Continuous washing device washing groove for band

A technology for cleaning equipment and cleaning tanks, which is applied to lighting and heating equipment, cleaning methods and utensils, and cleaning methods using liquids. Expansion, good anti-washing liquid diarrhea effect, good isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

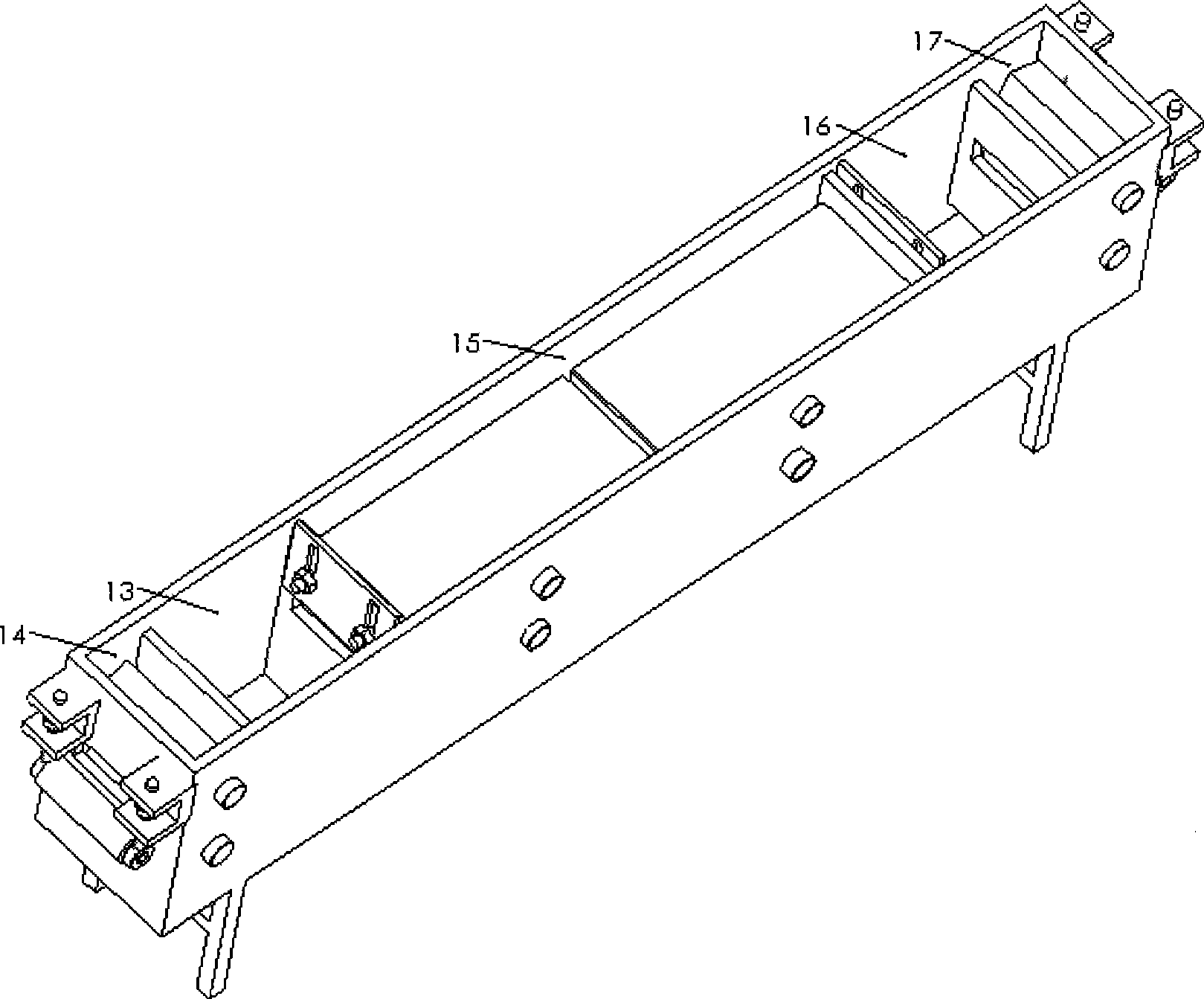

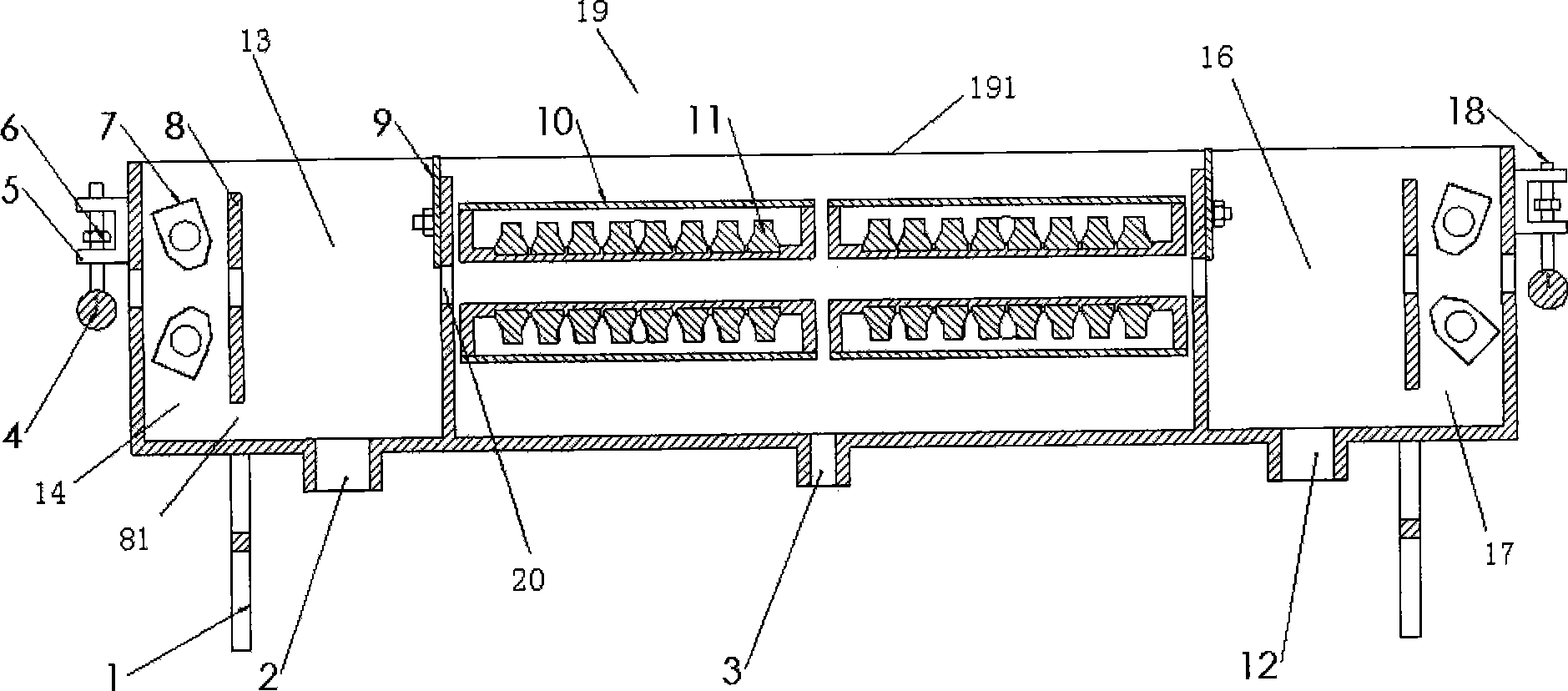

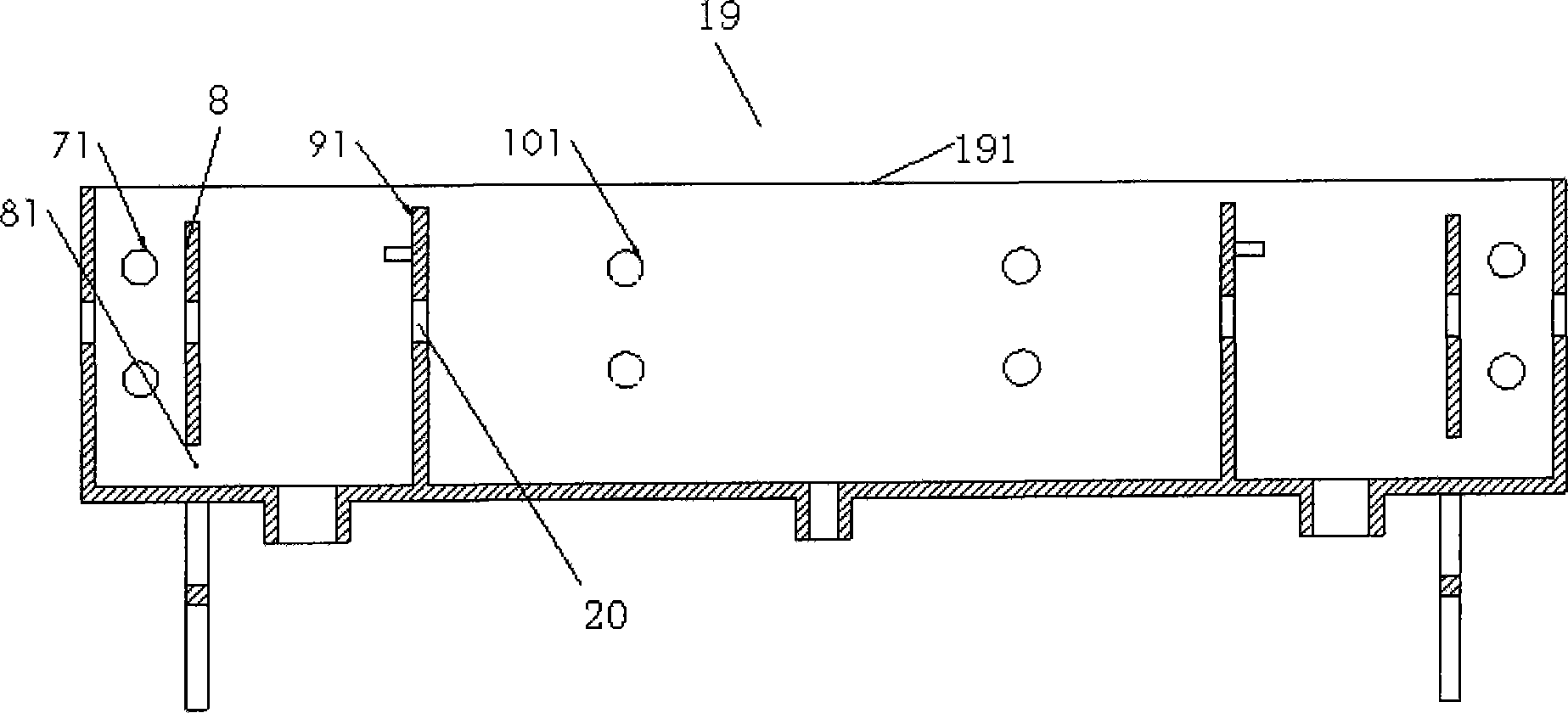

[0025] see figure 1 , figure 2 with Figure 4 As shown, a cleaning tank of continuous strip cleaning equipment consists of five chambers, including two wind shear chambers, two isolation chambers and a main cleaning chamber. The specific composition is as follows:

[0026] Including a frame 1 and a tank body 19 located on the frame 1; on the tank body 19, a right isolation chamber 13 and a left isolation chamber 16 for loading cleaning liquid to clean the strip are symmetrically arranged. Between the right isolation chamber 13 and the left isolation chamber 16, a main cleaning chamber 15 for ultrasonically cleaning the upper and lower surfaces of the strip is provided, and in the right isolation chamber 13 and the left isolation chamber 16, a main cleaning chamber 15 for conveying the strip is provided. The first water outlet 2 and the second water outlet 12 are respectively provided on the strip through hole 20 and the base plate, and the water inlet 3 is provided on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com