A steel pipe derusting machine

A technology for derusting machines and steel pipes, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, manufacturing tools, etc. It can solve the problems of inability to derust the inner wall of the steel pipe and the outer wall of the steel pipe, and the low efficiency of derusting the steel pipe. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

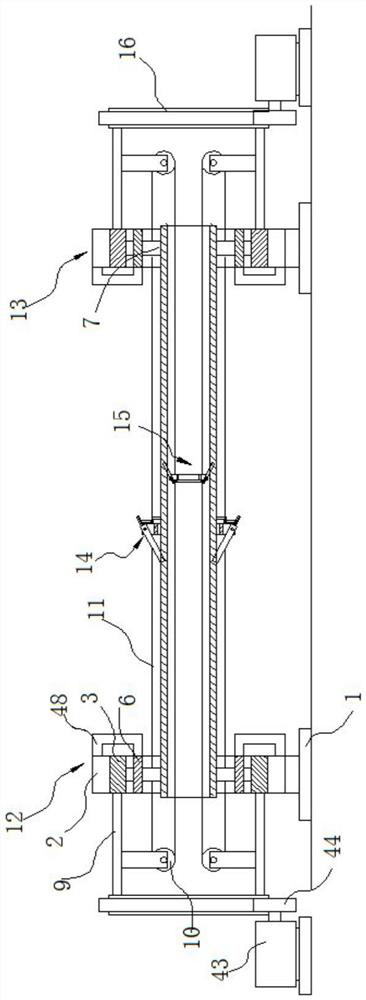

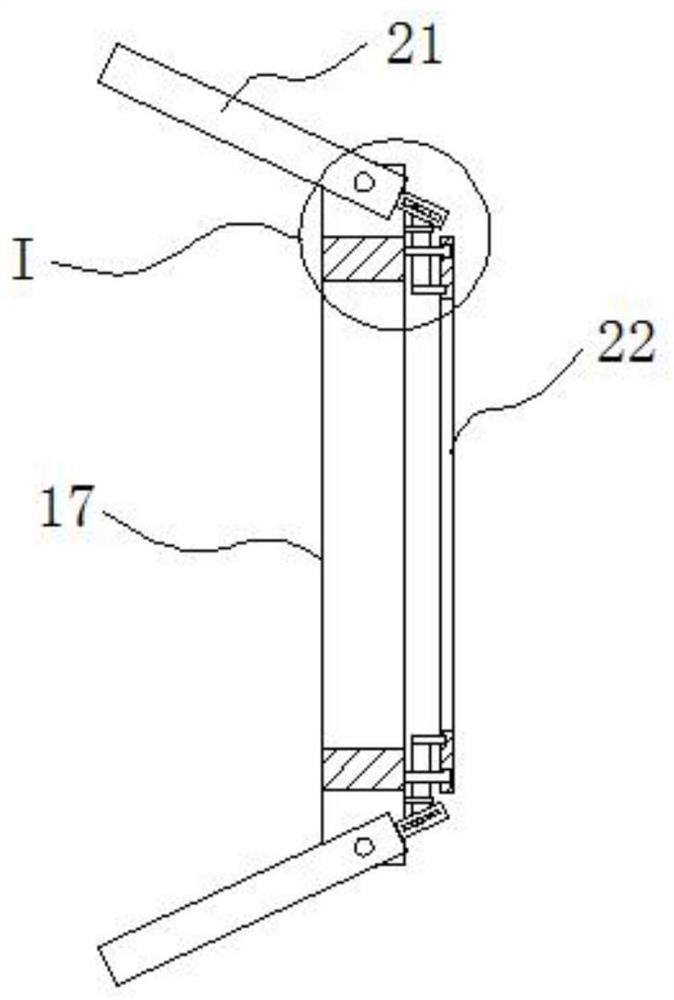

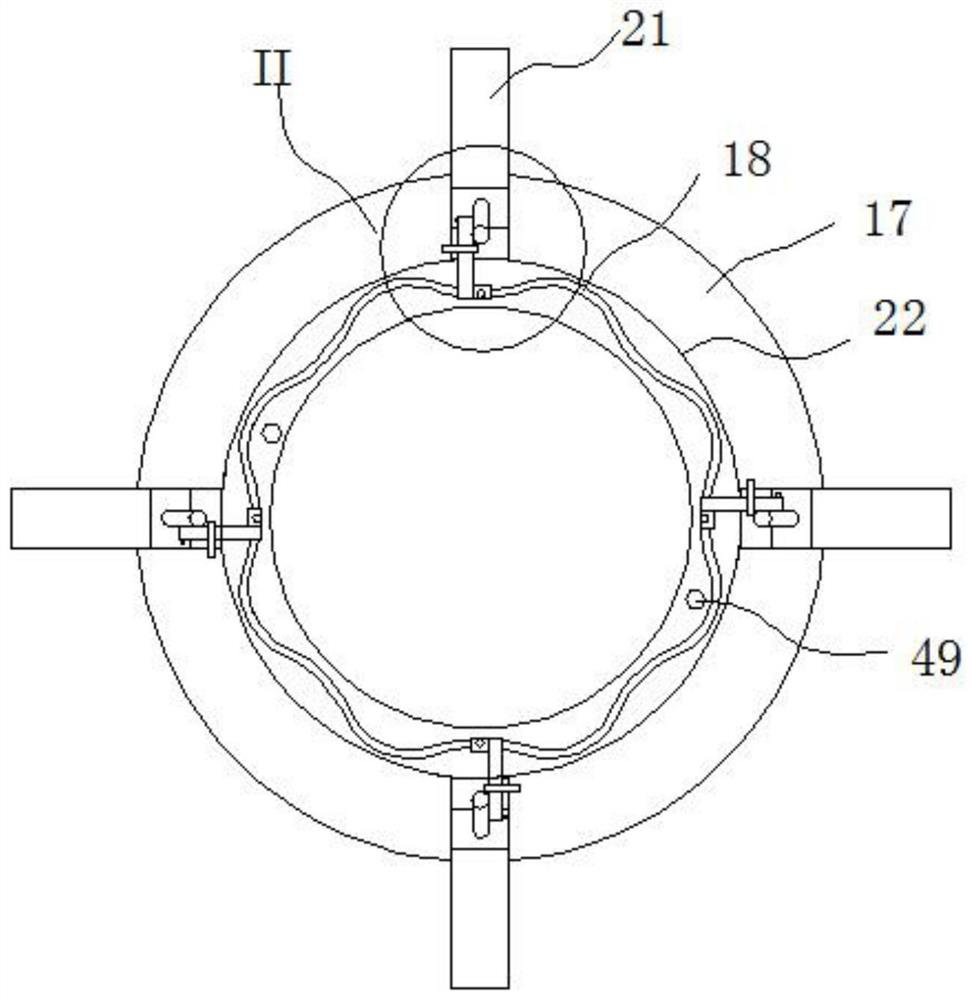

[0023] like figure 1As shown, a steel pipe removal machine includes a rack 1, and the frame 1 is provided with an end limit device clamping both ends of the steel pipe, the end limit device including a ring mount 2, which is The annular mount 2 is rotated and mounted oriented, and the inner circumferential surface of the annular mount is provided with a ring mounting groove, and the outer peripheral surface of the guide ring is provided with an active ring slider in the ring mounting groove. Thus, the guide ring is rotated in the ring mounting seat, the axis of the guide ring 3, and the axis of the ring mount 2, the inner surface of the guide ring 3 including an annular surface 4 and The curved concave surface 5, the end limit device further includes a restricted ring 6 located inside the guide ring 3, and the end surface of the limit ring and the end surface of the ring mounting seat are fixed together, in The end surface of the limit ring and the end surface of the ring mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com