Intelligent vertical warehouse with automatic storage function and control method thereof

A vertical and warehouse technology, applied to storage devices, conveyor objects, transportation and packaging, etc., can solve the problems of slow storage efficiency, inability to monitor equipment, and goods falling, so as to ensure stability, avoid wear and tear, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In the first aspect, an intelligent vertical warehouse for automatic storage, such as figure 1 and Figure 9 As shown, the intelligent vertical warehouse is composed of shelves, roadway stackers, storage workbenches, automatic feeding mechanism and monitoring and dispatching system;

[0050] Wherein, the roadway stacker is composed of a forklift and a bridge stacker;

[0051] The storage workbench includes an acquisition module, a processing module and a database;

[0052] The automatic feeding mechanism is composed of a cargo tray, a transmission mechanism and a manipulator;

[0053] The monitoring and dispatching system includes an abnormality monitoring unit, a power monitoring unit, an information receiving unit and a driving unit.

[0054] In the present invention, the monitoring and dispatching system can monitor the equipment in the intelligent vertical warehouse in real time, and the monitoring and dispatching system shares the database data information in th...

Embodiment 2

[0056] This embodiment is used to further define the first aspect, such as Figure 9 As shown, the shelves are distributed in different areas of the intelligent vertical warehouse, and the area classification information is entered in the storage workbench. The goods need to be sorted manually or by a sorting device before the storage planning. After the station makes the optimal storage plan according to the properties of the goods, it will notify the manual control roadway stacker to implement the preliminary storage of goods;

[0057] The database is used to store classification information of cargo areas and shelf working status information, and the processing module is used to perform optimal storage planning according to cargo properties, cargo capacity, and shape.

[0058] The cargo pallet described in this embodiment is used to place the cargo to be stored, and the cargo on the cargo pallet is transferred to the designated area through the transmission mechanism. plac...

Embodiment 3

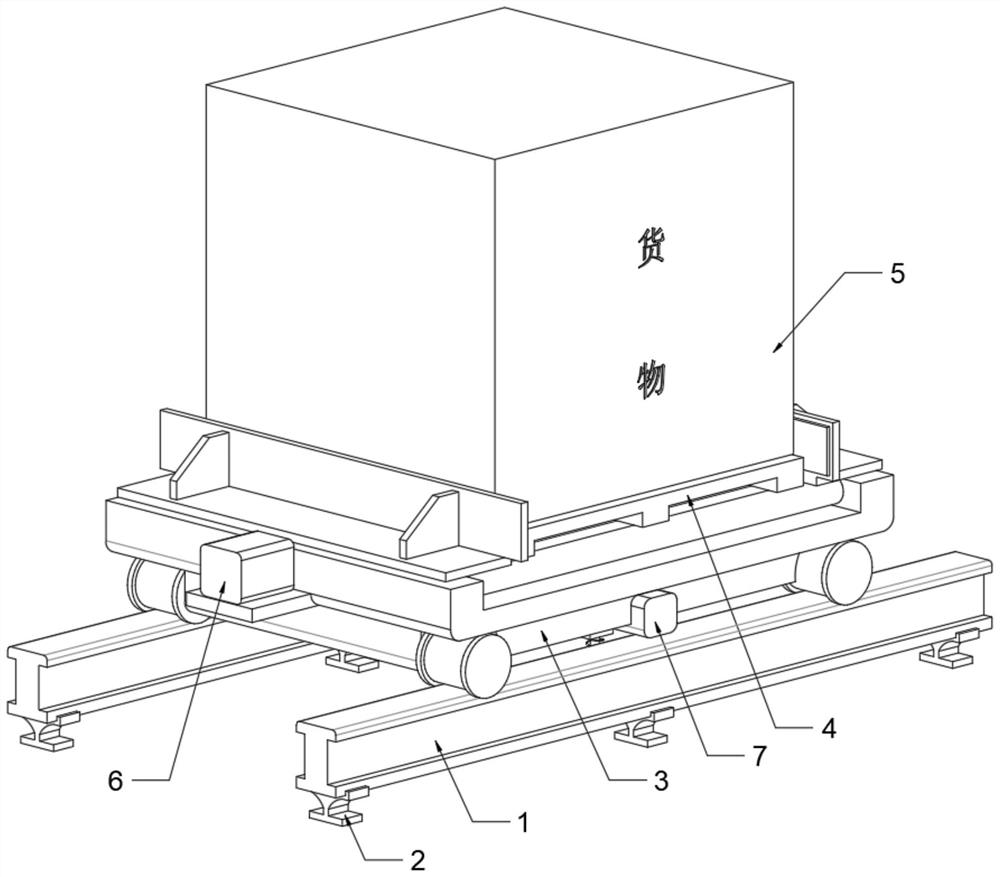

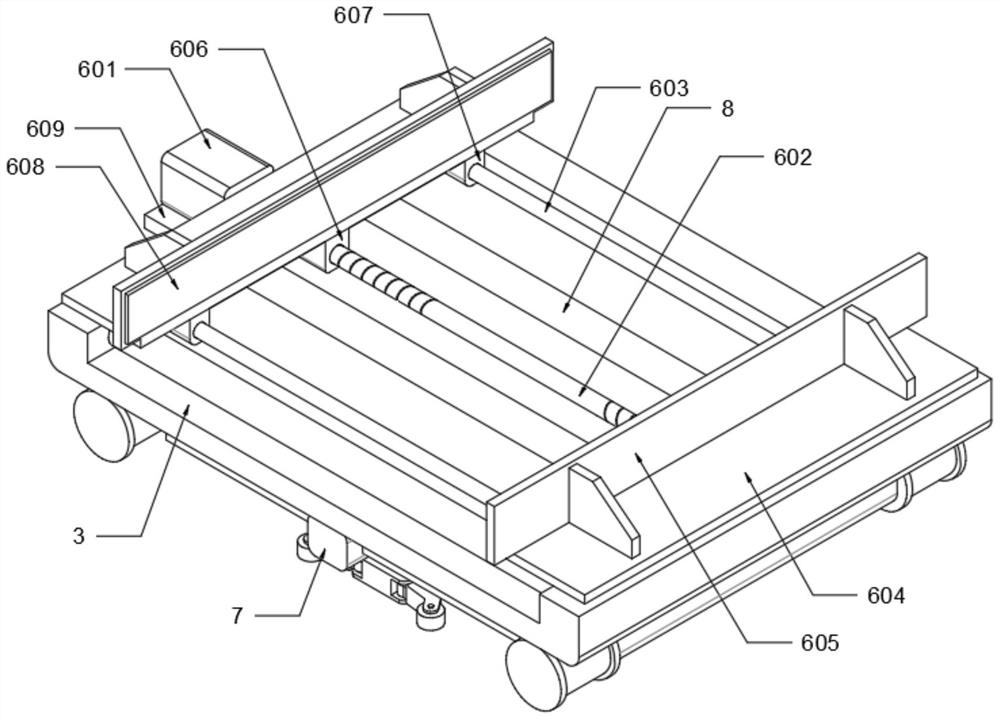

[0065] An intelligent vertical warehouse transfer mechanism for automatic storage, the following supplements are made for the first aspect, such as Figure 1 to Figure 2 As shown, the transmission mechanism includes a rail 1, a transmission unit 3, a cargo pallet 4 and a cargo body 5, the rail 1 is symmetrically arranged on the warehouse floor through the installation feet 2, and the transmission unit 3 is arranged above the rail 1, The cargo pallet 4 is placed above the conveying unit 3, and the cargo body 5 is placed above the cargo pallet 4, and the opposite side array of the conveying unit 3 is provided with rollers 8 for supporting the cargo pallet 4, characterized in that, The top of the transmission unit 3 is symmetrically provided with fixing components 6 , and the bottom of the transmission unit 3 is symmetrically provided with stabilizing components 7 .

[0066] like Figure 3 to Figure 4 As shown, the fixing assembly 6 in this embodiment includes a positive and neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com