Universal assembly tool

A jig and base technology, which is applied to manufacturing tools, workpiece clamping devices, etc., can solve the problems of inconvenient jig management and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

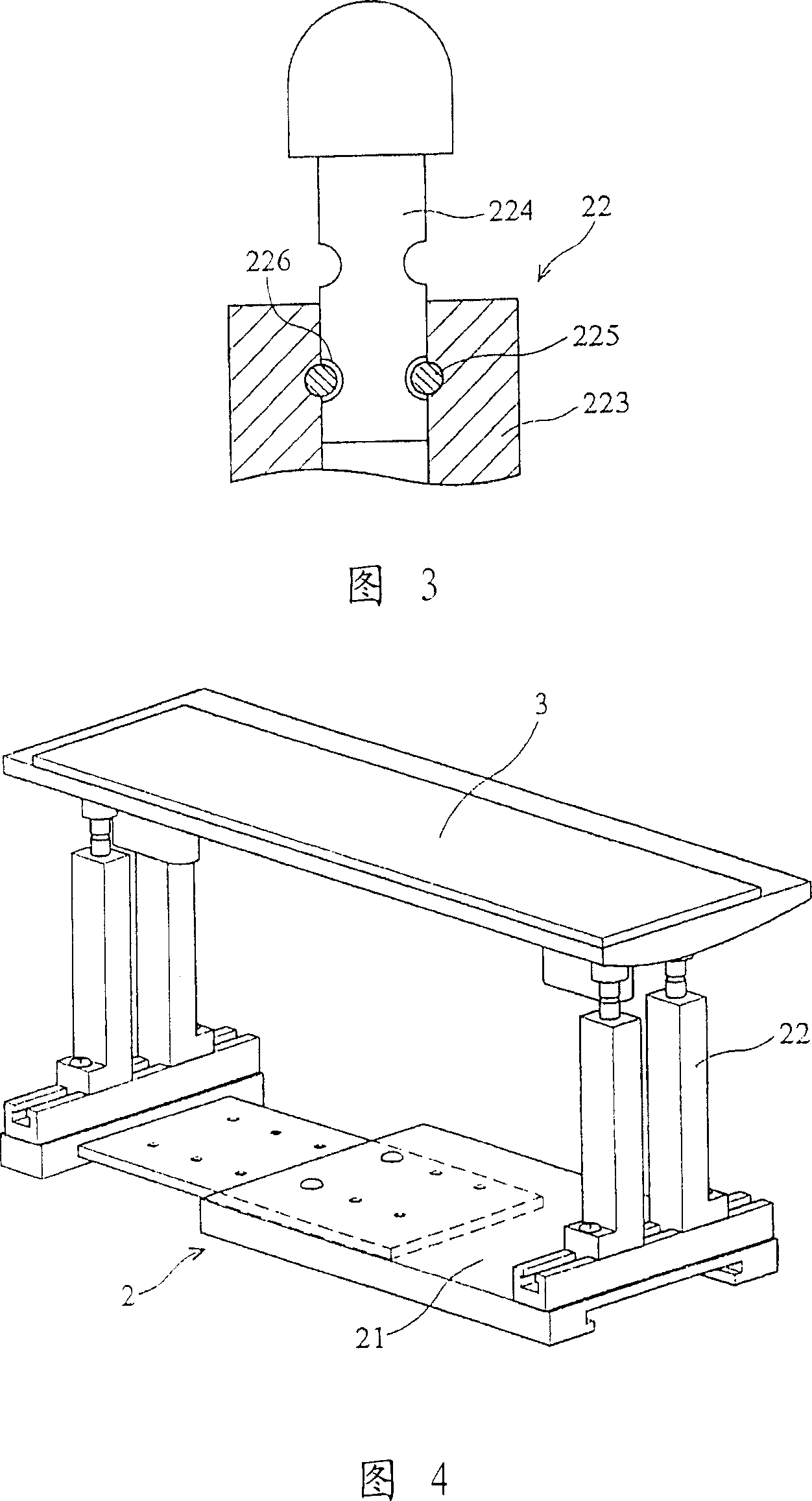

[0037] Please refer to Fig. 2, the assembly universal jig 2 includes a telescopic base 21 and a plurality of support members 22 located at the bottom. In this embodiment, two support members 22 are respectively arranged at the two ends of the telescopic base 21. When the LCD TV is assembled To provide support, the telescopic base 21 of this embodiment includes a first plate 211 and a second plate 212, the first plate 211 and the second plate 212 overlap each other and perform telescopic movements in the X-axis direction , so that the assembly universal jig 2 can obtain an appropriate length, and the first plate 211 is provided with a plurality of first positioning parts 213, and the second plate 212 is provided with a plurality of holes 214 in cooperation with the first positioning parts 213, when When the first plate 211 stretches to a proper position relative to the second plate 212, the first positioning portion 213 will overlap with the hole 214, and then a first positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com