Mixed excitation bisalient-pole permanent-magnet synchronous machine

A technology of permanent magnet synchronous motor and electric excitation double salient pole, which is applied in the direction of electrical components, electromechanical devices, static parts of magnetic circuits, etc., and can solve the problems of not being able to use AC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Since the structure of a multi-phase motor is similar to that of a three-phase motor, the following uses a three-phase motor as an example to illustrate the specific implementation.

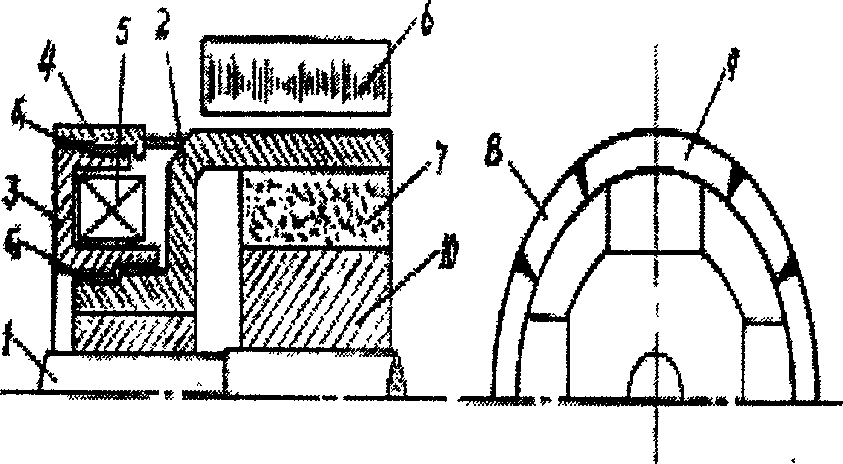

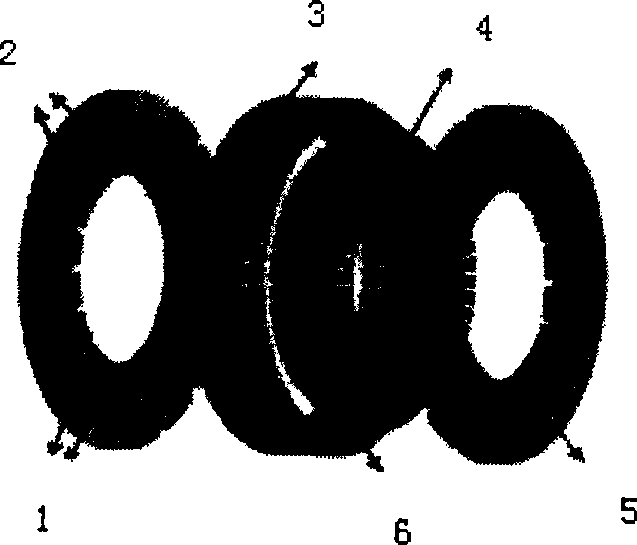

[0062] The cross-sectional structure diagram of the hybrid excitation double salient permanent magnet synchronous motor of the present invention is shown in Fig. 10, the electric excitation double salient pole motor and the permanent magnet synchronous motor are installed in the same housing and share a rotating shaft.

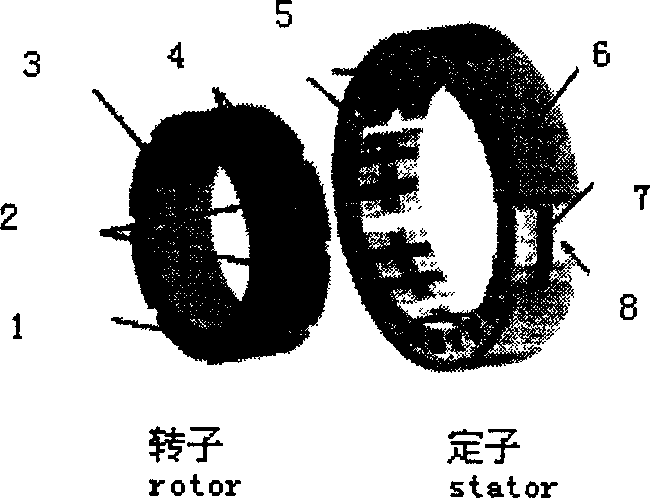

[0063] The structure of the three-phase electric excitation double salient pole motor is shown in Figure 10 and Figure 11a. The stator 1 and the rotor 6 are laminated by silicon steel sheets. The motor has a 6N / 4N structure, that is, the number of stator teeth is 6N, and the number of rotor teeth is 4N, N It is a positive integer, such as N=1, it is a 3-phase 6 / 4 structure; N=2, it is a 3-phase 12 / 8 structure. The stator teeth are evenly distributed, and the width of the stato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com