Patents

Literature

116results about How to "Play a reset role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

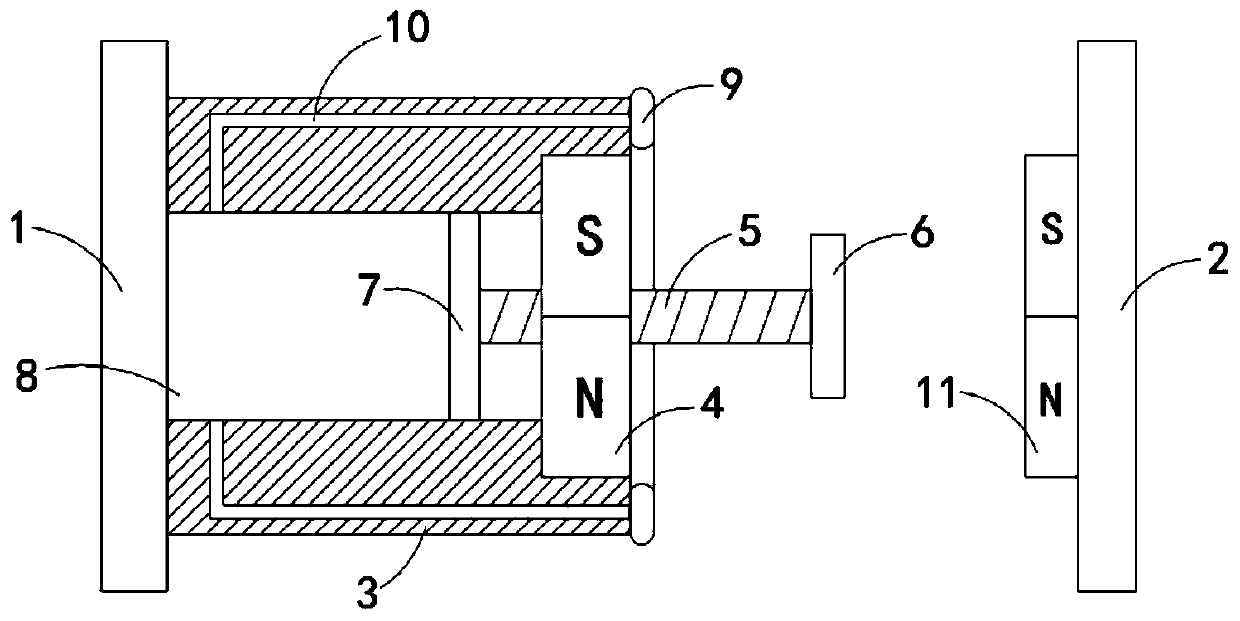

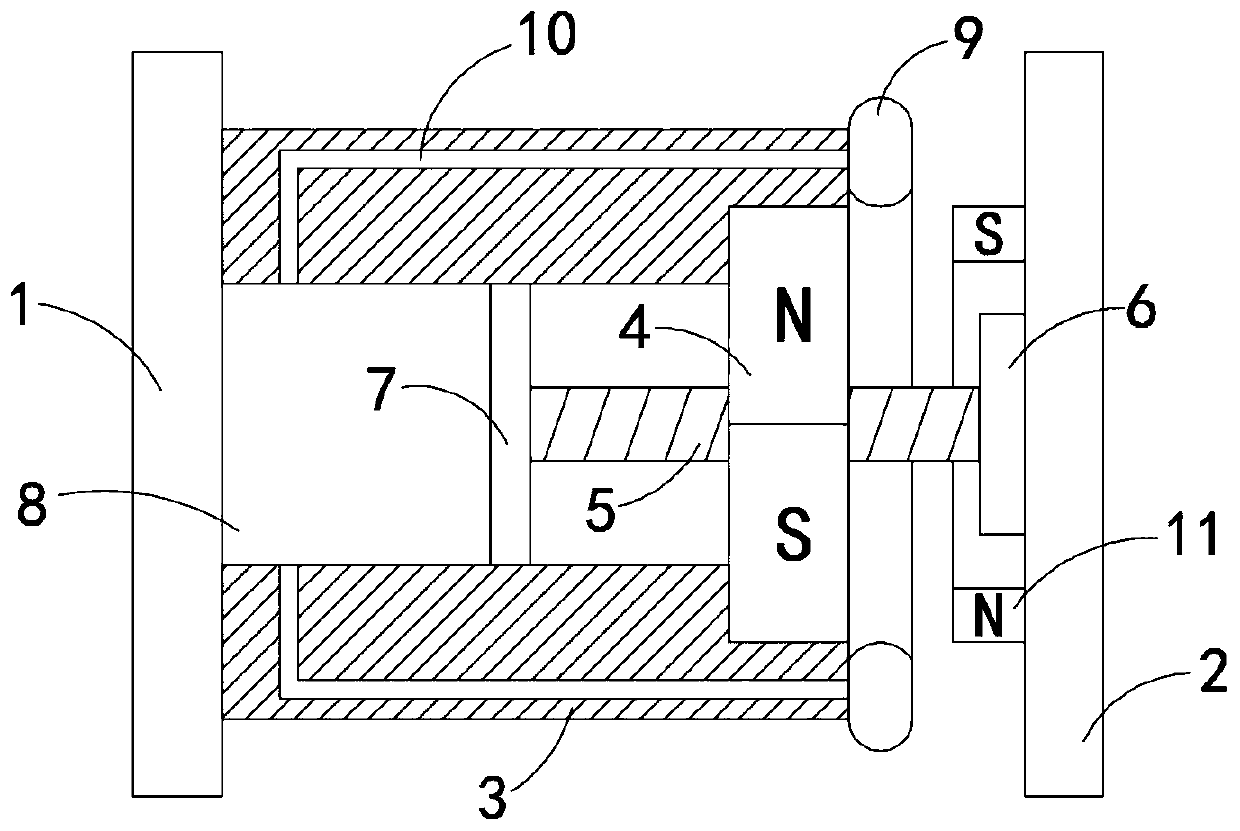

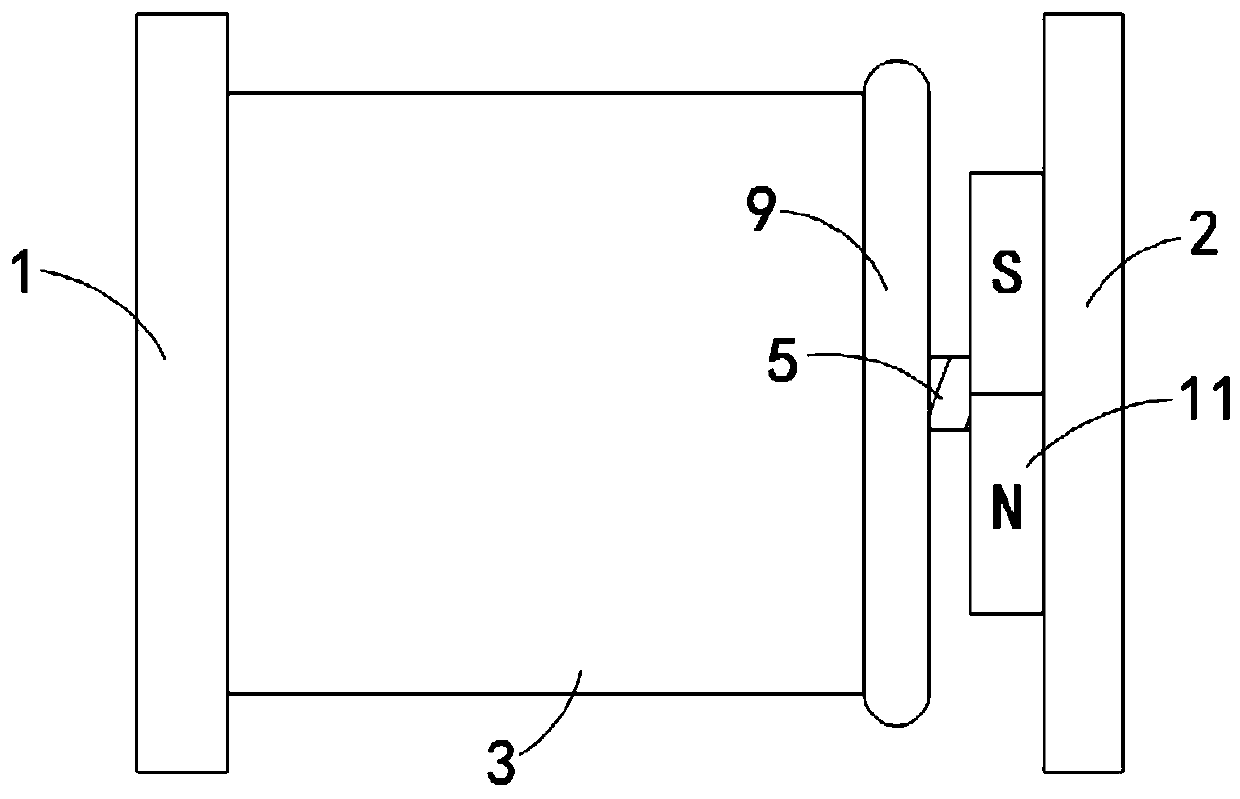

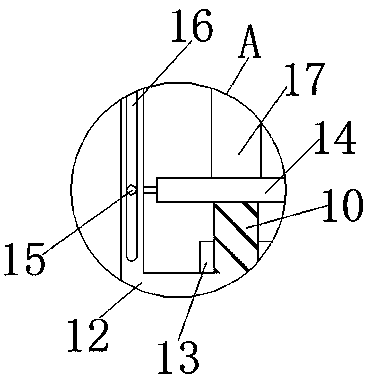

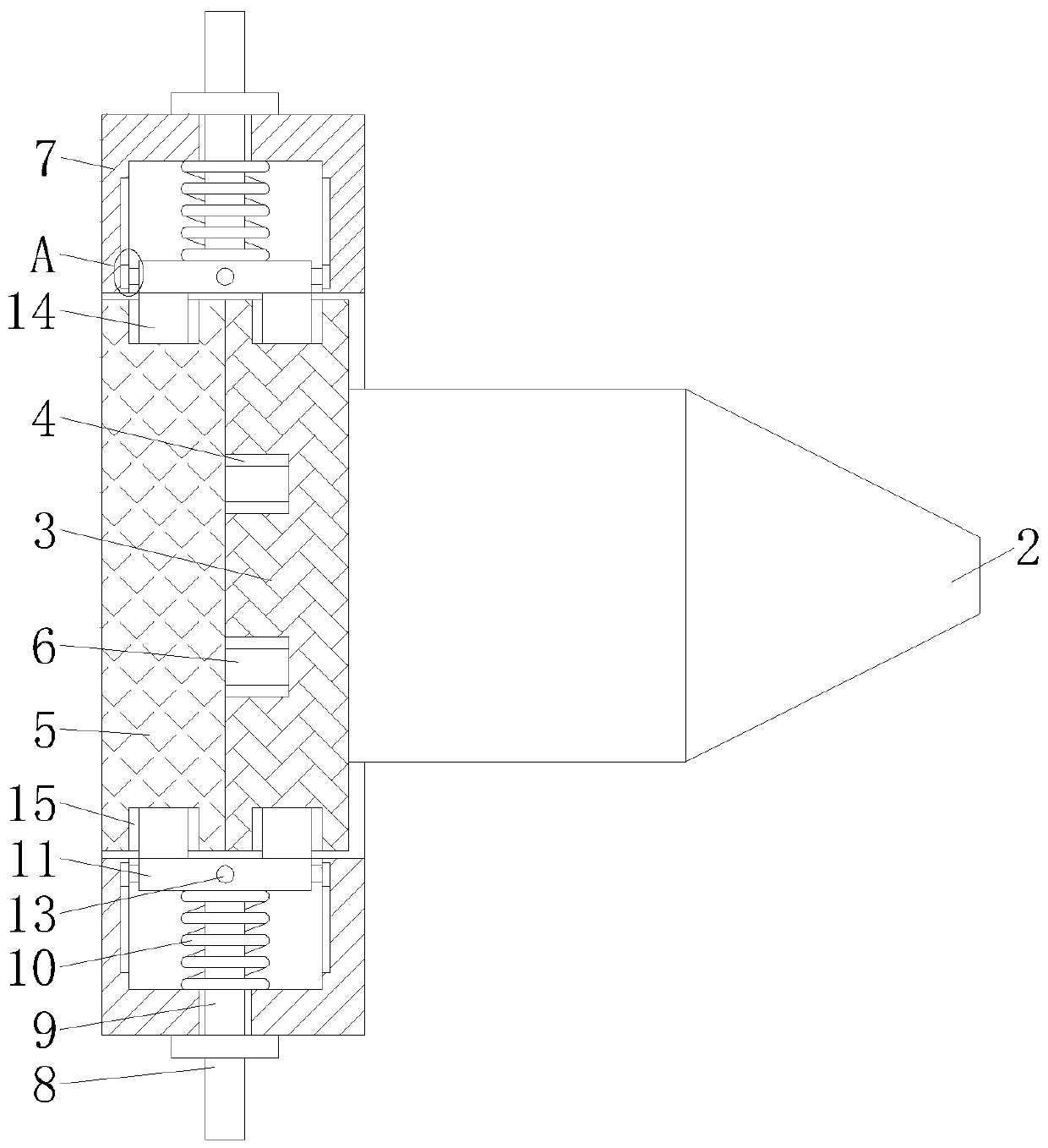

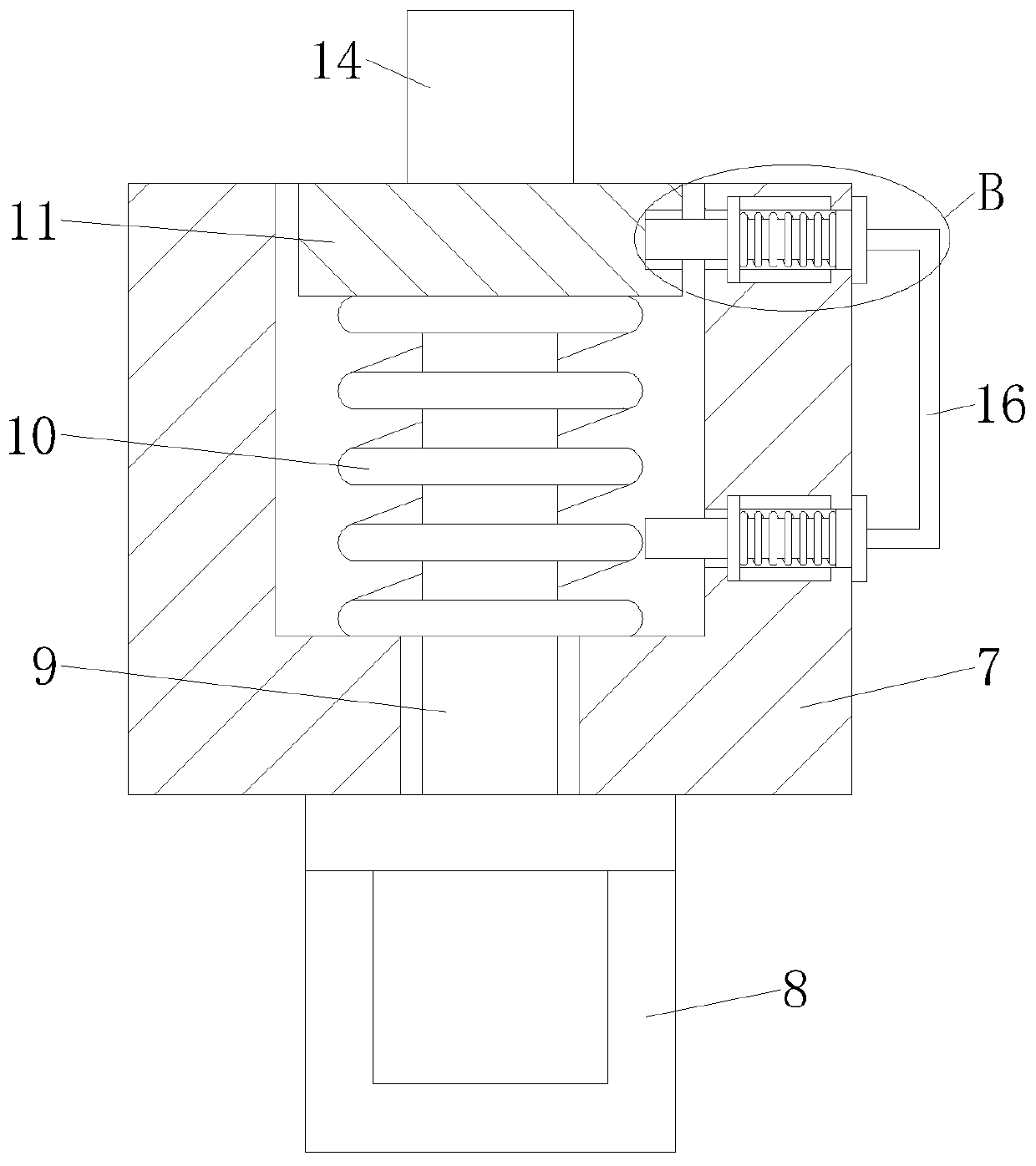

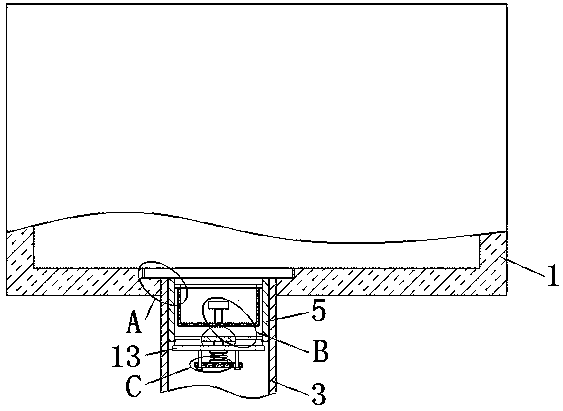

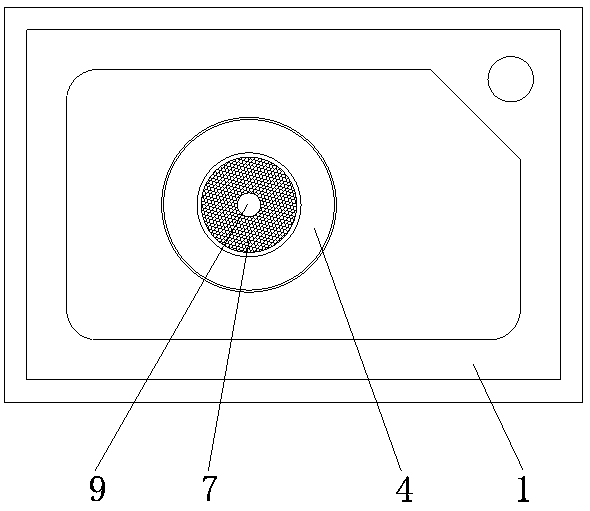

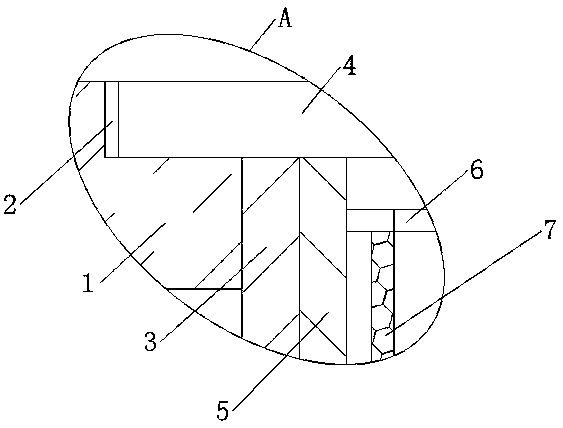

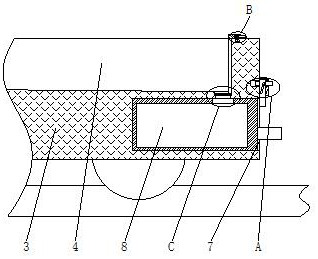

Buffer-type magnetic door stopper

ActiveCN110067457AImprove buffering effectPlay a reset roleBuilding braking devicesWing fastenersEngineeringAirbag

The invention belongs to the field of construction, and particularly relates to a buffer-type magnetic door stopper. The buffer-type magnetic door stopper comprises a first connecting plate fixedly mounted on a door body, and a second connecting plate fixedly mounted on a wall body; the side wall of the first connecting plate is fixedly connected with a cylinder, and a groove is formed in the endface, away from the first connecting plate, of the cylinder; a permanent magnetic rotating ring is rotatably connected into the groove, and a threaded hole is formed in the permanent magnetic rotatingring in a penetrating mode; a lead screw is connected into the threaded hole in a threaded mode, the end, outside the cylinder, of the lead screw is fixedly connected with a buffer block, and the end, in the cylinder, of the lead screw is fixedly connected with a sealing plate; the sealing plate and the inner side wall of the cylinder are slidably connected in a sealed mode, and the side wall, away from the lead screw, of the sealing plate and the cylinder form a sealed space; and the side wall, away from the first connecting plate, of the cylinder is fixedly connected with an annular bufferairbag, and the sealed space communicates with the annular buffer airbag through a plurality of channels. The buffer effect is good, magnets can be effectively prevented from being directly collided,and the service life of the door stopper is prolonged.

Owner:东海县常春门窗有限公司

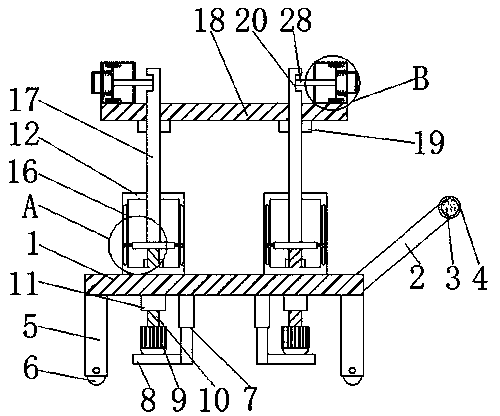

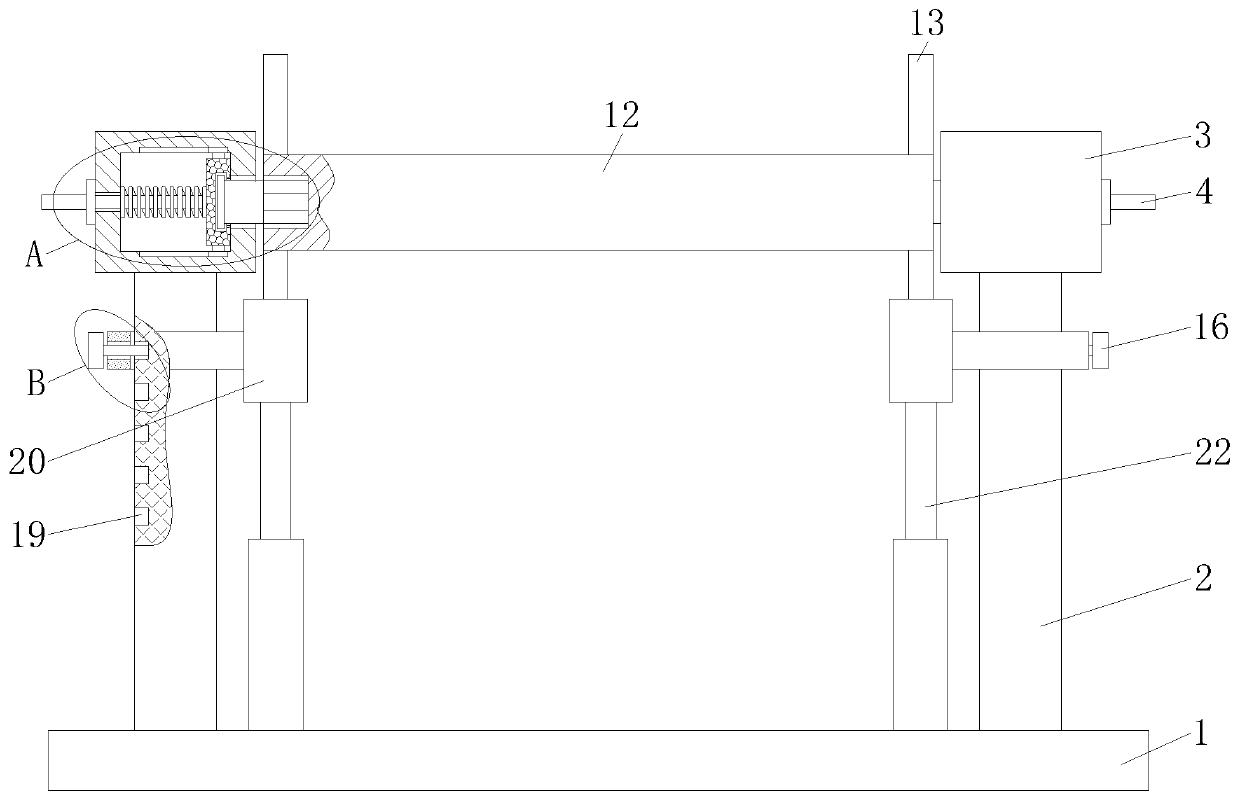

Supporting frame for textile machinery

InactiveCN107830316AImprove textile efficiencyHeight adjustablePortable framesLifting framesArchitectural engineeringThreaded rod

The invention relates to the technical field of textile machinery, and discloses a support frame for textile machinery, comprising a base and a support plate, one side of the base is fixedly connected with a push rod, the bottom of the base is fixedly connected with a support leg, and the bottom of the support leg is provided with a Roller, one side of the outrigger is provided with a telescopic rod fixedly connected to the bottom of the base, the bottom of the telescopic rod is fixedly connected with a horizontal plate, the upper surface of the horizontal plate is fixedly connected with a motor, and the output end of the motor is fixedly connected with a threaded rod. The outer surface of the threaded rod is provided with a reducer, and the top of the base is fixedly connected with a frame. The present invention achieves the effect of conveniently adjusting the height of the support frame for textile machinery through the setting of telescopic sleeve rods, horizontal plates, motors, threaded rods, reducers, nuts, load-bearing plates, sliders and chutes, thereby facilitating The use of the bracing frame for the textile machine also improves the use efficiency of the bracing frame for the textile machine, thus improving the weaving efficiency of the textile machine.

Owner:泰兴市长江密封材料有限公司

Preserved fruit kernel removing mechanism

The invention belongs to the technical field of food processing tools, and particularly relates to a preserved fruit kernel removing mechanism which comprises a bottom plate. A support is arranged on the bottom plate, the middle portion of the support is provided with a hollow locating sleeve and a kernel removing work table. Two clamping plates are hinged to the upper portion of the support and located on the two sides of the support respectively, the upper ends of the two clamping plates are connected through a pin shaft, the pin shaft is connected with a swing rod in a rotating mode, one end of the swing rod is connected with a tension spring, the other end of the tension spring is fixed on the lower portion of the support, a kernel removing needle is hinged to the swing rod, and the kernel removing needle penetrates through the hollow locating sleeve and is located on the kernel removing work table. The preserved fruit kernel removing mechanism enables the kernel removing needle to be flexibly moved, and kernel removing is more convenient.

Owner:ZHEJIANG MOCCAS FOOD IND

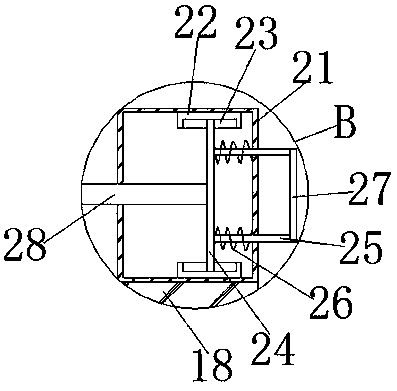

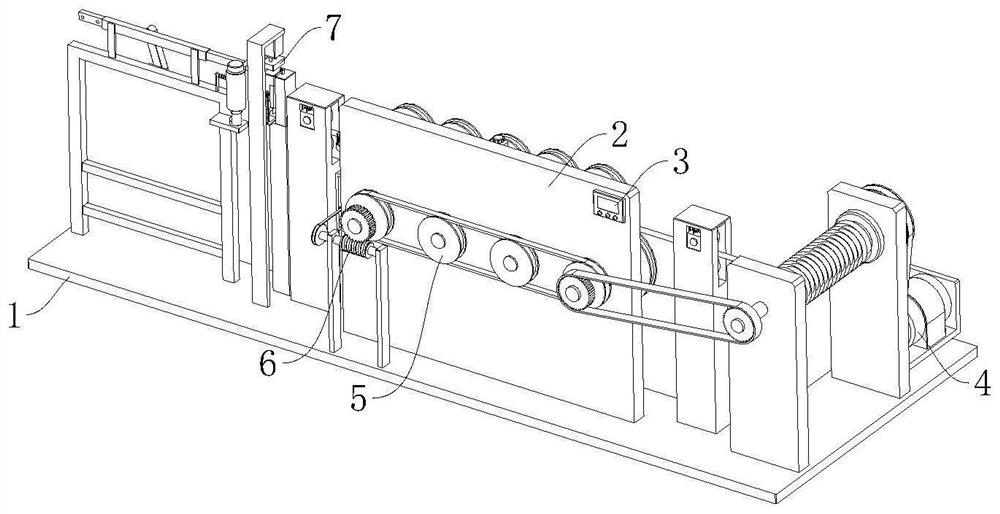

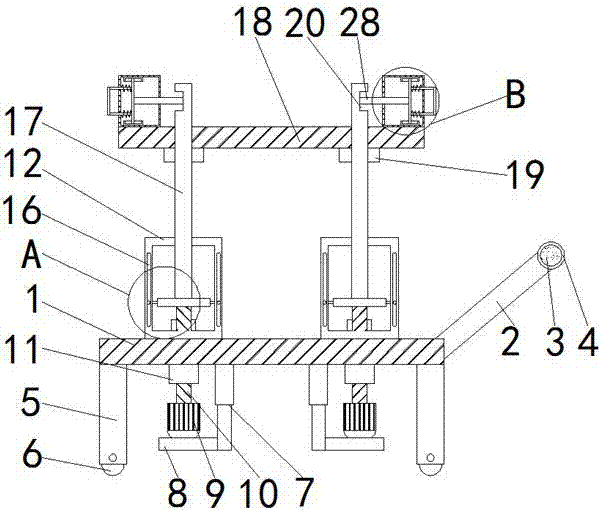

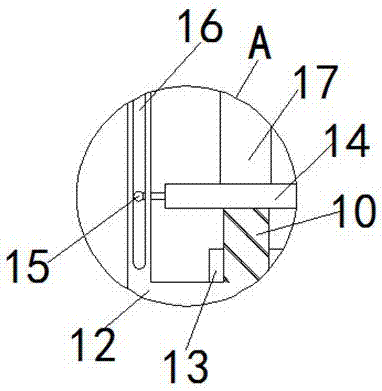

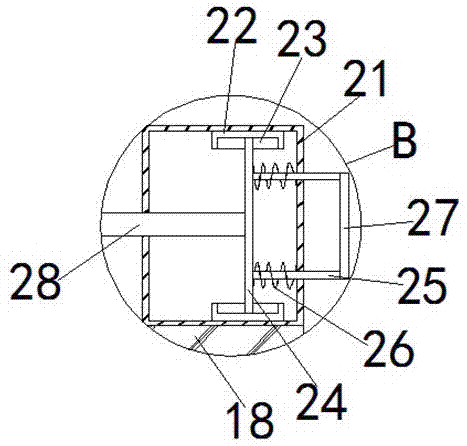

Spool mechanism for textile machinery

ActiveCN110127444AImprove the protective effectImprove stabilityFilament handlingEngineeringMaterial resources

The invention discloses a spool mechanism for textile machinery. The spool mechanism comprises a base, wherein fixed columns are fixedly connected with the two sides of the top of the base; and a shell is fixedly connected with the tops of the fixed columns. According to the spool mechanism, through cooperative application of the base, the fixed columns, the shell, a pull ring, a movable rod, a first spring, a movable plate, a stabilizing mechanism, a limiting plate, a connecting rod, a fixture block, a spool body, a protective plate, a clamping groove, a movable sleeve, a rotary knob, a threaded rod, a threaded hole, a threaded groove, a fixed plate, a groove and a support mechanism, the problems that the existing spool mechanism for textile machinery is inconvenient to dismantle, plentyof manpower and material resources are consumed, the labor intensity of a worker is increased, application is affected, and during the dismantling process, the protective effect is poor to cause slipof the spool and damage to a textile and inconvenience to a user are solved. The spool mechanism has the advantages of being convenient to dismantle and excellent in protective effect during the dismantling process and deserves popularization.

Owner:宁波市鄞州智伴信息科技有限公司

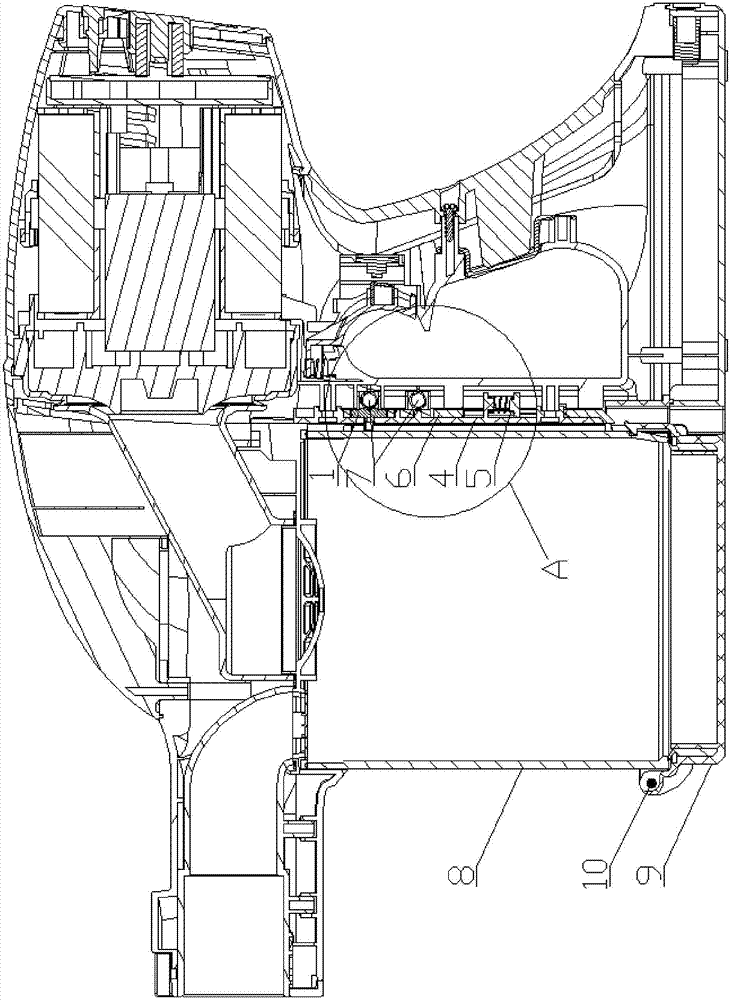

Dust cup orderly releasing mechanism and dust collector thereof

ActiveCN107080495ASimple and reliable release structurePrevent fallingSuction filtersEngineeringDust collector

The invention discloses a dust cup orderly releasing mechanism and a dust collector thereof. The dust cup orderly releasing mechanism includes a dust cup release button, a dust cup cover release button and a dust cup cover release key. The dust cup release button is used for releasing a whole dust cup, the dust cup cover release button drives the dust cup cover release key to open the dust cup cover, and the dust cup cover release key has an ejector rod; when the dust cup cover release button is not pressed down, the ejector rod abuts against the dust cup release button to stop the dust cup release button from releasing the whole dust cup, when the dust cup cover release button is pressed down, the ejector rod is disengaged the dust cup release button to allow the dust cup release button to release the whole dust cup. The dust cup cover release button is provided with an inclined plane, the inclined plane makes contact with the dust cup cover release key, and the inclined plane converts the horizontal concertina motion of the dust cup cover release button into the vertical-direction motion of the dust cup cover release key. The lower end of the dust cup cover release key is provided with a slanting rod, the slanting rod touches the button position of a dust cup cover when moving downward, and the dust cup cover is opened. By means of the dust cup orderly releasing mechanism and the dust collector, after the dust cup cover is opened and garbage is cleaned away, the whole dust cup can be taken out, and the dust cover is prevented from falling in wrong operation.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

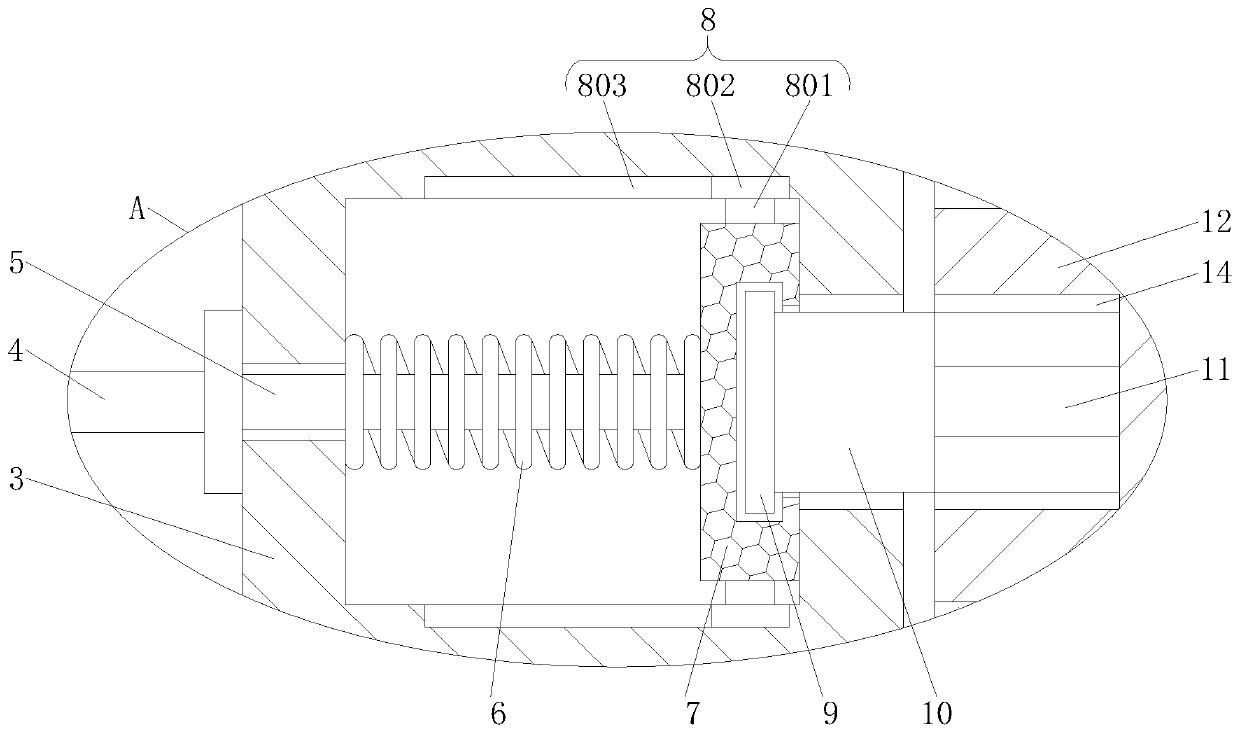

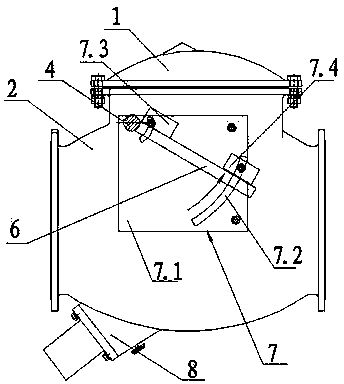

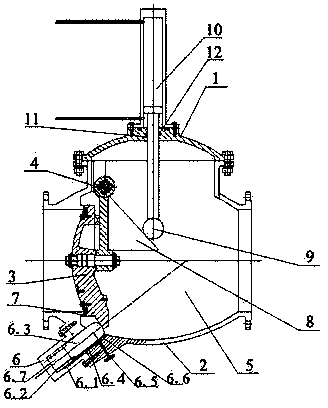

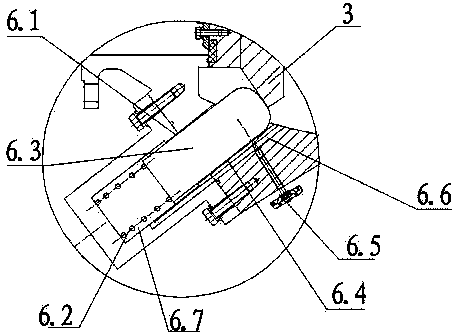

Self-washing damping and wear-resistant rotation type check valve

ActiveCN103775691ASimple structureReduce manufacturing costOperating means/releasing devices for valvesHollow article cleaningWear resistantEngineering

The invention relates to a self-washing damping and wear-resistant rotation type check valve, which belongs to the technical field of a control device on a medium pipeline. The self-washing damping and wear-resistant rotation type check valve comprises a valve body, a valve deck, a valve shaft, a tumbler and a valve clack, wherein the valve deck is arranged on the valve body; the valve shaft is arranged on the upper end in the valve body, which is near one end of a water inlet; the tumbler is fixedly connected to the valve shaft; the valve clack is fixedly connected to the outer side of the tumbler; the water inlet end of the valve body is provided with a valve seat used to be sealed with the valve clack; the valve shaft passes through the valve body to extend out of the valve body; the part of the valve shaft, which extends out of the valve body, is fixedly connected with a rotary arm; a rotary arm traction device is fixedly arranged out of the valve body. The automatic damping device in the self-washing damping and wear-resistant rotation type check valve disclosed by the invention has the characteristics of simple structure, low manufacture cost and blocking resistance, reliable adjustable damping can be realized without an externally-connected device, and the problem of the water hammer is solved. The valve clack mechanism is prevented from shaking under the hydraulic fluctuation via the rotary arm traction device so as to prevent the valve shaft from being abraded.

Owner:WUHAN DAYU VALVE

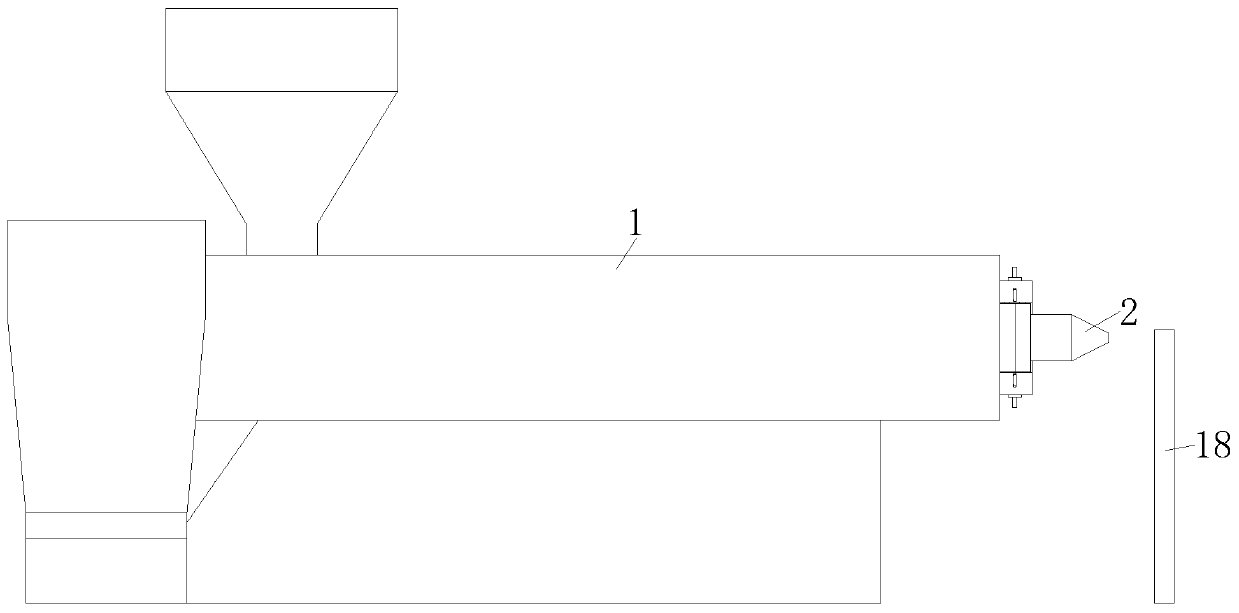

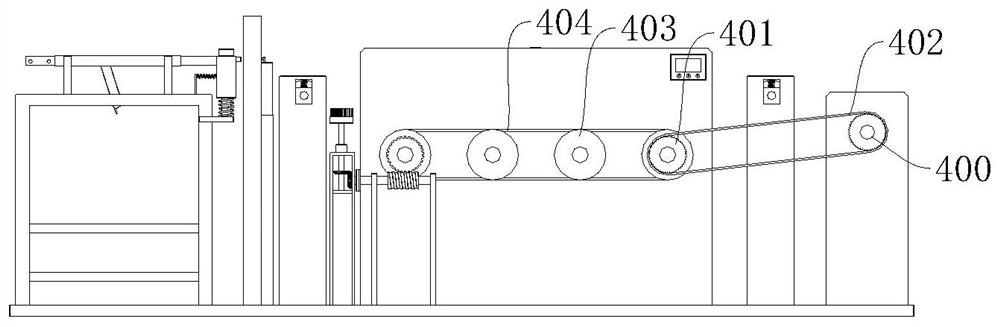

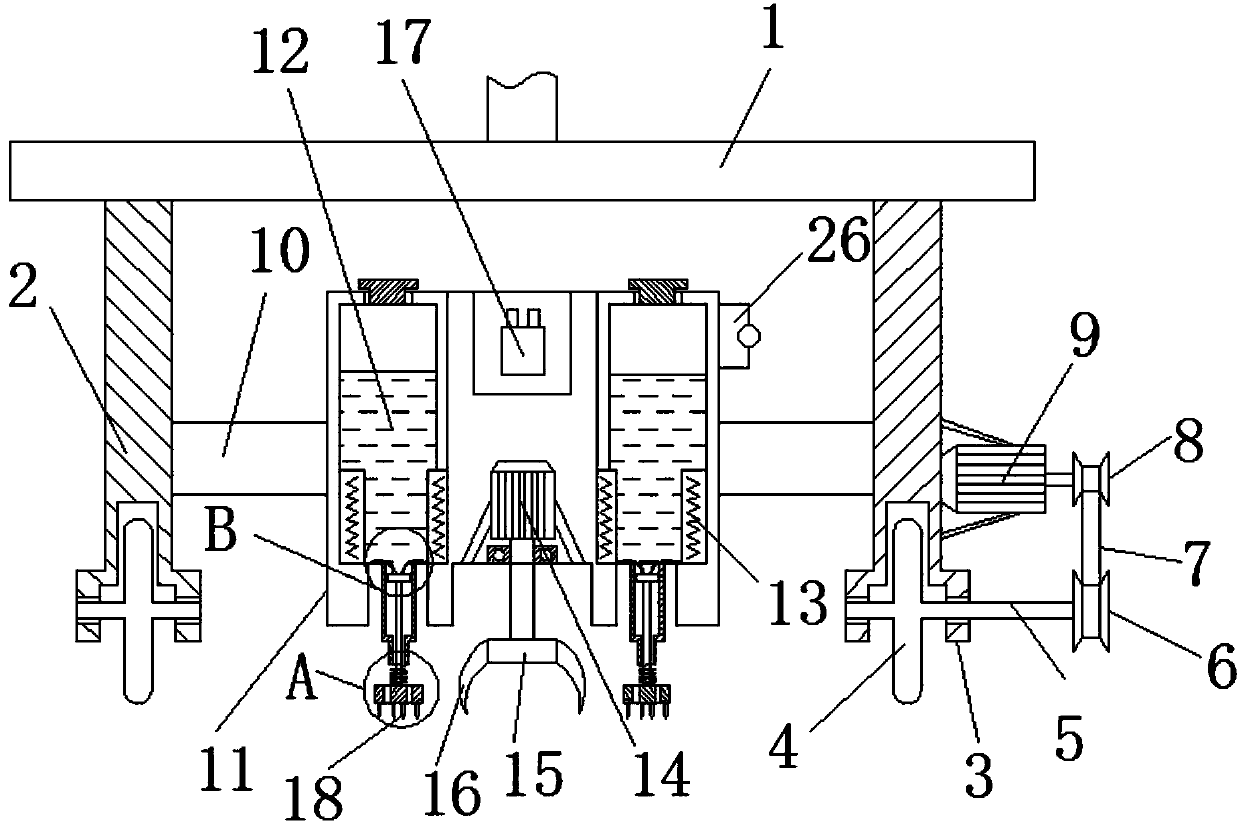

Automatic colloidal coating gluing mechanism suitable for plastic plates

ActiveCN113070180AImprove gluing efficiencyAvoid confusionLiquid surface applicatorsSpraying apparatusStructural engineeringManufacturing engineering

The invention relates to the technical field of gluing, in particular to an automatic colloidal coating gluing mechanism suitable for plastic plates. The automatic colloidal coating gluing mechanism comprises a base and a processing table, and further comprises a controller, a feeding device, an impurity removal device and a spraying device, the feeding device comprises a lifting plate, a jacking assembly and a pushing assembly, and the impurity removal device comprises a rolling brush and a traction assembly; and the spraying device comprises a spray head, an extrusion assembly and a sliding assembly, a top plate is fixedly arranged at the top of the base, the sliding assembly is arranged at the bottom of the top plate, the spray head and the extrusion assembly are both arranged on the sliding assembly, and the jacking assembly, the pushing assembly and the extrusion assembly are electrically connected with the controller. The plates are prevented from being clamped effectively, and feeding efficiency is high; and meanwhile, the gluing surface can be cleaned before gluing, smooth gluing is guaranteed, bubbles are prevented from being generated, and it is guaranteed that follow-up products adhere to the gluing surface firmly.

Owner:深圳市广德盛科技有限公司

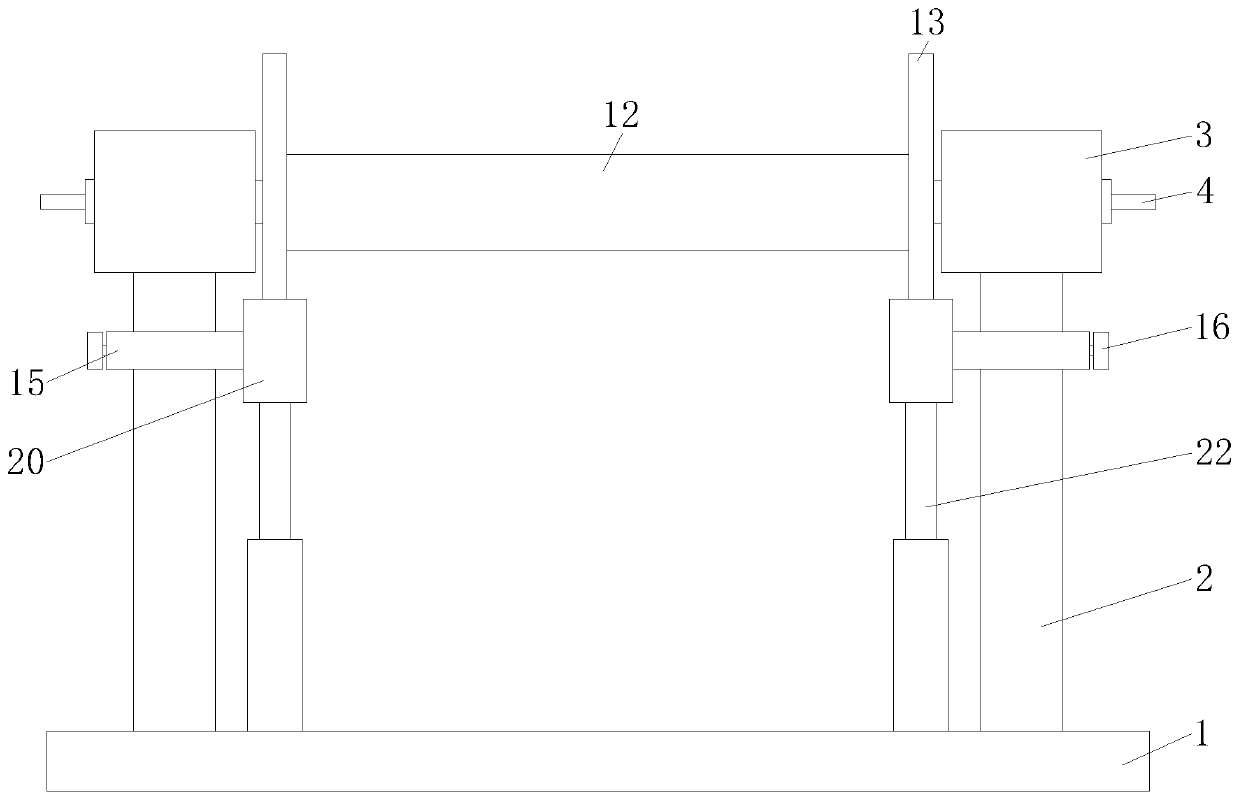

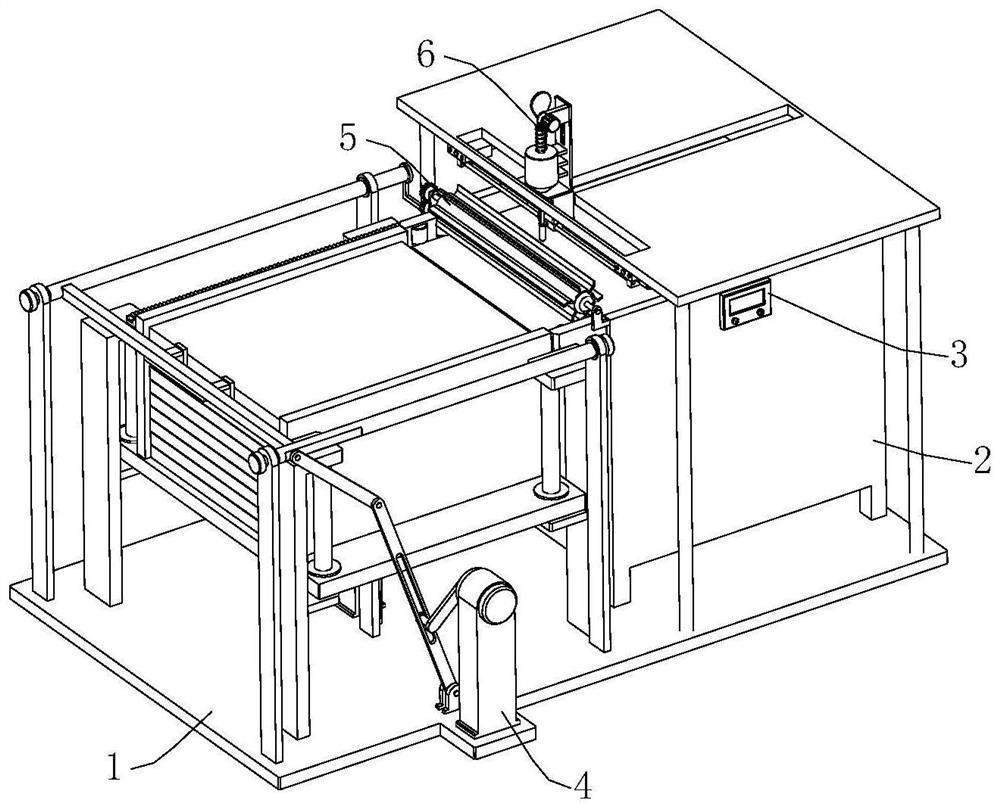

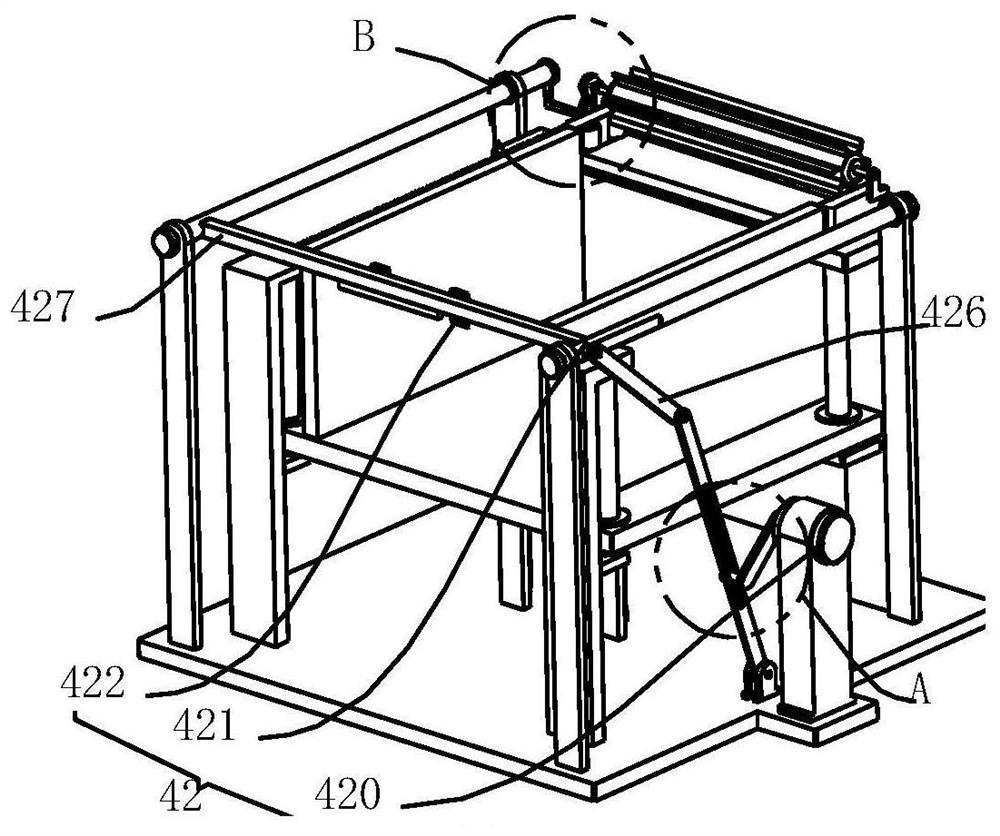

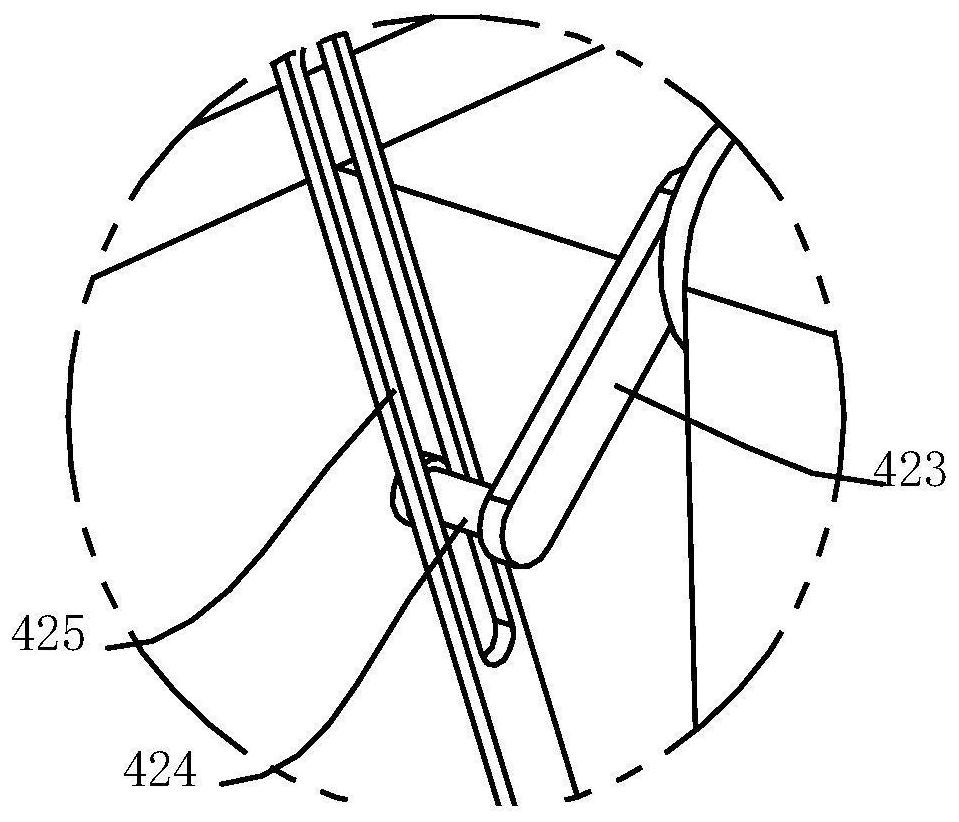

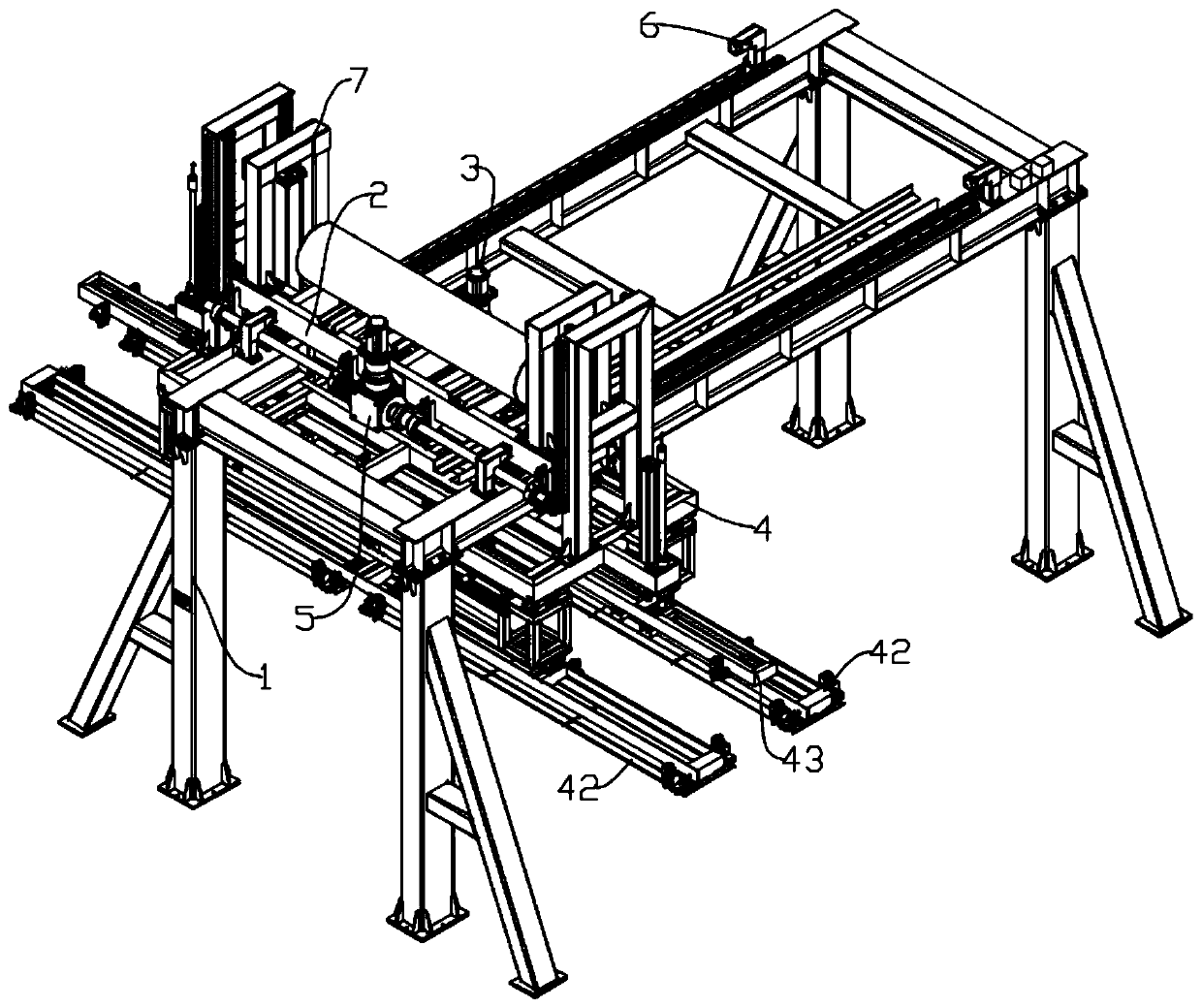

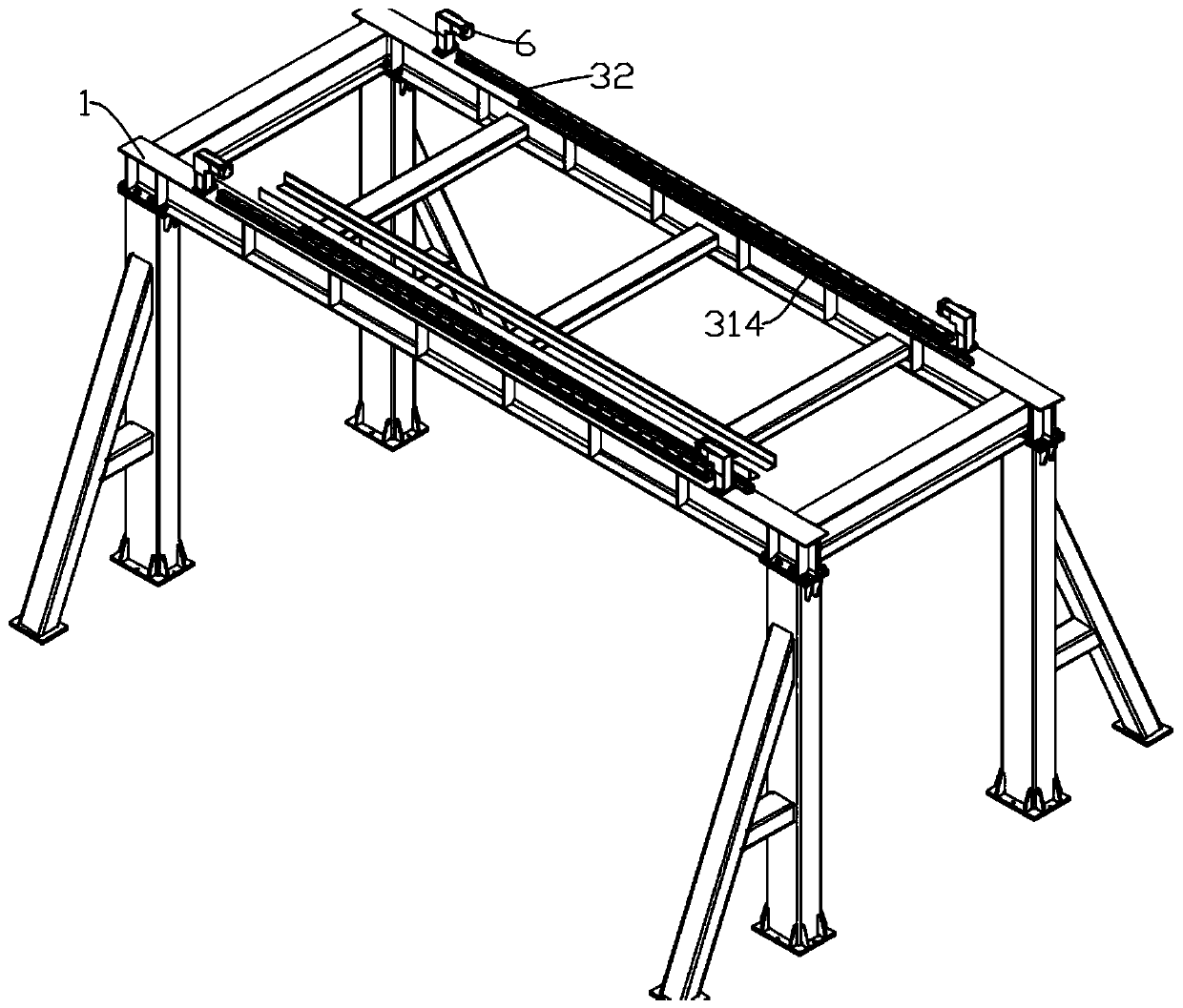

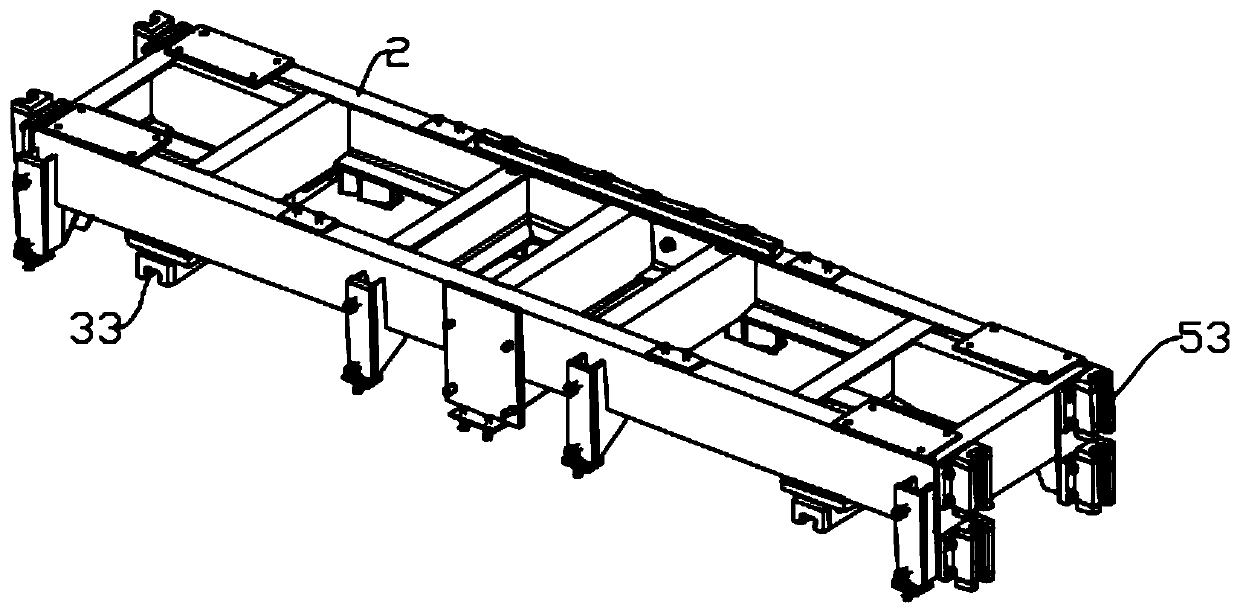

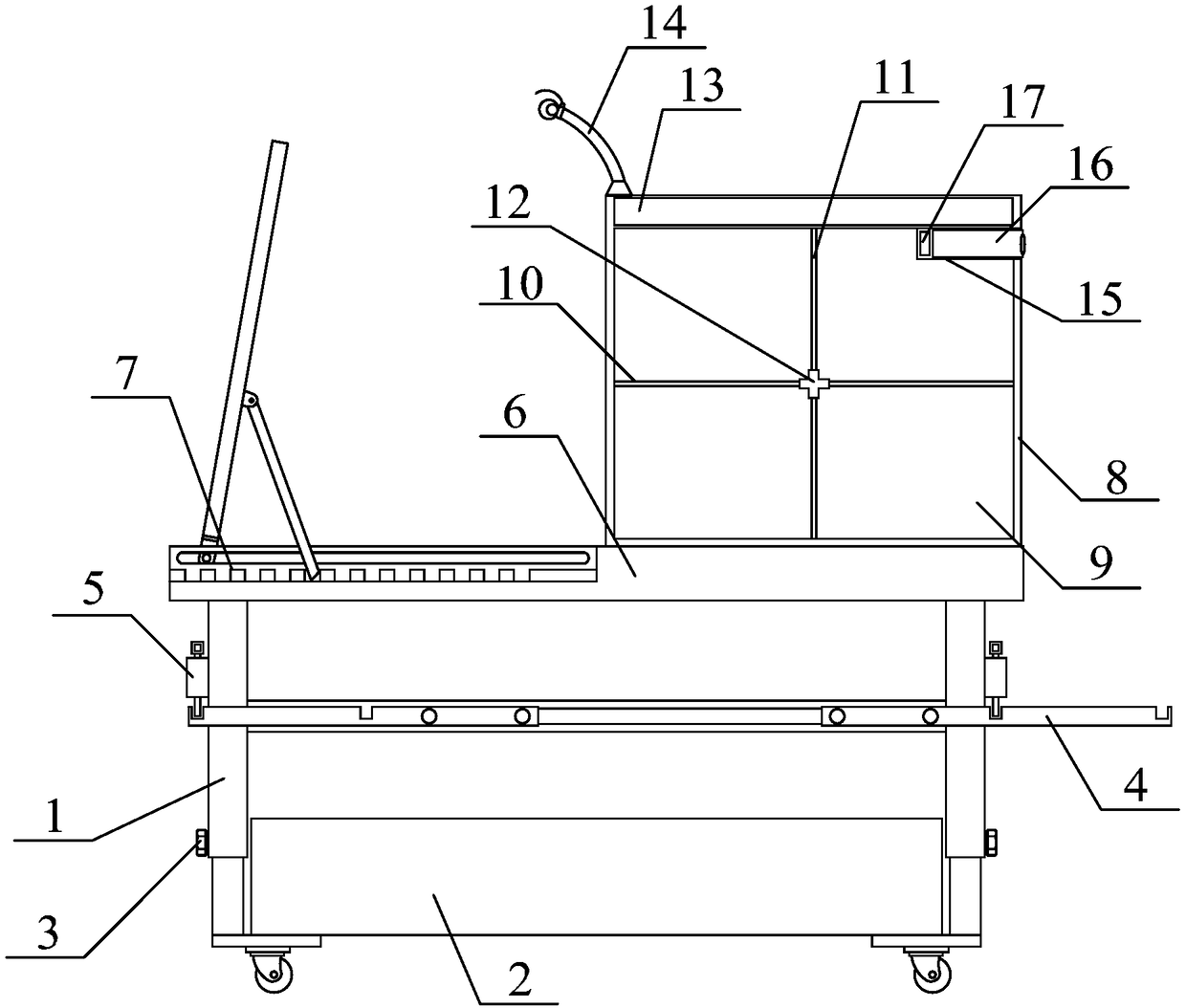

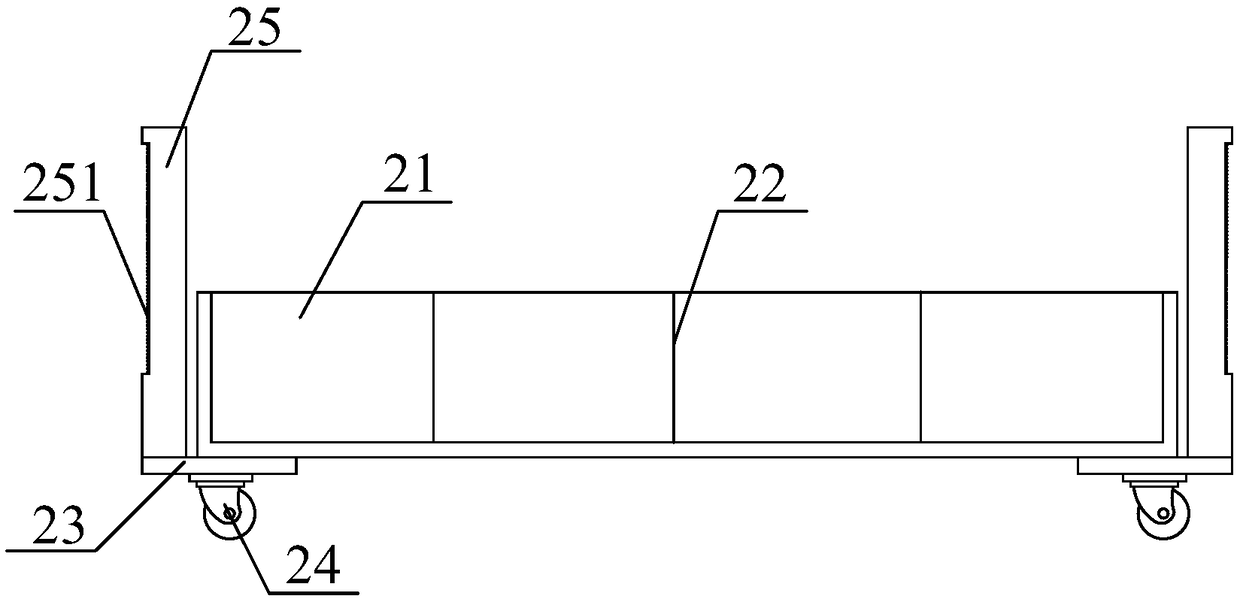

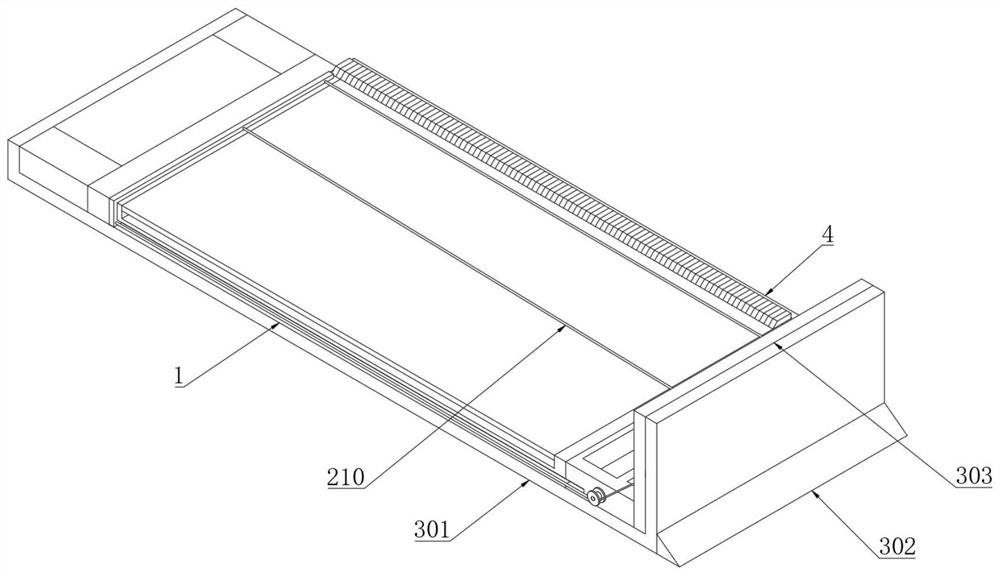

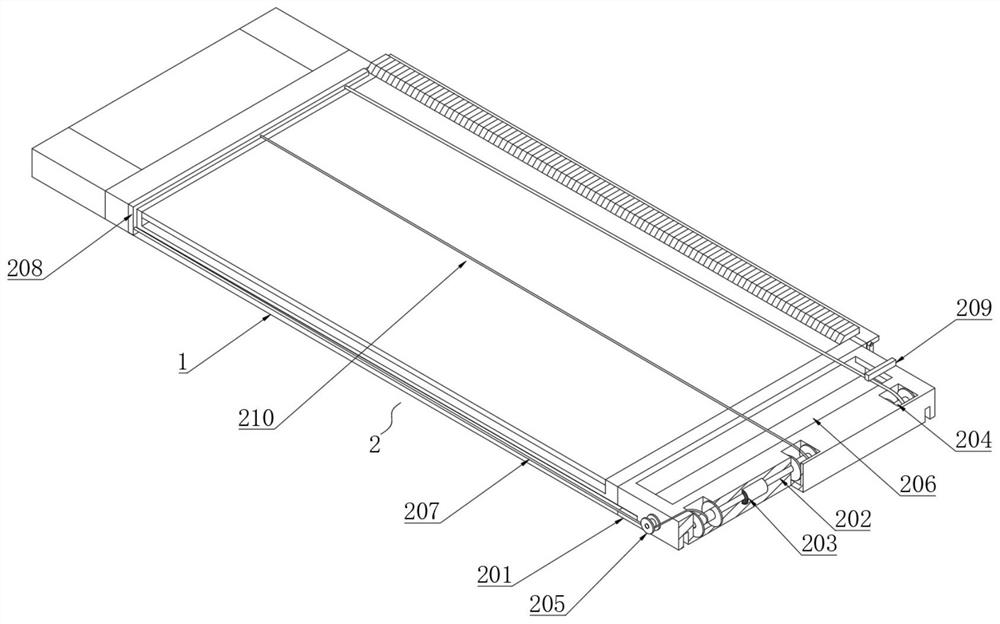

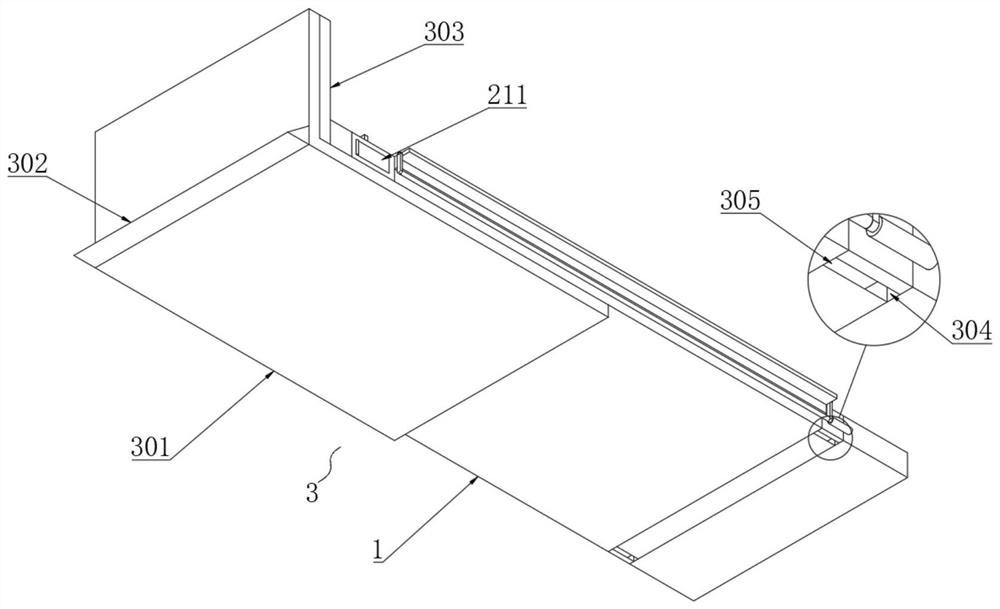

Mesh placement machine and mesh placement method

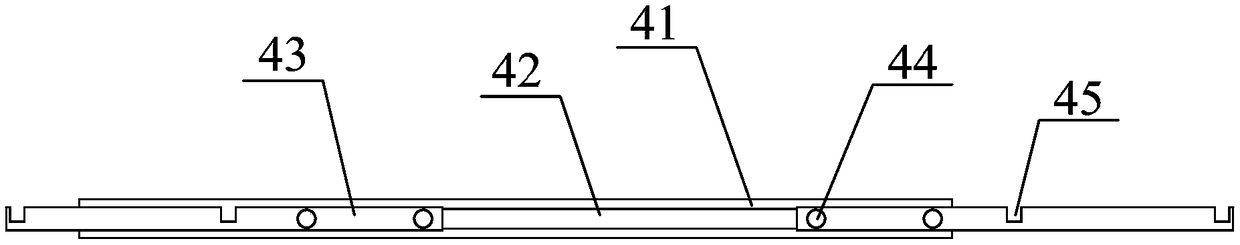

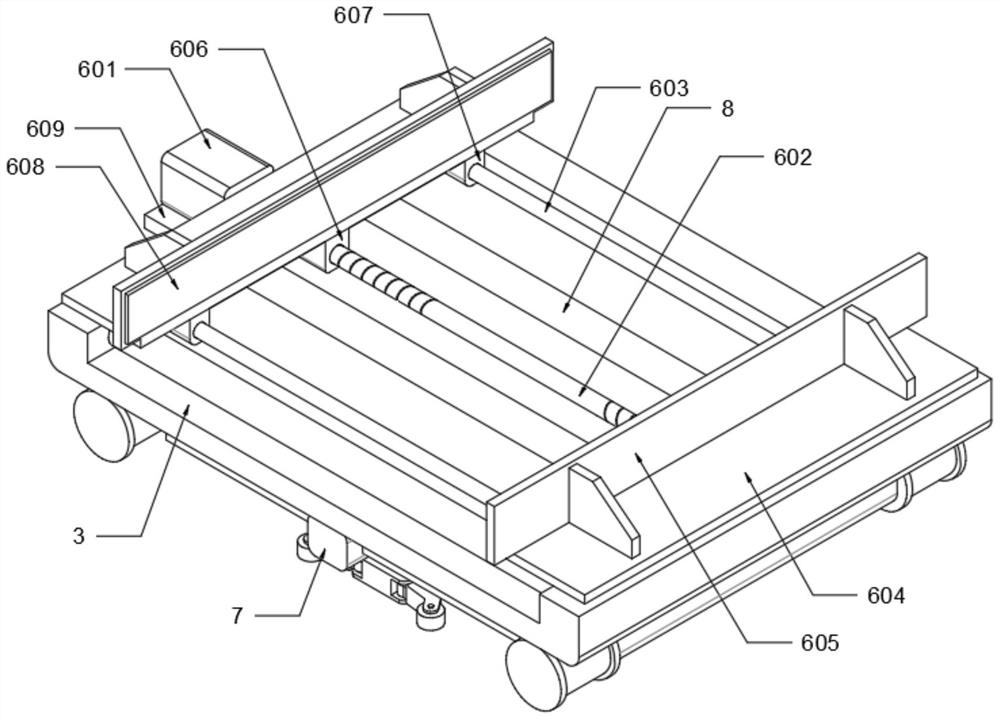

PendingCN111112514AIncrease productivityImprove placement efficiencyWire networkStructural engineeringMechanical engineering

The invention discloses a mesh placement machine and a mesh placement method, and belongs to the field of mesh cage production. The placement machine includes a rack, a vehicle body mounted on the rack, a horizontal driving device for driving the vehicle body to move in the horizontal direction, a mesh clamping device and a vertical driving device, the mesh clamping device can clamp meshes, overturn the meshes by 90 degrees and convey the meshes into a mesh placement zone, the meshes horizontally placed and stacked together can be automatically clamped and overturned, the spacing between everytwo meshes is adjusted, then the meshes are conveyed into a fixing zone for mesh cage manufacturing, and the production efficiency of mesh cages is effectively improved. The mesh placement method adopts the mesh placement machine for mesh placement, thus the meshes horizontally placed and stacked together can be efficiently adjusted into the dimensions and positions suitable for mesh cage manufacturing, automatic mesh arrangement is achieved, manual operation is saved, and the production efficiency of the mesh cages is improved.

Owner:ANHUI KEDA IND CO LTD

Discharging mechanism of extrusion molding mold for plastic production

The invention discloses a discharging mechanism of an extrusion molding mold for plastic production. The discharging mechanism comprises an extrusion molding mold body. An extrusion head body is arranged at the right side of the extrusion molding mold body. A first connecting sleeve sleeves the left side of the extrusion head body. By arranging the extrusion molding mold body, the extrusion head body, the first connecting sleeve, a first clamping groove, a second connecting sleeve, a first clamping block, a shell, a pull ring, a fixing rod, a first spring, a connecting plate, a stabilizing mechanism, a limiting groove, a second clamping block, a second clamping groove, a handle, a fixing handle, a fixing plate, a groove, a connecting rod and a movable sleeve, the problems that an existingdischarging mechanism of the extrusion molding mold for plastic production is not convenient to assemble or disassemble, a large amount of time and essence of a user can be consumed in the assemblingand disassembling process, the working efficiency of the user is affected, no supporting effect is achieved, a machined plastic product cannot be supported, and therefore the quality of the machined plastic product is affected, and inconvenience is brought to the user are solved.

Owner:张丽

Filtering mechanism for drain outlet of water tank

The invention discloses a filtering mechanism for a drain outlet of a water tank. The filtering mechanism comprises a water tank body, a groove is formed in the bottom of an inner cavity of the watertank body, the bottom of the water tank body communicates with a blow-off pipe used in cooperation with the groove, a fixing ring is movably connected to the inner cavity of the groove, and a connecting pipe is fixedly connected to the bottom of the fixing ring. The water tank body, the groove, the blow-off pipe, the fixing ring, the connecting pipe, a clamping ring, a filtering sleeve, a fixing rod, a fixing block, a flow guide block, a water outlet, a fixing column, a movable rod, a spring, a limiting plate, a clamping block and a stabilizing mechanism are arranged and used in a matched mode, the problem that an existing filtering mechanism of the drain outlet of the water tank does not have the function of preventing peculiar smell from diffusing, peculiar smell can be emitted out through the drain outlet, air pollution of a kitchen can be caused, and thus use of a user is affected is solved, and the filtering mechanism has the advantage of preventing peculiar smell from diffusing.

Owner:泰州浩邦科技发展有限公司

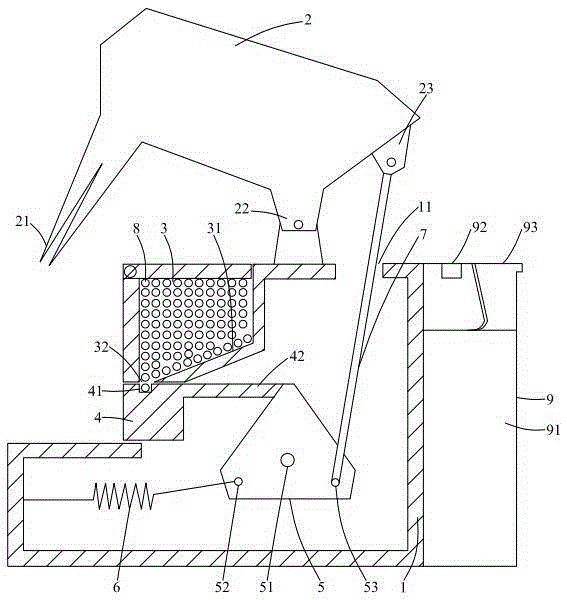

Fixed type cigarette ejection device capable of conducting ignition

The invention relates to the technical field of cigarette taking, in particular to a fixed type cigarette ejection device capable of conducting ignition. The fixed type cigarette ejection device comprises a box body, a cigarette taking mechanism arranged on the box body, and a cigarette containing cavity formed in the box body. A slide block is arranged on the lower portion of the cigarette containing cavity and communicated with the cigarette containing cavity. A linkage mechanism is arranged between the slide block and the cigarette taking mechanism and is connected with the box body through a tension spring. An ignition mechanism is arranged on one side of the box body. Cigarettes can not be ejected until the cigarettes are needed, cleanness and sanitation of the cigarettes are ensured, the sealing performance is good, and the cigarettes are not prone to being affected with damp or getting mildew; the containing amount is large, and the fixed type cigarette ejection device can be used by people in a shared mode. In addition, the ignition mechanism is arranged on one side of the box body, a user can immediately place the cigarettes on the ignition mechanism to ignite the cigarettes after taking the cigarettes, the fixed type cigarette ejection device is convenient and rapid to use, and the procedure of taking out lighters from users respectively is omitted.

Owner:关勇河

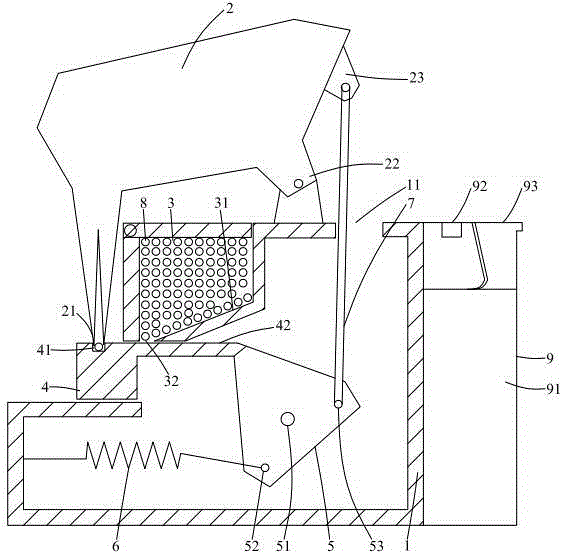

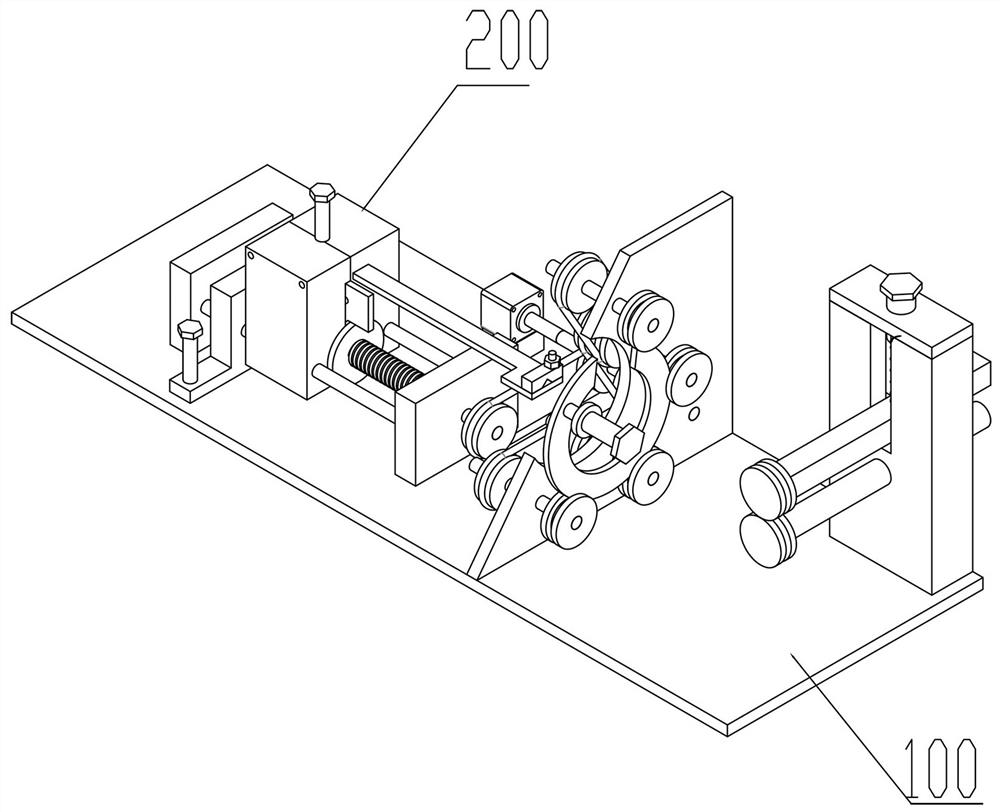

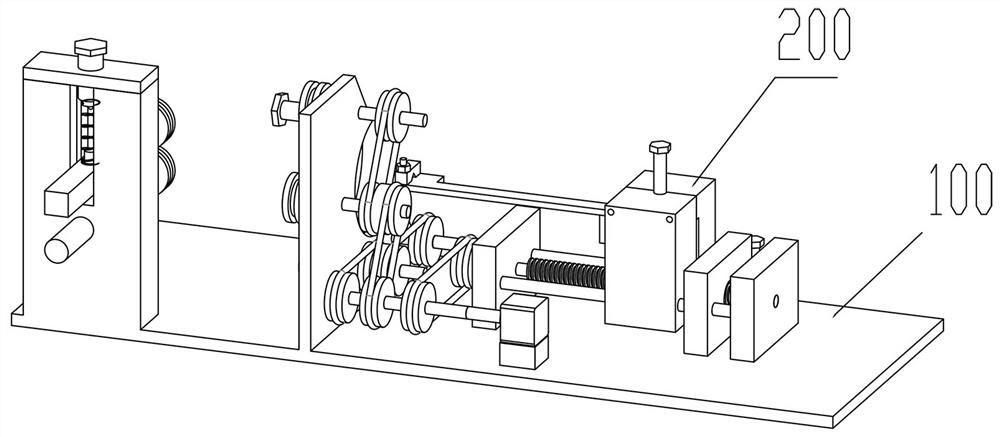

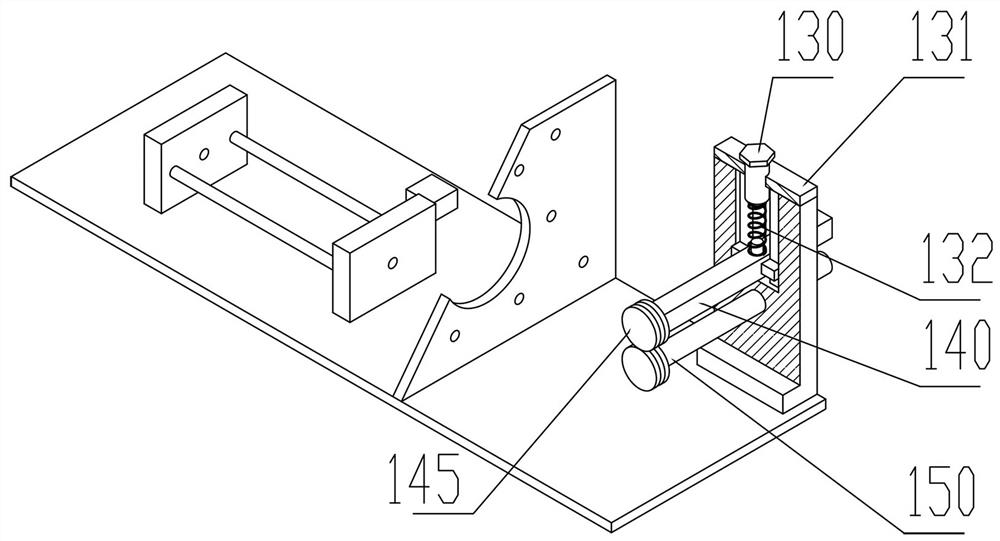

Multifunctional cable cutting equipment

ActiveCN113178810APlay a reset rolePrevent unevenApparatus for cutting/splicing cablesCleaning using toolsEngineeringStructural engineering

The invention relates to the field of cable processing, in particular to multifunctional cable cutting equipment which comprises a base and a vertical plate and further comprises a controller, an unwinding mechanism, a straightening mechanism, a cleaning mechanism and a downward cutting mechanism. The unwinding mechanism comprises an unwinding roller and a driving assembly, the cleaning mechanism comprises a brush and a rotating assembly, and the rotating assembly is arranged at the top of the base. The brush is rotatably arranged at the top of the base, the downward cutting mechanism comprises a cutter, a stamping block and a sliding assembly, the sliding assembly is arranged at the top of the base, the stamping block is arranged above the cutter, the cutter is arranged below the stamping block in a sliding mode, and the driving assembly is electrically connected with the controller. According to the multifunctional cable cutting equipment, the cutting efficiency is high, fixed-length cutting can be achieved, the fixed length can be adjusted, and meanwhile the effect of protecting the cutter can be achieved.

Owner:芜湖市科特电线电缆有限公司

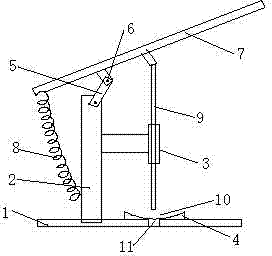

Linen yarn textile machine frame

InactiveCN107881632AHeight adjustableEasy to useLoomsContinuous wound-up machinesYarnArchitectural engineering

The invention relates to the technical field of textile machinery and discloses a linen yarn textile machine frame. The linen yarn textile machine frame comprises a base and a supporting plate, wherein one side of the base is fixedly connected with a push rod; supporting legs are fixedly connected to the bottom of the base; rollers are arranged at the bottoms of the supporting legs; telescopic loop bars which are fixedly connected to the bottom of the base are arranged on one sides of the supporting legs; transverse plates are fixedly connected to the bottoms of the telescopic loop bars; a motor is fixedly connected to the upper surface of the transverse plates; the output end of the motor is fixedly connected with a threaded rod; a reducer is arranged on the outer surface of the threadedrod; and a frame is fixedly connected to the top of the base. According to the arrangement of the telescopic loop bars, the transverse plates, the motor, the threaded rod, the reducer, nuts, bearing plates, slide blocks and chutes, an effect of conveniently adjusting the height of the linen yarn textile machine frame is achieved, so that convenience is brought to use of the linen yarn textile machine frame. Meanwhile, the service efficiency of the linen yarn textile machine frame is improved, and the textile efficiency of textile machinery is improved.

Owner:盐城金科亚麻纺织有限公司

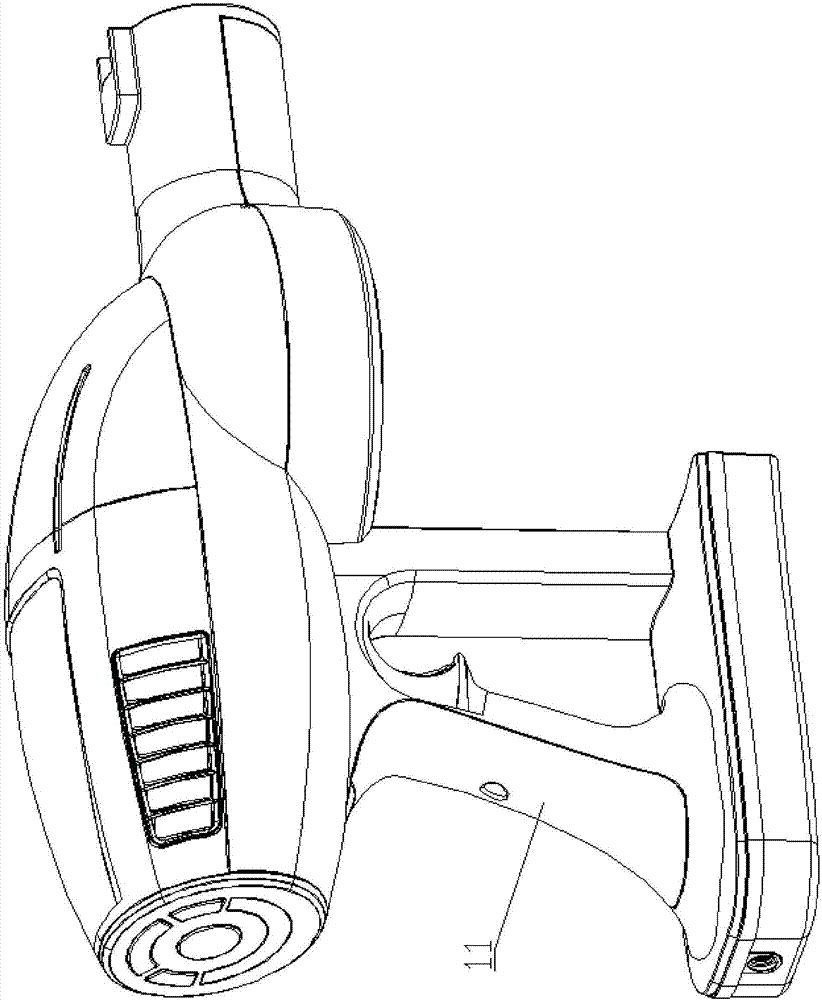

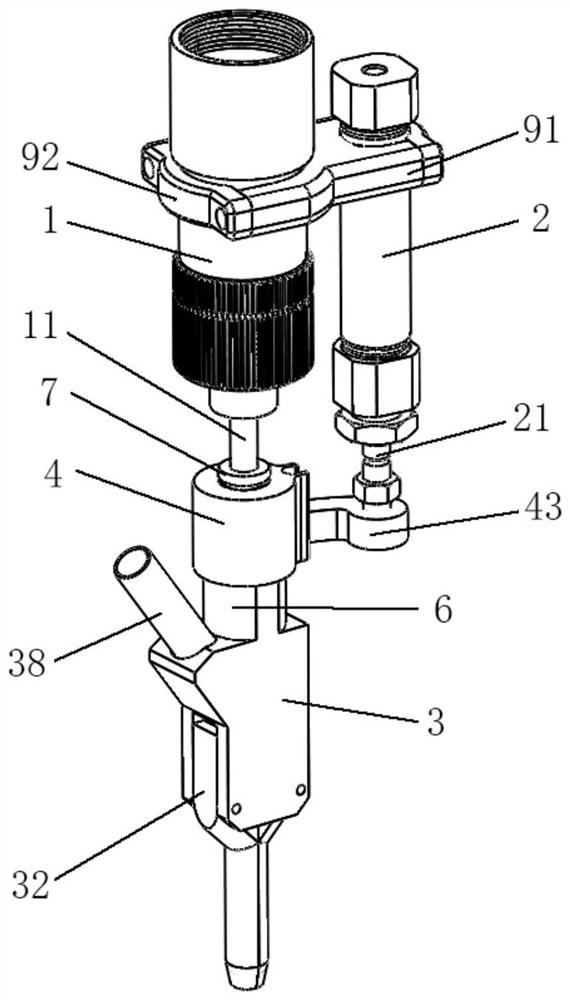

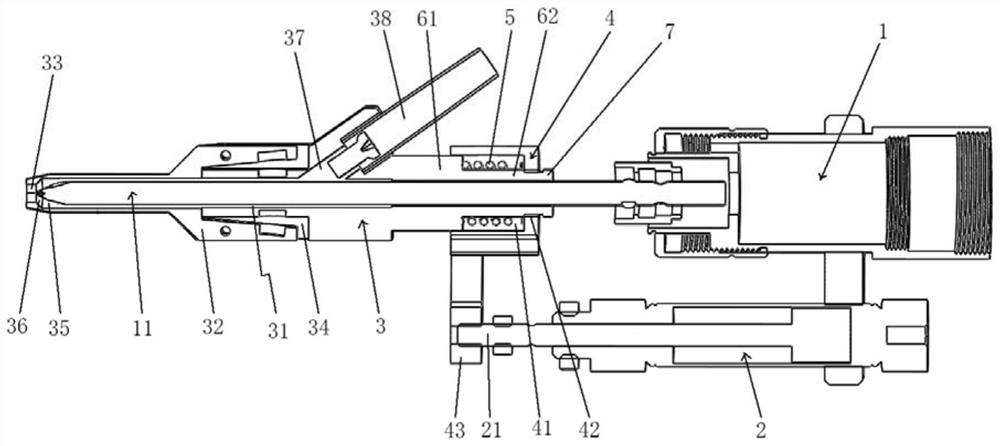

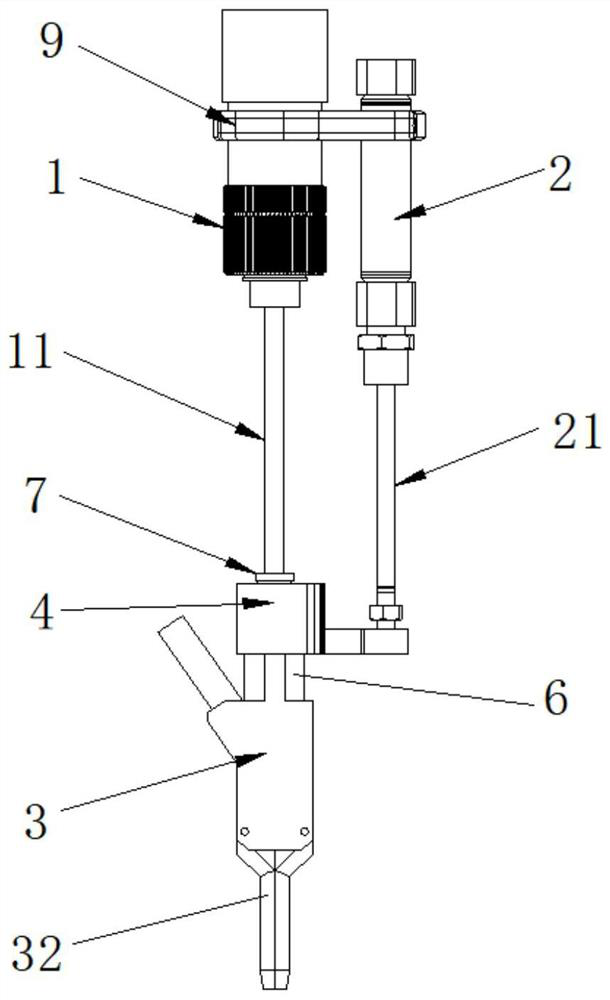

Handheld automatic screw machine

The invention discloses a handheld automatic screw machine. The handheld automatic screw machine comprises an electric screwdriver, a driving device and a clamping nozzle structure, the clamping nozzle structure comprises a clamping nozzle structure body provided with a material storage cavity and two clamping nozzle blocks rotationally arranged on the clamping nozzle structure body, the top end of the clamping nozzle structure body is movably sleeved with a transmission sleeve fixedly connected with a driving rod, an elastic piece is arranged between the transmission sleeve and the clamping nozzle structure body, a screw in the material storage cavity is pushed and positioned at a clamping opening between the two clamping nozzle blocks through a screwdriver head of the electric screwdriver, and by means of the design, the screwdriver head is kept in a vertical state when abutting against the screw, and can be quickly and accurately aligned with a hole position of a mounting position, and then the screw is inserted into the hole for locking through the screwdriver head. According to the automatic screw machine adopting the scheme, the perpendicularity when the screwdriver head and the screw are installed and locked can be guaranteed, the situation that the screw deflects and shakes is avoided, the use stability is good, the screw can be rapidly installed, installation is accurate and reliable, and the use performance and the market competitiveness of products are improved.

Owner:YUEQING WUHUAN AUTOMATION EQUIP

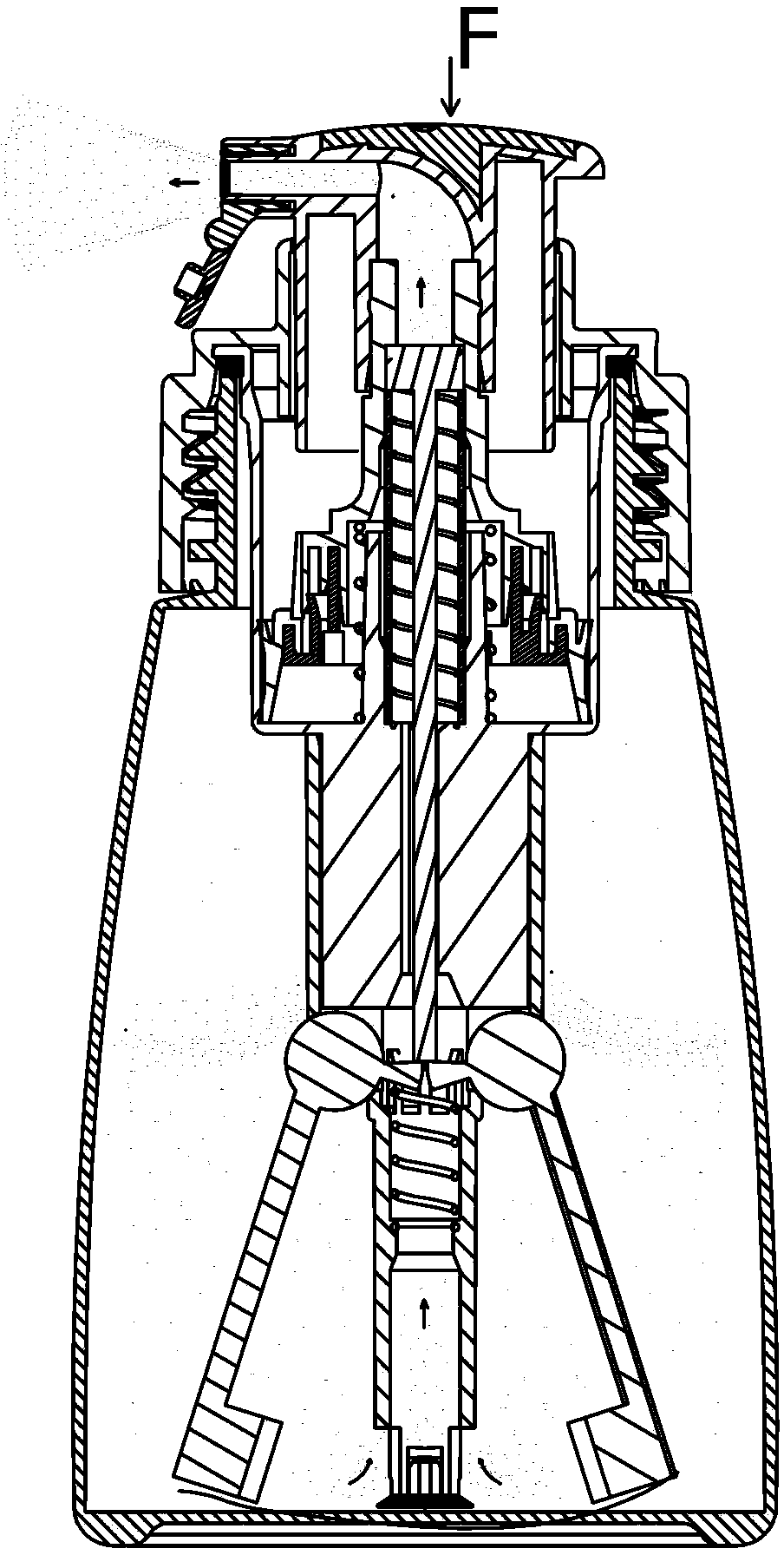

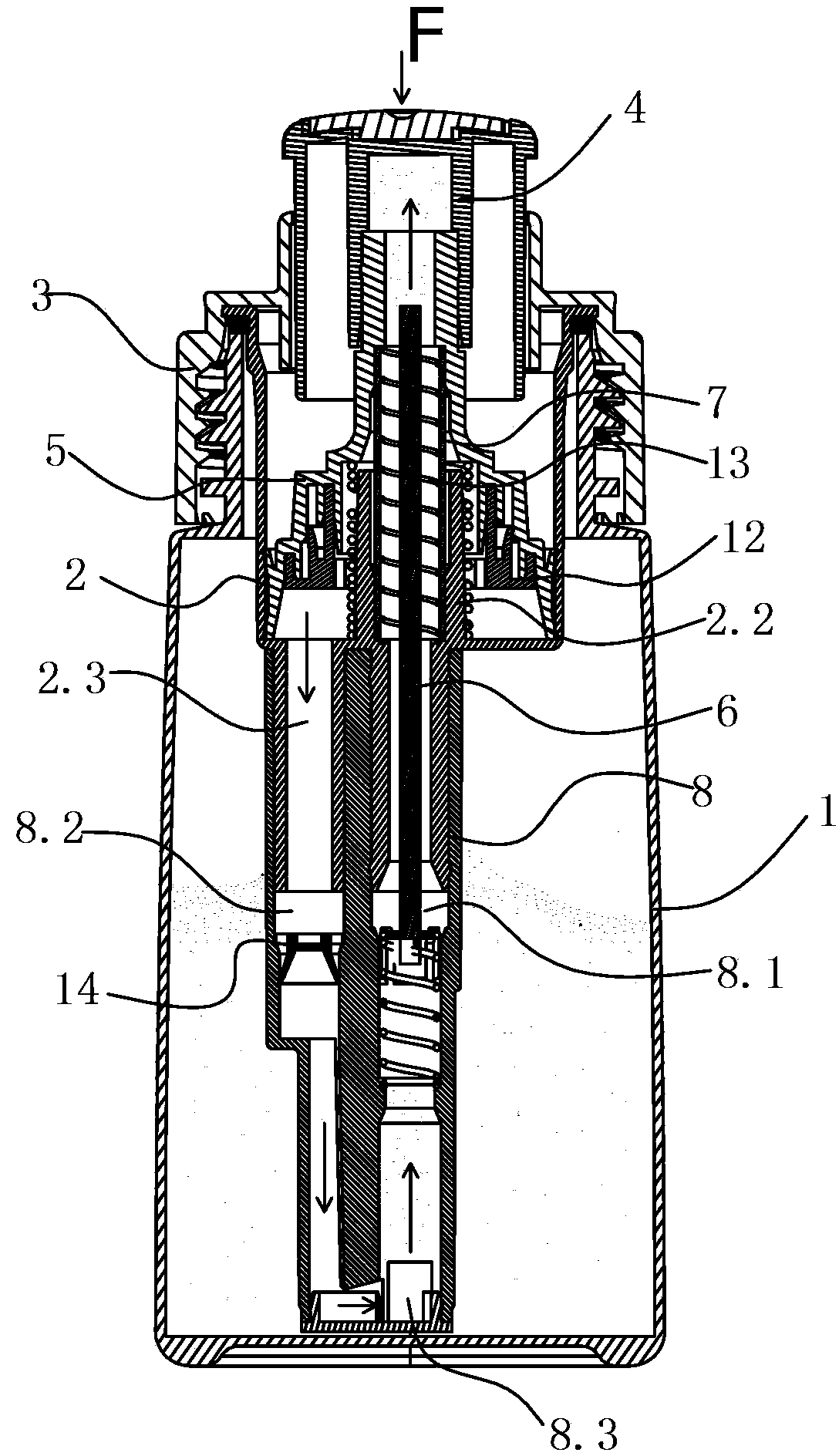

Dry powder sprayer

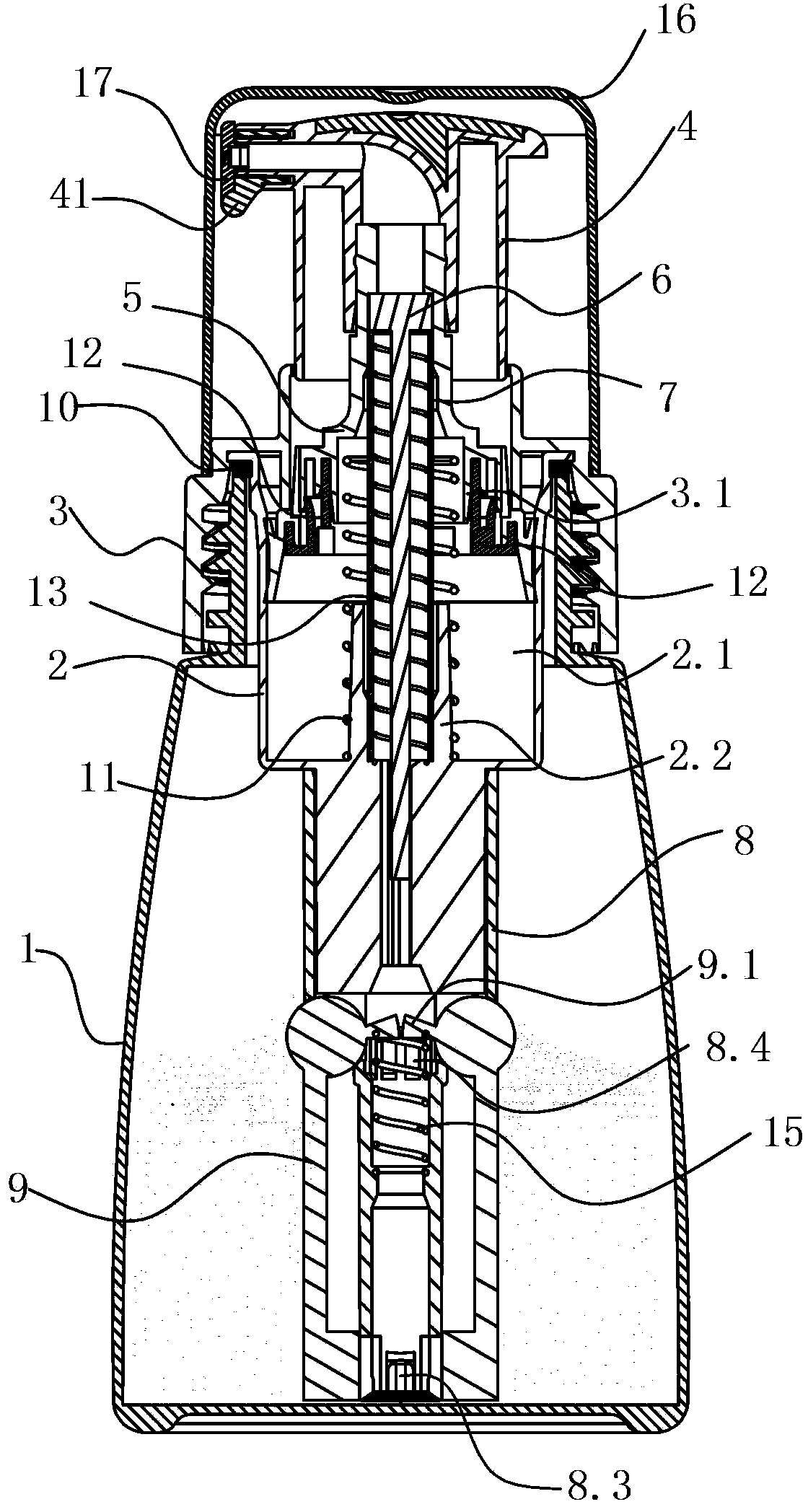

ActiveCN103381937AAvoid deformationGuaranteed smoothPowdered material dispensingClosuresSprayerEngineering

A dry powder sprayer comprises a bottle body accommodating dry powder, and is characterized by comprising a hollow conveying pipe, a connector, a group of manipulators and a push rod, wherein the upper end of the hollow conveying pipe is communicated with the nozzle of a head cap; the lower end of the hollow conveying pipe is fixed on a pillar body of a pump body, and is communicated with a central hole; the upper end of the connector is butted with the lower end of the pump body in a sealed manner; a powder discharge passage coaxially communicated with the conveying pipe is arranged in the middle of the connector; a base used for mixing powder and airflow is arranged at the bottom of the powder discharge passage; a powder inlet is formed in the side part of the base, and is communicated with the inner chamber of the bottle body; the manipulators are arranged at the side part of the connector; the upper end of each manipulator is rotationally mounted onto the connector; the lower end of the manipulator is matched with the powder inlet of the base; the push rod is movably inserted into an inner hole in the conveying pipe; the upper end of the push rod is connected with a piston; the lower end of the push rod penetrates the central hole of the pump body and is arranged in the powder discharge passage of the connector; the manipulators push dry powder in the bottle body into the base under the driving of the push rod. The dry powder sprayer has the advantages that the structure is simple and reasonable; the use is convenient and fast; the sealing performance is high; the possibility of blockage is low.

Owner:ZHEJIANG JM IND

Intelligent workbench special for civil engineering cost

InactiveCN108634597AAdjustable angleEasy to adjustVariable height tablesCombination furnitureDisplay boardTransverse groove

The invention provides an intelligent worktable special for civil engineering cost. The intelligent worktable comprises a supporting sleeve, an adjustable tool storage chassis structure, an adjustingbolt, an adjustable seat plate structure, a positioning insertion frame structure, a work table plate, an adjustable display frame structure, a tool storage frame, a storage tank, a transverse partition, a longitudinal partition, a cross-shaped mounting frame, a storage battery, an adjustable lamp rack structure, a fixed insertion frame, a projector and a wireless module, wherein the adjustable tool storage chassis structure is inserted and connected to the lower part of the supporting sleeve. According to the intelligent worktable, the matching of an auxiliary bracket, a transparent display board and an adjusting insertion groove is beneficial to conveniently adjusting the angle of the transparent display board according to the use requirement; the matching arrangement of the adjusting bolt, the supporting sleeve and a supporting rod is beneficial to conveniently adjusting the height of the workbench according to the use requirement; and the arrangement of a adjustable seat frame, a positioning slide bar and a transverse groove is favorable for a user to rest.

Owner:张文智

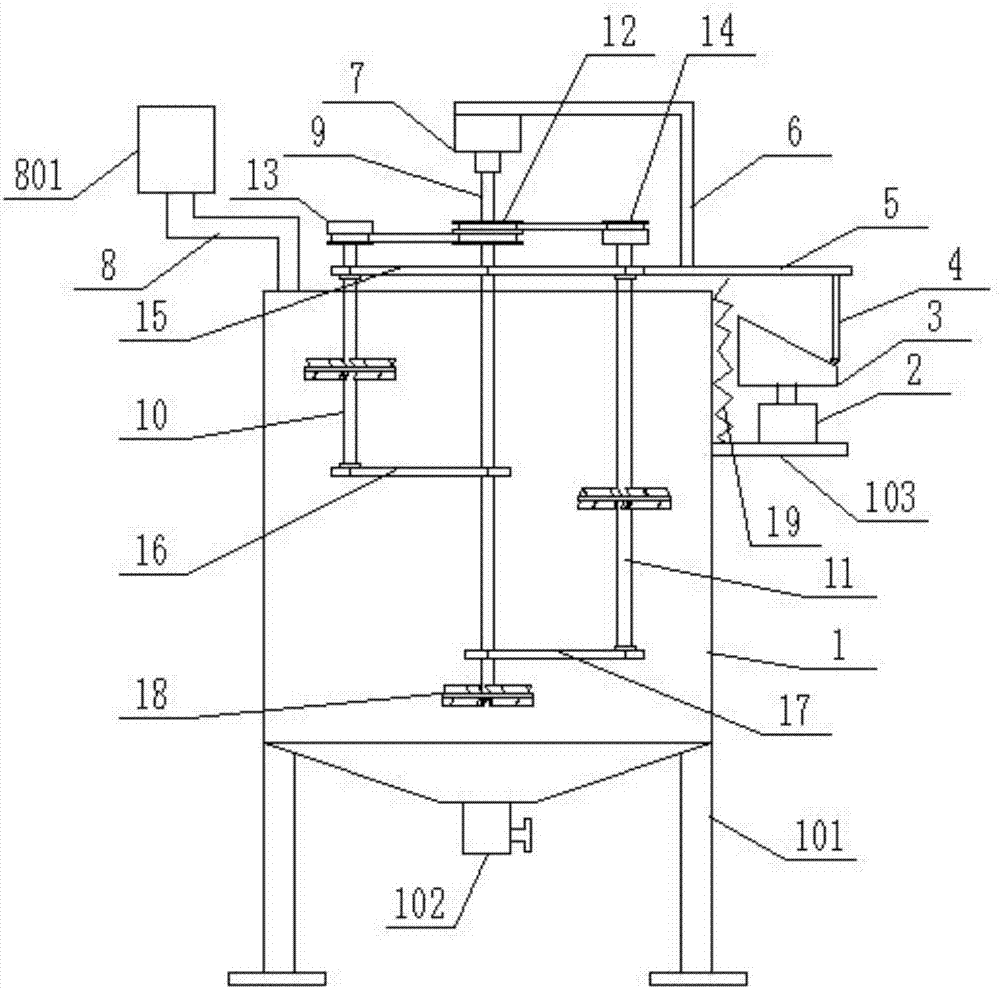

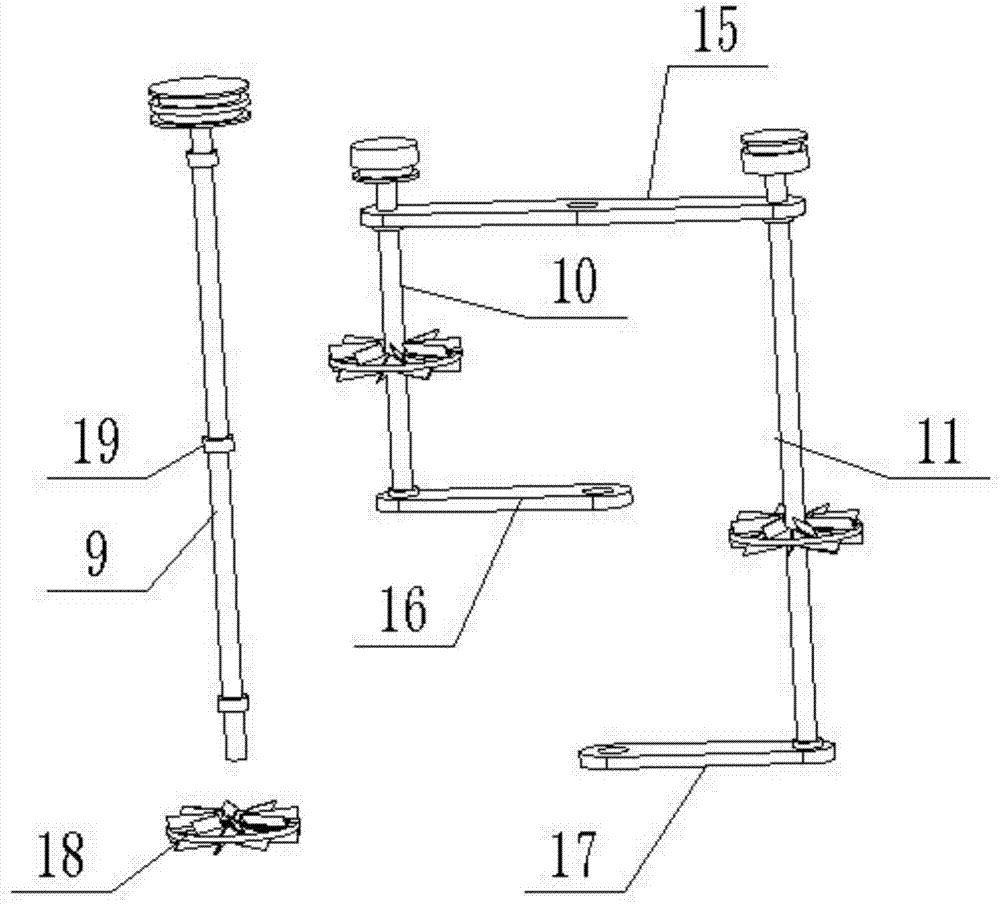

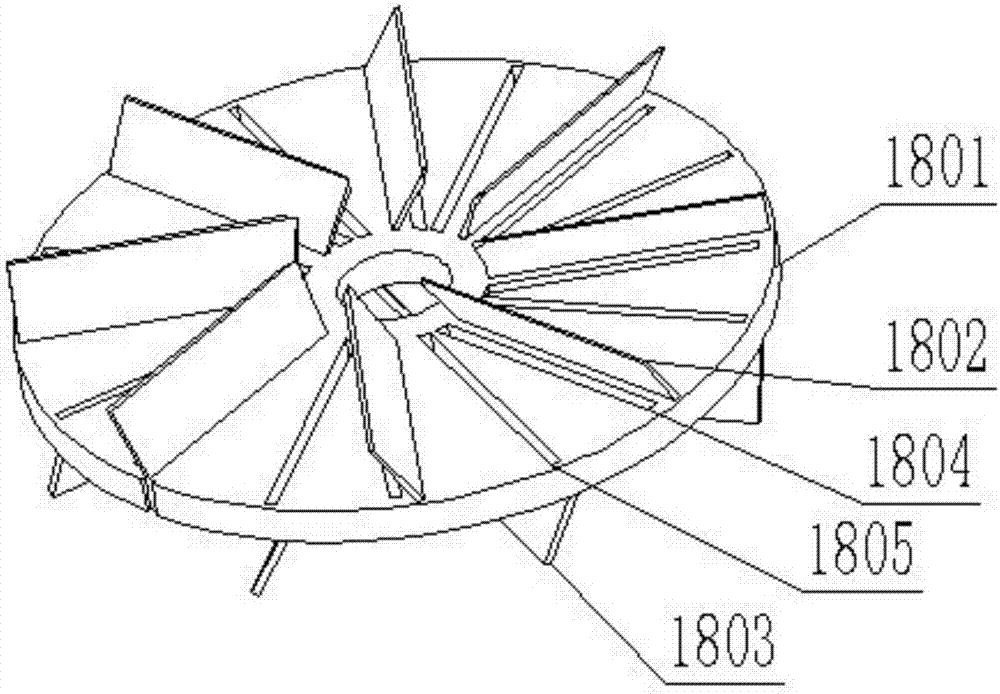

Multi-rotary shaft paint dispersing machine

InactiveCN107961718AAdd position changeImprove dispersion efficiencyRotary stirring mixersTransportation and packagingEngineering

The application discloses a multi-rotary shaft paint dispersing machine including a dispersing cylinder, a main frame body, a fixed plate and an L-shaped bracket; the top of the dispersing cylinder isprovided with a feeding port, and the bottom of the dispersing barrel is provided with a discharge port; the main frame body is arranged at the top of the dispersing cylinder and has a certain gap with a top cover of the dispersing cylinder, and the main frame body is arranged in parallel with the top cover of the dispersing cylinder; the fixed plate is fixedly connected to one side of the main frame body, and the fixed plate is located in a same plane with the main frame body; one end of the L-shaped bracket is fixed on the fixed plate, and the other end of the L-shaped bracket is fixedly connected to a second motor. The device can greatly improve the dispersing efficiency and the dispersing effect of the paint, and can also prolong the service life of the device.

Owner:湖南太子化工涂料有限公司

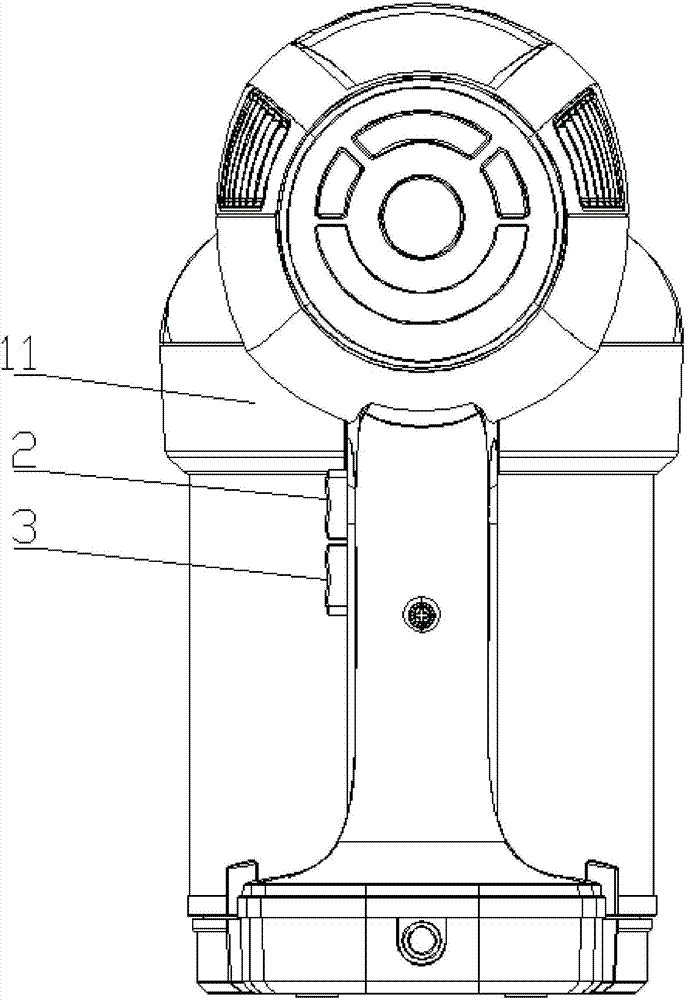

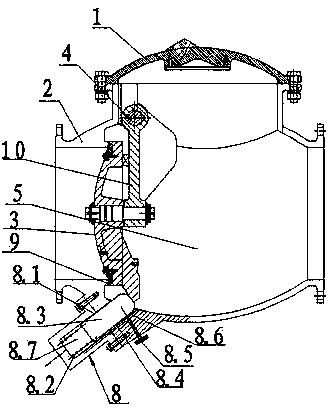

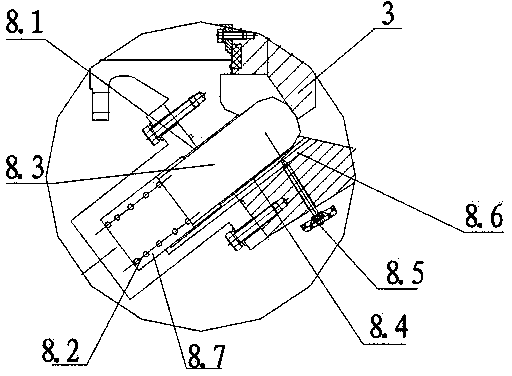

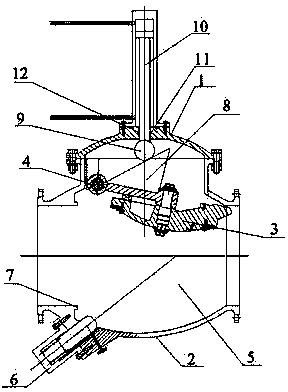

Lifting type closure swing check valve

InactiveCN103836230AReliable adjustable dampingWith interception (regulation) functionOperating means/releasing devices for valvesCheck valvesEngineeringCheck valve

The invention relates to a lifting type closure swing check valve, and belongs to the technical field of control devices on medium pipelines. The lifting type closure swing check valve comprises a valve body, a valve deck arranged on the valve body, a valve shaft which is arranged at the inner upper end of the valve body and is close to one end of a water inlet, and a valve clack fixedly connected to the valve shaft, wherein a valve seat used for being sealed with the valve clack is arranged at the water inlet end of the valve body, the inner side of the valve clack is fixedly connected with a position adjusting block, the valve deck is provided with an installation hole, a linear lifting driving device is installed inside the installation hole, the output end of the linear lifting driving device penetrates into the installation hole, and a position adjusting wheel matched with the position adjusting block is fixed to the output end of the linear lifting driving device. The lifting type closure swing check valve has the function of closure (flow adjustment), the linear driving lifting device is installed at the upper portion of the valve deck, and the shaft end of the linear driving lifting device acts on the position adjusting block to achieve adjustment of the opening degree of the valve.

Owner:WUHAN SHENGYU DRAINING SYST

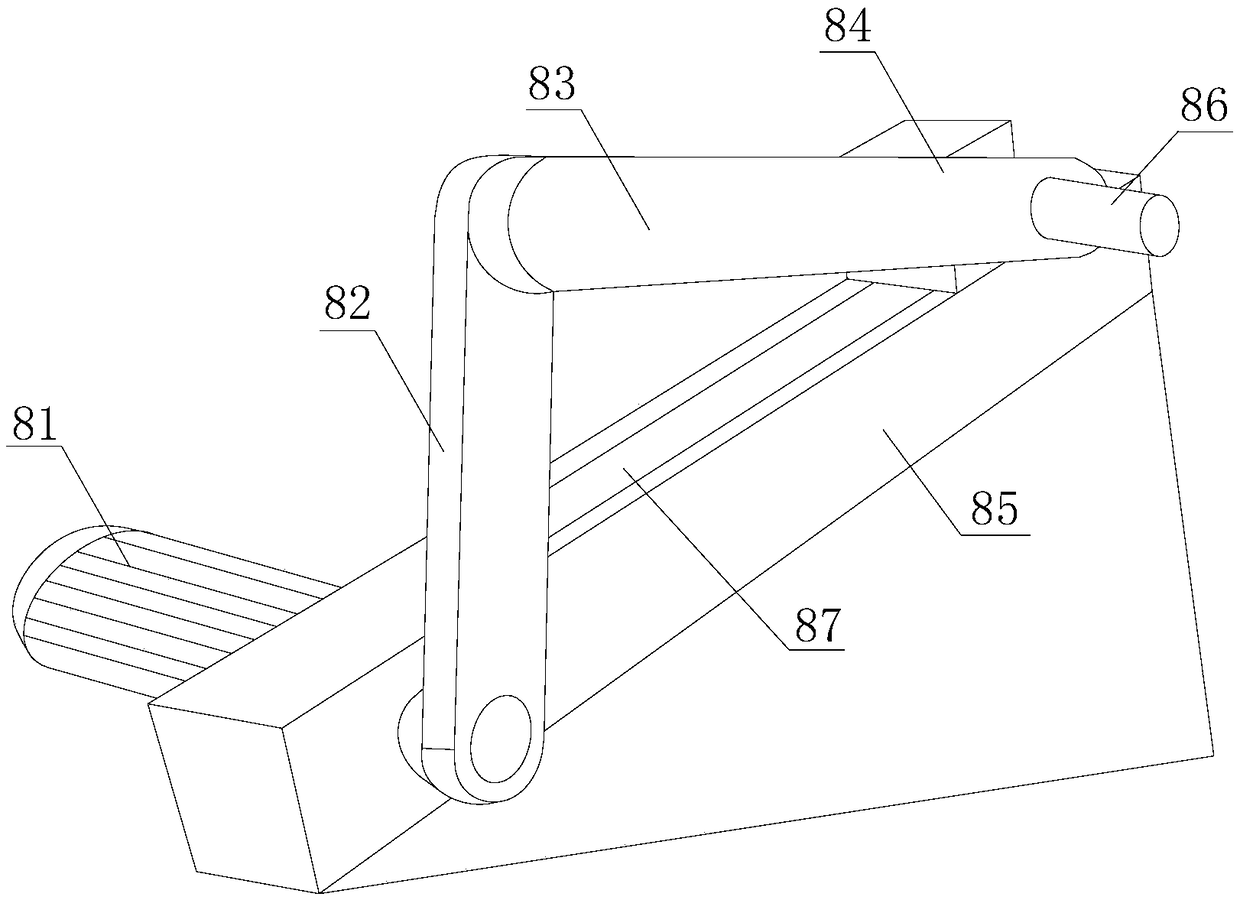

Soil ploughing device for agriculture

InactiveCN107926175ASimple structureConvenient and high-quality landSpadesWatering devicesElectric machineryFlywheel

The invention discloses a soil ploughing device for agriculture. The device comprises a cross beam, supporting legs and supporting frames; two ends of the cross beam are vertically connected with thesupporting legs; the lower end of each support leg is connected with one supporting frame; and the inner cavity of each supporting frame is provided with a roller. The soil ploughing device for agriculture has a simple structure; a first motor is controlled to drive a second flywheel to rotate; the second flywheel drives a first flywheel to rotate through a belt; and the first flywheel drives oneroller through a long shaft, so that the device provided by the invention walks on a ground. Due to the existence of uneven soil, plow plates contact the ground and move up and down to poke soil, andunder the action of the first motor, a land is plowed and the soil is ploughed; for hard soil, a second motor drives a turntable and rotary blades to rotate, a land is subjected to rotary ploughing ina crushing mode; and through the movement of the related structures with a cooperative relation, the soil is more thoroughly ploughed, and a convenient high-quality land is provided for planting crops.

Owner:林永清

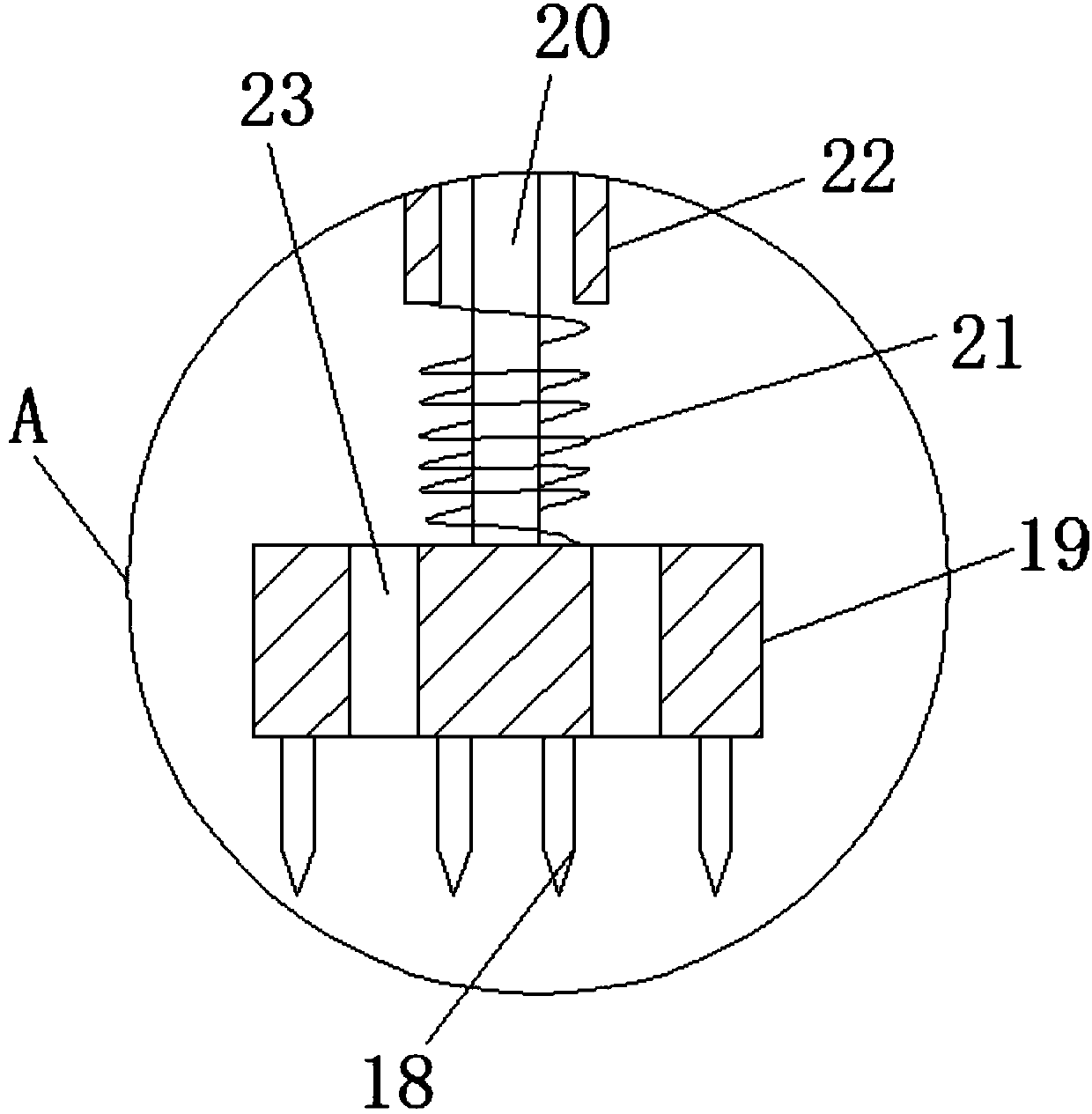

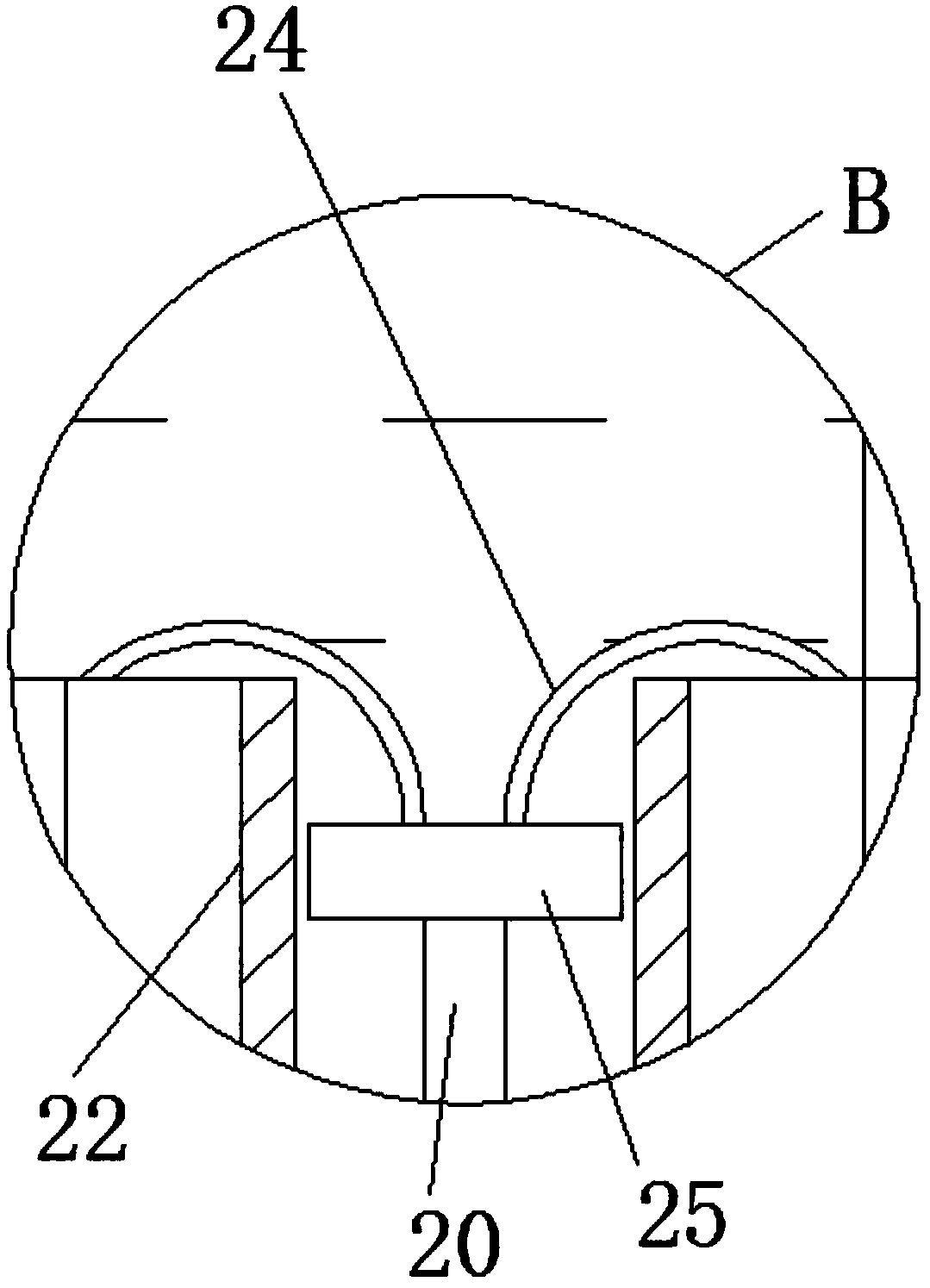

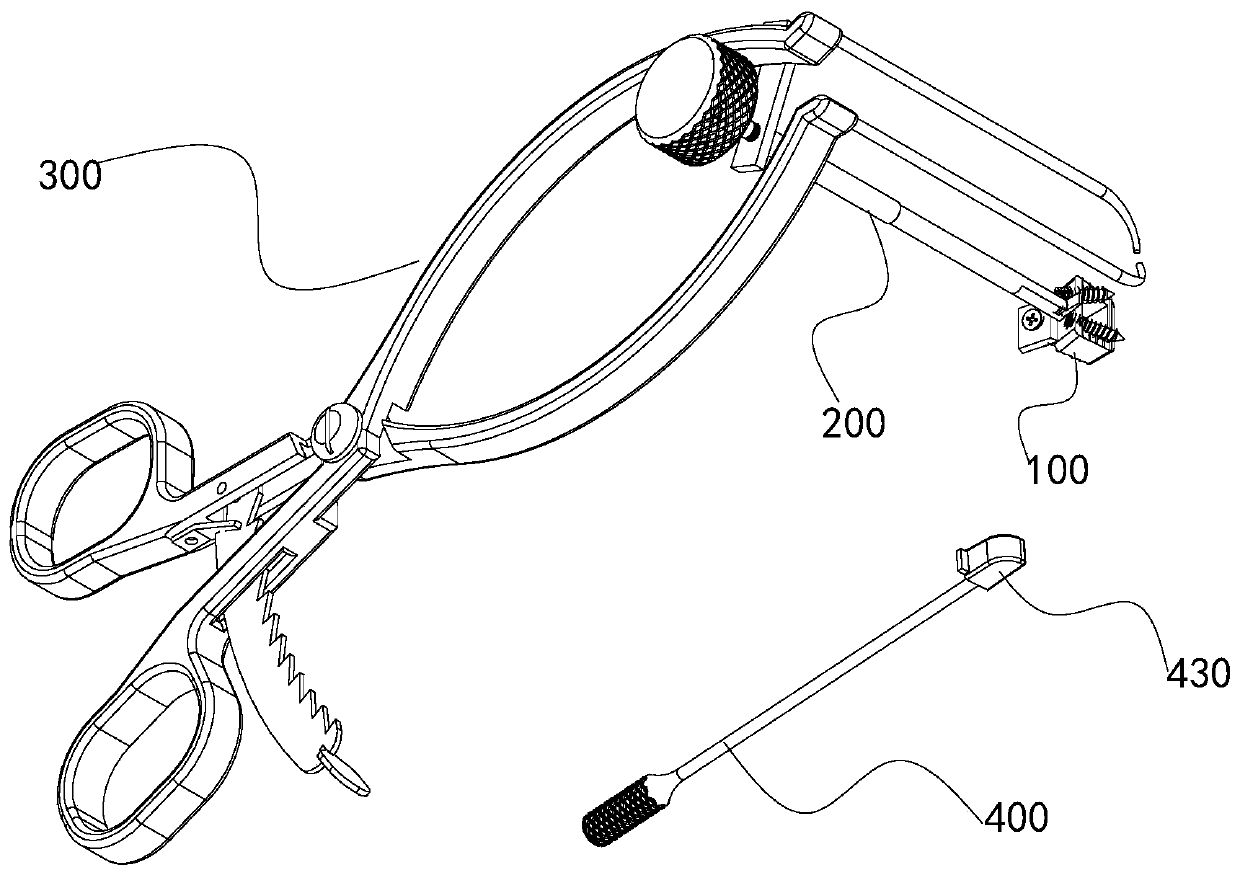

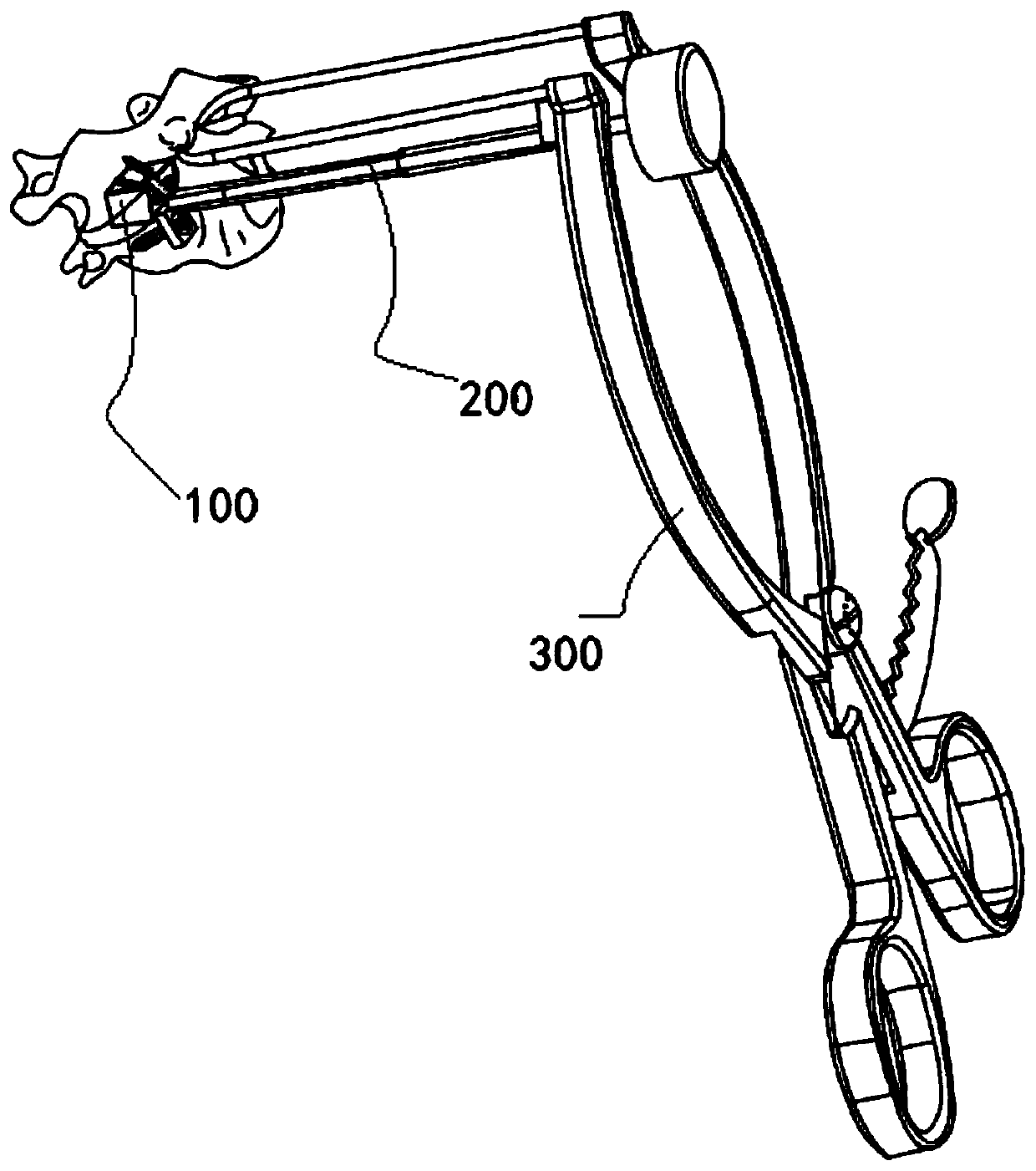

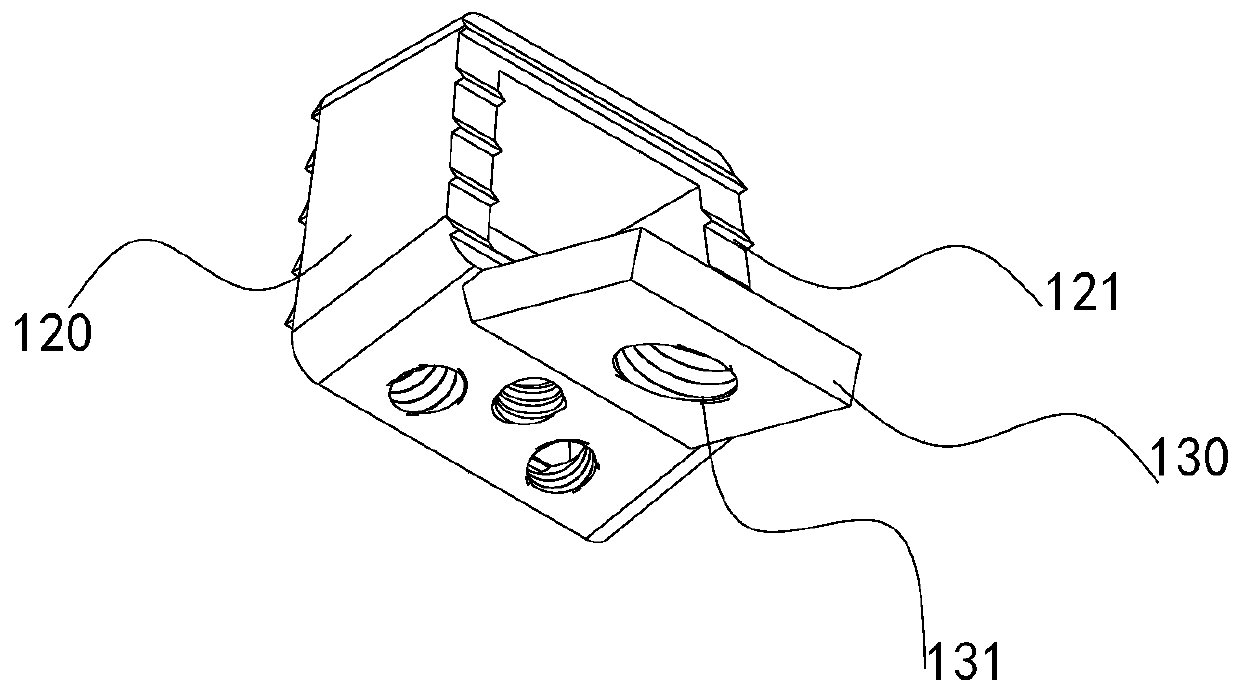

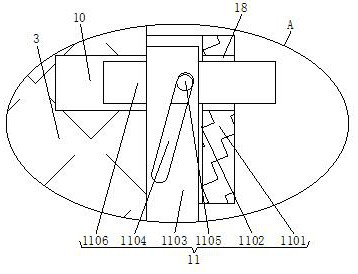

Transoral anterior atlantoaxial lateral mass embolia fusion cage system and using method thereof

ActiveCN109771106AImprove stabilityAvoid displacementSpinal implantsOsteosynthesis devicesAtlantoaxial dislocationEngineering

The invention discloses a transoral anterior atlantoaxial lateral mass embolia fusion cage system and a using method thereof. The system comprises a fusion fixing device, a holding restorer and lifting-pulling restoring pincers; a first connecting part is arranged on the fusion fixing device, a second connecting part is arranged on the holding restorer, the fusion fixing device is connected with the holding restorer through the first connecting part and the second connecting part, the lifting-pulling restoring pincers at least comprise a first conduction part and a second conduction part, andthe holding restorer is located between the first conduction part and the second conduction part. The system is used for an atlantoaxial dislocation and basilar invagination operation; meanwhile, whenthe system is in use, the atlantoaxial anterior release restoring and fusion interior fixation operation can be ideally completed simply through one operation incision.

Owner:杨进城

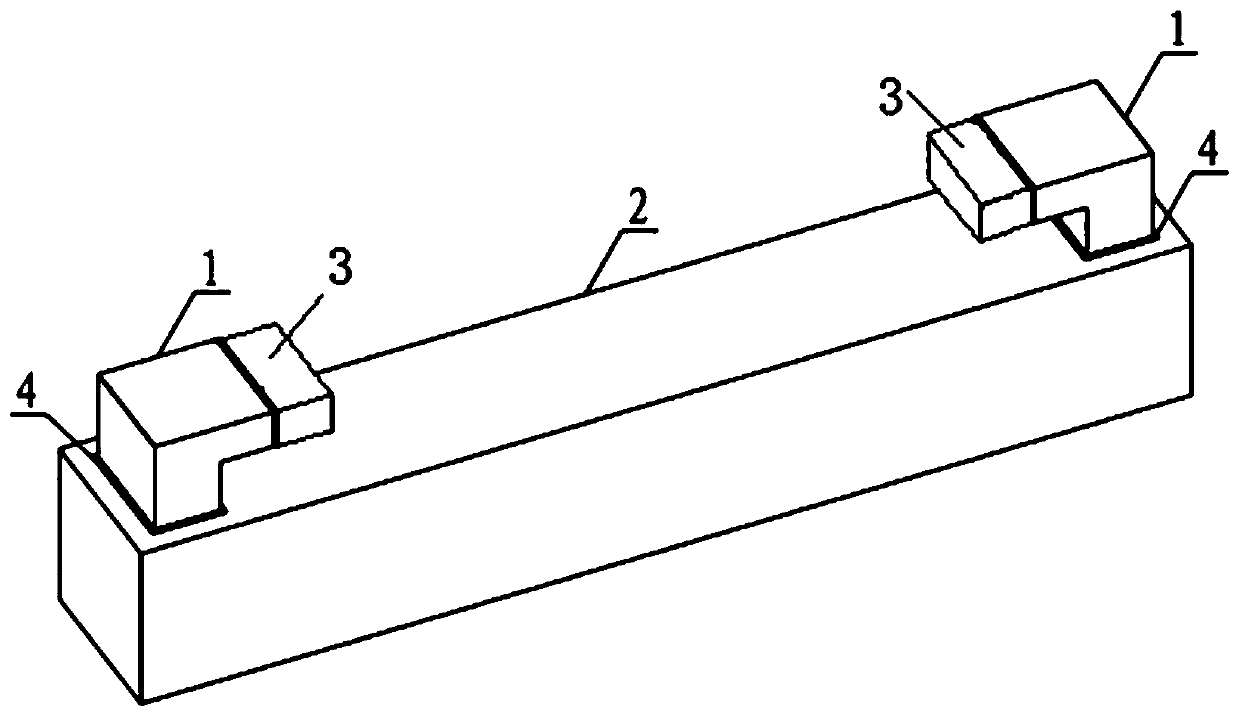

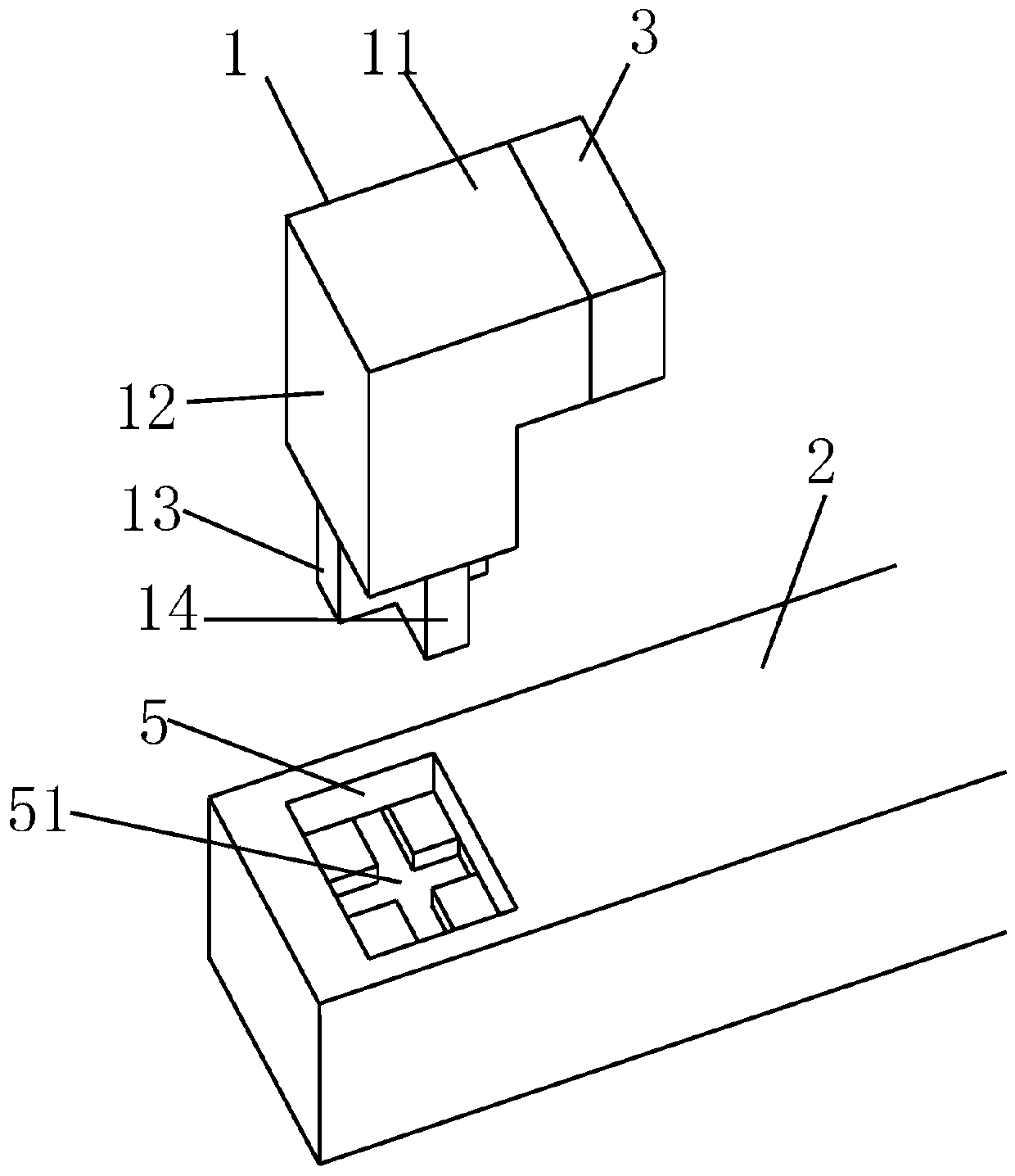

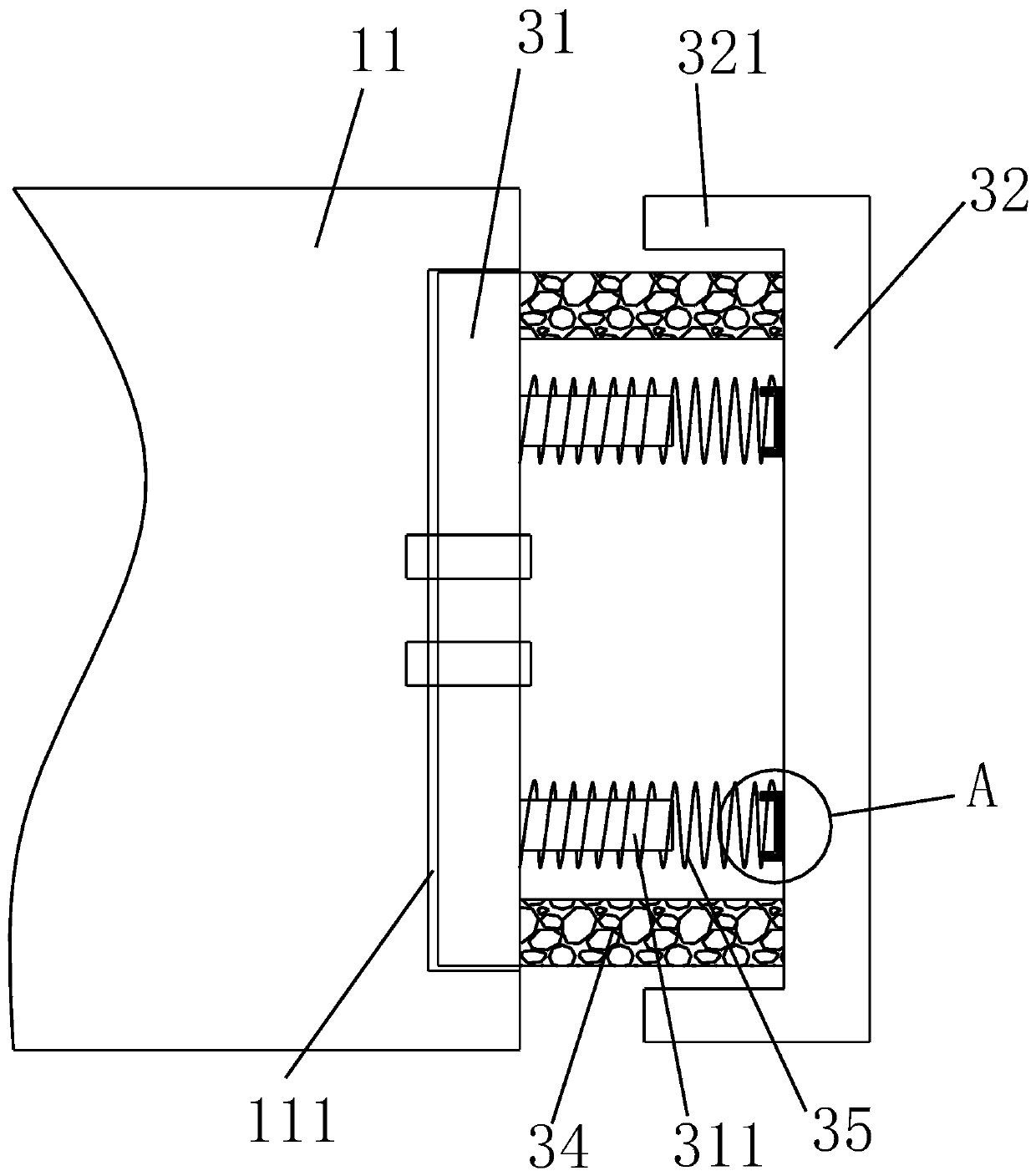

Prefabricated elastic concrete anti-seismic check block

PendingCN109930471ASimple structureEasy to operateBridge structural detailsBridge materialsEngineeringCement

The invention discloses a prefabricated elastic concrete anti-seismic check block. The prefabricated elastic concrete anti-seismic check block comprises a cross beam and elastic check blocks, whereinthe upper surfaces of the two ends of the cross beam are oppositely provided with preformed grooves, and the inner walls of the bottoms of the preformed grooves are provided with cross grooves; the elastic check blocks are inserted in the preformed grooves, and a high-strength non-shrinkage cement grouting material is poured into gaps between the elastic check blocks and the preformed grooves, wherein each elastic block comprises a longitudinal end arranged in the corresponding preformed groove and a transverse end perpendicular to the corresponding longitudinal end, the middle of the bottom of each longitudinal end is crosswise provided with a first clamping block and a second clamping block, each first clamping block and the corresponding second clamping block are vertically arranged, each first clamping block and the corresponding second clamping block are clamped in the corresponding cross groove, the front end of each transverse end is provided with a mounting groove, and each mounting groove is internally provided with a buffer mechanism. The prefabricated elastic concrete anti-seismic check block has the advantages of being simple in structure, practical, convenient and simple and rapid in construction, and being capable of being replaced immediately after damage.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD +1

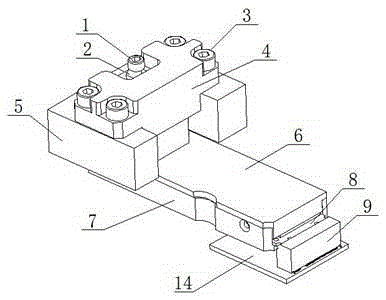

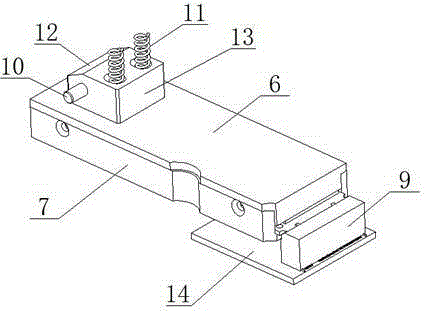

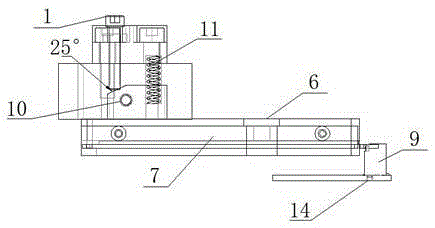

Automatic oblique inserting device for wireless network card

ActiveCN105390875ANot subject to wear and tearReduce operating intensityCoupling device detailsTest efficiencyEngineering

The invention relates to an automatic oblique inserting device for a wireless network card, which is used for oblique inserting test on the wireless network card and belongs to the technical field of auxiliary tools. The device of the invention comprises a positioning plate; an insulated cover plate is arranged on the positioning plate; the wireless network card is arranged between the positioning plate and the insulated cover plate; a supporting seat is arranged on the insulated cover plate; a slope is arranged behind the supporting seat; a rotation shaft is arranged on the supporting seat; two ends of the rotation shaft are inserted in a fixing plate; a fixing block is arranged above the supporting seat; the bottom surface of the fixing block is contacted with the slope; the fixing block is connected with the fixing plate via fixing screws; springs are also arranged on the fixing block and the supporting seat; and an adjusting bolt is arranged on the fixing block. A lifting mechanism of the existing stock is used, through a lever principle, conventional straight inserting thinking is broken, automatic oblique inserting and separating of the wireless network card are completed, the test efficiency is high, and the product is not damaged.

Owner:TESTRON SUZHOU ELECTRONICS

Winding component during acrylic fiber production

The invention discloses a winding component during acrylic fiber production. The winding component comprises a first mounting arm, a second mounting arm and a bobbin; a first motor is mounted on the first mounting arm; a rotating shaft is connected with the first mounting arm through a mounting frame and is sleeved with the bobbin; the bobbin is connected with a first pulley, a second pulley and ayarn cone through a silk thread; and an automatic adjusting component is arranged at the top end of the second mounting arm and comprises a supporting column, a sleeve, a round carrying plate and a spring. According to the winding component during acrylic fiber production, the tension change of the bobbin during rotation can be adjusted automatically by the aid of the automatic adjusting component, so that the stable tension of the silk thread can be guaranteed; the bobbin can move forwards and backwards by the aid of a swinging component, so that the silk thread on the bobbin can be prevented from being centralized in one position, the product quality of the bobbin can be guaranteed, during operation of the whole winding component, quick winding can be realized, the filament is stable fin tension during winding, and the thread quality is improved; and meanwhile, the thread set moves automatically, the silk thread is prevented from being centralized in one position, and the quality ofthe thread set is guaranteed.

Owner:马鞍山市金毫厘纺织有限公司

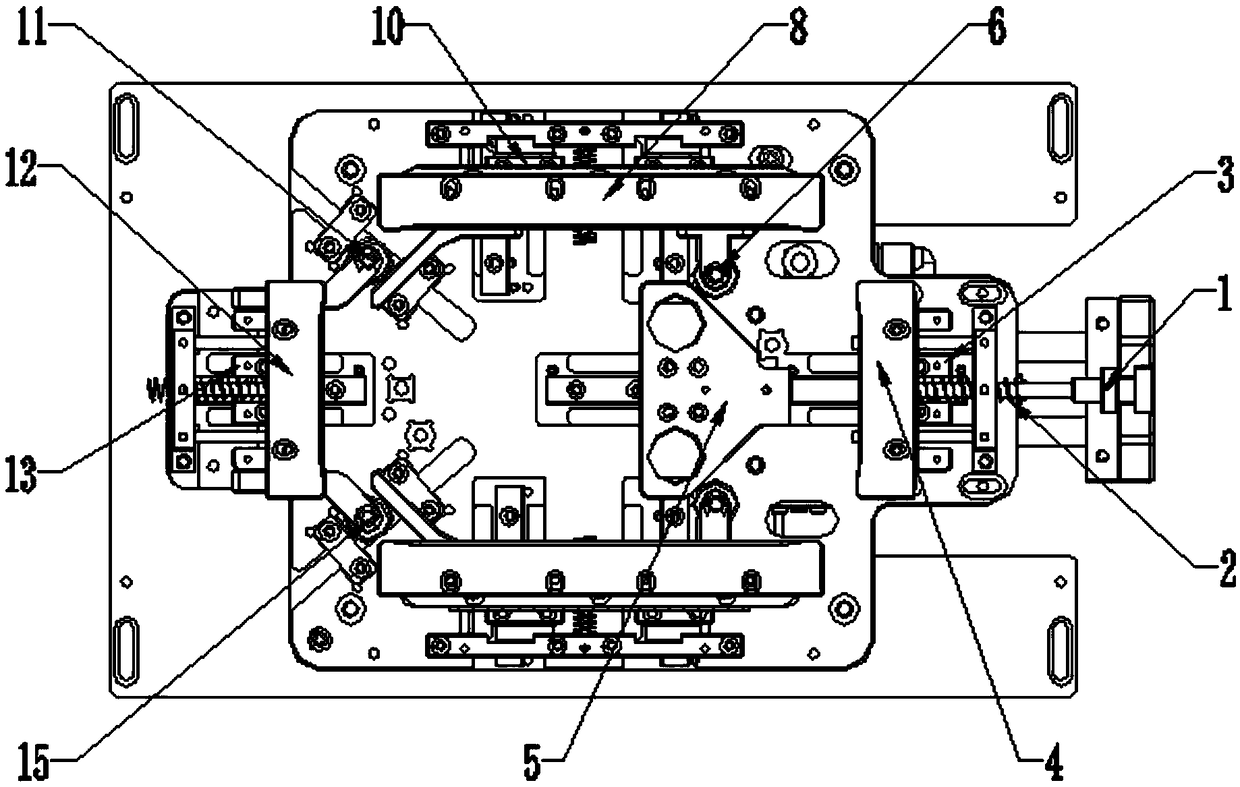

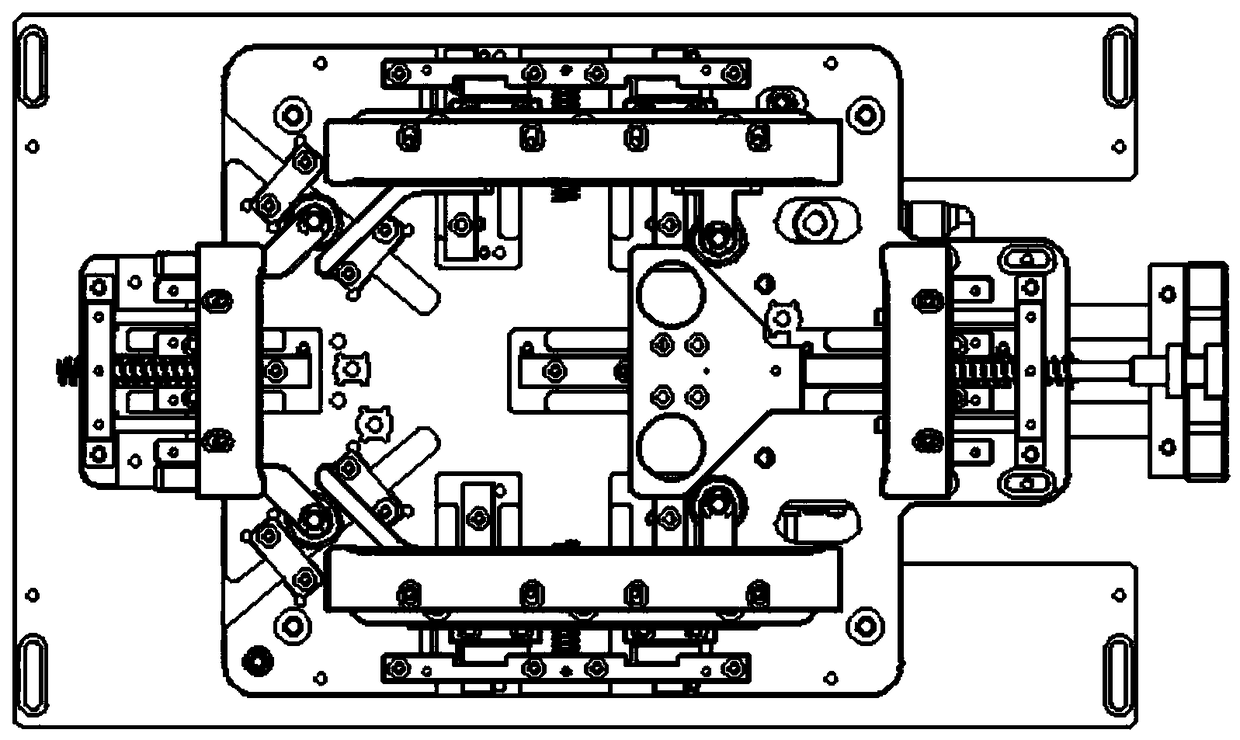

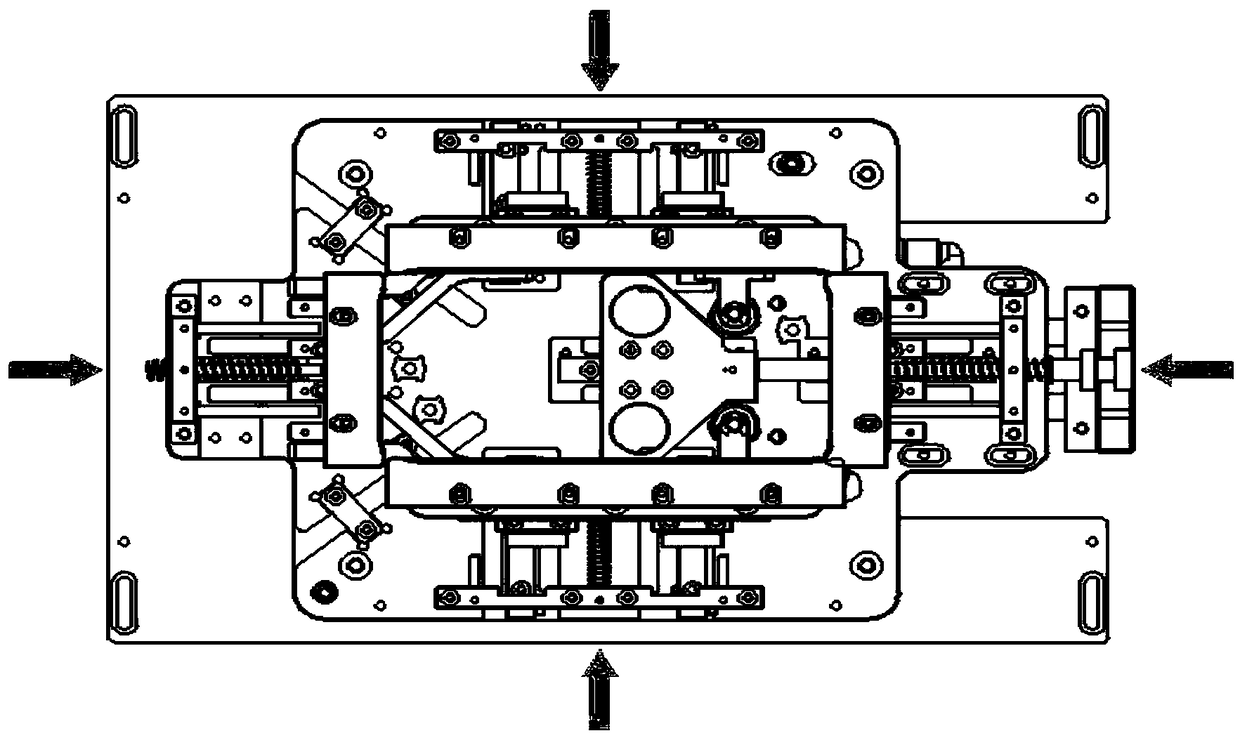

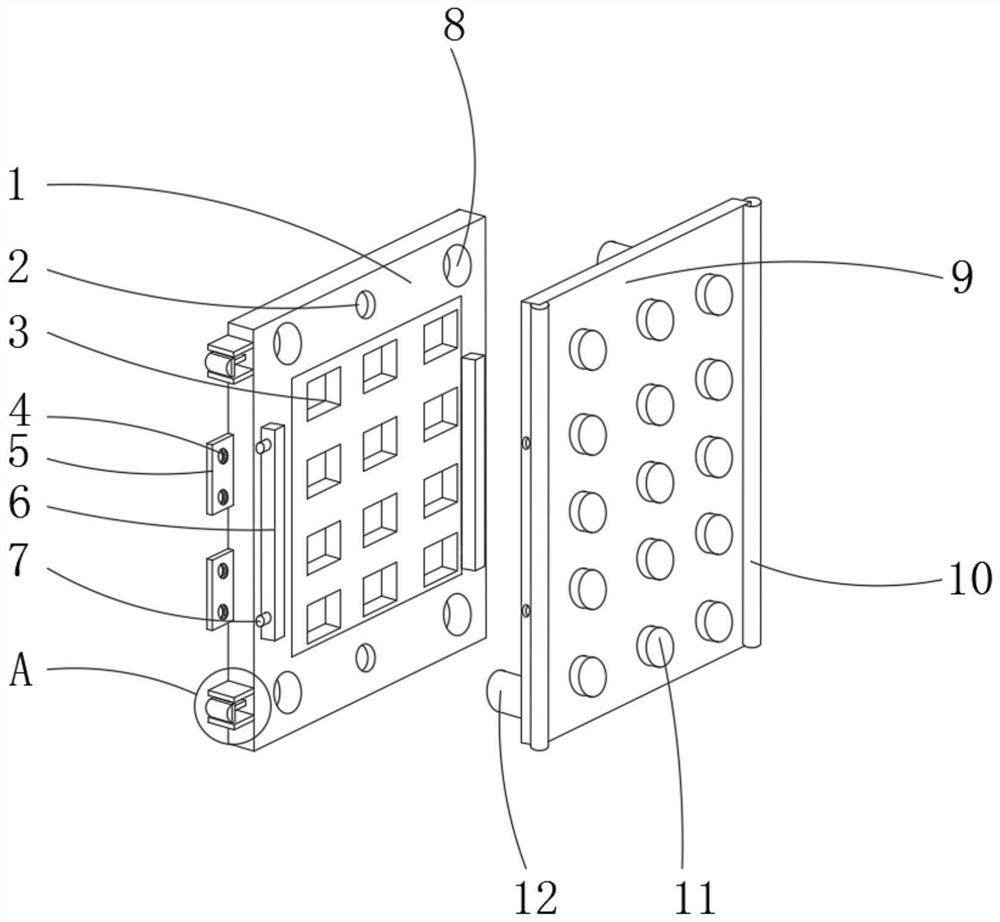

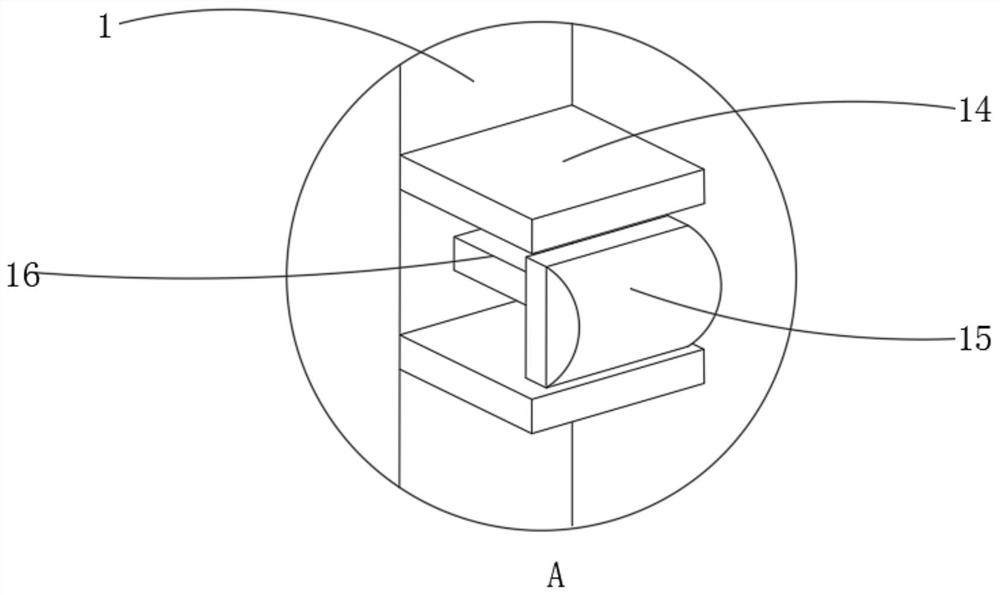

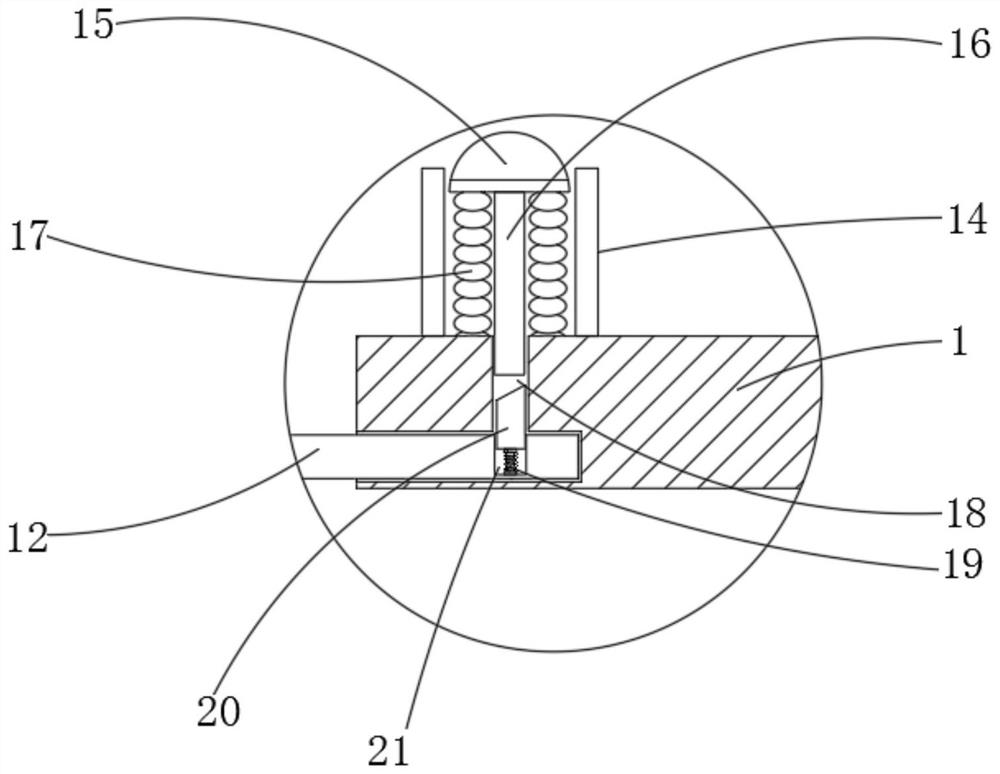

Peripheral clamping mechanism and operation method

ActiveCN109048418ARunning at the same speedEasy to operate and controlPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a peripheral clamping mechanism and an operation method. The peripheral clamping mechanism comprises a die holder and a driving mechanism, wherein the driving mechanism is horizontally arranged at the top edge position of the die holder and is fixedly connected to the die holder through a screw; a sliding block A is arranged at the bottom of the driving mechanism; the sliding block A is horizontally arranged in the middle of the bottom of the driving mechanism and is fixedly connected to the driving mechanism through the screw; a clamping block A is arranged at the topof the sliding block A; the clamping block A is horizontally arranged in the middle of the top of the sliding block A and is fixedly connected to the sliding block A through the screw; a transmissionblock is arranged on one side of the clamping block A; the transmission block is horizontally arranged at one end of the driving mechanism and is fixedly connected to the driving mechanism through thescrew; a sliding block B and a sliding block C which are parallel to each other are arranged at the top of the die holder; and the sliding block B and the sliding block C are horizontally arranged atthe top edge position of the die holder and are fixedly connected to the die holder through the screws. The peripheral clamping mechanism has the advantages of simple operation control, identical peripheral clamping force and consistent running speed of the clamping blocks.

Owner:上海莘翔自动化科技有限公司

Physical training device for long jump distance detection

The invention discloses a physical training device for long jump distance detection. The device comprises a training device body, wherein a cleaning mechanism is installed on one side of the trainingdevice body, and the cleaning mechanism comprises a fixing block, a rotating shaft, a spring roll, a winding wheel, a limiting wheel, a collecting groove, a sliding groove, a scraping rod, a limitingrod, a connecting rope and a sealing door; according to the device, through the cleaning mechanism, an athlete can conveniently clean impurities on the surface of the training device body, so workingdifficulty of impurity cleaning of the athlete is reduced, and practicability of the device is improved; the phenomenon that an athlete falls down when jumping down due to the fact that impurities areattached to the surface of the training device body is avoided, meanwhile, the athlete can conveniently collect the cleaned impurities, the phenomenon that the impurities drift away everywhere is avoided, the position of the moved scraping rod can be limited, and the phenomenon that the scraping rod is separated from the training device body is avoided.

Owner:盐城盐龙文化体育产业投资有限公司

Assembled soft and hard package convenient to splice

PendingCN112049346AImprove connection stabilityEasy to disassembleCovering/liningsBuilding material handlingEngineeringScrew thread

The invention discloses an assembled soft and hard package convenient to splice, and relates to the technical field of soft and hard packages. The assembled soft and hard package comprises a mountingplate and a package body, a fixed plate is fixedly connected to the side wall of the mounting plate, threaded holes are formed in the front end face of the fixed plate, fixed bolts are is in threadedconnection in the threaded holes, clamping holes are formed in the front end face of the mounting plate, clamping columns are fixedly connected to the side wall of the face, opposite to the mounting plate, of the package body, and the clamping columns stretch into the clamping holes and are slidably connected with the clamping holes. Sliding columns are slidably connected to the side wall of the mounting plate, sliding grooves are formed in the side wall of the mounting plate, the sliding columns are slidably connected in the sliding grooves, grooves are formed in the side walls of the clamping columns, ejecting blocks are slidably connected in the grooves, stretch into the sliding grooves and are slidably connected with the sliding grooves, the ejecting blocks make contact with the sliding columns, telescopic springs are arranged on the inner side walls of the grooves, and the ends, stretching out of the side wall of the mounting plate, of the sliding columns are fixedly connected with protruding blocks. The assembled soft and hard package solves the problem that an existing soft and hard package is difficult to disassemble and assemble.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Portable, foldable and environment- friendly sofa

The invention provides a portable, foldable and environment- friendly sofa, which belongs to the technical field of furniture, and solves the problems that the existing sofa is small in applicable range and the like. The portable, foldable and environment- friendly sofa comprises a sofa seat and a sofa backrest, wherein a pivot pin is arranged on the sofa backrest; two ends of the pivot pin are rotatably arranged on the sofa seat; a compression spring sleeves on the pivot pin; a handrail I and a handrail II are also fixed on two sides of the sofa seat; a groove is formed on the handrail I; a lifting air cylinder is arranged in the groove; an ashtray is arranged on the end part of a piston rod of the lifting air cylinder; a water outlet column is fixed on the ashtray; a piston is slidably arranged in the water outlet column; an extrusion rod is fixed on the piston; a foot pad is also arranged on the lower end of the sofa seat; a telescoping mechanism is also arranged between the sofa seat and the foot pad. The portable, foldable and environment- friendly sofa provided by the invention is provided with the ashtray and has the advantage that the foot pad can be flexibly adjusted.

Owner:HAINING JIALIAN SOFA

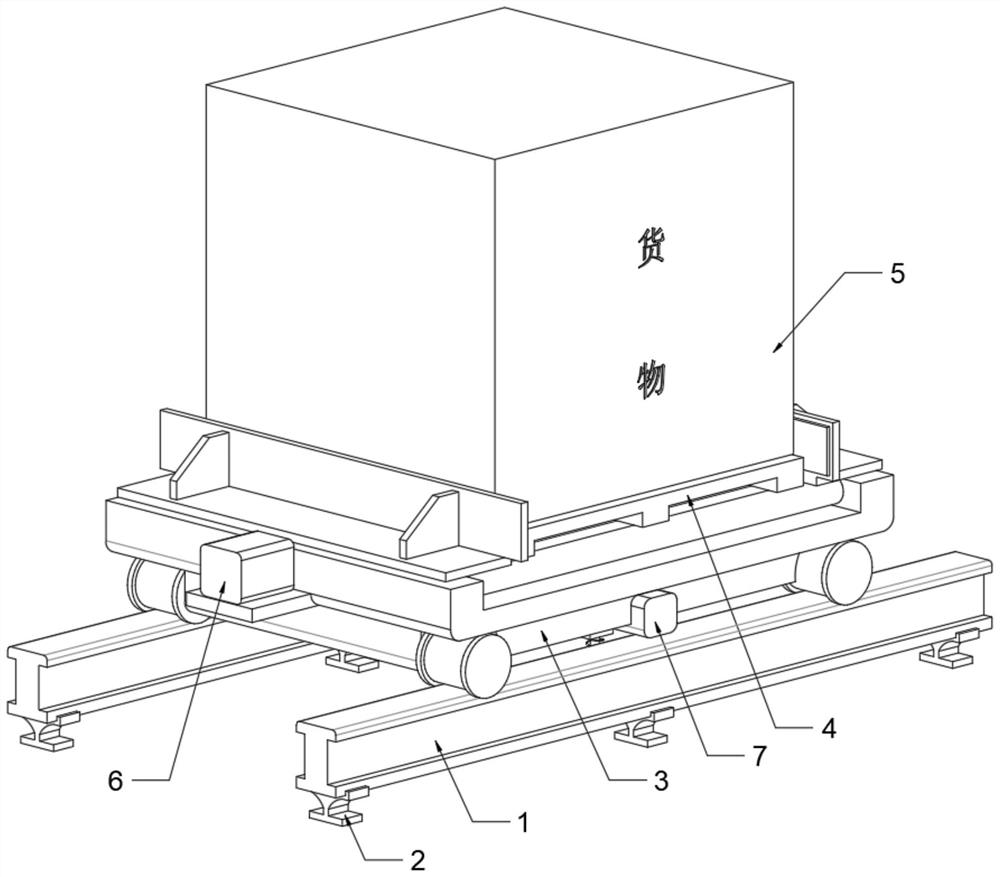

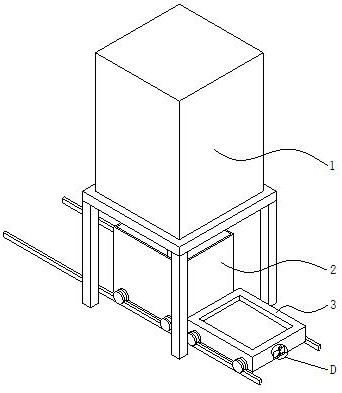

Intelligent vertical warehouse with automatic storage function and control method thereof

PendingCN114194693AImprove storage efficiencyPrevent dumpingStorage devicesConveyor partsRobot handData information

The invention discloses an intelligent vertical warehouse with an automatic storage function and a control method thereof.The intelligent vertical warehouse is composed of a goods shelf, a roadway type stacking machine, a warehousing workbench, an automatic feeding mechanism and a monitoring dispatching system.The roadway type stacking machine is composed of a forklift and a bridge type stacking machine; the warehousing workbench comprises an obtaining module, a processing module and a database, the automatic feeding mechanism is composed of a cargo tray, a conveying mechanism and a mechanical arm, and the monitoring and dispatching system comprises an abnormity monitoring unit, an electric quantity monitoring unit, an information receiving unit and a driving unit. According to the intelligent vertical warehouse, the monitoring and dispatching system can monitor equipment in the intelligent vertical warehouse in real time, the monitoring and dispatching system shares data information with the database in the warehousing workbench, the warehousing workbench can record classification information of the goods shelf in different areas of the intelligent vertical warehouse in advance, and optimal storage planning can be rapidly carried out according to goods attributes.

Owner:MINJIANG UNIV

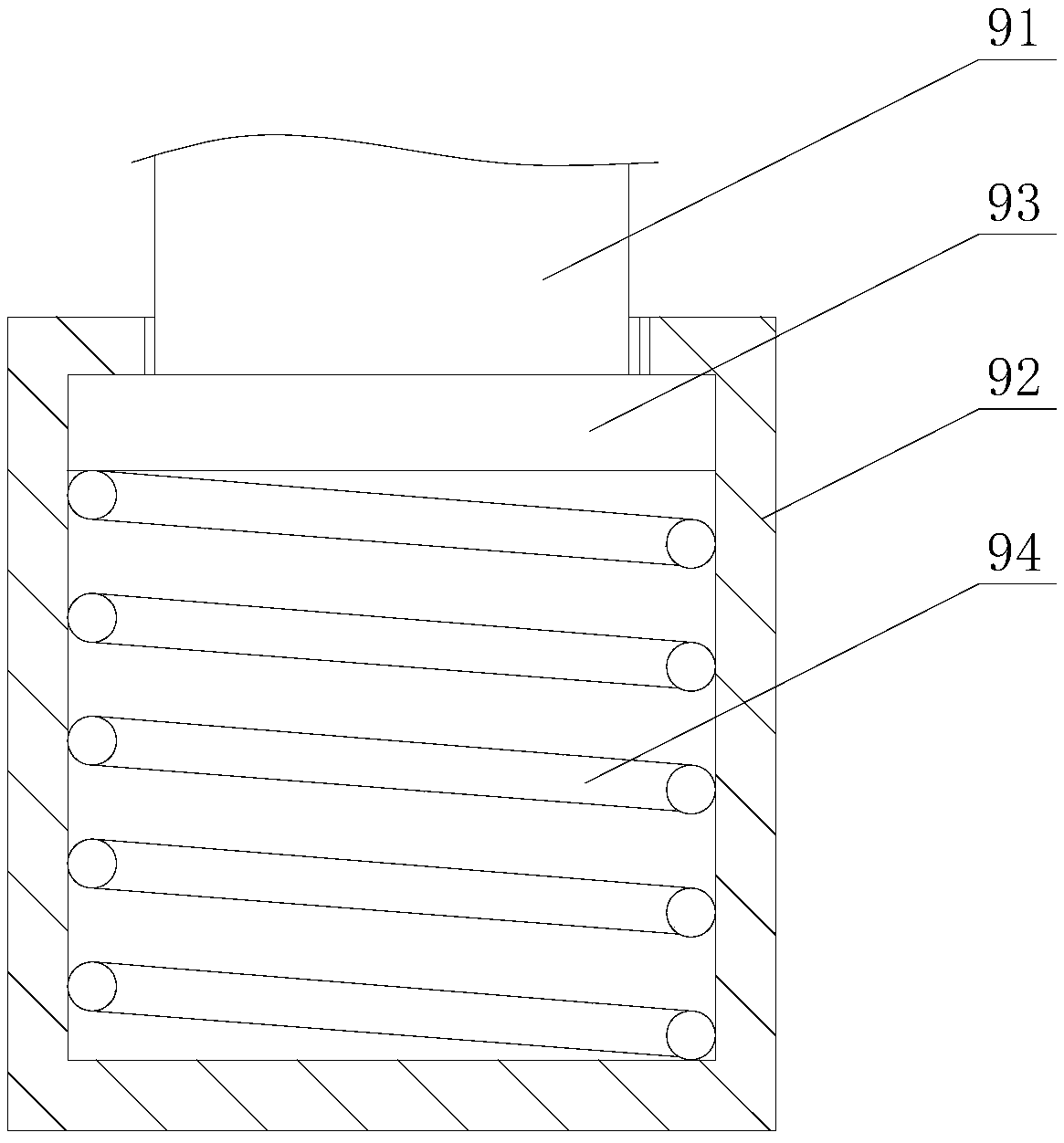

Quenching device for high-strength and high-toughness aluminum alloy machining

InactiveCN112708739ASolve the problem of waste, non-reuse, and saving raw materialsPlay a fixed roleFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention discloses a quenching device for high-strength and high-toughness aluminum alloy machining. The quenching device comprises a quenching furnace, wherein a quenching tank is formed in the bottom of the quenching furnace; a material conveying vehicle is arranged on the right side of the quenching tank; a collecting tank is formed in the top of the material conveying vehicle; a first through hole is formed in the right side of the bottom of an inner cavity of the collecting tank; and a filter screen is arranged in an inner cavity of the first through hole. Through cooperative use of the quenching furnace, the quenching tank, the material conveying vehicle, the collecting tank, the first through hole, the filter screen, a containing tank, a collecting box, a second through hole, a sliding groove, a fixing mechanism, a positioning block, a movable groove, a limiting mechanism, a clamping groove, a third through hole, a fifth through hole and a sixth through hole, the problems that quenching liquid is wasted and cannot be reutilized due to the fact that a certain amount of quenching liquid is brought out and drips on the top of the material conveying vehicle when workpieces are lifted from the quenching liquid in the quenching process of an existing quenching device are solved, and raw materials are saved.

Owner:ANHUI GAODE ALUMINUM

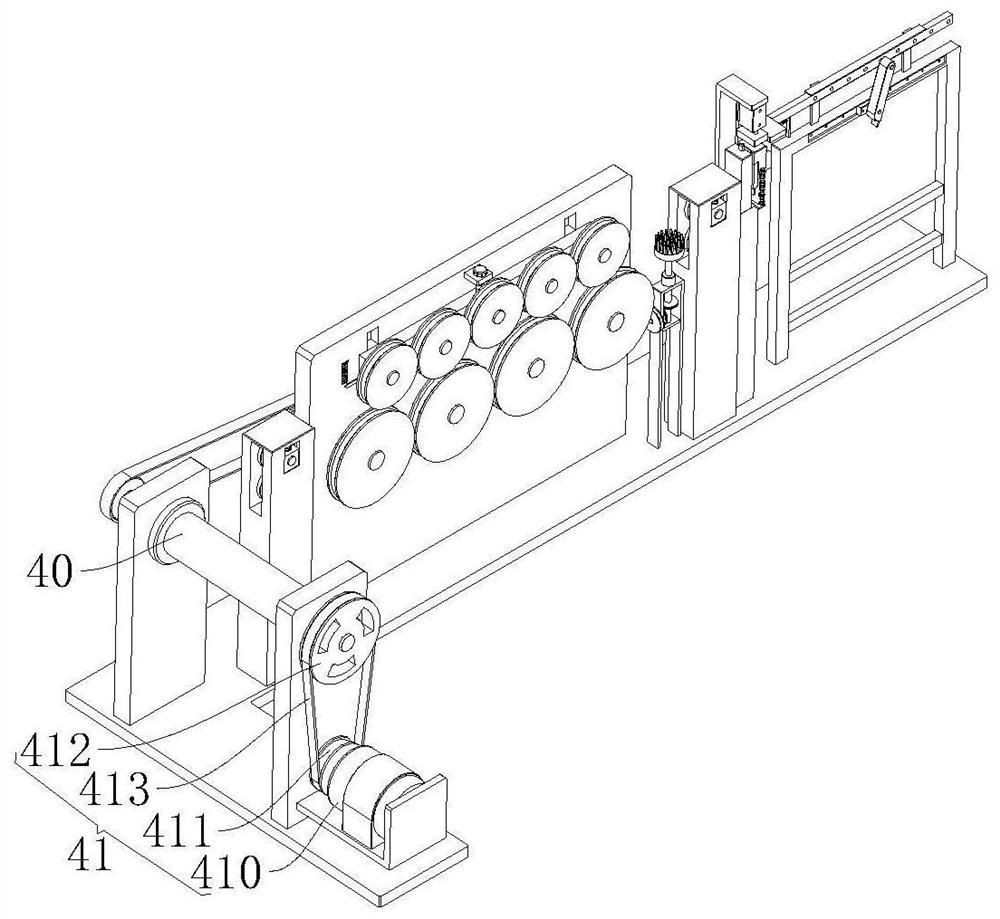

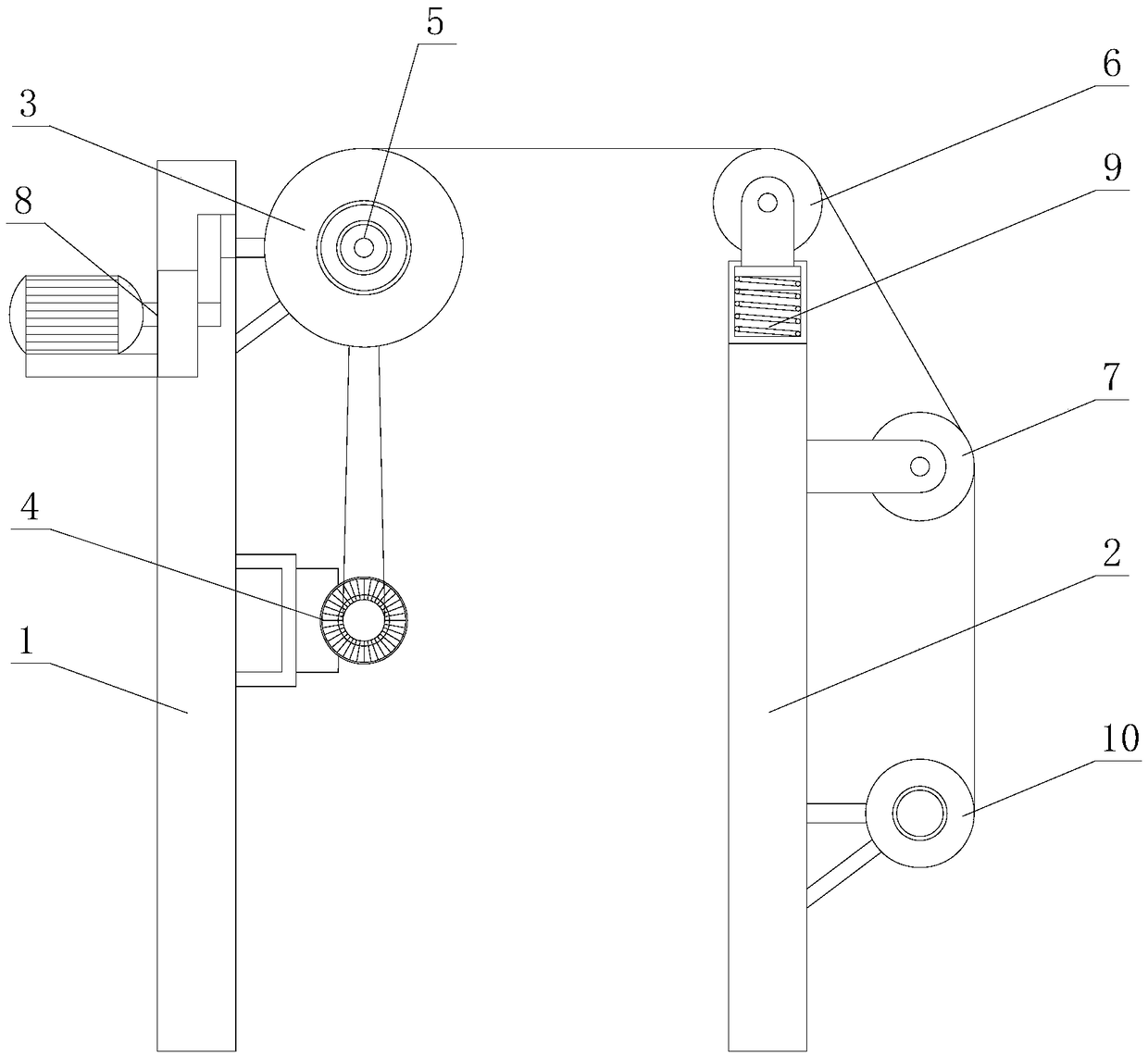

Wiring device for electronic information engineering construction

InactiveCN113541046AWind evenlyGuaranteed mutual positionApparatus for repairing insulation/armouring cablesApparatus for joining/termination cablesDrive shaftArchitectural engineering

The invention provides a wiring device for electronic information engineering construction. The wiring device comprises a winding device and a feeding device, wherein the winding device comprises a machine base, a square shaft, an upper guide wheel, a lower guide wheel, a material wheel and a C-shaped wheel, the feeding device comprises a front plate, a rear plate, a nut, a driving plate, a sliding block, a pressing block and a positioning block, a stand column is arranged on the right side of the machine base, a transverse groove is formed in the middle of the stand column, a vertical groove is formed in the vertical direction of the transverse groove, a stand column hole is arranged in the lower portion of the vertical groove, an inclined plate is arranged in the left side of the stand column, a half hole is formed in middle of the inclined plate, four shaft holes are evenly distributed in the outer side of the half hole, the lower portion of the rear side of the inclined plate is provided with a driving shaft hole, the left side of the inclined plate is provided with two vertical plates, the middles of the vertical plates are provided with lead screw holes, the two sides of the lead screw holes are respectively provided with a sliding rod connected with the two vertical plates, and the feeding device is connected with the two sliding rods in a sliding mode.

Owner:JIAMUSI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com