Patents

Literature

139 results about "Igbt inverter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional integrated charger for electric automobile having compensation charging function

InactiveCN101499673ARealize switchingEfficient multiplexingBatteries circuit arrangementsElectric powerCapacitancePower battery

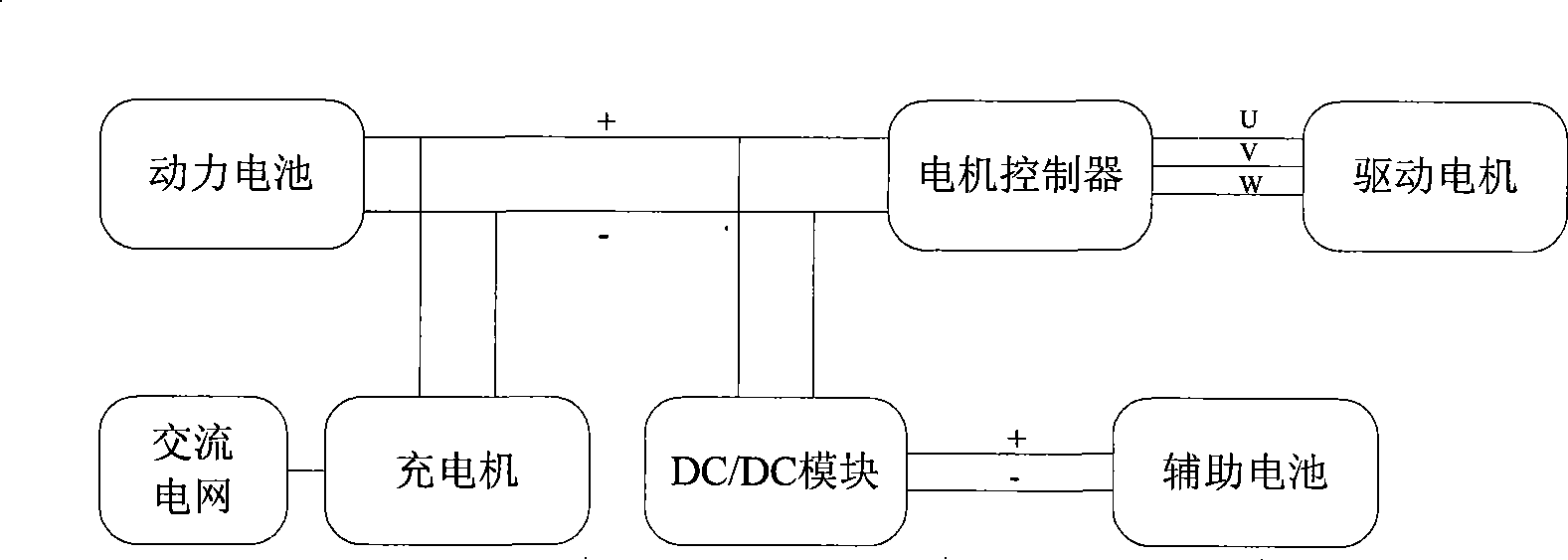

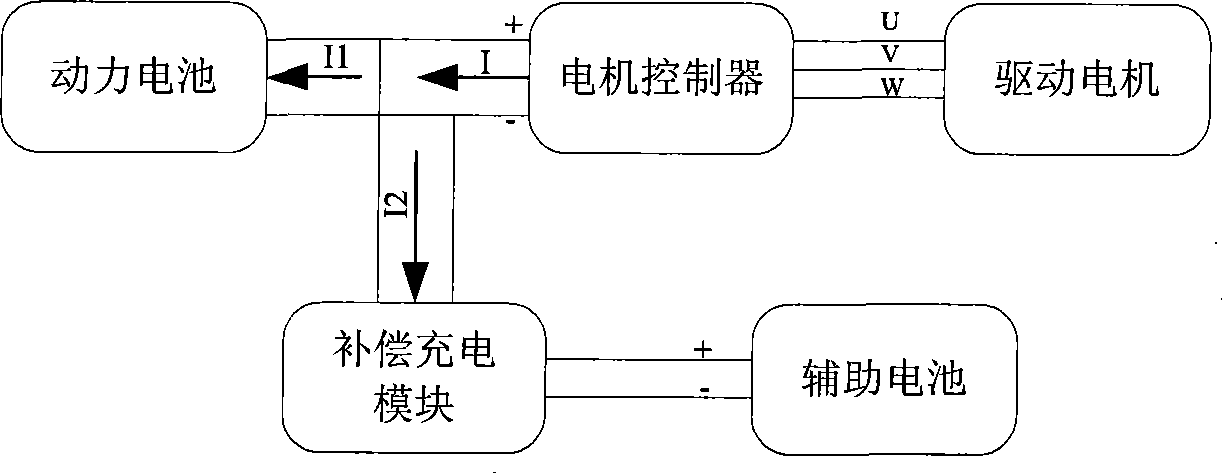

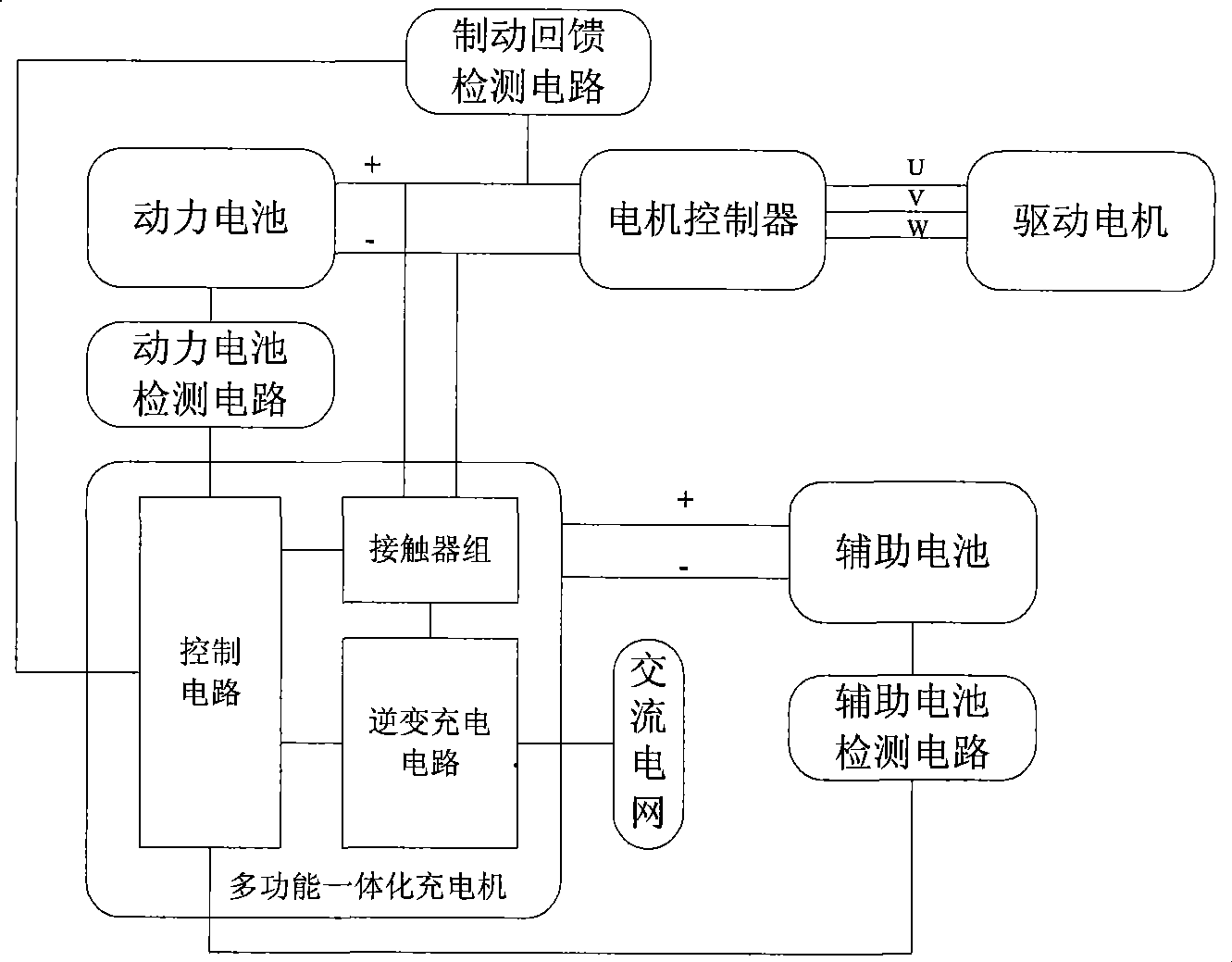

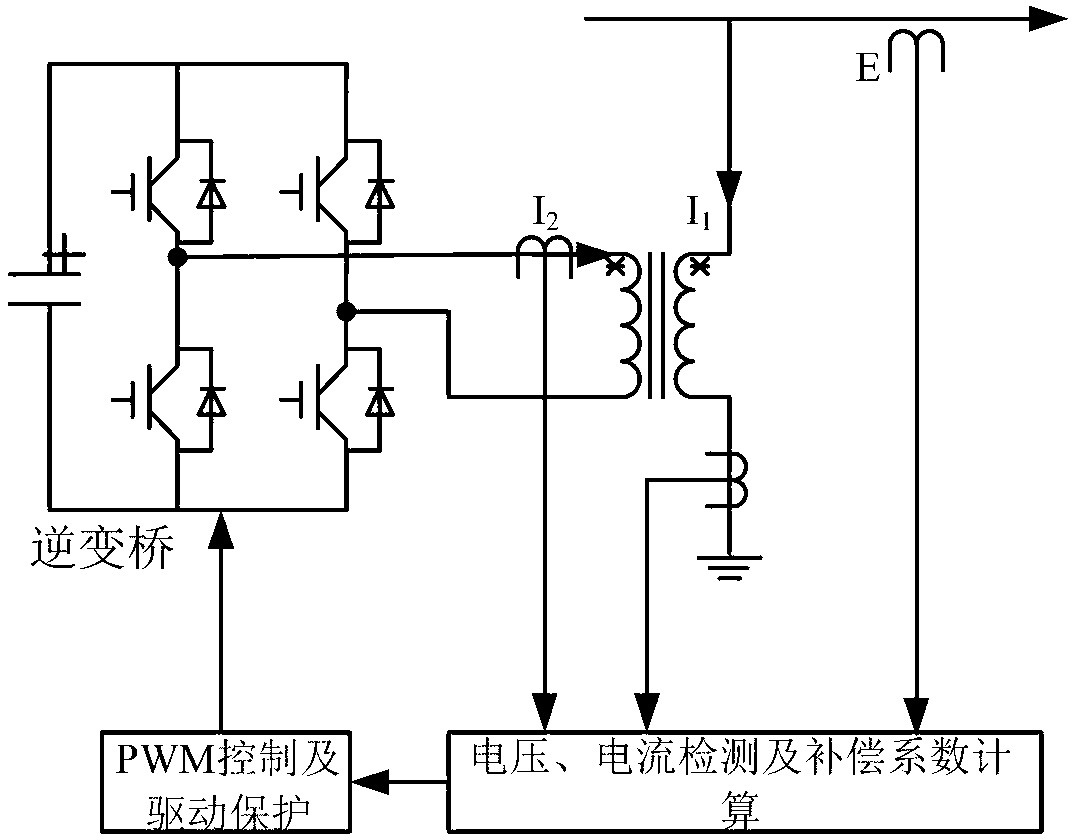

The invention belongs to the field of charging technology of an electric automobile and relates to a multifunctional integrated charging machine which is used for the electric automobile and has a compensation charging function. The multifunctional integrated charging machine comprises a rectifier bridge, an inverter charging circuit, a control circuit, a contactor group, a power battery, an auxiliary battery, a brake feedback energy detection circuit, a power battery energy detection circuit and an auxiliary battery energy detection circuit; the output terminal of the rectifier bridge is connected with the inverter charging circuit which comprises a capacitance filter circuit, an IGBT inverter bridge with the duty cycle controlled by the control circuit, a high-frequency transformer and a rectifier filter circuit; different charging modes are changed by controlling the contactor group. The multifunctional integrated charging machine highly integrates four charging functions including compensation charging and the like into a charging machine, improves the integrity of the charging machine and leads the electric automobile to recover more brake energy.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

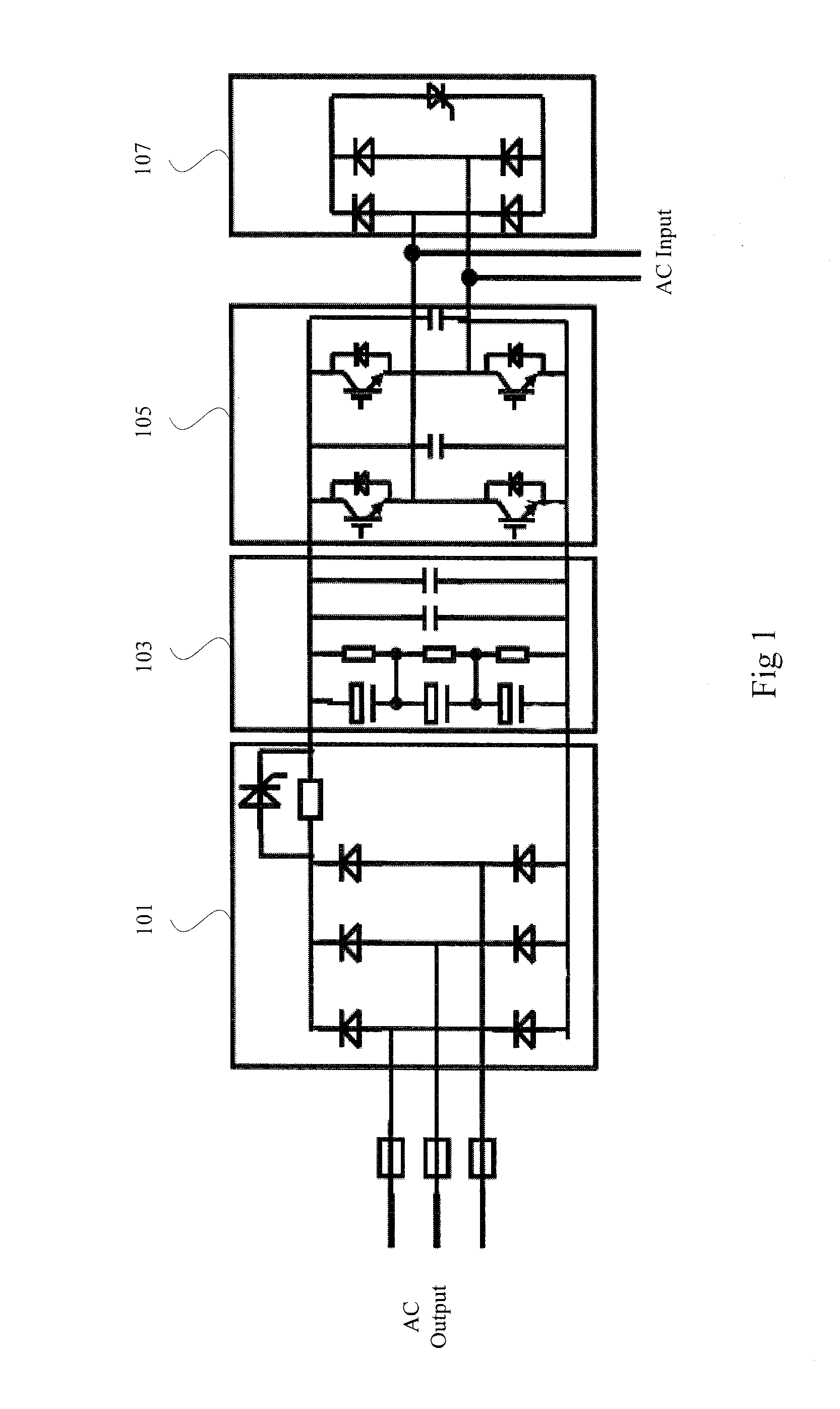

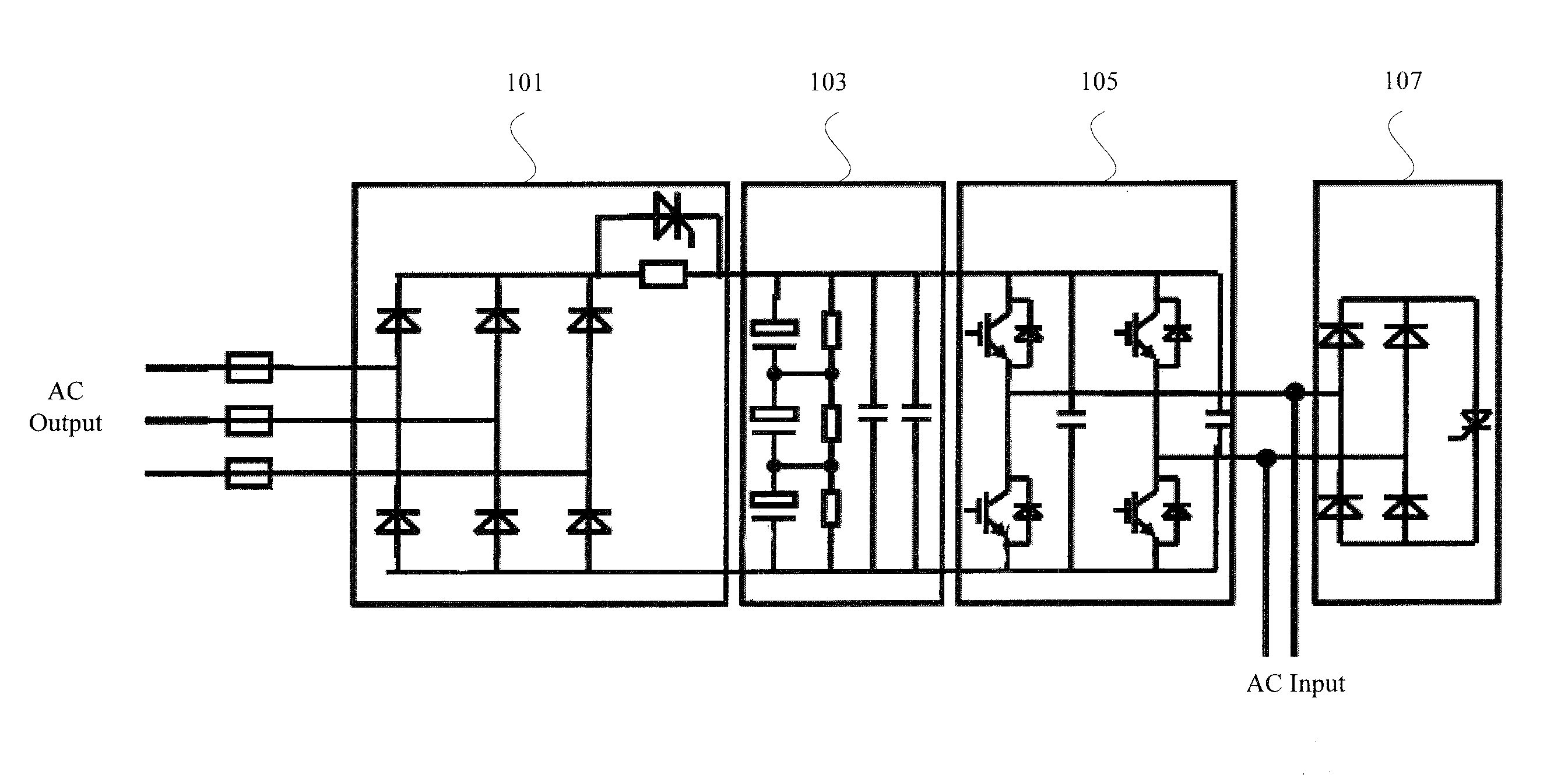

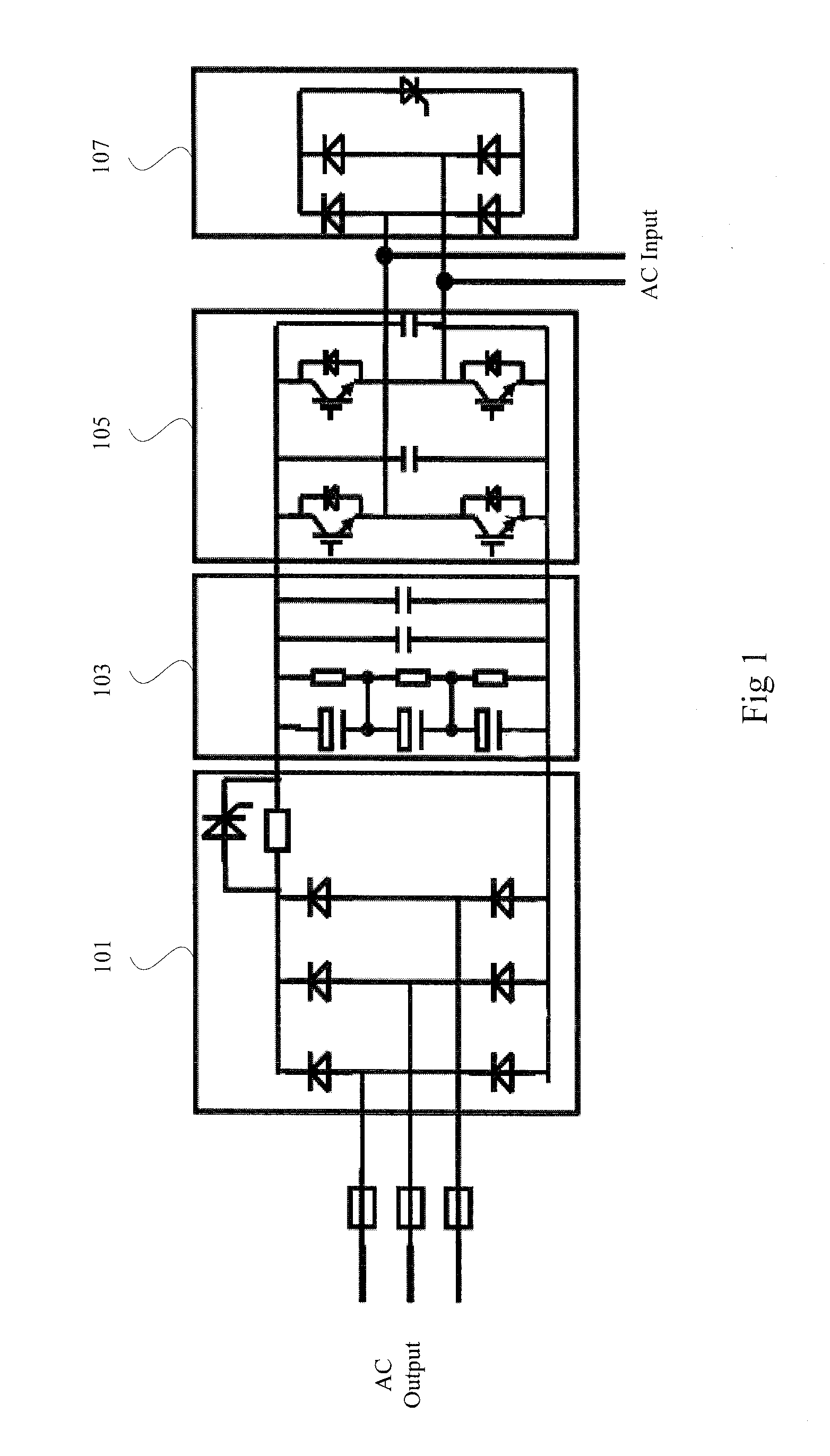

High-power medium-voltage drive power cell

ActiveUS20130100716A1Improve cooling efficiencyHeat dissipation fastConversion constructional detailsAc-ac conversionElectrical batteryComputer module

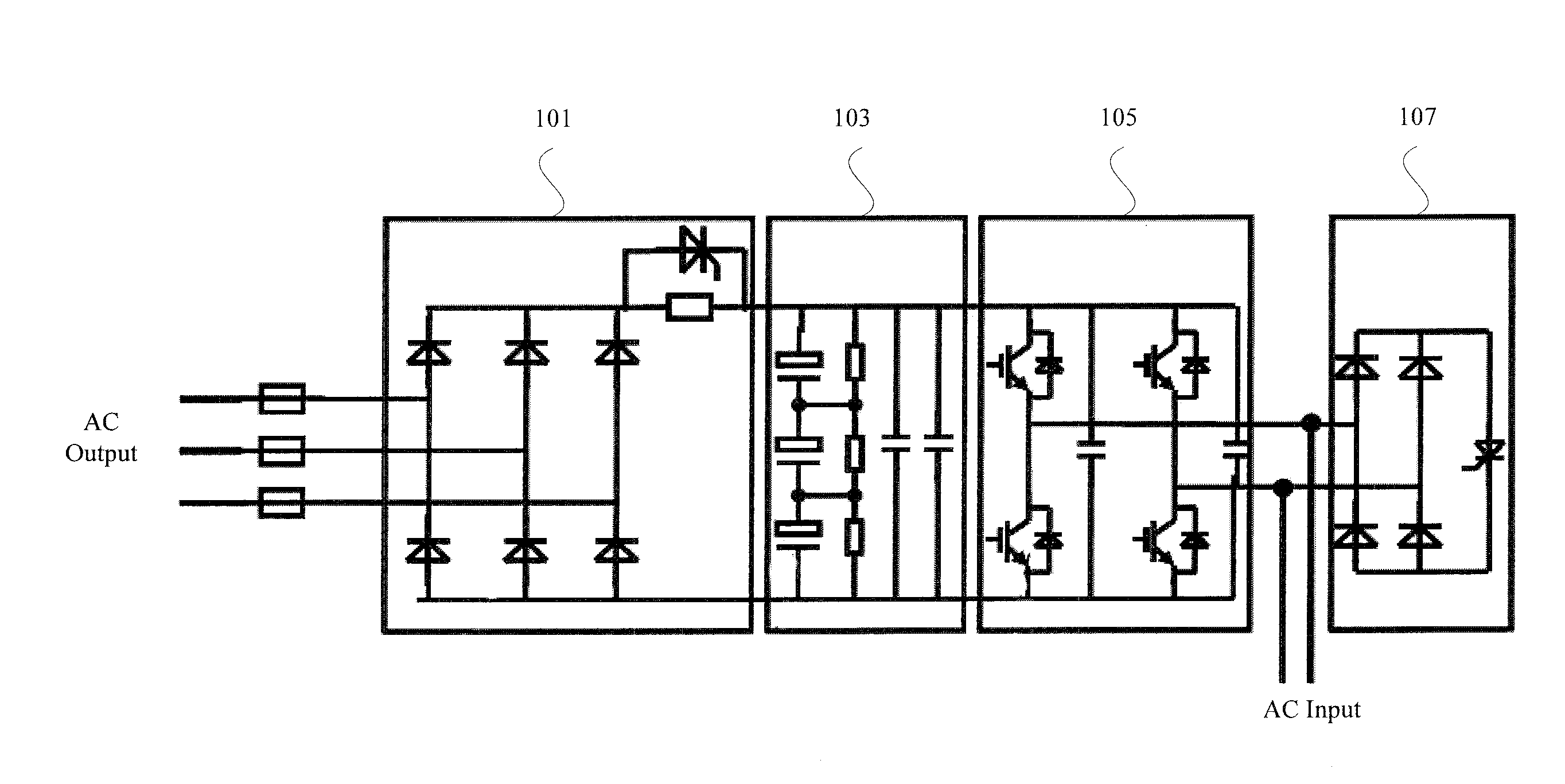

The present invention provides a high-power medium-voltage drive power cell, which comprises: a rectifier module for rectifying the three-phase AC input voltage to get a DC voltage; an IGBT (Insulated Gate Bipolar Transistor) inverter bridge connected to capacitors for converting the DC voltage into an AC voltage of which the frequency, the amplitude and the phase are adjustable; a bypass module connected to the IGBT inverter bridge for providing the bypass function when the IGBT inverter bridge works in an abnormal state; and a heat pipe heat sink having a base plate on both sides of which power elements of the high-power medium-voltage drive power cell are disposed.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

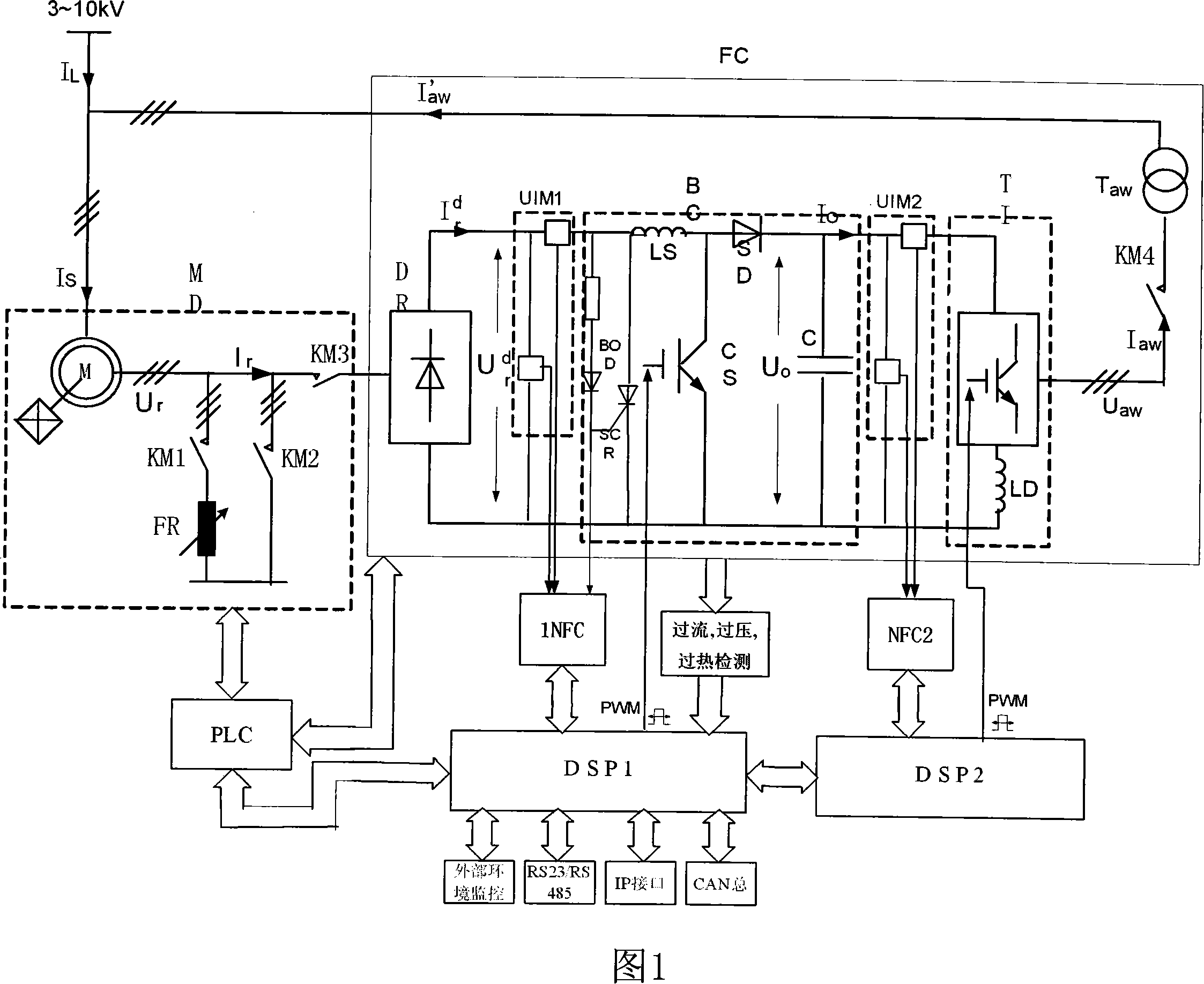

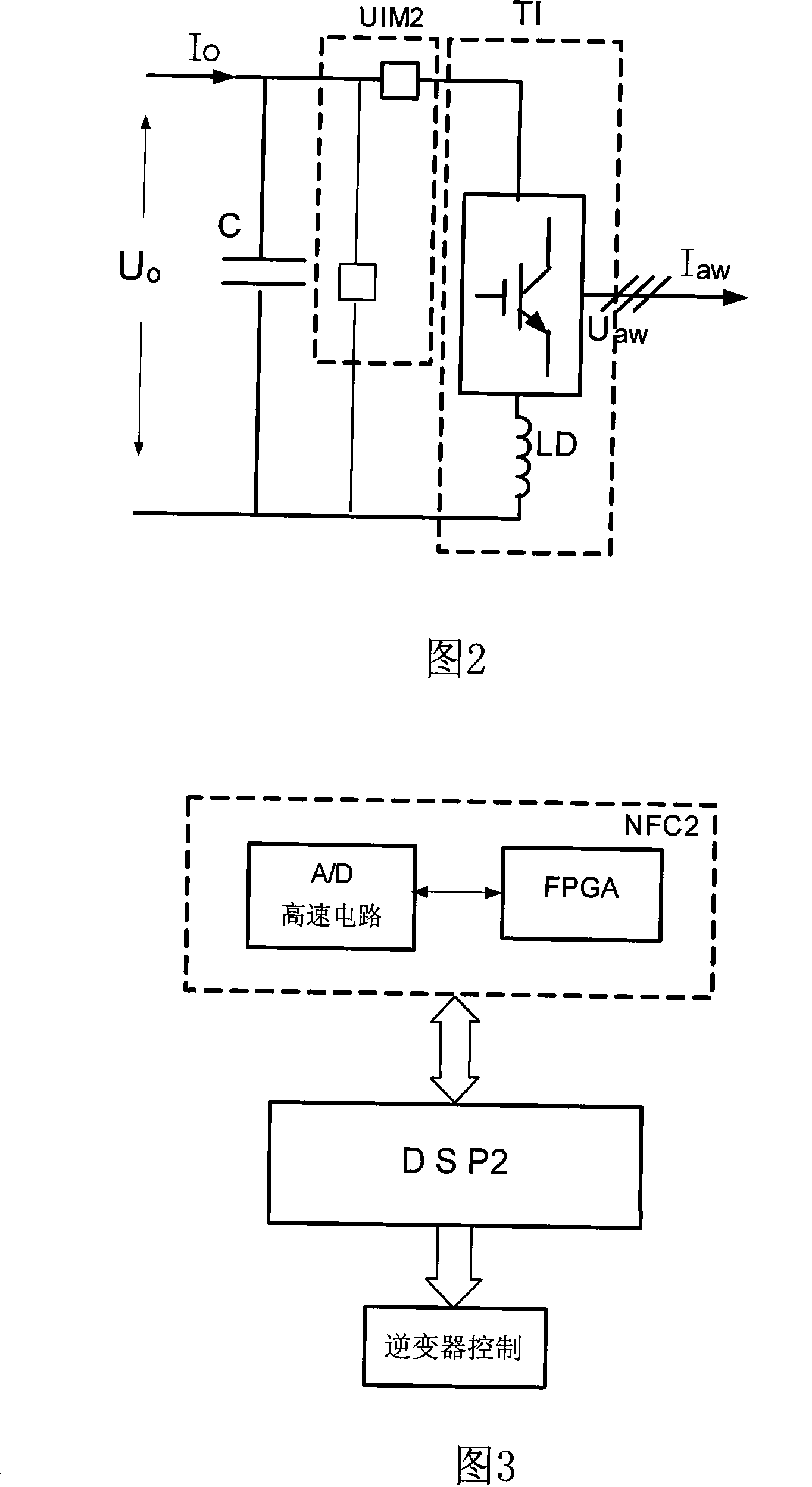

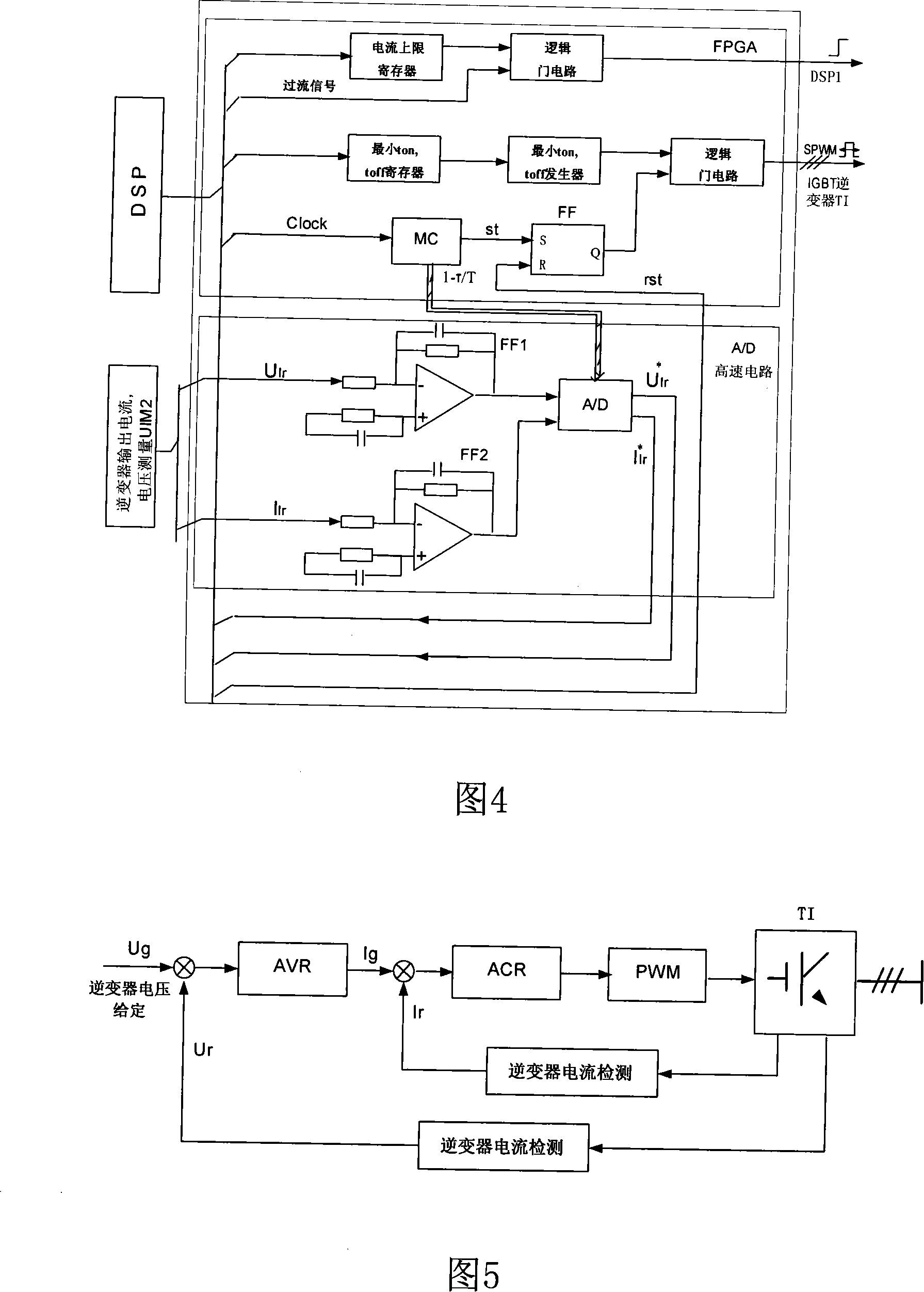

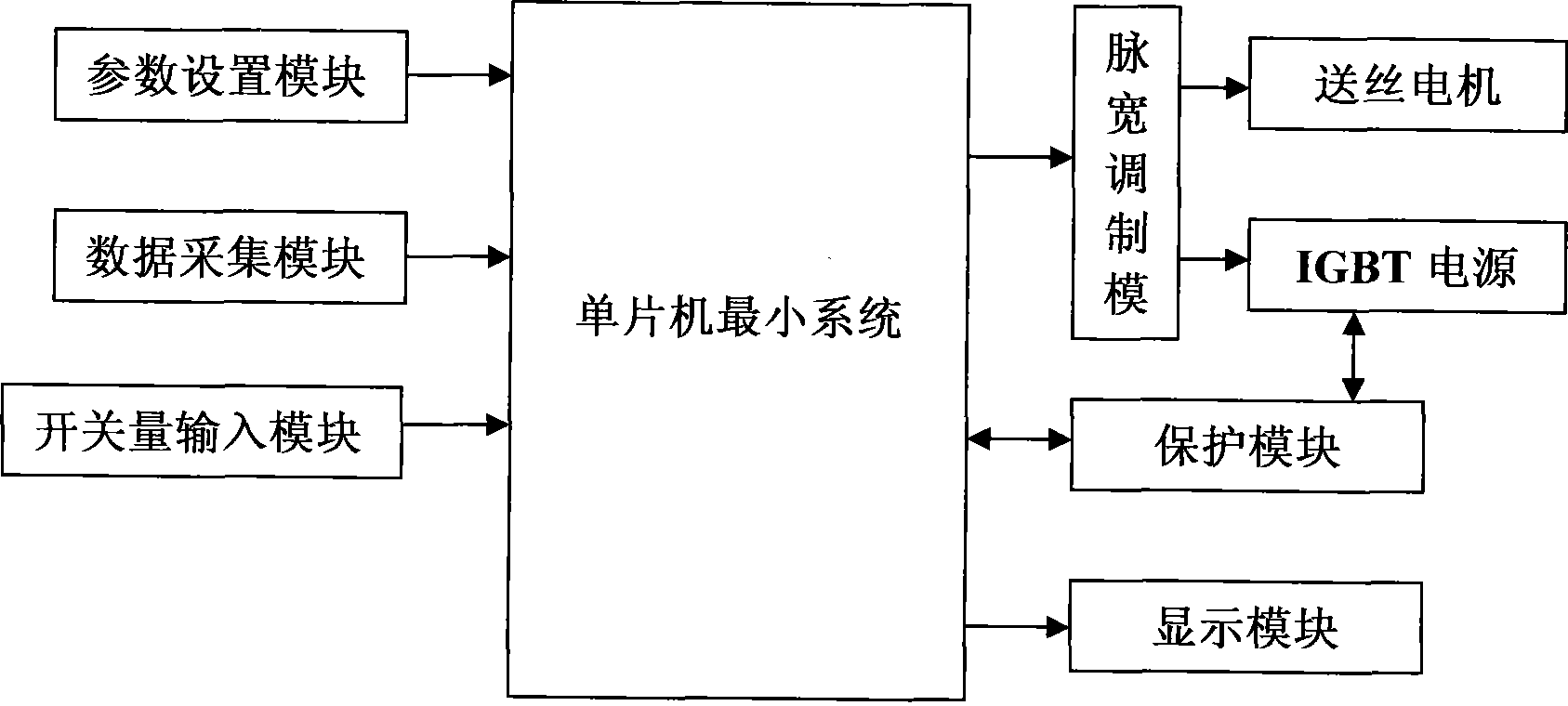

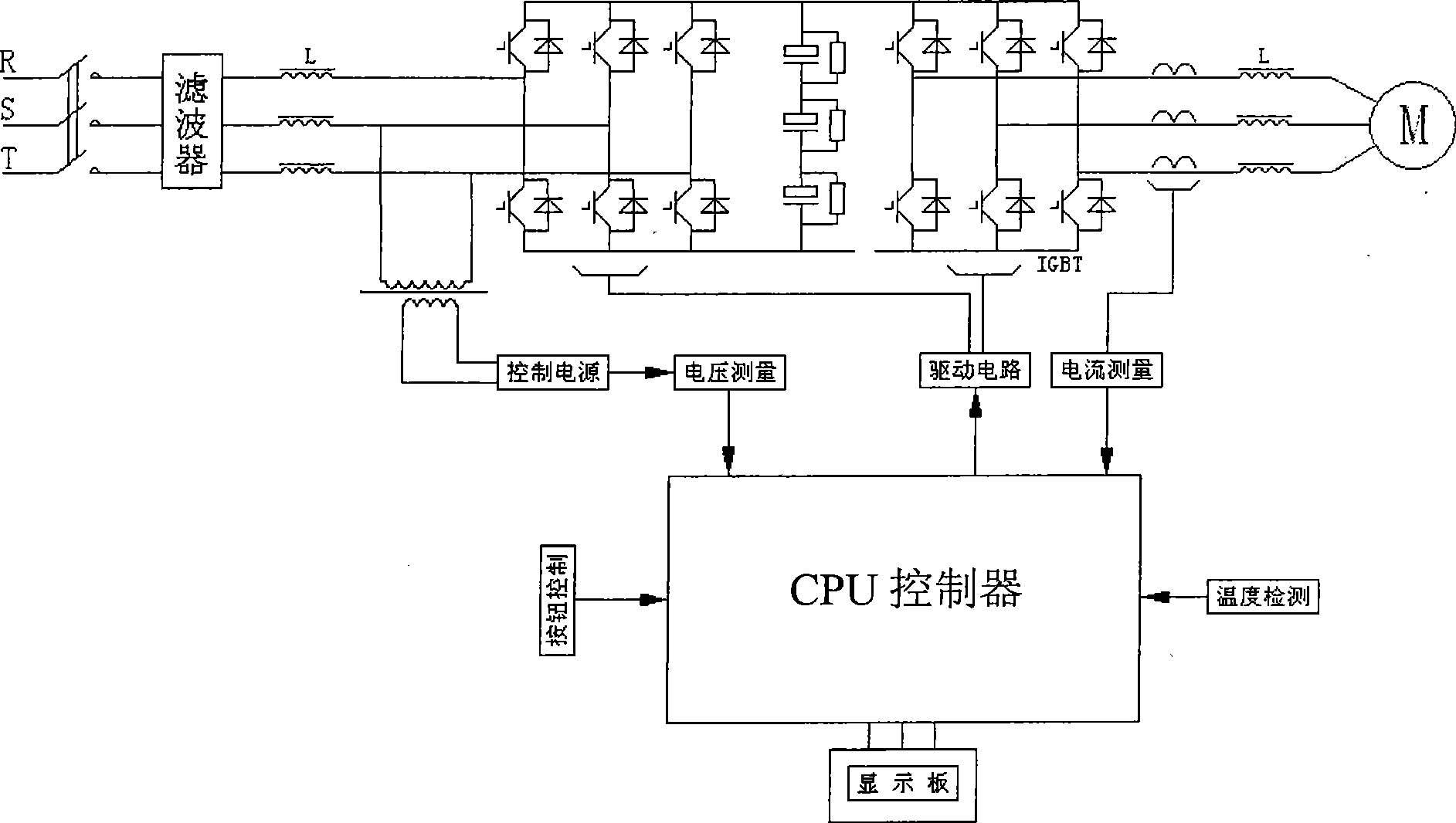

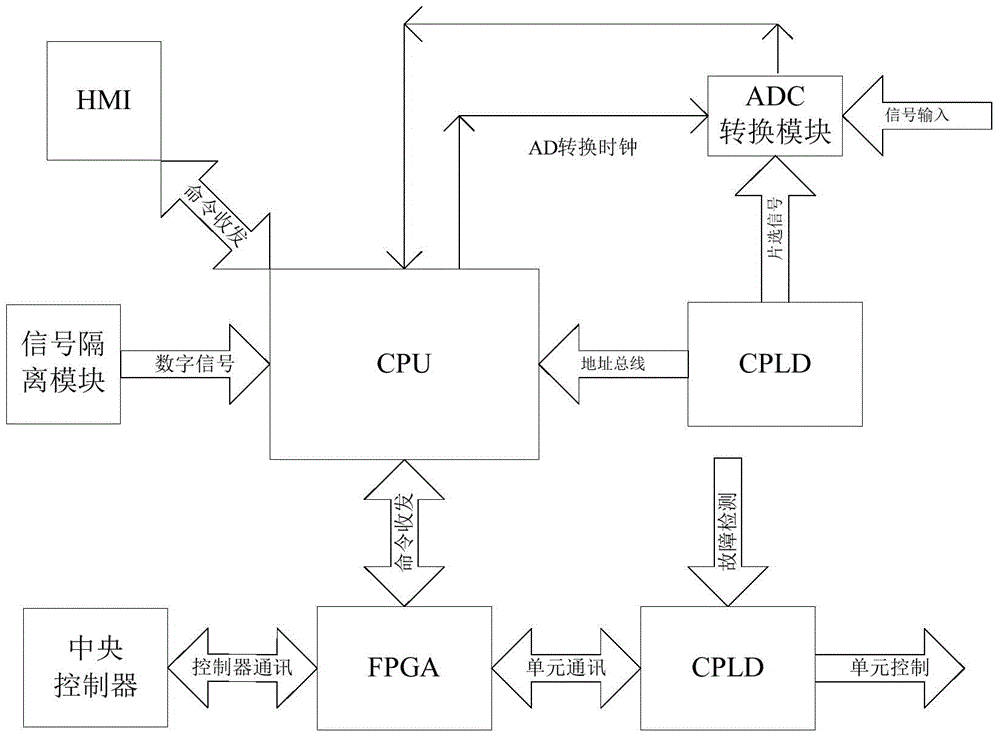

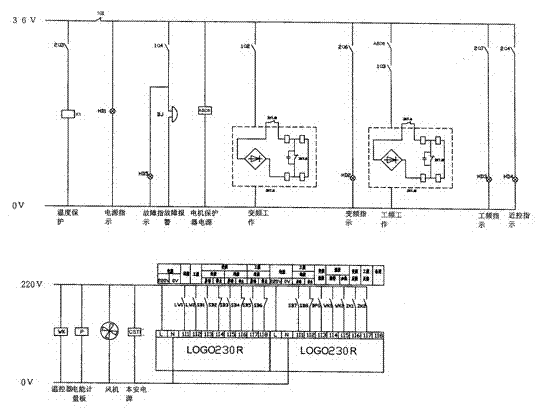

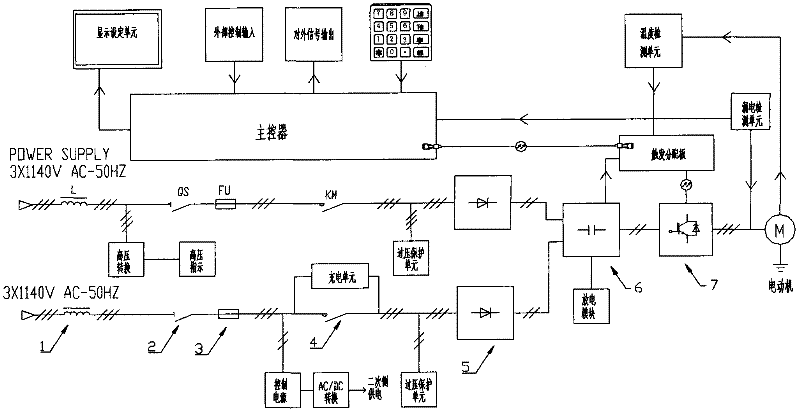

Middle voltage electromotor cutting wave dual DSP digital speed adjusting system for IGBT reverser

InactiveCN101123415ATroubleshoot broken equipmentEasy to useAC motor controlBrushless motorsHuman–machine interface

A chopping double-DSP digital speed governing system of a medium voltage motor having an IGBT inverter comprises an uncontrollable rectifier, a boosting chopper and an IGBT inverter. The boosting chopper and the IGBT inverter are controlled through two internal ring current controllers. The speed of an external ring of the speed governing system and the voltage of an external ring of the inverter are controlled through two DSPs. The speed governing system and a motor system are controlled in a programmable way through a programmable controller. The system is applicable for ordinary wound asynchronous motors, internal feedback wound asynchronous motors, wound-cage brushless doubly-fed motors and wound-cage internal feedback brushless motors, and eliminates the problem of damaging equipments because of inversion resulting from grid failure out and out. The invention is highly reliable, is simple and convenient to be used, has excellent man-machine interface, can achieve remote monitoring and management, is highly digitalized, saves energy and is environmentally protective; the control error is small; the means of communication is flexible; and the cost is low.

Owner:广东华拿东方能源有限公司

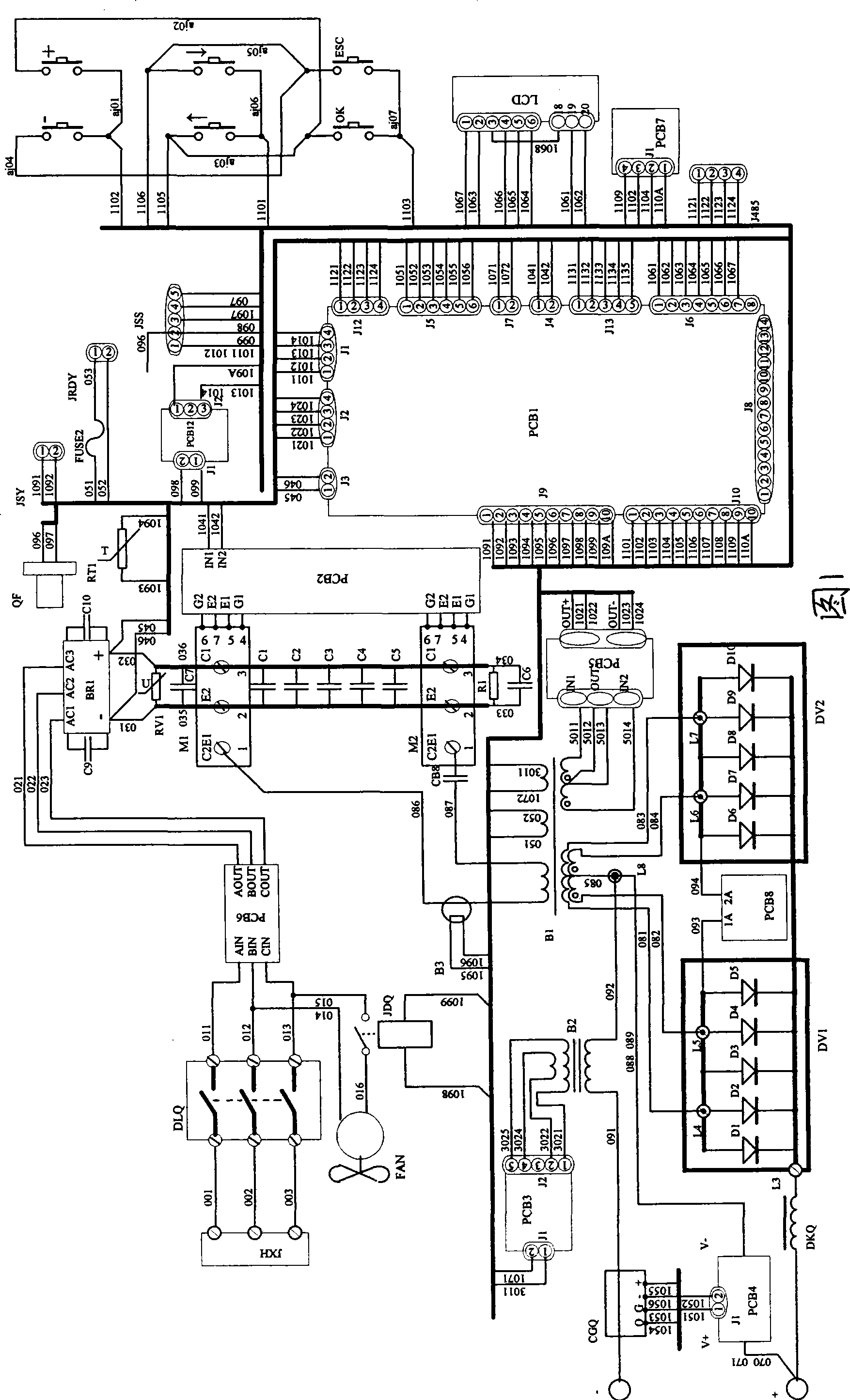

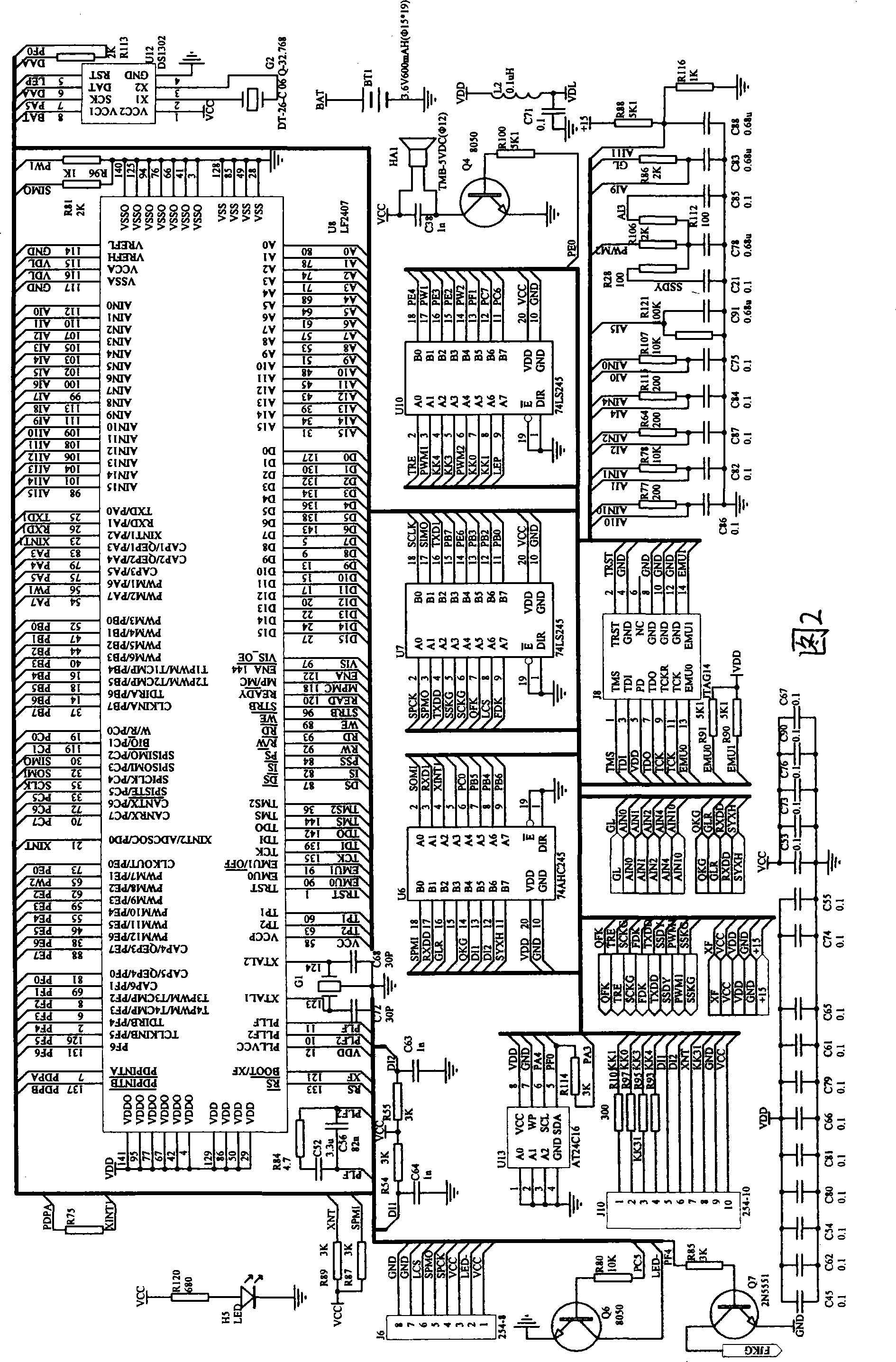

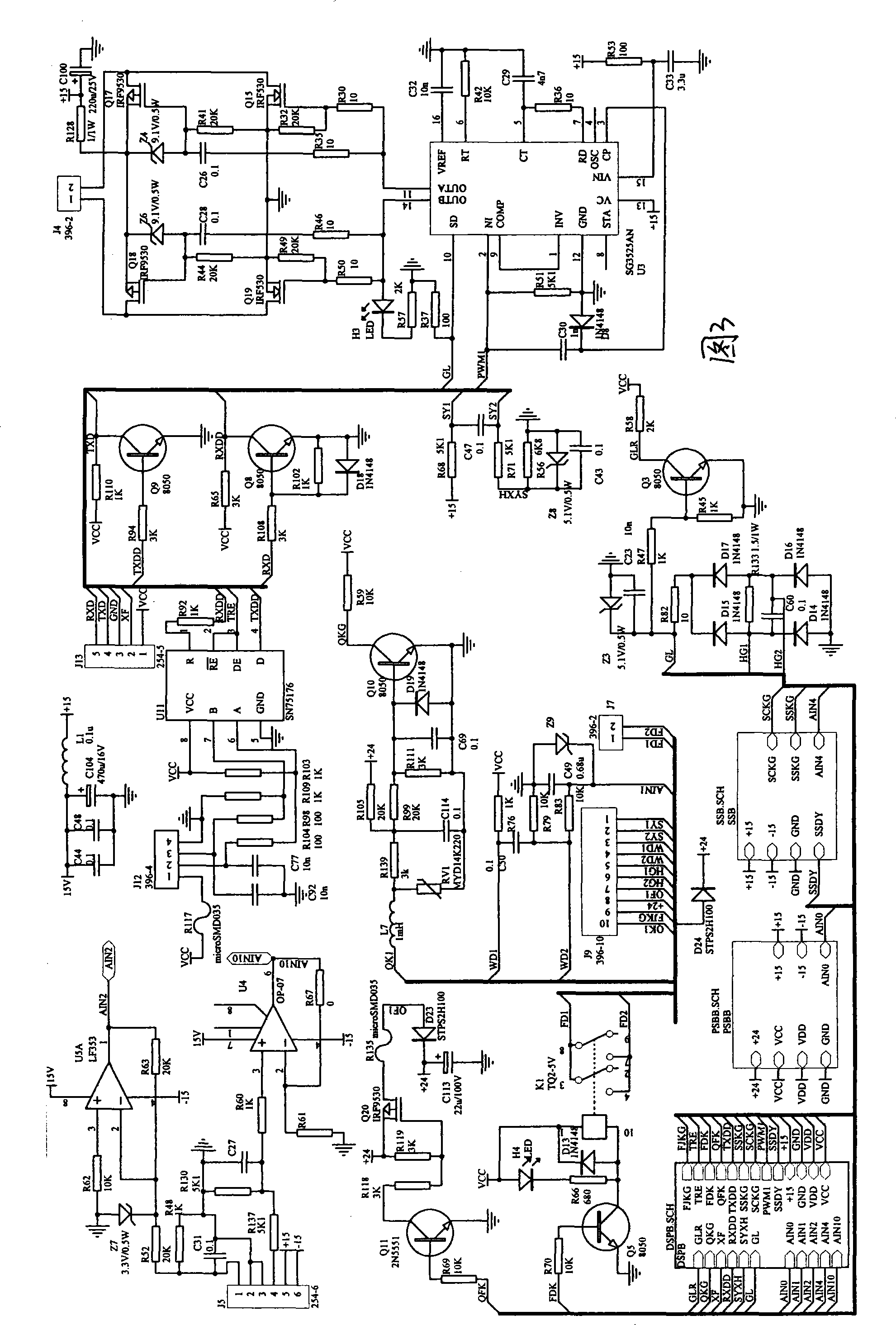

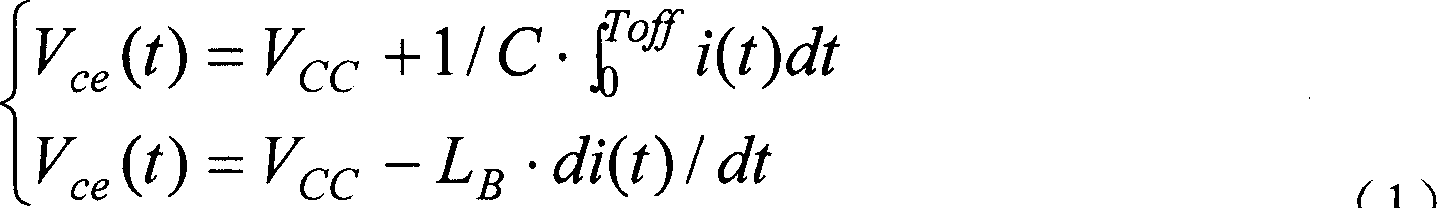

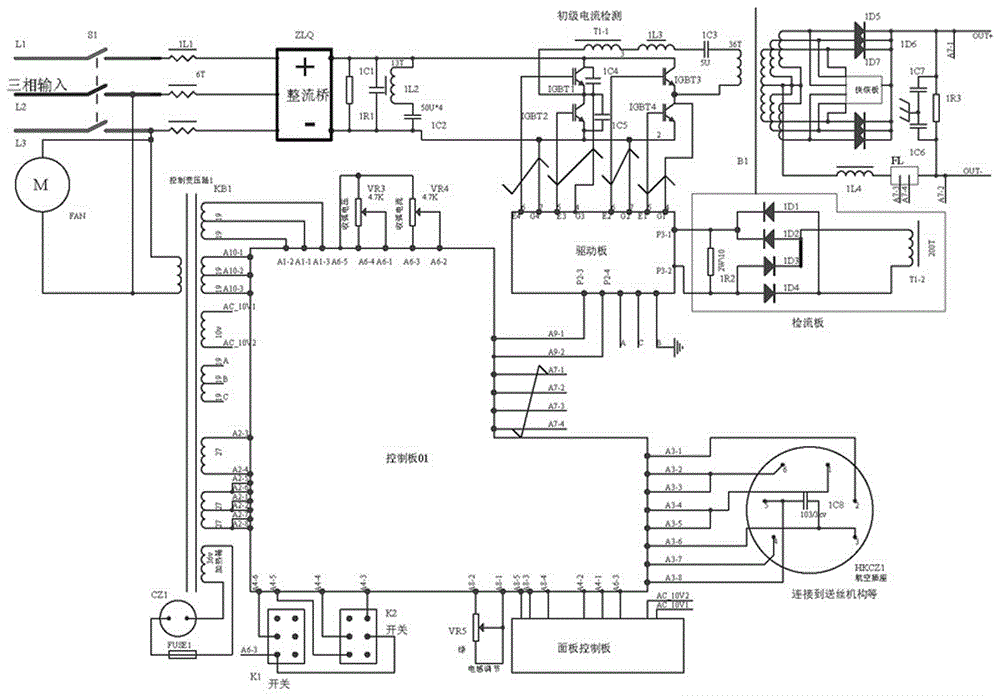

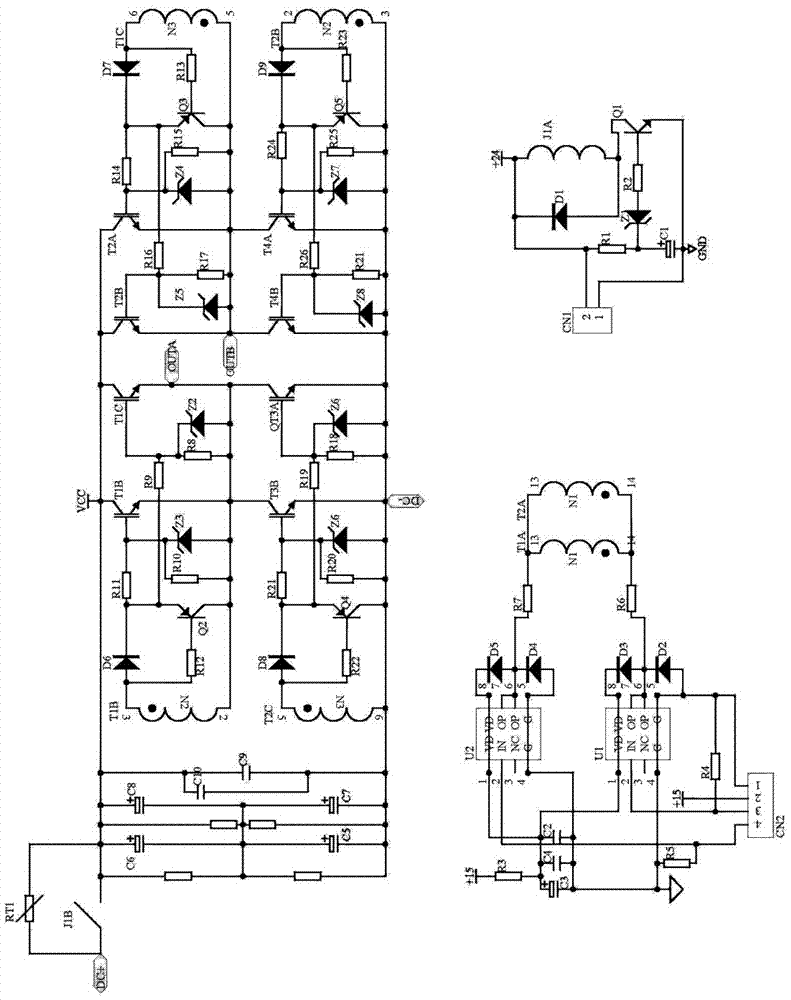

Multifunctional full-numeralization contravariant welding machine

InactiveCN101244479AControl power outputControl wire feed speedArc welding apparatusEngineeringIgbt inverter

The invention relates to an inverter welder, in particular to a multifunctional all-digital inverter welder, which resolves problem that the prior inverter welder can only achieve a single welding mode, the operating circuit of the multifunctional all-digital inverter welder comprises: a main circuit comprising an IGBT inverter rectifier bridge composed by connected of two double IGBT power tube integrated blocks M1, M2 and a control circuit controlling the IGBT inverter rectifier bridge guiding width, the control circuit comprises a DSP processor, a signal sampling circuit, a high-frequency pulse arc circuit, a wire feeding machine control circuit, a display circuit, a keyboard input circuit, a drive circuit of the IGBT inverter rectifier bridge, a trigger pulse generator circuit PCB2. The inverter welder has the advantages that using the advanced DSP processor, realizing the gas-welding, argon-arc welding, pulse argon-arc welding and other variety of different welding modes in a single welder through the pulse width modulation technique, and realizing the function of monitoring, promoting, networking operation, and diagnosing through the network.

Owner:SHENZHEN HUAYILONG ELECTRIC

Energy-saving frequency converter of induction motor direct torque control speed regulating system and structured approach

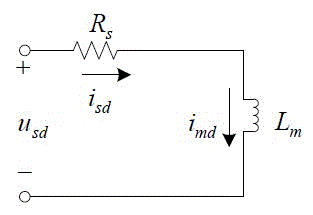

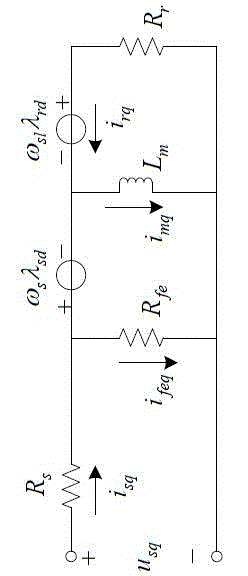

InactiveCN102882466AImprove performanceReduce power lossMotor parameters estimation/adaptationIgbt inverterFlux linkage

The invention relates to an energy-saving frequency converter of an induction motor direct torque control speed regulating system. The energy-saving frequency converter is characterized in that stator copper loss, iron core loss, total loss and motor total loss of an induction motor can be obtained according to an inductance motor approximately equivalent circuit model in a stator magnetic field orientation d-q coordinate system, and a stator flux linkage calculation module is structured and placed in a direct torque control system to form an inductance motor energy-saving variable-frequency controller which is combined with a power converter to jointly form an inductance motor energy-saving frequency converter. Control inverter switch signals output by a switch logic meter in the inductance motor energy-saving frequency converter are accessed to an input end of switch signals in a three-phase IGBT (insulated gate bipolar transistor) inverter in the power converter. The energy-saving frequency converter of the induction motor direct torque control speed regulating system has the advantage of capability of obviously reducing power loss of motor operation and improving integral comprehensive performance of a motor driving system, simple structure, reliability in operation, low realization cost and especial suitableness for application occasions in light-loaded running state frequently or with frequently changing load.

Owner:NANJING UNIV OF TECH

Method for controlling parallel power quality regulator through non-harmonic detection

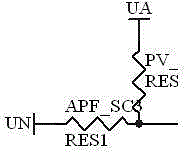

InactiveCN103762597AAvoid errorsAvoid delayReactive power adjustment/elimination/compensationReactive power compensationPower qualityCapacitance

The invention relates to a method for controlling a parallel power quality regulator through non-harmonic detection. A main circuit is only composed of a three-phase LCL filter and a three-phase IGBT inverter bridge and is connected to the output end of a three-phase power grid. The three-phase IGBT inverter bridge is composed of a three-phase IGBT bridge and a direct current side capacitor. Harmonics, negative sequences and unbalance of load currents do not need to be detected through a complex detection algorithm, only the load currents need to be sampled, active current components in the load currents are offset through direct current side voltage stabilizing commands, and then harmonic, negative sequence and unbalance current commands are acquired. The complex detection algorithm is omitted, errors and time delay caused by the detection algorithm are avoided, and the dynamic response speed is increased; meanwhile, resources of a control chip are saved, and economical efficiency is improved. Compared with an existing active power filter, an existing static var generator and an existing static synchronous compensator, the parallel power quality regulator has certain advantages, certain practical value and certain application prospect.

Owner:中国船舶重工集团公司第七0四研究所

Ultra-high frequency adjusting harmonic vibration testing power based on high power IGBT

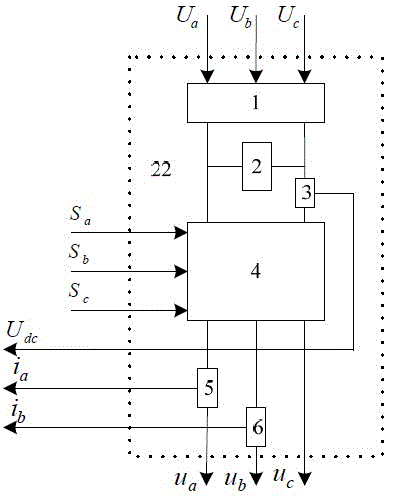

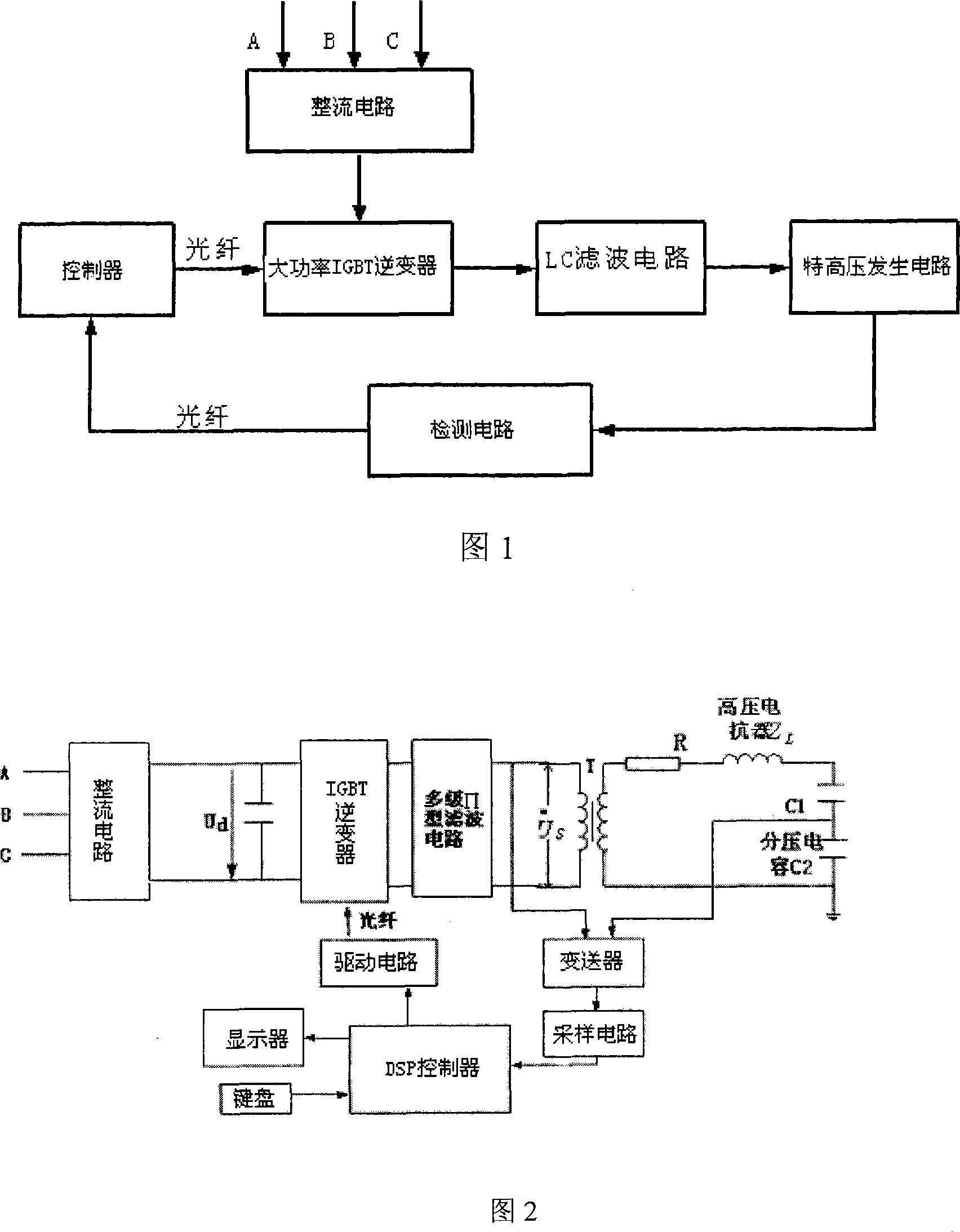

InactiveCN101127491ASimple structureImprove reliabilityConversion with intermediate conversion to dcUltra high voltageControl signal

The utility model discloses an ultra high voltage frequency modulation harmonic resonance testing power supply based on a high power IGBT, which comprising a rectification circuit, a controller, a high power IGBT inverter, an LC filter circuit, an ultra high voltage generating circuit and a detection circuit. The input terminal of the rectification circuit is connected with a three-phase AC input, the output terminal of the rectifier circuit supplies current toward the high power IGBT, the controller generates a PWM control signal for the high power IGBT inverter, the output signal of the high power IGBT inverter changes to a smooth sine signal through the LC filter, and then be sent to the input terminal of the ultra high voltage generating circuit, which generates high voltage, the detection circuit detects the output of the ultra high voltage generating circuit, transferring the detection signal to the controller via the optical fiber in high speed. The utility model has advantages of simple structure, light weight, low cost, high reliability and capability of graded outputting ultra high voltage.

Owner:HUNAN UNIV

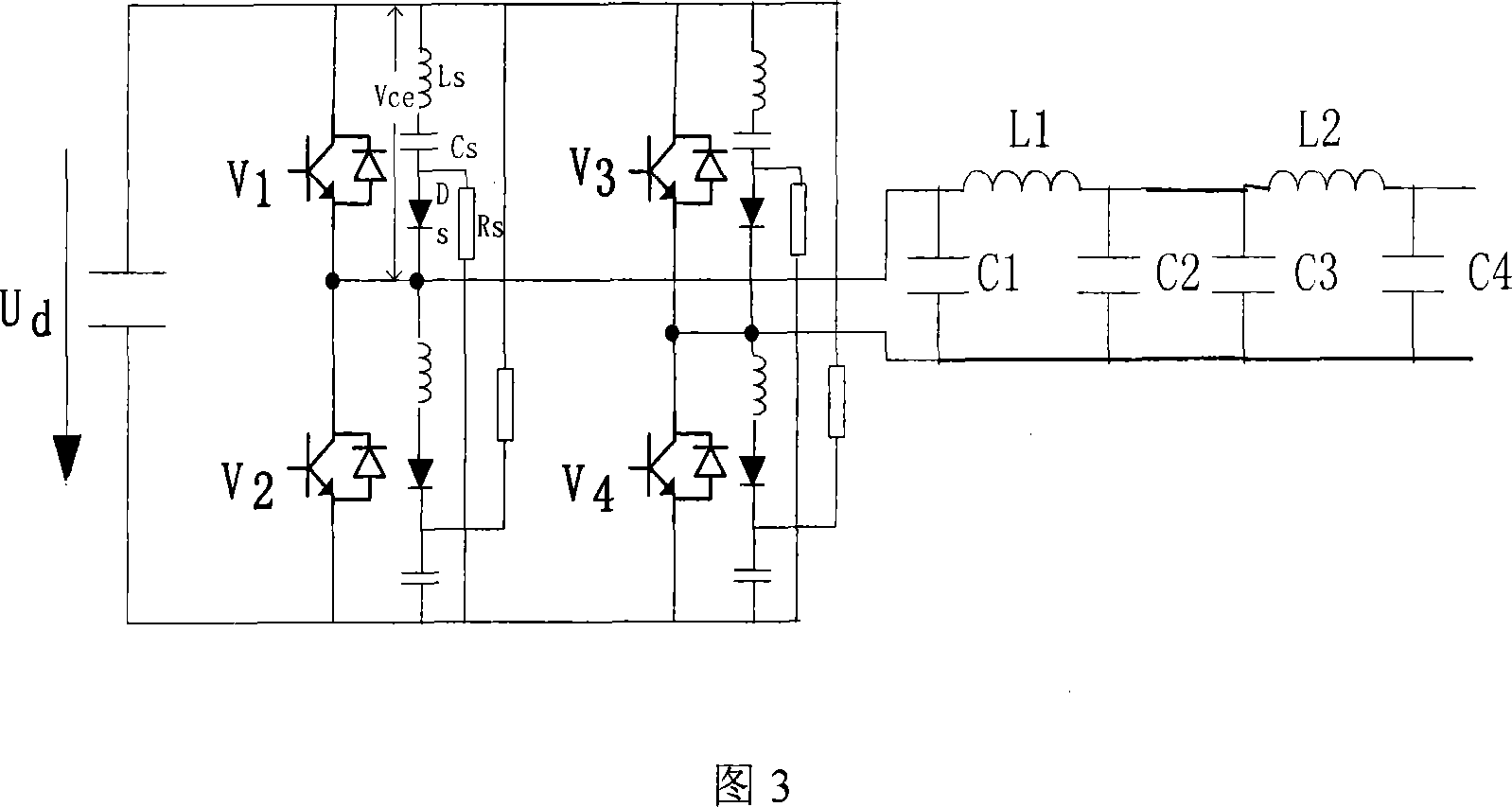

Control method of IGBT inversion submerged arc welding machine

InactiveCN101433993AReduce sensitivityRealize automatic submerged arc weldingArc welding apparatusMicrocontrollerMOSFET

The invention relates to a method for controlling an IGBT inverter type submerged arc welding machine. The method comprises the following steps: adopting a singlechip to sample welding current and voltage, and comparing the welding current and the voltage with preset current and voltage to obtain current deviation and voltage deviation; carrying out PI calculation according to the current deviation, outputting a control parameter, sending a voltage signal to a pulse width modulator after the control parameter is converted into the voltage signal to obtain two groups of mutually inverted pulse width signals, and controlling the on and off of a main circuit IGBT by the signals through power amplifying and driving; carrying out PI calculation according to the voltage deviation, outputting a control parameter, sending analog voltage which is converted by the control parameter to another pulse width modulator, modulating a pulse signal, and controlling the on and off of an MOSFET by the signal through driving and amplifying; and generating a PWM signal by the singlechip according to a given welding speed, driving the on and the off of the MOSFET by the signal after photoelectric isolation and signal amplification, and adjusting running speed of an electric motor of a trolley. The method has the advantages of stability, reliability and convenient use, and can achieve automatic submerged arc welding better.

Owner:上海气焊机厂有限公司

Alternating current permanent magnet synchronous machine control system for electric vehicle

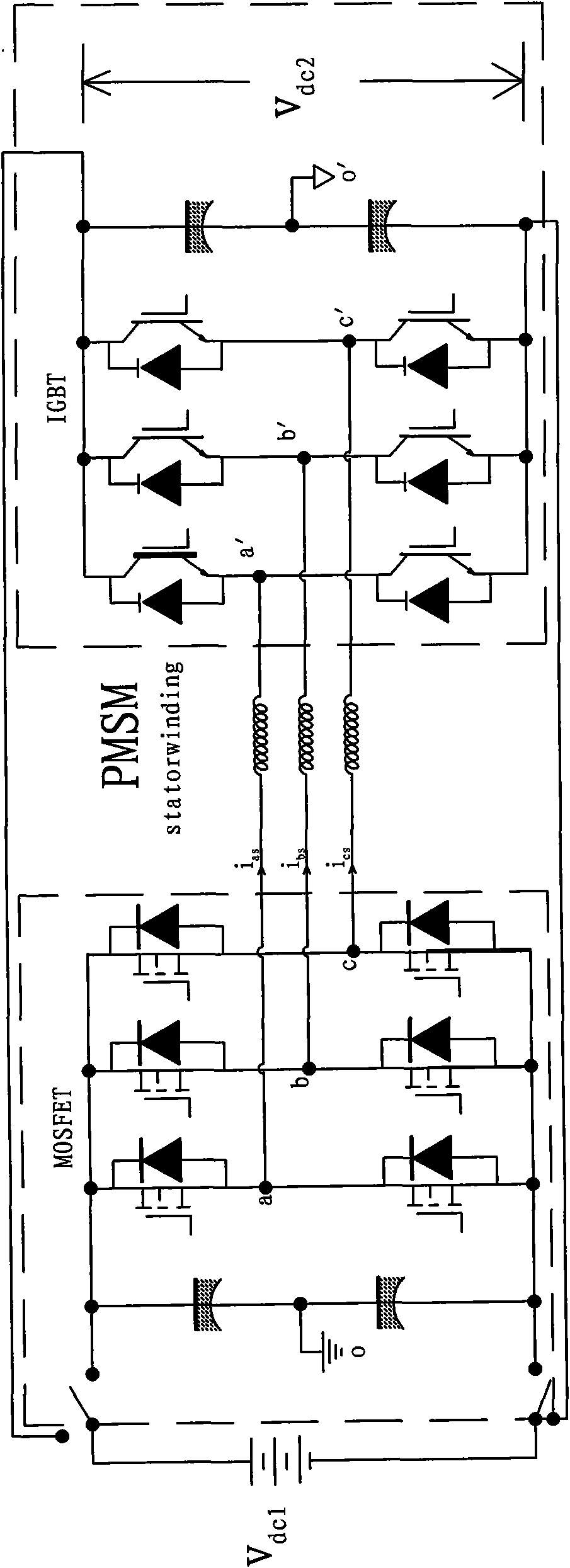

InactiveCN102377380AIncrease low speed torqueNo current shock phenomenonAC motor controlSingle motor speed/torque controlMOSFETPermanent magnet synchronous machine

The invention discloses an alternating current permanent magnet synchronous machine control system for an electric vehicle. The system comprises an alternating current permanent magnet synchronous machine, a power convertor, a controller and detectors; the controller is a digital signal processor (DPS); the detectors comprise a position detector and a current detector; the position detector and the current detector input rotor positions / speed signals and current signals, which are detected by the position detector and the current detector respectively, of the alternating current permanent magnet synchronous machine to the DSP; the DSP calculates the given value of the current according to the input rotor positions / the speed signals and compares the given value and the input current detection value to obtain a corresponding control signal, and the alternating current permanent magnet synchronous machine is driven by the power convertor; and the power convertor has a three-phase double-inversion bridge structure consisting of a metal-oxide-semiconductor field effect transistor (MOSFET) inverter and an insulated gate bipolar transistor (IGBT) inverter. The system has the advantages of compact and firm structure, reliable performance, high control efficiency and accuracy and the like and runs stably and a circuit is simple.

Owner:程基江

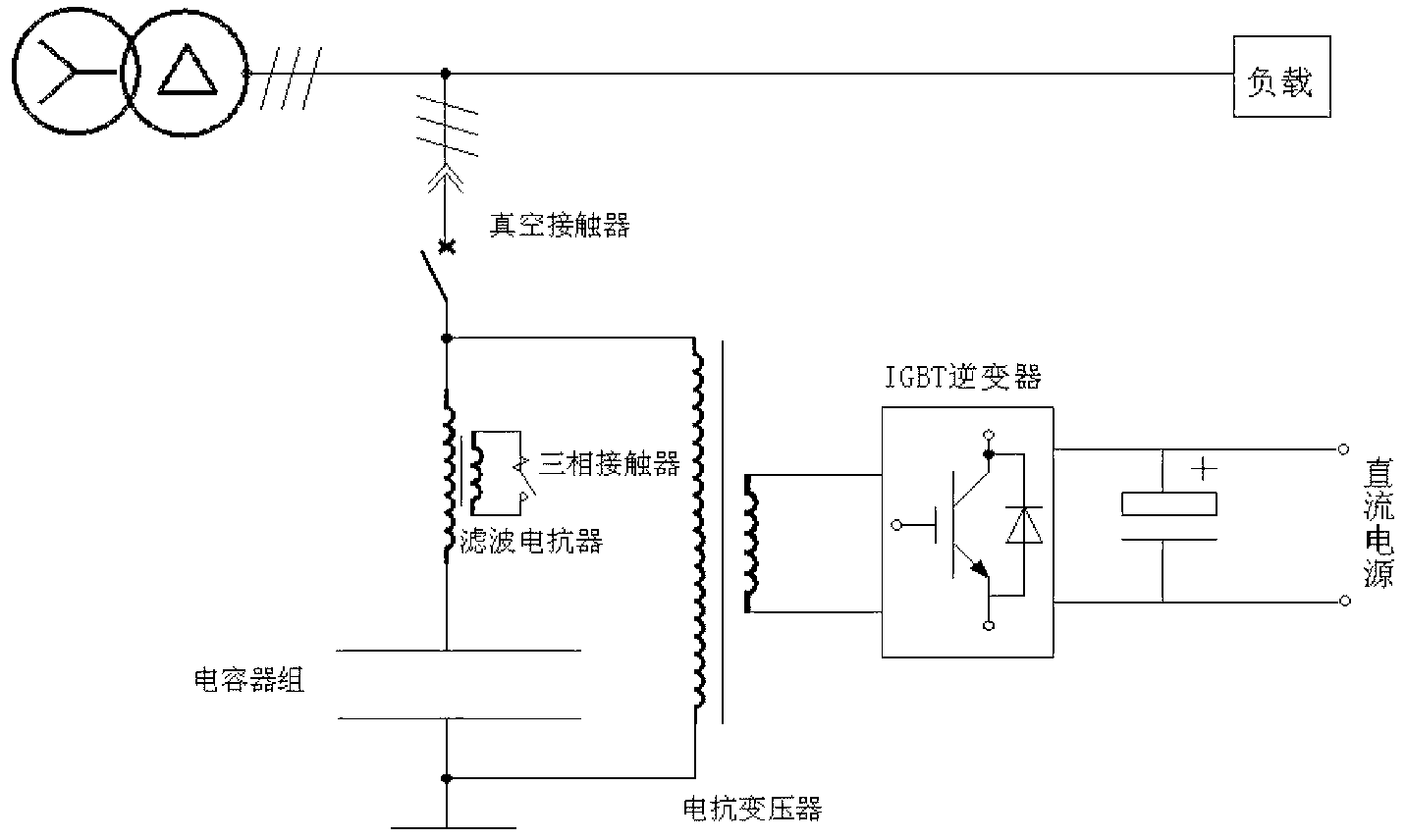

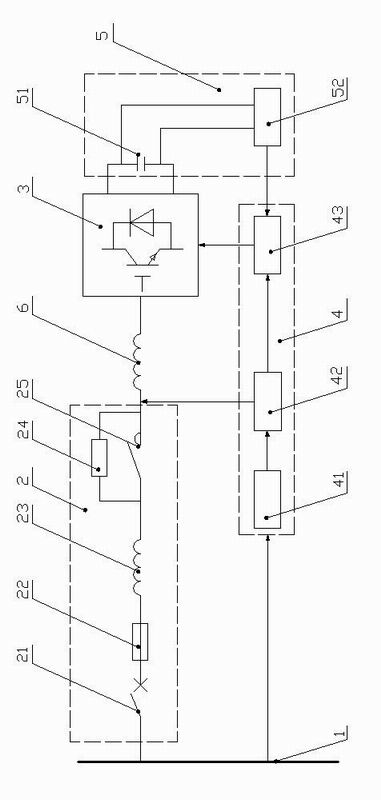

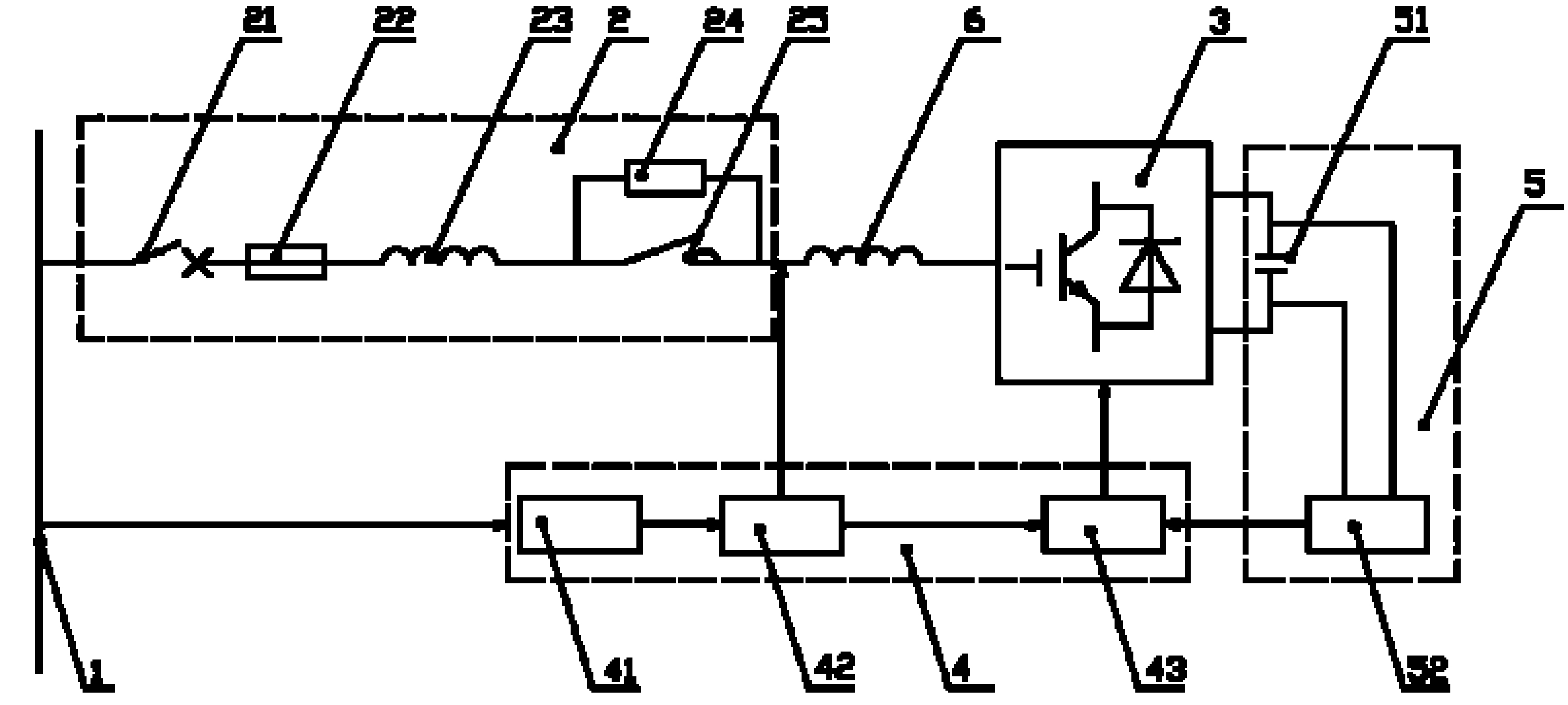

Dynamic idle compensation device for controlling high voltage based on IGBT (Insulated Gate Bipolar Translator)

InactiveCN102709917AIncrease the switching frequencyContinuously adjustable primary winding side impedanceReactive power adjustment/elimination/compensationReactive power compensationCapacitancePower factor

The invention discloses a dynamic idle compensation device for controlling high voltage based on an IGBT (Insulated Gate Bipolar Translator), comprising an idle compensation branch which is connected with a power transmission power grid in parallel and further comprising a reactance transformer, wherein the primary winding side of the reactance transformer is connected with two ends of the idle compensation branch in parallel; the secondary winding side of the reactance transformer is connected with a direct-current power supply through an IGBT inverter; and a control end of the IGBT inverter is connected with a control circuit for triggering the control pulse of the IGBT inverter. Alternating-current current is injected into the secondary winding side of the reactance transformer and a main controller is used for comparing a target power factor with a current power factor obtained by calculating collected voltage and current data; a control pulse PWM (Pulse-Width Modulation) waveform for triggering the IGBT inverter is adjusted through closed ring control, so that a current amplitude injected into the secondary winding side of the reactance transformer is changed, the continuous adjustment of a main magnetic flow of an electric transformer is realized, and then the continuous adjustment of the primary winding side of the reactance transformer is realized, and the stepless continuous adjustment of the capacitance and the inductance of the power transmission power grid is realized.

Owner:广州同汇盛南站产业发展有限公司

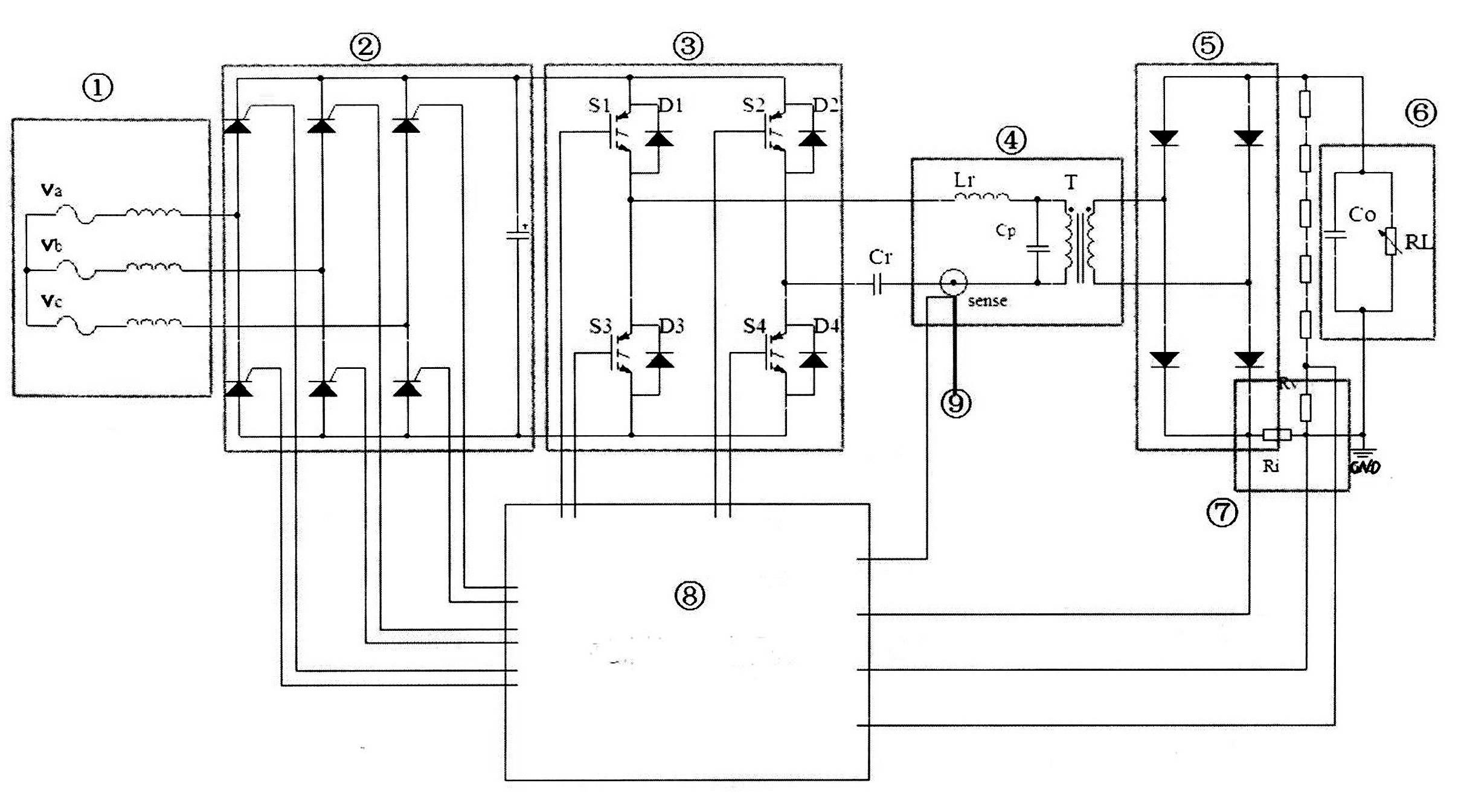

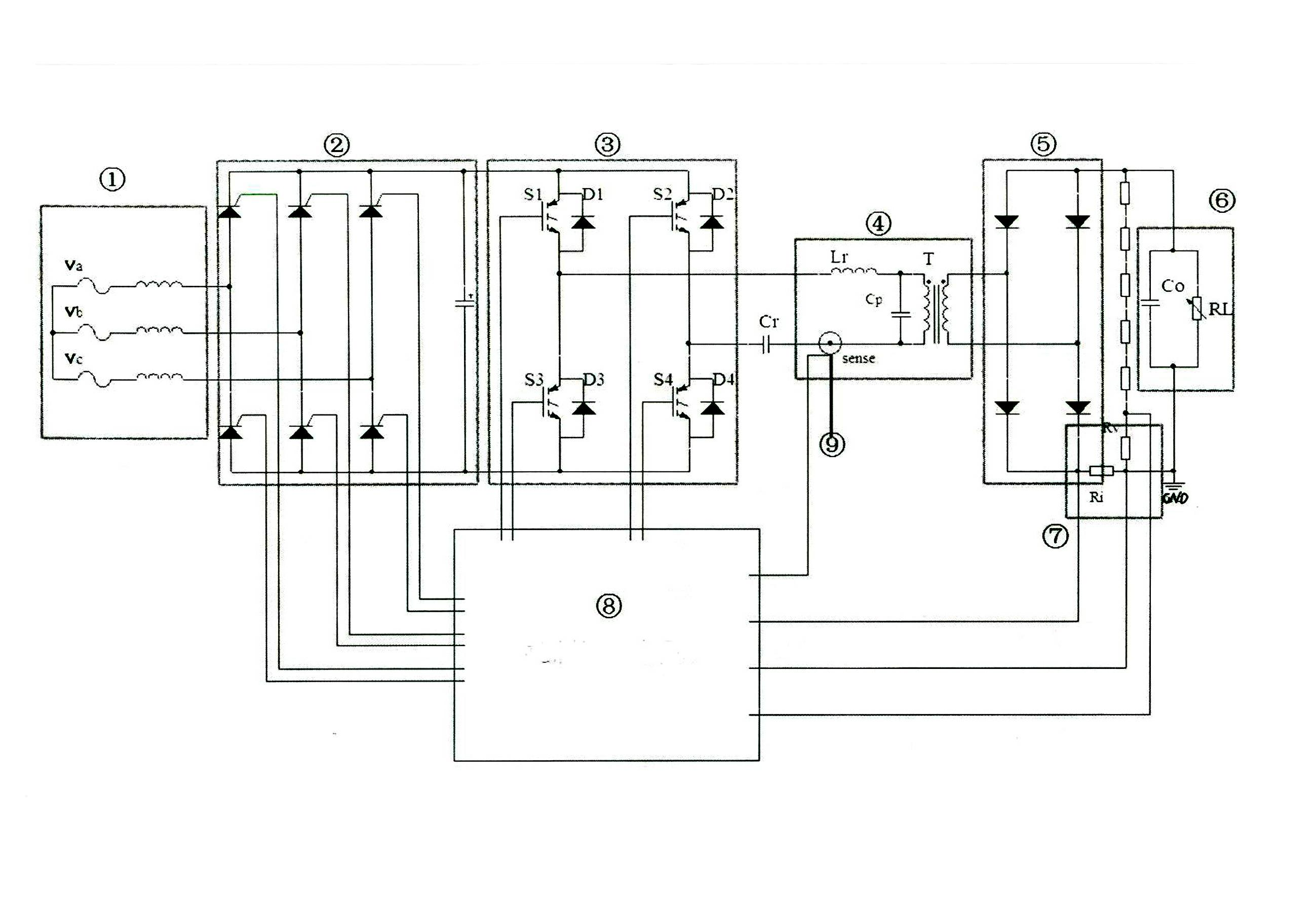

High-frequency high-voltage high-power power supply for electrostatic dust removal

InactiveCN102097956AImprove stabilityImprove control characteristicsAc-dc conversion without reversalDc-dc conversionCapacitanceFull bridge

The invention discloses a high-frequency high-voltage high-power power supply for electrostatic dust removal, which mainly comprises a three-phase power-frequency power supply, a rectification part, an inverter part, a resonant circuit, a high-frequency transformer, a high-voltage rectifier bridge, a load and a control module. The rectification part consists of a thyristor rectification module capable of rectifying the power-frequency electric energy output by the three-phase power supply into direct current, and a filter capacitor; the back of the rectification part is connected with the inverter part consisting of a high-frequency full-bridge Insulated Gate Bipolar Transistor (IGBT) inverter capable of inverting the direct current into high-frequency square wave; the resonant circuit consisting of a series inductor Lr, a series capacitor Cr and a parallel capacitor Cp and supplying power to the post-stage circuit in a resonant manner is connected behind the inverter part. By the invention, the deficiency of the conventional electrostatic dust removing power supply can be compensated, the dust removing effect is improved, and the utilization ratio of electric energy can be increased.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

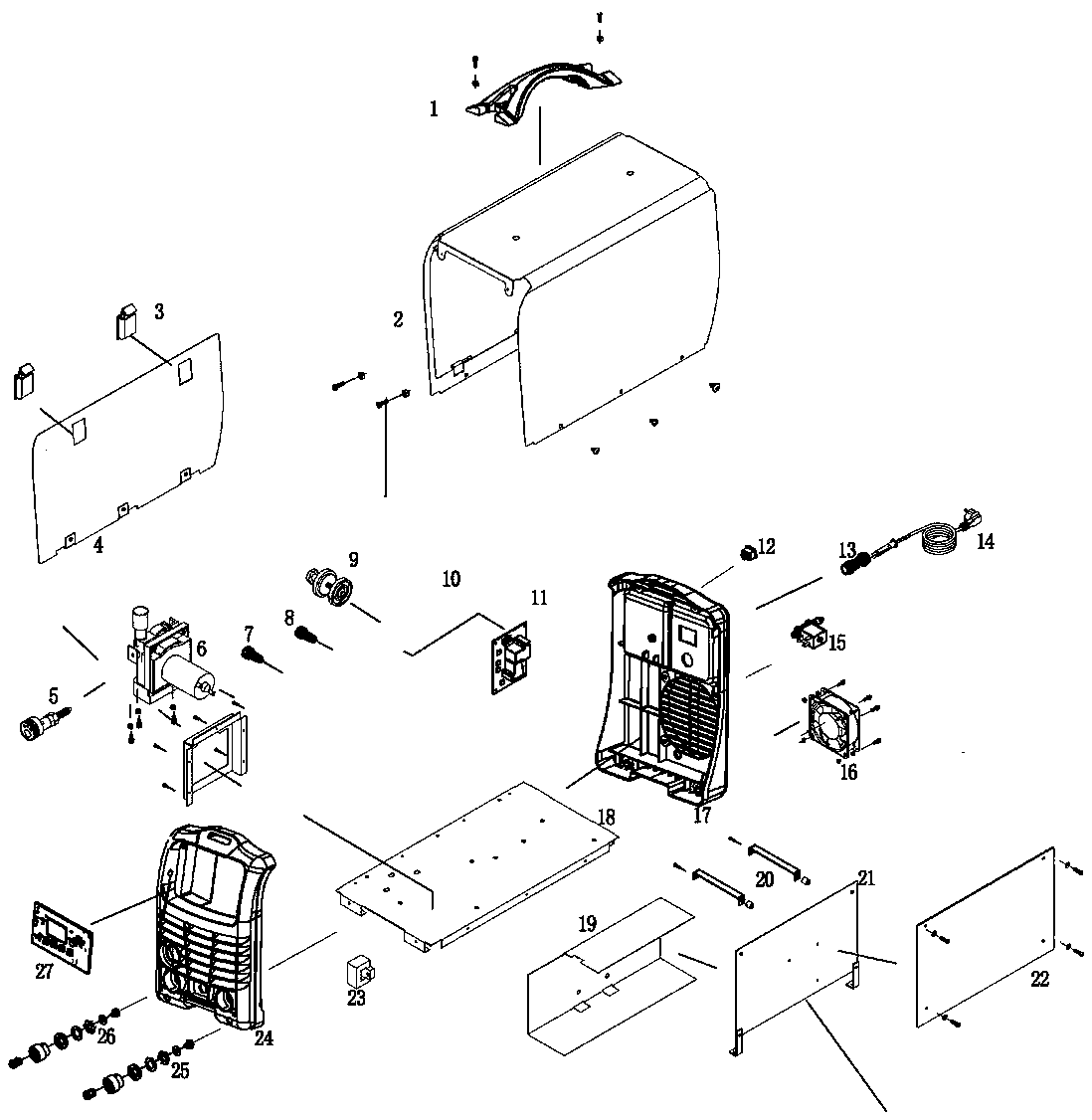

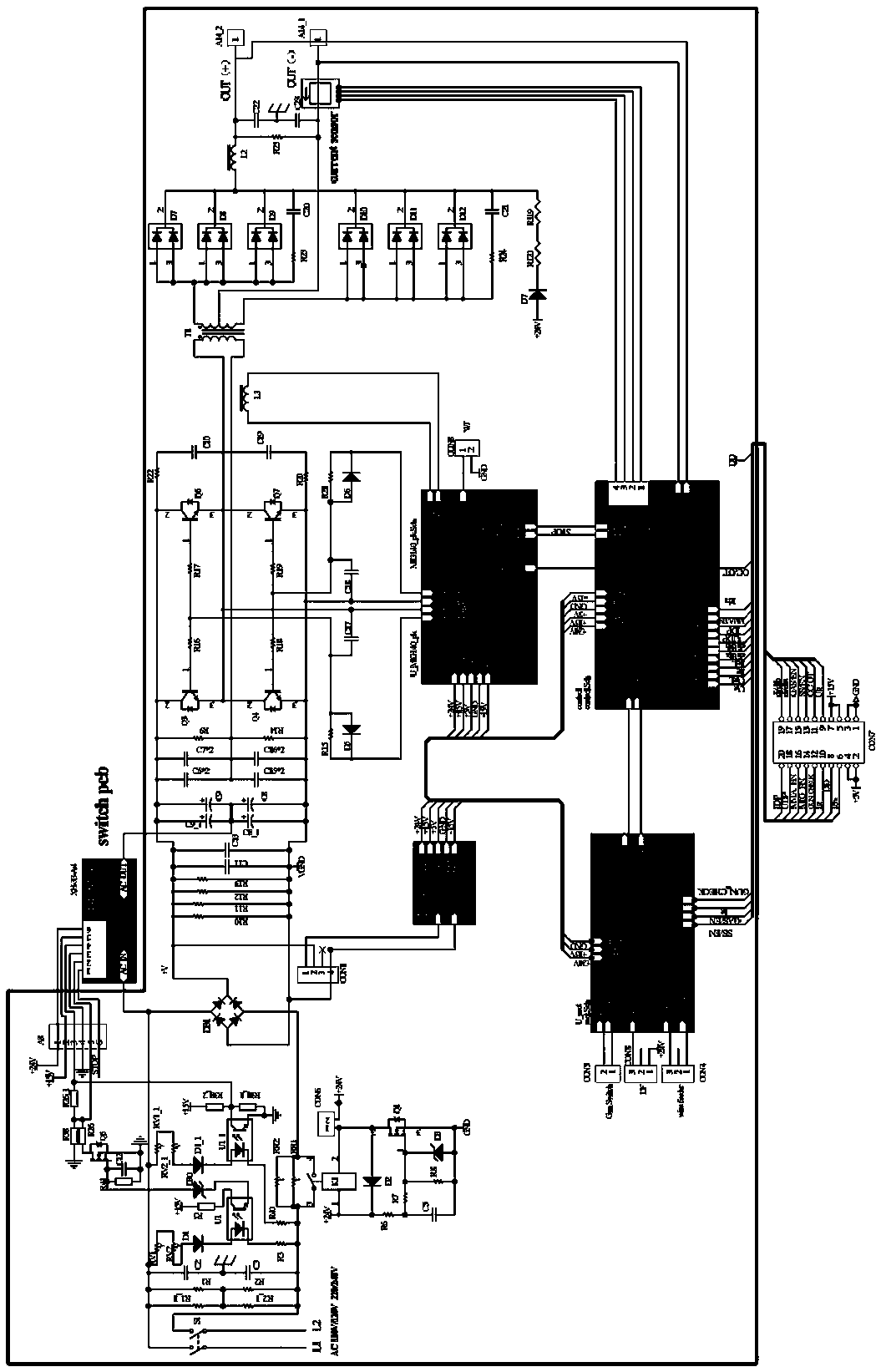

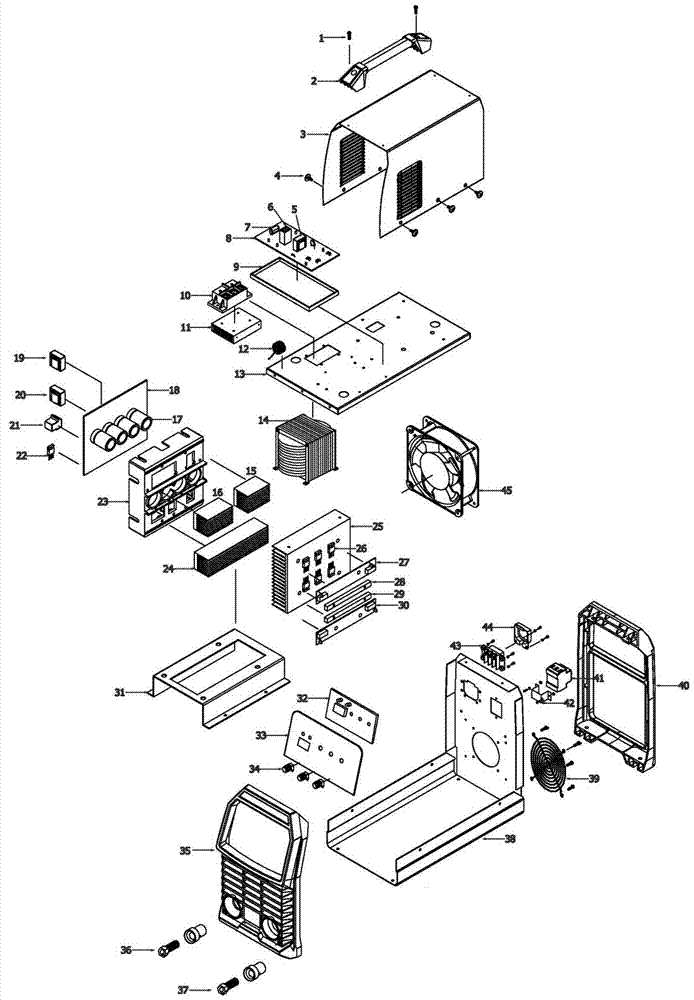

IGBT inverter multi-function welding machine with liquid crystal display and multi-input voice prompt functions

PendingCN109551085AProtection Circuit StructureProtection Design StructureWelding accessoriesMulti inputLiquid-crystal display

The invention relates to an IGBT inverter multi-function welding machine with liquid crystal display and multi-input voice prompt functions. The power source of the IGBT inverter multi-function welding machine is 220-240V or 110V-120V; and the interior of the IGBT inverter multi-function welding machine is designed to be of a left-and-right side structure. Components such as a circuit board, a cooling fan and the like are arranged on one side of the interior of the IGBT inverter multi-function welding machine; components such as a wire feeding mechanism and the like are arranged on the other side of the interior of the IGBT inverter multi-function welding machine; the circuit board is designed into three pieces, one piece is a liquid crystal display and operation control board, the secondpiece is a switching control board which can realize automatic identification, detection and conversion control of an input voltage, and the third piece is a main control board; and the IGBT invertermulti-function welding machine is mainly composed of an inverter main circuit consisting of input voltage detection, power-on buffering, rectification and filtering, IGBT inverter, a main transformer,output rectification, filtering and the like, a switching power circuit, an inverter PWM and IGBT drive circuit, a wire feeding and solenoid valve control circuit, an output characteristic control circuit and the like. The IGBT inverter multi-function welding machine not only has a multi-function welding method, but also solves the problem of narrow application range of a multi-power-source and single-function welding machine.

Owner:ZHEJIANG KENDE MECHANICAL & ELECTRICAL

On-line dynamic harmonic treatment device

InactiveCN101989746AImprove transmission performanceReduce active lossReactive power adjustment/elimination/compensationReactive power compensationHarmonicPower factor

The invention relates to an electronic device, in particular to an on-line dynamic harmonic treatment device which comprises a bus, a harmonic detection loop, a power supply transformation loop, an IGBT (Insulated Gate Bipolar Translator) inverter and a main loop. When current passes through the bus, the harmonic detection loop detects the power factor and the harmonic current of a power grid, and the IGBT inverter can generate a capacitive current having the same magnitude and a different direction compared with the current of the bus for the power grid to eliminate electronics. In the invention, the electronic detection loop only works when current passes through the bus, thus lagging conditions cannot occur, and the whole regulating speed is lower than 10ms.

Owner:国网南自控股(杭州)有限公司

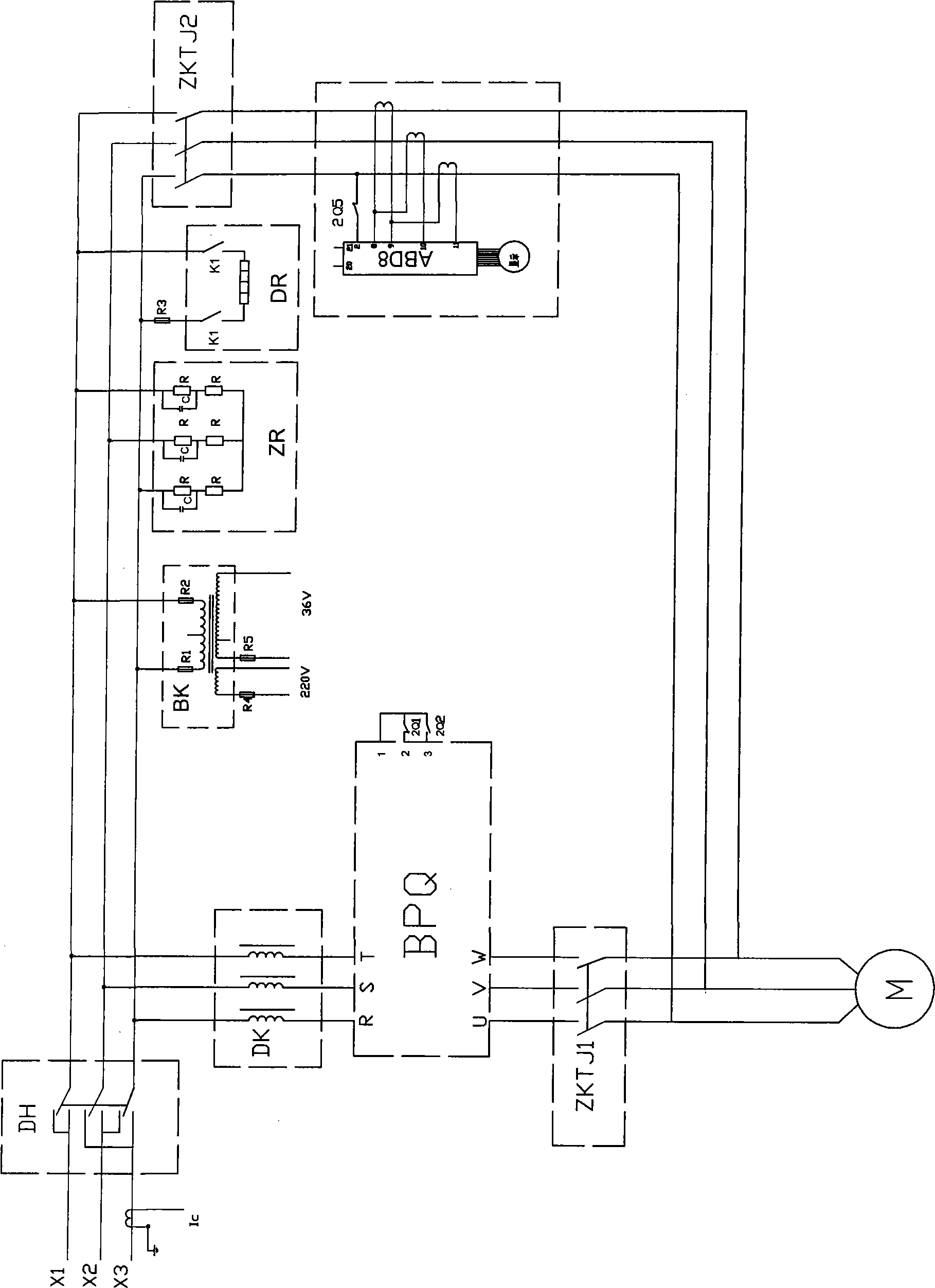

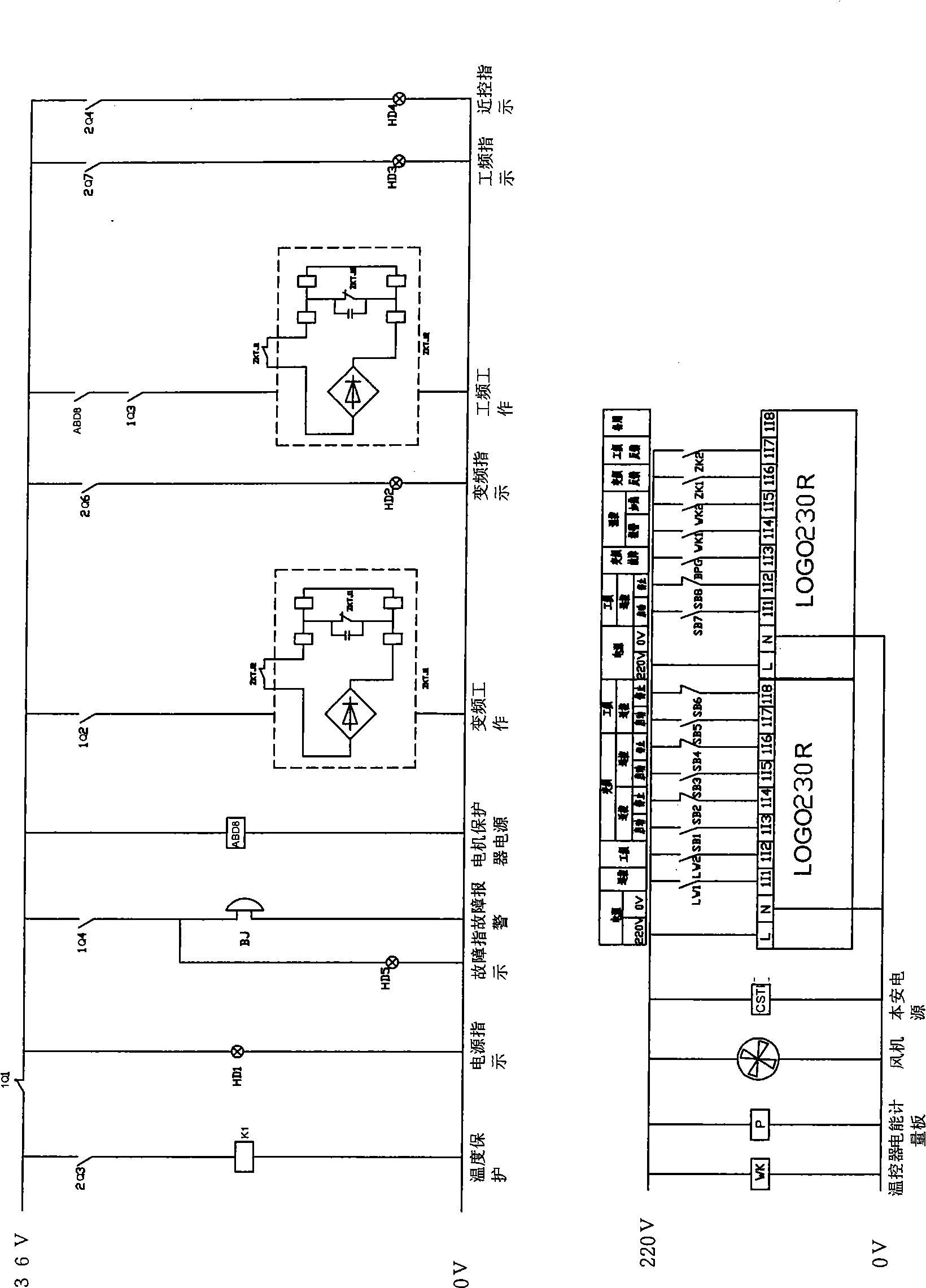

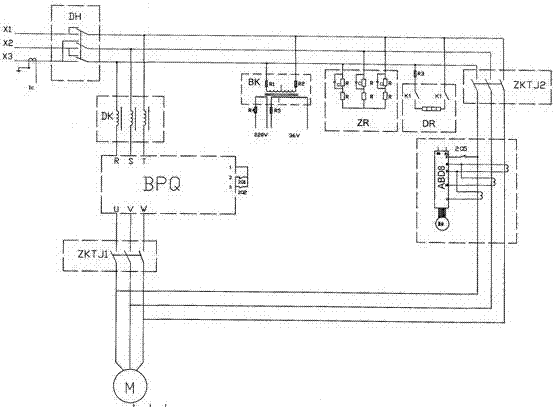

Mine flameproof and intrinsic safety type variable frequency speed control device

InactiveCN101534091AWith dustproofEasy to prevent dustAC motor controlEmergency protective circuit arrangementsFrequency changerDust control

The invention relates to a mine flameproof and intrinsic safety type variable frequency speed control device, which comprises a frequency converter consisting of a three-phase rectifier, a filtering capacitor and an IGBT inverter, a control device, and a flameproof case body, wherein the control device comprises an isolating switch, a power frequency and secondary control loop, and a variable frequency and control loop. The variable frequency speed control device has a variable frequency operating mode and a power frequency operating mode, and gives priority to the variable frequency operating mode complemented with the power frequency operating mode, thus the variable frequency speed control device not only can regulate the speed and save energy better, but also has the advantages of dust control, moisture protection, flame protection, and the like; and the variable frequency speed control device adopts digital display, which not only has a function of remote and approach controls, but also has functions of displaying electric energy, namely displaying load electric energy clearly, and temperature control, and has protection functions of surge protection, open phase protection, over voltage protection, under-voltage protection, and the like. The variable frequency speed control device can be applied to underground places with coal dust or gas coal dust explosion in coal mines to perform controls of starting, stopping and variable frequency speed control on a three-phase flameproof motor, and performs various protections on the motor. The variable frequency speed control device adopts a variable frequency speed control method which is advanced and can be widely popularized.

Owner:范鑫焱

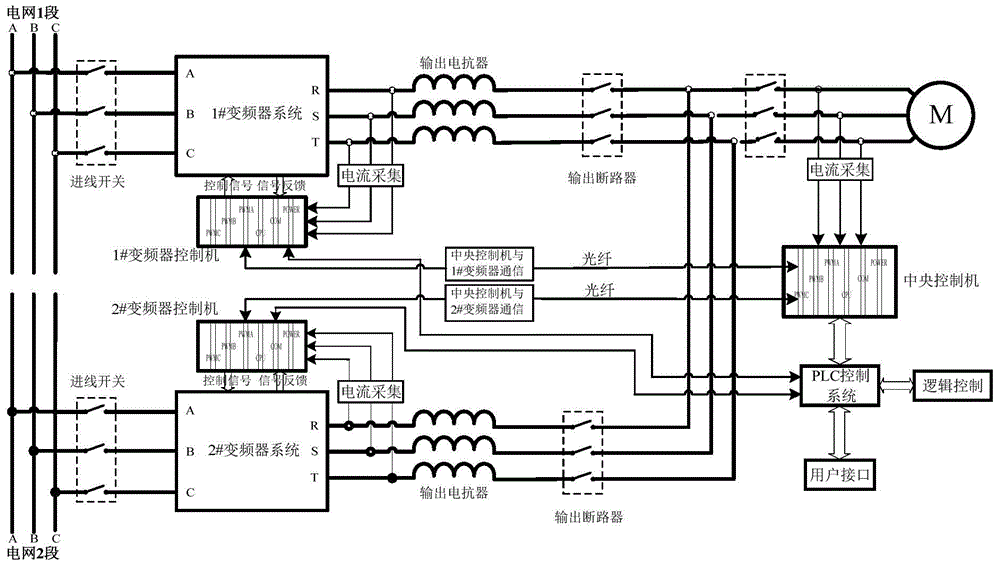

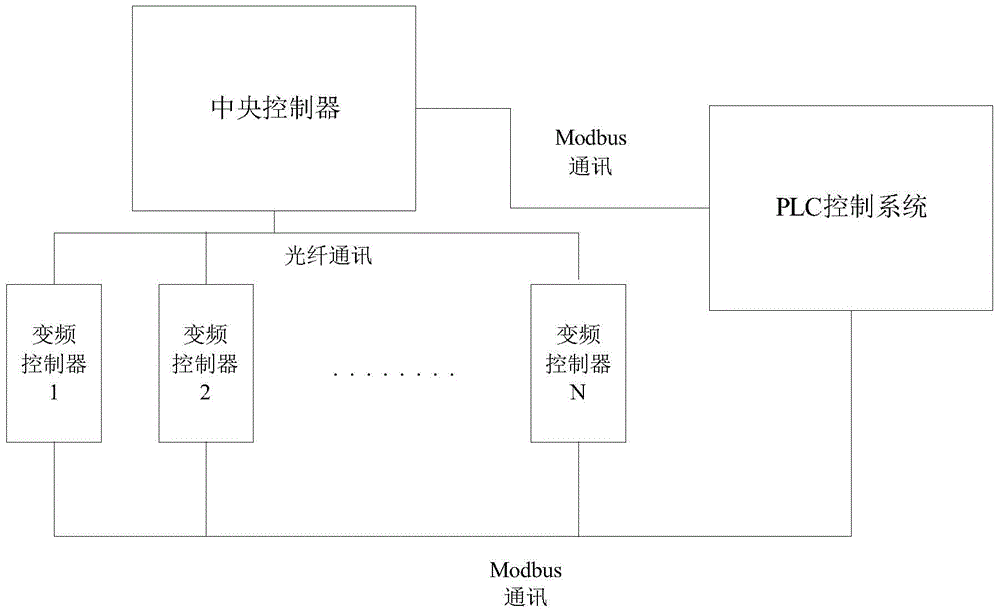

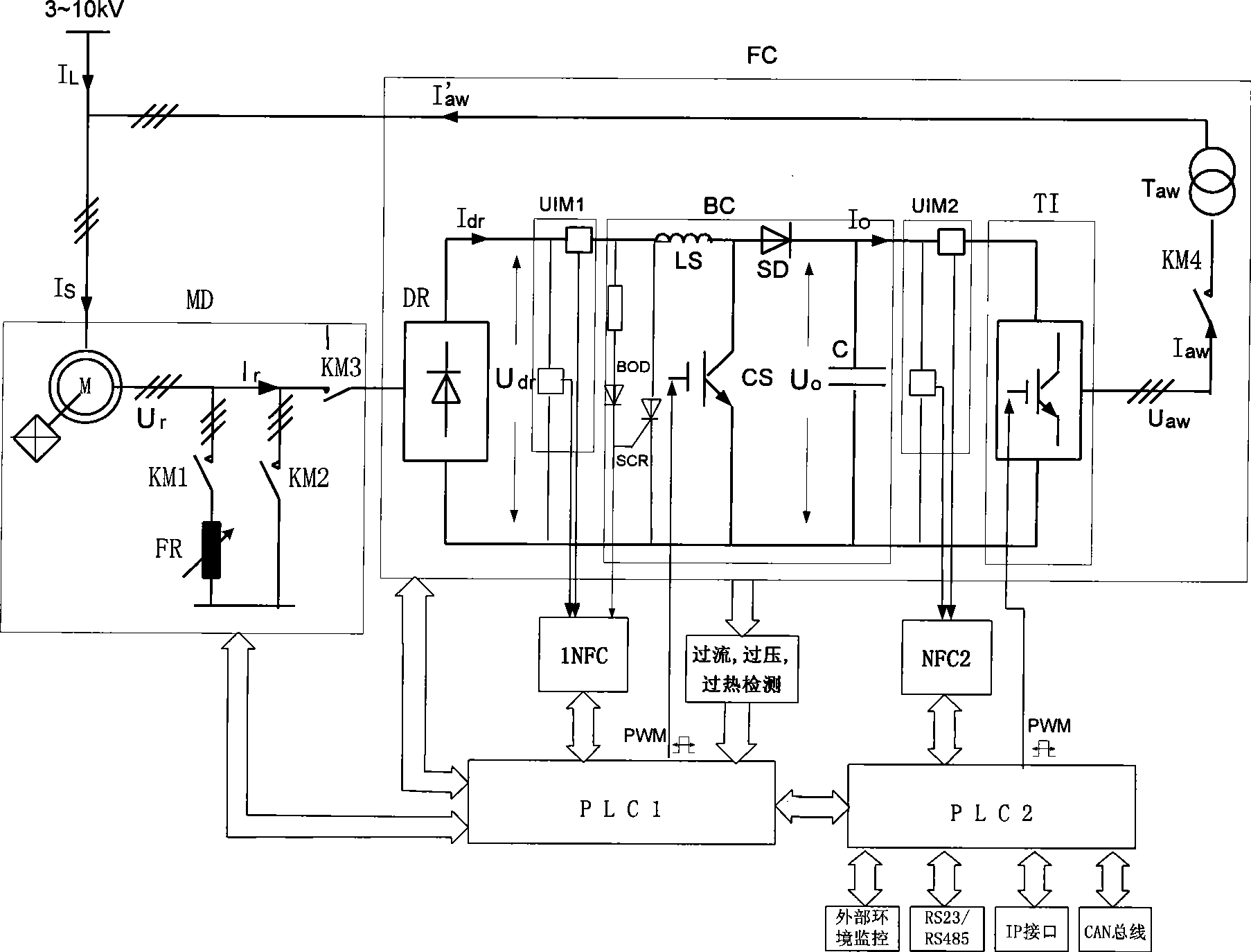

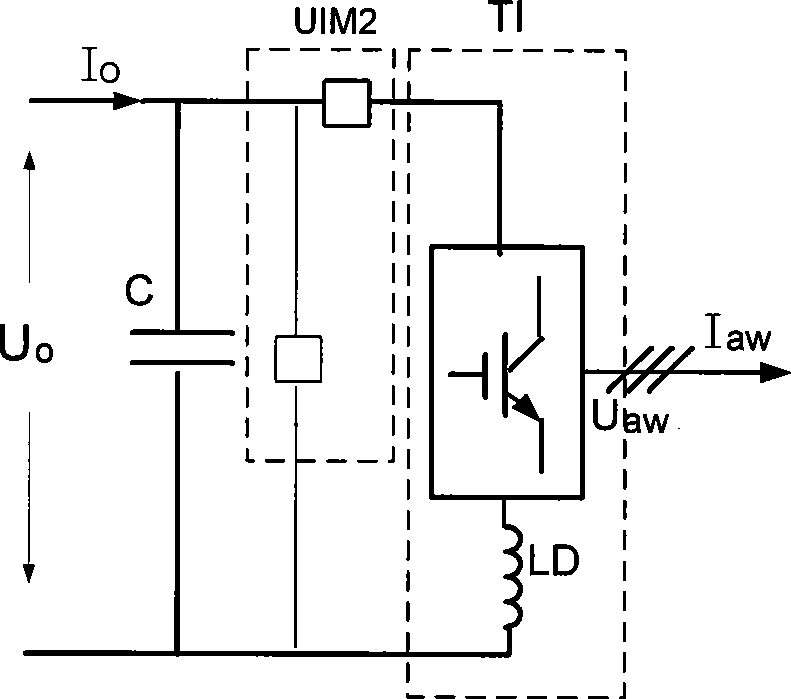

Multi-machine parallel control topological structure based on high-voltage inverters

ActiveCN104167907AIncrease redundancyImprove reliabilityAC motor controlEfficient power electronics conversionMulti machineSoft handover

The invention relates to a multi-machine parallel control topological structure based on high-voltage inverters. The cascade high-voltage inverters are connected in parallel, communicated with a PLC externally and communicated with each other through optical fibers. Coordination control over the inverters is performed through the same central controller. By means of multi-machine parallel connection, overall capacity expansion of the driving inverters is achieved, and the purpose that small-capacity power devices are connected in parallel to control a large motor is achieved. By means of the multi-machine parallel control topological structure, soft handover of the motor controlled by the inverters is achieved, the process of galloping starting of spare inverters required when shutting down of the inverters happens is avoided, therefore, the purpose of one inverter with a backup is achieved truly, control over the large-capacity motor is achieved by means of parallel connection of more than two inverters through the IGBT inverter bridge cascade topological structure, the multi-machine parallel control topological structure treads into the field where only an IEGT can tread in the past, and the problem of heat dissipation caused by operation of high-power devices in the past is avoided.

Owner:WOLONG ELECTRIC GRP CO LTD +1

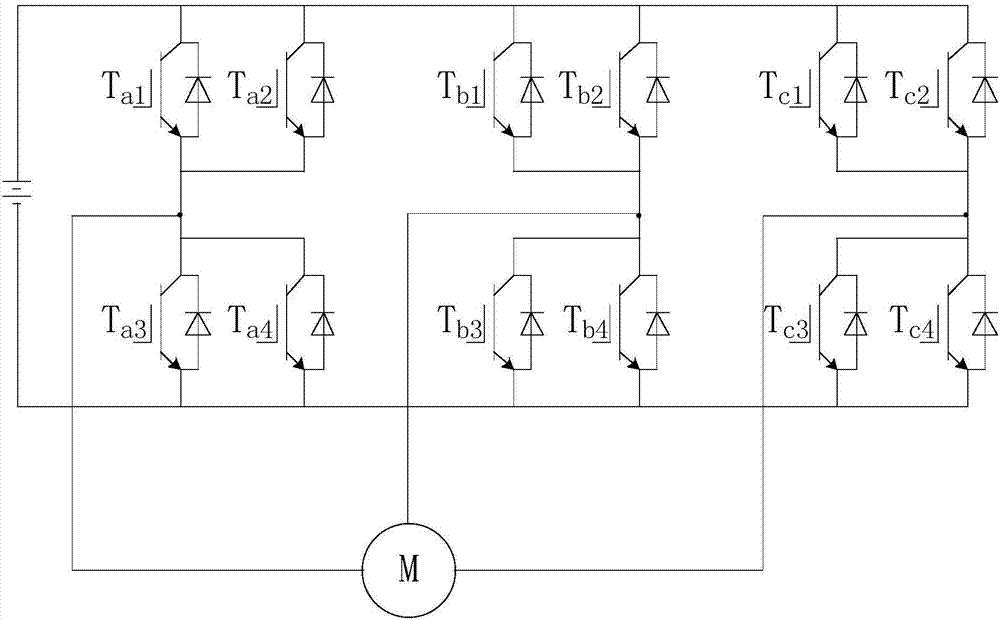

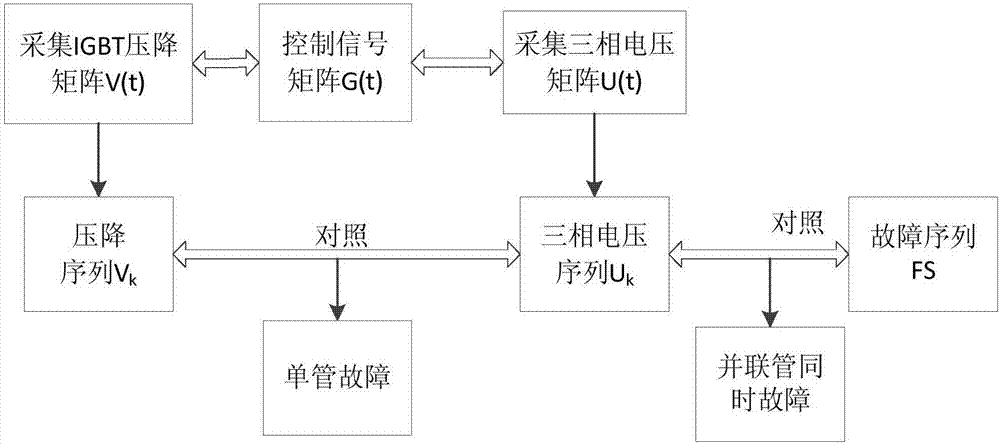

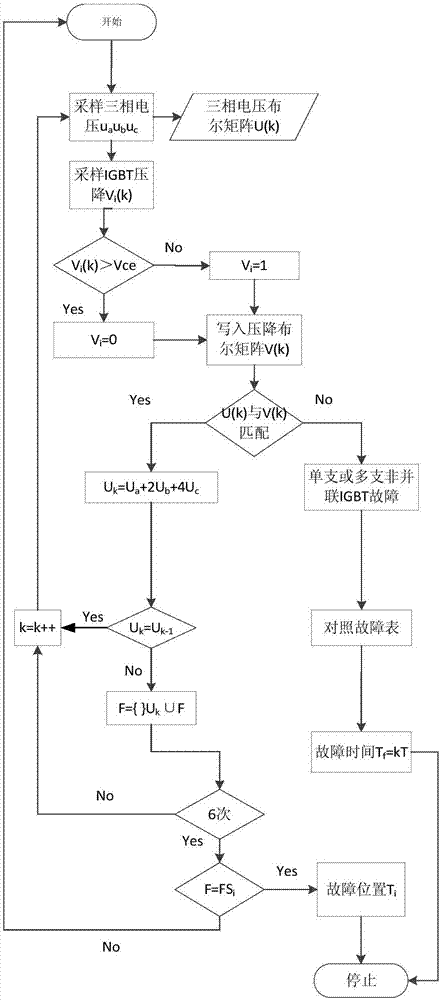

Method for diagnosing fault of parallel IGBT inverters

ActiveCN106908677AReduced open-circuit fault diagnosis delayReduce complexityElectrical testingVoltage dropThree-phase

The invention discloses a method for diagnosing fault of parallel IGBT inverters. The method comprises the steps of firstly, acquiring three phase voltages which are output from the inverter, establishing a three-phase voltage matrix, and obtaining a state amount Uk; then, acquiring an IGBT conduction voltage drop Vi(k), comparing the Vi(k) with a threshold voltage drop Vce, forming an IGBT voltage drop Boolean matrix according to the comparison result, and determining whether a fault occurs according to the V(k); if yes, further comparing the Uk with the state amount Vk obtained from the V(k), if Uk is not equal with Vk, determining fault of a single IGBT or multiple non-parallel IGBTs, and otherwise, determining simultaneous fault of the parallel IGBTs; inputting the Uk into a set F; if state change of Uk values which are obtained through sampling by six times occurs, comparing F with a fault set FSi, and determining position of the fault. The method can realize quick diagnosis for the fault of the inverters.

Owner:广州小加传媒有限公司

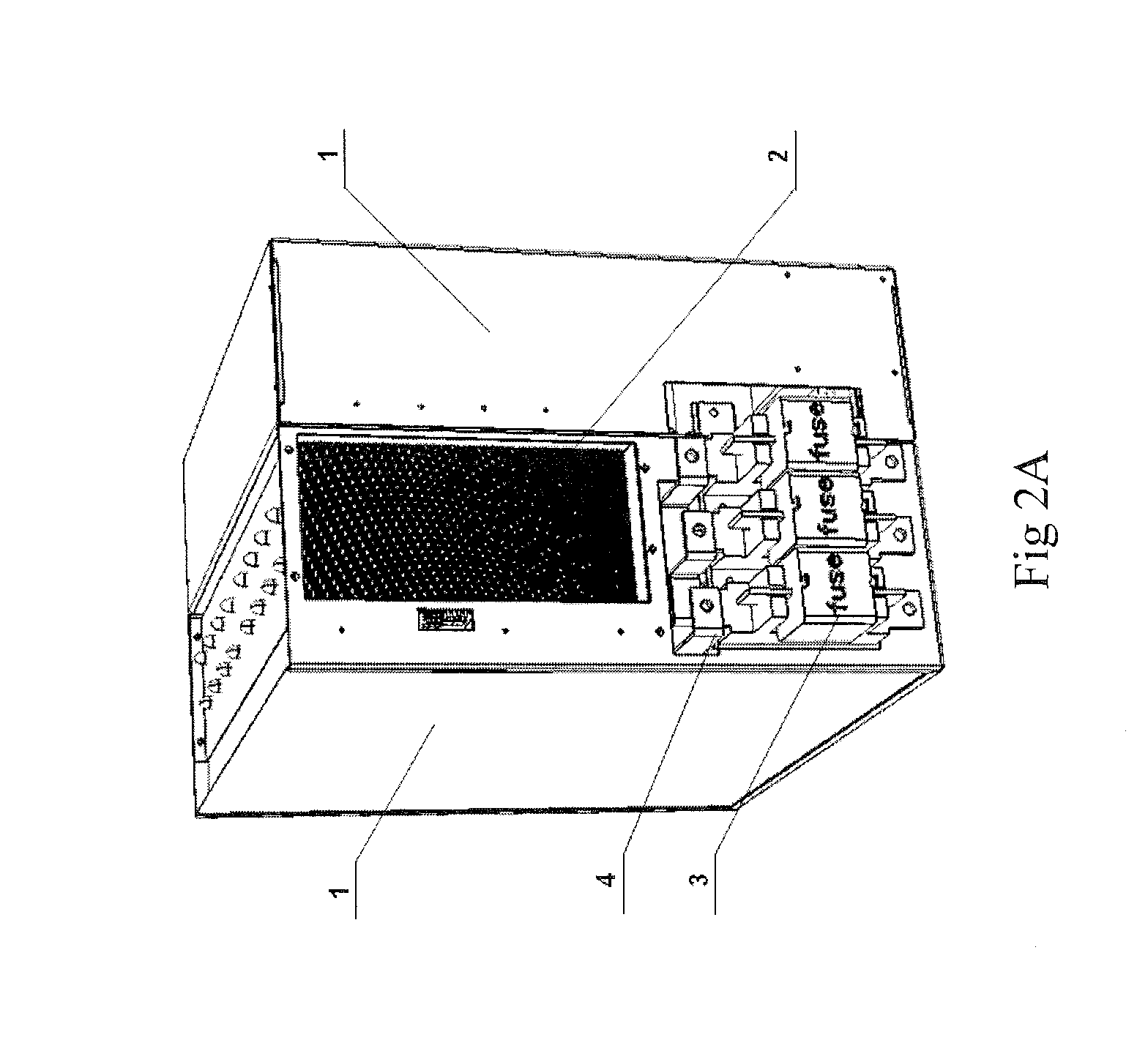

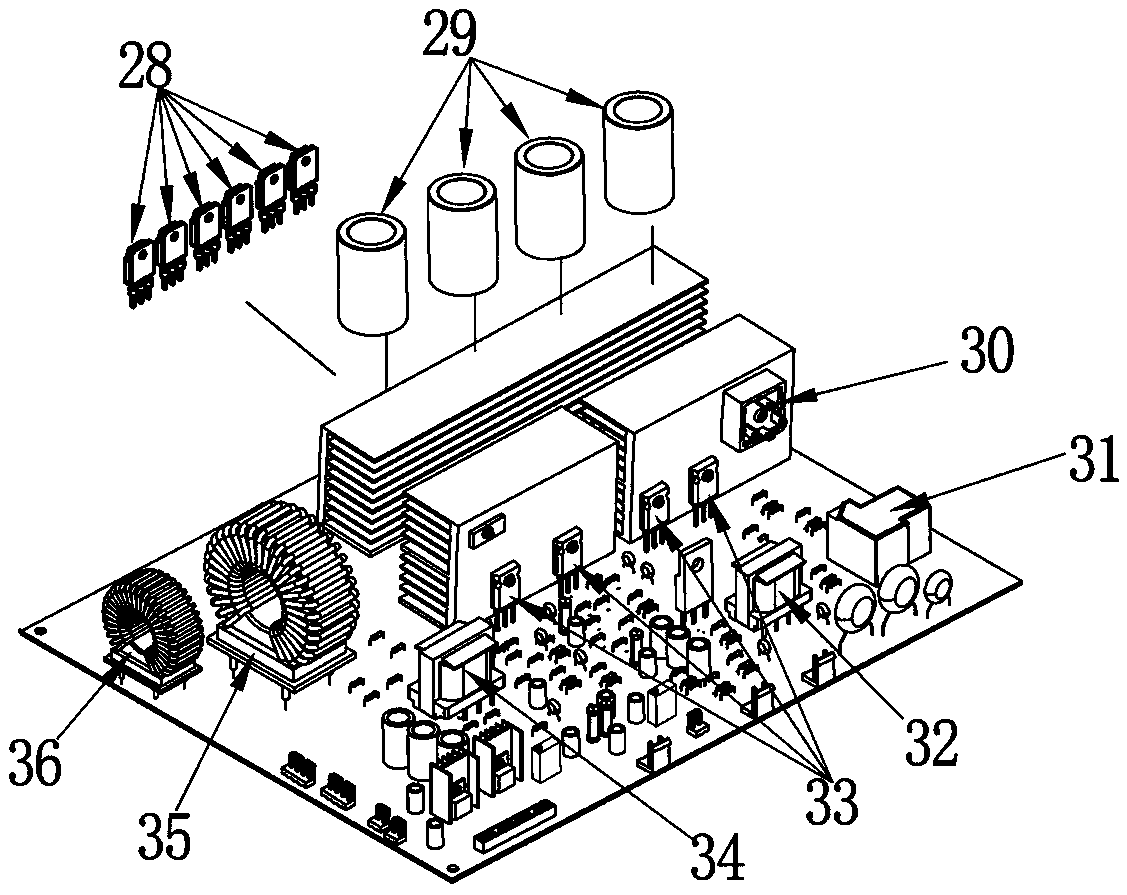

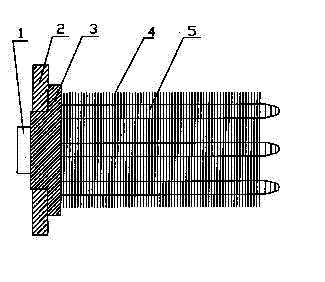

High-power medium-voltage drive power cell having power elements disposed on both sides of base plate

ActiveUS9019731B2Easy to disassembleShorten the transmission distanceConversion constructional detailsAc-ac conversionEngineeringThree-phase

The present invention provides a high-power medium-voltage drive power cell, which comprises: a rectifier module for rectifying the three-phase AC input voltage to get a DC voltage; an IGBT (Insulated Gate Bipolar Transistor) inverter bridge connected to capacitors for converting the DC voltage into an AC voltage of which the frequency, the amplitude and the phase are adjustable; a bypass module connected to the IGBT inverter bridge for providing the bypass function when the IGBT inverter bridge works in an abnormal state; and a heat pipe heat sink having a base plate on both sides of which power elements of the high-power medium-voltage drive power cell are disposed.

Owner:DELTA ELECTRONICS (SHANGHAI) CO LTD

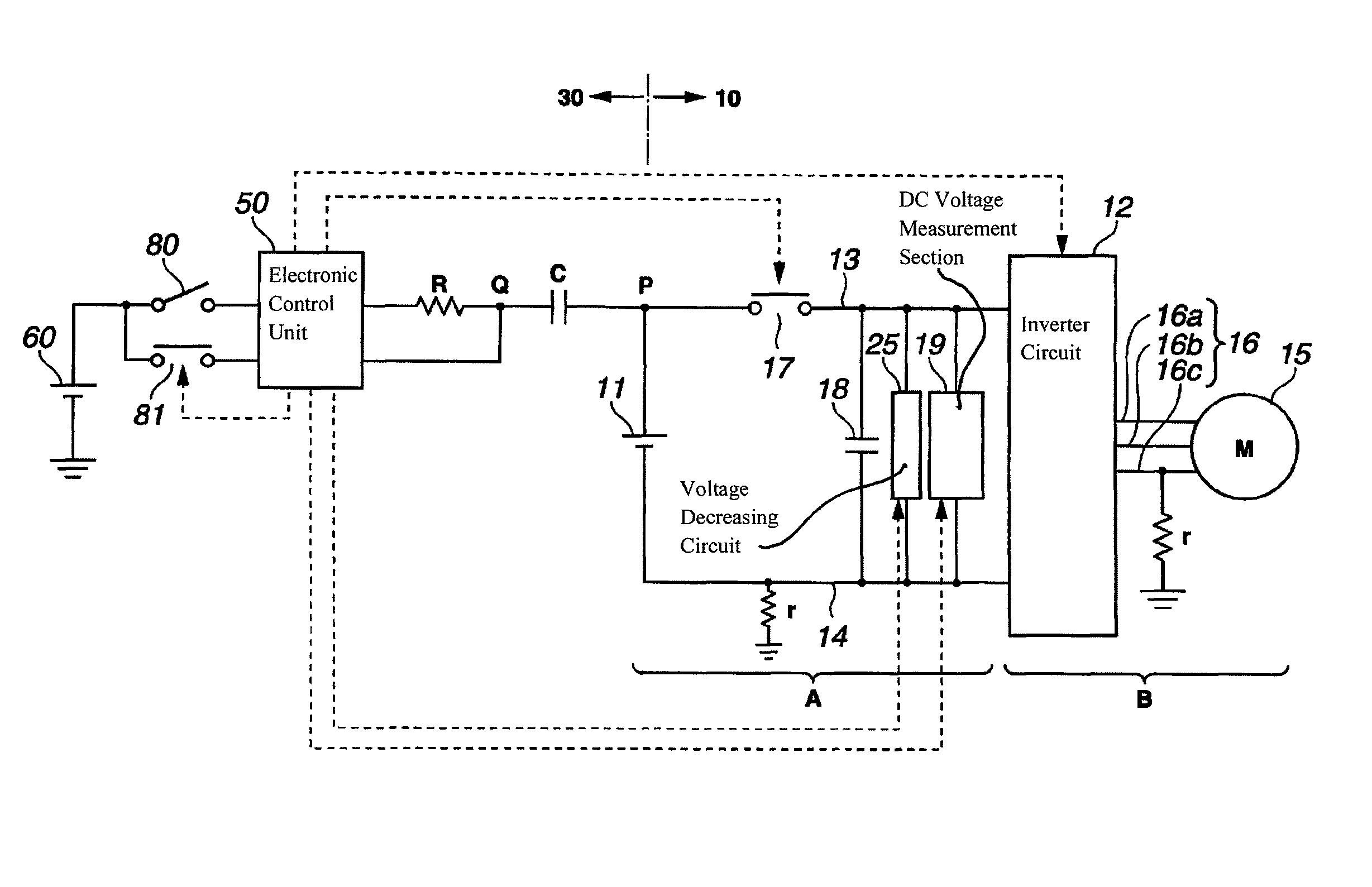

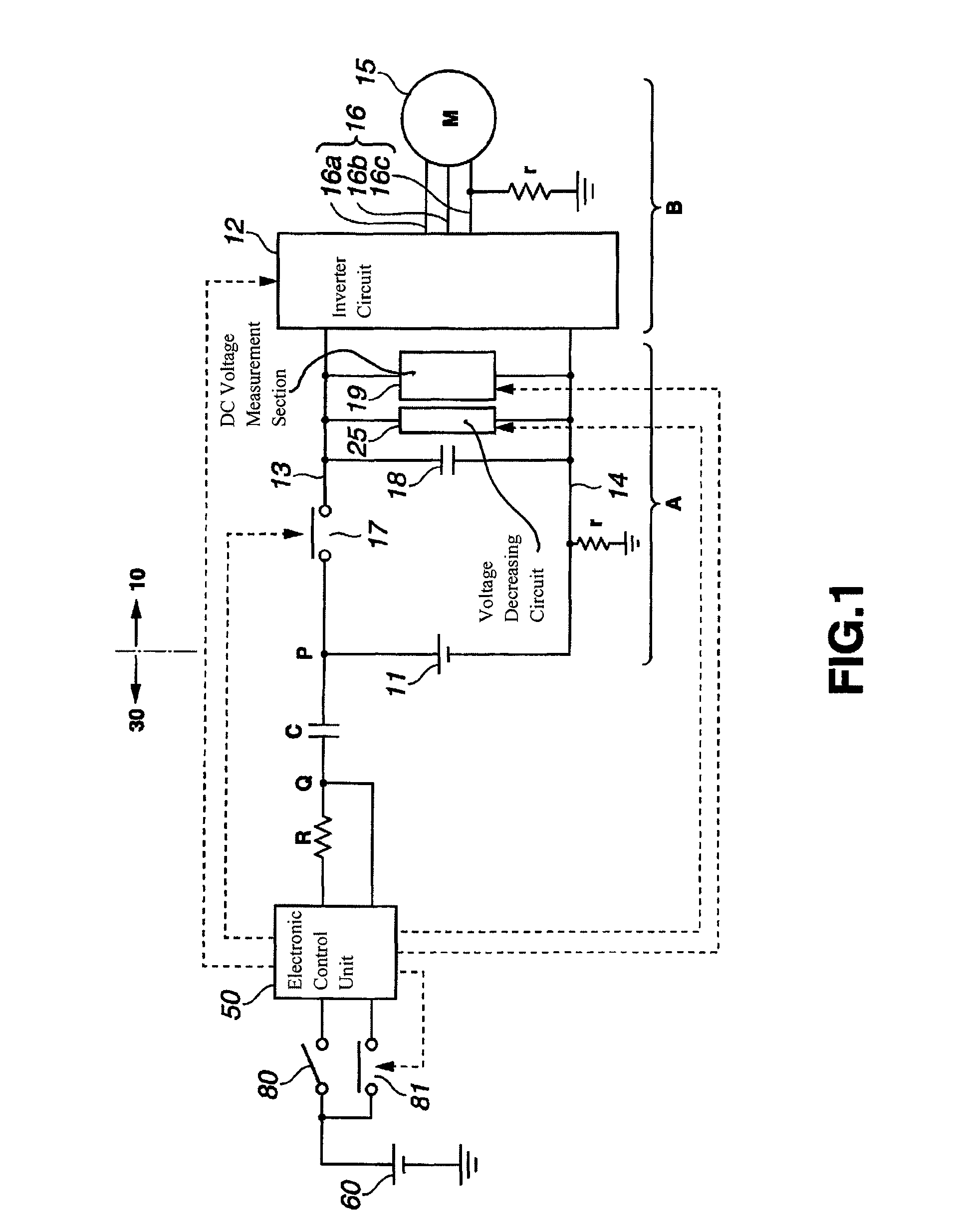

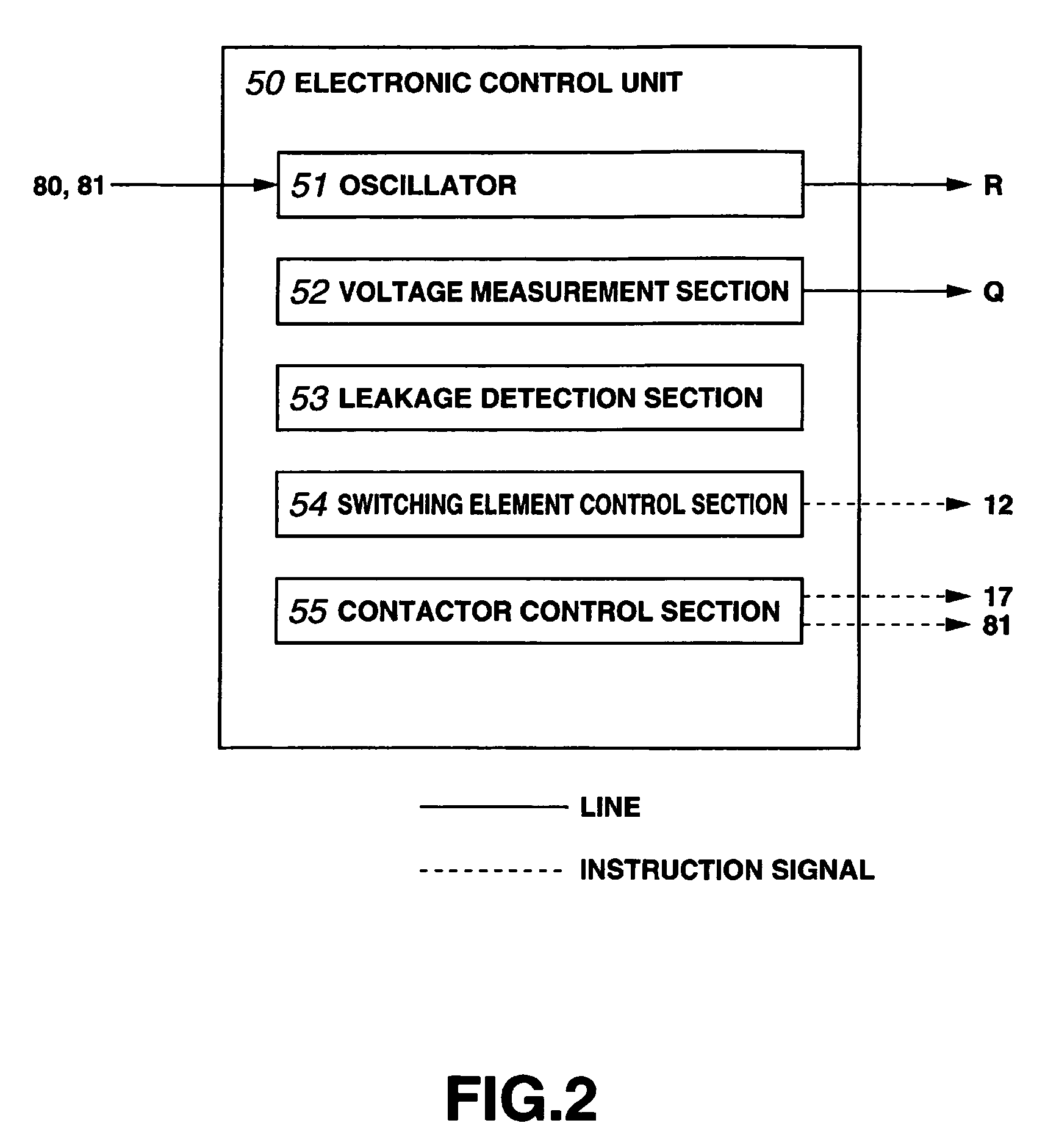

Leakage detection device of vehicle mounted power supply system

InactiveUS8004285B2Guaranteed uptimeBatteries circuit arrangementsElectric motor controlMeasurement pointEngineering

A leakage detection can be correctly performed both in a DC high voltage circuit and in an AC high voltage circuit in a vehicle-mounted power supply system. Under a state where a contactor 17 is turned off, all IGBT elements (switching elements) 76 in an IGBT inverter circuit 12 are turned on, and an AC signal Vs is applied to an applying point P. Then, a voltage measured at a voltage measurement point Q is compared with a threshold value to detect whether or not the leakage exists.

Owner:KOMATSU LTD

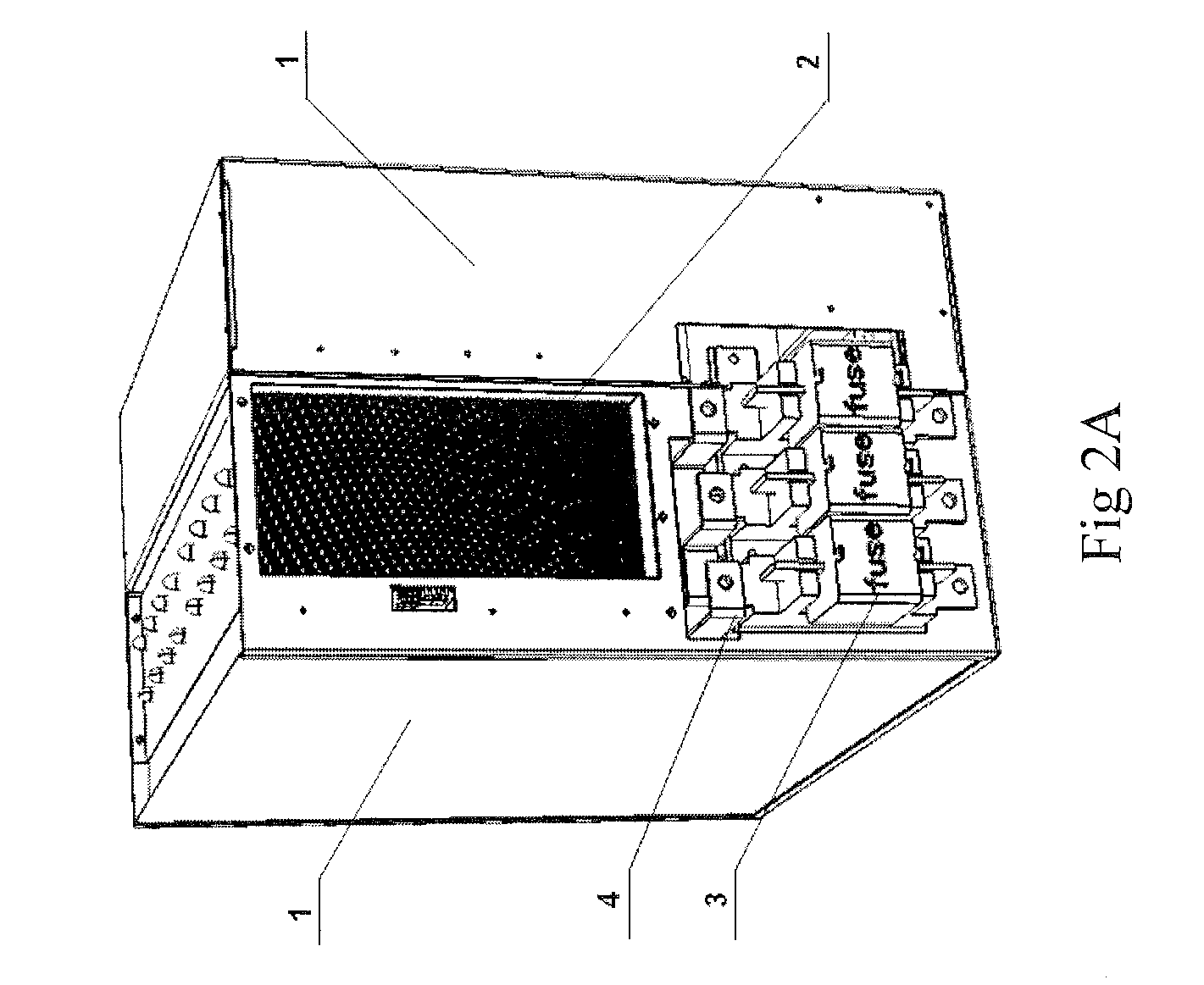

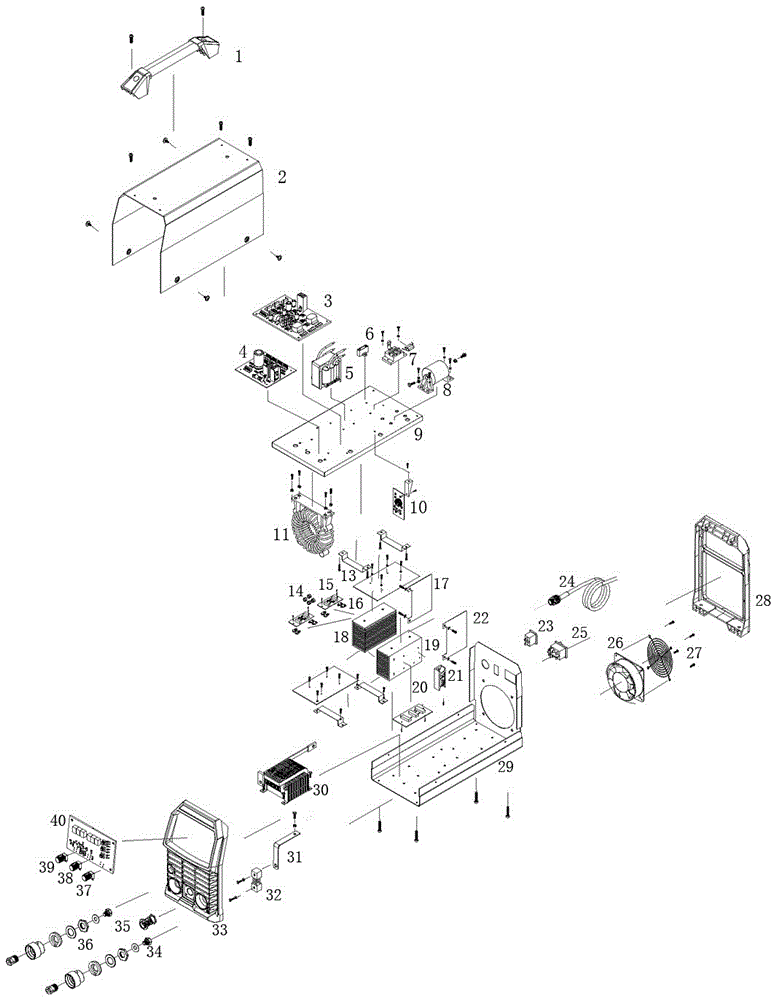

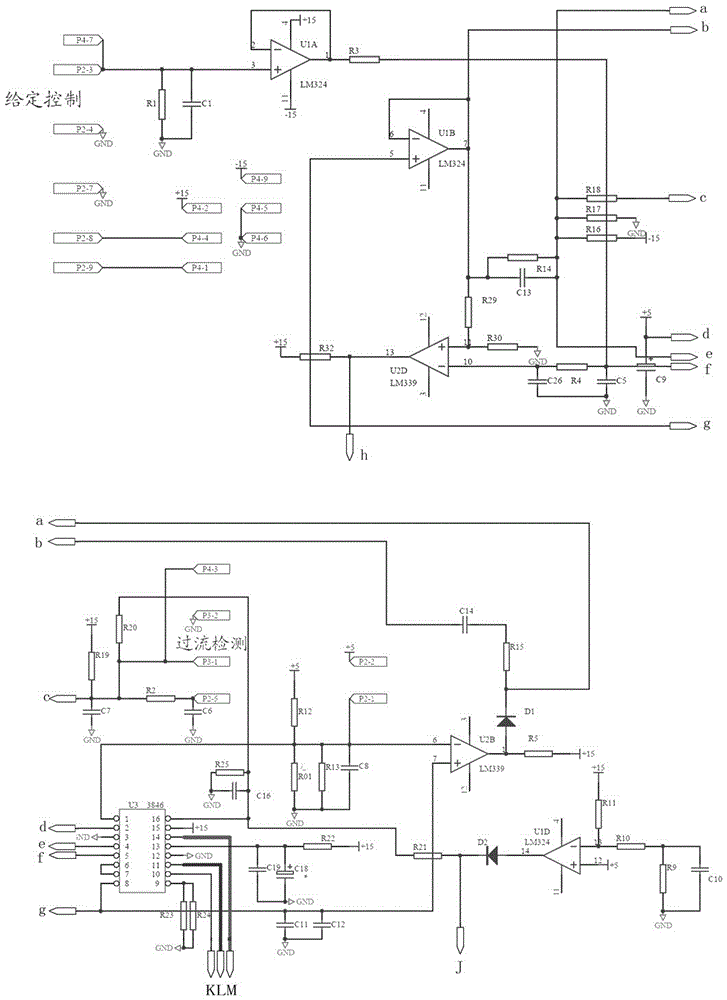

Structure of IGBT inverter welding machine with two welding functional modules

ActiveCN106112214AProtection Circuit StructureProtection Design StructureArc welding apparatusMachine controlTransformer

The invention relates to a structure of an IGBT inverter welding machine with two welding functional modules. The structure comprises an outer housing and an inner circuit board; the circuit board mainly comprises six parts which are separately a drive plate, a control panel, a current detecting plate, an IGBT plate, a fast recovery circuit board and a panel control board; the control panel is connected to the panel control board, a control transformer and the drive plate; the control transformer is used for supplying power to the control panel; the drive plate is connected to the control panel, the IGBT plate and the current detecting plate; and under the action of the control panel, the drive plate generates a drive signal which can reliably drive each IGBT to work, so that stable operation of an inverter circuit is guaranteed. According to the structure, the performance problem, the reliability problem, the production efficiency problem and the manufacturing and transporting cost problem of multifunctional welders are solved very well by adopting a control circuit system consisting of a two-chip micro processor, a single-chip micro processor and the like and optimizing the structural design of a welding machine control circuit, the structural design of a circuit board and the structural design of each part, so that market competitiveness of products is improved.

Owner:ZHEJIANG KENDE MECHANICAL & ELECTRICAL

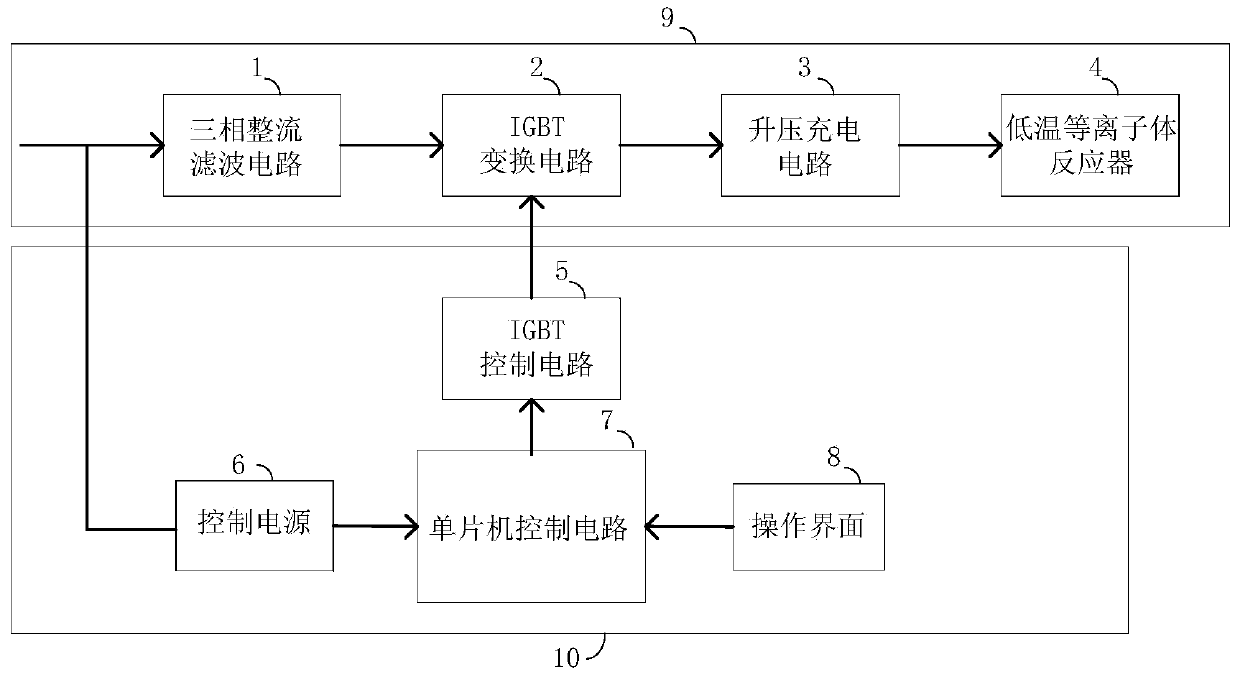

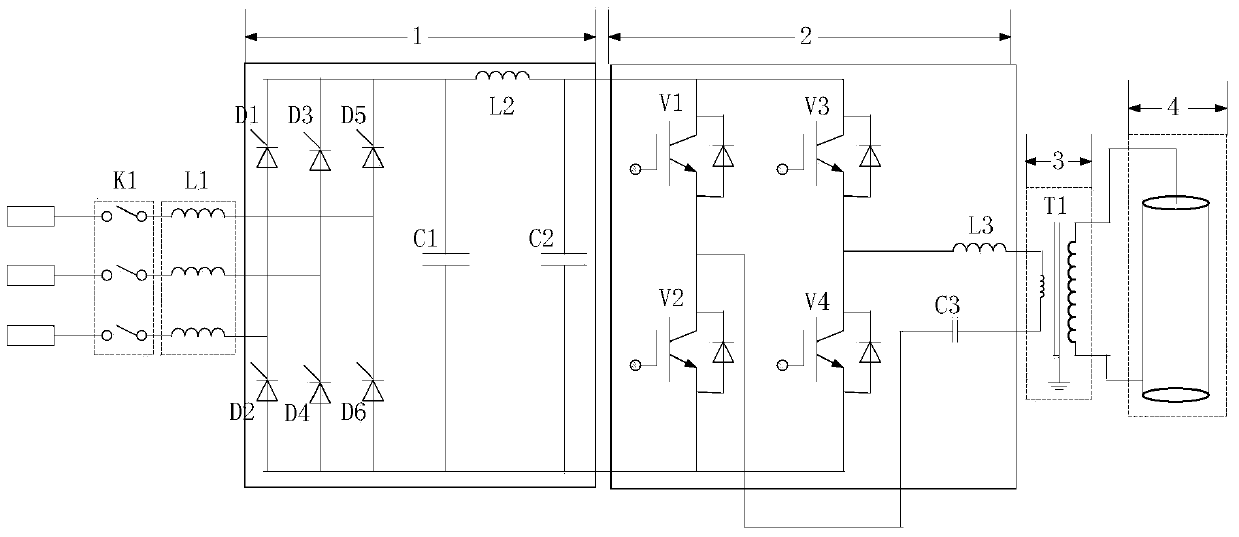

Bipolar pulse power supply used for generating low-temperature plasma

InactiveCN103795287AGood current distribution uniformityEasy injectionPlasma techniqueElectric consumptionThree-phase

The invention discloses a bipolar pulse power supply used for generating low-temperature plasma. The power supply is used for supplying power to a low-temperature plasma reactor generating low-temperature plasma and comprises a main circuit and a control circuit, wherein the main circuit is composed of a three-phase rectifier and filter circuit, an IGBT inverter and a boosted circuit, and the control circuit is composed of a single-chip microcomputer control circuit, an IGBT control circuit and an operation interface. According to the power supply, three-phase alternating voltage is converted into stable direct voltage through the rectifier and filter circuit, the direct voltage is converted into bipolar impulse voltage through the IGBT inverter, the bipolar impulse voltage is amplified through the boosted circuit, and electric energy is provided for the low-temperature plasma reactor; vibration loss of most energy in a system when traditional power supplies are used is effectively avoided, and as a result, energy injection of the reactor can be effectively improved, energy utilization efficiency can be improved, and electric consumption can be reduced.

Owner:ZHEJIANG UNIV

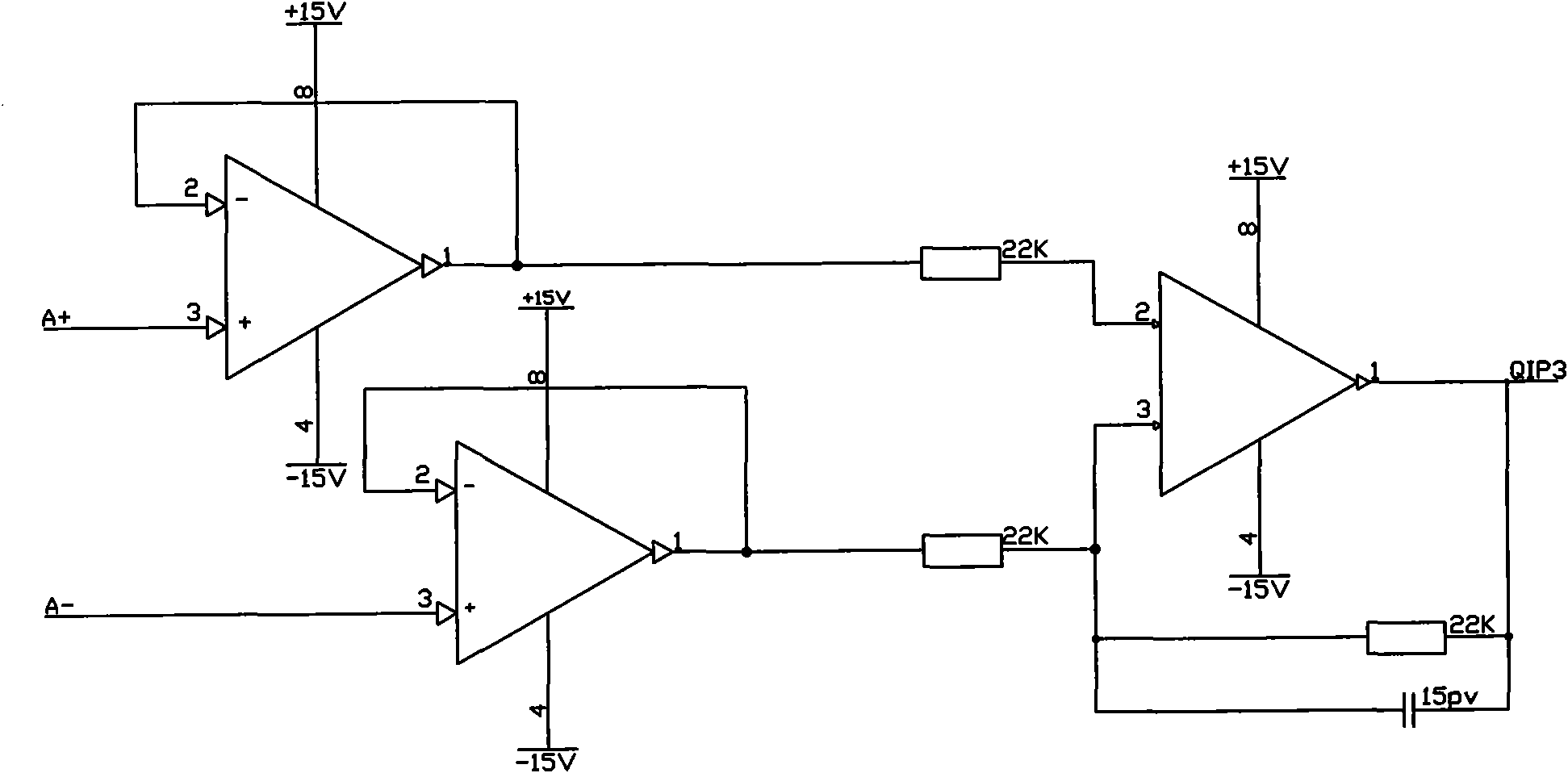

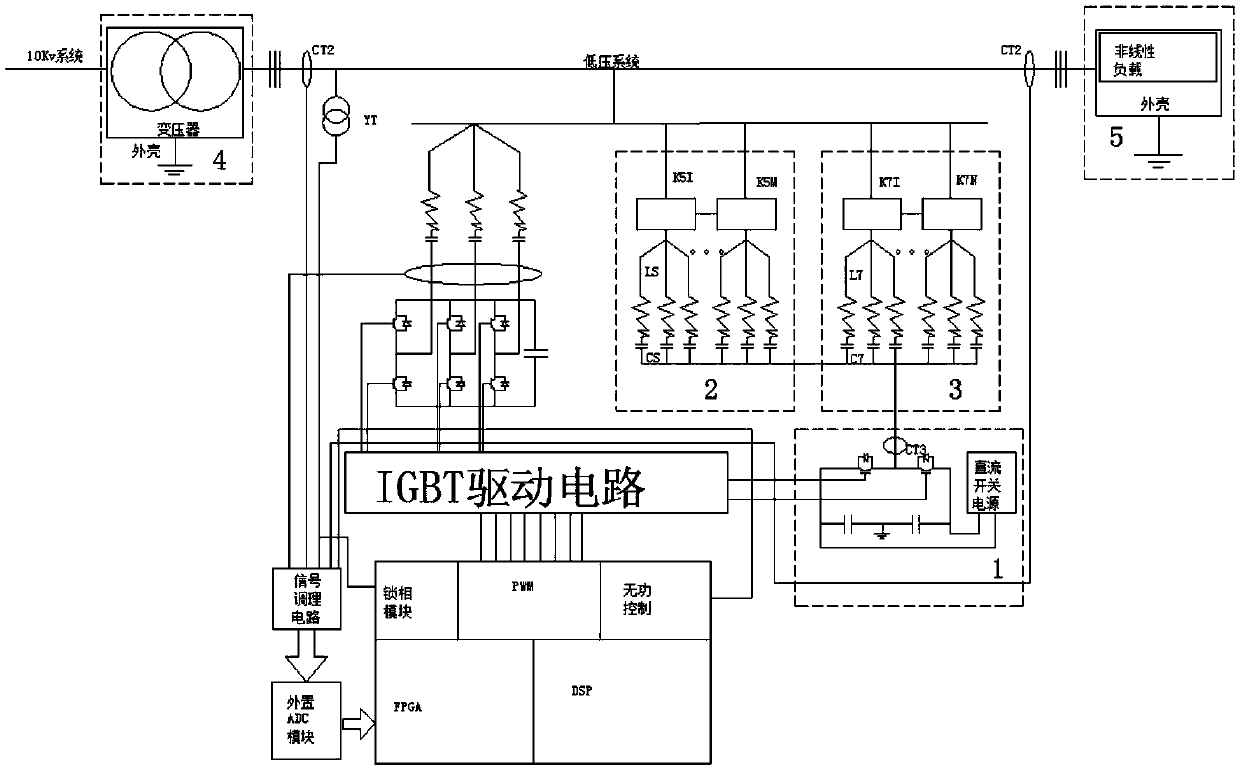

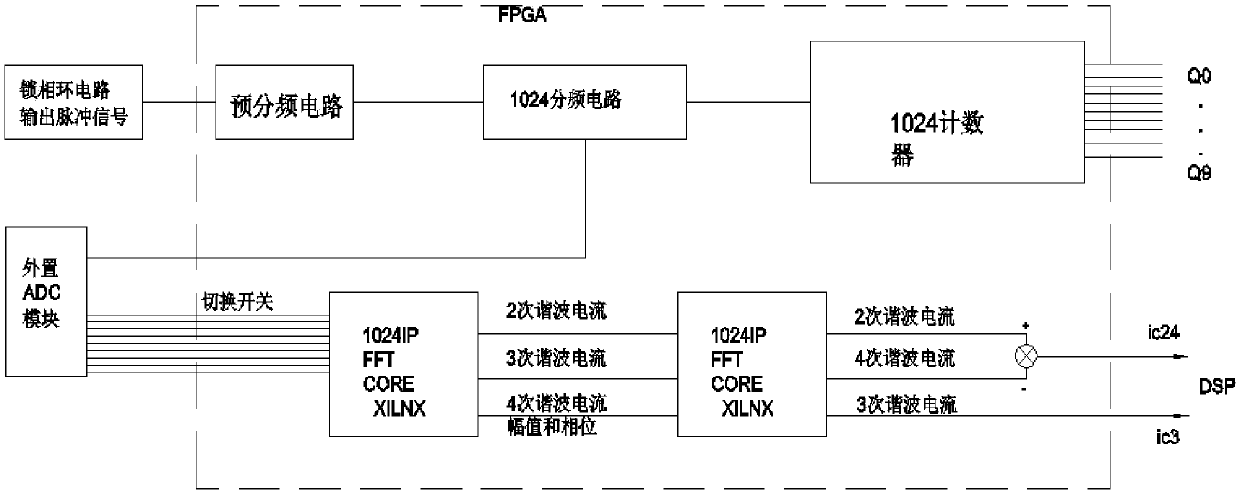

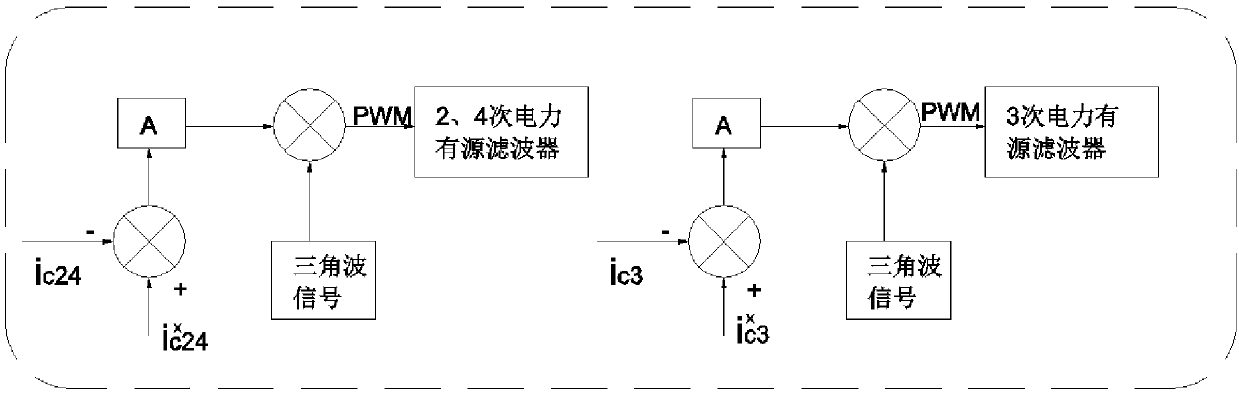

FFT-based hybrid reactive power compensation and harmonic suppression device

PendingCN108418219AEffective controlEffective filteringActive power filteringReactive power adjustment/elimination/compensationHybrid typeControl signal

The invention discloses an FFT-based hybrid reactive power compensation and harmonic suppression device, which comprises a passive filter, a hybrid power active filter for filtering 2nd and 4th harmonics, an IGBT driving circuit, a signal conditioning circuit and a DSP control circuit. The passive filter is composed of 5th, 7th and 11th single-tuned passive filters in star connection. The hybrid power active filter comprises a passive part and an active part in cascaded connection. The passive part is composed of a single-tuned passive filter tuned at 7.1th fundamental frequency. The active part uses a three-phase full-bridge IGBT inverter structure. The FFT-based hybrid reactive power compensation and harmonic suppression device extracts a signal of the 2nd and 4th harmonic currents fromnonlinear load as a control signal of the power active filter, thereby realizing effective control of the active power filter and effectively filtering out 2nd and 4th Harmonic current.

Owner:FUZHOU POWER SUPPLY COMPANY OF STATE GRID FUJIAN ELECTRIC POWER +2

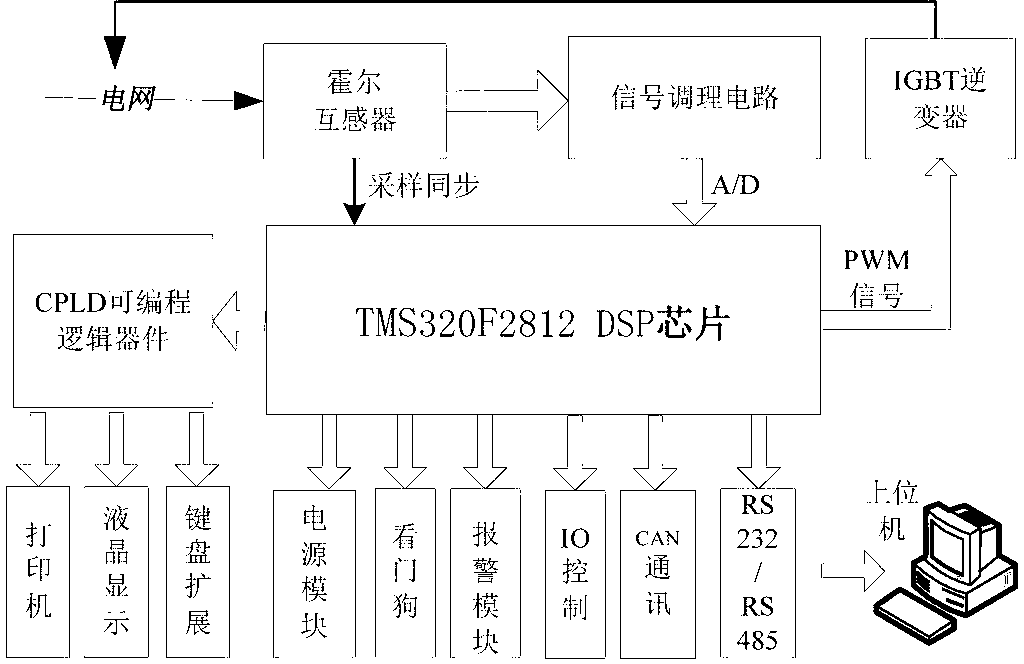

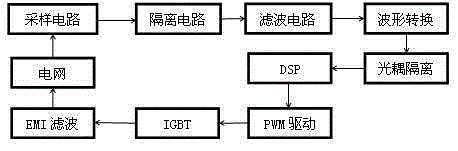

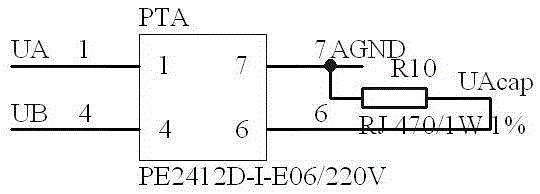

Islanding detection circuit and detection control method for microgrid power generation system

ActiveCN105406511AQuick checkQuick controlElectrical testingContigency dealing ac circuit arrangementsIslandingMicrogrid

The invention relates to an islanding detection circuit and detection control method for a microgrid power generation system. The detection circuit comprises a sampling circuit for sampling from a main power grid; the sampling circuit enables the sampling signal to pass through an isolating circuit, a filter circuit, a waveform conversion circuit and a photocoupling isolating circuit and then inputs the sampling signal to a DSP processor; after the sampling signal is processed by the DSP processor, a PWM signal is sent out from a PWM driver to drive an IGBT inverter; and the microgrid power generation equipment passes through the IGBT inverter, the filter circuit and a circuit breaker and then is connected to the main power grid. The invention relates to the islanding detection circuit and detection control method for the microgrid power generation system, and the islanding state can be detected in time and can be controlled.

Owner:JIANGSU FANGCHENG ELECTRIC SCI & TECHCO +1

Variable frequency speed regulation safety control device for mining industry

InactiveCN102480266AWith dustproofEasy to prevent dustAC motor controlEmergency protective circuit arrangementsFrequency changerSafety control

The invention relates to a variable frequency speed regulation safety control device for mining industry. The device comprises a frequency converter, a control device and an explosion-proof box, wherein the frequency converter consists of a three-phase rectifier, a filter capacitor and an IGBT (Insulated Gate Bipolar Transistor) inverter; and the control device comprises an isolating switch, a power frequency and secondary control loop and a frequency conversion and control loop. The device has two working modes, namely a variable frequency working mode and a power frequency working mode; priority is given to the variable frequency working mode which is supplemented by the power frequency working mode; better speed regulation and energy conservation can be realized; the device has the advantages of dust proofing, moisture proofing, explosion proofing and the like; digital display is adopted by the variable frequency speed regulation device; and the device has remote and near control functions, has electric energy display, namely clearly display electric energy of the load, and has a temperature control function and protection functions of overload protection, open phase protection, over-voltage protection, under-voltage protection and the like. The device can be used for occasions with coal dust or gas coal dust explosion in coal mines, is used for controlling start, stop, variable frequency speed regulation and the like of a three-phase explosion-proof motor and can be used for performing various protections on the motor.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

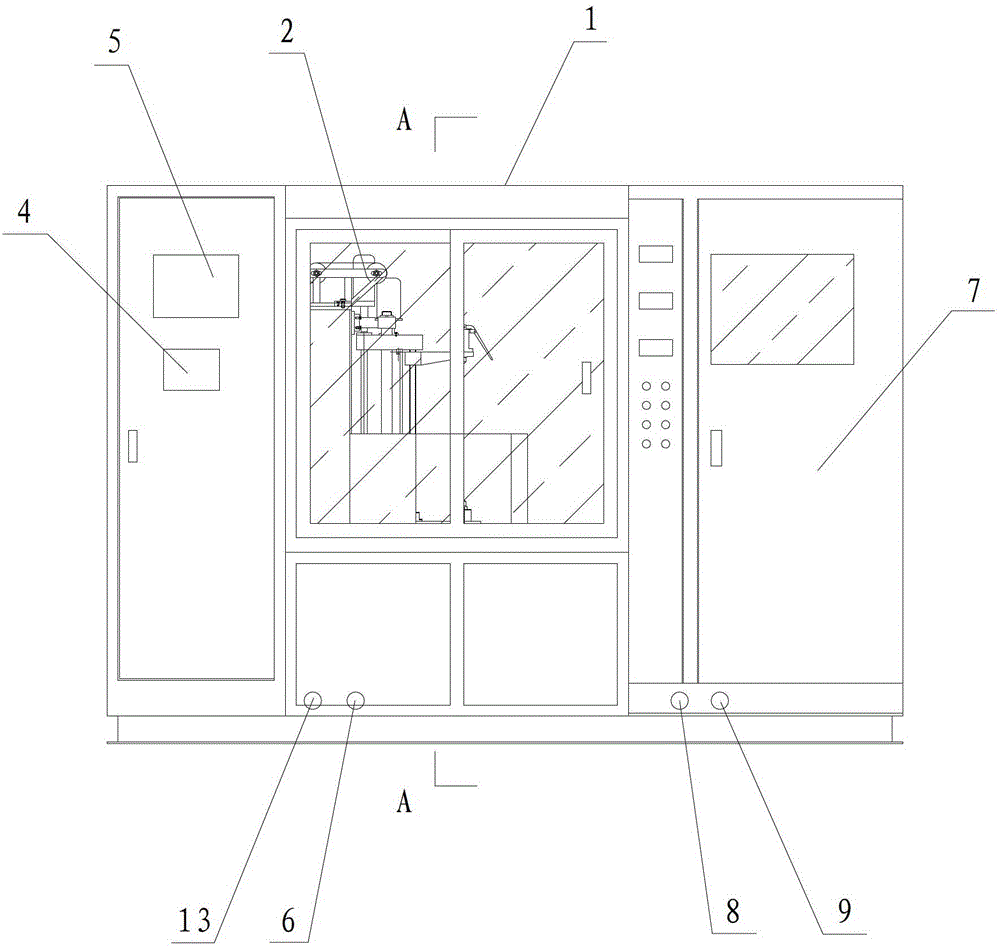

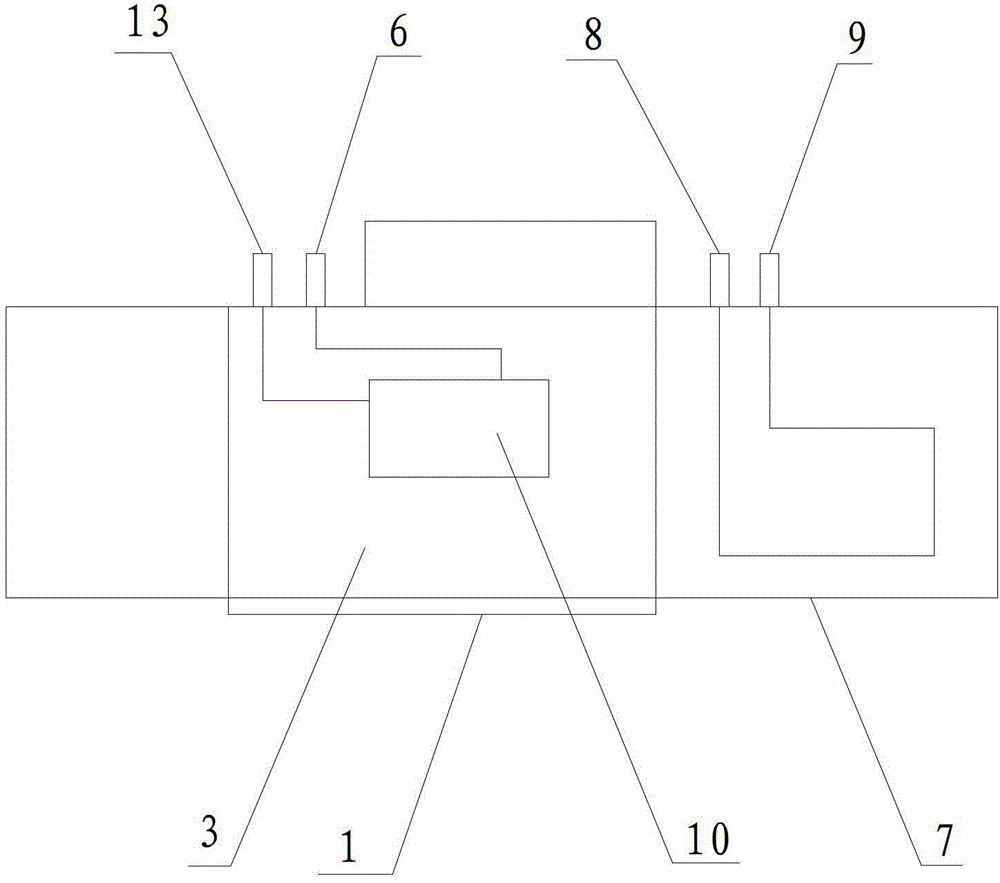

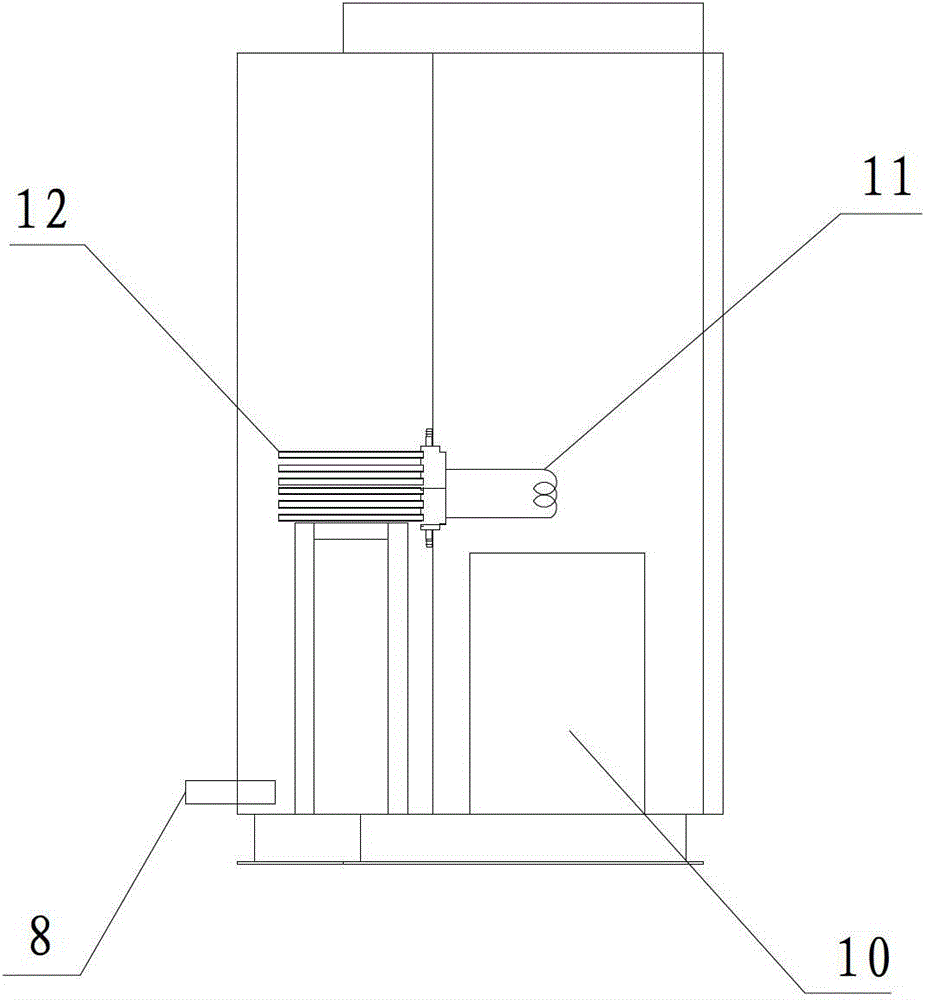

High-frequency induction heat-treatment system with IGBT (Insulated Gate Bipolar Translator)

InactiveCN103146897AReduce lossHigh electrothermal efficiencyIncreasing energy efficiencyOvervoltageSoft switching

The invention relates to a high-frequency induction heat-treatment system with an IGBT (Insulated Gate Bipolar Translator). The high-frequency induction heat-treatment system comprises an engine body, wherein a mechanical transmission system and a cooling water circulating system are arranged in the engine body, a working condition management system is arranged on the left side of the engine body, a touch screen control system is arranged on the working condition management system, a workpiece cooling liquid inlet and a workpiece cooling liquid outlet are arranged at the bottom of the working condition management system, an IGBT induction heating power supply is arranged on the right side of the engine body, and a power supply cooling liquid inlet and a power supply cooling liquid outlet are arranged at the bottom of the IGBT induction heating power supply. The high-frequency induction heat-treatment system has the beneficial effects that effects of high efficiency and energy saving are achieved, an IGBT power device is used as a power supply device, the switching loss of the IGBT is greatly reduced due to the adoption of a zero-passage soft switching IGBT inverter technology, the electrothermal efficiency is high, the frequency range is wide, the process adjustment is simple, the protective system is complete, multiple reliable protection functions such as overvoltage, overcurrent and overheating are arranged for monitoring the machining process, and the high-frequency induction heat-treatment system is safe to use and convenient to maintain.

Owner:WUXI ELECTRIC FURNACE CO LTD

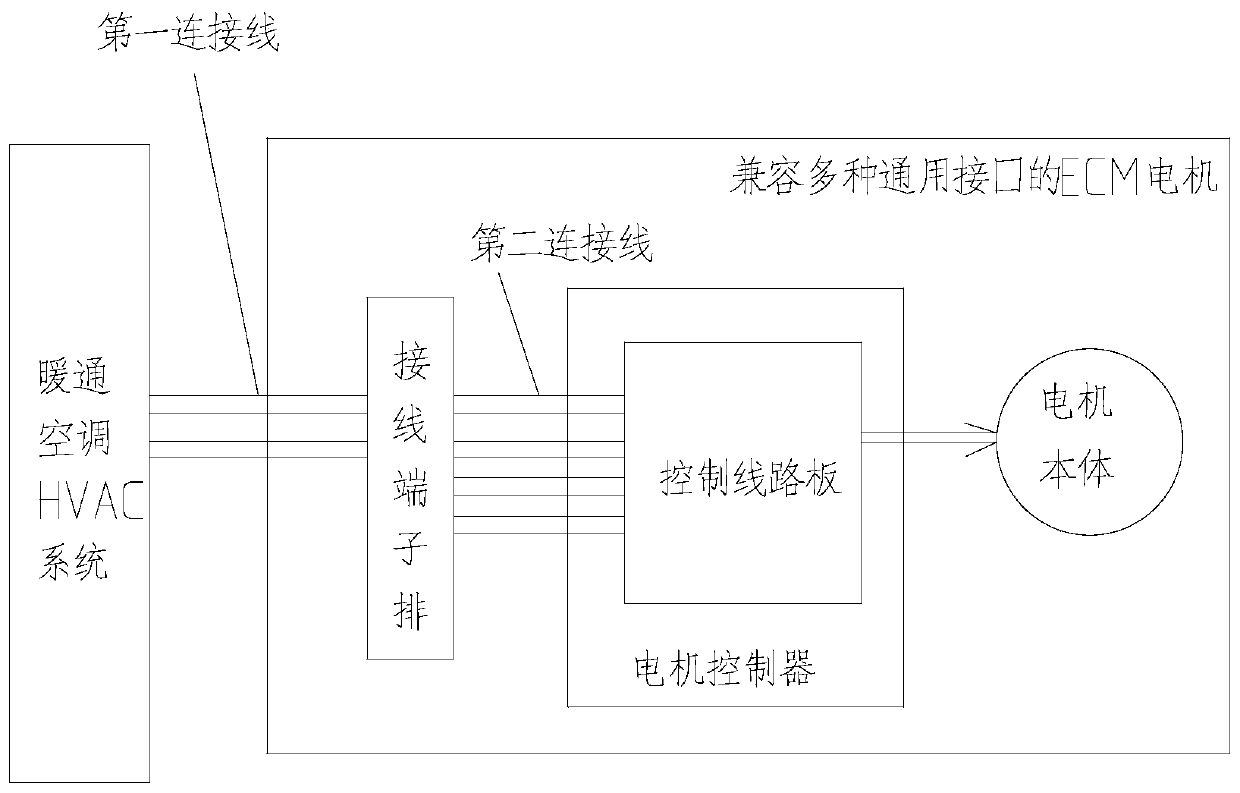

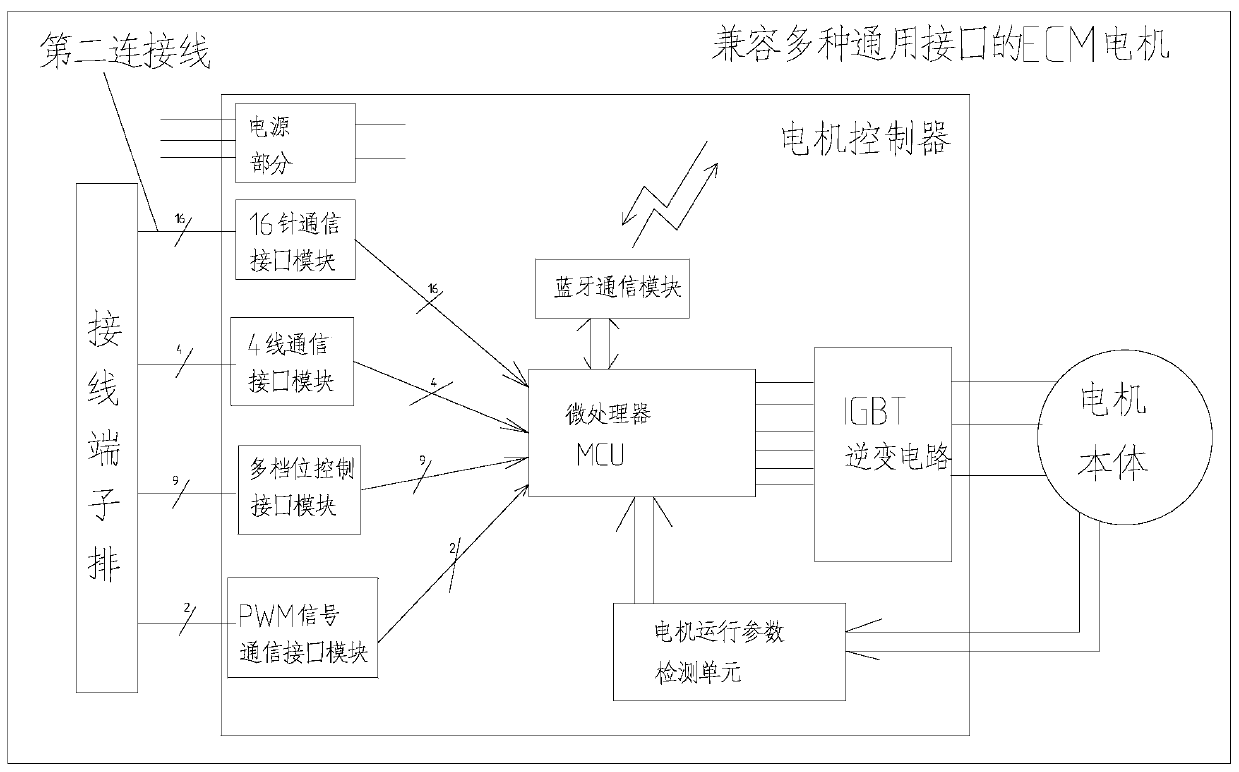

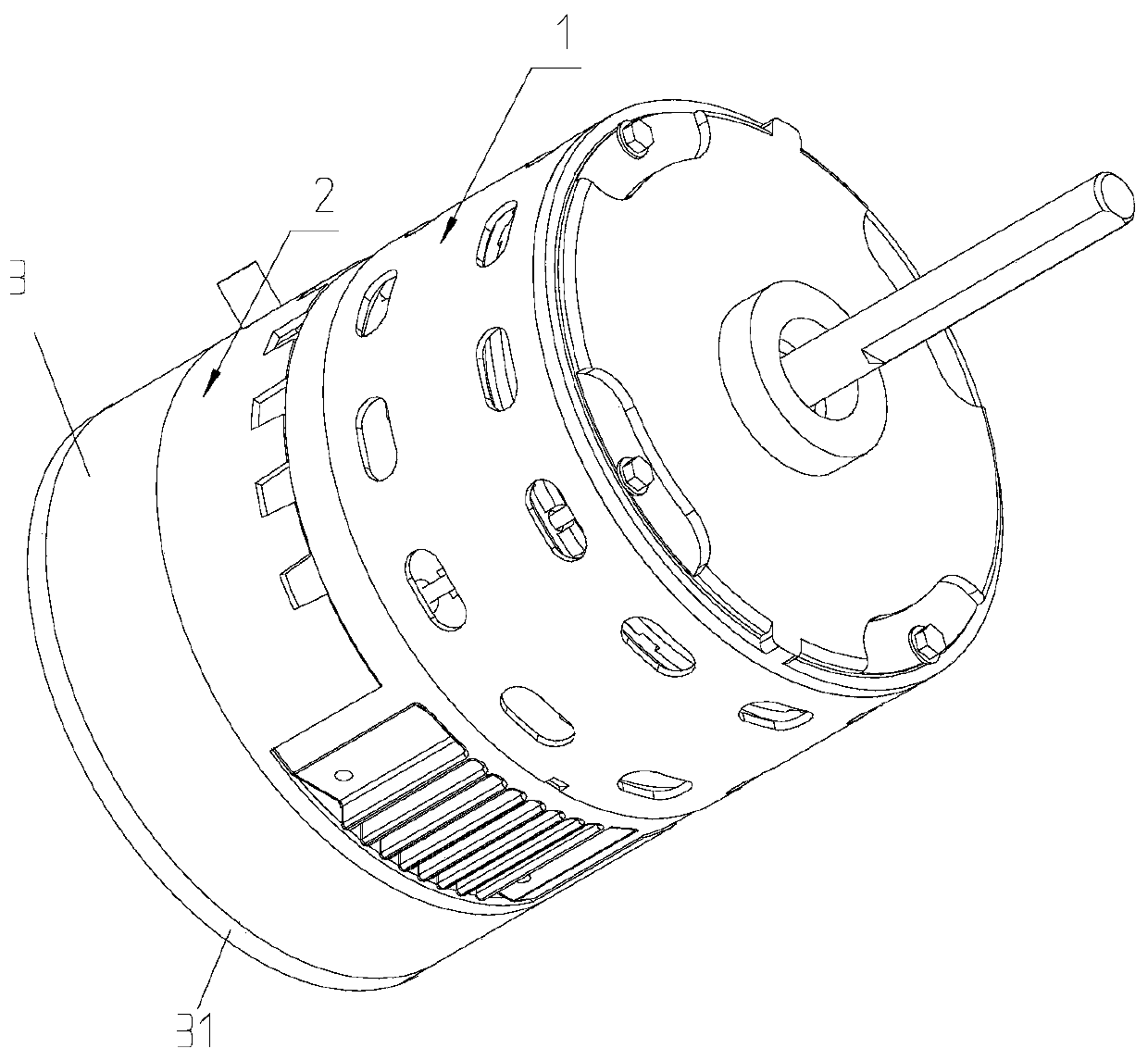

ECM motor compatible with multiple universal interfaces, heating, ventilation and air conditioning HVAC system and signal conversion method

PendingCN111431352ASimple structureEasy to useAssociation with control/drive circuitsMechanical apparatusCommunication interfaceControl engineering

The invention discloses an ECM motor compatible with multiple universal interfaces, a heating, ventilation and air conditioning HVAC system and a signal conversion method. The ECM motor comprises a motor body and a motor controller. Motor controller comprises a control circuit board, the control circuit board comprises a power supply part, a microprocessor, an IGBT inverter circuit and a pluralityof universal interface modules. The various universal interface modules refer to at least two of a multi-pin communication interface module, a multi-wire communication interface module, a multi-gearcontrol interface module or a PWM signal communication interface module. According to the interface signal condition of the connected heating ventilation air conditioner HVAC system, one universal interface module can be selected from the multiple universal interface modules so as to establish a communication mode connection between the microprocessor and the heating ventilation air conditioner HVAC system. Connection between a heating ventilation air conditioner HVAC system control main board and a motor can be well coordinated; compatibility is improved; and great convenience is brought to maintenance of the after-sales market.

Owner:ZHONGSHAN BROAD OCEAN

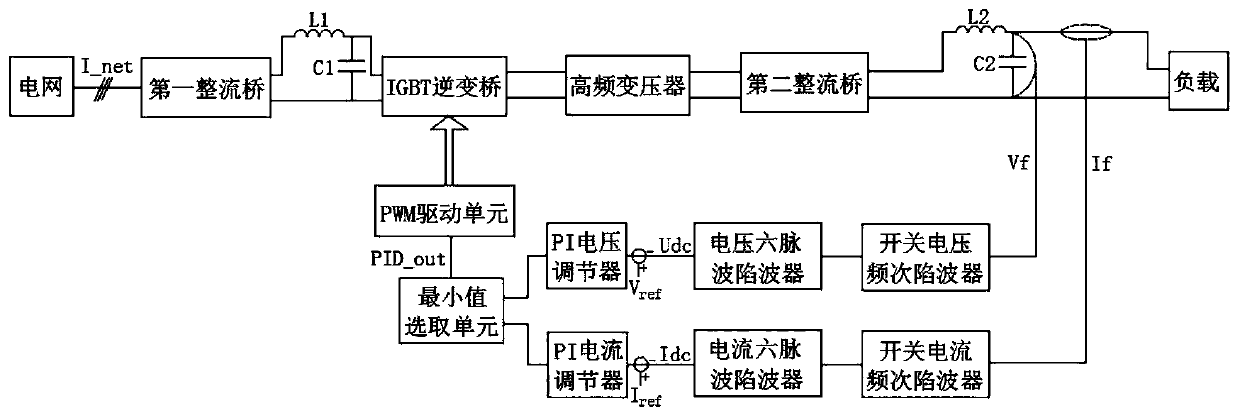

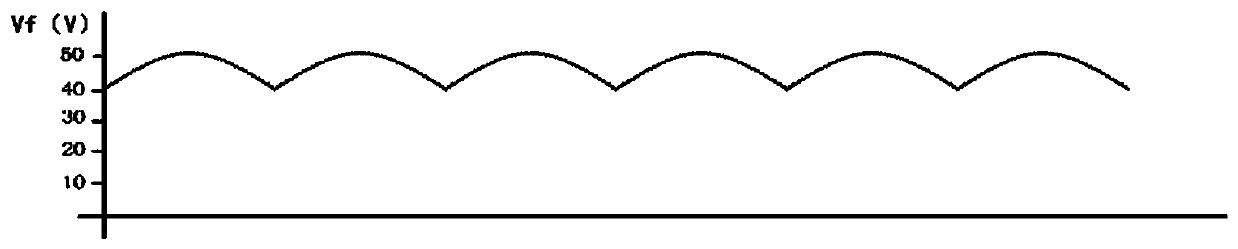

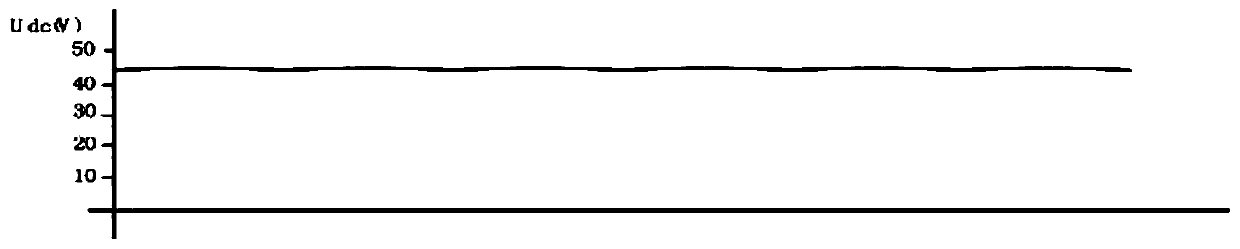

DC power supply unit control detection system and method

InactiveCN110798084AWork lessDoes not affect normal workAc-dc conversionDc-dc conversionPower gridSwitching frequency

The invention relates to a DC power supply unit control detection system and method. The DC power supply unit control detection system is connected with a DC power supply unit. The input end of the DCpower supply unit is connected with a power grid, and the output end is connected with a load. The system comprises a switching frequency trap filter, a six-pulse trap filter, a PI regulator, a minimum value selection unit and a PWM driving unit which are connected in sequence. The DC power supply unit comprises an IGBT inverter bridge. The input end of the switching frequency trap filter is connected with the bus output end of the DC power supply unit. The output end of the PWM driving unit is connected with the IGBT inverter bridge. High-frequency switching ripples and six-pulse ripples arefiltered through the trap filters, and quick response of feedback signals at the bus output end of the DC power supply unit cannot be affected. When the power grid suddenly changes or the load suddenly changes, the PWM duty ratio of the IGBT inverter bridge can be rapidly adjusted and controlled, so that the output of the DC power supply unit is rapidly reduced, shutdown faults such as over-current and overload cannot be caused, and loss and inconvenience brought to the load of a user side are avoided.

Owner:SICHUAN INJET ELECTRIC CO LTD

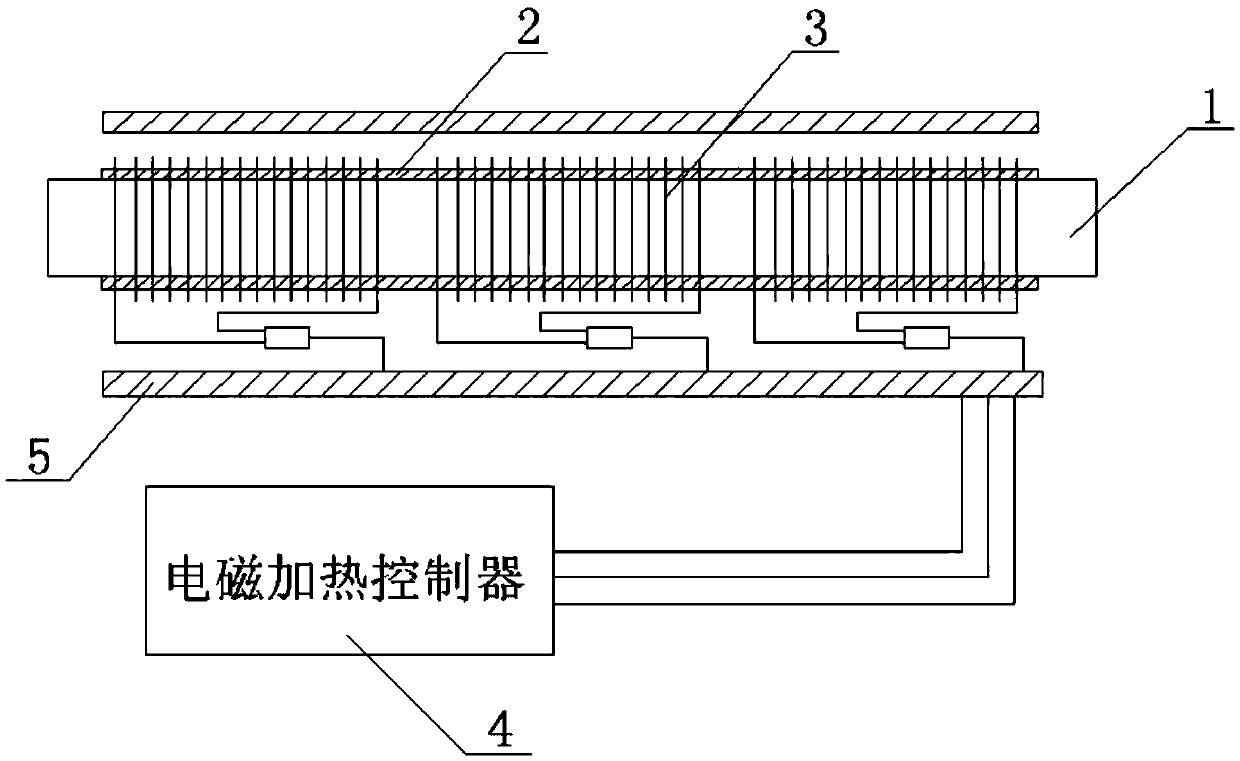

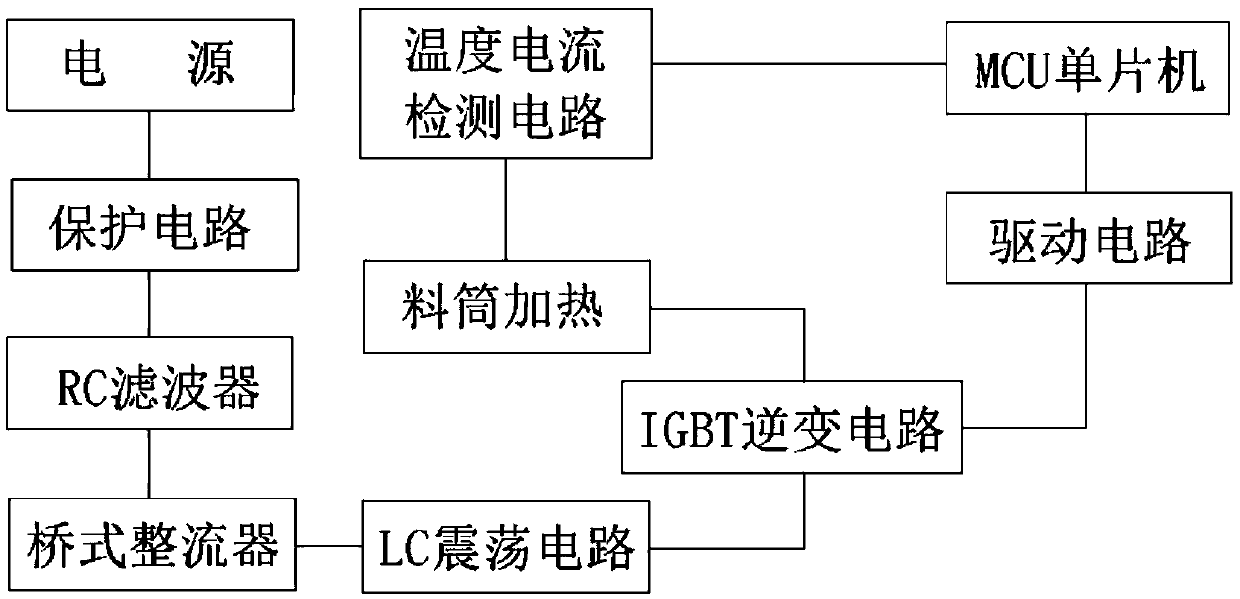

Electromagnetic induction heating system for injection molding machine

InactiveCN105365175AReduce pollutionFast heatingOhmic-resistance heatingInduction heating controlThermal insulationClosed loop

The invention discloses an electromagnetic induction heating system for an injection molding machine. The electromagnetic induction heating system comprises an electromagnetic heating barrel and an electromagnetic heating controller; the electromagnetic heating barrel comprises a charging barrel in the innermost layer, thermal-insulation cotton in the middle layer and winding electromagnetic induction coils in the outmost layer; and the electromagnetic heating controller comprises an RC filter, a bridge rectifier, an LC oscillating circuit and an IGBT inverter circuit, and the IGBT inverter circuit is connected with a plurality of electromagnetic induction coils which are in parallel connection. Due to the fact that the electromagnetic heating controller is connected with the electromagnetic induction coils of the electromagnetic heating barrel, quick heating and closed-loop control on heating temperature are achieved. The electromagnetic induction heating system for the injection molding machine has the advantages of being short in preheating time, high in heating speed, high in electric heating converting rate, small in environment pollution and simple to replace and maintain. In addition, the heating temperature is easy to control, energy conservation and environment friendliness are achieved.

Owner:ANHUI QINGLONGQUAN PRINTING TECH CO LTD

IGBT inverter welding machine with no-load voltages and various protection and control functions

InactiveCN106975821AProtection Circuit StructureProtection Design StructureArc welding apparatusFull bridgeShort circuit protection

The invention relates to an IGBT inverter welding machine with no-load voltages and various protection and control functions. The welding machine is welding equipment of a three-phase power supply source. The IGBT single-transistor full bridge inversion and a corresponding control technology thereof are adopted, and thus IGBT single-transistor inversion manual arc welding or manual welding / argon arc welding operation requirements can be met. Compared with other welding machine products on the market, a welding machine circuit disclosed by the invention has the control functions like no-load voltage control, VRD function, short-circuit protection, open-phase protection, three-way overheating protection, high-tension current suppression and the like; regulation and output of welding currents, arc striking currents and thrust currents, microprocessor digital display and state LED indication can be realized; and the IGBT inverter welding machine has the advantages of being good in performance, low in cost, capable of taking various protection measures, high in reliability and the like.

Owner:朱宣辉

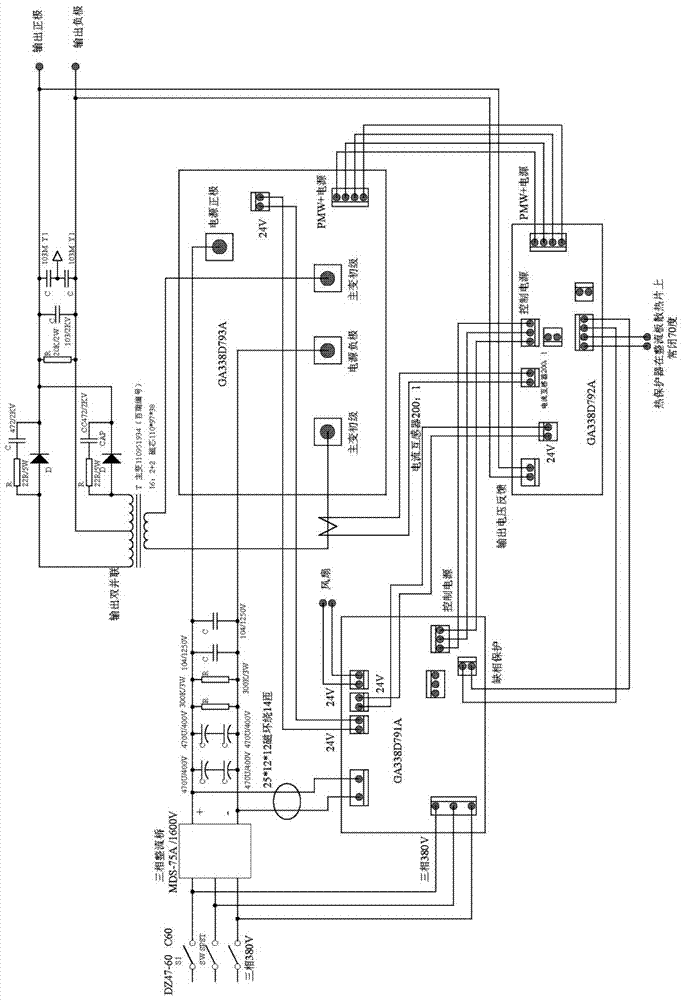

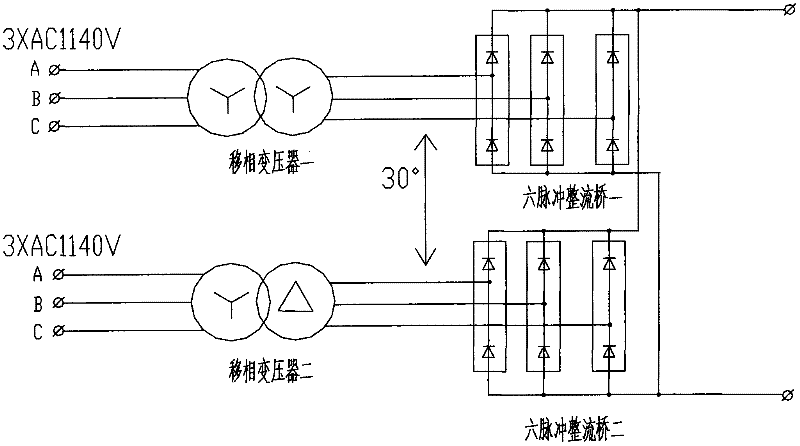

1000KW/1140V mining explosion-proof twelve-pulse power supply frequency conversion device

InactiveCN102403915AReduce the impactPurify the environmentAc-dc conversion without reversalAc-ac conversionCapacitancePhase difference

The invention relates to a 1000KW / 1140V mining explosion-proof twelve-pulse power supply frequency conversion device comprising a filter unit, a rectifier unit, an inverter unit and an auxiliary circuit. The filter unit comprises an input filter unit and an intermediate filter unit, wherein the input filter unit is a line reactor; and the intermediate filter unit is a capacitor filter unit. The rectifier unit is a six-pulse rectifier bridge. The inverter unit is an IGBT (insulated gate bipolar transistor) inverter module. Two groups of 1140V and 50Hz three-phase alternating-current supplies with phase difference of 30 degrees are respectively rectified to direct current by a path of circuit connected by the line reactor, an isolating switch, a vacuum contactor and the six-pulse rectifier bridge, and two paths of the direct current are connected in parallel and are inverted to the alternating current with adjustable frequency by the intermediate filter unit and the IGBT inverter module. A main circuit of the invention adopts an alternating-direct-alternating voltage source transducer structure and adopts a twelve-pulse rectifier mode, therefore, a smooth direct current voltage can be obtained, impact on a power grid by harmonic wave is greatly reduced, the power grid environment is purified, and the consumption of the reactive current is controlled at the same time.

Owner:华夏天信智能物联股份有限公司

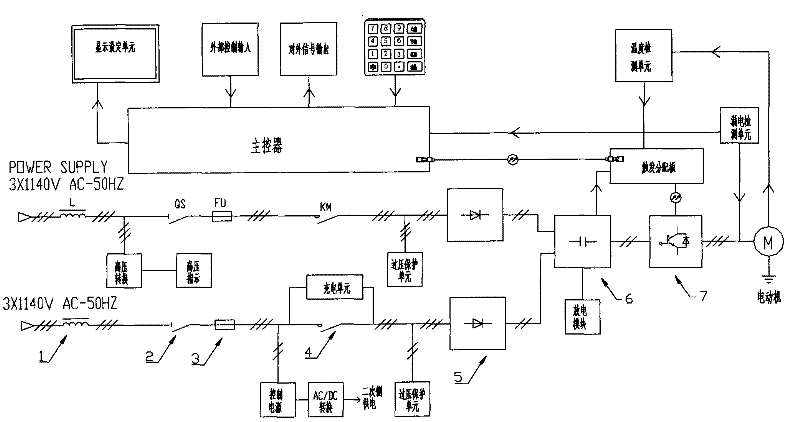

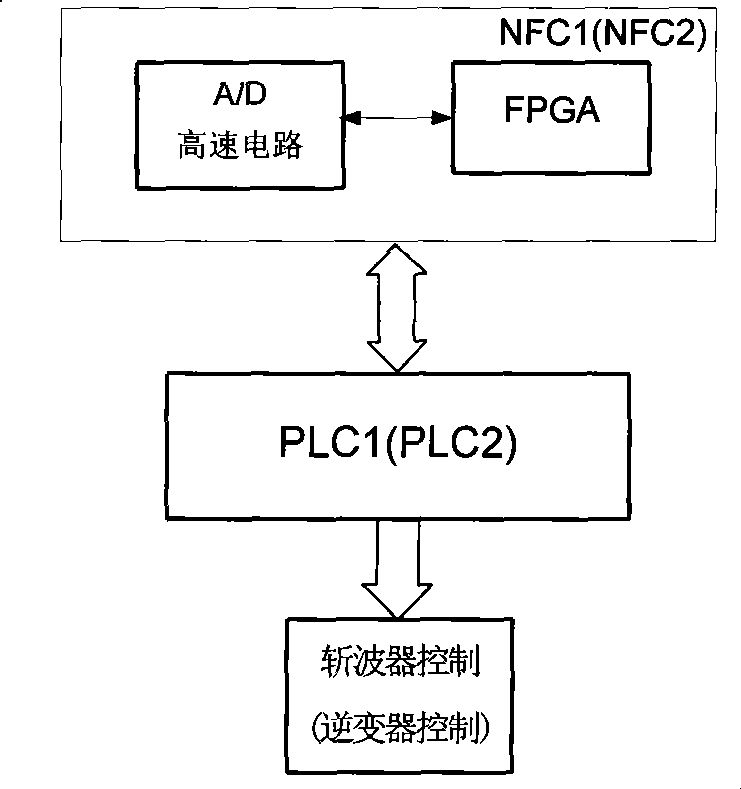

Chopping type bumpless switching bis-PLC intelligent speed-governing system of medium-pressure motor

InactiveCN101471623AConstant speedGood dynamic and static qualityAC motor controlComputer controlBrushless motorsHuman–machine interface

A dual PLC intelligent speed regulating system with chopping-type non-disturbance switching for medium-voltage motors includes an uncontrollable rectifier, a boost chopper, and an IGBT inverter. The boost chopper and the IGBT inverter are controlled via two inner-loop current controllers respectively, and two PLC control the outer-loop speed of the regulating system and the outer-loop voltage of the inverter respectively, as well as perform the program control to the speed regulating system and a motor system. The system suitable for ordinary winding asynchronous motors, internal feedback winding asynchronous motors, cage brushless doubly-fed motors and cage internal feedback brushless motors completely solves the problem of equipment damage caused by inversion stalling due to grid failures, and has incremental enhancement of various performance; the non-disturbance switching can be realized either from a full speed to a regulated speed or from the regulated speed to the full speed; and the motor even in the event of a regulating system failure can have continuous speed regulating operation. The system has the advantages of high system reliability, low control error, easy and convenient operation, good man-machine interface, and flexible method of communication. The remote supervision and management can be served, and the high degree of digitalization can be achieved with low cost, low energy consumption, and good environmental protection.

Owner:广东华拿东方能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com