Medium pipe deruster

A rust removal machine and pipeline technology, which is applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of falling off, being thrown on the construction personnel by the angle grinder, occupational health hazards of construction personnel, and difficult to handle and install. and other problems, to achieve the effect of high rust removal efficiency, good effect and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

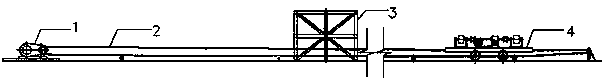

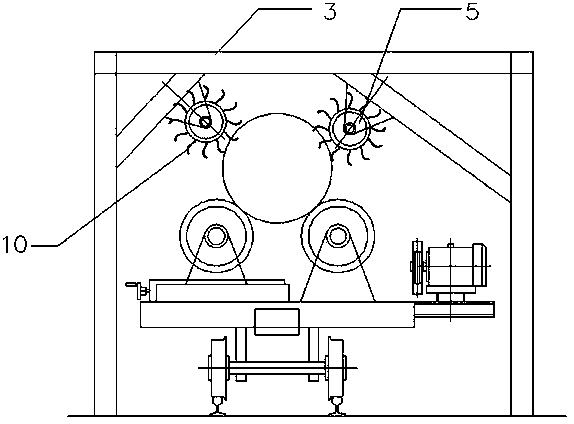

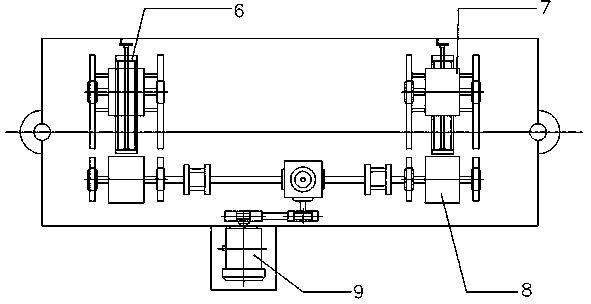

[0016] exist figure 1 , figure 2 , image 3 Among them, a medium-sized pipeline derusting machine mainly includes two parts: a traveling trolley 4 and a derusting rack 3, and its characteristic is that the traveling trolley 4 is a mining flatbed transport vehicle, on which a transmission motor 9 and two driving wheels 8 are installed And two driven wheels 7, adjust screw mandrel 6 to adjust the gap between driven wheel 7 and driving wheel 8, so that the workpiece of different specifications is placed. The pipeline is placed on the trolley 4, and the drive motor 9 on the trolley 4 drives the driving wheel 8 to rotate, thereby driving the pipeline and the driven wheel 7 to rotate. The traction winch 1 drives the steel wire rope 2 to pull the walking trolley 4 and the pipeline on the load to perform linear reciprocating motion on parallel tracks. Two small-sized derusting motors 5 are placed on the derusting frame 3, and a brush head 10 made of a wire rope head is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com