Patents

Literature

44results about How to "Achieve rust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional metal surface treatment solution

InactiveCN102925883AThe formula is scientific and reasonableAchieve rust removalMetallic material coating processesAluminium hydroxidePhosphoric acid

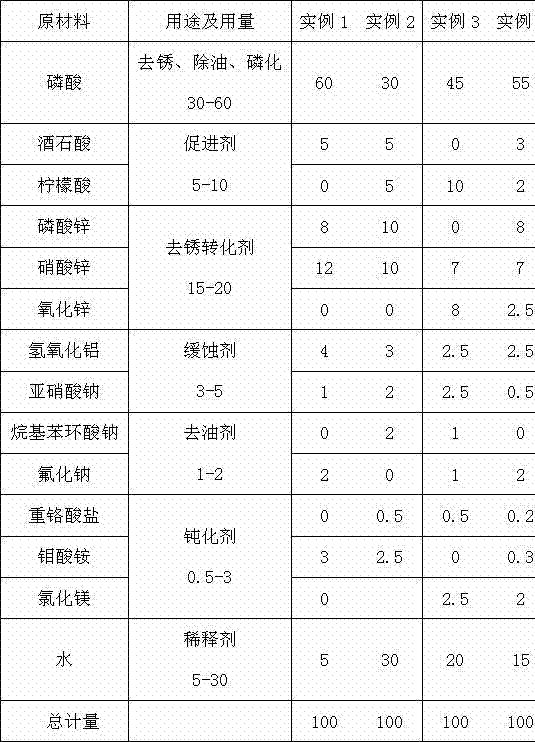

The invention discloses a multifunctional metal surface treatment solution which comprises the following components in percentage by mass: 30-60 percent of phosphoric acid, 5-10 percent of accelerator, 15-20 percent of derusting transforming agent, 3-5 percent of corrosion inhibitor, 1-2 percent of degreaser, 0.5-3 percent of passivator and 5-30 percent of water, wherein the accelerator is tartaric acid or / or citric acid, the derusting transforming agent is zinc phosphate or / and zinc nitrate or / and zinc oxide; the corrosion inhibitor is aluminium hydroxide or / and sodium nitrite, the degreaser is sodium alkylbenzenesulfonate or / and sodium fluoride; and the passivator is bichromate or / and ammonium molybdate or / and magnesium chloride. The multifunctional metal surface treatment solution has the advantages of scientific and reasonable formula, capability of removing rust, preventing rust and removing grease by being directly sprayed on the surface of metal, and also capability of replacing an anti-corrosive primer.

Owner:郭衡怀

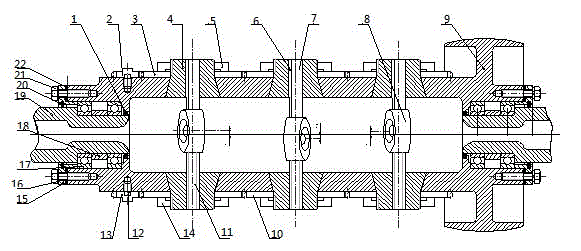

Large-inside-diameter steel pipe inner wall derusting device for machining

InactiveCN107263288AAchieve rust removalReasonable designRevolution surface grinding machinesGrinding drivesGear wheelDrive shaft

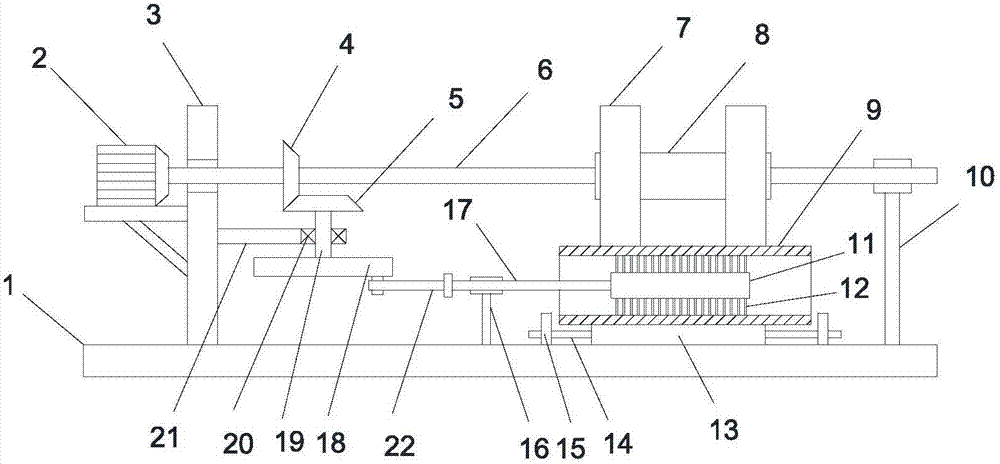

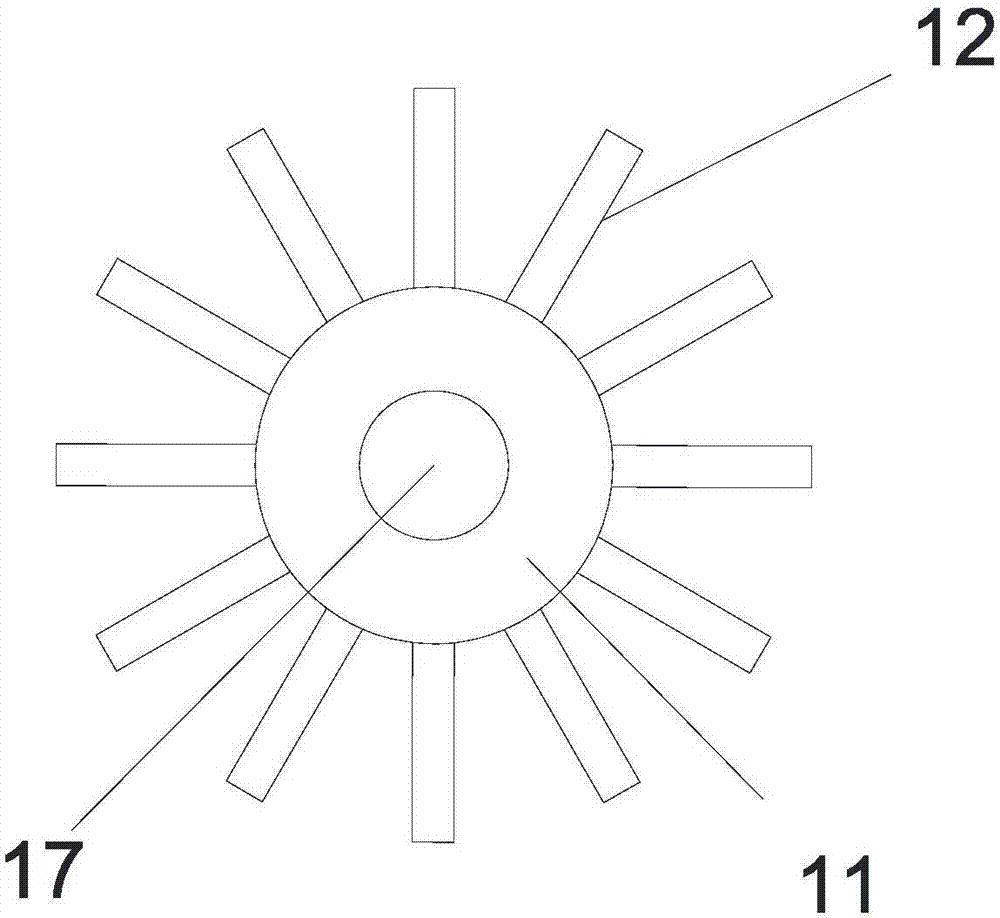

The invention discloses a large-inside-diameter steel pipe inner wall derusting device for machining. The device comprises a bottom plate, wherein a first shaft support is vertically and fixedly mounted on the bottom plate and is movably connected with a right end of a driving shaft; a first bevel gear is coaxially and fixedly mounted on the driving shaft; a second bevel gear is coaxially and fixedly mounted on an upper end of a driven shaft and is connected with the first bevel gear in a meshed manner; a rotating wheel is coaxially and fixedly mounted at a lower end of the driven shaft; a second shaft support is vertically and fixedly mounted on the bottom plate; a first connecting rod is horizontally arranged on the second shaft support in a horizontal sliding manner; a limiting roller is coaxially and fixedly mounted on the rotating shaft; a steel pipe for derusting is placed on the limiting roller; a derusting roller is fixedly mounted on the first connecting rod; steel wire brushes are uniformly arranged on a surface of the derusting roller; guiding wheels are fixedly mounted on the rotating roller in a sleeving manner and are pressed against an outer surface of the derusting roller. According to the device disclosed by the invention, axial and annular derusting effects on the inner wall of the steel pipe can be realized at the same time, so that the derusting effect on the inner wall of the steel pipe is preferable.

Owner:深圳市海帮国际商务服务有限公司

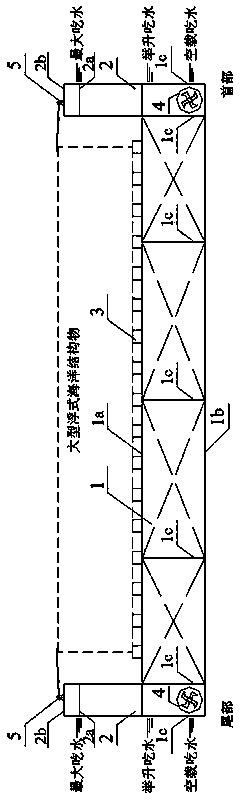

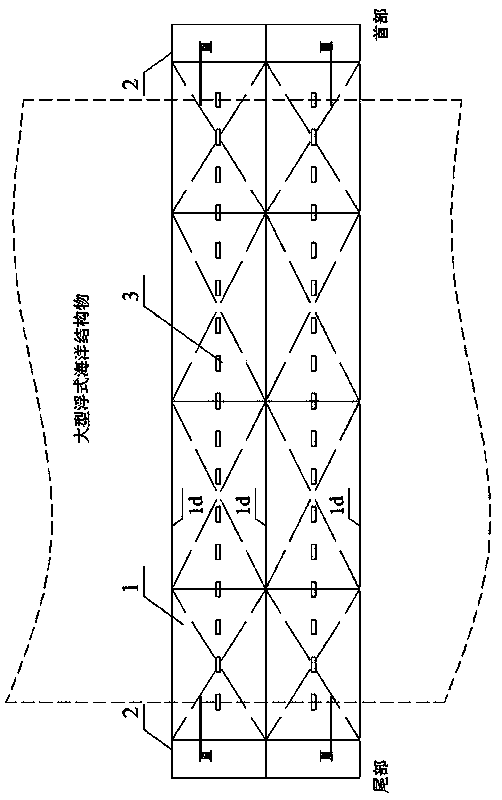

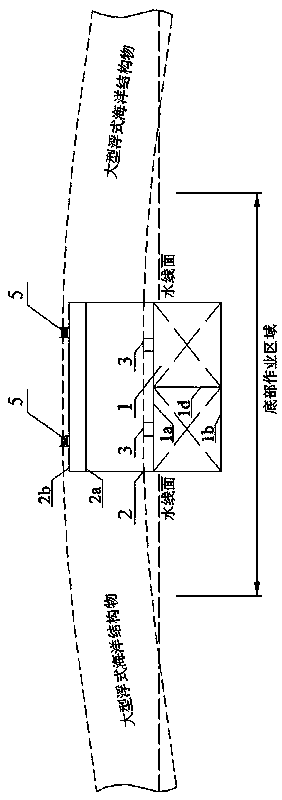

Large-scale floating type ocean-structure semi-submersible lifting platform and application method thereof

InactiveCN103910044AAchieve rust removalRealize painting workFloating buildingsBallast tankMarine structure

The invention relates to a large-scale floating type ocean-structure semi-submersible lifting platform and an application method thereof and belongs to the field of large-scale floating type ocean-structure maintenance devices and processes. The technical scheme of the semi-submersible lifting platform includes that two ends of a floating box in the length direction are provided with a head floater and a tail floater, transverse moving devices are arranged in the floating box below the head floater and the tail floater, longitudinal moving devices are arranged on the tops of the head floater and the tail floater, a ballast tank and a ballast system are arranged in the floating box, and floater safety decks of the head floater and the tail floater are provided with various functional cabins. The semi-submersible lifting platform can effectively solve the problem about maintenance of the underwater part of the large-scale floating ocean structure with higher length-moulded depth ratio during operation, can realize maintenance, derusting and coating of the large-scale floating type ocean structure on the premise of not docking in, displacing or dismounting, or even not affecting the normal work of the large-scale floating type ocean structure and has the advantages of low construction cost, short period, simple process, wide application range and the like.

Owner:DALIAN UNIV OF TECH

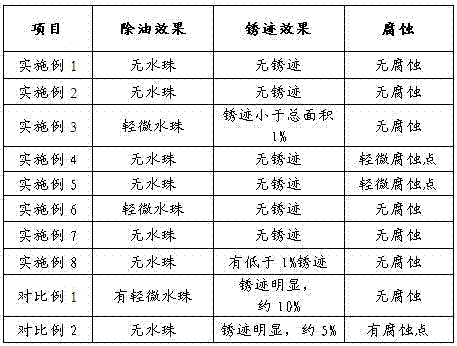

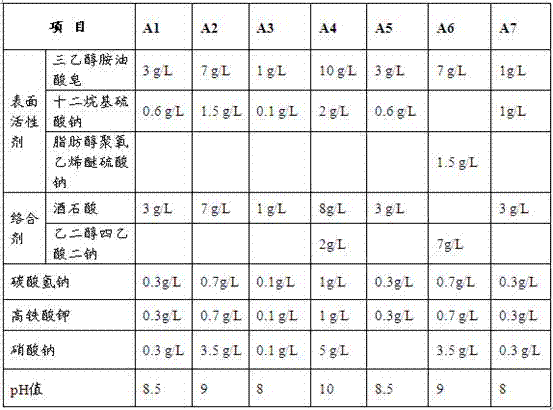

Metal surface cleaning agent, preparation method, and method for cleaning metal surface

The invention relates to a metal surface cleaning agent. The cleaning agent is an aqueous solution containing surfactants, emulsifiers, complexing agents, carbonate and ferrate. The invention also provides a preparation method of the metal surface cleaning agent, and a method for cleaning metal substrate with the cleaning agent. The cleaning agent provided by the invention can be used for removing oil and rust simultaneously, so that the processing steps are reduced. Moreover, corrosion to the metal surface is avoided while removing the rust from the substrate surface.

Owner:BYD CO LTD

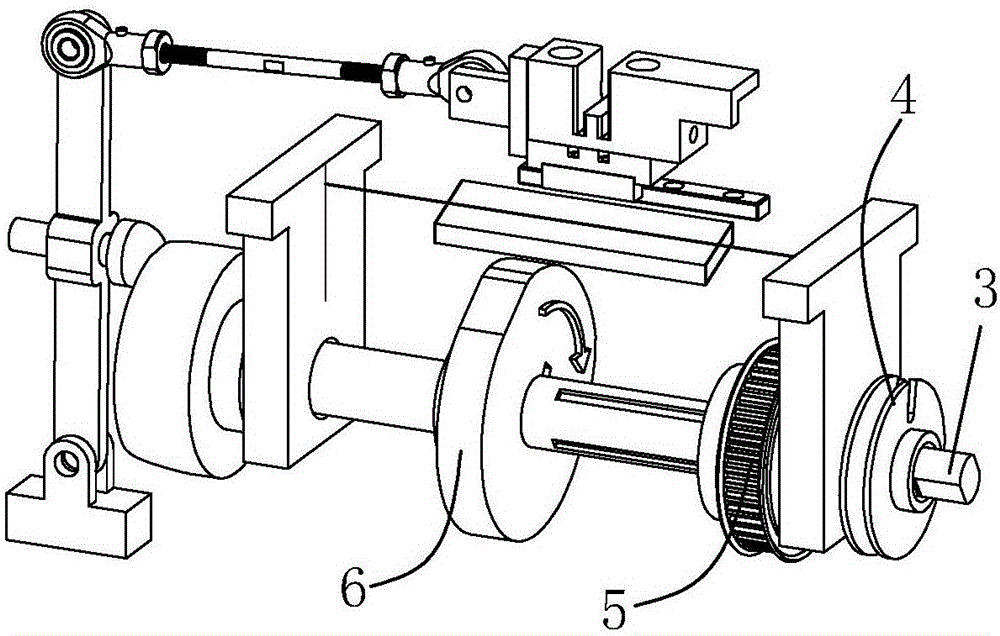

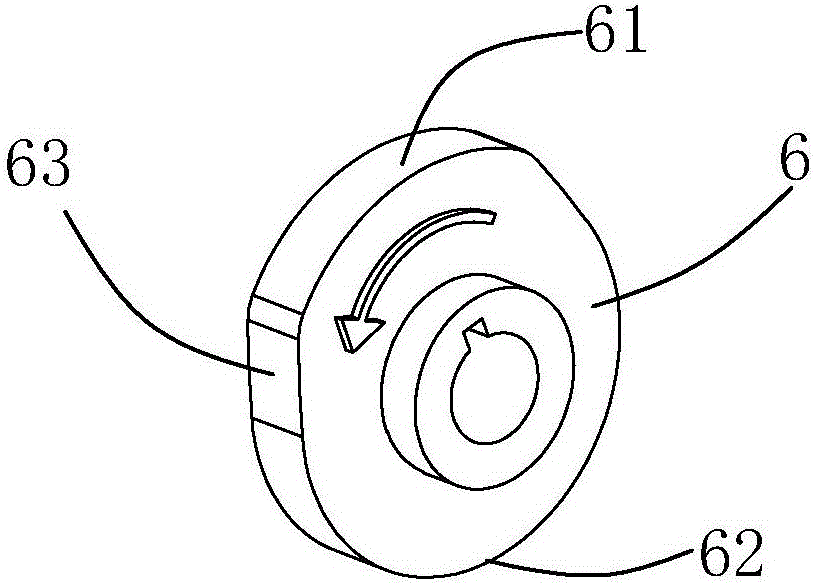

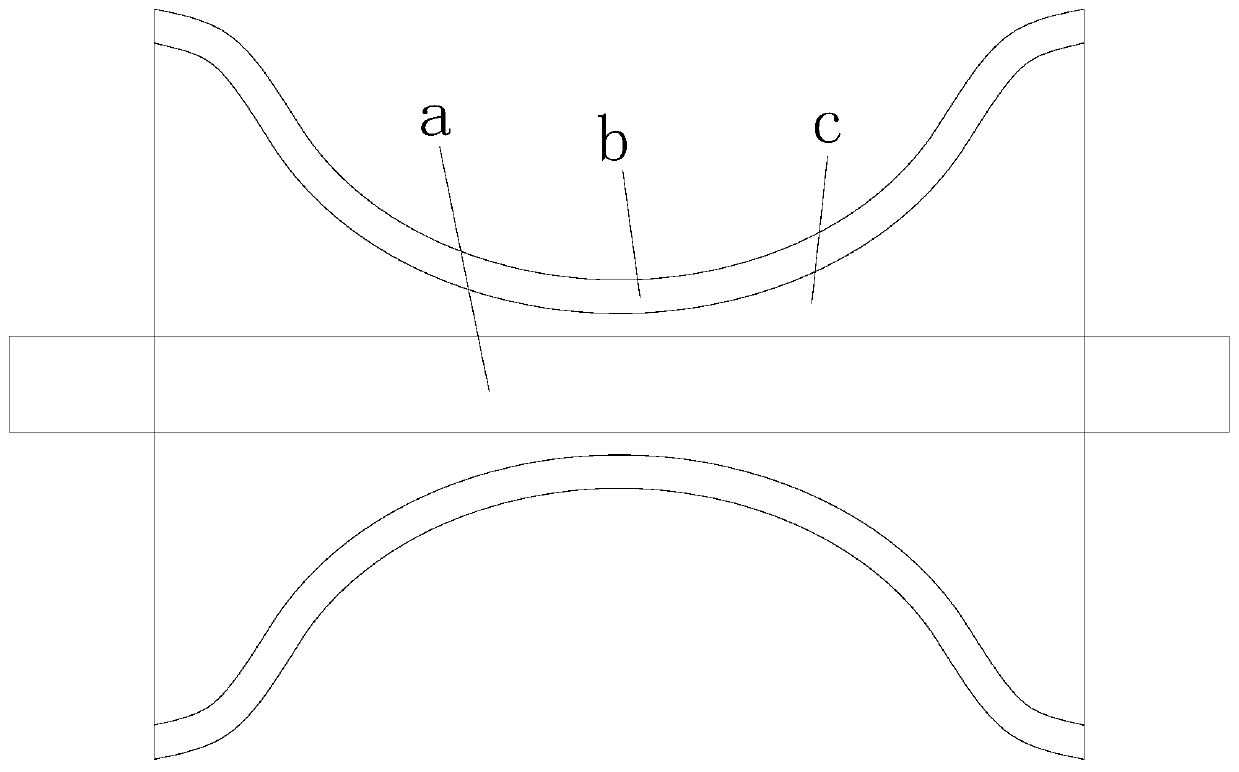

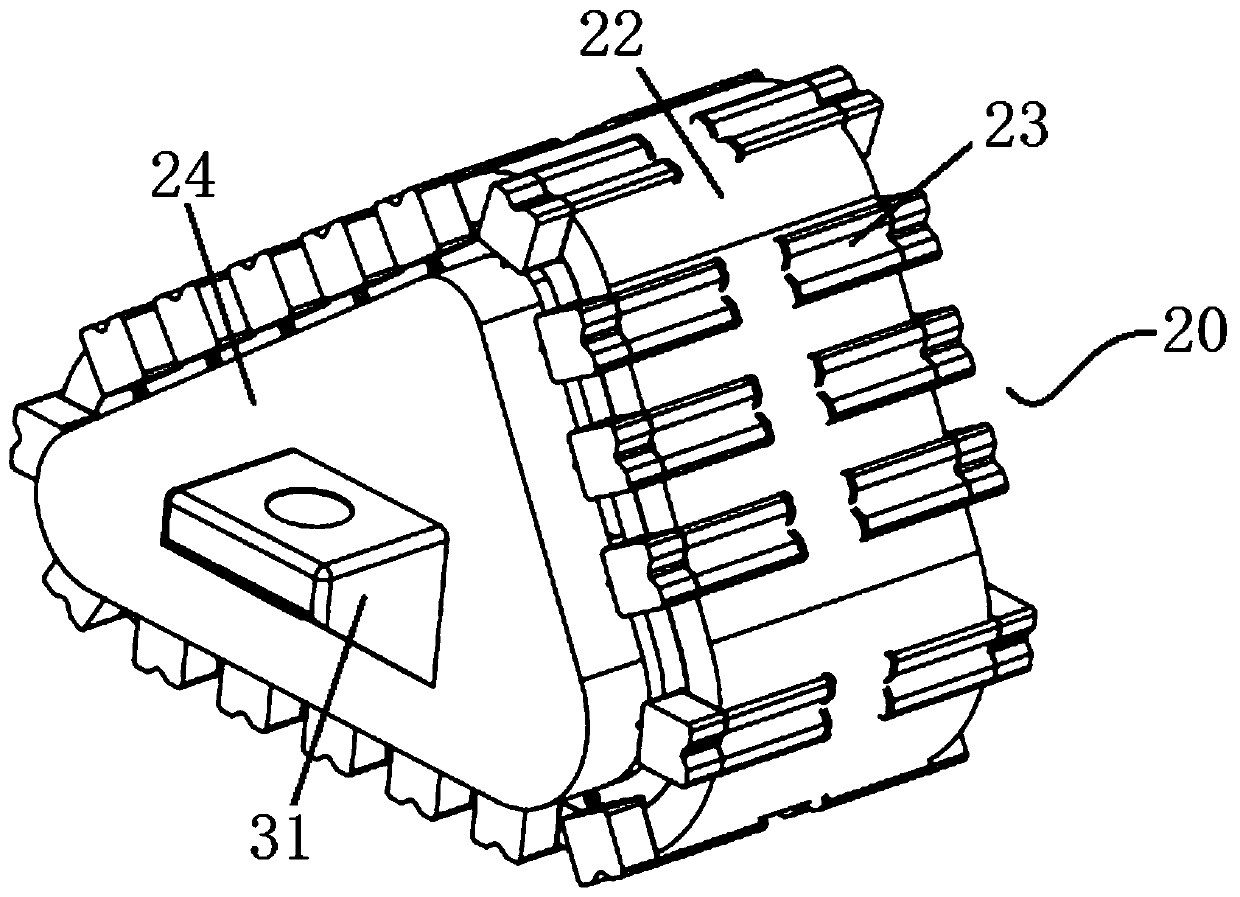

Straightening rotary drum device

InactiveCN105057507AAchieve rust removalMove quicklyExtrusion cleaning devicesEngineeringMechanical equipment

The invention relates to a straightening rotary drum device for straightening steel bars, and belongs to metallurgic and building mechanical equipment. The straightening rotary drum device comprises a straightening rotary drum and a rotating hub support, wherein a back hat mounting hole is formed in the straightening rotary drum; a steel bar straightening structure with forwarding line which is a snake-shaped curve is arranged in the straightening rotary drum. The straightening rotary drum of the straightening rotary drum device is mounted on a straightening machine base; power is input through a belt and drives the straightening rotary drum to rotate; a steel bar enters from an inlet in the left side of the straightening rotary drum; under the action of traction force, the steel bar moves forwards along a curve through three straightening blocks which are arranged in a snake-shaped manner in the straightening rotary drum and is pulled out from an outlet in the right side, so that the steel bar is straightened by repeated straightening and pulling; in the process, under the action of pulling, the steel bar can be derusted, tempered and strengthened. When the straightening rotary drum works, the coiled type steel bar moves quickly in the straightening rotary drum after being uncoiled, so that continuous production can be realized, the production efficiency is high, and the straightening effect is good.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

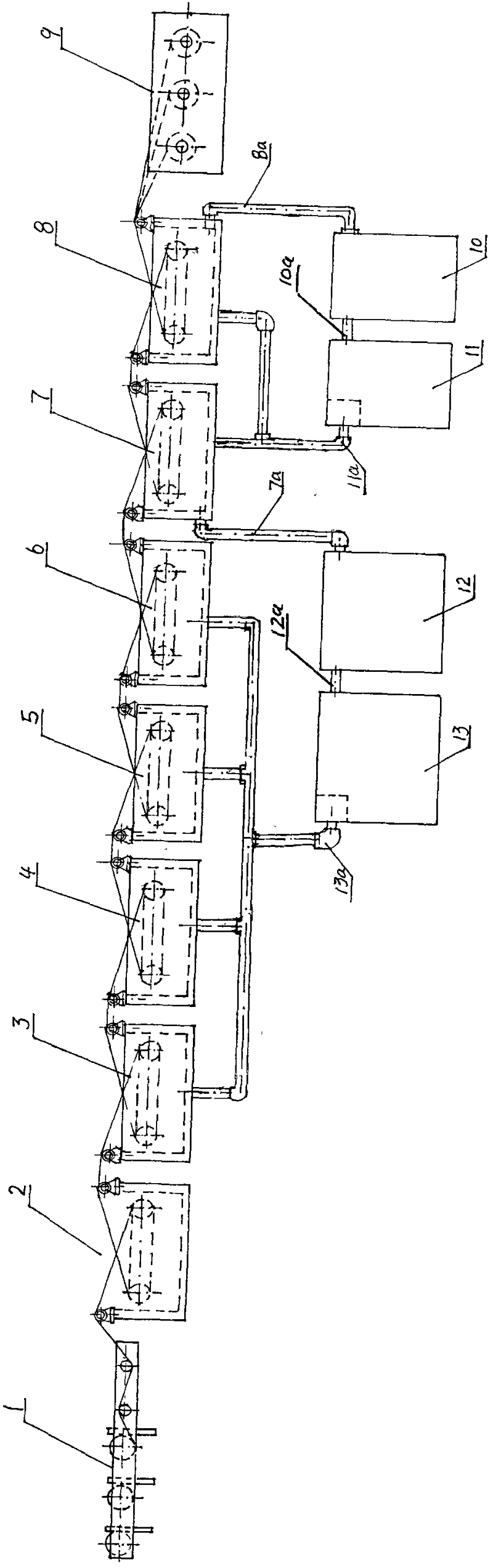

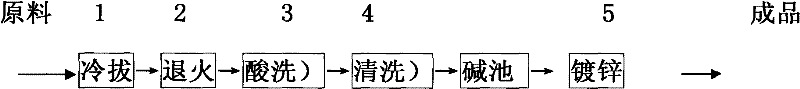

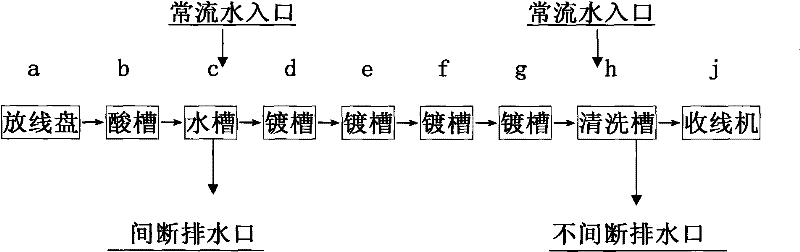

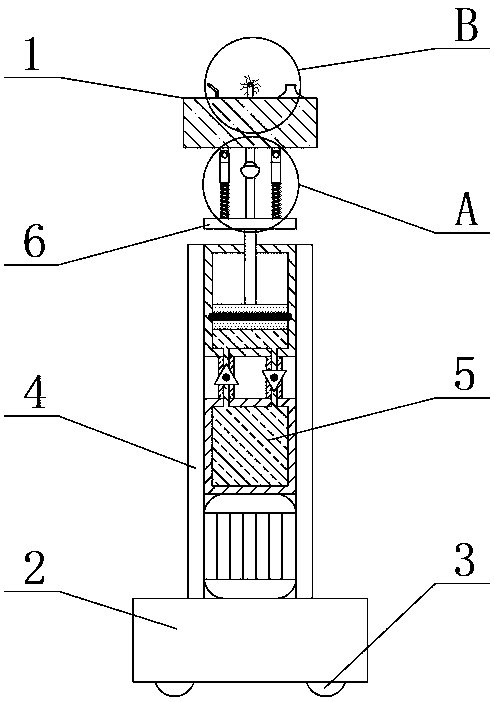

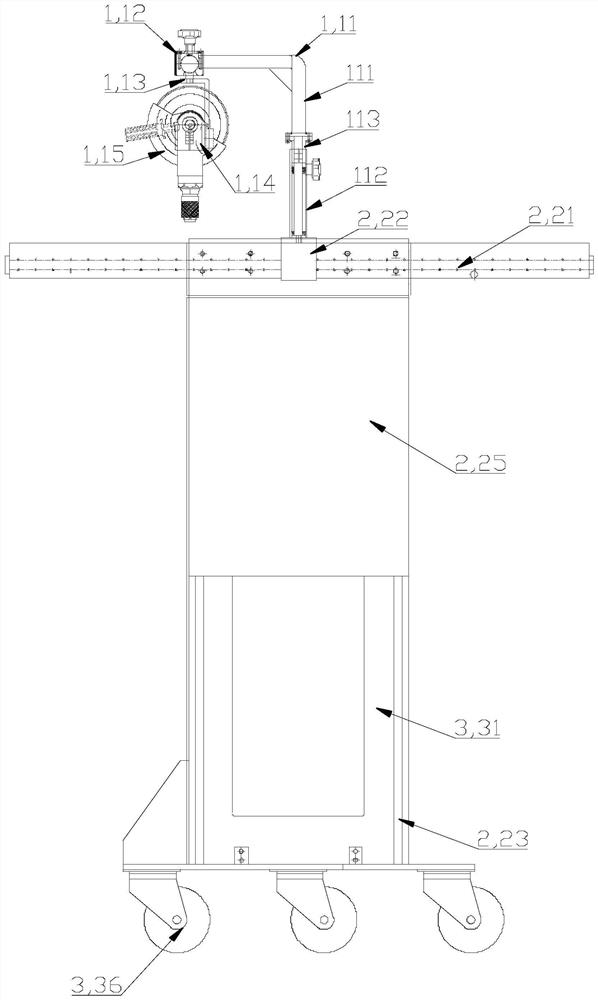

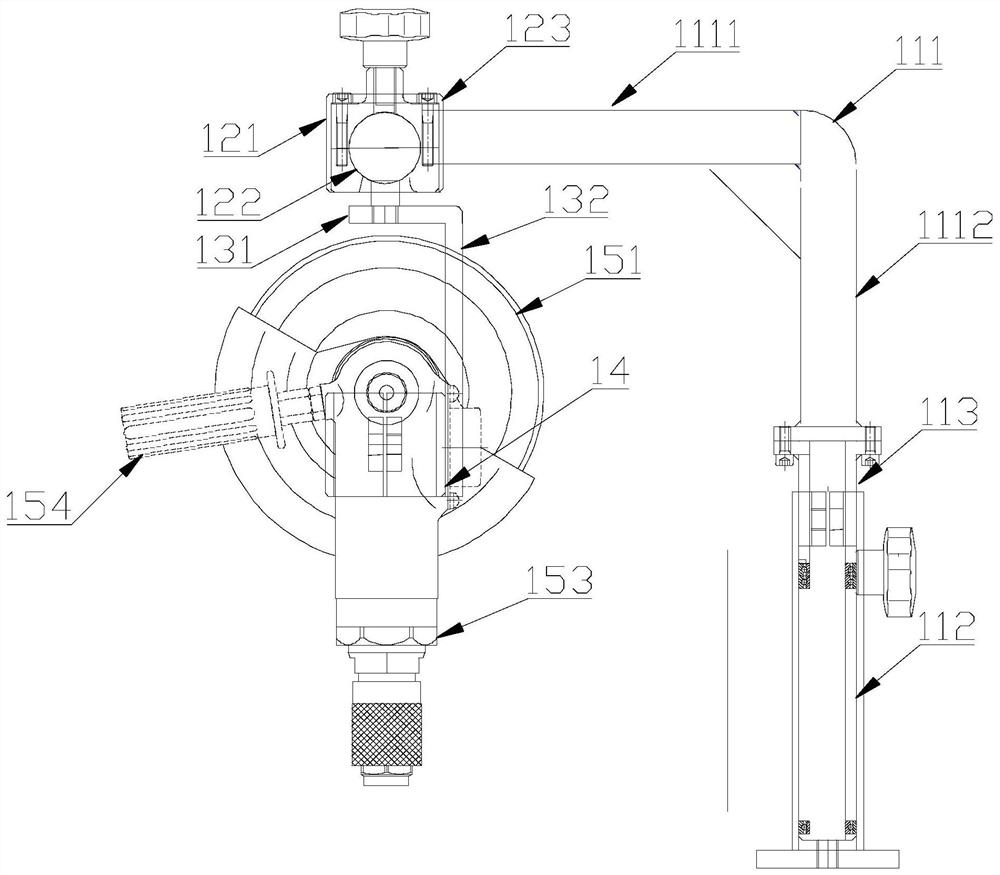

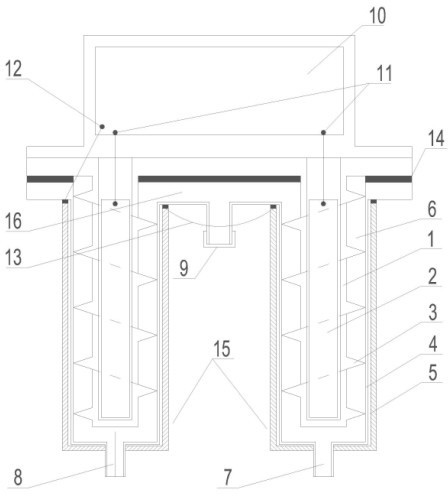

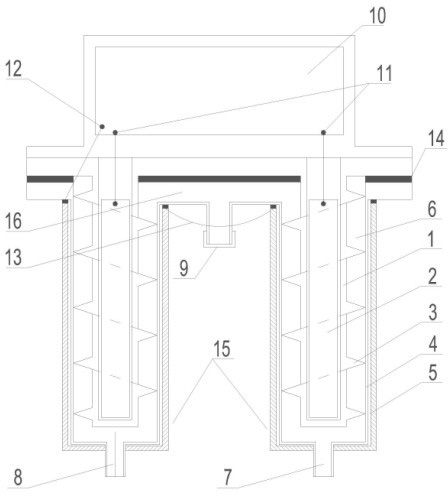

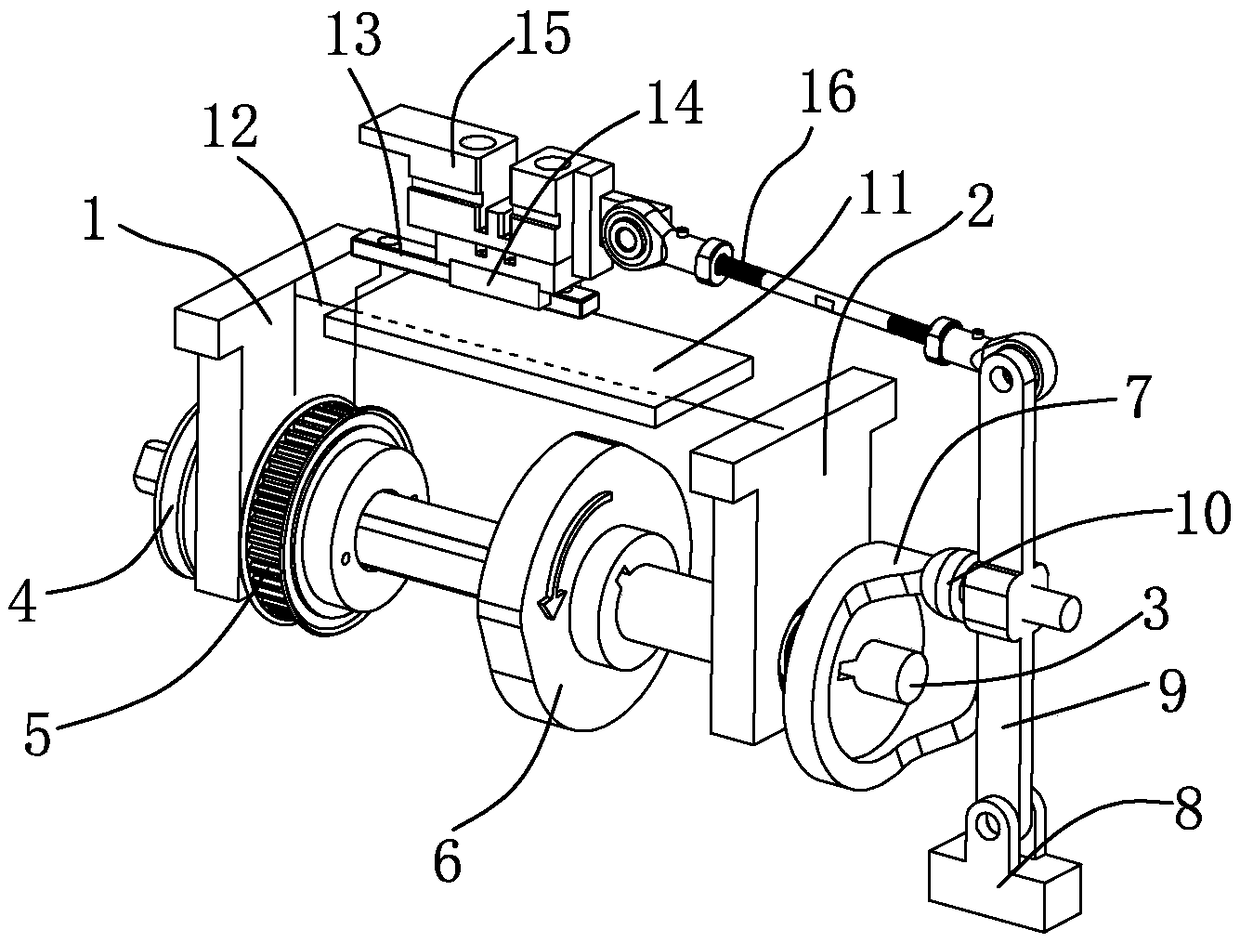

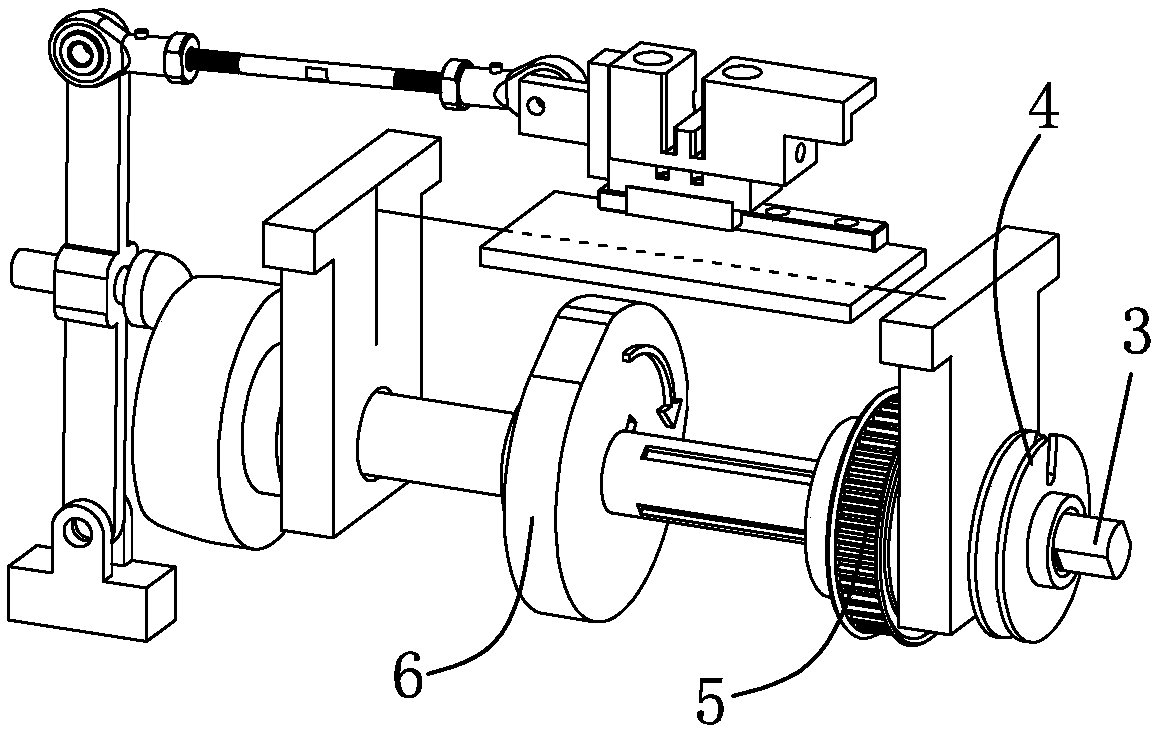

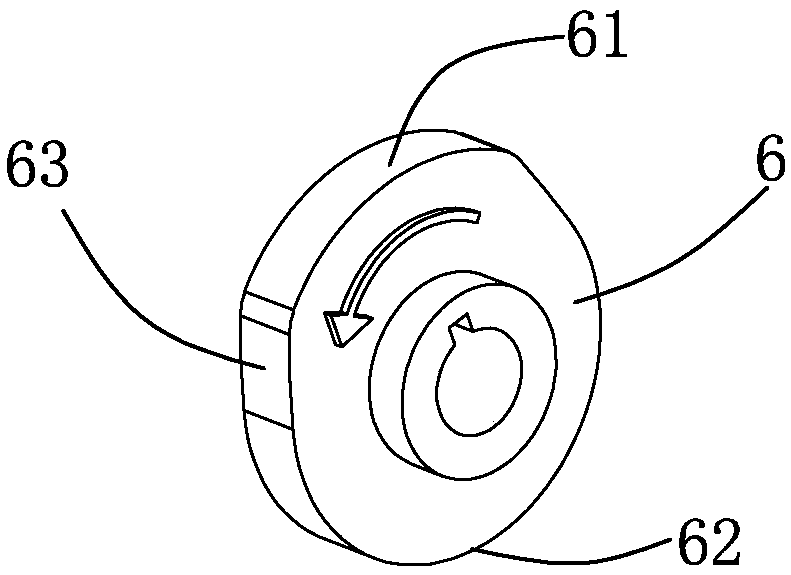

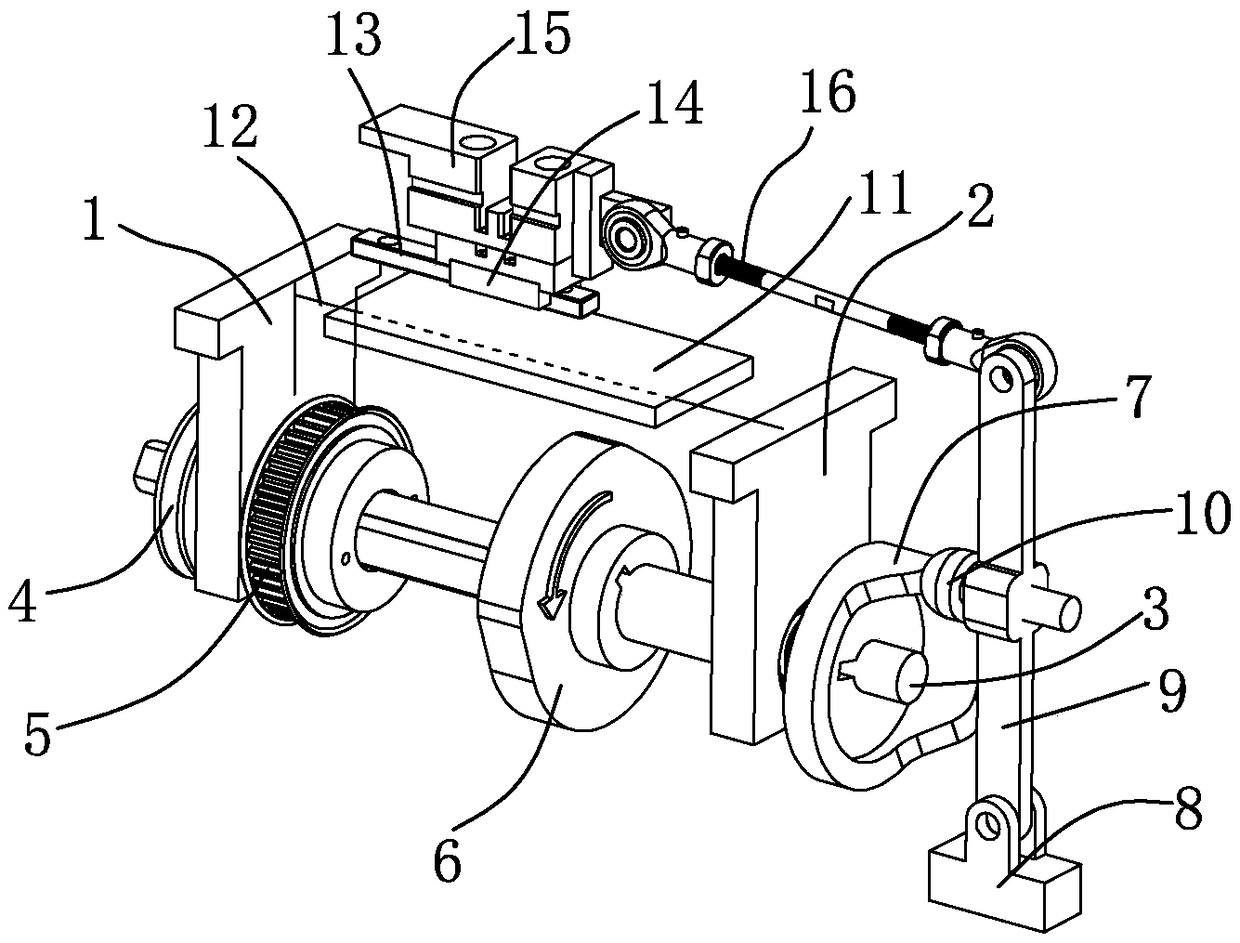

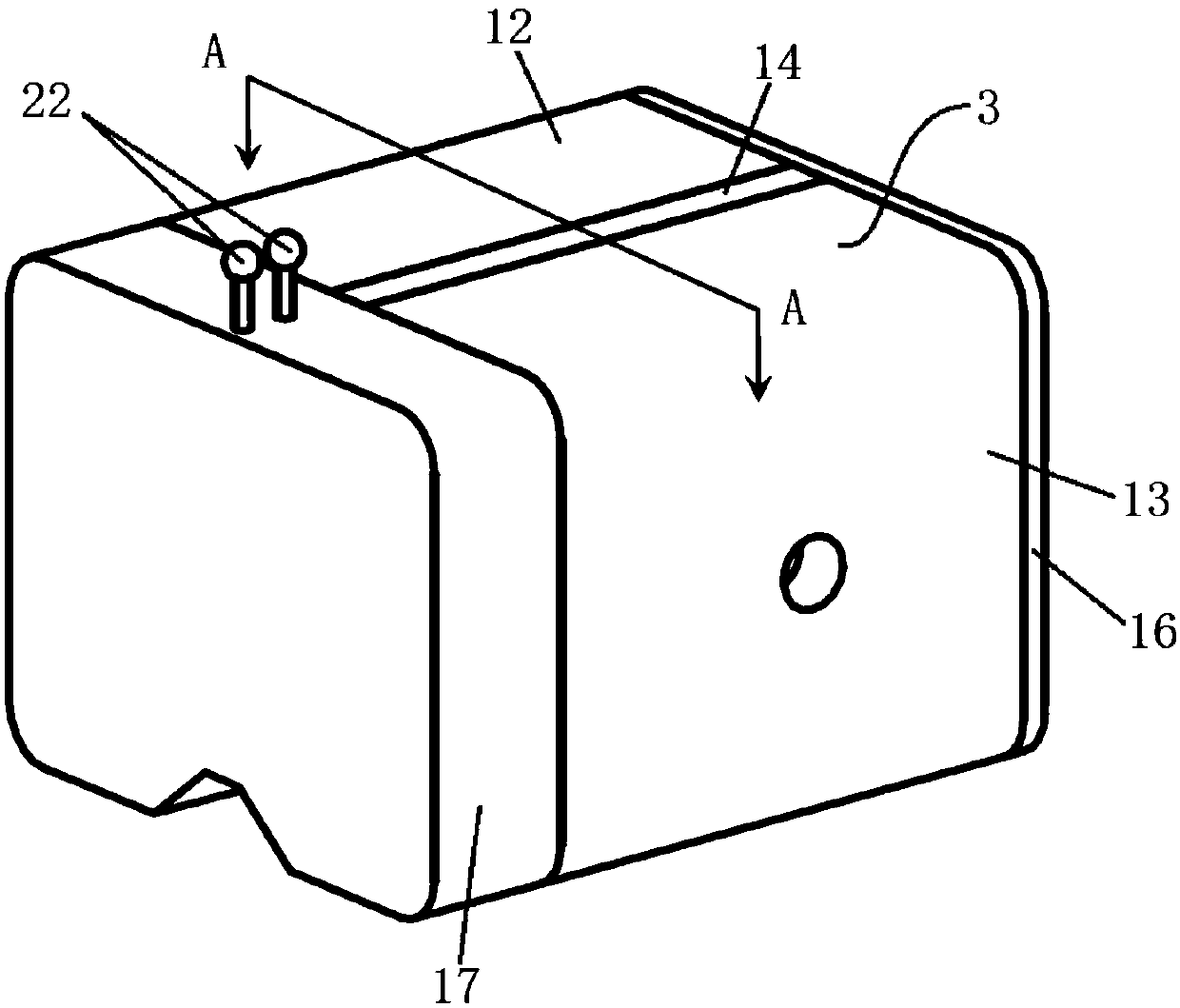

Clean and environment-friendly iron wires galvanizing apparatus and its technology

The invention relates to a clean and environment-friendly iron wires galvanizing apparatus and its technology. The iron wires galvanizing apparatus mainly comprises a paying-out machine (1), a polishing machine (2), a water tank (3), a first galvanizing tank (4), a second galvanizing tank (5), a third galvanizing tank (6), a cold water tank (7), a hot water tank (8) and a take-up machine (9), wherein, roller groups are provided on the paying-out machine (1), the polishing machine (2), the water tank (3), the first galvanizing tank (4), the second galvanizing tank (5), the third galvanizing tank (6), the cold water tank (7), the hot water tank (8) and the take-up machine (9), the iron wires of the paying-out machine (1) and the iron wires of the take-up machine (9) are connected end to endthrough each roller group. The invention also relates to a clean and environment-friendly iron wire galvanizing technology; the invention has the characteristics that no cyanogen or no pickling is contained, circulating water is not discharged which is clean and environment-friendly, the iron wires galvanizing apparatus provided in the invention can replace the traditional equipment of iron wiresgalvanizing, the invention has advantages of water saving and no environmental pollution, and the labor intensity of operators can be reduced, so that operators can get rid of work environment of strong acid mist, thereby the invention is capable of alleviating the damage of acid to operators body, reducing production cost of galvanizing iron wires and raising the competitiveness of enterprises.

Owner:秦学刚

Ship bottom cleaning device for shipping of ship

ActiveCN108482611AQuick cleanImprove practicalityVessel cleaningHullsMarine engineeringEconomic benefits

The invention relates to the technical field of shipping of a ship, in particular to a ship bottom cleaning device for shipping of a ship. The ship bottom cleaning device for shipping of the ship comprises a cleaning device and a base, wherein the top of the base is fixedly connected with a supporting column; the top end of the supporting column is fixedly connected with a cross plate; the top endsurface of the cross plate is fixedly connected with a supporting rod; the top end of the supporting rod is fixedly connected with a ball and socket joint; the top end of the ball and socket joint isfixedly connected with a connecting rod; a loop bar is arranged on the outer side of the supporting rod; the top end of the loop bar is in sleeve connection with a sleeve; a compression spring is arranged on the outer side of the loop bar; and the top end of the sleeve is fixedly connected with a connector. In the ship bottom cleaning device for shipping of the ship, by arrangement of the ball and socket joint, the connector, the loop bar, the sleeve and the compression spring, the irregular bottom end of the ship can be mechanically cleaned, the cleaning efficiency is ensured, and the cleaning efficiency is further ensured. The ship bottom cleaning device for shipping of the ship is novel in design concept and scientific in design, has huge economic benefit and extensive market prospect,and is worthy of being popularized and used.

Owner:飞马滨(青岛)智能科技有限公司

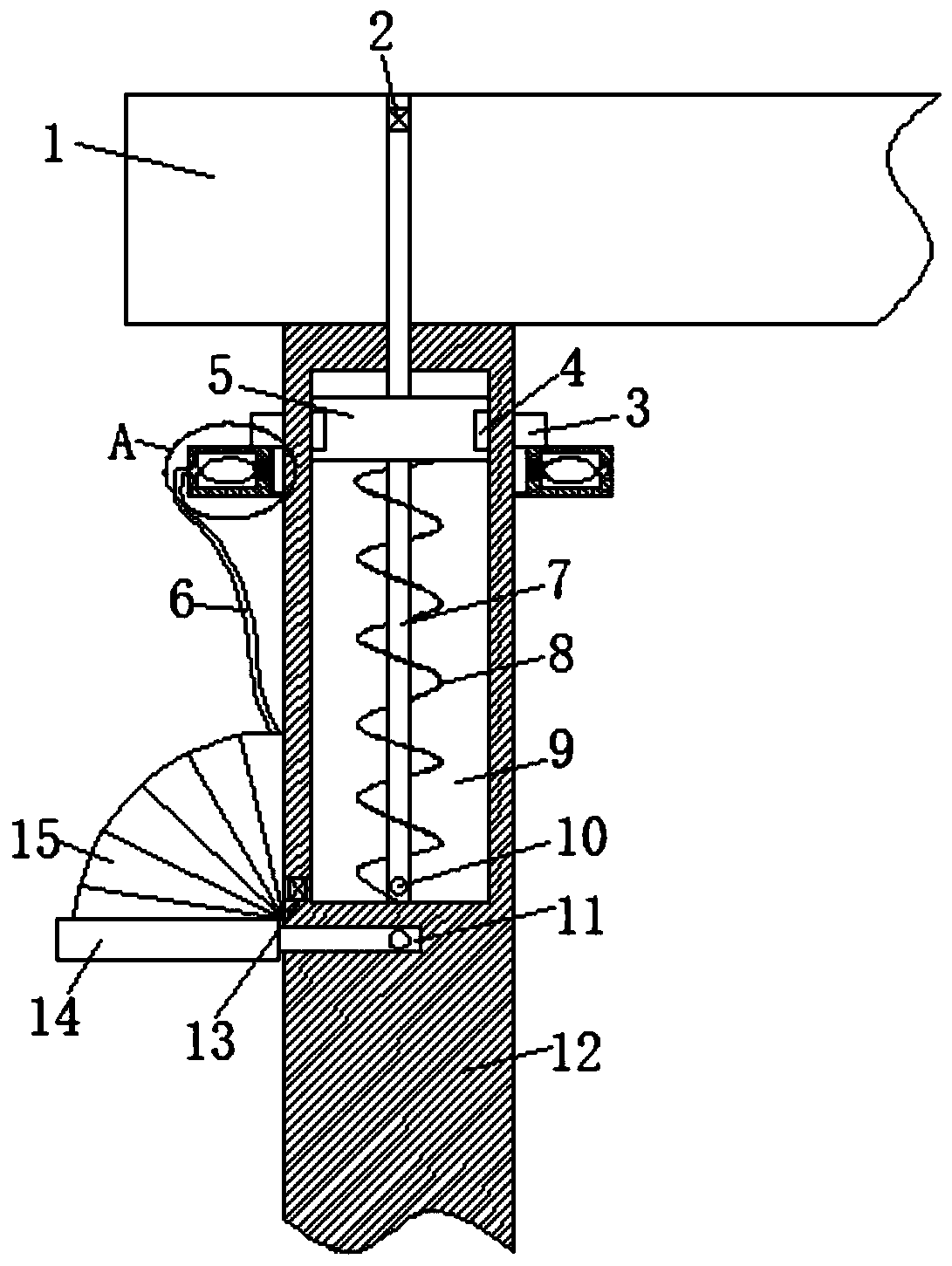

Wave type rust removing device of offshore drilling platform

ActiveCN110228001AEfficient removalMove down automaticallyGrinding machinesGrinding headsWell drillingSea waves

The invention discloses a wave type rust removing device of an offshore drilling platform. The wave type rust removing device of the offshore drilling platform comprises a drilling platform body and multiple fixing columns. The two sides of the fixing columns are rotationally connected with rotating rods. The tail ends of the rotating rods are fixedly connected with wave blocking plates. An fan-shaped elastic air bag is connected between the upper side of each wave blocking plate and the side wall of the corresponding fixing column. Cylindrical cavities are arranged in the fixing column. The cylindrical cavities communicate with the fan-shaped elastic air bag through an intake tube. A guide pipe is fixedly arranged at the inner bottom of each cylindrical cavity. Each guide pipe communicates with the corresponding cylindrical cavity through an air hole. Each guide pipe is provided with a piston in a sliding sealed manner and sleeved with a reset spring. The upper end of the guide pipe penetrates through a drilling platform body. A valve is installed at a pipe opening of each guide pipe. The outer side wall of each piston is provided with a first annular magnet in an embedded manner.The wave type rust removing device of the offshore drilling platform is reasonable in structure, capable of utilizing the wave to automatically remove rust on the fixing columns, safer and good in rust removal effect.

Owner:德清博发智能科技有限公司

Granite rust remover

The invention relates to a granite rust remover which is prepared by mixing the following components in parts by weight: 15-50 parts of one or more of inorganic acids and organic acids, 1-15 parts of surface active agent, 1-15 parts of hydrogen peroxide and 30-80 parts of polar solvents. The inorganic acid is preferably phosphoric acid and / or hydrochloric acid, the organic acid is preferably at least one of glycolic acid, glyoxylate, oxalic acid, phytic acid, citric acid, malic acid, maleic acid and fumaric acid, and the surface active agent is sodium dodecyl benzene sulfonate or op-10 emulsifier. The rust remover of the invention is smeared on the granite surface, can form a stable colorless complex with iron after reacting for 1-2 days, remove rusty points and rusty lines of the granitein a short time without influencing the granite luster or leaving trails and rapidly remove rust on the granite surface with high efficiency.

Owner:BEIJING ZHONGJIE JINGGONG TECH DEV

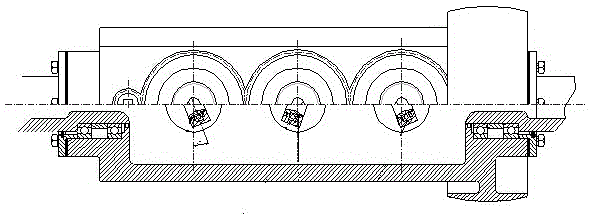

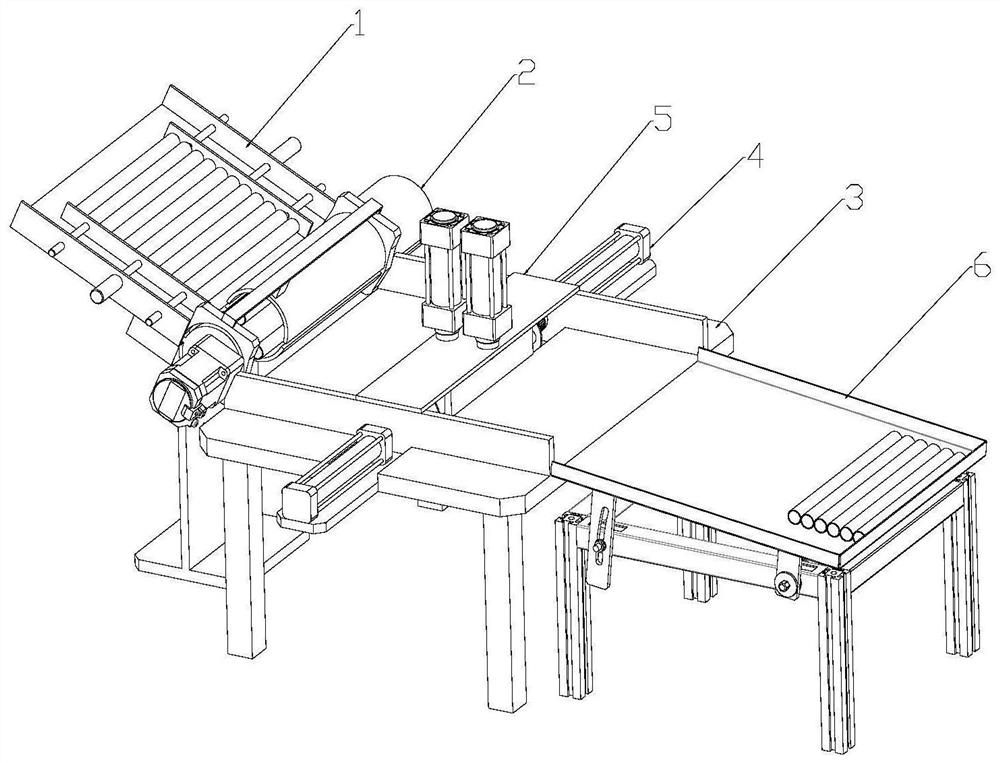

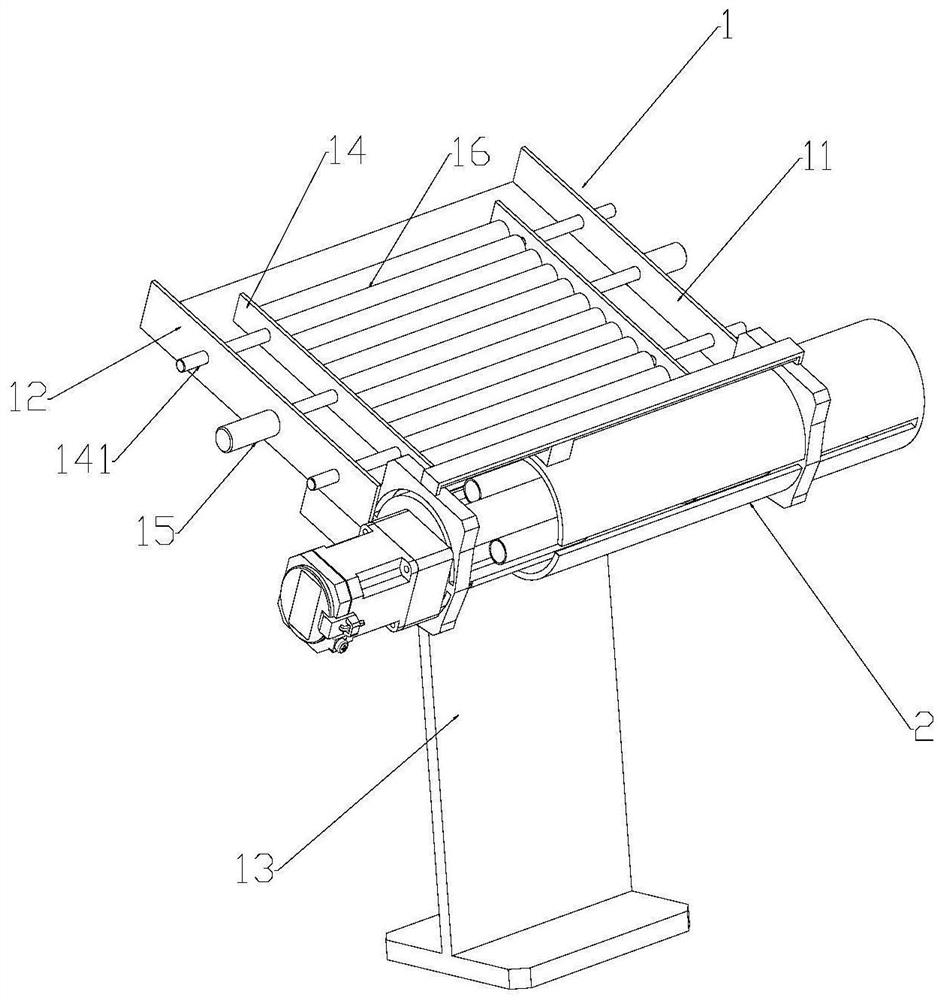

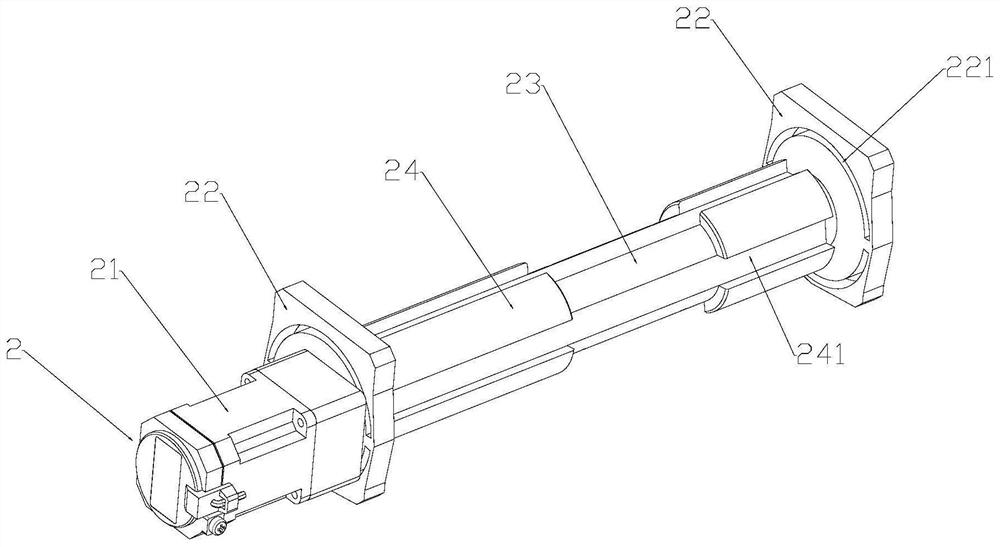

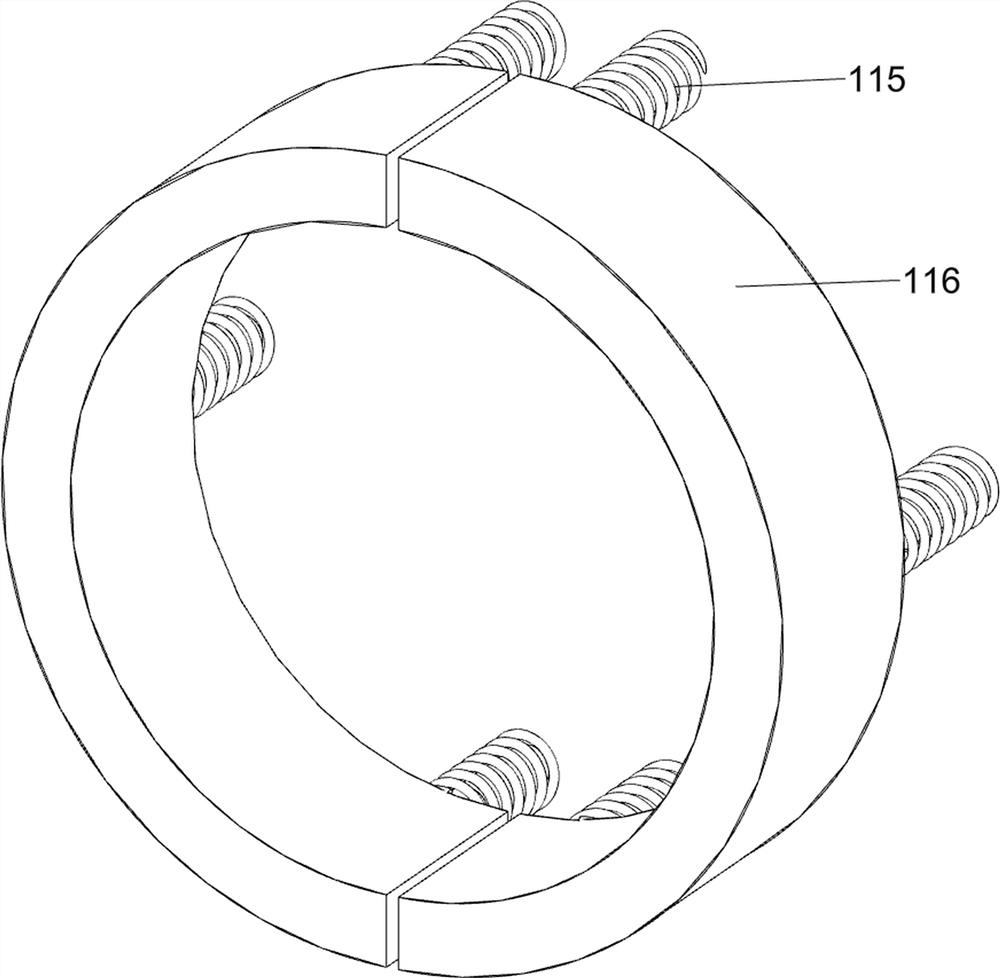

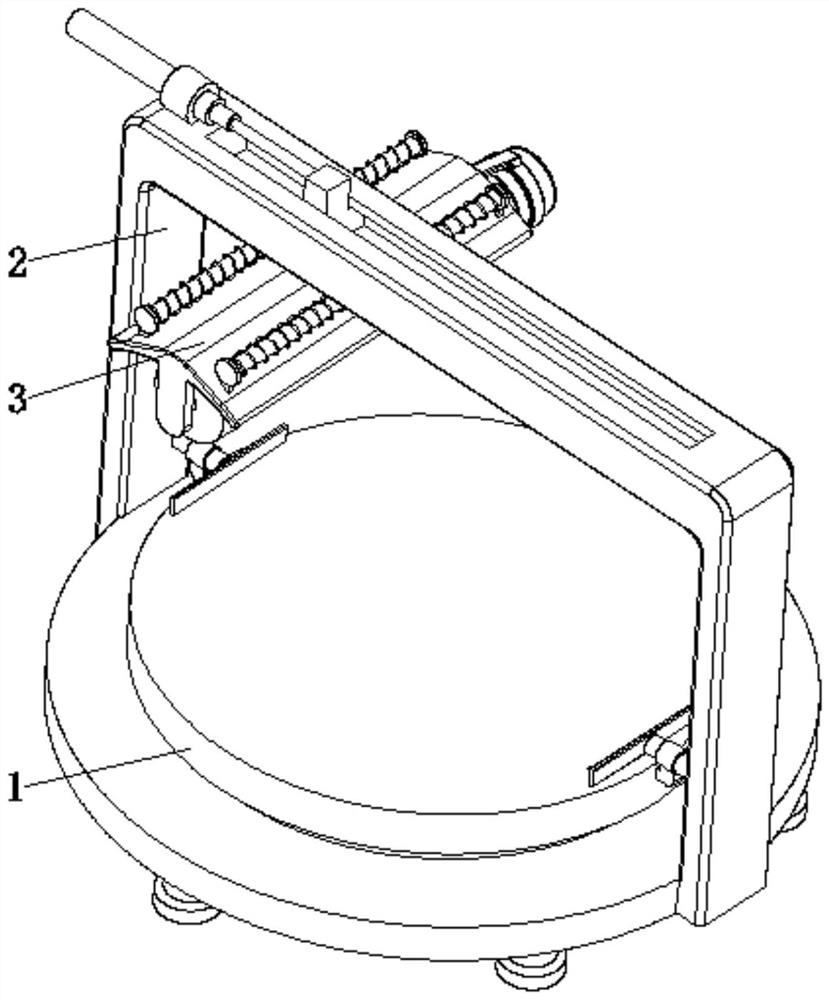

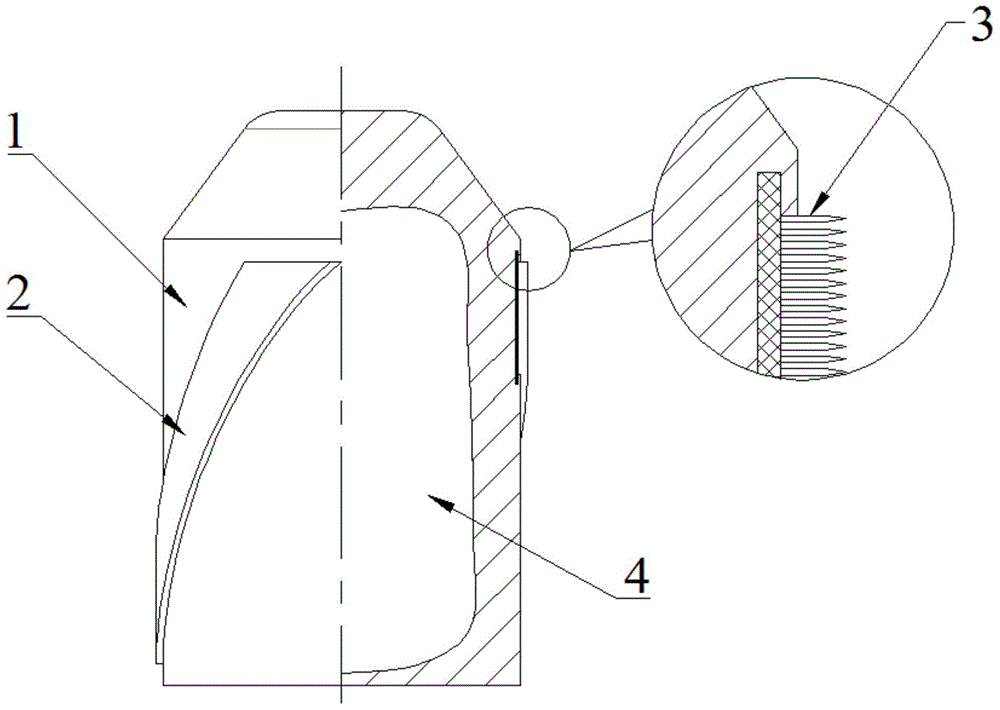

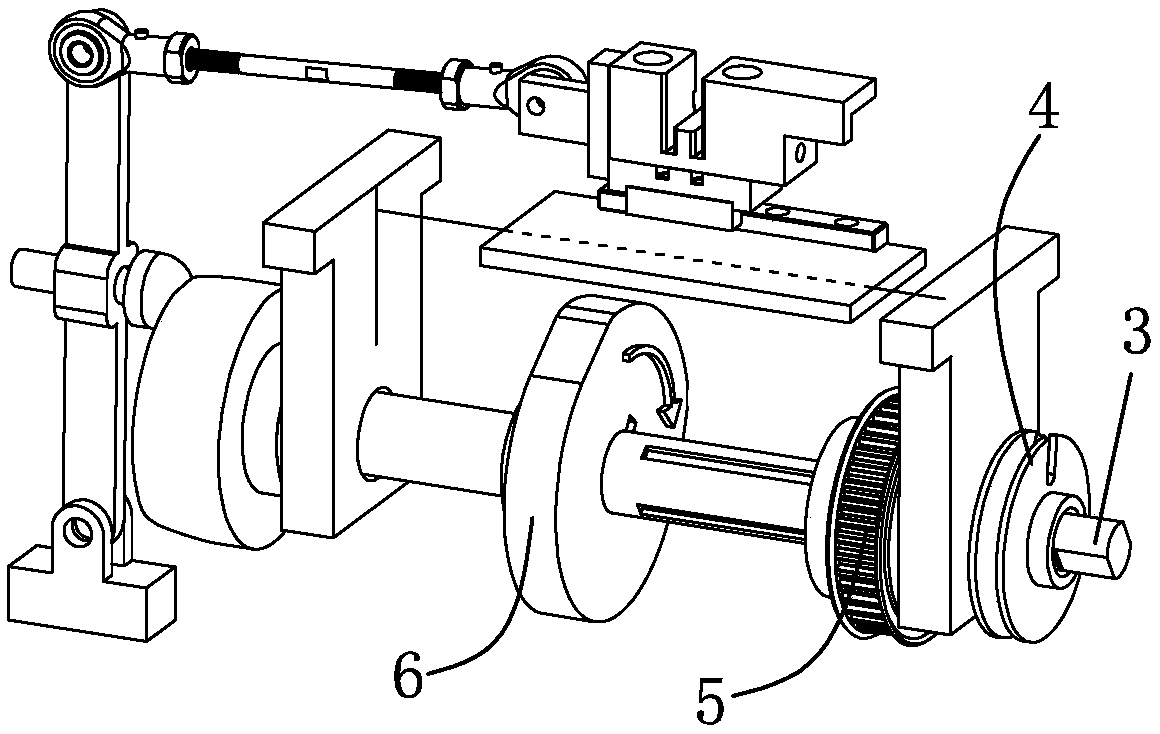

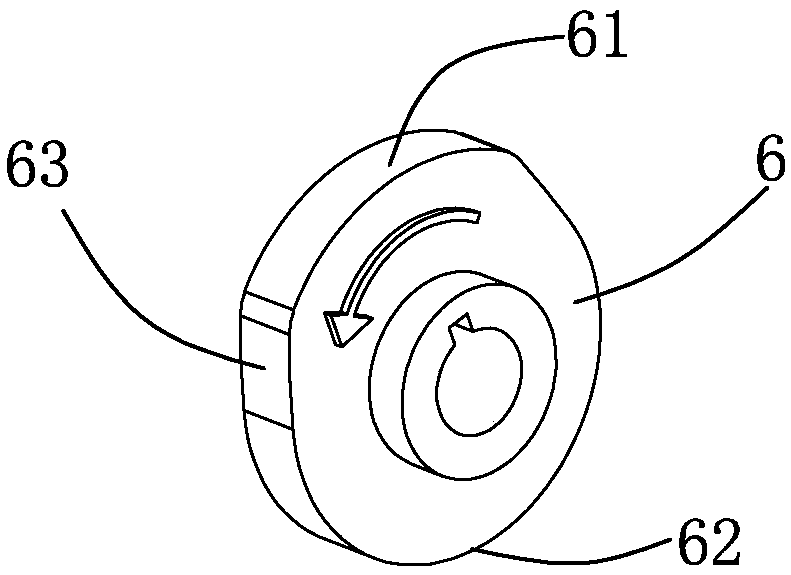

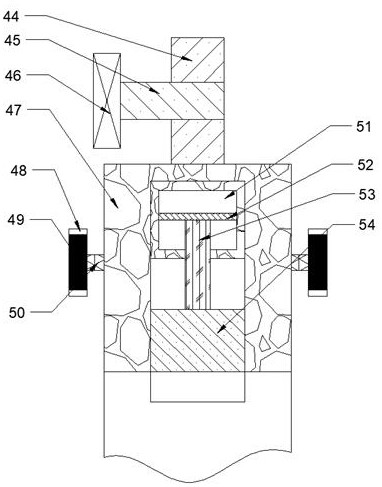

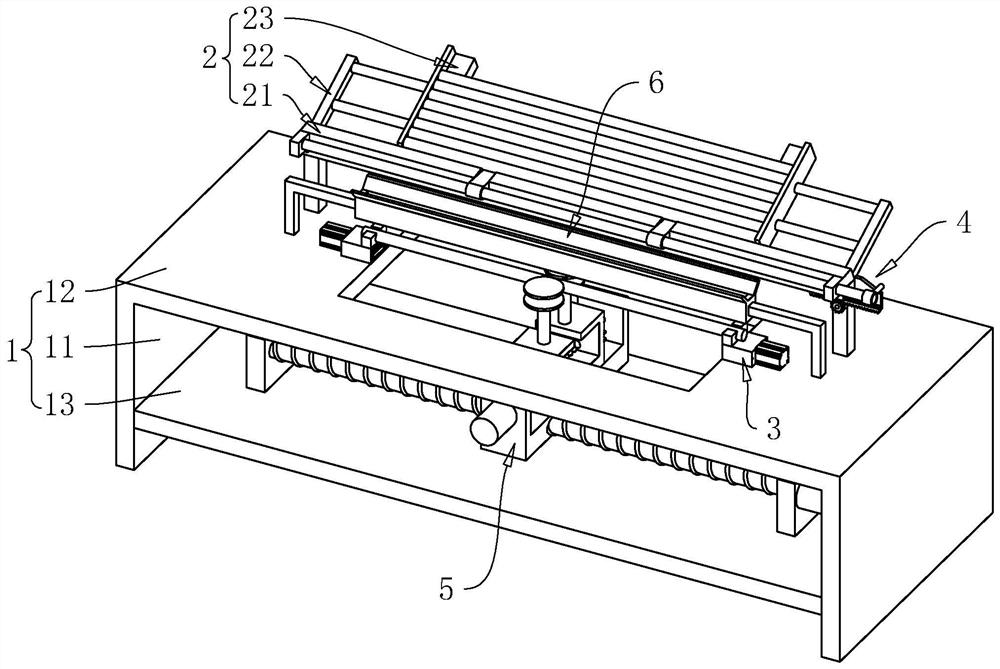

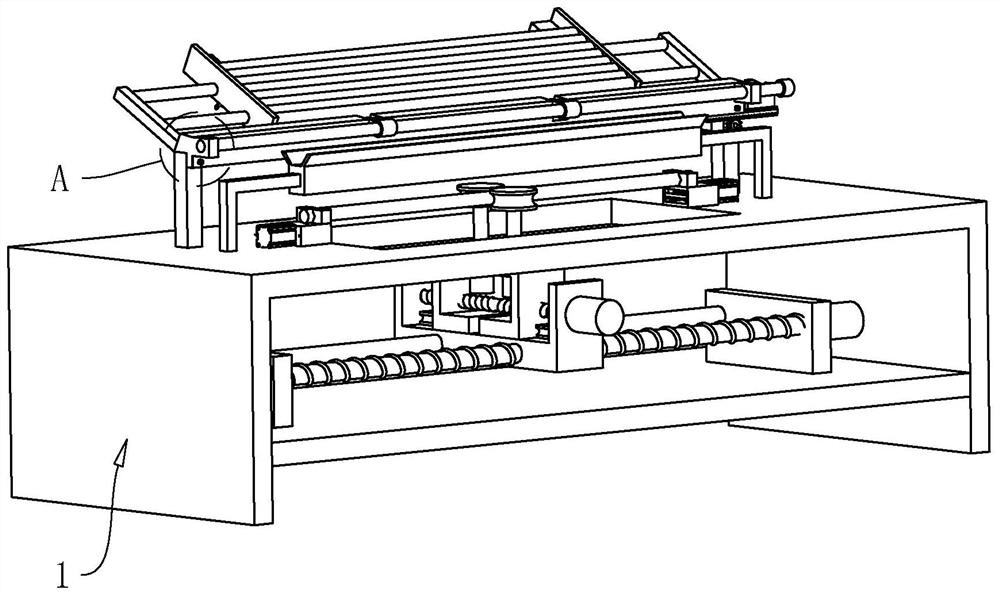

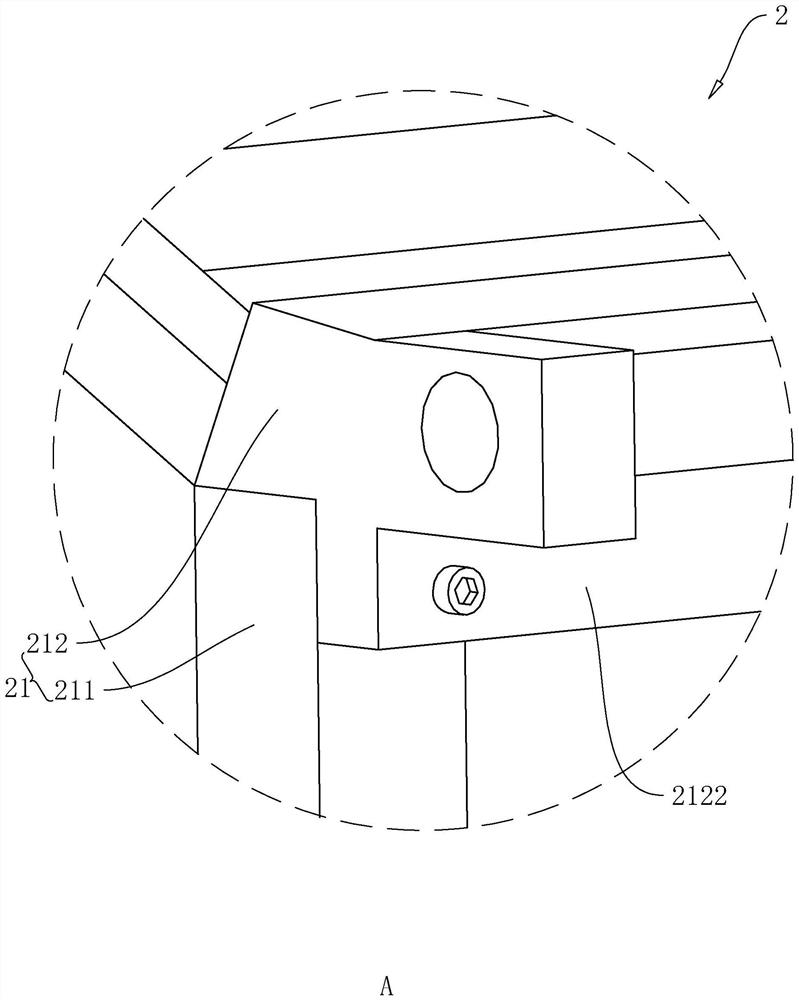

Surface treatment device of stainless steel pipe for building construction and working method of surface treatment device

InactiveCN112975587AAchieve grindingAchieve rust removalGrinding carriagesGrinding drivesPolishingElectric machinery

The invention relates to the field of stainless steel pipes, in particular to a surface treatment device of a stainless steel pipe for building construction and a working method thereof. The surface treatment device comprises a discharging mechanism, a side wall treatment mechanism, a supporting mechanism, an end face treatment mechanism, a blocking mechanism and a material collecting mechanism. During use, stainless steel pipes in the discharging mechanism are released to fall into a limiting groove, a first motor, a rotating roller and the three stainless steel pipes are driven to rotate, the stainless steel pipes and the frosted inner wall of an arc-shaped plate are polished and derusted, other parts do not need to be moved during polishing, and sufficient polishing can be achieved through rotation of the rotating roller. the side walls of three stainless steel pipes can be treated through one-time polishing, the working efficiency is improved, after the steel pipes fall down, a second motor drives a polishing wheel to move towards the inner side until a limiting column enters the inner walls of the stainless steel pipes, so that the side walls of the polishing wheel are attached to the ends of the stainless steel pipes, and the polishing wheel rotates to polish the ends of the stainless steel pipes. The number of stainless steel polished at a time is three, and the working efficiency is improved.

Owner:潘文超

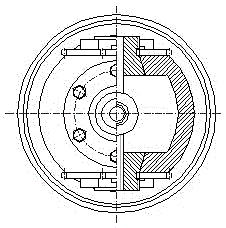

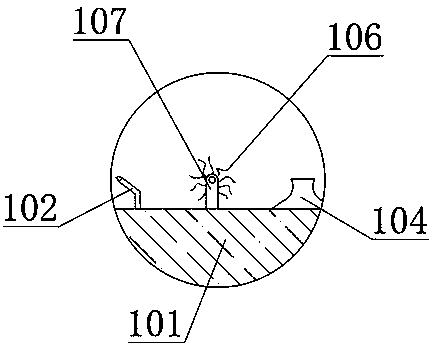

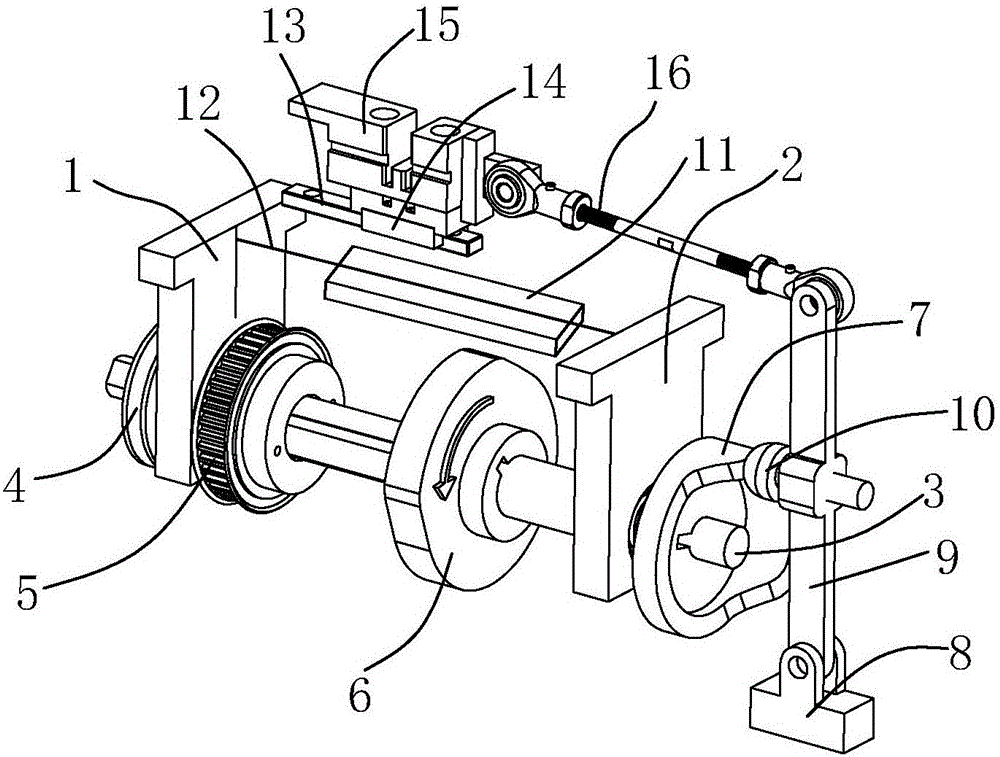

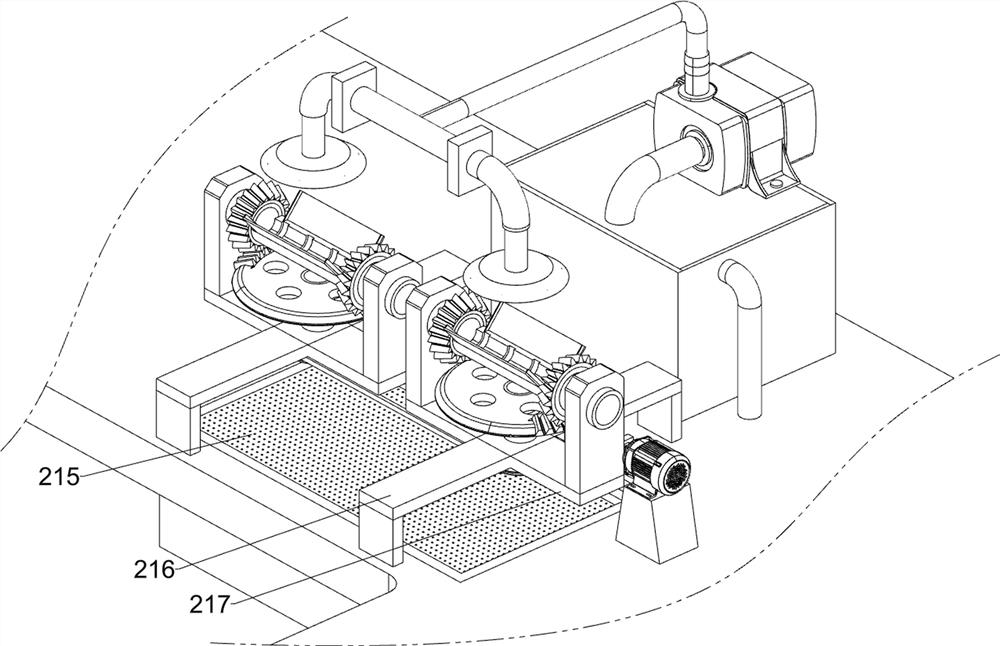

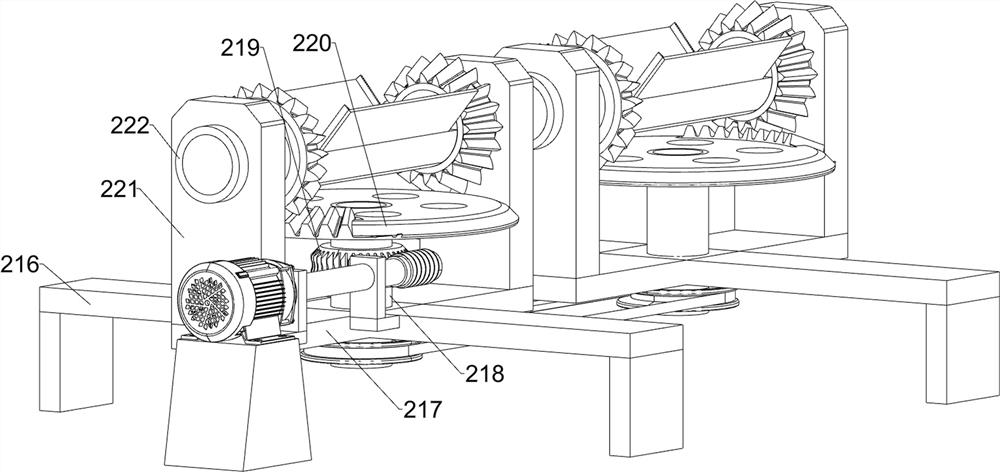

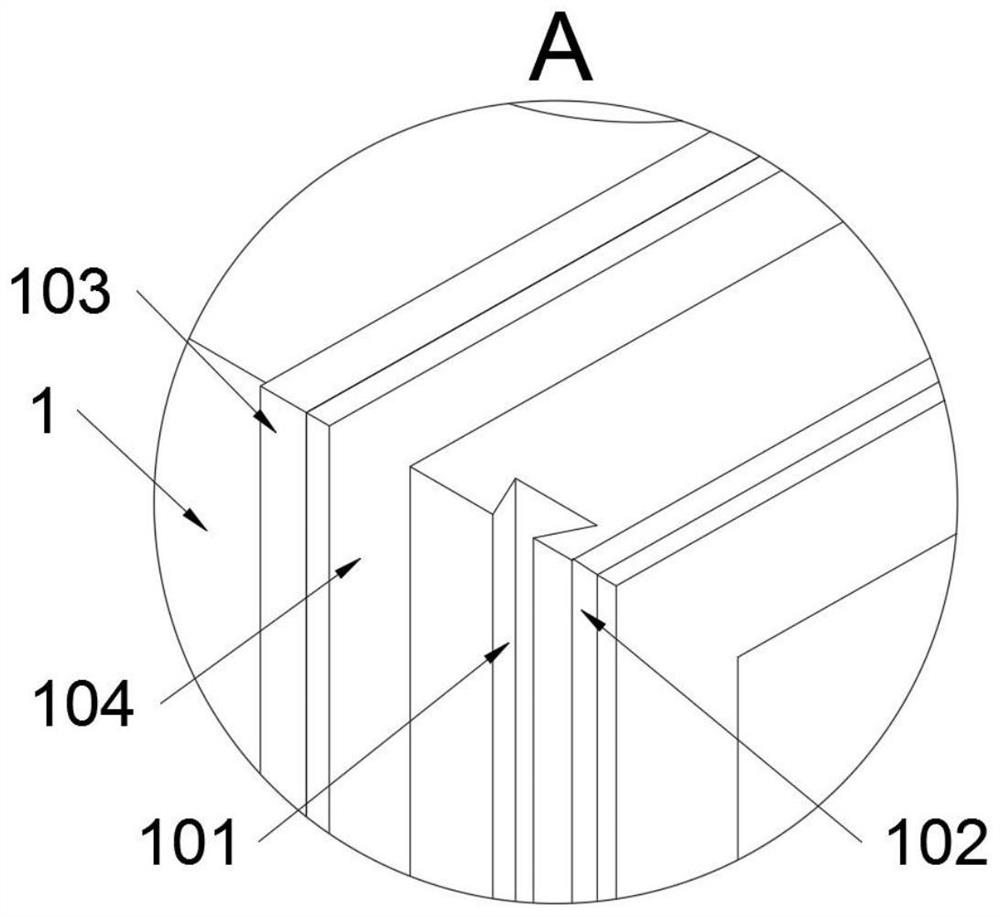

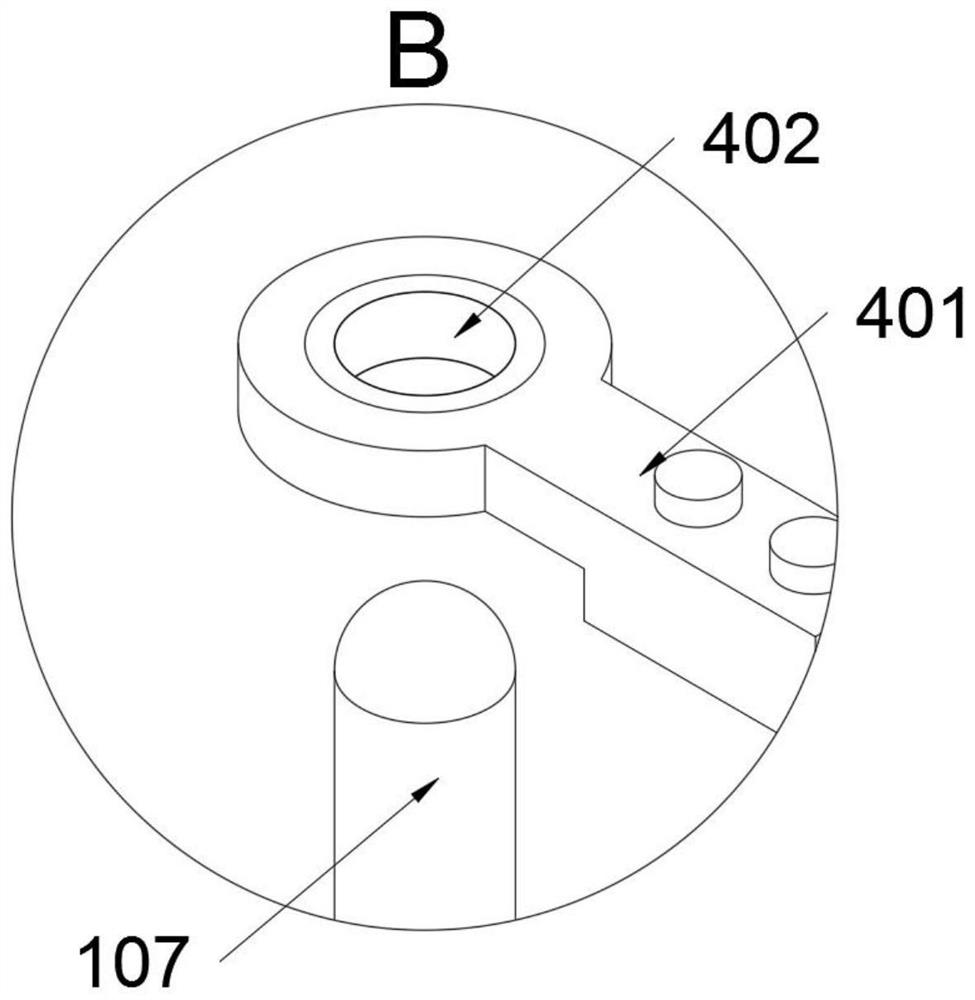

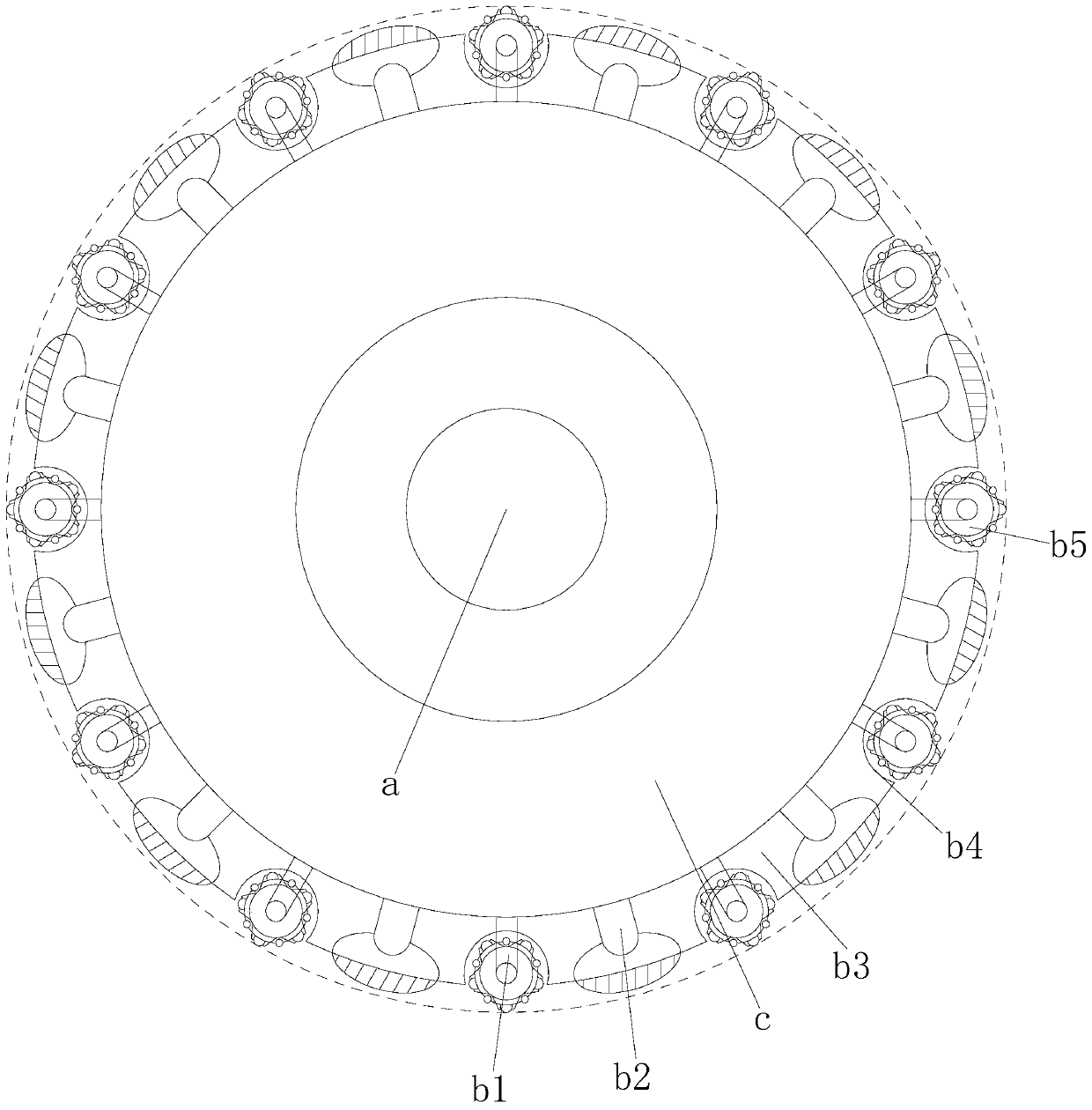

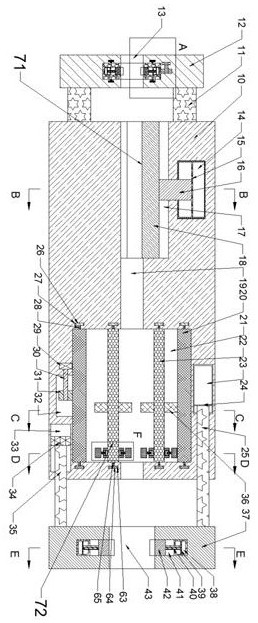

Rust removing device for steel I-column embedded in building foundation

ActiveCN106826500AAchieve rust removalAutomatic rust removalGrinding carriagesGrinding drivesArchitectural engineeringRust

The invention relates to a rust removing device for steel I-column embedded in a building foundation. A rotating shaft sequentially penetrates through a calibration disc, a support block a, a track disc, a top disc, a support block b and a shift disc, wherein slots are formed in middles of tops of the support block a and the support block b, a penetrating rod penetrates through a top plate block, and two tail ends of the penetrating rod are placed in the slots of the support block a and the support block b respectively; a base block is hinged with one end of a pull rod, a ball rod is fixed in the middle of the pull rod, and a ball end of the ball rod abuts against the annular surface of the shift disc. An iron brush plate can automatically remove rust on I-shaped section steel according to a preset track through linkage of the top disc, the shift disc and a clamping part; different kinds of welding faces are polished according to different welding requirements by using the technical means that the iron brush plate can be divided into 2-5 specifications according to different I-steel section polishing fineness; besides, the designed product is simple in structure and easy to operate by constructors.

Owner:福建兴旺建设发展有限公司

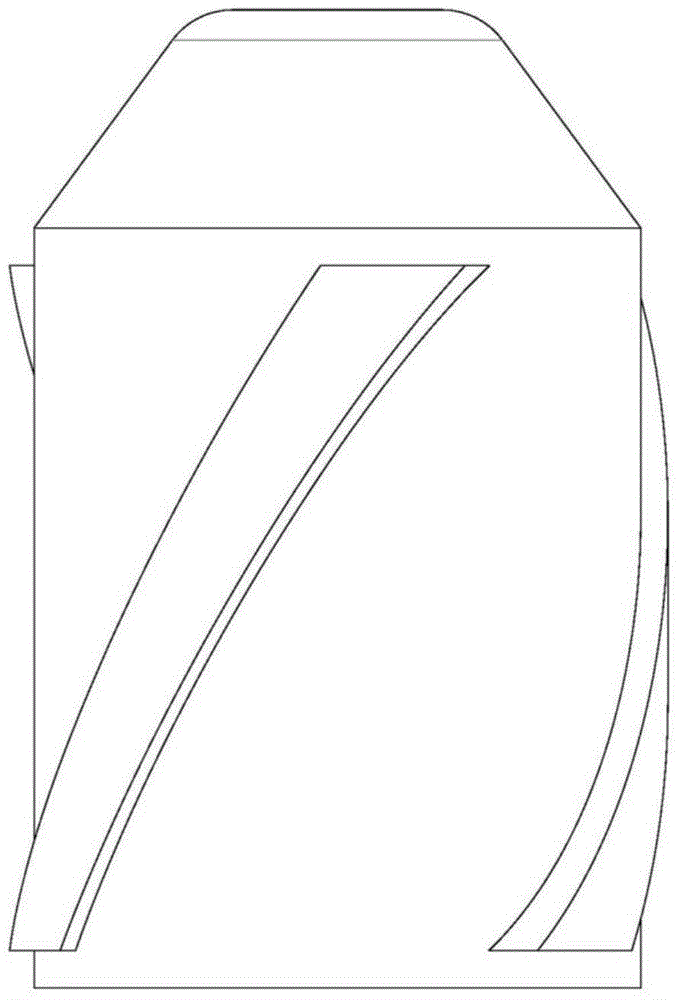

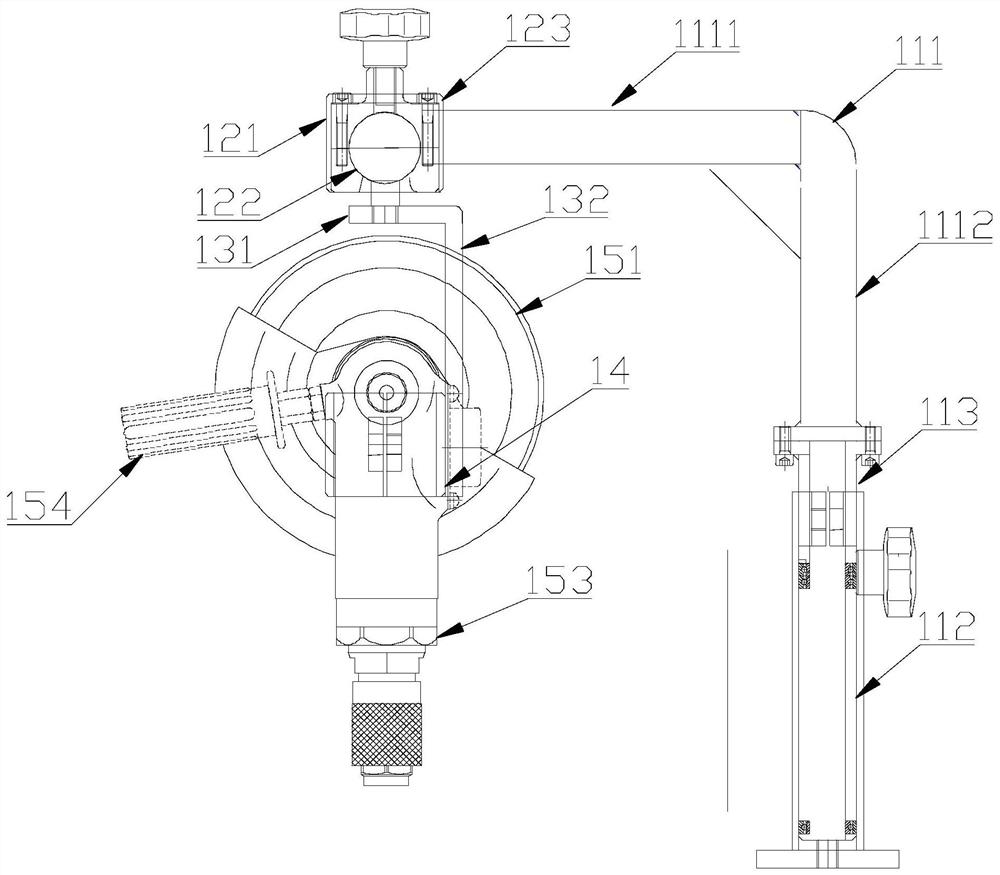

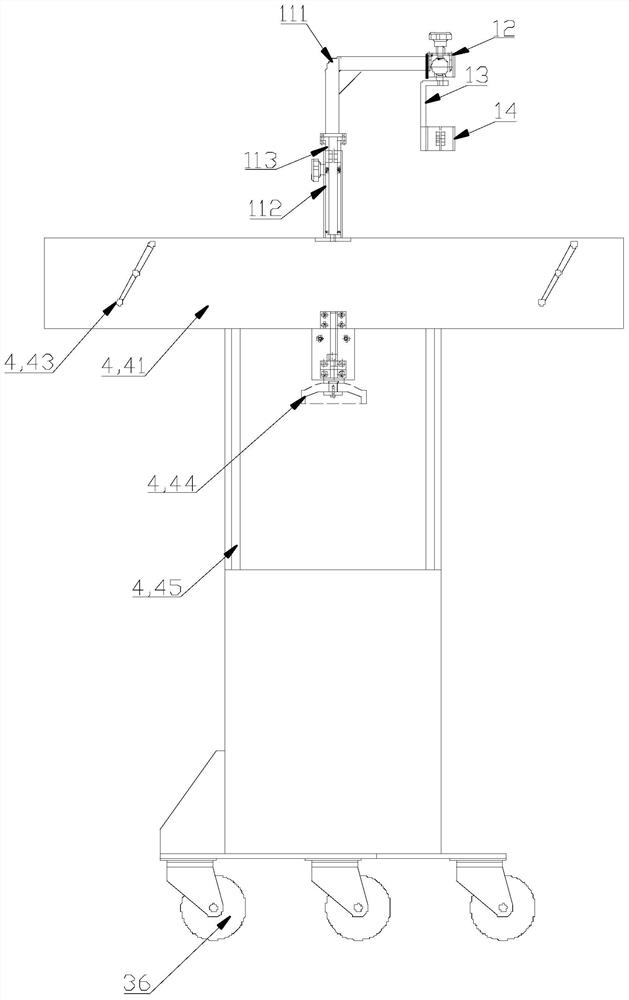

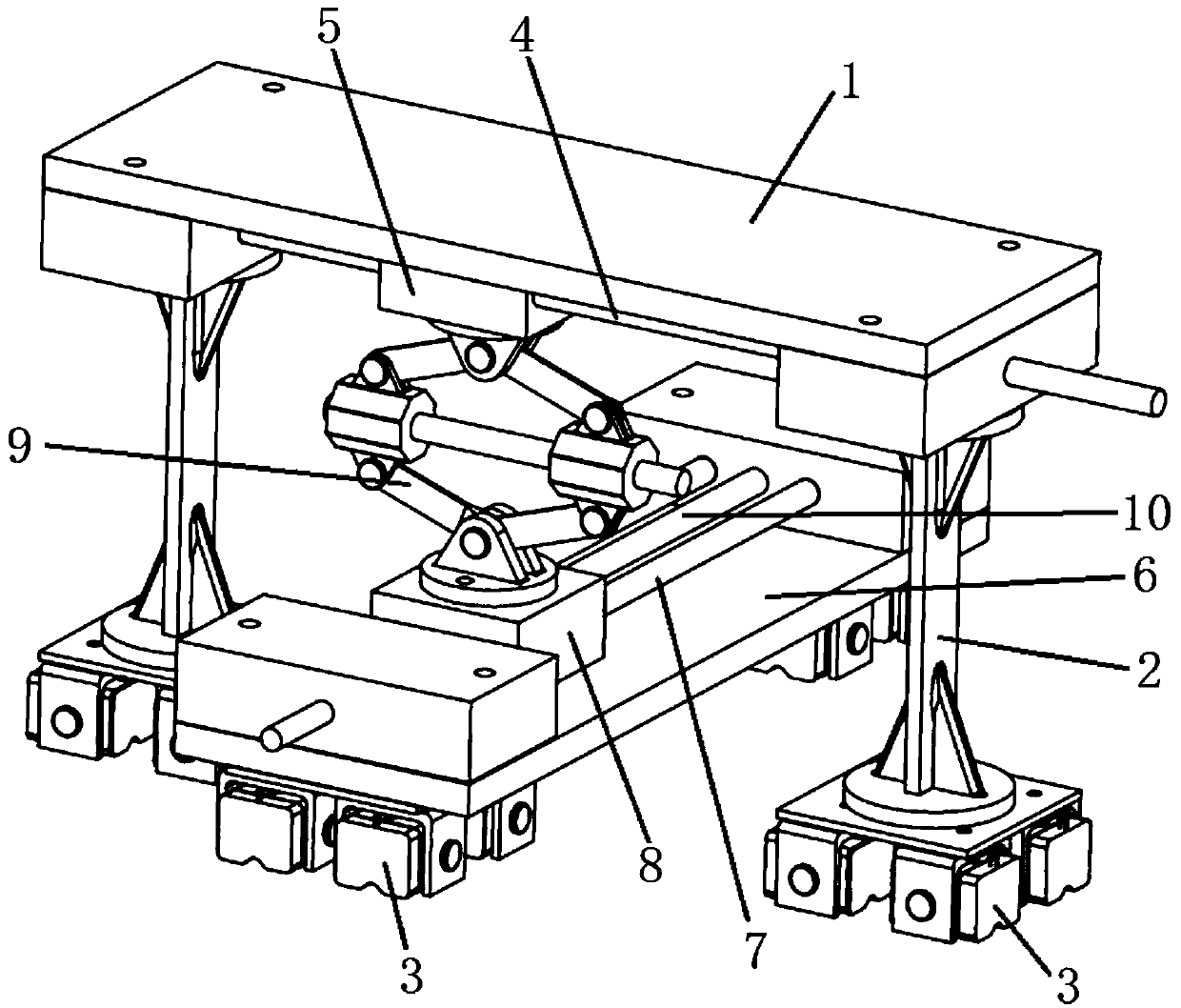

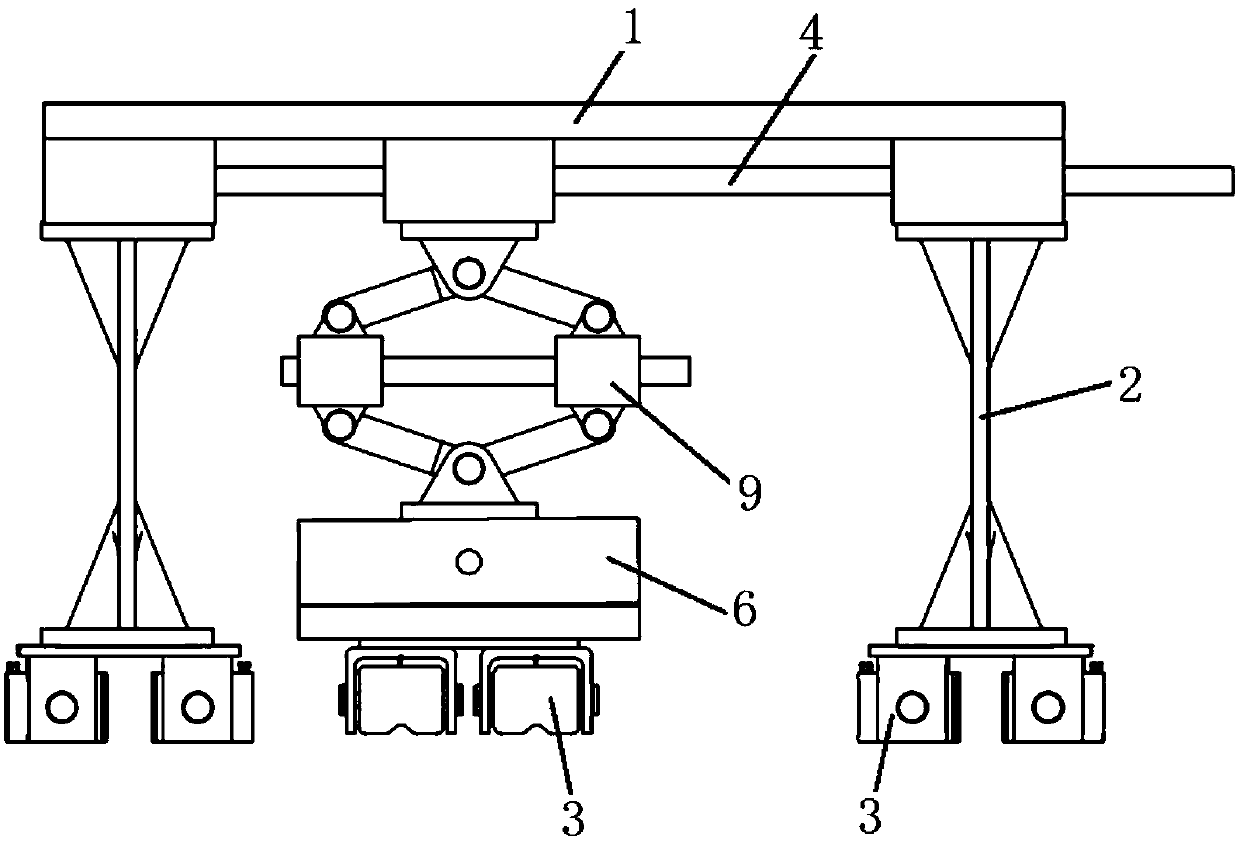

Grinding equipment with angle adjusting function

ActiveCN112405256AReduce labor intensitySatisfy the fine grinding operationGrinding carriagesPortable grinding machinesEngineeringGrinding

The invention discloses grinding equipment with an angle adjusting function. The grinding equipment with the angle adjusting function comprises a driving system and a grinding tool system, wherein thegrinding tool system is fixed to the driving system, the grinding tool system comprises a universal adjusting device and a grinding tool, one end of the universal adjusting device is fixedly connected with the driving system, and the other end of the universal adjusting device is rotationally connected with the grinding tool. According to the grinding equipment with the angle adjusting function,by arranging the universal adjusting device, the angle of the grinding tool can be adjusted according to needs, then 360-degree dead-corner-free grinding is achieved, the use requirements of differentoperators are met, the operators can work in good postures, and the labor intensity of the operators is reduced, and meanwhile, the grinding tool system is fixed to the driving system, the driving system drives the grinding tool system to move in the horizontal direction or the vertical direction so that the grinding tool system can be adjusted according to the position of a workpiece, and practicability is better.

Owner:CRRC QINGDAO SIFANG CO LTD

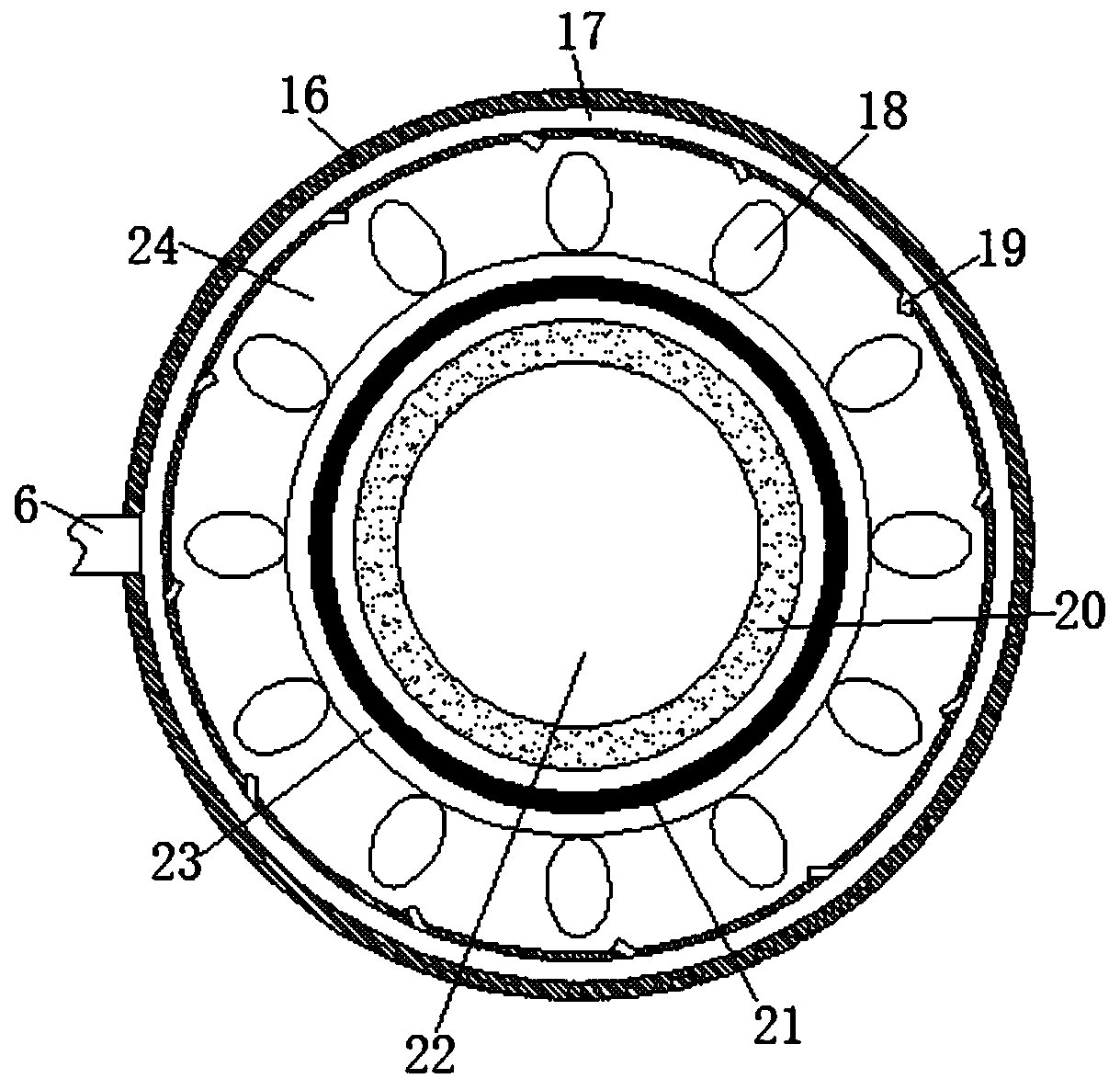

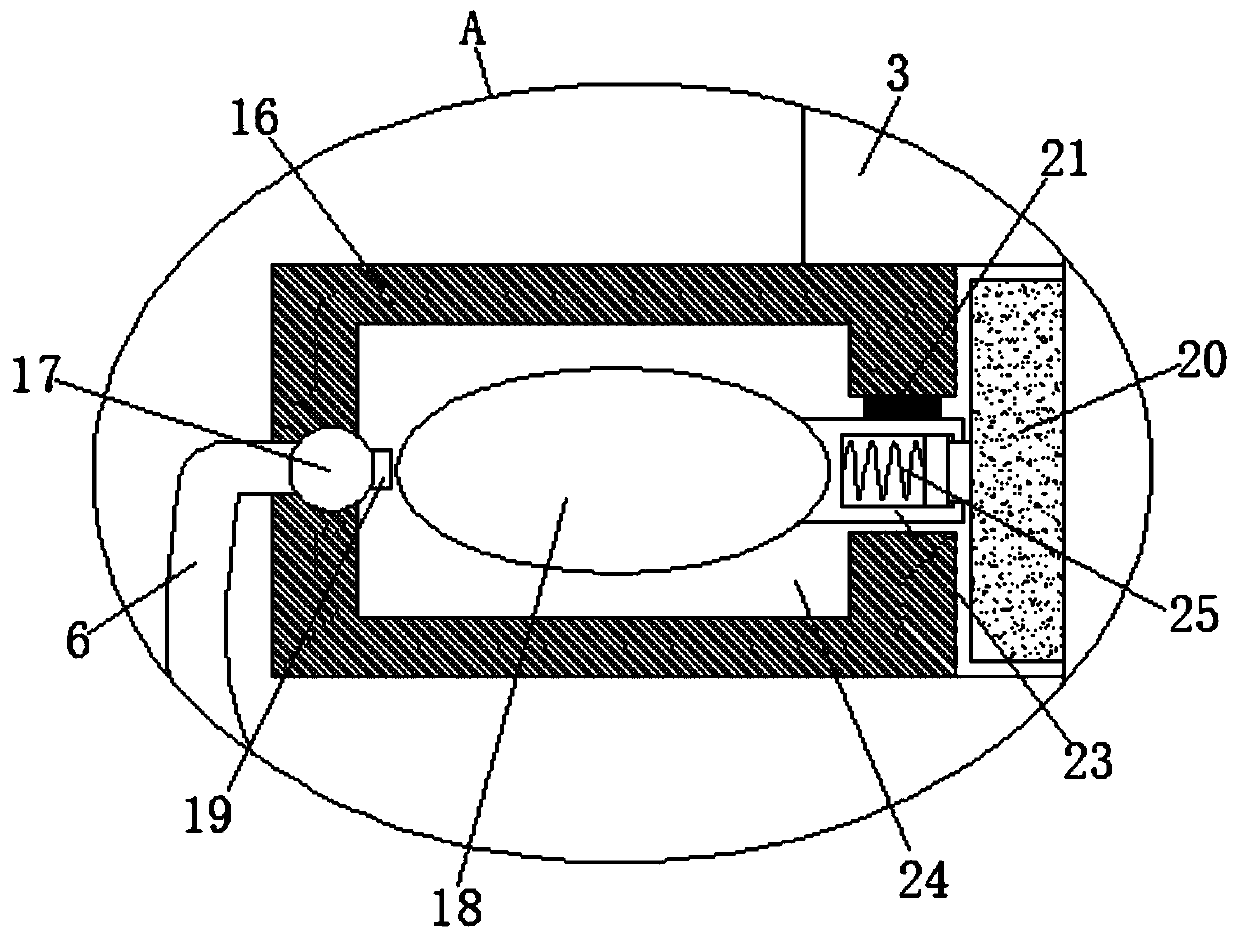

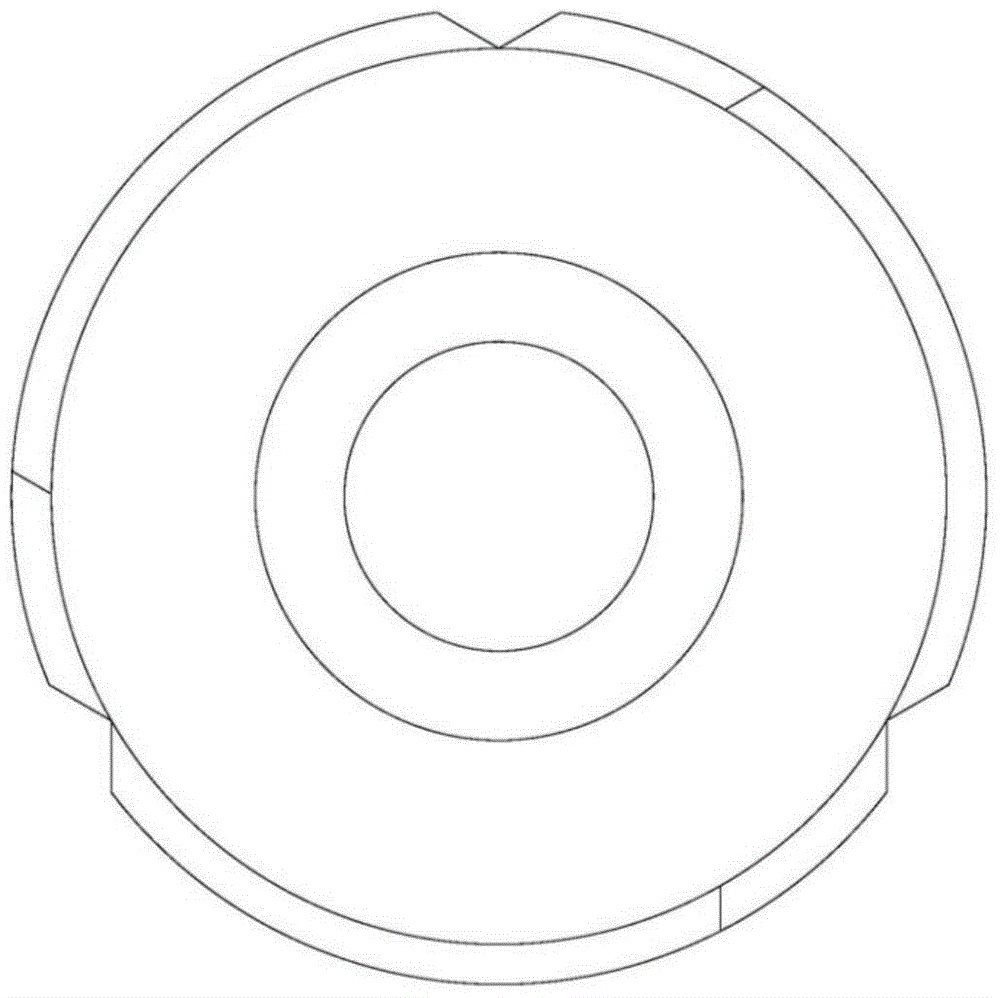

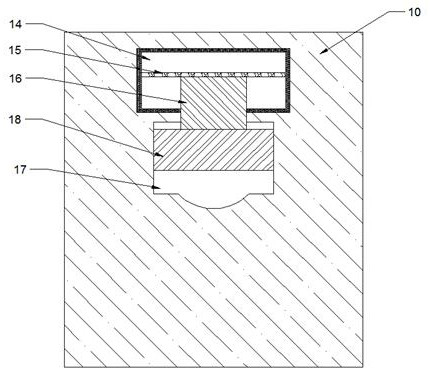

Small-flow electromagnetic water quality treatment device

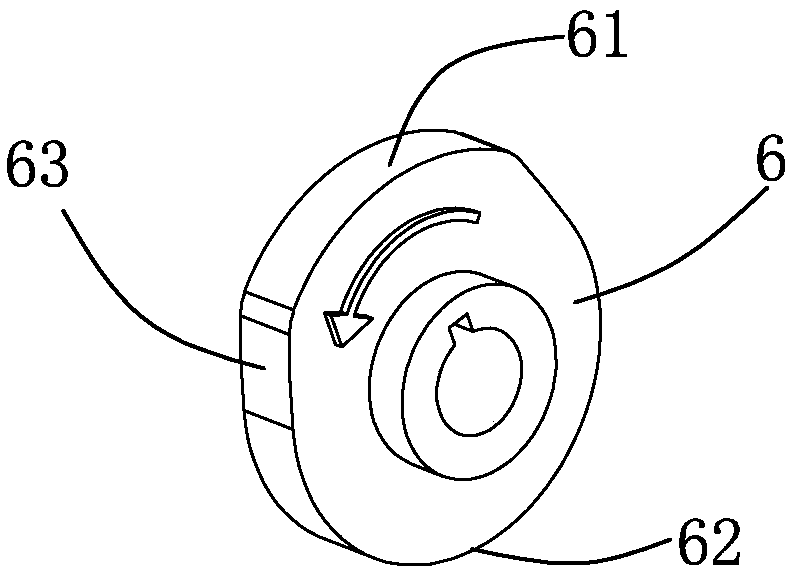

InactiveCN102206008AIncrease the lengthGood effectScale removal and water softeningWater qualityCell membrane

The invention relates to a small-flow electromagnetic water quality treatment device, which comprises a high-frequency oscillator, a water flow channel, a water inlet and a water outlet, and is characterized in that: a screw type anode shell is arranged in the water flow channel; an anode electrode is arranged in the anode shell; the anode shell is a spiral layer which rotates by taking the anode electrode as a rotation center; the spiral layer is assembled in the water flow channel in a tight fit manner to form a thin-layer water backflow channel; a cathode electrode is arranged at the periphery of the water flow channel; and the anode electrode and the cathode electrode are connected to an output end of the high-frequency oscillator respectively. A structure of thinning a water layer and increasing the length of the water flow channel is adopted, the length of the water flow channel is increased, a dead zone of an electromagnetic field is eliminated, the dissolved oxygen in water which is treated through a high-frequency electric field is activated, an ion channel on a cell membrane is damaged by an external electric field, and a survival condition for bacteria and algae is lost, so that the effects of preventing scale, removing scale, sterilizing, removing algae, removing rust, benefiting human health, and saving a large amount of electric energy are achieved. The small-flow electromagnetic water quality treatment device is particularly suitable for scale prevention of a small water household electrical appliance. Besides, the water treatment effect is improved.

Owner:NINGBO RAVO IND GRP CO LTD

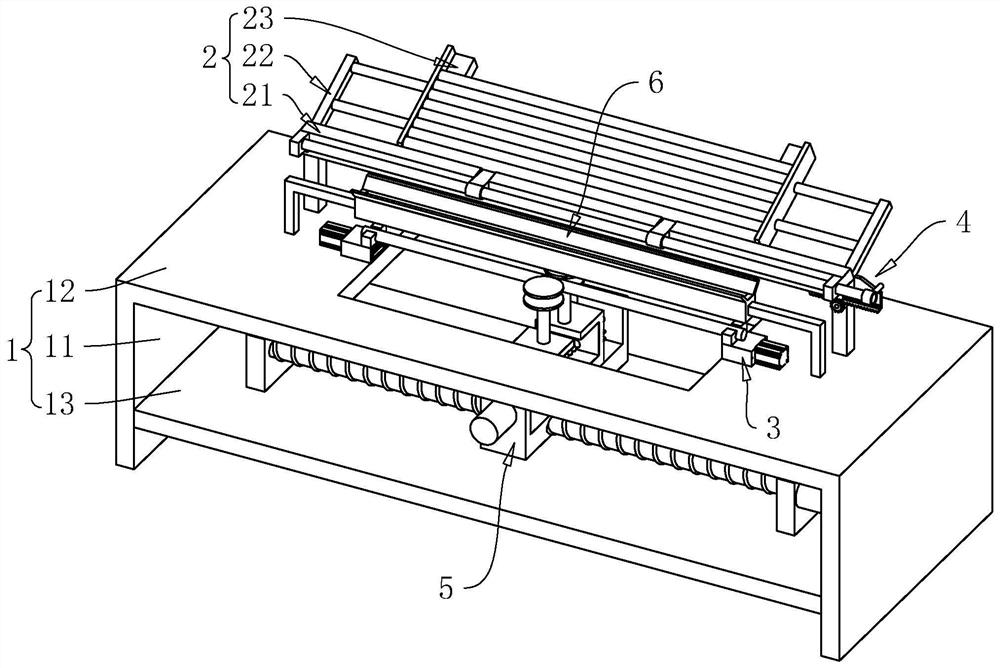

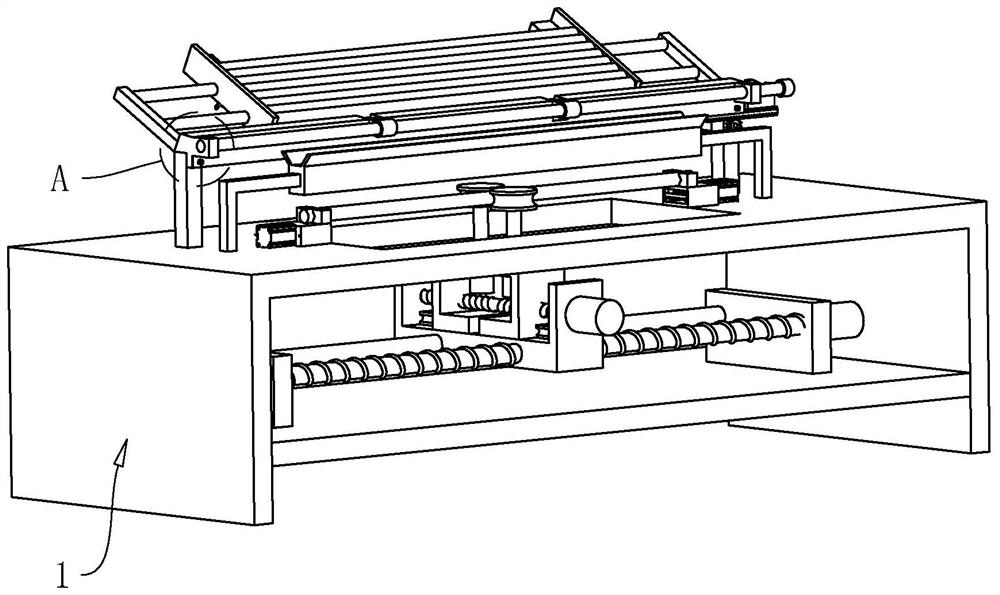

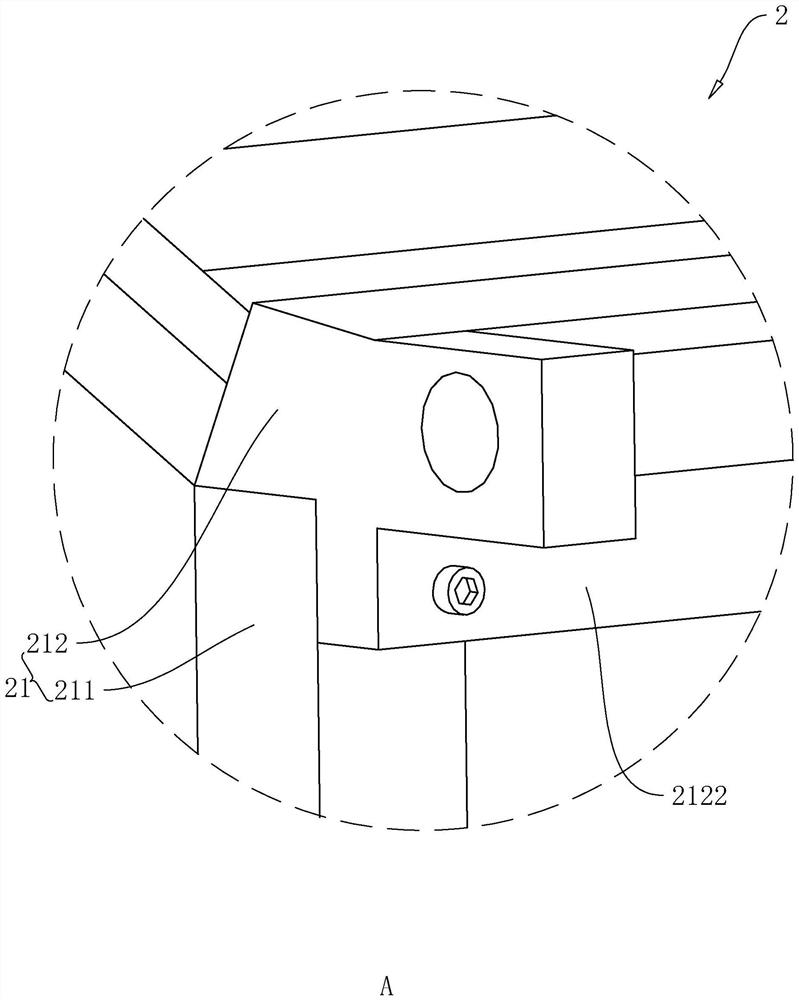

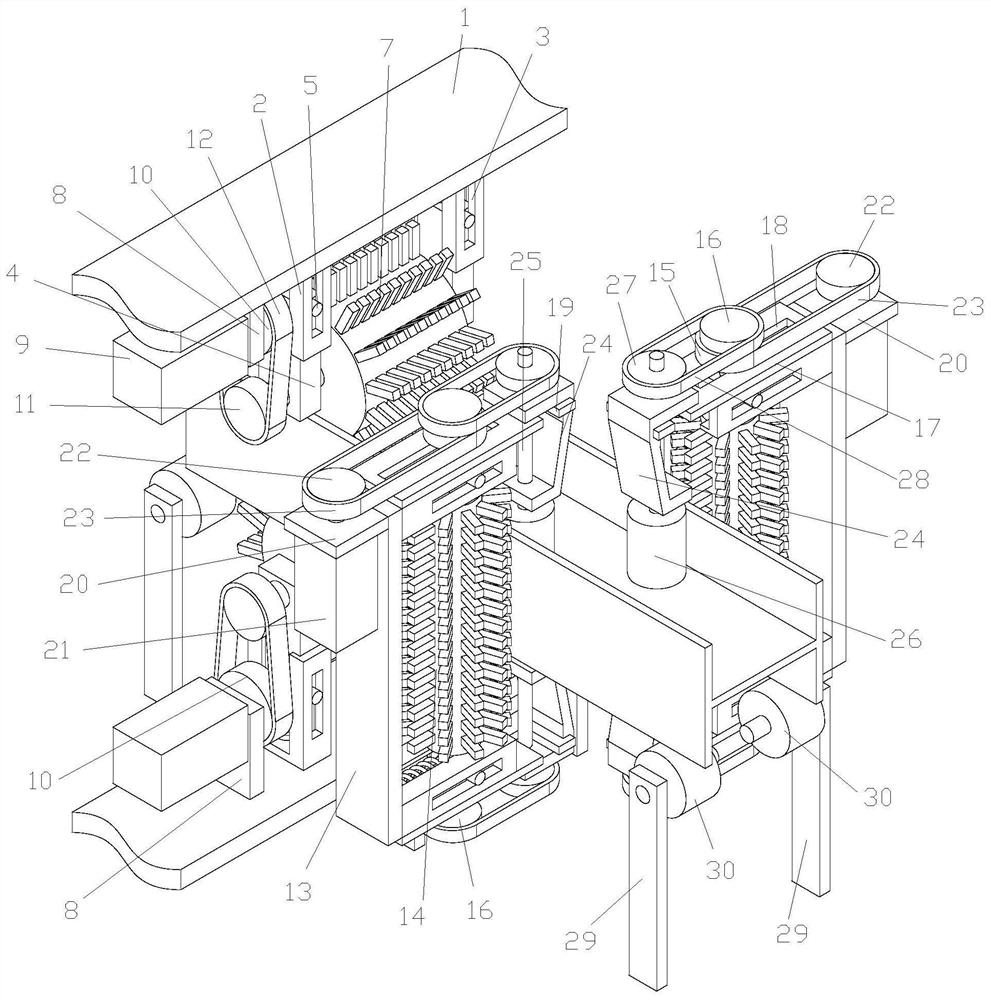

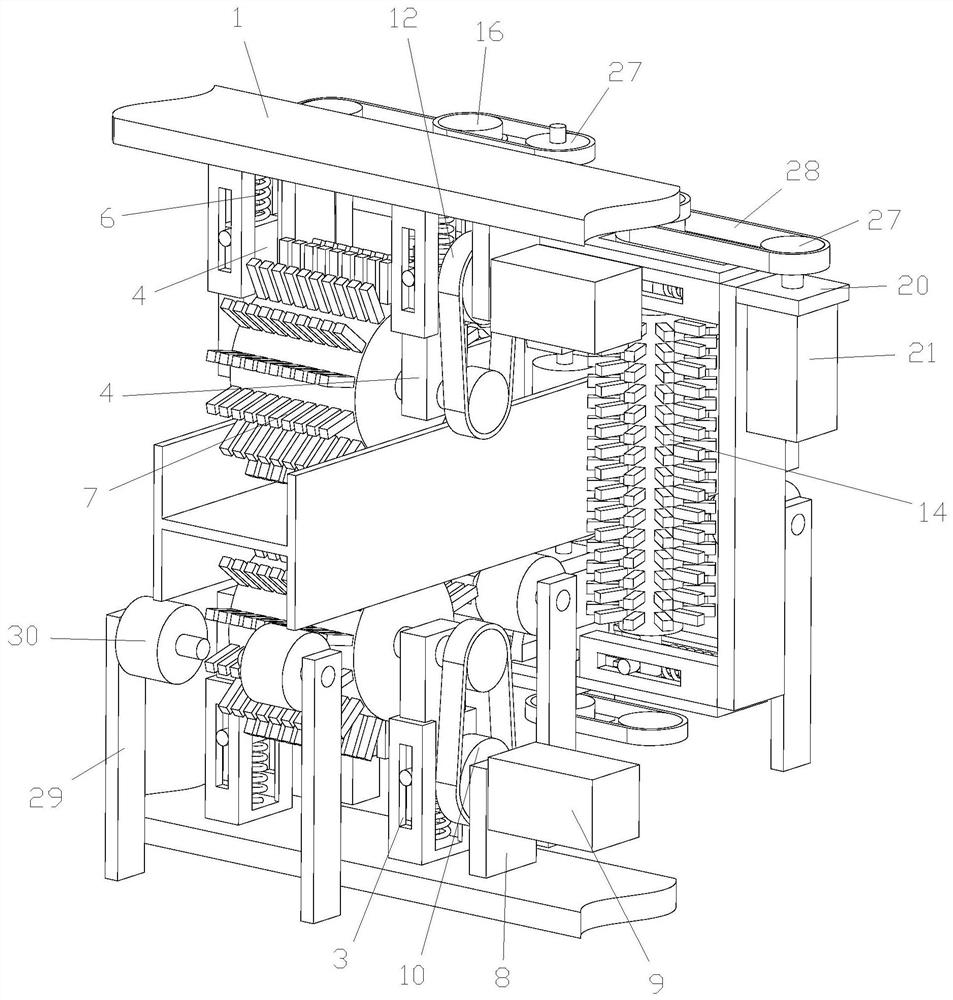

Rust removal device and rust removal process for steel structure

The invention discloses a rust removal device for a steel structure.The rust removal device for the steel structure comprises a workbench, wherein the workbench is sequentially provided with an emptying mechanism, a clamping mechanism, a discharging mechanism and a rust removal mechanism, wherein the emptying mechanism is used for placing steel bars or steel pipes; the clamping mechanism is located below the emptying mechanism, and used for clamping the steel bars or the steel pipes; the discharging mechanism is used for conveying the steel bars or the steel pipes on an emptying frame to the clamping mechanism; and the rust removal mechanism is used for carrying out rust removal on the steel bars or the steel pipes. According to the invention, the labor intensity of workers can be reduced.

Owner:东莞市联泰钢构有限公司

Profile steel surface rust removal device

PendingCN113146446APlay a supporting roleAvoid bendingGrinding drivesGrinding machinesSurface cleaningElectric machinery

The invention discloses a profile steel surface rust removal device, and belongs to the technical field of steel structures. Two horizontal surface cleaning and brushing parts are arranged, under driving of two first driving motors, rotation of two horizontal steel brushes is achieved, cleaning and brushing of profile steel are achieved, and the rust removal effect is achieved; two ends of vertical steel brushes are connected onto a transverse supporting seat, in the rust removal process of the vertical steel brushes, and a compression spring in the transverse supporting seat can play a role in damping; two vertical surface cleaning and brushing parts are arranged, under driving of two second driving motors, rotation of the two vertical steel brushes is achieved, cleaning and brushing of the profile steel are achieved, and the rust removal effect is achieved; small brush sets are arranged and can be driven by the second driving motors to remove rust on the inner surface of the H-shaped steel, and when the small brush sets are removed, the first driving motors and the second driving motors drive the two vertical steel brushes and the two horizontal steel brushes to rotate, so that the surface of a rectangular steel pipe is cleaned and brushed.

Owner:绍兴三雄钢结构有限公司

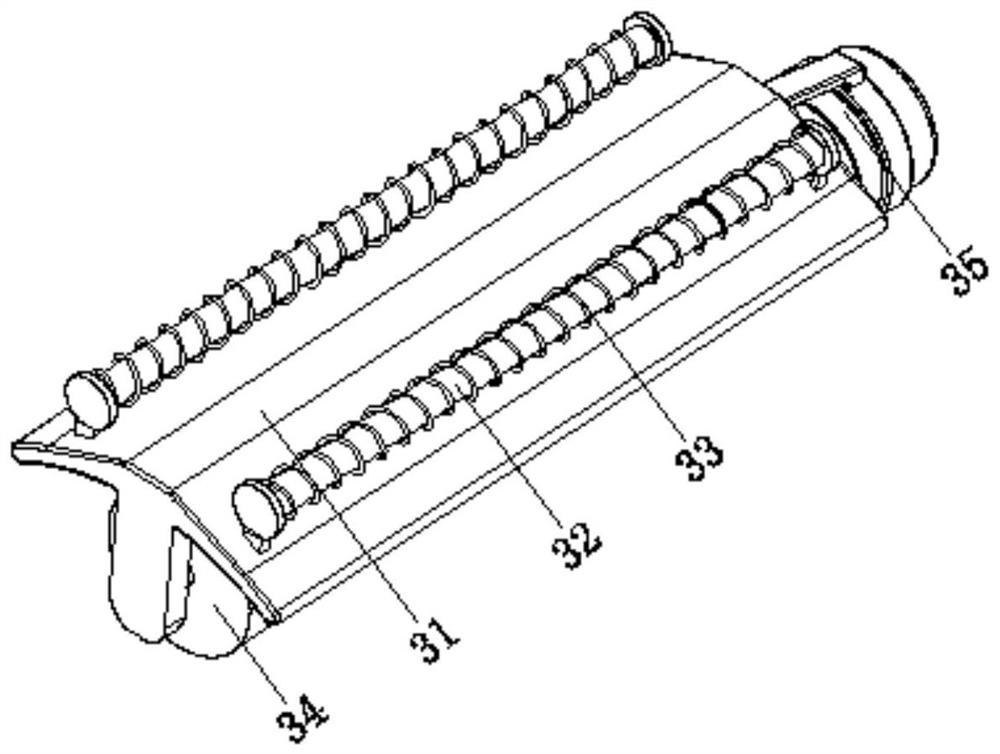

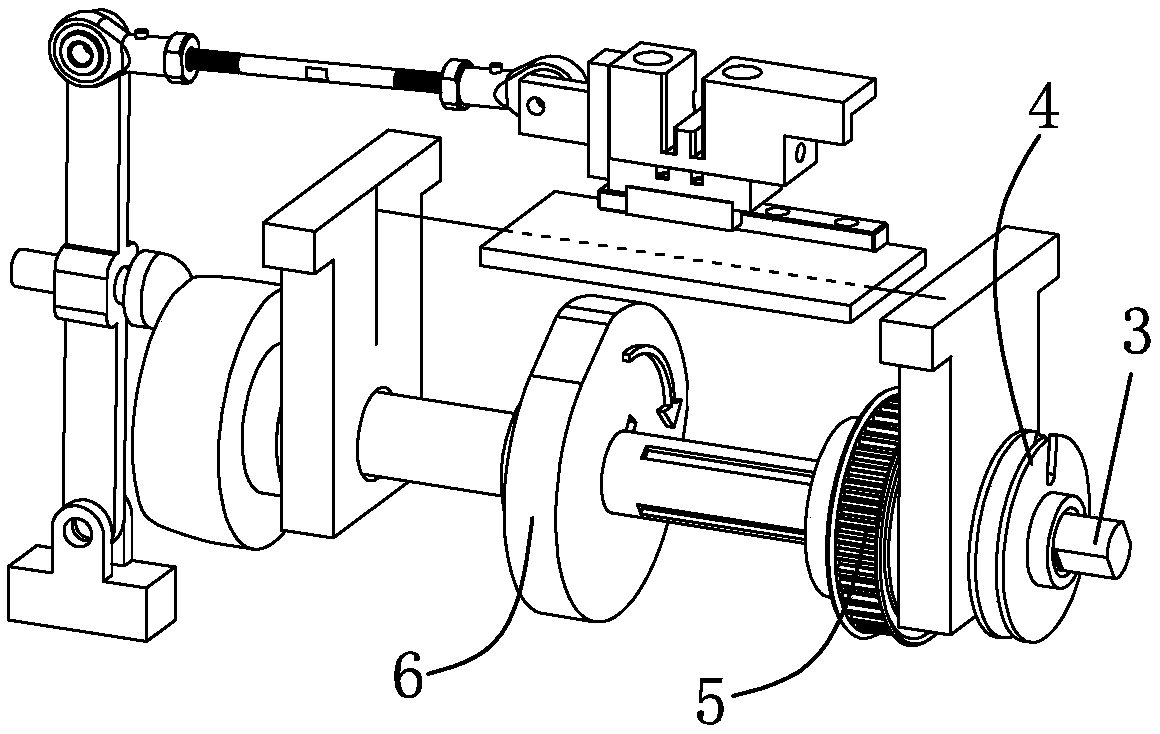

Rust removal equipment capable of treating bent steel bars

PendingCN114273301AAchieve rust removalAchieve clearingGrinding machinesCleaning using liquidsRebarRust remover

The invention relates to the field of reinforcing steel bars, in particular to rust removal equipment capable of treating bent reinforcing steel bars. The technical problems that dents and bends on reinforcing steel bars cannot be well treated, and meanwhile rust in some gaps cannot be removed, so that the effect is poor are solved. According to the technical implementation scheme, the rust removal equipment capable of treating the bent steel bars comprises a bottom frame, a straightening system, a first rust removal system and the like; a straightening system is connected to the front part of the upper side of the underframe; a first derusting system is connected to the middle of the upper side of the underframe. The first rust removal system is designed, rust on the upper surfaces and in gaps of the steel bars is removed through a rust remover, meanwhile, rust at the bottoms of the steel bars is removed, and iron rust on the gaps and the outer surfaces of the steel bars is removed at the same time.

Owner:李超龙

Transformer with lightning protection function

InactiveCN112420325AImprove waterproof performanceReduce infiltrationTransformers/reacts mounting/support/suspensionTransformers/inductances casingsLightning rodTransformer

The invention provides a transformer with a lightning protection function, relates to the technical field of transformers, and solves the problem that rainwater cannot be guided after infiltration through structural improvement so as to achieve the purpose of improving the waterproof performance, and the problem that the rust removal of the lightning rod cannot be automatically realized while thecover plate is dismounted through structural improvement. The transformer comprises a transformer shell and a cleaning base. A base is welded to the transformer shell, a fixing base is fixedly connected to the base, and a cleaning structure is installed on the transformer shell. The three grooves are connected with one another to form a concave groove structure, and the three grooves form an auxiliary drainage structure together, so that rainwater infiltrating between the transformer shell and the cover plate can be drained through the grooves, and the probability that the rainwater infiltrates into the transformer shell is reduced.

Owner:芜湖腾飞信息科技有限公司

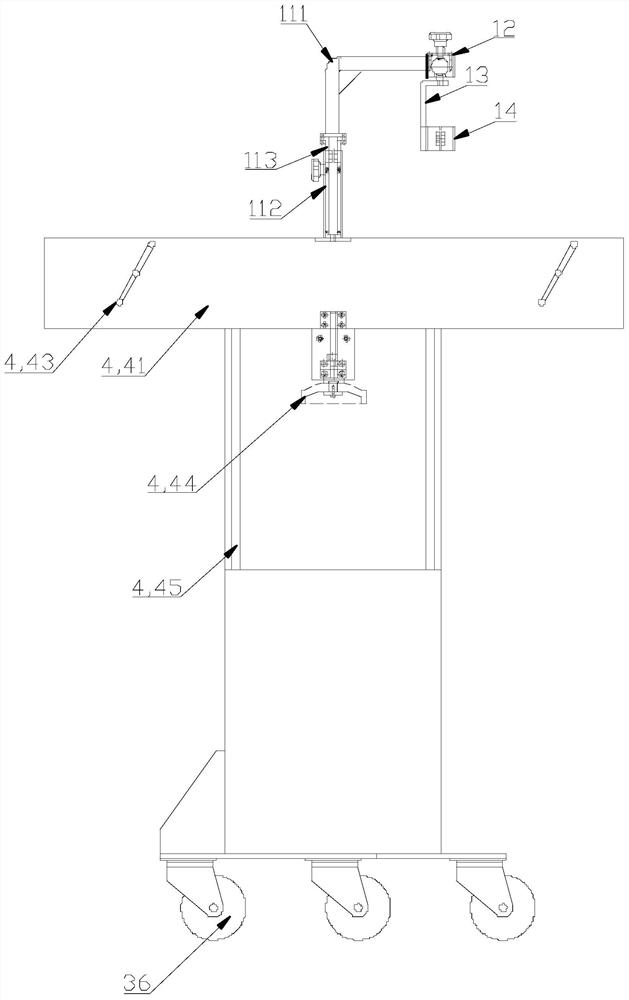

Mechanical burnishing equipment

ActiveCN112548716AAchieve rust removalNo frequent replacementPlane surface grinding machinesGrinding/polishing safety devicesElectric machineryDust control

The invention discloses mechanical burnishing equipment. The mechanical burnishing equipment comprises a lifting machine body, a bracket linear transmission mechanism and a surface treatment device, wherein the bracket linear transmission mechanism is fixed to the center of the top of the surface of the lifting machine body, and the surface treatment device is arranged in the bracket linear transmission mechanism and located above the lifting machine body. Iron rods are fixed to the two corresponding sides of the top of a housing deslagging device, a coil is arranged on the surface of each ofthe iron rods, a burnishing device is arranged at the bottom of the housing deslagging device through a bracket, and a driving motor is fixed to the end of the housing deslagging device through a machine frame. The invention relates to the technical field of burnishing equipment. The mechanical burnishing equipment achieves the effect of being high in adaptability, rust slag can be collected, thesituation that the surface burnishing quality is affected due to accumulation of the rust slag is avoided, besides, grinding can be performed, grinding, burnishing and dust removing are integrated, equipment does not need to be replaced frequently, limitation is reduced, and the working efficiency and the using performance are improved.

Owner:南京宁宣机械制造有限公司

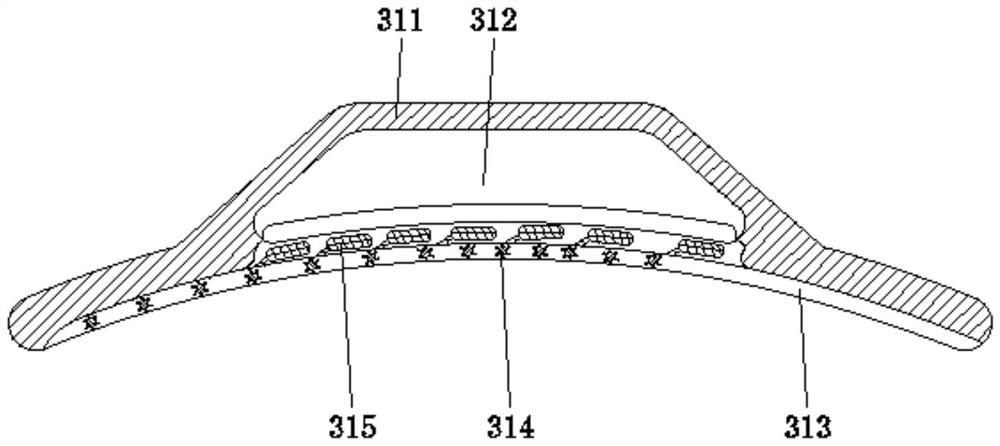

Airbag type decomposable water pressure spin thorn column pig

The invention discloses an airbag type stab columnar pipe cleaner capable of dissolving water pressure and automatically rotating. The airbag type stab columnar pipe cleaner comprises a column body, wherein the column body is provided with a conical head part; three groups of rotary flow guiding plates are arranged on the outer wall of the column body and are equidistantly distributed along the circumferential direction of the column body at intervals; a pressure-proof airbag is arranged in an inner cavity of the column body; steel brushes are arranged on the flow guiding plates; each steel brush comprises a plurality of groups of comb teeth which are arranged in parallel; the comb teeth are firmly embedded in the flow guiding plates by steel nails or adhered to the flow guiding plates by steel wires; the flow guiding plates are fixed with the column body in an embedded way; the pressure-proof airbag adopts a sealed structure; the range of external pressure borne by the pressure-proof airbag is 0.6-1.0MPa; the column body is made of a high-strength polyurethane foam material; a polyurethane elastic material coating layer is paved on the surface of the column body. According to the airbag type columnar pipe cleaner disclosed by the invention, automatic rotation forwarding and steel brush cleaning of the pipe cleaner in a pipe through water flow pressure are realized, the pipe cleaner is enabled to successfully pass through a blocking point by an airbag type structure, higher hardness and higher strength are ensured by a steel nail type steel brush, and efficient cleaning on long, short and complicated pipelines can be realized.

Owner:SHANDONG DINGNUO ENERGY SAVING ENVIRONMENTAL PROTECTION SERVICE

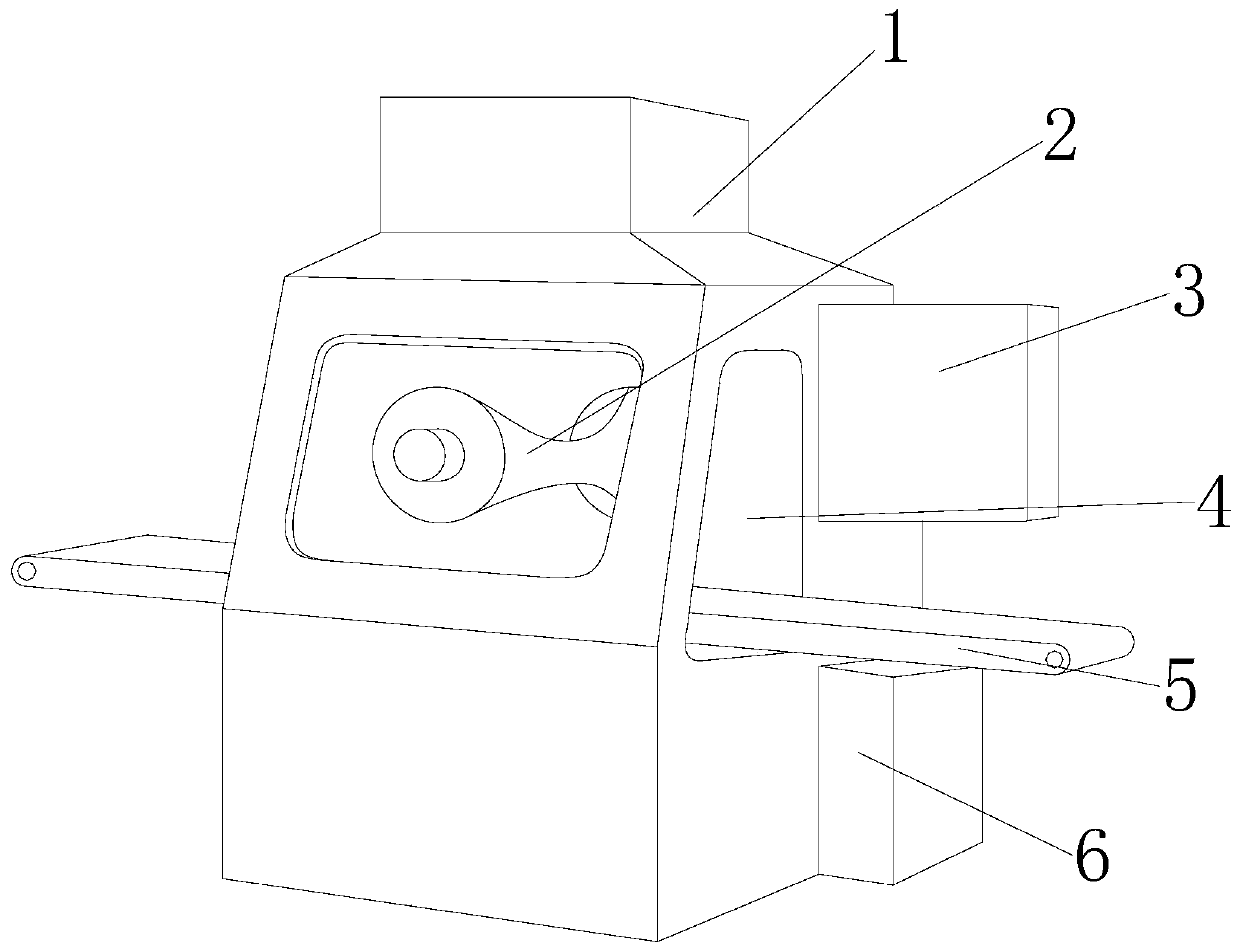

Hardware paint spraying machine with polishing and rust removing functions

ActiveCN111168546AAchieve rust removalIncrease frictionGrinding machinesGrinding feedersComputer hardwarePolishing

The invention discloses a hardware paint spraying machine with polishing and rust removing functions. The hardware paint spraying machine structurally comprises a housing, a rust removing device, a distribution box, a working cavity, a conveying belt and a fixed base, wherein the housing is mounted on the fixed base, the fixed base is fixedly connected with the housing, and the rust removing device is arranged in the working cavity. The hardware paint spraying machine has the beneficial effects that a polishing layer is arranged in an arc-shaped inwards-sunken mode, so that the polishing layeris matched with the joints between the surfaces of a hardware workpiece in the rotating working process, and the joints between the surfaces of the workpiece are always in an obtuse angle state; in the process that a grinding wheel and a fixed grinding block rotate along with a grinding head, the friction force between the hardware workpiece and the grinding head is increased through clamping lines on the fixed grinding block; and through annular protrusions on protrusions and trapezoidal protrusions rotating along with a hub, the annular protrusions and the trapezoidal protrusions rapidly collide and rub with the surface of the hardware workpiece to remove rust on the surface of the hardware workpiece, and rust removing of the hardware workpiece is achieved on the premise that the safetyof using the hardware workpiece by operators in the later period is guaranteed.

Owner:江门市新会建塔五金制品有限公司

A grinding device with angle adjustment function

ActiveCN112405256BReduce labor intensitySatisfy the fine grinding operationGrinding carriagesPortable grinding machinesControl engineeringAngular degrees

The invention discloses a grinding equipment with an angle adjustment function, which comprises a drive system and a grinding tool system. The grinding tool system is fixed on the drive system. The grinding tool system includes a universal adjustment device and a grinding tool. The universal adjustment One end of the device is fixedly connected with the drive system, and the other end of the universal adjustment device is connected with the grinding tool in rotation. The grinding equipment with angle adjustment function provided by the present invention can adjust the angle of the grinding tool according to the demand by setting the universal adjustment device, and then realize 360-degree grinding without dead angle, so as to meet the needs of different operators, so that the operator can Work in the best posture, which reduces the labor intensity of the operator. At the same time, the grinding tool system is fixed on the drive system, and the drive system drives the grinding tool system to move in the horizontal or vertical direction to realize the adjustment of the grinding tool according to the position of the workpiece. Sharpening tool system, more practical.

Owner:CRRC QINGDAO SIFANG CO LTD

Civil engineering I-steel column cross section derusting construction method

InactiveCN108818270AAchieve rust removalAutomatic rust removalGrinding carriagesGrinding drivesSteel columnsFineness

The invention relates to a civil engineering I-steel column cross section derusting construction method. A rotating shaft sequentially passes through a calibration plate, a frame block a, a crawler disk, a top plate, a frame block b, and a displacement plate; slots are opened in the middle positions of tops of the frame block a and the frame block b; a through rod penetrates through a top plate block, and the two ends of the through rod are respectively placed in the slots of the frame block a and the frame block b; a base block is hinged to one end of a pull rod, and a ball rod is fixed in the middle of the pull rod; the ball end of the ball bar is in contact with the vertical end surface of the displacement plate. The invention adopts the linkage of the top plate, the displacement plateand the clamping member to realize the automatic derusting of the iron brush plate on the I-shaped section steel according to the predetermined trajectory; the iron brush plate can be divided into five kinds of technical means according to the degree of grinding fineness of the cross section of the I-steel, and the welding surface of different types of shapes is polished according to different welding requirements;in addition, the design of the product is simple in structure and easy for the construction personnel to get started.

Owner:冯卫花

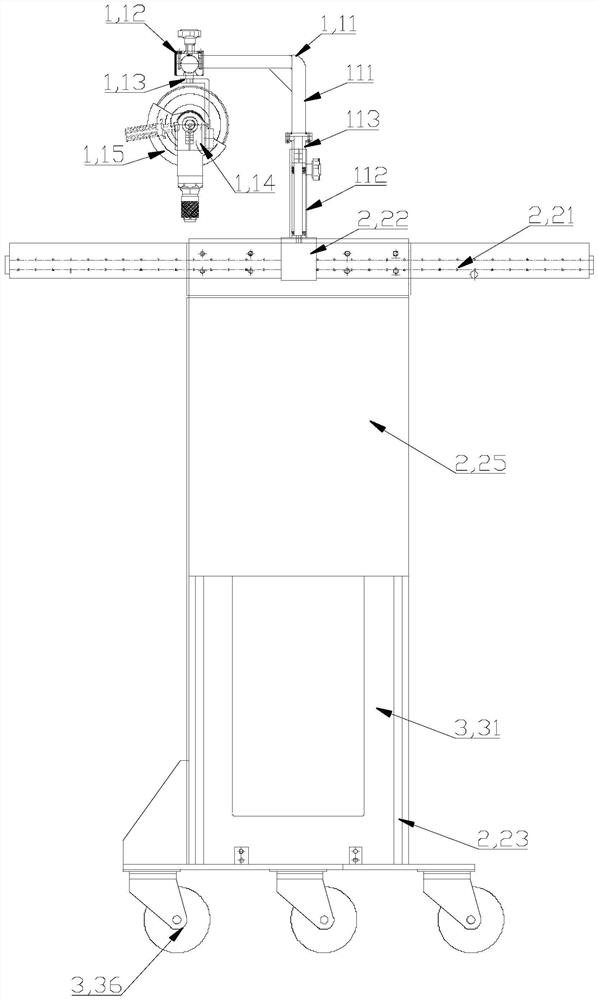

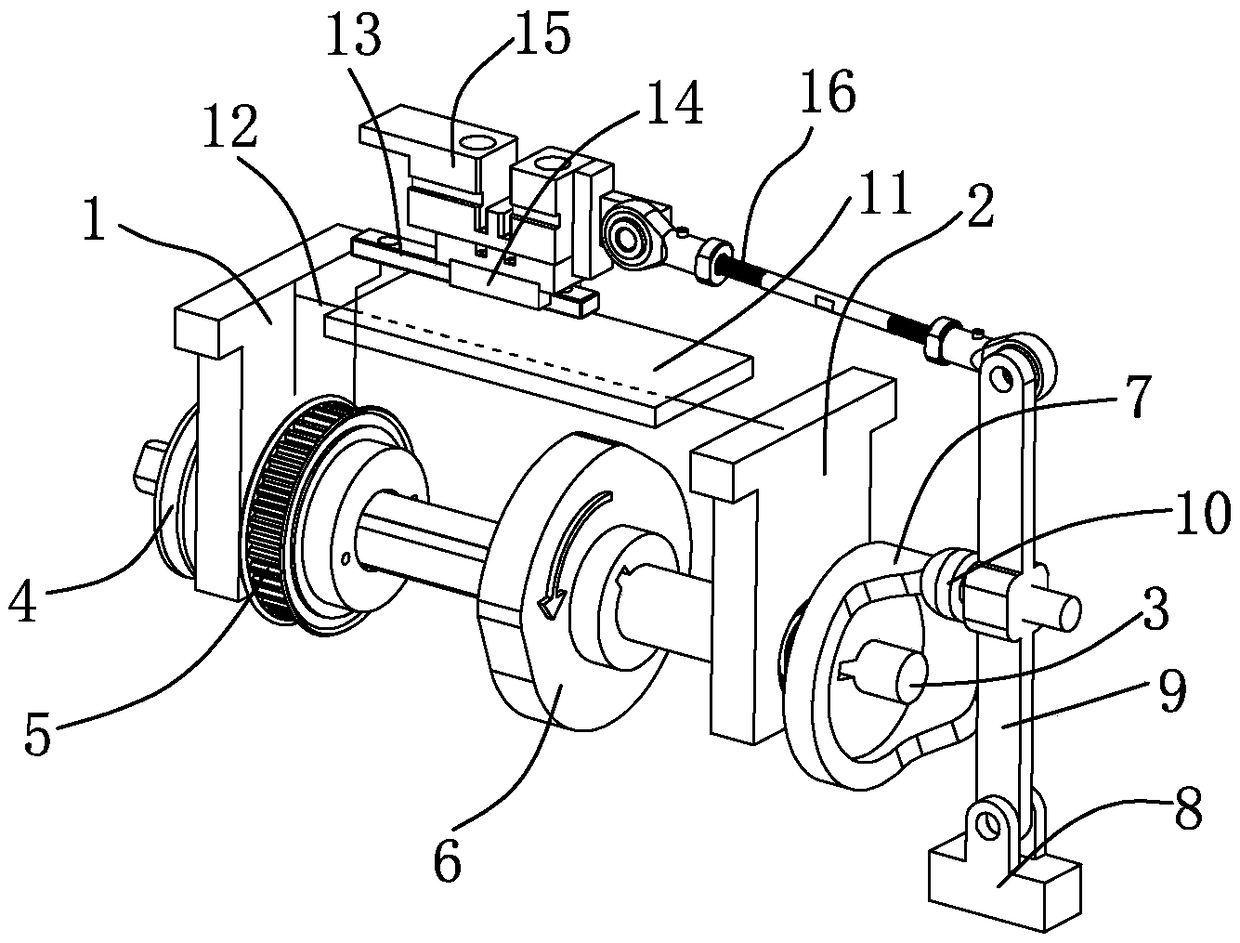

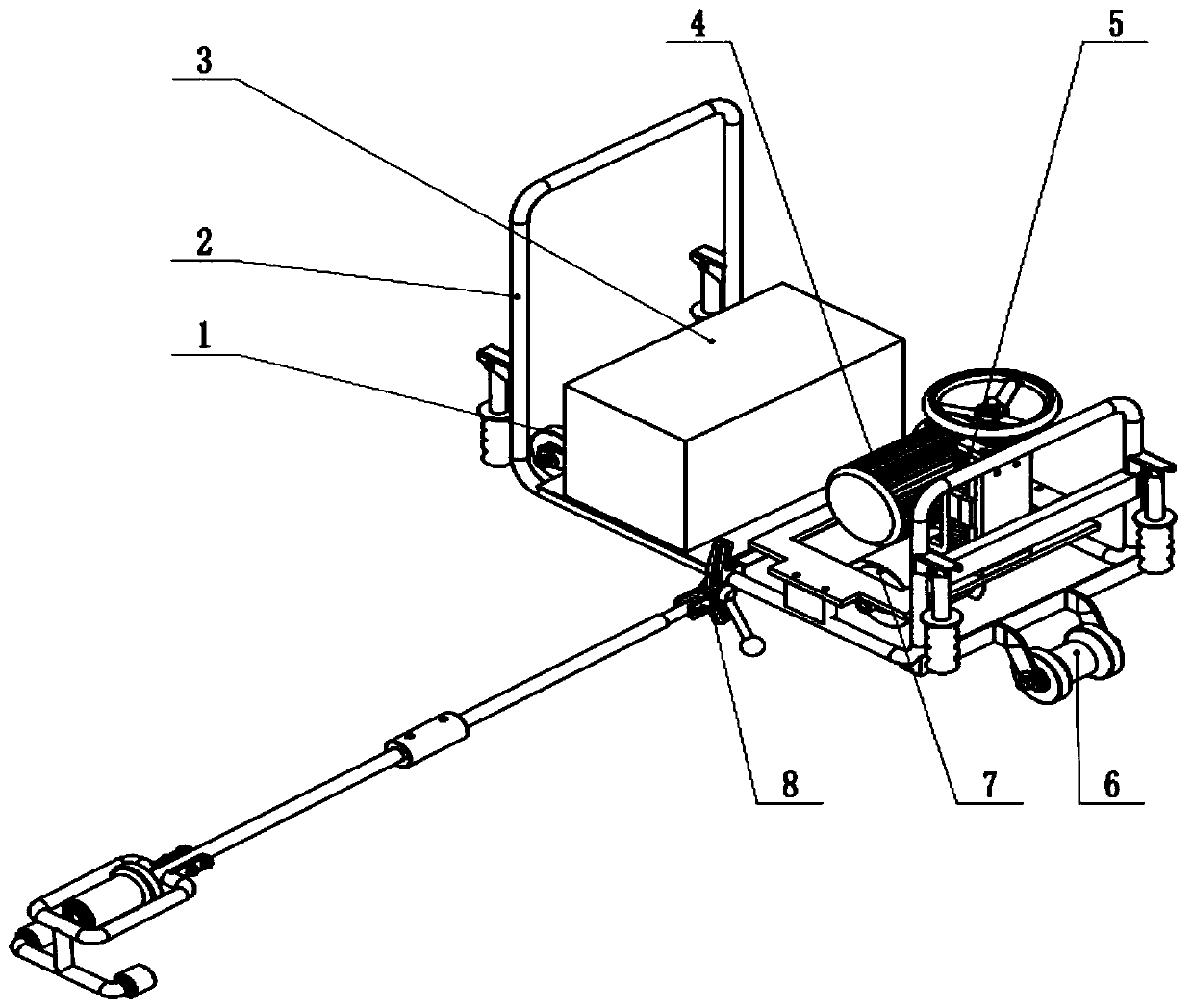

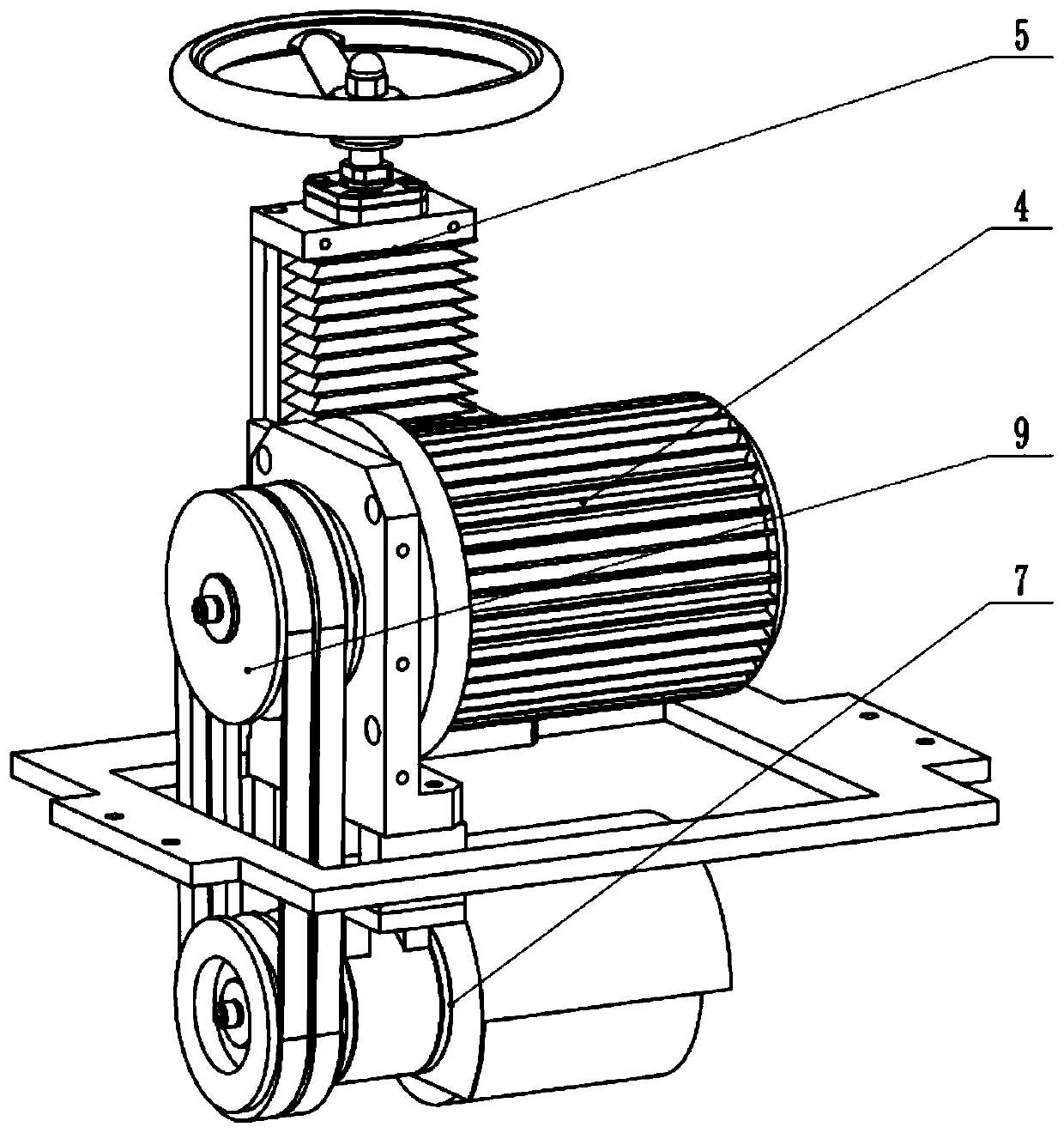

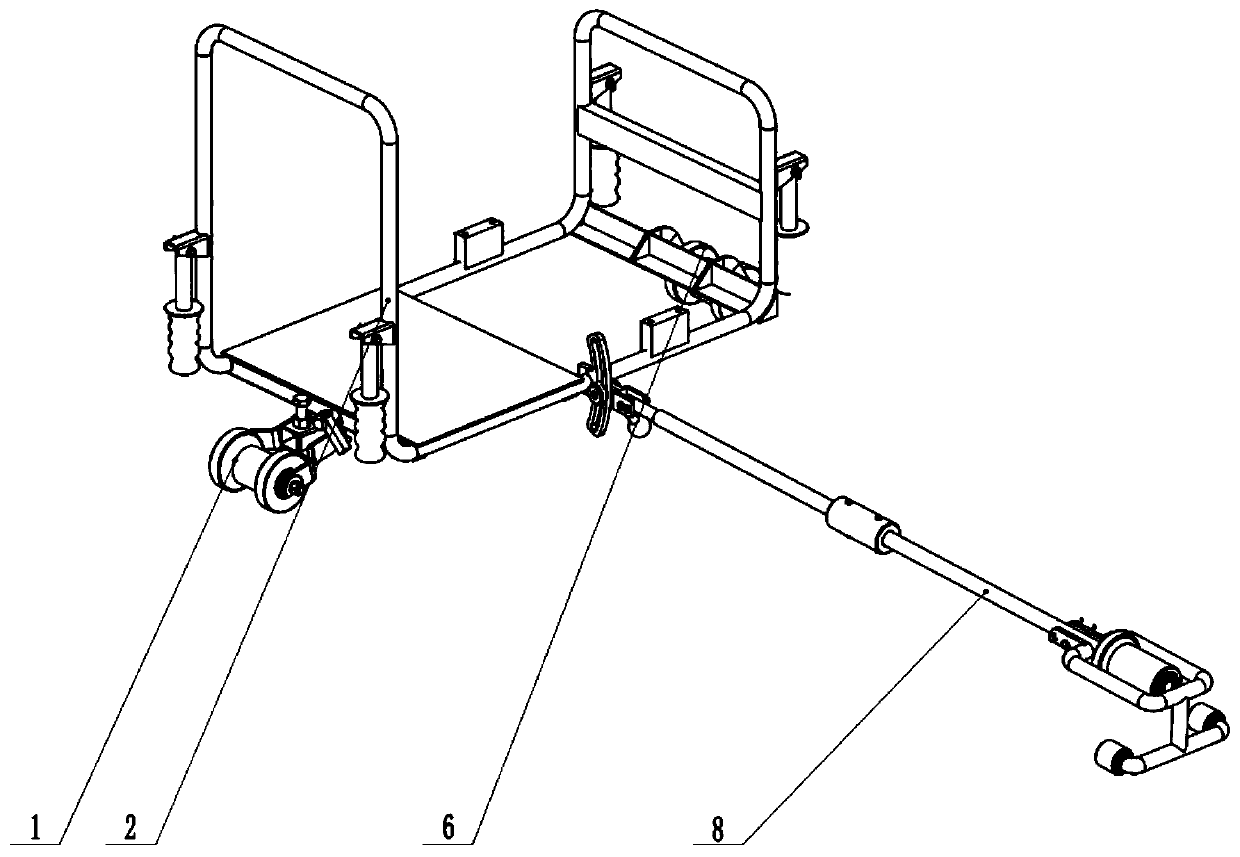

Electric steel rail derusting and polishing machine

PendingCN111472219AImprove work efficiencyGuaranteed smoothnessRailway track constructionRail profilePolishing

The invention provides an electric steel rail derusting and polishing machine. The machine comprises a supporting frame, a derusting grinding head, a motor, a lifting device, a power supply device anda deflection mechanism. According to the electric steel rail derusting and polishing machine, the derusting grinding head is adopted as a derusting or polishing tool, and the derusting grinding headis fixed to any height through the lifting device, so the smoothness of the profile cambered surface of a steel rail after operation is guaranteed; the electric steel rail derusting and polishing machine is provided with the deflection mechanism, and transverse rotation of the derusting grinding head in the horizontal direction is achieved through manual transverse force application to guarantee that the area required by the steel rail profile cambered surface can be derusted or polished, so derusting or polishing operation of the whole steel rail profile is achieved, the derusting or polishing operation efficiency is improved, and the labor intensity of operators is relieved; and in addition, the electric steel rail derusting and polishing machine is driven in an electric mode, so the operation process is low in noise, environment-friendly and pollution-free.

Owner:山东博砺思轨道交通装备科技有限公司

Derusting construction method for cross section of constructional steel I-column

InactiveCN108818267AAchieve rust removalAutomatic rust removalGrinding carriagesGrinding drivesBall screwEngineering

Owner:冯卫花

Production integrated spraying process

InactiveCN112264273AUniform curing and drying operationsGood removal effectPretreated surfacesCoatingsAcid washingEngineering

The invention discloses a production integrated spraying process, and relates to the technical field of integrated spraying. The production integrated spraying process specifically comprises the following operation steps of A, workpiece cleaning; B, primer spraying; C, finish paint spraying; and D, workpiece drying. According to the production integrated spraying process, integrated assembly linemanagement is achieved through the four procedures of the workpiece cleaning, the primer spraying, the finish paint spraying and the workpiece drying, the spraying efficiency is improved, the two steps of alkali washing and acid washing in the workpiece cleaning process are beneficial to removal of organic matter and oxide on the surface of a workpiece, rust removal, oil removal and dirt removal are achieved, subsequent spraying operation is facilitated, two spraying procedures of primary finish paint spraying and secondary finish paint spraying are set in the finish paint spraying process, the front face of the workpiece can be comprehensively sprayed through the primary finish paint spraying, multiple edges or dead corners of the workpiece can be sprayed through the secondary finish paint spraying, a repeated continuous turning-over spraying mode is adopted, and the phenomenon of spraying missing does not likely to happen.

Owner:ZHANJIANG XIHONG GROUP

Rust removal construction method for road I-shaped steel foundation

InactiveCN108818266AAchieve rust removalAutomatic rust removalGrinding carriagesGrinding drivesRustFineness

Owner:冯卫花

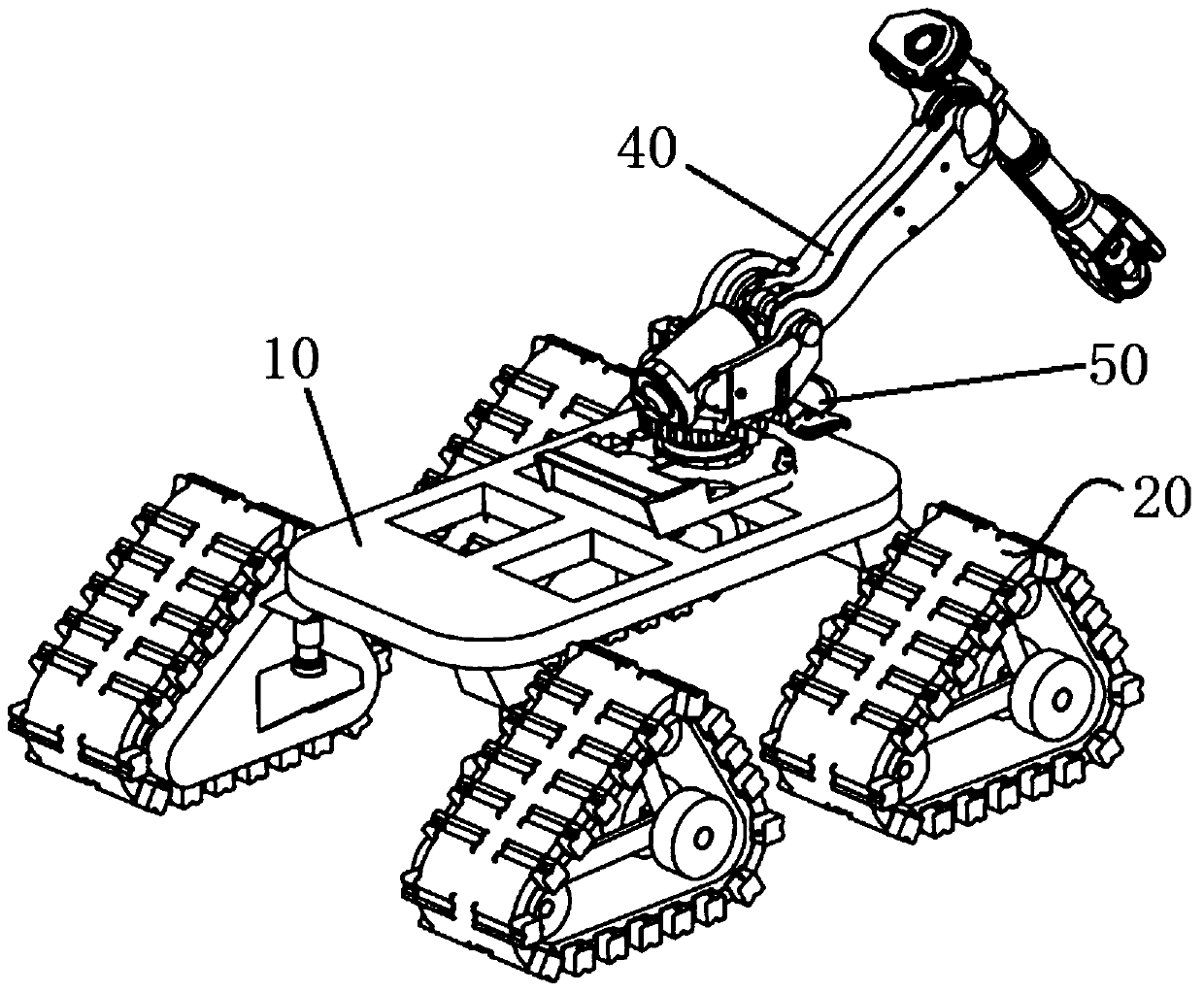

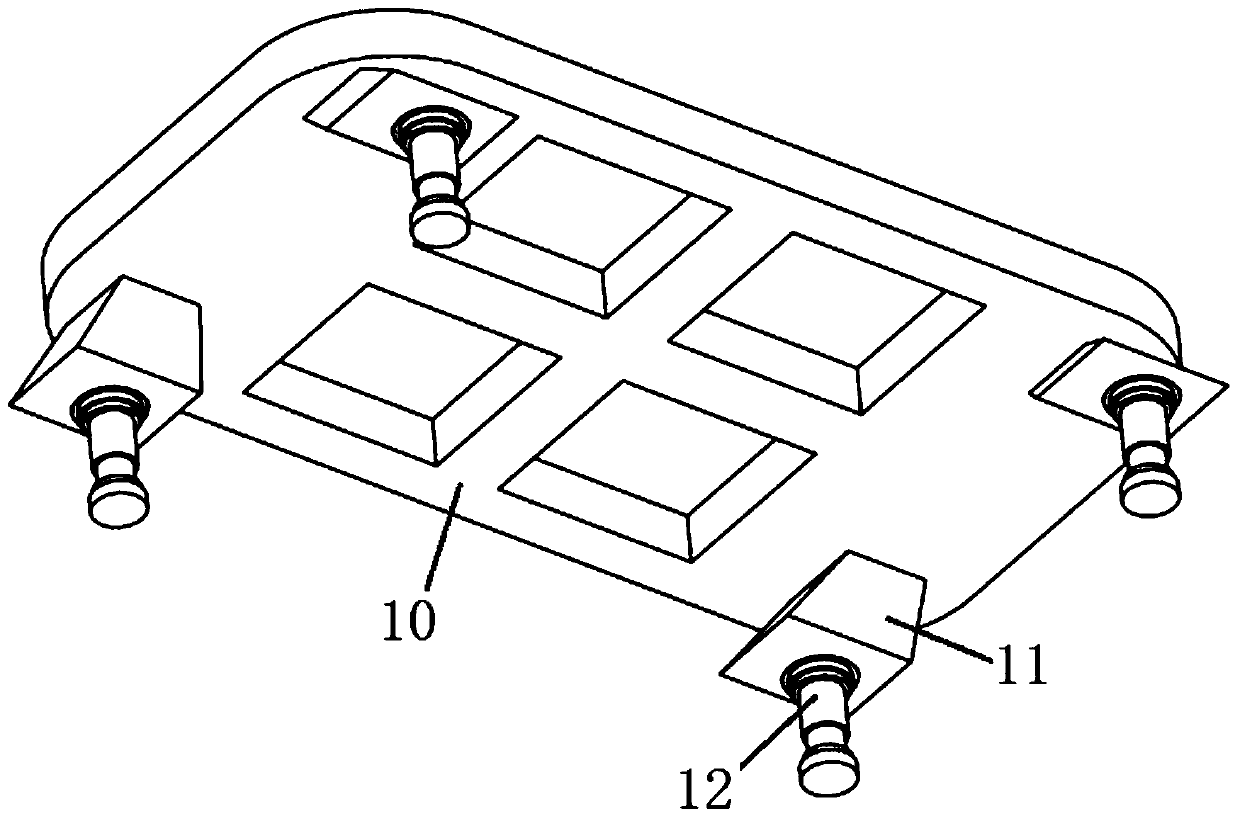

A crawler-type wall-climbing robot that can steer freely

The invention relates to a track type wall climbing robot capable of randomly steering. The track type wall climbing robot capable of randomly steering comprises a frame; four steering motors are arranged at the bottom of the frame; an output end of each steering motor is tightly connected with a telescopic cylinder; an output end of each telescopic cylinder is tightly connected with a track component; the track components include rubber tracks and multiple magnetic absorbing units tightly connected with the tracks; the magnetic absorbing units include cylindrical permanent magnets, left yokes, right yokes, upper separation magnetic blocks, lower separation magnetic blocks and steering engines; the cylindrical permanent magnets are rotationally arranged in a hollow cylinder surrounded by the left yokes, the right yokes, the upper separation magnetic blocks and the lower separation magnetic blocks; one end of the hollow cylinder is tightly connected with a back cover plate; output ends of the steering engines are connected with the cylindrical permanent magnets through couplings; the steering engines has two angle states of 0 degree and 90 degrees; when the steering engines are located in the angle state of 0 degree, the magnetic absorbing units are located in a magnetizing state; and when the steering engines are located in the state of 90 degrees, the magnetic absorbing units are located in a demagnetizing state.

Owner:BEIJING SHIHE TECH CO LTD

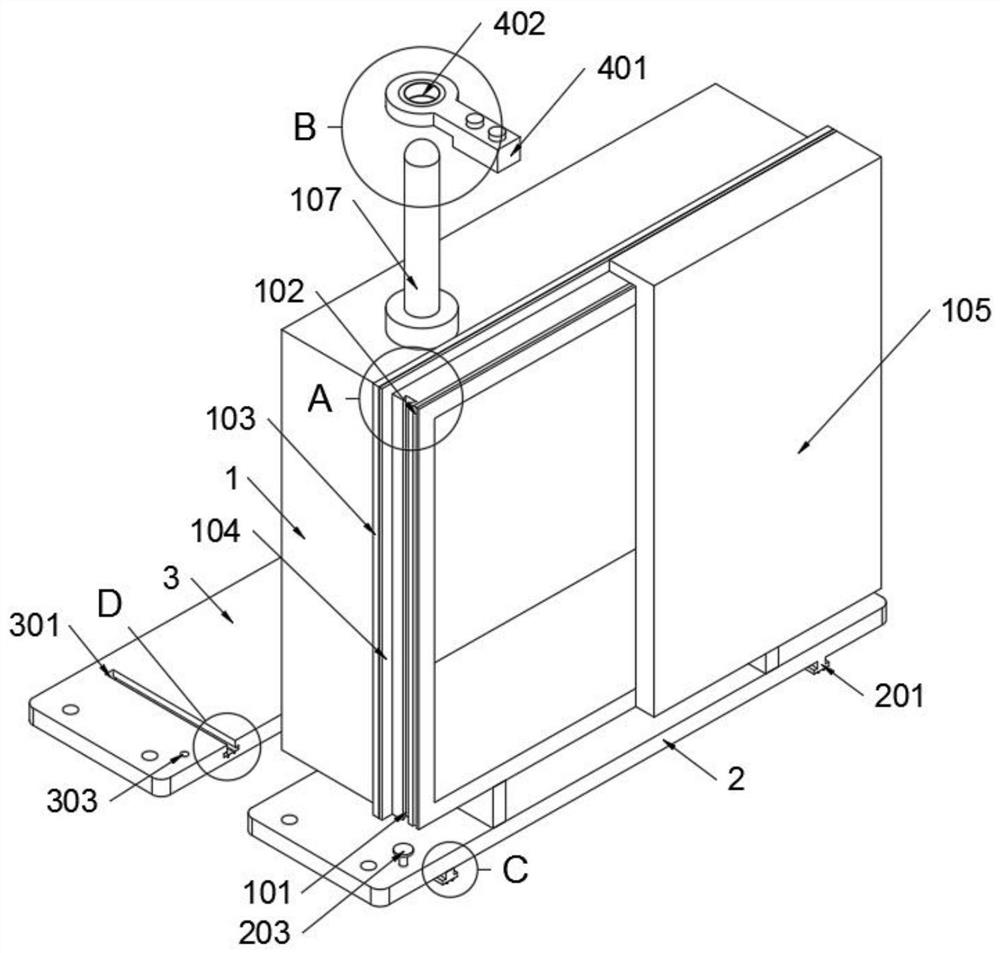

Recycling treatment device for waste steel bars generated in house removal process

InactiveCN111702626AAchieve straighteningAchieve rust removalGrinding drivesGrinding machinesEnvironmental engineeringHydraulic equipment

The invention discloses a recycling treatment device for waste steel bars generated in the house removal process. The recycling treatment device comprises an equipment body, and a straightening mechanism is arranged on the left portion of the equipment body and comprises a straightening hydraulic cavity formed in the left side of the equipment machine body. A straightening hydraulic plate is slidably arranged in the straightening hydraulic cavity. A straightening hydraulic rod is fixedly arranged on the lower end face of the straightening hydraulic plate, and a straightening sliding cavity isformed in the portion, on the lower side of the straightening hydraulic cavity, in the equipment body. The lower end of the straightening hydraulic rod penetrates through the straightening sliding cavity, and a straightening sliding block is fixedly arranged on the lower end face of the straightening hydraulic rod. The waste steel bars can be straightened and derusted through the device. Specifically, the waste steel bars are straightened through hydraulic equipment firstly, a better straightening effect is obtained by rotating the angle of the waste steel bars in the straightening process, and then the waste steel bars are ground and derusted. The waste steel bars are ground through three grinding wheels at the same time, and the two ends of each waste steel bar are fixed in the grindingprocess to avoid secondary bending.

Owner:YIWU ZIYING MASCH TECH CO LTD

A kind of steel structure derusting device and derusting process

The application discloses a steel structure derusting device, which includes a workbench, and the workbench is sequentially provided with: a discharge mechanism, the discharge mechanism is used to place steel bars or steel pipes; a clamping mechanism, the clamping mechanism Located below the discharging mechanism, the clamping mechanism is used to clamp steel bars or steel pipes; the unloading mechanism is used to transport the steel bars or steel pipes on the discharging rack to the clamping mechanism; The derusting mechanism is used for derusting steel bars or steel pipes. The application can reduce the labor intensity of staff.

Owner:东莞市联泰钢构有限公司

An obstacle-climbing robot

The invention relates to an obstacle-crossing wall-climbing robot which comprises an upper frame, wherein a supporting leg is arranged at the bottom at each of the two ends of the upper frame; a plurality of magnetic adsorption units are arranged at the bottom of each supporting leg; a first screw rod is arranged at the bottom of the upper frame and between the two supporting legs; a first sliding block is connected with the first screw rod through threaded fit; a first motor used for driving the first screw rod to rotate is arranged on the upper frame; a lower frame is arranged under the upper frame; a plurality of magnetic adsorption units are arranged at the bottom at each of the two ends of the lower frame; a second screw rod is arranged at the top of the lower frame; a second sliding block is connected with the second screw rod through threaded fit; a second motor used for driving the second screw rod to rotate is arranged on the lower frame; the first sliding block is connected with the second sliding block through a stretching frame.

Owner:BEIJING SHIHE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com