Patents

Literature

229results about How to "Easy to adjust pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

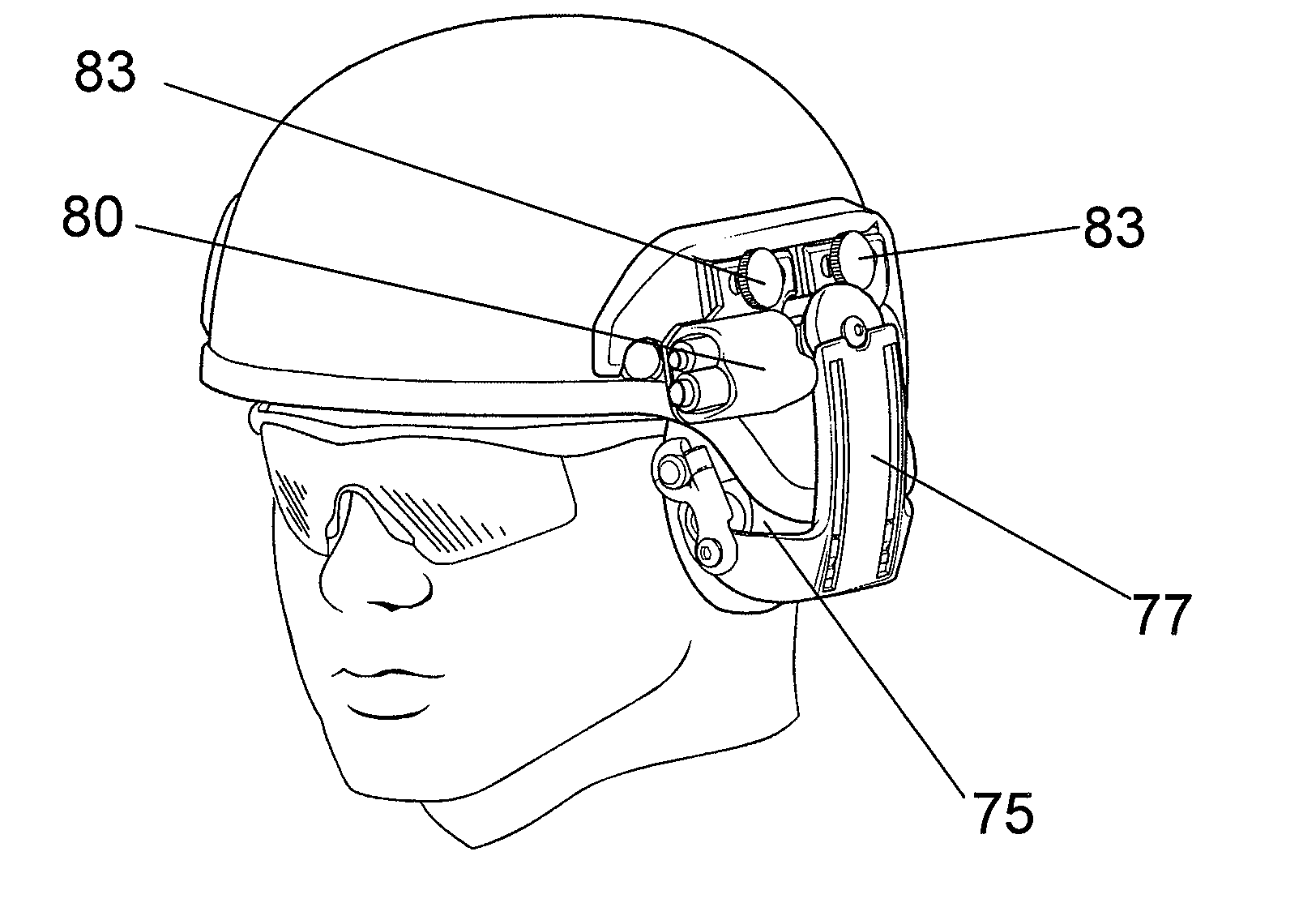

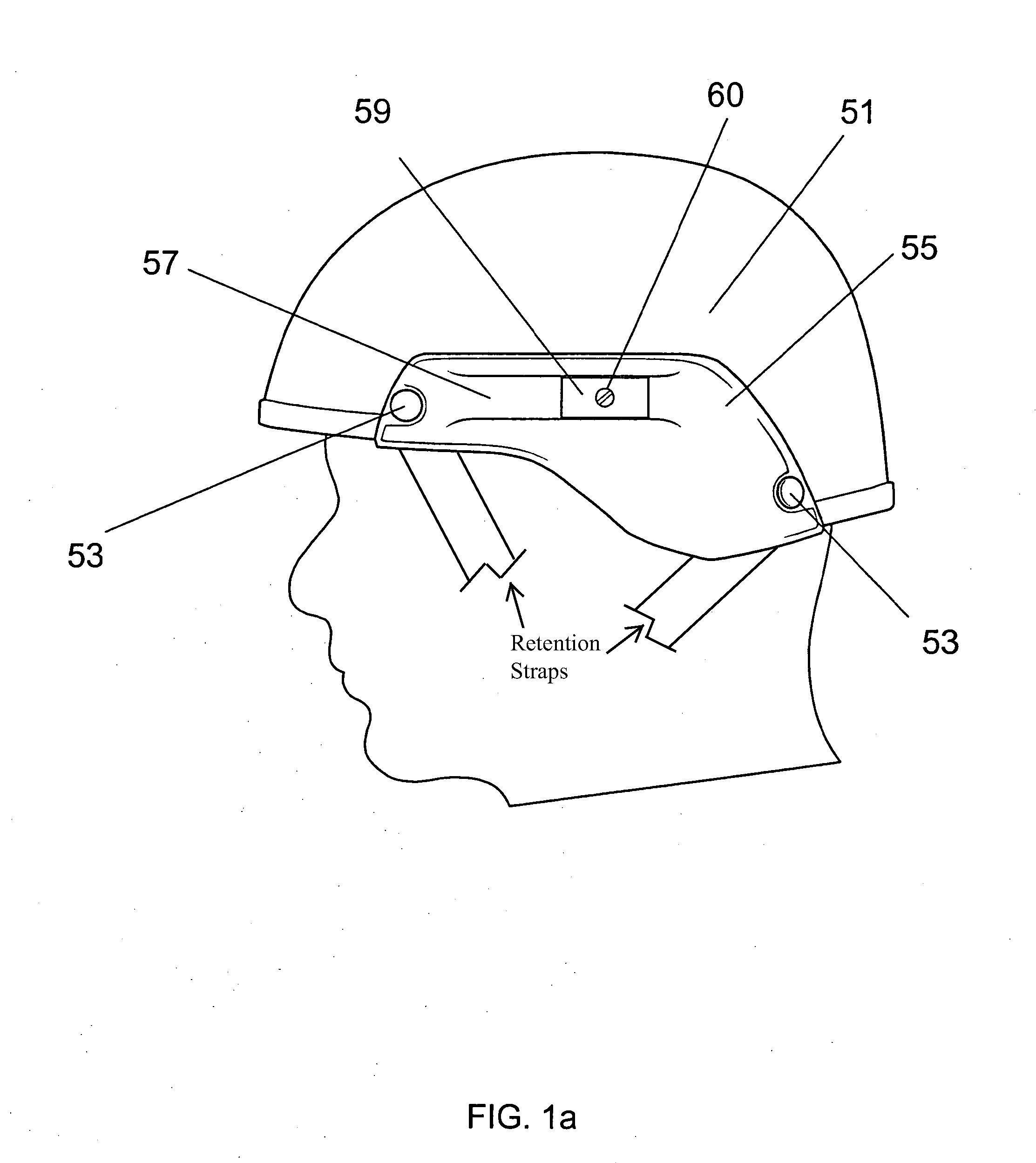

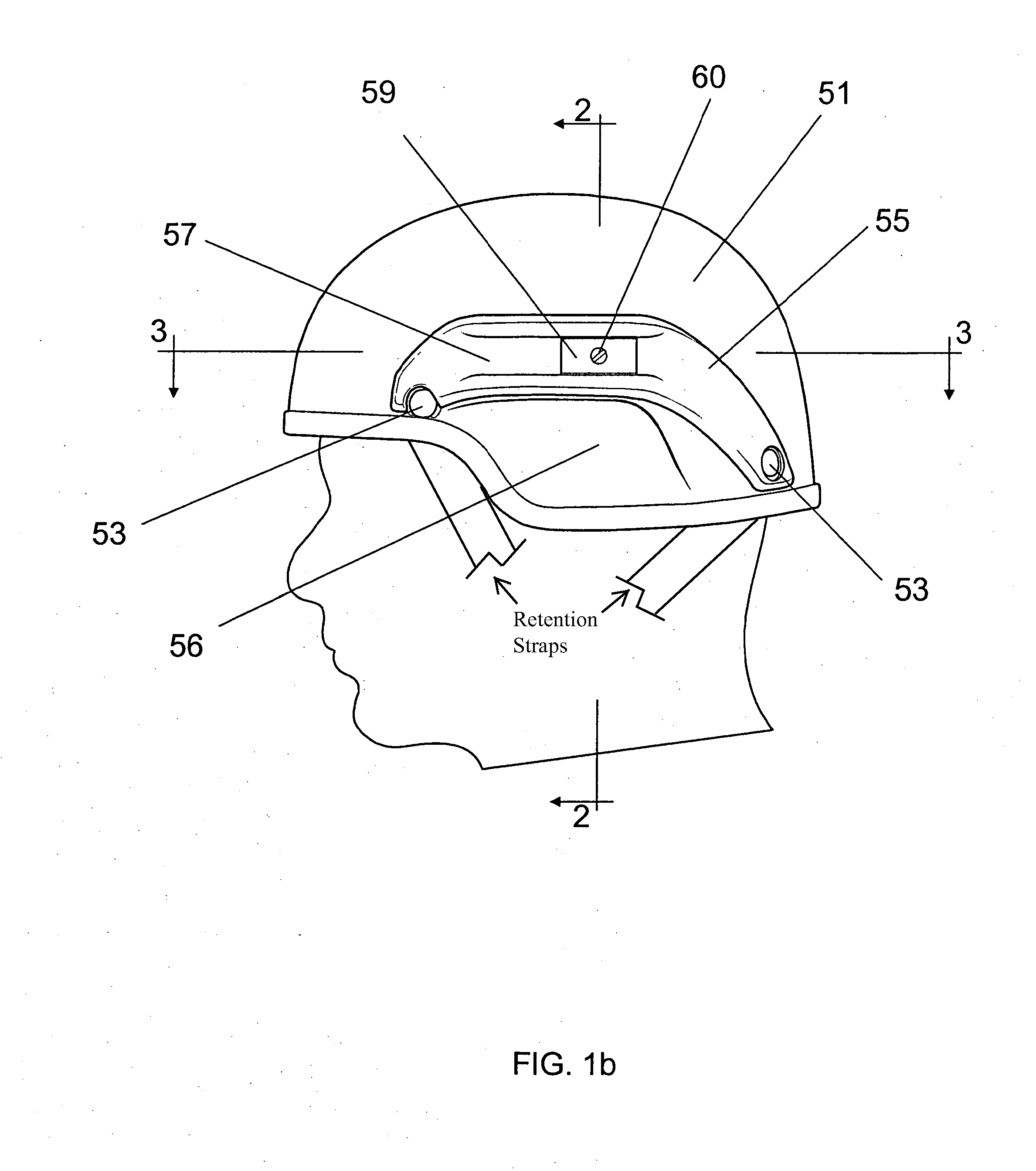

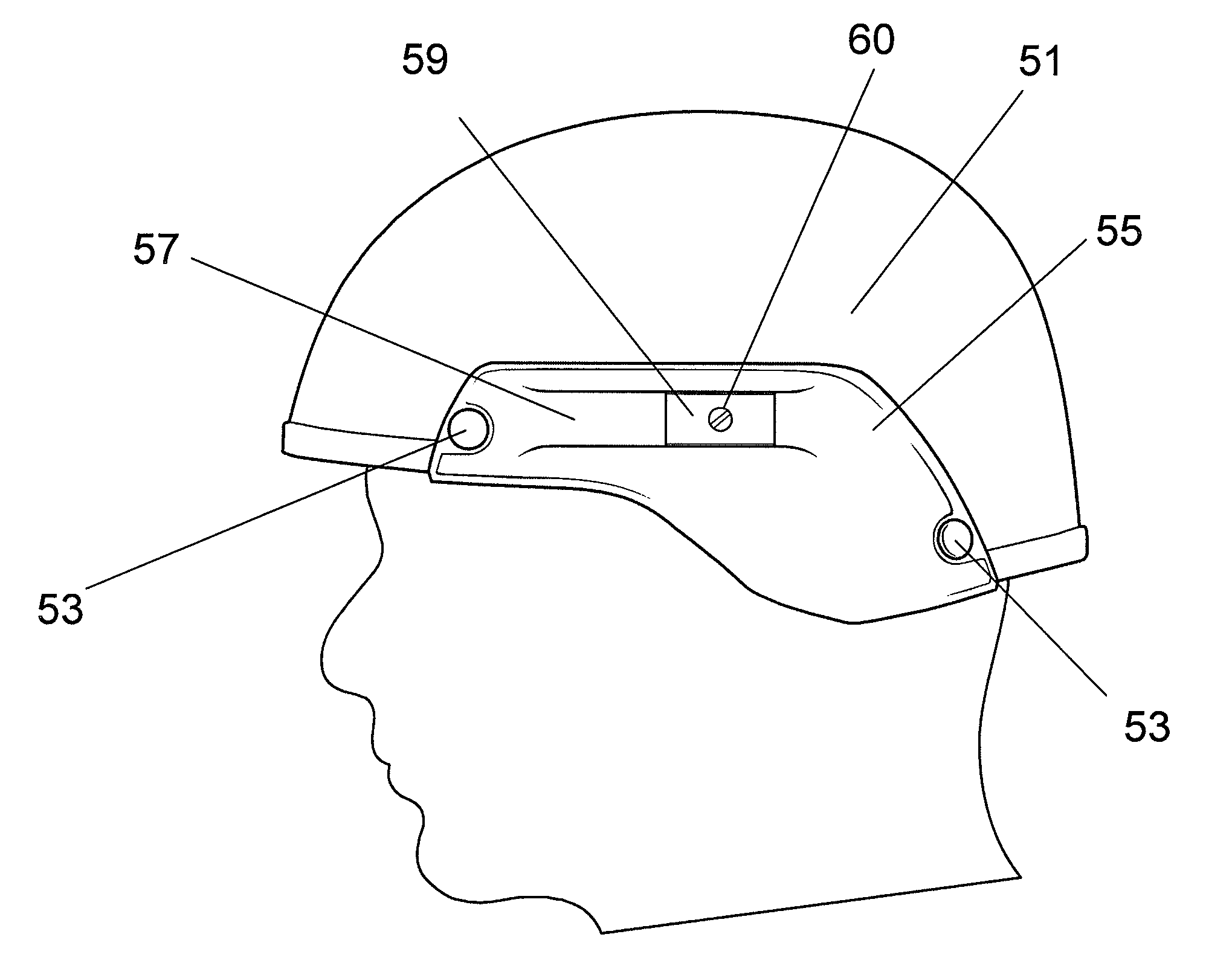

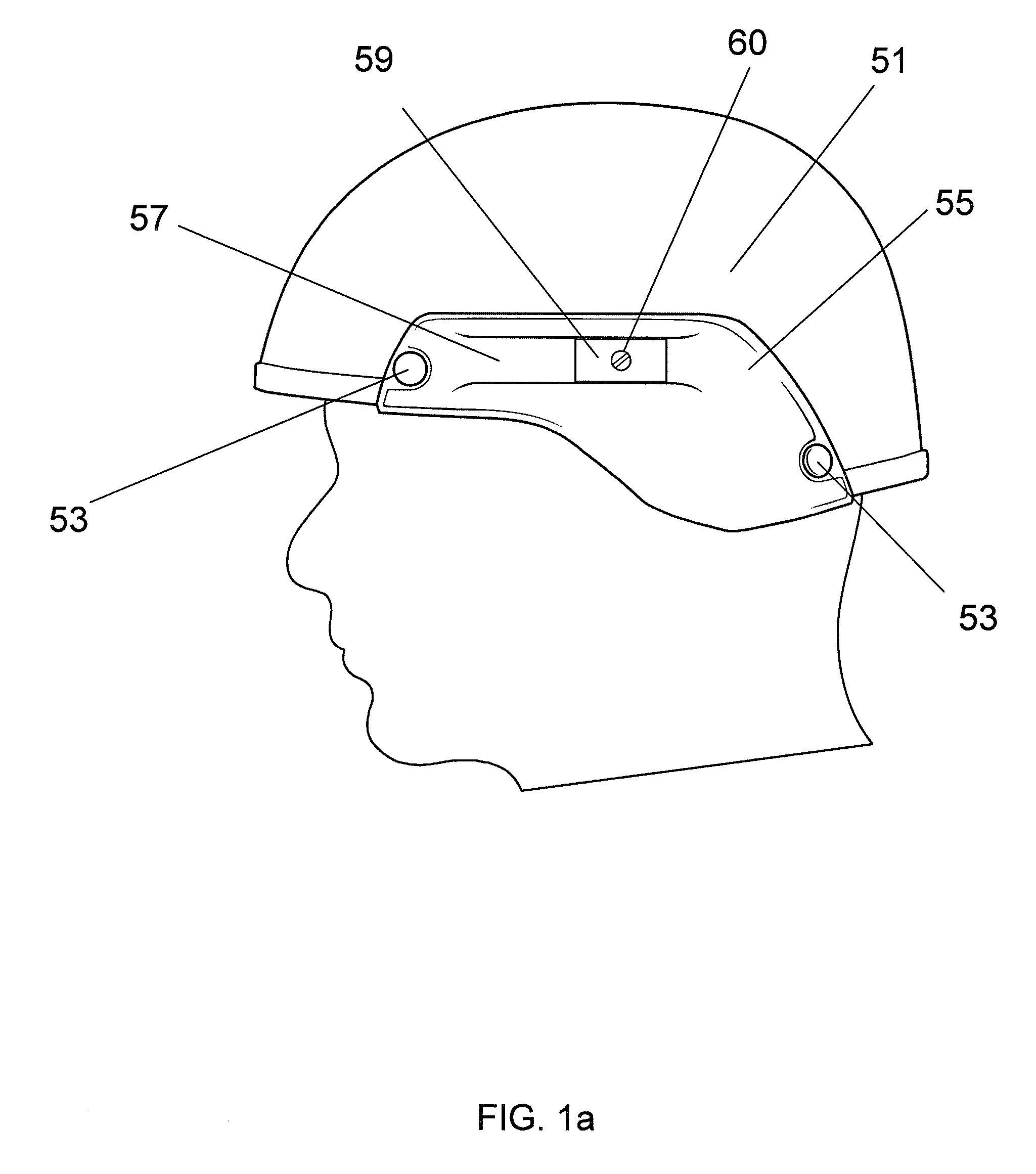

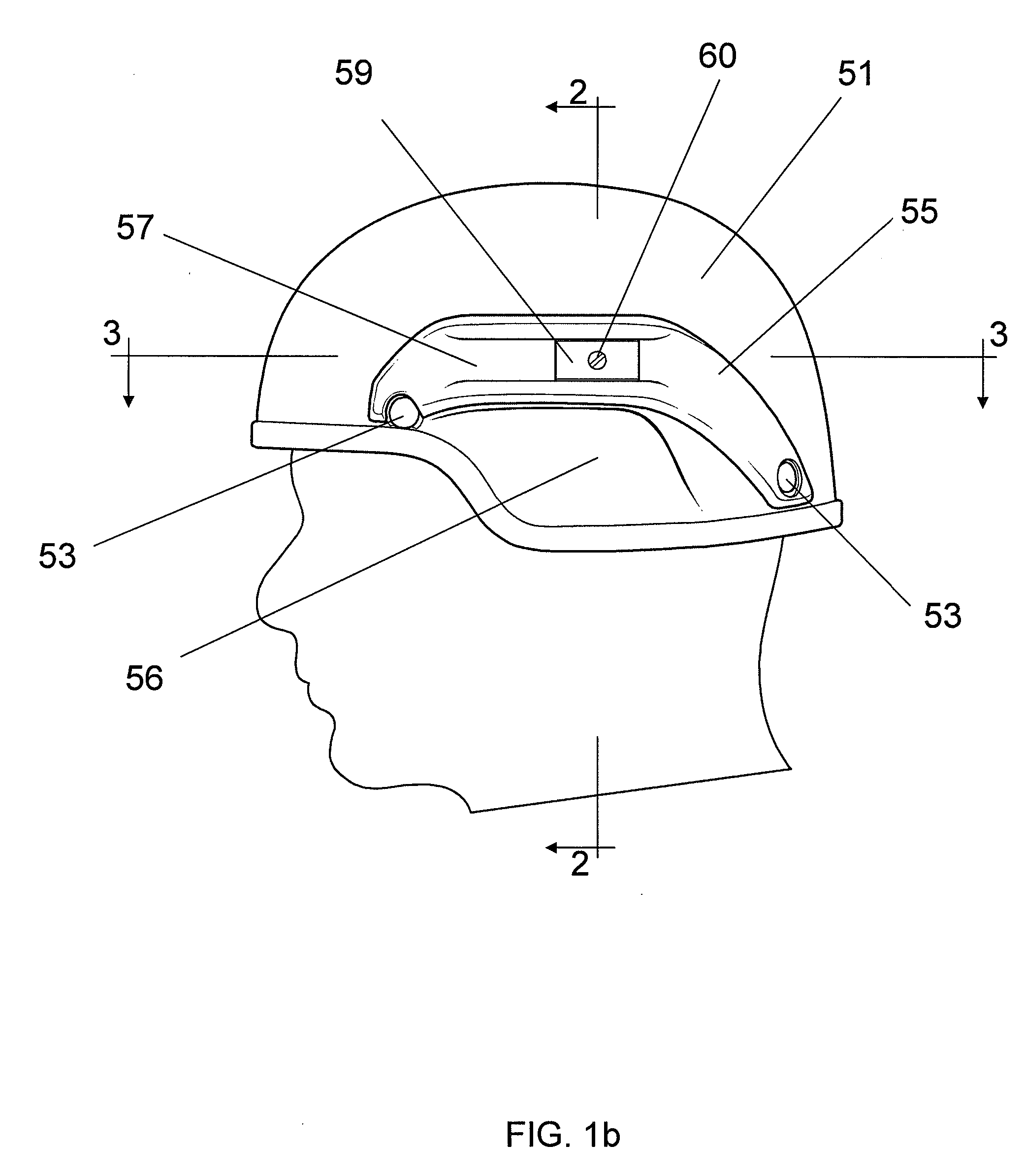

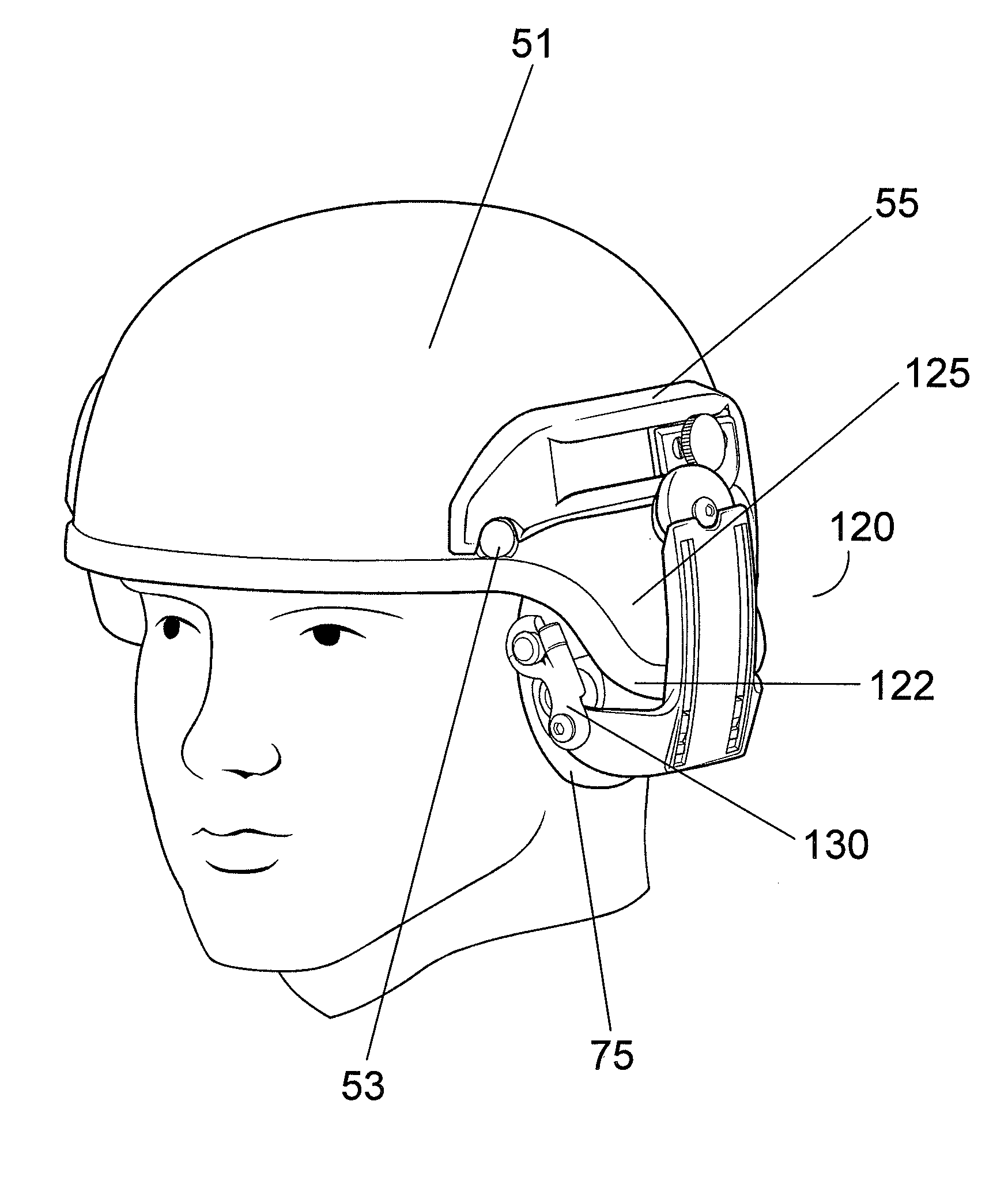

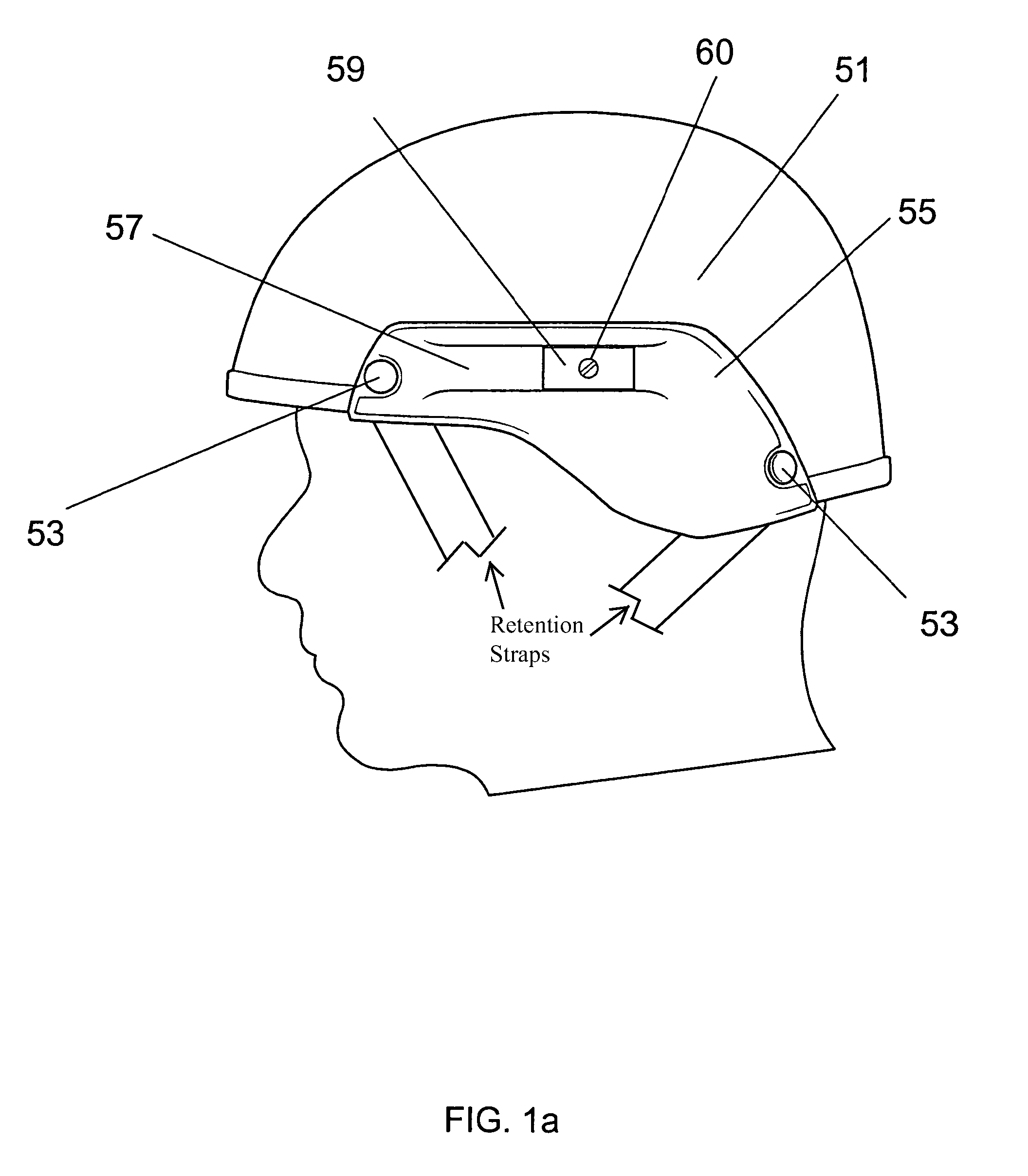

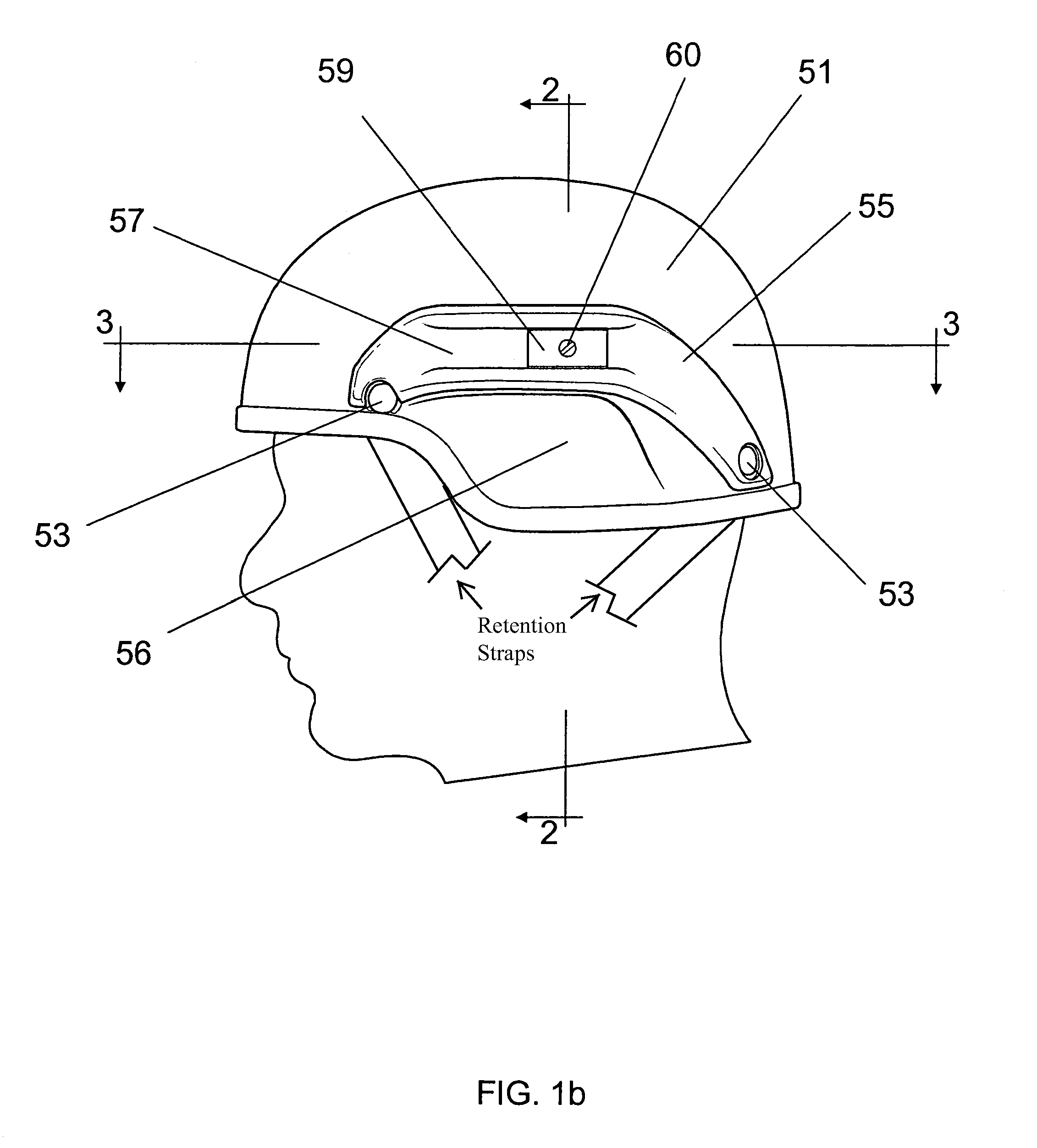

Hinged Attachment of Headgear to a Helmet

ActiveUS20110314594A1Facilitate insertionHelp positioningHatsTelescopesMechanical engineeringPhysical medicine and rehabilitation

Owner:GENTEX CORP

Hinged Attachment of Headgear to a Helmet

Owner:GENTEX CORP

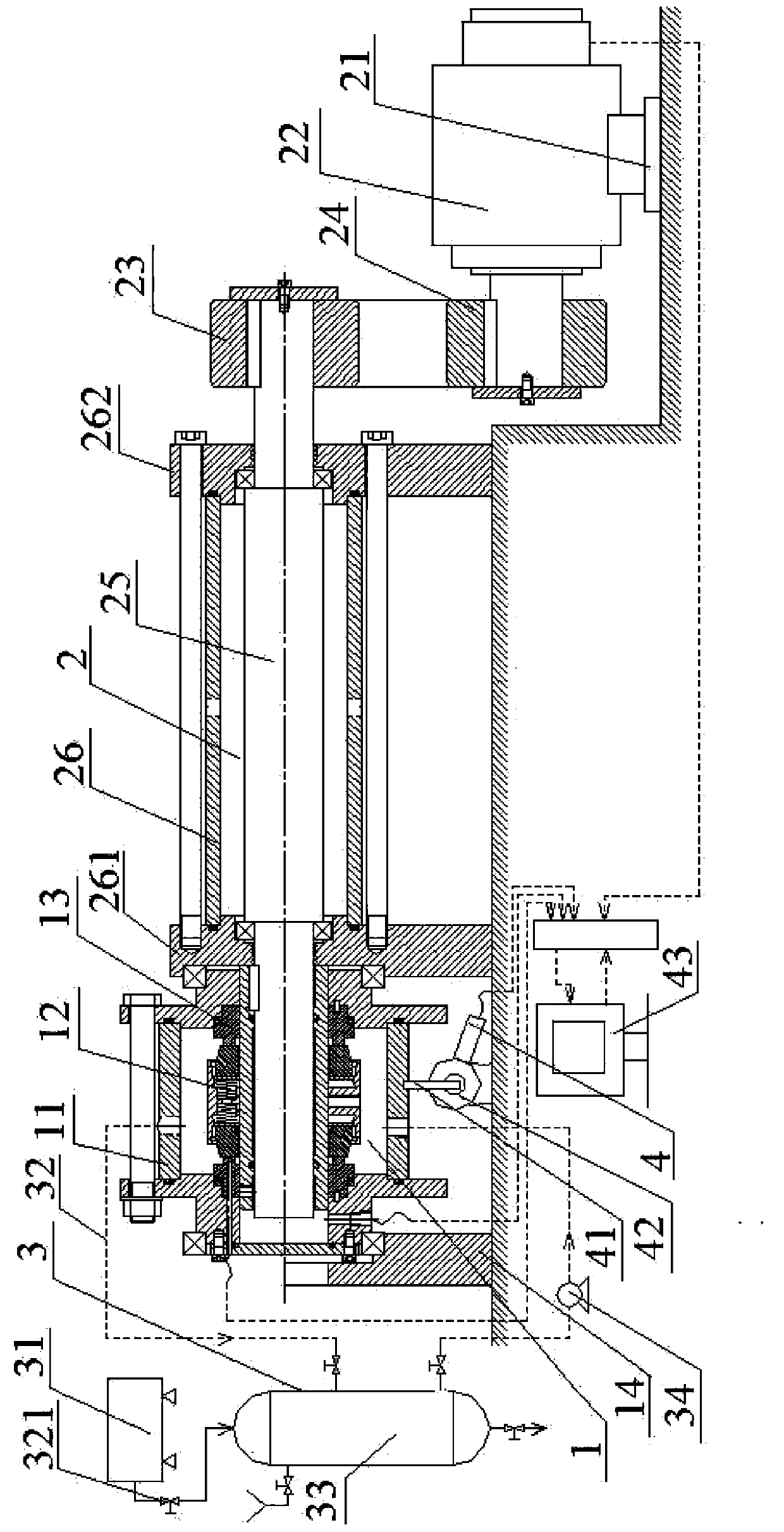

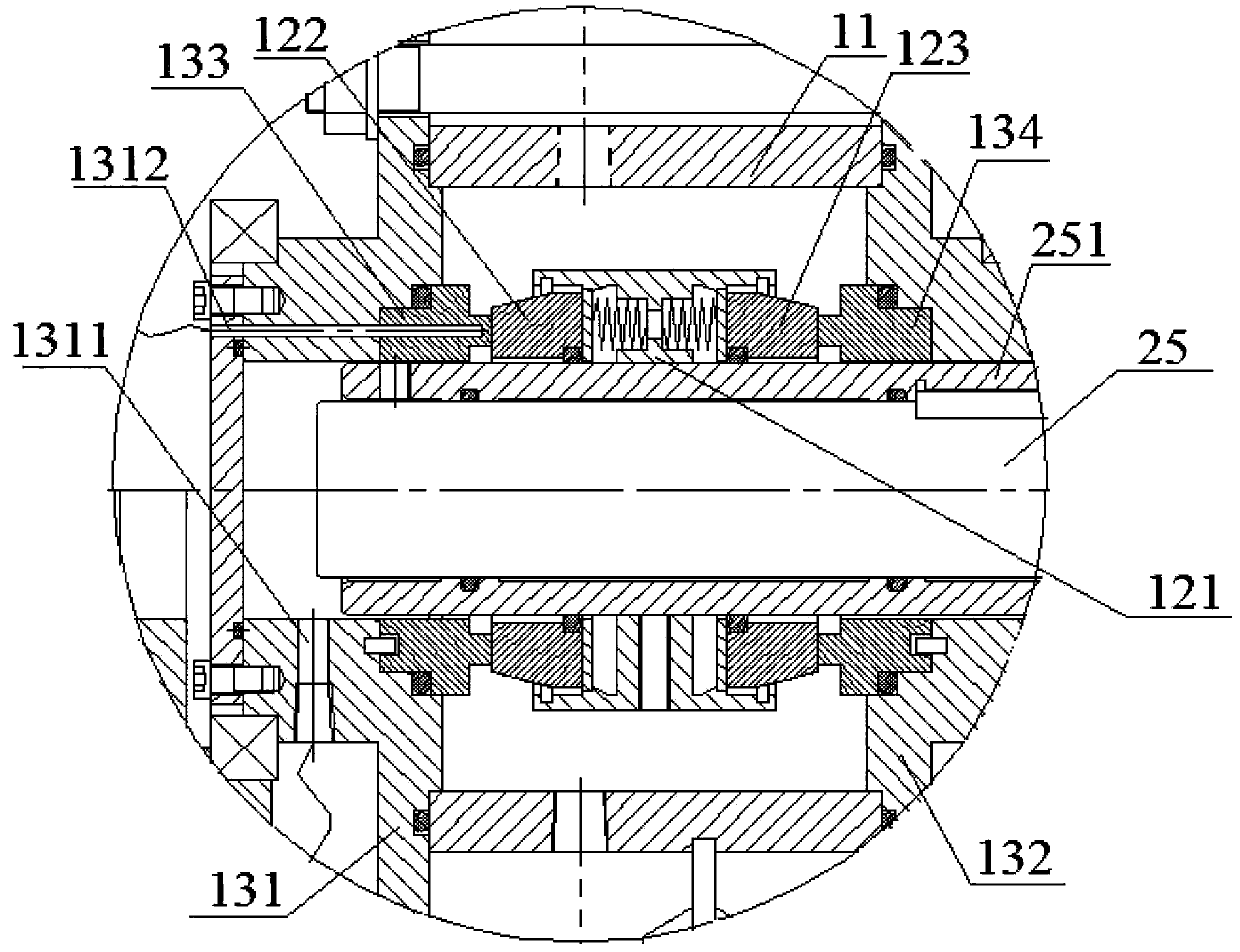

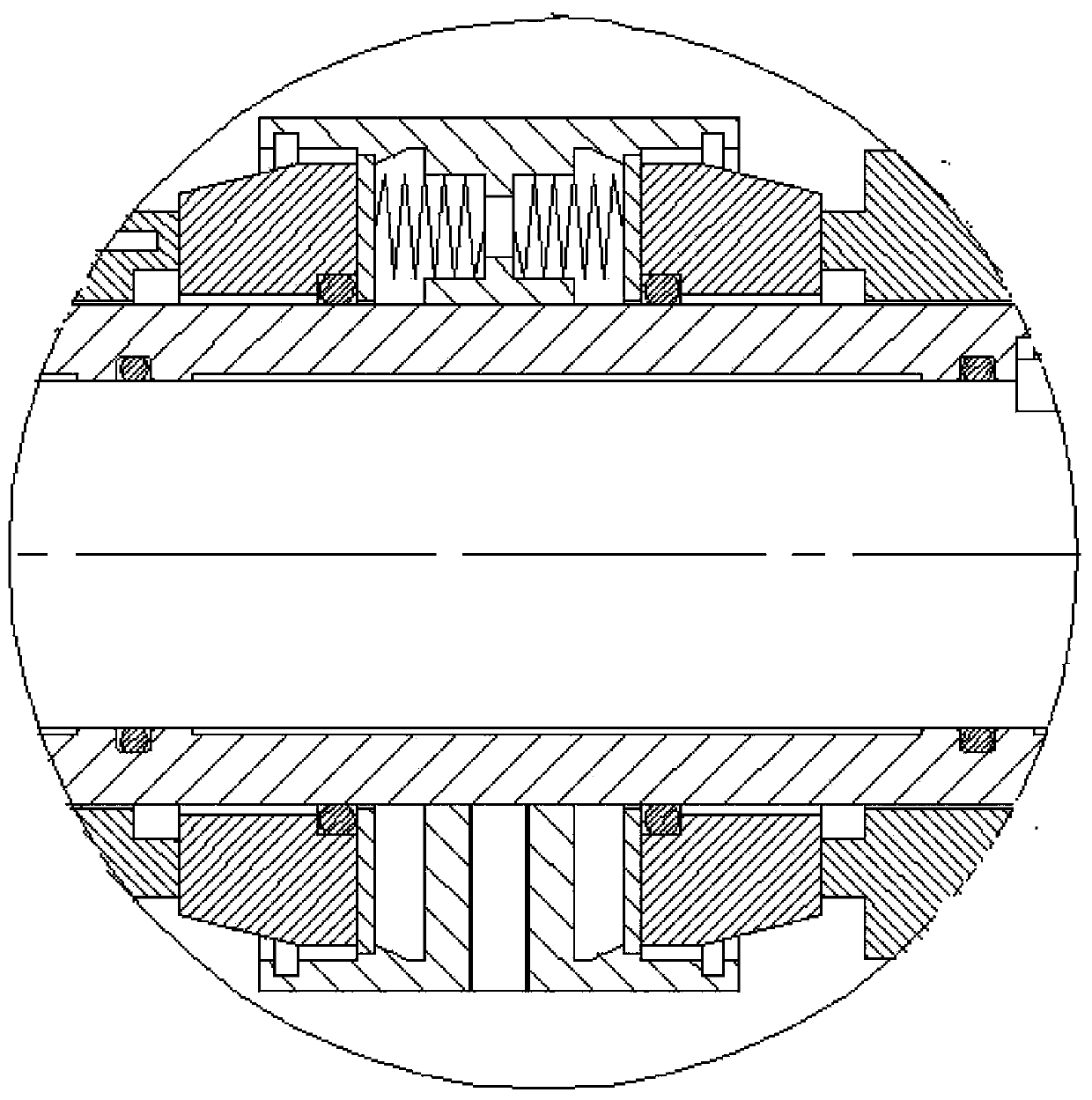

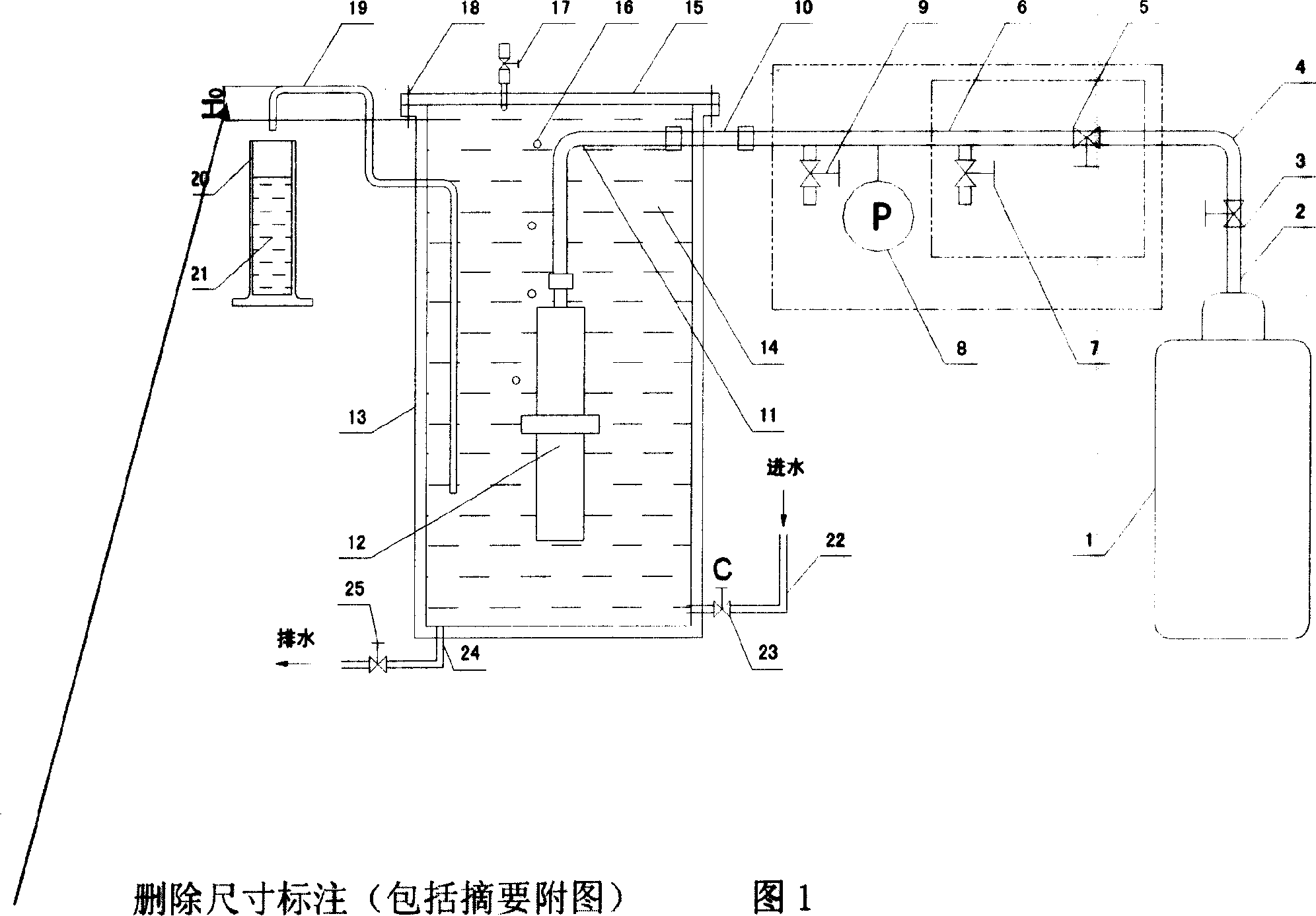

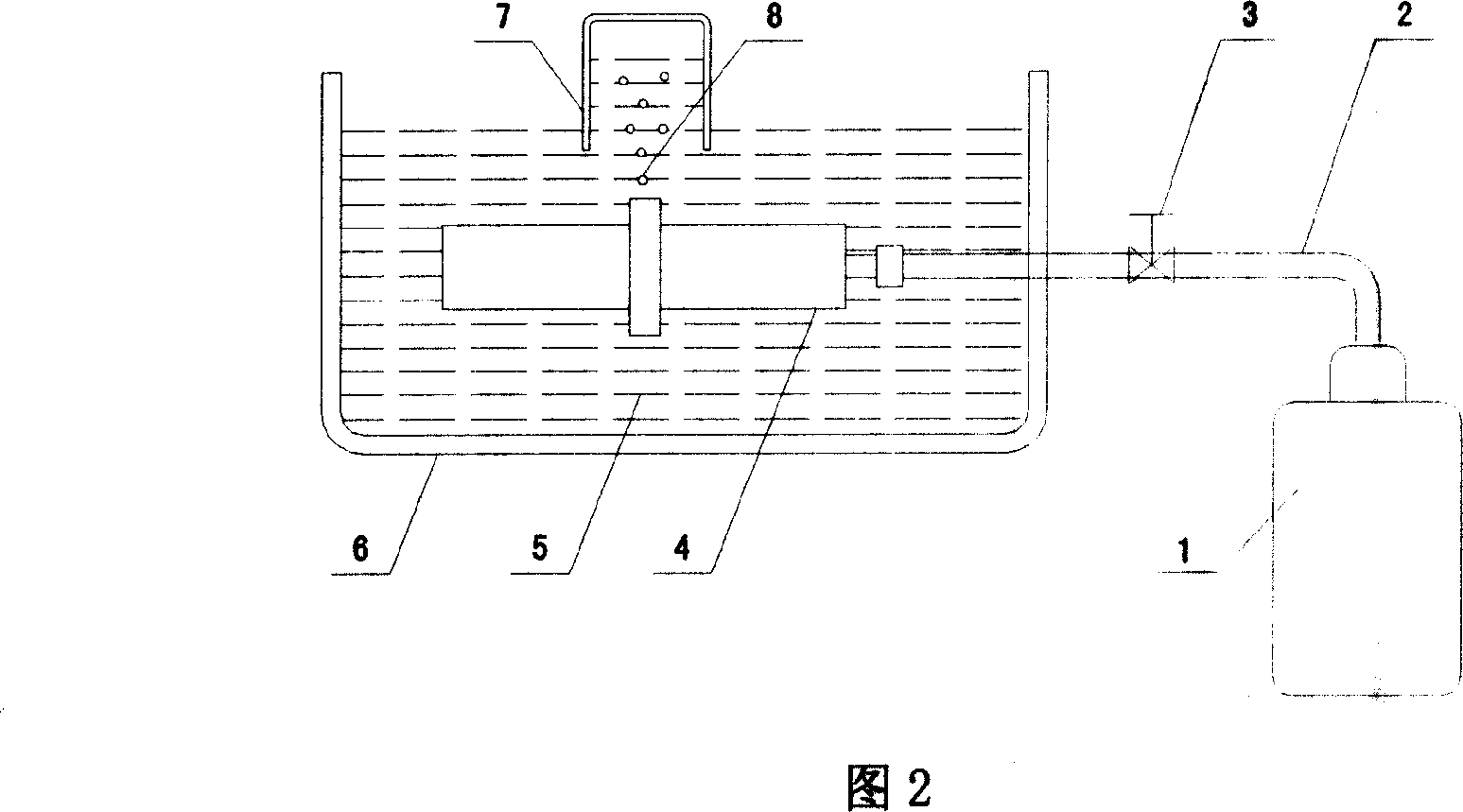

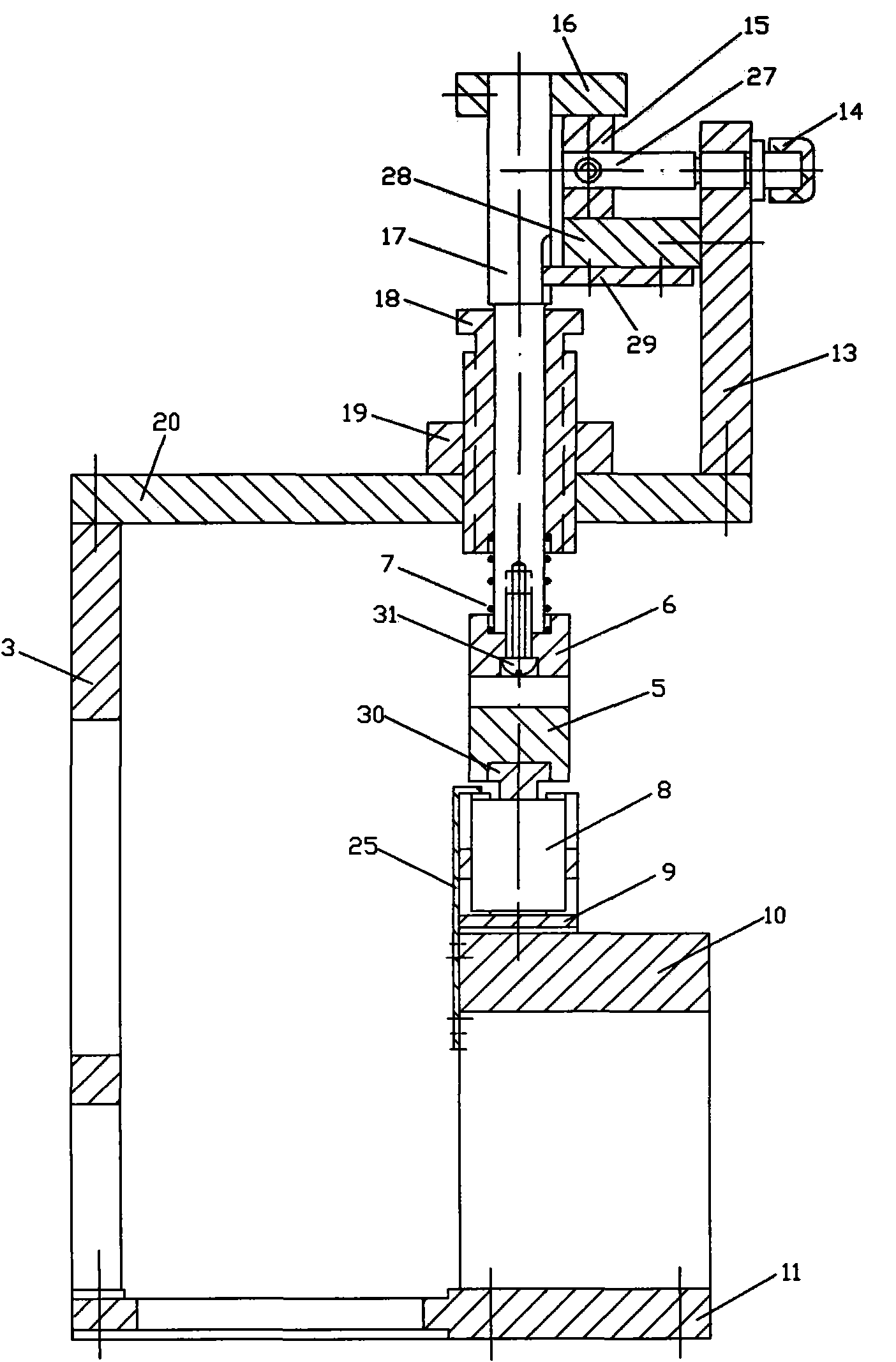

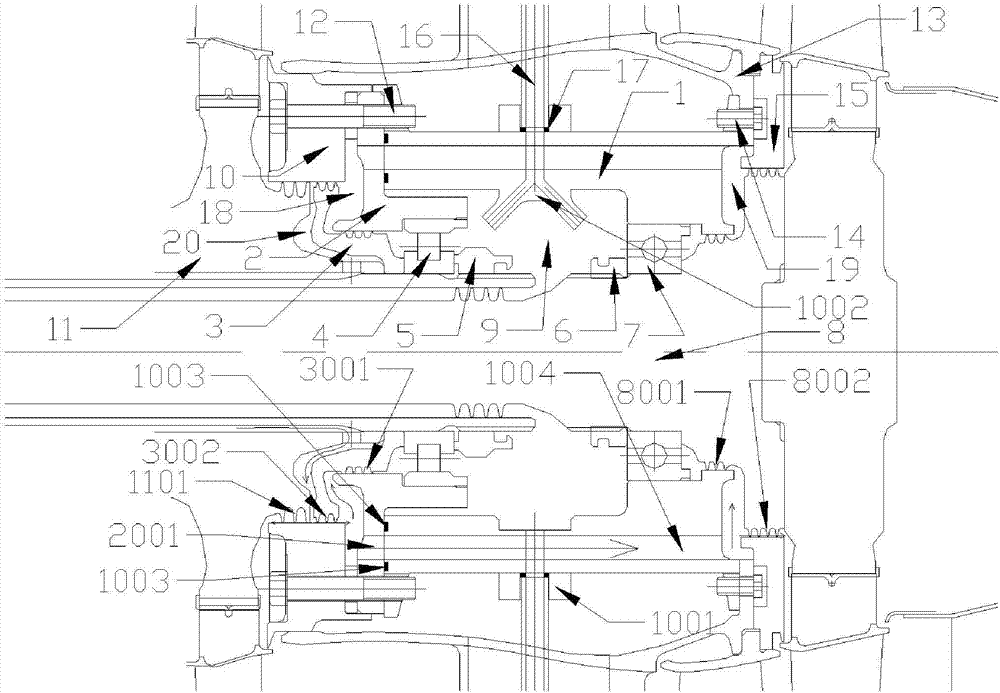

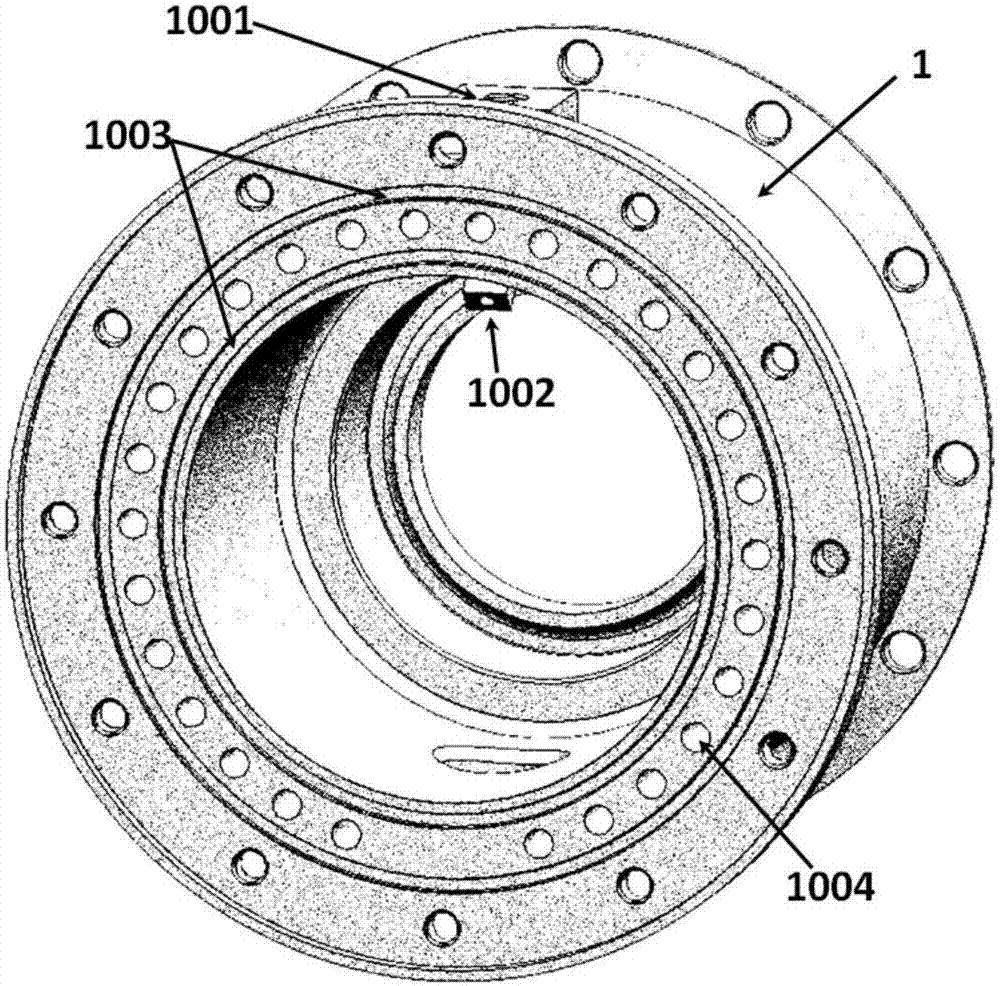

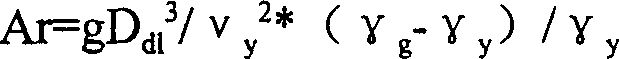

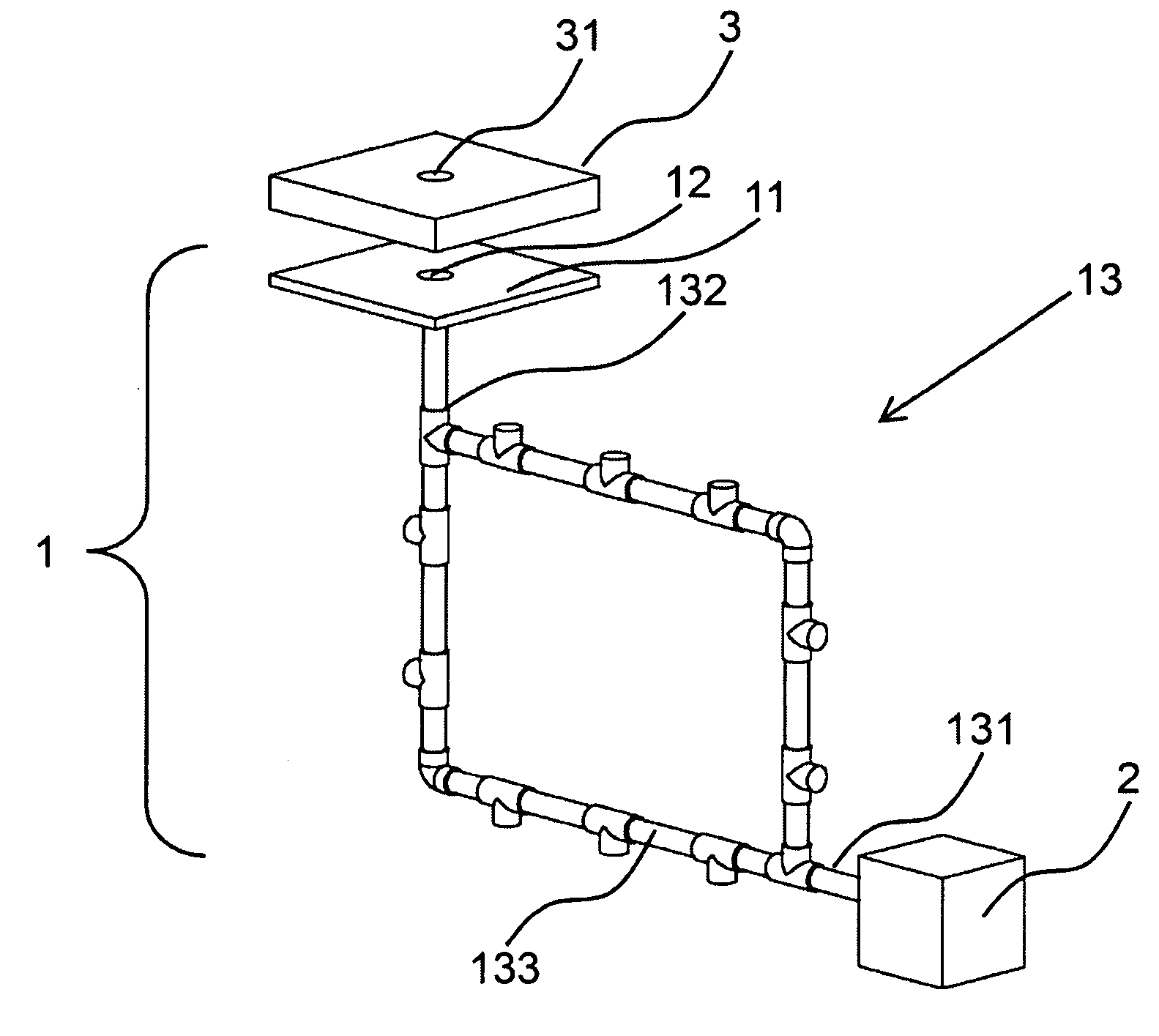

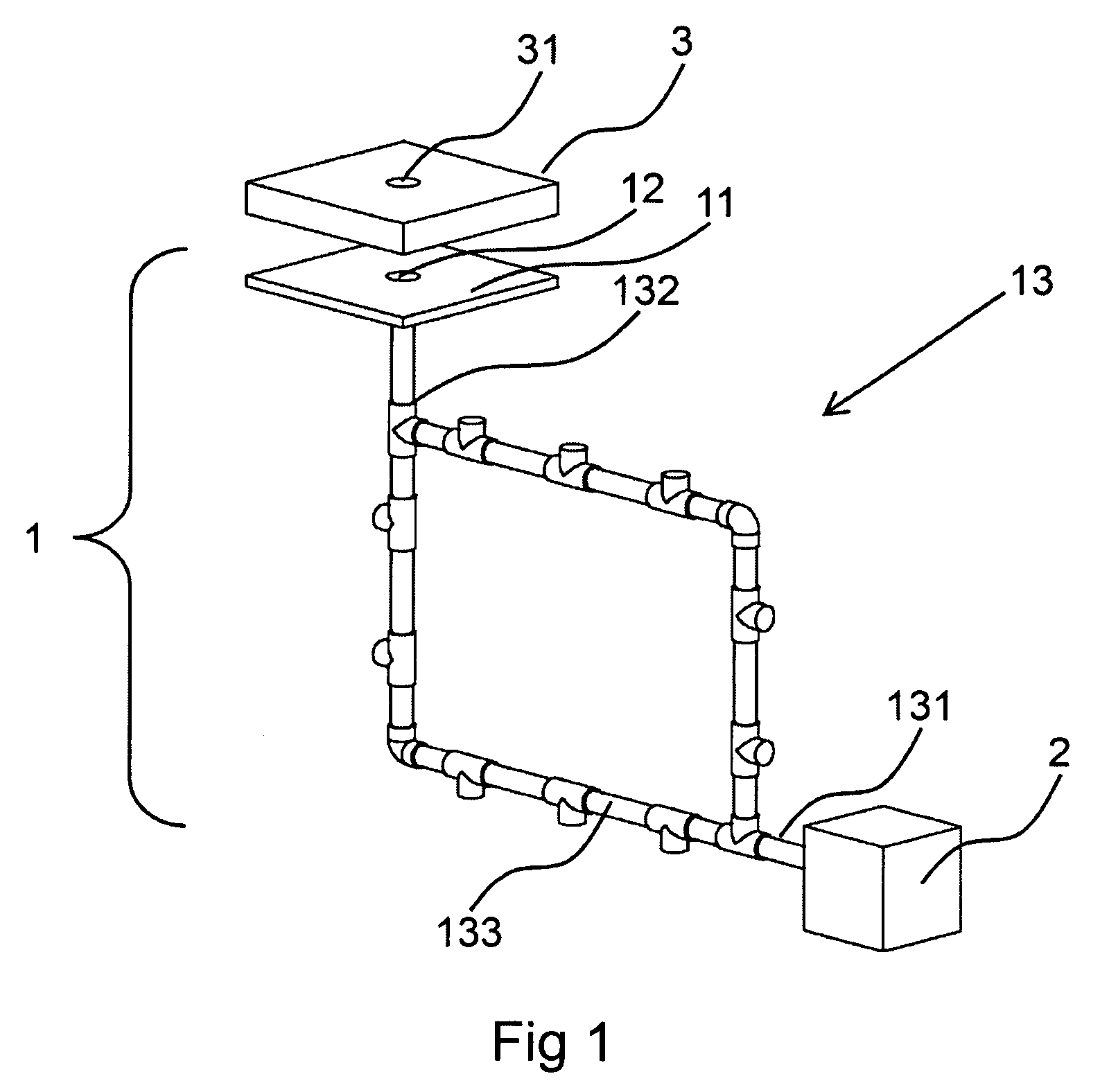

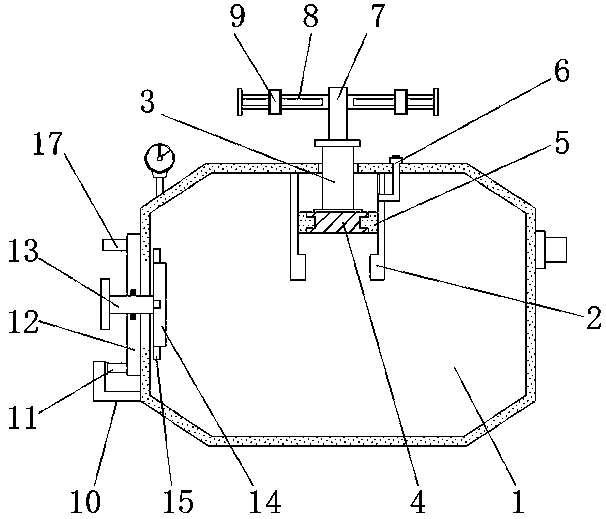

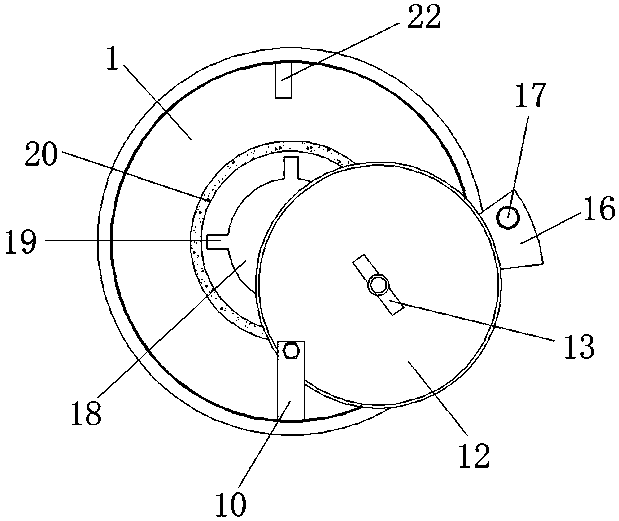

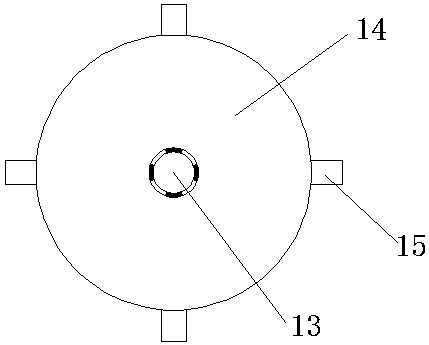

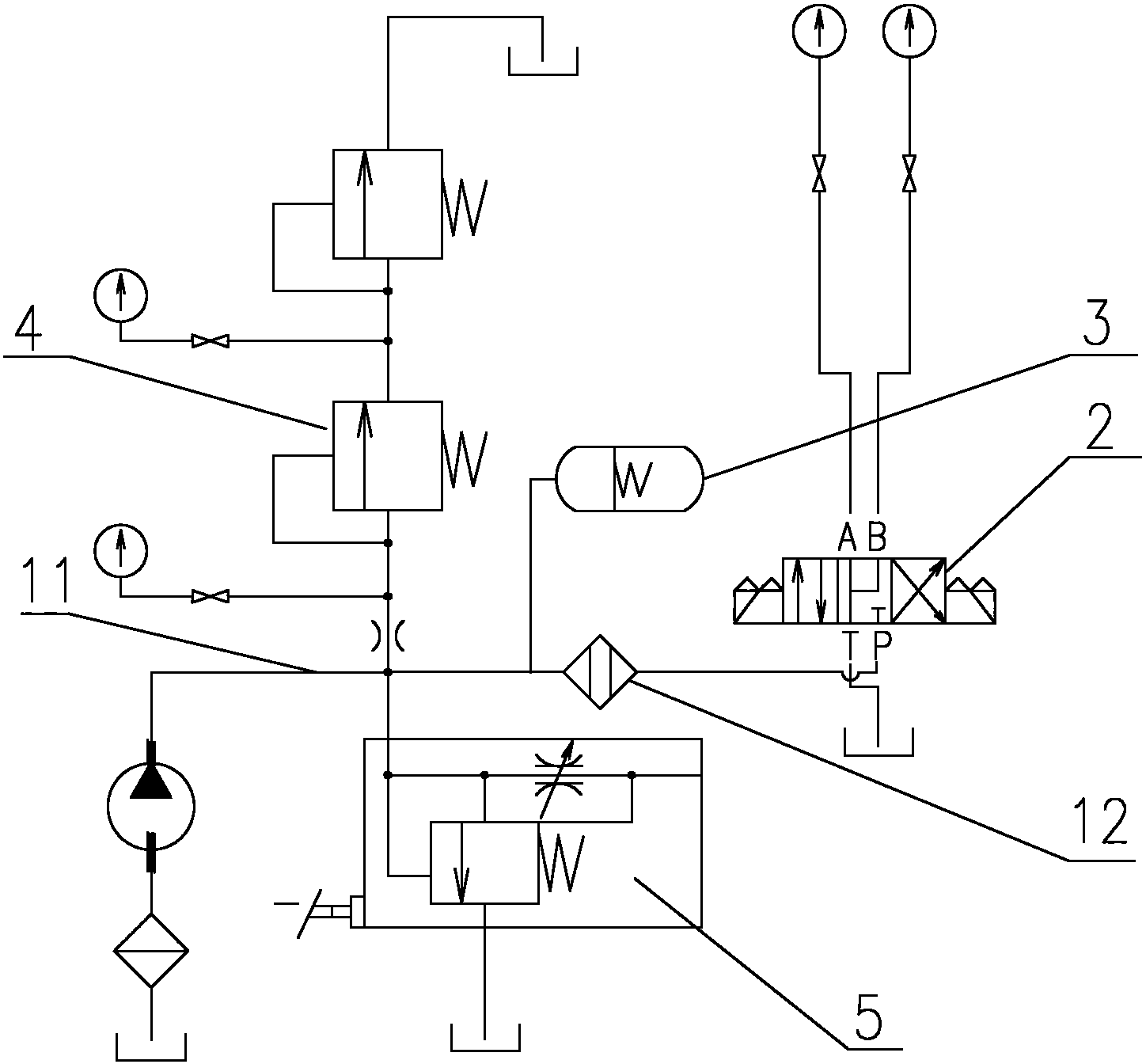

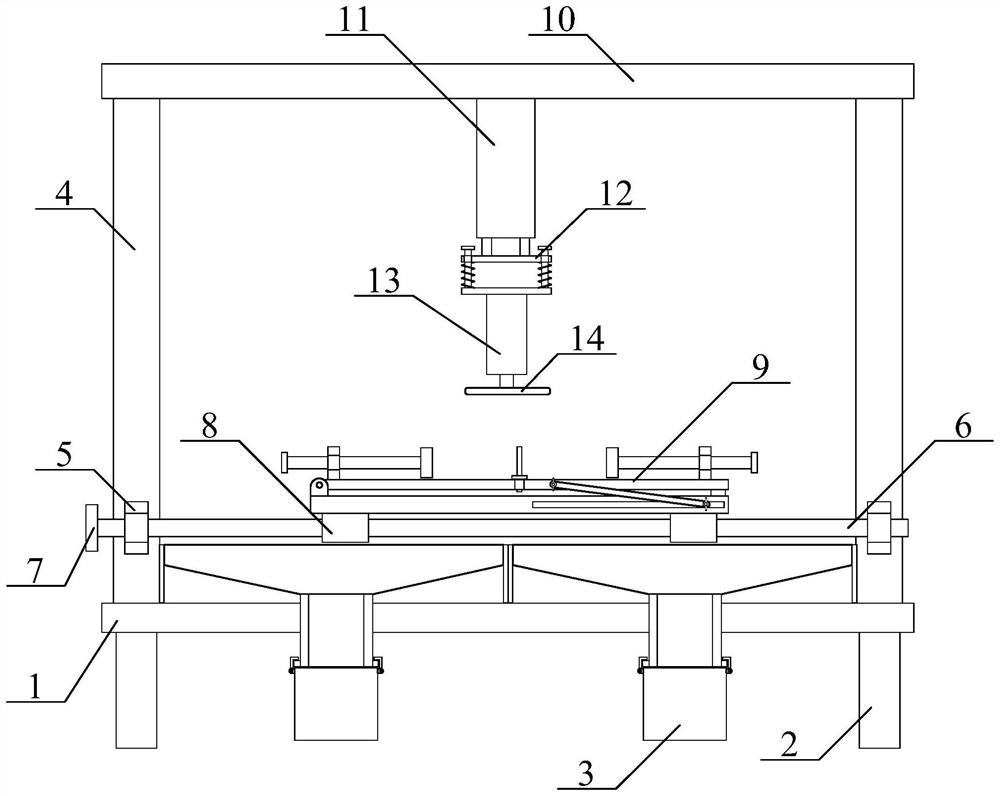

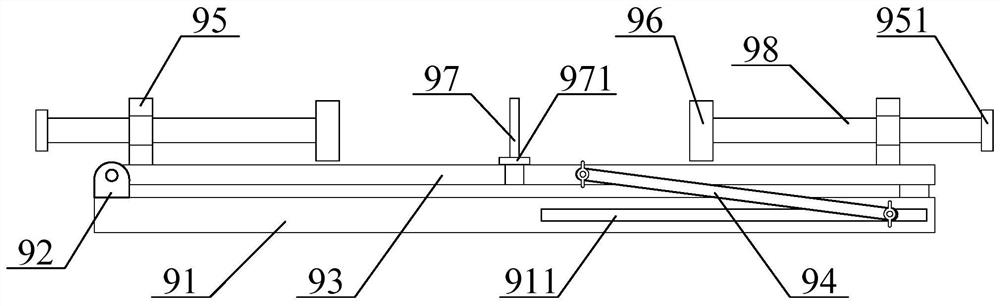

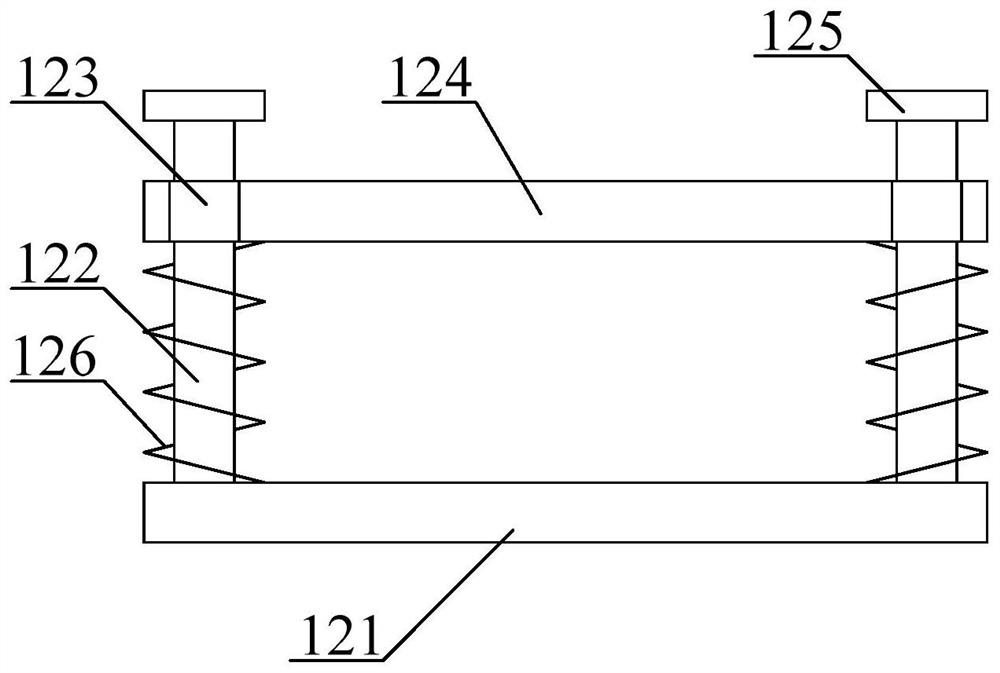

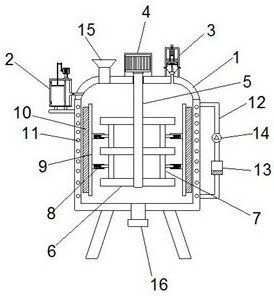

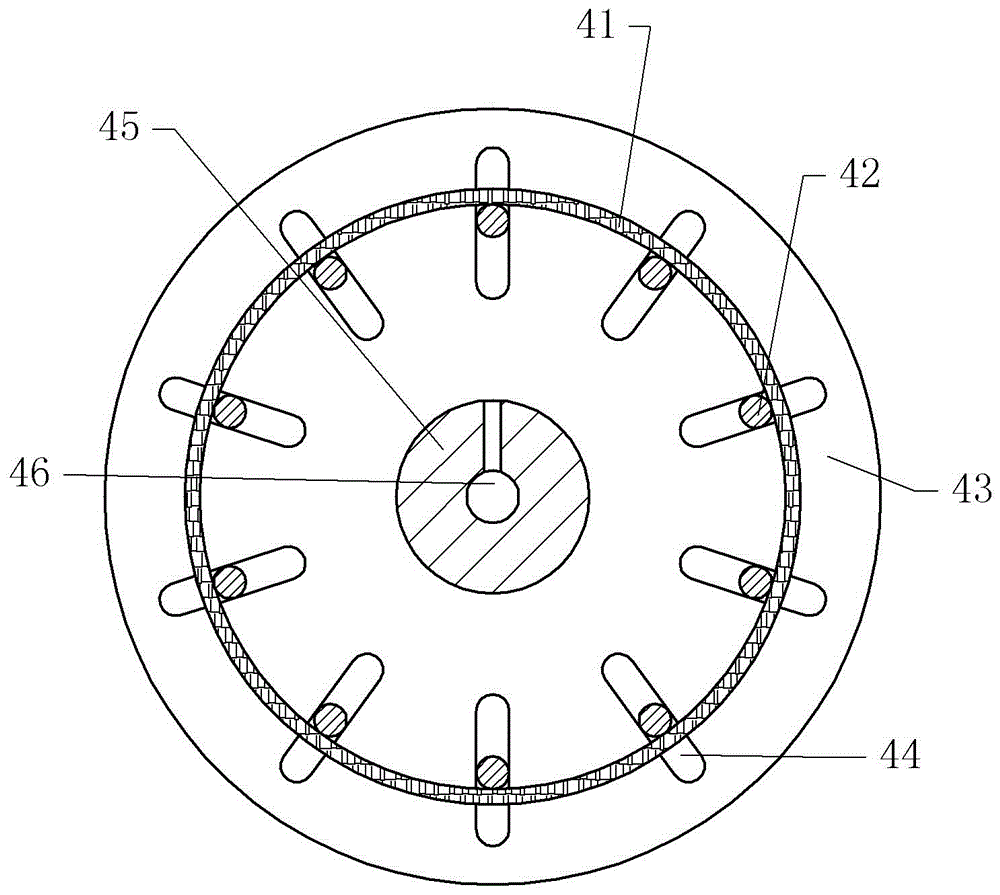

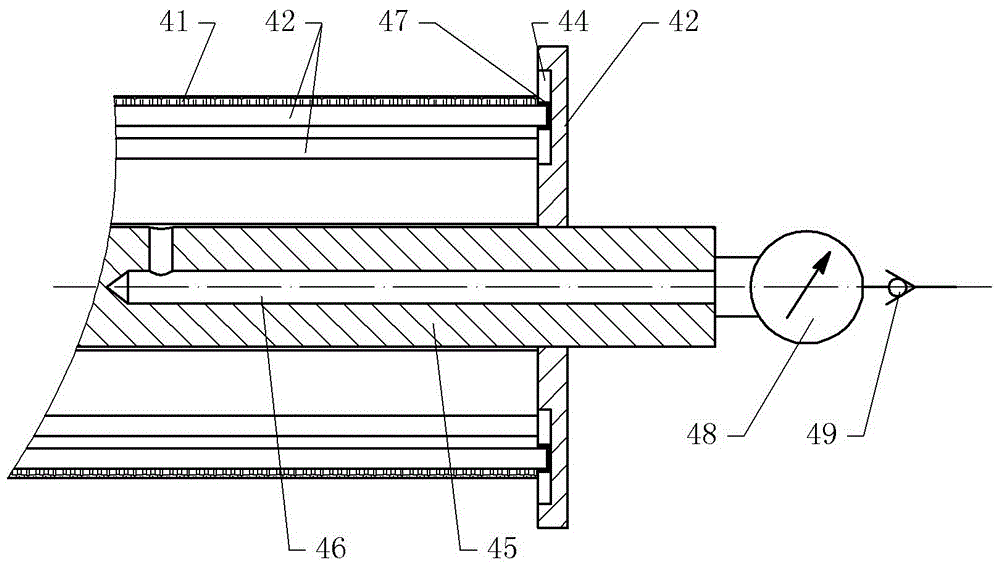

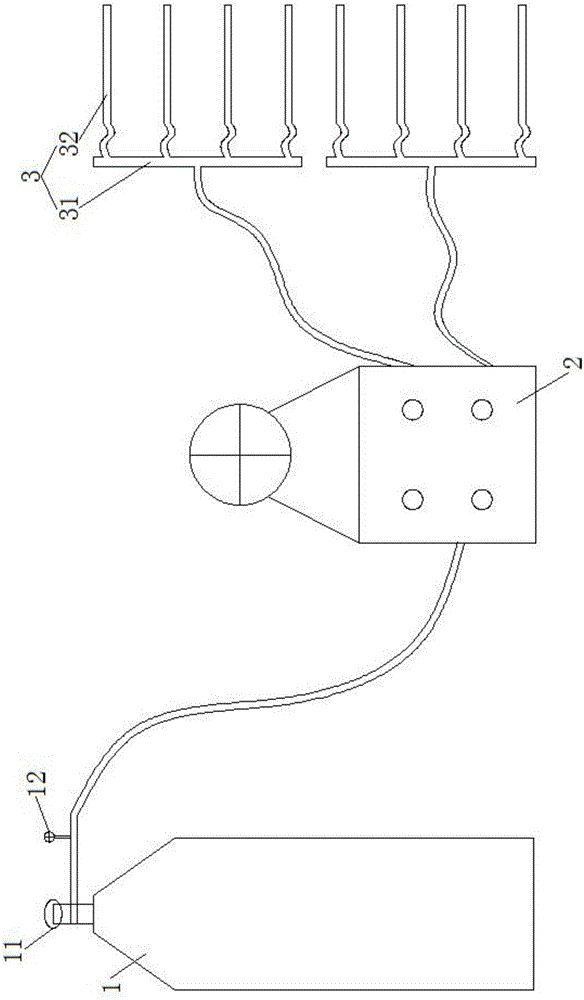

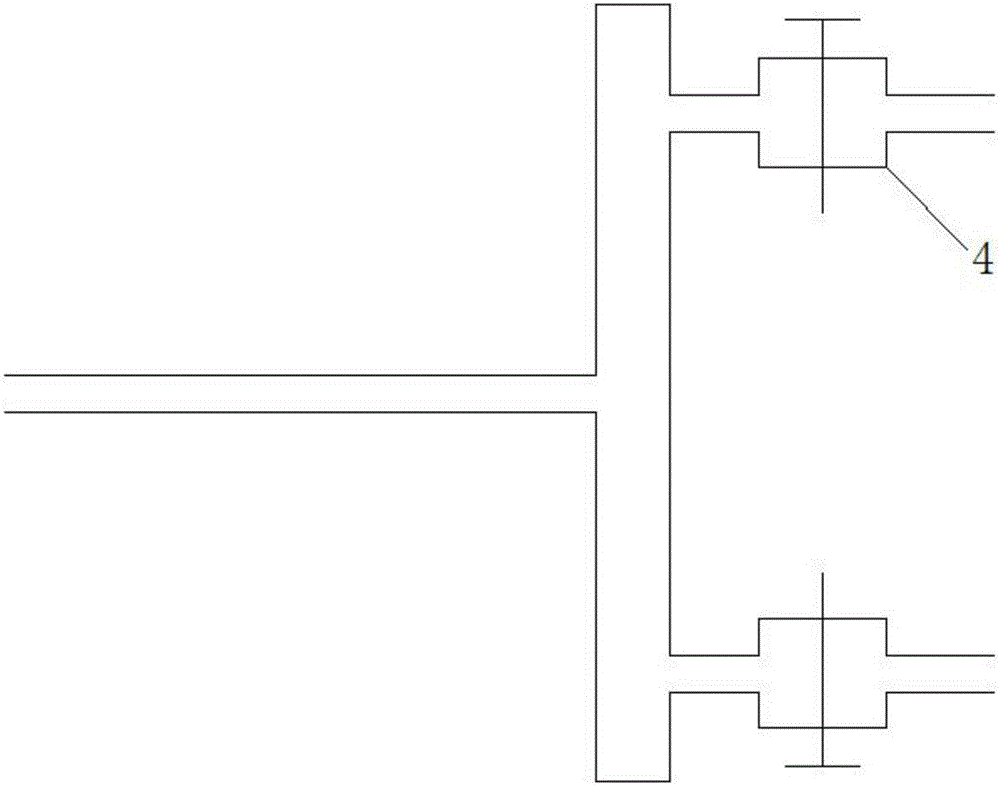

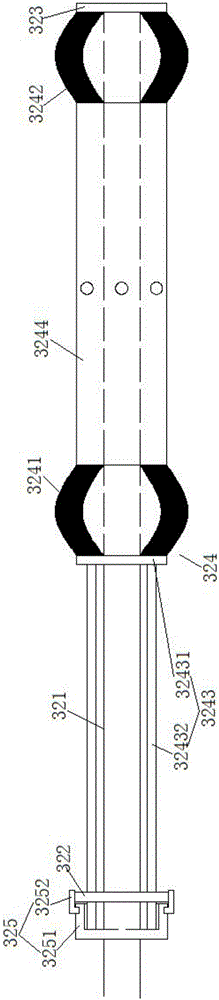

Method for testing liquid lubrication machine seal sealing performance and devices thereof

ActiveCN103630301AOvercoming large vibrationEasy to adjust pressureMeasurement of fluid loss/gain ratePhysicsElectric machinery

Provided are a method for testing the liquid lubrication machine seal sealing performance and devices thereof. The method comprises the steps of adding a sealing medium to a liquid storage tank, starting a compressor to supply pressure to sealing pressure, starting a circulating pump and measuring the temperature, the leakage rate and the friction torque of an end face through a thermocouple sensor, an electronic analytical balance and a pressure sensor respectively. The devices of the method comprise a sealing device, a driving device, an auxiliary device and a testing device. The sealing device includes a sealing cavity with sealing liquid inlet and outlet, and movable assemblies and static assemblies which are installed in the sealing cavity; the driving device includes a bracket, a motor, a synchronous belt wheel, a synchronous belt, a rotating shaft and a bearing box; and the testing device includes a dowel bar, a pressure sensor, a thermocouple sensor, an electronic balance and a computer. The method and the devices have the following advantages: friction torque, temperature rise and leakage rate of various sealing end faces can be acquired accurately, conveniently and automatically; vibration and noise are low; and the structure is compact and disassembly and assembly alignment is convenient.

Owner:ZHEJIANG UNIV OF TECH

Hinged attachment of headgear to a helmet

ActiveUS8028344B2Help positioningEasy to adjust pressureTelescopesHatsEngineeringMechanical engineering

Owner:GENTEX CORP

Airtight type tested pieces air-leakage detecting device

ActiveCN1932464AThe collection method is scientific and reliableEnsure consistencyDetection of fluid at leakage pointVolume measurement apparatus/methodsAir compressionWater storage

The invention discloses a detecting device for the leakage of gas-tight test piece including the aqua storage tank of the watertight test piece and the air compressing device to fill the pressure to the gas-tight test piece and the measuring cup to collect the leaking gas. The aqua storage tank is connected with the test piece inside and the conduit of the air compressing device in outside which is installed with the stabilizing voltage device. The water storage vessel has a flooding pipe connected to the out and a measuring cup. The invention transforms the reverse scale reading of the original air volume to the forward scale reading of the liquid volume by the liquid drained by leaking gas of the closed test piece. Therefore, it can assure the coherence of the reading and the fact leaking quantity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

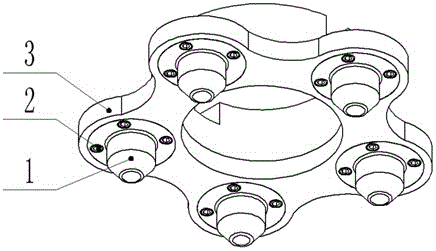

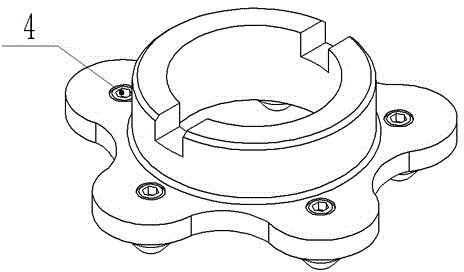

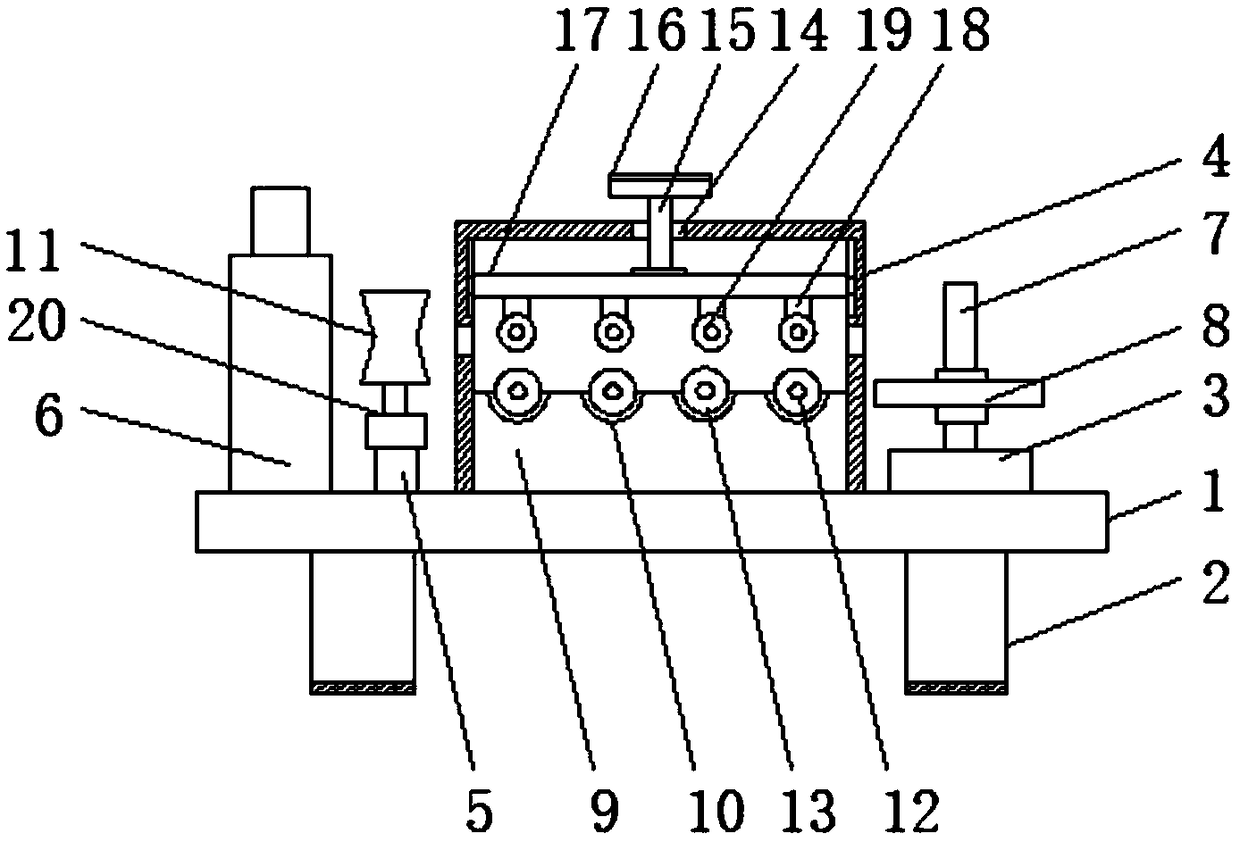

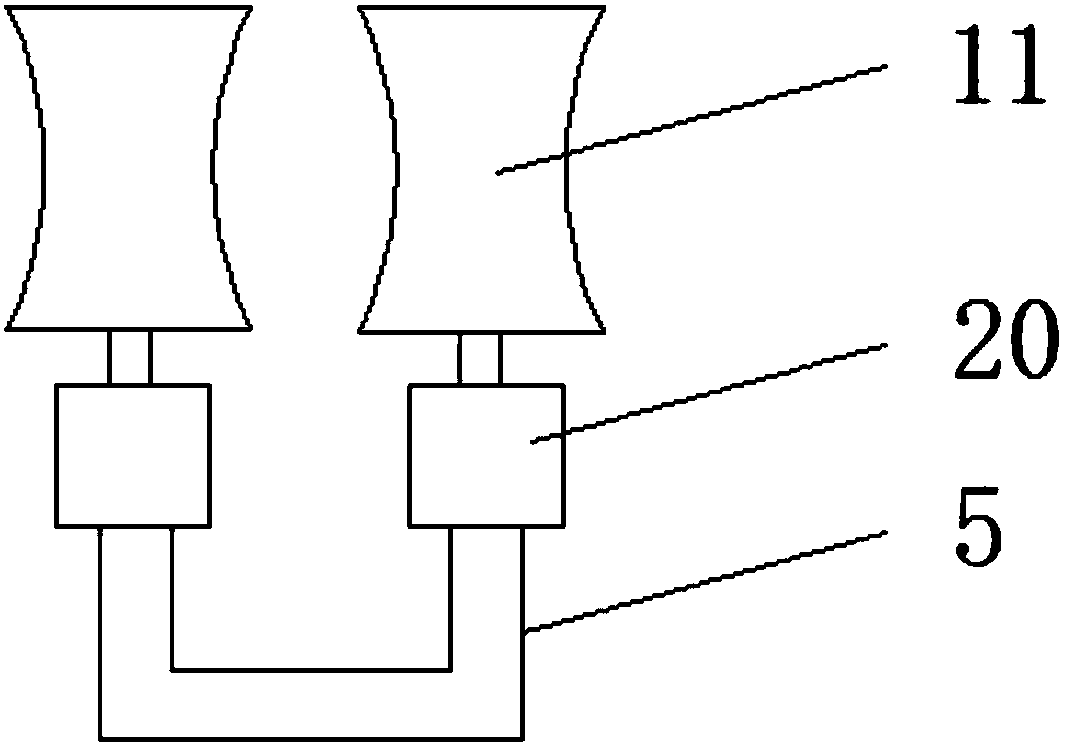

Multi-head rolling surface polishing cutter

InactiveCN104827239AEasy to adjust pressureSolve the problem of unregulated pressureWear resistantEngineering

The invention discloses a multi-head rolling surface polishing cutter, and belongs to the technical field of machining cutters. The multi-head rolling surface polishing cutter comprises a cutter rest and five cutter bits, wherein the cutter bits are rolling bits, and mainly consist of balls, support frames, wear resistant plates, lower pressing plates, compression springs, upper pressing plates, pressing screws and the like. The cutter rest can be connected with a machine tool spindle through a Morse taper handle and the like; the balls are put into the support frames, and are pressed with the wear resistant plates having circular grooves; the wear resistant plates are pressed with the lower pressing plates and the upper pressing plates; and the compression springs are mounted between the upper and lower pressing plates. The multi-head rolling surface polishing cutter has the following advantages: through the cutter bit mechanical rolling effect, the material surface smoothness and levelness are improved, the surface pressure stress is improved, the material surface grain size is reduced, and the material surface performance is enhanced; and through the cutter multi-head design, the cutter machining efficiency and using performance are improved.

Owner:UNIV OF JINAN

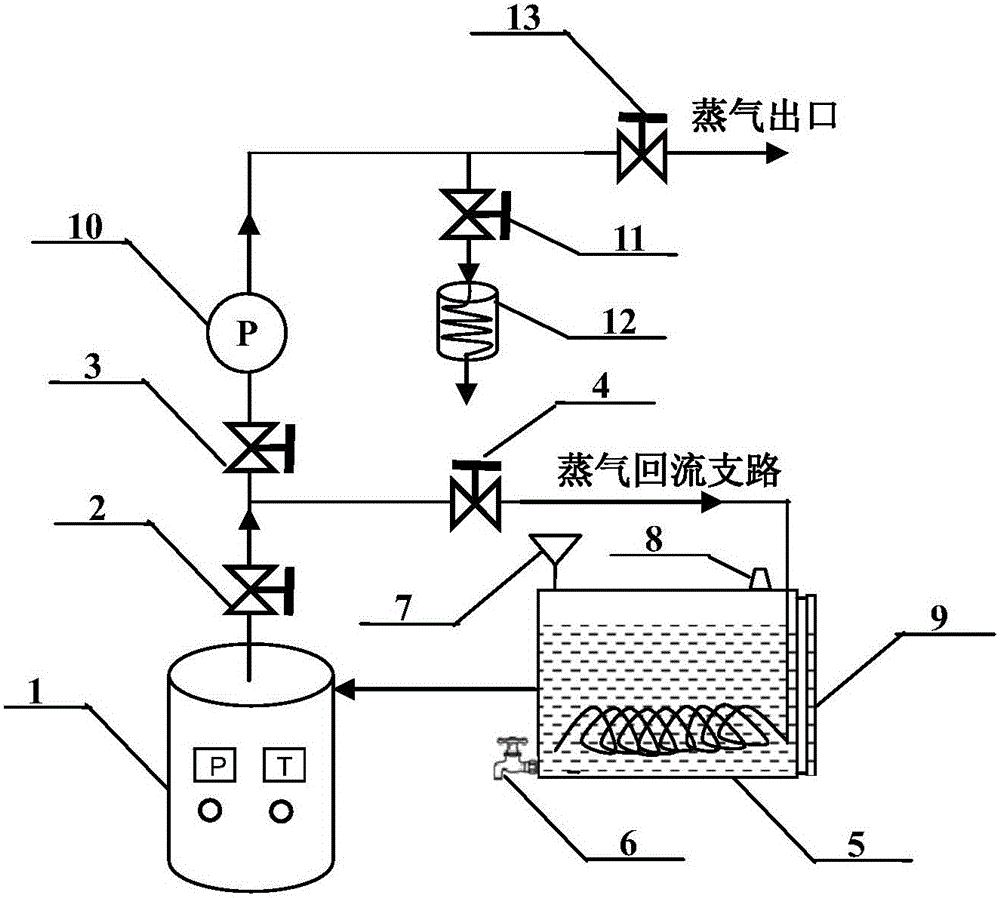

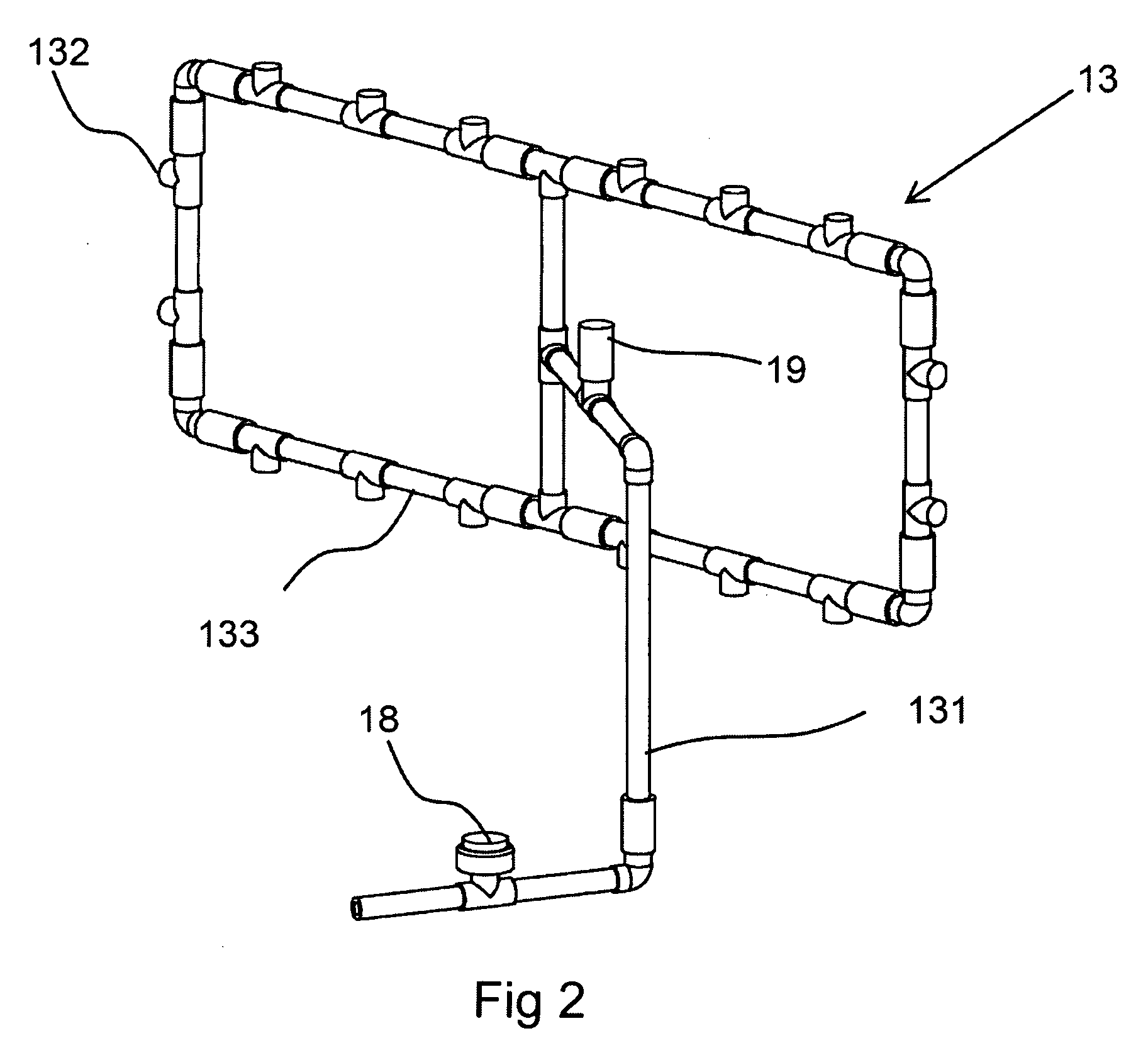

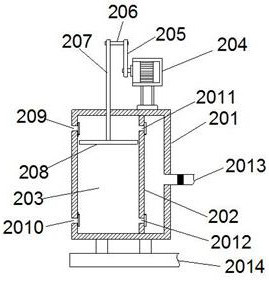

Water steam generation device for quantitatively controlling steam amount of outlet and use method

ActiveCN105716062AAchieving Quantitative ControlSimple processSteam generation heating methodsBoiler controlWater storageWater vapor

The invention discloses a water steam generation device for quantitatively controlling the steam amount of an outlet and a use method. The water steam generation device comprises a steam generator and a condenser. The outlet of the steam generator is connected with a first adjusting valve through a water steam output pipe. A pipeline passing through the first adjusting valve is divided into two branch ways, namely the steam outlet branch way and the steam backflow branch way. The steam outlet branch way sequentially passes through a second adjusting valve and a pressure gauge and then passes through a fifth adjusting valve to output steam. The steam backflow branch way passes through a third adjusting valve and is then connected with a water storage box. By means of the water steam generation device for quantitatively controlling the steam amount of the outlet and the use method, quantitative control over the steam output amount of the water steam generation device is achieved, the blank that a traditional steam flow meter or a traditional steam flow sensor or a liquid metering pump is not suitable for some occasions is filled up, in addition, the technological processes are simple, installation is convenient, a water tank and an electric tank are independent from each other, safety and reliability are achieved, and maintenance and repairing are convenient.

Owner:NORTHWEST UNIV

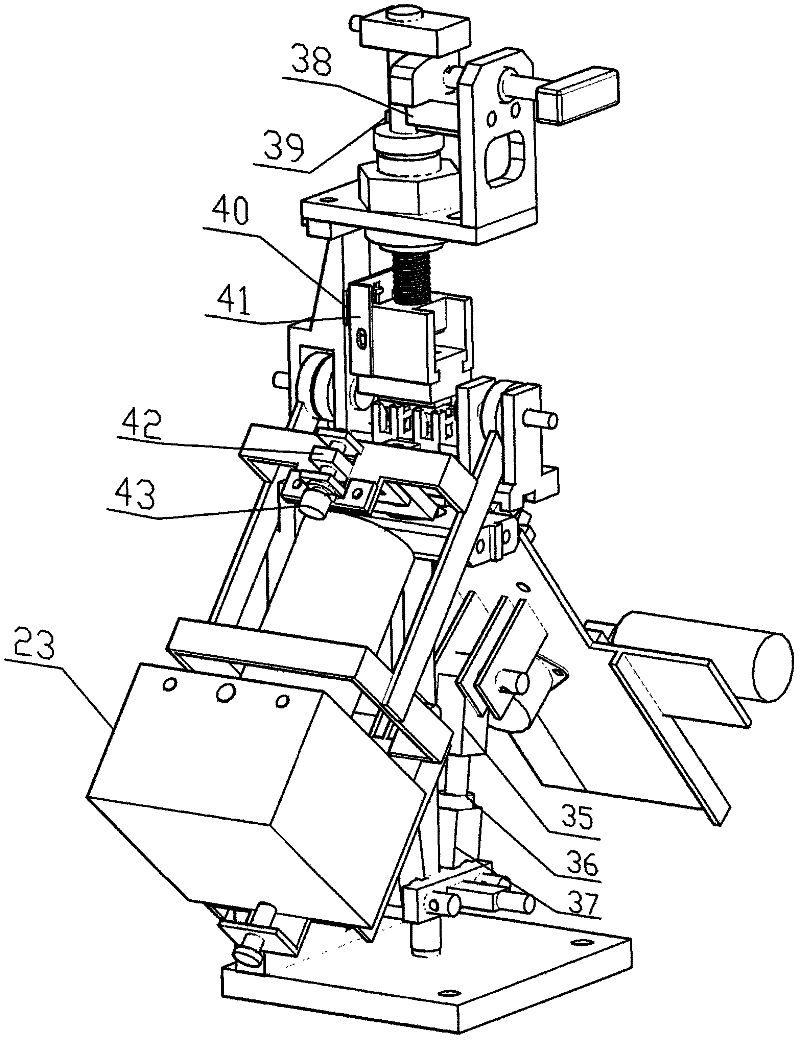

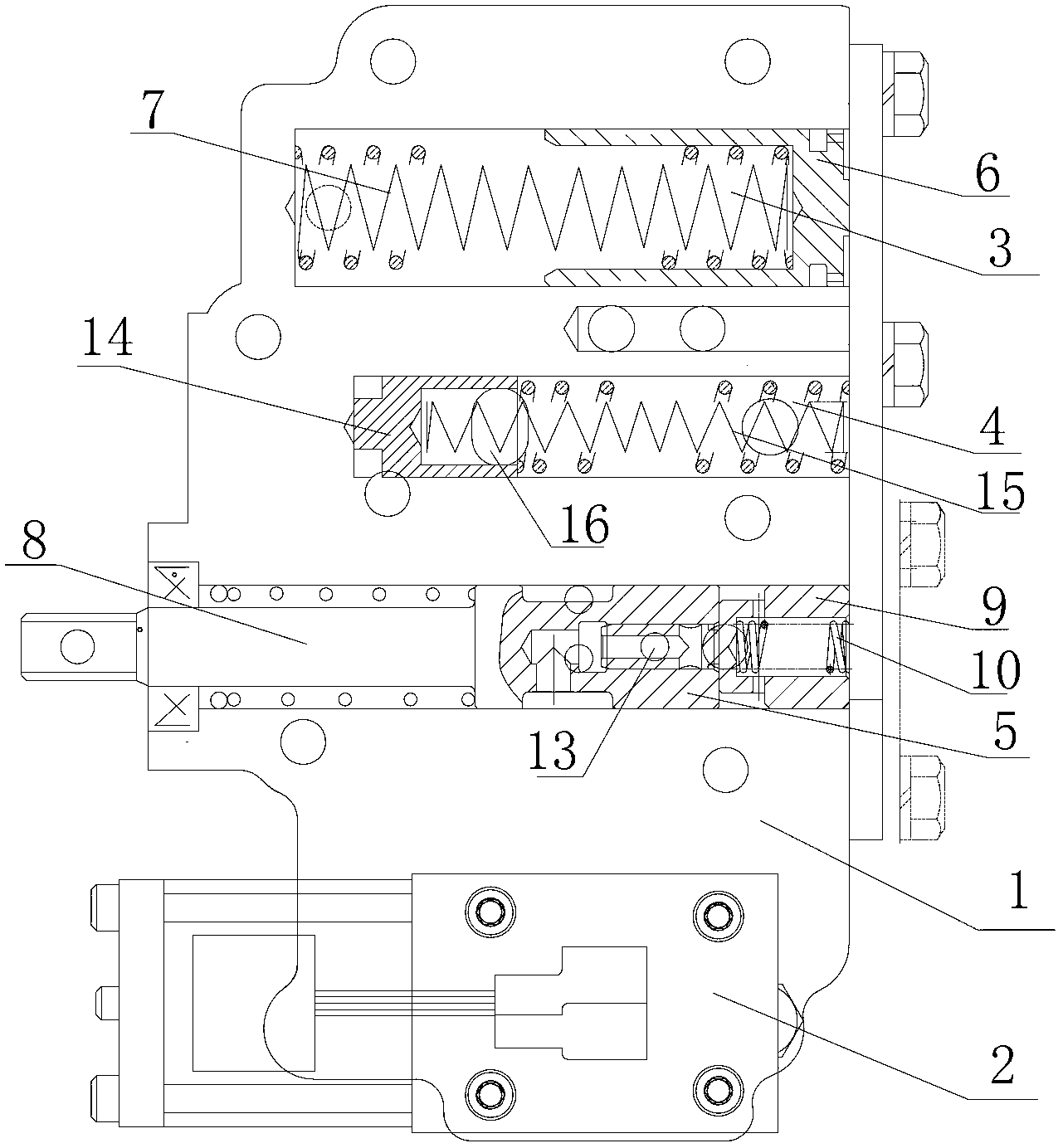

Hot-pressing heads and hot-pressing device consisting of same

ActiveCN101697345AUniform output pressureEasy to adjust pressureSemiconductor/solid-state device manufacturingWorking fluidReciprocating motion

The invention relates to hot-pressing heads and a hot-pressing device consisting of the same, which belong to hot-pressing heads and a hot-pressing device. The hot-pressing heads and the hot-pressing device solve the problems of complicated pressure adjustment of the traditional hot-pressing heads and unbalanced pressure of the hot-pressing heads of the traditional hot-pressing device. In the hot-pressing heads, piston cylinders are arranged between a heating component and an installation component; and the heating component performs reciprocating motion relative to the installation component through the piston cylinders. The hot-pressing device consisting of the hot-pressing heads comprises a chassis, a first pressing plate, a second pressing plate, a first reciprocator and the hot-pressing heads, wherein the piston cylinders of the hot-pressing heads are connected with a pressure control system in parallel; and the pressure control system controls the pressure difference at both ends of pistons of the piston cylinders. The output pressure of the hot-pressing heads is controlled by regulated the pressure of working fluid in the piston cylinders, and the process of the regulating the pressure is convenient to control; and the pressure control system performs the multichannel control of the hot-pressing heads of the hot-pressing device to regulate the output pressure of the hot-pressing heads uniformly so as to prevent the hot-pressing heads from being regulated one by one, and the hot-pressing heads and the hot-pressing device is suitable to be used in the process of encapsulating electronic chips.

Owner:GUANGDONG SYGOLE INTELLIGENT TECH CO LTD

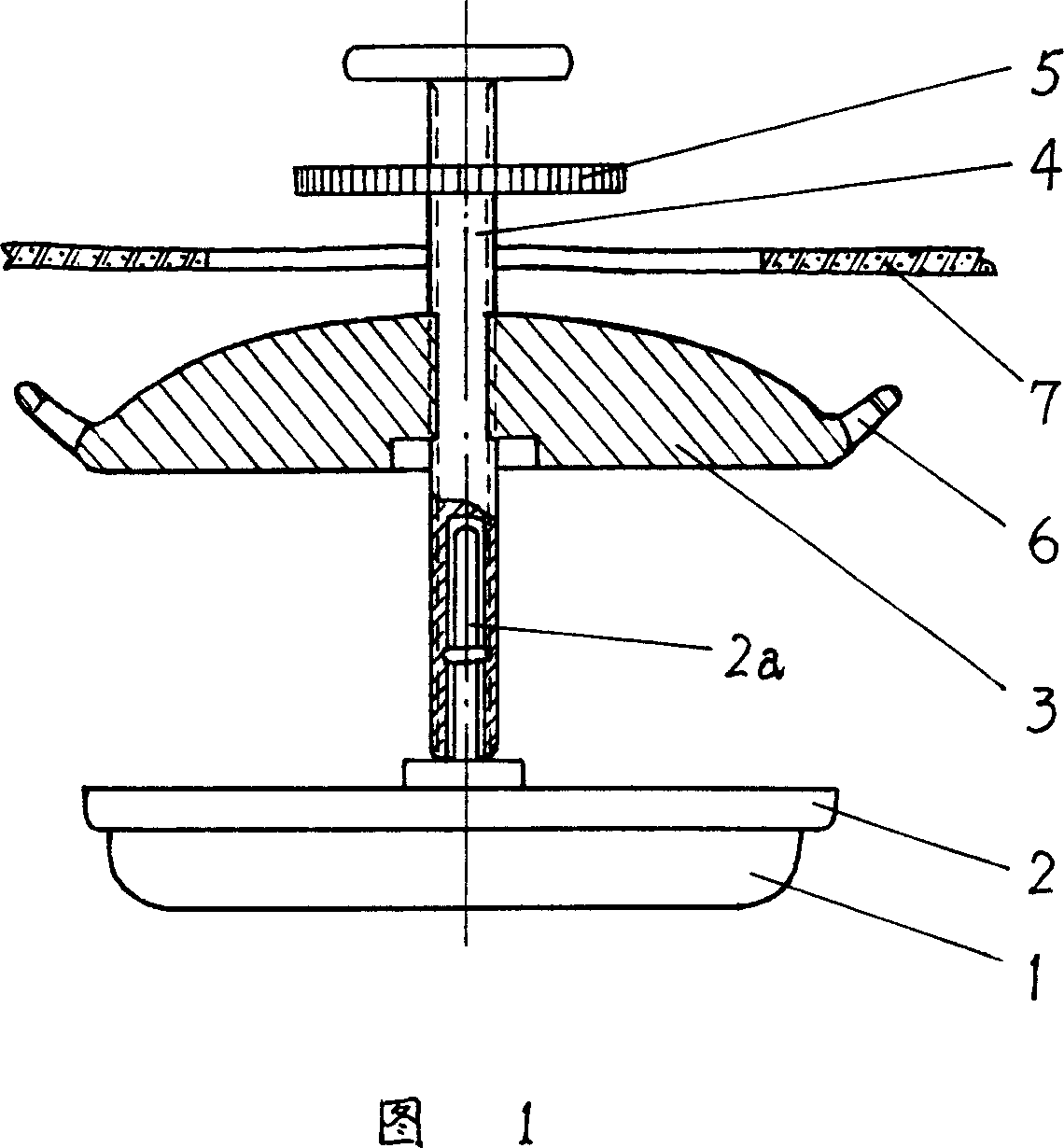

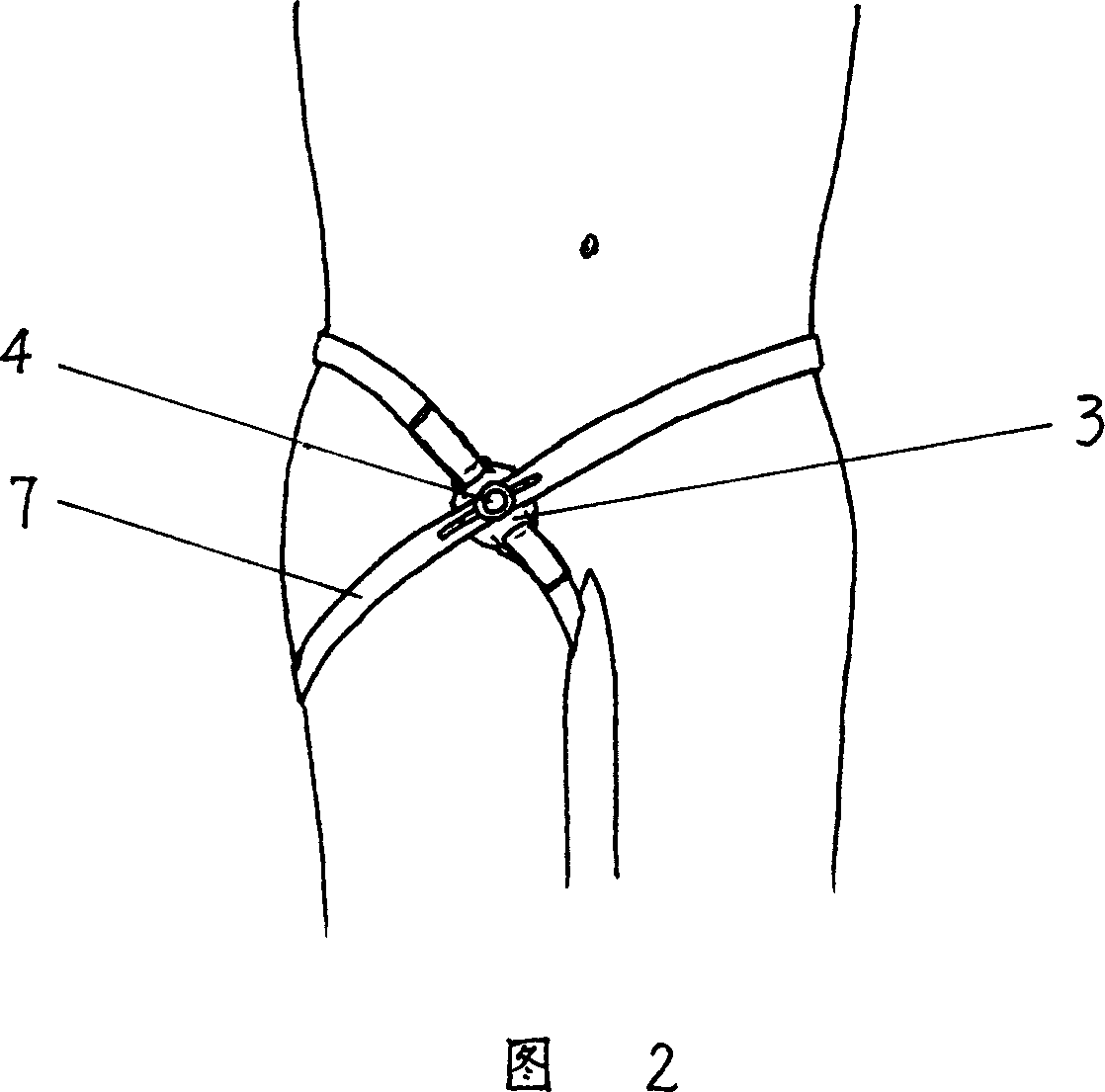

Disposable arteria femoralis compression hemostat

The invention is concerned with the one-off femoral artery oppress hemostat and it includes: the pressure adjusting compasses, the center screw hole with adjustment screw that connects the compression compasses, the two opposite lead back fastener on the adjusting compasses, and the fixation band for the adjustment screw. It improves the quality and efficiency of henostasis dressing and reduces mistakes.

Owner:杭州艾力康医药科技有限公司

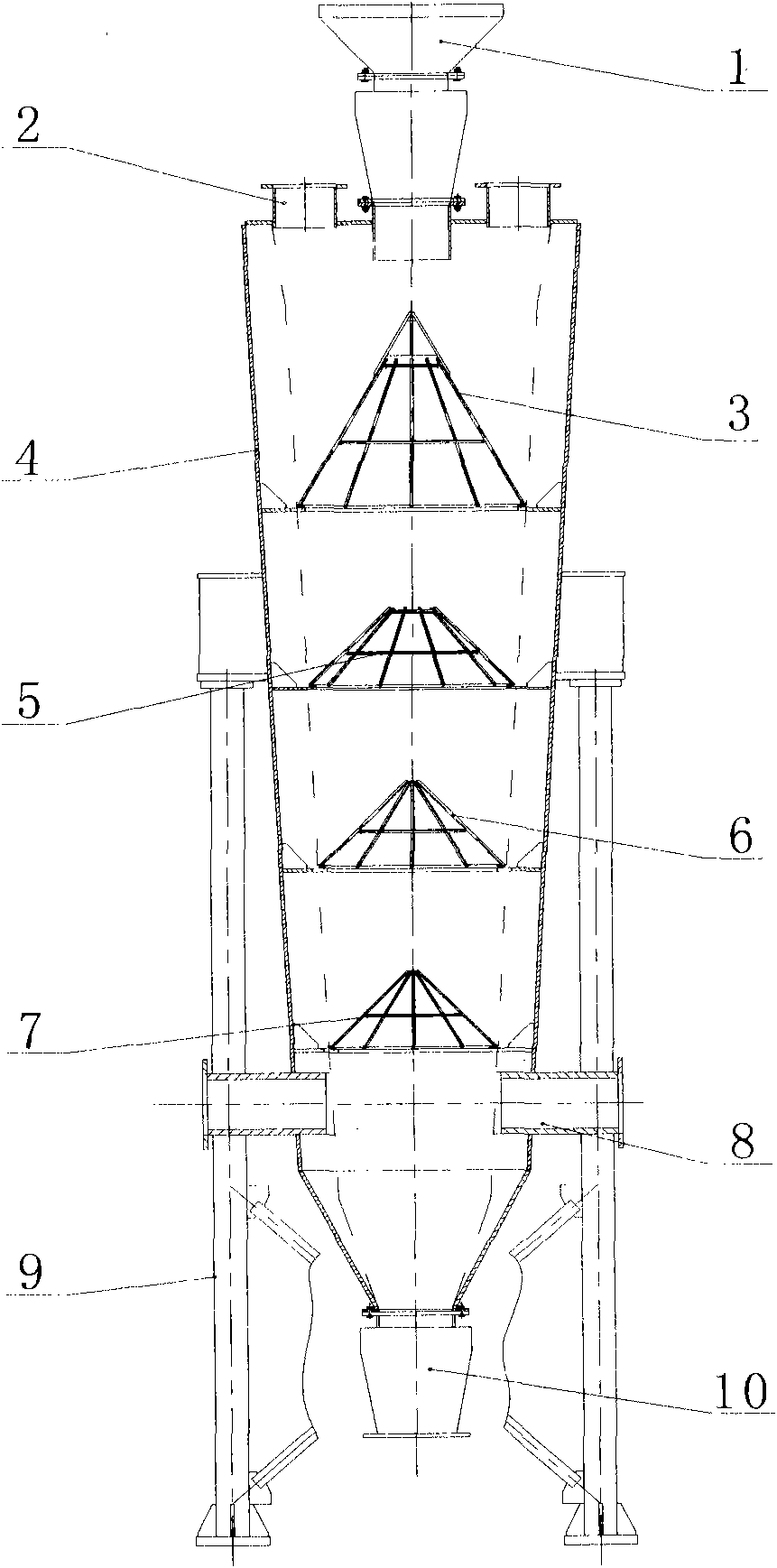

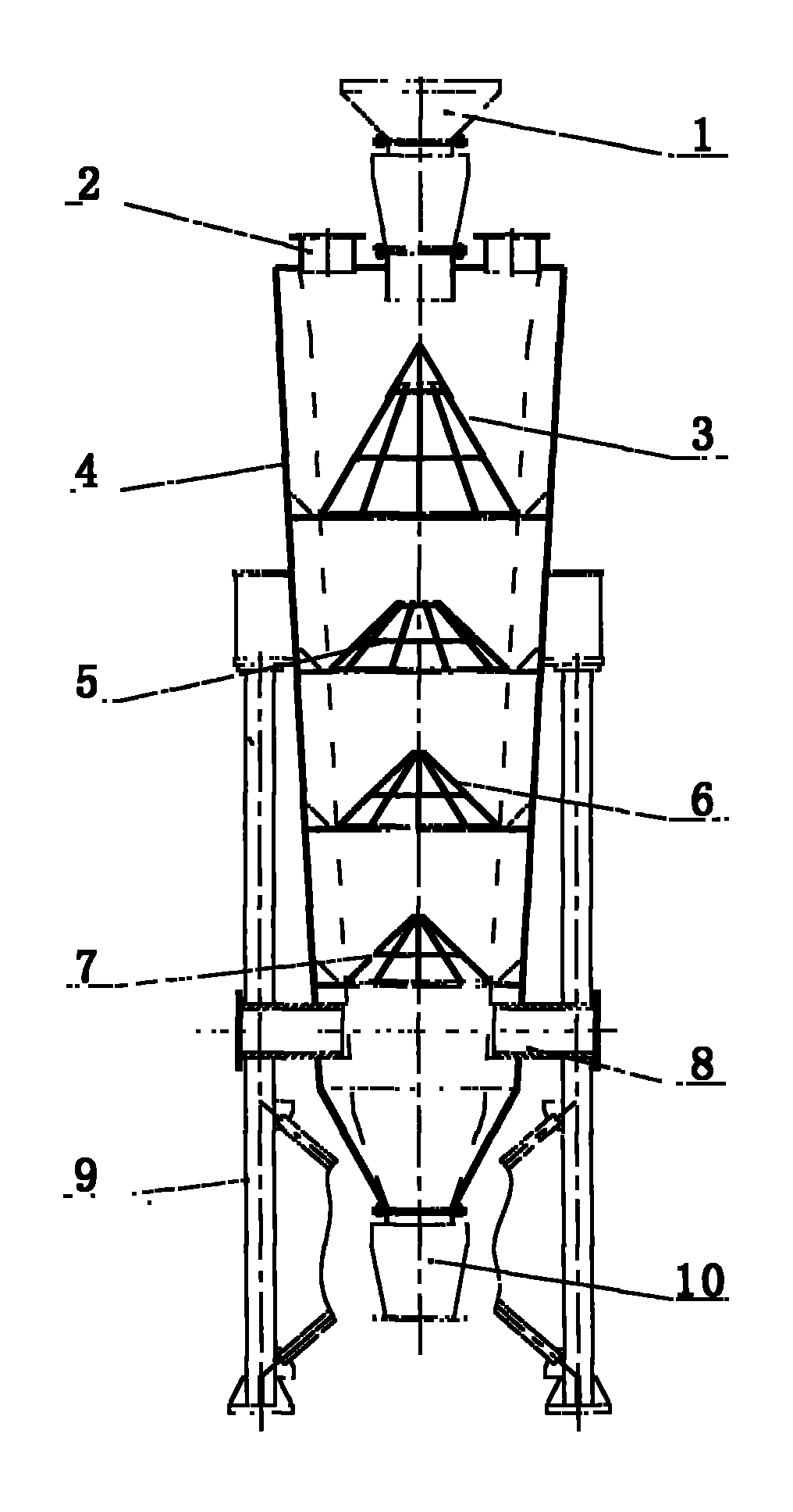

N-level incineration treatment technology for domestic garbage

InactiveCN101776269AAchieve full utilizationExtended stayCement productionIncinerator apparatusWater contentHot blast

The invention relates to an N-level incineration treatment method for domestic garbage, which comprises that: an N-level incinerator (N is more than or equal to 2) is arranged between a rotary kiln and a decomposing furnace; tertiary hot-blast air is introduced into the N-level incinerator, so that spiral upcurrent with the temperature of 850 DEG C is formed; the domestic garbage of which the moisture content is less than 10 percent is crushed into garbage materials of which the granularity is less than 30 millimeters, and a small quantity of the garbage materials are fed into a furnace body slowly through an air-lock feeder, and meet N-level dividing grates which are arranged from top to bottom to undergo the combustion, decomposition and gasification of organic matters; and generated acidic fume is discharged to the decomposing furnace through smoke outlets distributed at multiple positions uniformly, and after the decomposing furnace reaches the furnace temperature of over 900 DEG C and is in the state of alkalinity, the acidic fumes can be further subjected to neutralization treatment to reach discharging standards finally. Ash residues of the garbage are discharged out of the furnace body by a totally-enclosed electric vibrating discharger, are conveyed to a kiln hood of the rotary kiln by conveying equipment to enter the rotary kiln, and are used as a raw component for producing cement for calcination and solidified in the cement finally, so that the treatment aim of the 'harmlessness, reduction and recycling' of the domestic garbage is fulfilled.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

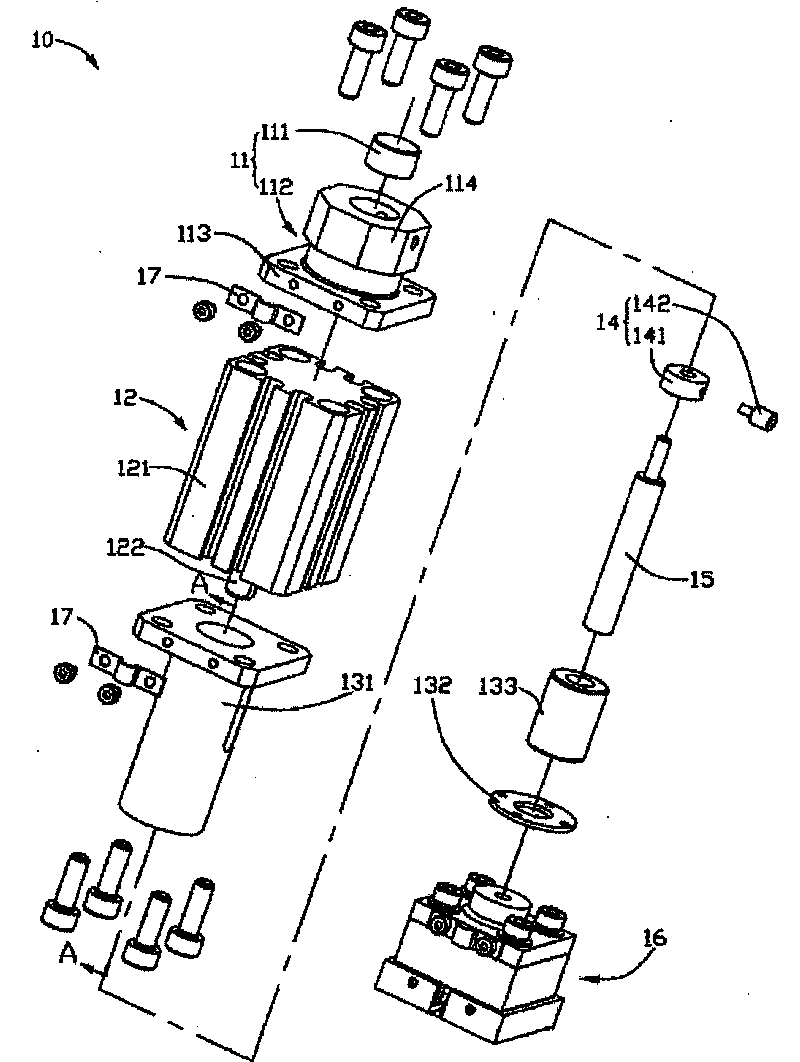

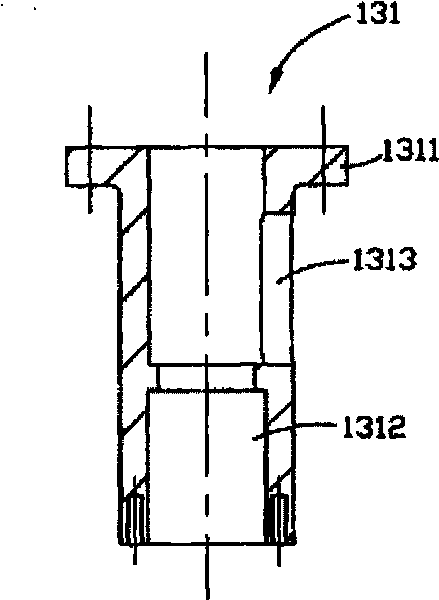

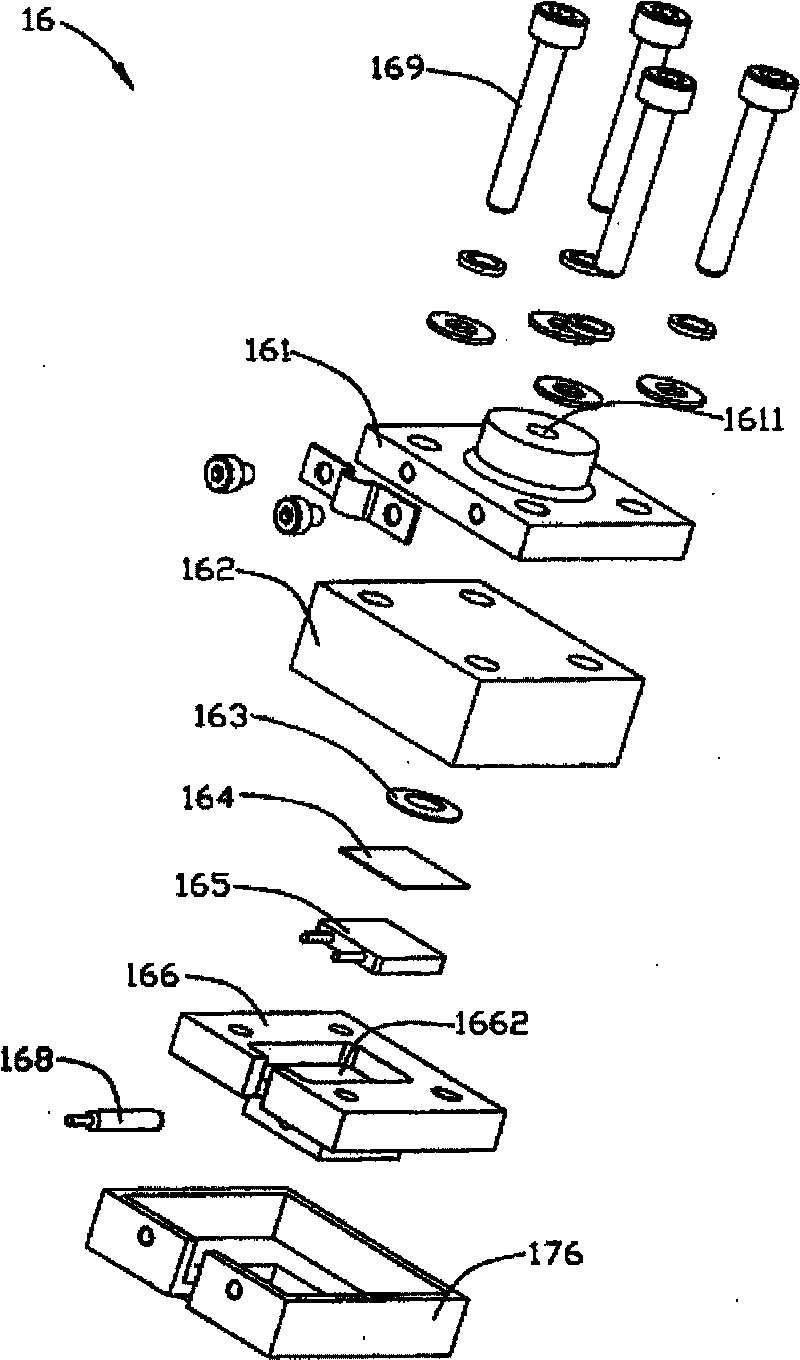

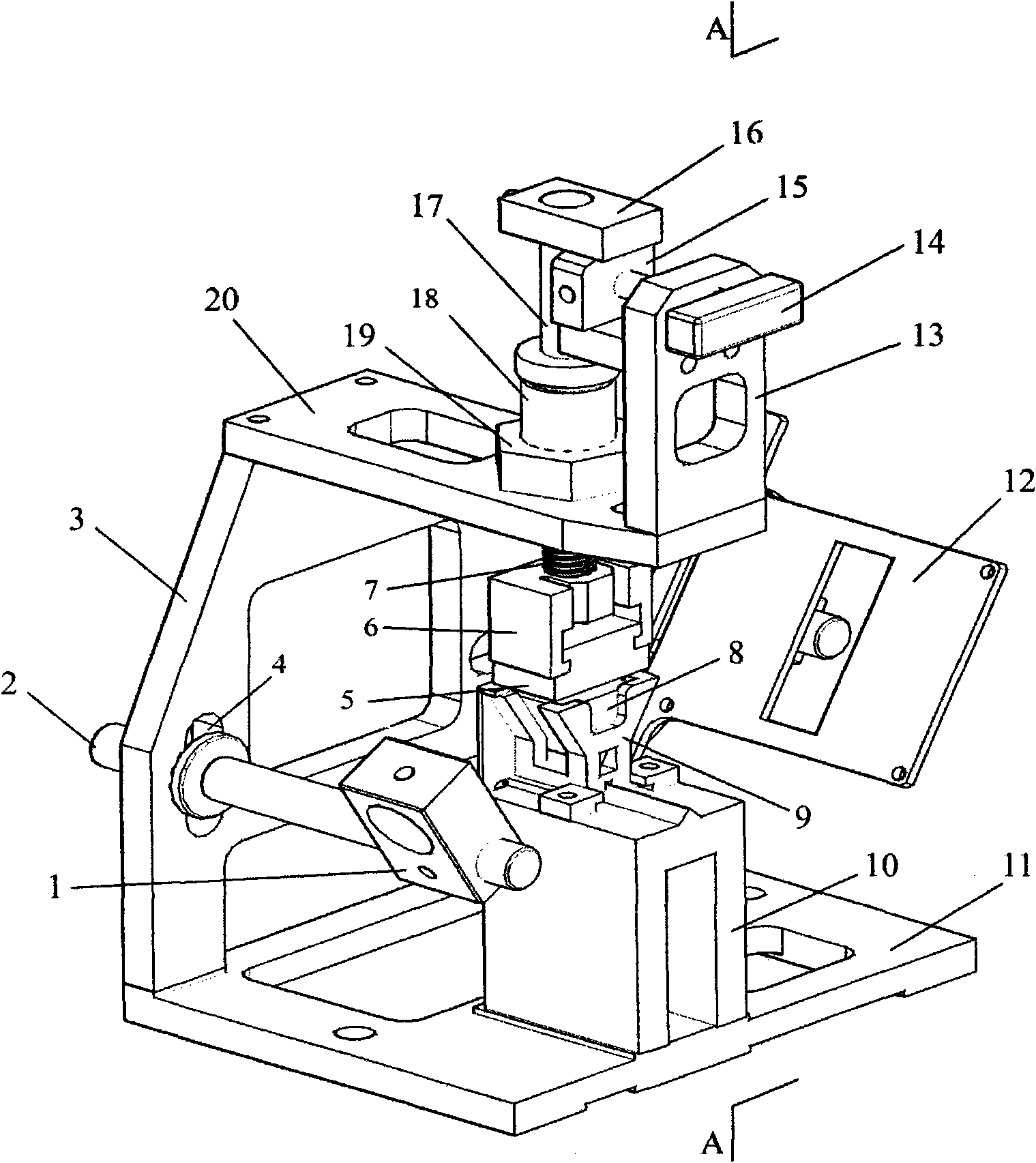

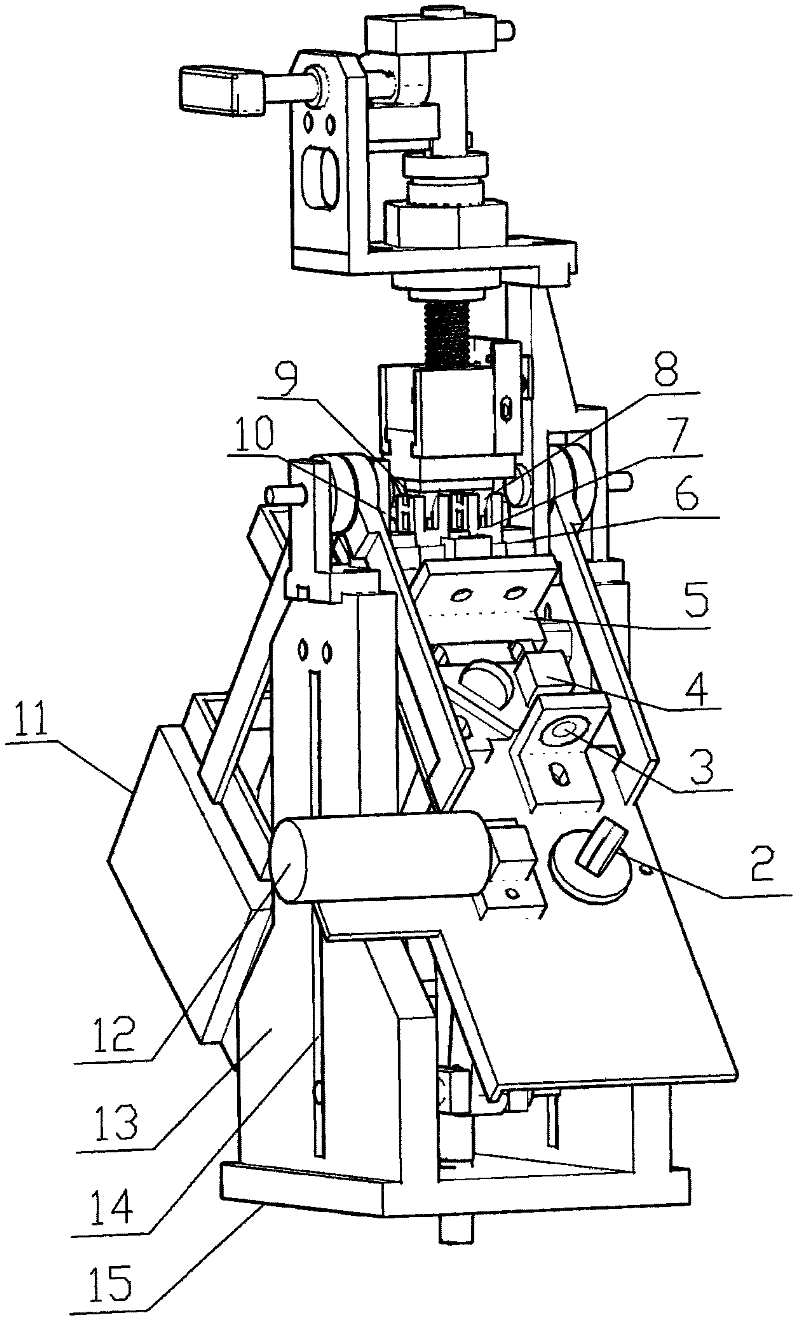

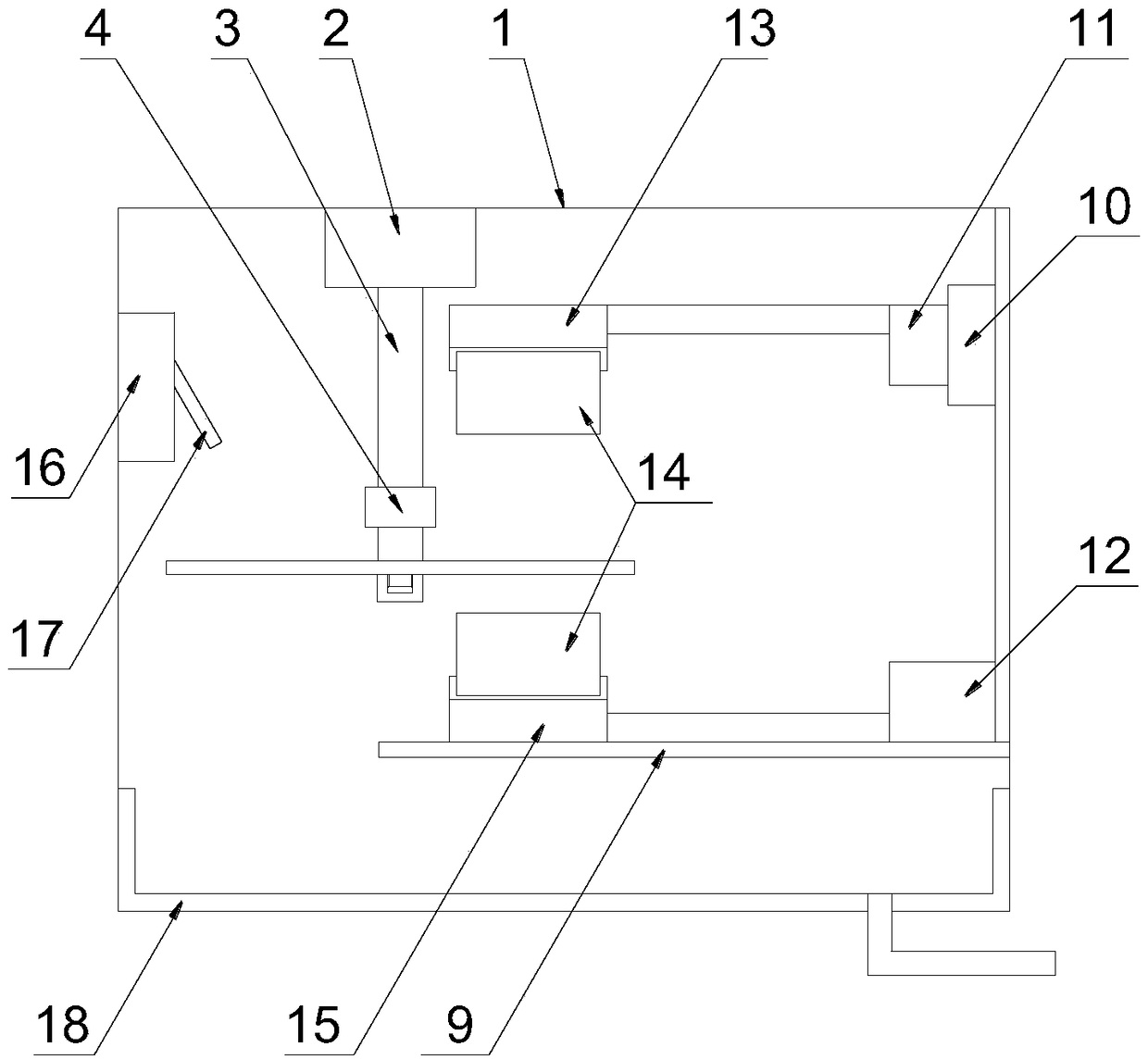

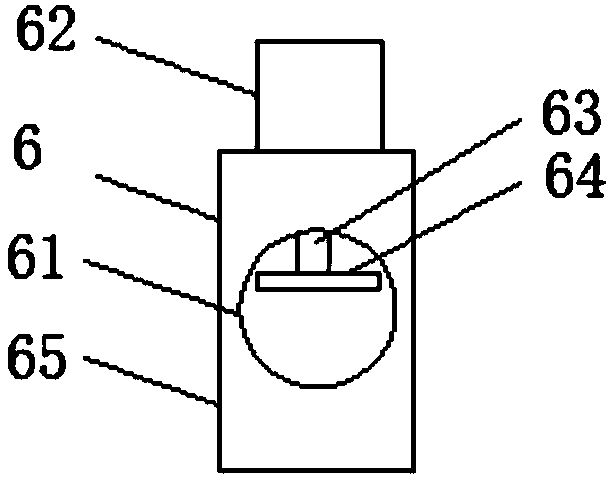

Multiple-DOF (degree of freedom) adjusting mechanism of optical surface plasma resonance biosensor

InactiveCN102095684APrecise positioningEasy to adjust pressurePhase-affecting property measurementsFlow cellRefractive index

The invention relates to a multiple-DOF (degree of freedom) adjusting mechanism of an optical SPR (surface plasma resonance) biosensor. The mechanism comprises a laser regulating unit, a biochip component, a CCD (charge coupled device) regulating unit, a support plate and a base used for mounting the support plate, wherein the laser regulating unit and the CCD regulating unit are symmetrically arranged at the two sides of the prism bracket, and certain light paths can be formed among a laser, the biochip component and a CCD by adjusting the relative position of the laser regulating unit and the CCD regulating unit. The mechanism provided by the invention has the advantages that the structural design is delicate, and the location is accurate, thus the consistency of the light paths among the laser, the biochip component and the CCD can be conveniently adjusted; the pressure between a flow cell and the biochip component can be conveniently adjusted; the flow cell can maintain to be circulated after being lifted and reset and the accurate location of the biochip component can be guaranteed; the problems that debugging is difficult and the refractive index is difficult to match as the biochip provided with a glass substrate is replaced only are solved, the analysis accuracy of the biosensor is improved, and the use cost and the maintenance cost of the optical SPR sensor are greatly reduced.

Owner:HENAN AGRICULTURAL UNIVERSITY

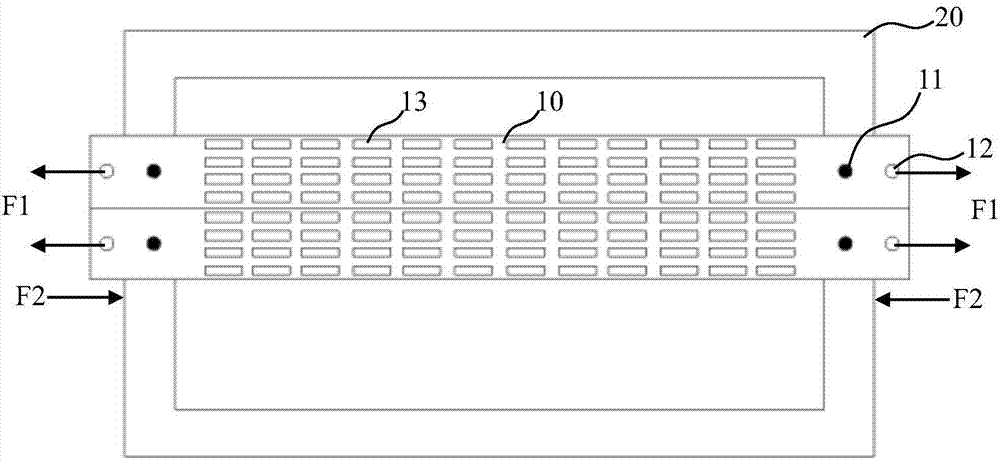

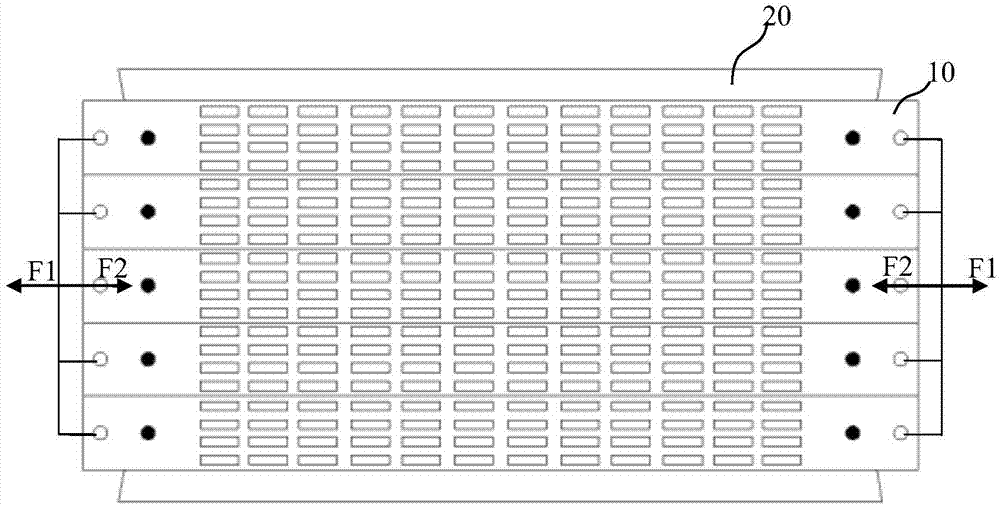

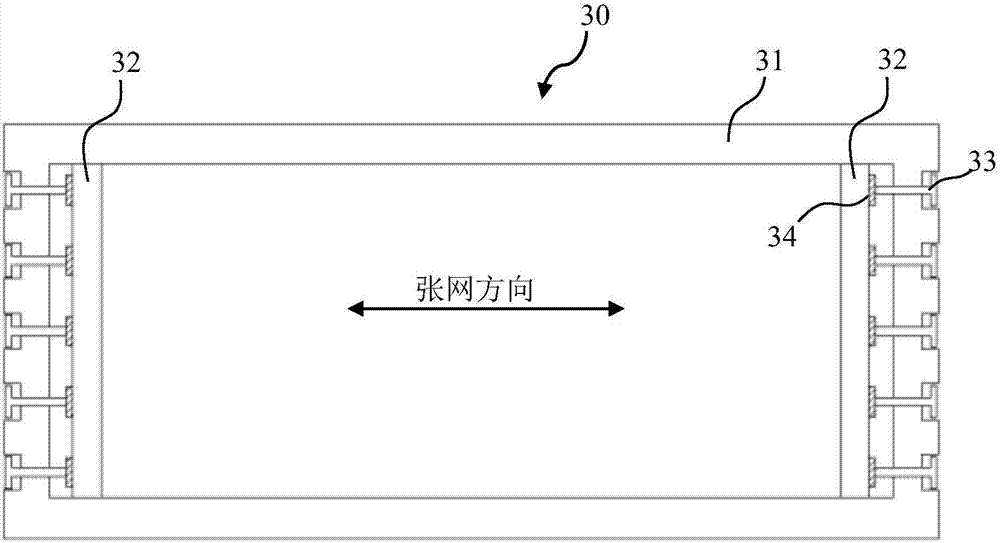

Mask frame, mask and production method thereof

ActiveCN107419219AEasy to adjust pressureAvoid differencesVacuum evaporation coatingSputtering coatingPressure senseEngineering

The invention discloses a mask frame, a mask and a production method thereof. The mask frame comprises a frame main body, fixing parts, extrusion devices and pressure sensing devices, wherein the fixing parts are located in two opposite sides of the frame main body; the extrusion devices are used for passing through the frame main body and applying pressure to the fixing parts; the pressure sensing devices are used for sensing pressure applied to the fixing parts by the extrusion devices. According to the mask frame, the mask and the production method thereof, the extrusion devices are used for applying pressure to the fixing parts, so that the pressure is applied to the mask frame; the pressure sensing devices are used for sensing the pressure applied to the fixing parts by the extrusion devices, so that the pressure applied by the extrusion devices can be adjusted, and then the proper pressure can be applied to the fixing parts in different positions; the problem of difference or positional deviation of pixel images on mask bars can be avoided, so that the accuracy of the formed mask patterns can be improved.

Owner:BOE TECH GRP CO LTD +1

Sealing structure capable of achieving bearing cavity-sharing and bearing external cavity pressure equalizing

ActiveCN107269396AReduce in quantitySimple flow pathGas turbine plantsTurbine/propulsion lubricationEngineeringCantilever

The invention relates to a sealing structure capable of achieving bearing cavity-sharing and bearing external cavity pressure equalizing. The sealing structure is provided with front and rear bearing supporting points, one of the bearing supporting points is designed by adopting a simple supporting structure, the other one of the bearing supporting points is designed by adopting a cantilever supporting structure, so that two adjacent bearings are close in space, a front bearing seat and a rear bearing seat are connected together, the cavity-sharing design between the adjacent bearings is achieved, and thus pressure in a bearing cavity is convenient to adjust. A plurality of air hole structures are arranged on the front bearing seat and the rear bearing seat in the circumferential direction correspondingly, the angular positions, the shapes and the sizes of the air hole structures on the two bearing seats are mutually matched, and the air hole structures on the two bearing seats correspond one to one, channels communicating with two bearing external cavities are formed, and therefore pressure equalizing of the front bearing external cavity and the rear bearing external cavity is achieved; flow path of an air system is simplified, the design difficulty of the air system sealing the bearing cavity is reduced, and moreover the reliability of operating is high; and pressure of the bearing external cavities is adjusted by adjusting comb tooth gaps of inlet-outlet ports, build-up of the pressure of the bearing external cavities is facilitated, and the sealing effect is enhanced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI +1

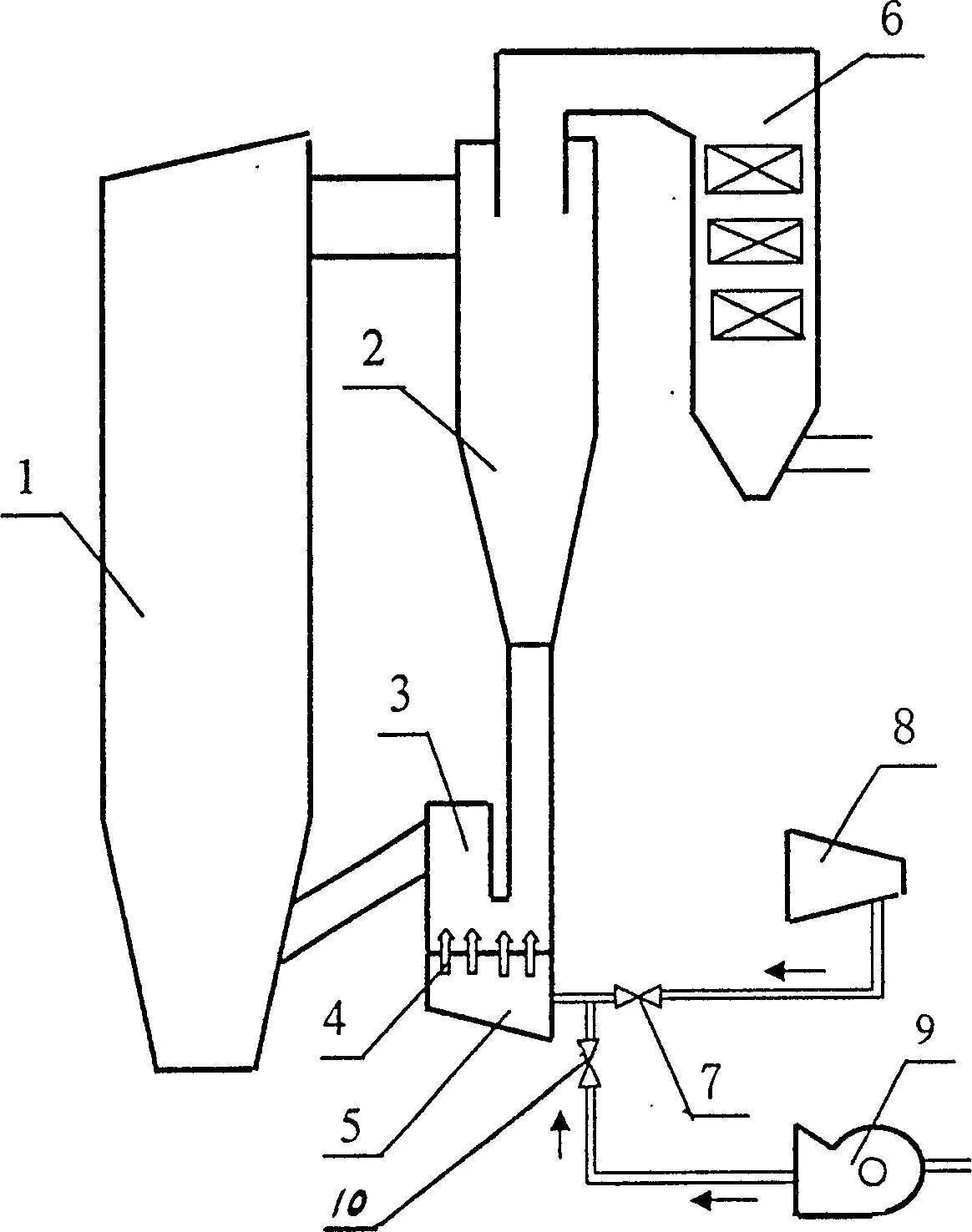

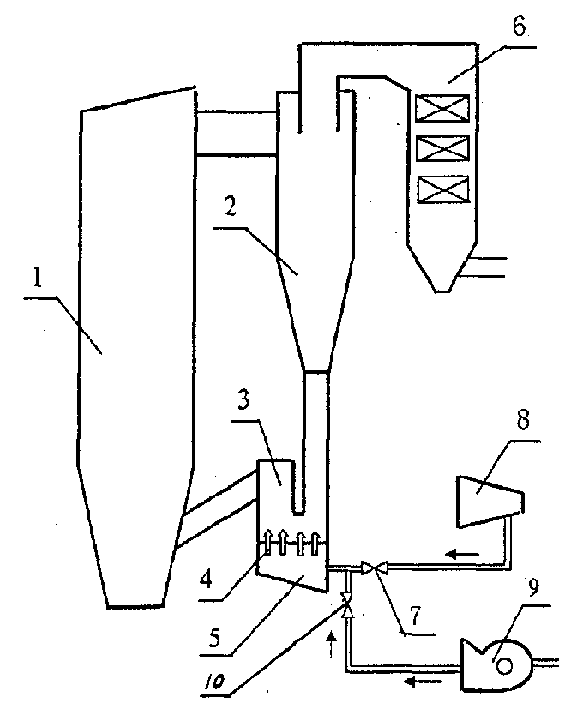

Method of fluidizing wind at high pressure using steam to replace air

InactiveCN1566749AAvoid cokingAvoid burnsFluidized bed combustionApparatus for fluidised bed combustionEngineeringHigh pressure

The invention relates to a method of implementing high pressure fluidization blast using steam in place of air, characterized in that: steam is used for high pressure fluidization blast in normal running of a boiler. The method includes: connecting a turbine exhaust or intermediate extraction with a stock recycler using a steam conduit; starting high pressure fluidization blower and fluidizing recycle material in the stock recycler using air when the boiler begins to start; opening stop valve of the turbine steam conduit, fluidizing recycle material in the stock recycler using steam, shutting down the high pressure fluidization blower and closing the stop valve when the temperature of recycle material in the stock recycler is above 300 Celsius degree, the fluidization steam vapor source pressure parameter is greater than 60Kpa, and the superheat degree is larger than 30 Celsius degree; starting the high pressure fluidization blower, fluidizing recycle material in the stock recycler using air, and closing the stop valve on steam turbine when the temperature of the stock recycler is under 300 Celsius degree in blow off process of the boiler. Advantages of the invention consist in that coking of the stock recycler or other high temperature zones can be prevented or abated and boiler operation reliability can be improved by using steam for replacing high pressure fluidization blast. At the same time, circulating fluid bed boiler desulfurizer utilization rate can be improved, Nox discharge concentration can be reduced, and power plant running cost can be saved by utilizing steam fluidization.

Owner:SHANGHAI BOILER WORKS

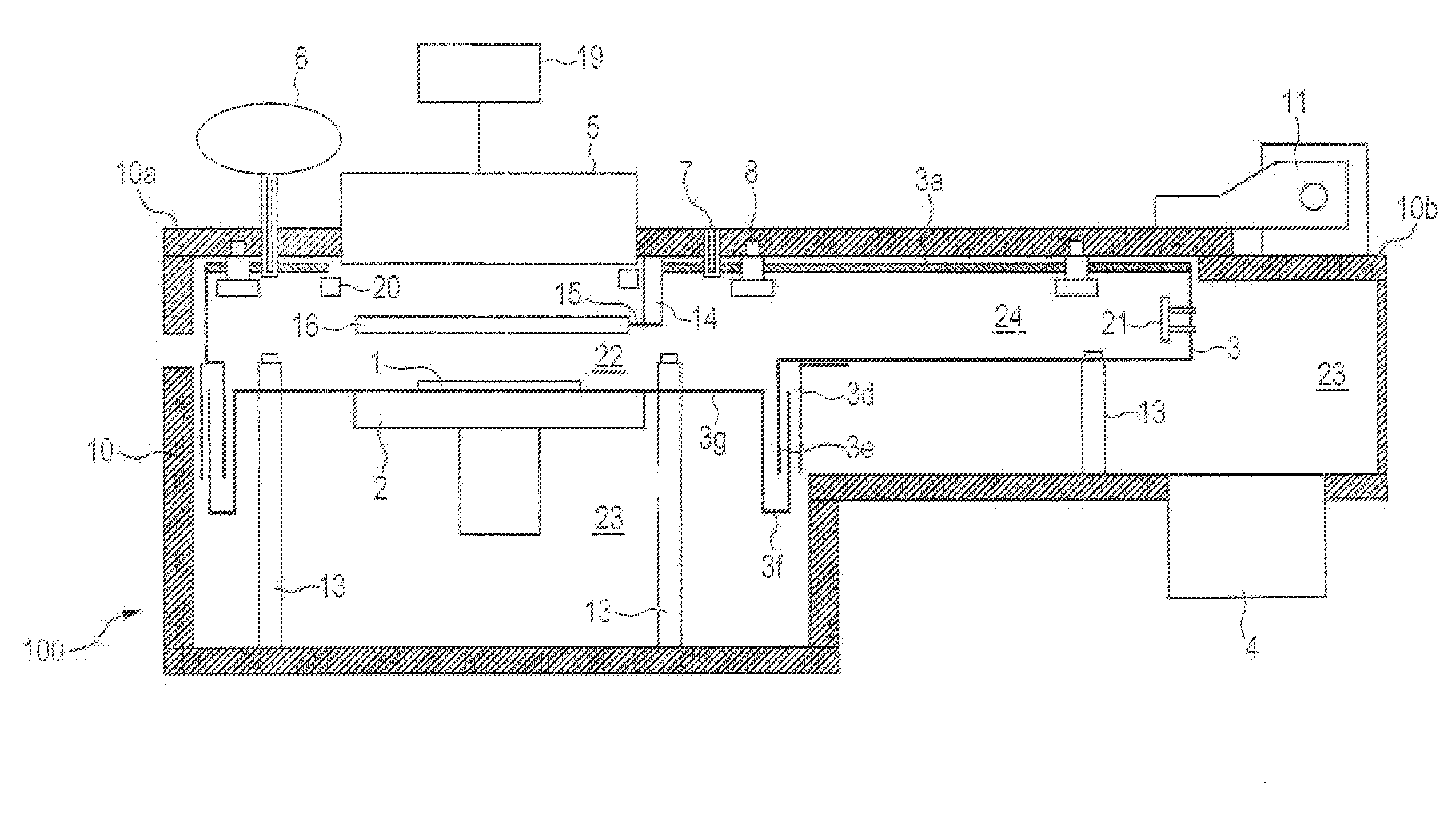

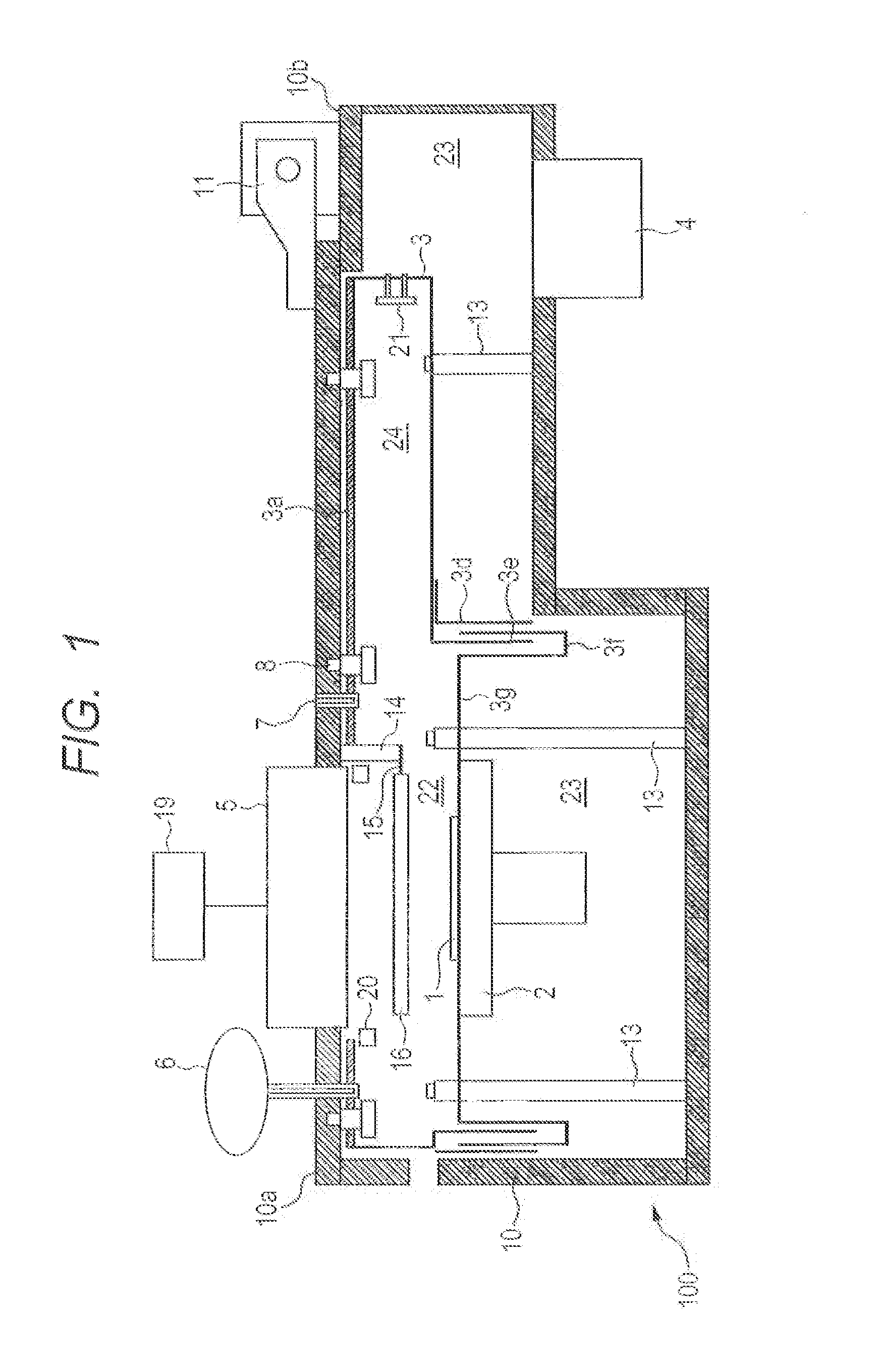

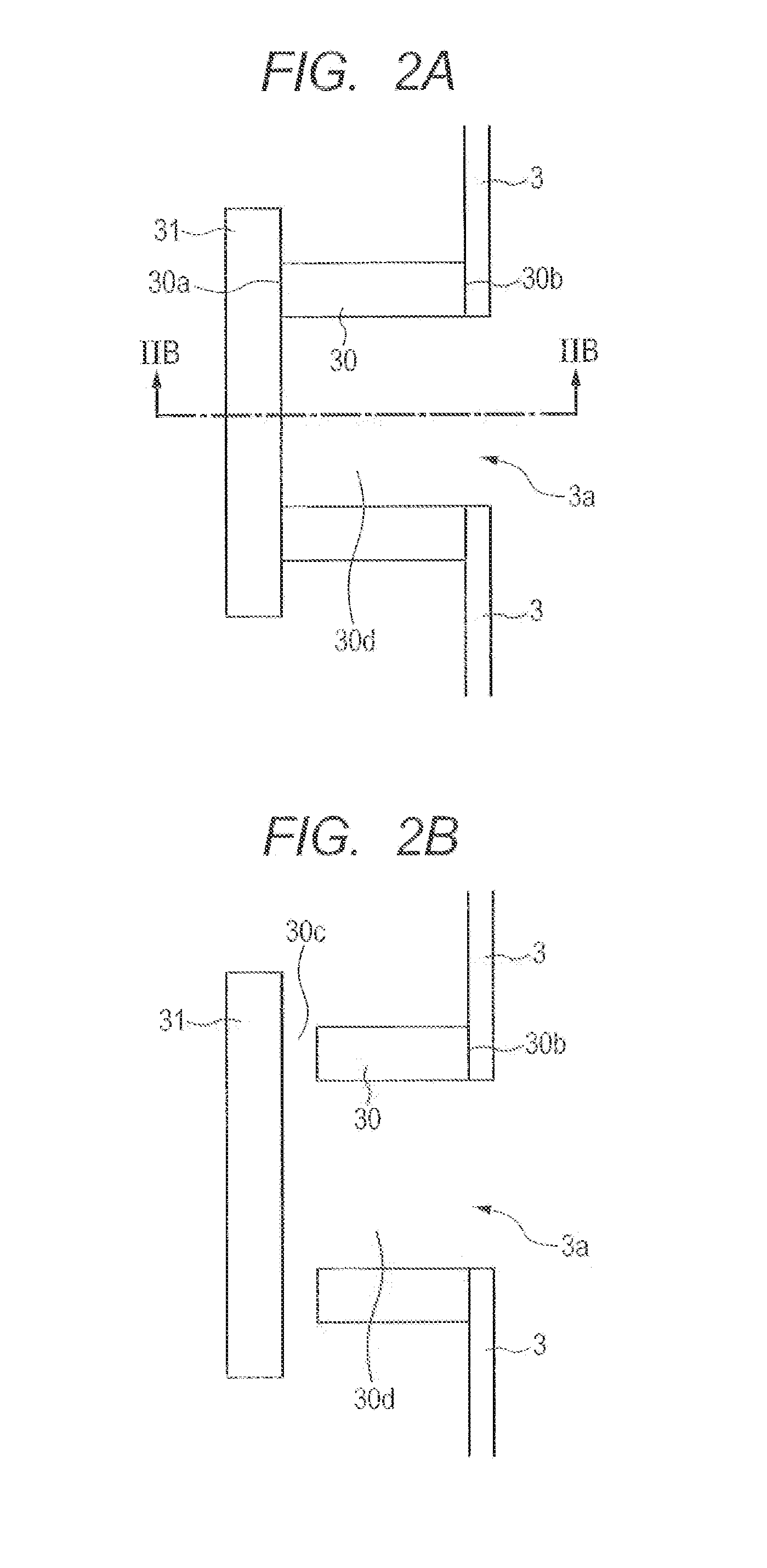

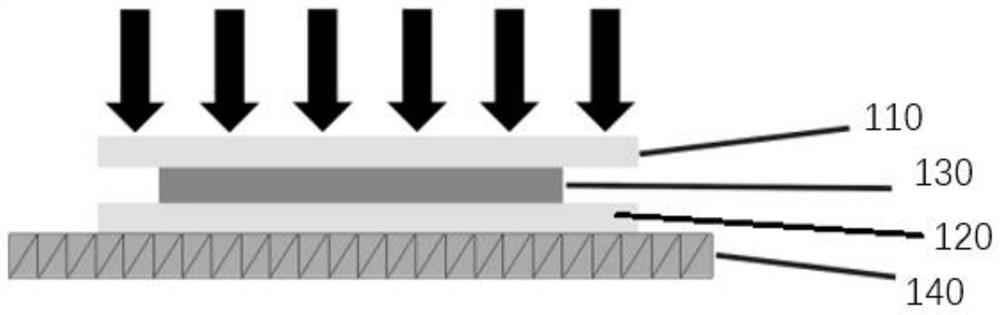

Substrate processing apparatus

ActiveUS20140261182A1Reduce attachmentEasy to adjust pressureVacuum evaporation coatingSputtering coatingEngineeringProduct gas

The present invention provides a vacuum processing apparatus capable of reducing attachment of particles generated in a processing space to an inner wall of a chamber, and of easily adjusting pressure in the processing space while introducing a gas into the processing space at a desired flow rate. A vacuum processing apparatus according to one embodiment includes: a container; a gas exhaust portion; a substrate holder configured to retain a substrate; a shield provided to surround the substrate holder and dividing an inside of the container into a processing space and an outside space; a gas introducing portion; a plasma generating portion; and an exhaust portion provided to the shield having a communication path through which the processing space and the outside space communicate, wherein at least part of the communication path is hidden from a region where the plasma generating portion generates the plasma.

Owner:CANON ANELVA CORP

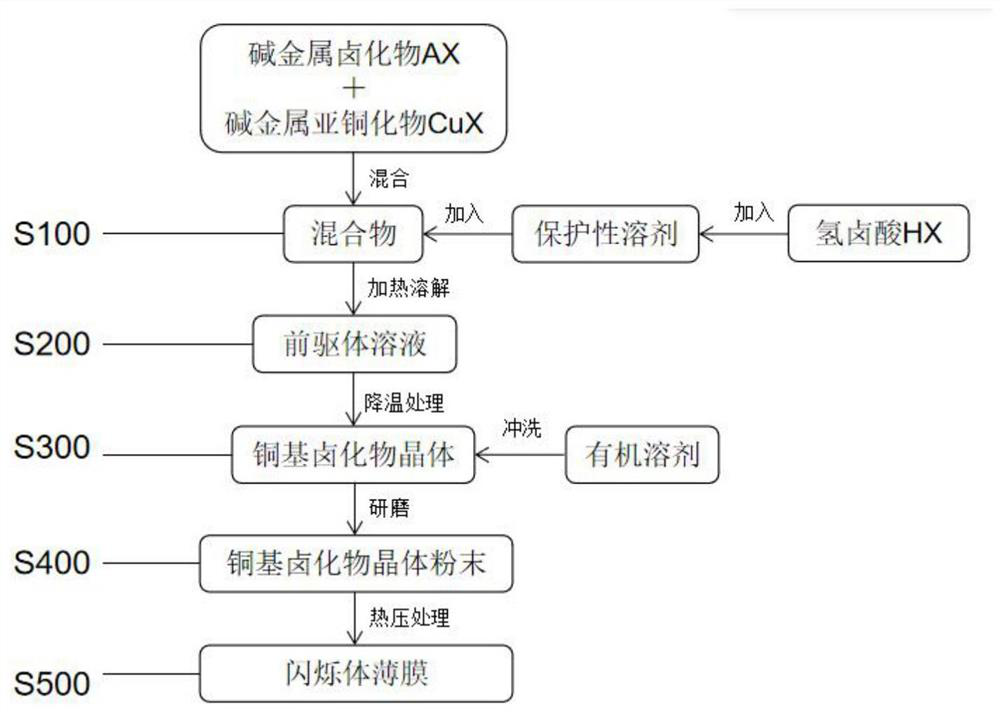

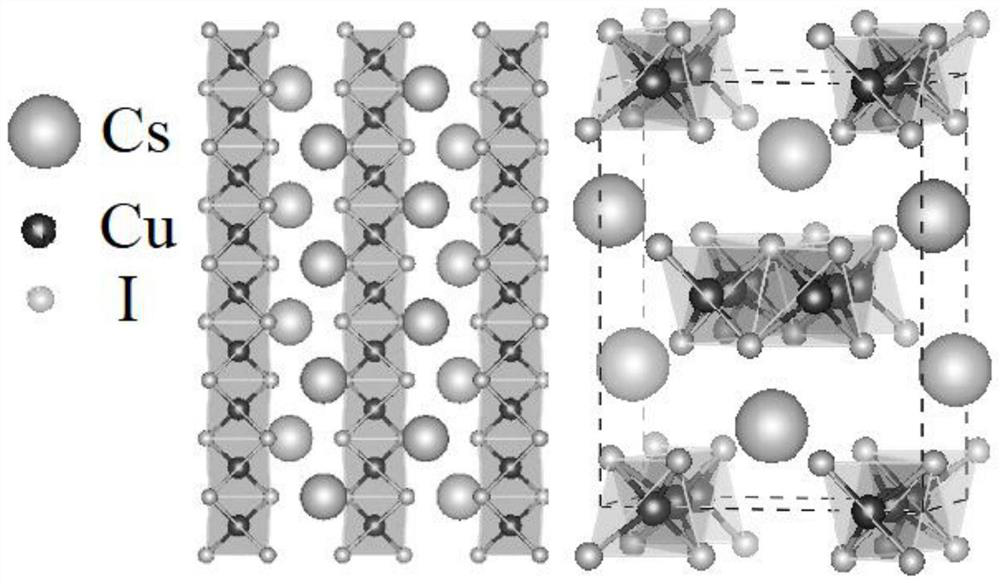

Preparation method of non-lead copper-based halide scintillator film

The invention provides a preparation method of a non-lead copper-based halide scintillator film, which comprises the following steps: preparing copper-based halide crystal AxCuyXz powder, and paving the powder on a first matrix; heating the first matrix to obtain a copper-based halide crystal powder melt; preheating a second matrix, covering the copper-based halide crystal powder melt with the second matrix, and applying pressure to the non-lead copper-based halide crystal powder melt; and after cooling, removing the first matrix and the second matrix to obtain a copper-based halide scintillator film, wherein the first matrix and the second matrix are both high-temperature-resistant matrixes. The hot pressing method is simple to operate, universal and low in cost, and the prepared scintillator film is excellent in performance, free of heavy metal lead, non-toxic and free of environmental pollution.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

Gas filling apparatus

ActiveUS20090159151A1Improve stabilityFacilitates equalizing pressure and flow rateLiquid fillingSemiconductor/solid-state device manufacturingClosed loopEngineering

This present invention provides a gas filling apparatus for filling a gas into a storage apparatus for storing a semiconductor element or a reticle. The gas filling apparatus is connected with an air feed source, and includes a base, a first inlet port and a set of air feed source route. The storage apparatus is loaded on the base, and the first inlet port which is disposed on the base corresponds with the second inlet port of the storage apparatus. The set of air feed source route includes an entrance part, a supply part and a branch part. The entrance part is connected with the air feed source, and the supply part is connected with the first inlet port. The branch part is a closed loop, which transmits the gas from the entrance part into the supply part.

Owner:GUDENG EQUIP CO LTD

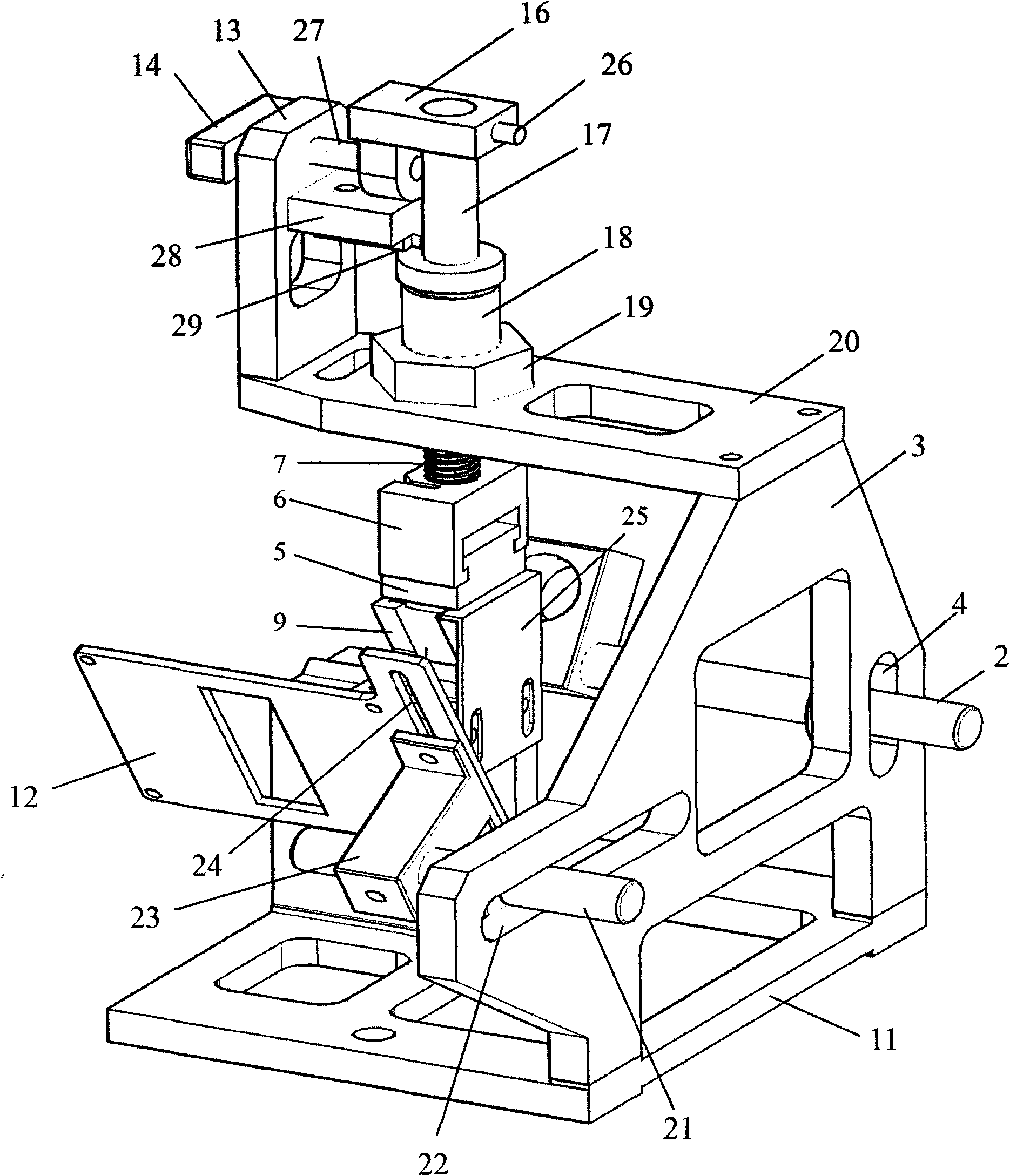

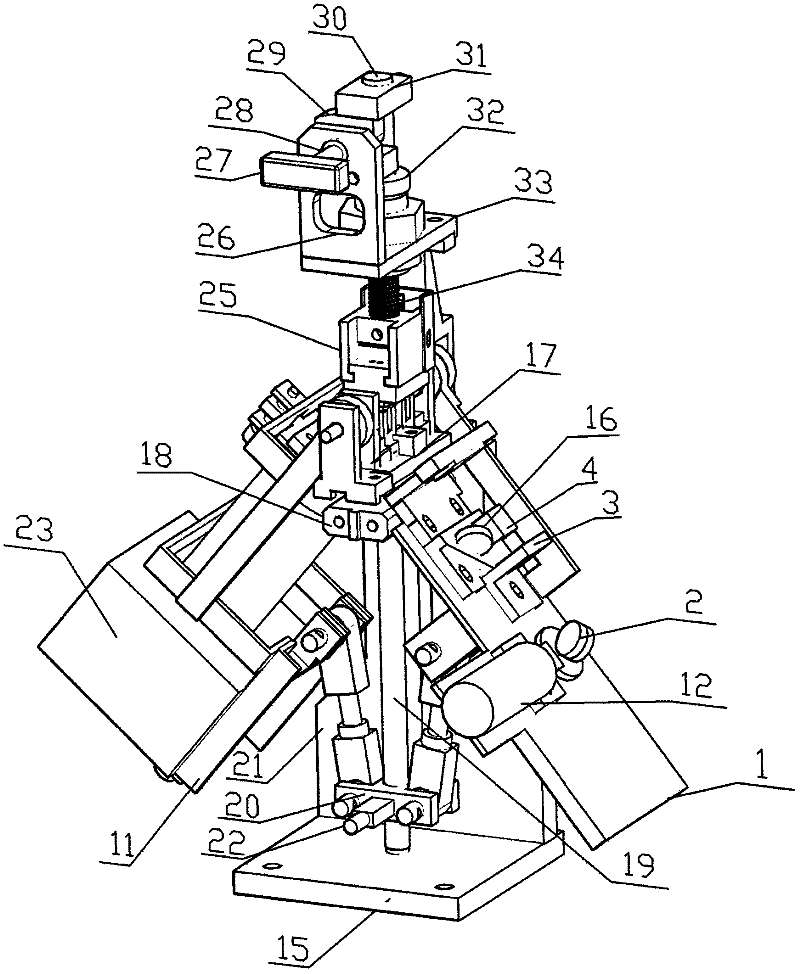

Dual-channel MDOF (multidegree of freedom) adjustment mechanism of optical surface plasma resonance biosensor

InactiveCN102410989APrecise positioningEasy to adjust pressurePhase-affecting property measurementsRefractive indexEngineering

The invention relates to a dual-channel MDOF (multidegree of freedom) adjustment mechanism of an optical surface plasma resonance biosensor. The mechanism comprises a biochip assembly regulating unit, an optical path regulating unit, an angle regulating unit and a supporting and guiding unit, wherein the optical path regulating unit comprises a laser swing frame and a charge coupled device (CCD) swing frame; the angle regulating unit comprises an elevating assembly, a rotating support arm, a transmission shaft and a driving device; driven by the driving device, the transmission shaft drives the elevating assembly to complete the elevating travel, and at the same time, drives the laser swing frame and the CCD swing frame to form an included angle within a certain range via the corresponding rotating support arm, and form two corresponding optical path detection passages among laser, a CCD image sensor and the biochip assembly. The dual-channel MDOF adjustment mechanism provided by the invention is convenient for operation and accurate in positioning and has high testing precision, and solves the problems, such as debugging difficulty and hard refractivity matching caused when only the biochip with a glass substrate is replaced, thereby increasing the analytic precision of the biosensor and also substantially reducing the using and maintaining cost of the optical surface plasma resonance (SPR) sensor.

Owner:HENAN AGRICULTURAL UNIVERSITY

Pressure vessel with adjustable pressure

PendingCN108895160AEasy to change volumeAvoid breakingEqualizing valvesFluid pressure control with auxillary non-electric powerPistonPiston cylinder

The invention discloses a pressure vessel with adjustable pressure, includes a pressure tank and a first cover, a piston cylinder is installed inside the pressure tank, and the inside of the piston barrel is inserted into the upright post, the air pipe connected to the right side of the piston barrel is communicated with the upper surface of the pressure tank, a fixing rod is arranged above the upright post, the left side of the pressure tank is provided with a support block, and a movable shaft mounted on the inner side of the support block is welded to the surface of the pressure tank, a positioning block is mounted on the outer side of the first cover body, a feeding port and a limiting groove are arranged on the left surface of the pressure tank, a second sealing ring is arranged on the inner surface of the first cover body, and a stopper is fixed on the left surface of the pressure tank. The piston moves up and down inside the piston barrel of the pressure-adjustable pressure vessel, which is convenient to change the volume inside the pressure vessel, plays the role of regulating the pressure, avoids the breakage of the vessel caused by the excessive internal pressure, and plays the role of releasing the pressure when the ventilation pipe is communicated with the outside world.

Owner:YANCHENG DAMING CHEM MACHINERY

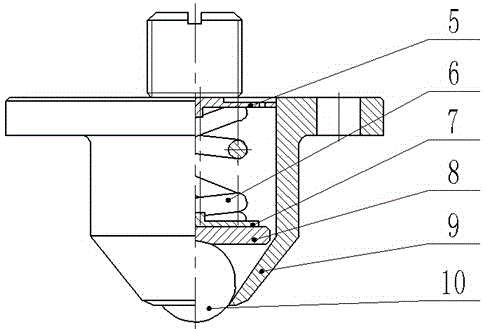

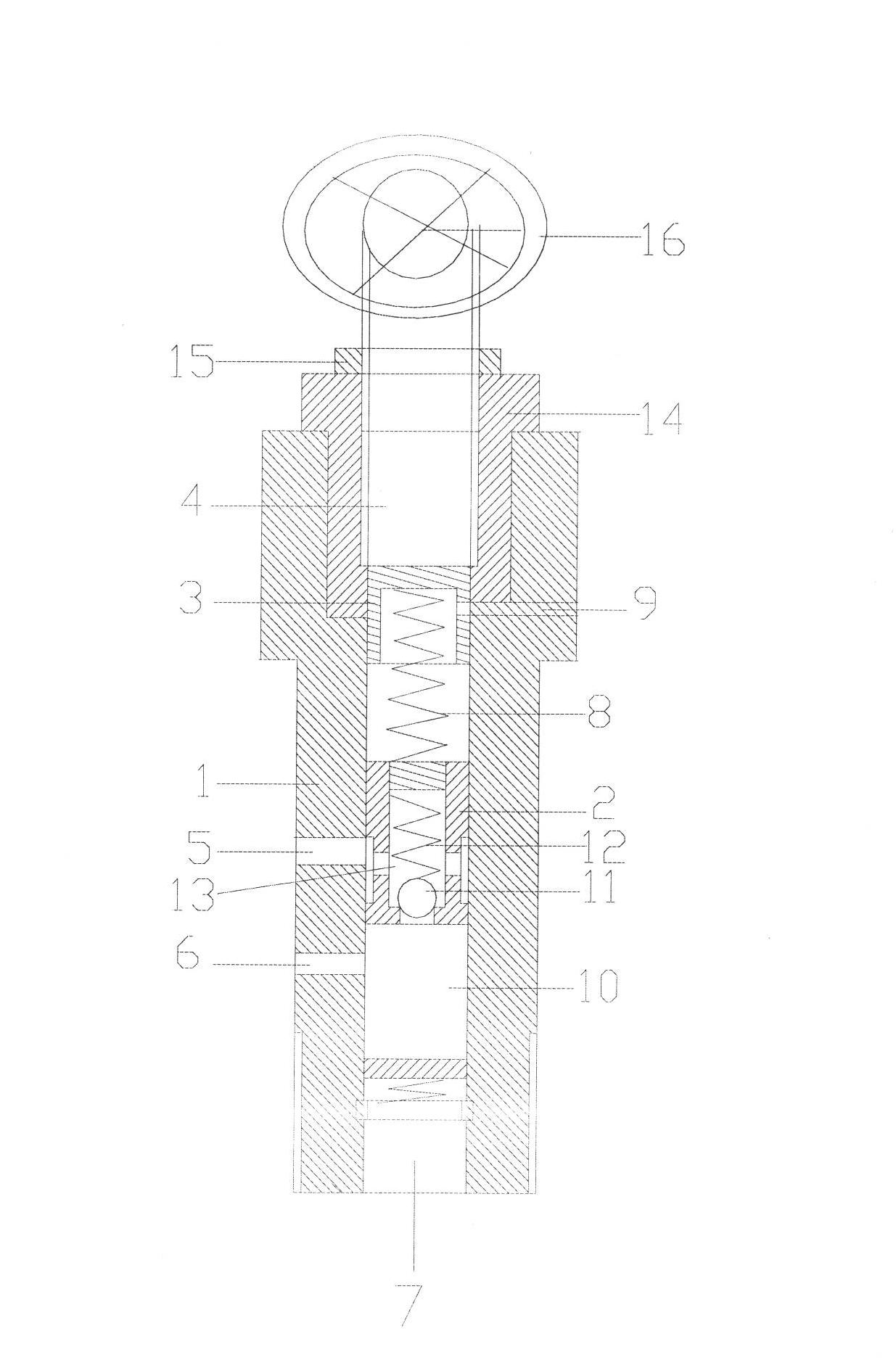

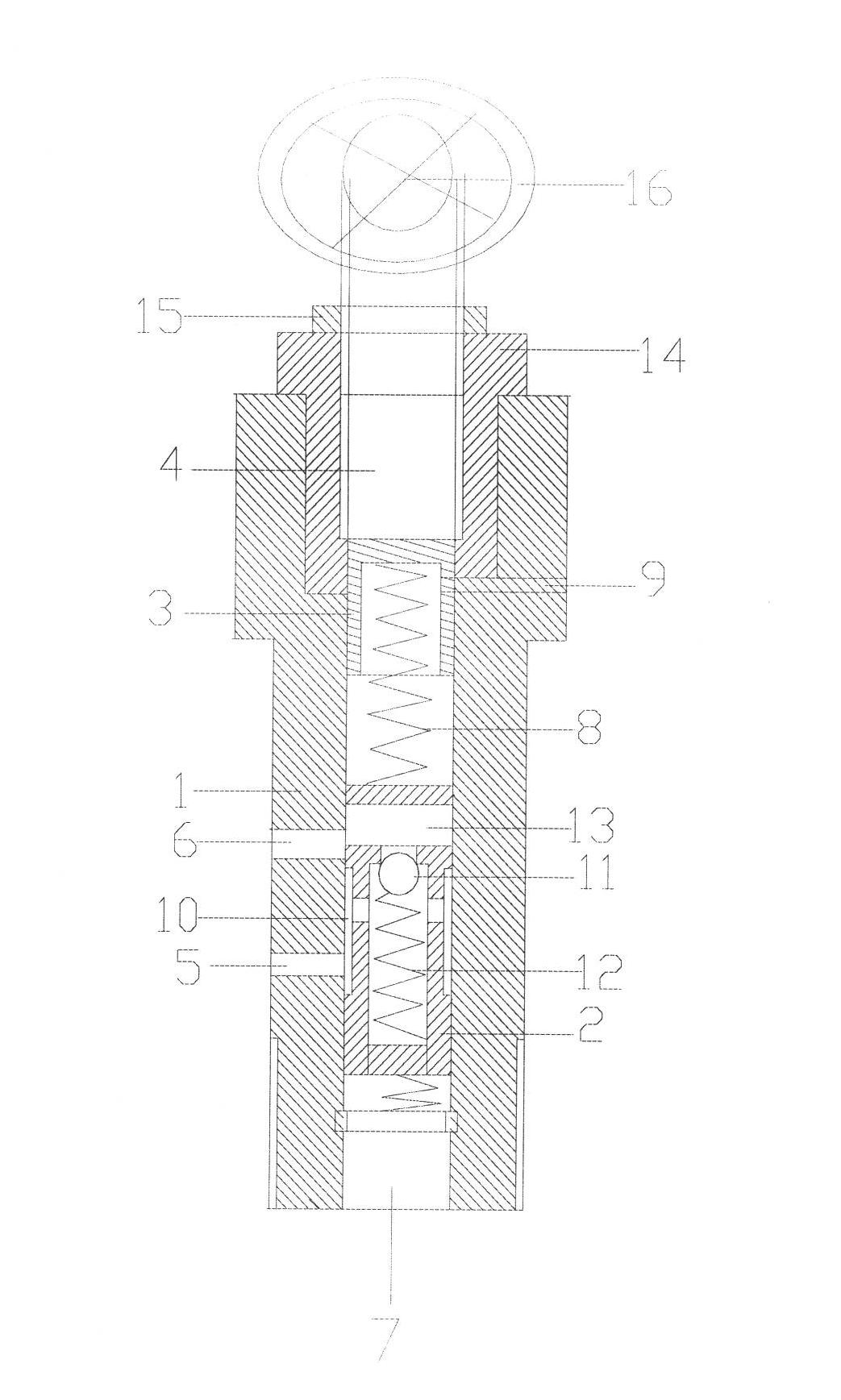

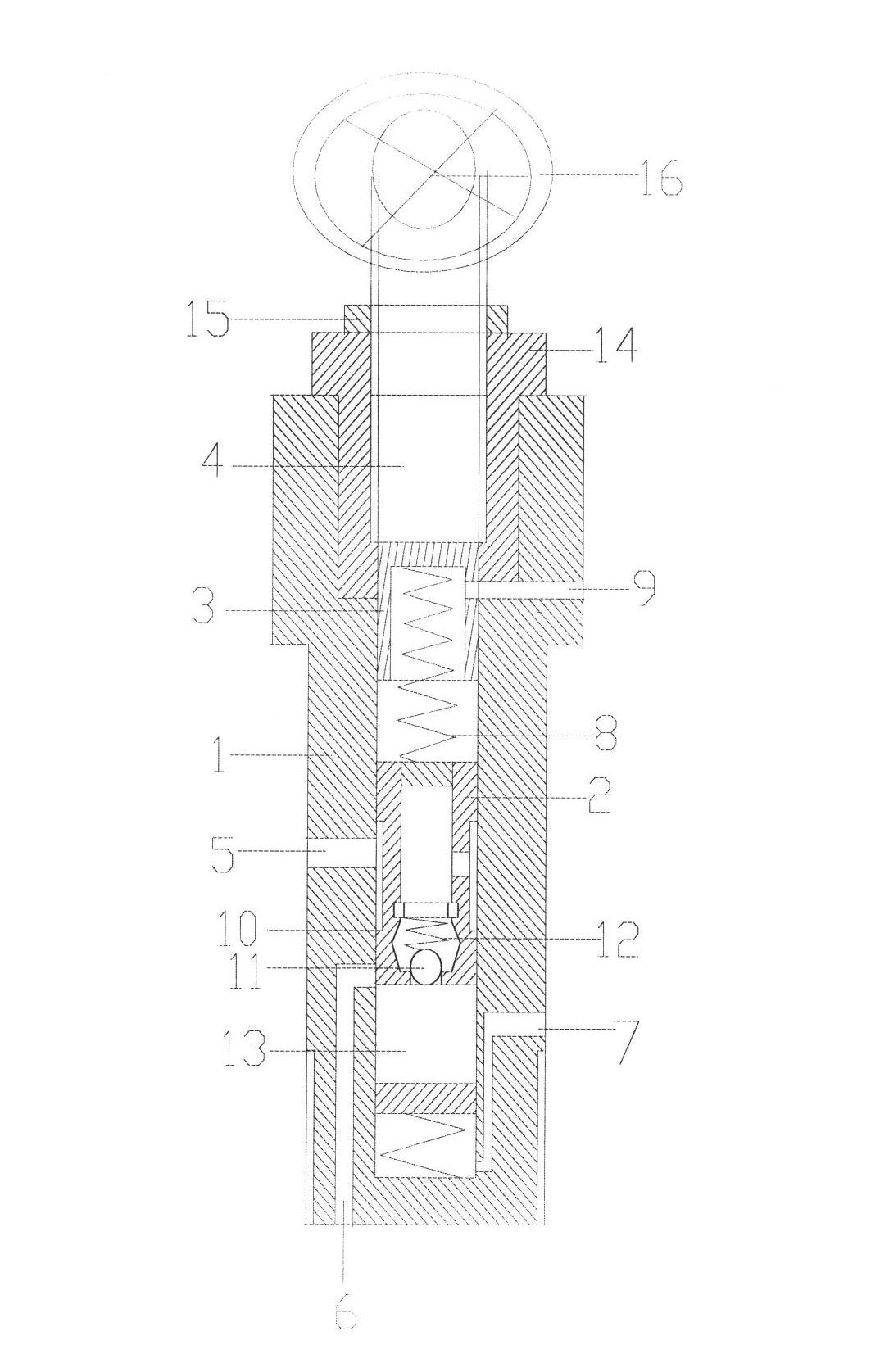

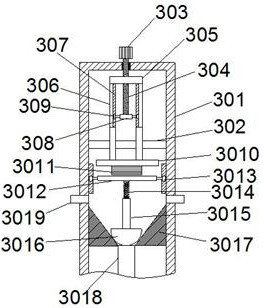

Direct-acting externally piloted one-way sequence valve

InactiveCN102563183APlay a connecting roleReasonable layoutOperating means/releasing devices for valvesValve housingsBiomedical engineeringHydraulic pressure

The invention discloses a direct-acting externally piloted one-way sequence valve, which comprises a valve body (1), a main valve spool (2) and a reset spring (8). A liquid inlet (5), a liquid outlet (6) and a control liquid inlet (7) are arranged on the valve body (1), the main valve spool (2) is arranged in the valve body (1), the outer diameter of the head at the upper end of the valve body (1) is larger than that of a portion below the head, an external thread is arranged on the portion below the head of the valve body (1), one end of the reset spring (8) is connected onto the main valve spool (2), the other end of the reset spring (8) is fixed onto the valve body, the head at the upper end of the valve body is closed, and a cavity between the main valve spool (2) and the upper end of the valve body is communicated with the outside through a drainage channel (9). The external shape of the valve body is equivalent to that of a hinged bolt, a hydraulic part and a pipeline can be connected by the valve body, and the hinged bolt and the direct-acting externally piloted one-way sequence valve are integrated.

Owner:林友根

Grinding sheet machining device of diamond

InactiveCN108927708AImprove work efficiencyImprove sanding qualityOther manufacturing equipments/toolsFastenerMoving parts

The invention discloses a grinding sheet machining device of diamond. The grinding sheet machining device of the diamond comprises a machine frame, a third driving mechanism, a lifting device, a motor, a rotating part and a fastener, and further comprises a moving part, a first clamping device, a second clamping device, a grinding part and a supporting plate, wherein the third driving mechanism isarranged at the top of the machine frame, the motor is arranged at the bottom of the lifting device, and the rotating part is arranged at the bottom of the motor; the bottom of the rotating part is provided with a downward protrusion, the protrusion is in threaded fit connection with the fastener, the supporting plate is horizontally arranged, the second clamping device is arranged on the supporting plate in a sliding mode, and a second driving mechanism is arranged at one end of the supporting plate; and the grinding part is arranged on the second clamping device, the moving part is arrangedon the side face of the machine frame in a sliding mode, a first driving mechanism is arranged on the moving part, and the grinding part is arranged on the first clamping device. According to the device, the process of simultaneously grinding the two end faces of a to-be-machined grinding sheet is realized, the grinding quality of the to-be-machined grinding sheet is high, and the grinding effectis good.

Owner:WUHU CHANGLING DIAMOND TOOL CO LTD

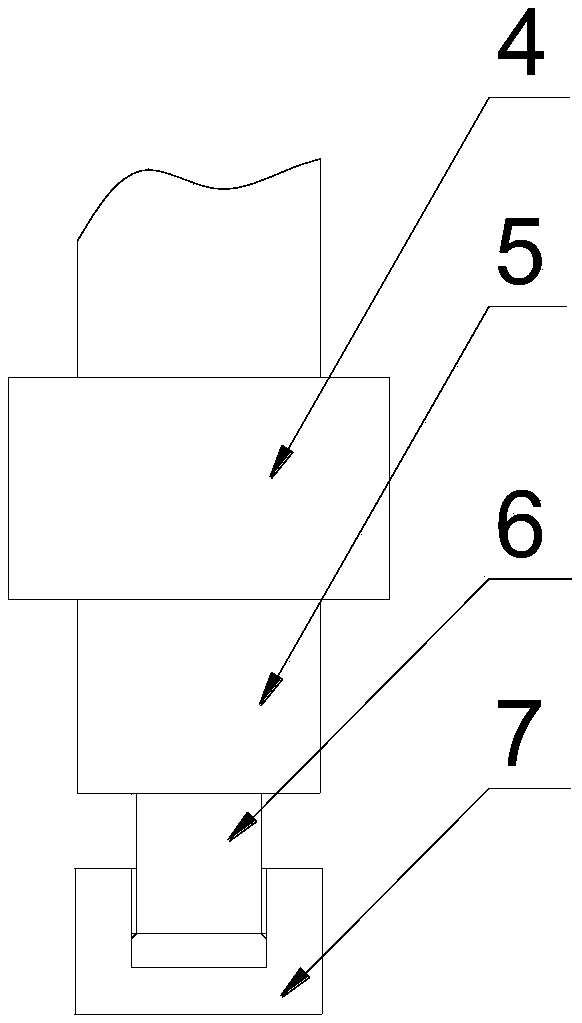

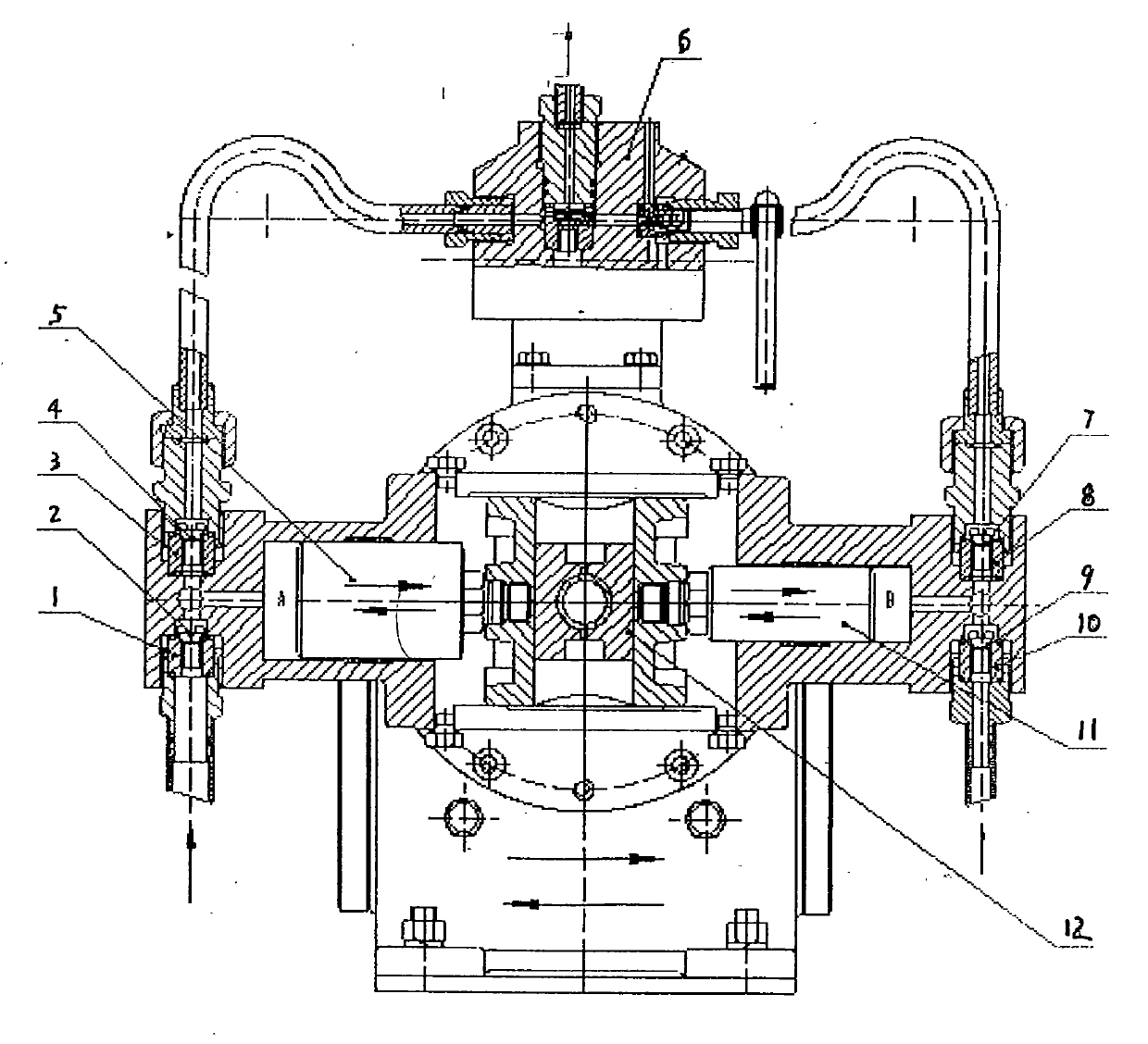

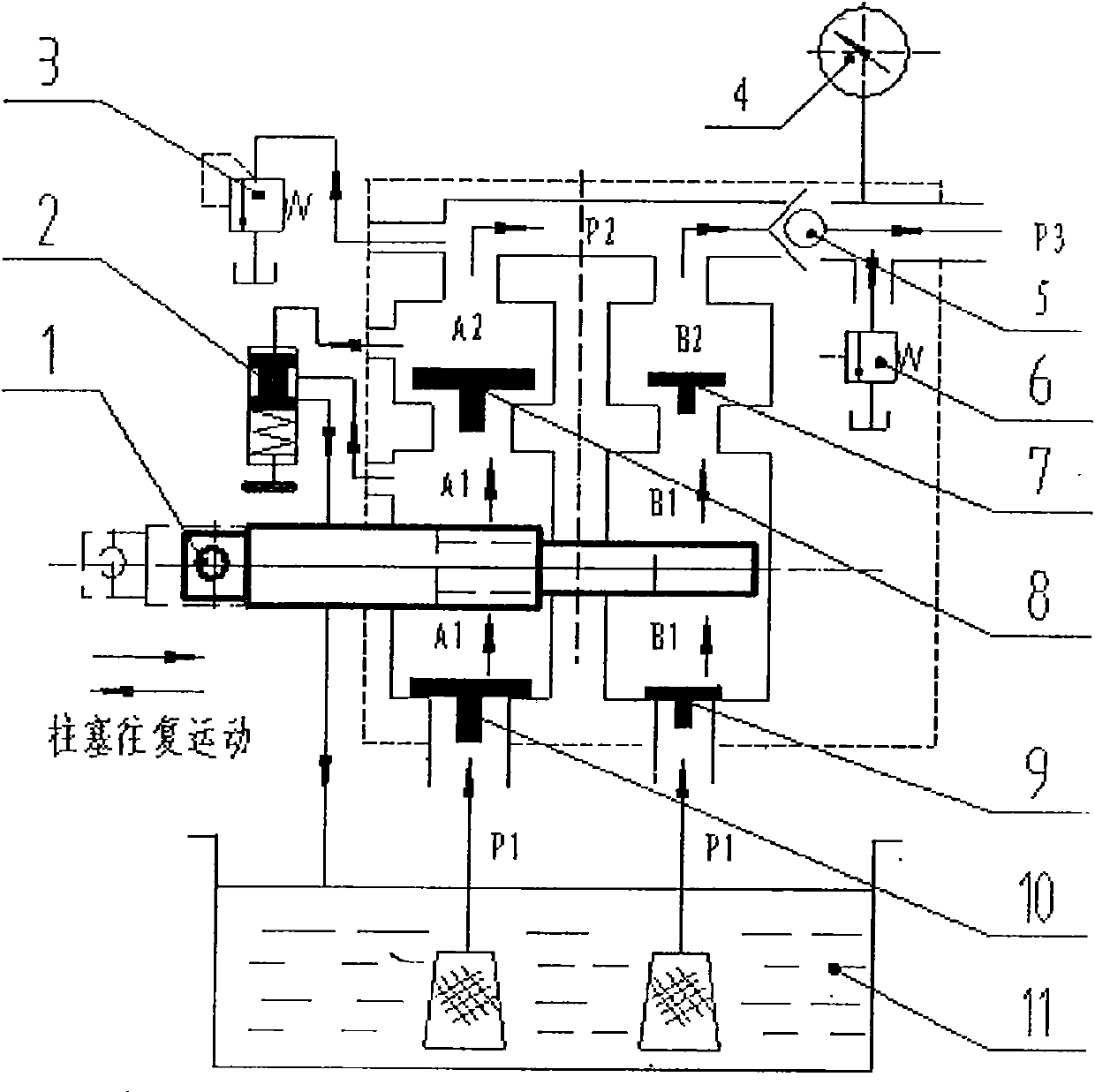

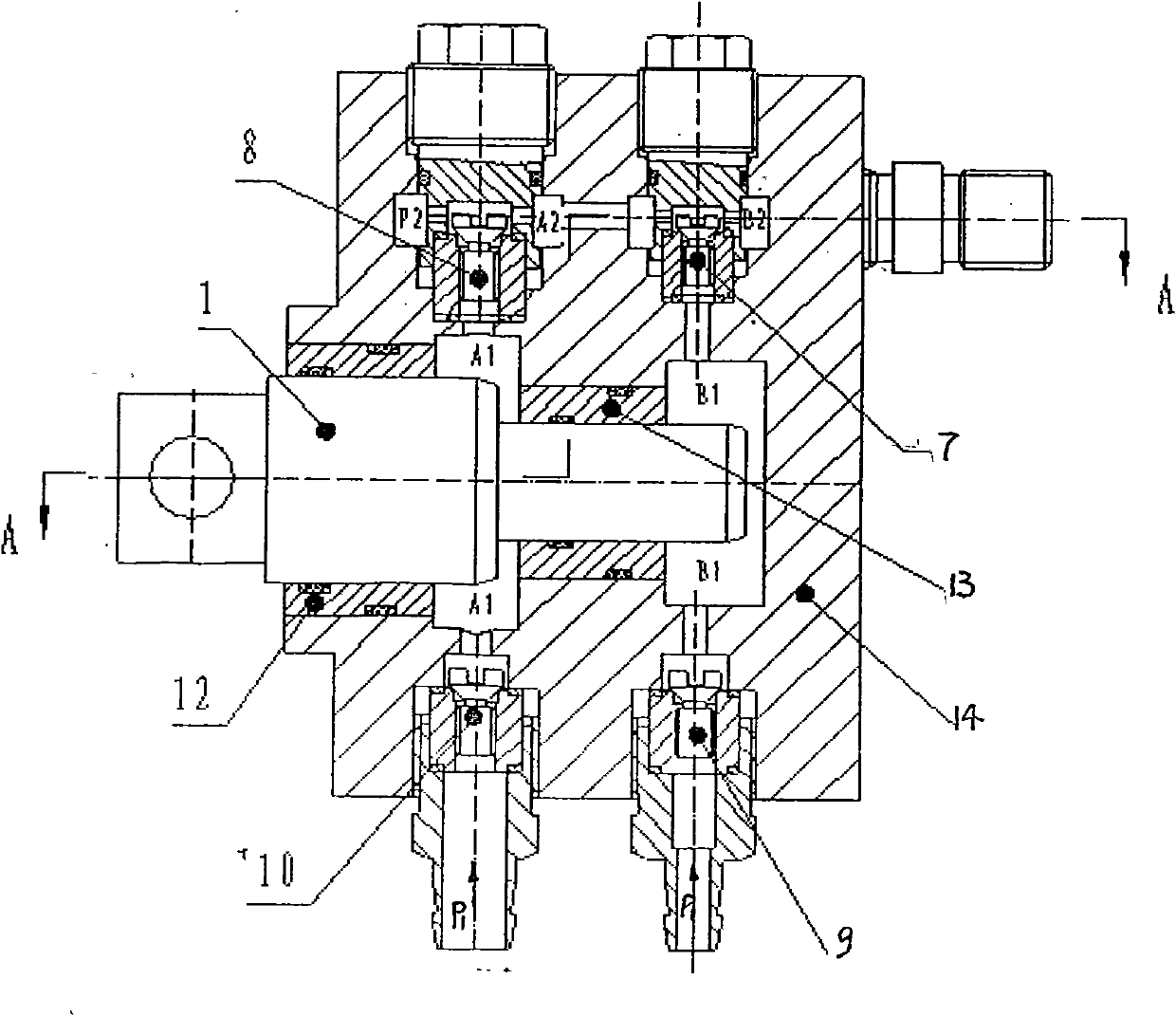

Combined type high and low pressure cylinder hydraulic end

ActiveCN102003365ASimple installation structureOptimize layoutPiston pumpsPositive-displacement liquid enginesInlet valveEngineering

The invention provides a combined type high and low pressure cylinder hydraulic end, which is used for solving the problems that the structure of the prior hydraulic end is complicated, the manufacturing cost of the existing hydraulic end is high, and the existing hydraulic end is inconvenient to install and maintain. Two combined cylinders are respectively matched with one stepped plunger (1); a high-flow low pressure chamber (A1) is connected with a low-pressure water inlet passageway P1 by a high-flow inlet valve (10); the high-flow low pressure chamber (A1) is communicated with a high-flow high pressure chamber (A2) by a high-flow inlet valve (8); the high-flow high pressure chamber (A2) is communicated with a working pressure passageway P3 by a high pressure water outlet passageway P2; a low-flow low pressure chamber B1 is connected with the low pressure water inlet passageway P1 by a low-flow inlet valve (9); a low-flow low pressure chamber B1 is connected with a low-flow high pressure chamber B2 by a low-flow outlet valve (7); the low-flow high pressure chamber B2 is connected with a working pressure passageway P3 by the high pressure water outlet passageway P2; and the upper end of the valve chest of a hydraulic control communication valve is connected with the high pressure water outlet passageway P2, the lower end of a valve plug is connected with a pressure-regulating spring, and the upper and lower holes on the side wall of the valve chest are respectively connected with the high-flow low pressure chamber (A1) and the passageway of a water intake box (11).

Owner:四川杰特机器有限公司

Electromagnetic hydraulic combined control valve

The invention relates to an electromagnetic hydraulic combined control valve. The electromagnetic hydraulic combined control valve comprises a valve body and a magnetic exchange valve; a cushion valve, a constant pressure valve and an inching valve are arranged inside the valve body in a parallel and concentrate mode; the cushion valve is capable of respectively performing buffering on a forward gear and a backward gear; the magnetic exchange valve is installed on the valve body; a main oil circuit is connected into an oil circuit input port sequentially through the inching valve and the cushion valve; and in the main oil circuit, the constant pressure valve is arranged on one side of an oil circuit inlet end of the inching valve. The electromagnetic hydraulic combined control valve has the advantage of being convenient to overhaul due to the facts that the oil circuit is simple and the control valve size is reduced by one third.

Owner:HEFEI AUTOMOBILE OIL PUMP

Polishing and grinding device with intelligent positioning function for machining

PendingCN111922828AEasy to polishEasy to holdEdge grinding machinesGrinding carriagesThreaded pipePolishing

The invention discloses a polishing and grinding device with an intelligent positioning function for machining. The polishing and grinding device comprises a bottom plate, supporting columns, waste collecting frame structures, stand columns, fixing plates, a threaded rod, a hand wheel, threaded pipes, an inclinable workbench structure, a top plate, an extendable air cylinder, a pressure adjustingframe structure, a grinding motor and a grinding disc, wherein the supporting columns are welded to the four corners of the lower portion of the bottom plate, and the waste collecting frame structuresare connected to the left side and the right side of the upper portion of the bottom plate through bolts. The polishing and grinding device has the beneficial effects that through the arrangement ofa lug plate, a workpiece placement table and a supporting rod, the bolts on the left side and the right side of the supporting rod are unscrewed, the connecting position between the lower portion of the supporting rod and a mounting frame is adjusted, the right side of the workpiece placement table is rotated towards the left side, and the right side of the workpiece placement table is supported through the supporting rod so that a workpiece can be inclined to the lower portion of a grinding disc, the chamfer or the inclined surface of the workpiece can be polished and ground favorably, and the application range of the device is widened.

Owner:张家港市卓华金属科技有限公司

Method and device for synthesizing phthalimide multifunctional organic light-emitting material

ActiveCN112403424AConstant pressureImprove securityProcess control/regulationOrganic chemistryImideElectric machinery

The invention discloses a synthesis device of a phthalimide multifunctional organic light-emitting material. The device comprises a tank body, a first motor is arranged at the top of the tank body, anoutput shaft of the first motor is connected with a stirring shaft, the stirring shaft penetrates through the top wall of the tank body and extends into the tank body, a plurality of stirring teeth are arranged on the stirring shaft, a fixing rod is connected among the plurality of stirring teeth, an adjusting mechanism is vertically connected to the fixing rod, and the adjusting mechanism is connected with a scraping plate; brushing hair is arranged on a hanging plate; a pressurizing mechanism is arranged at the position, close to the top, of the side wall of the tank body, and a constant-pressure mechanism is arranged at the top of the tank body; by arranging a circulating system, accurate temperature is provided for the tank body, and the reaction rate is increased; through the combined action and mutual cooperation of the pressurizing mechanism and the constant pressure mechanism, the effect of constant pressure in the tank body is achieved, unsafe factors such as accidents causedby overlarge pressure are prevented, and the use safety is improved.

Owner:ZHENGZHOU UNIV OF IND TECH

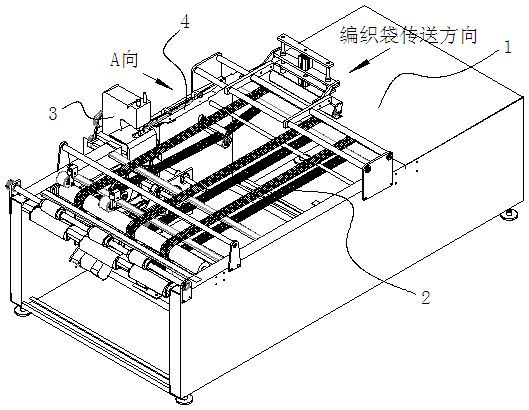

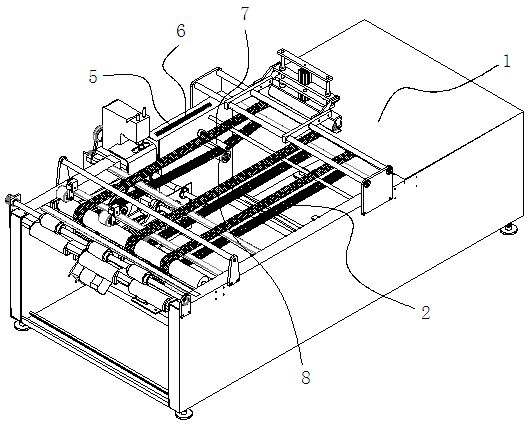

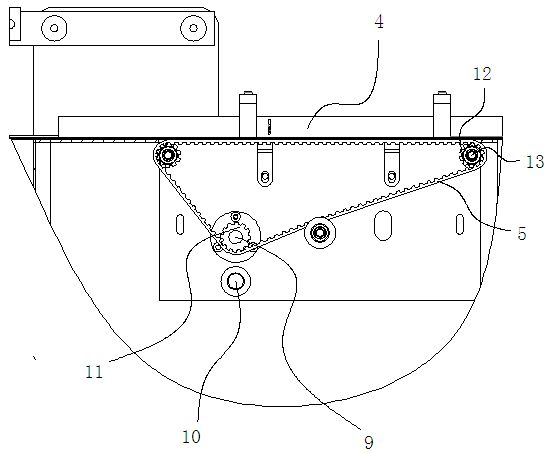

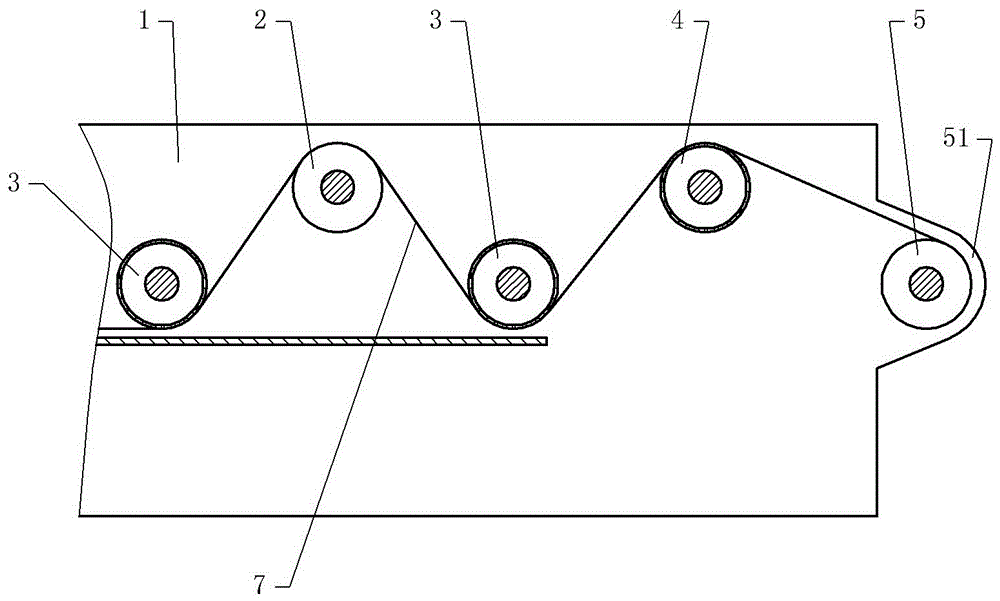

Assistance mechanism for bottom seaming machine of woven bag

InactiveCN102644168AQuality improvementNo creasesWork-feeding meansSewing-machine control devicesProduction lineEconomic benefits

The invention discloses an assistance mechanism for a bottom seaming machine of a woven bag, comprising a stander, wherein a first ring-shaped conveyor belt is arranged on the stander, the stander is provided with an edge coiling device at the outer side of the first conveyor belt, the stander is provided with a synchronous conveying mechanism at the lower side of the edge coiling device, the conveying speed and the conveying direction of the synchronous conveying mechanism are matched with those of the first conveyor belt. The assistance mechanism has the beneficial effects that the conveying speed lost by coiling the edge at the bottom of the woven bag is effectively compensated, so that the woven bag is tidy in edge coiling, and good in sewing quality, the wrinkles can be avoided when the woven bag is conveyed, the sewing speed of the bottom seaming machine can be improved in multiples, and the original quality bottleneck of the woven bag can be broken through, so that about sixty woven bags can be seamed pre minute; and the bottom seaming machine is smooth to run, so that the number of the production line operator can be reduced from four to one, therefore, the assistance mechanism has considerable economic benefit in the current market that the labor cost is constantly improved.

Owner:WENZHOU NINGTAI MACHINERY

Cold-drawn steel disc round material straightening and shearing device

The invention discloses a cold-drawn steel disc round material straightening and shearing device in the technical field of steel equipment. The device comprises a base; a fixed base, a straightening box, an U-shaped base and a shearing device are mounted at the top of the base in sequence from right to left; a connecting rod is mounted at the top of the fixed base; a turntable is mounted on the connecting rod through a bearing; a fixed plate is mounted at the bottom of an inner cavity of the straightening box; grooves are uniformly formed in the top of the fixed plate; lower straightening rollers are arranged in the grooves; a through hole is formed in the top of the straightening box; a push rod is inserted in the through hole; through twisting of a rotating handle, the push rod downwardsmoves to drive downward movement of a pressing plate, so that upper straightening rollers and the lower straightening rollers straighten bent reinforcements, both convenience and speediness are achieved, and the deformation of the reinforcements caused by manual beating is prevented; and meanwhile, buffer columns are uniformly mounted at the bottom of a pressing plate for conveniently adjusting the pressure of the upper straightening rollers to the reinforcements to prevent damage of the reinforcements, the upper straightening rollers and the lower straightening rollers, so that the service life is prolonged.

Owner:扬州八方冷拉型钢有限公司

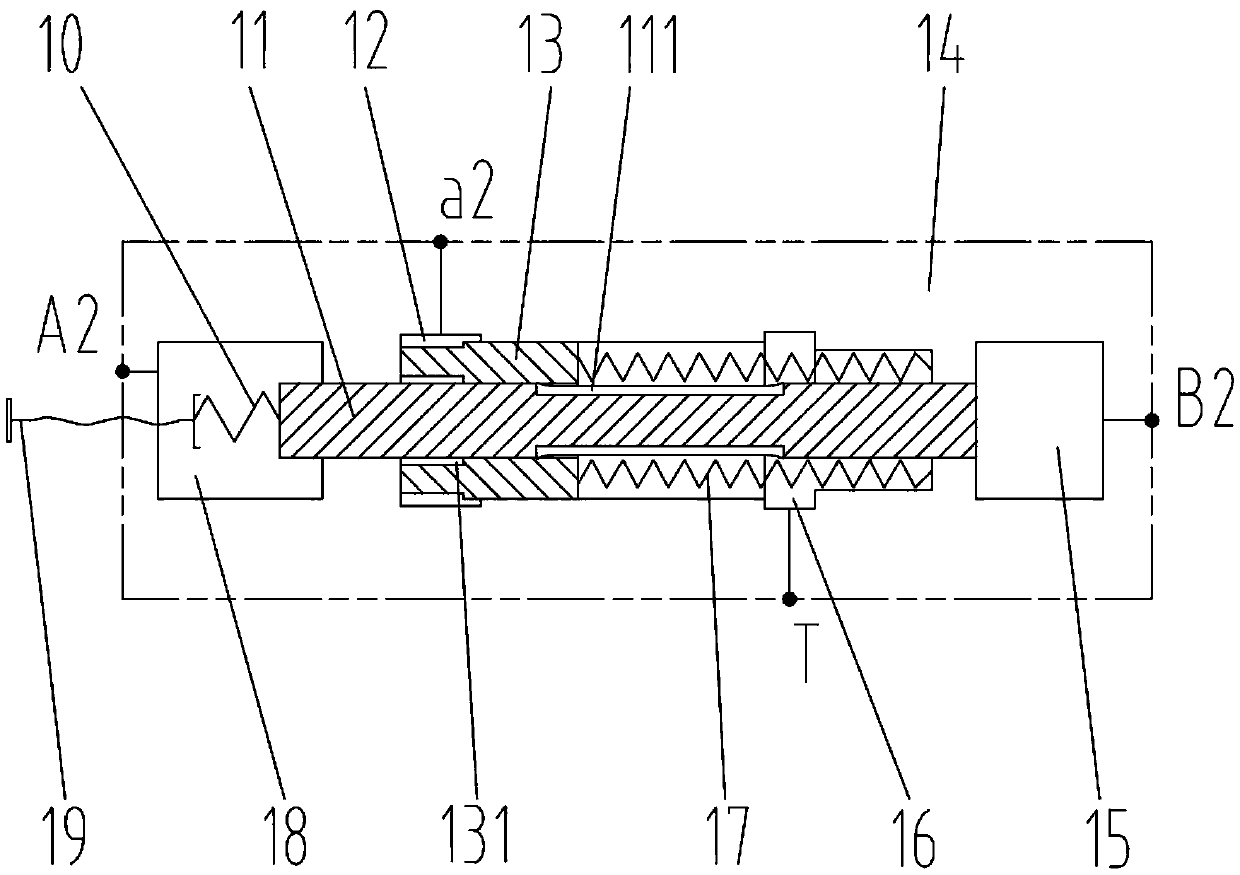

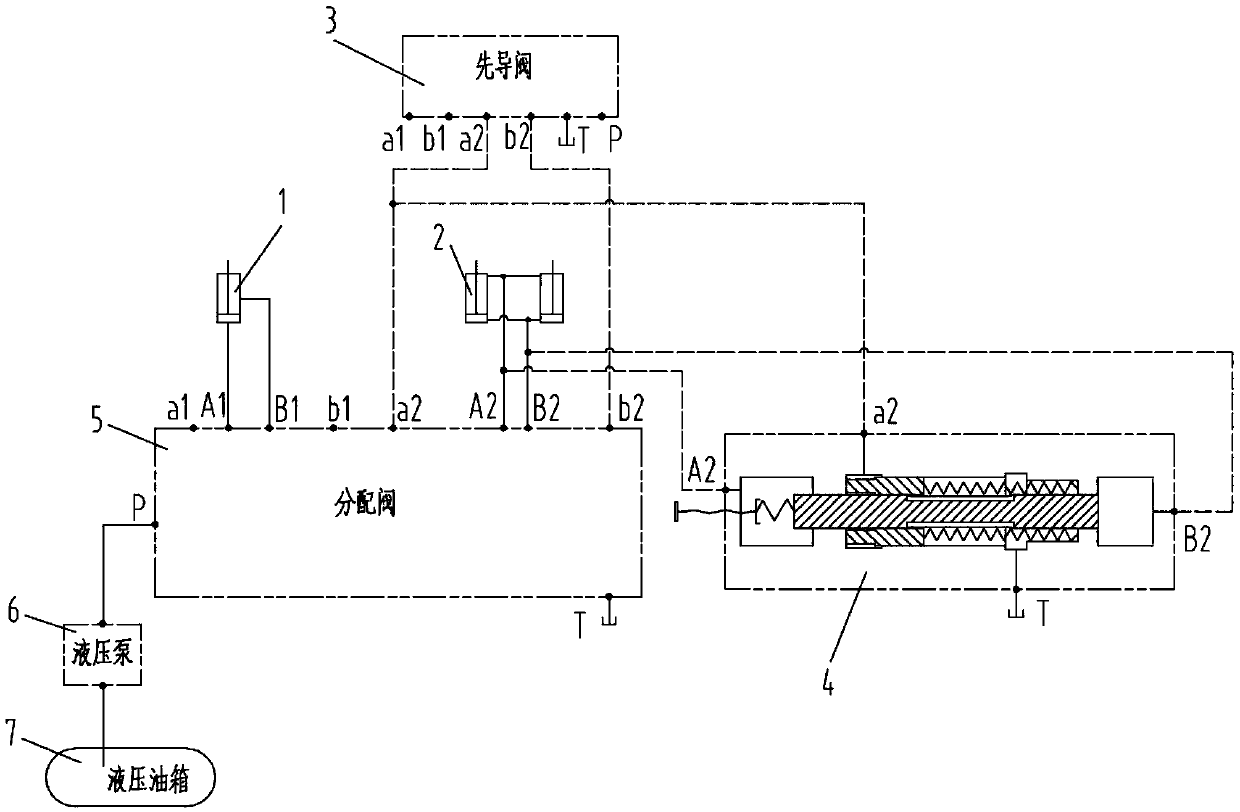

Control valve and hydraulic control system of loading machine

ActiveCN105508339AImprove stabilityImprove comfortServomotor componentsMechanical machines/dredgersWork statusHydraulic control

The invention relates to a hydraulic control valve, aims to solve the problem that the floating descent stability of a movable arm of an existing ultra-long arm loading machine is reduced, and provides a control valve. The control valve comprises a valve element, wherein the valve element is located in a valve body. A first cavity and a fourth cavity are formed in the valve body, the first cavity is communicated with a working opening A2, hydraulic oil in the first cavity acts on the left end of the valve element, the fourth cavity is communicated with a working opening B2, and hydraulic oil in the fourth cavity acts on the right end of the valve element. A valve sleeve is located in a middle cavity and arranged on the valve element in a sleeving mode, and the middle cavity is divided by the valve sleeve into a second cavity and a third cavity. A valve element spring which acts on the left end of the valve element is arranged in the first cavity, and a valve sleeve spring which acts on the right end of the valve sleeve is arranged in the third cavity. An oil return opening T is communicated with the third cavity, and a guide opening a2 is communicated with the second cavity. An oil drain channel which is used for communicating the second cavity with the third cavity in the working process and being closed in the initial state is arranged between the valve element and the valve sleeve. According to the invention, the initial state means the state of being free of floating descent, and the working state means the state of floating descent.

Owner:GUANGXI LIUGONG MASCH CO LTD

Plastic film winding device

The invention discloses a plastic film winding device and relates to the field of plastic manufacture. The plastic film winding device comprises a support, a feed roller, spreading rollers, a discharge roller, and a driving motor that drives the feed roller and the discharge roller to rotate. The feed roller is located between and higher than the spreading rollers that are disposed at a right side of the support. The feed roller rotates faster than the discharge roller. A tensioning roller is disposed between and slightly higher than one spreading roller and the discharge roller. The tensioning roller comprises a roller body, a roller shaft, and end caps fixed to two ends of the roller shaft. The roller body defines an air chamber, and comprises a rubber layer and steel bars fixed thereto. A plurality of bar-shaped grooves are radially formed in each end cap. Ends of the steel bars are embedded in the corresponding bar-shaped grooves. An air hole communicating with the air chamber is formed in the roller shaft, and an air connector is disposed at an end of the roller shaft. The tensioning roller provided in the plastic film winding device has a flexible body, i.e., is capable of deforming under pressure produced by a film; thus, the tension of the film can be controlled within a reasonable range.

Owner:重庆敏驰塑胶有限公司

Air pressure blasting device used for simulating excavation with tunnel drill blasting method

ActiveCN106405053AGuarantee safe and reliableSimple structureEarth material testingLiquid nitrogen containerEngineering

The invention relates to an air pressure blasting device used for simulating evaluation with a tunnel drill blasting method. The air pressure blasting device comprises a self-boosting liquid nitrogen container, a control panel and two blasting-pipe modules, two SMC high-pressure pressure switches and a control module are arranged in the control panel, the control module is connected with the SMC high-pressure pressure switches respectively through a circuit to control opening and closing of the SMC high-pressure pressure switches, the air outlet of the self-boosting liquid nitrogen container is connected with the SMC high-pressure pressure switches respectively through a high-pressure hose, the SMC high-pressure pressure switches are respectively communicated with the blasting-pipe modules through the high-pressure hose, and air blasting holes are formed in the blasting-pipe modules. The air pressure blasting device has the advantages of simpleness in structure and convenience in use, construction procedure of evaluation with the tunnel drill blasting method can be accurately simulated, simpleness in operation is achieved, safety and reliability in tunnel simulation test process is guaranteed, and the air pressure blasting device can be widely used in similar simulation test of various small-equivalent tunnel blasting excavation.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com