Metal pipeline rust removal and painting all-in-one machine

A metal tube and integrated machine technology, applied in metal processing equipment, parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, etc. high strength issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the drawings and specific embodiments.

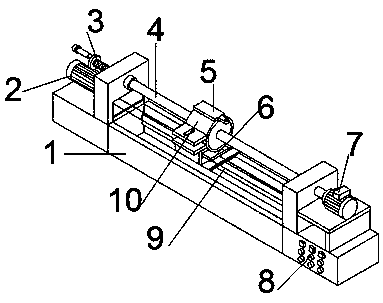

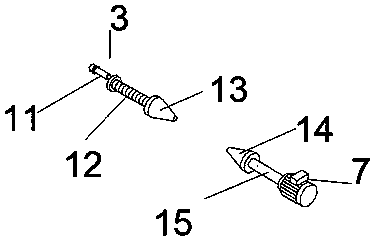

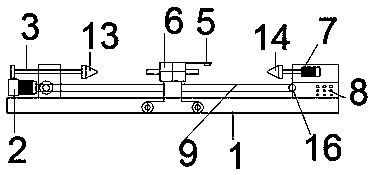

[0015] Such as figure 1 , figure 2 with image 3 As shown, an integrated machine for removing rust and painting for metal pipelines includes a guide rail frame 1, a traction winch 2, a rotary positioning screw 3, a metal pipe 4, a painting system 5, a traveling block 6, an auxiliary rotating device 7, and an electronic control switch 8. , Traction wire rope 9, grinding and descaling machine 10, traveling block 6 is installed on the guide rail inside the guide rail frame 1, the upper end of traveling block 6 is bolted fixedly installed with polishing and descaling machine 10, and the top of both sides of the rail frame 1 are respectively installed with rotating positioning screws 3 and auxiliary rotating device 7, the metal pipe 4 passes through the grinding hole of the grinding and descaling machine 10, the top of the metal pipe 4 is equipped with rotating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com