Patents

Literature

35results about How to "Rust removal achieved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

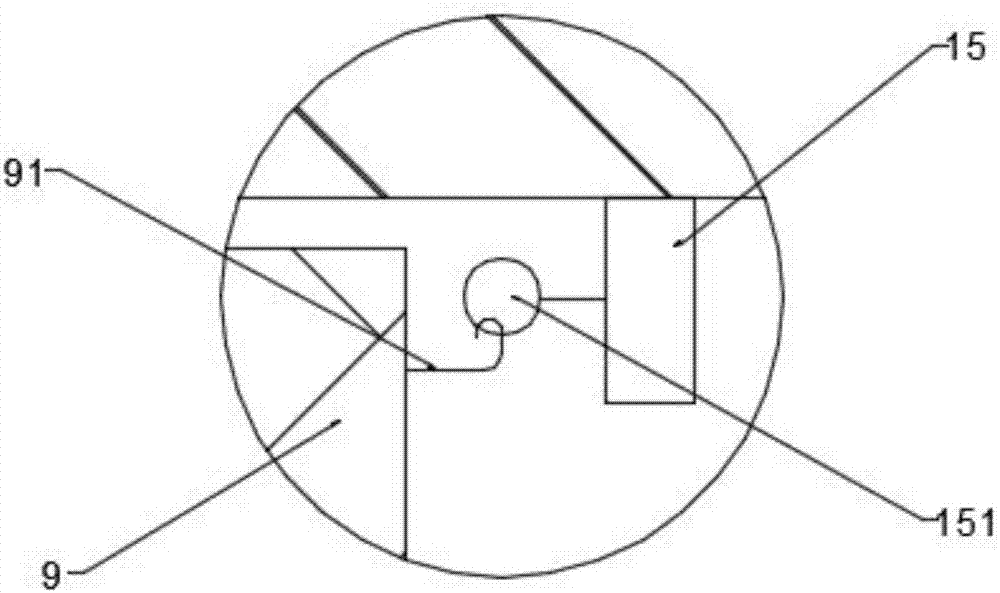

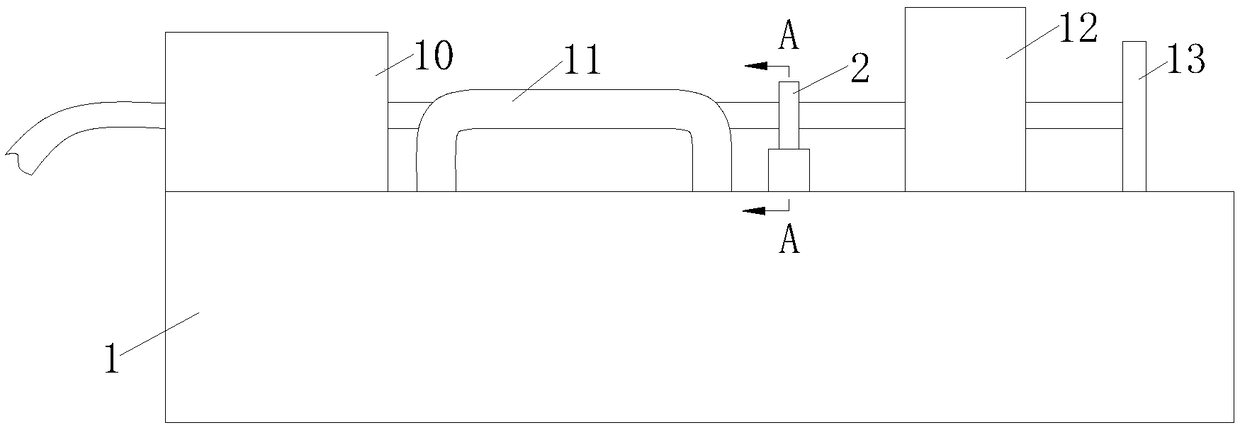

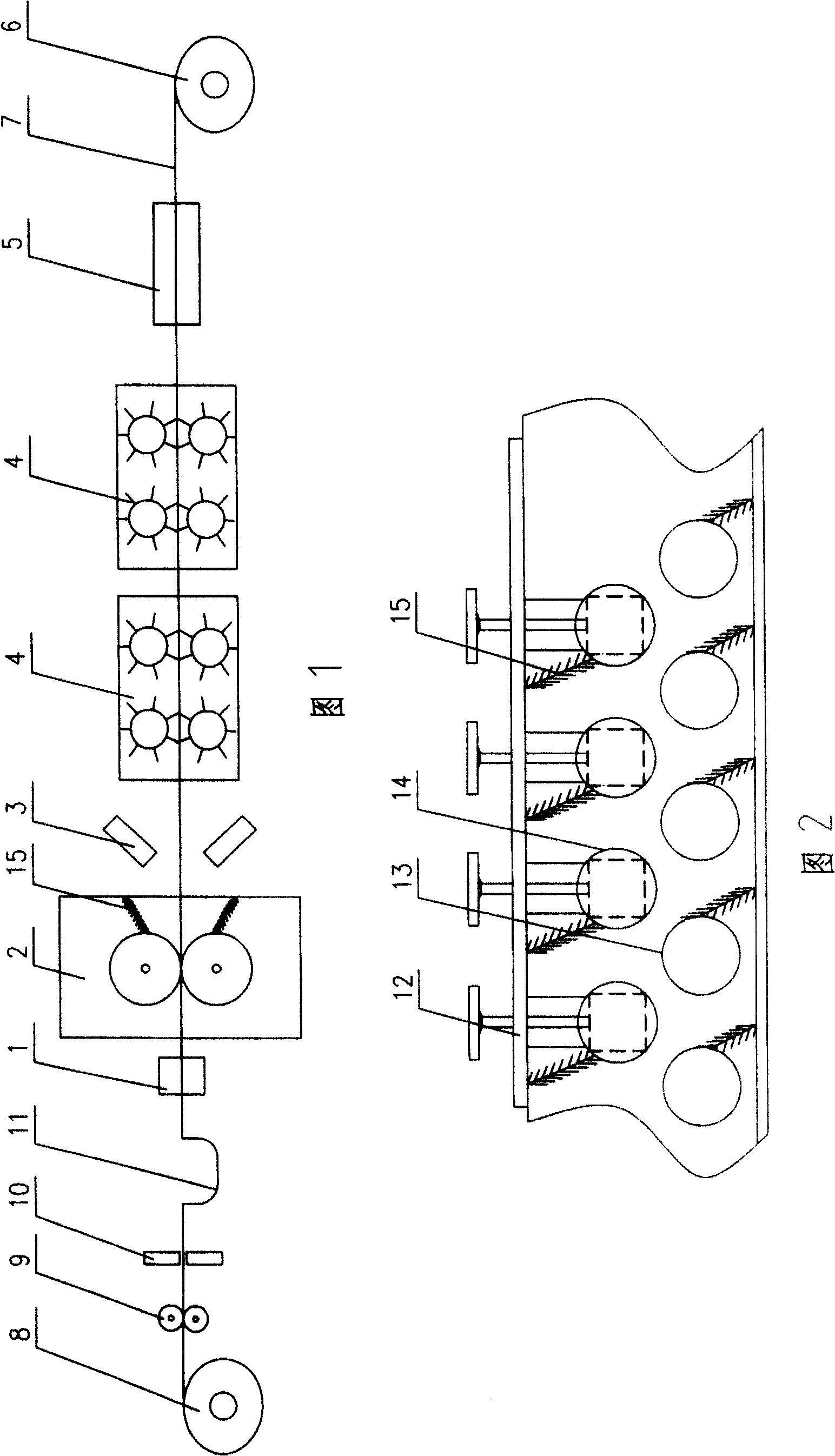

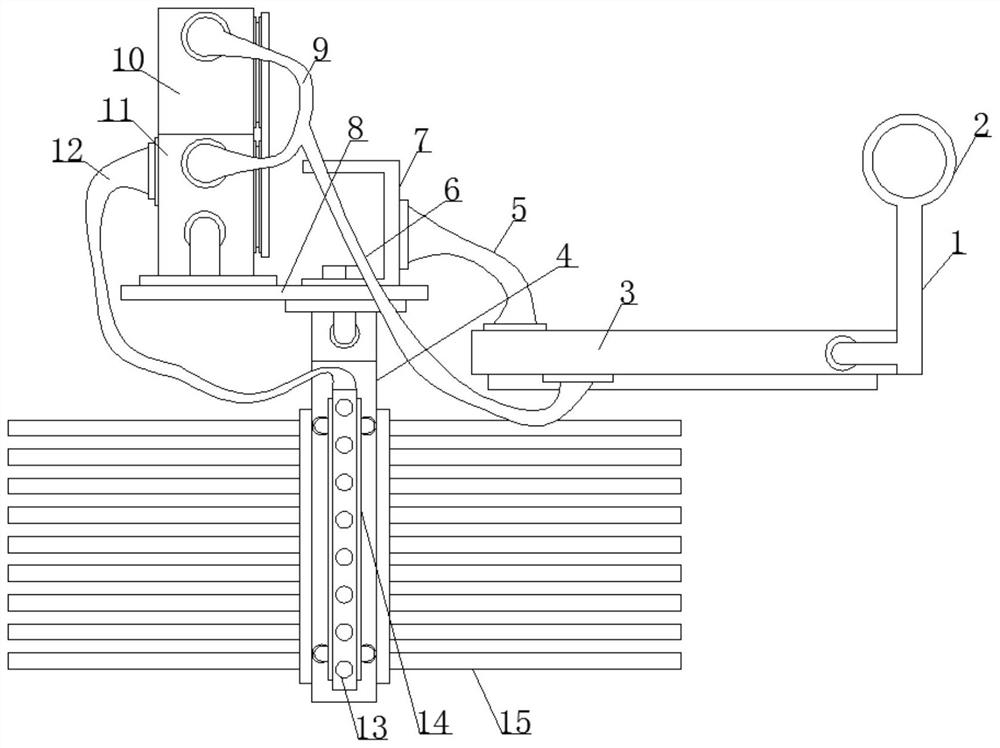

Leveling machine, black strip acid-free derusting device using the same and method thereof

InactiveCN1962105ARust removal achievedEliminate corrosionRoll mill control devicesWork treatment devicesEmulsionEngineering

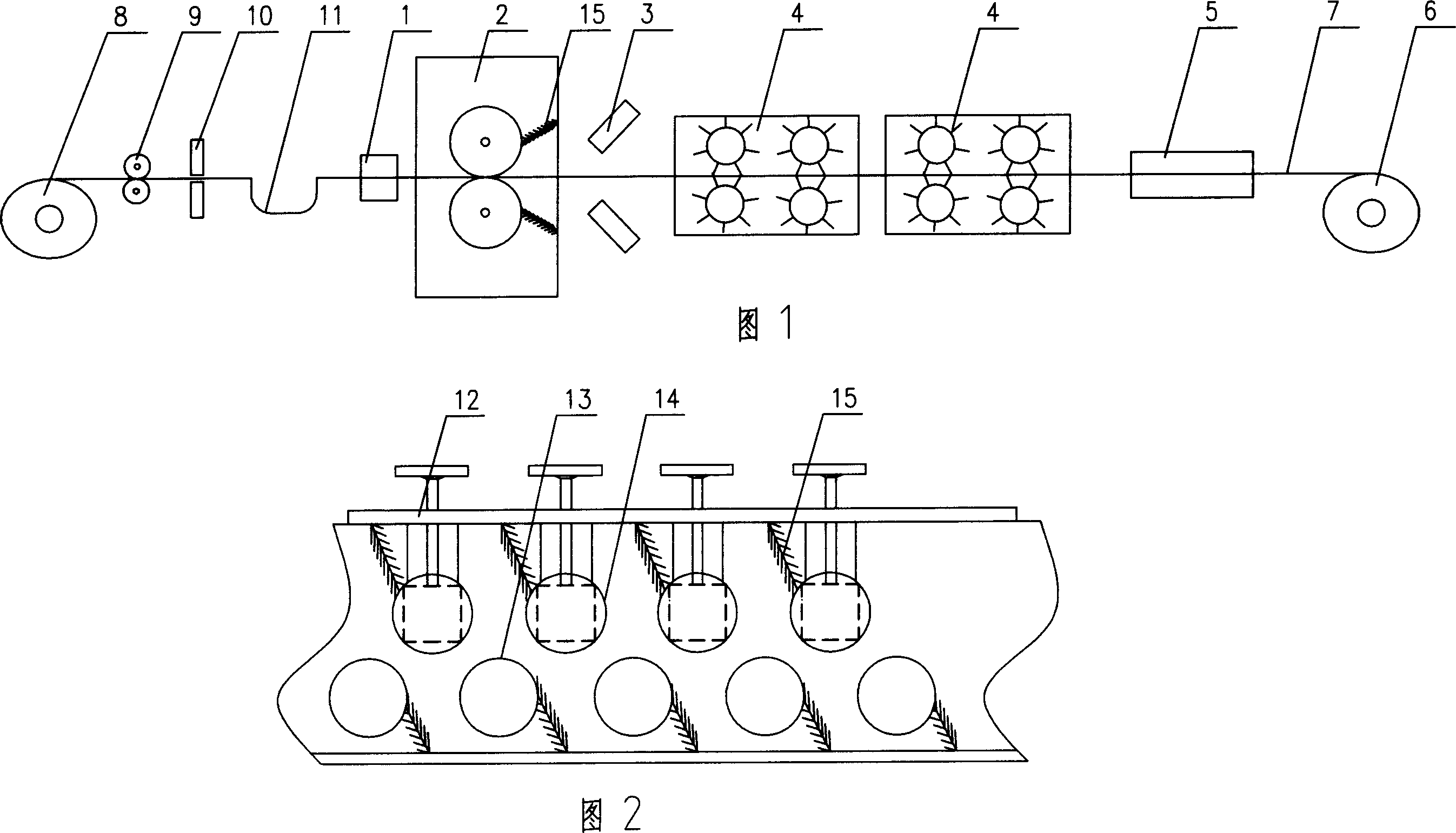

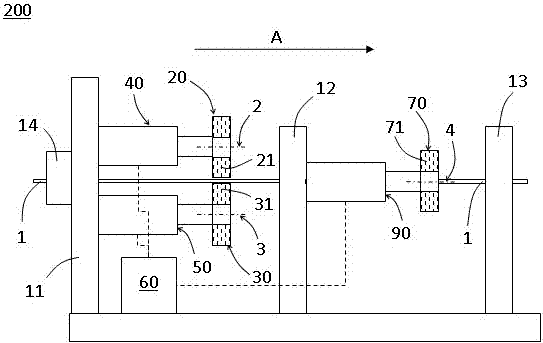

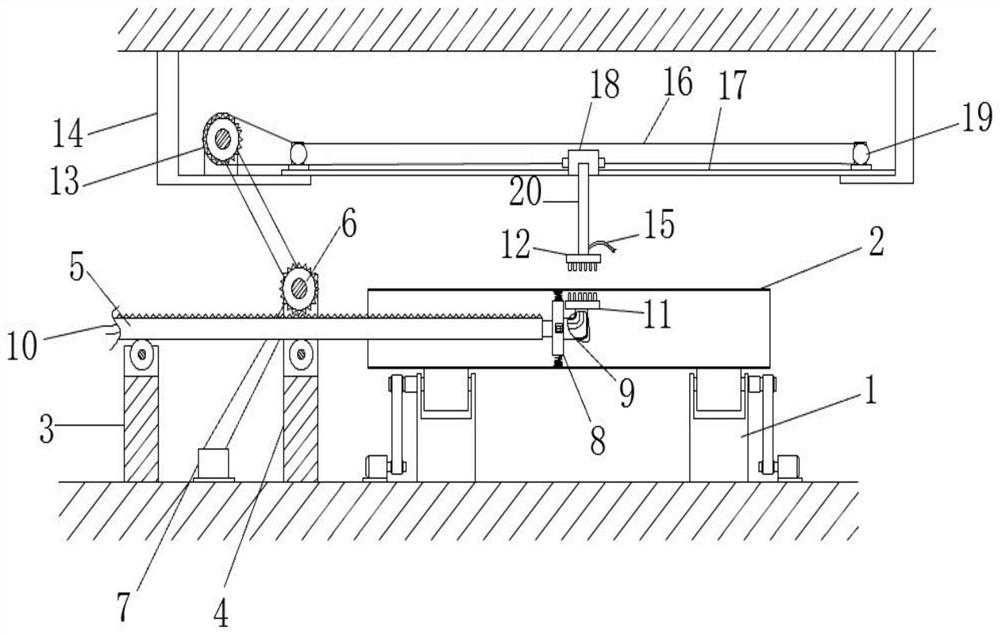

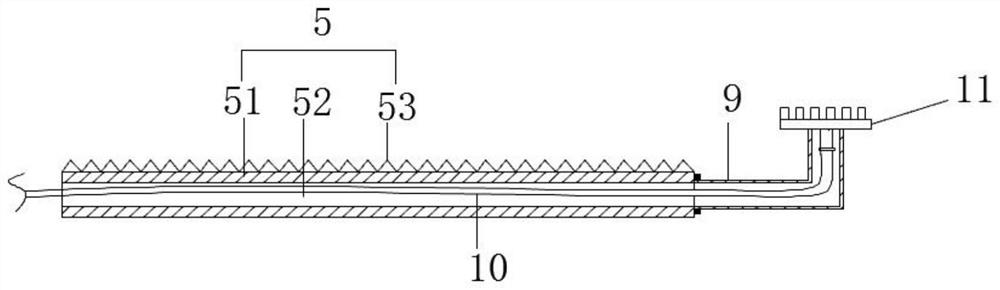

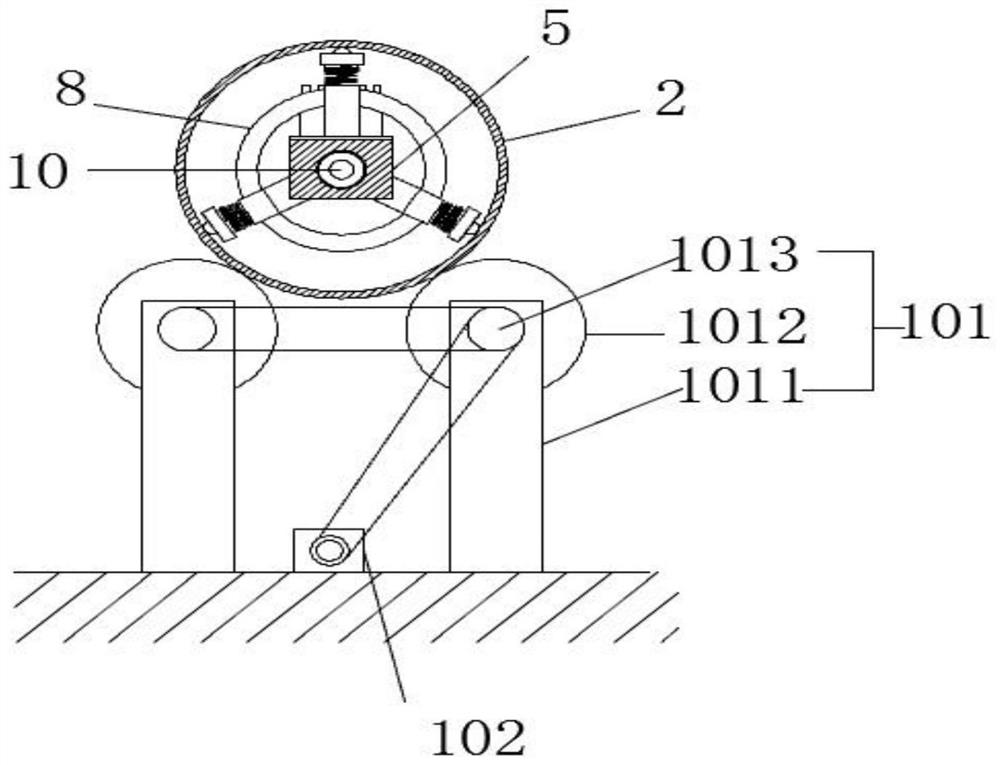

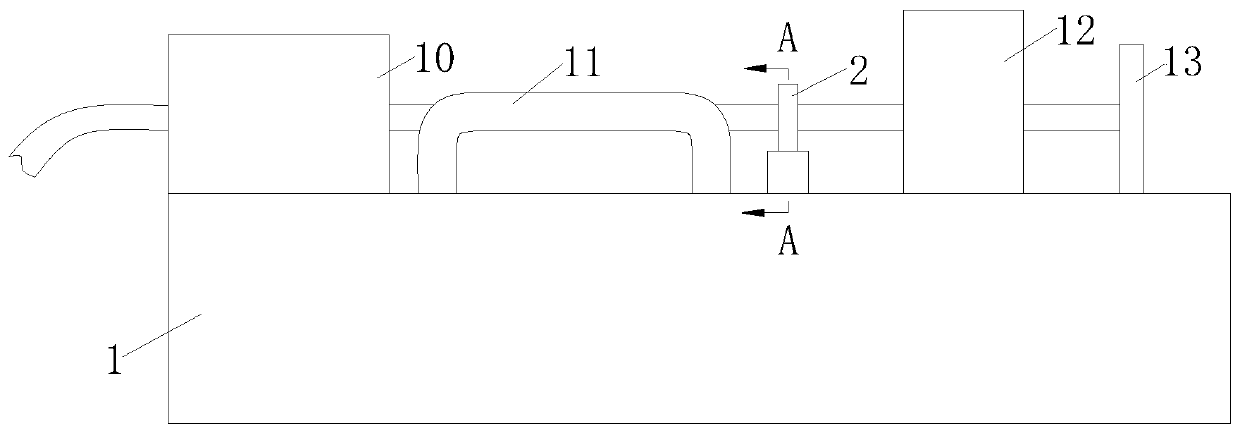

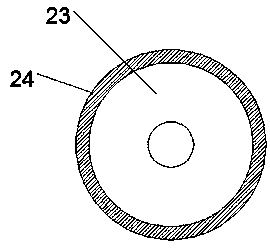

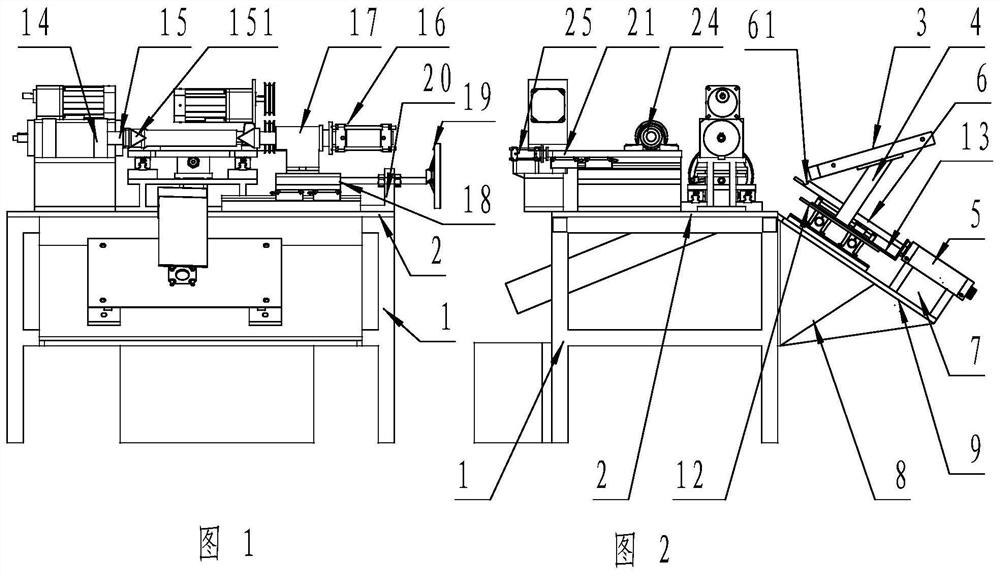

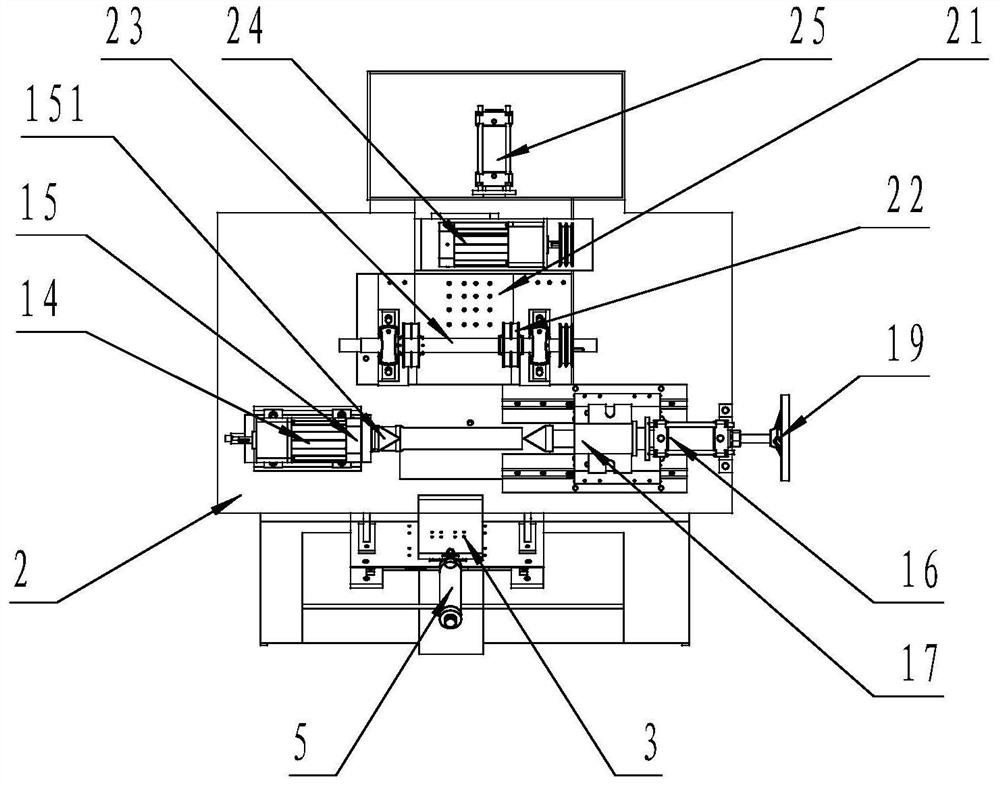

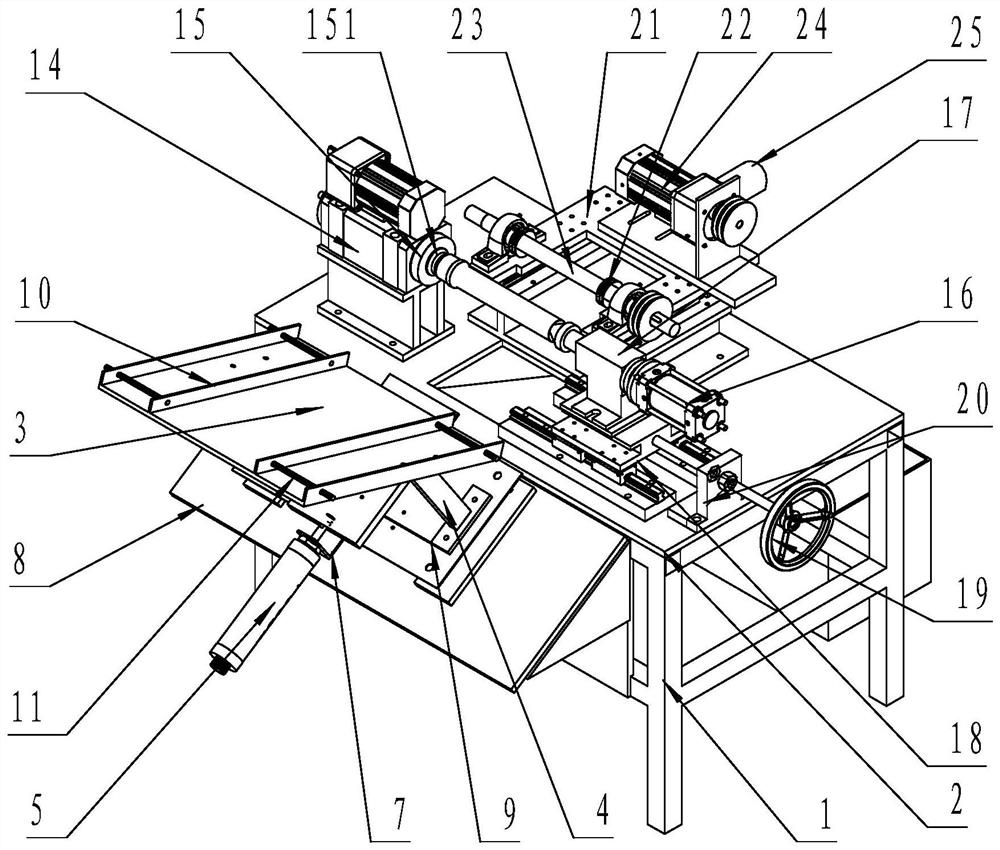

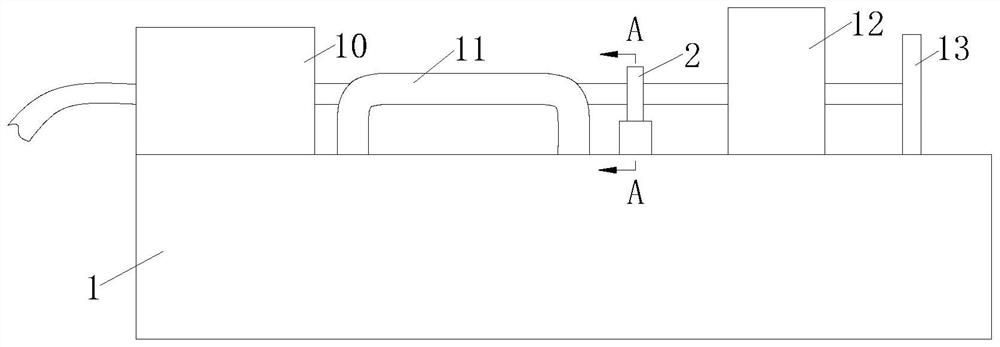

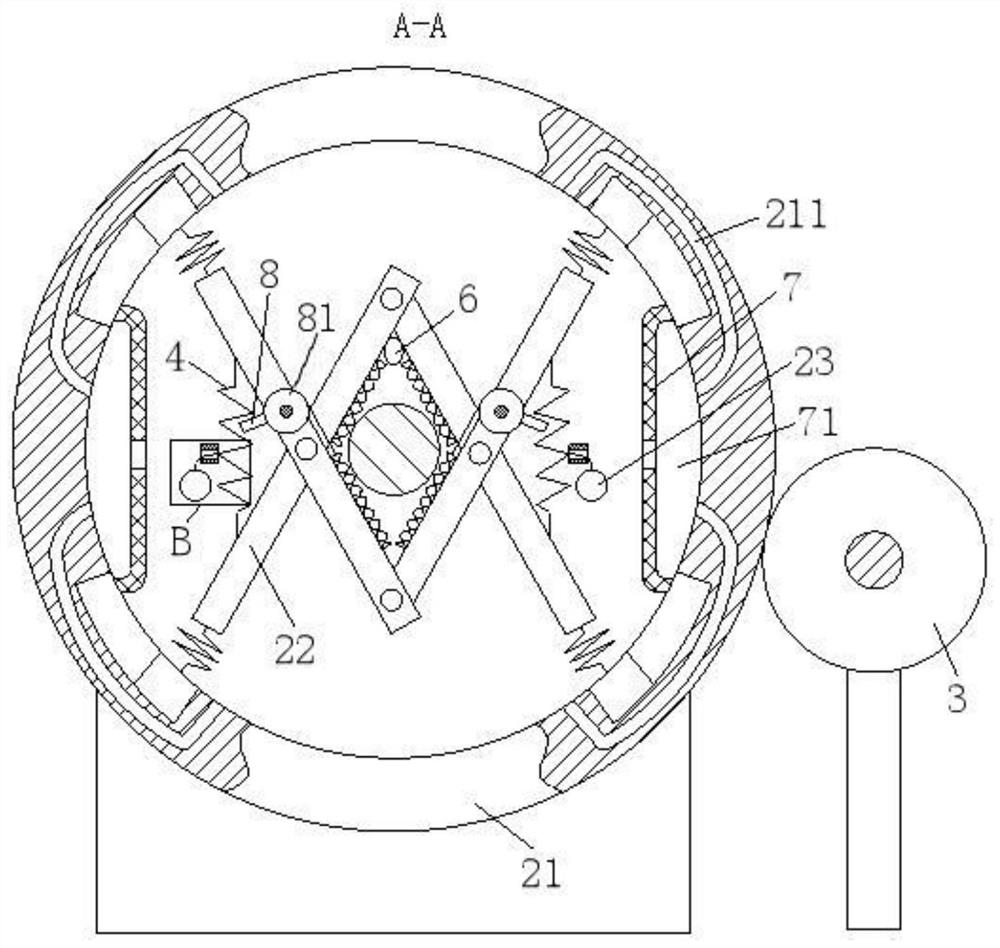

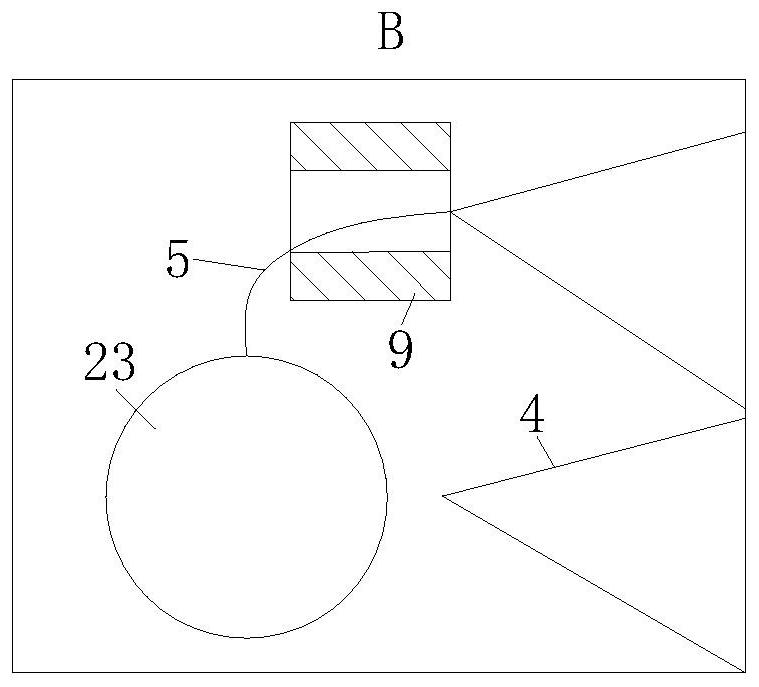

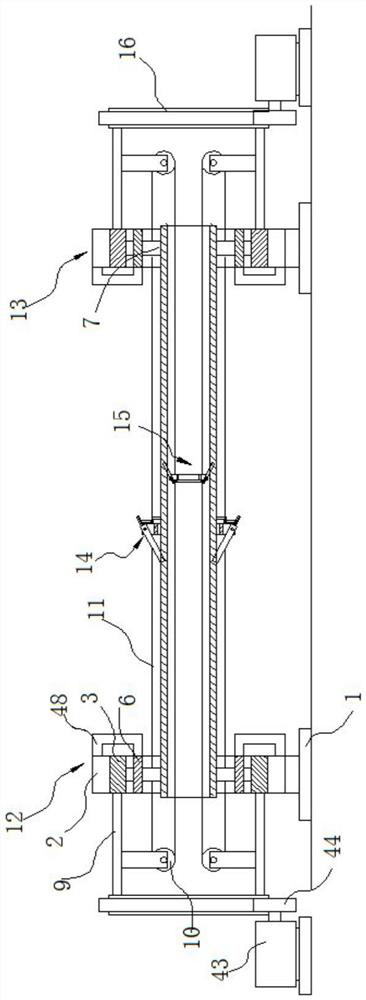

The invention relates to a flattener, relative thermal rolling band steel non-acid scaling device and method, wherein said flattener comprises a roller cleaner (15) whose end contacts the lower roller and compression lower roller (14); the cleaner (15) can clean the ferric oxide in each rotation of roller, to improve work efficiency. And the scaling device comprises emulsion feeder (1), flattener (2), high-pressure water injector (3), iron brush (4), washing drier (5), and coiling machine (6). The invention can improve the service life and effect of iron brush. And the method comprises that adjusting the injected amount of emulsion to adjust the scaling quality and save cost.

Owner:武钢集团有限公司

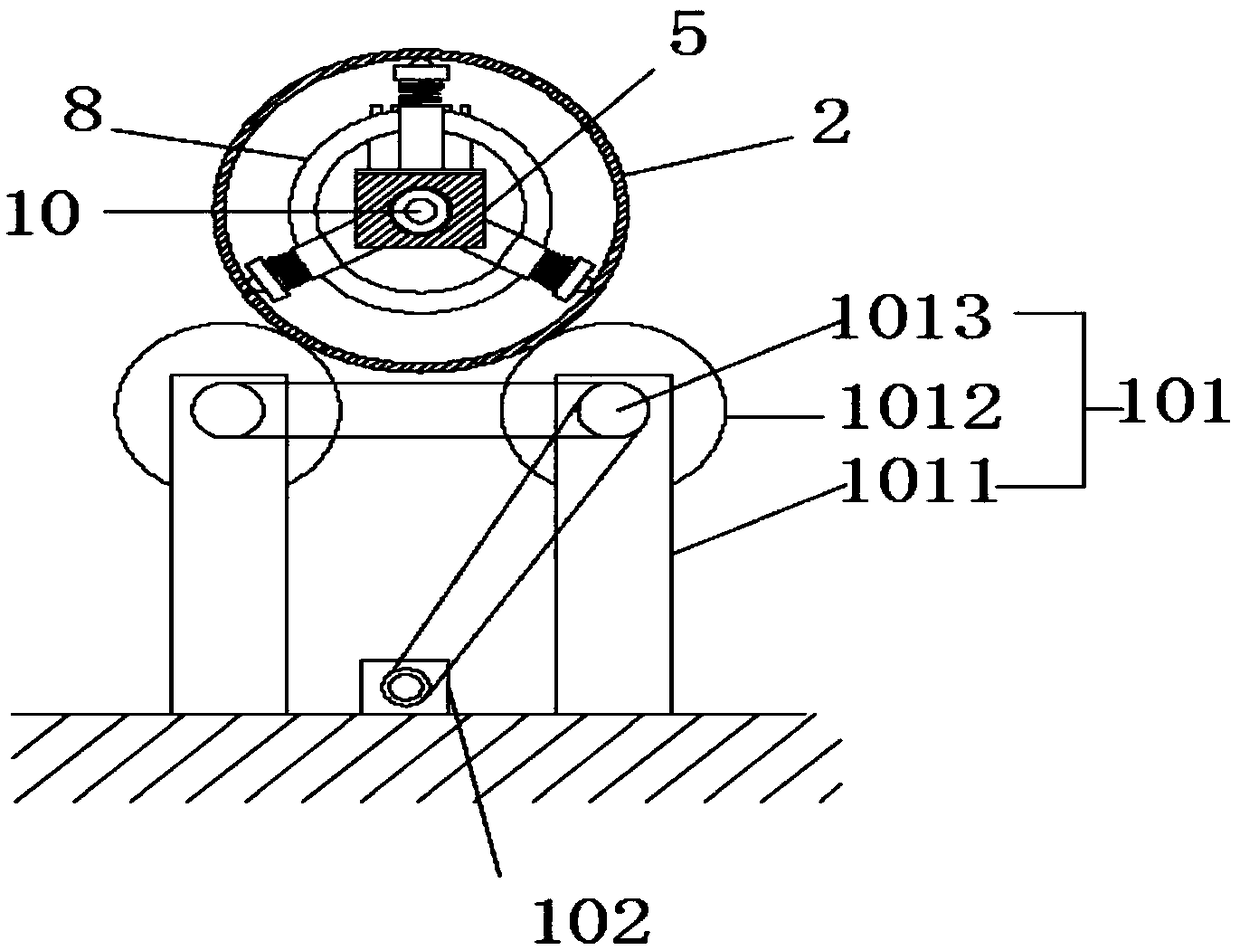

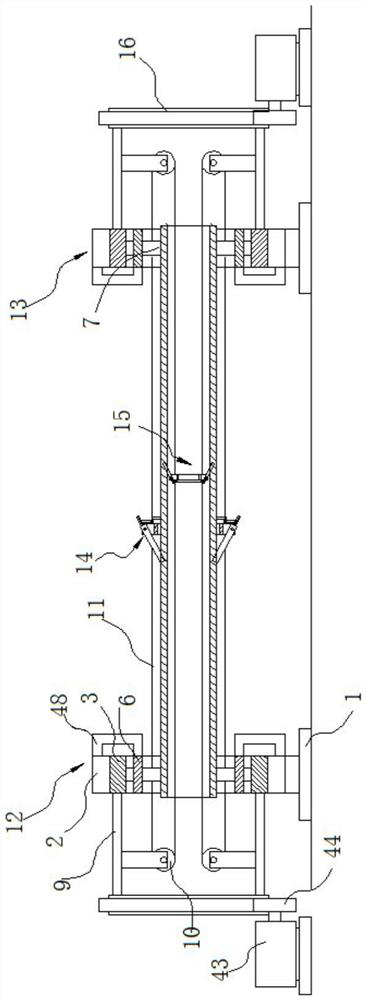

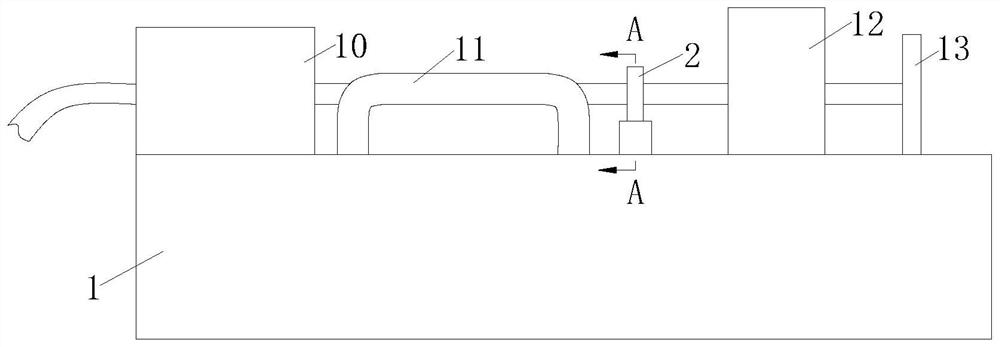

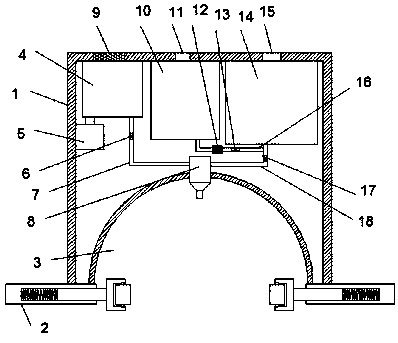

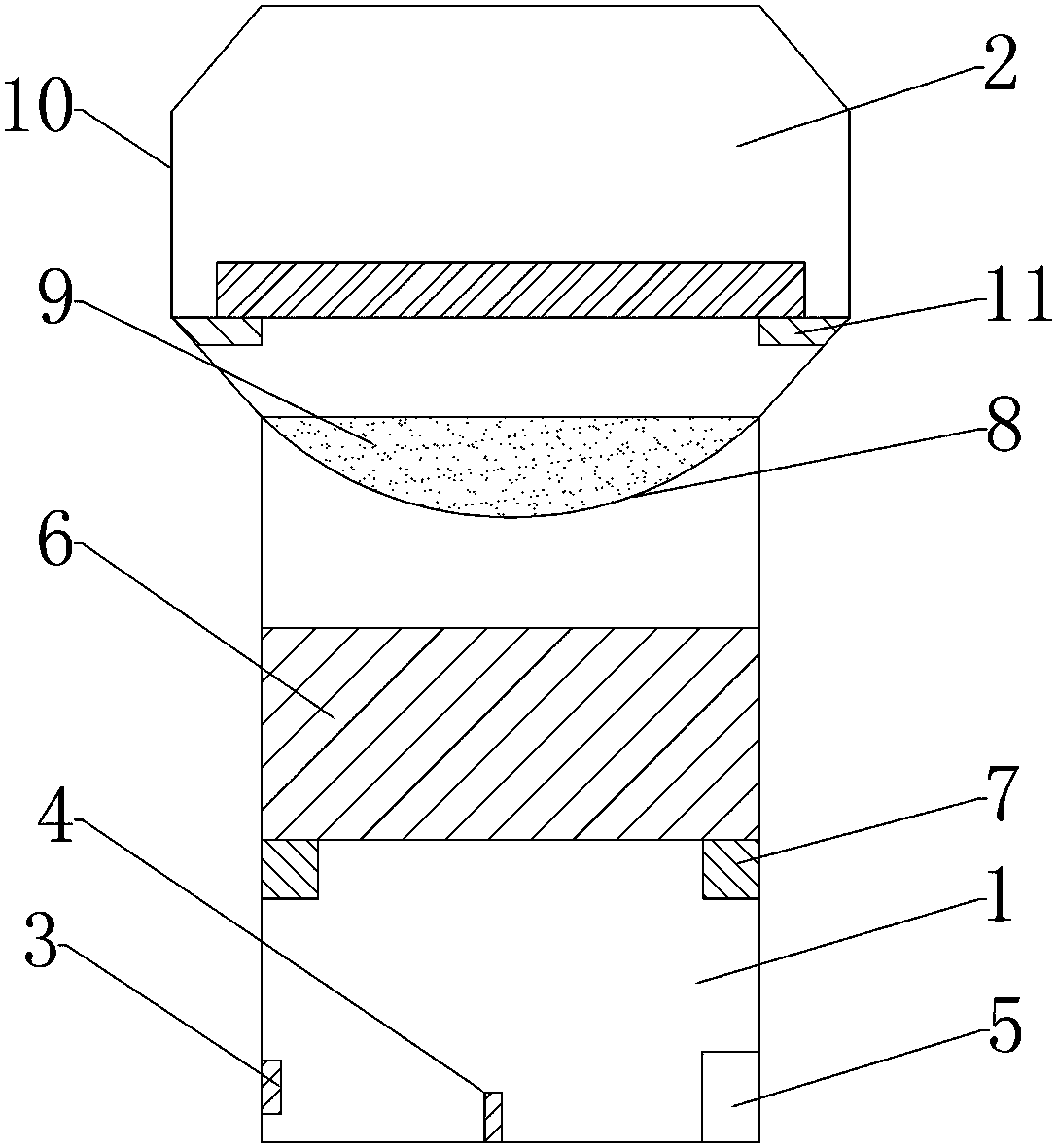

Steel bar surface rust removal device for constructional engineering

PendingCN110948361AEasy straighteningFacilitate subsequent rust removalGrinding wheel securing apparatusGrinding drivesClassical mechanicsEngineering

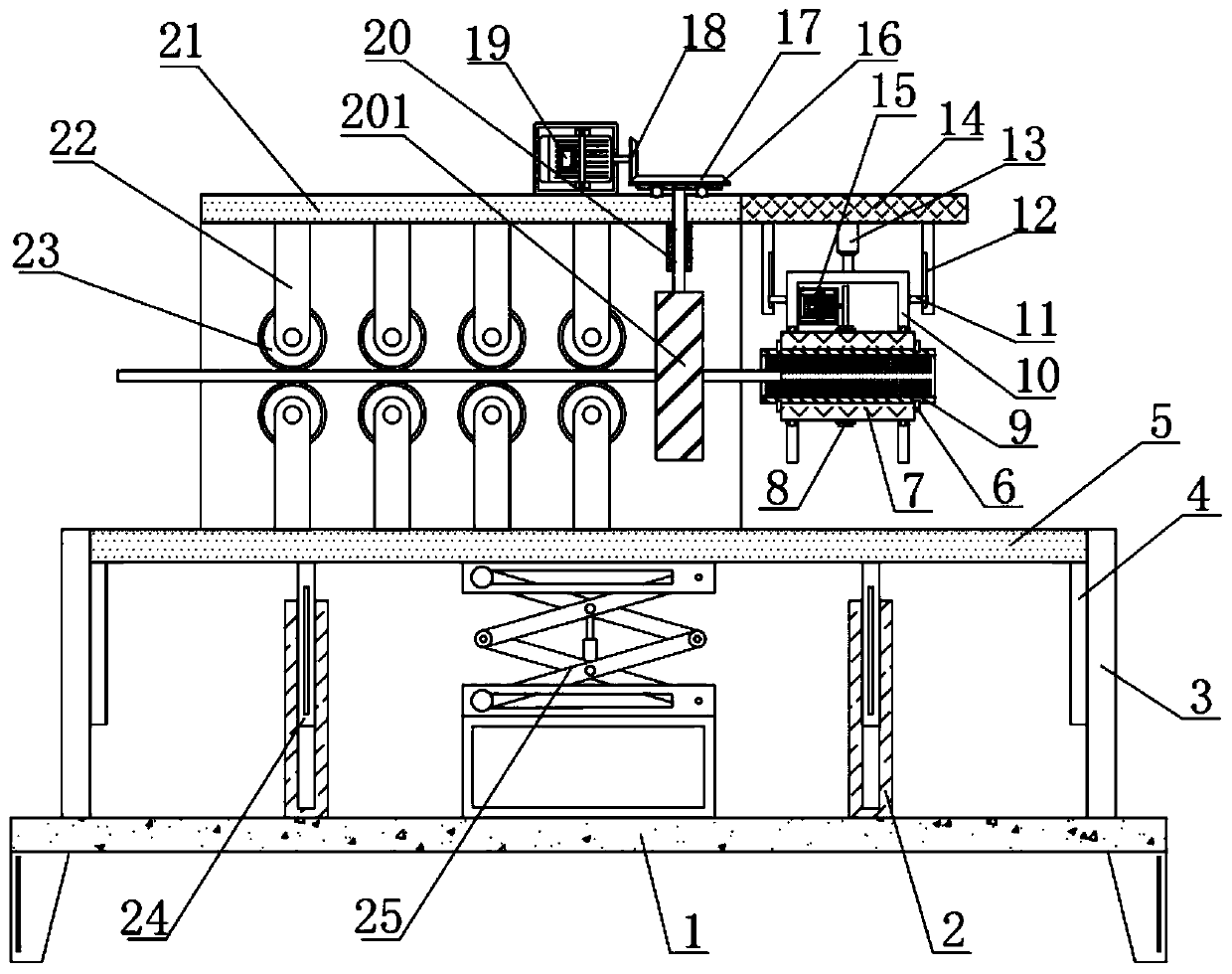

The invention belongs to the technical field of constructional engineering and especially relates to a steel bar surface rust removal device for constructional engineering. For the problem that a traditional device can conduct rust removal only on straight steel bars, the invention proposes the following scheme: the device comprises a base and a mounting plate, wherein supporting legs are welded to the four corners of the bottom of the base. A lifting mechanism is mounted on the side, opposite to the mounting plate, of the base; and a straightening box is installed at the top end of the mounting plate; an installing top plate is horizontally welded to one side of the top end of the straightening box; an efficient grinding mechanism is installed on the installing top plate; supports which are symmetrically distributed at equal intervals are welded to the inner two ends of the straightening box; and straightening rollers are rotatably connected to the two corresponding supports. Throughthe arrangement of the straightening box, bent steel bars can be straightened in advance through the arrangement of the straightening rollers, thereby facilitating subsequent rust removal; and throughthe arrangement of the lifting mechanism, the distance between the straightening rollers can be adjusted, and the steel bars of different thicknesses can be straightened conveniently.

Owner:王毅

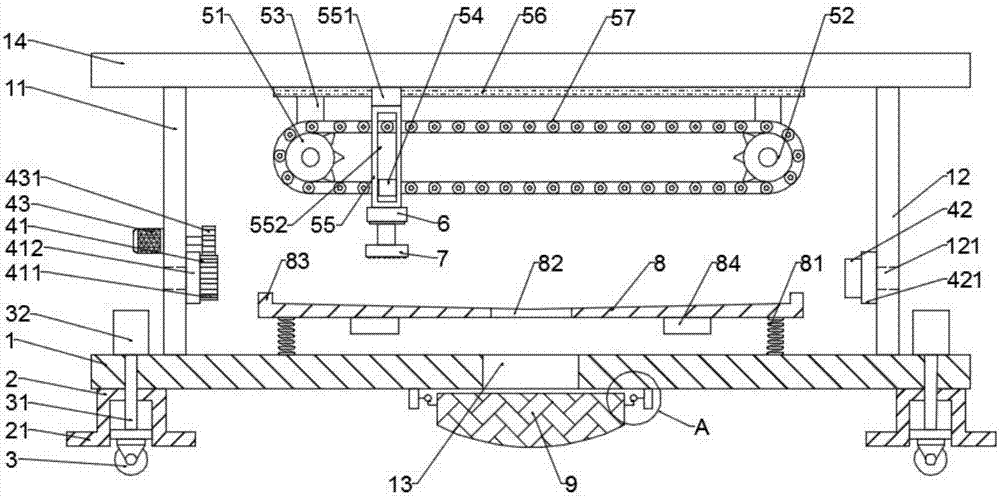

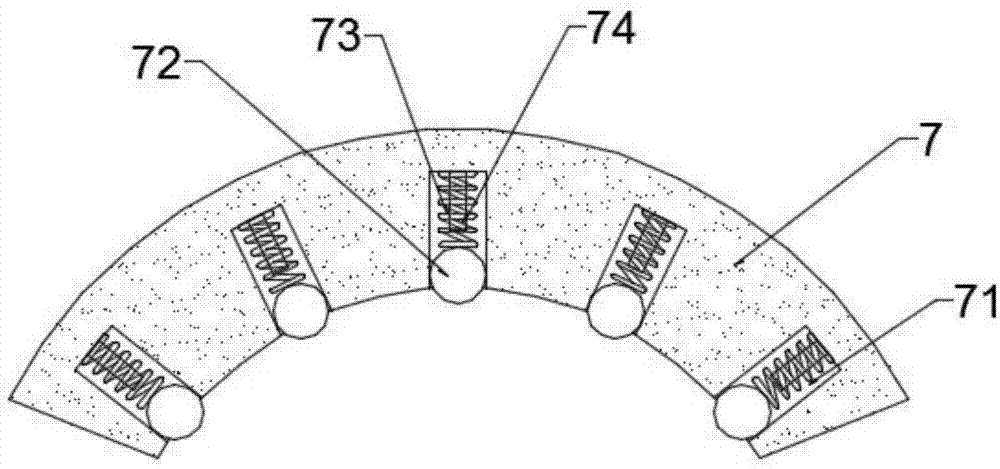

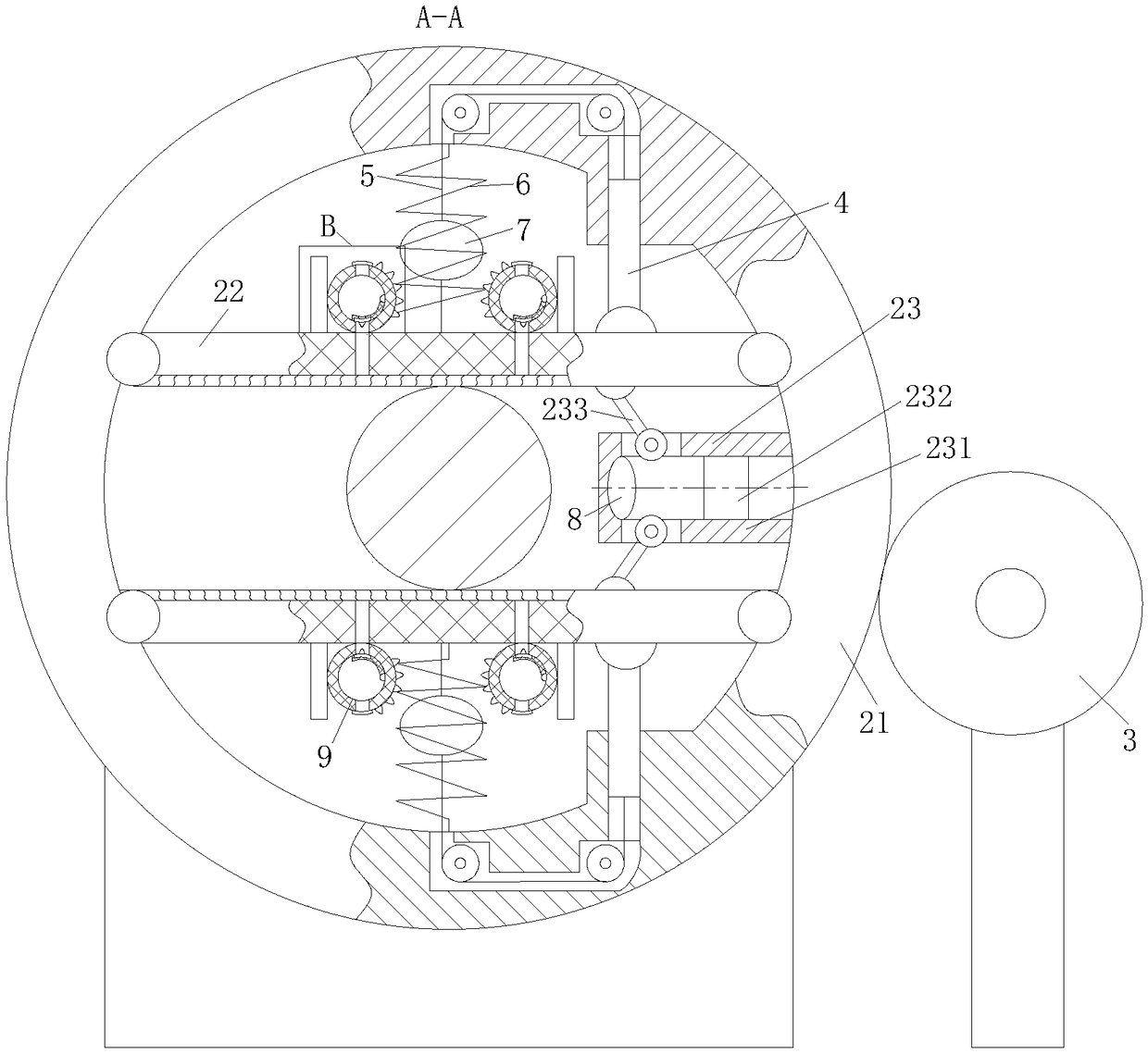

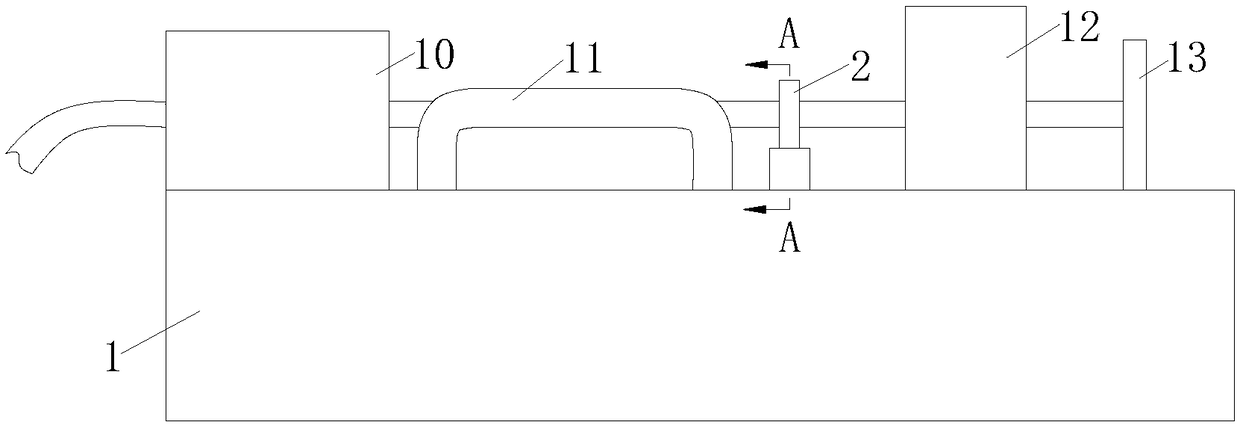

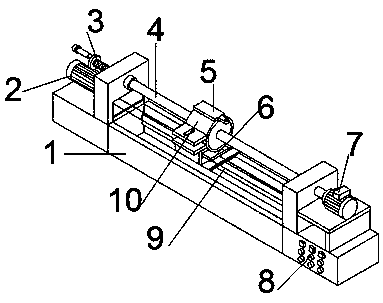

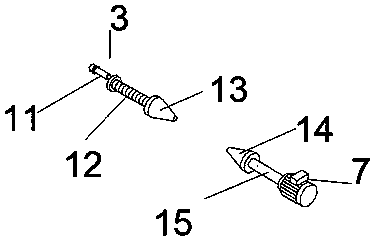

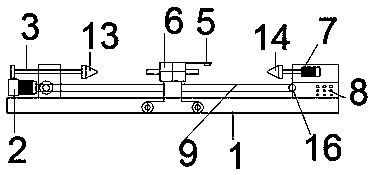

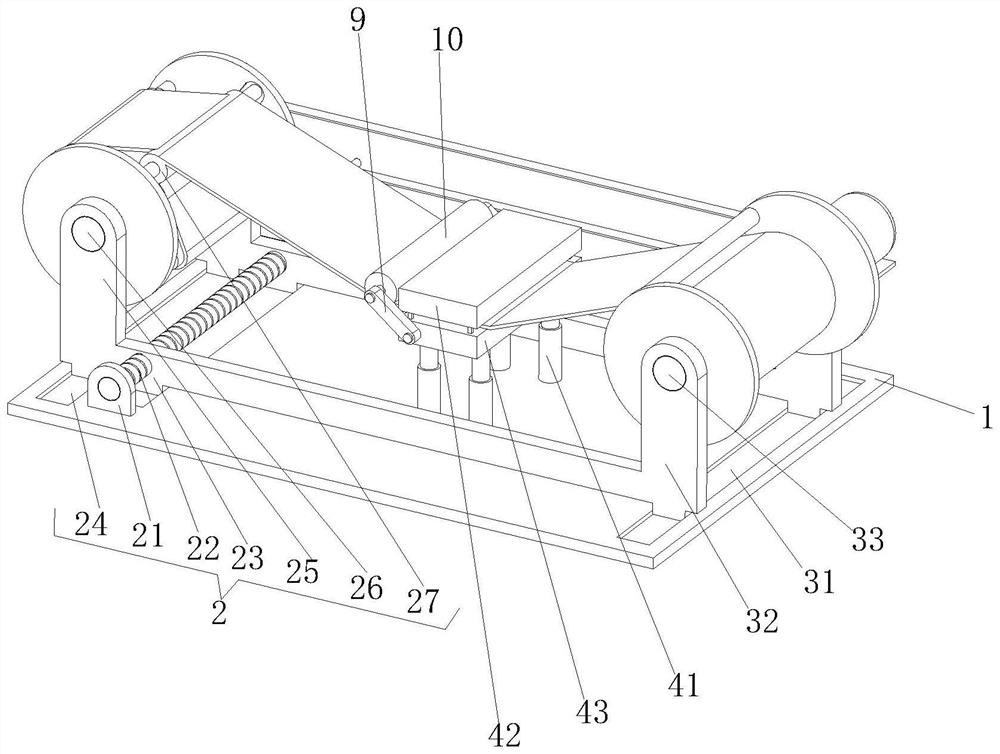

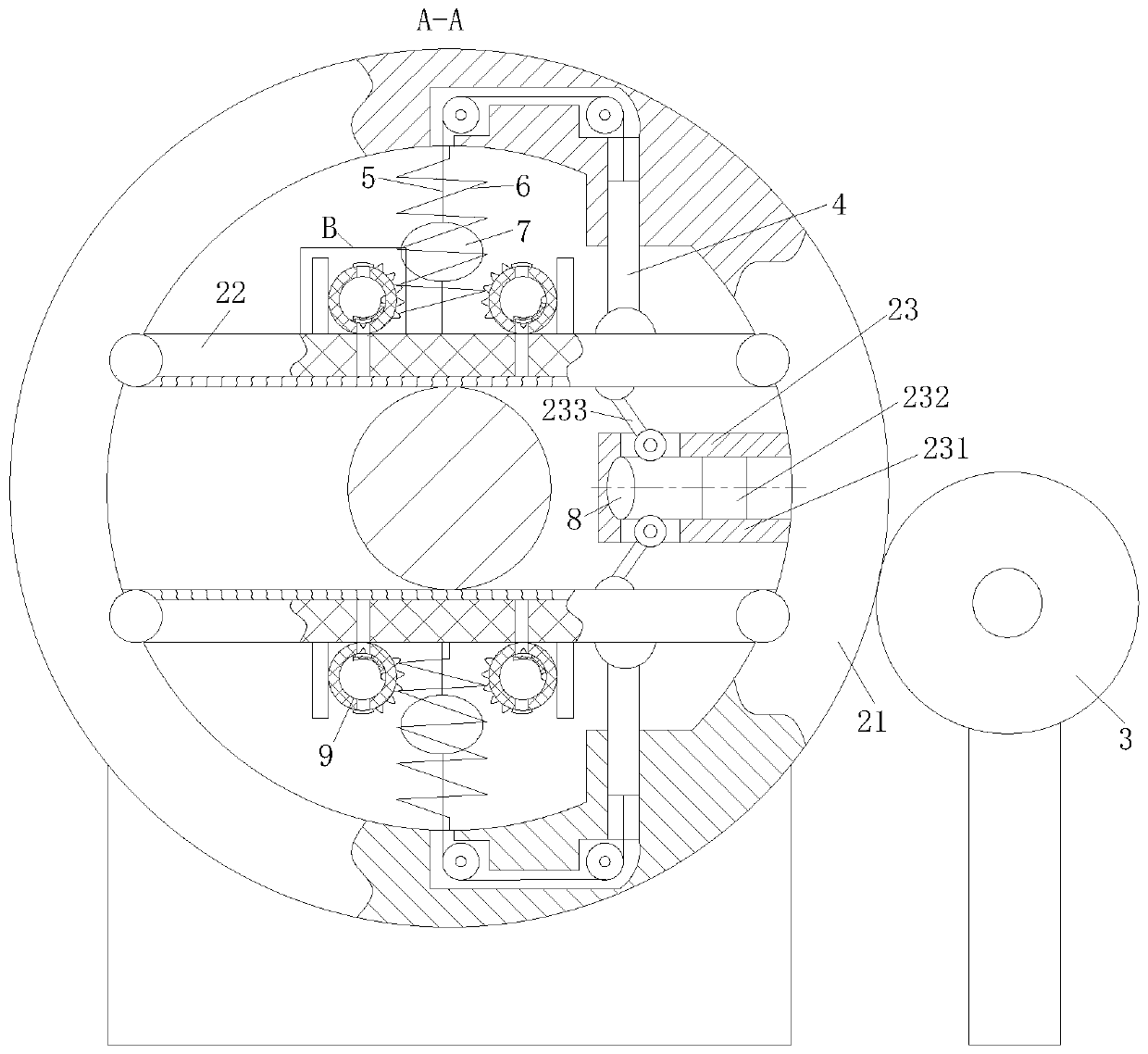

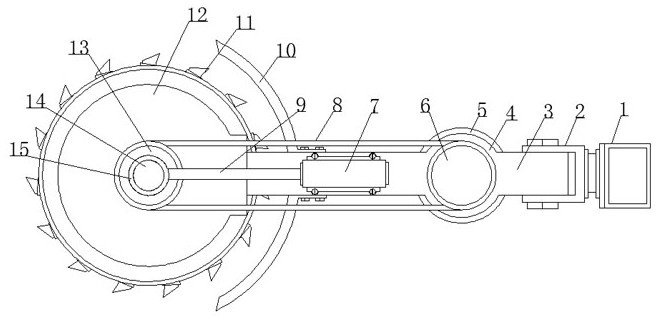

Portable efficient steel bar rust removing device

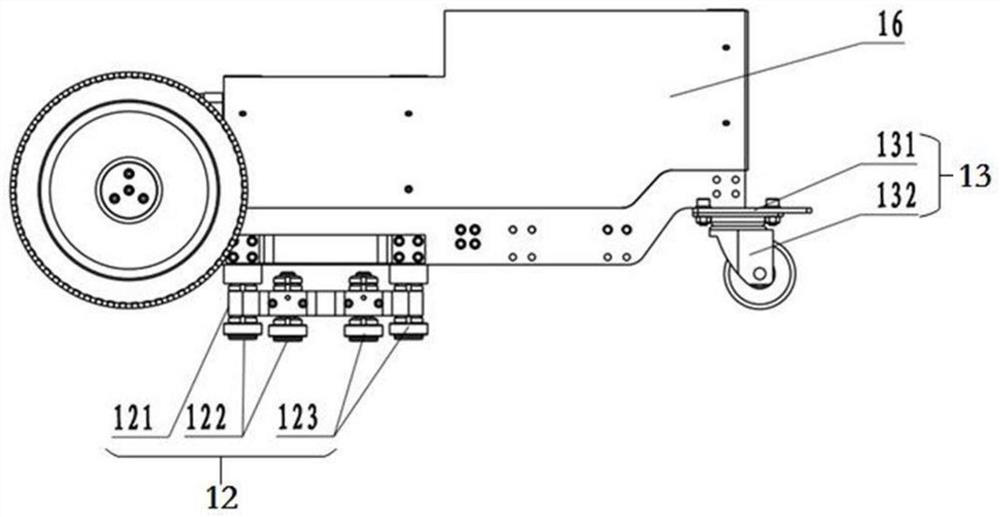

InactiveCN107471052ARust removal achievedAvoid pollutionGrinding carriagesGrinding drivesArchitectural engineeringRebar

The invention discloses a portable efficient steel bar rust removing device. The portable efficient steel bar rust removing device comprises a base, fixing assemblies, a walking assembly and a rust removing disc. A left support and a right support are symmetrically fixed to the two sides of the top of the base. Column legs are arranged at the bottom of the base and are designed to be hollow, and wheels capable of ascending and descending are arranged in the column legs. The fixing assemblies are arranged in the left support and the right support and can fix steel bars and drive the steel bars to rotate. The walking assembly can drive the rust removing disc to reciprocate left and right. The rust removing disc is in an arc shape and is provided with elastic floating type rust removing balls. A waste scrap table is arranged below the walking mechanism, a waste scrap collecting frame is arranged below the base, and waste scrap collection can be finished through cooperative usage of the waste scrap table and the waste scrap collecting frame. The steel bar rust removing device is good in portability and excellent in rust removing effect; and meanwhile, the structure is reasonable, operation is convenient and fast, and the portable efficient steel bar rust removing device is worthy of popularization and usage.

Owner:广西综改咨询服务有限公司

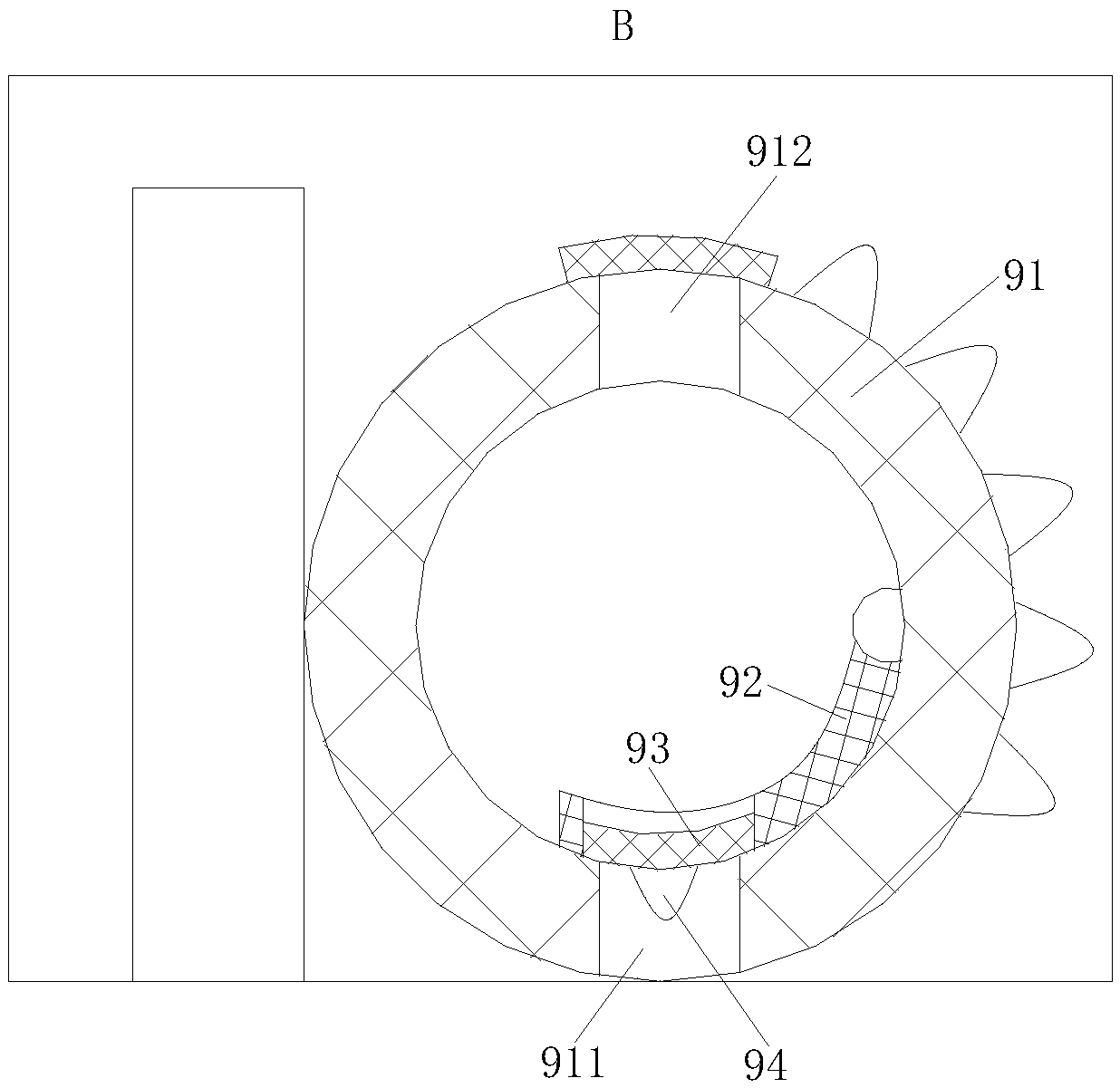

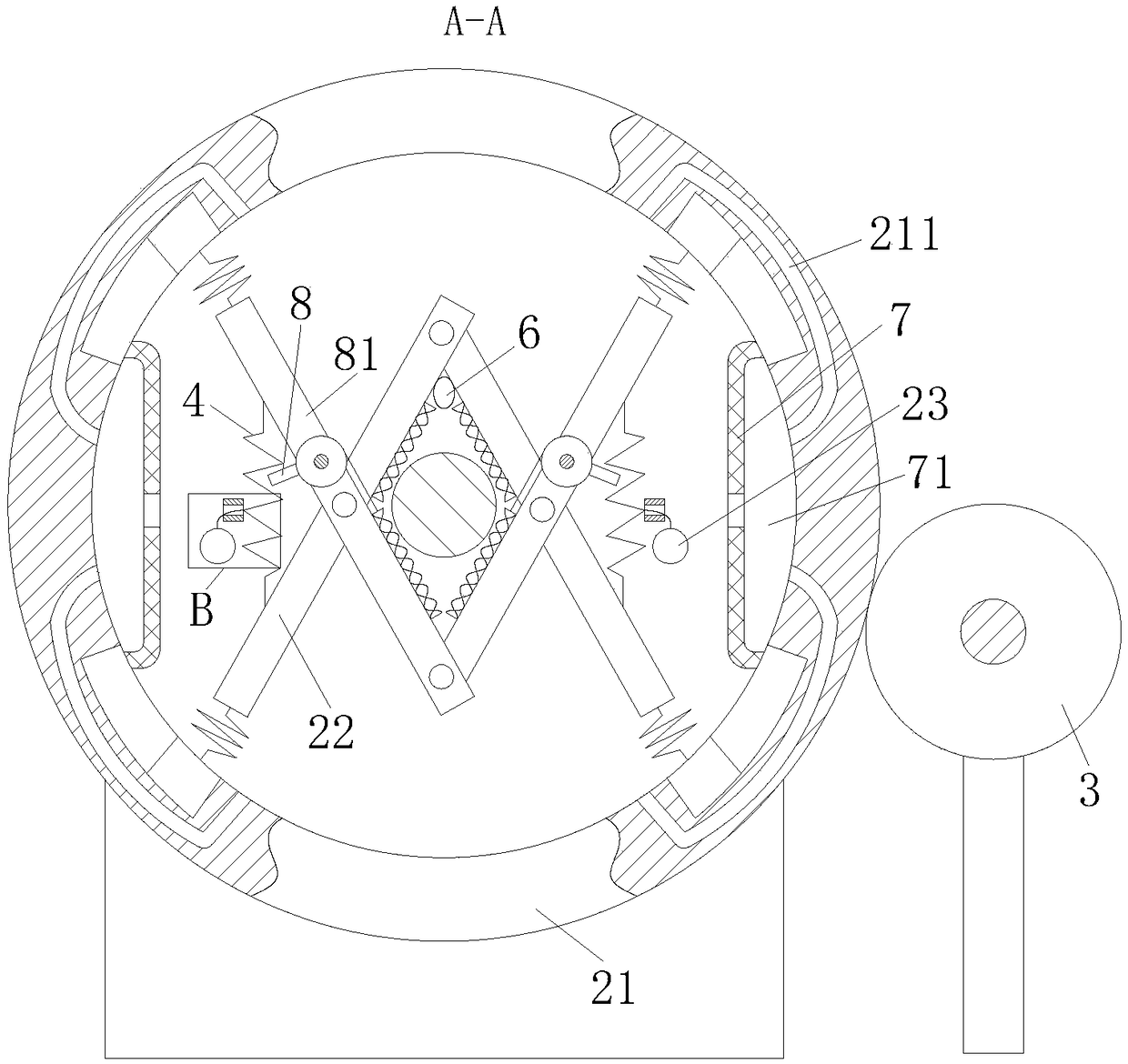

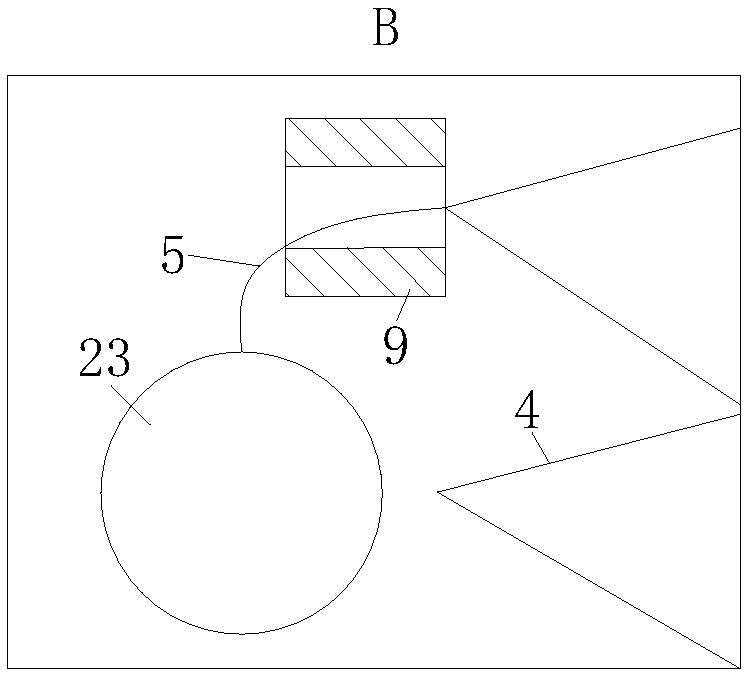

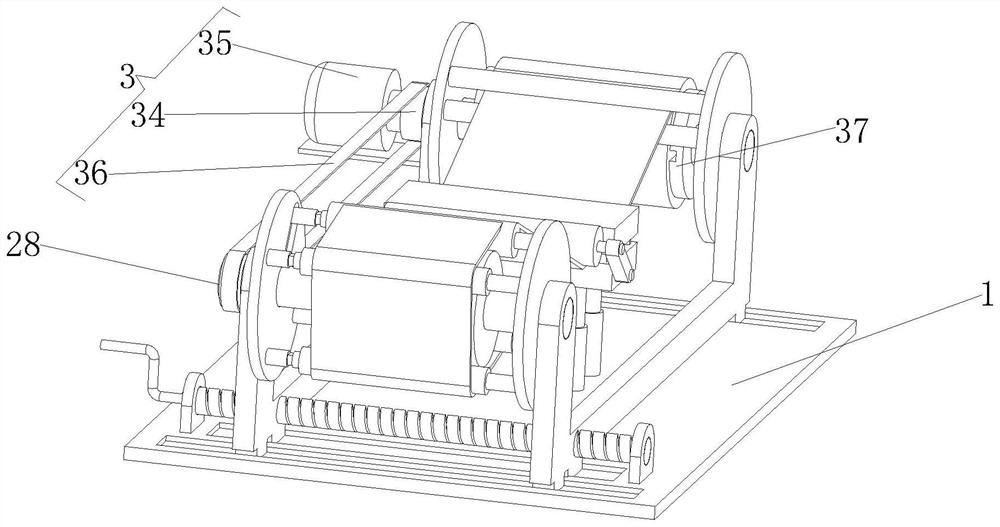

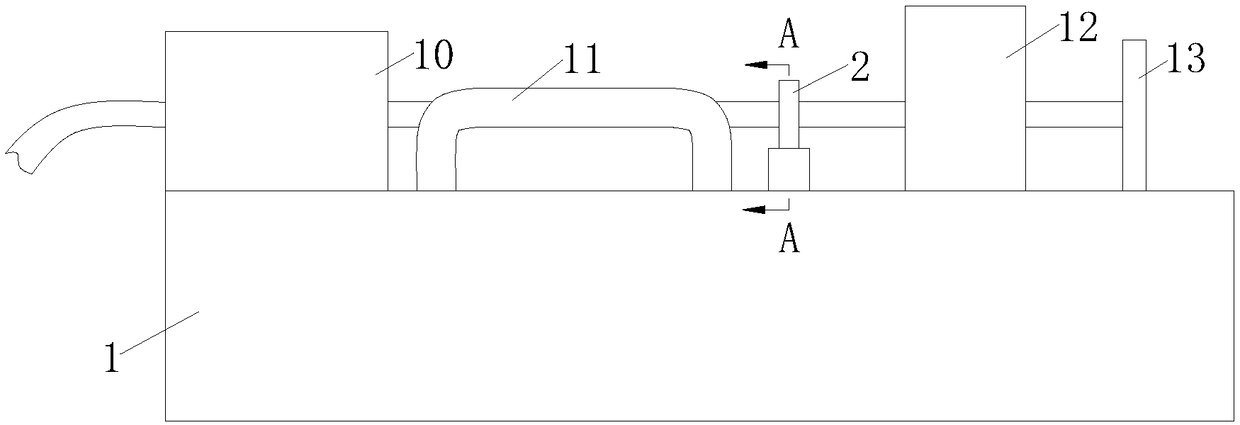

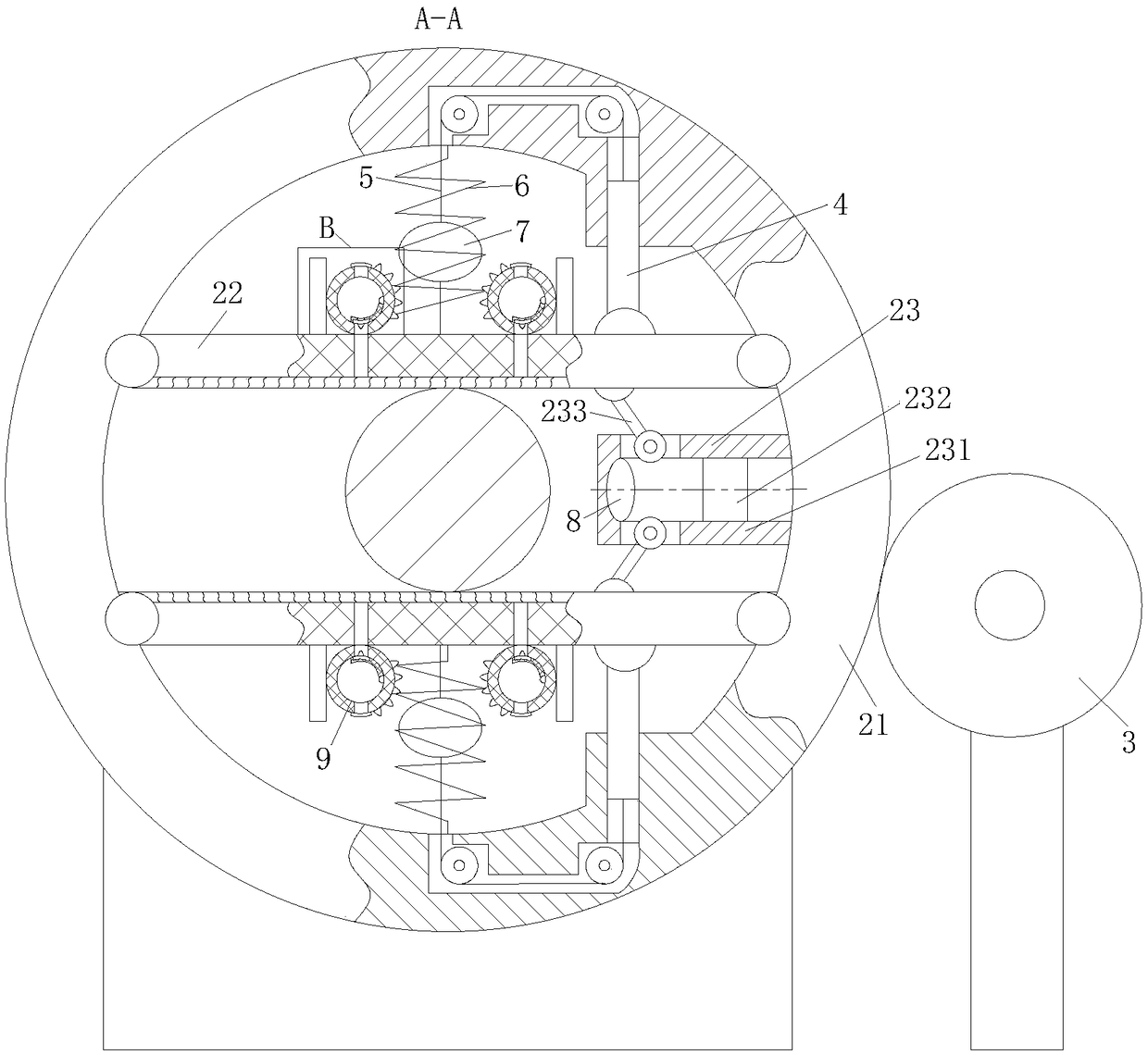

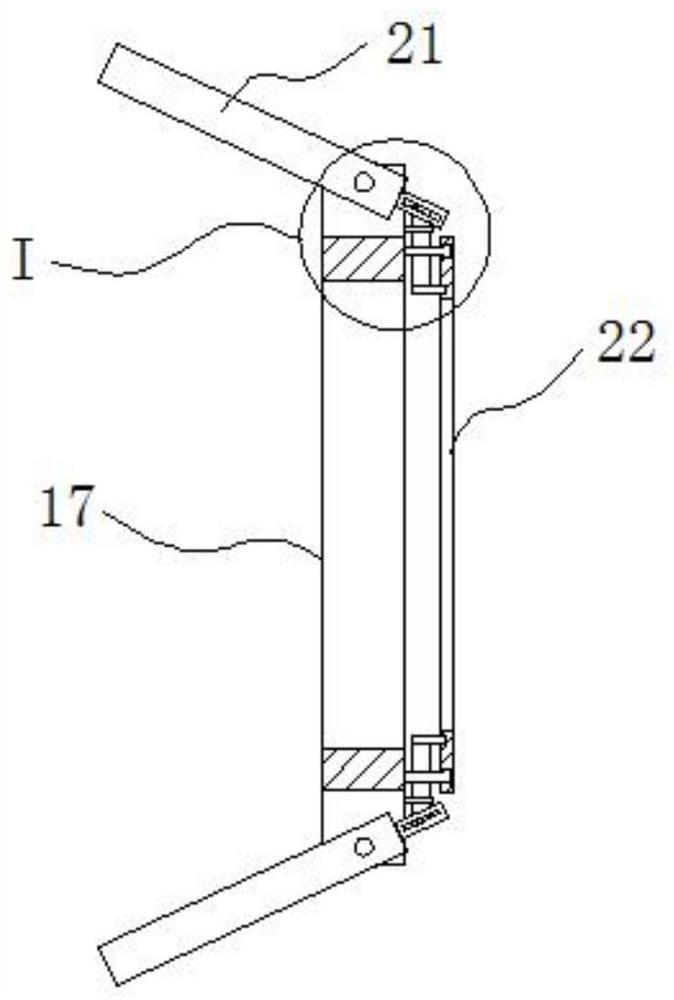

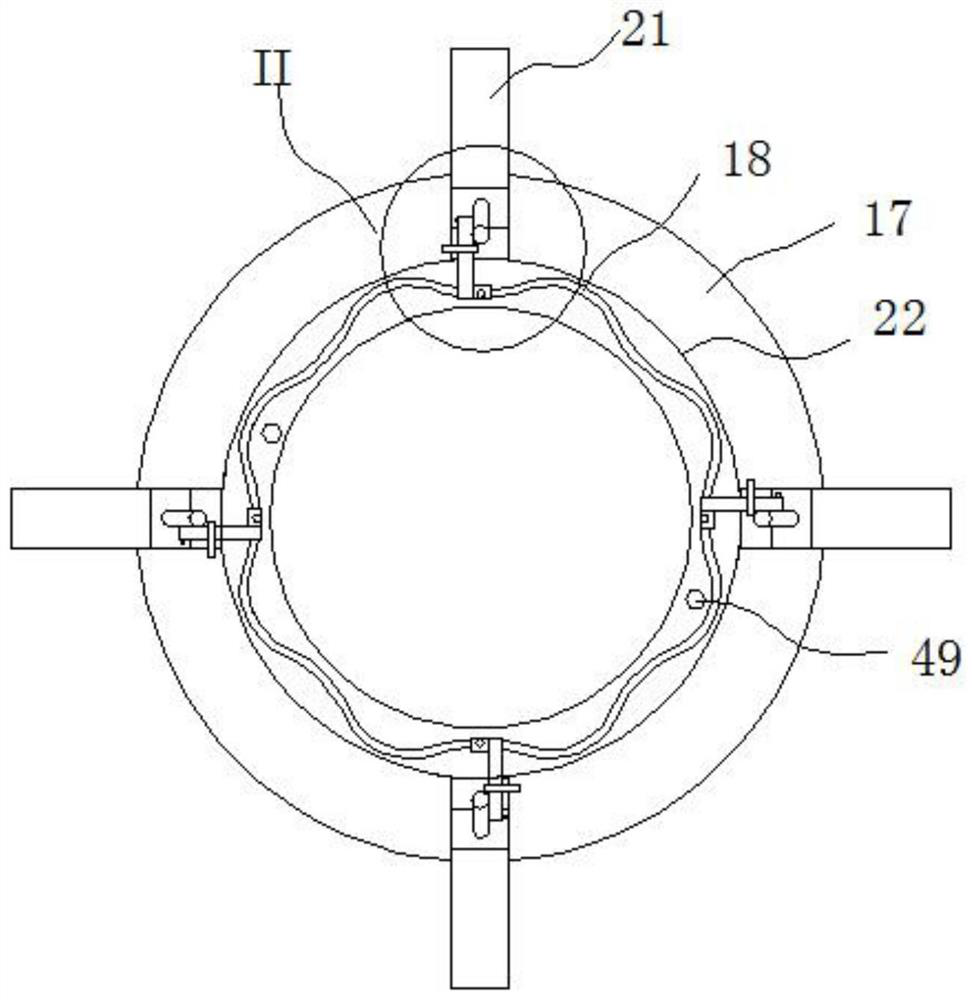

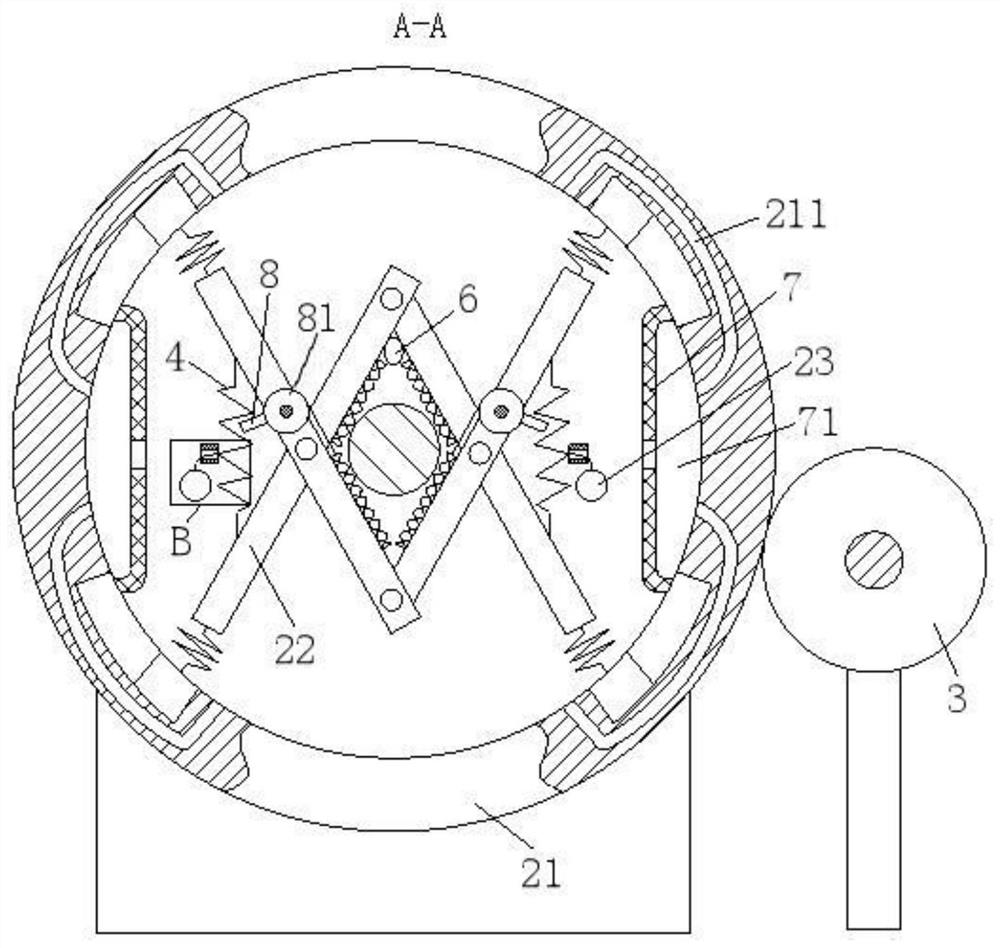

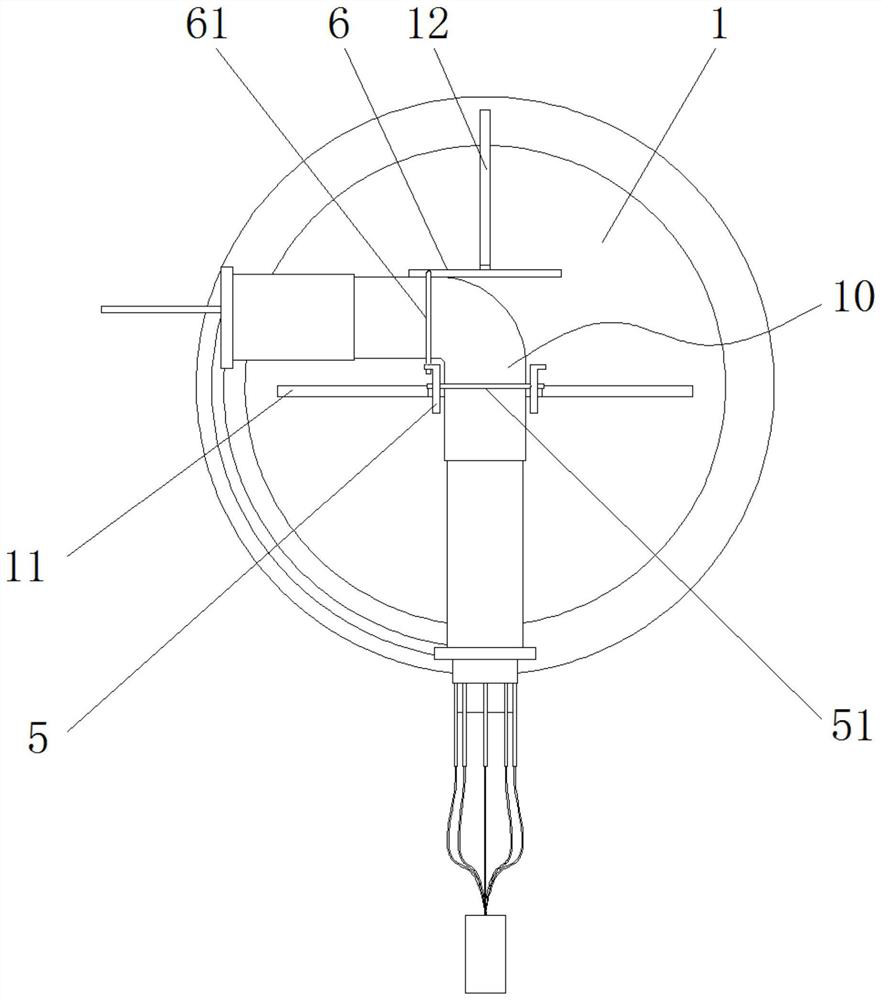

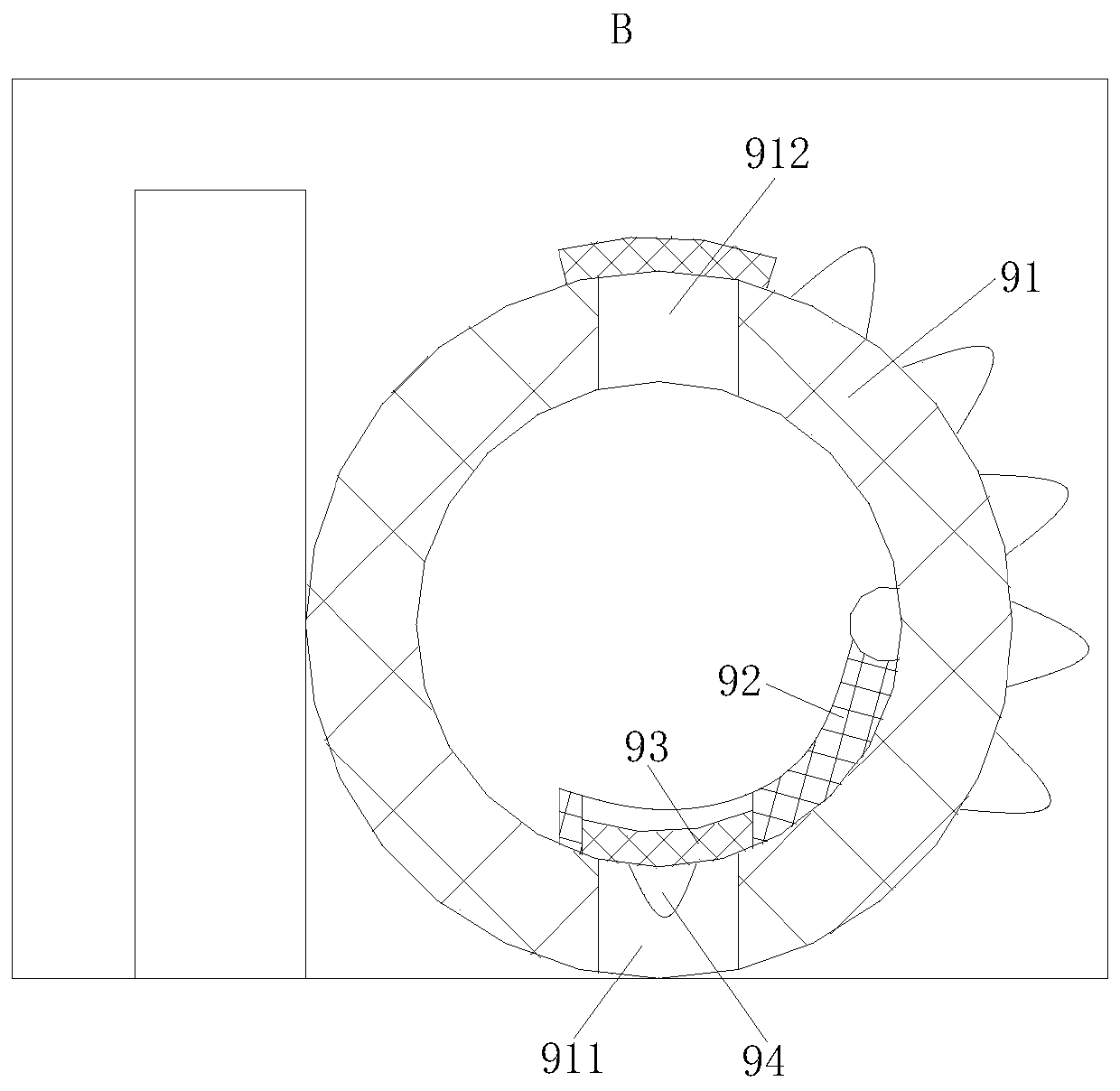

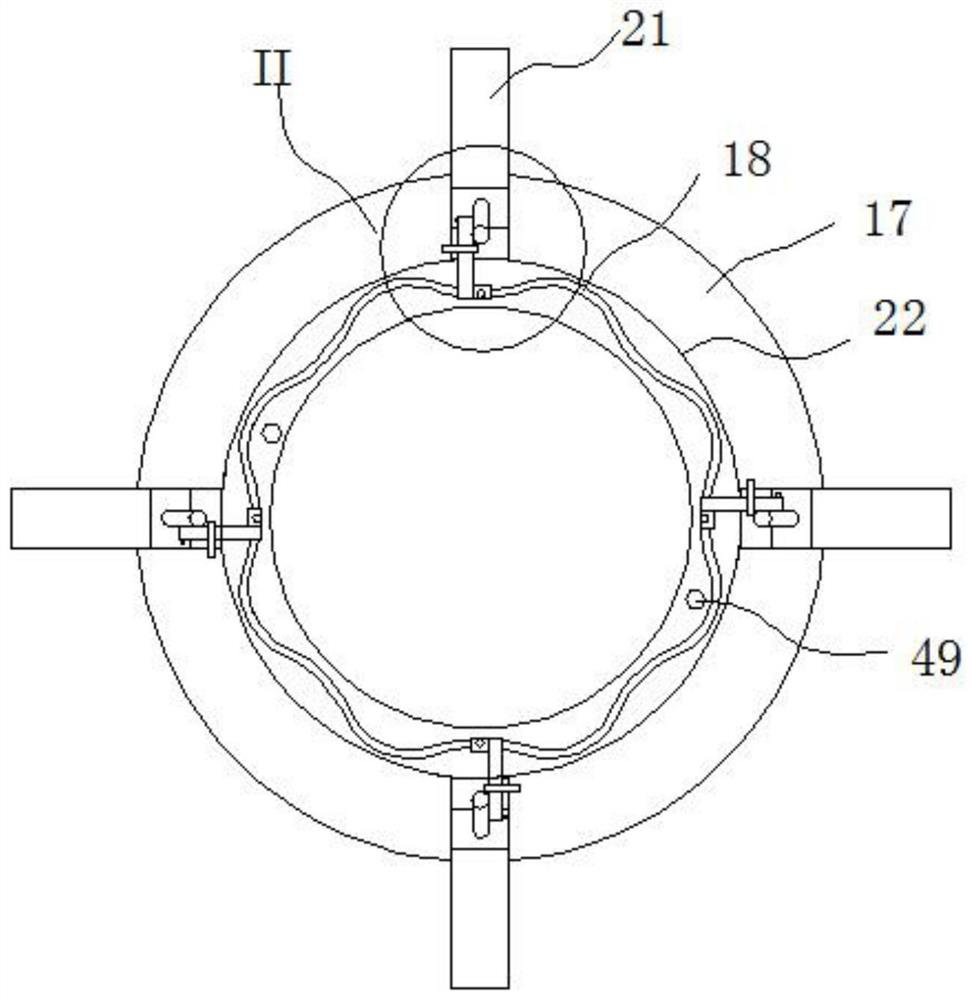

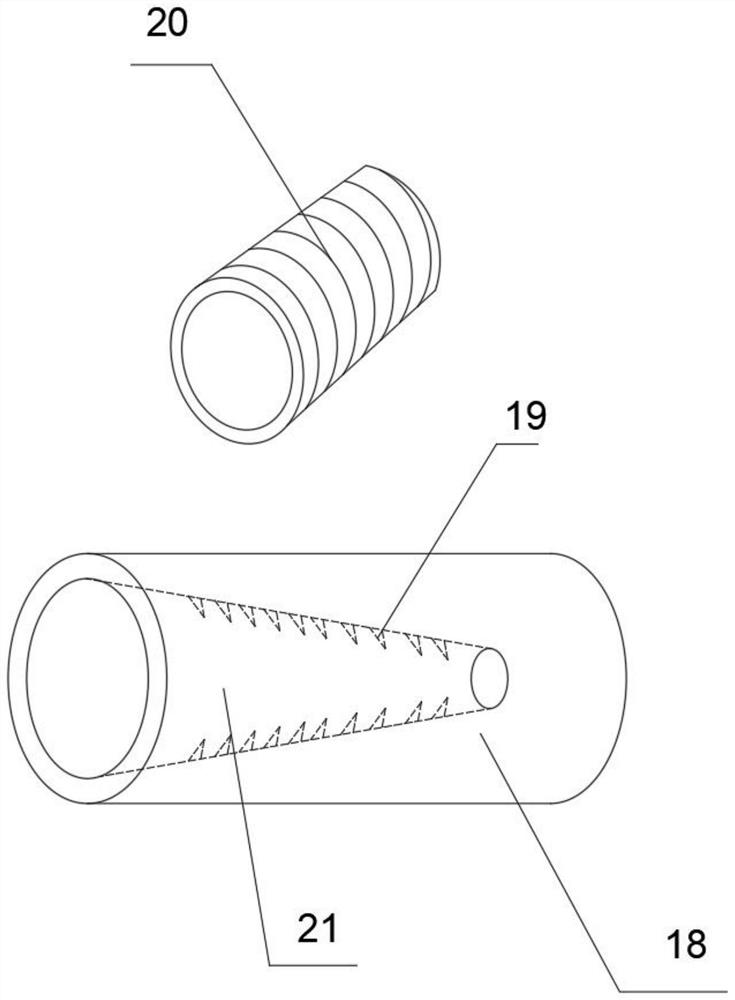

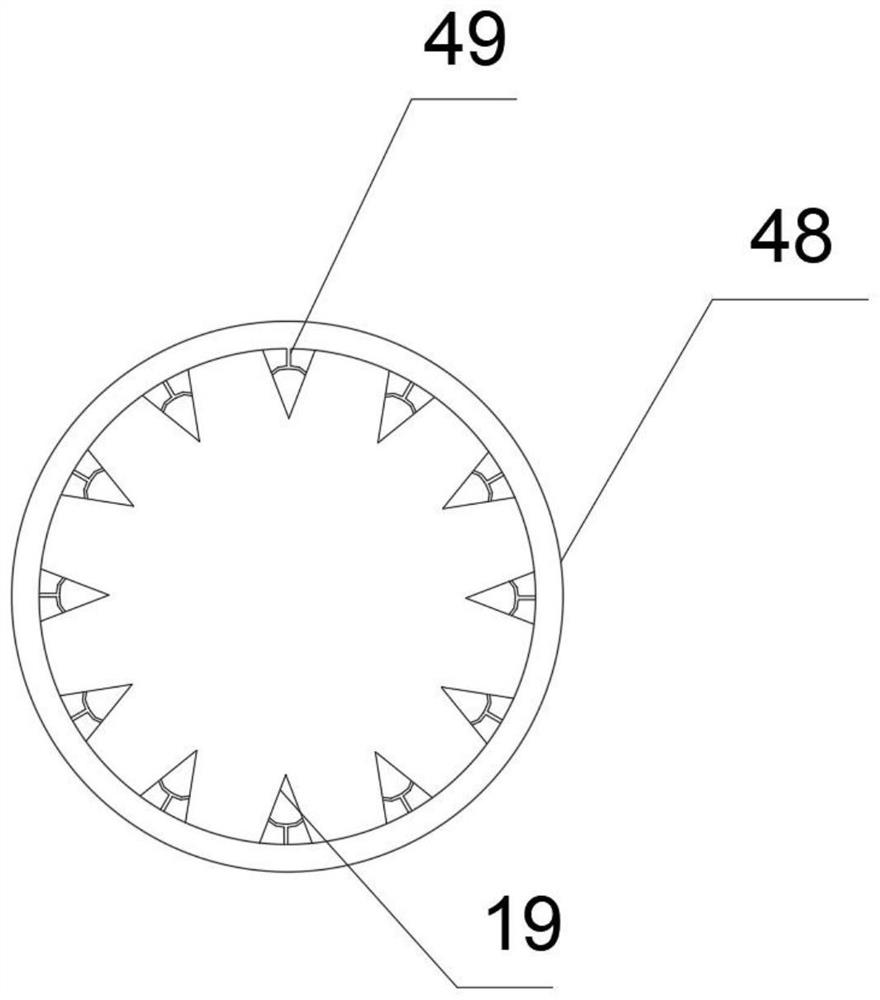

Rebar straightening rust removing machine

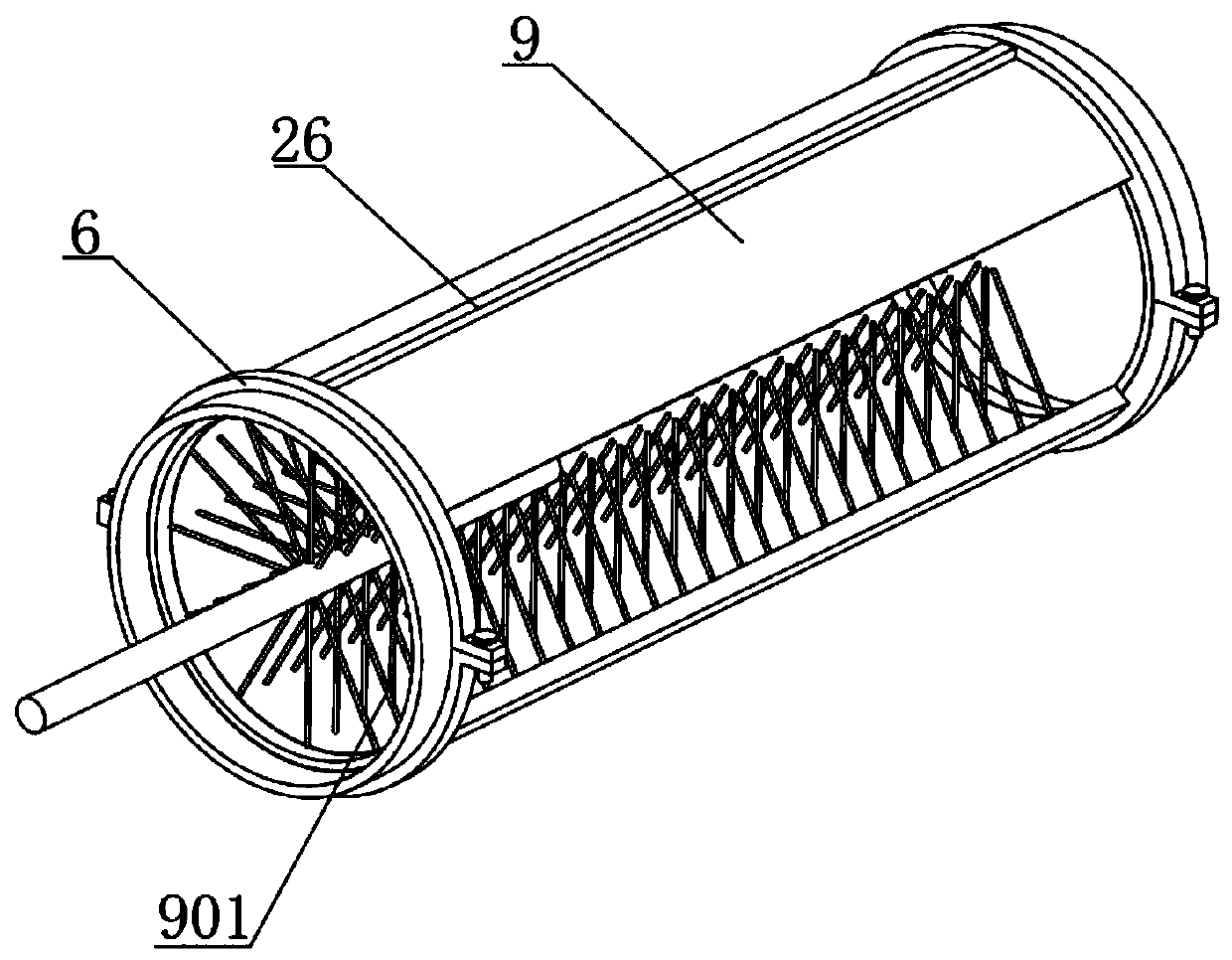

ActiveCN109500297ARust removal achievedImprove surface qualityGrinding machinesGrinding feedersWork performanceSlag

The invention belongs to the technical field of rebar machining devices, and particularly relates to a rebar straightening rust removing machine. A rack is included, and is sequentially provided witha straightening device, a conveying belt, a fixed cut-off device and a limiting material blocking plate; a rust removing module is arranged between the conveying belt and the fixed cut-off device, andcomprises a rotating ring, elastic strips and a shaking unit; the rotating ring is connected to rebar in a sleeving manner; the two elastic strips are symmetrically connected to the inner ring of therotating ring; the sides, close to the rebar, of the elastic strips are provided with steel wire nets; one side of the rotating ring is provided with the shaking unit which comprises a sleeve, a slider and swinging rods, and the slider is installed in the sleeve in a sliding manner; and gears are arranged on the sleeve, and the swinging rods are fixedly connected to the gears. According to the rebar straightening rust removing machine, due to the fact that the rebar is wiped by the rust removing module in the peripheral direction, and therefore rust removing of the rebar is achieved, the elastic strips are driven by the shaking unit to shake, so that rust slag wiped off by the steel wire nets falls off, and then the surface quality of the rebar and the work performance of the rebar are improved.

Owner:科尼起重机设备制造(江苏)有限公司

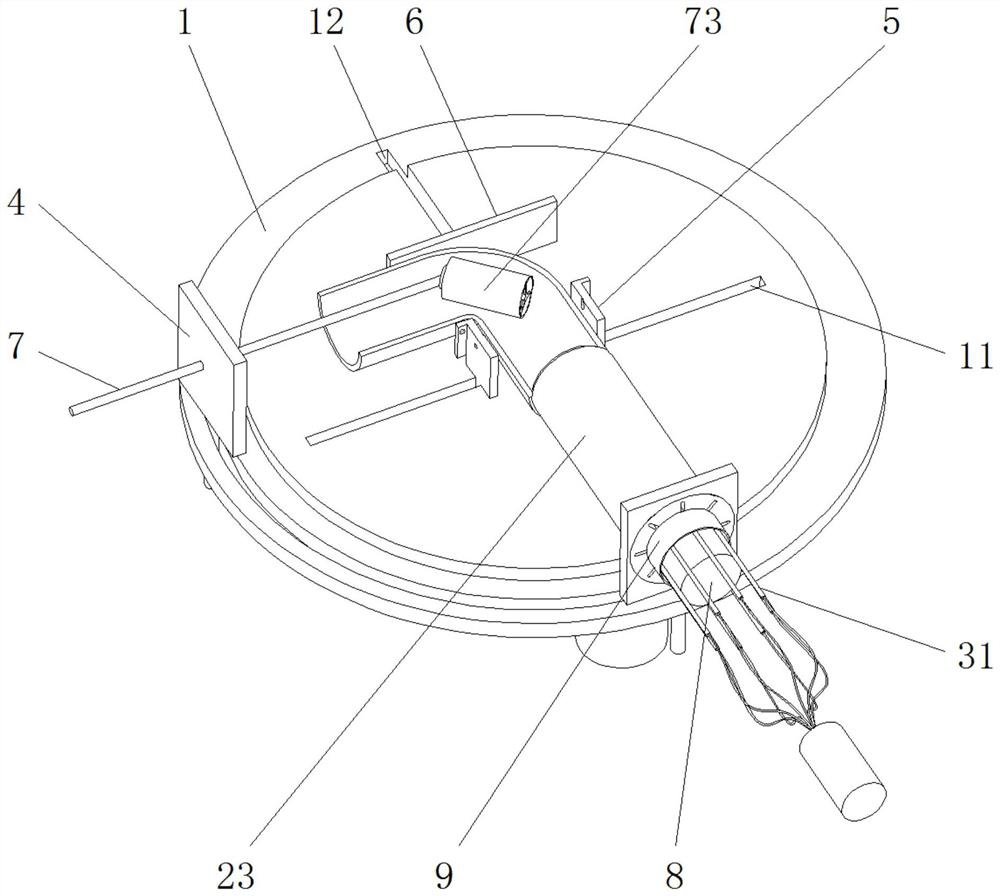

Rust removing maintaining device of steel structure parking device

ActiveCN109454564ARust removal achievedAchieve rotationAbrasive machine appurtenancesAbrasive blasting machinesLeft–right symmetryRust

The invention discloses a rust removing maintaining device of a steel structure parking device in the technical field of garage rust removing devices. Two sets of supporting rotating mechanisms are included, and are distributed in a left-right symmetry manner; a rusted steel pipe is connected to the upper portions of the supporting rotating mechanisms in a rolling portion; and the left side of thesupporting rotating mechanisms is sequentially provided with a first supporting base and a second supporting base from left to right. According to the rust removing maintaining device of the steel structure parking device, by arranging a rack pushing plate and a gear structure, a spray head is stably pushed into the inner wall of the steel pipe to remove rust, and rust removing on the inner wallof the steel pipe is achieved; due to the arrangement of a cylindrical gear, a chain gear and a chain, synchronous rust removing of inner and outer pipelines can be achieved, and the rust removing progress of the inner pipe wall can be conveniently known about; meanwhile, part of stress can be eliminated; due to the arranged supporting rotating mechanisms, rotating of the steel pipe can be achieved, so that rust removing is through; and due to an arranged supporting ring structure, the front end spray head can be supported to smoothly move in an inner cavity of the pipeline.

Owner:ANHUI HUAXING INTELLIGENT PARKING EQUIP

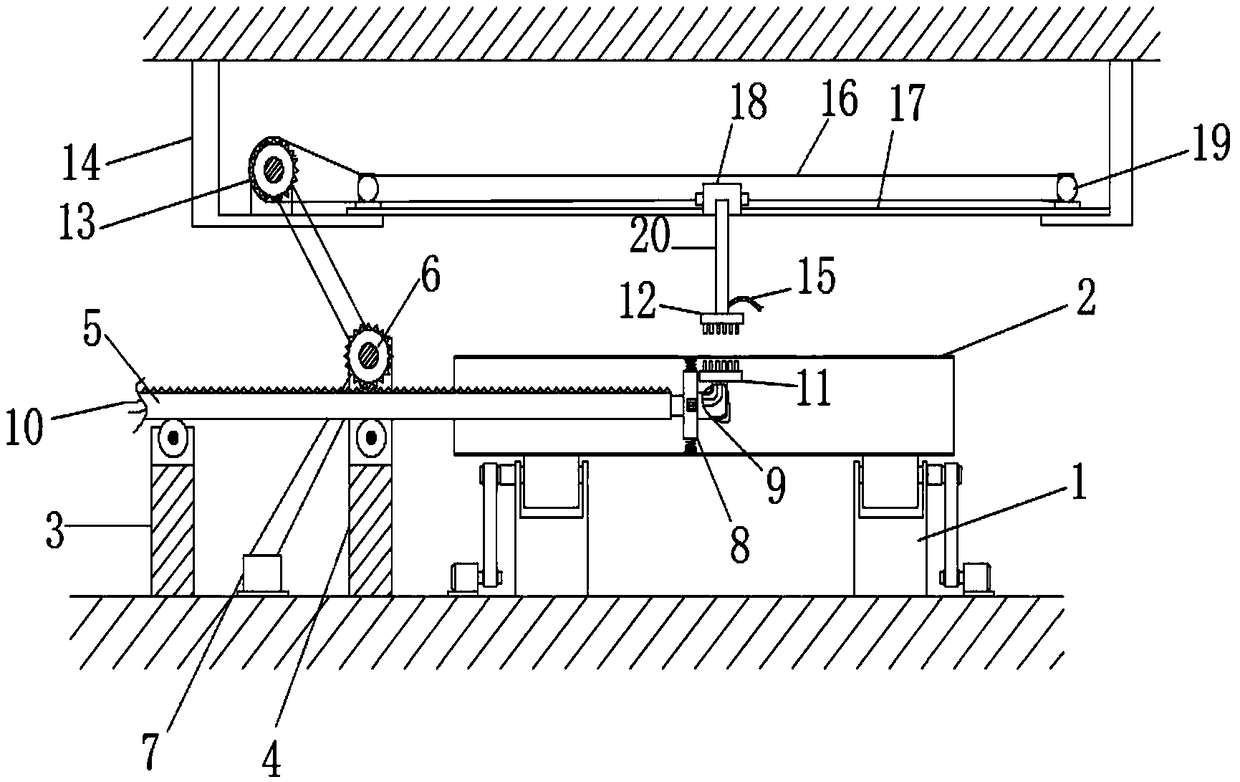

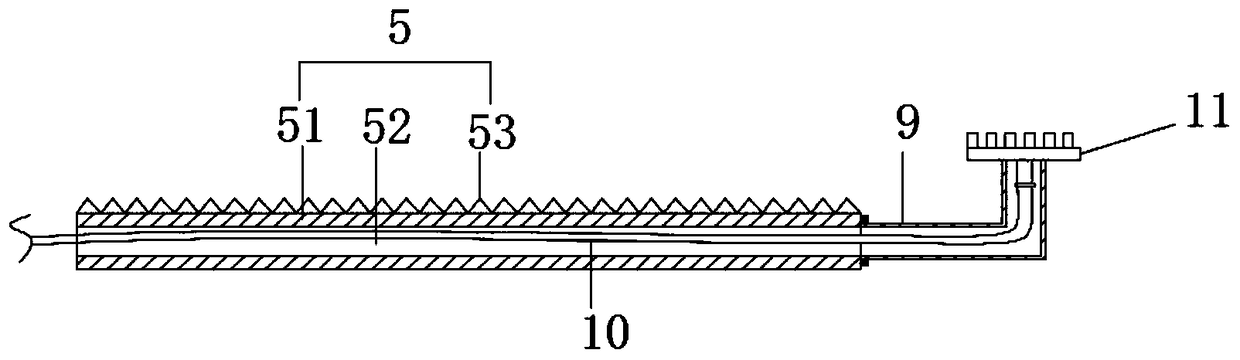

Steel bar straightening and cutoff machine

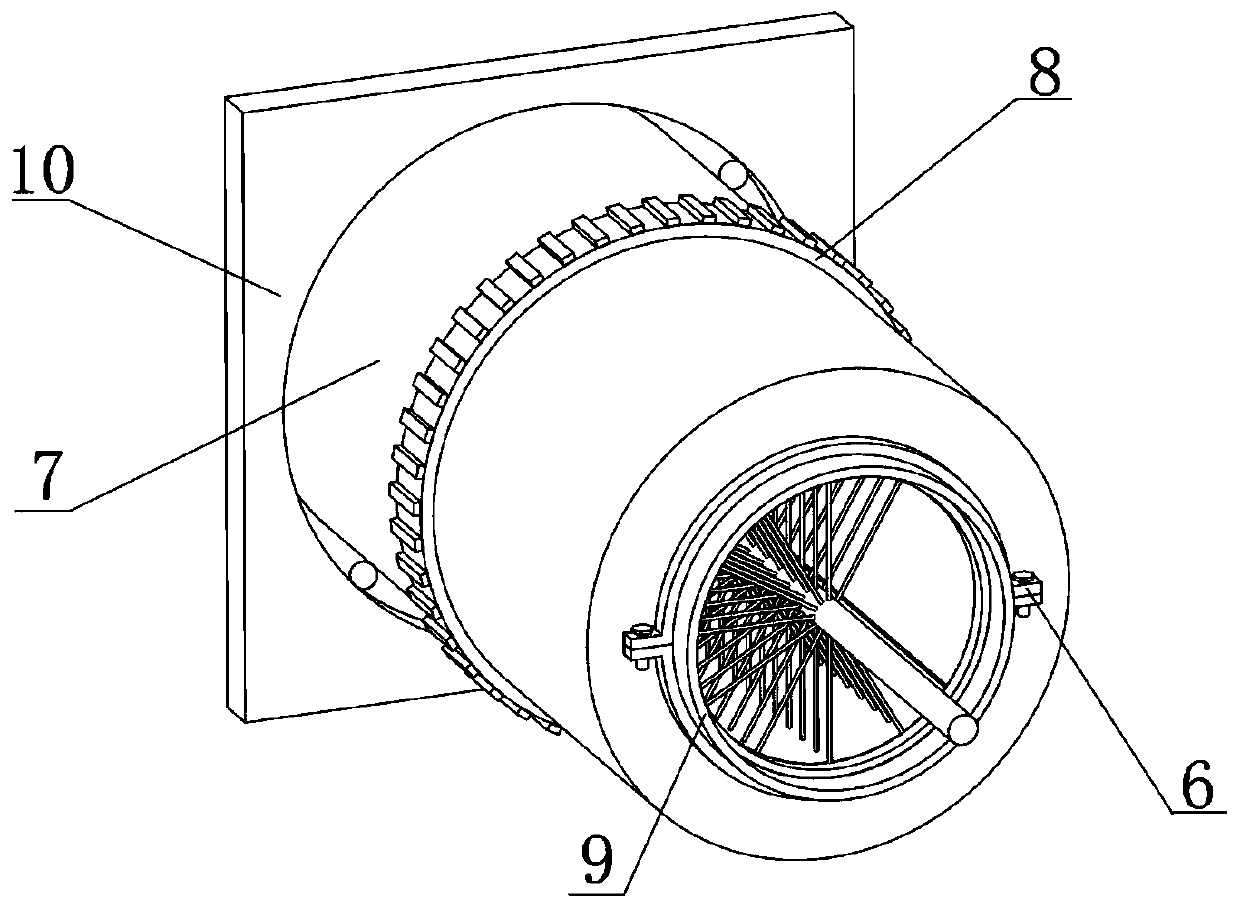

ActiveCN109290487AImprove surface qualityImprove rust removal efficiencyGrinding machinesCleaning using gasesRebarWork performance

The invention belongs to the technical field of steel bar processing equipment and particularly relates to a steel bar straightening and cutoff machine. The steel bar straightening and cutoff machinecomprises a machine frame; a straightening device, a conveying belt, a fixing cutoff device and a limiting baffle are sequentially arranged on the machine frame; a dedusting module is arranged betweenthe conveying belt and the fixing cutoff device and comprises a rotating ring, shear fork mechanisms and centrifugal balls; the rotating ring sleeves a steel bar, the outer circle of the rotating ring is provided with a tooth part, and a rotating gear is arranged on one side of the rotating ring; the shear fork mechanism is formed by crossed hinge of a set of connecting rod ends with the two middles being hinged; a steel wire band is arranged on the side, close to the steel bar, of each shear fork mechanism; shaking springs are connected to the positions, between the adjacent connecting rod ends, of the two sides of the rotating ring; and each centrifugal ball is connected to the corresponding shaking spring through an elastic rope. The steel bar is rubbed in the circumference direction through the dedusting module so as to be dedusted, and therefore, the surface quality and the working performance of the steel bar are improved.

Owner:李美娇

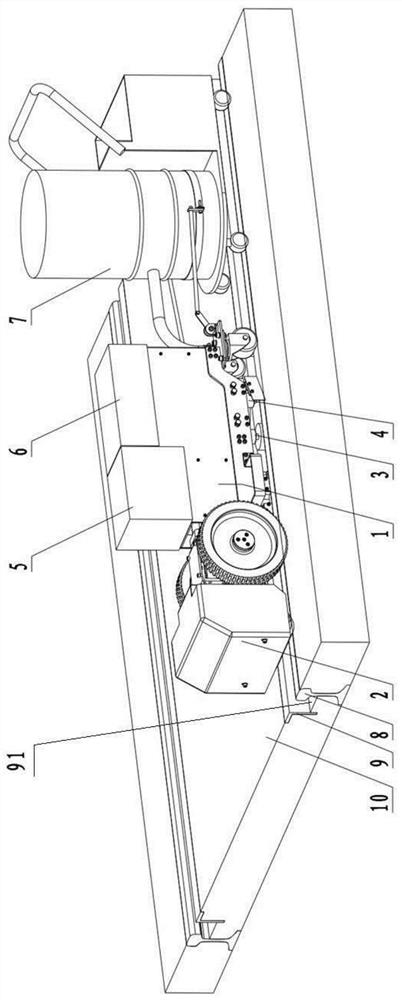

Metal pipeline rust removal and painting all-in-one machine

InactiveCN109848817ARust removal achievedRevolution surface grinding machinesGrinding drivesLacquerEngineering

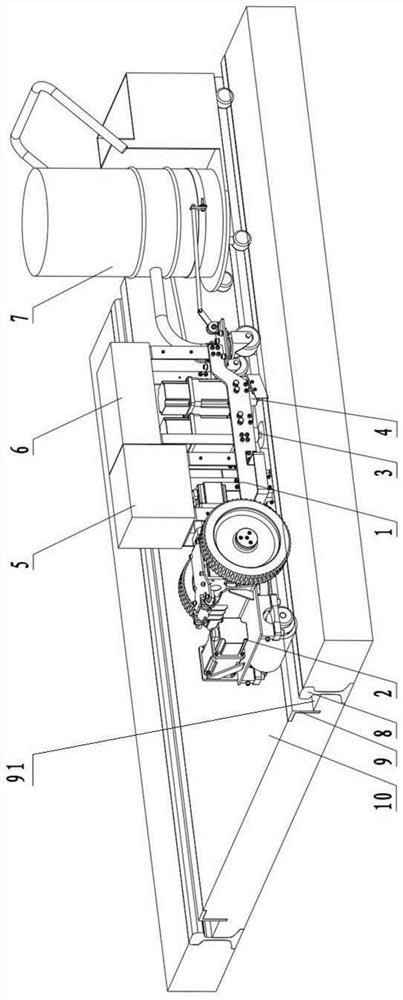

The invention discloses a metal pipeline rust removal and painting all-in-one machine. The metal pipeline rust removal and painting all-in-one machine comprises a guide rail frame, a traction winch, arotary positioning screw, a metal pipe, a painting system, an advancing tackle, an auxiliary rotating device, an electric control switch, a traction steel wire rope, and a grinding rust removal machine; the advancing tackle is arranged on a guide rail in the guide rail frame, the grinding rust removal machine is arranged on the upper end of the advancing tackle, a metal pipe penetrates through agrinding hole of the grinding rust removal machine, the rotary positioning screw and the auxiliary rotating device are arranged on the top of the two sides of the metal pipe, the traction winch is drawn to be connected with the advancing tackle through the traction steel wire rope and a pulley, and the painting system is arranged on the upper end of the grinding rust removal machine. According tothe metal pipeline rust removal and painting all-in-one machine, the metal pipe is placed on the inner diameter of the grinding rust removal machine, the rotary positioning screw is adjusted to enablethe metal pipe and the auxiliary rotating device to be fixed, a motor rotates to drive the metal pipe to rotate, the grinding rust removal machine begins to carry out rust removal, the traction winchdraws the advancing tackle to move on the guide rail frame, whole rust removal of the metal pipe is achieved, and the painting system sprays paint to the metal pipe.

Owner:TIANCHEN COAL MINE OF ZAOZHUANG MINING GRP

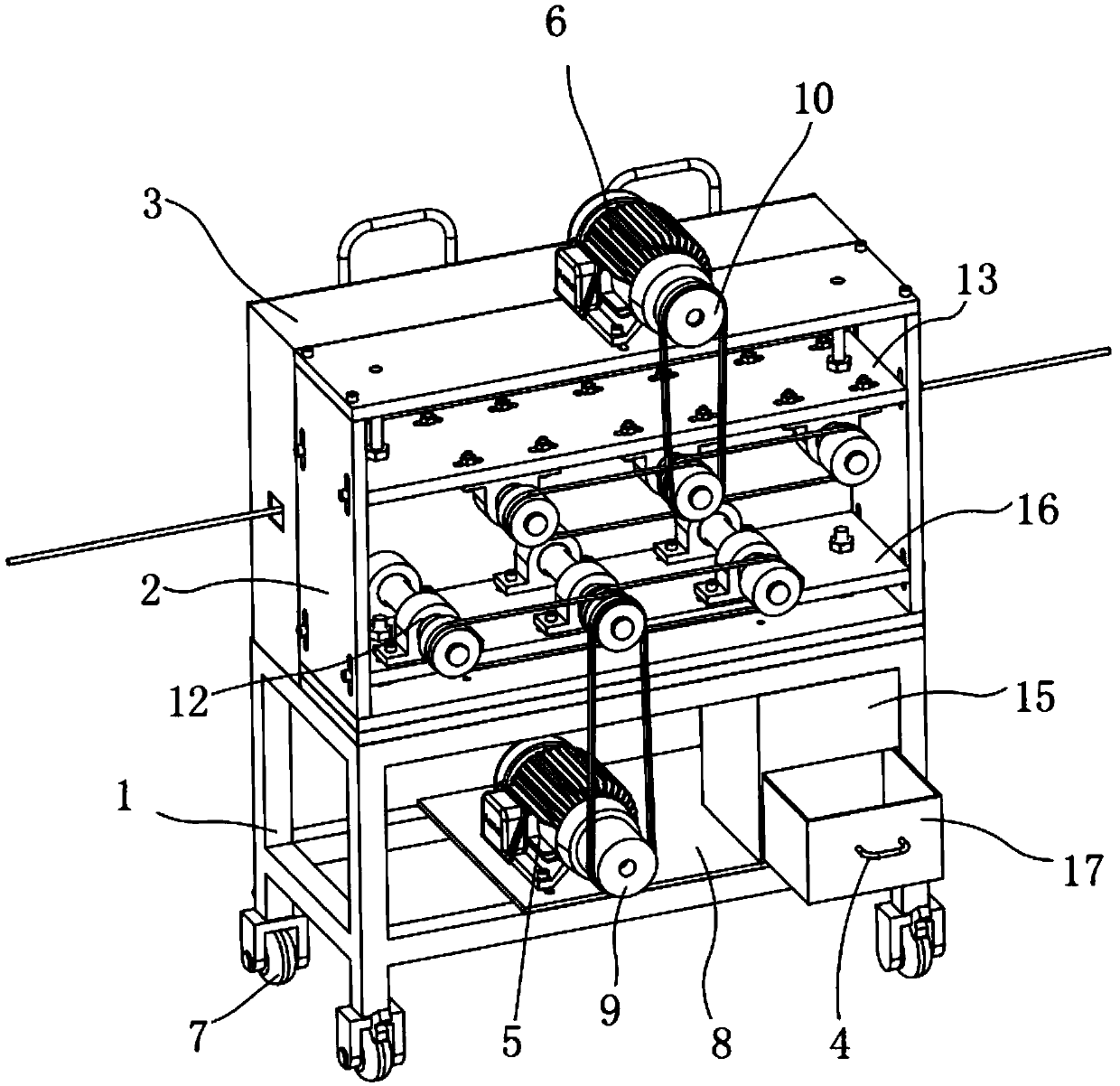

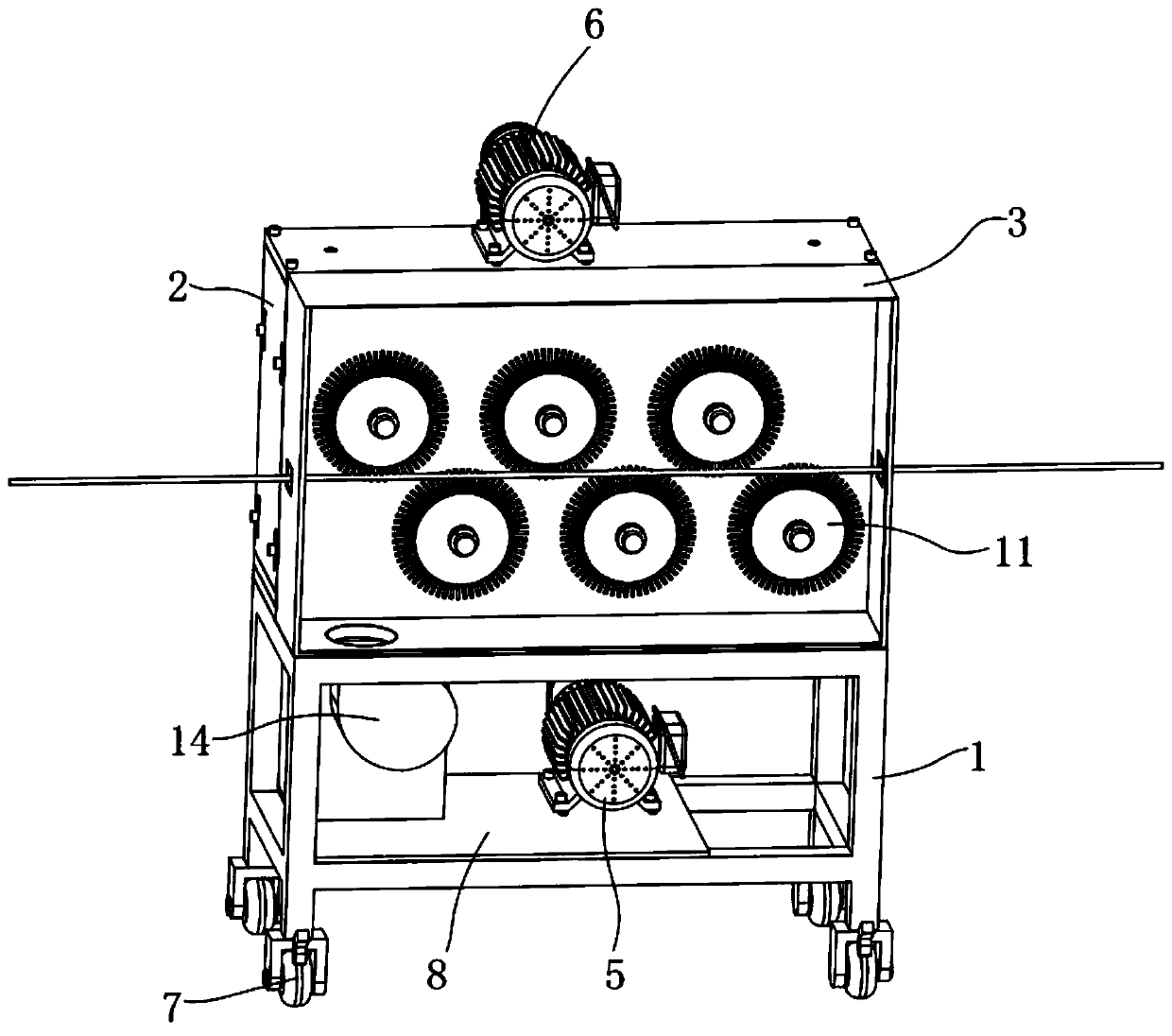

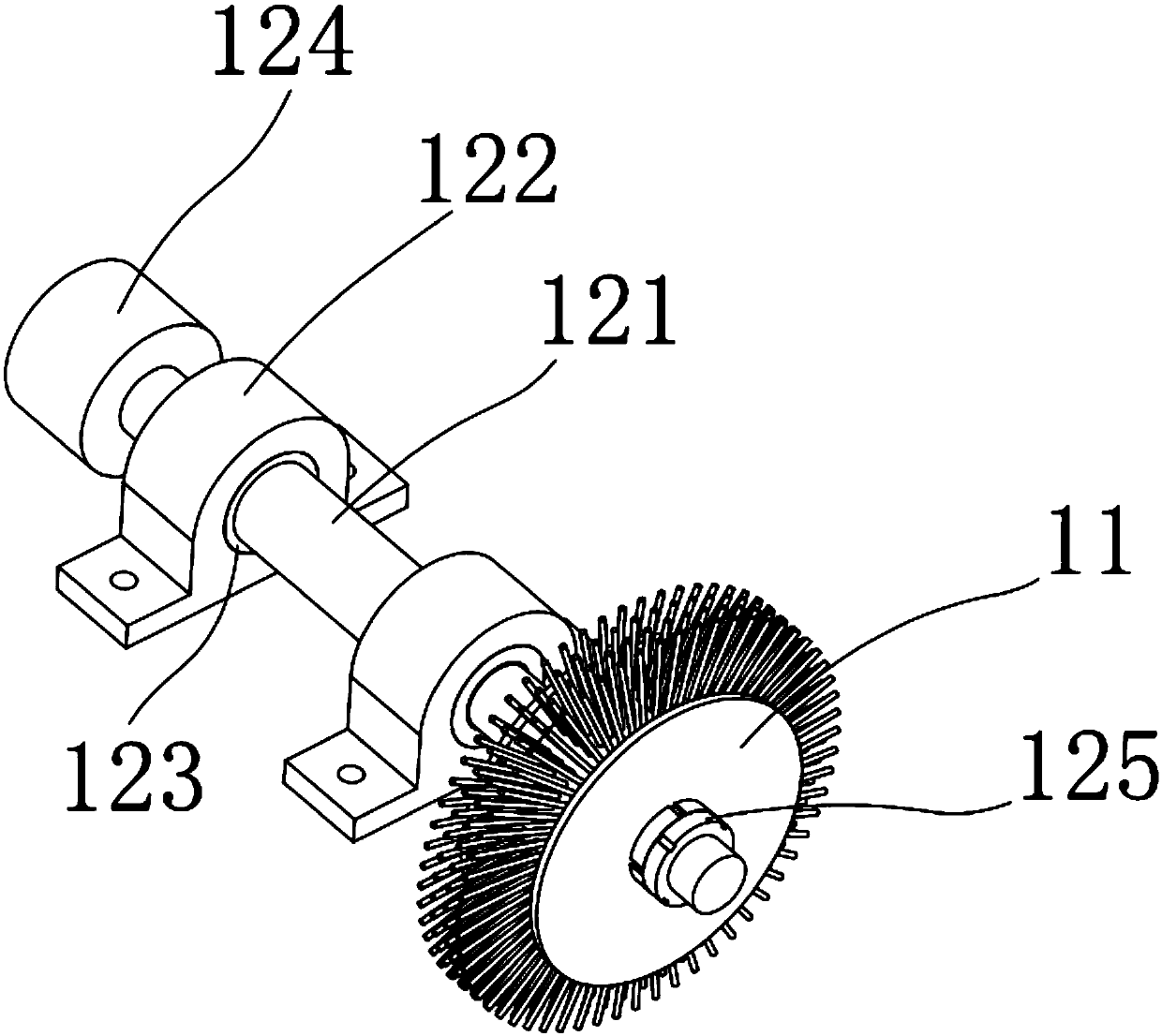

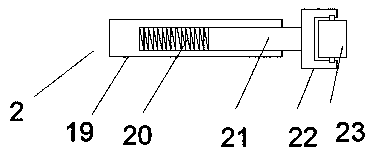

Automatic rust removal device of wire rod steel bars for rolling mill

InactiveCN109551350ARust removal achievedAchieve comprehensive rust removalGrinding carriagesGrinding drivesWire rodTransmission belt

The invention discloses an automatic rust removal device of wire rod steel bars for a rolling mill. The automatic rust removal device of the wire rod steel bars for the rolling mill comprises a machine frame, a machine body is arranged at the upper end of the machine frame, a second mounting plate is fixed to the middle of the machine body, a third mounting plate is fixed below the second mountingplate, and rust removal mechanisms are fixed to the second mounting plate and the third mounting plate. A second servo motor is fixed to the top end of the machine body, a second belt pulley is fixedto the second servo motor, and the second belt pulley is in transmission connection with the rust removal mechanisms through a transmission belt. A first mounting plate is fixed to the machine frame,a first servo motor is fixed to the upper end of the first mounting plate, a first belt pulley is fixed to the first servo motor, and the first belt pulley is in transmission connection with a thirdbelt pulley through the transmission belt. A protective cover is arranged on the side surface of the machine body, a dustbin is fixed to the first mounting plate, and a dust collector is fixed to thedustbin. According to the automatic rust removal device of the wire rod steel bars for the rolling mill, automatic rust removal for the steel bars is realized, the working efficiency is high, the rustremoval quality is high, no pollution is achieved, and popularization is worthy.

Owner:天台鑫广祥汽车用品有限公司

Carbon steel wire machining process

ActiveCN107058690ARust removal achievedReduce recycling costsMetallic material coating processesProcess efficiency improvementHydrogenAlloy

The invention relates to the technical field of carbon steel wire machining, in particular to a carbon steel wire machining process. Compared with the prior art, in the scheme, a hydrogen explosion rust removal device is adopted for removing rust of carbon steel alloy materials, hydrogen is inflated into the device, shake generated by hydrogen explosion is used for achieving mutual friction of abrasive materials and carbon steel in the device, rust removal of the carbon steel is achieved, matter generated after hydrogen explosion only contains water, and therefore direct discharging can be achieved without retreatment. In this way, the problem that a large amount of waste acid will be generated in the existing process, special equipment and method are needed for recycling, and enterprise cost generated by treating waste is increased can be solved.

Owner:重庆方略精控金属制品有限公司

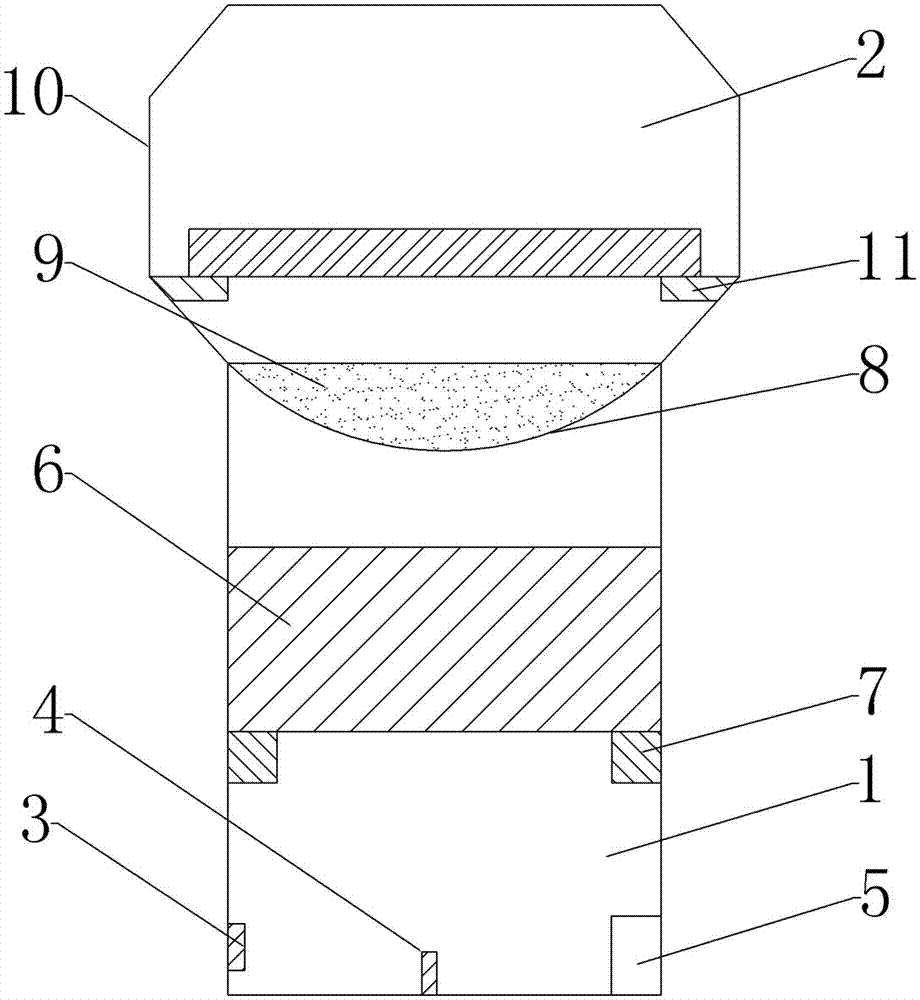

Tinned sheet manufacturing and machining method

InactiveCN112875362ARust removal achievedFull grinding and rust removalGrinding carriagesGrinding drivesTinningElectric machine

The invention relates to a tinned thin plate manufacturing and machining method. The method uses rust removal equipment, the rust removal equipment comprises a base, an unwinding device, a winding device and a middle rust removal device. A sheet is wound and passes through a primary rust removal rod, the primary rust removal rod carries out primary rust removal on the sheet; a winding motor is started, And the output end of the winding motor drives a winding roller to rotate, so that the sheet clamped on the winding roller can be wound, and therefore unwinding and winding can be carried out at the same time; a driving motor is started, and the output end of the driving motor drives a gear to rotate, so that the upper end face and the lower end face of the sheet can be subjected to full polishing and rust removal by the opposite or relative movement of a upper rust removal roller and a lower rust removal roller; a suction pump is started, the upper end face and the lower end face of the sheet make contact with an upper dust collection roller and a lower dust collection roller correspondingly, the suction pump sucks out impurities and dust on the surface of the sheet from through holes, and the two dust collection rollers roll, so that dust absorption glue above the dust absorption rollers can wipe impurities and dust which are not absorbed on the upper end face and the lower end face of the sheet.

Owner:南京健昌机电科技有限公司

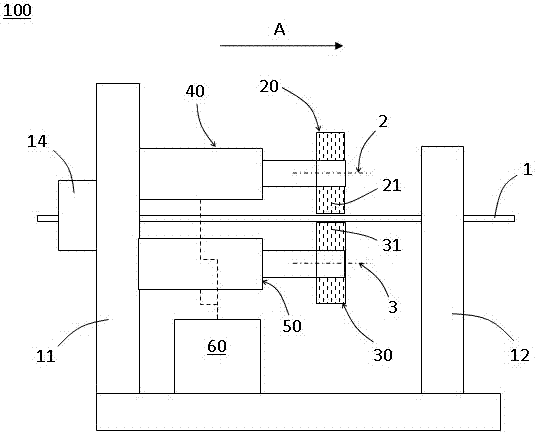

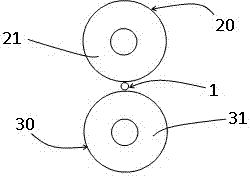

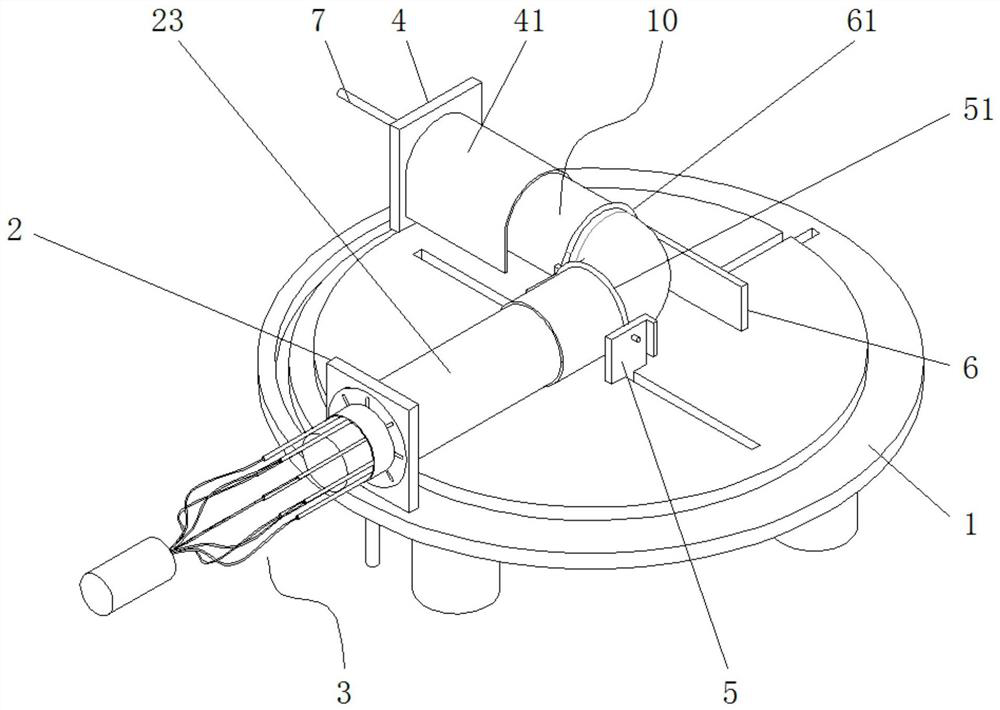

Mechanical derusting equipment for wire rods

PendingCN107097134ARust removal achievedGuaranteed derusting effectGrinding carriagesGrinding machinesWire rodEngineering

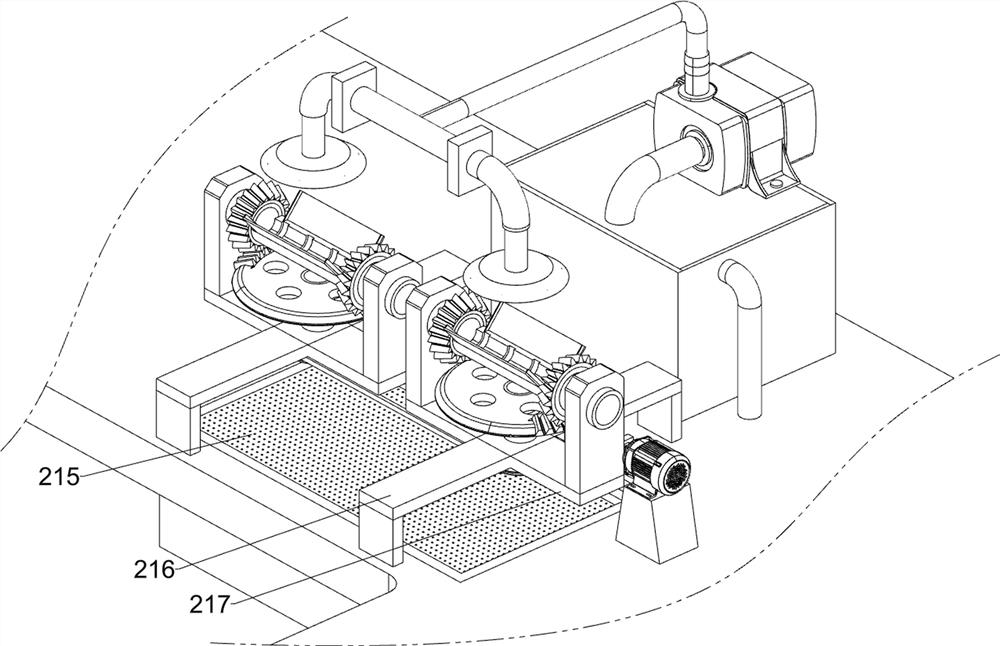

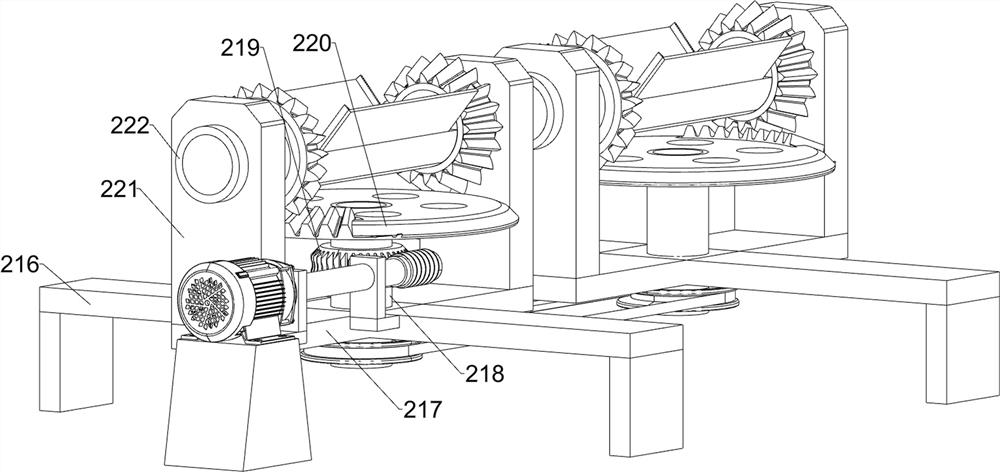

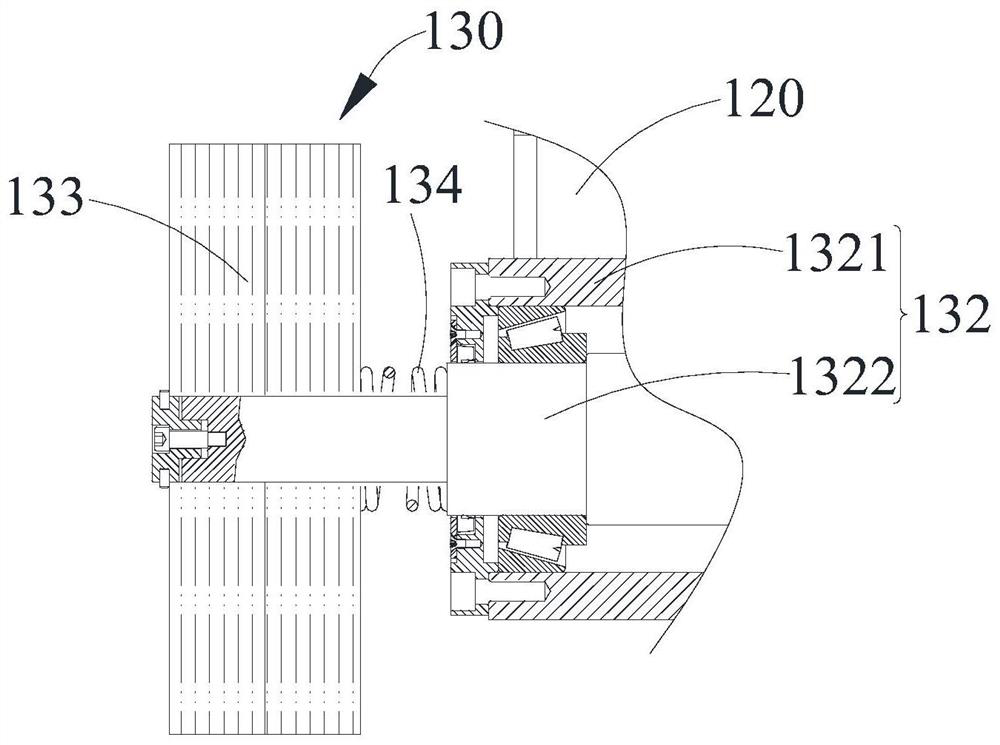

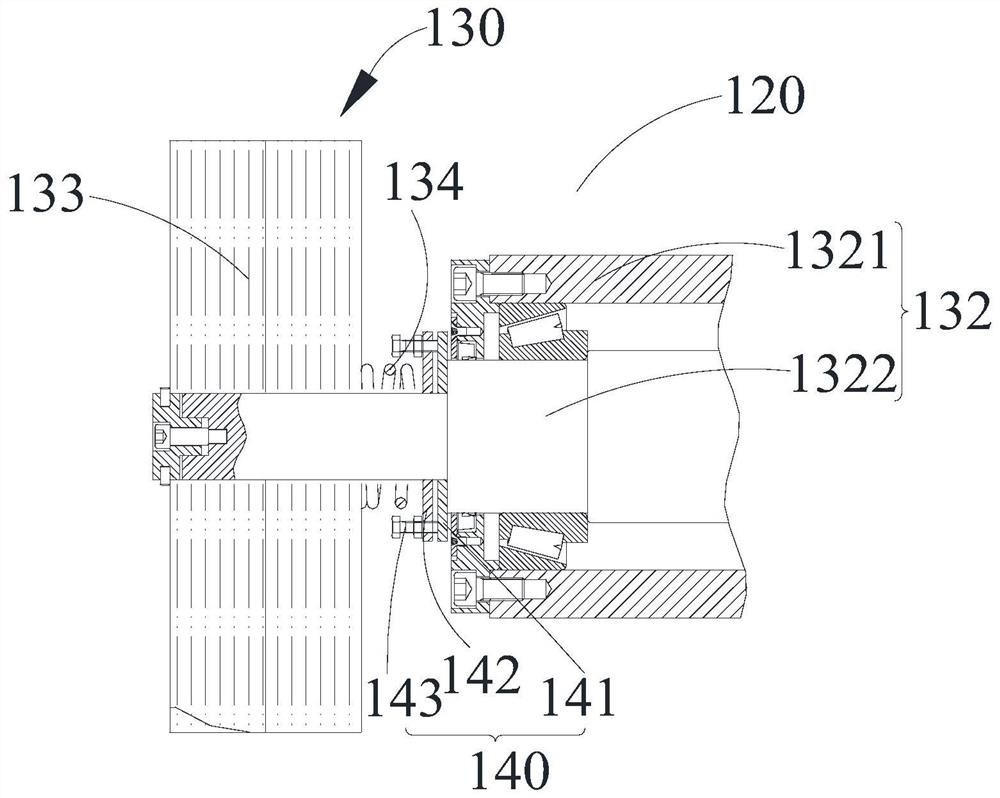

The invention provides mechanical derusting equipment for wire rods. The equipment comprises a support, a first turnplate, a second turnplate, a first transmission part, a second transmission part and a drive part. A first boss and a second boss of the support are provided with wire rod penetrating holes allowing a to-be-derusted wire rod to penetrate through in a wire rod arranging direction correspondingly. The first turnplate and the second turnpalte are provided with a first friction part rotating along the first axis and a second friction part rotating along the second axis correspondingly. The second turnplate and the first turnplate are symmetric with respect to the to-be-derusted wire rod penetrating through the wire rod penetrating holes. The to-be-derusted wire rod is located between the first friction part and the second friction part and tightly abuts against both the first friction part and the second friction part. The drive part enables the first turnplate to rotate through the first transmission part, so that the first friction part is driven to rub the to-be-derusted wire rod; and the drive part also enables the second turnplate to rotate through the second transmission part, so that the second friction part is driven to rub the to-be-derusted wire rod. By adoption of the mechanical derusting equipment, the wire rod can be automatically and mechanically derusted, and the working efficiency is improved on the premise that the derusting effect is guaranteed.

Owner:葛云杰

Rust removal equipment capable of treating bent steel bars

PendingCN114273301AAchieve rust removalAchieve clearingGrinding machinesCleaning using liquidsRebarRust remover

The invention relates to the field of reinforcing steel bars, in particular to rust removal equipment capable of treating bent reinforcing steel bars. The technical problems that dents and bends on reinforcing steel bars cannot be well treated, and meanwhile rust in some gaps cannot be removed, so that the effect is poor are solved. According to the technical implementation scheme, the rust removal equipment capable of treating the bent steel bars comprises a bottom frame, a straightening system, a first rust removal system and the like; a straightening system is connected to the front part of the upper side of the underframe; a first derusting system is connected to the middle of the upper side of the underframe. The first rust removal system is designed, rust on the upper surfaces and in gaps of the steel bars is removed through a rust remover, meanwhile, rust at the bottoms of the steel bars is removed, and iron rust on the gaps and the outer surfaces of the steel bars is removed at the same time.

Owner:李超龙

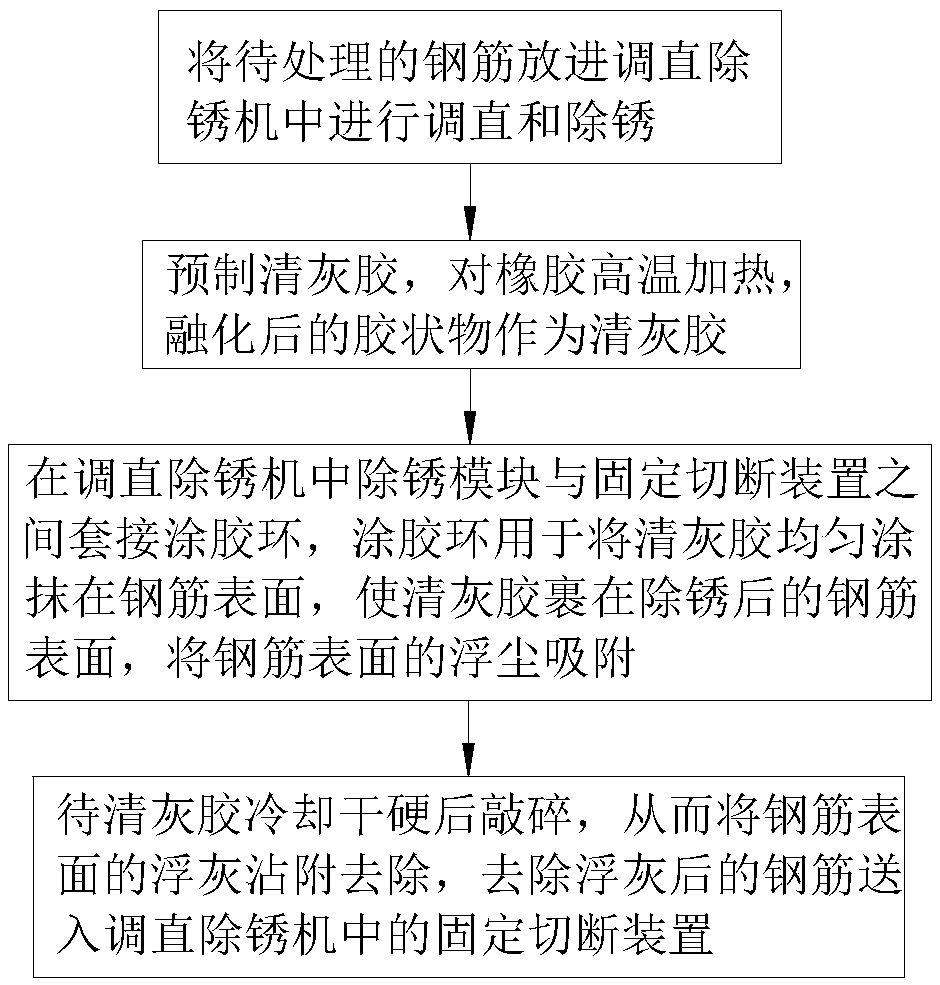

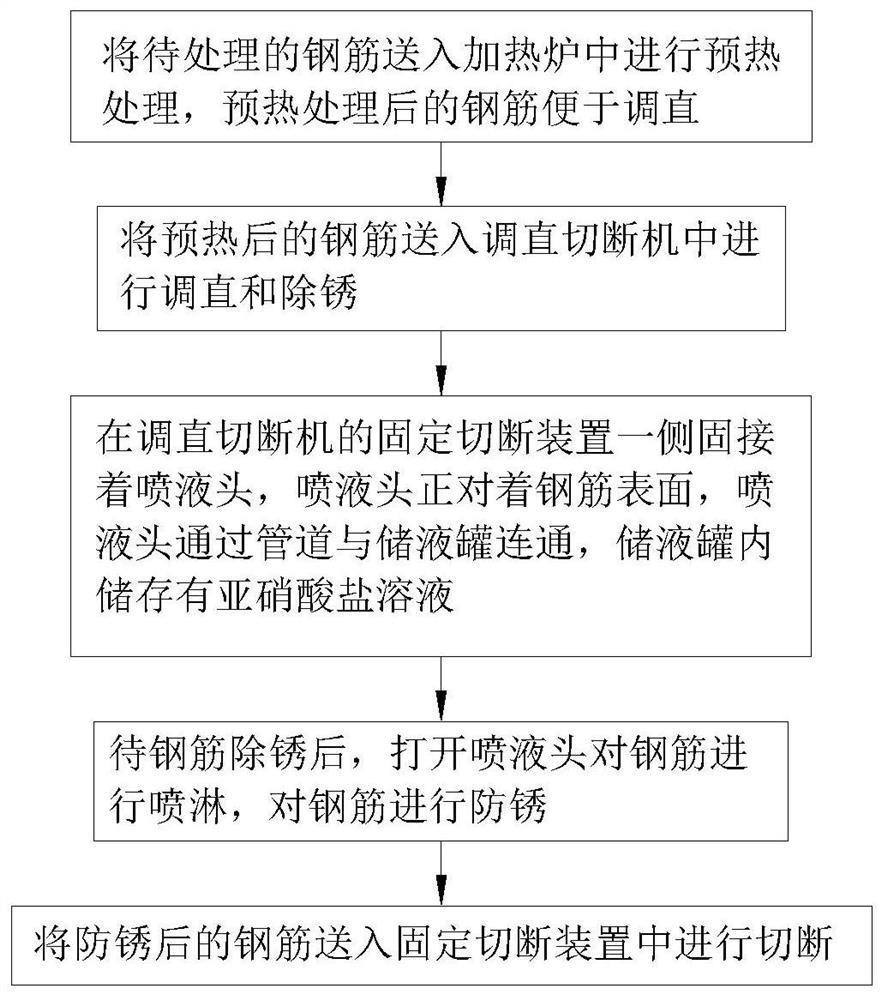

Rebar rust removing method

InactiveCN109333299ARust removal achievedQuick rust removalGrinding machinesGrinding/polishing safety devicesGear wheelEngineering

The invention belongs to the technical field of rebar machining, in particular to a rebar rust removing method. A straightening and rust removing machine adopted by the method comprises a machine frame; the machine frame is sequentially provided with a straightening device, a conveyor belt, a fixing and cutting-off device and a limiting material baffle; a rust removing module is arranged between the conveyor belt and the fixing and cutting-off device and comprises a rotating ring, elastic strips and a shaking unit; the rotating ring is connected with a rebar in a sleeving mode; the two elasticstrips are symmetrically connected to an inner ring of the rotating ring; wire meshes are arranged on the sides, close to the rebar, of the elastic strips; the shaking unit is arranged on one side ofthe rotating ring; the shaking unit comprises a sleeve, a sliding block and a swing rod; the sliding block is slidably mounted in the sleeve; gears are arranged on the sleeve; and the gears are fixedly connected with the swing rod. Dust on the surface subjected to rust removing of the rebar is removed through rubber melted at a high temperature, thus, rapid rust removing of the rebar is achieved,and the surface quality and the working properties of the rebar are improved.

Owner:刘见虎

Steel pipe derusting machine

ActiveCN112025428ARust removal achievedImprove rust removal efficiencyRevolution surface grinding machinesGrinding drivesPilot holeClassical mechanics

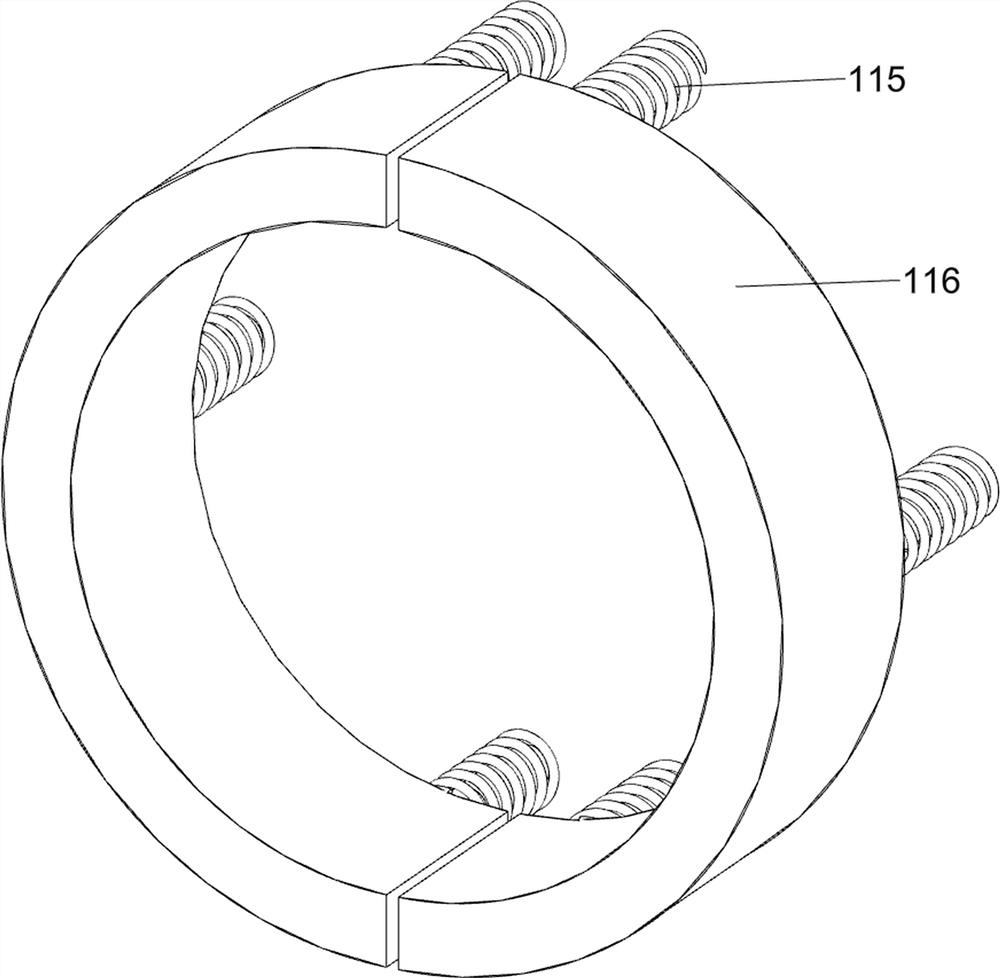

The invention relates to a steel pipe derusting machine. The steel pipe derusting machine comprises a rack, end limiting devices are arranged on the rack, each end limiting device comprises an annularmounting base and a guide ring, the inner surface of the guide ring comprises an annular face and an arc-shaped concave face, each end limiting device further comprises a limiting ring, at least fourguide holes are formed in the limiting ring, pressing columns are movably mounted in the guide holes, the inner ends of the pressing columns are pressed on the outer circumferential face of a steel pipe, the outer ends of the pressing columns abut against the inner circumferential face of the guide ring, a supporting rod is fixedly installed on the guide ring, a guide wheel is rotatably installedon the supporting rod, a connecting rope is arranged between the guide wheels of the end limiting devices and connected with an outer wall derusting brush and an inner wall derusting brush, and a part, located on the outer side of the steel pipe, of the connecting rope directly faces the arc-shaped concave face. When the pressing column makes contact with the arc-shaped concave face, the pressingcolumn does not abut against the outer circumferential face of the steel pipe, the connecting rope can pass through a gap between the steel pipe and the pressing column, and simultaneous derusting ofthe inner wall and the outer wall of the steel pipe can be achieved.

Owner:衡阳鸿大精密制造有限责任公司

Leveling machine, black strip acid-free derusting device using the same and method thereof

InactiveCN100455370CRust removal achievedEliminate corrosionWork treatment devicesRoll mill control devicesEmulsionEngineering

The invention relates to a flattener, relative thermal rolling band steel non-acid scaling device and method, wherein said flattener comprises a roller cleaner (15) whose end contacts the lower roller and compression lower roller (14); the cleaner (15) can clean the ferric oxide in each rotation of roller, to improve work efficiency. And the scaling device comprises emulsion feeder (1), flattener (2), high-pressure water injector (3), iron brush (4), washing drier (5), and coiling machine (6). The invention can improve the service life and effect of iron brush. And the method comprises that adjusting the injected amount of emulsion to adjust the scaling quality and save cost.

Owner:武钢集团有限公司

Steel rail rust removal robot

ActiveCN112796184ARust removal achievedRealize automatic derusting operationRailway track constructionEngineeringMaterials science

The invention discloses a steel rail rust removal robot which comprises a movably-arranged chassis, a horizontal rust removal mechanism provided with a horizontal rust removal part and a vertical rust removal mechanism provided with a vertical rust removal part. The horizontal derusting piece is matched and contacted with the upper surface of the steel rail; the vertical derusting piece extends into the rail groove and is matched and contacted with the side surface, exposed in air, of the steel rail; the horizontal rust removal mechanism and the vertical rust removal mechanism are both installed on the chassis. In the rust removal process, the steel rail rust removal robot can be suitable for rust removal of the embedded steel rail, automatic rust removal operation on the upper surface of the embedded steel rail and the side face, exposed in the air, of the embedded steel rail is achieved, the labor cost is reduced, and the rust removal efficiency is improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

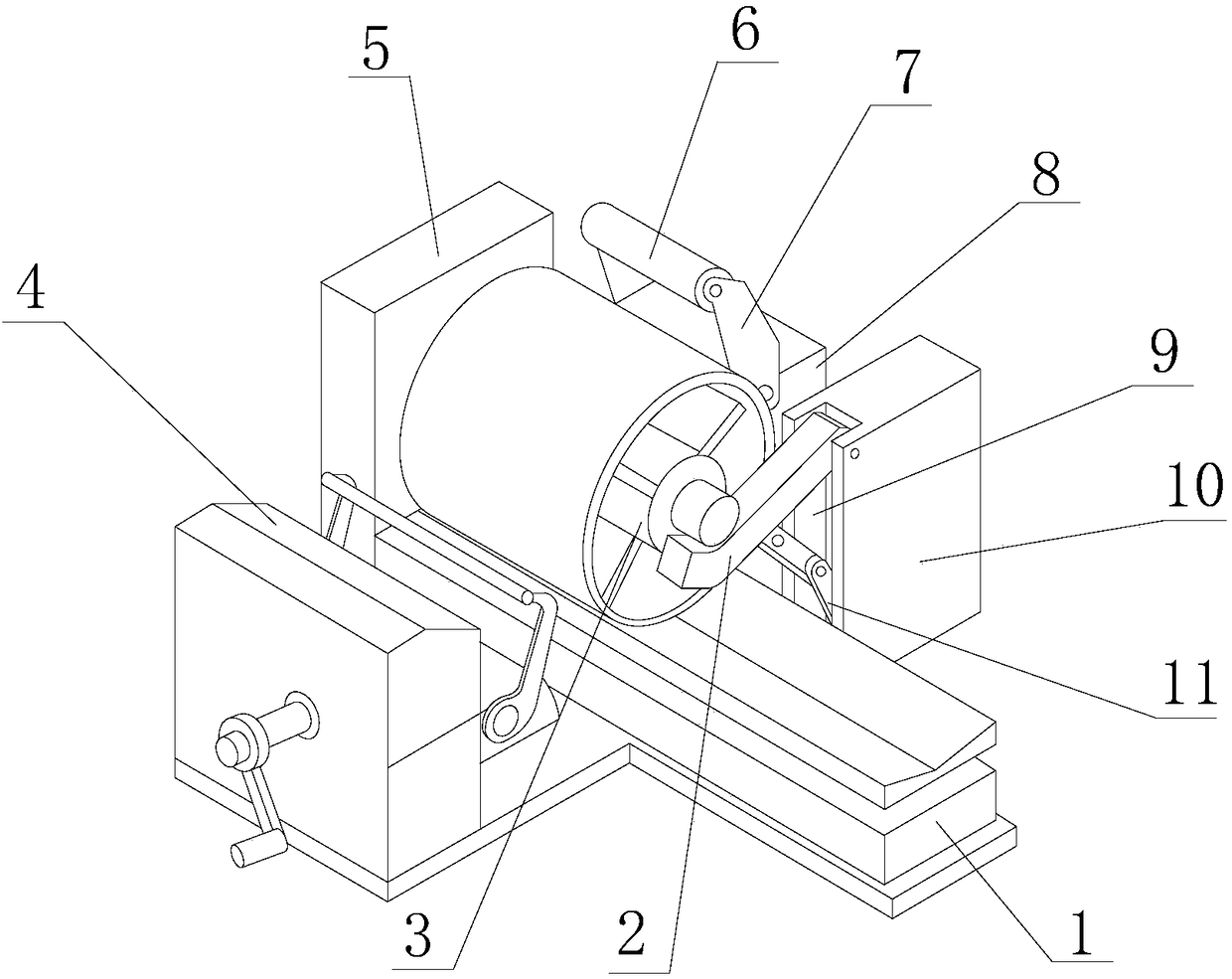

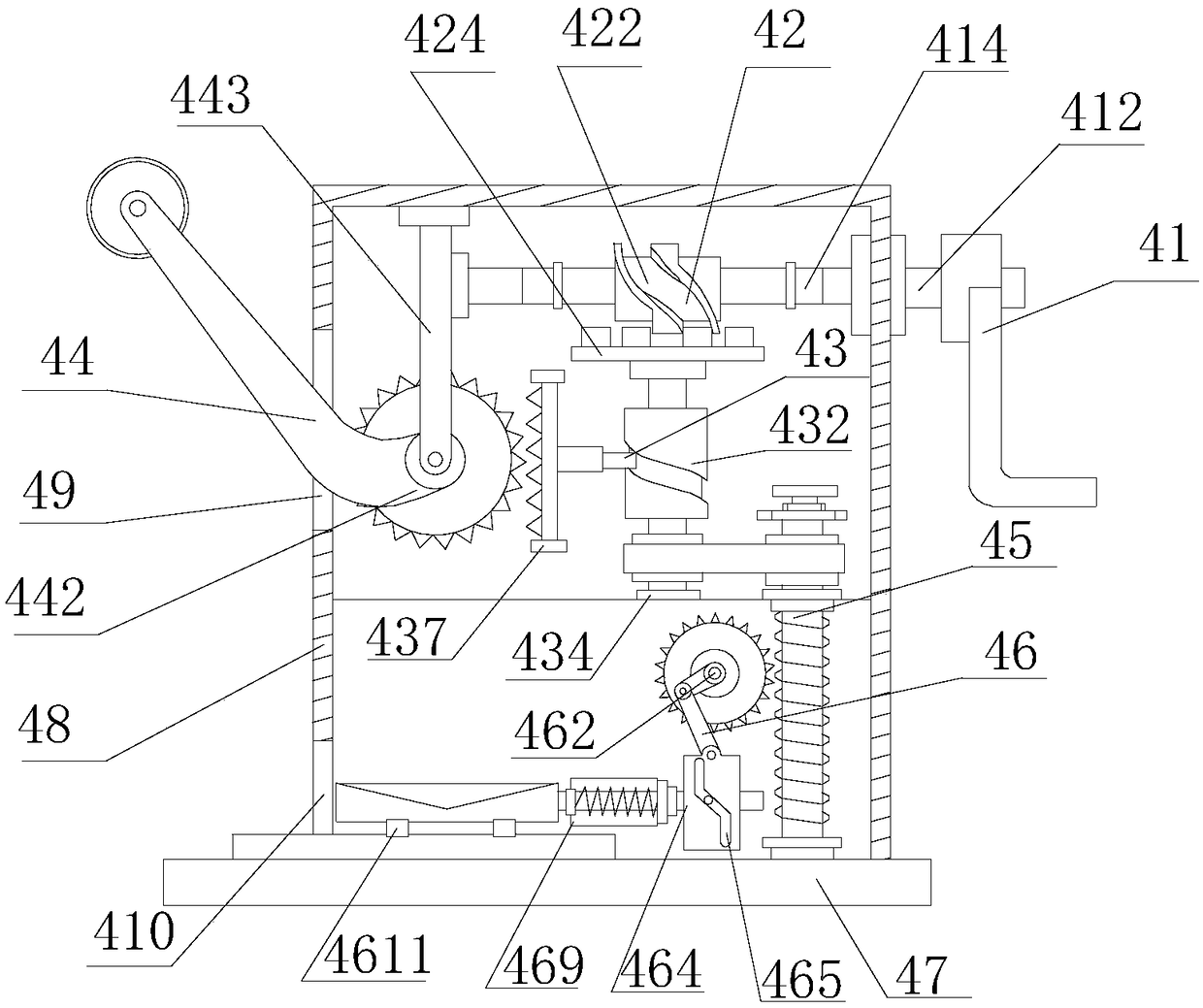

Inner supporting type paint device for outer wall of cylinder

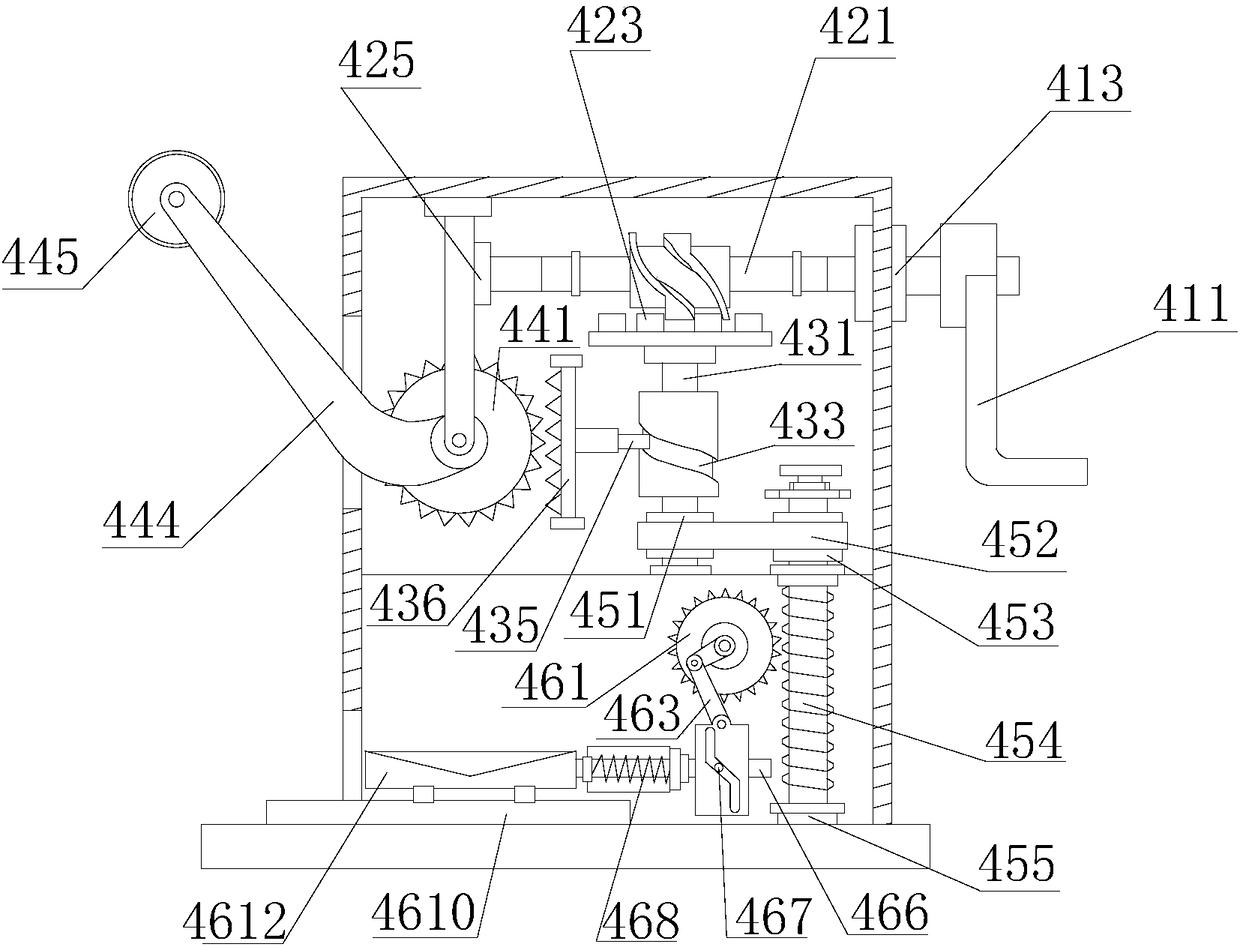

InactiveCN108466153ARust removal achievedSolve the problem of easy falling offGrinding drivesGrinding machinesScrapSprocket

The invention discloses an inner supporting type paint device for an outer wall of a cylinder. The device structurally comprises a fixed base, a primary supporting arm, an inner supporting rotary shaft, a dedusting device, a limiting side plate, a paint brush, a paint brush supporting rod, a paint cabin, a movable groove, a supporting device and a secondary supporting arm, wherein the dedusting device comprises a manual adjusting structure, a cam transmission mechanism, a sheave transmission mechanism, a dedusting roller transmission mechanism, a chain wheel transmission mechanism, a scrap iron collecting mechanism, a device base, a device shell, an upper opening and a lower opening. The inner supporting type paint device for the outer wall of the cylinder solves the problem that the paintsurface, which is directly sprayed, of the outer wall of the cylinder is easy to fall as the surface of the outer wall of the cylinder cannot be dedusted before the conventional inner supporting typepaint device for the outer wall of the cylinder sprays paint to the cylinder, and can dedust the outer wall of the cylinder and collect scrap iron, so that the paint spraying quality is improved.

Owner:莆田市荔城区浩旺贸易有限公司

A method for straightening steel bars

The invention belongs to the technical field of steel bar processing, and specifically relates to a method for straightening steel bars. The straightening and cutting machine used in the method includes a frame, and the frame is sequentially provided with a straightening device, a conveyor belt, and a fixed cutting device. and a limit stopper; a derusting module is provided between the conveyor belt and the fixed cutting device, and the derusting module includes a swivel, a scissor mechanism and a centrifugal ball; the swivel is sleeved on the steel bar, and the swivel The ring is provided with teeth, and one side of the swivel is provided with a rotating gear; the scissors mechanism is composed of a set of connecting rod ends hinged in the middle, and the side of the scissors mechanism close to the steel bar is provided with a steel wire belt; A vibrating spring is connected between the ends of adjacent connecting rods on both sides of the swivel; a centrifugal ball is connected to the vibrating spring through an elastic rope; The solution is used to brush the surface of the steel bar to prevent rust, thereby improving the surface quality of the steel bar and the working performance of the steel bar.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

Machine tool gap rust removal protection device

ActiveCN113020127AEasy to remove rustEasy to remove impuritiesMaintainance and safety accessoriesCleaning processes and apparatusStructural engineeringMachine tool

In order to solve the problem that rust removal can be hardly conducted on gaps, the invention discloses a machine tool gas rust removal protection device. The machine tool gap rust removal protection device comprises a mounting plate, a connecting frame is fixedly mounted on the right side of the upper surface of the mounting plate, a material spraying pump is fixedly mounted on the left side of the upper surface of the mounting plate, and a material storage box is fixedly mounted on the upper side of the material spraying pump. A second guide pipe is connected between the material storage box and the material spraying pump, a universal rod is fixedly installed on the right side of the connecting frame, a material containing box is fixedly installed at the right end of the universal rod, a connecting rod is fixedly connected to the right side of the material containing box, a holding ring is fixedly installed at the top end of the connecting rod, and a mounting rod is fixedly installed on the lower side of the mounting plate. Connecting lines are evenly connected to the left side face and the right side face of the mounting rod, and a material passing pipe is fixedly mounted on the surface of the mounting rod. According to the machine tool gas rust removal protection device, through guiding of the connecting lines, wax is introduced into the connecting lines, rust and impurities in a gap can be brought out by means of the rapid coagulability of the wax, and rust removal of the gap of a machine tool is achieved.

Owner:广东艾普升智能装备有限公司

A laser rust remover for removing rust on the surface of iron metal pipes

ActiveCN113634557BRust removal achievedRust removal is simple and easyCleaning processes and apparatusLaser processingLight beam

The invention provides a laser rust remover for removing rust on the surface of an iron metal pipe, and relates to the field of laser processing. A workbench, the top of the workbench is slidably fitted with two clamping plates, and the top of the workbench is slidably fitted with abutting plates, the clamping plates and the abutting plates are used to clamp the pipe body. The laser rust remover for removing rust on the surface of ferrous metal pipes uses a beam rod to inject laser light into the pipe, and the reflector is matched with the insertion rod to drive the reflector to move back and forth in the pipe, so that the laser is reflected toward the pipe. The bend of the inner wall can be used to remove rust at the bend of the pipe. Improve the coordination of beam rod, turntable, expansion block and belt to achieve the effect of adjustment, so that the whole device can derust pipes of various diameters and improve the scope of application. It further makes it simple and easy to remove rust on the inner wall of the pipe.

Owner:SHAOXING UNIVERSITY

Rust removal and maintenance equipment for steel structure parking equipment

ActiveCN109454564BRust removal achievedAchieve rotationAbrasive machine appurtenancesAbrasive blasting machinesGear wheelSprocket

Owner:ANHUI HUAXING INTELLIGENT PARKING EQUIP

A steel bar straightening and derusting machine

ActiveCN109500297BRust removal achievedImprove surface qualityGrinding machinesGrinding feedersGear wheelClassical mechanics

The invention belongs to the technical field of rebar machining devices, and particularly relates to a rebar straightening rust removing machine. A rack is included, and is sequentially provided witha straightening device, a conveying belt, a fixed cut-off device and a limiting material blocking plate; a rust removing module is arranged between the conveying belt and the fixed cut-off device, andcomprises a rotating ring, elastic strips and a shaking unit; the rotating ring is connected to rebar in a sleeving manner; the two elastic strips are symmetrically connected to the inner ring of therotating ring; the sides, close to the rebar, of the elastic strips are provided with steel wire nets; one side of the rotating ring is provided with the shaking unit which comprises a sleeve, a slider and swinging rods, and the slider is installed in the sleeve in a sliding manner; and gears are arranged on the sleeve, and the swinging rods are fixedly connected to the gears. According to the rebar straightening rust removing machine, due to the fact that the rebar is wiped by the rust removing module in the peripheral direction, and therefore rust removing of the rebar is achieved, the elastic strips are driven by the shaking unit to shake, so that rust slag wiped off by the steel wire nets falls off, and then the surface quality of the rebar and the work performance of the rebar are improved.

Owner:科尼起重机设备制造(江苏)有限公司

Hydraulic engineering construction pipeline rust removal device

InactiveCN109318131ABig impactRust removal achievedBlast gunsAbrasive blasting machinesWater storage tankEngineering

The invention discloses a hydraulic engineering construction pipeline rust removal device which comprises a device main body and sliding devices. An arc groove is formed in the middle position of thebottom of the device main body, the sliding devices are arranged on the two sides of the bottom of the device main body, and an air compressor is arranged inside the device main body. According to therust removal device, since the air compressor, a water storage tank and a sand storage tank are arranged inside the device main body, the sand storage tank is connected with a spray gun through a sand conveying pipe, the water storage tank is connected with the sand conveying pipe through a water conveying pipe, flowing sand in the sand conveying pipe enters the spray gun, the air compressor is connected with the spray gun through a gas conveying pipe, sand sprayed by the spray gun has the high impact force, therefore, rust on the surface of the water conveying pipe is removed, the rust removal effect is ensured, the device main body slides on the water conveying pipe since the sliding devices are arranged, rolling wheels on the sliding devices can stretch and retract through inner rods,therefore, using requirements of different pipes are met, and applicability is higher.

Owner:SHAANXI HANTAI WATER CONSERVANCY & HYDROPOWER SURVEY & DESIGN CO LTD

Steel pipe threaded pipe fitting rust removal equipment

PendingCN112108979ARust removal achievedRealize automatic feeding processGrinding carriagesGrinding drivesPipe fittingThreaded pipe

The invention discloses steel pipe threaded pipe fitting rust removal equipment. The steel pipe threaded pipe fitting rust removal equipment comprises a machine frame and a workbench installed on themachine frame, and further comprises a steel pipe threaded pipe fitting feeding device installed on the part, on the front side of the workbench, of the machine frame, a steel pipe threaded pipe fitting jacking, clamping and rotating device longitudinally installed on the front side of the top face of the workbench in the left-right direction, and a steel pipe threaded pipe fitting rust removal device mounted on the top surface of the rear side of the workbench. An air pressure and electric appliance control device is further included; and the steel pipe threaded pipe fitting rust removal equipment further comprises a steel pipe threaded pipe fitting rolling feeding groove bottom transverse width adjusting device, and a large sliding base pushes a positioning device. By means of the steelpipe threaded pipe fitting rust removal equipment, automatic feeding and automatic rust removal of steel pipe threaded pipe fitting rust removal are achieved, the labor intensity of rust removal workers and the rust removal cost of the steel pipe threaded pipe fitting are reduced, and the rust removal efficiency of the steel pipe threaded pipe fitting is improved; and the steel pipe threaded pipefitting rust removal equipment is also suitable for rust removal of steel pipe threaded pipe fittings with different specifications and sizes.

Owner:济南迈科管道科技有限公司

A steel bar straightening and cutting machine

ActiveCN109290487BRust removal achievedImprove surface qualityGrinding machinesCleaning using gasesGear wheelRebar

The invention belongs to the technical field of steel bar processing equipment, and specifically relates to a steel bar straightening and cutting machine, which includes a frame on which a straightening device, a conveyor belt, a fixed cutting device and a limit blocking plate are sequentially arranged; A rust removal module is provided between the conveyor belt and the fixed cutting device, and the rust removal module includes a swivel, a scissor mechanism and a centrifugal ball; the swivel is sleeved on the steel bar, and the outer ring of the swivel is provided with teeth. There is a rotating gear on one side of the swivel; the scissor mechanism is composed of a set of connecting rod ends hinged in the middle, and the side of the scissor mechanism close to the steel bar is equipped with a steel wire belt; the two sides of the swivel are connected A vibrating spring is connected between the ends of adjacent connecting rods; the vibrating spring is connected with a centrifugal ball through an elastic rope; the present invention rubs the steel bar circumferentially through the derusting module, thereby realizing the derusting of the steel bar and further improving the rust removal of the steel bar. The surface quality and working performance of steel bars.

Owner:李美娇

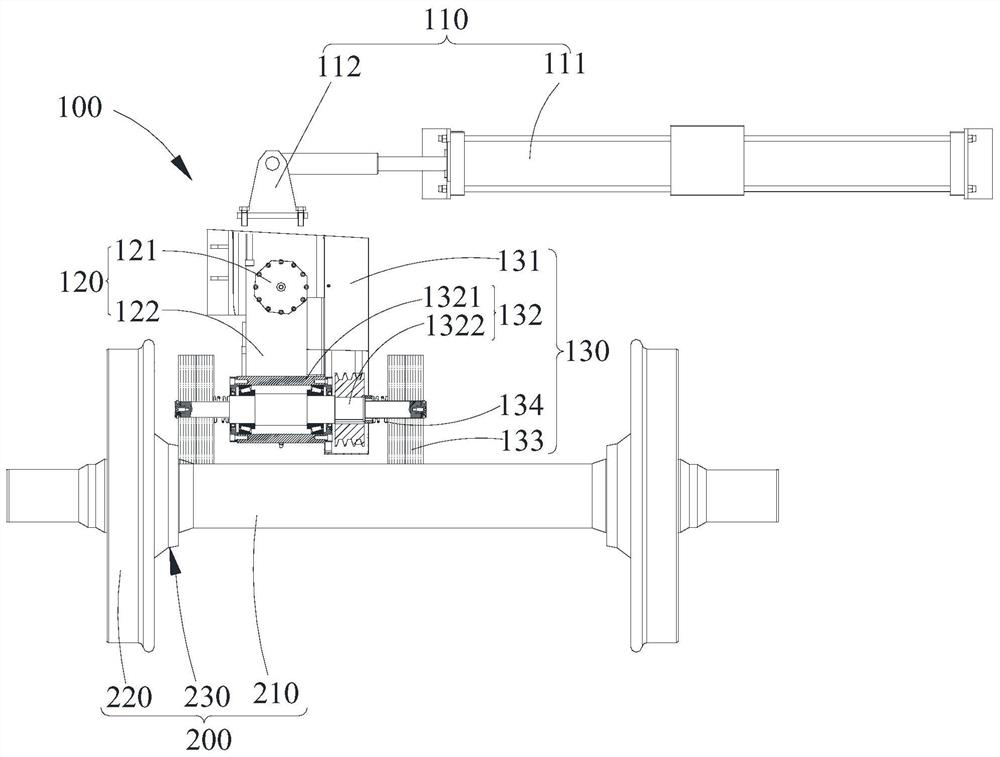

Derusting machine for railway wagon wheel set and derusting device for axle body

The invention relates to a derusting machine for railway wagon wheelsets and a derusting device for an axle body. The shaft derusting device includes: an axial movement mechanism installed on the installation frame; a radial feed mechanism arranged on the axial movement mechanism; a brush shaft mechanism including a drive assembly, a brush shaft assembly, a buffer elastic member and A wire brush, the wire brush is arranged on the brush shaft assembly, and the buffer elastic member is arranged on the brush shaft assembly and abuts against the wire brush. During rust removal, the radial feed mechanism drives the brush shaft assembly to make the wire brush contact the shaft body of the wheel set, and the axial movement mechanism drives the radial feed mechanism and the brush shaft assembly to move to realize the derusting of the shaft body; at the same time, the buffer The elastic part provides elastic pre-tightening force, which makes the wire brush close to the root of the wheel set, keeps the wire brush close to the root, ensures that the root of the wheel set can fully contact with the wire brush, and ensures the cleaning effect.

Owner:SHENHUA RAIL & FREIGHT WAGONS TRANSPORT

A steel pipe derusting machine

ActiveCN112025428BRust removal achievedImprove rust removal efficiencyRevolution surface grinding machinesGrinding drivesPilot holeClassical mechanics

The invention relates to a steel pipe derusting machine, which comprises a frame, and an end limiting device is arranged on the frame. The end limiting device includes an annular mounting seat and a guide ring. The inner surface of the guide ring includes an annular surface and an arc-shaped Concave surface, the end limit device also includes a limit ring, which is provided with at least four guide holes, and a compression column is installed in the guide hole, and the inner end of the compression column is pressed against the outer peripheral surface of the steel pipe, and the compression The outer end of the column is against the inner peripheral surface of the guide ring, the guide ring is fixedly installed with a support rod, the guide wheel is rotated on the support rod, and a connecting rope is arranged between the guide wheels of the limit device at both ends, and the connecting rope is connected with a The rust removal brush on the outer wall and the rust removal brush on the inner wall, the part of the connecting rope located on the outside of the steel pipe is facing the arc-shaped concave surface. When the compression column touches the arc-shaped concave surface, the compression column does not press against the outer peripheral surface of the steel pipe, and the connecting rope can pass through the steel pipe And the gap between the compression column can realize the simultaneous derusting of the inner wall and outer wall of the steel pipe.

Owner:衡阳鸿大精密制造有限责任公司

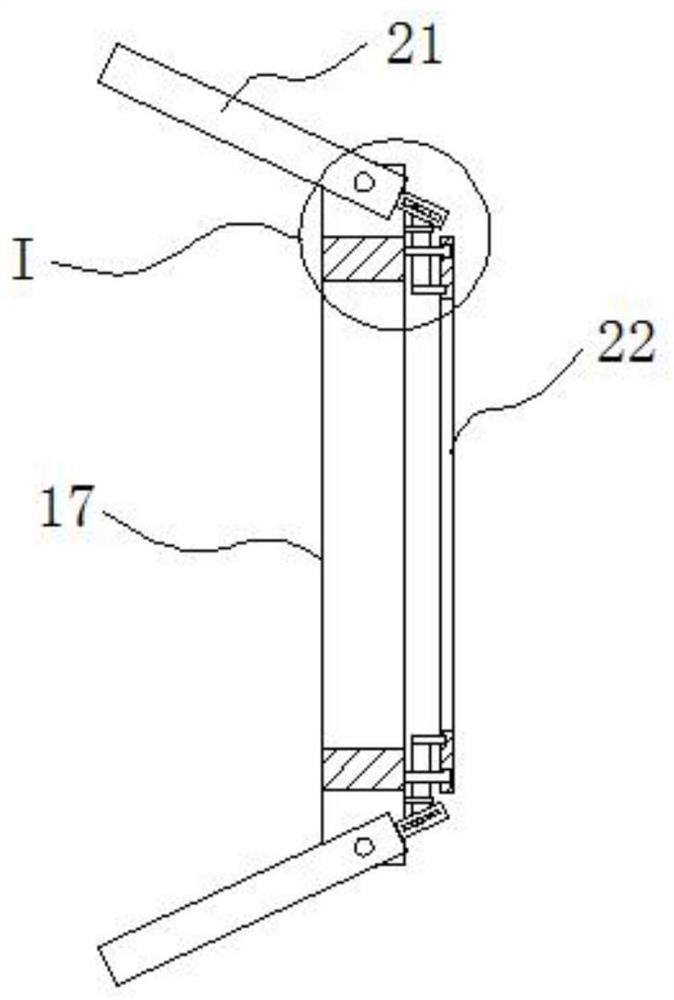

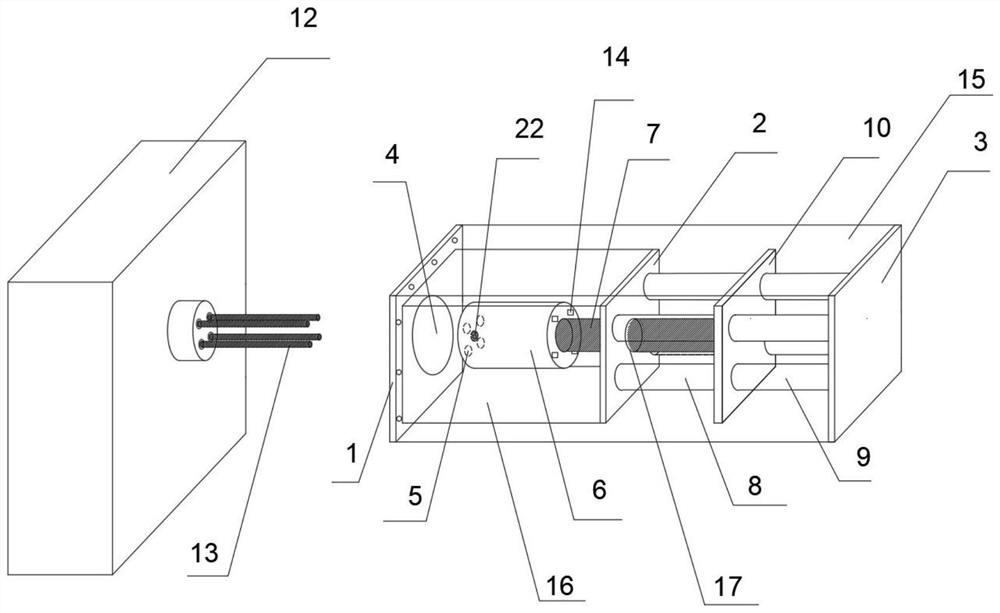

Stay cable whole bundle intelligent tensioning equipment

InactiveCN112176881AImprove gripEqual tensionBridge structural detailsBridge erection/assemblyArchitectural engineeringJackscrew

The invention discloses stay cable whole bundle intelligent tensioning equipment which comprises a front fixing plate, a rear fixing plate and an outer supporting frame and is characterized in that the front fixing plate and the rear fixing plate are supported and connected through the outer supporting frame, an inner fixing plate and an inner supporting frame are further arranged in the front fixing plate, the rear fixing plate and the outer supporting frame, the inner supporting frame is connected with the front fixing plate, the inner supporting frame supports and fixes the inner fixing plate, tensioning anchors are arranged in the inner fixing plate and the inner supporting frame, the rear ends of the tensioning anchors are fixedly connected with tensioning columns, second open holes are formed in the center of the inner fixing plate, the diameter of the second open holes is larger than that of the tensioning columns, movable base plates are arranged at the other ends of the tensioning columns, the tensioning columns penetrate through the second open holes to be fixedly connected with the movable base plates, four first jacks are arranged between the movable base plates and theinner fixing plate, and four second jacks are arranged between the movable base plates and the rear fixing plate. The stay cable whole bundle intelligent tensioning equipment has the beneficial effects of being consistent in tensioning strength and capable of preventing slipping.

Owner:盐城市双强管桩有限公司

Water mist sand blasting derusting device for ships

PendingCN112809560AHigh strengthRust removal achievedAbrasive feedersAbrasive blasting machinesGear wheelMarine engineering

In order to solve the problem that the sand blasting force is not easy to control in the prior art, the invention discloses a water mist sand blasting derusting device for ships, which comprises a mounting rack, a connecting frame is fixedly mounted at the right end of the mounting rack, a handle is fixedly mounted on the right end surface of the connecting frame, a connecting rack is fixedly connected to the right side in the mounting rack, a motor is fixedly mounted on the rear surface of the connecting rack, a first gear is mounted at the front end of the motor, a water mist sand blasting machine is fixedly mounted on the left side of the surface of the mounting rack, a spray pipe is mounted on the left side of the water mist sand blasting machine, a lantern ring is fixedly connected to the left end of the spray pipe, a rotating shaft is sleeved with the lantern ring, the front end of the surface of the rotating shaft is fixedly sleeved with a second gear, a chain is connected between the first gear and the second gear, and the surface of the rotating shaft is fixedly sleeved with a rotating disc. The rotating disc can be driven by the motor to rotate, the water mist sand blasting force can be enhanced through centrifugal force, and therefore derusting through water mist sand blasting is effectively achieved.

Owner:ZHOUSHAN LIGANG SHIPBUILDING CO LTD

Carbon steel wire processing technology

ActiveCN107058690BRust removal achievedReduce recycling costsMetallic material coating processesProcess efficiency improvementHydrogenAlloy

The invention relates to the technical field of carbon steel wire machining, in particular to a carbon steel wire machining process. Compared with the prior art, in the scheme, a hydrogen explosion rust removal device is adopted for removing rust of carbon steel alloy materials, hydrogen is inflated into the device, shake generated by hydrogen explosion is used for achieving mutual friction of abrasive materials and carbon steel in the device, rust removal of the carbon steel is achieved, matter generated after hydrogen explosion only contains water, and therefore direct discharging can be achieved without retreatment. In this way, the problem that a large amount of waste acid will be generated in the existing process, special equipment and method are needed for recycling, and enterprise cost generated by treating waste is increased can be solved.

Owner:重庆方略精控金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com