1Rotary table thinnerFluid actuated brakesPrecision positioning equipmentEngineeringMechanical engineering

A rotary table includes a brake mechanism capable of providing a large and sufficient brake force. The brake mechanism includes an inner peripheral surface and outer peripheral surface of a sleeve formed coaxially with an axis of a rotatable table, an outer stationary portion provided to a stationary member rotatably supporting the rotatable table and defining an outer hydraulic chamber, and an inner stationary portion provided to the stationary member, arranged radially inward from the outer stationary portion and defining an inner hydraulic chamber. The outer stationary portion is elastically deformed in a radial direction by expansion of the outer hydraulic chamber to push the outer peripheral surface of the sleeve formed on the rotatable table, while the inner stationary portion is elastically deformed in a radial direction by expansion of the inner hydraulic chamber to push the inner peripheral surface of the sleeve formed on the rotatable table.

Owner:NIKKEN KOSAKUSHO WORKS LTD

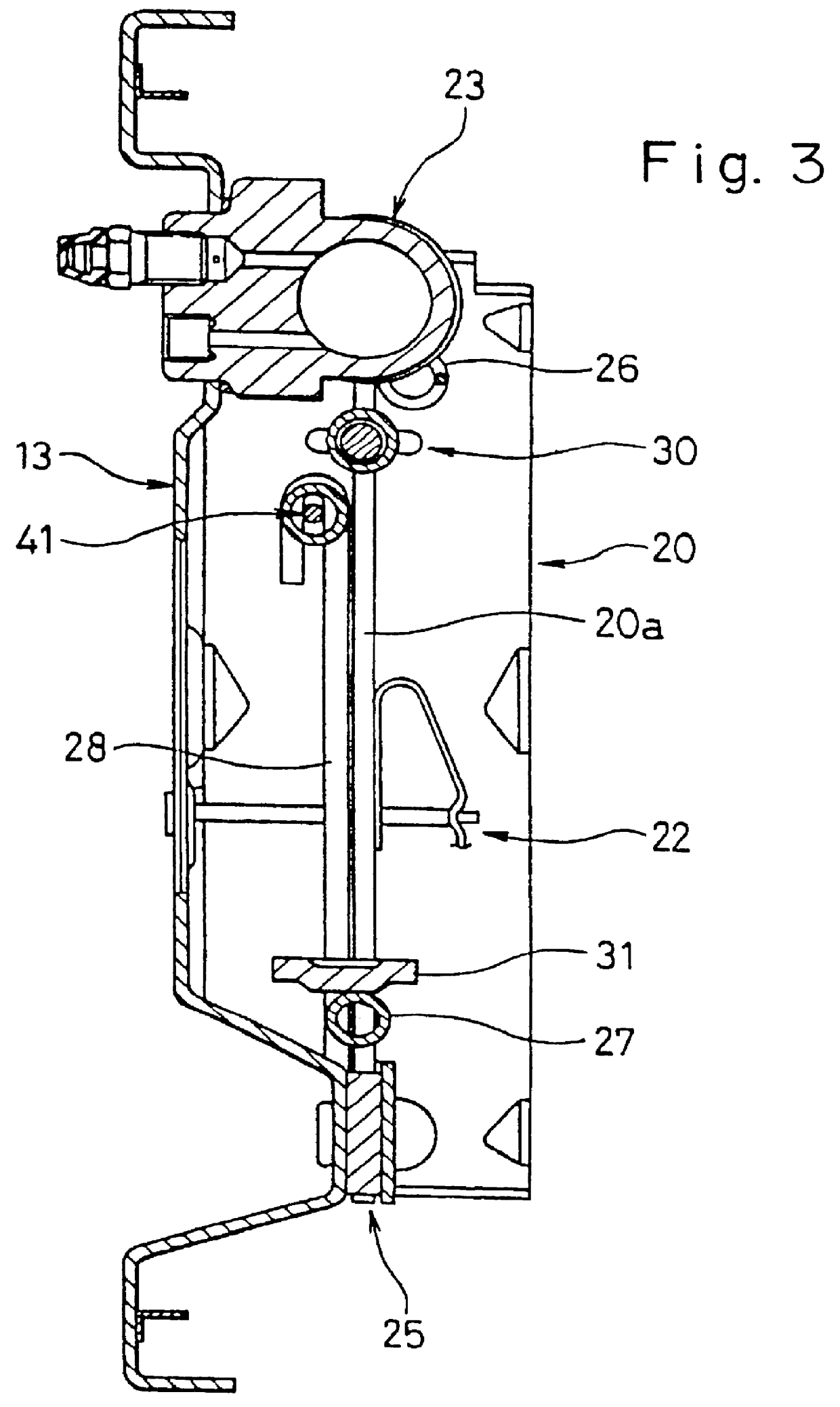

Drum brake and brake shoe for one such brake

InactiveUS7182182B2Easy to replaceImproved torque stabilityMechanically actuated brakesFluid actuated drum brakesMechanical engineeringDrum brake

A drum brake comprising a plate on which at least one shoe having a friction lining is mounted. A lever moves the shoe against a wheel drum in response to a braking command to effect a brake application. A resilient return spaces the shoe apart from the drum when braking ceases. The shoe is mounted to slide along an essentially radial axis between two guide walls secured to the plate The lever for applying the shoe bears against the inside wall of the shoe for exerting a substantially radial force.

Owner:ROBERT BOSCH GMBH

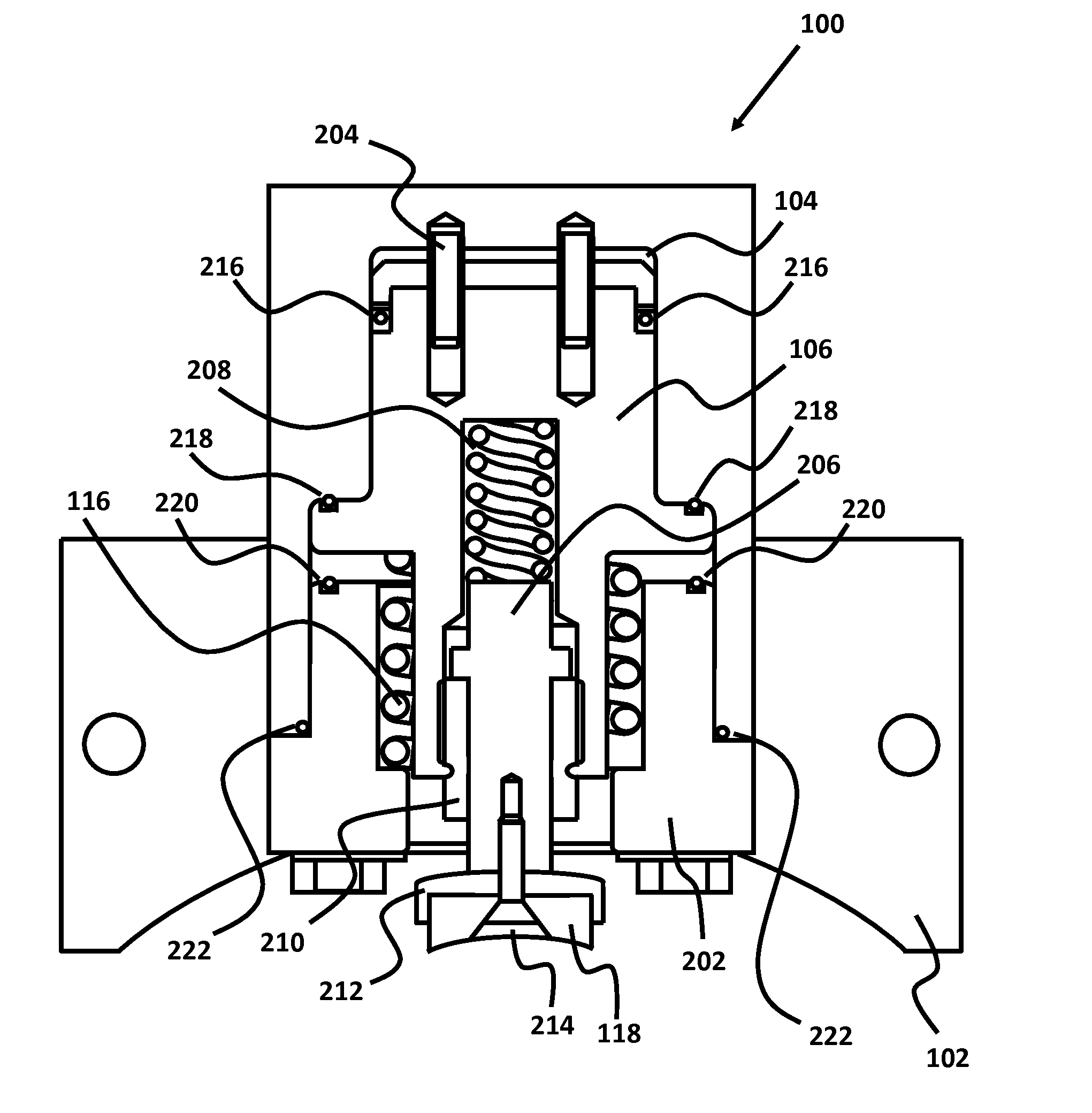

Shaft Holding System for Cryogenic Pumps or Expanders

InactiveUS20100300818A1Fluid actuated drum brakesBrake actuating mechanismsEngineeringHydraulic brake

A shaft holding system for cryogenic pumps or expanders comprising of a set of hydraulic brakes surrounding the shaft of turbomachinery. Fluid or gas is introduced into the bellows chamber of a brake assembly. The bellows chamber expands due to the increase in pressure, thus exerting a force on the piston of the brake assembly. The piston in turn exerts a force on a brake rod, which pushes a brake pad attached to the end of the brake rod against the shaft. A feed line supplies fluid or gas to the hydraulics of the brake assembly. Two or more brakes can be used to secure the shaft of the turbomachine. A turbomachine including more than one shaft can use a set of brakes for each shaft of the turbomachine.

Owner:ELLIOTT CO

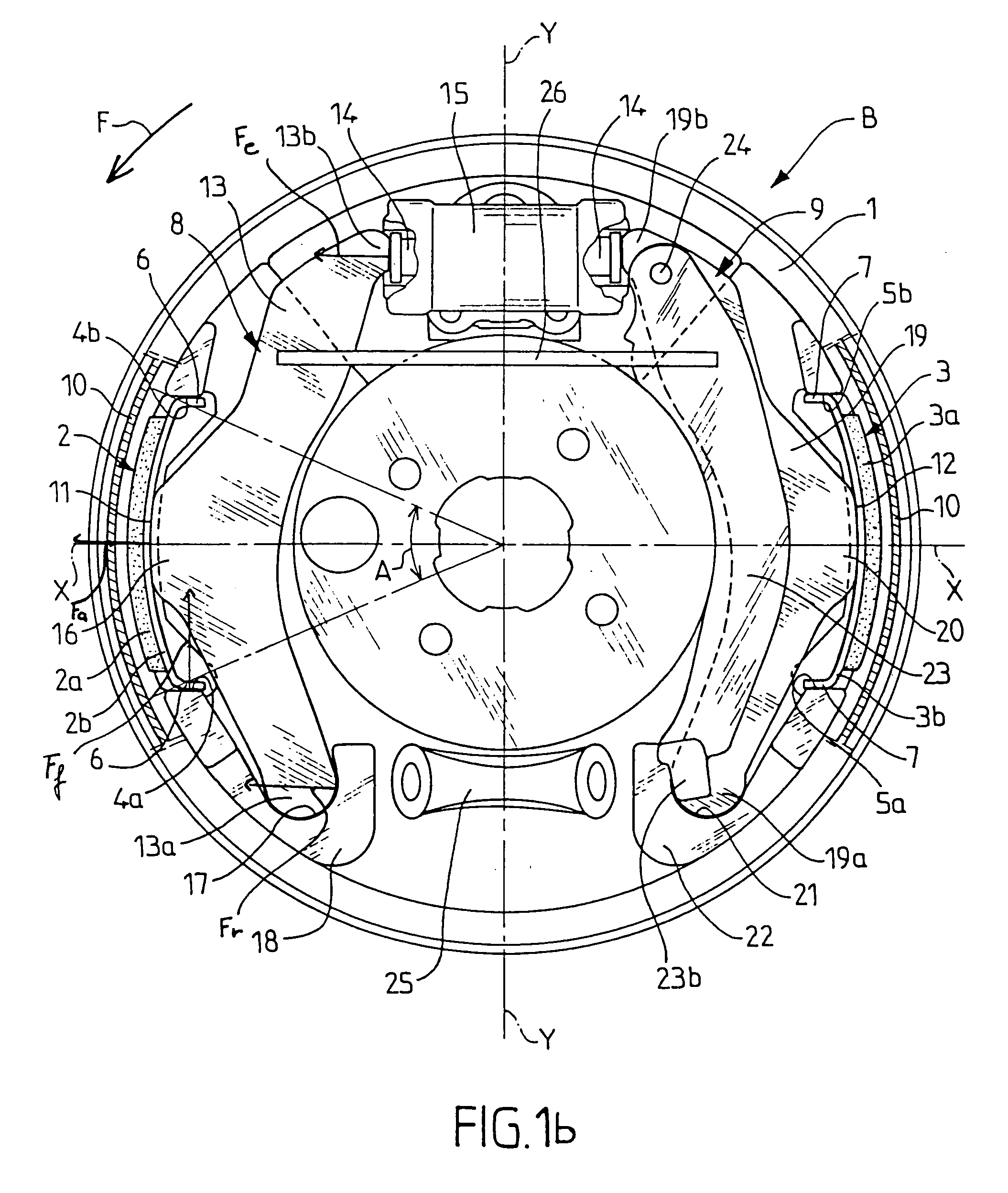

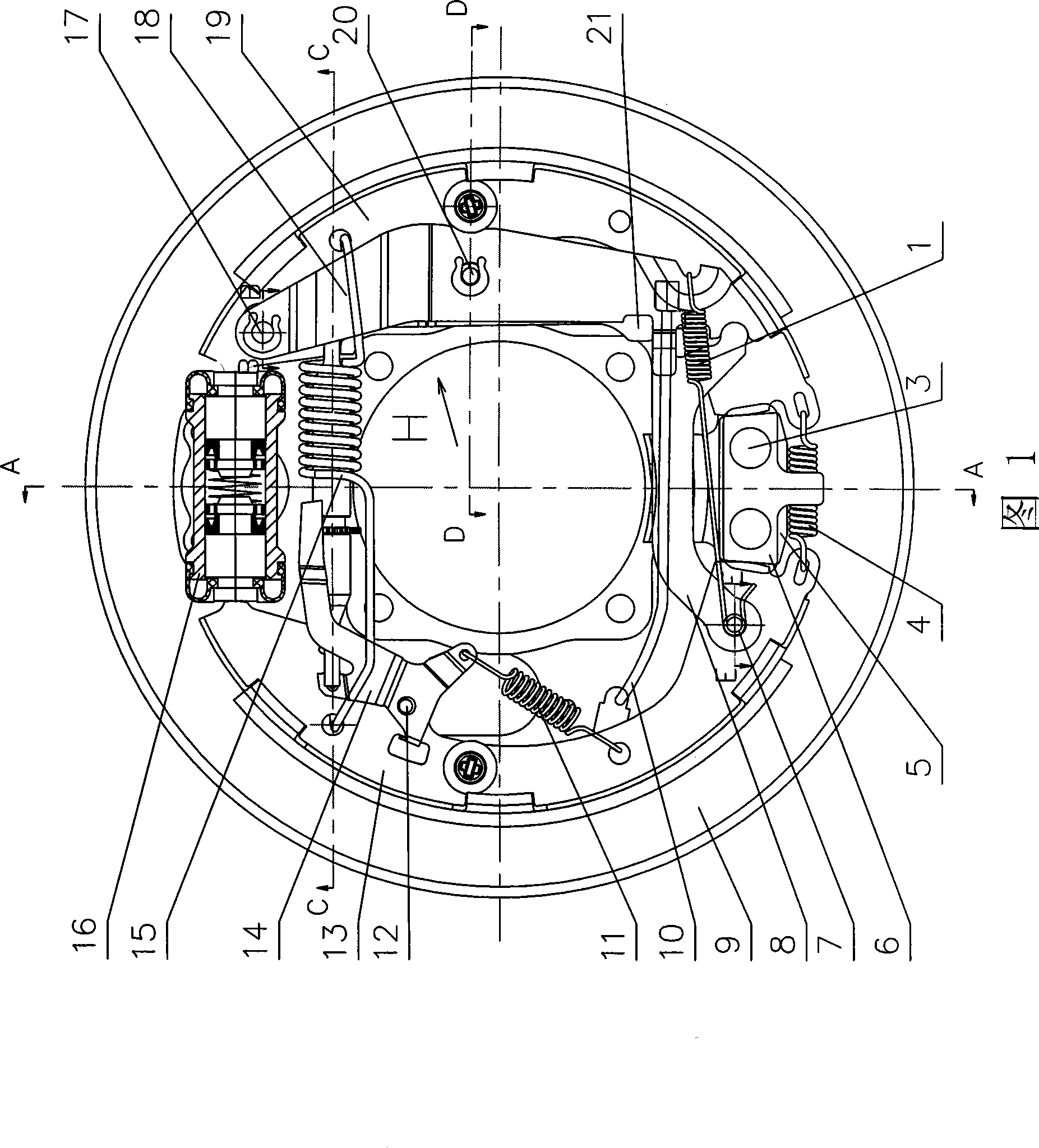

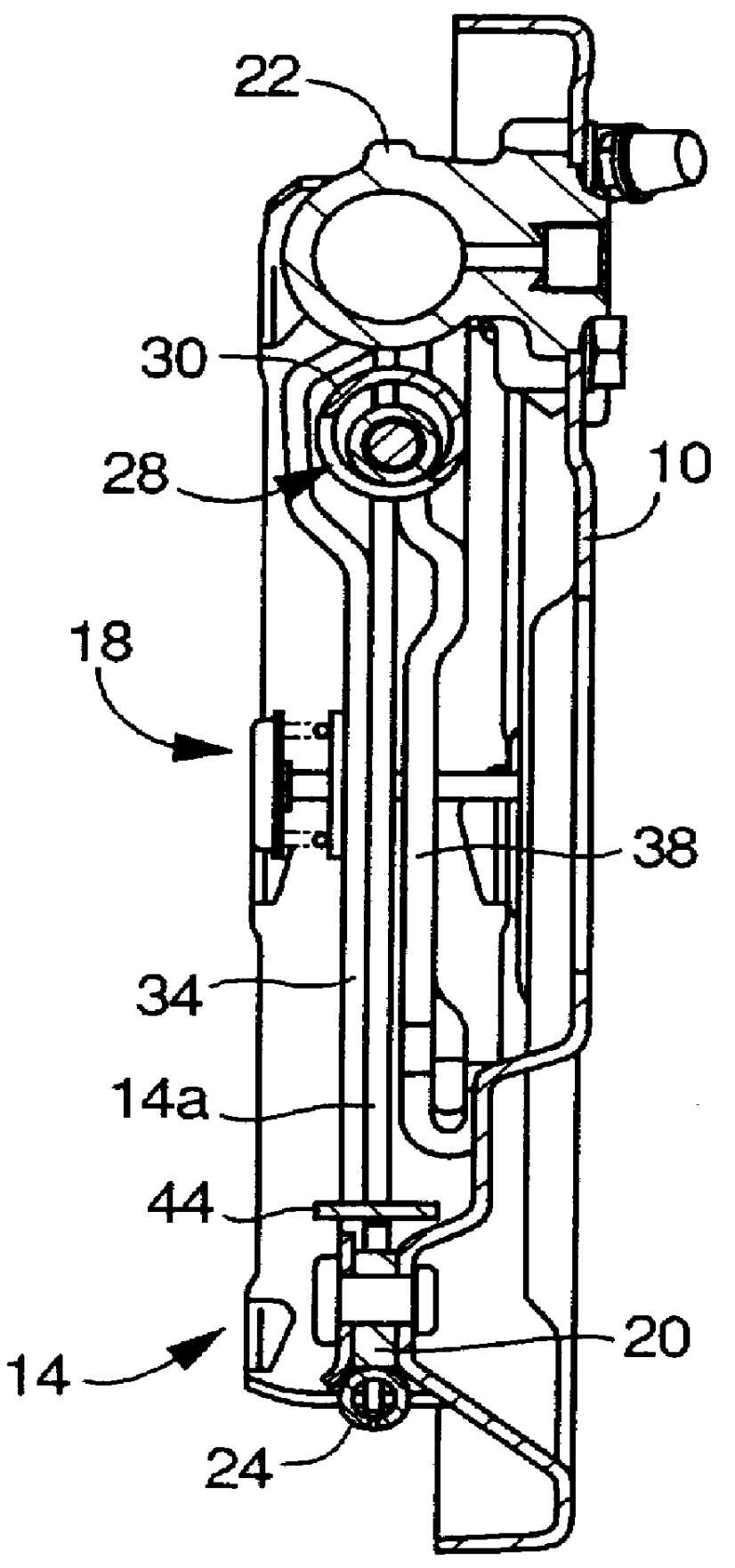

Dual-mode drum brake having parking lever pivotable about an axis perpendicular to backing plate

InactiveUS6044938AReduce the applied forceReduce tensionFluid actuated drum brakesBrake actuating mechanismsDual modeEngineering

A dual-mode drum brake assembly including a stationary backing plate opposed to a brake drum, a wheel cylinder disposed on the backing plate and having a pair of outwardly extendible pistons, an anchor fixed to the backing plate and opposite to said wheel cylinder diametrically of the backing plate, two brake shoes movably supported by the backing plate and having a first pair of adjacent ends opposite to the wheel cylinder and a second pair of adjacent ends opposite to the anchor, a parking lever disposed substantially along one of the two brake shoes and having a pivot axis perpendicular to the backing plate, at a portion thereof closer to the wheel cylinder, and a cable fixing portion closer to the anchor, and a link mechanism disposed between the parking lever and the brake shoes, and operating to move the adjacent ends of the second pair of the brake shoes away from each other, with a pivotal movement of the parking lever about the pivot axis when a torque acts on the brake drum.

Owner:TOYOTA JIDOSHA KK +1

Self-compensating filament tension control device employing a friction band

InactiveUS6435445B1Easy to adjustUniform tensionFilament handlingFluid actuated drum brakesTension controlPull off force

A self-compensating tension control device for regulating the payout of filamentary material from a spool includes a fixed support and a spindle assembly pivotably mounted to the fixed support, wherein the spindle assembly rotatably carries the spool of filamentary material. A pull-off force imparted by the filamentary material causes angular movement of the spindle assembly and rotation of the spool. A braking assembly mounted to the fixed support and coupled to the spindle assembly applies a braking force corresponding to an angular position of the spindle assembly.

Owner:RJS

Actuator driven by gear having axial guide rail, and drum brake and braking device provided with same

InactiveCN106164525AReduce wearPrecise positioningBraking membersFluid actuated drum brakesMobile vehicleMotorized vehicle

The invention relates to an actuator for brake shoes inside a drum brake of a motor vehicle, in particular with an electric motor. The invention also relates to a brake provided with such an actuator, for example a drum-in-hat composite brake or a dual-mode brake combining a service brake in simplex mode and a parking brake in duo-servo mode. The actuator includes a linear actuator assembly including a screw-and-nut system and is capable of separating the ends of the brake shoes. Said screw-and-nut system is driven by a transmission sub-assembly which in turn is driven by an electric motor. Said transmission sub-assembly rotates an element for actuating the linear actuation assembly by using a guide rail connection. In particular, said actuator element is translatably movable in a single direction and rotatably fixed to a gear of the transmission sub-assembly.

Owner:CHASSIS BRAKES INT BV

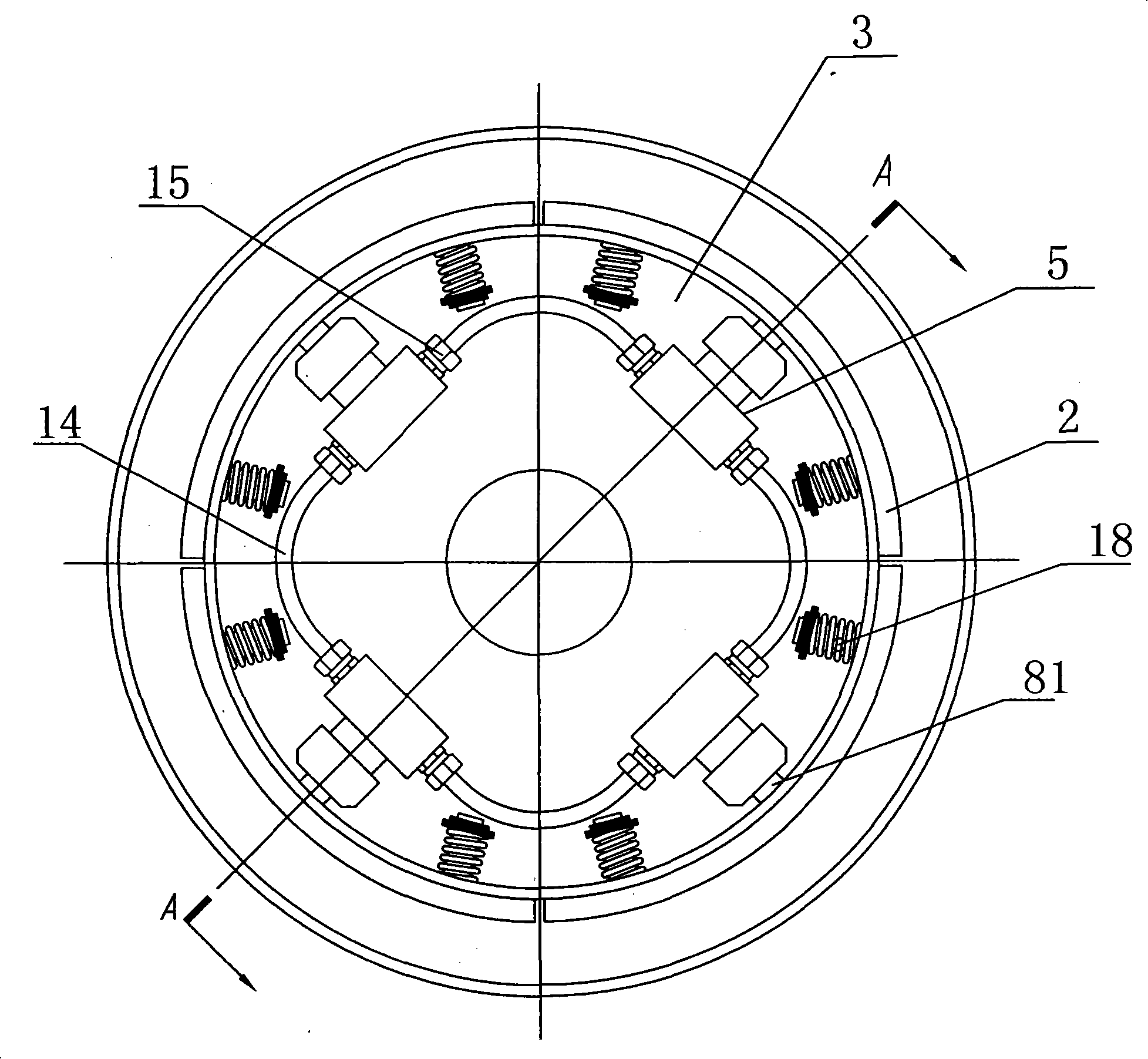

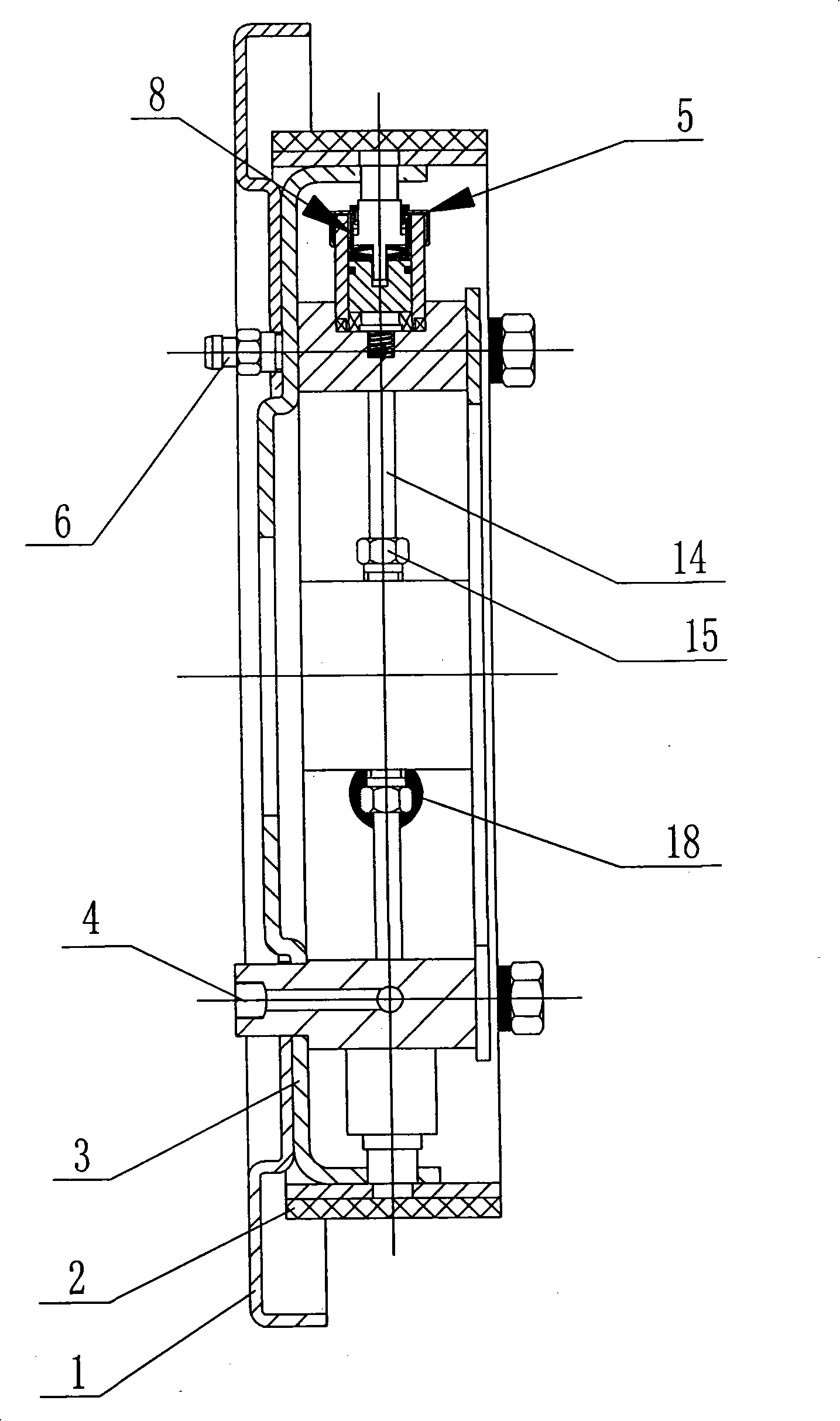

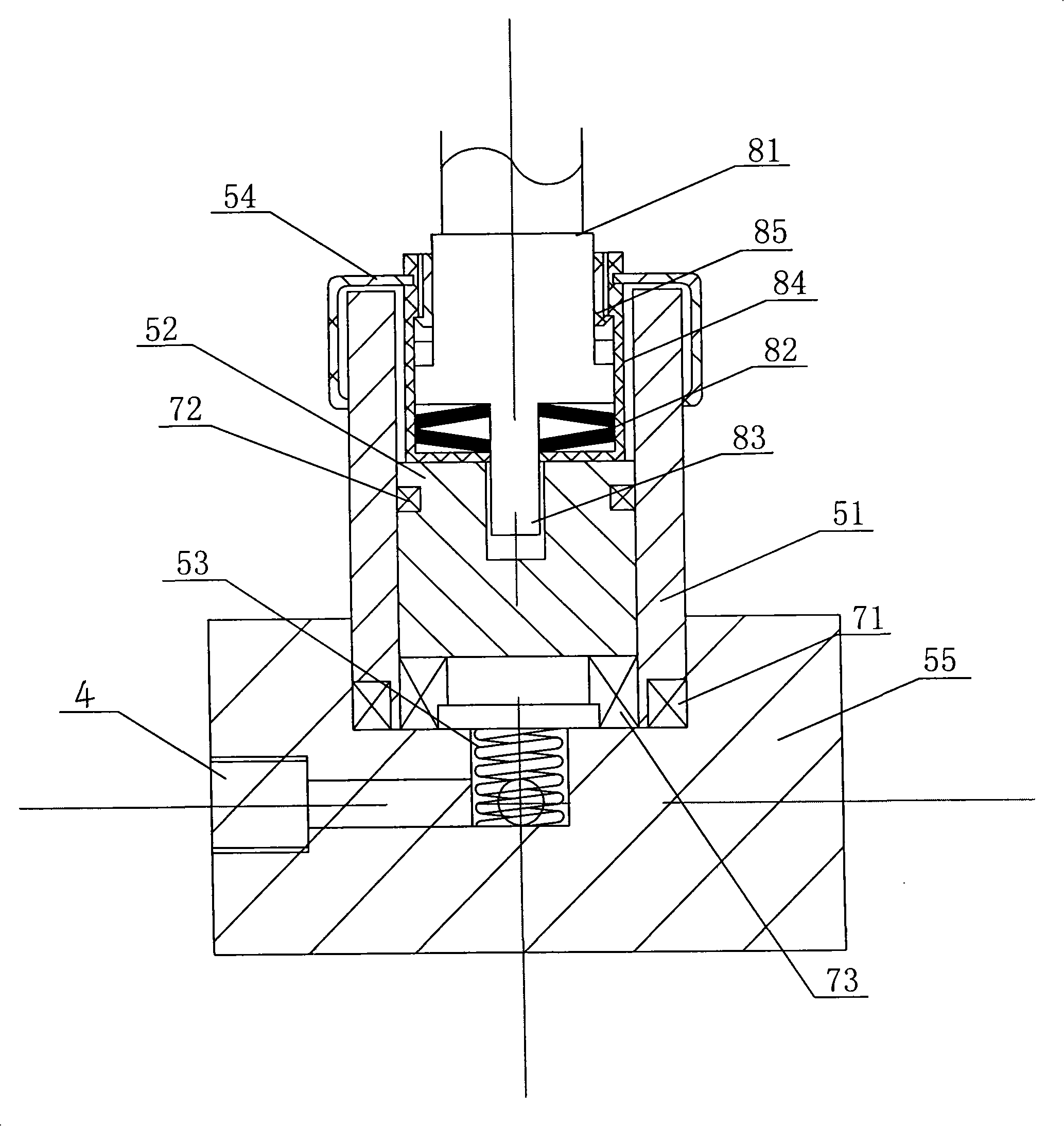

Dual-hydraulic drum type braking device

InactiveCN105202070AExtended use timeEasy to installBraking membersFluid actuated drum brakesHydraulic cylinderEngineering

The invention discloses a dual-hydraulic drum type braking device which comprises a brake disc sleeved with a hub. A left brake shoe and a right brake shoe are symmetrically arranged in the brake disk. The top end of the left brake shoe and the top end of the right brake shoe are connected through an upper telescopic hydraulic cylinder. The bottom end of the left brake shoe and the bottom end of the right brake shoe are connected through a lower telescopic hydraulic cylinder symmetrical to the upper telescopic hydraulic cylinder. The upper end of the left brake shoe and the upper end of the right brake shoe are connected with the two ends of an upper extension spring respectively. The lower end of the left brake shoe and the lower end of the right brake shoe are connected with the two ends of a lower extension spring respectively. By arranging the upper telescopic hydraulic cylinder and the lower telescopic hydraulic cylinder which are symmetrical to each other at the top ends and the bottom ends of the left brake shoe and the right brake shoe, during braking, the upper ends and the lower ends of the left brake shoe and the right brake shoe are moved outwards at the same time, the contact area of the brake shoes and the hub is large, the concentration of friction force in the braking process is reduced, the problem that the brake shoes dissipate heat in an excessive concentrated mode when the friction force is excessively concentrated is solved, and durability of the brake shoes is improved.

Owner:QINZHOU UNIV

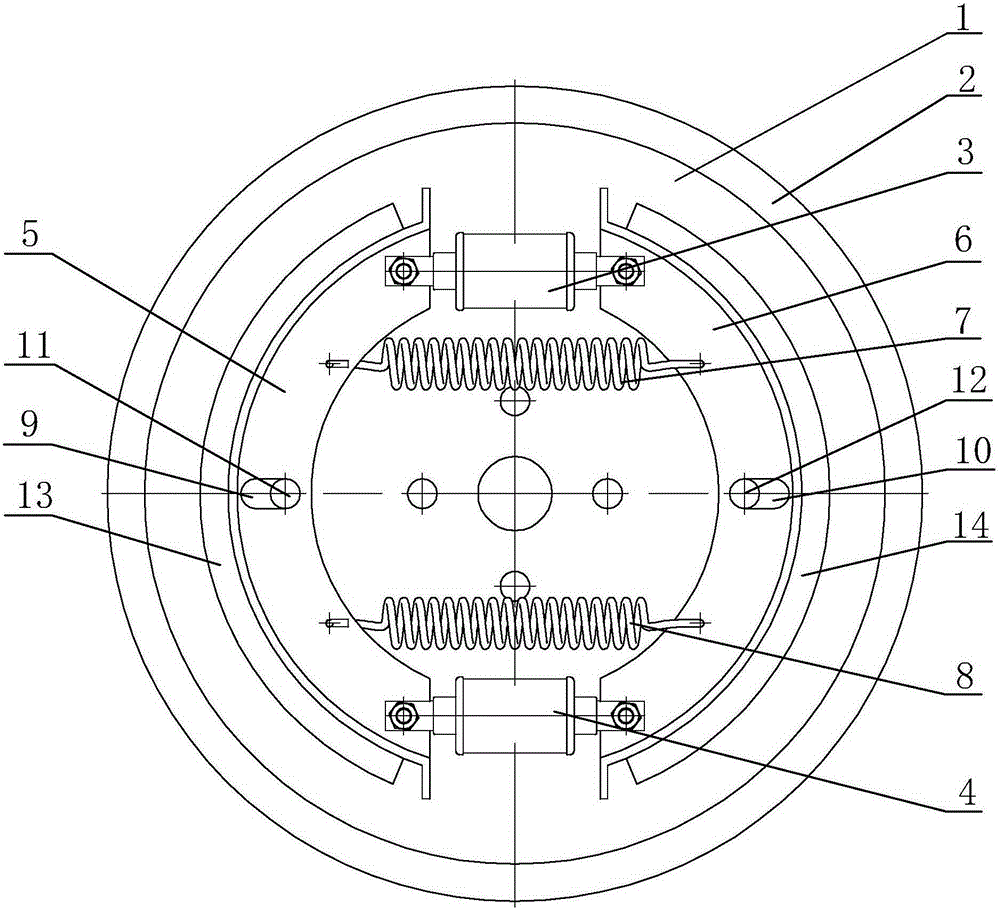

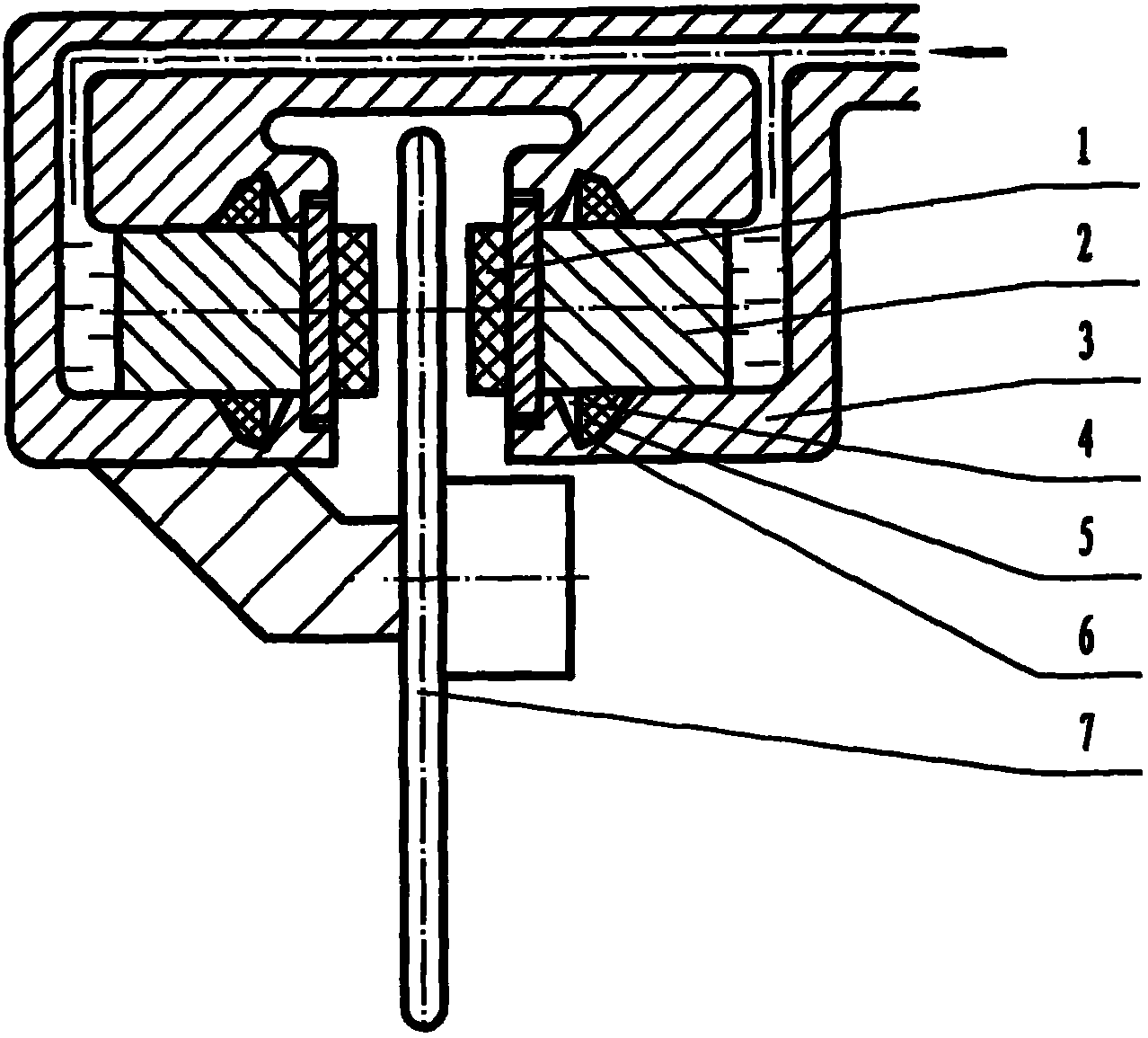

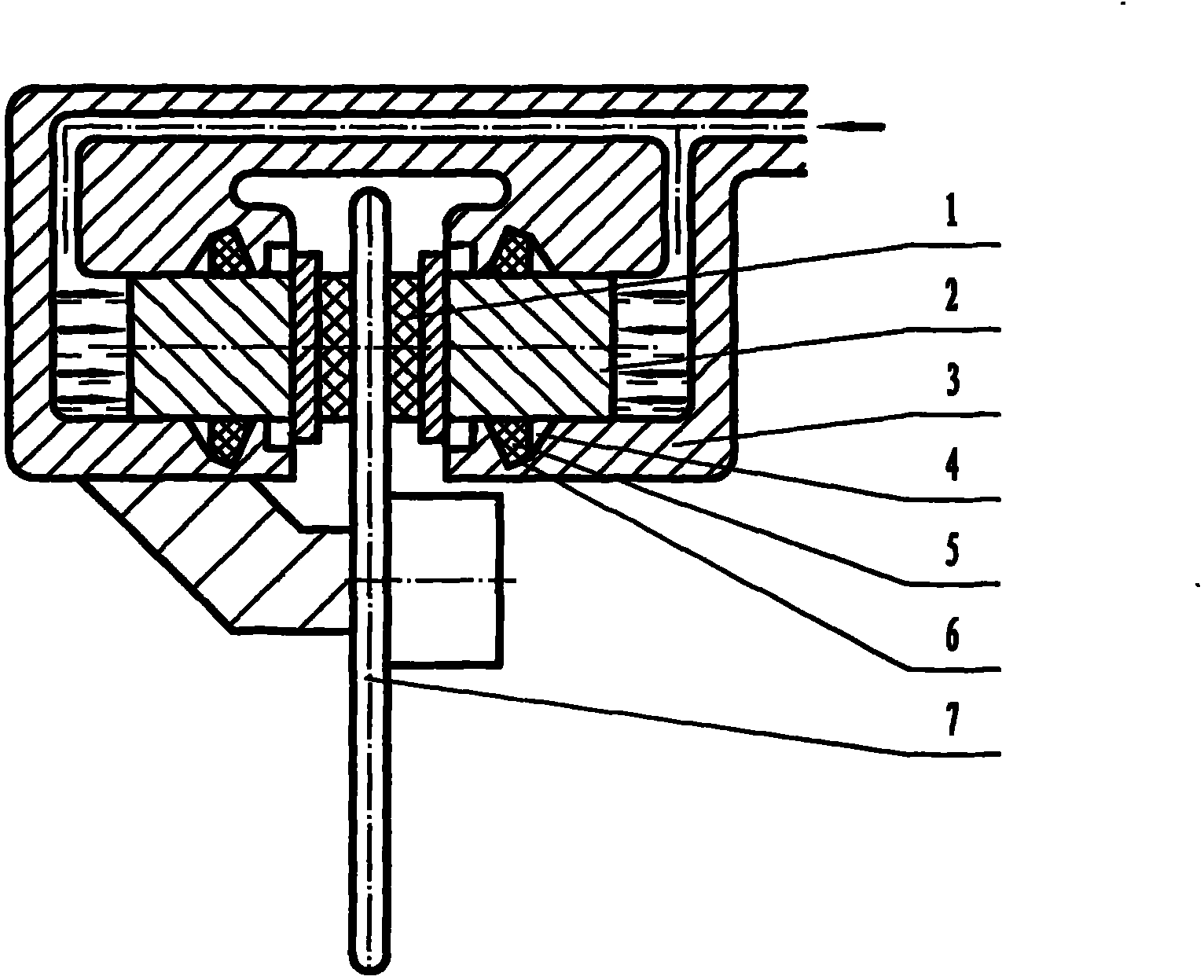

Vehicular ring-shaped brake

InactiveCN101162030APrevent lockIncrease braking powerEngine sealsFluid actuated drum brakesBraking distancePiston

The invention relates to an automobile skid device, in particular to an automobile ring-shaped brake. The ring-shaped brake comprises a brake bottom plate (3) and friction plates (2) and is characterized in that the brake bottom plate (3) is fixed with a plurality of piston oil cylinder components (5) which are provided inside with seal spring components (8); the outer end of a telescopic link (81) of each the seal spring component (8) is fixed with the friction plate (2); each two of the piston oil cylinder components (5) are connected through an oil pipe connected with a nut (15) and a sealed ring-shaped oil pipe (14); a return spring (18) is arranged on the brake bottom plate (3) and the friction plates (2). The invention can prevent the locking of a brake drum, thereby strengthening the automobile stopping power; when braking, the automobile does not have the phenomena of off tracking and sideslip with shortened braking distance and improved braking safety of the automobile.

Owner:张勇

Hydraulic brake

InactiveCN101988550ASimple structureReduce manufacturing costAxially engaging brakesFluid actuated drum brakesMachine partsHydraulic brake

The invention discloses a disk hydraulic brake capable of adjusting automobile brake clearance automatically. In the disk hydraulic brake, an annular space for a sealing ring to move axially is reserved in a sealing ring groove. The cross sections of the space, the sealing ring and the sealing ring groove are approximately trapezoid or V-shaped or triangular; and the sealing ring is pressed by the piston and the bottom of the sealing ring groove and performs static sealing basically. In braking, the piston and the inner ring of the sealing ring are driven by an oil pressure, the deformation resistance to axial movement of the inner ring of the sealing ring is overcome, a force for pulling back is stored, and a braking friction piece is linked to eliminate axial movement space and brake clearance and press a braked part at the same time, and thus, friction brake is realized. When braking is not needed, the oil pressure is withdrawn, and under the action of the pull-back force of the sealing ring, the machine parts and the two space clearances are restored. Thus, when braking is not needed, the machine parts are protected from friction, heating, damage oil leakage and long repair and replace period, and are energy-saving, emission-reducing, low in consumption and safe. The structure of the disk hydraulic brake is simple, and the production cost is unchanged basically.

Owner:王世新

Vehicle hydraulic master cylinder

ActiveCN1517579AAvoid distortionIncreased durabilityEngine sealsPiston ringsHydraulic cylinderMaster cylinder

A hydraulic master cylinder for vehicle has: a cylinder main body; a sleeve; a plurality of seal rings; a plug, a lid member comprising the sleeve and the plug; and a piston inserted into the cylinder bore so as to form a hydraulic pressure chamber between the piston and the lid member; wherein the sleeve is inserted into the cylinder main body with an open end thereof being made to face an interior of the cylinder main body so as to dispose the seal rings between a circumferential wall of the cylinder bore and the sleeve and in such a manner that the seal rings hold the outlet port therebetween, and the plug is fixedly threaded in the opening at the one end so as to prevent the dislocation of the sleeve.

Owner:AUTOLIV NISSIN BRAKE SYST JAPAN CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com