Buffer-type magnetic door stopper

A door stopper and magnetic technology, applied in door/window accessories, building fastening devices, wing leaf fastening devices, etc., can solve the problems of poor use effect, magnetic block wall peeling, etc., to prolong the service life, Avoid collisions and improve the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

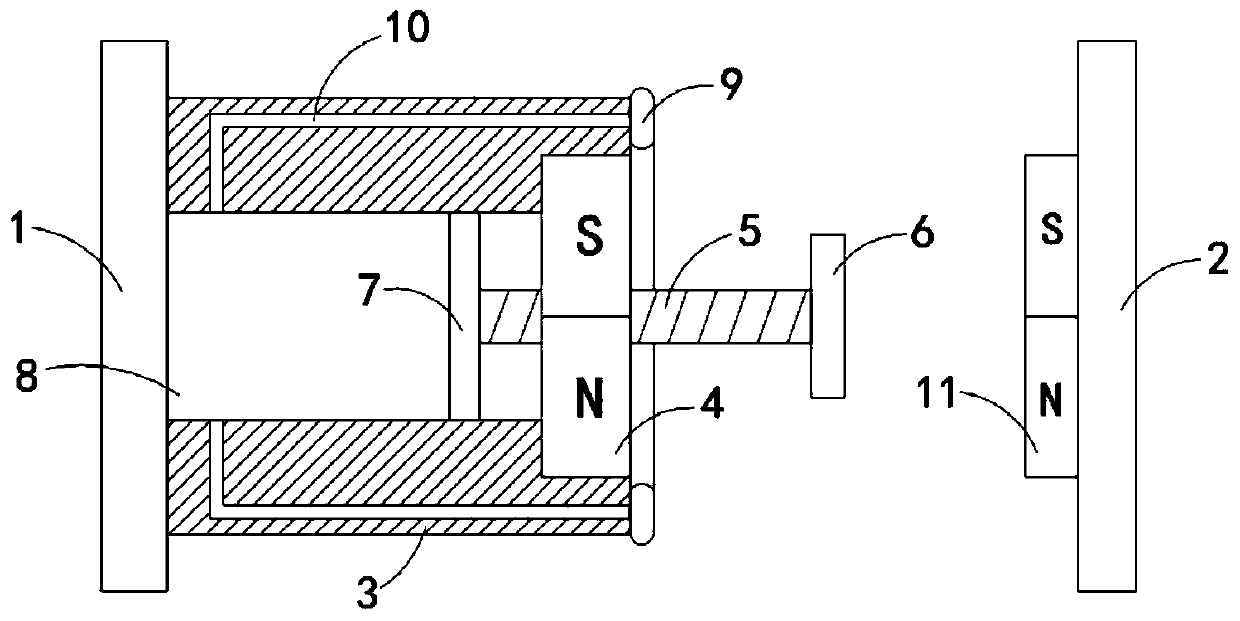

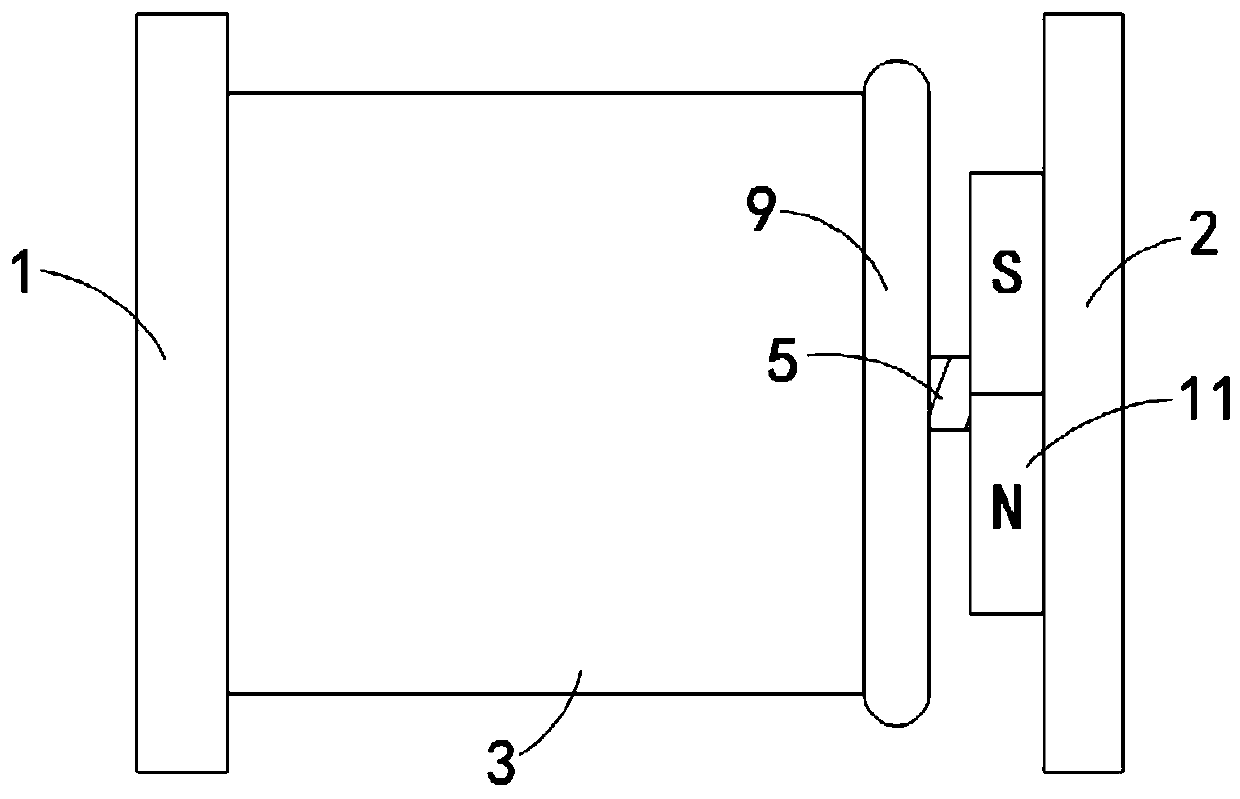

[0022] like Figure 1-3 As shown, a buffer type magnetic door stopper includes a first connecting plate 1 fixedly installed on the door body and a second connecting plate 2 fixedly installed on the wall, the side wall of the first connecting plate 1 is fixedly connected with Cylinder body 3, grooves are provided on the end surface of cylinder body 3 away from the first connecting plate 1, and permanent magnet rotating ring 4 is rotatably connected in the groove, and threaded holes are formed on the permanent magnet rotating ring 4, and the threaded holes are internally threaded. There is a screw rod 5, one end of the screw rod 5 located outside the cylinder body 3 is fixedly connected with a buffer block 6, and one end of the screw rod 5 located inside the cylinder body 3 is fixedly connected with a sealing plate 7, and the sealing plate 7 slides with the inner side wall of the cylinder body 3 Sealed connection, the side wall of the sealing plate 7 away from the screw rod 5 fo...

Embodiment 2

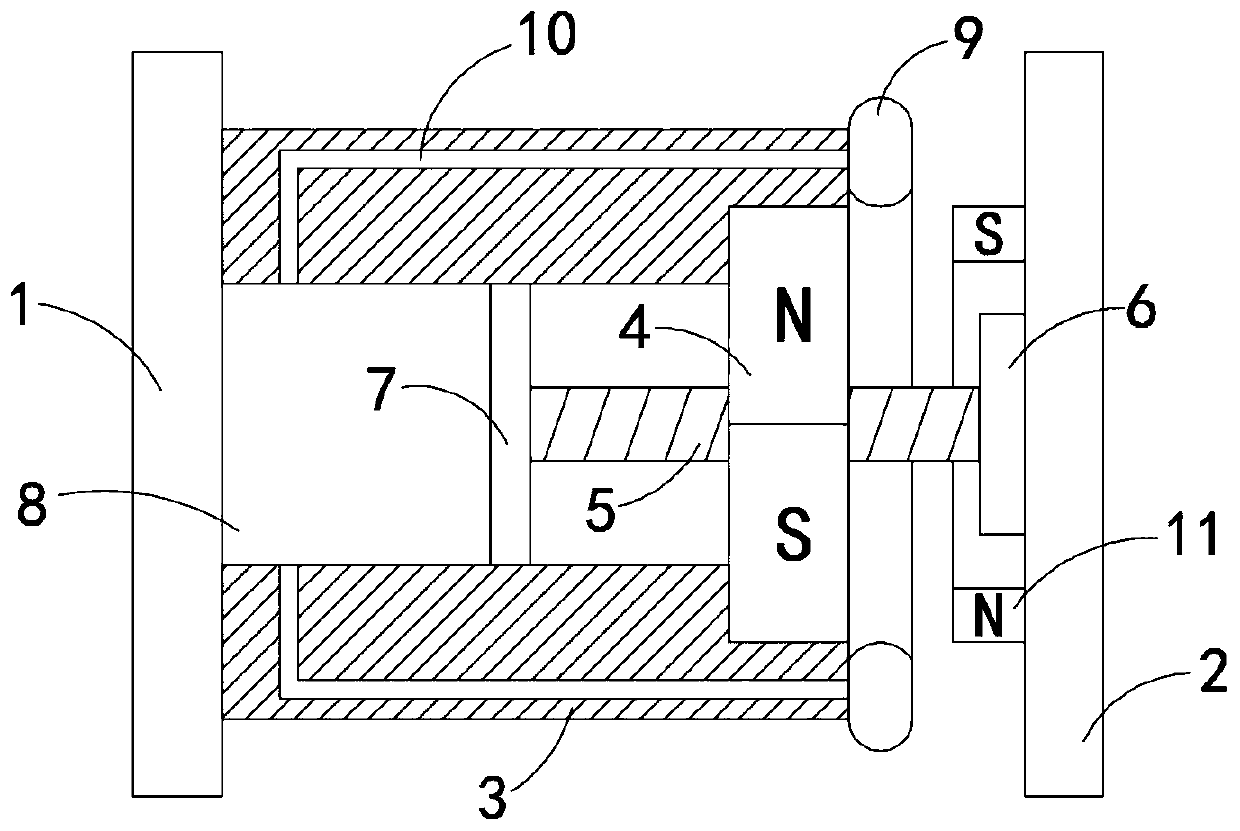

[0026] like Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that a fixed ring 12 is provided between the permanent magnet rotating ring 4 and the sealing plate 7, and the fixed ring 12 is fixedly connected with the inner side wall of the cylinder body 3, and the fixed ring 12 and the A plurality of telescopic bellows 13 are fixedly connected between the sealing plates 7, and the telescopic bellows 13 expand and contract along the axial direction thereof. The hole 14 and the buffer block 6 are arranged in a cover shape. Specifically, the buffer block 6 is made of elastic rubber, and the inside of the buffer block 6 communicates with the end of the screw rod 5 away from the sealing plate 7 .

[0027] In this embodiment, when the sealing plate 7 moves to the inside of the cylinder body 3, since the position of the fixed ring 12 is fixed, the telescopic bellows 13 will be elongated, so that the telescopic bellows 13, the hollow screw rod 5 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com