Hardware paint spraying machine with polishing and rust removing functions

A paint spraying machine and functional technology, which can be used in paint spraying rooms, grinding machine parts, grinding machines, etc., and can solve problems such as safety and hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

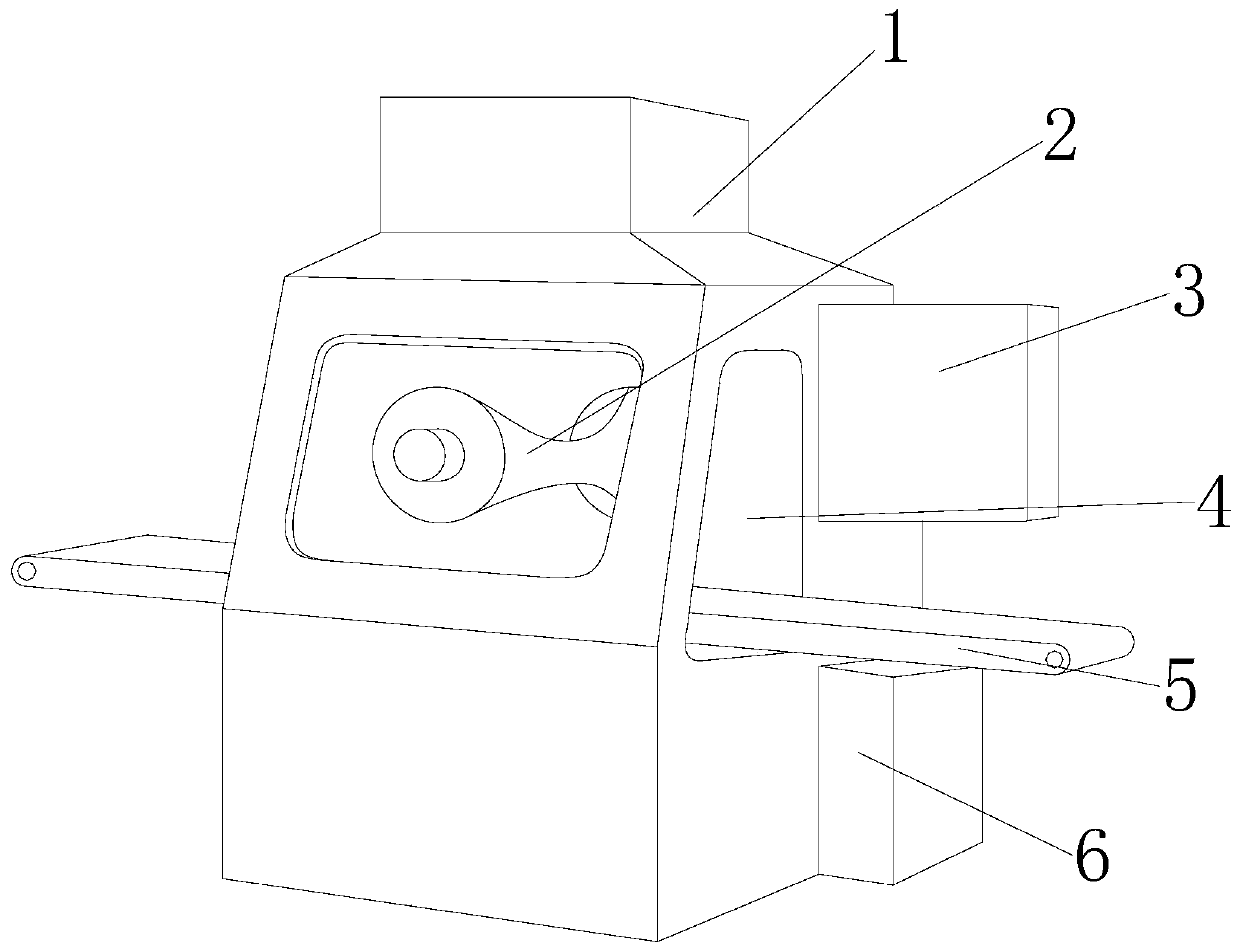

[0024] see Figure 1-Figure 6 , the present invention provides a hardware painting machine with the function of grinding and derusting. On the fixed base 6, the fixed base 6 is fixedly connected with the housing 1, the cavity surrounded by the inner wall of the housing 1 is the working chamber 4, and the rust removal device 2 is arranged in the working chamber 4, and the rust removal device 2 is arranged in the working chamber 4. A distribution box 3 is provided on the outer wall of the housing 1, the conveyor belt 5 is installed on a fixed base 6, the conveyor belt 5 passes through the working chamber 4, and cooperates with the derusting device 2 in the working chamber 4;

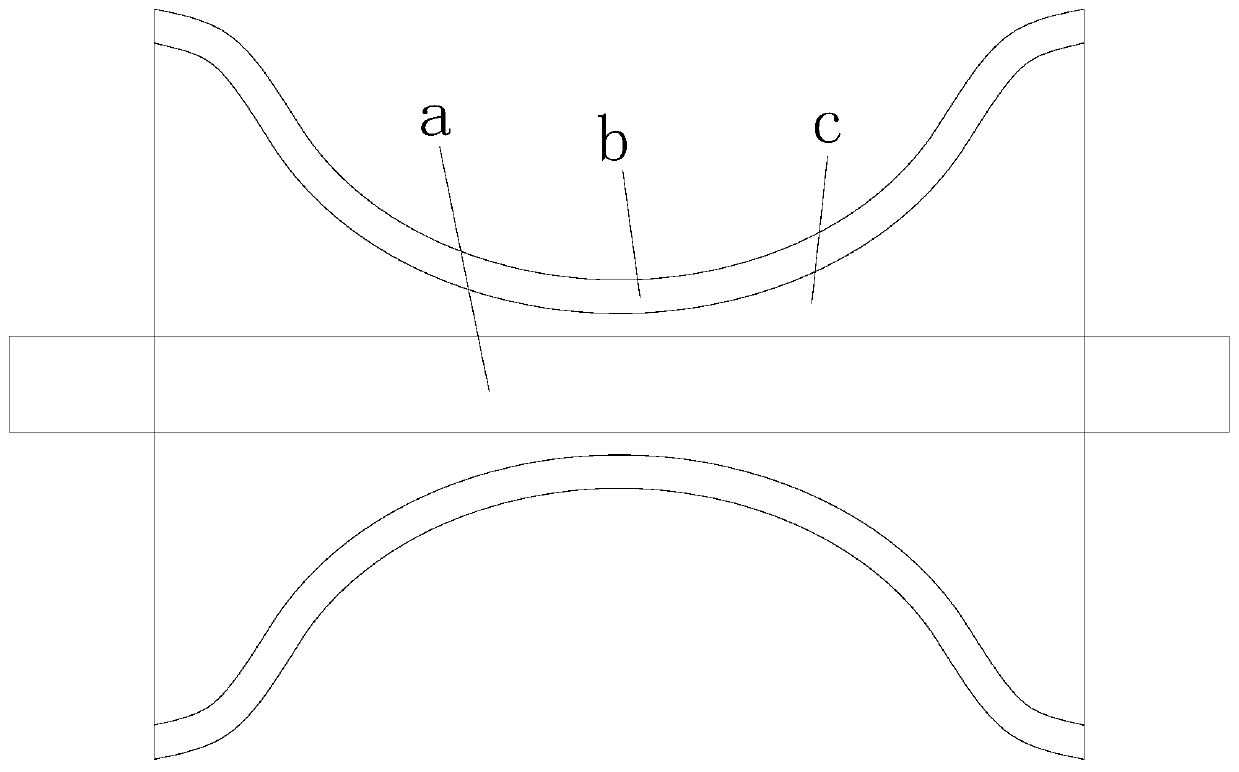

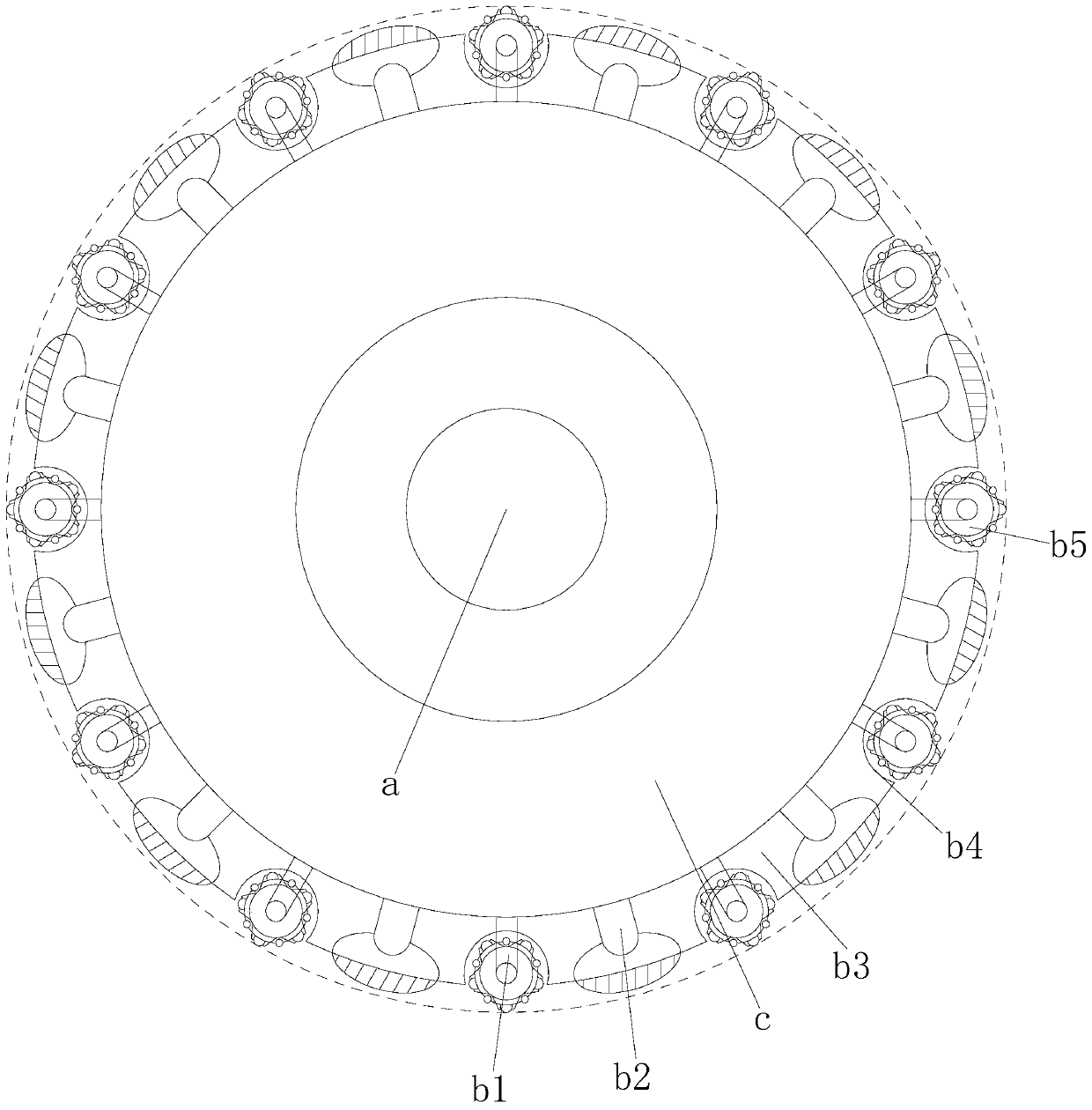

[0025] The derusting device 2 is composed of a rotating shaft a, a grinding layer b, and a grinding head c, the rotating shaft a is arranged on the grinding head c, the rotating shaft a penetrates the grinding head c, and the rotating shaft a is connected with an external mechanical force , the grinding l...

Embodiment 2

[0032] see figure 1 , Figure 3-Figure 4 , the present invention provides a hardware painting machine with the function of grinding and derusting. On the fixed base 6, the fixed base 6 is fixedly connected with the housing 1, the cavity surrounded by the inner wall of the housing 1 is the working chamber 4, and the rust removal device 2 is arranged in the working chamber 4, and the rust removal device 2 is arranged in the working chamber 4. The outer wall of the housing 1 is provided with a distribution box 3, the conveyor belt 5 is installed on the fixed base 6, the conveyor belt 5 passes through the working chamber 4, and cooperates with the derusting device 2 in the working chamber 4; The rust device 2 is composed of a rotating shaft a, a grinding layer b, and a grinding head c. The rotating shaft a is arranged on the grinding head c, and the rotating shaft a penetrates the grinding head c. The rotating shaft a is connected with an external mechanical force. The grinding l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com