Patents

Literature

329 results about "Load generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

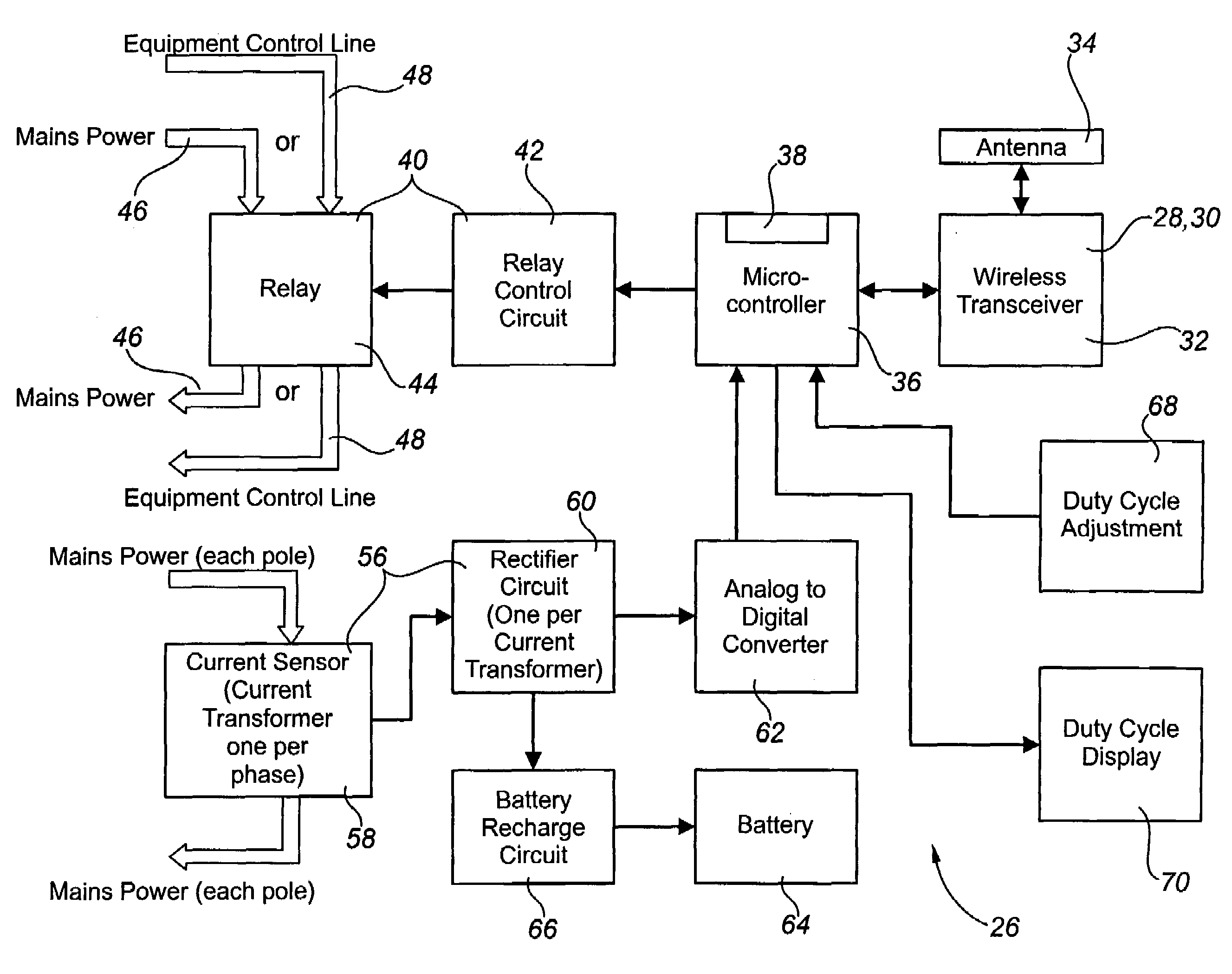

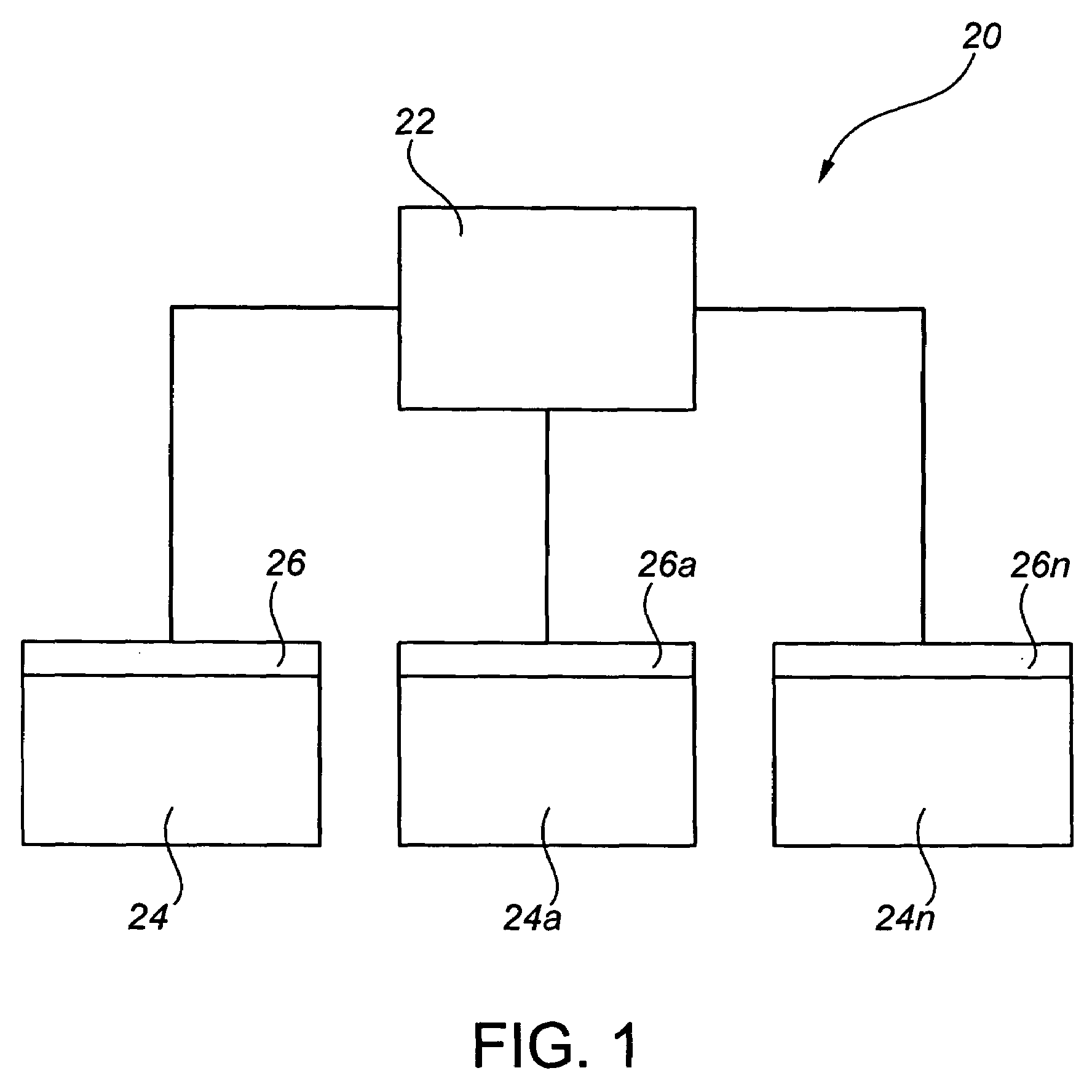

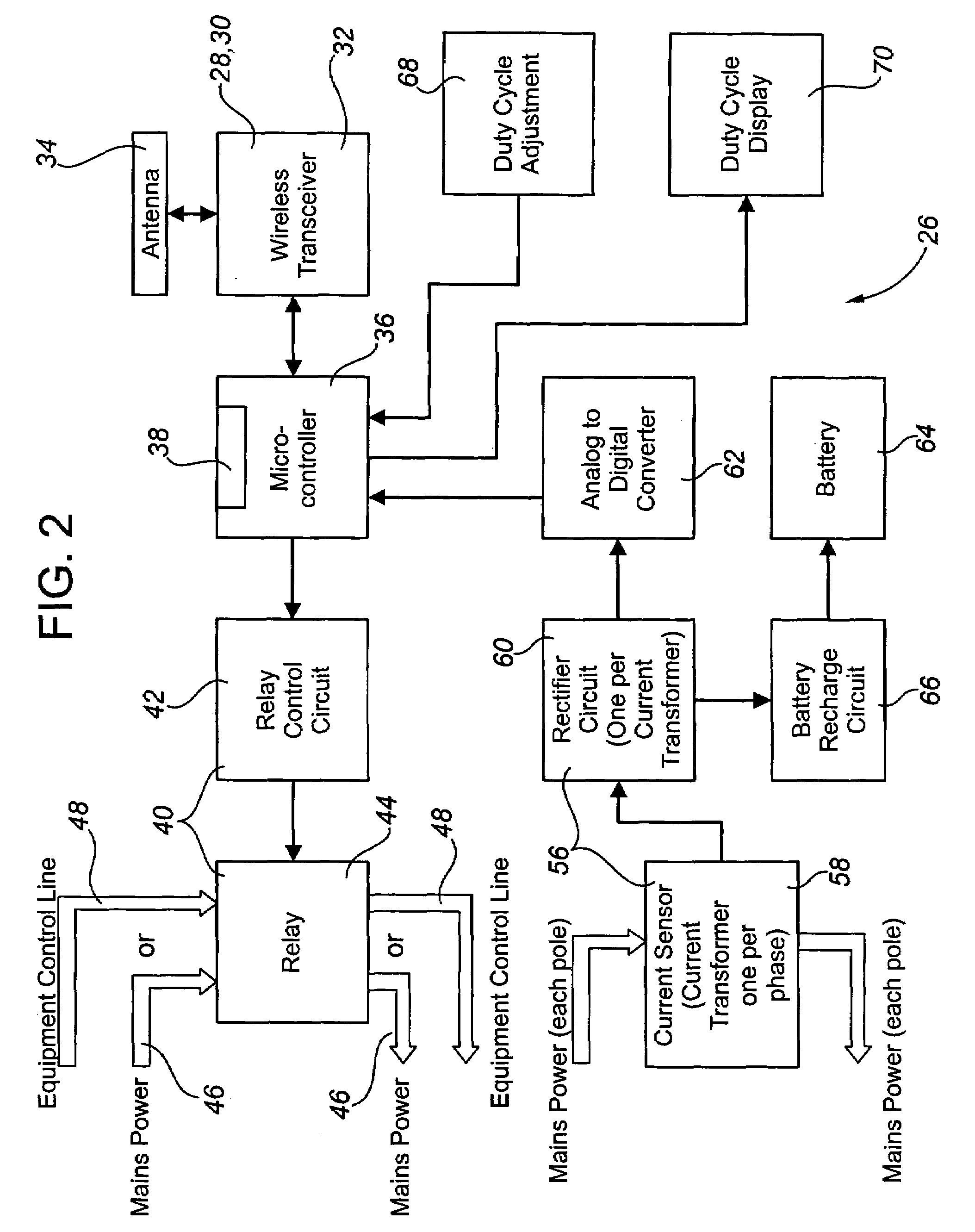

Method and apparatus for managing an energy consuming load

ActiveUS20080015742A1Reduce energy consumptionGuaranteed growthMechanical power/torque controlDc network circuit arrangementsLoad generationEngineering

A method for managing an energy consuming load in a group of energy consuming loads and a method for managing the group of energy consuming loads. The method includes generating sets of load state data from the loads, making enablement state decisions for one or more loads independently of the other loads using the sets of load state data, and implementing the enablement state decisions. An apparatus for managing an energy consuming load in a group of energy consuming loads, including a transmitter for transmitting a set of load state data generated from the load, a receiver for. receiving sets of load state data from other loads, a processor for processing the sets of load state data to make an enablement state decision for the load, and a controller for implementing the enablement state decision.

Owner:ENCYCLE CORP

Temperature control of exhaust gas catalytic converters in vehicles

InactiveUS6057605AIncreased the braking torqueDecreased the driving torqueElectrical controlInternal combustion piston enginesBrake torqueTemperature control

A vehicle powertrain comprises an internal combustion engine 10 and an electric motor 14 capable of producing driving or braking torque for the vehicle. The exhaust system for the engine 10 includes a catalytic converter 22. A control unit 18 monitors the temperature of the catalytic converter 22 using a sensor 32 and controls the driving or braking torque produced by the electric motor 14 so that the load on the engine produces exhaust gases of a suitable temperature to keep the catalytic converter within its optimum operating temperature range while maintaining the desired total output of torque from the powertrain.

Owner:BAYERISCHE MOTOREN WERKE AG

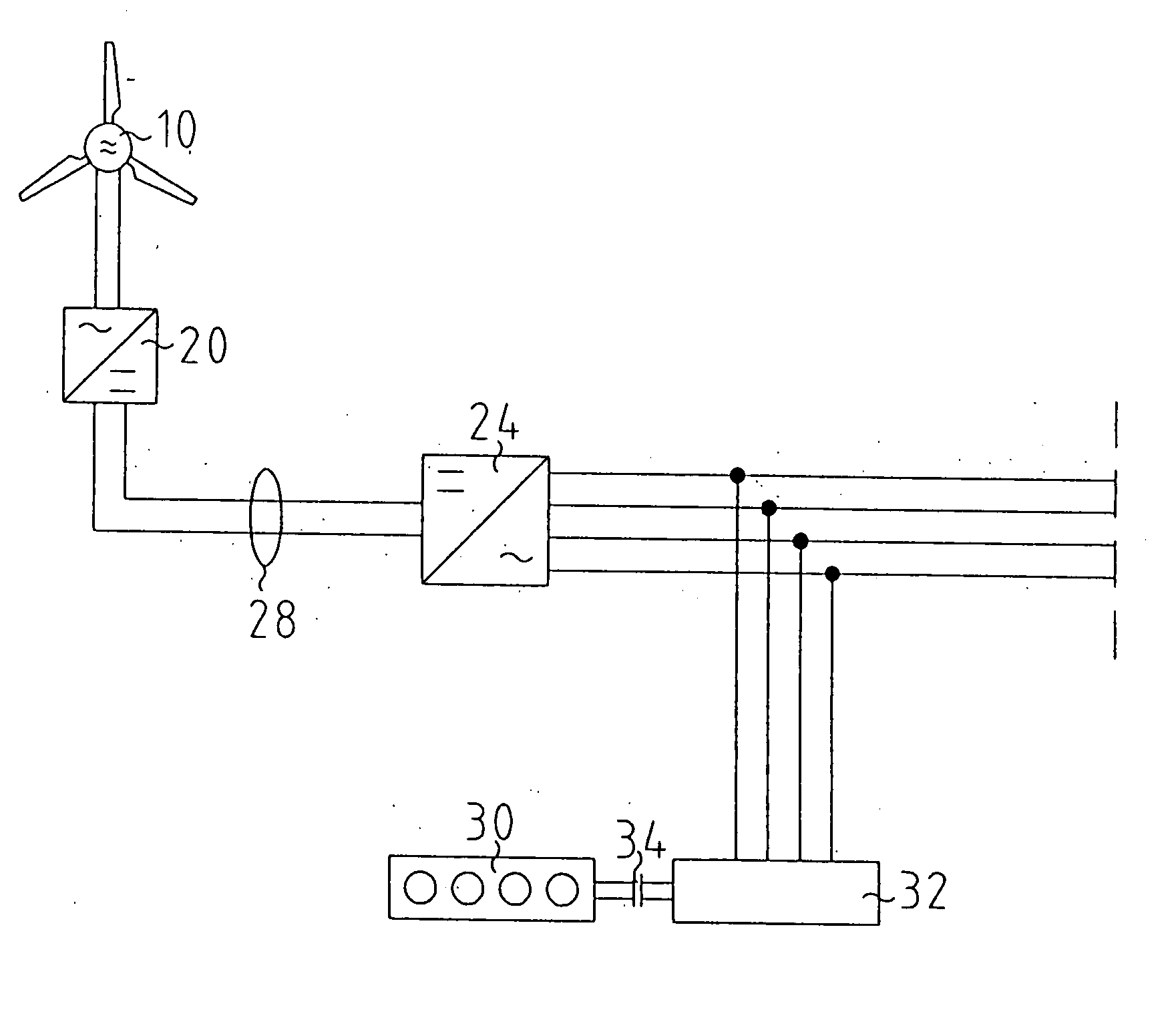

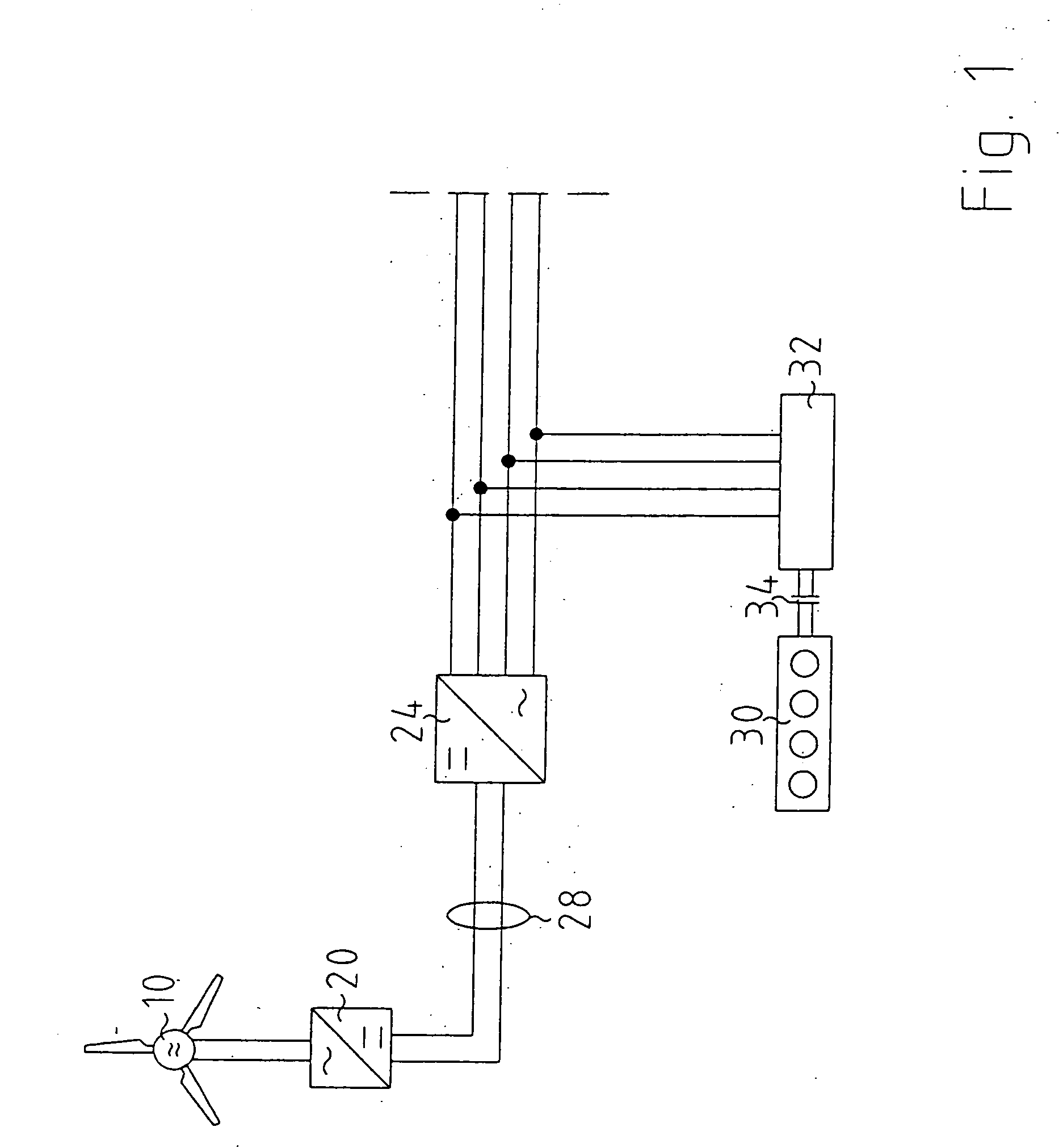

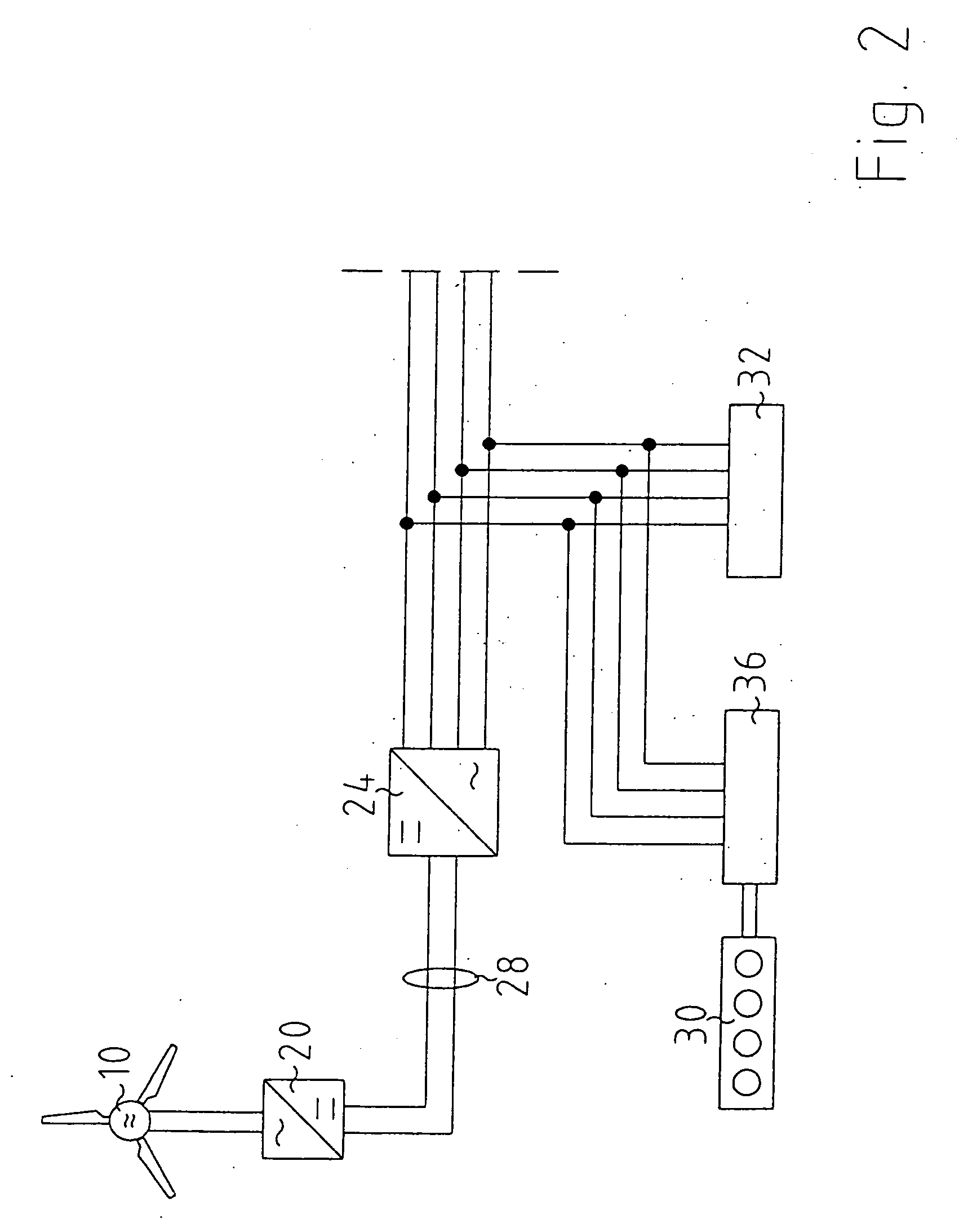

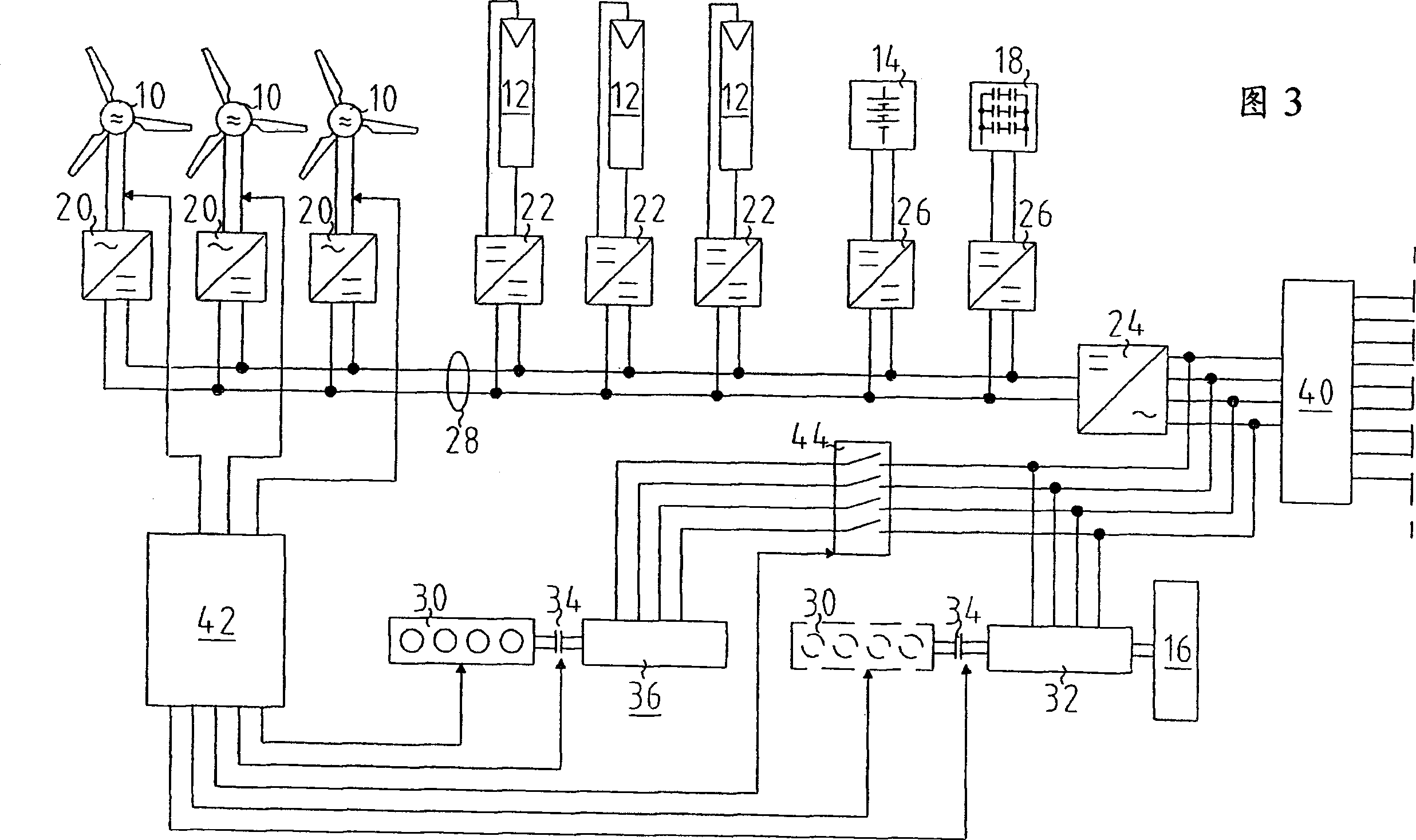

Separate network and method for operating a separate network

InactiveUS20050200133A1Improve efficiencyBatteries circuit arrangementsMagnetic circuitElectromagnetic couplingLoad generation

The present invention relates to an isolated network with at least one power generator, which uses renewable energy sources, wherein the power generator is preferably a wind-power station with a first synchronous generator, with a dc voltage intermediate circuit with at least a first rectifier and an inverter, with a second synchronous generator and an internal combustion engine that can be coupled to the second synchronous generator. To realize an isolated network, for which the internal combustion engine can be deactivated completely, as long as the wind-power station generates sufficient power for all connected loads at the highest possible efficiency, a completely controllable wind-power station and an electromagnetic coupling between the second synchronous generator and the internal combustion engine are provided.

Owner:WOBBEN ALOYS

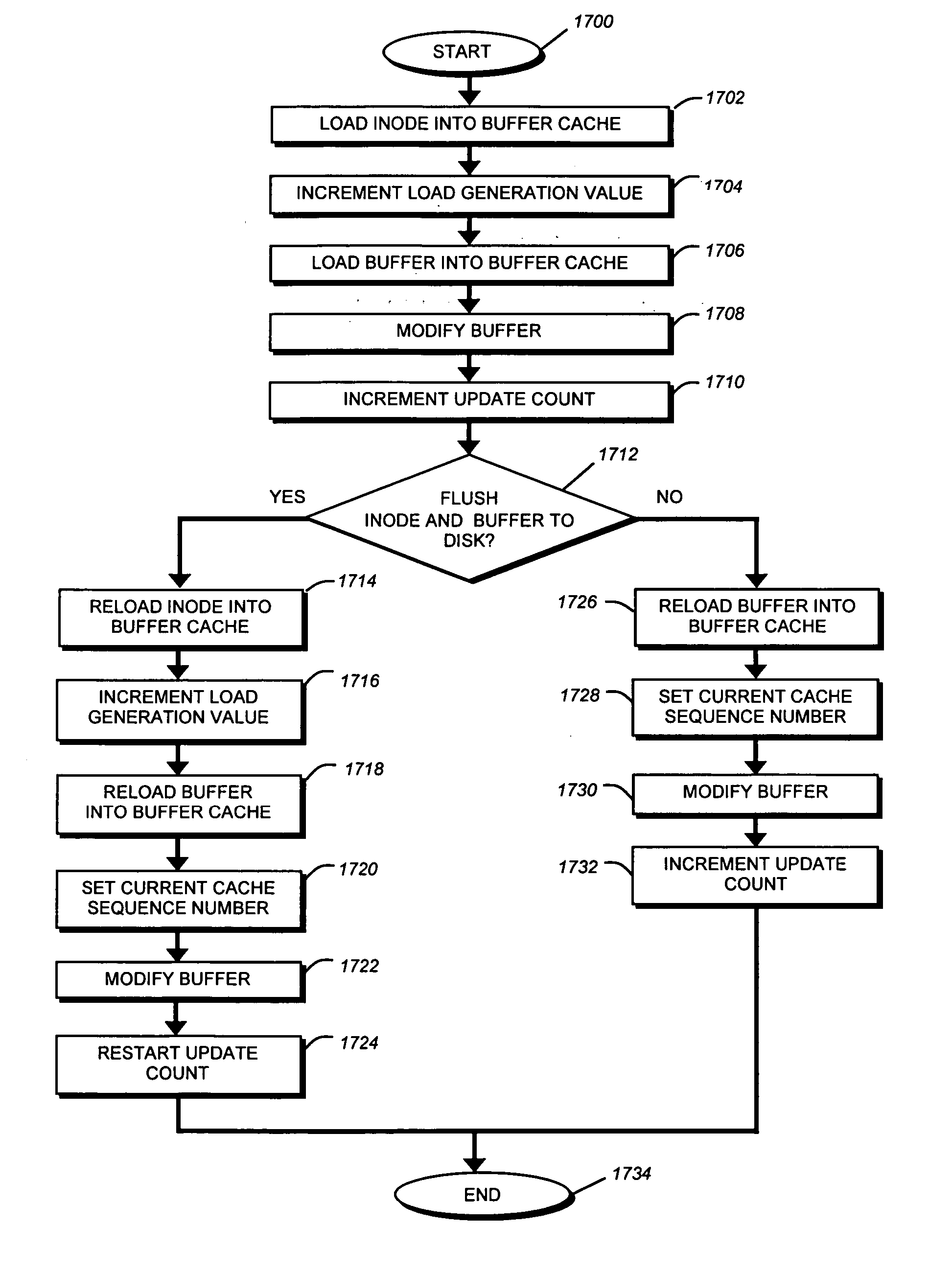

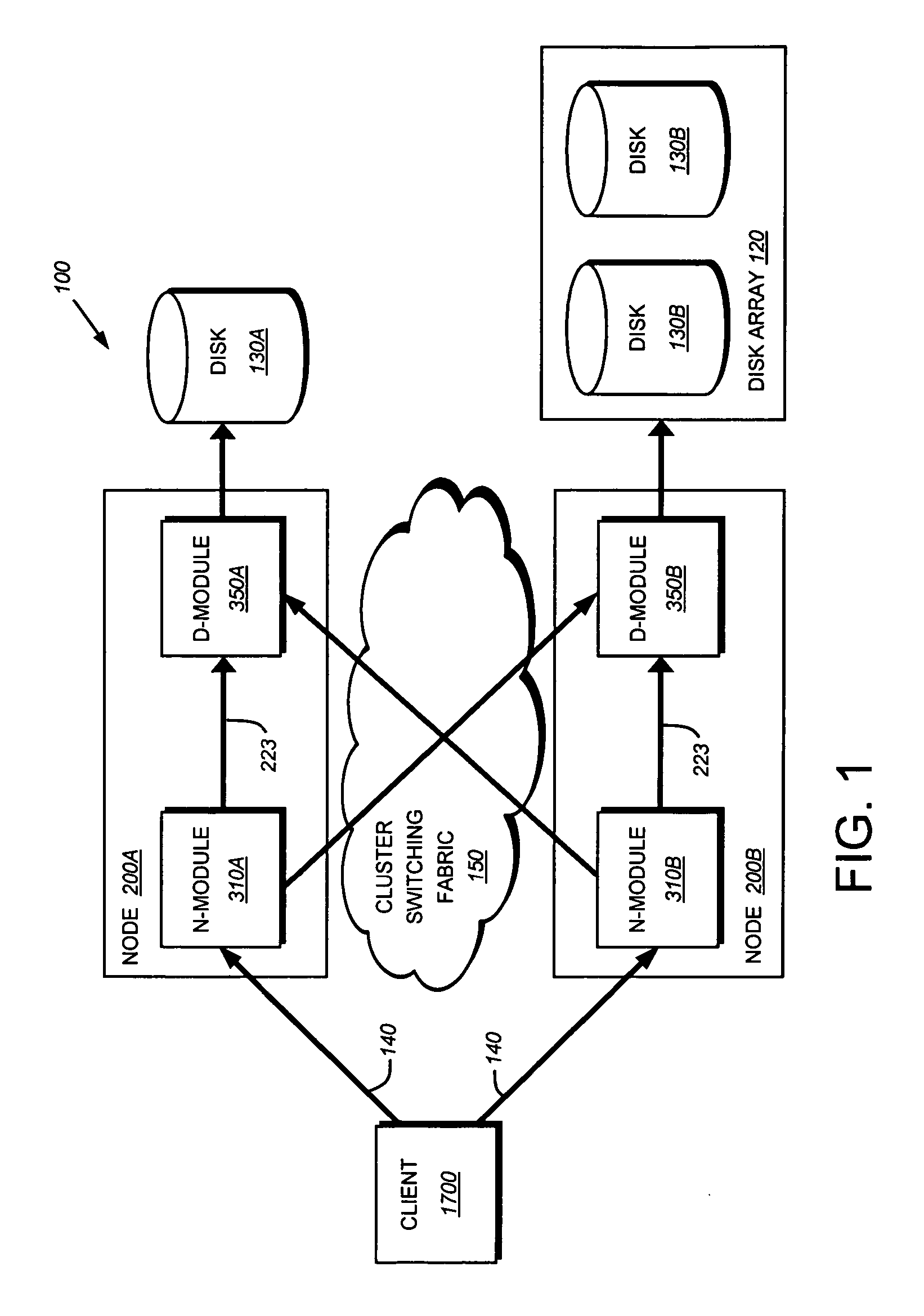

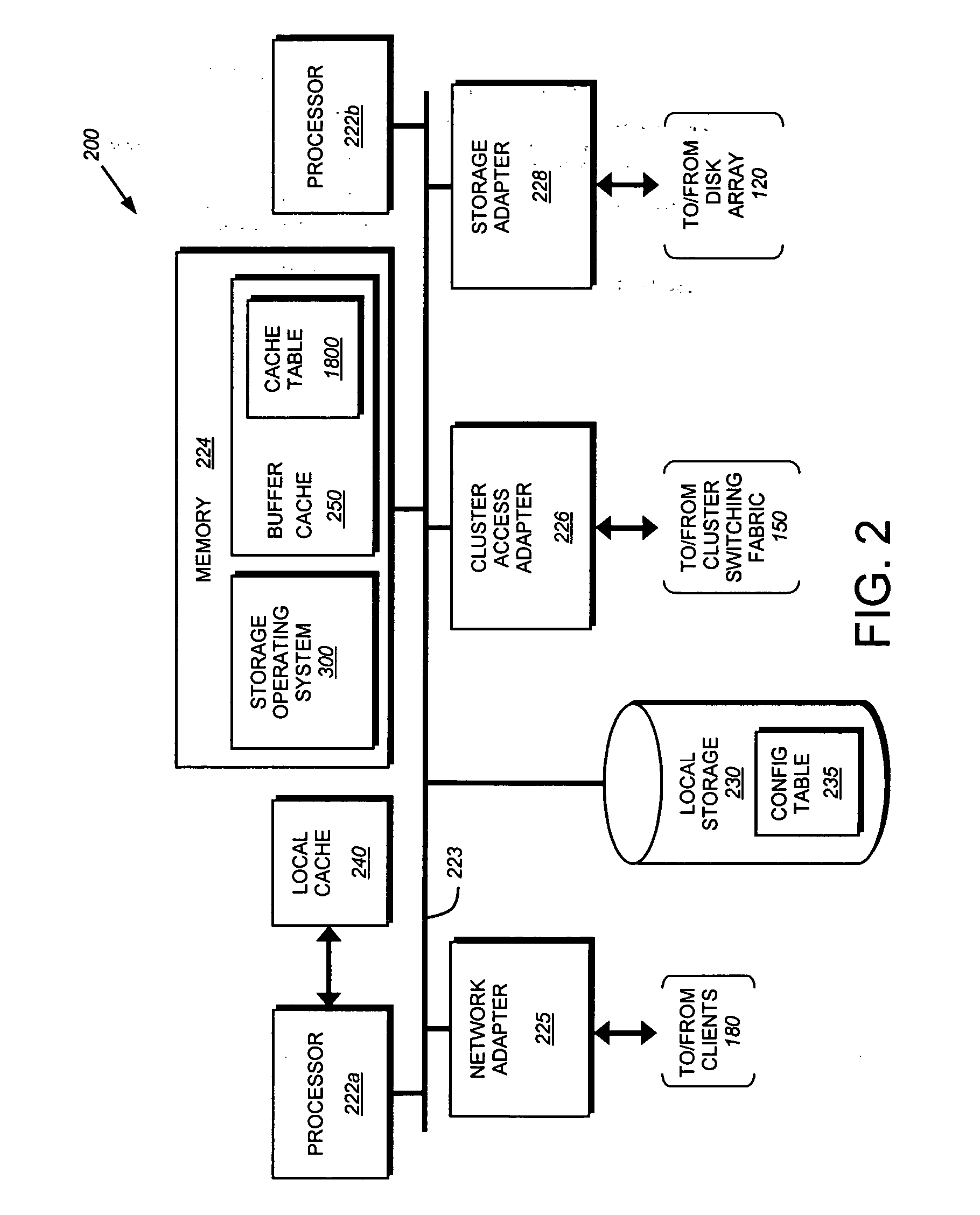

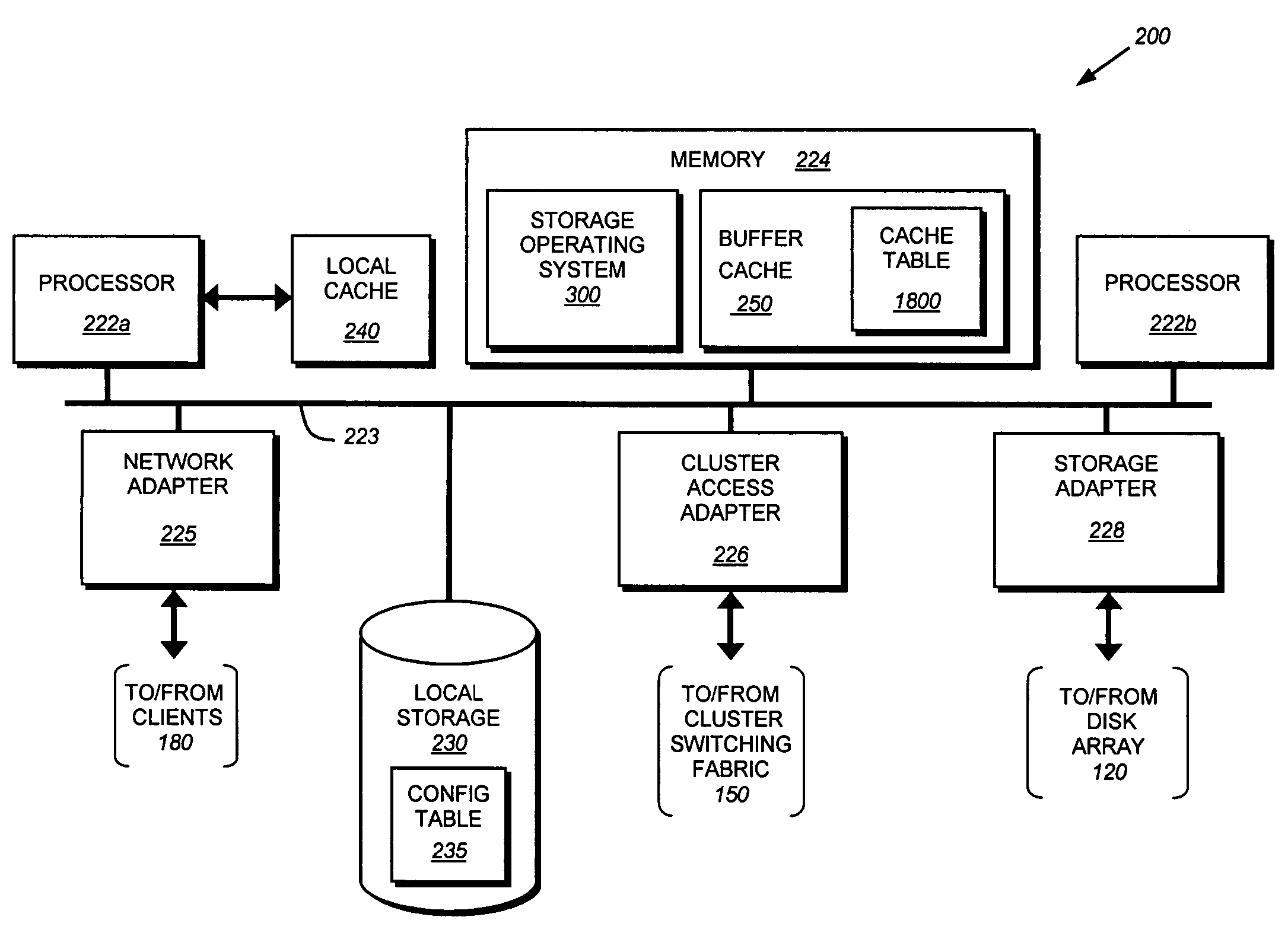

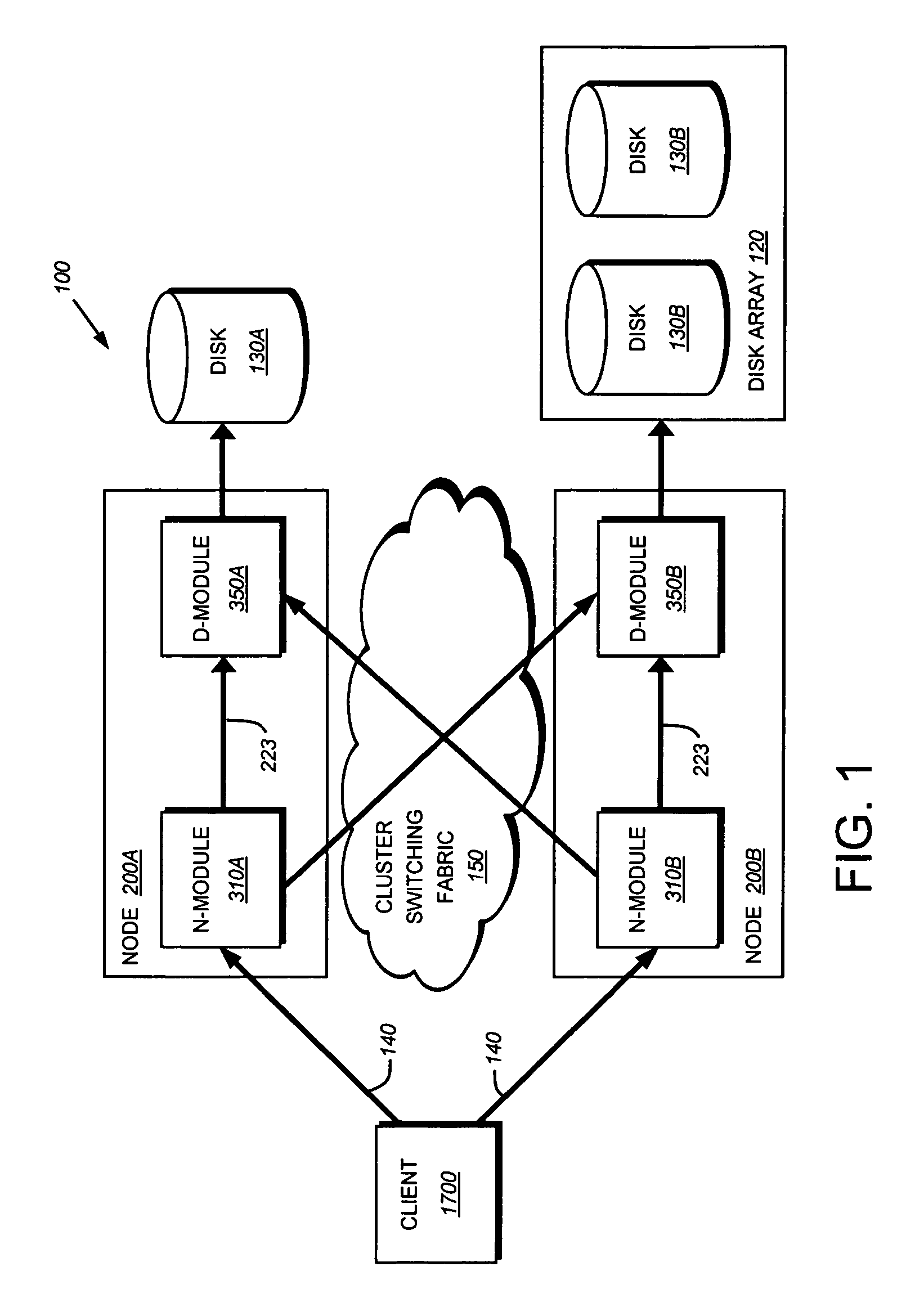

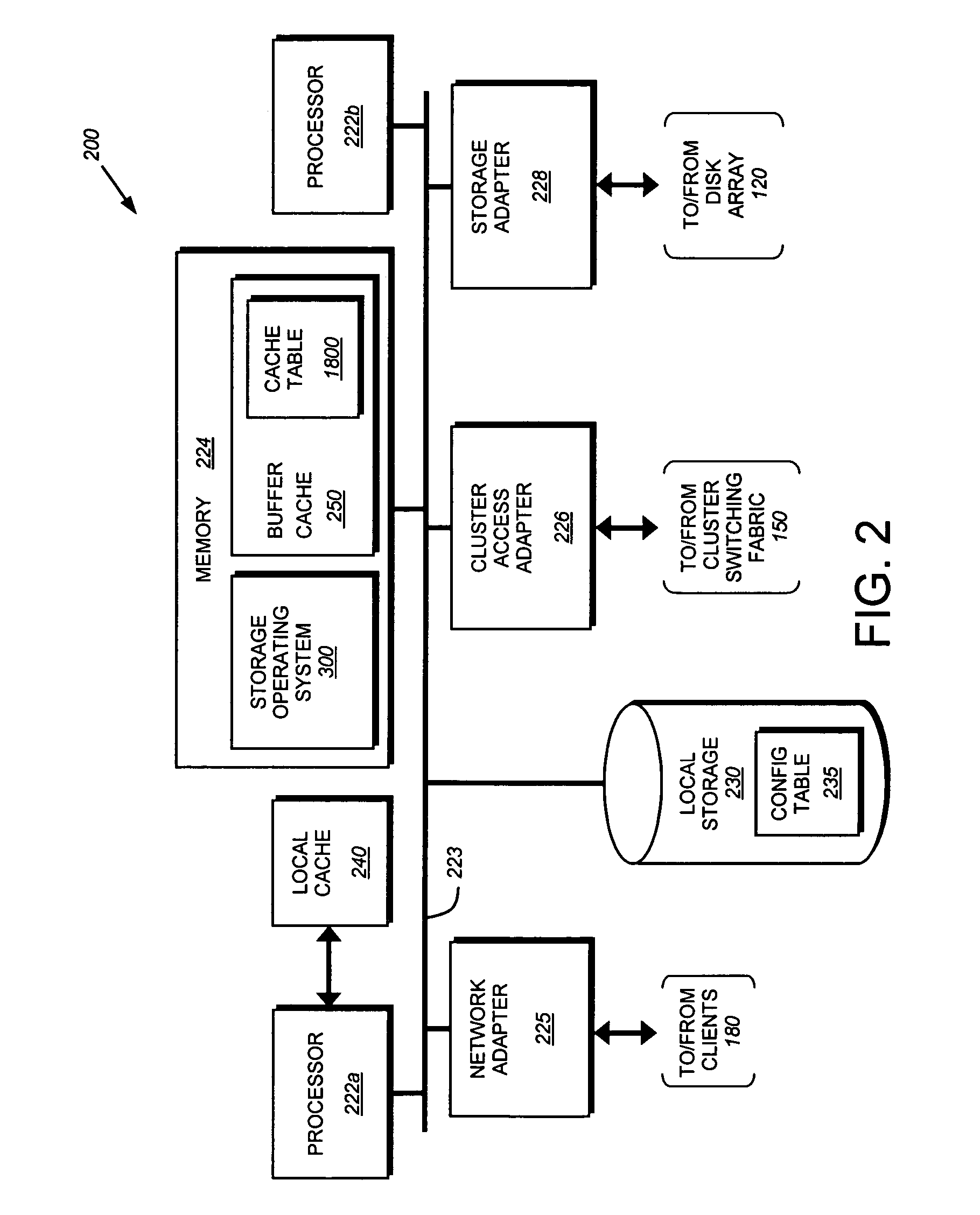

Lightweight coherency control protocol for clustered storage system

ActiveUS20070101069A1Memory architecture accessing/allocationMemory systemsLoad generationParallel computing

A lightweight coherency control protocol ensures consistency of data containers, such as a file, and associated data buffers stored on one or more volumes served by a plurality of nodes, e.g., storage systems, connected as a cluster. Each data buffer is associated with a current cache sequence number comprising a load generation value and an update count value. The load generation value is incremented every time an inode of a file is loaded into a memory of the storage system. Once the inode is loaded and its load generation value is set, then the appropriate buffer of a buffer tree for the file is loaded into the memory. The update count value is incremented each time the buffer is updated with a write request / operation. Therefore, each buffer loaded into memory is tagged with the load generation value and an update count from the time that buffer is loaded.

Owner:NETWORK APPLIANCE INC

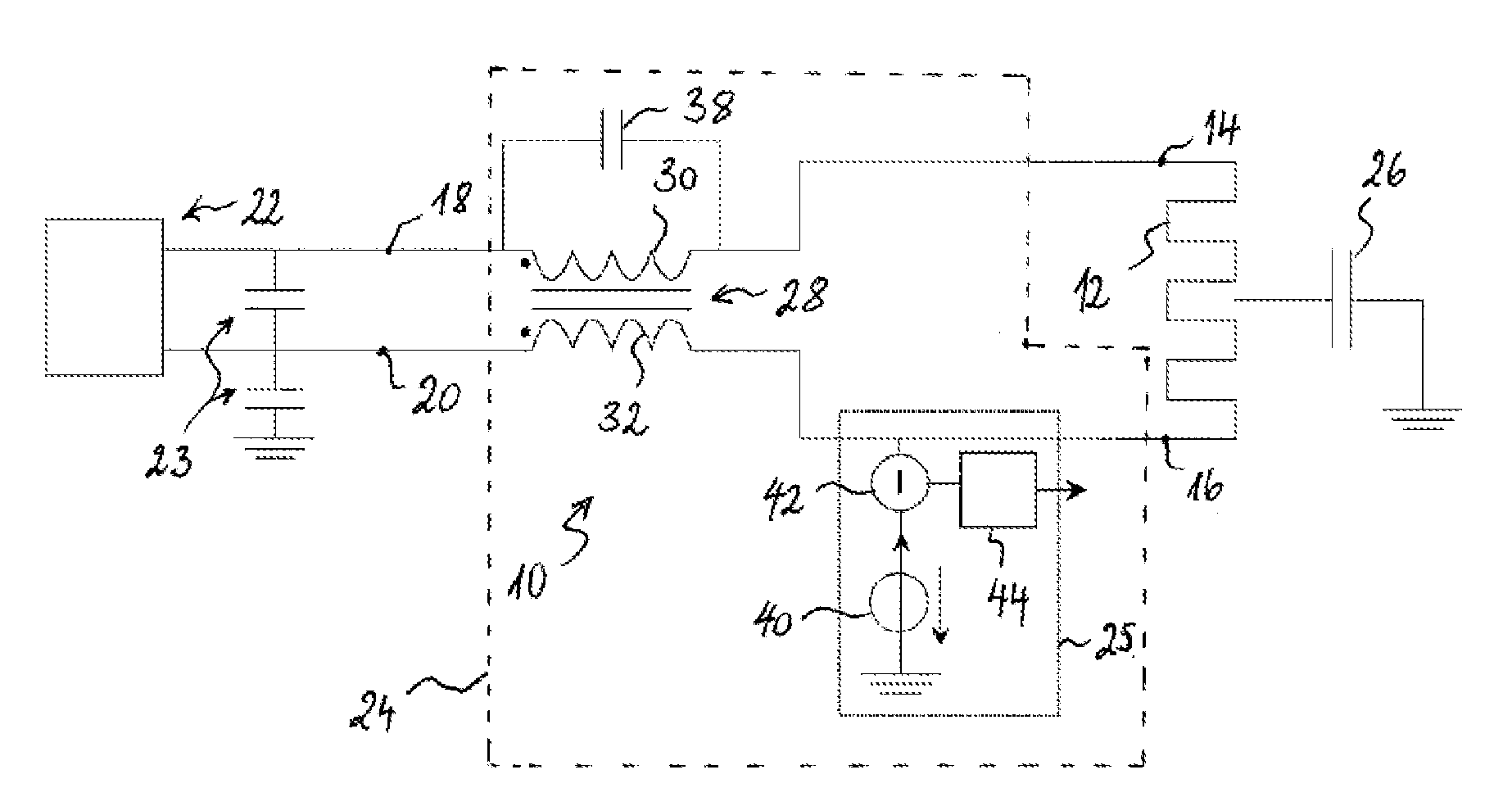

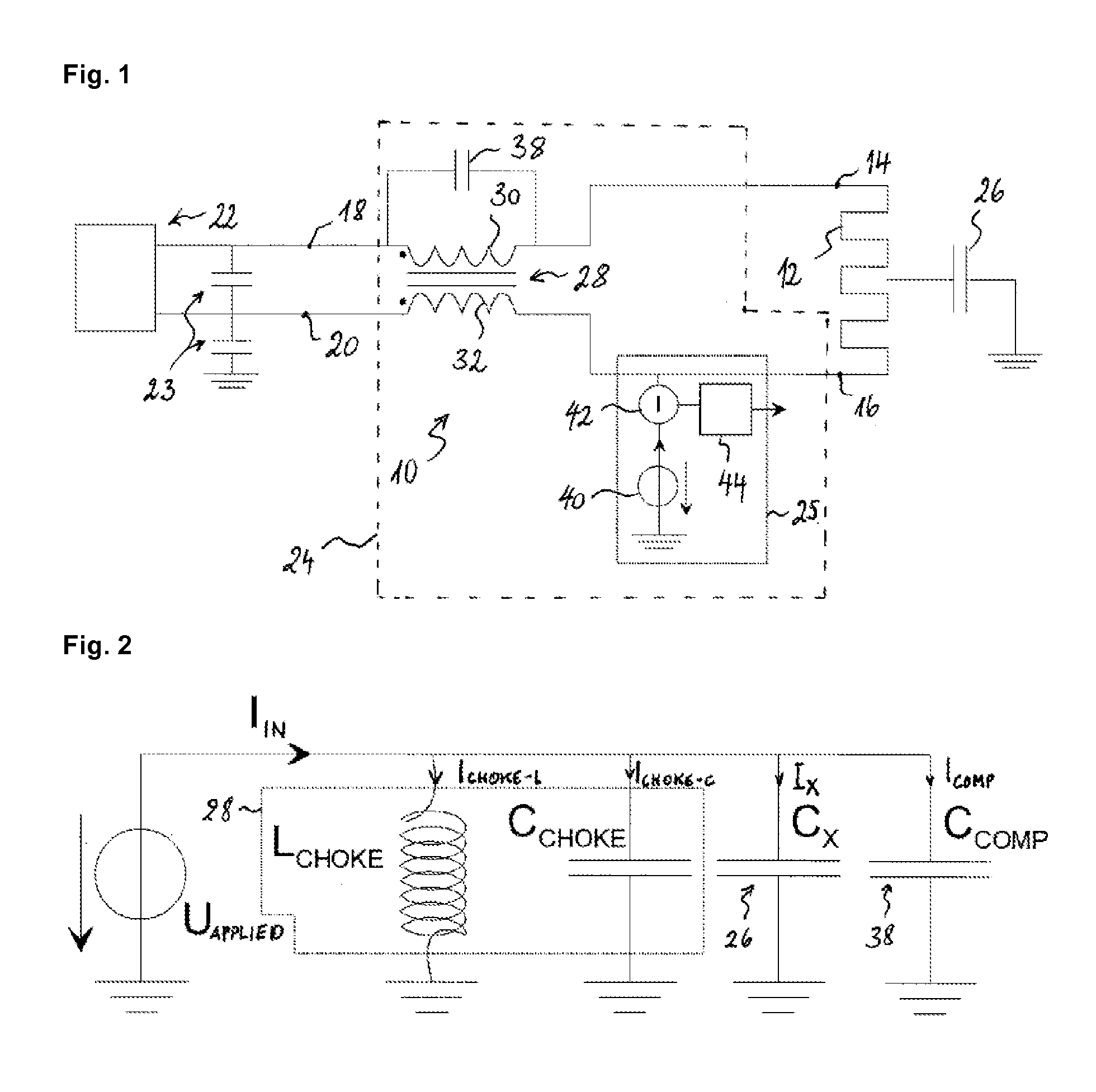

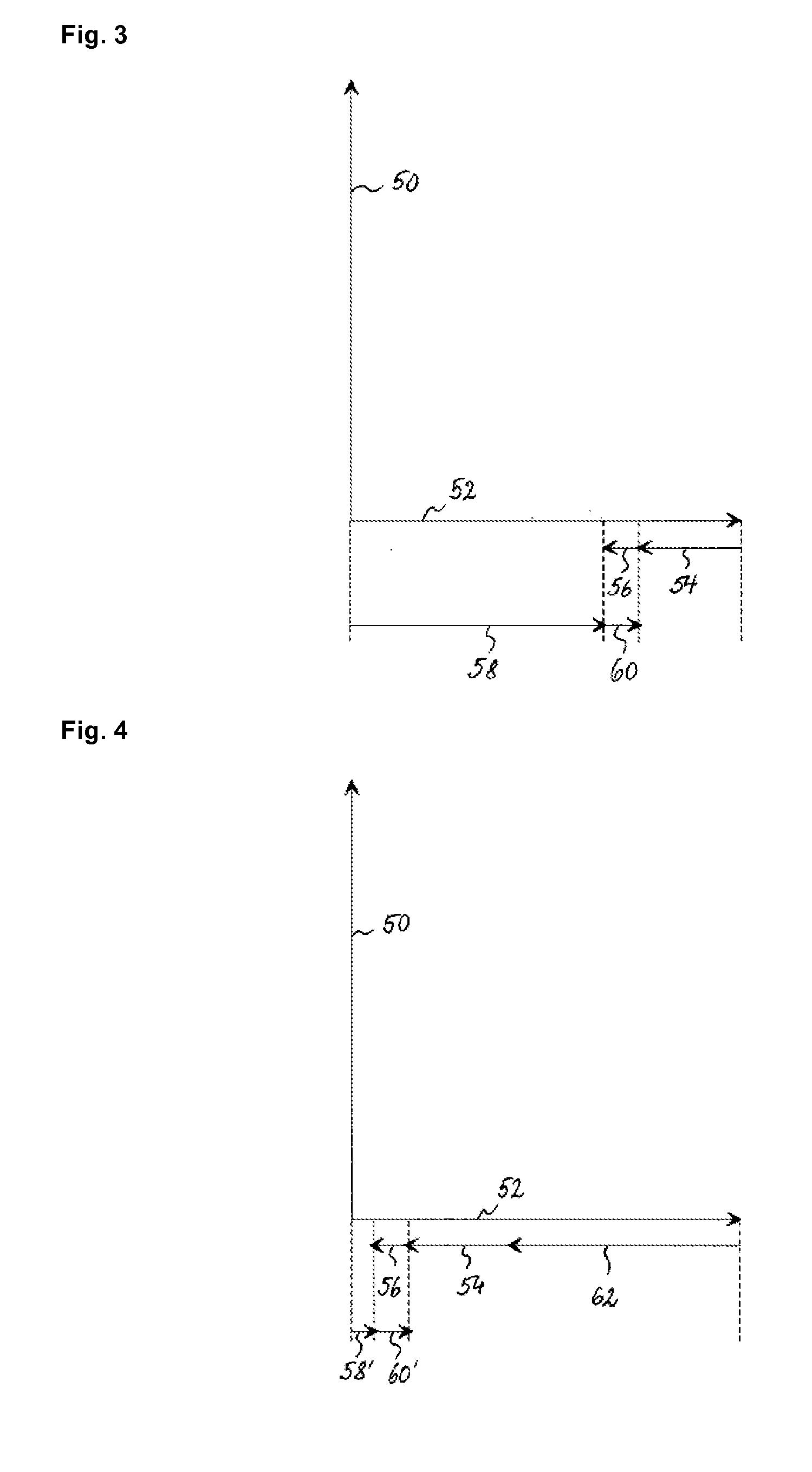

Capacitive sensing system configured for using heating element as antenna electrode

A capacitive sensing system for a heating element comprises a capacitive detector connectable to the heating element and a common mode choke for connecting the heating element with a heating current supply. The detector drives an alternating current into the heating element and produces an output depending on the capacitive load, which the alternating current is subject to. Depending on the object sensed, the load varies in a range between a minimum and a maximum value. The choke represents an inductive load in parallel of the capacitive load. The capacitive load and the inductive load contribute to a complex impedance dominated by the inductive load. A compensation capacitor arranged parallel to the choke represents an additional capacitive load also contributing to the complex impedance. The compensation capacitor is dimensioned such that the sum of additional capacitive load and maximum value amounts to at least 50% of the inductive load.

Owner:IEE INT ELECTRONICS & ENG SA

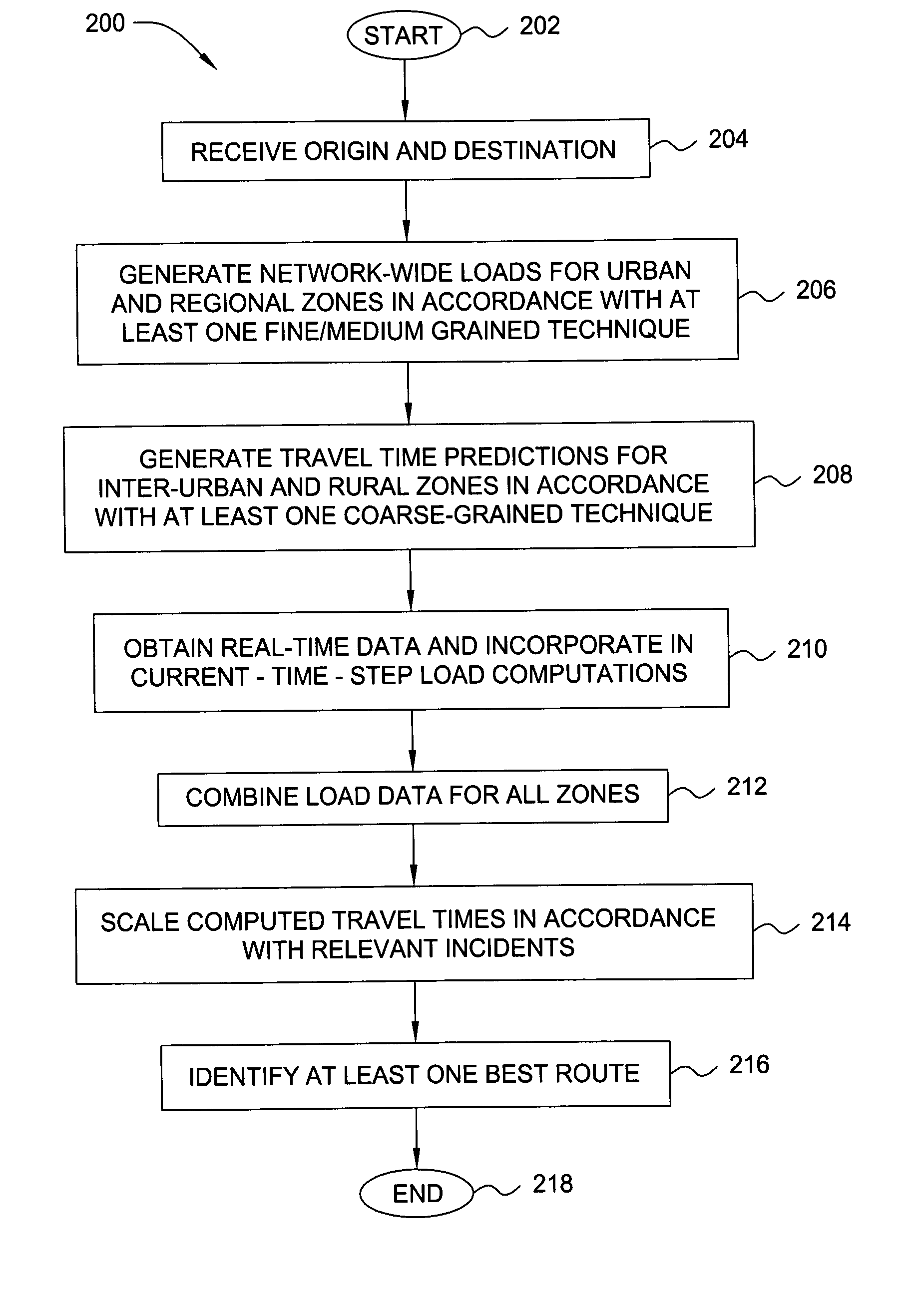

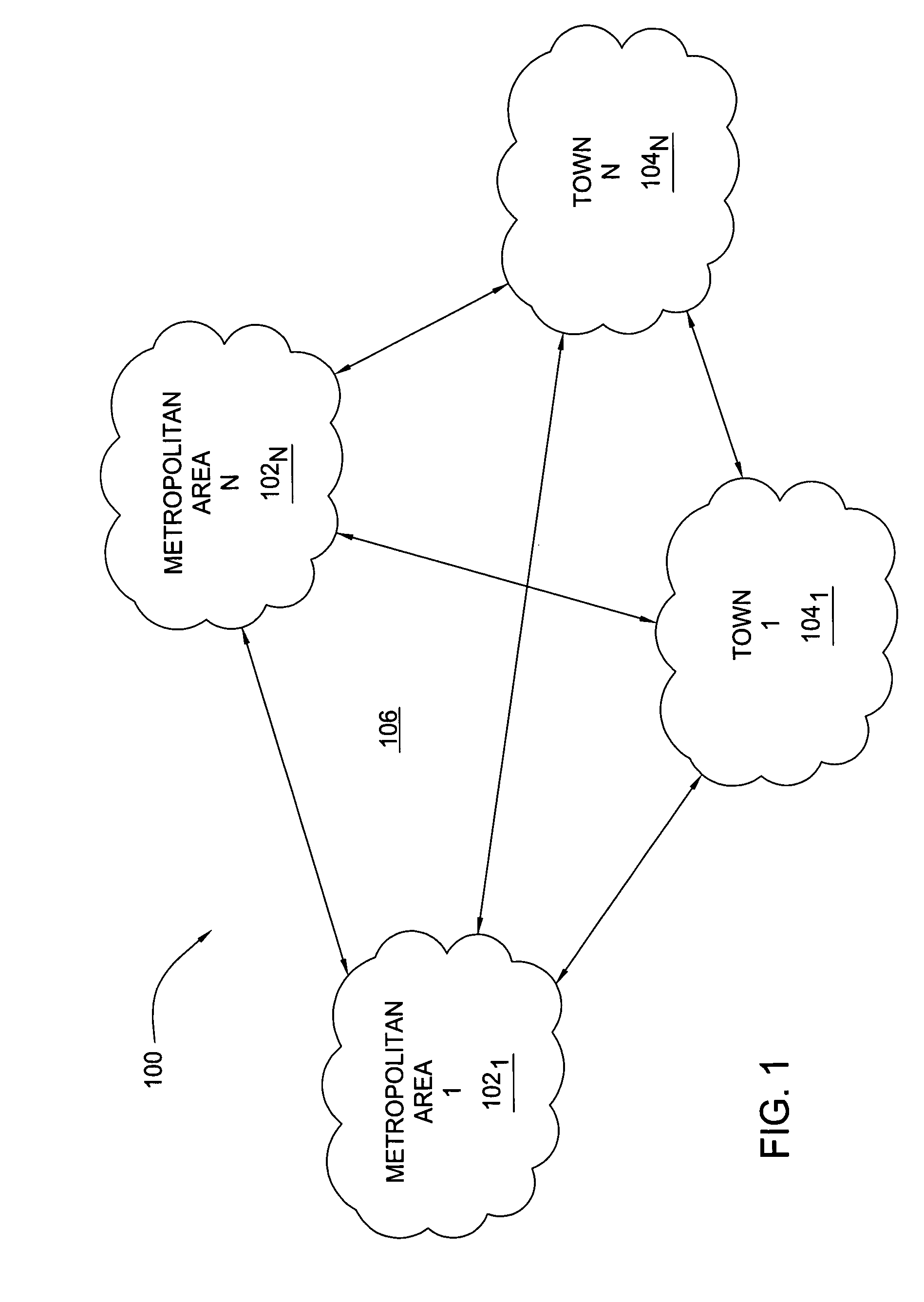

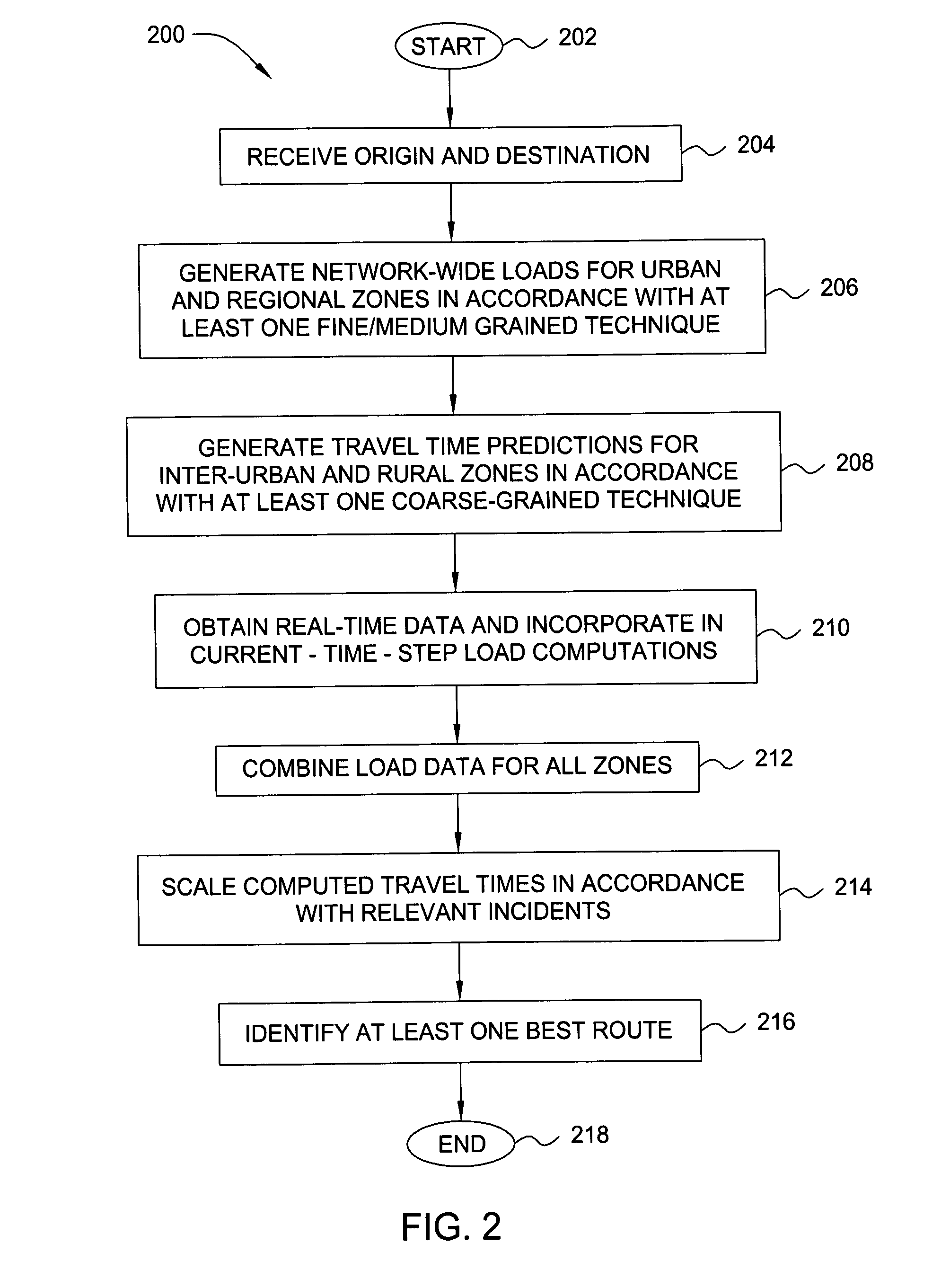

Method and apparatus for end-to-end travel time estimation using dynamic traffic data

ActiveUS7236881B2Identification of best and fastAnalogue computers for vehiclesInstruments for road network navigationReal-time dataLoad generation

The present invention is a method and an apparatus for end-to-end travel time estimation using dynamic traffic data. In one embodiment, a method for estimating a fastest route between a first point in a transportation network and a second point in the transportation network includes receiving static data relating to static characteristics of a first zone and a second zone in the transportation network. In addition, real-time data relating to real-time traffic conditions in the first zone is also received. The static and real-time data is processed in accordance with at least one fine-grained load-generation technique to generate a first load for the first zone, and the static data is generated in accordance with at least one coarse-grained load-generation technique to generate a second load for the second zone. These first and second loads are then combined, converted to travel times, and scaled to facilitate the identification of a best or fastest route.

Owner:GOOGLE LLC

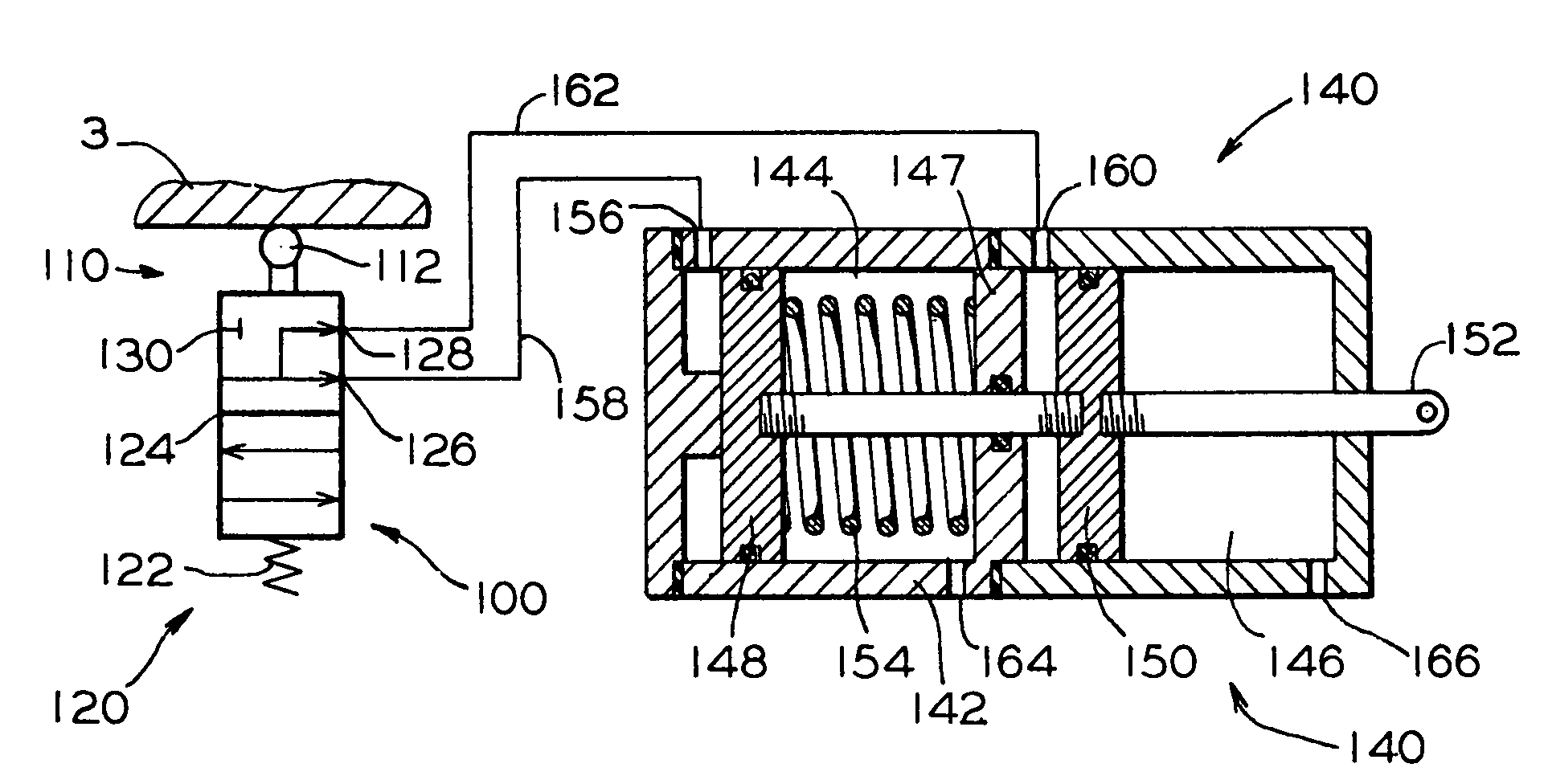

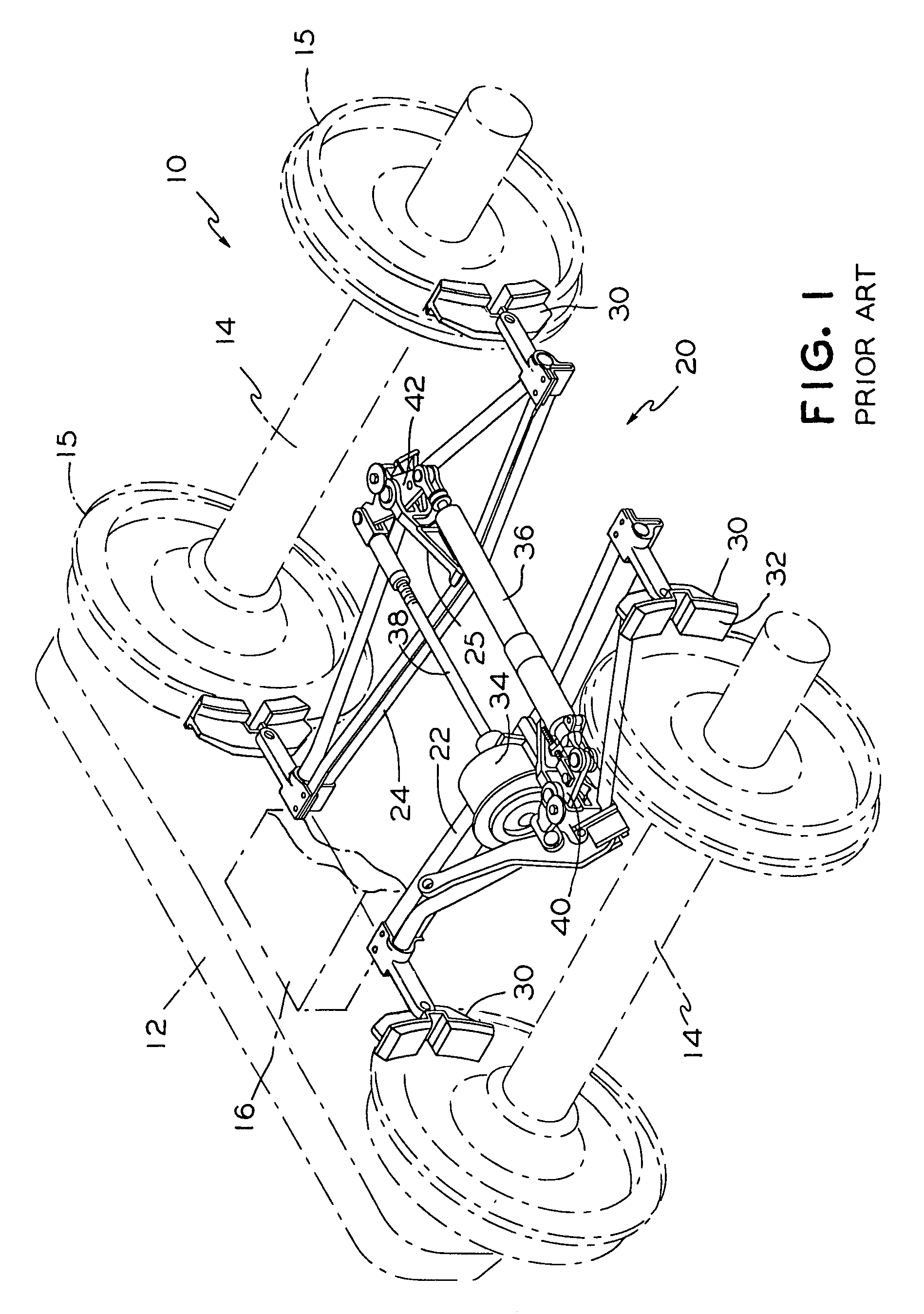

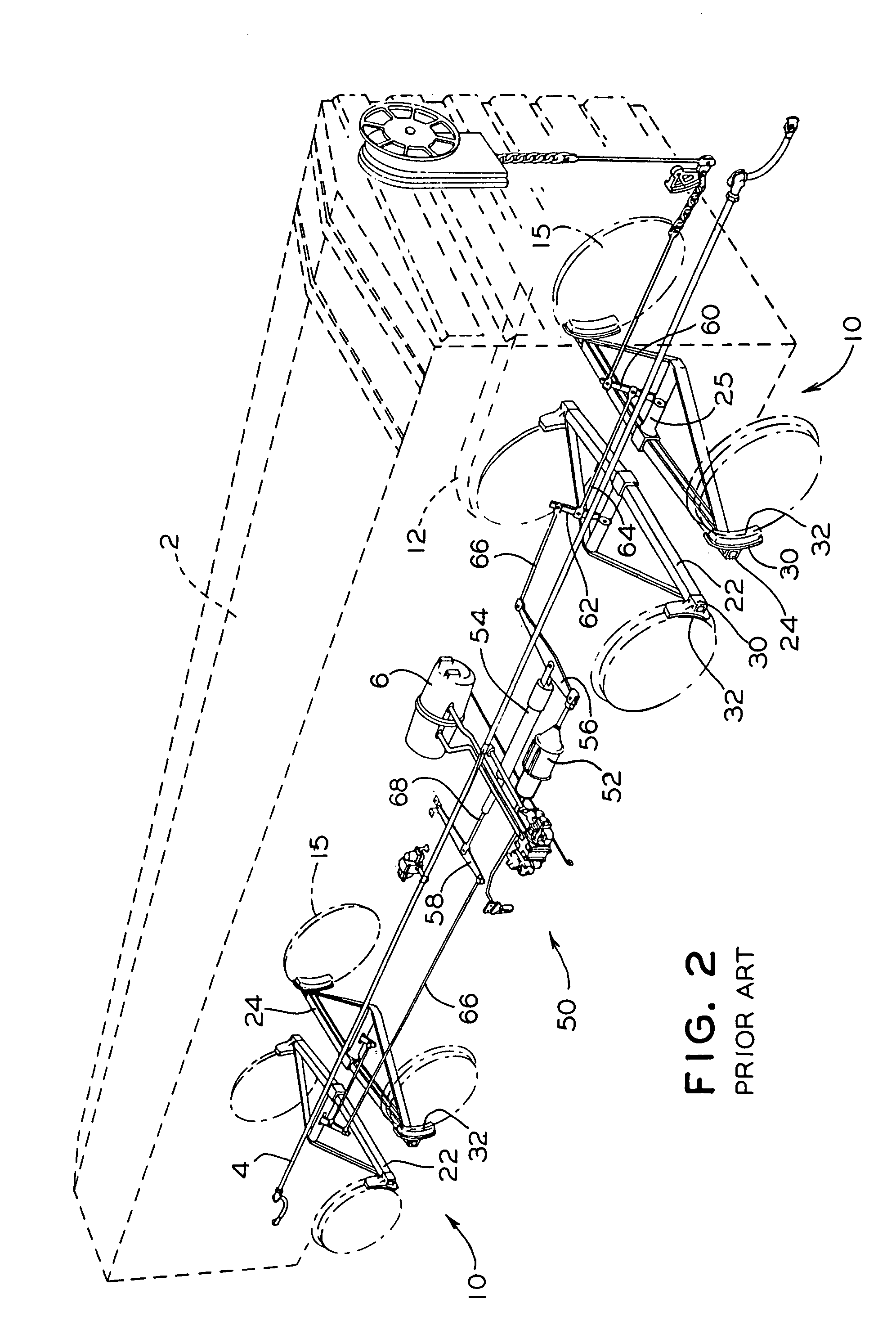

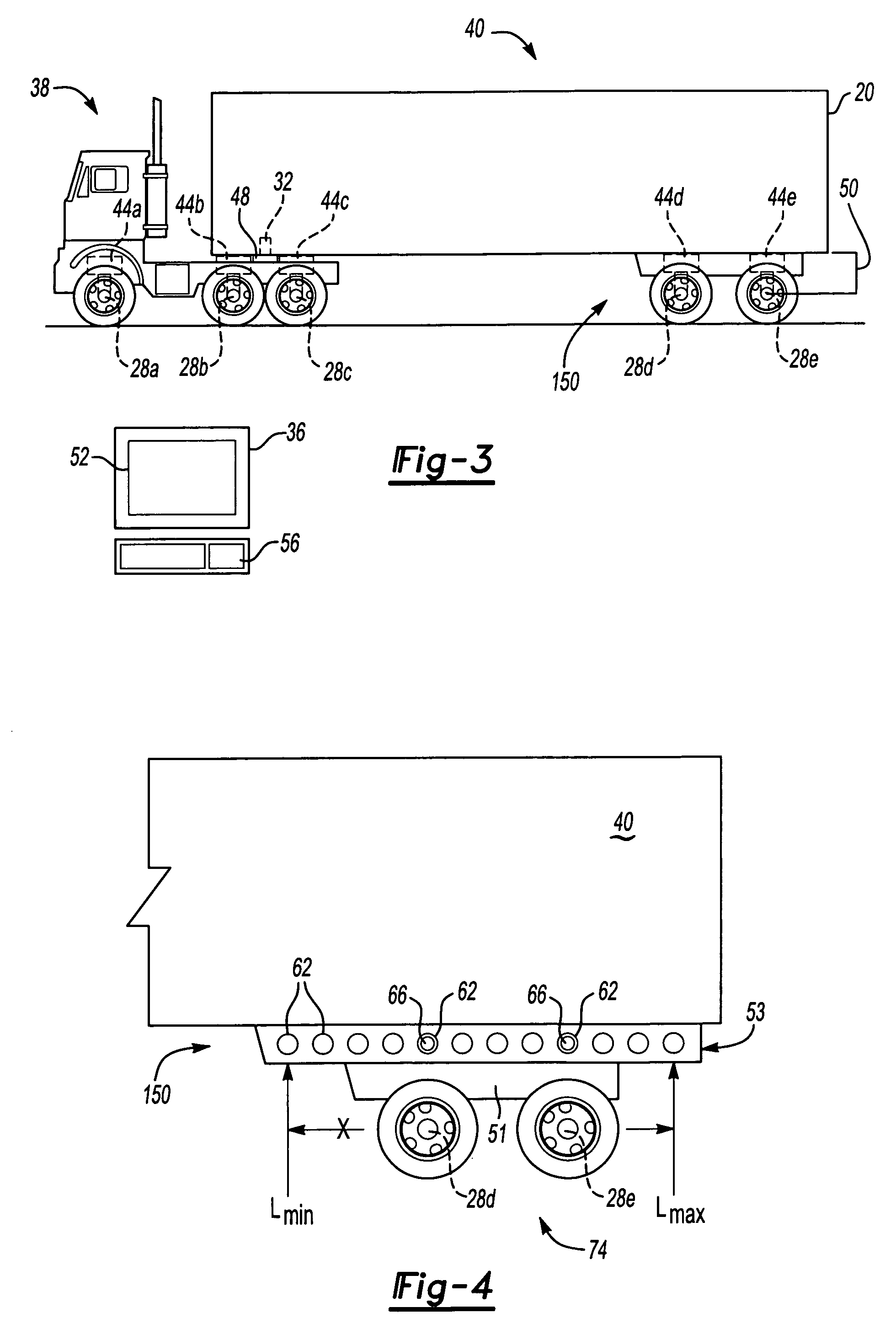

Brake system with integrated car load compensating arrangement

ActiveUS7416262B2Improve efficiencyBraking action transmissionRail brake actuationLoad generationTruck

A railway car brake system comprising a control device engageable with a predetermined portion of such railway car for compensating braking force in response to a load carried by such railway car. The control device includes a sensor mechanism engageable with a truck bolster or a movable car structure for sensing a vertical position thereof corresponding to a load carried by the railway car. There is a control valve engageable with the sensor mechanism which generates a fluid pressure signal responsive to such load. A pneumatic actuator engageable with a predetermined brake beam disposed on such truck assembly and connected to such control valve. This pneumatic actuator generates a predetermined braking force responsive to the fluid pressure signal and further responsive to the load carried by the railway car as sensed by the sensor mechanism. Such predetermined braking force may be proportionally adjusted to variations in the load carried by the railway car.

Owner:WABTEC HLDG CORP

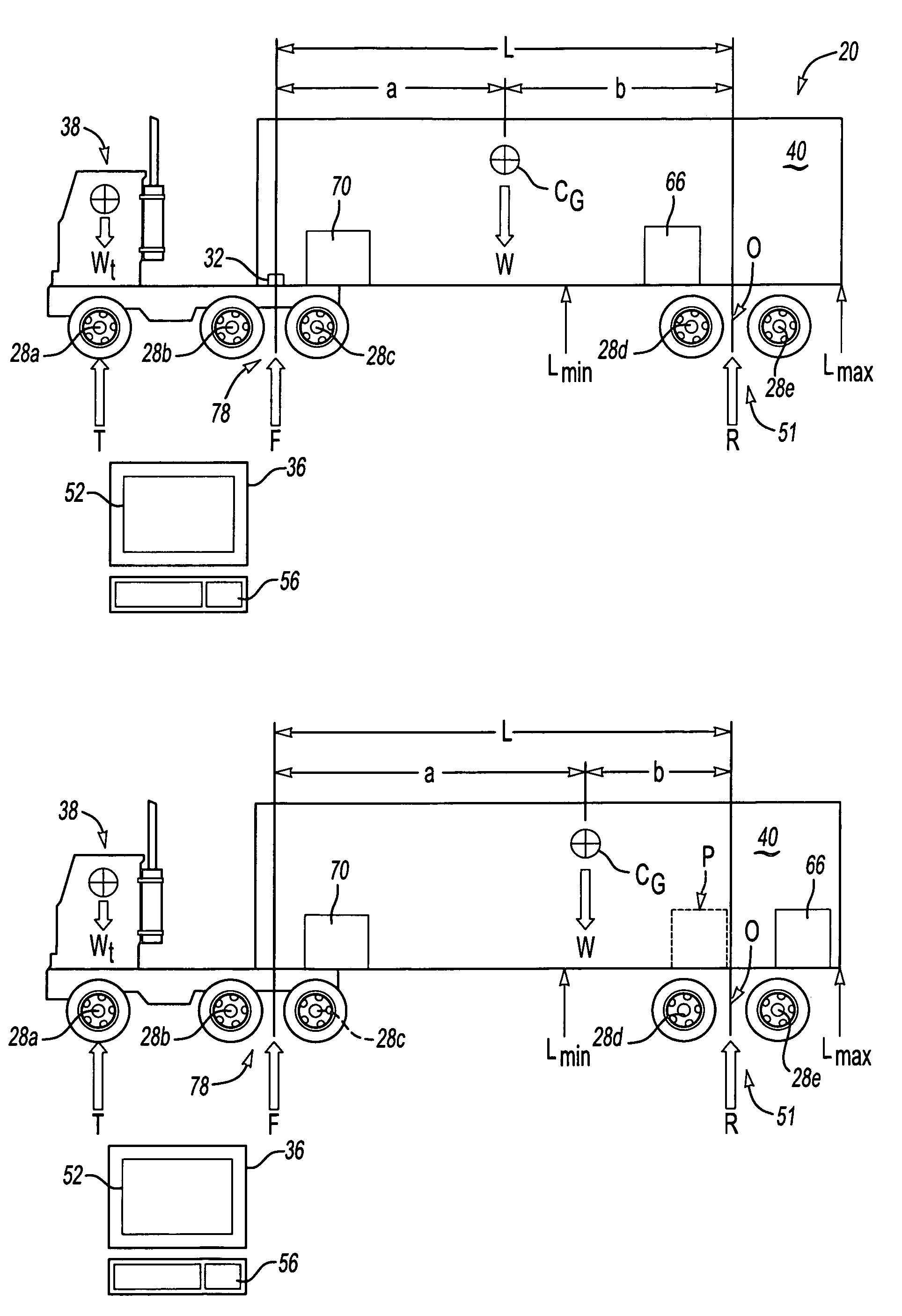

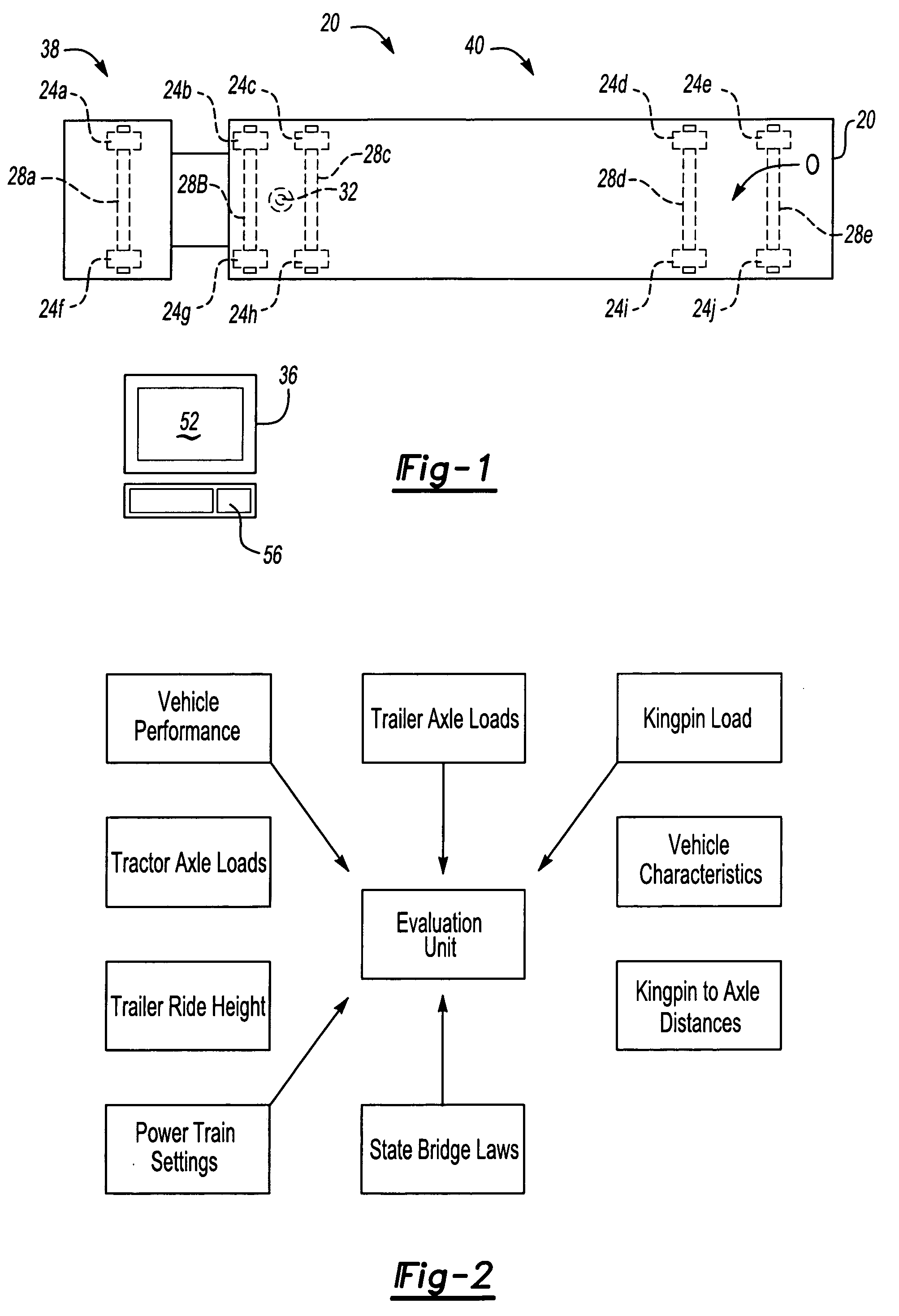

Intelligent load distribution system

InactiveUS7072763B2Improve performanceWeighing apparatus testing/calibrationDigital computer detailsLoad generationEngineering

A vehicle information system has a first load sensor for generating a first load signal based on a first vehicle load. A first position sensor generates a first position signal based on a position of a vehicle axle. A second position sensor generates a second position signal based on a position of a vehicle kingpin. A memory unit stores vehicle optimization data. An evaluation unit is in communication with the first load sensor, the first position sensor, the second position sensor and the memory unit. A general user interface for receiving input is also in communication with the evaluation unit. The evaluation unit makes an evaluation of the first load signal, the first position sensor, the second position signal, and any input and generates a vehicle optimization instruction relating to a distance between the axle and the kingpin.

Owner:ARVINMERITOR TECH

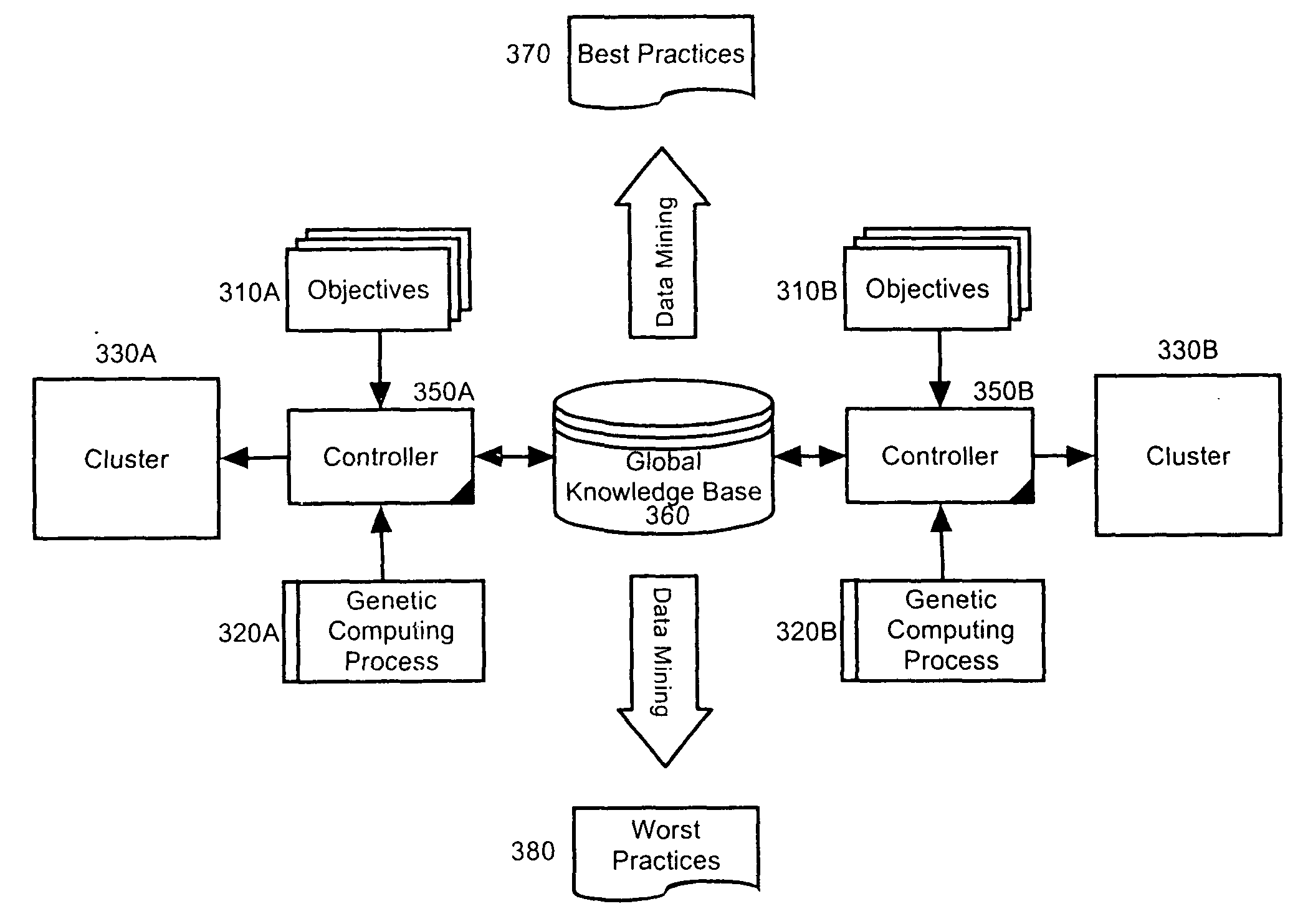

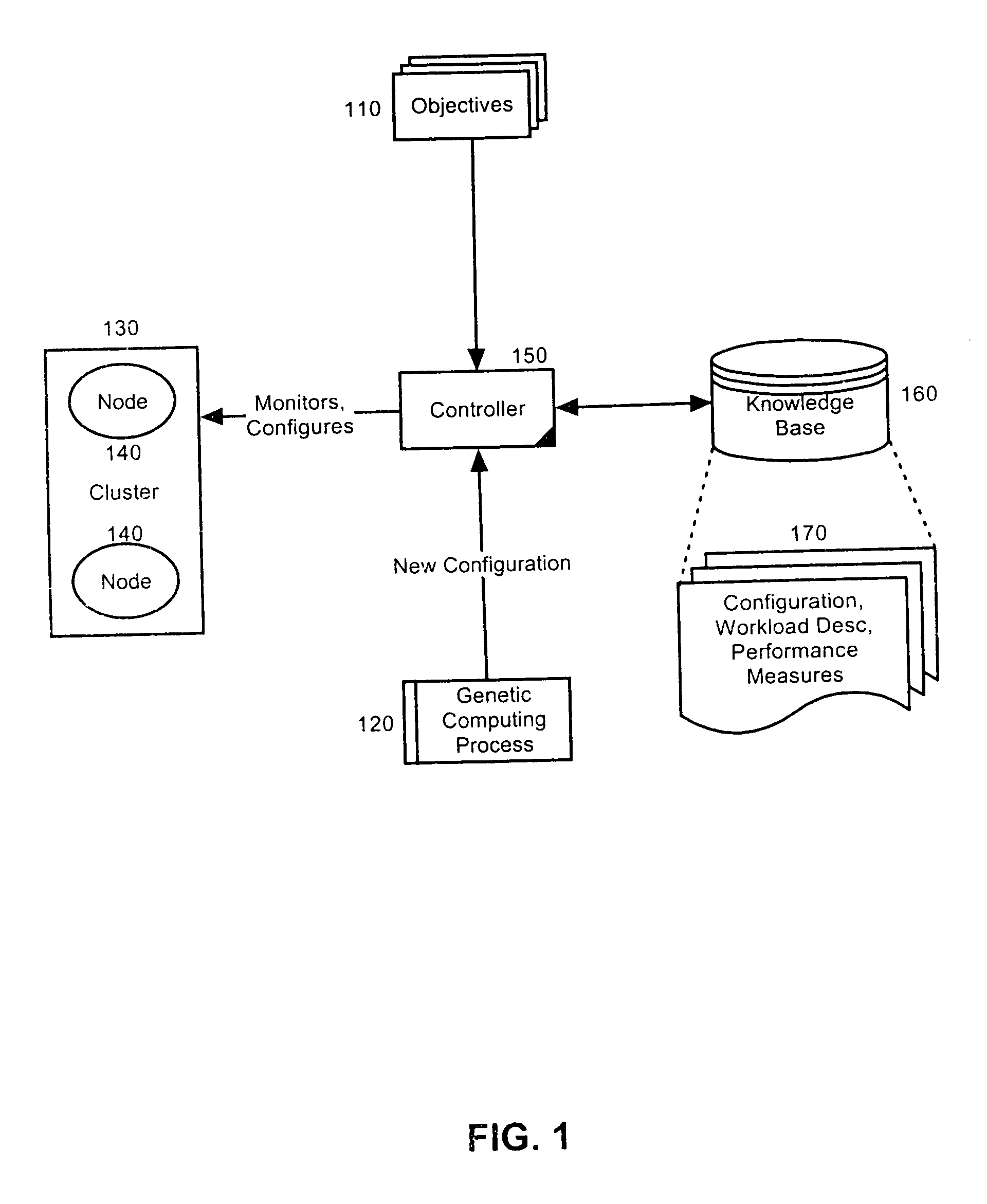

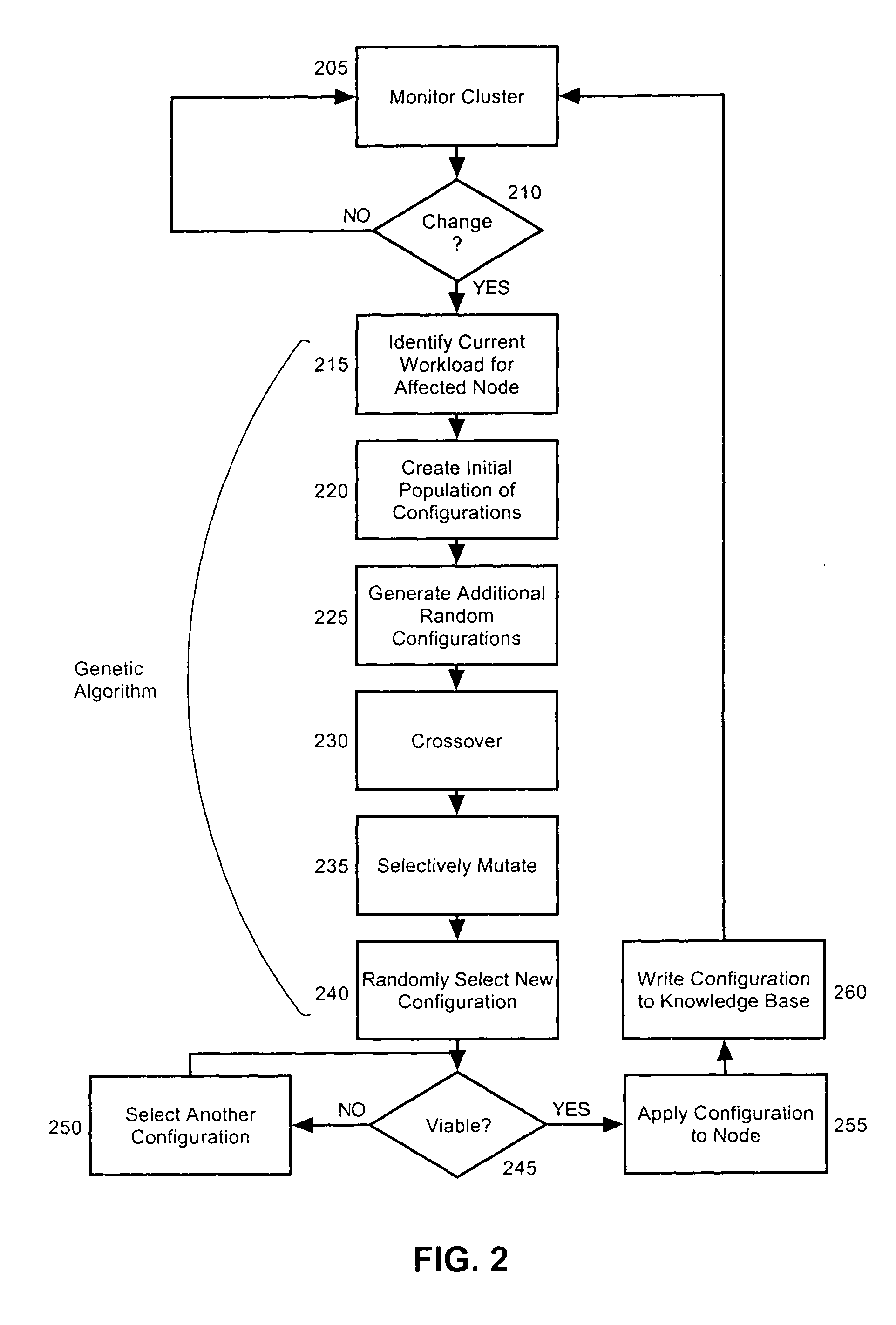

Autonomic cluster-based optimization

InactiveUS20050060391A1Easy to operateDigital computer detailsBiological neural network modelsLoad generationWorkload

A system for autonomically configuring a cluster of nodes can include a knowledge base of workload descriptions and associated configuration parameters, a genetic computing processor programmed to produce a selection of configuration parameters for a particular workload based upon a set of existing configuration parameters in the knowledge base, and, a controller coupled to the knowledge base and the cluster of nodes. The controller can include programming for monitoring the cluster of nodes and for applying individual ones of the selection of configuration parameters to the cluster of nodes to achieve an improved state of operation.

Owner:IBM CORP

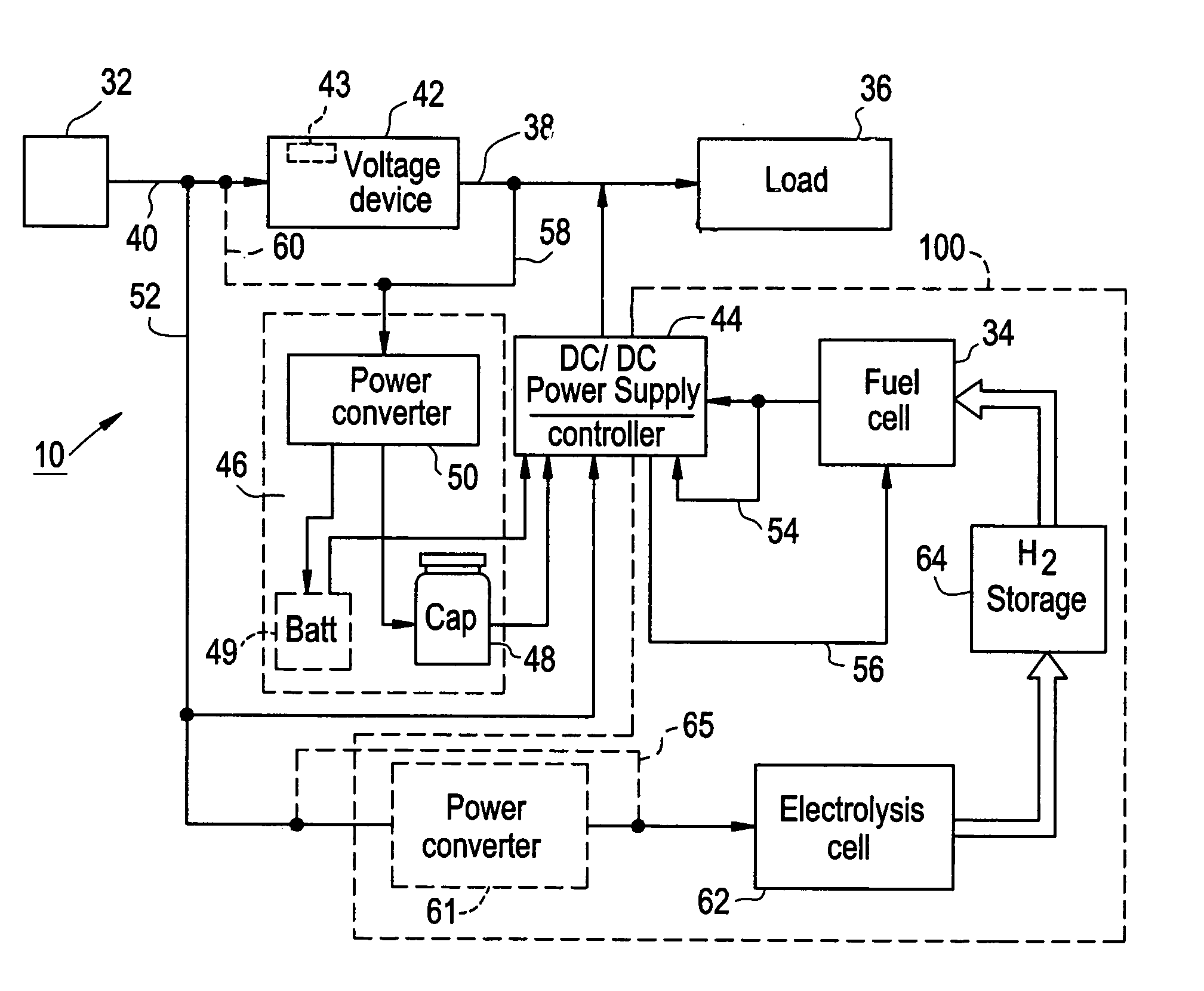

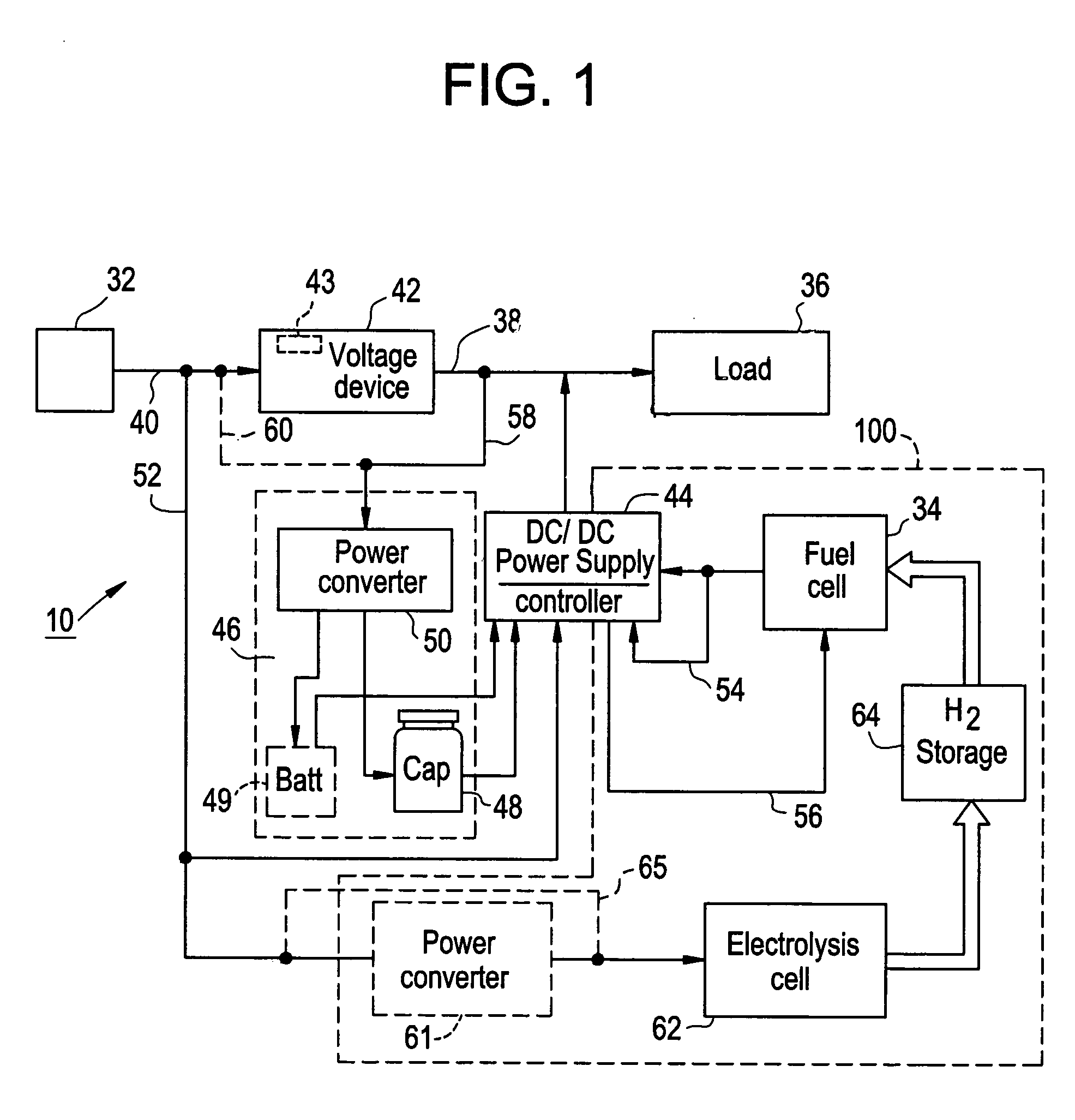

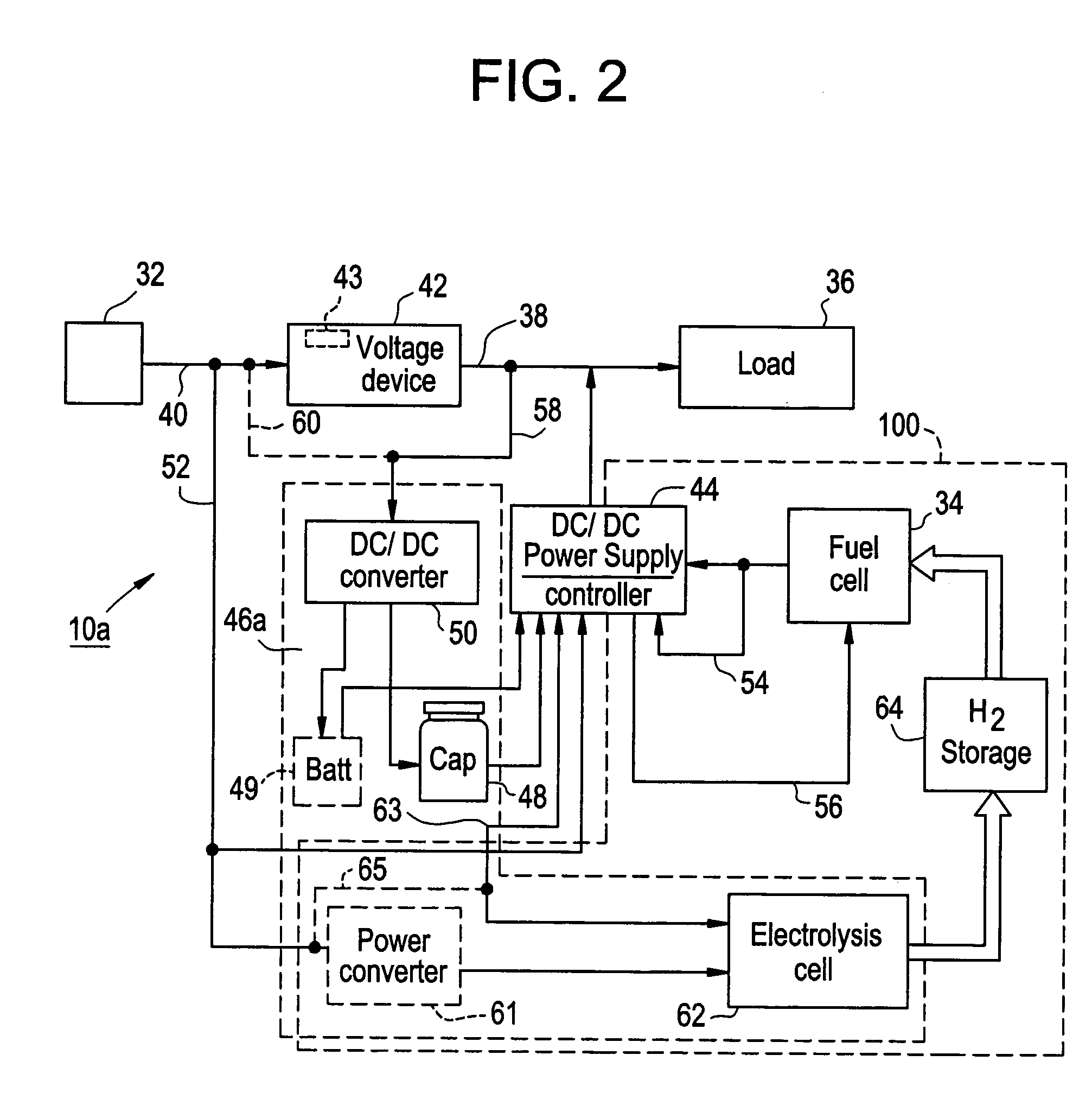

Method and system for controlling and recovering short duration bridge power to maximize backup power

InactiveUS20060078773A1Dc network circuit arrangementsBatteries circuit arrangementsFuel cellsPower capability

A system for providing back-up power to a load powered by a primary power source comprises: a fuel cell arrangement for generating back-up power for the load, a bridging power source for generating bridge power for the load, and a controller in operable communication with the fuel cell arrangement and the bridging power source. The controller is adapted to initiate application of the bridge power to the load upon detecting a deterioration of power from the primary power source, and is further adapted to initiate application of the back-up power to the load upon detecting a power capability of the back-up power to power the load.

Owner:SPERANZA A JOHN +4

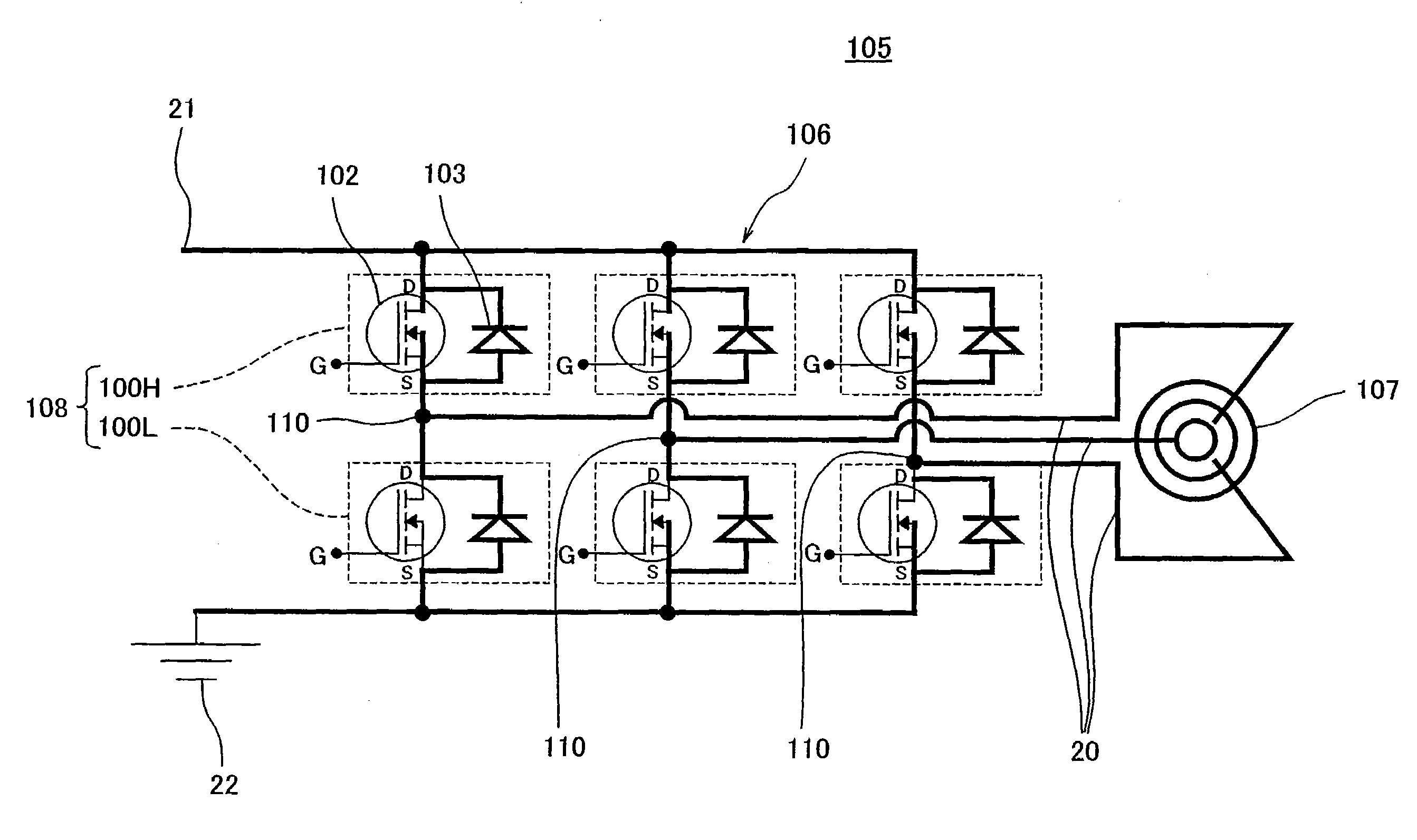

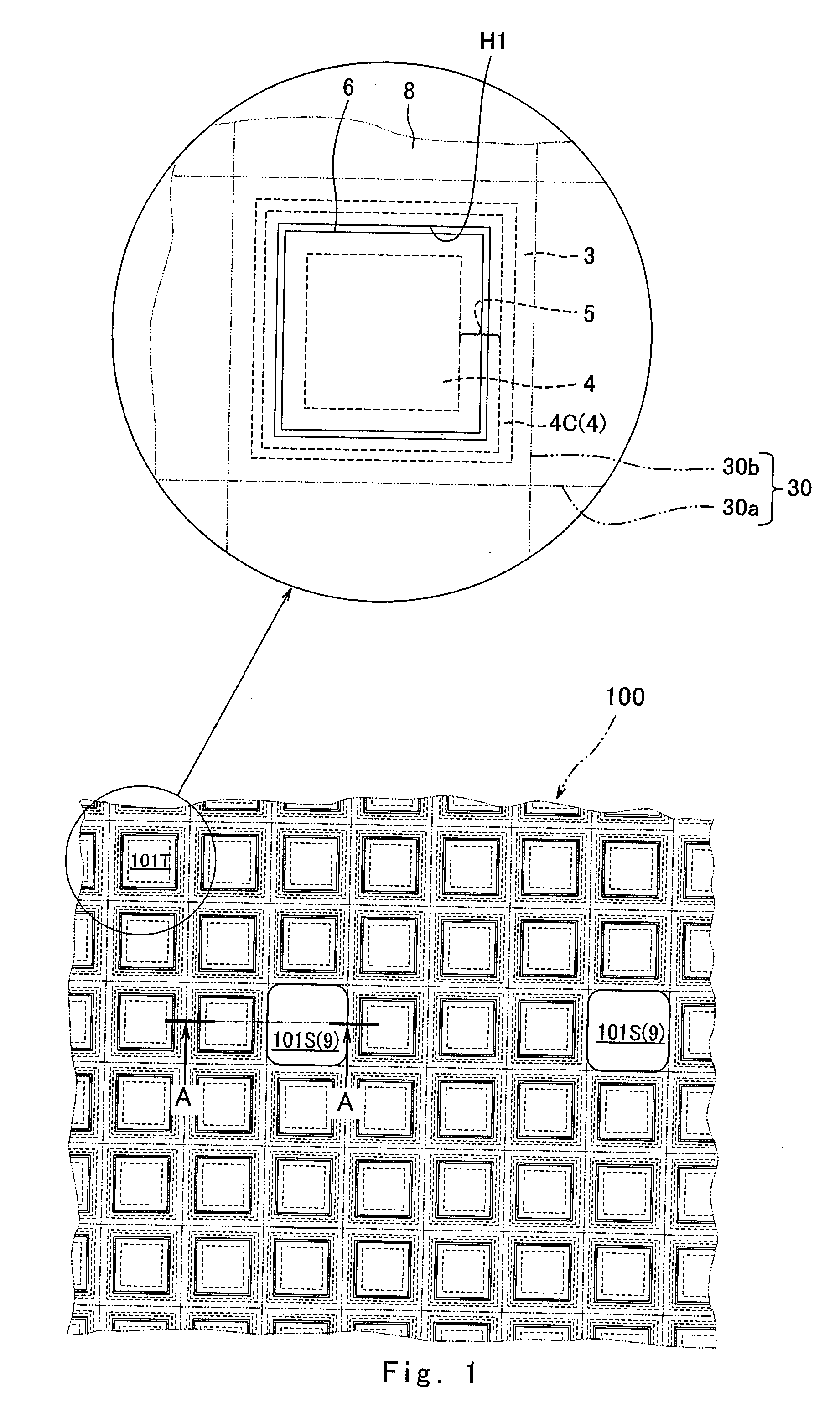

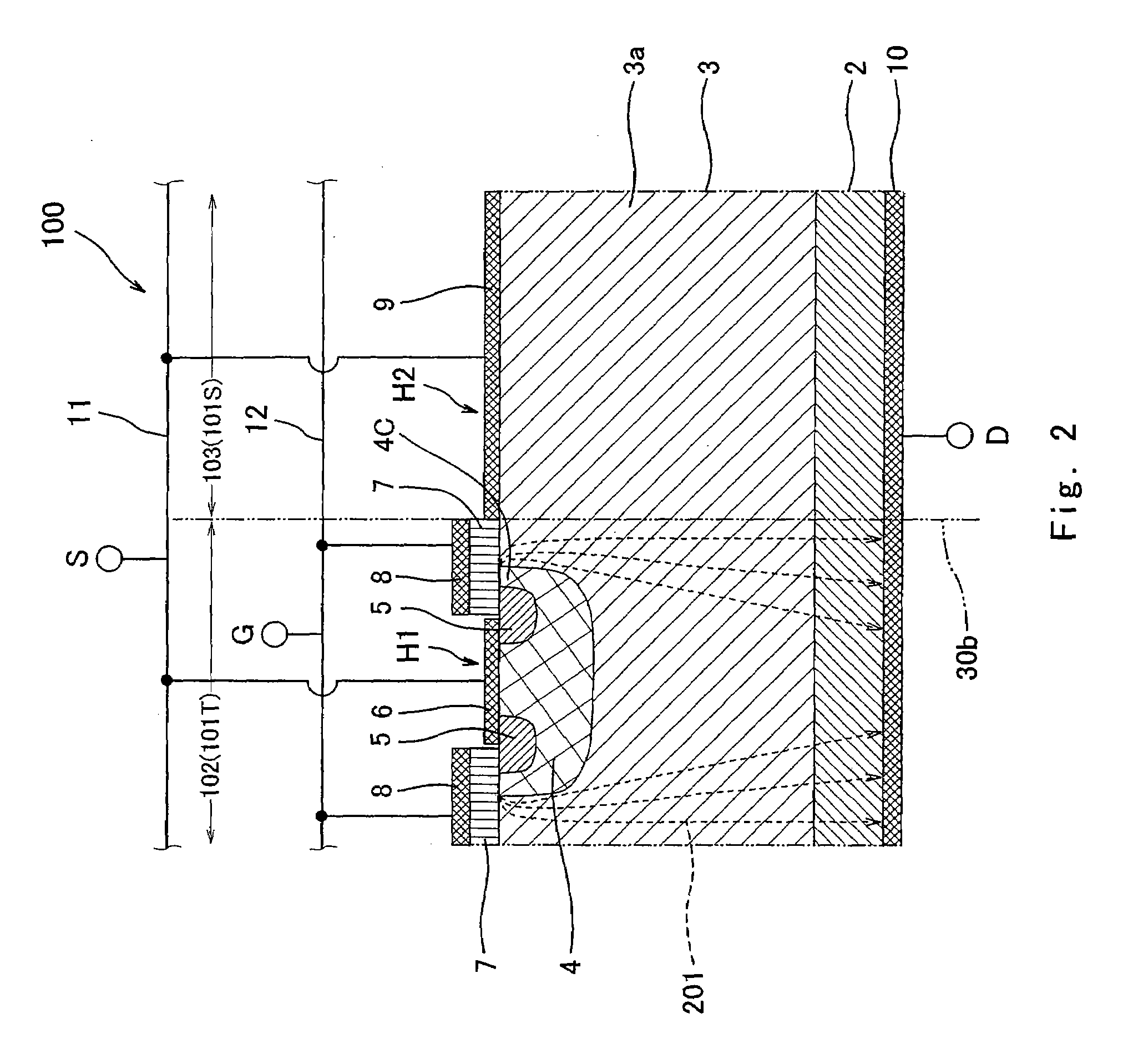

Semiconductor device and electric apparatus

ActiveUS20090225578A1Outstanding resistanceRun at high speedAc-dc conversionDiodeLoad generationBorder line

The present invention provides a semiconductor device and an electric apparatus each of which can realize both high-speed switching operation and energy loss reduction and excels in resistance to current concentration based on a counter electromotive voltage generated by, for example, an inductance load of the electric apparatus. A semiconductor device (100) of the present invention includes: a semiconductor layer (3) made of a first conductivity type wide band-gap semiconductor; a transistor cell (101T) in which a vertical field effect transistor (102) is formed, the vertical field effect transistor (102) causing a charge carrier to move in a thickness direction of the semiconductor layer (3); and a diode cell (101S) in which a schottky diode (103) is formed, the schottky diode (103) being formed such that a schottky electrode (9) forms a schottky junction with the semiconductor layer (3), wherein the semiconductor layer 3 is divided into a plurality of square subregions (101T and 101S) based on virtual border lines (30) in plan view, and includes the subregion (101T) as the transistor cell and the subregion (101S) as the diode cell.

Owner:PANASONIC CORP

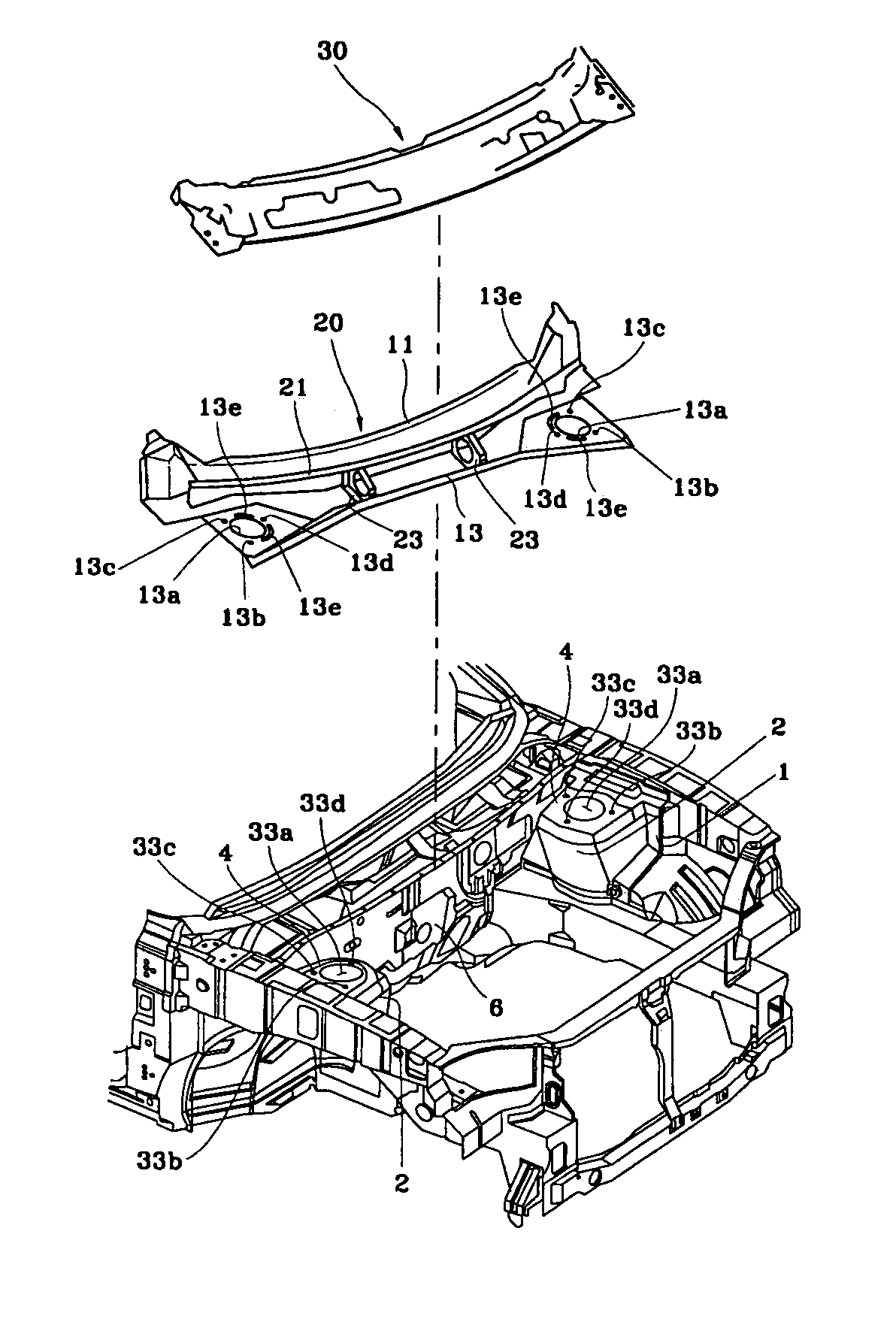

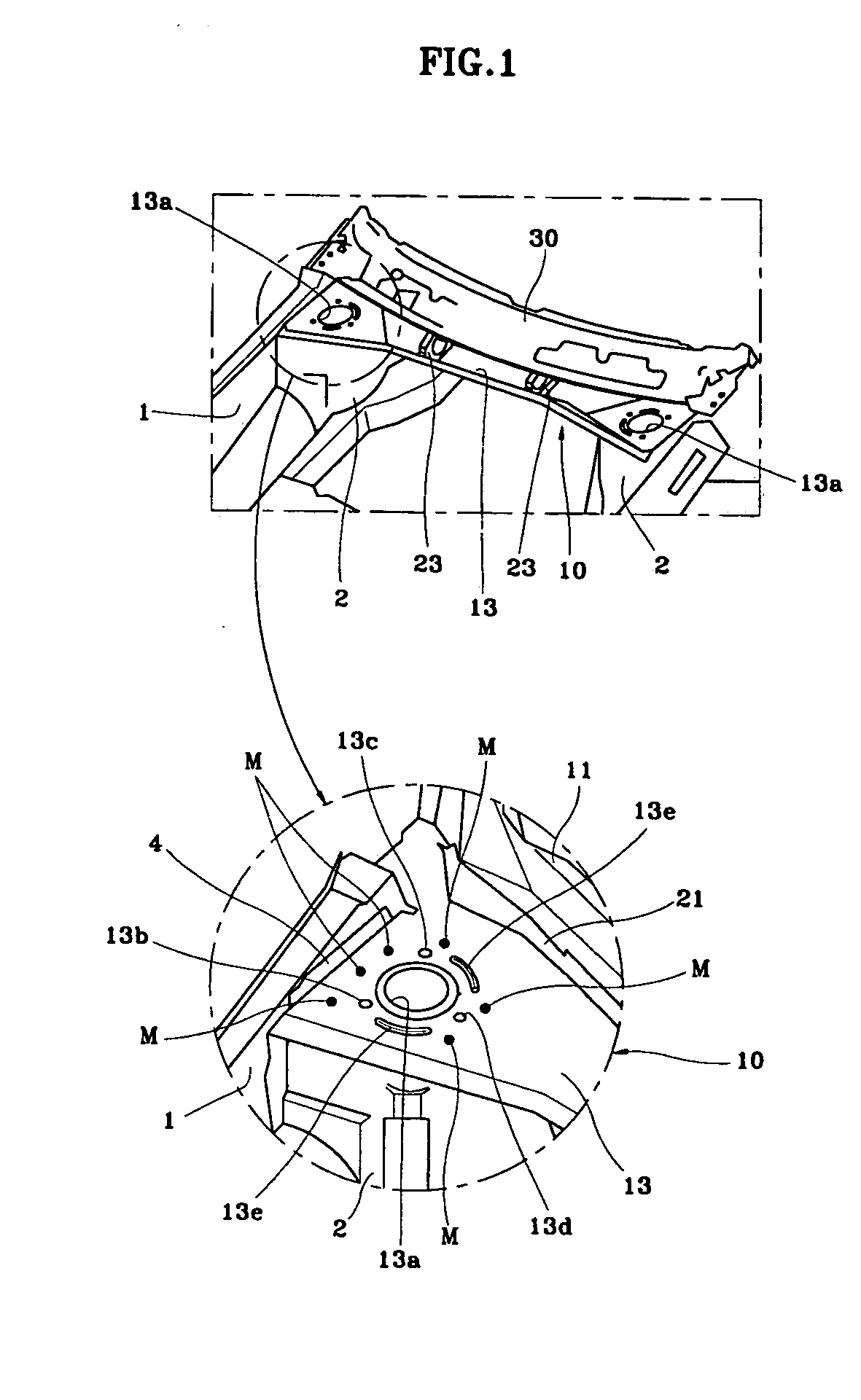

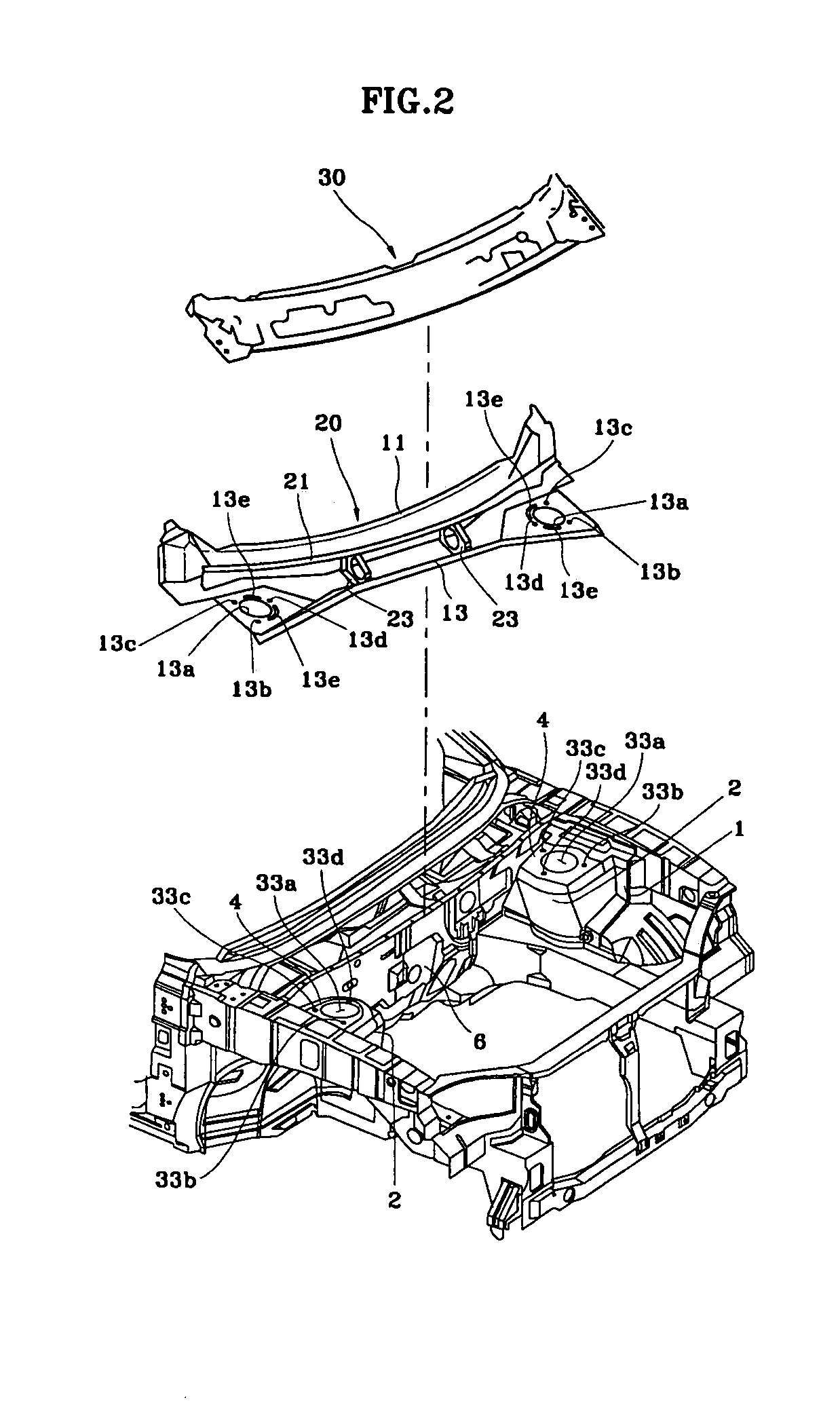

Upper mounting part structure of front strut assembly

InactiveUS20050067858A1Improve rigidityMinimize resonanceSuperstructure subunitsVehicle cleaningResonanceLoad generation

An upper mounting part of a front strut assembly adapted to reinforce the rigidity of the periphery of a frontal mounting hole, rear mounting hole, and central mounting hole by a lower cowl panel mounted for integrally welding to the shock absorber housing upper panel placed at both sides of the engine room, and a lower cowl reinforcing means welded onto the lower cowl panel is disclosed. The structure minimizes resonance generated by the load transmitted from the outside of the vehicle, reduces driving noise and improves the vehicle ride and steering.

Owner:HYUNDAI MOTOR CO LTD

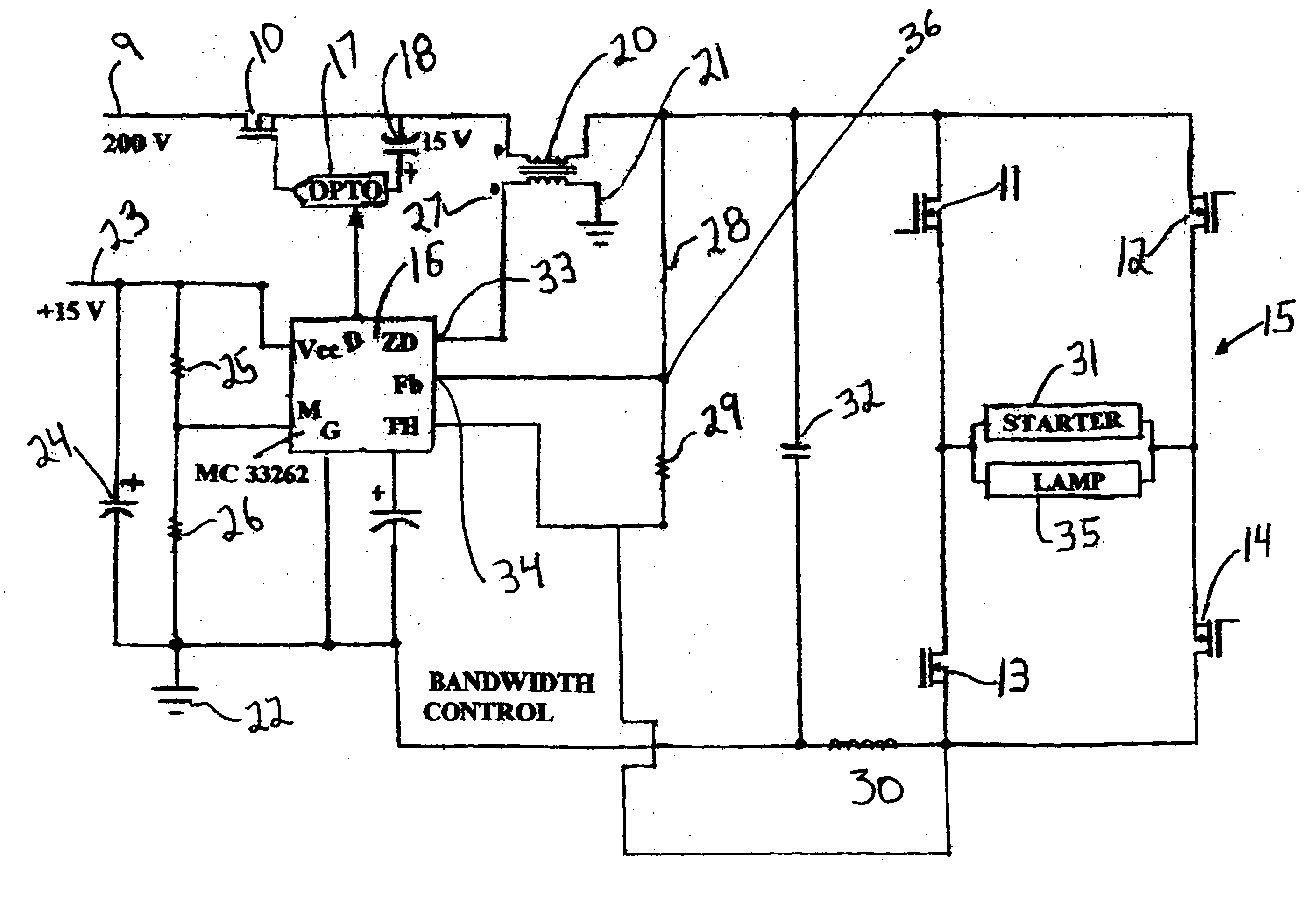

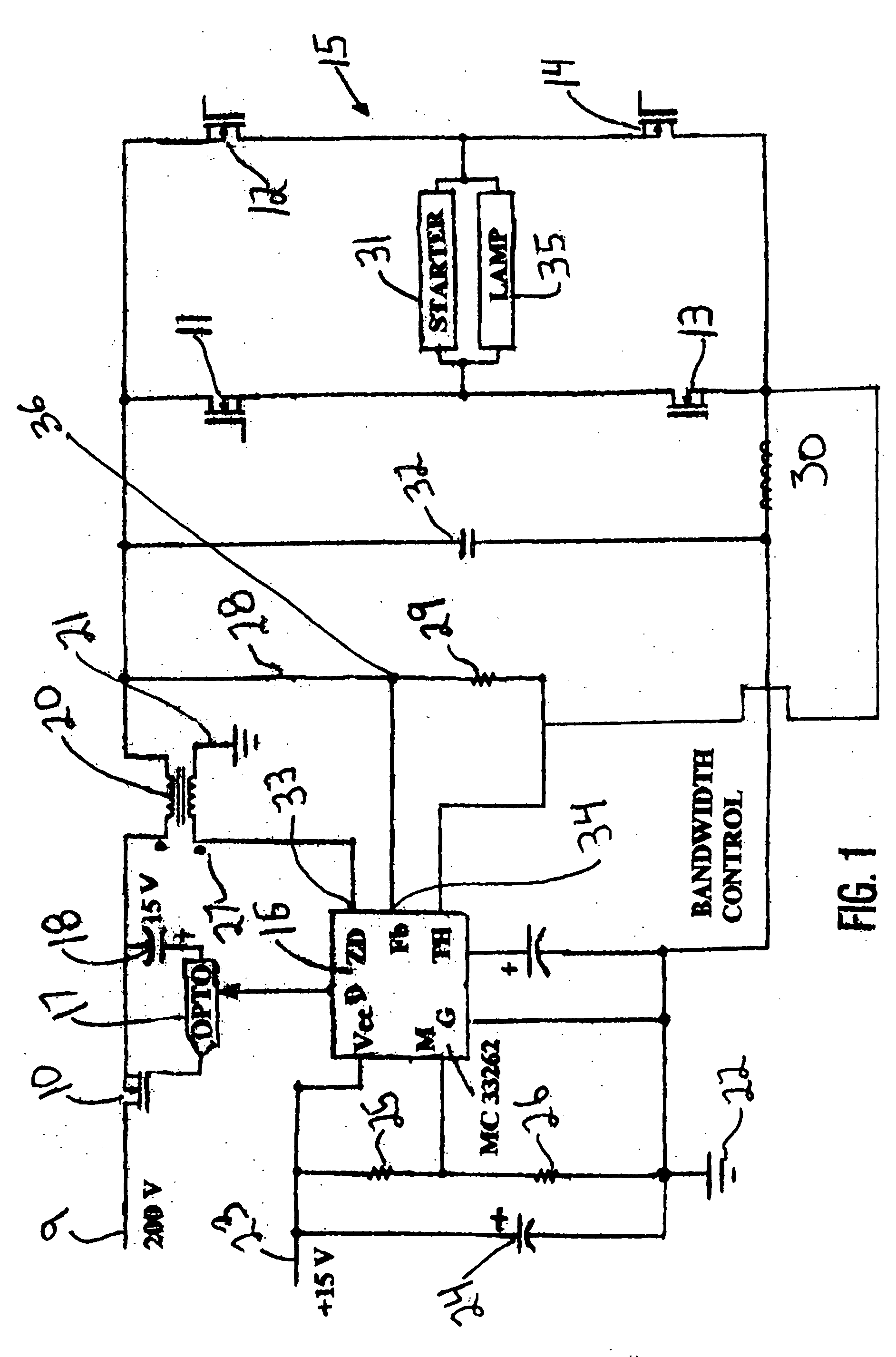

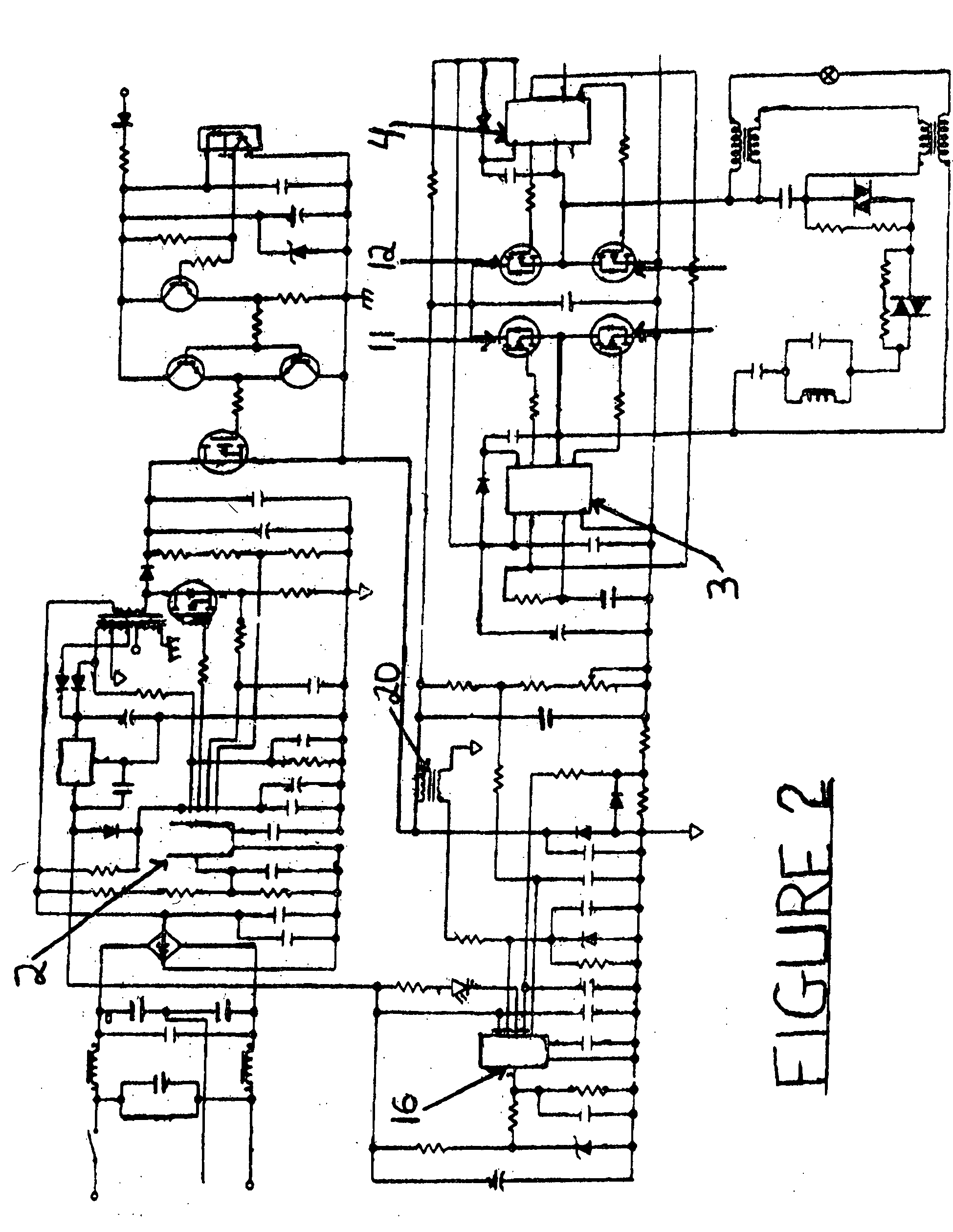

Electronic ballast with closed loop control using composite current and voltage feedback and method thereof

InactiveUS20050212458A1Consume moreReliable ignitionElectrical apparatusElectric light circuit arrangementLoop controlAverage current

An electronic control system especially for non-linear loads, such as high pressure sodium (HPS) lamps, includes an active power factor correction circuit (APFC). The system provides a power factor correction of above 0.95; total harmonic distortion (THD) below 5%; lamp crest factor (LCF) close to unity; efficient power consumption and reliable open circuit voltage (OCV) under all power line conditions. A ballast would include integrated circuits (ICs) and a four-arm transistor bridge which is directly driven by integrated circuits. The bridge generates reversal of polarity to the load. An approximate average current feedback is derived from a load current. A resistor divider in parallel with the load provides voltage feedback. The average current feedback and voltage feedback are added together to provide an approximation of power consumed by the load, without the complex circuitry required for a true power feedback of current multiplied by voltage. That composite feedback signal is transmitted to the integrated circuit (IC) which compares it with an internal reference voltage and which adjusts the IC output to minimize the error.

Owner:FIREBIRD RES

Lightweight coherency control protocol for clustered storage system

ActiveUS7376796B2Memory architecture accessing/allocationMemory adressing/allocation/relocationLoad generationParallel computing

A lightweight coherency control protocol ensures consistency of data containers, such as a file, and associated data buffers stored on one or more volumes served by a plurality of nodes, e.g., storage systems, connected as a cluster. Each data buffer is associated with a current cache sequence number comprising a load generation value and an update count value. The load generation value is incremented every time an inode of a file is loaded into a memory of the storage system. Once the inode is loaded and its load generation value is set, then the appropriate buffer of a buffer tree for the file is loaded into the memory. The update count value is incremented each time the buffer is updated with a write request / operation. Therefore, each buffer loaded into memory is tagged with the load generation value and an update count from the time that buffer is loaded.

Owner:NETWORK APPLIANCE INC

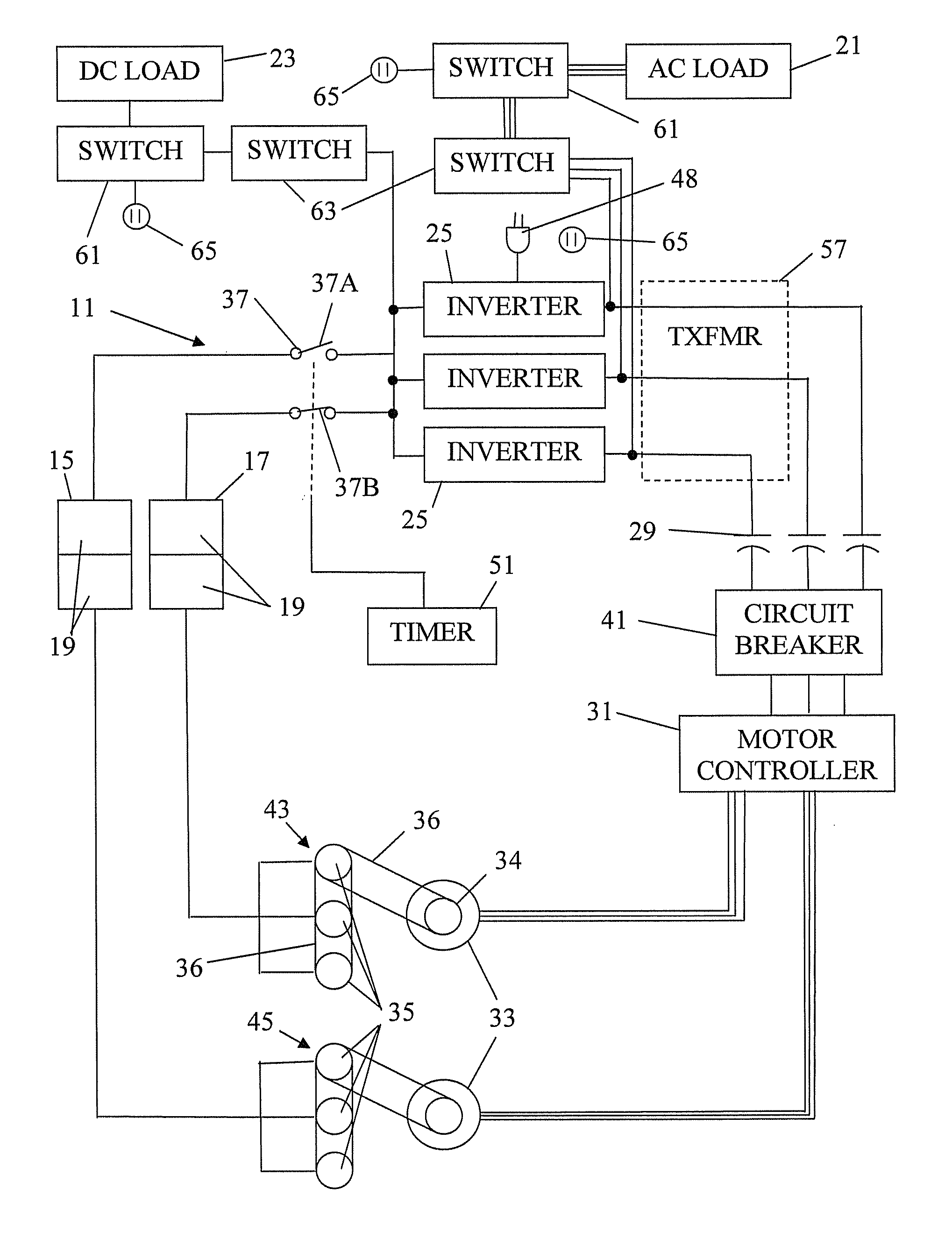

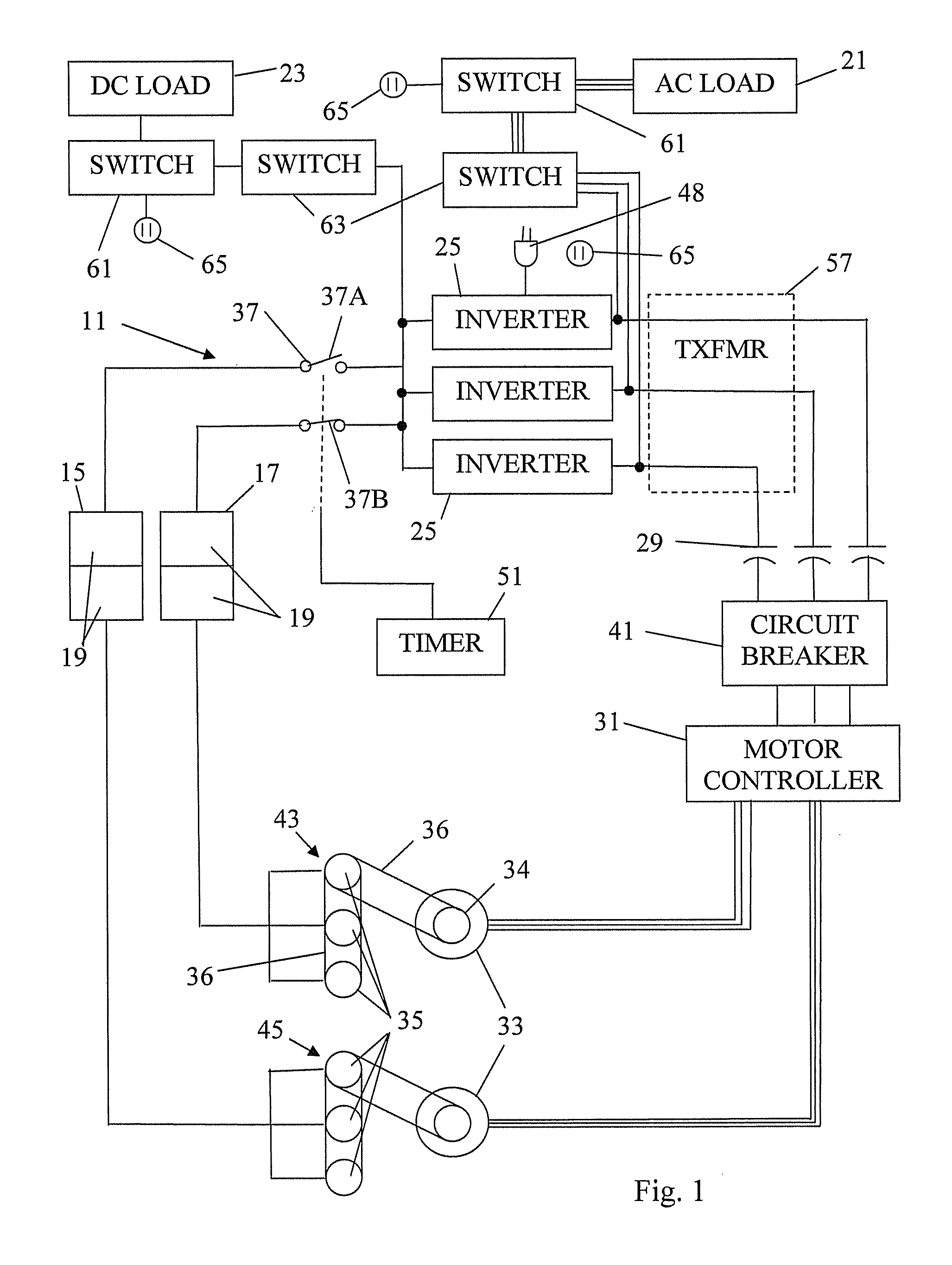

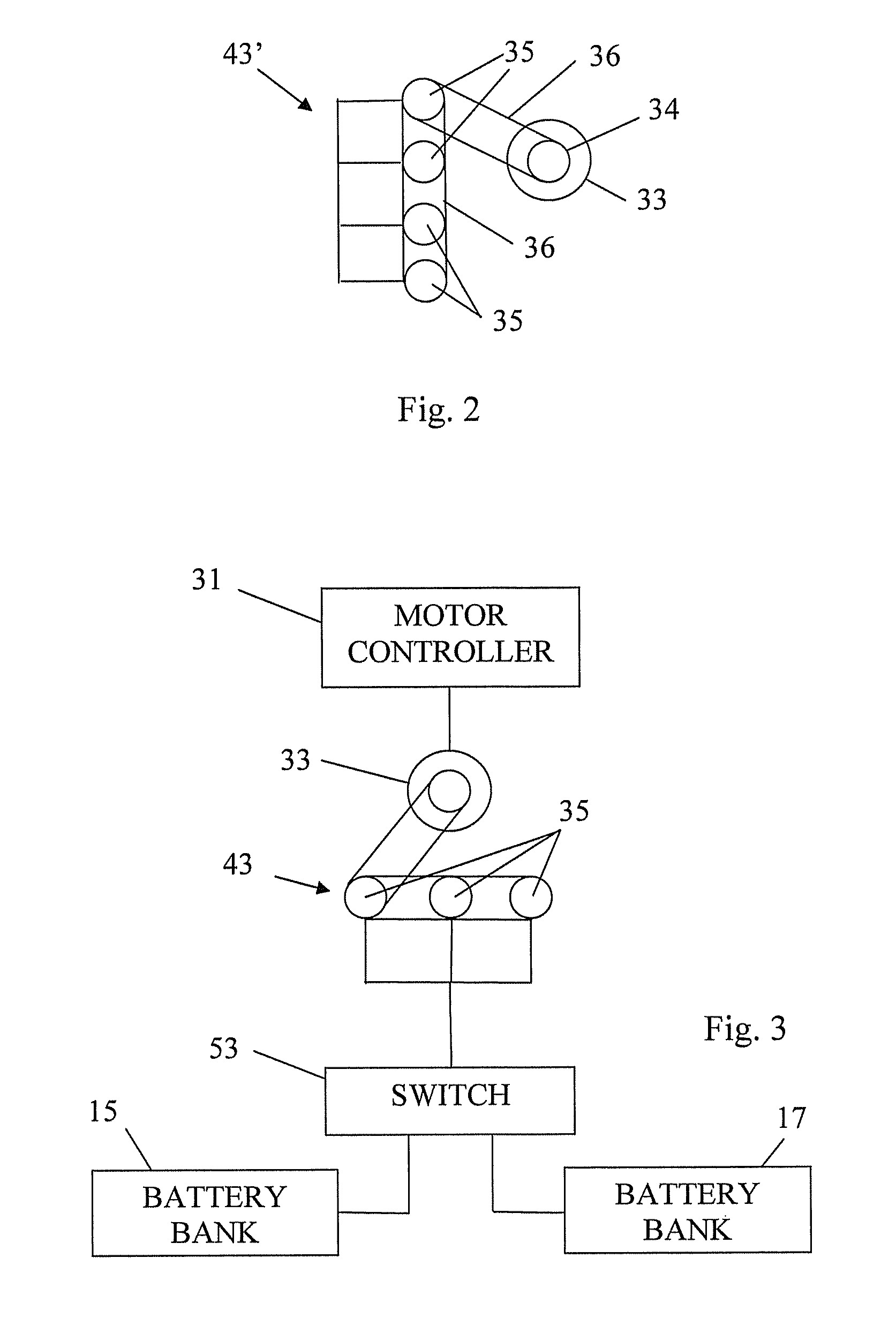

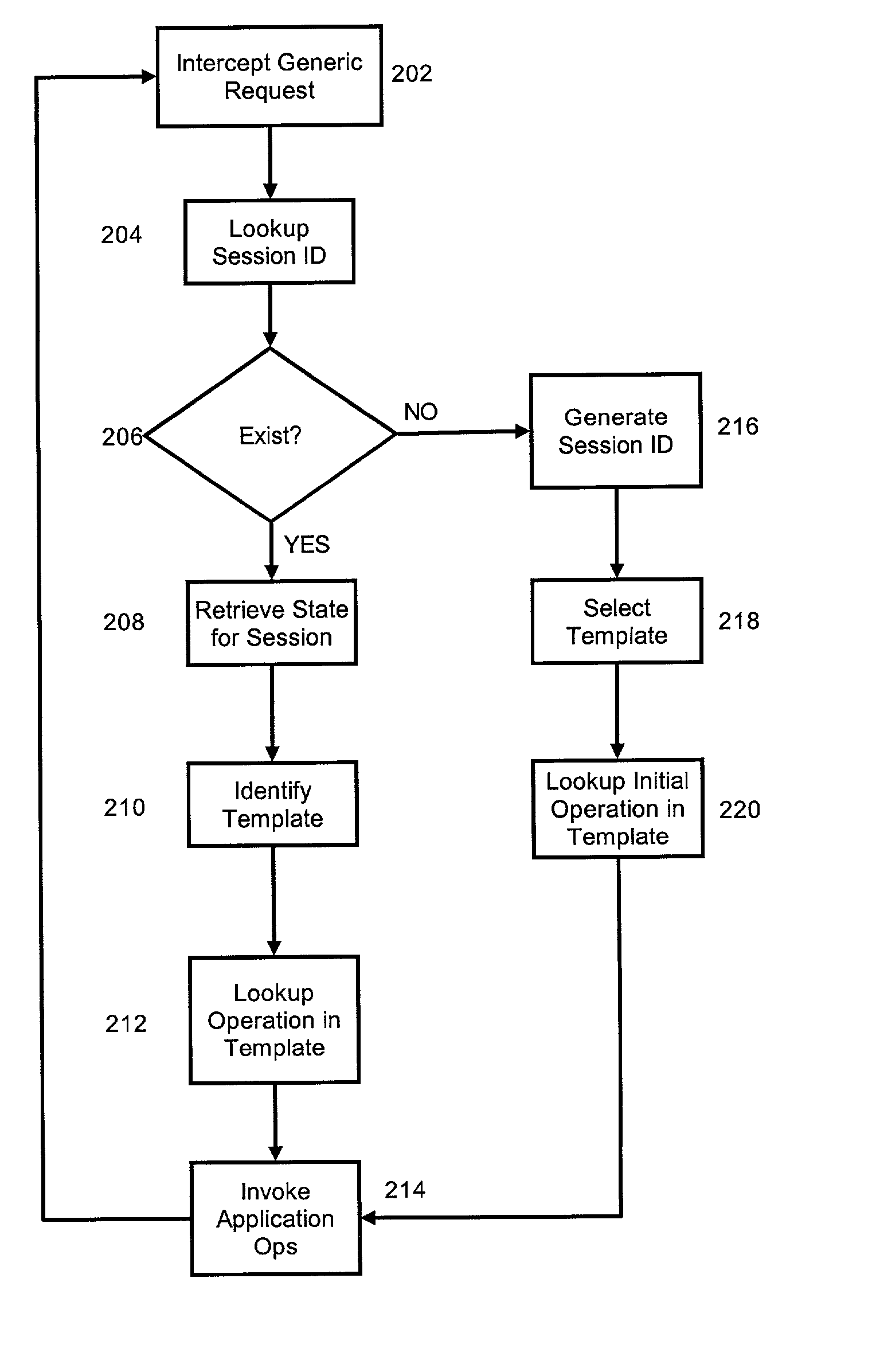

Electric power system

A system and method produces electrical power for a load. First and second battery banks are provided, as is an inverter bank, which produces three phase. A switch alternately connects one of the first or second battery banks to the load and to the inverter bank with the other of the first or second battery banks being disconnected from the load and the inverter bank. A motor is connected to the output of the inverter bank. The motor drives an alternator bank, which alternator bank is electrically connected to, and recharges, the other of the first or second battery banks. A timer periodically alternates the battery banks between a load mode and recharge mode.

Owner:B J AARON ENTERPRISE

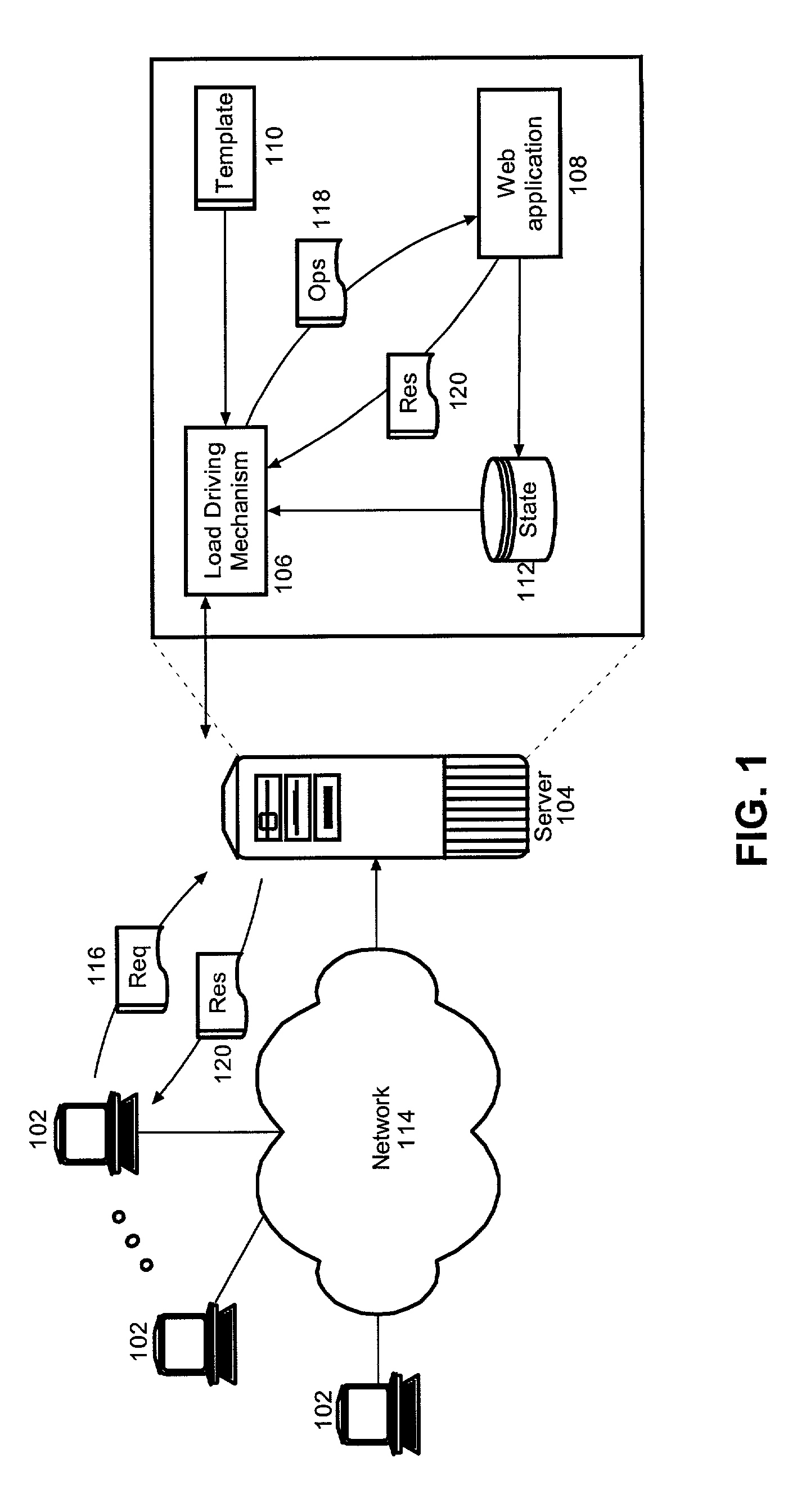

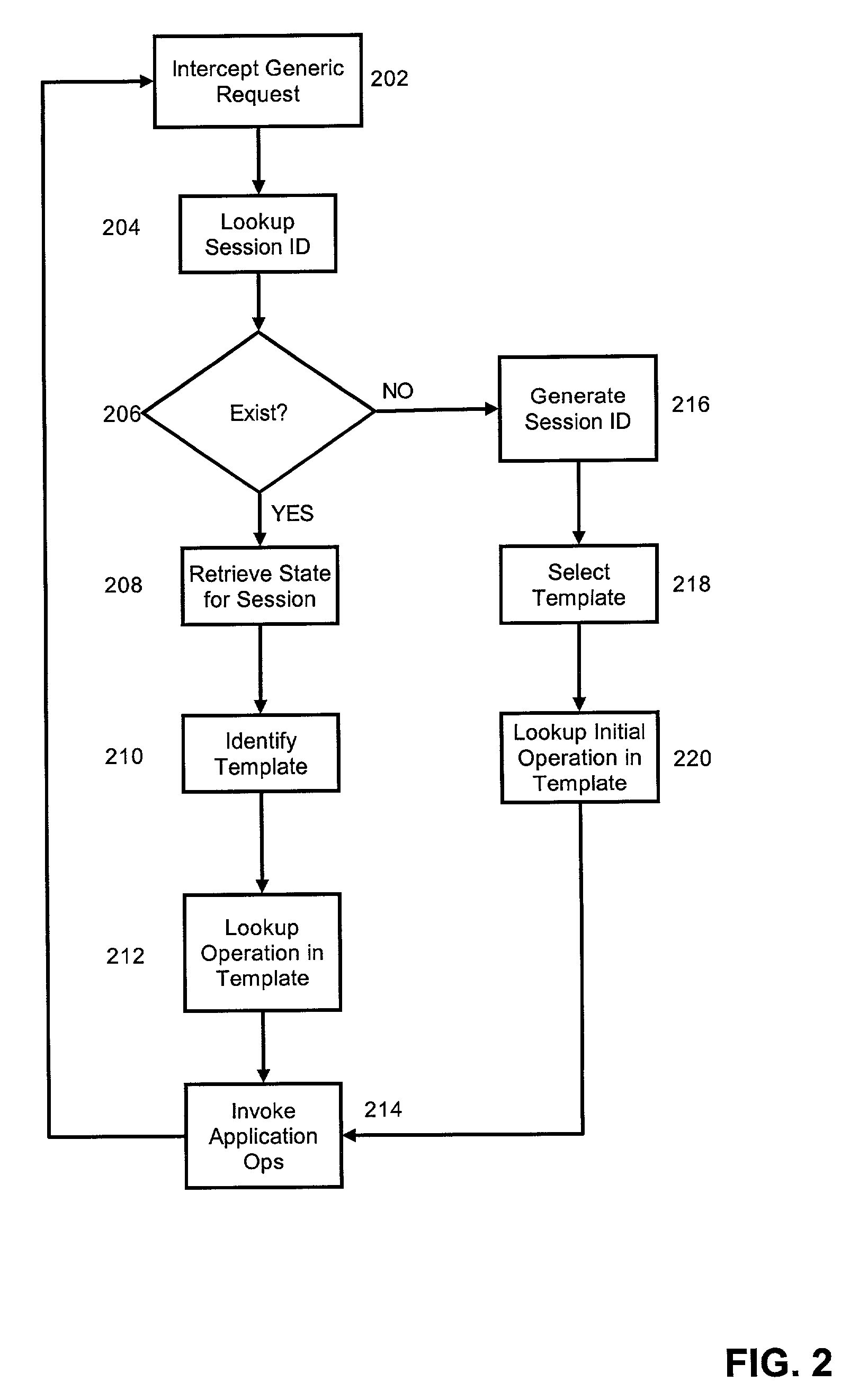

Scenario based testing and load generation for web applications

InactiveUS7295953B2Overcome deficienciesReduce complexityResistance/reactance/impedenceDigital computer detailsWeb applicationTemplate based

In a Web application testing method which has been configured in accordance with the present invention, a network message from one of several network clients can be intercepted. Session data in the network message can be identified and state information retrieved for the session in the Web application. An operation and corresponding associated parameters can be selected from a Web scenario template based upon the retrieved state information. Finally, operations can be invoked in the Web application, the operations corresponding to the operation and associated operational parameters selected from the Web scenario template.

Owner:GOOGLE LLC

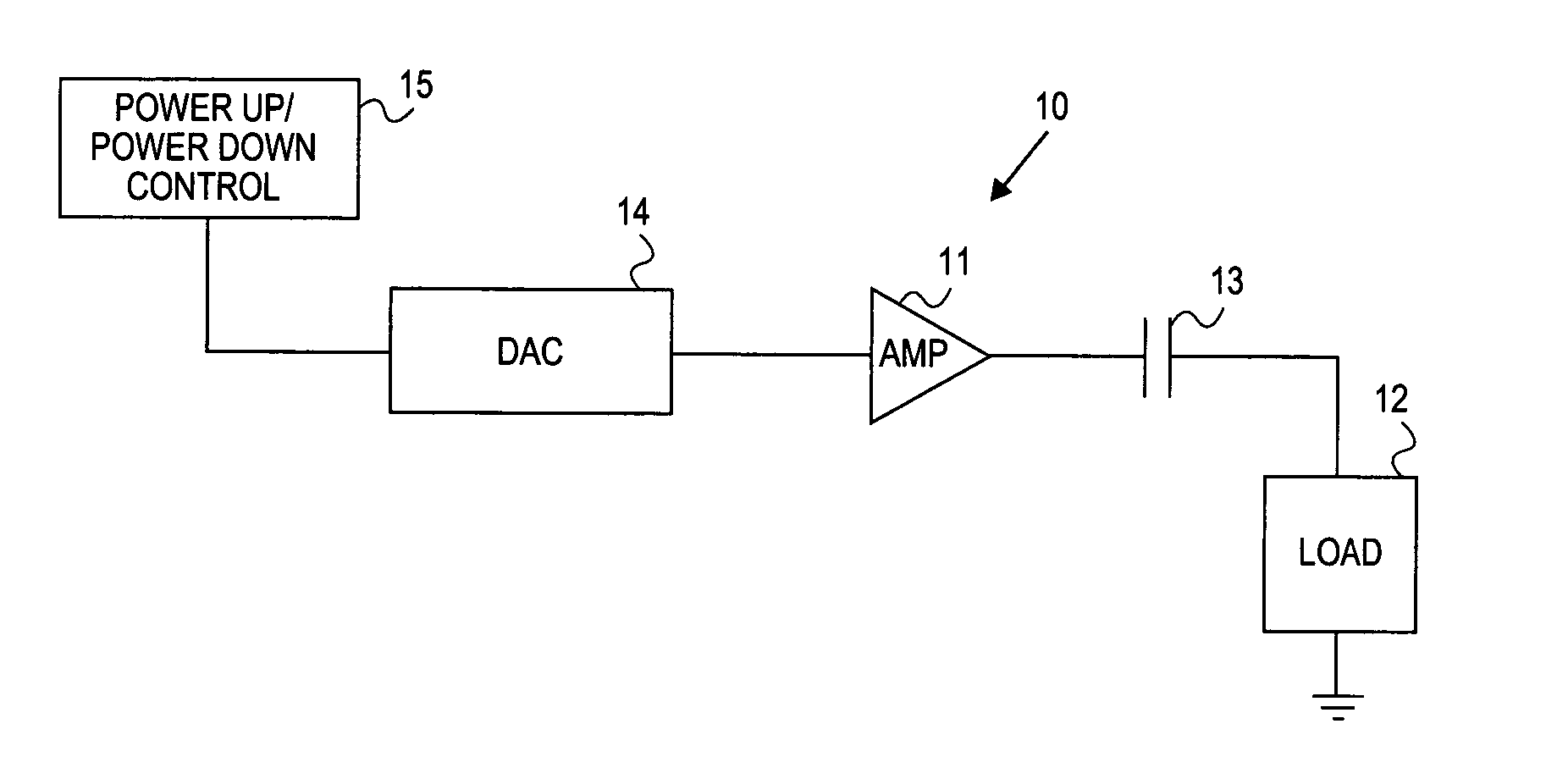

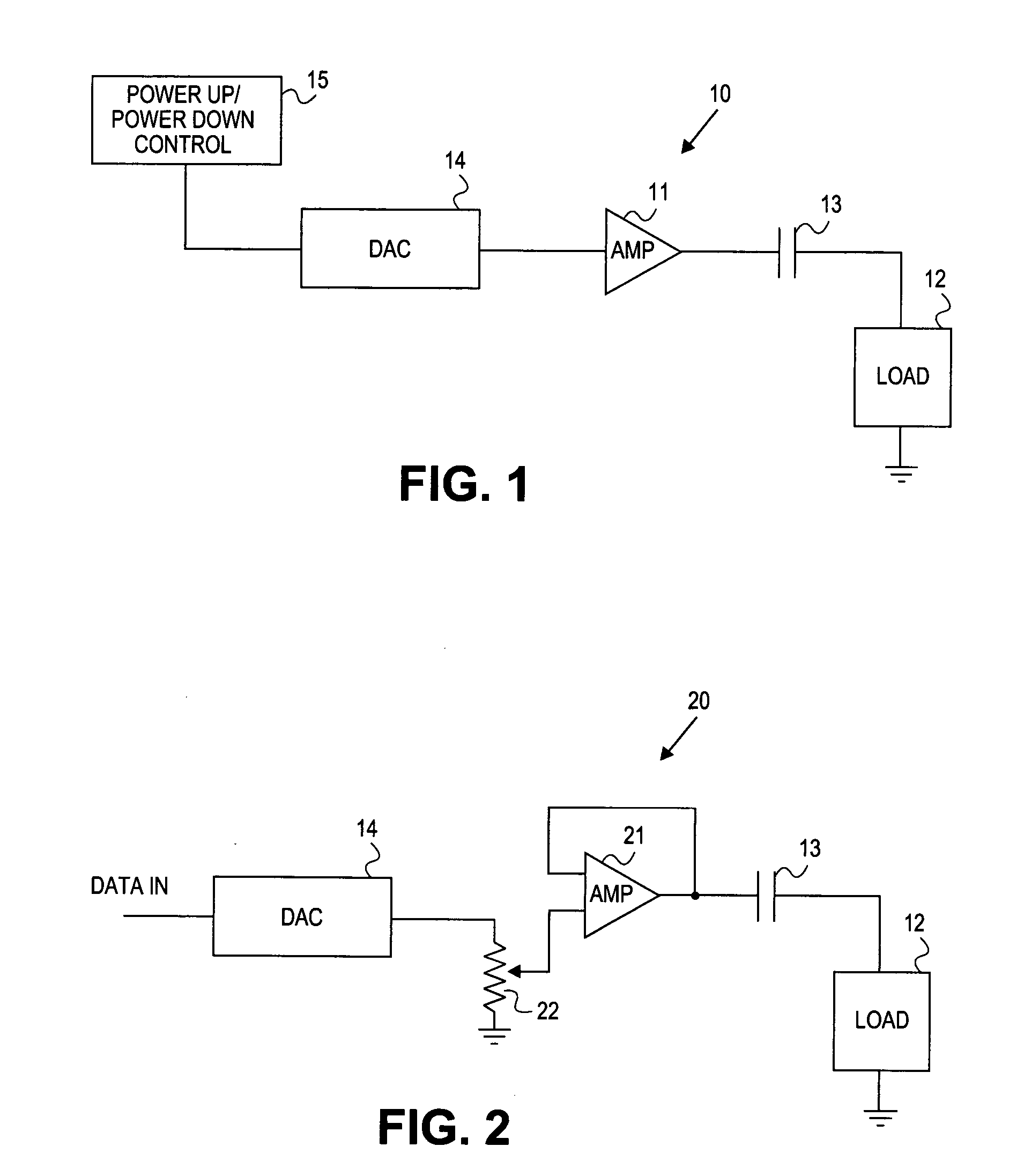

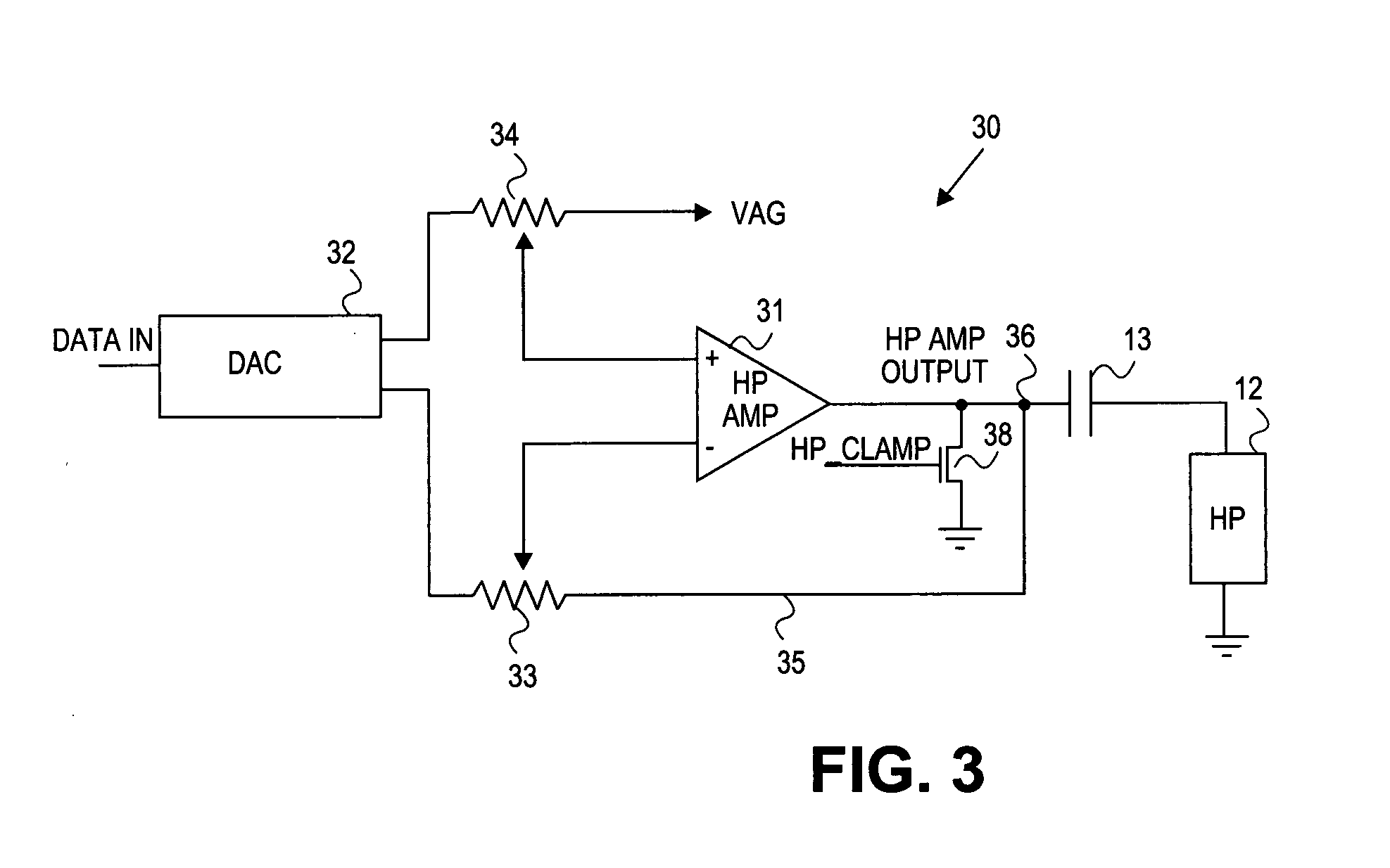

Pop and click reduction using DAC power up and power down processing

InactiveUS20050025322A1Amplifier modifications to reduce noise influenceAmplifier modifications to reduce temperature/voltage variationAudio power amplifierLoad generation

An audio amplifier generates an output to a load, in which a digital-to-analog converter drives the amplifier during powering up and powering down the amplifier. The digital-to-analog converter controls the amplifier to ramp the voltage at the output at a predetermined rate to reduce rapid voltage changes from being sent to the load during the powering up or powering down sequence.

Owner:NORTH STAR INNOVATIONS

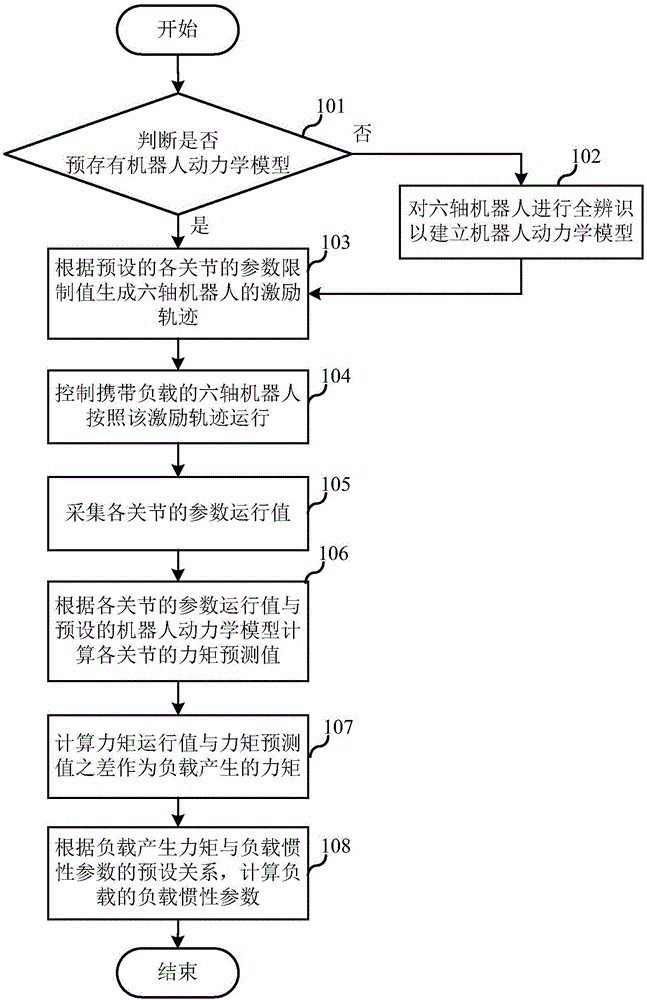

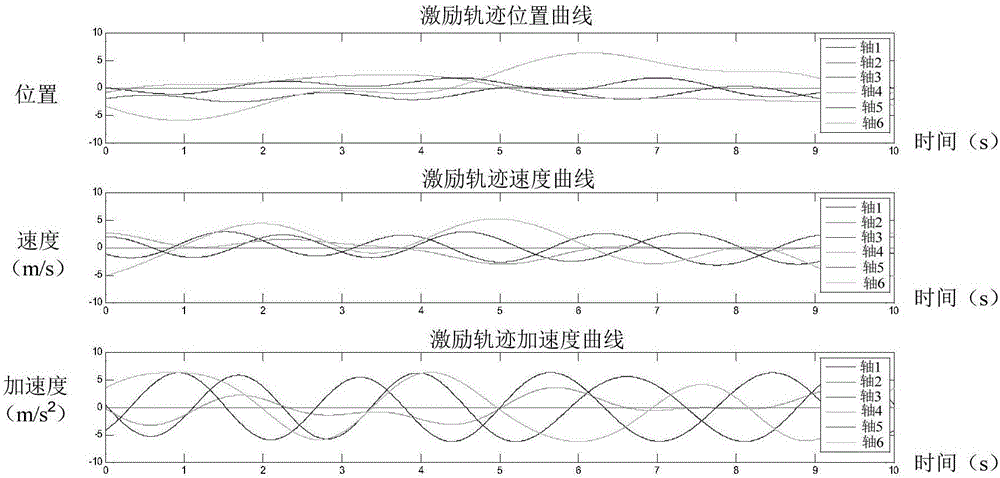

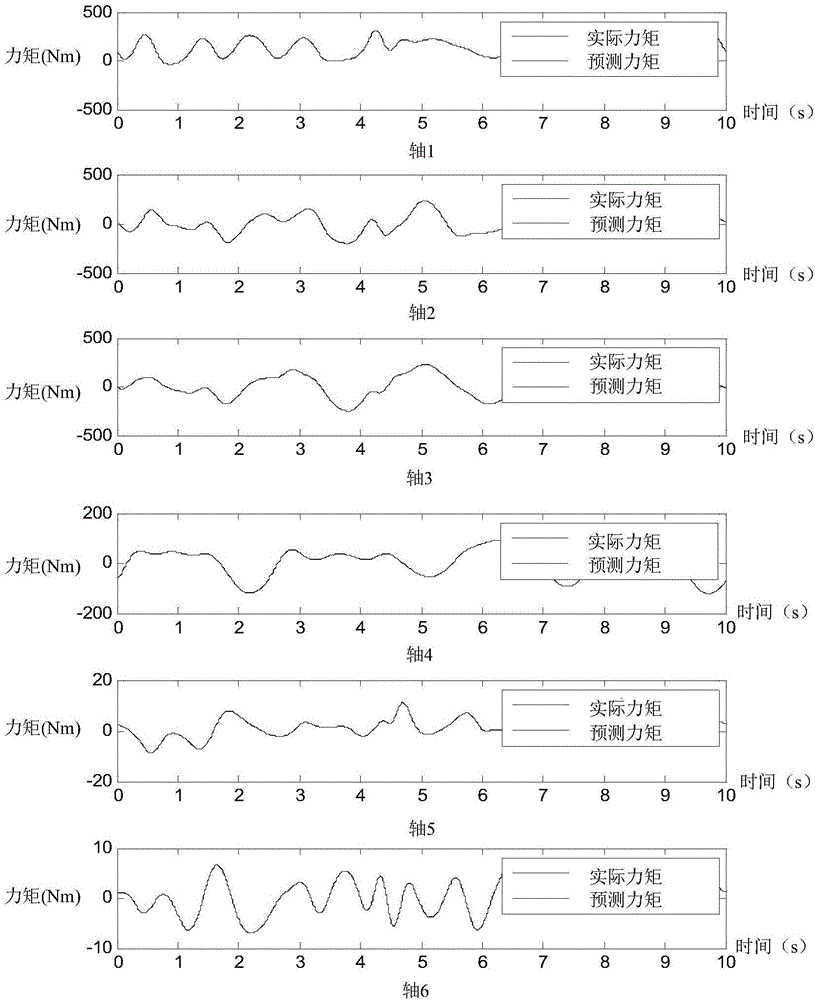

Method and module for distinguishing load of six-axis robot

ActiveCN106346477ASimple installation and debuggingImprove working precisionProgramme-controlled manipulatorLoad generationComputer module

The embodiment of the invention relates to the technical field of robot control, and discloses a method and a module for distinguishing a load of a six-axis robot. The method for distinguishing the load of the six-axis robot comprises the following steps: according to a preset parameter limiting value of each joint, generating an excitation track of the six-axis robot; when the six-axis robot carrying the load is controlled to run along the excitation track, collecting a parameter running value of each joint; according to the parameter running value of each joint and a preset robot dynamics model, calculating a torque predicting value of each joint; calculating a difference between the torque running value and the torque predicting value, the difference serving as torque produced by the load, and according to preset relationship of the torque produced by the load and a load inertia parameter, calculating the load inertia parameter. The embodiment of the invention also provides the module for distinguishing the load of the six-axis robot. The module for distinguishing the load of the six-axis robot disclosed by the embodiment has the advantage that compared with the prior art, the parameter running value of the robot is collected on line, and the load inertia parameter of the robot is distinguished; because a six-dimensional force sensor is not used, the cost is reduced.

Owner:SHANGHAI STEP ELECTRIC +1

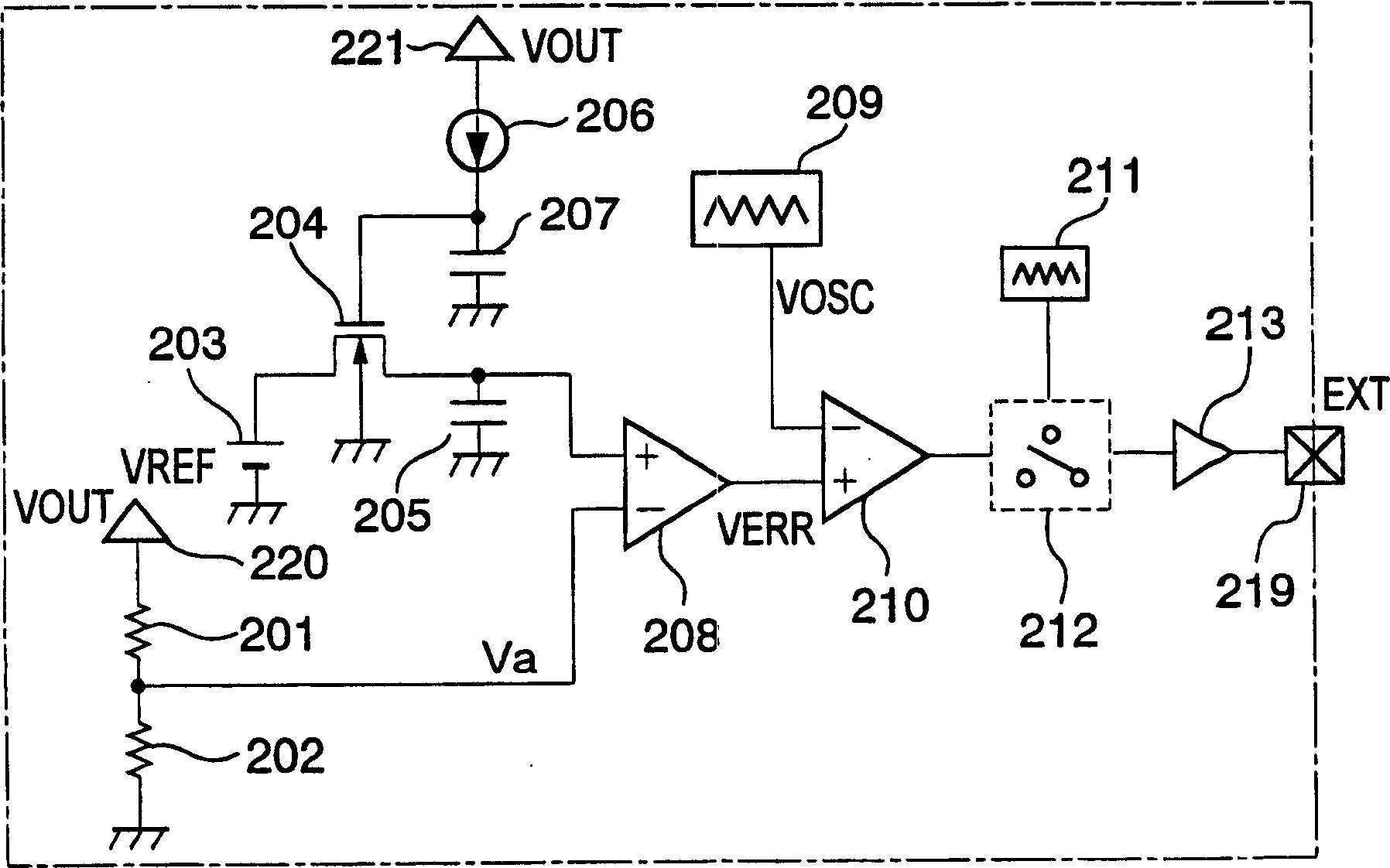

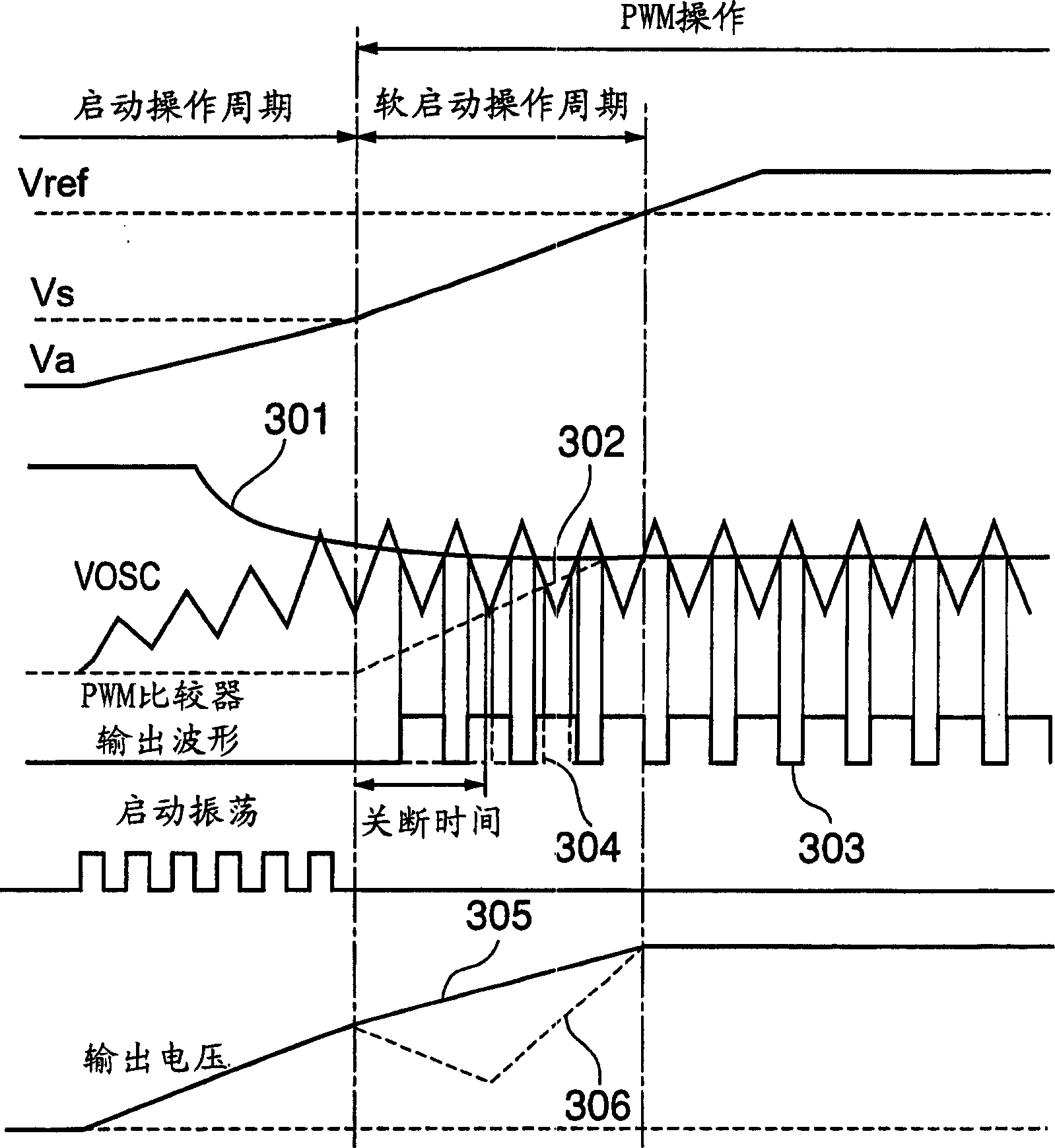

Pwm switching regulator control circuit

InactiveCN1578085APrevent output voltage from droppingReduce ripple voltageDc-dc conversionPulse duration/width modulationLoad generationVoltage reference

Provided is a PWM switching regulator control circuit, which is small in the ripple voltage without a drop of the output voltage which, is attributable to a load at the time of a soft start. A PWM switching regulator control circuit is provided, in which an offset voltage that is lower than a reference voltage is inputted to an error amplifier at the time of a soft start, to thereby prevent an off-time from occurring in the PWM comparator output, prevent the output voltage that is attributable to the load from dropping, and make the ripple voltage small.

Owner:SEIKO INSTR INC

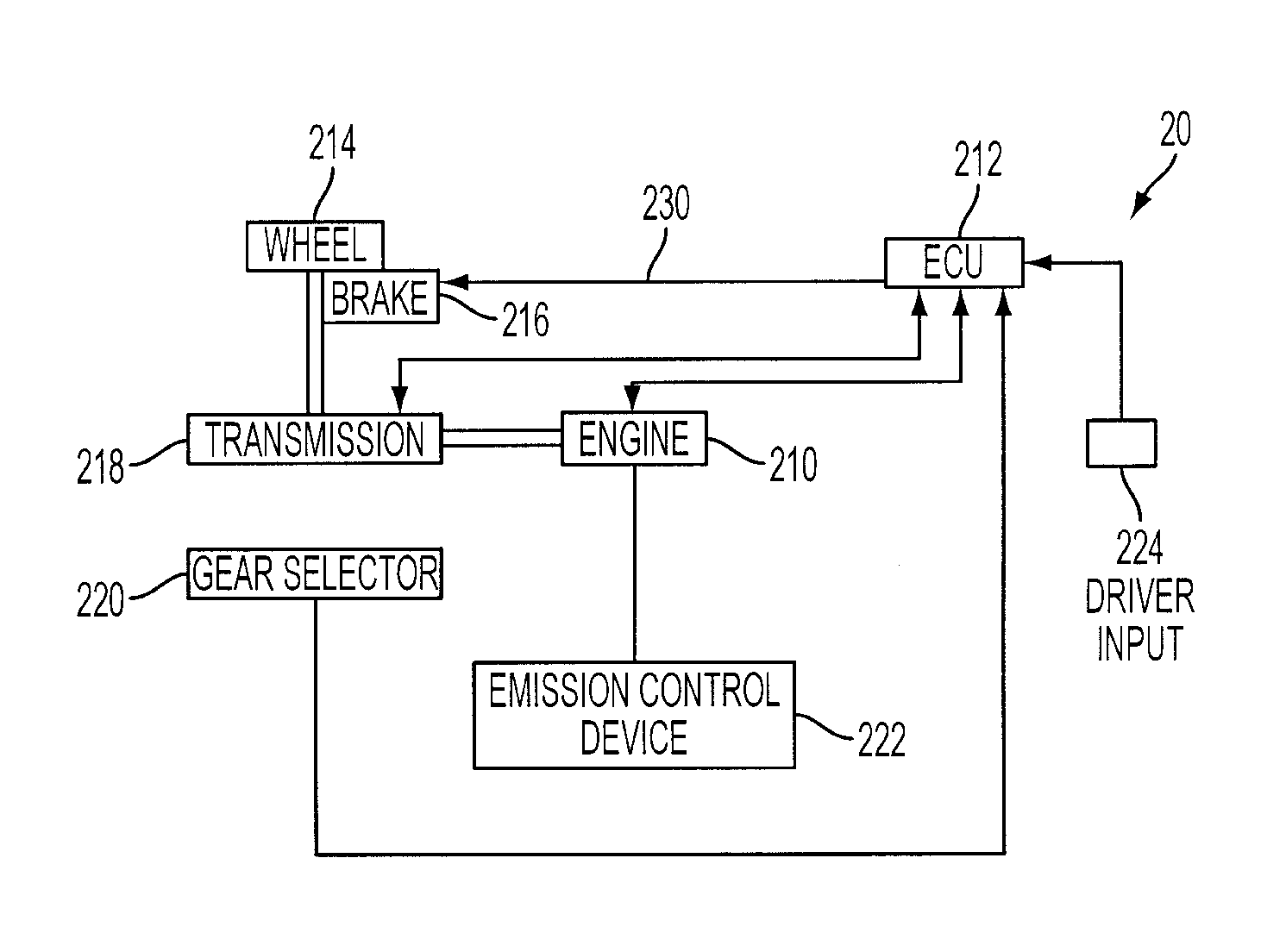

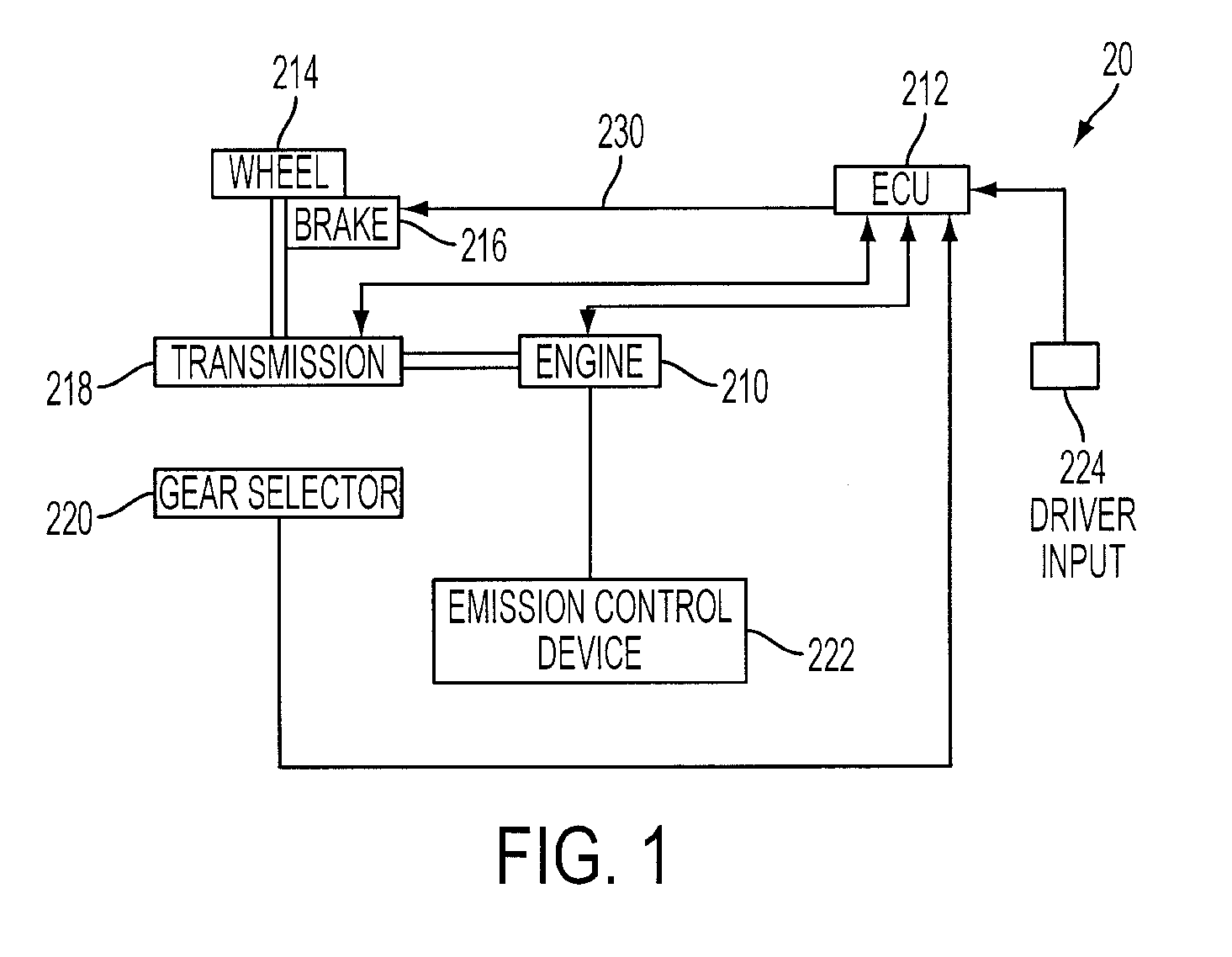

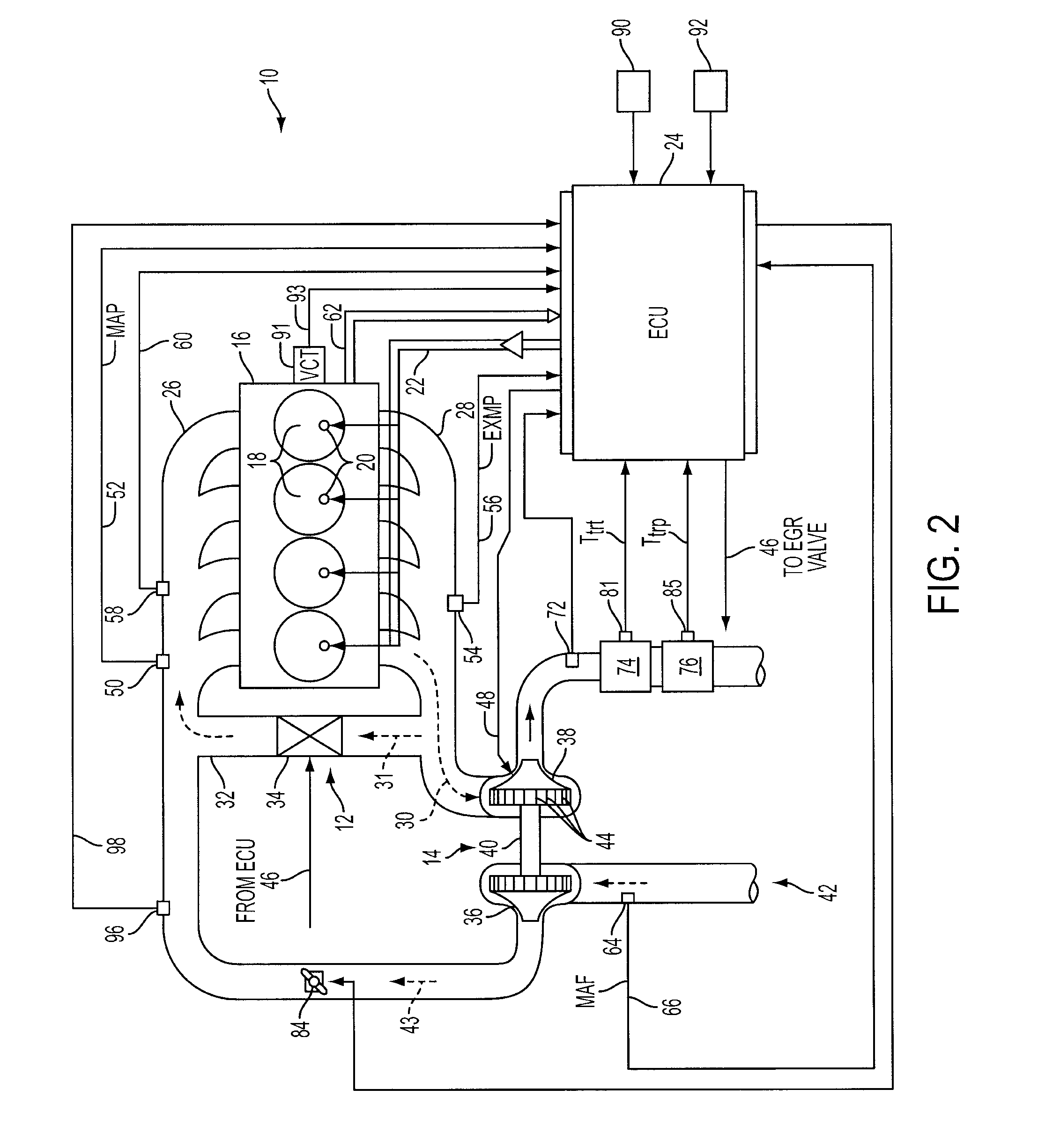

Brake Torque Load Generation Process for Diesel Particulate Filter Regeneration and SOx Removal from Lean NOx Trap

InactiveUS20070251220A1Increasing engine loadIncreasing engine torqueElectrical controlInternal combustion piston enginesBrake torqueRegenerative brake

A method of regeneration of an emission control device in a diesel engine of a vehicle having a wheel brake comprises receiving a generation request by an operator of the vehicle; activating the wheel brake; increasing engine torque; and regenerating the emission control device.

Owner:FORD GLOBAL TECH LLC

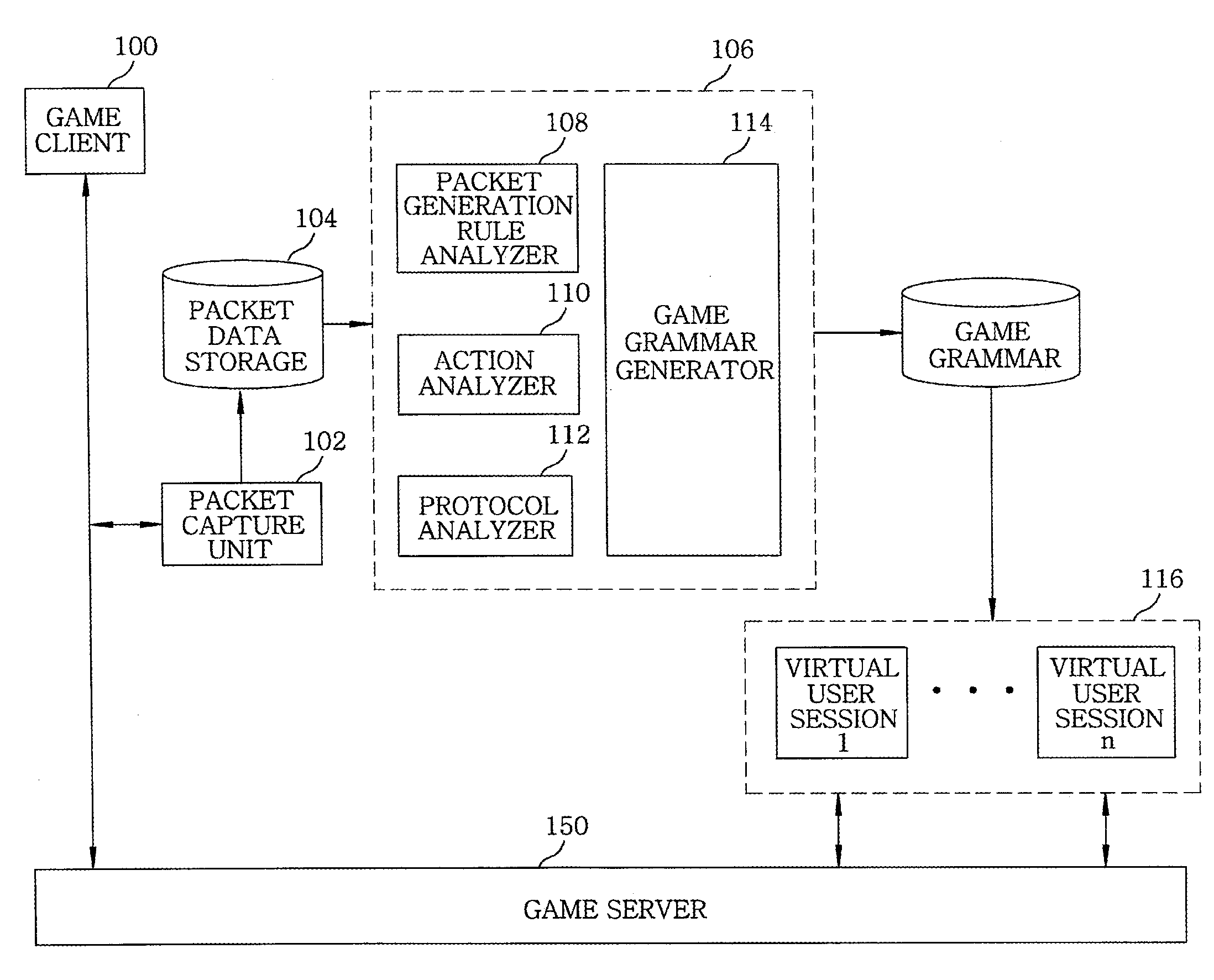

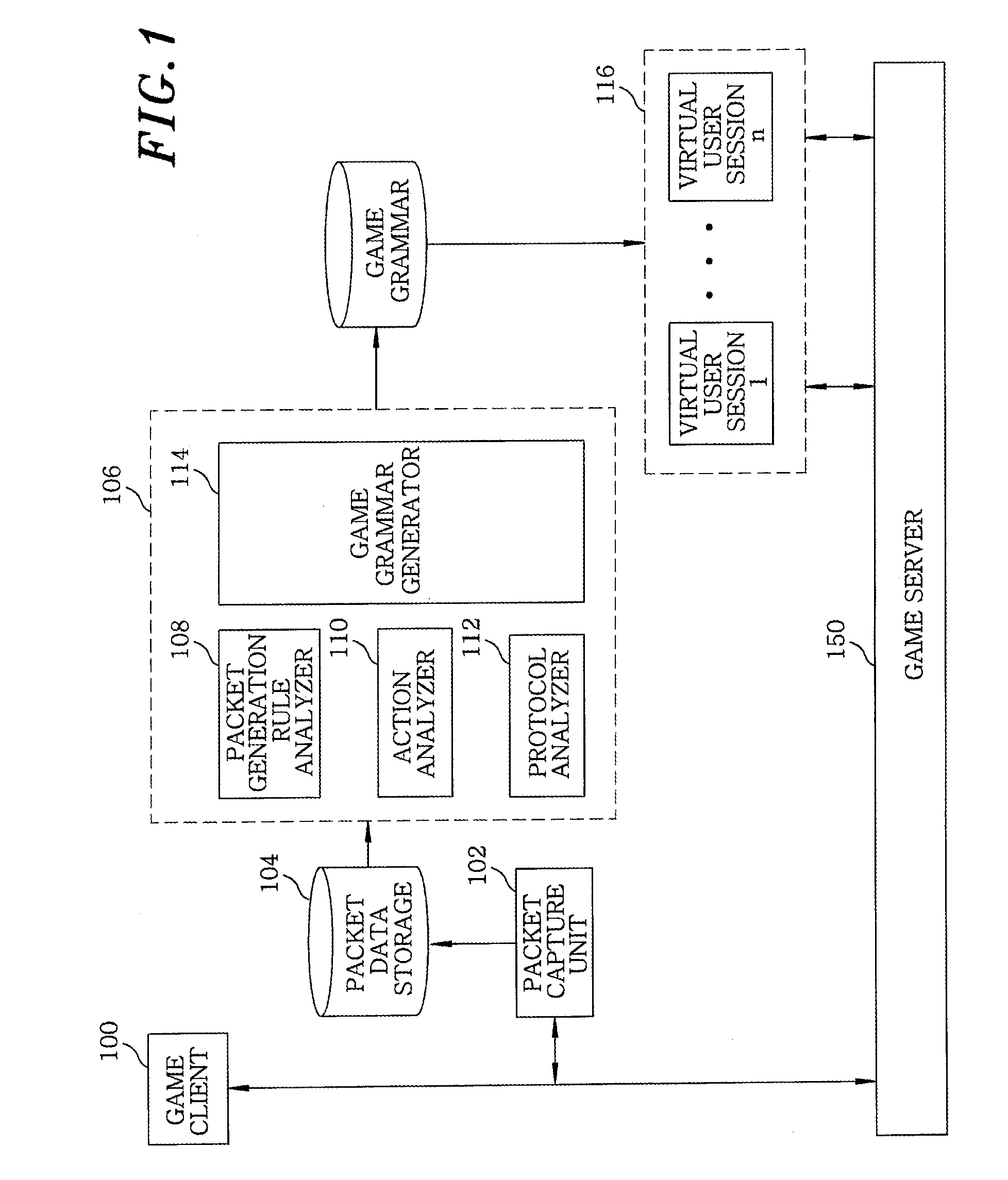

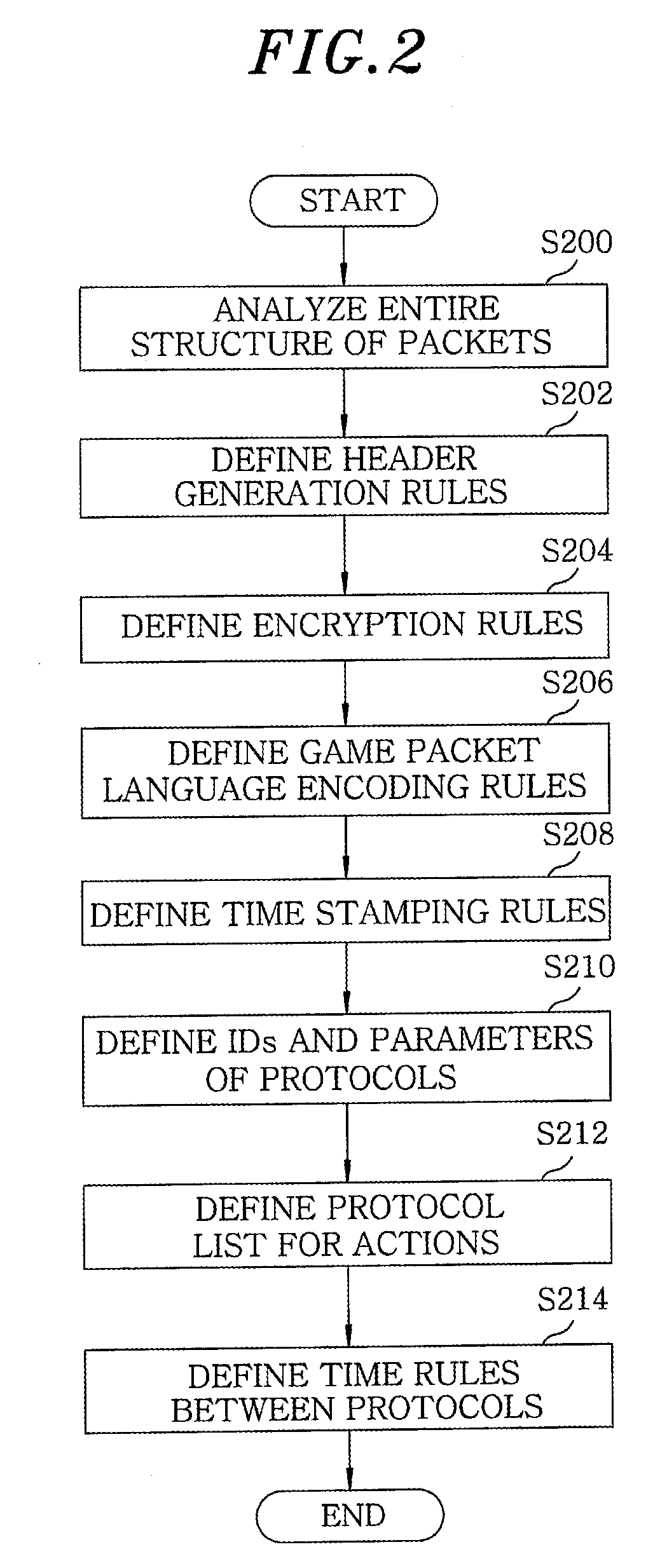

Game grammar-based packet capture and analysis apparatus and method for conducting game test

InactiveUS20110130205A1Multiple digital computer combinationsVideo gamesNetwork packetLoad generation

A game grammar-based packet capture and analysis apparatus for conducting game test, includes: a packet capture unit for capturing packets of game data transmitted and received between a game client and a game server; a packet analysis unit for analyzing the packets captured by the packet capture unit to generate a game grammar based on analyzed results. Further, the game grammar-based packet capture and analysis apparatus includes a load generation unit for generating packets in compliance with the game grammar to apply the packets to the game server as a load.

Owner:ELECTRONICS & TELECOMM RES INST

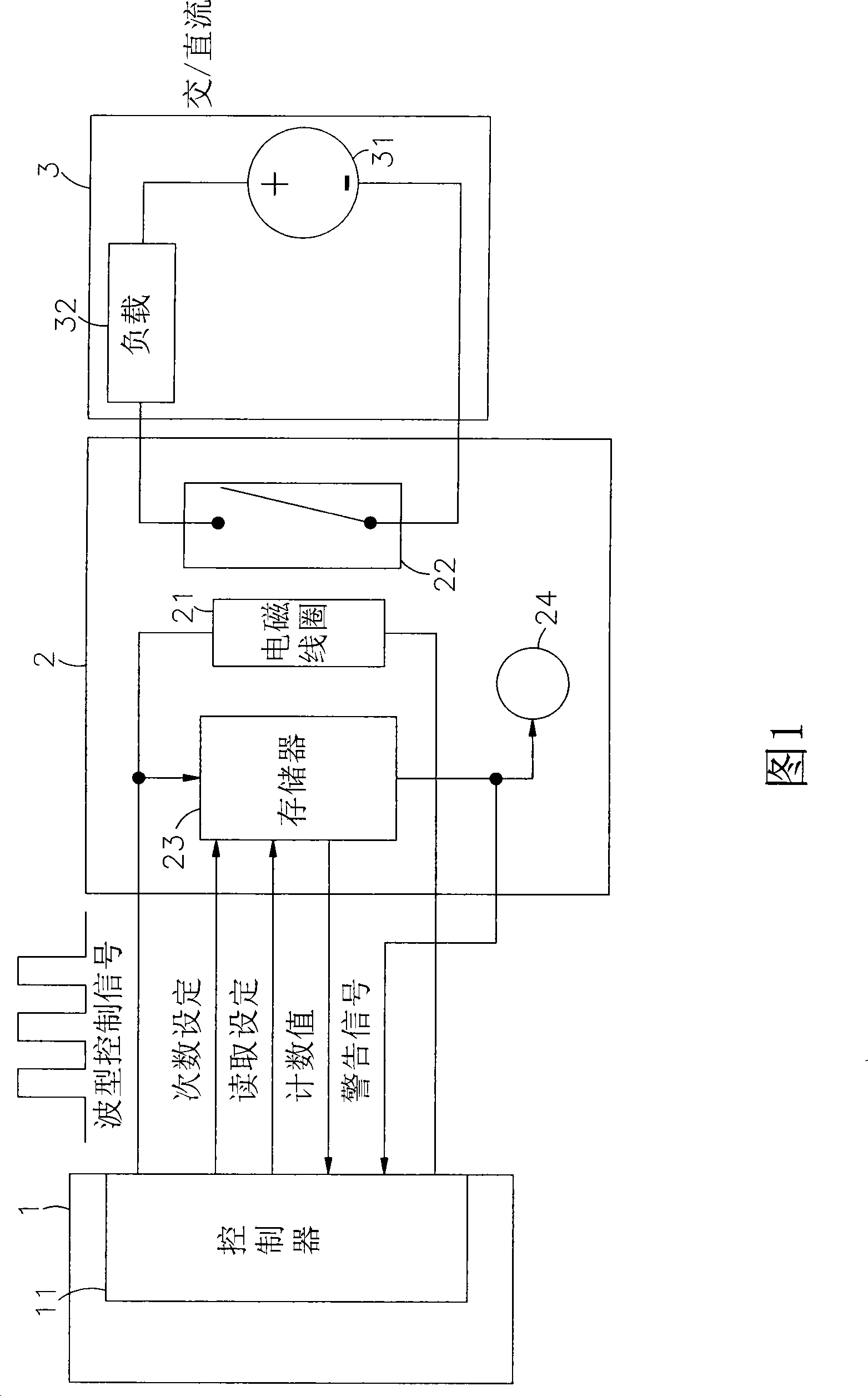

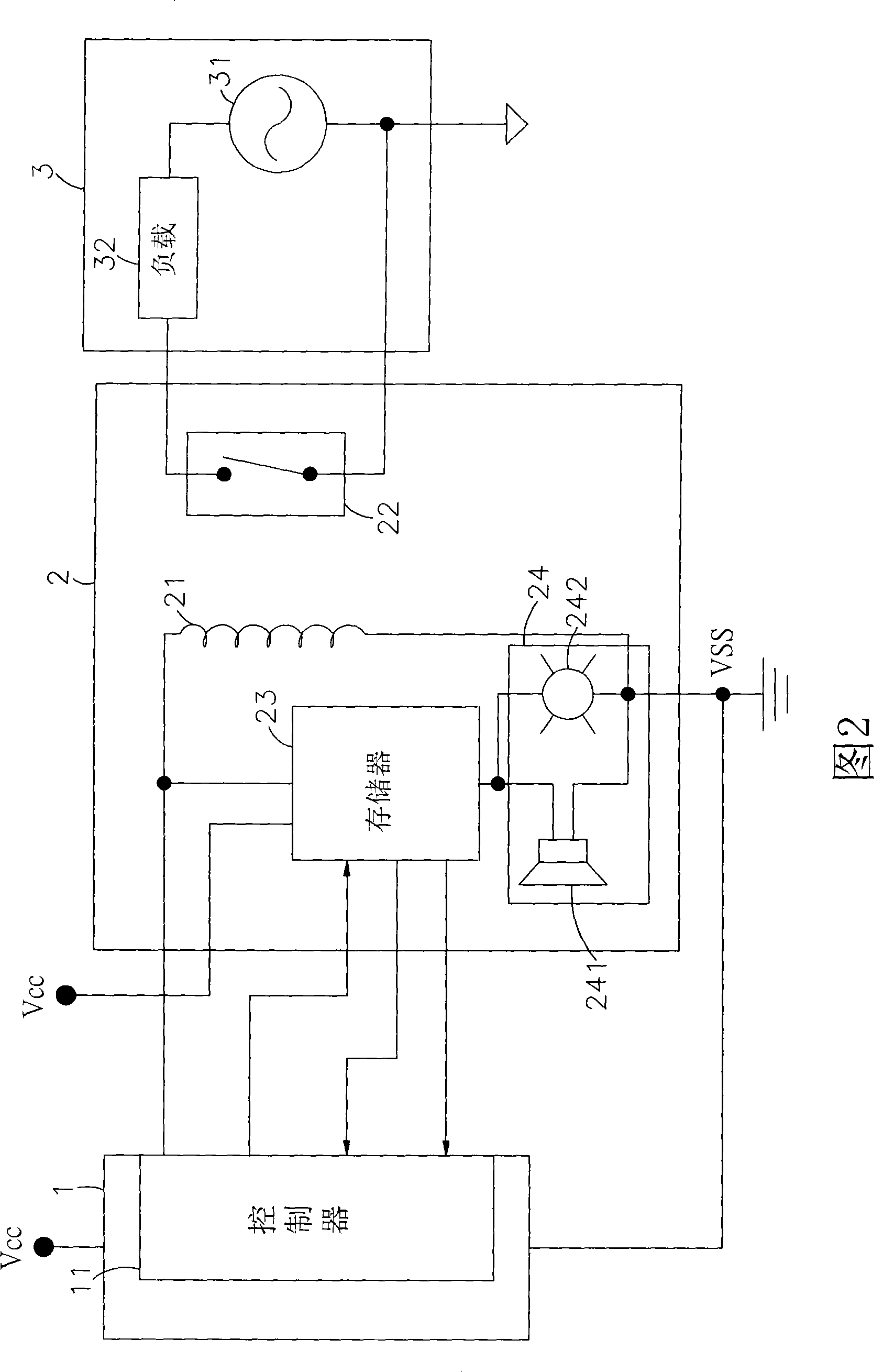

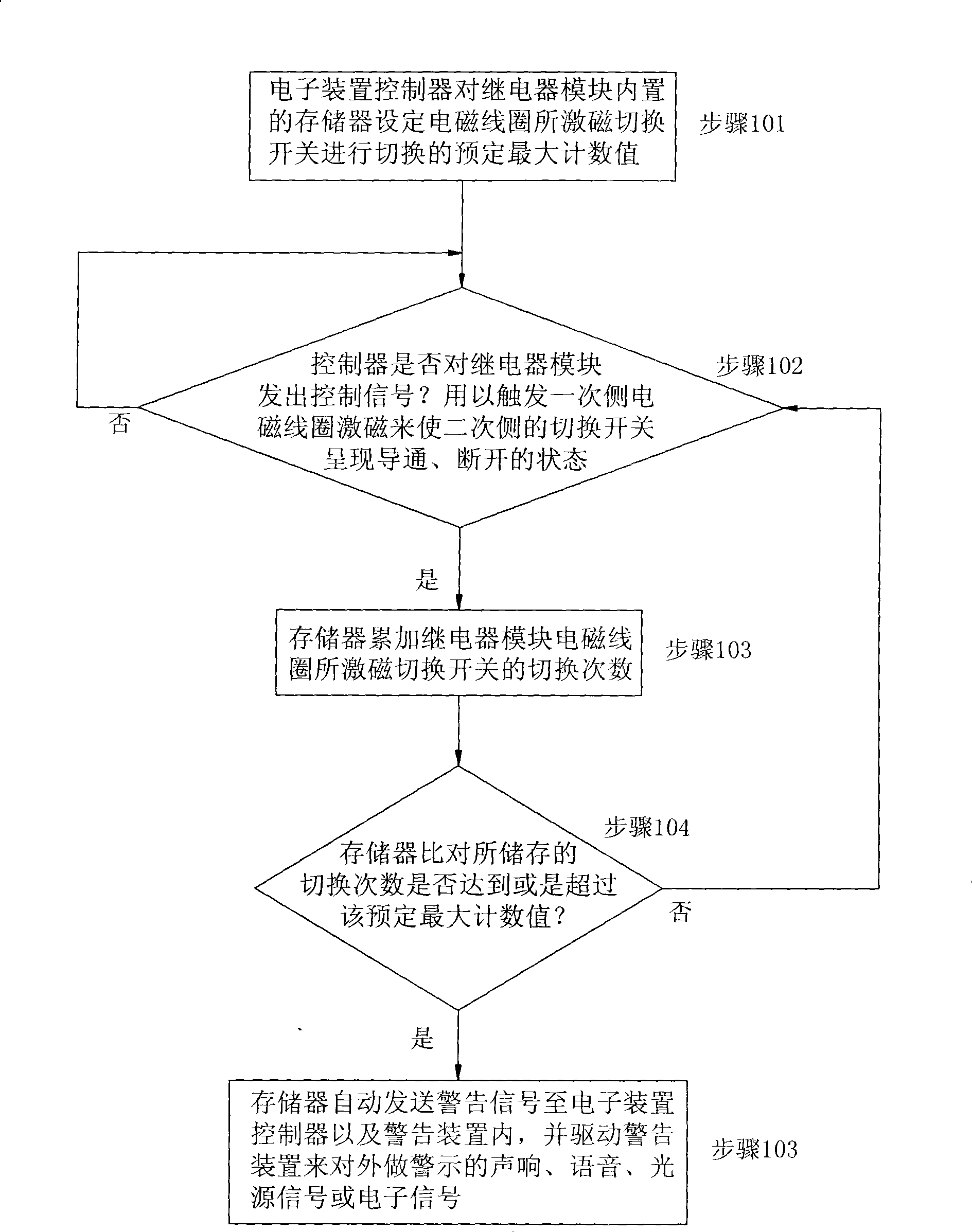

Electric relay having life memory function and apparatus thereof

InactiveCN101459014ABatteries circuit arrangementsElectric/electromagnetic visible signallingControl signalLoad generation

The invention relates to a relay with service-life memory function and a device thereof. A solenoid coil capable of receiving control signals transmitted by an electronic device controller is positioned in a relay module, the control signals are utilized to trigger excitation of a primary side solenoid coil so as to lead a secondary side change-over switch to present on or off states, the change-over switch is connected with a power input device and a load of a power control circuit, further, with the controller, the motion frequency of the change-over switch of the relay module can be stored in a memory, and when the switching frequency reaches the predetermined counting value, warning signals can be automatically sent to warn and inform users to substitute the relay module which is about to fault or at the end of service life due to contact aging in advance, thereby avoiding shortages of damages, stoppage or burning-out of the controlled load due to short circuit or faults of the relay module.

Owner:MOXA INC

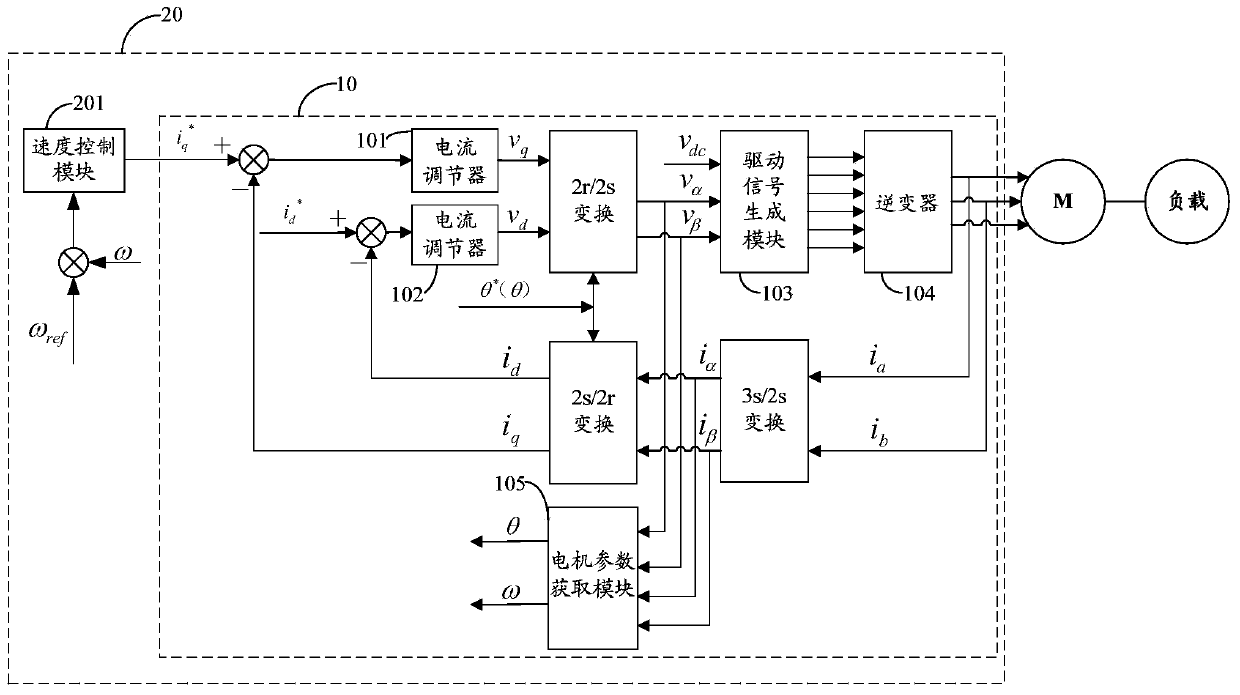

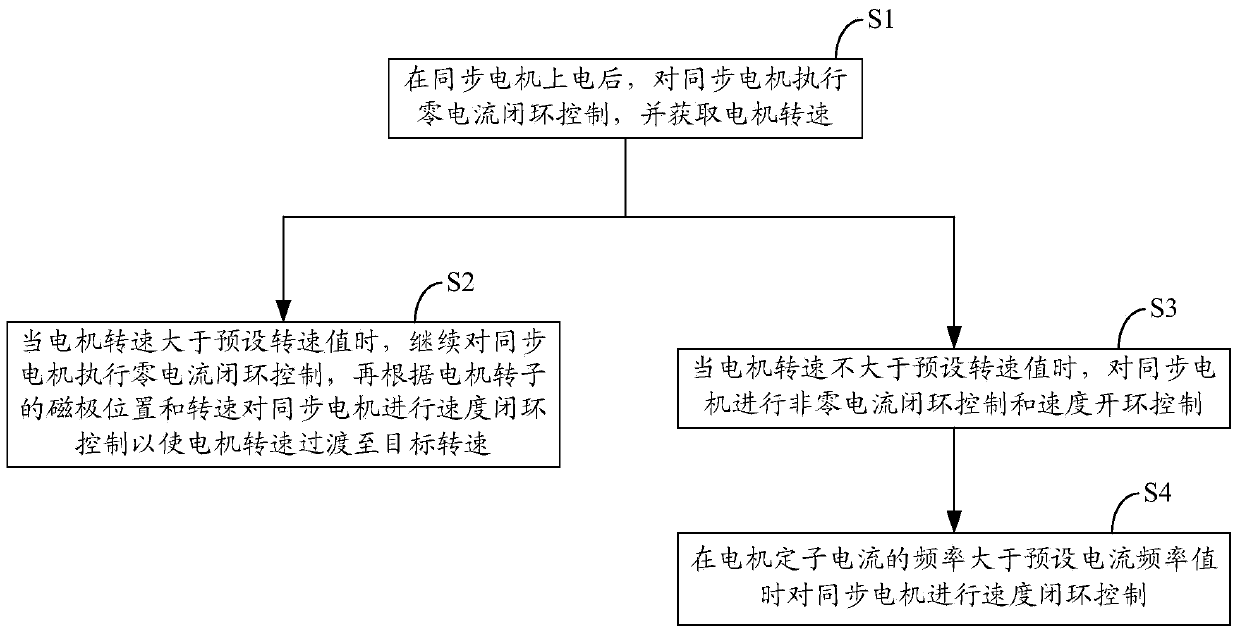

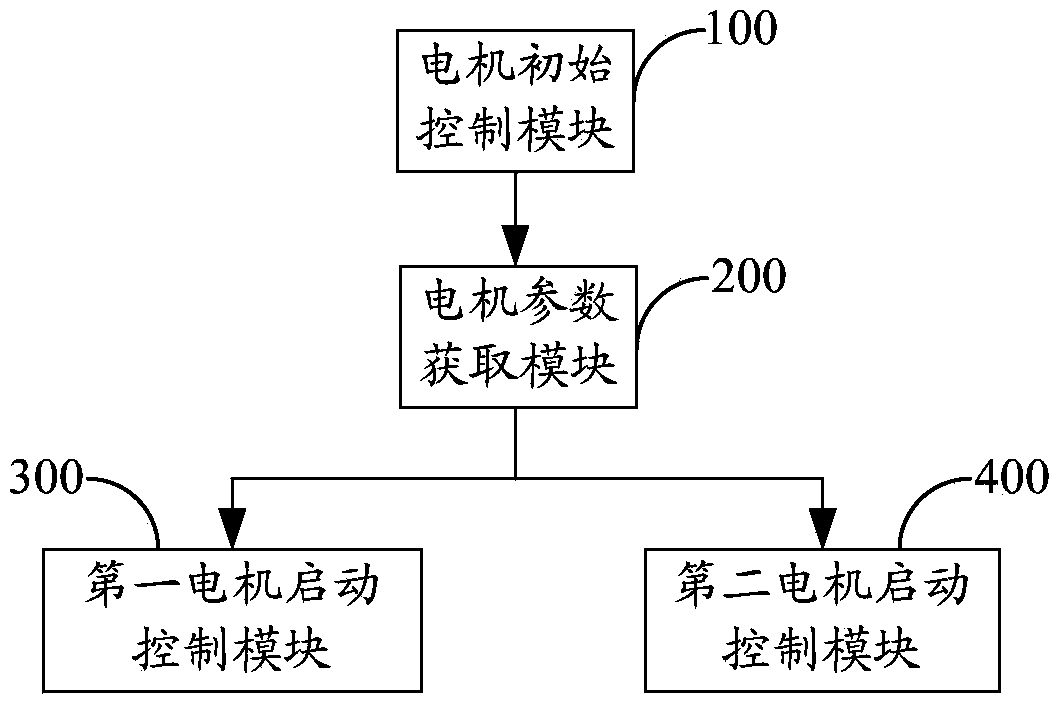

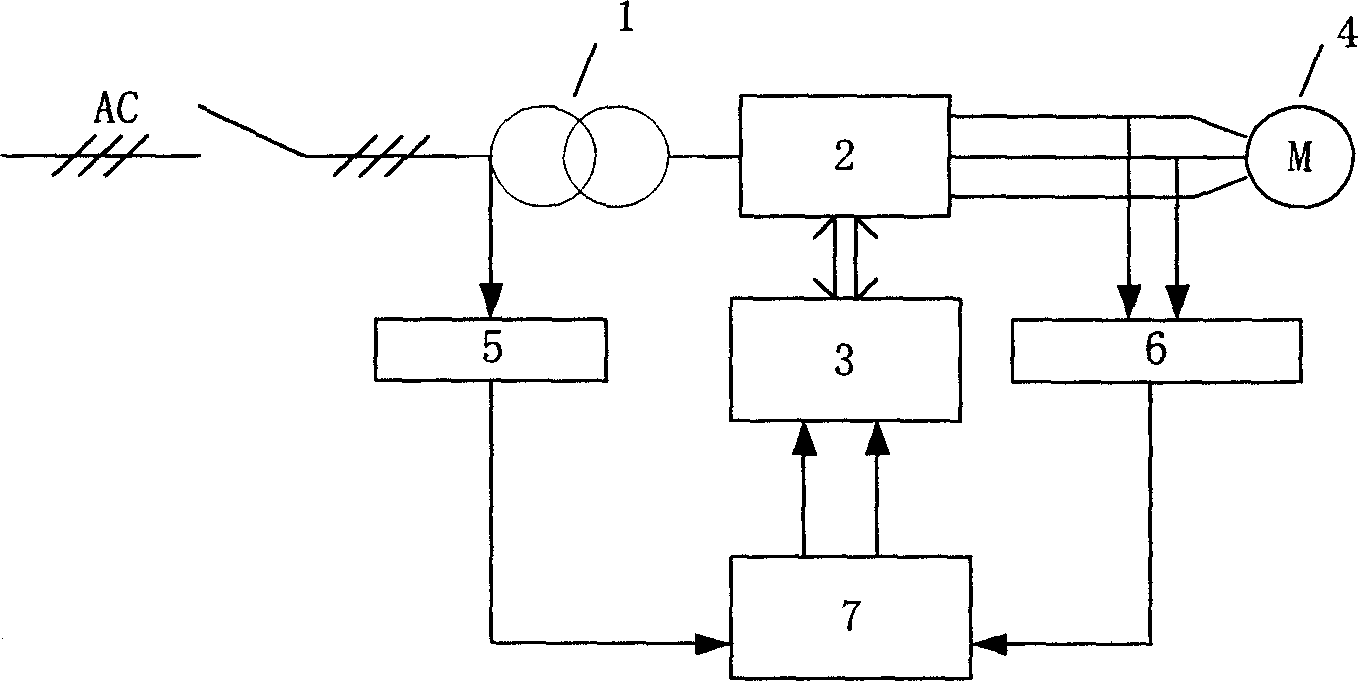

Synchronous motor start control method and system

ActiveCN103746619ASolve the speed is not zero,Solve the problem of not being able to start successfullySingle motor speed/torque controlLoop controlSynchronous motor

The invention pertains to the technical field of synchronous motor control, and provides a synchronous motor start control method and system. According to the invention, after the synchronous motor is powered on, zero-current closed-loop control is performed on the synchronous motor at first, and the motor rotating speed is acquired at the same time to detect the initial rotating speed of the synchronous motor, and then when the motor rotating speed is greater than a preset rotating speed value (i.e., the initial rotating speed is greater than the preset rotating speed value), zero-current closed-loop control is performed on the synchronous motor continuously, and speed closed-loop control is performed on the synchronous motor according to the magnetic pole position and the rotating speed of the motor rotor so as to make the motor rotating speed smoothly changed to the object rotating speed to successfully complete the start process when the initial speed of the synchronous motor is greater than the preset rotating speed value, and no current abrupt change will occurs, no torque impact will be generated on loads, so the problem that the start process cannot be performed successfully with an existing synchronous motor which is not provided with a position sensor caused by the reason that the rotating speed of the motor before starting is not zero can be solved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

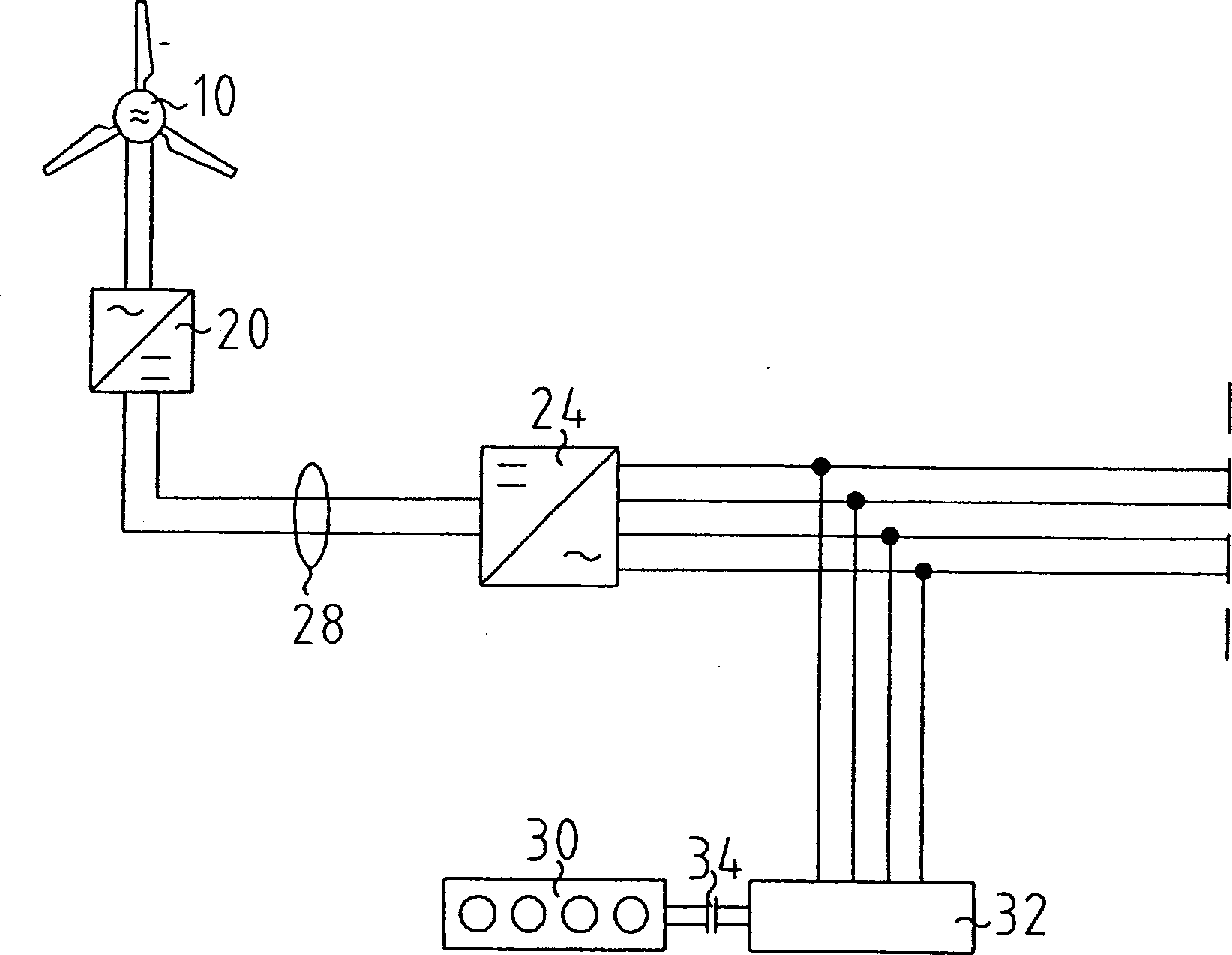

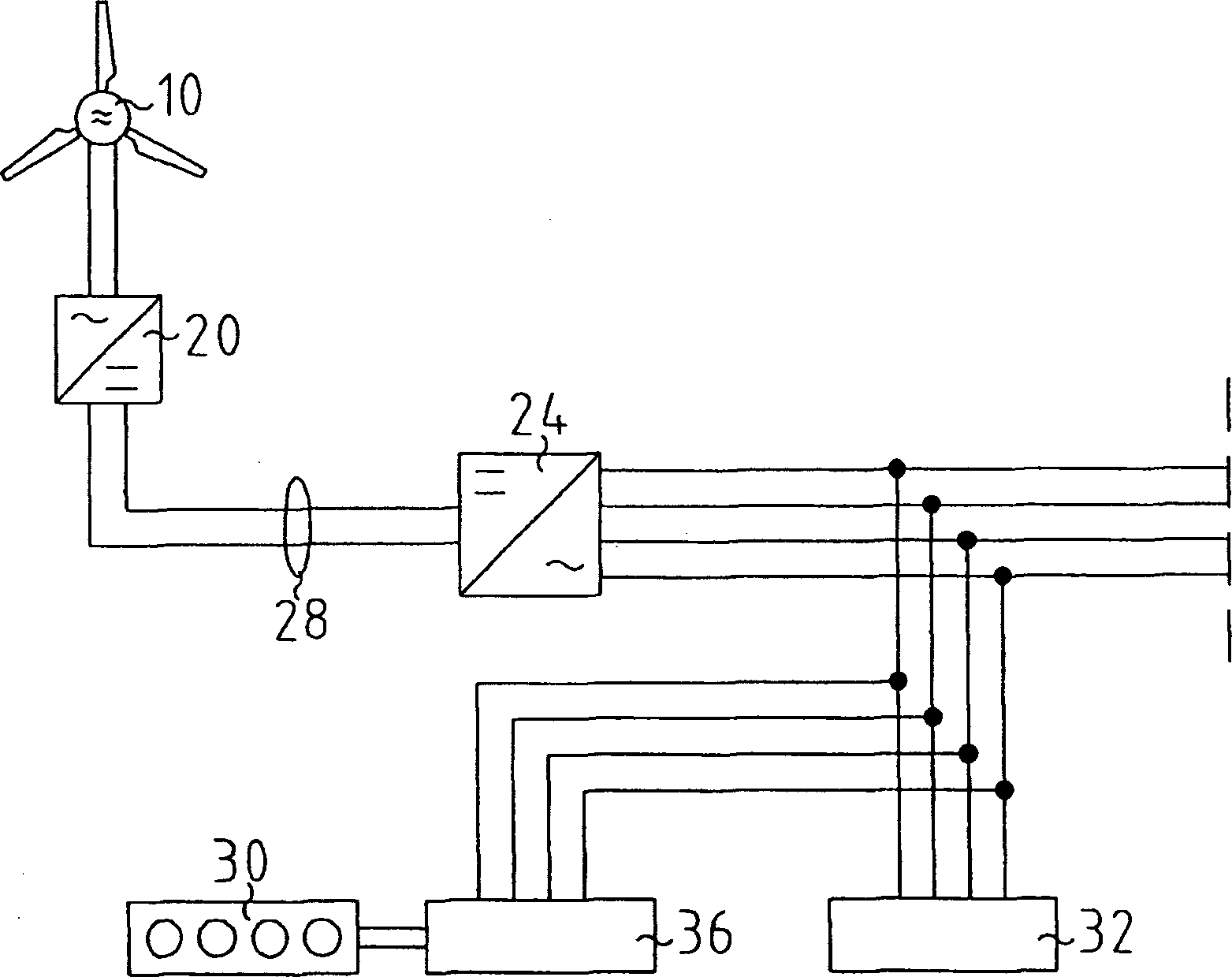

Island network and method for operation of an island network

InactiveCN1470092ALow priceWind motor controlWorking fluid for enginesElectromagnetic couplingLoad generation

The arrangement has at least one first energy generator using a regenerative energy source, preferably a wind power system (10) with a generator, and a second generator (32) for coupling to an internal combustion engine (30). The revolution rate and blade setting of the wind power generator can be controlled and there is an electromagnetic coupling (34) between the second generator and internal combustion engine. Independent claims are also included for the following: a method of operational control of an electrical island network with at least one wind power system and the use of a synchronous generator as a network mimic for a mains inverter.

Owner:阿洛伊斯沃本

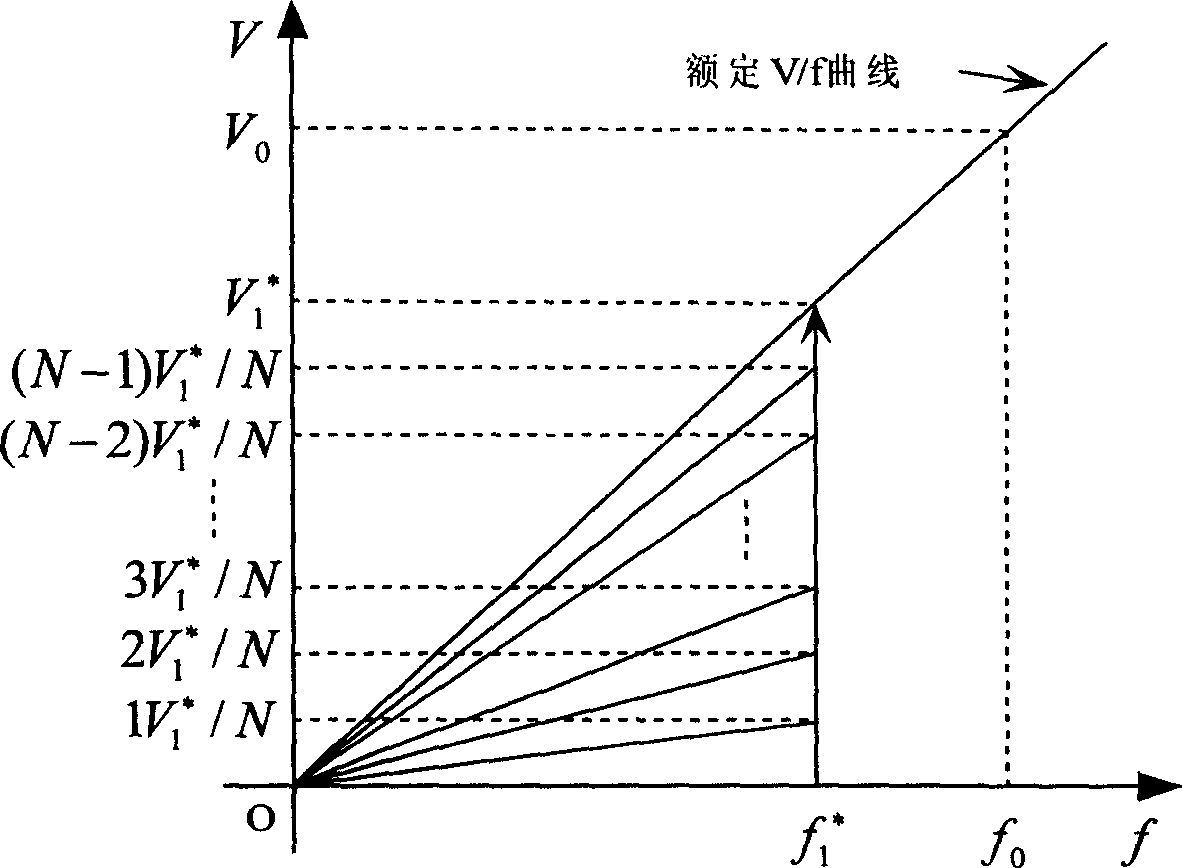

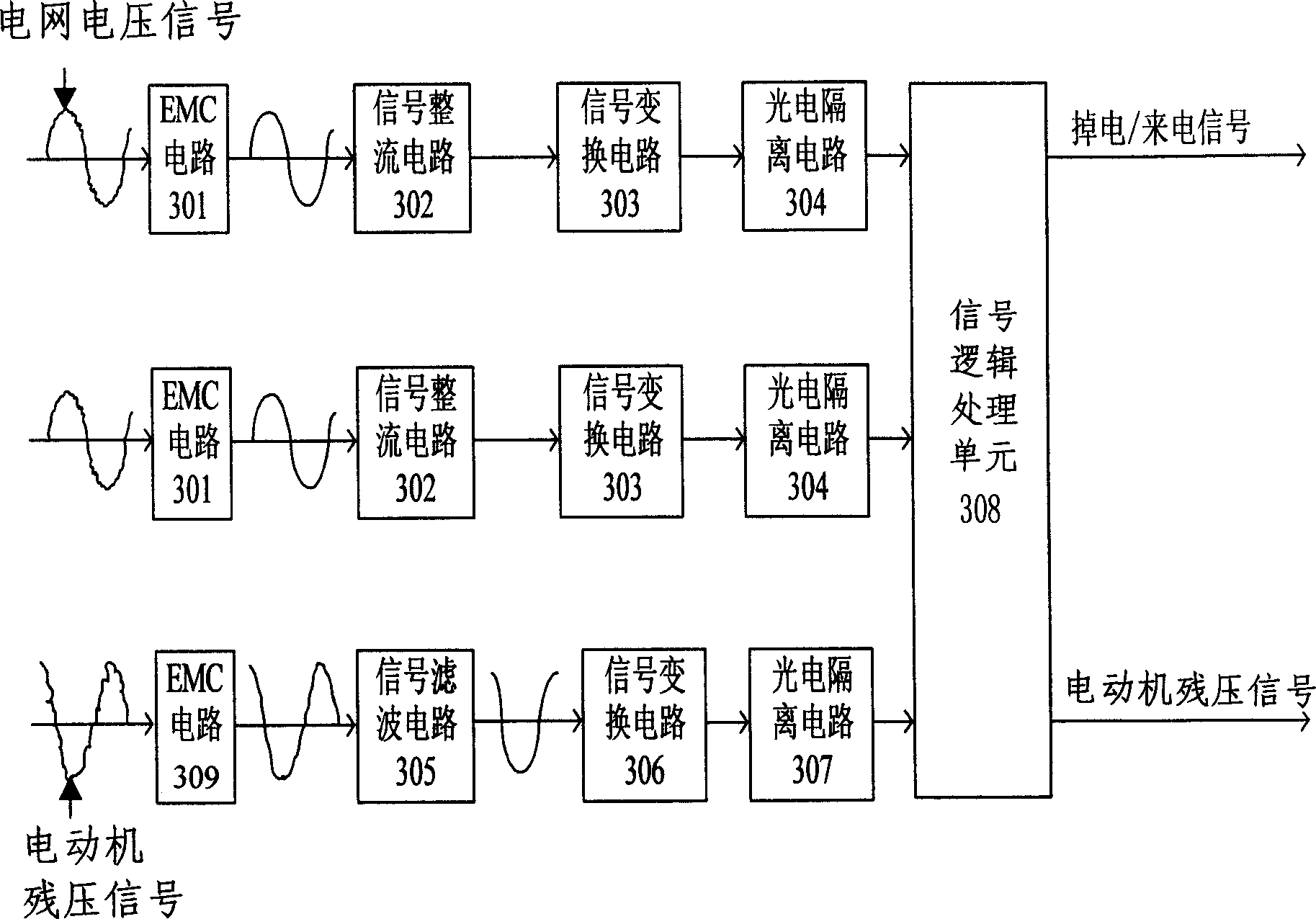

Instantaneous power cut restaring method and apparatus for frequency change speed regulating system

InactiveCN1719717AShort restart timeImprove work efficiencyStarter detailsPolyphase induction motor starterElectricityConstant frequency

This invention relates to a method and a system for restarting when a high voltage conversion velocity-regulation system is off instantly, which boosts the output voltage of a converter to a nominated V / F curve voltage value corresponding to its residual frequency in constant frequency, then accelerates it to the system frequency according to the normal start program.

Owner:DONGFANG HITACHI CHENGDU ELECTRICAL CONTROL EQUIP CO LTD

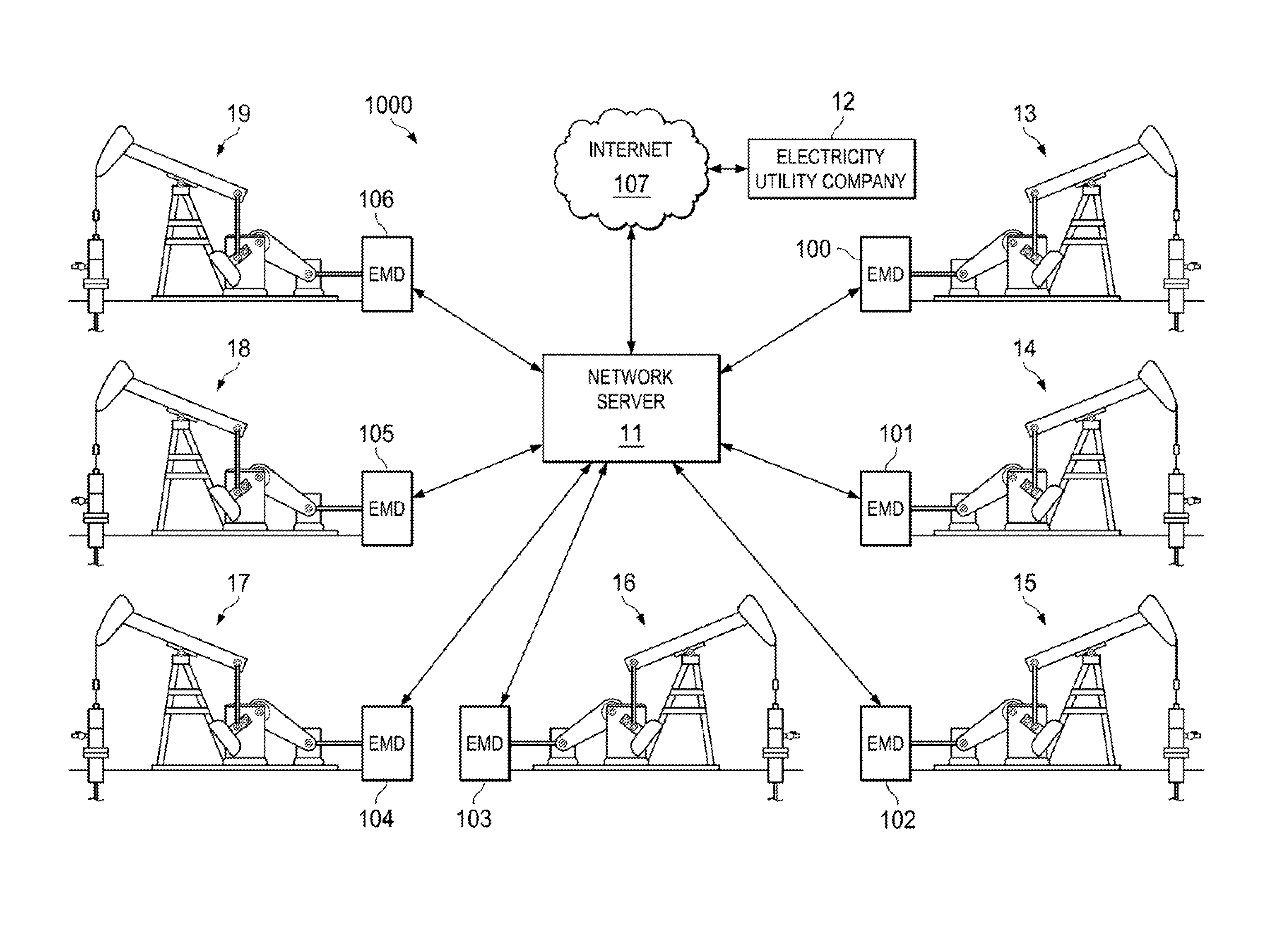

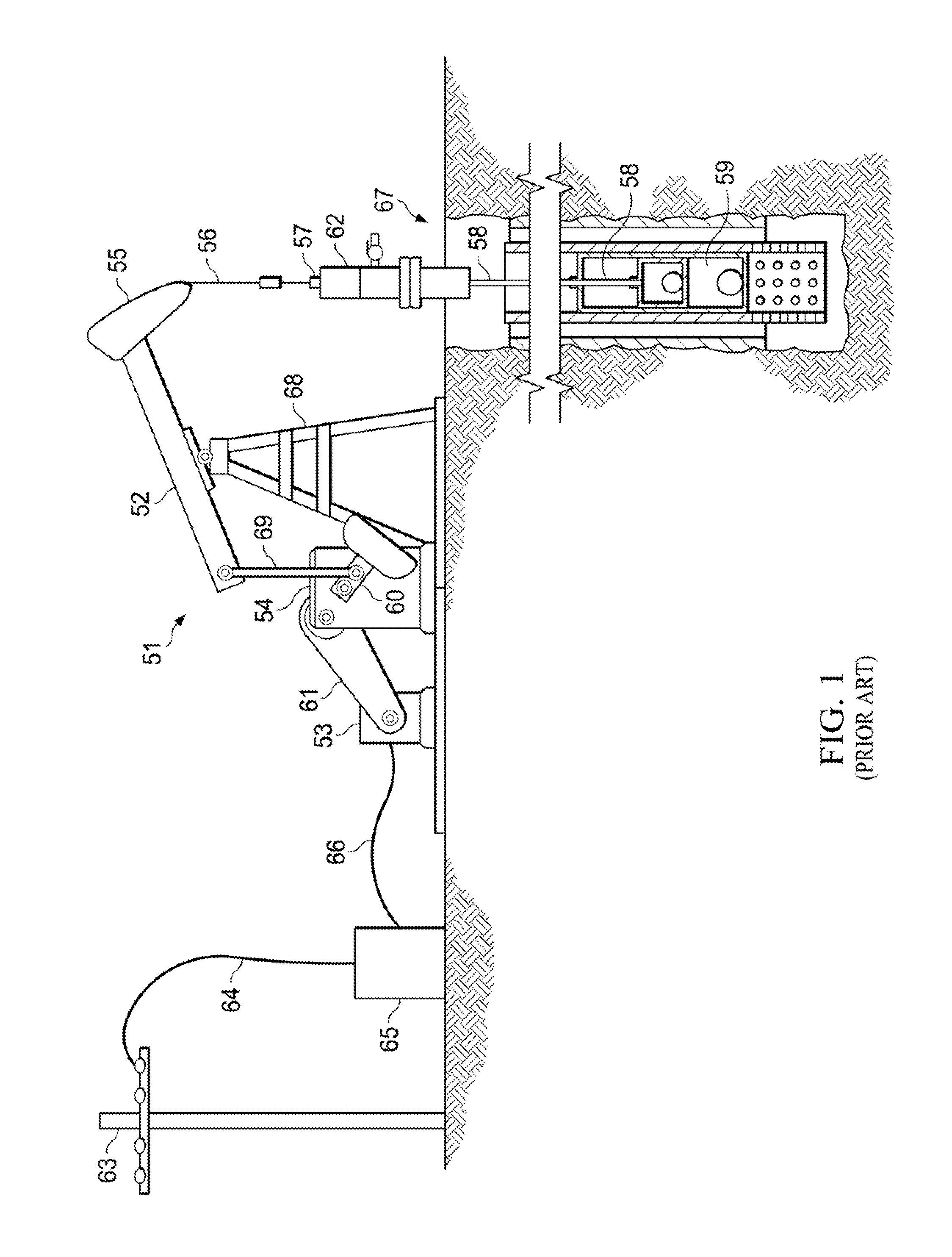

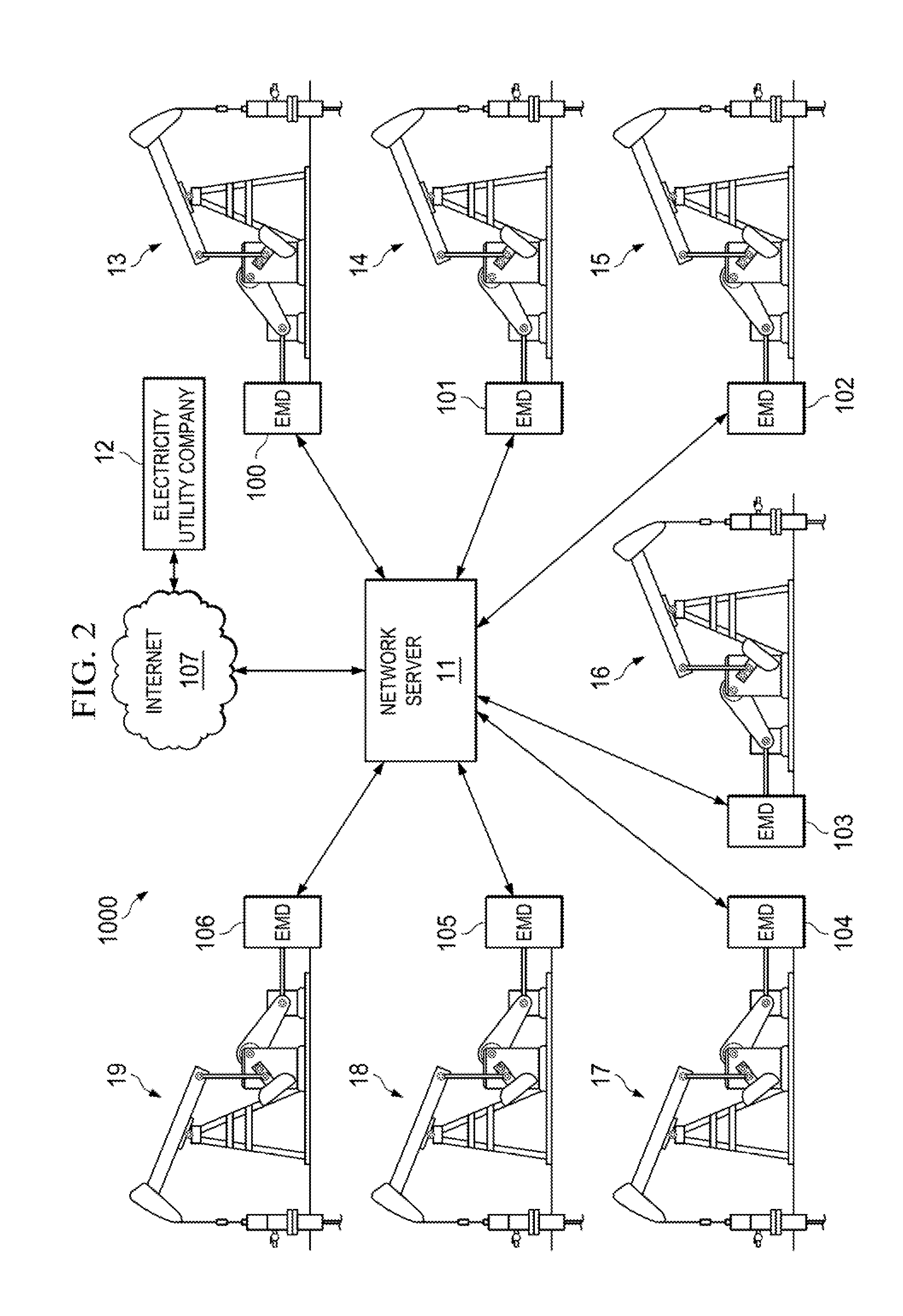

System, method and apparatus for computing, monitoring, measuring, optimizing and allocating power and energy for a rod pumping system

PendingUS20140343743A1Mechanical power/torque controlData processing applicationsElectricityLoad generation

A system and method for correcting energy consumption for a set of loads in an oil and gas field lease includes a network, a network server connected to the network, a set of energy monitoring devices connected to the network, the set of loads connected to the set of energy monitoring devices, an electricity meter connected to the set of loads and the set of energy monitoring devices, a power supply connected to the electricity meter, and an electricity utility company connected to the network and to the power supply. The method includes the steps of receiving an electricity meter reading, receiving an amount of energy consumed by each load, receiving an amount of energy generated by each load, and determining a correct net energy consumption for each load of the set of loads from the electricity meter reading, the amount of energy consumed, and the amount of energy generated.

Owner:LONG MEADOW TECH

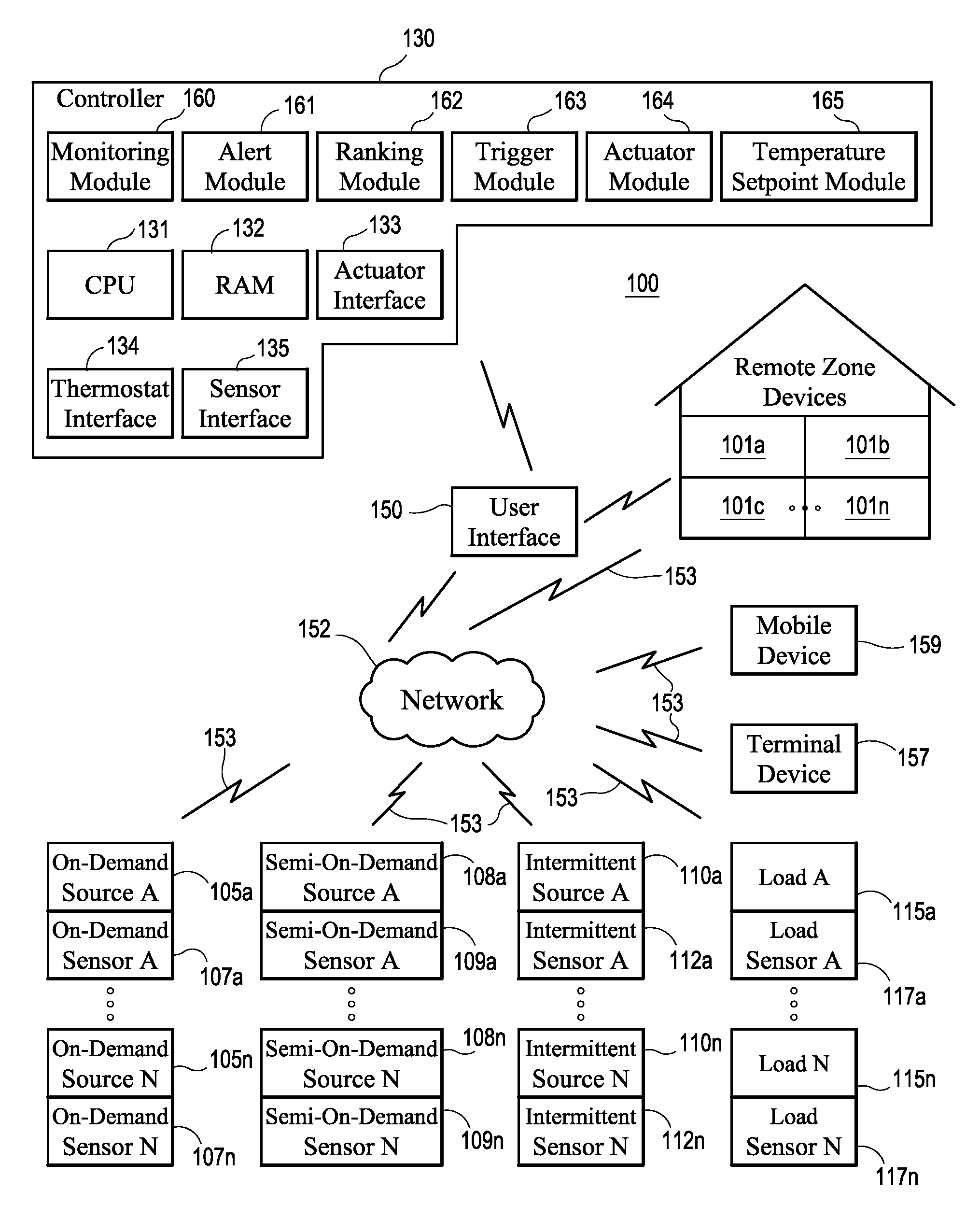

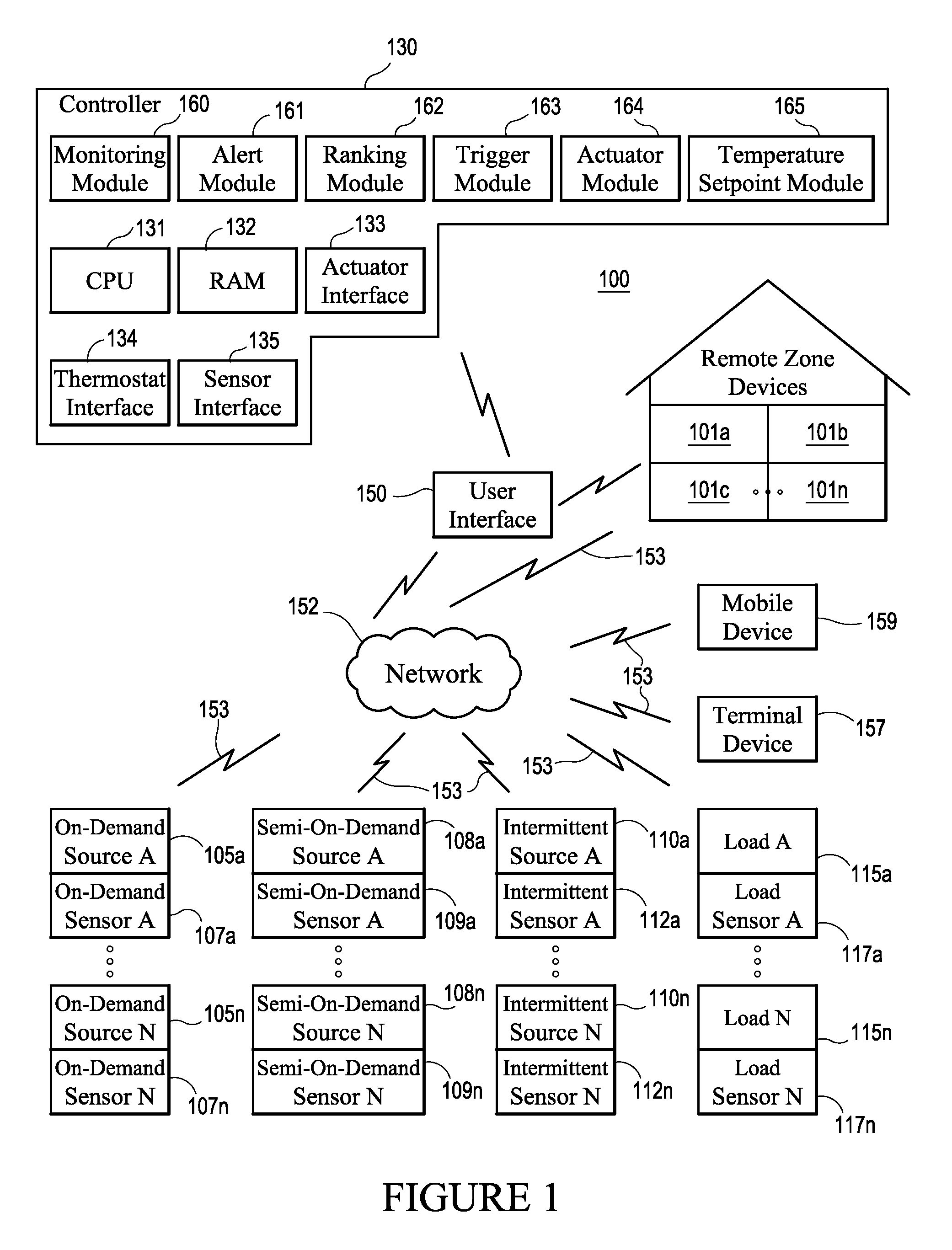

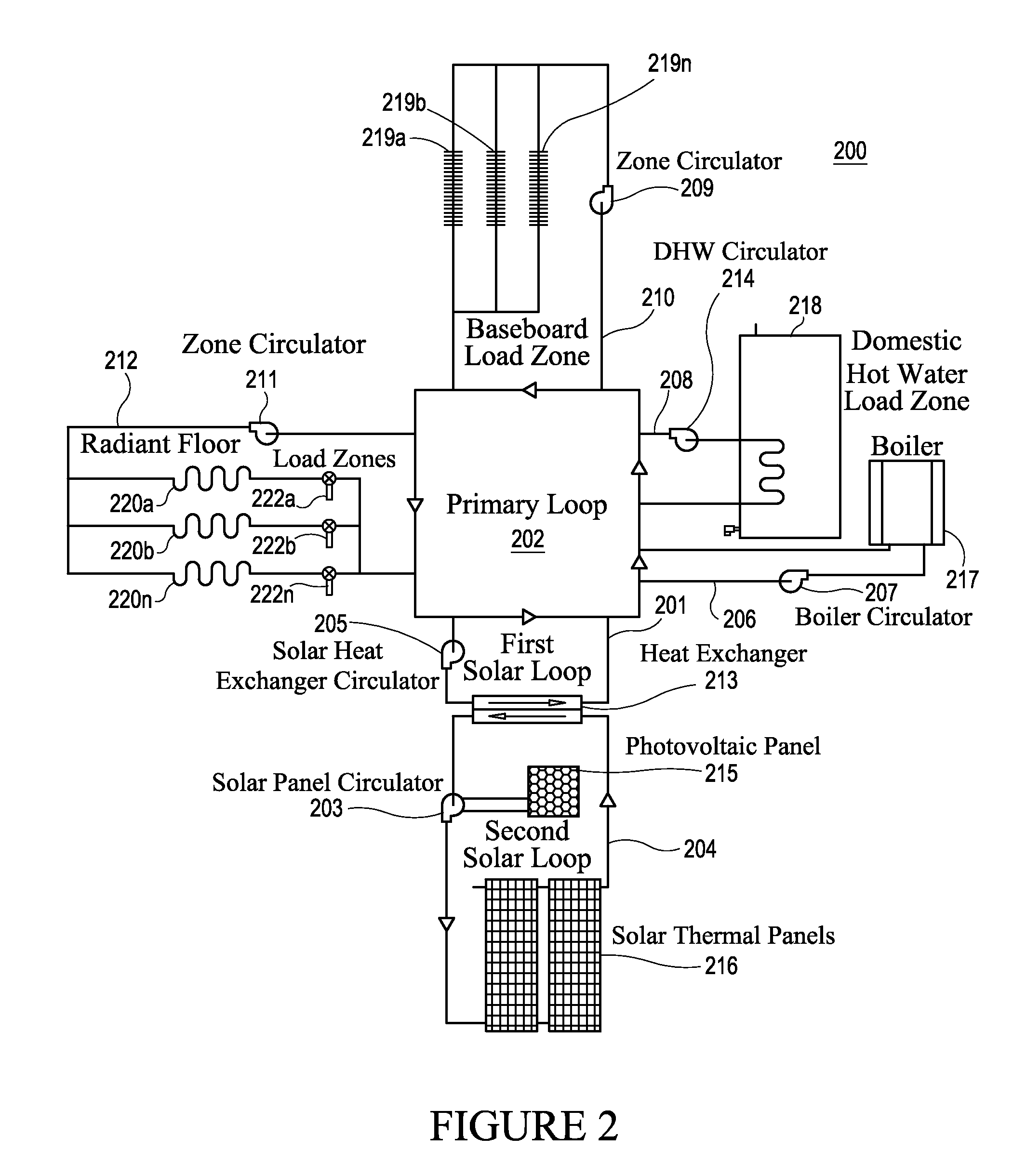

System and method for controlling hydronic systems having multiple sources and multiple loads

A system and method are provided to control hydronic systems having a plurality of on-demand sources, semi-on-demand sources, and intermittent sources that are fluidly or thermally coupled to a plurality of load zones. The hydronic system device obtains performance measurements for system components to provide system metrics, including failure diagnostics, energy capture, and usage optimization. The hydronic system device may also calculate British Thermal Units produced and used by the plurality of sources and loads to calculate incentives, including renewable energy credits.

Owner:SOLARLOGIC

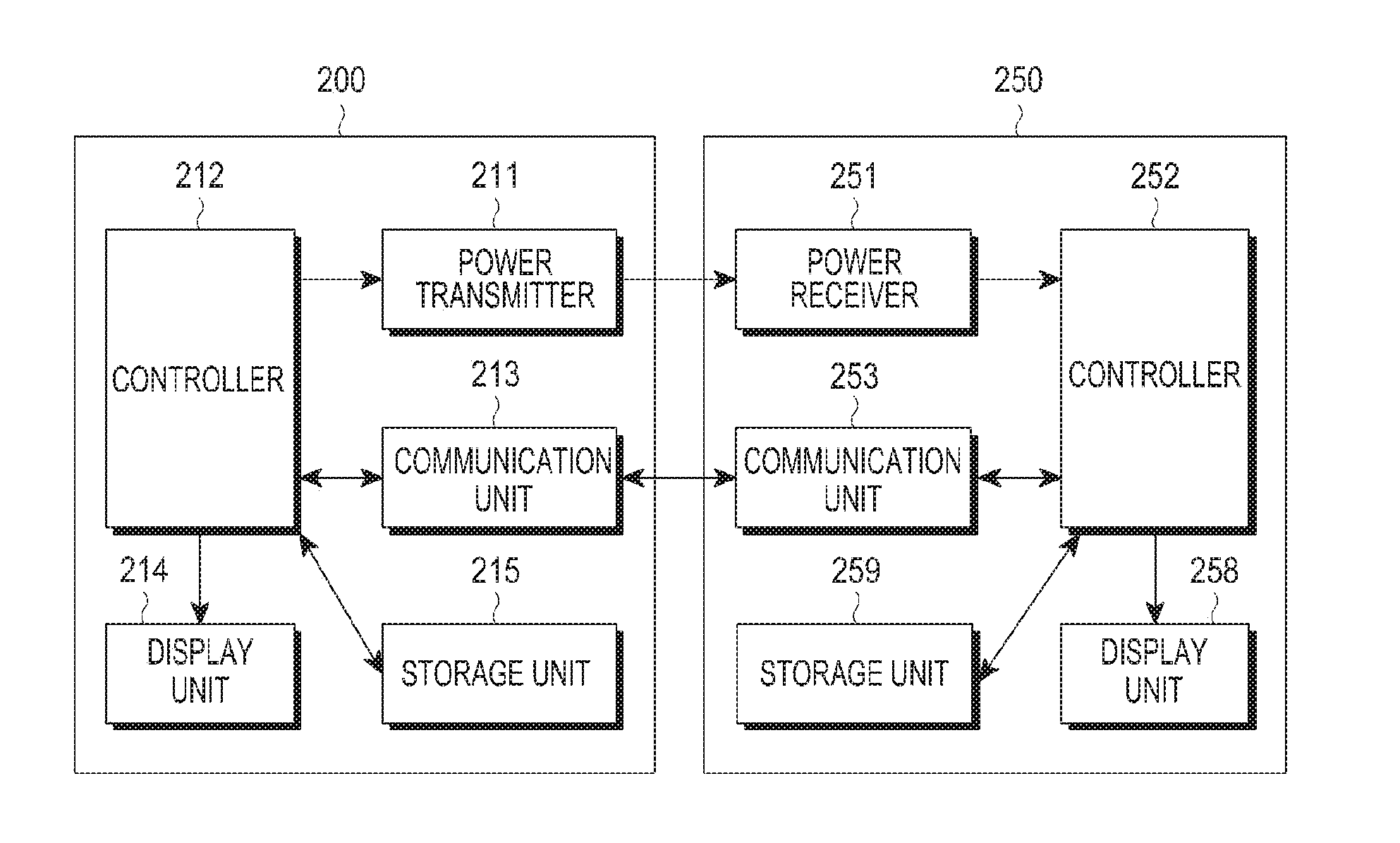

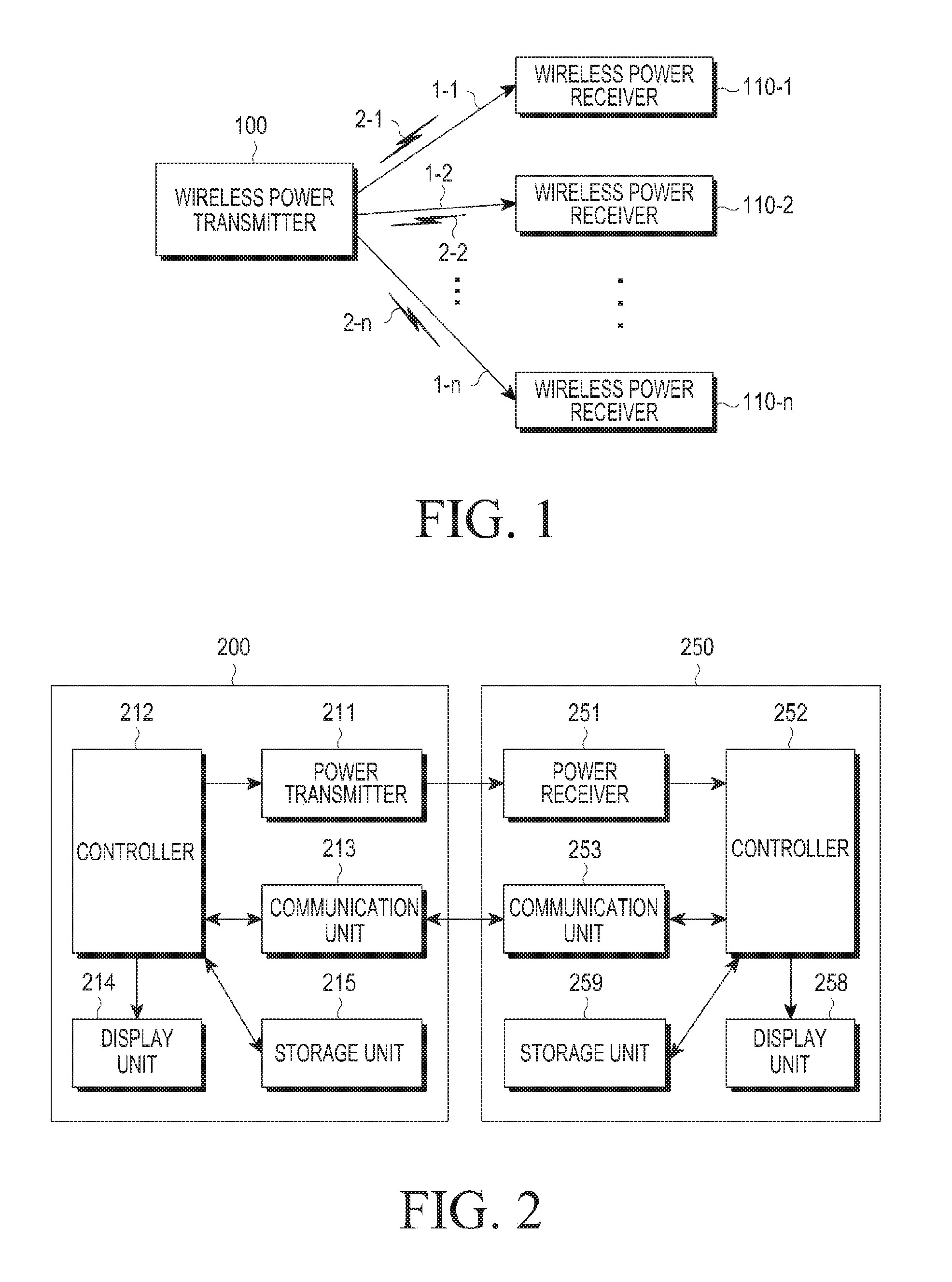

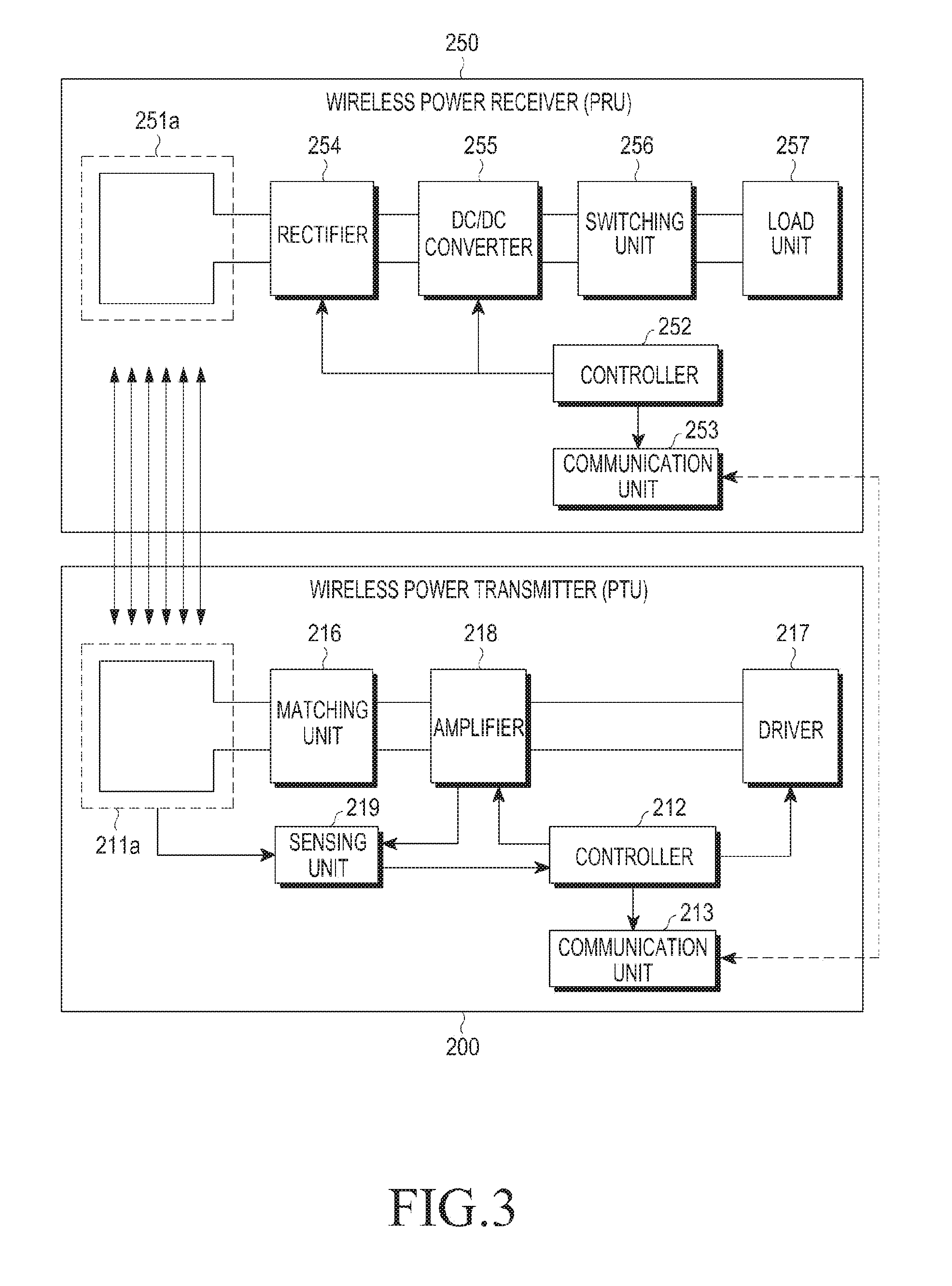

Method for generating load of wireless power receiver in wireless charging system and wireless power receiver

ActiveUS20160268815A1Efficient detectionNear-field transmissionElectric powerLoad generationDirect current

A wireless power receiver (PRU) and a method for generating a load of the PRU for detecting the PRU in a wireless charging system are provided. The method includes receiving a wireless power signal from a wireless power transmitter (PTU), rectifying the received wireless power signal into a direct current (DC) signal, and generating a load for detecting the PRU by controlling a current flowing across a resistor connected in parallel with a load charged with power of the DC signal.

Owner:SAMSUNG ELECTRONICS CO LTD

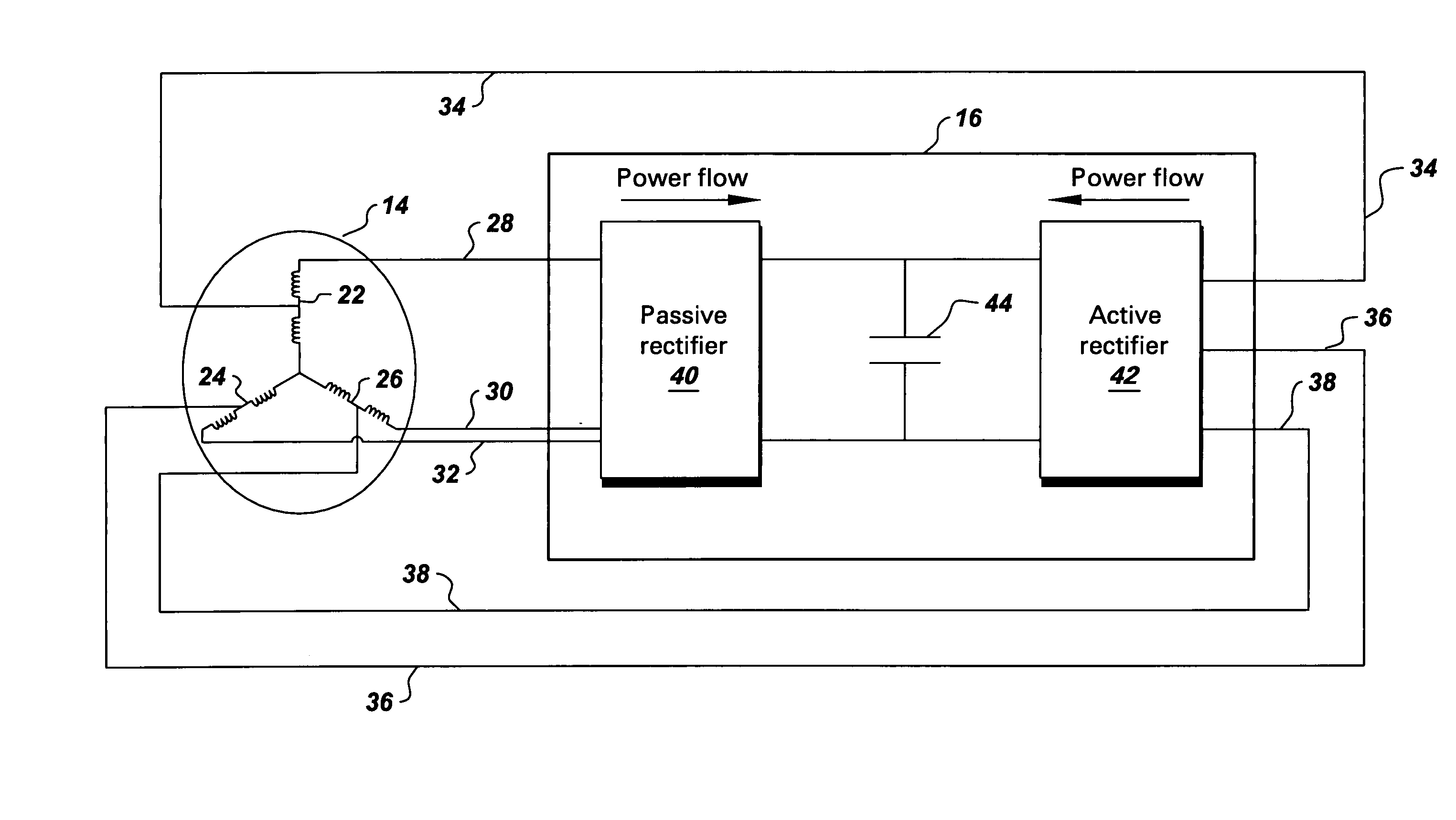

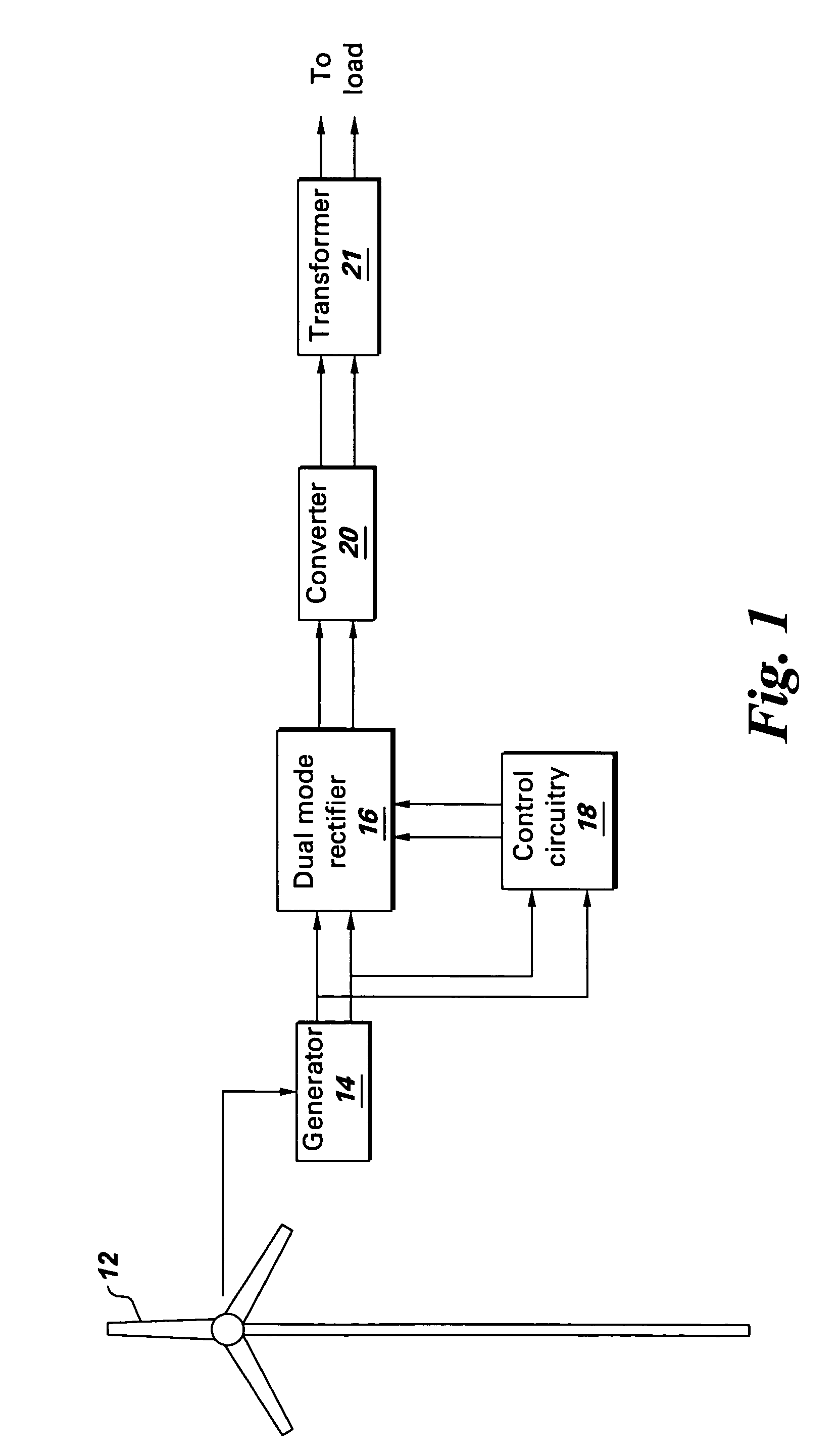

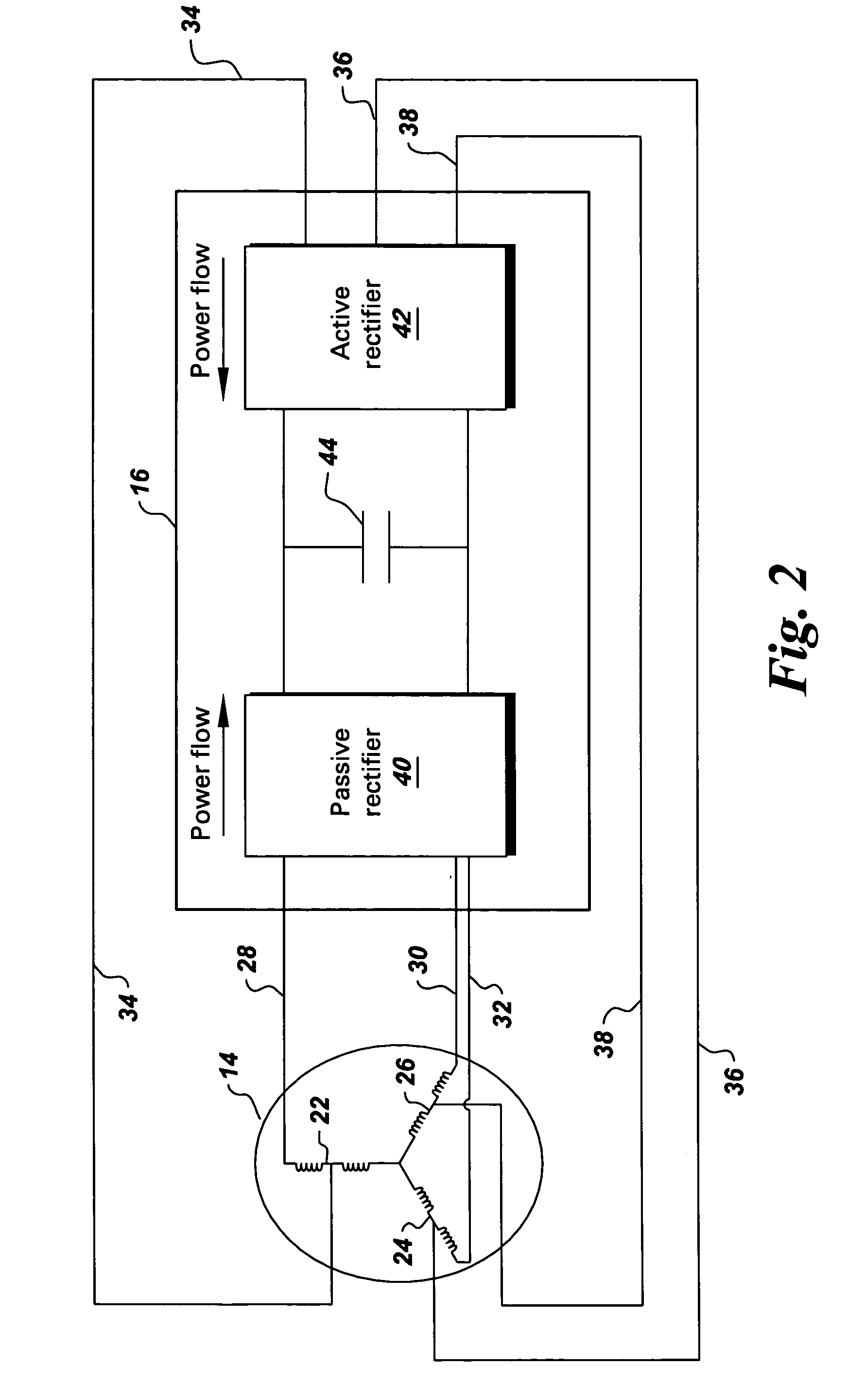

Dual mode rectifier, system and method

InactiveUS7203078B2Ac-dc conversion without reversalConversion with intermediate conversion to dcDual modeLoad generation

Owner:GENERAL ELECTRIC CO

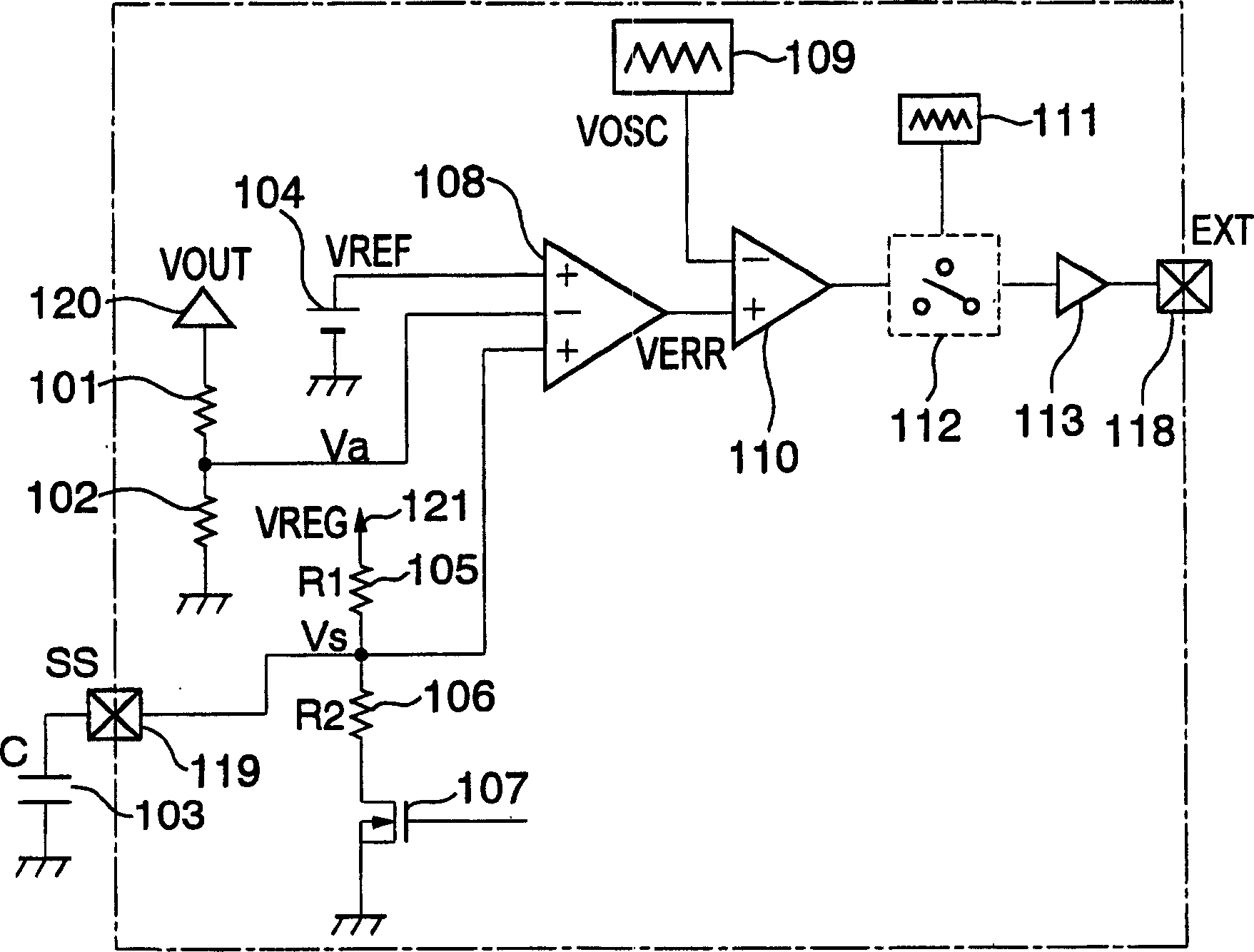

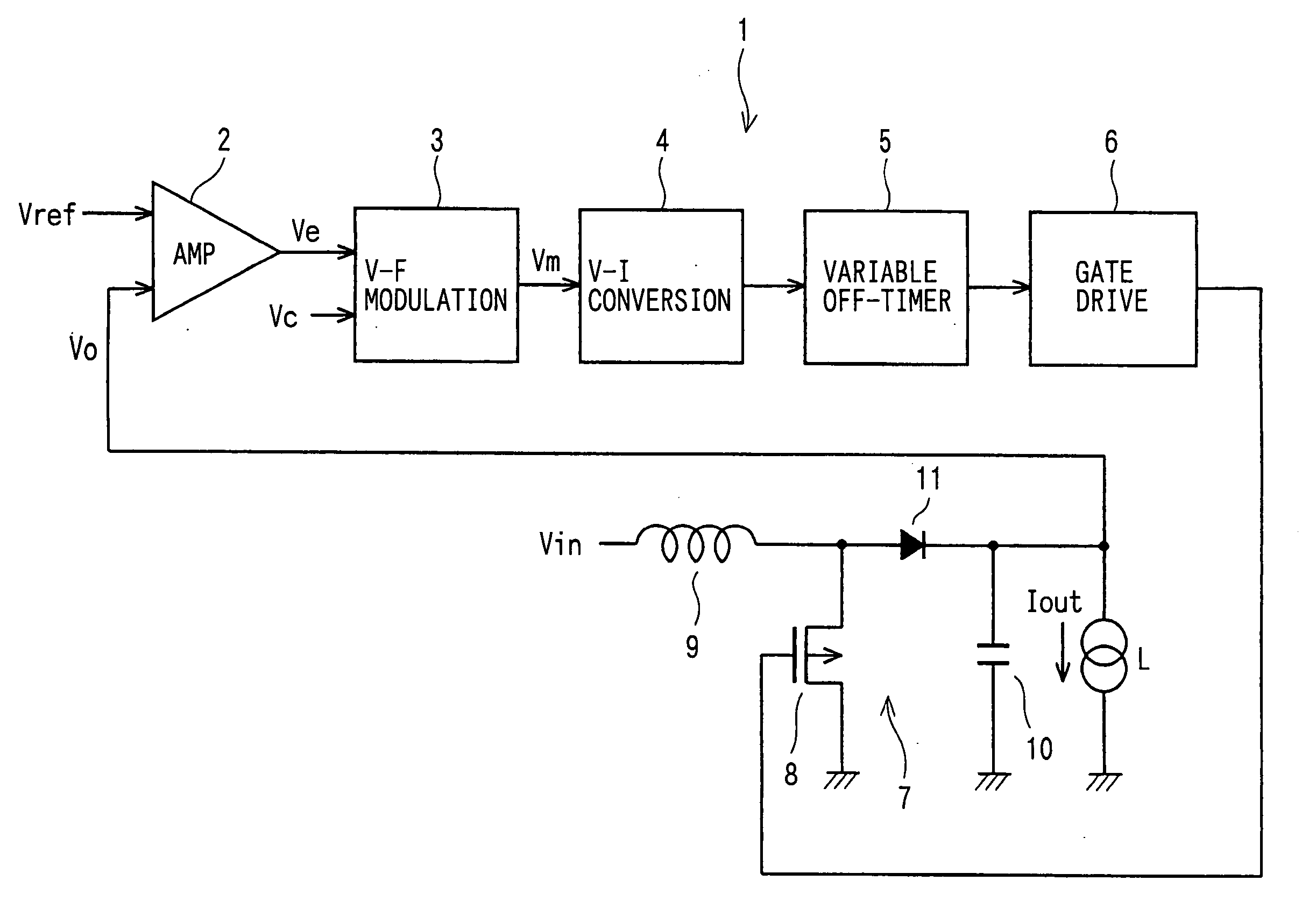

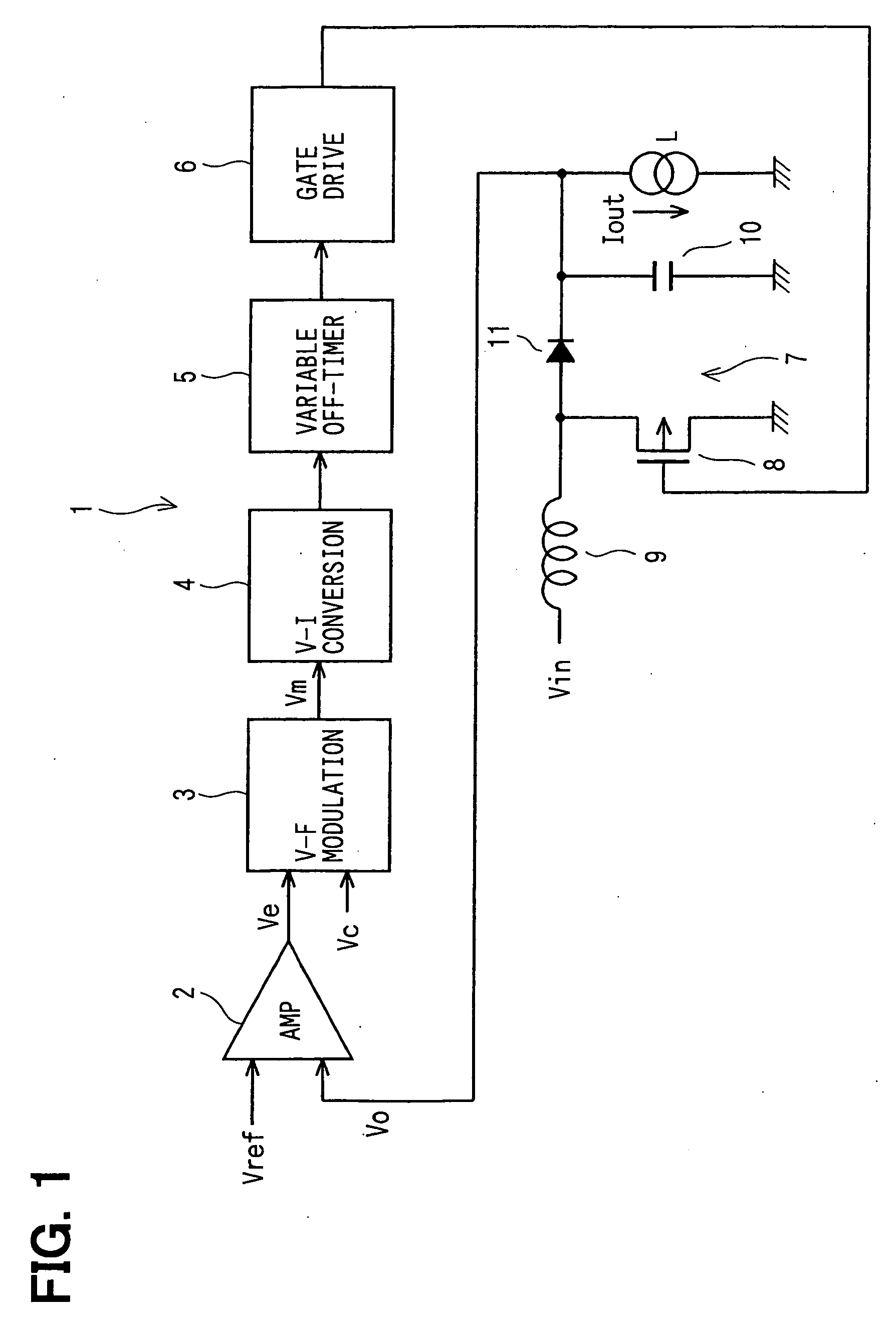

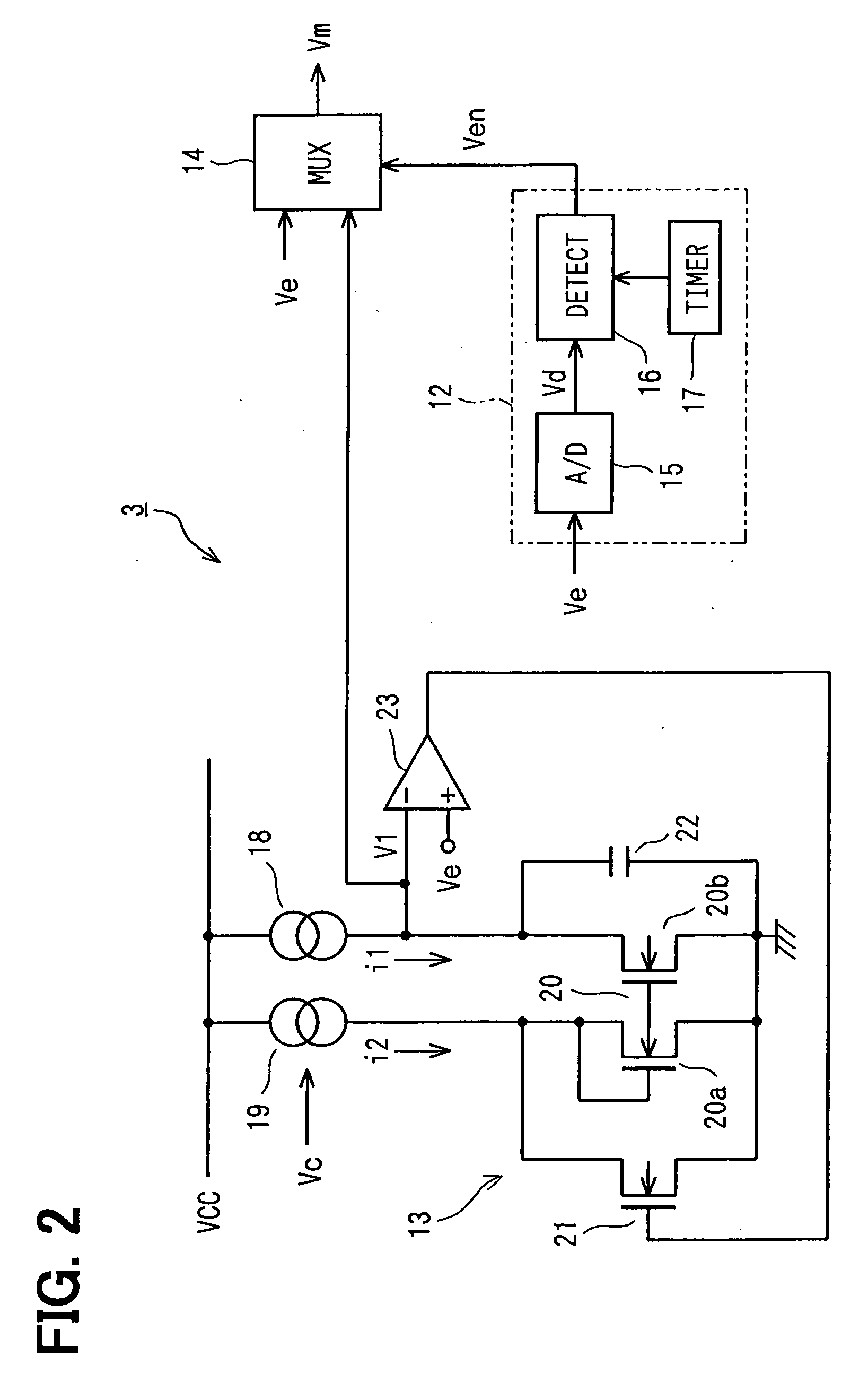

Switching regulator and control method therefor

InactiveUS20050200343A1Reduce noise levelImprove noise levelDc network circuit arrangementsDc-dc conversionNoise levelLoad generation

In a frequency modulation type switching regulator for producing an output voltage to a load, an error amplifier produces an error voltage indicative of a difference between the output voltage and a reference voltage. A switching device is turned on and off at a switching frequency corresponding to the error voltage. A voltage-frequency modulation circuit monitors an operation condition of the load. The modulation circuit generates a varying voltage, which varies around the error voltage, when the monitored operation condition is substantially unchanged. The switching frequency is switched to another frequency corresponding to the varying voltage, so that noise level may be reduced.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com