Patents

Literature

159 results about "Permanent magnet synchronous machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

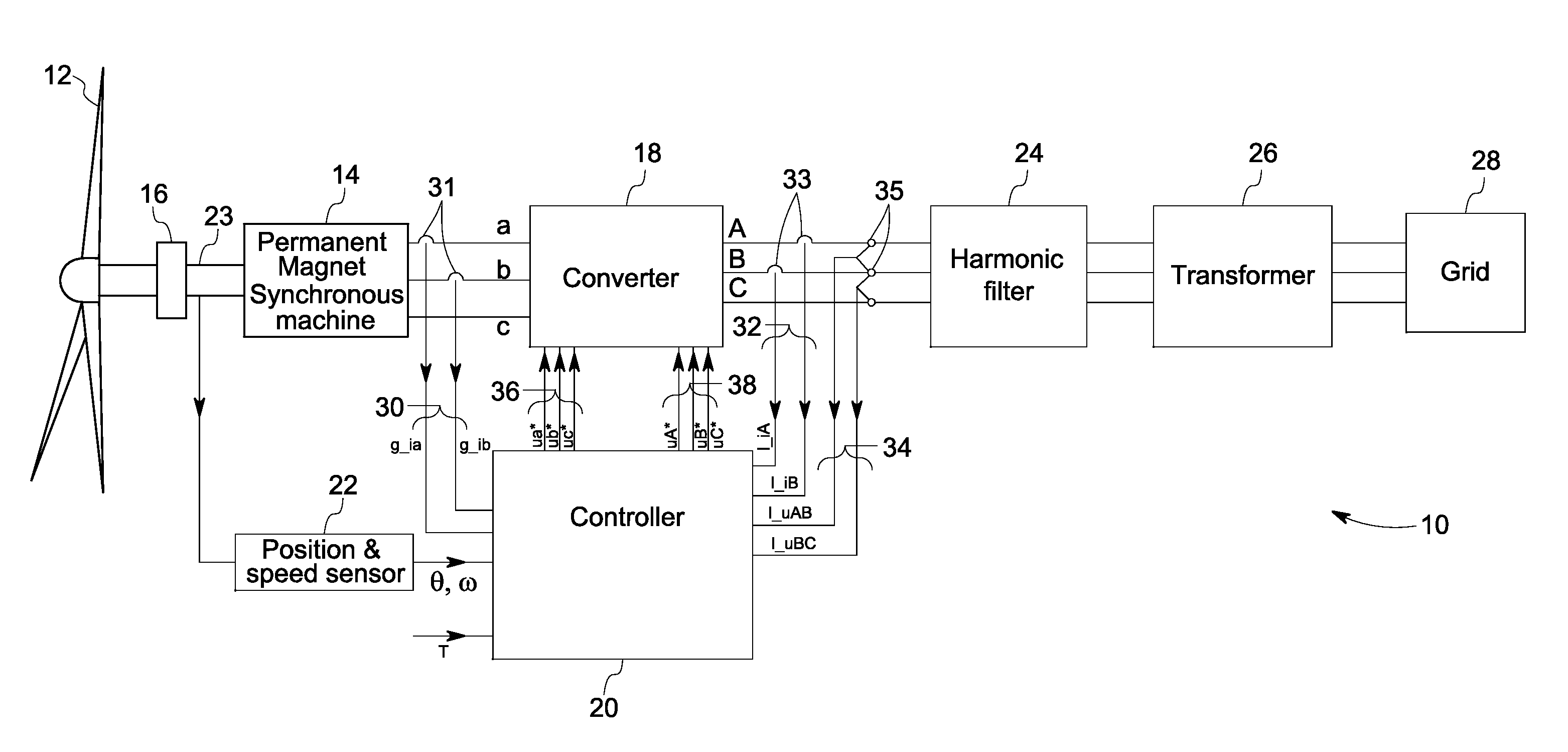

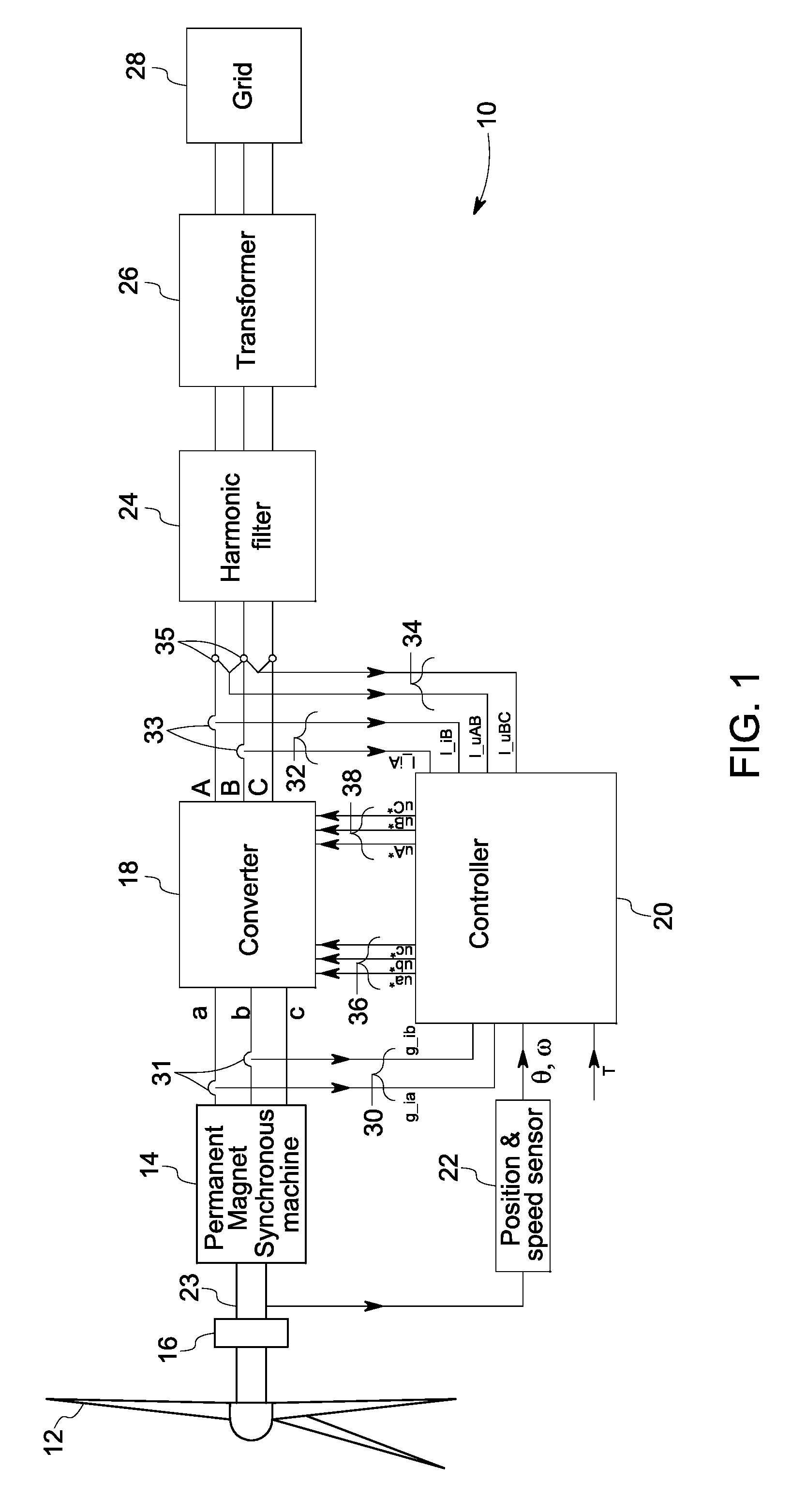

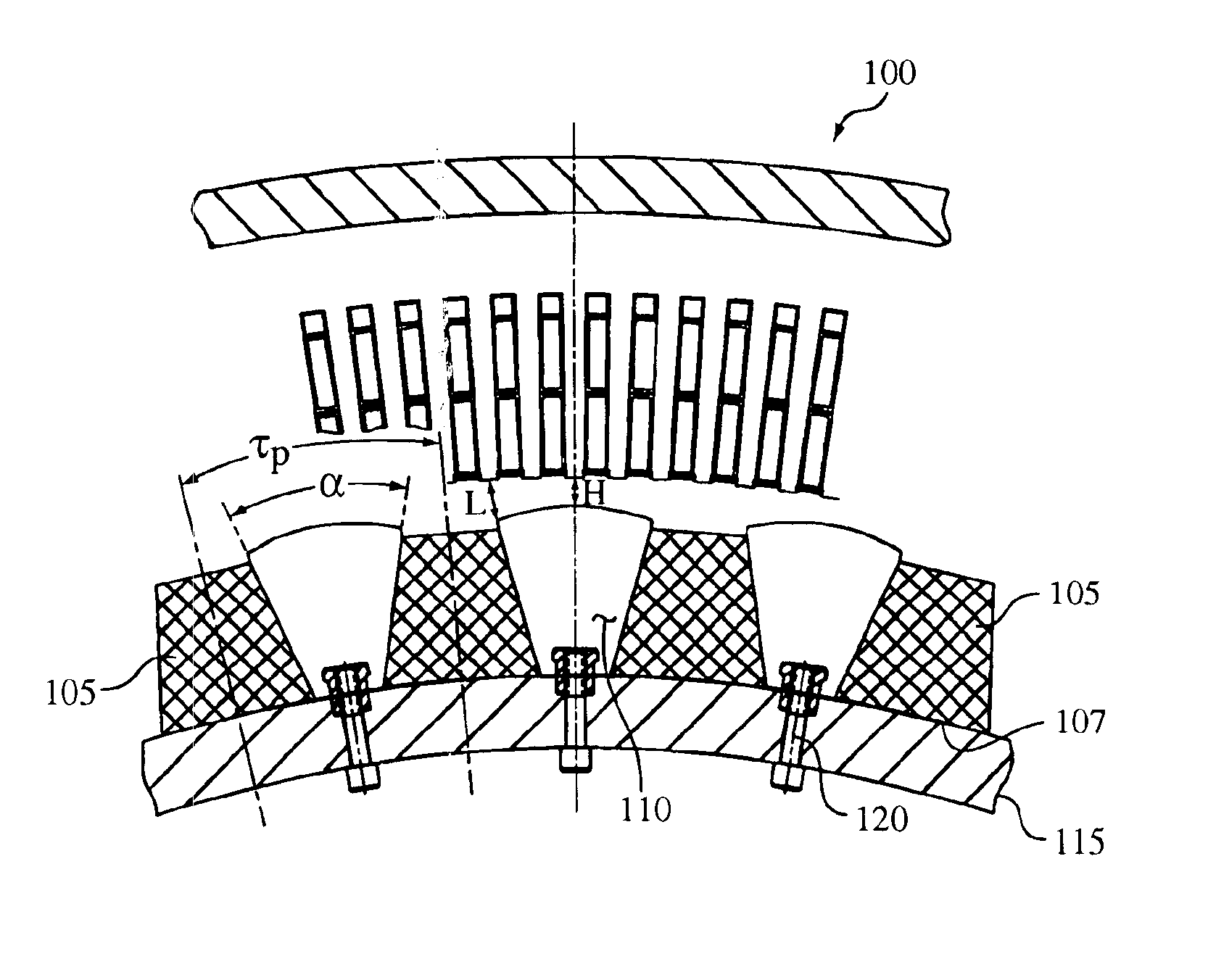

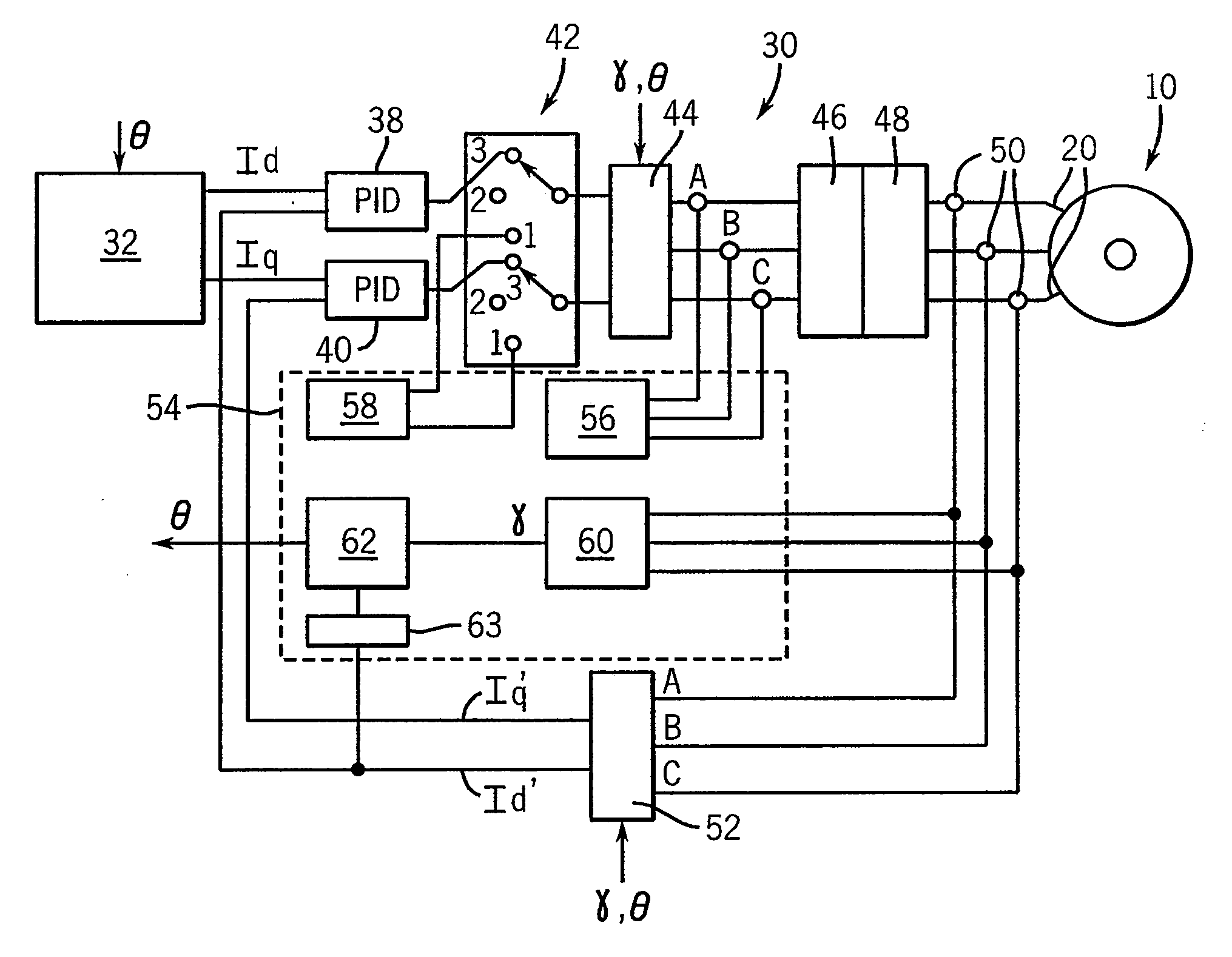

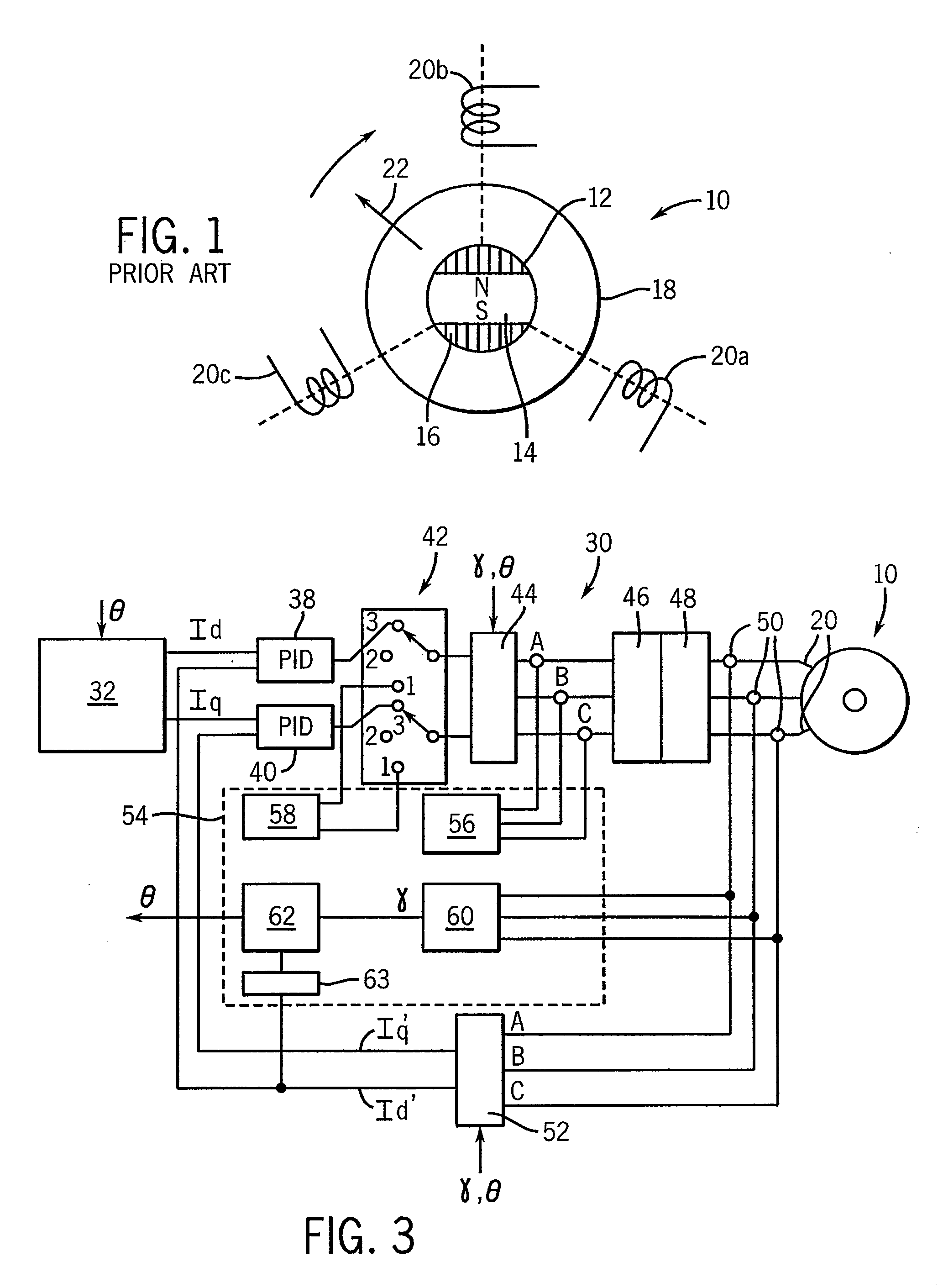

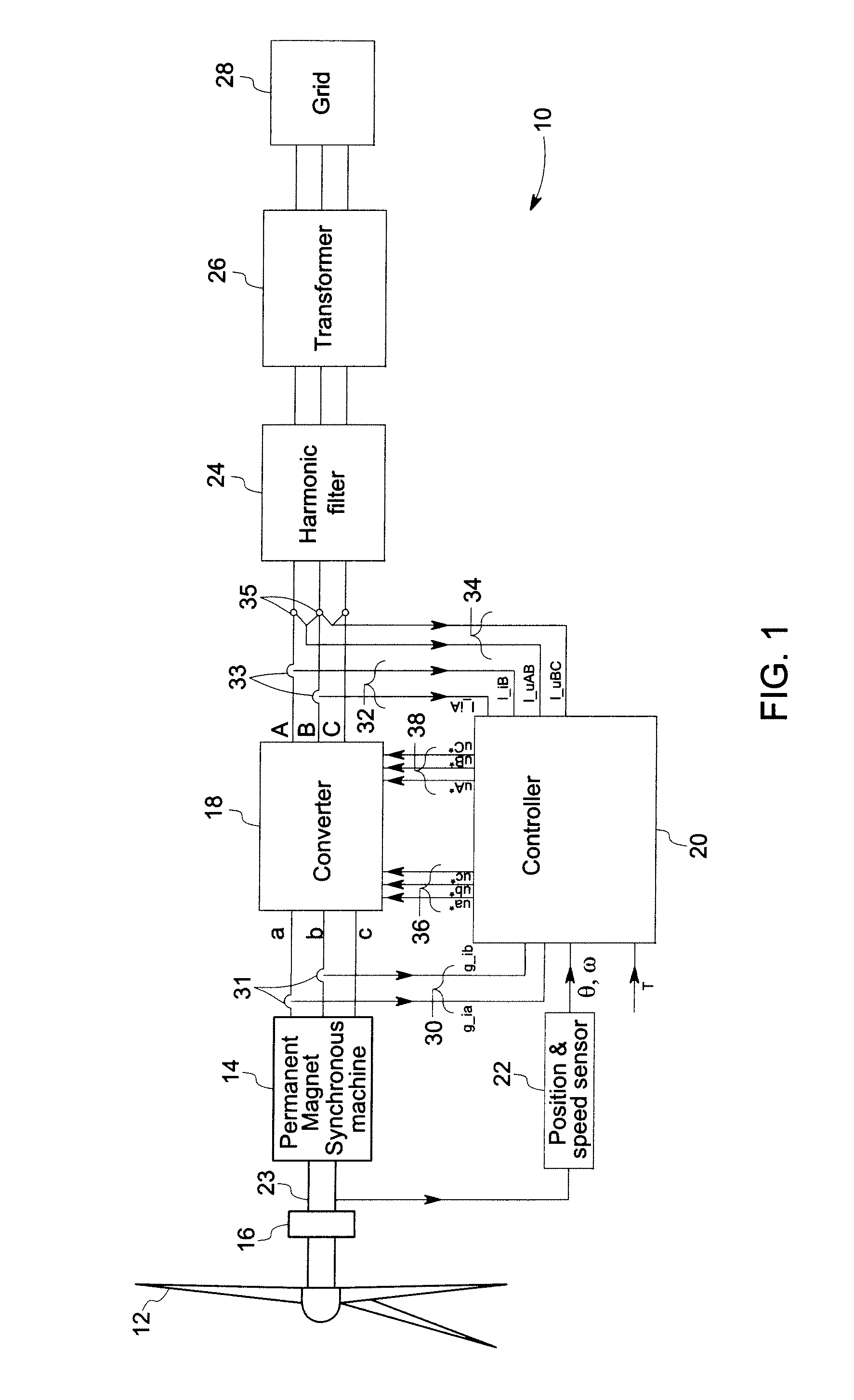

System and method for controlling torque ripples in synchronous machines

InactiveUS20090085354A1Torque ripple controlMotor/generator/converter stoppersPermanent magnet synchronous machineControl signal

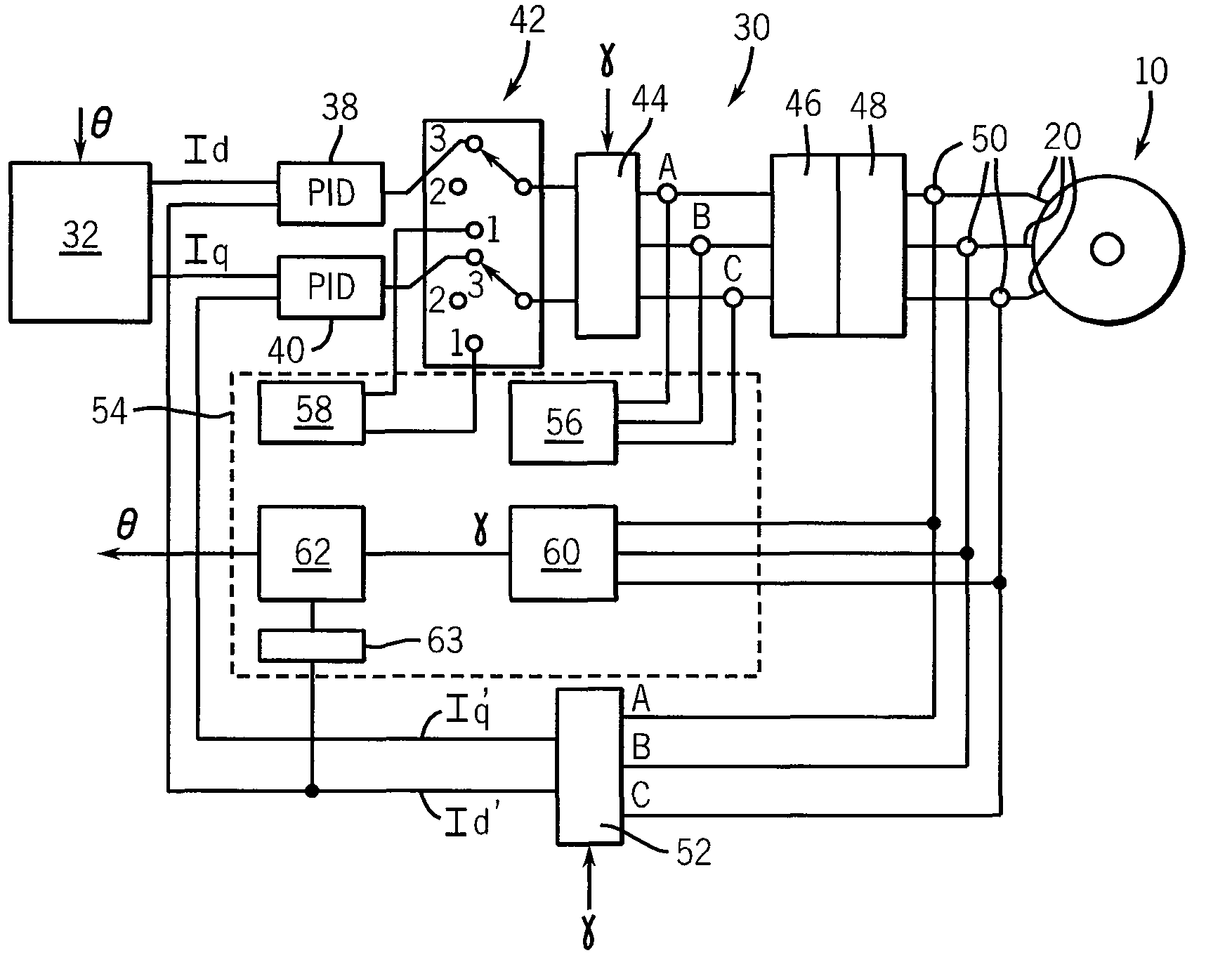

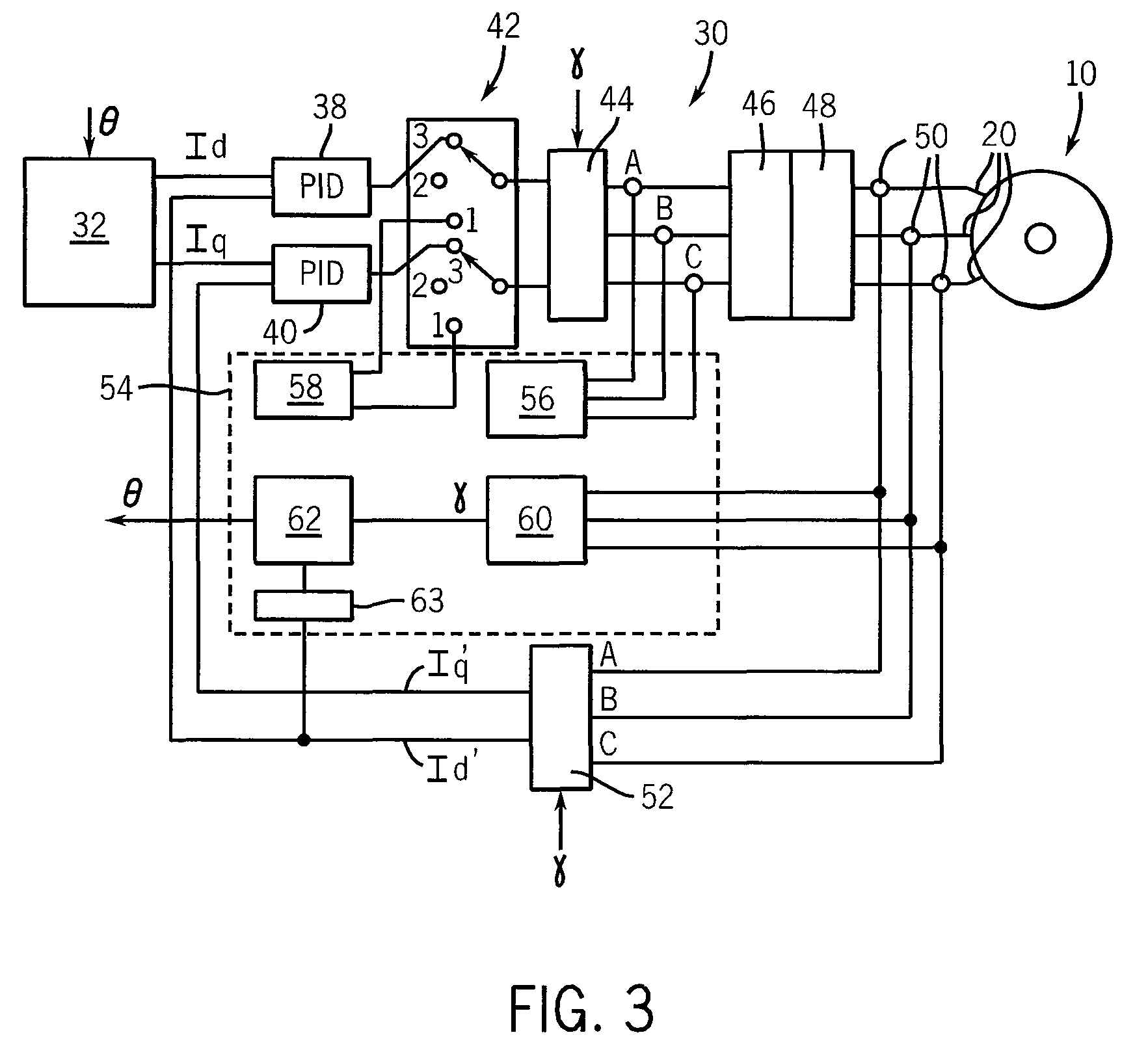

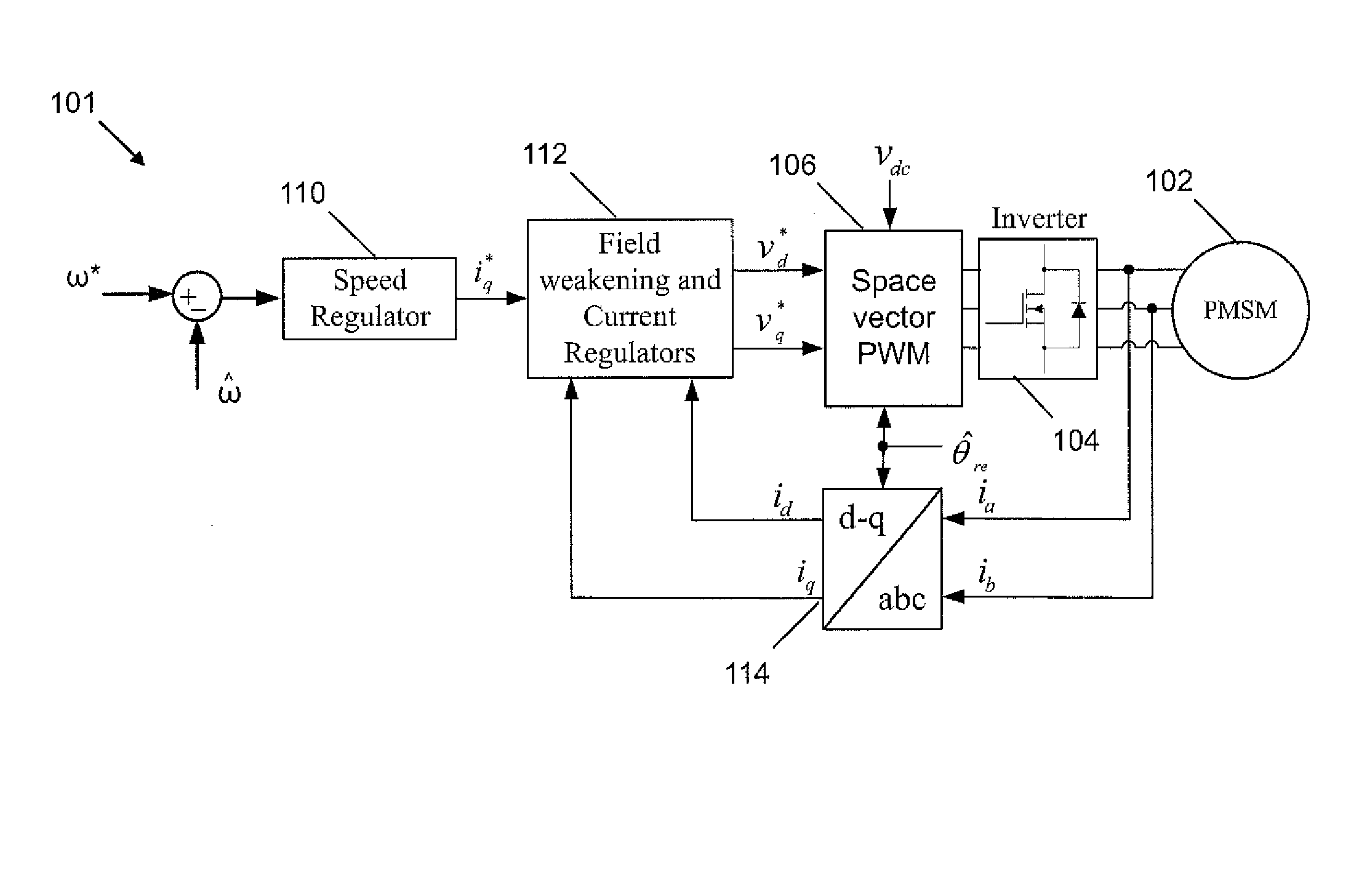

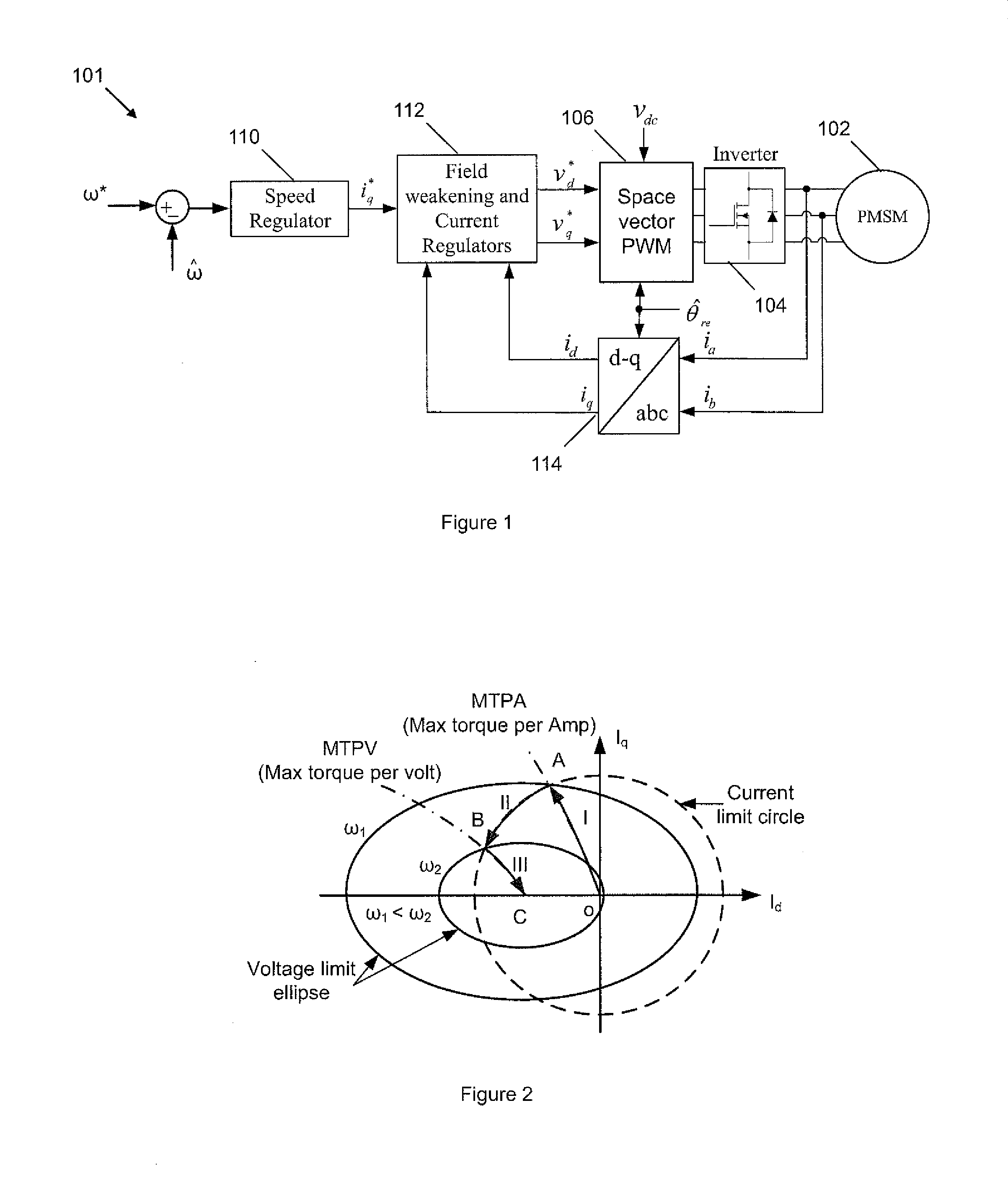

A system for controlling torque ripple in a permanent magnet synchronous machine includes a power converter configured to be coupled to the permanent magnet synchronous machine and to receive converter control signals and a system controller coupled to the power converter. The system controller includes a fundamental current controller configured for providing fundamental voltage commands, a harmonic current controller configured for using harmonic current commands, current feedback signals from the permanent magnet machine, and fundamental current commands in combination with positive and negative sequence regulators to obtain harmonic voltage commands, and summation elements configured for adding the fundamental voltage commands and the harmonic voltage commands to obtain the converter control signals.

Owner:GENERAL ELECTRIC CO

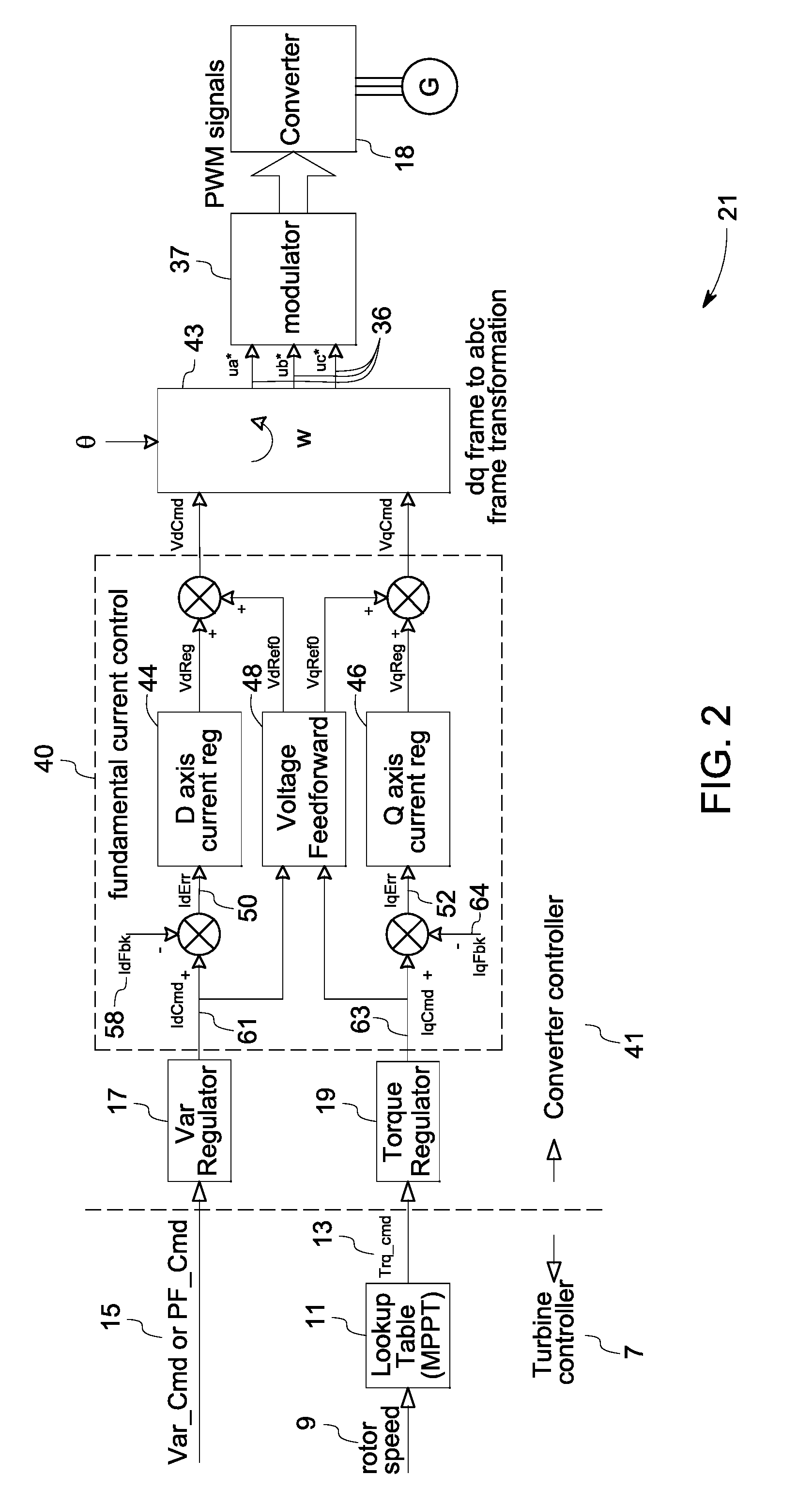

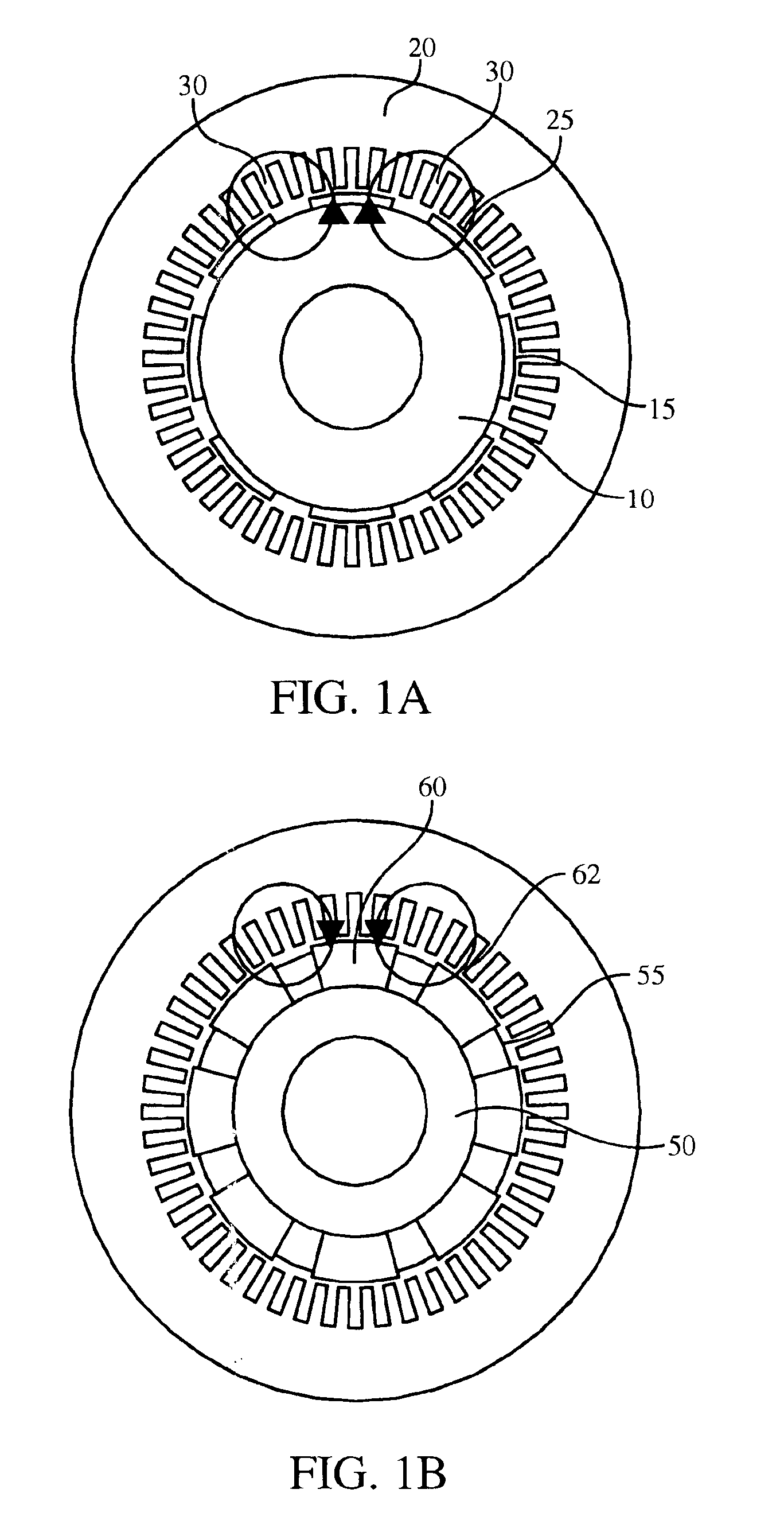

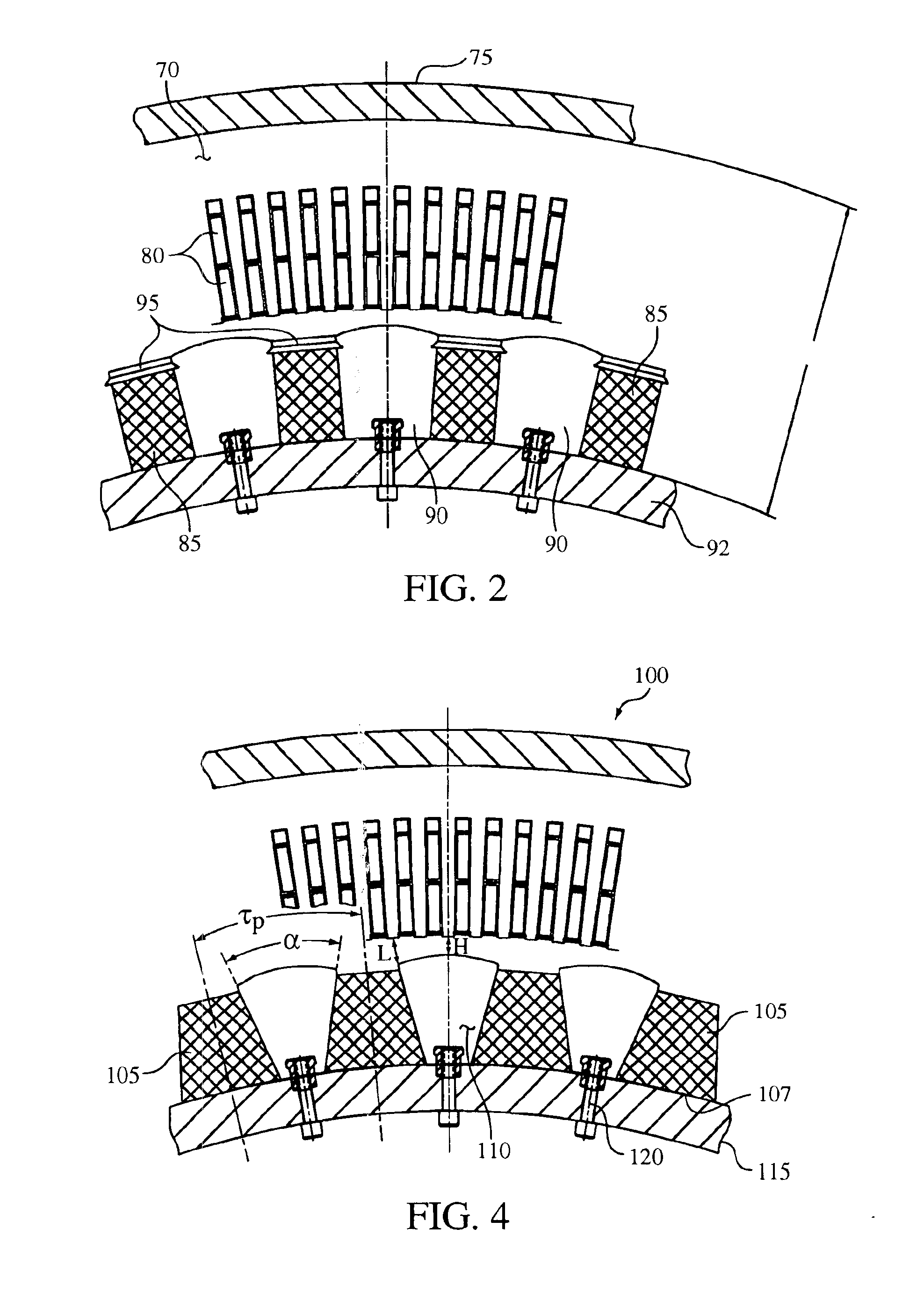

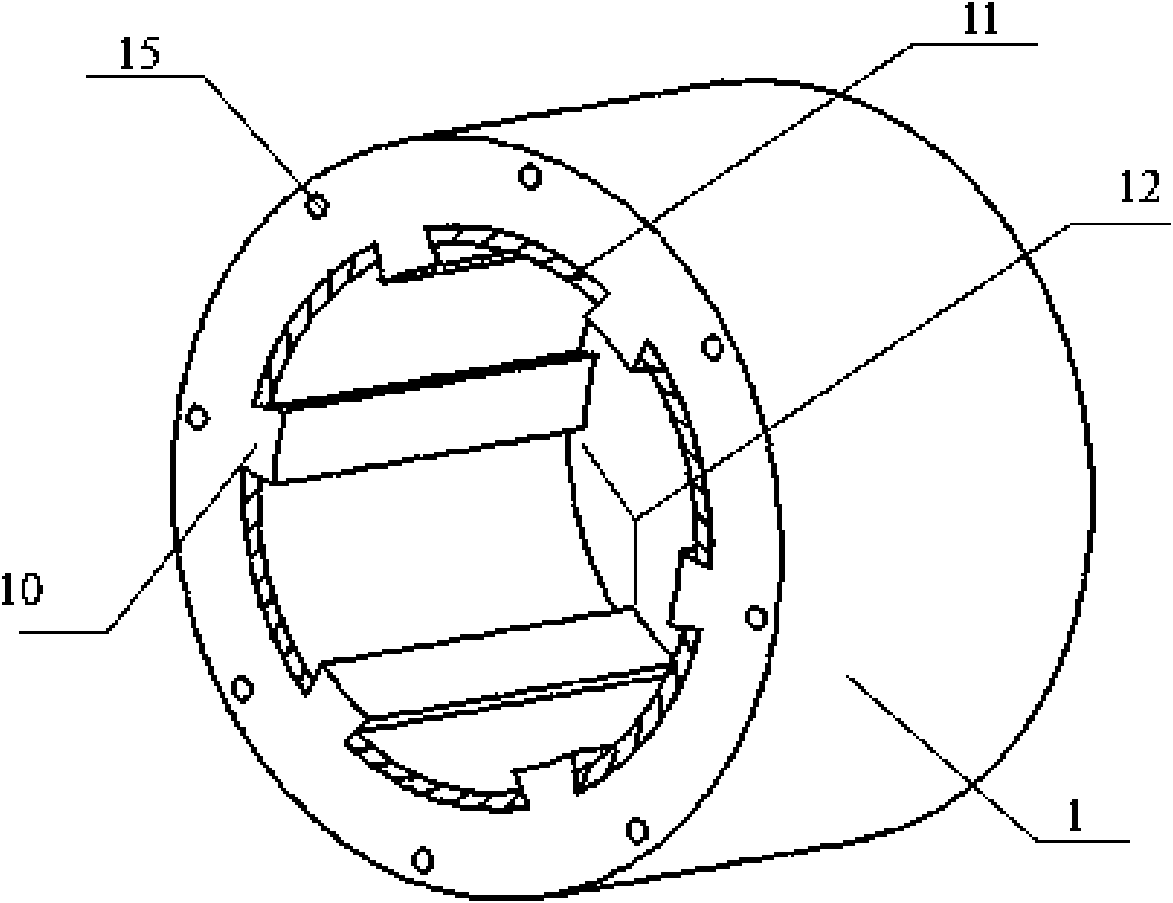

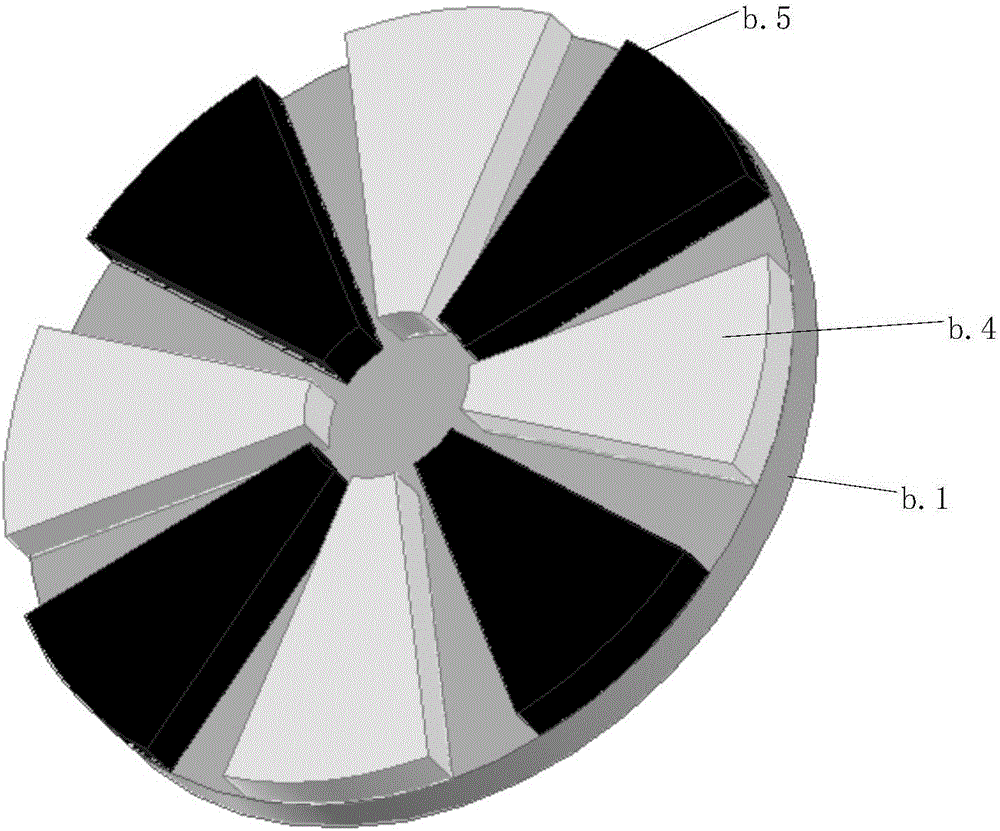

Trapezoidal shaped magnet flux intensifier motor pole arrangement for improved motor torque density

InactiveUS6879075B2Increase torqueImprove power characteristicsSynchronous generatorsWindingsPermanent magnet synchronous machineElectric machine

A permanent magnet synchronous machine with improved torque and power characteristics. A circumferential-oriented rotor assembly is provided with alternating permanent magnets and magnetic pole pieces. In order to reduce the amount of leakage flux in the rotor and increase the effective length of the permanent magnet, a trapezoidal or otherwise tapered permanent magnet structure is used. By alternating trapezoidal permanent magnet, and magnetic pole pieces, a higher intensity magnetic field is created in the air gap utilizing the same radial space in the motor without altering the weight or volume of the motor compared to conventional machines.

Owner:CURTISS WRIGHT ELECTRO MECHANICAL

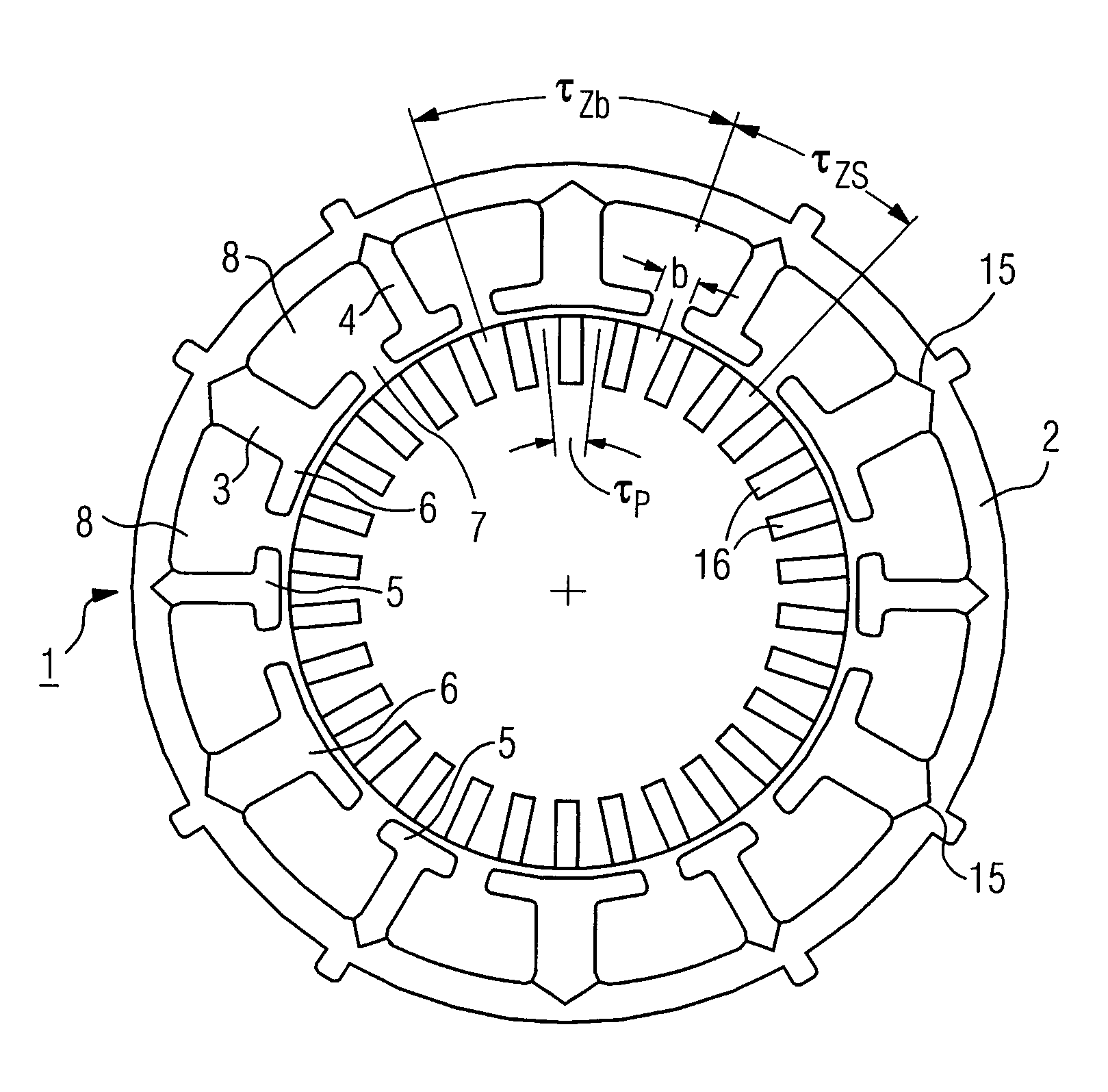

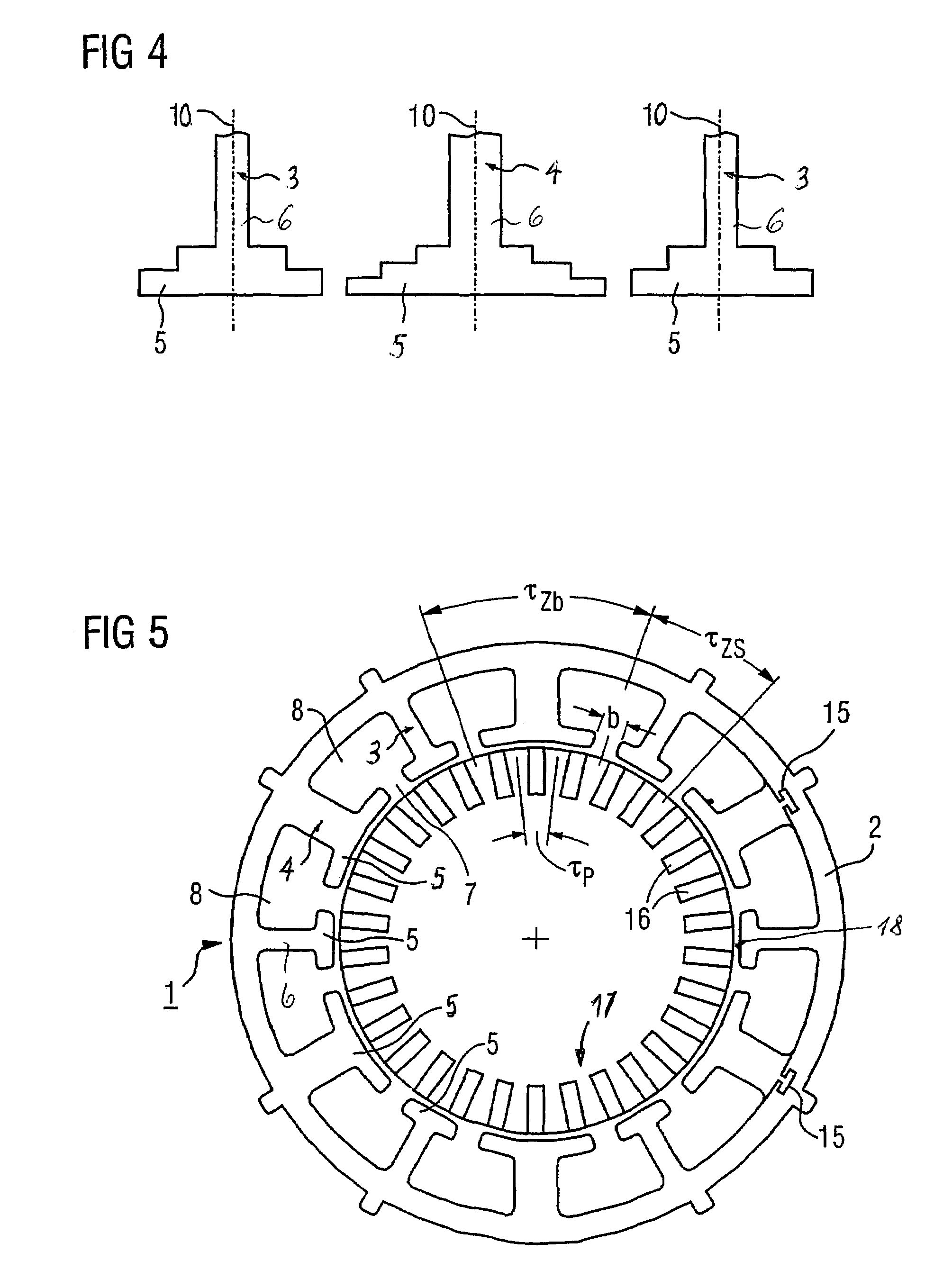

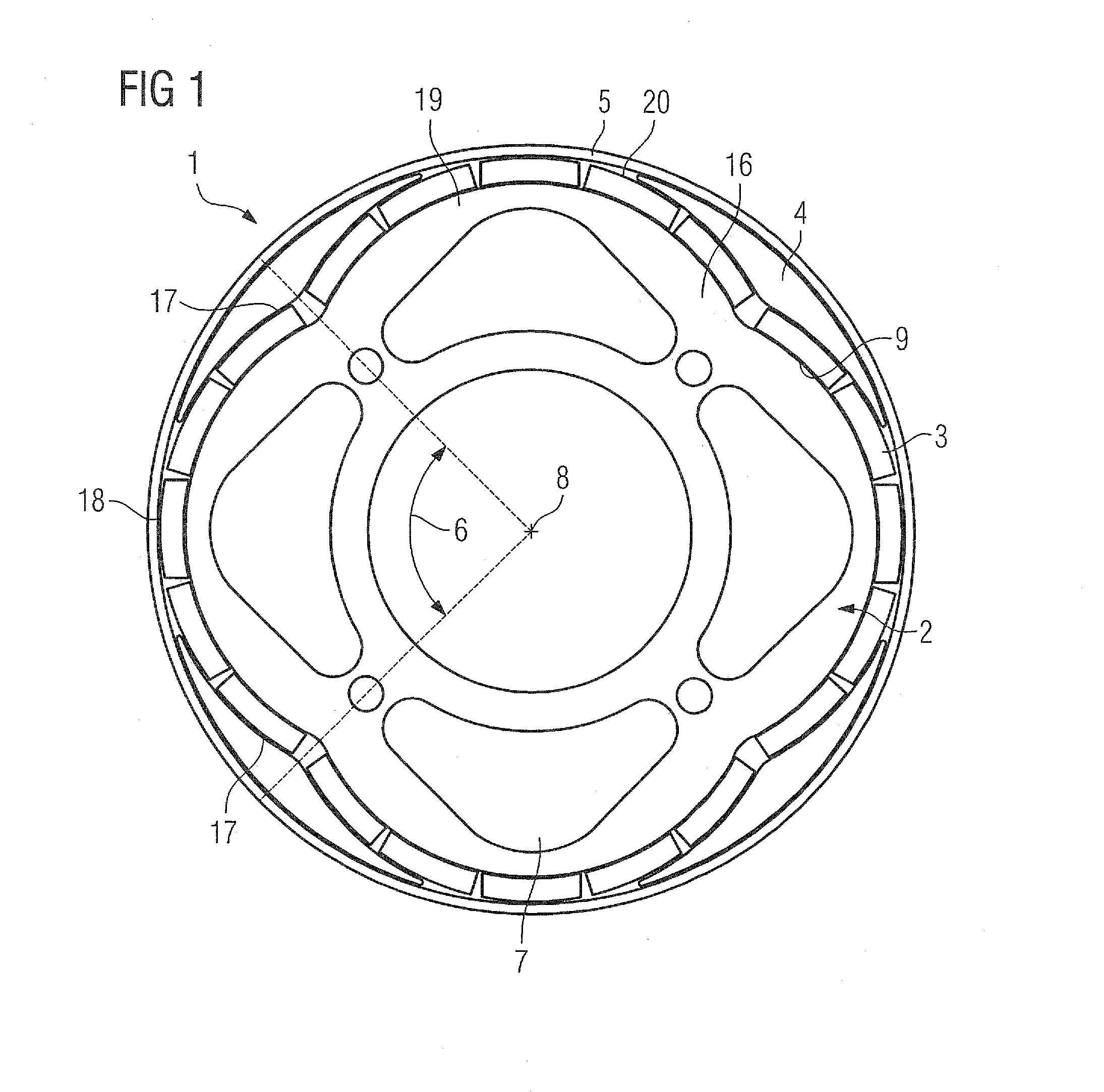

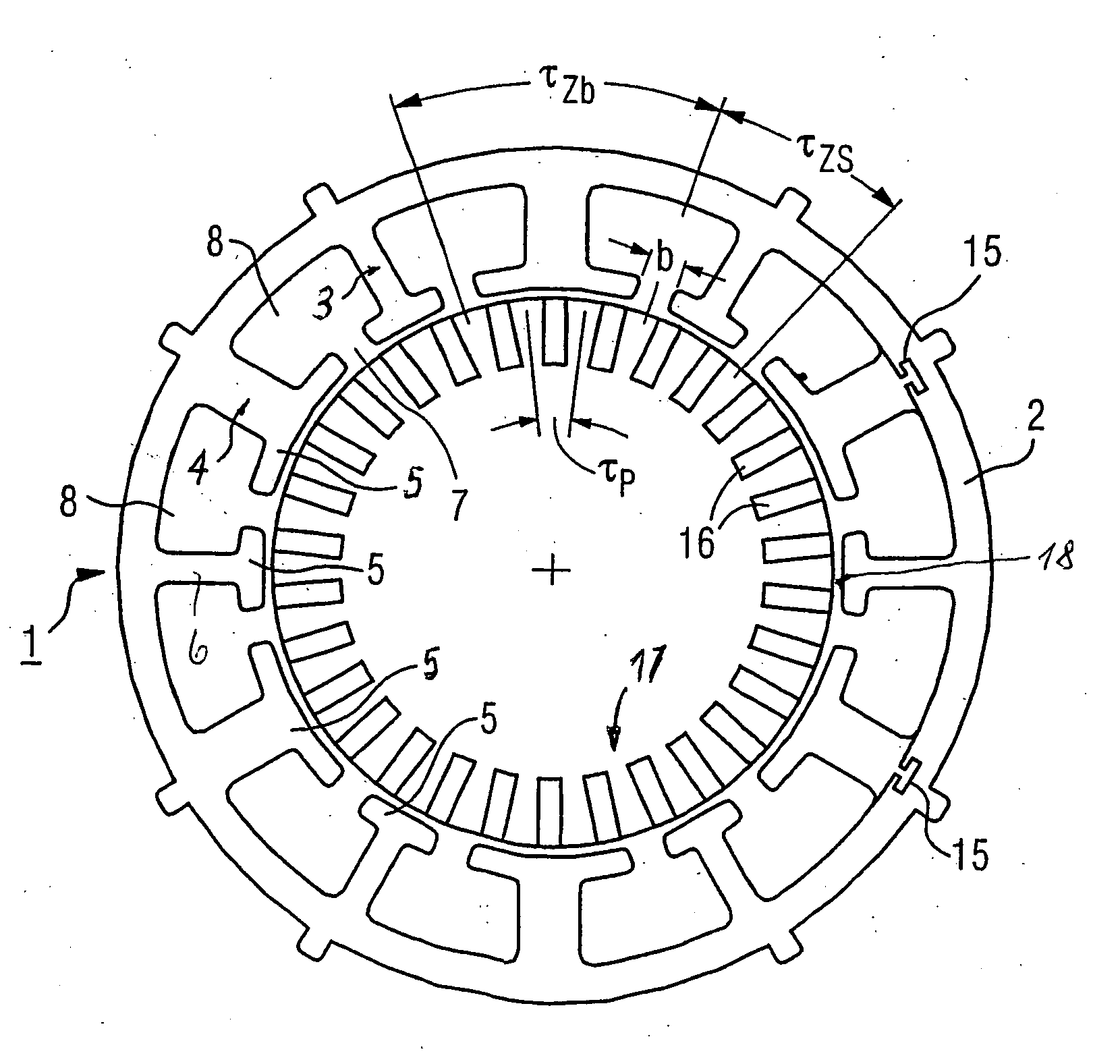

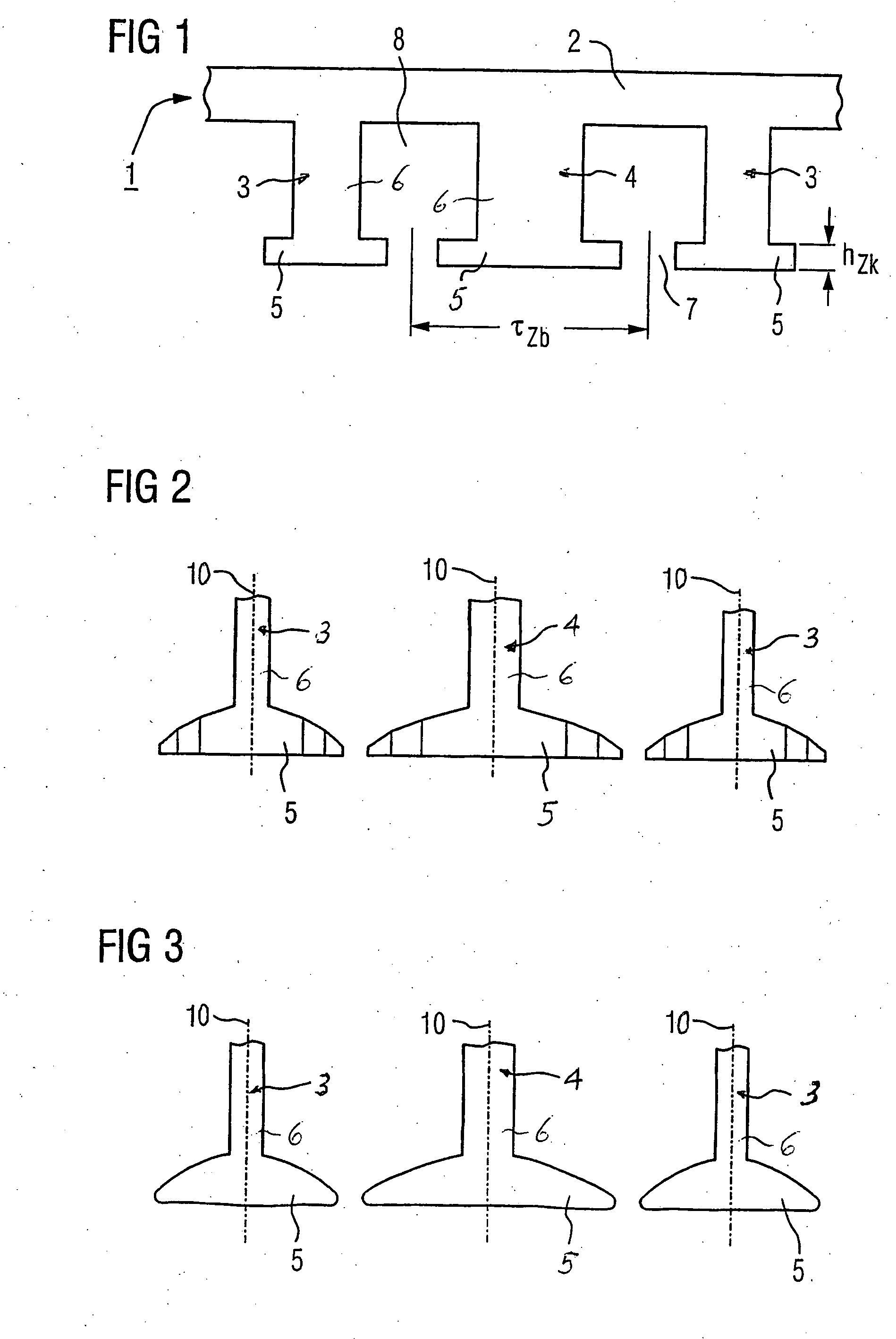

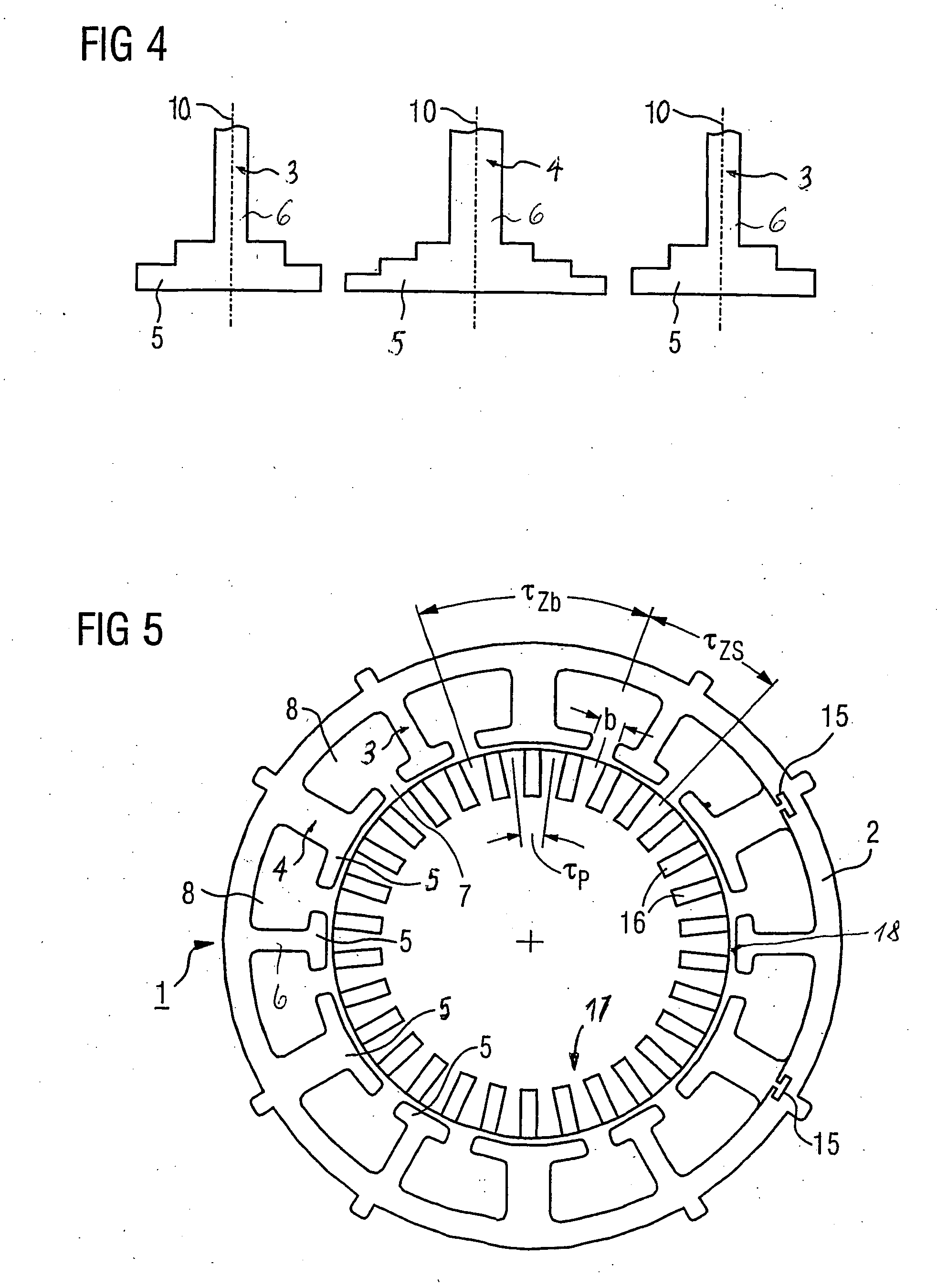

Permanent magnet synchronous machine

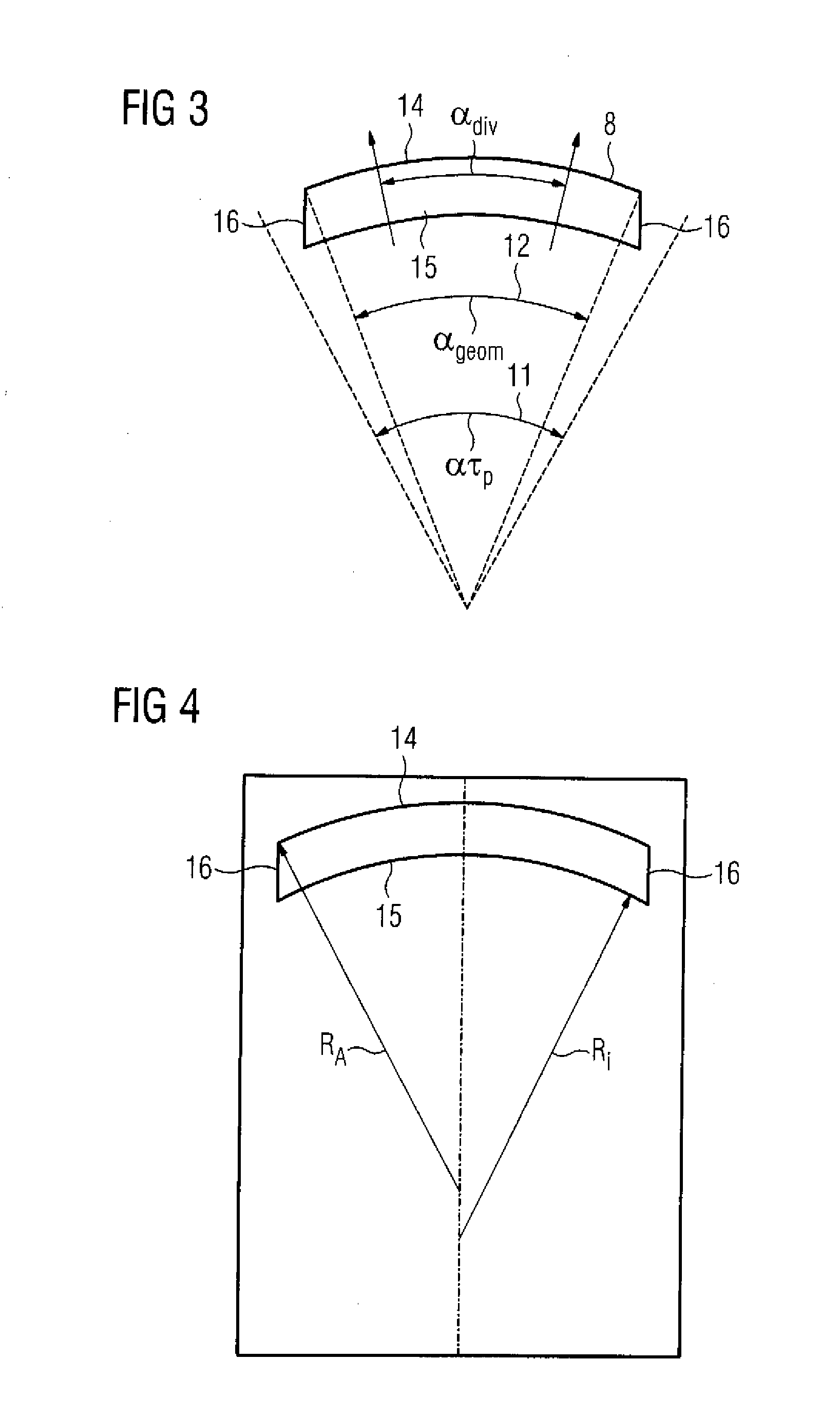

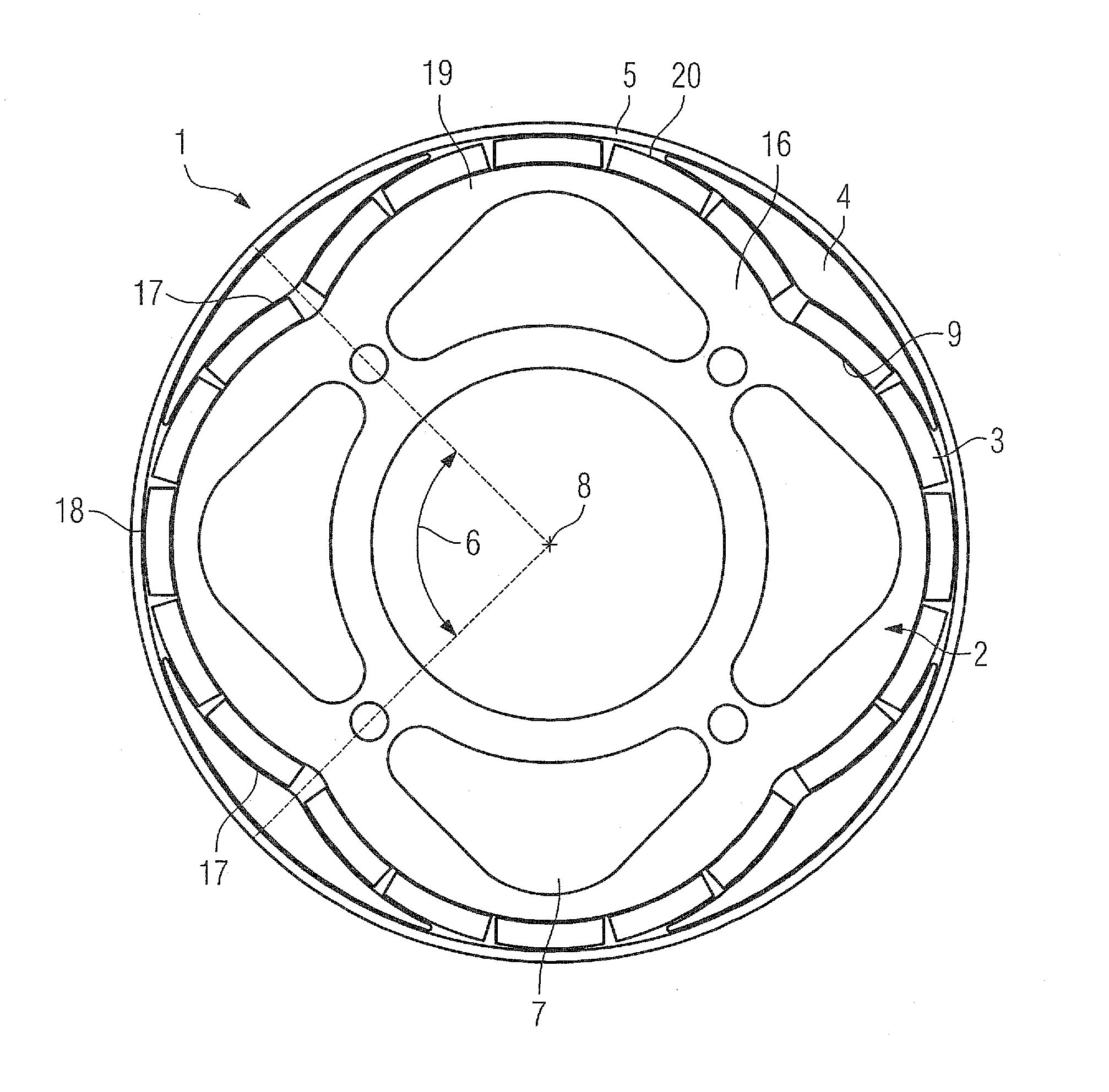

InactiveUS7141905B2InhibitionSmall heightMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet synchronous machinePermanent magnet synchronous generator

A permanent magnet synchronous machine includes a stator, and a rotor which defines with the stator an air gap. The stator includes a plurality of teeth which are disposed in spaced-apart circumferential relationship and separated from one another by a tooth pitch. Each of the teeth has a shaft which terminates in a tooth head adjacent the air gap, with the tooth heads of neighboring teeth being separated from one another by a slot. The tooth heads are constructed to prevent saturation. The rotor has permanent magnets which are aligned in flux concentration direction and arranged to define a pole pitch, wherein a pitch ratio of tooth pitch to pole pitch is ≧2.5.

Owner:SIEMENS AG

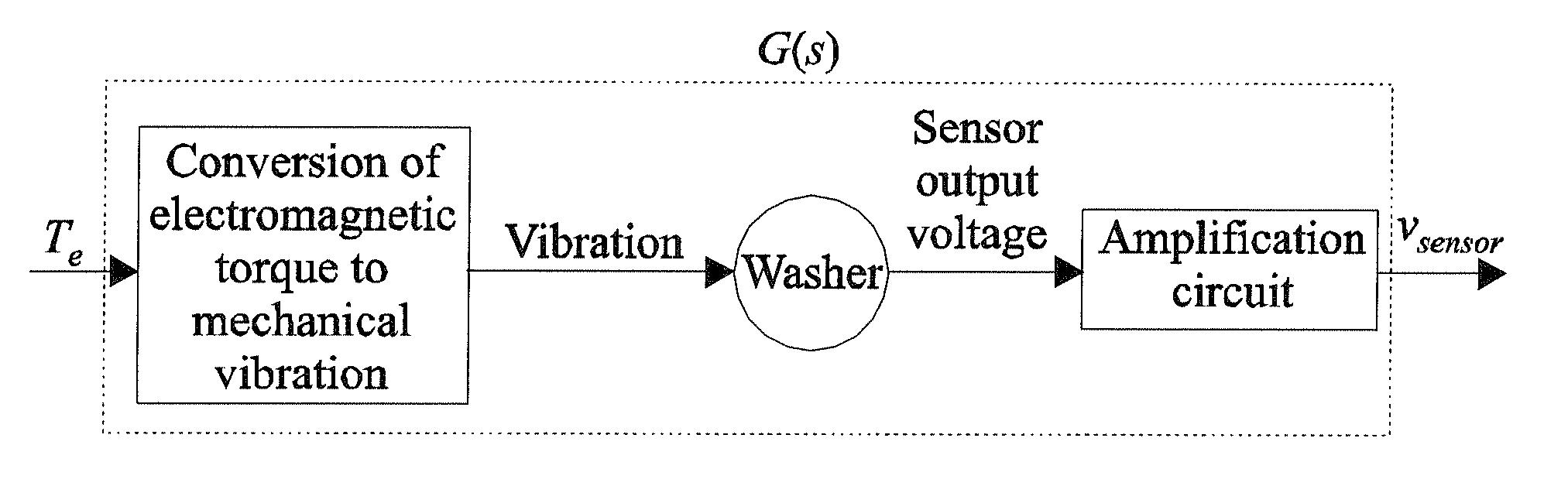

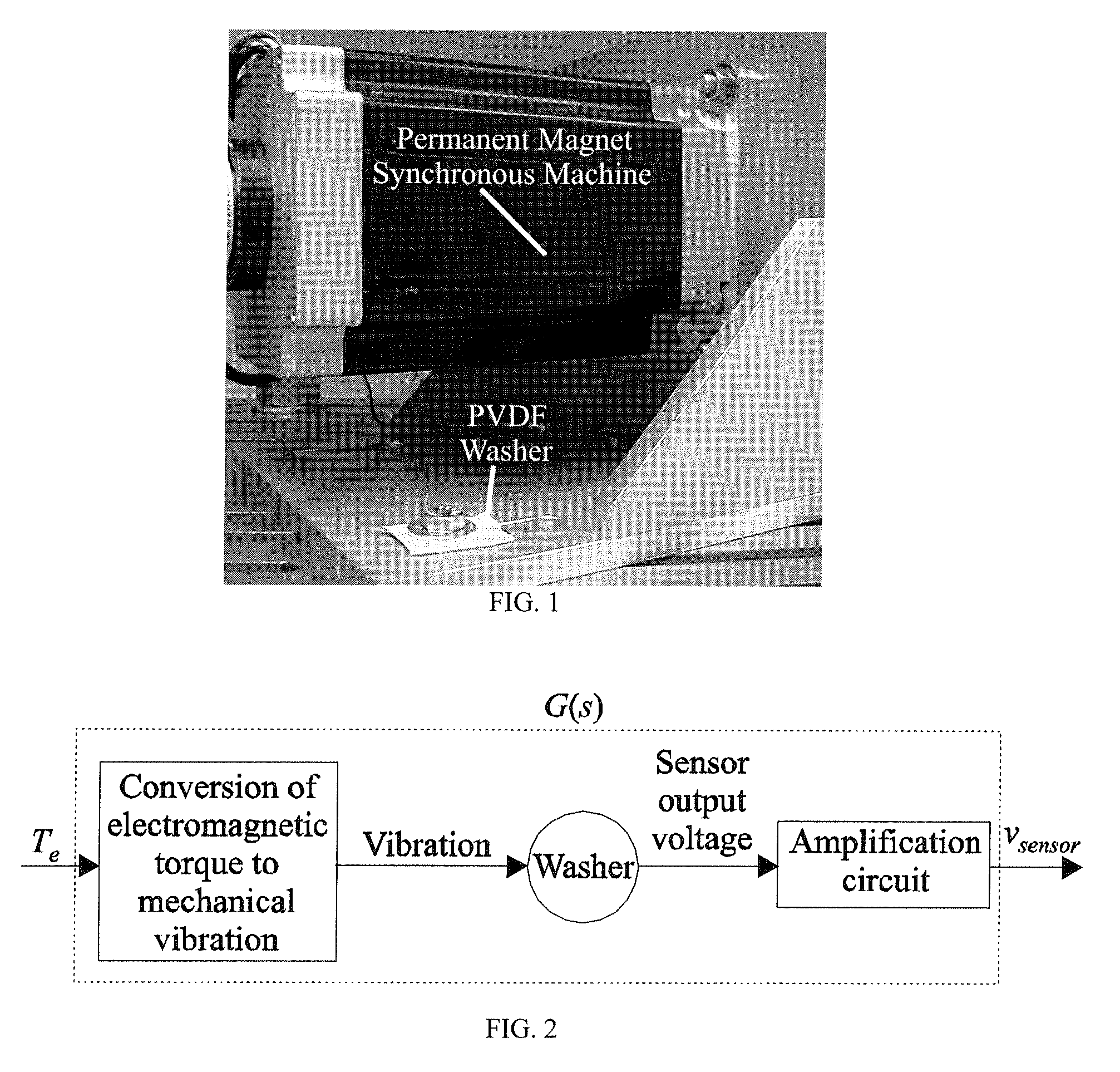

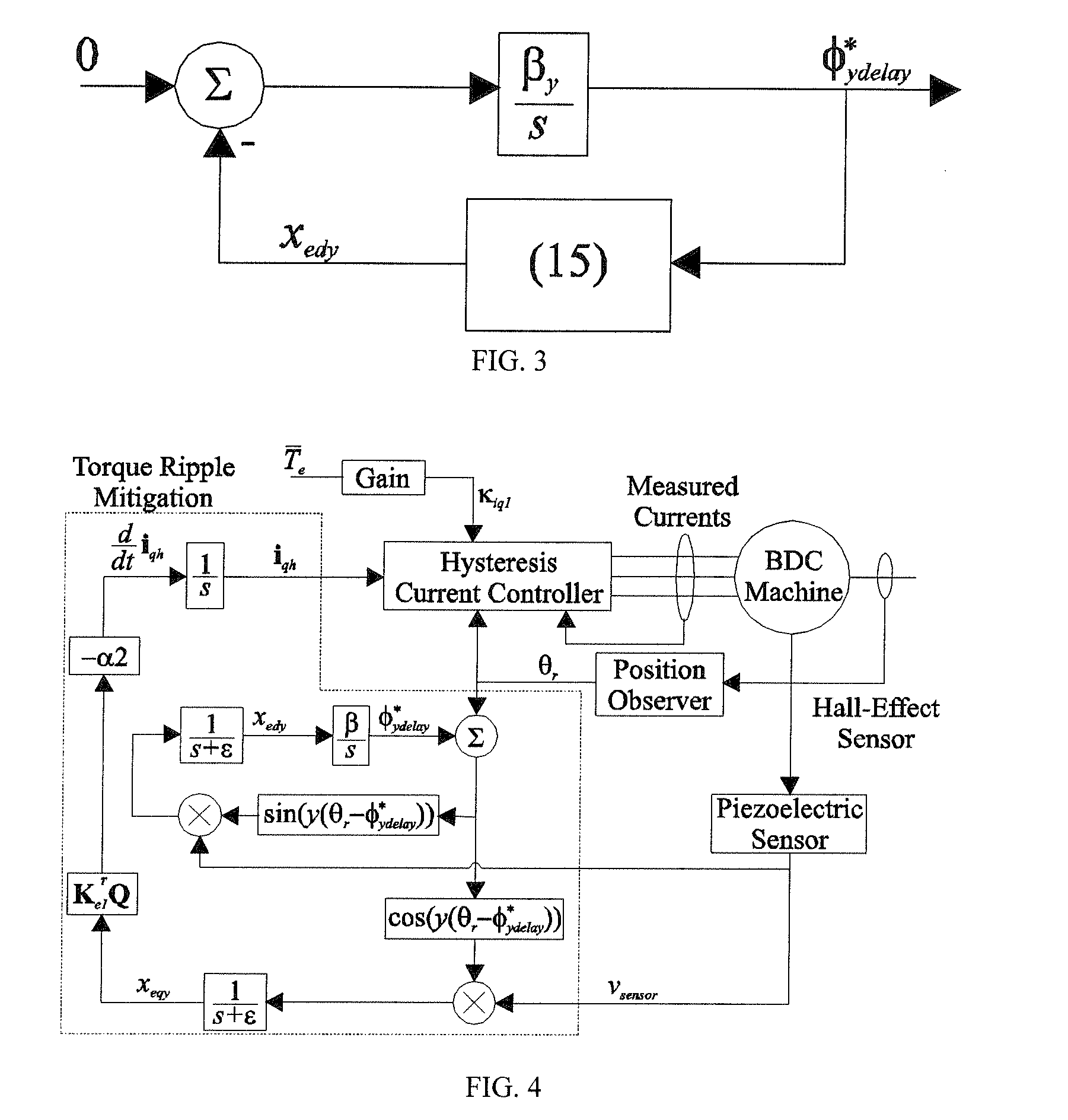

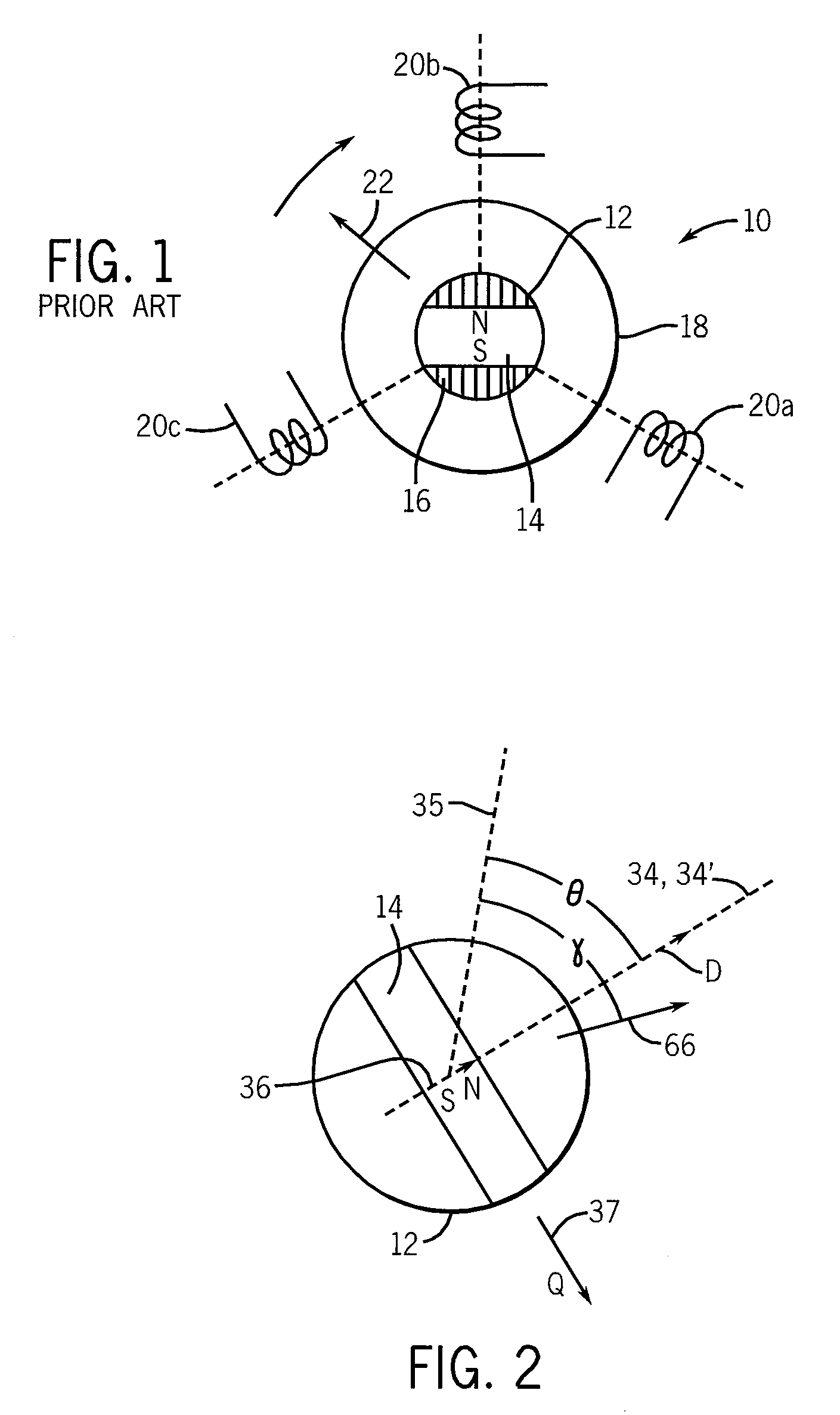

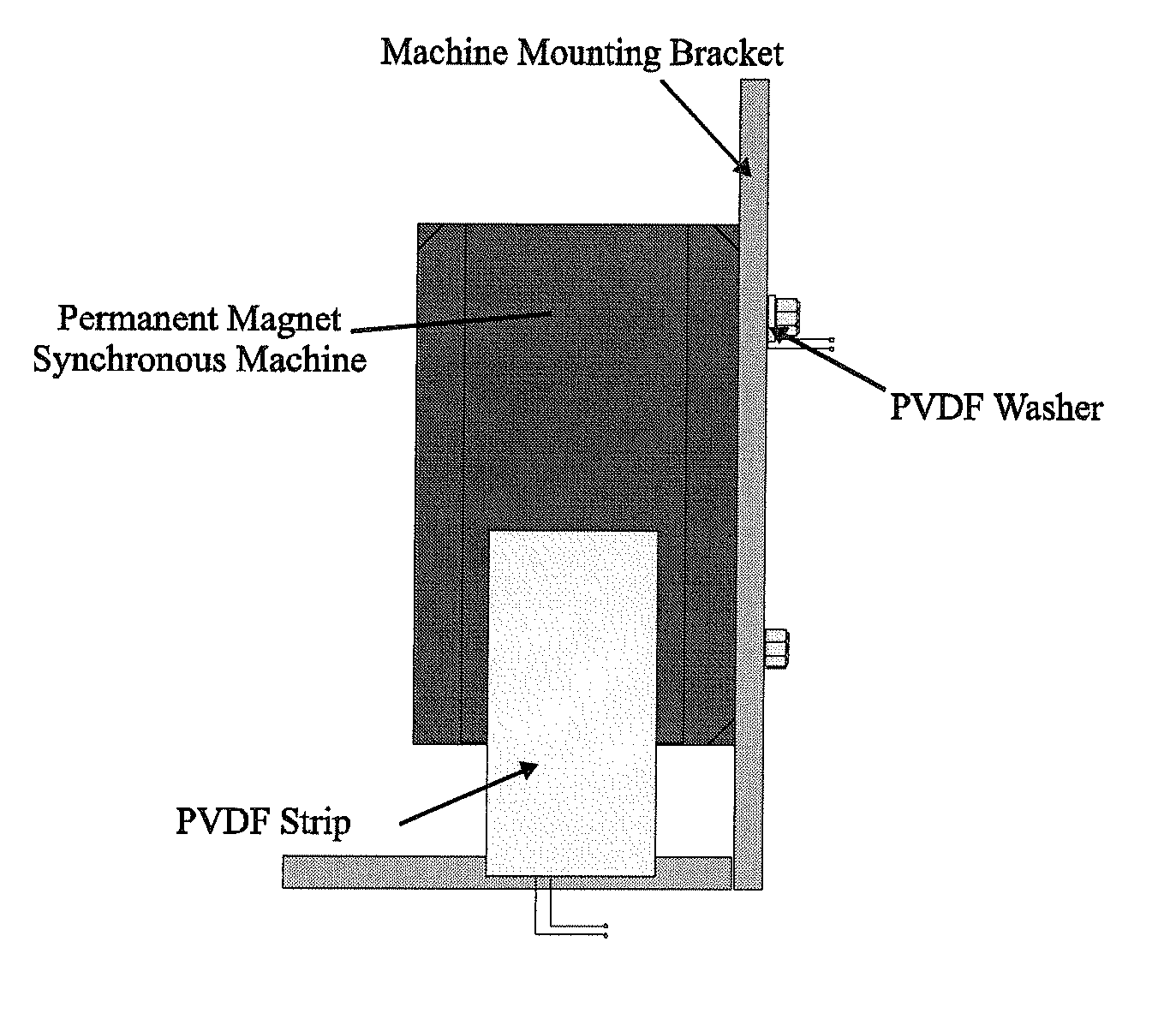

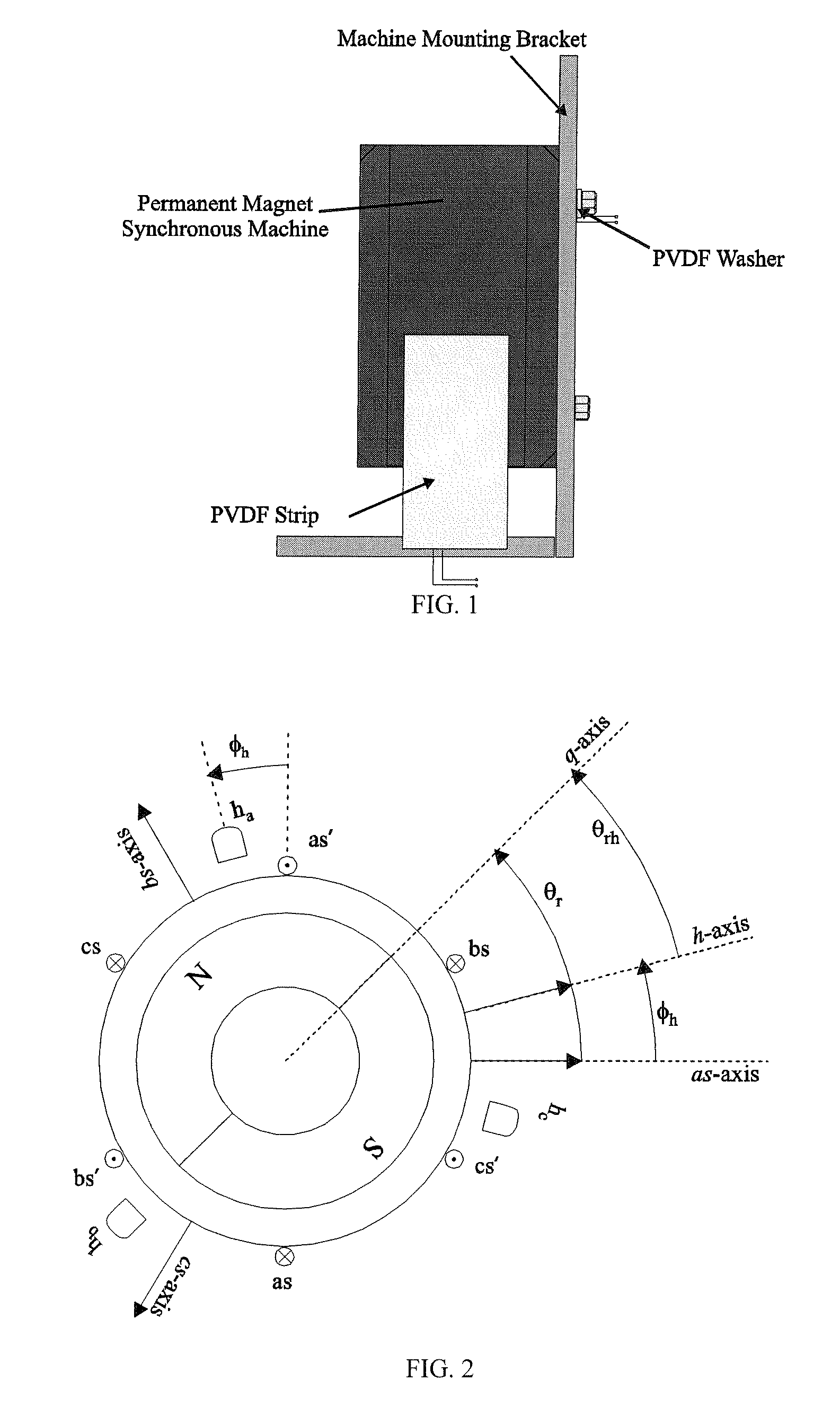

Rotor position sensing apparatus and method using piezoelectric sensor and hall-effect sensor

InactiveUS7885785B1Near-maximum start-up torqueSolve the lack of precisionTorque ripple controlSynchronous motors startersLow speedPermanent magnet synchronous machine

A position observer for control-based torque ripple mitigation in permanent magnet synchronous machines (PMSMs). Rotor position is determined using data from two sources: a piezoelectric sensor for initial position and low-speed detection, and a single Hall-effect sensor for high-speed detection.

Owner:PURDUE RES FOUND INC

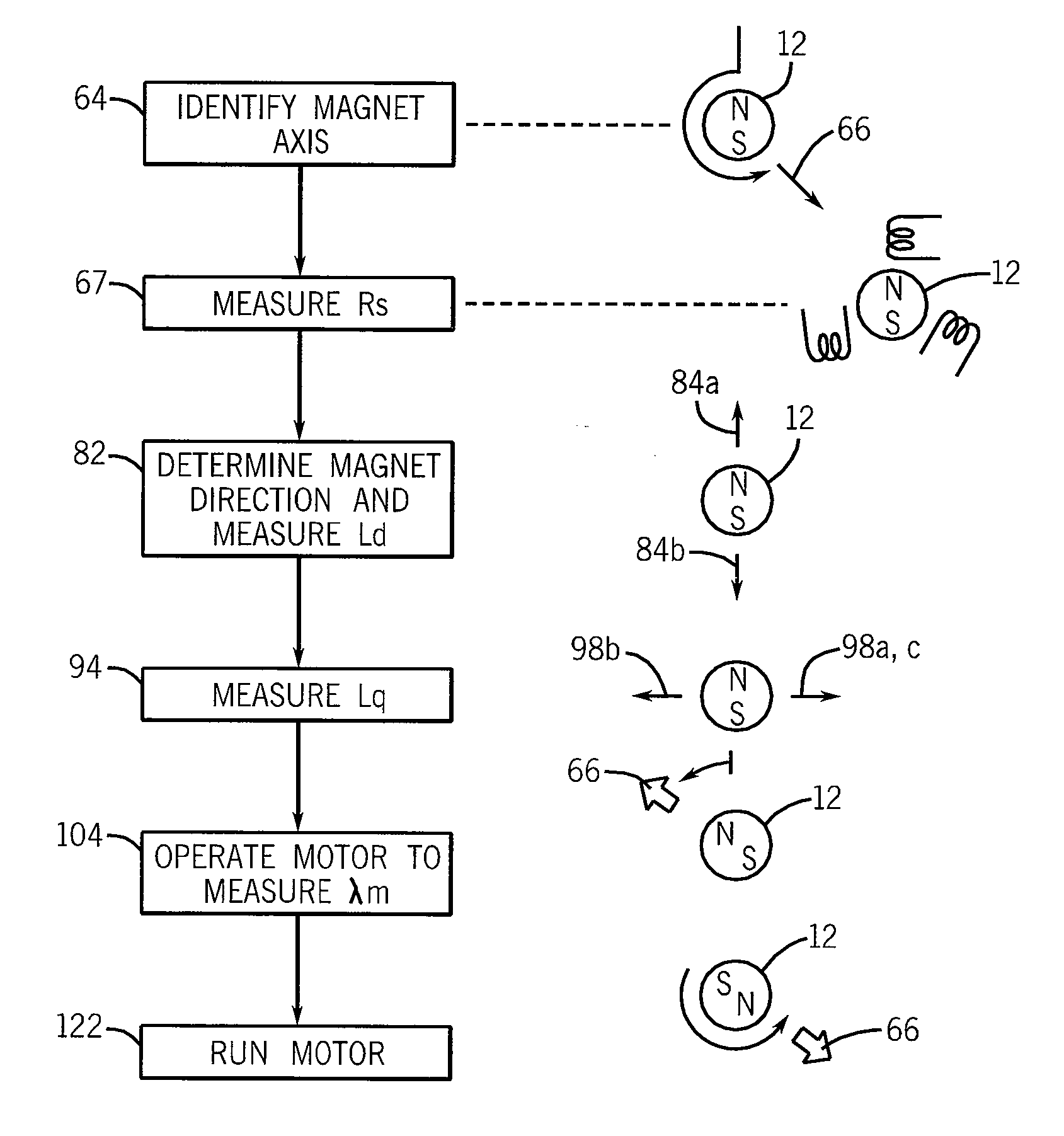

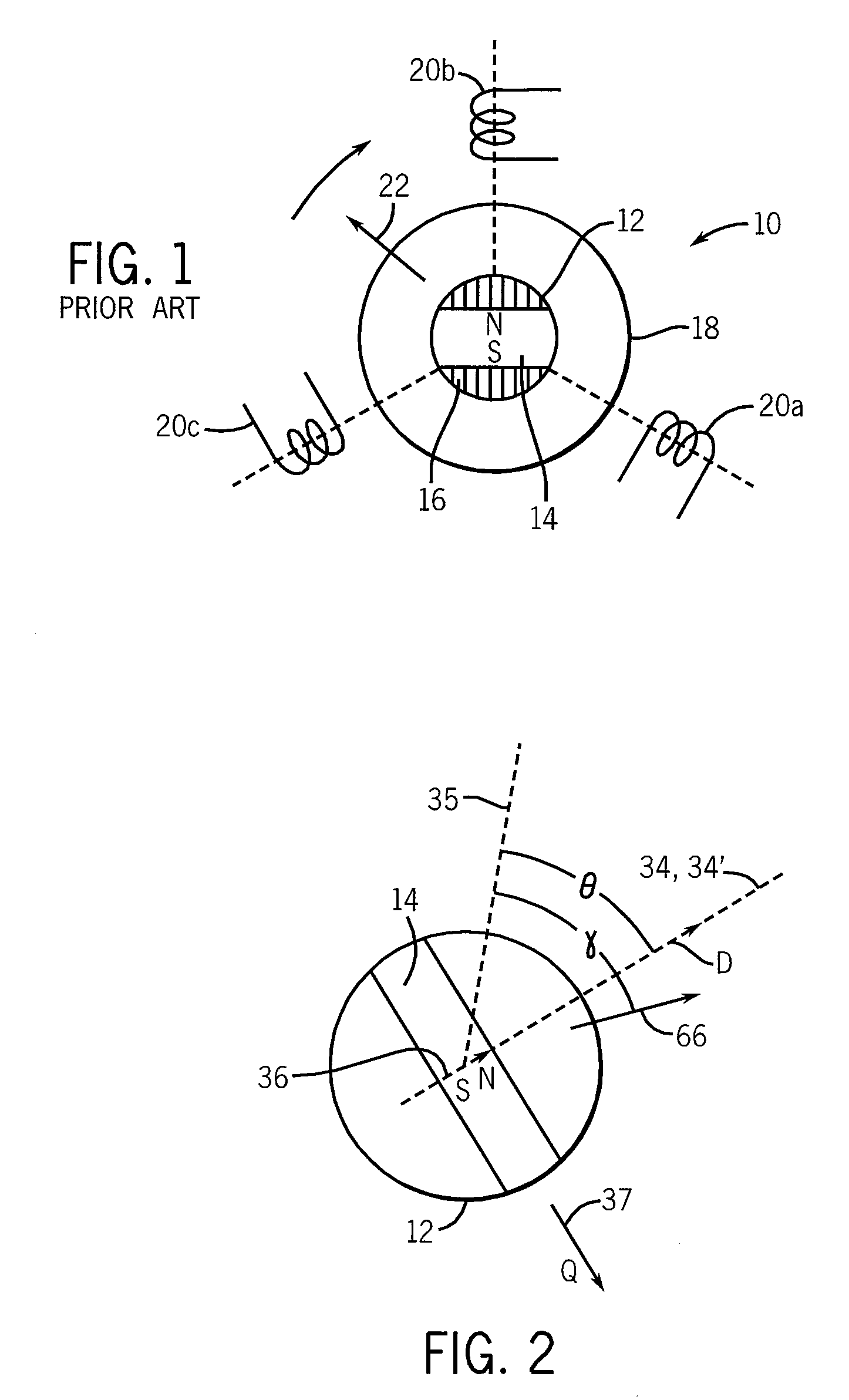

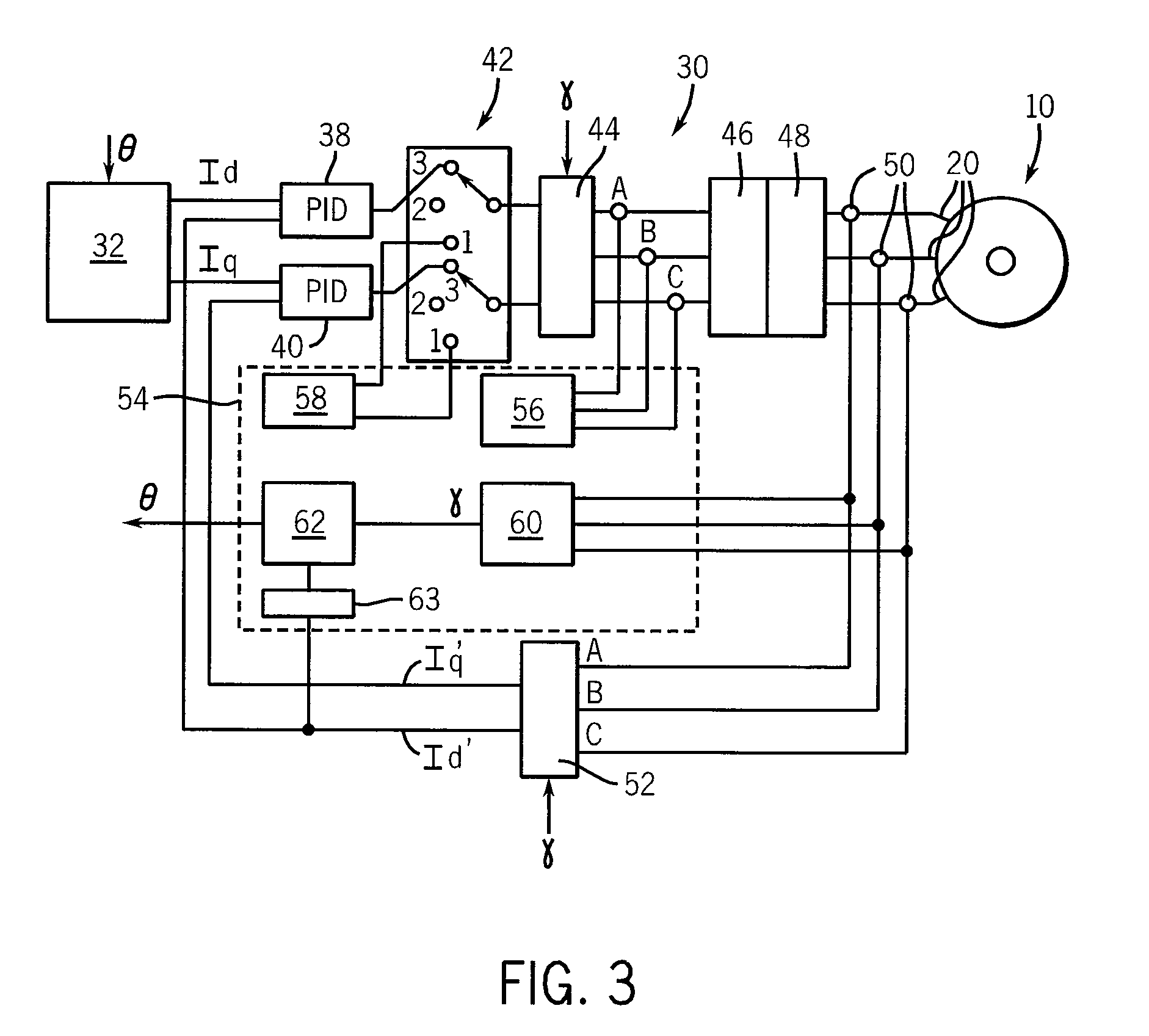

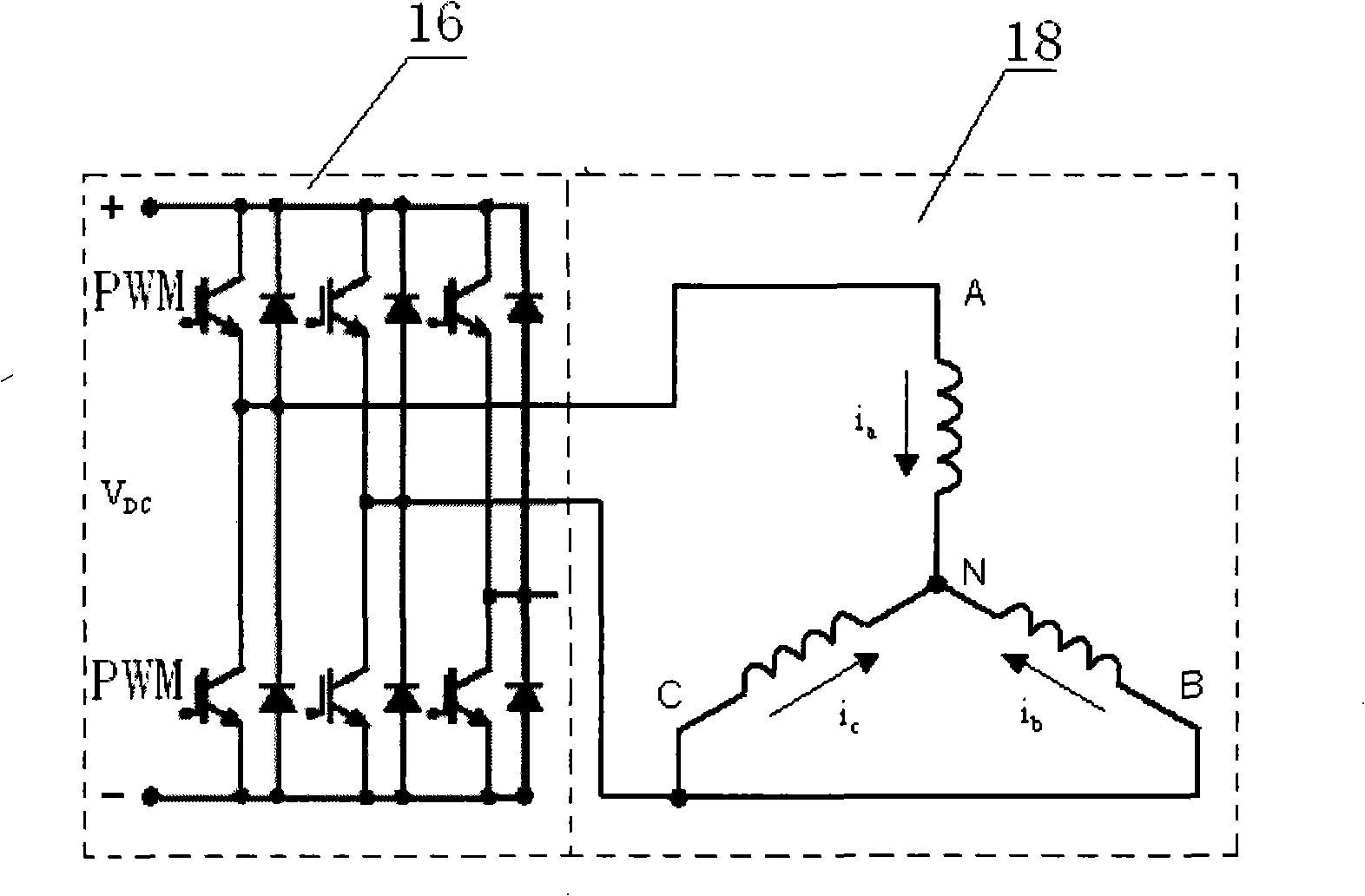

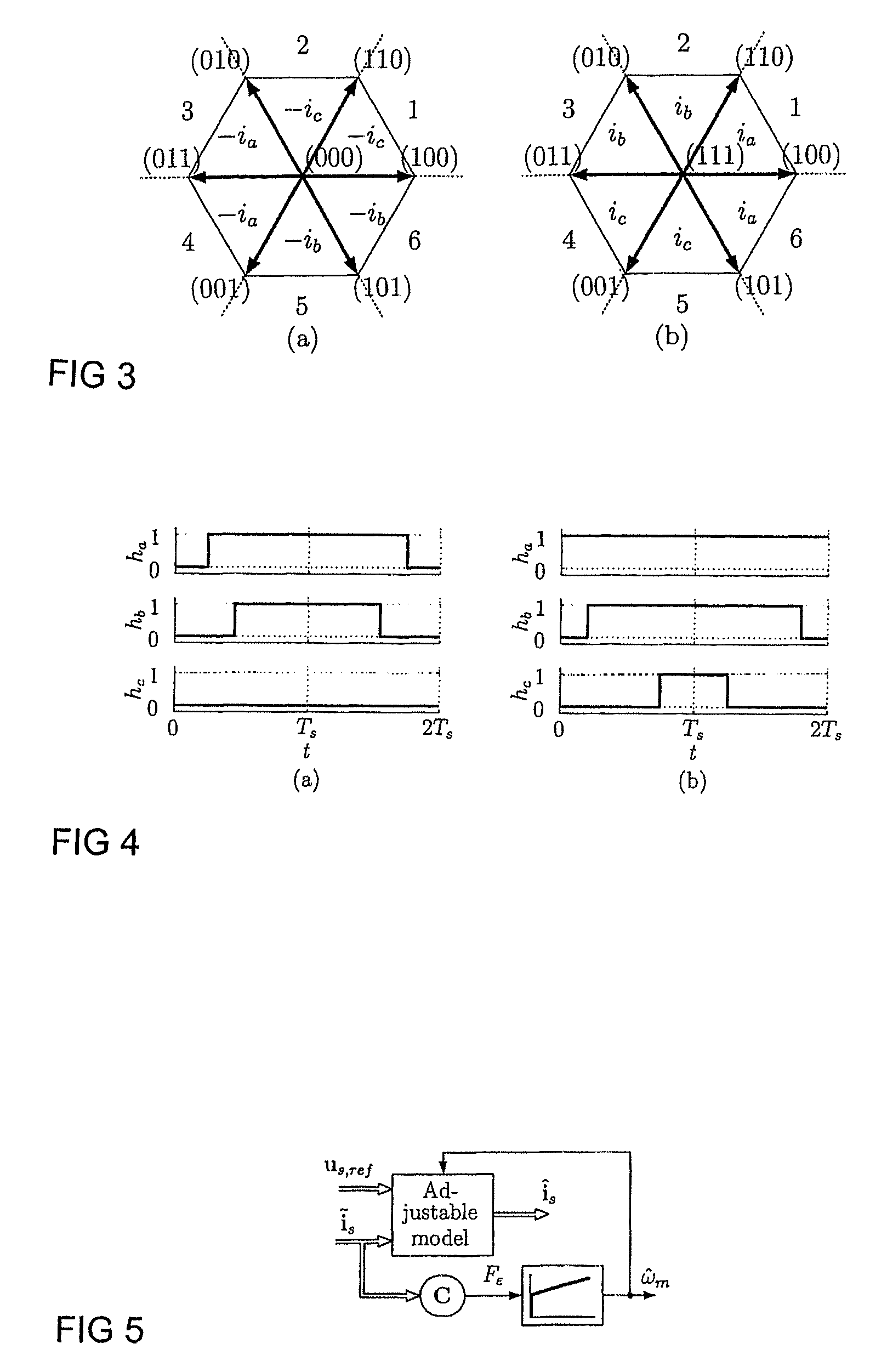

Method and apparatus for automatically identifying electrical parameters in a sensor-less pmsm

ActiveUS20100060210A1Effective parameter estimationAccurately model saturation effectElectronic commutation motor controlMotor/generator/converter stoppersElectricityPermanent magnet synchronous machine

A method and apparatus for determining electrical parameters for commissioning a sensor-less permanent magnet synchronous machine uses knowledge of the rotor position to apply balanced pulses along the rotor magnet axis and perpendicular to the rotor magnet axis allowing measurement of q- and d-inductance at multiple current levels without substantial rotor movement.

Owner:ROCKWELL AUTOMATION TECH

Permanent magnetism synchronous electric machine test system and method

ActiveCN101275988AResistance/reactance/impedenceDynamo-electric machine testingPermanent magnet synchronous machineElectric machine

The present invention discloses a permanent magnet synchronous machine test system and a test method thereof. The test system comprises an inverter, a permanent magnet synchronous machine, a test computer and a temperature sensor. The invention is characterized in that the side of the permanent magnet synchronous machine is provided with a rotor position sensor which is connected with the test computer through a DSP chip. The rotating axis of the rotor is also connected with a rotation-blocking device. As the test system and test method are adopted, the inductor parameter measurement of the permanent magnet motor is executed through the rotor position sensor and the rotation-blocking device which fixes the position of the magnetic pole of the rotor. The position of the rotor is detected through a device which fixes the position of rotor with simple regulation and a DSP chip. The rotor of electric machine is finally fixed to the test position through a method of testing together with regulating. The inductor parameter test is realized through a voltage integrating method. Compared with prior art, the invention uses a simple device and uncomplicated method for realizing an accurate measurement to the inductor parameter of the permanent magnet synchronous machine.

Owner:CHERY AUTOMOBILE CO LTD

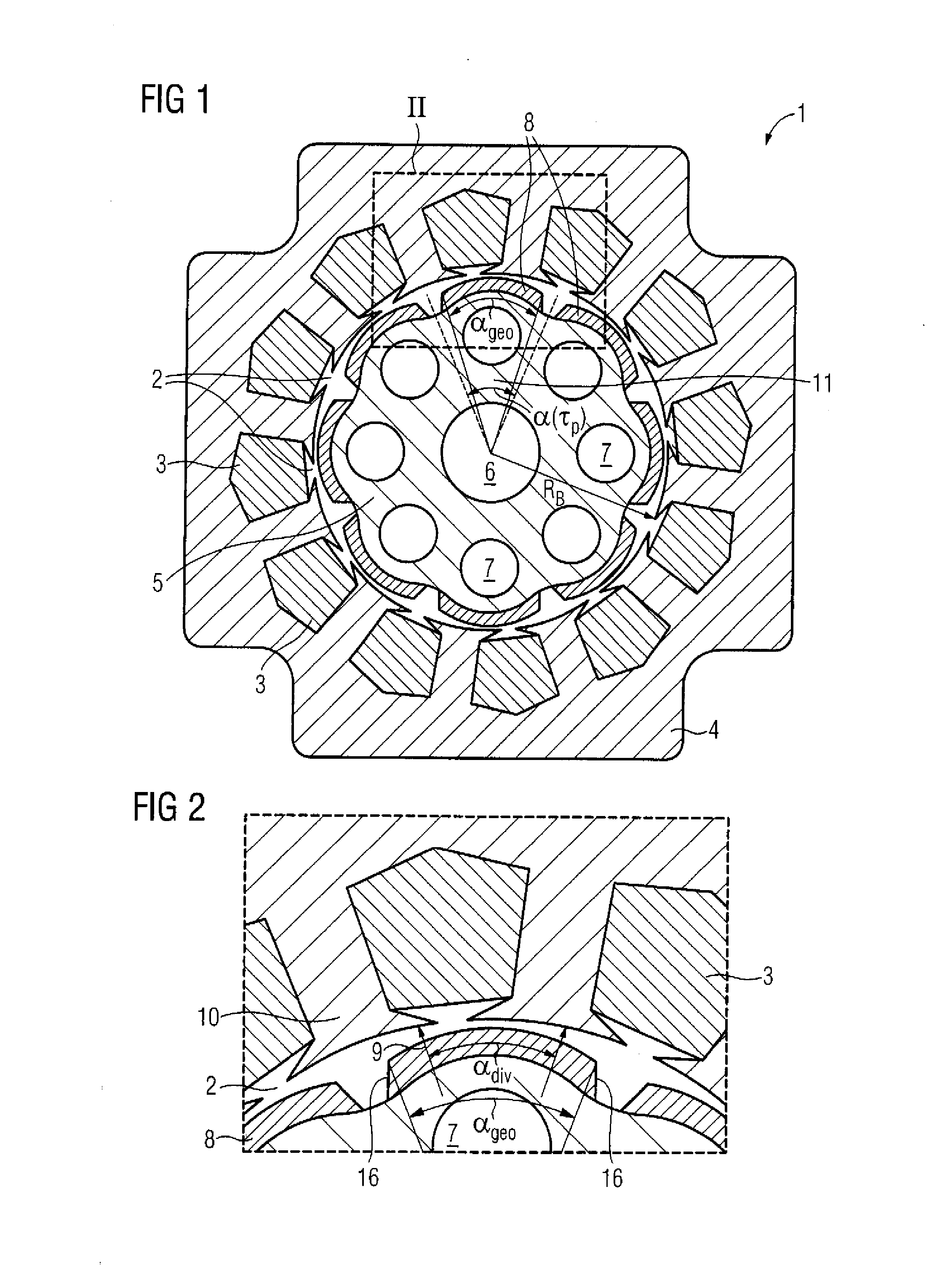

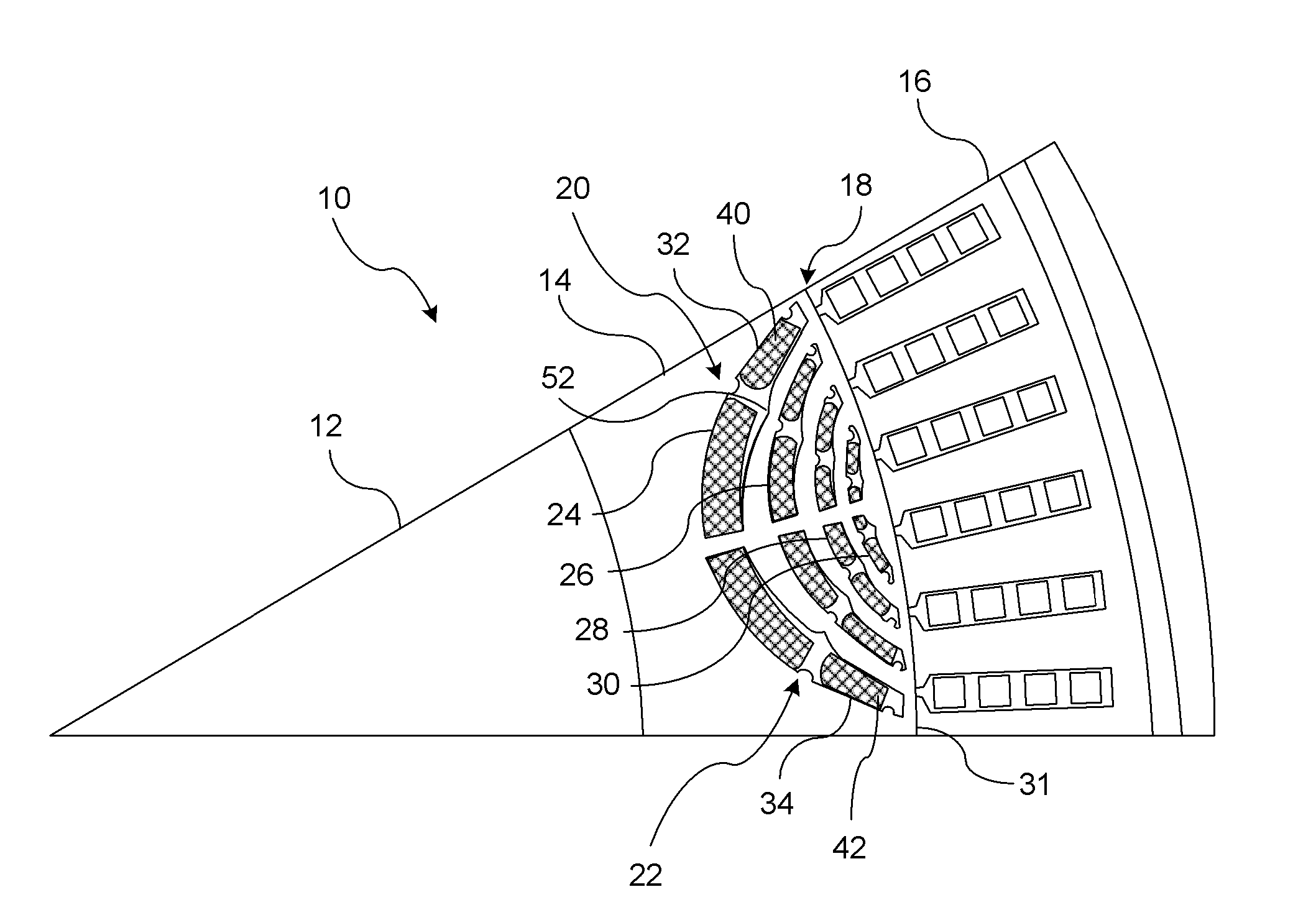

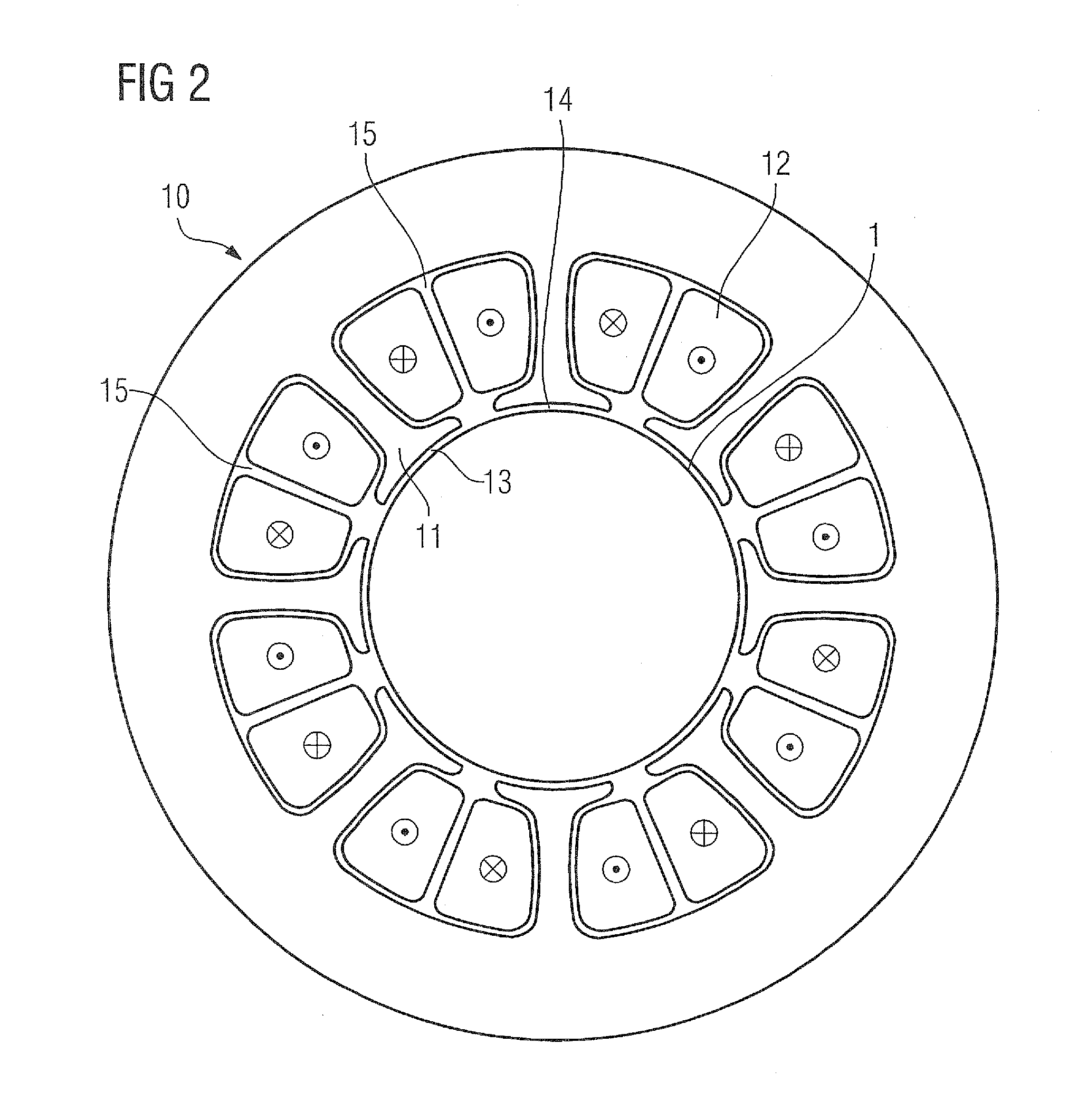

Permanent magnet synchronous machine with shell magnets

InactiveUS20090315424A1Reduce torque rippleReduction in torque rippleMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet synchronous machineMagnetic poles

A permanent-magnet synchronous machine includes a stator that has slots and a rotor that has permanent magnets which form magnet poles. The permanent magnets are shell magnets having two curved surfaces. Each shell magnet covers a predetermined part of a magnet pole. The external radius of the shell magnets is less than 0.6 times the radius of the stator bore. Each shell magnet has a quasi-radial magnetic preferred direction that is directed substantially perpendicular to its outer surface.

Owner:SIEMENS AG

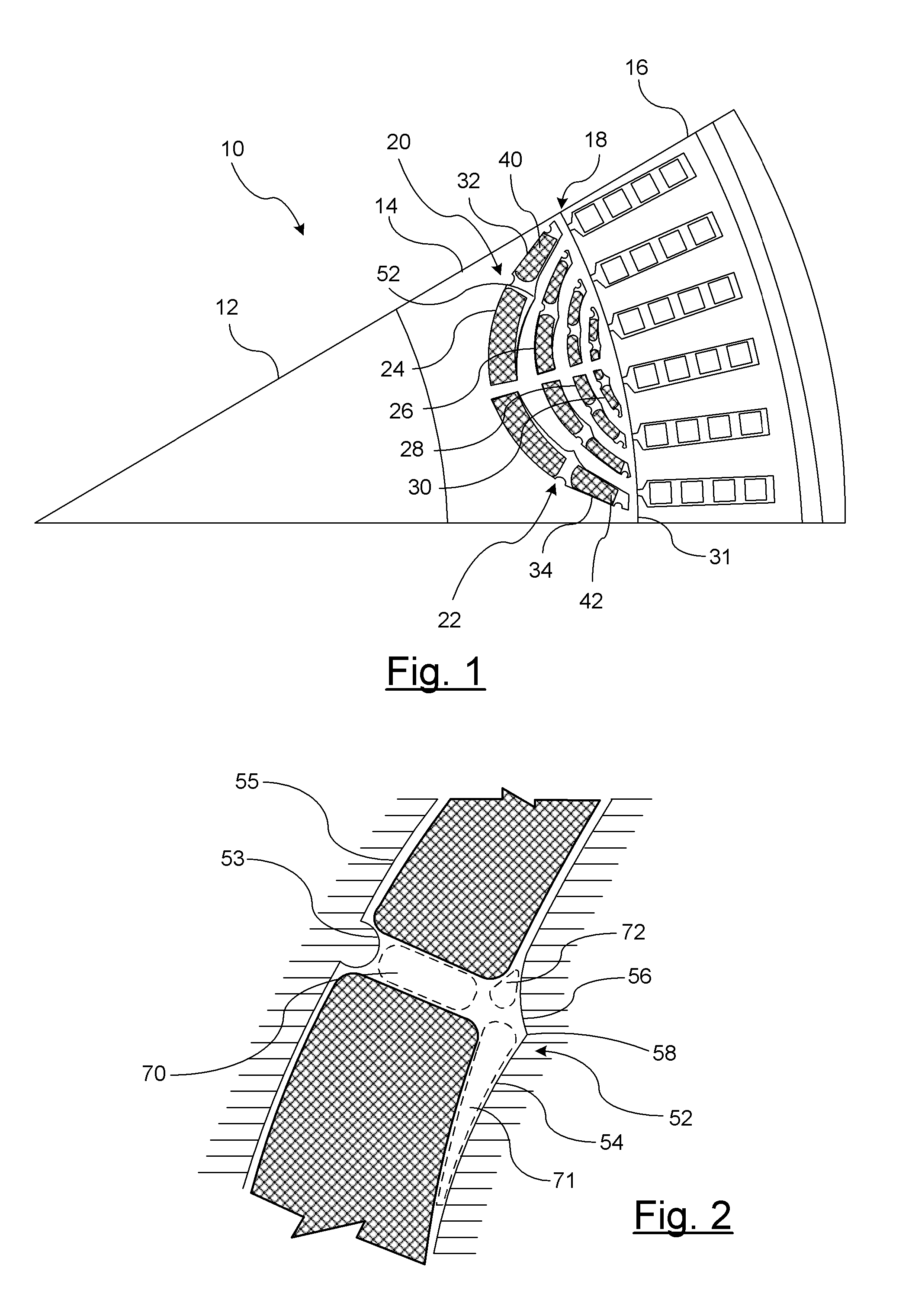

Magnetic barrier for minimizing demagnetization in bi-permanent magnet synchronous machines

ActiveUS20130320797A1Low costReduce in quantityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic barrierPermanent magnet synchronous machine

A rotor for a permanent synchronous machine includes a rotor having a plurality of arcuately-shaped cavities formed within a rotor core structure. The plurality of arcuately-shaped cavities substantially concentrically layered with respect to an outer cylindrical wall of the rotor core structure. A plurality of permanent magnets is inserted within the plurality of arcuately-shaped cavities. Each cavity layer retains a permanent magnet of a first magnetic field strength disposed in end sections and a permanent magnet of a second magnetic field strength in a center section of each cavity layer. Each respective cavity includes an air barrier formed between the magnets having different magnetic field strengths. The air barrier generates a reluctance within an air barrier gap for directing a flow of flux generated by each third permanent magnet in a preceding layer in a direction toward each third permanent magnet in a succeeding layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

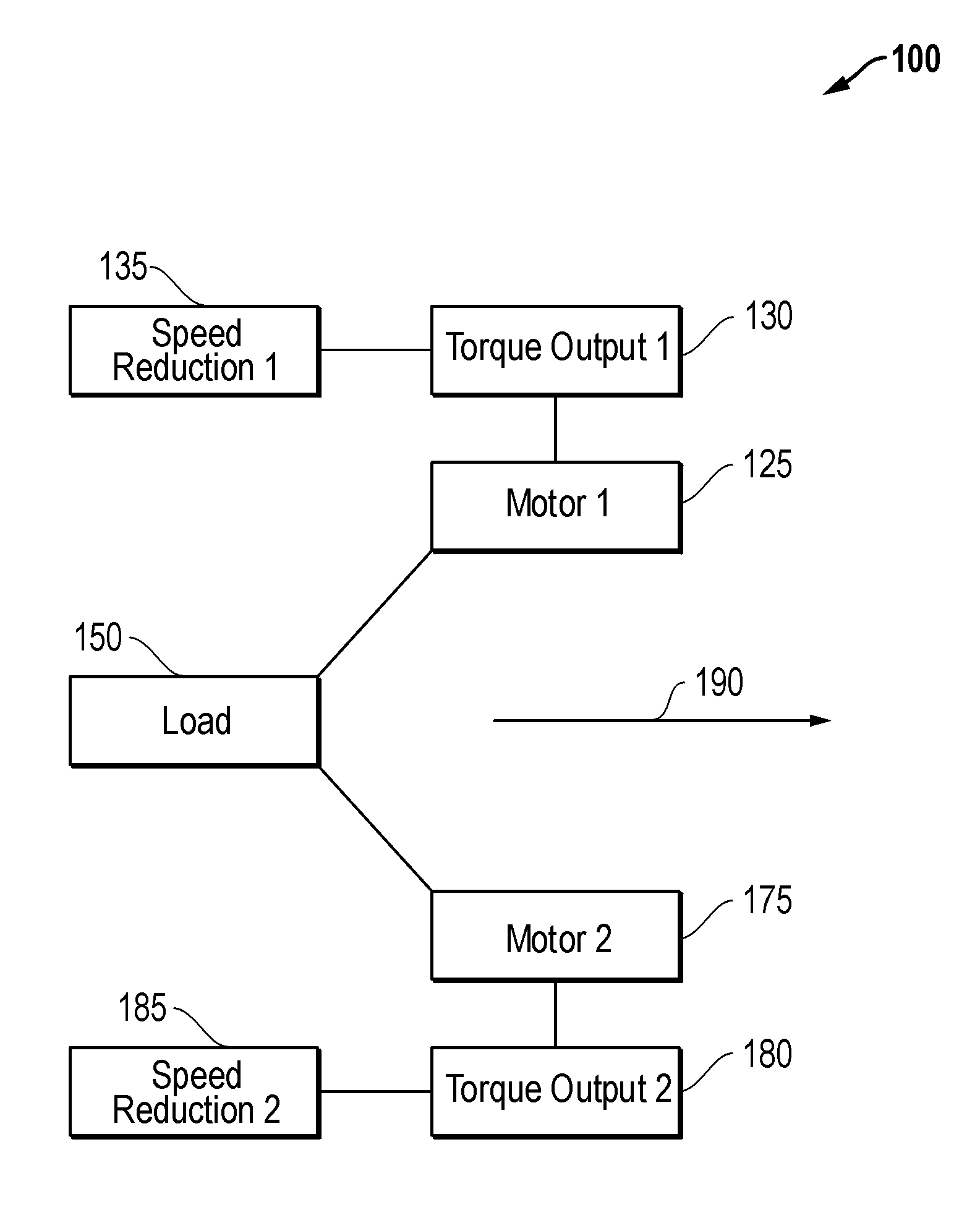

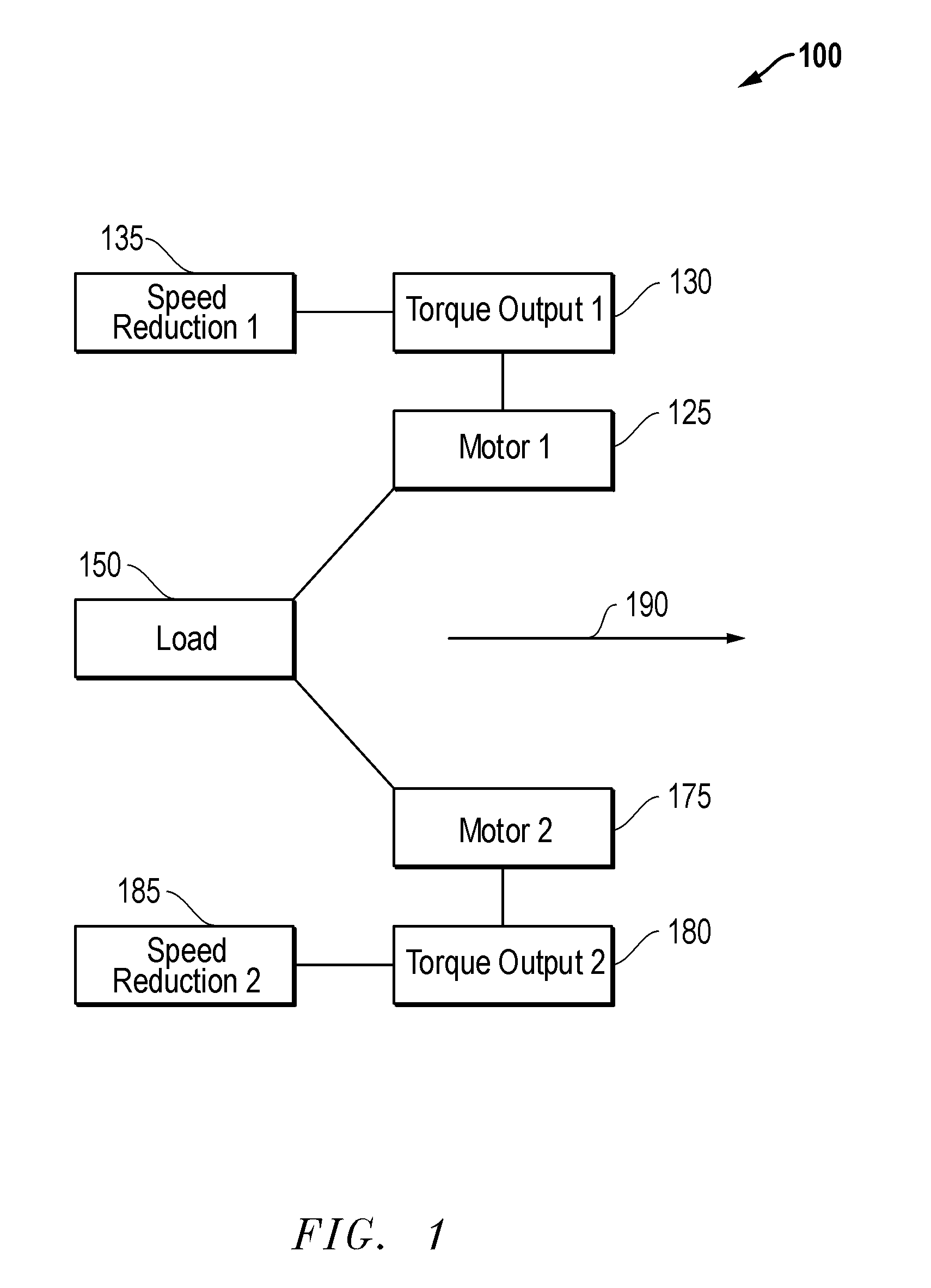

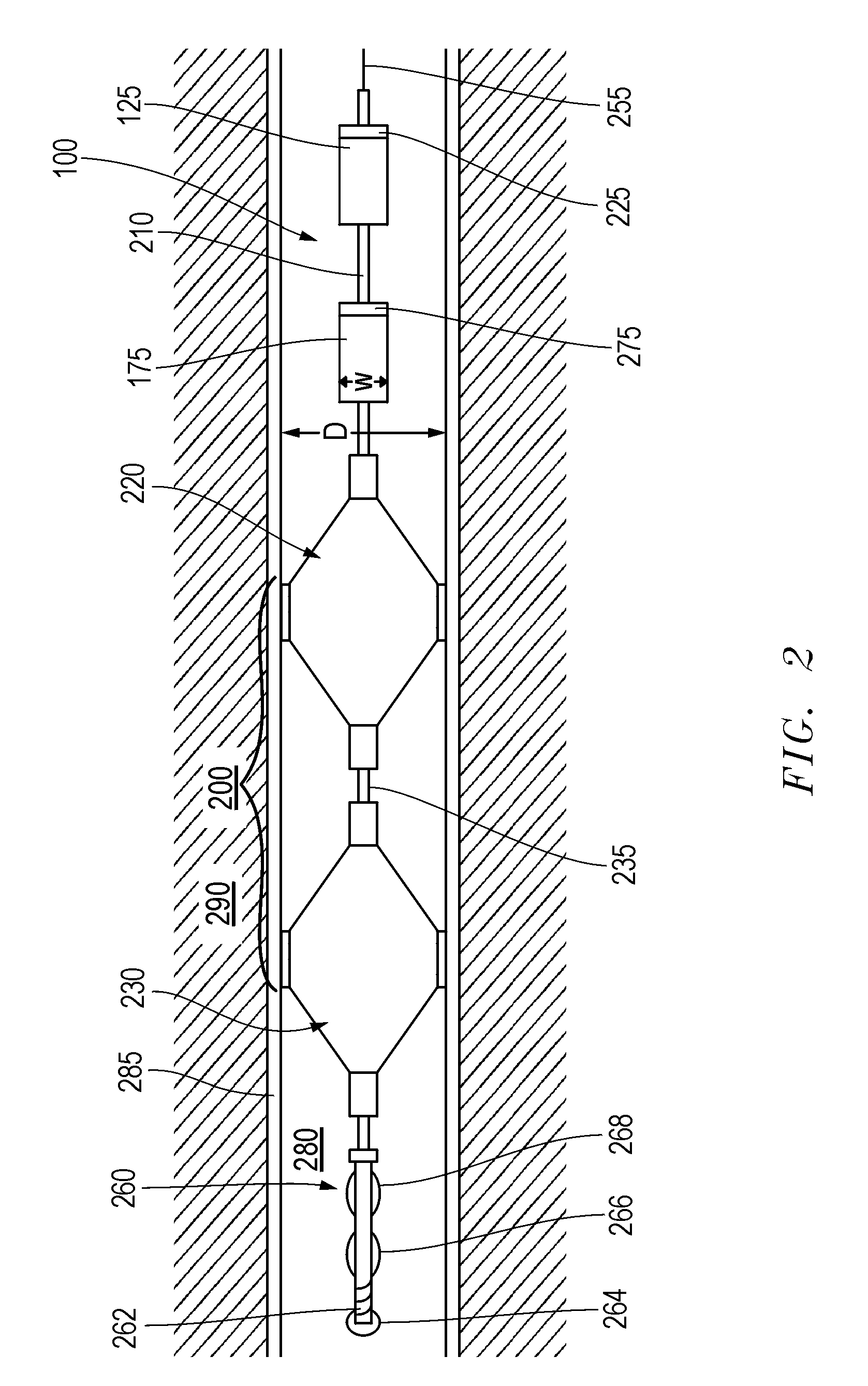

Downhole Load Sharing Motor Assembly

InactiveUS20090091278A1Shorten speedCommutation monitoringMotor/generator/converter stoppersPermanent magnet synchronous machinePermanent magnet synchronous motor

A motor assembly of multiple motors for use in driving a shared downhole load within a well. In particular, the assembly may employ substantially constant adjustable speed motors. These may include permanent magnet synchronous machine motors. The motors may be configured to operate at given speeds that may be downwardly adjusted depending on the amount of torque output independently exhibited by the individual motors. In this manner, a significant divergence in torque output between the motors may be avoided so as to ensure substantial load sharing between all of the motors of the assembly.

Owner:SCHLUMBERGER TECH CORP

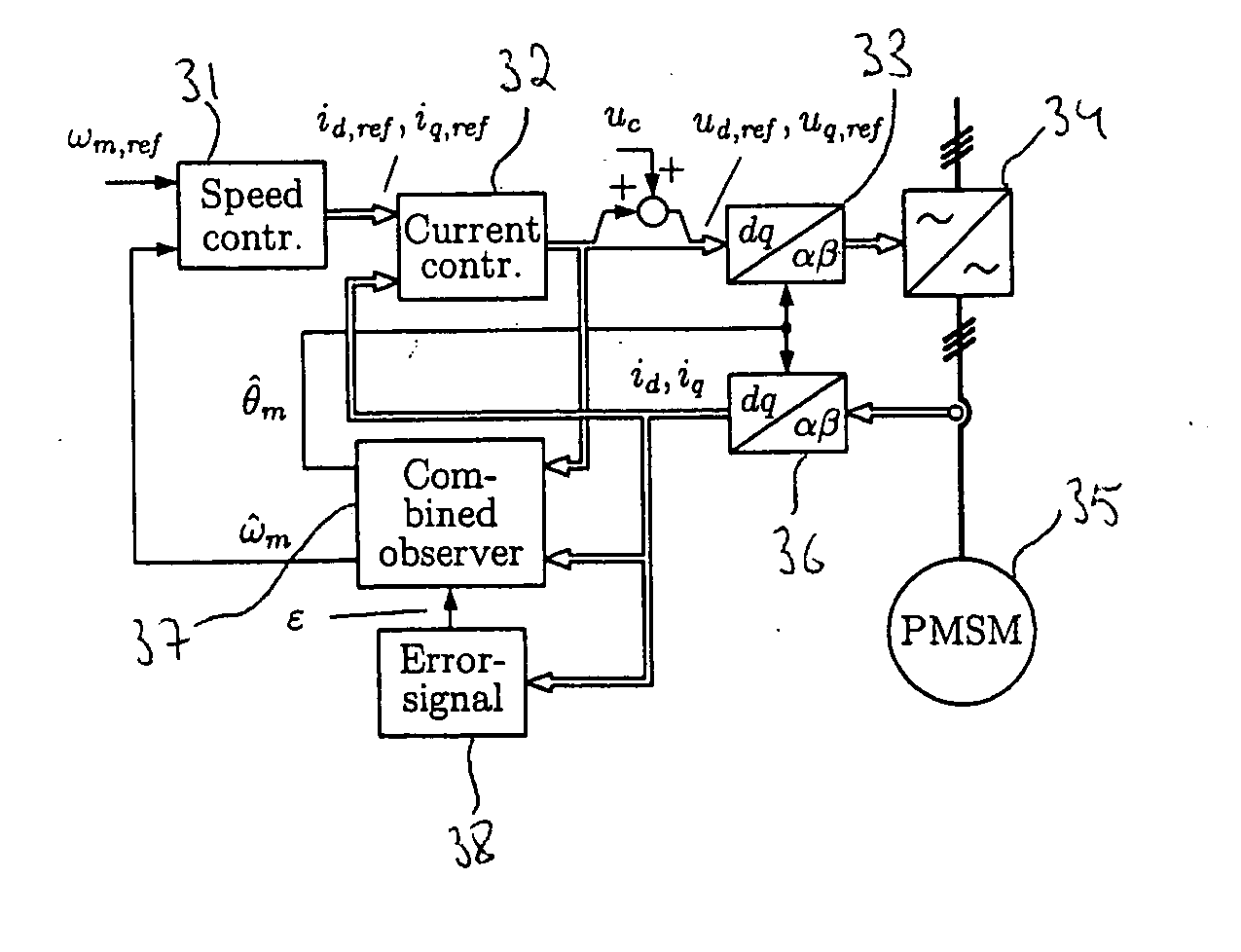

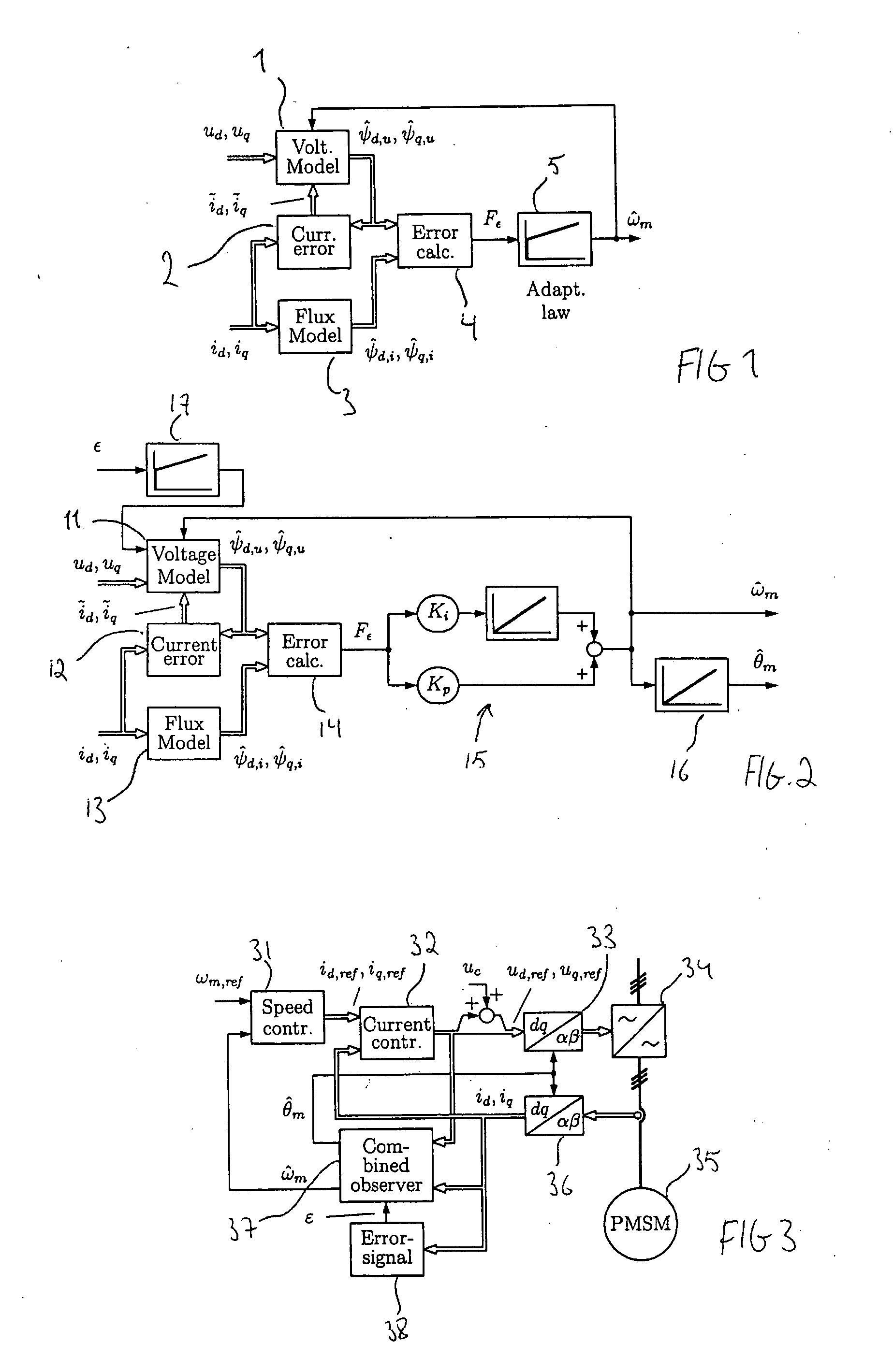

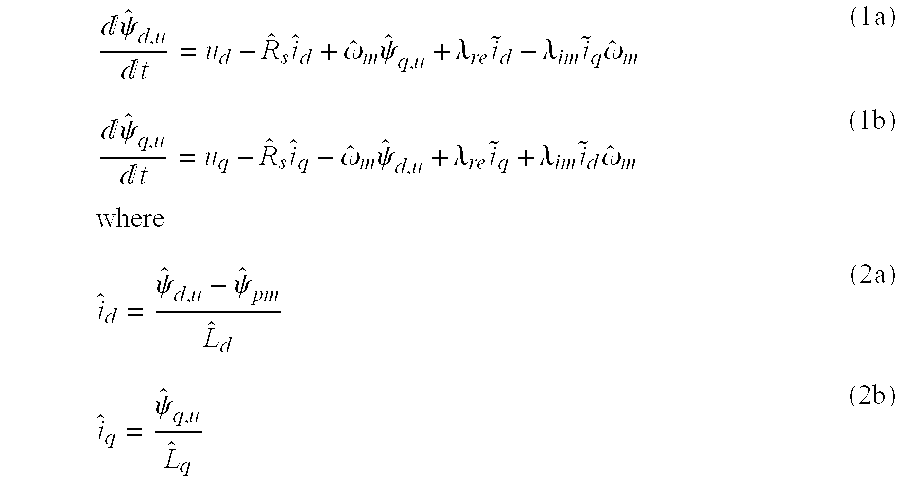

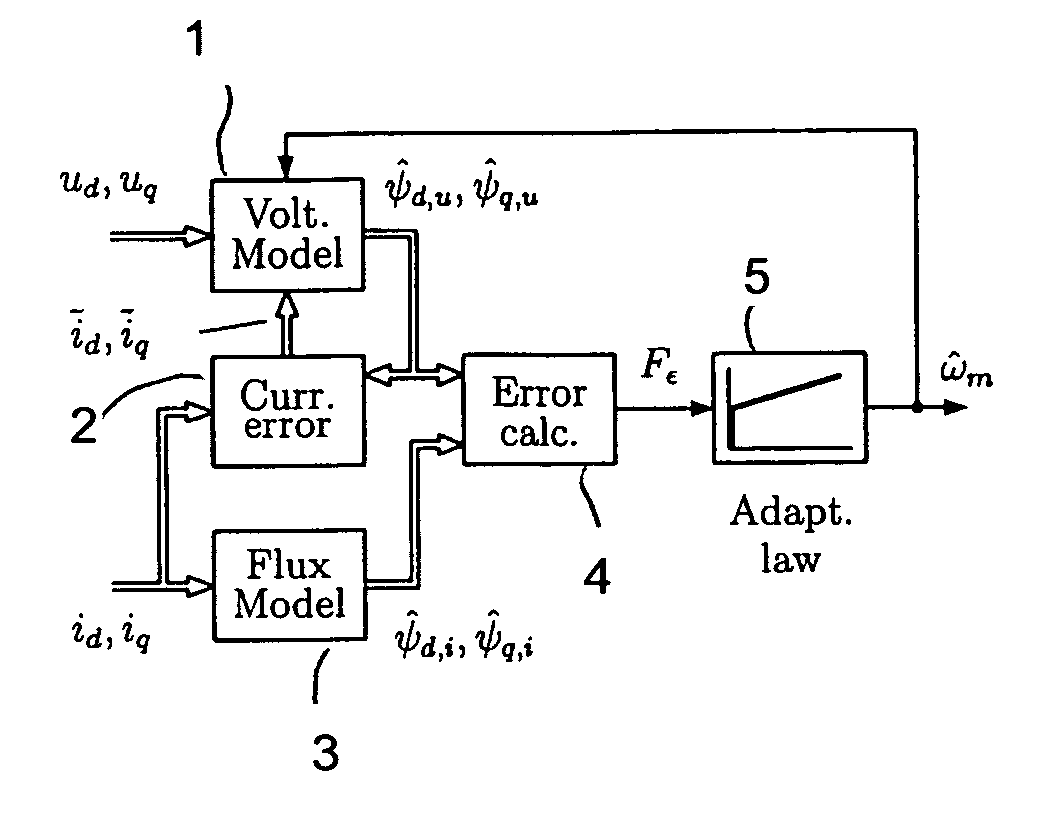

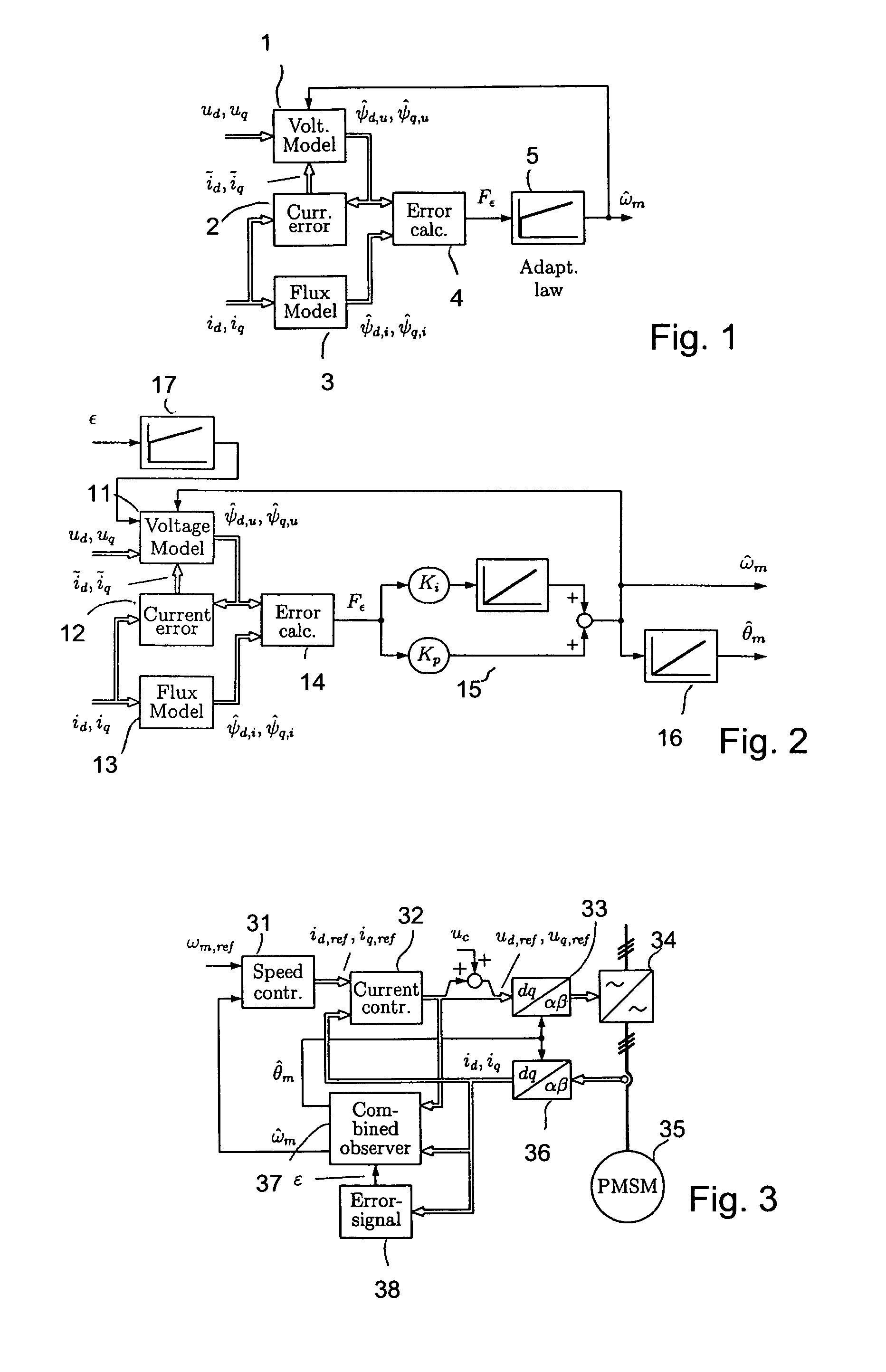

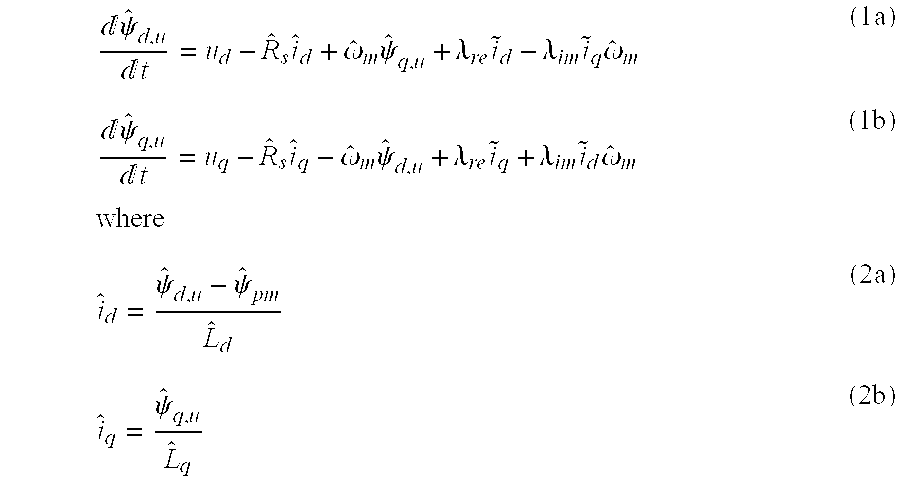

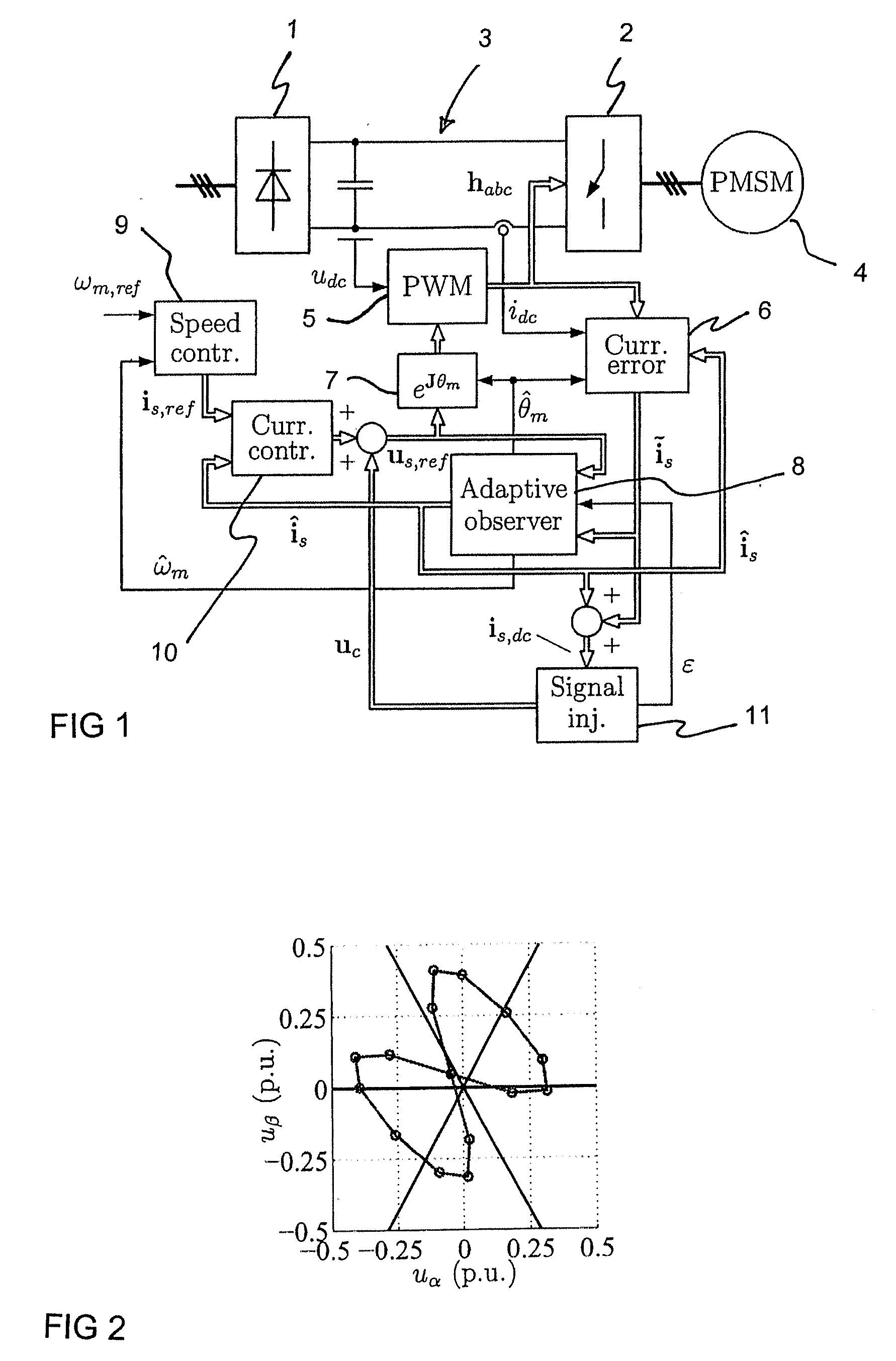

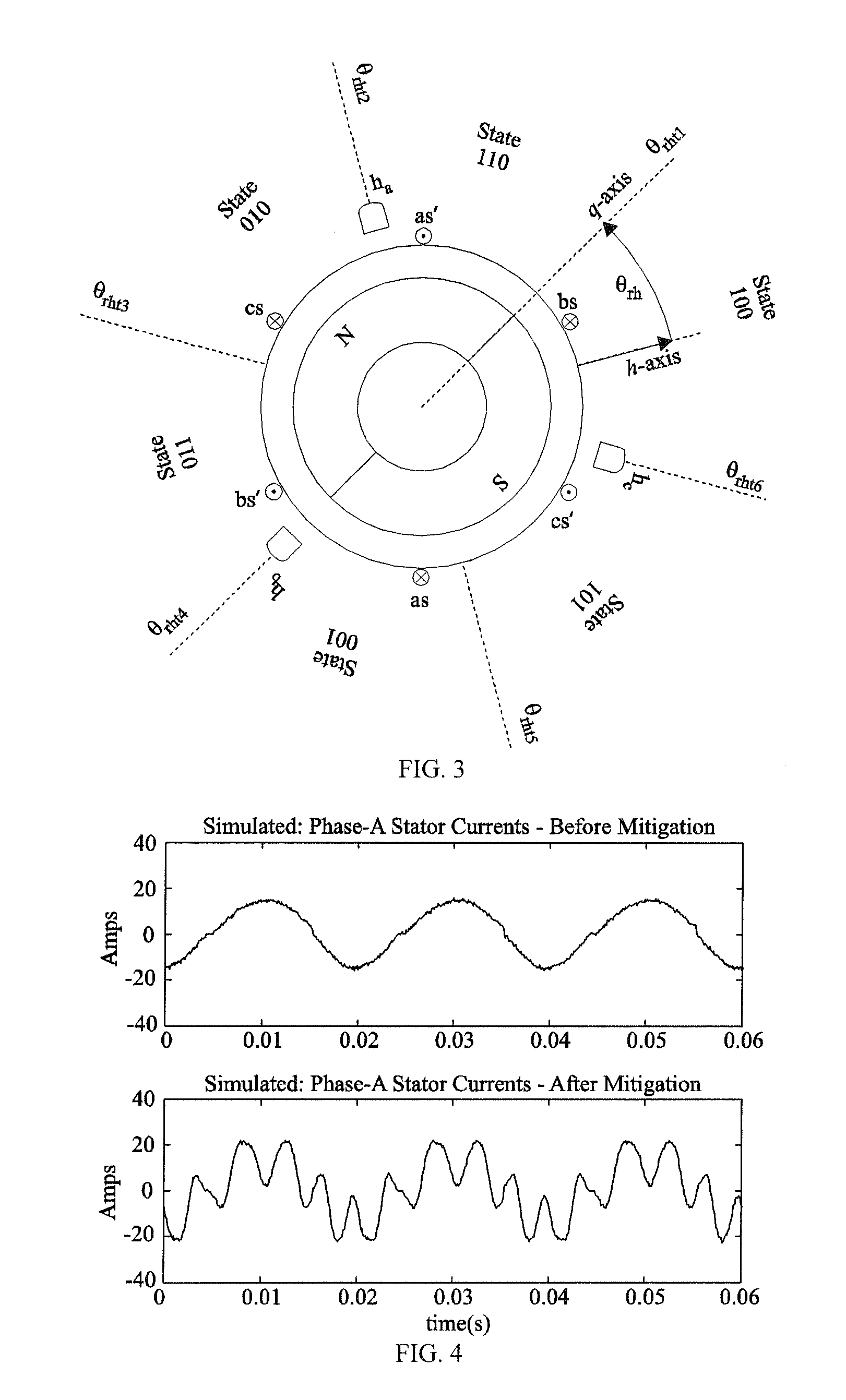

Method in connection with permanent magnet synchronous machines

InactiveUS20060091847A1Small speedSmall position estimation errorSingle-phase induction motor startersElectronic commutation motor controlStator voltagePermanent magnet synchronous machine

A method for sensorless estimation of rotor speed and position of a permanent magnet synchronous machine the method comprising the steps of calculating first stator flux vector estimate ({circumflex over (ψ)}d,i+j{circumflex over (ψ)}q,i) using the flux model and measured stator currents, calculating second stator flux vector estimate ({circumflex over (ψ)}d,u+j{circumflex over (ψ)}q,u) using the voltage model and measured stator voltages, comparing the directions of the first and second flux vectors to achieve a first error signal (Fε), using speed adaptation to achieve estimates for the rotor angular speed ({circumflex over (ω)}m) and angular position ({circumflex over (θ)}m) from the first error signal (Fε), injecting a known voltage signal (uc) to the stator voltage, detecting a current signal (iqc) from the stator current to form a second error (ε) signal, which is dependent on the estimation error of the rotor position, augmenting the voltage model by the second error signal (ε) to keep the first and second flux vector estimates aligned and so to correct the rotor angular speed ({circumflex over (ω)}m) and angular position ({circumflex over (θ)}m) estimates.

Owner:ABB OY

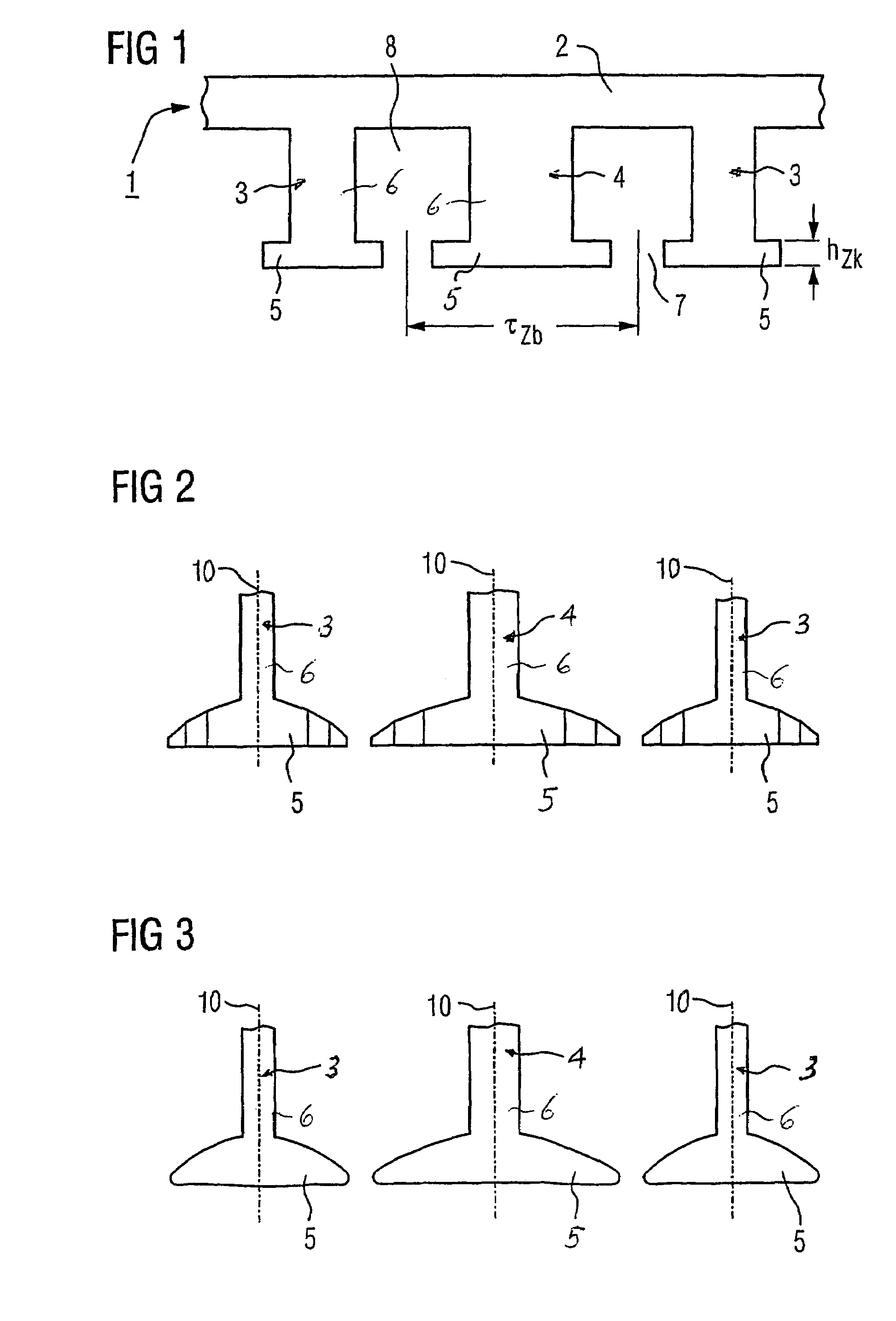

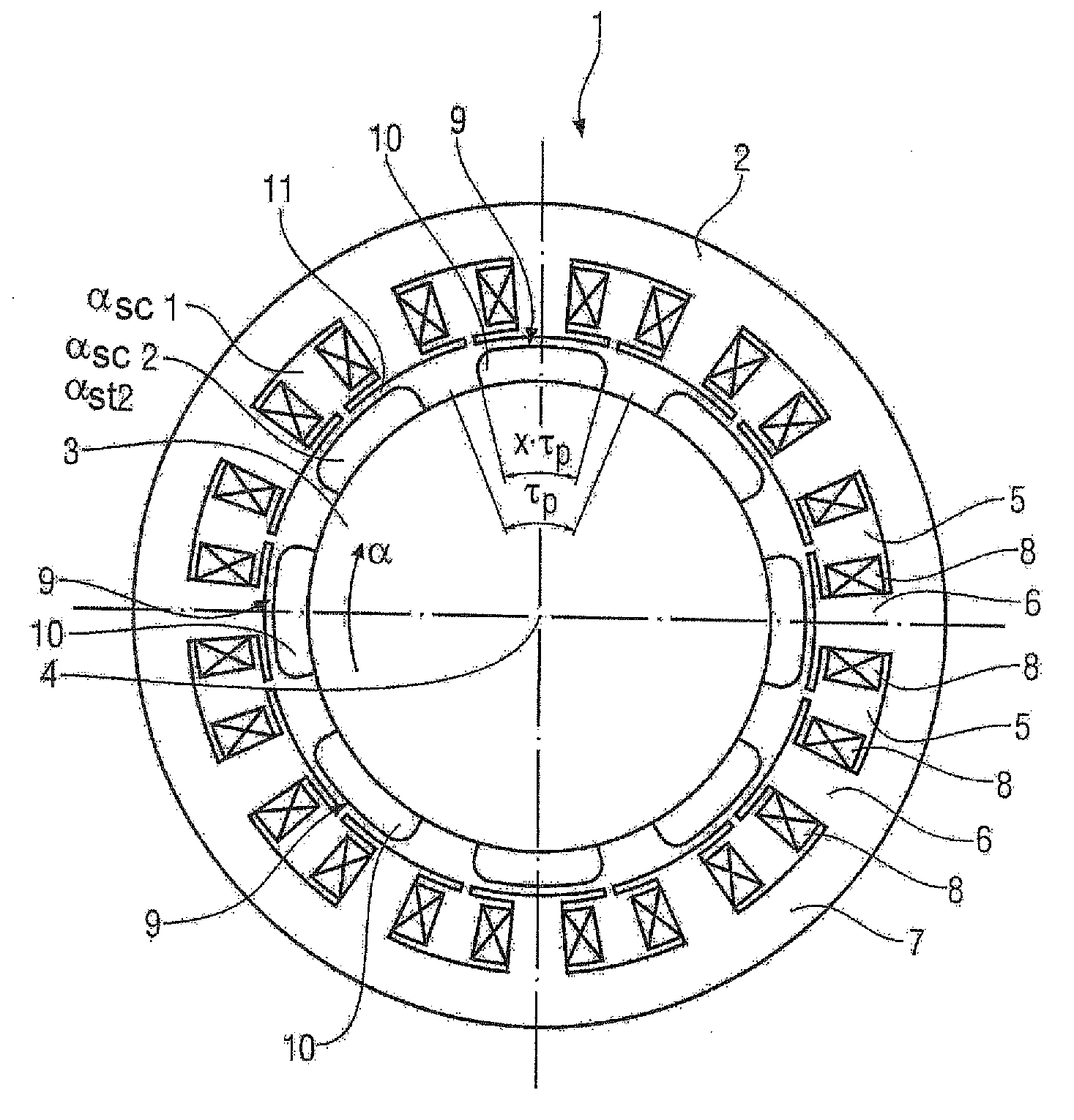

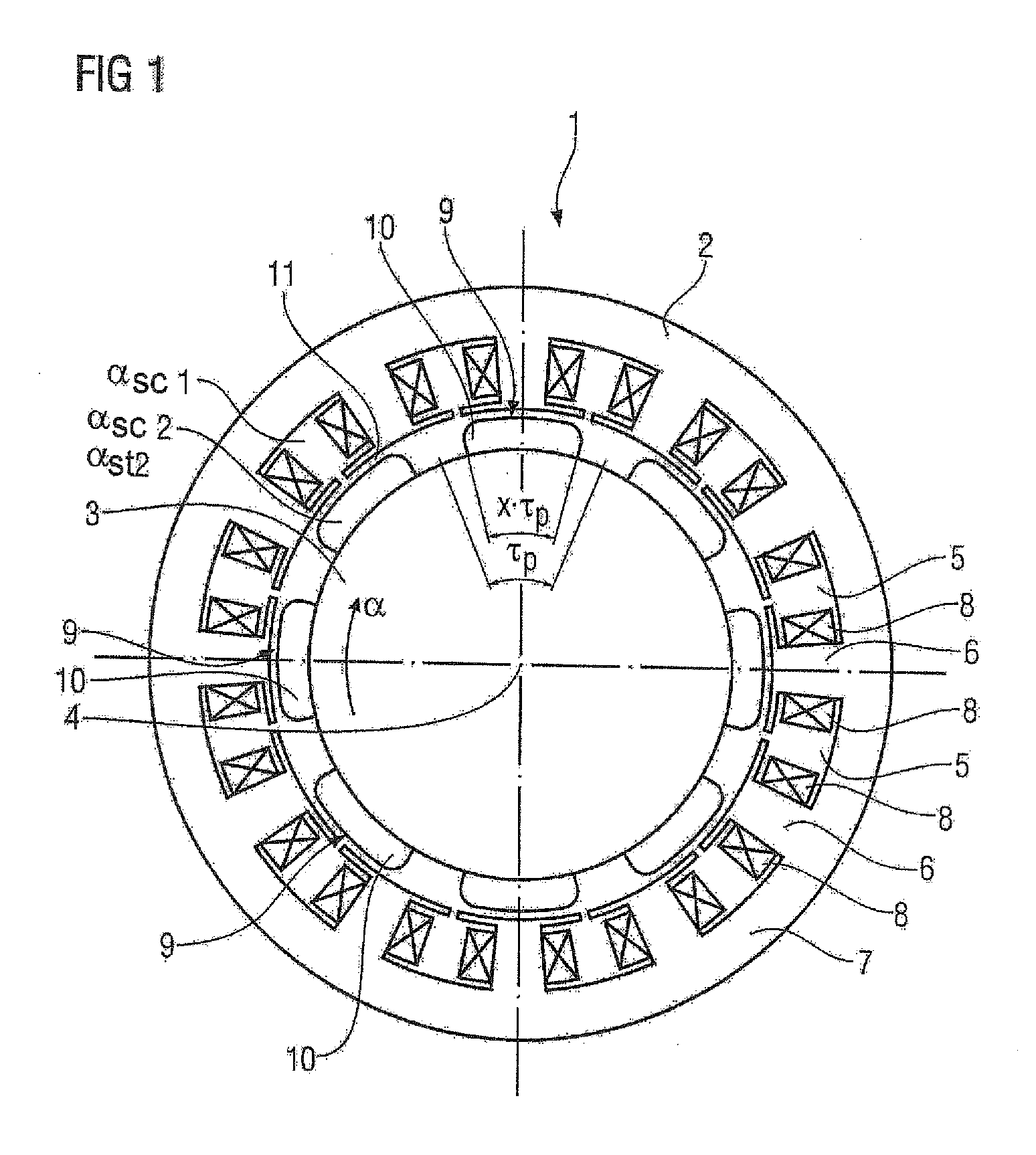

Permanent-magnet synchronous machine with suppression means for improving the torque ripple

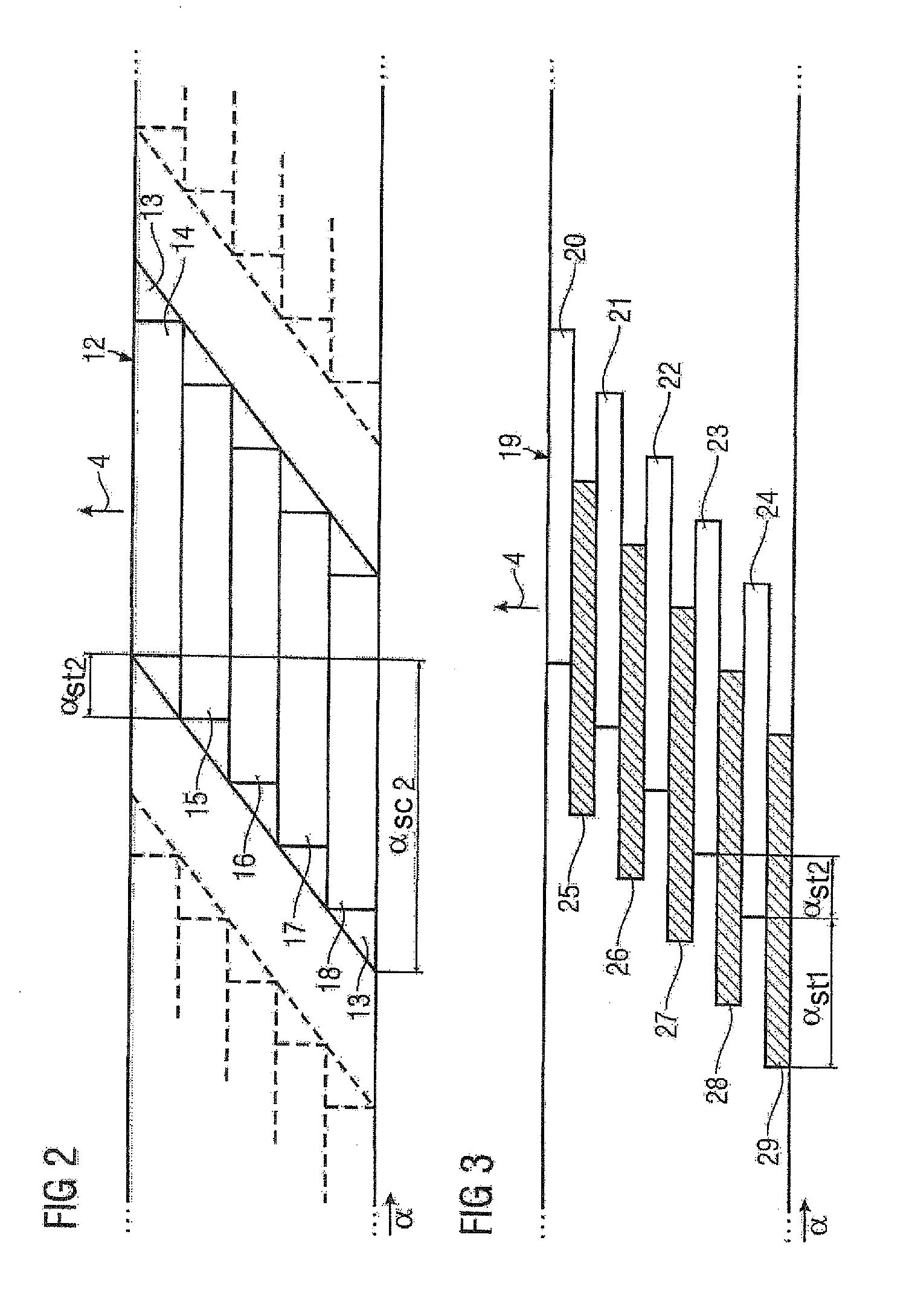

InactiveUS20100264770A1Easy to manufactureEasy to solveMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet synchronous machineSkew angle

A permanent-magnet synchronous machine for suppressing harmonics includes a stator and a rotor with permanent magnets. Each permanent magnet represents a magnetic pole and is, when viewed in the circumferential direction of the rotor, shaped as a parallelogram or an arrow. The pole coverage is less than one. The permanent magnets are staggered at a staggering angle, wherein the permanent magnets of one pole are arranged in the axial direction with an increasing offset of a circumferential angle in relation to a first permanent magnet of this pole. Each permanent magnet is skewed at a skew angle defined by a circumferential angle of a projection of a tip portion of the parallelogram or arrow. The optimal skew and staggering angles are calculated from the design parameters for the stator and the number of pole pairs and the number of poles in the axial direction of the rotor.

Owner:SIEMENS AG

Method and apparatus for automatically identifying electrical parameters in a sensor-less PMSM

ActiveUS8228013B2Effective estimateThe effect is accurateElectronic commutation motor controlMotor/generator/converter stoppersElectricityPermanent magnet synchronous machine

A method and apparatus for determining electrical parameters for commissioning a sensor-less permanent magnet synchronous machine uses knowledge of the rotor position to apply balanced pulses along the rotor magnet axis and perpendicular to the rotor magnet axis allowing measurement of q- and d-inductance at multiple current levels without substantial rotor movement.

Owner:ROCKWELL AUTOMATION TECH

Method of controlling an ac machine and controller for controlling an ac machine

InactiveUS20140203754A1Guaranteed uptimeConducive to stable operationElectronic commutation motor controlMotor/generator/converter stoppersStability parameterPermanent magnet synchronous machine

A method of controlling an AC machine that includes a stator and a rotor. The method includes observing a stability parameter that is indicative of the stability of the AC machine and dependent on a current state of the AC machine; and controlling the AC machine based on the observed stability parameter so as to promote stable operation of the AC machine. The method may include controlling the AC machine to operate as a motor or as a generator. The AC machine may be a permanent magnet synchronous machine. A controller suitable for performing the method is also disclosed.

Owner:ROLLS ROYCE PLC

Rotor of a permanent magnet synchronous machine

InactiveUS20120025654A1Increase powerReduction in the harmonics of the magnetic air-gap fieldMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet synchronous machineMagnetic poles

A rotor for a permanent magnet synchronous machine includes a basic body defining a center. Permanent magnets are arranged on a circumferential surface of the basic body to thereby form magnetic poles. Each magnetic pole is formed in a circumferential direction by at least two permanent magnets and defined by a pole center and a pole edge, wherein the pole edge is spaced from the center of the basic body at a distance which is smaller than a distance of the pole center to the center of the basic body. Positioned in sections between the pole centers of adjacent pole are filling elements, with a banding securing the filling elements on the permanent magnets in such a way that the rotor has a substantially cylindrical circumferential surface.

Owner:SIEMENS AG

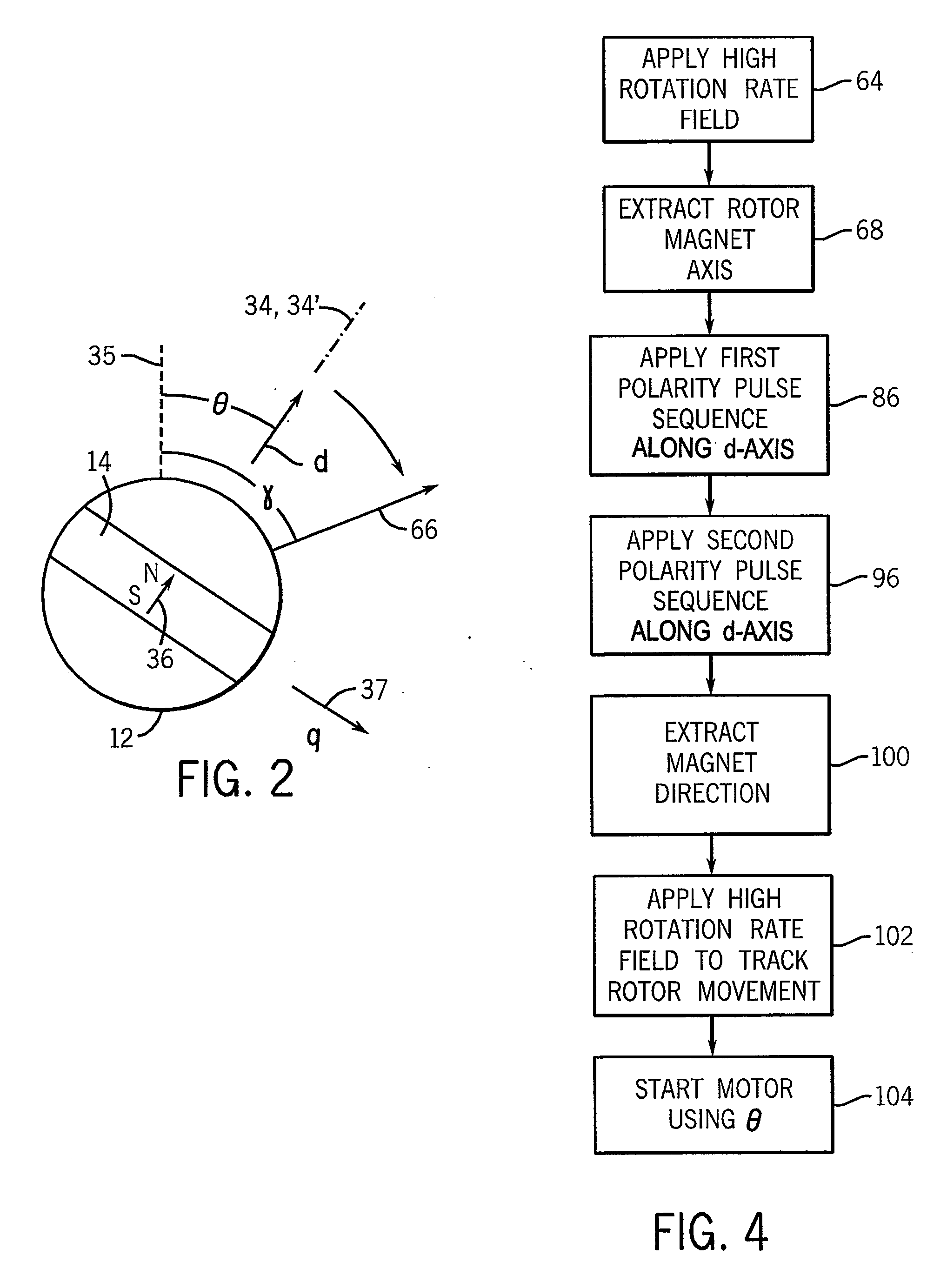

Method and apparatus for identifying orientation of a stationary rotor in a sensor-less pmsm

ActiveUS20100026223A1Rapid assessmentMotor/generator/converter stoppersSynchronous motors startersPermanent magnet synchronous machineMagnetic axis

A method and apparatus for determining rotor position in a stationary rotor of a sensor-less permanent magnet synchronous machine that employs a rotating magnetic field to identify a magnetic axis of the stator without a magnetic direction and then determines magnetic direction by applying pulses along the magnet axis in two polarities.

Owner:ROCKWELL AUTOMATION TECH

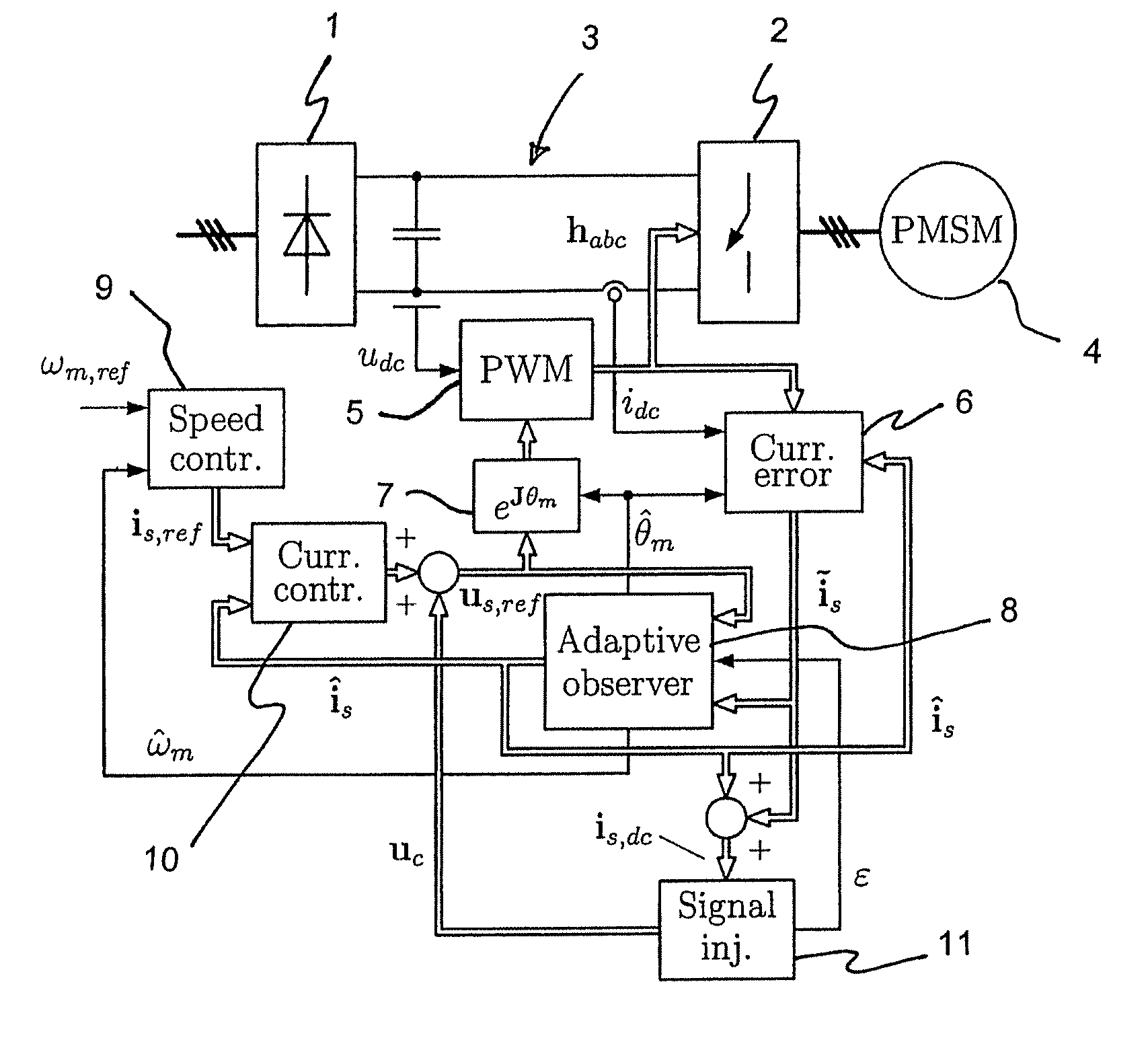

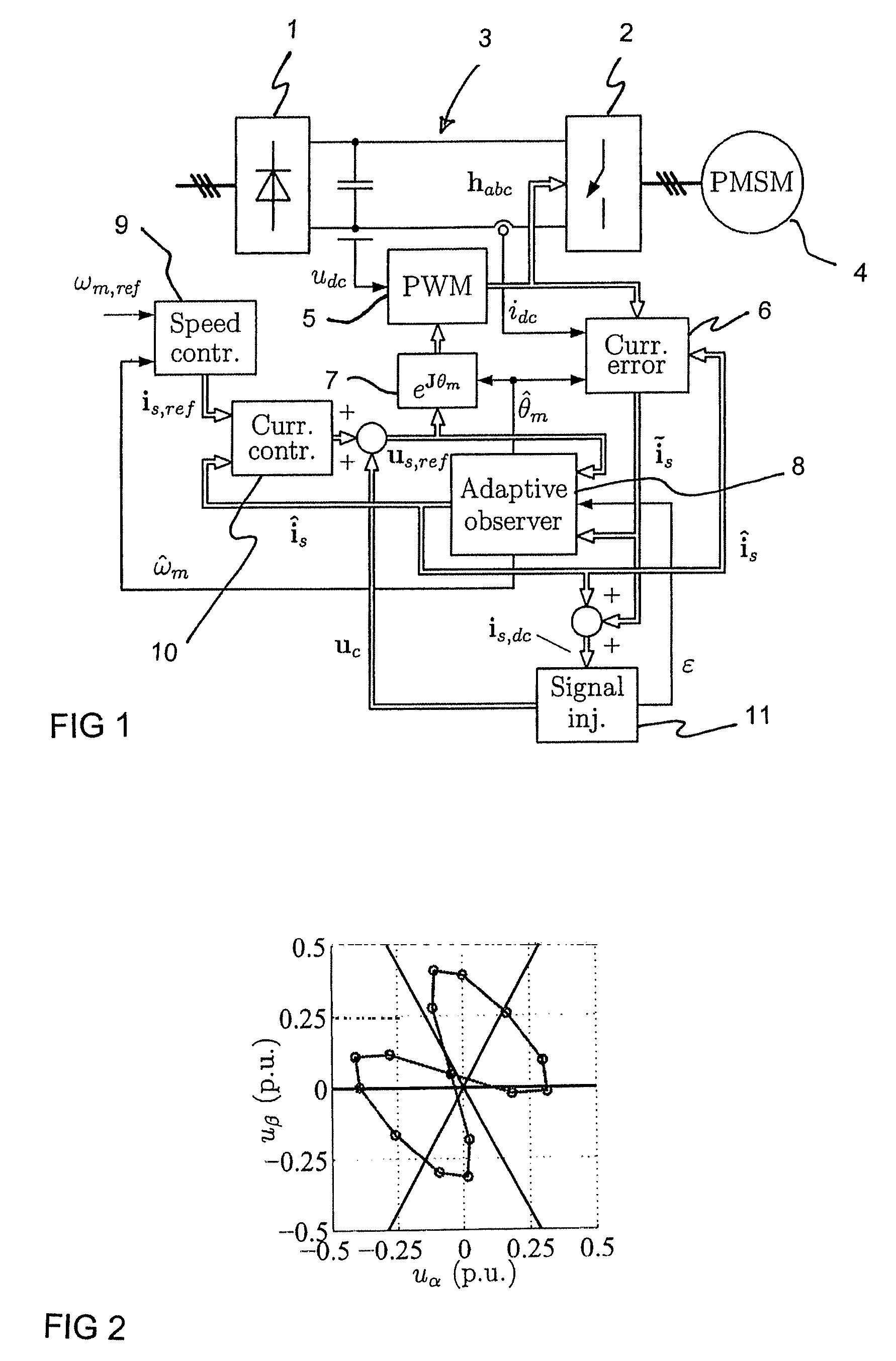

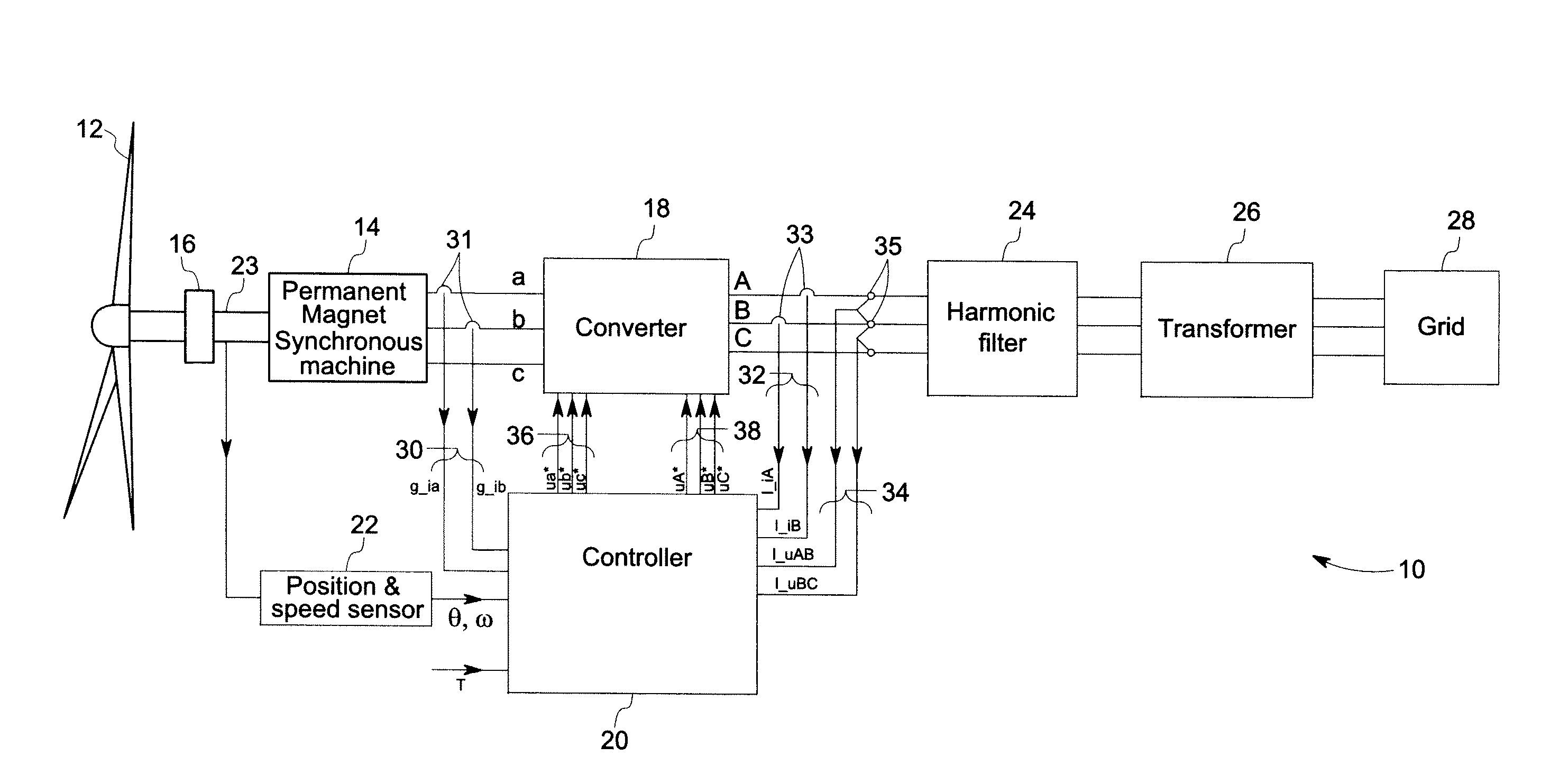

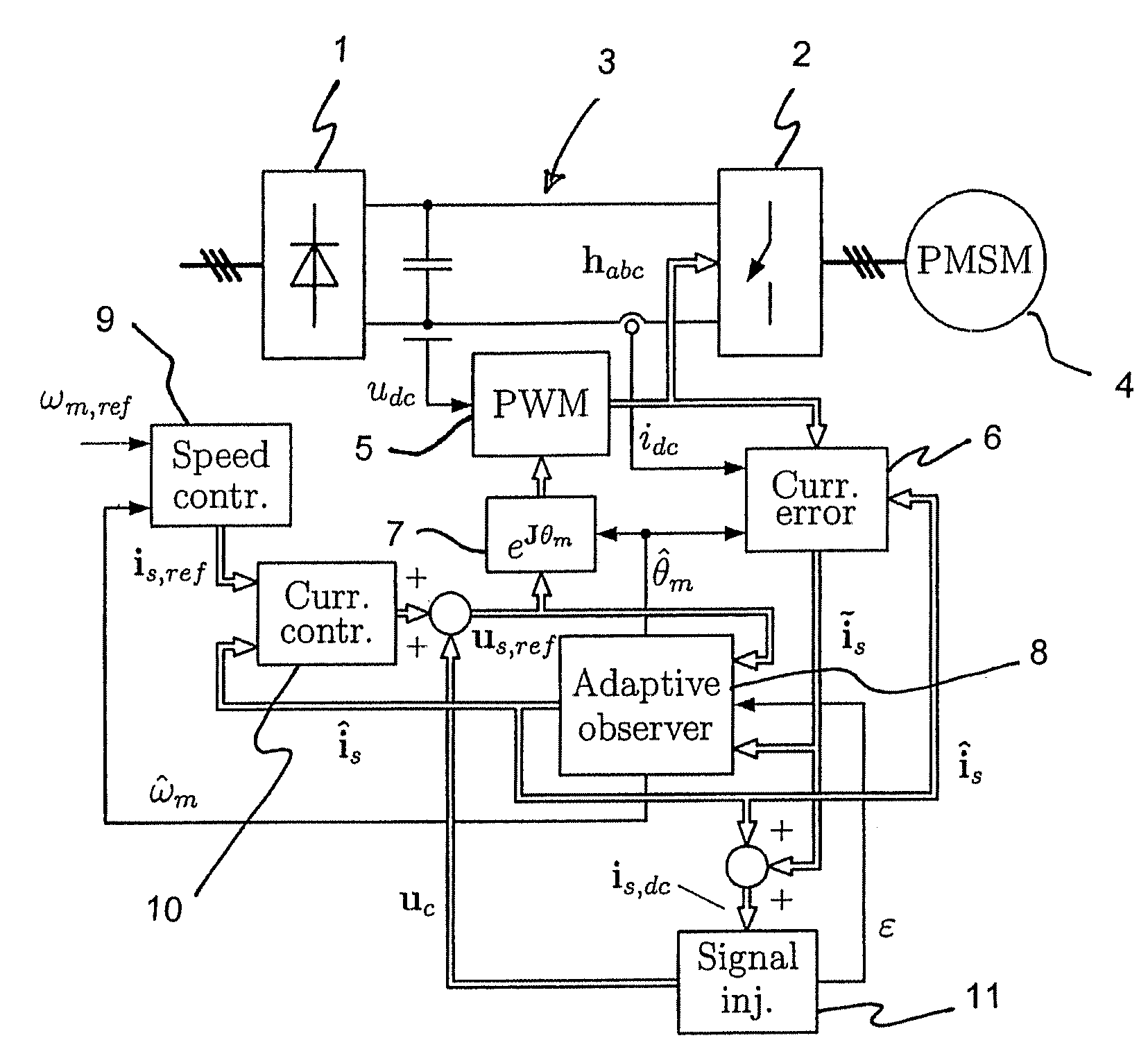

Method for sensorless estimation of rotor speed and position of a permanent magnet synchronous machine

ActiveUS7759897B2Stabilize estimationGuaranteed uptimeSingle-phase induction motor startersElectronic commutation motor controlStator voltageFrequency changer

A method for sensorless estimation of rotor speed and position of a permanent magnet synchronous machine, when the permanent magnet synchronous machine is fed with a frequency converter, the method comprising the steps of forming a stator voltage reference for the permanent magnet synchronous machine, injecting a high frequency signal (uc) into the stator voltage reference, measuring a DC-link current (idc) of the frequency converter when the permanent magnet synchronous machine (4) is fed with a voltage (us,ref) corresponding to a sum of the stator voltage reference and the injected signal, calculating a stator current estimate (îs), calculating a current error (ĩs) as a difference between the stator current estimate and the measured DC-link current, and estimating a rotor speed ({circumflex over (ω)}m) and position ({circumflex over (θ)}m) of the permanent synchronous machine based on the current error. The injected high frequency signal (uc) comprises a direct axis component and a quadrature axis component, the direct axis component having a first frequency and the quadrature axis component having a second frequency, the first and second frequencies being different.

Owner:ABB (SCHWEIZ) AG

Method in connection with permanent magnet synchronous machines

InactiveUS7098623B2Improve dynamic performanceSmaller positionSingle-phase induction motor startersElectronic commutation motor controlStator voltagePermanent magnet synchronous machine

A method for sensorless estimation of rotor speed and position of a permanent magnet synchronous machine the method comprising the steps of calculating first stator flux vector estimate ({circumflex over (ψ)}d,i+j{circumflex over (ψ)}q,i) using the flux model and measured stator currents, calculating second stator flux vector estimate ({circumflex over (ψ)}d,u+j{circumflex over (ψ)}q,u) using the voltage model and measured stator voltages, comparing the directions of the first and second flux vectors to achieve a first error signal (Fε), using speed adaptation to achieve estimates for the rotor angular speed ({circumflex over (ω)}m) and angular position ({circumflex over (θ)}m) from the first error signal (Fε), injecting a known voltage signal (uc) to the stator voltage, detecting a current signal (iqc) from the stator current to form a second error (ε) signal, which is dependent on the estimation error of the rotor position, augmenting the voltage model by the second error signal (ε) to keep the first and second flux vector estimates aligned and so to correct the rotor angular speed ({circumflex over (ω)}m) and angular position ({circumflex over (θ)}m) estimates.

Owner:ABB OY

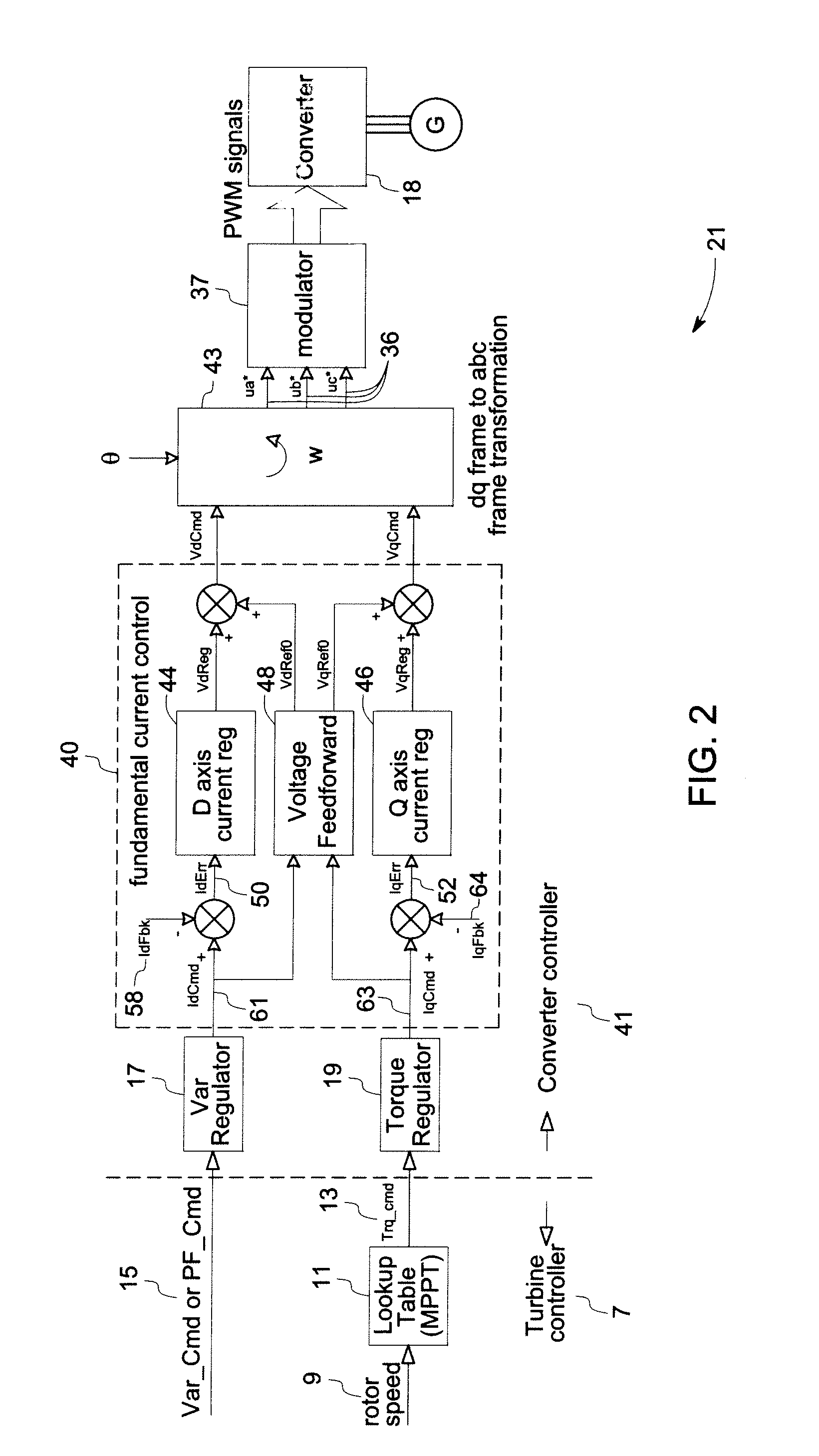

System and method for controlling torque ripples in synchronous machines

InactiveUS20110018281A1Electronic commutation motor controlElectric motor controlPermanent magnet synchronous machineHarmonic

A system for controlling torque ripple in a permanent magnet synchronous machine includes a power converter configured to be coupled to the permanent magnet synchronous machine and to receive converter control signals and a system controller coupled to the power converter. The system controller includes a fundamental current controller configured for providing fundamental voltage commands, a harmonic current controller configured for using harmonic current commands, current feedback signals from the permanent magnet machine, and fundamental current commands in combination with positive and negative sequence regulators to obtain harmonic voltage commands, and summation elements configured for adding the fundamental voltage commands and the harmonic voltage commands to obtain the converter control signals.

Owner:GENERAL ELECTRIC CO

Method for sensorless estimation of rotor speed and position of a permanent magnet synchronous machine

ActiveUS20080169782A1Stabilize estimationGuaranteed uptimeSingle-phase induction motor startersAC motor controlFrequency changerStator voltage

A method for sensorless estimation of rotor speed and position of a permanent magnet synchronous machine, when the permanent magnet synchronous machine is fed with a frequency converter, the method comprising the steps of forming a stator voltage reference for the permanent magnet synchronous machine, injecting a high frequency signal (uc) into the stator voltage reference, measuring a DC-link current (idc) of the frequency converter when the permanent magnet synchronous machine (4) is fed with a voltage (Us,ref) corresponding to a sum of the stator voltage reference and the injected signal, calculating a stator current estimate (îs), calculating a current error (ĩs) as a difference between the stator current estimate and the measured DC-link current, and estimating a rotor speed ({circumflex over (ω)}m) and position ({circumflex over (θ)}m) of the permanent synchronous machine based on the current error. The injected high frequency signal (uc) comprises a direct axis component and a quadrature axis component, the direct axis component having a first frequency and the quadrature axis component having a second frequency, the first and second frequencies being different.

Owner:ABB (SCHWEIZ) AG

Torque ripple mitigation controller with vibration sensor delay compensation

ActiveUS8018193B1Low costSignificant progressTorque ripple controlCommutation monitoringPermanent magnet synchronous machineControl theory

An enhanced torque ripple mitigation algorithm for permanent magnet synchronous machines (PMSMs), the algorithm including compensation for sensor delay.

Owner:PURDUE RES FOUND INC

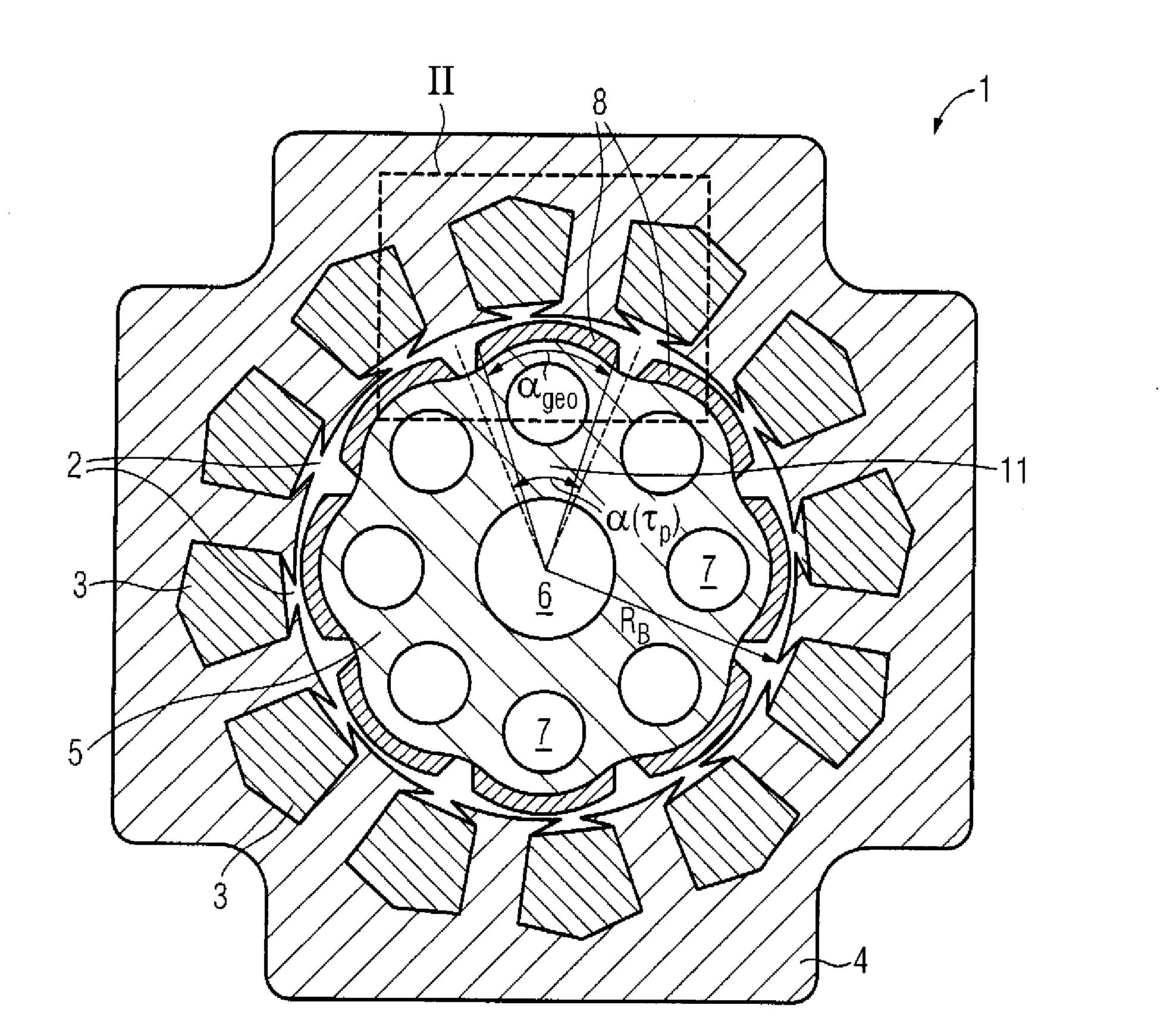

Permanent magnet synchronous machine

InactiveUS20050231060A1InhibitionSmall heightMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet synchronous machineEngineering

A permanent magnet synchronous machine includes a stator, and a rotor which defines with the stator an air gap. The stator includes a plurality of teeth which are disposed in spaced-apart circumferential relationship and separated from one another by a tooth pitch. Each of the teeth has a shaft which terminates in a tooth head adjacent the air gap, with the tooth heads of neighboring teeth being separated from one another by a slot. The tooth heads are constructed to prevent saturation. The rotor has permanent magnets which are aligned in flux concentration direction and arranged to define a pole pitch, wherein a pitch ratio of tooth pitch to pole pitch is ≧2.5.

Owner:SIEMENS AG

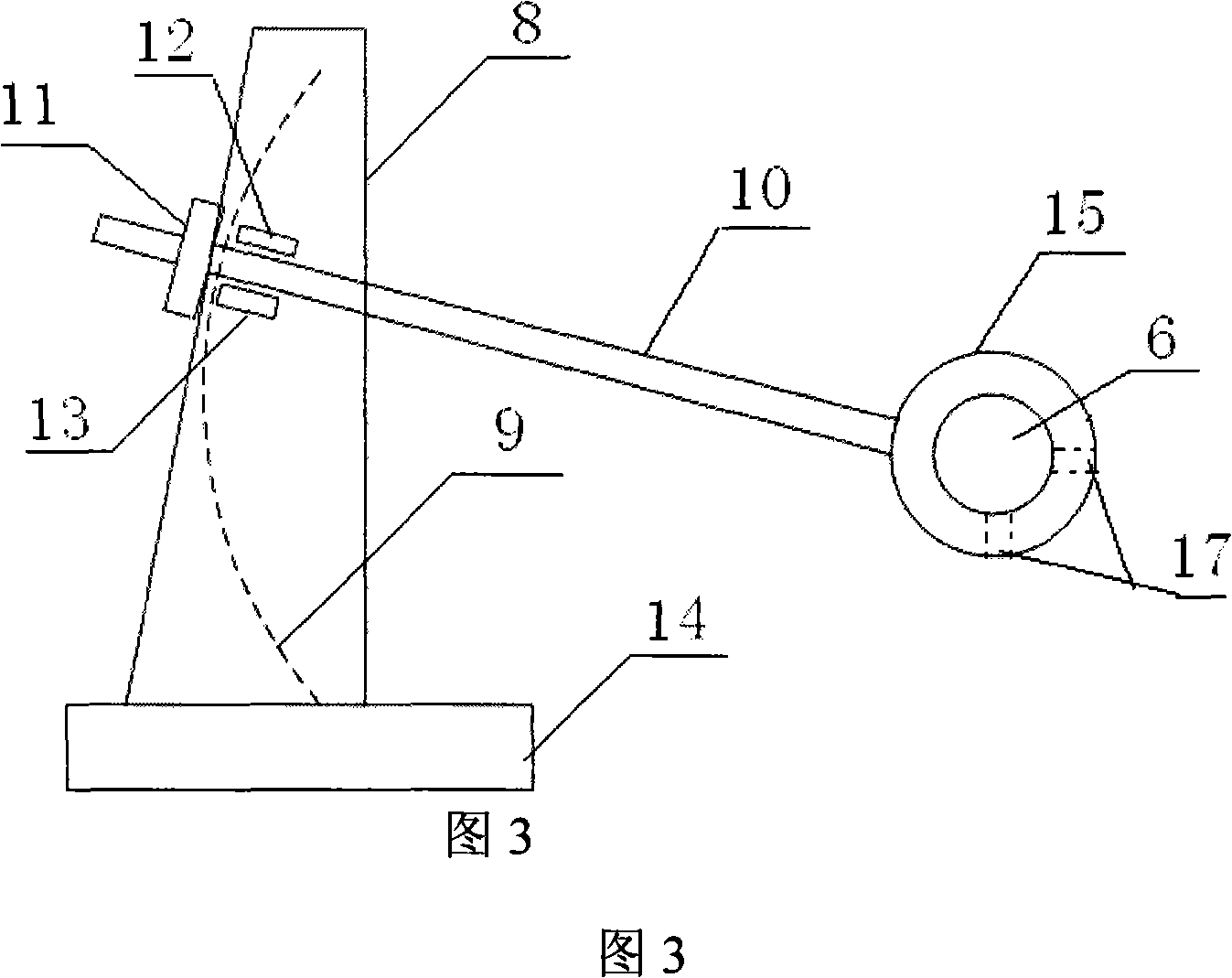

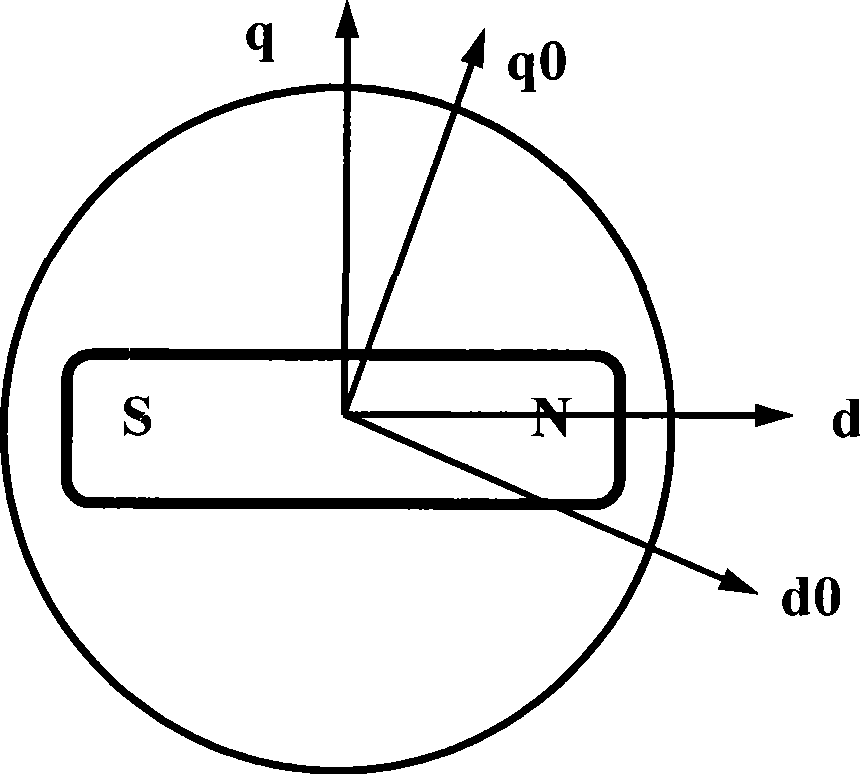

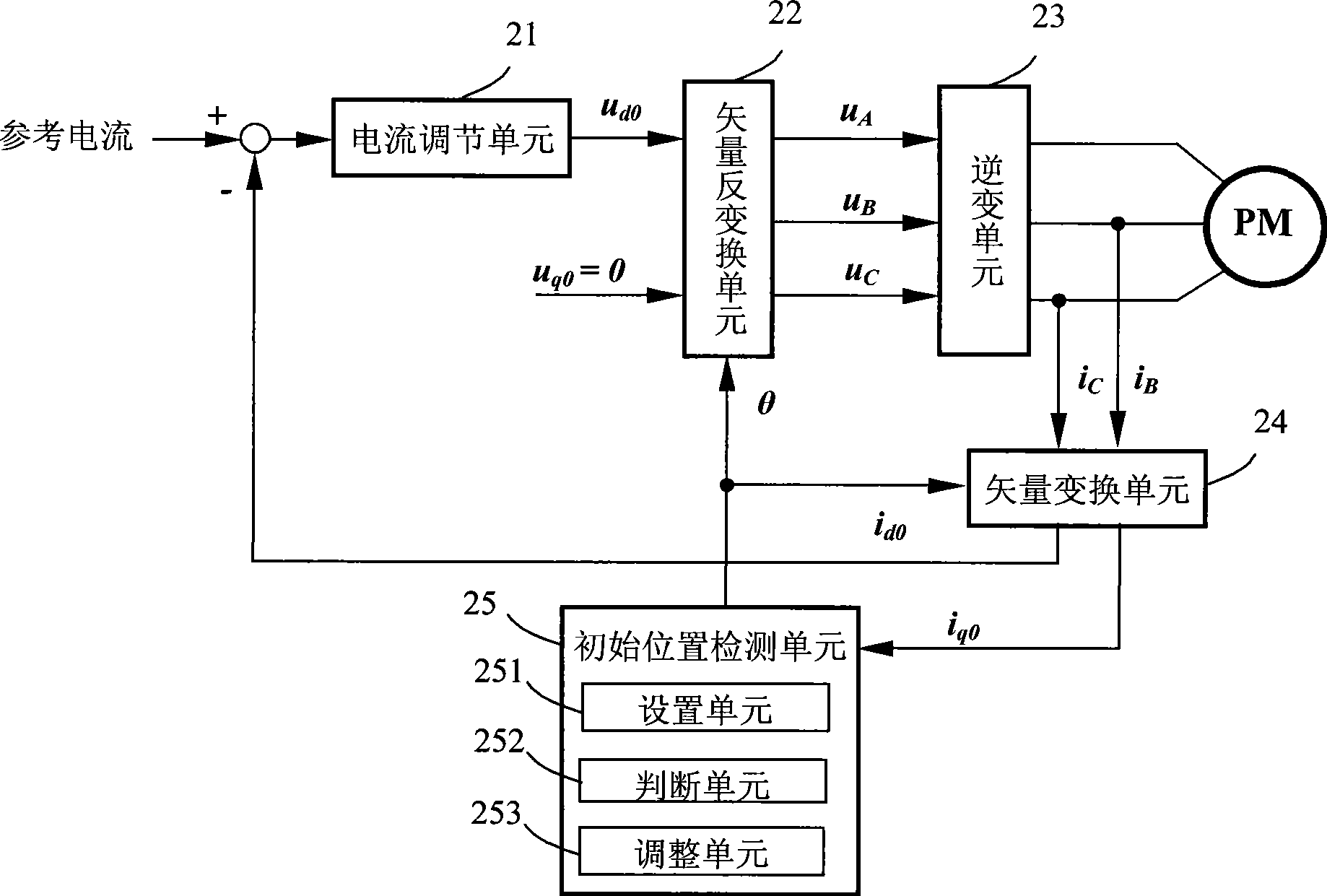

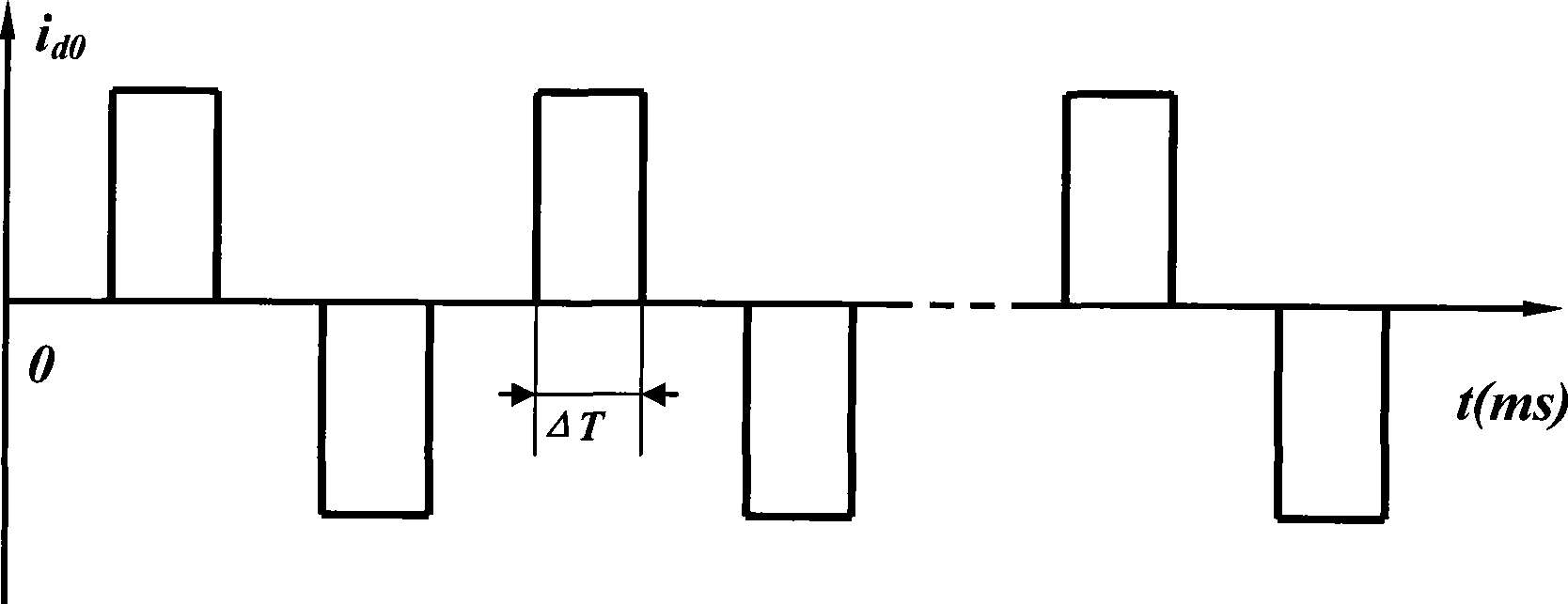

Method and system for detecting rotor magnetic pole initial position of permanent magnet synchronous machine

ActiveCN101369796ASolve starting problemsAccurate detectionElectronic commutation motor controlVector control systemsPermanent magnet synchronous machineControl vector

The present invention relates to a method for a method for detecting initial position of a permanent magnet synchronous motor rotor, including the steps of (a) setting hypothesis magnetic pole position; (b) inputting d0 shaft current into the motor for periodic variation of positive direction and negative direction, the motor being static during the period; (c) judging whether the accumulation current of the d0 shaft is more than a presetting threshold value or not during a period, if 'yes', implementing step (d); otherwise implementing step (e); (d) regulating the hypothesis magnetic pole position based on the polar of the d0 shaft accumulation current and implementing step (b); (e) determining the hypothesis magnetic pole position being the rotor initial position, detection being over. The invention also provides a corresponding system. The invention obtains the initial position angle of the rotor magnetic pole before starting up the motor using the characteristics of the permanent magnet synchronous motor, thus maximum rotary torque starting of the permanent magnet synchronous motor can be implemented with vector control mode.

Owner:SHENZHEN INOVANCE TECH

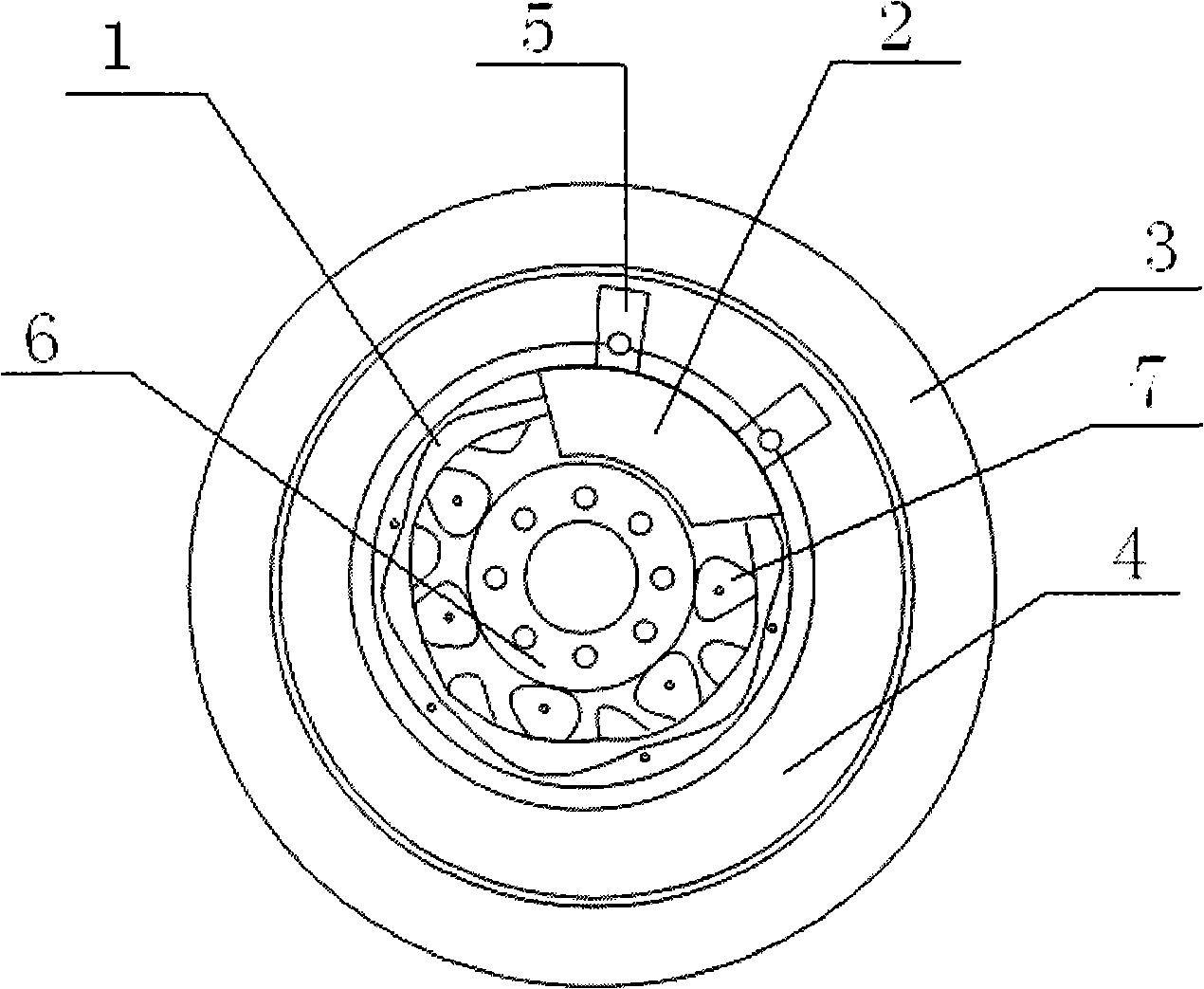

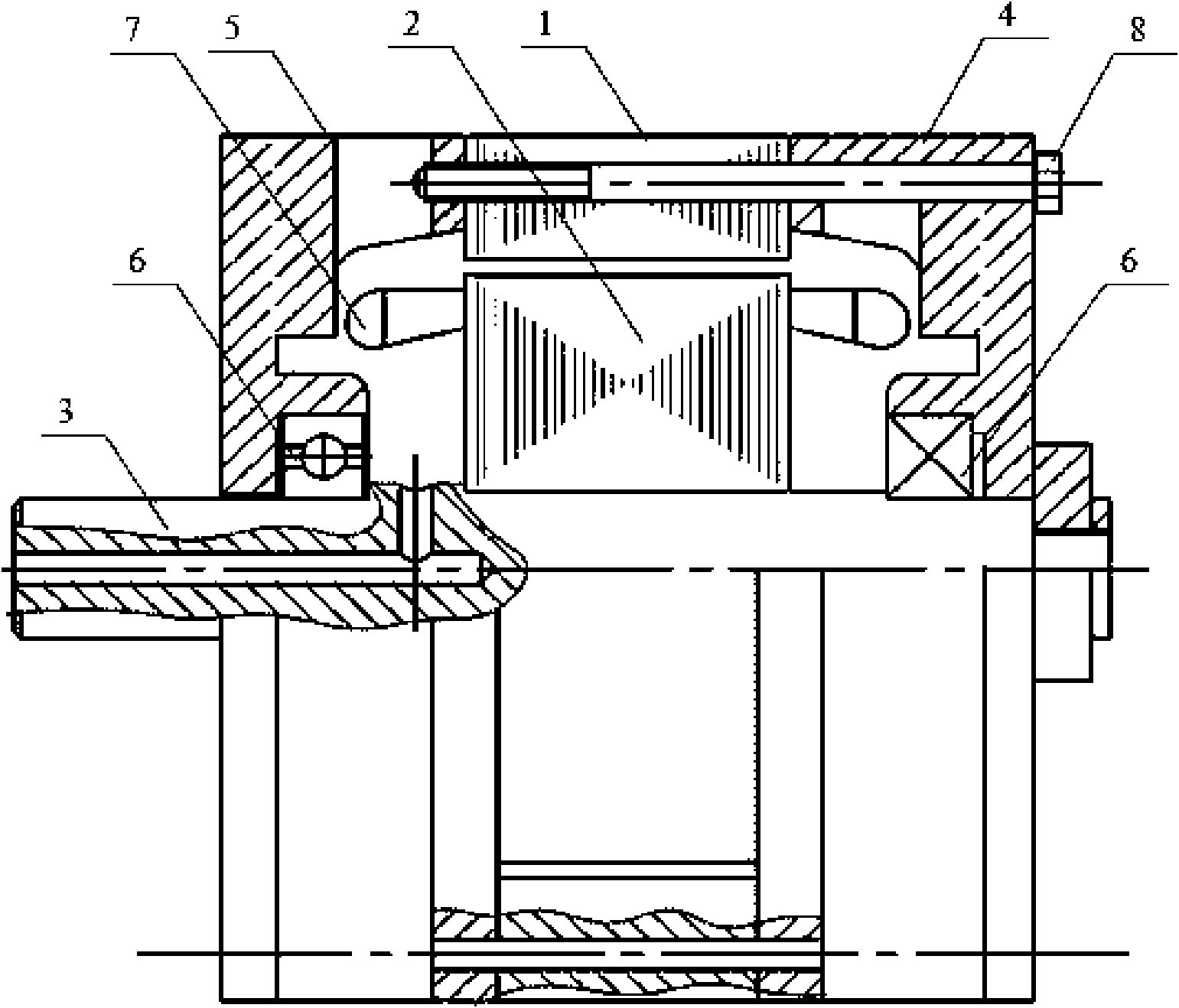

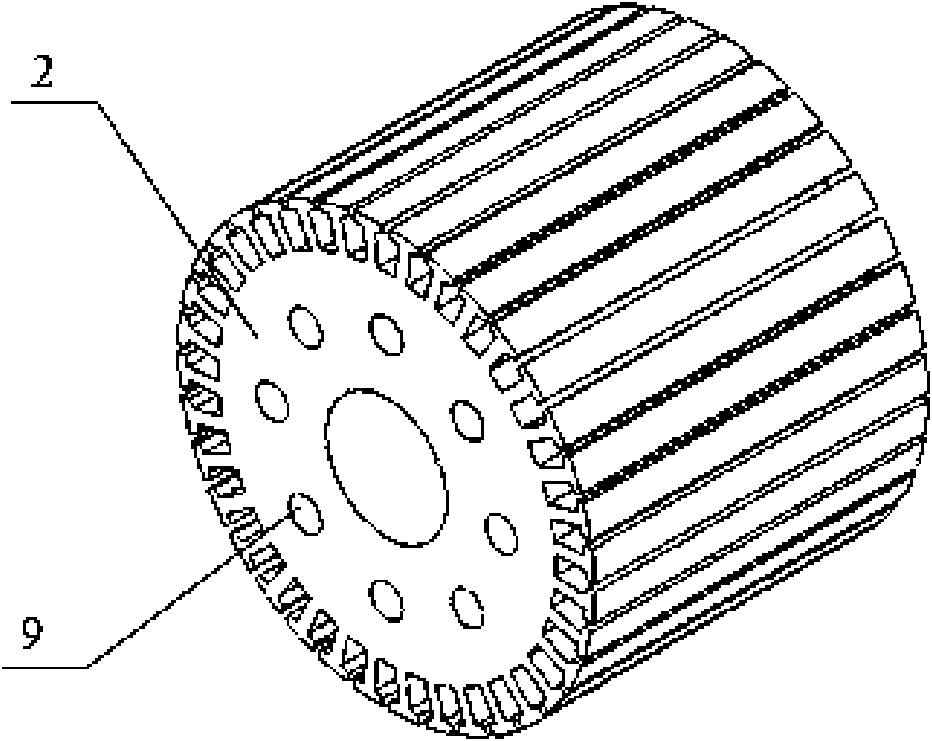

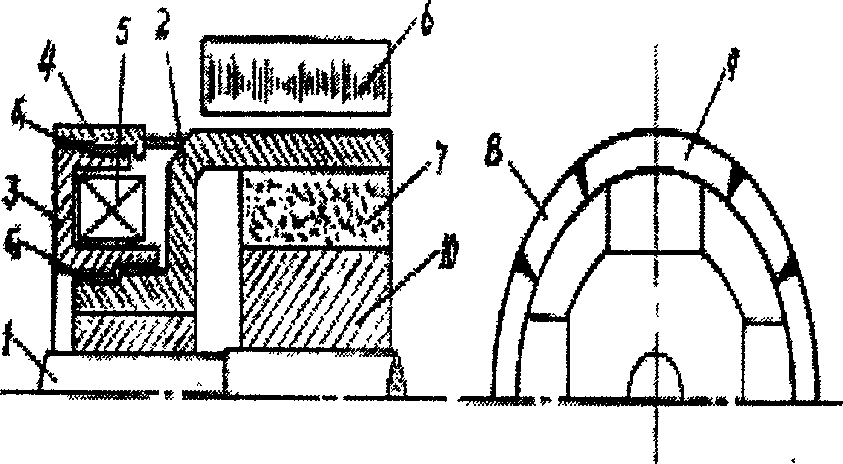

Self-ventilation cooling device of external rotor permanent magnet synchronous machine

InactiveCN101645629AReduce heat transferSmooth dischargeMagnetic circuit rotating partsMagnetic circuit stationary partsCold airPermanent magnet synchronous machine

The invention provides a self-ventilation cooling device of external rotor permanent magnet synchronous machine. A front end cover and a back end cover, both of which are provided with fan wheels therein, are respectively mounted at the two ends of an outer rotor iron core of a motor. The fan wheel is provided with a wheel hub and a plurality of vanes; and the wheel hub is sleeved on a motor shaft. Gaps are among the circumference of the front end cover and the vanes. The end surface of the front end cover is provided with an annular air inlet. The circumference of the back end cover is connected with the vanes; and air outlet is formed between the adjacent vanes on the circumference of the back end cover. The stator iron core is provided with a plurality of stator iron core vent holes therein. The rotor gears at the inner sidewall of the outer rotor iron core are projected out of the permanent magnet; and outer rotor vent channels are formed between the adjacent rotor gears. The invention sucks in the cool air from the centrifugal fan on the front end cover to direct air-cool the motor and finally exhausts the air with the motor inner heat energy out of the motor body by the centrifugal fan on the back end cover. The invention can keep the smooth flow of the cooling air in the inner part of the motor, thereby having good air-cooling effect and ensuring continuous work reliability of the permanent magnet motor.

Owner:HUAZHONG UNIV OF SCI & TECH

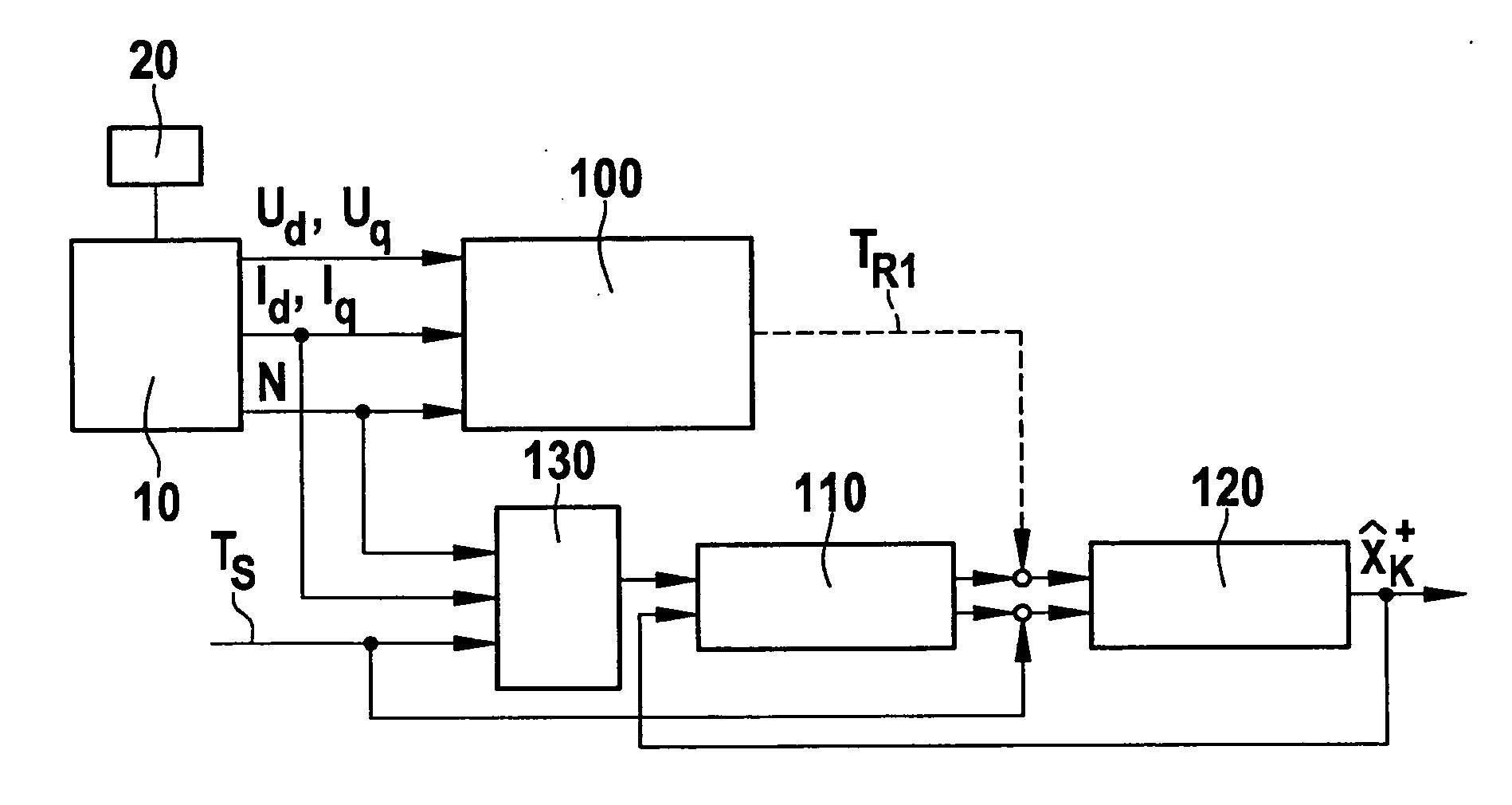

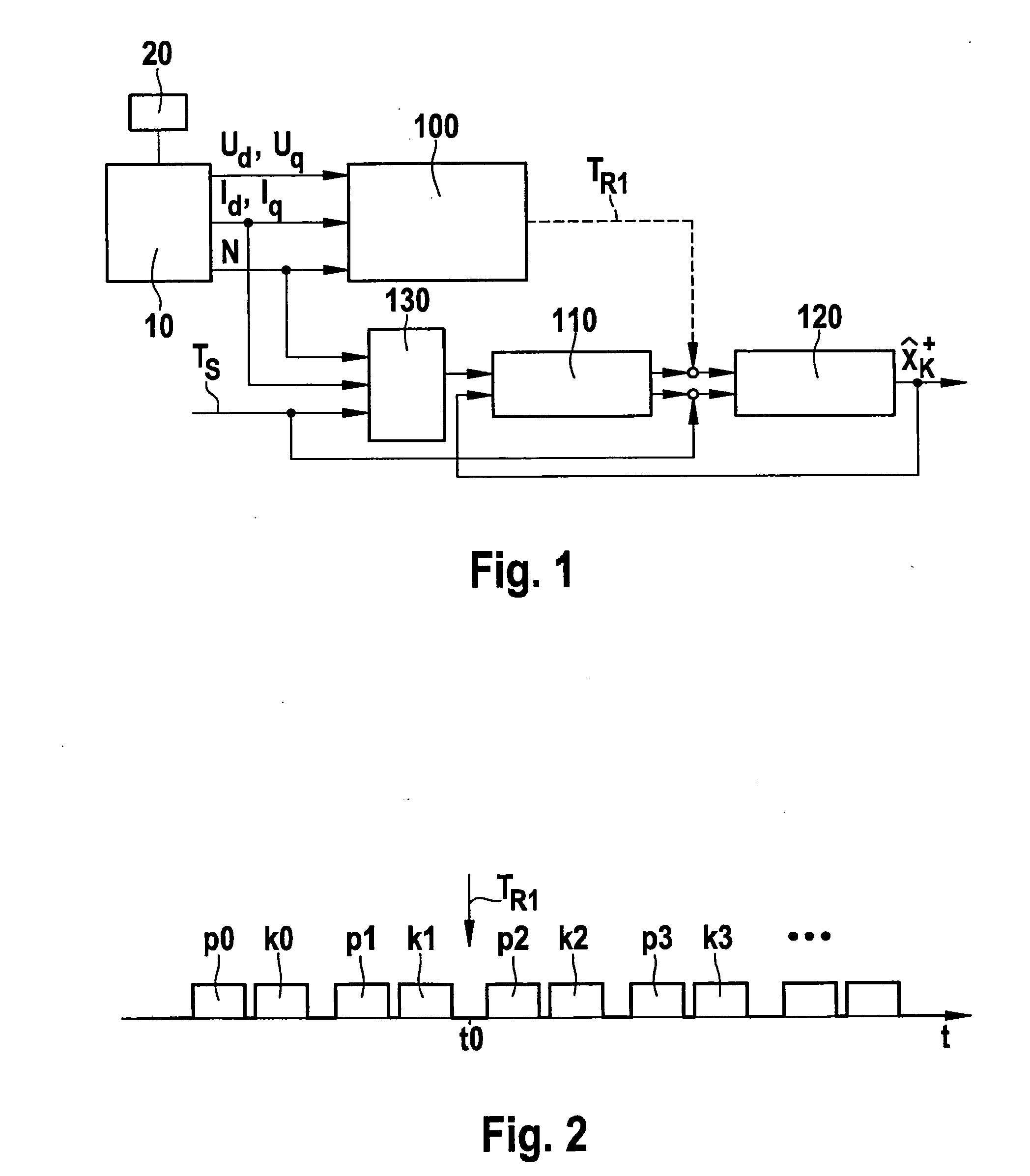

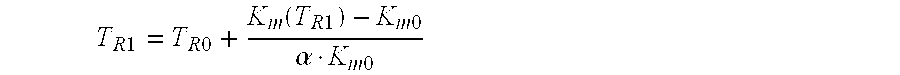

Method and device for ascertaining the rotor temperature of a permanent-magnet synchronous machine

ActiveUS20110181217A1High precisionAccurate temperatureElectronic commutation motor controlTemperature measurement in motorsKaiman filterPermanent magnet synchronous machine

A method for ascertaining the rotor temperature of a permanent-magnet synchronous machine (10), in which a first estimate (TR1) for the rotor temperature is ascertained as a function of a remanent flux density of permanent magnets contained in a rotor of the synchronous machine (10). A second estimate (TR2) for the rotor temperature is ascertained via a Kalman filter containing a thermal model of the synchronous machine (10), the first estimate (TR1) for the rotor temperature being supplied at least intermittently to the Kalman filter.

Owner:ROBERT BOSCH GMBH

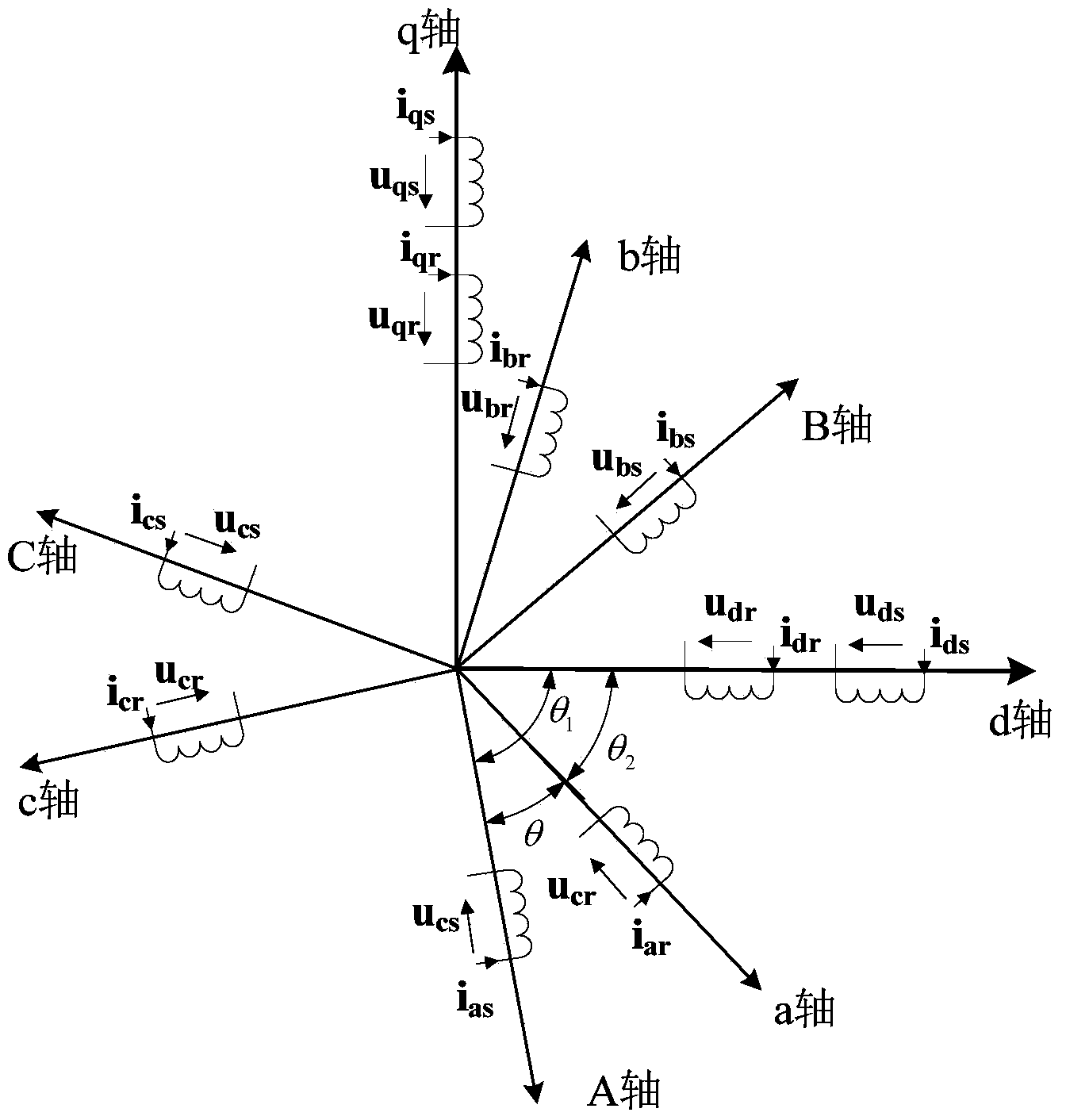

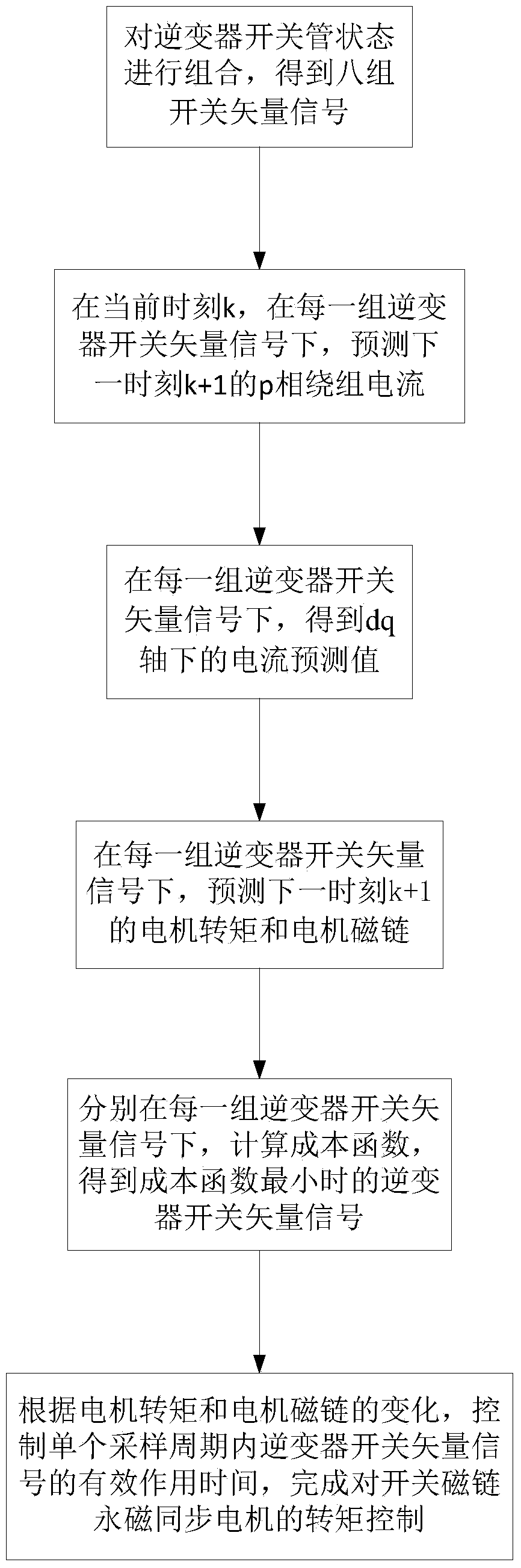

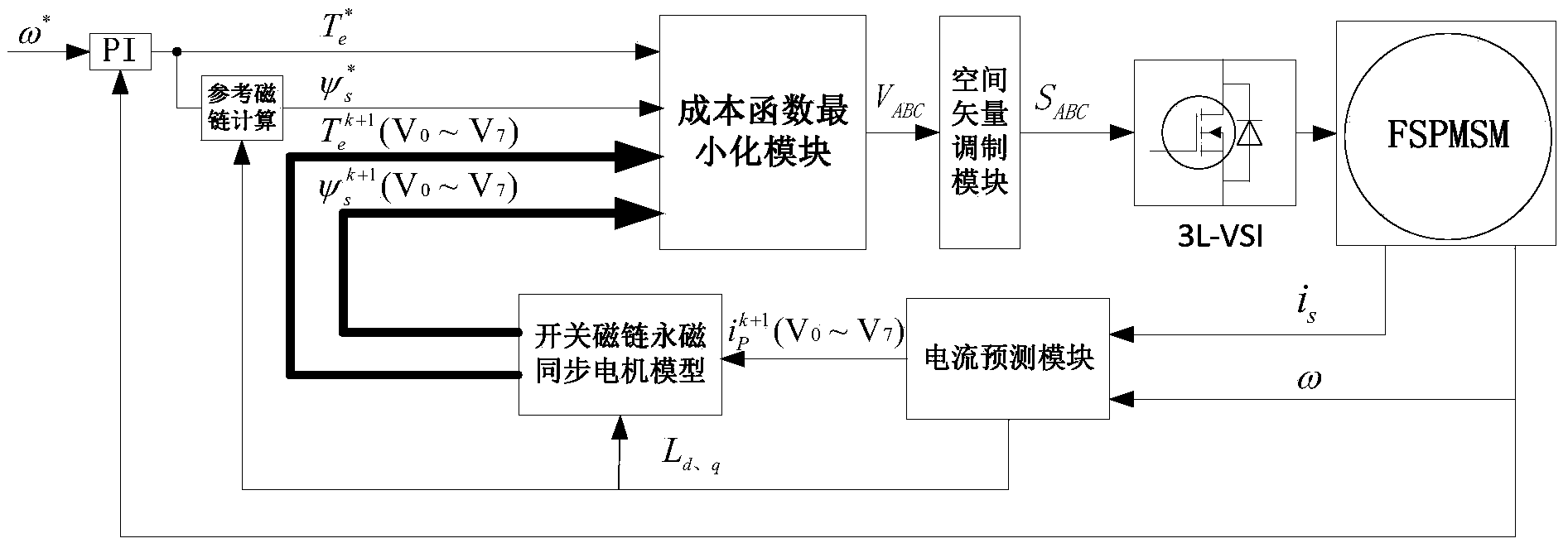

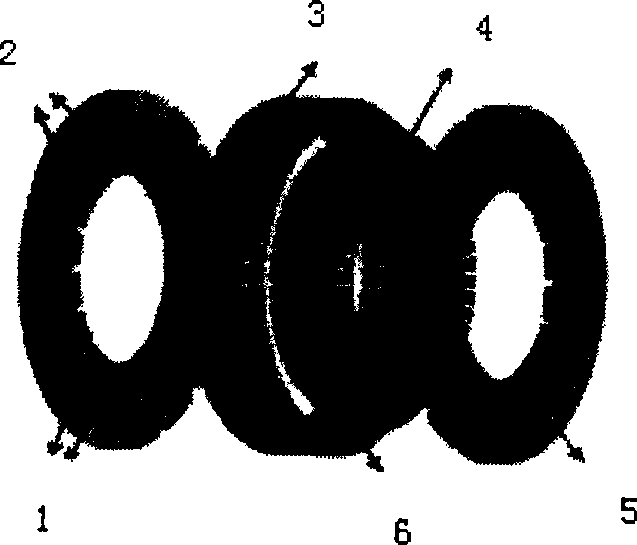

Model prediction-based torque control method for flux-switching permanent magnet synchronous machine

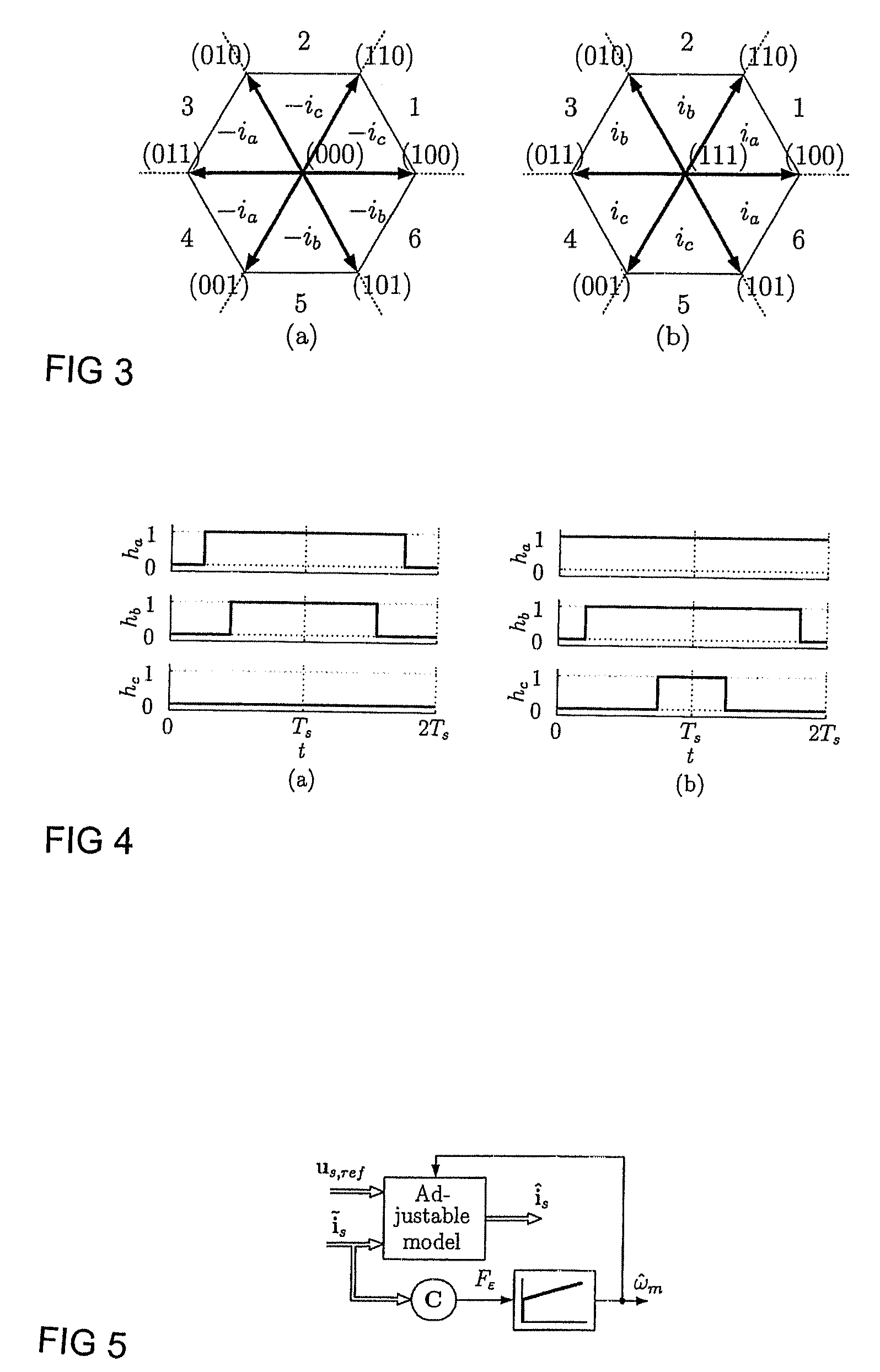

ActiveCN103762926APrecise control of switching vector changesPrecise control workElectronic commutation motor controlAC motor controlPermanent magnet synchronous machineEffective action

The invention discloses a model prediction-based torque control method for a flux-switching permanent magnet synchronous machine. The model prediction-based torque control method comprises the following steps: combining the switch tube states of a motor inverter to obtain eight sets of switch vector signals; at the current moment K, under each set of vector signals of the inverter switch, predicting a p-phase winding current (please see the specification for the formula) at the next moment K+1 to obtain current prediction values (please see the specification for the formula) of a shaft d and a shaft q; predicting motor torque (please see the specification for the formula) and motor flux linkage (please see the specification for the formula) at the next moment k+1; calculating a cost function (please see the specification for the formula) to obtain the vector signal of the inverter switch when the cost function is the smallest; defining m (please see the specification for the formula), controlling the effective acting time of the vector signal of the inverter switch when the cost function is the smallest in a single sampling period according to a value of m to complete torque control of the flux-switching permanent magnet synchronous machine. The method can accurately control change of the vectors of the inverter switch, enables the motor torque fluctuation and the flux linkage fluctuation to be the smallest, and the effective acting time of the inverter switch is adjusted through the duty ratio, so that the on and off frequency of the inverter can be effectively reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

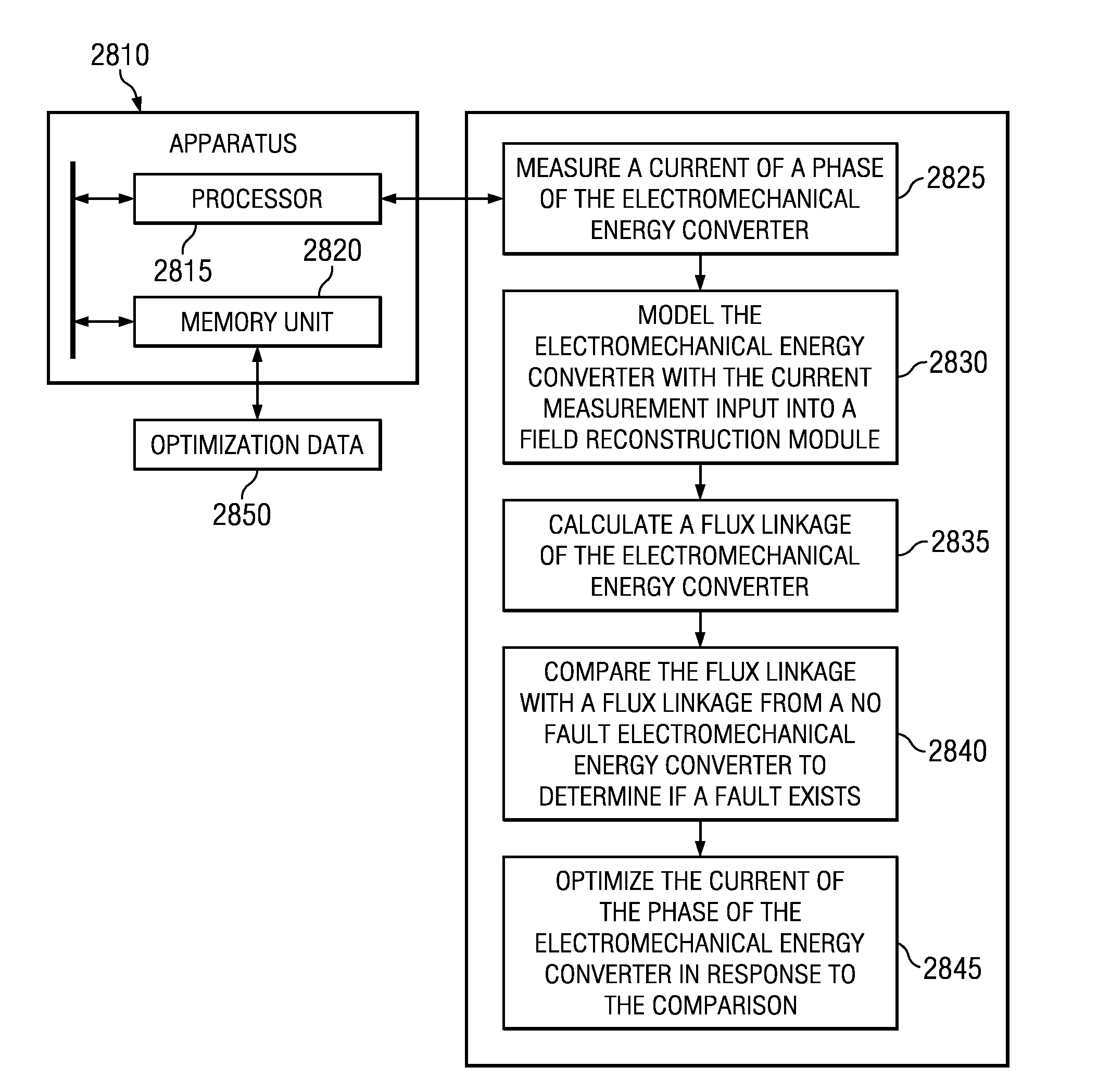

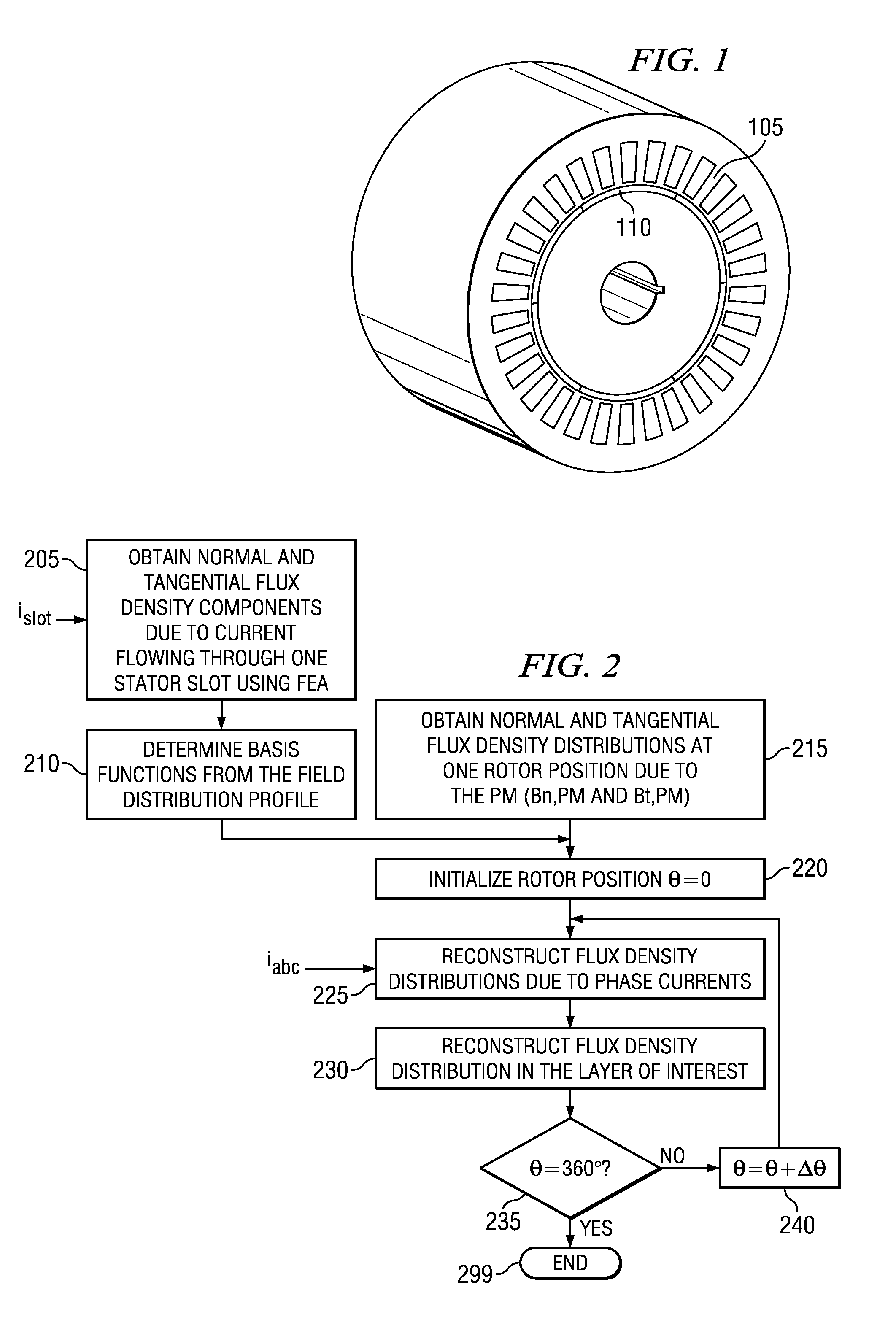

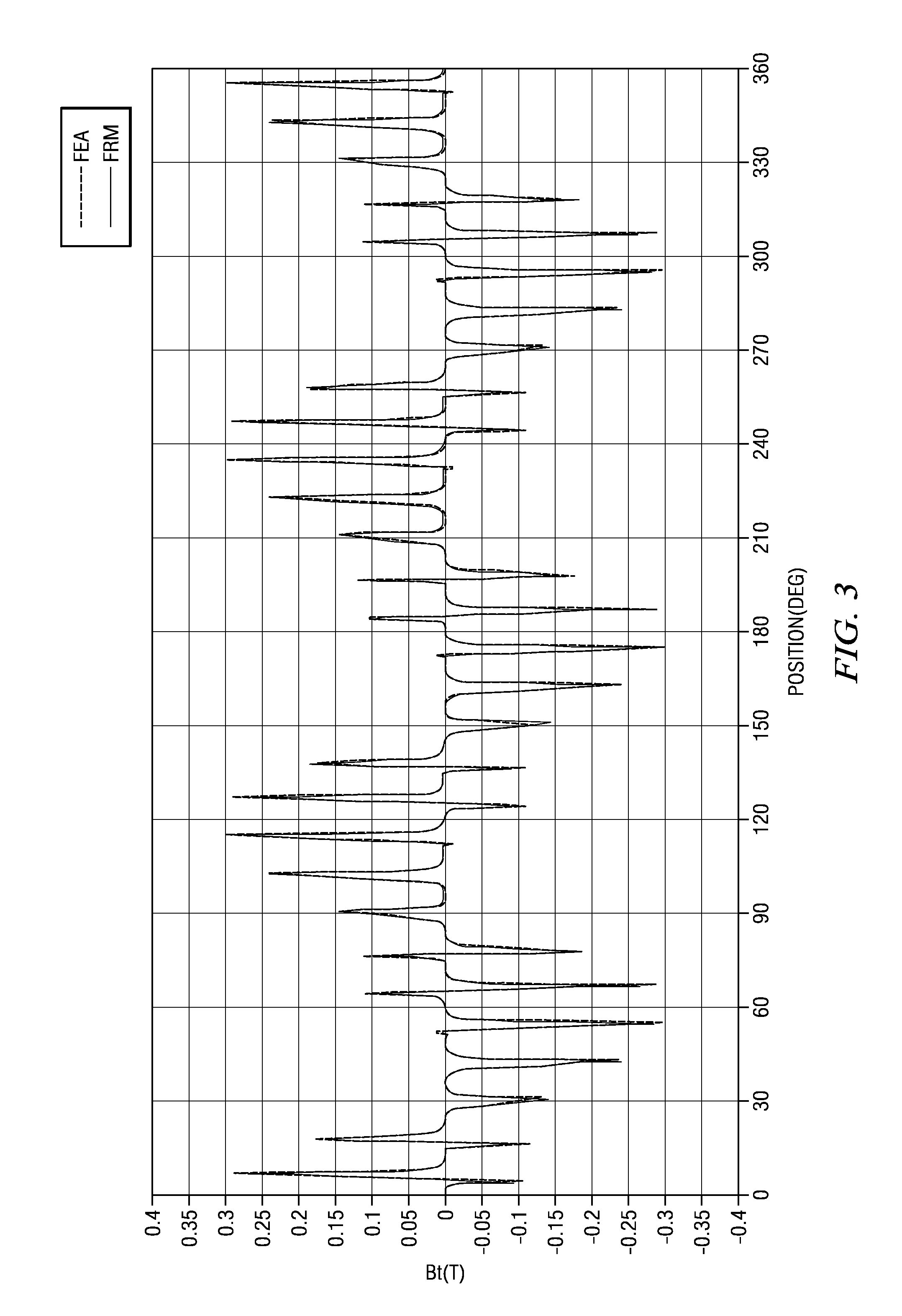

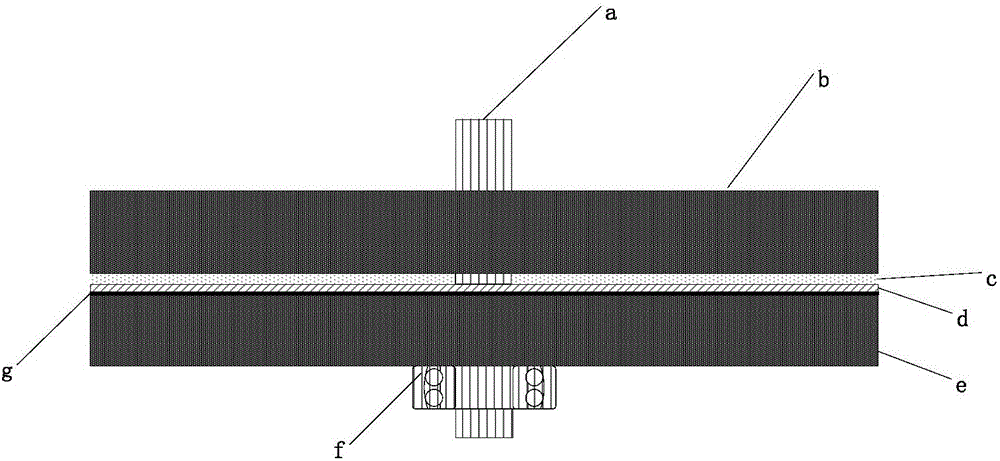

Methods and apparatuses for fault management in permanent magnet synchronous machines using the field reconstruction method

InactiveUS8314576B2Commutation monitoringMotor/generator/converter stoppersPhase currentsPermanent magnet synchronous machine

Methods and apparatuses for detecting faults and optimizing phase currents in an electromechanical energy converter are disclosed. An example method comprises: measuring a current of a phase of the electromechanical energy converter, modeling the electromechanical energy converter with the current measurement input into a field reconstruction module, calculating a flux linkage of the electromechanical energy converter, comparing the flux linkage with a flux linkage from a no fault electromechanical energy converter, and optimizing the current of the phase of the electromechanical energy converter in response to the comparison. Other embodiments are described and claimed.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

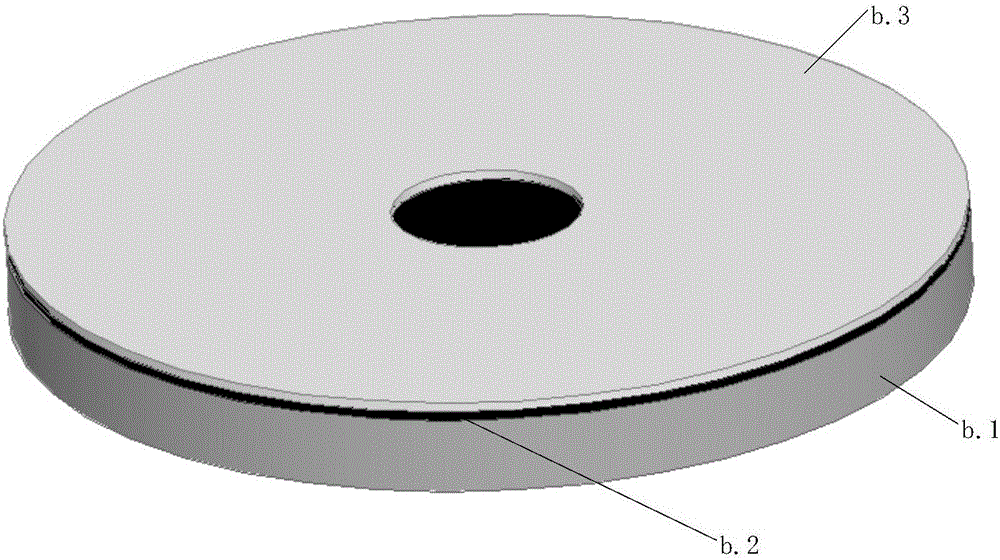

Printed alternating-current motor

ActiveCN106374643AReduce volumeLight in massMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous machineEngineering

Owner:CHINA UNIV OF MINING & TECH

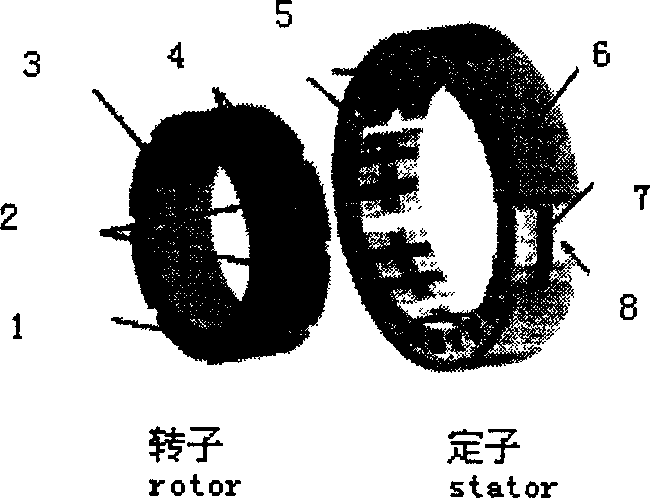

Mixed excitation bisalient-pole permanent-magnet synchronous machine

InactiveCN1658478ASimple structureImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric forcePermanent magnet synchronous machine

A mixed excitation double-convex pole permanent magnet synchronous motor. It is composed of magnet double-convex pole motor and the permanent magnet synchronous motor. The stators and the rotors of the two motors are independent, and share the shell and the revolving axis. The teeth of the stator of the double-convex pole motor has armature winding and excitation winding, the rotor does not have winding. The teeth of the stator of the permanent magnet synchronous motor have the armature winding. The armature windings of the two motors are in series. Adjust the amount and direction of the excitation current, the phase electric force can be modulated. Change the length proportion along the axes direction of the excitation double-convex pole motor and the permanent magnet synchronous motor, the breadth value of electric force will change correspondingly. It can be used as three-phase motor and multi-phase motor, AC motor or DC motor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

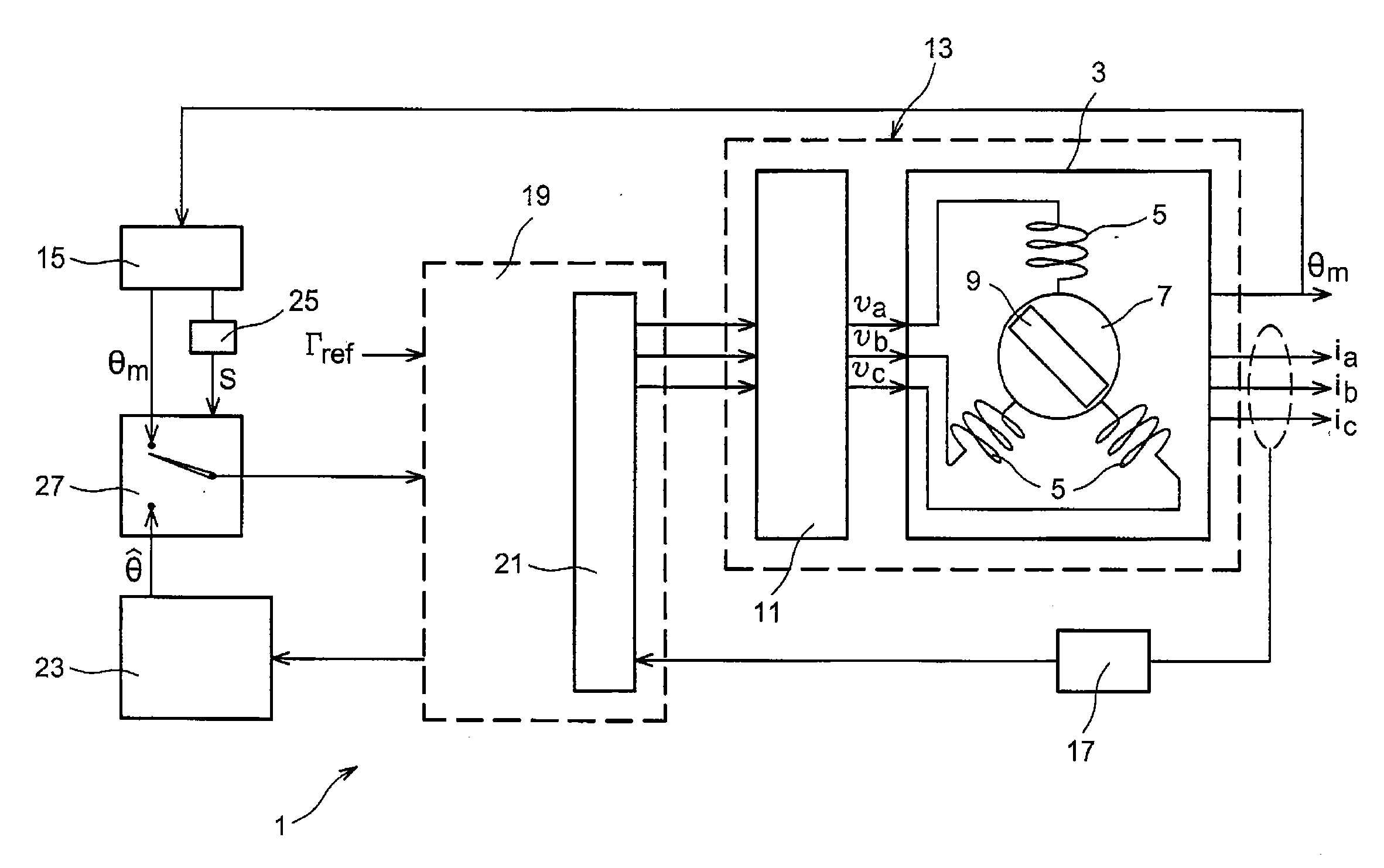

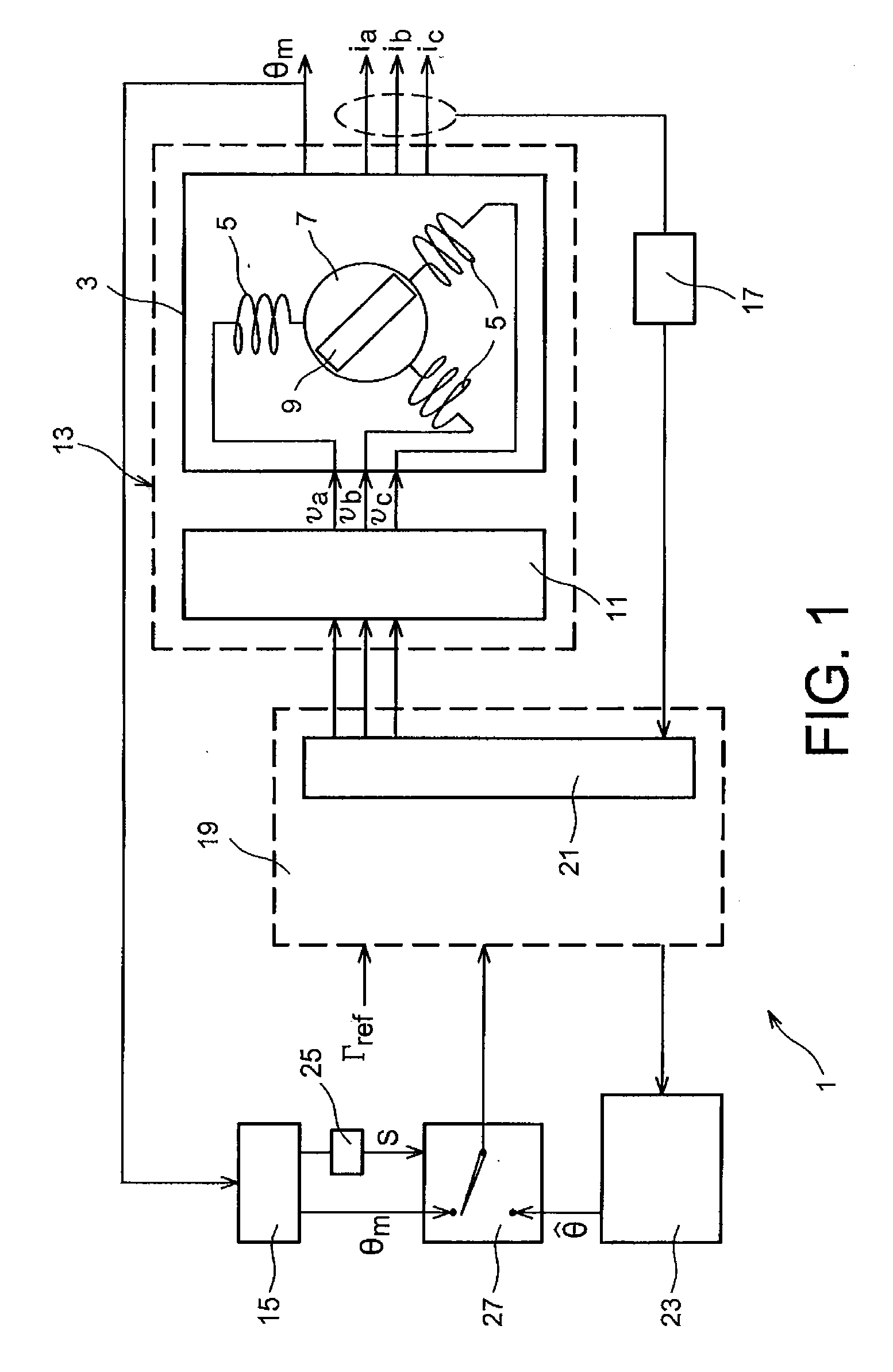

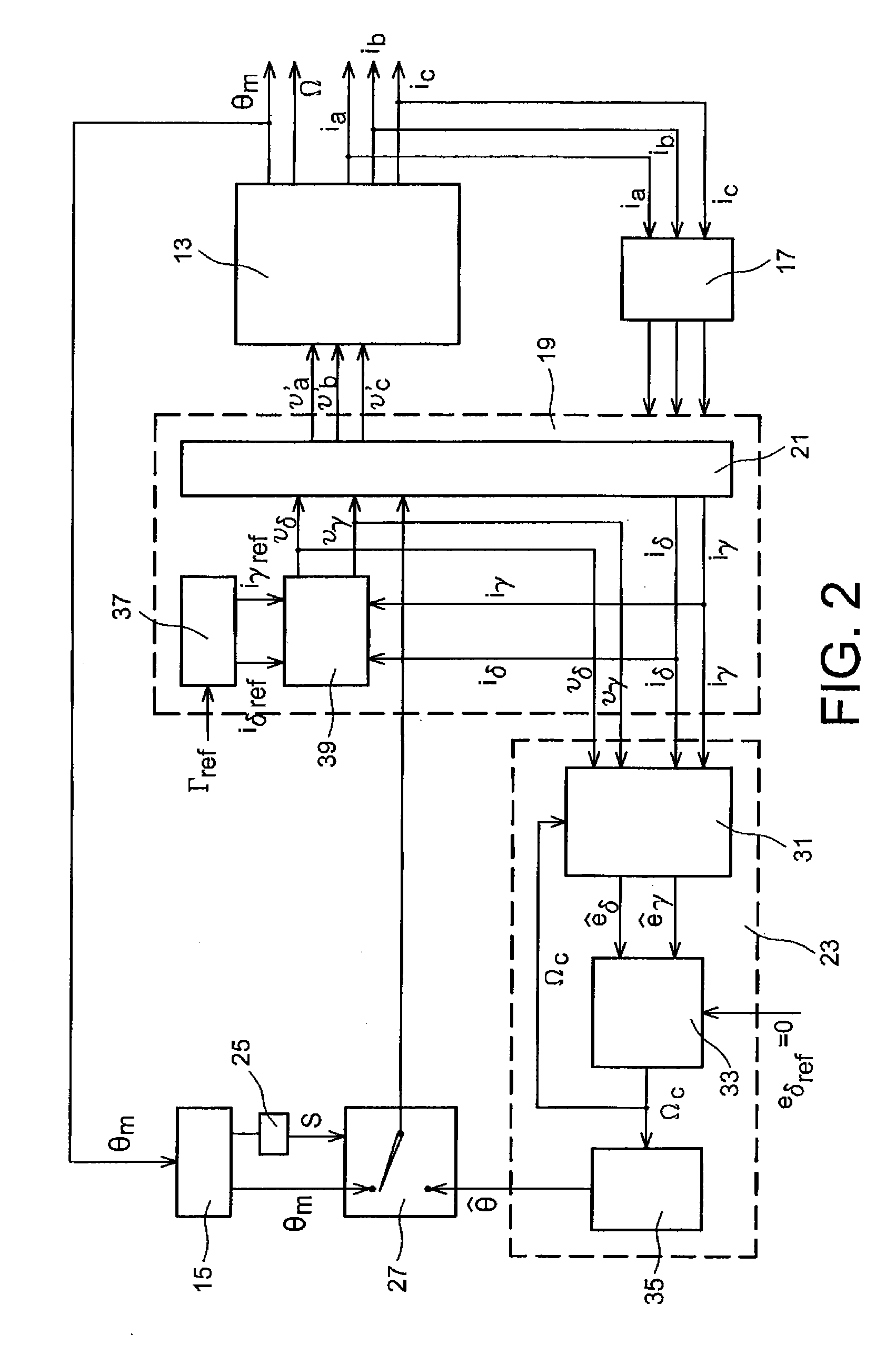

Device for control of a pmsm

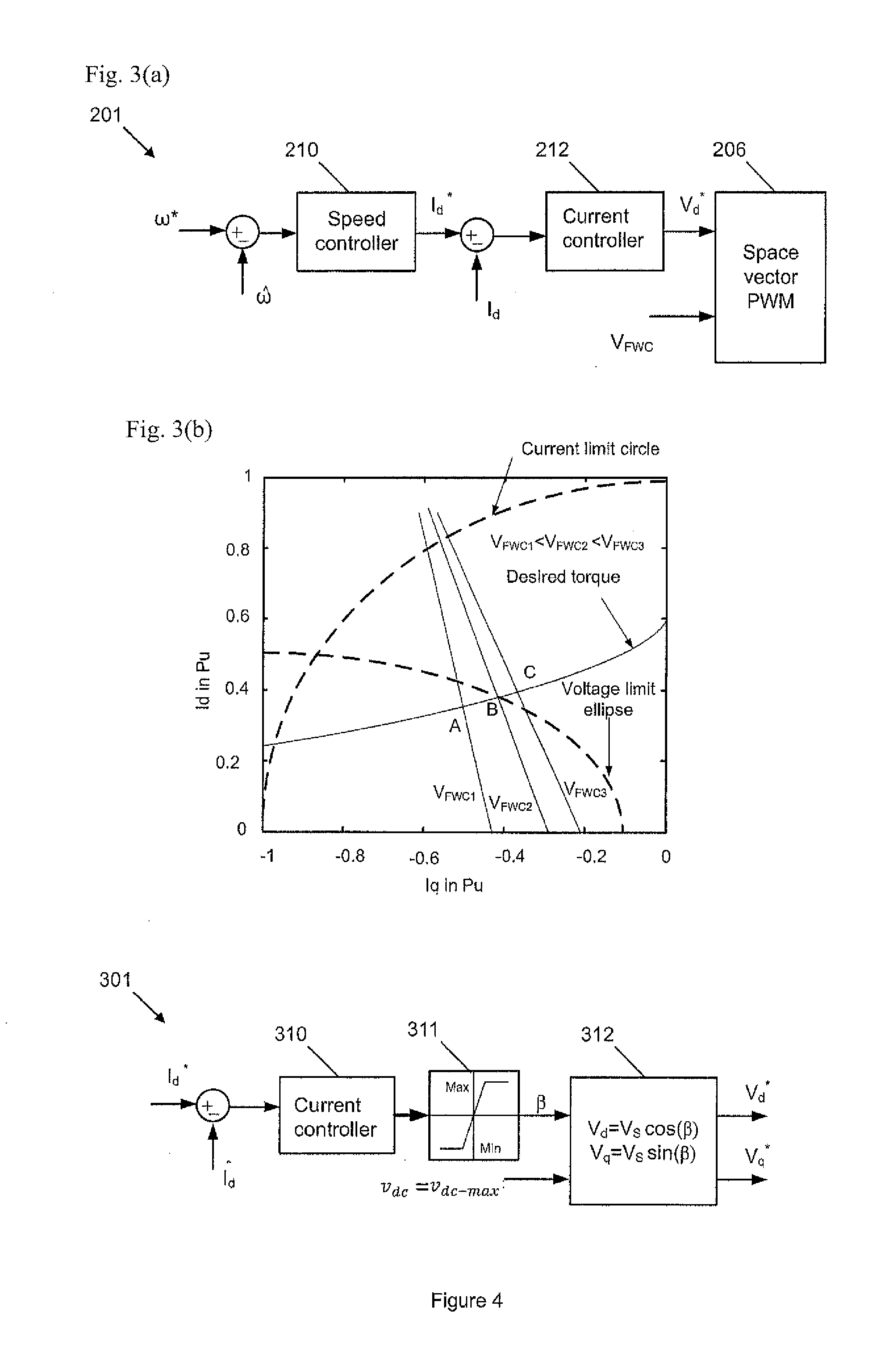

ActiveUS20120280641A1Easy to produceLong life-timeMotor/generator/converter stoppersSynchronous motors startersOperating pointPermanent magnet synchronous machine

A permanent magnet synchronous machine (PMSM) includes a stator and rotor powered by an inverter. A device to control the PMSM includes a sensor to sample a measurement θm of the position of the rotor, a control unit to control an operating point of the PMSM according to the position of the rotor and settings, and an estimation unit to determine an estimate {circumflex over (θ)} of the rotor position. The device also includes a malfunction detector to detect a malfunction of the sensor and a switch to connect the control unit to the sensor so that the control unit receives the measured position θm of the rotor while the malfunction detector does not indicate any sensor malfunction, and otherwise to connect the control unit to the estimation unit so that the control unit receives the estimated position {circumflex over (θ)} of the rotor when the malfunction detector indicates a sensor malfunction.

Owner:SAFRAN ELECTRICAL & POWER

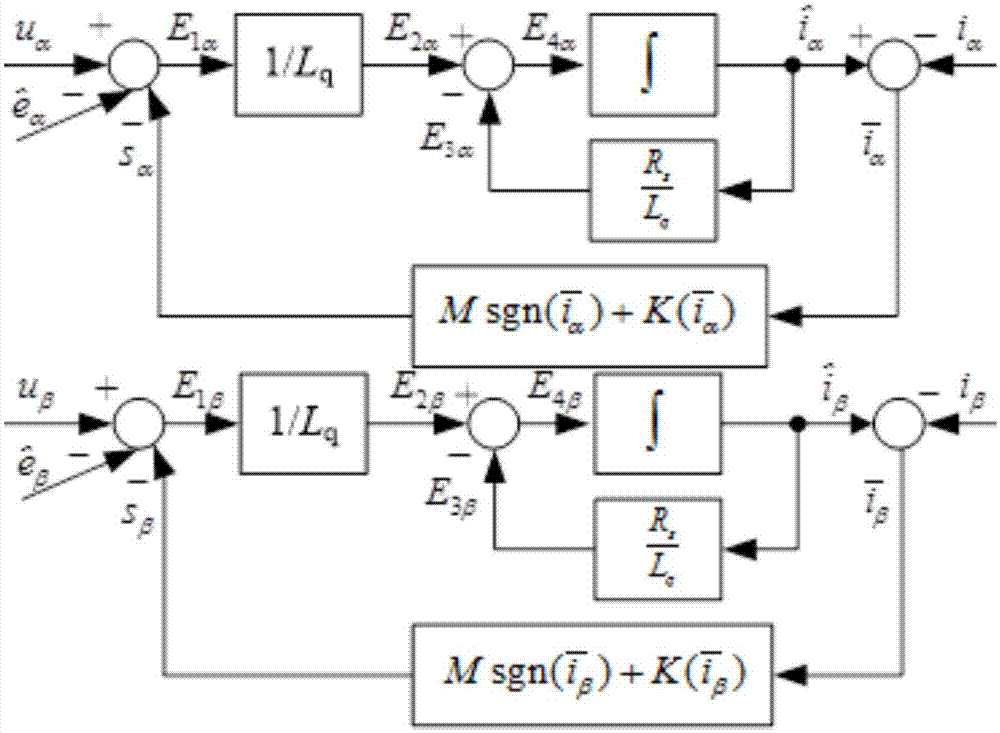

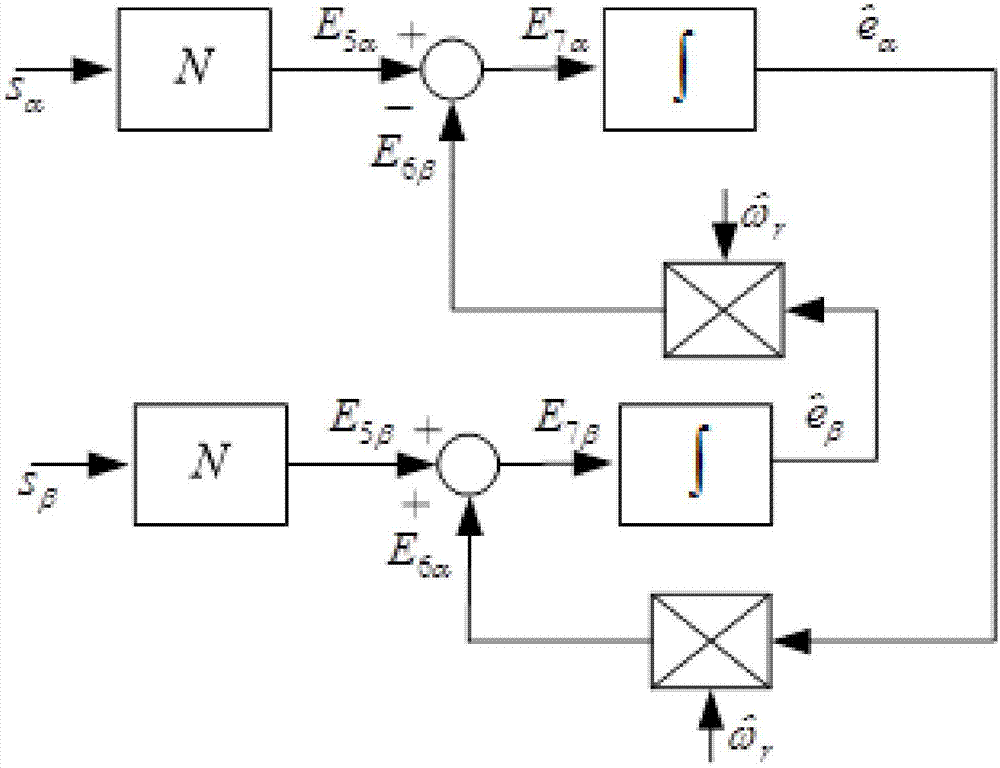

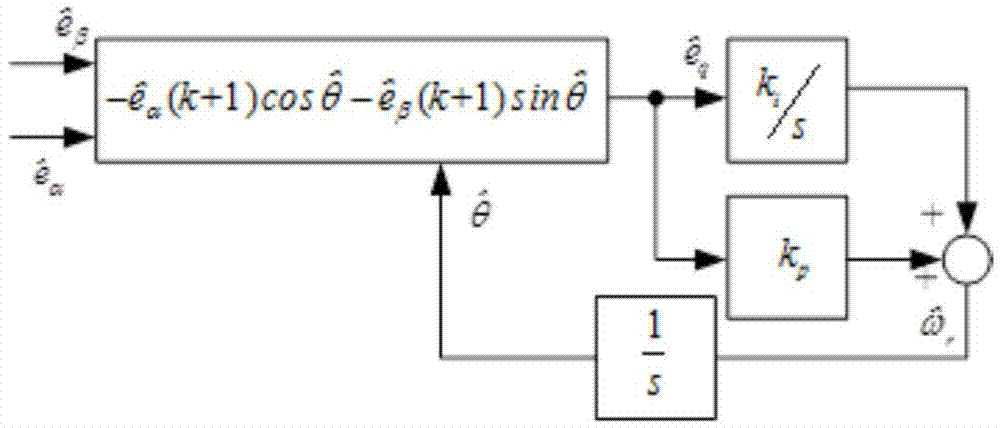

Method for controlling salient pole permanent magnet synchronous machine in speed sensorless mode

ActiveCN103904973AElectronic commutation motor controlVector control systemsMotor speedStator voltage

The invention discloses a method for controlling a salient pole permanent magnet synchronous machine in a speed sensorless mode, and belongs to the field of motor speed regulation. The method is characterized by including the steps of estimating effective counter electromotive force through an established full-order state sliding-mode observer according to the stator voltage and stator current measured in real time, and then obtaining the position and the rotating speed of a rotor through a locking phase ring. By means of the method, the problem of controlling the salient pole permanent magnet synchronous machine in the speed sensorless mode is solved, influences of motor parameters on speed sensorless control are smaller, robustness of deviation between position estimation and rotating speed estimation of the rotor is improved, sliding-mode noise is prevented from being amplified, and stability of the system is ensured.

Owner:黄山市开发投资集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com