Automatic plastic bag adsorption and separation device

An adsorption separation and plastic bag technology, applied in packaging and other directions, can solve the problems of difficult automatic production and low production efficiency, and achieve the effects of simple structure, high production efficiency, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

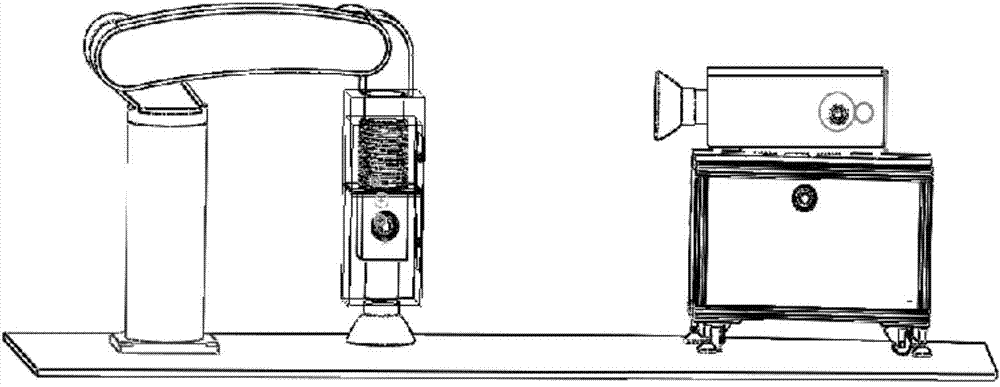

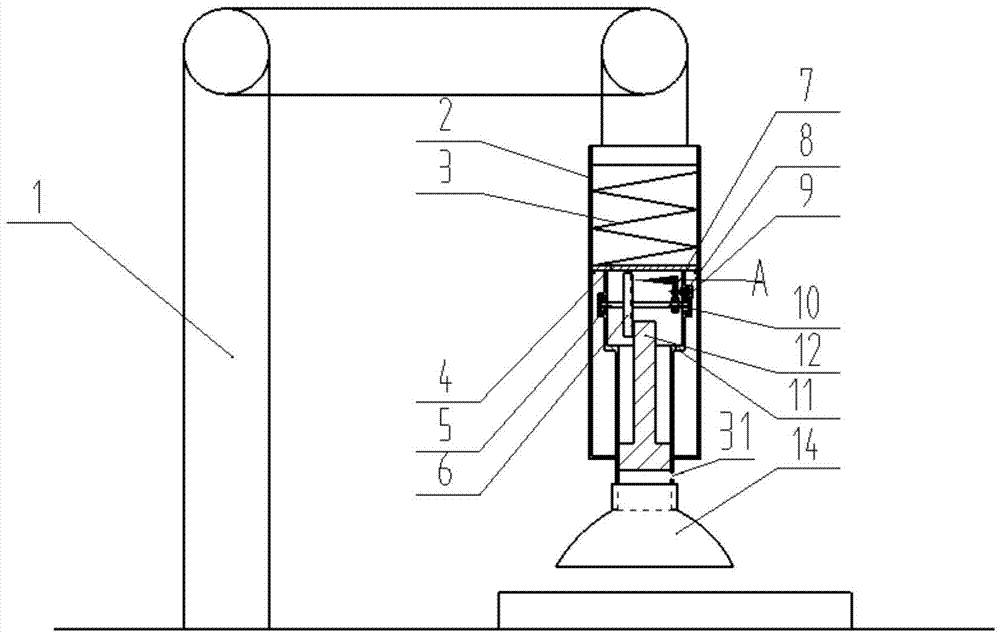

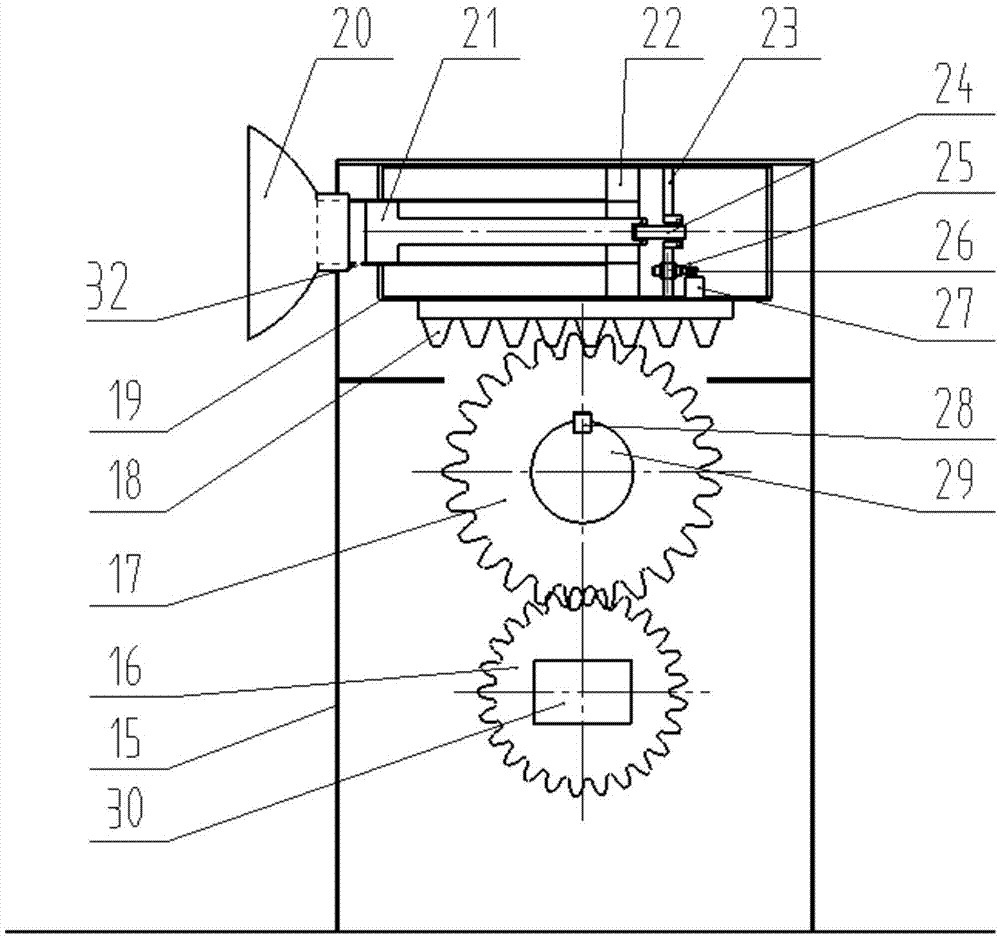

[0026] Such as Figure 1-3 As shown, the present invention provides a kind of automatic adsorption separation device for plastic bags, comprising a manipulator 1, an adsorption mechanism and a separation mechanism; the adsorption mechanism is used for absorbing plastic bags, and then by the manipulator 1, the adsorption mechanism and the plastic bag are rotated 90 degrees, so that It is opposite to the separation mechanism; the separation mechanism is used to separate the two-layer structure of the plastic bag.

[0027] The adsorption mechanism includes a connection protection cover 2, a spring 3, a pressure plate 4, an adsorption piston cylinder 11, an adsorption piston rod 12, an adsorption suction cup 14 and an adsorption piston rod driving unit. On, it can be driven by the manipulator 1 to make a rotary motion. An openable door ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com