Patents

Literature

180results about How to "Achieve straightening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

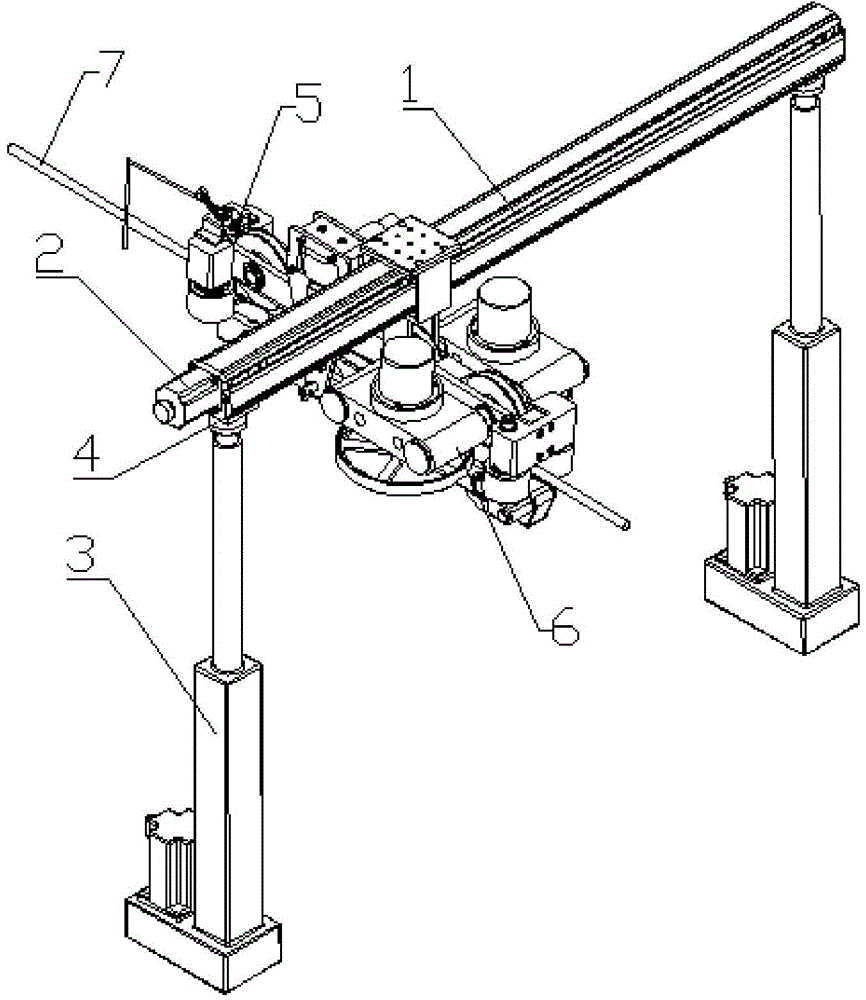

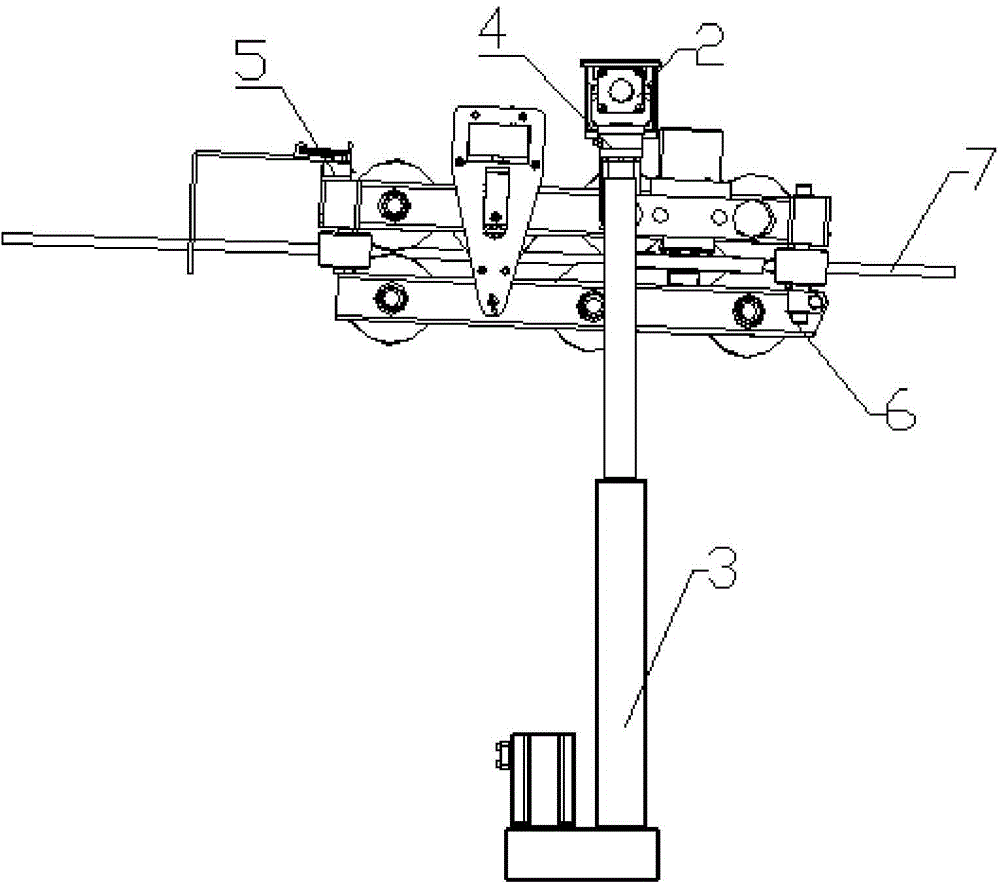

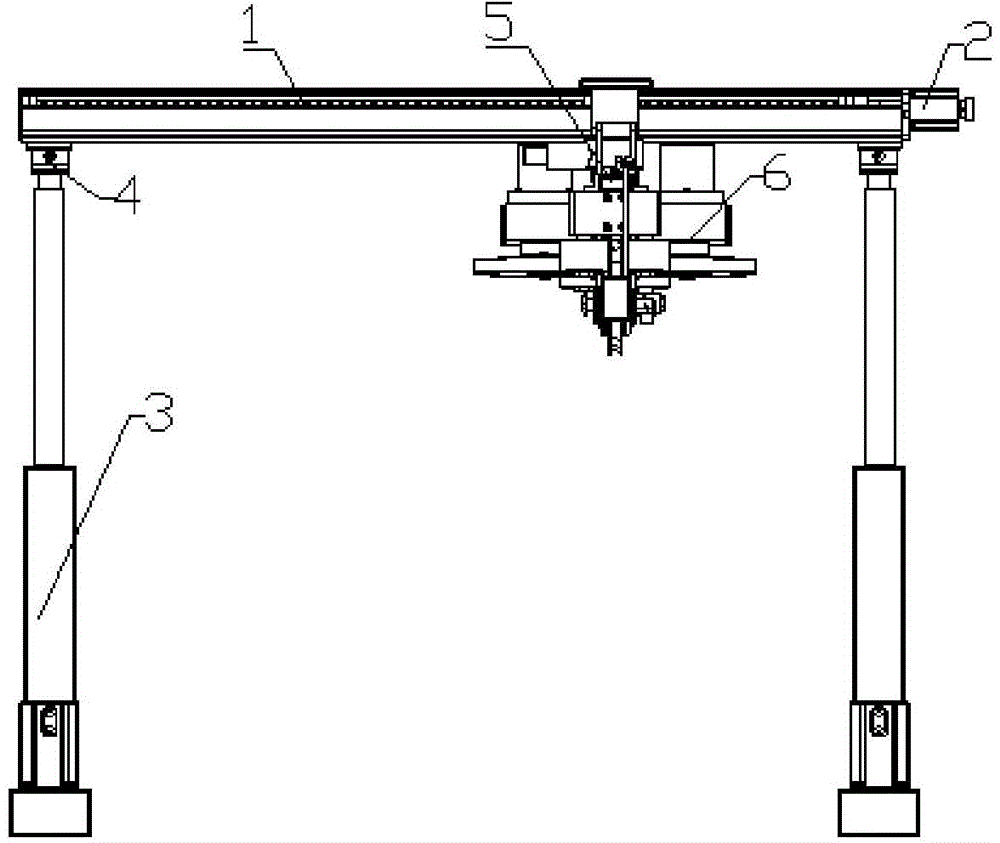

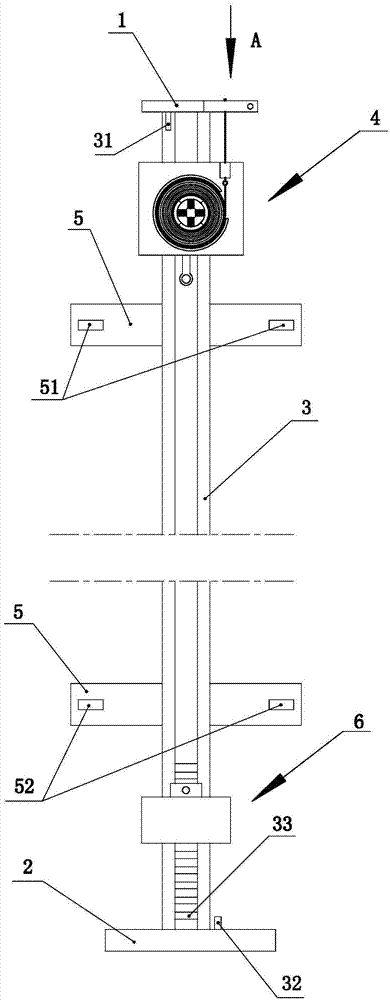

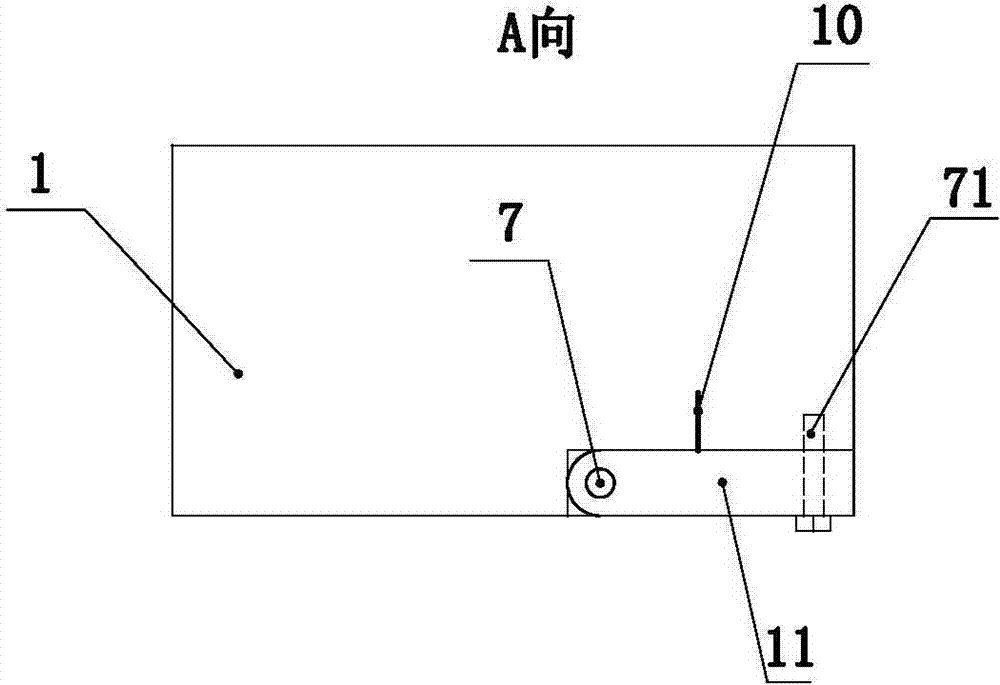

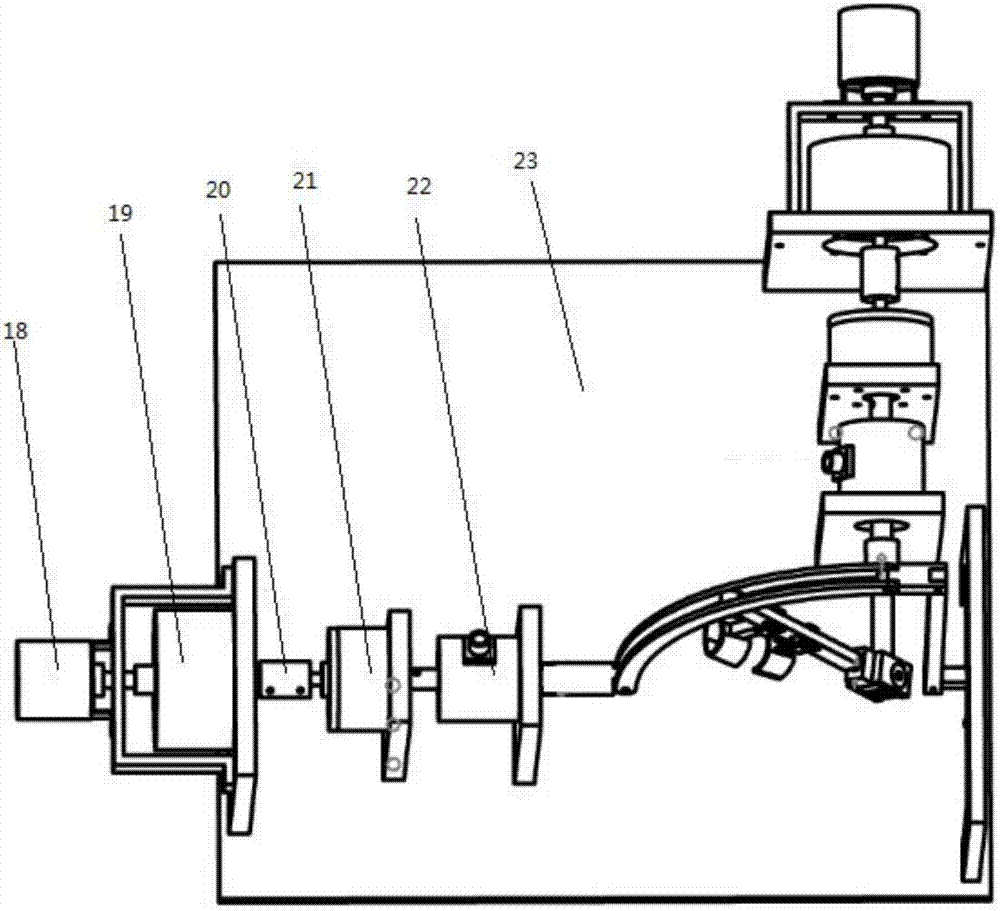

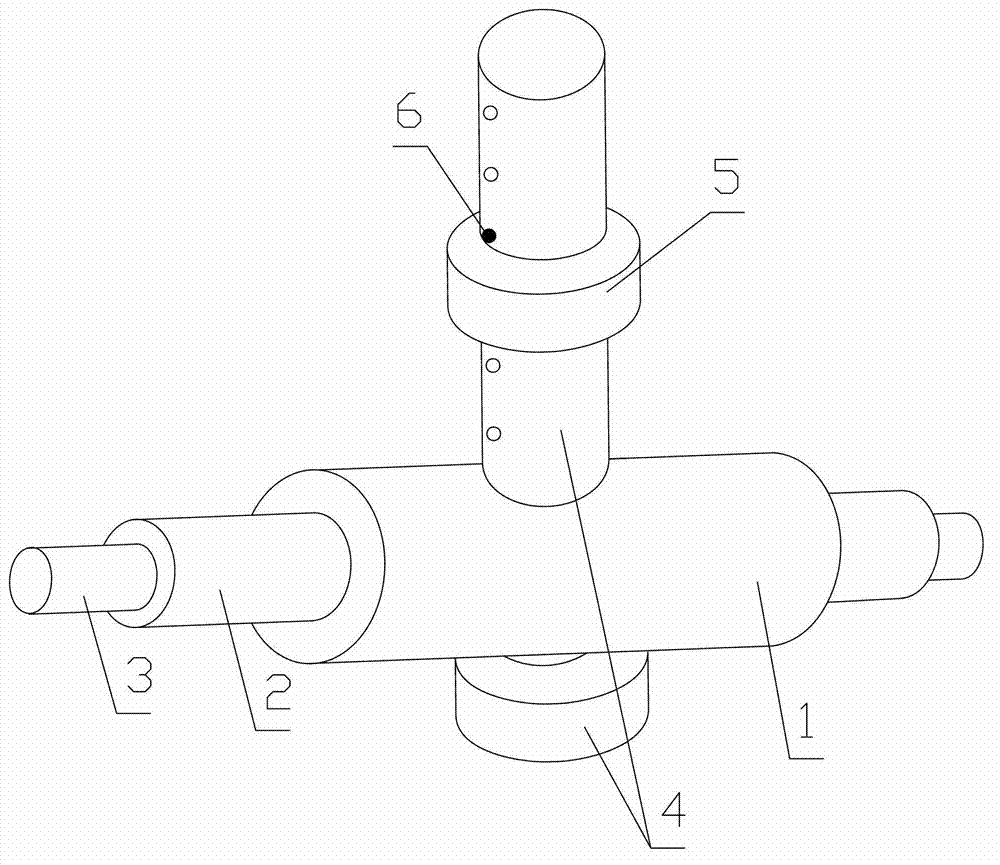

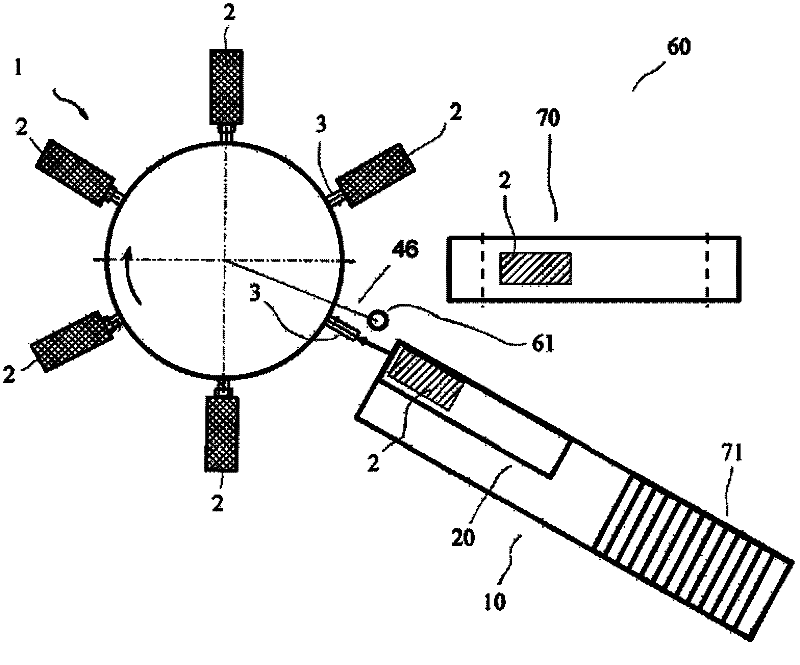

Electrically driven automatic rope ranging device

InactiveCN104477710AIt has the function of automatic alignment of the ropeRealization of automatic alignment of rope arrangementFilament handlingElectricityForce sensor

The invention provides an electrically driven automatic rope ranging device, which comprises a controller, an electrically driven lifting cylinder, a moving mechanism, a martin decker and a pressure sensor, wherein the martin decker is electrically connected with the controller, is electrically driven, and is glidingly connected with the lifting cylinder through the moving mechanism, and the pressure sensor is arranged at a connecting part of the lifting cylinder and the moving mechanism and is electrically connected with the controller. The electrically driven automatic rope ranging device has the advantages that the martin decker is adopted for achieving the automatic rope ranging goal, in addition, the automatic rope ranging device has an initial automatic self-centering function, in addition, the rope ranging angle of a cable can be automatically regulated in the operation process, and the cable is enabled to be regularly wound on a rolling tube.

Owner:ASSURE TECH DRIVE TIANJIN CO LTD

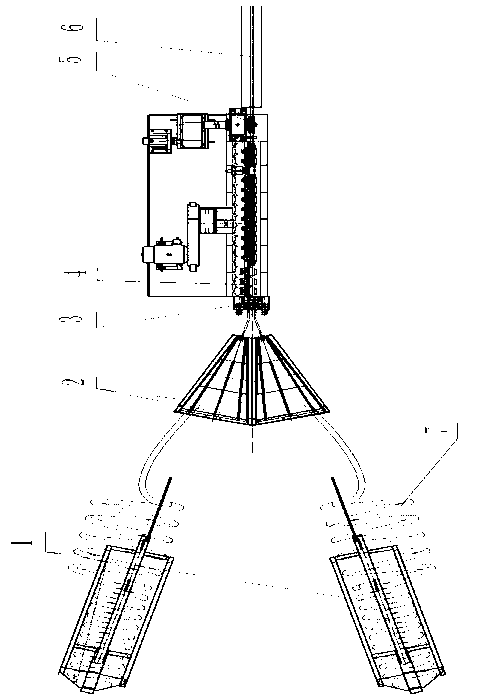

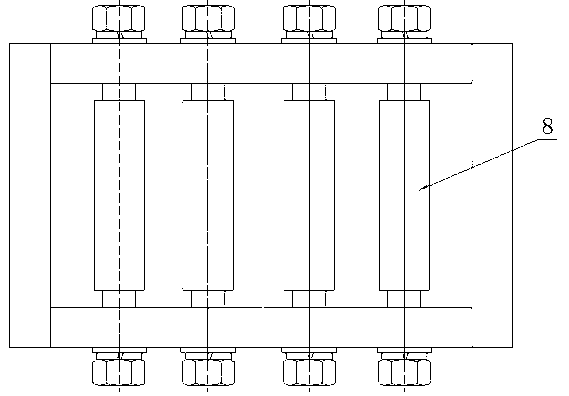

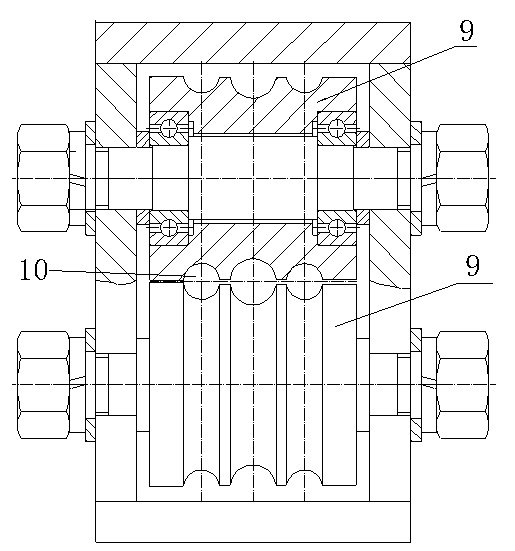

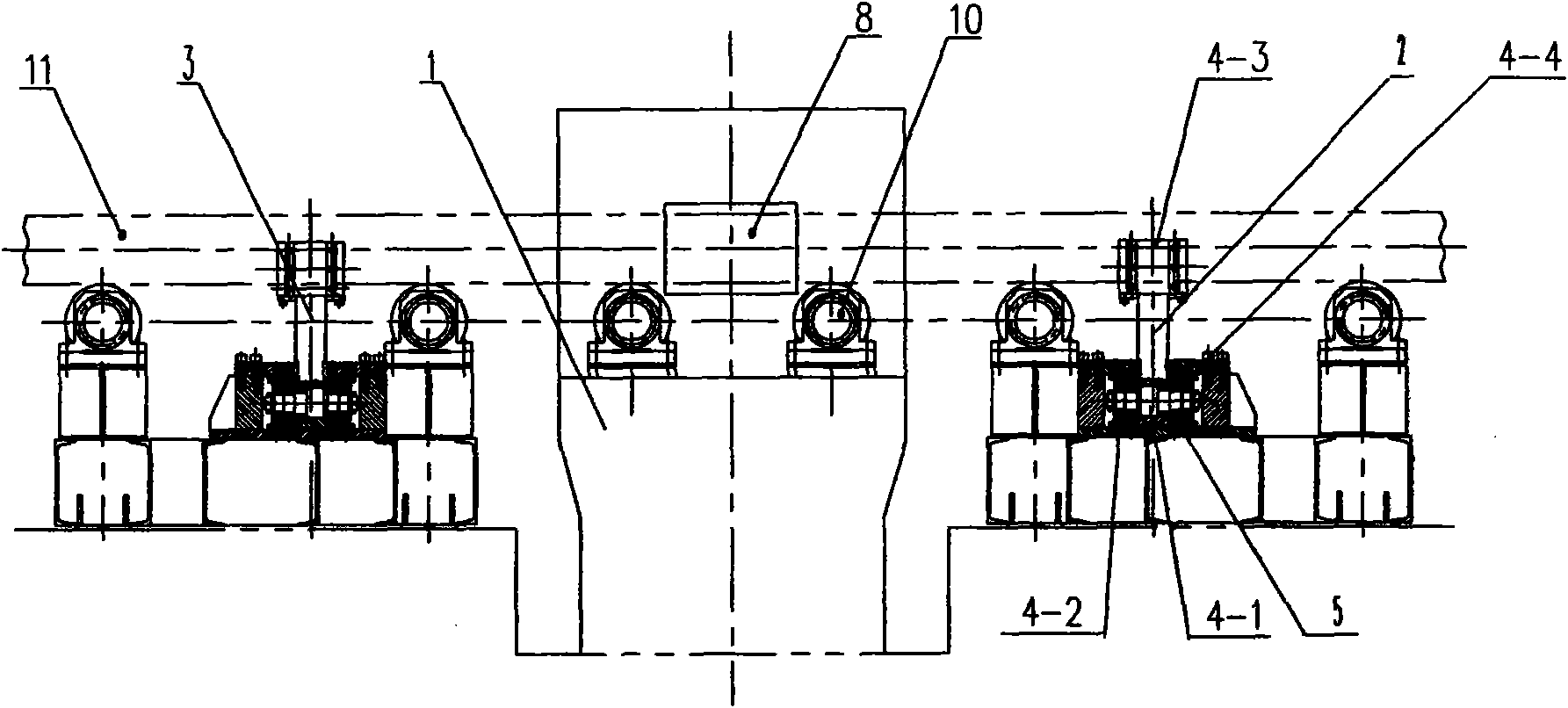

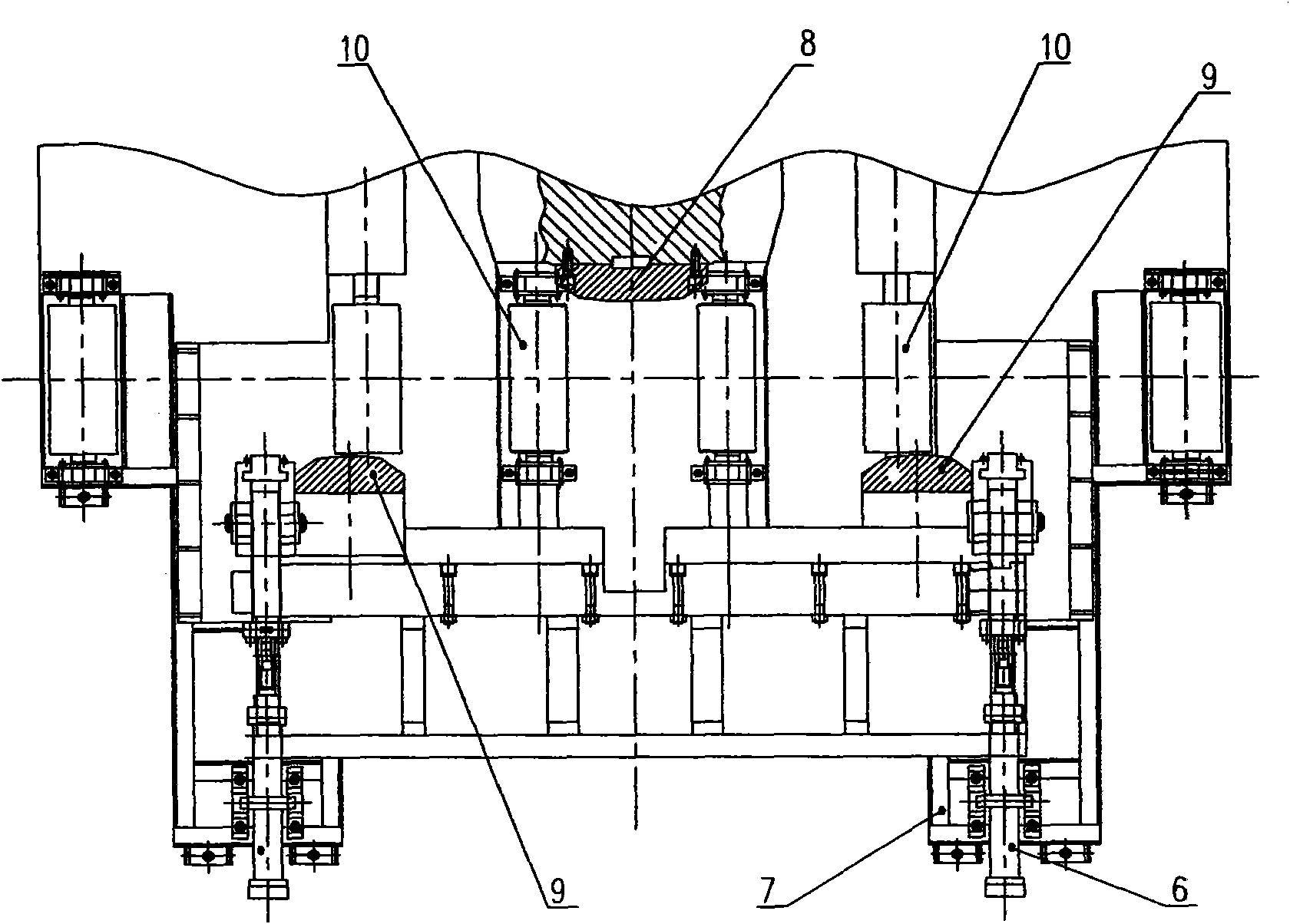

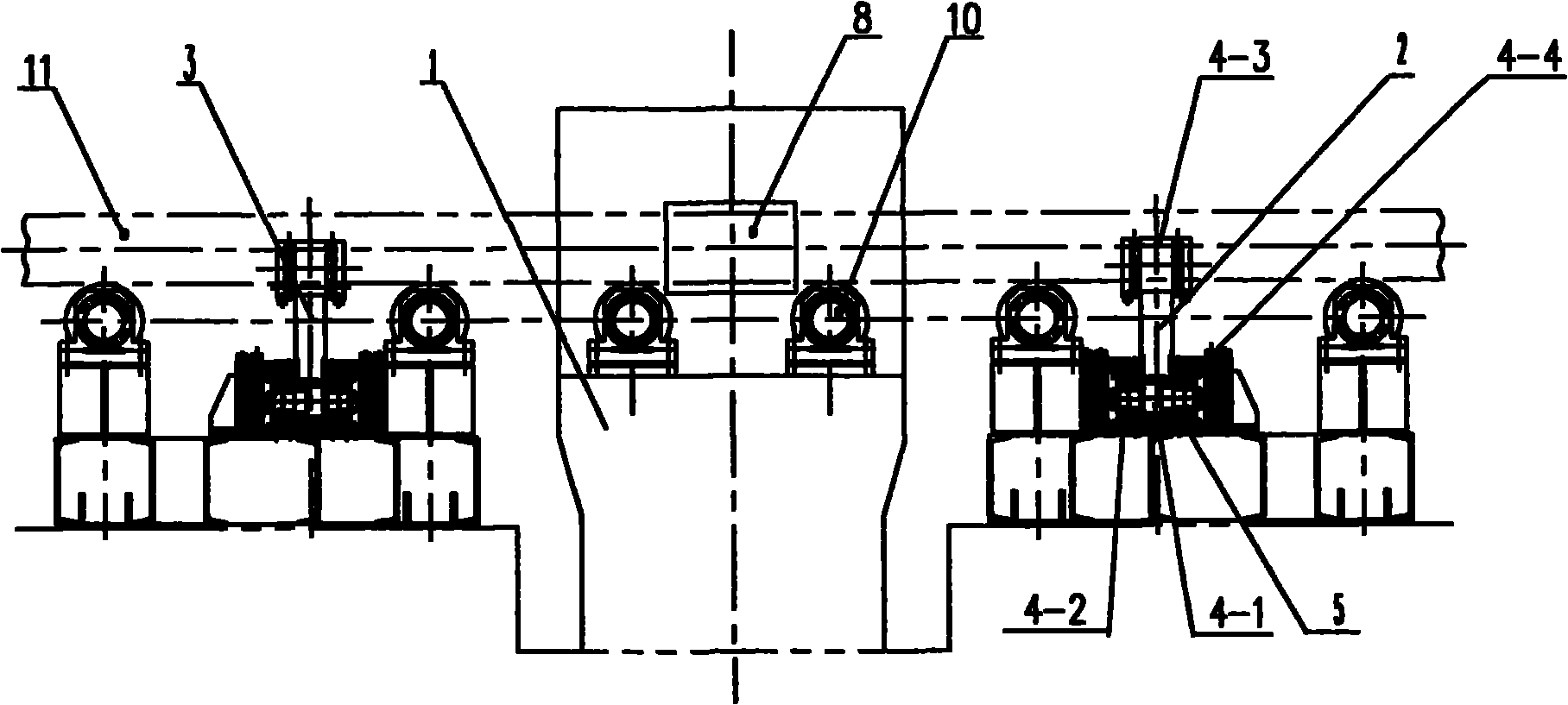

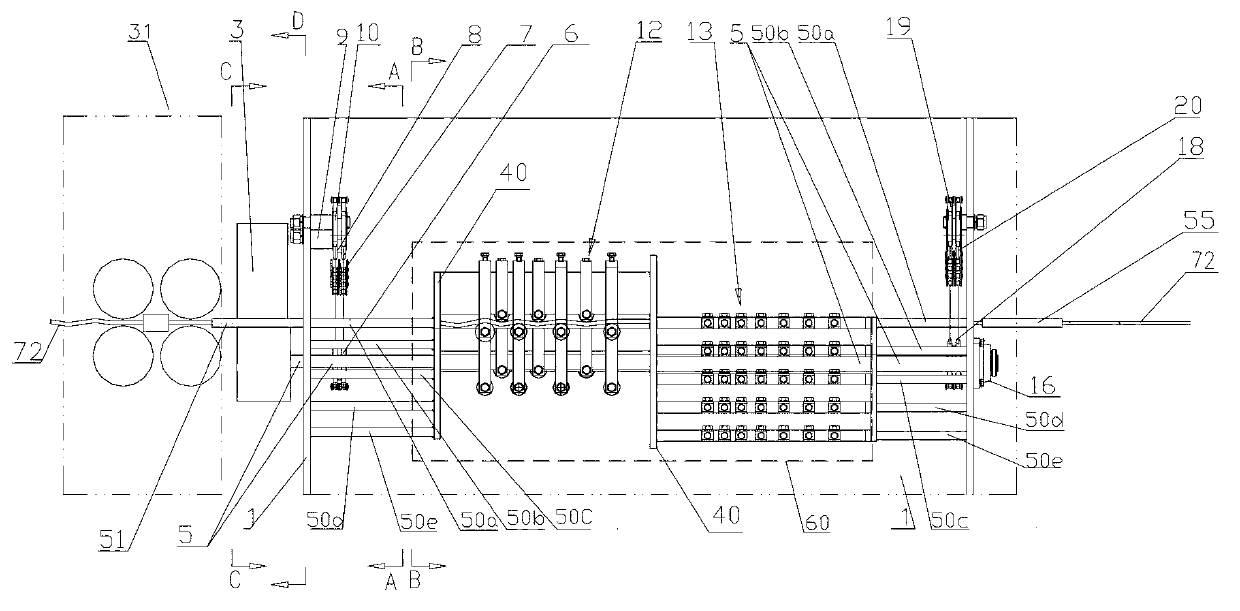

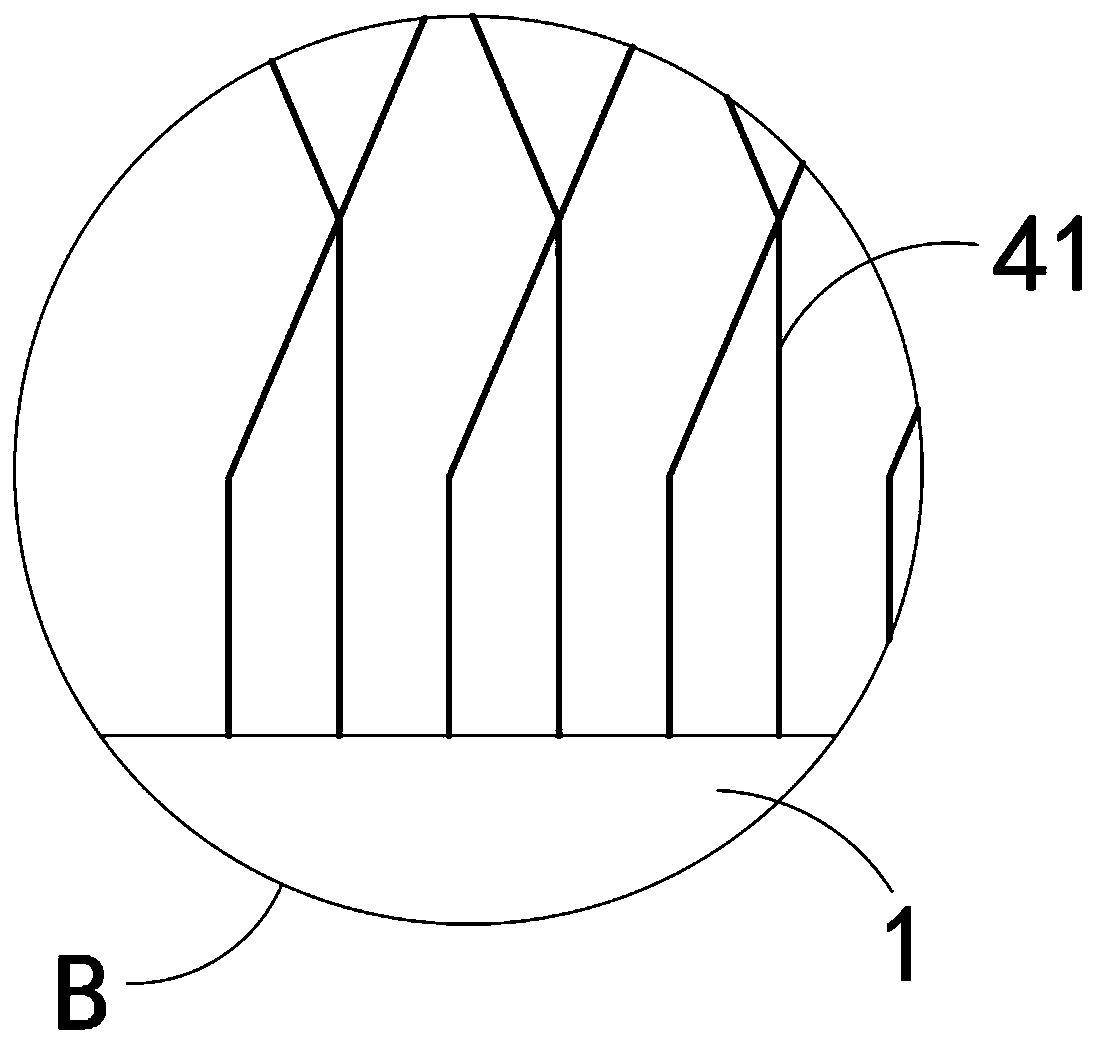

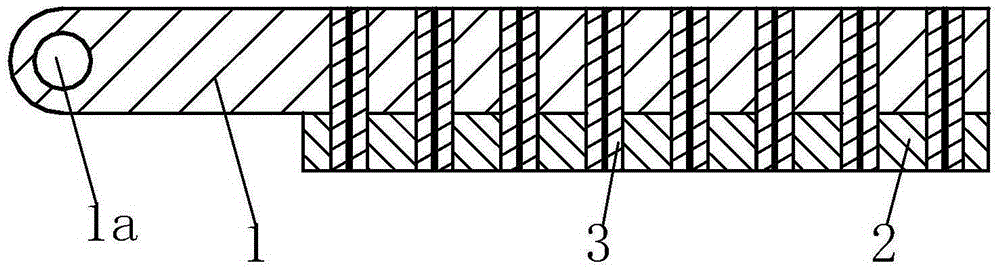

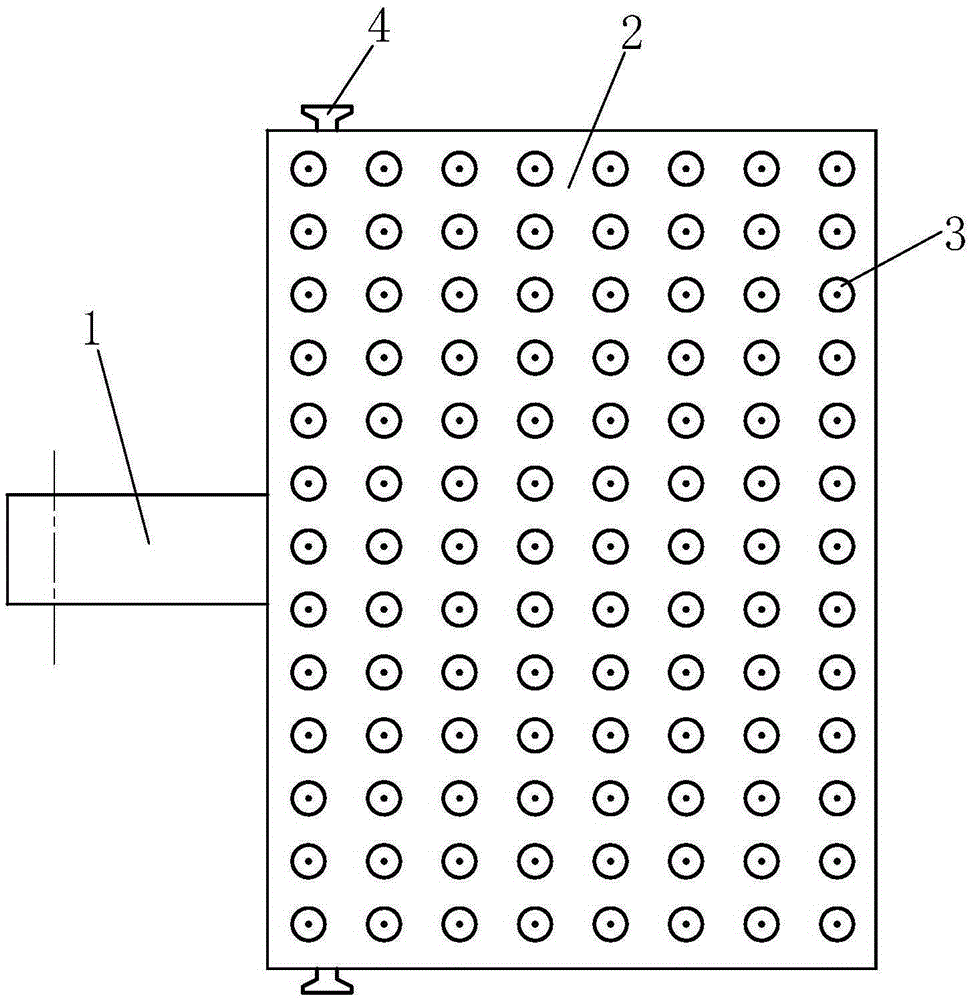

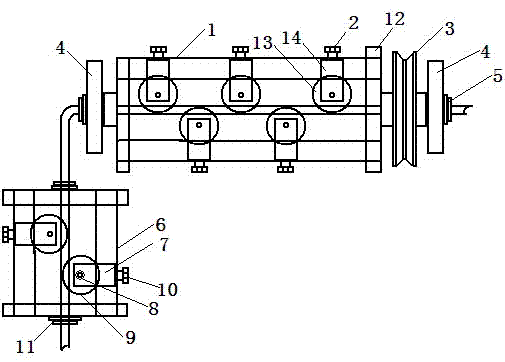

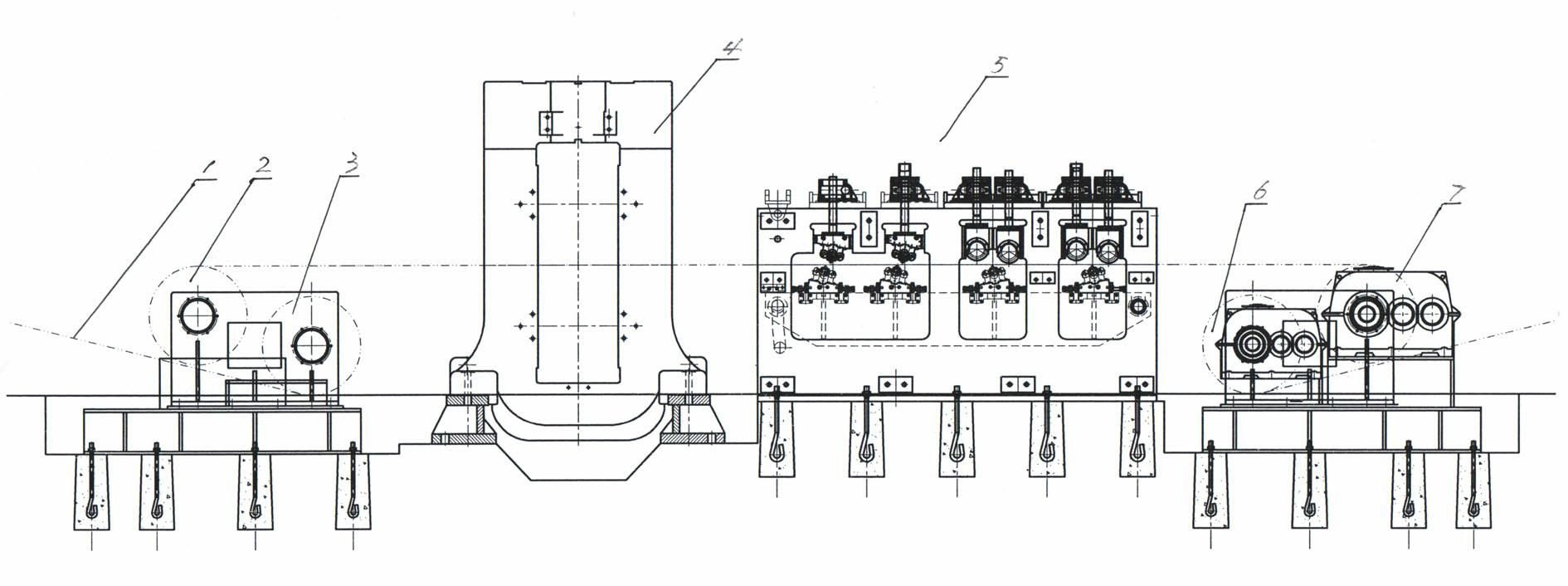

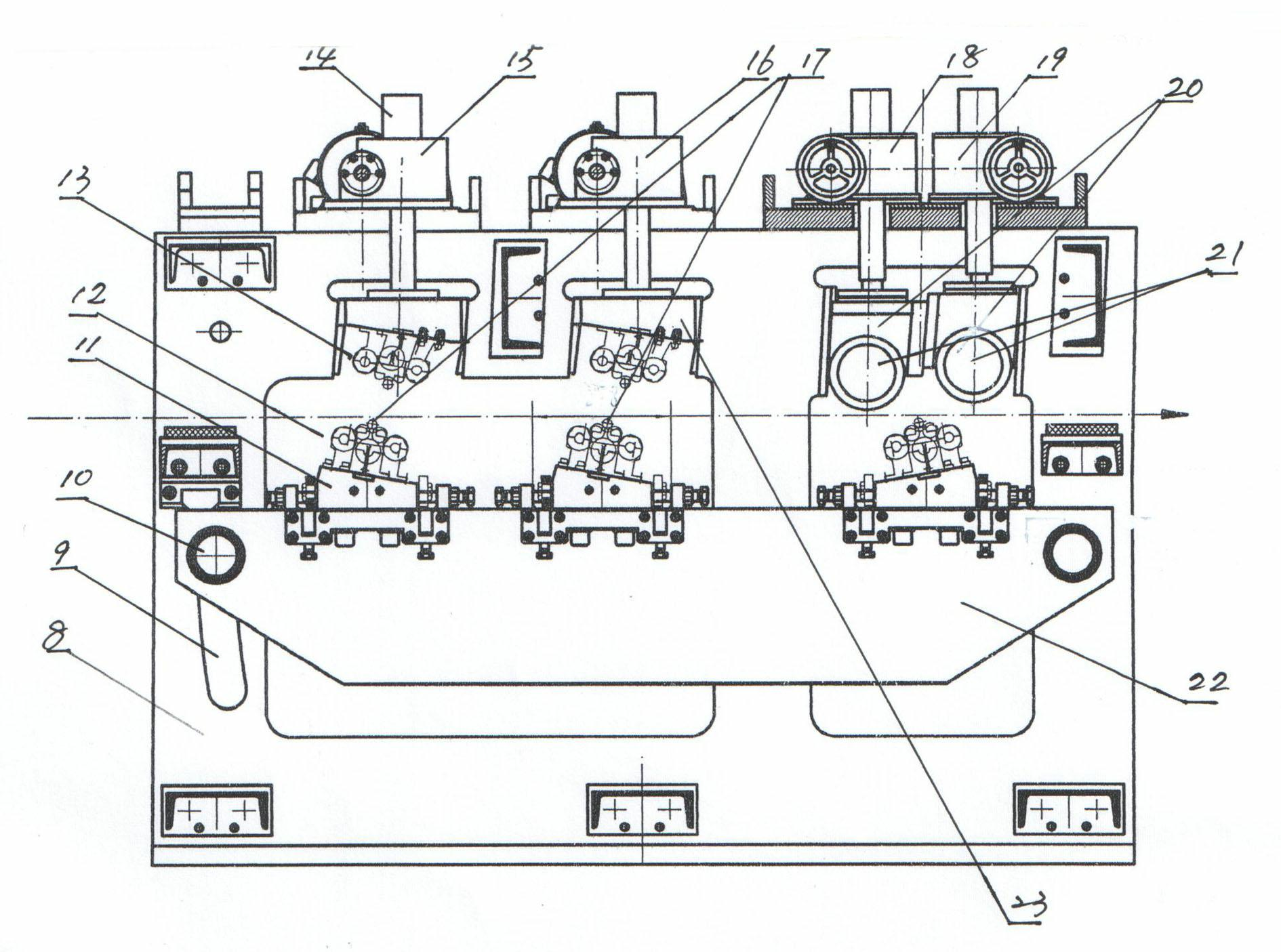

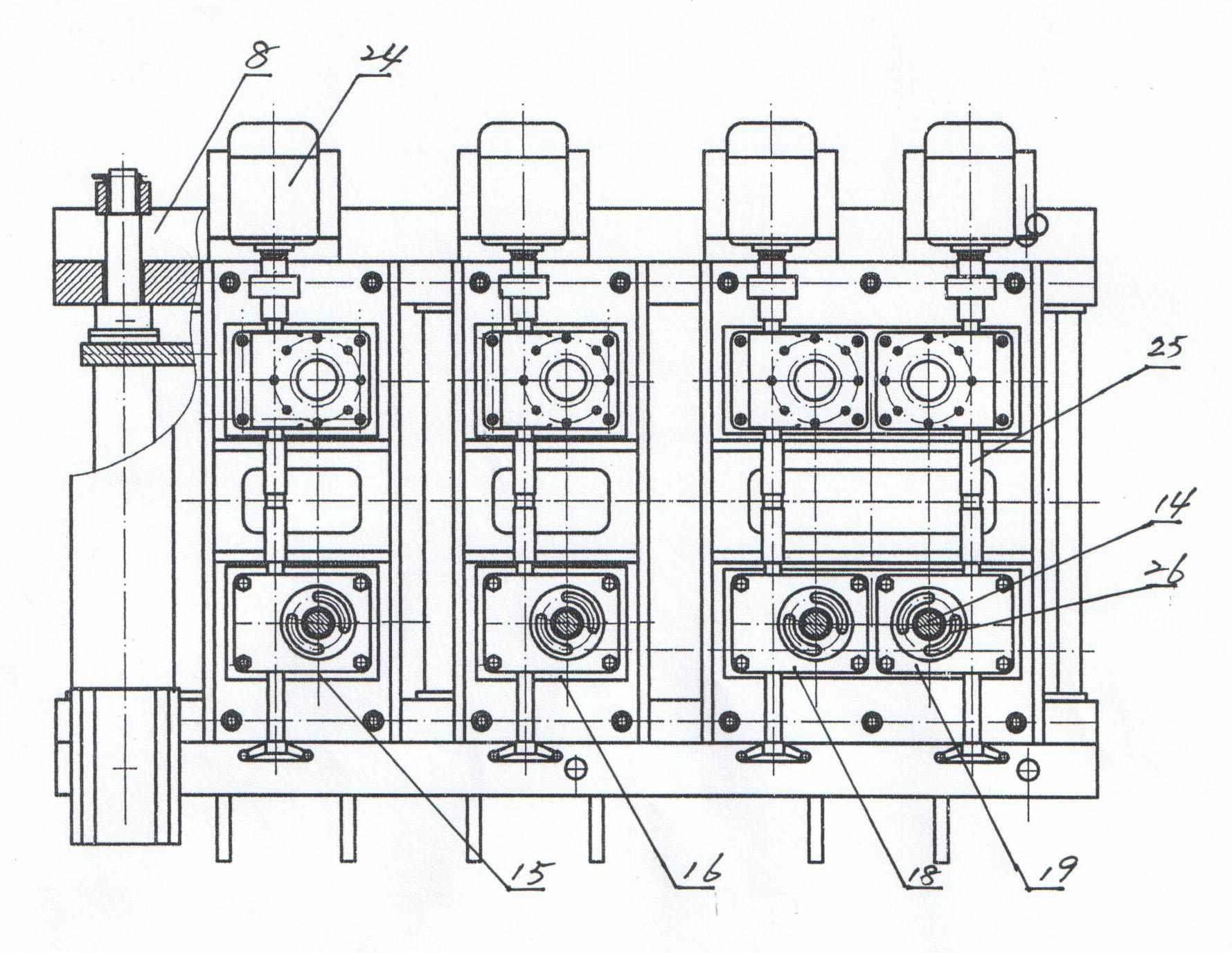

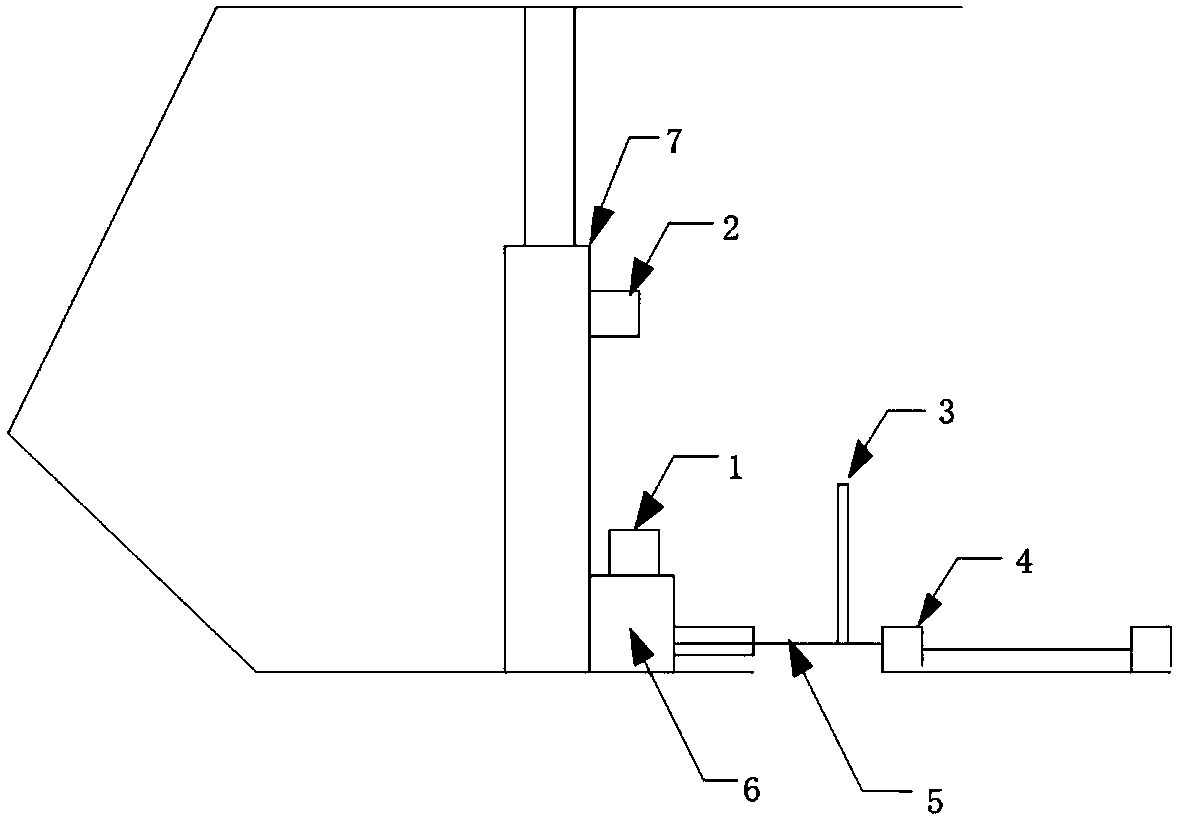

Alignment production line capable of simultaneously straightening multiple steel bars once

The invention discloses a steel bar alignment production line capable of simultaneously straightening multiple steel bars once. The steel bar alignment production line comprises a pay-off rack, an anti-twist cage, a branching device, a straightening main engine, a shearing machine and a frame which are sequentially arranged, wherein the branching device is of a frame structure, and the front end of the branching device is provided with at least three vertical rollers which are arranged at intervals; at least two thread penetrating channels are formed among the vertical rollers; the rear end of the branching device is provided with two horizontal rollers which are arranged up and down; annular grooves are formed on cylindrical surfaces of the upper and lower horizontal rollers at intervals; every two annular grooves of the upper and lower horizontal rollers are opposite to each other to form thread penetrating holes respectively; the thread penetrating holes correspond to the positions of the thread penetrating channels one by one; and at least two V-shaped grooves for straightening the steel bars are formed on each straightening roller of the straightening main engine. According to the steel bar alignment production line, multiple steel bars can be simultaneously straightened once, and the working efficiency of the steel bar alignment production line is improved.

Owner:重庆亨尔通冶金新技术股份有限公司

Rotating mechanism for tubes and bars on horizontal straightening machine

A rotating mechanism for tubes and bars on a horizontal straightening machine relates to an assistant device of the horizontal straightening machine. The rotating mechanism solves the problems that the rotating mechanism of a traditional horizontal straightening machine has a complicated structure, is large and bulky, and has high manufacture cost. The rotating mechanism is characterized in that a right pushing device and a left pushing device are symmetrically installed on both sides of a straightening machine body; the right pushing device comprises a material pushing mechanism, a guide rail, an oil cylinder and a base, and the left pushing device also comprises a material pushing mechanism, a guide rail, an oil cylinder and a base; each material pushing mechanism comprises a rolling shaft, a rolling bearing, a roller and a pushing plate; each rolling bearing and each roller are assembled together and then are installed on each rolling shaft; each roller is arranged on each guide rail; each pushing plate is connected with each rolling shaft; each material pushing mechanism is driven by each oil cylinder; and each material pushing mechanism, each guide rail and each oil cylinder are fixed on each base. Compared with the traditional rotating mechanism of the horizontal straightening machine, the rotating mechanism has the advantages as follows: the volume is small, the structure is simple, a plurality of rotating carrier rollers and lifting mechanisms are omitted, and the manufacture cost is lowered.

Owner:TAIYUAN HEAVY IND

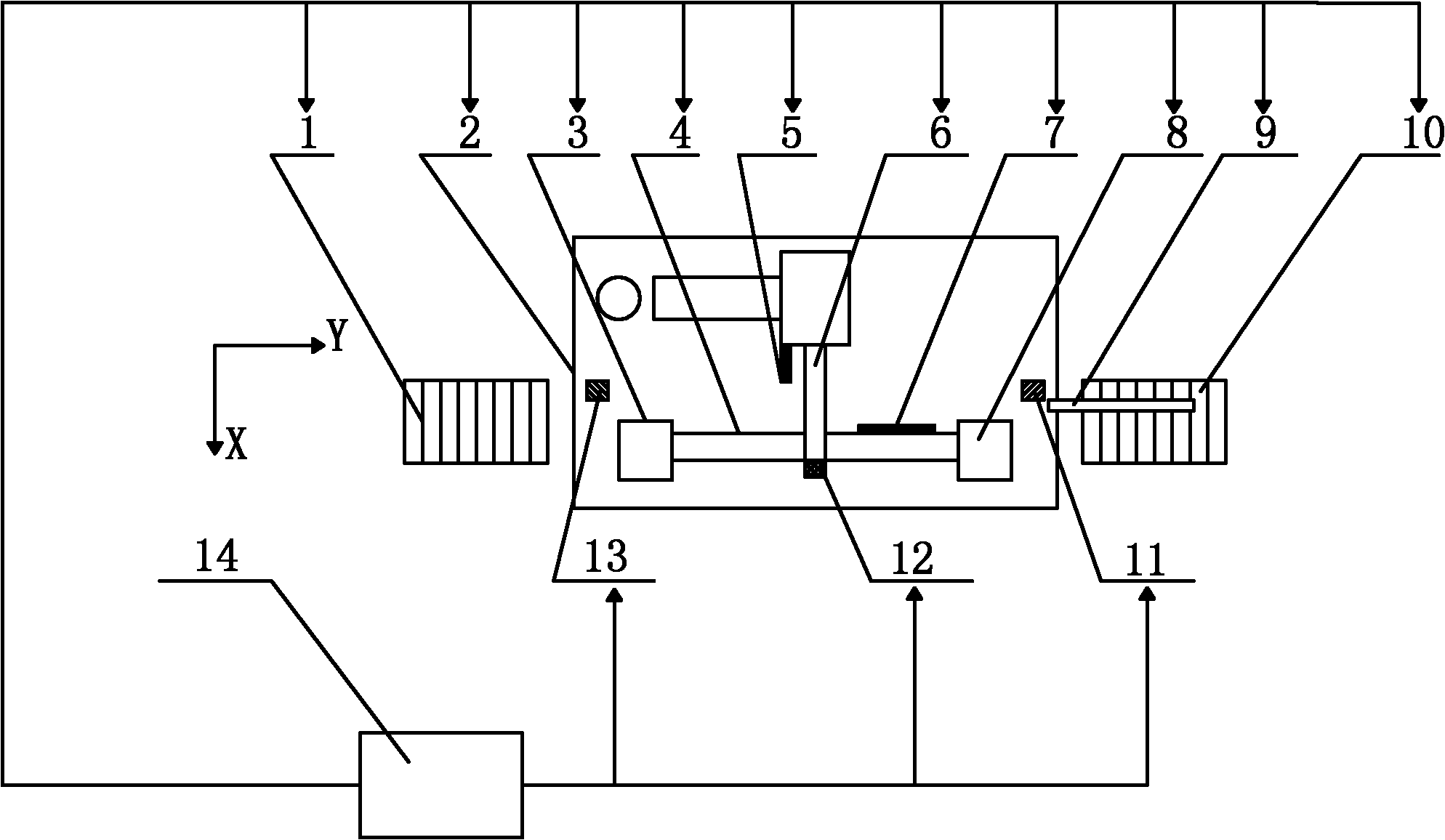

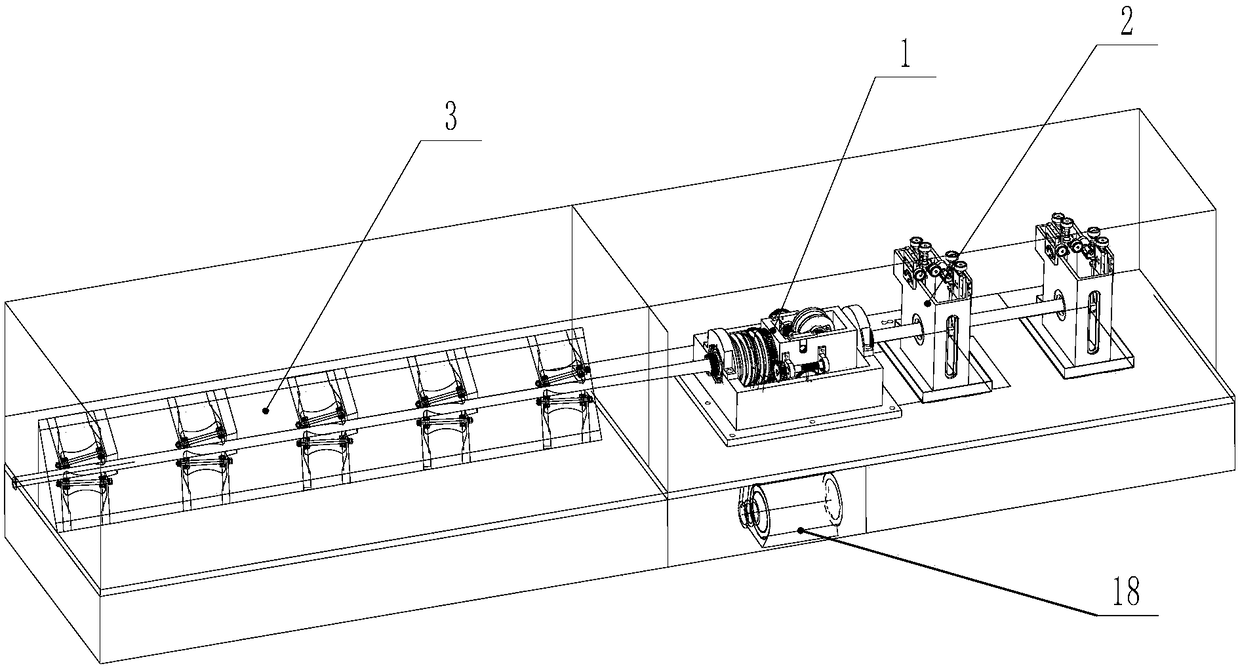

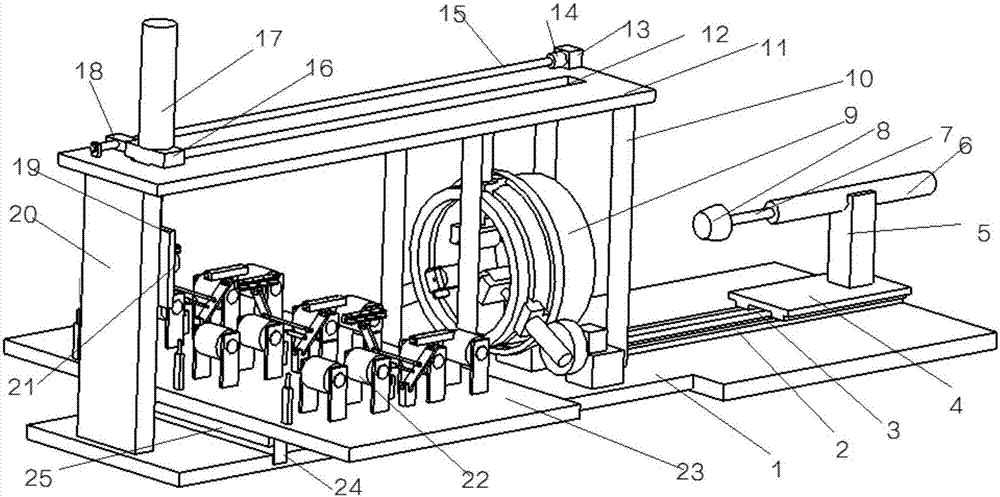

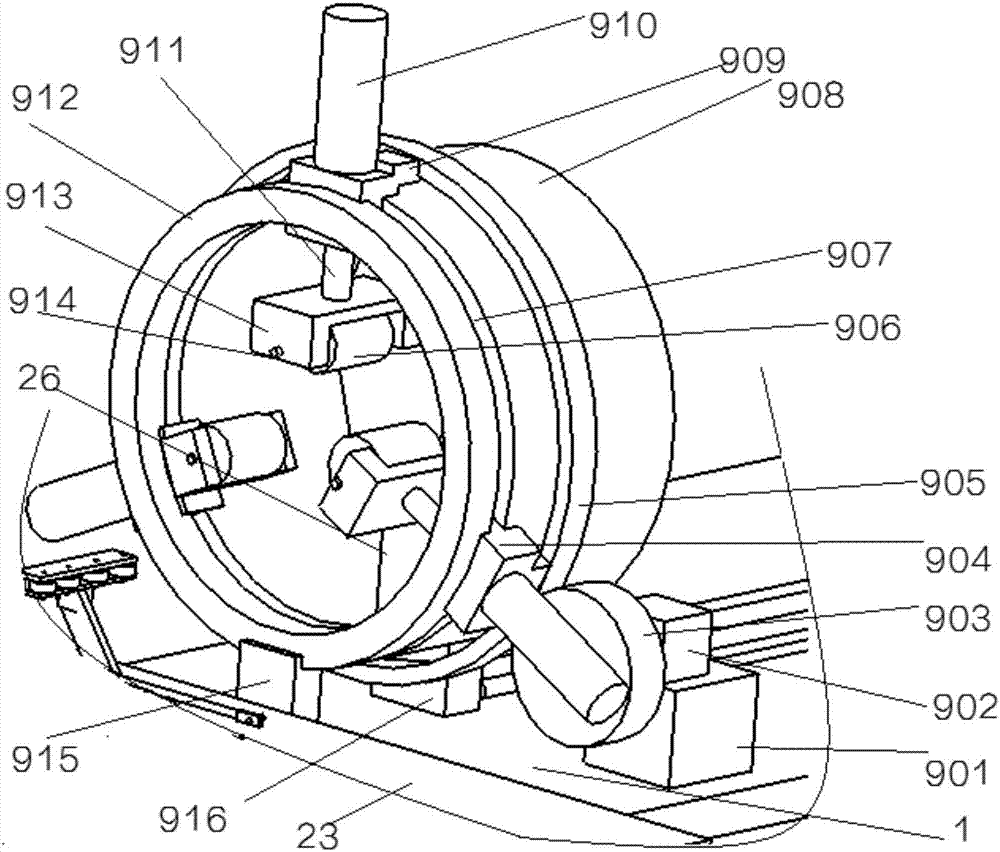

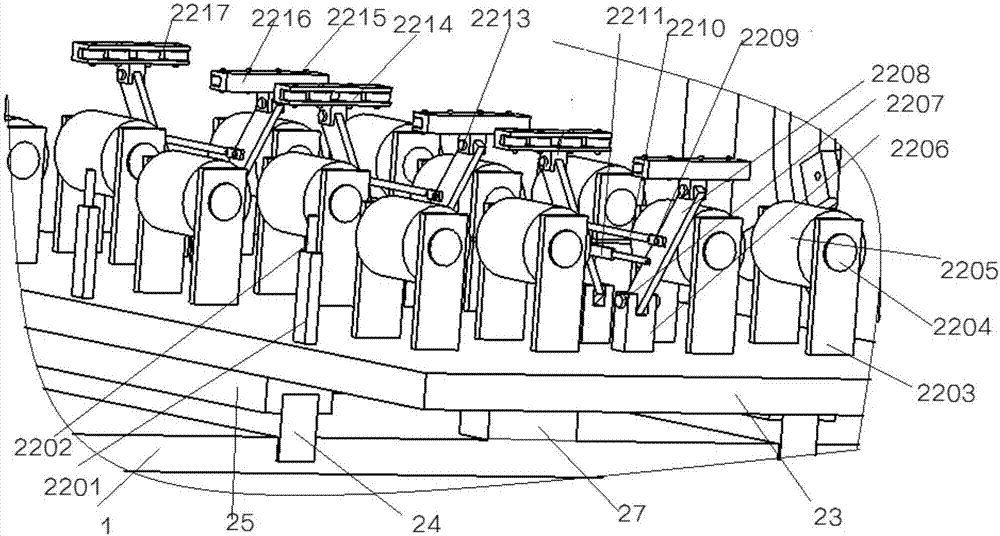

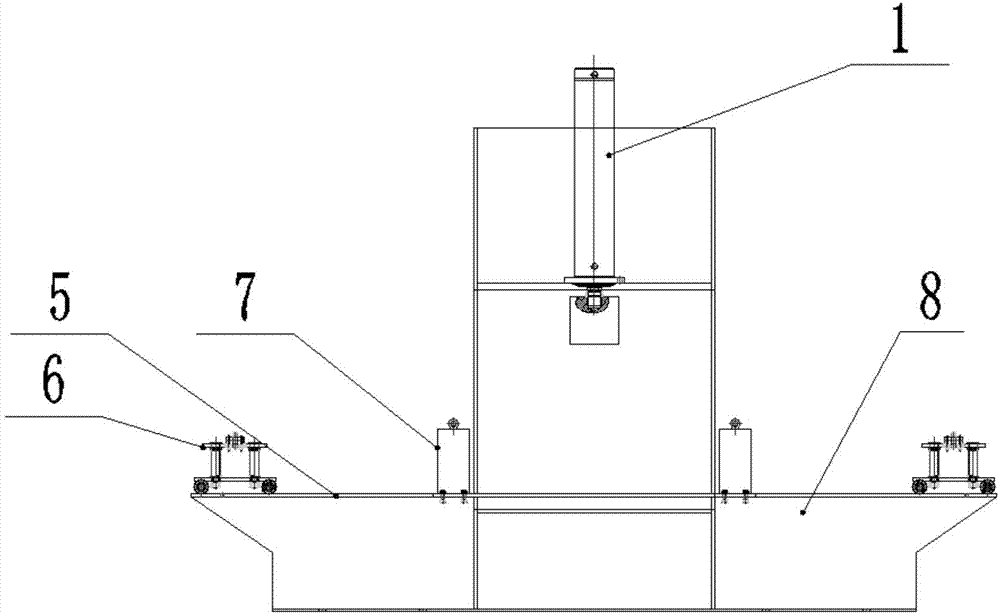

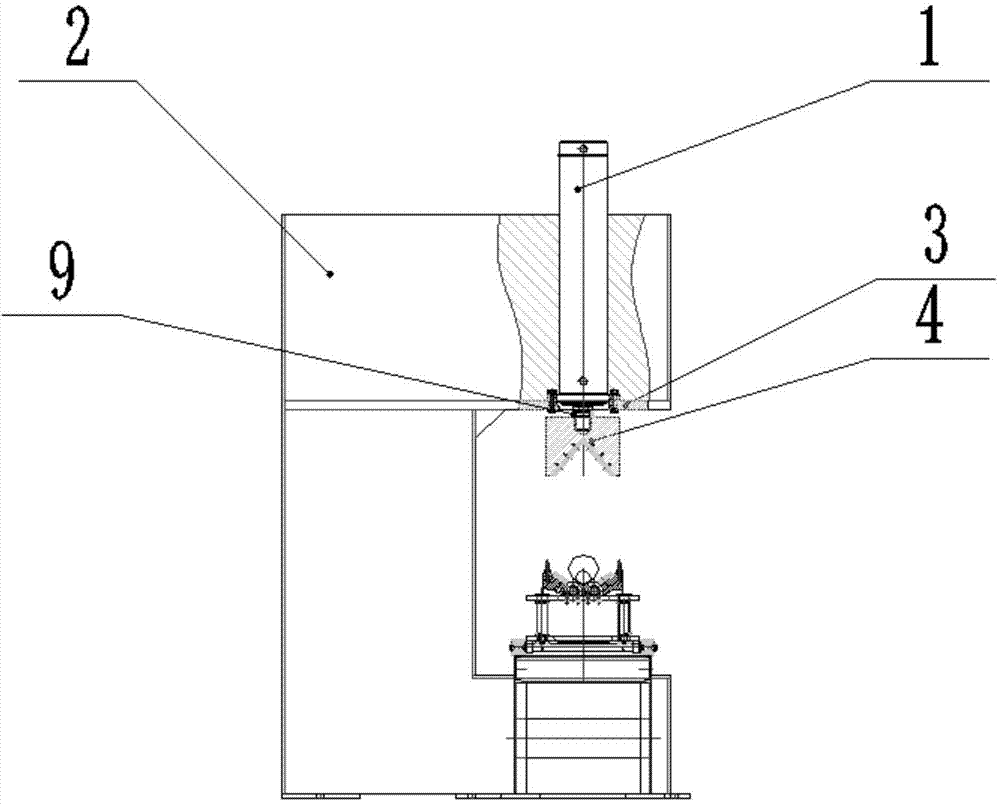

Horizontal adaptive mechanical precision straightening device for linear bars

InactiveCN102069111AStraighten and bendAchieve straighteningMetal-working feeding devicesMetal working apparatusAxial displacementMeasurement device

The invention relates to a horizontal adaptive mechanical precision straightening device for linear bars. The straightening device provided by the invention comprises a main engine foundation, a left-workpiece presence sensor, a right-workpiece presence sensor, a support / drive assembly, a straightening mechanism, a left feed mechanism, a right feed mechanism, an axial displacement meter, a workpiece bending-modulus measurement device, a left workpiece clamping assembly, a right workpiece clamping assembly, a straightening stroke displacement meter and an electrical / software processing controlsystem, wherein the left-workpiece presence sensor, the right-workpiece presence sensor, the support / drive assembly and the straightening mechanism are connected with the main engine foundation; the left feed mechanism and the right feed mechanism are respectively arranged at the two sides of the main engine foundation; the axial displacement meter and the workpiece bending-modulus measurement device are connected with the support component of the support / drive assembly; the left workpiece clamping assembly and the right workpiece clamping assembly are respectively connected with the two sides of the support component; the straightening stroke displacement meter is connected with the straightening mechanism; and the electrical / software processing control system is used for controlling thecomponents to operate. By using the precision straightening device provided by the invention, the continuous bending of a workpiece can be subjected to straightening on adaptive support-span adjustment and straightening stroke adjustment, the length of the workpiece is not restricted, the rigidity of a mechanical dynamical mechanism is large, and the precision of closed-loop servo control on support span and straightening stroke is high without being affected by the gravity deformation of a long workpiece in the vertical direction.

Owner:WUHAN UNIV OF TECH

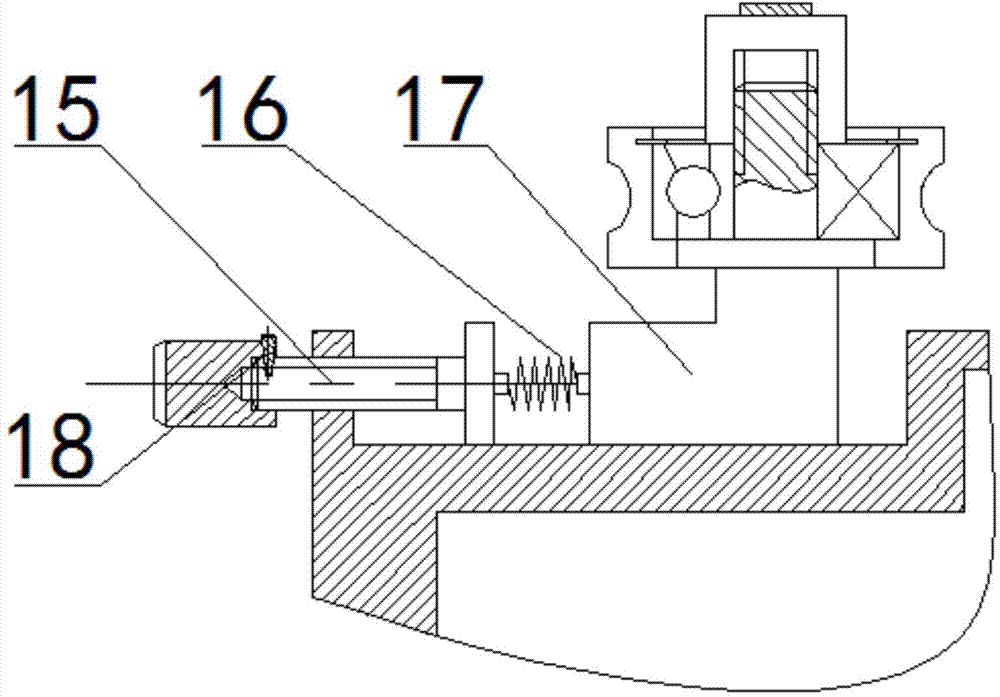

Pay-off device

InactiveCN104843537AAvoid looseAchieve straighteningFilament handlingMechanical engineeringScratching

The invention discloses a pay-off device and aims to solve the problems that resource waste and hand scratching are easily caused when a user straightens hard wires with hands directly. The pay-off device is characterized in that a front fixed plate and a back fixed plate are fixedly arranged on the ground at an interval, a pair of guide rails is laid between the front fixed plate and the back fixed plate, rail wheels capable of traveling along the guide wheels are arranged at the bottom of a flat plate, a C-shaped retainer ring is arranged at the top of the flat plate, a fixer is arranged in a cavity of the retainer ring, a plurality of arc-shaped movable plates are arranged around the fixer, a first spring is arranged between each movable plate and the fixer, a fixed press plate and a movable press plate which are used for clamping hard wires are arranged on the flat plate, a support is in sliding connection with the guide rails, a projection is formed on one side, close to the flat plate, of the support, a groove is formed in one side of the projection, a movable pin only capable of moving up and down is arranged on the projection, and a hook on the flat plate extends into the groove and then can be penetratingly arranged on the movable pin. The pay-off device is driven by a motor, and accordingly, human hands can be protected from being scratched when used for straightening the hard wires directly.

Owner:国网山东济南市历城区供电公司 +1

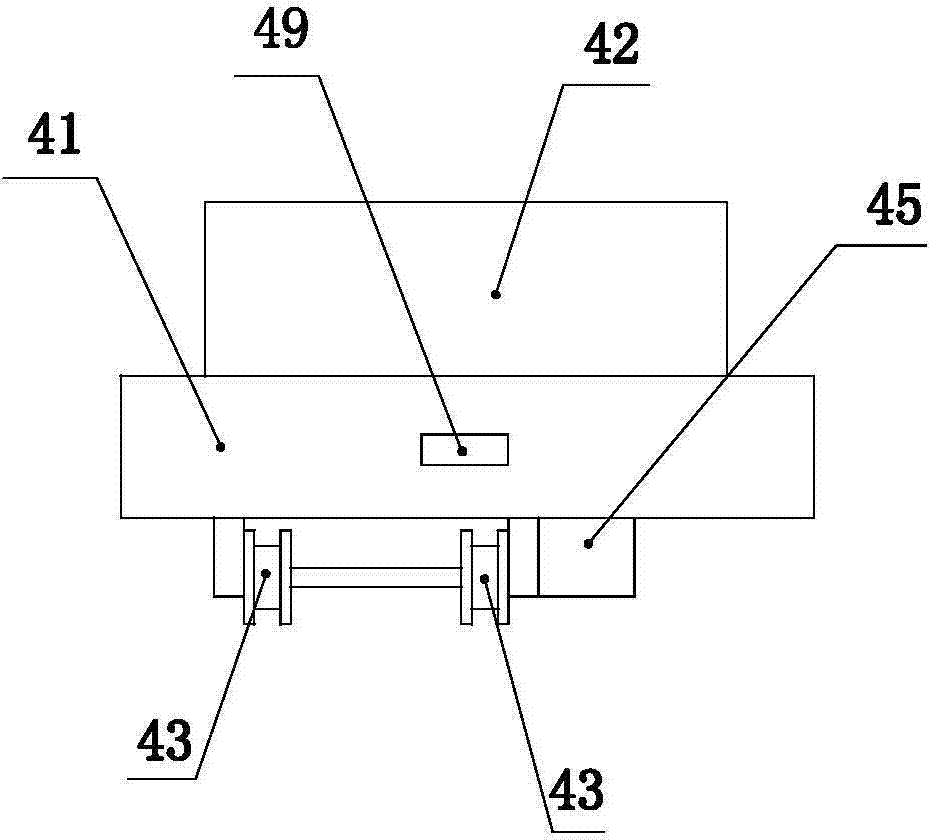

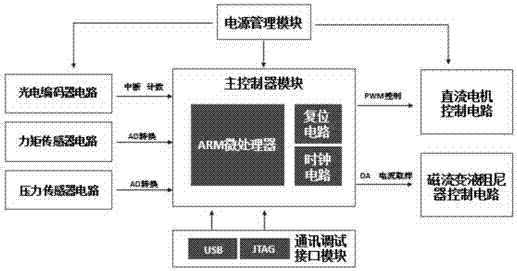

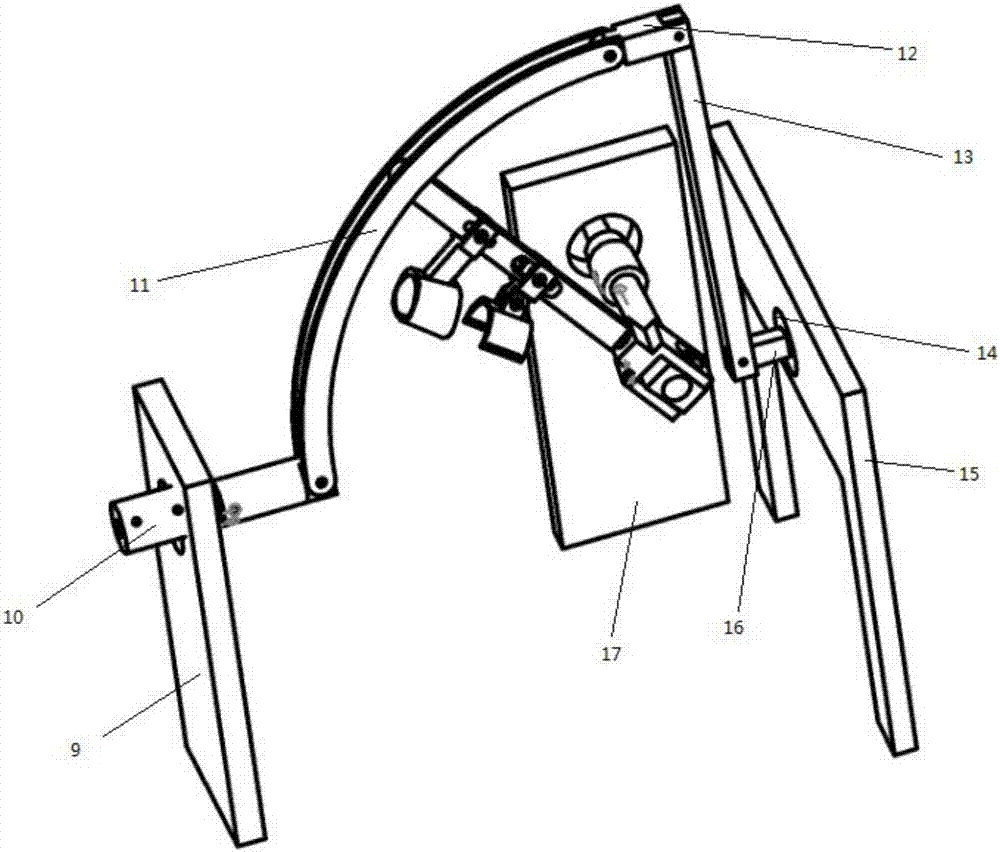

Thumb rehabilitation training device with multiple degrees of freedom for hemiplegic patients

ActiveCN107233190AImprove recovery qualityAchieve bendingChiropractic devicesMuscle exercising devicesHemiplegic gaitMagnetorheological fluid

The invention discloses a thumb rehabilitation training device with multiple degrees of freedom for hemiplegic patients. The device includes a supporting base, a driving sensing mechanism I and a driving sensing mechanism II, wherein the driving sensing mechanism I and the driving sensing mechanism II are fixed on the supporting base, and composed of optical-electricity encoders, direct-current torque motors, magnetorheological fluid dampers and torque sensors; the output end of the driving sensing mechanism I is connected to one end of an arc-shaped guiding rail through a coupler I, and the other end of the arch-shaped guiding rail is fixed on a supporting plate I successively through a connecting rod I, a connecting rod II and a connecting rod III; the connecting rod III is fixed on the supporting plate I through a bearing I, and the supporting plate I is fixed on the supporting base; the output end of the driving sensing mechanism II is connected to a driving shaft of a finger training mechanism through a coupler II, the finger training mechanism includes a training rod, a front finger sleeve, a rear finger sleeve, a driving connector and the driving shaft, and the driving shaft is connected with a training rod in a transmission mode through the driving connector; the front end of the training rod is embedded into the arc-shaped guiding rail and slides along the arc-shaped guiding rail.

Owner:SOUTHEAST UNIV

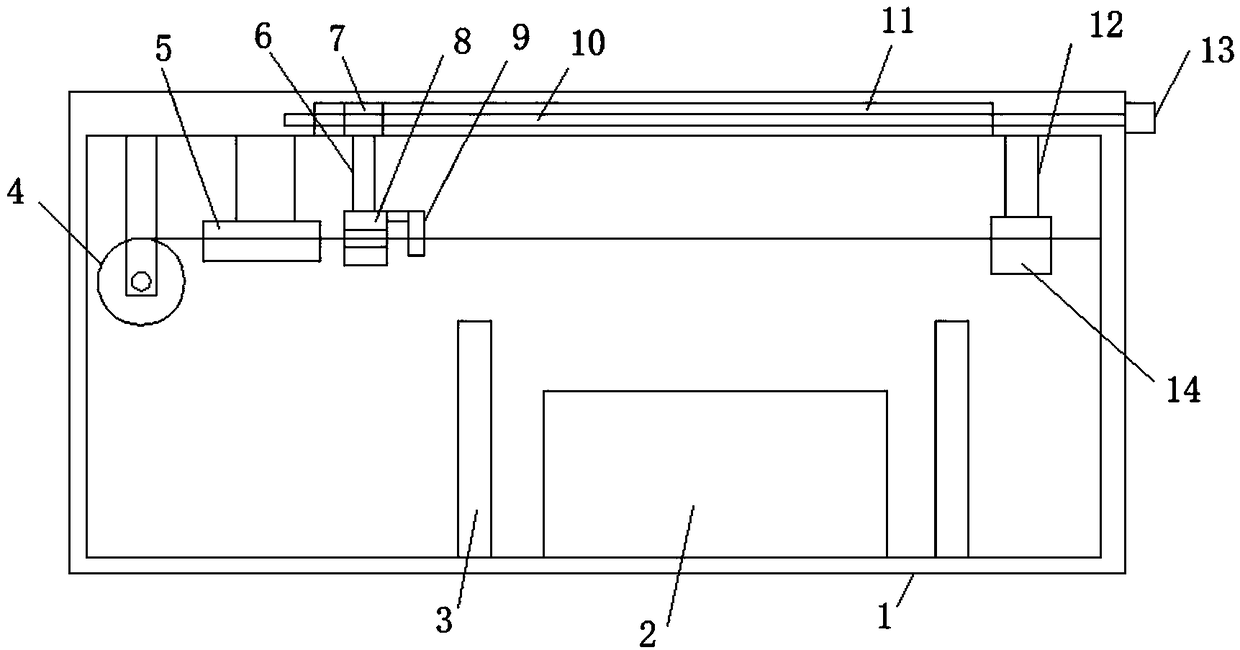

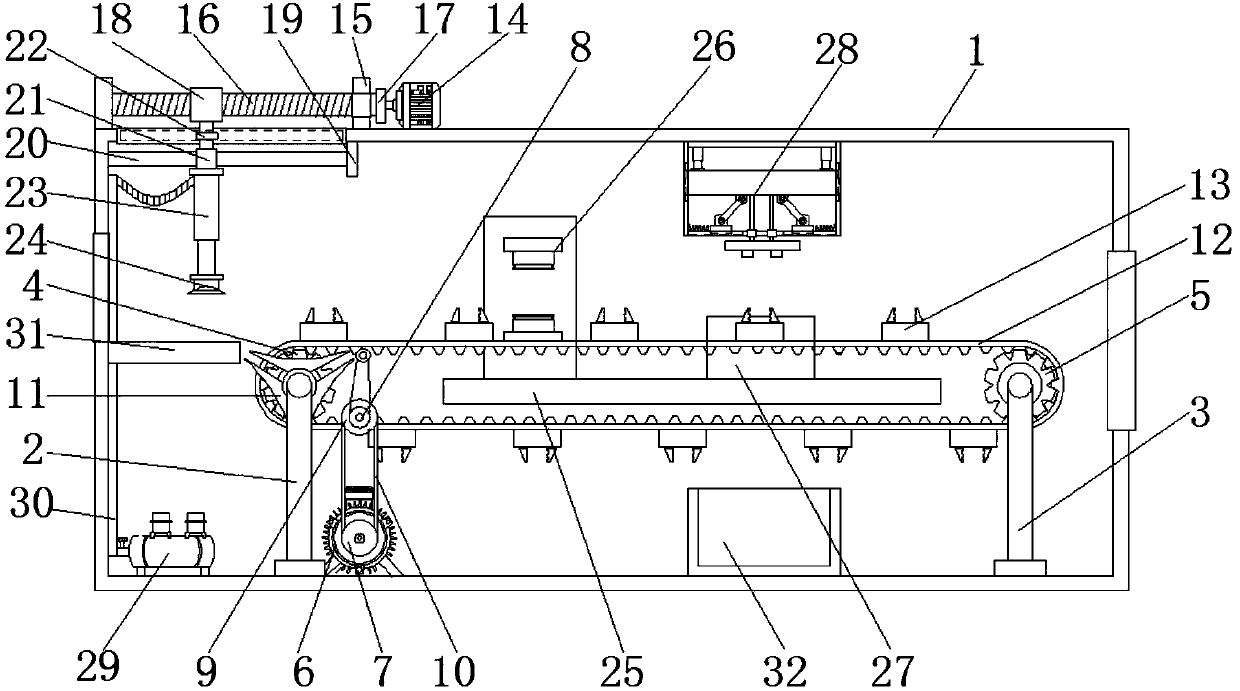

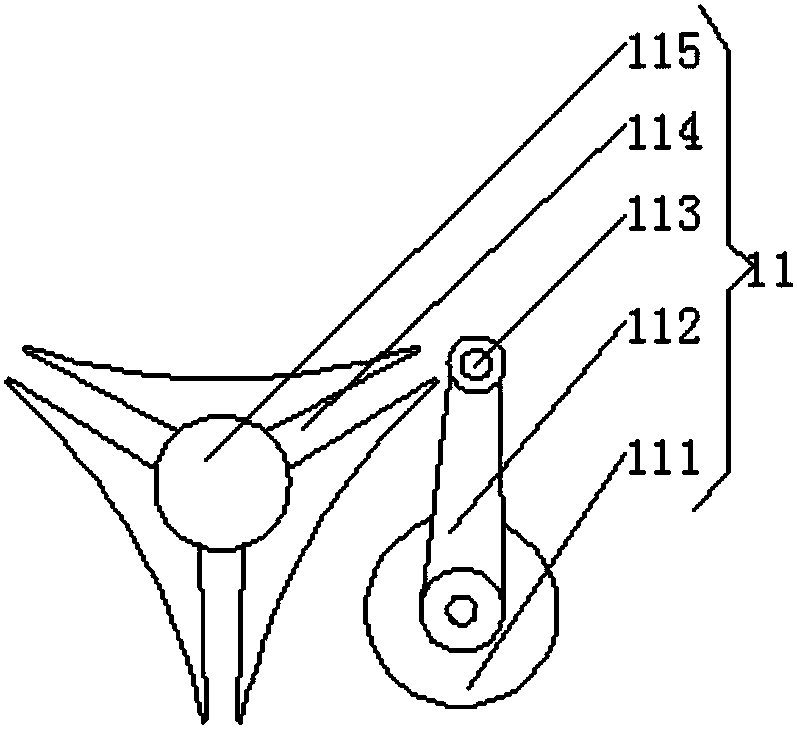

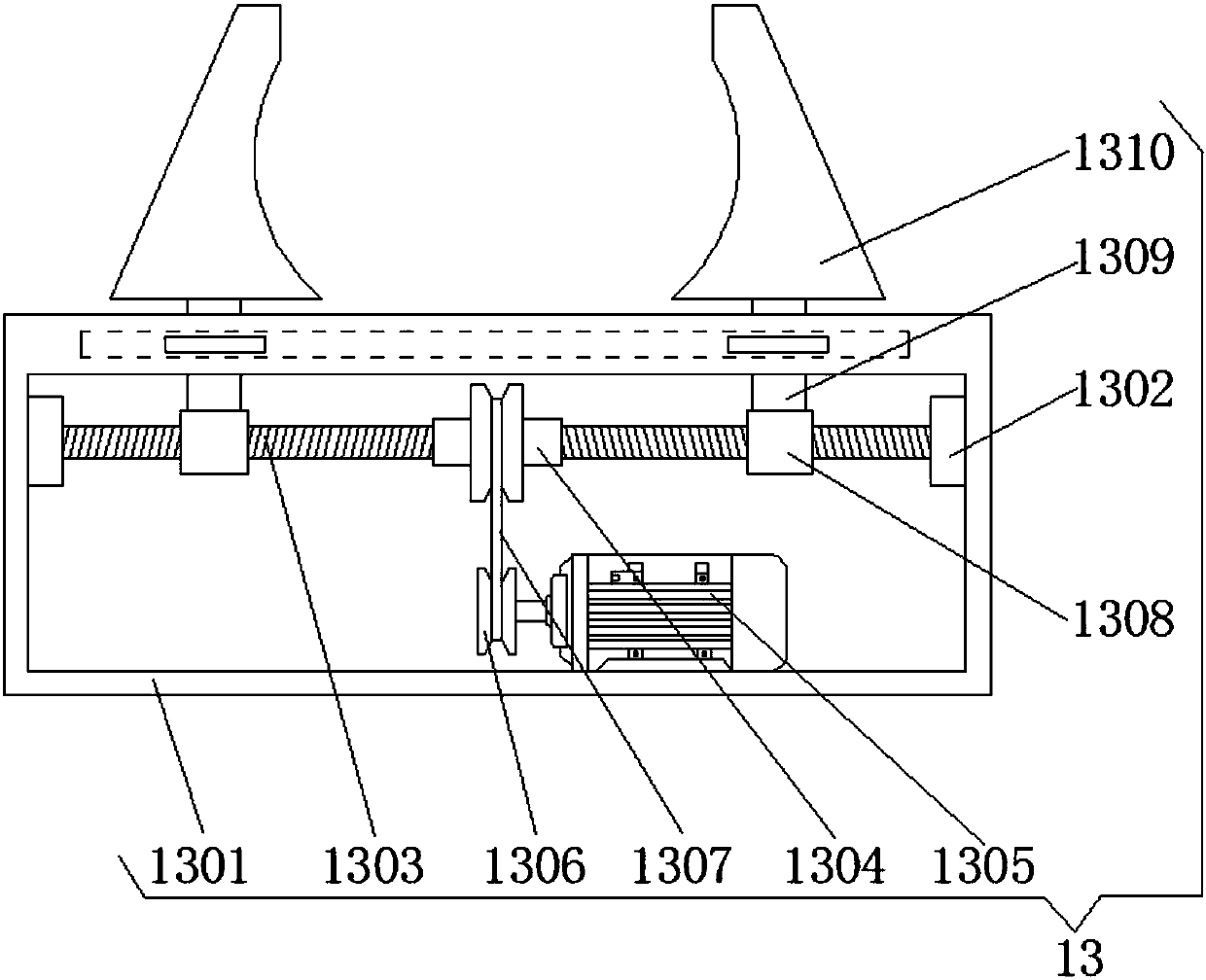

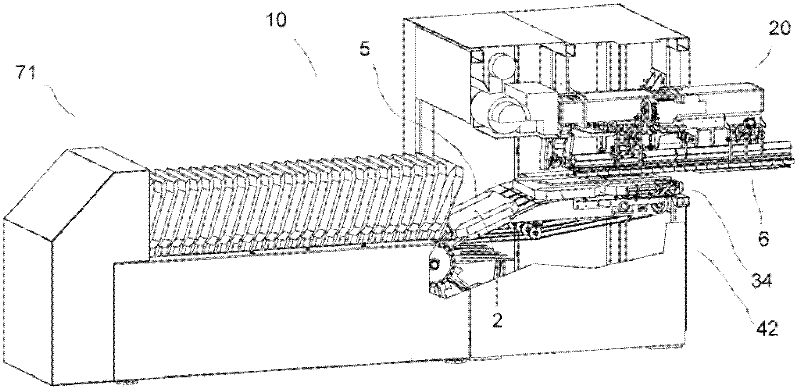

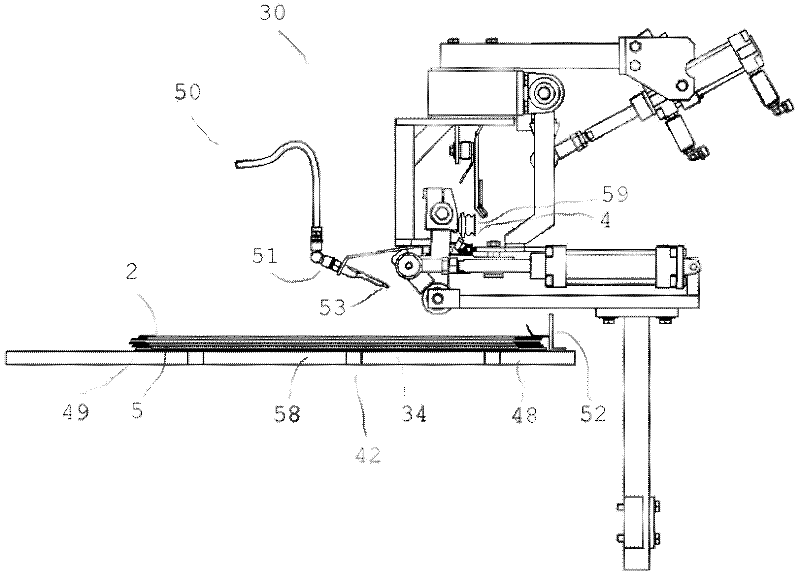

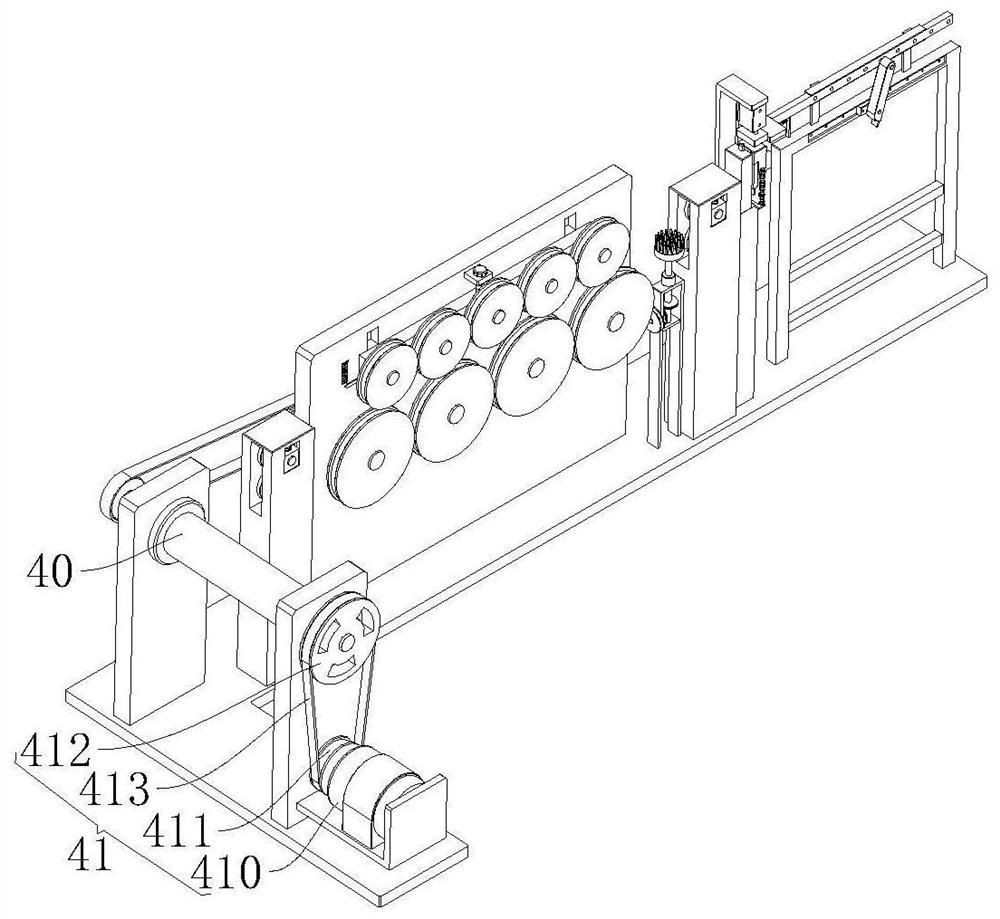

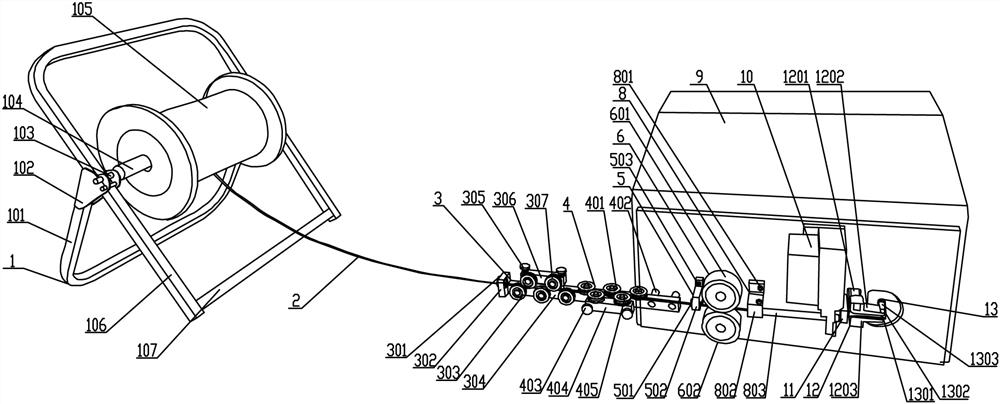

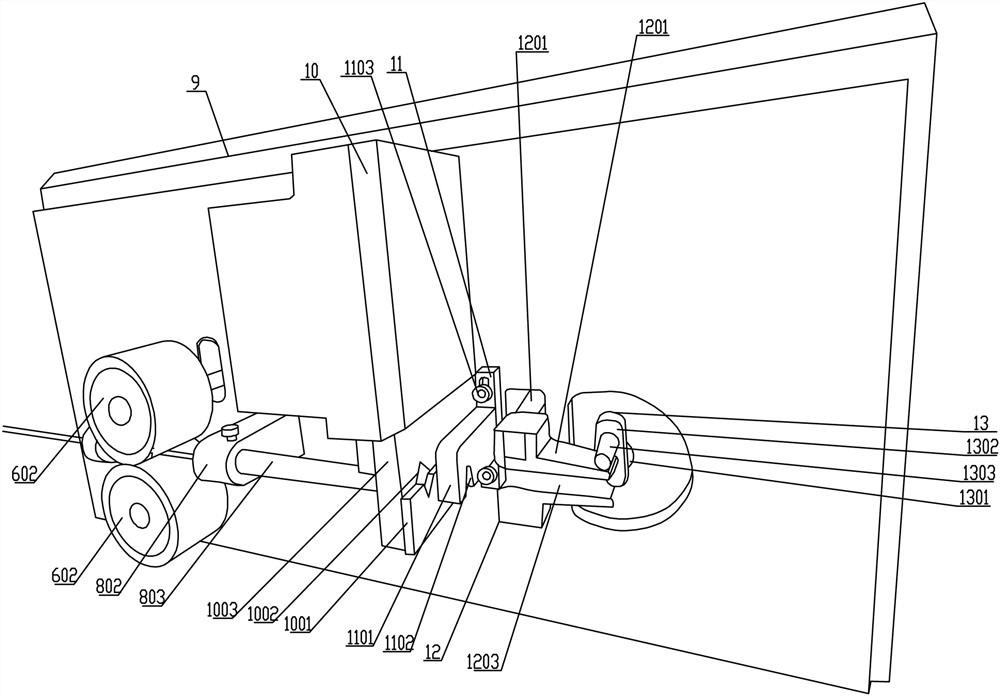

Full-automatic intelligent manufacturing equipment for railway hanging strings

InactiveCN108543896ARealization of fully automatic intelligent manufacturingRealize automatic feeding processWire articlesFixed frameScrew thread

The invention discloses full-automatic intelligent manufacturing equipment for railway hanging strings. The full-automatic intelligent manufacturing equipment comprises a fixed frame, one side of thetop end of the fixed frame is rotationally provided with a winding roller through a first support, the winding roller is wound with a metal rope, one side of the winding roller is provided with a horizontally-arranged straightening barrel, the straightening barrel is fixed to the inner wall of the top end of the fixed frame through a second support, a horizontally-arranged sliding groove is formedin the inner wall of the top end of the fixed frame, a sliding block is in sliding connection into the sliding groove, a first motor is installed on the top end the side wall of one side of the fixedframe through a screw, a threaded rod rotationally connected into the sliding groove is connected to an output shaft of the first motor and is in threaded connection with the sliding block, a first connecting rod is welded to the bottom end of the sliding block, a guide barrel is welded to the bottom end of the first connecting rod, and one side of the guide barrel is provided with a first clamping mechanism. By means of the full-automatic intelligent manufacturing equipment, full-automatic intelligent manufacturing of the railway hanging strings can be achieved, the machining efficiency is high, and manual operation strength is reduced.

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

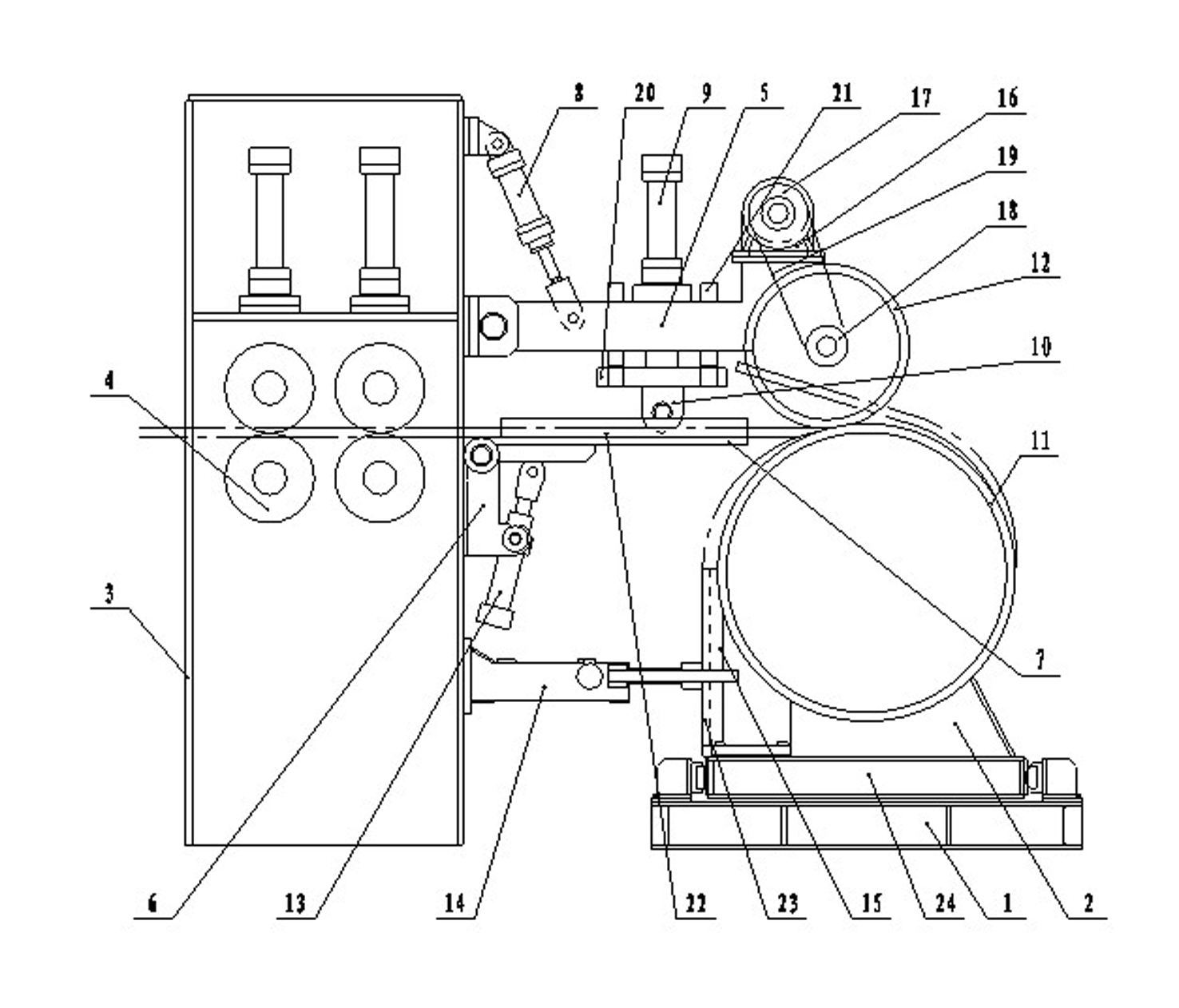

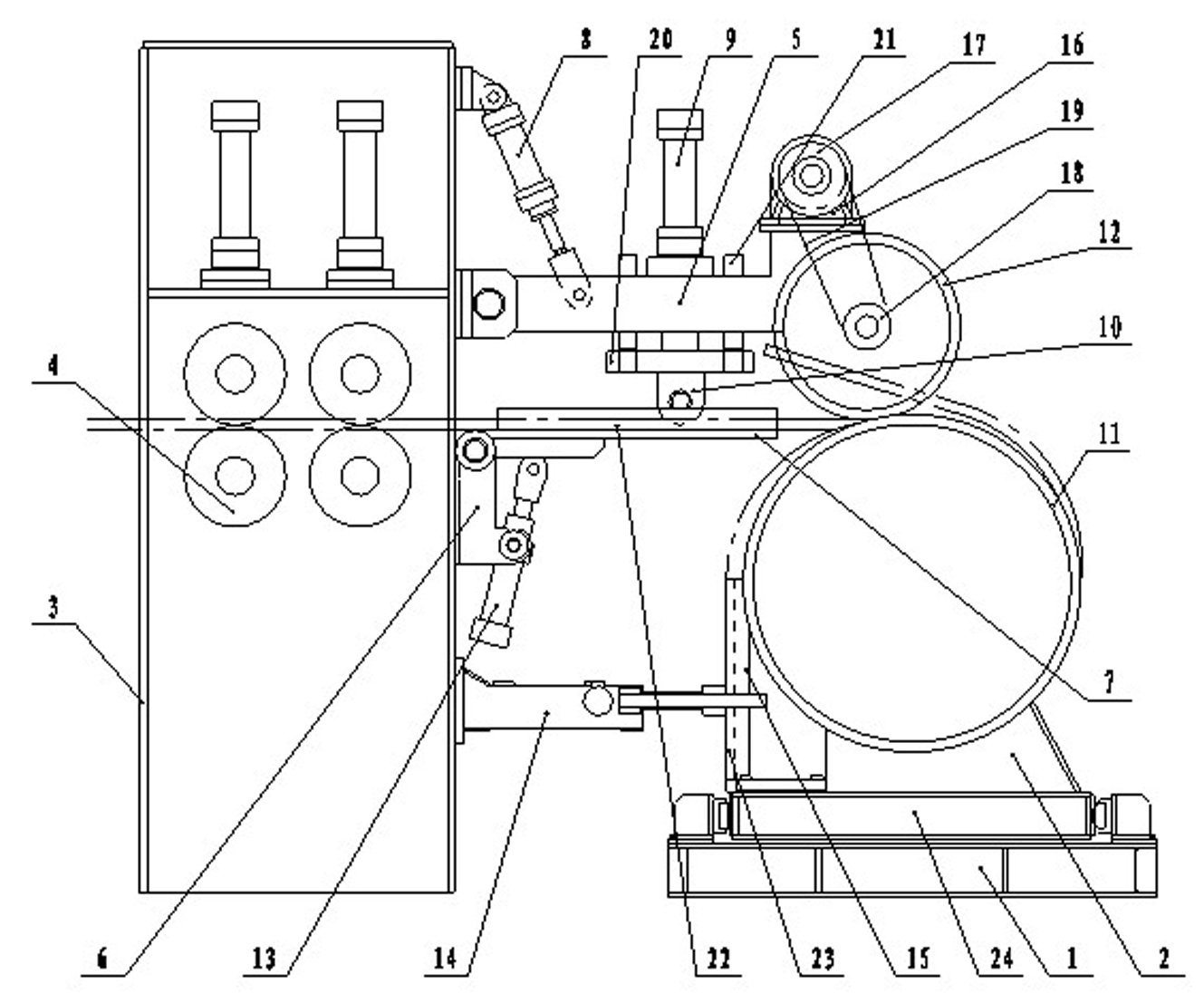

Large cross-section coiling steel uncoiling equipment

InactiveCN101920280AReasonable and reliable transmission structureIncrease motivationMechanical engineeringEngineering

The invention relates to large cross-section coiling steel uncoiling equipment, solving the problem that the rough straightening can not be carried out on large cross-section coiling steel because no large cross-section coiling steel uncoiling equipment exists at present. The rear wall of a stand is articulated with a press plate and fixed with a support seat; the upper part of the support seat is articulated with a support plate; a first oil cylinder articulated with the press plate and a machine base is arranged between the press plate and the rear wall of the machine base, and a second oil cylinder is fixed on the press plate; the end part of the second oil cylinder is provided with a pinch roller; the rear part of the press plate is provided with a press roll; the press roll is provided with a rotary driving mechanism; a third oil cylinder articulated with the support plate and the support seat is arranged between the support plate and the lower part of the support seat; and a shovelling plate lower than the axle center of a sleeve in height is placed on the machine base. The invention has reasonable and reliable structure design, not only enhances the power of the head straightening of the large cross-section coiling steel, but also plays a role of pinching coiled bar steels, realizes the uncoiling and the integral straightening of the large cross-section coiling steel and has the advantages of reasonable structure, convenient operation and lower cost.

Owner:TAIYUAN PLS ENG & TECH

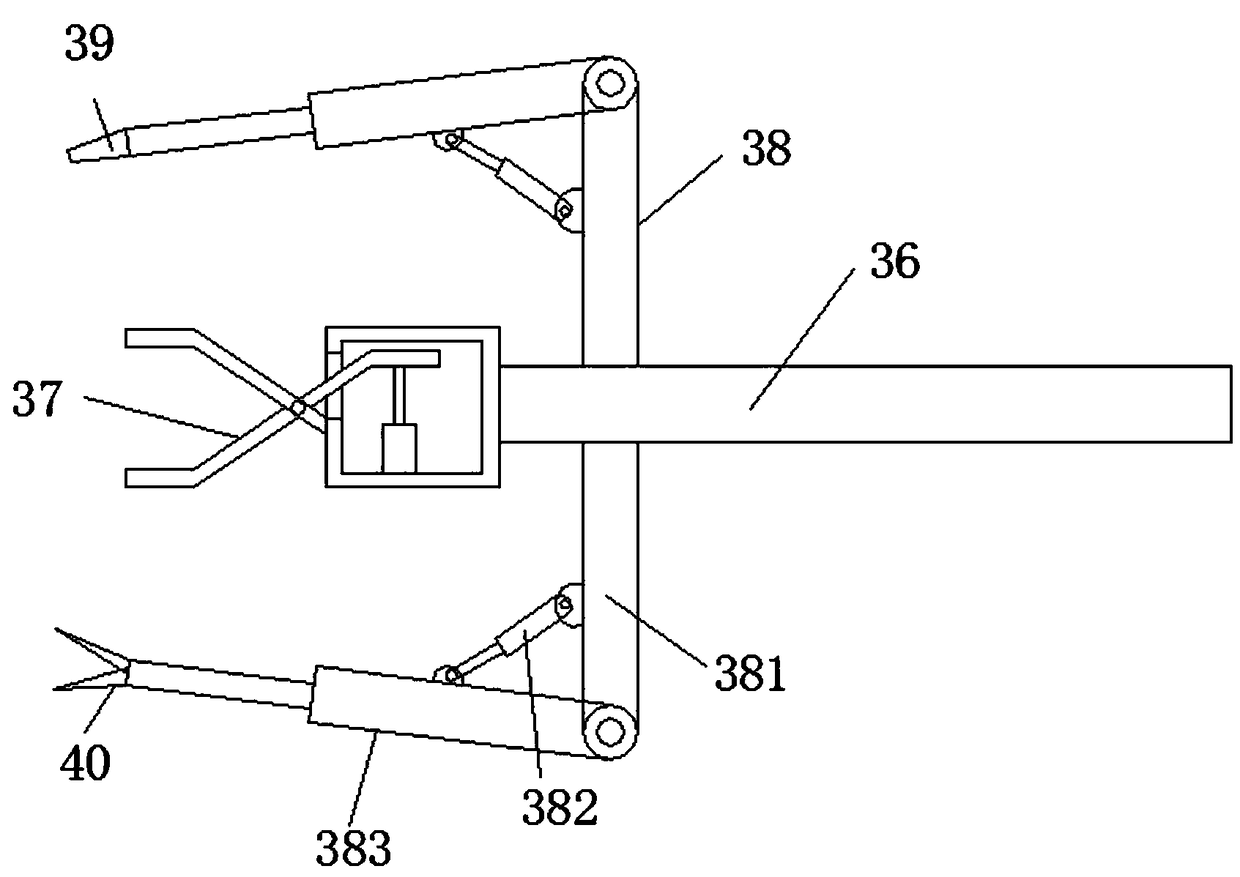

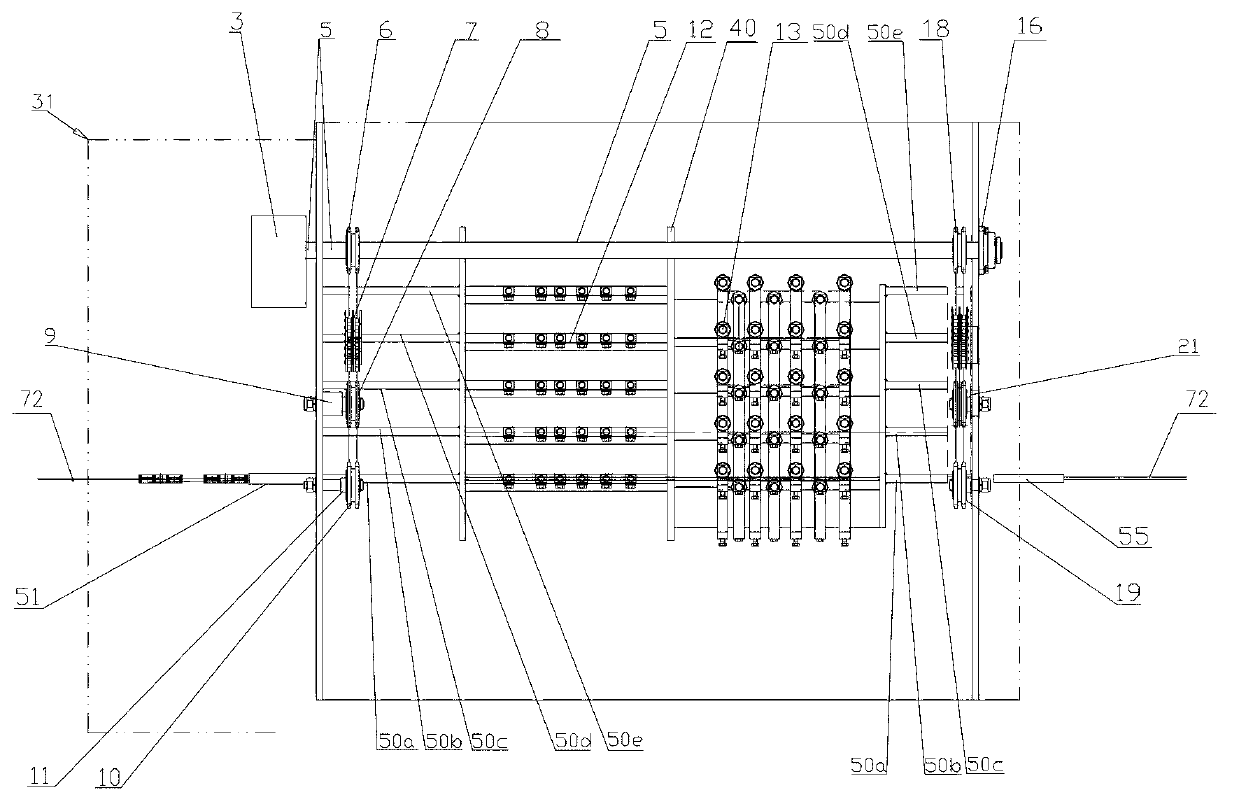

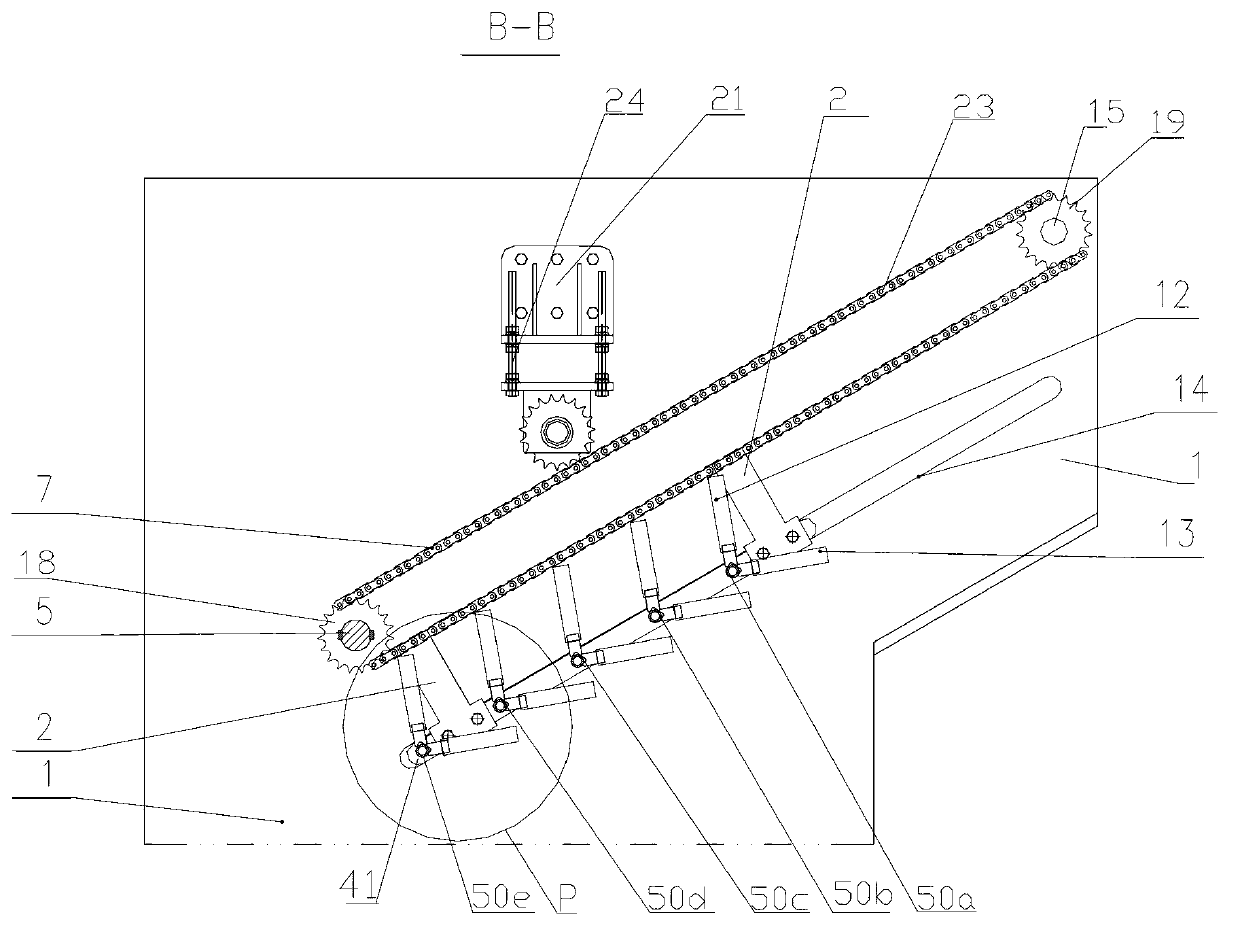

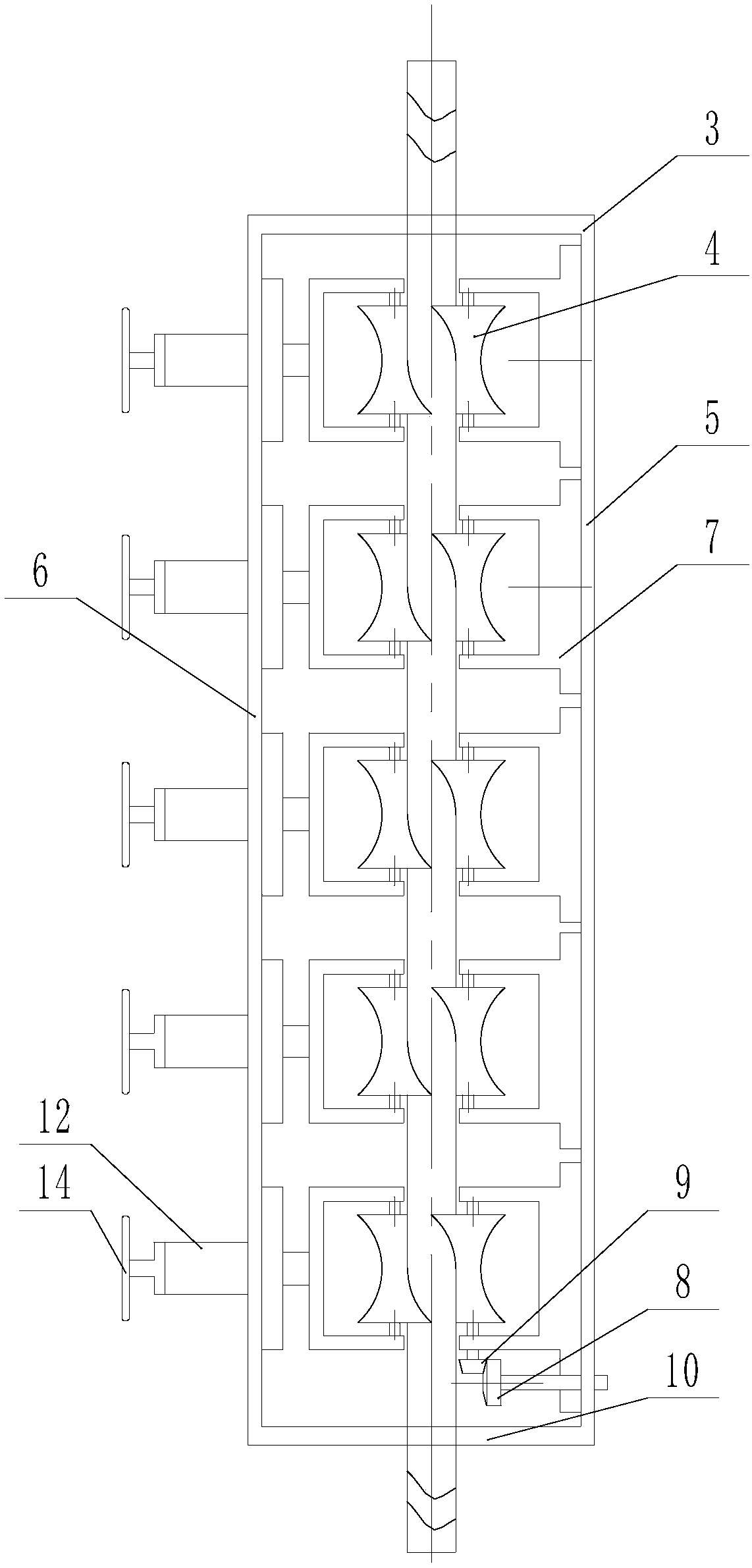

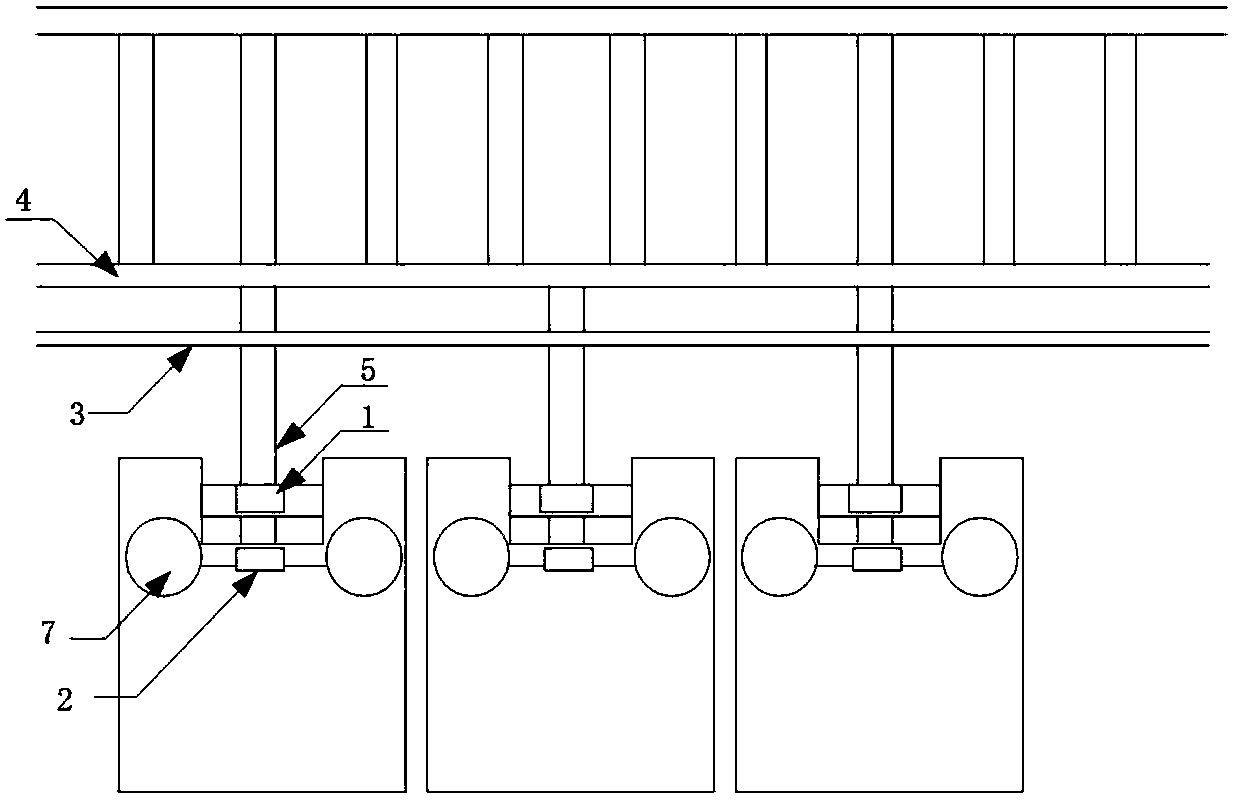

Multi-specification movement alignment mechanism of reinforcement bar straightening machine

ActiveCN103128197AAchieve straighteningStraightening saves time and effortReciprocating motionEngineering

The invention discloses a multi-specification movement alignment mechanism of a reinforcement bar straightening machine. The multi-specification movement alignment mechanism of the reinforcement bar straightening machine comprises a rack, and a multi-thread steel-bar straightening group is arranged between an inlet guide pipe and an outlet guide pipe. Two sides of the multi-thread steel-bar straightening group are fixed at a connecting board of an alignment group, two outer side faces of the connecting board of the alignment group are respectively fixed at one ends of multiple steel-bar guide pipes with different hole diameters, and the other ends of the multiple steel bars are respectively fixed at two movable blocks, the two movable blocks are respectively arranged at two sliding channels of the rack in a sliding mode, and the two movable blocks are respectively connected with two reciprocating motion mechanisms which are operated synchronously. The multi-specification movement alignment mechanism of the reinforcement bar straightening machine has the advantages that when steel bars of different diameters are aligned, only the two movable blocks needing to be moved and one of the specification steel-bar guide pipes and one of specification steel-bar alignment roller ways are enabled to be directly faced at the inlet guide pipe and the outlet guide pipe to achieve alignment of steel bars of different specifications, the multi-specification movement alignment mechanism of the reinforcement bar straightening machine is small in impaction, stable in transmission, and labor-saving and time-saving in alignment, and a tensioning roller arranged on the rack enables a chain to achieve a best tensioning effect.

Owner:TJK MACHINERY TIANJIN

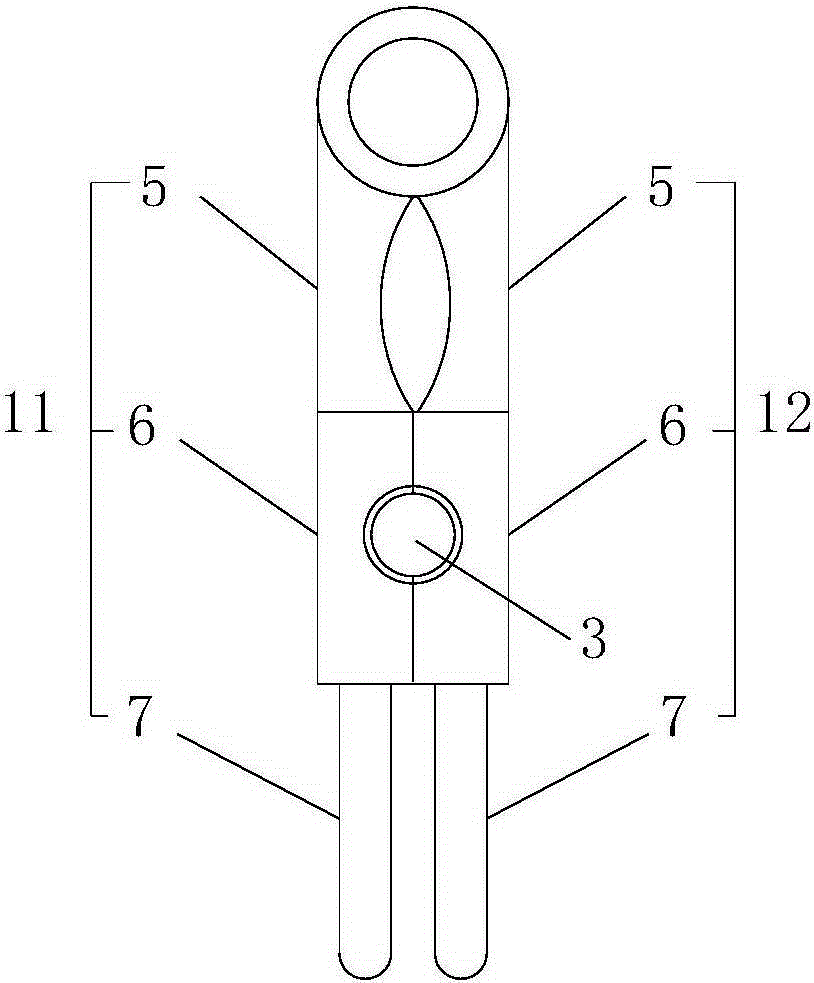

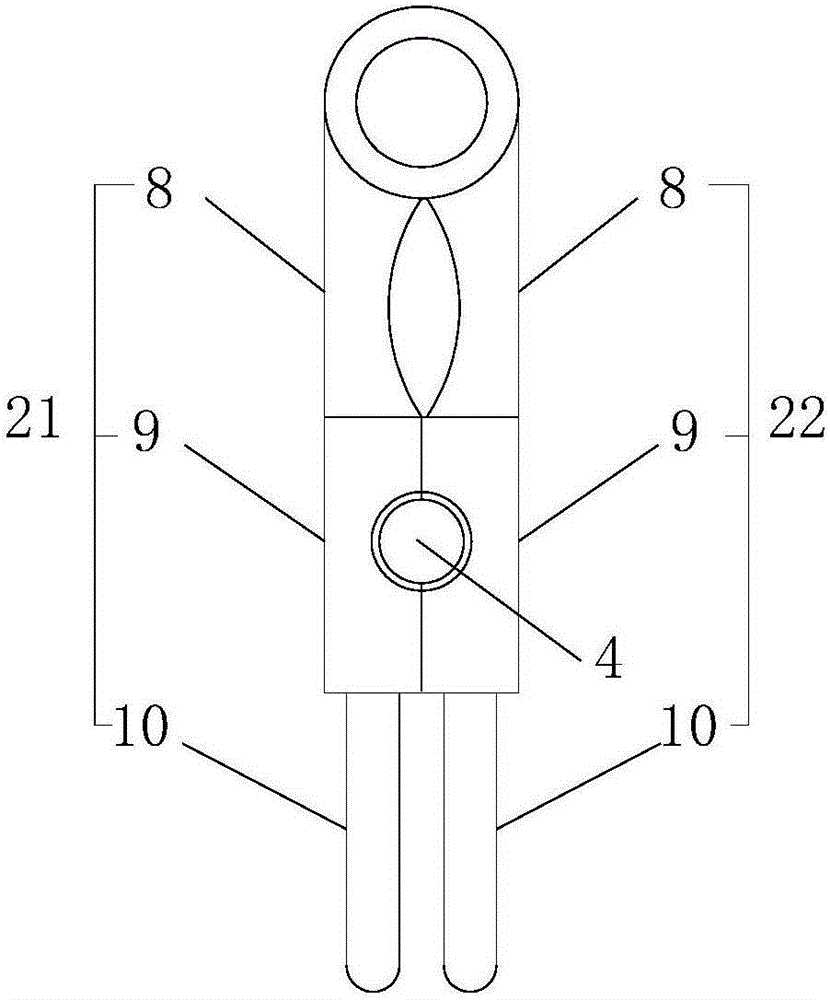

Cable straightening device

The invention discloses a cable straightening device. The cable straightening device comprises a first clamping mechanism and a second clamping mechanism, wherein one end of the first clamping mechanism and one end of the second clamping mechanism are hinged; the first clamping mechanism comprises a clamping handle A and a clamping handle B; the top ends of the clamping handle A and the clamping handle B are hinged, the clamping handle A and the clamping handle B relatively rotate, and accordingly, opposite surfaces of the clamping handle A and the clamping handle B are attached to form a first clamping hole allowing a cable to penetrate through; the second clamping mechanism comprises a clamping handle C and a clamping handle D, the top ends of the clamping handle C and the clamping handle D are hinged, the clamping handle C and the clamping handle D relatively rotate, accordingly, opposite surfaces of the clamping handle C and the clamping handle D are attached to form a second clamping hole allowing the cable to penetrate through, and the second clamping hole is in interference fit with the cable. According to the cable straightening device, time and labor are saved, the problems of time consumption and labor consumption during manual straightening of the cable during power construction is effectively solved, and the work efficiency is improved.

Owner:ANHUI WUZHOU SPECIAL CABLE GRP

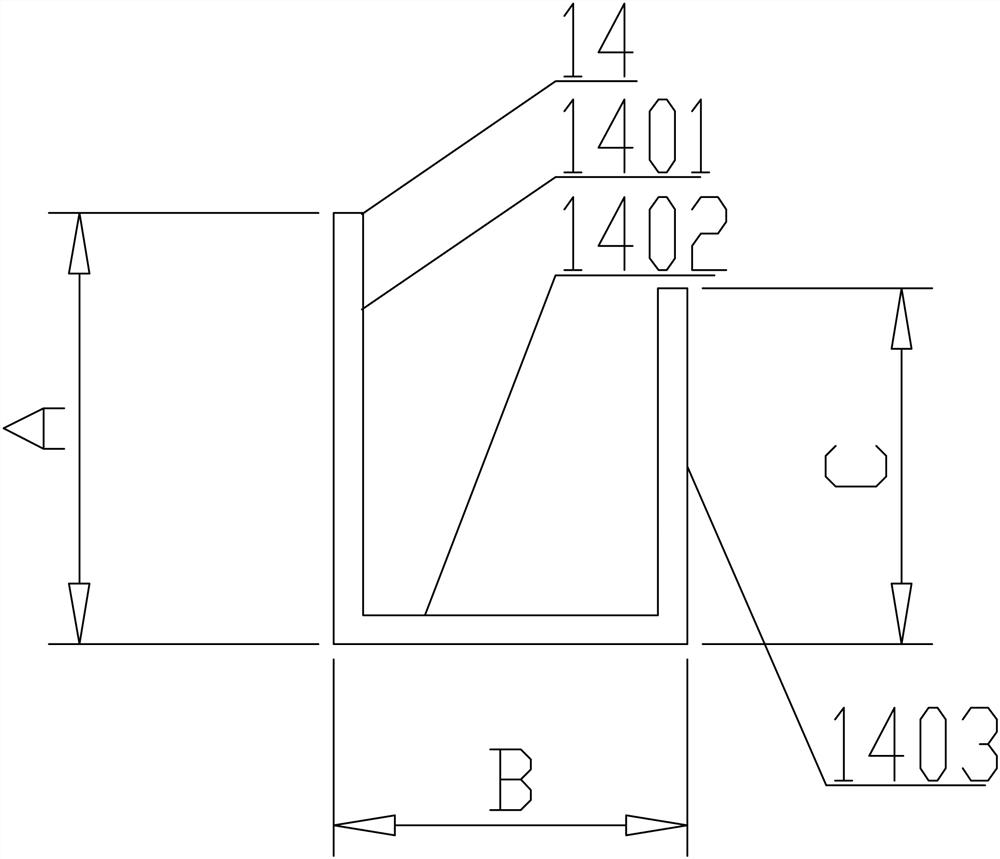

Parallel wing flange steel channel straightening device

ActiveCN108421851AAchieve straighteningRealize continuous straightening in large batchesSloping shouldersEngineering

A parallel wing flange steel channel straightening device comprises an equipment machine frame, an upper straightening assembly and a lower straightening assembly. The upper straightening assembly comprises an upper straightening roller, an upper straightening plate and an upper washer. The lower straightening assembly comprises a lower straightening roller, a lower straightening plate and a lowerwasher. The straightening force outer edge and the top end of the outer edge of the lower straightening plate are arranged in a spaced mode and form a straightening gap used for allowing steel channel webs to pass. Based on the structure, steel channel wing flanges are located in a space formed by the upper straightening assembly and the lower straightening assembly after combination, a straightening transition face is formed between the straightening plane of the lower straightening plate and a straightening boss and can limit the size of the steel channels, thus, deformation of the steel channels in the steel channel straightening process can be avoided, and the defect of sloping shoulder of the steel channel webs is avoided. The problem of the sloping shoulder defect of the outer sidesof the steel channel webs can be effectively solved, the operation stability of workpieces in the straightening process is improved, thus, the production efficiency and product percent of pass are improved, and the straightening device is suitable for batch straightening operation.

Owner:SHANDONG IRON & STEEL CO LTD

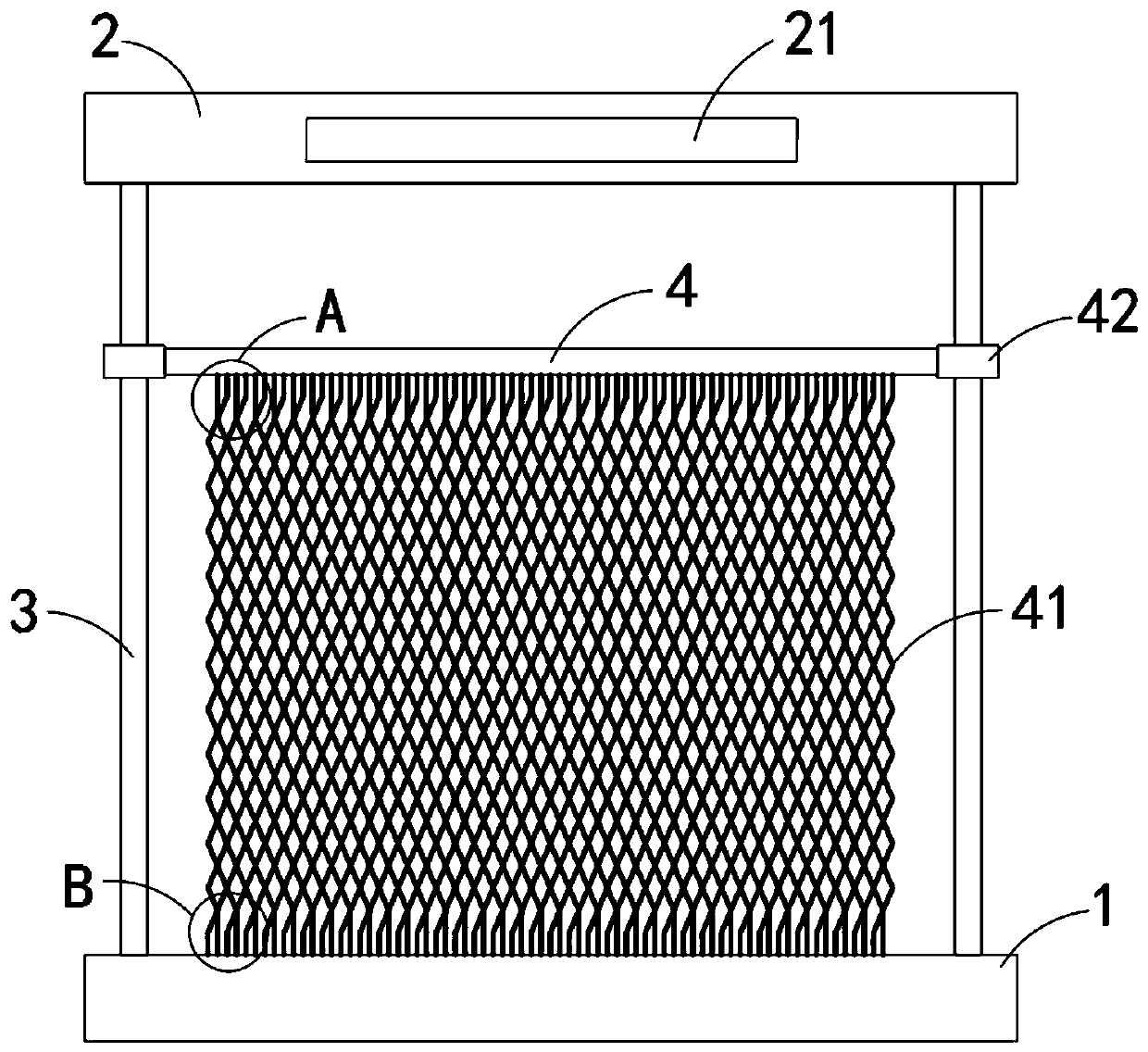

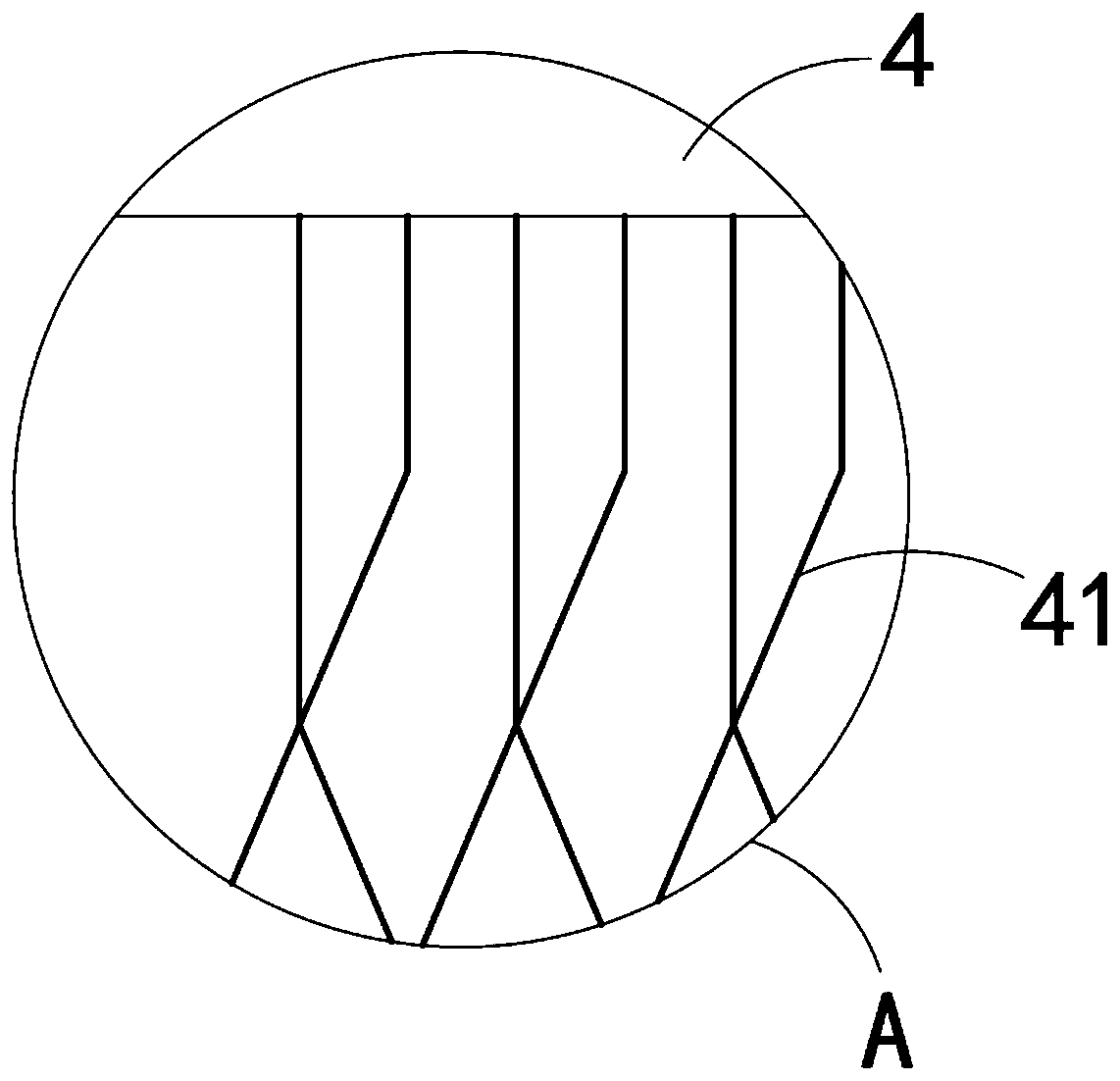

Plate-and-frame dust remover filter core

InactiveCN110585827AAchieve straighteningRealize resetDispersed particle filtrationTransportation and packagingHoneycombEngineering

Belonging to the field of air purifiers, the invention particularly relates to a plate-and-frame dust remover filter core, which comprises a pedestal and a top seat. Two parallel sliding rods are fixedly connected between the pedestal and the top seat, a movable plate made of a ferromagnetic material is slidably connected between the two sliding rods, an electromagnetic element capable of generating attraction force to the movable plate is mounted in the top seat, a plurality of wavy and elastic filter paper plates are fixedly connected between the movable plate and the pedestal, the wave crests and wave troughs of the filter paper plates extend along a vertical direction, and the wave crests and the wave troughs between every two adjacent filter paper plates are correspondingly arranged,so that a honeycomb-shaped dust collection space is formed among the plurality of filter paper plates. By means of the electromagnetic element and the movable plate made of the ferromagnetic material,resetting and straightening of the filter paper plates can be achieved only by powering on and powering off the electromagnetic element according to certain frequency, and dust on the filter paper plates can be shaken off easily, thus realizing cleaning of the filter core.

Owner:商丘寅越网络科技有限公司

Shuttlecock feather ironer

The invention relates to a shuttlecock feather ironer which comprises a pressing plate, a straightening plate and steam injection heads. A hinging portion which extends outward is arranged on the left of the pressing plate to bring convenience to the pressing plate to be connected with other equipment which is connected externally, the straightening plate is fixed on the lower end face of the right portion of the pressing plate, the steam injection heads are uniformly and symmetrically embedded on the straightening plate, the lower end face of each steam injection head is flush with that of the straightening plate, the upper portion of each steam injection head penetrates the pressing plate, and dovetail guide rails are symmetrically arranged on the front side and the rear side of the pressing plate and can be matched with the externally-connected equipment to realize up-down movement of the pressing plate. The shuttlecock feather ironer has the advantages of reasonable structure design, low production cost and convenience in operation, and can iron feathers so as to assist in straightening of shuttlecock feathers, and straightening quality is ensured, so that production benefit of factories is increased.

Owner:安徽省无为县奥宇体育用品有限公司

Method for performing rotary feed straightening on metal pipes

ActiveCN109420691AAchieve straighteningImprove the effect of flaw detectionMetal-working feeding devicesPositioning devicesMetal

The invention discloses a method for performing rotary feed straightening on metal pipes. The method comprises the step of realizing feed straightening on the metal pipes by means of straightening rollers arranged in pairs in the process that the metal pipes move forwards in the axial direction, and is characterized in that the metal pipes rotate while moving forwards, and thus, the metal pipes spirally move forwards, and the metal pipes are straightened in the process that the metal pipes spirally move forwards. According to the method disclosed by the invention, the metal pipes can be straightened when being fed before flaw detection so as to improve the flaw detection effect, and the method has the advantages of being simple to implement and having a good straightening effect.

Owner:宝武特冶航研科技有限公司

Straightening method of micro metal tube

The invention provides a straightening method of a micro metal tube. The straightening method comprises the following steps of: 1, penetrating a metal wire into the micro metal tube; 2, arranging the micro metal tube penetrated with the metal wire on a wire straightening machine for straightening; and 3, taking the straightened micro metal tube down from the metal wire, and cleaning and drying the micro metal tube to obtain the micro metal tube with the straightness not more than 5mm / m. According to the invention, the straightening method is skillful in design, stable in process and strong in operability; the straightening principle of hyperbola straightening is utilized fully, and the conventional wire straightening machine is adopted to provide a straightening deflection hyperbola for the micro metal tube, so that the micro metal tube is forced to be bent according to the deflection hyperbola and is finally straightened; and the straightening method can be widely applied to straightening of various micro metal tubes and particularly can be used for straightening the micro metal tubes which are poor in plasticity and difficult to deform.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

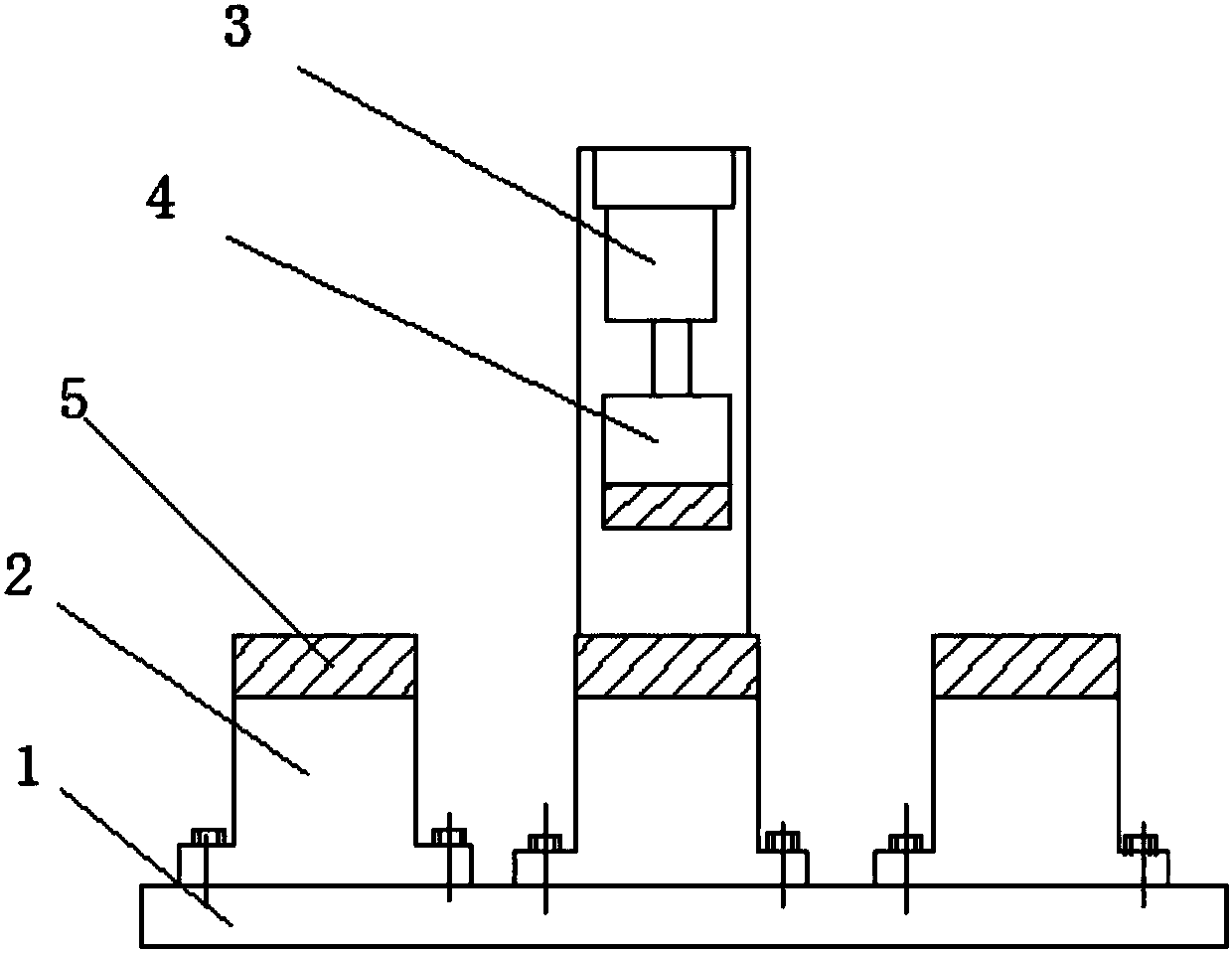

Novel seamless steel tube straightening machine

PendingCN107971367AStrong structural stabilityFit closelyMetal-working feeding devicesPositioning devicesSteel tubeEngineering

The invention provides a novel seamless steel tube straightening machine. The novel seamless steel tube straightening machine comprises a base and a material supporting plate; multiple same positioning mechanisms are arranged on the material supporting plate; a first cylinder is arranged on a guiding block; a first ejector rod is connected with a side plate by passing through the guiding block andthe side plate is provided with an end positioning block; the end, which is far away from a supporting frame, of a top plate is connected with the base by positioning rods and a straightening mechanism is arranged on the base within the position; a sliding plate is connected with the side, which is far away from the material supporting plate, of the straightening mechanism in a sliding manner anda second cylinder is arranged on the sliding plate by a replaceable fixing seat; an end pushing block is arranged on a second ejector rod; the supporting frame is arranged on the straightening mechanism. By means of the novel seamless steel tube straightening machine, the integral operation of positioning, feeding and straightening of a steel tube can be realized, all the parts can coordinate with each other closely, the time that straightening requires can be saved, the better straightening effect can be guaranteed, the structural style of the related coordination of all the parts during straightening can be novel and the service life of equipment can be relatively high.

Owner:天津腾飞钢管有限公司

Automatic pin processing device of capacitor

InactiveCN107919239AImprove processing efficiencyReduce manual involvementCapacitor manufactureCapacitanceEngineering

The invention discloses an automatic pin processing device of a capacitor. The device comprises a box body; a first driving wheel and a second driving wheel are in rotation connection with two sides of the bottom of the inner wall of the box body by a first support post and a second support post; and the surfaces of the first driving wheel and the second driving wheel are fixedly connected with clamping devices by a conveying belt. A second motor is fixedly connected to the top side of the box body; an output shaft end of the second motor is fixedly connected to a first electric telescopic rodby a first screw rod and a moving block; and a sucking plate is fixedly connected to the bottom of the first electric telescopic rod. A fixed plate is fixedly connected between two opposite sides ofthe inner wall of the box body; a straightening device and a cutting seat are fixedly connected to the top of the fixed plate successively; and a cutting device is fixedly connected to the top of theinner wall of the box body. The invention relates to the technical field of capacitor processing. With the automatic pin processing device, automatic capacitor material feeding, moving, and pin processing are realized; the manual labor is reduced; the production cost is lowered; and the processing efficiency of the capacitor is improved.

Owner:湖州宏跃电子器件厂

Device and method for fitting sacks

The device has a gripping unit and an insertion unit for gripping sacks The insertion unit is transferred in a partly hanging position for insertion. An alignment unit is provided to ensure defined vertical alignment of the sacks to be inserted. A storage table is provided for retaining a flatly lying sack bundle. The alignment unit comprises a blower with an air nozzle. The blower outputs partly upward aligned air blast. The alignment unit aligns the sacks against a system unit with an upper stop. An independent claim is also included for a method for insertion of valve sacks on a filler neck of a pack machine.

Owner:HAVER & BOECKER

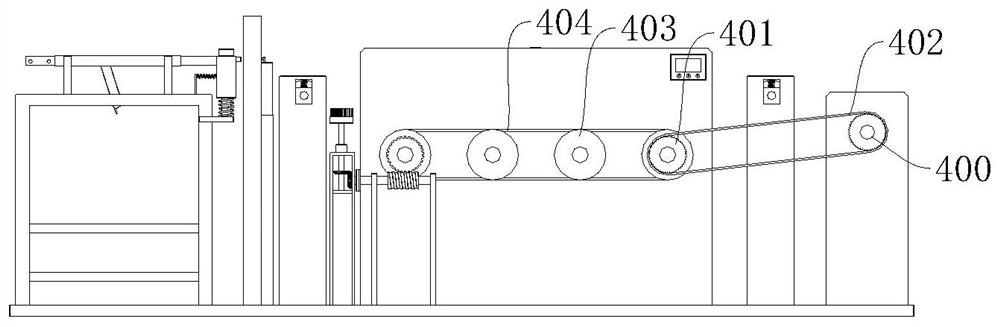

Reinforcement bar straightening machine

The invention belongs to the field of machining devices, and particularly relates to a reinforcement bar straightening machine. The reinforcement bar straightening machine comprises a horizontal module and a vertical module, and the horizontal model can drive a frame to rotate through a belt wheel. The reinforcement bar straightening machine has the advantages that due to the arrangement of the vertical module and the horizontal module, the vertical module provides tractive force through a driving wheel to enable reinforcement bars to move forwards so as to primarily straighten the reinforcement bars, then the reinforcement bars enter the horizontal module to be further straightened at multiple angles and in multiple directions through pressing among multiple rolling wheels and rotation of the horizontal module, machining efficiency is improved, and quality of the straightened reinforcement bars is improved as well.

Owner:安徽力盛新材料有限公司

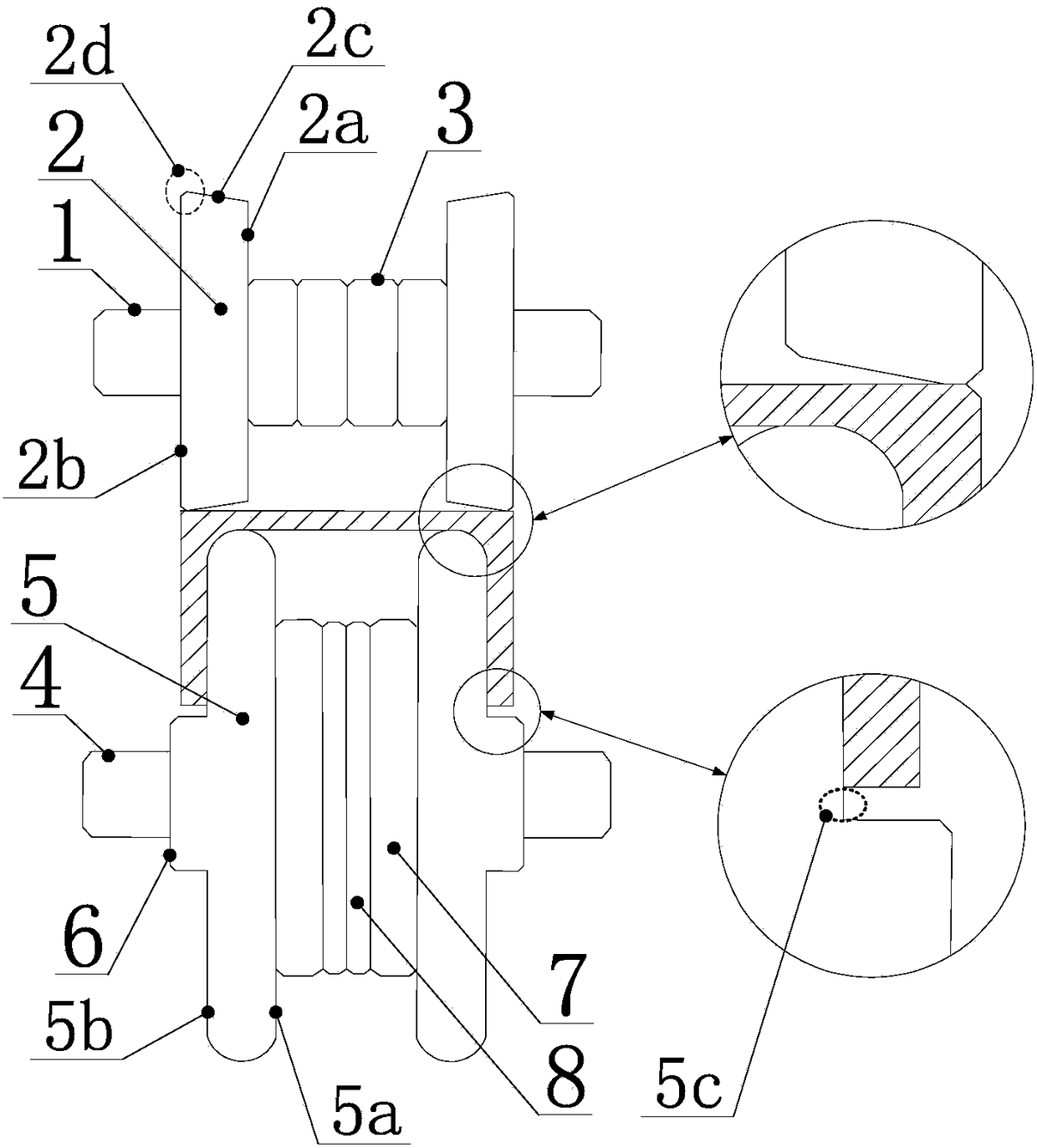

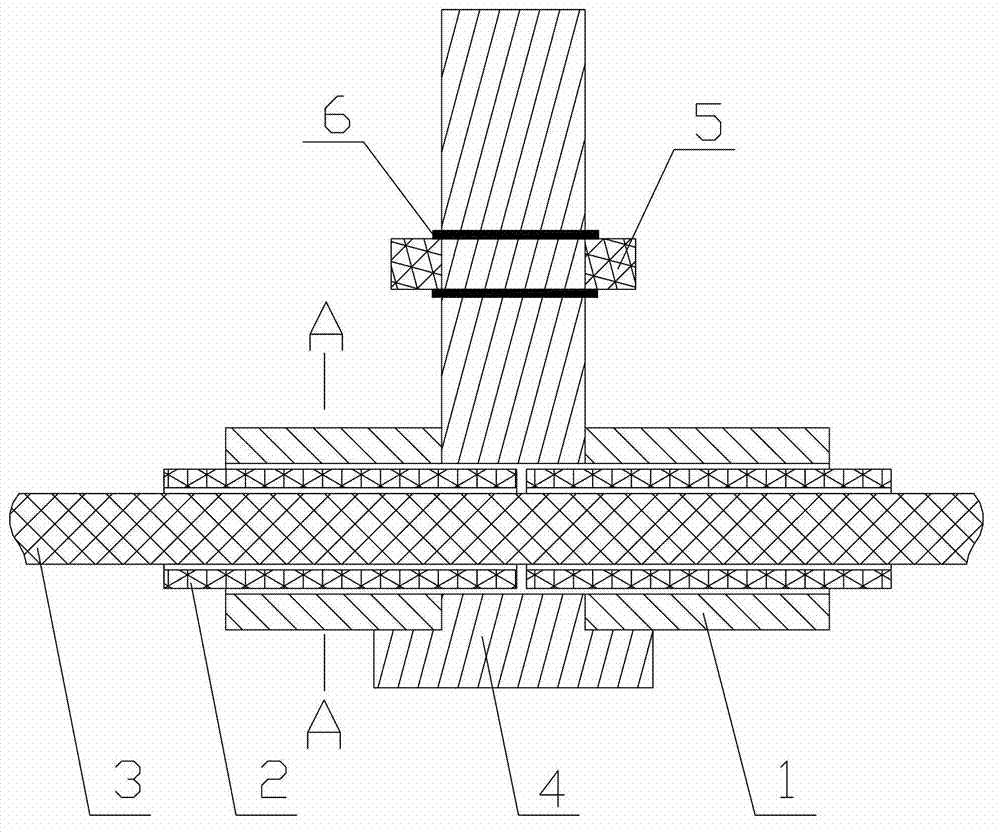

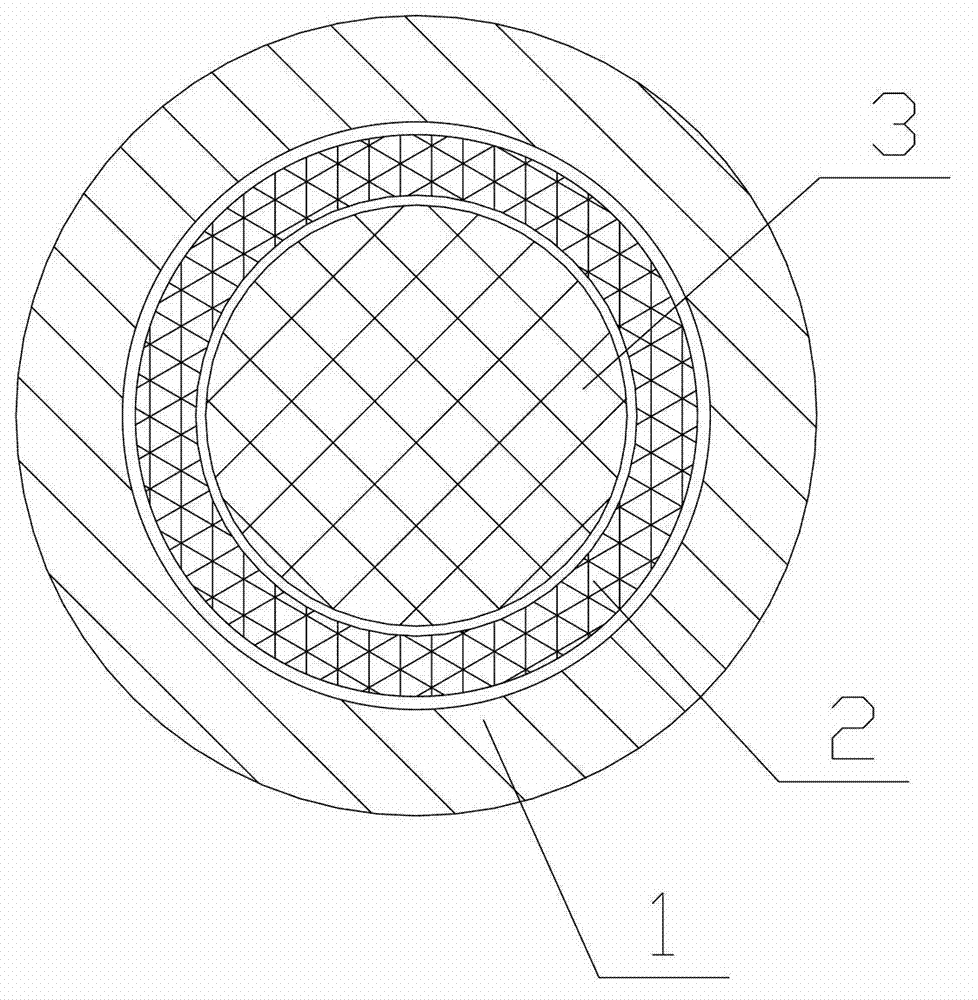

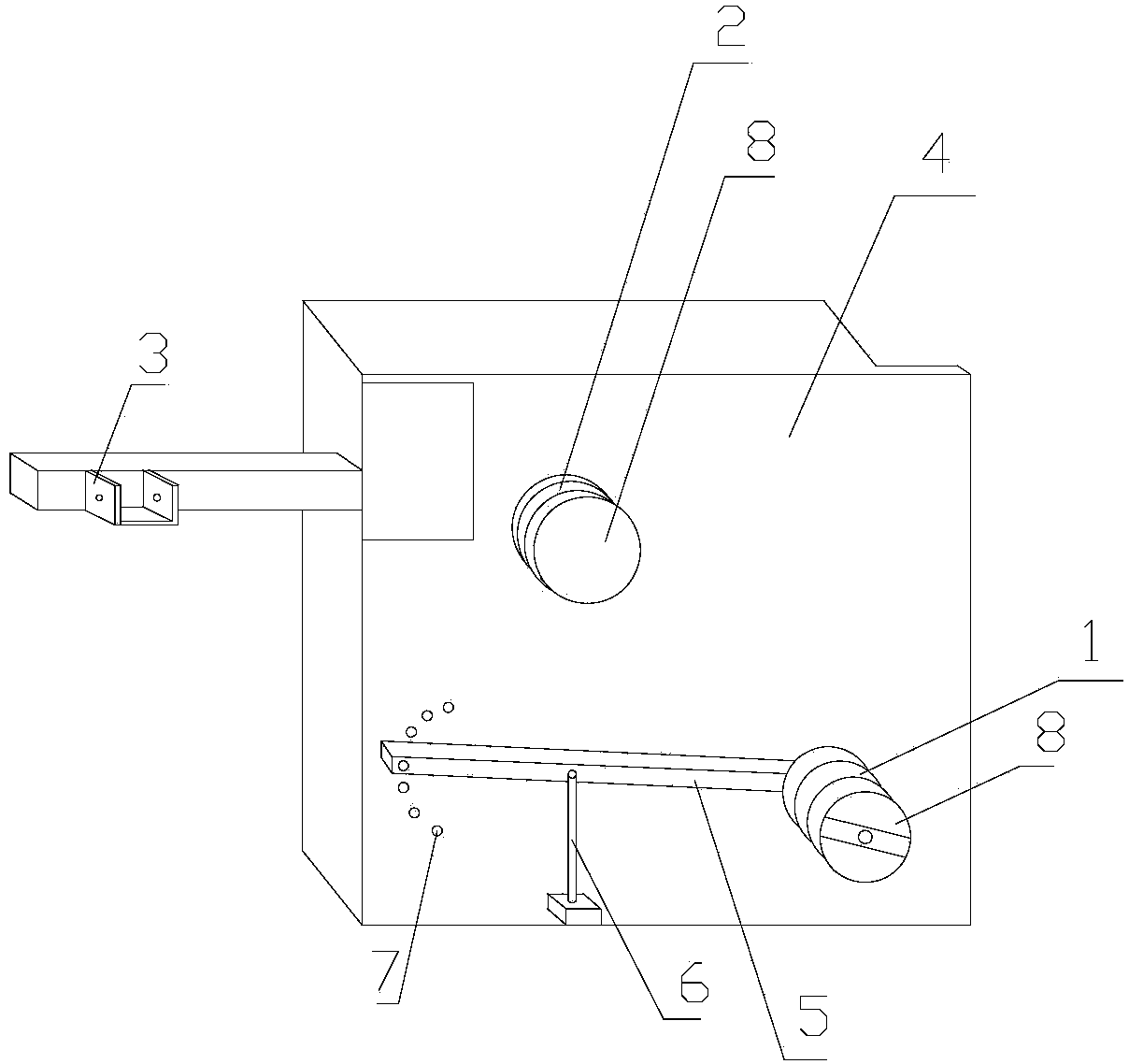

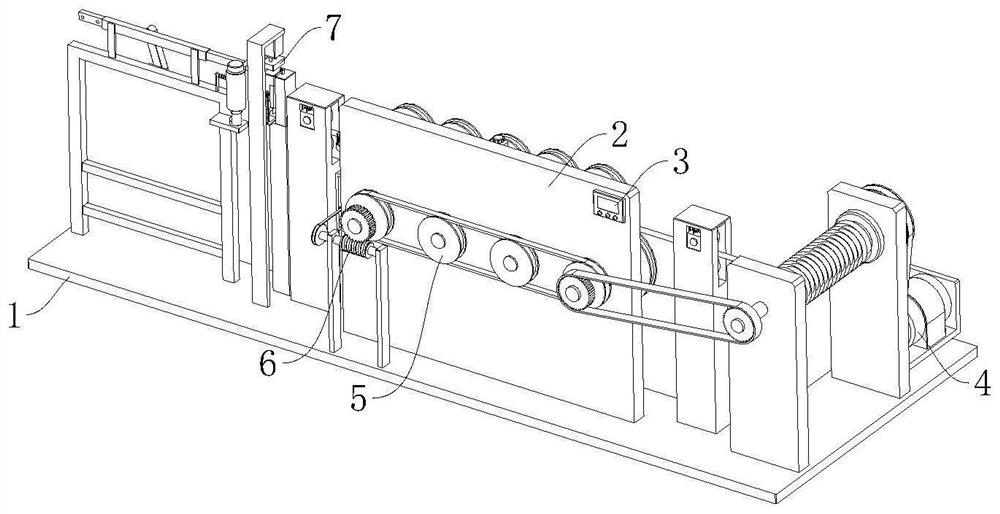

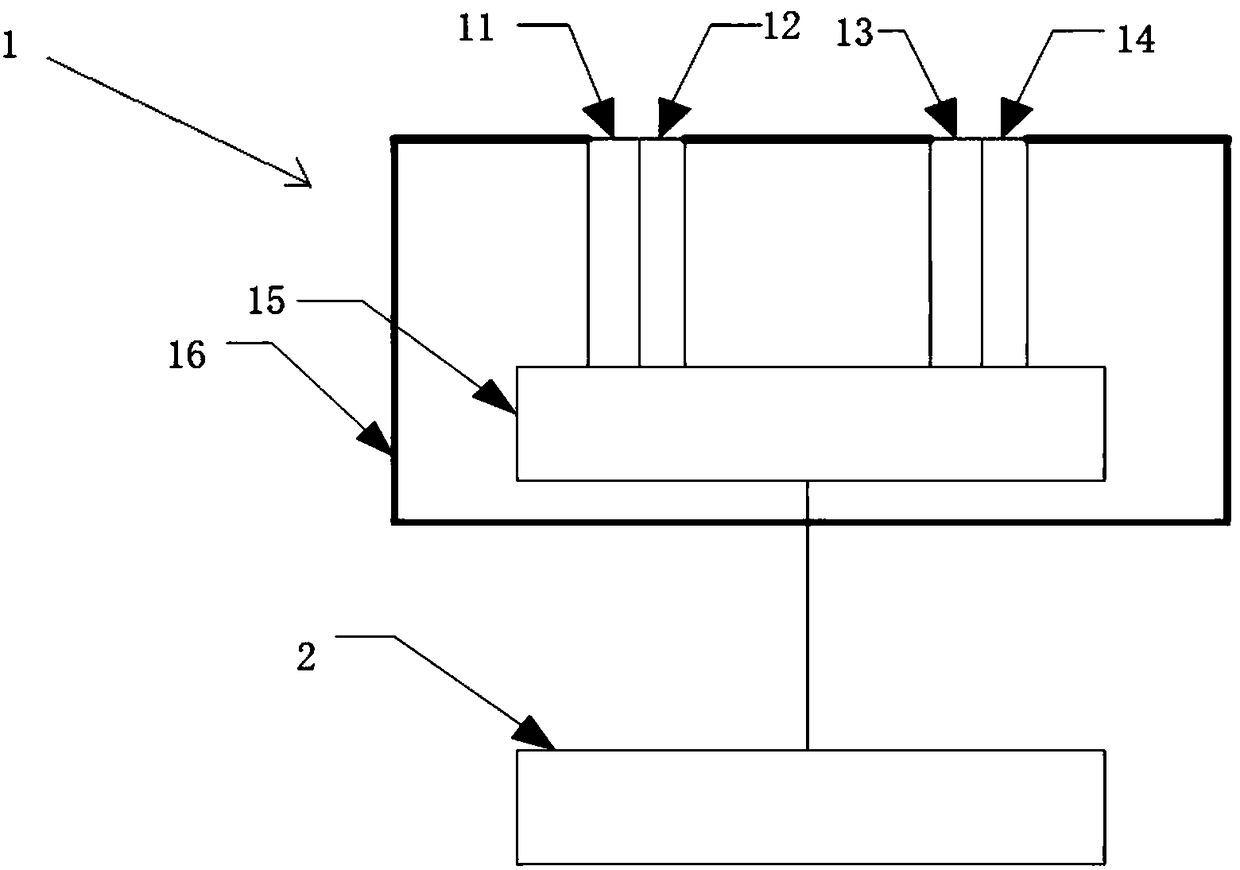

Cable straightening machine

ActiveCN104200923AOvercoming Leveler ProblemsAchieve straighteningCable/conductor manufactureElectrical and Electronics engineering

The invention discloses a cable straightening machine. The cable straightening machine comprises a first wire coil (1), a second wire coil (2) and a wire outlet portion (3), wherein a cable sequentially passes through the first wire coil (1), the second wire coil (2) and the wire outlet portion (3). The cable straightening machine overcomes the problem that few cable straightening machines are used in the prior art, and achieves the purpose of straightening the cable.

Owner:WUHU EXCELLENCE WIRE HARNESS SYST

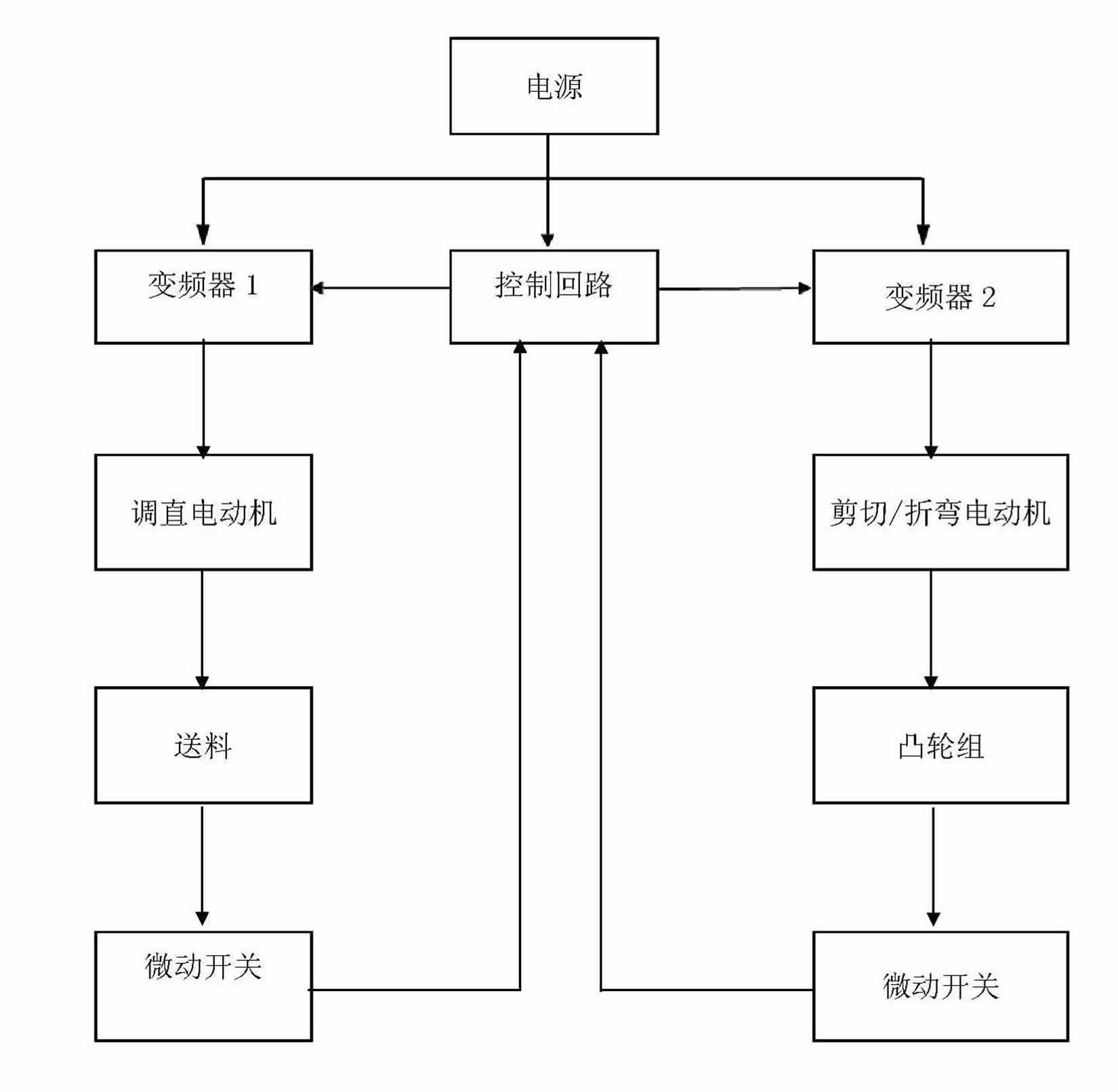

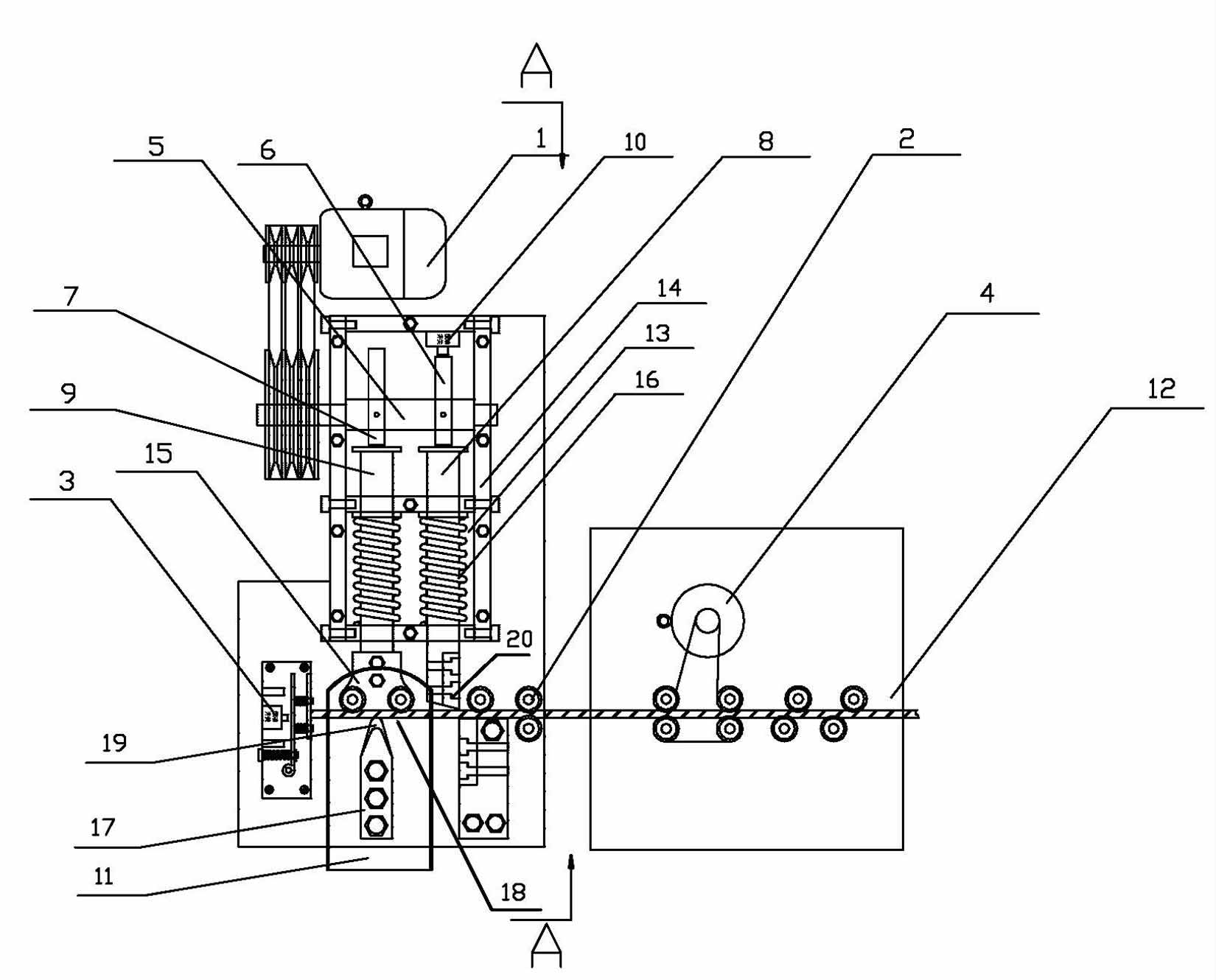

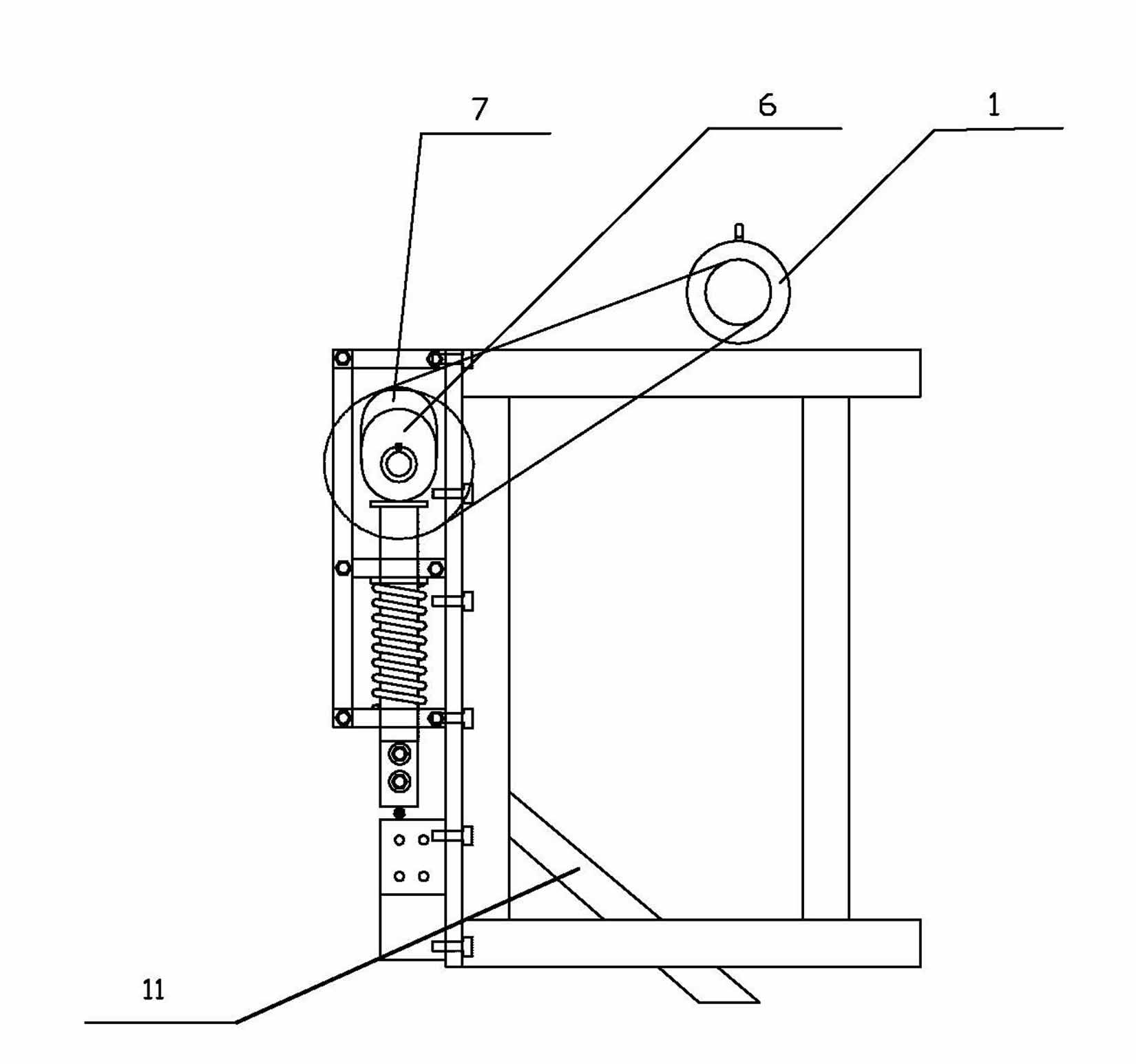

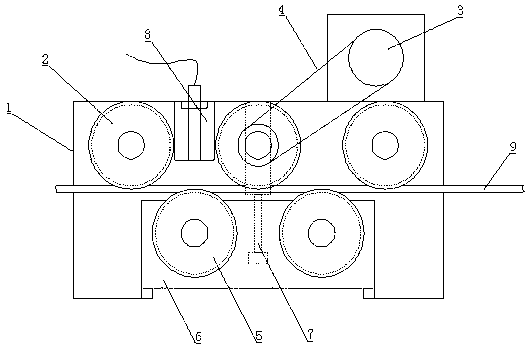

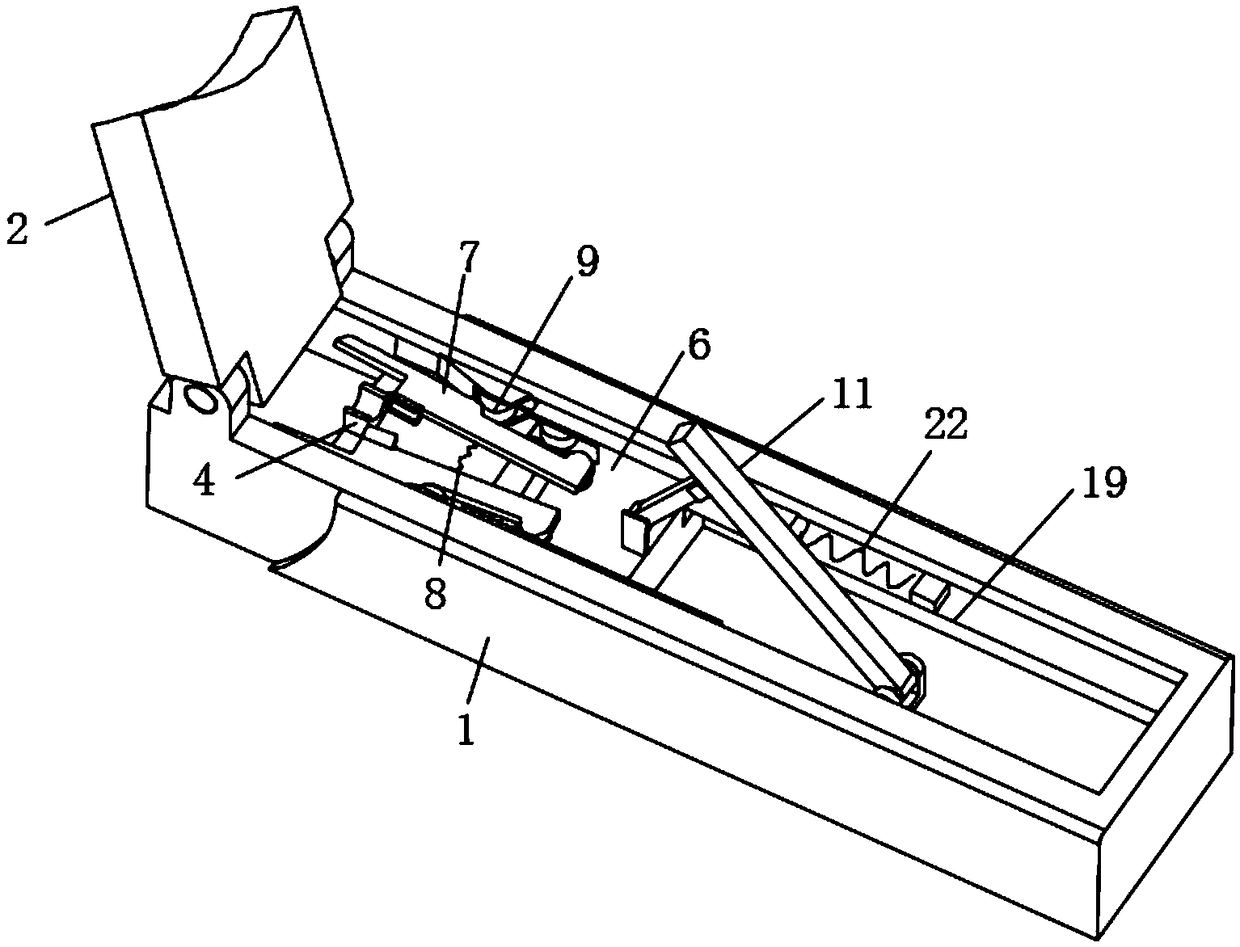

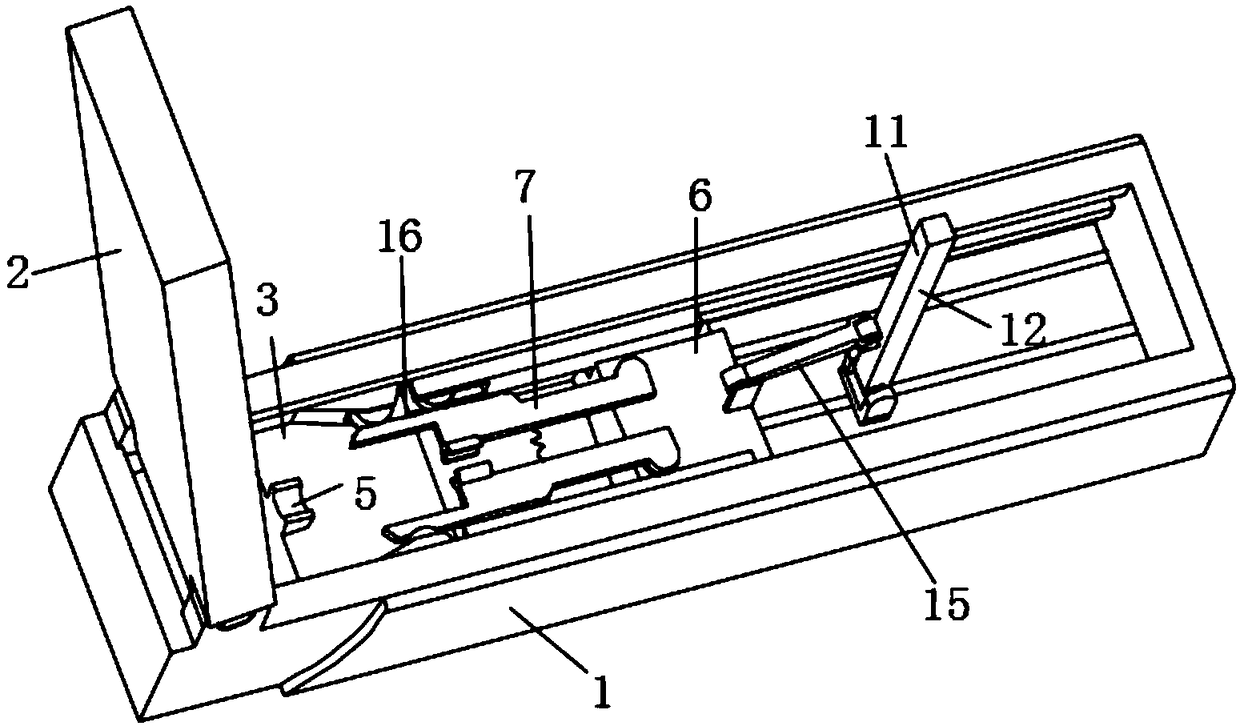

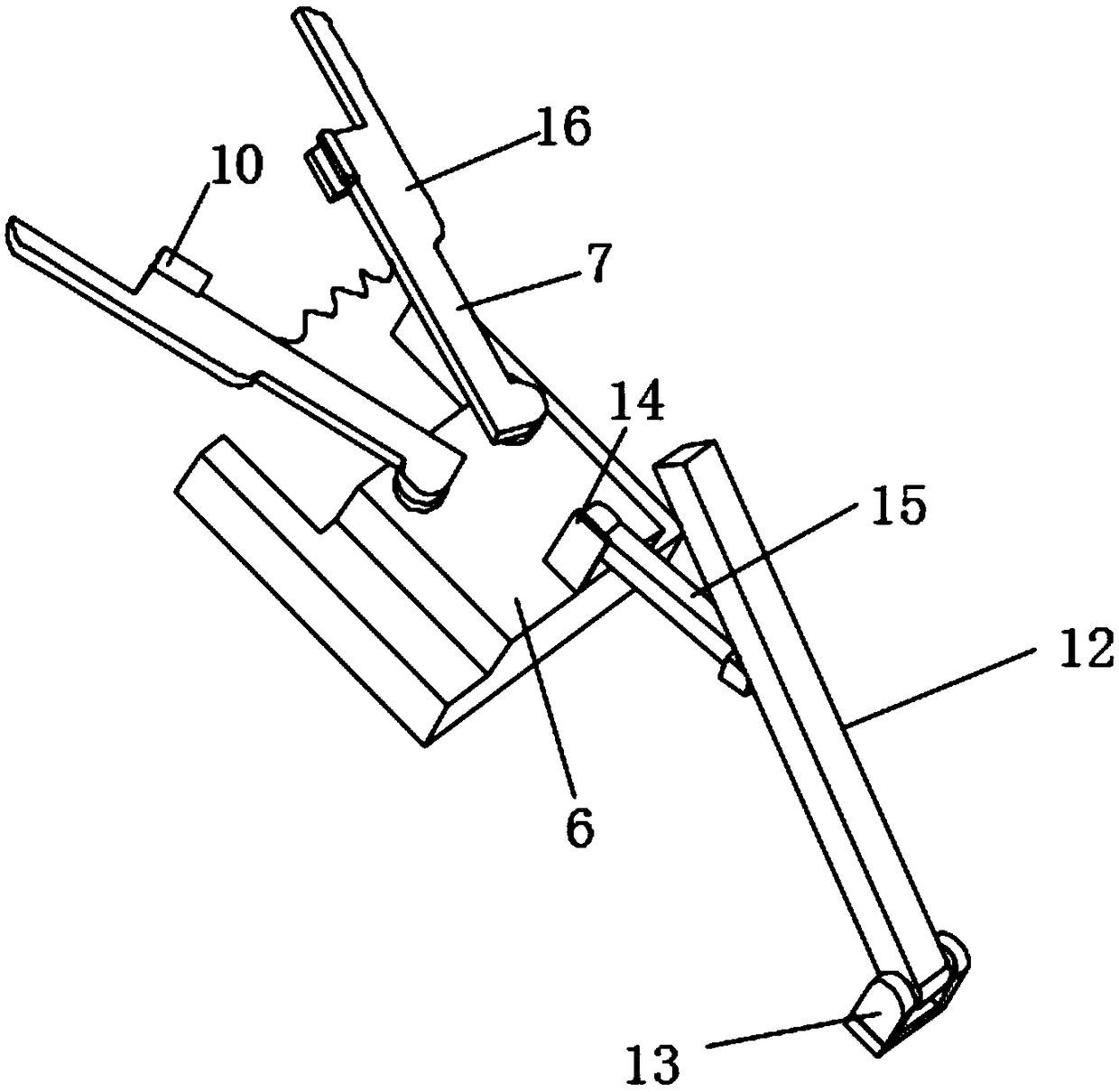

Straightening, shearing and bending machine for steel bars

The invention belongs to the field of metal bending equipment, in particular to a straightening, shearing and bending machine for steel bars. The machine comprises a feeding mechanism (12), a shearing / bending component (13), a micro-switch (3) and a shearing / bending motor (1), wherein the hearing / bending component (13) comprises a frame body (14), a camshaft (5), a shearing cam (6) and a bending cam (7); a movable shearing shaft (8) and a bending shaft (9) are arranged in the frame body (14); a shearing knife (20) and a bending head (15) are sequentially fixedly arranged at one end part of the shearing shaft (8) and one end part of the bending shaft (9); a bending fixture (17) is fixedly arranged in the corresponding position of the bending head (15); return springs (16) are fixedly arranged on the shearing shaft (8) and the bending shaft (9); the working end of the micro-switch (3) corresponds to a steel bar channel (18) to be processed; and a cam micro-switch (10) is arranged in the frame body (14). The straightening, shearing and bending machine for the steel bars is convenient for operation, high in degree of automation, safe and reliable.

Owner:营口东邦环保科技股份有限公司

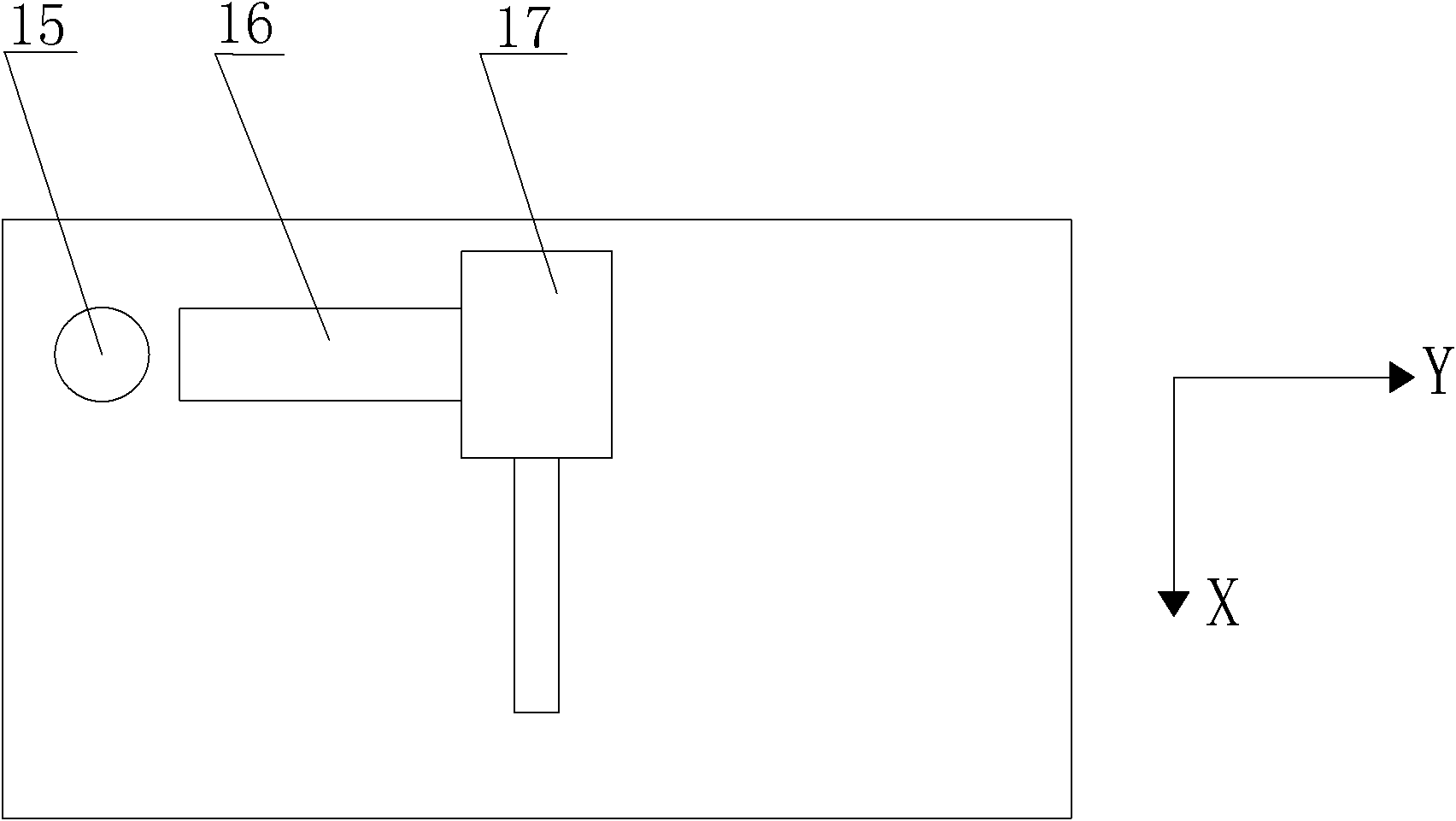

Precise automatic straightening and material returning control system of high-speed cold heading machine used for manufacturing steel balls

ActiveCN103230998AAchieve straighteningReduce labor intensityForging press drivesControl systemProgrammable logic controller

The invention relates to a precise automatic straightening and material returning control system of a high-speed cold heading machine used for manufacturing steel balls. The control system is characterized by comprising a base, a fixed swaging wheel set, a sliding block, a movable swaging wheel set, a motor and a tailing detecting system, wherein fixed swaging wheels of the fixed swaging wheel set are arranged at the upper part of the base; the middle one of the fixed swaging wheels is a material returning wheel driven by the motor; the movable swaging wheels of the movable swaging wheel set are mounted on the sliding block; the sliding block is mounted at the lower part of the upper base; and a pneumatic cylinder is arranged between the sliding block and the base. The system has the advantages that when delivering materials, the movable swaging wheel set on the sliding block is matched with the fixed swaging wheel set to clamp the steel wire and realize the straightening of the steel wire; when the diameter of the steel wire is changed, the pneumatic cylinder can be automatically adjusted to ensure the movable swaging wheel set to compress the steel wire; no manual adjustment is needed; the use is convenient; when the tailings of the steel-wire go through a material sensor of the tailing detecting system, the signal of the material sensor is changed; a motor controller is controlled by a programmable logic controller to start the motor to withdraw the steel wire; and no manual work is needed to pull out the steel wire.

Owner:JIANGSU LIXING GENERAL STEEL BALL

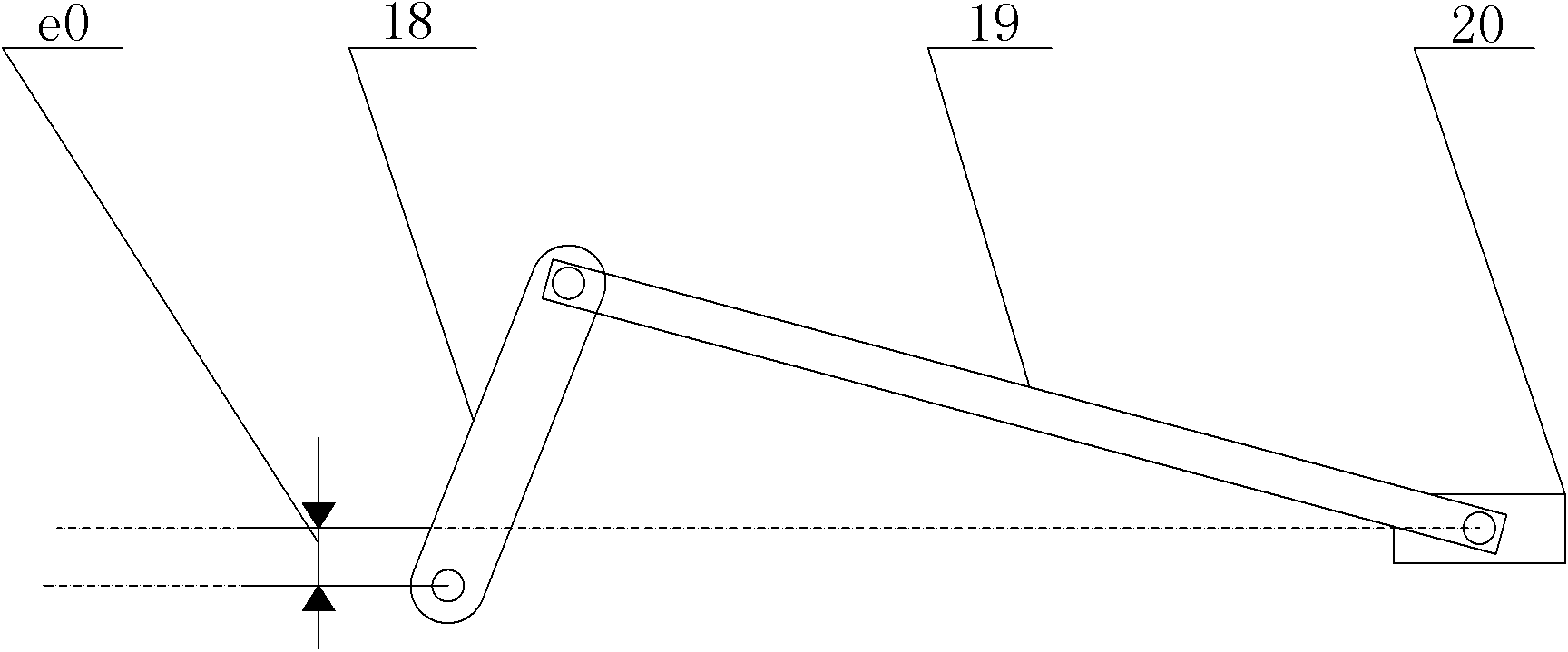

Stretching-bending straightening machine

InactiveCN102553924AQuality improvementAvoid side-to-side situationsMetal rolling arrangementsVertical projectionMetal strips

The invention relates to a stretching-bending straightening machine which is characterized in that a front tension mechanism and a back tension mechanism are respectively arranged at front and back sides of a rolling mill. The front tension mechanism comprises a first roller and a second roller, wherein the first roller and the second roller are parallel in an axial direction and are arranged from left to right in a manner that one is high and the other one is low; and a gap is reserved between vertical projections of the first roller and the second roller. One end of a rolling shaft of the first roller and one end of the rolling shaft of the second roller are provided with first power mechanisms. The back tension mechanism comprises a third roller and a fourth roller, wherein the third roller and the fourth roller are parallel to the axial direction and are arranged from left to right in a manner that one is low and the other one is high; and a gap is reversed between the vertical projections of the third roller and the fourth roller. One end of the rolling shaft of the third roller and one end of the rolling shaft of the fourth roller are connected with the first power mechanisms. By utilizing the stretching-bending straightening machine to roll metal strips, defects of edge waves, middle waves, warping and the like can be eliminated, so that the quality of the strip is improved. The stretching-bending straightening machine is suitable for rolling the metal strip.

Owner:无锡亚新通用机械有限公司

Multifunctional cable cutting equipment

ActiveCN113178810APlay a reset rolePrevent unevenApparatus for cutting/splicing cablesCleaning using toolsEngineeringStructural engineering

The invention relates to the field of cable processing, in particular to multifunctional cable cutting equipment which comprises a base and a vertical plate and further comprises a controller, an unwinding mechanism, a straightening mechanism, a cleaning mechanism and a downward cutting mechanism. The unwinding mechanism comprises an unwinding roller and a driving assembly, the cleaning mechanism comprises a brush and a rotating assembly, and the rotating assembly is arranged at the top of the base. The brush is rotatably arranged at the top of the base, the downward cutting mechanism comprises a cutter, a stamping block and a sliding assembly, the sliding assembly is arranged at the top of the base, the stamping block is arranged above the cutter, the cutter is arranged below the stamping block in a sliding mode, and the driving assembly is electrically connected with the controller. According to the multifunctional cable cutting equipment, the cutting efficiency is high, fixed-length cutting can be achieved, the fixed length can be adjusted, and meanwhile the effect of protecting the cutter can be achieved.

Owner:芜湖市科特电线电缆有限公司

Steel bar bending part straightening equipment

The invention provides steel bar bending part straightening equipment which comprises a working platform, and U-shaped iron with an upward opening is arranged on the working platform; the working platform is further provided with an air cylinder, a piston rod of the air cylinder is arranged downwards, and a pressing head is connected to the end of the piston rod of the air cylinder and right facesthe U-shaped iron. The steel bar bending part straightening equipment is simple in structure; the air cylinder drives the pressing head to move downwards, downward acting force is applied to the steel bar bending part, and the center of the steel bar bending part deforms till the bending part is straightened.

Owner:新昌县扬中磨具有限公司

Coal mine underground scraper conveyor straightening and personnel locking system

The invention relates to a coal mine underground scraper conveyor straightening and personnel locking system which comprises a scraper conveyor chute and a plurality of hydraulic support devices connected with the scraper conveyor chute. Each hydraulic support device comprises a hydraulic support front vertical column. Lifting oil cylinder seats are fixedly arranged at the bottoms of the hydraulicsupport front vertical columns, and push-moving oil cylinder connecting rods at the driving ends of the lifting oil cylinder seats are connected with the scraper conveyor chute; a chute baffle is further arranged on the position, between the lifting oil cylinder seats and the scraper conveyor chute, on the push-moving oil cylinder connecting rods; non-contact distance meters are arranged on the lifting oil cylinder seats, and hydraulic support controllers are arranged on the side faces of the hydraulic support front vertical columns; the non-contact distance meters are used for measuring thedistances between the non-contact distance meters and the chute baffle; and the hydraulic support controllers are used for adjusting the distances between the hydraulic support front vertical columnsand the scraper conveyor chute. According to the coal mine underground scraper conveyor straightening and personnel locking system, the two functions of coal mine underground scraper conveyor straightening and personnel locking can be achieved through a set of equipment.

Owner:王海军

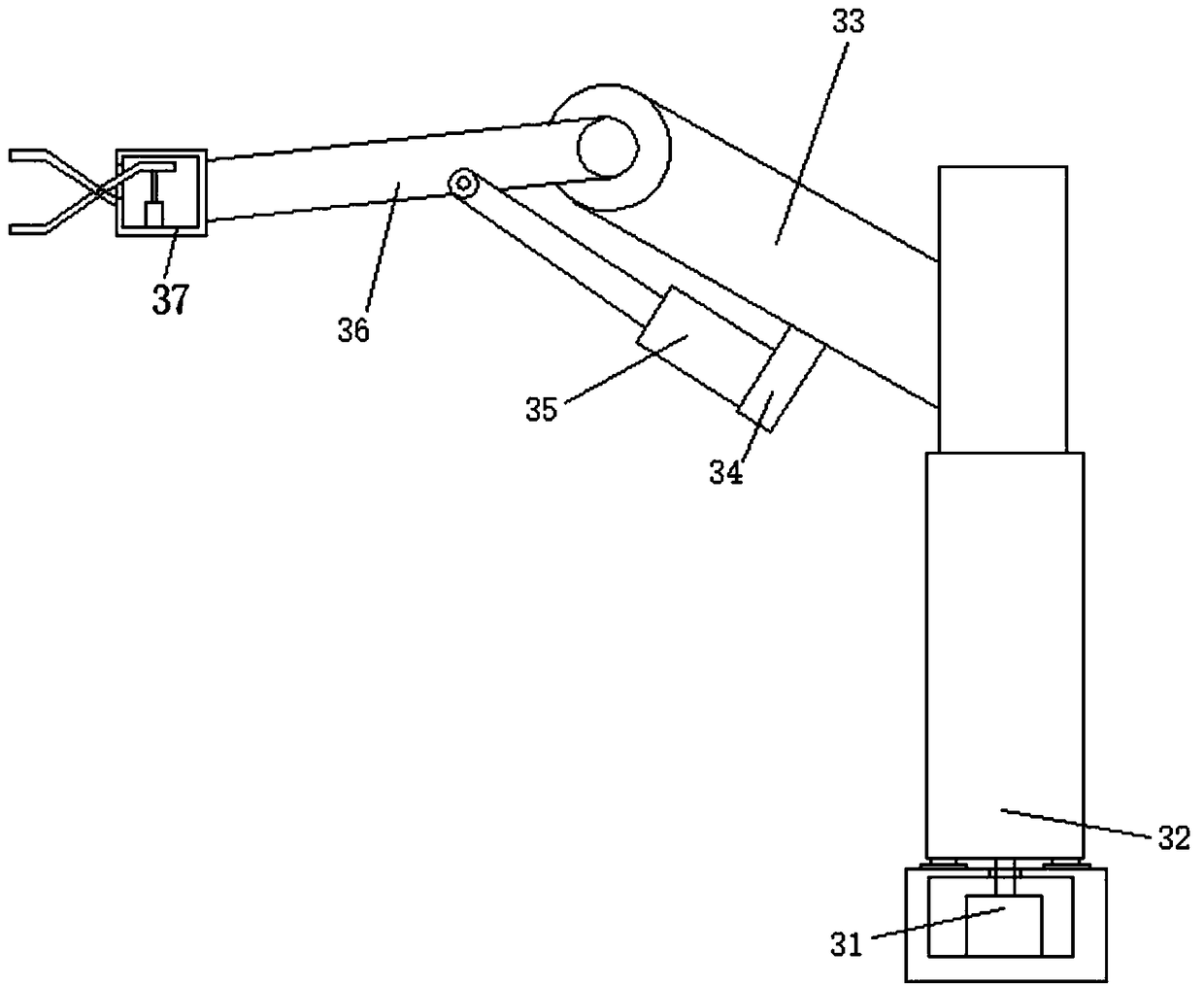

Automatic forming machine and method for transformer enameled wire U-shaped coils

PendingCN111952072AGuaranteed molding accuracyRealize automated productionCoils manufactureCopper wireTransformer

The invention provides an automatic forming machine and method for a transformer enameled wire U-shaped coil, and the method comprises the steps: fixing a feeding guide structure for the feeding guideof a copper wire raw material on the front side wall of a main case, and arranging a traction power device for the traction of a copper wire at a station behind the feeding guide structure; the output end of the traction power device is provided with a discharging guide structure used for guiding straightened copper wires, the output end of the discharging guide structure is provided with a cutting-off mechanism used for cutting off the copper wires, and a rear guide plate structure is arranged on a station behind the cutting-off mechanism; the telescopic pressing mechanism used for pressingthe copper wire is arranged behind the rear guide plate structure, and a bending mechanism is arranged at the station behind the telescopic pressing mechanism. A conventional manual operation mode isreplaced, and the working efficiency is greatly improved.

Owner:亚元科技(宜昌)电子有限公司

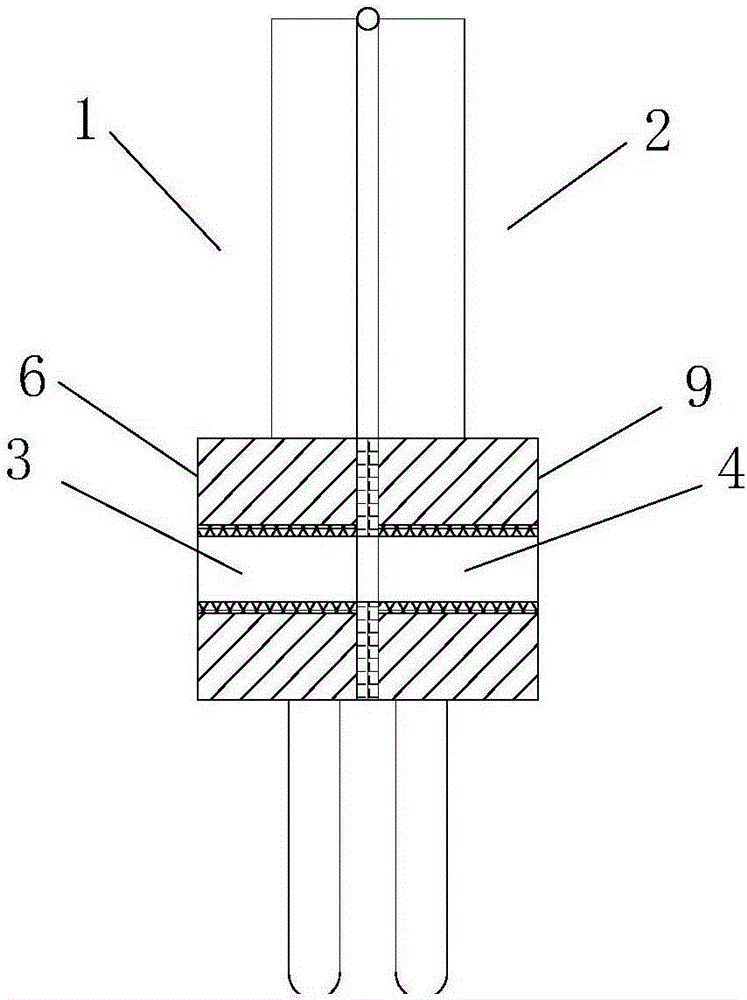

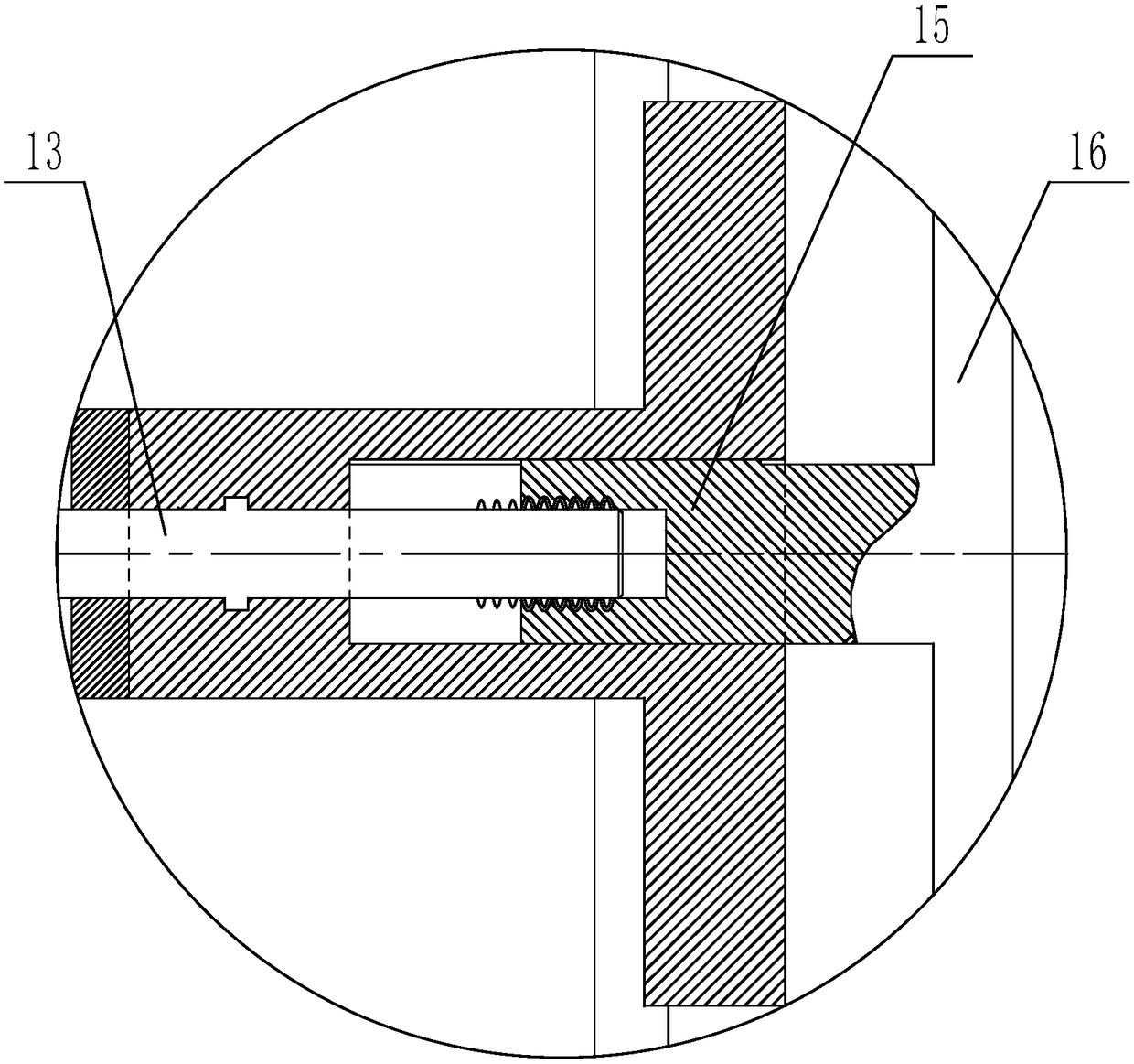

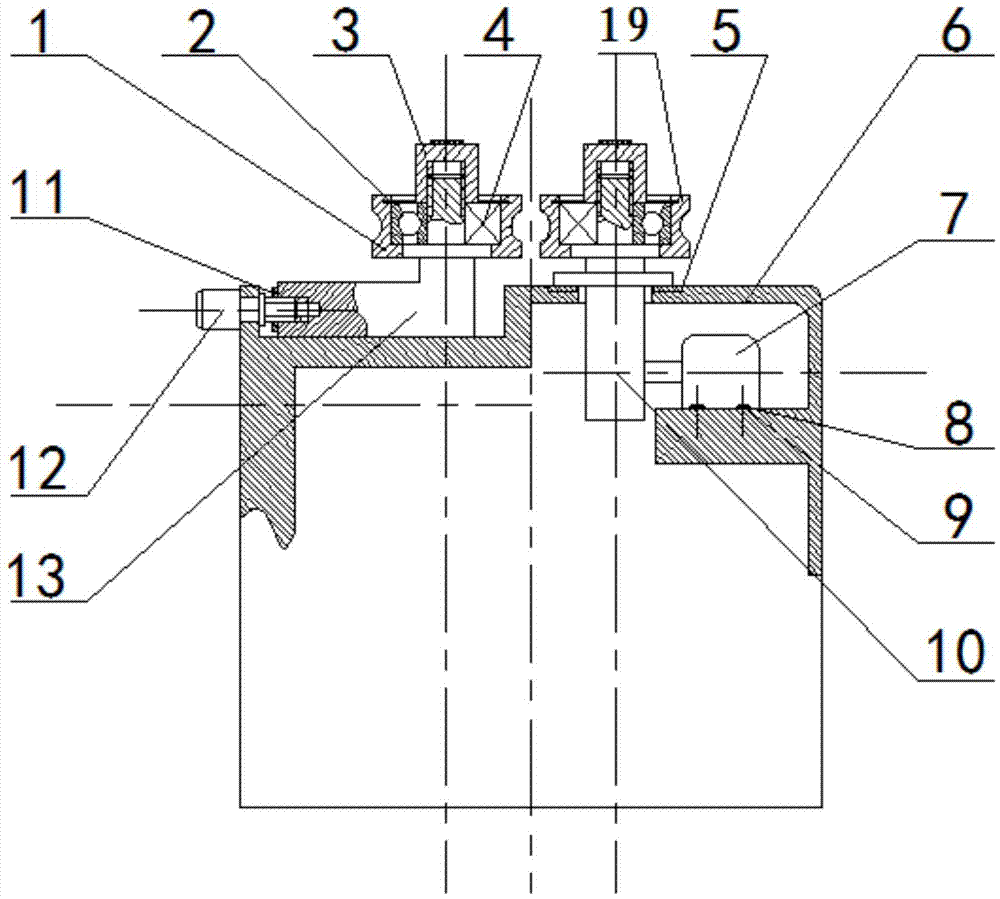

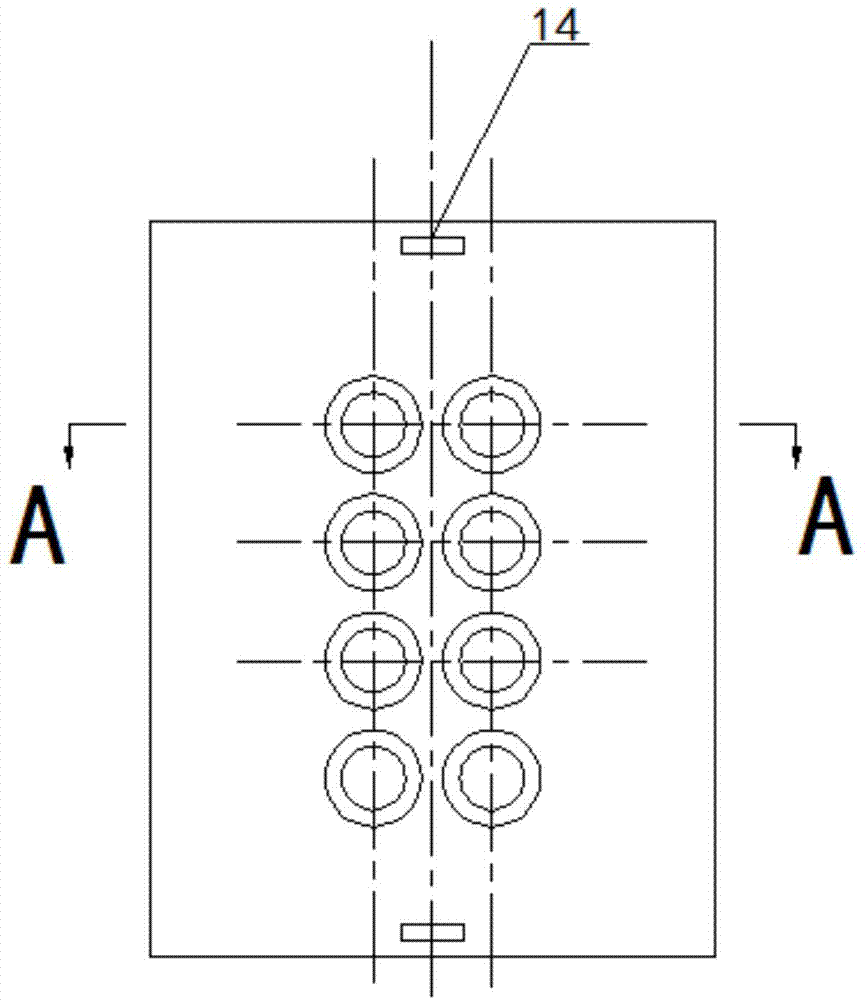

High-frequency vibration wire rod straightening device and using method thereof

The invention discloses a high-frequency vibration wire rod straightening device and a using method thereof. The high-frequency vibration wire rod straightening device comprises a casing and at least two groups of clamping devices, wherein each group of clamping devices comprises a first clamping unit and a second clamping unit. The first clamping unit comprises a first mold, a spring clamping ring, a bearing and a pressing end cover, the second clamping unit comprises a second mold, a spring clamping ring, a bearing and a pressing end cover, the first mold sleeves a distance adjusting shaft, the second mold sleeves a high-frequency vibration shaft, the lower portions of the first mold and the second mold are provided with bosses, the bearings, the spring clamping rings and the pressing end covers are sequentially arranged on the bosses, and the high-frequency vibration shaft is connected with a high-frequency vibration motor. The wire rod straightening is achieved by replacing the molds to straighten wire rods different in diameter and adjusting a distance between the centers of the molds to compensate mold abrasion. Most of stress of straightened materials is quickly eliminated through high-frequency vibration force, the wire rod straightening efficiency and quality are improved, straightening of wire rods different in material and diameter is achieved, and economic benefits of products is improved.

Owner:NANTONG HUALIANG FITNESS EQUIP CO LTD

Waste steel bar straightening device for construction

The invention provides a waste steel bar straightening device for construction. The waste steel bar straightening device comprises a straightening box body, the straightening box body is a box body structure with the upper end being open, and the opening portion of the straightening box body is provided with a straightening box body cover in a hinged manner. According to the waste steel bar straightening device for the construction, when the waste steel bar straightening device is used, the head portion of a steel bar which needs to be straightened is placed into a steel bar head placing groove, a pushing block pulling device drives a sliding pushing block to slide forwards, when cambered surface protrusions on the side faces of moving clamping rods are separated from corresponding clamping rod guiding idler wheels, the moving clamping rods will spread outwards under the elastic force action of a strutting spring, later, the pushing block pulling device pulls the sliding pushing blockbackwards, the cambered surface protrusions are connected with the corresponding clamping rod guiding idler wheels again, the moving clamping rods are made to be closed inwards, a steel bar clamping head is made to clamp the steel bar, this moment, the pushing block pulling device drives the sliding pushing block to slide backwards sequentially, and the steel bar clamping head will straighten thesteel bar by pulling the steel bar backwards.

Owner:屈雷涛

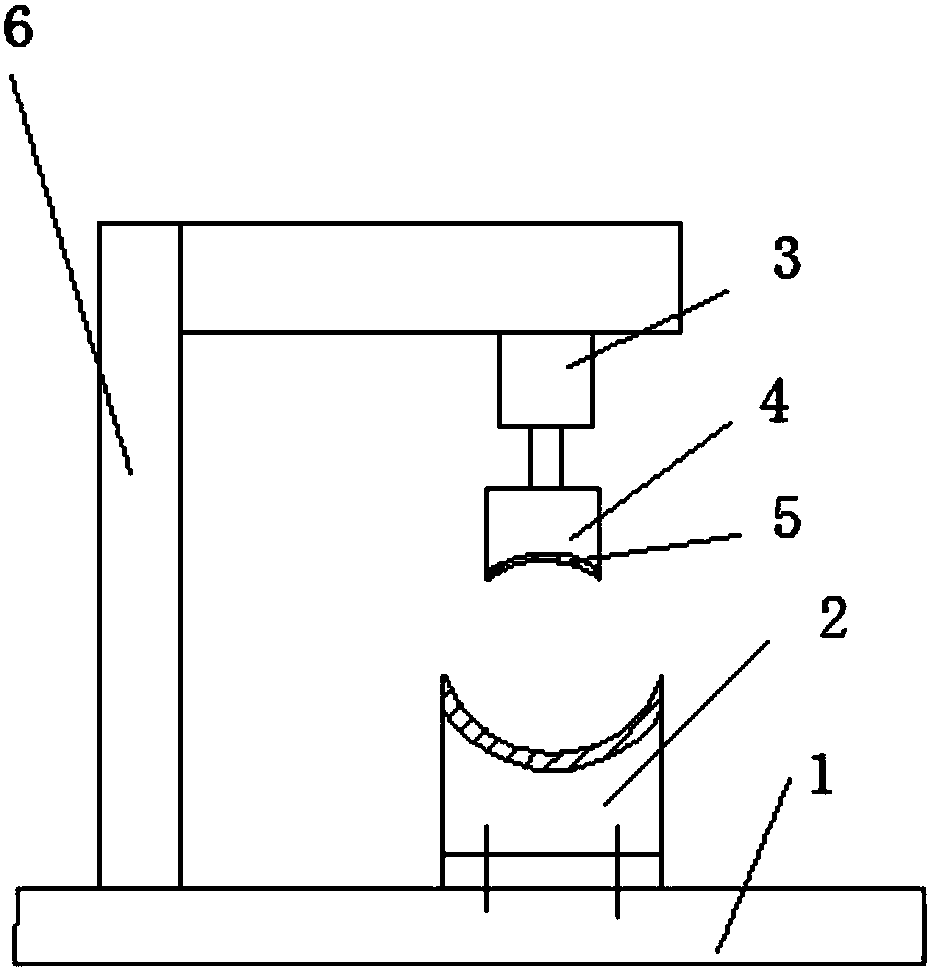

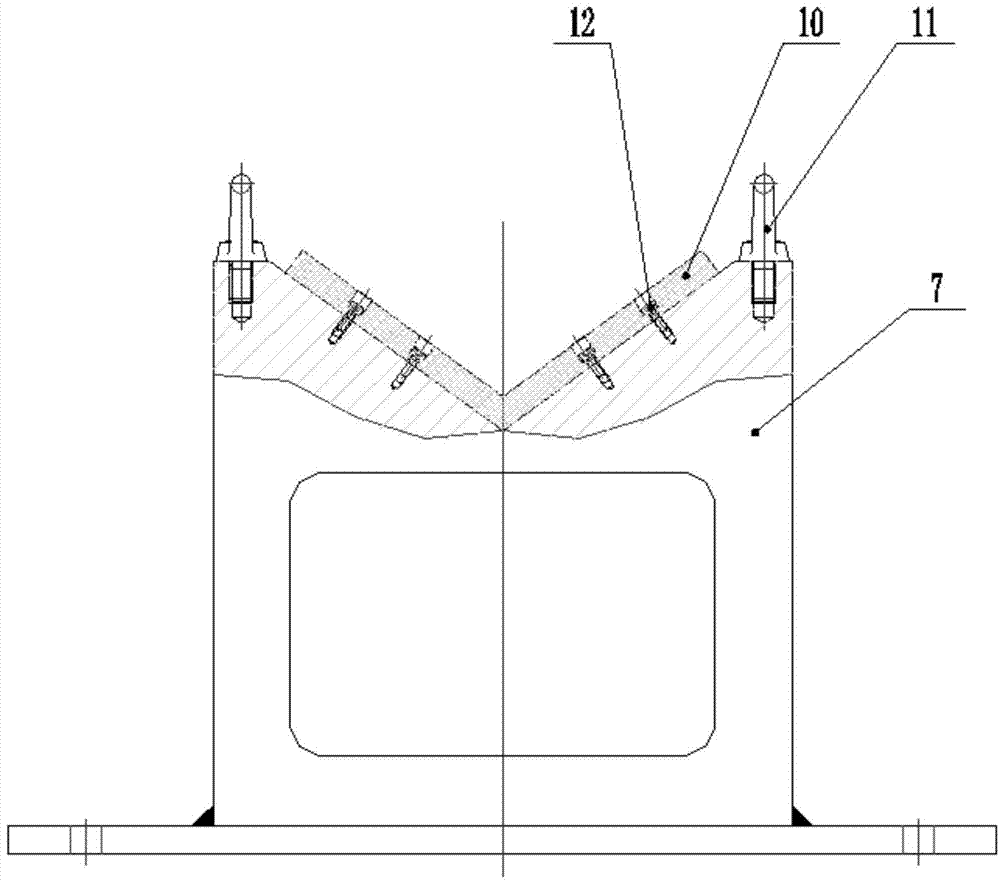

Straightening device for eliminating bending defects of high frequency longitudinal seam welded pipe

The invention discloses a straightening device for eliminating bending defects of a high frequency longitudinal seam welded pipe, which comprises a press-down device with an inverted V-shaped block, a lower V-shaped seat, a supporting trolley and a lower supporting plate. The press-down device comprises an upper supporting plate, a hydraulic cylinder arranged on a rack and the inverted V-shaped block; the upper supporting plate is provided with a through hole; a screw thread shaft head at the lower part of the hydraulic cylinder passes through the through hole on the upper supporting plate to be matched with a built-in screw thread at the bottom of the inverted V-shaped block; the lower supporting plate is fixed on a stage; a lower V-shaped seat is arranged at the middle part of the lower supporting plate; the supporting trolley is arranged at the end part of the lower supporting plate; the V-shaped block above the lower supporting plate moves down under the drive of a piston rod in the hydraulic cylinder so as to act on the welded pipe placed on the lower V-shaped seat and the supporting trolley. According to the straightening device, not only are the bending defects of the welded pipe effectively eliminated and high surface quality of the welded pipe is ensured, but also straightening on local bending of the welded pipe can be implemented by regulating the position of the lower V-shaped seat and quality of a processed finished product is improved.

Owner:SHANDONG TAIFENG STEEL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com