Patents

Literature

129results about How to "Easy speed adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

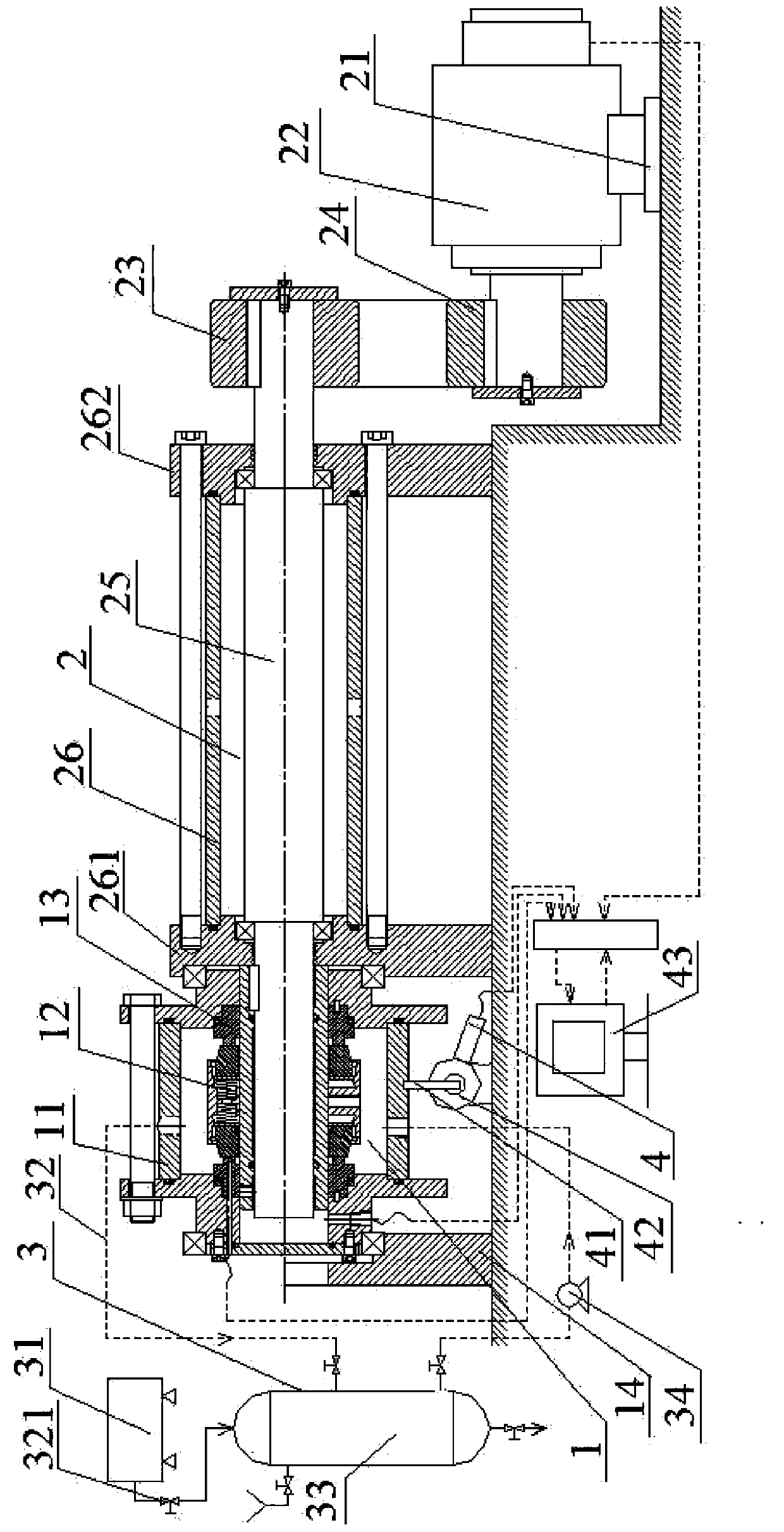

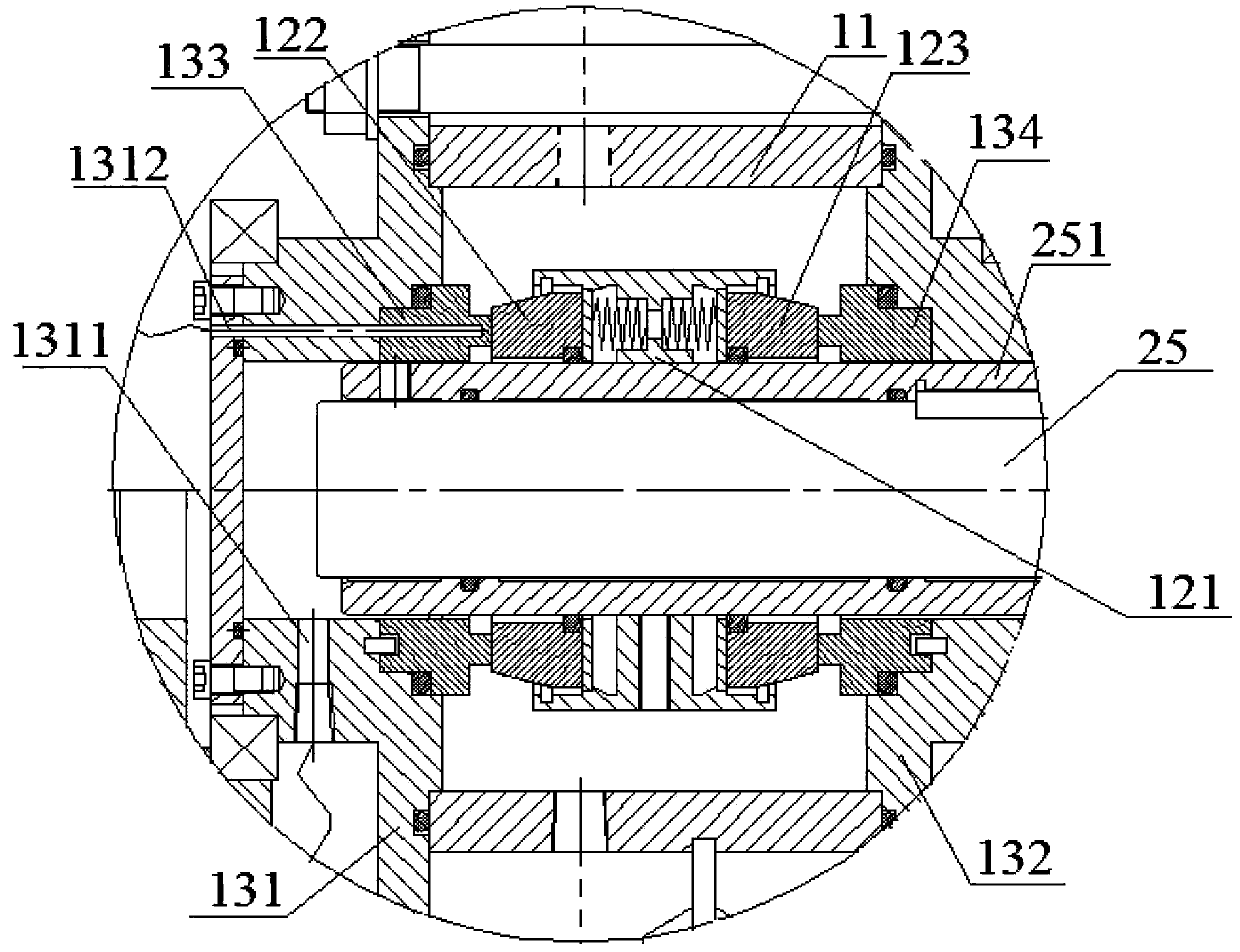

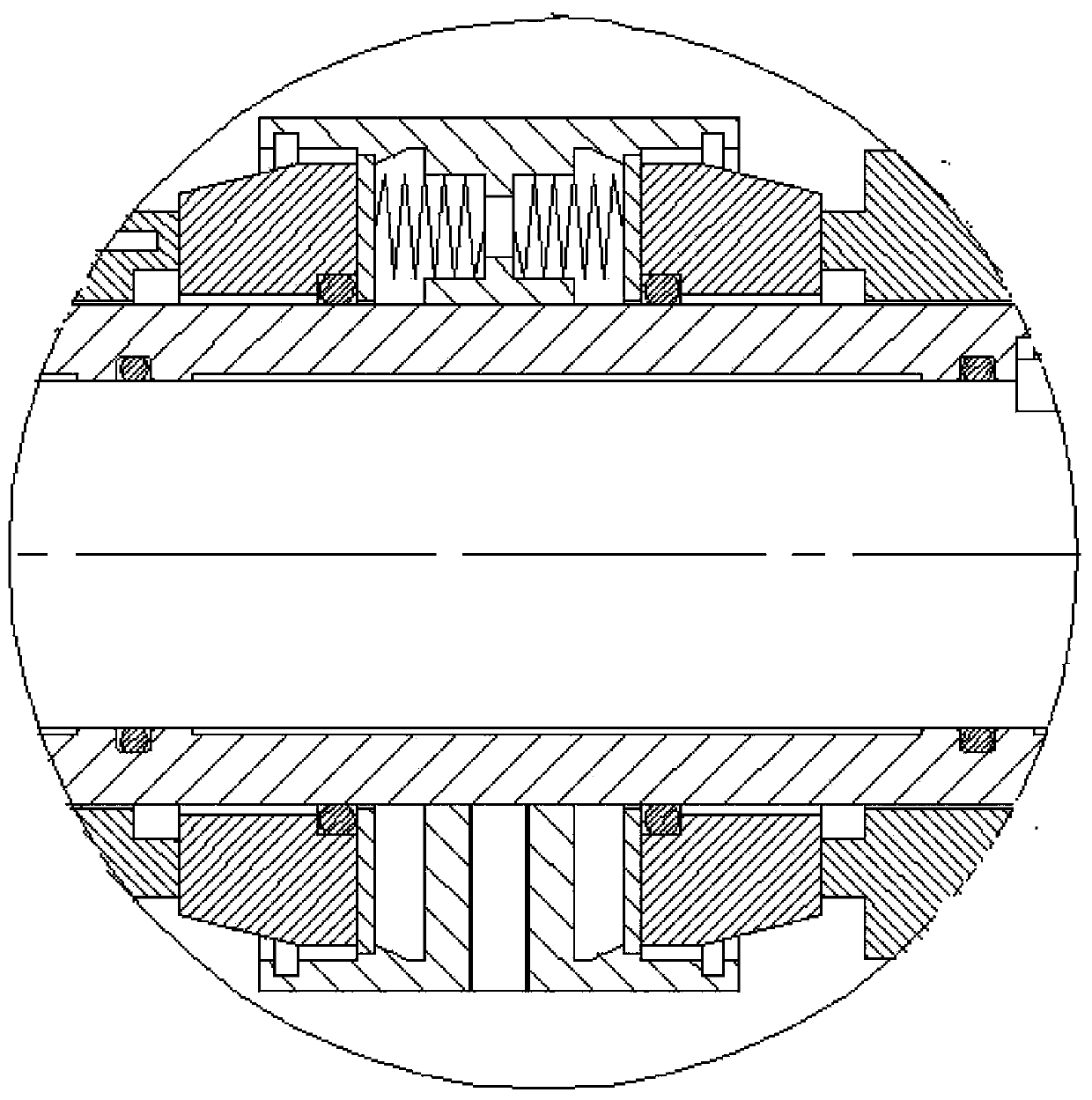

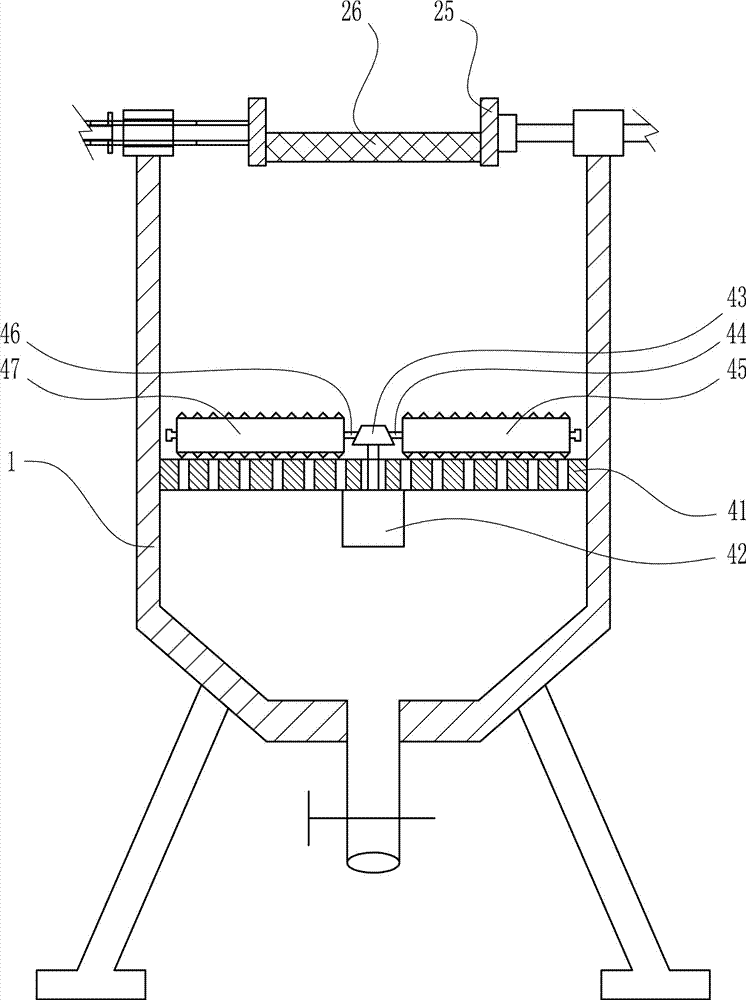

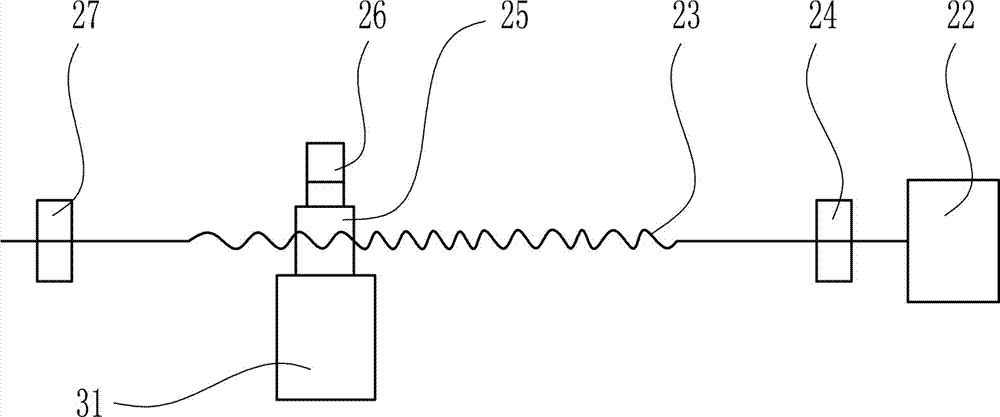

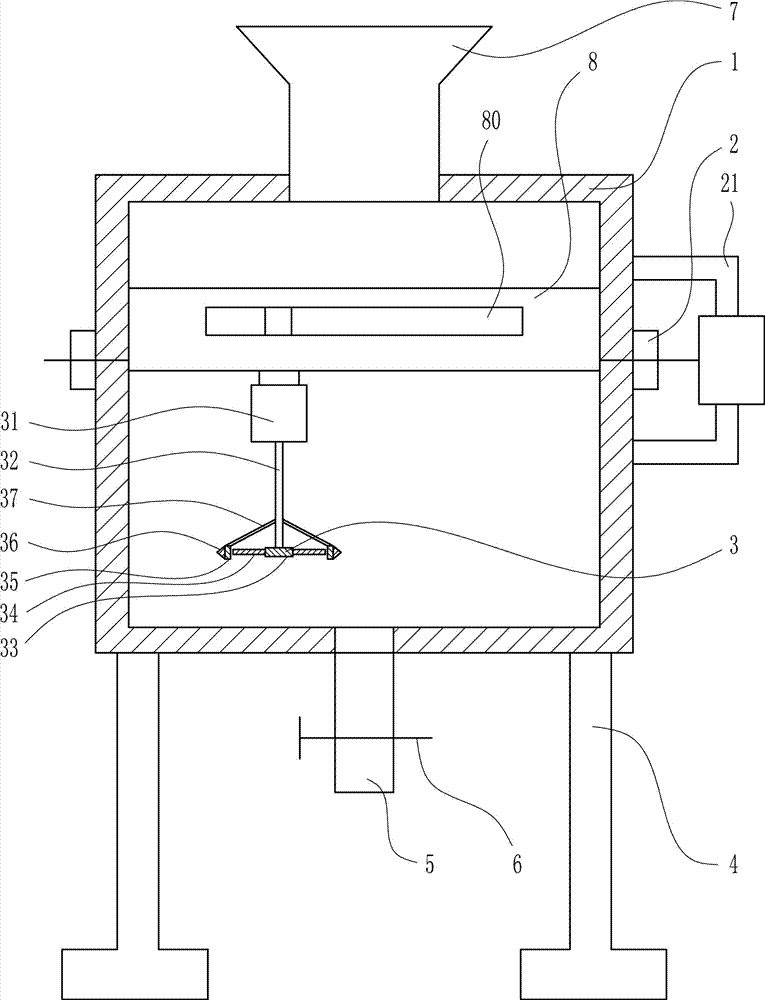

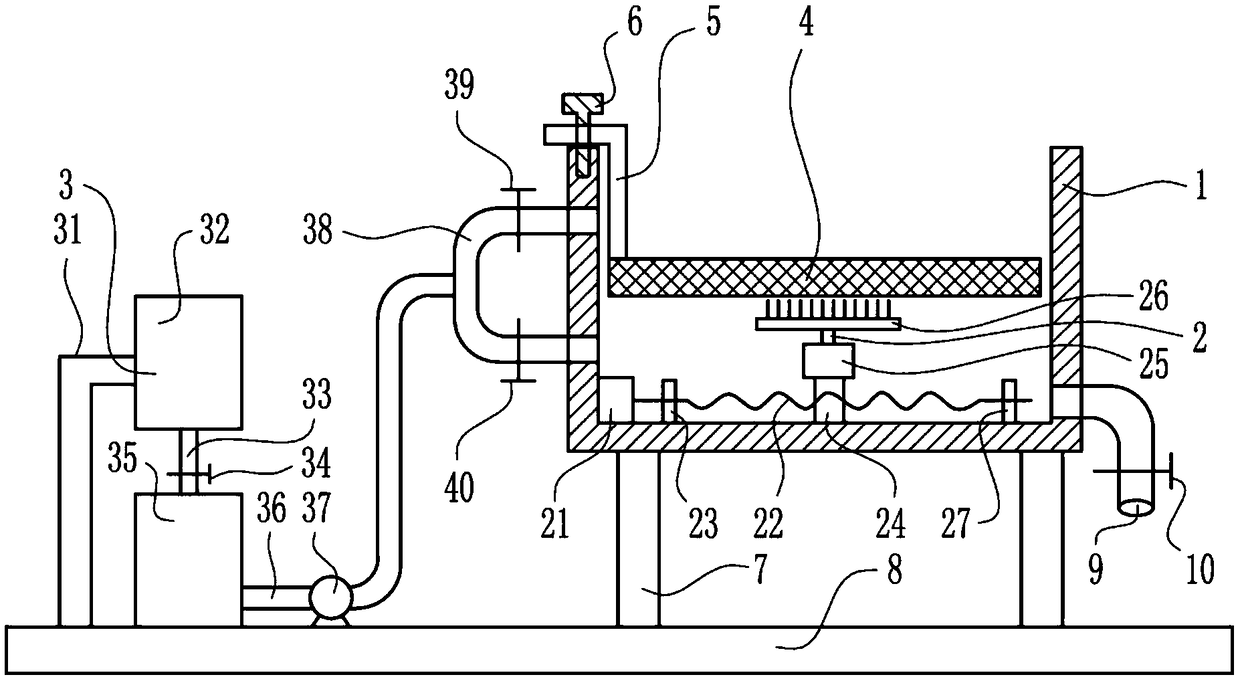

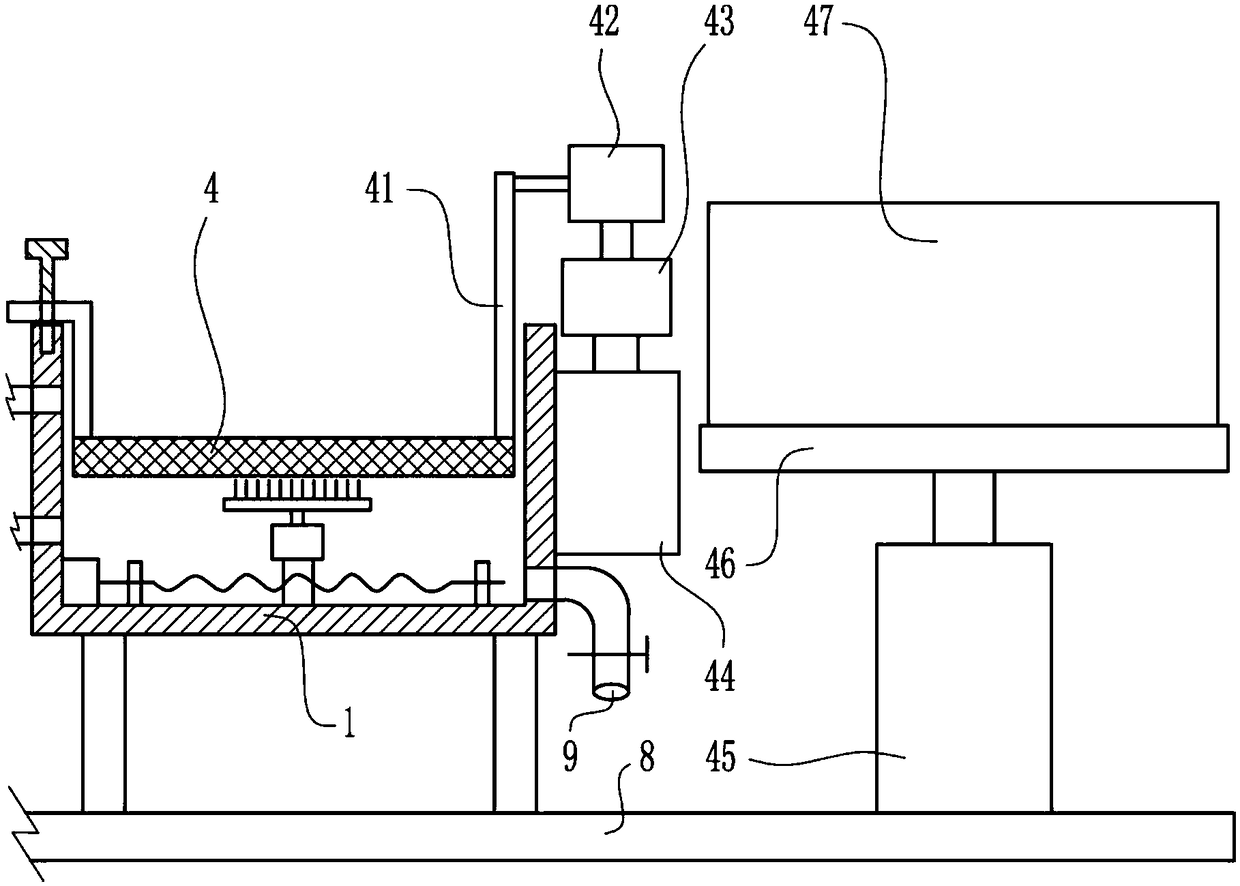

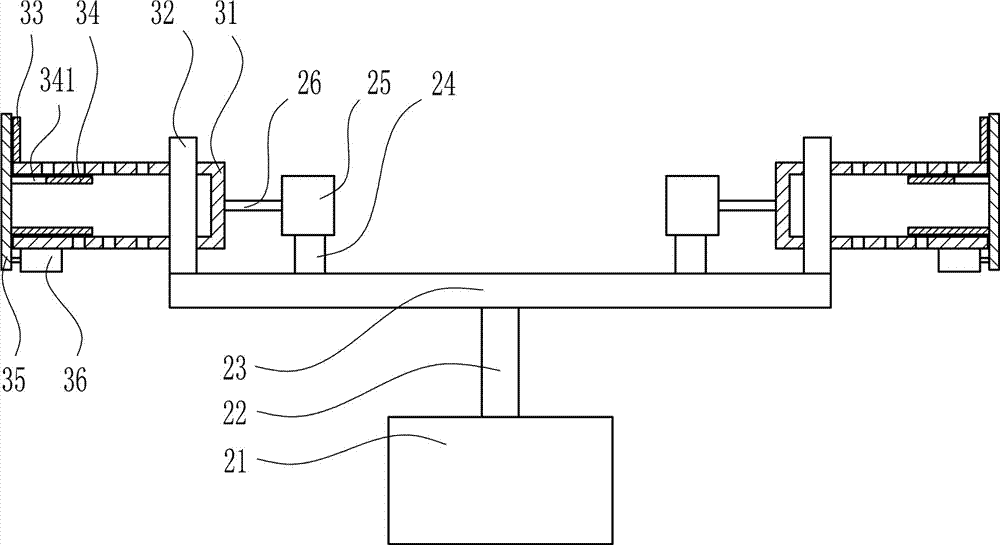

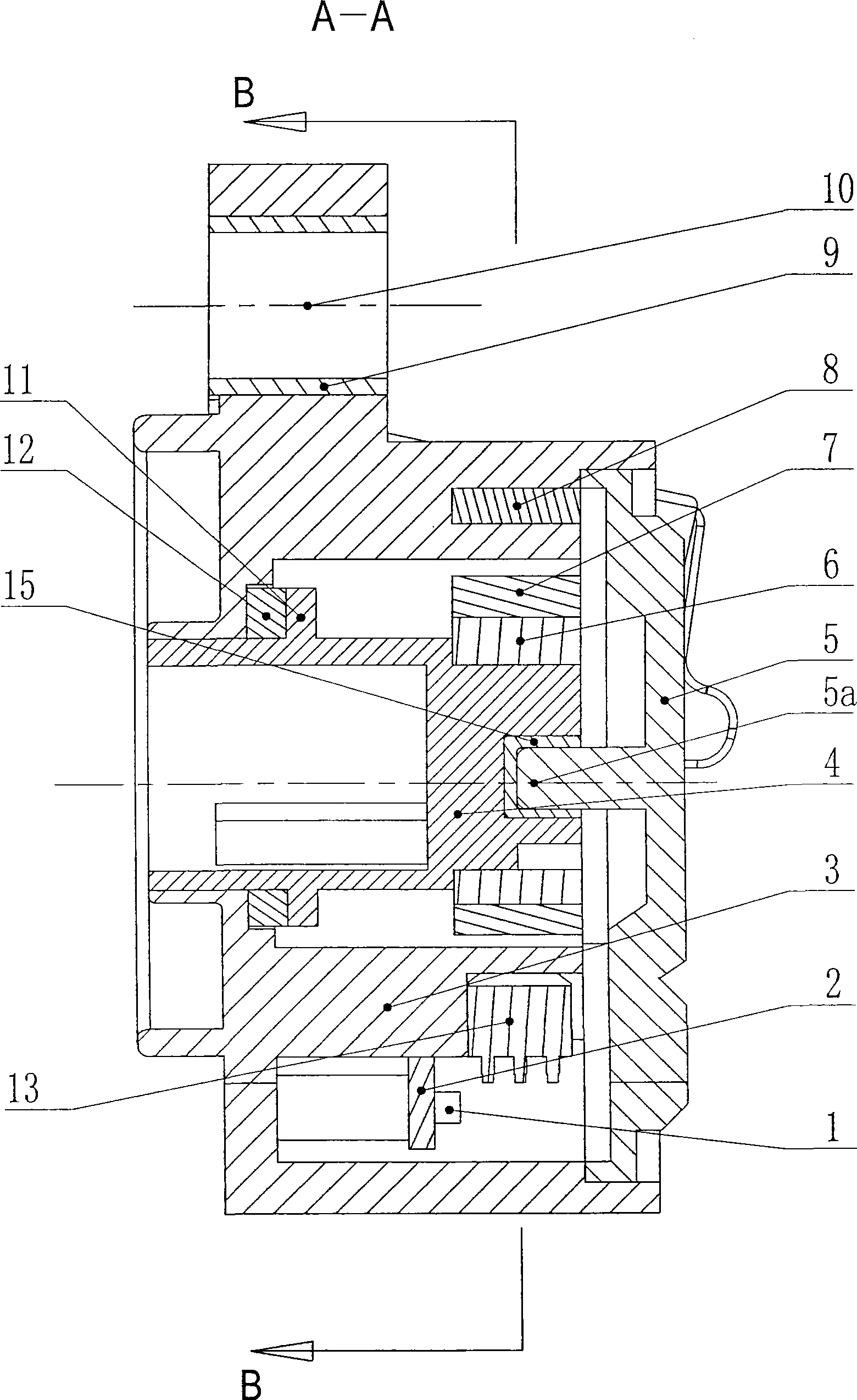

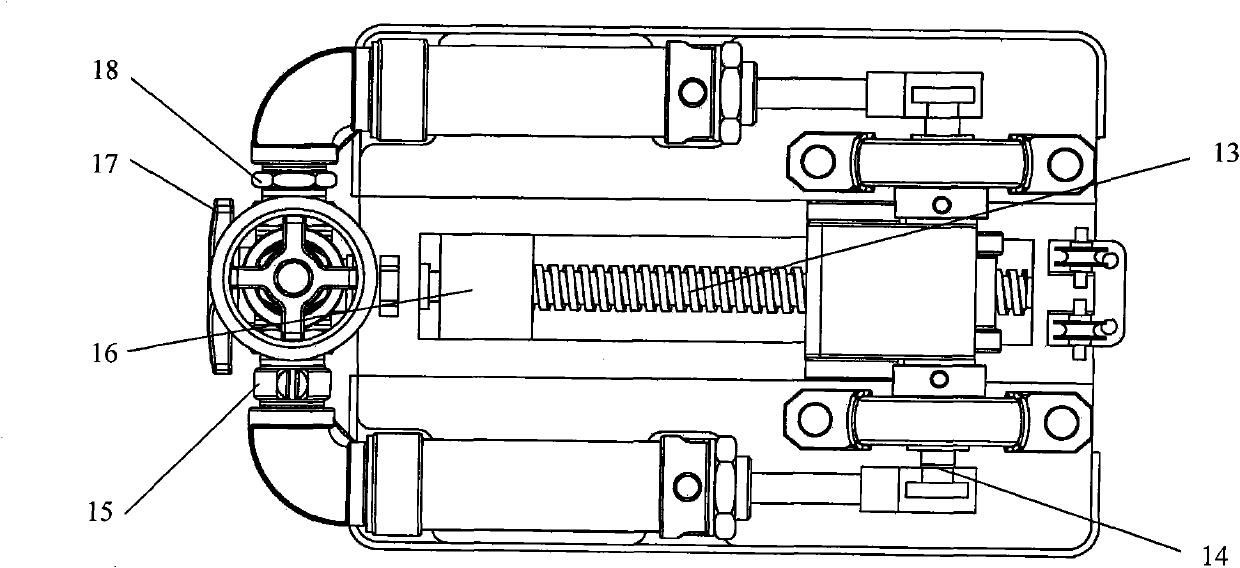

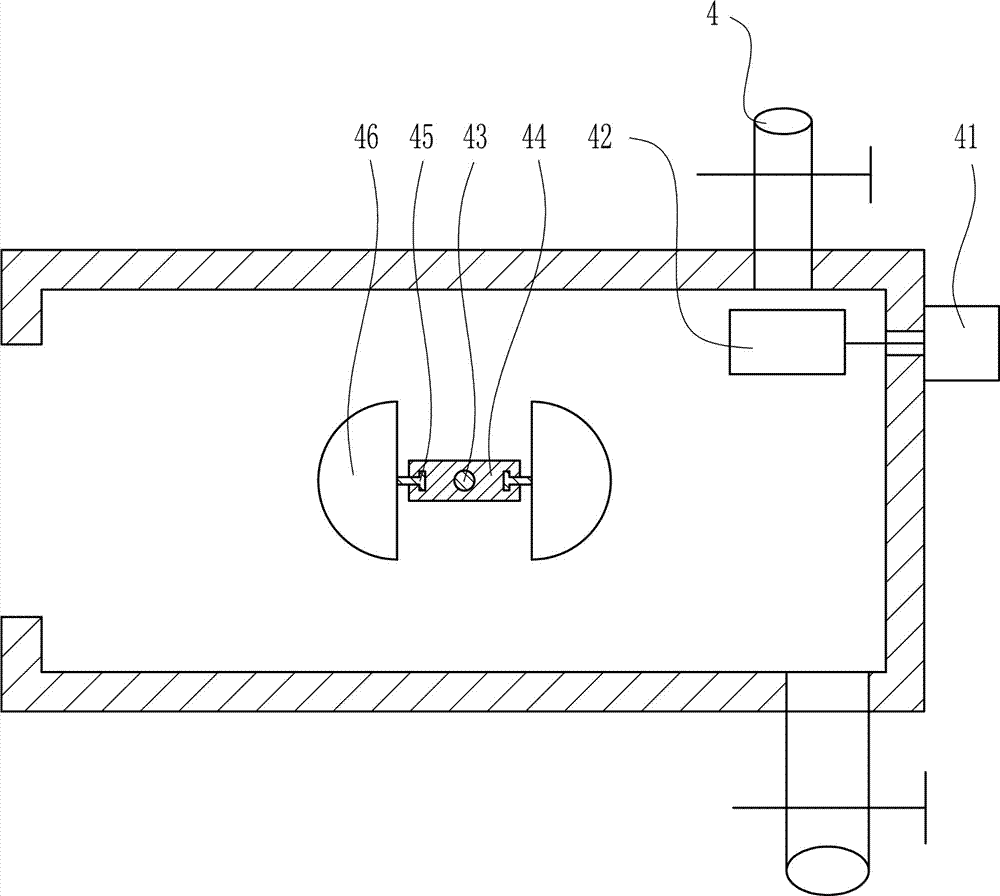

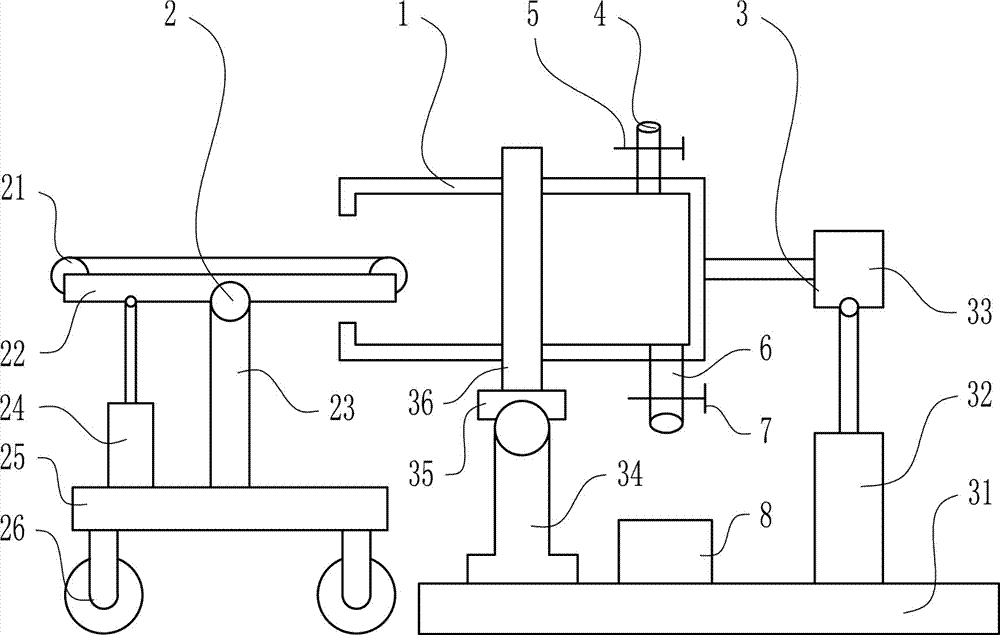

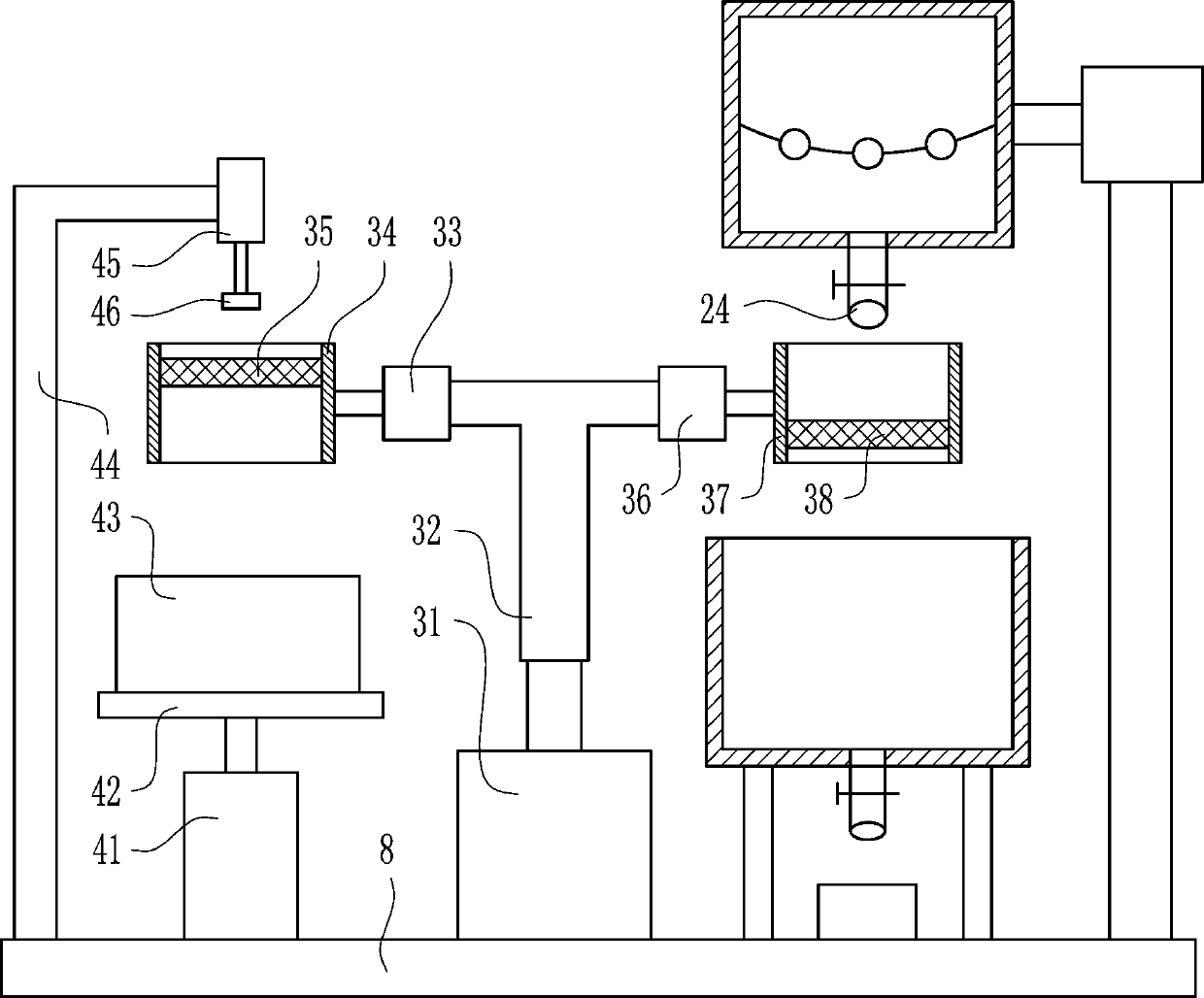

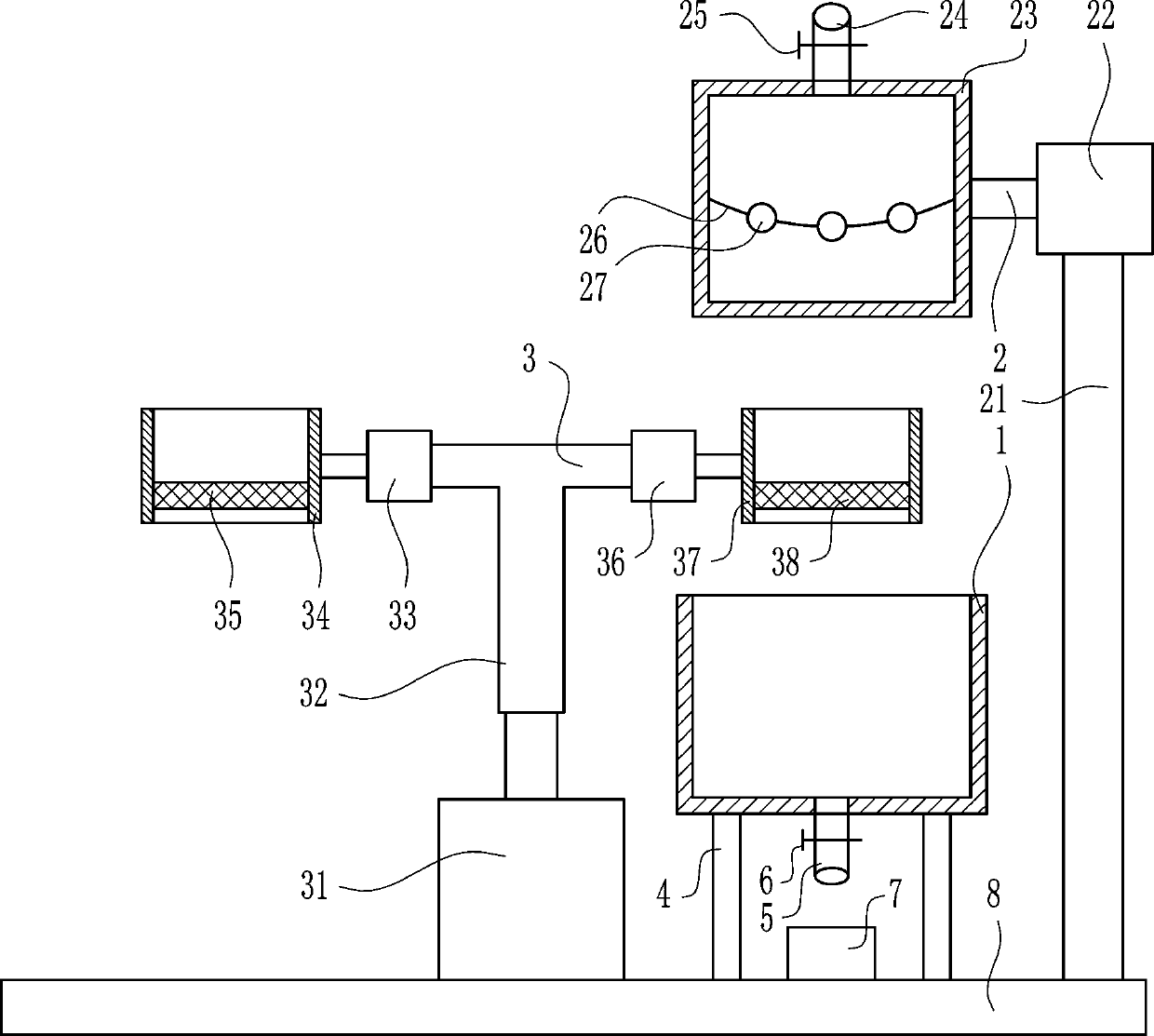

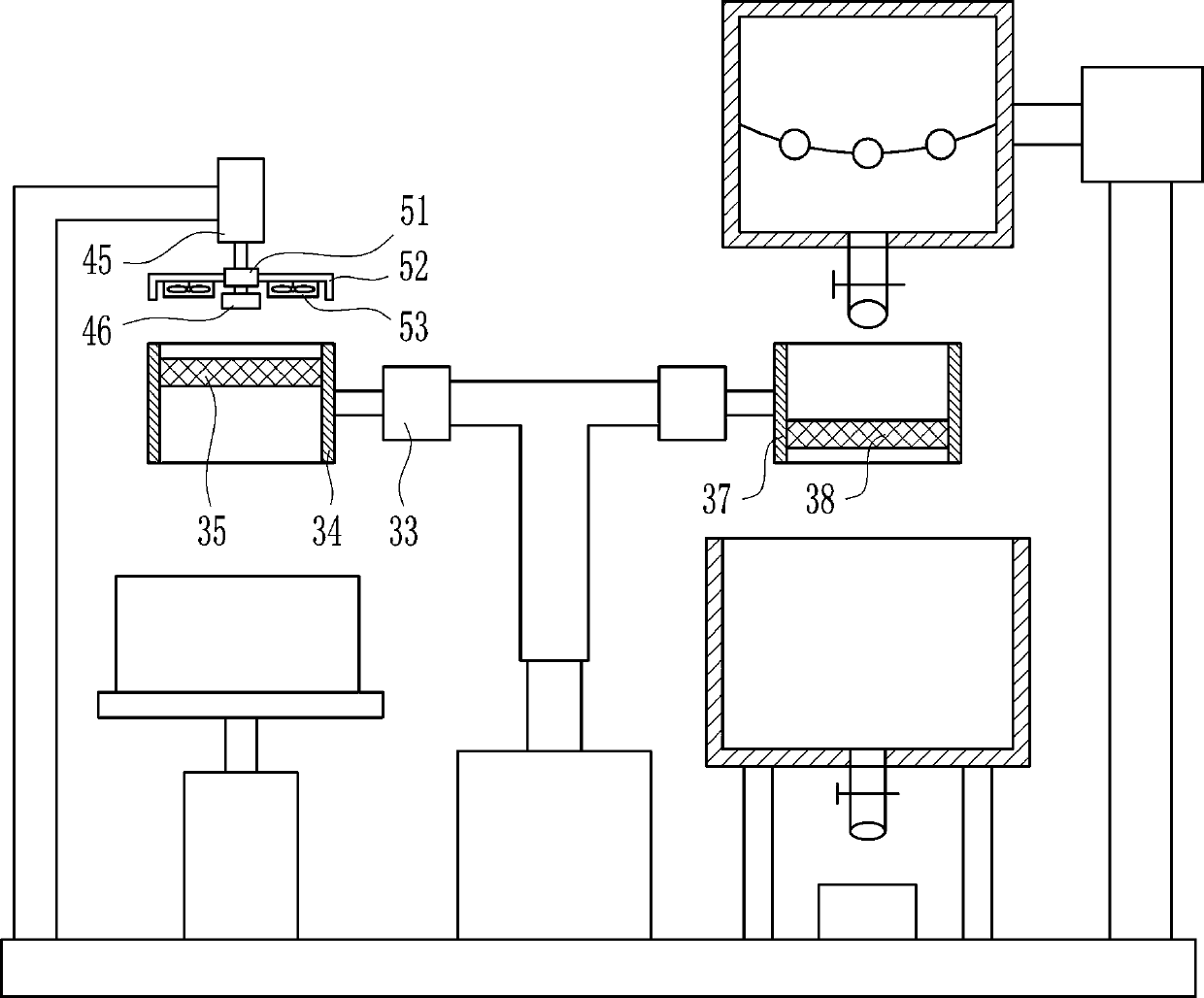

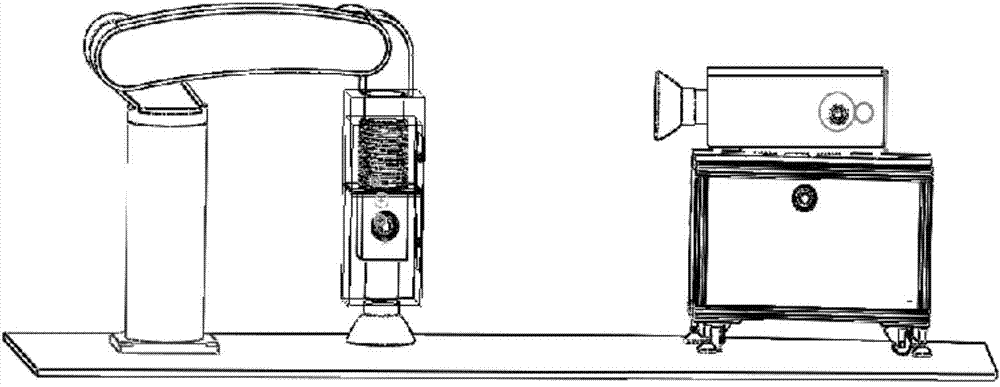

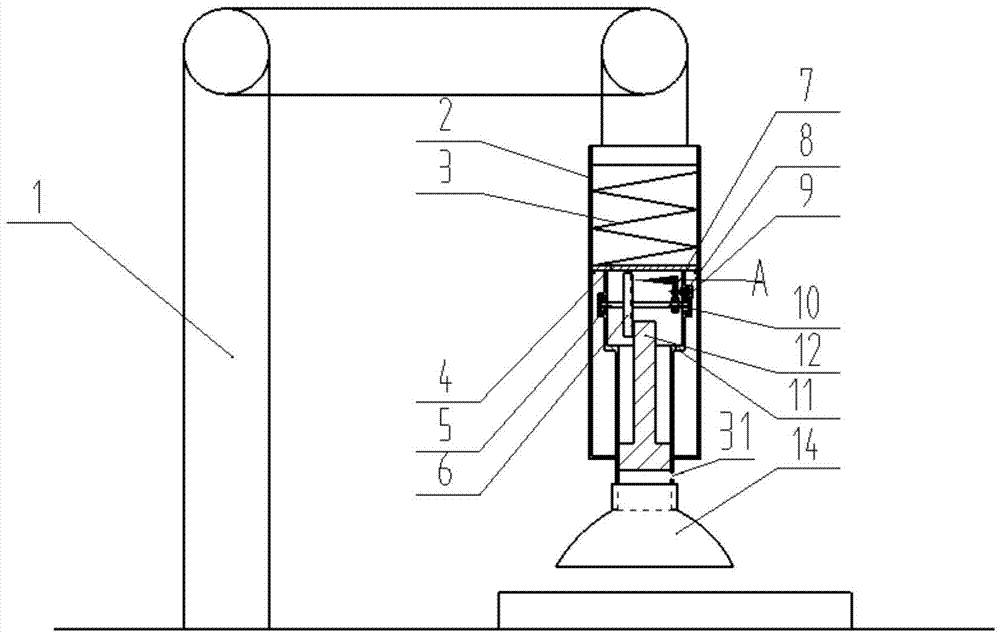

Method for testing liquid lubrication machine seal sealing performance and devices thereof

ActiveCN103630301AOvercoming large vibrationEasy to adjust pressureMeasurement of fluid loss/gain ratePhysicsElectric machinery

Provided are a method for testing the liquid lubrication machine seal sealing performance and devices thereof. The method comprises the steps of adding a sealing medium to a liquid storage tank, starting a compressor to supply pressure to sealing pressure, starting a circulating pump and measuring the temperature, the leakage rate and the friction torque of an end face through a thermocouple sensor, an electronic analytical balance and a pressure sensor respectively. The devices of the method comprise a sealing device, a driving device, an auxiliary device and a testing device. The sealing device includes a sealing cavity with sealing liquid inlet and outlet, and movable assemblies and static assemblies which are installed in the sealing cavity; the driving device includes a bracket, a motor, a synchronous belt wheel, a synchronous belt, a rotating shaft and a bearing box; and the testing device includes a dowel bar, a pressure sensor, a thermocouple sensor, an electronic balance and a computer. The method and the devices have the following advantages: friction torque, temperature rise and leakage rate of various sealing end faces can be acquired accurately, conveniently and automatically; vibration and noise are low; and the structure is compact and disassembly and assembly alignment is convenient.

Owner:ZHEJIANG UNIV OF TECH

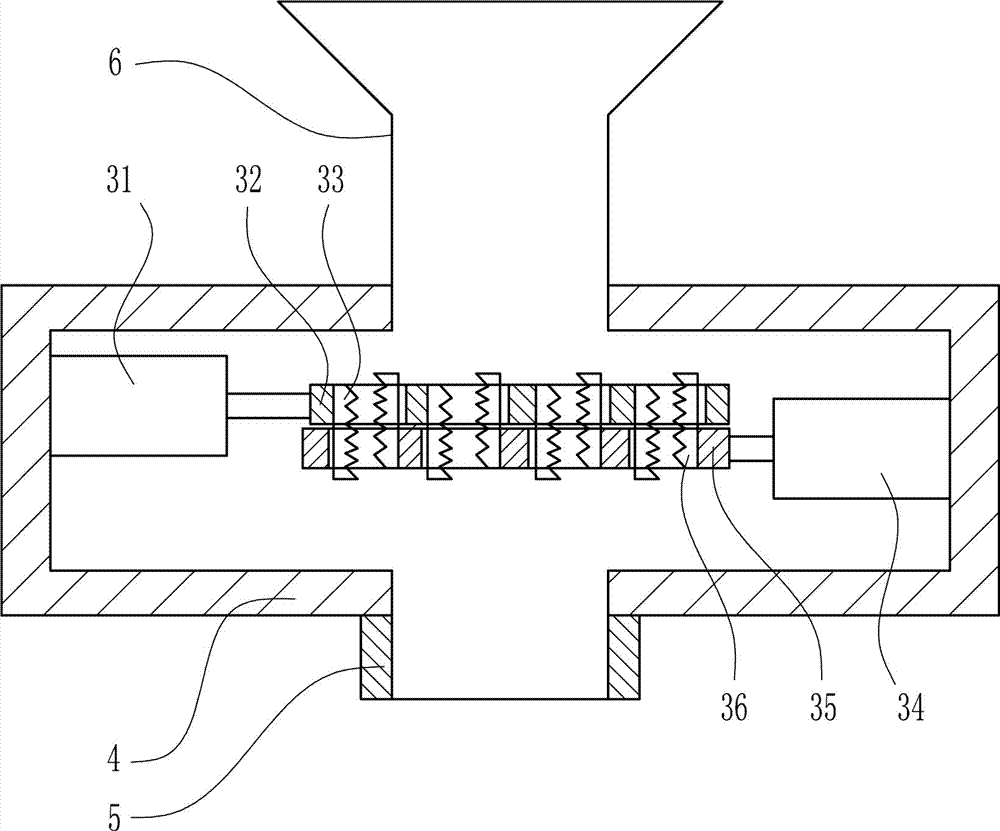

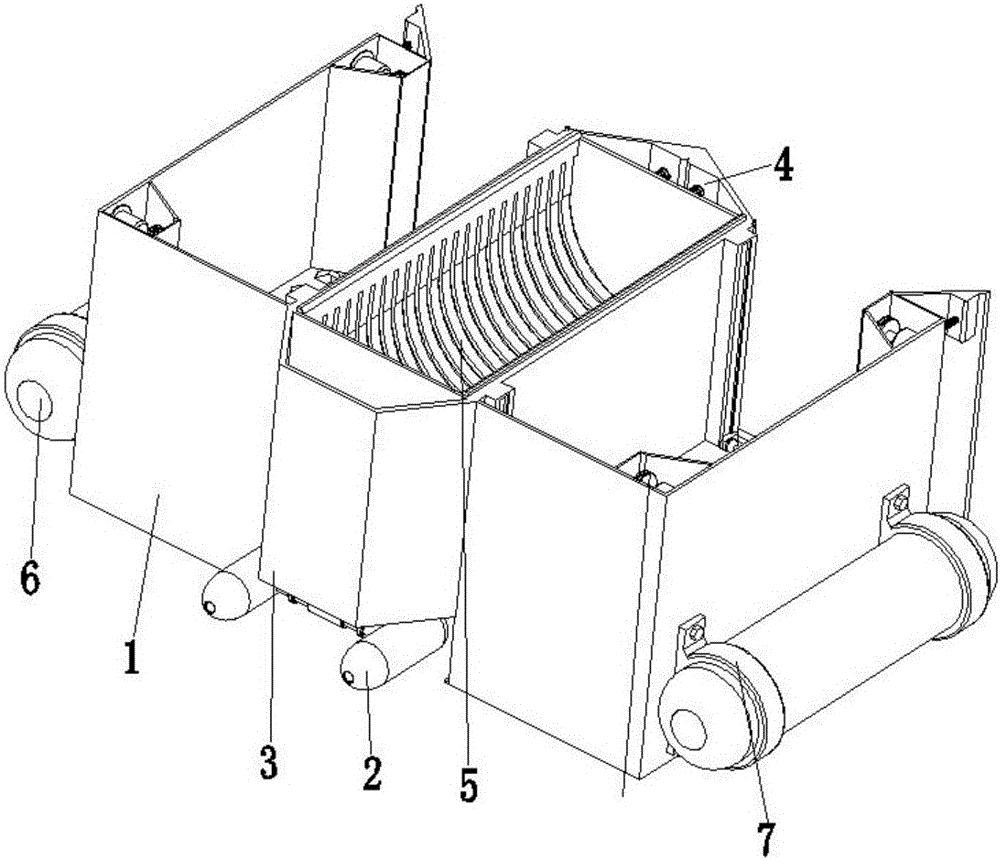

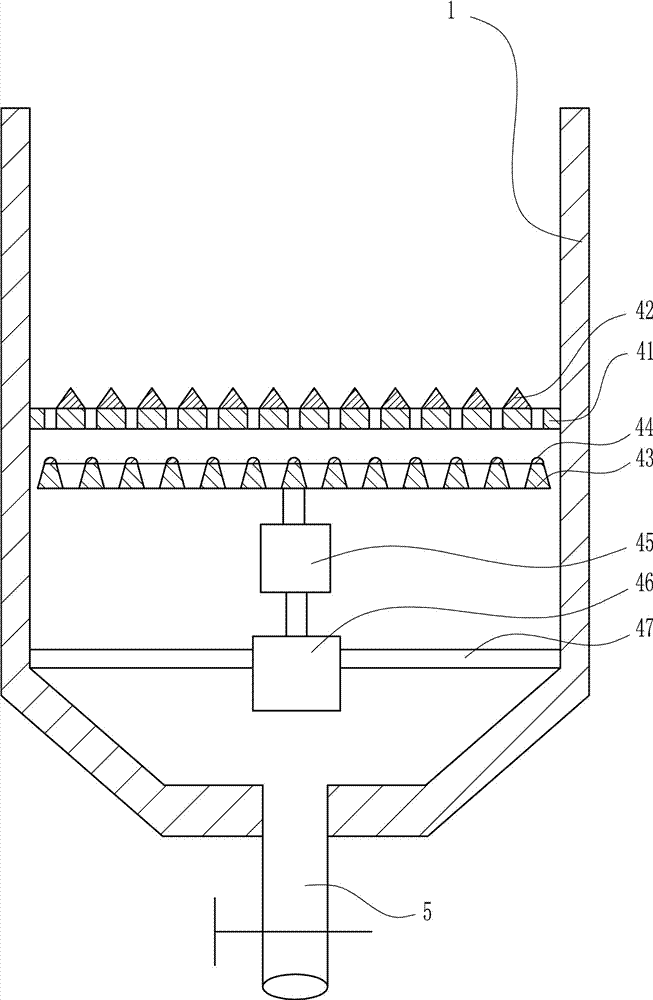

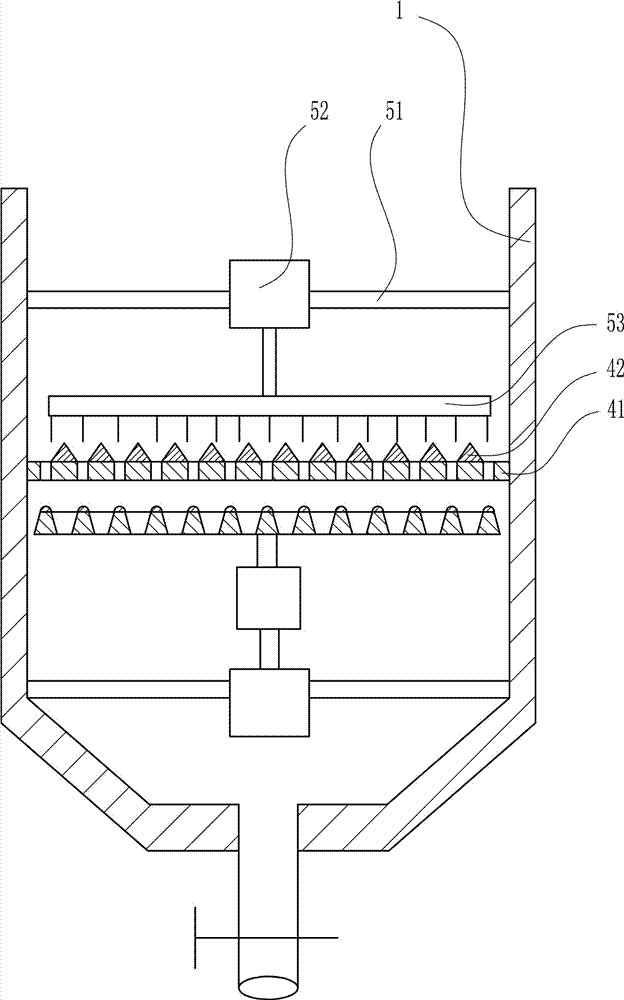

Efficient screening crushing device used for rare earth carbonate

The invention relates to a screening crushing device, in particular to an efficient screening crushing device used for rare earth carbonate. In order to solve the technical problems, the invention provides the efficient screening crushing device used for rare earth carbonate. The efficient screening crushing device used for rare earth carbonate comprises a barrel body, a screening device, a crushing device, a crushing bin, a discharge tube, a charging hopper and the like, wherein the screening device is arranged above the barrel body; the crushing device is arranged above the screening device; the crushing device is arranged in the crushing bin; the bottom of the crushing bin is welded with a discharge tube; the discharge tube communicates with the crushing bin; the charging hopper is welded on the top of the crushing bin; and the charging hopper communicates with the crushing bin. The invention provides the efficient screening crushing device used for rare earth carbonate. The screening device is combined with the crushing device, so that efficient screening and crushing can be performed on rare earth carbonate.

Owner:玉环墨痕机电科技有限公司

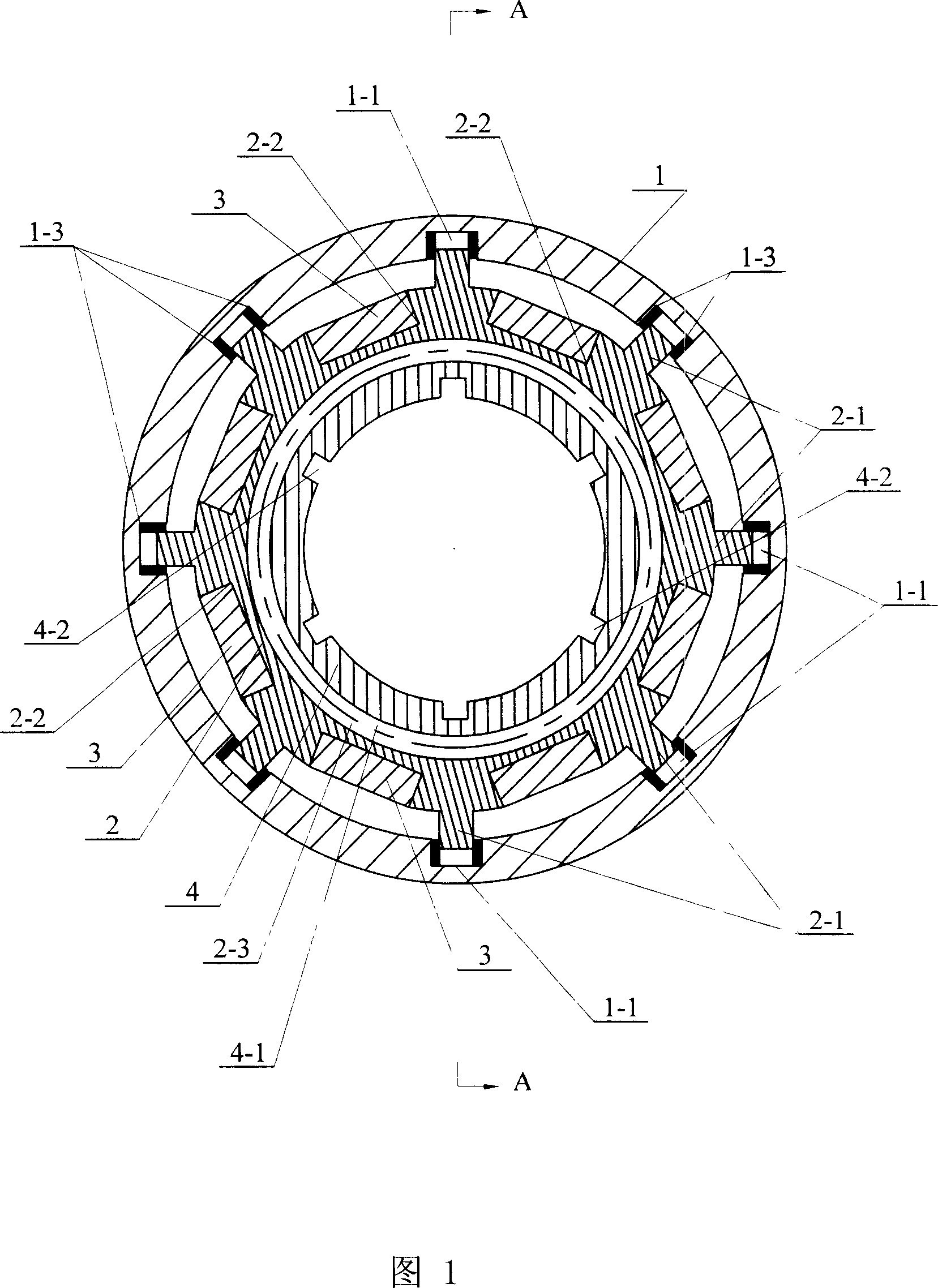

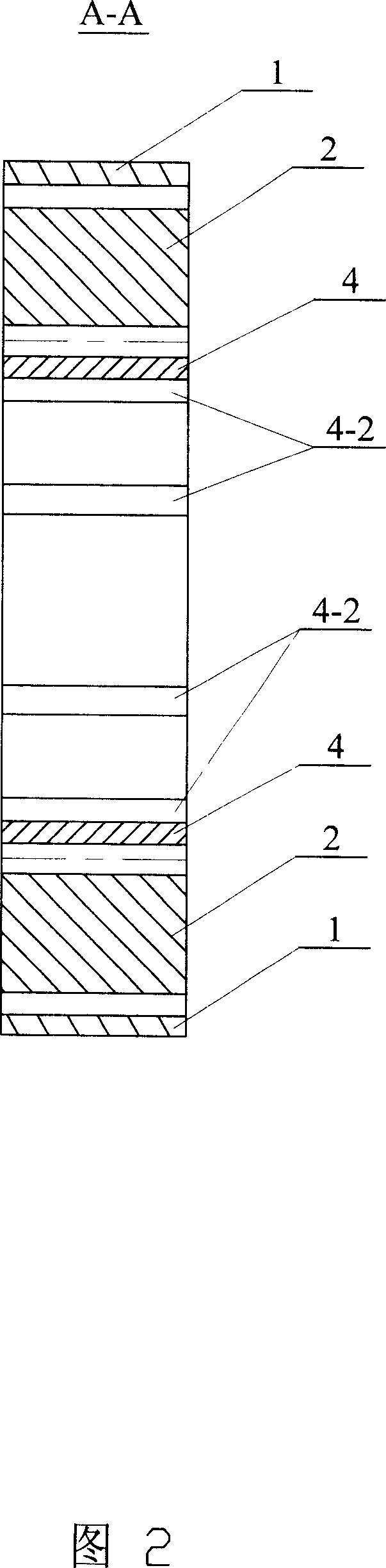

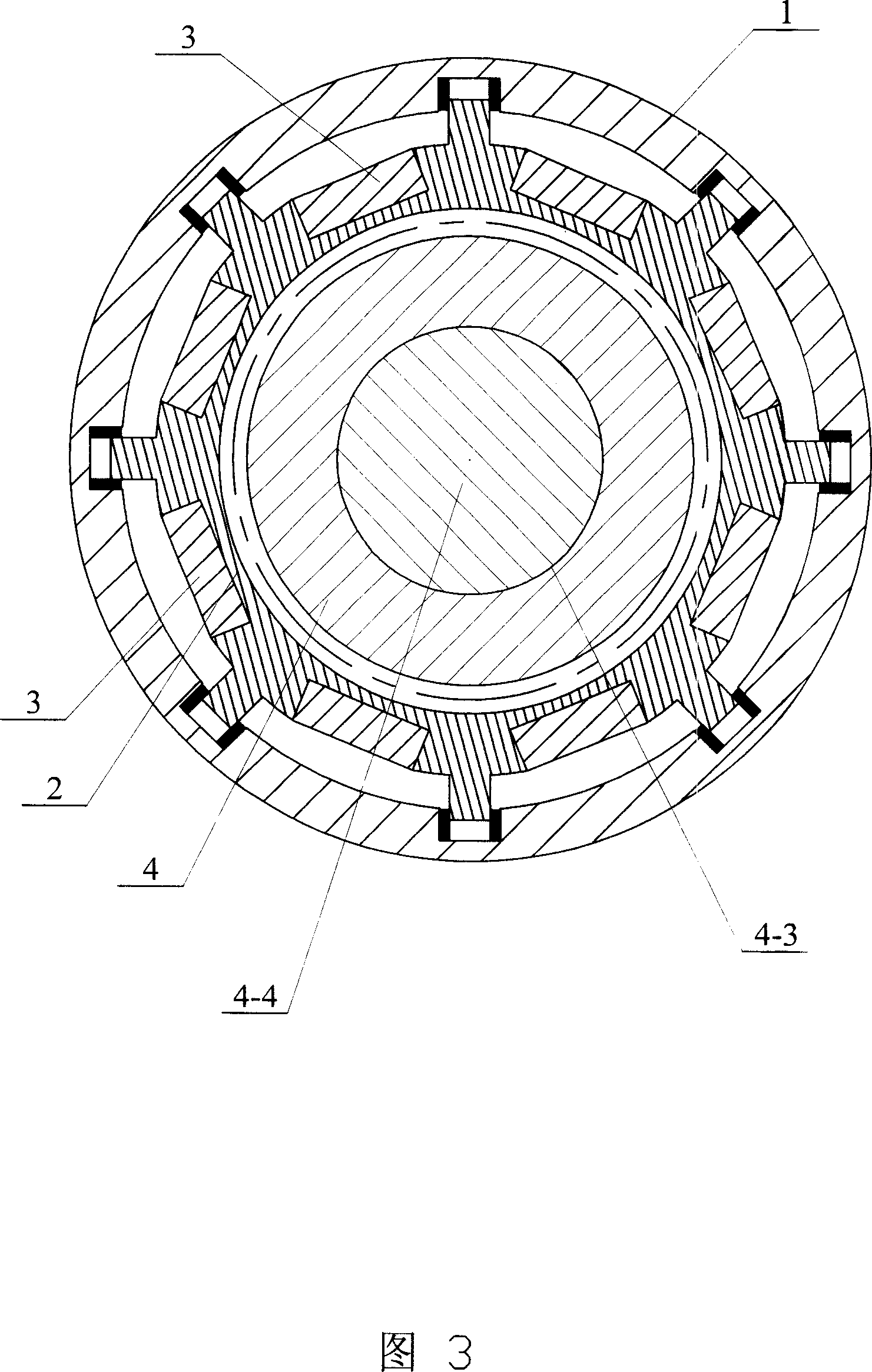

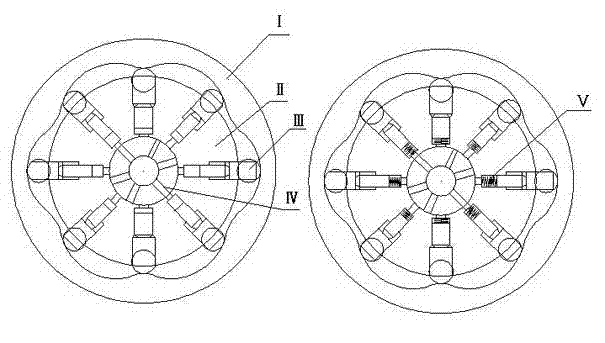

Displacement superposed piezoelectric engaging motor and its exciting method

ActiveCN101051799ALarge displacementSimple structurePiezoelectric/electrostriction/magnetostriction machinesToothed gearingsHigh energyElectromagnetic interference

The invention is in order to solve issues that the current piezoelectric harmonic motor possesses disadvantages of large non-effective deformation, large power loss, complicated structure of motor, large abrasion, and low drive efficiency. Multiple rectangular through grooves are made on the excircle face of internal tooth elastic wheel. One piece of piezoelectric ceramic body is inserted to each through groove. Stretchy direction of electrified piezoelectric ceramic body is parallel to tangent of the excircle face. Through corresponding multiple grooves to inner circle, bulges on the excircle face are connected to each other. Internal teeth of internal tooth elastic wheel engage to external teeth of external tooth rigid wheel partially. Advantages of the invention are: output of large torque in low speed, high energy conversion efficiency, long service life, high precision of rotation, and no electromagnetic interference etc.

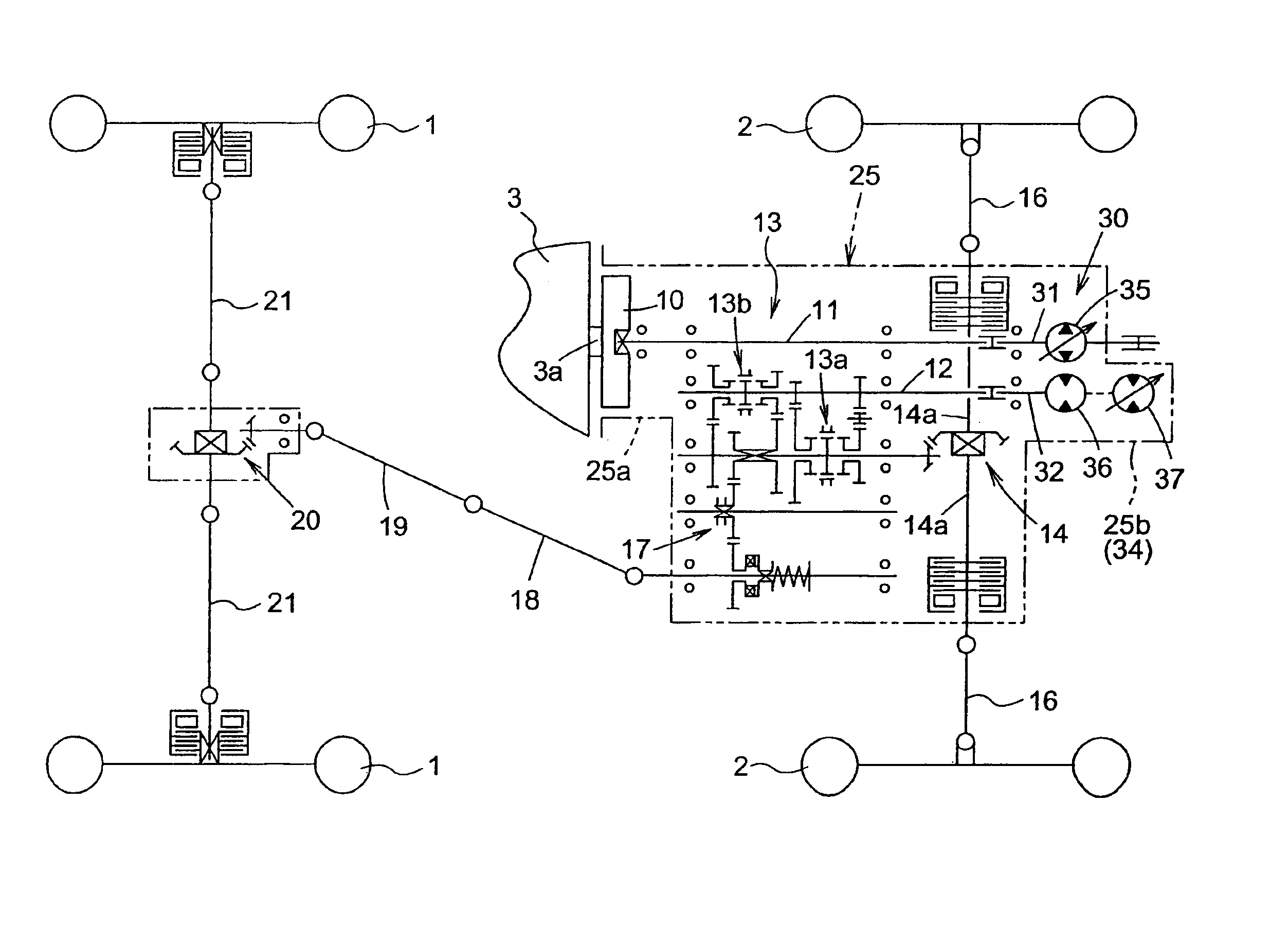

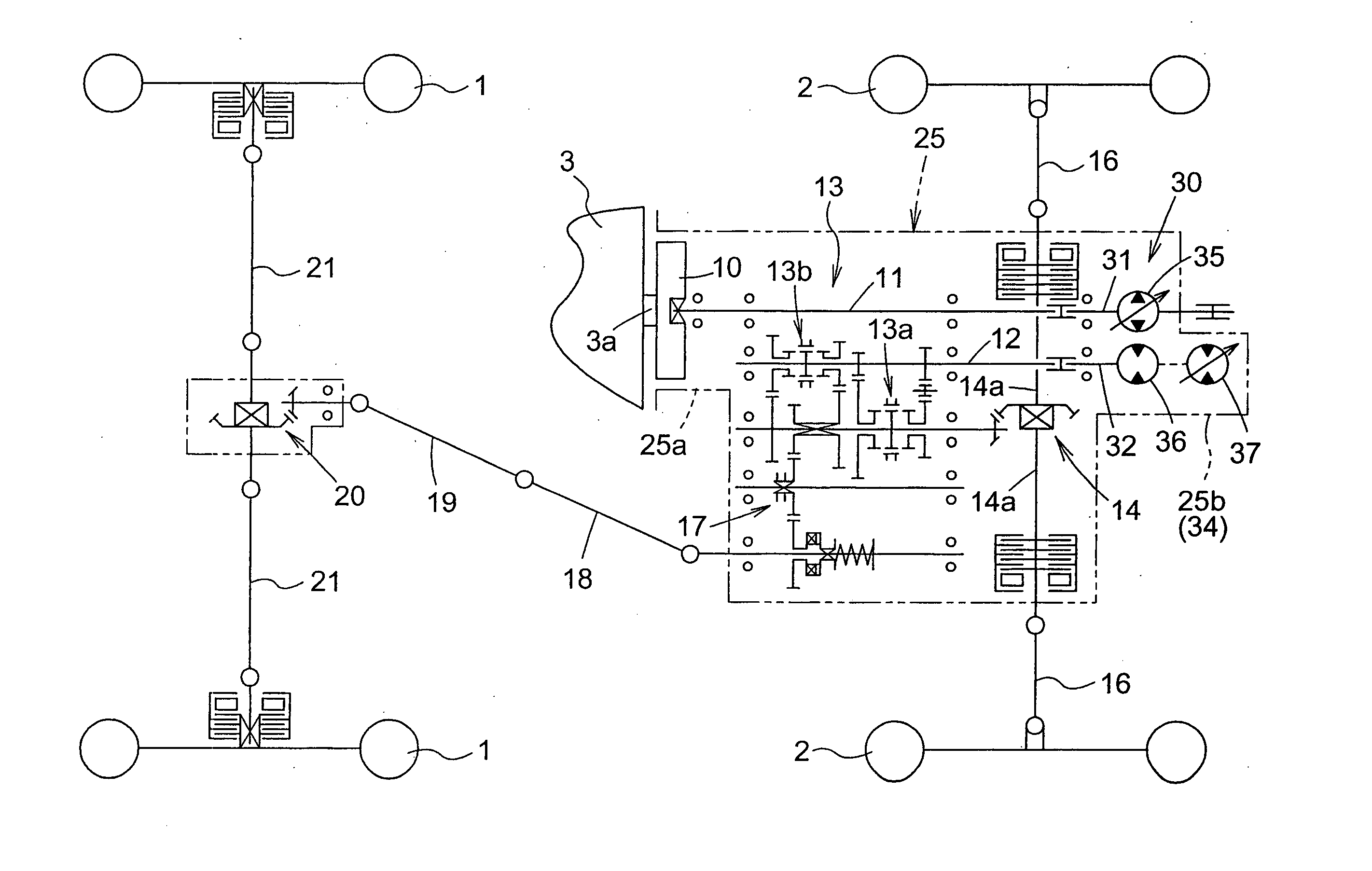

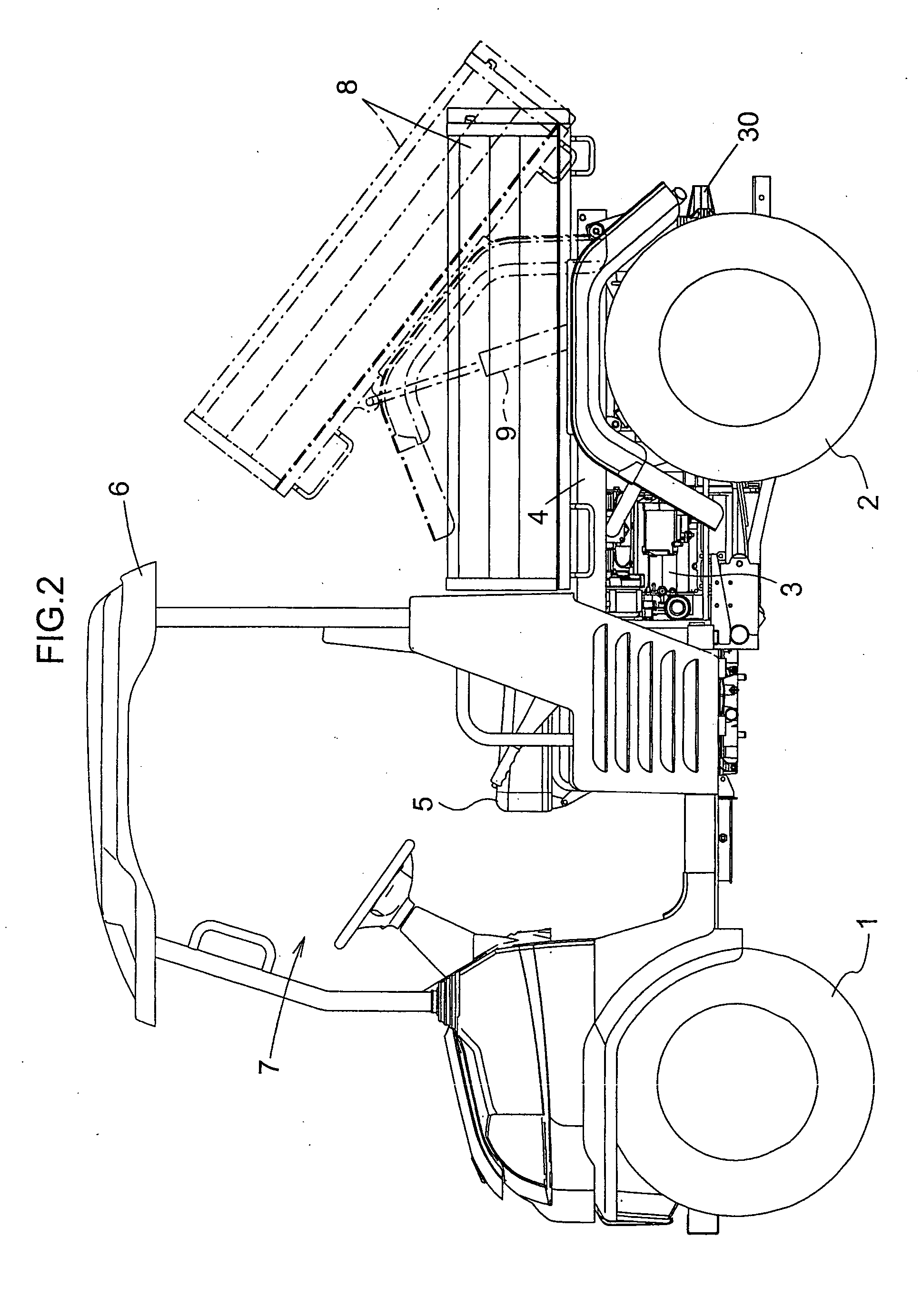

Change-speed control system for utility vehicle having stepless change-speed apparatus for speed-changing engine output and transmitting the speed-changed output to traveling unit

InactiveUS6887182B2Easy speed adjustmentSmooth startGear lubrication/coolingGearing controlDroop speed controlSpeed control system

A change-speed control system is provided for a utility vehicle having a stepless change-speed apparatus for speed-changing an engine output and transmitting the speed-changed output to a traveling unit. The system includes an engine speed governor for adjusting speed of the engine, an accelerator controller and a change-speed control linkage device for providing operative displacements in the stepless change-speed apparatus and the engine speed governor in association with an operation of the accelerator controller. The change-speed control linkage device sets an operation amount for the stepless change-speed apparatus and an operation amount for the engine speed governor in correlation with the operation amount of the accelerator controller, such that an acceleration ratio for the engine speed is greater than an acceleration ratio for the stepless change-speed apparatus until the engine reaches a predetermined speed and also the stepless change-speed apparatus reaches a predetermined speed.

Owner:KUBOTA LTD

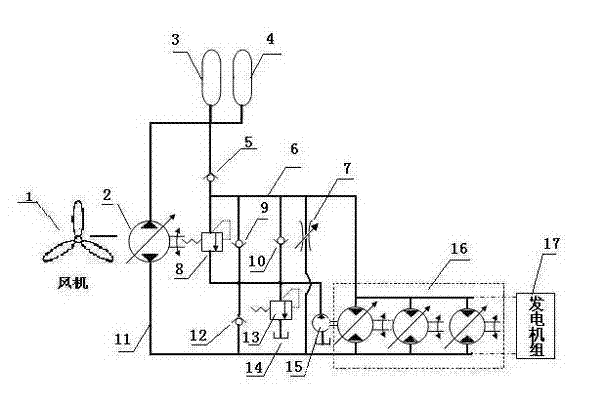

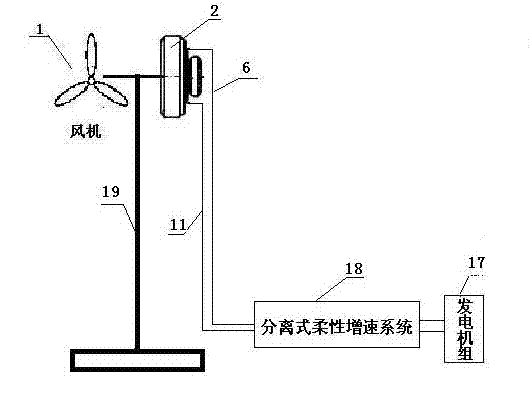

Separating flexible speed increasing device based on inner-curve hydraulic motor

InactiveCN102654105ALight in massReduce manufacturing costMachines/enginesMechanical power transmissionHydraulic motorElectricity

The invention discloses a separating flexible speed increasing device based on an inner-curve hydraulic motor. The separating flexible speed increasing device based on the inner-curve hydraulic motor comprises a fan, the inner-curve hydraulic motor, a high-pressure end energy accumulator, a one-way valve, an overflow valve, a throttling valve, a hydraulic pipe, a hydraulic motor set, a power generator unit and an oil tank, wherein the inner-curve hydraulic motor is connected with the hydraulic motor and is arranged above a tower frame, and other devices are arranged below the tower frame. The inner-curve hydraulic motor of the invention belongs to a low-speed large-torsion motor, and is also used as a hydraulic pump. The inner-curve hydraulic motor has the characteristics of low speed and large torsion, requirements on wind power utilization are met, working condition of a wind-power machine is adapted, transmission of wind power is convenient, a speed increasing device of a large wind-power system is simplified, the load of the top of the tower frame is reduced, maintenance and installation are convenient and the development cost is reduced.

Owner:JIANGSU UNIV

High-performance PC (Polycarbonate)/ABS (Acrylonitrile Butadiene Styrene) alloy prepared by waste electrical PC/ABS material and preparation method and application thereof

The invention discloses a high-performance PC (Polycarbonate) / ABS (Polyacrylonitrile) alloy prepared by waste electrical PC / ABS material and a preparation method and an application of high-performance PC (Polycarbonate) / ABS (Polyacrylonitrile) alloy. The PC / ABS alloy comprises the following material components by weight: 95-97 parts of waste electrical PC / ABS crushed materials, 0.2-0.4 part of B-215 long-acting heat stabilizer, 2-4 parts of SBS (sodiumbisulfite) flexibilizer, 1-2 parts of EMA flexibilizer and 0.3-0.5 part of anti-ultraviolet agent. The PC / ABS alloy provided by the invention has the characteristics of high performance, high flame retardance, high impact resistance, high coldness resistance, high stability and static electricity resistance and the like, can be used for manufacturing an intelligent electric meter housing, a meter housing, a fax machine housing or a copier housing and the like.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

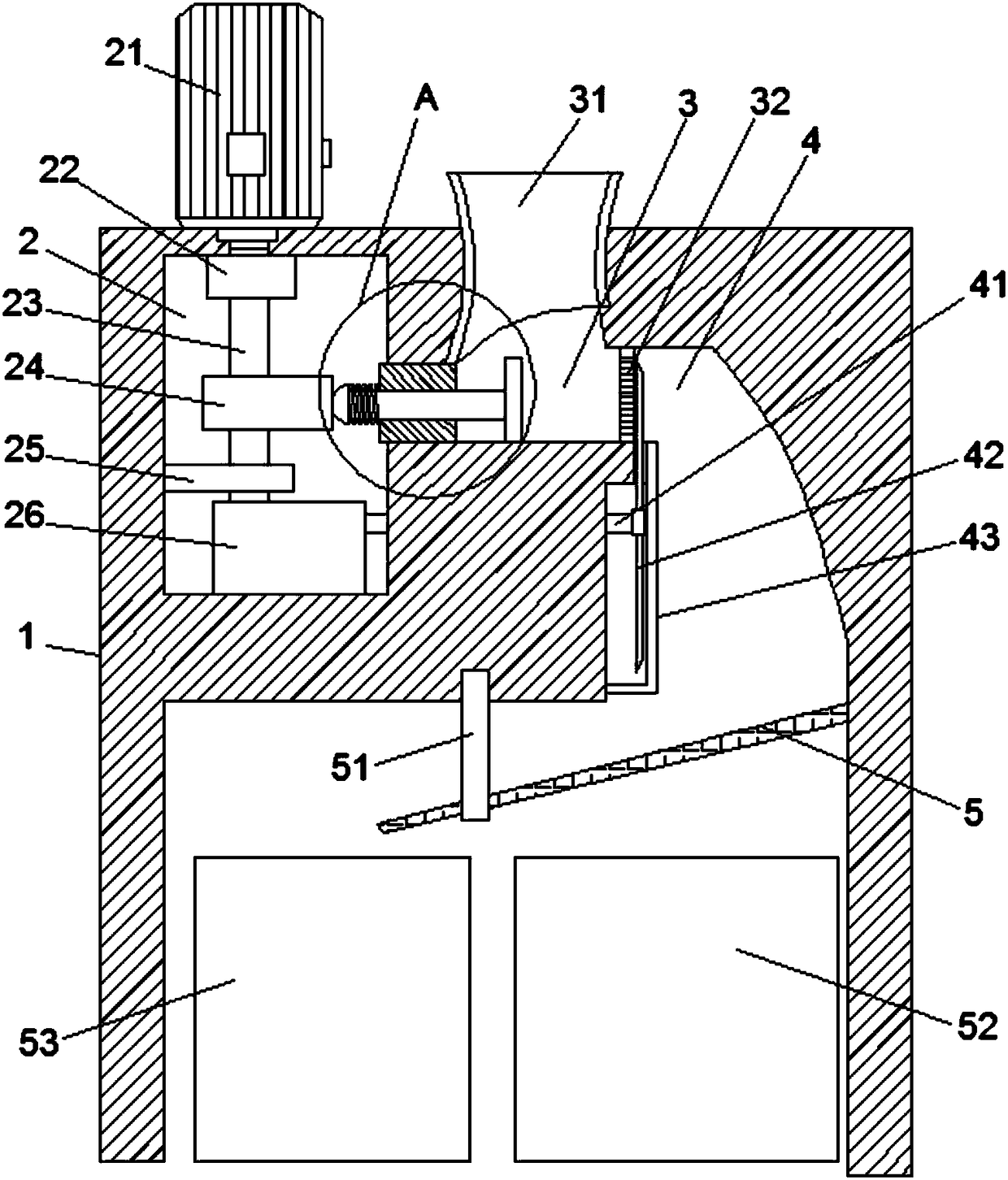

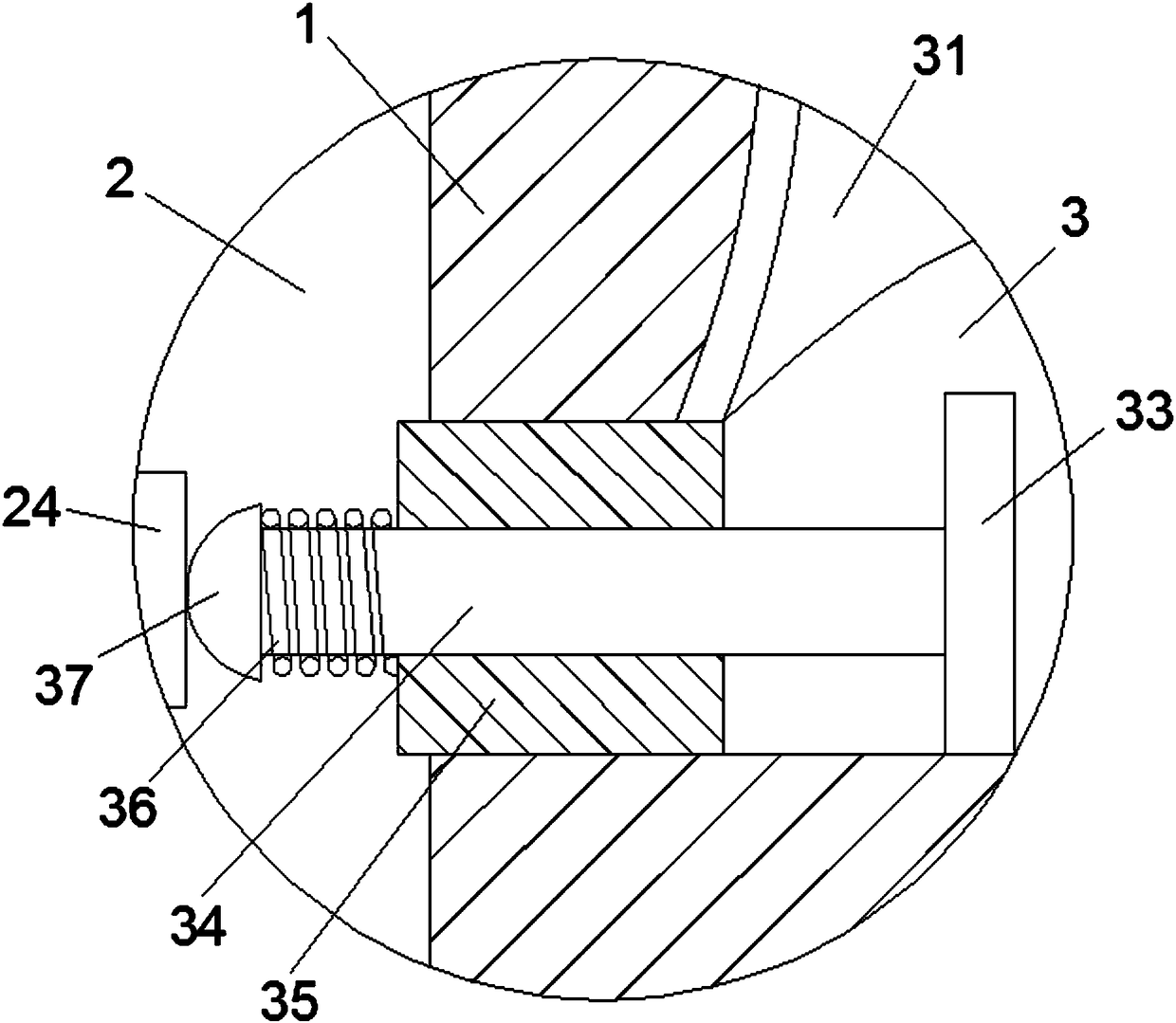

Coal-briquette-processing efficient stamp mill for clean coal technology

ActiveCN106269029AEasy speed adjustmentRun accuratelyGrain treatmentsCoal briquetteArchitectural engineering

The invention belongs to the technical field of clean coal and particularly relates to a coal-briquette-processing efficient stamp mill for the clean coal technology. The coal-briquette-processing efficient stamp mill comprises a base plate, a left rack, a right rack, a top plate, an electric push rod, a fixing rod, a collecting frame, a hinge part, a stamping frame, a hinge, a retaining plate, a movable frame, a first support rod and the like, wherein the left rack is welded to the left end of the top of the base plate, a guide sleeve is welded to the upper portion of the right of the left rack, and a guide rod is nested into the guide sleeve. The coal-briquette-processing efficient stamp mill is fast, even and thorough in stamping.

Owner:SHANDONG DONGSHAN XINYI COAL MINE CO LTD

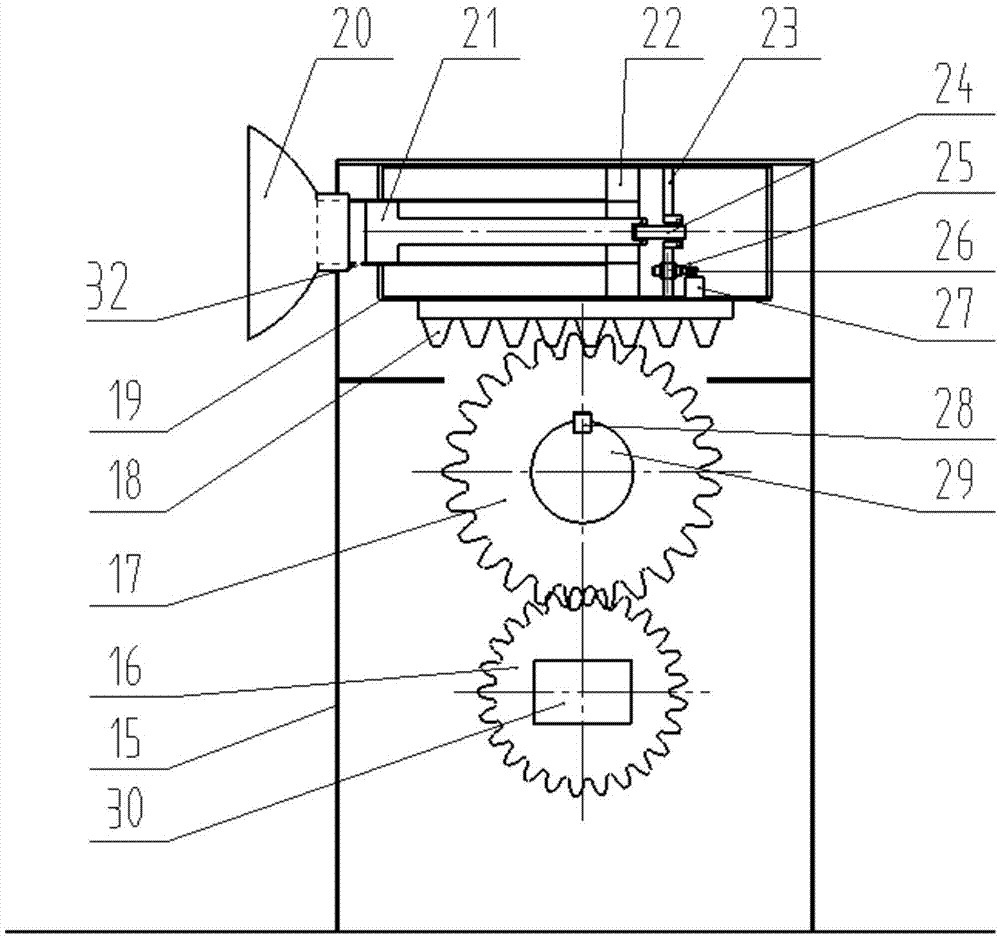

Fruit and vegetable dicing equipment

InactiveCN108406921AEasy to adjust the speedImprove stabilitySievingScreeningGear wheelElectric machinery

The invention discloses fruit and vegetable dicing equipment comprising a machine body. The upper portion of the machine body is internally provided with a transmission cavity, a dicing cavity and a falling cavity from left to right in sequence; a motor is arranged on the left side of the upper end of the machine body, the motor is connected with a first rotating shaft through a speed reducer arranged at the top end of the transmission cavity, the first rotating shaft extends to the bottom of the transmission cavity to be connected with the input end of a gearbox set, and the middle of the first rotating shaft is provided with a cam; a pushing plate is arranged on the inner left side of the dicing cavity, the pushing plate is connected with a jacking block in the transmission cavity through a pushing rod, and the jacking block abuts against the cam; a guiding sleeve allowing the pushing rod to pass through is arranged between the dicing cavity and the transmission cavity, and a reset spring is arranged on the position, between the guiding sleeve and the jacking block, of the pushing rod in a sleeving mode; and the upper end of the dicing cavity is provided with a feeding inlet extending out of the machine body. The fruit and vegetable dicing equipment is convenient to use, dicing operation of fruits and vegetables can be automatically completed, and the dicing efficiency is greatly improved.

Owner:安徽省宇洲食品有限公司

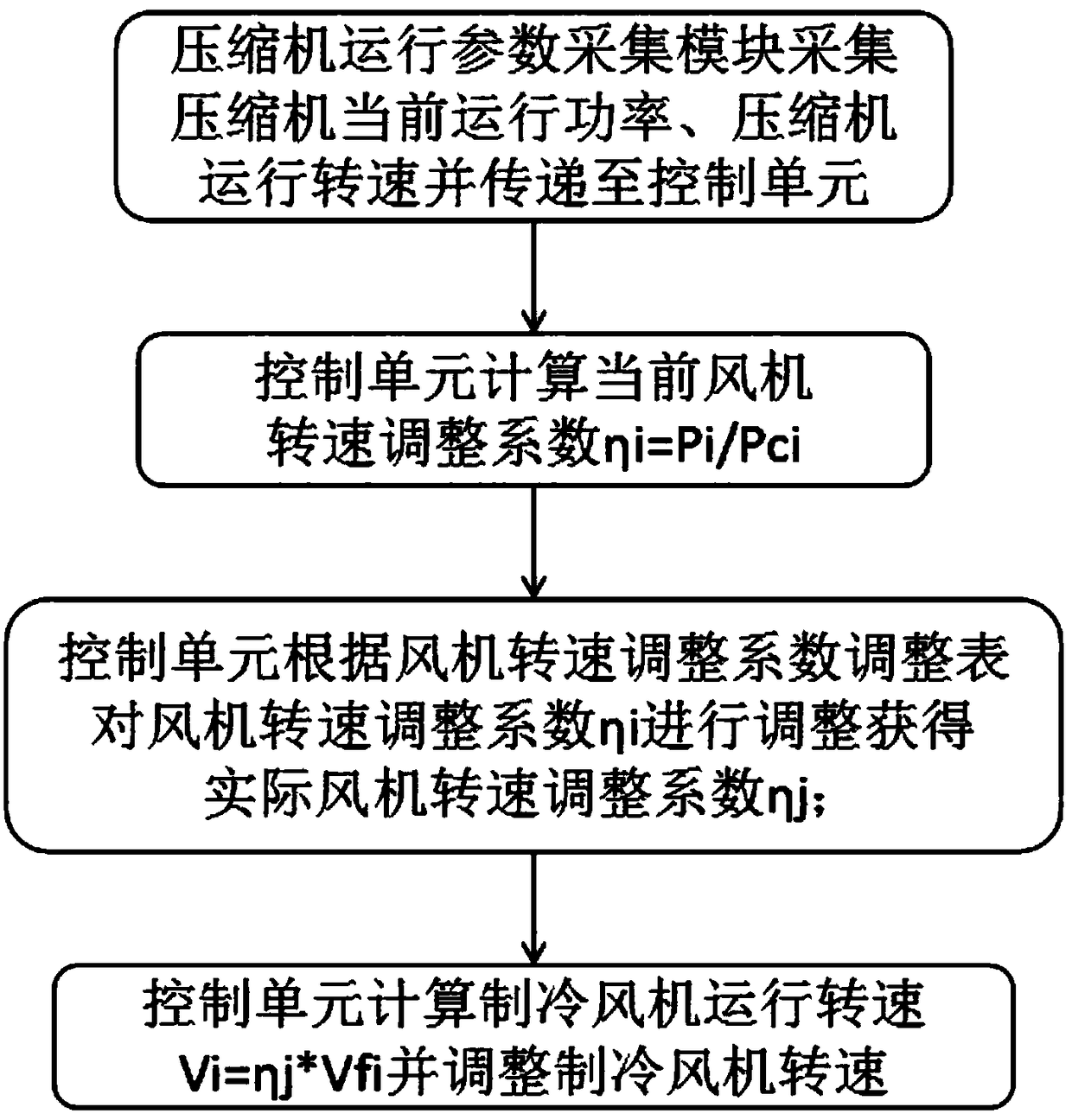

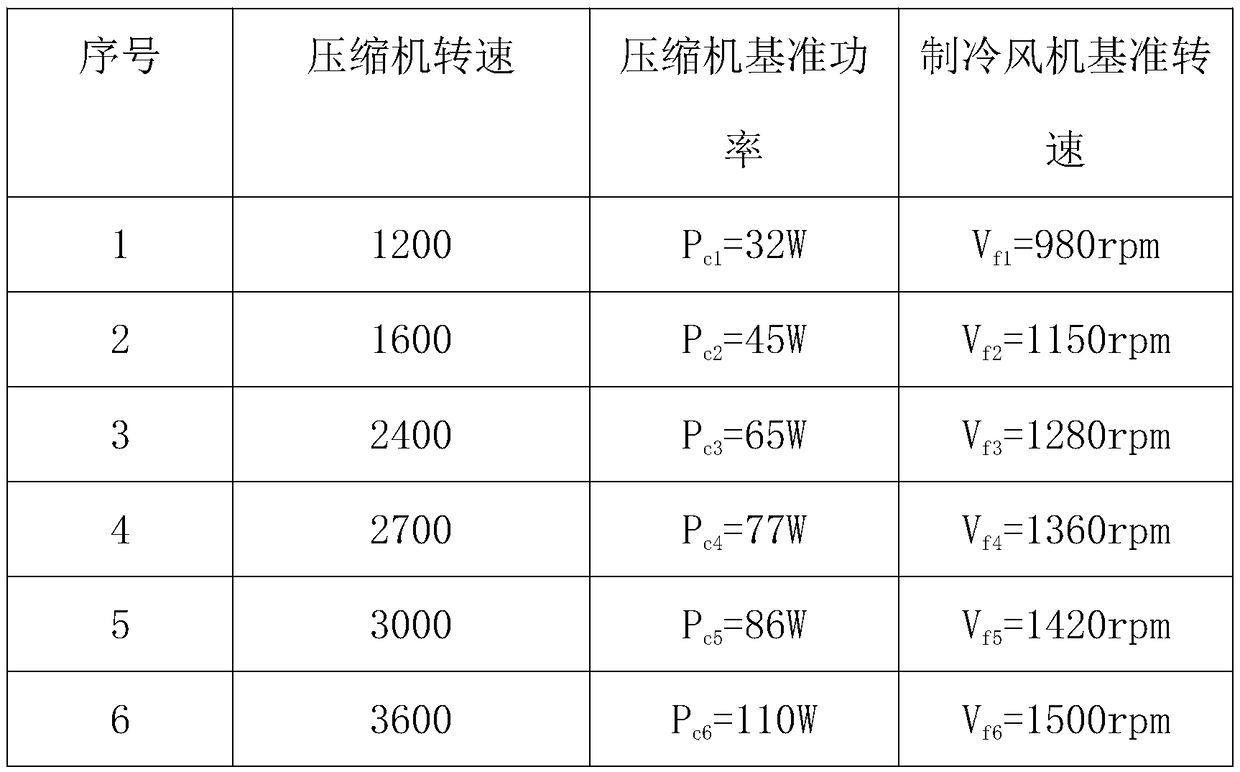

Rotation speed control method for fan of air-cooling refrigerator

ActiveCN108759296AReduce speedEasy speed adjustmentDomestic cooling apparatusRefrigeration safety arrangementTemperature differenceControl theory

The invention discloses a rotation speed control method for a fan of an air-cooling refrigerator and relates to the technical field of rotation speed control for fans of air-cooling refrigerators. Therefrigeration fan, a control unit and a compressor running parameter collection module are included; the control unit is electrically connected with the compressor running parameter collection moduleand the refrigeration fan; the compressor running parameter collection module is electrically connected with a compressor; and the control unit is used for dynamically adjusting the rotation speed ofthe refrigeration fan according to changes of the compressor running power. By controlling the rotation speed of the compressor to be unchanged, the rotation speed of the refrigeration fan is adjusted to make the overall energy consumption be minimum. The running power of the compressor is obtained as reference power Pc, the reference rotation speed Vf of the refrigeration fan is obtained, and the controller adjusts the rotation speed of the refrigeration fan according to the current compressor rotation speed and the ratio of the actual running power to the corresponding reference power. Therefrigeration fan rotation speed adjusting method is simple, various conditions such as environment temperature, set temperature and temperature difference do not need to be judged, energy consumptionis saved, and overall noise of the refrigerator is effectively reduced.

Owner:CHANGHONG MEILING CO LTD

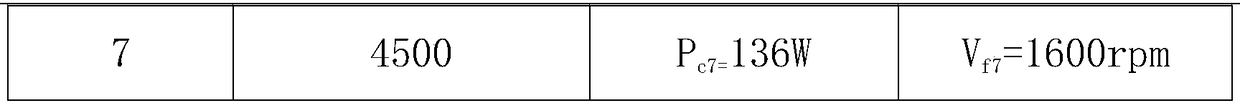

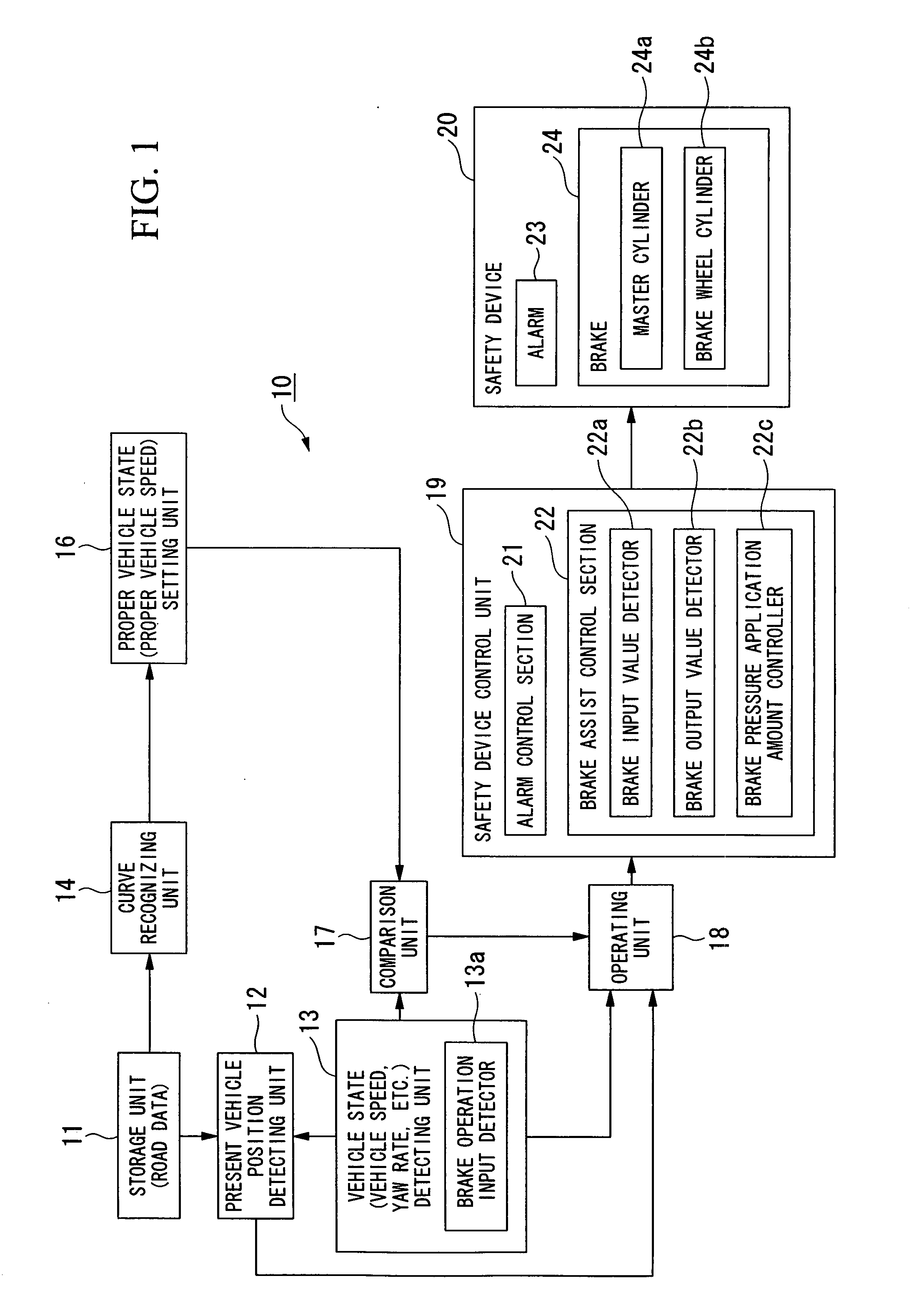

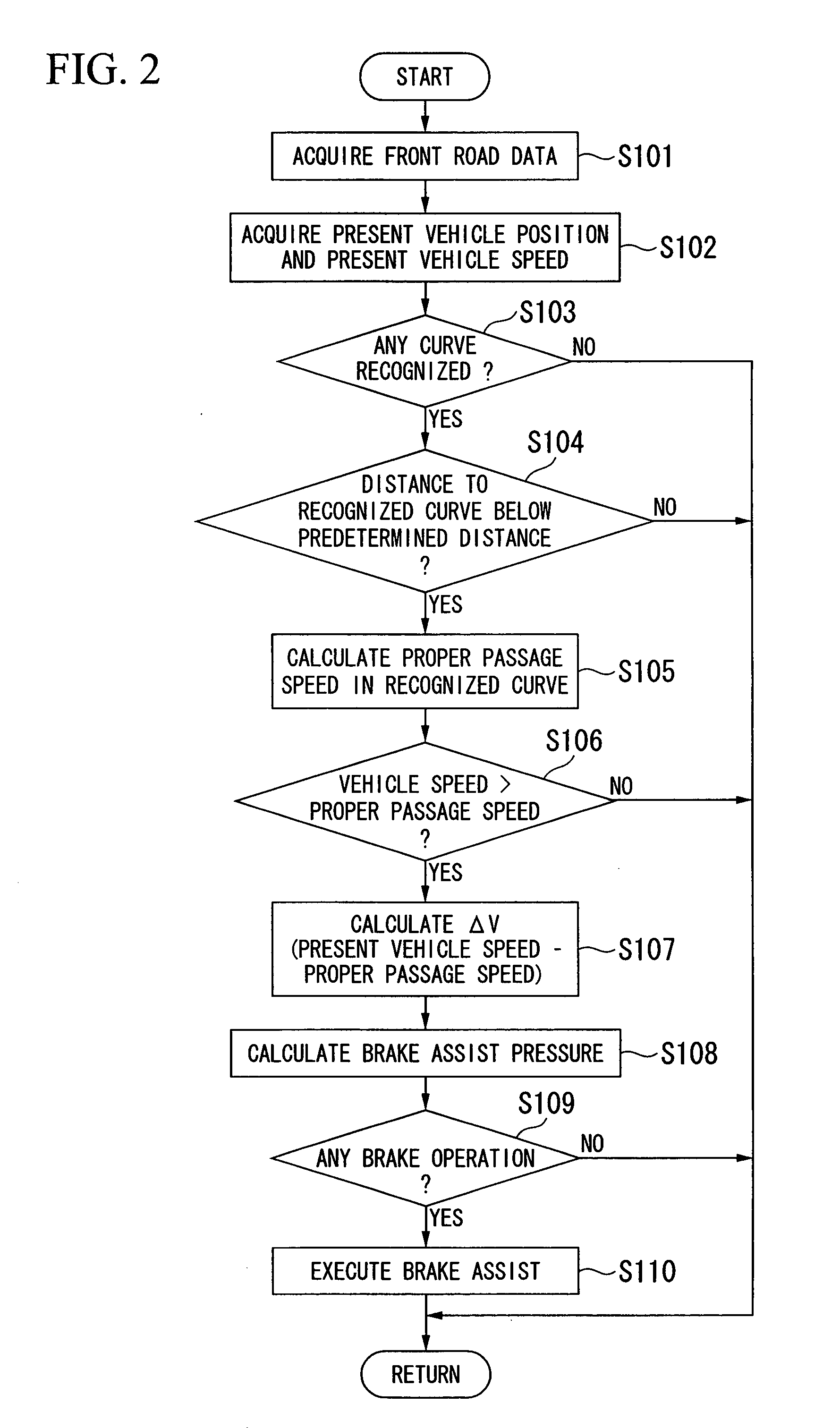

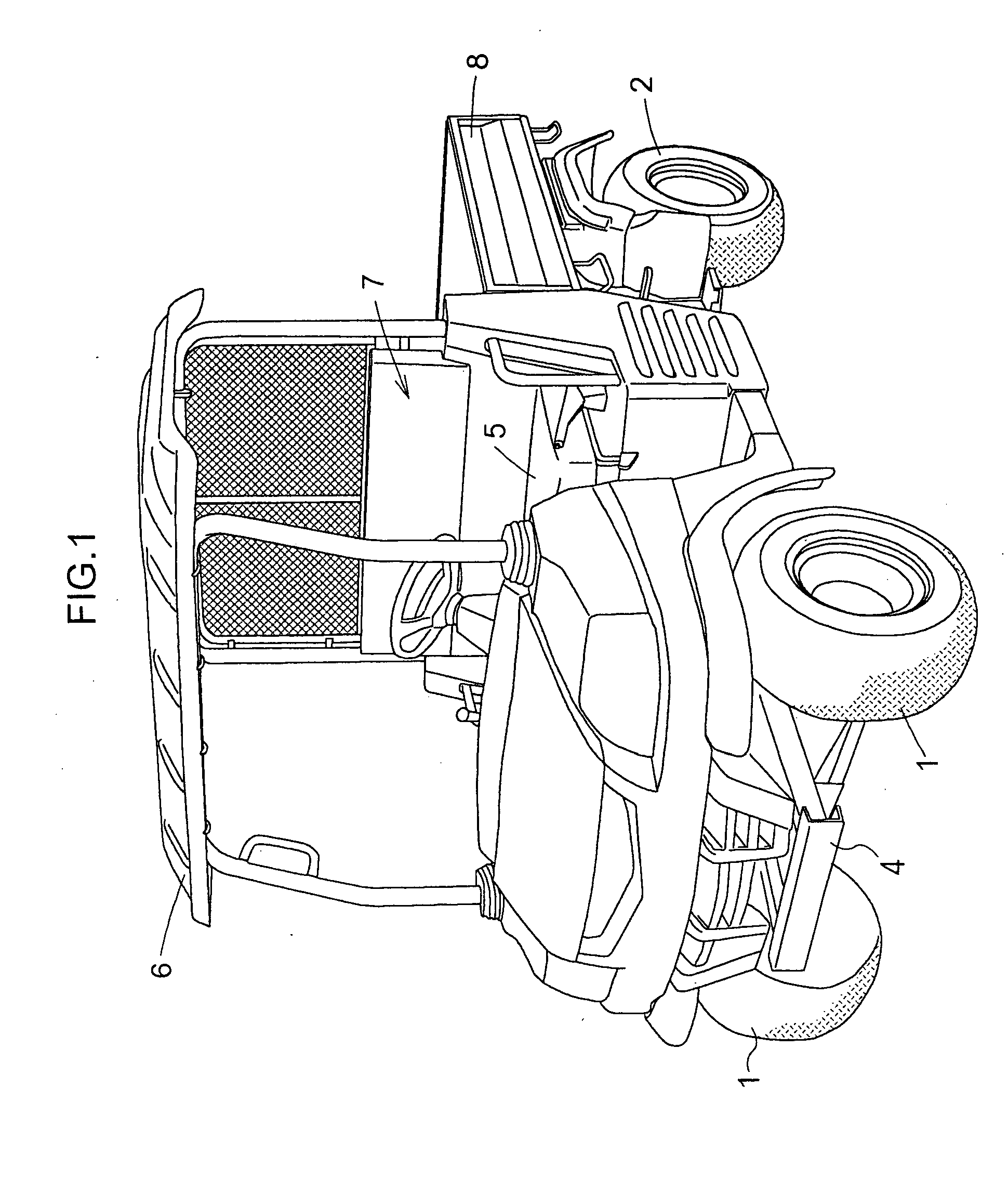

Traveling safety device for vehicle

InactiveUS20080015765A1Increasing and reducing brake pressureEasy speed adjustmentInstruments for road network navigationHand manipulated computer devicesLocation detectionAutomotive engineering

A traveling safety device for a vehicle of the present invention includes a brake device, a brake operation detecting device, a storage device, a present vehicle position detecting device, a vehicle state detecting device, a road shape recognizing device, a proper vehicle state setting device, a comparing device, a brake assist control device, a brake assist control device. The brake assist control device calculates an initial brake assist pressure based on a comparison result of the comparing device, and changes a brake assist pressure in proportion to the brake operation of the driver when a change in the brake operation by the driver has been detected after start of brake assist control based on the initial brake assist pressure.

Owner:HONDA MOTOR CO LTD

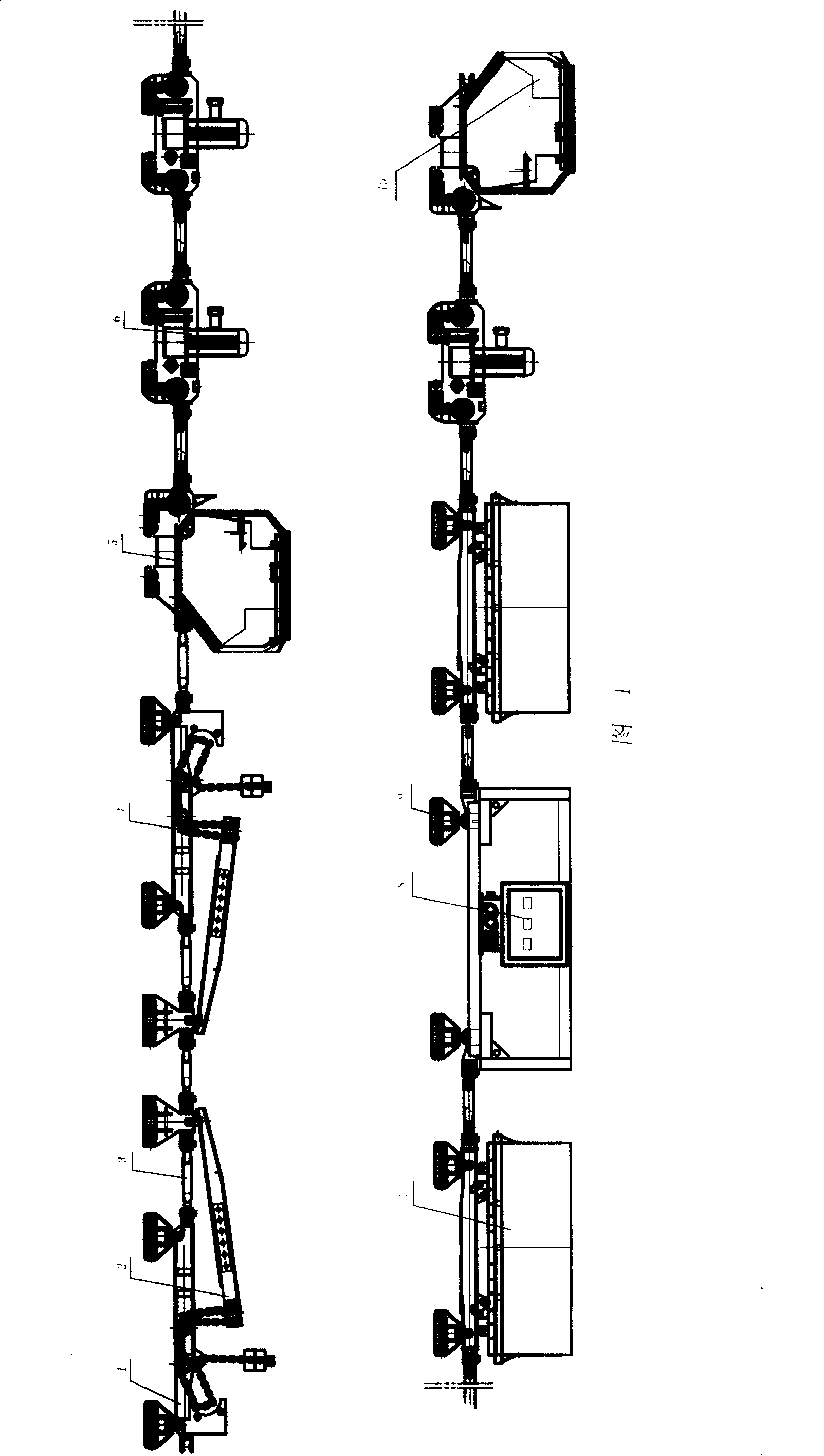

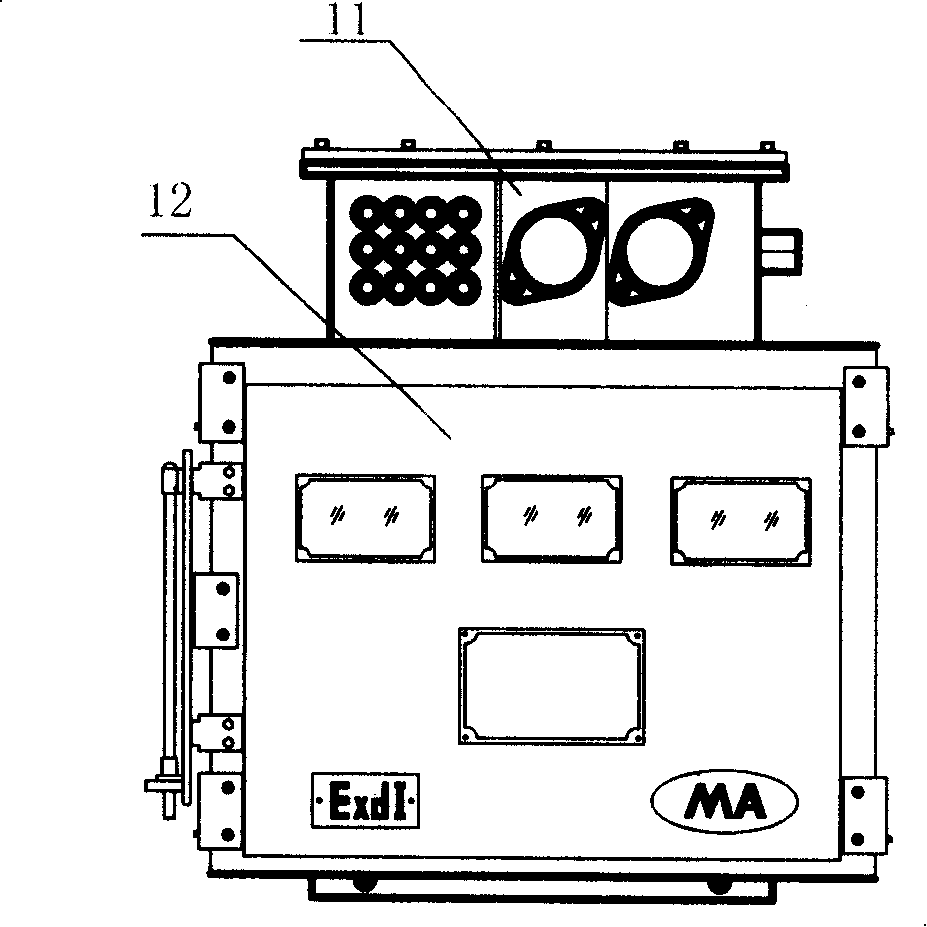

Mine trackless transport engine

InactiveCN101204958AReduce weightReduce volumeSpeed controllerElectric locomotivesDisplay boardDashboard

The invention relates to a mine trackless transport locomotive used for underground subsidiary transport, which comprises a pre driver chamber and a post driver chamber, a driving device, a battery, a load-bearing wheelbarrow, a hoist apparatus, a hydraulic system, an electrical control system, etc. A traction motor in the driving device and a hydraulic pump motor of the hydraulic system both adopt three-phase AC motors, which are provided with AC by the battery through a transducer. The electrical control system comprises of a programmable controller, the transducer, a speed and direction sensor, a pressure sensor, a photoelectric conversion isolation plate, a dashboard, a display board, an intrinsic safety power source, an explosion septal and intrinsic safe electric control box, etc. The traction motor of the trackless motor and the hydraulic pump motor adopt alternating current motors which have the advantages of light weight, small size, low price, convenient maintenance and wide application. The direct current in the battery is transferred into three-phase alternating current by the transducer to reduce attack of starting current on the motors and the battery, prolong the service life of the motors and improve power factor. When the transport locomotive is running declivous, the kinetic energy can be transferred into electric power to charge the battery, so as to realize power regenerative braking.

Owner:佟强

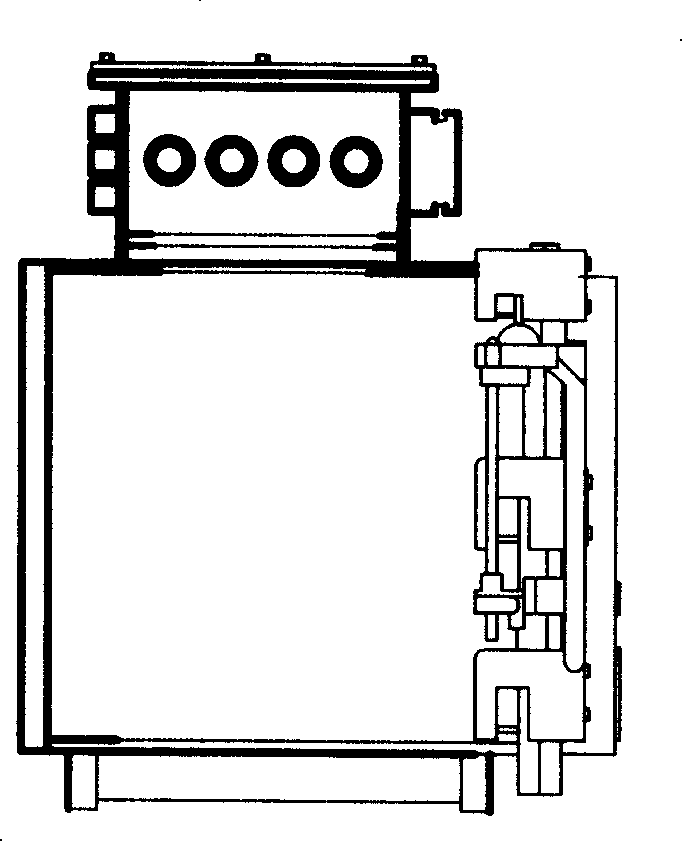

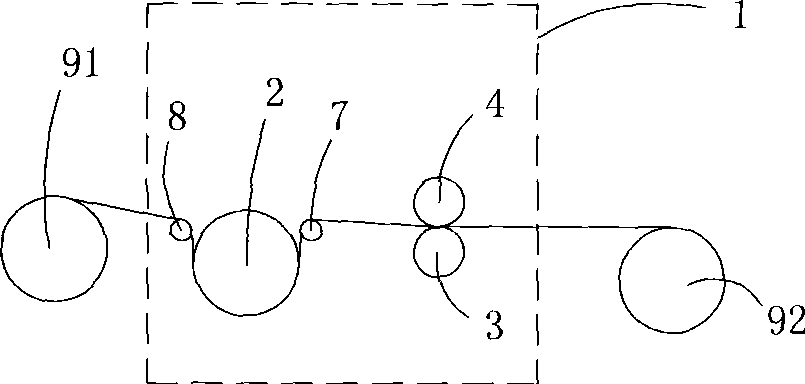

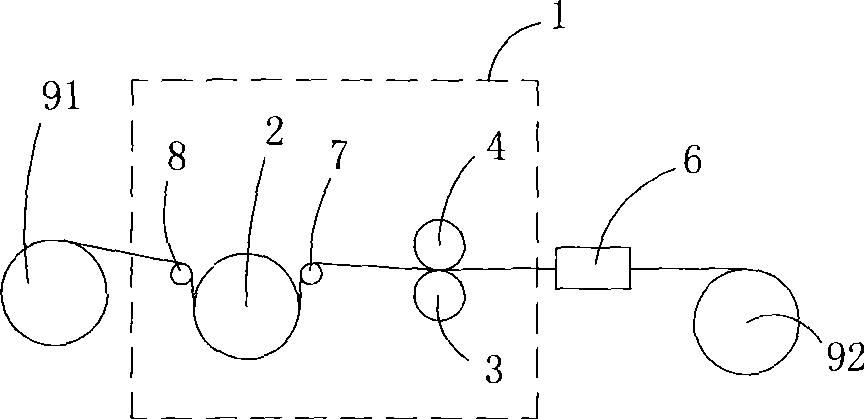

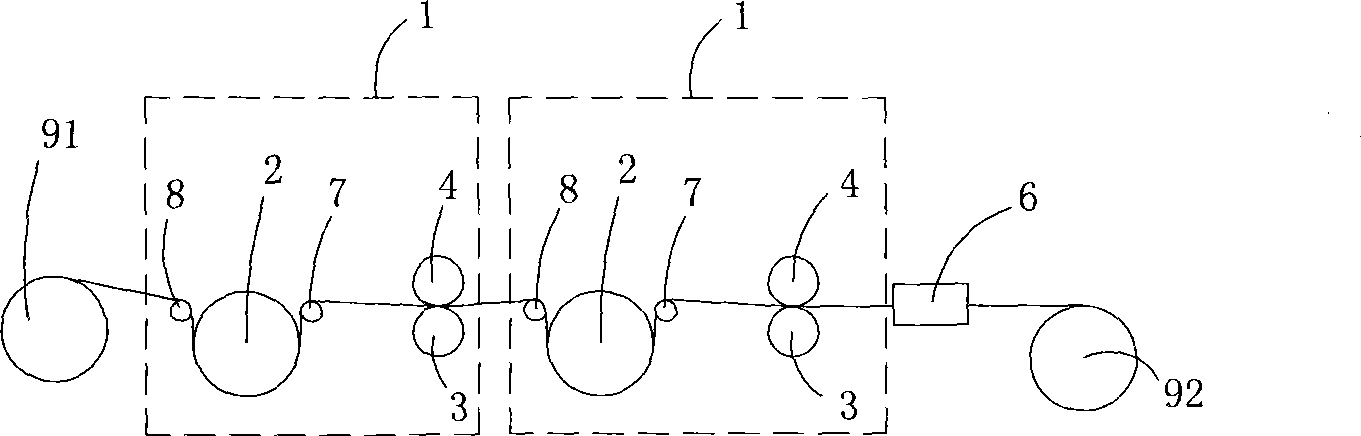

Equipment for manufacturing easy-tear type thin plastic film

Owner:ZHEJIANG GOLDSTONE PACKING

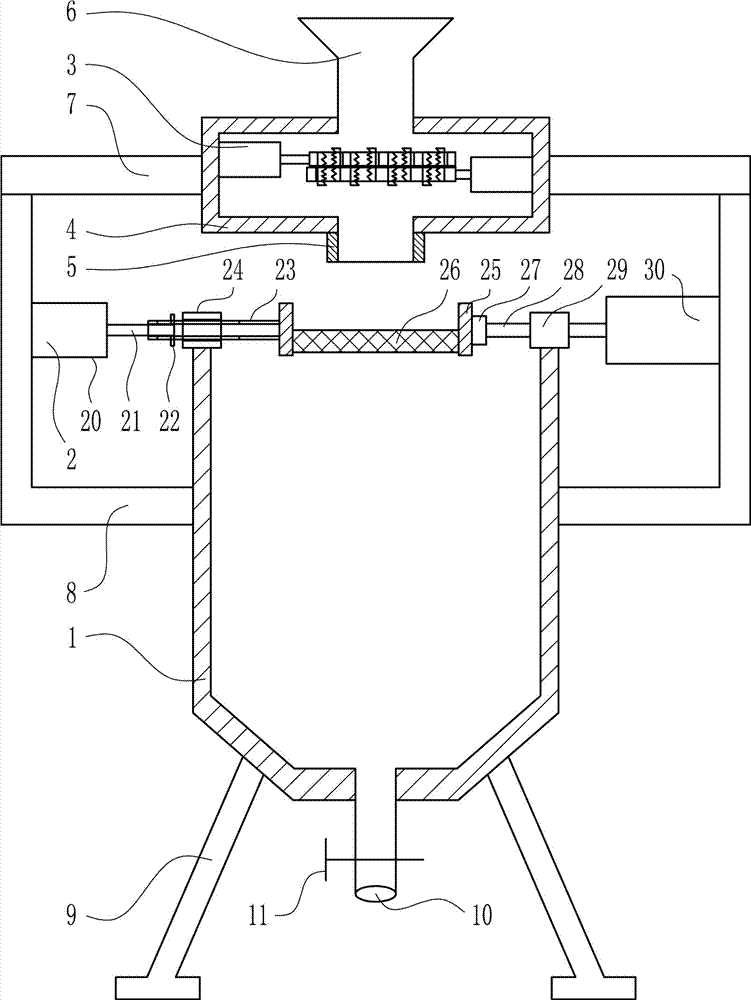

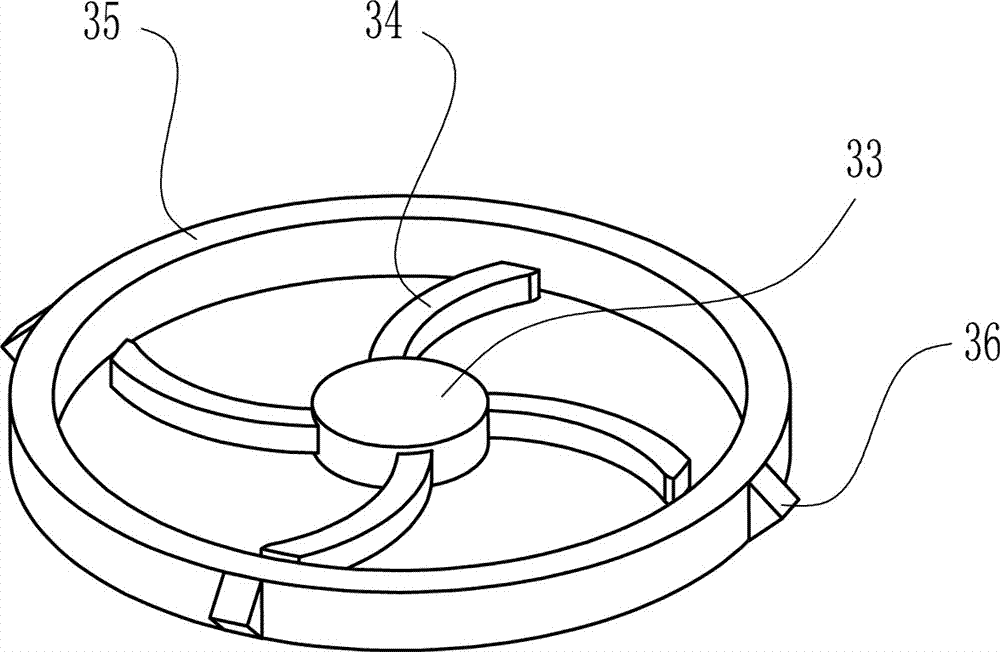

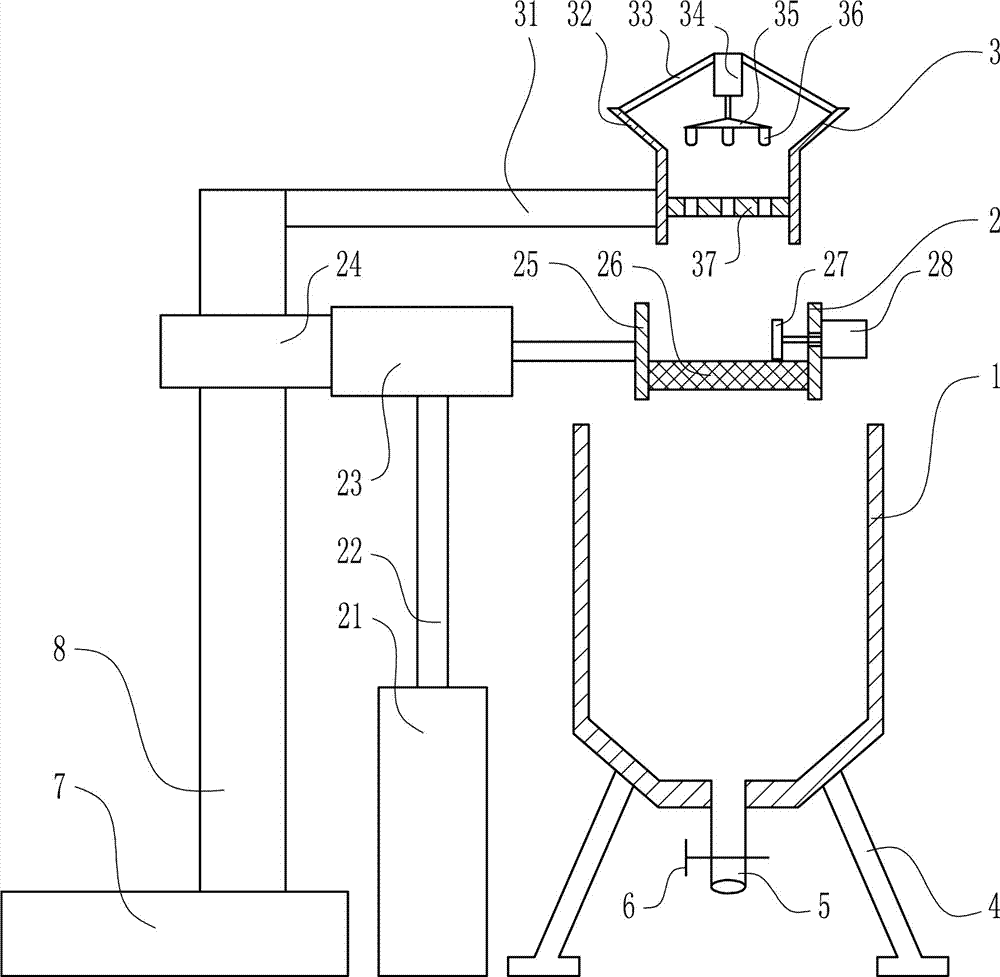

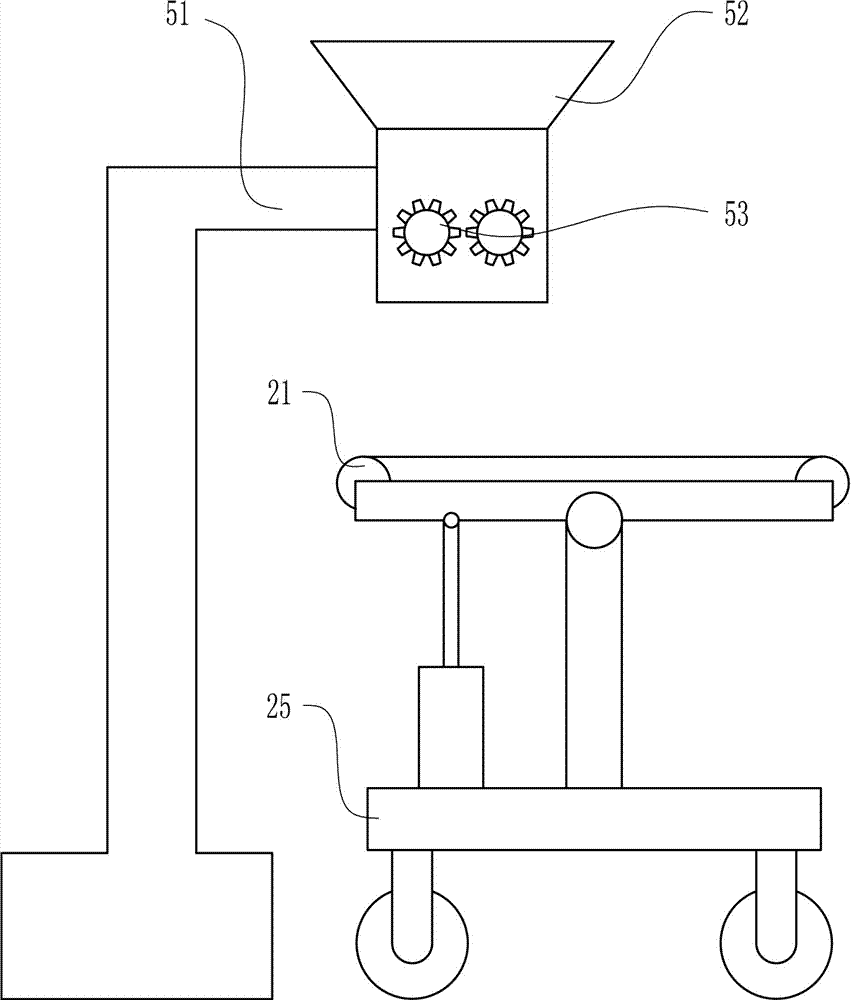

Pulping device of rare earth ore

ActiveCN107224905AUndamagedGood mixing and stirringTransportation and packagingRotary stirring mixersRare earthEngineering

The invention relates to a pulping device and particularly relates to a pulping device of rare earth ore. The pulping device of rare earth ore solves the technical problem of rare earth ore pulping. The pulping device comprises a stirring cylinder, a moving device, a stirring device, support legs, a discharge pipe and a discharge valve. The stirring device is arranged in the stirring cylinder. The stirring device is connected to the moving device. The support legs are welded to the bottom of the stirring cylinder. The upper end of the discharge valve is welded to the middle of the bottom of the stirring cylinder. The discharge pipe is provided with the discharge valve. A feeding hopper is welded to the middle of the top of the stirring cylinder. The feeding hopper is communicated with the stirring cylinder. Through combination of the moving device and the stirring device, the stirring device can move left and right in the stirring cylinder so that a stirring range is expanded.

Owner:连云港浩森矿产品有限公司

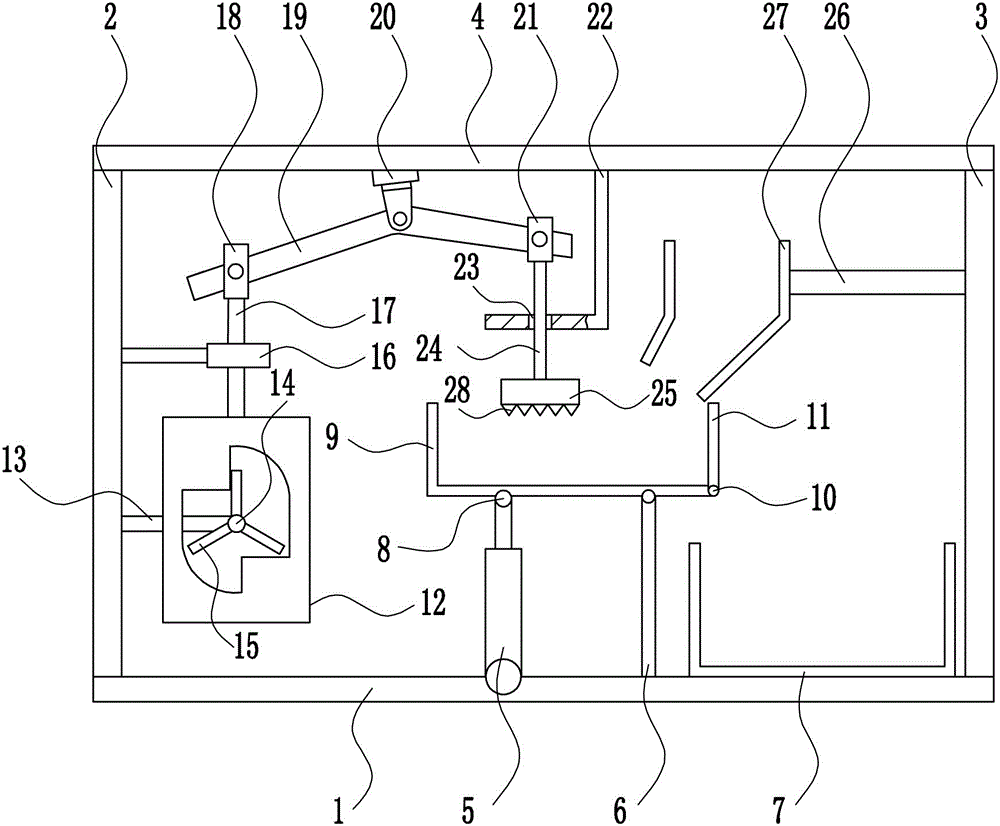

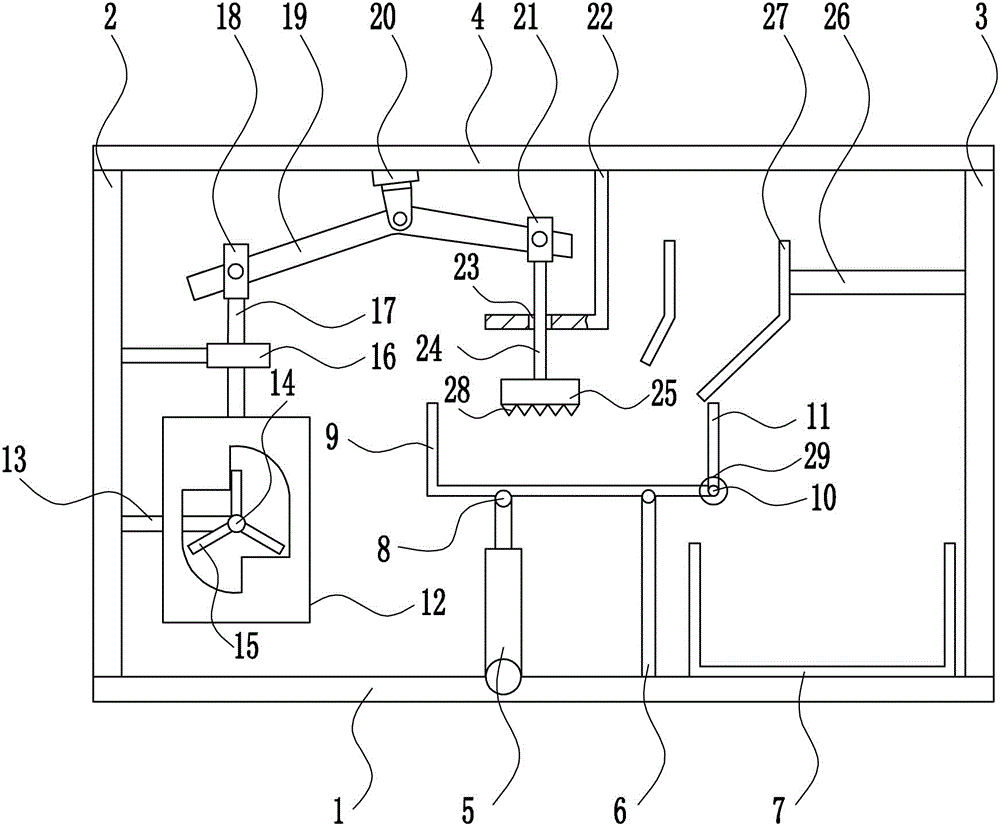

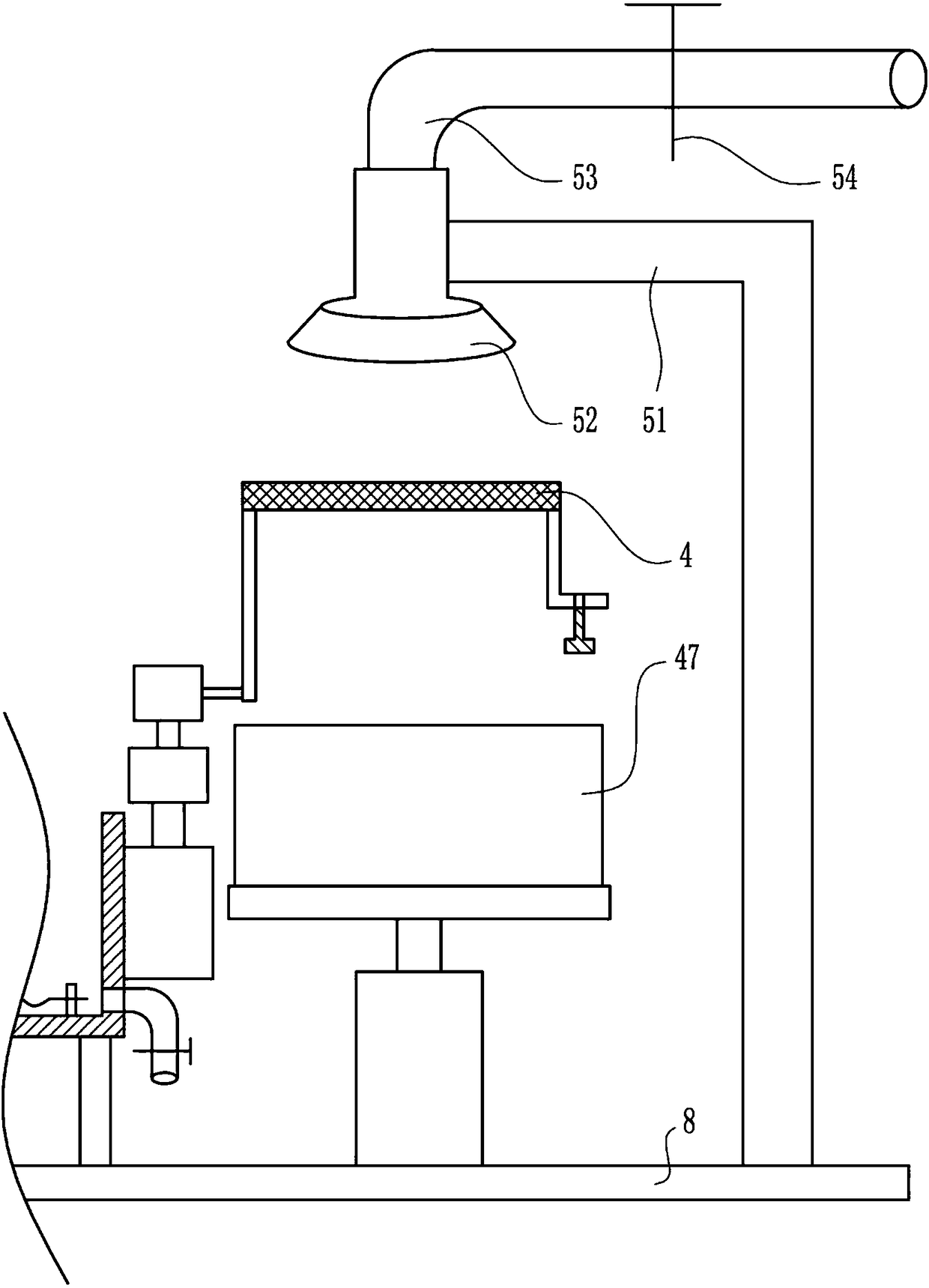

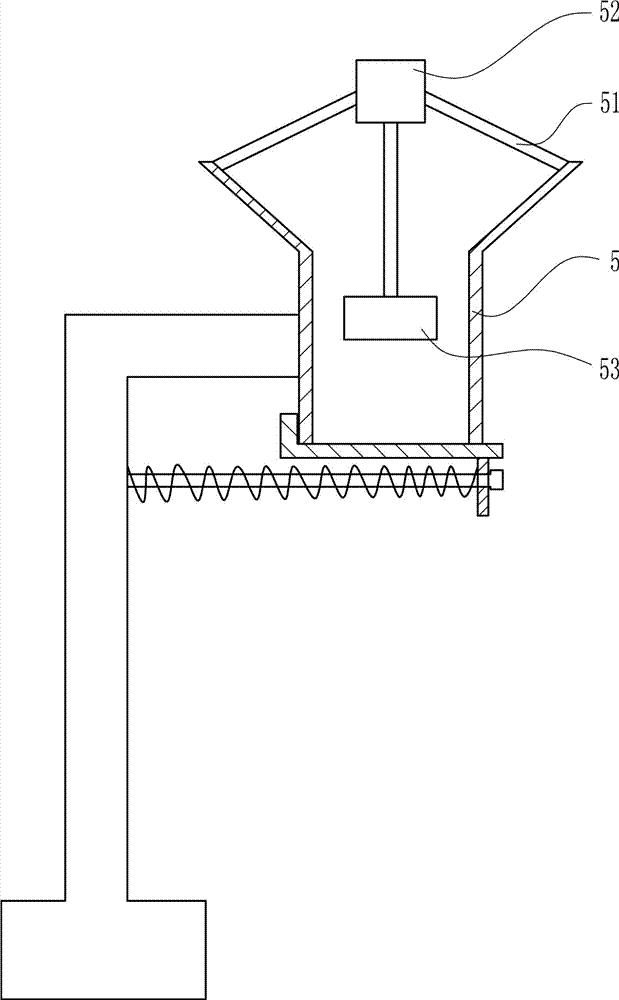

Full-automatic robot for cleaning garbage on water

ActiveCN106013023ARealize multifunctionality of one machineHigh degree of intelligenceWater cleaningWaterborne vesselsRefuse collectionFixed frame

The invention relates to a full-automatic robot for cleaning garbage on water. The full-automatic robot for cleaning the garbage on water comprises a rack, a pneumatic reversing device, charging dumping devices, garbage stopping doors, a filtering net, air barrels and fixing buckles, wherein rectangular fixing frames are symmetrically arranged at the left side and the right side of the rack; the middle part of the rack consists of an upper layer and a lower layer; the upper layer of the rack is of a semi-cylindrical housing structure of which the upper end is opened; the pneumatic reversing device is positioned at the lower rear end of the middle part of the rack; the charging dumping devices are correspondingly positioned in rectangular frame bodies at the left side and the right side of the rack; the garbage stopping doors are correspondingly positioned in front of the rectangular frame bodies at the left side and the right side of the rack; the filtering net is mounted in the upper layer of the semi-cylindrical housing structure of the rack; the air barrels are symmetrically positioned at the left side and the right side of the rack and are connected to the rack through the corresponding fixing buckles. The full-automatic robot for cleaning the garbage on water integrates the garbage collecting performance, the garbage dumping performance and the garbage storing performance, so that the robot is multifunctional; in addition, the full-automatic robot is high in intelligence degree, can fully automatically clean the garbage floating on water, and is high in working efficiency and good in cleaning effect.

Owner:江苏弘汉生物科技有限公司

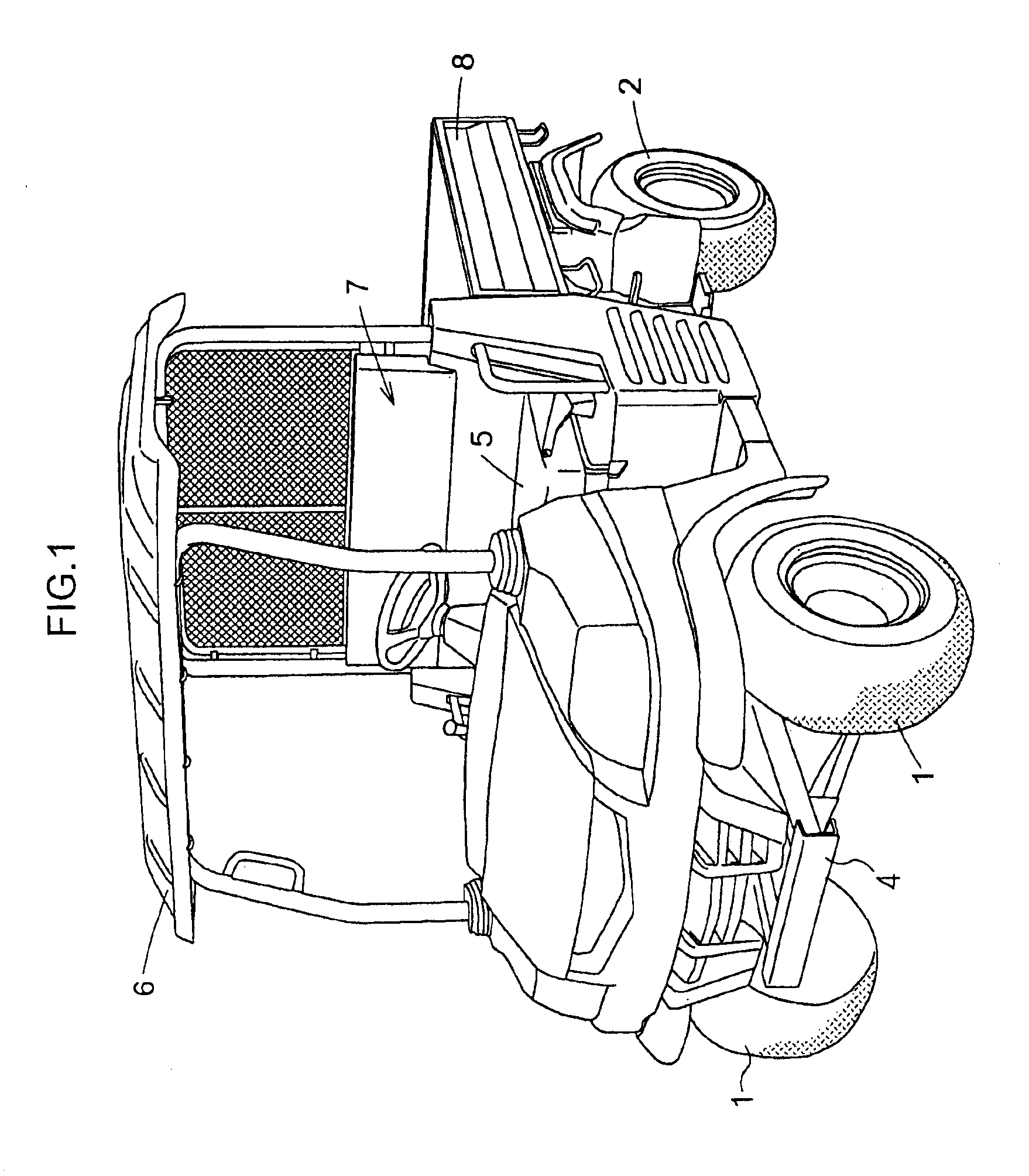

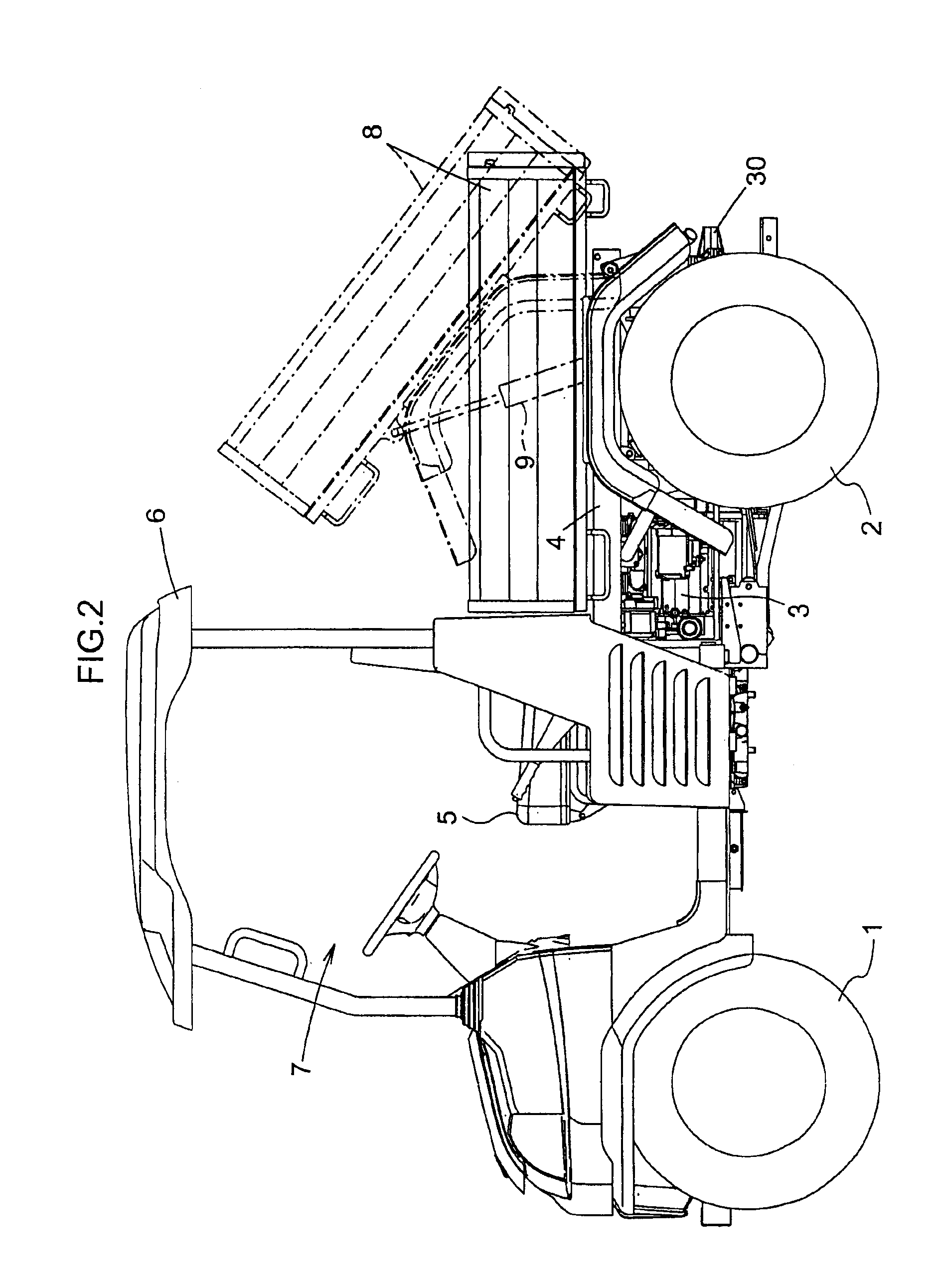

Change-speed control system for utility vehicle having stepless change-speed apparatus for speed-changing engine output and transmitting the speed-changed output to traveling unit

ActiveUS20050037892A1Avoid troubleEasy speed adjustmentGear lubrication/coolingGearing controlDroop speed controlSpeed control system

A change-speed control system is provided for a utility vehicle having a stepless change-speed apparatus for speed-changing an engine output and transmitting the speed-changed output to a traveling unit. The system includes an engine speed governor for adjusting speed of the engine, an accelerator controller and a change-speed control linkage device for providing operative displacements in the stepless change-speed apparatus and the engine speed governor in association with an operation of the accelerator controller. The change-speed control linkage device sets an operation amount for the stepless change-speed apparatus and an operation amount for the engine speed governor in correlation with the operation amount of the accelerator controller, such that an acceleration ratio for the engine speed is greater than an acceleration ratio for the stepless change-speed apparatus until the engine reaches a predetermined speed and also the stepless change-speed apparatus reaches a predetermined speed.

Owner:KUBOTA LTD

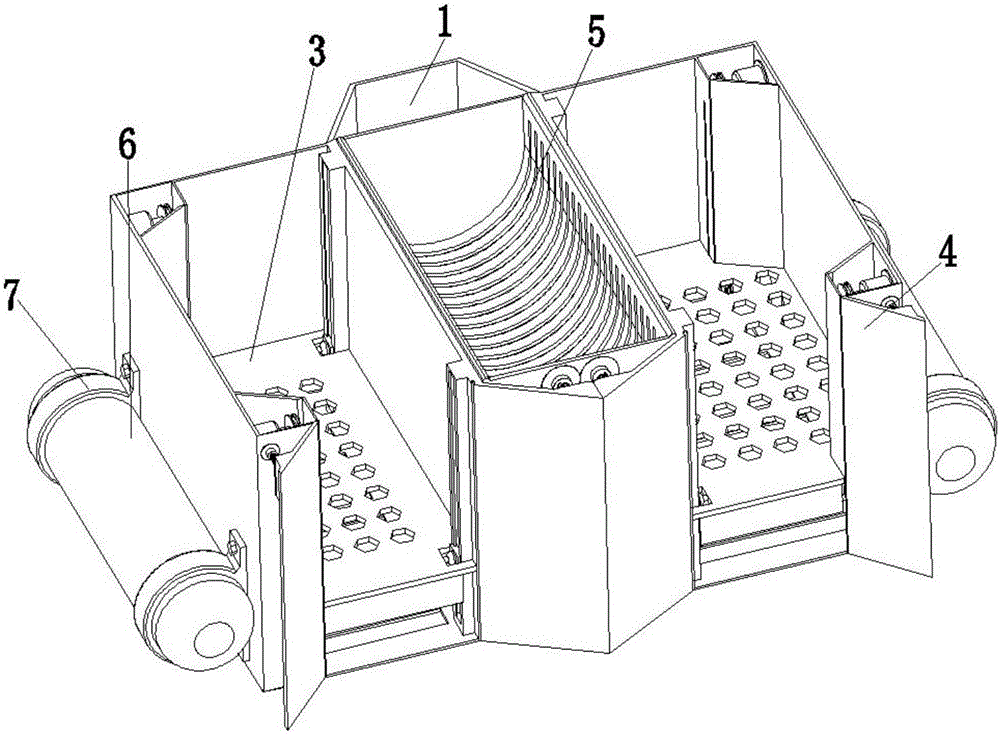

High-speed screening and crushing device for rare earth carbonate

The invention relates to a screening and crushing device, in particular to a high-speed screening and crushing device for rare earth carbonate. The high-speed screening and crushing device for the rare earth carbonate comprises a barrel body, a material-screening device, a material-charging device, landing legs, a discharging pipe and the like. The material-screening device is arranged above the barrel body, the material-charging device is arranged above the material-screening device, and the landing legs are arranged below the barrel body in a left-right symmetrical mode; and the upper ends of the landing legs are connected with the lower inclined wall of the barrel body in a welded mode, and the discharging pipe is arranged under the barrel body. According to the high-speed screening and crushing device for the rare earth carbonate, through the combination of the material-charging device and the material-screening device, the rare earth carbonate can be screened and crushed at a high speed, and the working efficiency is high.

Owner:安徽鑫科生物环保有限公司

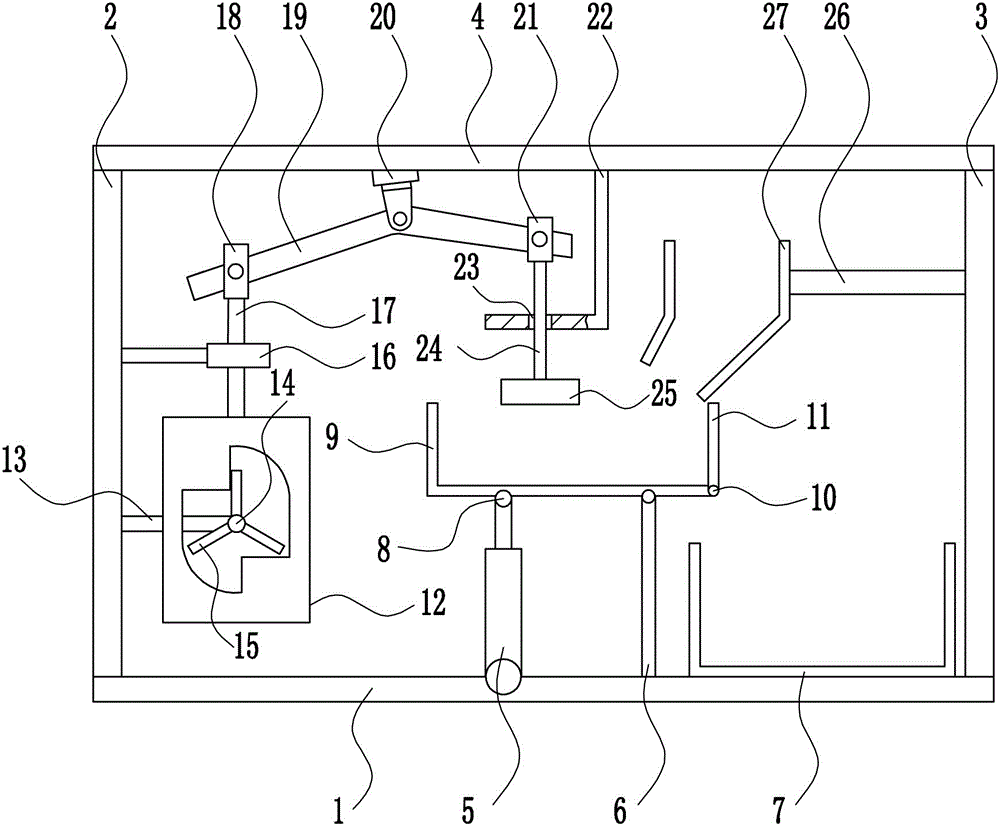

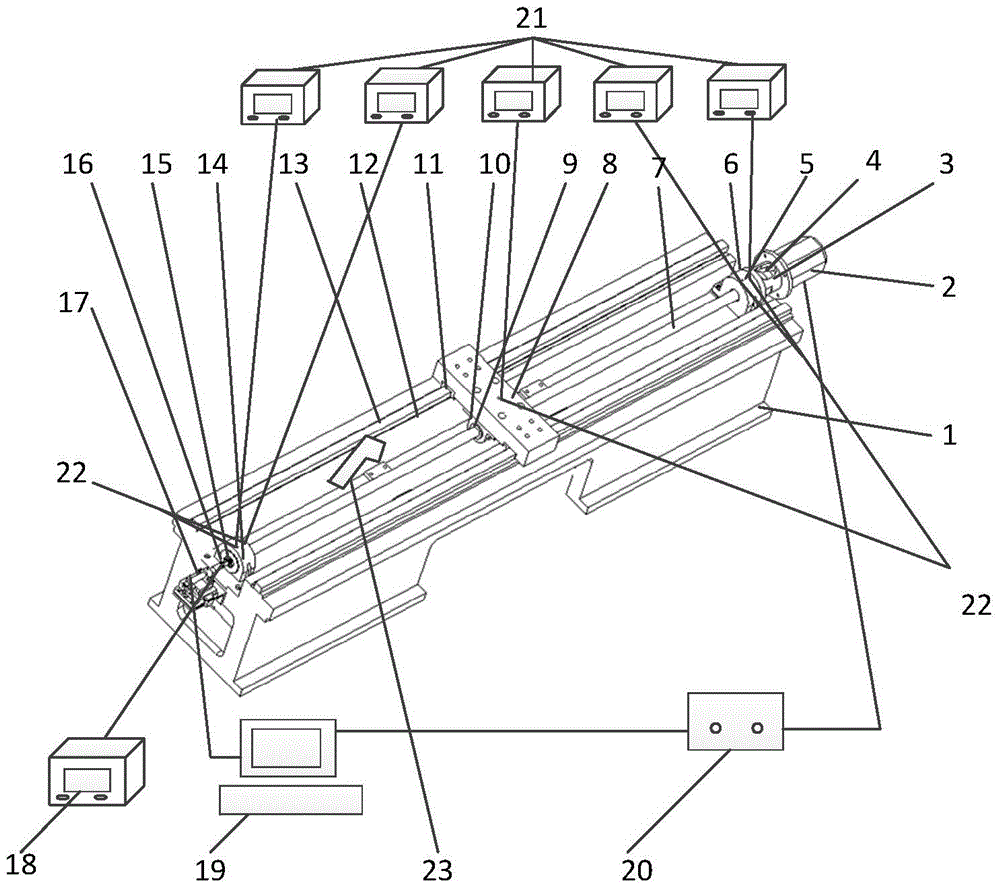

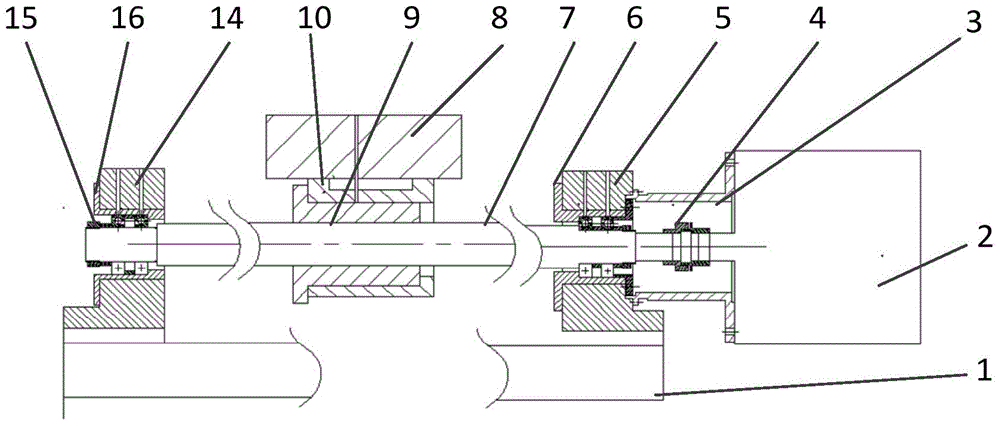

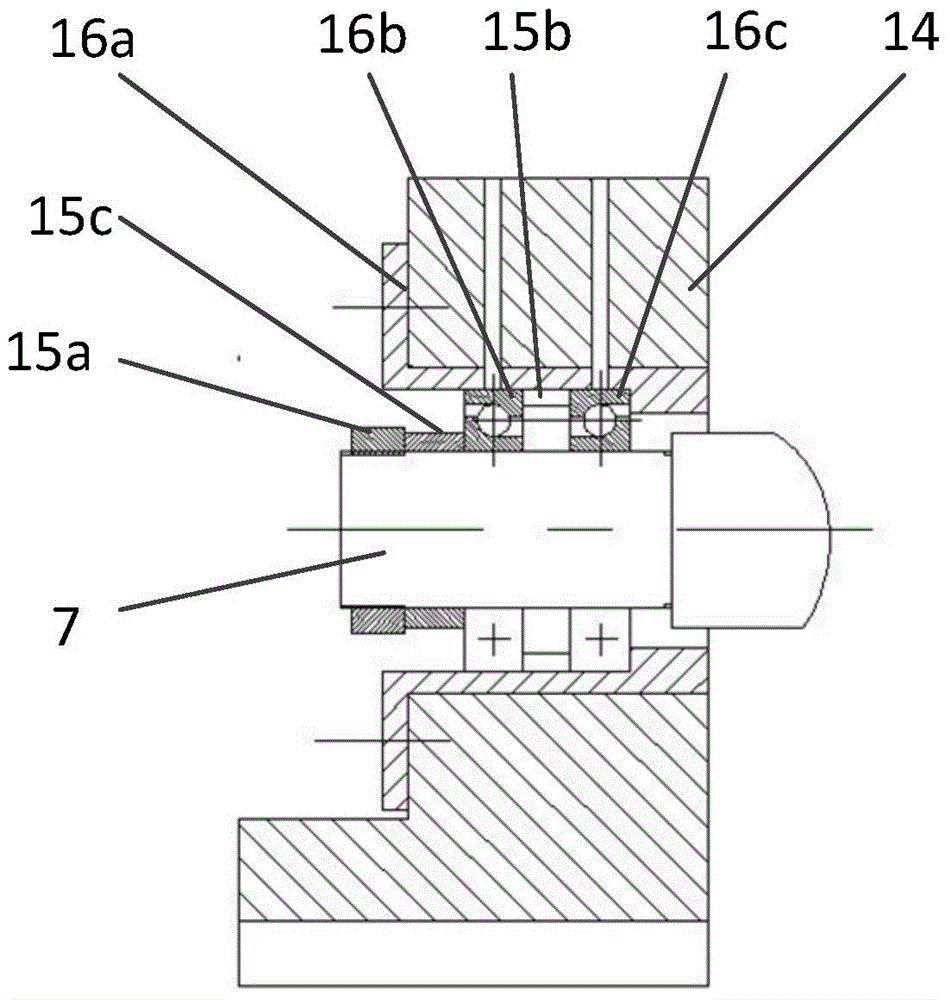

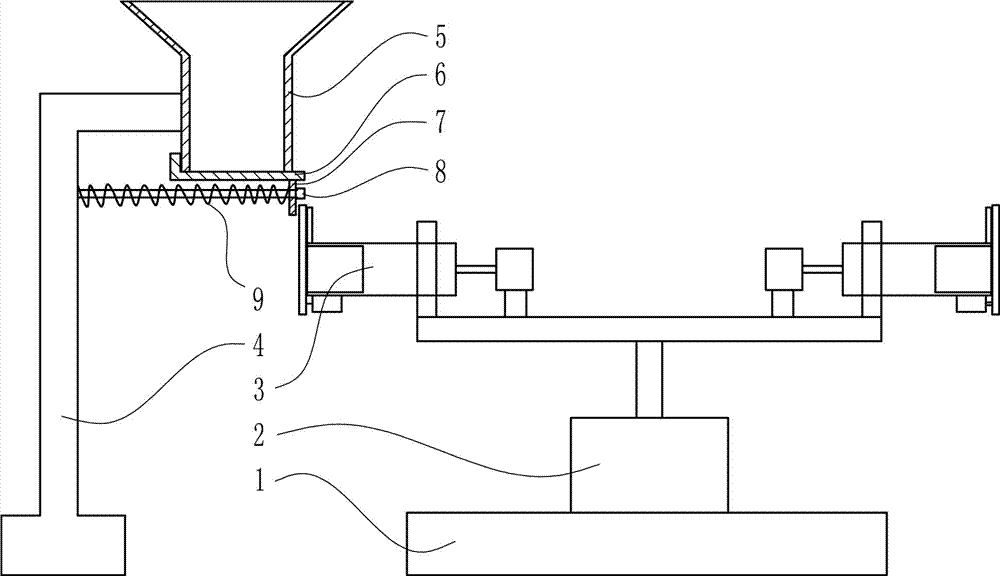

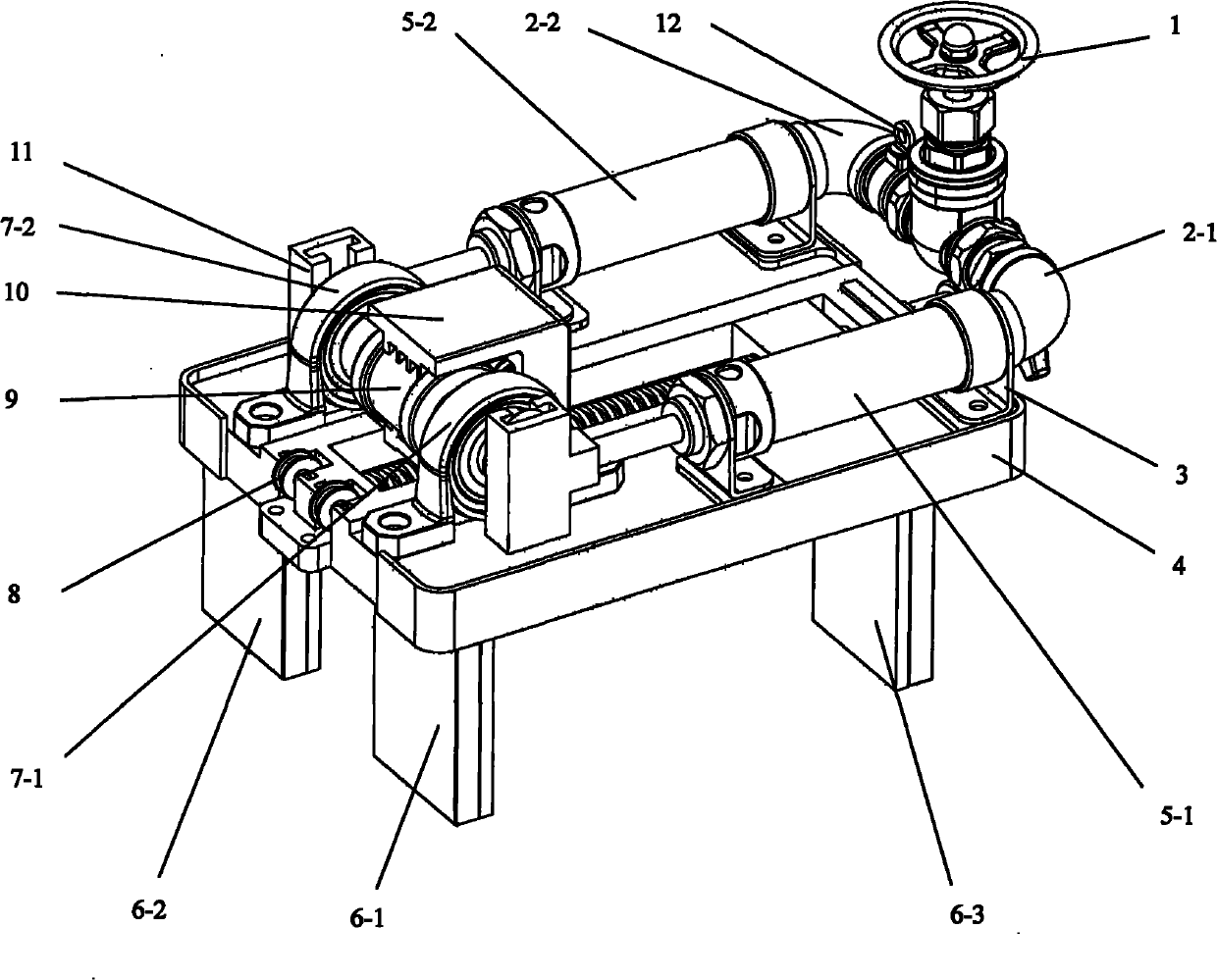

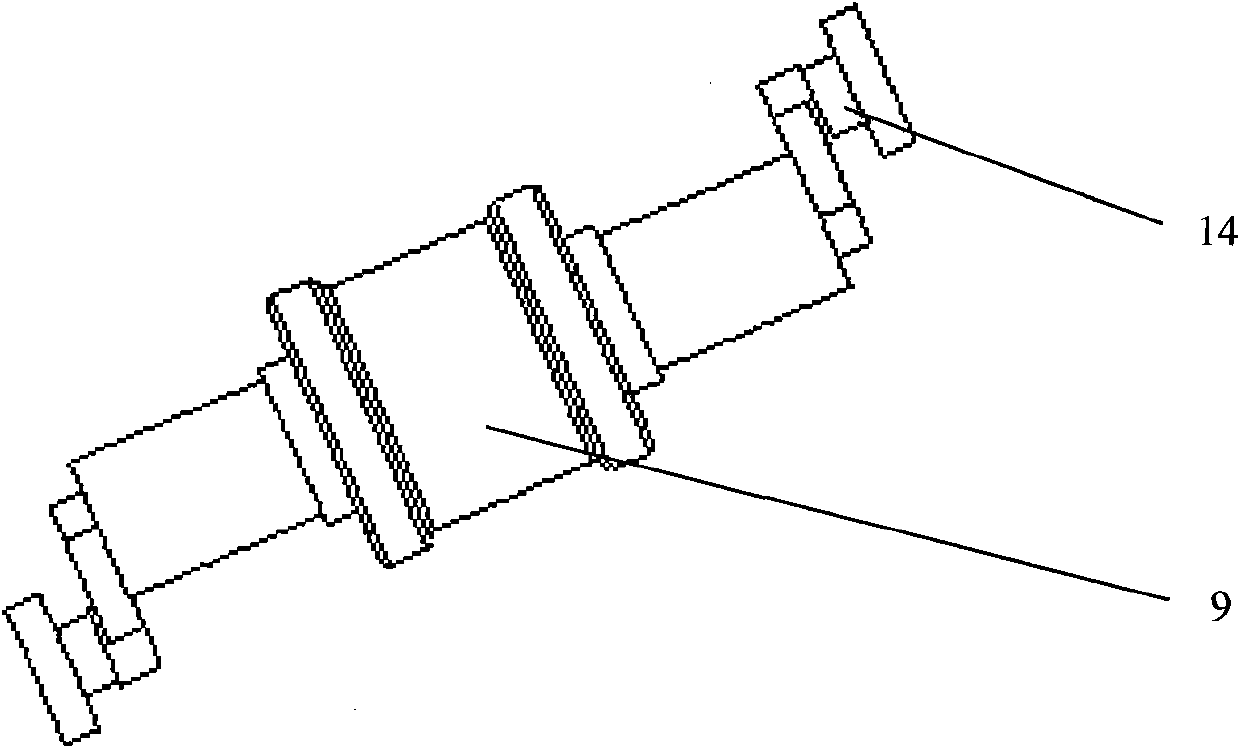

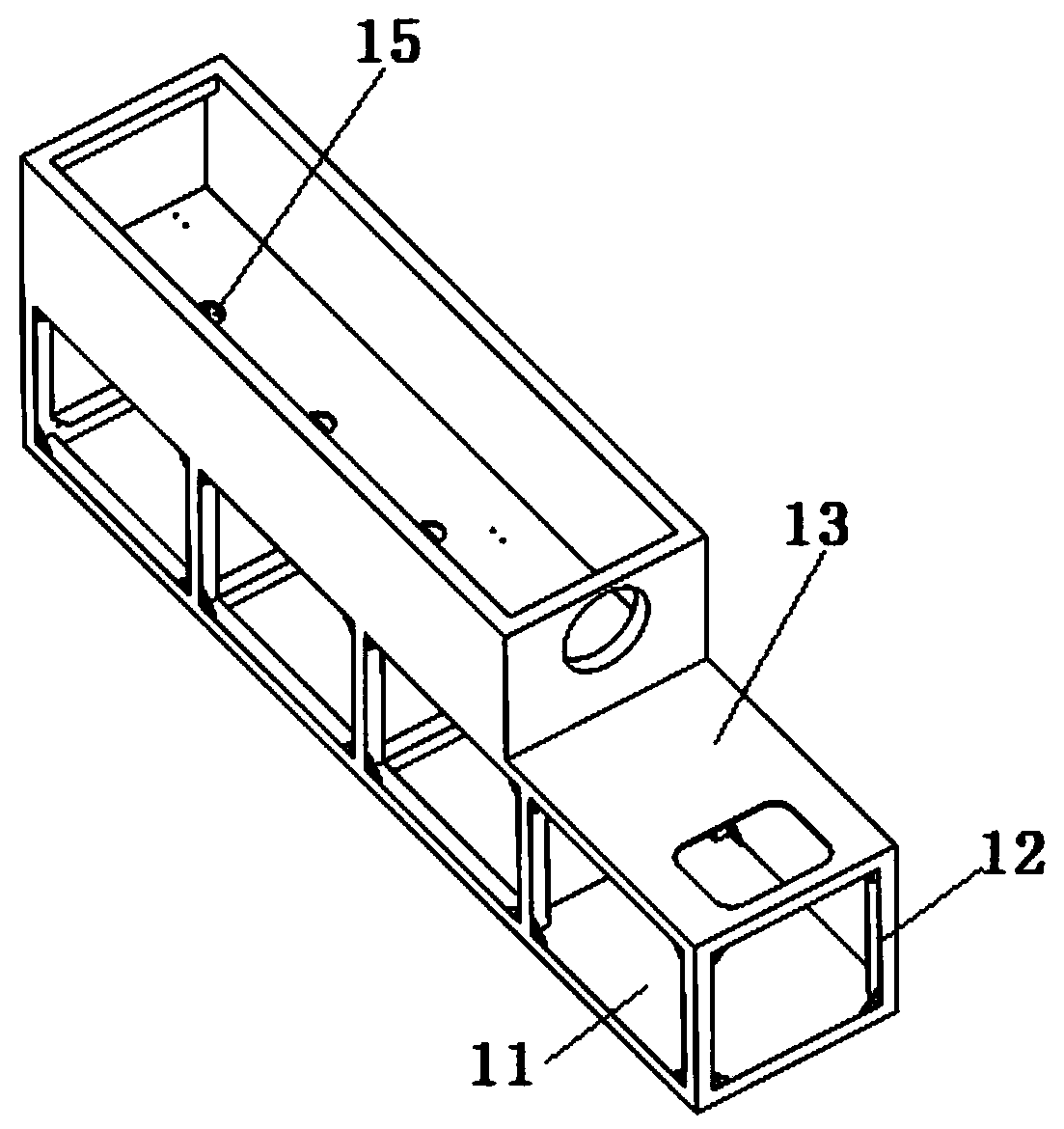

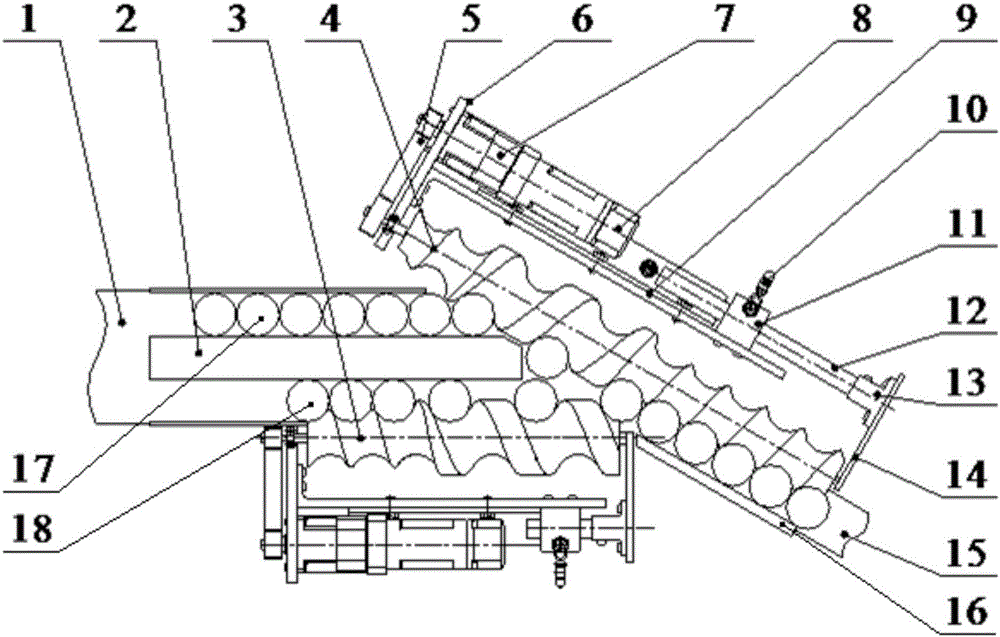

Device for testing thermal state characteristics of feeding system

InactiveCN104165767AEasy to operateImprove general performanceMachine gearing/transmission testingBall bearingThermal state

The invention relates to a device for testing the thermal state characteristics of a feeding system. The device for testing the thermal state characteristics of the feeding system comprises a base experiment table, a servo motor, a motor base, a coupler, a right bearing seat, a right bearing assembly, a ball screw, a lead screw nut base, a lead screw base, a working table, a rolling guide rail, a wedge-shaped block, a rolling guide rail sliding block, a left bearing seat, a left bearing assembly, an axial pre-stretching device, a PC, a pressure sensor, a thermal resistance sensor, an infrared thermometer, a chromatic dispersion confocal displacement meter, a force sensor displayer, a thermal resistance sensor displayer, a servo amplifier and the like. The device for testing the thermal state characteristics of the feeding system has the advantages that the mechanical structure is simple, the testing principle is distinct and the testing precision is high, angular contact ball bearings with different diameters and ball screws can be adopted for testing for various feeding systems, real-time working conditions such as the axial force and the rotation speed are simulated, and the temperature field and the axial thermal displacement of the feeding system are tested.

Owner:NANJING UNIV OF SCI & TECH

Conveniently-cleaned recovery treatment apparatus for rare earth waste liquid

ActiveCN108159749AEasy to fixPrecise and precise rotationProcess efficiency improvementStationary filtering element filtersLiquid wasteRare earth

The invention relates to a recovery treatment apparatus, and especially relates to a conveniently-cleaned recovery treatment apparatus for a rare earth waste liquid. A technical problem to be solved in the invention is to provide the conveniently-cleaned recovery treatment apparatus for the rare earth waste liquid. The conveniently-cleaned recovery treatment apparatus for the rare earth waste liquid, provided to solve the technical problem, comprises a filtering cylinder, a sweeping device and a conveying and cleaning device; and the conveying and cleaning device is arranged at the left side of the filtering cylinder, a filter screen is arranged in the filtering cylinder, the filter screen is made of a steel wire mesh, the filter screen is positioned above the sweeping device, and the leftend of the top of the filter screen is connected with the right lower end of an L-shaped connecting rod in a welding manner. The conveniently-cleaned recovery treatment apparatus for the rare earth waste liquid has the advantages of convenience in cleaning of the filtering cylinder and the filter screen, high cleaning efficiency and good cleaning effect through combining the filtering cylinder, the sweeping device and the conveying and cleaning device.

Owner:JIAN XINTAI TECH

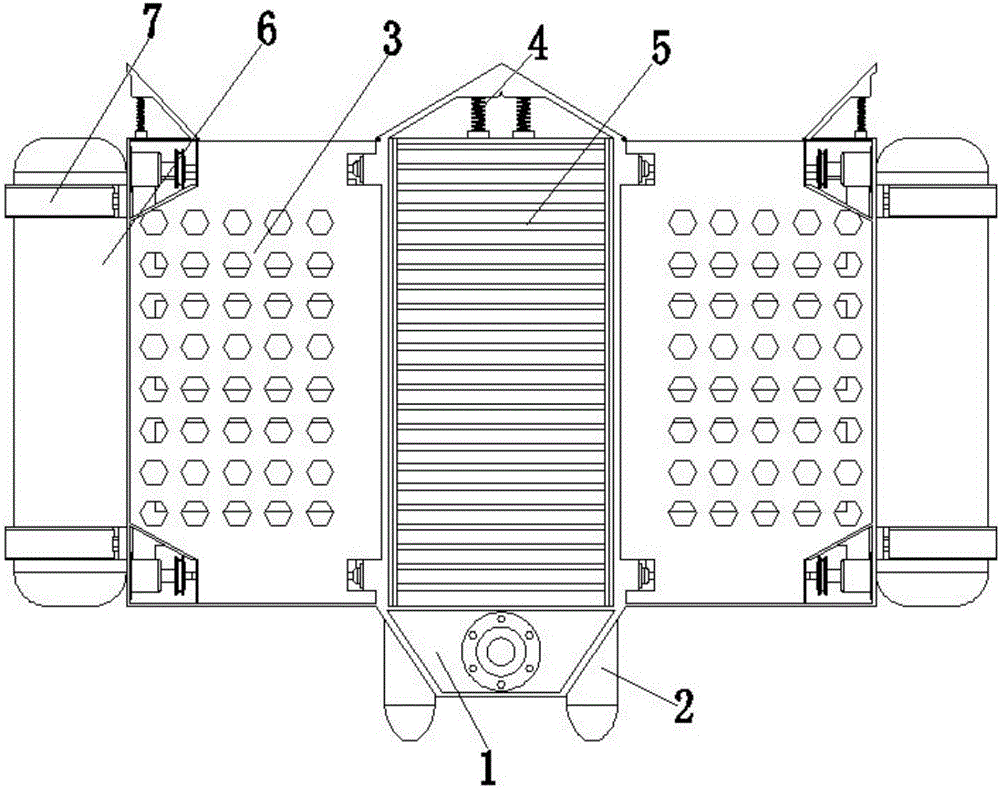

New type dewatering device used for rare earth carbonate

ActiveCN107202478AEasy to pushImprove dehydration efficiencyDrying solid materialsDrying machines with non-progressive movementsStructure of the EarthRare earth

The invention relates to a dewatering device, in particular to a new type dewatering device used for rare earth carbonate. According to the technical purpose, the new type dewatering device used for the rare earth carbonate is provided. In order to achieve the technical purpose, the new type dewatering device used for the rare earth carbonate is provided, and comprises a base, a rotating device, a dewatering device body, an L-shaped support, a feeding hopper, an L-shaped baffle and the like; the dewatering device body is arranged above the rotating device, and is arranged in a left-right symmetry manner; the L-shaped support is arranged on the left side of the dewatering device body; the upper right end of the L-shaped support is connected with the left side wall of the feeding hopper in a welded manner; and the L-shaped baffle is arranged below the feeding hopper. According to the new type dewatering device used for the rare earth carbonate, by means of combination of the rotating device and the dewatering device body, the rare earth carbonate can be conveniently dewatered, and the split type structure is adopted.

Owner:威海博思医疗科技有限公司 +1

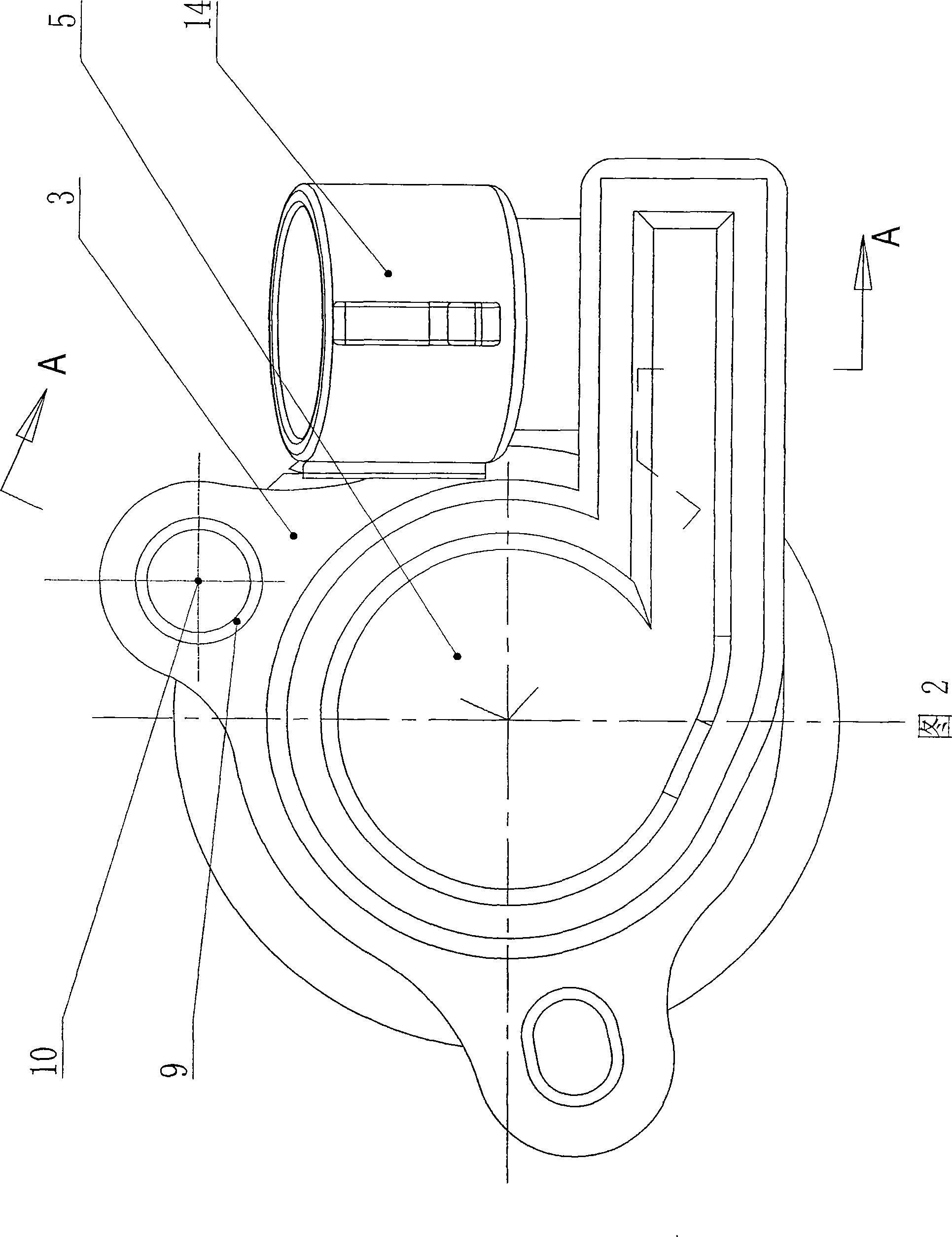

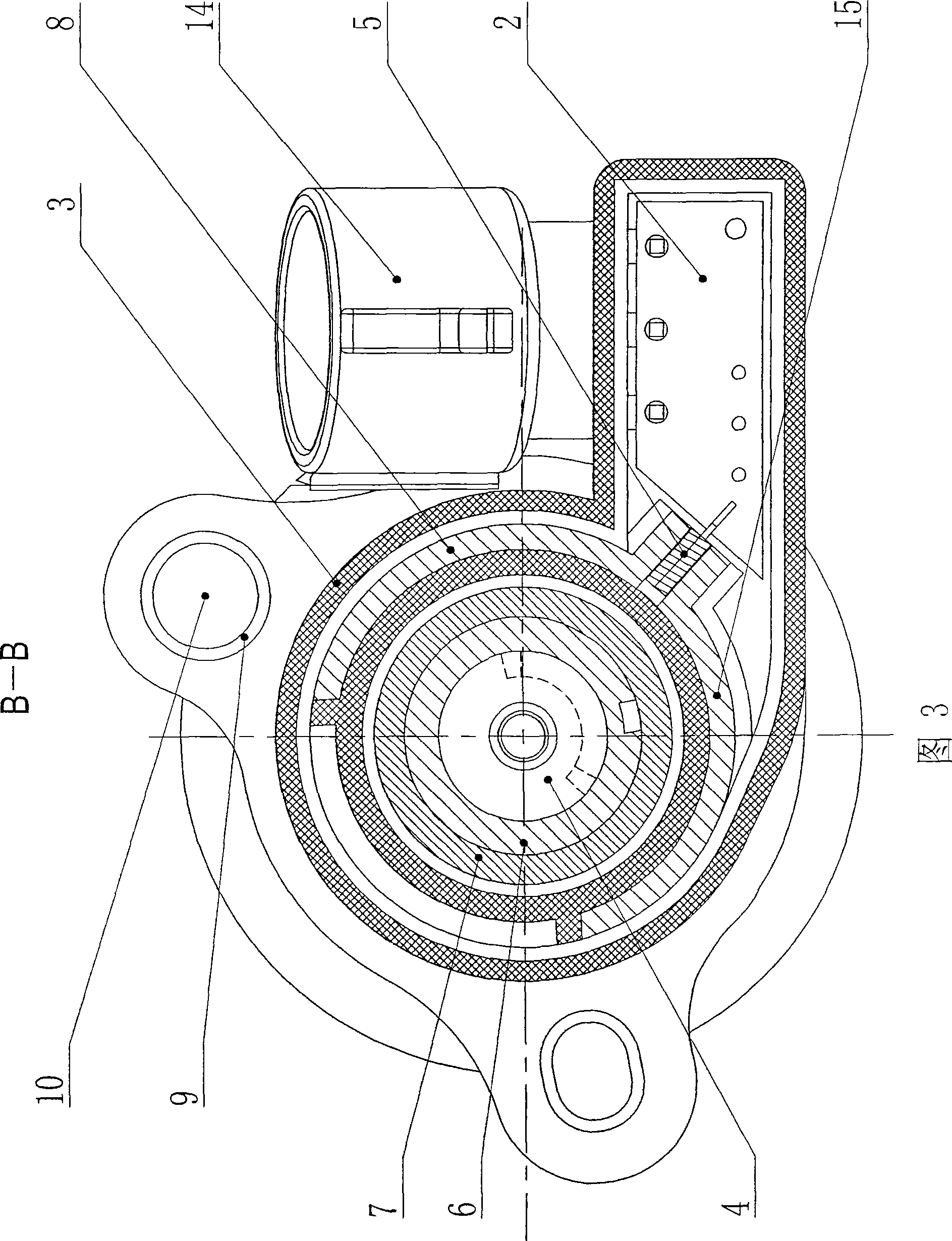

Non-contact single signal throttle position sensor

InactiveCN101451858AReduce volumeReduce weightElectrical controlMachines/enginesAutomatic controlEngineering

This invention discloses a non-touch single signal air damper position sensor in the sensor field, comprising a shell and a converting circuit. The shell is provided with a rotator which is linkable with a rotating shaft of the air damper. A shielding cover is fixed to the periphery of the rotor. A magnetic steel is fixed to the periphery of the shielding cover. Two sections of magnetic bunchers symmetrically arranged in the arch are fixed to shell located at the outer side of the magnetic steel. The magnetic buncher, the shielding cover, the magnetic steel and the rotor are coaxially arranged. A Hall component of input end of the converting circuit is mounted between two magnetic bunchers. When working, the rotor drives the magnetic steel to rotate, the Hall component transfers the voltage change signal to an electric unit via the converting unit so as to control the accelerator opening by the electric unit. This invention with small size, light weight, wide frequency response, wide dynamic range, good temperature property, convenient speed regulating, reliable use and long life does not have friction and noise, and can be applied to the automatic control of the motor so as to control the mixing ratio of the oil and gas thereof.

Owner:YANGZHOU UNIV

High-rise escape device capable of adjusting speed easily

InactiveCN101947365AEasy to achieve recurring useIncrease profitBuilding rescueHydraulic cylinderReciprocating motion

The invention discloses a novel high-rise escape device. The novel high-rise escape device comprises a rope-winding device, a hydraulic passage device, a connecting device and a clamping device, wherein the rope-winding device and the hydraulic passage device is fixedly connected to the upper part of the clamping device; and the rope-winding device is connected with the hydraulic passage device through the connecting device. The novel high-rise escape device adopts a pure mechanical structure device and has the advantages of light weight, flexibility, simple operation and capacity of excellently fulfilling a high-rise escape task in the period of a fire disaster. An escape rope is wound on a shaft, and drives a main shaft to rotate in a descending process; the main shaft drives two hydraulic cylinders to do straight reciprocating motion through a crank sliding block mechanism in a rotating process; a passage which is filled with liquid is formed by the two hydraulic cylinders, a damping pipe and a valve; the liquid does reciprocating motion along with the motion of pistons of the hydraulic cylinders; the liquid flows through a damping sheet and the valve during the motion; and the flowing speed of the liquid in a flowing process is controlled well through the damping action of the damping sheet and the flow limiting action of the valve, so that the aim of slowing down the descending speed is fulfilled.

Owner:NANJING UNIV OF SCI & TECH

Horizontal slurrying device for rare earth mineral

ActiveCN107099683AGuaranteed uptimeSafe and reliable performanceRotating receptacle mixersTransportation and packagingInlet valveEngineering

The invention relates to a slurrying device, in particular relates to a horizontal slurrying device for rare earth mineral. The technical problem to be solved is to provide the horizontal slurrying device for rare earth mineral. In order to solve the problem, the invention provides the horizontal slurrying device for rare earth mineral. The device comprises a stirring barrel, a conveying device, a rotation device, a water inlet pipe, a water inlet valve, a discharging pipe and the like, wherein the conveying device is arranged on the left side of the stirring barrel; the rotation device is arranged on the right lower part of the stirring barrel; the right part of the top of the stirring barrel is welded with the water inlet pipe; a water inlet valve is mounted on the water inlet pipe; the right part of the bottom part of the stirring barrel is welded with the discharging pipe; a discharging valve is mounted on the discharging pipe; and a material collection cylinder is arranged under the discharging pipe. According to the horizontal slurrying device for rare earth mineral provided by the invention, a separation structure of the conveying device and the stirring barrel is adopted, so that the using of components is reduced, the structure is simple, and the maintenance and the repair are convenient.

Owner:承德市创远科技开发有限公司

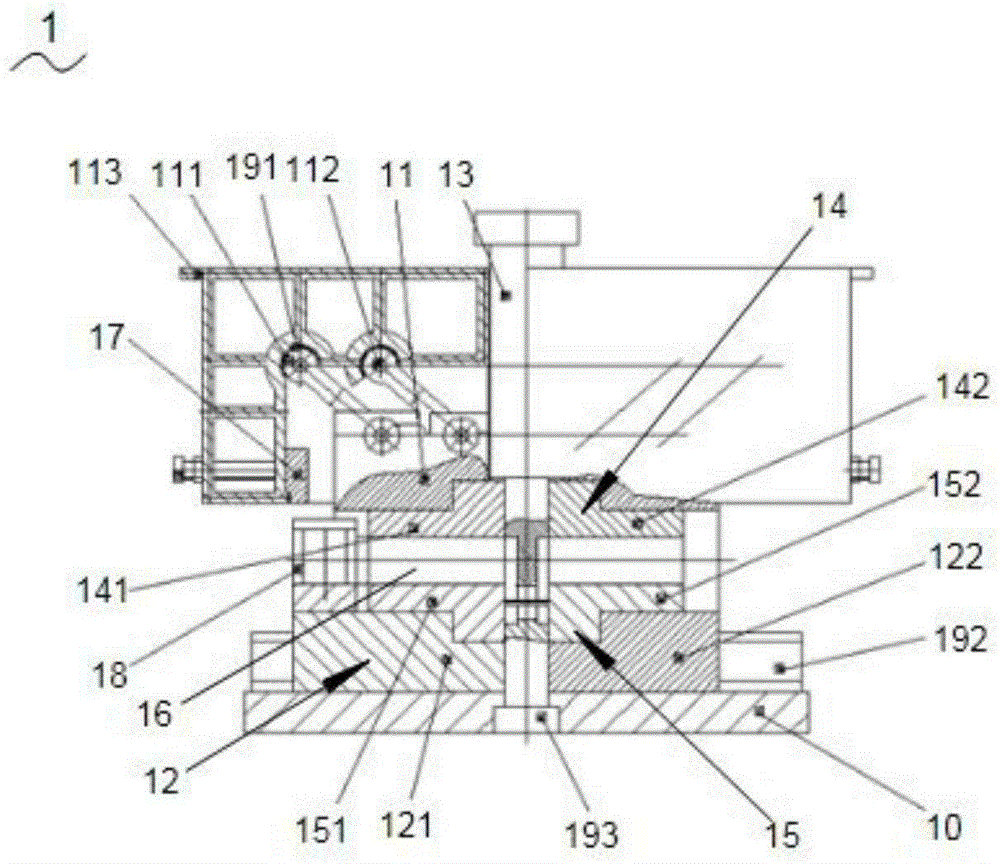

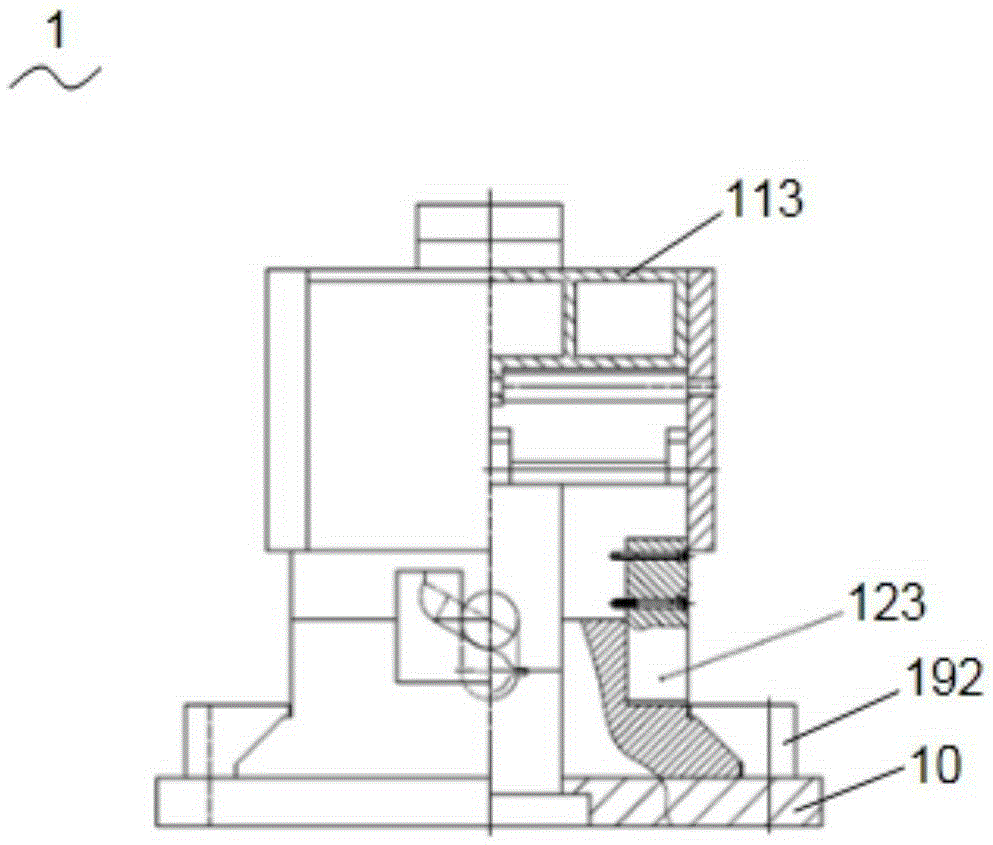

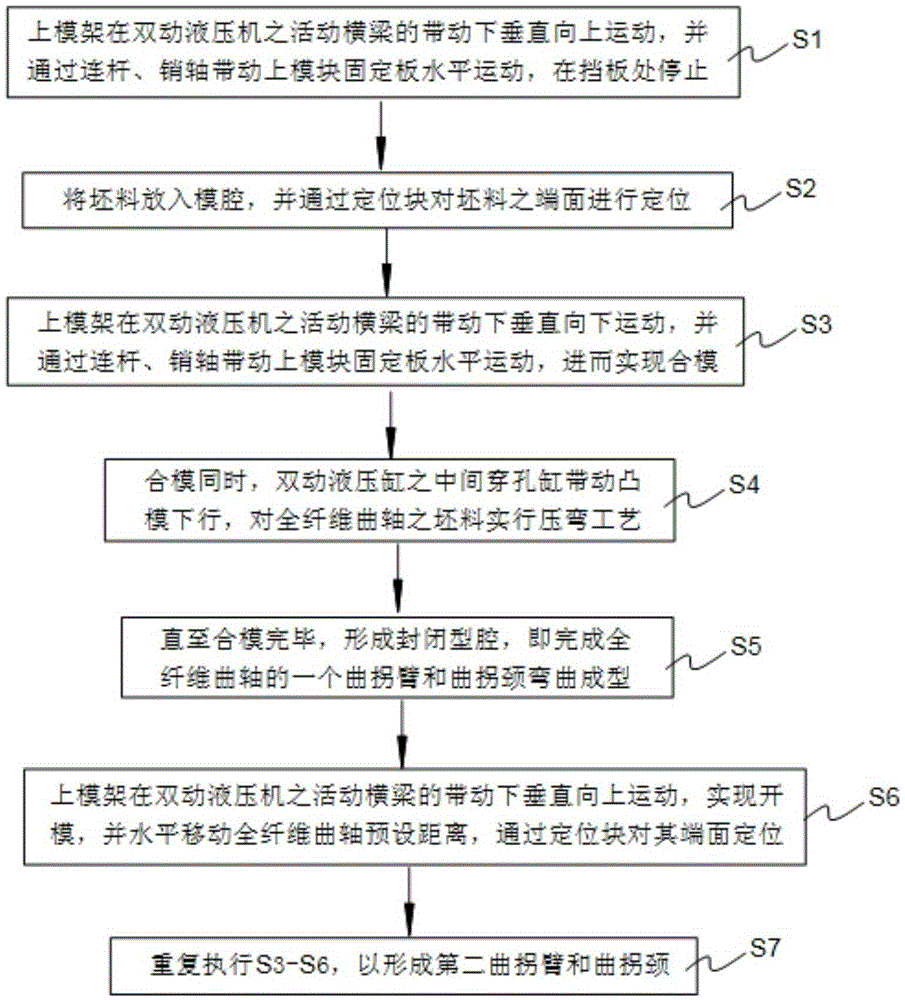

Double-acting forging tool for all-fiber crankshafts and forging method thereof

InactiveCN105290292AEasy speed adjustmentSimple structureForging/hammering/pressing machinesEngine componentsEngineeringCrankshaft

A double-acting forging tool for all-fiber crankshafts comprises a base, upper die block fixing plates, lower die block fixing plates, a convex die, upper die blocks and lower die blocks. The base is fixedly arranged on a work table. The upper die block fixing plates comprise the upper left die block fixing plate and the upper right die block fixing plate and are movably connected with an upper die frame through connecting rods and pin shafts. The lower die block fixing plates comprise the lower left die block fixing plate and the lower right die block fixing plate and are movably connected with the upper die block fixing plates through square keys. The convex die is connected with a middle punching cylinder of a double-acting hydraulic machine. The upper die blocks comprise the upper left die block and the upper right die block. The lower die blocks comprise the lower left die block and the lower right die block. A die cavity is formed between the upper die blocks and the lower die blocks. A forging method of the double-acting forging tool for the all-fiber crankshafts is adopted, the upsetting speed and the bending speed are regulated by driving a movable cross beam and the punching cylinder through a die closing cylinder of the double-acting hydraulic machine, and therefore speed regulation is easy. In addition, the tool is simple in structure and convenient to assemble and disassemble, volume production can be easily achieved, and the production efficiency can be improved.

Owner:SHANGHAI DIANJI UNIV

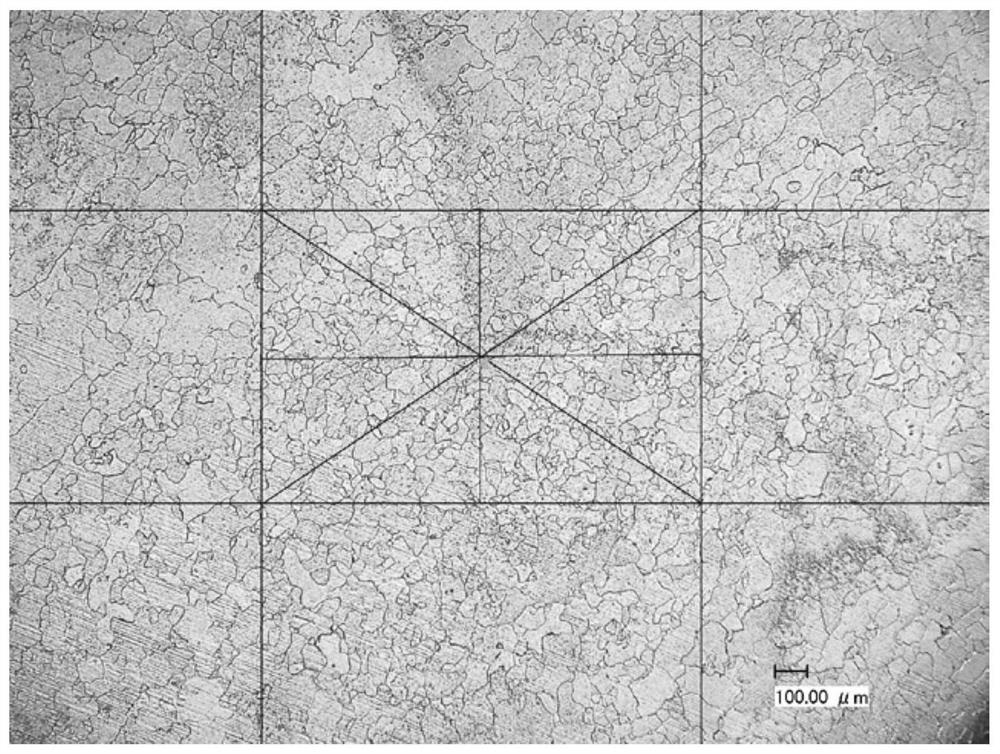

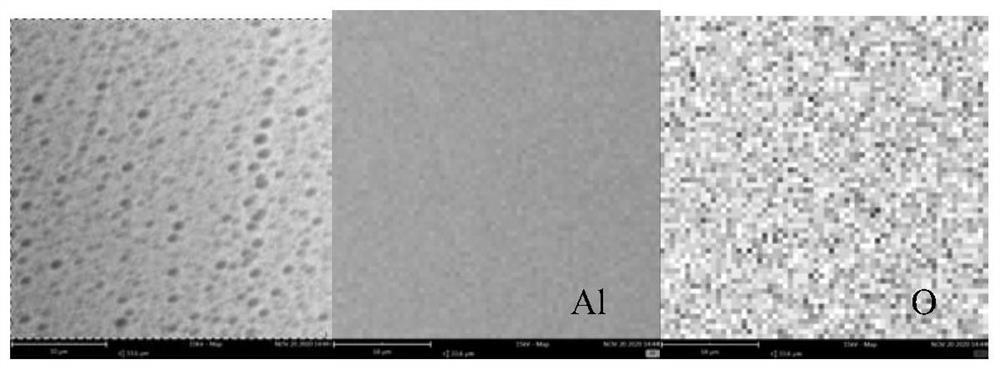

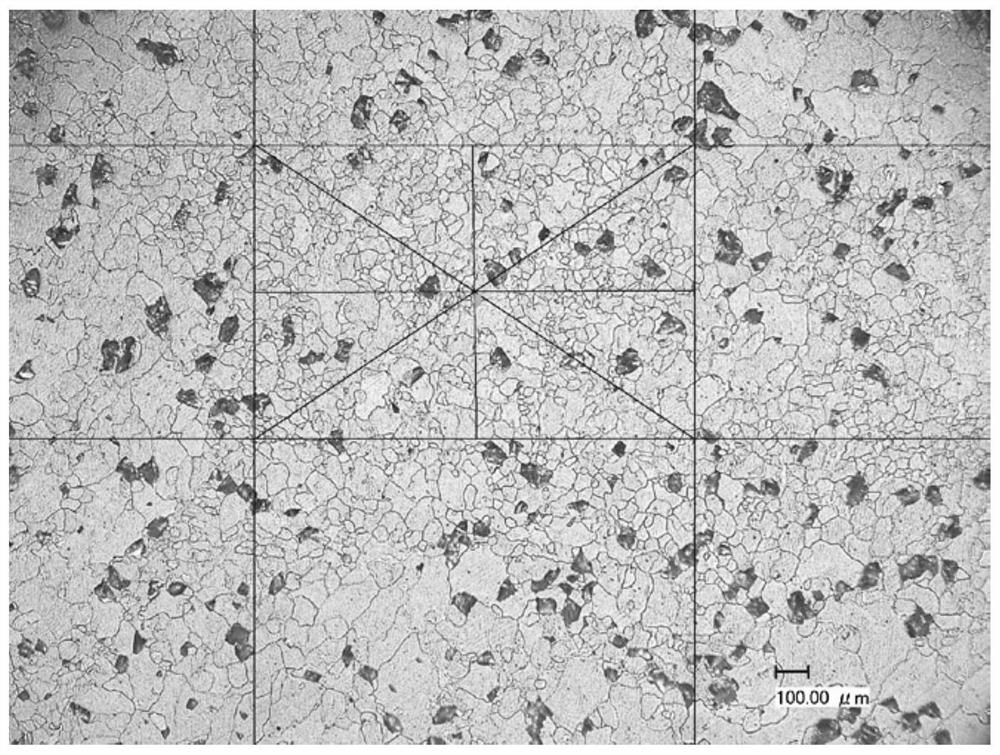

Method for manufacturing aluminum-silicon target material

ActiveCN112538598AGuaranteed mechanical propertiesGuaranteed film qualityVacuum evaporation coatingSputtering coatingIngot castingHeat conservation

The invention relates to a method for manufacturing an aluminum-silicon target material. The method comprises the following steps of: providing an AlSi ingot casting step, a drawing step, a primary upsetting step, an intermediate heat treatment step, a secondary upsetting step, a preheating treatment step, a calendaring step and an annealing heat treatment process step, wherein cold drawing operation is used in the drawing step, and a forging ratio X1 in the cold drawing operation is gerater than or equal to 1 and less than 2; in the primary upsetting step, a forging ratio X2 is greater than or equal to 2 and smaller than 3, and cold heading operation is used for primary upsetting; in the intermediate heat treatment step: a product is kept within a first preset temperature range, and is quickly put into cold water after being subjected to heat preservation for first preset time; in the secondary upsetting step, a forging ratio X3 is greater than or equal to 2 and smaller than 3, and cold heading operation is used for secondary upsetting; in the calendaring step: multi-pass calendaring is performed on the product, and reducing rolling reduction along with increase of calendaring passes; and in the annealing heat treatment process step: in an annealing temperature range, heat preservation is performed for third time, and water cooling treatment is performed to form a final targetproduct. According to the method, the forging ratio is reasonably controlled, water cooling is adopted for cooling, so that Si element precipitation is reduced, and therefore the microstructure and the machining performance of the target material are guaranteed.

Owner:爱发科电子材料(苏州)有限公司

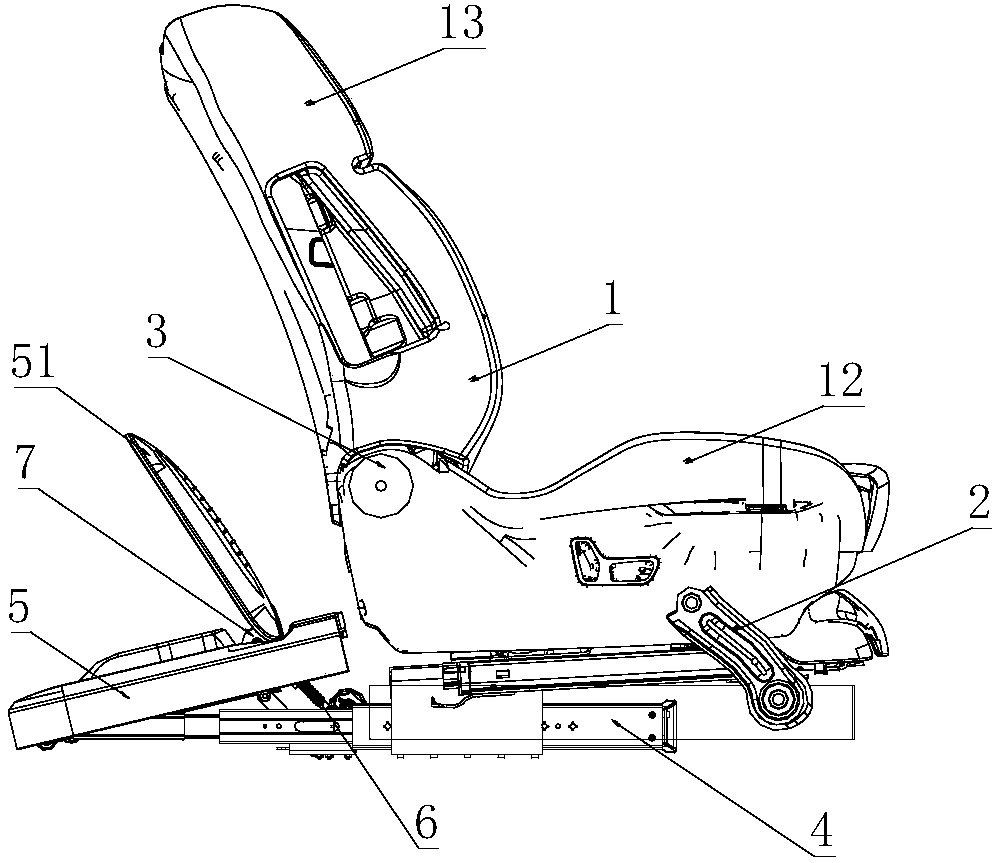

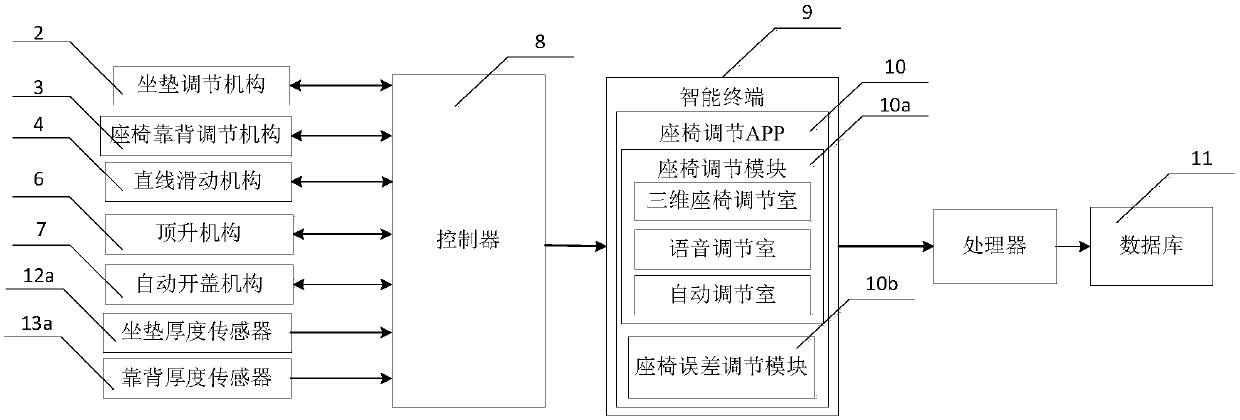

Car seat APP adjusting system with foot massage device

ActiveCN107696923ARealize virtual controlTo achieve the purpose of real controlThigh restsElectric/fluid circuitCar seatMassage

The invention discloses a car seat APP adjusting system with a foot massage device. The car seat APP adjusting system comprises a seat body and further comprises a cushion adjusting mechanism, a seatbackrest adjusting mechanism, a linear sliding mechanism, a jacking mechanism and an automatic uncovering mechanism which are connected with a controller. The controller is further connected with anyone intelligent terminal, each seat adjusting APP is mounted on the corresponding intelligent terminal and provided with a car seat adjusting module, and a three-dimensional seat adjusting chamber isarranged in each seat adjusting module. A three-dimensional view of the seat body with a massager box body is arranged in each three-dimensional seat adjusting chamber. The intelligent terminals are used for obtaining touch operation conducted on the three-dimensional view by a user, so that the massager box body or the seat body is controlled to complete moving operation corresponding to touch operation. The car seat APP adjusting system has the beneficial effects that reality and virtuality are combined, convenience and intelligence are achieved, operation occupies a very small space, and safety is high.

Owner:CHONGQING YANFENG ADIENT AUTOMOTIVE COMPONENTS CO LTD

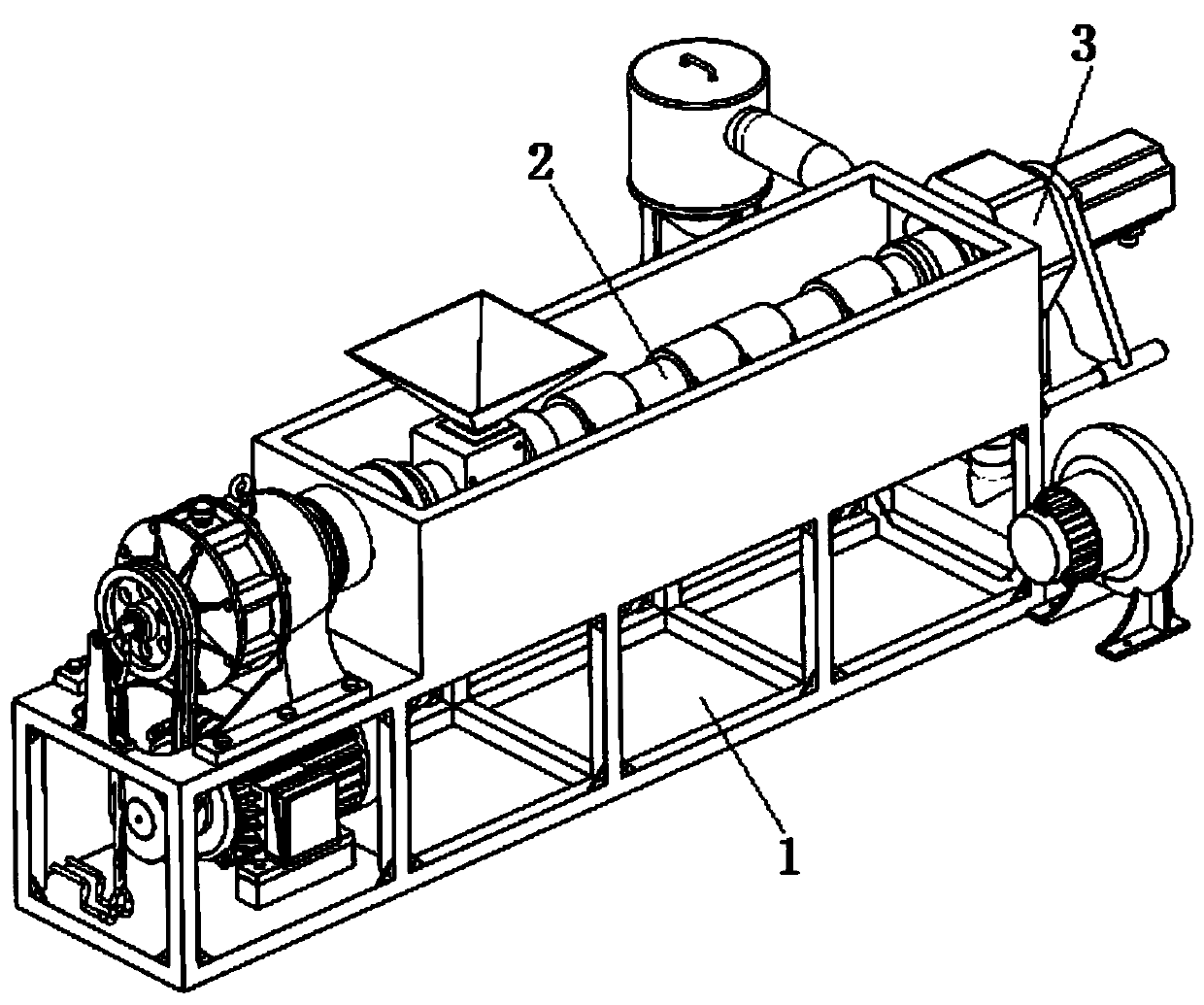

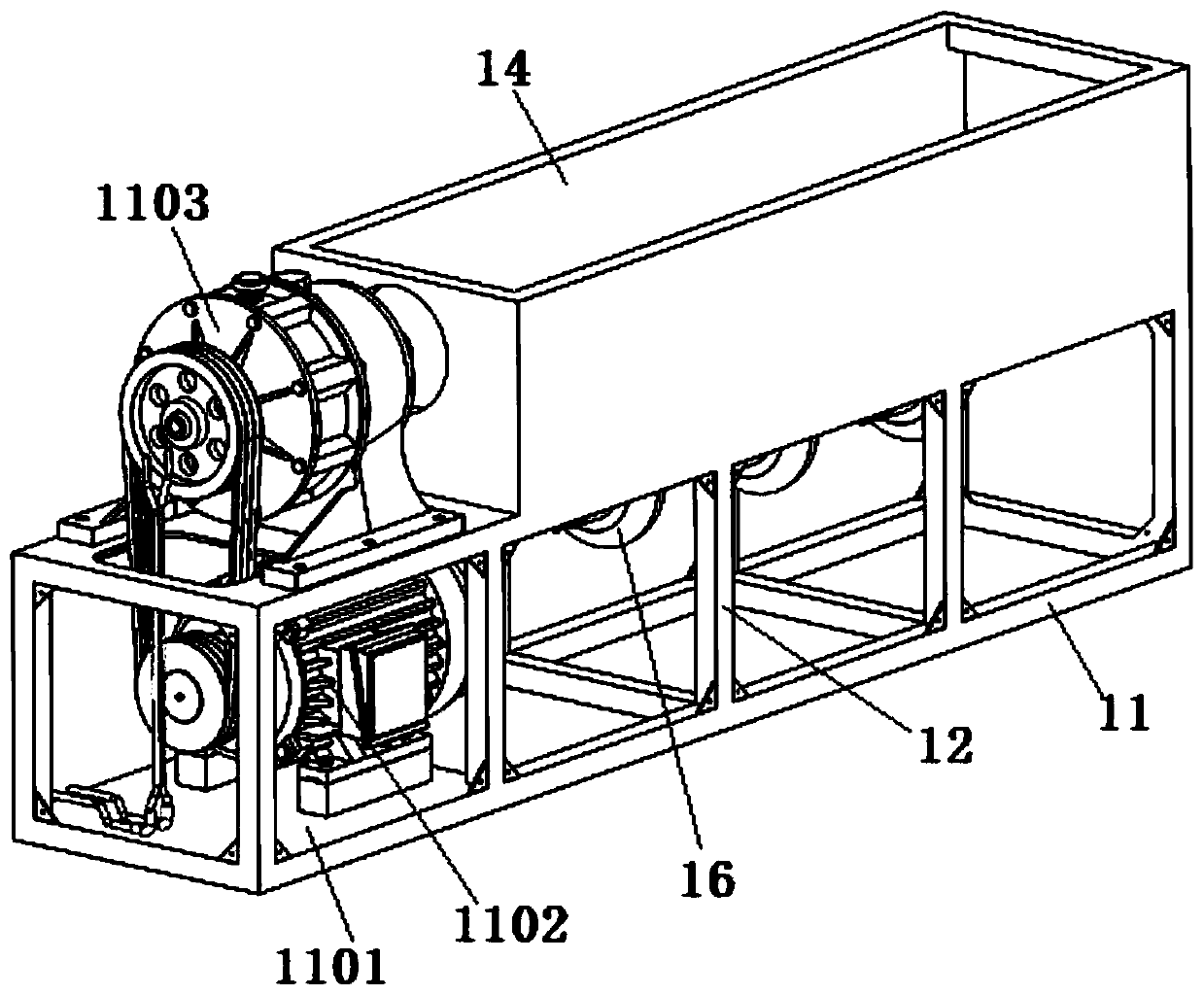

Extrusion granulation equipment for plastic recycling and processing and operation method thereof

InactiveCN111497067AHigh degree of automationImprove granulation efficiencyPlastic recyclingMetal working apparatusPelletizingOrifice plate

The invention discloses extrusion granulation equipment for plastic recycling and processing. The equipment comprises a bearing frame body, a granulation mechanism and a cutting collection device. Thegranulation mechanism comprises a water cooling device, a screw rod device and an extrusion device, the screw rod device comprises a screw rod, one end of the screw rod is connected with the output end of a cycloidal pin wheel speed reducer through a coupler, the screw rod is positioned in a cylindrical shell, and the cylindrical shell is fixed on a second vertical plate in a penetrating manner;the extrusion device comprises an orifice plate, the orifice plate is embedded on the inner surface of the circumferential side of the cylindrical shell, extrusion holes are uniformly formed in the surface of the orifice plate, plastic is extruded through the extrusion holes to form strips, and then the strips enter the cutting collection device through a granulation plate to be cut into granules.After the screw rod is connected with the cycloid pin wheel speed reducer, the rotating speed of the screw rod is conveniently adjusted, the rotating speed of the screw rod influences the advancing speed and the mixing degree of plastic, waste plastic can be extruded in one step and cut into granules, the automation degree is high, the granulation efficiency is high, the investment cost of enterprises is reduced, and the benefits are improved.

Owner:界首市云锋再生资源有限公司

High-speed recovering treatment device for waste rare earth liquid

ActiveCN107930207APrevent splashing and splashingEasy to recycleStationary filtering element filtersLiquid wasteRare earth

The invention relates to a recovering treatment device, and in particular relates to a high-speed recovering treatment device for waste rare earth liquid to solve the technical problem. The device comprises a cylinder body, a waste liquid stirring and conveying device, etc., wherein a filtering device is arranged at the left side of the cylinder body; supporting legs are symmetrically arranged atthe lower left and the lower right of the cylinder body; the upper ends of the supporting legs are connected to the bottom part of the cylinder body by welding; a liquid draining pipe is positioned between the supporting legs which are symmetrically arranged at the left and right; the upper end of the liquid draining pipe is connected to the middle part of the bottom part of the cylinder body by welding. According to the device, a mode integrating the waste liquid stirring and conveying device and the filtering device is adopted, so that the waste rare earth liquid can be filtered at high speed without frequent stopping, and as a result, the filtering effect is high, and the effect is good.

Owner:大庆鑫东祥机械制造有限公司

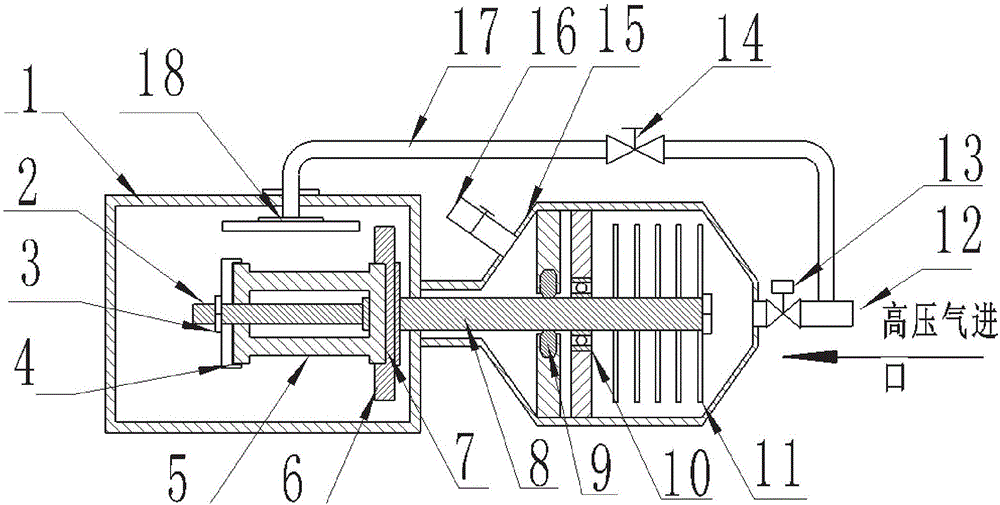

Pneumatic dedusting device

PendingCN106704055AIncrease coverageSimple structureMachines/enginesAir cleaners for fuelImpellerHigh pressure

The invention provides a pneumatic dedusting device which comprises a barrel welded to the upper end of a shell. A rotary shaft is arranged in a hollow inner cavity of the shell. A sealing piece is installed between the rotary shaft and the shell. A bearing arranged on the rotary shaft in a sleeving mode is installed on the shell. A plurality of impellers are fixedly connected to the rotary shaft. A gas inlet communicates with a gas tube. A valve is installed on the gas tube. A groove is formed in a turnplate. A screw is installed at the upper end of the turnplate. The pneumatic dedusting device is simple in structure, high-pressure flowing gas is utilized for blowing the impellers to drive the rotary shaft and the turnplate on the rotary shaft to rotate at a high speed, a filter rotates at a high speed while conducting flushing with the high-pressure gas, and the high-pressure gas can cover the surface of the filter quickly; when the filter rotates, impurities inside the filter are hard to gather to the surface of the filter due to the effect of centrifugal force, and the high-pressure gas can quickly blow off the remnant impurities inside the filter; and the cleaning and dedusting efficiency is high, energy is saved, the environment is protected, and the rotating speed is convenient to adjust.

Owner:天津恩卓尼尔科技有限公司

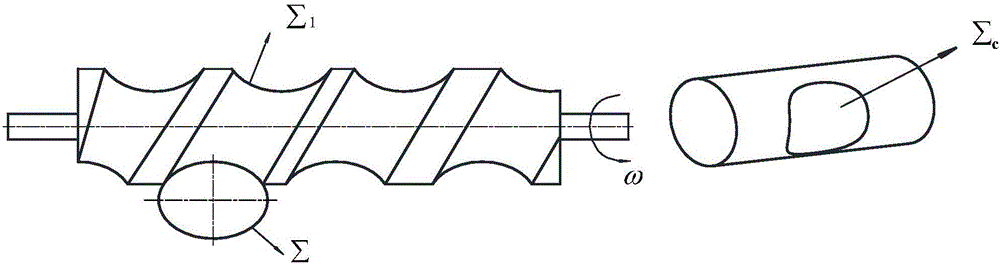

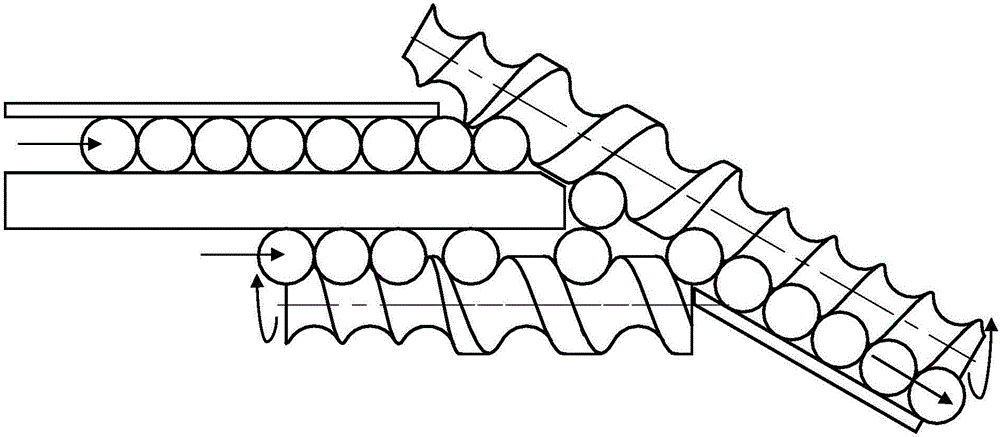

Continuous material flow collecting and conveying device based on special-shaped screw rods

ActiveCN106429360ASimple structureImprove performancePackagingConveyor partsProduction lineModular design

The invention belongs to the technical field of material packaging and conveying equipment, and provides a continuous material flow collecting and conveying device based on special-shaped screw rods. The device comprises a feeding conveying belt, a discharging conveying belt, an introduction screw rod and a flow collecting screw rod; the introduction screw rod is the special-shaped screw rod which is located on one side of the upper end of the feeding conveying belt and is parallel to the feeding conveying belt, the flow collecting screw rod is the special-shaped screw rod which is located on one side of the upper end of the discharging conveying belt and is parallel to the discharging conveying belt, two rows of same-shape parallel conveyed materials are input from one ends of the two special-shaped screw rods, along with changes of the screw pitches and the groove depths of the two special-shaped screw rods, the two rows of parallel materials are collected into one row alternatively, and the materials are output of the other end of the flow collecting screw rod; the screw rod rotating speed is adjusted according to the production requirement, the device is matched with a production line, and the whole process is high in speed and stable, and free of motion rigid impact; modular design is adopted in the device, and the beneficial effects of being low in cost, simple and compact in structure, convenient to mount and debug, efficient, stable in performance and the like are achieved.

Owner:YANSHAN UNIV

Automatic plastic bag adsorption and separation device

The invention provides an automatic plastic bag adsorption and separation device. The automatic plastic bag adsorption and separation device comprises a manipulator, an adsorption mechanism and a separation mechanism, wherein the adsorption mechanism comprises a connection protection cover, a spring, a pressing board, an adsorption piston barrel, an adsorption piston rod, an adsorption suction cup and an adsorption piston rod drive unit; the connection protection cover is connected and fixedly installed on the manipulator through threads and can be driven by the manipulator to rotate; after the connection protection cover rotates, the adsorption mechanism and the separation mechanism are opposite; the separation mechanism comprises a machine shell, a square barrel, a fixing piston barrel, a separation piston rod, a separation suction cup, a square barrel drive unit and a separation piston rod drive unit. A plastic bag is adsorbed by the adsorption mechanism, the adsorption mechanism and the plastic bag can rotate by 90 degrees through the manipulator, and the separation mechanism separates the plastic bag; after the plastic bag is separated, the suction of the suction cup disappears, and the plastic bag automatically falls off. The automatic plastic bag adsorption and separation device is simple in structure, convenient to operate, high in working efficiency, capable of completely replacing a manual plastic bag separation mode, and capable of being embedded into an assembly line for packaging working.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com