Permanent magnetism synchronous electric machine test system and method

A technology of permanent magnet synchronous motor and test system, which is applied in the direction of motor generator test, measurement device, measurement of electrical variables, etc., can solve the problems of high test device requirements, rotor cross, complex straight-axis magnetic circuit, cross saturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

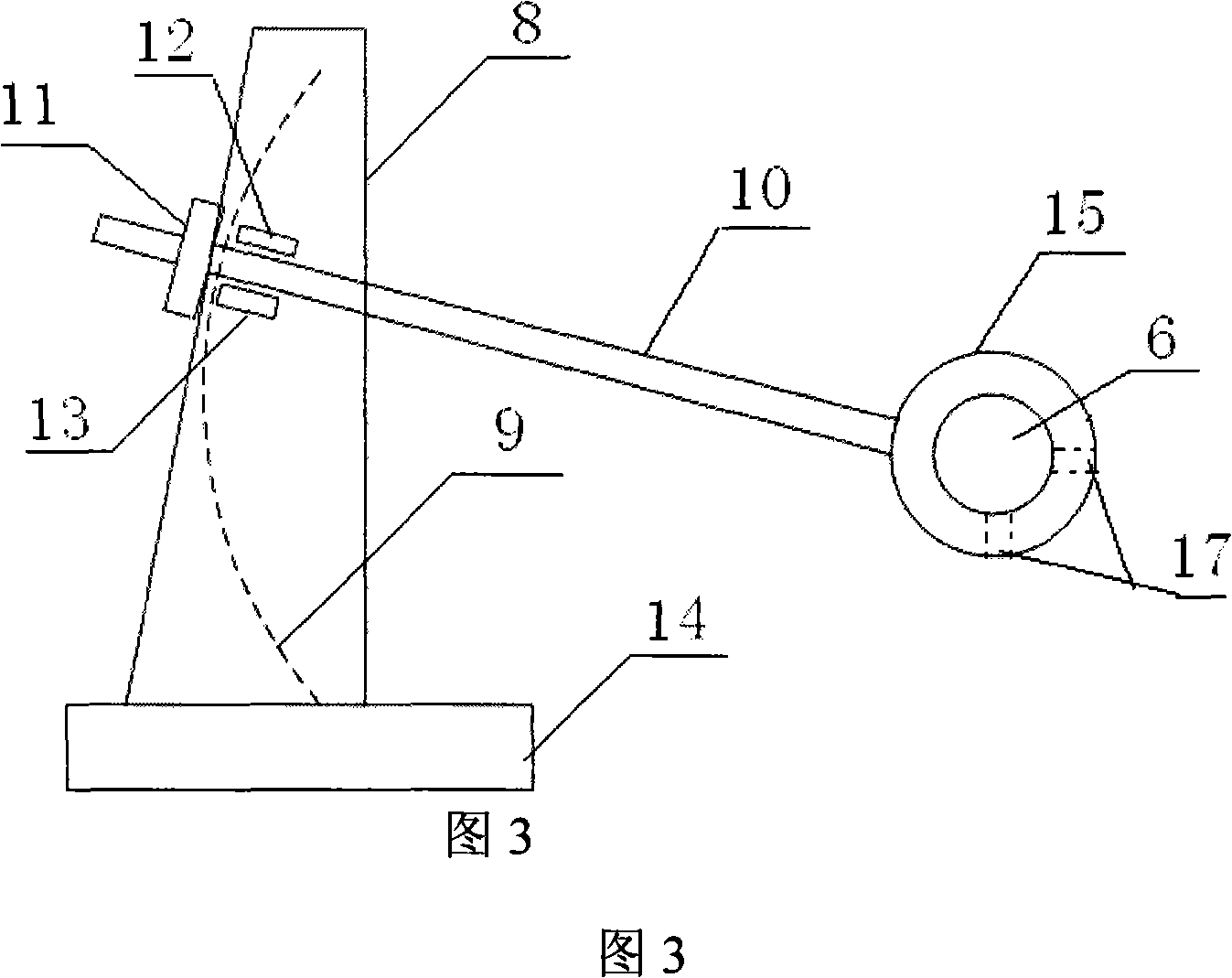

[0029] Referring to the accompanying drawings, through the description of the embodiments, the specific implementation of the present invention, such as the shape, structure, mutual position and connection relationship between each part, the function and working principle of each part, and the test method etc., to make further detailed descriptions to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

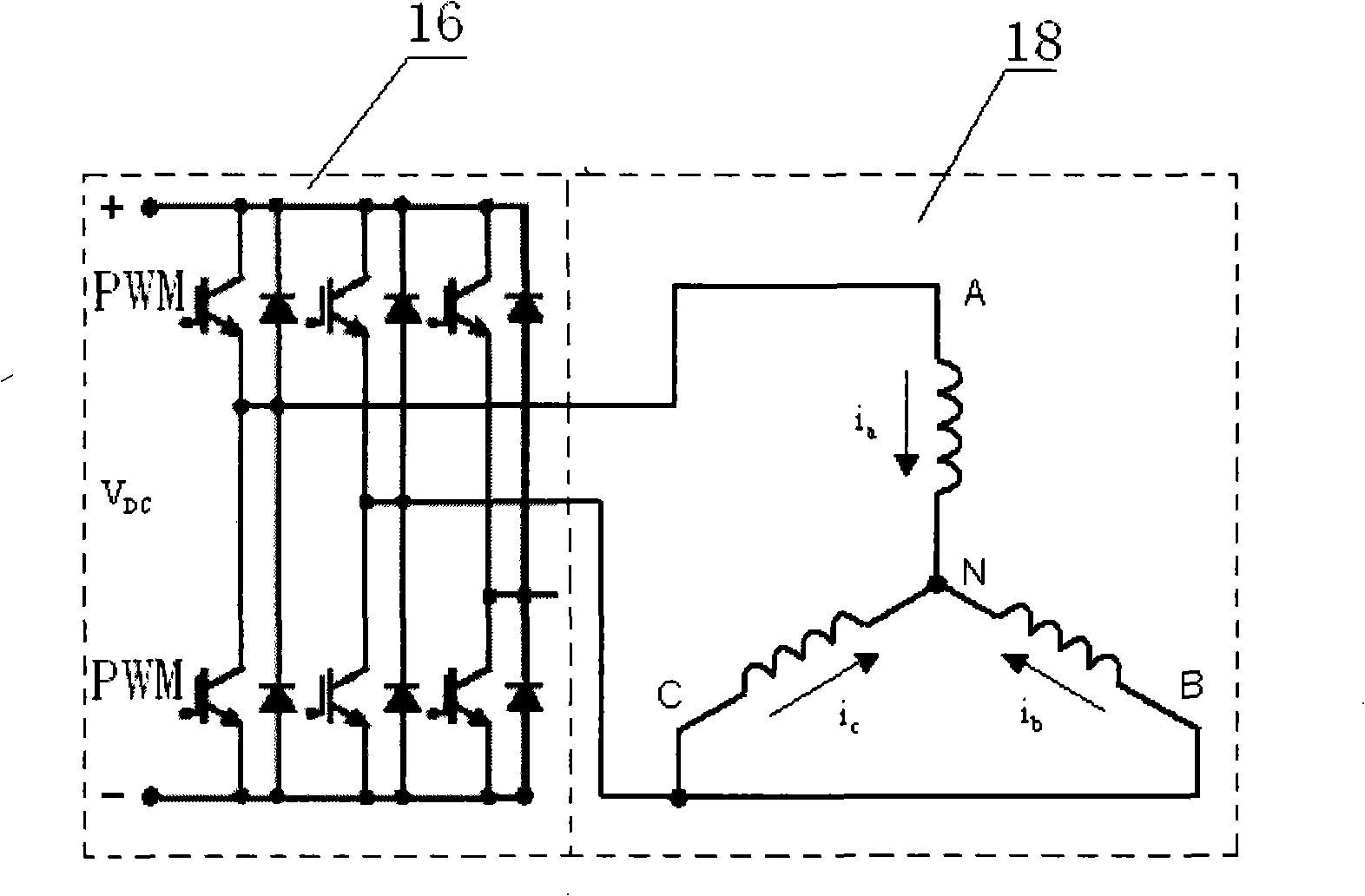

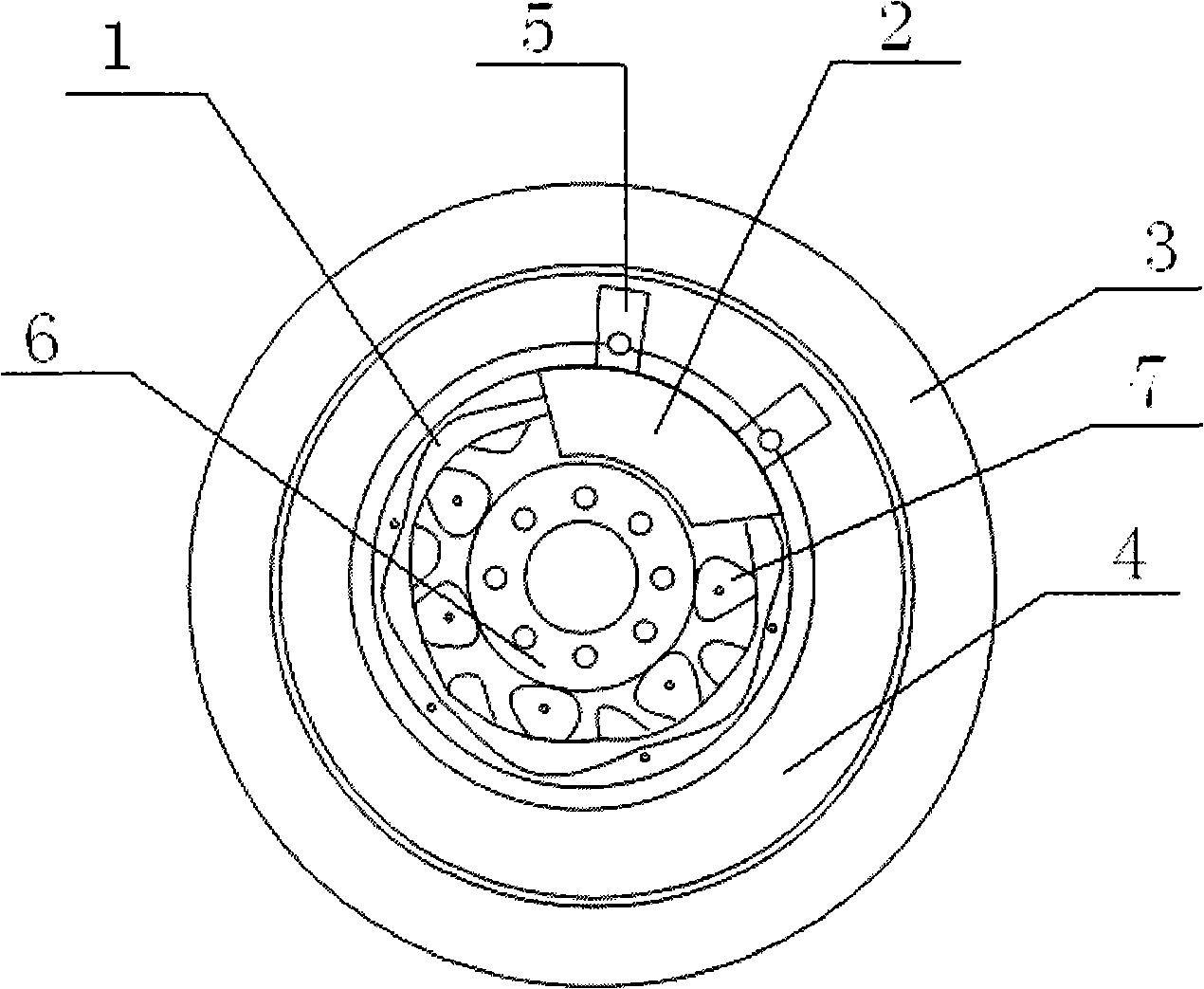

[0030] Such as figure 1 , figure 2 , shown in Fig. 3, a kind of permanent magnet synchronous motor testing system comprises inverter (16), permanent magnet synchronous motor, motor controller, temperature sensor, A phase of synchronous motor stator winding 18 and inverter 16 first The bridge arms are connected, the B phase and the C phase are short-circuited and then connected to the second bridge arm of the inverter 16, and the third bridge arm is suspended. One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com