Handheld automatic screw machine

A screw machine and hand-held technology, applied in the field of hand-held automatic screw machines, can solve problems such as screw deflection and shaking, poor use stability, and affecting product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

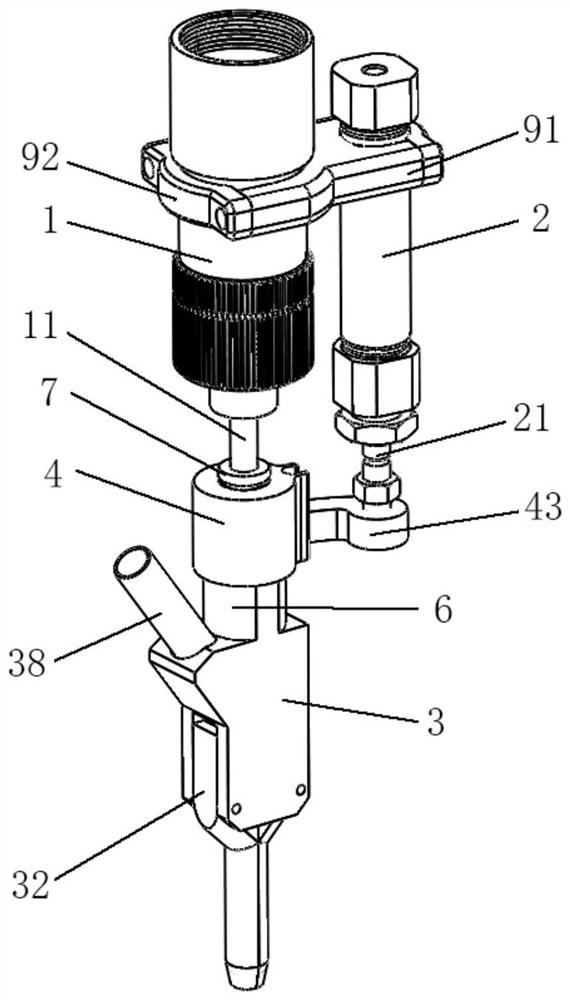

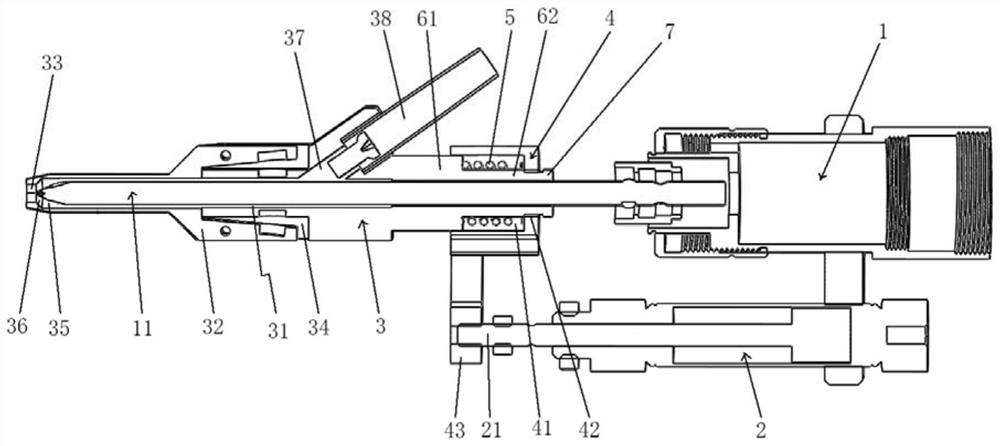

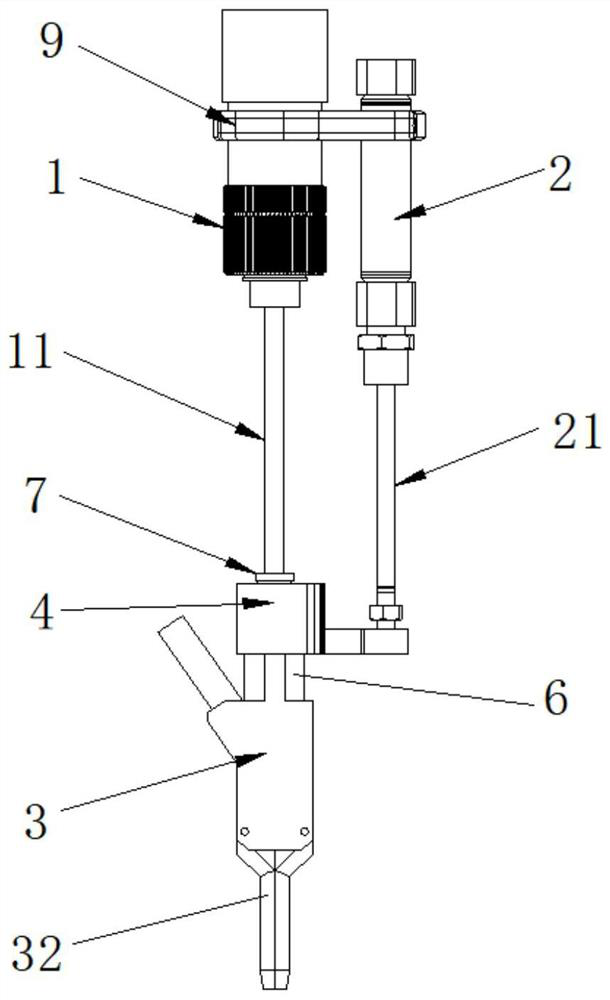

[0039] This embodiment is provided Figure 1-7 A hand-held automatic screw machine, including:

[0040] Electrodification 1, including batch 11 for locking the screw, A represents the screw;

[0041] The drive device 2 is disposed outside the electron batch 1, which includes a drive rod 21 that performs an elevation movement along the axial direction of the batch 11;

[0042] The nap structure 3 includes a storage chamber 31 that connects the feed structure, and two clamp blocks 32 disposed on the bottom end portion thereof, and formed between the two clamp blocks 32 and along the batch. 11 The axial direction of the storage chamber 31 is connected to the fixture port 33;

[0043] The drive rod 21 moves the hose structure 3 by the transmission structure to move along the axial direction of the batch 11, the transmission structure comprising: a moving sleeve in the top end of the hose structure 3 and The drive rod 21 is fixedly coupled to the drive sleeve 4, and the elastic member 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com