Device for testing thermal state characteristics of feeding system

A feed system, characteristic testing technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of lack of pertinence, the pre-stretching amount may not meet the actual situation, etc., to achieve a wide adjustment range, speed adjustment is convenient and fast, precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The thermal characteristic testing device of the feed system of the present invention is suitable for the environment where the dimensions of the screw and the bearing vary. The testing device can simulate different pretightening forces and rotation speeds of the screw. Temperature, the infrared thermometer measures the temperature of the lead screw, and the dispersion confocal displacement meter realizes the measurement of the axial thermal displacement of the lead screw.

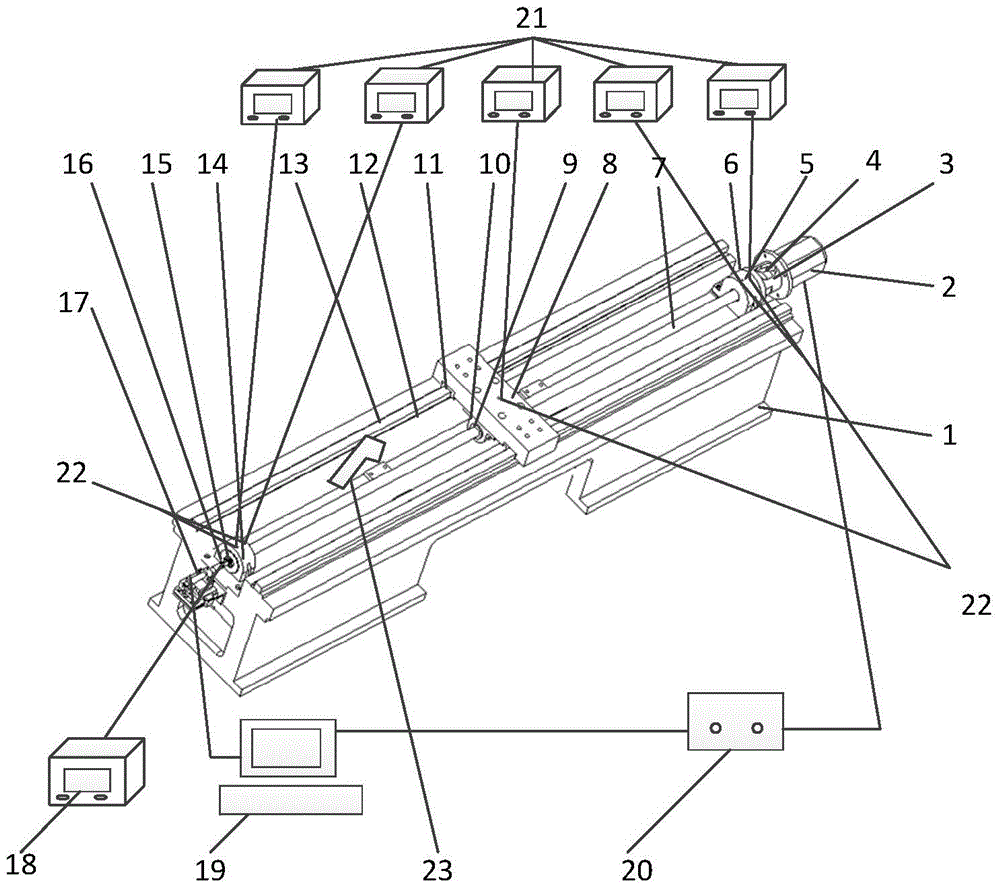

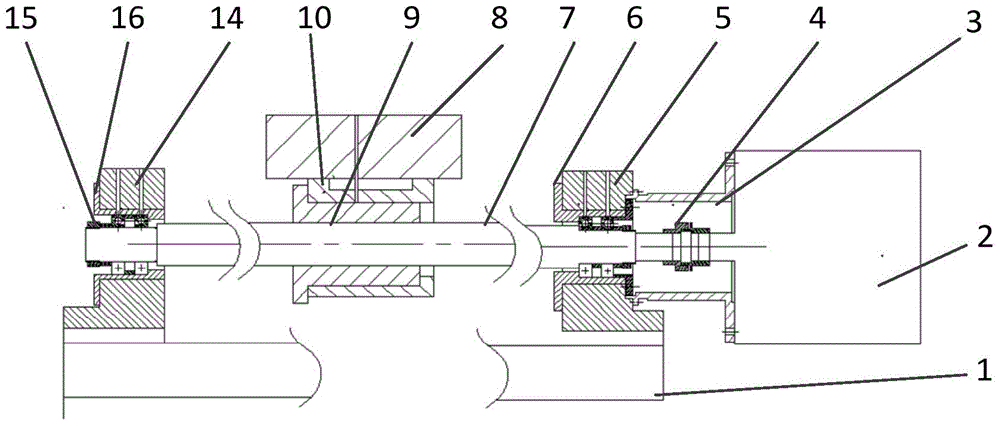

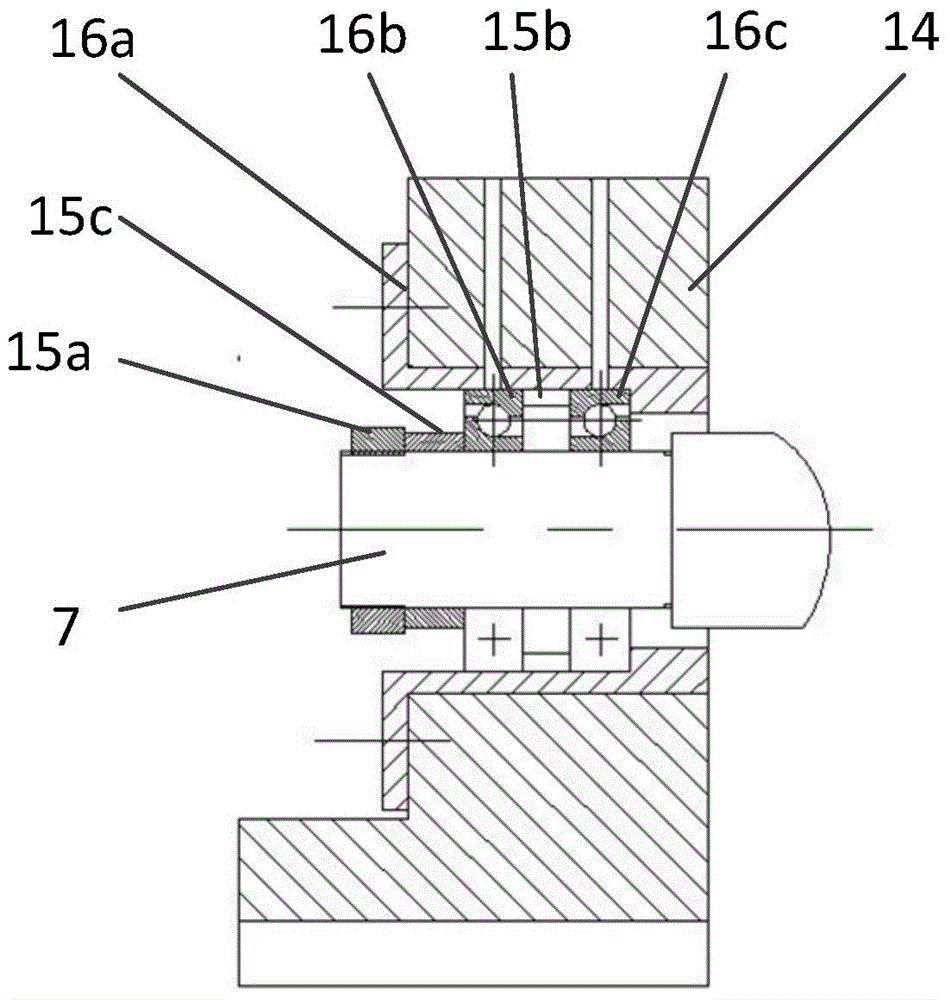

[0019] combine figure 1 , figure 2 , image 3 and Figure 4 , a feed system thermal characteristic test device of the present invention, comprising a base test bench 1, a servo motor 2, a motor base 3, a shaft coupling 4, a right bearing seat 5, a right bearing assembly 6, a ball screw 7, Workbench 8, lead screw nut 9, lead screw nut seat 10, rolling guide slider 11, wedge block 12, rolling guide 13, left bearing seat 14, axial pretensioning device 15, left bearing assembly 16, dispersion commo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com