IGBT inverter welding machine with no-load voltages and various protection and control functions

A no-load voltage, protection control technology, applied in arc welding equipment, manufacturing tools, welding equipment and other directions, can solve the problems affecting product sales and market competitiveness, product performance, reliability, different production processes, etc., to meet high efficiency and low-cost production, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

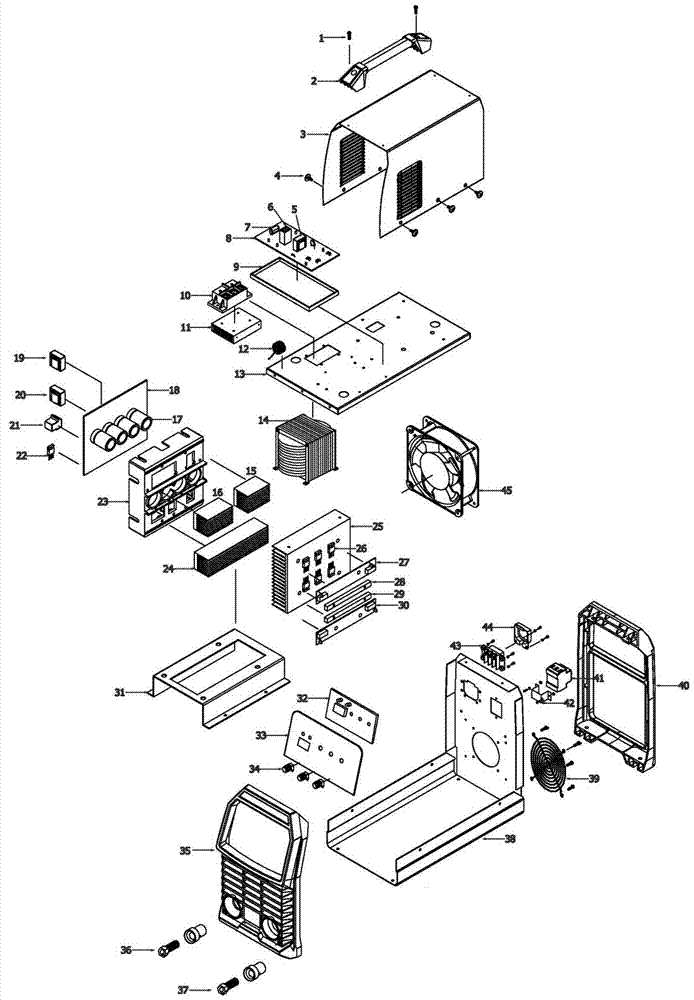

[0026] as attached figure 1 Shown is a schematic structural view of an example manual welding machine made by the present invention. The main components of the welding machine include:

[0027] 1) Shell part. Parts mainly include: handle 2, casing 3 and base plate 38 and other parts.

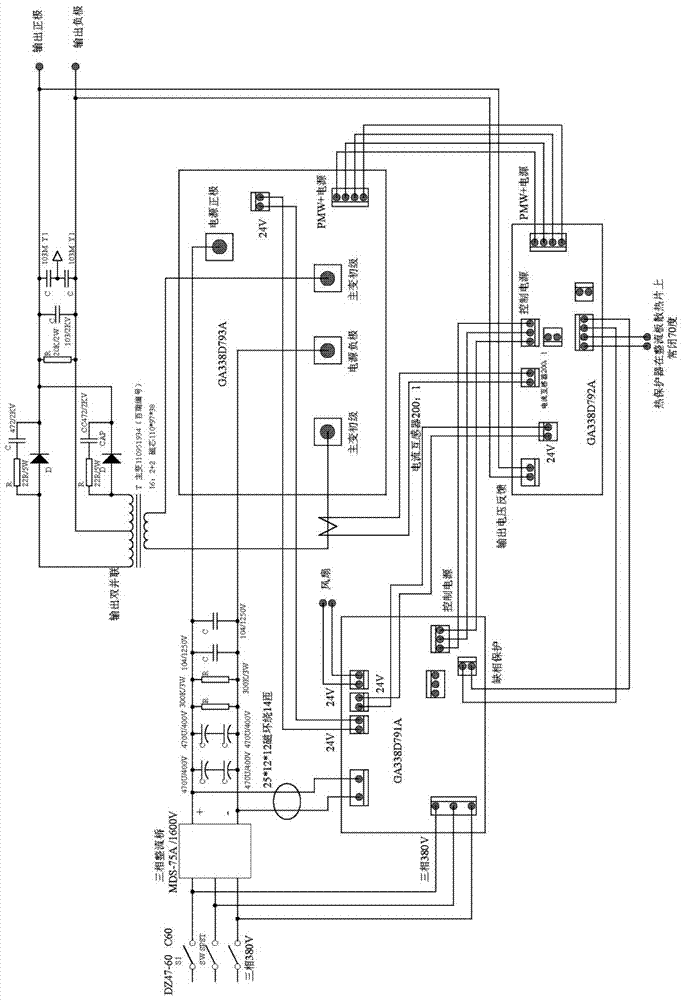

[0028] 2) The internal part of the welding machine. Including: PCB1 circuit board 8 and its switching tube and radiator IV 6, transformer I 5, capacitor 7 and other devices on the circuit board. After the PCB1 circuit board 8 is processed, it is placed in the plastic protective box 19 and filled with insulating material, which can ensure that the PCB1 circuit board 8 has the protection performance of waterproof, mildew proof, vibration proof, corrosion proof and dust proof. The plastic protective box 19 is fixed on the middle partition 13 below it by four pillars and screws. The input three-phase rectifier bridge (MDS, 75A / 1600V) 10 is installed on its radiator I 11 . The radiator I 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com