Three-function inverter welding machine with high electromagnetic compatibility

An electromagnetic compatibility, inverter welding machine technology, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve problems affecting product performance, market competitiveness, and different layouts of circuit boards and complete machines, and improve the market. Competitive, efficient and low-cost production, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

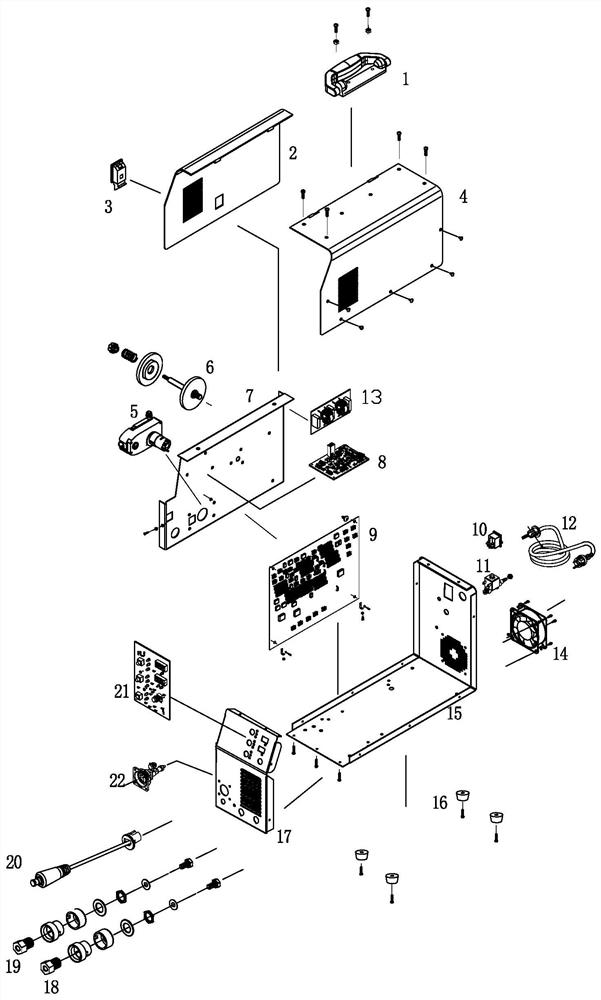

[0028] attached figure 1 It is a structural design diagram of a high electromagnetic compatibility three-function inverter welding machine made by the present invention.

[0029] like Figure 1-6 As shown, the main components of the welding machine include:

[0030] 1) Wire feeding part. Mainly include: wire feeder 5 for gas shielded welding, the numbers in brackets represent the attached figure 1 The serial numbers of the parts in , the same below, will not be repeated), the welding wire spool 6, the welding torch European interface assembly 22 and the wire feeding control circuit part on the control circuit board. The wire feeder 5 and the welding wire spool shaft 6 are installed on the inner middle partition 7 . The wire feeder 5 is close to the front panel 17 of the welder. The wire feeder 5 is connected with the welding torch European interface assembly 22 installed on the front panel 17 accordingly. During gas-shielded welding, the gas-shielded welding torch is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com