Instantaneous power cut restaring method and apparatus for frequency change speed regulating system

A variable frequency speed regulation and restarting technology, which is applied to motor generators/starters, starters of single polyphase induction motors, starter components, etc., can solve the problems of low efficiency and long restart time, and achieve the The effect of short starting time, stable starting process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

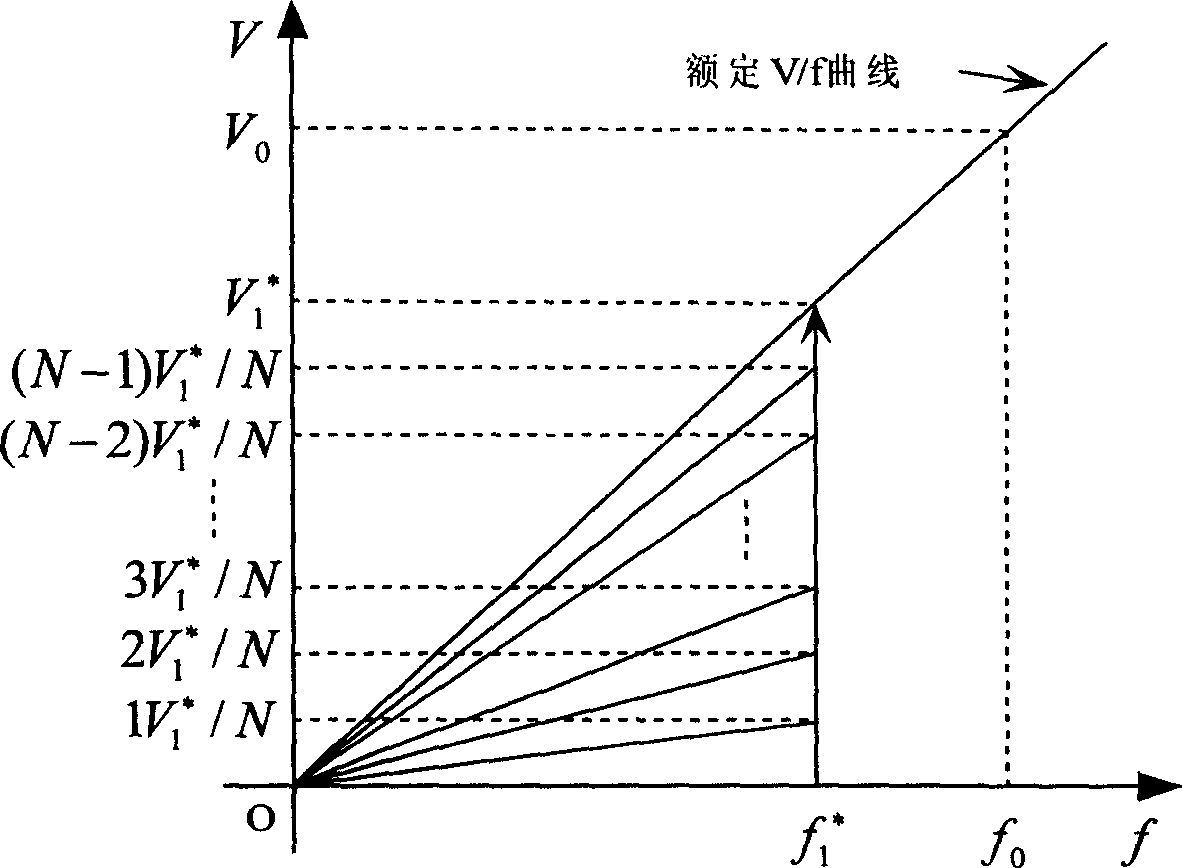

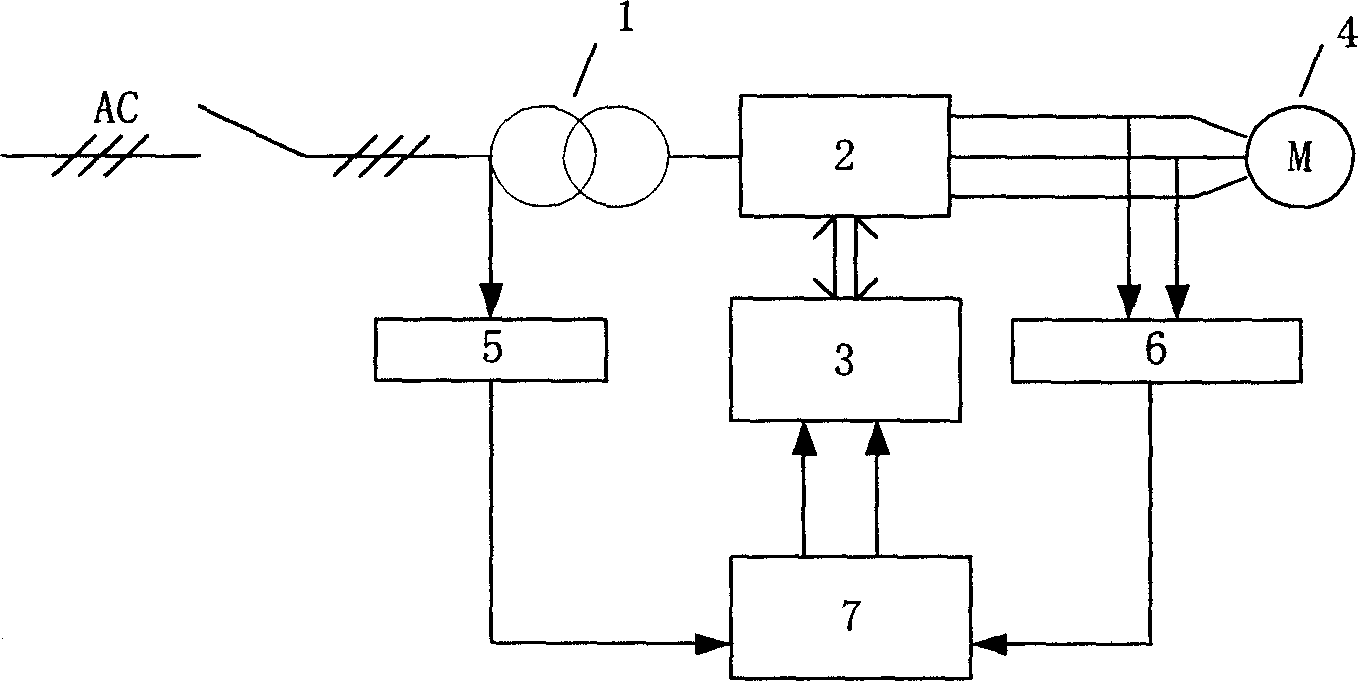

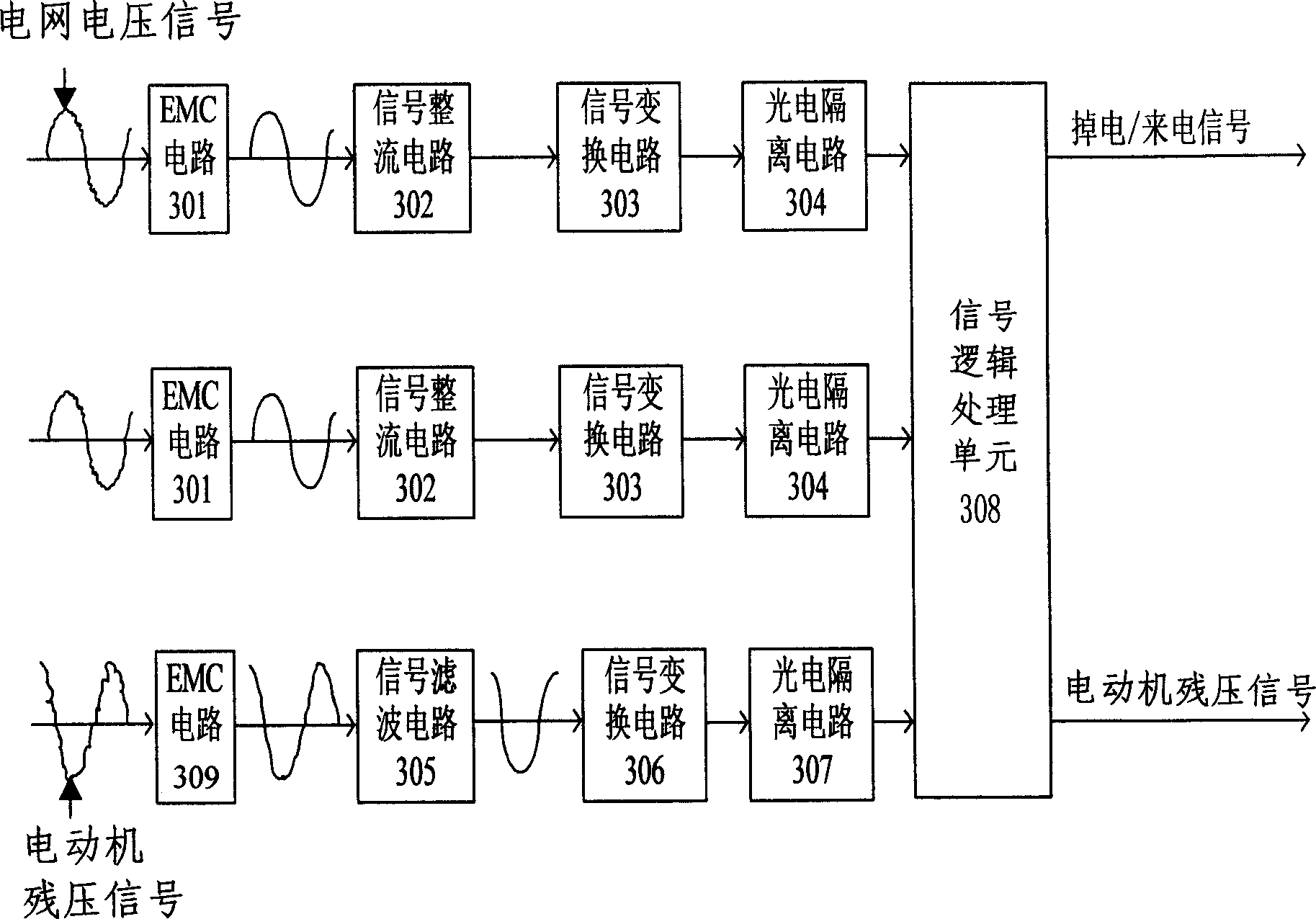

[0042] In the inverter control system, set a system setting frequency value f through the man-machine interface 0 , and set the allowable instantaneous power failure time threshold t 1 , allowing constant frequency boost time threshold t 3 , allowing the minimum starting frequency f 1 , according to the load characteristics, f 1 The setting range is: 0Hz~motor rated frequency. When the considered motor is in a state of free rotation, the residual voltage drops rapidly, which may lead to the searched residual voltage frequency f 1 * Inaccurate, when setting the parameter t 1 When , the attenuation characteristics of the residual pressure should be considered to determine t 1 the size of.

[0043] After starting the frequency converter, make the system gradually accelerate to f 0 , enter the normal running state, and the control system saves the output frequency value of the inverter in real time.

[0044] When the high-voltage incoming line of the power supply system l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com