Patents

Literature

441results about How to "Improve rust removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

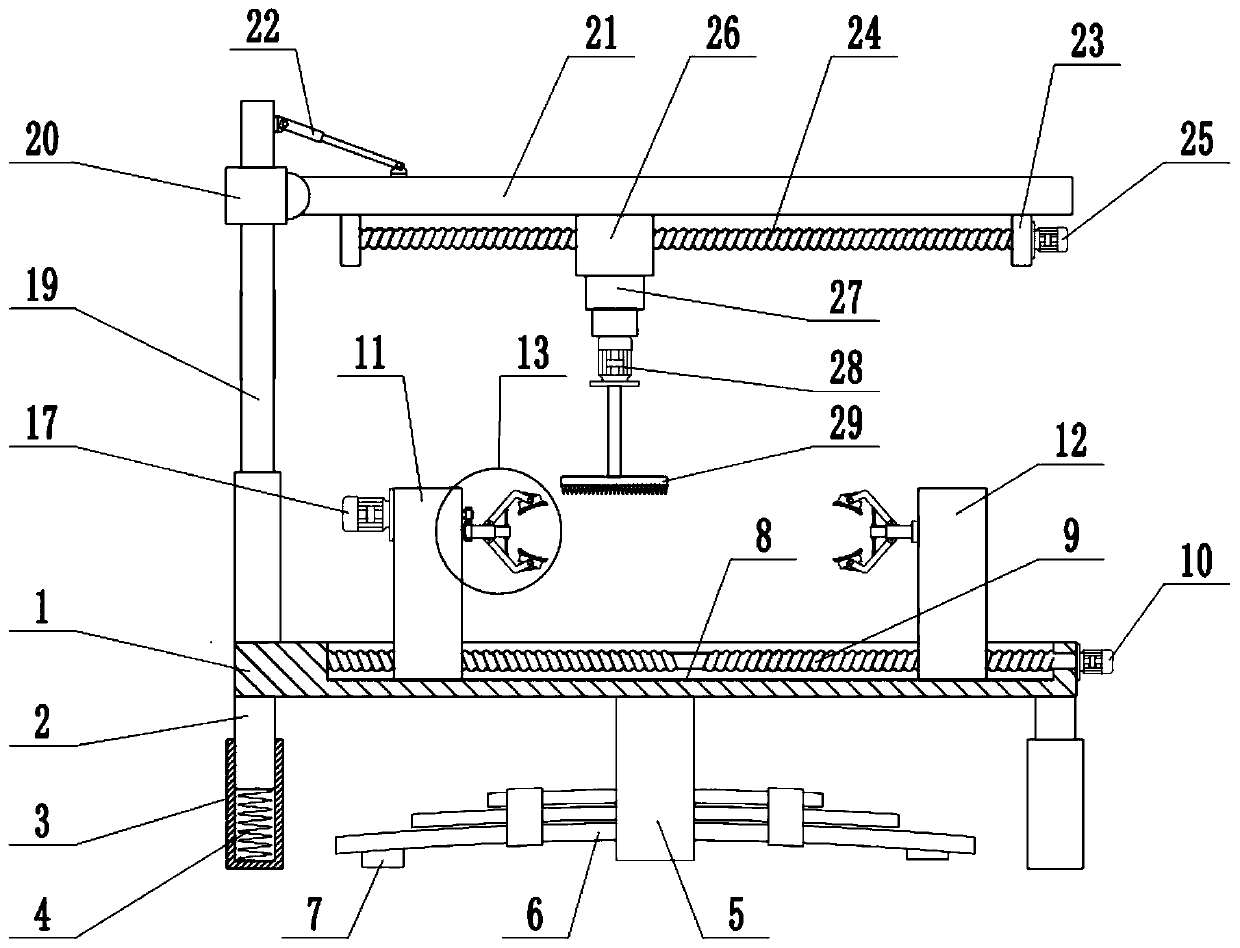

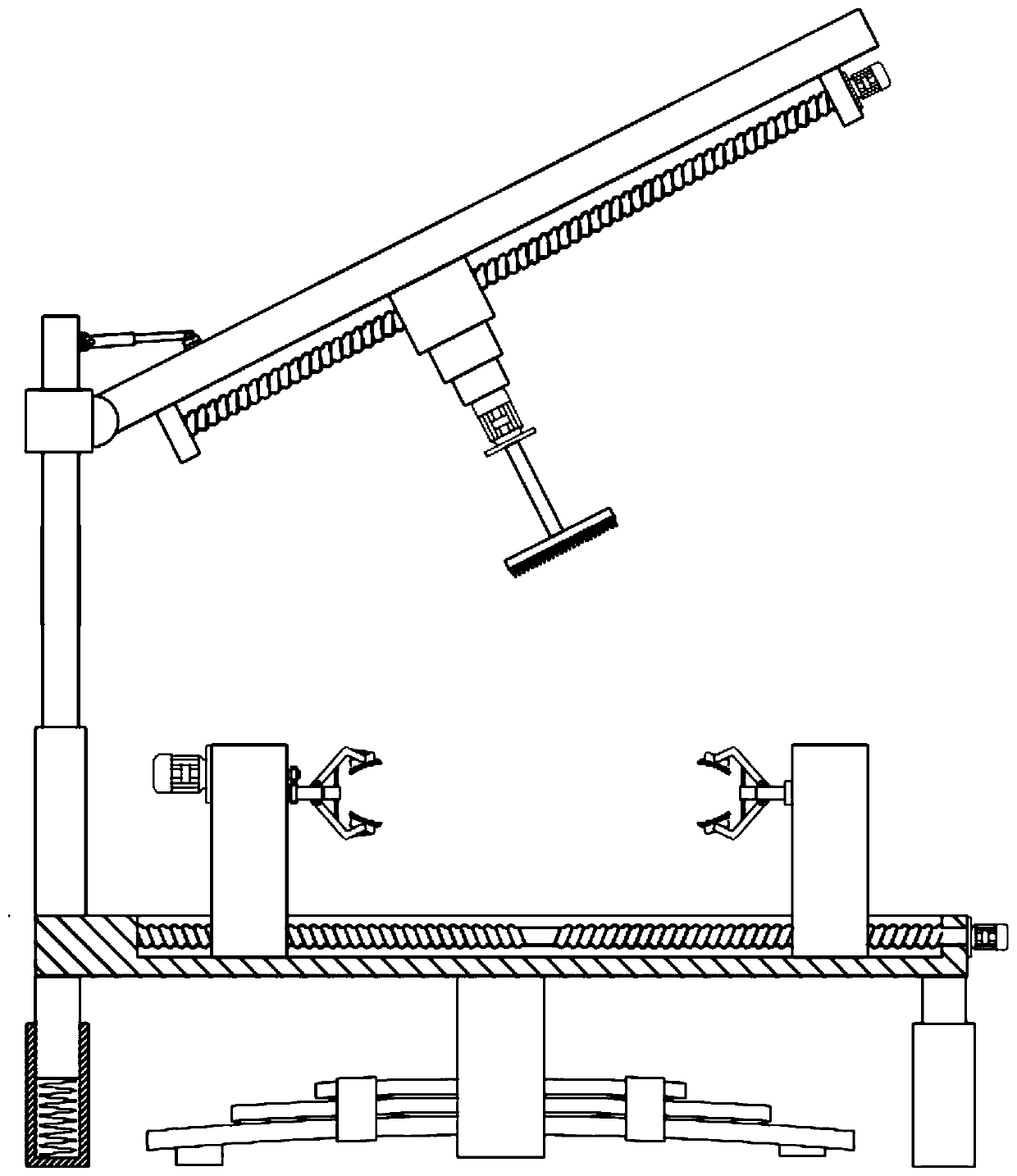

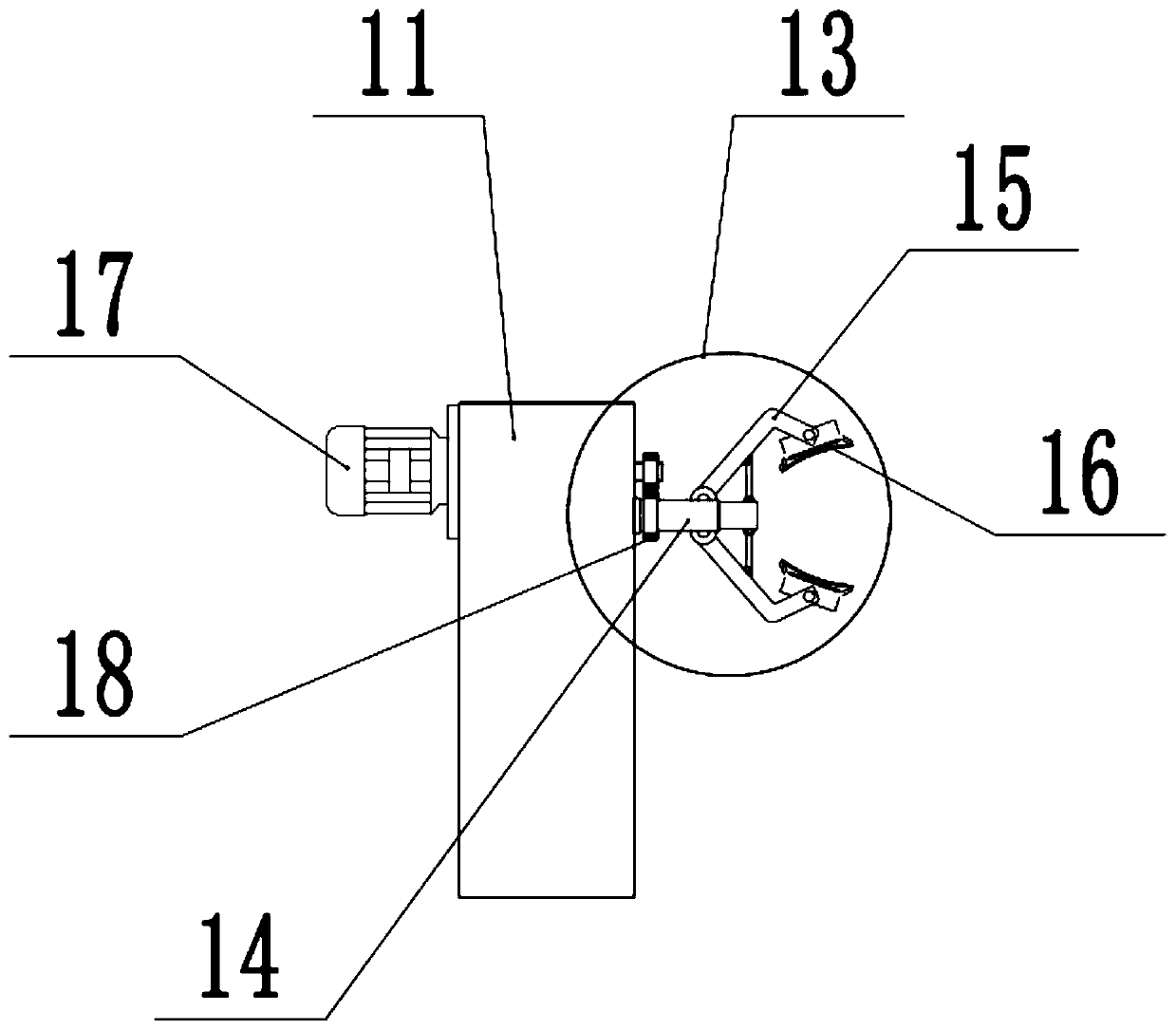

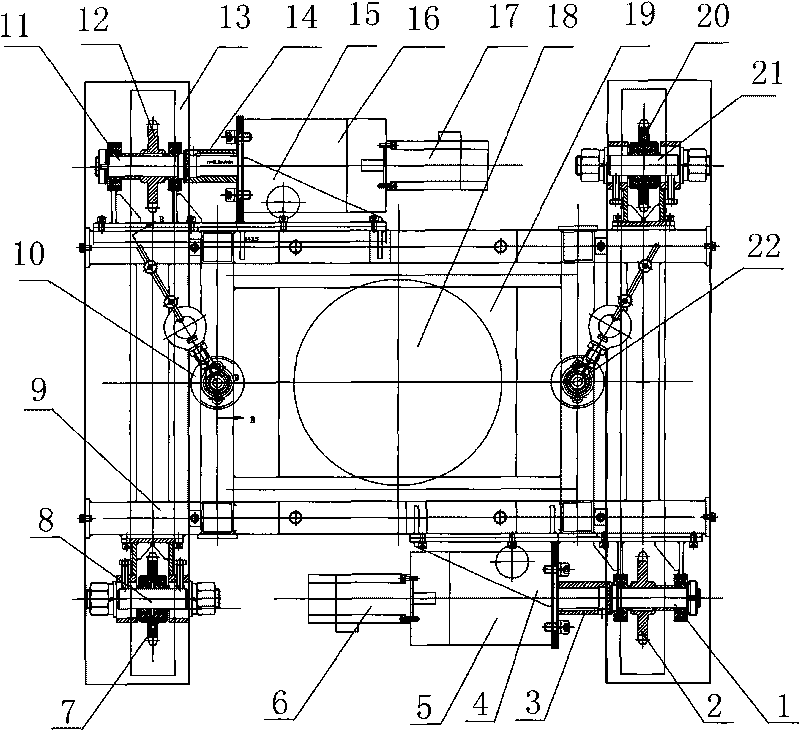

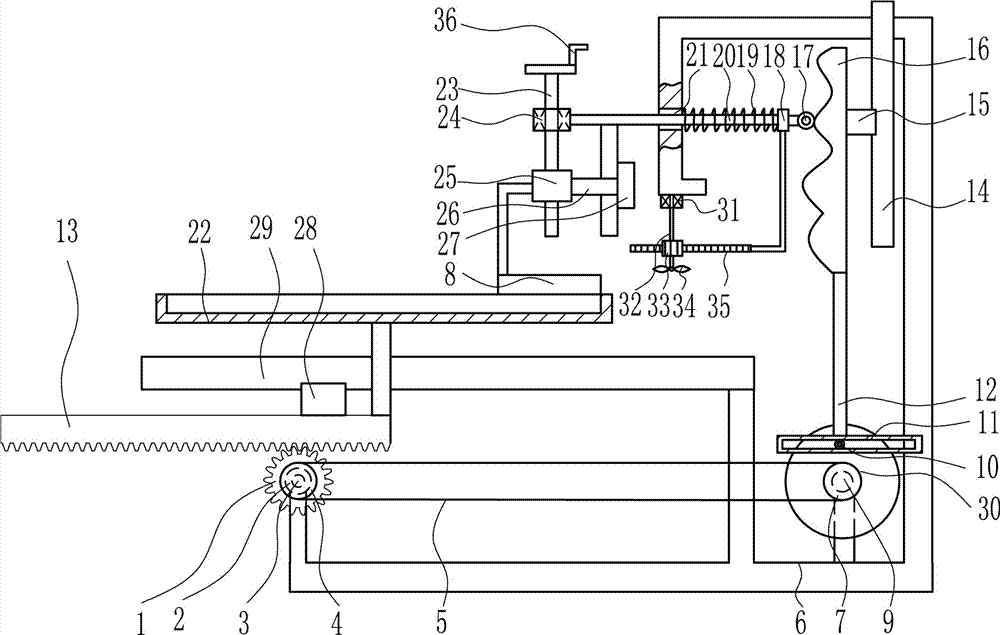

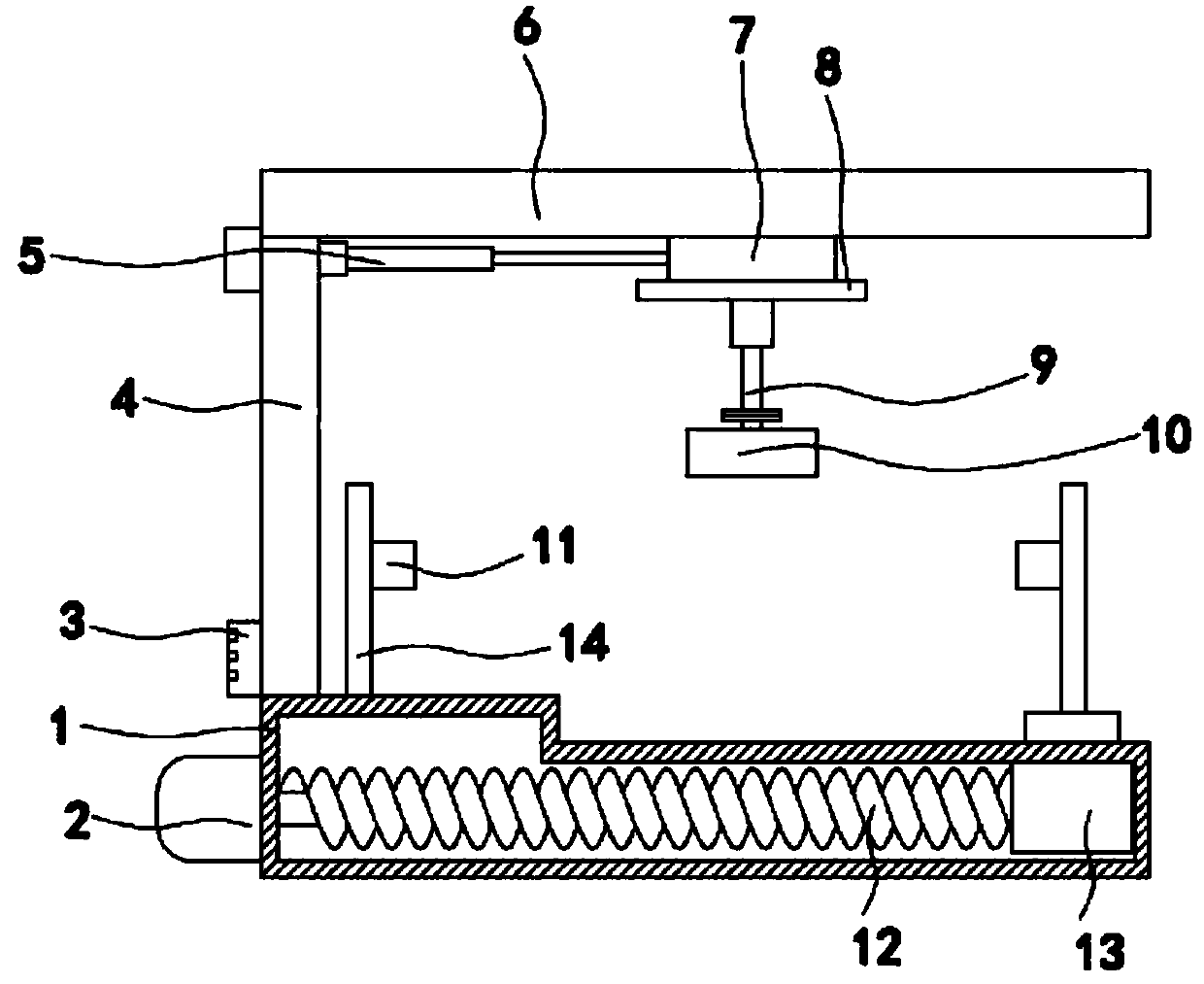

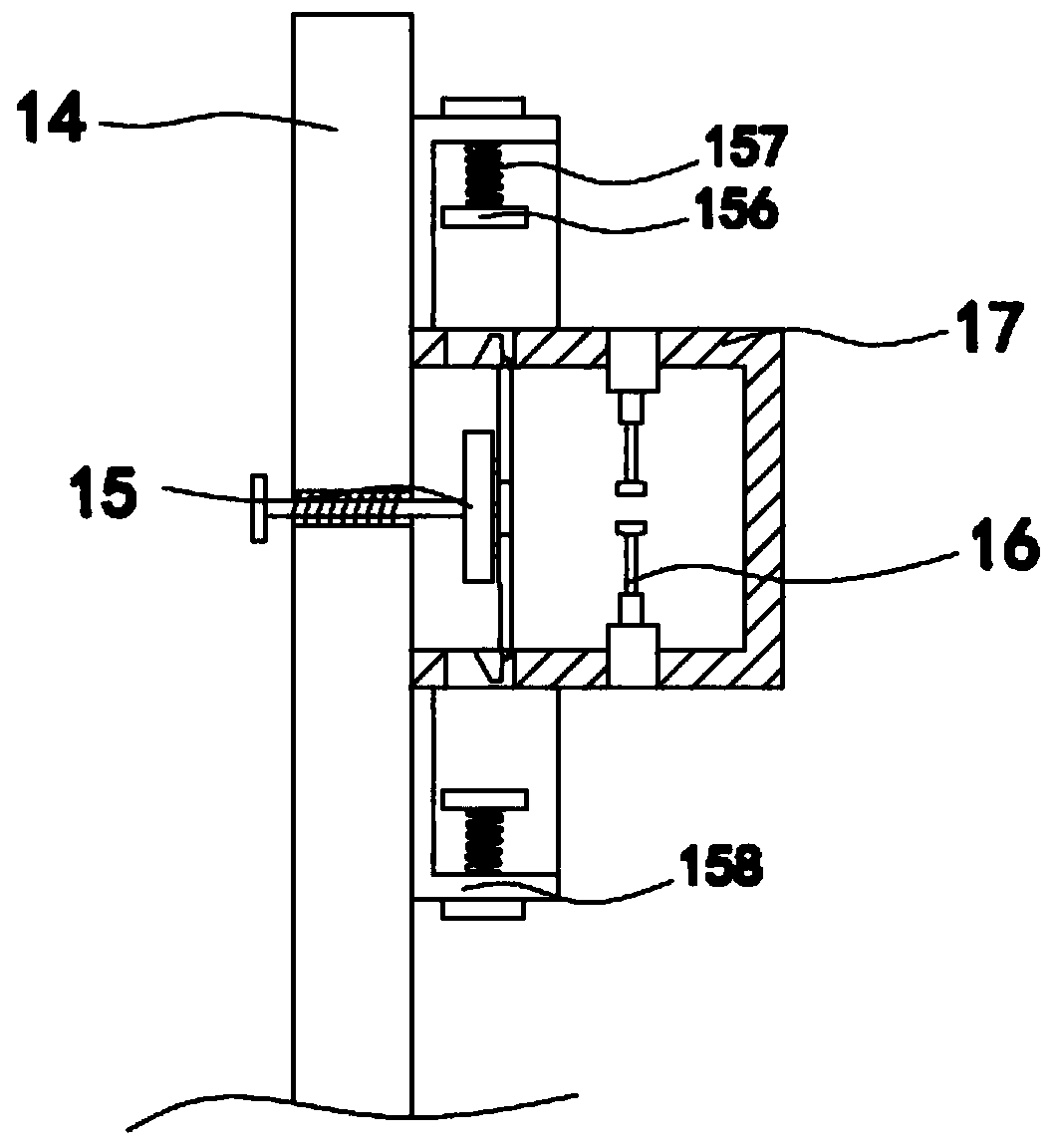

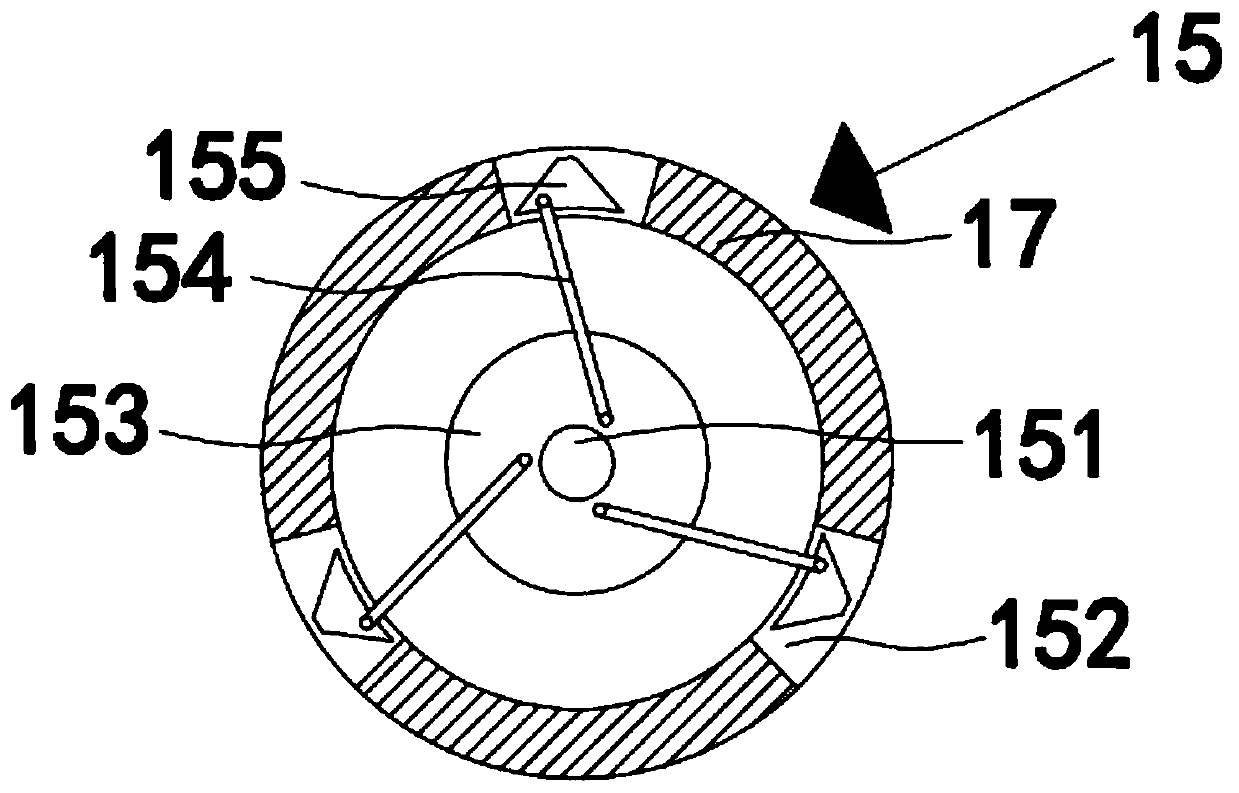

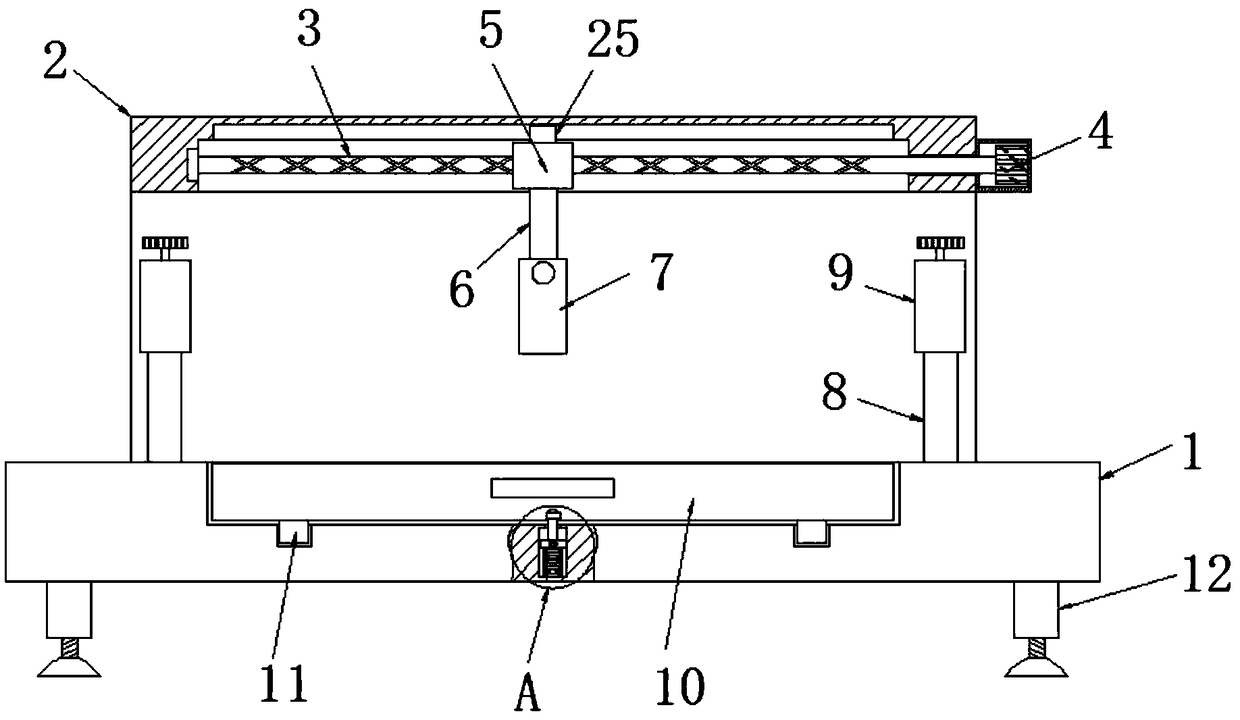

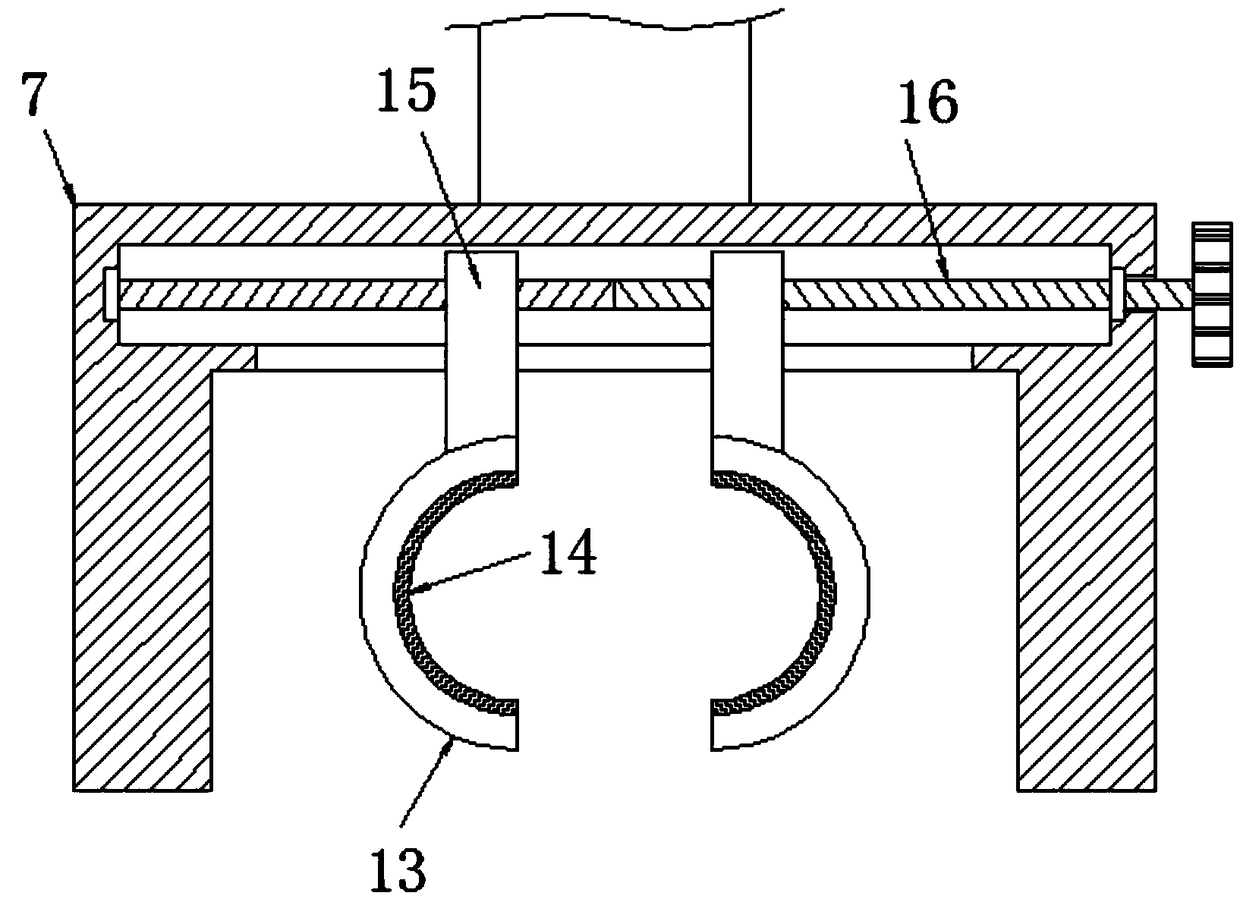

Overturning grinding rust removal device for metal plate

InactiveCN110142678AFast clamping speedEasy to remove rustGrinding carriagesGrinding drivesEngineeringMechanical engineering

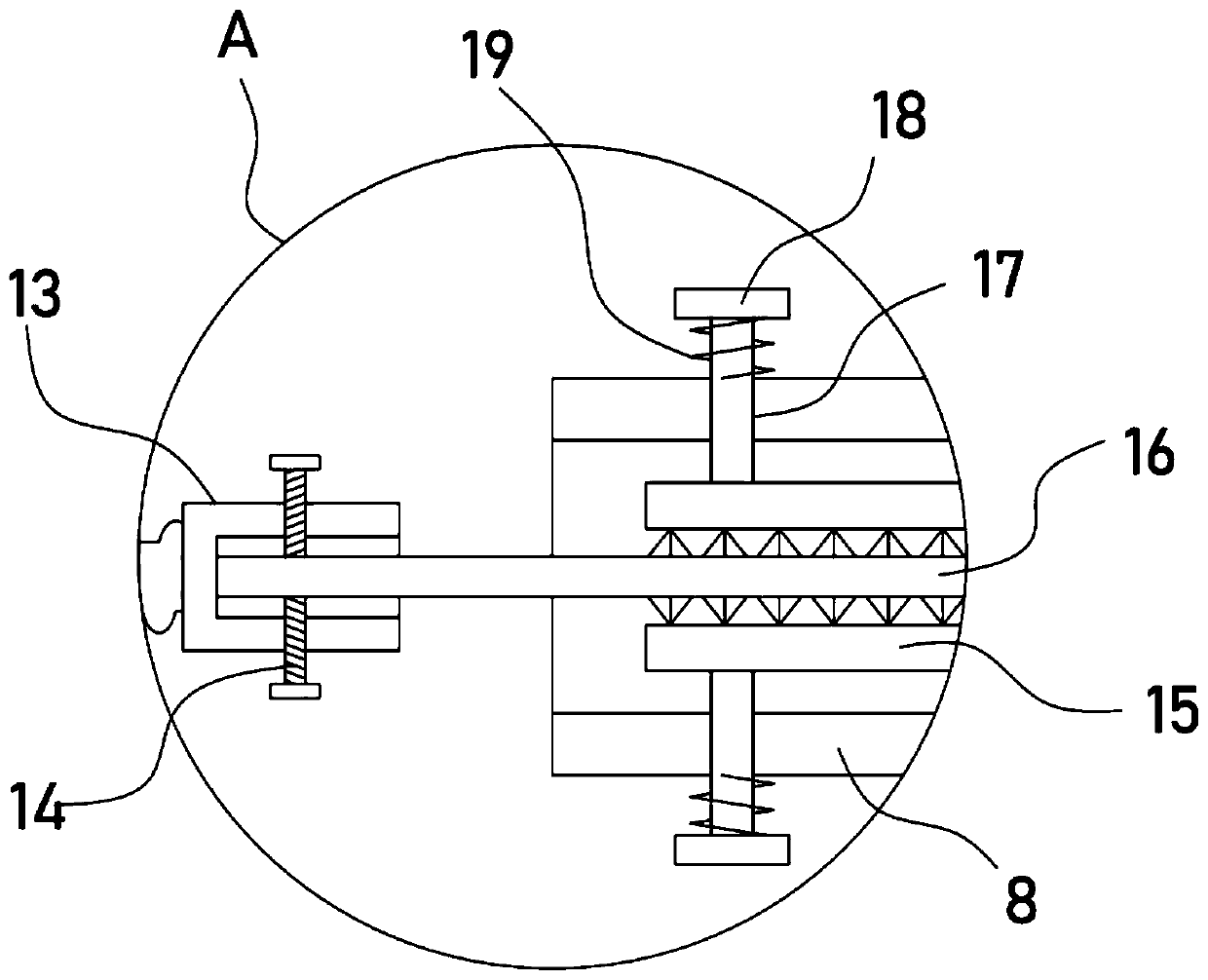

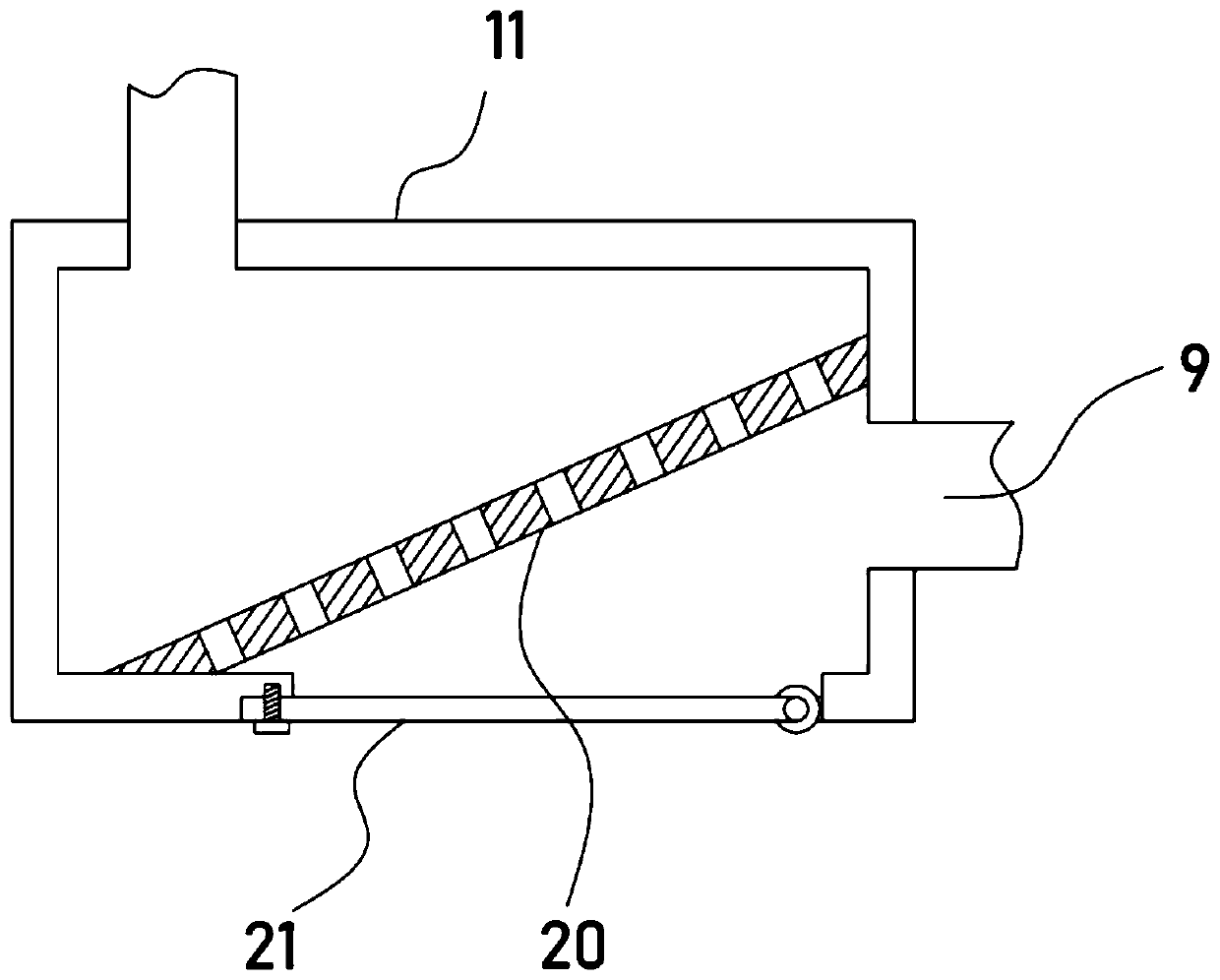

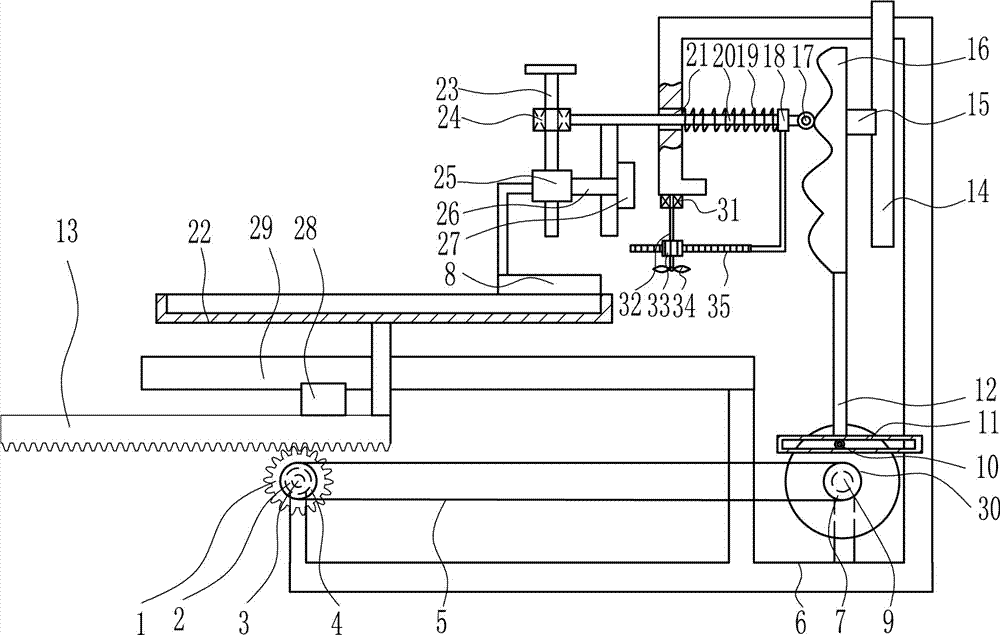

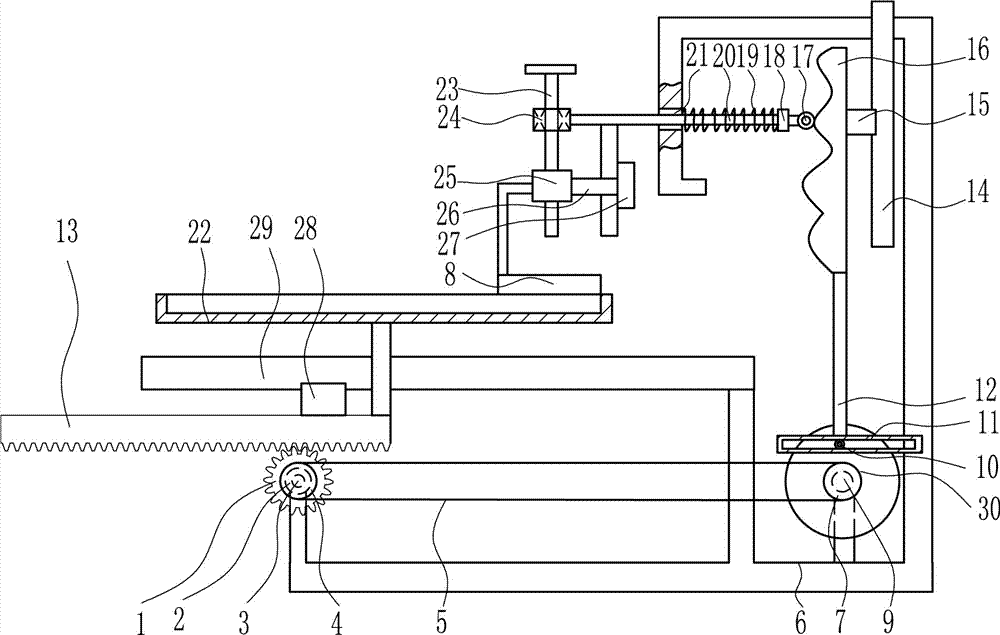

The invention relates to the field of metal processing equipment, and more specifically relates to an overturning grinding rust removal device for a metal plate. The overturning grinding rust removaldevice for the metal plate comprises a workbench, a left clamping block, a right clamping block and a rust removal brush plate, wherein a slide groove is formed in the upper surface of the workbench;a bidirectional screw rod is installed in the slide groove; the left clamping block and the right clamping block sleeve the bidirectional screw rod; a second telescoping mechanism is fixedly connectedto the upper surface of the workbench; a lifting block sleeves a stretching end of the second telescoping mechanism; an installation plate is hinged to the sidewall of the lifting block; a displacement screw rod is arranged below the installation plate; a movable block sleeves the middle part of the displacement screw rod; a fourth telescoping mechanism is fixedly connected to the lower surface of the movable block; and a rust removal motor is fixedly connected to the lower end of the fourth telescoping mechanism. The metal plate is clamped by virtue of the clamping plate to keep fixed, and high clamping speed is achieved; in a rust removal process, the rust removal brush plate moves to left and right, so that a rust removal range is expanded; and through arrangement for a rotary motor, rust removal can be conveniently carried out on the front surface and the back surface of the metal plate.

Owner:蒋艳红

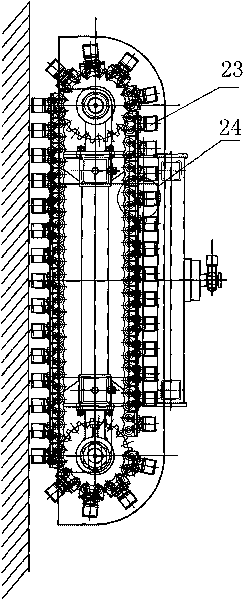

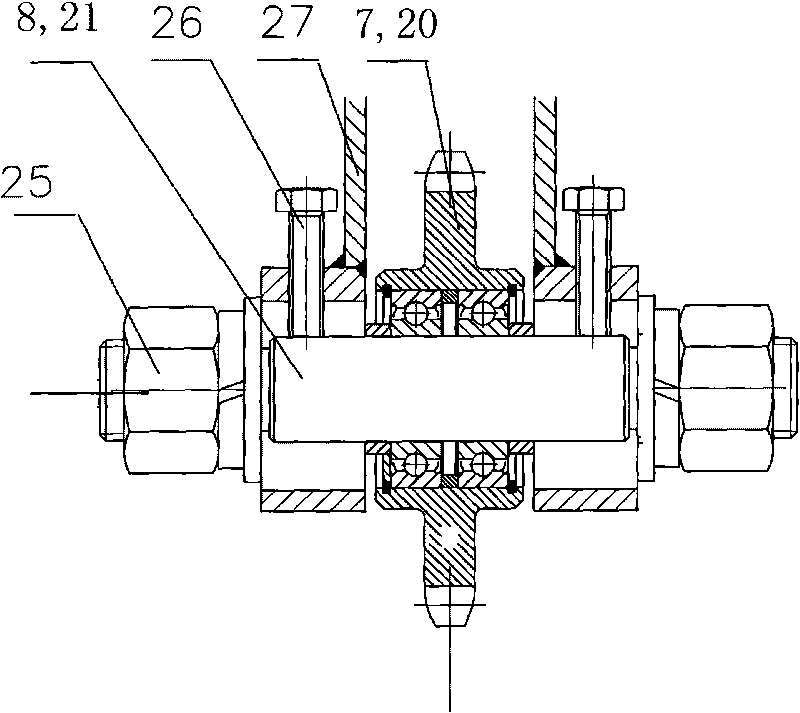

Wall-climbing robot for removing rust on wall surfaces of ships and working method thereof

InactiveCN101704241ARealize high-altitude and heavy-duty operationsImprove adsorption capacityProgramme-controlled manipulatorCleaning using liquidsDrive motorEngineering

The invention discloses a wall-climbing robot for removing rust on wall surfaces of ships and a working method thereof. The wall-climbing robot comprises a frame, a chain track walking mechanism, a permanent magnetic adsorption unit, a left-upper drive motor, a left-upper decelerator, a right-lower drive motor and a right-lower decelerator, wherein the chain track walking mechanism consists of a left chain track and a right chain track, the permanent magnetic adsorption unit is mounted on the chain track walking mechanism, and an ultrahigh pressure water jet vacuum rust-removing cleaner is externally connected with a vacuum source and the permanent magnetic adsorption unit to form vacuum permanent magnetic mixed adsorption. The method comprises the steps of regulation of the tension of chains, height adjustment and movement control. In the invention, by adopting the vacuum permanent magnetic mixed adsorption mode to design the wall-climbing robot and effectively utilizing and recycling negative pressure of the rust vacuum in combination with permanent magnetic adsorption force, the wall-climbing robot achieves reliable adsorption, safe working and compact adsorption structure and is capable of realizing working with large load at high altitude.

Owner:DALIAN MARITIME UNIVERSITY

Neutral oil removal rust remover and preparation method thereof

The invention discloses a neutral oil removal rust remover, which is mainly prepared from deionized water and the following components by mass fraction: 4-8% of physical dispersing agent, 8-10% of chemical chelating agent, 4-6% of oil-removing emulsifier and 1-4% of corrosion inhibitor. The preparation method disclosed by the invention comprises the following steps: firstly, preparing the components according to the proportioning requirements; weighting the ingredients in the chemical chelating agent to put into a container; adding the deionized water to evenly agitate, so as to obtain a solution A; adding the physical dispersing agent and the corrosion inhibitor to the solution A; agitating to obtain a solution B; additionally, adding the prepared components of the oil-removing emulsifier to the container; adding the deionized water to dissolve; adding a functional additive to obtain a solution C; and evenly mixing the solution B with the solution C under the agitation condition to obtain the neutral oil removal rust remover. By adopting the product disclosed by the invention, the oil and rust removal work can be quickly and efficiently finished, and the neutral oil removal rust remover is free of damage to a substrate.

Owner:HUNAN UNIV

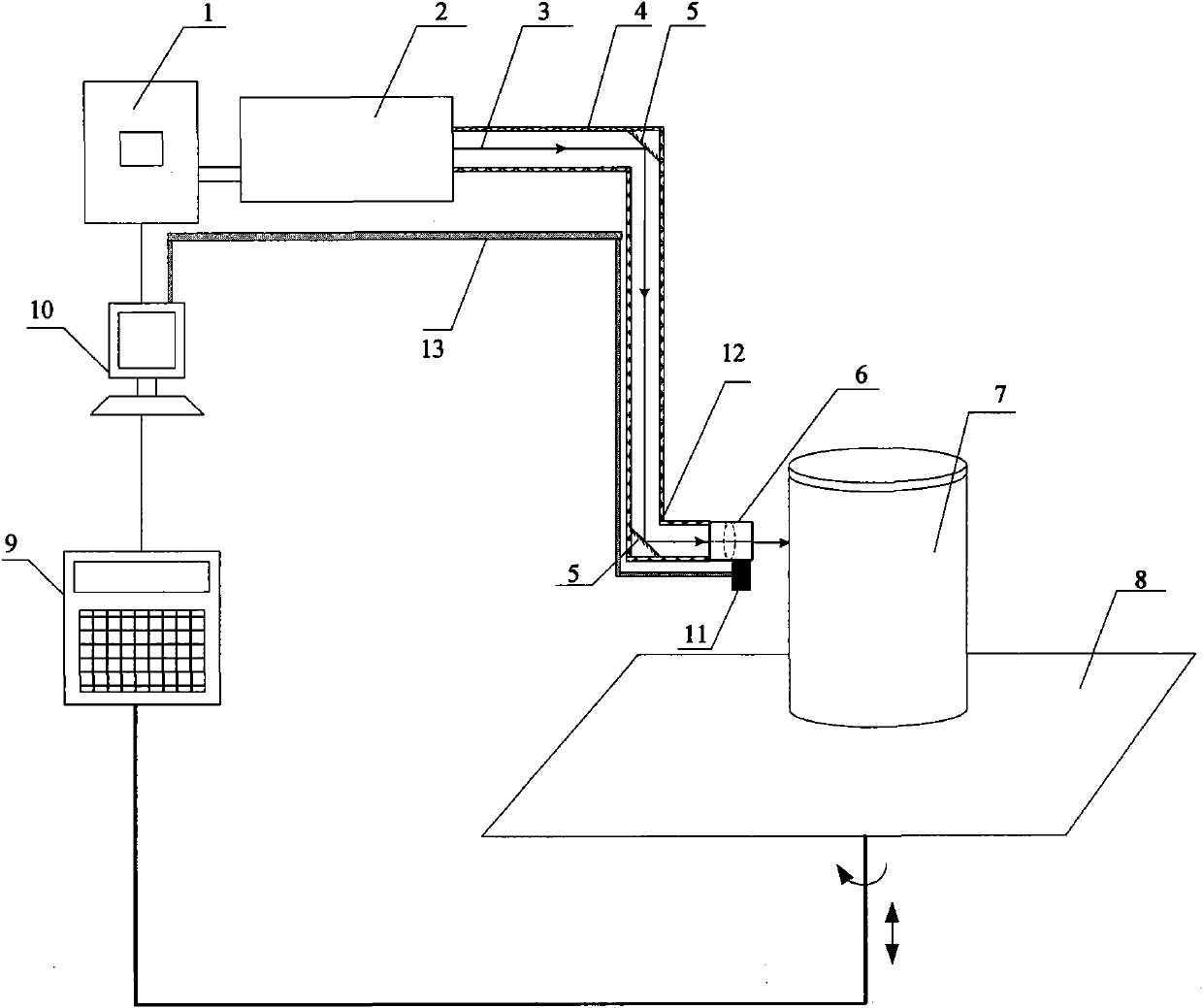

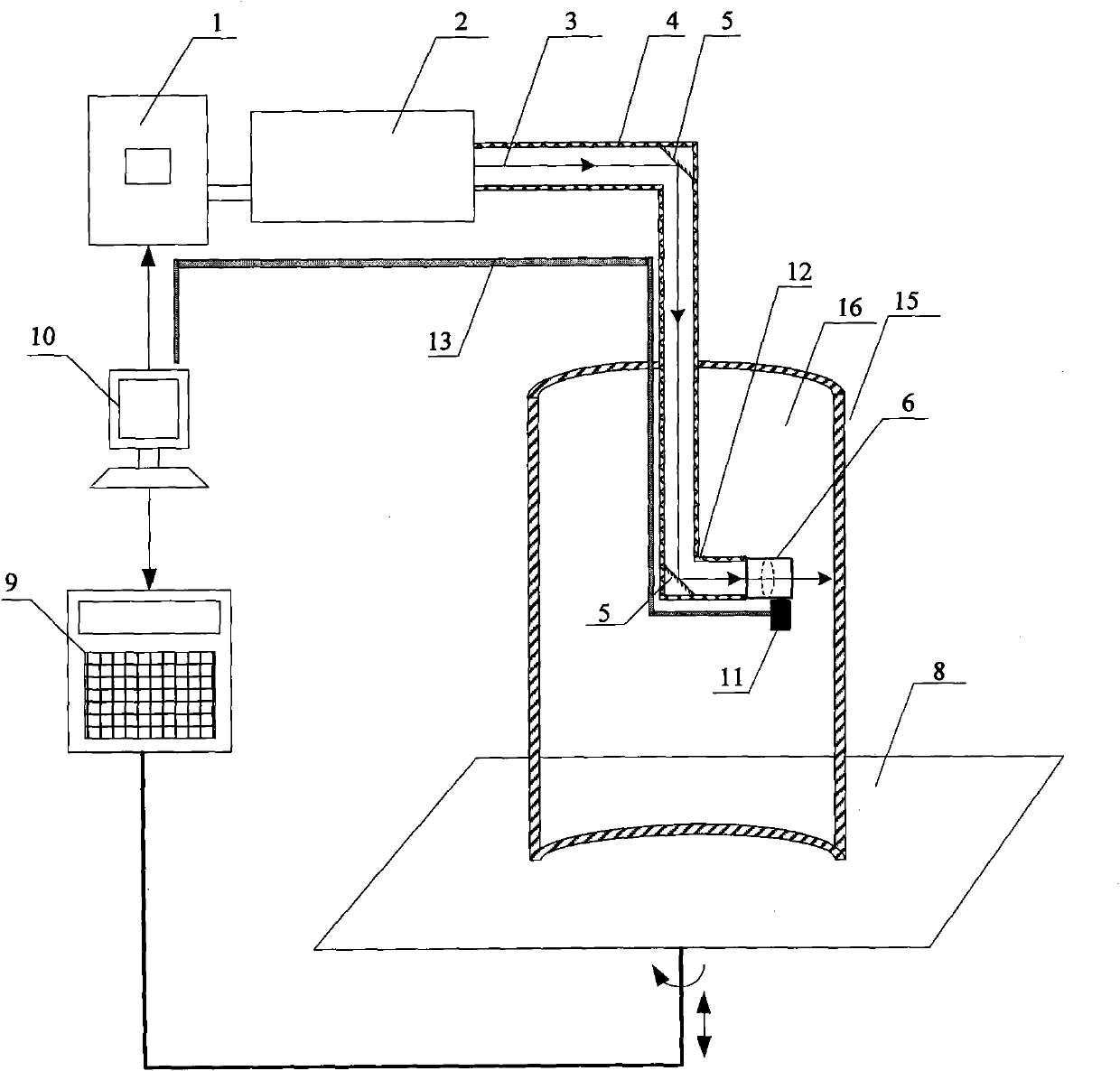

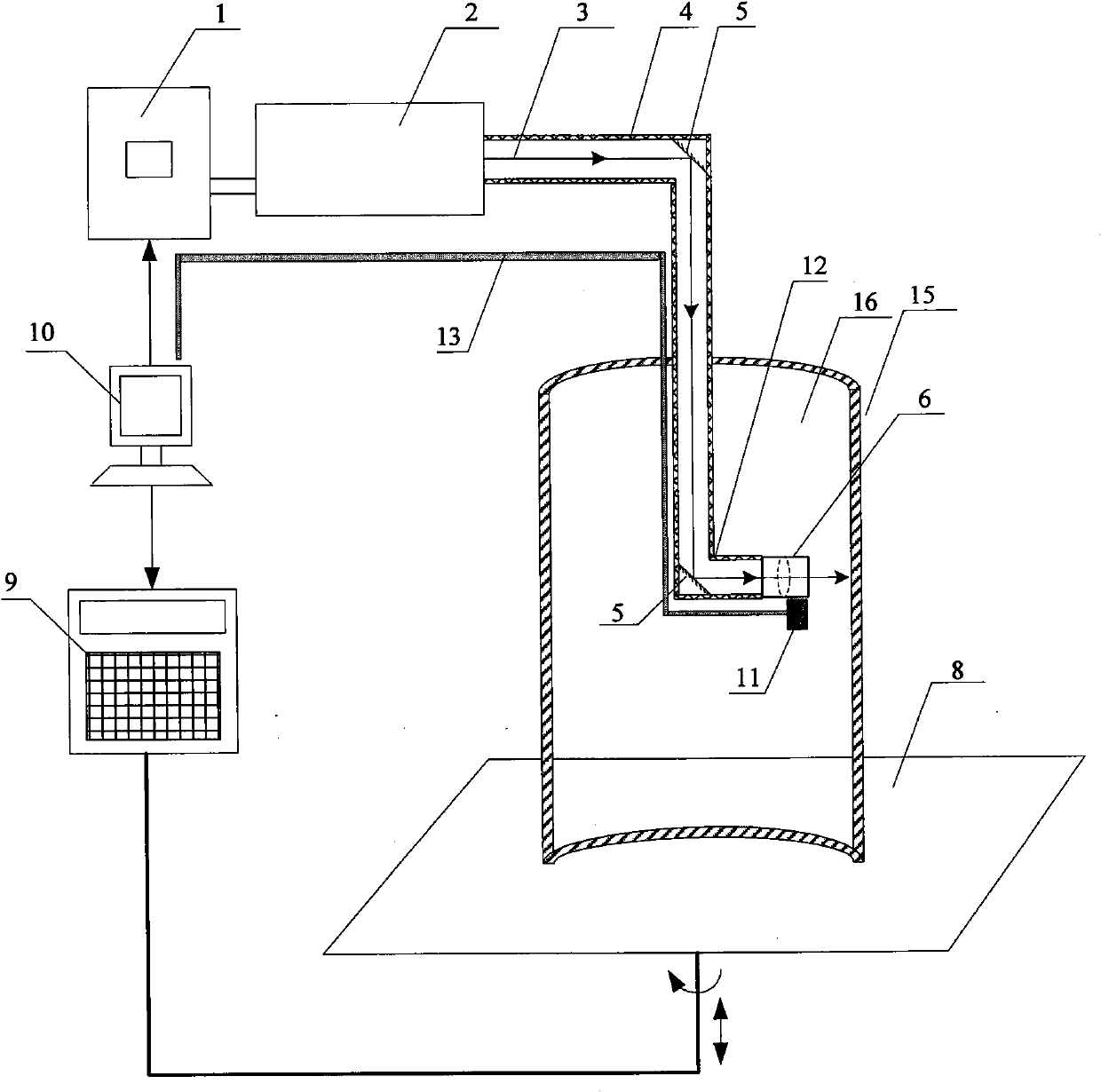

Laser rust-removing device

InactiveCN101947694AAchieve laser rust removalOvercoming Difficult Rust Removal ProblemsLaser beam welding apparatusAutomatic controlLight guide

The invention discloses a laser rust-removing device, which comprises a central controller, a laser, a working table controller, a working table, an acoustic sensor and a rust-removing head. The laser is guided into the cylindrical rust-removing head through a light guide pipe; a light outlet is vertical to the cylindrical metal inner wall; and the automatic control and precise positioning in the laser rust-removing process are realized by combining the acoustic sensor, the central controller and the working table. The laser rust-removing device solves the problem of removing rust on the cylindrical metal inner wall and other special surfaces.

Owner:JIANGSU UNIV

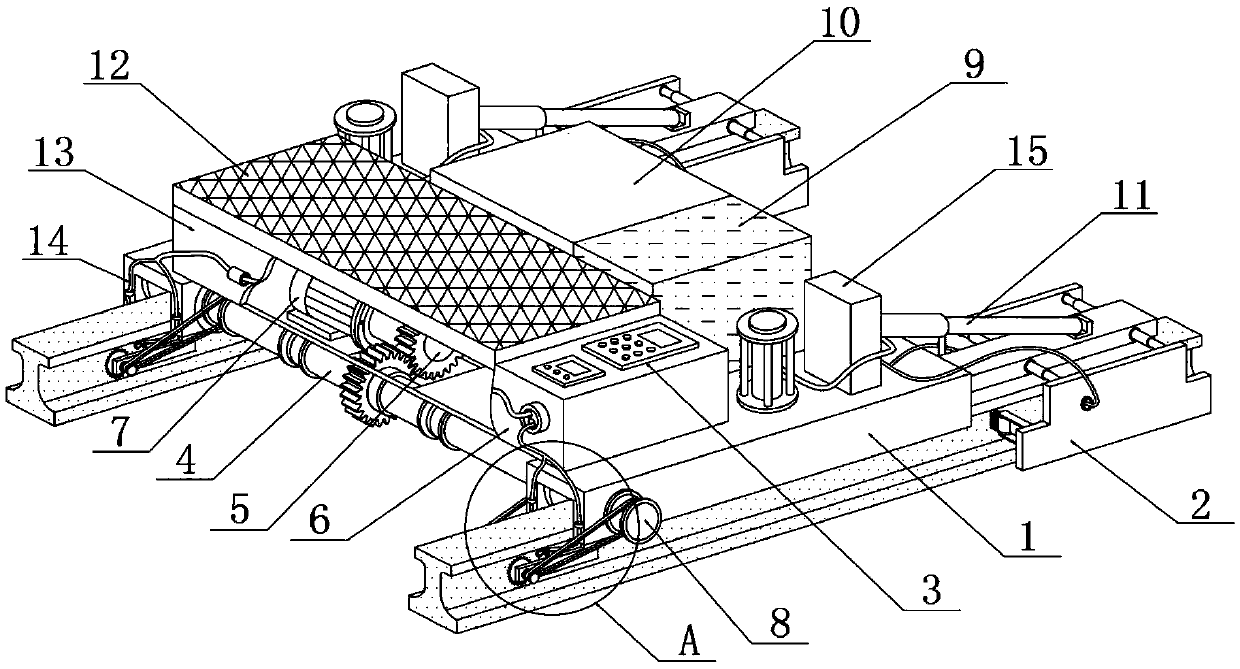

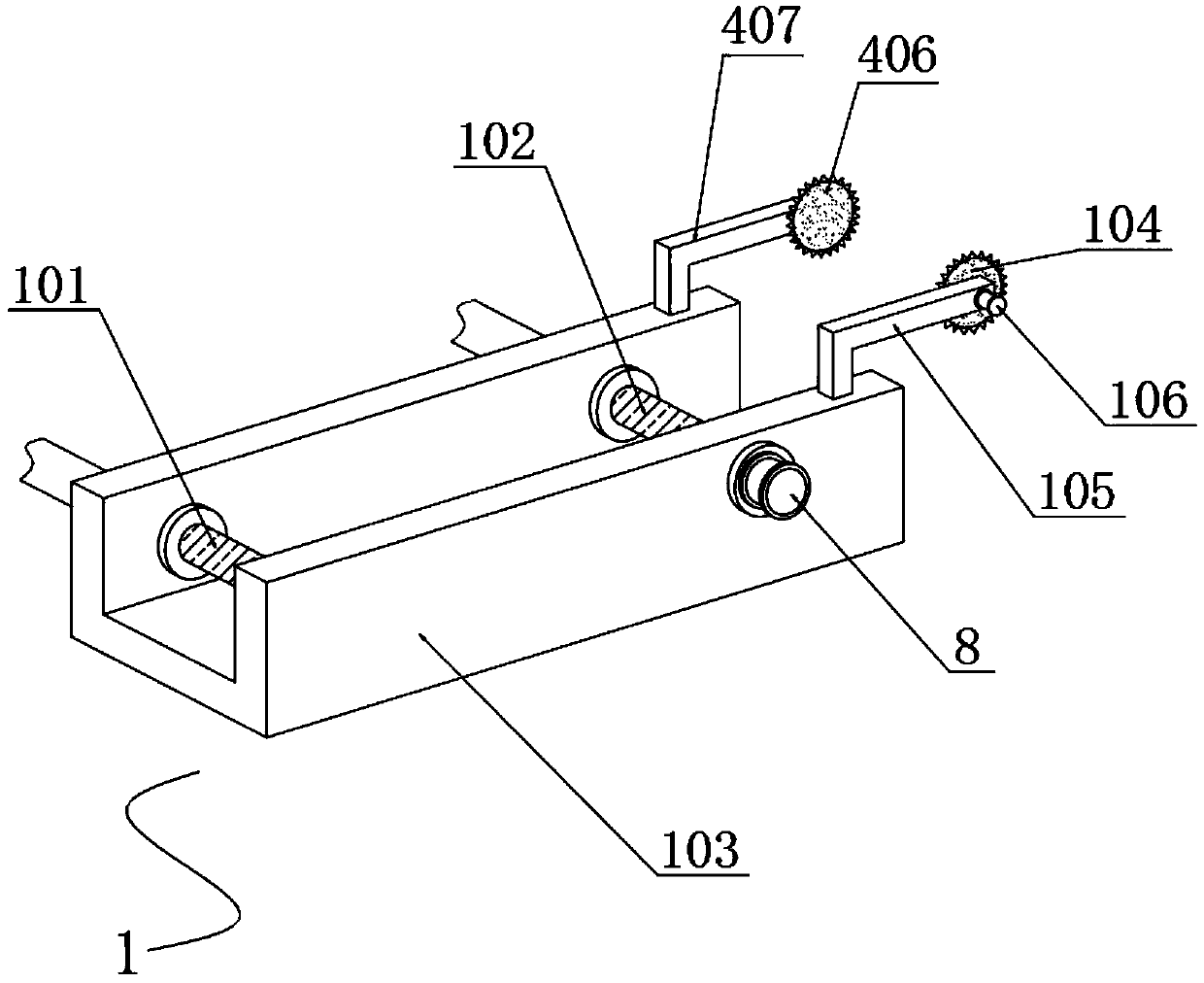

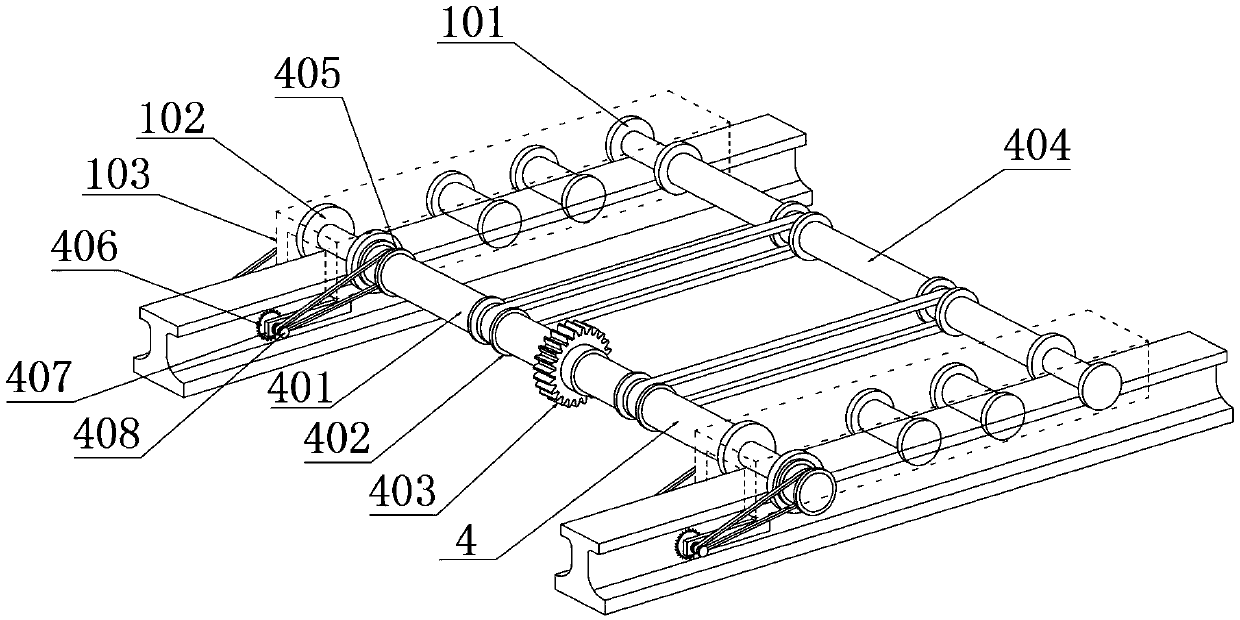

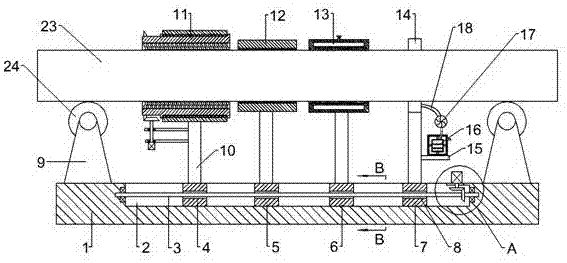

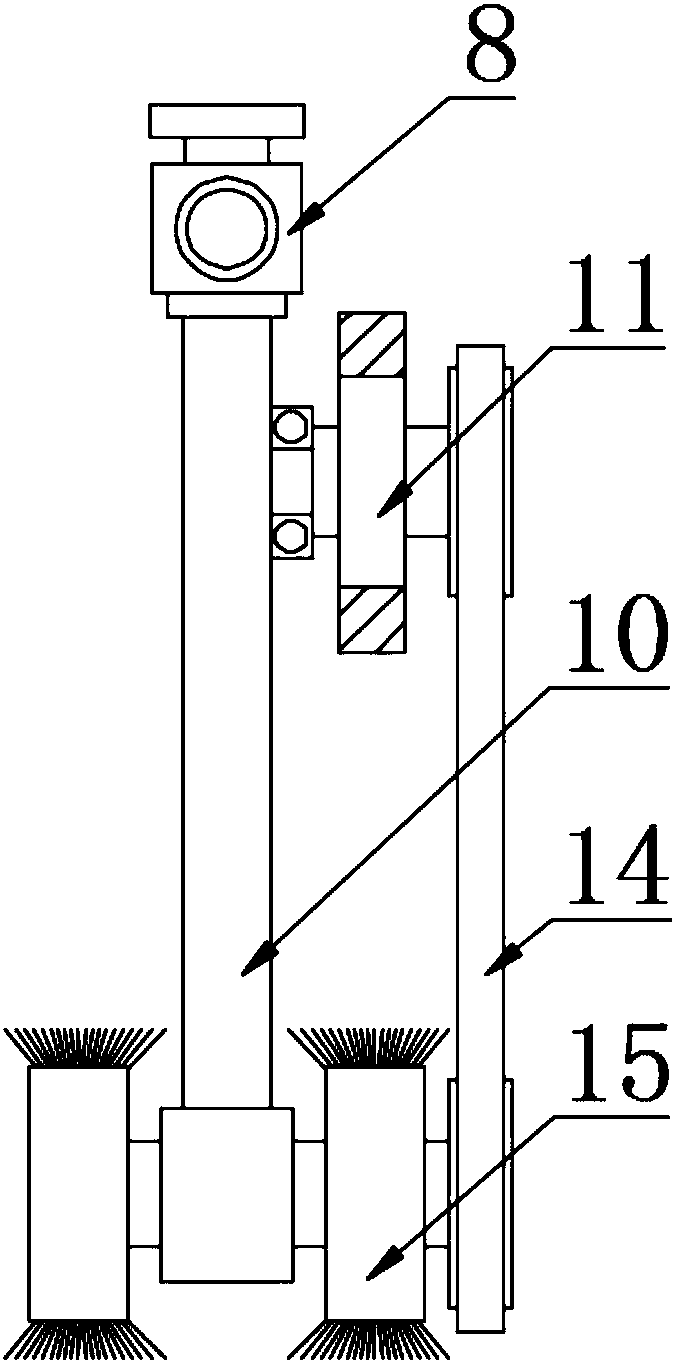

Self-propelled rust-removal grinding device for rail maintenance and with dust removal function

ActiveCN109629355AAffect the quality of useImprove rust resistanceRailway track constructionSpray nozzleEngineering

The invention discloses a self-propelled rust-removal grinding device for rail maintenance and with a dust removal function and relates to the technical field of rail rust removal. The device comprises two symmetrically-arranged walking mechanisms and fan boxes arranged at the upper ends of the walking mechanisms and used for placing fans, and control panels are arranged on the upper surfaces of the fan boxes. According to the device, the walking mechanisms are adopted for achieving self-propelled grinding, the upper surface, inner side and outer side of a rail are synchronously ground, one-time dust removal is achieved, and the dust is thoroughly cleared away; in cooperation with a blowing head, dust can be blown away, and the situation is avoided that since the dust falls on the rail, the application quality of the rail and spraying of an anti-rust solution in the later period are influenced; by adopting a sweeping mechanism, the ground rail is swept, in cooperation with a spray nozzle and a brush roller, the two side faces are sprayed with the anti-rust solution, the anti-dust effect of the rail is improved, and the service life of the rail is prolonged; the device is provided with a solar cell panel, and the cruising capacity during outdoor work is improved, so that the device continuously works.

Owner:成都中轨轨道设备有限公司

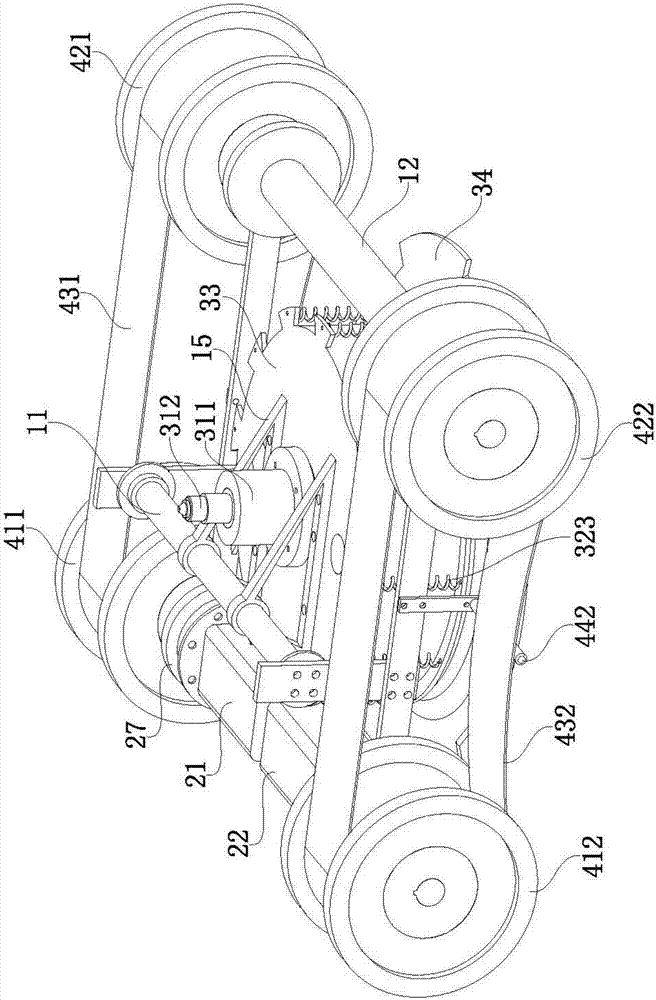

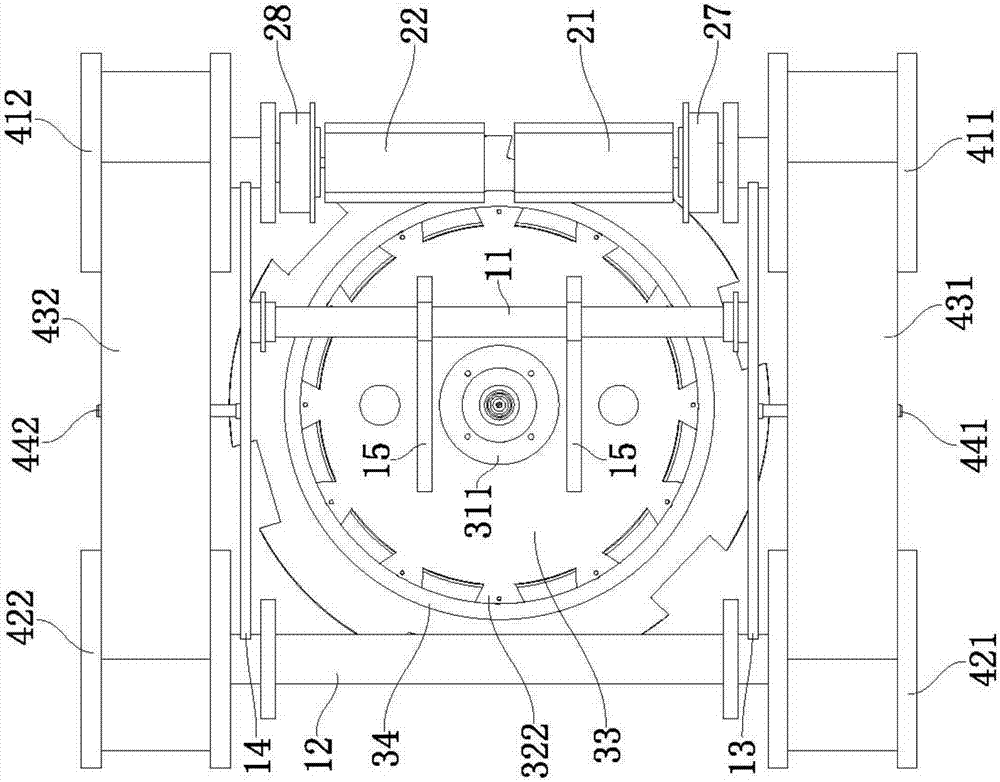

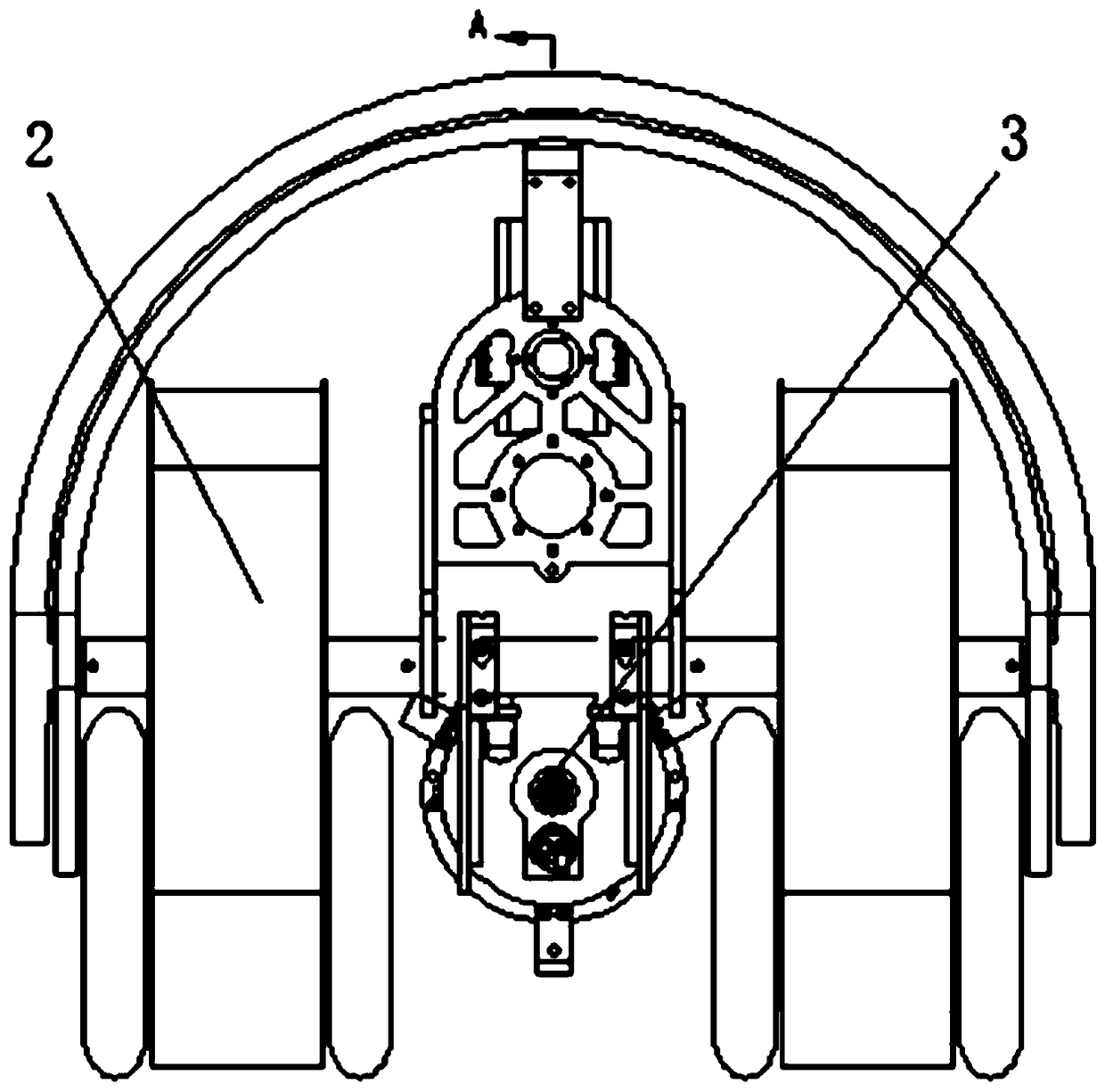

Wall-climbing robot for rust removal of ship

ActiveCN107117223AImprove adsorption capacityImprove obstacle performanceVessel cleaningHullsPulp and paper industryPollution

The invention belongs to the technical field of wall-climbing robots and particularly relates to a wall-climbing robot for rust removal of a ship. The wall-climbing robot comprises a rack, a driving mechanism, a vacuum cleaning mechanism and an adsorption travelling mechanism; the adsorption travelling mechanism comprises an active magnetic wheel set, a slaved magnetic wheel set and a belt set which are mounted on the side portions of the rack; the driving mechanism drives the active magnetic wheel set and the slaved magnetic wheel set to rotate; the vacuum cleaning mechanism comprises a water-jet-flow flushing mechanism body, a floating mechanism body, a vacuum cover and a rubber bladder; and the vacuum cover and the rack are connected and located below the middle of the rack, the water-jet-flow flushing mechanism body is mounted on the vacuum cover, the rubber bladder is connected to the peripheral edge of the vacuum cover, and the floating mechanism body is connected between the rubber bladder and the top of the vacuum cover so as to drive the rubber bladder to move in the up-down direction. According to the wall-climbing robot for rust removal of the ship, the adsorption capacity and the obstacle crossing capacity of the wall-climbing robot for rust removal of the ship are greatly improved, the adaptive capacity over the ship wall surface is reinforced, and rust removal efficiency is improved, so that non-pollution and high-efficiency dust removal operation is achieved.

Owner:SHENZHEN XINGZHIXING ROBOT TECH CO LTD

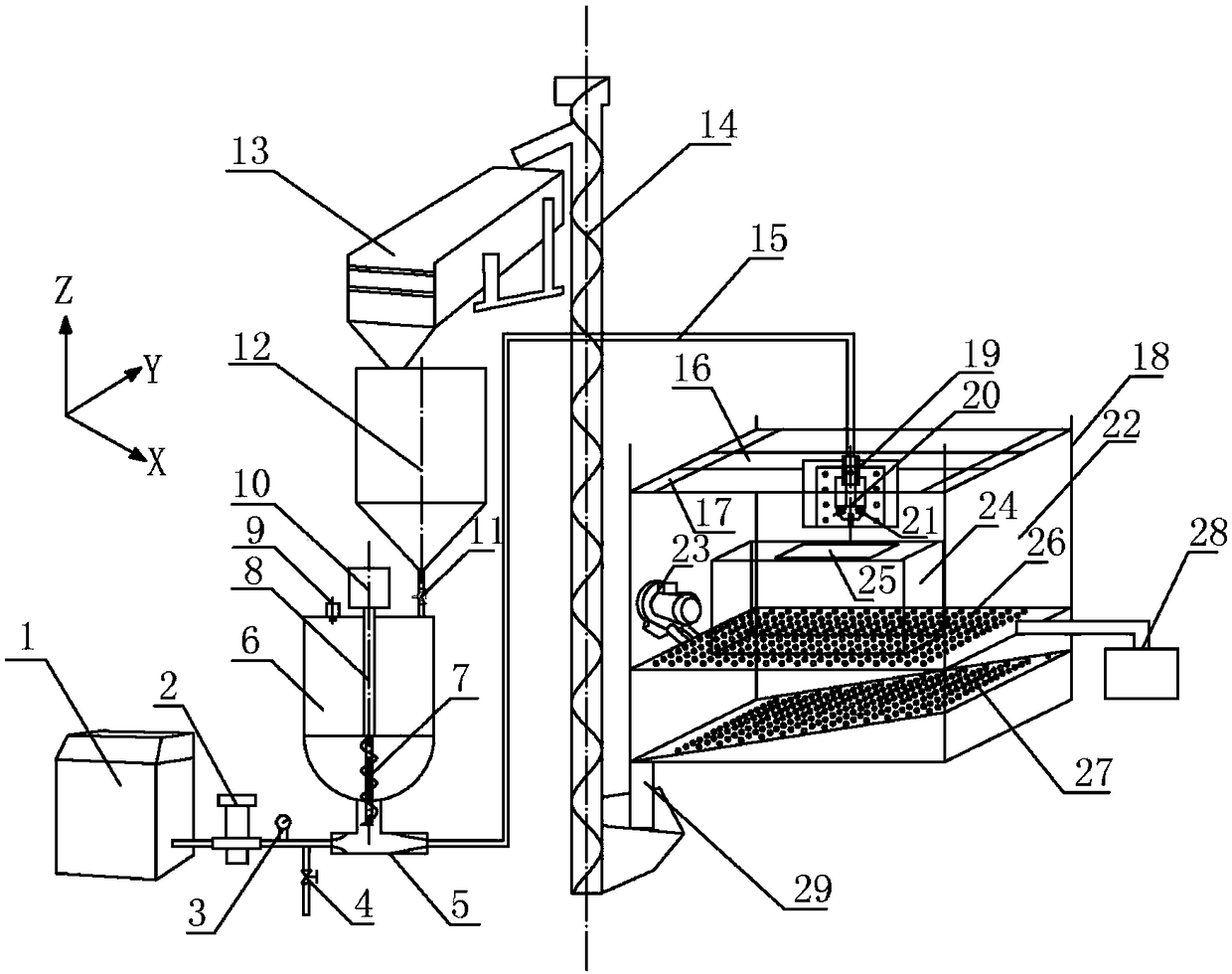

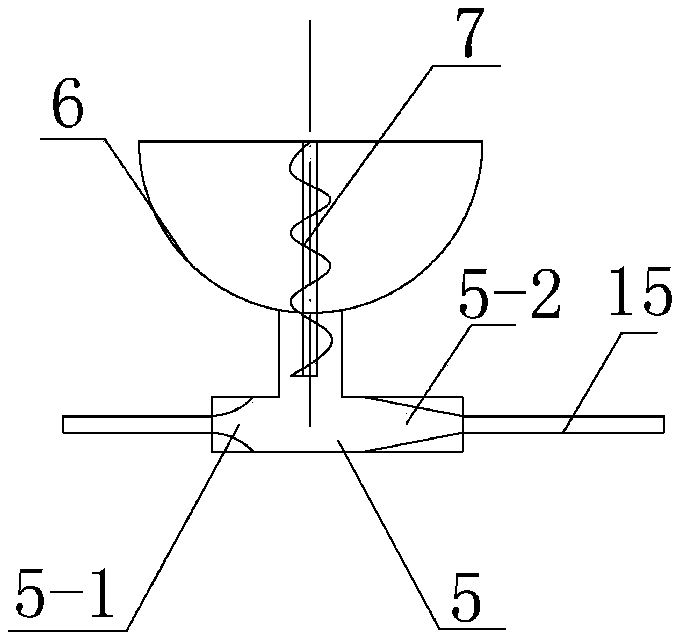

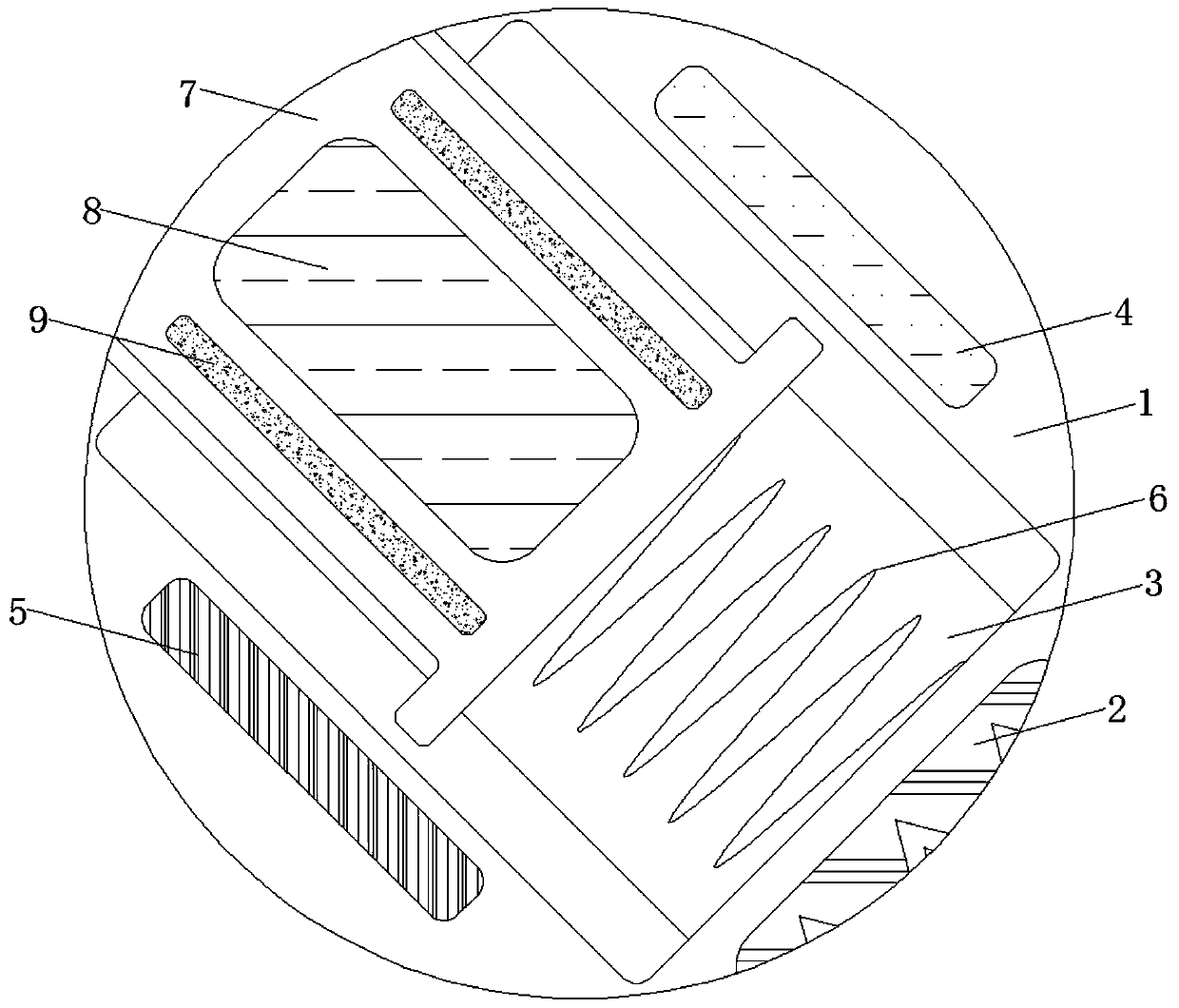

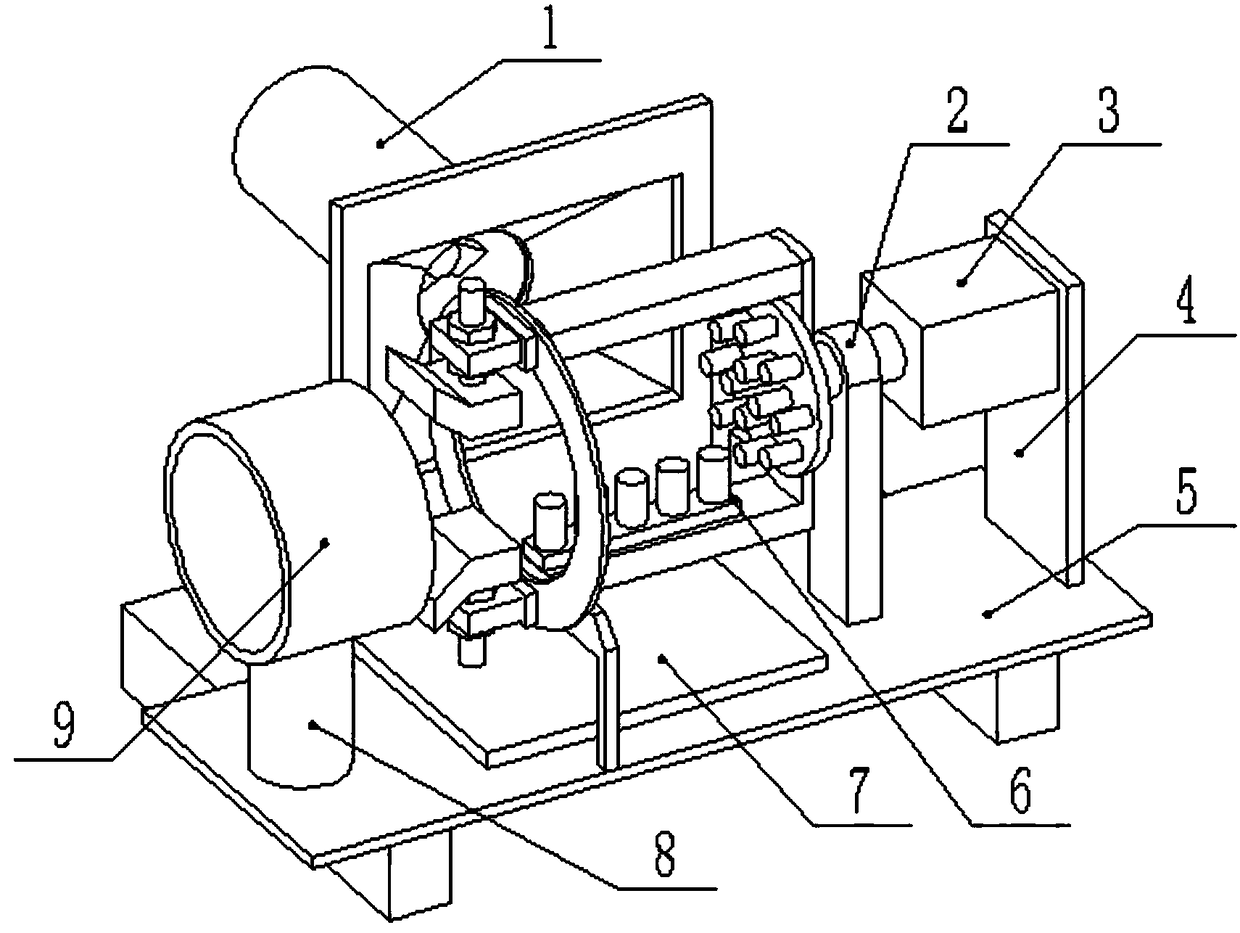

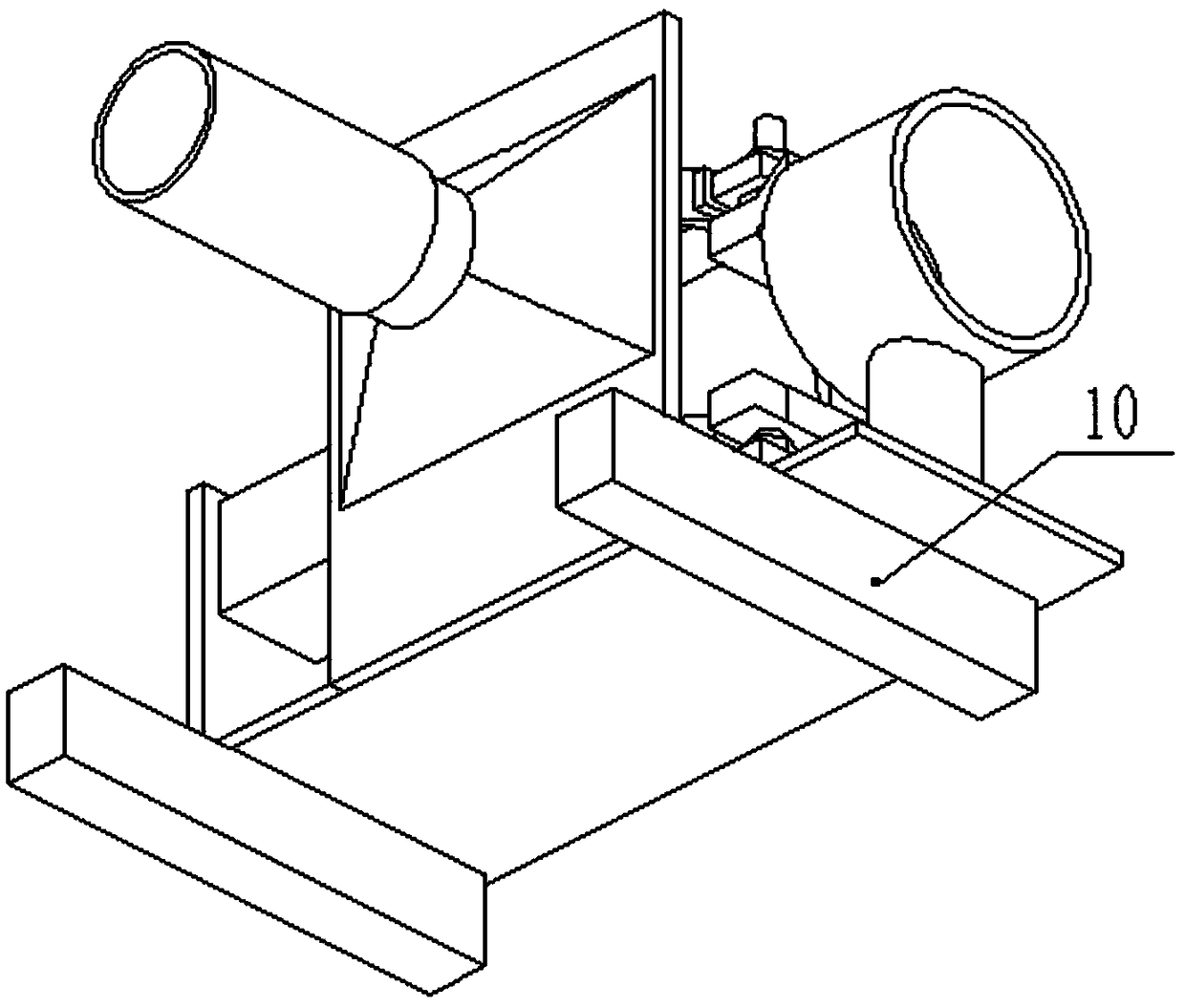

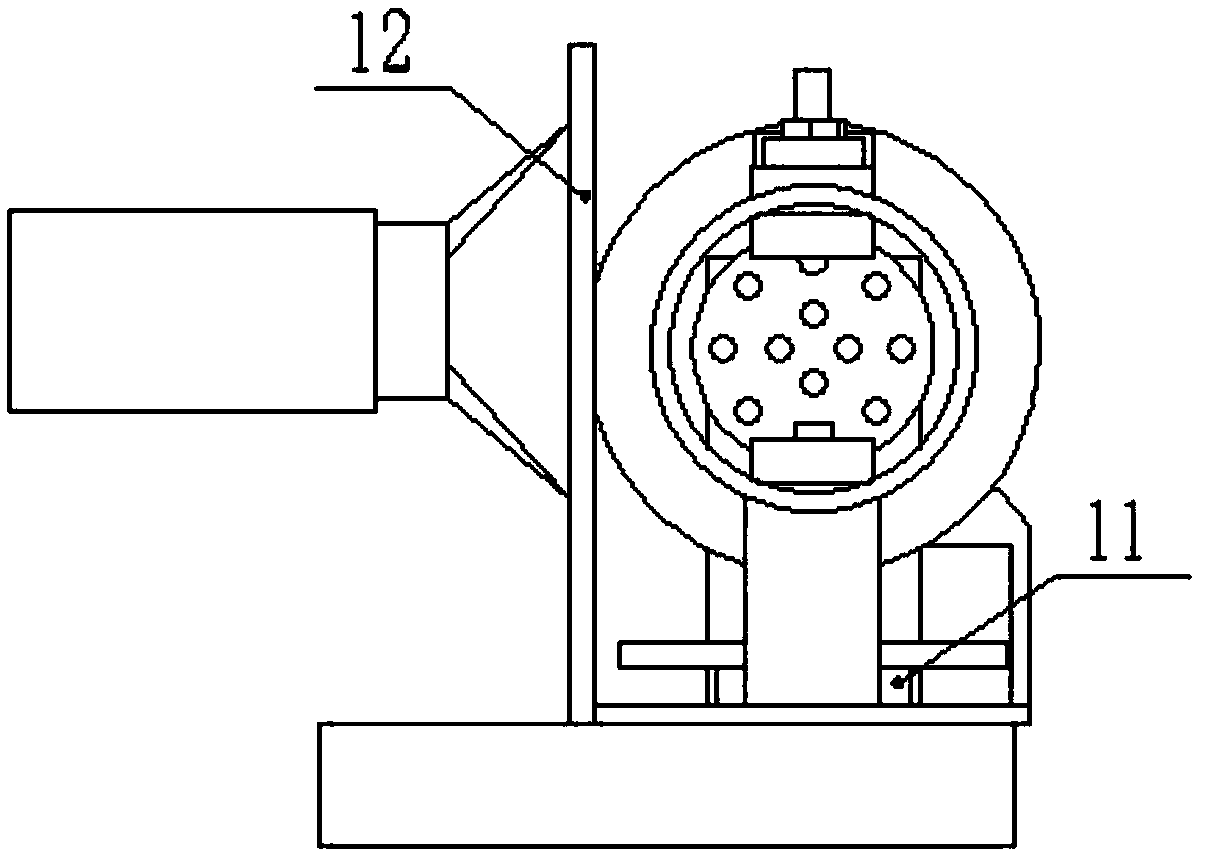

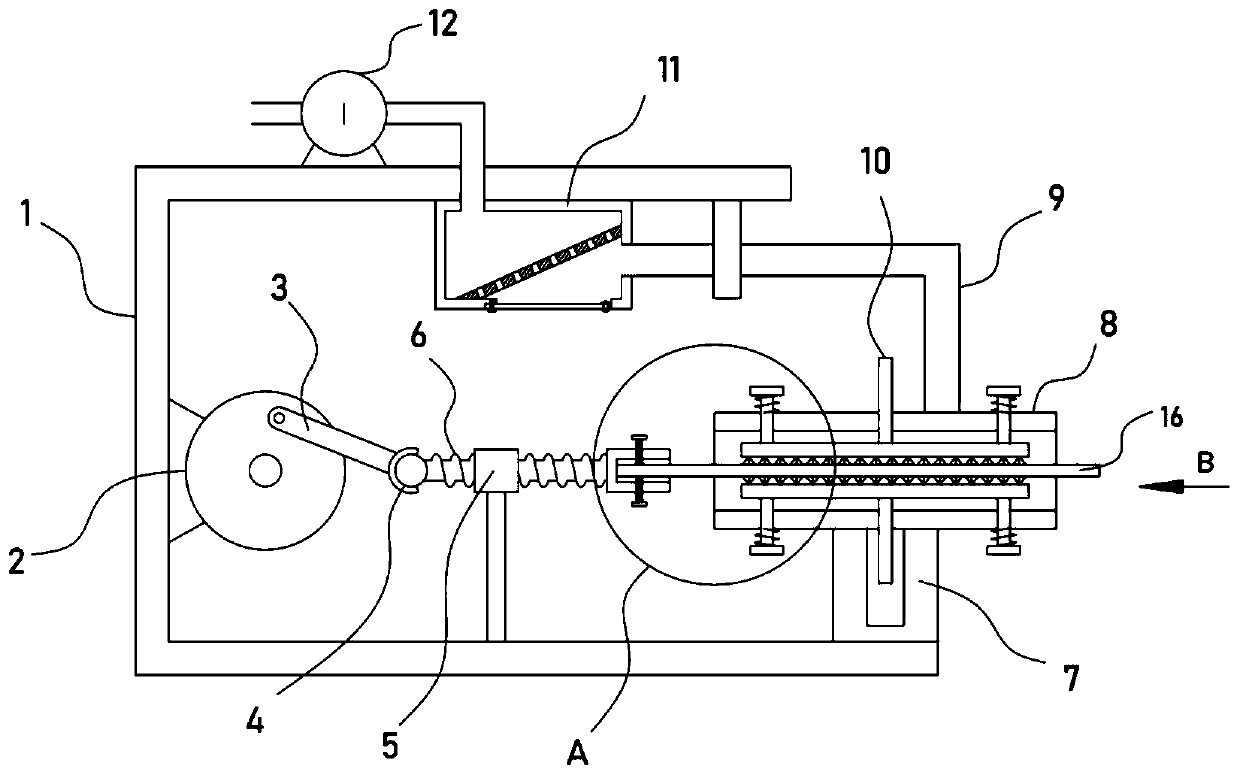

Recyclable particle jet descaling device

ActiveCN108772784AEfficient recyclingImprove rust removal efficiencyAbrasive machine appurtenancesGas solidEngineering

The invention belongs to the field of rust surface treatment, in particular relates to a recyclable particle jet descaling device comprising an air compressor, a pressure dividing valve, a mixing chamber, a high pressure particle tank, a screw, a 3D particle amount detector, a speed regulating motor, a particle storage tank, a double-layer vibrating screen, a vertical screw conveyor, an X-direction rail, a Y-direction rail, a Z-direction rail, a nozzle assembly, a nozzle, a dust cover, a blower, a horizontal filter pore plate, an inclined filter pore plate, a dust removal cloth bag, and the like. The recyclable particle jet descaling device can realize rapid particle addition, real-time particle amount monitoring, uniform, stable and controllable gas-solid mixing, injection position three-dimensional movement and angle adjustment, multi-stage particle separation and recycling, effective dust recovery, significant improvement of part surface rust removal efficiency, and enhancing of part surface strength.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

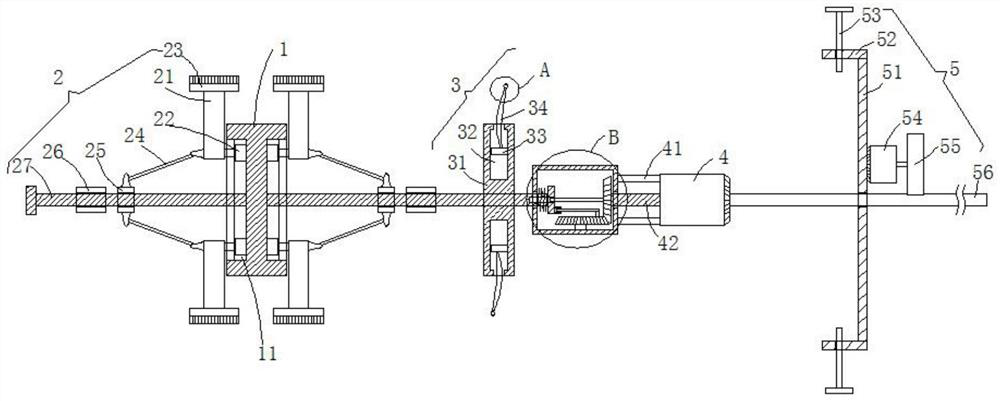

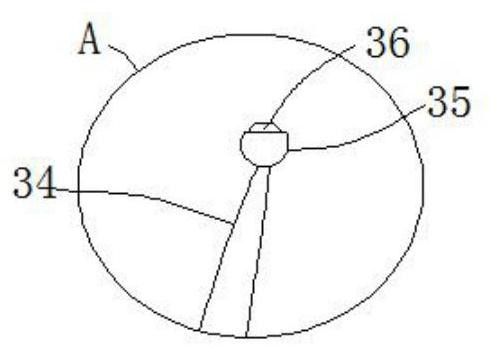

Automatic steel rail duplex rust removing machine

ActiveCN104631234AHard and wear-resistant working surfaceEasy to attachTrack superstructureRailway track constructionCouplingEngineering

The invention discloses an automatic steel rail duplex rust removing machine. The automatic steel rail duplex rust removing machine comprises a rack, engines and wheels connected to the lower portion of the rack, and is characterized in that the two engines are adopted and distributed on steel rails on the two sides respectively, the automatic steel rail duplex rust removing machine further comprises two soft shafts and two steering gears, one ends of the soft shafts are connected with rotating shafts of the engines through couplers, the other ends of the soft shafts are connected with input shafts of the steering gears, output shafts of the steering gears are connected with blade grinding wheels, the rack is fixedly connected with two connecting pieces, vertical adjusting pieces are arranged above the steering gears and elastically connected with the steering gears, connecting rods of the connecting pieces are connected with the vertical adjusting pieces, a transverse spring pull rod is connected between the vertical adjusting pieces of the steel rails on the two sides, and the rack is connected with a drive component. The kinetic energy of the engines is directly transmitted to the blade grinding wheels through the soft shafts, a duplex structure is adopted, synchronous automatic constant-speed rust removing can be carried out on pedal faces of the two steel rails at the same time, and the rust removing quality and efficiency are greatly improved.

Owner:德阳路安恒轨道技术开发有限公司

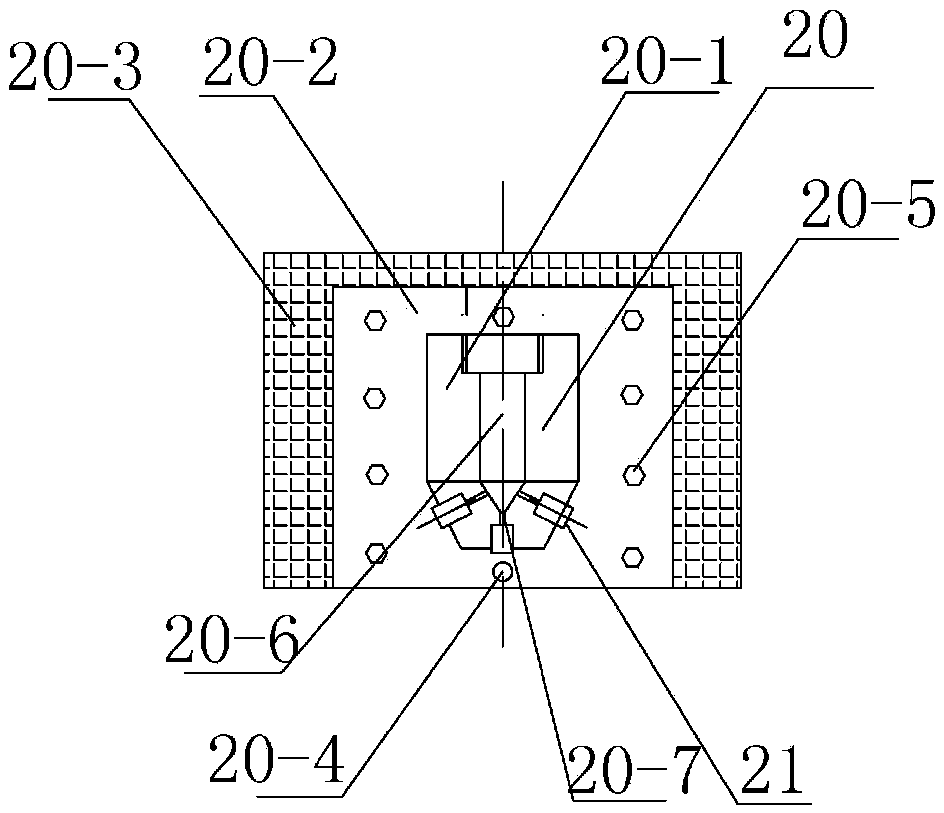

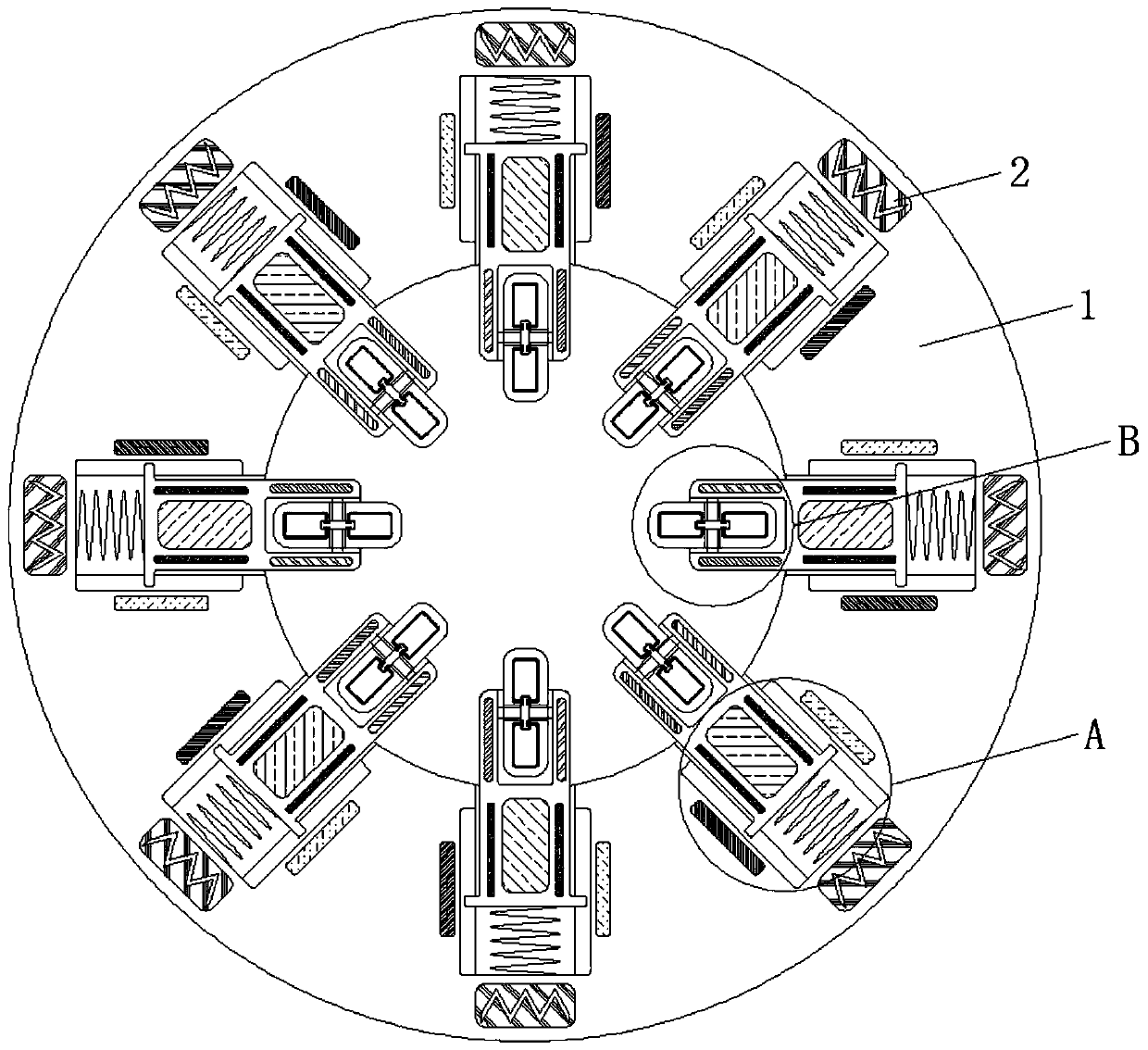

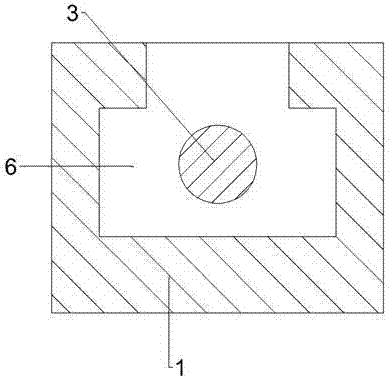

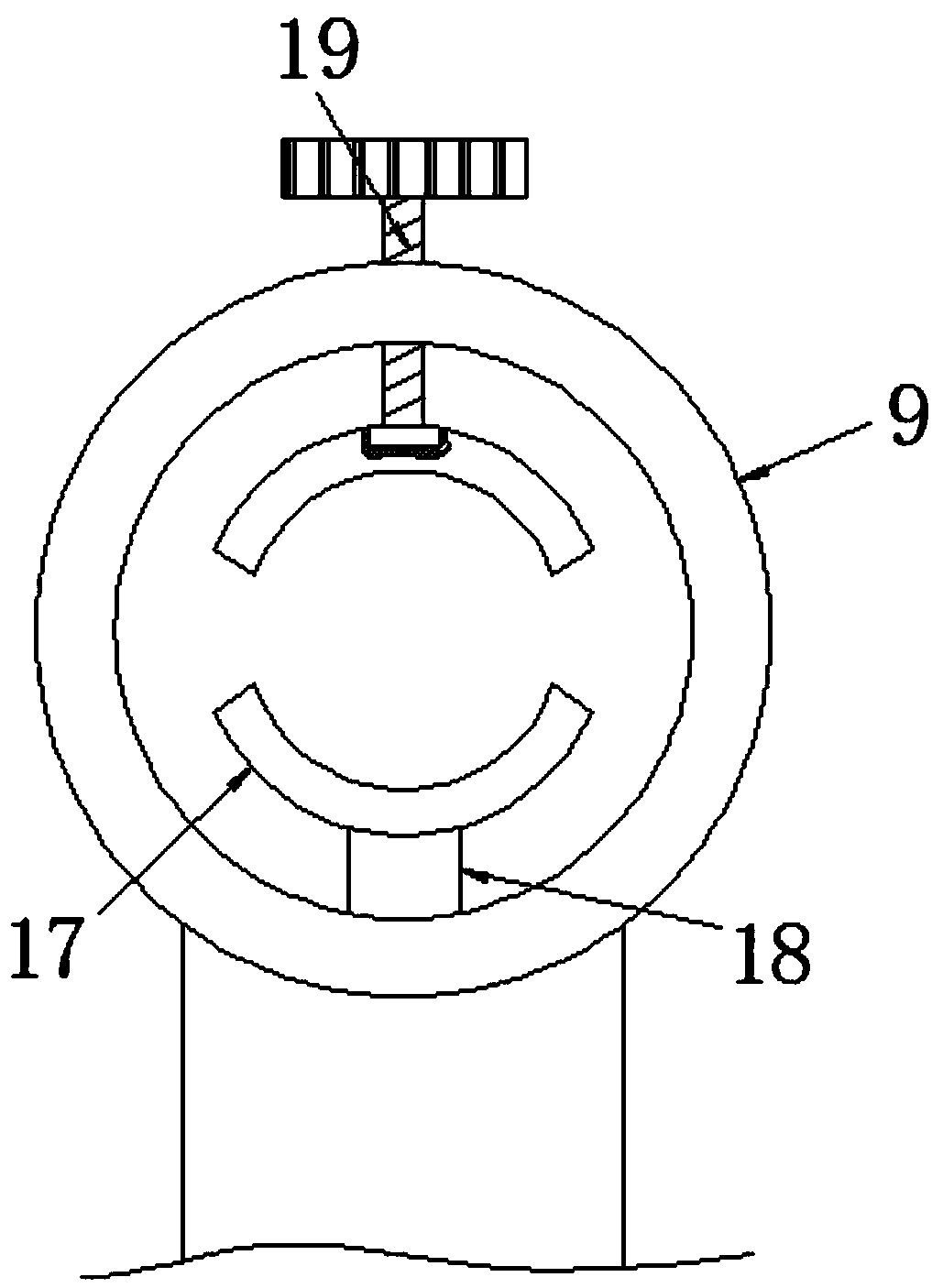

Centring and self-generating fixing device for environment-friendly steel pipe rust removal

ActiveCN110883668AEven contactTo achieve a calming effectGrinding drivesGrinding machinesEngineeringMechanical engineering

The invention provides a centring and self-generating fixing device for environment-friendly steel pipe rust removal relates to the technical field of environmental protection. The device comprises afixing pipe, an inner wall of the fixing pipe is fixedly connected with uniformly distributed electromagnetic devices 1, and the inner wall of the fixing pipe is provided with uniformly distributed movable grooves. According to the fixing device, the electromagnetic devices 2 and electromagnetic devices 2 are matched for use, since all the electromagnetic devices 1 have the same magnetism, the electromagnetic devices 2 have the same magnetism and the magnetism of inner sides of the electromagnetic devices 1 is the same as that of the outer sides of the electromagnetic devices 2, the electromagnetic devices 1 and the electromagnetic devices 2 repel each other, meanwhile, movable blocks can move towards the inner sides by the same length under the repulsive action of the electromagnetic devices 1 and the electromagnetic devices 2 such that rolling wheels are clamped and located in the center of the fixing pipe, the centering effect is achieved, the rust removal work is effectively guaranteed, an outer side of a steel pipe makes uniform contact with the rust removal device, and the rust removal quality is improved.

Owner:山东东正钢构有限公司

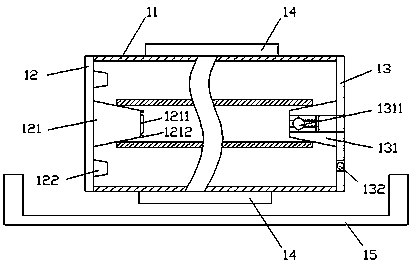

High pressure rust cleaning device and method of hydraulic pipe fittings

InactiveCN103990627AImprove rust removal efficiencyHollow article cleaningCleaning using liquidsPipe fittingSpray nozzle

The invention relates to the technical field of rust cleaning of hydraulic pipe fittings, in particular to a high pressure rust cleaning device and method of the hydraulic pipe fittings. The high pressure rust cleaning device comprises a rust cleaning fluid box body connected with a machine body, and the machine body comprises a tubular barrel body, a front end cover which is fixedly arranged, a rear end which is movably arranged, a spray nozzle arranged on the front end cover, and a thimble which is arranged on the rear end cover. The spray nozzle is a conical pressurizing nozzle, a large spray hole is formed in the middle of the spray nozzle, a plurality of small spray holes are evenly distributed in the side wall of the spray nozzle, and the spray nozzle is connected with the rust cleaning fluid box through a pipeline. The thimble is conical, a drainage hole is formed in the middle of the thimble, and a one-way pressure relief valve is arranged in the drainage hole. The rust cleaning of the hydraulic pipe fittings has the advantages that high pressure rust cleaning is achieved, and the rust cleaning efficiency is improved.

Owner:CHANGDE WEILONG PIPE CO LTD

Rust removal device of environment-friendly steel pipe end surface

ActiveCN109159006AReduce pollutionProtect your bodyRevolution surface grinding machinesPlane surface grinding machinesEngineeringWaste treatment

The invention discloses a rust removal device of an environment-friendly steel pipe end surface, and belongs to the field of environmental protection engineering equipment. An exhaust device is fixedbehind a third support, a motor is fixed at the top of a motor base, a grinding device is fixed on a main shaft of the motor, a magnet is fixed at the top of a second support, is positioned right below the grinding device, and a limiting support is fixed at the top of a first support. According to the device, a steel pipe is clamped by a first pressing block and a second pressing block, the grinding device is driven by the motor to rotate at a high speed, an end eliminating device and a surface eliminating device are used for grinding an end head and an outer surface of the steel pipe, and thecompletion of steel pipe derusting operation is replaced with manual operation, iron scraps generated by the magnet attraction and grinding are prevented from splashing to hurt people, poisonous smoke dust generated in a grinding process is adsorbed by the exhaust device, and the poisonous smoke dust is discharged into a waste treatment device, the environment pollution is reduced, the damage tothe body of workers is reduced, and the safety of the workers is guaranteed.

Owner:佛山市南海岐丰钢管有限公司

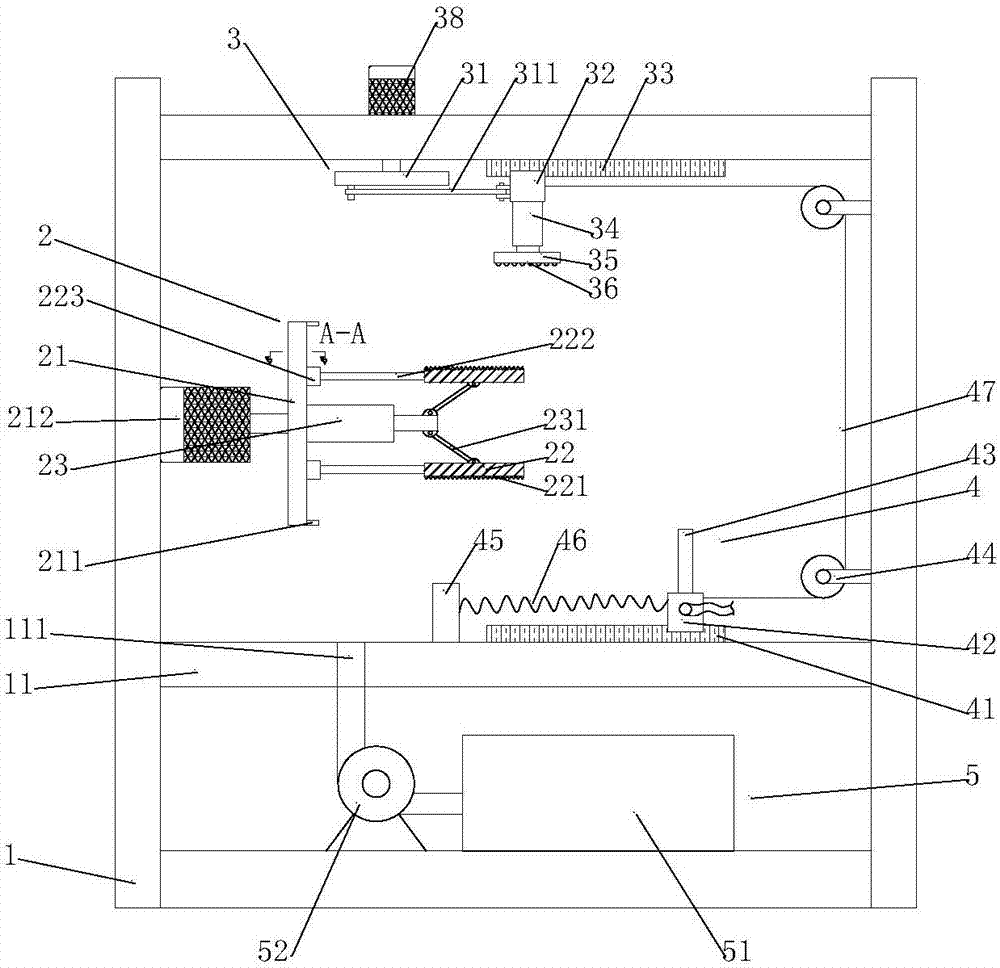

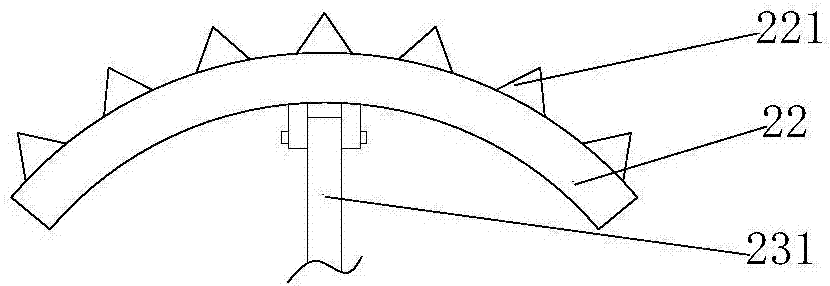

Grinding rust-removal device for processing surfaces of steel bars

InactiveCN110465872AAdjustable spacingImprove rust removal efficiencyGrinding drivesGrinding machinesRelative displacementEngineering

The invention discloses a grinding rust-removal device for processing surfaces of steel bars, and relates to the technical field of steel bar processing. The grinding rust-removal device for the processing surfaces of the steel bars comprises a rack, wherein a support frame is vertically fixed to the rack; a grinding sleeve allowing the steel bars to penetrate through is fixed to the support frame; two arc-shaped grinding plates used for grinding the steel bars are symmetrically arranged in the grinding sleeve; an adjustment mechanism used for adjusting the arc-shaped grinding plates to longitudinally move is arranged on the grinding sleeve; and a clamping mechanism used for clamping the steel bars is connected to one end away from a rotary wheel, of a transmission rod, through a precession mechanism. According to the grinding rust-removal device for the processing surfaces of the steel bars, the clamping mechanism clamping the steel bars is driven through the arranged precession mechanism, rotation is realized while the transversal reciprocating movement of the steel bars is realized, then the arc-shaped grinding plates are capable of generating a circumferential relative displacement with the steel bars, and capable of generating a transversal relative displacement, and grinding rust-removal with a larger range can be carried out in the length direction of the steel bars, sothat the rust removal efficiency is effectively increased.

Owner:张海燕

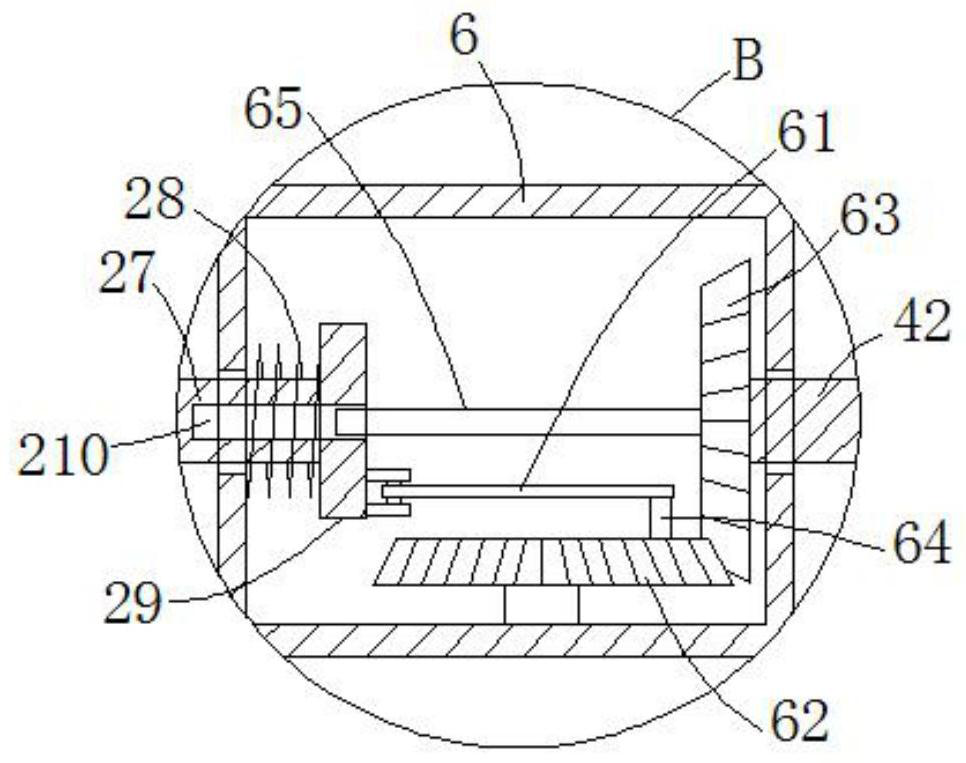

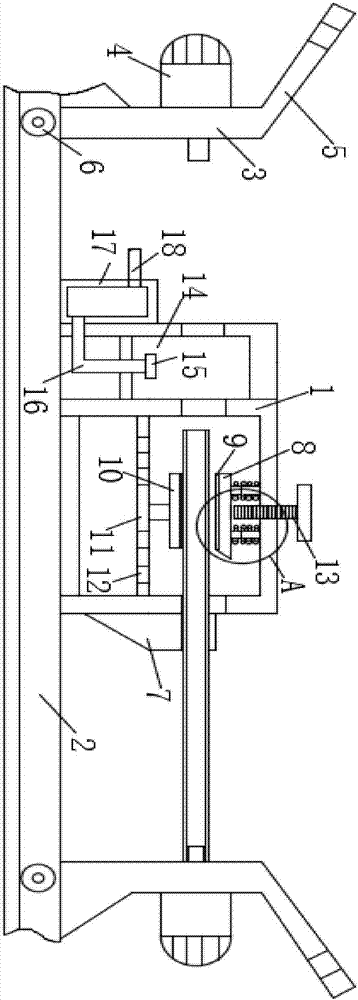

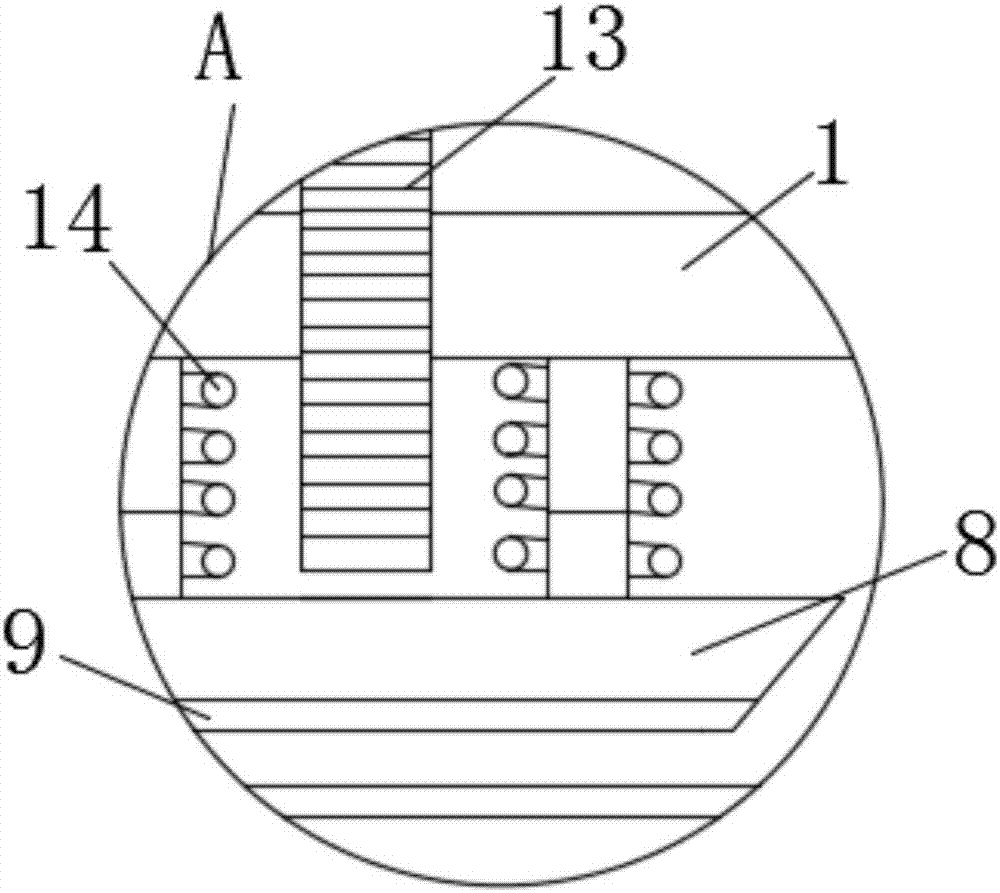

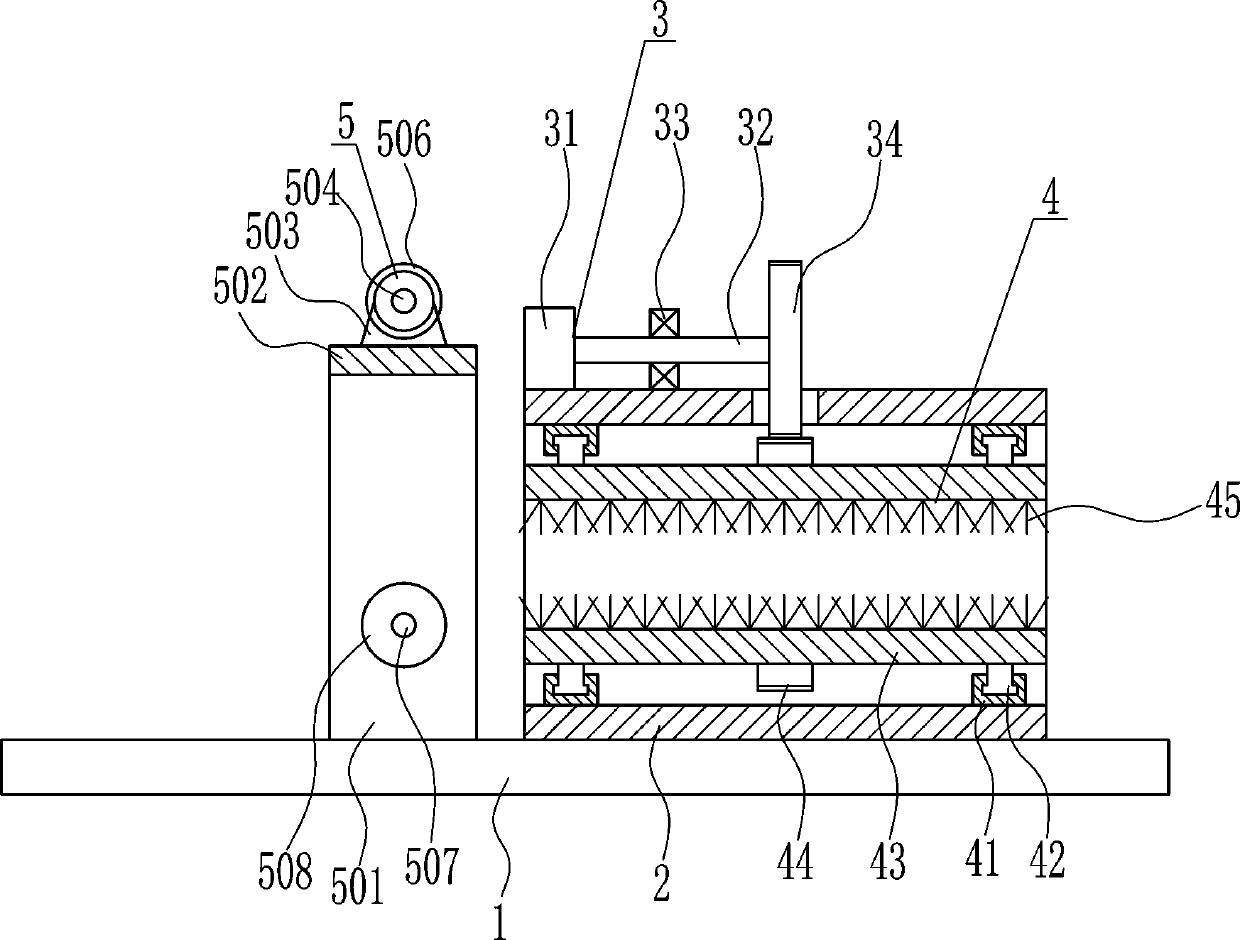

High-performance rust removal equipment for hardware plate

InactiveCN107042459AEasy to useImprove rust removal efficiencyGrinding drivesGrinding machinesSide effectEngineering

The invention relates to a derusting device, in particular to a high-performance derusting device for metal plates. The technical problem to be solved by the present invention is to provide a high-performance derusting equipment for metal plates with high derusting efficiency, convenient use and accelerated working process. In order to solve the above technical problems, the present invention provides such a high-performance derusting equipment for metal plates, which includes a first gear, a first bearing seat, a first rotating shaft, a first pulley, a connecting belt, a fixed frame, and a second pulley , derusting blocks, motors, rollers, etc.; the first shaft is provided with the first shaft, the first shaft is provided with the first pulley and the first gear, the second slide rail is provided with the second slider, and the second The bottom of the slider is provided with a first rack. The invention achieves the effects of high derusting efficiency, convenient use and accelerated working process, can derust the metal plate very conveniently and quickly, saves manpower, and enables repeated and efficient utilization of resources.

Owner:南昌诺义弘科技有限公司

Integral equipment for surface maintenance of building pipelines

ActiveCN107288333AImprove rust removal efficiencyImprove oiling effectScaffold accessoriesBevel gearCoating

The invention provides integral equipment for surface maintenance of building pipelines. The equipment includes a base, both ends of the base are fixedly connected with a supporting base separately, the supporting bases are rotatably connected with supporting rollers, and a pipeline is erected between the two supporting rollers, wherein the base is provided with a mobile device which comprises a mobile groove with an opening facing upwards; the mobile groove is internally provided with a first mobile block, a second mobile block, a third mobile block and a fourth mobile block which are sequentially arranged from left to right; threaded through holes are formed in the first mobile block, the second mobile block, the third mobile block and the fourth mobile block; the threaded through holes are all internally in threaded connection with a threaded rod, both ends of the threaded rod are rotatably connected with the two ends of the mobile groove, and the right portion of the threaded rod is fixedly connected with a first bevel gear. The integral equipment for the surface maintenance of the building pipelines has the advantages of having an integrated function of rust cleaning, polishing, coating and drying, improving maintenance efficiency of the pipelines to a great degree, and having a certain value of popularization and application.

Owner:滨州市科创孵化器有限公司

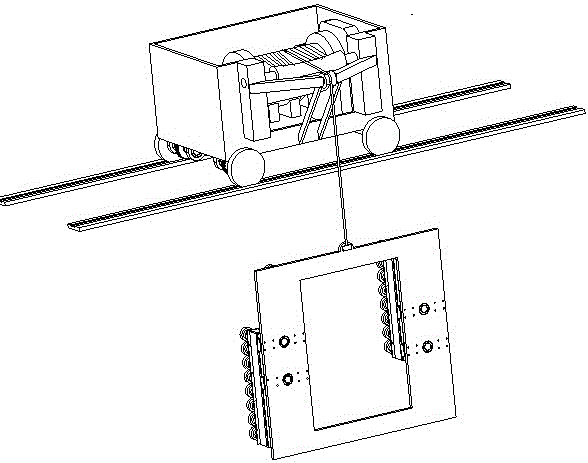

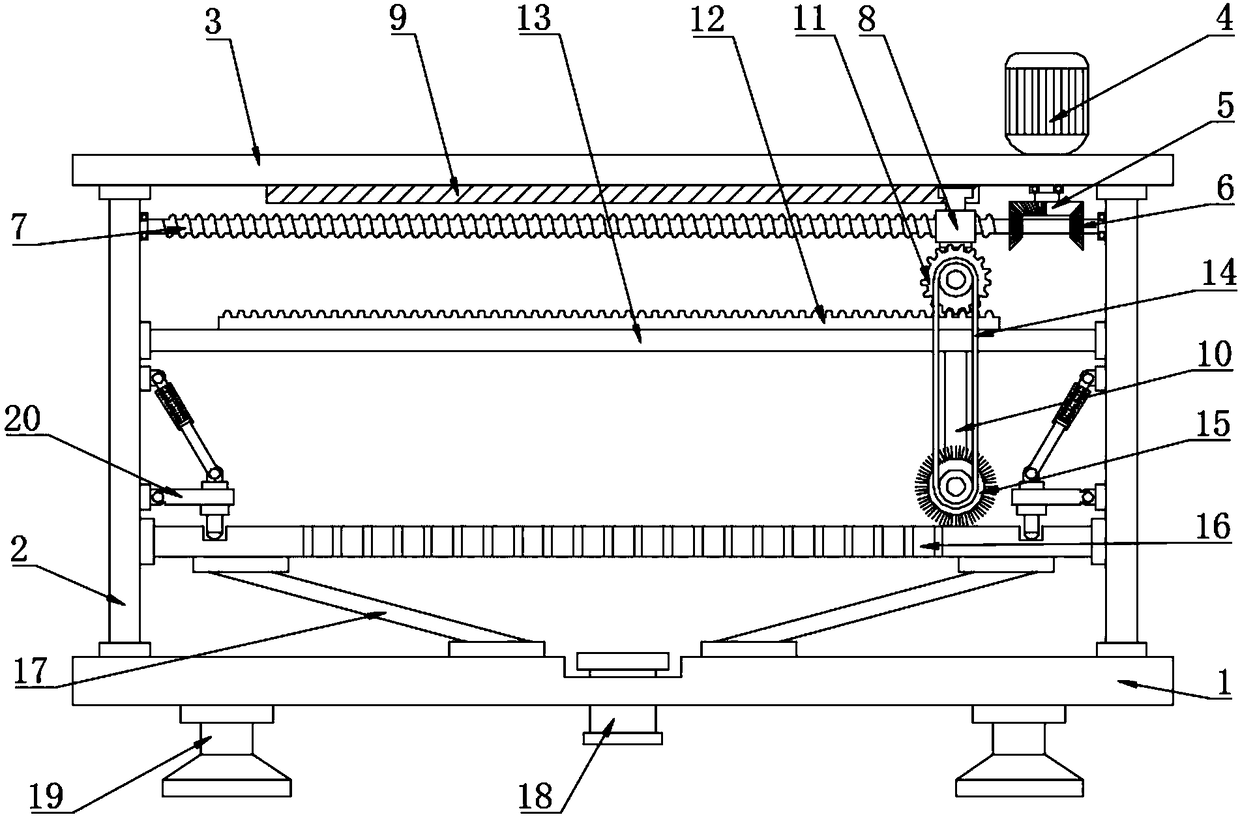

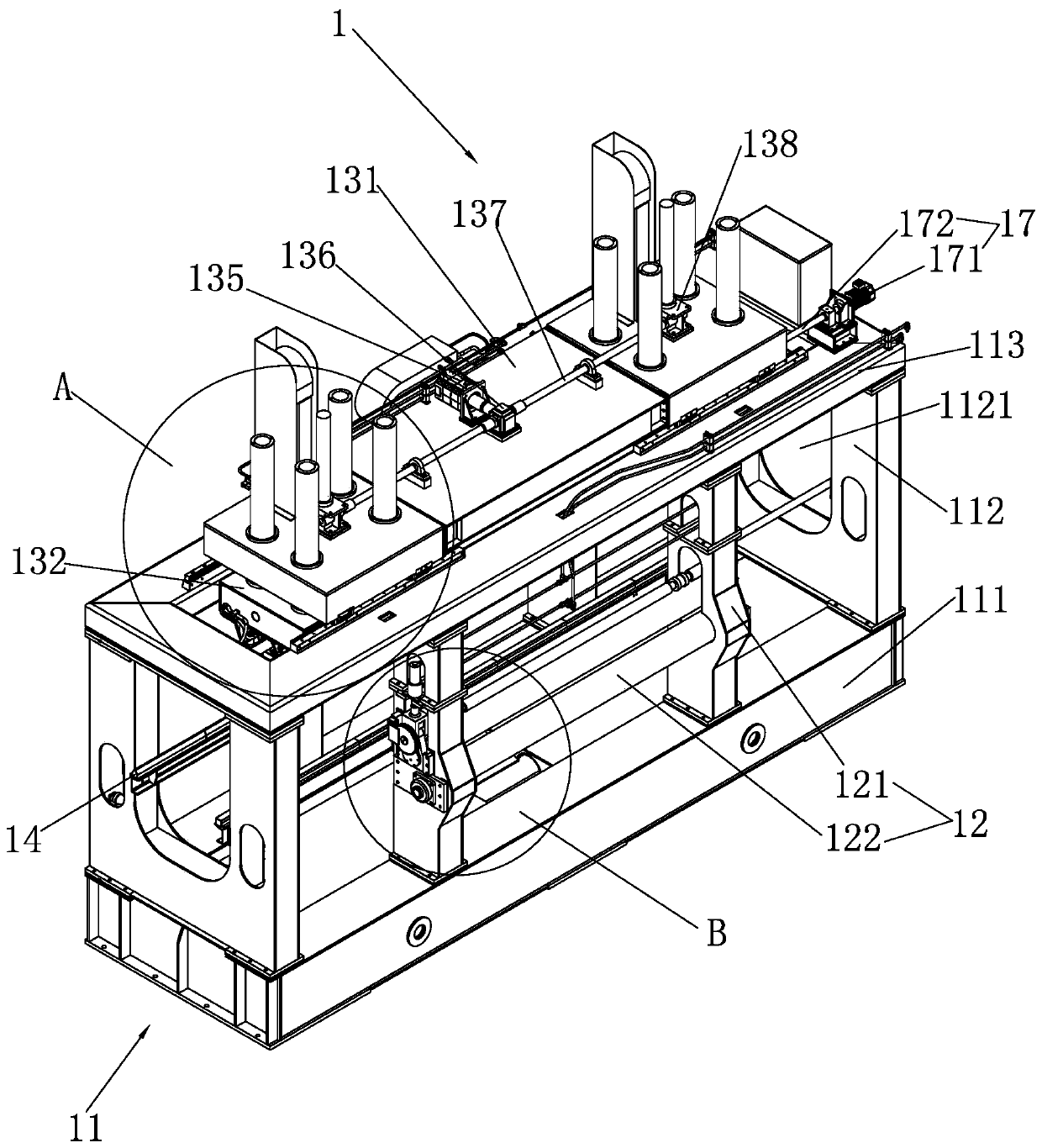

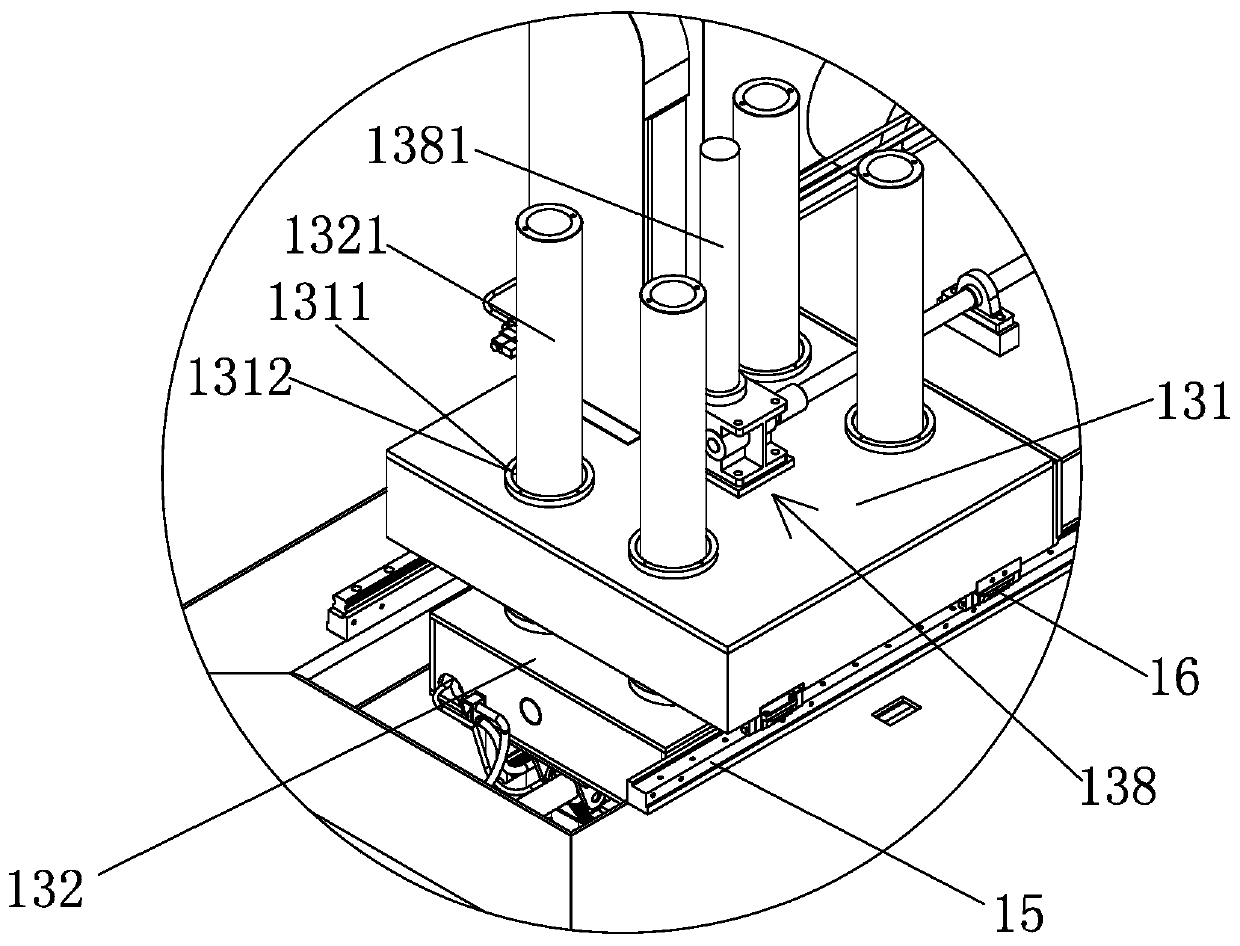

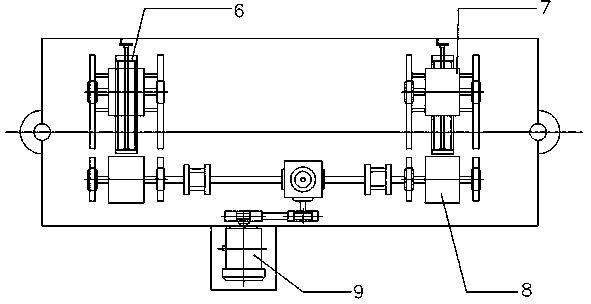

Steel plate derusting production line

InactiveCN110744417AReduce pollutionImprove rust removal efficiencyGrinding wheel securing apparatusGrinding carriagesStructural engineeringManufacturing line

The invention relates to a steel plate derusting production line. The steel plate derusting production line comprises a plurality of steel plate surface derusting machines and a plurality of steel plate side surface derusting machines which are arranged in the moving direction of the production line and a trolley rail which is parallelly arranged on one side of the production line; at least one roller changing trolley which can slide along the rail back and forth along the rail is arranged on the trolley rail; a roller changing mechanism is arranged on the roller changing trolley; and when thetrolley moves to the front side surface of a steel plate surface derusting machine, the roller changing mechanism can extend into the steel plate surface derusting machine for roller changing operation. According to the steel plate derusting production line, a steel plate is subjected to surface derusting treatment by adopting a physical derusting mode; pollution is little; the derusting efficiency is high; the surface of the steel plate can be derusted seamlessly; meanwhile, a damaged roller in the steel plate surface derusting machines is automatically changed through the roller changing trolley, so that the automation level is high; and time and labor are saved.

Owner:ZHEJIANG MOPPER ENVIRONMENTAL TECH CO LTD

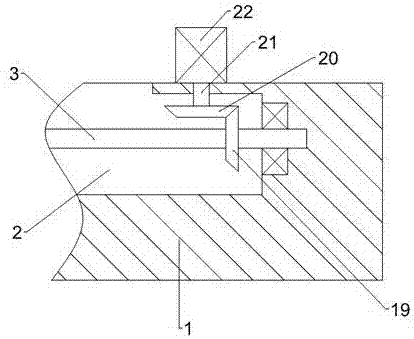

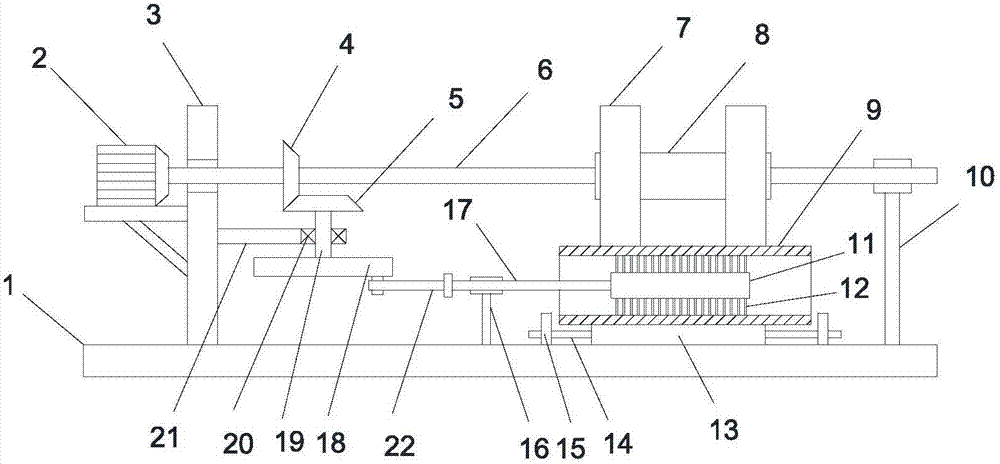

Large-inside-diameter steel pipe inner wall derusting device for machining

InactiveCN107263288AAchieve rust removalReasonable designRevolution surface grinding machinesGrinding drivesGear wheelDrive shaft

The invention discloses a large-inside-diameter steel pipe inner wall derusting device for machining. The device comprises a bottom plate, wherein a first shaft support is vertically and fixedly mounted on the bottom plate and is movably connected with a right end of a driving shaft; a first bevel gear is coaxially and fixedly mounted on the driving shaft; a second bevel gear is coaxially and fixedly mounted on an upper end of a driven shaft and is connected with the first bevel gear in a meshed manner; a rotating wheel is coaxially and fixedly mounted at a lower end of the driven shaft; a second shaft support is vertically and fixedly mounted on the bottom plate; a first connecting rod is horizontally arranged on the second shaft support in a horizontal sliding manner; a limiting roller is coaxially and fixedly mounted on the rotating shaft; a steel pipe for derusting is placed on the limiting roller; a derusting roller is fixedly mounted on the first connecting rod; steel wire brushes are uniformly arranged on a surface of the derusting roller; guiding wheels are fixedly mounted on the rotating roller in a sleeving manner and are pressed against an outer surface of the derusting roller. According to the device disclosed by the invention, axial and annular derusting effects on the inner wall of the steel pipe can be realized at the same time, so that the derusting effect on the inner wall of the steel pipe is preferable.

Owner:深圳市海帮国际商务服务有限公司

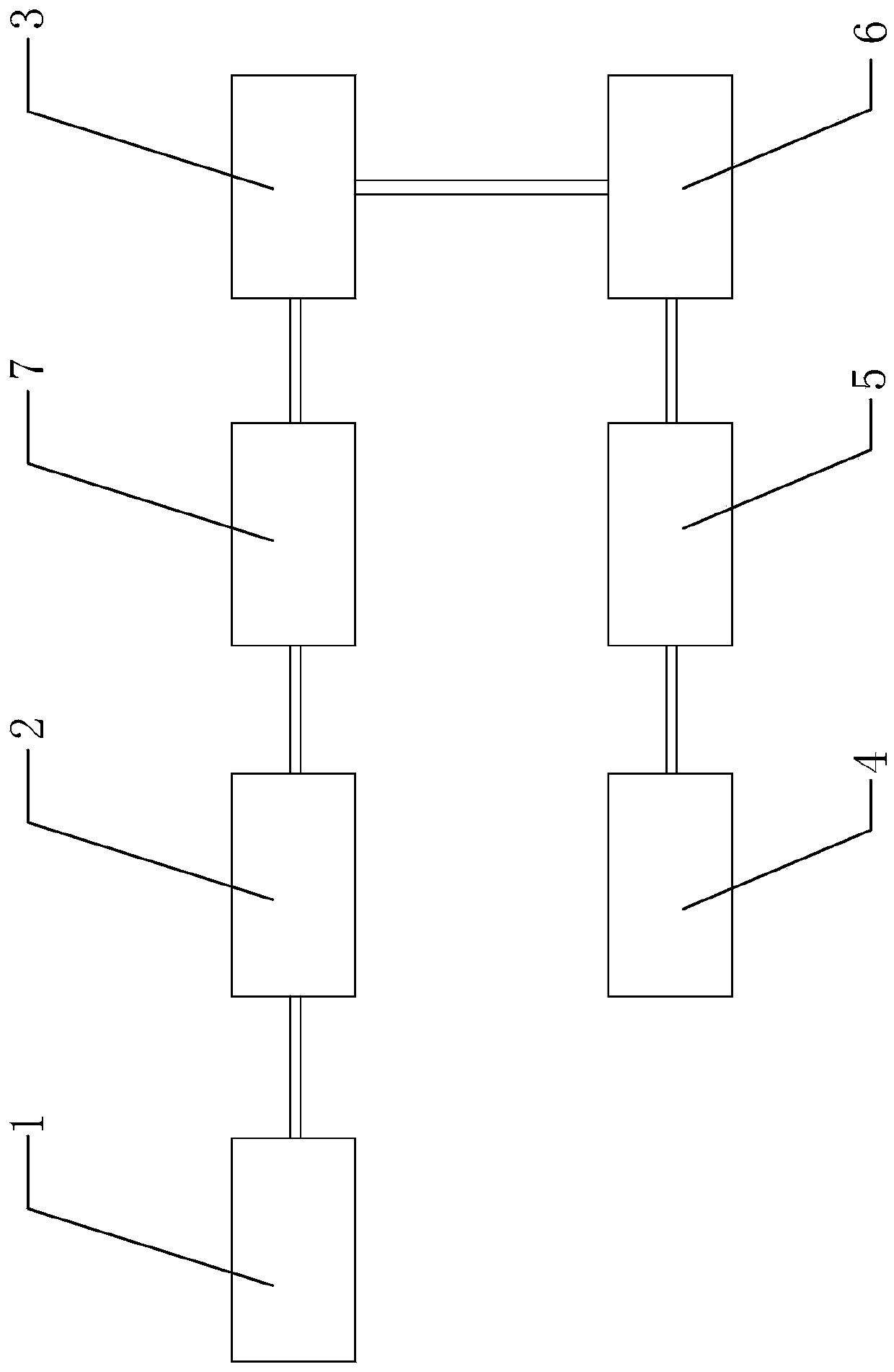

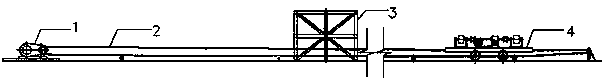

Steel wire rust removal production line and rust removal process

InactiveCN110936274AReduce pollutionImprove rust removal efficiencyGrinding carriagesMetallic material coating processesManufacturing lineManufacturing engineering

The invention relates to a steel wire rust removal production line and a rust removal process. The production line comprises an uncoiling machine, a rust removal device and a coiling machine which aresequentially arranged in the running direction of the production line, wherein a steel wire penetrates through the uncoiling machine, the rust removal device and the coiling machine in sequence, andthe uncoiling machine is used for pulling the steel wire to be straight and pull the steel wire into the rust removal device and performing preliminary rust removal treatment on the surface of the steel wire; the rust removal device is used for further processing the surface of the steel wire; and the coiling machine is used for coiling the steel wire subjected to rust removal treatment. The rustremoval production line and the rust removal process are small in pollution and high in rust removal efficiency.

Owner:ZHEJIANG MOPPER ENVIRONMENTAL TECH CO LTD

Pull-type metal wall surface working wall-climbing robot

InactiveCN106240664AEasy to controlSimple structureVessel cleaningHullsVertical displacementControl theory

The invention provides a pull-type metal wall surface working wall-climbing robot. The pull-type metal wall surface working wall-climbing robot comprises a pulling mechanism and a climbing mechanism. The climbing mechanism is suspended on a metal wall surface by the pulling mechanism through pulling ropes. The horizontal displacement of the robot is completed through walking of a pulling car, the vertical displacement of the robot is completed through the pulling ropes and a rack and pinion mechanism, an obstacle crossing function of the robot is achieved through up-down displacement of a foot mechanism, and an adsorption function of the robot is achieved through electromagnets. The pull-type metal wall surface working wall-climbing robot has the characteristics of being large in load capacity, high in obstacle crossing capacity and the like.

Owner:SHANGHAI UNIV

Building steel plate derusting device

InactiveCN108356672AImprove rust removal efficiencyReasonable structural designSievingScreeningGear driveSheet steel

The invention discloses a building steel plate derusting device. The lower portion of a driving motor is rotatably connected with a driving shaft. The lower end of the driving shaft is fixedly connected with a semicircular bevel gear. Bevel gears are arranged on the two sides of the semicircular bevel gear. The bevel gears are fixedly connected with a threaded rod. The toothed part of the semicircular bevel gear is engaged with the bevel gears. A movable block is in threaded connection with the threaded rod. The lower end of the movable block is fixedly connected with a vertical supporting rod. A gear is engaged with a rack. The lower portion of the vertical supporting rod is rotatably connected with a cleaning roll. The front portion of the cleaning roll and the front portion of the gearare both fixedly connected with belt pulleys. The belt pulleys are connected through a driving belt. According to the building steel plate derusting device, a steel plate is pressed onto a filter plate through pressure springs and rubber blocks; the rotatable semicircular bevel gear drives the threaded rod to do reciprocating forward and reverse rotation so as to drive the movable blocks to move left and right along a guide rail; the movable block drives the vertical supporting rods to move left and right accordingly; the gear is driven to move left and right and rotate simultaneously under the action of the rack; the gear drives the cleaning roll to move left and right and rotate simultaneously to conduct cleaning through the driving belt accordingly. The building steel plate derusting device is good in cleaning effect and high in automation degree.

Owner:张炳强

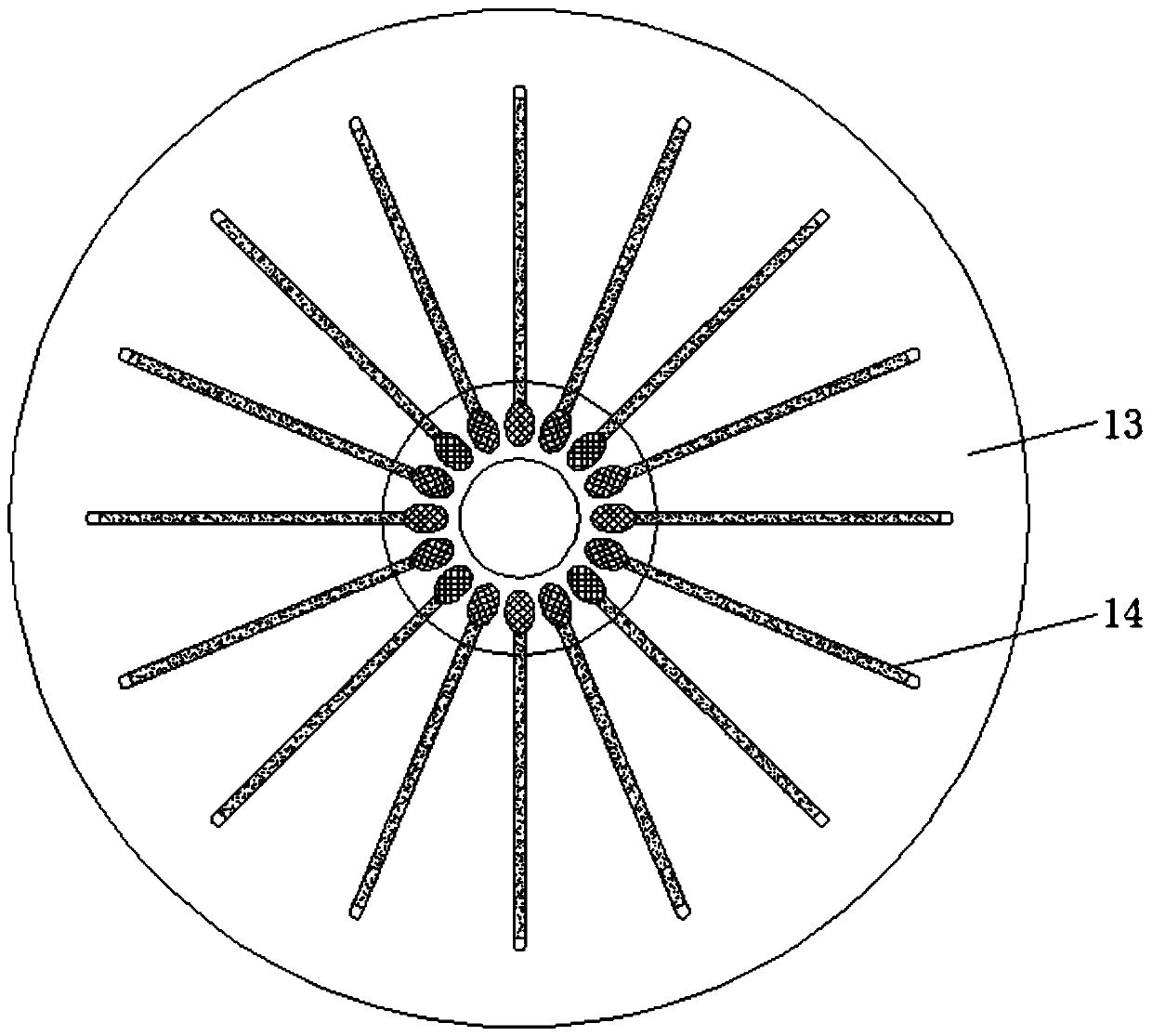

Pipeline inner wall derusting device

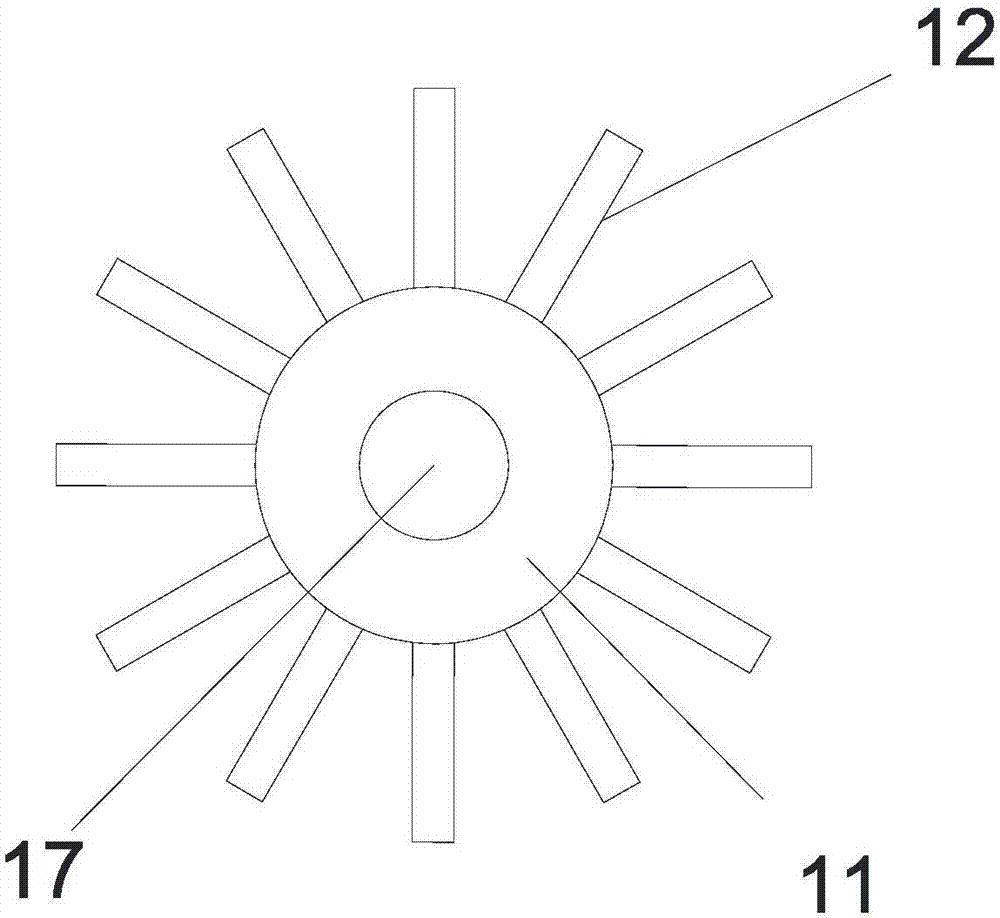

InactiveCN111702640AAchieve full coverageRealize all-round rust removal operationRevolution surface grinding machinesGrinding drivesElectric machineStructural engineering

The invention discloses a pipeline inner wall derusting device. The pipeline inner wall derusting device comprises a fixing mechanism, a driving motor, a connection seat and two bilaterally-symmetrical derusting mechanisms with the connection seat as a center; the fixing mechanism comprises a fixing plate, two positioning plates, a conveying motor and a threaded conveying rod; the center positionof the right end surface of the driving motor is rotationally connected with the left end of the threaded conveying rod, the left end surface of the driving motor is connected with a hollow box with an inner cavity being of a hollow structure through two connection rods, the driving motor rotationally penetrates through the right end surface of the hollow box through a power shaft and is connectedwith a first bevel gear located in the inner cavity of the hollow box, and the side wall of the front side of the inner cavity of the hollow box is rotationally connected with a second bevel gear through a hinge pin; and the two derusting mechanisms each comprise a threaded rod, a threaded sleeve, a sliding sleeve, a plurality of adjusting blocks annularly and uniformly distributed at intervals,and a plurality of cleaning hairbrushes annularly and uniformly distributed at intervals. The pipeline inner wall derusting device can adapt to pipelines different in opening diameter conveniently, quickly conduct feeding and derusting and blow away removed iron rust.

Owner:缪静

Rust removing and paint spraying device for outer wall of steel pipe

InactiveCN107185748AEasy to operateImprove rust removal efficiencyPretreated surfacesLiquid spraying apparatusSteel tubeEngineering

The invention discloses a rust removal and painting device for the outer wall of a steel pipe. The center of the upper surface of the main body is connected with a knob bolt through a threaded hole. A movable pressure plate is arranged above the main body of the derusting device, a fixed plate is arranged under the main body of the derusting device, and a spray booth is provided on the left surface of the main body of the derusting device. The invention pushes the steel pipe into the body of the derusting device, the steel pipe is closely attached to the movable plate between the fixed plates, the rotation of the steel pipe enables the derusting frosted sheet to derust the steel pipe, and when the left end of the steel pipe moves into the paint spraying room, the compressed gas will The paint in the paint tube is sprayed onto the surface of the steel pipe through the nozzle to complete the steel pipe painting work, which improves the rust removal efficiency of the steel pipe, and can also spray the steel pipe to prevent the steel pipe from rusting again.

Owner:桐乡市锦格家纺有限公司

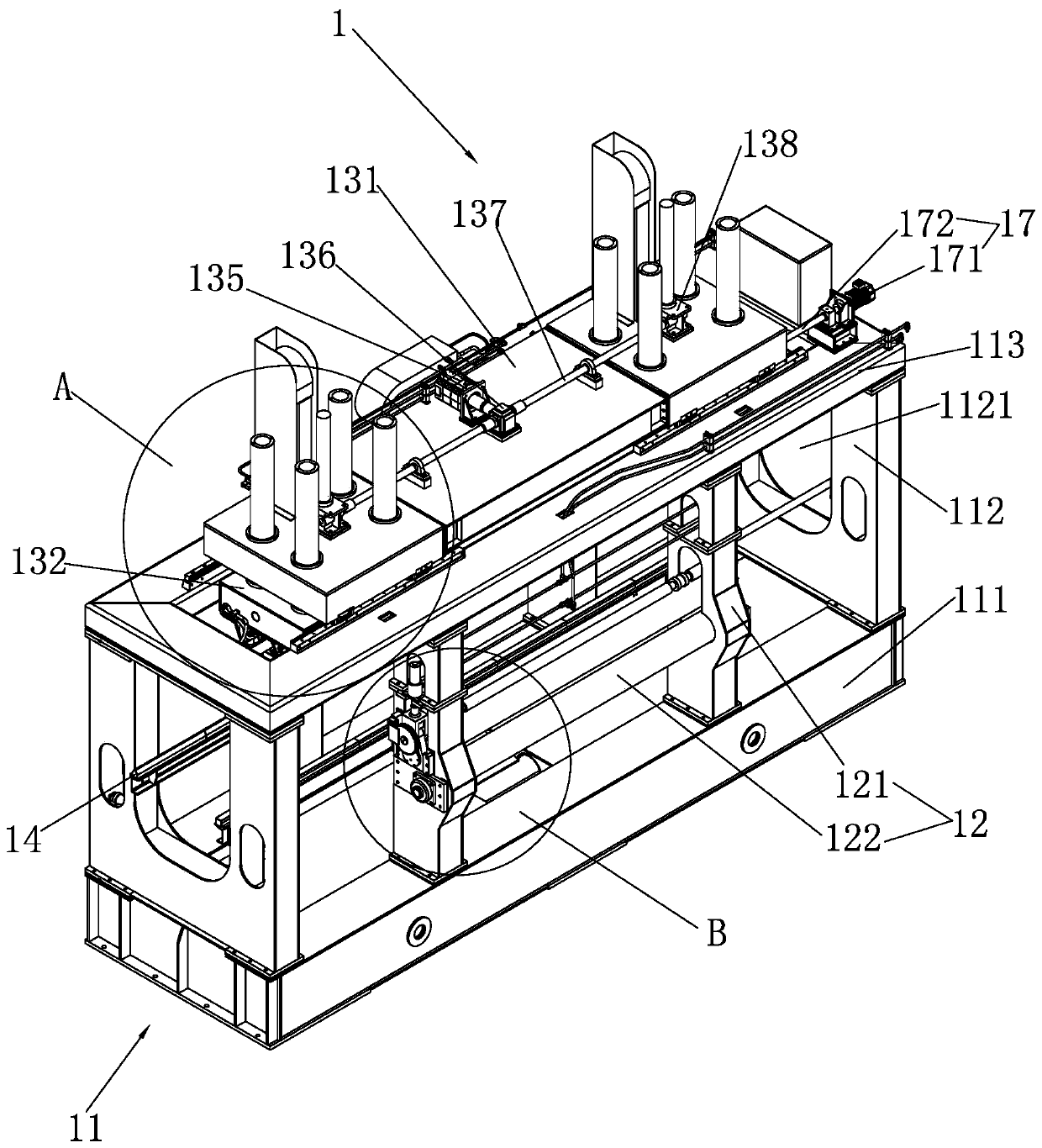

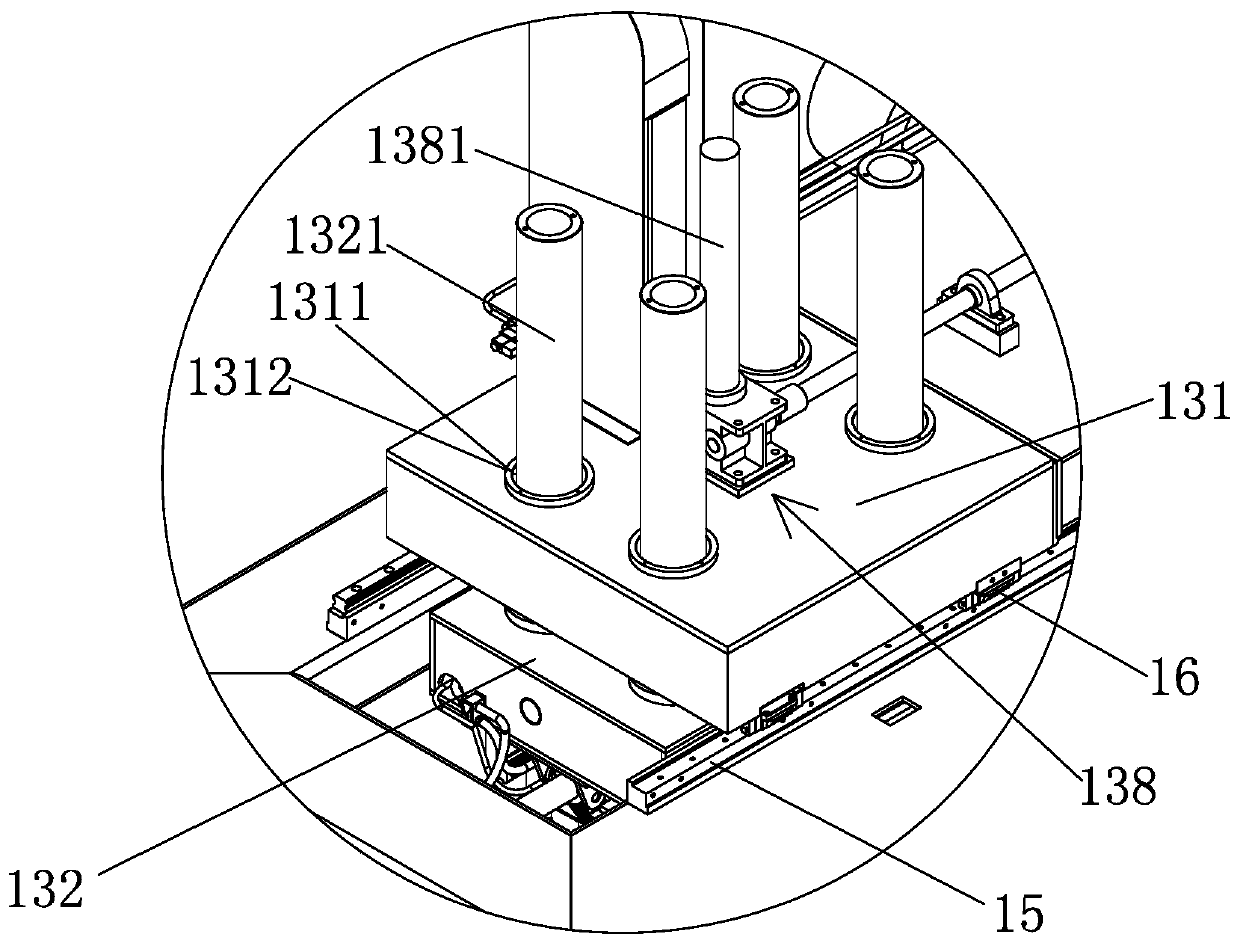

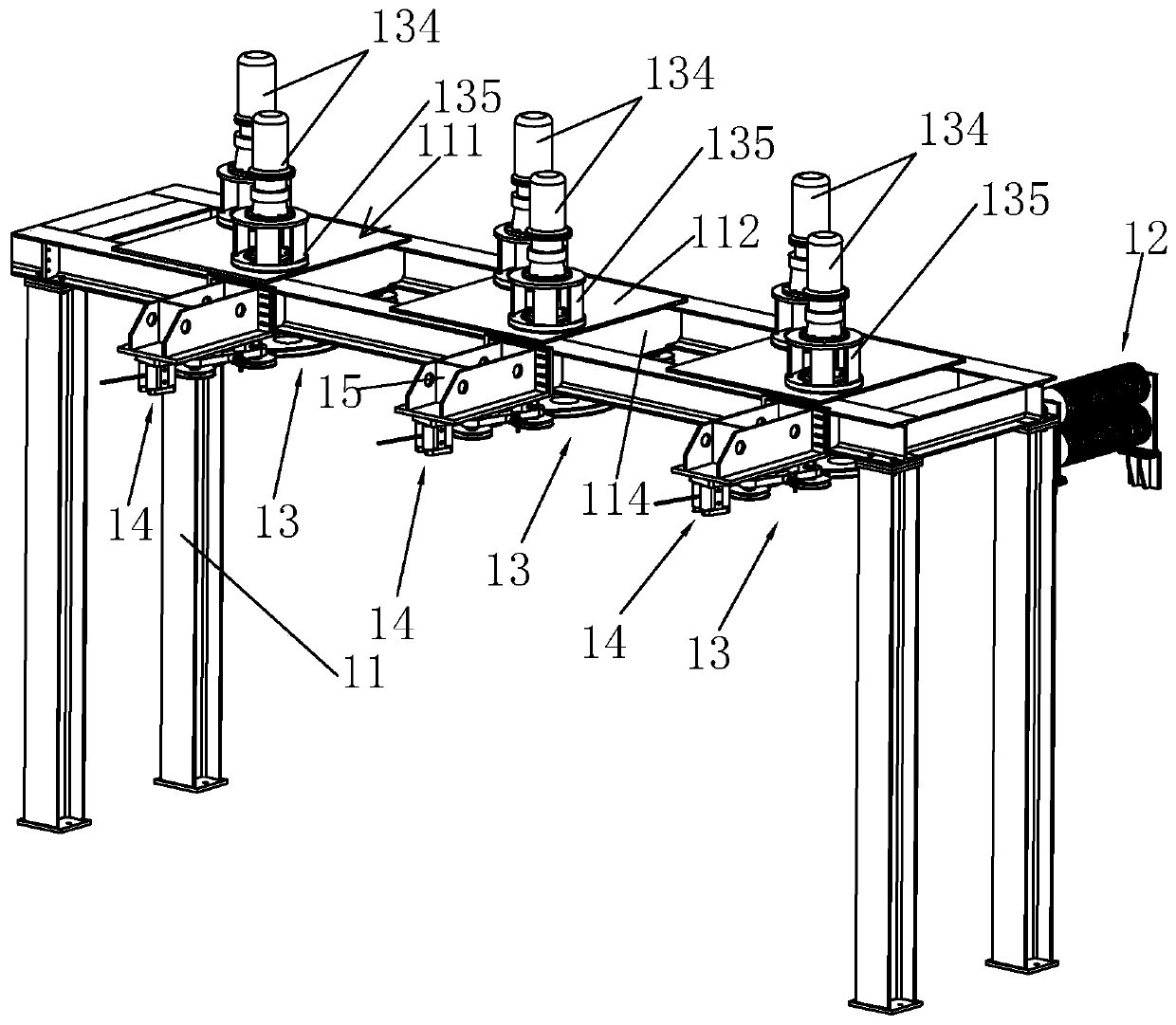

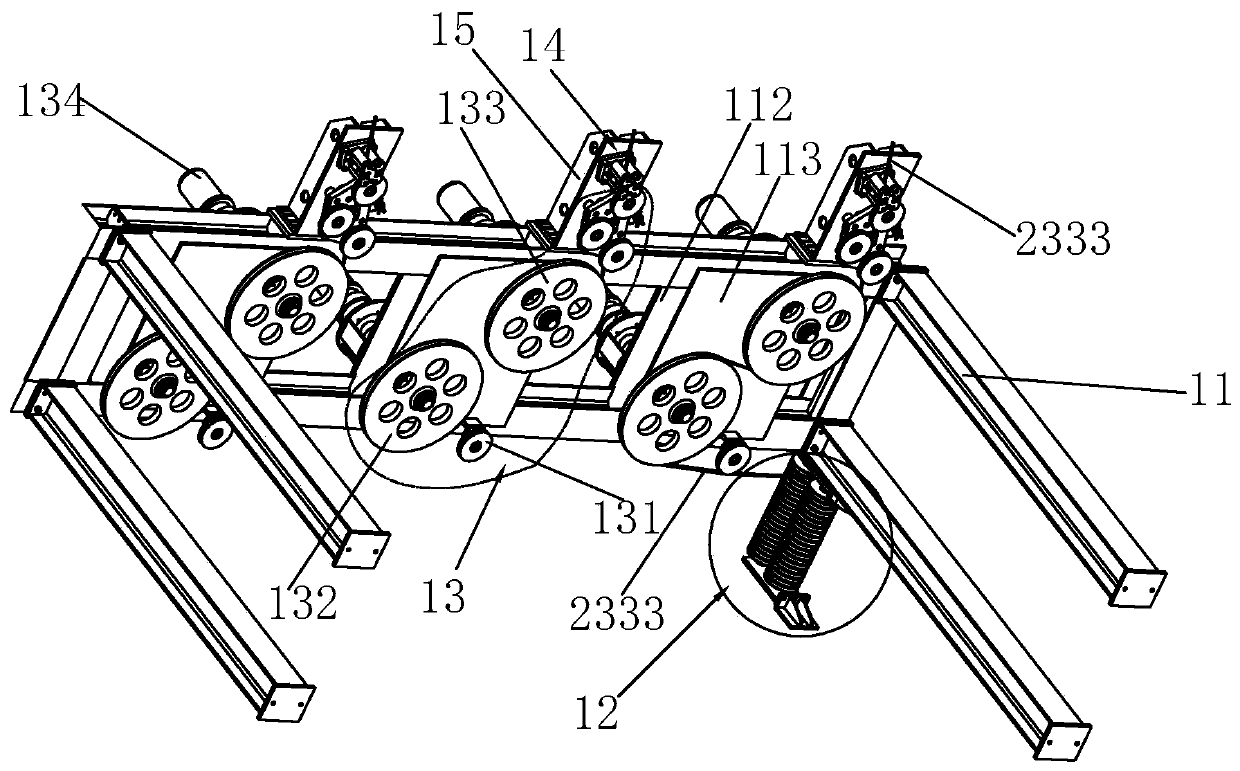

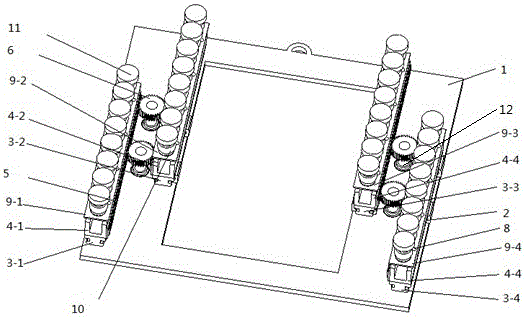

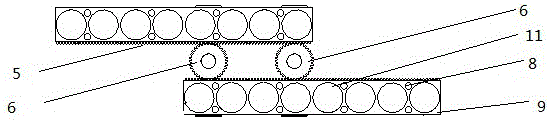

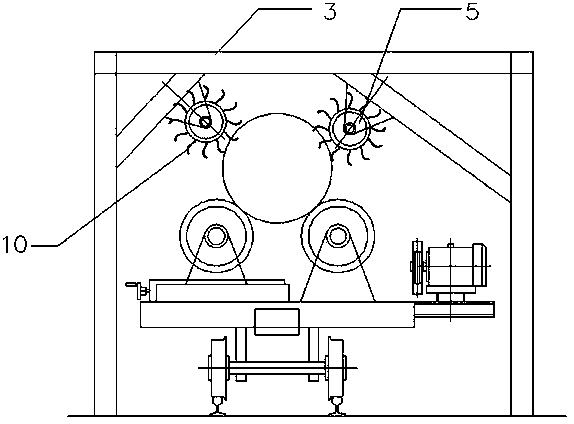

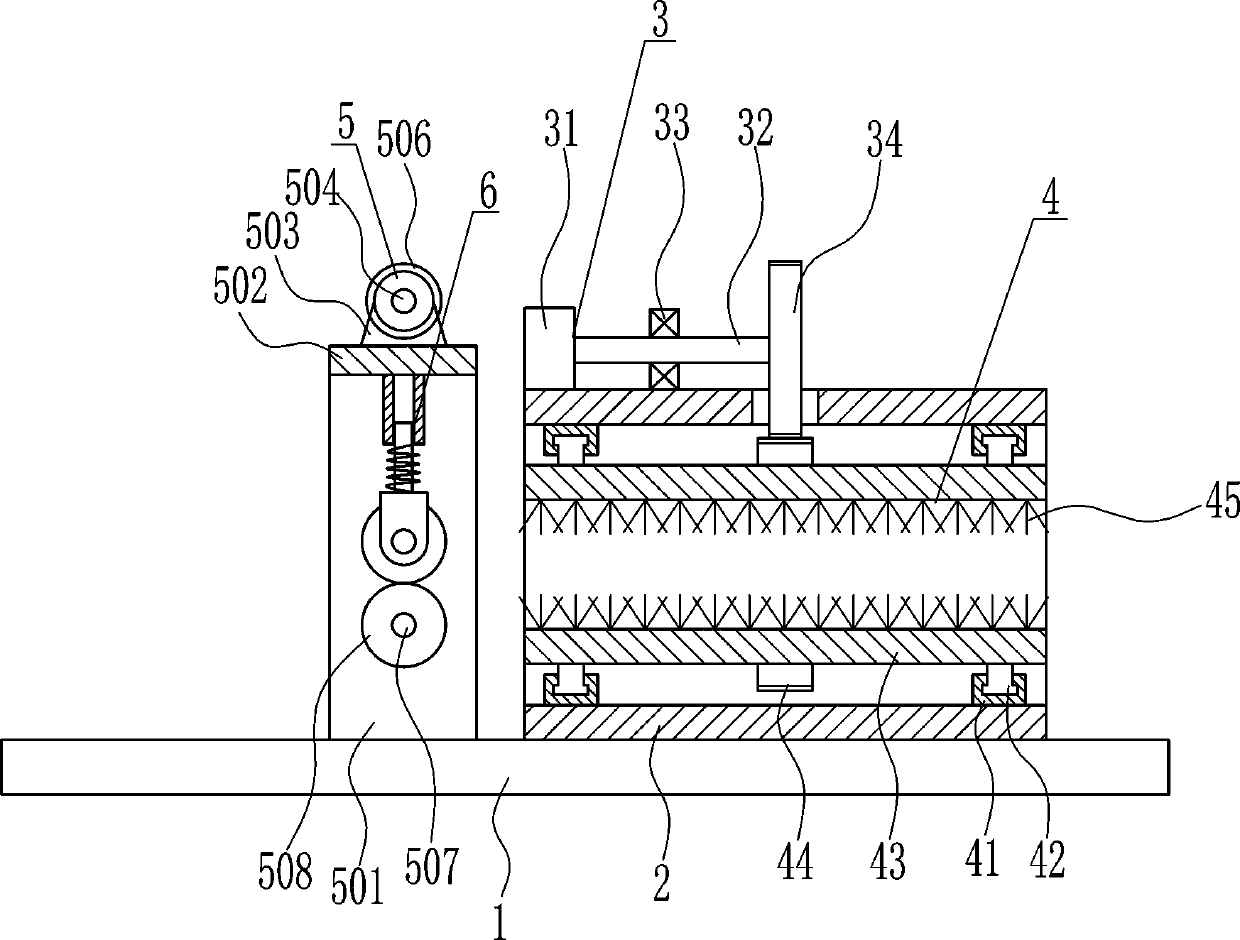

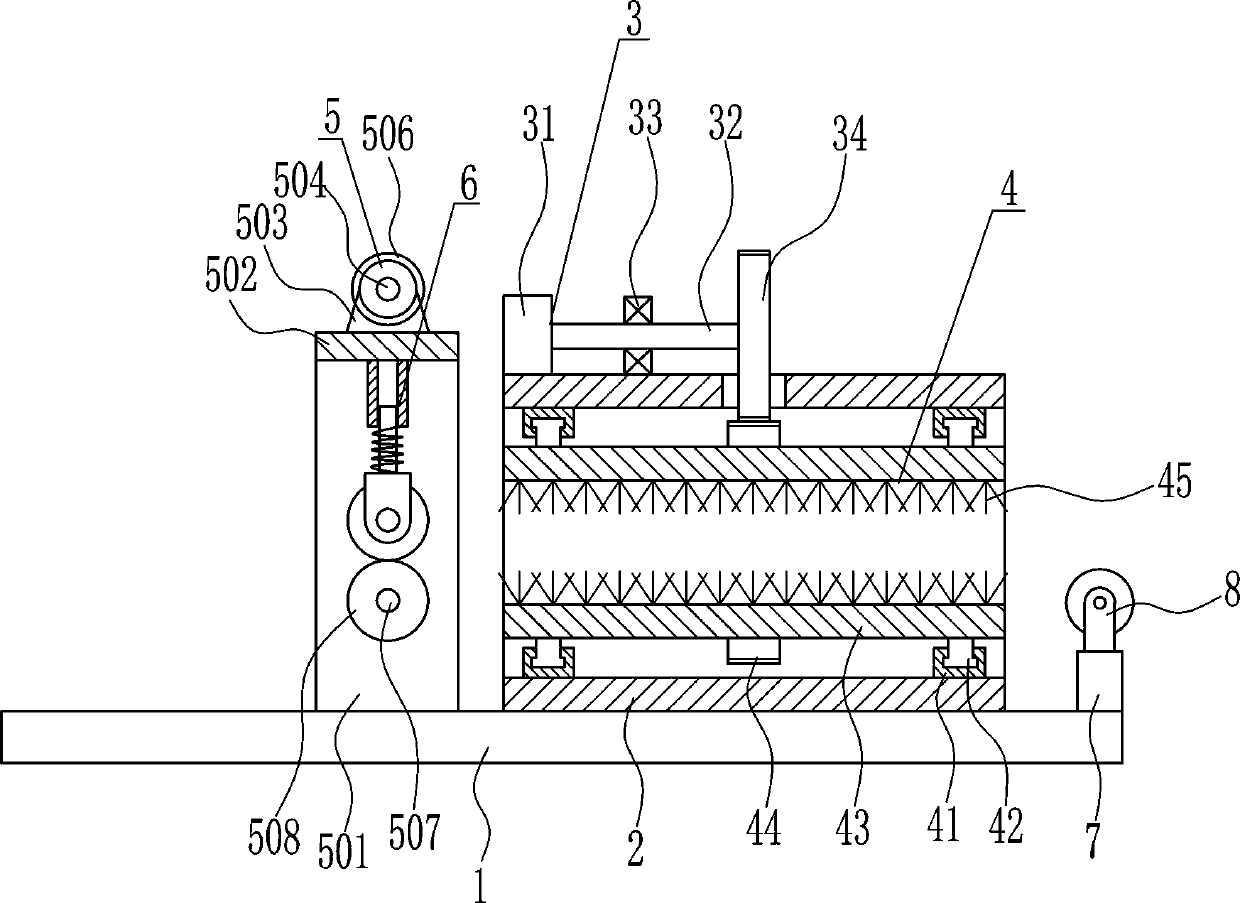

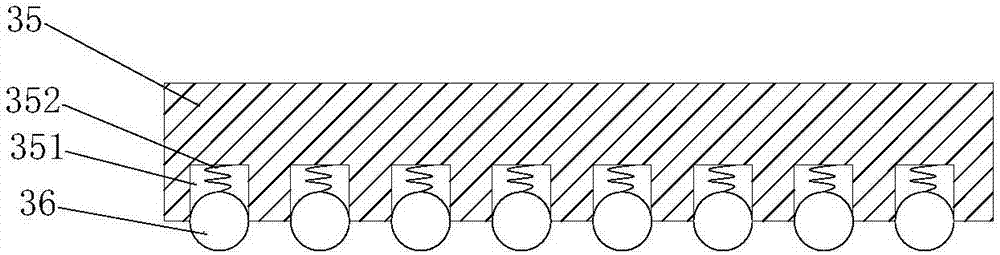

Automatic scale breaking roller replacing mechanism of steel plate surface rust removing device

InactiveCN110744415AReduce pollutionImprove rust removal efficiencyGrinding wheel securing apparatusGrinding carriagesGear wheelClassical mechanics

The invention relates to an automatic scale breaking roller replacing mechanism of a steel plate surface rust removing device. The automatic scale breaking roller replacing mechanism comprises an upper beam, a main working beam, bearing pedestals and a scale breaking roller, wherein the main working beam moves up and down relative to the upper beam; the bearing pedestals are arranged at the two ends of the main working beam; the upper beam drives the main working beam to move horizontally; the bearing pedestals comprise the first bearing pedestal and the second bearing pedestal; the first bearing pedestal moves left and right relative to the main working beam; the two bearing pedestals are each provided with an elastic auxiliary mechanism; each elastic auxiliary mechanism comprises a base;each base drives an inner gear to rotate through a screw; a gear shaft is engaged in each inner gear; outer gears are fixed to the two ends of the scale breaking roller; and the exposed ends of the gear shafts retract inwards relative to the front end faces of the inner gears to reserve spaces. During roller assembling, the inner gears rotate and get close to the outer gears at the same time, theinner gears retreat under the pressure action of the outer gears when the inner gears and the outer gears are not engaged, and when teeth of the outer gears are aligned with gear tooth gaps of the inner gears, the inner gears reversely push under the elastic action to enable the outer gears to enter the spaces and be engaged with the inner gears. Manual work is replaced, and time and labor are saved.

Owner:ZHEJIANG MOPPER ENVIRONMENTAL TECH CO LTD

Rapid and efficient rust removal device and method

ActiveCN111230682AEasy to removeImprove rust removal efficiencyAbrasive feedersGrinding machinesIron powderRebar

The invention discloses a rapid and efficient rust removal device and method. The device comprises a base, a left side plate is welded to the upper portion of the left side of the base, a transversely-arranged sliding rail is connected to the top of the left side plate, a sliding block is movably connected to the lower portion of the sliding rail, the left side end of the sliding block is connected with the movable end of an electric extendable rod, and the fixed end of the electric extendable rod is connected with the left side plate; and an air cylinder is installed on the bottom face of thesliding block through an installation plate, the movable end of the air cylinder is connected with a rust removal assembly through a flange, supporting plates are symmetrically arranged above the base, and fixing assemblies are installed on the side faces of the supporting plates. According to the device, the rust removal efficiency of a steel pipe and a steel bar is improved through multiple motion states of the rust removal assembly, iron powder can be effectively removed and collected, the collected iron powder can be circularly sprayed to the surface of the steel pipe and the surface of the steel bar, the rust removal effect can be further enhanced in cooperation with rotation of a rust removal wheel, and it can be guaranteed that the surrounding environment is friendly all the time in the working state.

Owner:迁安市仁泰金属制品有限公司

Building rebar rust removal device with high degree of automation

InactiveCN109318101AHigh degree of automationImprove rust removal efficiencyGrinding carriagesGrinding drivesRebarDrive motor

The invention relates to the technical field of building equipment and discloses a building rebar rust removal device with high degree of automation. The building rebar rust removal device comprises abase and an L-shaped support plate fixedly arranged at the upper end of the base, wherein a strip-shaped groove is transversely formed in the lower end of the horizontal part of the L-shaped supportplate; a reciprocating screw rod is transversely arranged in the strip-shaped groove; one end of the reciprocating screw rod is rotatably connected with the side wall of the strip-shaped groove through a first rolling bearing; the other end of the reciprocating screw rod penetrates through the side wall of the strip-shaped groove and extends outwards; a motor case is fixedly arranged on the side wall of the horizontal part of the L-shaped support plate; a drive motor is fixedly arranged in the motor case; the end, outside the L-shaped support plate, of the reciprocating screw rod penetrates through the side walls of the motor case and is fixedly connected with the output end of the drive motor; and a reciprocating sliding block is in sliding fit with the rod wall of the reciprocating screwrod. The building rebar rust removal device is high in degree of automation and improves the rebar rust removal efficiency and effect.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

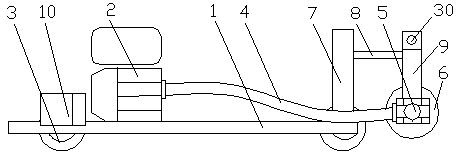

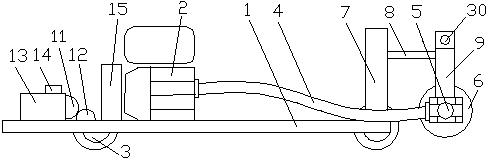

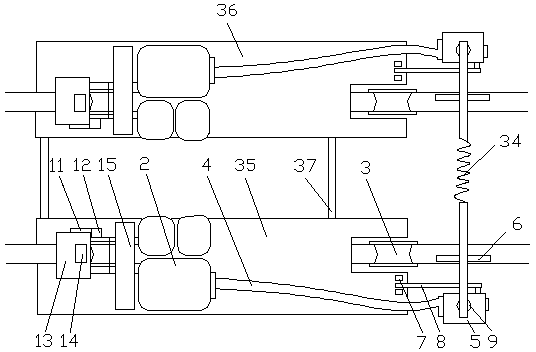

Medium pipe deruster

InactiveCN104128864AComply with installation and constructionConform to construction rust removal requirementsGrinding machinesDrive wheelMotor drive

The invention discloses a medium pipe deruster. The medium pipe deruster comprises a traveling trolley and a derusting frame, wherein the traveling trolley is a mining flat carrier vehicle; a transmission motor, two driving wheels and two driven wheels are mounted on the traveling trolley; a pipe is placed on the traveling trolley; and a roller is driven by motors on the traveling trolley to rotate so as to drive the pipe to rotate. Two small motors are arranged on the derusting frame; a brush head made of a steel wire head is mounted on one of the motors; and when the medium pipe is passed below the brush head of the derusting frame, the derusting motors drive the brush head to operate with high speed to remove the rust and dirt of a workpiece so as to finish the derusting operation. The medium pipe deruster has the benefits of simple structure, easy production, convenience for mounting, easy transportation and assembly, high derusting efficiency and excellent effect, accords with the pipe mounting construction characteristics, and satisfies the pipe construction derusting requirements.

Owner:枣庄矿业集团中兴建安工程有限公司

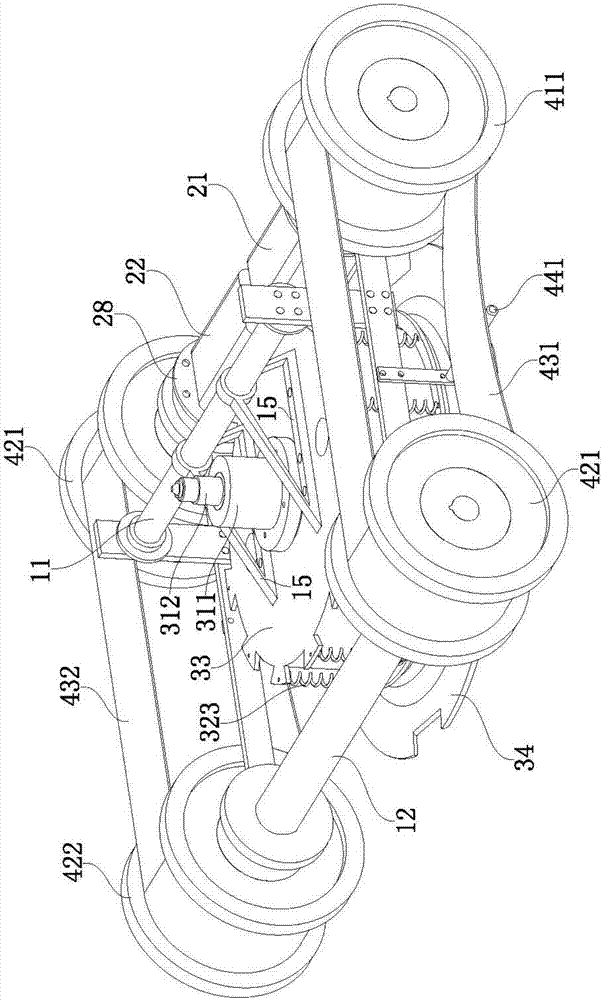

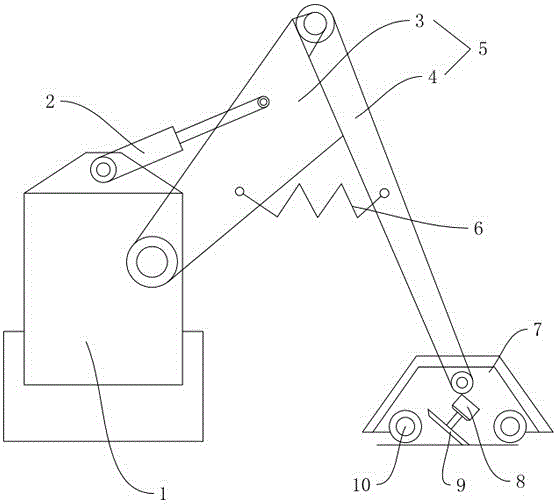

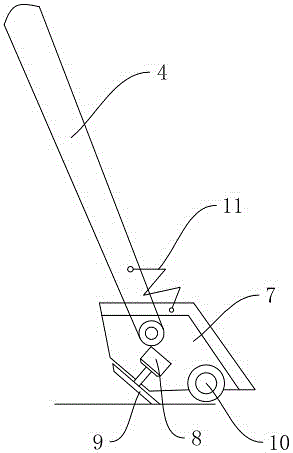

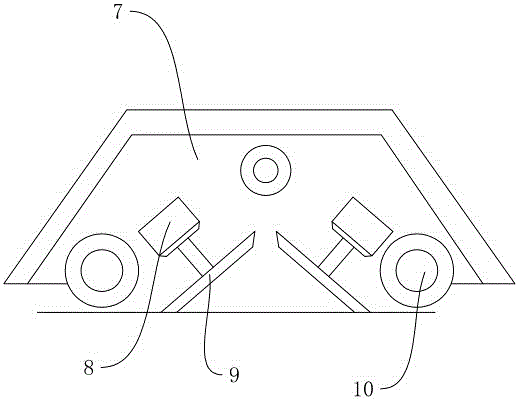

Ship rust removing equipment

The invention relates to ship rust removing equipment. By adoption of the ship rust removing equipment, the defect that existing automatic dust removing equipment adopts a high-pressure water gun, a ship applies reactive force to the equipment to affect the supporting stability of the equipment is overcome. The ship rust removing equipment comprises a magnetic caterpillar band adsorption device capable of moving on the surface of a ship, an extensible swinging arm arranged on the magnetic caterpillar band adsorption device and a dust removing device arranged at the end of the swinging arm. The dust removing device adopts an abrasive wheel polishing device. The magnetic caterpillar band adsorption device travels on the surface of the ship smoothly and cannot fall off outside the ship, the abrasive wheel is adopted for dust removing and is rotatable, the reactive force generated by the ship is small, and in this way, impact to the magnetic caterpillar band adsorption device is small, and the moving stability of the magnetic caterpillar band adsorption device is ensured, the swinging arm can be unfolded, so that the rust removing area of the rust removing device is broadened, rust removing efficiency is improved, the abrasive wheel moves along with unfolding of the swinging arm, and the ship dust removing equipment can adapt to the ship surface with large curvature.

Owner:ZHEJIANG OCEAN UNIV

Scaffold rust removing device for bridge construction

InactiveCN107671676AImprove rust removal efficiencyPrevent slidingGrinding drivesGrinding machinesEngineeringBolt connection

The invention relates to a rust removing device, in particular to a scaffold rust removing device for bridge construction. The scaffold rust removing device for bridge construction is high in rust removing efficiency, small in size and low in cost. In order to achieve the technical aims, the scaffold rust removing device for bridge construction comprises a base plate and the like. The middle partof the top of the base plate is connected with a box body in a bolted connection mode, and a driving device is arranged at the top of the box body. A rust removing device body is arranged inside the box body. According to the scaffold rust removing device for bridge construction, the driving device drives the rust removing device body to operate, the rust removing device body can remove iron ruston the scaffold surface, a pulling device is used for pulling a scaffold to move, and therefore efficiency is improved and the effects of being high in rust removing efficiency, small in size and lowin cost are achieved.

Owner:程新锋

Rust/oil removing agent

The invention discloses a rust / oil removing agent. The formula of the rust / oil removing agent comprises 150-250 g / L citric acid, 100-200 g / L polyvinyl acid, 15-50 g / L sodium hydroxide, 5-20 g / L tetrazole, 10-30 g / L sodium sulfite and the balance of deionized water. The rust / oil removing agent disclosed by the invention is reasonable in formula, friendly to environment and safe to operate, causes no pollution, can simultaneously remove rust and oil, and has high rust removing efficiency.

Owner:黄小飞

Efficient short pipe rust removing device easy to fix

InactiveCN107283277AImprove rust removal efficiencyEasy to operateGrinding drivesBonded abrasive wheelsSlide plateArchitectural engineering

The invention discloses an efficient and easy-to-fix short tube derusting device, which includes a frame body, a fixing assembly and a derusting assembly arranged in the frame; the fixing assembly is located on the upper part of the frame body, and the fixing assembly includes a mounting plate and an expansion tight plate; the derusting assembly is arranged above the fixed assembly, and the derusting assembly includes a disc, a first sliding seat, a first slide rail and a derusting plate, and a floating derusting ball is arranged on the lower end of the derusting plate. The invention can efficiently complete the rust removal work on the outer surface of the short pipe, has good rust removal effect, and is easy to complete the fixing of the pipe.

Owner:王少平

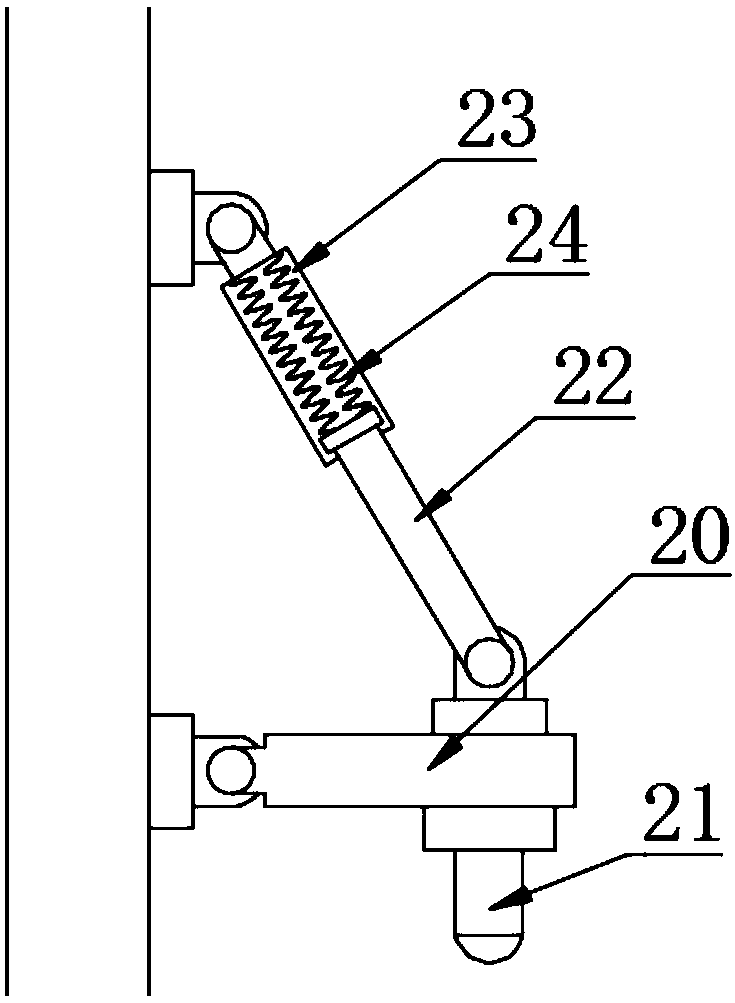

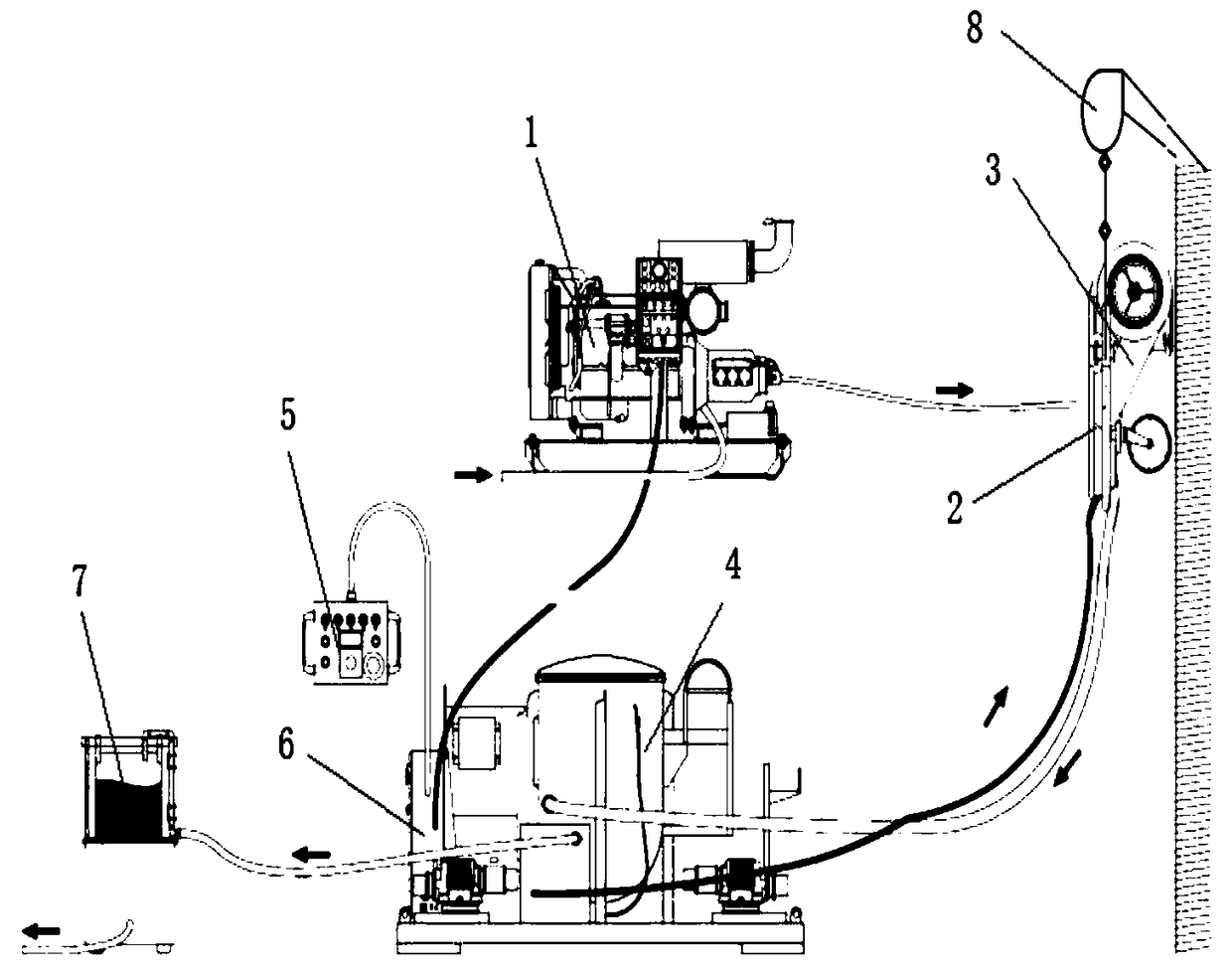

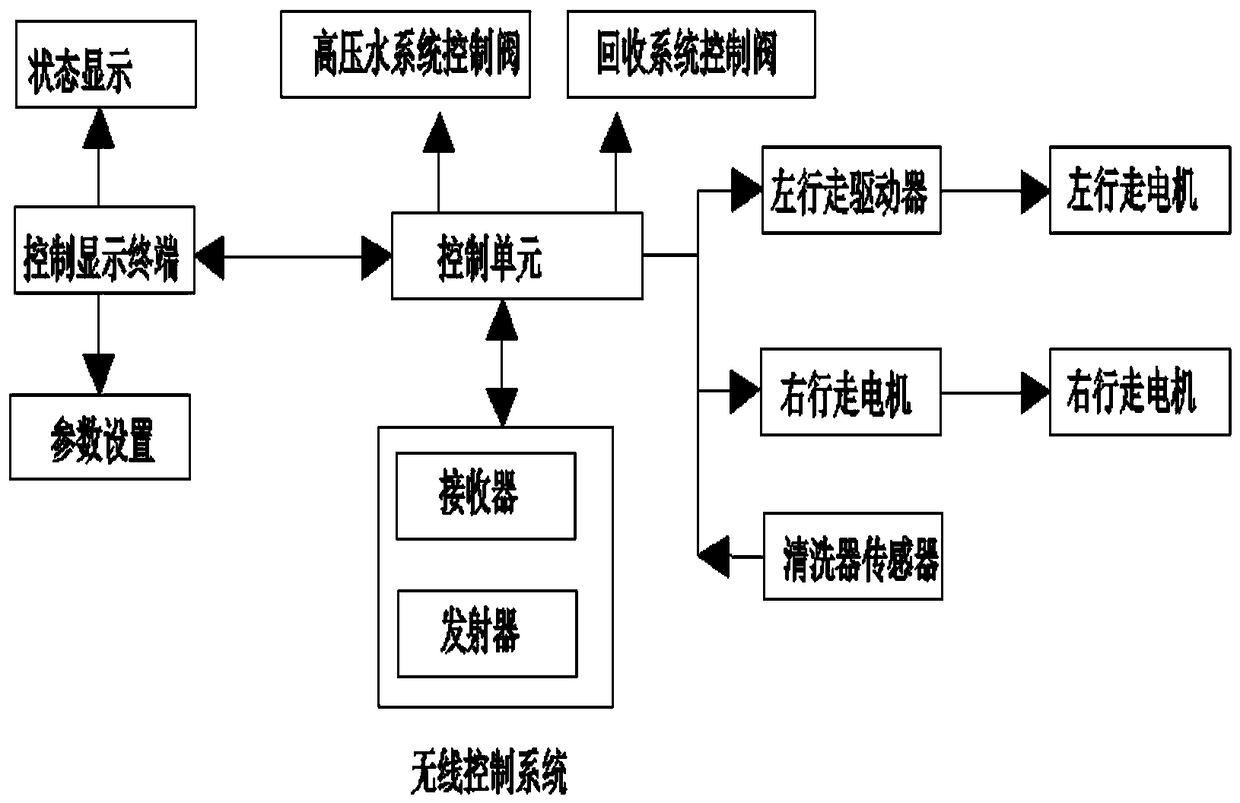

Working system of wall-climbing derusting robot for walls of ships and petrochemical storage tanks

PendingCN108655135AHarm reductionImprove rust removal efficiencyVessel cleaningHollow article cleaningRemote controlWastewater

The invention discloses a working system of a wall-climbing derusting robot for walls of ships and petrochemical storage tanks. The wall-climbing robot is connected with a falling preventer through aflexible protection rope. The falling preventer is connected to the walls of ships and petrochemical storage tanks. The wall-climbing robot is fixedly connected with a vacuum cleaner. By means of theworking system, the problems that as for derusting operation, manpower is adopted and a large number of auxiliary facilities need to be built are solved, the derusting efficiency is improved, harm ofdust to construction personnel is reduced, and the derusting cost is reduced. By adoption of the mode that a recycling device is separated from waste water, pollution to the environment is effectivelyreduced, and the environment protection requirements are met. The wall-climbing robot and a high-pressure water system are controlled in a remote control mode, all control operations can be conductedon a display set terminal, and operation is more convenient. The vacuum cleaner is installed at the belly portion of the wall-climbing robot, is provided with an adaptive device and can adapt to uneven outer surfaces, so that the environmental adaptability of the derusting operation is improved.

Owner:LUOYANG SHENGRUI INTELLIGENT ROBOT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com