Self-ventilation cooling device of external rotor permanent magnet synchronous machine

A permanent magnet synchronous motor, outer rotor technology, applied in cooling/ventilation devices, electromechanical devices, electric components, etc., can solve the problems of inability to install fans, high overall heat dissipation requirements, and difficulty in stator heat dissipation, to maintain smooth flow, ensure Continuous working reliability, good air cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments will be described in detail below in conjunction with the accompanying drawings.

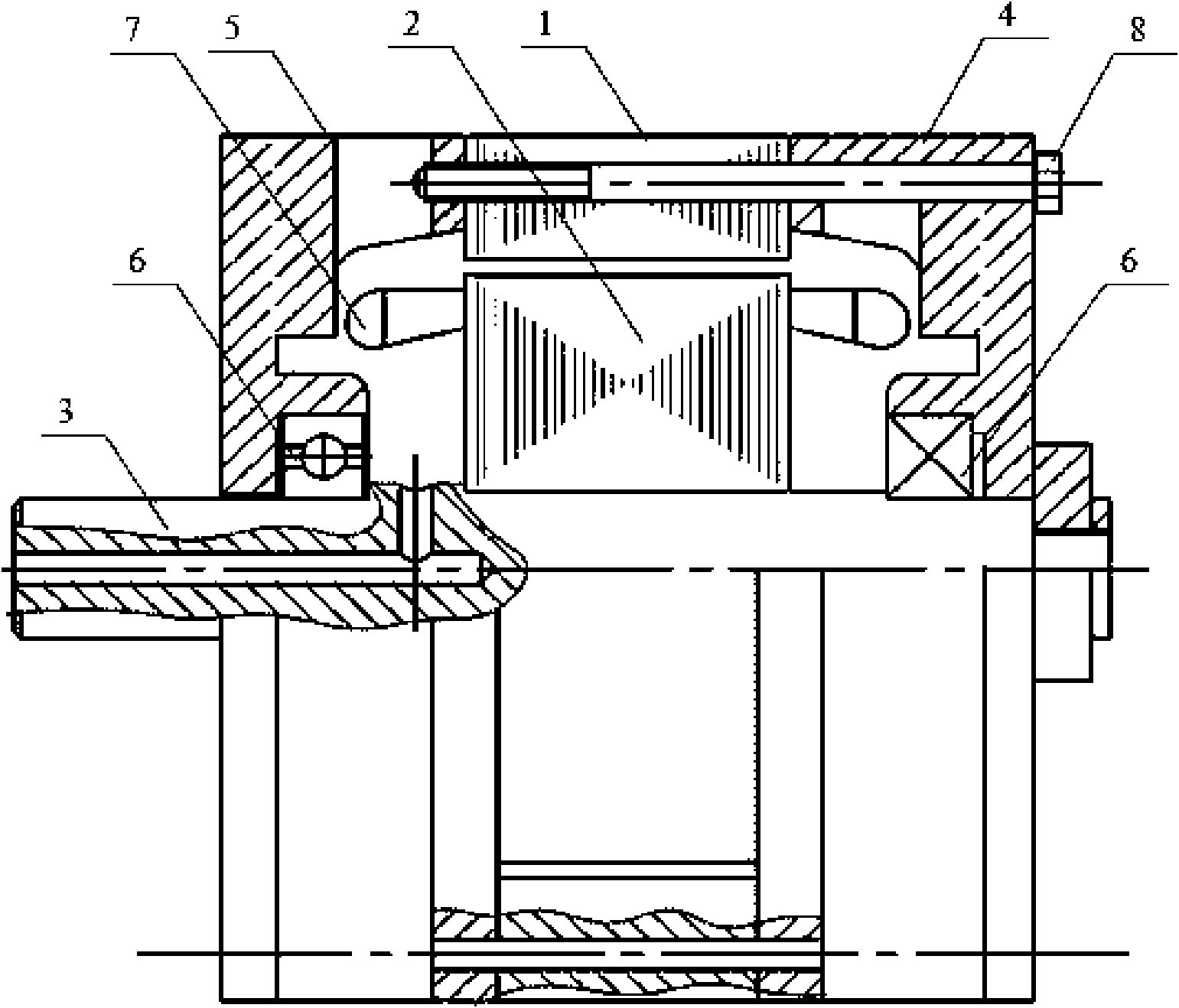

[0018] figure 1 It is a schematic diagram of the overall structure of the cooling air passage shown in the longitudinal section of the motor. The cooling air passage includes: the front cover 4, the axial straight air passage of the stator core 2, the inner air passage of the rotor core 3 and the rear end cover 5.

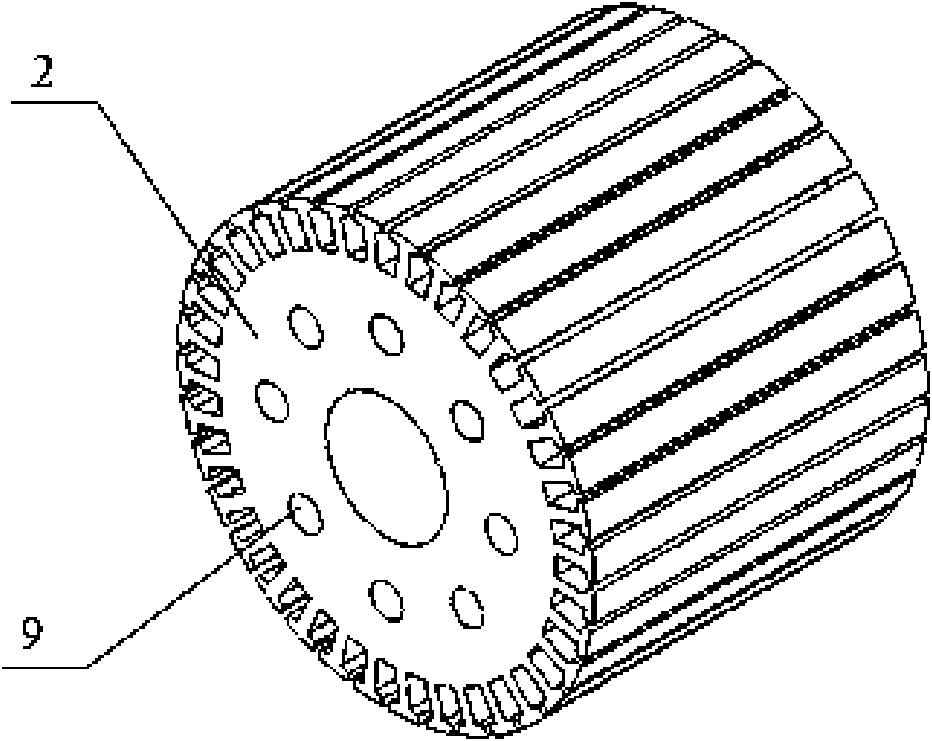

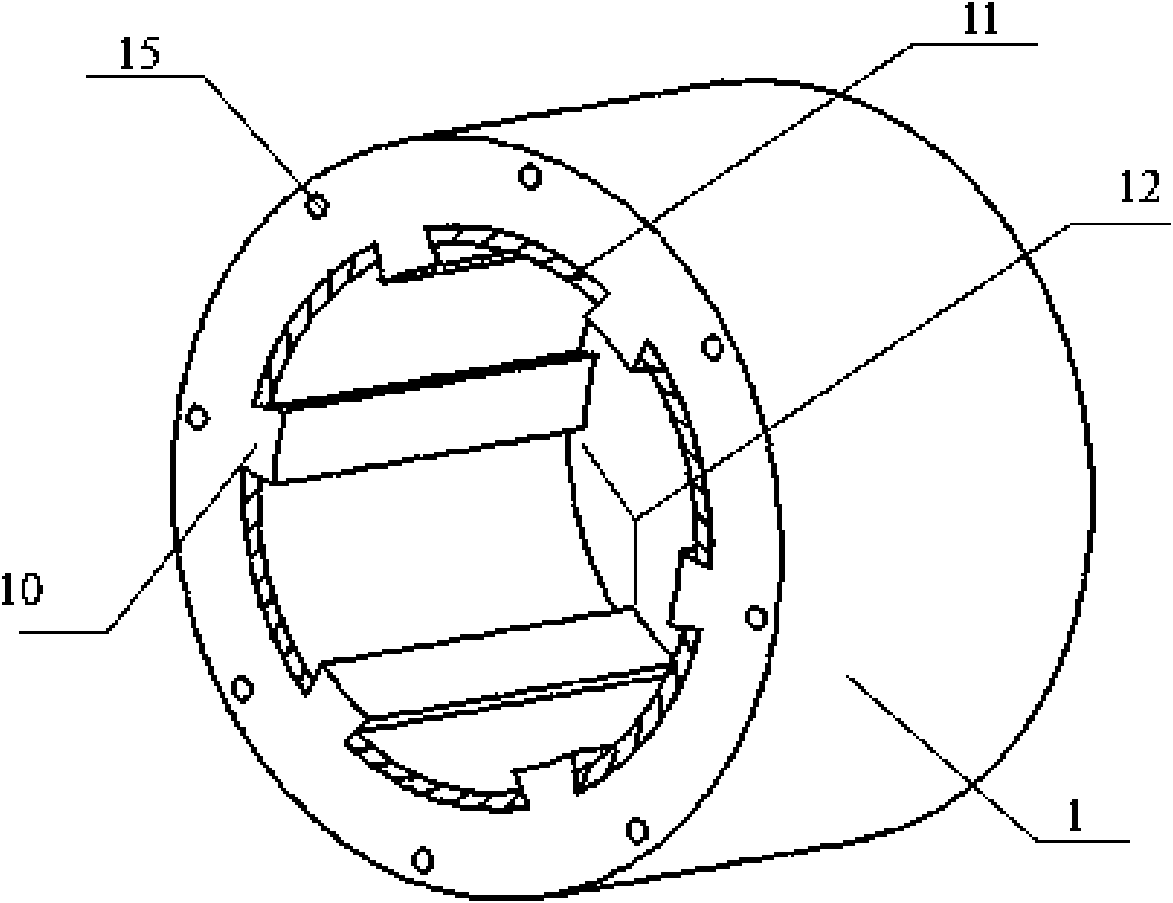

[0019] The front and rear end covers 4 and 5 are installed at both ends of the outer rotor core 1 of the motor, are fixedly connected with the rotor core 1 by screws 8, and are set on the motor shaft 3 through the bearing 6, and the end covers are of a centrifugal fan structure. The stator core 2 is perforated to form an axial ventilation channel. The inner side of the rotor 1 relies on protruding rotor teeth to form a plurality of air passages, which can be designed as axial straight air passages or spiral air passages according to different examples.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com