Patents

Literature

35results about How to "Running at the same speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

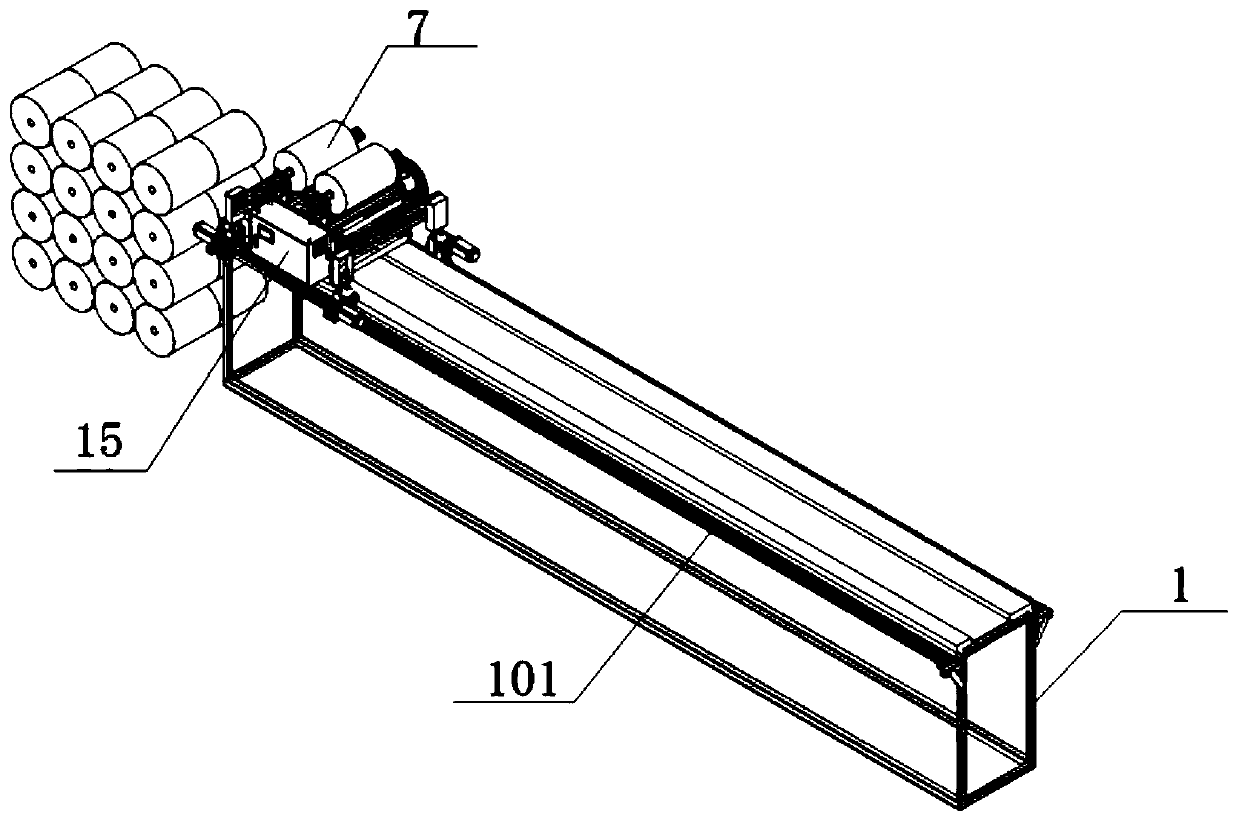

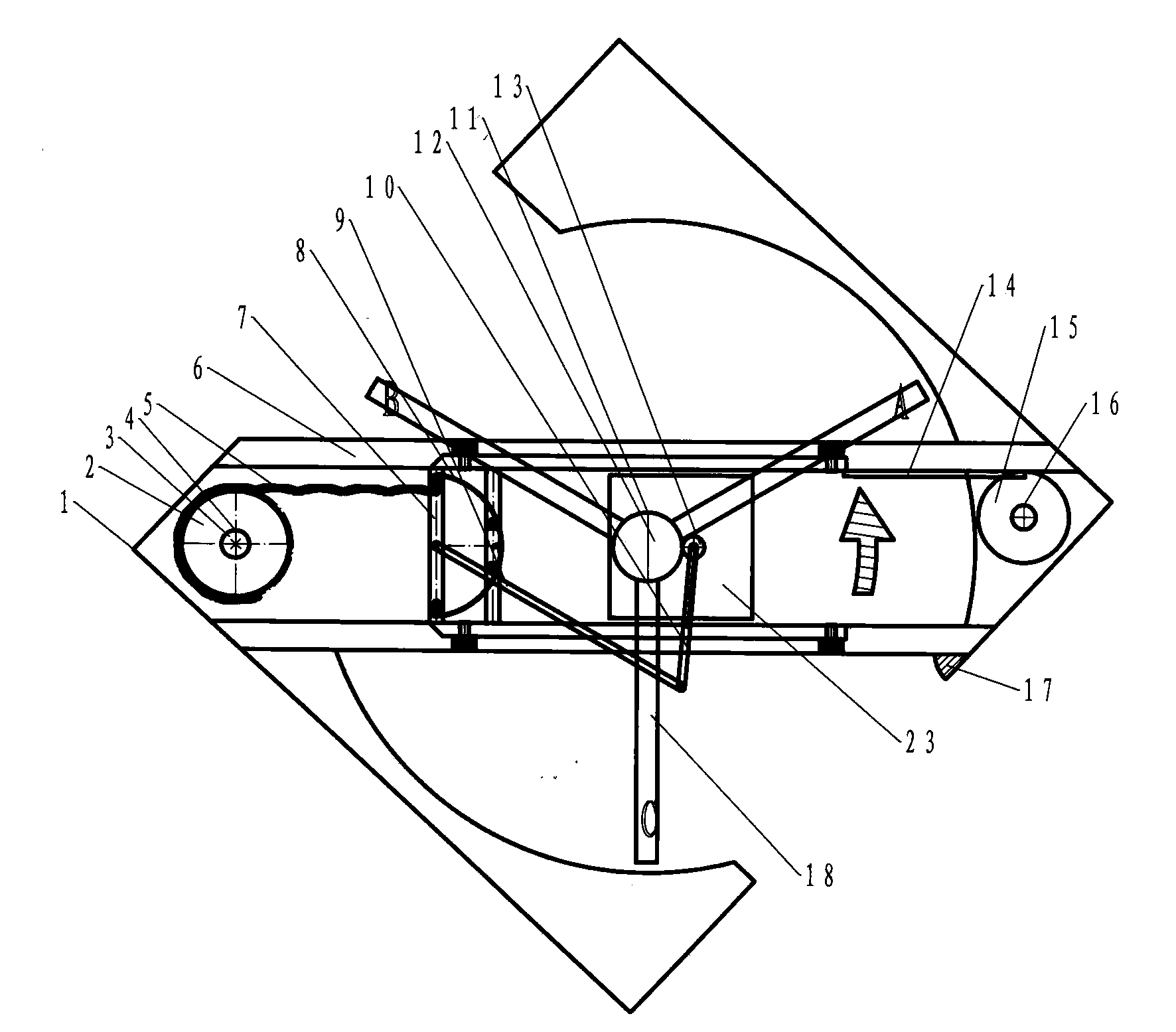

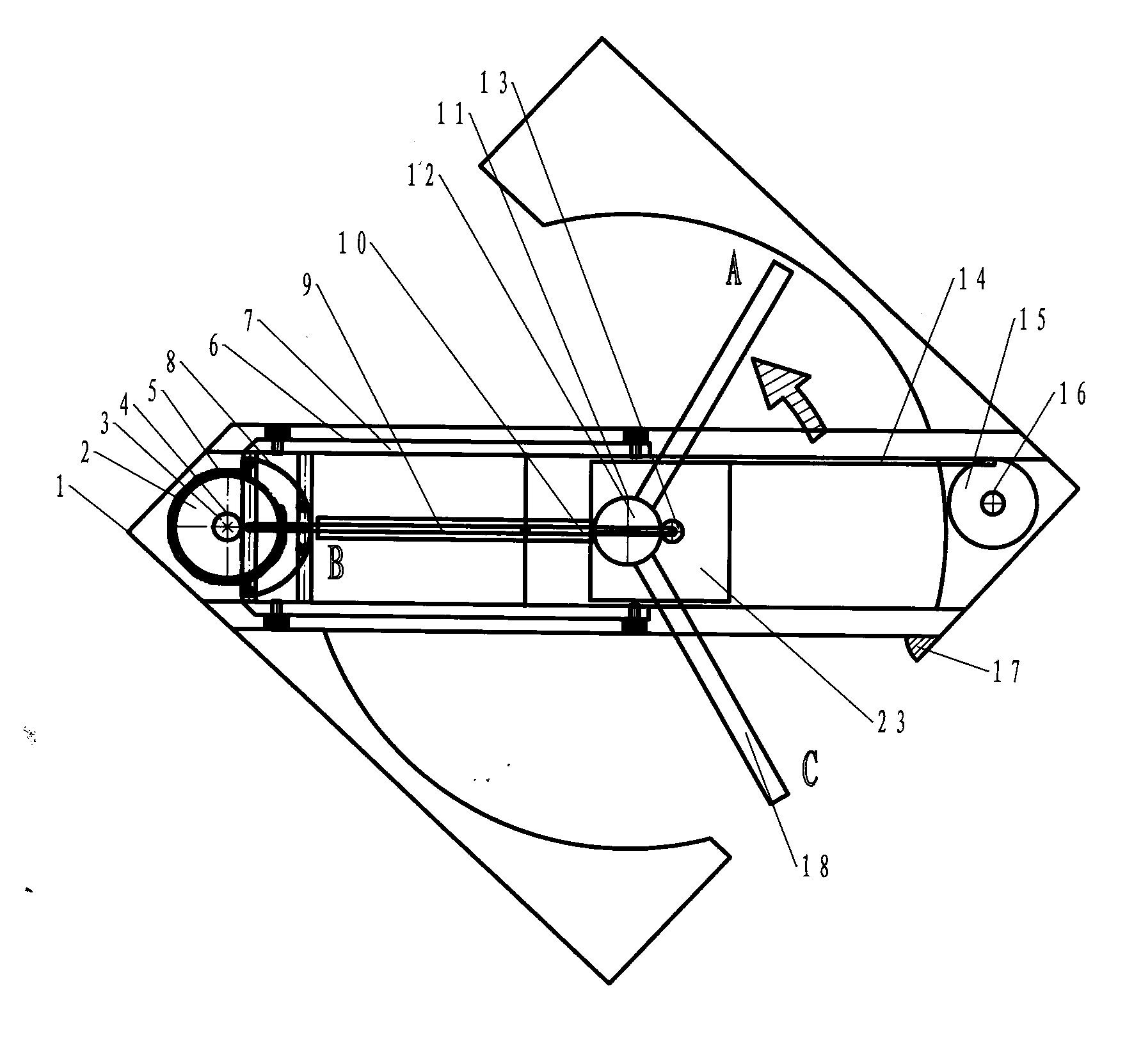

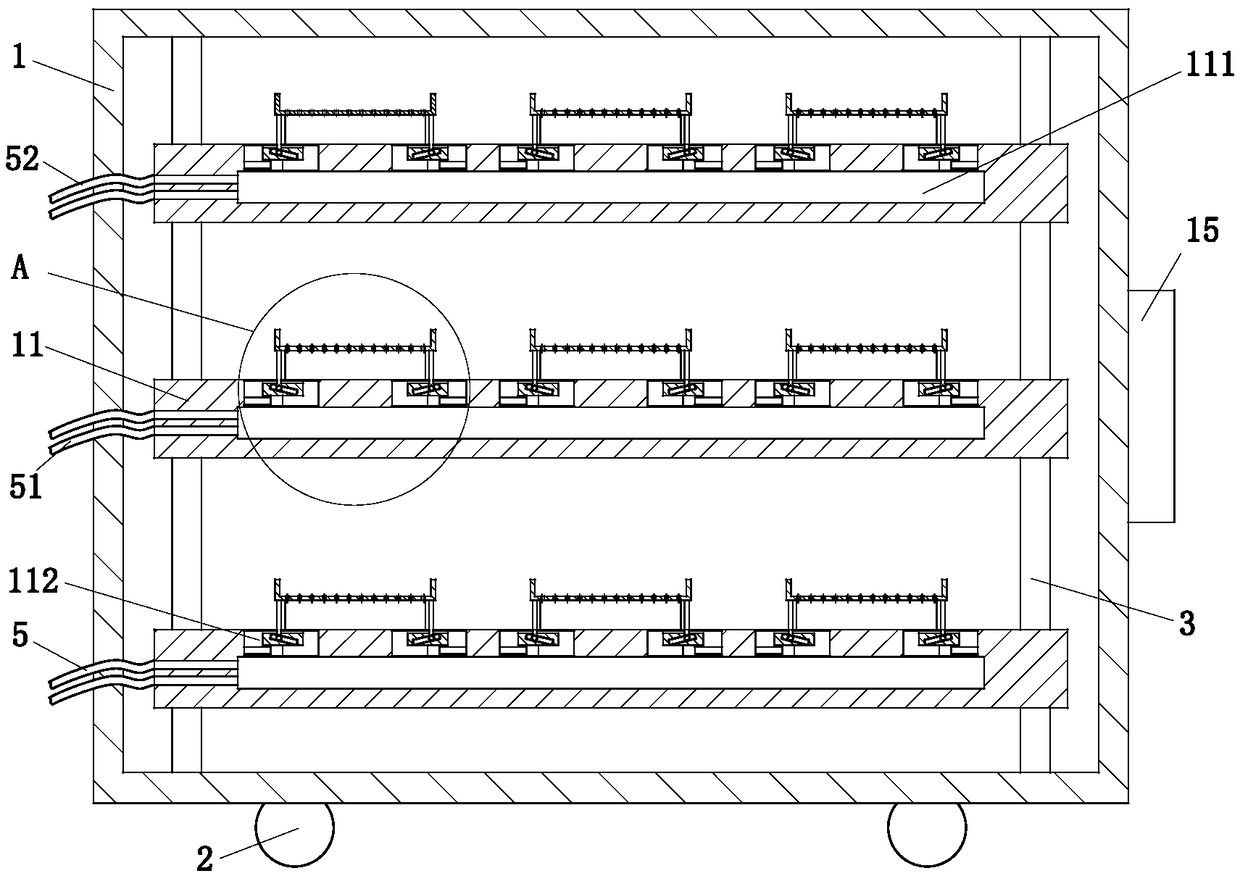

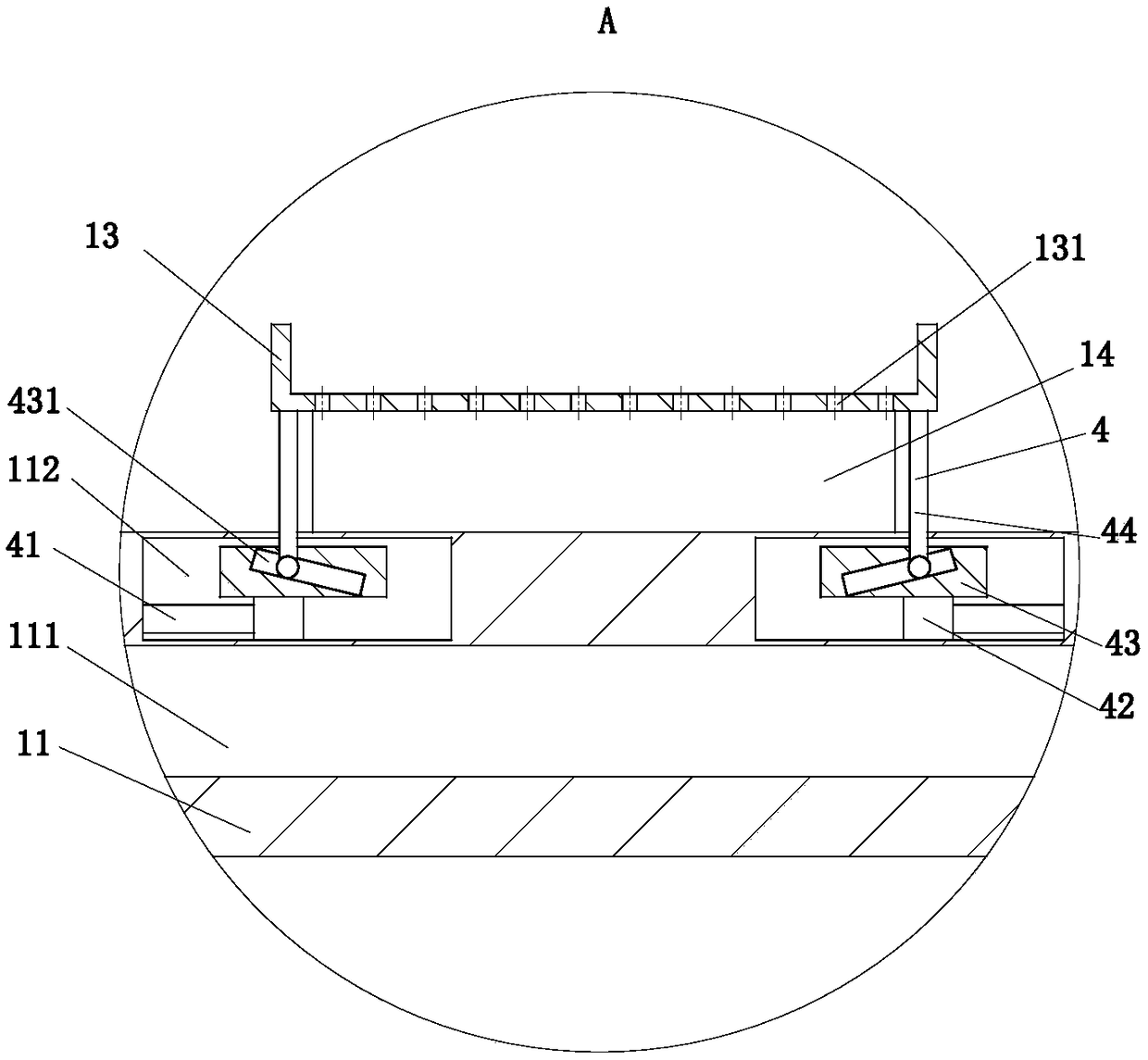

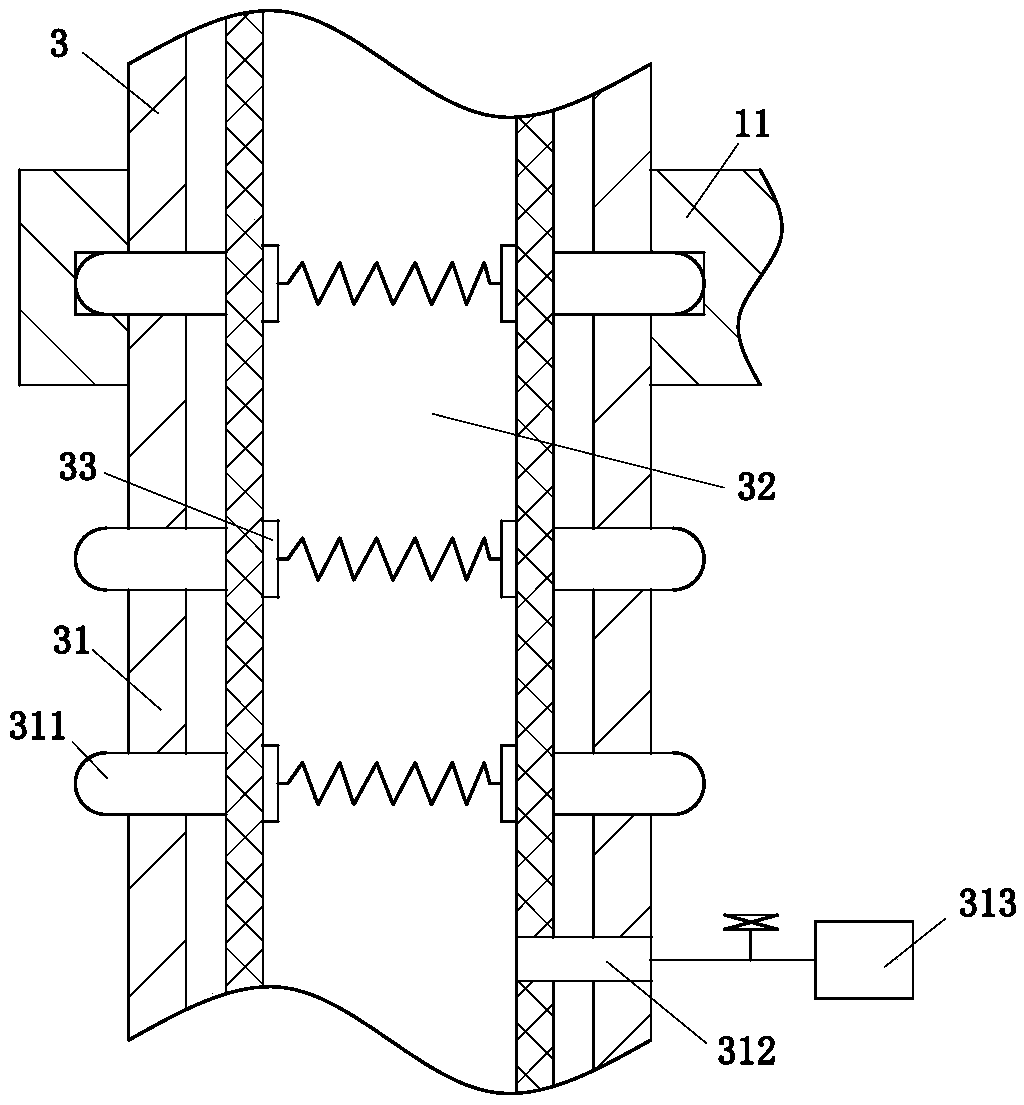

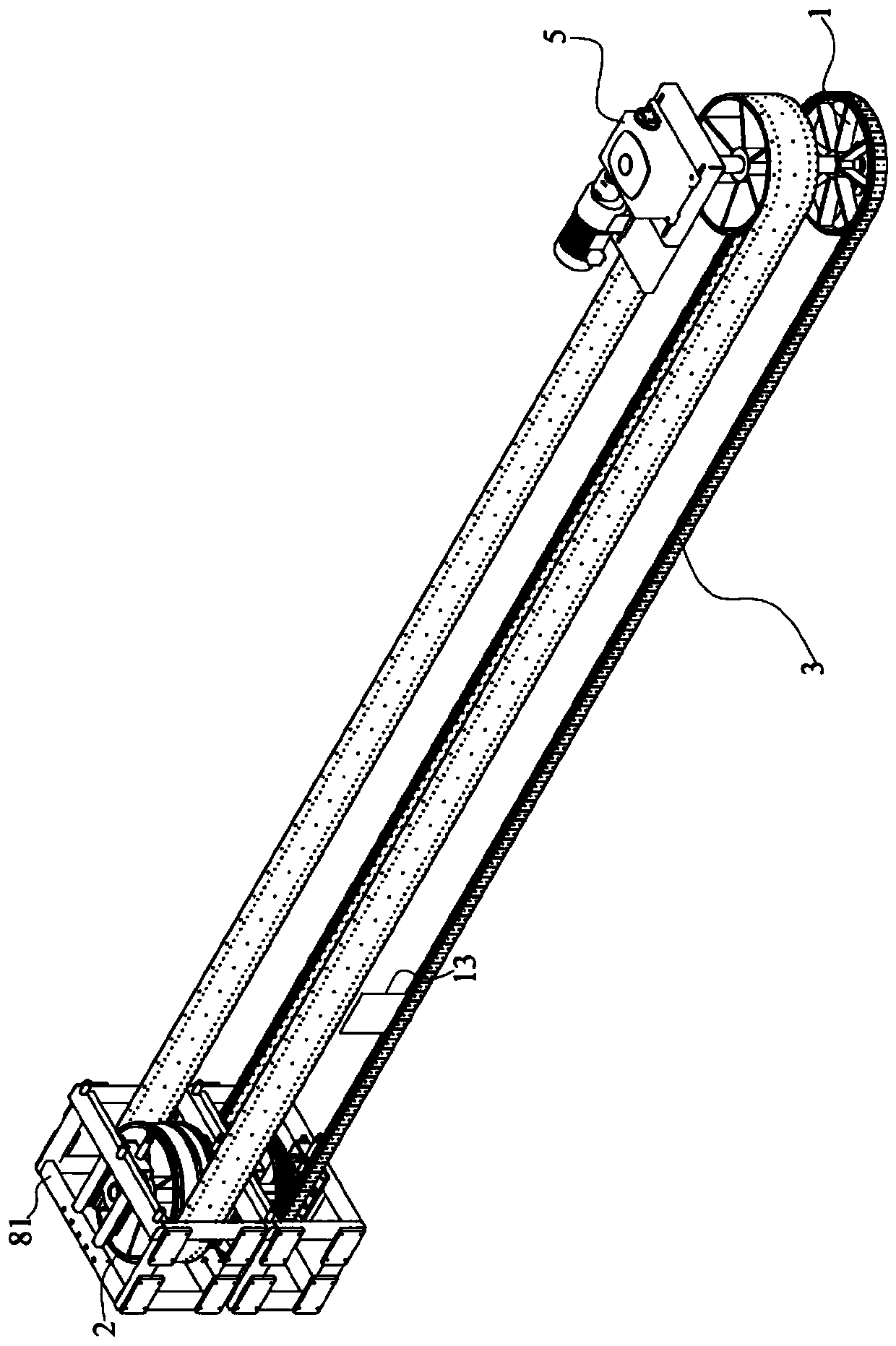

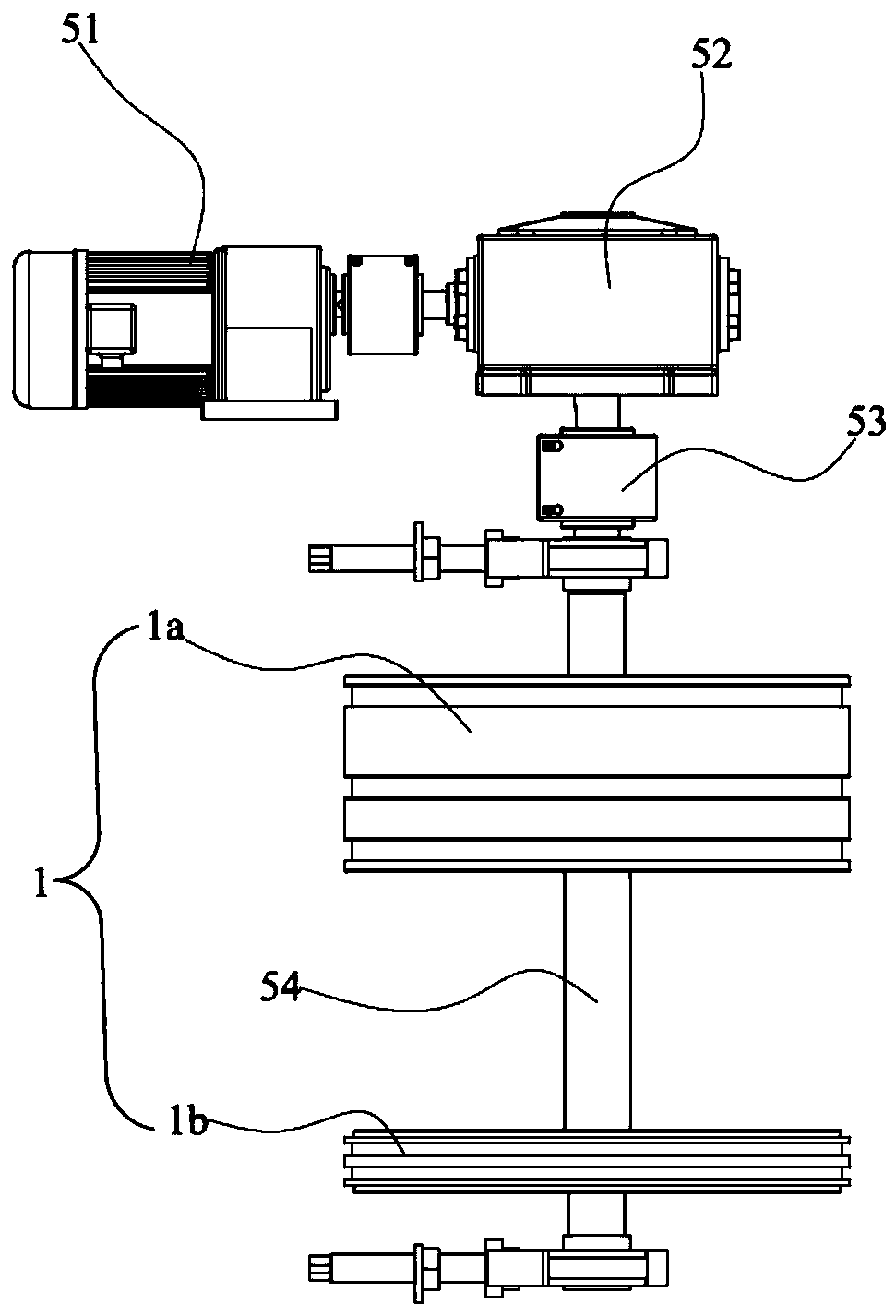

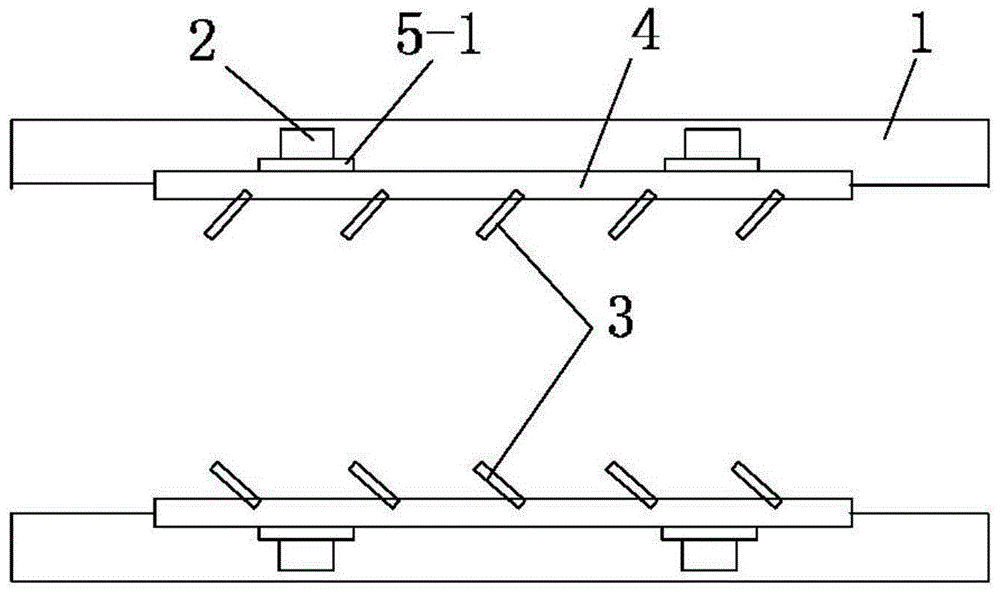

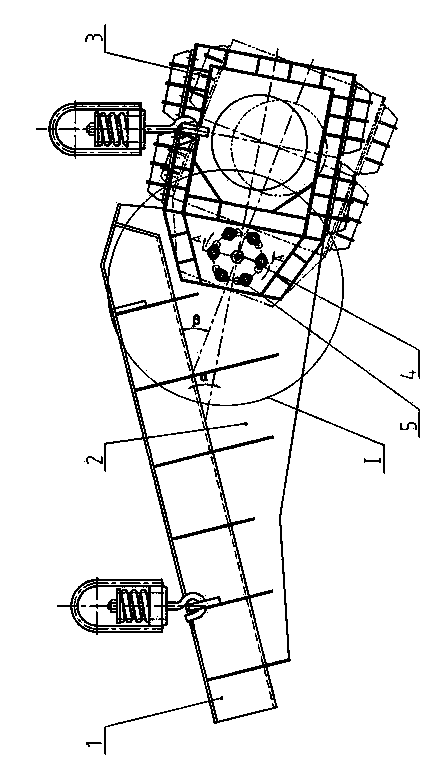

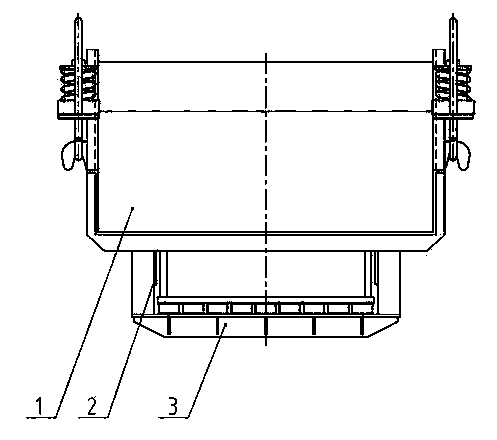

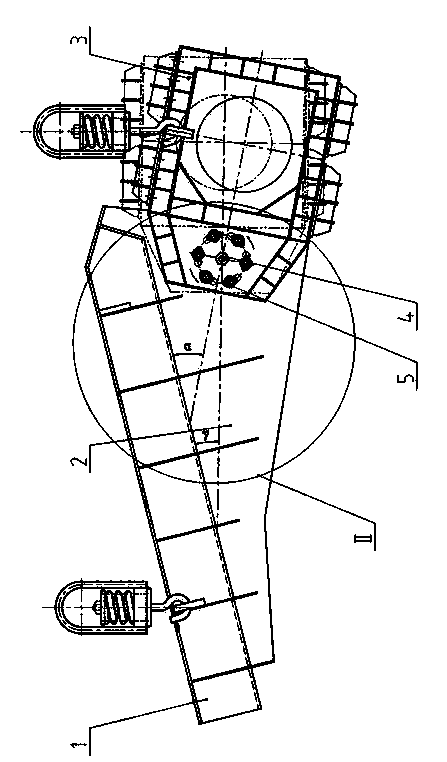

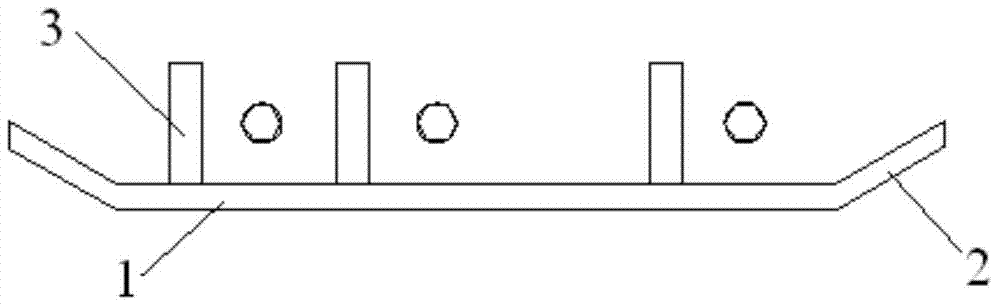

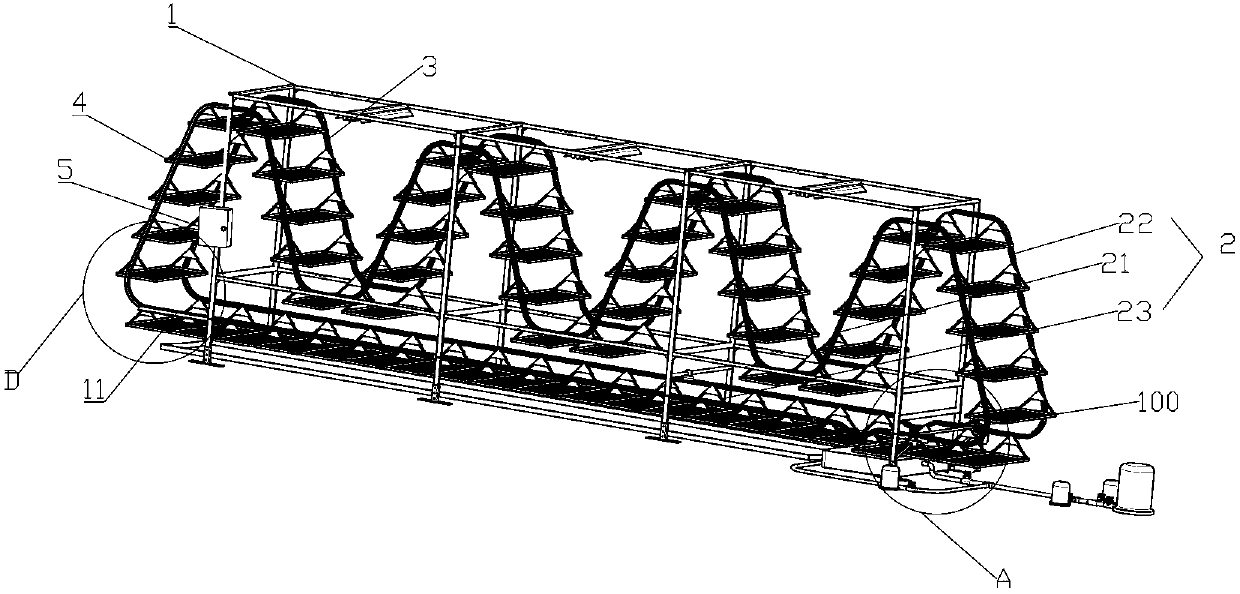

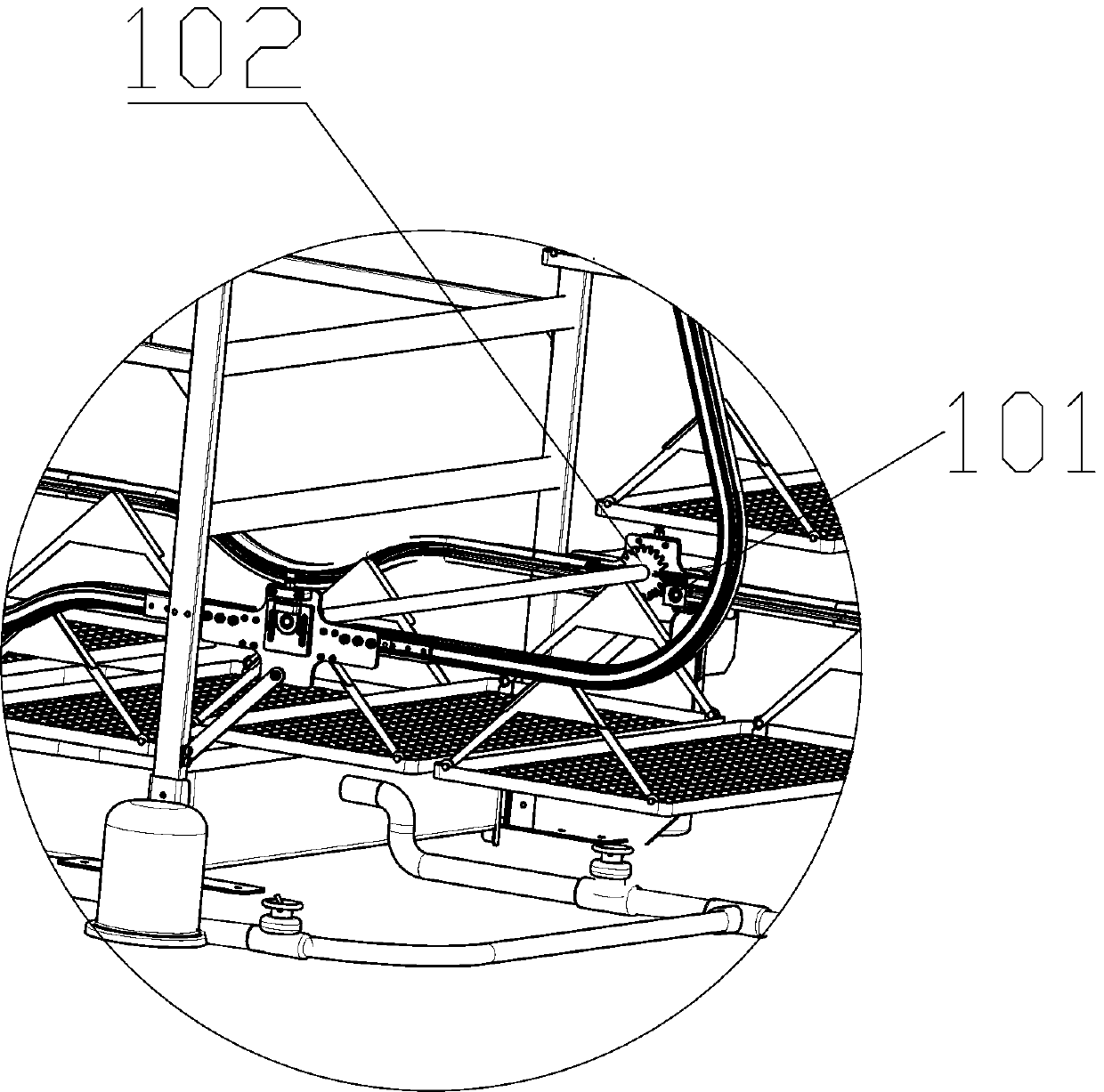

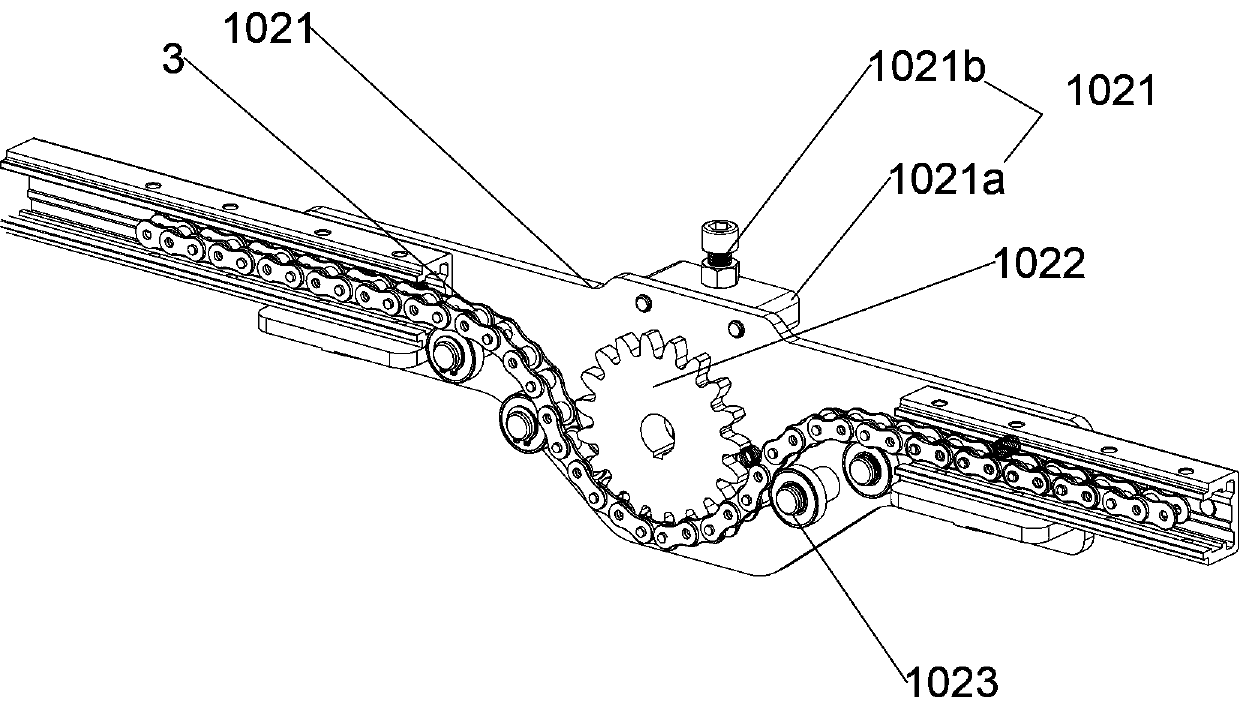

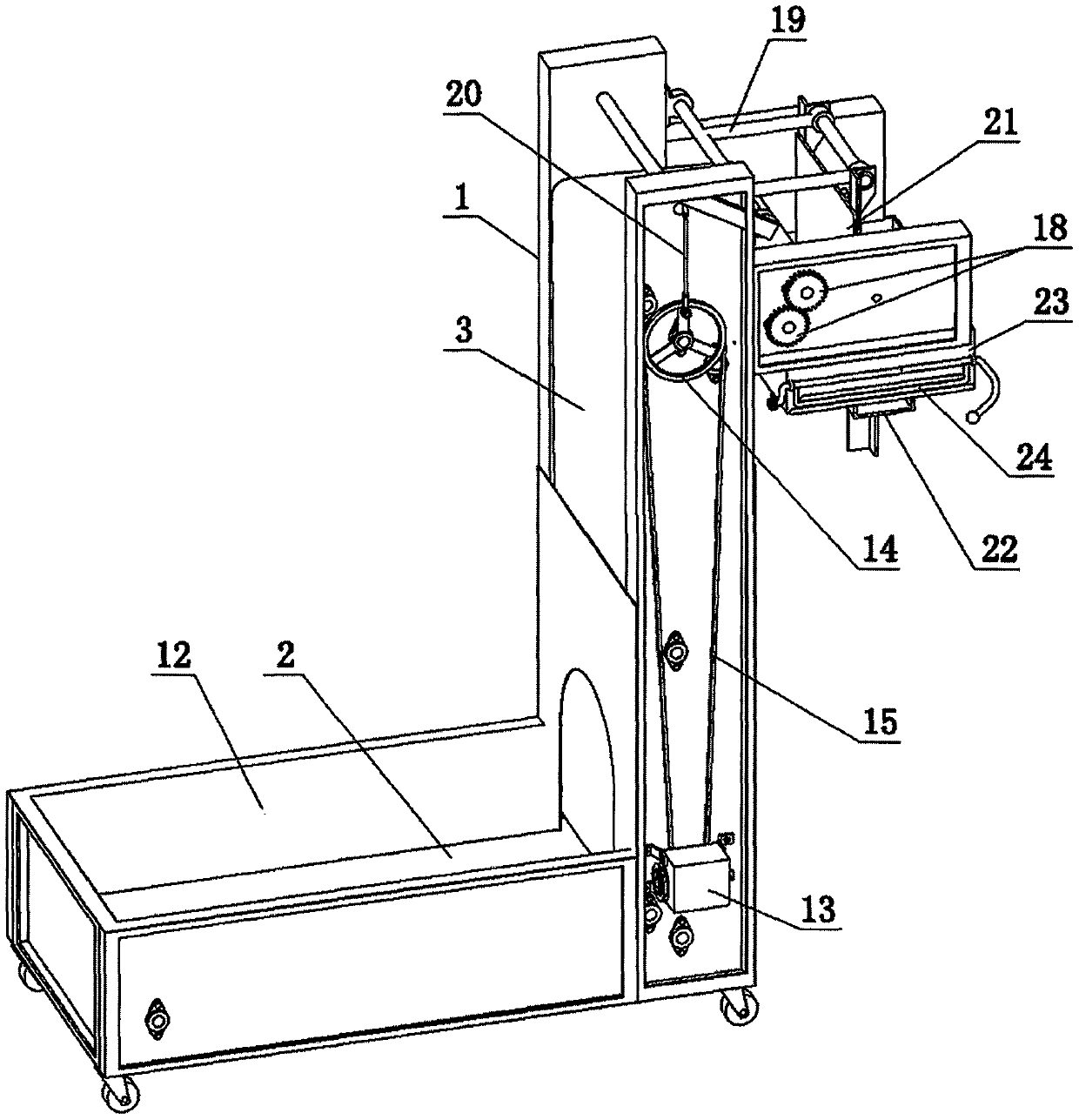

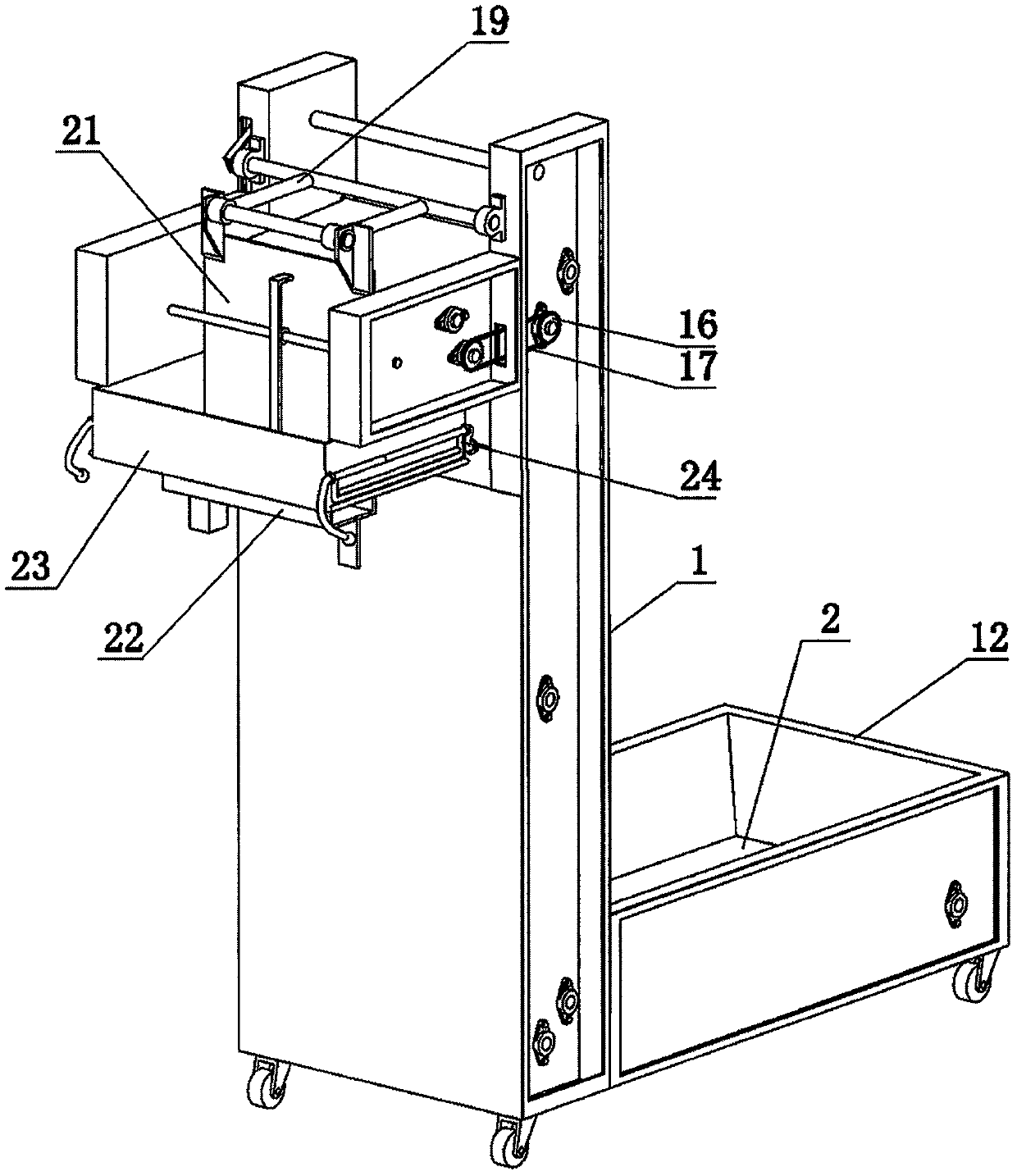

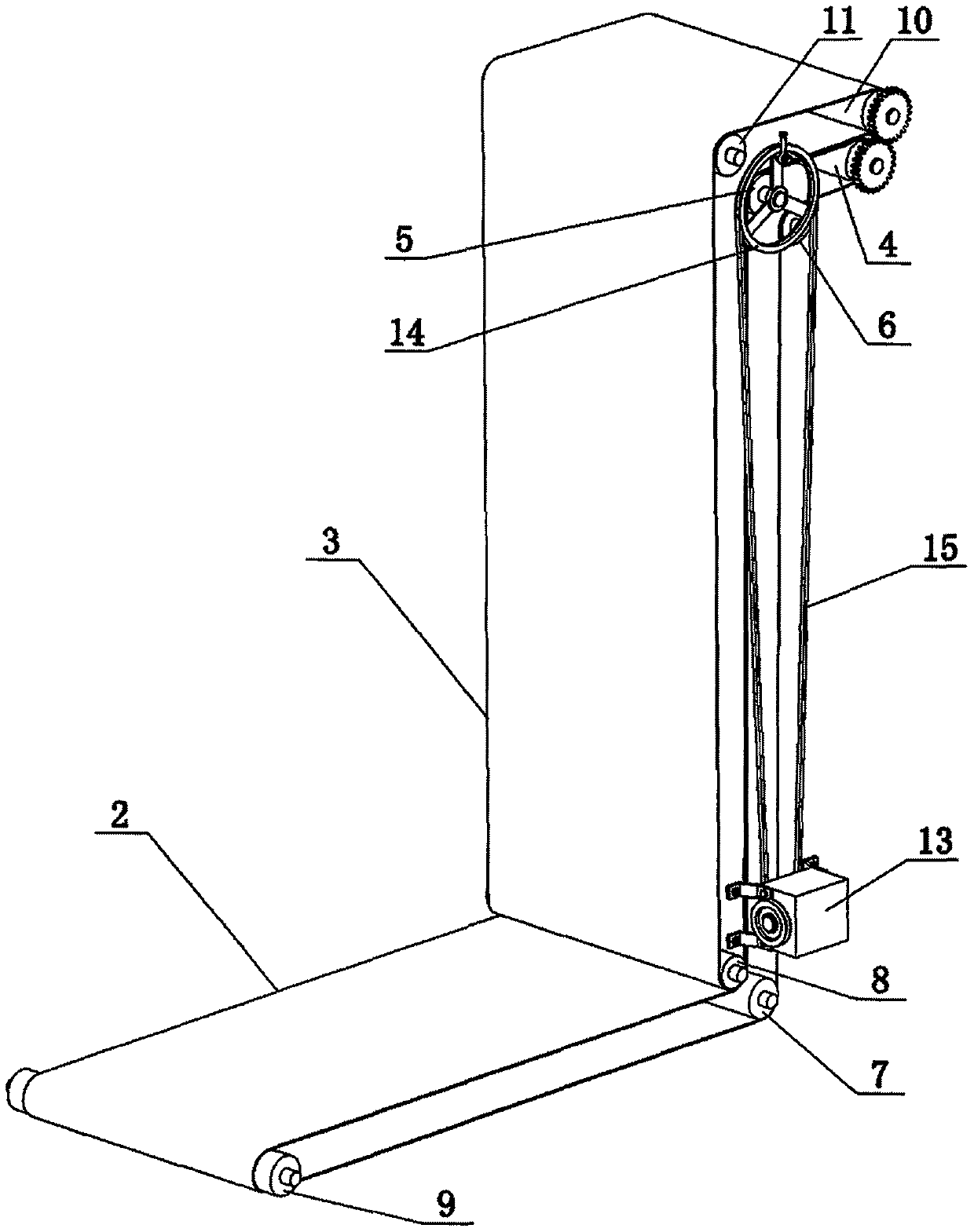

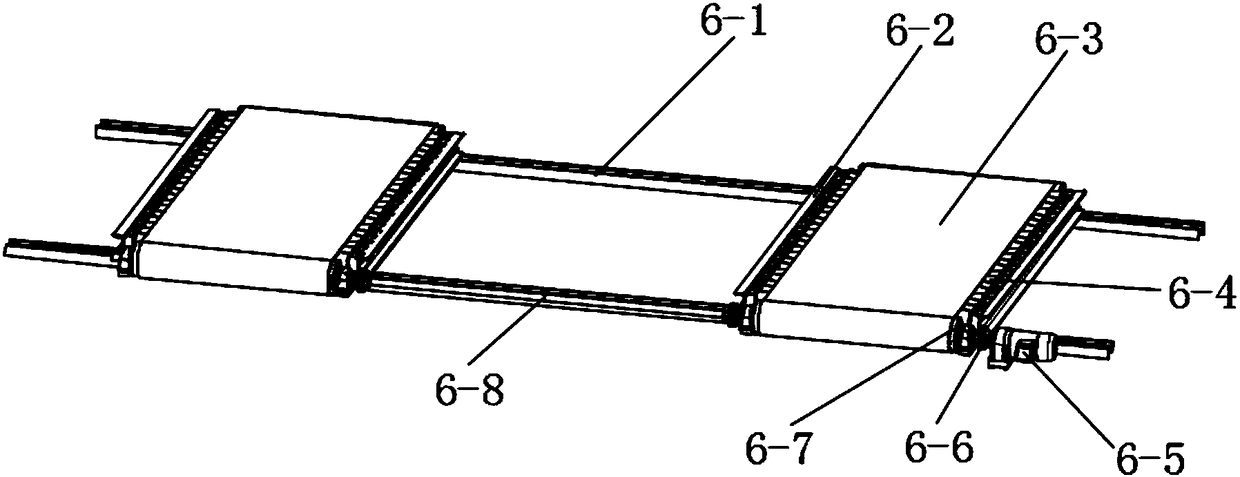

Wind power blade main beam cloth laying device

PendingCN111497286AImprove laying qualityReduce manual labor intensityDomestic articlesStructural engineeringMechanical engineering

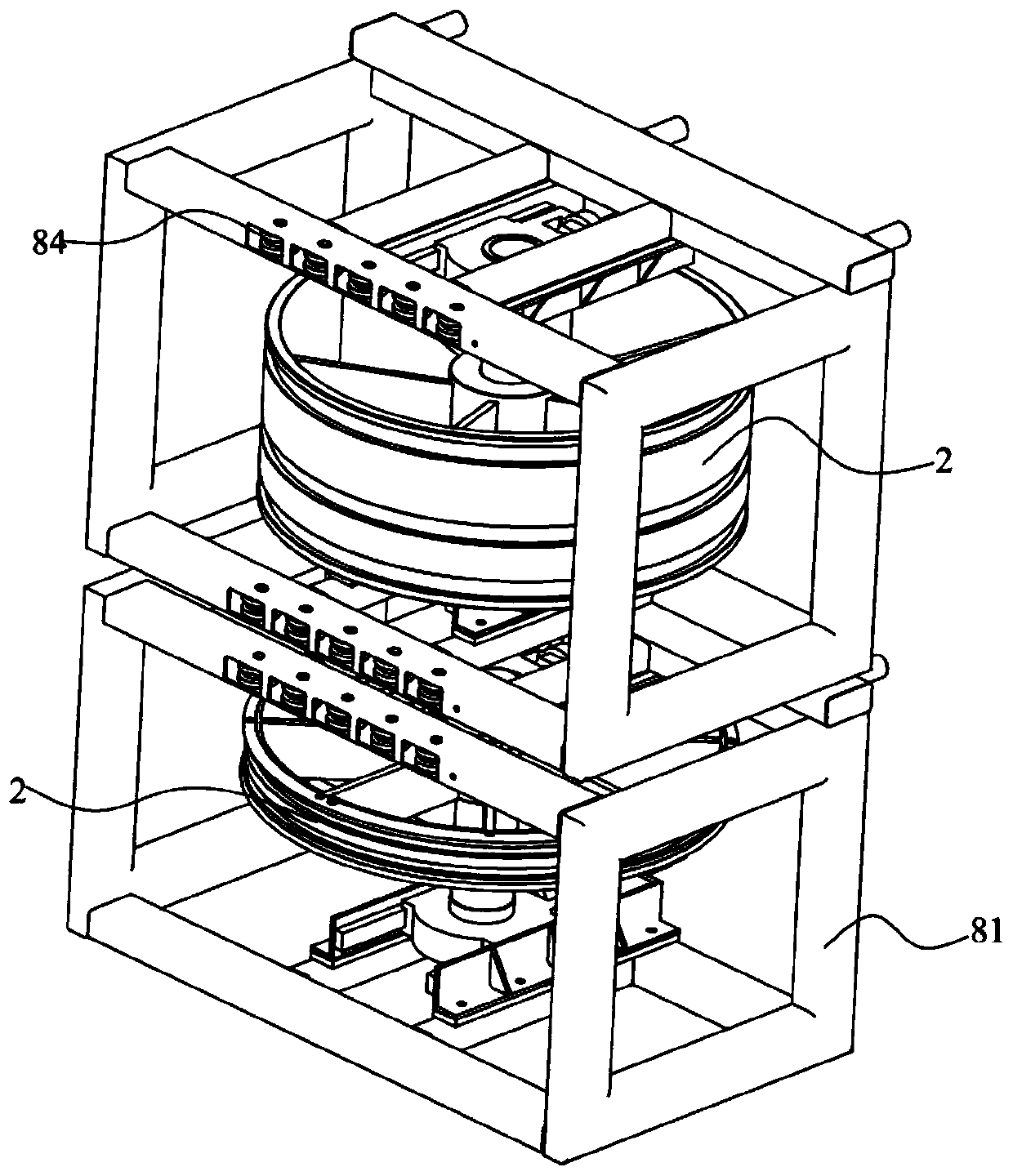

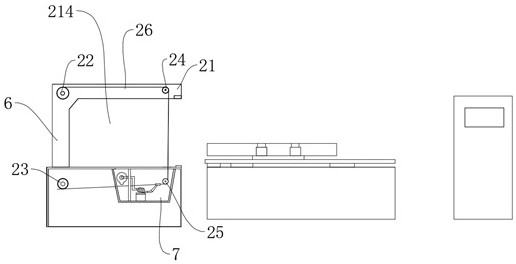

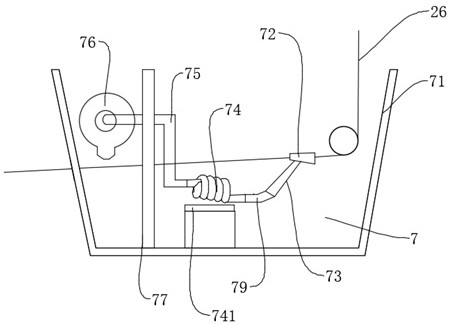

The invention discloses a wind power blade main beam cloth laying device. The wind power blade main beam cloth laying device comprises a cloth laying moving frame, a rotary transverse moving mechanismis arranged on the cloth laying moving frame, an unwinding frame is arranged on the rotary transverse moving mechanism, two cloth rolls which are parallel front and back are erected on the unwindingframe, the rotary transverse moving mechanism comprises a transverse moving assembly and a rotating assembly, the transverse moving assembly is used for controlling the unwinding frame to transverselymove in the chordwise direction of a blade main beam mold, and the rotating assembly is used for controlling the unwinding frame to rotate. The wind power blade main beam cloth laying device has theadvantages that the labor intensity of workers is reduced, the laying quality is improved, the blade forming period is shortened, and the laying efficiency is improved.

Owner:江阴市科诚技术有限公司

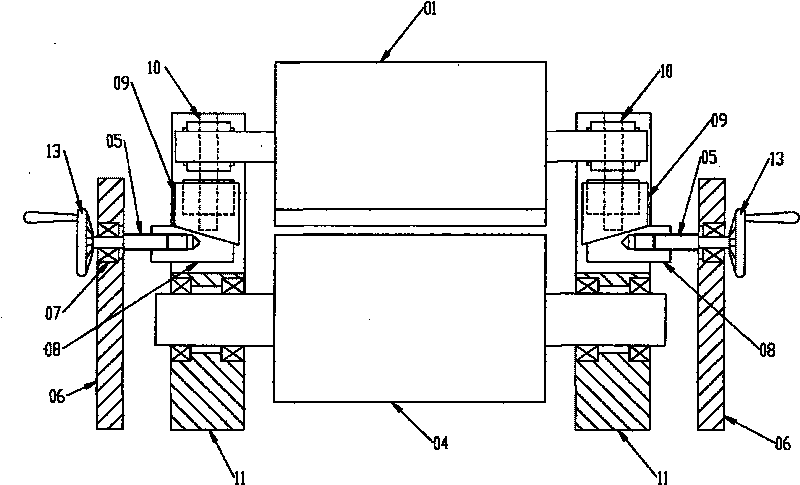

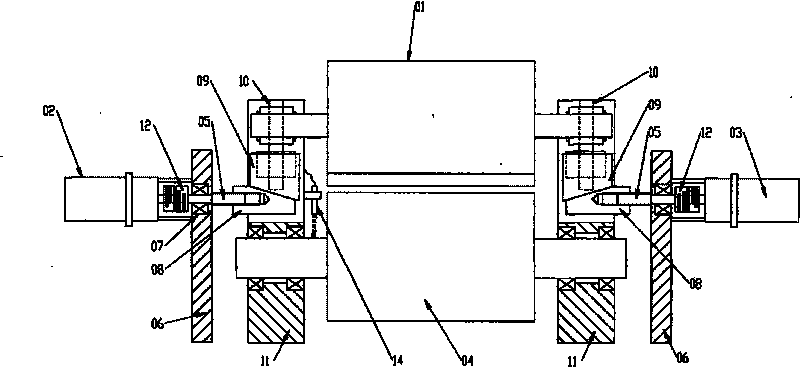

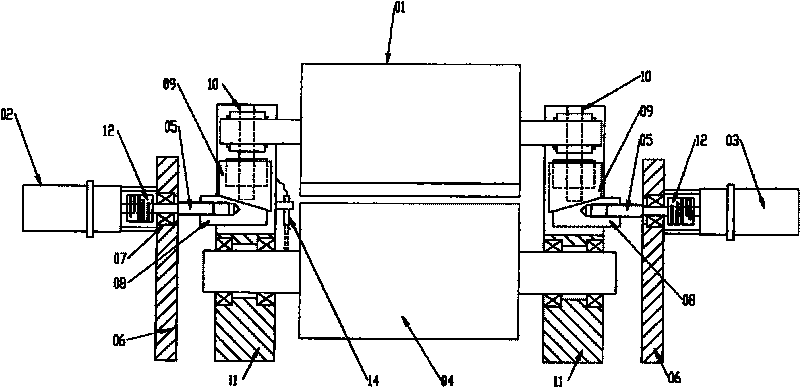

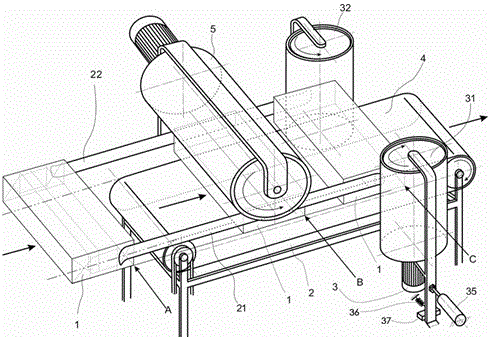

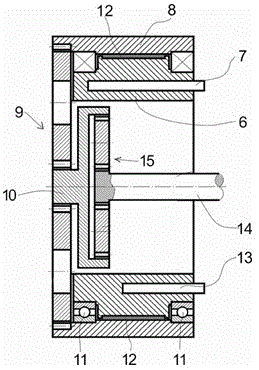

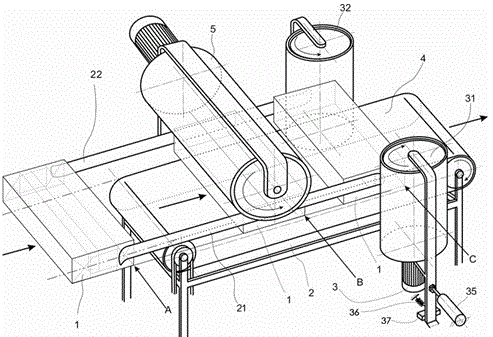

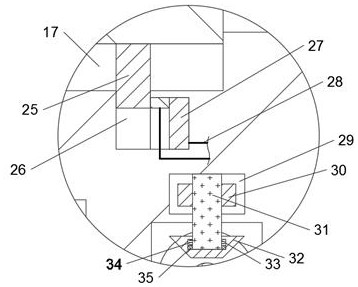

Device capable of automatically adjusting coating machine scraper gap

InactiveCN101712021AEasy to adjustRegulation stabilityLiquid surface applicatorsElectrode manufacturing processesAuto regulationCoupling

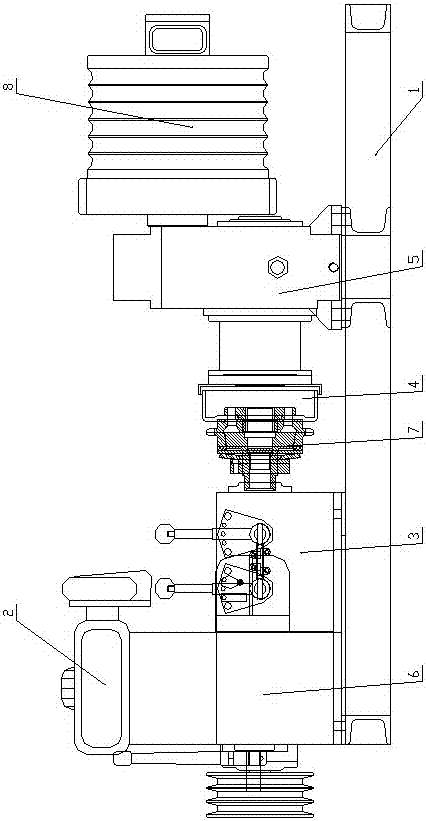

The invention discloses a device capable of automatically adjusting coating machine scraper gap, comprising a scraper, a coating roll, a screw, a stationary inclined block, a movable inclined block and a linear guide. The device is characterized in that the device is provided with two servo motors which are respectively connected with the movable inclined blocks at two ends of the scraper by a coupler, a bearing, a screw base and the screw; two servo motors adopt the same PLC to intensively control; the stationary inclined block is also provided with a high-precision displacement transducer and is connected with the PLC; the high-precision displacement transducer collects and adjusts gap feedback information in due time and sends the gap feedback information to the PLC control center to form a closed loop control system. The invention has the beneficial effect that the device adopts the closed loop control system to adjust the height of a scraper; the minimum effective stroke for adjustment is small, so that the gap precision can be accurately controlled; the servo motor operation consistency effectively avoids the problem of inconsistent adjustment height of two ends of the scraper.

Owner:东莞市九州浩德新能源设备有限公司

Graphene film and preparation method thereof

The invention relates to a preparation method of a graphene film, which comprises the following steps: (1) dispersing graphene oxide in a solvent to obtain a mixture; (2) pouring the mixture into a knifing machine, carrying out continuous knifing on a substrate at a speed V, and sending the film and substrate into a blast drying tunnel at the speed V to perform drying, thereby obtaining a substrate-bearing graphene oxide film; (3) continuously sending the substrate-bearing graphene oxide film into a pipe furnace at the speed V, and carrying out graphitizing in an inert atmosphere to reduce the graphene oxide and repair the structure defects on the surface, thereby obtaining a substrate-bearing graphene film; and (4) rolling the substrate-bearing graphene film from the pipe furnace, and peeling the substrate to obtain the graphene film. The invention also relates to a graphene film.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

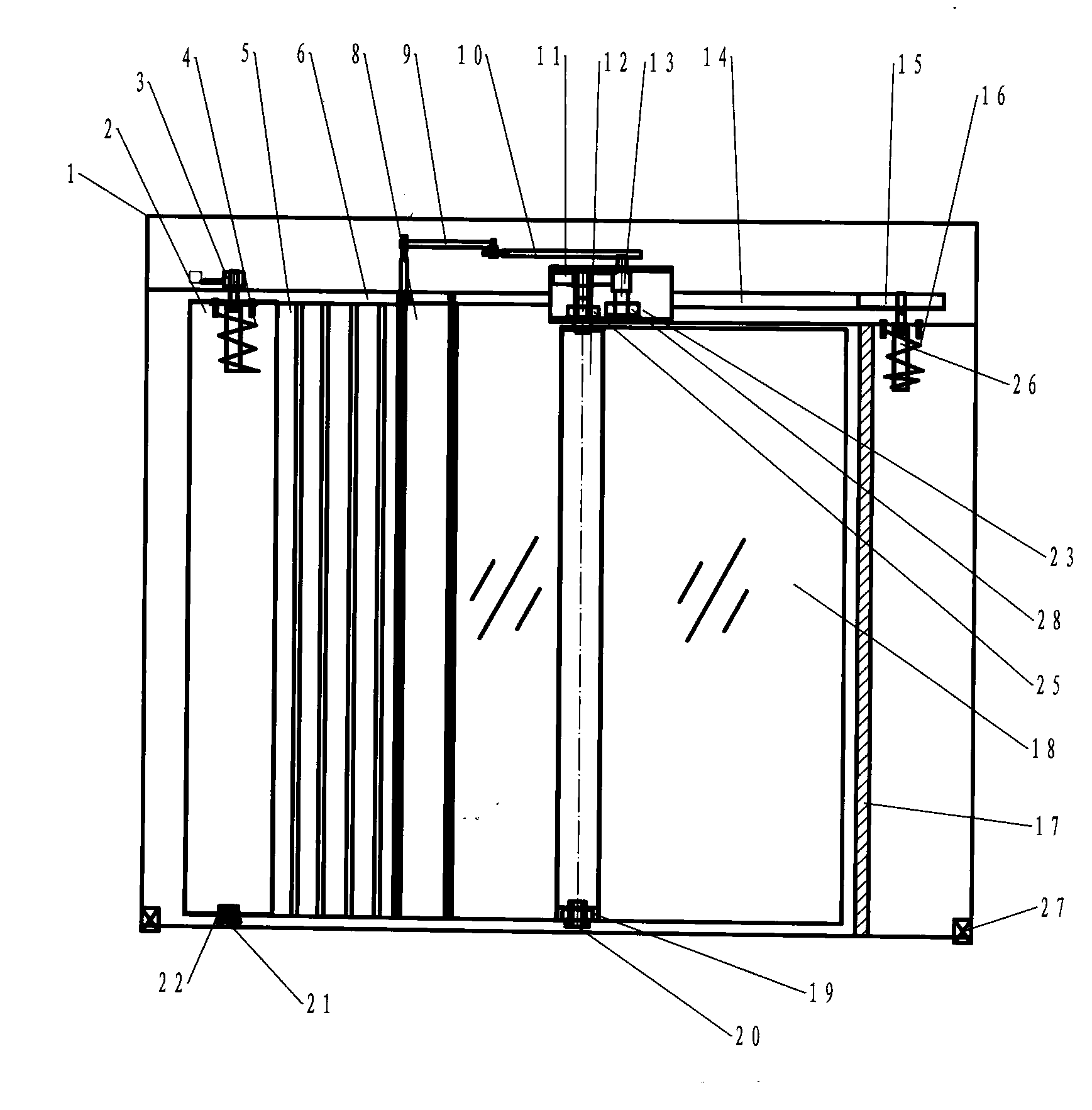

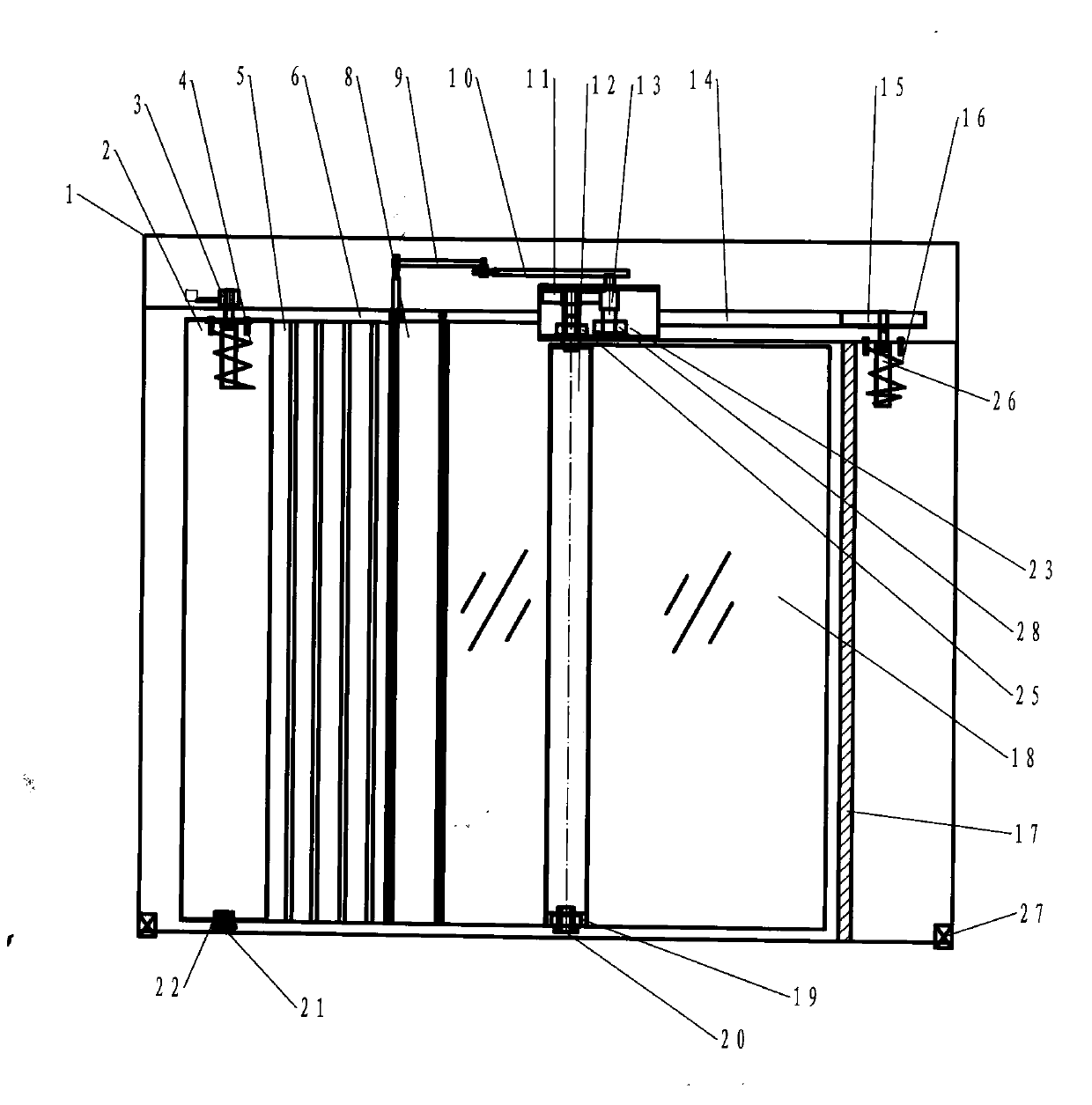

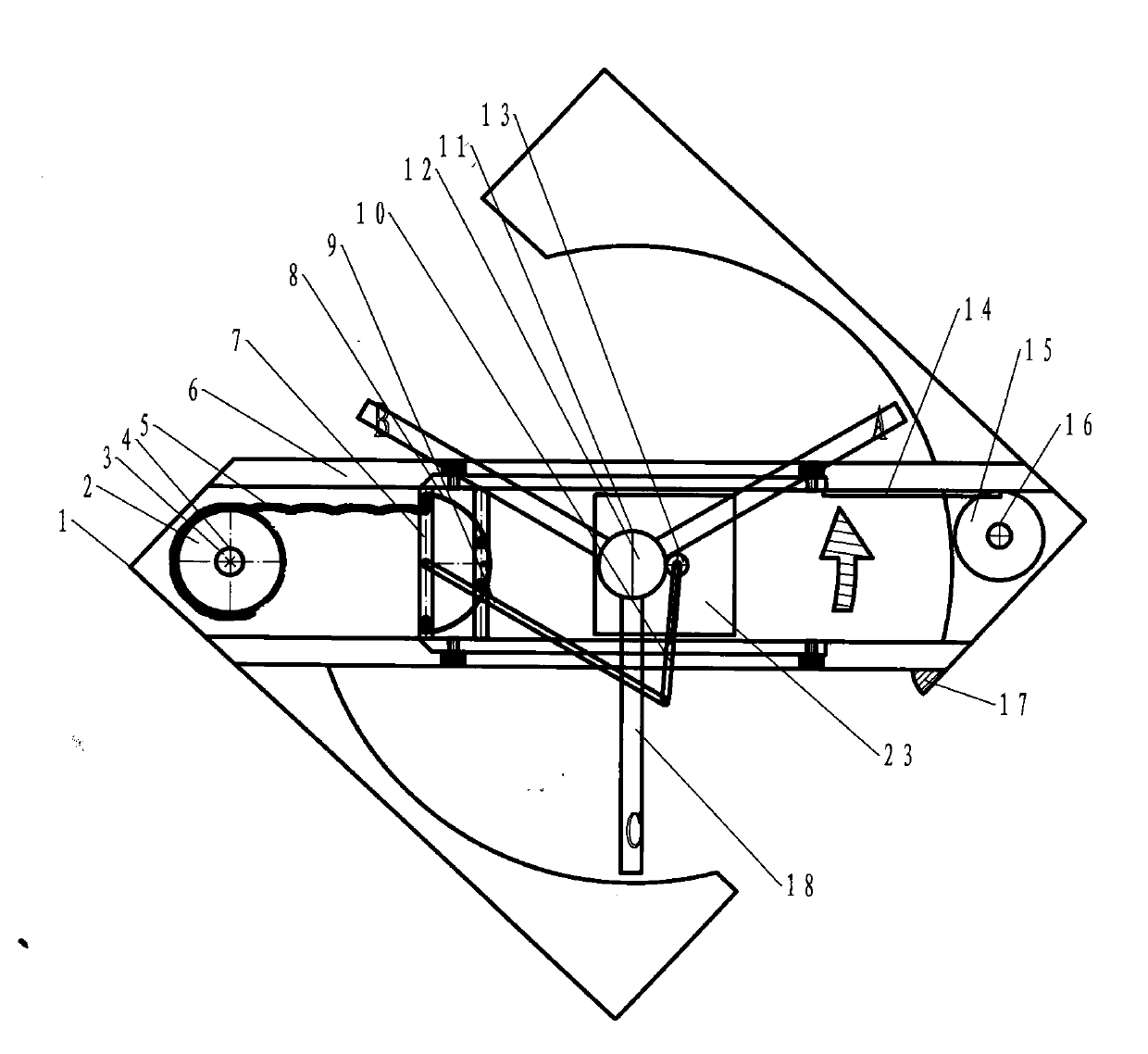

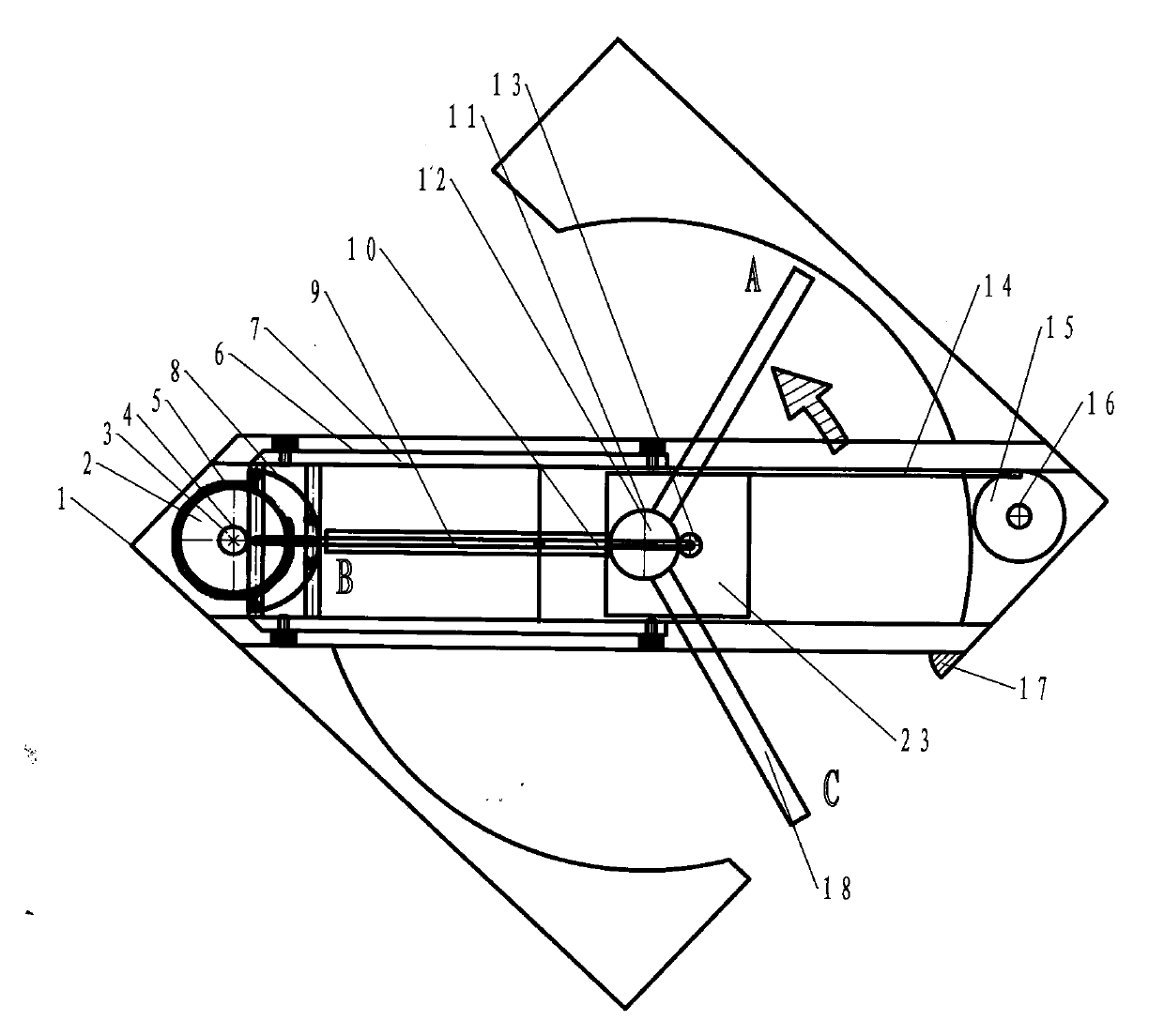

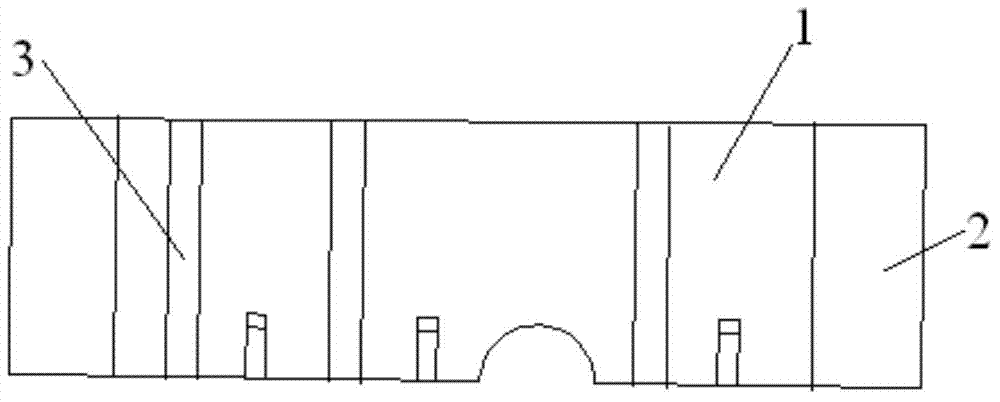

One-way door with planar door leaves

ActiveCN103352641AGuaranteed widthRunning at the same speedRevolving doorsShutters/ movable grillesReducerTraveling block

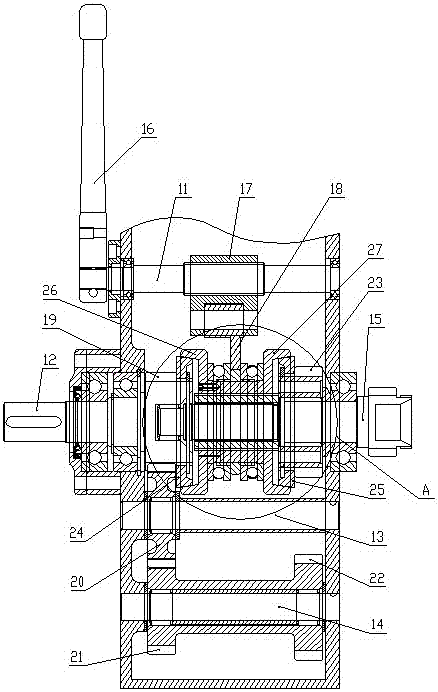

The invention provides a one-way door with plane door leaves and relates to a plate-shaped one-way revolving door capable of being opened in the positive direction and being closed in the reverse direction. The one-way door mainly solves that problem that the gap between the secondary door and the main door of the known plate-shaped one-way door cannot completely block reverse walking of pedestrian and the problems that one end of a folding type secondary door is directly fixed on a connecting rod, a crank connecting rod and a folding door are hinged unstably, the folding secondary door has great inertia during operation, and vibration and noise cannot be overcome. The one-way door comprises three main doors and a secondary door, wherein the three main doors are fixed on a main shaft; the secondary door is connected with the main shaft through a crank connecting rod mechanism; the top of the main shaft is connected with a driving gear of a speed reducer through a key. The one-way door is characterized in that an output shaft of the speed reducer is connected with a pulley through the crank connecting rod mechanism; the pulley is mounted on a rail at the upper end of a door body; the lower part of the pulley is connected with an arc-shaped secondary door edge of the secondary door; the other end of the secondary door is hinged with a secondary door winding drum; a torsional spring is fixed at the end part of the secondary door winding drum; the other end of the torsional spring is fixed on a torsional spring fixing shaft; the upper end of the pulley is connected with a balance belt wheel through a balance belt; the balance belt wheel is fixedly connected to a wheel shaft; one end of the wheel shaft is fixedly connected to the door body through the a balance torsional spring. In the rotating process of the main doors, one main door and the secondary door are contacted all the time and maintain a small gap, so pedestrian only can walk in one way. The one-way door is reasonable and compact in structure, and has a good effect and operates stably through repeated tests.

Owner:XIANGYANG SIXIANG ELECTROMECHANICAL SCI & TECH CO LTD

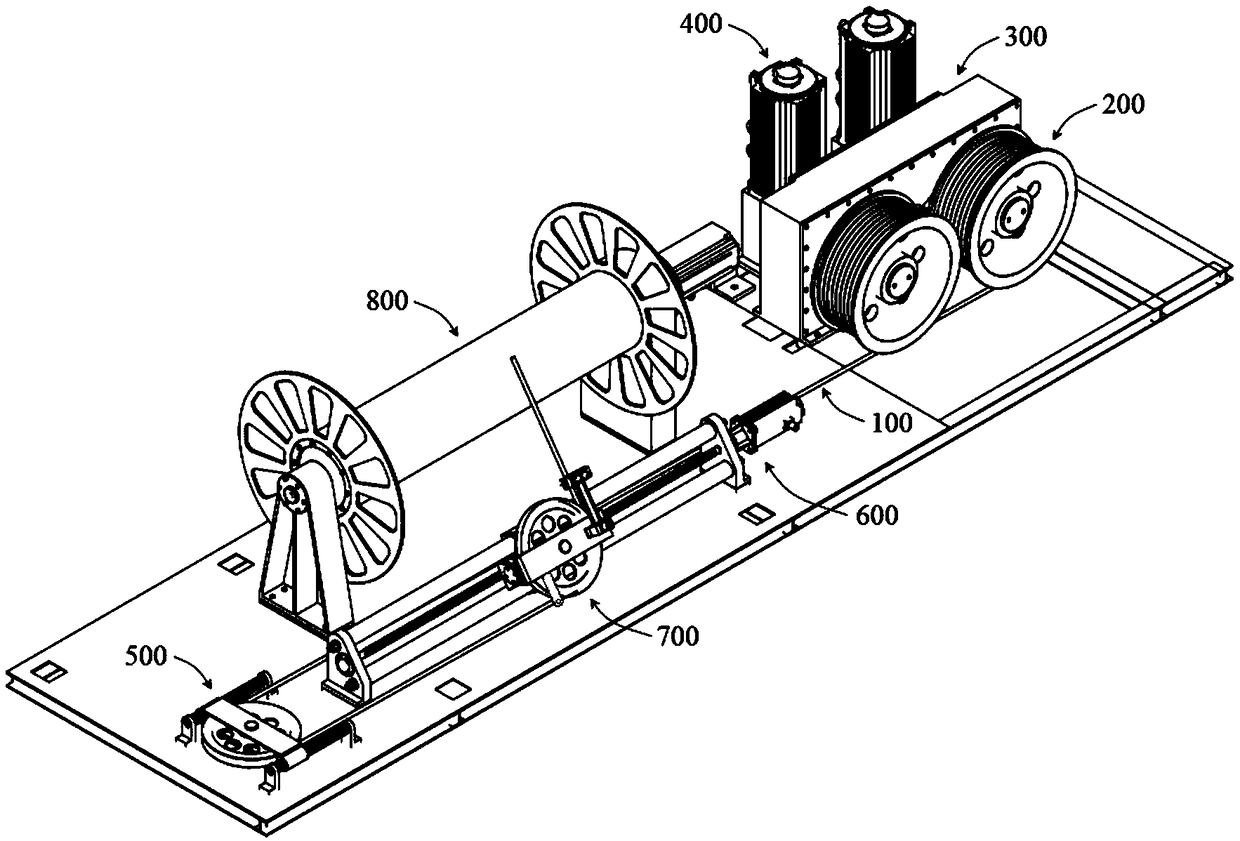

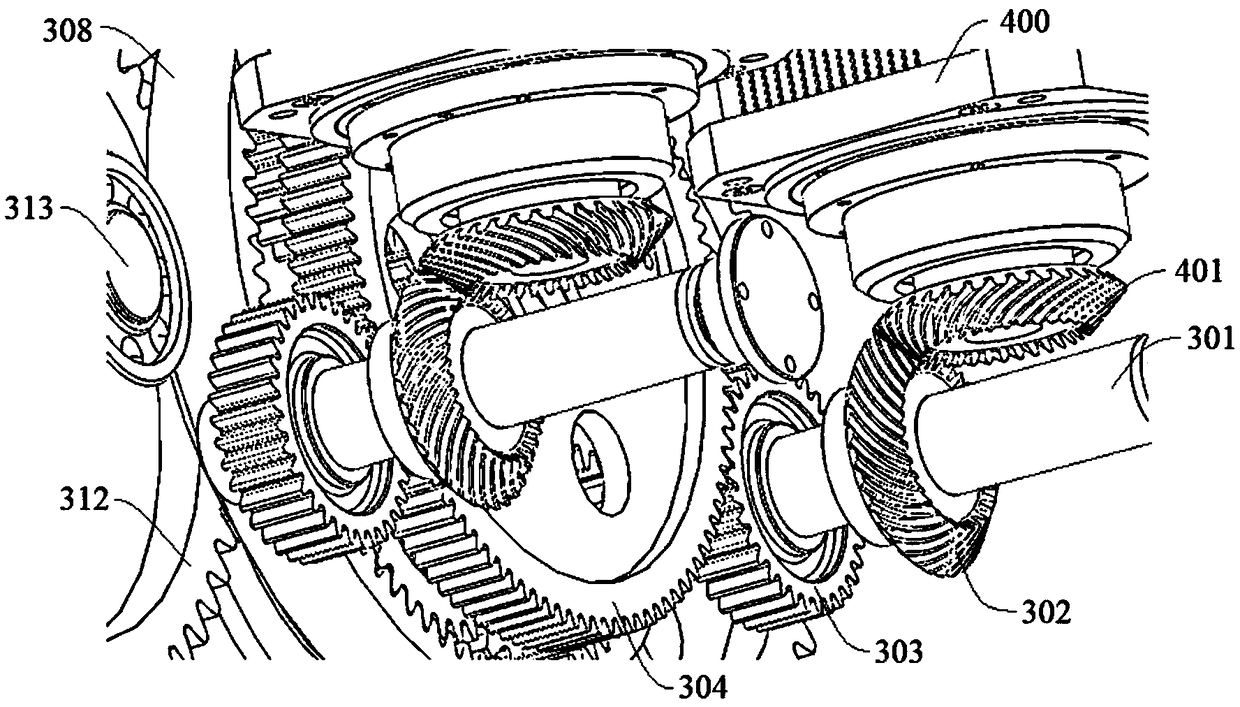

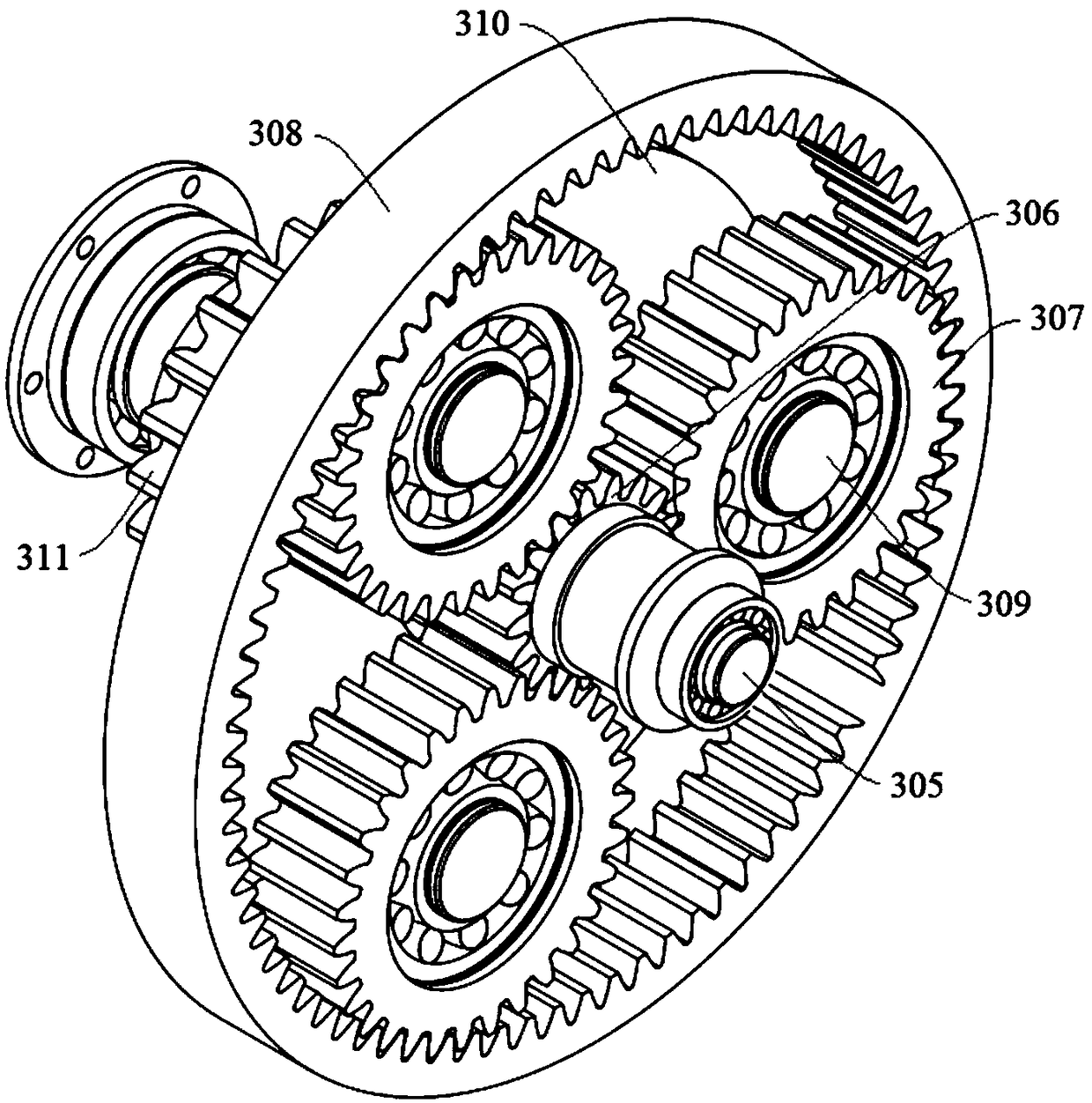

High-transmission-efficiency cable winding device and method

The invention discloses a high-transmission-efficiency cable winding device, and belongs to the technical field of cable winding. The high-transmission-efficiency cable winding device comprises a cable, a traction reel, a gear transmission unit, reel driving motors, a redirection unit, a cable unwinding unit and a cable storing unit; the gear transmission unit is arranged between the traction reeland the reel driving motors; the reel driving motors control the traction reel to rotate through the gear transmission unit; and the cable is wound on the traction reel, output through the traction reel, redirected through the redirection unit, and then wound on the cable storing unit through the cable unwinding unit. Power dividing transmission is adopted, that is, the mode that dividing is conducted firstly and then confluence is conducted is adopted, and the stability of stable winding and unwinding can be controlled through the two reel driving motors with the low power; gear transmissionis further adopted, the occupied area of the device is effectively reduced, and the transmission efficiency is improved; and through mutual cooperation of all the units, the cable is efficiently andstably wound on a cable storing reel, and the cable can be stored and can also be released.

Owner:马鞍山市方正机械制造有限责任公司

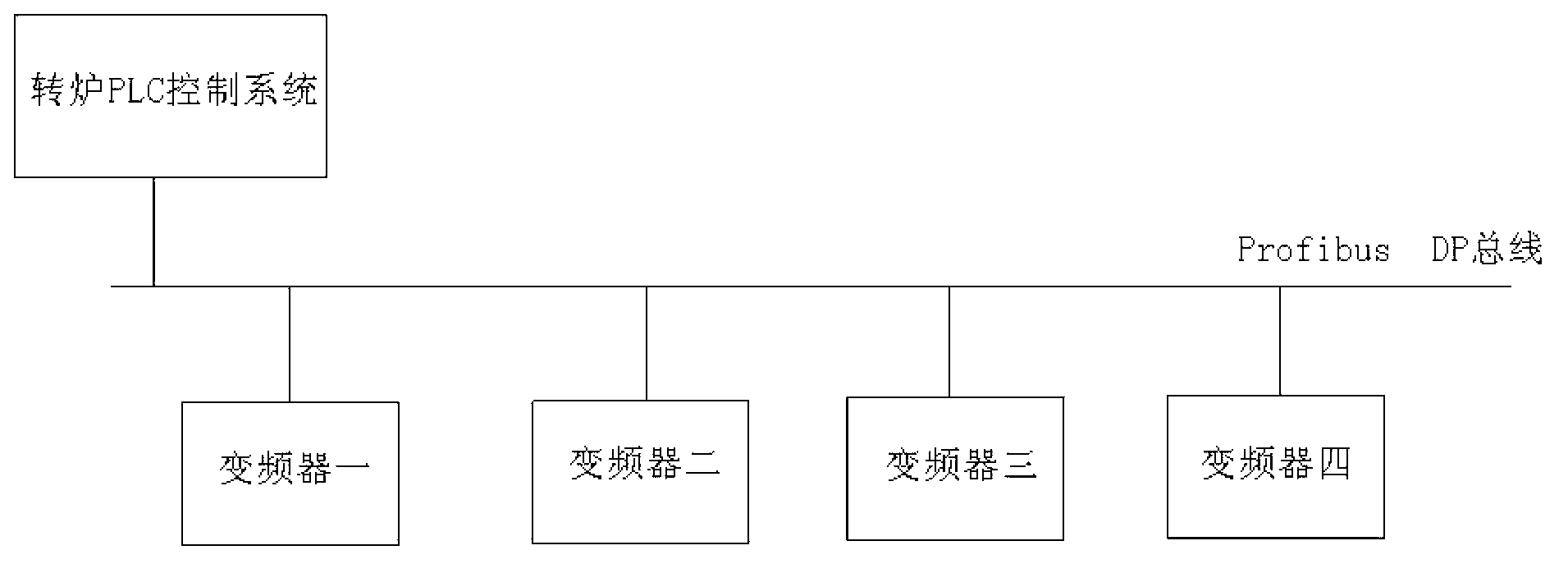

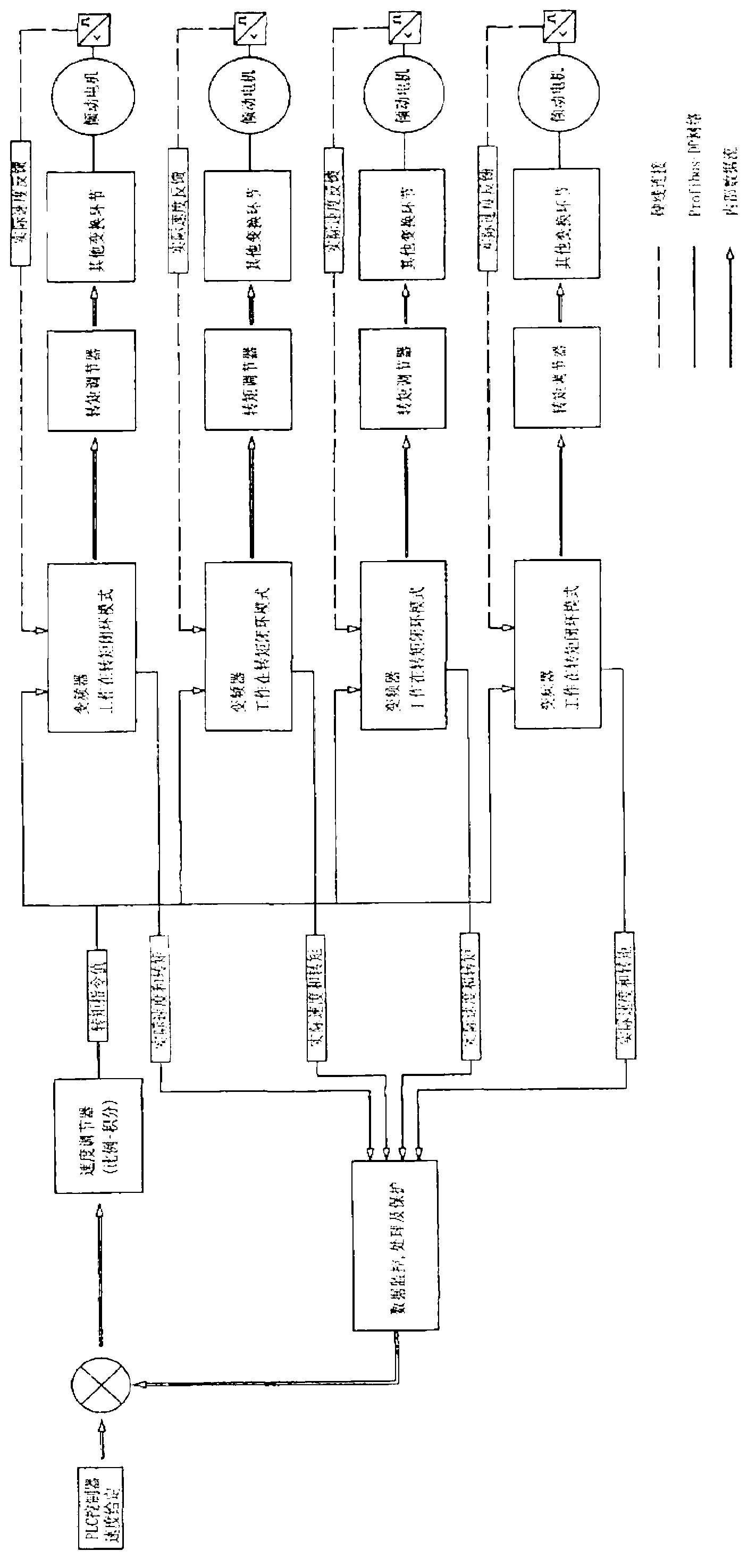

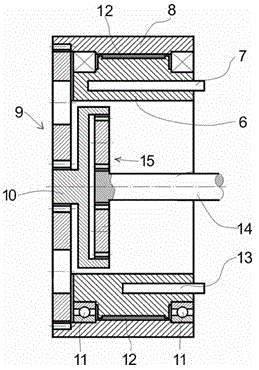

Converter tilting frequency conversion timing control system

InactiveCN103060516ARunning at the same speedStart and stop smoothlyManufacturing convertersTotal factory controlFrequency changerFrequency conversion

The invention relates to a converter tilting frequency conversion timing control system which comprises four inverters, a tilting motor and a converter PLC (Programmable Logic Controller)control system which are respectively controlled by the inverters, wherein a ring structure network is formed by an optic cable serial communication link among four inverters, and in the ring structure network, a host and three slave machines are determined for the four inverters in the ring structure network by the converter PLC control system; communications of a speed reference, a torque reference, a control word and a status word between each inverter and the converter PLC control system are realized by a Profibus-DP(Decentralized Periphery) network; and the system consists of a speed control loop and a torque control loop. Compared with the prior art, the system has the following beneficial effects: the operation speeds and torque values of motors which are respectively controlled by the four inverters are ensured to be basically consistent, so that loads can be evenly distributed among four drive motors, and the converter is smooth and stable to operate, start and stop and is energy-saving.

Owner:鞍钢集团自动化有限公司

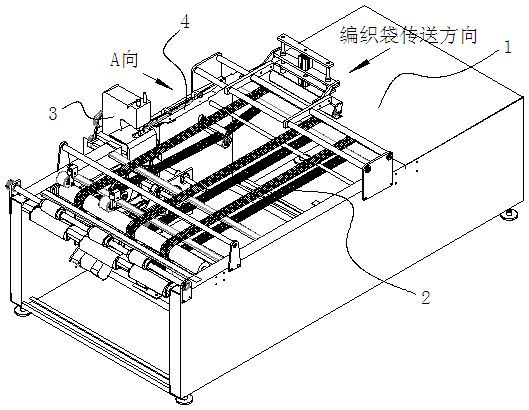

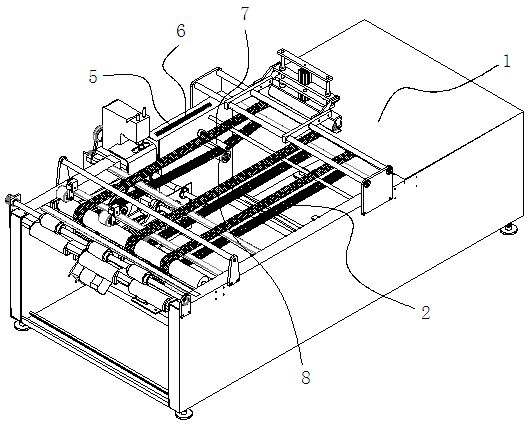

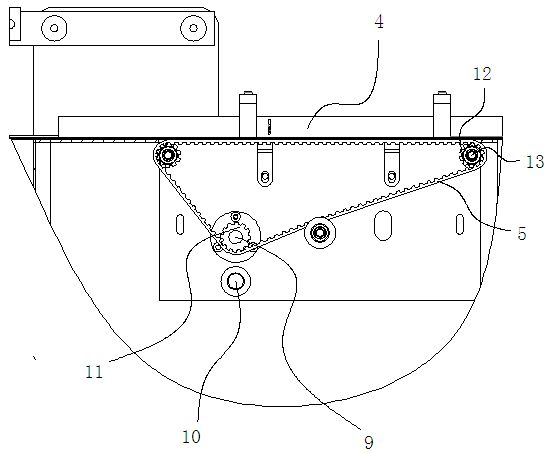

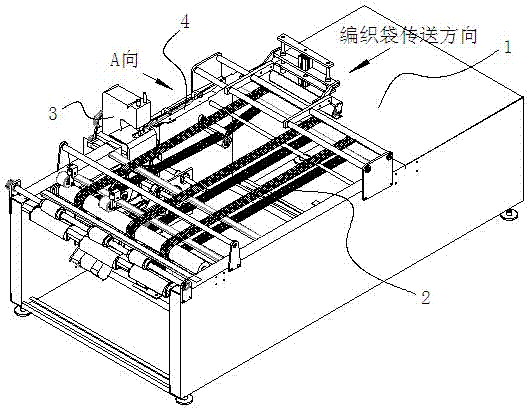

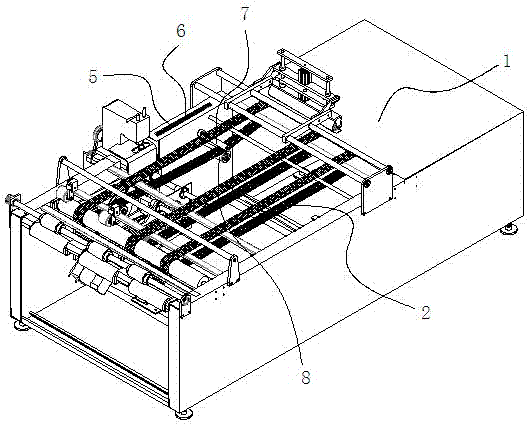

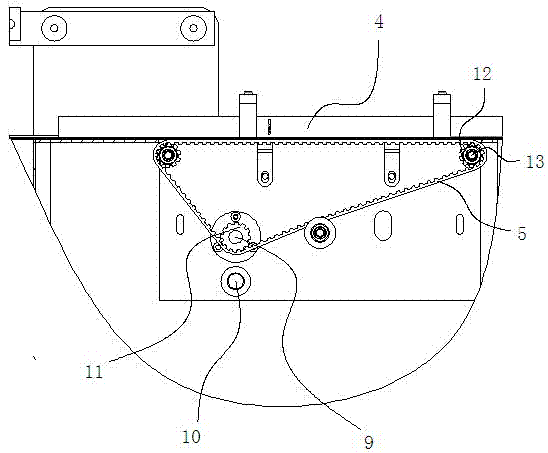

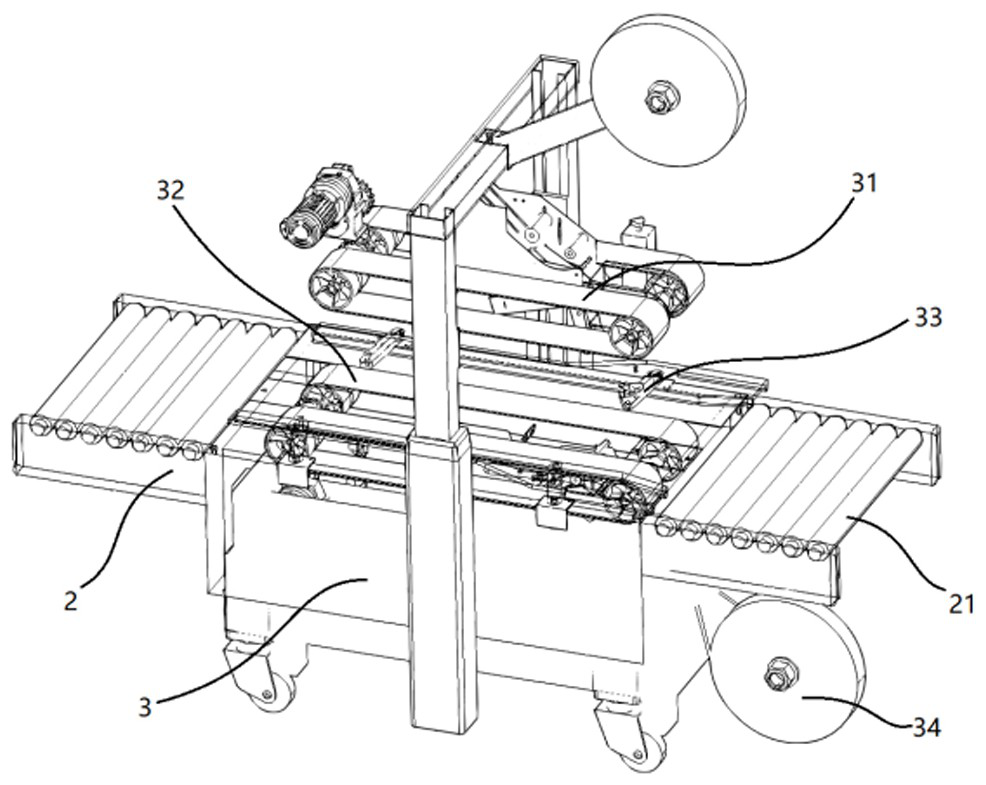

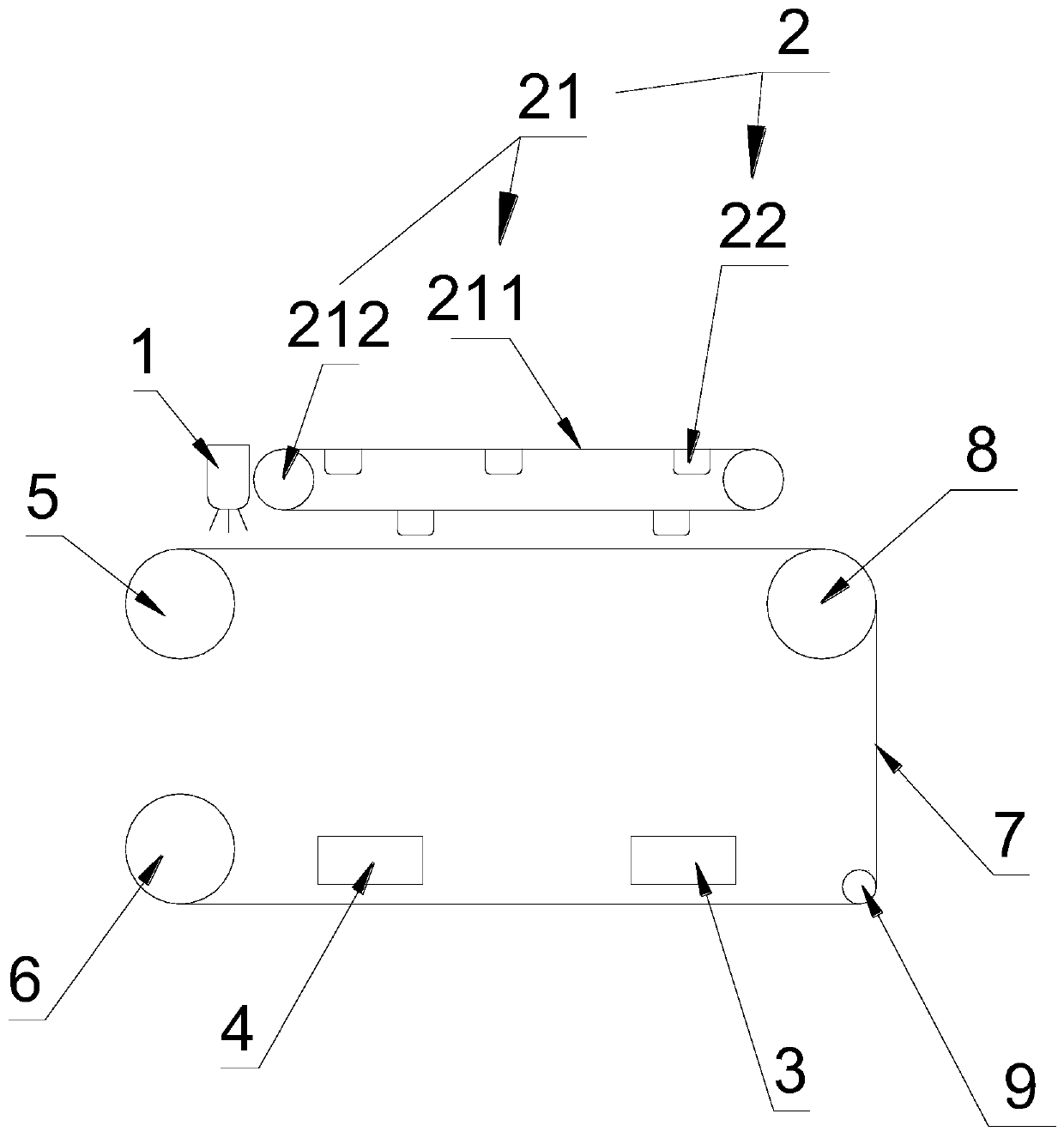

Assistance mechanism for bottom seaming machine of woven bag

InactiveCN102644168AQuality improvementNo creasesWork-feeding meansSewing-machine control devicesProduction lineEconomic benefits

The invention discloses an assistance mechanism for a bottom seaming machine of a woven bag, comprising a stander, wherein a first ring-shaped conveyor belt is arranged on the stander, the stander is provided with an edge coiling device at the outer side of the first conveyor belt, the stander is provided with a synchronous conveying mechanism at the lower side of the edge coiling device, the conveying speed and the conveying direction of the synchronous conveying mechanism are matched with those of the first conveyor belt. The assistance mechanism has the beneficial effects that the conveying speed lost by coiling the edge at the bottom of the woven bag is effectively compensated, so that the woven bag is tidy in edge coiling, and good in sewing quality, the wrinkles can be avoided when the woven bag is conveyed, the sewing speed of the bottom seaming machine can be improved in multiples, and the original quality bottleneck of the woven bag can be broken through, so that about sixty woven bags can be seamed pre minute; and the bottom seaming machine is smooth to run, so that the number of the production line operator can be reduced from four to one, therefore, the assistance mechanism has considerable economic benefit in the current market that the labor cost is constantly improved.

Owner:WENZHOU NINGTAI MACHINERY

One-way door with planar door leaves

ActiveCN103352641BGuaranteed widthRunning at the same speedRevolving doorsShutters/ movable grillesReducerEngineering

Owner:XIANGYANG SIXIANG ELECTROMECHANICAL SCI & TECH CO LTD

Intelligent rail vehicle automatic catering trolley

ActiveCN108839605AImprove freshnessImprove drinking tasteWorkshop/display transportationCold airEngineering

The invention belongs to the technical field of rail transit, and particularly relates to an intelligent rail vehicle automatic catering trolley. The catering trolley comprises a trolley frame and wheels, and further comprises condensation plates, supporting columns, first shafts, placement boxes, first control units and condensation units. The condensation units and the first control units are arranged, and the first control units and the condensation units are matched with each other, so that on the one hand, the freshness of beverages is improved, the beverages are not likely to go bad, andtherefore the drinking taste of beverages is improved; on the other hand, adjustment can be conducted according to actual needs of beverages, so that the beverages are evenly frozen, and the beveragerefrigerating effect is improved; meanwhile, in the process that the placement boxes move downwards, first air bags are extruded by the placement boxes, the first air bags blow out cold air, and thecold air directly acts on the beverages through first holes, so that the beverage refrigerating efficiency is improved.

Owner:宿州迅驰电子科技有限公司

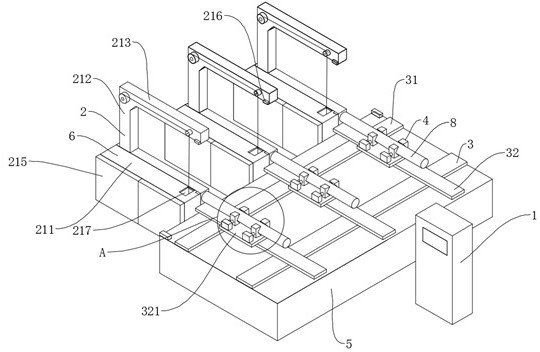

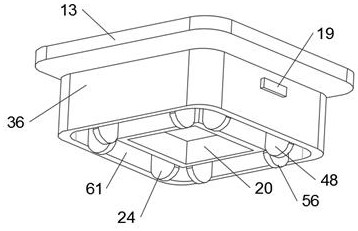

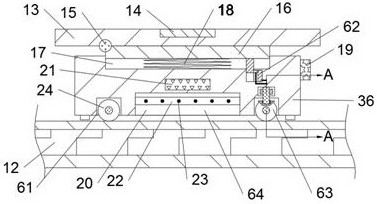

Circuit board conveying structure and electroplating equipment

PendingCN109941751AAvoid wrinklesUniform thicknessElectrolysis componentsConveyorsEngineeringOperating speed

The invention provides a circuit board conveying structure. The circuit board conveying structure comprises a first transmission mechanism, a second transmission mechanism, at least one clamp, at least one material clamp and a driving mechanism, wherein the first transmission mechanism and the second transmission mechanism are arranged in parallel in the vertical direction; the at least one clampis arranged on the first transmission mechanism, is used for clamping the upper end of a circuit board and can be driven by the first transmission mechanism to move synchronously with the first transmission mechanism; the at least one material clamp is arranged on the second transmission mechanism and under the corresponding clamps, is used for clamping the lower end of the circuit board, and canbe driven by the second transmission mechanism to move synchronously with the second transmission mechanism, and the operating speed of the clamps are the same as that of the material clamps; and thedriving mechanism is connected with the first transmission mechanism and the second transmission mechanism and drives the first transmission mechanism and the second transmission mechanism to move synchronously. By means of the circuit board conveying structure, the lower end of the circuit board does not lag behind the upper end of the circuit board, and the board surface of the circuit board isprevented from being wrinkled in the conveying process.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

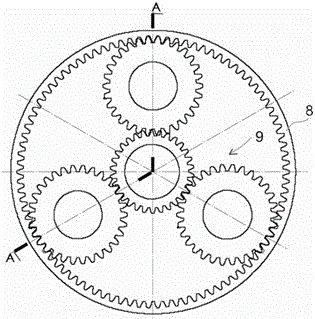

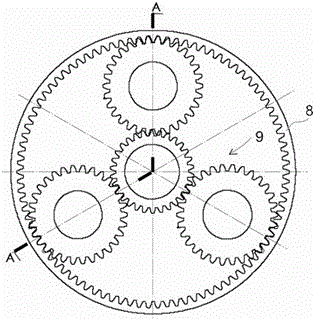

Double Drum Winch Mill

InactiveCN105564444BRunning at the same speedSame tractionRope railwaysTorque limiterTransmission system

The invention discloses a double-drum winching machine. The double-drum winching machine comprises a base. An engine, a speed changing device, an external urgent braking device and a transmission system are arranged on the base, wherein the engine, the speed changing device, the external urgent braking device and the transmission system are sequentially connected in a transmission mode; a forward and backward gear mechanism is arranged at the portion, between the engine and the speed changing device, of the base; a torque limiter is arranged at the portion, between the speed changing device and the external urgent braking device, of the base; a first drum and a second drum are respectively connected to the power output end of the transmission system in a transmission mode. The double-drum winching machine is reliable in work, easy and convenient to operate, high in safety, good in braking performance and wide in application range; as the forward and backward gear mechanism is arranged, reversing is convenient, and it is guaranteed that forward traction and backward traction are same; when reversing is carried out, the forward state, the idling state and the backward state can be achieved only by operating a reversing rod, and operation is quite easy; as the torque limiter is arranged, overload operation can be effectively controlled, and overload accidents can be avoided.

Owner:河南旭德隆机械有限公司

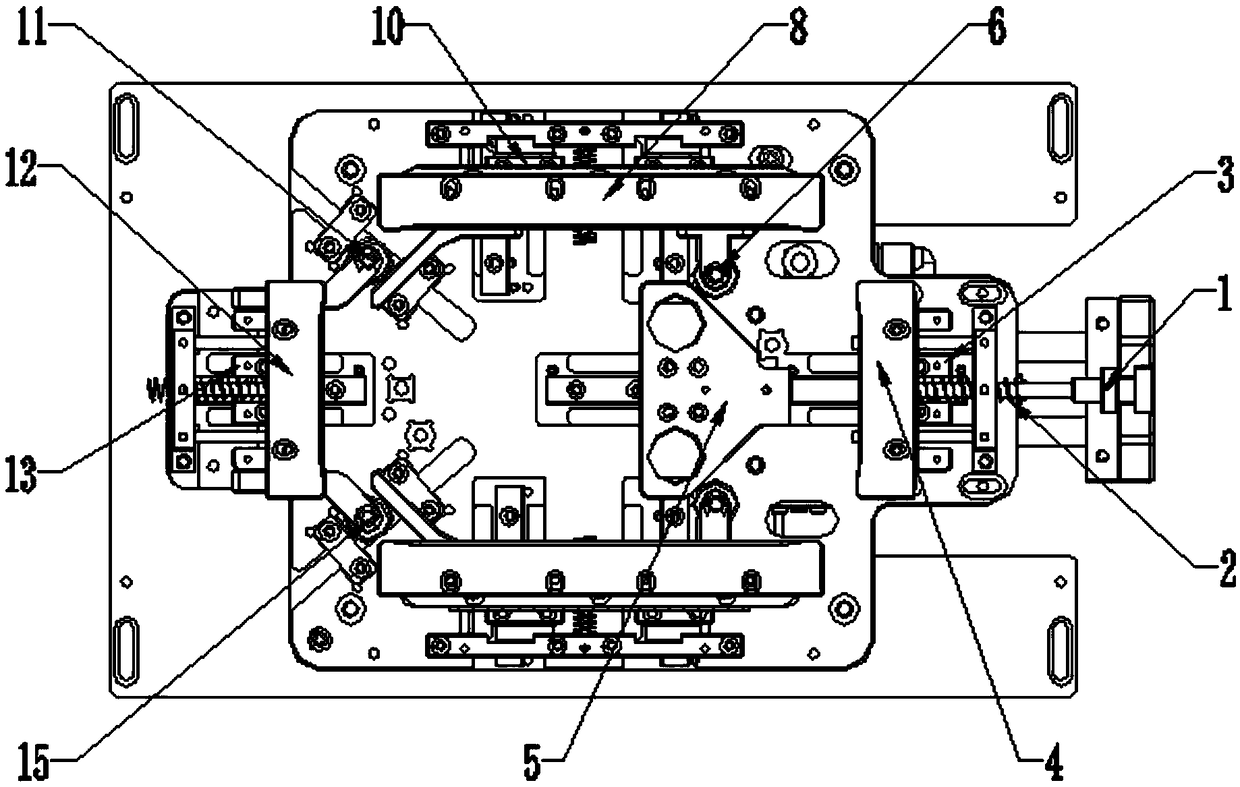

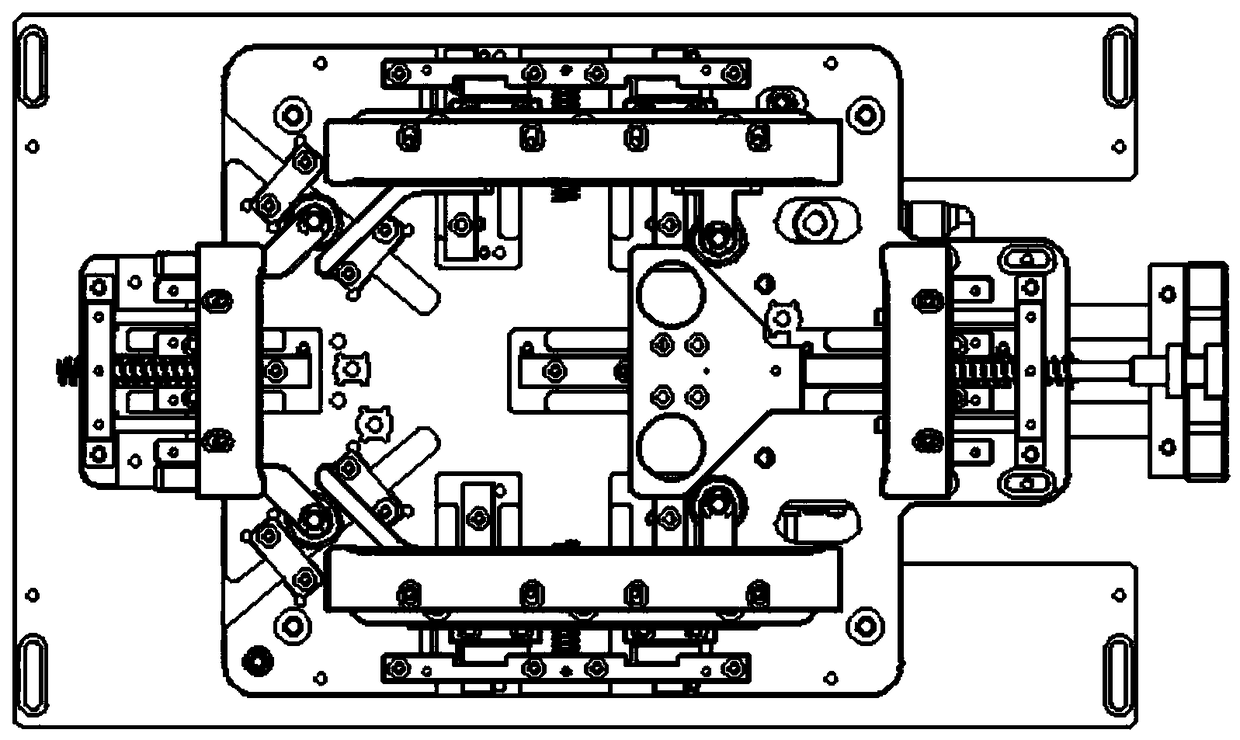

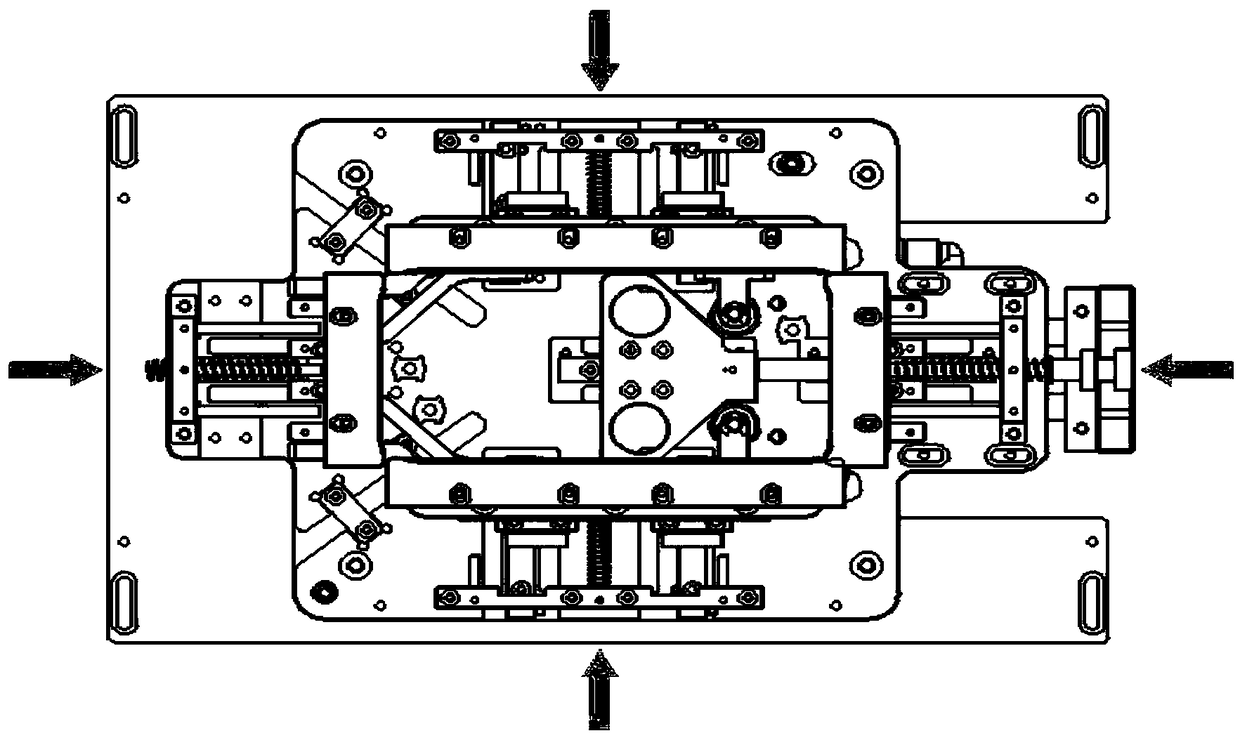

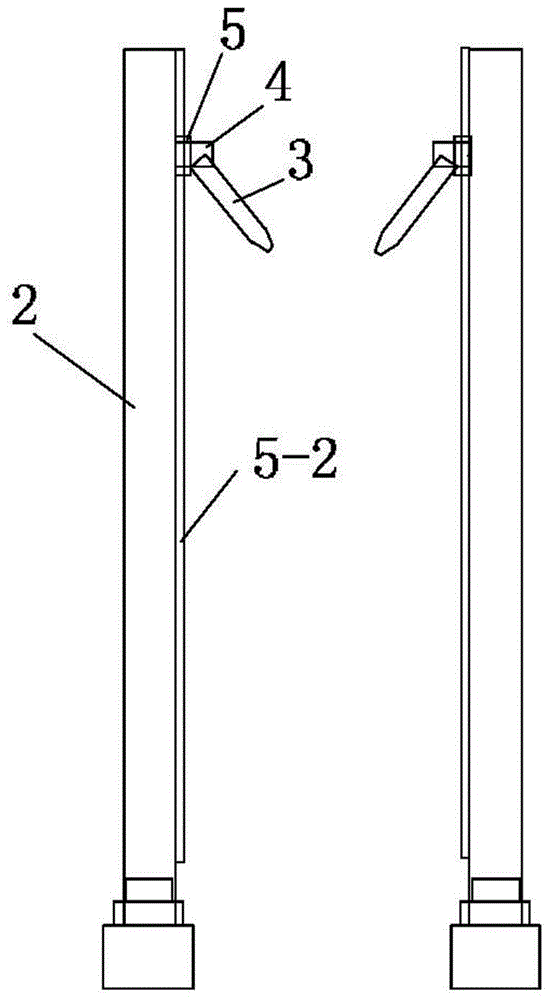

Peripheral clamping mechanism and operation method

ActiveCN109048418ARunning at the same speedEasy to operate and controlPositioning apparatusMetal-working holdersEngineeringMechanical engineering

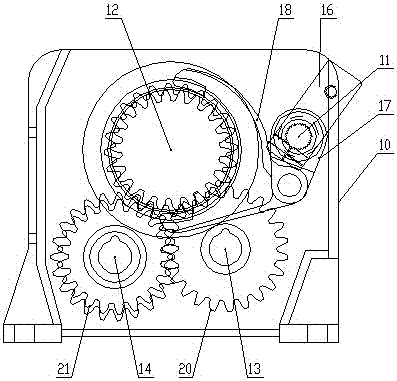

The invention discloses a peripheral clamping mechanism and an operation method. The peripheral clamping mechanism comprises a die holder and a driving mechanism, wherein the driving mechanism is horizontally arranged at the top edge position of the die holder and is fixedly connected to the die holder through a screw; a sliding block A is arranged at the bottom of the driving mechanism; the sliding block A is horizontally arranged in the middle of the bottom of the driving mechanism and is fixedly connected to the driving mechanism through the screw; a clamping block A is arranged at the topof the sliding block A; the clamping block A is horizontally arranged in the middle of the top of the sliding block A and is fixedly connected to the sliding block A through the screw; a transmissionblock is arranged on one side of the clamping block A; the transmission block is horizontally arranged at one end of the driving mechanism and is fixedly connected to the driving mechanism through thescrew; a sliding block B and a sliding block C which are parallel to each other are arranged at the top of the die holder; and the sliding block B and the sliding block C are horizontally arranged atthe top edge position of the die holder and are fixedly connected to the die holder through the screws. The peripheral clamping mechanism has the advantages of simple operation control, identical peripheral clamping force and consistent running speed of the clamping blocks.

Owner:上海莘翔自动化科技有限公司

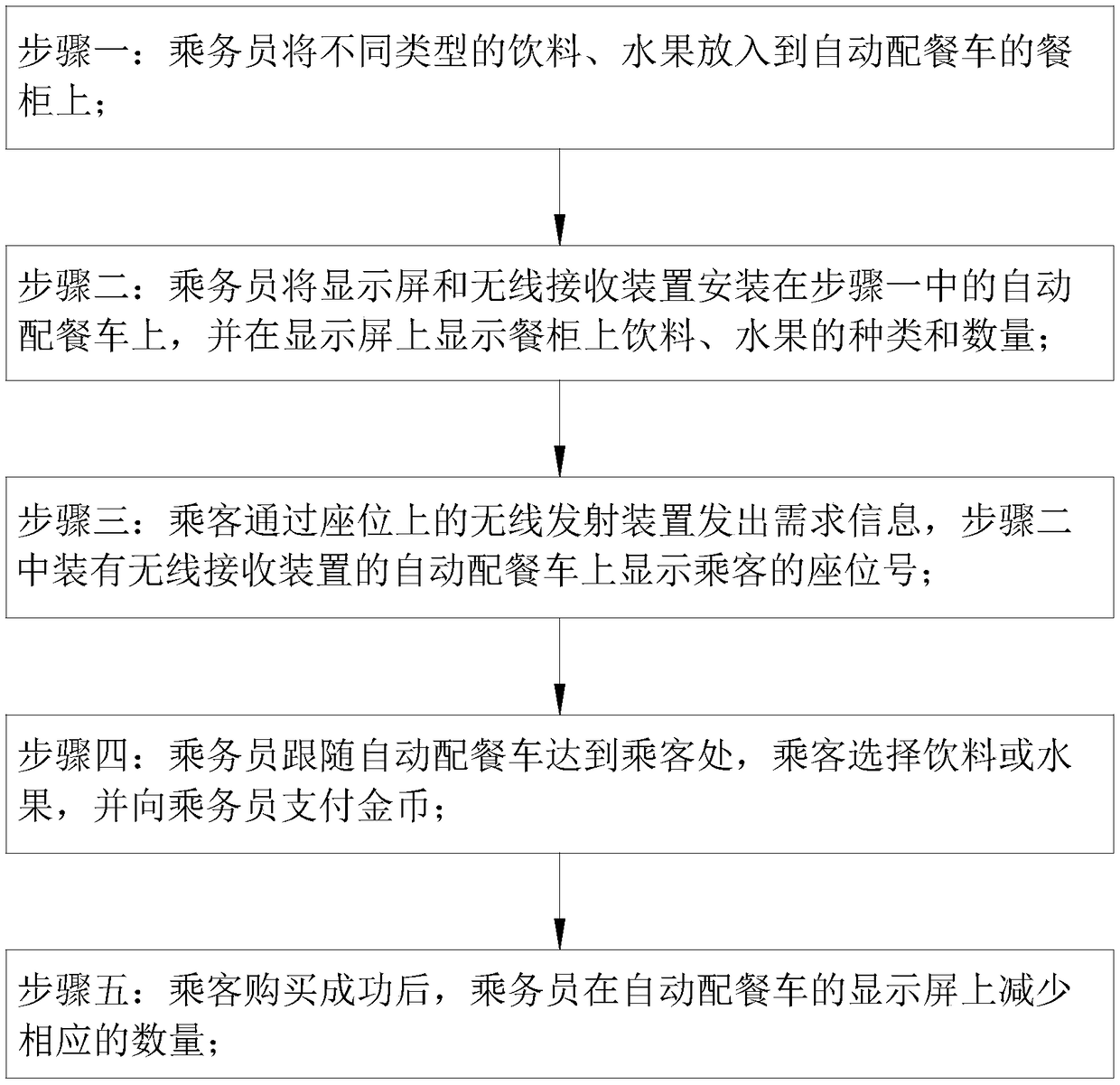

Rail vehicle food and beverage delivery method

ActiveCN109109723AImprove freshnessImprove drinking tasteWorkshop/display transportationLogisticsCold airVehicle frame

The invention belongs to the technical field of intelligent food delivery, in particular to a rail vehicle food and beverage delivery method. The method adopts an automatic food delivery vehicle whichcomprises a vehicle frame and wheels, and also including a condensing plate, struts, a first shaft, a placement box, a first control unit and a condensing unit. By arranging the condensing unit and the first control unit, through the mutual cooperation of the first control unit and the condensing unit, the freshness of the beverage is improved, so that the beverage is not easy to deteriorate, andthe taste of the beverage is improved; according to the actual needs of drinks to adjust, so that the drinks are uniformly frozen so as to improve the refrigeration effect of drinks; at that same time, during the downward movement of the placement box, the first air bag is squeezed by the placement box, and the first airbag bulges clod air, and the cold air directly acts on the beverage through the first hole, thereby improving the refrigeration efficiency of the beverage.

Owner:ANHUI HUITENG INTELLIGENT TRANSPORTATION TECH CO LTD

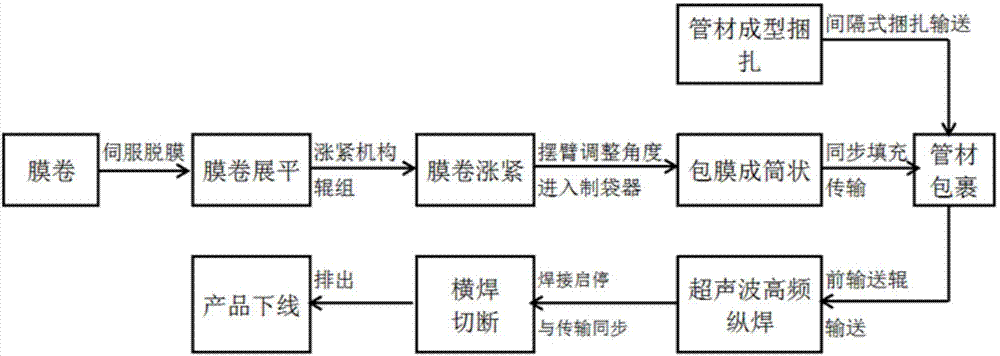

Pipe packaging technology

InactiveCN104118590AAvoid damageRunning at the same speedConveyor wrappingWrapper twisting/gatheringEngineeringUltimate tensile strength

The invention discloses a pipe packaging technology. The pipe packaging technology is characterized by including the following steps that first, pipes are formed and bound; second, the pipes are wrapped; third, ultrasonic high-frequency longitudinal welding is performed; fourth, transverse welding cutting is performed; fifth, the products are discharged off the line. The pipe packaging technology is reasonable in design, a sorting machine, a binding machine and a packaging machine are fully utilized, it is guaranteed that the running speed of the pipes is consistent with that of packaging film, the pipes are stationary relative to the packaging film, damage to the pipes is prevented, labor intensity can be reduced, working efficiency can be improved, and the packaging effect can be guaranteed.

Owner:BEIJING XINSHI CREATIVE PACKAGING MACHINERY

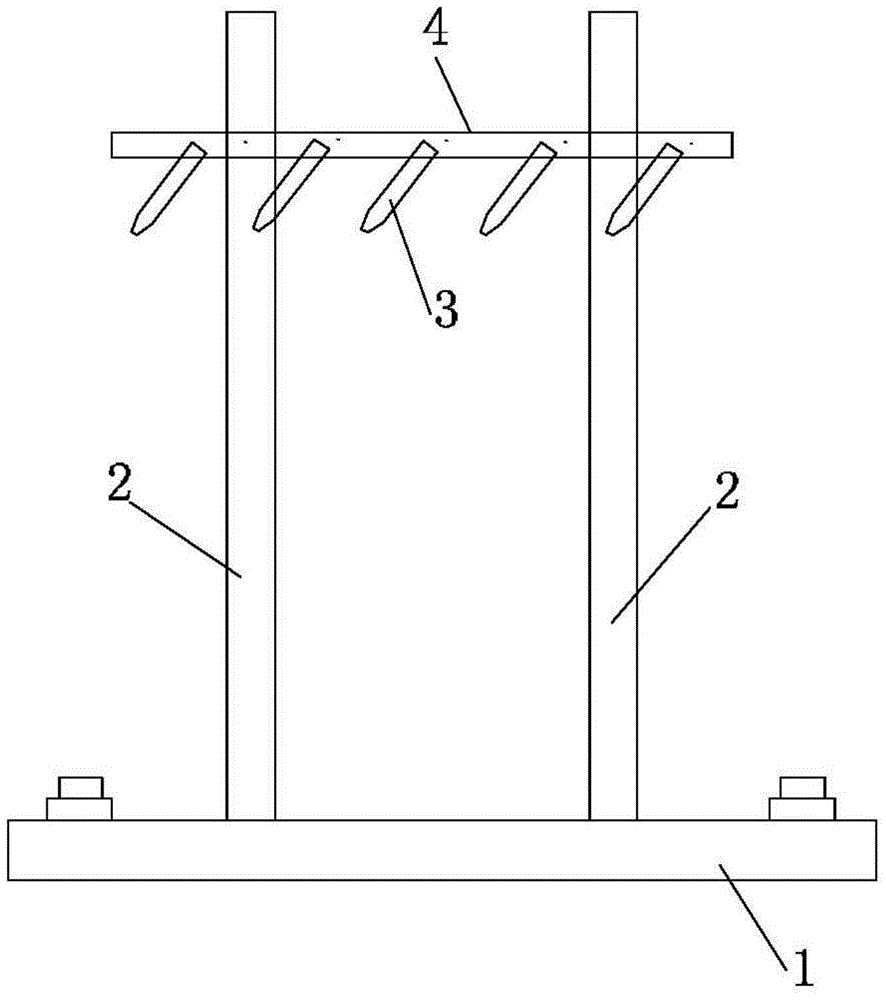

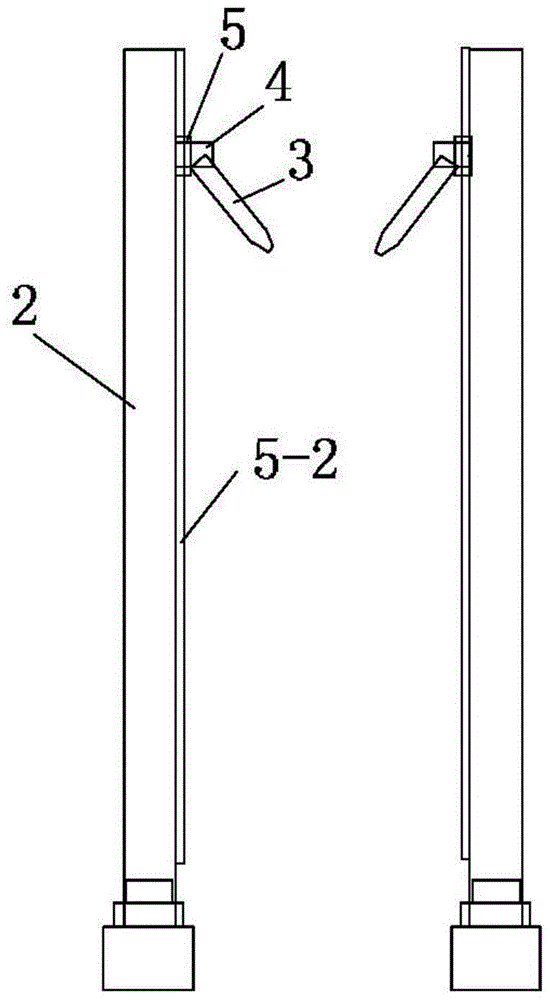

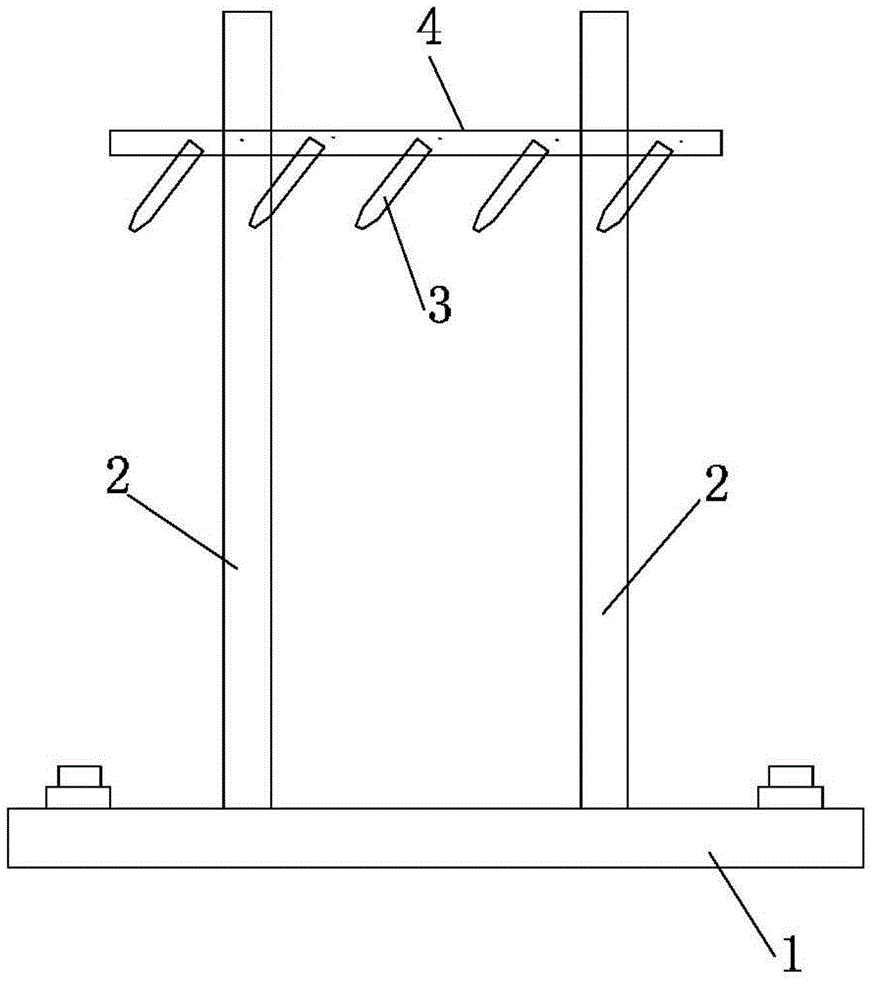

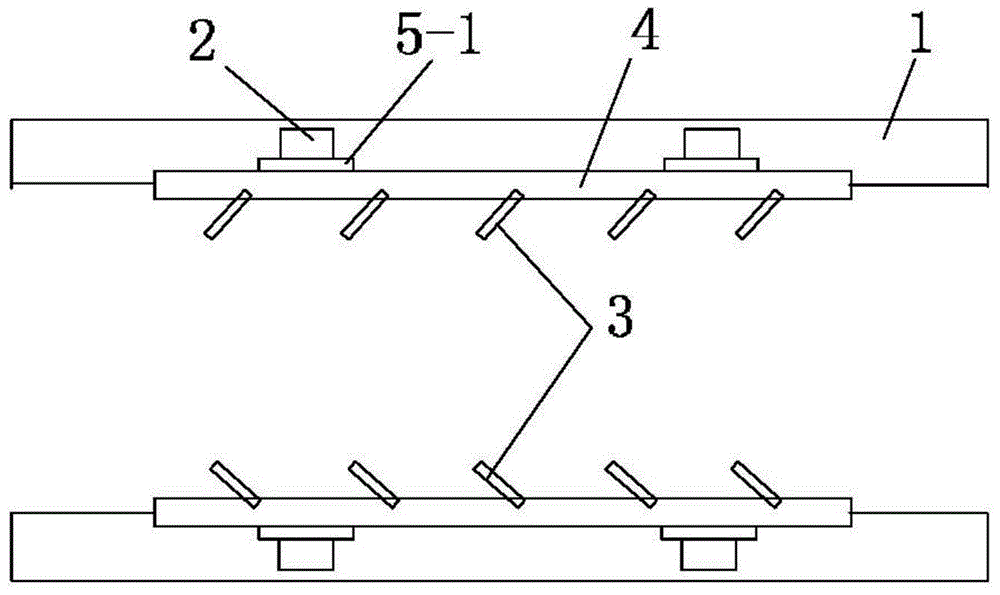

Water blowing method and water blowing device for electrophoretic coating

InactiveCN104562152BChange duty cycleRunning consistentElectrophoretic coatingsProduction lineElectrophoresis

The invention relates to a water blowing method and a water blowing device used for an electrophoretic coating production line. The invention aims at providing a method and a device which can complete water blowing operation before a coated part enters a drying oven to reduce the production cost and ensure the quality of the coated part. According to the technical scheme, an electrophoretic coating water blowing device comprises at least one water blowing mechanism, wherein each water blowing mechanism comprises a base, at least one pillar, at least one beam, a group of spraying nozzles, at least one cross sliding platform and a driving mechanism for the cross sliding platform; and the pillar is vertically fixed on the base, the beam is installed on the pillar through the cross sliding platform and arranged perpendicular to the pillar, a longitudinal sliding rail of the cross sliding platform is fixed on the pillar, a transverse sliding rail of the cross sliding platform is fixed on the beam, and the group of spraying nozzles is installed on the beam and arranged along the length direction of the beam. An electrophoretic coating water blowing method comprises the following steps: (1) air blowing: blowing off water on the surface of the coated part; and (2) air sweeping: blowing the water on the surface of the coated part completely until the coated part is dry.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Adhesive device for transparent packaging film

ActiveCN104443568BSolve the problem of lack of transparencyRunning at the same speedWrapper twisting/gatheringAdhesiveEngineering

The invention discloses an adhesion device for a transparent packaging film. An adhesion interface of the packaging film is smooth, the adhesion intensity is reliable and transparency is good. The adhesion device comprises a rack and a conveyor belt arranged on the rack. Barrier strips are arranged on the two sides of the conveyor belt and used for protecting packaging film folding lapping openings in the two ends of a packaging case and guiding and positioning the packaging case. The two sides of the conveyor belt are each vertically provided with first rotary iron, and the first rotary iron is used for adhesion of the packaging film folding lapping openings in the two ends of packaging case. Second rotary iron is horizontally arranged above the conveyor belt and used for adhesion of a long edge lapping opening of the packaging film of the packaging case. The first rotary iron and the second rotary iron are both driven by a motor. Local air left between two layers of films to be bonded as well as between multiple layers of films at the folding position when existing planar iron and a transparent film adhere integrally can be effectively eliminated, and the problem that adhesion of the film lapping opening is not firm and transparency is not high when air cannot be exhausted is solved.

Owner:CHINA TOBACCO YUNNAN IND

Electrophoretic coating water blowing method and water blowing device

InactiveCN104562152AChange duty cycleRunning consistentElectrophoretic coatingsSpray nozzleEnvironmental geology

The invention relates to a water blowing method and a water blowing device used for an electrophoretic coating production line. The invention aims at providing a method and a device which can complete water blowing operation before a coated part enters a drying oven to reduce the production cost and ensure the quality of the coated part. According to the technical scheme, an electrophoretic coating water blowing device comprises at least one water blowing mechanism, wherein each water blowing mechanism comprises a base, at least one pillar, at least one beam, a group of spraying nozzles, at least one cross sliding platform and a driving mechanism for the cross sliding platform; and the pillar is vertically fixed on the base, the beam is installed on the pillar through the cross sliding platform and arranged perpendicular to the pillar, a longitudinal sliding rail of the cross sliding platform is fixed on the pillar, a transverse sliding rail of the cross sliding platform is fixed on the beam, and the group of spraying nozzles is installed on the beam and arranged along the length direction of the beam. An electrophoretic coating water blowing method comprises the following steps: (1) air blowing: blowing off water on the surface of the coated part; and (2) air sweeping: blowing the water on the surface of the coated part completely until the coated part is dry.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

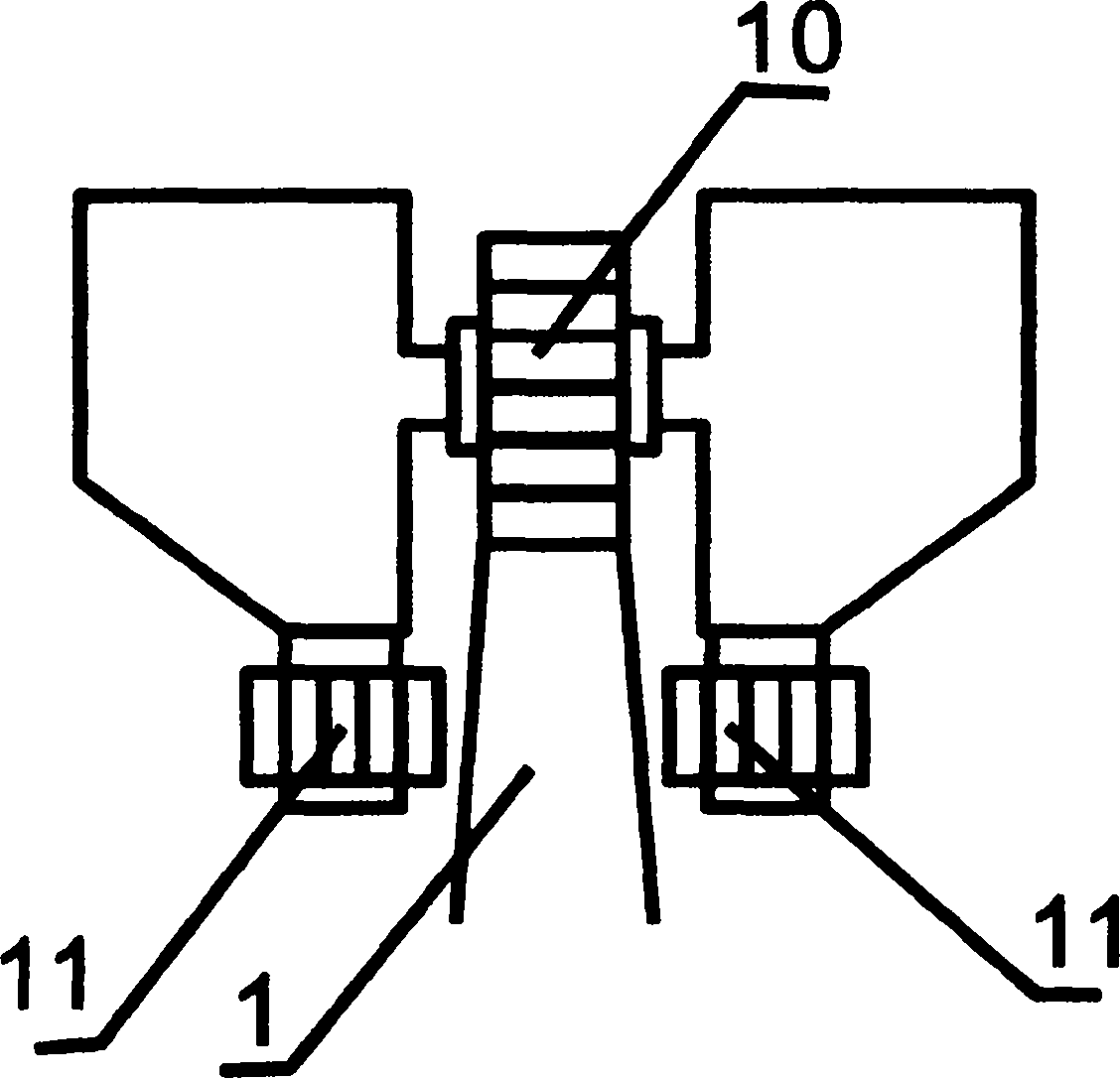

Vibrating direction angle adjustable two-mass vibrating feeder

The invention discloses a vibrating direction angle adjustable two-mass vibrating feeder which completely solves the problem that the vibrating direction angle of an existing two-mass vibrating feeder is permanent. At present, the vibrating direction angle of the existing vibrating feeder used in Chinese industries such as metallurgy and coal is permanent, feeding quantity is small and very uneven in the material conveying process, the maximum potential of the vibrating feeder cannot be made full use of, and particularly, the feeding quantity is affected due to different running speeds of materials at the front end and the rear end of a long vibrating feeder. The vibrating direction angle adjustable two-mass vibrating feeder comprises a vibrating tank, a thrust plate, a vibrator, a center pin and fixing bolts. The vibrator and the thrust plate are fastened together by the fixing bolts and accordingly are connected. When the vibrating direction angle of the vibrating feeder needs to be enlarged, the fixing bolts are loosened, the vibrator rotates clockwise by a certain angle, and then the fixing bolts are fastened. Conversely, when the vibrating direction angle needs to be decreased, a vibration exciter rotates anticlockwise by a certain angle, and then the fixing bolts are fastened.

Owner:鹤壁市煤化机械有限责任公司

Rear steel moving push plate of cogging mill

The invention discloses a rear steel moving push plate of a cogging mill, and the rear steel moving push plate is used for rolling large-size blanks by the cogging mill. Bends (2) are arranged at the two ends of a push plate (1); the bending direction of the bends (2) is opposite to a steel pushing direction. According to the technical scheme, the push plate is compact in structure, easy to arrange, high in driving force, easy to replace and maintain and resistant to wear due to unique structure; the rear push plate and a push machine have the same running speed and stable running and accurate speed and position control of the push plate are realized through coupling of the push plate and a push machine; the push plate is very suitable for blanks with increasing sizes and lengths; the big difficult problem of steel moving after the cogging mill is radically solved; more importantly, the manufacturing and mounting costs of the push plate are very low, so that the production cost is saved.

Owner:WUHU XINXING DUCTILE IRON PIPES

Adhesion device for transparent packaging film

ActiveCN104443568ASolve the problem of lack of transparencyRunning at the same speedWrapper twisting/gatheringEngineeringMultiple layer

The invention discloses an adhesion device for a transparent packaging film. An adhesion interface of the packaging film is smooth, the adhesion intensity is reliable and transparency is good. The adhesion device comprises a rack and a conveyor belt arranged on the rack. Barrier strips are arranged on the two sides of the conveyor belt and used for protecting packaging film folding lapping openings in the two ends of a packaging case and guiding and positioning the packaging case. The two sides of the conveyor belt are each vertically provided with first rotary iron, and the first rotary iron is used for adhesion of the packaging film folding lapping openings in the two ends of packaging case. Second rotary iron is horizontally arranged above the conveyor belt and used for adhesion of a long edge lapping opening of the packaging film of the packaging case. The first rotary iron and the second rotary iron are both driven by a motor. Local air left between two layers of films to be bonded as well as between multiple layers of films at the folding position when existing planar iron and a transparent film adhere integrally can be effectively eliminated, and the problem that adhesion of the film lapping opening is not firm and transparency is not high when air cannot be exhausted is solved.

Owner:CHINA TOBACCO YUNNAN IND

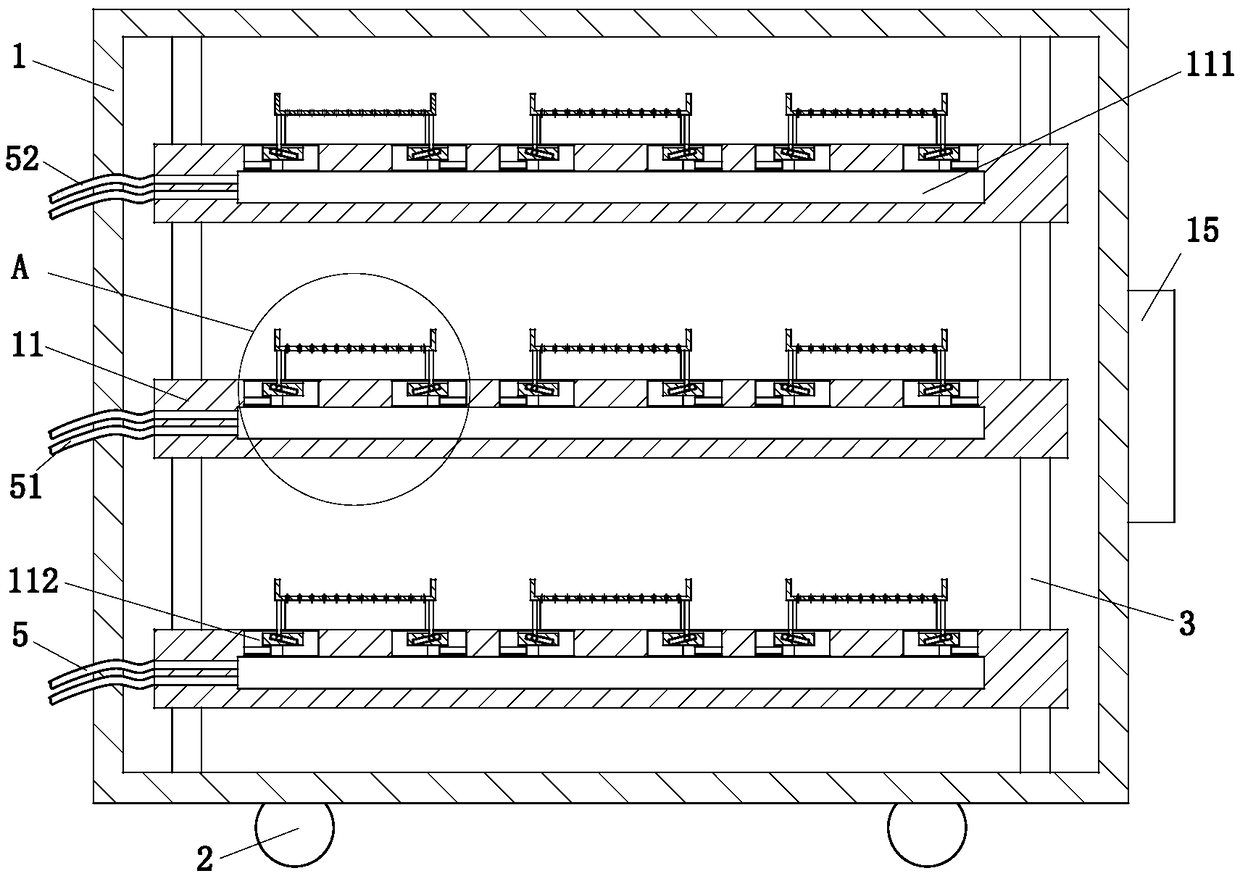

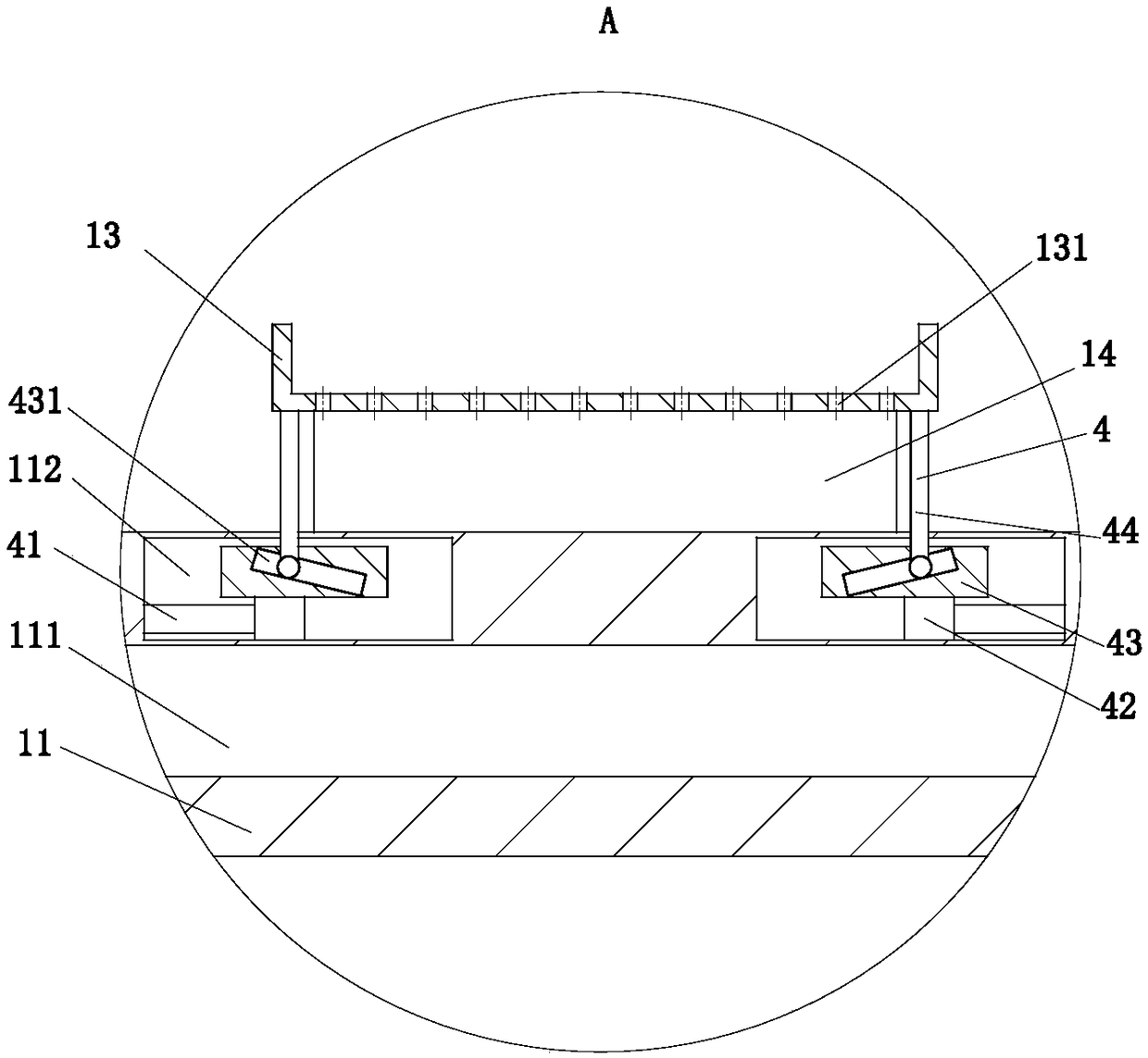

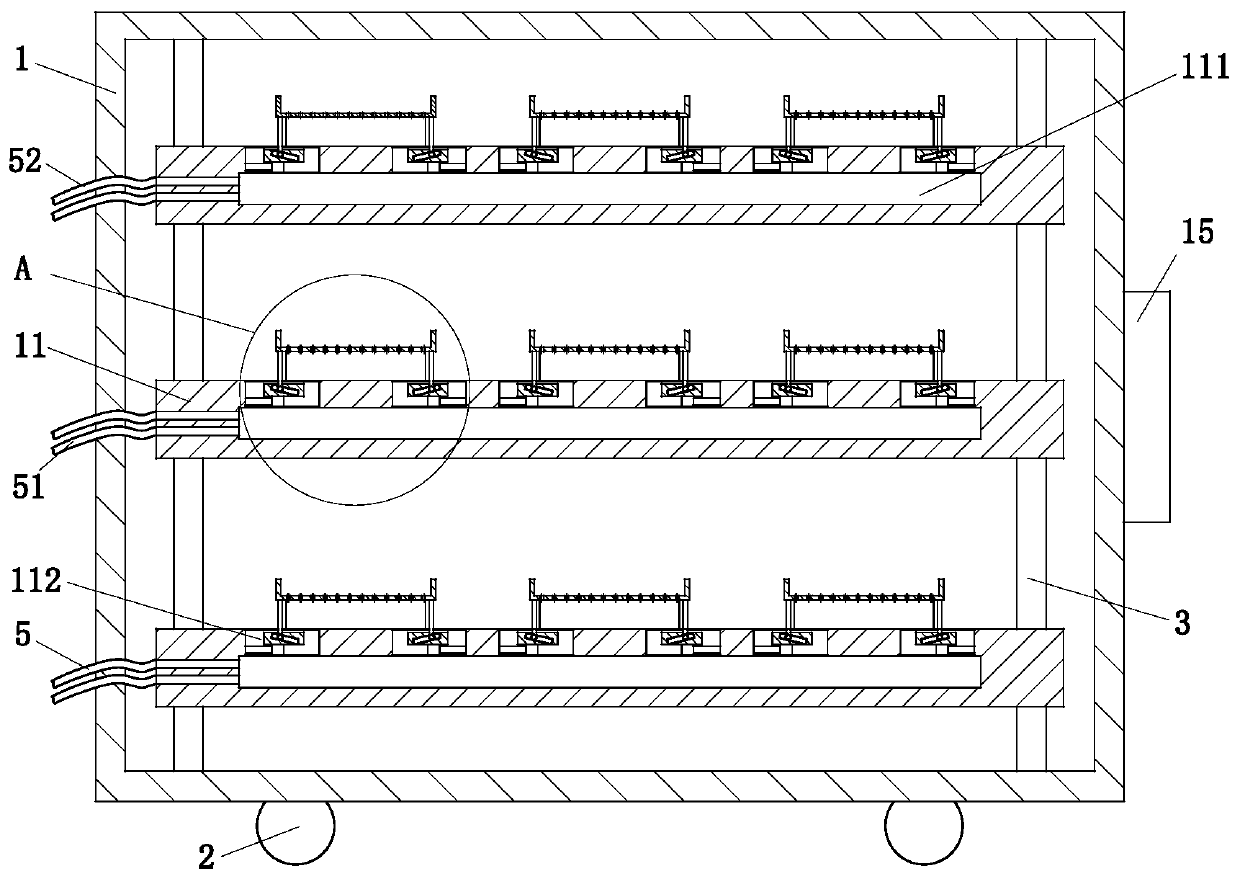

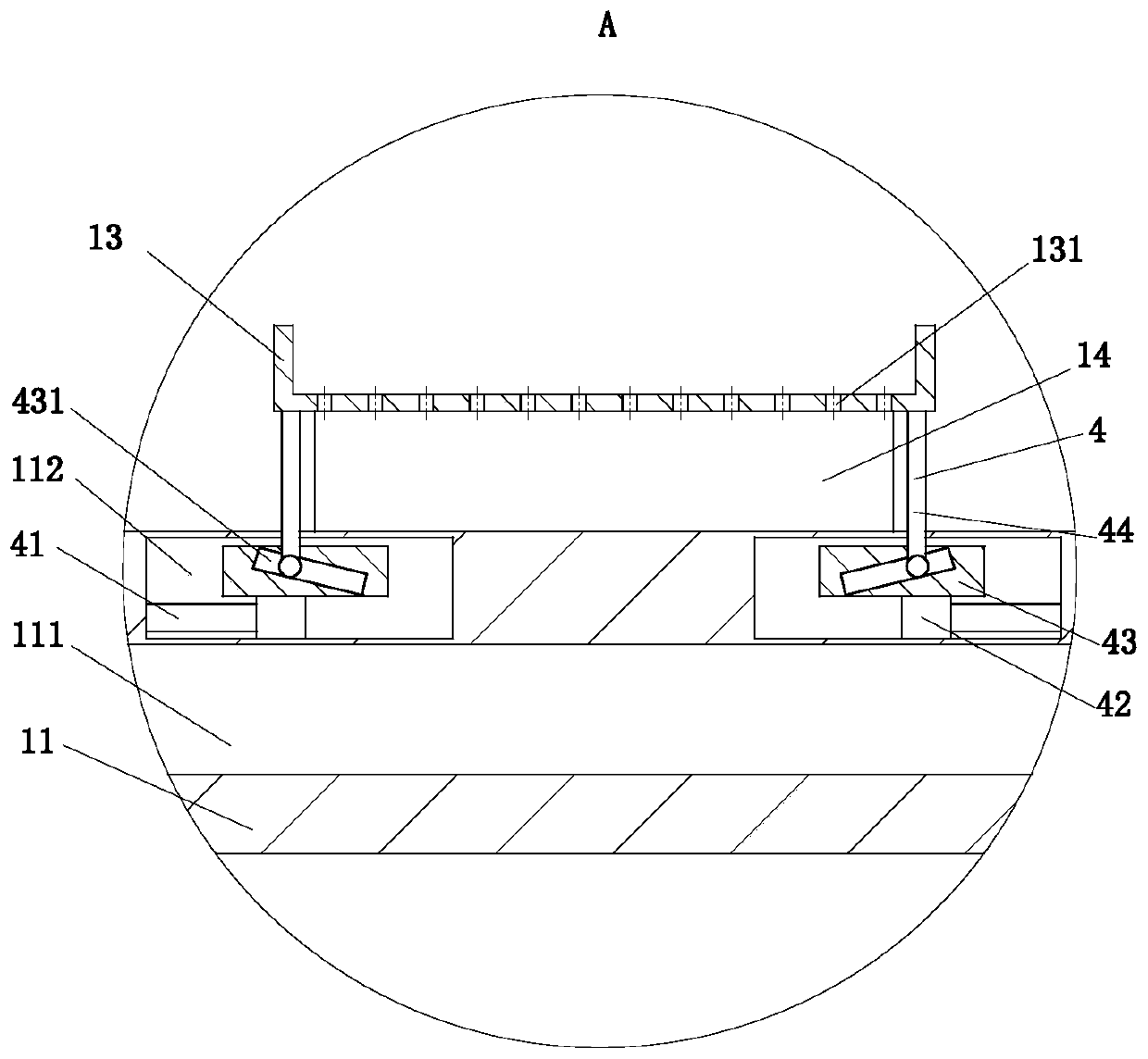

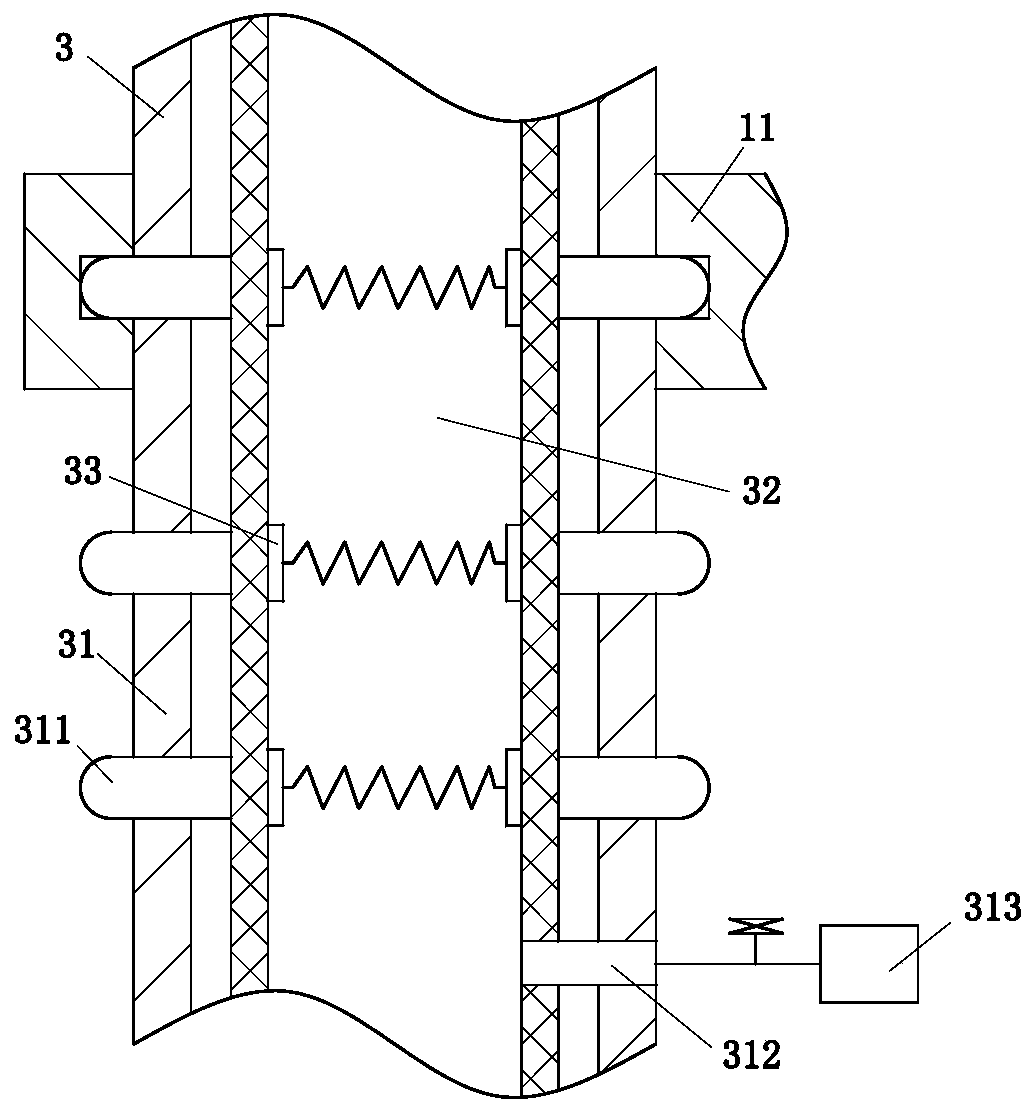

Automatic speed adjusting cultivation machine

ActiveCN108012916AIncrease the effective light-receiving areaPromote photosynthesisAgriculture gas emission reductionCultivating equipmentsAgricultural engineeringPhotosynthesis

The invention relates to the field of agricultural planting equipment, in particular to an automatic speed adjusting cultivation machine. The automatic speed adjusting cultivation machine includes a main support, a rail, conveying chains, a drive system, planting trays, a main controller and a movement recording system which is used for recording movement of the conveying chains; the movement recording system includes RFID labels and an electronic label reading and writing device which is used for reading movement of the RFID labels; the RFID labels are arranged on the planting trays; the electronic label reading and writing device is arranged on the main support frame; the electronic label reading and writing device is connected with the main controller. According to the automatic speed adjusting cultivation machine, through a stereoscopic frame, the illuminated degrees of plants are improved, photosynthesis is accelerated, the plants grow better by controlling the operation speed ofthe stereoscopic cultivation machine, and therefore more good-quality products are obtained.

Owner:XINGGUANG AGRI MACHINERY

Diamond wire cutting equipment for water treatment membrane element

PendingCN114227499ARealize the purpose of automatic cuttingHigh degree of automationGrinding carriagesGrinding drivesFixed bedWire cutting

The invention discloses a water treatment membrane element diamond wire cutting device which comprises a man-machine interaction system, and the man-machine interaction system comprises an electric cabinet, an intelligent touch screen device, a diamond wire winding and unwinding system, a sliding rail moving system, a membrane element fixing mechanism, a fixed bed, a rack and an air cooling scrap removing mechanism. The sliding rail moving system is arranged on the fixed bed, the membrane element fixing mechanism is installed on the sliding rail moving system, the diamond wire winding and unwinding system is arranged on the machine frame, and the air cooling scrap removing mechanism is arranged in the machine frame. The cutting efficiency is higher, the cutting face is smooth and flat, cutting chippings and burrs of the cutting face are avoided, the film aperture ratio is high, the equipment cost is low, multi-head and multi-line simultaneous cutting can be achieved through expansion, the cutting efficiency can be multiplied according to the number of expanded line ends, and the production cost can be greatly reduced.

Owner:HUZHOU INST OF ZHEJIANG UNIV

Advertising board device and advertising communication method

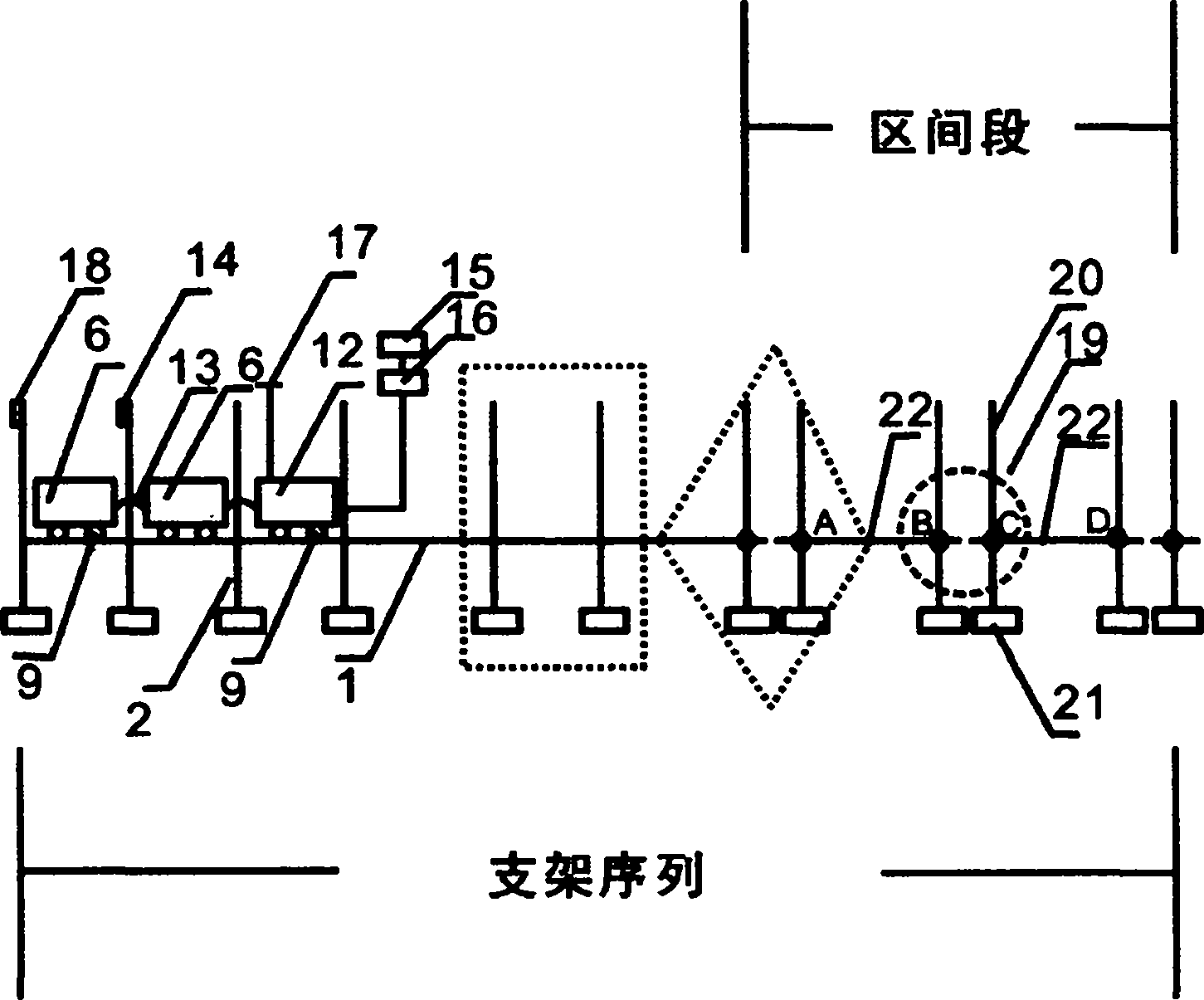

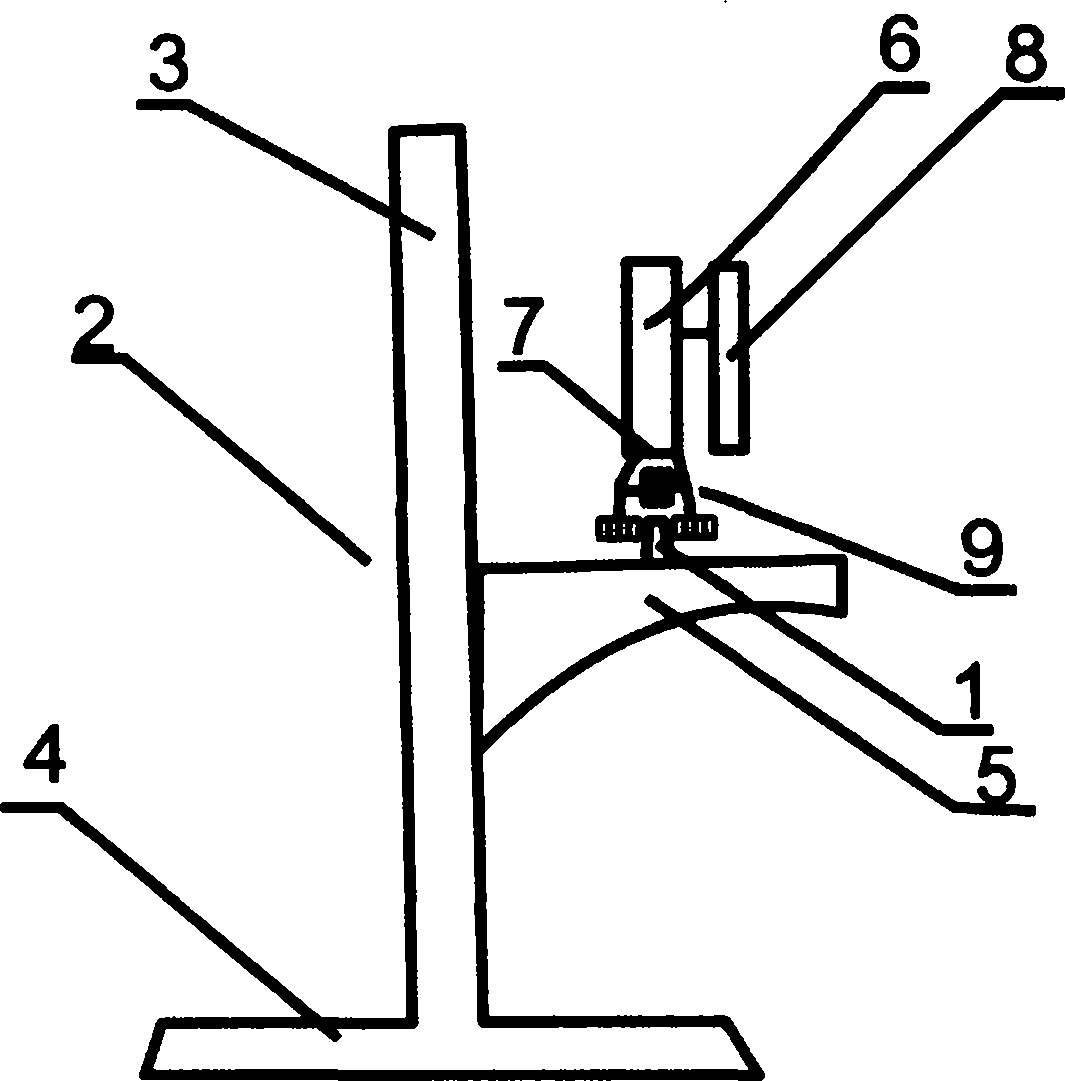

InactiveCN104112412AFast driveRunning at the same speedMobile visual advertisingBoardsTraction systemFixed frame

The invention discloses an advertising board device for enabling passengers sitting in vehicles running at high speeds to clearly see the contents of an advertisement in an advertising board close to a road. The advertising board device comprises vehicle bodies, a fixing frame provided with an advertising board, a rail, supports and a power traction system, wherein the fixing frame provided with the advertising board is connected with the vehicle bodies, and the supports are adjacently arranged at an interval in pairs; the support is provided with a base and support columns, and the bases of the supports are fixedly connected with the ground, and adjacently arranged at an interval in pairs, so as to form a support sequence; support frames are arranged on the support columns of the support, and are fixedly connected with the rail; side wheels are arranged at the edges of the vehicle bodies, and side wheels are arranged at the edge of the power traction system; the power traction system and at least one vehicle body connected with the fixing frame provided with the advertising board are arranged on the rail, and the vehicle body and the power traction system are in rolling connection with the rail through the side wheels; the vehicle body and the power traction system which are arranged on the rail are connected through pull hooks, and a plurality of the vehicle bodies are connected through pull hooks. The power traction system is used for driving the upper side wheels and the lower side wheels to roll on two rails respectively through the driving of a power drive mechanism, and drive the fixing frame to move through the pull hooks.

Owner:刘东升

Assistance mechanism for bottom seaming machine of woven bag

InactiveCN102644168BEasy to adjust pressureQuality improvementWork-feeding meansSewing-machine control devicesProduction lineEconomic benefits

The invention discloses an assistance mechanism for a bottom seaming machine of a woven bag, comprising a stander, wherein a first ring-shaped conveyor belt is arranged on the stander, the stander is provided with an edge coiling device at the outer side of the first conveyor belt, the stander is provided with a synchronous conveying mechanism at the lower side of the edge coiling device, the conveying speed and the conveying direction of the synchronous conveying mechanism are matched with those of the first conveyor belt. The assistance mechanism has the beneficial effects that the conveying speed lost by coiling the edge at the bottom of the woven bag is effectively compensated, so that the woven bag is tidy in edge coiling, and good in sewing quality, the wrinkles can be avoided when the woven bag is conveyed, the sewing speed of the bottom seaming machine can be improved in multiples, and the original quality bottleneck of the woven bag can be broken through, so that about sixty woven bags can be seamed pre minute; and the bottom seaming machine is smooth to run, so that the number of the production line operator can be reduced from four to one, therefore, the assistance mechanism has considerable economic benefit in the current market that the labor cost is constantly improved.

Owner:WENZHOU NINGTAI MACHINERY

Cashmere full-automatic bagging machine

PendingCN107934038ASimple mechanical structureReduce manufacturing costPackagingFailure rateCentral belt

The invention discloses a cashmere full-automatic bagging machine which comprises a rack, a conveying device, a compaction device and an opening device. The conveying device comprises a conveying drive mechanism, a conveying belt A and a conveying belt B. The conveying belt A is composed of a lower horizontal conveying segment, a middle vertical conveying segment and an upper horizontal conveyingsegment. The conveying belt B is composed of a middle vertical conveying segment and an upper horizontal conveying segment. The conveying belt A and the conveying belt B are each supported and drivenby multiple roll wheels. A cashmere collection hopper is arranged on the lower horizontal conveying segment of the conveying belt A. The opening device is arranged on the lower sides of the ends of the upper horizontal conveying segments of the conveying belt A and the conveying belt B, and the compaction device is arranged on the upper portion of the opening device. The cashmere full-automatic bagging machine is simple in structure, low in manufacturing cost, low in failure rate and convenient to use and operate, and cashmere cannot fall off.

Owner:赤峰圣伦绒毛制品有限公司

Soft plastic forming packaging machine and using method thereof

PendingCN113619073AGuaranteed efficiencyRunning at the same speedPackagingBlow moldingMolding machine

The invention discloses a soft plastic forming packaging machine and a using method thereof. The soft plastic forming packaging machine comprises a conveying mechanism, a packaging mechanism and a forming mechanism, the packaging mechanism and the forming mechanism are arranged near the conveying mechanism, the conveying mechanism comprises a conveying belt formed by splicing a plurality of conveying rollers and a clamping device arranged at the tail end of a conveying path of the conveying belt, and the forming mechanism, the packaging mechanism and the clamping device are sequentially arranged on the conveying path of the conveying belt; the forming mechanism comprises a plurality of mold cavities and blow molding openings in one-to-one correspondence with the mold cavities, and the conveying belt is tightly attached to the forming mechanism; the packaging mechanism is arranged in the middle of the conveying path of the conveying belt, the packaging mechanism comprises a packaging material roller and a discharging plate, and the packaging material roller and the discharging plate are correspondingly arranged; and the clamping device comprises a multi-shaft manipulator and a branch belt corresponding to the position of the multi-shaft manipulator. According to the machine, flexible plastic forming and packaging integrated operation can be achieved, the flexible plastic backing material deformed in the packaging process can be repaired, and the output quantity and quality are ensured.

Owner:江苏爱舍伦医疗科技集团股份有限公司

Solar cell buffer layer preparation device

PendingCN111244225AGuaranteed uniformityLittle change in concentrationFinal product manufacturePhotovoltaic energy generationSolar cellDeposition process

The invention relates to the technical field of solar cells, in particular to a solar cell buffer layer preparation device which comprises a liquid medicine supply device, a liquid medicine supplementing device, a cleaning device and a drying device which are sequentially arranged in the moving direction of a substrate material. The liquid medicine sprayed on the substrate material is deposited into a buffer layer material through a deposition system, and then passes through a cleaning and drying system and is rolled; through the additionally-arranged liquid medicine supplementing device, liquid medicine is continuously sprayed to the substrate layer in the buffer layer deposition process, and the situation that in the deposition process, due to solution volatilization, the solution concentration changes, and consequently the buffer layer film thickness deposition nonuniformity is caused is reduced; and the deposited buffer layer material is uniform.

Owner:鸿翌科技有限公司

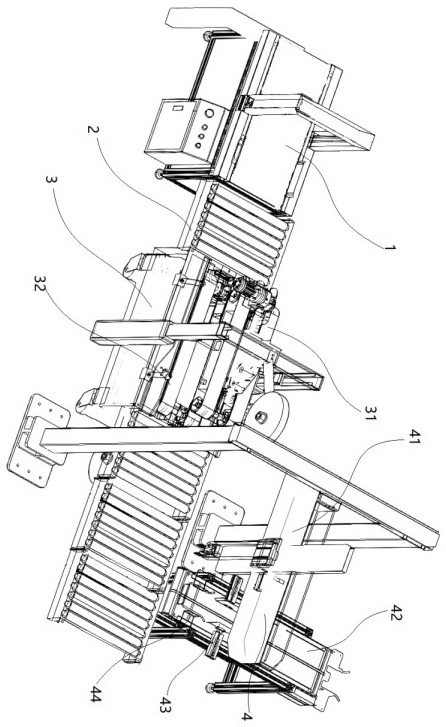

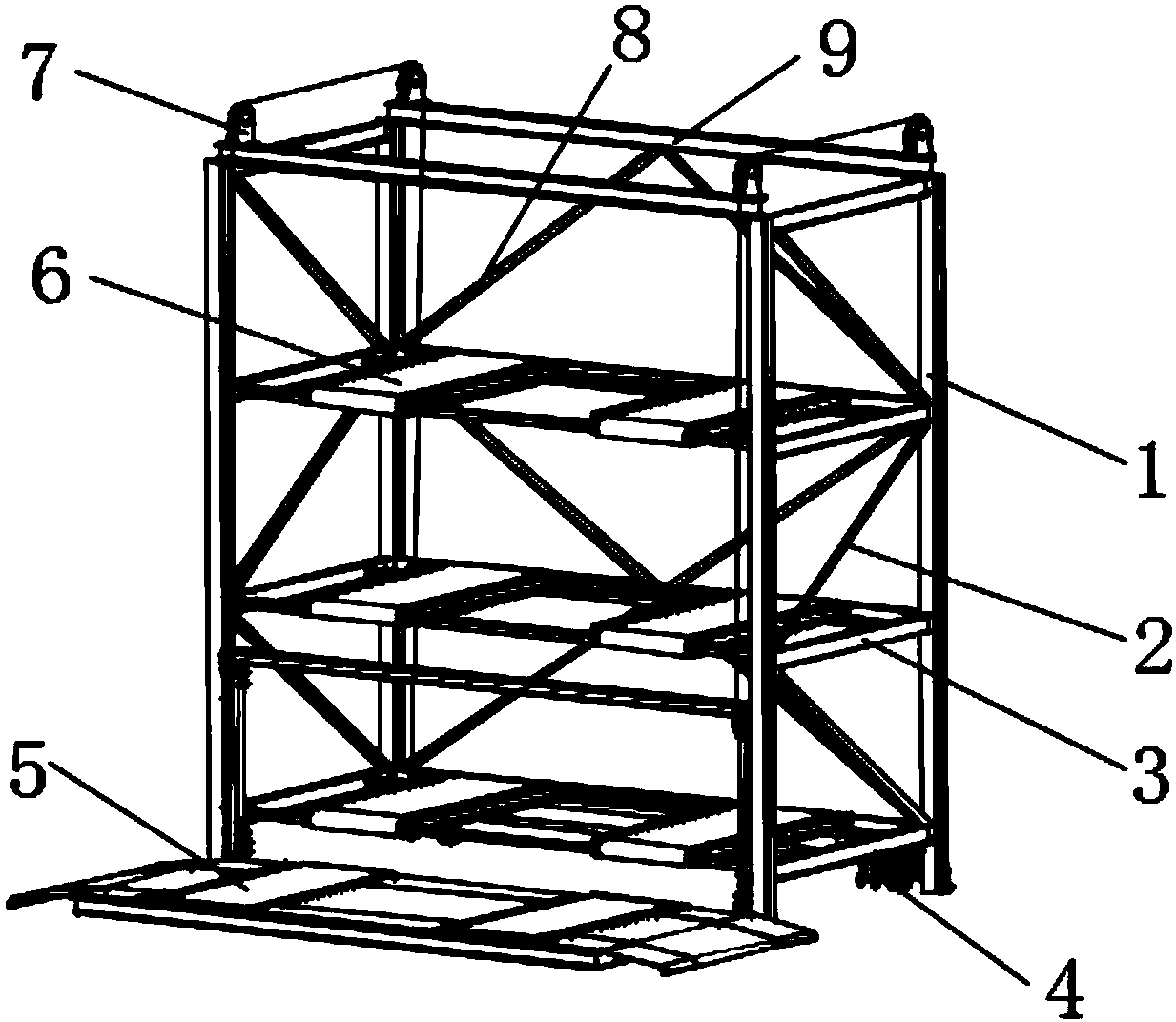

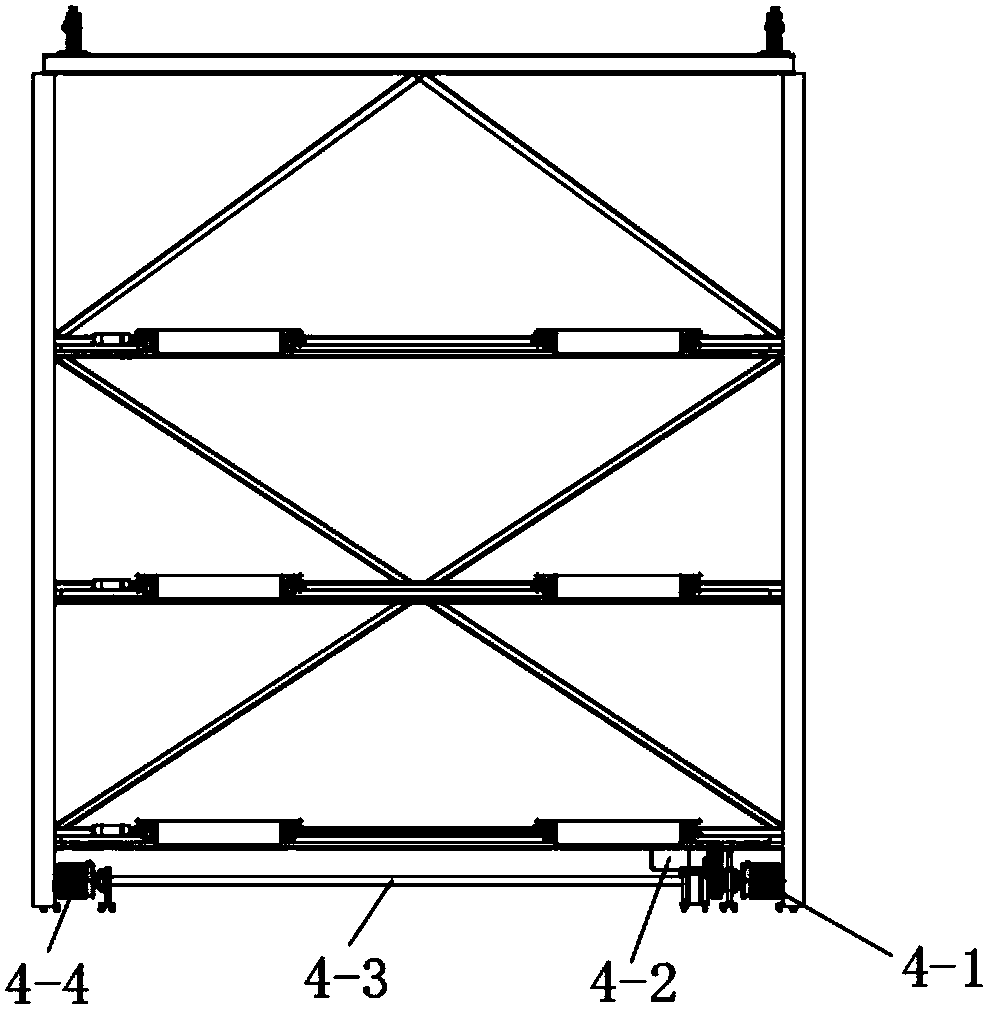

Conveyer belt type three-dimensional parking and picking-up device

The invention belongs to the field of three-dimensional parking equipment, and particularly relates to a conveyer belt type three-dimensional parking and picking-up device. Guide rails for lifting ofa lifting mechanism are arranged on the inner sides of two front stand columns, a supporting guide wheel is arranged on a top longitudinal beam, one end of a steel wire rope is connected with a lifting mechanism, the other end of the steel wire rope is connected with a lifting transmission mechanism through bypassing the supporting guide wheel, the lifting transmission mechanism is arranged on therear side of the conveyer belt type three-dimensional parking and picking-up device, each of the lifting mechanism and a parking platform consists of two conveyor belt roller devices, the conveyor belt roller device of the lifting mechanism and the conveyor belt roller device of the parking platform are arranged oppositely. The invention provides a conveyer belt type three-dimensional parking andpicking-up device which can park and pick up cars conveniently and rapidly, is simple in structure, small in occupied area, high in space utilization rate, high in intelligentization degree, energy-saving, steady and reliable to run, fast in parking and picking-up speed, high in efficiency and capable of solving the city side parking difficulty.

Owner:天津知时捷科技发展有限公司

Material sorting robot

PendingCN114082681ARunning at the same speedReduce cloggingBatteries circuit arrangementsElectric powerElectric machineryStructural engineering

The material sorting robot comprises a shell, a weight sliding groove with an upward opening is formed in the upper end face of the shell, a lifting rod is slidably arranged in the weight sliding groove, and a weight spring is fixedly arranged between the lower end face of the lifting rod and the bottom face of the weight sliding groove; the weight of the express is detected, then the output power of the motor is adjusted, the express with different weights can be kept at the consistent running speed, the possibility of blockage is reduced, dangerous goods in the express can be detected through the dangerous goods detector arranged in the storage tray, workers can be informed, and the work efficiency is improved. The two pairs of walking wheels are used for achieving non-turning-radius movement of the device so as to reduce the requirement for the width of the channel, in addition, the electromagnetic induction principle is used, in the moving process of the device, the device can be charged while moving, the independent charging time is saved, and the sorting efficiency is improved.

Owner:郭兰

An intelligent rail vehicle automatic catering car

ActiveCN108839605BImprove freshnessImprove drinking tasteWorkshop/display transportationCold airCool storage

Owner:宿州迅驰电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com