Liquid silicon fertilizer and technique for producing the same

A technology of liquid silicon and fulvic acid, which is applied to nitrogen fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of troublesome proportioning operation, failure to achieve the use effect, and low utilization rate of silicon, so as to improve the utilization rate and enhance the resistance Sexuality and high fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

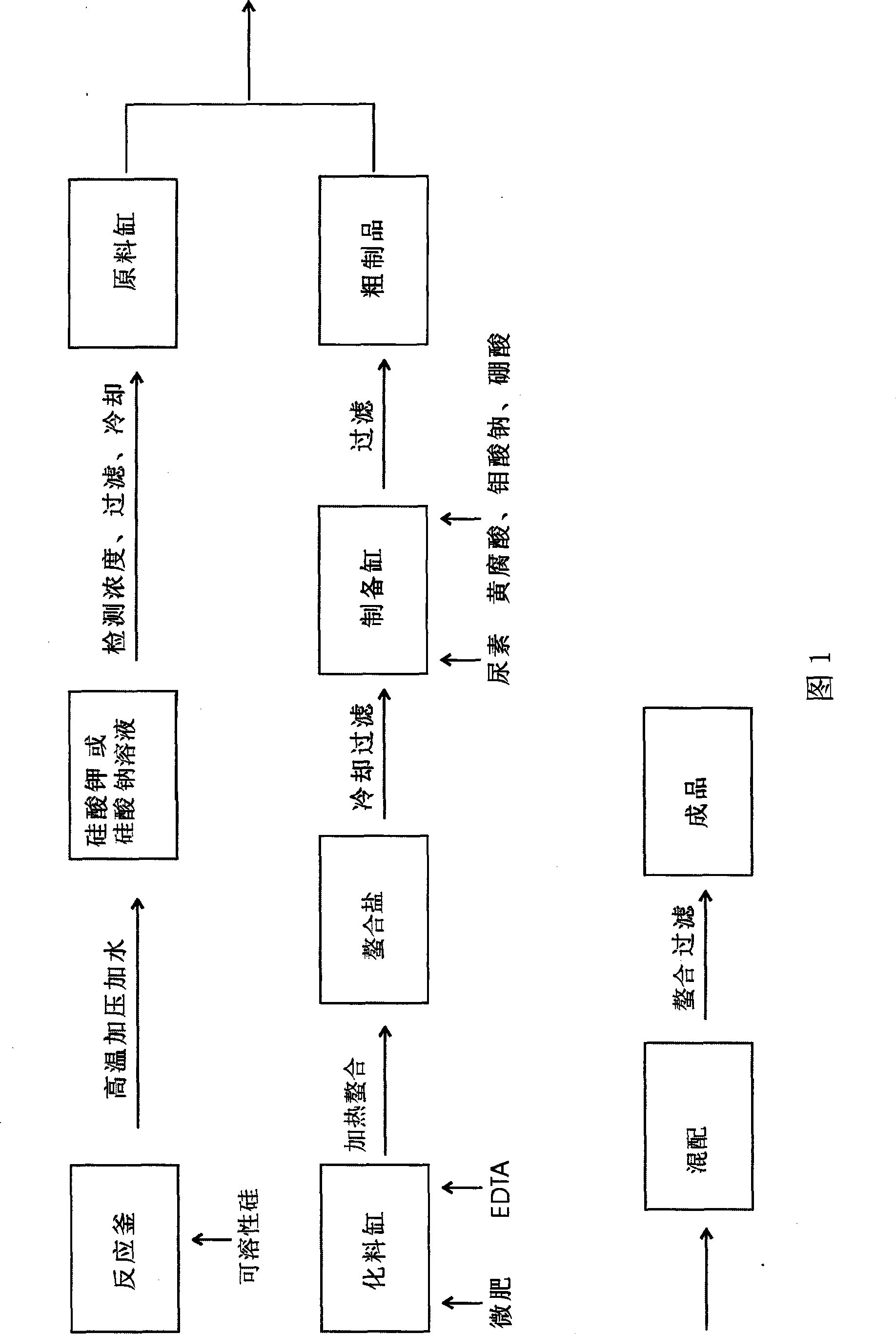

Method used

Image

Examples

Embodiment 1

[0023] A kind of liquid silicon fertilizer, its raw material is soluble silicon, urea, trace element chelate, fulvic acid, establishes the liquid fertilizer of balance and compound; According to weight ratio: Potassium silicate 15-25%, trace element chelate salt 6 -12%, urea 10-15%, fulvic acid 10-15%, the balance is water;

[0024] Soluble silicon is liquid potassium silicate, modulus (M) 3.19-3.31, Baume degree Be" is 40-50°; trace element chelate uses EDTA (ethylenediaminetetraacetic acid) as a chelating agent to chelate metals Elements Fe (iron), Cu (copper), Mg (magnesium), Zn (zinc), Mn (manganese), B (boron), Mo (molybdenum), the weight ratio of EDTA to metal elements is 1.8-2.2:1; Fulvic acid is biochemical fulvic acid, its PH (pH) 5-6, BFA (fulvic acid) ≥ 75%, HA (amino acid) > 15%, N (nitrogen) P (phosphorus) K (potassium) ≥ 13 %, insoluble matter <5%;

[0025] The liquid silicon fertilizer produced has fulvic acid ≥ 8%, SiO 2 (Silicon dioxide) ≥ 12%, NPK ≥ 12%, F...

Embodiment 2

[0031] 1. Dissolve 15 kg of zinc sulfate, 25 kg of magnesium sulfate, 4 kg of copper sulfate, 4 kg of manganese sulfate, and 15 kg of ferrous sulfate in 250 kg of water, add 120 kg of EDTA, heat at 90-100°C, and react 1- After 3 hours, add 25 kilograms of boric acid, 2 kilograms of ammonium molybdate, 160 kilograms of fulvic acid, and 180 kilograms of urea into the cooling filtrate, stir and chelate fully to form 800 kilograms of trace element chelated salt solution.

[0032] 2, 1200 kilograms of potassium silicate solutions with a concentration of 30% are mixed and chelated with 800 kilograms of the above-mentioned products to become 2000 kilograms of liquid silicon fertilizer of the present invention.

Embodiment 3

[0034] 1. Dissolve 25 kg of zinc sulfate, 40 kg of magnesium sulfate, 5 kg of copper sulfate, 8 kg of manganese sulfate, and 30 kg of ferrous sulfate in 376 kg of water, add 210 kg of EDTA, heat at 90-100°C, and react 1- After 3 hours, add 35 kg of boric acid, 1 kg of ammonium molybdate, 220 kg of fulvic acid, and 250 kg of urea into the cooled filtrate, stir and chelate thoroughly to form a 1200 kg trace element chelated salt solution.

[0035] 2, 800 kilograms of potassium silicate solutions with a concentration of 44% are mixed and chelated with 1200 kilograms of the above-mentioned products to become 2000 kilograms of liquid silicon fertilizer of the present invention.

[0036]The liquid silicon fertilizer and the preparation method thereof of the above embodiments, aiming at the problem that some crops need silicon fertilizer and inconvenient application of quick-acting silicon fertilizer, establish a balanced composite system with liquid potassium silicate, macroelements,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com