Patents

Literature

107results about How to "Advanced manufacturing technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

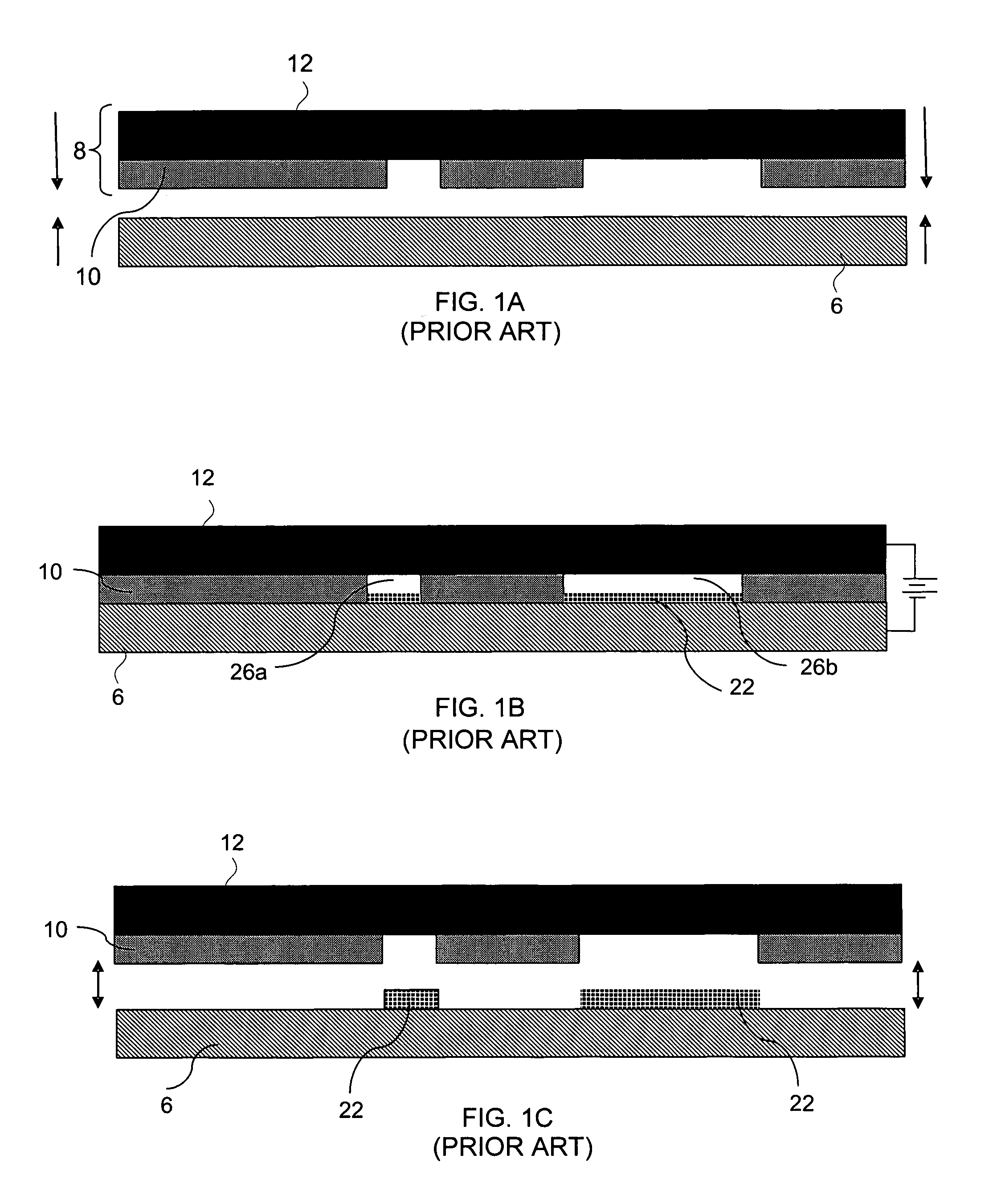

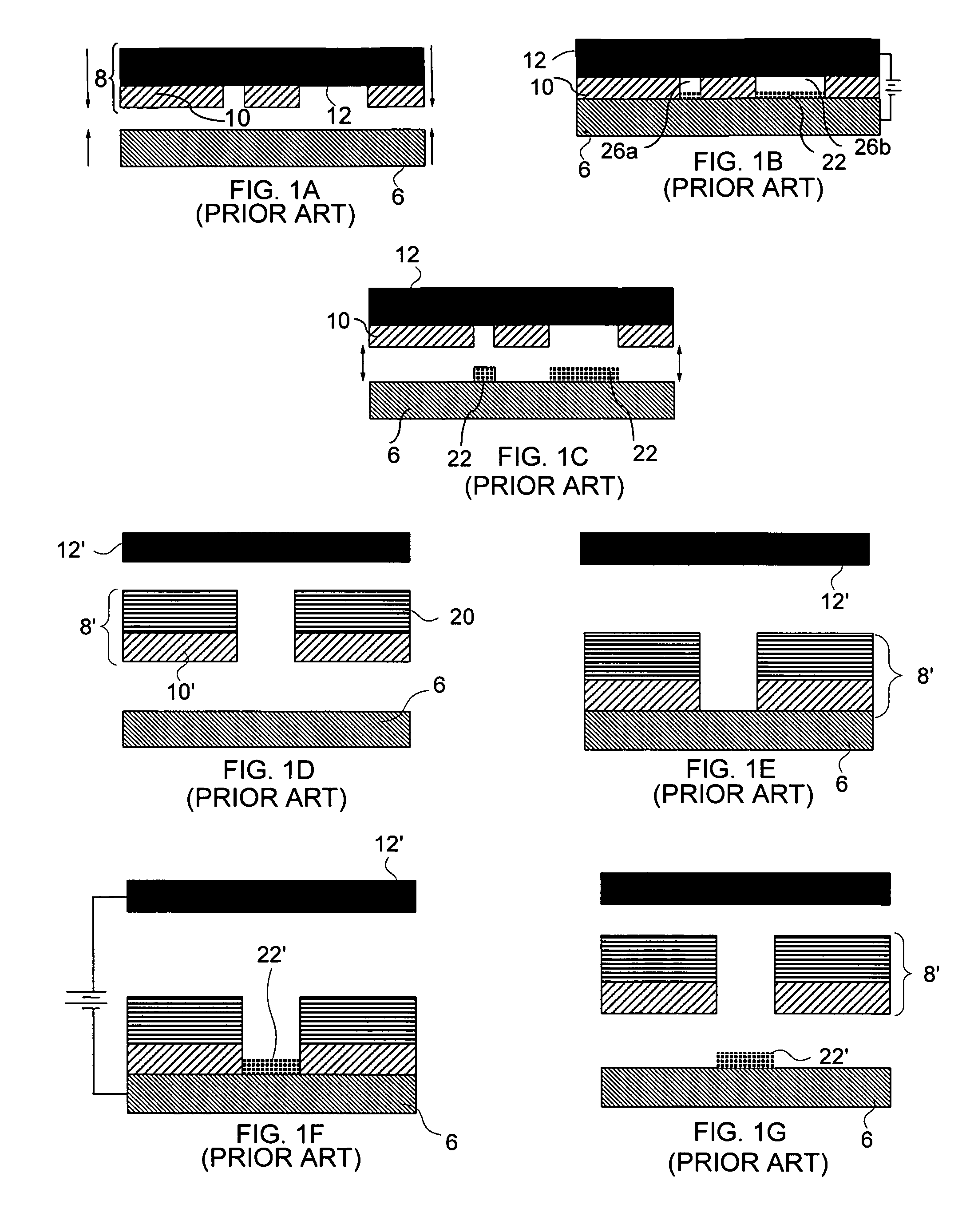

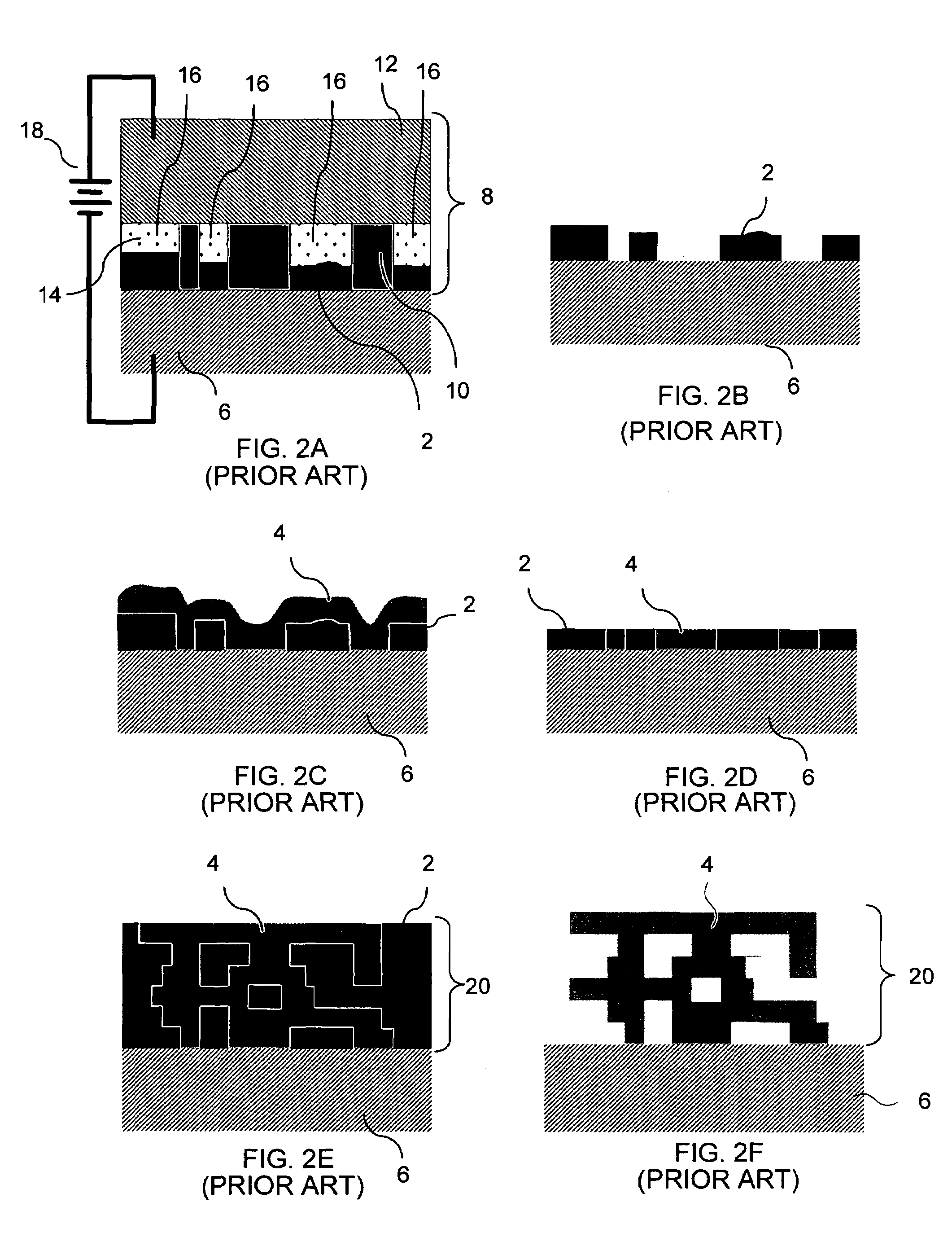

Methods of and apparatus for electrochemically fabricating structures via interlaced layers or via selective etching and filling of voids

ActiveUS7252861B2Advanced manufacturing technologyImprove propertiesAcceleration measurement using interia forcesPretreated surfacesOrder of operationsEngineering

Multi-layer structures are electrochemically fabricated by depositing a first material, selectively etching the first material (e.g. via a mask), depositing a second material to fill in the voids created by the etching, and then planarizing the depositions so as to bound the layer being created and thereafter adding additional layers to previously formed layers. The first and second depositions may be of the blanket or selective type. The repetition of the formation process for forming successive layers may be repeated with or without variations (e.g. variations in: patterns; numbers or existence of or parameters associated with depositions, etchings, and or planarization operations; the order of operations, or the materials deposited). Other embodiments form multi-layer structures using operations that interlace material deposited in association with some layers with material deposited in association with other layers.

Owner:MICROFAB

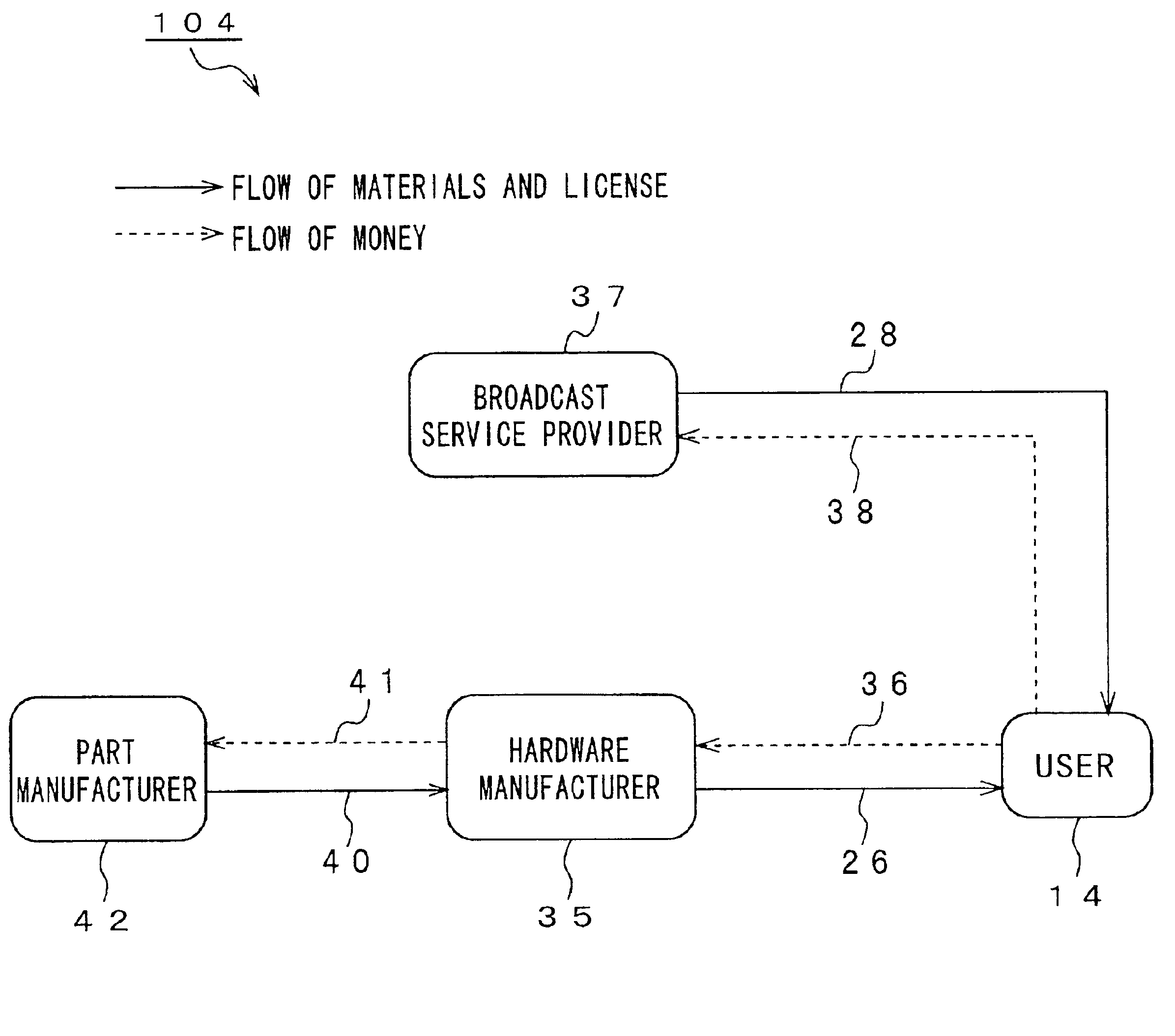

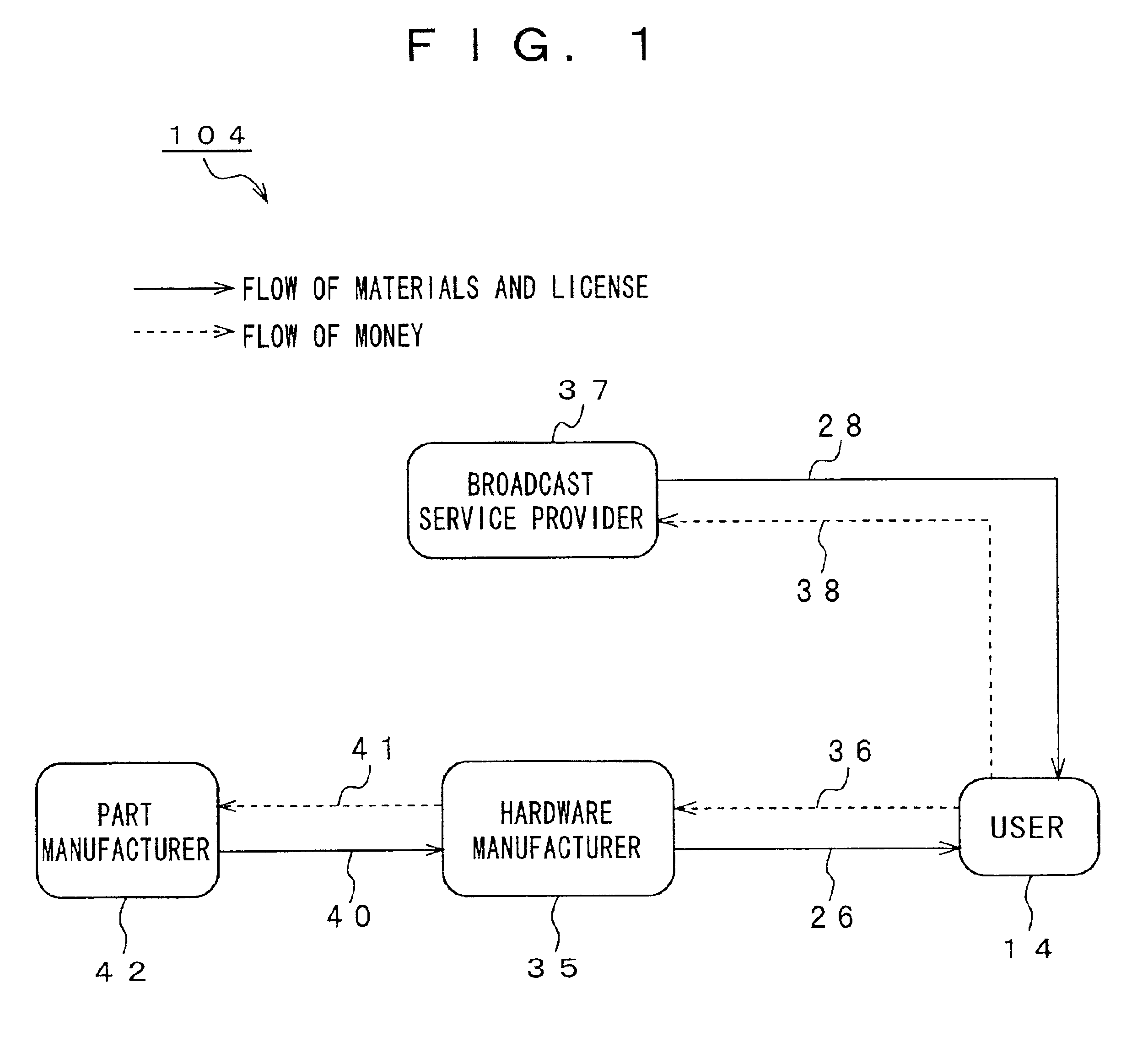

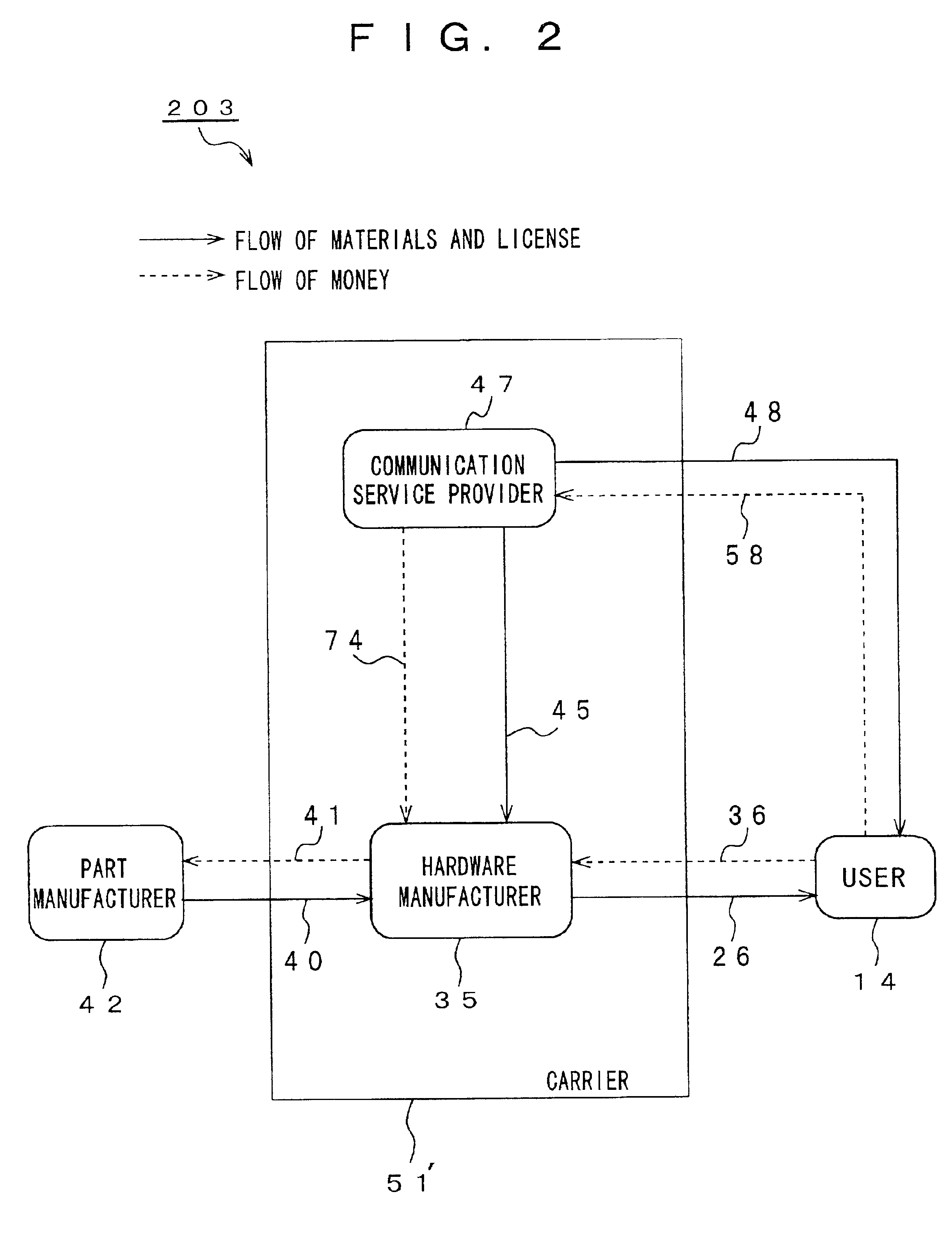

Sales activity management system, sales activity management apparatus, and sales activity management method

InactiveUS6910015B2Promote salesAdvanced manufacturing technologyDiscounts/incentivesFinanceLibrary scienceLicense

To automatically manage payment of charge produced between an apparatus manufacturer and an information provider, and to promote sales of an information processing apparatus and information contents.There are provided: a terminal device 11 to managed so as to manufacture and manage an information processing apparatus 16 and so as to sell to a user 14 an information processing apparatus at a price lower than a desired sales price of an apparatus manufacturer 15; a terminal device 12 managed so as to provide to the user 14 available information contents 18 at the information processing apparatus 16, and then, collect charge; and a sales activity management apparatus 13 for managing the terminal devices 11 and 12 based on a license agreement made in advance between an apparatus manufacturer 15 and an information provider 17, wherein this sales activity management apparatus 13 issues an instruction for the terminal device 12 to return to the terminal device 11 an amount of money corresponding to a difference produced because the apparatus manufacturer 15 has provided the information processing apparatus 16 to the user 14 at a low price according to an amount of money for a charge collected from the user 14.

Owner:SONY CORP

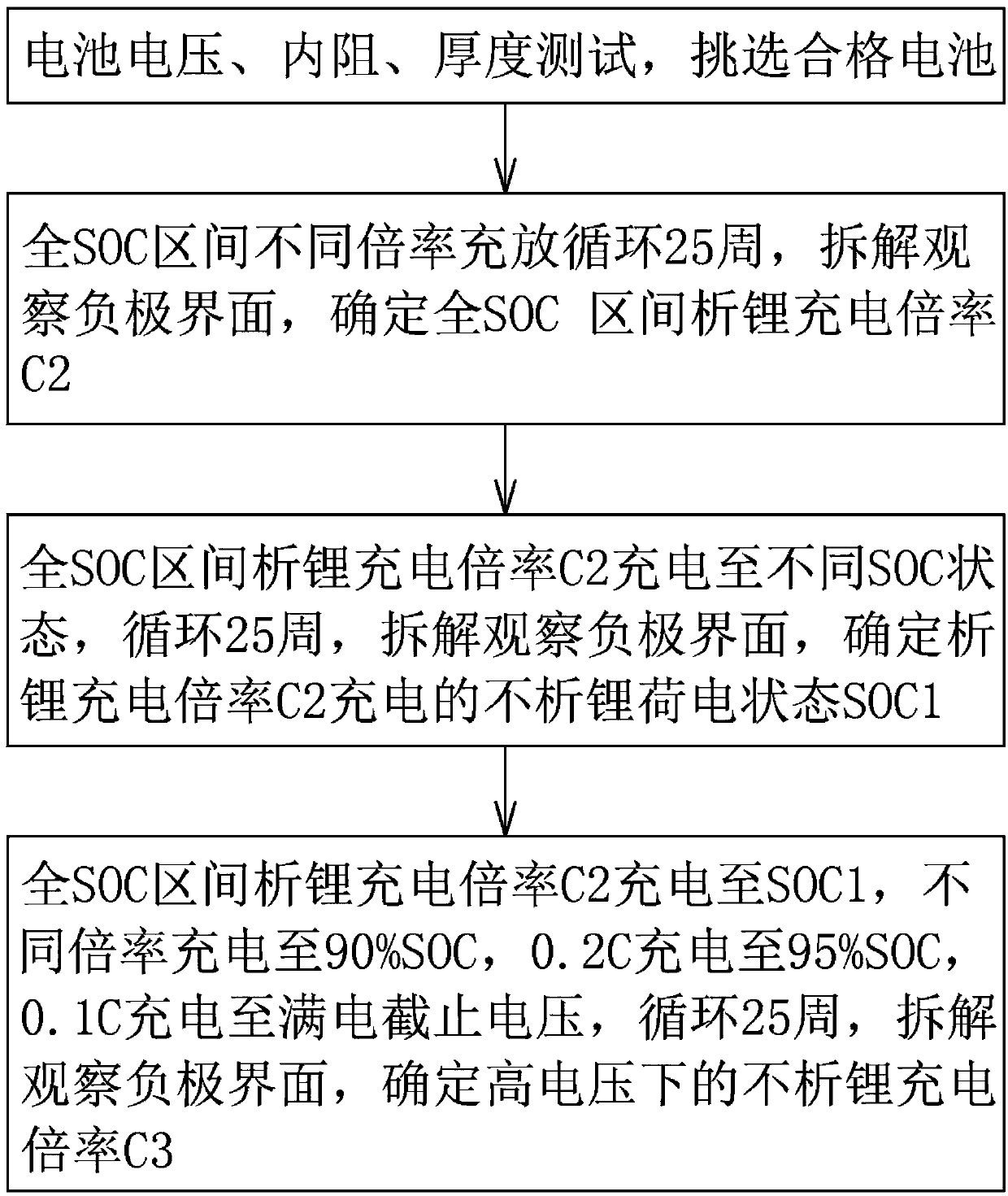

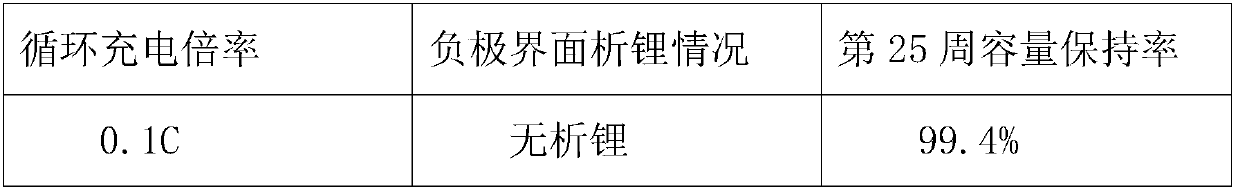

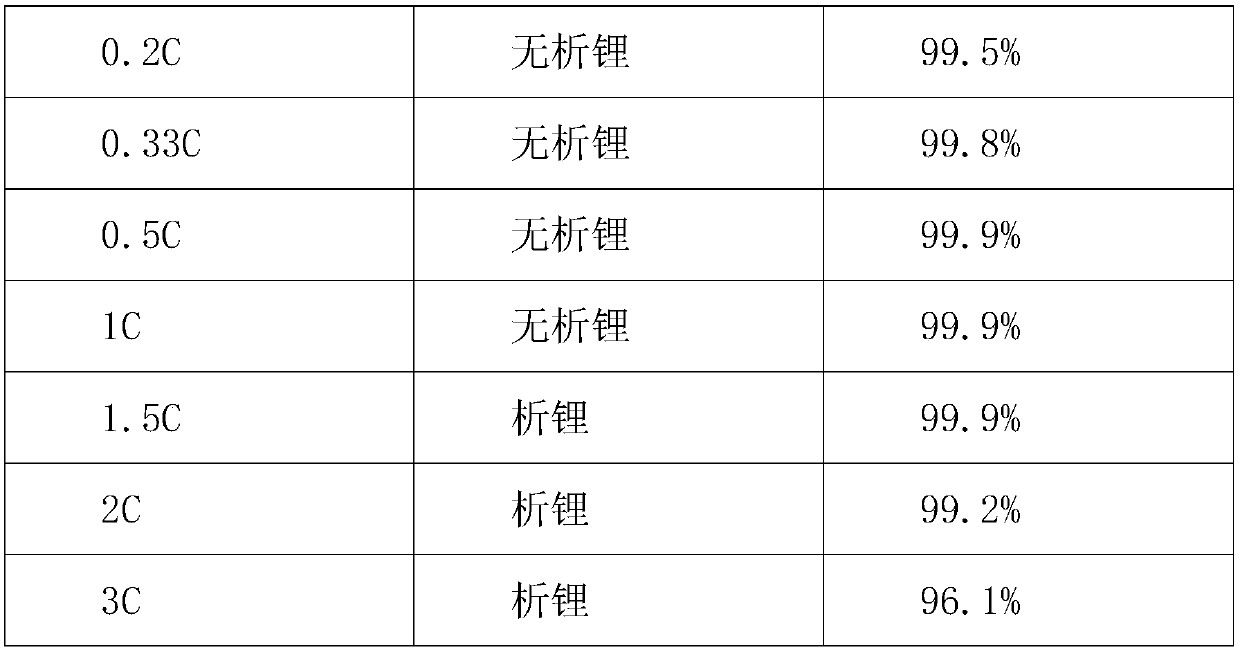

Optimization method for charging strategy of lithium-ion batteries

ActiveCN109546248AGuaranteed cycle performanceShorten charging timeSecondary cells charging/dischargingLithium electrodeBattery charge

The invention discloses an optimization method for the charging strategy of lithium-ion batteries. In a first stage, the lithium precipitation charging rate C2 is determined. In a second stage, the non-lithium-precipitation SOC1 under the lithium precipitation charging rate C2 is determined. In a third stage, the non-lithium-precipitation charging rate C3 under high voltage is determined. According to the optimization method for the charging strategy of lithium-ion batteries disclosed by the invention, a reasonable battery charging strategy is determined by determining the allowable maximum continuous rate of battery charging and the corresponding cut-off SOC state. The method is simple and fast, has guiding significance for the selection of the charging rate parameters of a vehicle charging strategy, ensures the cycle performance of batteries, reduces the actual charging time of batteries, can be used in the benchmarking of the charging performance of batteries from different manufacturers, and is conducive to improving battery design and manufacture technologies.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

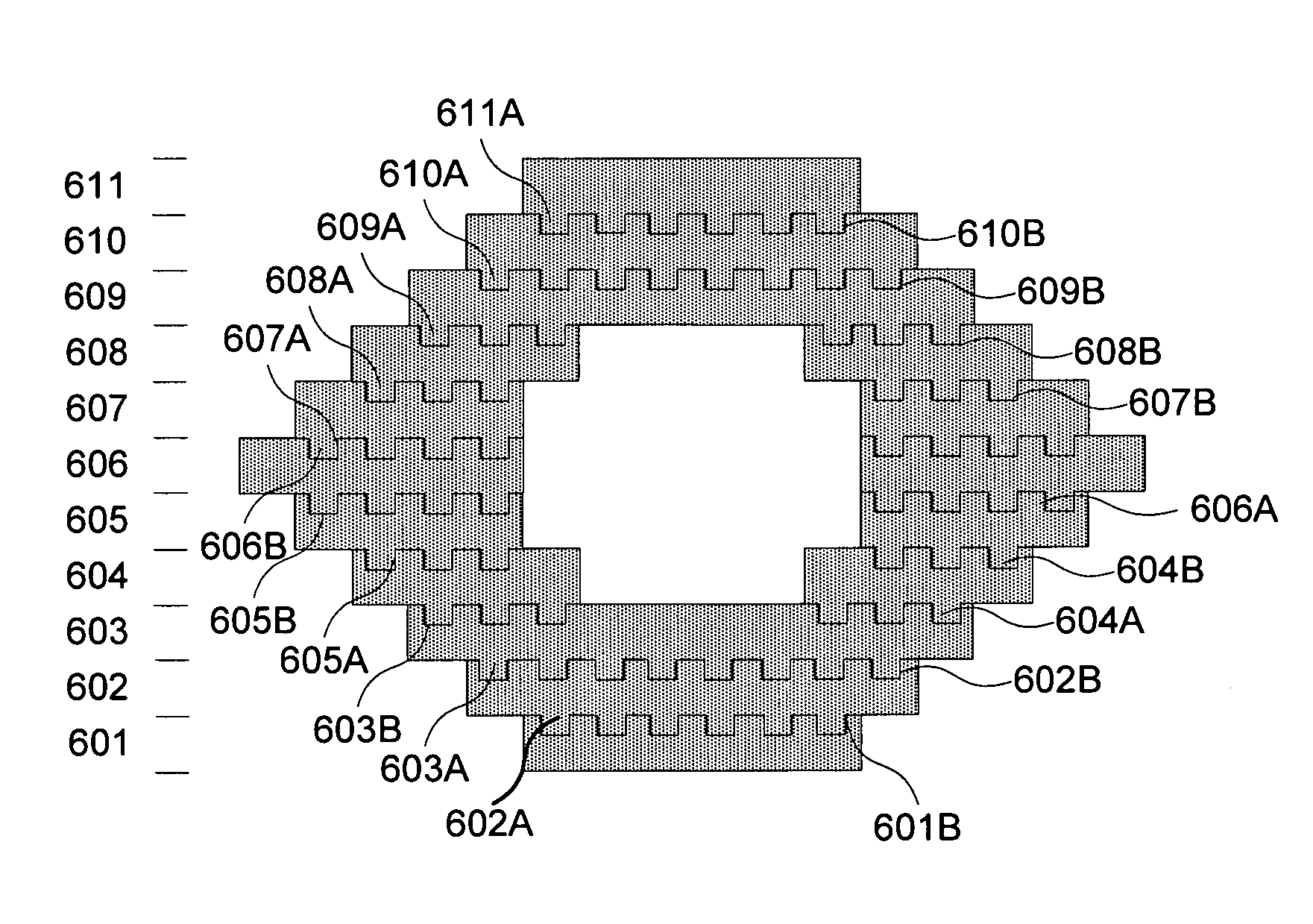

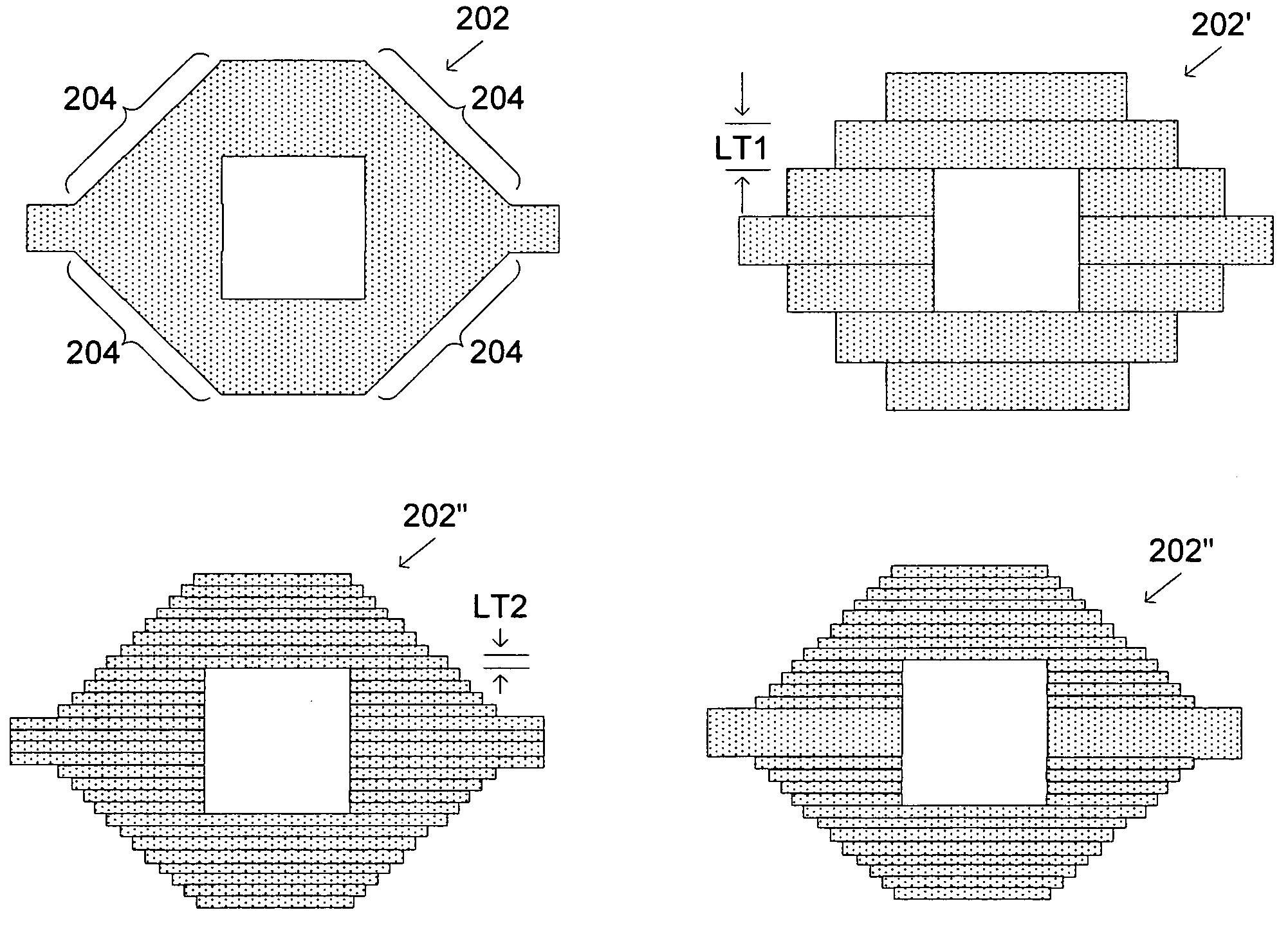

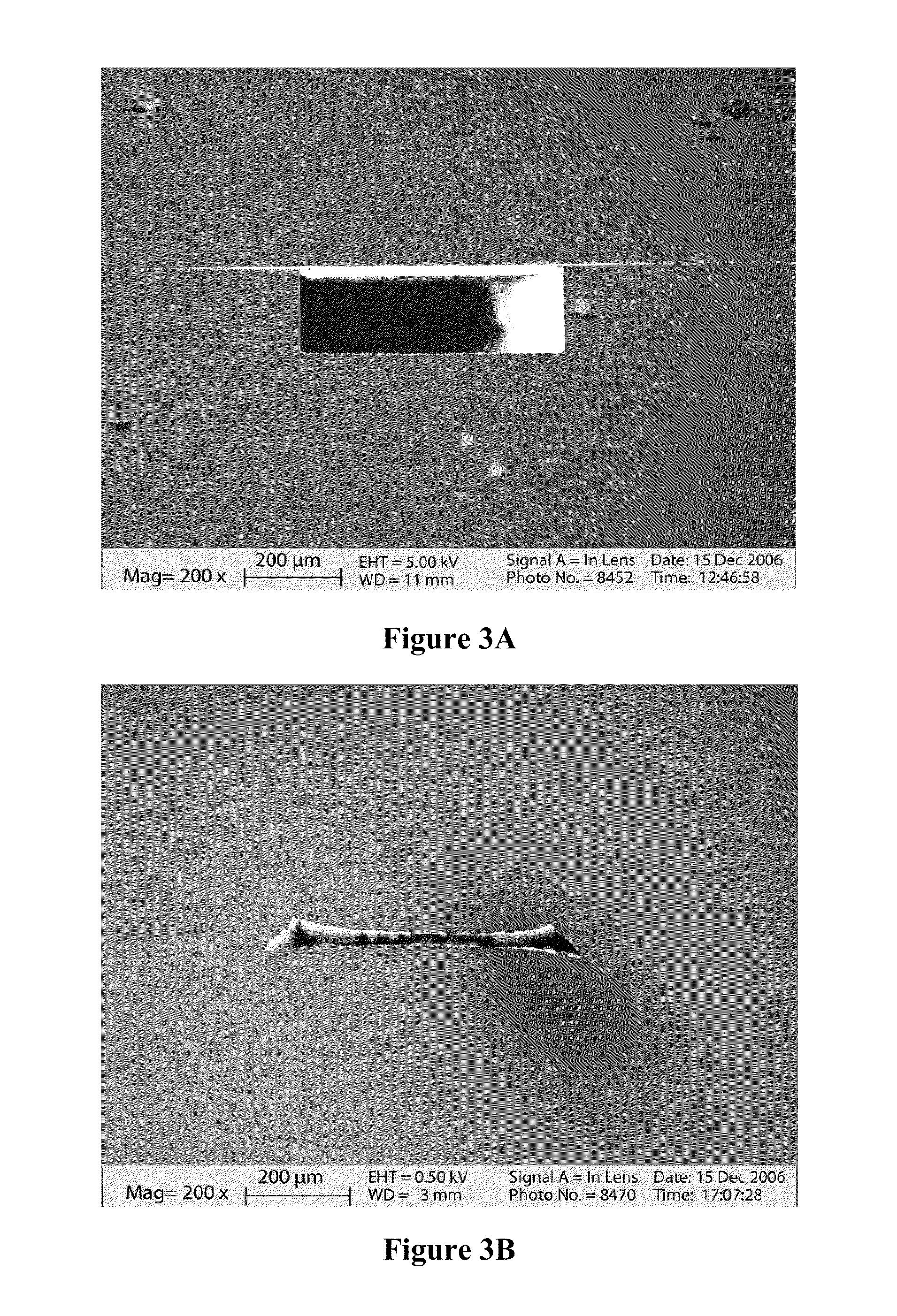

Methods of reducing interlayer discontinuities in electrochemically fabricated three-dimensional structures

ActiveUS7198704B2Enhanced electrochemical fabrication techniqueSmall sizeAdditive manufacturing apparatusElectrolysis componentsEngineeringElectrochemistry

Disclosed methods reduce the discontinuities between individual layers of a structure that are formed at least in part using electrochemical fabrication techniques. Discontinuities may exist between layers of a structure as a result of up-facing or down-facing regions defined in data descriptive of the structure or they may exist as a result of building limitations, e.g., limitations that result in non-parallel orientation between a building axis and sidewall surfaces of layers. Methods for reducing discontinuities may be applied to all regions or only to selected regions of the structure. Methods may be tailored to improve the accuracy between an original design of the structure and the structure as fabricated or they may simply be used to smooth the discontinuities between layers. Methods may include deposition operations that selectively favor filling of the discontinuities and / or etching operations that selectively favor removal of material from protrusions that define discontinuities.

Owner:MICROFAB

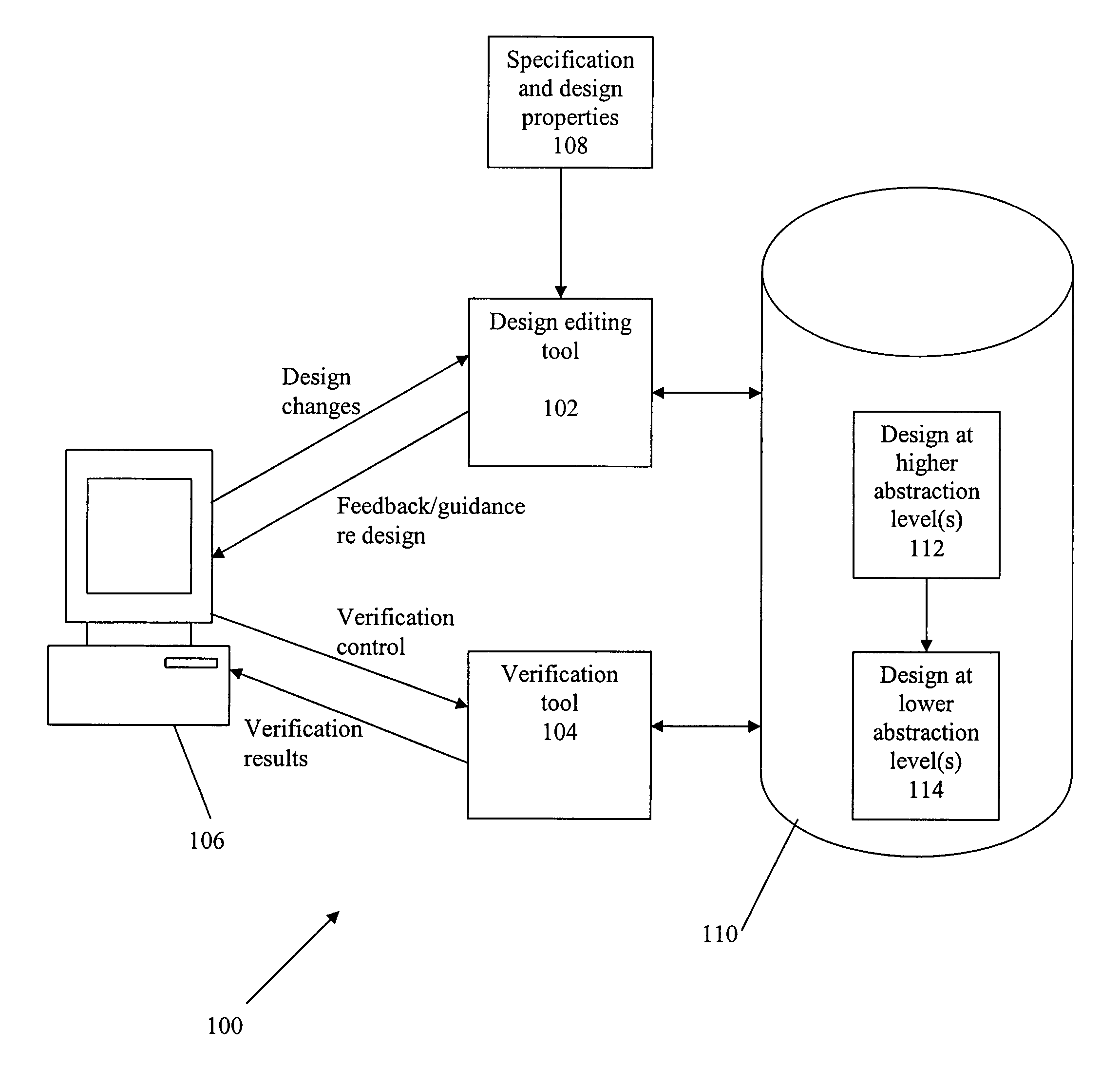

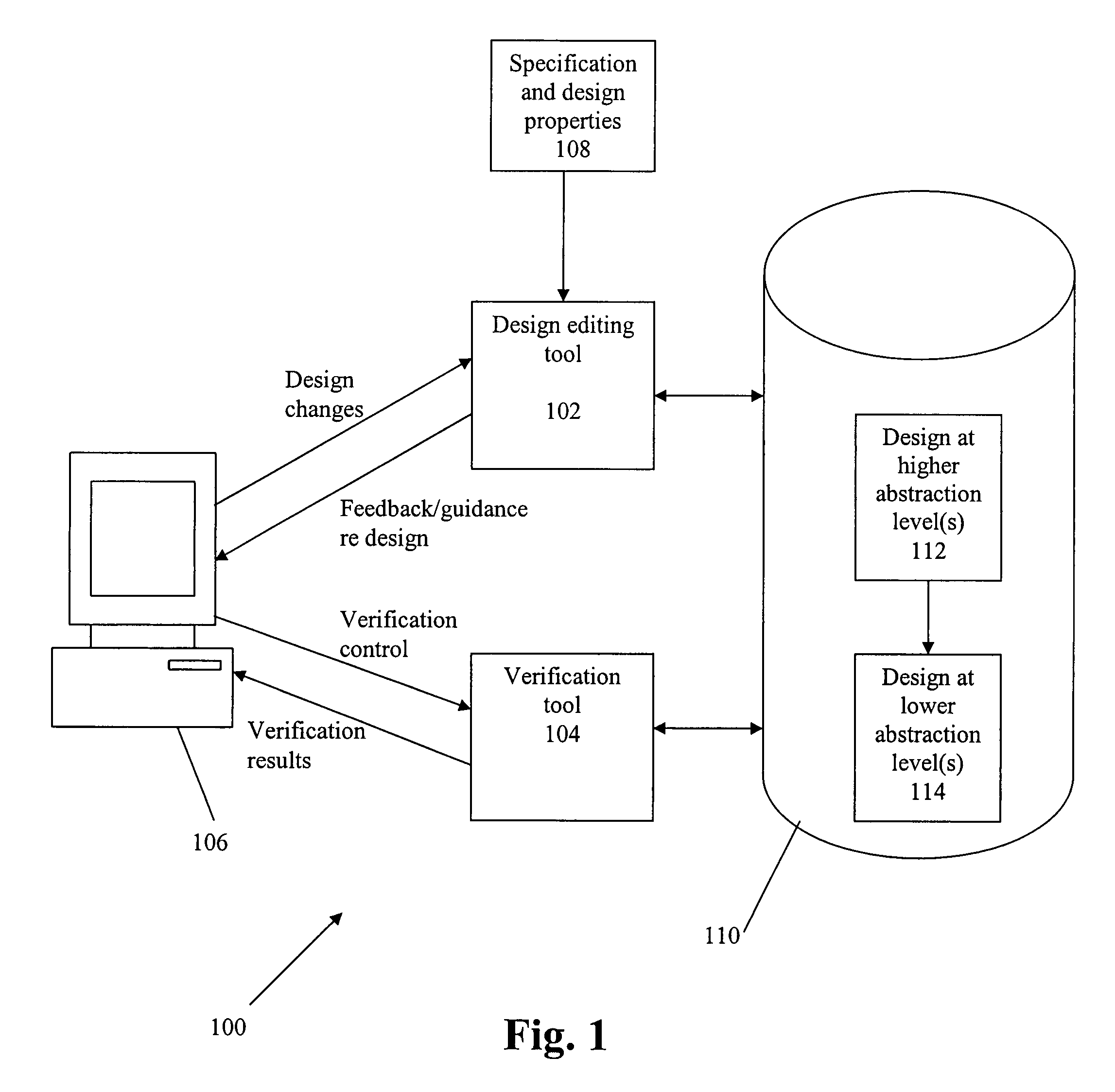

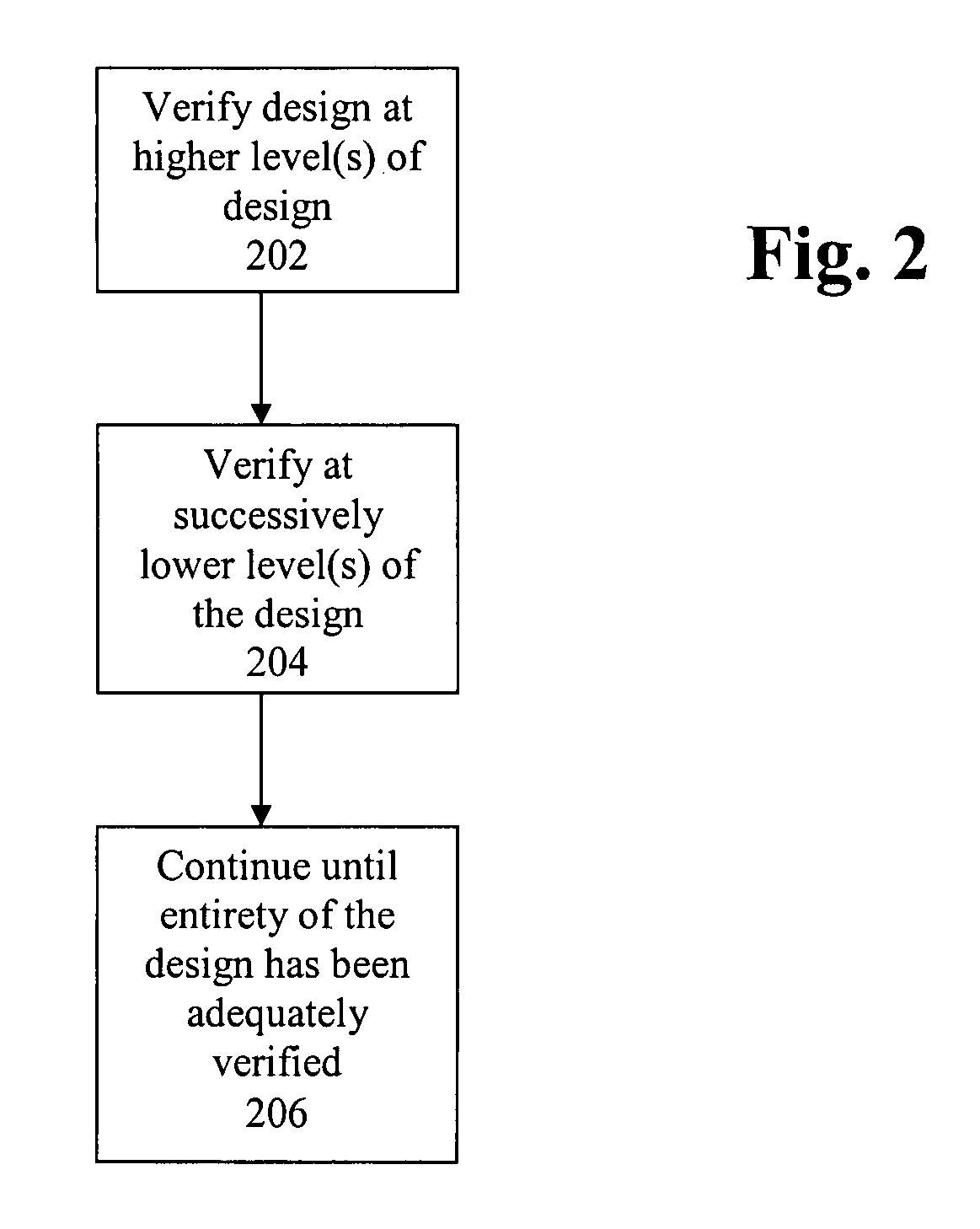

Method and system for implementing top down design and verification of an electrical circuit design

InactiveUS7937673B1Effectively and efficiently scaleIncreased complexityComputer aided designSpecial data processing applicationsImage resolutionEngineering

Disclosed is a method and system for performing design and verification using stepwise refinement techniques, which can also include or be referred to as “top-down” design verification. With the present stepwise refinement approach, the electronic design can be acted upon at different levels of abstraction, but with approximately the same level of resolution at each abstraction level. A strong relationship of consistency exists between the successive abstraction levels of the design. On account of this consistency, properties that are established or true at one level of the design remain true for all subsequent levels of abstraction of the design.

Owner:CADENCE DESIGN SYST INC

Homogeneous titanium tungsten alloys produced by powder metal technology

The present disclosure is related to homogeneous alloys comprising titanium and 9% to less than 20% by weight of tungsten, wherein the alloy has a yield strength of at least 120,000 psi and ductility of least 20% elongation; and with further alloying an ultimate tensile strength of at least 200,000 psi and useful ductility of at least 2% elongation; and with the addition of ceramic particulate reinforcements can exhibit an ultimate tensile strength of at least 180,000 psi. Products and metal matrix composites comprising such homogeneous alloys are also disclosed. The metal matrix composites further comprise a discontinuous reinforcement chosen from TiC, TiB2, or TiB, particles or combinations of such particles. Method of making such alloys and composites as well as products made from such alloys and composites are also disclosed.

Owner:DYNAMET TECH

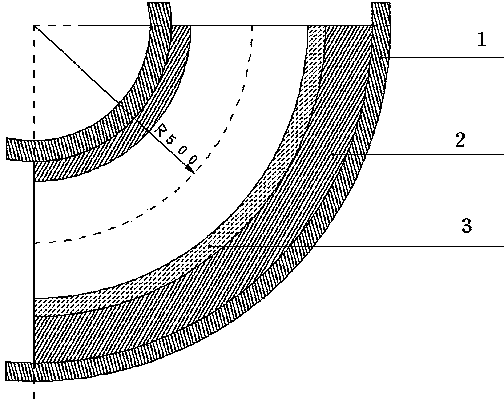

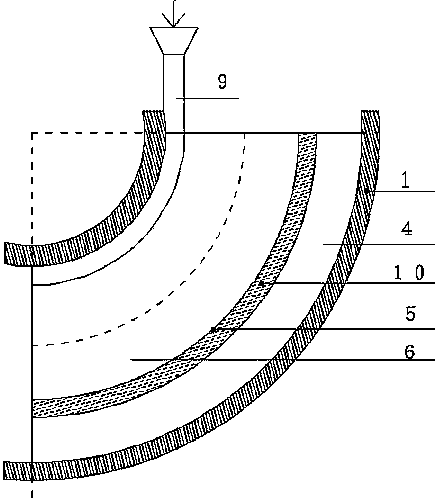

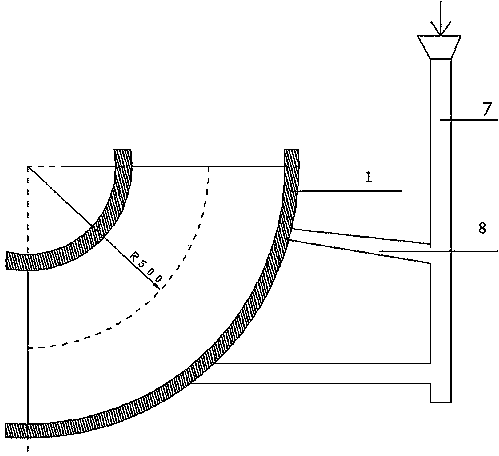

Multi-metal composite wear-resistant elbow pipe and preparation method thereof

InactiveCN103667876AAvoid replacementProtection wearFoundry mouldsFoundry coresManufacturing technologyWear resistant

The invention discloses a multi-metal composite wear-resistant elbow pipe and a preparation method thereof, wherein the inner side wall of the elbow pipe is formed through the composition of carbon cast steel on an outer layer and high-chromium iron on an inner layer, and is characterized in that the outer side wall of the elbow pipe is formed through the composition of three layers of different materials, namely a carbon cast steel outer layer (1), a high-chromium iron intermediate layer (2) and a wolfram carbide particle ceramic inner layer (3); the preparation method of the multi-metal composite wear-resistant elbow pipe comprises the following steps: foam model making, painting and baking, elbow pipe outer layer model packing, smelting, sand box vacuum pumping and pouring, taking out and cleaning castings on a carbon cast steel outer layer of the elbow pipe, elbow pipe interlayer model assembling, wolfram carbide particulate material paste painting, coating painting and baking, binning, smelting, sand vacuum pumping and pouring, taking elbow pipe castings out, cleaning and detecting, heat treating to the elbow pipe castings, detecting the hardness of the end surface of the multi-metal composite wear-resistant elbow pipe, and then warehousing; the prepared multi-metal composite wear-resistant elbow pipe has the advantages that the comprehensive mechanical property is excellent, the service life is long, the manufacturing technology is advanced, the maintenance and the installation are convenient, and a wide cost performance competition space is provided.

Owner:YANTAI BRANCH NO 52 INST OF CHINA NORTH IND GRP

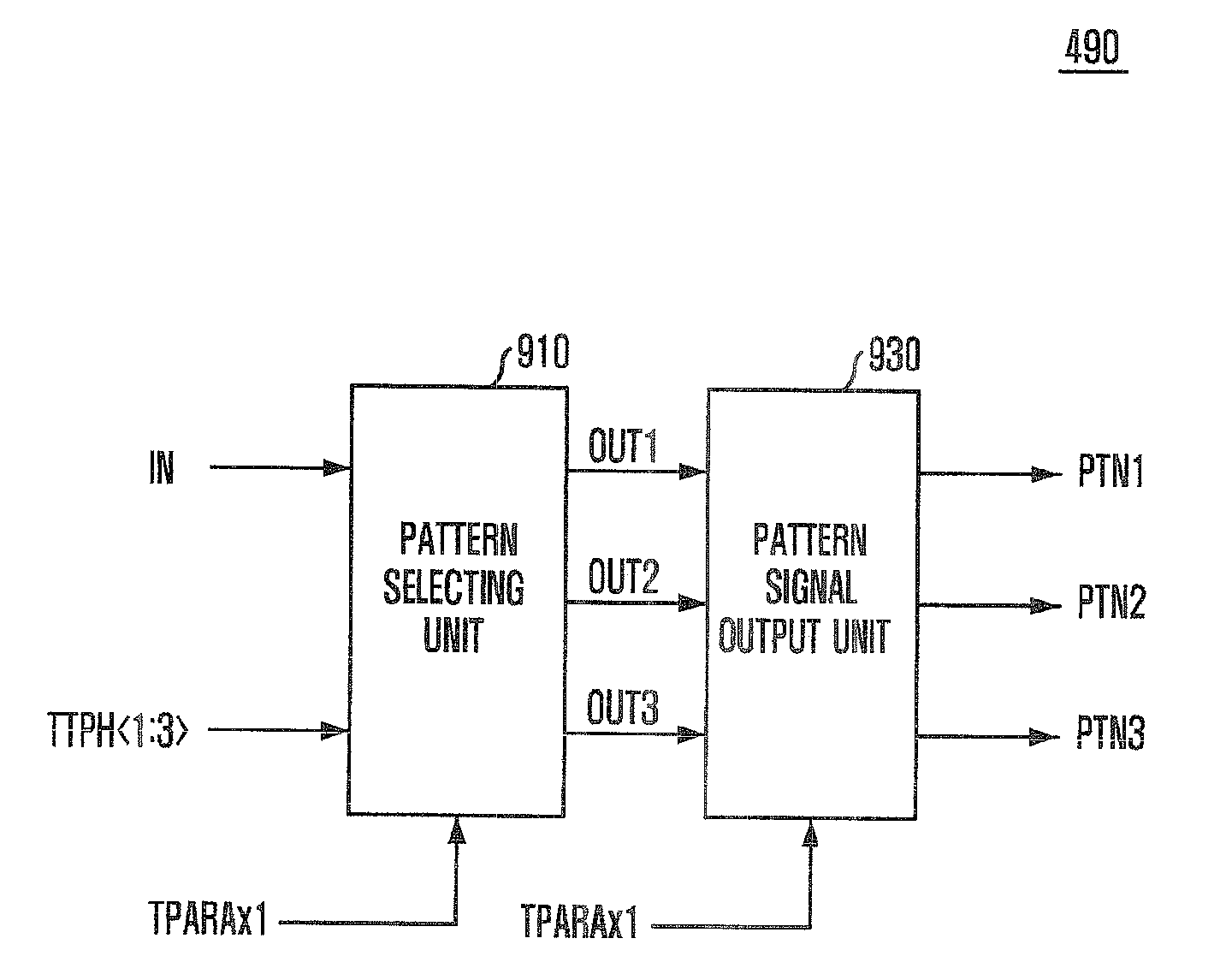

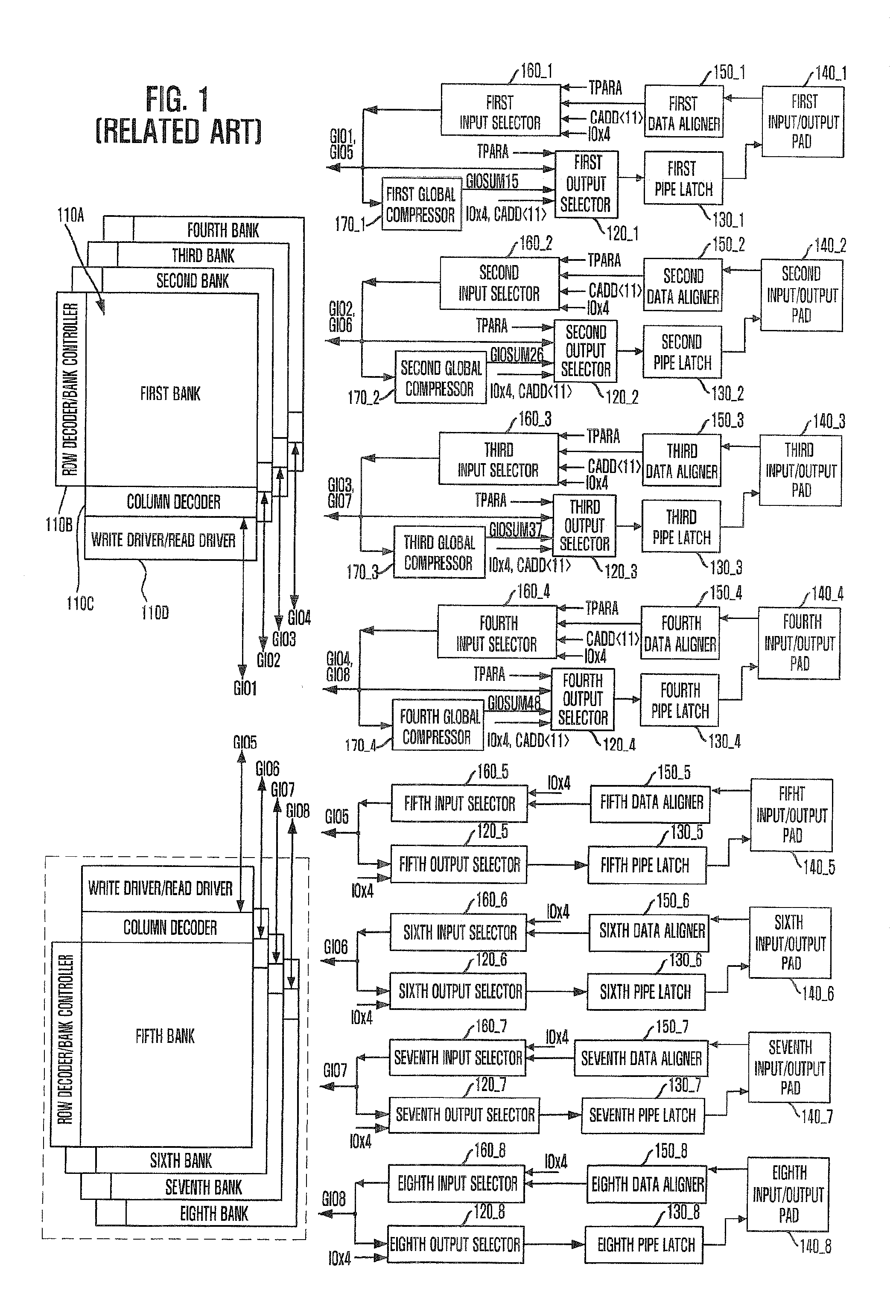

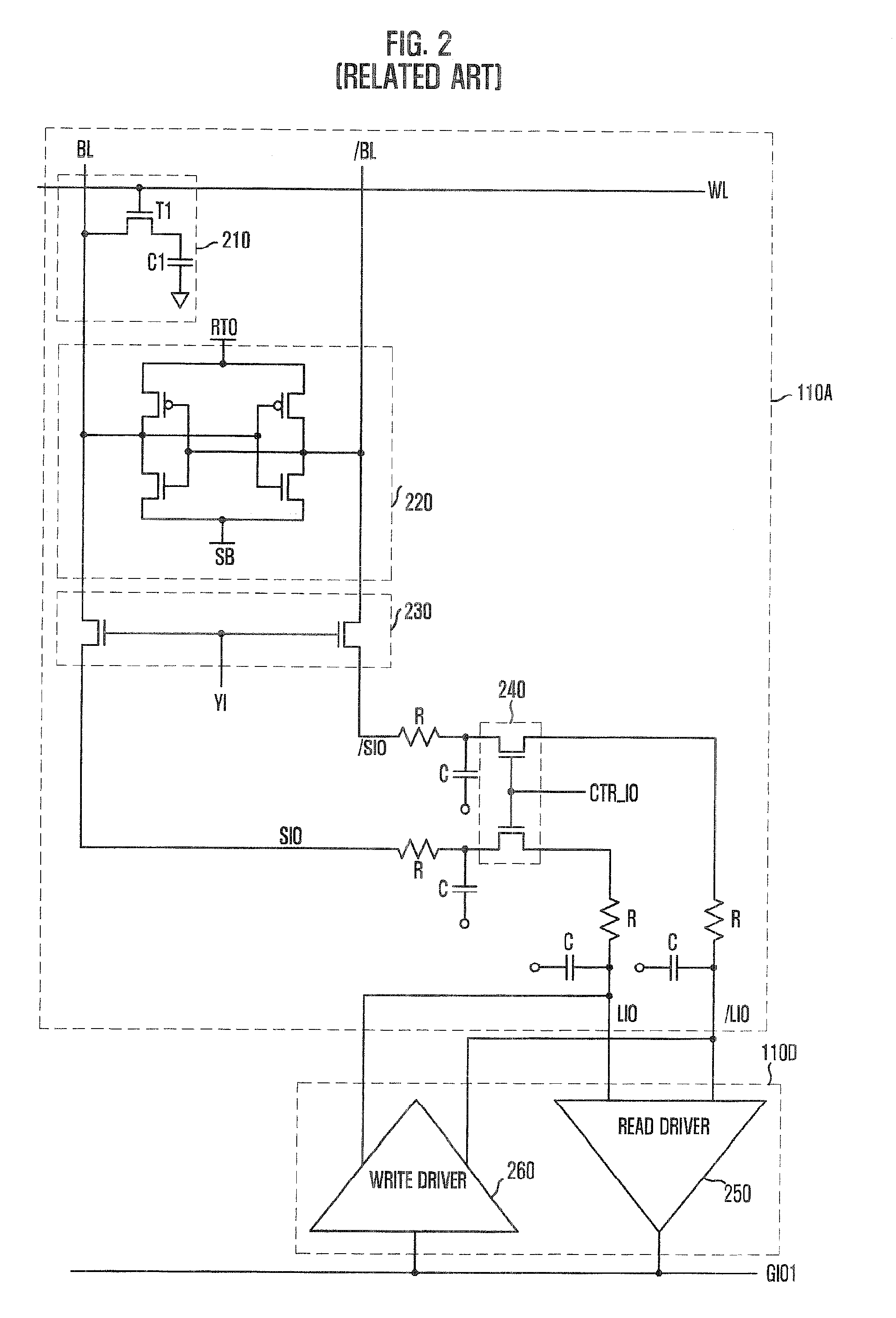

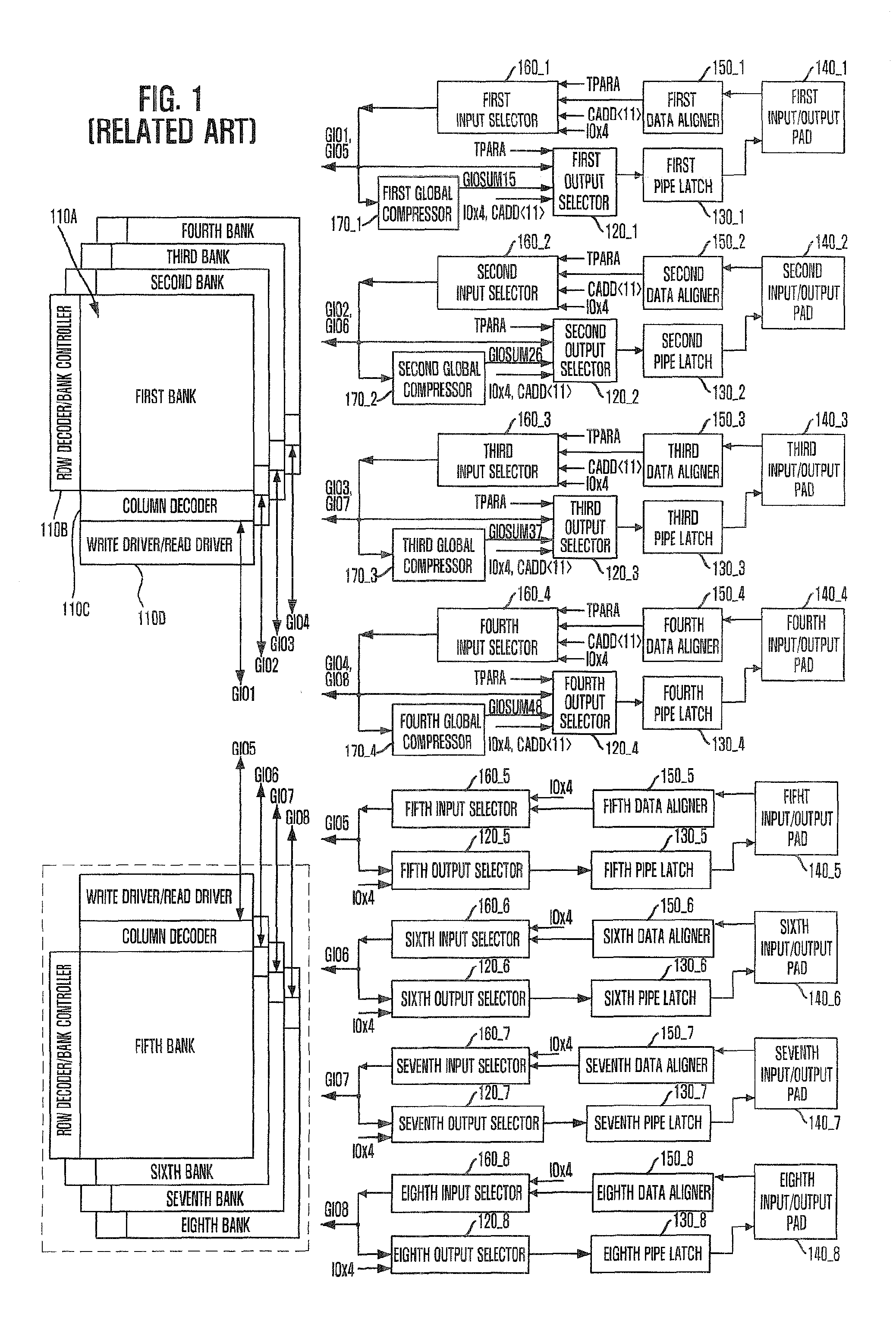

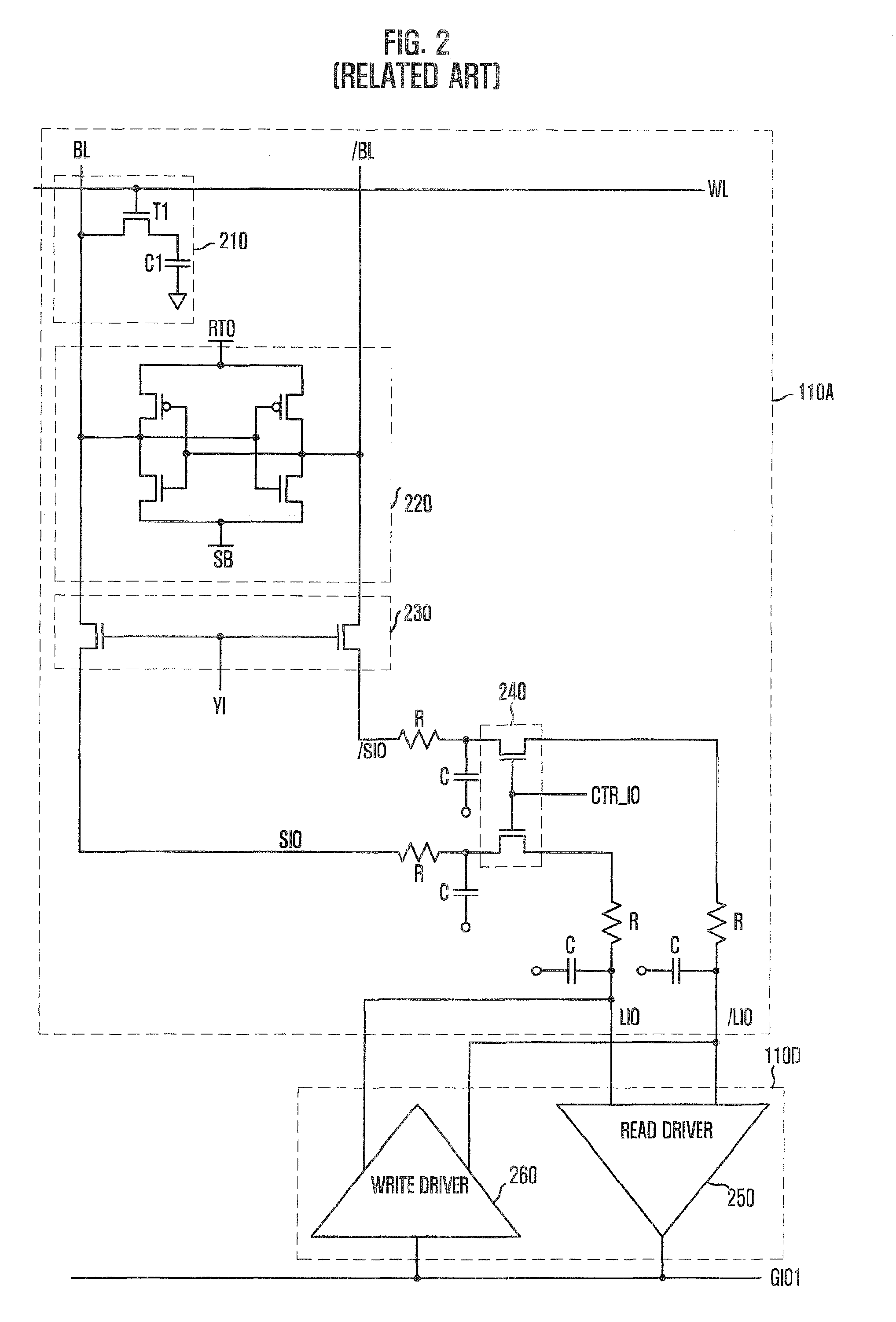

Semiconductor memory device, operating method thereof, and compression test method thereof

InactiveUS20090273991A1Minimal numberAdvanced manufacturing technologyElectronic circuit testingError detection/correctionEngineeringSignal generator

A semiconductor memory device including a plurality of banks, each including a plurality of memory cells, a pattern signal generator configured to generate pattern signals having combinations in response to an input signal applied through an arbitrary pad in a compression test mode. Input paths are configured to transfer the plurality of pattern signals to the corresponding banks.

Owner:SK HYNIX INC

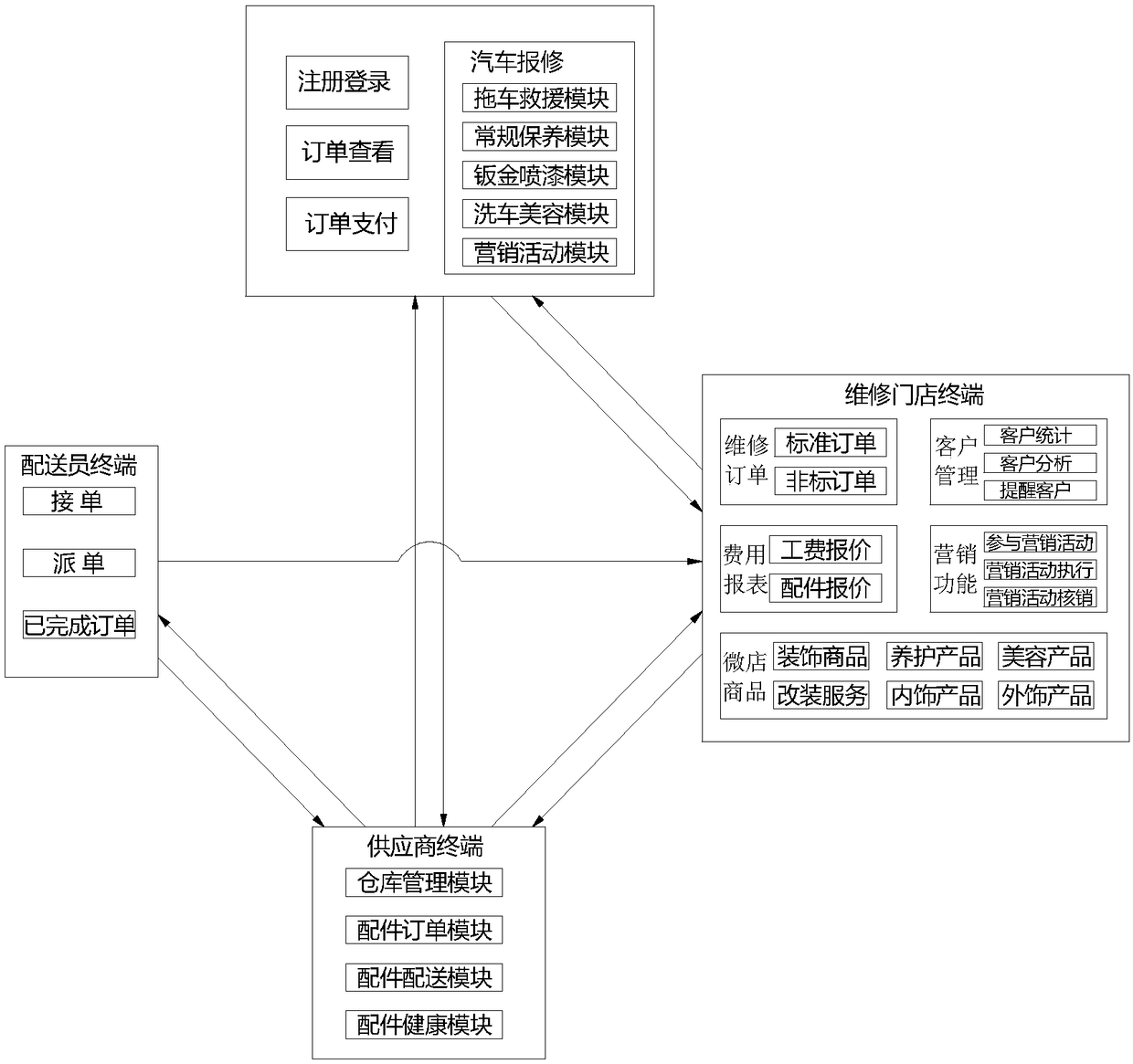

Internet marketing transaction management system for an automobile maintenance store

ActiveCN109344982AAvoid being overchargedAdvanced manufacturing technologyBuying/selling/leasing transactionsPersonalizationRepair shop

the invention discloses an Internet marketing transaction management system for an automobile maintenance store.including the management platform, Customer Service Terminal, Maintenance Store Terminal, Supplier Terminal, Distributor Terminal, Established Automobile Maintenance Store, Parts Supplier, Parts Distributor, Customer Service Integrated Marketing Transaction Management, Through Internet Appointment Maintenance, Personalized Order Maintenance, Big Data Statistics and Analysis, Improve User Experience, Optimize Management Process, Improve Work Efficiency; Between the parts supplier andthe auto repair shop, the labor cost of the repair shop and the spare parts shop is greatly reduced through the distribution system; By analyzing the data of automobile maintenance and the source anddestination of automobile parts, the quality of different brands of automobiles and parts can be judged directly, which is helpful to screen out high-quality manufacturers and promote the developmentof China's automobile manufacturing industry.

Owner:海南安桥网络科技有限公司

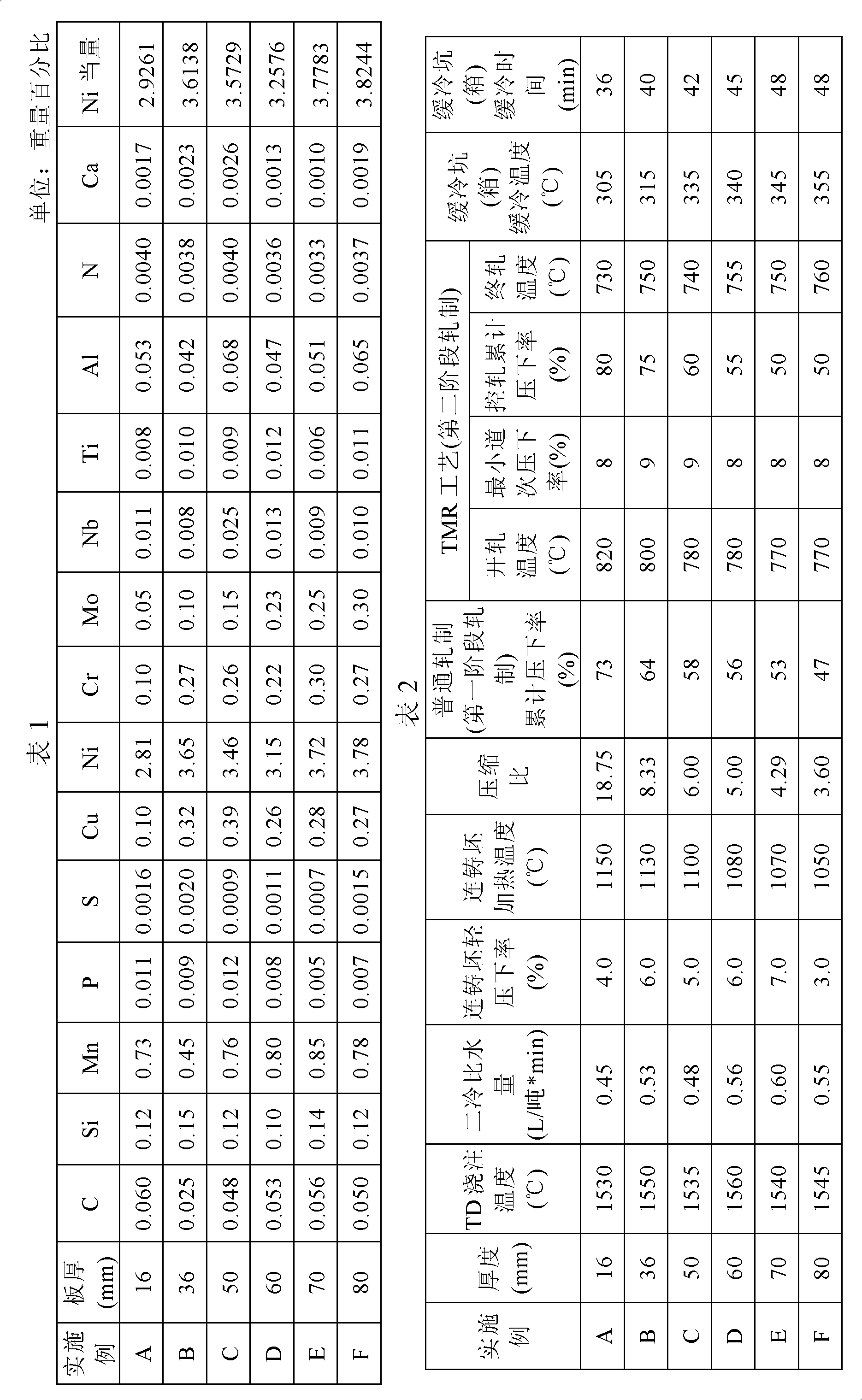

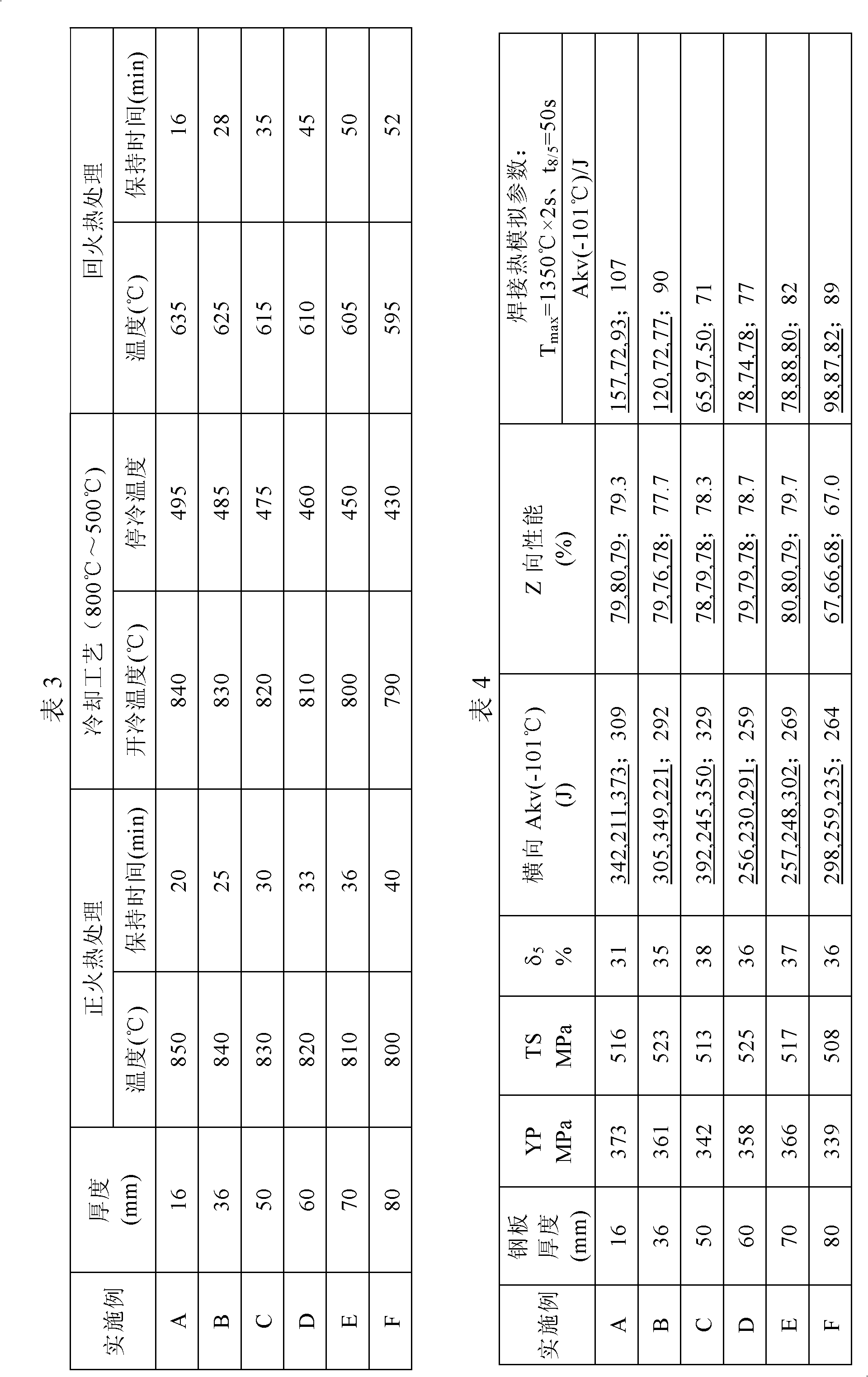

High tempering parameter SR embrittlement resistant cryogenic nickel steel and manufacture method thereof

ActiveCN102691006AExcellent resistance to high tempering parameter SR embrittlement characteristicsIncrease the content of acid-soluble AlsTemperature control deviceToughnessMaterials science

A high tempering parameter SR embrittlement resistant cryogenic nickel steel and a manufacture method thereof. The nickel steel comprises, by weight, 0.025%-0.060% of C, Si no more than 0.15%, 0.45%-0.85% of Mn, P no more than 0.012%, S no more than 0.0020%, 0.10%-0.40% of Cu, 2.80%-3.80% of Ni, 0.10%-0.30% of Cr, 0.05%-0.30% of Mo, 0.040%-0.070% of Als, 0.006%-0.012% of Ti, 0.008%-0.025% of Nb, N no more than 0.0040%, 0.001%-0.003% of Ca, residual iron and unavoidable inclusions. According to optimized controlled rolling and a normalizing plus tempering technology, the nickel steel gains extremely high ultralow temperature toughness, excellent HIC / SCC resistance, weldability and bearing capacity of high heat input welding; besides, the nickel steel has excellent high tempering parameter SR embrittlement resistance characteristic, and is especially suitable for manufacture of large-scale LPG low temperature storage tank, low temperature storage tank for ship and large-scale steel structure for ice ocean and polar region.

Owner:BAOSHAN IRON & STEEL CO LTD

Homogeneous titanium tungsten alloys produced by powder metal technology

InactiveUS20110233057A1Improve ductilityAdvanced manufacturing technologyPropellersVacuum evaporation coatingParticulatesTitanium

The present disclosure is related to homogeneous alloys comprising titanium and 9% to less than 20% by weight of tungsten, wherein the alloy has a yield strength of at least 120,000 psi and ductility of least 20% elongation; and with further alloying an ultimate tensile strength of at least 200,000 psi and useful ductility of at least 2% elongation; and with the addition of ceramic particulate reinforcements can exhibit an ultimate tensile strength of at least 180,000 psi. Products and metal matrix composites comprising such homogeneous alloys are also disclosed. The metal matrix composites further comprise a discontinuous reinforcement chosen from TiC, TiB2, or TiB, particles or combinations of such particles. Method of making such alloys and composites as well as products made from such alloys and composites are also disclosed.

Owner:RMI TITANIUM

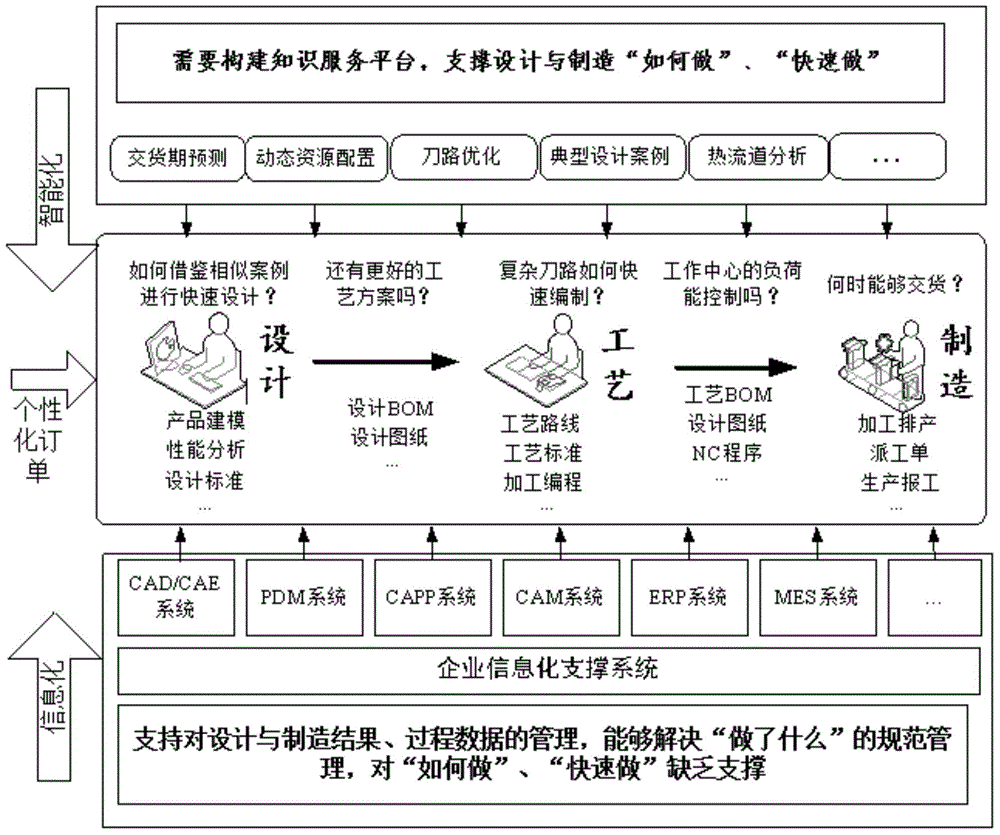

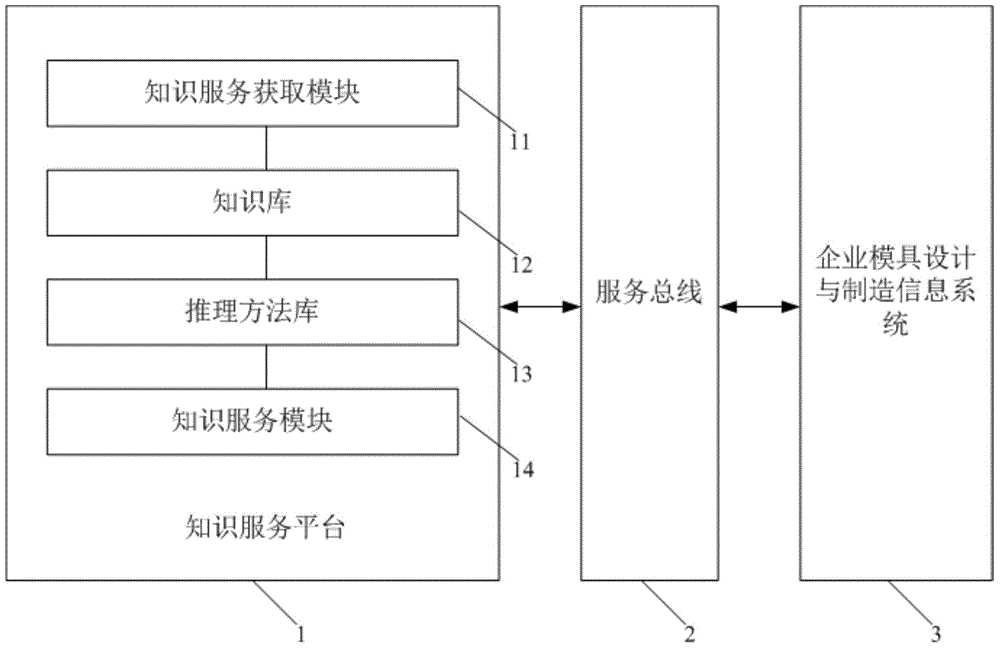

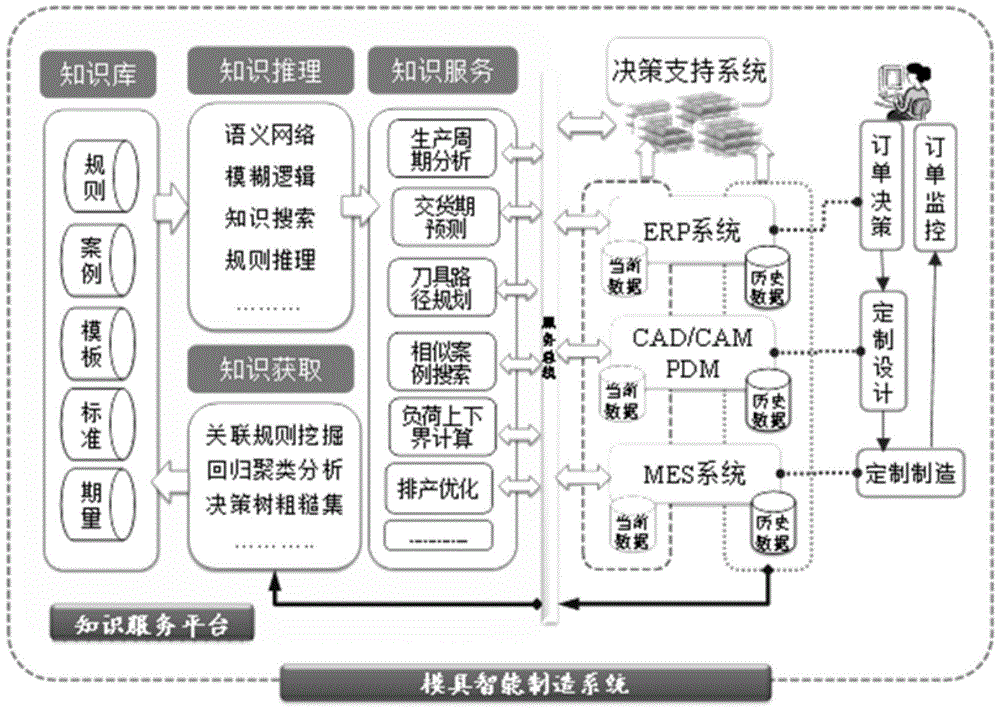

Knowledge service system and method for die designing

InactiveCN104951590ASustainable Knowledge ServiceRealize knowledge precipitation and reuseData processing applicationsSpecial data processing applicationsInformation systemService bus

The invention discloses a knowledge service system and method for die designing. The method is suitable for a knowledge service platform communicating with an enterprise die deigning and manufacturing information system through a service bus. The method includes the steps: extracting historical data from the enterprise die designing and manufacturing information system, and acquiring die designing and manufacturing knowledge according to a preset data mining algorithm; storing the acquired die designing and manufacturing knowledge into a knowledge base; acquiring knowledge service needs for die designing and manufacturing from the enterprise designing and manufacturing information system, calling a corresponding knowledge service control according to the knowledge service needs, and generating needed knowledge service by calling the die designing and manufacturing knowledge in the knowledge base and utilizing a prestored reasoning algorithm in a reasoning method base through the knowledge service control.

Owner:GUANGDONG UNIV OF TECH

Sunscreen composition with improved aesthetic properties

InactiveUS20150202145A1Improve aestheticsNice aesthetic propertyCosmetic preparationsToilet preparationsCross-linkZinc

Owner:MD SOLARSCI

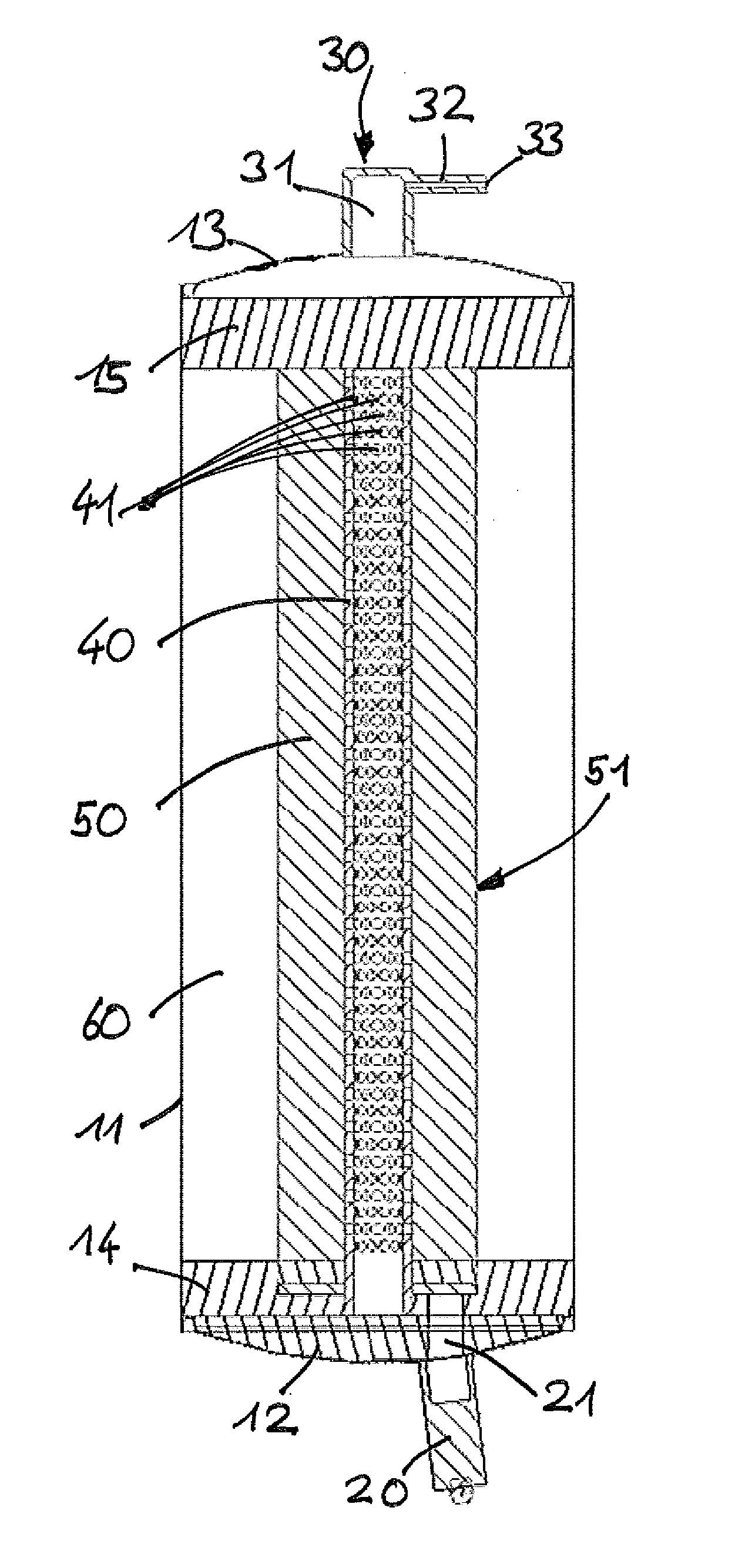

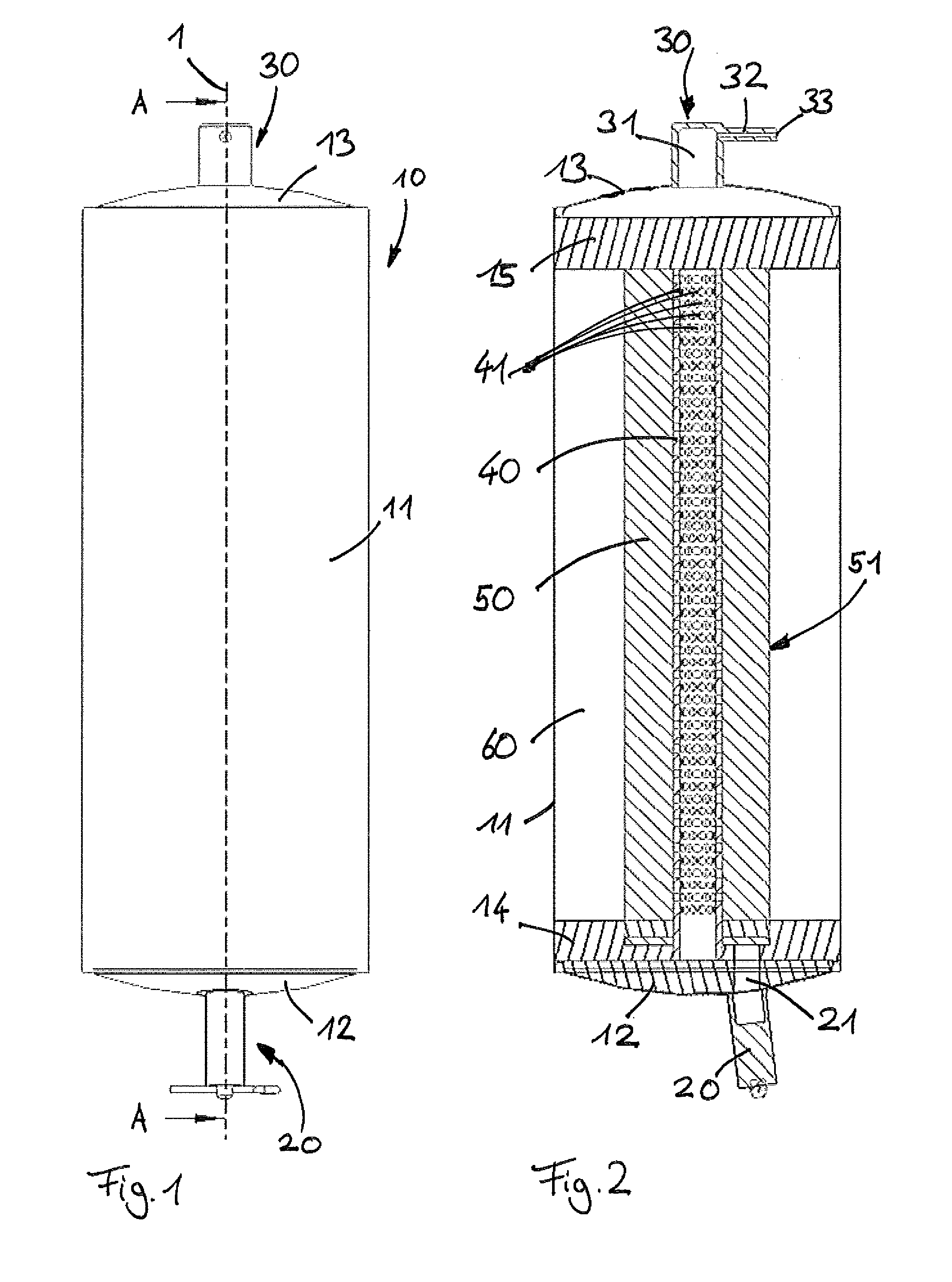

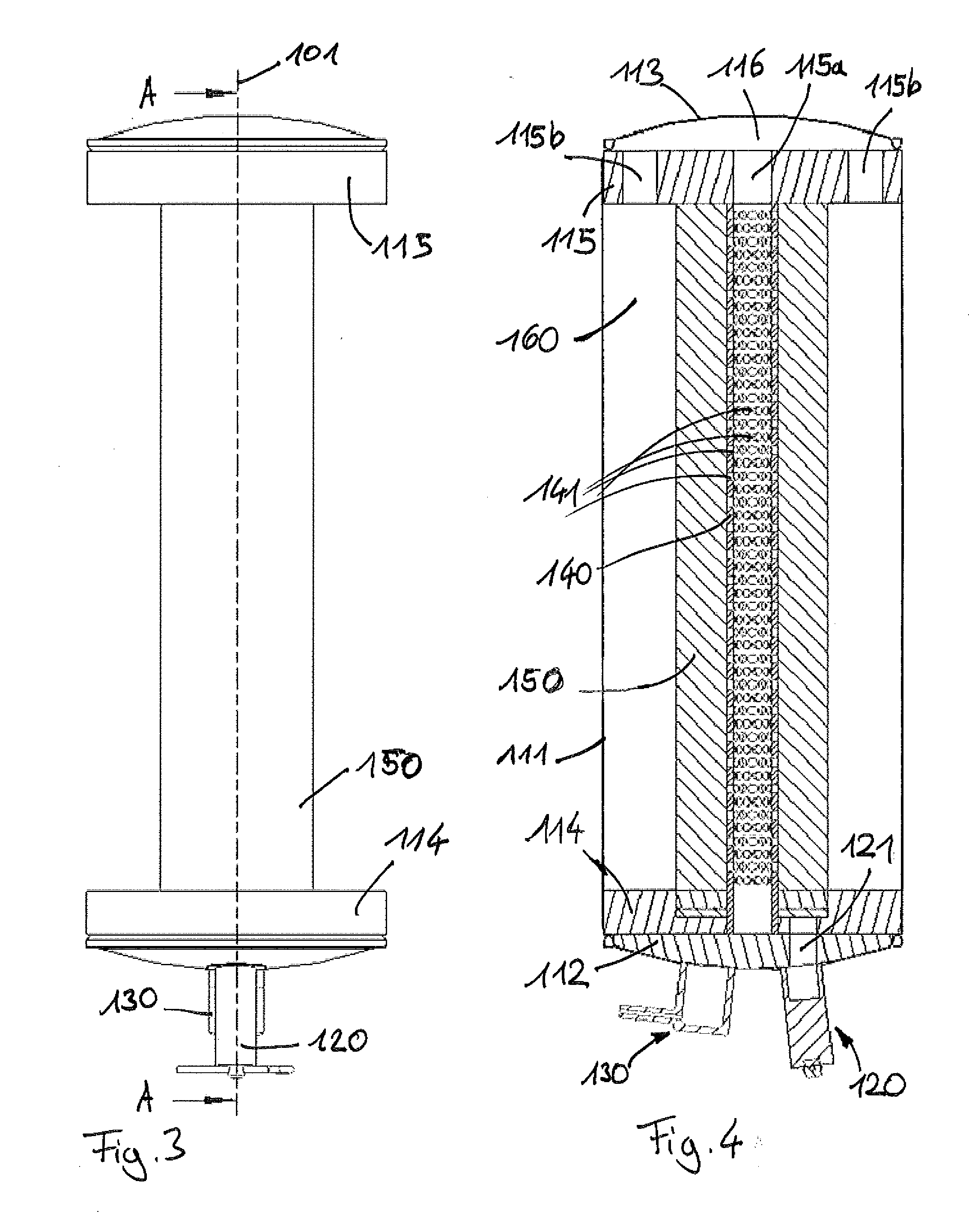

Chemical oxygen generator with core channel tube for an emergency oxygen device

ActiveUS20130192596A1Good controlPrevent misuseRespiratorsBreathing masksInterior spaceChemical oxygen generator

Embodiments of the invention relate to a chemical oxygen generator for an emergency oxygen device, comprising an outer housing defining an interior space and comprising an outlet opening, a solid oxygen source within said interior space containing a material which is able to produce oxygen in a chemical reaction. According to embodiments of the invention, a hollow tube within said interior space is embedded in said solid oxygen source.

Owner:SAFRAN AEROTECHNICS

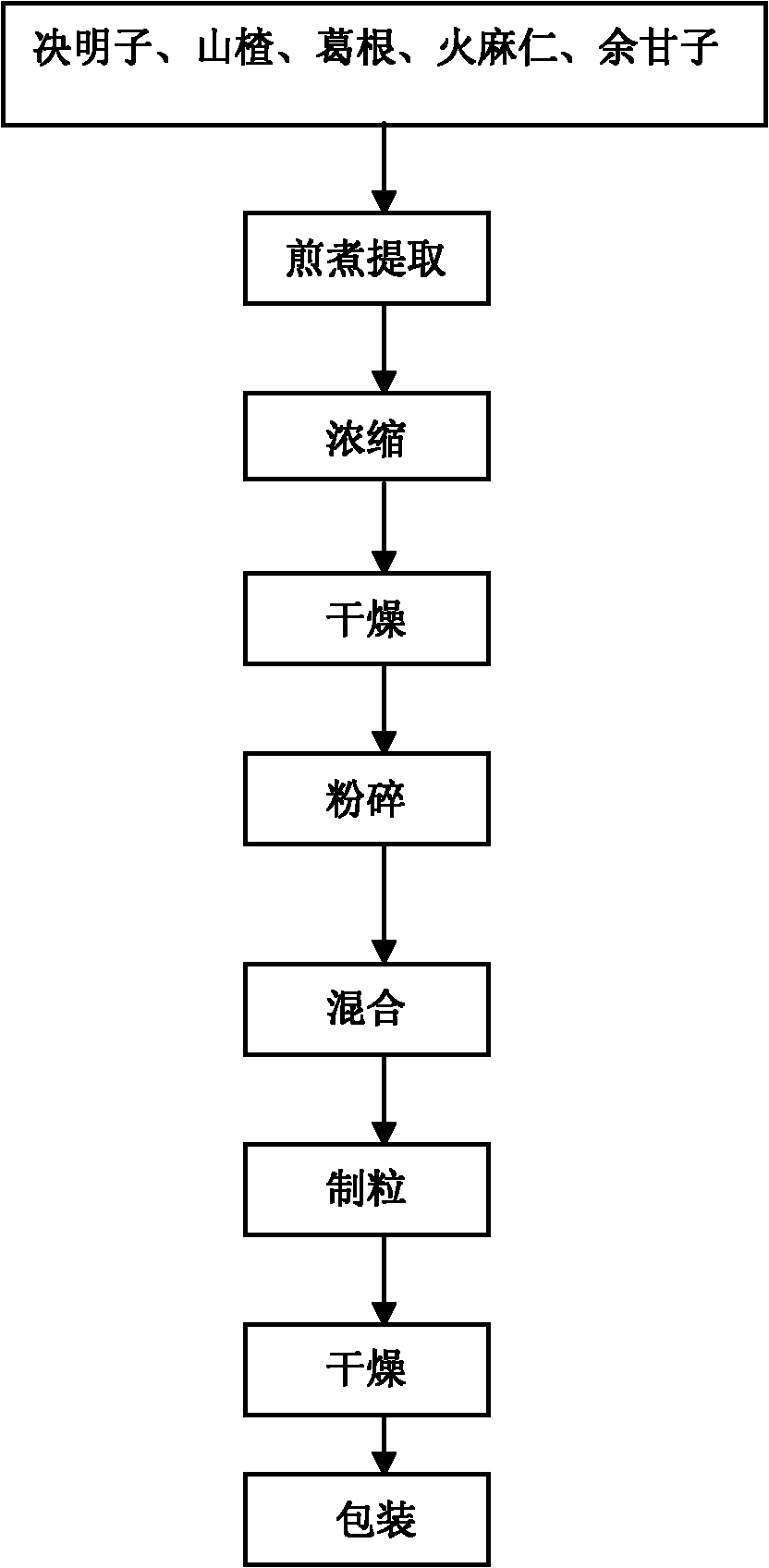

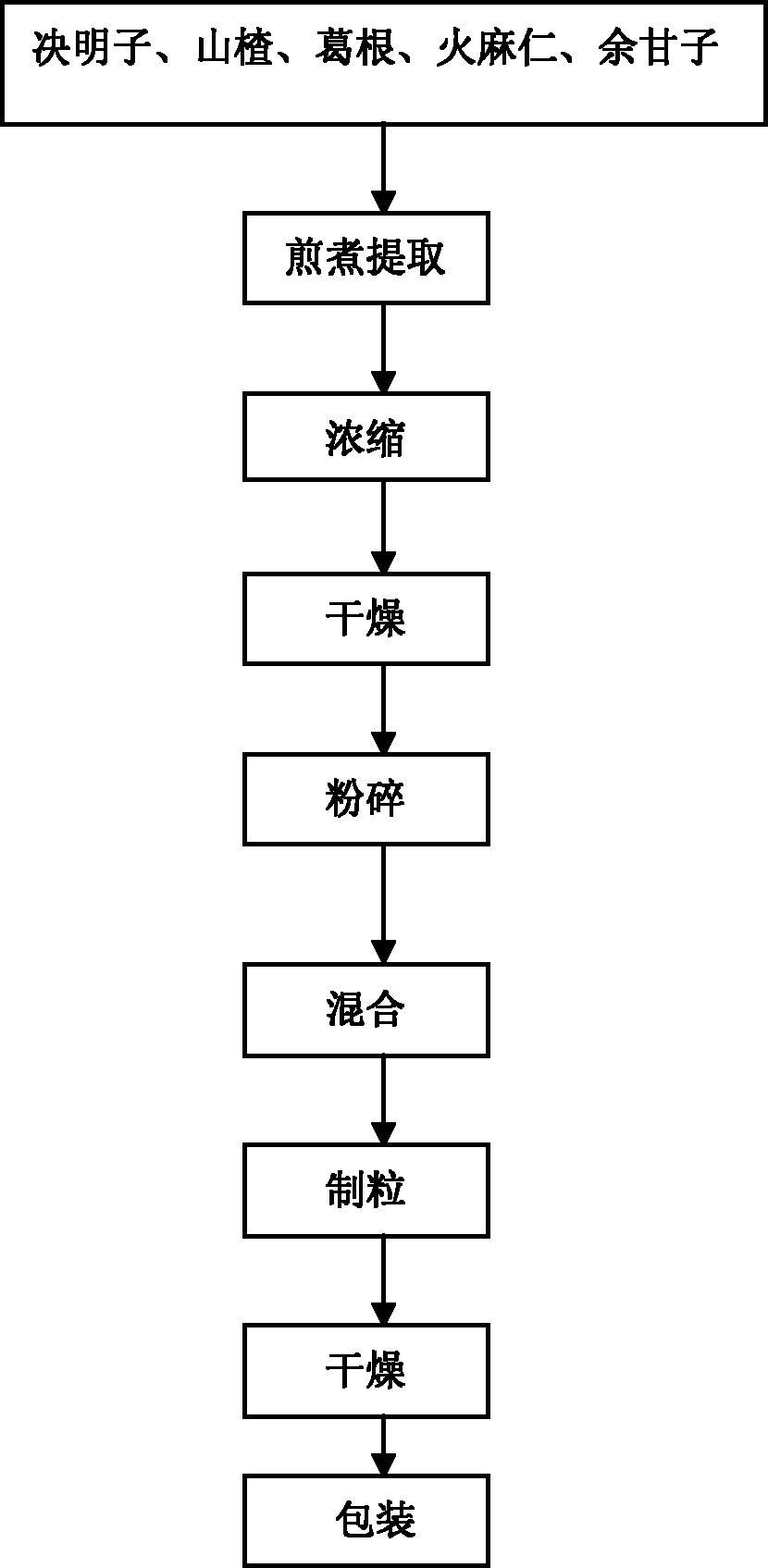

Cassia seed lipid-lowering tea and preparation method thereof

ActiveCN102106429ACompatibility is scientific and reasonableGood effectTea substituesCannabisBULK ACTIVE INGREDIENT

The invention relates to cassia seed lipid-lowering tea and a preparation method thereof, in particular to health food which takes plants as raw materials as well as a preparation method thereof, belonging to natural health food for people. The cassia seed lipid-lowering tea comprises the following raw materials for preparing active ingredients: cassia seed, hawthorn, kudzuvine root, semen cannabis, fructus phyllanthi and the like. The preparation method comprises the following steps: decocting for extraction; concentrating into extract; and drying and granulating. The prepared cassia seed lipid-lowering tea has the advantages of fewer raw materials for preparing the active ingredients, and reasonable and scientific raw material formula, and can really play a role of lowering lipid.

Owner:四川回春堂生物科技有限公司

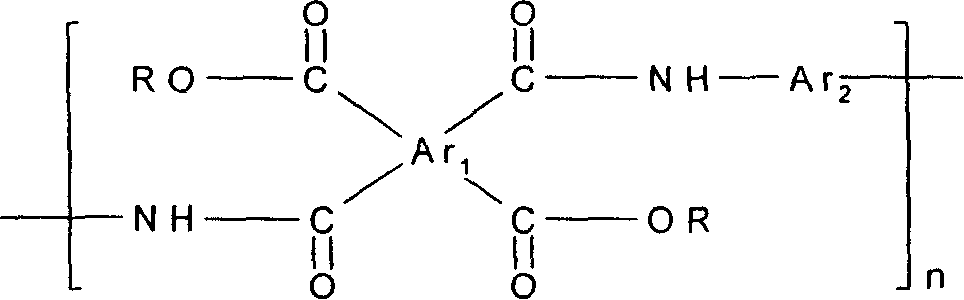

Method of preparing ultra low dielectric constant polyimide membrane by polyamide ester precursor phase transformation

The invention discloses a preparing method of ultra-low dielectric constant polyimide film, which comprises the following steps: dissolving polyesteramide in the N, N-dimethyl acetamide, N, N-dimethyl formamide or N-methyl pyrrolidone to obtain the filming liquid with density at 15-30%; filtering the filming liquid; degassing; scraping on the stainless steel support to form liquid film with thickness at 50-500 um; solidifying support with liquid film in the hardening bath; immersing film to clean through alcohol or acetone; drying to obtain former film of polyesteramide; disposing the former film of polyesteramide in the nitrogen or argon gas to heat to obtain the product.

Owner:ZHEJIANG UNIV

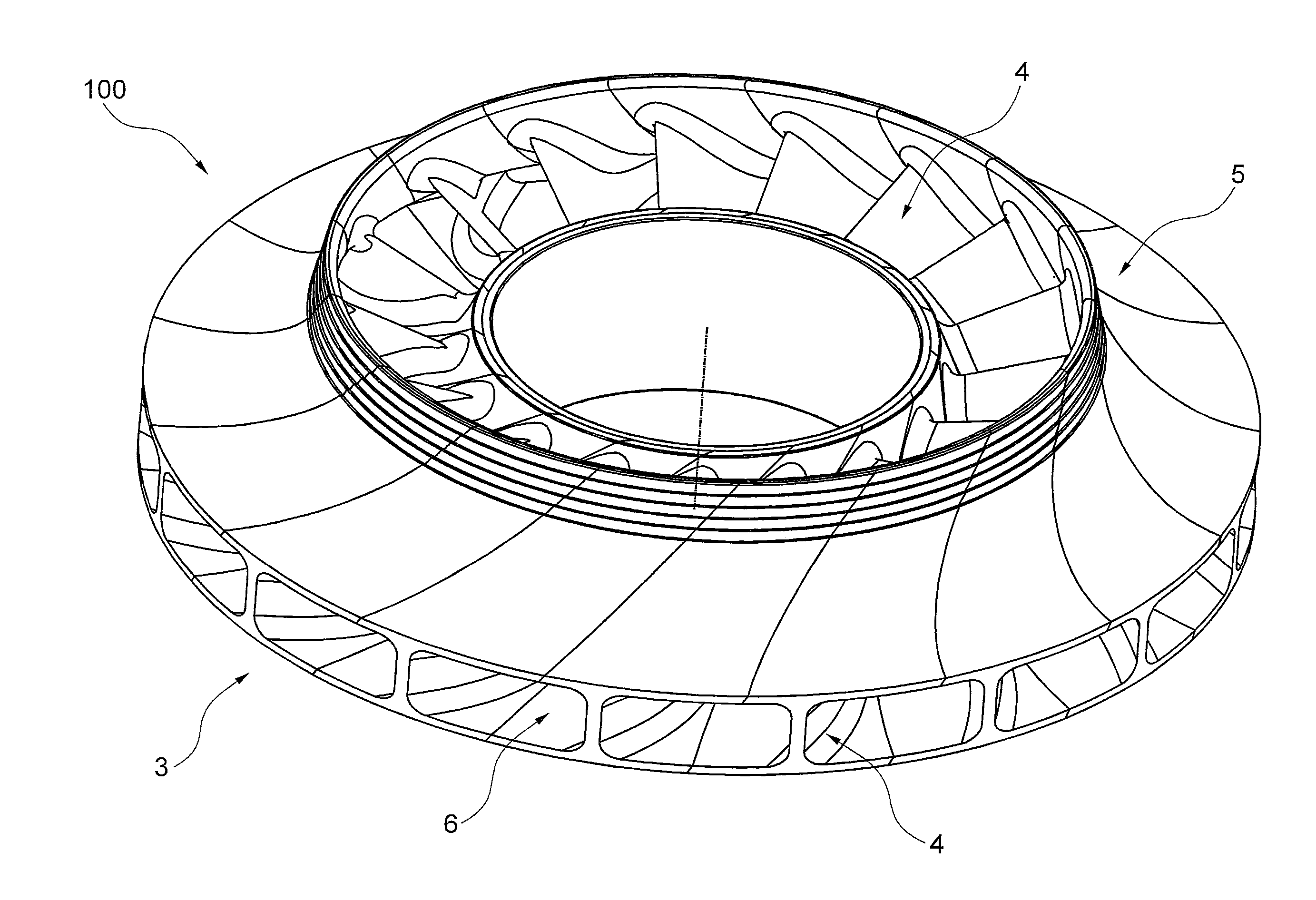

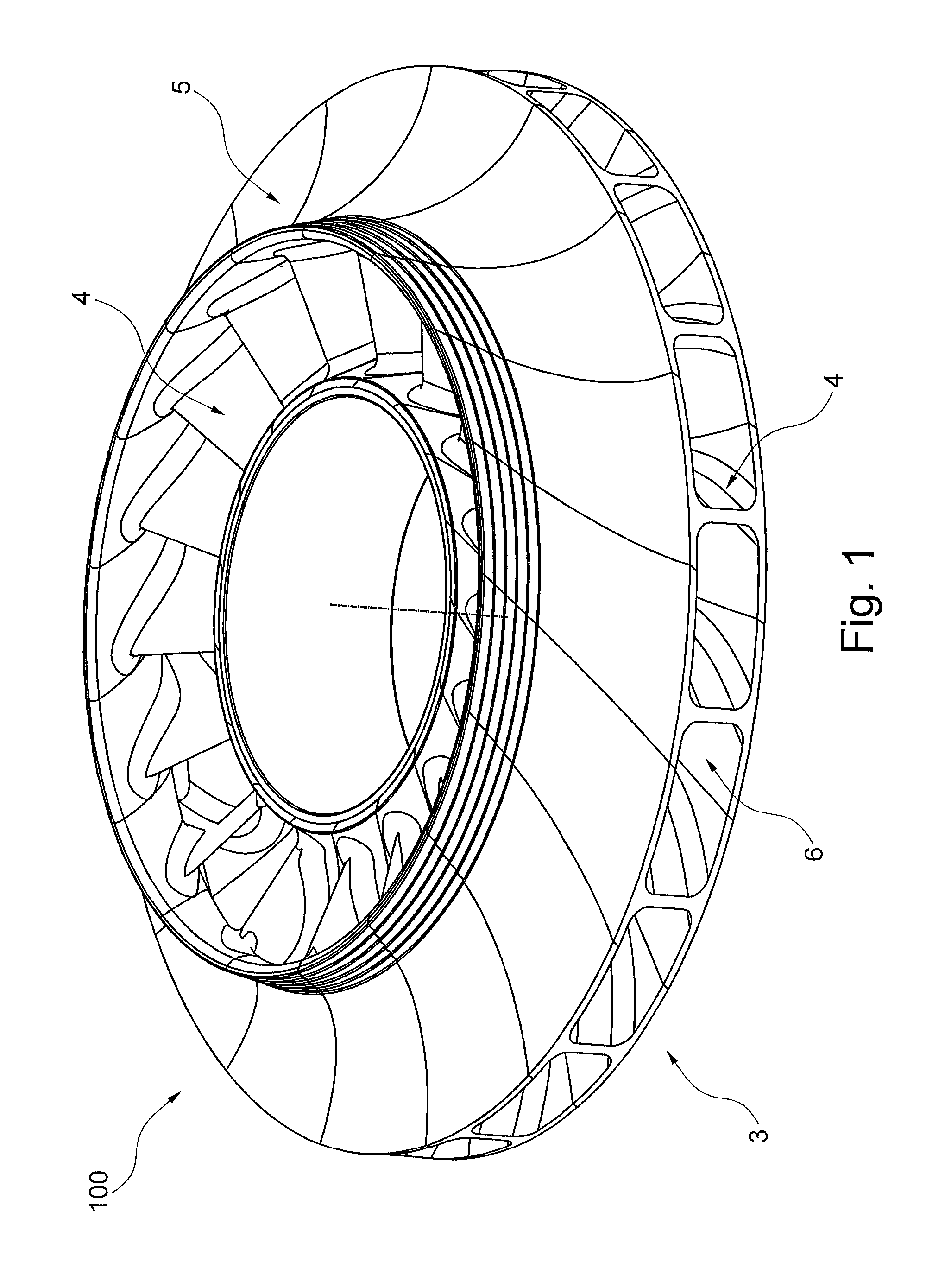

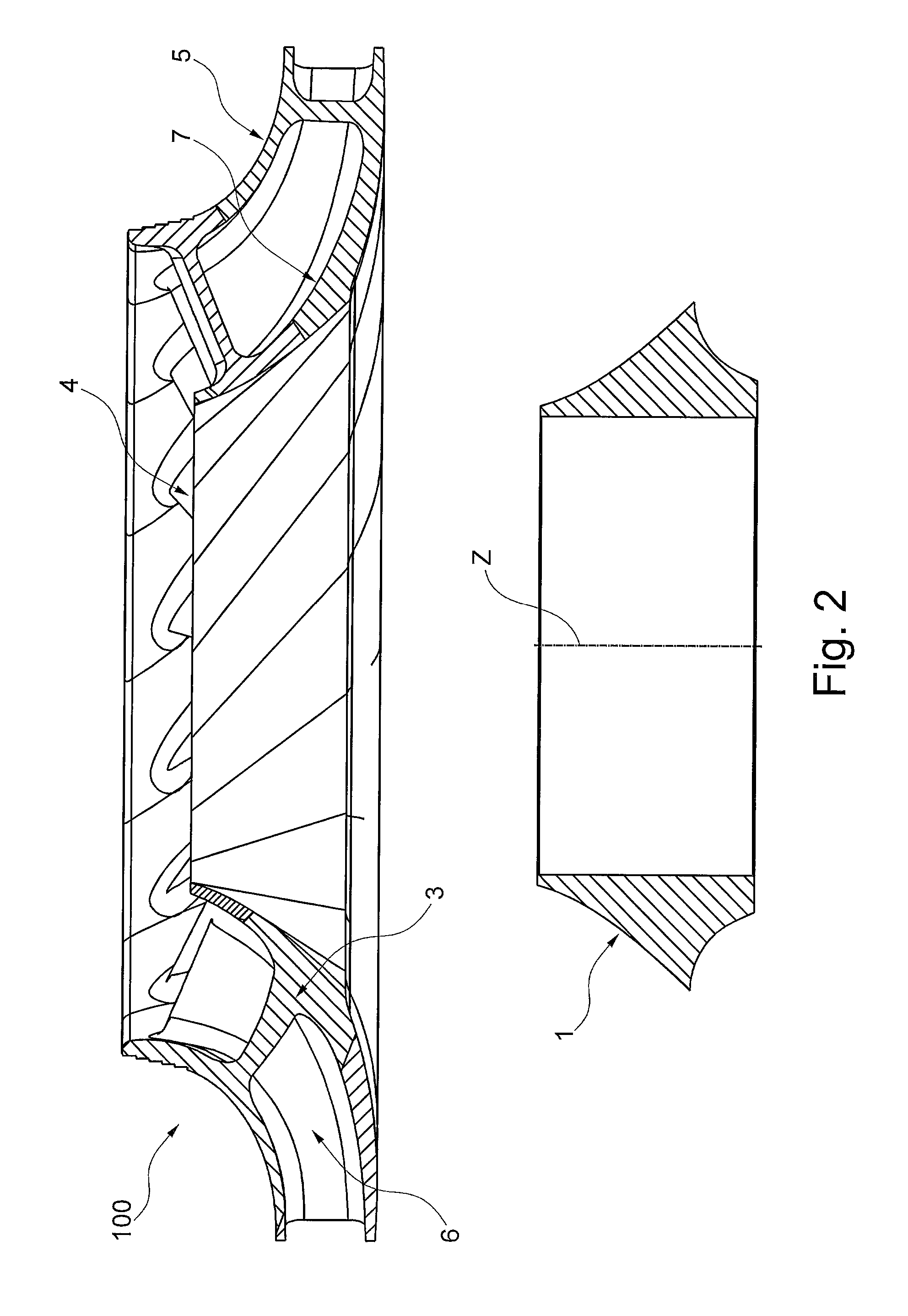

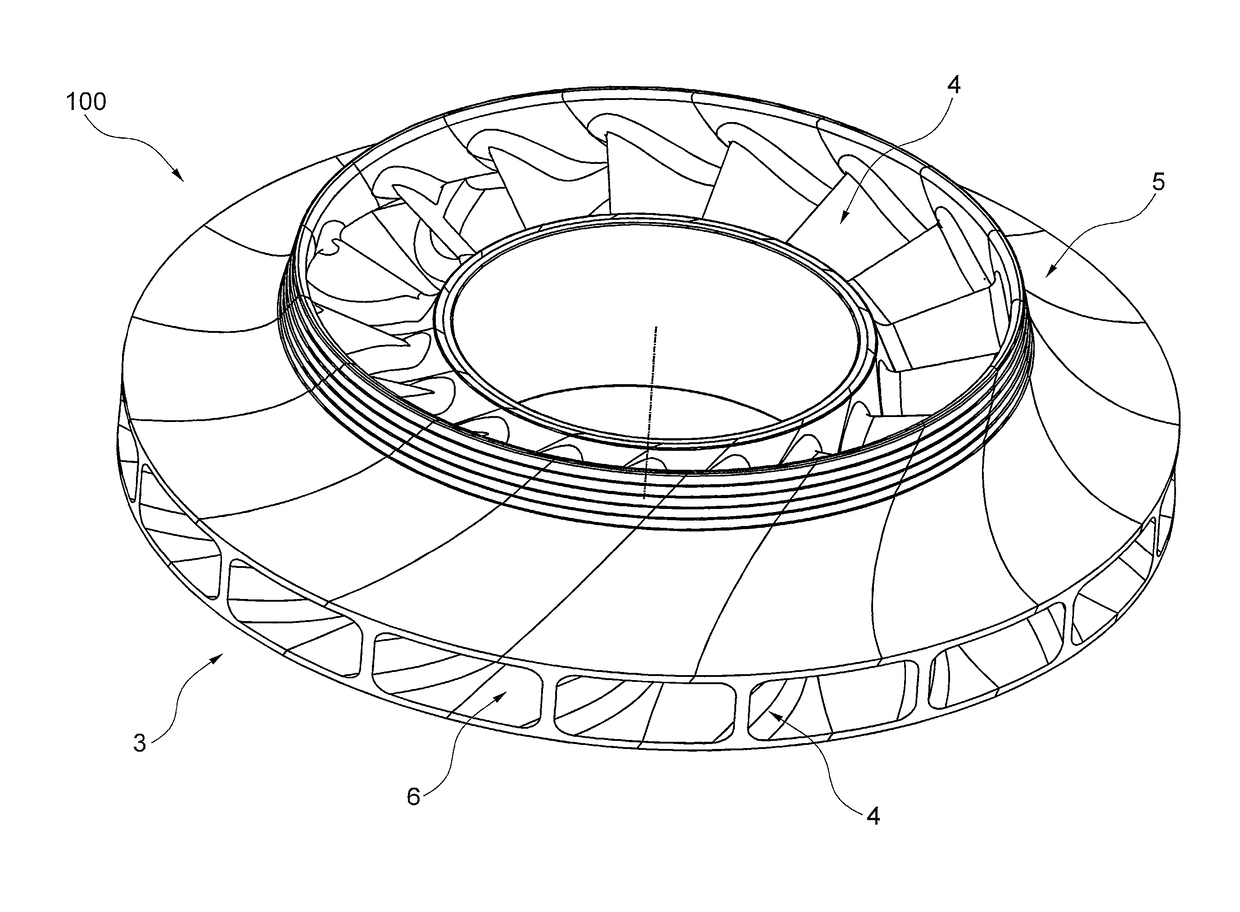

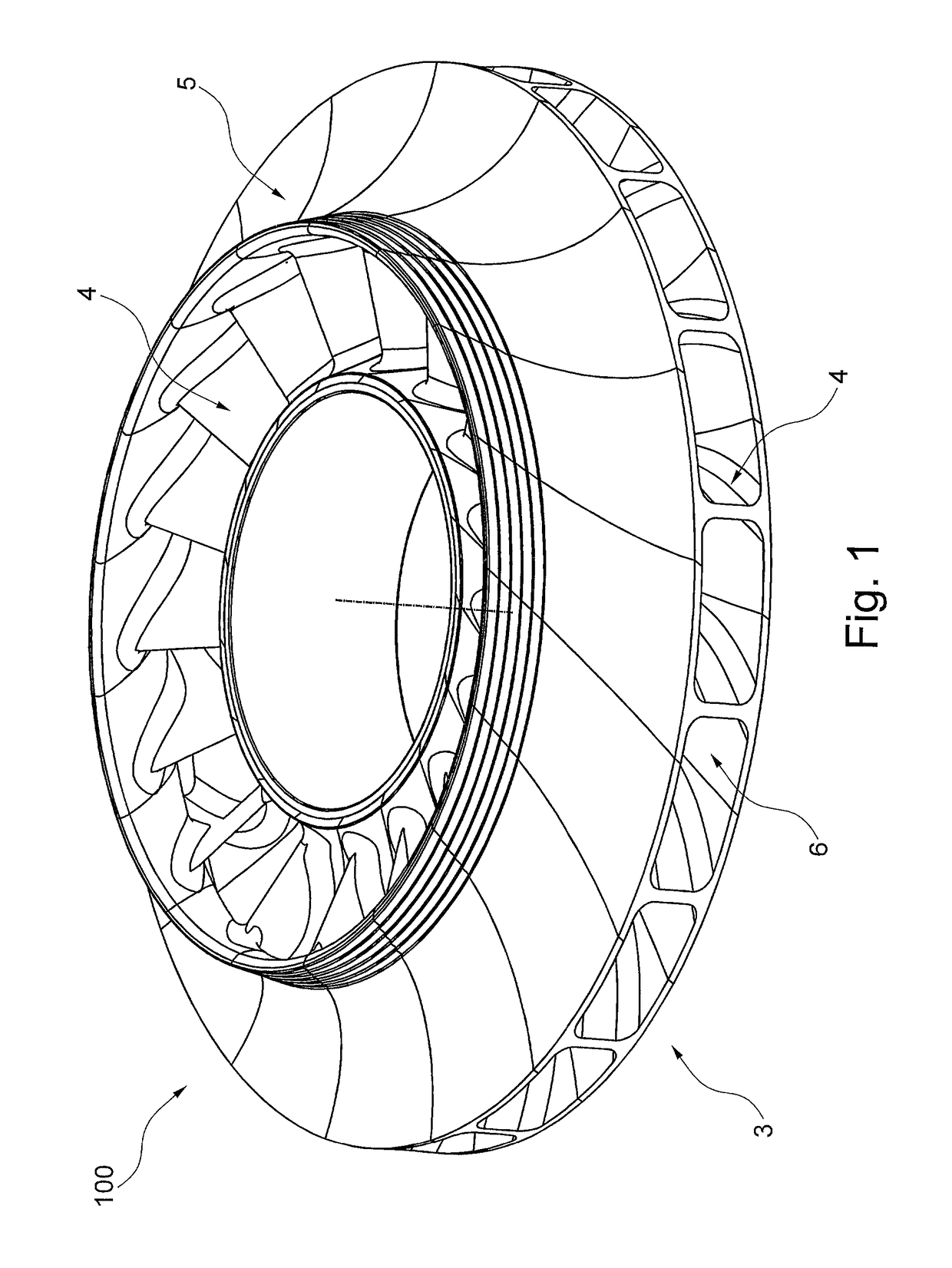

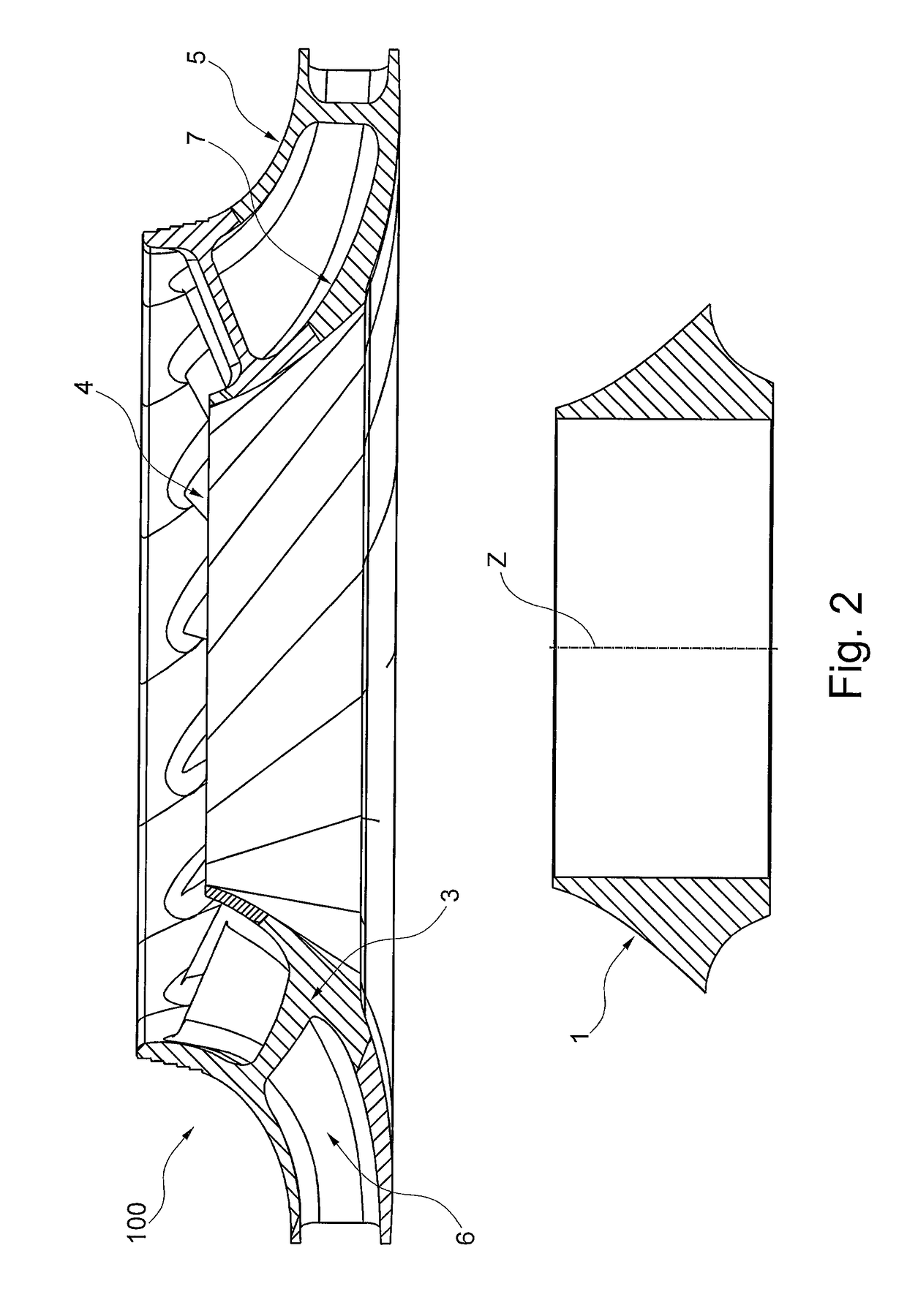

Method for making an impeller from sector segments

ActiveUS20160003257A1Short processing timeQuality improvementTurbinesPropellersImpellerFriction welding

A manufacturing technique for impellers for a centrifugal rotating machine is provided. The impeller is made by composition of single vanes pieces that fit to the hub or directly to the rotor shaft by welding, friction welding or a mechanical locking system. The manufacturability of the segments is easy fast and cheap and make it possible to use advanced manufacturing technologies like additive manufacturing of the type of Direct Metal Laser Melting.

Owner:NUOVO PIGNONE TECH SRL

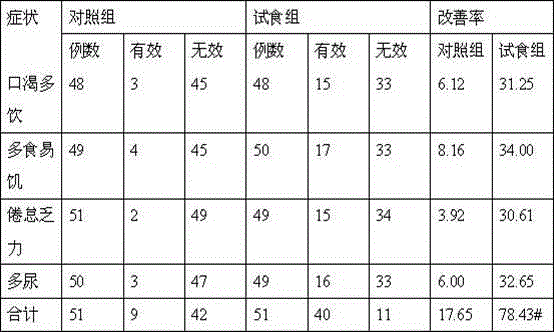

Bitter gourd peptide tea Composition and preparation method thereof

ActiveCN104621287ACompatibility is scientific and reasonableMedicines complement each otherPre-extraction tea treatmentBiotechnologyAnimal science

The invention discloses a bitter gourd peptide tea composition and a preparation method thereof. The bitter gourd peptide tea is also named b-cell active peptide tea and is prepared from the following components by weight: 300-400g of bitter gourd, 50-140g of soybean peptide powder, 20-60g of corn peptide powder, 200-400g of radix puerariae, 100-300g of radix polygonati officinalis, 100-300g of semen cassiae, 100-200g of poria cocos and 100-300g of green tea. The composition disclosed by the invention has the advantages that the compatibility of the bitter-gourd peptide tea material is scientific and reasonable, the taste is good, the nutrition is comprehensive, the active-component content is high and the problems of high blood sugar and high blood fat of people at current can be really solved.

Owner:LIAONING DESHAN PHARMA CO LTD

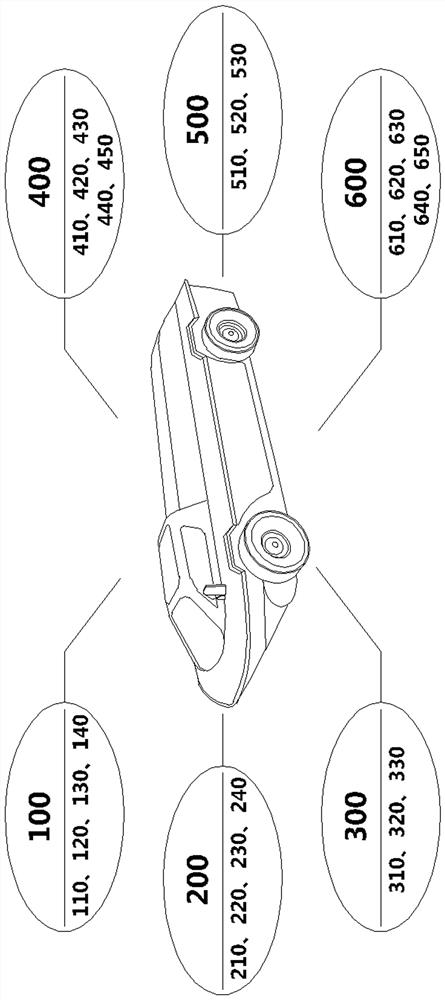

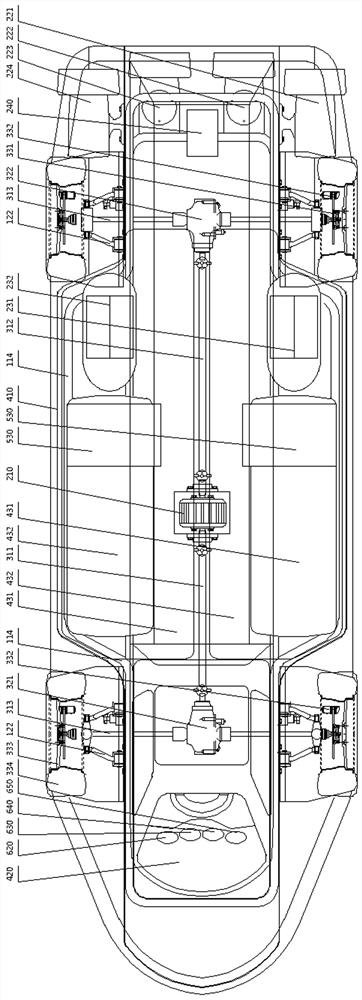

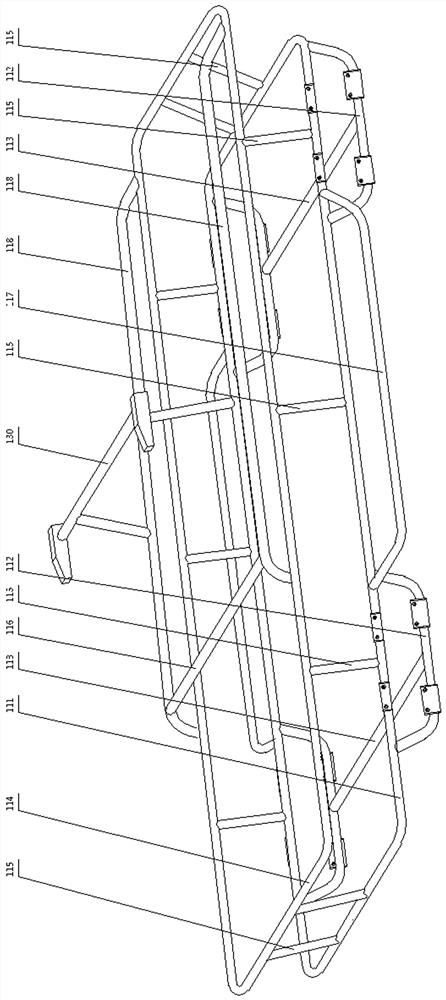

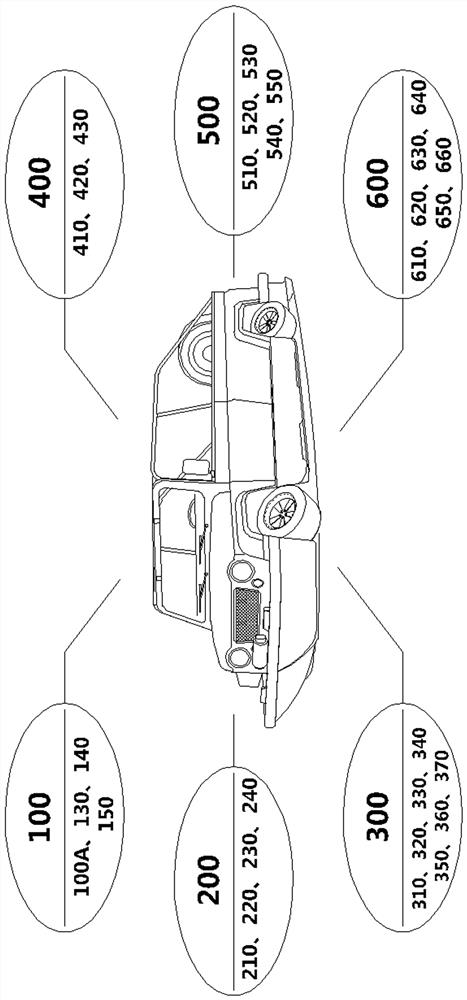

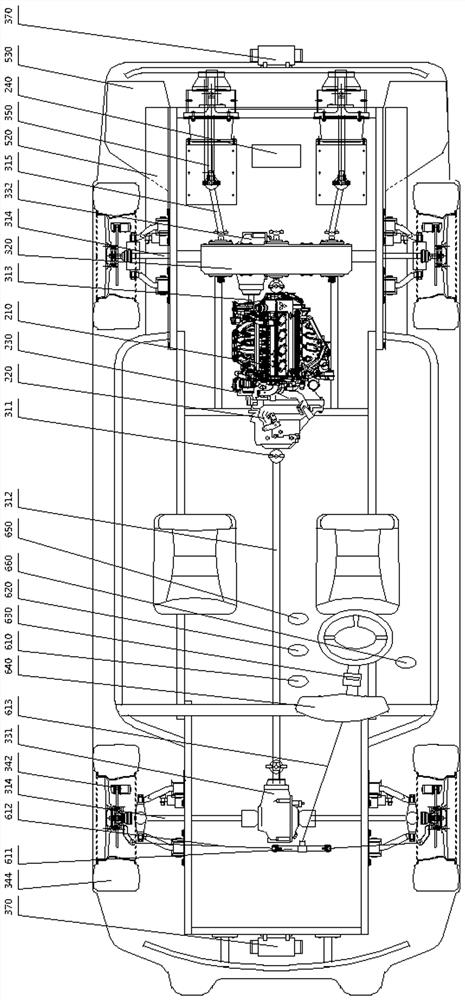

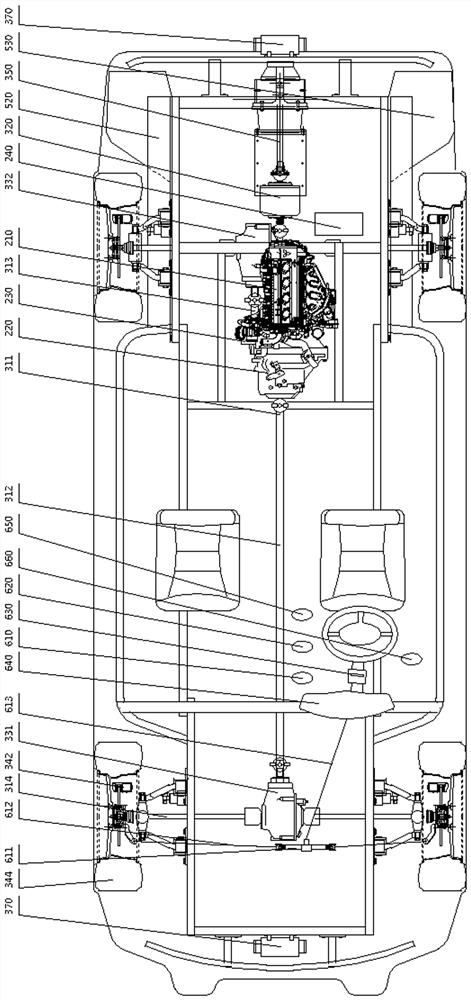

Light high-speed amphibious submersible vehicle

InactiveCN112265419AImprove performanceDesign scienceAmphibious vehiclesUnderwater vesselsElectric machineryOxygen supply

The invention discloses a light high-speed amphibious submersible vehicle. The light high-speed amphibious submersible vehicle is composed of six system modules including a vehicle frame, a power module, a drive module, a buoyancy module, an electrical module and a control module, the vehicle frame module comprises a vehicle frame assembly, a suspension mechanism, a weapon hanger assembly and an outer cover assembly, and the power module comprises a drive motor, a guide pipe propeller, a power battery pack and a hydraulic station. The driving module comprises a transmission part, a differential mechanism assembly and a wheel assembly; the buoyancy module comprises a hull shell, a driver cabin, a buoyancy air bag, a high-pressure air storage tank and an oxygen supply device, the electricalmodule comprises a mobile power station, an air compressor station and an equipment box, and the control module comprises a land running control device, a water surface running control device, a submarine navigation control device, an instrument integration device and a wheel lifting control device. The vehicle adopts a plurality of unique advanced technologies, has excellent amphibious maneuvering and underwater navigation performances, and can better meet a plurality of actual requirements in military and commercial fields.

Owner:益阳天华两栖车艇有限公司

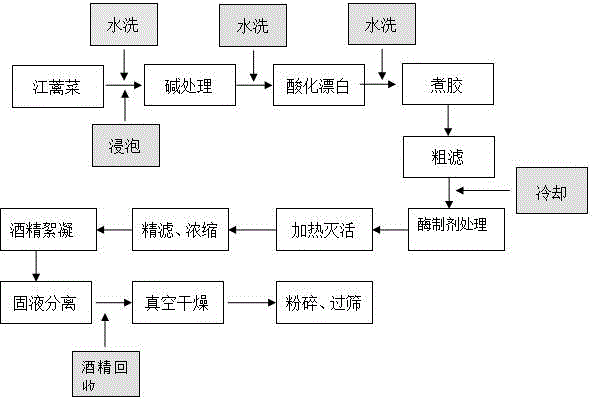

Preparation method of instant gracilaria agar with low freezing point

ActiveCN104829753AReduce the melting temperature and solidification temperatureBroaden the field of applicationEnzymeSeaweed food

The invention discloses a preparation method of an instant gracilaria agar with a low freezing point. The preparation method comprises the following steps: taking gracilaria as the raw material, removing the salt and sand from gracilaria by a roller, processing gracilaria by alkali, acidifying and bleaching the gracilaria, cooking gracilaria to obtain gel, crudely filtering the gel, cooling to a temperature of 55 DEG C to obtain an agar crudely-filtered solution; then processing the solution by a compound enzyme preparation, heating to inactivate the enzyme, carrying out fine filtration, condensing the solution under vacuum, adding alcohol into the solution to trigger flocculation, separating the solid from the liquid, drying the solid in vacuum, grinding the solid, and sieving so as to obtain the instant gracilaria agar with a low freezing point. In the agar crude filtration step, a compound enzyme preparation is added to process the gel solution so as to maximally degrade the alga fibers, and thus the enzyme preparation can be completely inactivated more easily. The alcohol is used to flocculate the gel solution, thus the safety and hygiene of the gracilaria agar can be guaranteed, and at the same time the yield of agar is increased. The technologies of diaphragm press filtration and vacuum drying can guarantee that alcohol is fully recycled and utilized. The freezing point of the prepared agar is not higher than 30 DEG C, the agar can be completely dissolved in 10 minutes at a temperature of 80 DEG C, the extraction yield is not less than 15.5%, the lead (Pb) content is not more than 0.5 mg / kg, the arsenic (As) content is not more than 0.3 mg / kg, and the total number of bacterium is not more than 1000 cfu / g.

Owner:FUJIAN PROVINCE LVQI FOOD COLLOID

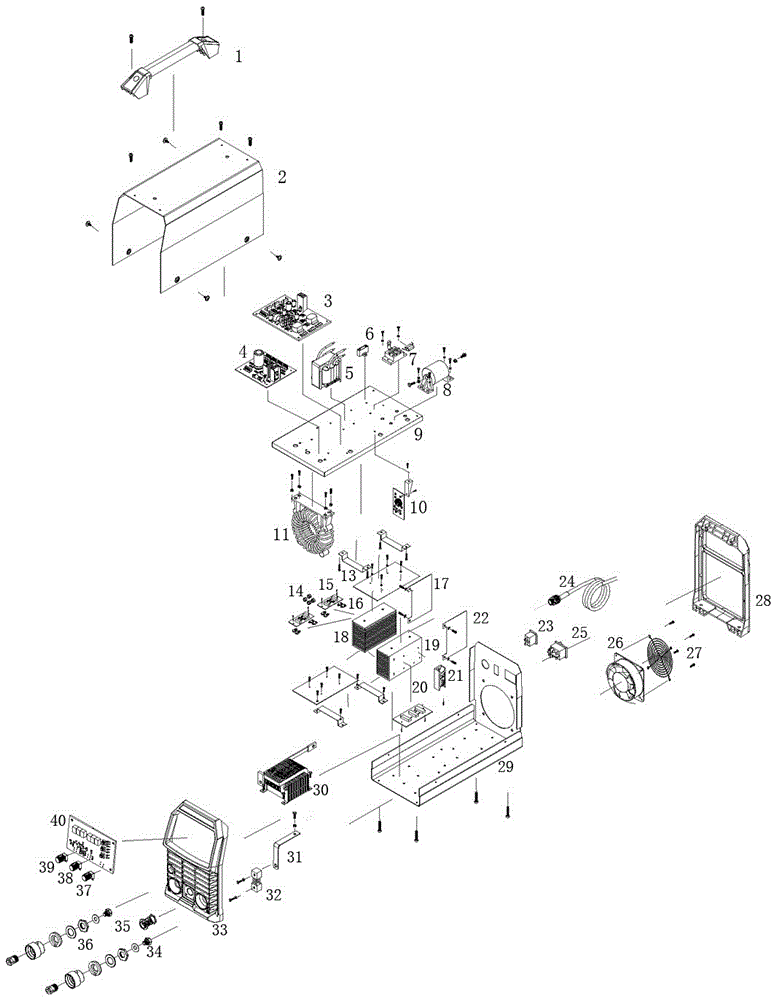

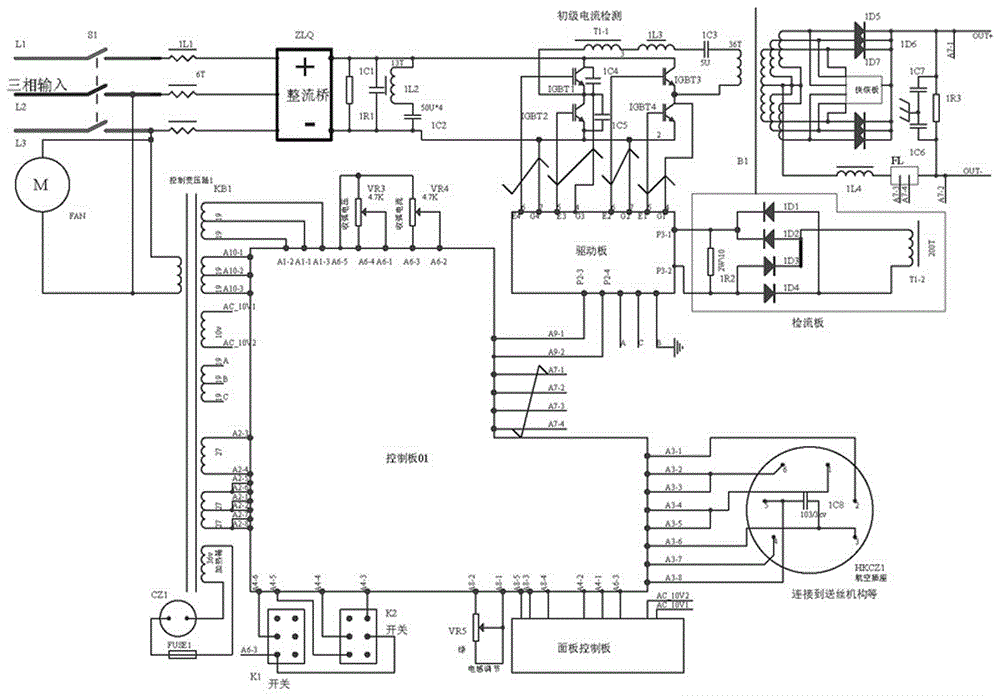

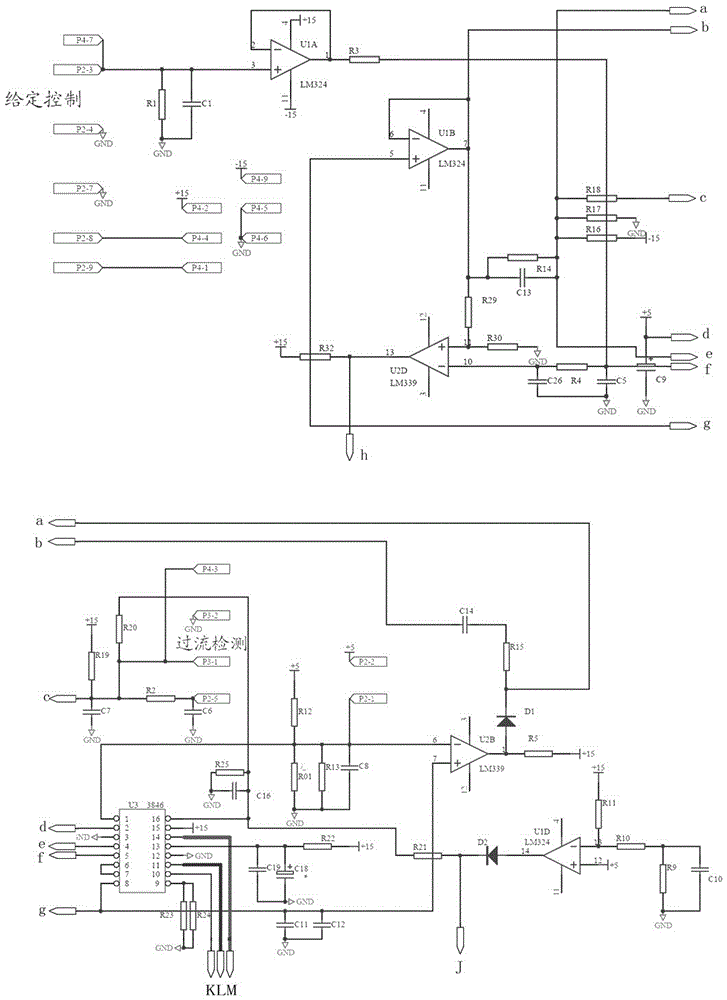

Structure of IGBT inverter welding machine with two welding functional modules

ActiveCN106112214AProtection Circuit StructureProtection Design StructureArc welding apparatusMachine controlTransformer

The invention relates to a structure of an IGBT inverter welding machine with two welding functional modules. The structure comprises an outer housing and an inner circuit board; the circuit board mainly comprises six parts which are separately a drive plate, a control panel, a current detecting plate, an IGBT plate, a fast recovery circuit board and a panel control board; the control panel is connected to the panel control board, a control transformer and the drive plate; the control transformer is used for supplying power to the control panel; the drive plate is connected to the control panel, the IGBT plate and the current detecting plate; and under the action of the control panel, the drive plate generates a drive signal which can reliably drive each IGBT to work, so that stable operation of an inverter circuit is guaranteed. According to the structure, the performance problem, the reliability problem, the production efficiency problem and the manufacturing and transporting cost problem of multifunctional welders are solved very well by adopting a control circuit system consisting of a two-chip micro processor, a single-chip micro processor and the like and optimizing the structural design of a welding machine control circuit, the structural design of a circuit board and the structural design of each part, so that market competitiveness of products is improved.

Owner:ZHEJIANG KENDE MECHANICAL & ELECTRICAL

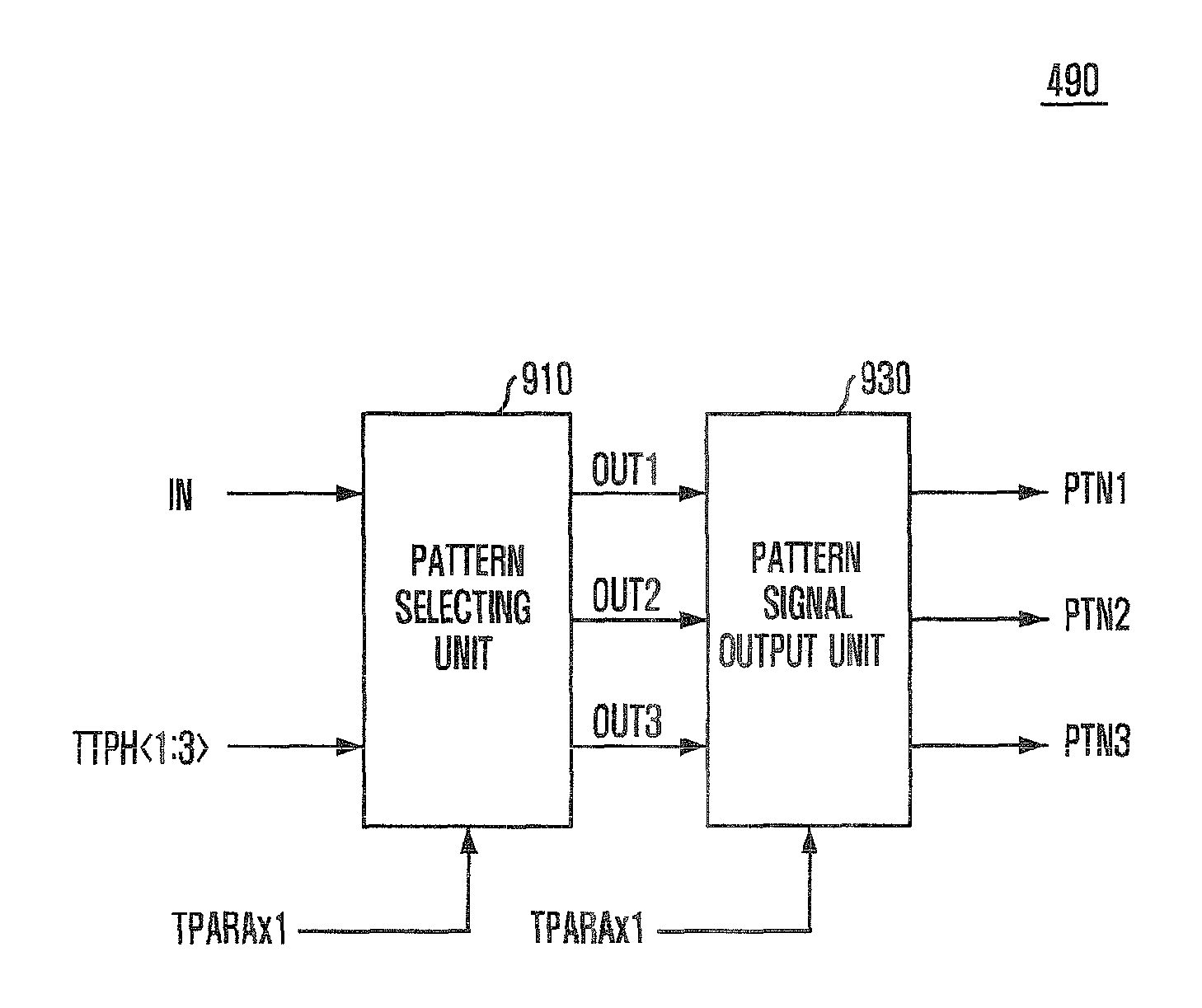

Semiconductor memory device, operating method thereof, and compression test method thereof

InactiveUS8024627B2Minimal numberAdvanced manufacturing technologyElectronic circuit testingError detection/correctionEngineeringSignal generator

A semiconductor memory device including a plurality of banks, each including a plurality of memory cells, a pattern signal generator configured to generate pattern signals having combinations in response to an input signal applied through an arbitrary pad in a compression test mode. Input paths are configured to transfer the plurality of pattern signals to the corresponding banks.

Owner:SK HYNIX INC

All-aluminum back surface field aluminum paste for crystalline silicon solar cell and preparation method thereof

ActiveUS20170148936A1Increase contactLower bulk resistanceConductive materialInksSilver pasteOrganic solvent

The invention discloses an all-aluminum back surface field aluminum paste for a crystalline silicon solar cell and a preparation method thereof. The all-aluminum back surface field paste mainly comprises 60-70% aluminum powder, 5-10% nanometer metal oily solution, 1-10% inorganic binder, 10-20% organic binder, 5-30% organic solvent and 1-5% accessory ingredient. According to the aluminum paste prepared by the present invention, the back surface preparing process of an all-aluminum back surface field can be implemented preferably; moreover, the paste has great adhesive force, is easy to be better adhered to silver paste printed afterwards; meanwhile, the paste can be in good contact with a silicon chip through the nanometer metal oily solution added into the paste, the aluminum back surface is prevented from falling off, and good ohm contact can be formed, so that the photoelectric conversion efficiency is increased, and the economic benefits of enterprises are increased.

Owner:NANTONG T SUN NEW ENERGY CO LTD

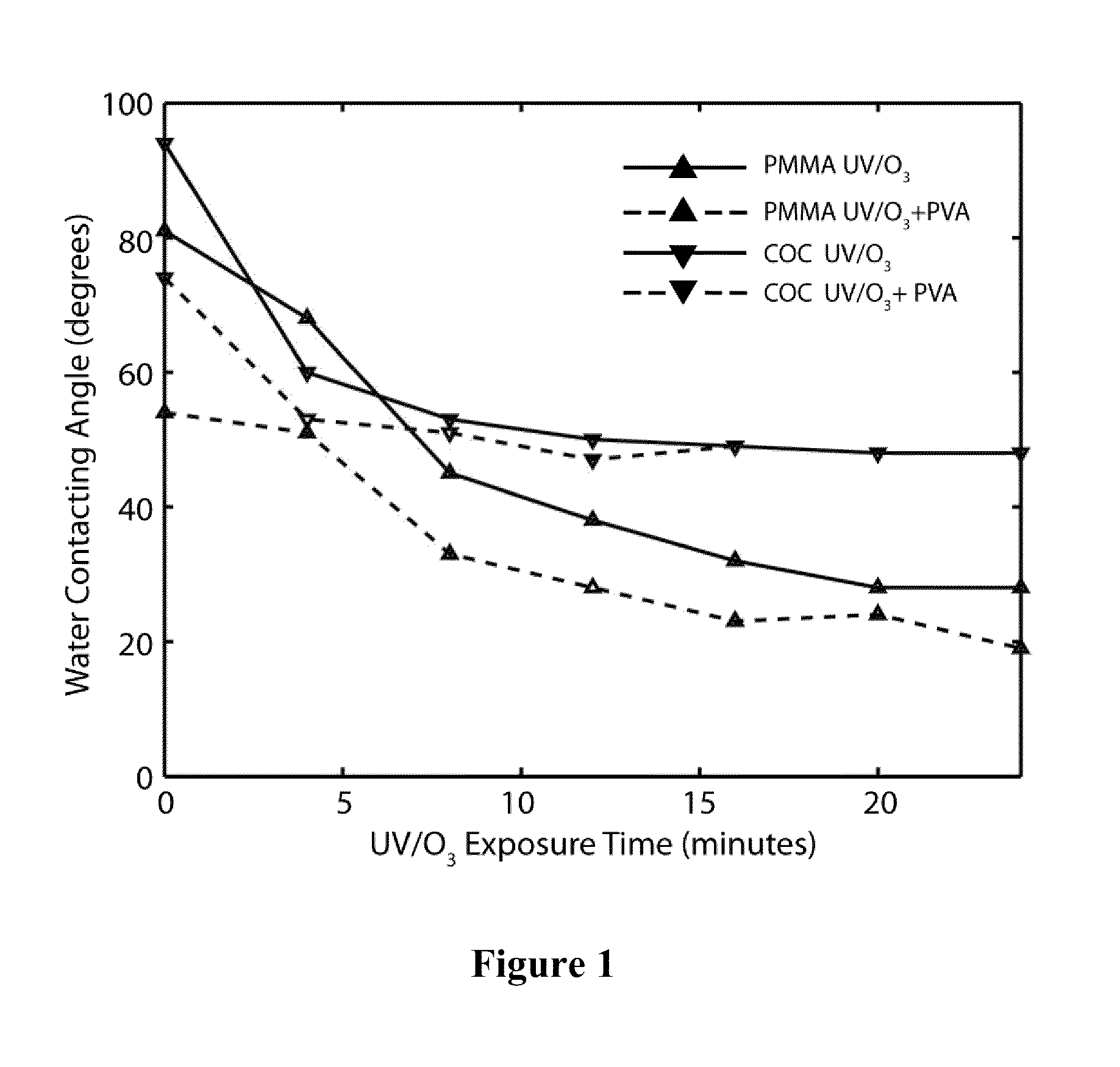

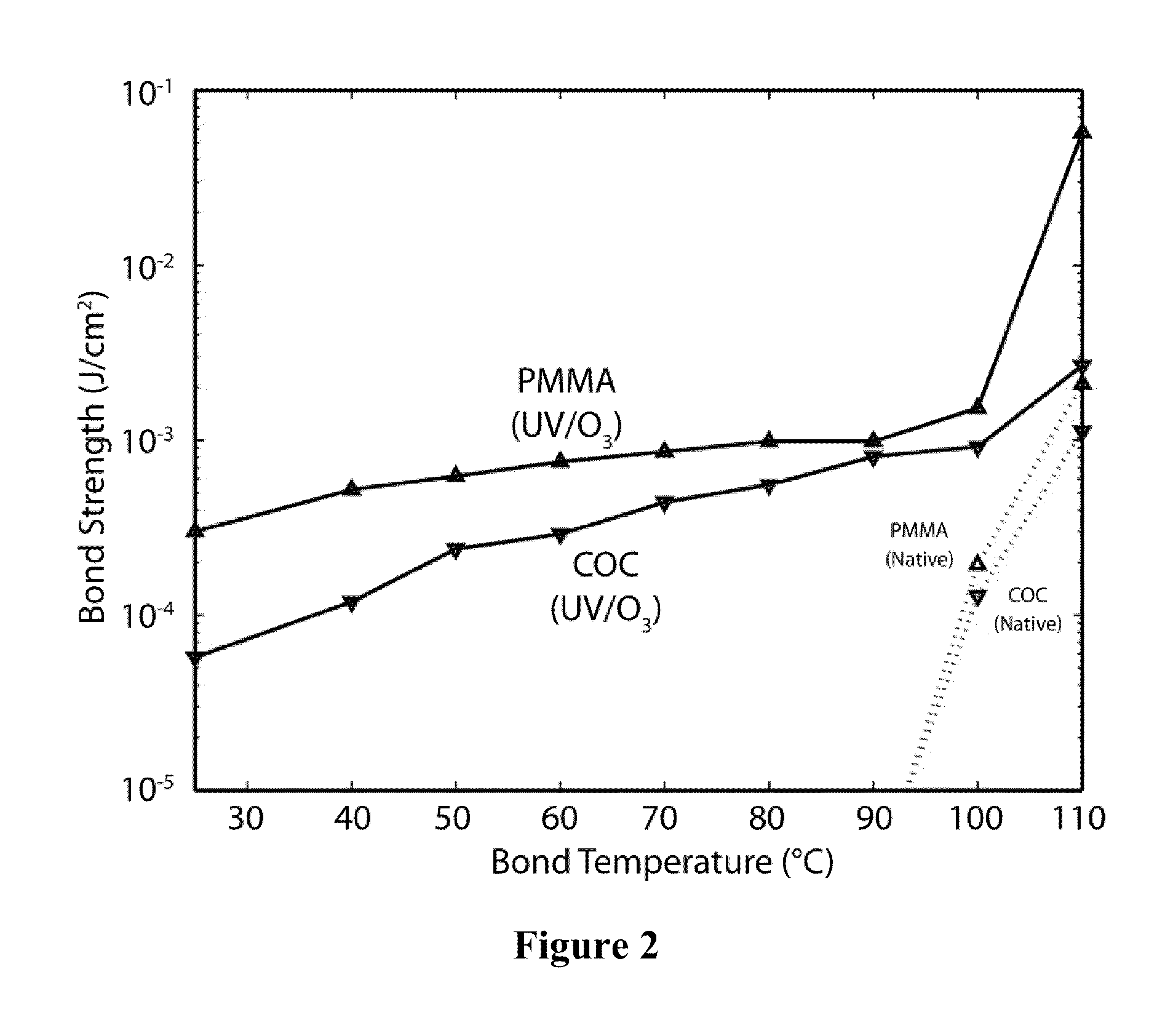

Low temperature polymer bonding using UV/ozone surface treatment

InactiveUS8293061B2High bonding strengthZero-deformation methodPretreated surfacesGroup 3/13 element organic compoundsThermoplasticPoly(methyl methacrylate)

The present invention relates to a method for bonding two surfaces to one another. The invention particularly pertains to the use of such method in which one of the surfaces is a polymeric plastic (and more preferably a polymeric thermoplastic (especially poly-(methyl methacrylate) (“PMMA”) or cyclic olefin copolymer (“COC”)). More particularly, the invention relates to treating at least one of the contacting surfaces with UV in the presence of oxygen to thereby generate ozone (O3) and atomic oxygen under conditions of temperature below that of the glass transition temperature of the polymeric plastic. The UV / O3-mediated bonding results in high bond strength and zero-deformation method. This bonding method can be applied to micro / nano-scale polymer devices, and particularly to microfluidic devices, for a low cost, high throughput, high yield advantage.

Owner:UNIV OF MARYLAND

Method for making an impeller from sector segments

ActiveUS9945388B2Quality improvementShort processing timeTurbinesPump componentsImpellerFriction welding

A manufacturing technique for impellers for a centrifugal rotating machine is provided. The impeller is made by composition of single vanes pieces that fit to the hub or directly to the rotor shaft by welding, friction welding or a mechanical locking system. The manufacturability of the segments is easy fast and cheap and make it possible to use advanced manufacturing technologies like additive manufacturing of the type of Direct Metal Laser Melting.

Owner:NUOVO PIGNONE TECH SRL

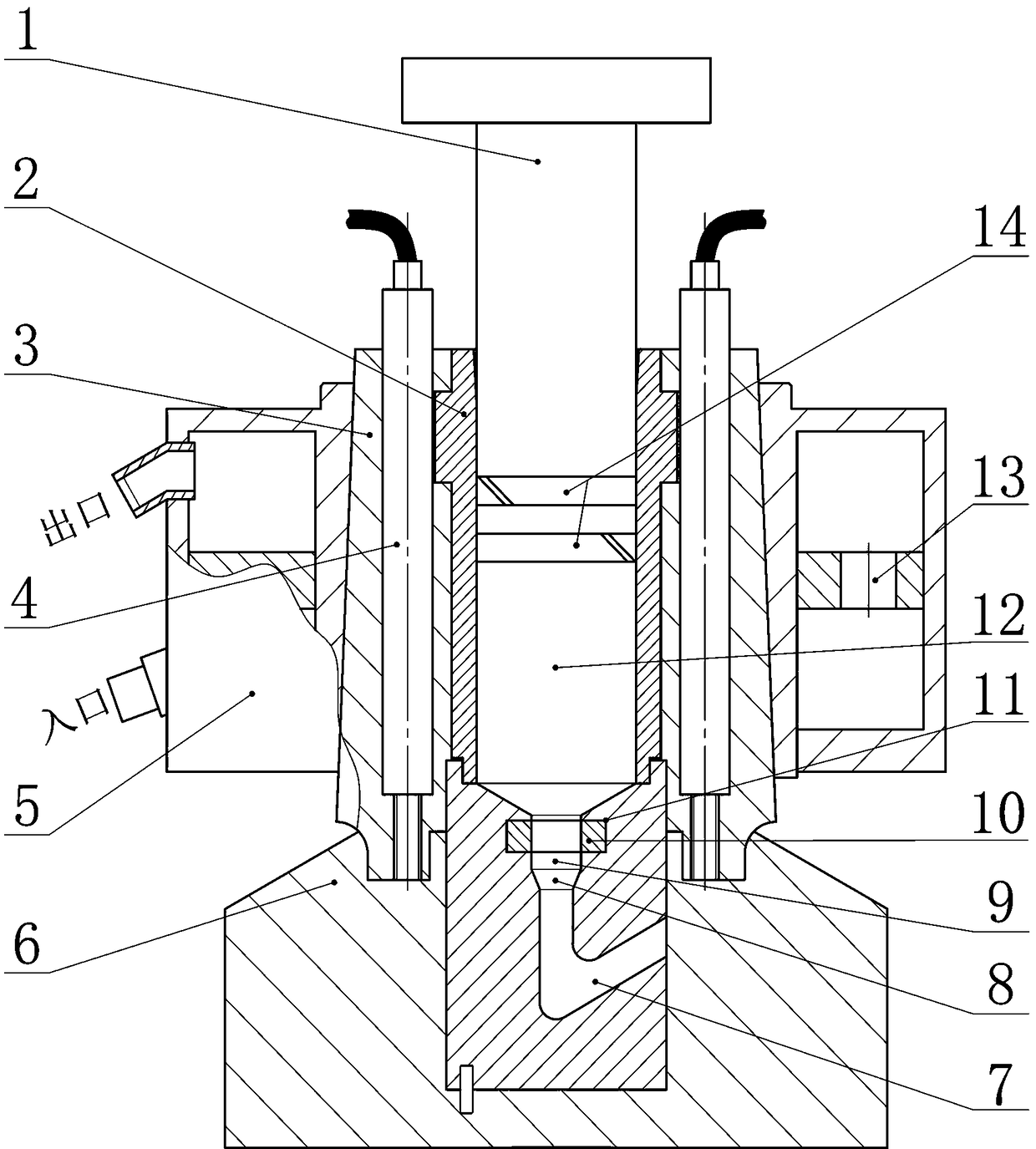

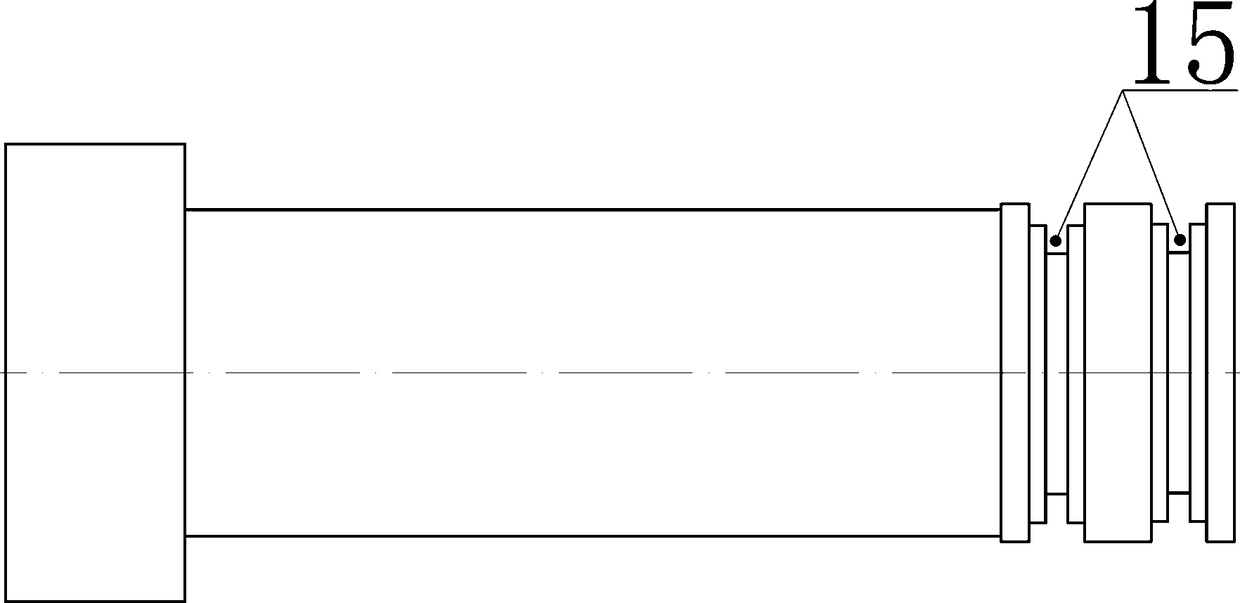

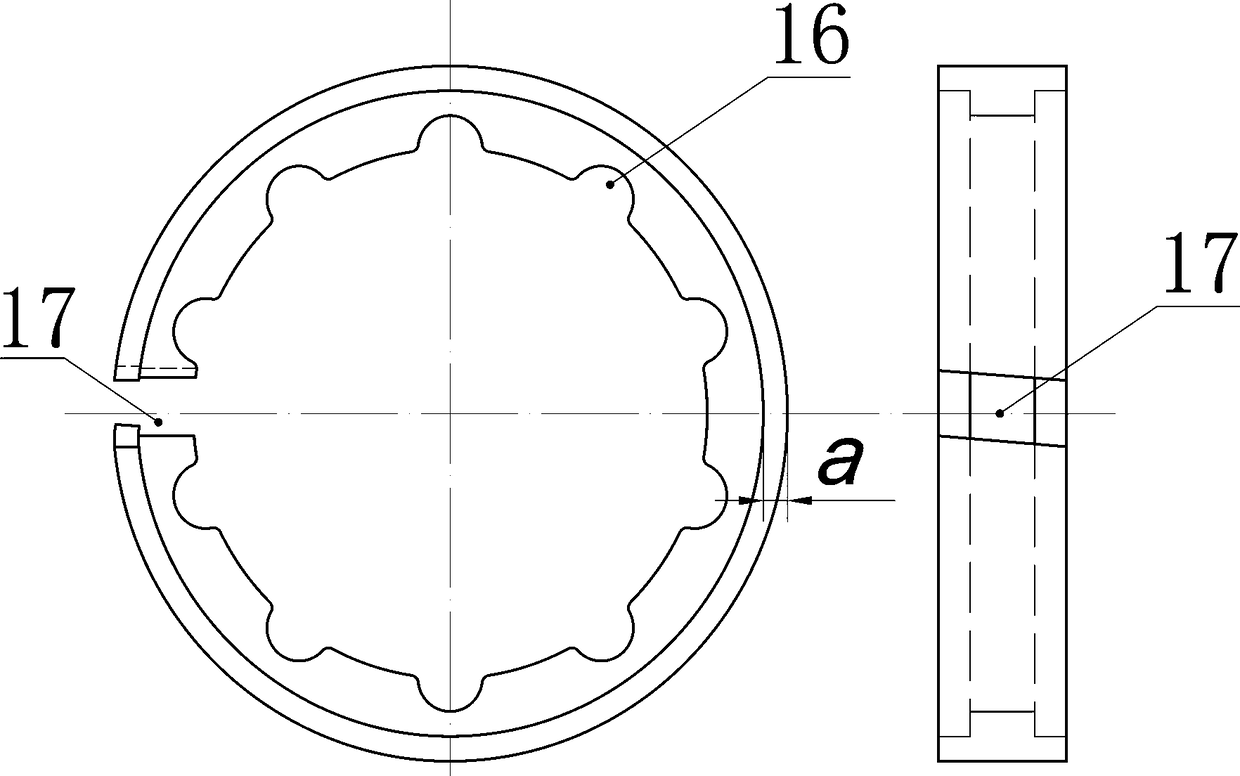

Composite preparation die made from high-performance wrought magnesium alloy

The invention discloses a composite preparation die made from high-performance wrought magnesium alloy. The composite preparation die integrates alloy melting, high specific pressure speed-control condensation, reducing extrusion and equal channel angular extrusion and specifically comprises a cavity, an extruding cavity, a reducing extrusion belt and an equal channel angular extrusion cavity which are sequentially connected, the upper end of the cavity is provide with a convex die matched with the cavity, a movable insertion plate is arranged in an extruding cavity area at the lower end, theperiphery is provided with an inner sleeve and a heating sleeve wrapping the inner sleeve, the heating sleeve is uniformly provided with 6-8 heating tubes in the peripheral direction, the periphery isprovided with a circular cooling chamber, thermocouples are arranged in the cavity, the heating sleeve and the circular cooling chamber, the thermocouples, the heating tubes and the circular coolingchamber are jointly controlled by a control system, and real-time acquisition and adjustment of die temperature are achieved. The composite preparation die can achieve accurate control of process parameters in a whole preparation period while die-change-free continuous production including alloy melting, cooling and pressure machining, and finally the high-performance wrought magnesium alloy material is obtained.

Owner:SOUTHWEST UNIVERSITY

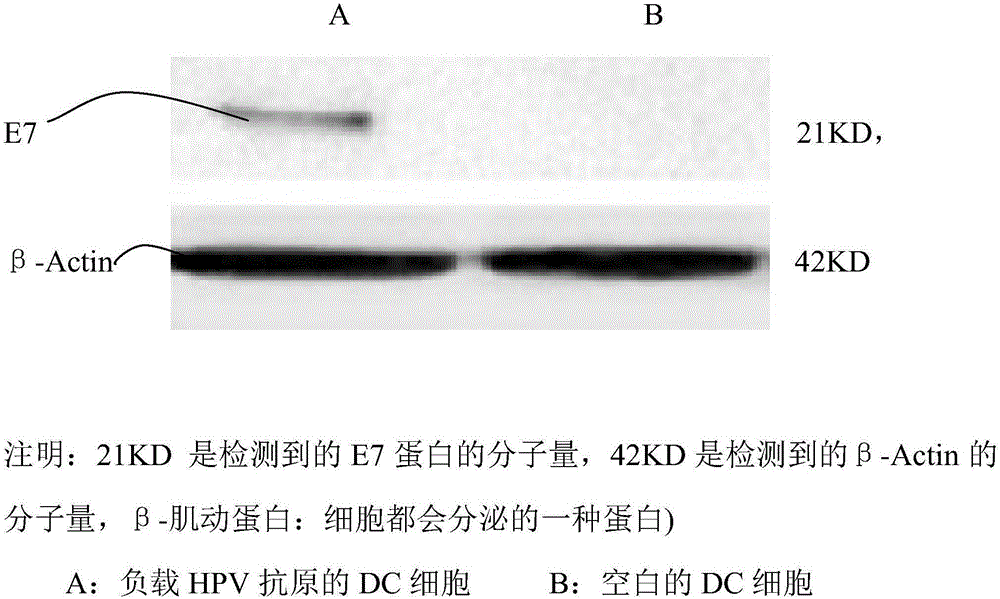

DC cell-based HPV virus vaccine preparation method

InactiveCN104998260AAdvanced manufacturing technologyPromote secretionAntiviralsBlood/immune system cellsAntigenCD80

The invention provides a DC cell-based HPV virus vaccine preparation method. The method comprises the following steps: separating CD14+ cells from blood to obtain the CD14+ cells; inducing the CD14+ cells in a medium to obtain immature DC cells; adding HPV16 chimeric virus-like particles to the medium to promote proliferation of the immature DC cells, and co-culturing the HPV16 chimeric virus-like particles and the immature DC cells for a period of time to carry out antigen loading; and promoting maturation of antigen supported immature DC cells. The CD80 expression level and the CD83 expression level of the DC cells generated after culture are obviously improved, and the IL-12 secretion ability of the DC cells is also greatly increased. More importantly, the CD80 expression level and the CD83 expression level of a DC cell vaccine prepared through the preparation method provided by the invention are higher than those of DC cell vaccines in the prior art.

Owner:SHEN ZHEN ISTEM REGENERATIVE MEDICINE SCI TECH CO LTD

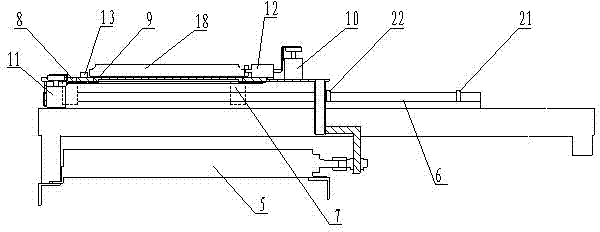

Air dryer of screen plate

ActiveCN104329926ASafe and reliable dry processingEfficient and reliable drying processDrying gas arrangementsHigh volume manufacturingPulp and paper industry

The invention relates to the field of drying of solid materials or products without heating, and particularly relates to an air dryer used for drying a photovoltaic cell piece screen plate. In the current process of manufacturing the screen plate by solar cell manufacturing enterprises, the screen plate is commonly dried by a manual manner and the manual drying of the screen plate has the problems that the drying time is long, the efficiency is low, the drying effect is not ideal, the drying quality is not easy to control and the like, so that the requirements of industrial large-batch production cannot be met. The invention discloses an automatic screen plate air dryer; clean compressed air with adjustable temperature, humidity and air speed can be used for drying the screen plate; the drying efficiency is high and the drying effect is hood; in a drying process, the screen plate and a printing pattern thereof are not damaged and the requirements of the industrial large-batch production are met. The air dryer is simple and compact in design, easy to implement and lower in energy consumption cost; the air dryer is suitable for large-batch drying treatment on a plurality of solid parts and has a wide application and popularization prospect.

Owner:HEBEI JING LONG SUN EQUIP

Low-temperature instant agar and preparation method thereof

The invention discloses low-temperature instant agar and a preparation method thereof. The method comprises the steps: soaking seaweeds in an alkaline solution, and executing heating and filtering toobtain alkali-treated seaweeds; filtering and washing the alkali-treated seaweeds to obtain seaweeds washed for the first time; soaking the seaweeds in a bleaching agent, and executing even mixing, standing and filtering to obtain bleached seaweeds; soaking the bleached seaweeds in an acidic solution, and executing even mixing, standing and filtering to obtain acidified seaweeds; filtering and washing the acidified seaweeds to obtain seaweeds washed for the second time; adding the seaweeds washed for the second time into water, executing even mixing, heating and centrifuging to obtain a glue solution; adding a hydrogen peroxide solution, carrying out a methoxy group removing reaction, adding a biological enzyme, executing even mixing, and introducing ozone-containing gas into the glue solution; executing drying, crushing and sieving to obtain the low-temperature instant agar. The low-temperature instant agar prepared by the preparation method has low dissolving temperature, high gel strength, no introduction of other substances, high safety and good quality.

Owner:SOUTH CHINA UNIV OF TECH

Full-floating amphibious vehicle

InactiveCN112659829AImprove performanceDesign scienceAmphibious vehiclesVehicle frameEmergency department

The invention discloses a full-floating amphibious vehicle which is composed of six system modules including a vehicle frame module, a power module, a driving module, a buoyancy module, a vehicle body module and a control module. The brand-new light high-speed amphibious vehicle which does not need to be sealed and never sinks adopts a plurality of advanced technologies such as the titanium alloy frame assembly, the spray pump type ducted propeller, the high-slip hull shell, the wheel lifting device and the combined buoyancy tank filled with EPP foam, so that the vehicle can always suspend on the water surface and never sinks. The vehicle has the remarkable technical characteristics of high-speed and safe operation on the water surface, excellent amphibious maneuvering performance, excellent tidal flat passing capacity and the like, so that various urgent needs of military and emergency departments can be better adapted and met.

Owner:益阳天华两栖车艇有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com