Multi-metal composite wear-resistant elbow pipe and preparation method thereof

An elbow pipe, multi-metal technology, applied in metal processing equipment, elbows, pipes/pipe joints/fittings, etc., can solve the problems of low hardness of 16Mn elbow pipe, high brittleness of elbow pipe, short service life, etc. Achieve the effect of broad cost-effective competition space, advanced manufacturing technology and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

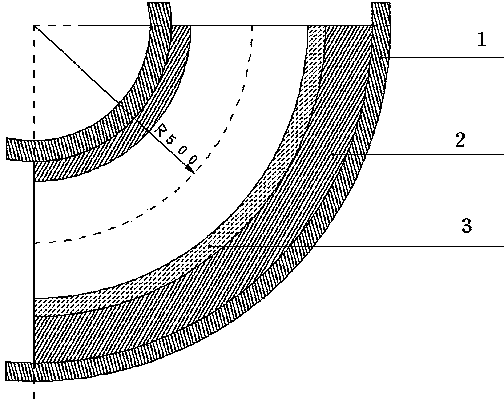

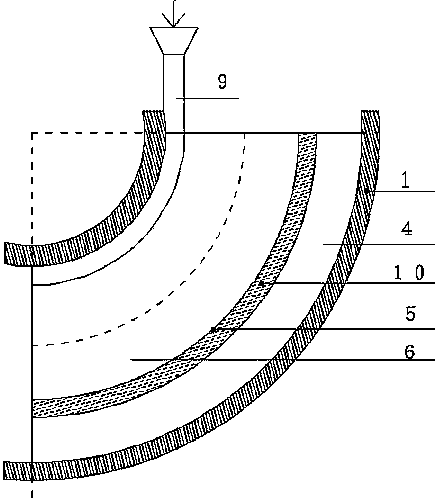

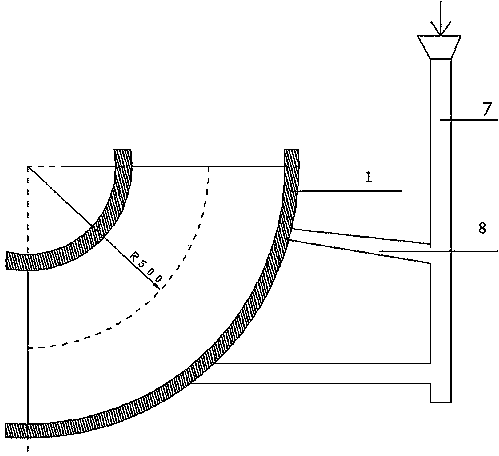

[0041] Example 1: see figure 1 , 2, 3. The material composition of the outer layer 1 of carbon cast steel is: C: 0.20%, Si: 0.45%, Mn: 0.80%, S≤0.04%, P≤0.04%, and the rest is iron; high chromium cast iron The material composition of the middle layer 2 is: C: 2.60%, Si: 0.50%, Mn: 2.60%, Cr: 15%, S≤0.06%, P≤0.10%, and the rest is iron; the inner layer of tungsten carbide granular ceramics 3 The material composition is by weight percentage: tungsten carbide: 20%, C: 2.60%, Si: 0.50%, Mn: 2.60%, Cr: 10%, S≤0.06%, P≤0.10%, and the rest is iron; Die vacuum casting multi-metal composite wear-resistant elbow pipe, the inner wall of the elbow pipe is composed of outer layer of carbon cast steel and inner layer of high chromium cast iron, and the outer wall is made of carbon cast steel outer layer 1, high chromium cast iron The middle layer 2 and the tungsten carbide granular ceramic inner layer 3 are composed of three layers of different materials.

[0042] The specific preparatio...

Embodiment 2

[0063] Example 2: see figure 1 , 2 , 3. The material composition of the outer layer 1 of carbon cast steel is: C: 0.24%, Si: 0.47%, Mn: 0.82%, S≤0.04%, P≤0.04%, and the rest is iron; high chromium cast iron The material composition of the middle layer 2 is: C: 2.70%, Si: 0.60%, Mn: 2.70%, Cr: 16.0%, S≤0.06%, P≤0.10%, and the rest is iron; the inner layer of tungsten carbide granular ceramics 3 The material composition is by weight percentage: tungsten carbide: 25%, C: 2.70%, Si: 0.60%, Mn: 2.70%, Cr: 14%, S≤0.06%, P≤0.10%, and the rest is iron; Die vacuum casting multi-metal composite wear-resistant elbow pipe, the inner wall of the elbow pipe is composed of outer layer of carbon cast steel and inner layer of high chromium cast iron, and the outer wall is made of carbon cast steel outer layer 1, high chromium cast iron The middle layer 2 and the tungsten carbide granular ceramic inner layer 3 are composed of three layers of different materials.

[0064] The specific prepara...

Embodiment 3

[0085] Embodiment 3: see figure 1 , 2, 3. The material composition of the outer layer 1 of carbon cast steel is: C: 0.28%, Si: 0.49%, Mn: 0.84%, S≤0.04%, P≤0.04%, and the rest is iron; high chromium cast iron The material composition of the middle layer 2 is by weight percentage: C: 2.90%, Si: 0.70%, Mn: 2.90%, Cr: 16.5%, S≤0.06%, P≤0.10%, and the rest is iron; the inner layer of tungsten carbide granular ceramics 3 The material composition is by weight percentage: tungsten carbide: 30%, C: 2.90%, Si: 0.70%, Mn: 2.90%, Cr: 18%, S≤0.06%, P≤0.10%, and the rest is iron; Die vacuum casting multi-metal composite wear-resistant elbow pipe, the inner wall of the elbow pipe is composed of outer layer of carbon cast steel and inner layer of high chromium cast iron, and the outer wall is made of carbon cast steel outer layer 1, high chromium cast iron The middle layer 2 and the tungsten carbide granular ceramic inner layer 3 are composed of three layers of different materials.

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com