Patents

Literature

348results about How to "Eliminate corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

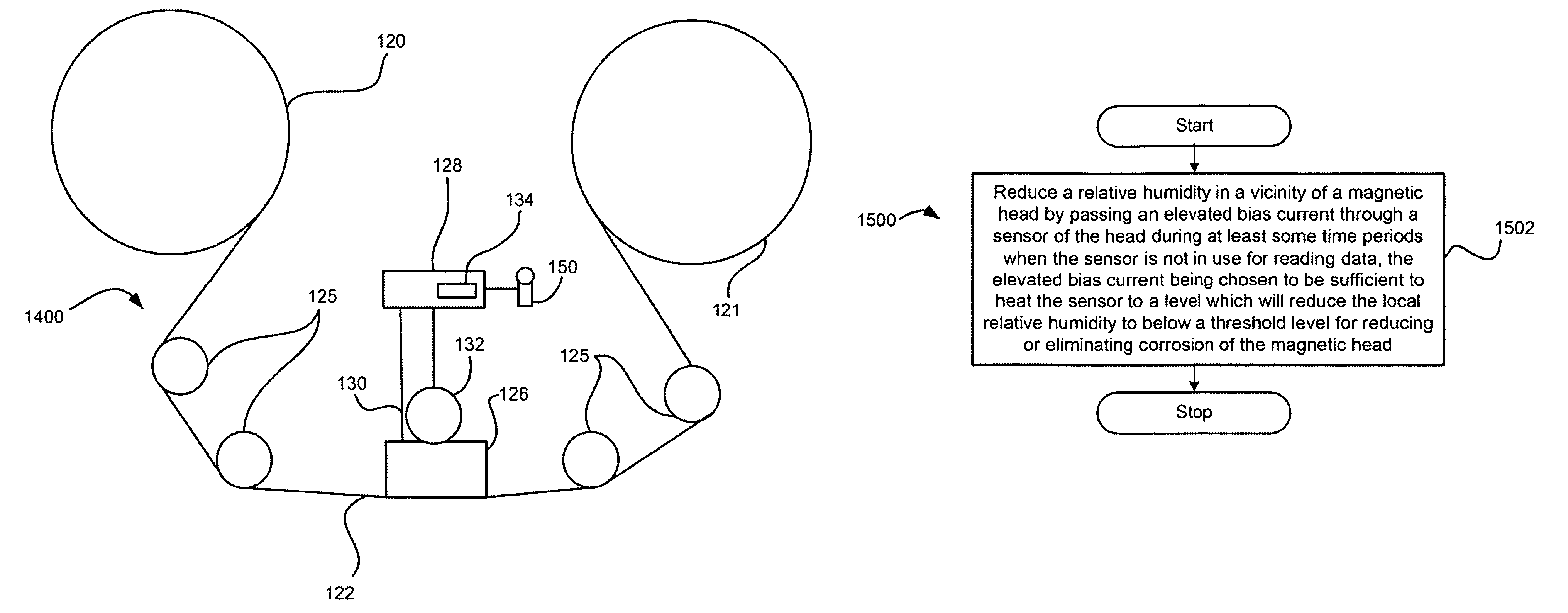

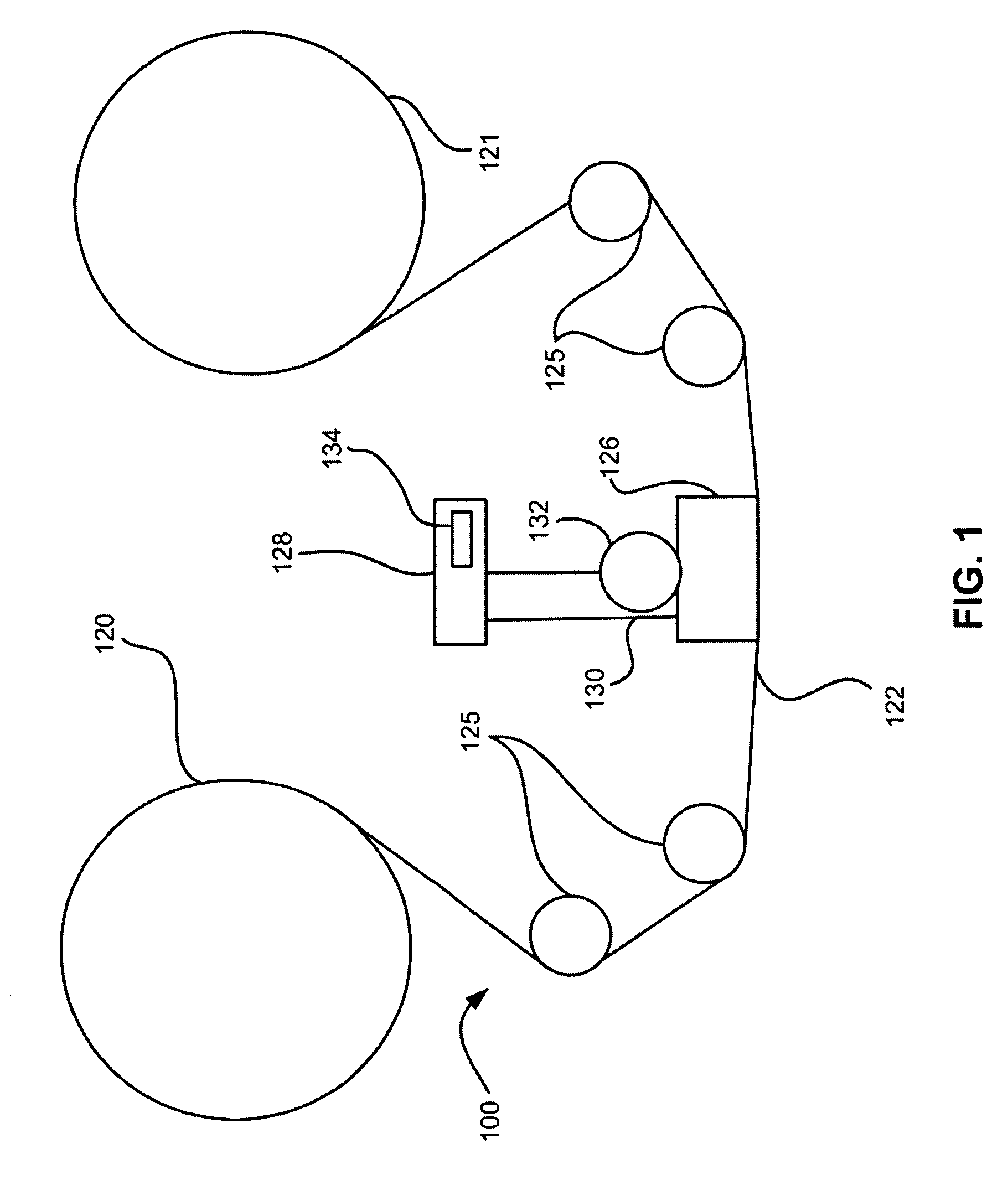

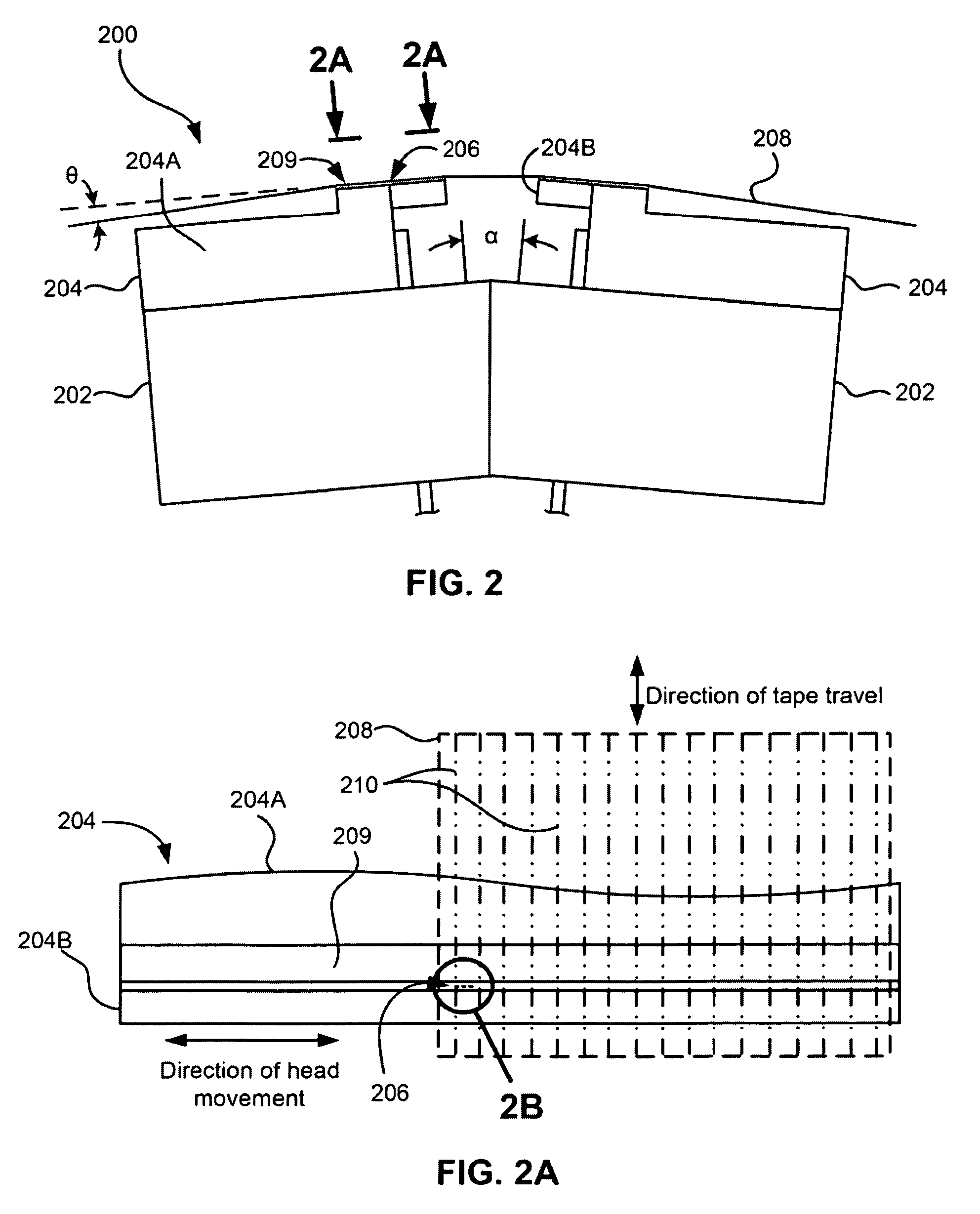

Systems and methods for protecting a sensitive device from corrosion

ActiveUS7656602B2Reduce humidityEliminate corrosionUndesired vibrations/sounds insulation/absorptionRecord information storageTime segmentEngineering

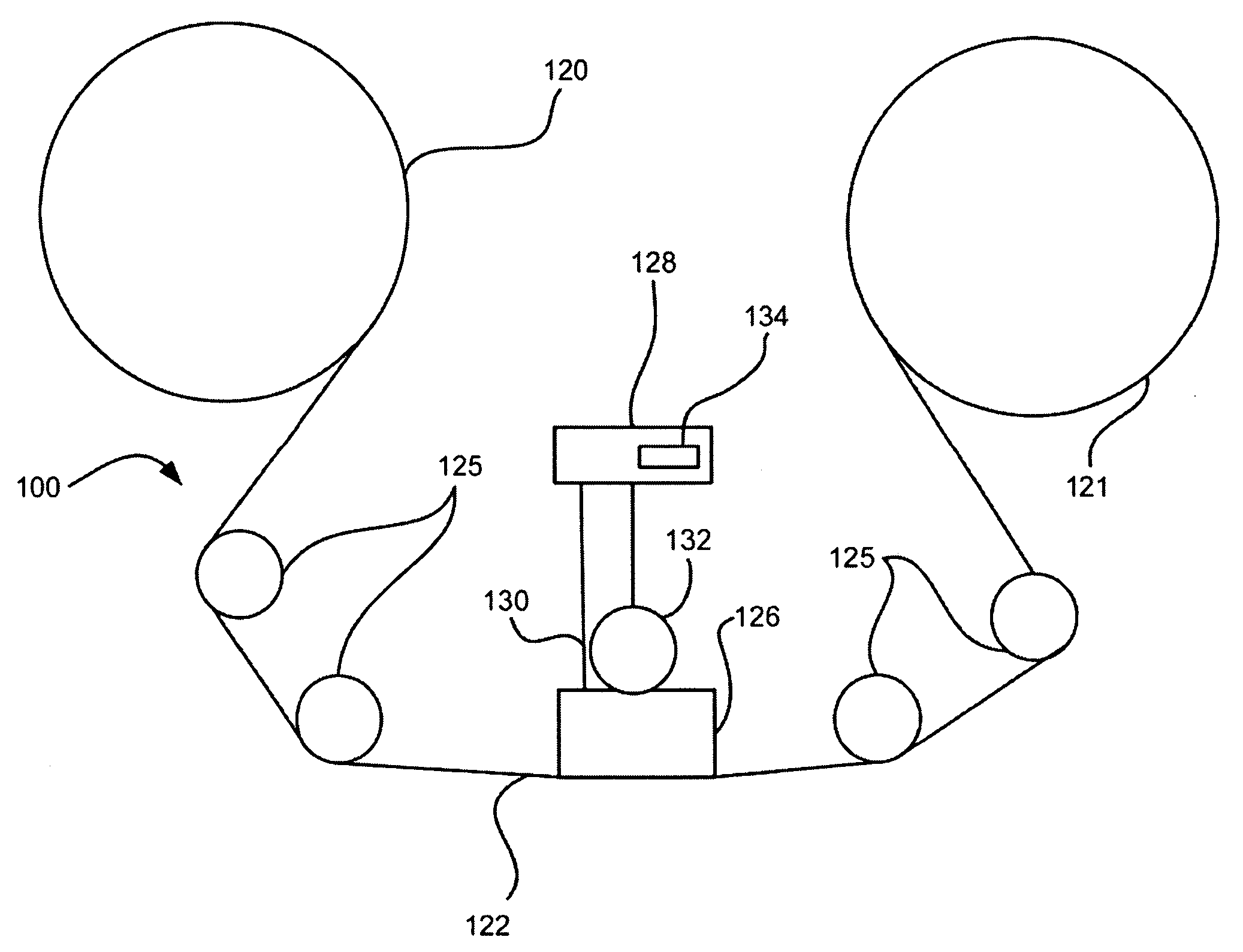

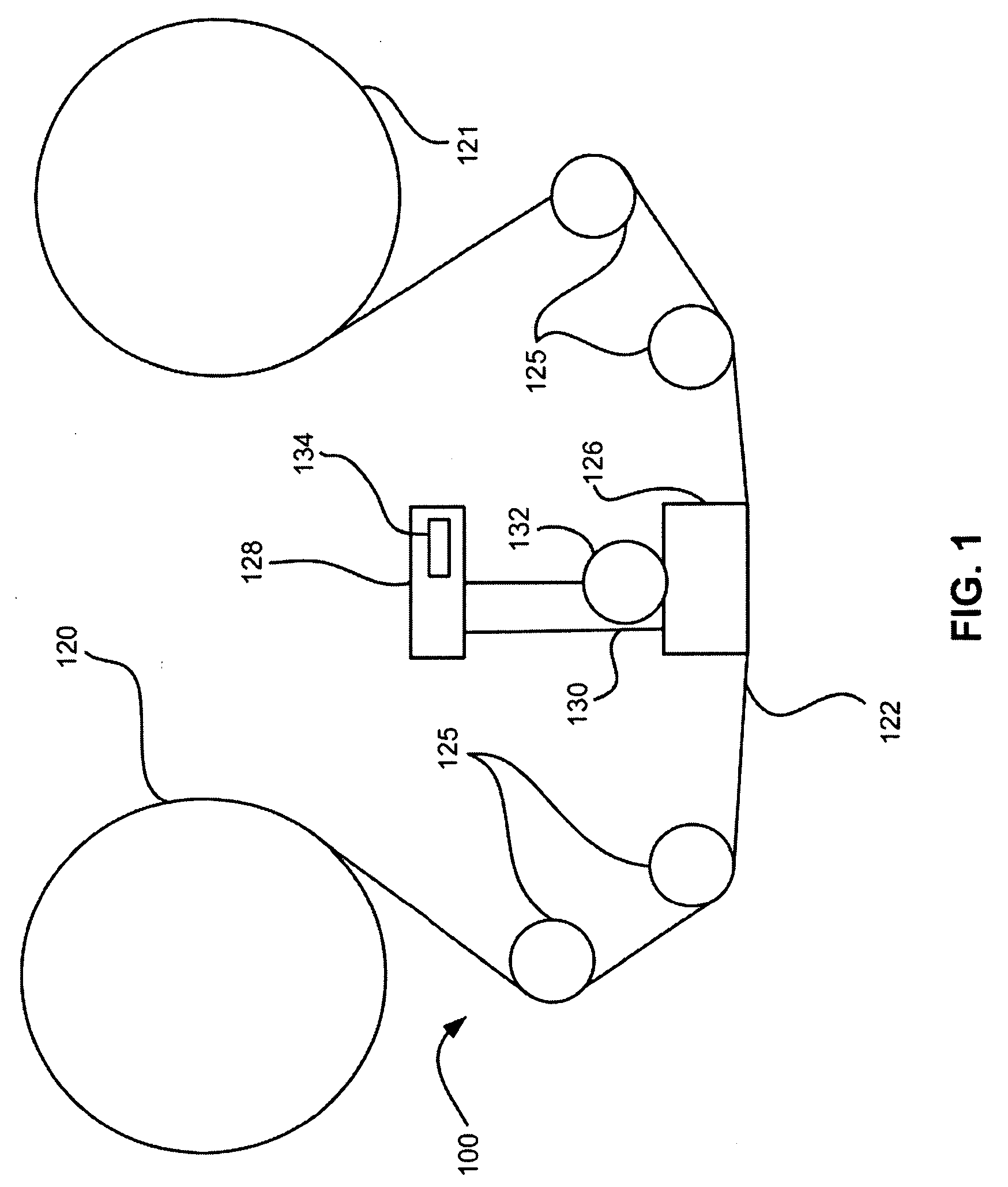

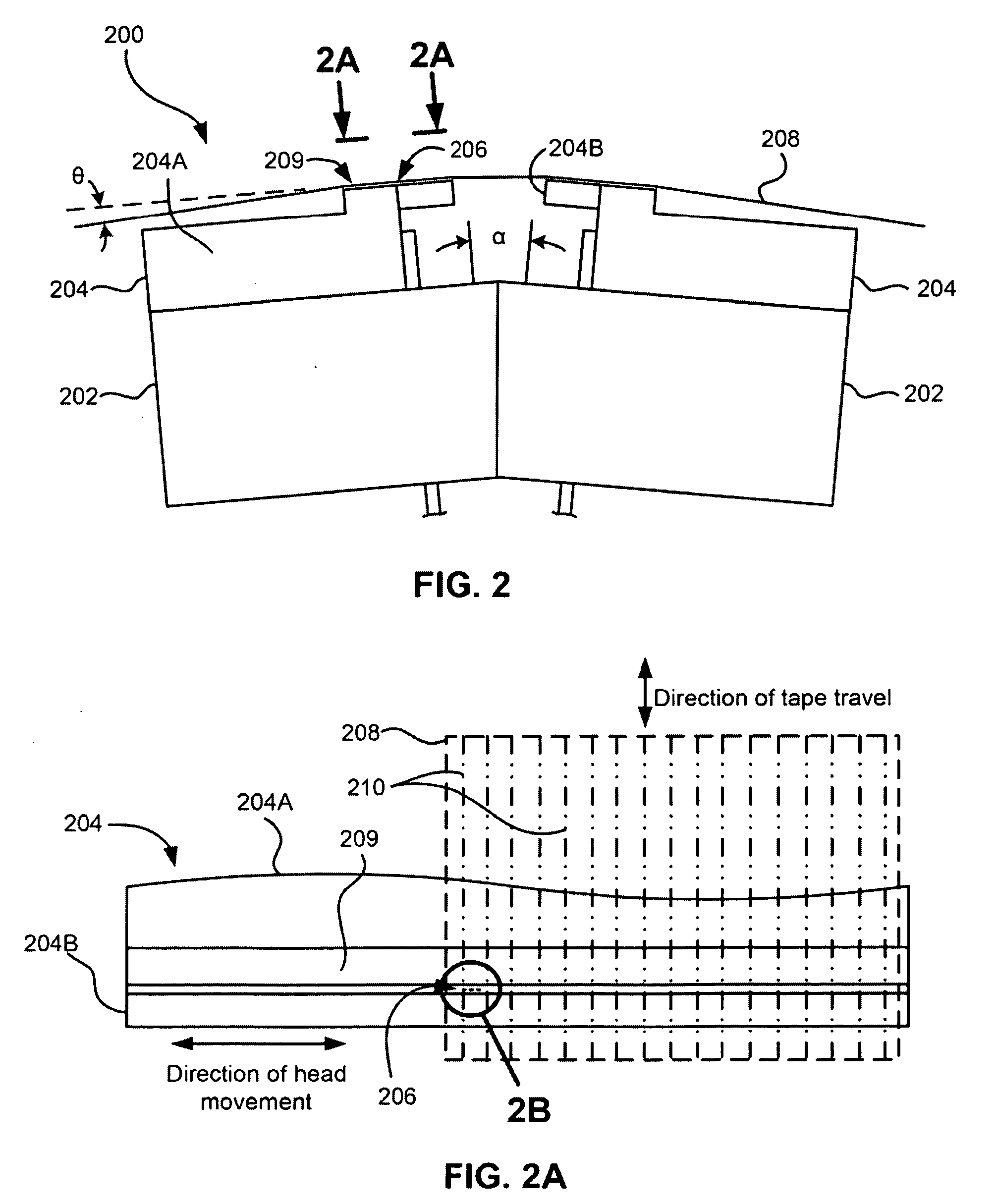

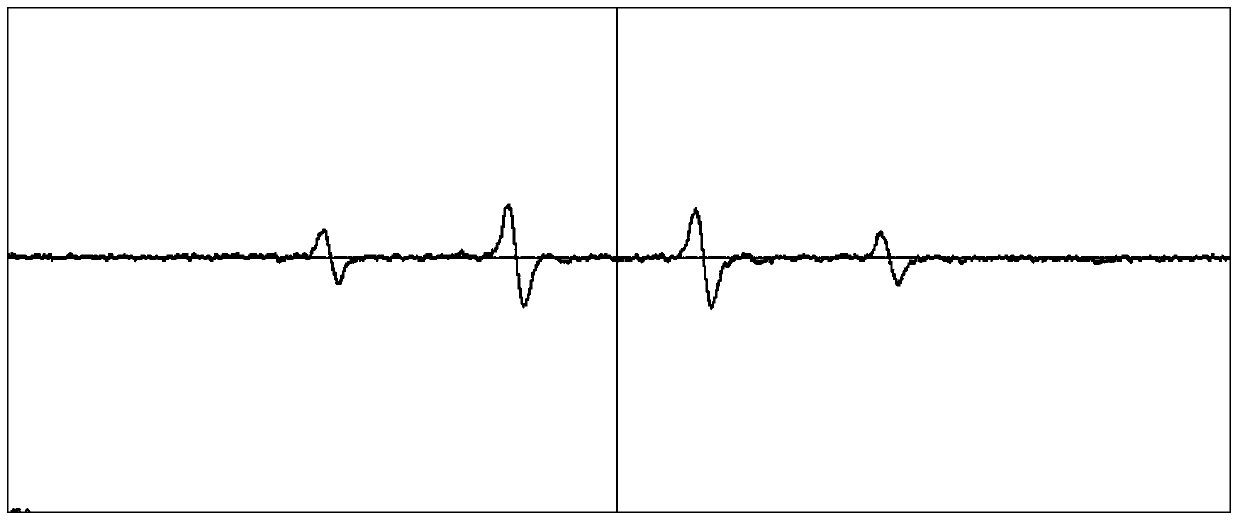

A method for protecting a magnetic head according to one embodiment includes reducing a relative humidity in a vicinity of a magnetic head by passing an elevated bias current through a sensor of the head during at least some time periods when the sensor is not in use for reading data, the elevated bias current being chosen to be sufficient to heat the sensor to a level which will reduce the local relative humidity to below a threshold level for reducing or eliminating corrosion of the sensor. Additional methods are also presented.

Owner:INT BUSINESS MASCH CORP

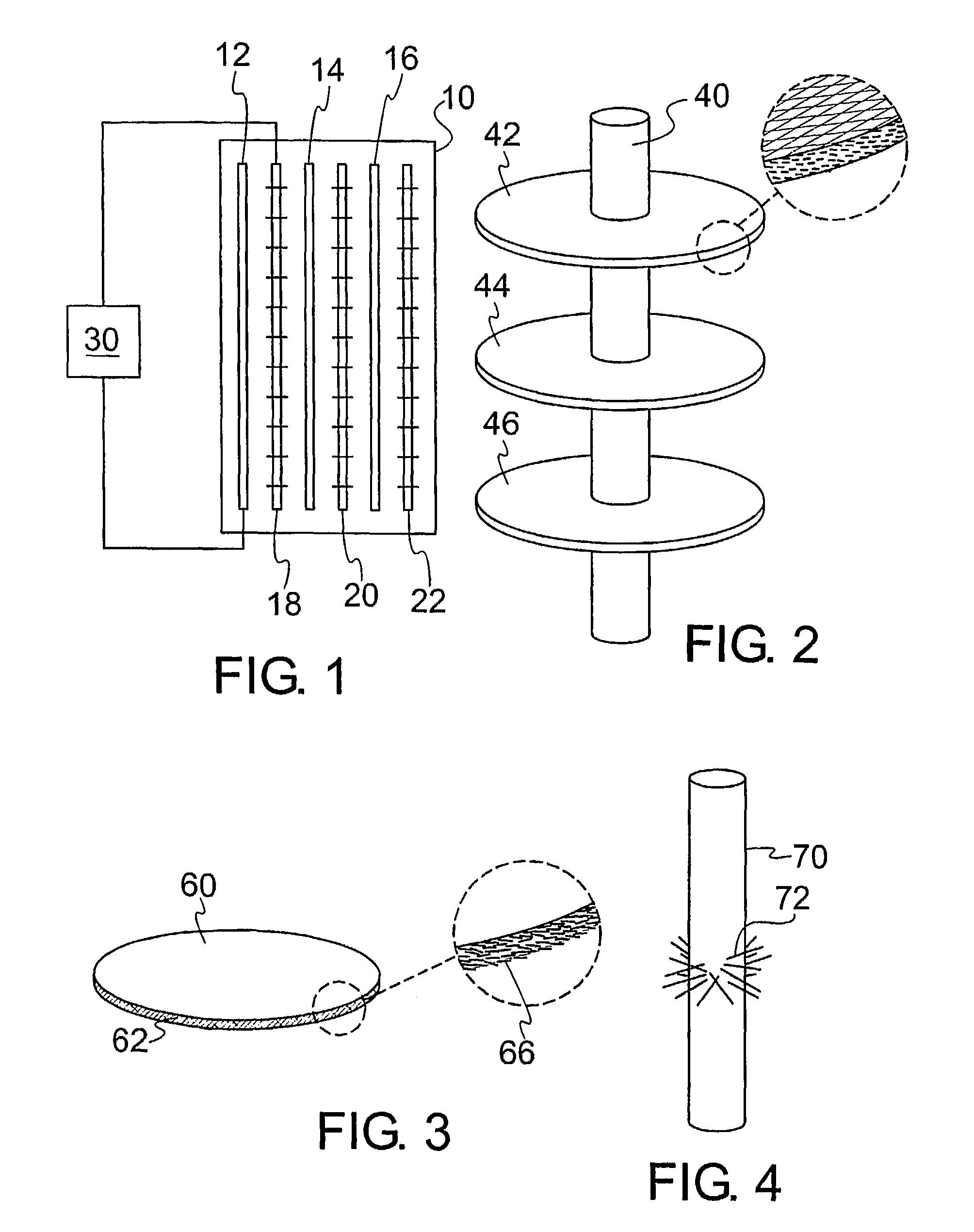

Coatings for encapsulation of photovoltaic cells

InactiveUS20040244829A1Eliminate corrosionIncreased durabilityPV power plantsPhotovoltaic energy generationPhysical chemistryThin membrane

Thin film photovoltaic cells having a protective coating as an encapsulant are disclosed. The protective coating is one that imparts durability, moisture resistance and / or abrasion resistance to the photovoltaic layer of the cell. One or more coating layers, either alone or in combination with one or more primer or adhesive layers, can be used. Powder, liquid and electrodeposited coatings can all be used according to the present invention. Methods of making such cells are also disclosed.

Owner:PPG IND OHIO INC

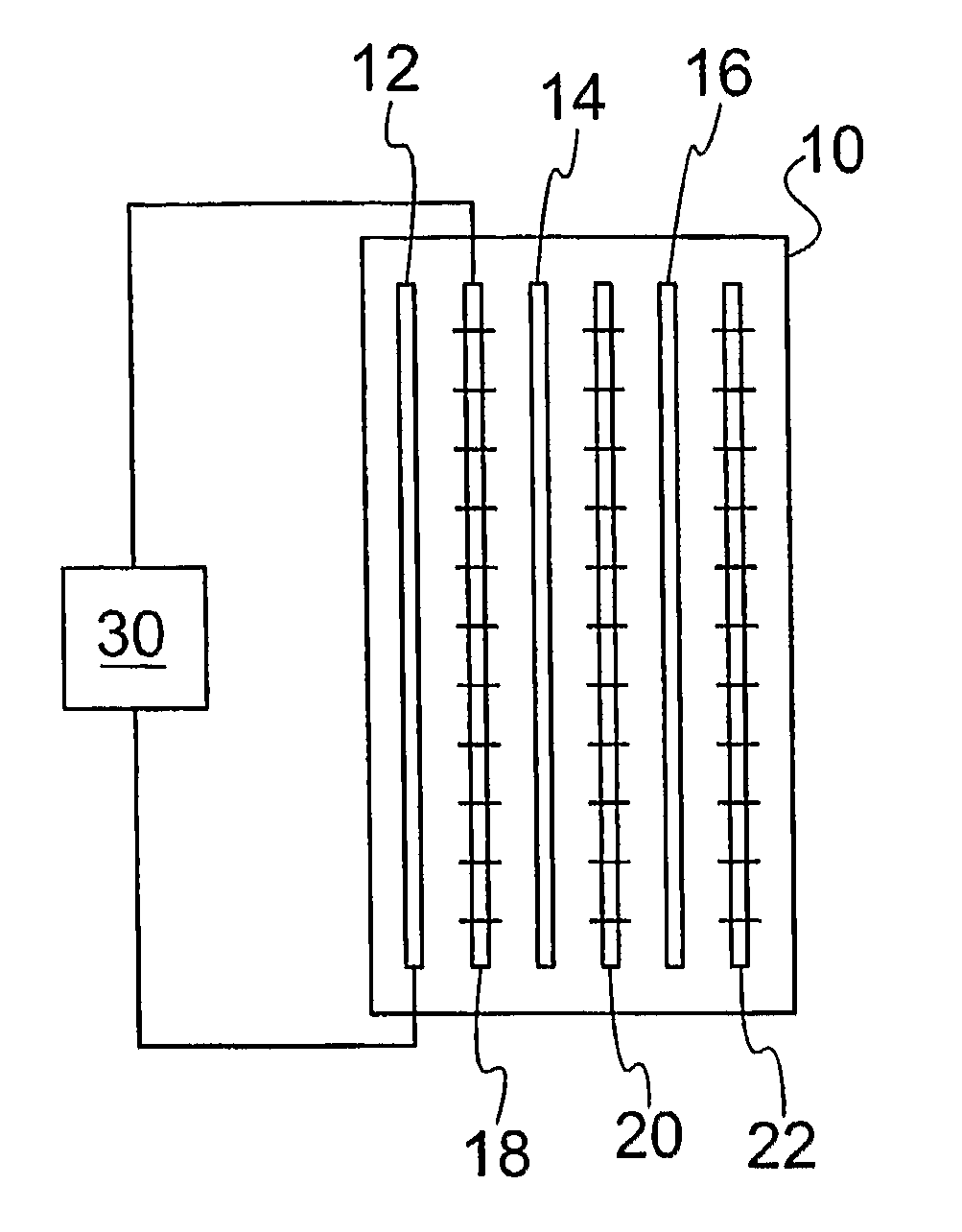

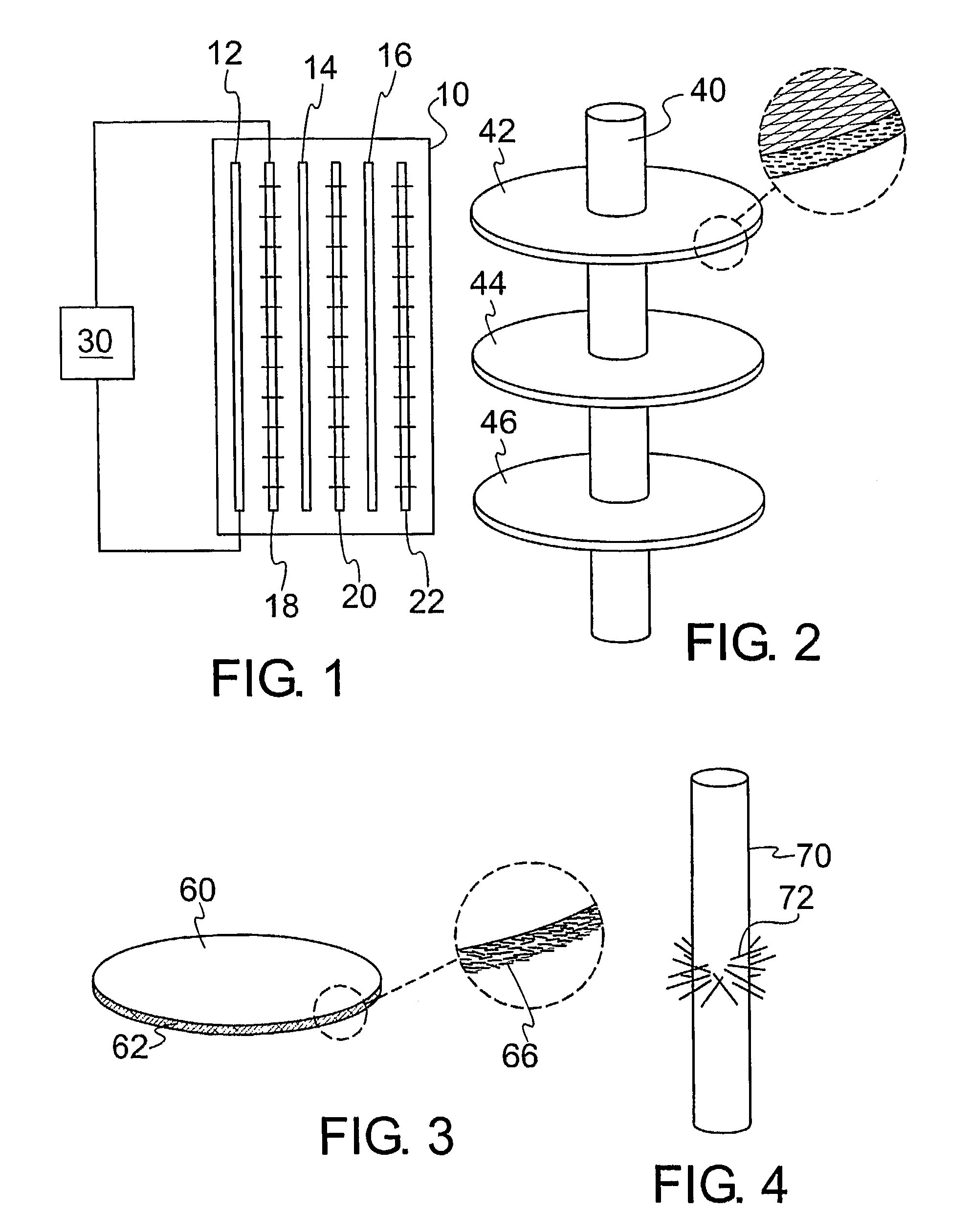

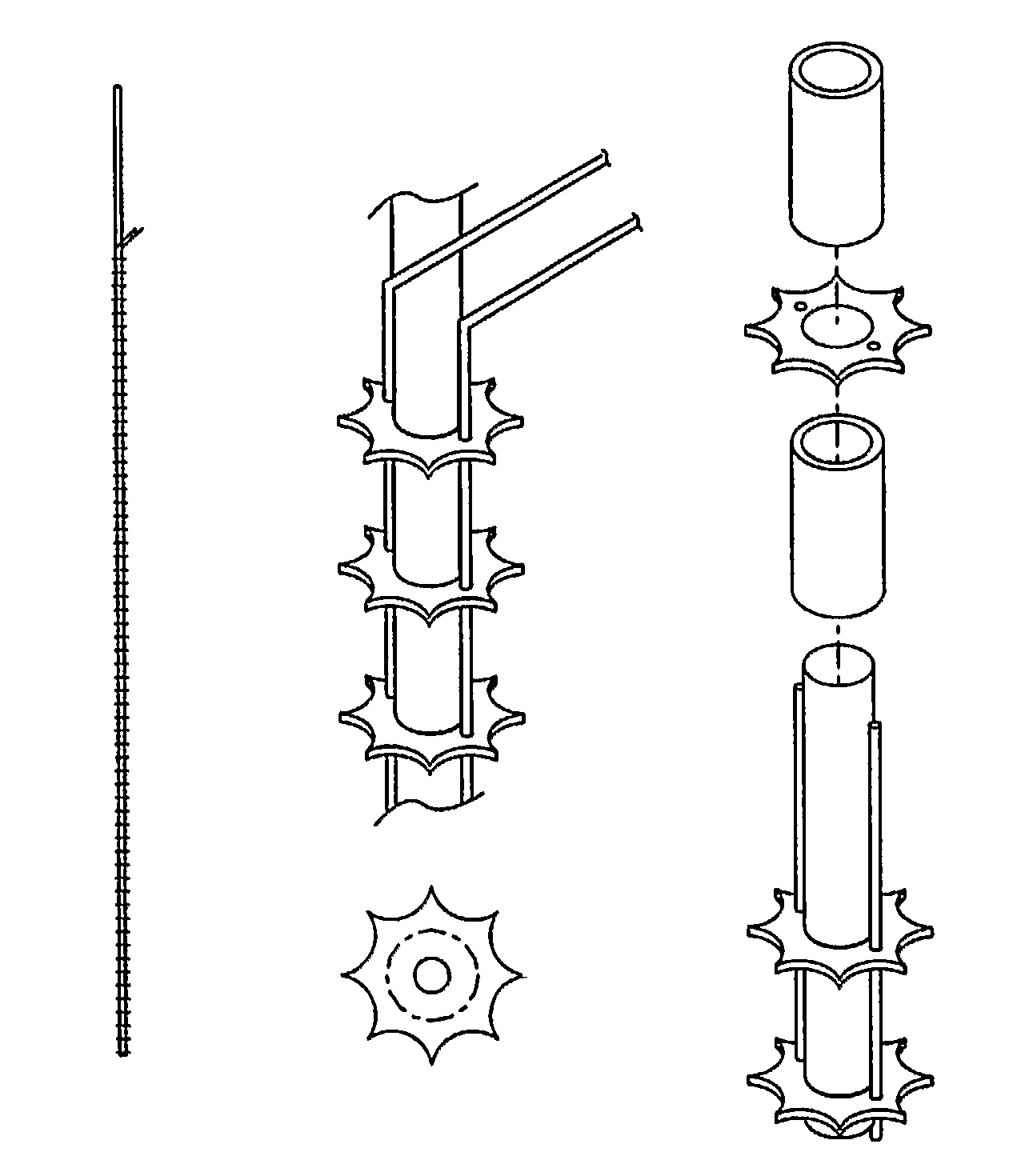

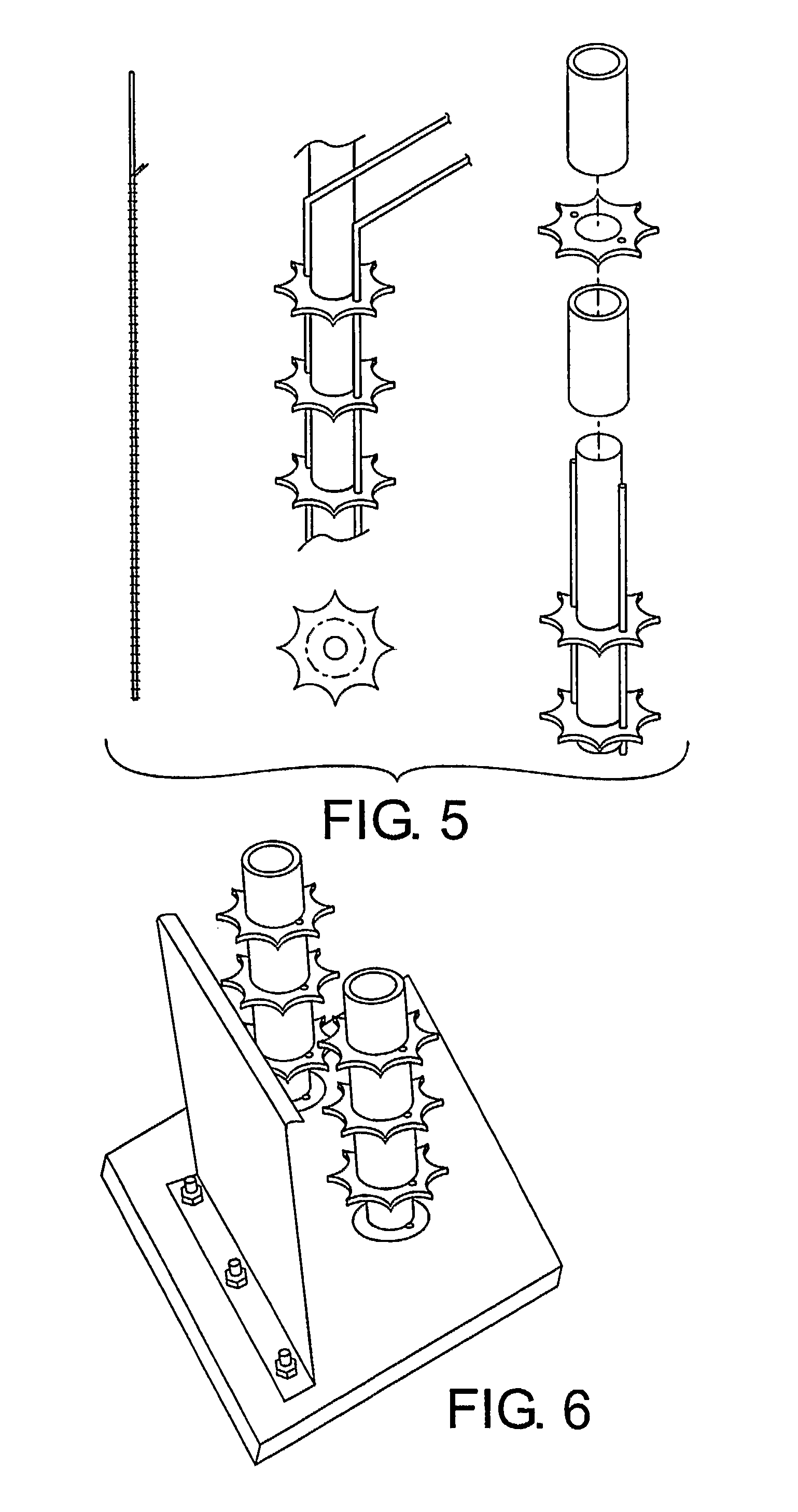

Composite Discharge Electrode

InactiveUS20080190296A1Low costReduce weightDischarge tube main electrodesElectrode constructionsFiberElectricity

The invention is a discharge electrode in an electrostatic precipitator having a power supply connected to at least one collection electrode and a flow of gas across the collection electrode. The discharge electrode has a plurality of conductive fibers electrically connected to the power supply and fiber tips exposed to the flow of gas. The fiber tips preferably extend from a composite in which the fibers reinforce a matrix material, but alternatively can be a large number of filaments extending from a composite rod.

Owner:OHIO UNIV

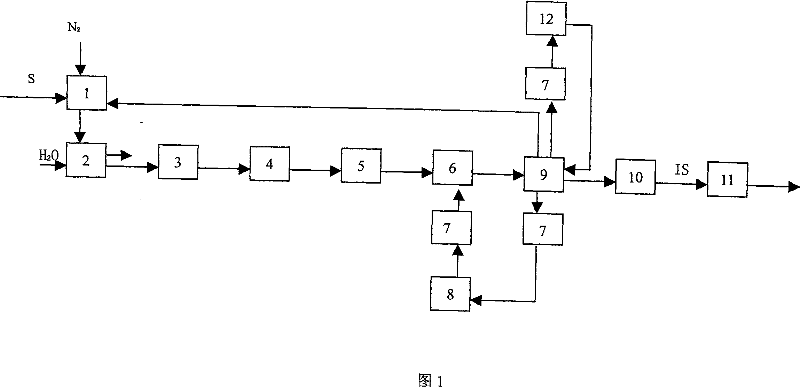

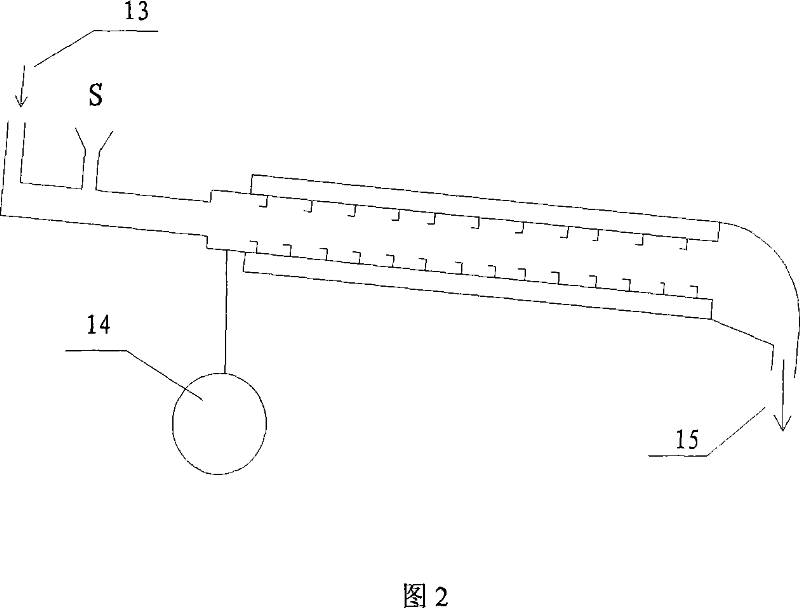

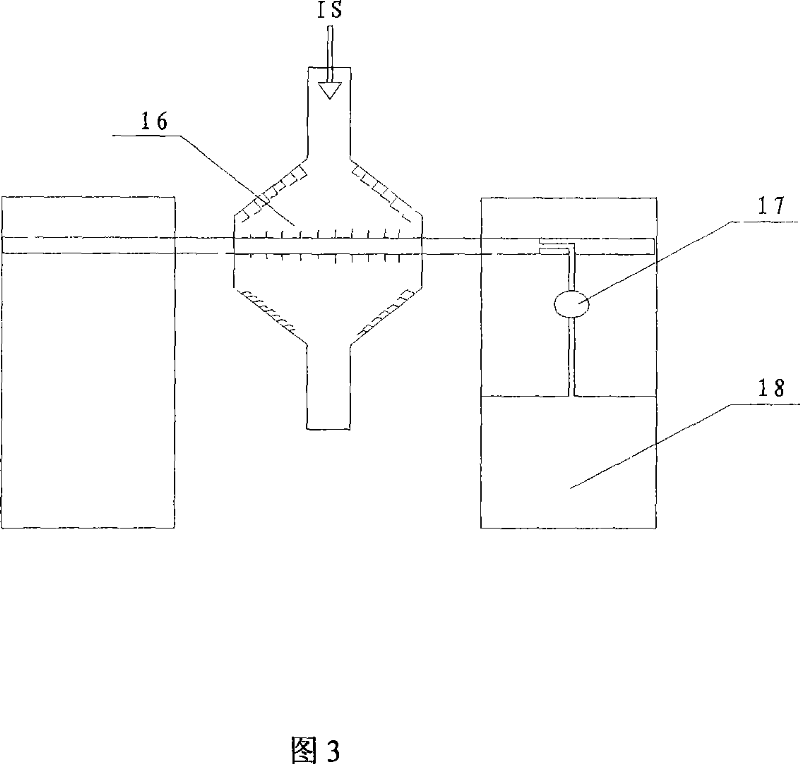

Preparation method of oil-filled insoluble sulphur

InactiveCN101037191AImprove one-way yieldColor has no effectSulfur preparation/purificationThermal insulationSolvent

The present invention relates to a preparation method of insoluble sulfur of special vulcanizing agent used for rubber, in particular to a preparation method of oil charge type insoluble sulfur, which comprises the steps of: using ordinary sulfur as raw material which is added with composite stabilizer; putting into a reaction kettle which is provided with a heating controller and a stirring device; nitrogen blanketting; melt polymerization at 200~300 DEG C; thermal insulation for 25~120 min; quenching, curing, drying, size reduction and sieving; extracting by using a mixed solvent as extractant, centrifugal separation of the liquid after extraction, fluidized drying of the residue, and then obtaining insoluble sulfur; and then executing oil charge to obtain oil charge type insoluble sulfur with high stability. The operation has a strong continuity, the recovery energy consumption of the extractant is low and the product has high thermal stability.

Owner:NANJING UNIV OF TECH

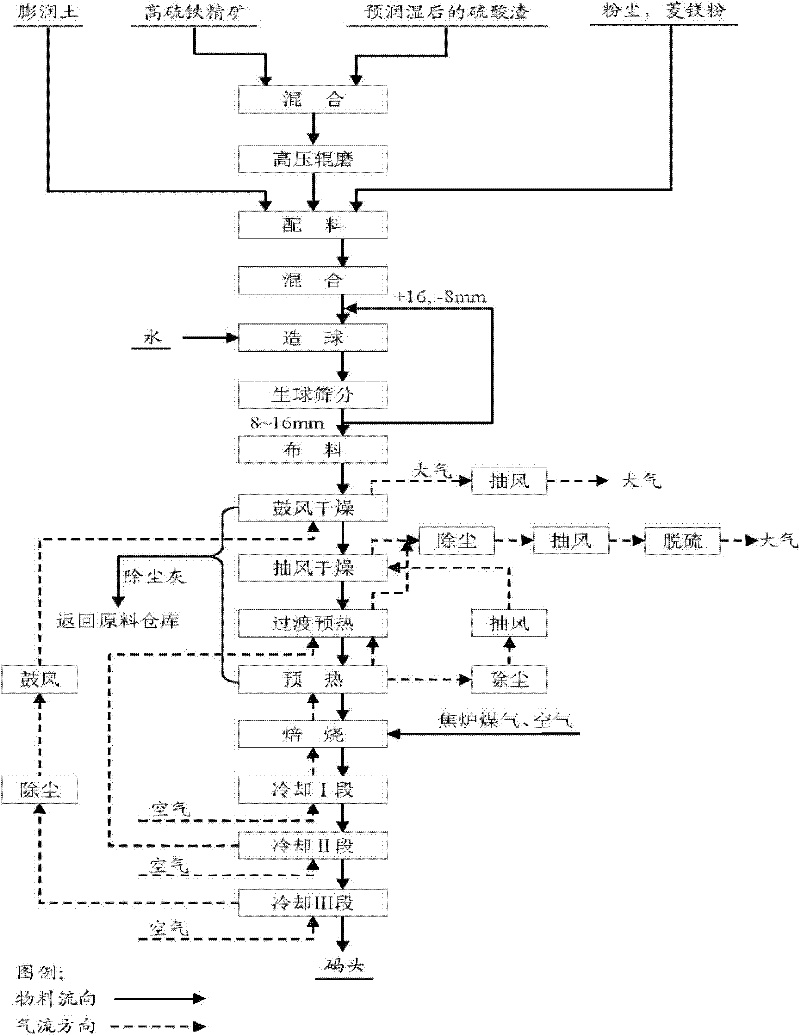

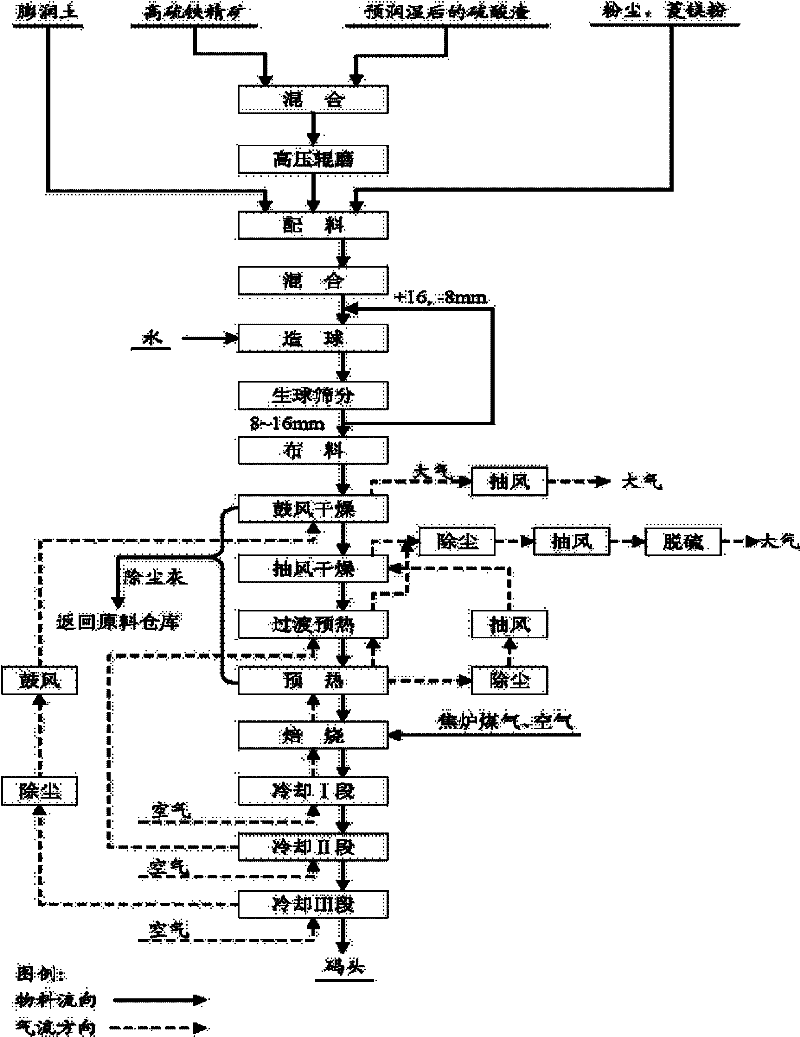

High sulfide pyrite pellet reinforced roasting consolidation technology

ActiveCN102242254ASolve roasting problemsImprove dynamic conditionsBlast furnace detailsDecompositionSlag

The invention discloses a high sulfide pyrite pellet reinforced roasting consolidation technology. Pellets are produced by adopting the technology of drying grate--rotary kiln--ring type refrigeration machine--flue gas desulphurization. The basic flow is as follows: prebatching--mixing--high press roll grinding--batching--mixing--pelletizing--drying--preheating--roasting--cooling--finished product output--flue gas desulphurization. From the perspectives of the occurrence state of sulfur in raw materials, the decomposition behavior of sulfur during the heating process, the iron ore pellet forming theory and the iron ore pellet consolidation mechanism, the system integration reinforced high sulfide pyrite pellet forming and pellet consolidating technology, which includes the improvement of pyritic slag pellet forming dynamics condition, the reinforcement of high sulfur pellet desulphurization and consolidation during the preheating and roasting processes and the control of high SO2 concentration flue gas features and migration rules, is adopted to solve the roasting problem of high sulfide pyrite, make the sulfur content of the finished pellets and the pellet ore strength reach related technical requirements and basically prevent flue gas from corroding equipment. The invention provides a new approach for effective utilization of high sulphur-containing iron concentrate and sulfuric acid slag resource.

Owner:CENT SOUTH UNIV +1

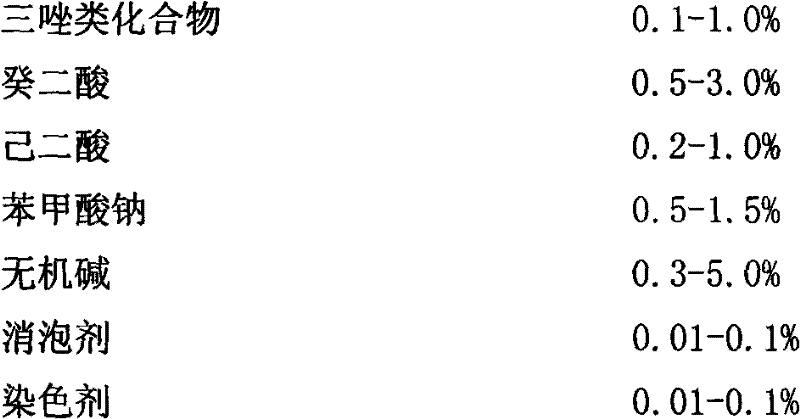

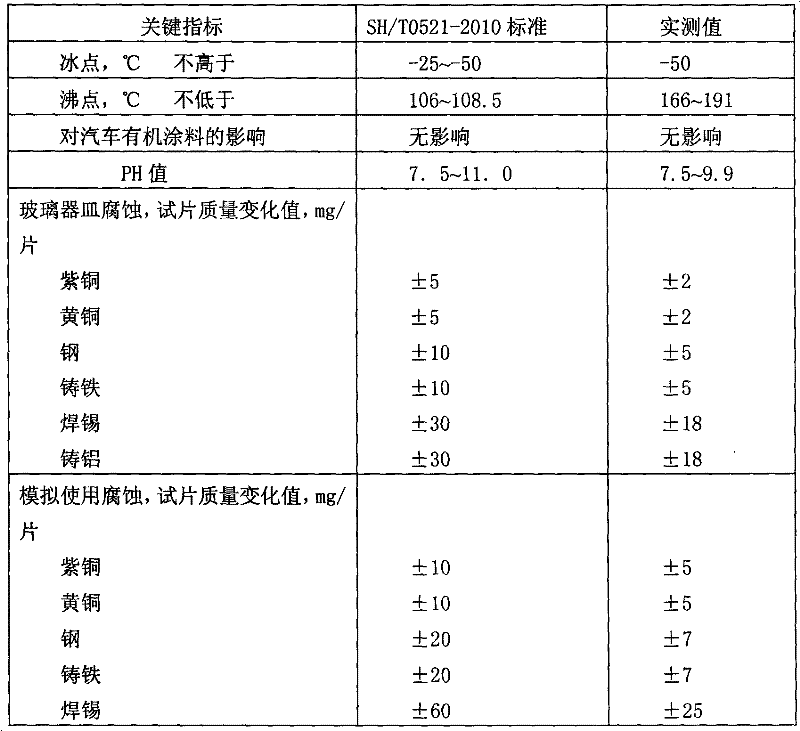

Life-cycle water-free cooling solution

The invention relates to a life-cycle water-free cooling solution which is characterized by comprising the following components in percent by weight: 10-50 percent of propylene glycol, 50-80 percent of ethylene glycol, 0.1-10 percent of triazole compounds, 0.5-3.0 percent of sebacic acid, 0.2-1.0 percent of adipic acid, 0.5-1.5 percent of sodium benzoate, 0.3-5 percent of inorganic base, 0.01-0.1 percent of antifoaming agent and 0.01-0.1 percent of colouring agent. The cooling solution has a freezing point of below -50 DEG C and a boiling point of 166-191 DEG C; and because the cooling solution does not contain water, problems of boiling, gas etching, evaporating, scaling, rusting and the like caused by water existing in the cooling solution are thoroughly eliminated, a steam air resistance layer seriously influencing heat radiation is avoided from generating, power of an engine can be effectively improved and fuel is saved. Because the cooling solution does not contain water and has a reasonable corrosion inhibition system, the problem of corrosion is thoroughly solved; and the cooling solution has a service life of reaching up to 8 hundred thousand kilometers, is added once without replacement, is a life-cycle cooling solution, is especially suitable for military vehicles, high-end vehicles and high-power heavy-loading trucks and passenger cars, and can ensure that the vehicles safely run under extremely hot weather, severe cold weather, and severe environments such as desert, plateau, snowfield and the like.

Owner:JIANGXI CHEPU IND CO LTD

Method for preparing silica aerogel composite material by adopting chloride-free and alcohol-free process

The invention discloses a method for preparing a silica aerogel composite material by adopting a chloride-free and alcohol-free process. The method comprises the following steps: S1, adopting a water-based silicon source as a raw material, regulating the pH value of sol with a chloridion-free acid, adding an additive after desalting, and uniformly stirring to obtain a first mixed solution; S2, immersing a fiber reinforced material into the first mixed solution, and completing gel curing; S3, standing the obtained composite gel material so as to obtain an aged composite gel material; S4, placing the aged composite gel material in a chloride-free and alcohol-free displacer to realize uniform solution infiltration; S5, performing surface methylsilane modification on the composite gel by usinga chloride-free surface modifier; S6, drying the modified composite gel, thereby obtaining the silica aerogel composite material. The invention provides a method for preparing the silica aerogel composite material without any chloride ion or alcohol substance in the formula.

Owner:SHENZHEN AEROGEL TECH CO LTD

Composite discharge electrode

InactiveUS7976616B2Low costReduce weightDischarge tube main electrodesElectrode constructionsFiberElectricity

The invention is a discharge electrode in an electrostatic precipitator having a power supply connected to at least one collection electrode and a flow of gas across the collection electrode. The discharge electrode has a plurality of conductive fibers electrically connected to the power supply and fiber tips exposed to the flow of gas. The fiber tips preferably extend from a composite in which the fibers reinforce a matrix material, but alternatively can be a large number of filaments extending from a composite rod.

Owner:OHIO UNIV

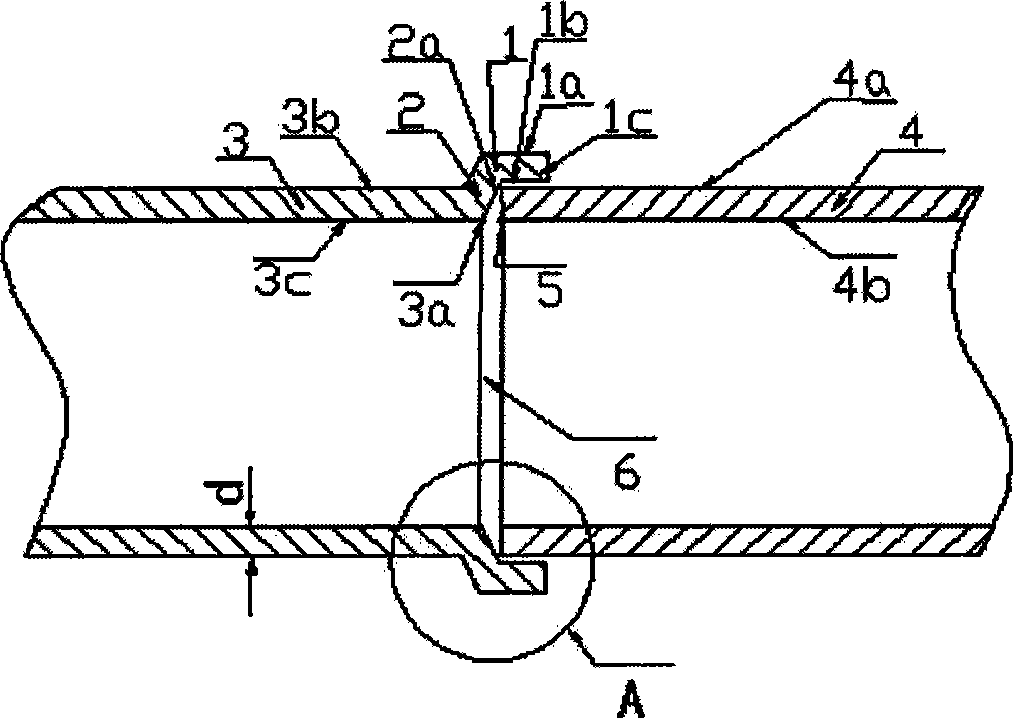

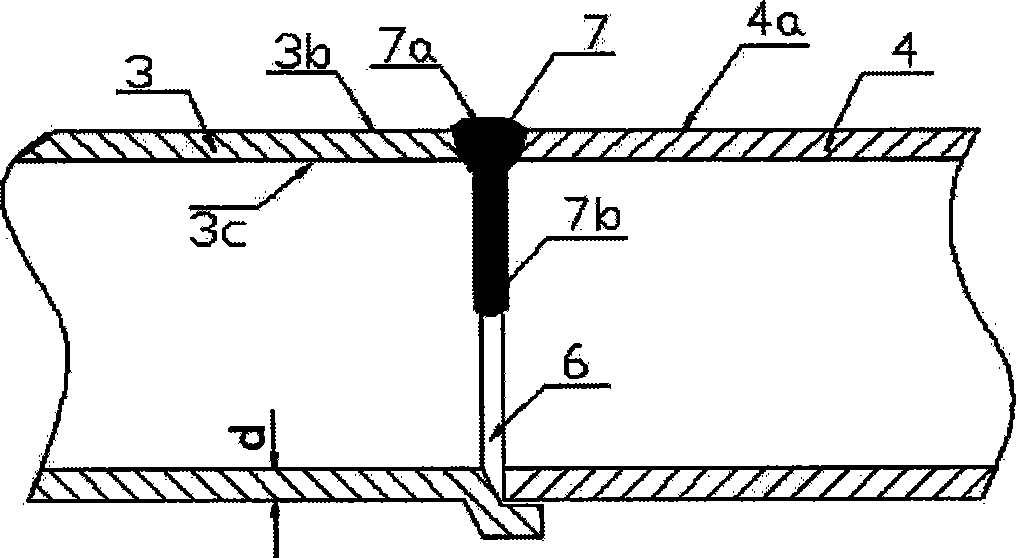

Metal welded pipe joint and assemble-welding method

InactiveCN101486130AEliminate the slitAccurate quick-fit joint methodWorkpiece edge portionsResistance welding apparatusButt weldingEngineering

The invention discloses a tube welding joint. The tube welding joint comprises a tube piece body and a connecting tube. The tube welding joint is characterized in that a joint socket of the tube piece body is provided with a conicity section part; the connecting tube is inserted into the joint socket of the tube piece body to form socket lapping and butt welding and molding. The invention also discloses a method for welding the tube welding joint. The method is characterized in that the method sequentially comprises the following steps: 1) pretreatment and preconfiguration; 2) placing of an inner gas protective device; 3) interface in-place of the socket lapping tube piece; 4) temporary fixing; and 5) butt welding and molding. A socket lapping mode and a tube joint mounting structure realize a smooth welding joint of which weld joint is in butt welding and double-sided molding, radically remove the existence of crack between socket cylinder bodies and remove silt of the tube port at the same time to form the smooth tube welding joint without any crack and clearance. The mounting mode realizes accurate and rapid joint mounting mode and has convenient operation and simple and reliable mounting. The tube welding joint can be widely applied to socket mounting of water, gas, steam and equipment supply for building, industrial fluid, food and medicine fluid and other pipe assembly.

Owner:SHENZHEN ARTWAY PIPING CORP

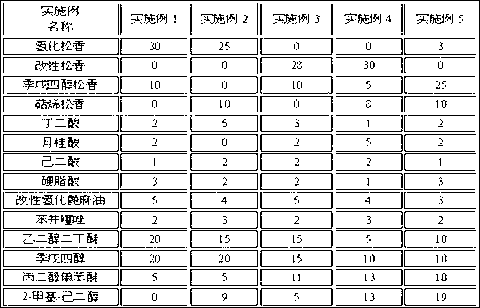

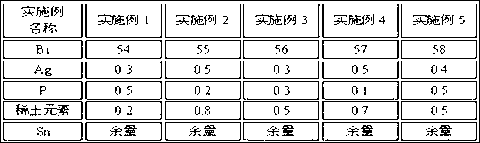

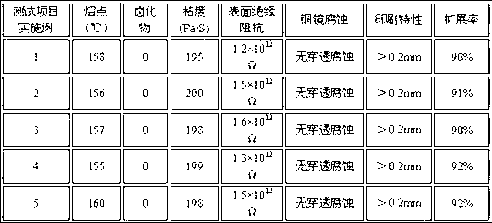

Low-temperature halogen-free lead-free solder paste

InactiveCN102990242AStir wellLow melting pointWelding/cutting media/materialsSoldering mediaRare-earth elementSlag (welding)

The invention relates to a low-temperature halogen-free lead-free solder paste. The solder paste is mixed by Sn-Ag-Bi-based lead-free solder powder added with P or rare earth elements and a rosin-based soldering flux. The soldering flux is basically composed of, by weight, 30-45% of rosin resin, 2-10% of an organic acid activator, 3-5% of a thixotropic agent, 2-5% of a corrosion inhibitor, 3-5% of a surfactant and the balance solvents. The solder paste has the advantages that the welding temperature is low, slag is reduced, and the solder paste is suitable for manual welding and printing welding with poor thermal shock resistance.

Owner:郴州金箭焊料有限公司

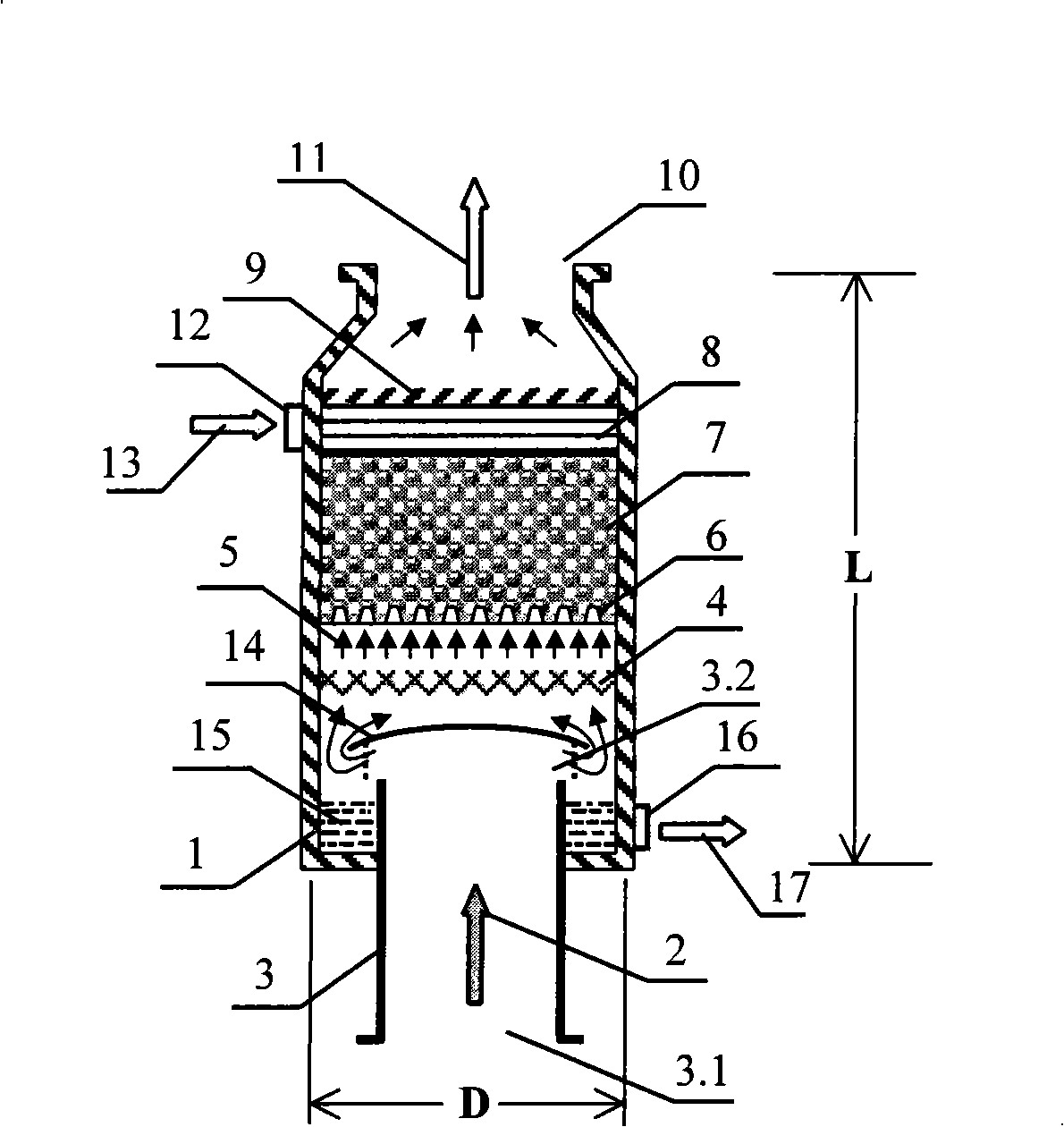

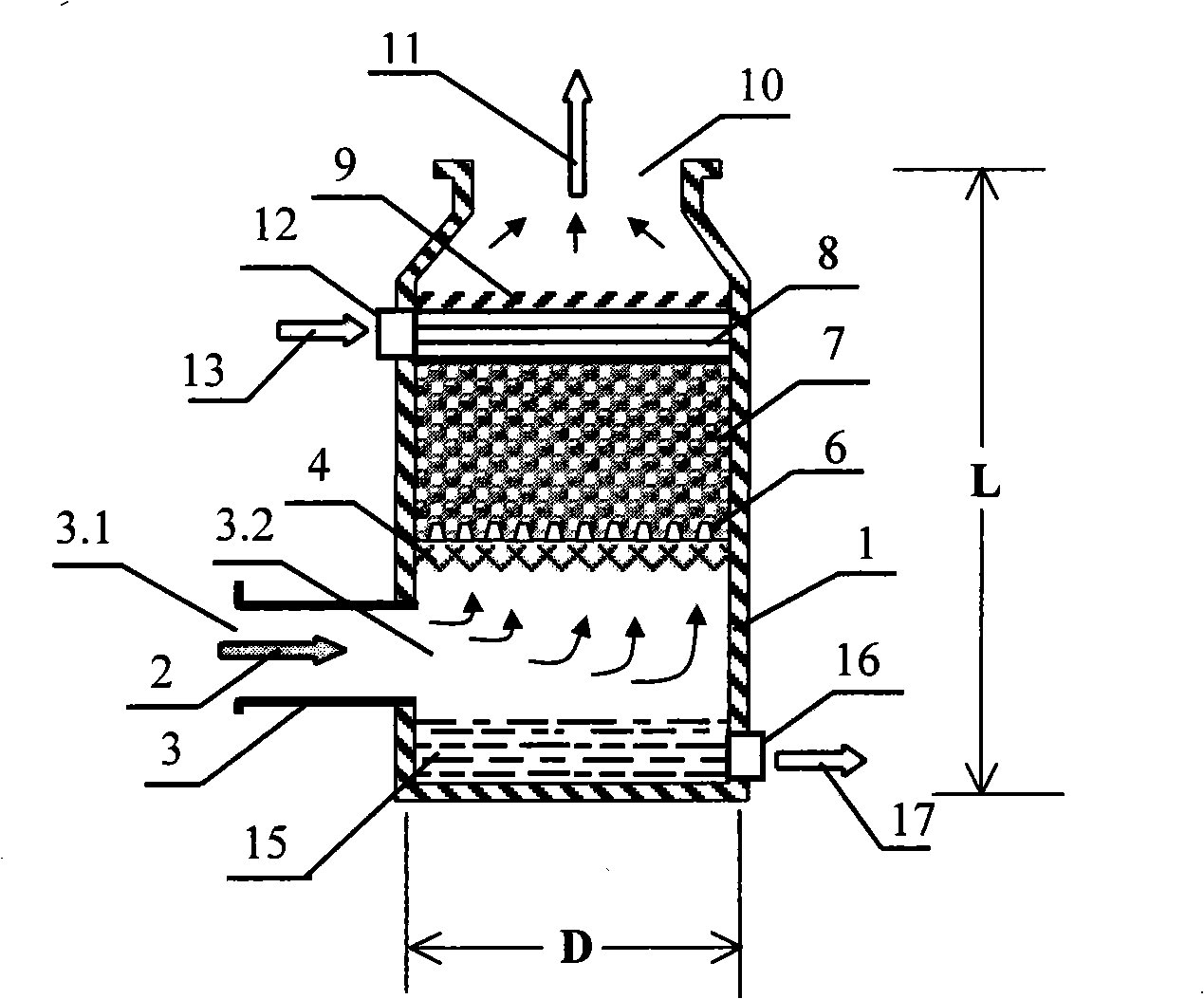

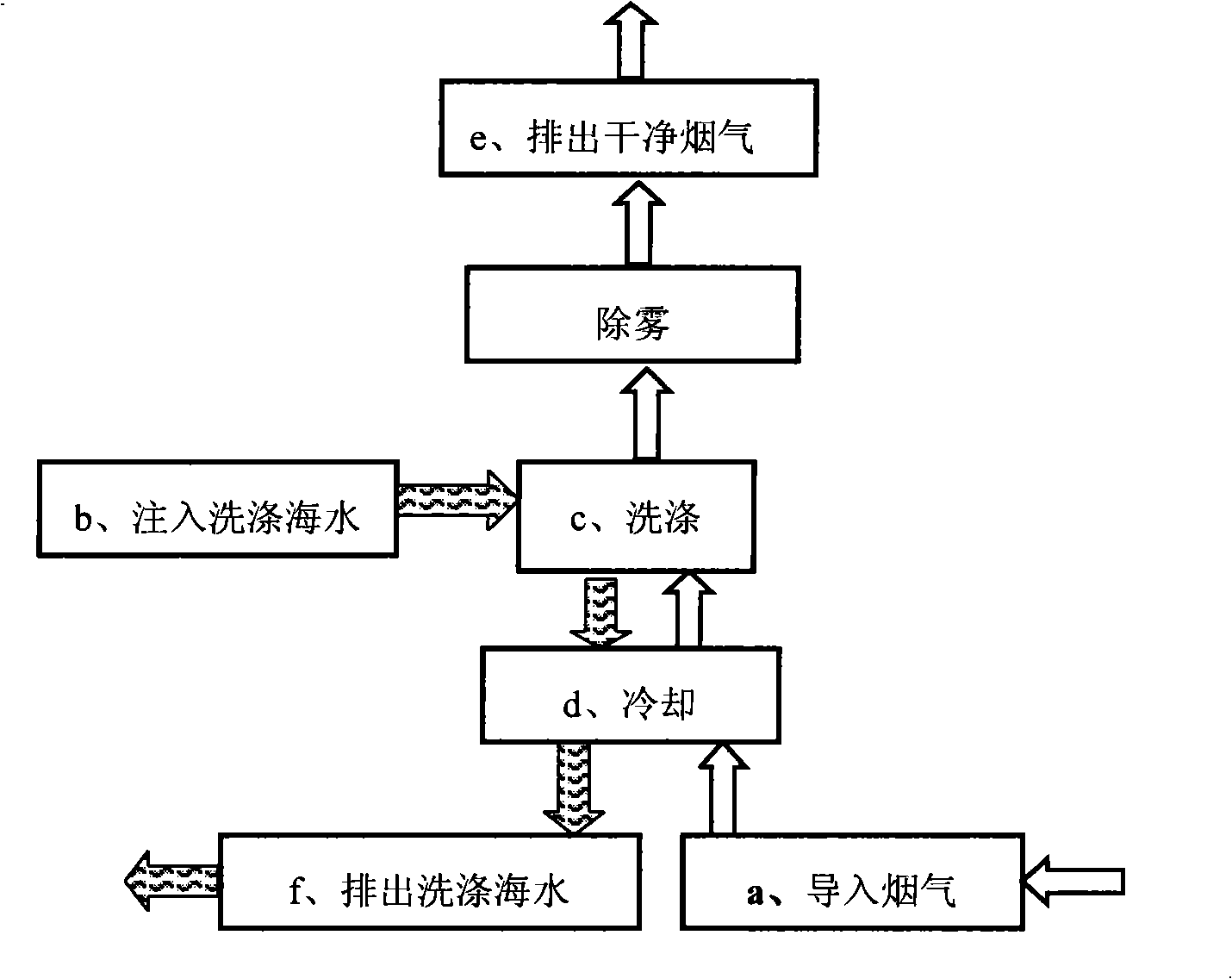

Sea boat smoke evacuation washing device and its washing method

InactiveCN101288823AGood technical effectEfficient washingDispersed particle separationSeawaterProcess engineering

The invention relates to a sea boat smoke exhaust washing device and a washing method. The device comprises a shell, a washing layer which is arranged at the upper part in the shell, a liquid collecting pool which is arranged at the lower part in the shell, a shell internal flue gas guide-in port arranged between the washing layer and the liquid collecting pool, a washing seawater inlet which is arranged above the washing layer and the cooler of the flue gas passage which is arranged between the shell external flue gas inlet and the washing layer; the method comprises the steps such as guiding in the flue gas, cooling and injecting the washing seawater and washing, etc. The invention provides the high-effect smoke exhaust absorption washing device and method which are suitable for high smoke temperature and narrow space of the sea boat, and has the advantages of high exhaust reduction efficiency, low running energy consumption, small volume and long service life.

Owner:武汉晶源环境工程有限责任公司

Systems and methods for protecting a sensitive device from corrosion

ActiveUS20090273857A1Reduce humidityEliminate corrosionUndesired vibrations/sounds insulation/absorptionRecord information storageEngineeringRelative humidity

A method for protecting a magnetic head according to one embodiment includes reducing a relative humidity in a vicinity of a magnetic head by passing an elevated bias current through a sensor of the head during at least some time periods when the sensor is not in use for reading data, the elevated bias current being chosen to be sufficient to heat the sensor to a level which will reduce the local relative humidity to below a threshold level for reducing or eliminating corrosion of the sensor. Additional methods are also presented.

Owner:IBM CORP

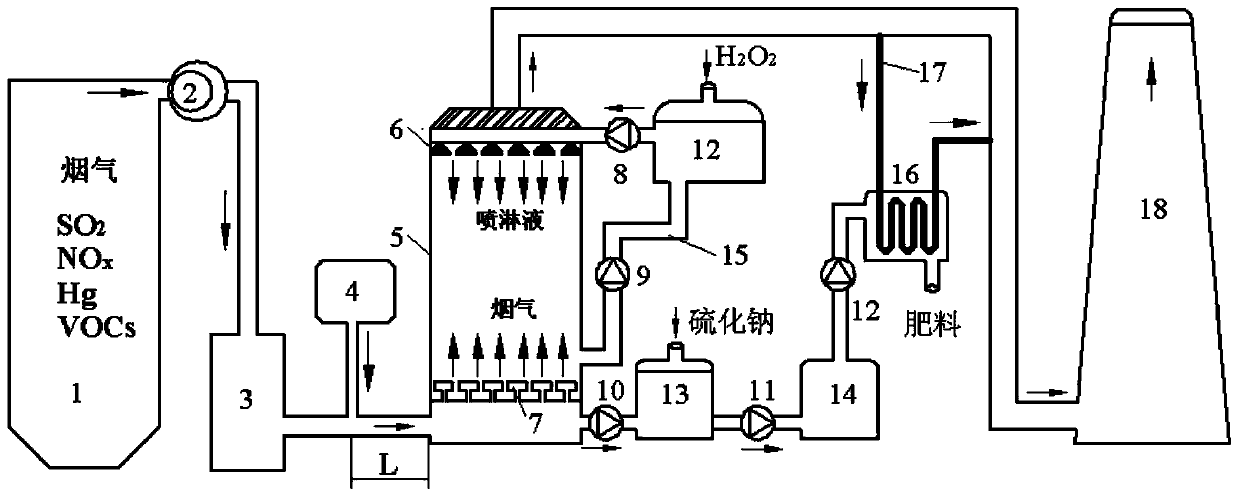

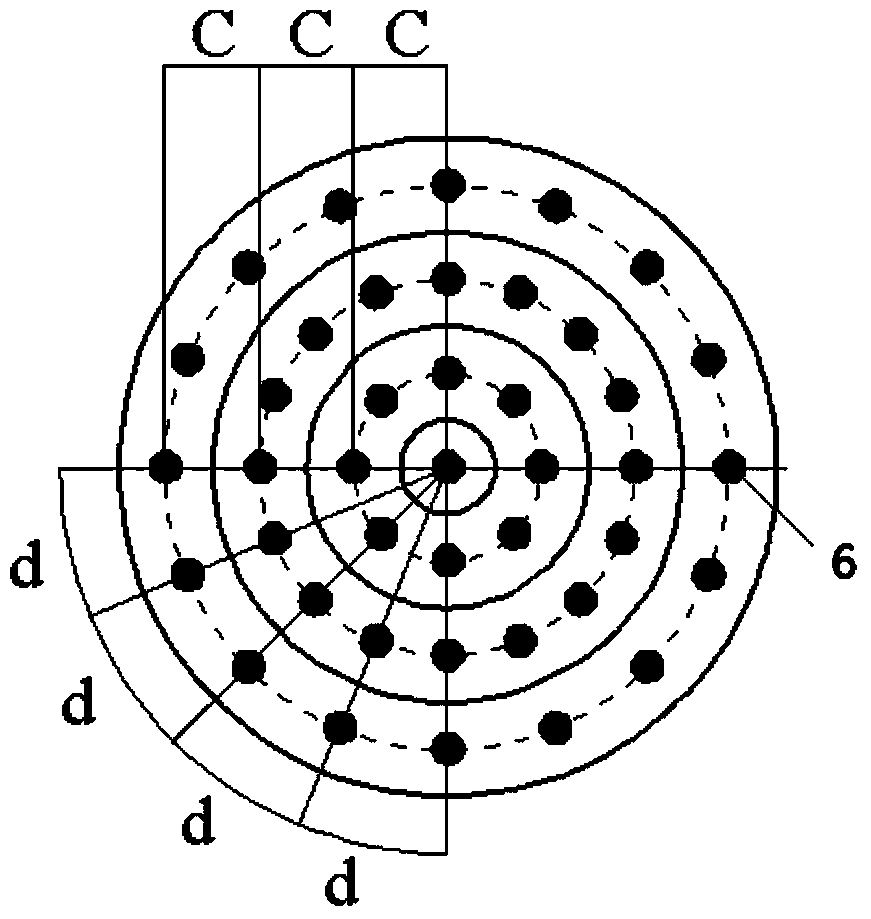

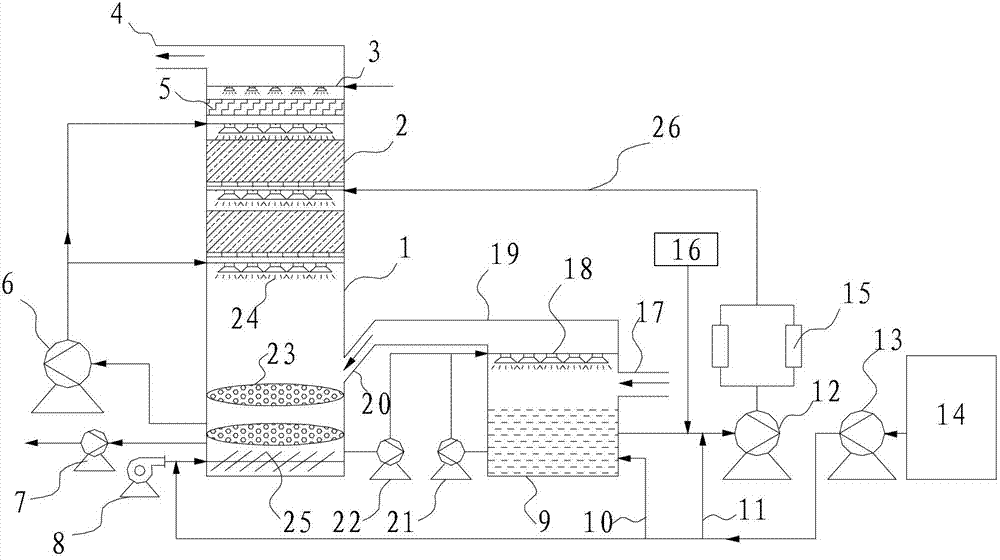

Method and system for purifying flue gas by inducing free radicals by virtue of ozone and hydrogen peroxide

InactiveCN103990365ATo achieve the purpose of removalLow investment costDispersed particle separationEnergy inputPollutionHydrogen peroxide

The invention discloses a method and a system for purifying flue gas by inducing free radicals by virtue of ozone and hydrogen peroxide. The system is characterized in that a flue of a boiler is connected with one end of a flue gas heat exchanger, wherein the other end of the flue gas heat exchanger is connected to the bottom of a spraying washer; an injection hole of an ozone injection system is formed in a pipeline located between the flue gas heat exchanger and the spraying washer; a solution circulating by-pass system is connected with the top end and lower part of the spraying washer, respectively; the bottom of the spraying washer is sequentially connected with a mercury separation system, an ammonification neutralizing system and a product concentrating and crystallizing system; the top of the spraying washer is connected with a chimney through the pipeline and a flue gas waste heat system. According to the method, hydroxyl free radicals with strong oxidizing property are generated in an induction manner after the ozone in the flue gas is contacted with the hydrogen peroxide in spraying liquid; four main pollutants in the flue gas can be simultaneously removed, equipment is simple and reliable, and no secondary pollution is generated in a removal process. The method and the system are novel and have wide application prospects.

Owner:JIANGSU UNIV

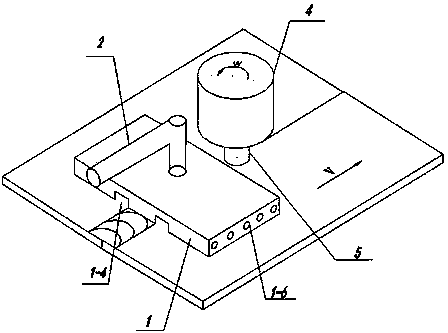

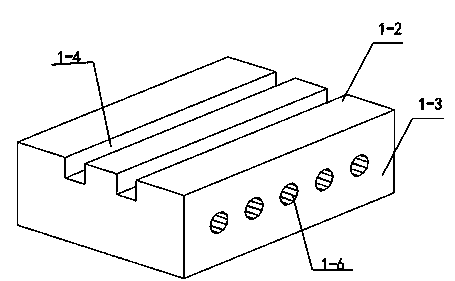

Solid state heat sink device used for friction stir welding and welding method of solid state heat sink device

InactiveCN103639588AImprove performanceReduce unevennessWelding/cutting auxillary devicesAuxillary welding devicesWater channelEngineering

The invention discloses a solid state heat sink device used for friction stir welding and a welding method of the solid state heat sink device. The solid state heat sink device comprises a solid state heat sink, a push rod connected with the solid state heat sink and a cooling water pipe, wherein the solid state heat sink comprises an upper bottom face, a lower bottom face and a side face, heat dissipation through grooves are formed in the lower bottom face, cooling water channels are formed in the side face, the cooling water channels are connected with the cooling water pipe, and an installation hole used for installation of the push rod is formed in the upper bottom face of the solid state heat sink. The solid state heat sink device synchronously moves in the welding direction along with a friction stir welding device, and the lower bottom face makes full contact with the surface of a weldment so that heat conduction can be achieved, heat dissipation and cooling can be conducted on a weld joint which is still at a high temperature, and the peak temperature of the weld joint can be effectively lowered. Meanwhile, cooling water is injected into the water channels formed inside the heat sink to conduct forced heat dissipation and cooling. According to the solid state heat sink device and the welding method, the weld joint can be prevented from being overheated, weld joint crystalline grains are refined, the well-formed formation is improved, residual stress and strain of a welded joint can be eliminated or reduced, and the aims of improving the quality of the weld joint and improving the comprehensive performance of the joint are achieved.

Owner:JIANGSU UNIV OF SCI & TECH

Preparation method of porous slurry green body

The invention relates to a preparation method of a porous slurry green body, belonging to the technical field of ceramic and refractory materials. The method comprises five steps of: foam preparation, slurry blending, foam and slurry mixing, green body pouring and green body maintenance. The invention specifically comprises the following steps of: prefabricating bubbles in advance under the action of compressed air through a foaming device by adopting a physical foaming agent so as to provide fine, uniform and stable bubbles; and mixing high-alumina cement, Suzhou clay, pyrophyllite, lime and calcium carbonate according to a required proportion and then adding water to prepare a prefabricated slurry, wherein in the slurry, the high-alumina cement is used as one of ingredients to provide aluminum oxide and calcium oxide, and meanwhile, the characteristics of fast-solidification and fast-hardening of the high-alumina cement are adopted to accelerate the solidification and the hardening of pouring a green pouring body so as to ensure that on one hand, the bubbles are fixed as soon as possible to reduce bubble loss, and on the other hand, the green body is enhanced to reduce the deformation of the green body. The invention can easily prepare a green body with a drying density of 0.34-0.45kg / m<3>, and the compression strength of a corresponding drying green body is 0.15-0.50MPa.

Owner:NANJING TECH UNIV

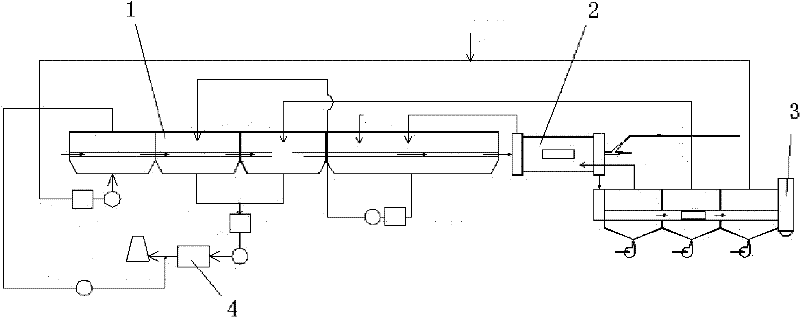

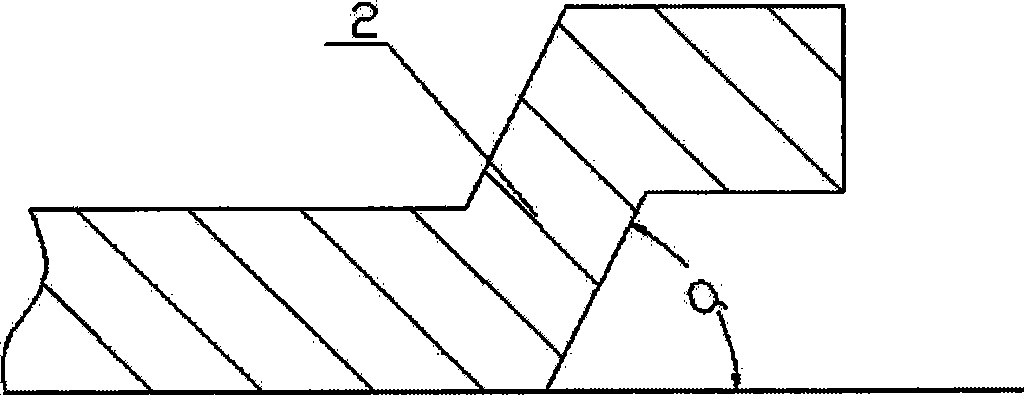

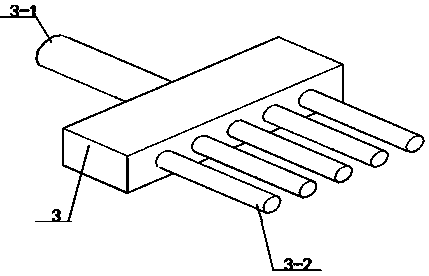

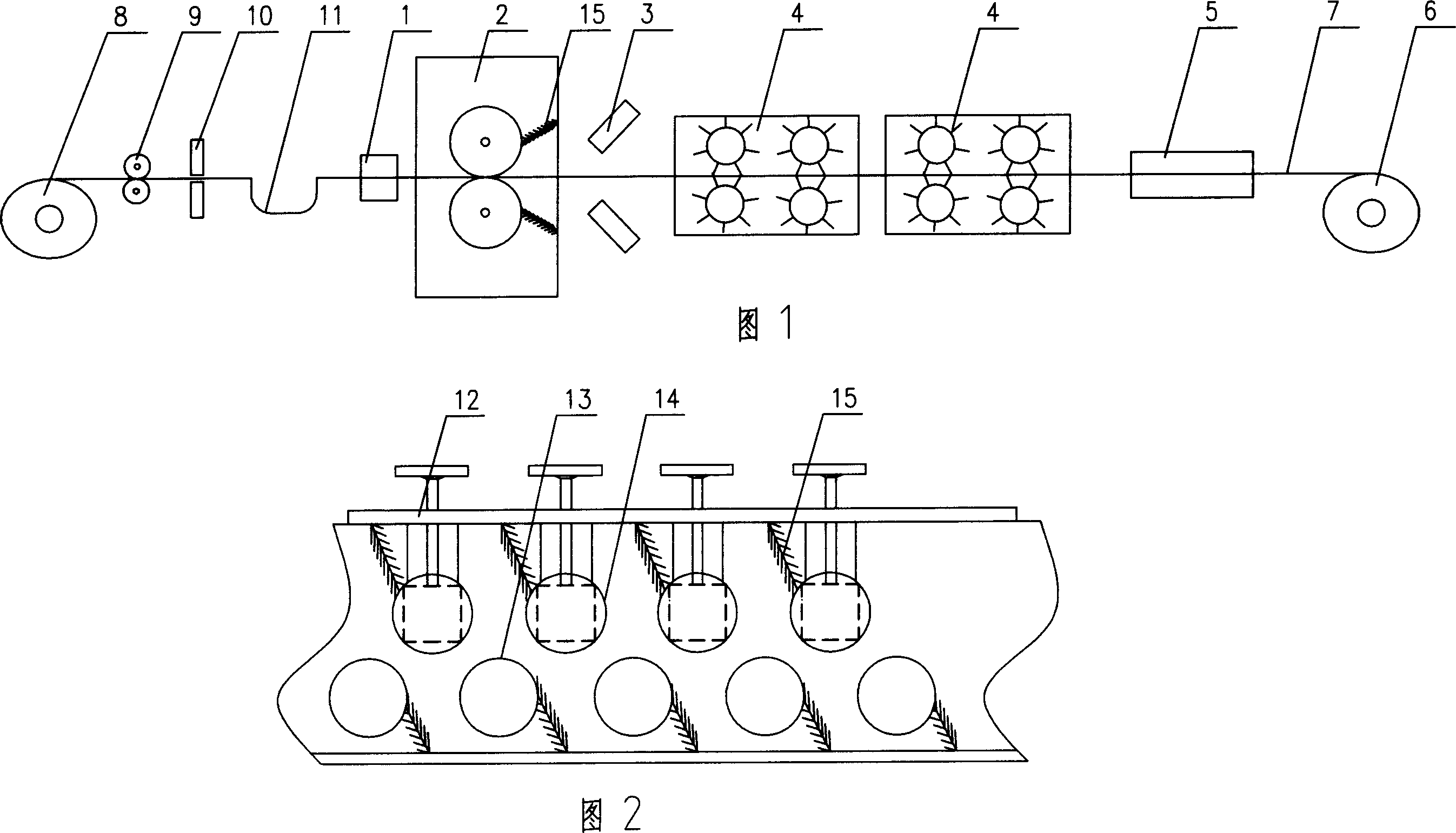

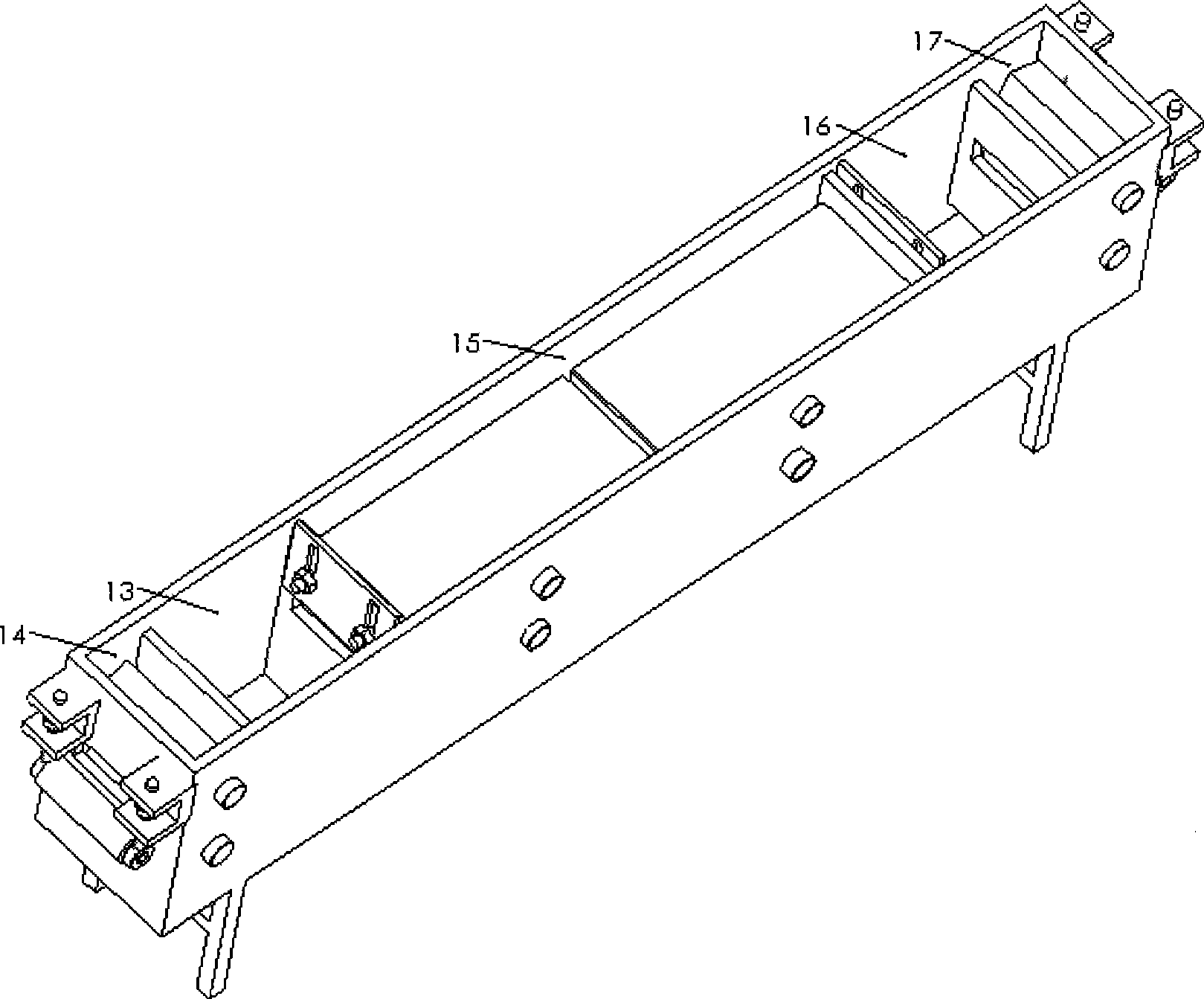

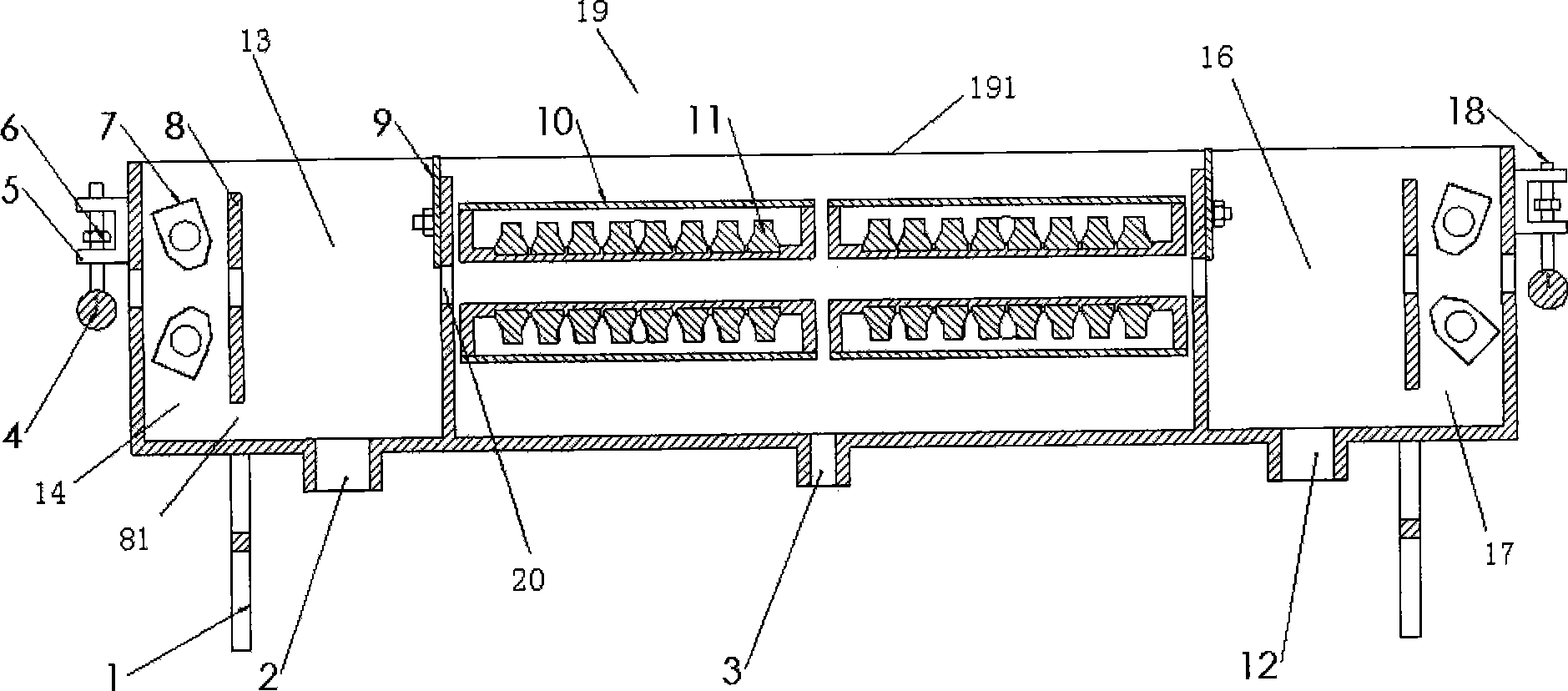

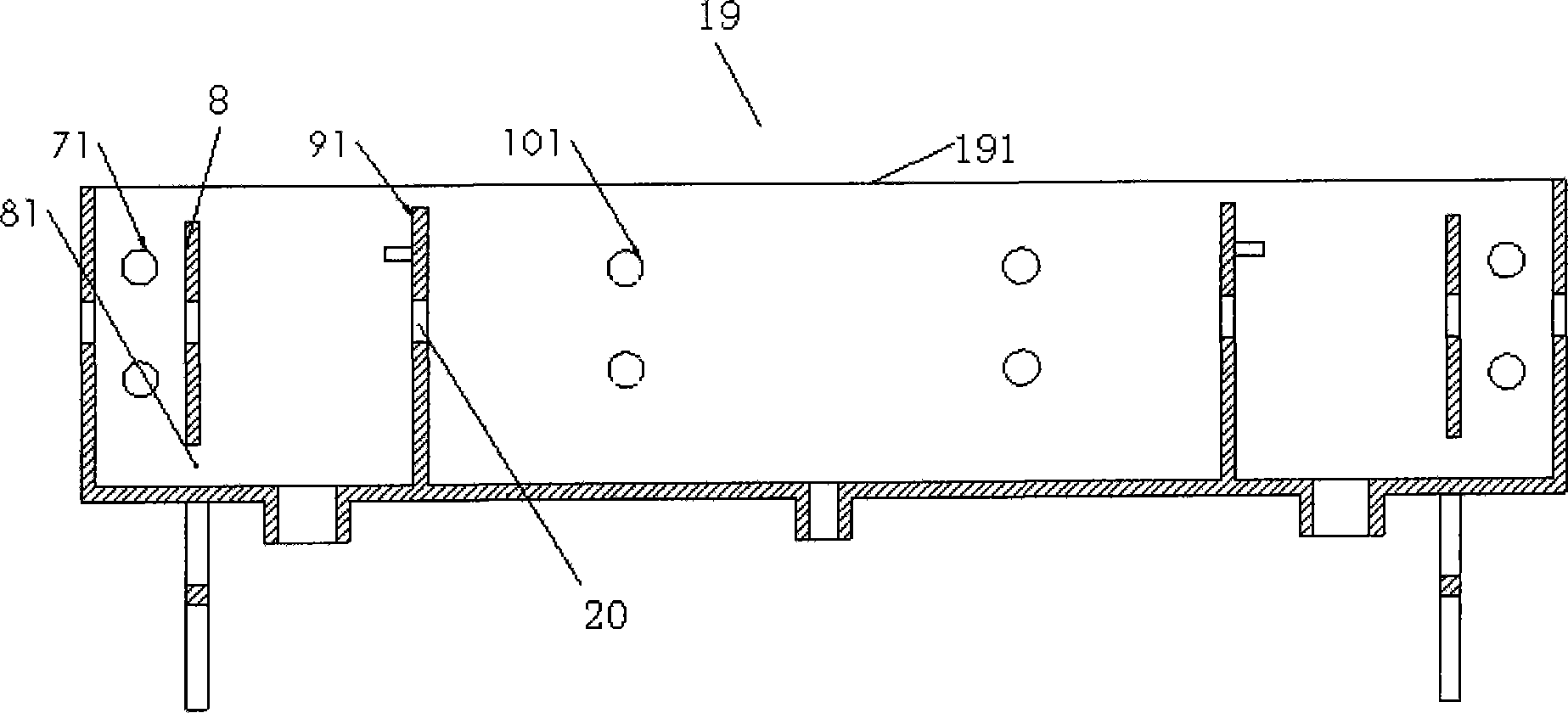

Leveling machine, black strip acid-free derusting device using the same and method thereof

InactiveCN1962105ARust removal achievedEliminate corrosionRoll mill control devicesWork treatment devicesEmulsionEngineering

The invention relates to a flattener, relative thermal rolling band steel non-acid scaling device and method, wherein said flattener comprises a roller cleaner (15) whose end contacts the lower roller and compression lower roller (14); the cleaner (15) can clean the ferric oxide in each rotation of roller, to improve work efficiency. And the scaling device comprises emulsion feeder (1), flattener (2), high-pressure water injector (3), iron brush (4), washing drier (5), and coiling machine (6). The invention can improve the service life and effect of iron brush. And the method comprises that adjusting the injected amount of emulsion to adjust the scaling quality and save cost.

Owner:武钢集团有限公司

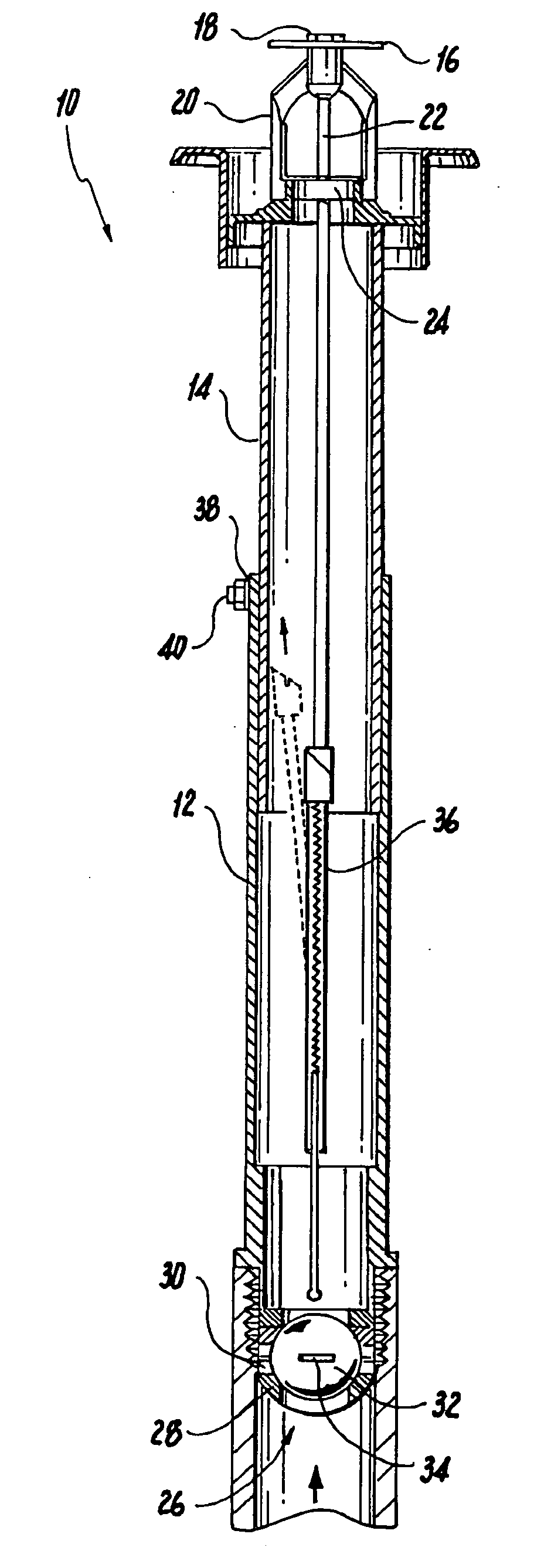

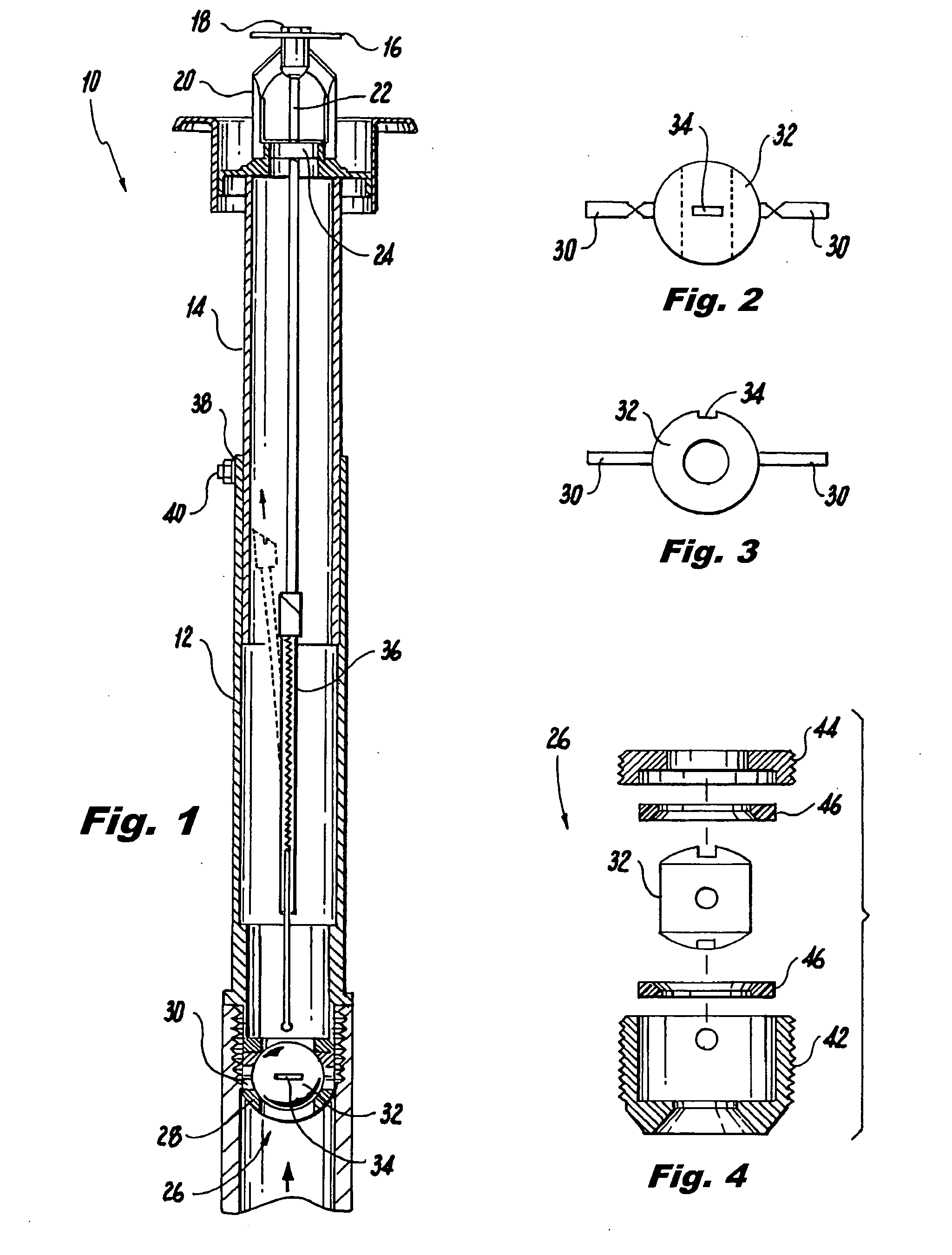

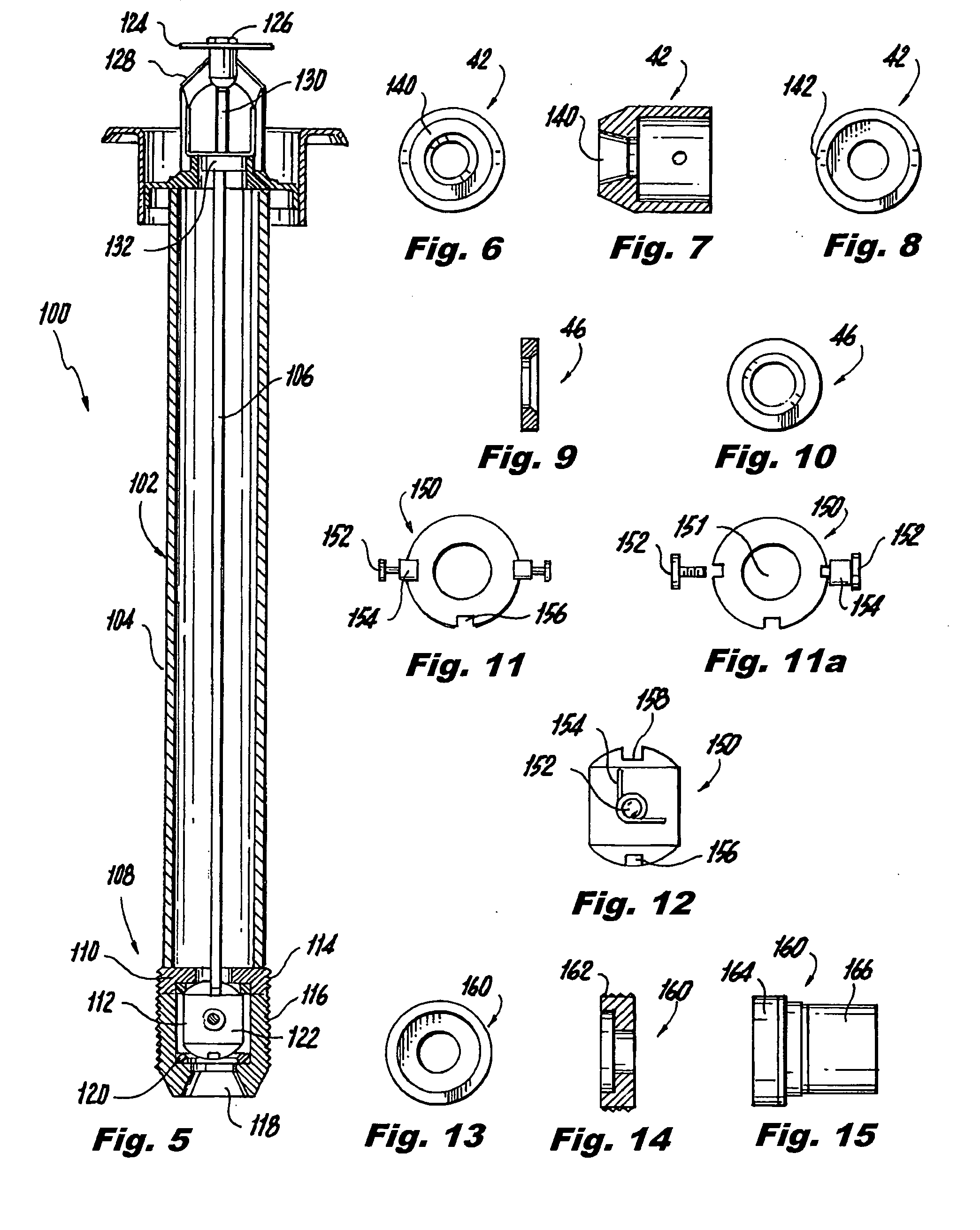

Dry Sprinkler head

Owner:CAPPYS CONCEPTS

Continuous circulating type oil-gas adsorption recovery method

InactiveCN101259358AEasy to realize fully automatic controlEasy to realize remote monitoringDispersed particle separationHigh concentrationRecovery method

The invention discloses a sustained circulating type method for adsorbing and recycling oil gas , which consists of the following steps: (1) adsorbing and recycling the oil gas by means of an active carbon bed in an adsorption tower; (2) the desorption and regeneration of the adsorption tower saturated is carried out; (3) the oil gas desorbed with high concentration enters a recovery tower to be absorbed by the body of liquid meager gasoline; (4) the tail gas in the recovery tower reenters the adsorption tower to be cycled in a sustaining way, wherein, at least two adsorption tanks in the adsorption tower alternately carry out adsorption and desorption generation, thus leading the oil gas adsorption to be carried out in a sustained circulating way, at the same time, the remote monitoring can be realized by using an automatic control program. The sustained circulating type method for adsorbing and recycling oil gas of the invention is characterized by high efficiency, low energy consumption, convenient operation and safe and reliable running.

Owner:BAY ENVIRONMENTAL TECH BEIJING

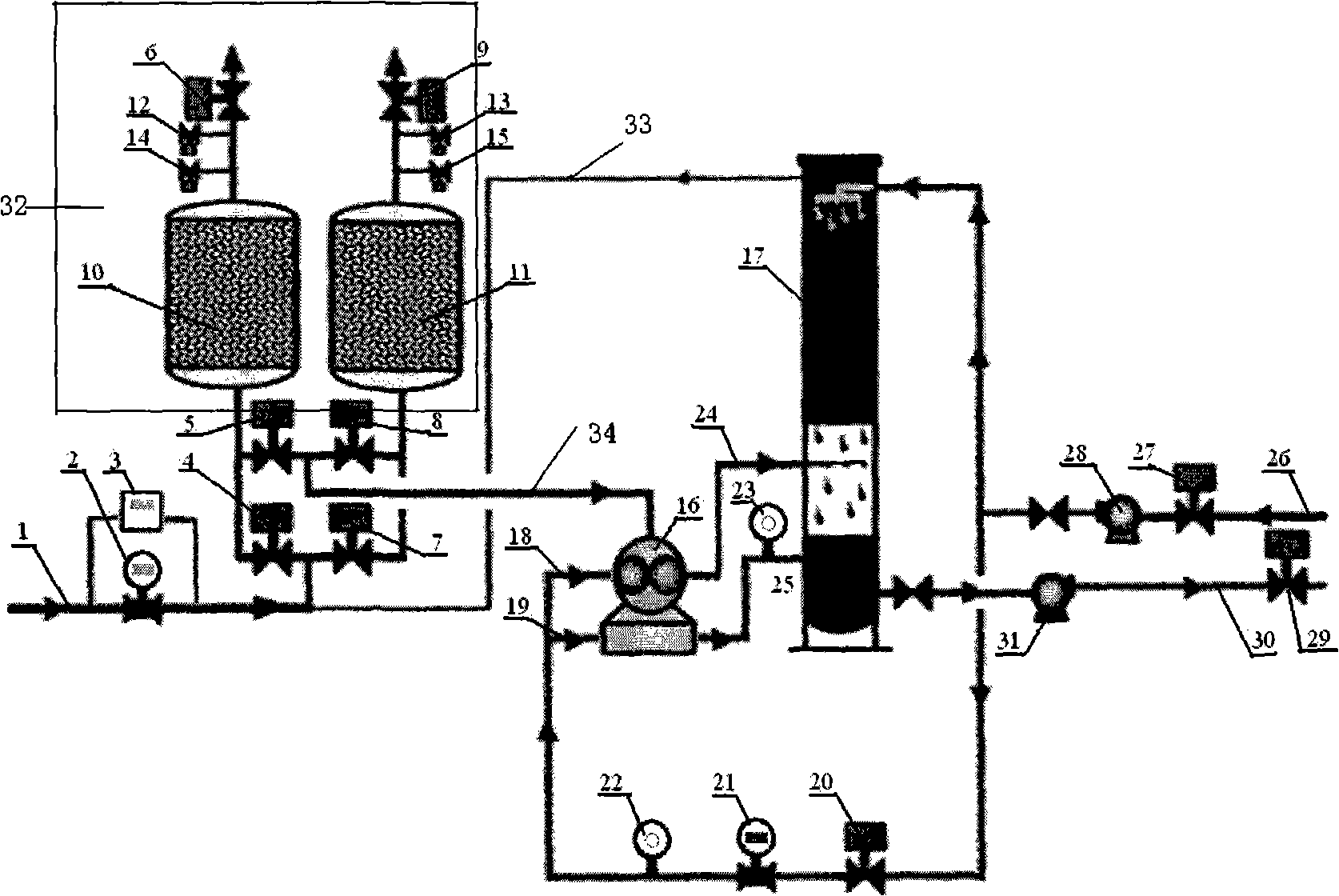

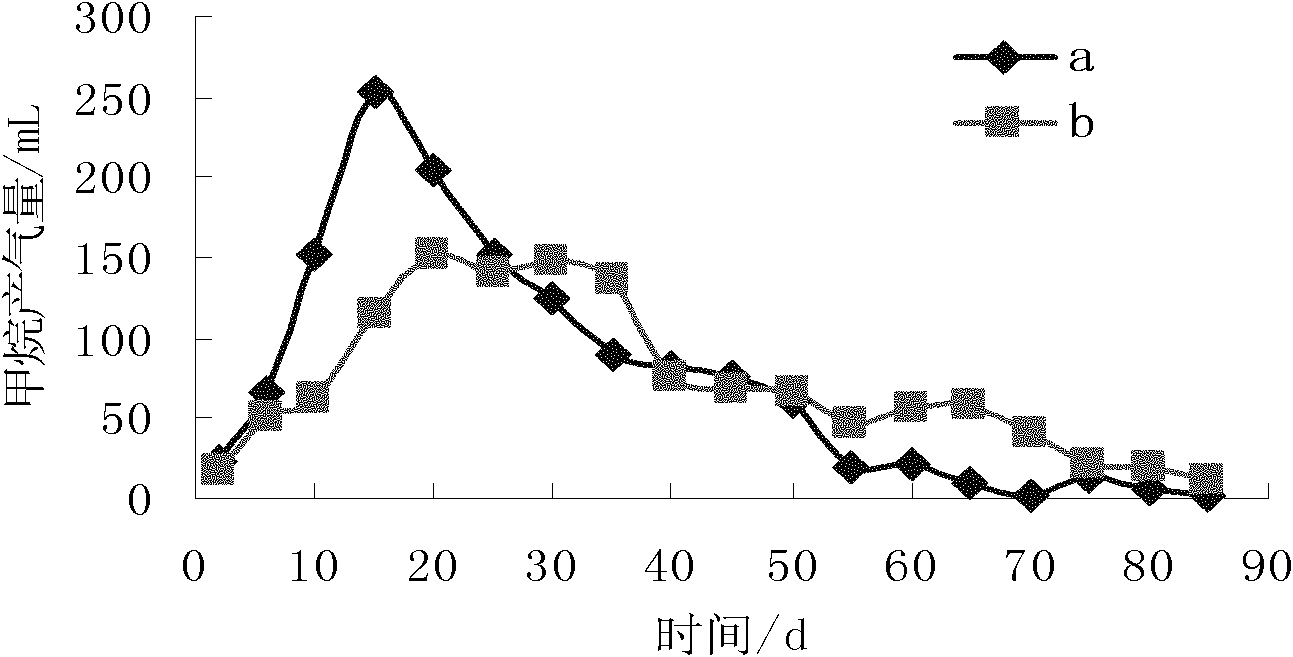

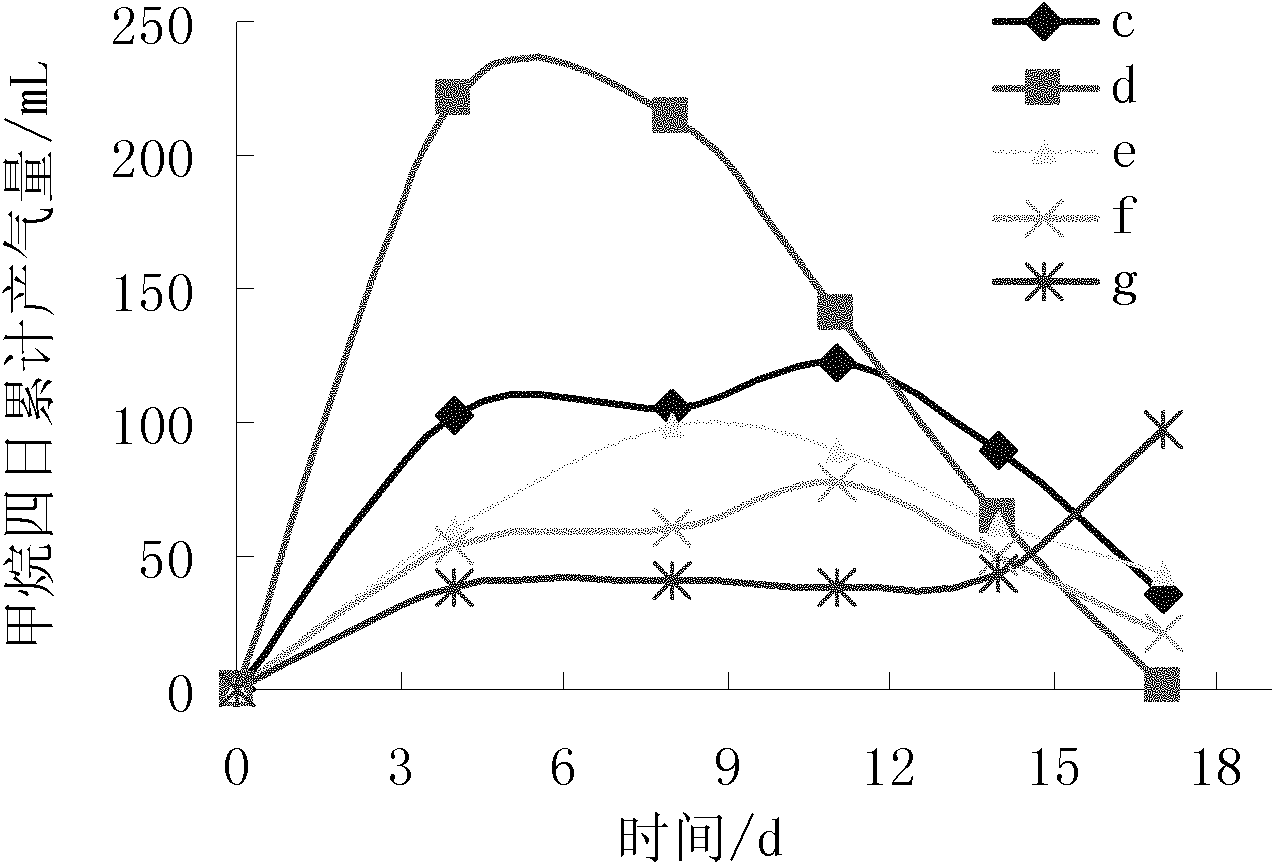

Method for increasing methane production efficiency in organic waste anaerobic process

ActiveCN102140001APromote hydrolysisImprove metabolic activityGas production bioreactorsWaste based fuelGeneration rateFeces

The invention discloses a method for increasing methane production efficiency in organic waste anaerobic process. The method is characterized in that powder containing no less than 15% of free ferric iron oxides is added into an anaerobic biochemical system to be uniformly blended, wherein the anaerobic biochemical system produces methane by utilizing organic wastes; and ferric ions released when microbes reduce the ferric iron oxides in the anaerobic process can promote the activity of anaerobic bacteria such as methane bacteria and the like, thus increasing the production rate and yield of methane by utilizing organic wastes. The method can be widely used for increasing the methane production rate and yield of an energy utilization system for biogas production of municipal domestic waste, agriculture product processing wastes, excess sludge of sewage treatment plants, feces of intensifying raising farms and the like and improves the utilization rate of renewable energy sources of organic wastes.

Owner:HEFEI UNIV OF TECH

Composite modifying alcohol ether fuel and catalytic fuel agent

InactiveCN1944596AImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCombustion

The composite modifying catalyst for alcohol-ether fuel is compounded with zinc peroxide 5-15 weigh portions, dimethyl carbonate 15-35 weigh portions, vat yellow GCN 5-15 weigh portions, cyclohexylamine 3-10 weigh portions, and isooctyl nitrate 15-30 weigh portions, and through mixing at normal temperature. The alcohol-ether fuel with the composite modifying catalyst may have great methanol adding ratio while ensuring the combustion efficiency, fuel consumption, dynamic performance and other indexes.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

Continuous washing device washing groove for band

ActiveCN101428282AReduce mutual interferenceImprove scalabilityDrying solid materials without heatCleaning using liquidsBilateral symmetryCorrosion

The invention discloses a cleaning trough for strip continuous cleaning equipment. The cleaning trough comprises a frame and a trough body arranged on the frame, wherein, a right isolation chamber and a left isolation chamber which are equipped with washing liquid for cleaning strips are arranged on the trough body in a bilateral symmetry manner; a main cleaning chamber used for conducting the ultrasonic cleaning on the upper and the lower surfaces of strips is arranged between the right isolation chamber and the left isolation chamber; strip passing holes for delivering strips are formed in the right isolation chamber and the left isolation chamber; a first water outlet and a second water outlet hole are respectively formed on each of bottom boards of the right isolation chamber and the left isolation chamber; and a water inlet is formed on a bottom board of the main cleaning chamber. The invention adopts the design of a multi-chamber structure to have good isolation function, reduce the mutual interference between the trough bodies, facilitate multi-trough type cleaning, and better utilize the strip cleaning equipment system; and the corrosion to the external parts, which is caused by the washing liquid leakage, is eliminated.

Owner:四川中科百博太阳能科技有限公司

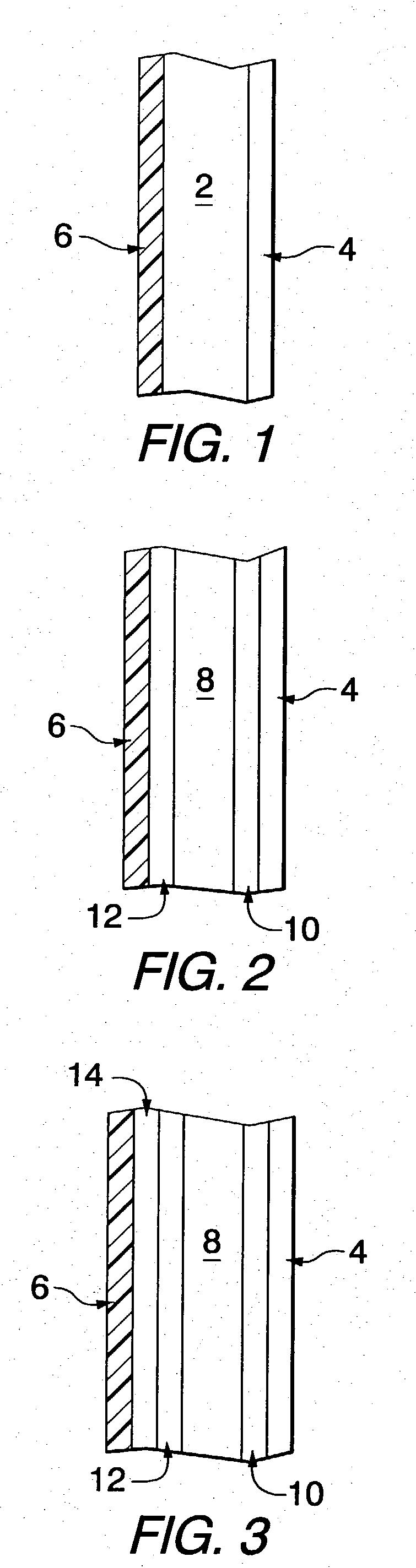

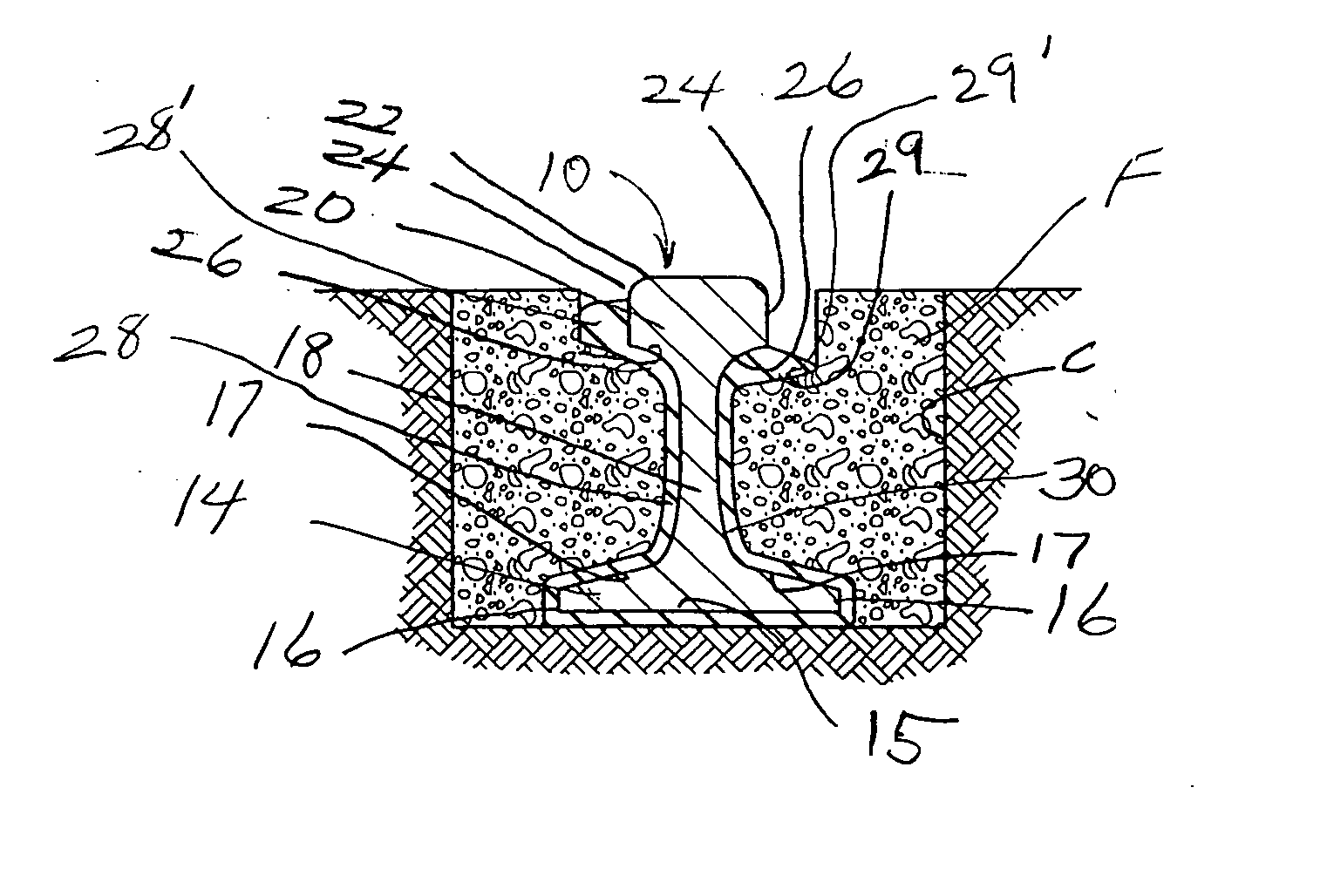

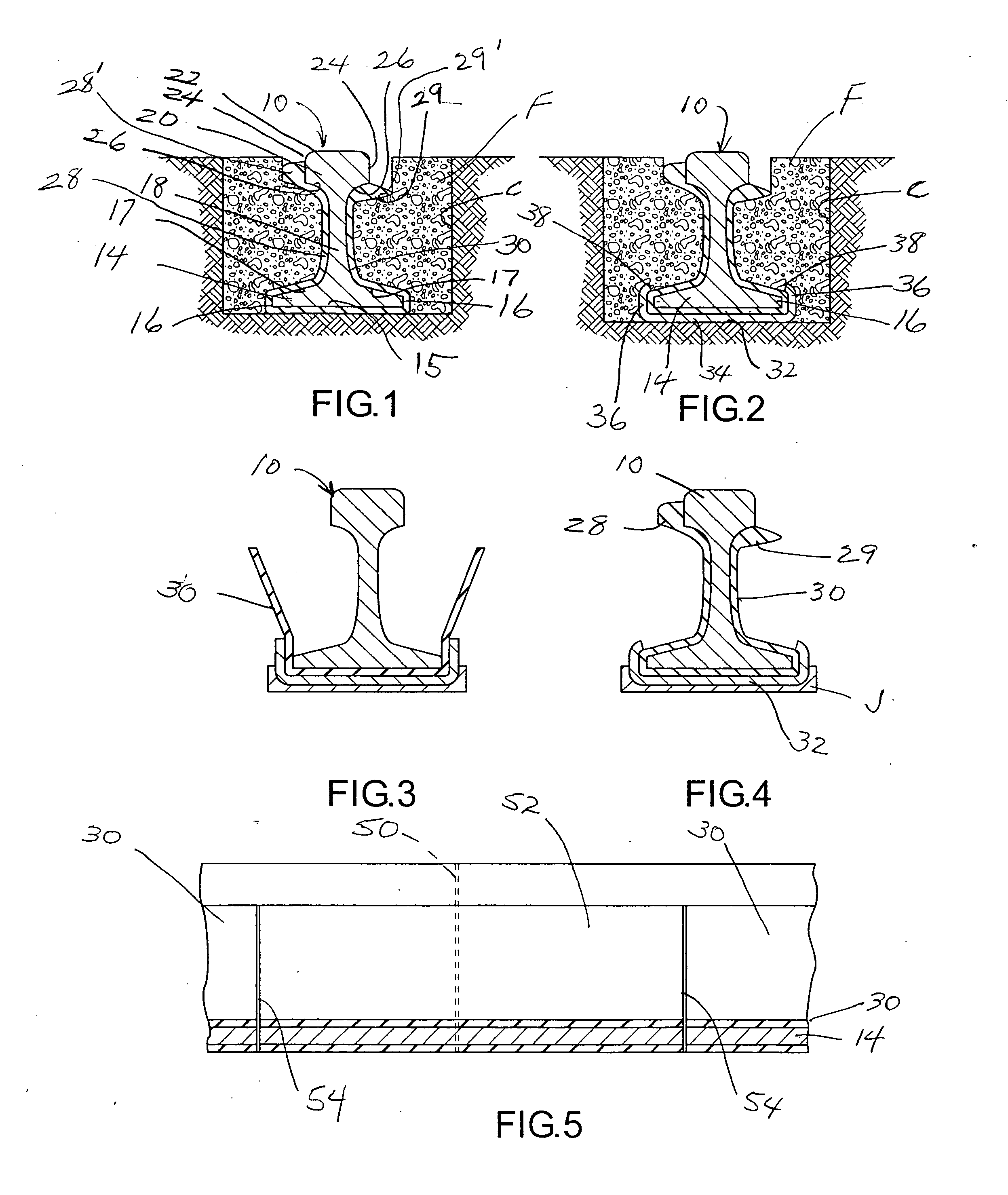

Insulated rail for electric transit systems and method of making same

InactiveUS20070034705A1Eliminate corrosionSimple installationBallastwayTemporary pavingsSkid plateElectricity

A rail cover and support for mounting and insulating the rails of an electric transit system in which the rail cover is vulcanized both to the rail and outer skid support at the manufacturing site prior to delivery to the field and a rail cover completely surrounds both the base flange and web portion of each rail and terminates along the undersides of the top flange. In one form, the upper free ends of the rail cover are increased in thickness to form bumpers along opposite sides of the rail to cushion it against undue shifting or vibration. In fabricating the rail, a sheet dielectric material is vulcanized to the rail with or without a skid plate.

Owner:METROSHIELD

Method for preparing 5-hydroxymethylfurfural by taking cellulose as raw material

ActiveCN101628901AEliminate contamination and corrosionHigh reaction conversion and selectivityOrganic chemistryBulk chemical productionChemistryPre treatment

The invention discloses a method for preparing 5-hydroxymethylfurfural by taking cellulose as a raw material, which comprises the steps of: pretreating a biomass material rich in the cellulose by utilizing acid or alkali, neutralizing the biomass material, filtering to remove hemicellulose and lignin, washing obtained cellulose filter residue with water, and drying the cellulose filter residue; mixing the cellulose filter residue or pure cellulose with the water, loading the mixture into a high-pressure reactor, sealing the high-pressure reactor, and injecting liquid carbon dioxide into the reactor for reaction; and separating supercritical carbon dioxide dissolved with the 5-hydroxymethylfurfural through a separator during the reaction, discharging the 5-hydroxymethylfurfural from the bottom of the separator, and obtaining a 5-hydroxymethylfurfural product through drying, dehydration and crystallization. The method has the advantages of high selectivity, suitable continuous production, high product content, green and environment-friendly process, and easy industrialized production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Neutral blockage removing agent composition used for oil recovery formation in oilfield and preparation method thereof

ActiveCN104194758ALow corrosion rateUnblocking safetyDrilling compositionButanedioic acidSuccinic acid

The invention relates to a neutral blockage removing agent composition used for an oil recovery formation in an oilfield. The neutral blockage removing agent composition is prepared from the following raw materials in parts by weight: 10-14 parts of polyepoxysuccinic acid amine, 35-40 parts of diethylenetriaminepentaacetic acid amine, 33-37 parts of hydroxyl succinic acid amine, 20-25 parts of polyacrylamide, 7-10 parts of sodium polyaspartate, 10-14 parts of sodium gluconate, 10-15 parts of activated clay, 20-25 parts of potassium peroxodisulfate, 9-11 parts of hydroxyl butanedioic acid amine, 4-7 parts of sodium salicylate, 5-9 parts of hexamethylene tetramine, 0.2-0.3 part of vanadium pentoxide, 2-5 parts of starch, 5-8 parts of alpha-sulphonated fatty acid methyl ester and derivative thereof (MES) and 0.1-0.3 part ofdiethyl ethanolamine. The neutral blockage removing agent composition is used for the blockage removal of an oil pumping well and a screw pump well in the oilfield, can effectively solve the problems of cleaning blockage removal of the oil pumping well and the screw pump well in the oilfield and the corrosion of oil recovery equipment, has high blockage removing speed, is neutral and is free of corrosion; waste liquid for blockage removal can be degraded and does not need to be discharged onto the ground to be subjected to sewage treatment, no corrosion, dead angle, precipitation or secondary well blockage are generated, and more safety and more reliability are realized as compared with traditional pickling blockage removing, biological blockage removing and solvent blockage removing.

Owner:兰州熙瑞化工科技有限公司

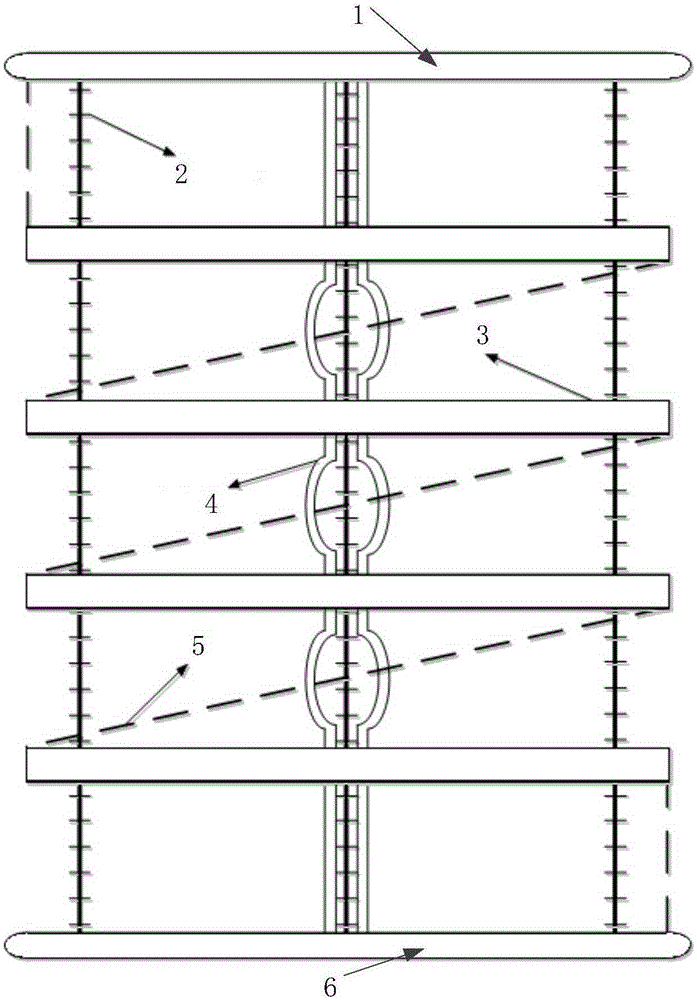

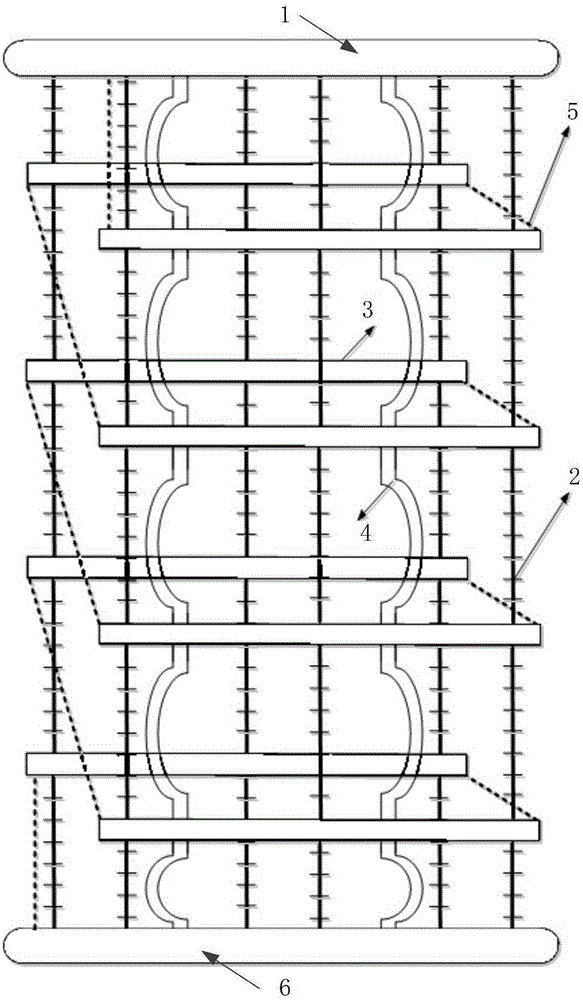

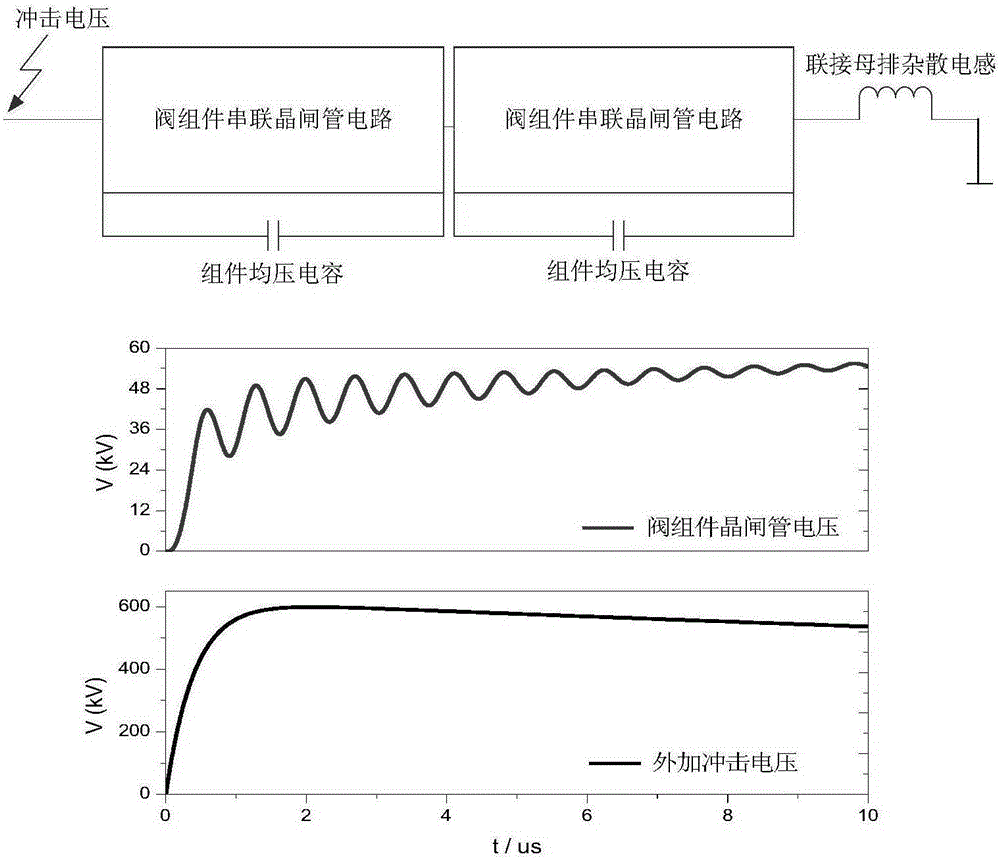

High-voltage DC transmission converter valve single-row valve tower

ActiveCN105207498ASimple structureImprove space utilizationElectric power transfer ac networkAc-dc conversionStructural engineeringMechanical engineering

The invention provides a high-voltage DC transmission converter valve single-row valve tower which comprises a top shielding cover, a bottom shielding cover and a converter valve arranged between the top shielding cover and the bottom shielding cover, wherein the top shielding cover and the bottom shielding cover are arranged horizontally. The converter valve is connected with the top shielding cover and the bottom shielding cover through suspension insulators. The converter valve is formed by connecting converter valve modules, forming an inclination angle with the horizontal direction, in series in sequence in the vertical direction in the form of a zigzag rule. The high-voltage DC transmission converter valve single-row valve tower is more compact in overall structure and more reasonable in layout, and meanwhile, better solves the problems of high-frequency oscillation due to cooling water circuit insulation and connecting busbar inductance, reduces operational risks, and meets the design requirement for higher voltage and current level of the (ultra) high-voltage DC transmission converter valve.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Method for preparing biodiesel by utilizing high-acid value oil

InactiveCN103173293ALow acid valueNo post-processingFatty acid esterificationBiofuelsMonoglyceridePtru catalyst

The invention relates to a method for preparing biodiesel by utilizing high-acid value oil. The method comprises the following steps of: esterifying the raw materials of the high-acid value oil, enabling glycerol and the raw materials of the high-acid value oil to esterify with each other under the catalyzing action of an ionic liquid, and thus obtaining a mixture of a low-acid value esterification product-monoglyceride, diglyceride or triglyceride; then carrying out interesterification on the esterified oil, namely carrying out interesterification on the mixture of the low-acid value esterification product-monoglyceride, diglyceride or triglyceride and methanol under the action of a base catalyst, and thus generating crud low-acid value biodiesel fatty acid methyl ester; and vacuum distilling and refining the low-acid value biodiesel fatty acid methyl ester so as to obtain the high-purity low-acid value fatty acid methyl ester biodiesel. The details of the method are described in a specification. The method has the advantages that the method does not need post treatment and is shortened in reaction process, lowered in technological energy consumption and clean in process, equipment corrosion caused by conventional sulfuric acid catalyzing is eliminated, the equipment investment and production cost are lowered, and the yield of a target product-biodiesel (fatty acid methyl ester) is high.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

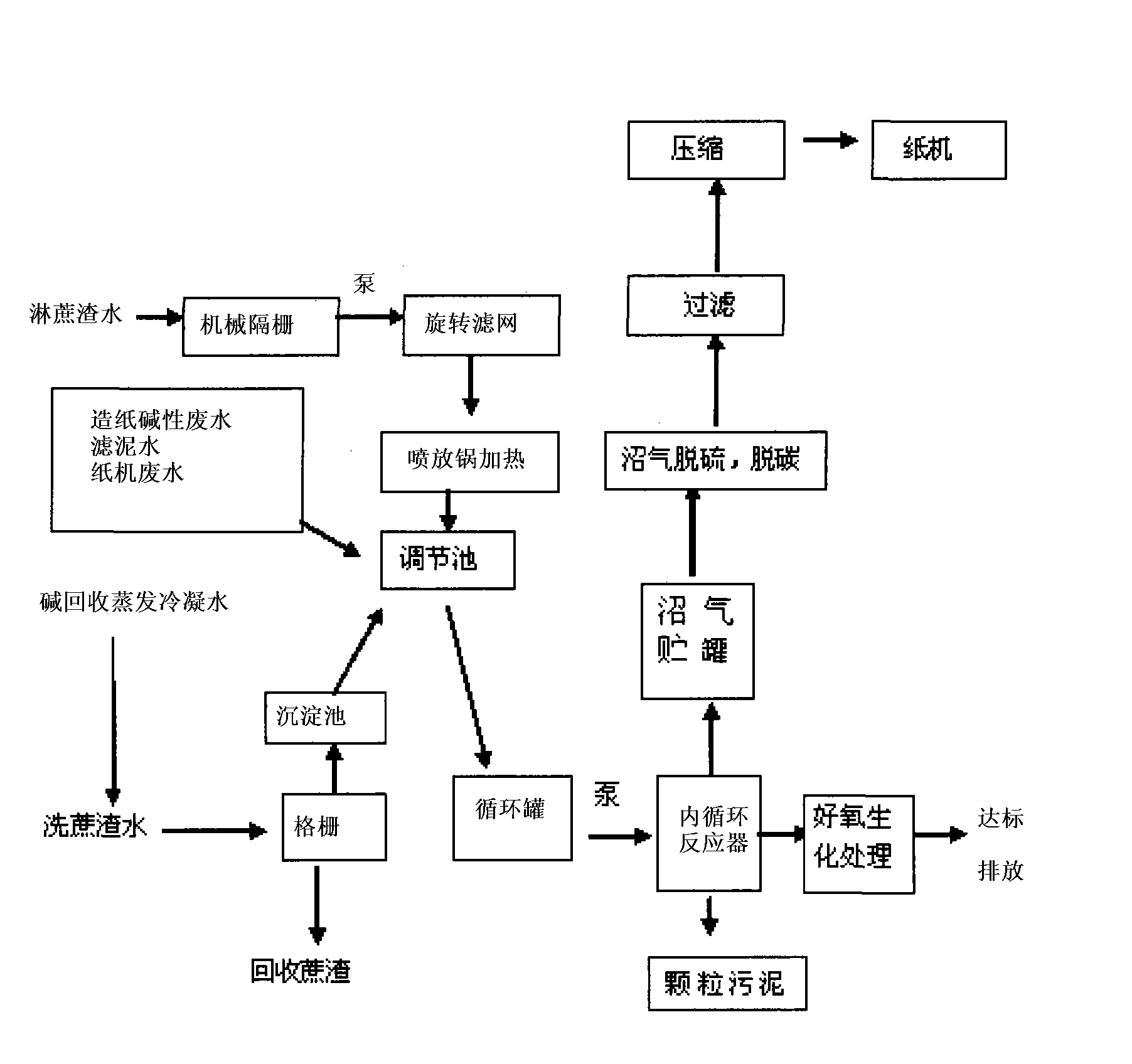

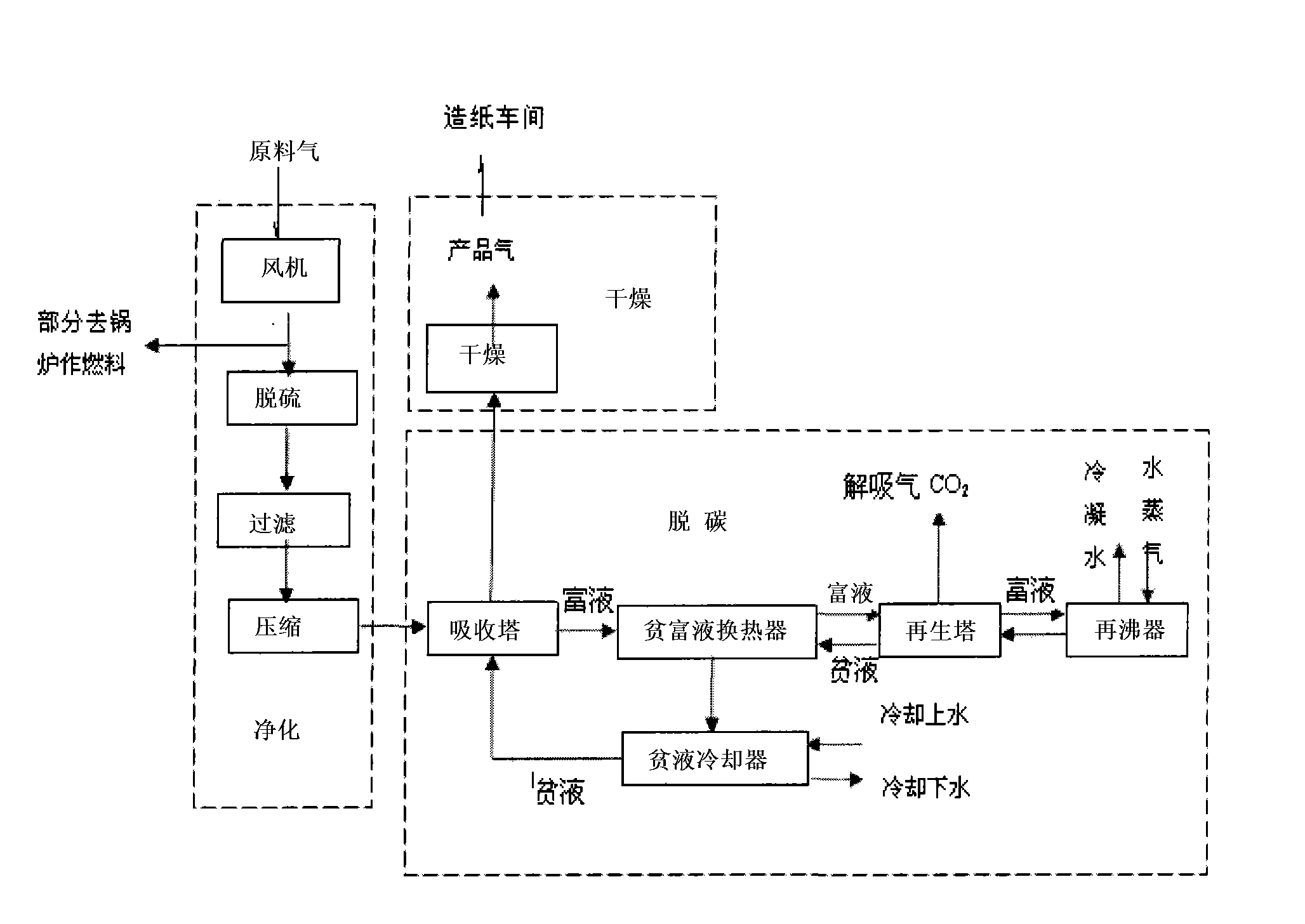

Method for comprehensive treatment of wastewater and sludge gas utilization of cane sugar factory

InactiveCN101492222AEliminates corrosive and pollutingHigh calorific valueSulfur preparation/purificationSewage/sludge fertilisersFertilizerChemistry

The invention discloses a method for treating cane sugar factory wastewater comprehensively and using methane, which comprises the following steps: removing fibers and depositing coarse dregs in pretreated bagasse spray water, bagasse washing water, lime sludge filtered water, part of cooling water, papermaking alkaline wastewater, alkali reclaiming vaporization condensation water, and part of paper machine wastewater after reclaiming white slime of a cane sugar factory; mixing and properly heating all the water and delivering the mixture into an anaerobic reactor to perform anaerobic reaction; desulfurizing, decarburizing, purifying, filtering and compressing the obtained methane, and using the methane for heating a paper machine; and performing aerobic biochemical treatment on the sewage generated by the reaction in the anaerobic reactor so that the sewage reaches the discharge standard and is discharged, wherein sludge can be applied to preparing an organic compound fertilizer. The method can treat the sewage of the cane sugar factory comprehensively, can reclaim part of energy generated in the process of the wastewater treatment and apply the energy to production, thereby greatly reducing the production cost and bringing about better economic benefits and social benefits.

Owner:GUANGXI YUEGUI GUANGYE HOLDINGS CO LTD

Ammonia flue gas desulfuration and denitration combined process and device

InactiveCN103041678APromote denitrificationImprove denitrification efficiencyUsing liquid separation agentPerfluorocarbons/hydrofluorocarbons captureFomesChemistry

The invention discloses an ammonia flue gas desulfuration and denitration combined process and device. The process comprises the following steps: liquid ammonia is fed into a desulfurization tower, flue gas to be processed is sprinkled and pre-washed and then fed into the desulfurization tower for sprinkling desulfuration and denitration, and the flue gas subjected to sprinkling desulfuration and denitration is demisted and dried and then discharged out of the desulfurization tower; cleaning solution in a prewashing tower and for sprinkling and washing comes from serous fluid in a tower kettle of the desulfurization tower, and meanwhile, liquid ammonia is injected into the prewashing tower to adjust the pH value of the cleaning solution to be 2-4.5; and the cleaning solution in the prewashing tower is led out and added with lime milk, liquid ammonia is injected into the cleaning solution added with lime milk to adjust the pH value to be 6.0-7.5, and then the mixture is filtered and returned to a sprinkling layer of the desulfurization tower to sprinkle and wash the flue gas. The flue gas denitration efficiency, the natural oxidation rate of (NH4)2SO3 and the purity of the by-product (NH4)2SO4 are all improved to a larger extent; and corrosion of the serous fluid to the desulfuration system is eliminated and the service life of the desulfuration equipment is prolonged.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Dechlorinated alkali residue solidified soil for road engineering

The invention discloses dechlorinated alkaline residue solidified soil for road engineering. The dechlorinated alkaline residue solidified soil comprises components in percentage by weight as follows: 8%-20% of a curing agent, 45%-55% of dry soil and 35%-40% of water, wherein the curing agent comprises components as follows: flue gas desulfurization gypsum, dechlorinated alkaline residues, coal powder ash, slag and an activator; the dry soil is obtained by grinding dried silt clay. According to the dechlorinated alkaline residue solidified soil for road engineering, the alkaline residue pretreatment technology is effectively developed, the silt clay with poor engineering properties is improved into engineering construction soil, and sustainable resource utilization is realized.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

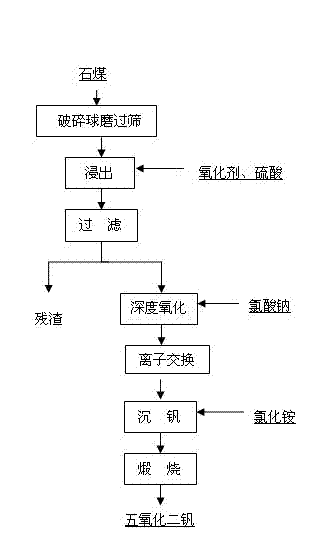

Process for leaching vanadium out of stone coal by using oxidant and sulfuric acid

InactiveCN102899487AEliminate pollutionImprove leaching rateProcess efficiency improvementIon exchangeCrushed stone

The invention discloses a process for leaching vanadium out of stone coal by using an oxidant and sulfuric acid. The process comprises the following steps of: crushing the stone coal, ball-grinding and sieving the crushed stone coal, leaching by using the oxidant and the sulfuric acid, deeply oxidizing, carrying out ion-exchange, carrying out molybdenum precipitation with an ammonium salt, calcining and the like to prepare a V2O5 product. The process is characterized in that the oxidant is a nitrite such as NaNO2, KNO2 and Ca(NO2)2, the consumption of the oxidant is 0.5-15 percent of the weight of stone coal mineral powder, the leaching rate of vanadium is above 95 percent, and the recycling rate of the vanadium is more than 80 percent. Compared with the traditional process for leaching the vanadium, the process has the advantage that the leaching rate of the vanadium is increased by 10-25 percent. The process has the advantages of eliminating pollution of Cl2 and HCl gases to the environment, saving energy resources, and greatly increasing leaching rate and recycling rate of the vanadium because a technology of leaching vanadium by using oxidized acid is adopted and a roasting process is eliminated.

Owner:JISHOU UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com