Non-contact single signal throttle position sensor

A throttle position, non-contact technology, applied in the field of sensors, can solve the problems of signal distortion, poor contact, affecting the reliable use of the engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

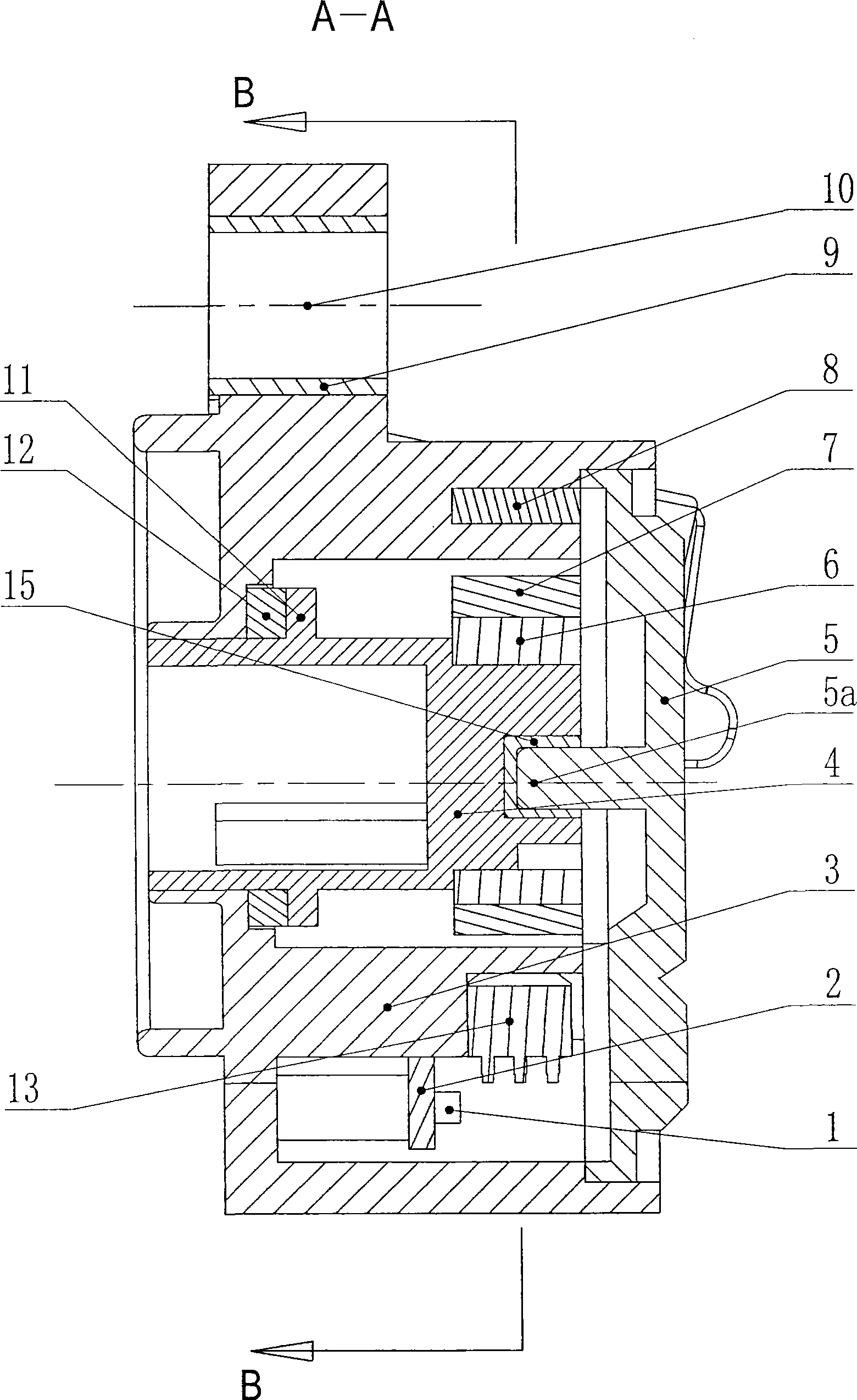

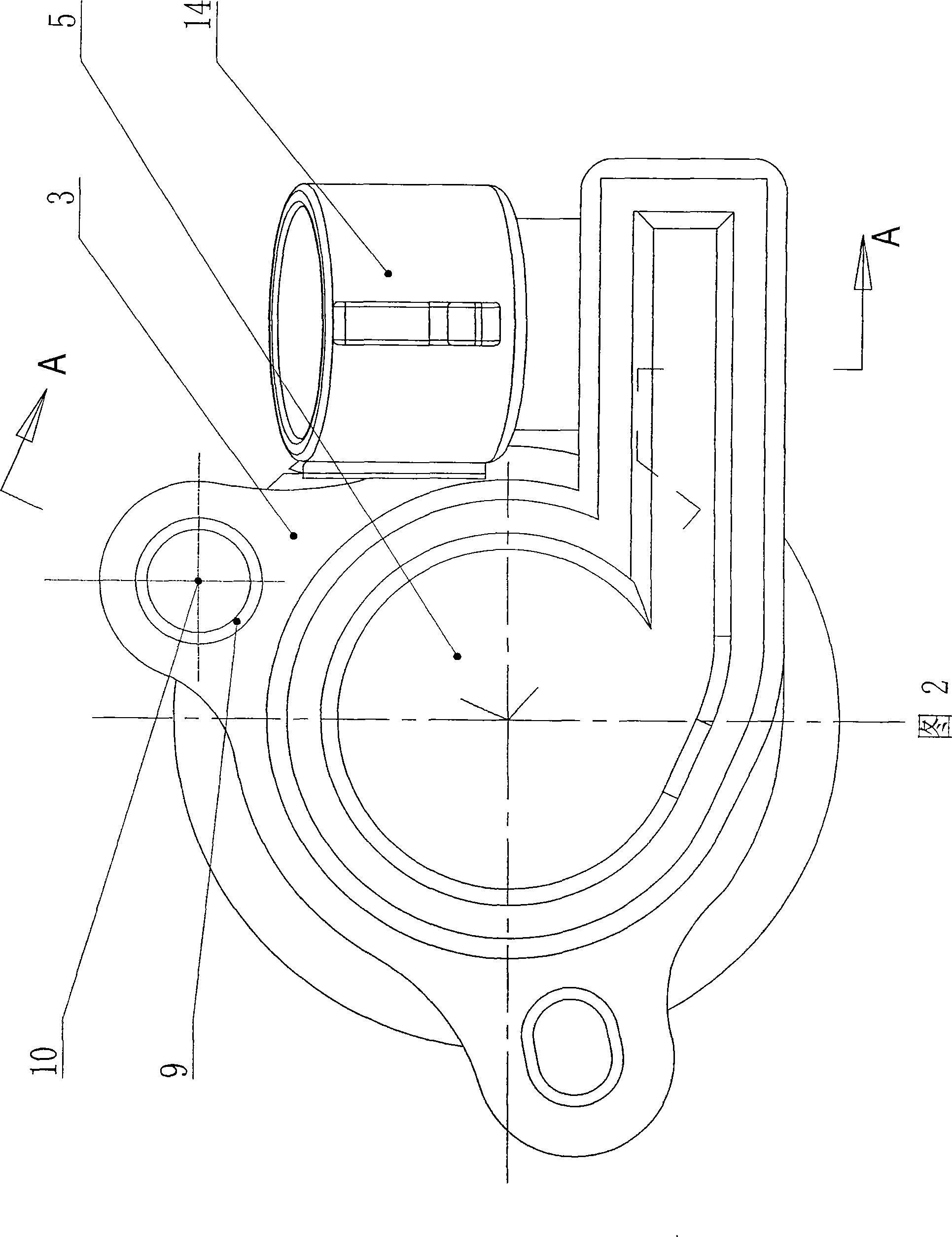

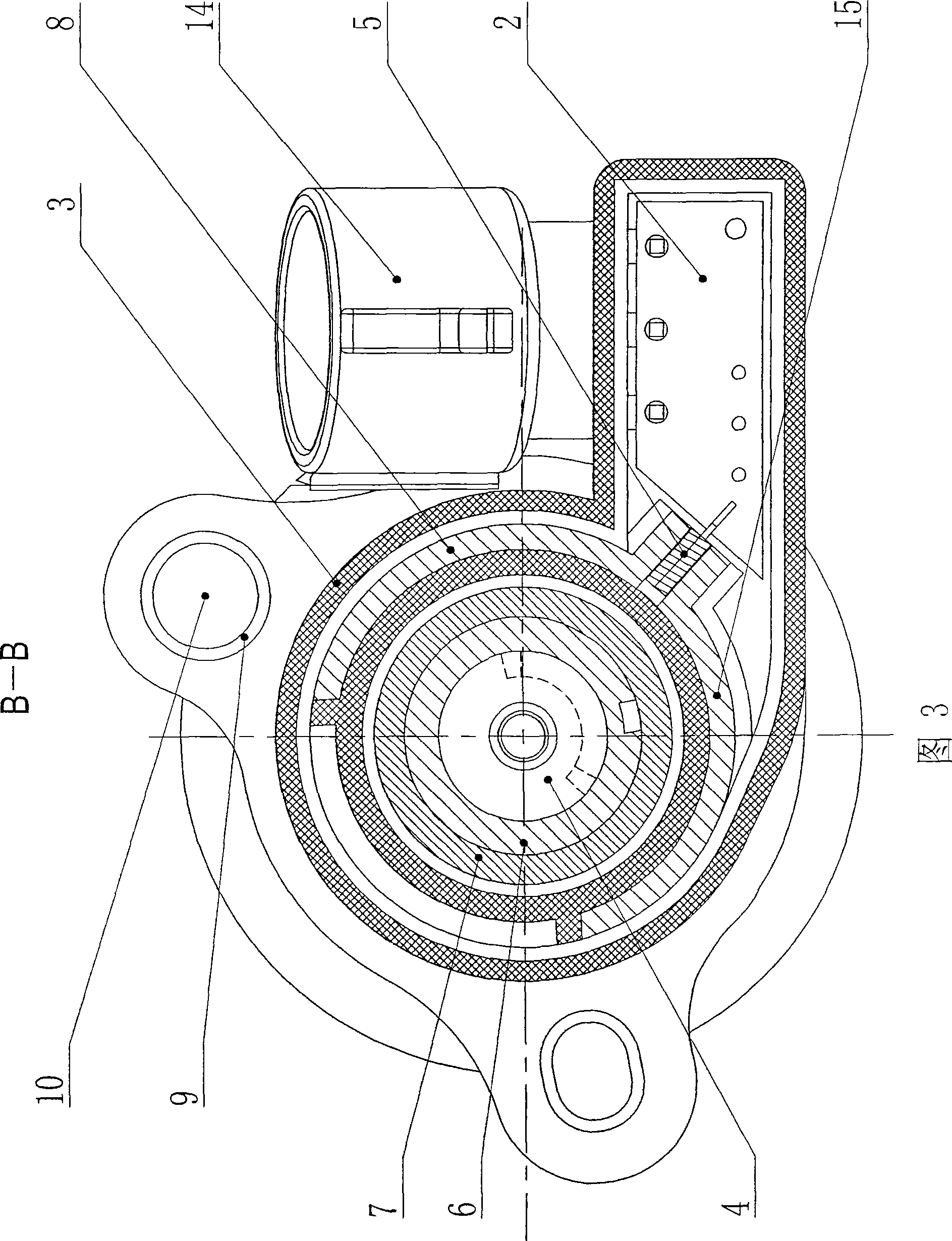

[0013] As shown in the figure, it is a non-contact single-signal throttle position sensor. Its structure mainly includes a housing 3, and a mounting hole 10 is provided on the housing 3 for connecting and fixing the housing 3 on the throttle housing. The housing 3 consists of Made of plastic, in order to improve the connection strength, a metal bushing 9 is provided in the installation hole 10; a rotor 4 that can be linked with the throttle shaft is provided in the housing 3, and a shielding cover 6 is fixed on the outer periphery of the rotor 4, and the shielding cover 6 Made of soft iron, it can shield the throttle shaft to avoid its influence on the signal output of the Hall element, and at the same time make the magnetic lines of force concentrate outward; the outer periphery of the shield 6 is fixed with a magnet 7, and the shield 6 and the magnet 7 are both It is in the shape of a ring; the housing 3 is located outside the magnetic steel 7 and is fixed with two sections o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com