Patents

Literature

321 results about "Throttle position sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A throttle position sensor (TPS) is a sensor used to monitor the air intake of an engine. The sensor is usually located on the butterfly spindle/shaft so that it can directly monitor the position of the throttle. More advanced forms of the sensor are also used, for example an extra closed throttle position sensor (CTPS) may be employed to indicate that the throttle is completely closed. Some engine control units (ECUs) also control the throttle position electronic throttle control (ETC) or "drive by wire" systems and if that is done the position sensor is used in a feedback loop to enable that control.

Vehicle engine control device

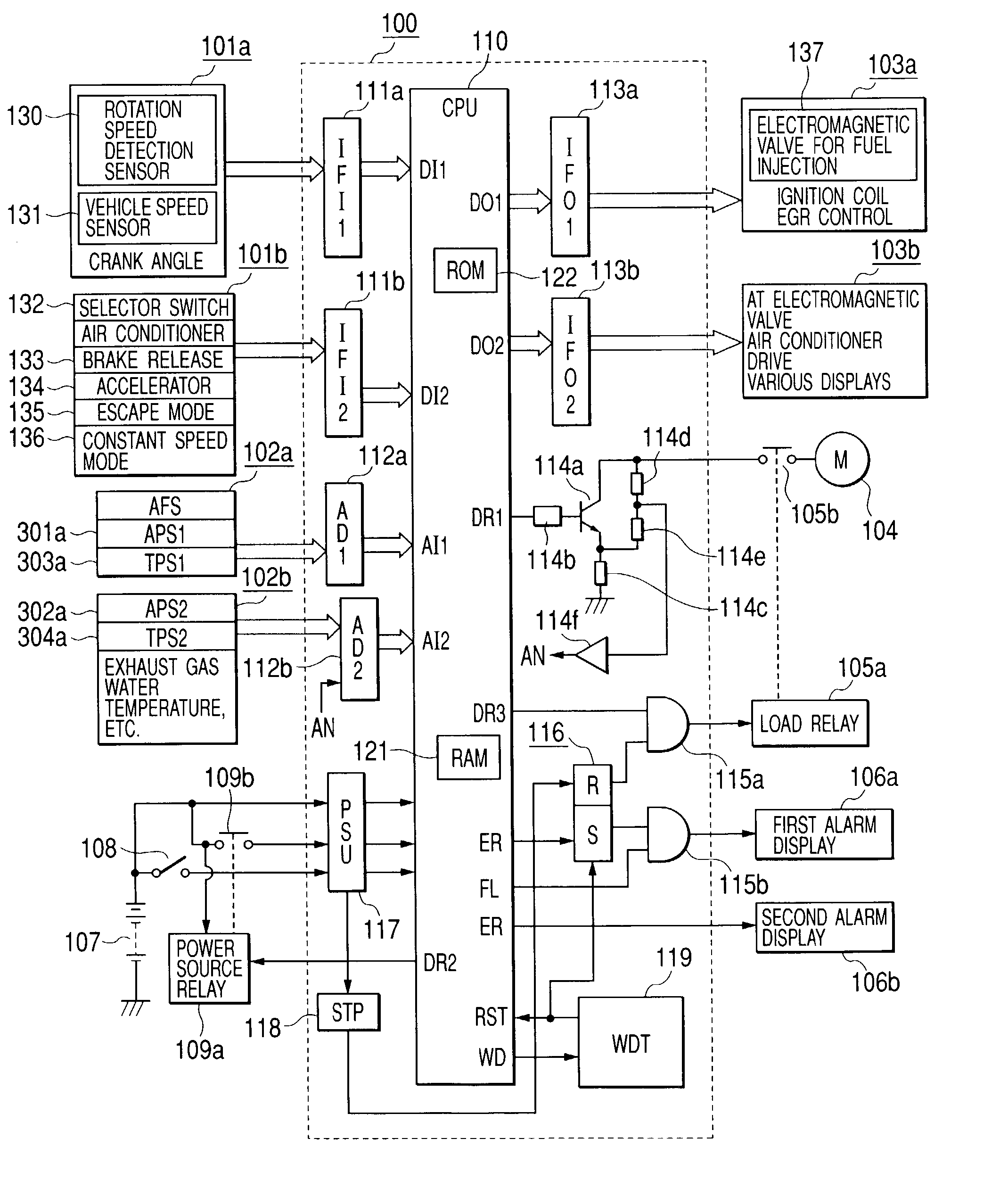

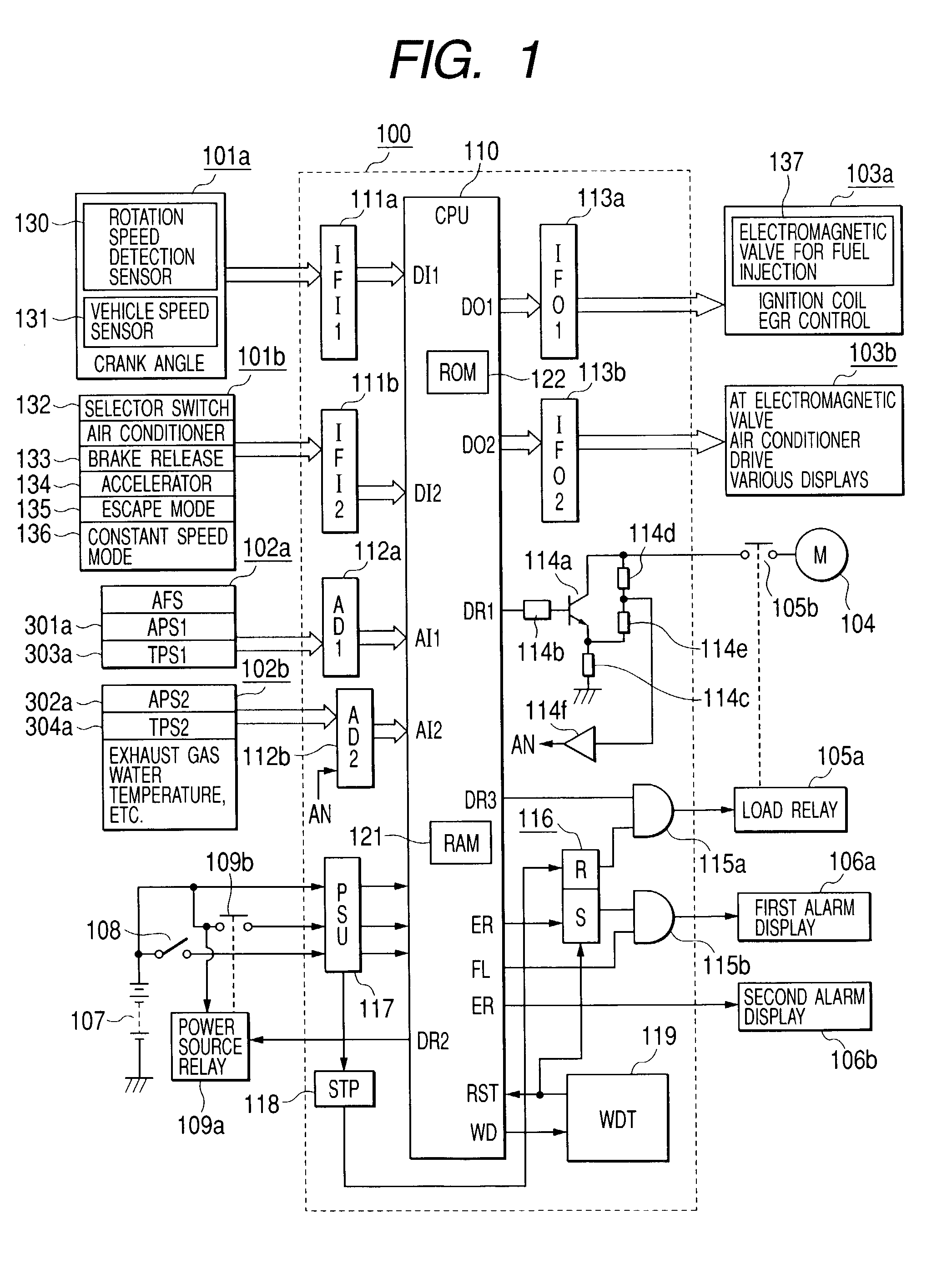

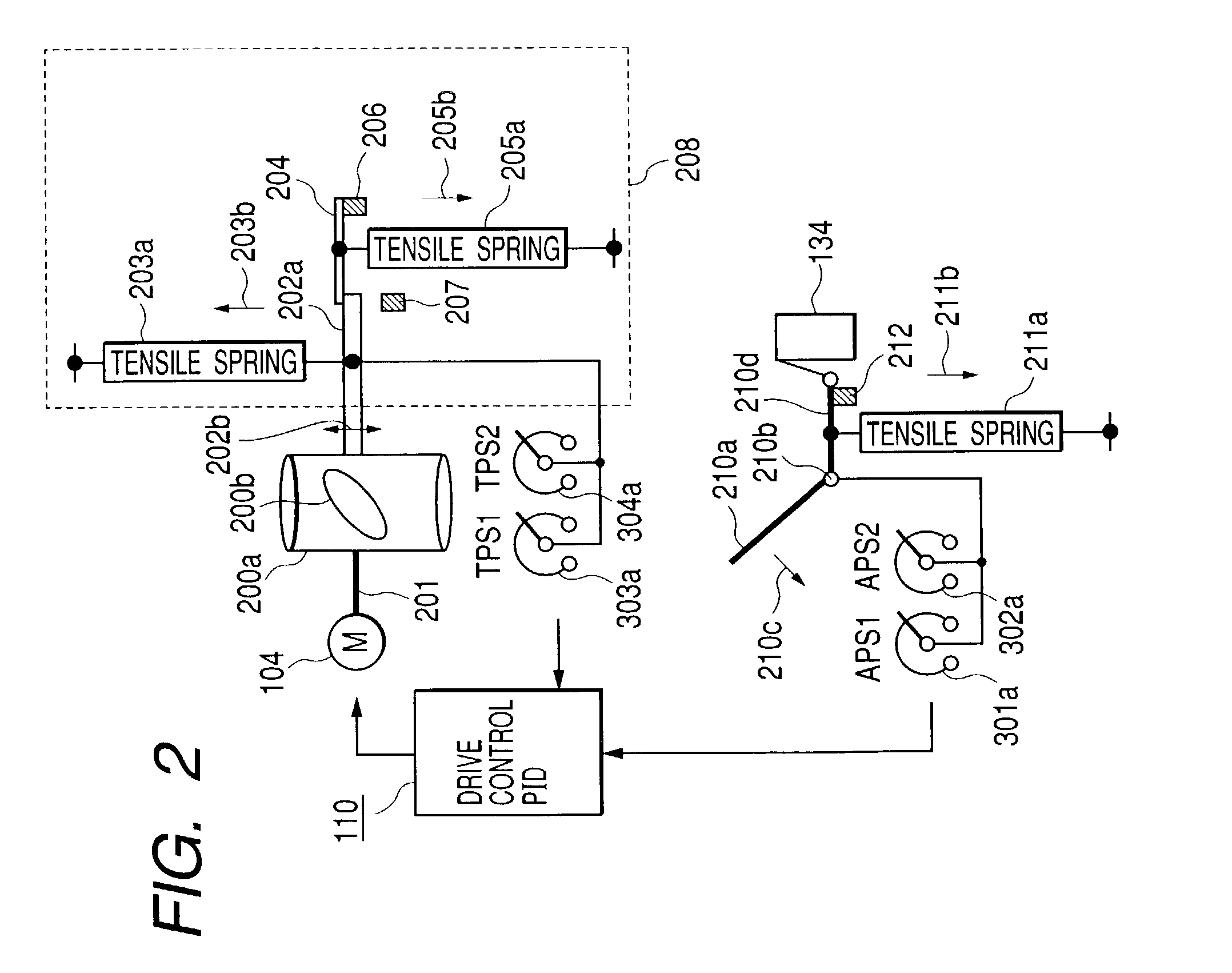

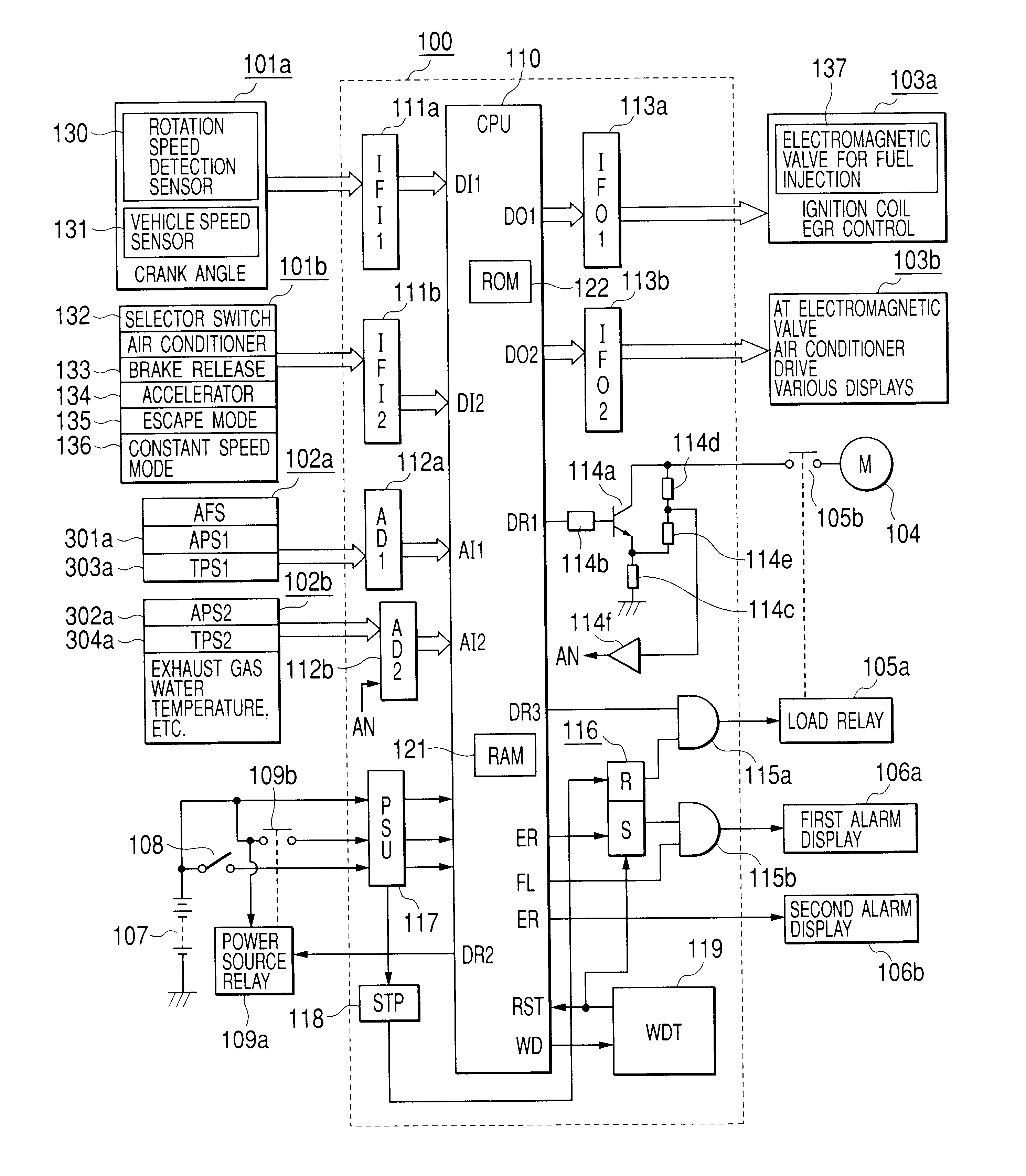

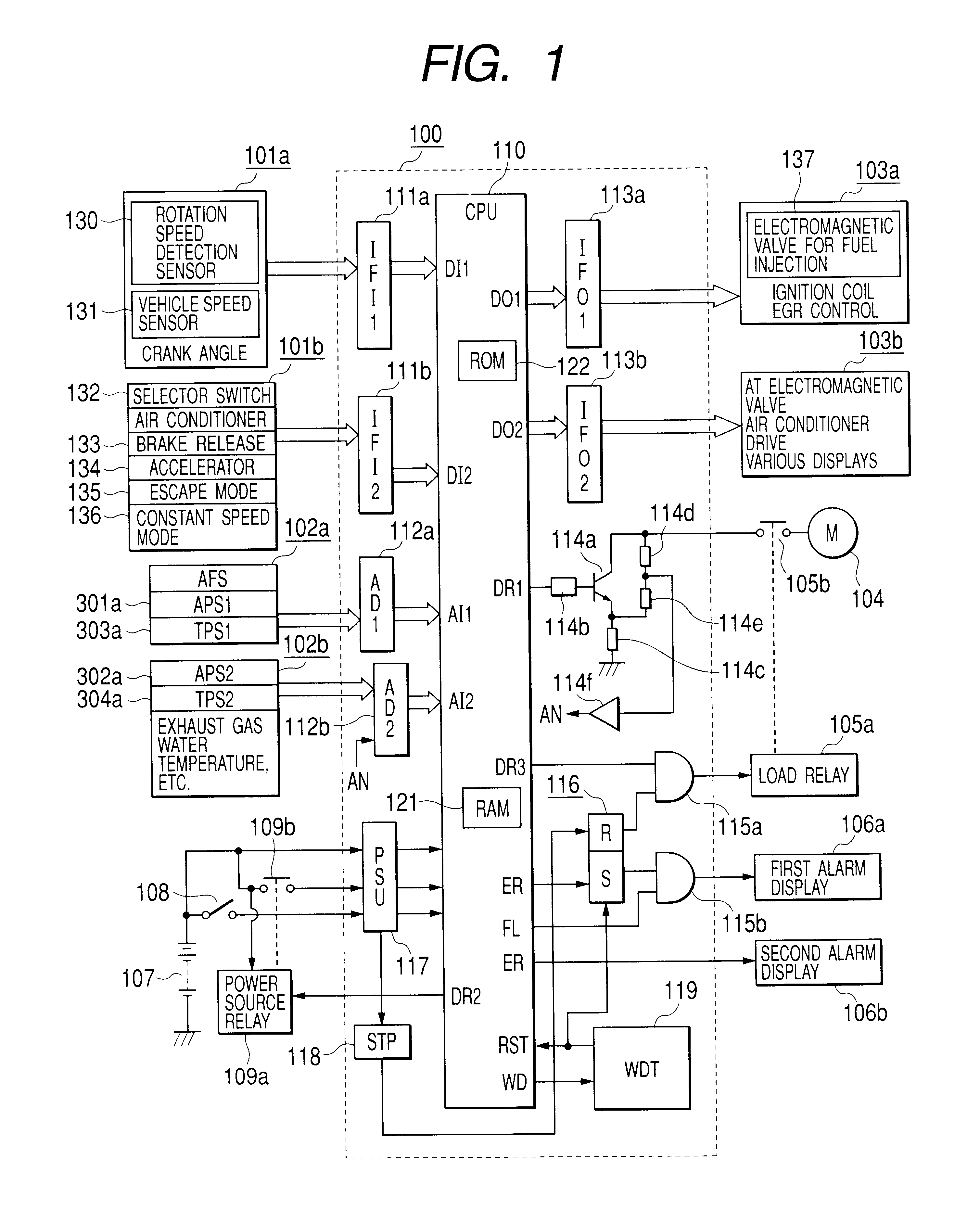

Escape running performance at the time of the occurrence of an abnormality in an electronic throttle control system is improved. At the time of the occurrence of a severe abnormality, an abnormality storage element is operated, and an electric supply load relay of a throttle valve driving motor is de-energized to return a throttle valve to the default, and further, an alarm display is actuated, and an upper limit engine rotational speed is suppressed by control of a fuel injection valve, and escape running is carried out. As a suppression rotational speed, a lower limit threshold at a stop, a rotational speed substantially in proportion to the output of an accelerator position sensor, a rotational speed substantially in inverse proportion to the output of a throttle position sensor, or a default threshold rotational speed is selected, and multiple escape running can be carried out.

Owner:MITSUBISHI ELECTRIC CORP

Vehicle engine control device

Owner:MITSUBISHI ELECTRIC CORP

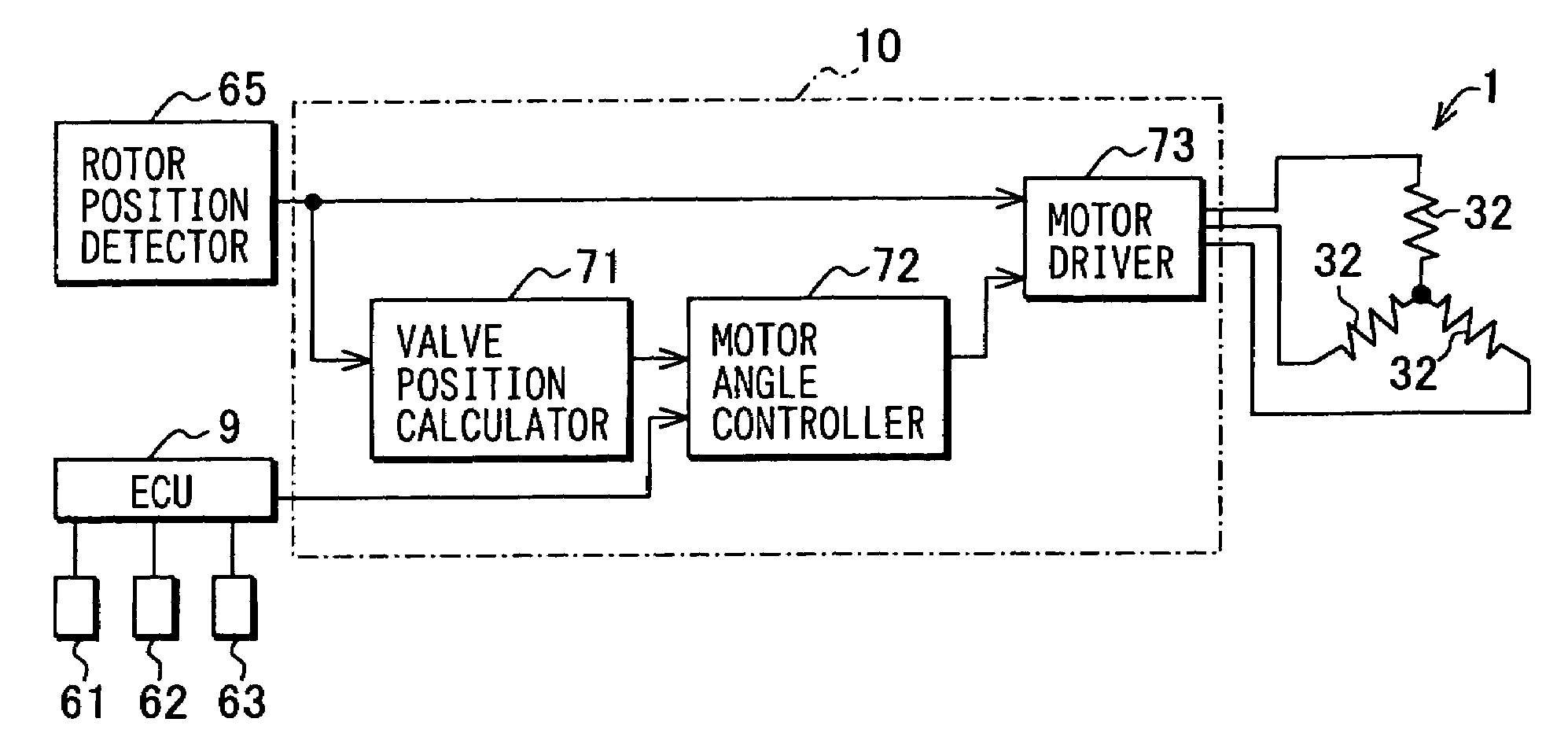

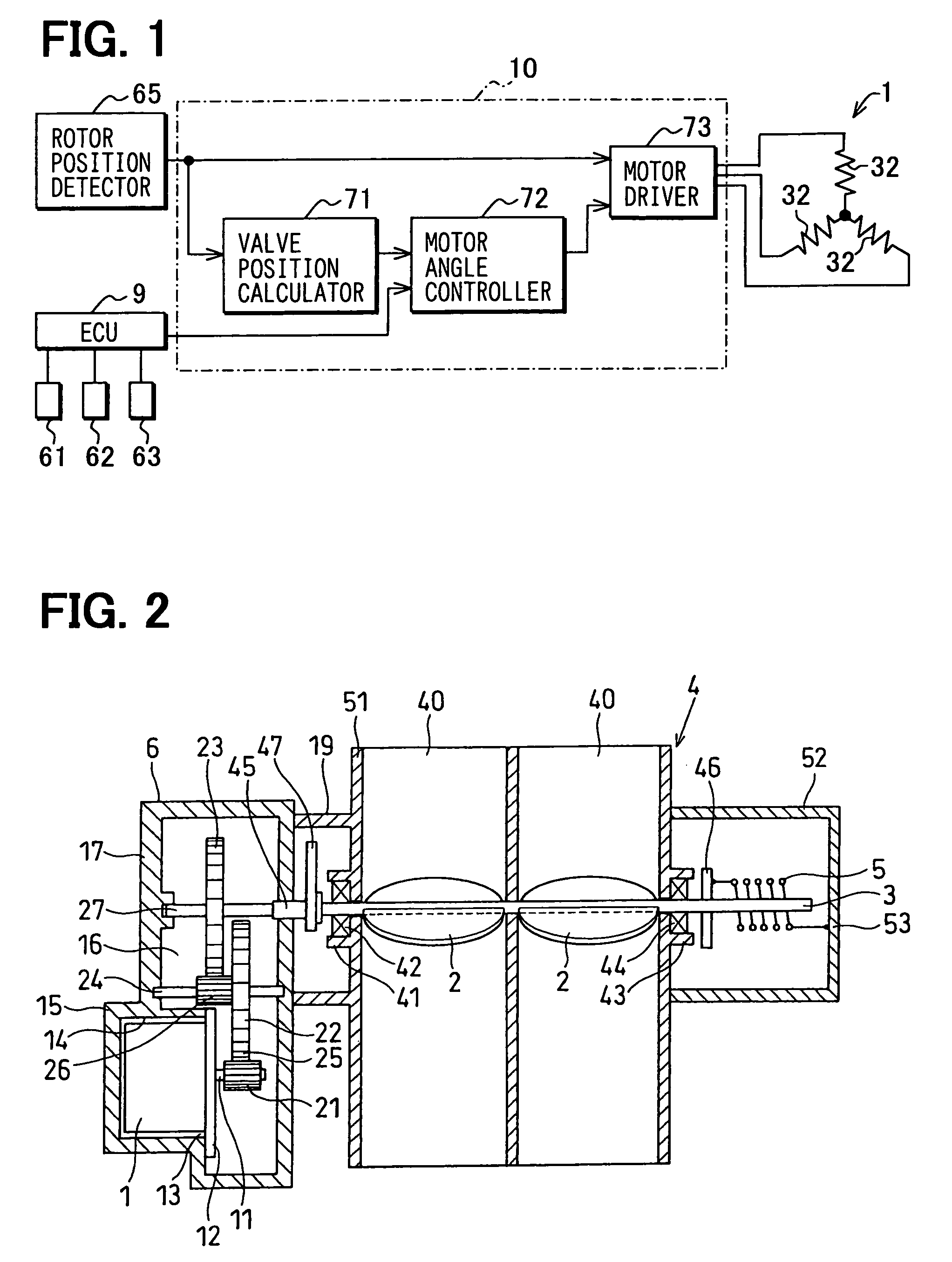

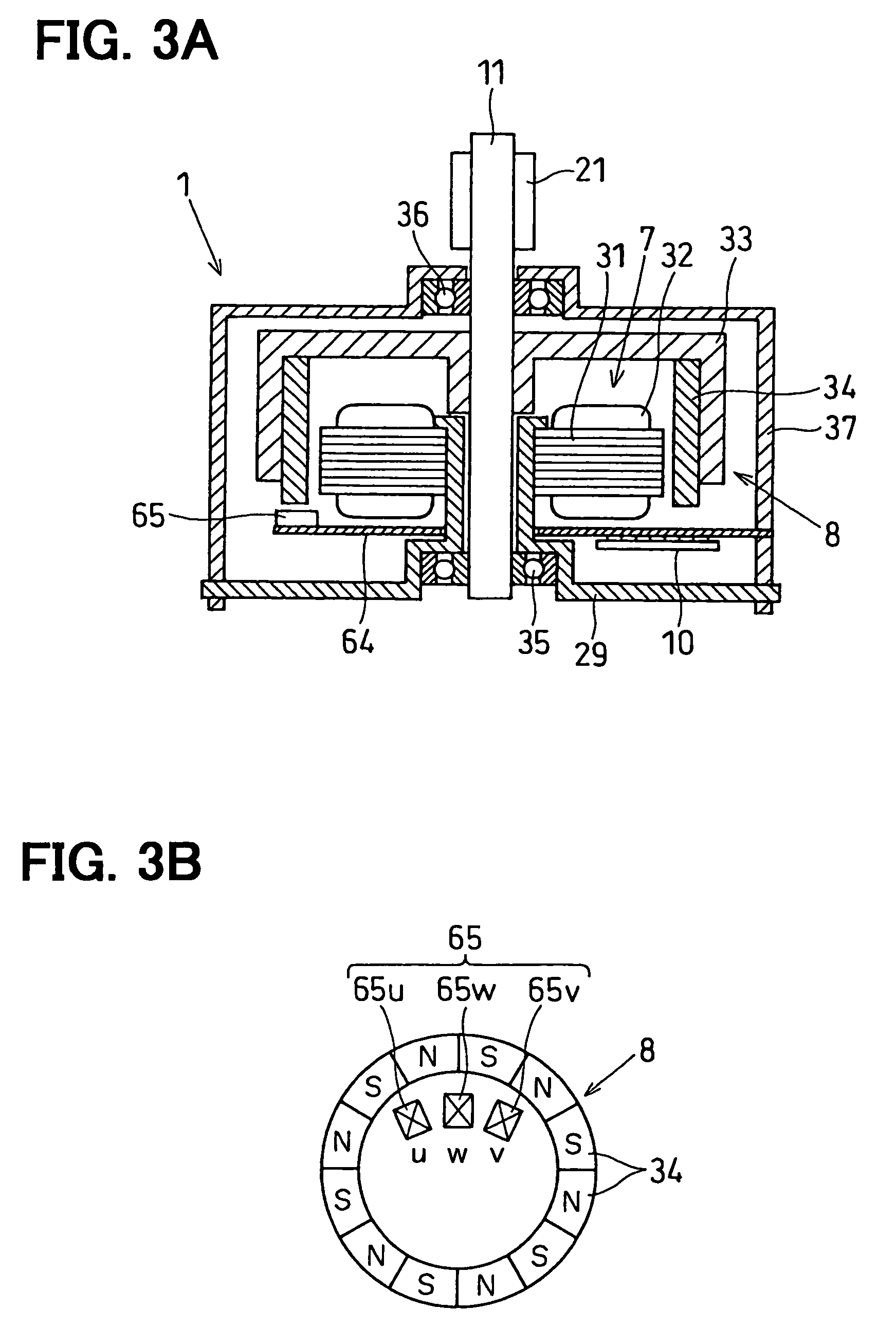

Valve position controlller

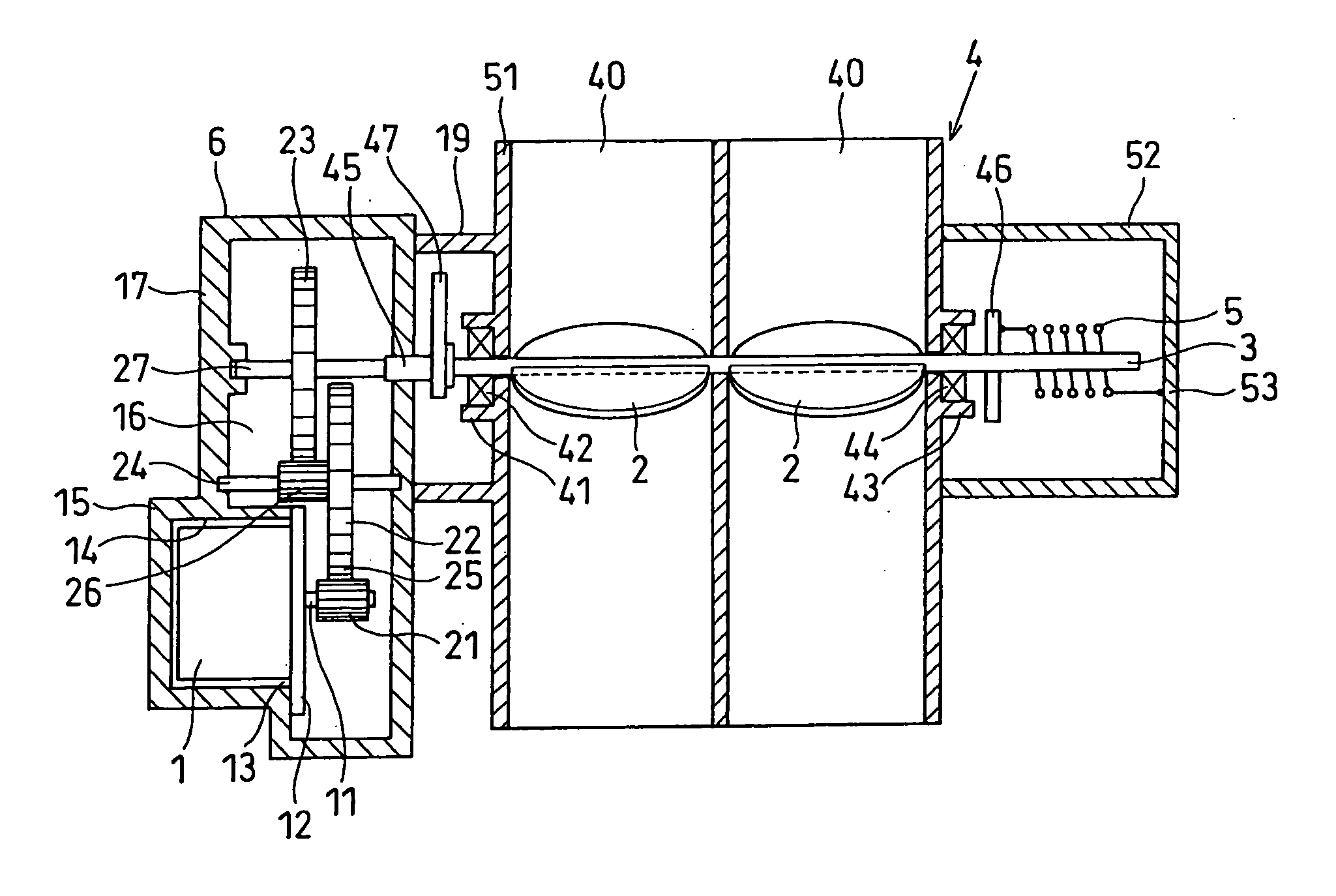

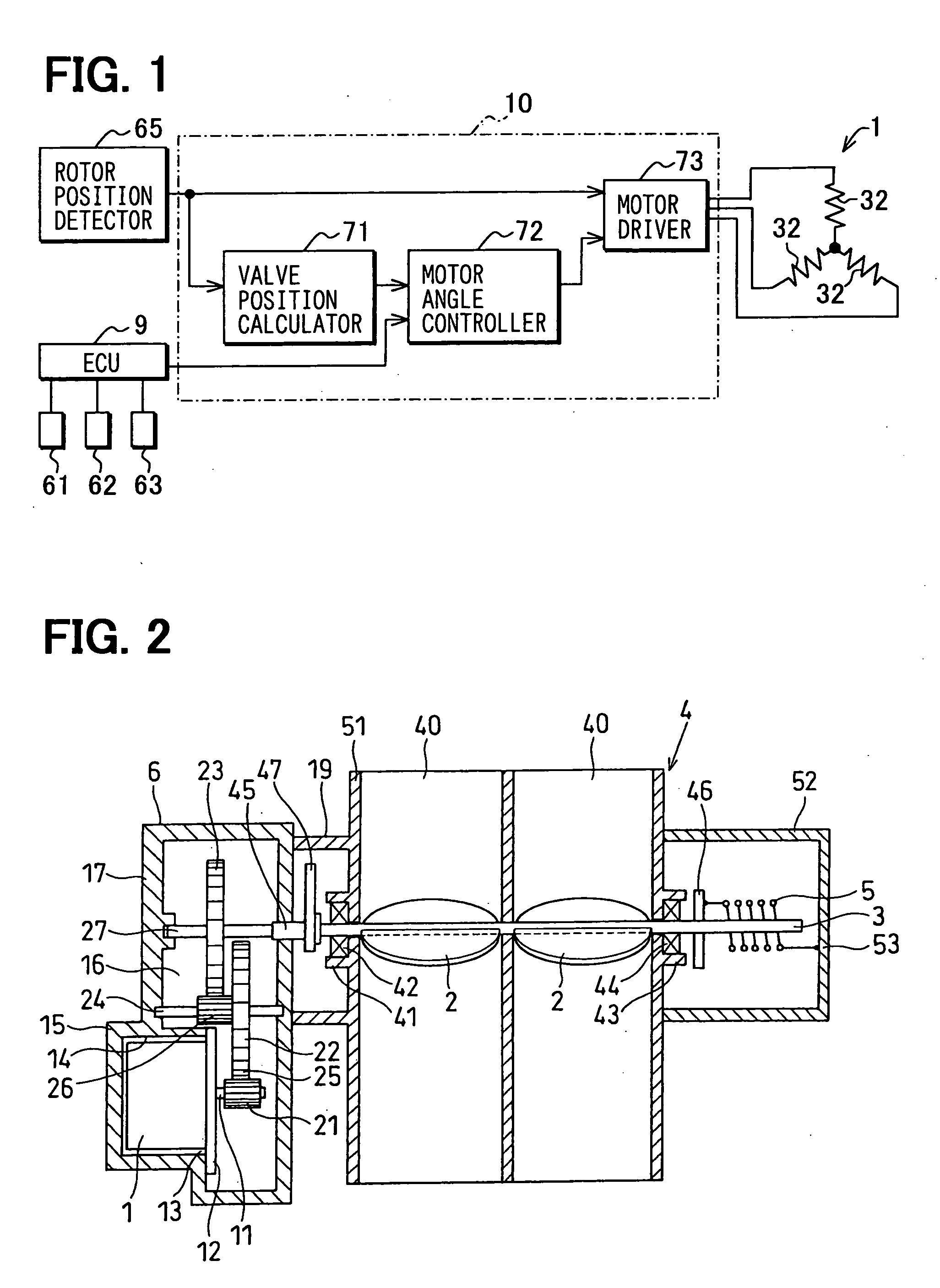

InactiveUS20060016427A1Low costReduce the numberElectrical controlMachines/enginesThrottle position sensorPosition control

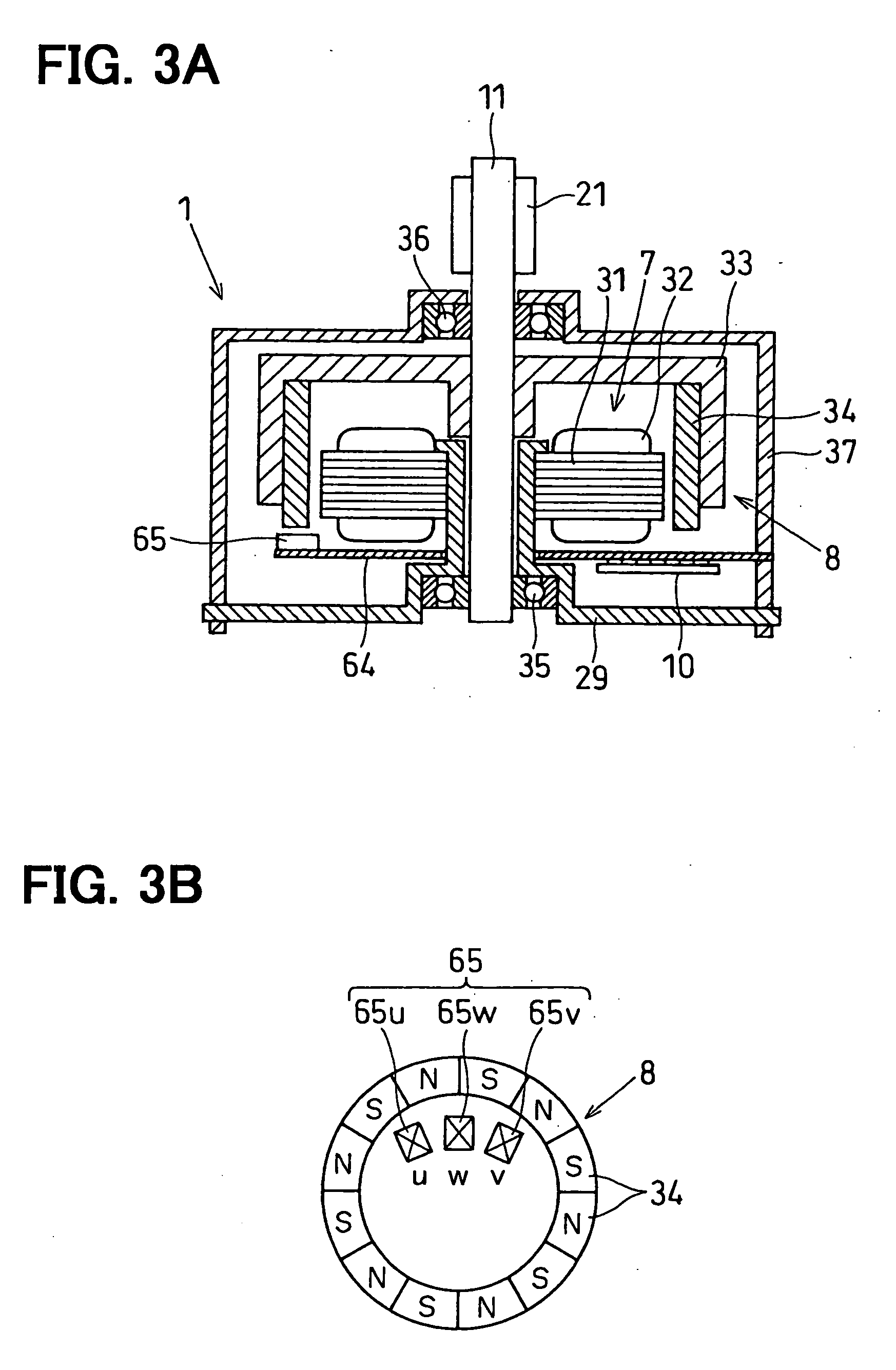

The throttle position corresponding to the rotational angle of the throttle valve is calculated based on electric signals output from a rotor position detector constituted by three Hall ICs that detect the rotational position of a magnet rotor of a brushless DC motor. A valve position control quantity of the throttle valve is so calculated as to eliminate the difference between the thus calculated valve position and a target valve position. The motor current control quantity of the brushless DC motor is so determined as to eliminate the difference between the calculated valve position and the target valve position. Though the throttle position sensor is omitted, the electric signals output from the rotor position detector are used for calculating both the valve position control quantity and the motor current control quantity.

Owner:DENSO CORP

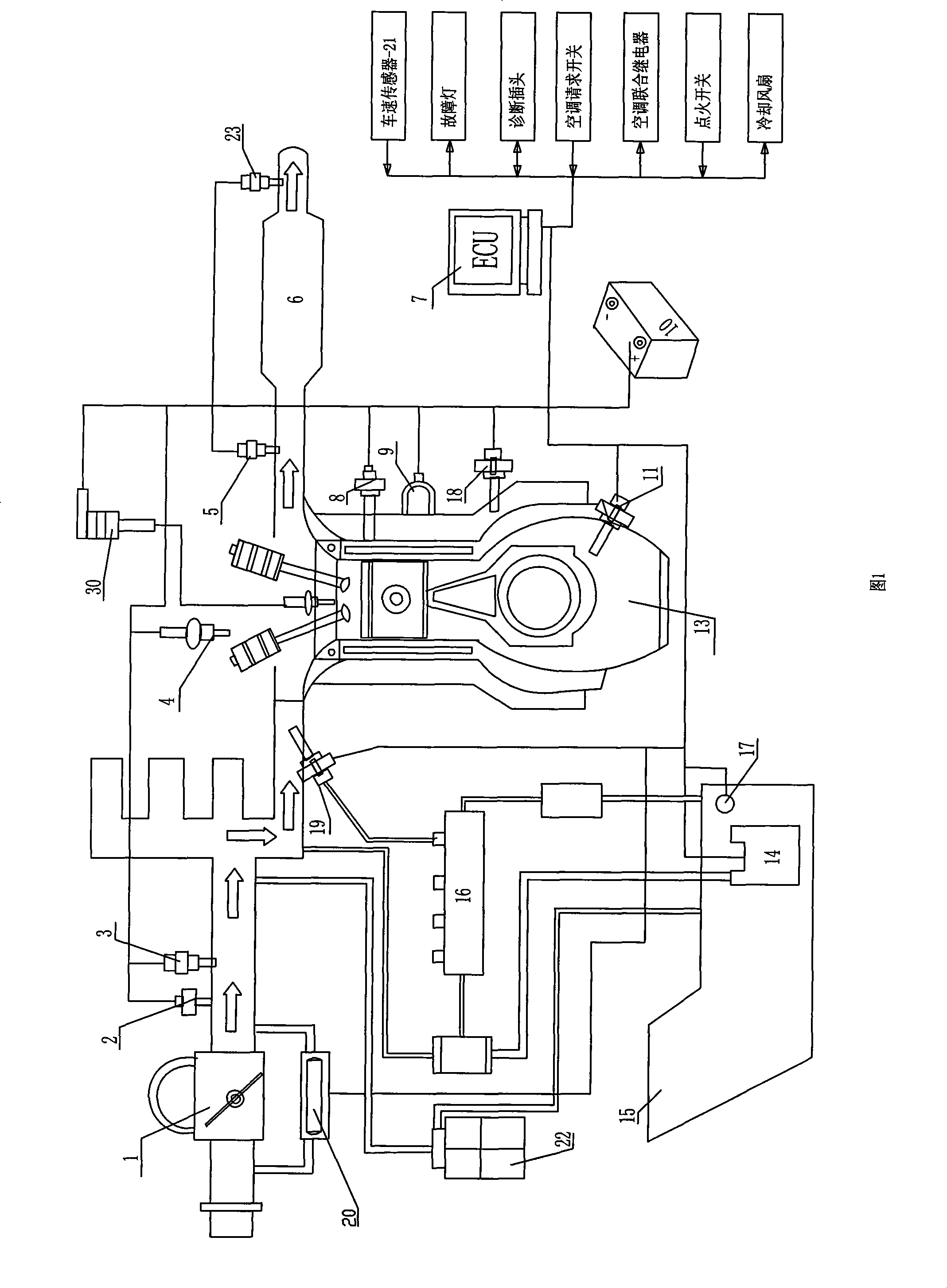

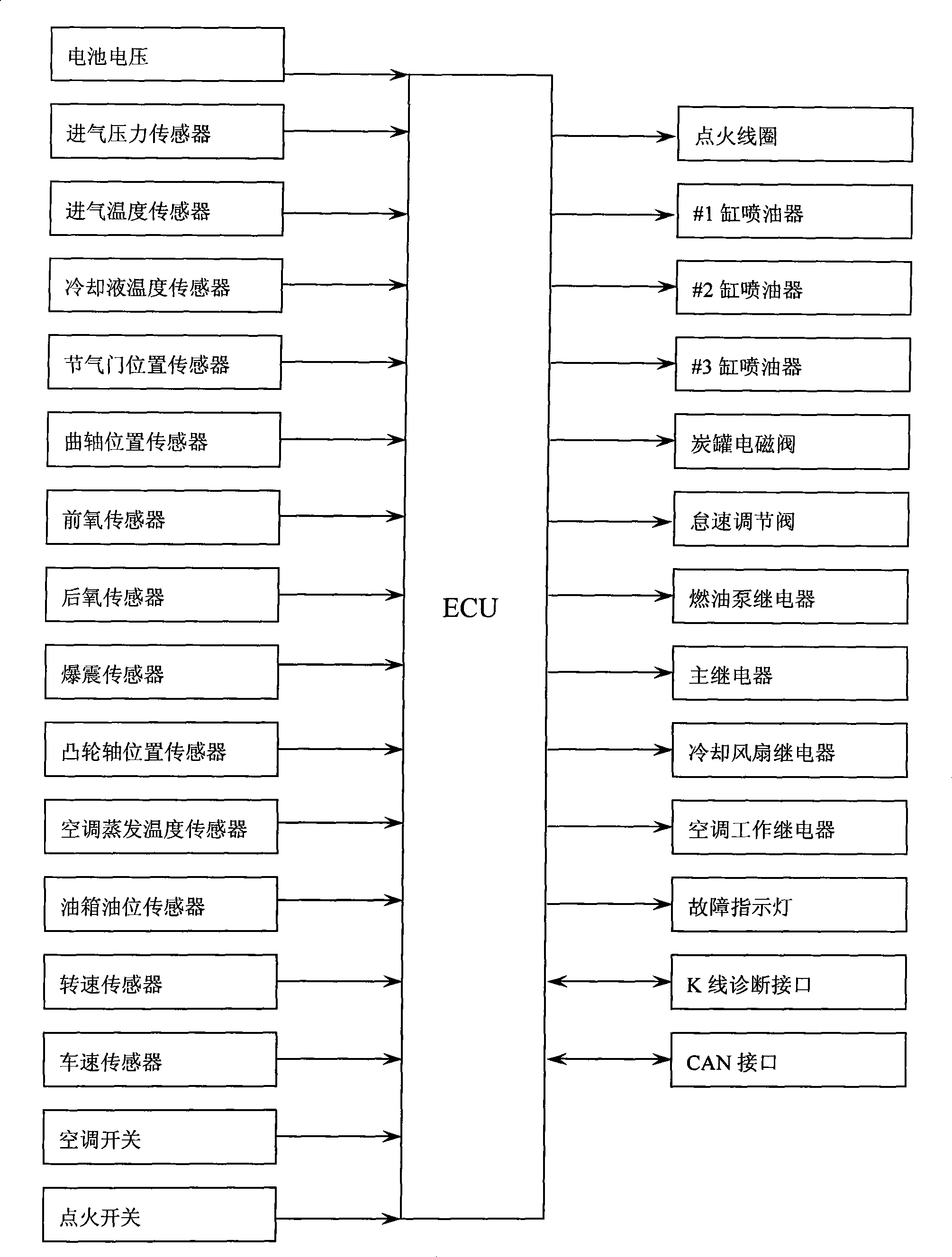

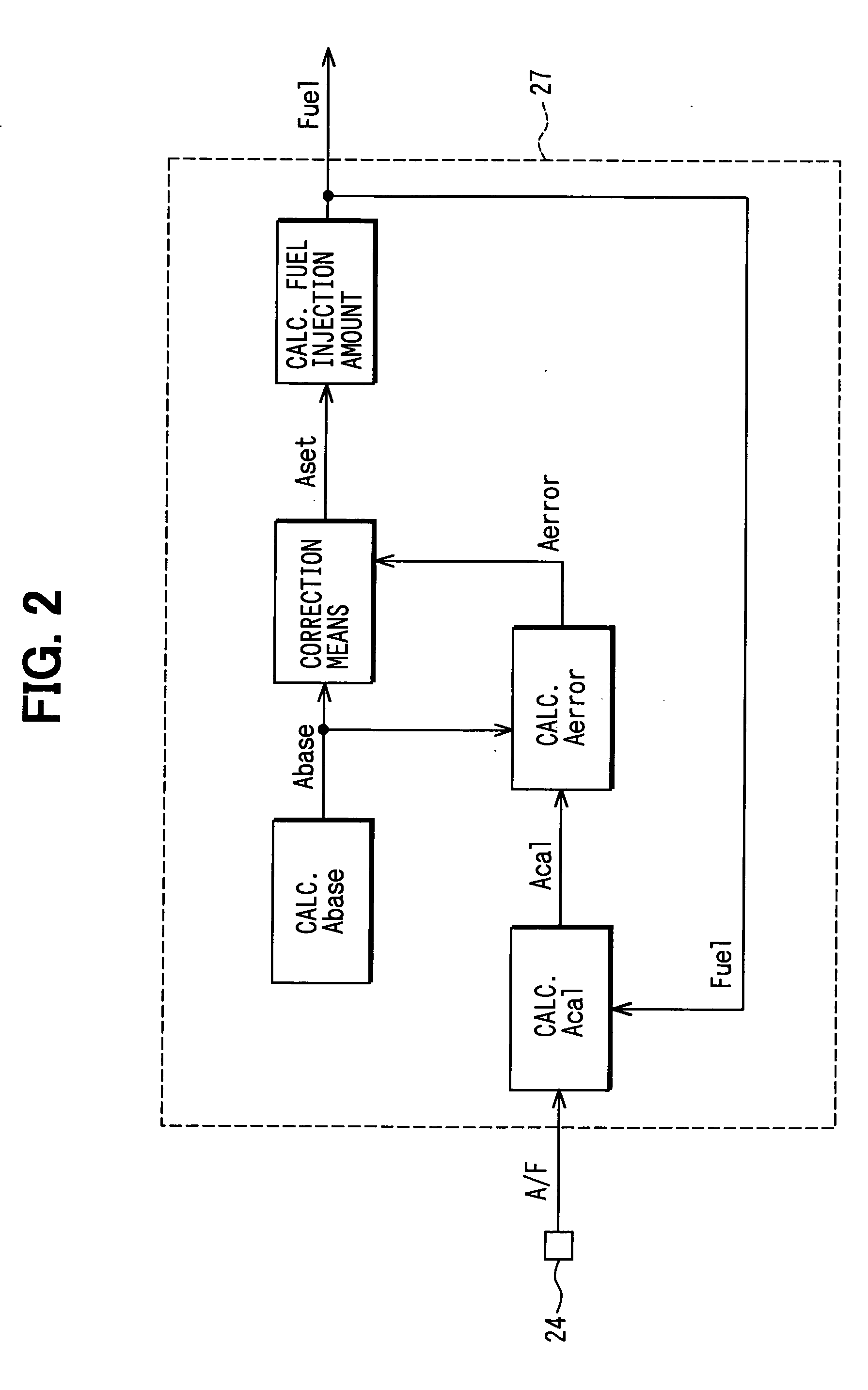

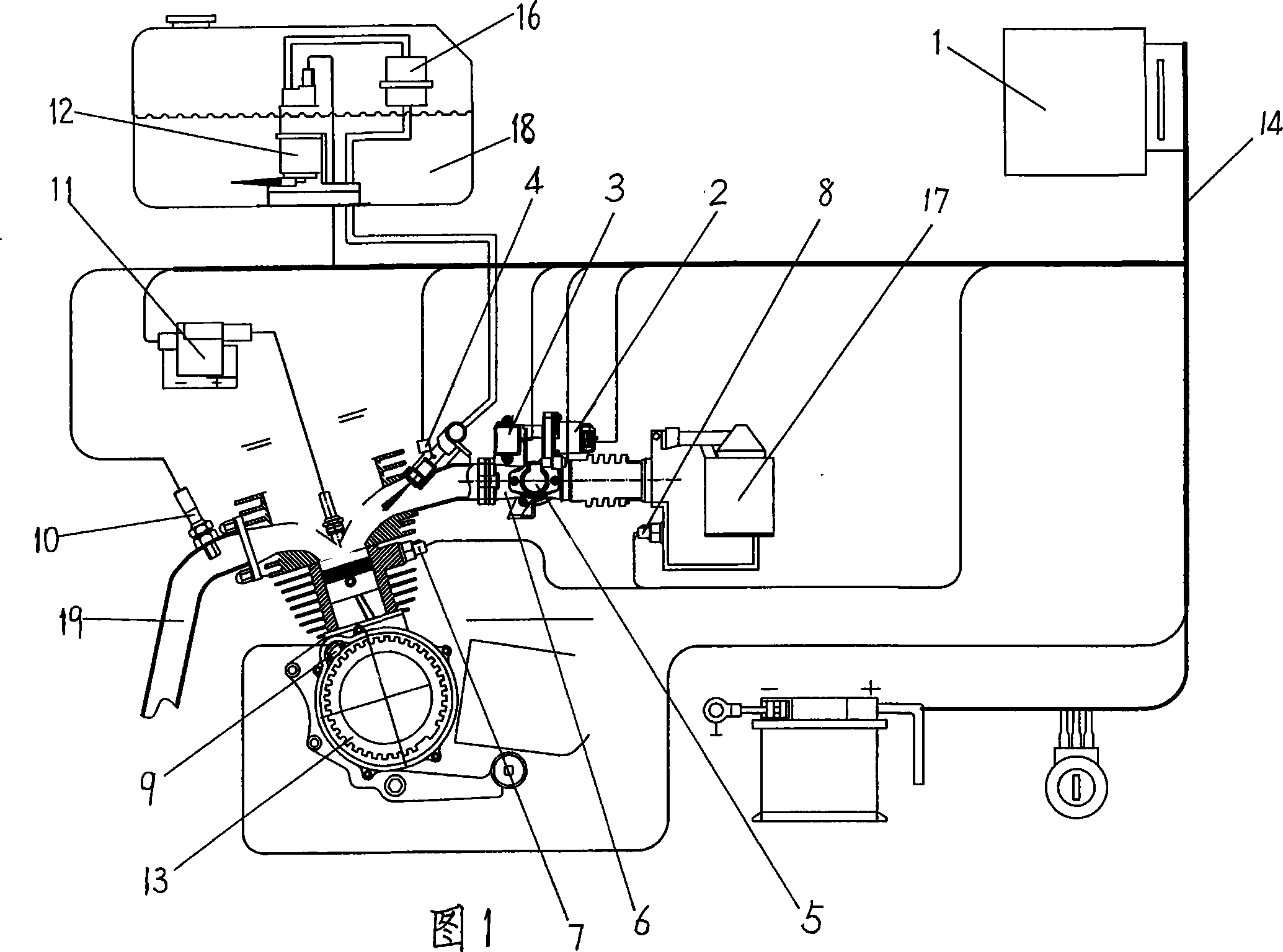

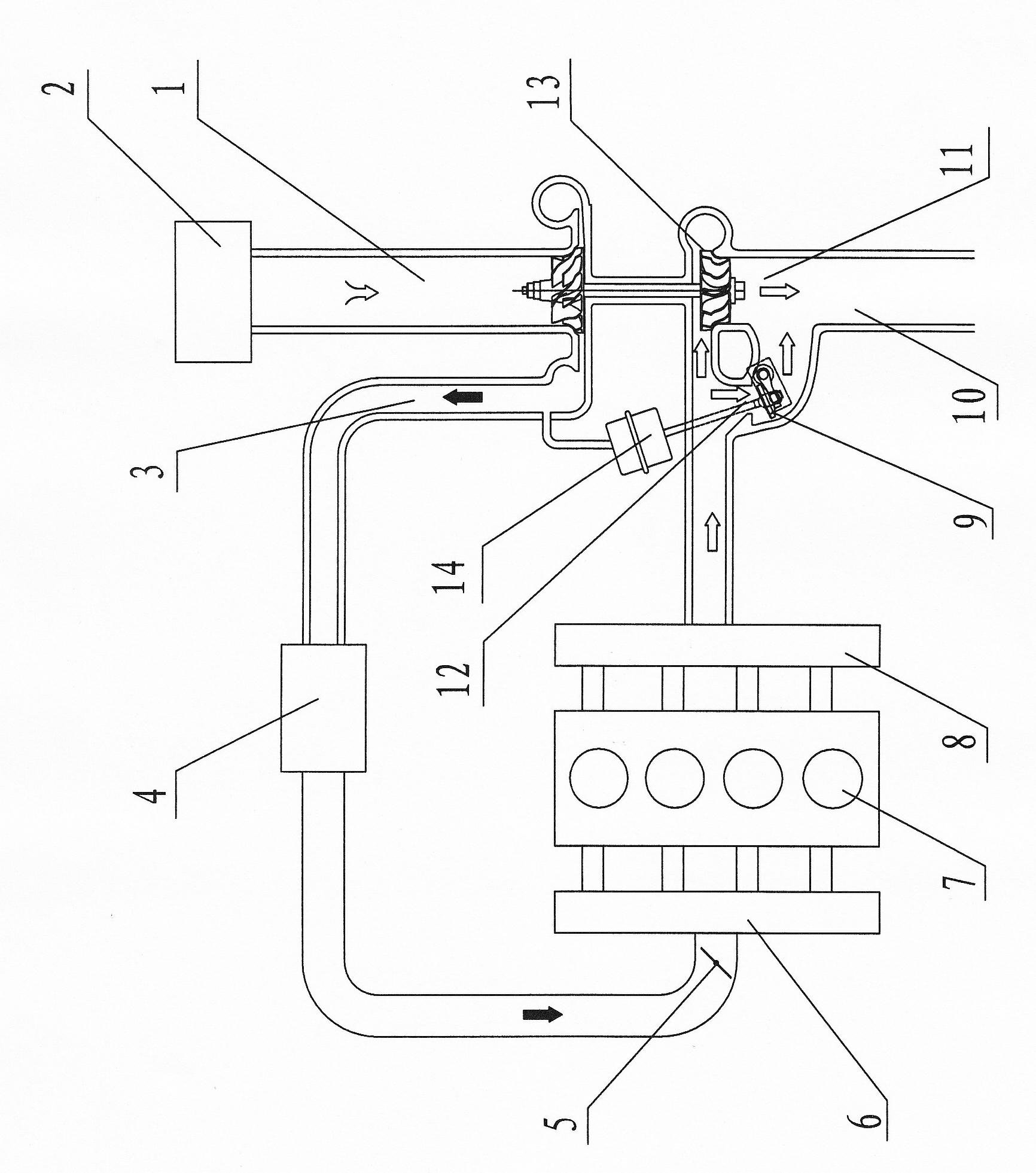

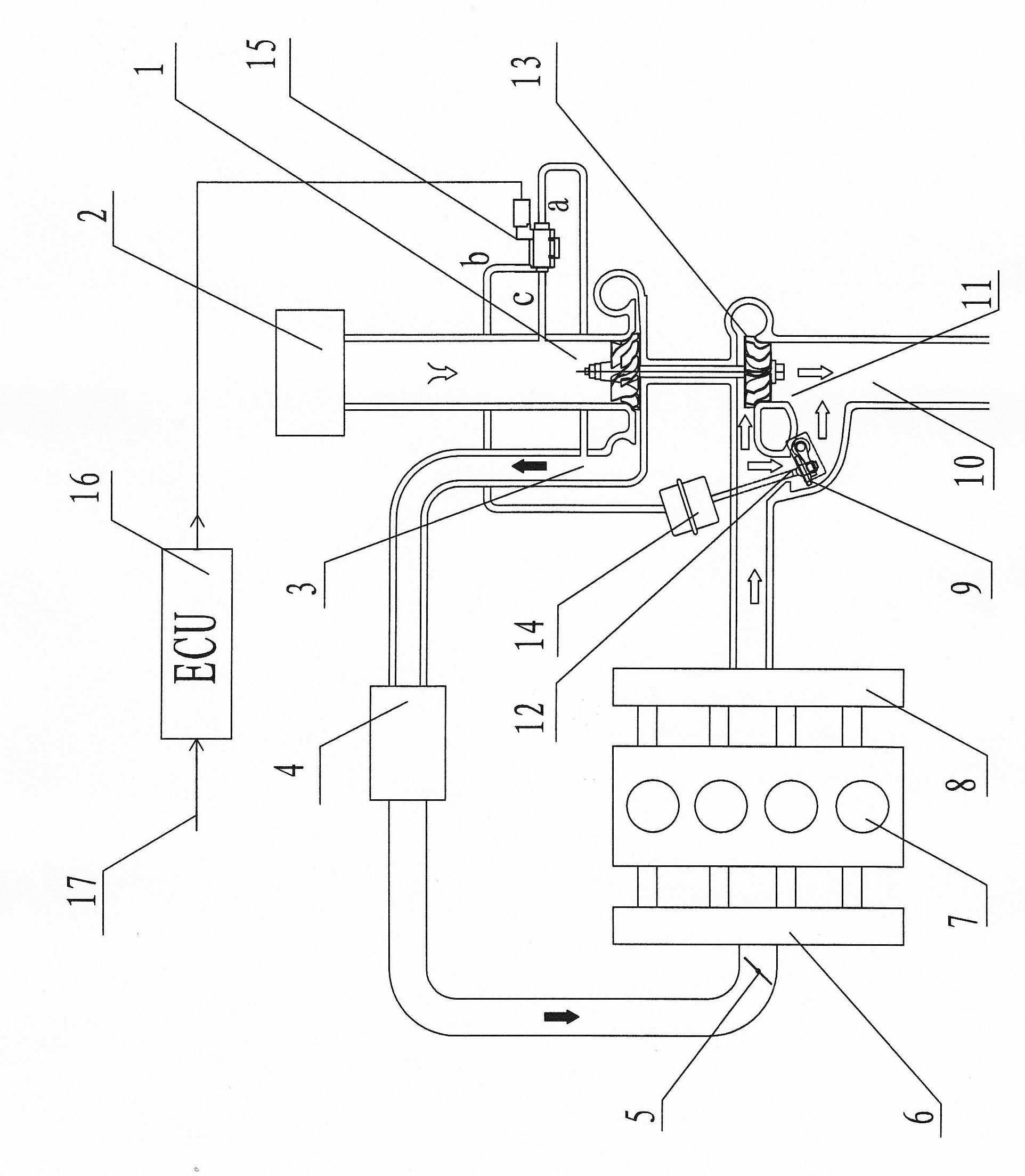

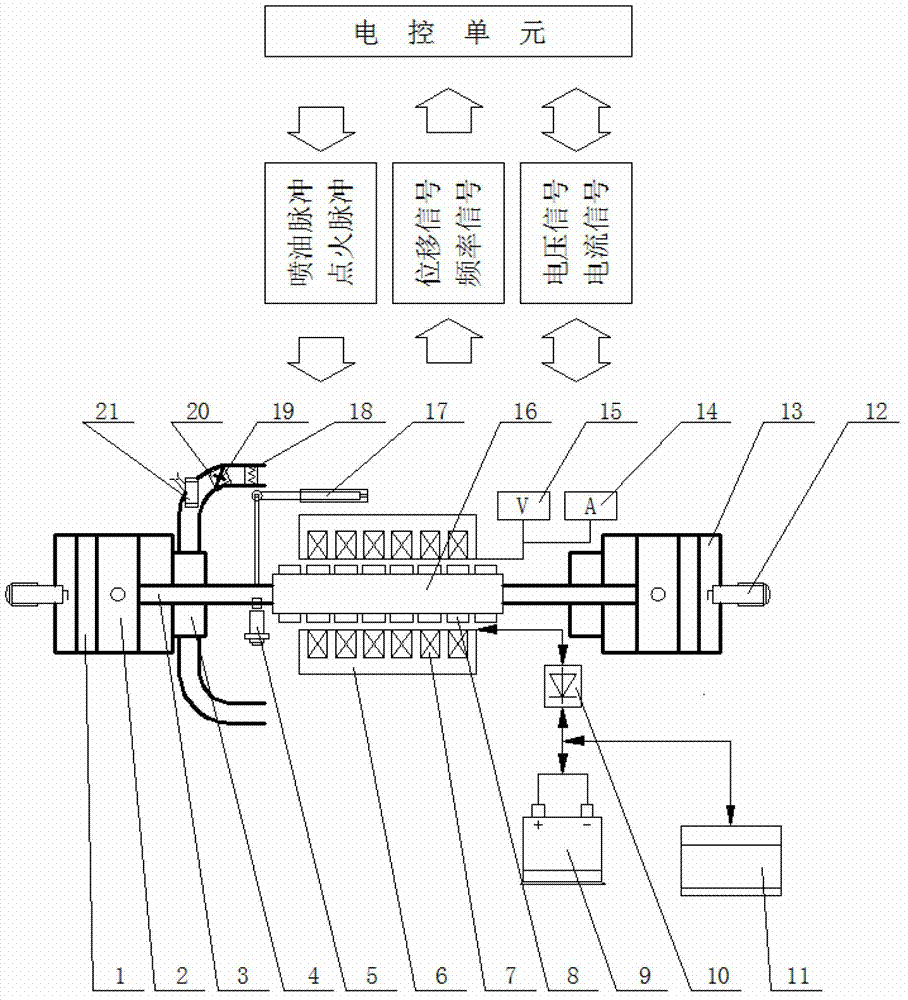

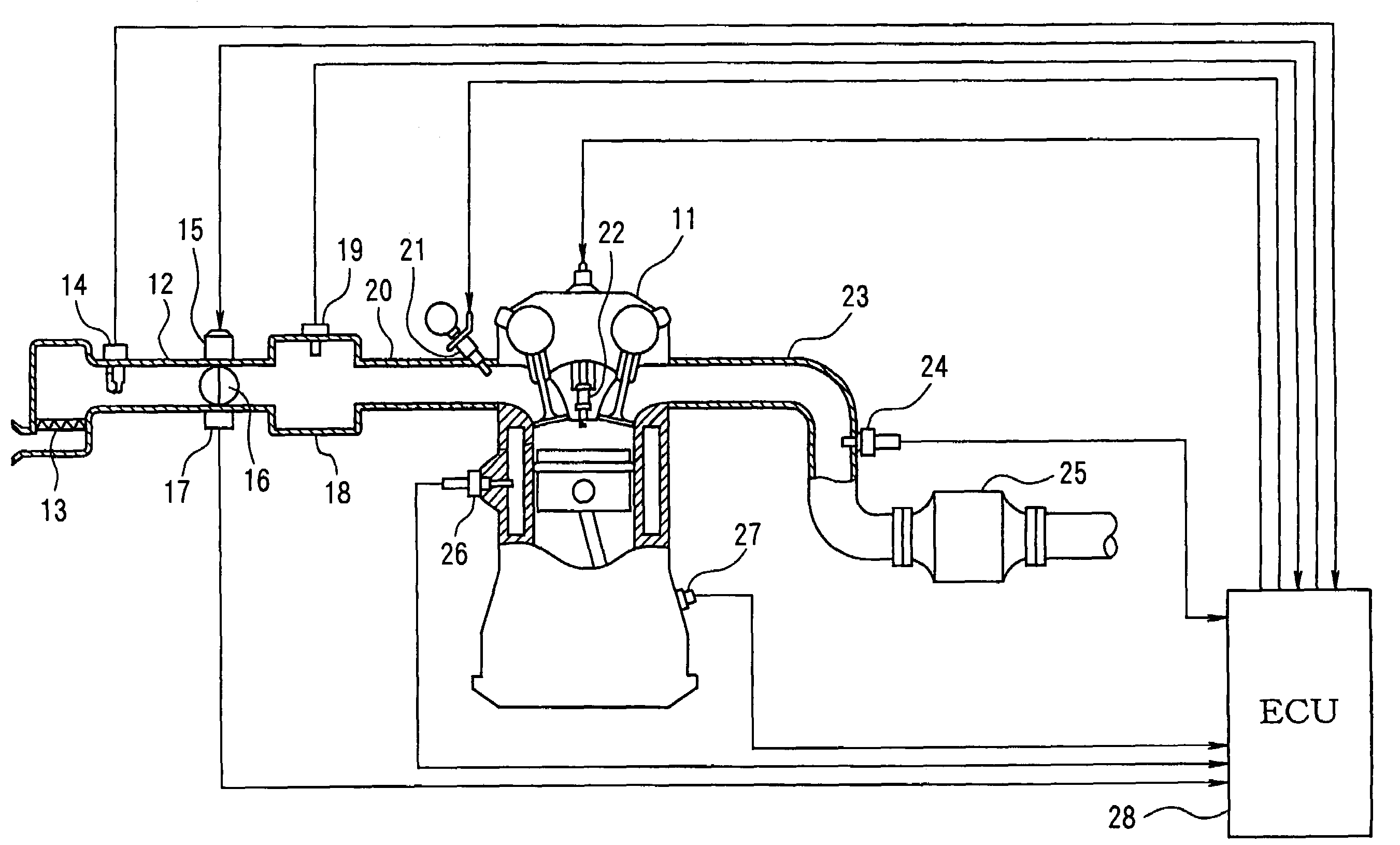

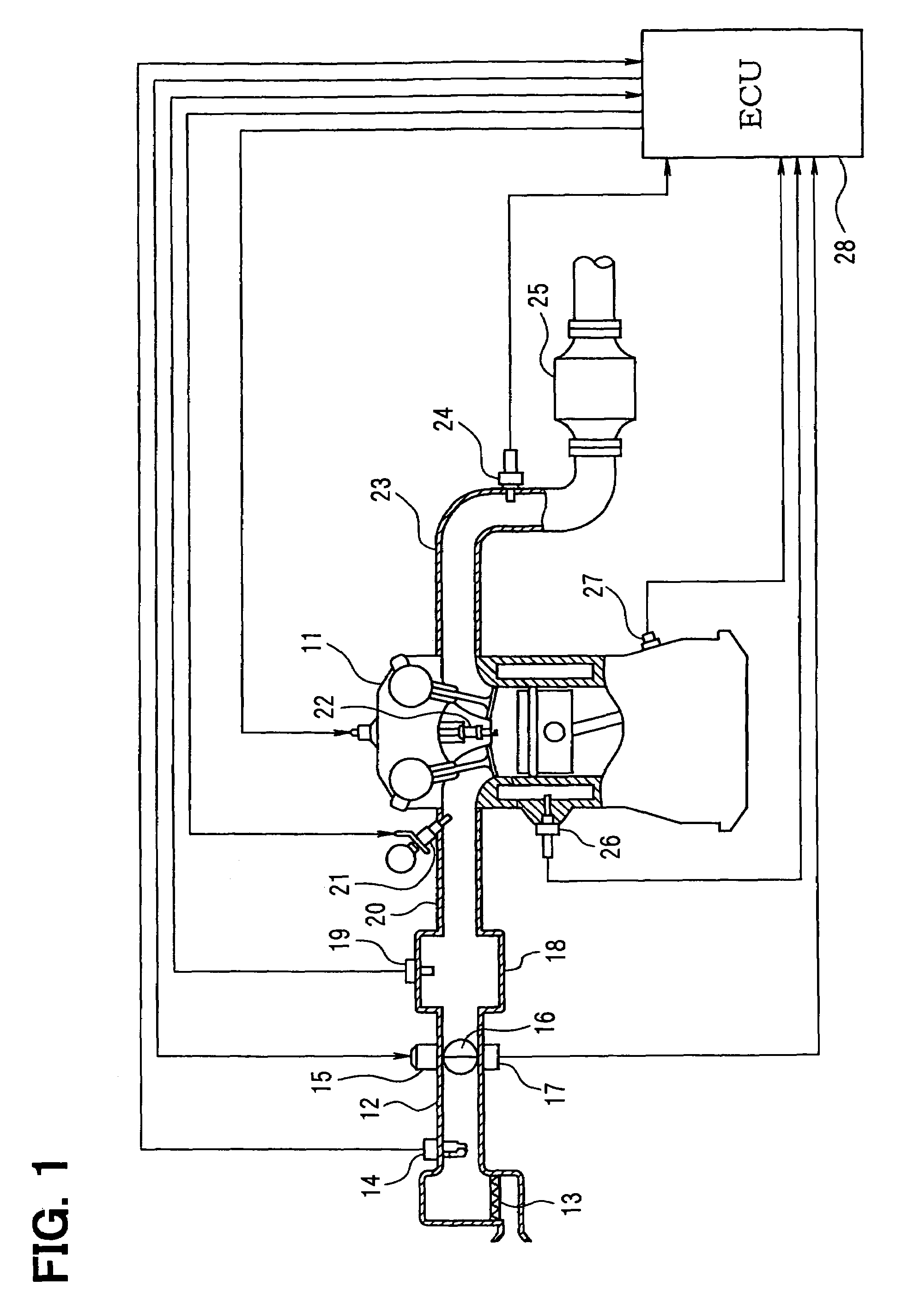

Electric-controlled petrol engine work system

InactiveCN101363380ARich control functionsGood control function integration performanceElectrical controlMachines/enginesIdle speed controlIgnition coil

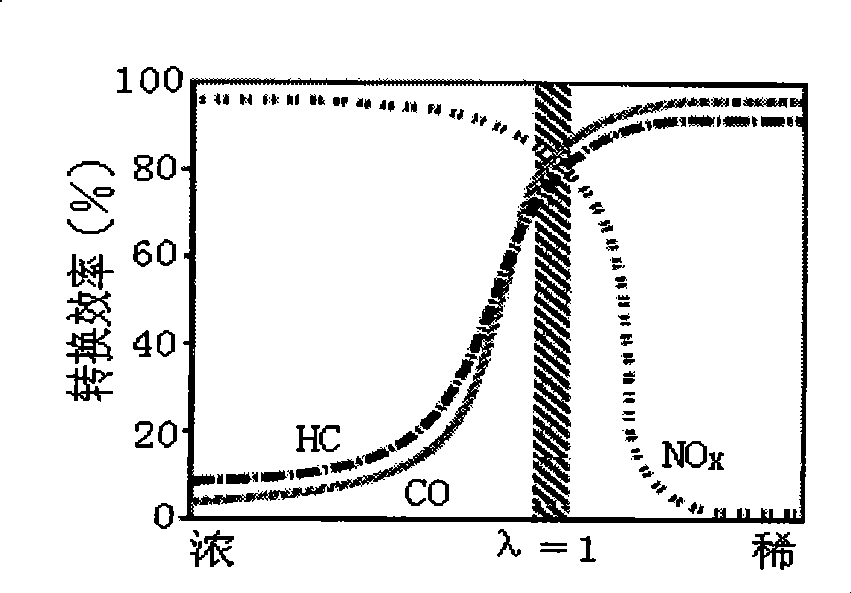

The invention provides a work system of an electronically controlled gasoline engine, comprising an air intake system, a fuel oil supply system, an ignition system as well as an electronic control system; the electronic control system consists of a sensor section, an electronic control unit ECU and an actuator section, wherein, the sensor section includes a throttle position sensor, an intake pressure and temperature sensor and an intake temperature sensor which are arranged on an intake pipe of an intake system, a camshaft position sensor, a coolant temperature sensor and a crankshaft position sensor which are arranged on the engine, a front oxygen sensor arranged in front of a three-way catalyst converter on an exhaust pipe of the engine, and the components of the sensor section are all connected with the ECU, and the actuator section consists of an electric fuel pump, an oil sprayer, an idle speed regulating valve and an ignition coil; the components of the actuator section are all connected with the ECU, and the ECU includes a fuel injection control program, an ignition control program and an idle speed control program; the system adopts reasonable control strategy and has comprehensive control function, good integrated performance of control function and fine system portability.

Owner:张和君 +1

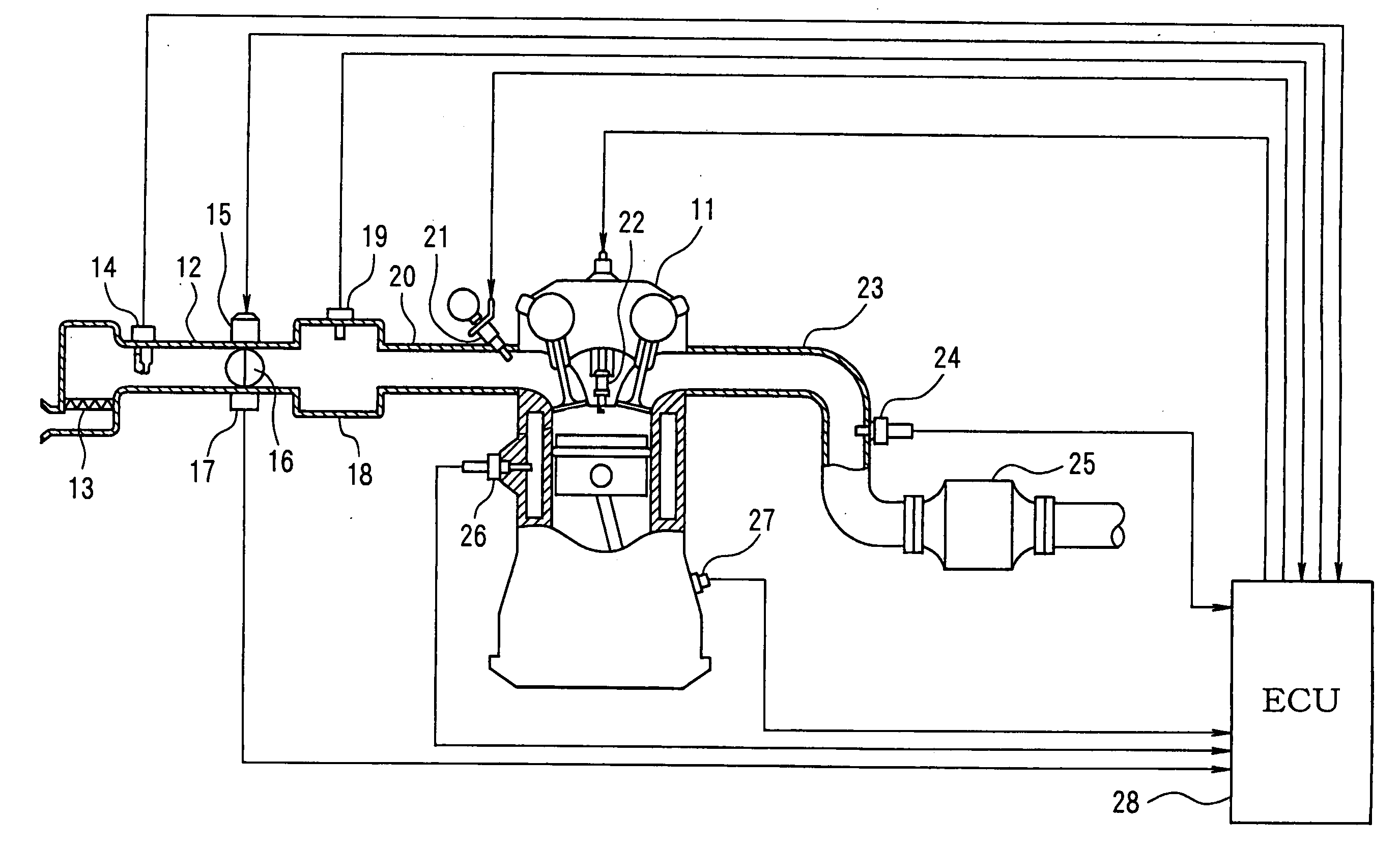

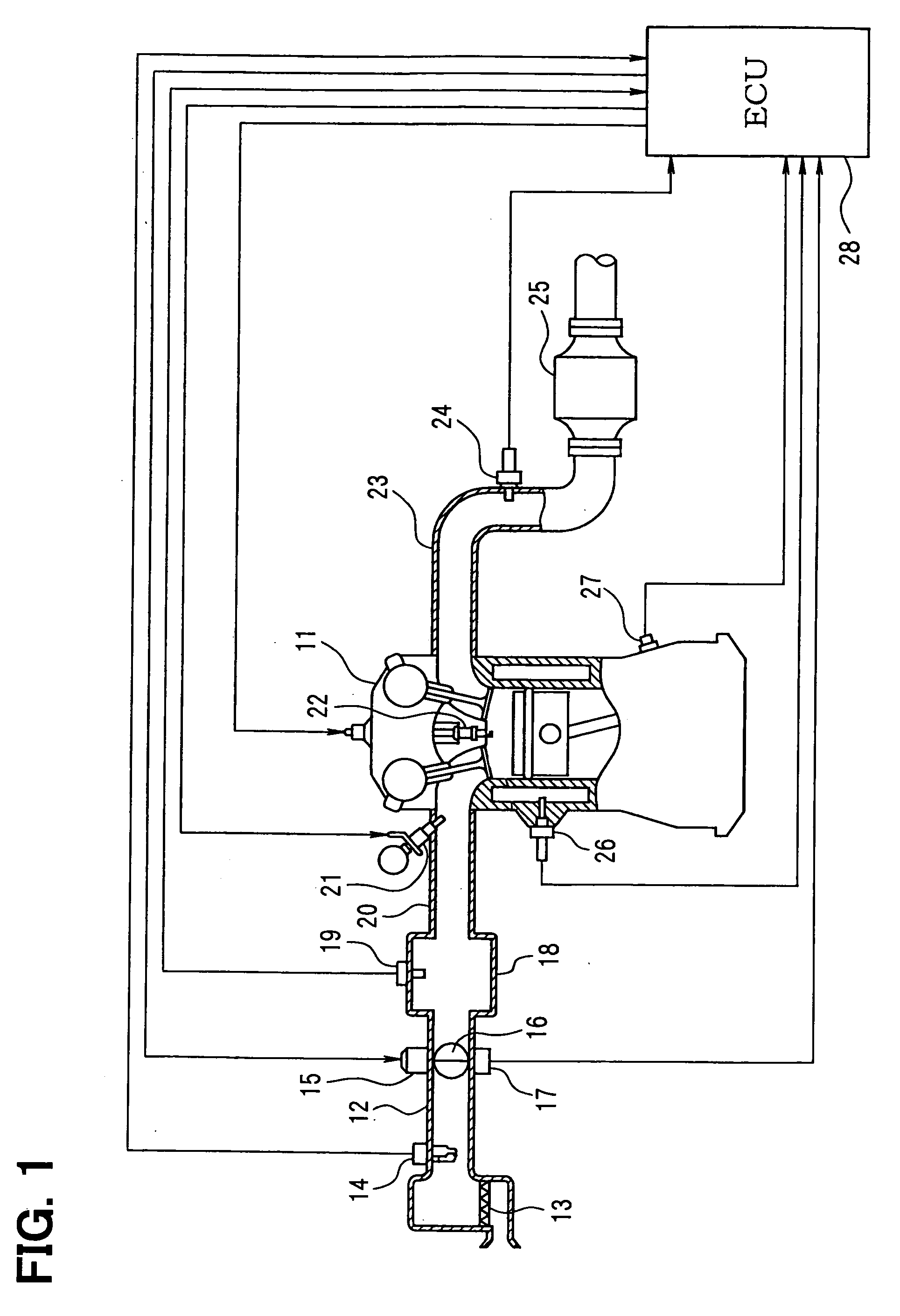

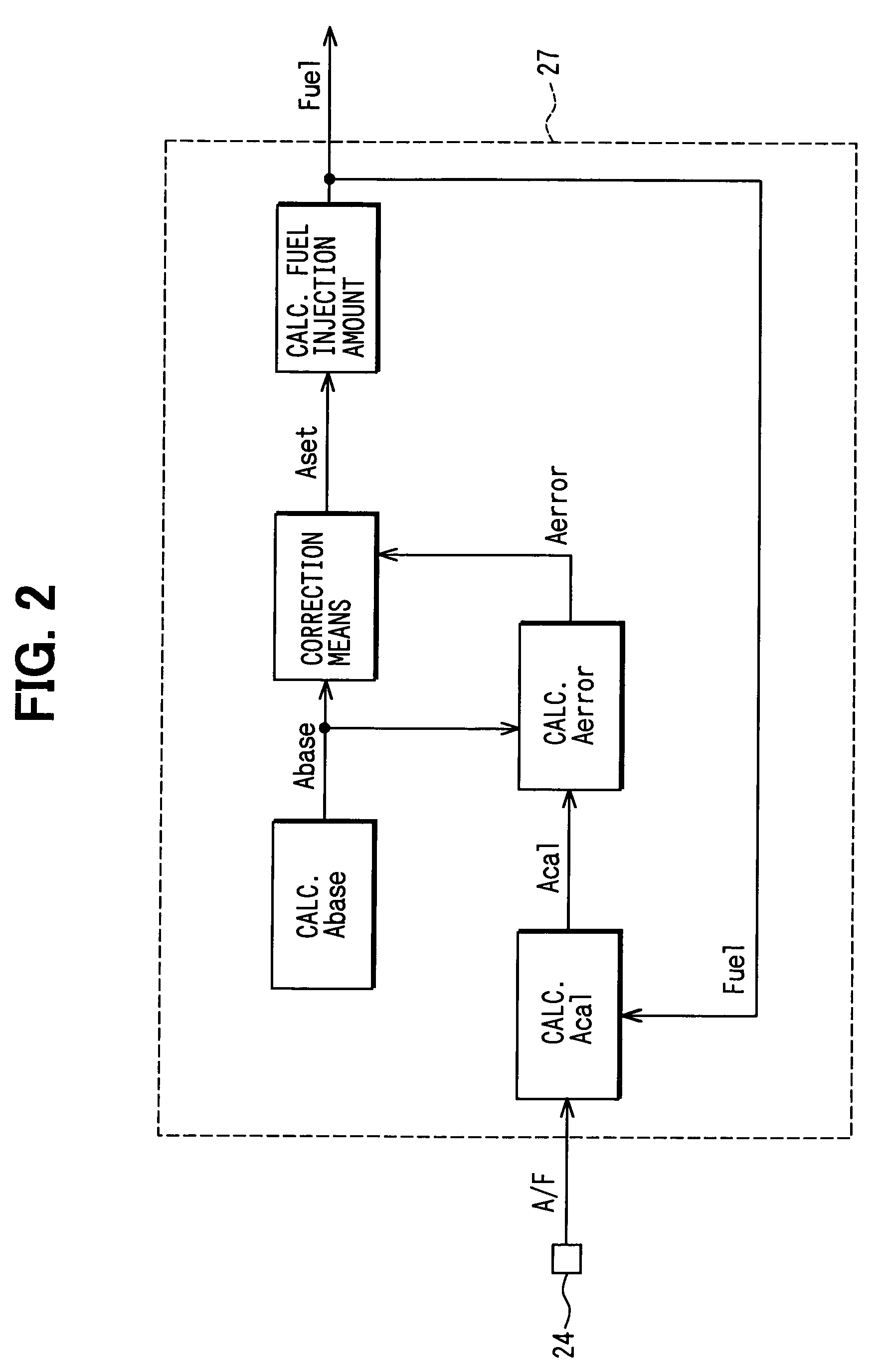

Air-fuel ratio controller for internal combustion engine and diagnosis apparatus for intake sensors

InactiveUS20060005821A1Improve accuracyLimited robustnessElectrical controlEngine testingLow-pass filterThrottle position sensor

A computer calculates an estimated cylinder-intake-air amount based on outputs from an airflow meter and a throttle position sensor, and then calculates a reference cylinder-intake-air amount based on an air-fuel ratio in an exhaust gas and fuel injection amount. An error of the estimated cylinder-intake-air amount is calculated by comparing the reference cylinder-intake-air amount with an estimated cylinder-intake-air amount base value. The error is low-pass filtered. The estimated cylinder-intake-air amount base value is corrected to obtain the final estimated cylinder-intake-air amount.

Owner:DENSO CORP

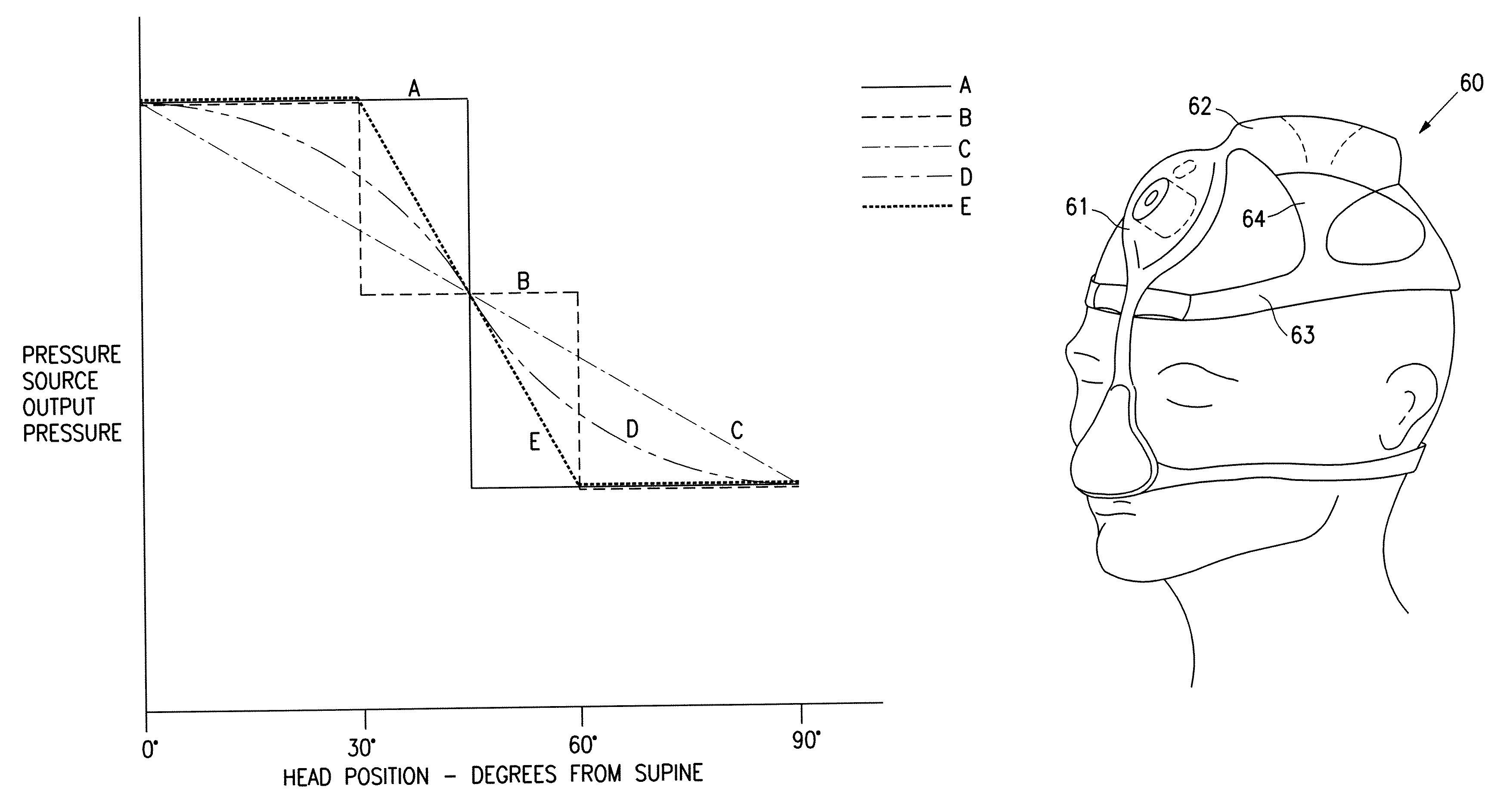

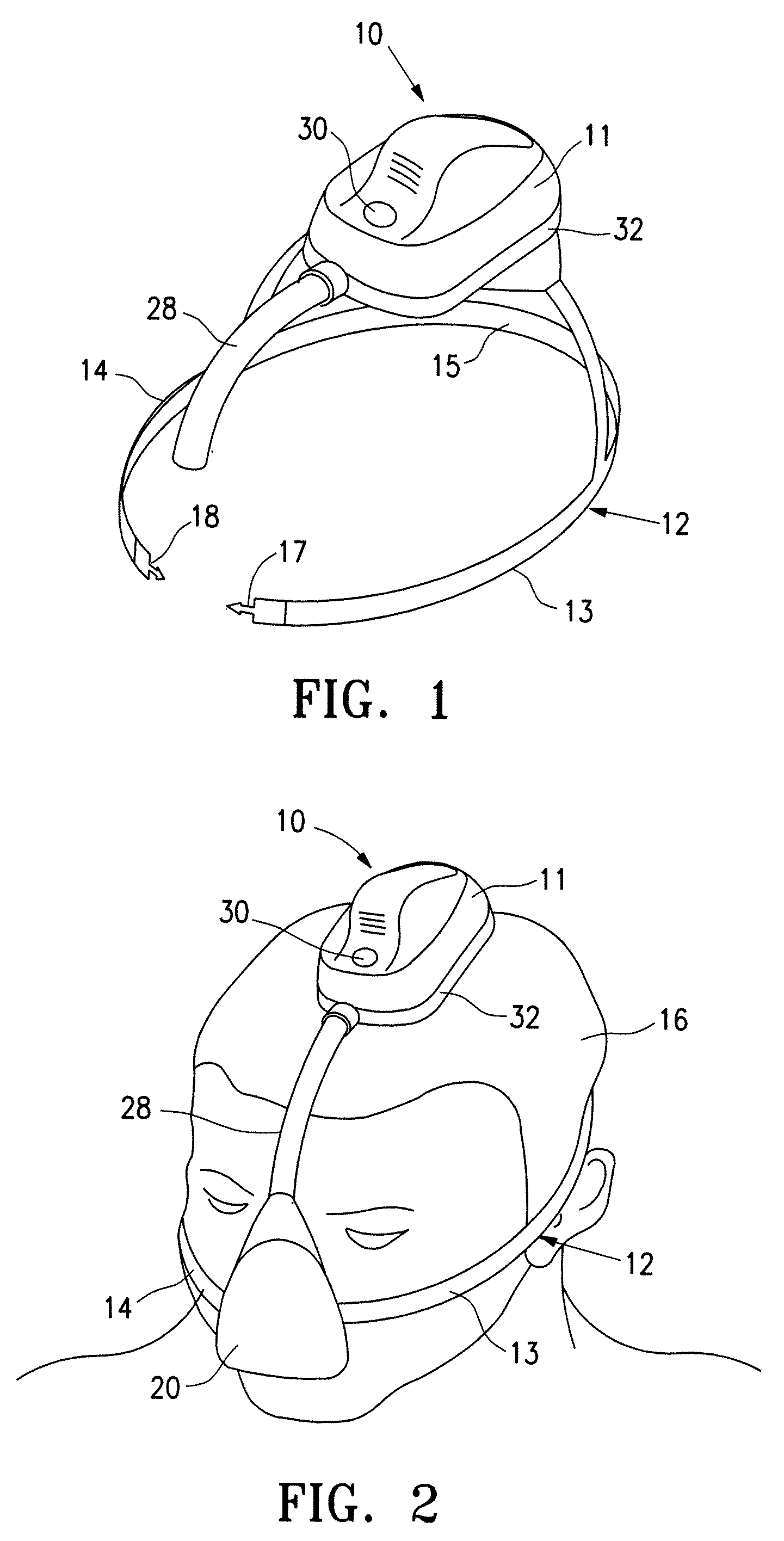

Positive airway pressure system with head position control

ActiveUS8327846B2Control pressureImprove patient comfortRespiratorsOperating means/releasing devices for valvesPositive airway pressureAccelerometer

The invention is directed to a positive airway pressure (PAP) system with a head mounted harness assembly with a housing and a head position sensor located within or secured to the housing that detects the position of a patient's head, and communicates this head position information to a controller of the system which may be disposed within the housing having the position sensor or a second housing. The controller varies the output pressure of the pressure source, e.g. a rotary compressor, based, at least in part, on the head position information provided by the head position sensor. In a preferred embodiment, the position sensor is an accelerometer.

Owner:RESMED INC

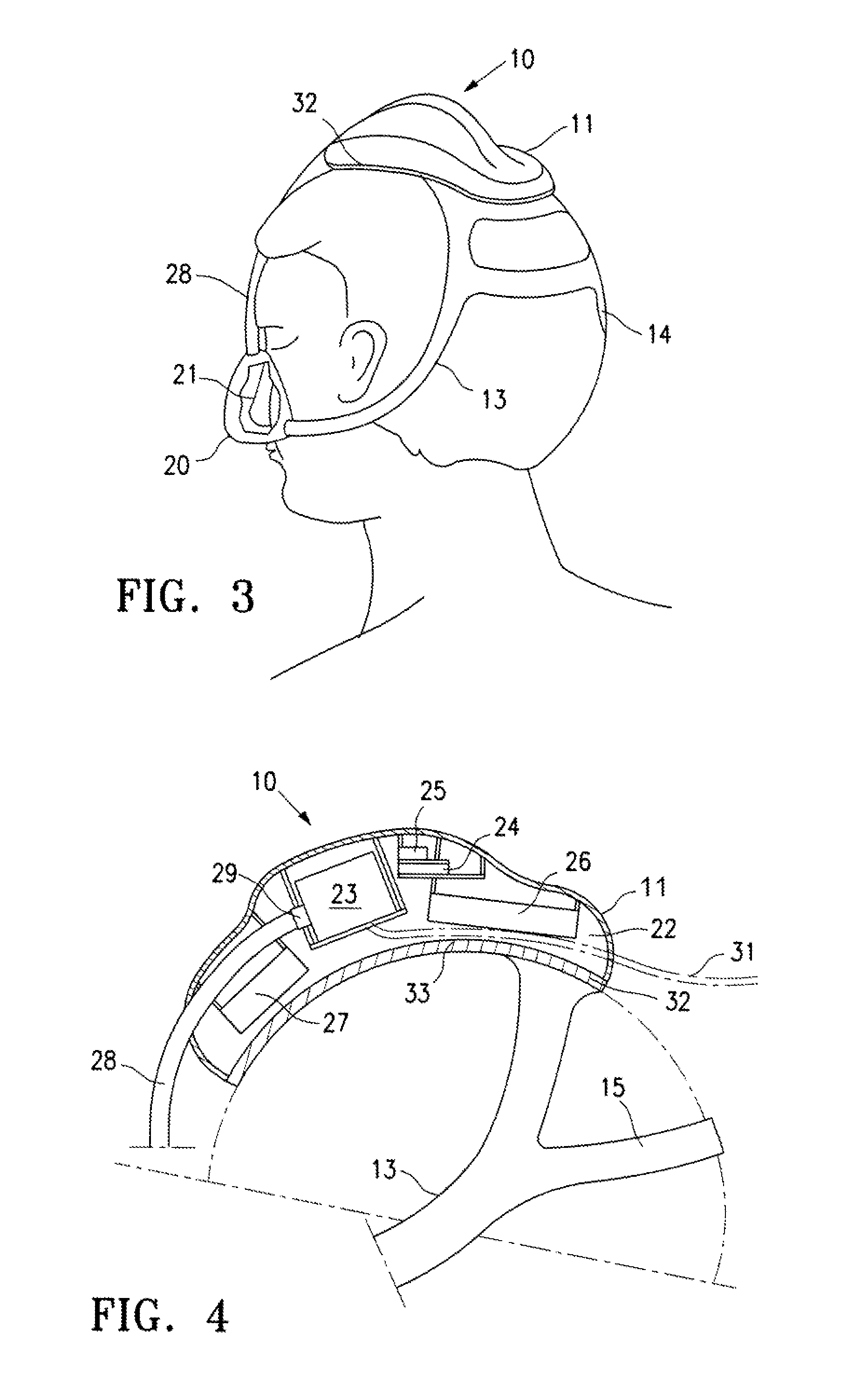

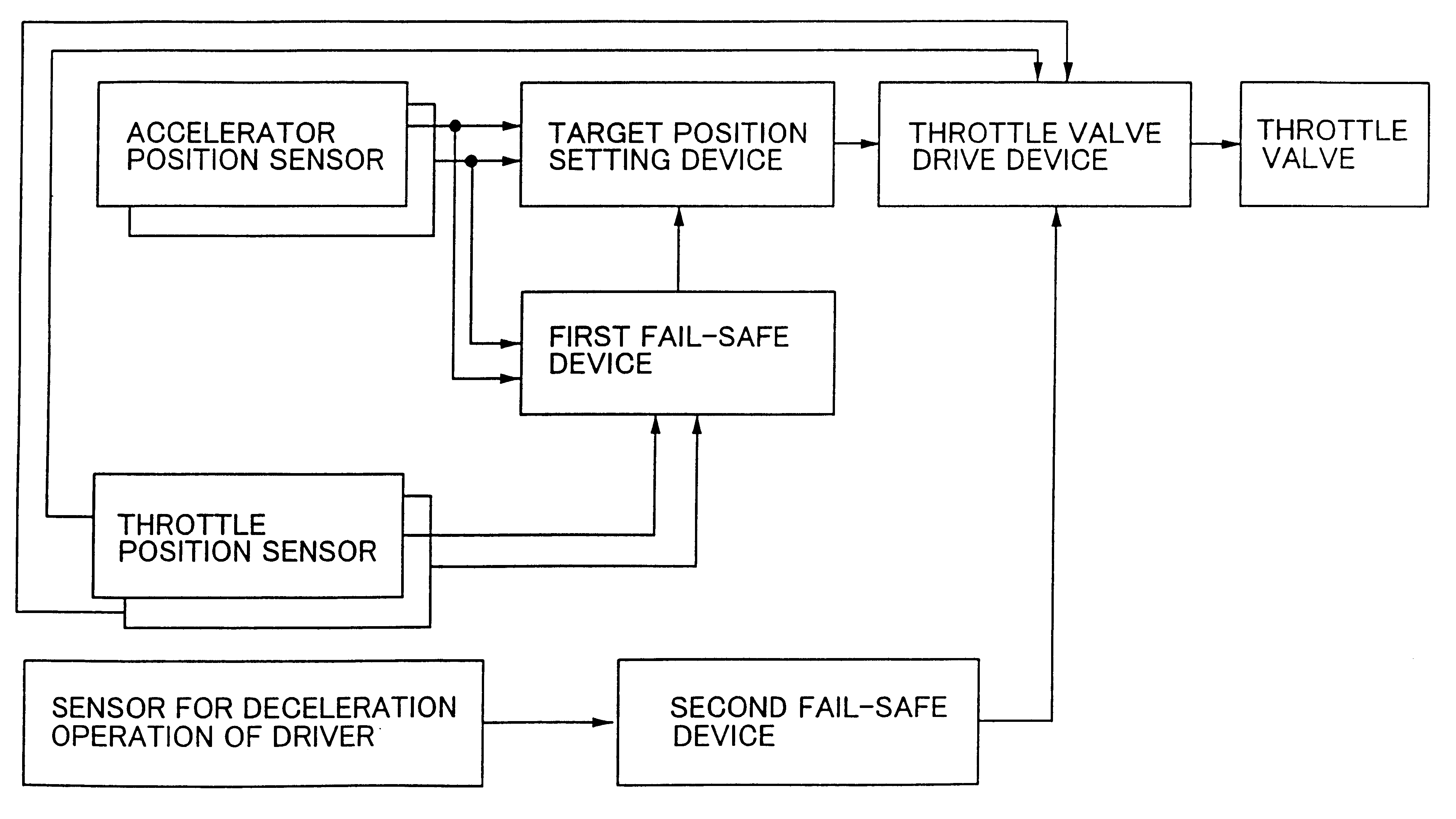

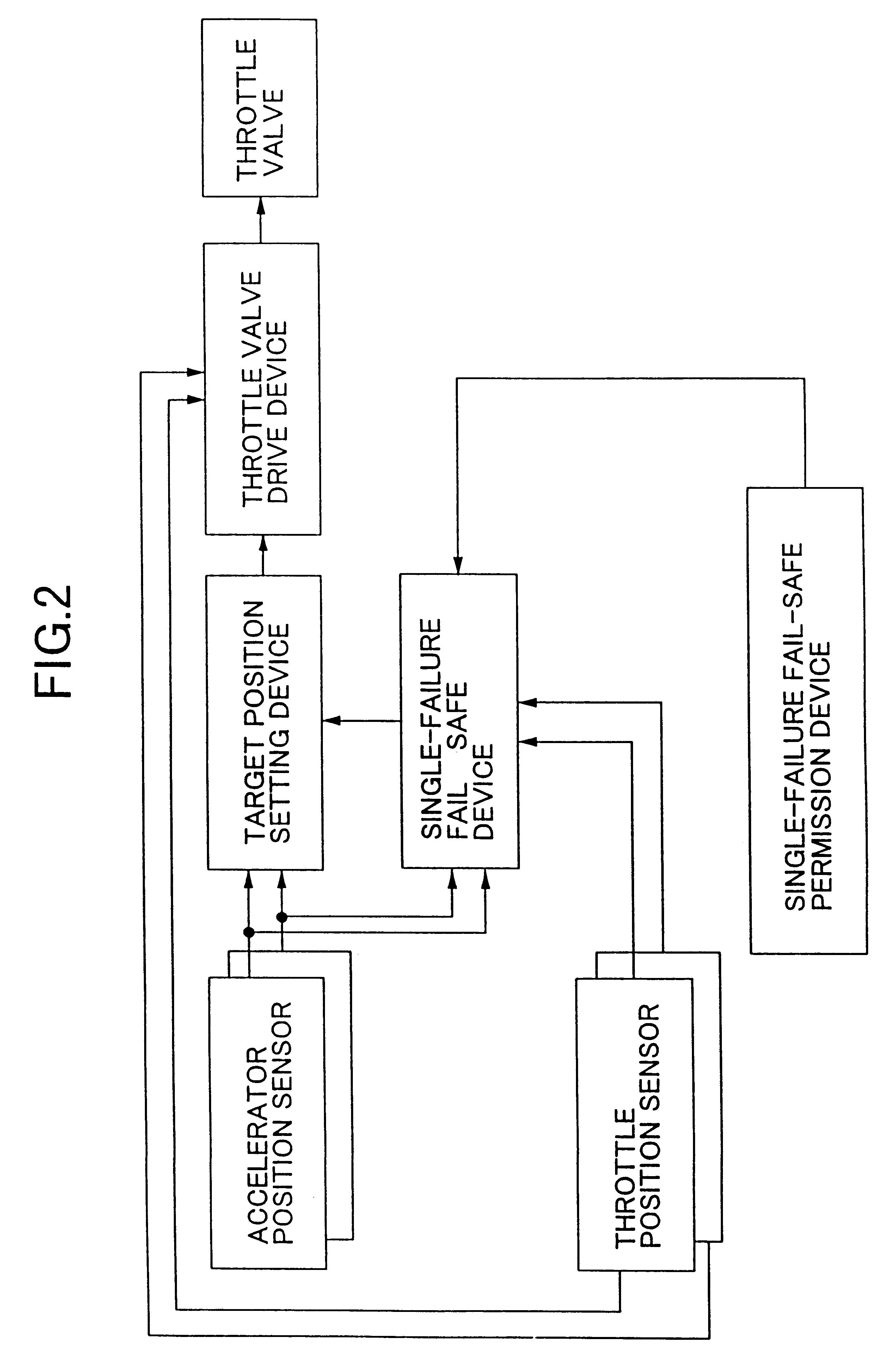

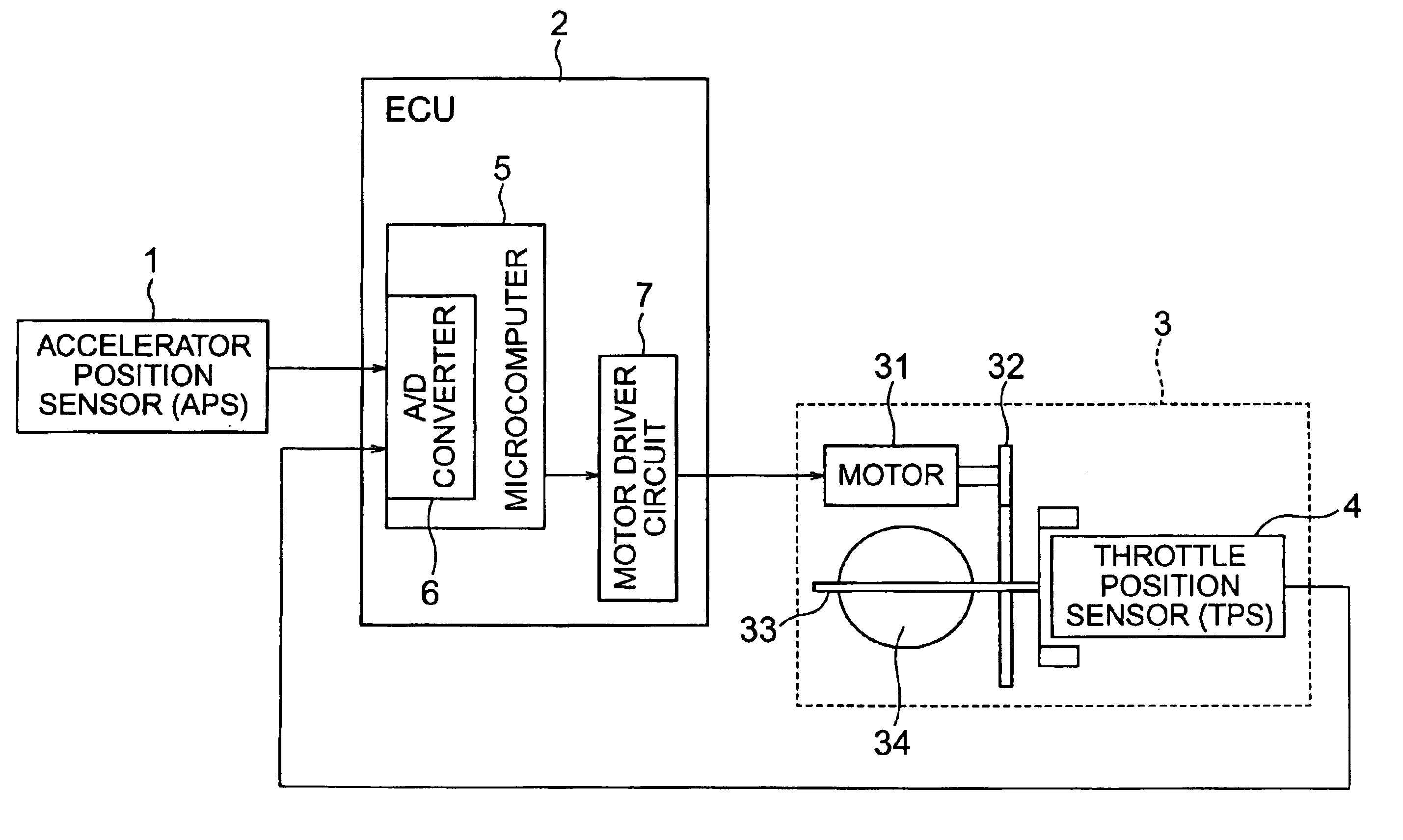

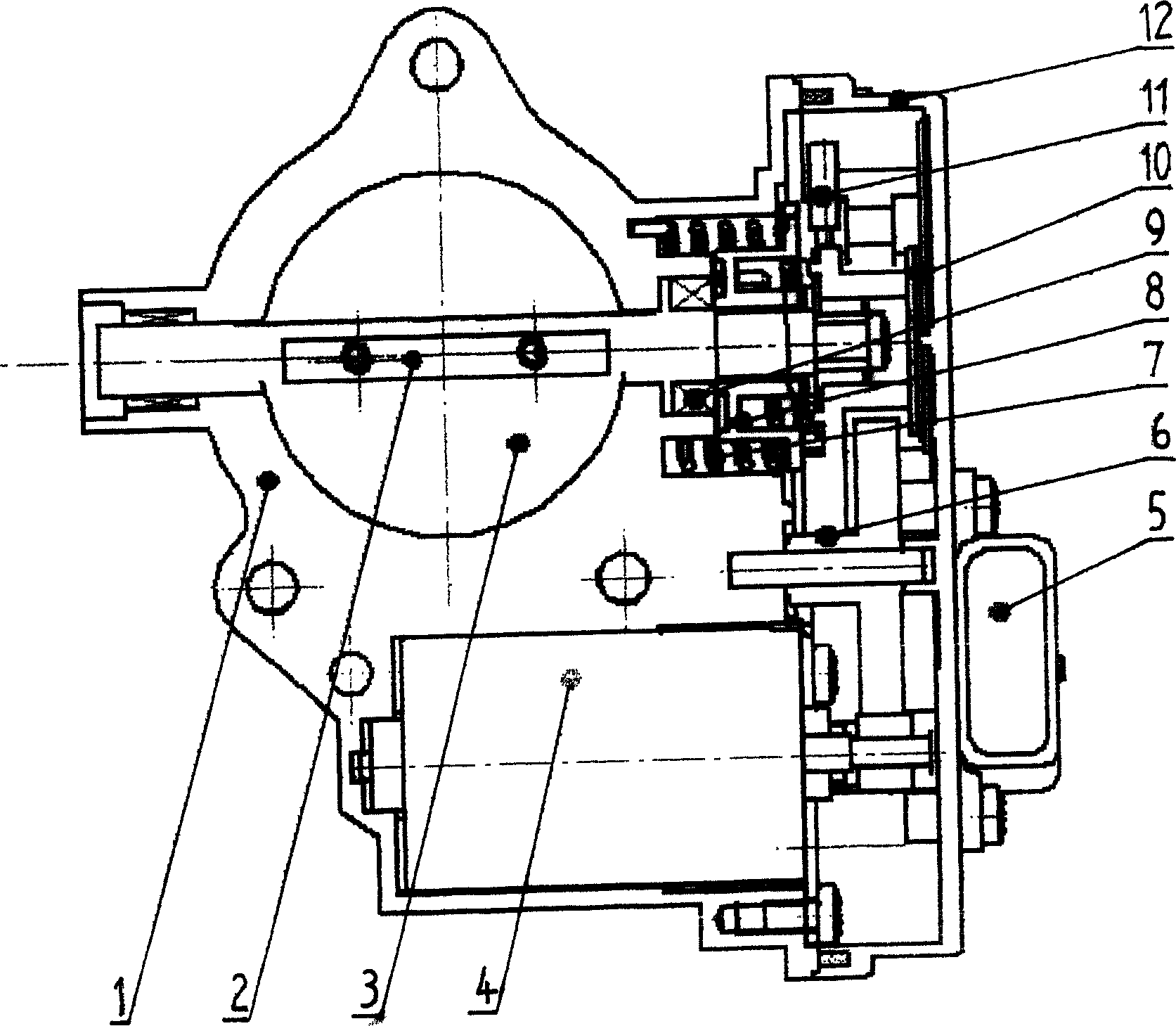

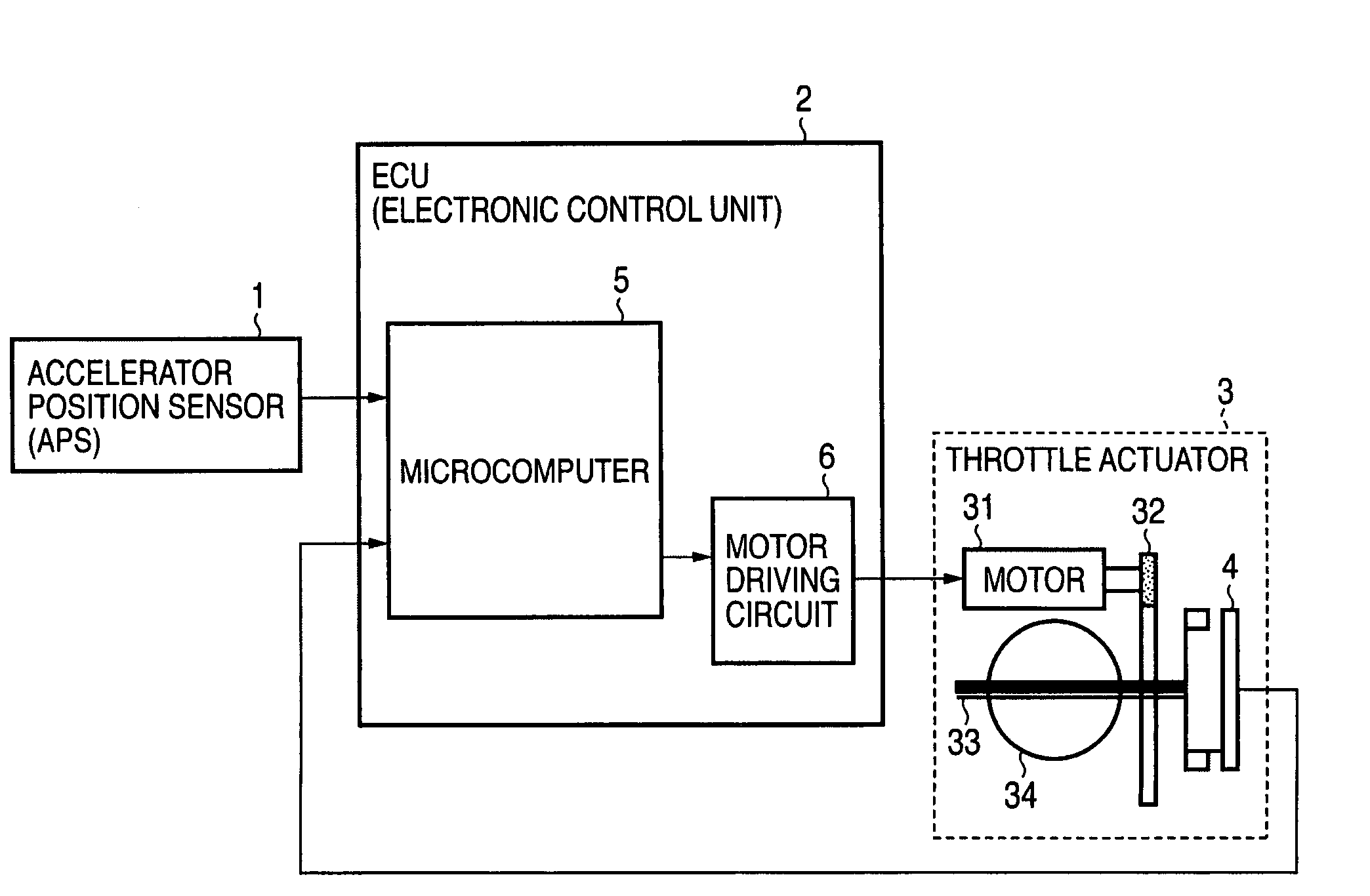

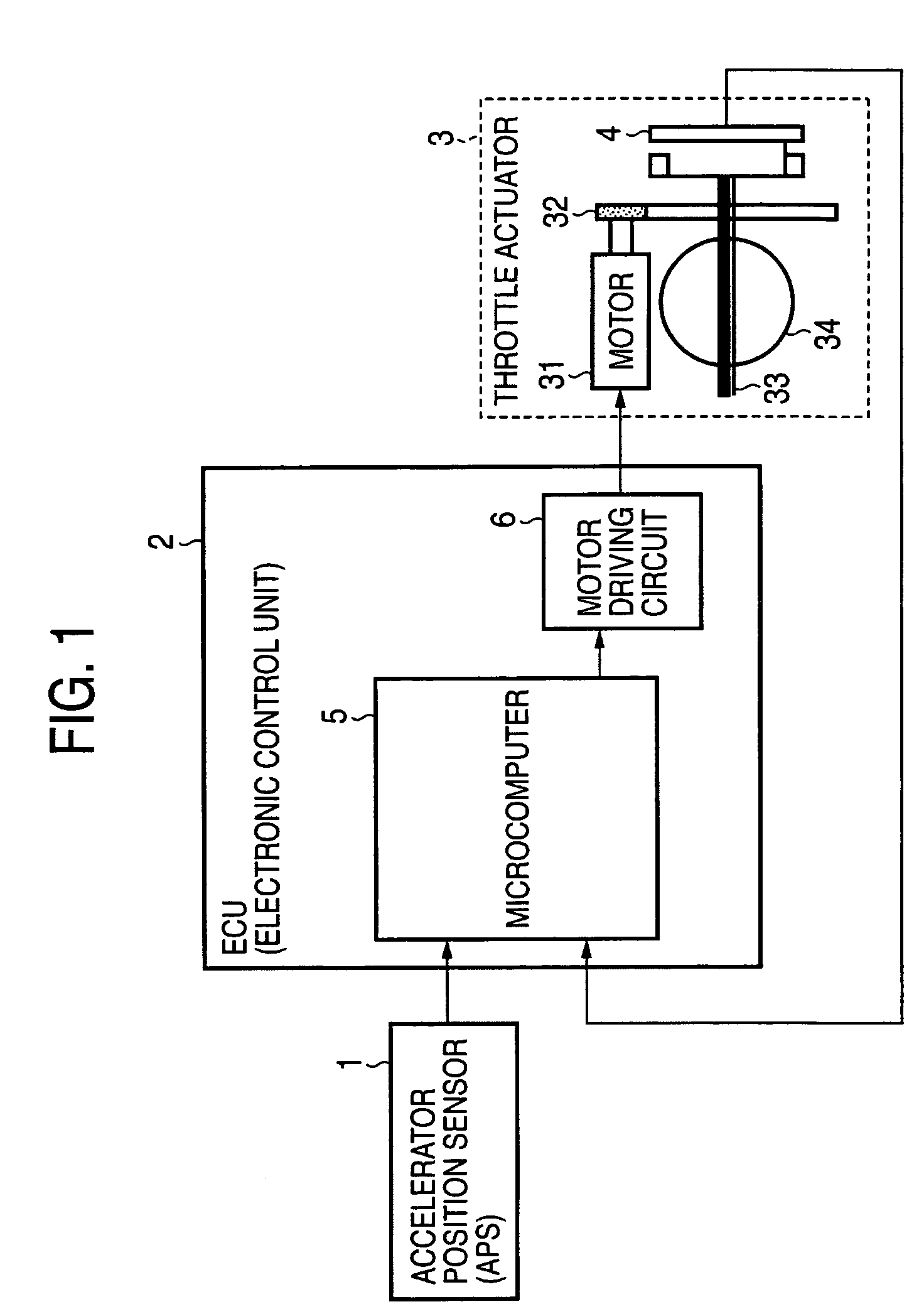

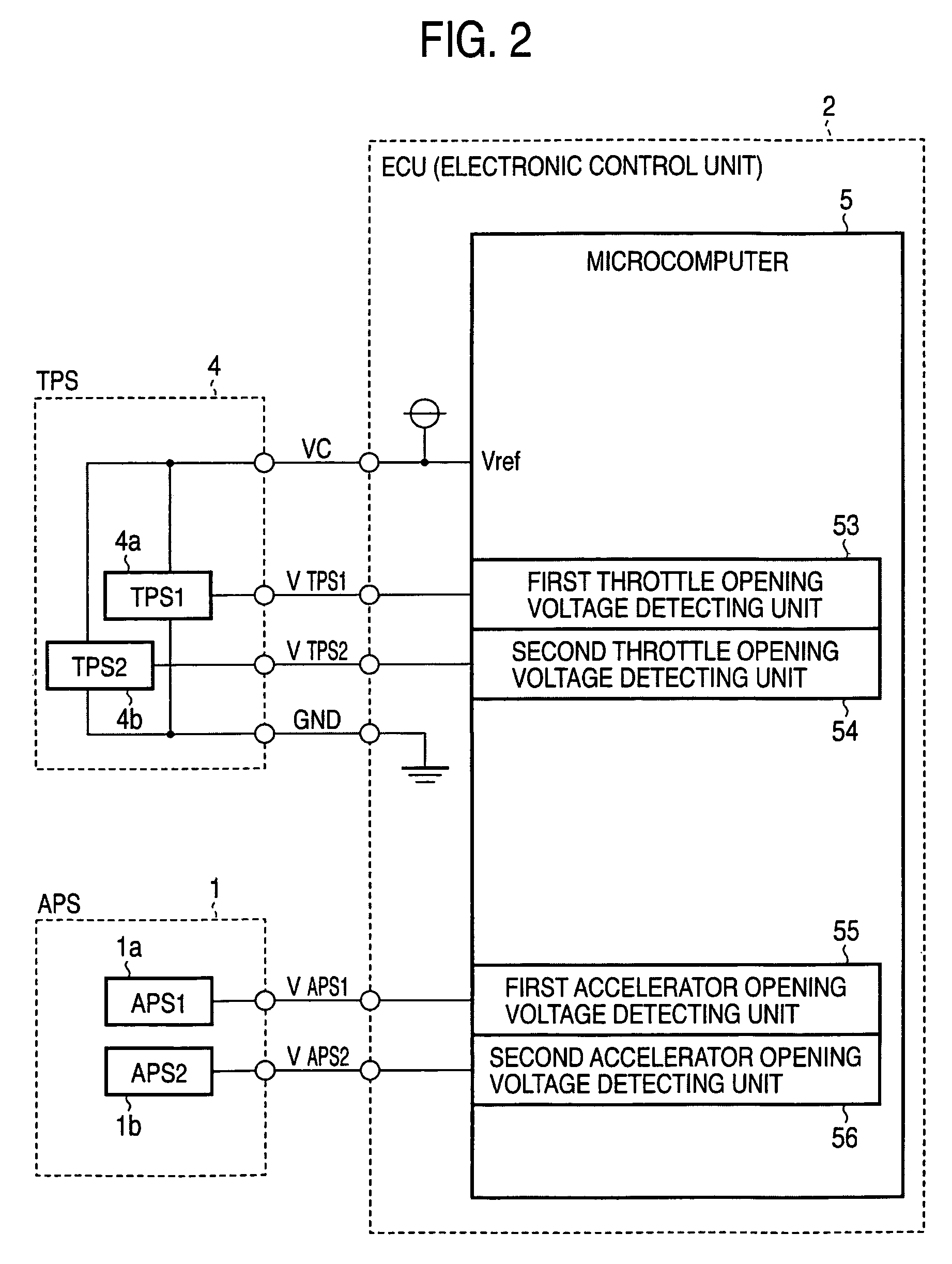

Method and apparatus for fail safe control of an electronically controlled throttle valve of an internal combustion engine

InactiveUS6209518B1Avoid it happening againEliminate failure problemsElectrical controlMachines/enginesLow speedThrottle position sensor

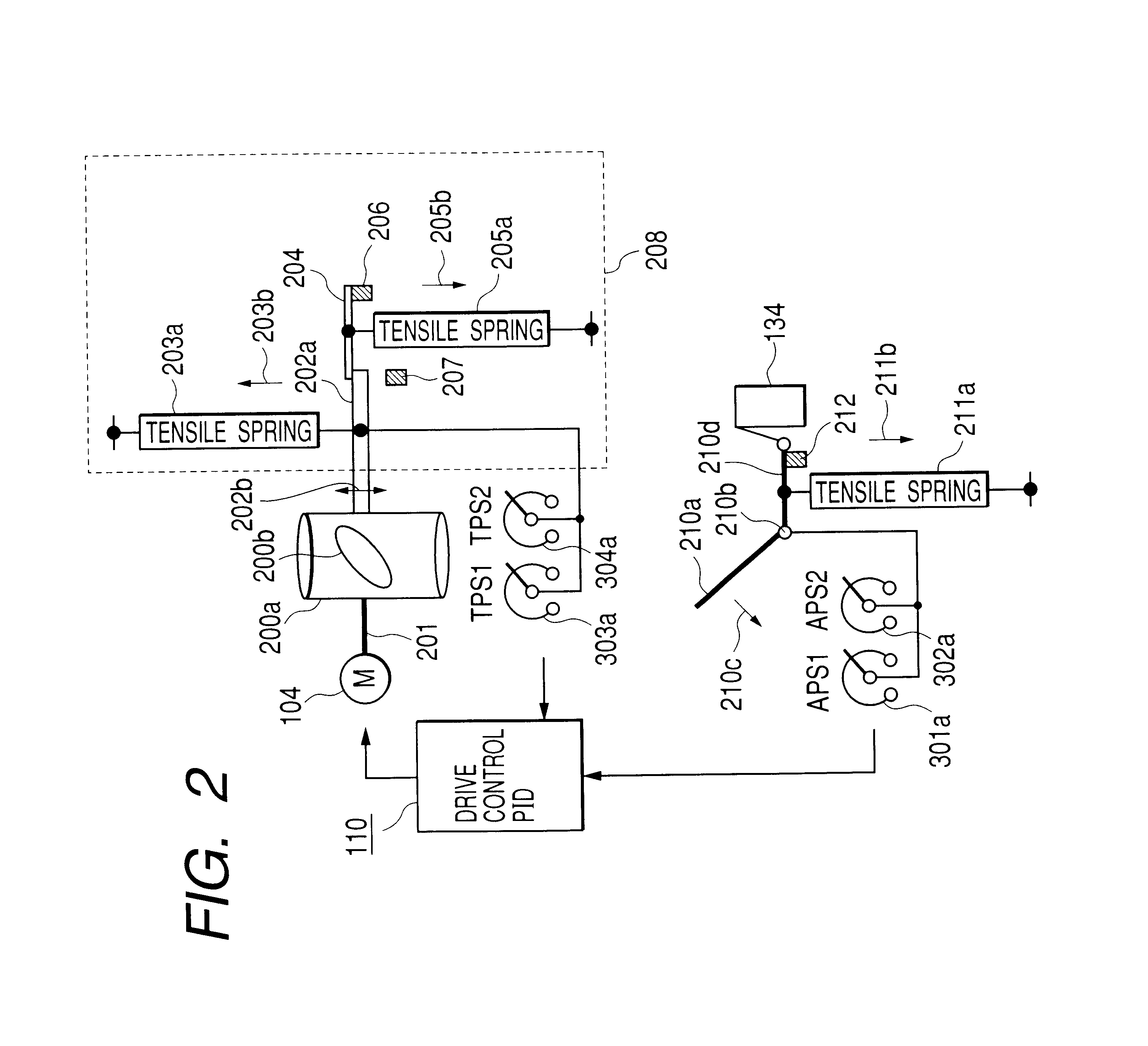

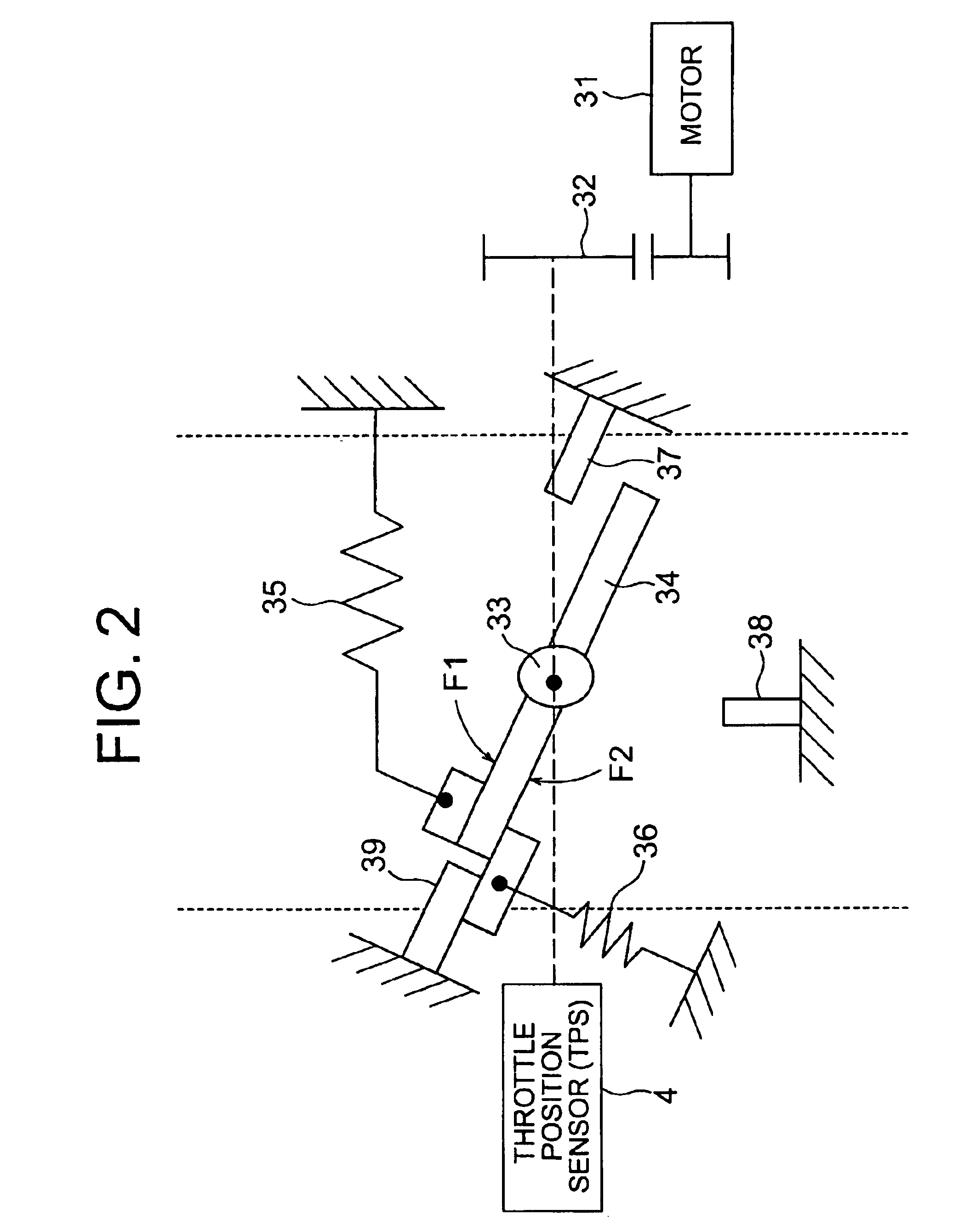

In a method and apparatus for fail-safe controlling an electronically-controlled throttle-type internal combustion engine, provision is made of two accelerator position sensors and two throttle position sensors. When either one of the two accelerator position sensors or either one of the two throttle position sensors fails to operate, a low-speed fail-safe operation of a minimum compensation, that is, an operation for maintaining a minimum output required for limp-home control operation of the engine, is executed and, then, a first fail-safe control operation is executed for controlling the position of the throttle valve using a value detected by the remaining sensor. Therefore, the throttle valve is not unintentionally opened, and the operation can be smoothly shifted to the first fail-safe control operation. When the operation for decelerating the engine is detected by a sensor of a system separate from the above-mentioned sensors, the first fail-safe control operation is interrupted and, instead, a second fail-safe control operation is executed for holding the throttle valve at a predetermined position in order to assure the low-speed fail-safe operation of the minimum compensation.

Owner:UNISIA JECS CORP +1

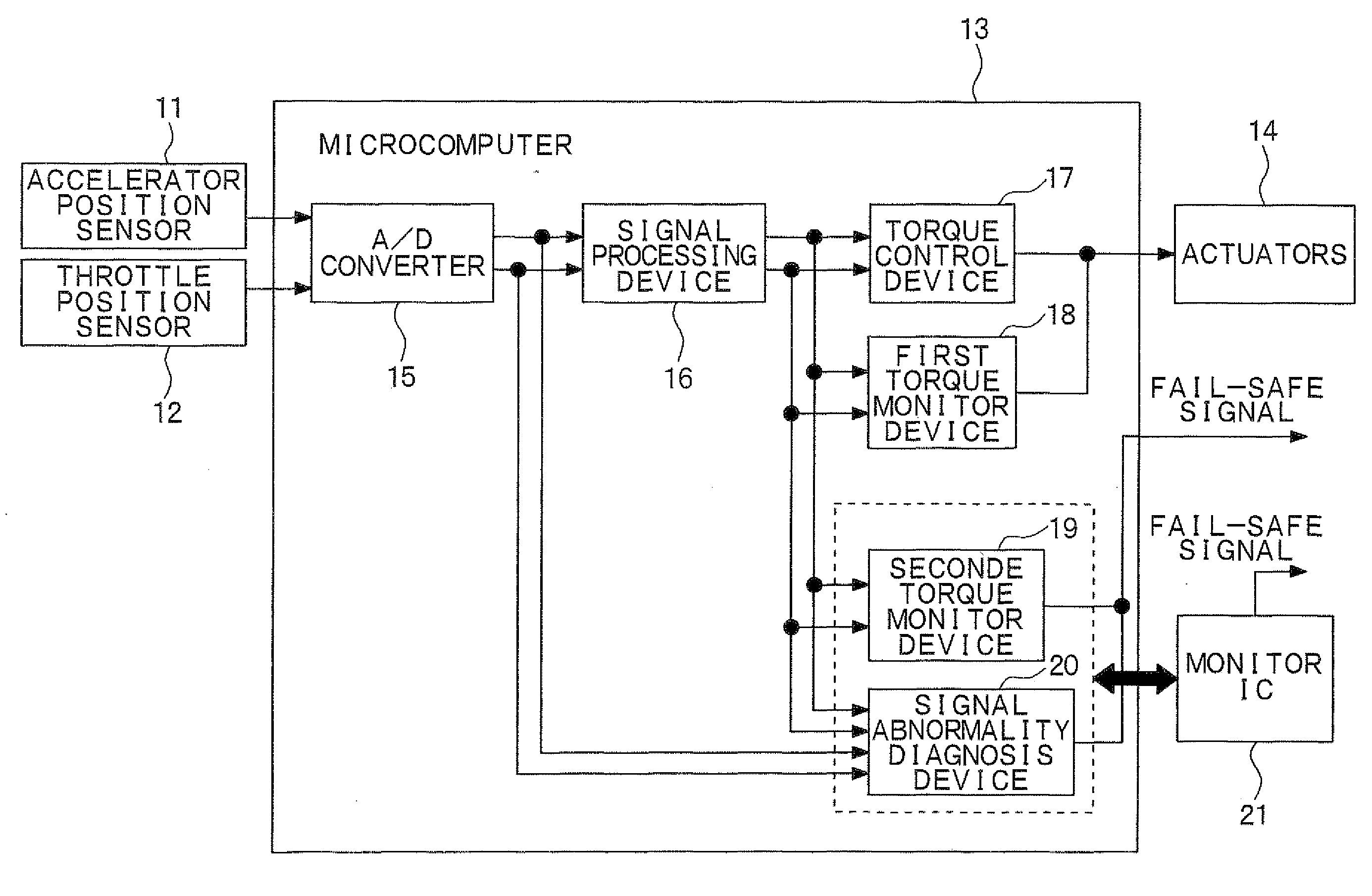

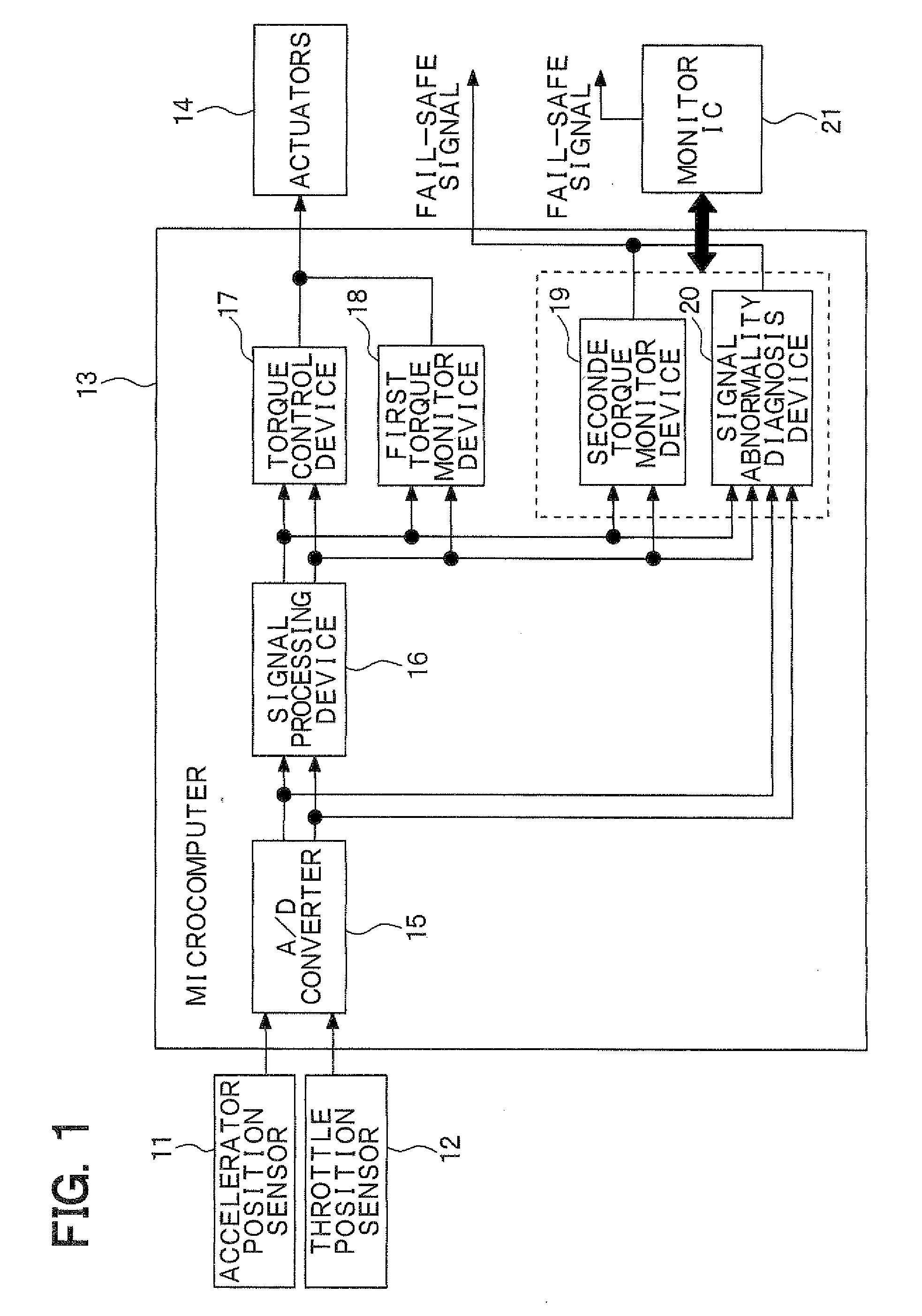

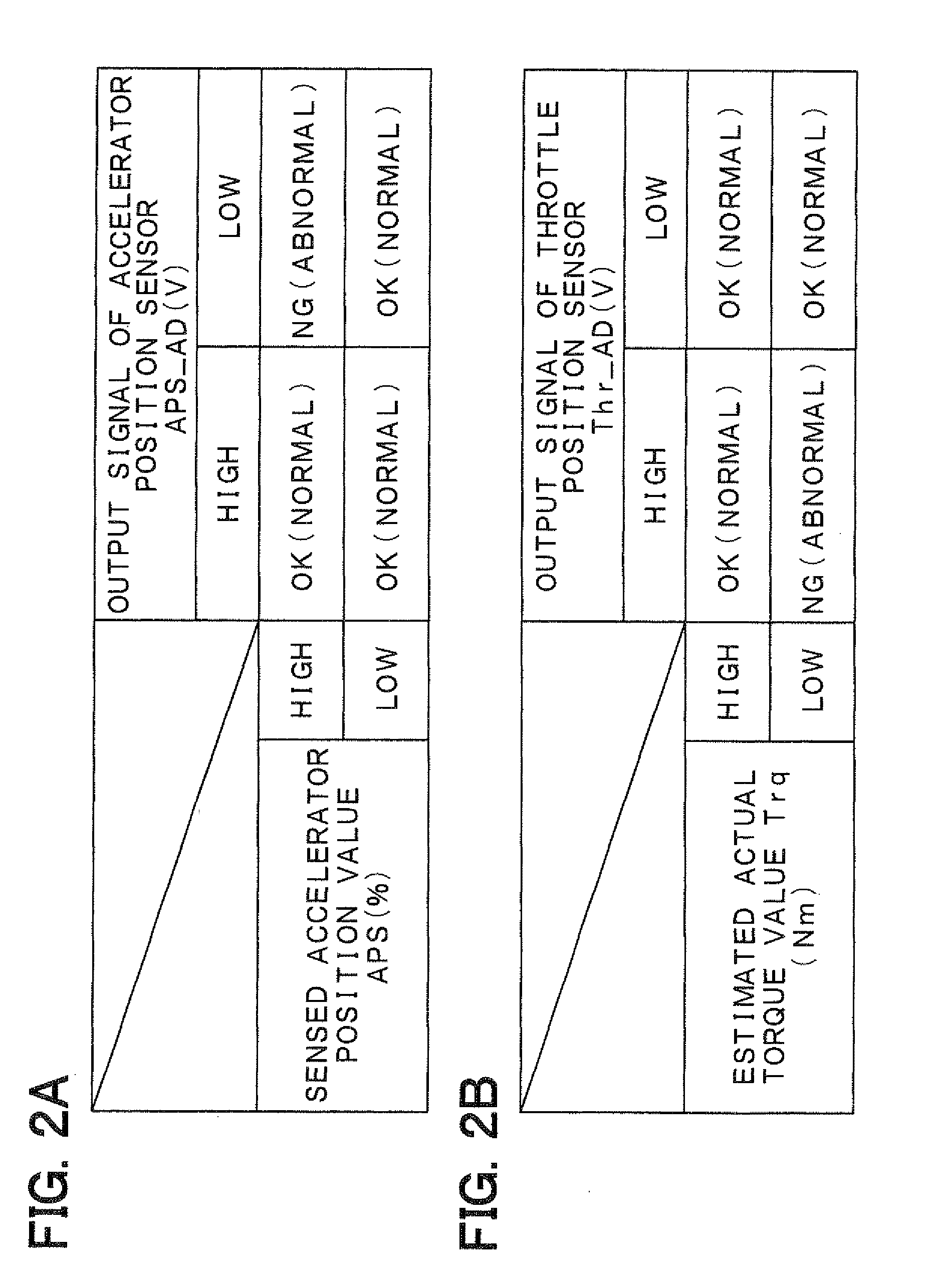

Control apparatus for vehicle

ActiveUS20100036558A1Low costGuaranteed uptimeVehicle testingElectrical controlMicrocomputerControl signal

In a microcomputer, a signal processing device computes a control signal, such as an accelerator position, a throttle position, based on a sensor output signal, such as an output signal of an accelerator position sensor, an output signal of a throttle position sensor. A torque control device executes a torque control operation to coincide an actual torque with a requested torque based on the control signal. Furthermore, a torque monitor device determines whether a torque increase abnormality exists based on the control signal. A signal abnormality diagnosis device determines whether an operational abnormality of the signal processing device exists based on a relationship between the sensor output signal and the control signal. A monitor IC monitors operational states of the torque monitor device and of the signal abnormality diagnosis device and determines whether an operational abnormality of the torque monitor device or of the signal abnormality diagnosis device exists.

Owner:DENSO CORP

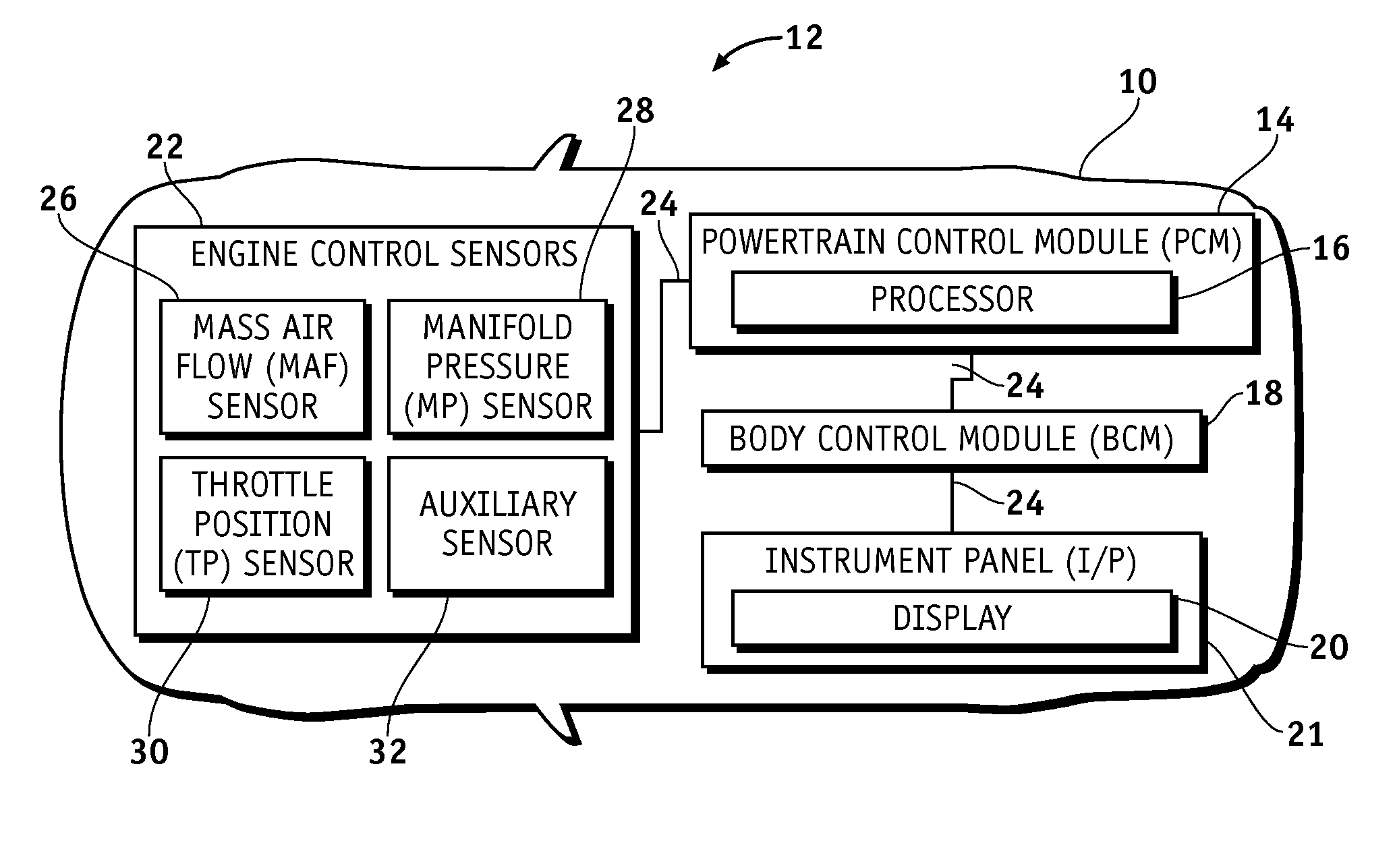

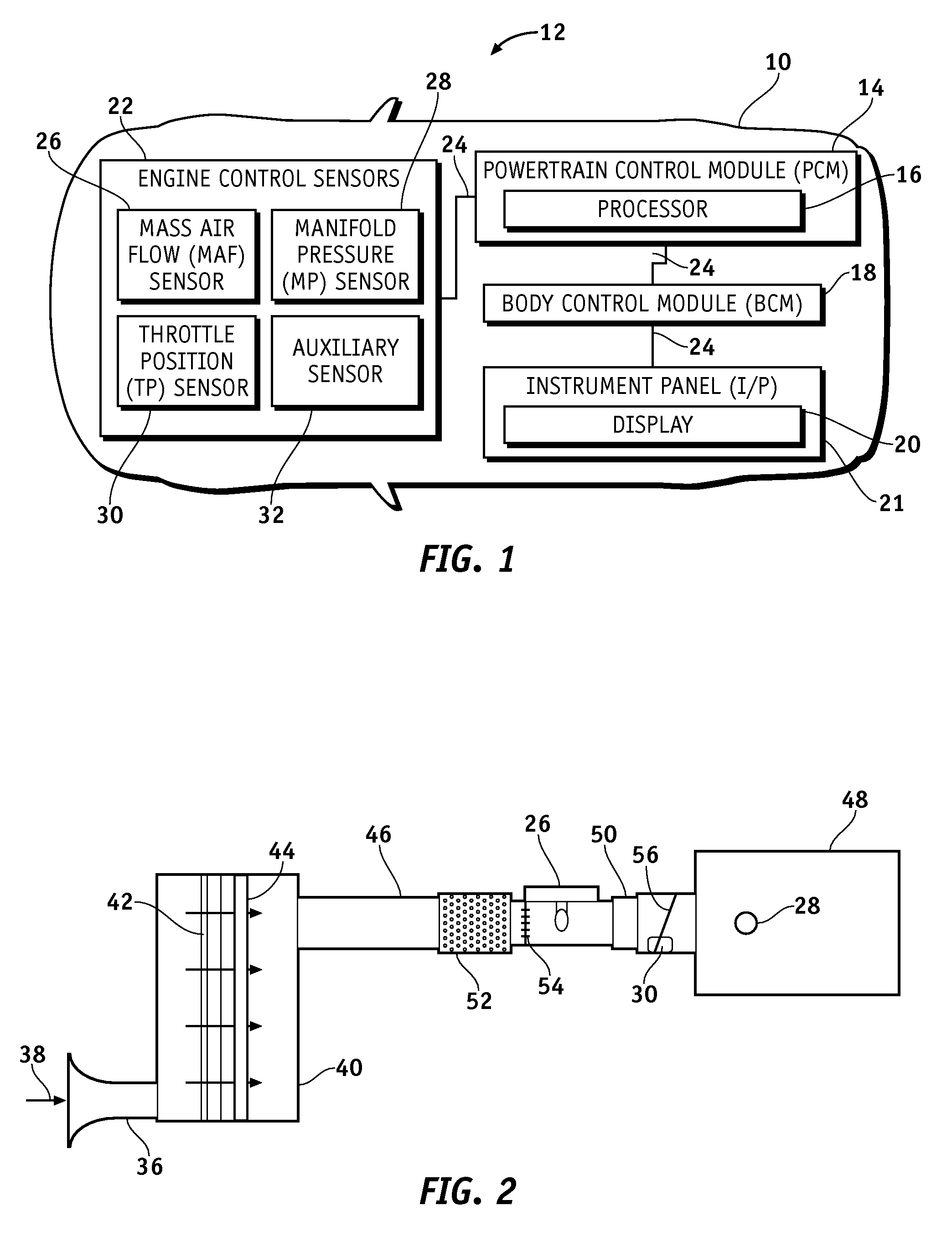

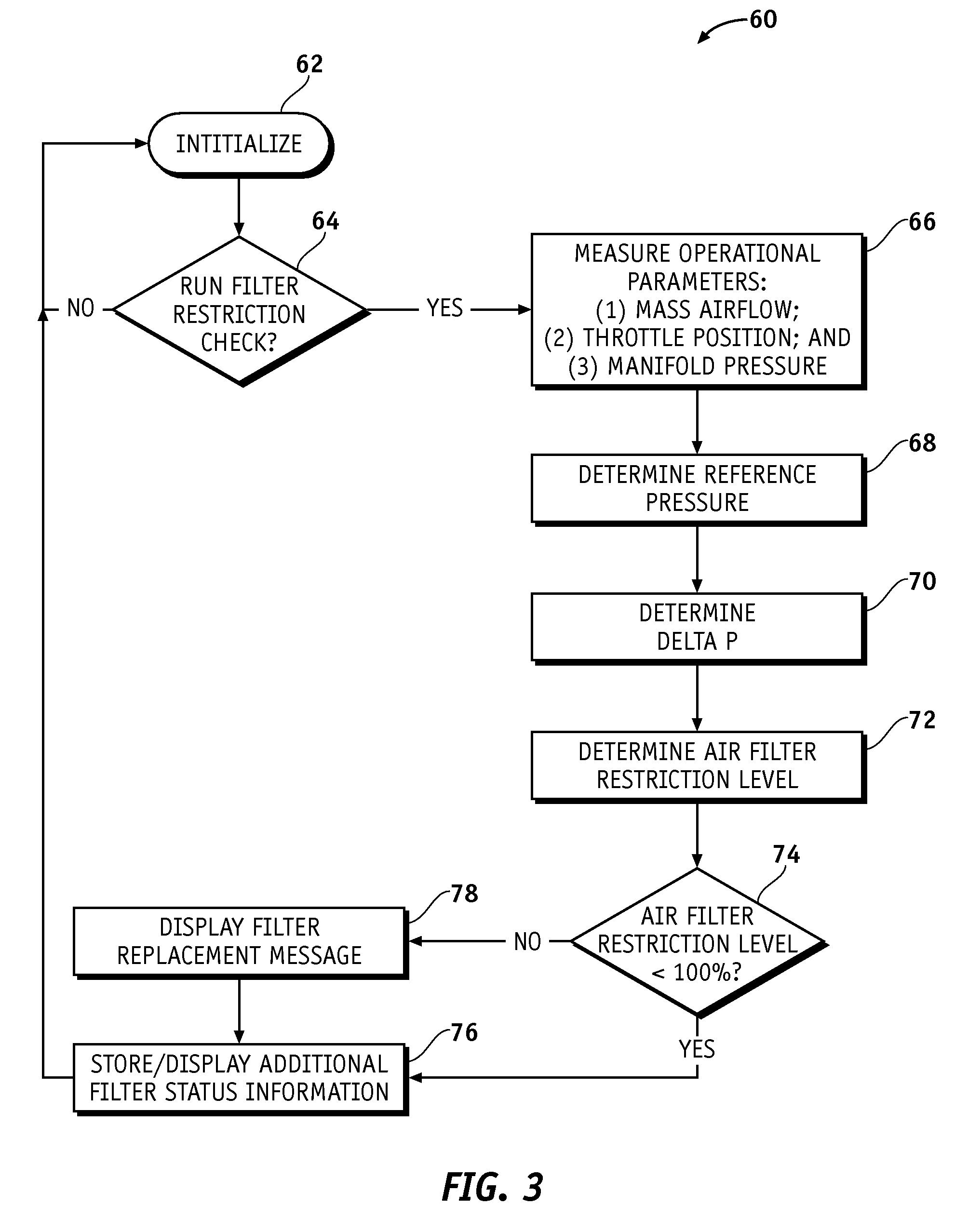

Method and Apparatus for Monitoring the Restriction Level of a Vehicular Air Filter Element

ActiveUS20080229720A1Combination devicesDispersed particle filtrationDifferential pressureEngineering

A process is provided for monitoring the filter restriction level of a filter element. The filter element is utilized by an air induction system deployed on a vehicle that includes a mass air flow sensor, a manifold pressure sensor, and a throttle position sensor. The process includes receiving (i) throttle position from the throttle position sensor, (ii) mass flow rate from the mass air flow sensor, and (iii) manifold pressure from the manifold pressure sensor. A reference pressure is determined from the received mass flow rate and the received throttle position, a pressure differential is established between the reference pressure and the received manifold pressure, and a filter restriction level is identified from the established pressure differential and the received mass flow rate.

Owner:GM GLOBAL TECH OPERATIONS LLC

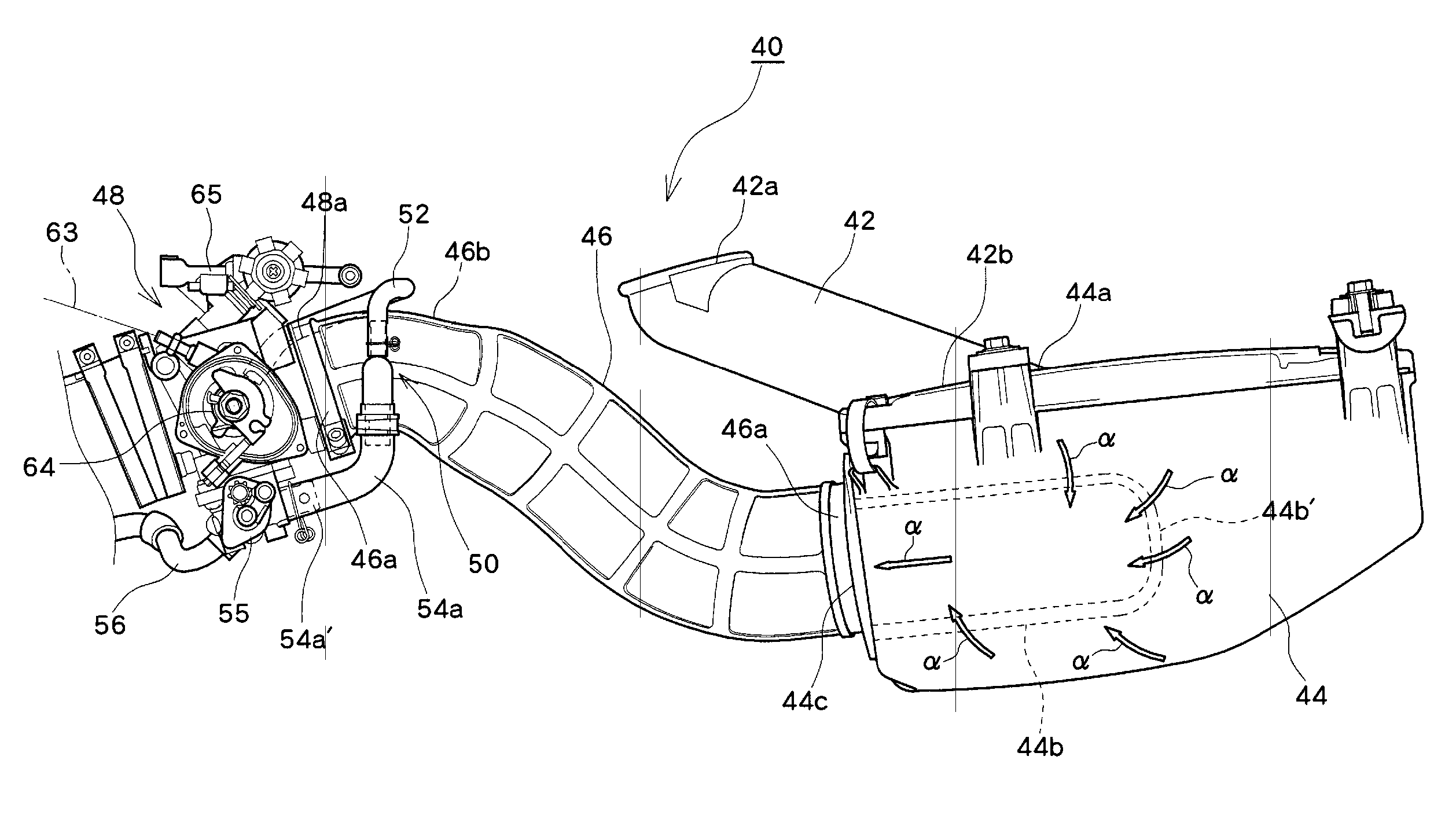

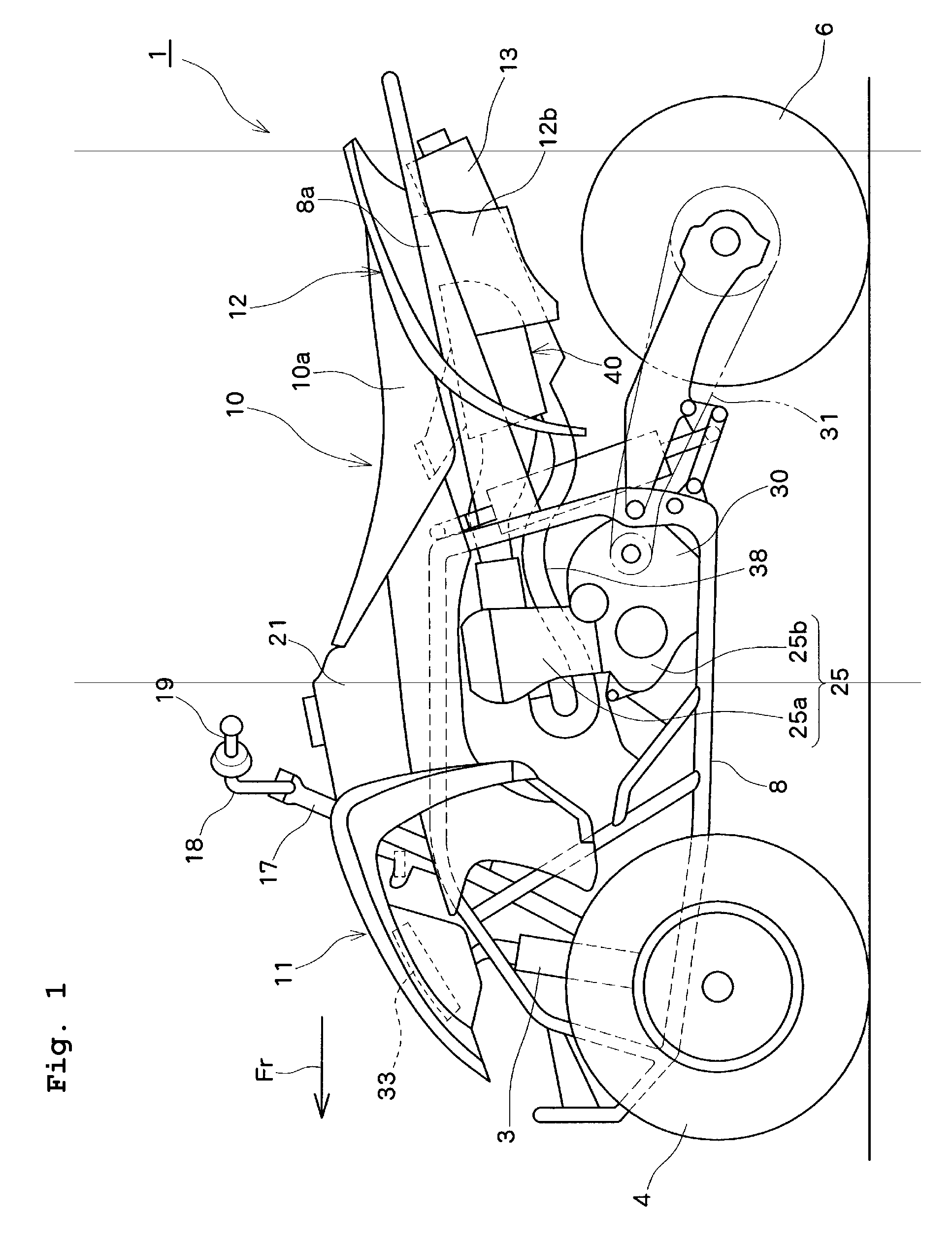

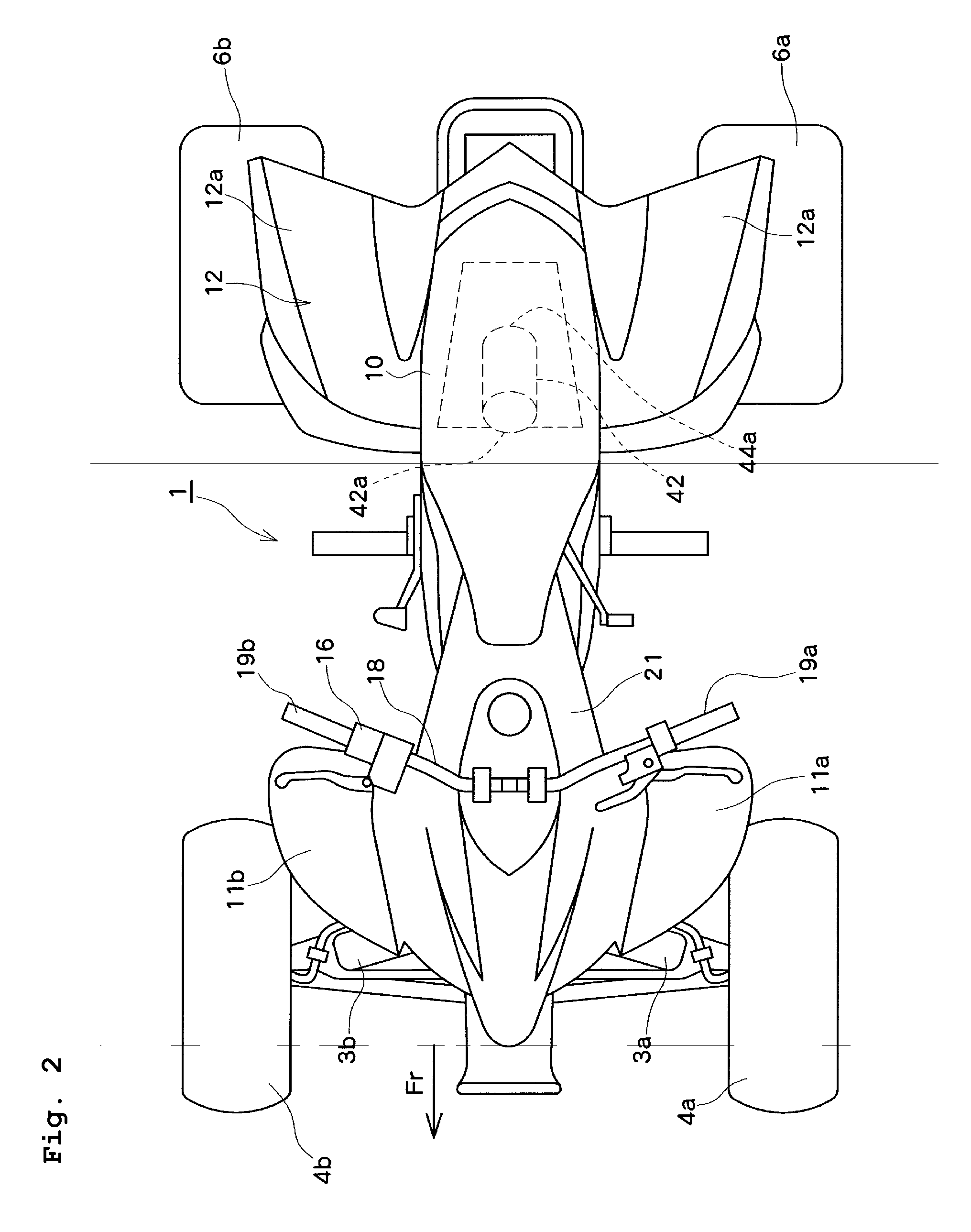

Throttle body having fuel return passage and vehicle

InactiveUS20060236980A1Smooth returnAvoid accumulationElectrical controlIdling devicesThrottle position sensorControl theory

A throttle body includes a housing that accommodates a connector for a rotation shaft of a throttle valve disposed in the throttle body and a throttle position sensor, a fuel return passage that communicates the housing with an air intake passage in the throttle body, a T-shaped pipe that communicates with the air intake passage upstream from the throttle body to function as a pressure control chamber, and an air inflow passage that communicates the housing with the T-shaped pipe. The throttle body smoothly returns the fuel accumulated in a housing that accommodates a connector that connects a throttle position sensor to the end of the rotation shaft of a throttle valve to an air intake passage.

Owner:YAMAHA MOTOR CO LTD

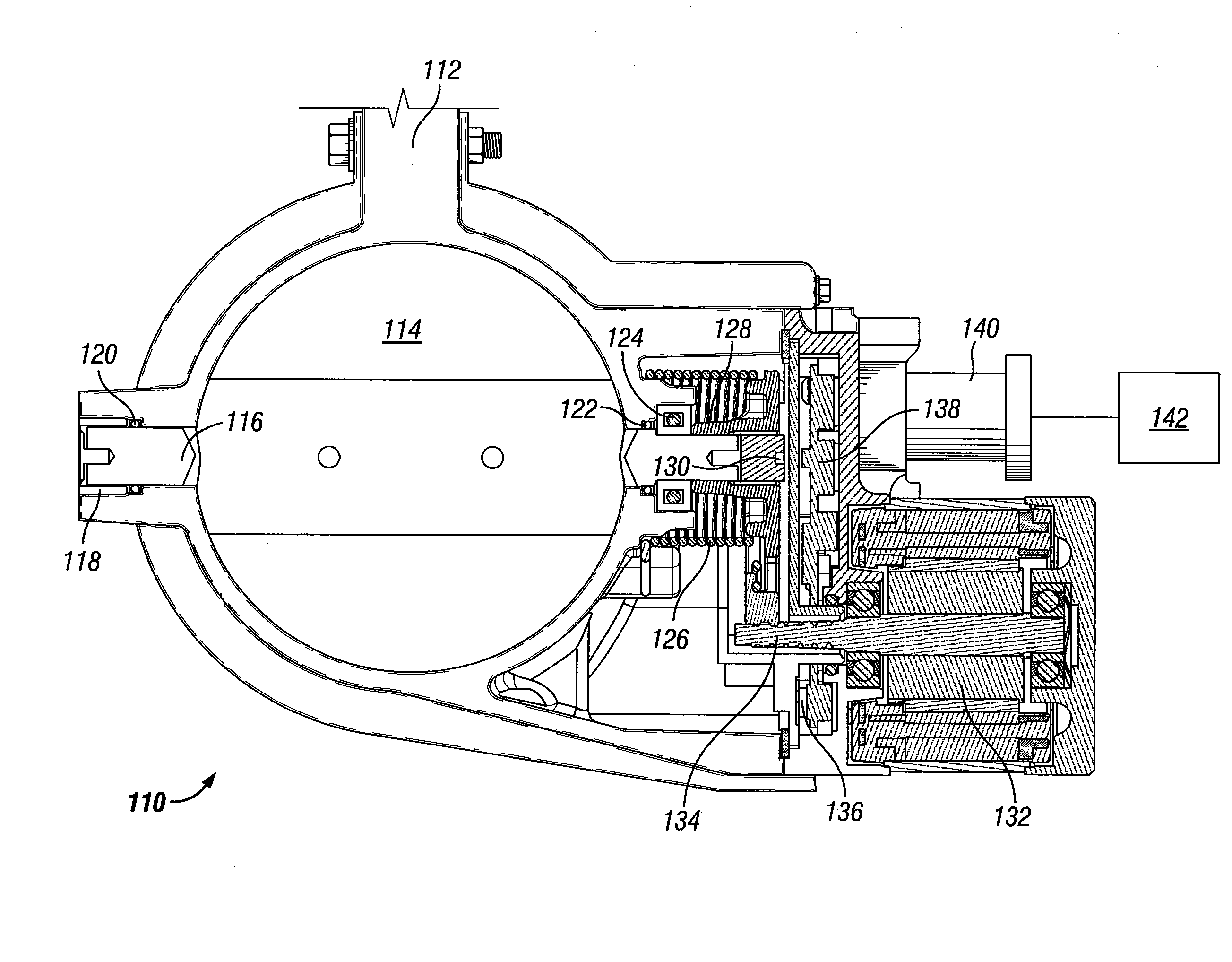

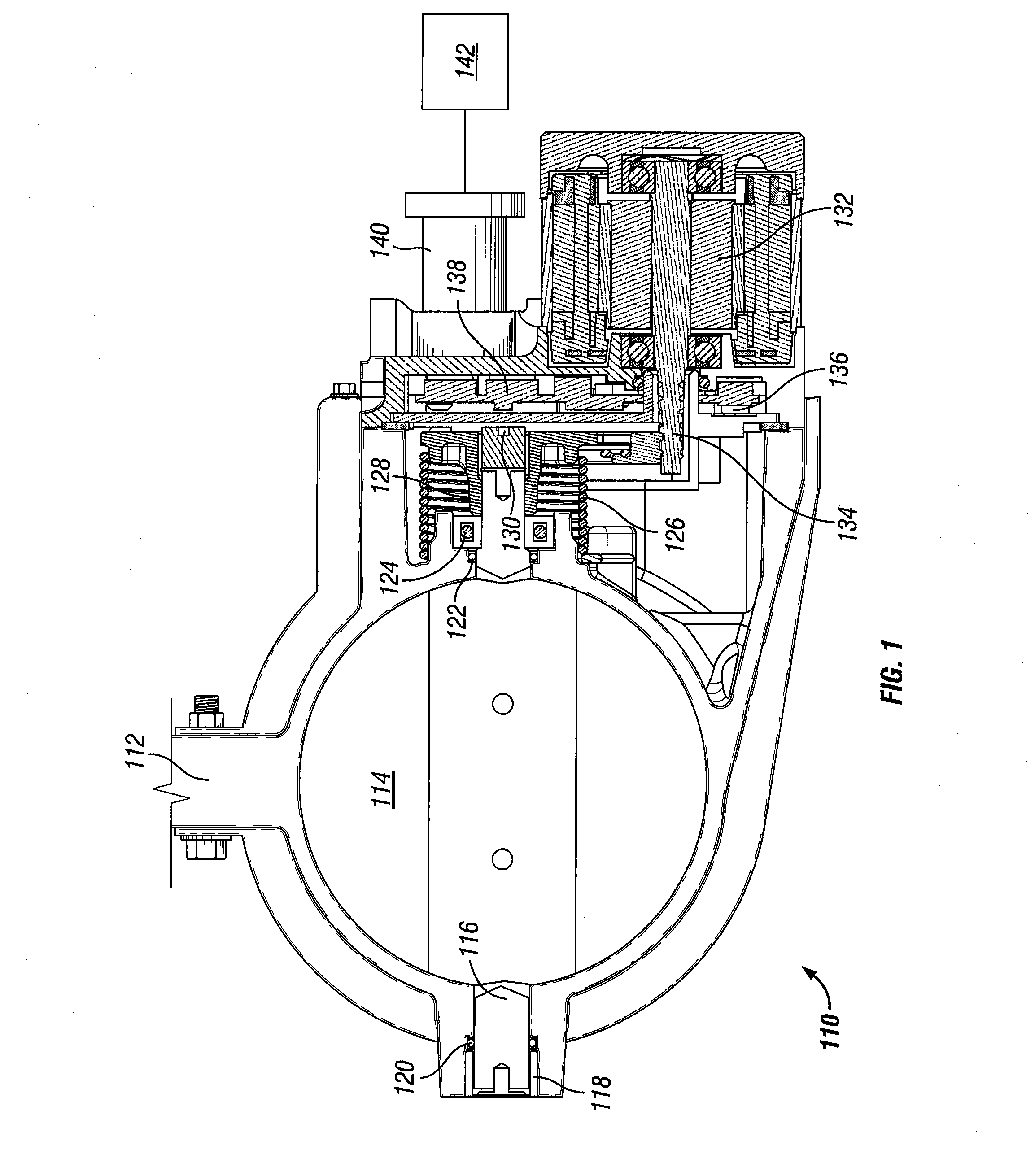

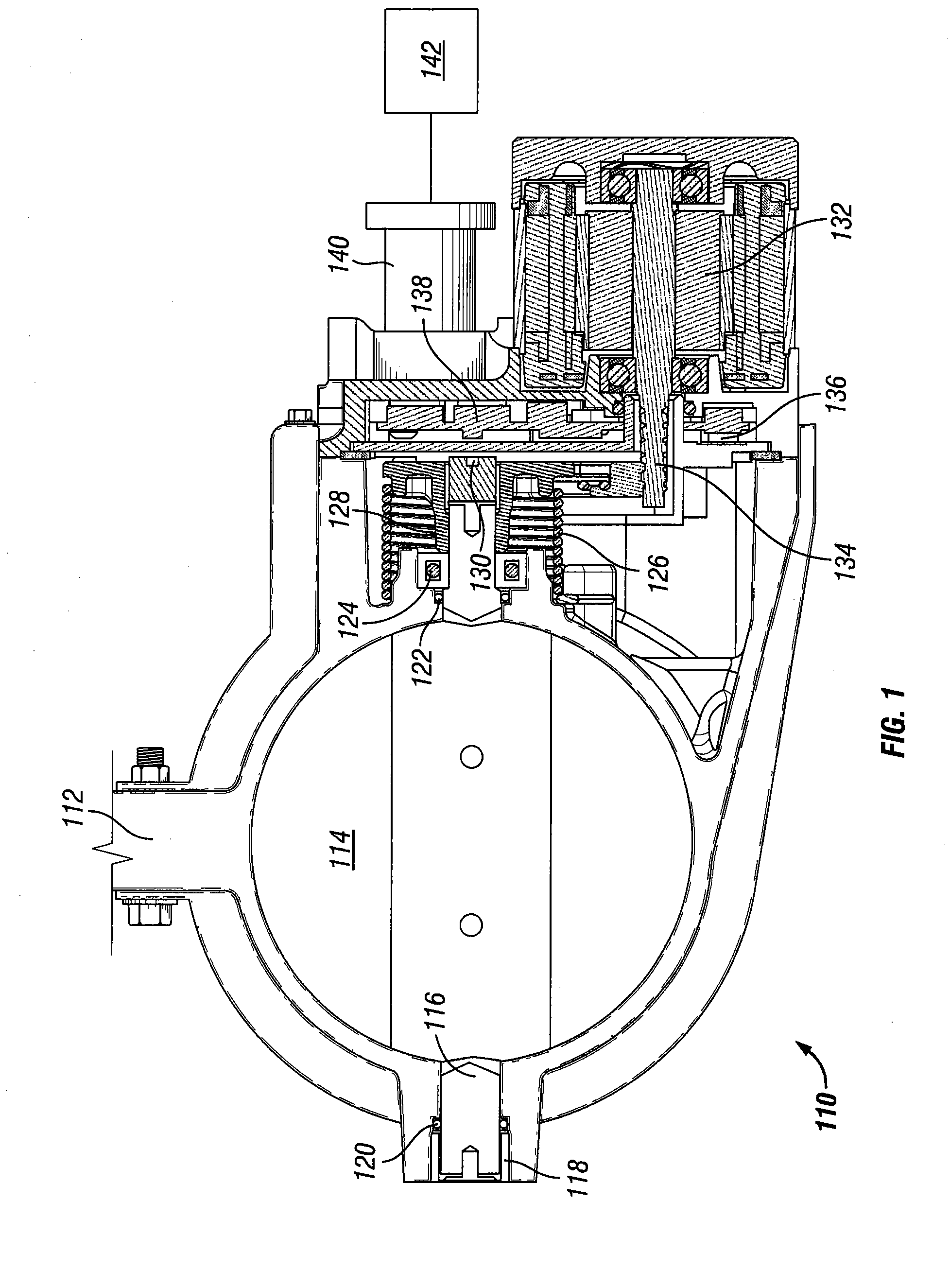

Air valve and method of use

An air valve and its method of use including an air valve housing; a throttle plate disposed on a throttle shaft; a driven gear attached on the throttle shaft; a brushless direct current motor assembly in connection via a pinion with the driven gear; an integrated electronic valve controller including digital signal processing on a circuit board; and a throttle position sensor on the circuit board, wherein the throttle position sensor includes at least one non-contact type sensor. In a preferred embodiment, the air valve includes an inlet port and an outlet port connected to an engine via an air intake manifold, such that re-circulated exhaust gas is introduced into the air intake manifold.

Owner:BRIGHT DAIRY & FOOD +1

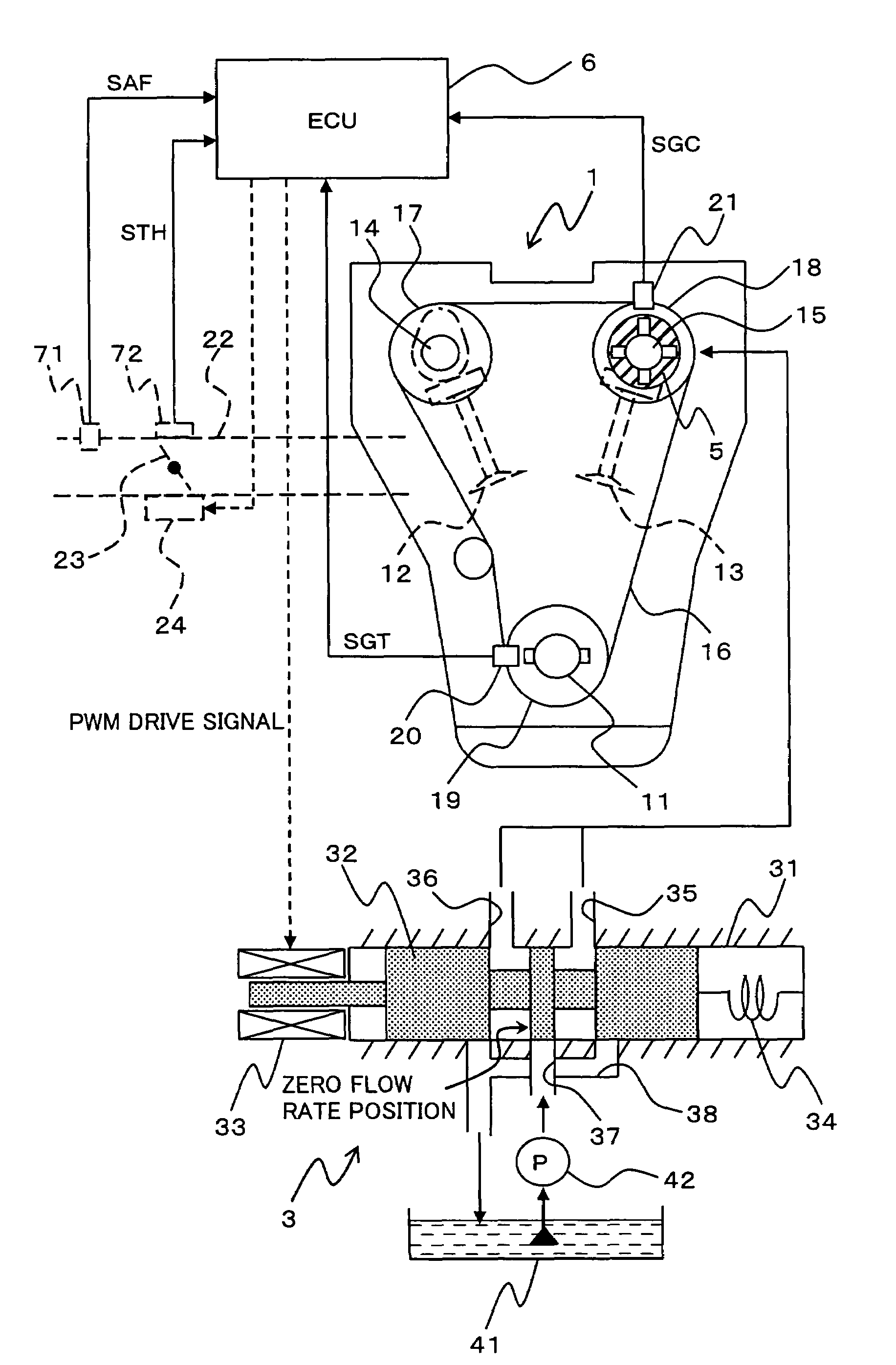

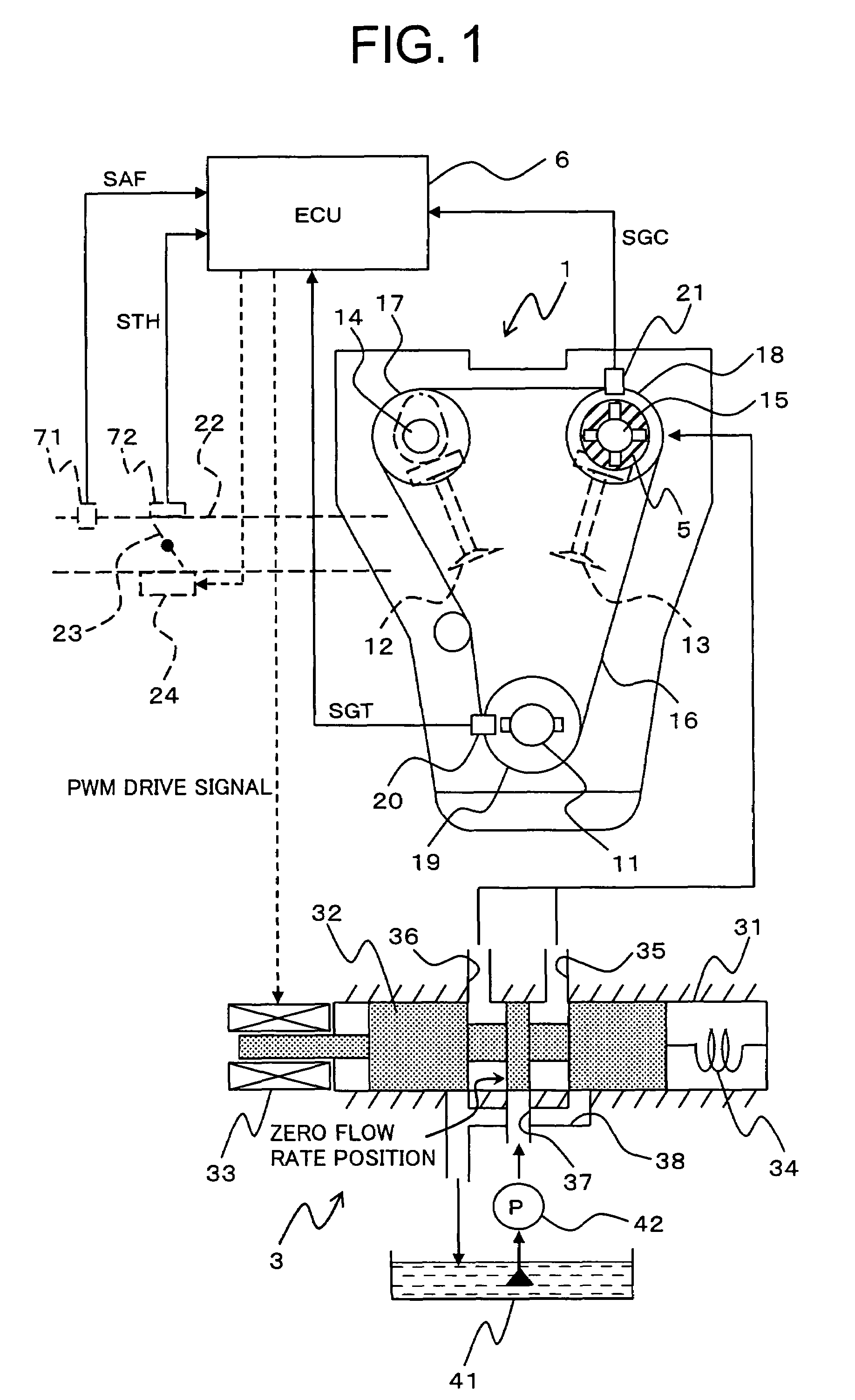

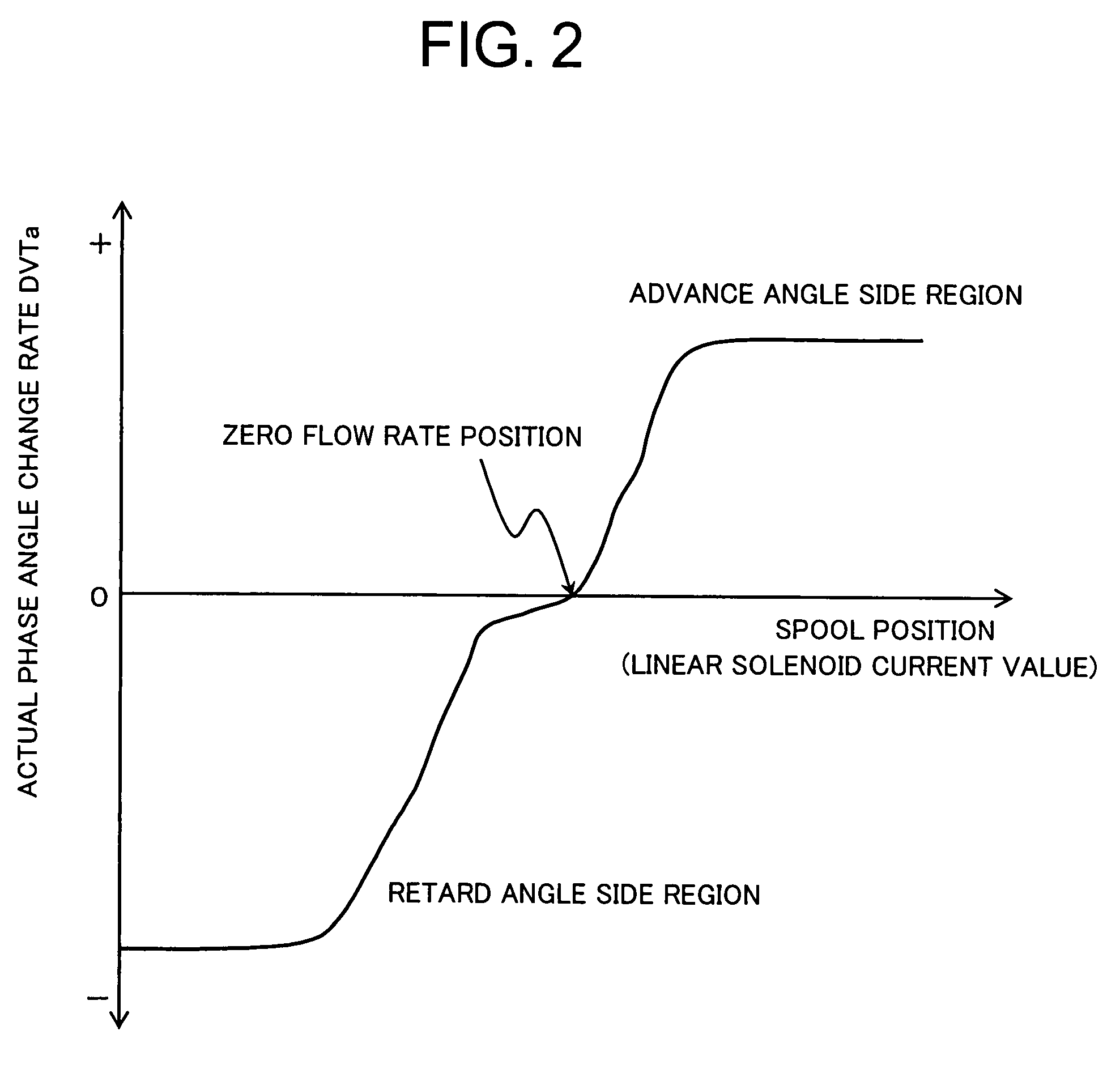

Control apparatus for an internal combustion engine

ActiveUS7403849B1Control delay timeShort response timeAnalogue computers for vehiclesValve arrangementsThrottle position sensorInternal combustion engine

A control apparatus for an internal combustion engine can control an actual operating characteristic with high precision by shortening a response time thereof. The control apparatus capable of changing an actual phase angle of a camshaft by an OCV includes a crank angle sensor for detecting a crank angle of a crankshaft and generating a crank angle signal, an actual phase angle detection section for detecting the actual phase angle of the camshaft, an air flow sensor and a throttle position sensor for detecting an operating state of the engine, a target phase angle calculation section for calculating a target phase angle based on the operating state, and a phase angle feedback control section for calculating an operation amount to the OCV so as to make the actual phase angle coincide with the target phase angle. The phase angle feedback control section calculates the operation amount in synchronization with the crank angle signal.

Owner:MITSUBISHI ELECTRIC CORP

Motor engine electric control fuel oil spraying system

InactiveCN101144437AReasonable designSimple structureElectrical controlMachines/enginesIdle speed controlIgnition coil

The invention discloses a motorcycle engine electronic control fuel injection system, and comprises an electronic control unit, and a sensor and an executive mechanism connected with the electronic control unit; the sensor comprises a crankshaft position signal generator, a crankshaft position sensor and a throttle position sensor corresponding to the crankshaft position signal generator, an intake pressure sensor communicated with an air intake tube, an intake air temperature sensor communicated with the air intake tube, a cylinder body temperature sensor installed on the engine body, and an oxygen sensor arranged on an exhaust tube, wherein, the executive mechanism comprises an idle speed control valve, an electric fuel pump, a fuel pressure regulator, an oil ejector and an ignition coil. The invention has the advantages that the design is reasonable, the structure of the system is perfect, the operating performance is stable and reliable, and the engine combines the electronic control system with the exhaust gas aftertreatment technology, to lead the exhaust gas emission to meet the requirements of the motorcycle country more than three issues emission regulation as well as the more than Euro III exhaust emission regulation.

Owner:西安易道汽车电器有限责任公司 +2

Air valve and method of use

An air valve and its method of use including an air valve housing; a throttle plate disposed on a throttle shaft; a driven gear attached on the throttle shaft; a brushless direct current motor assembly in connection via a pinion with the driven gear; an integrated electronic valve controller including digital signal processing on a circuit board; and a throttle position sensor on the circuit board, wherein the throttle position sensor includes at least one non-contact type sensor. In a preferred embodiment, the air valve includes an inlet port and an outlet port connected to an engine via an air intake manifold, such that re-circulated exhaust gas is introduced into the air intake manifold.

Owner:NAVISTAR

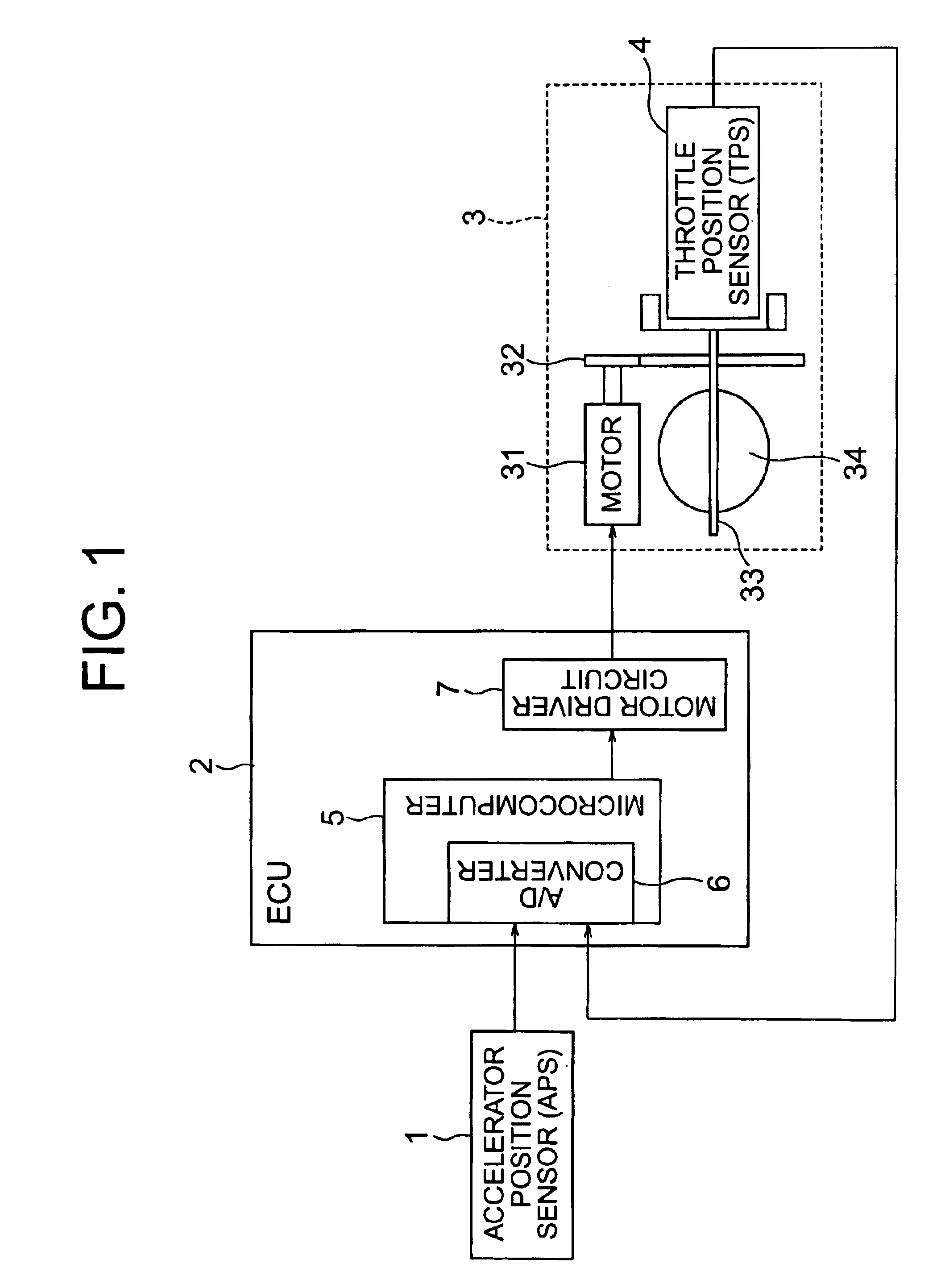

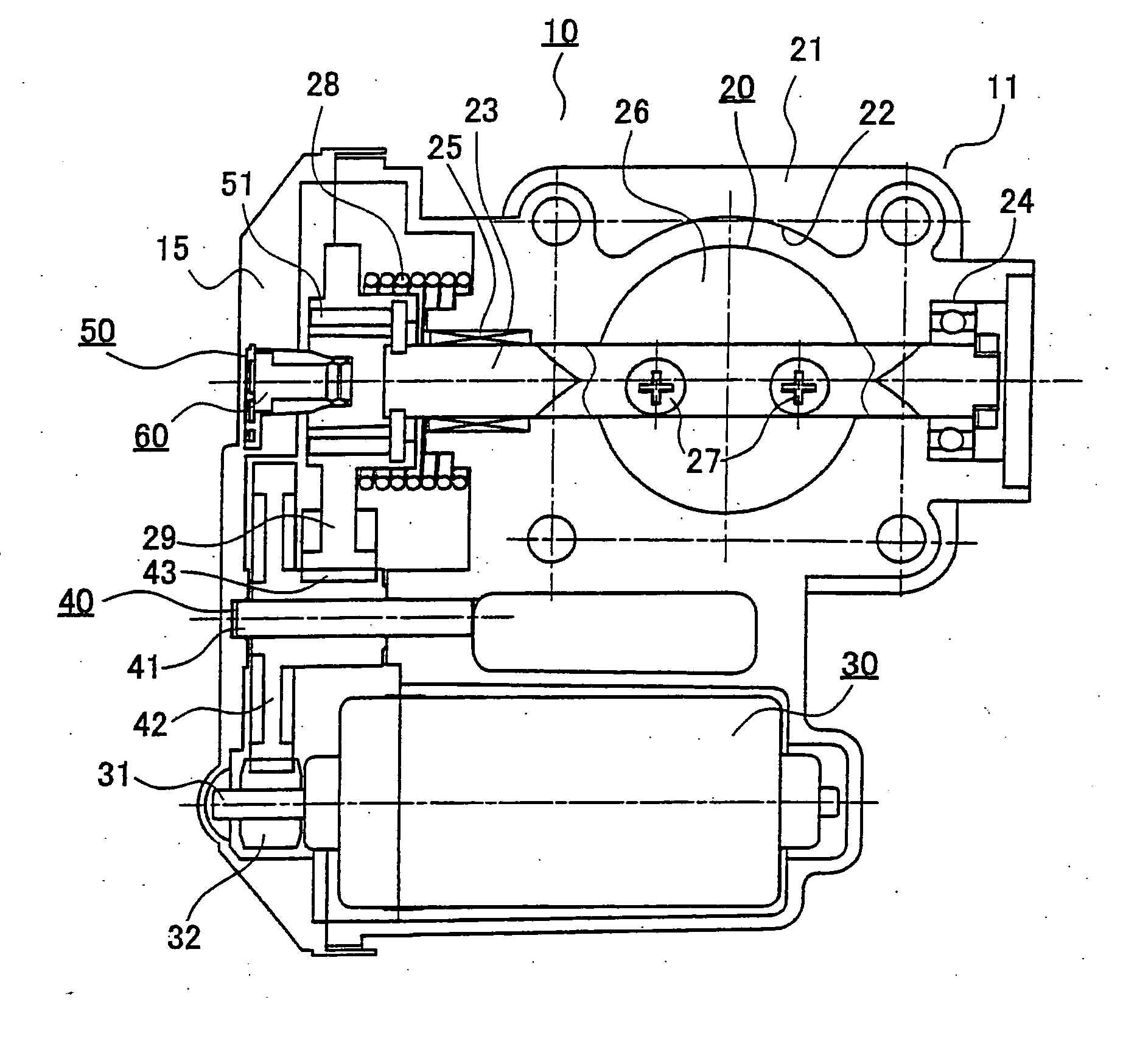

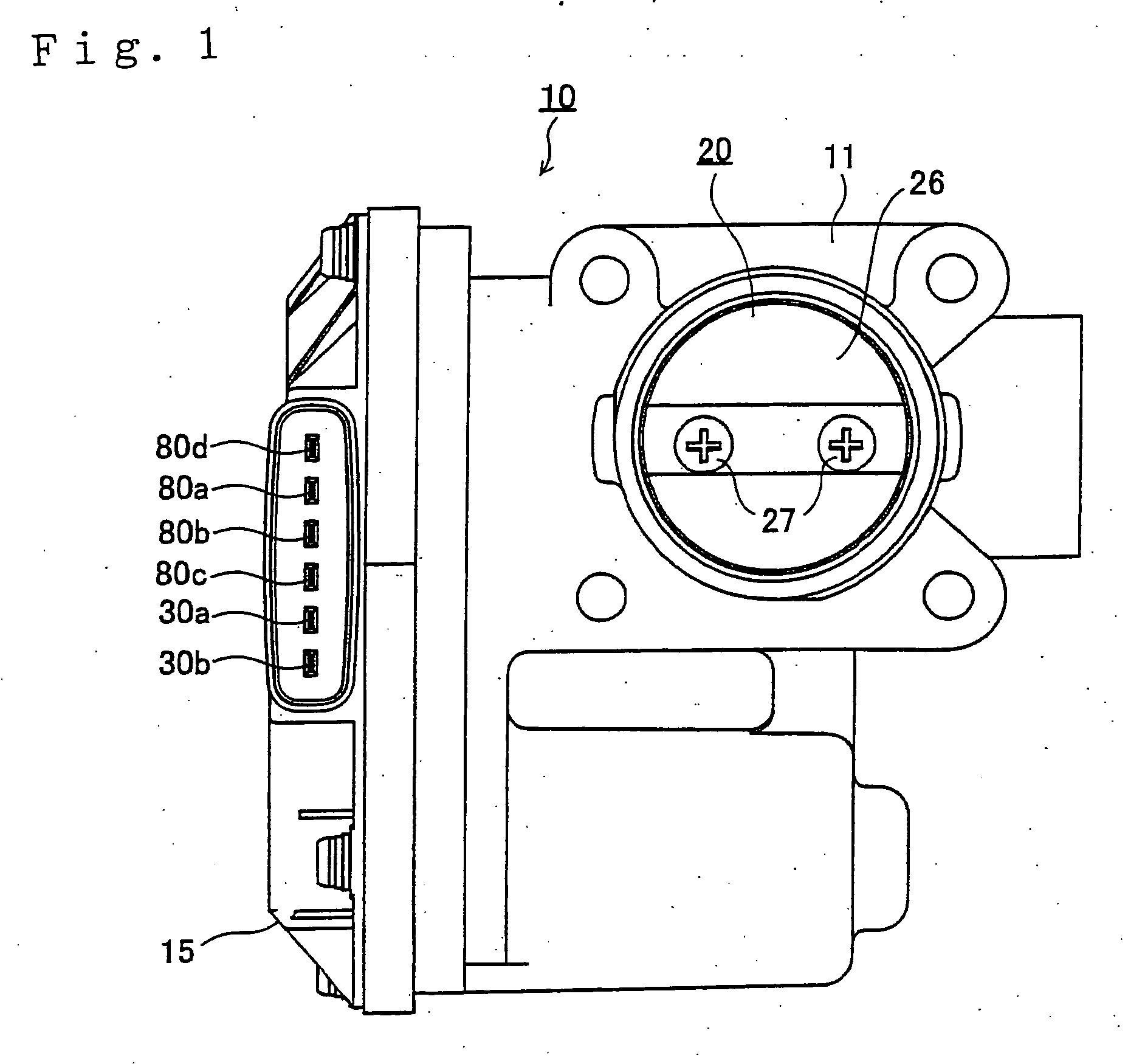

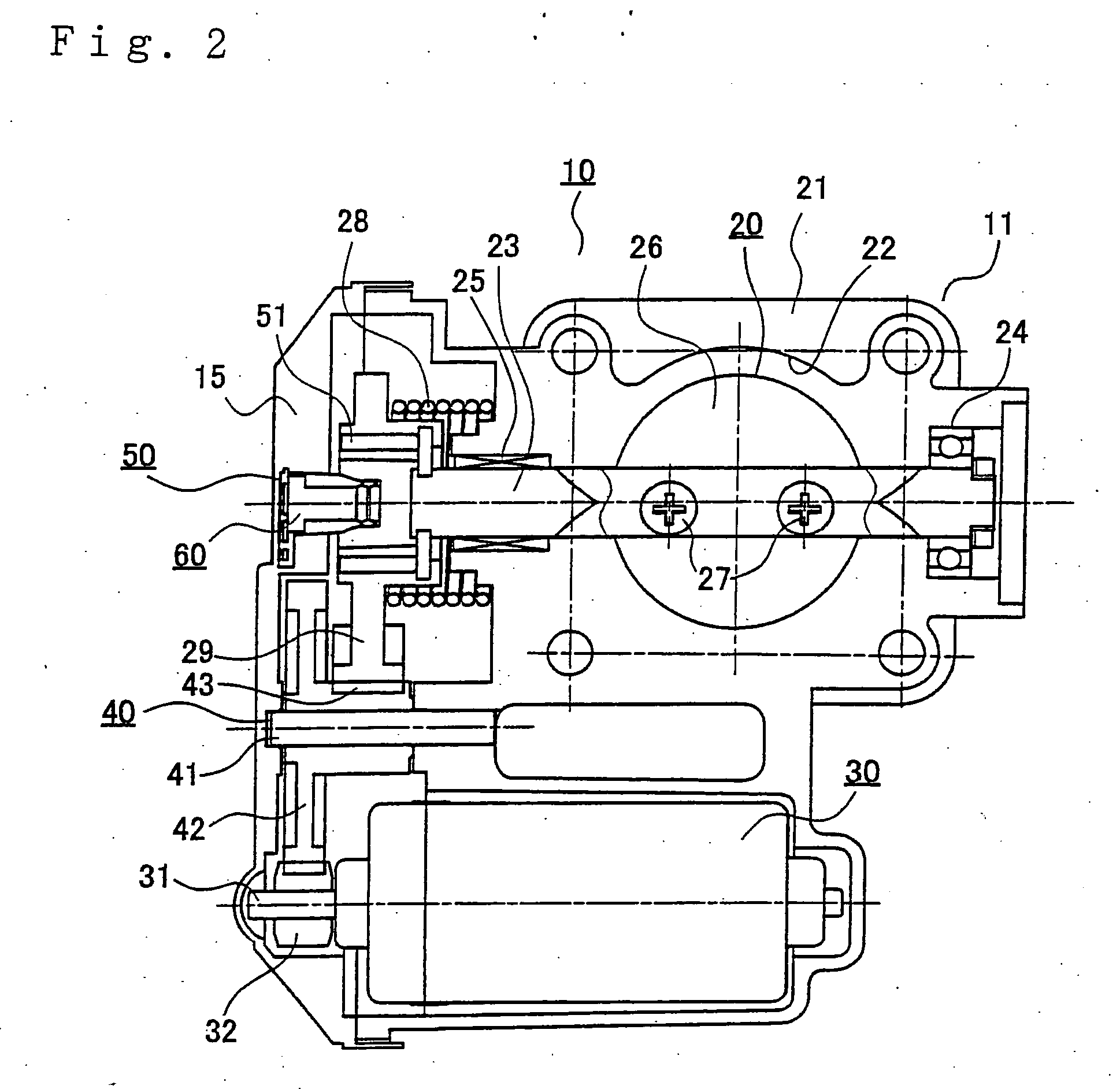

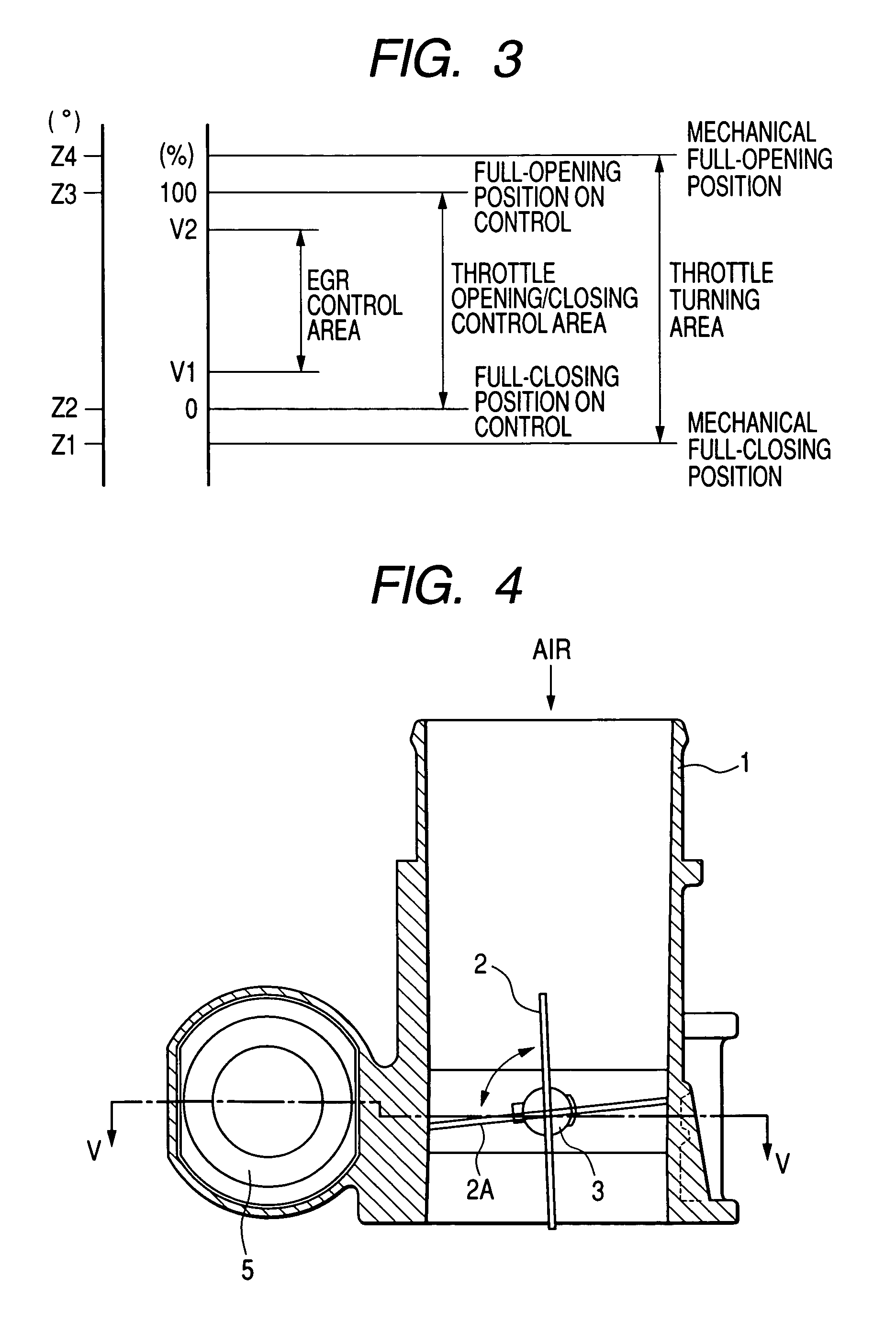

Throttle valve control device

ActiveUS6874468B2Avoid breakingGood precisionElectrical controlSpeed sensing governorsThrottle position sensorElectric power

An ECU 2 performs ON / OFF judgments on an ignition switch. When the ignition switch is OFF, a judgment is made whether or not voltage learning for a fully opened position of a throttle valve 34 is complete. If complete, an electric power for a DC motor 31 is cutoff. A TPS output voltage value is read in, and a judgment is made whether or not a given period of time has elapsed. If the given period of time has elapsed, and if a throttle position sensor output voltage value VTPS is equal to or greater than a given value, then a judgment is made that there is a return spring 35 breakage failure. Breakage to the return spring 35 can thus be reliably detected.

Owner:MITSUBISHI ELECTRIC CORP

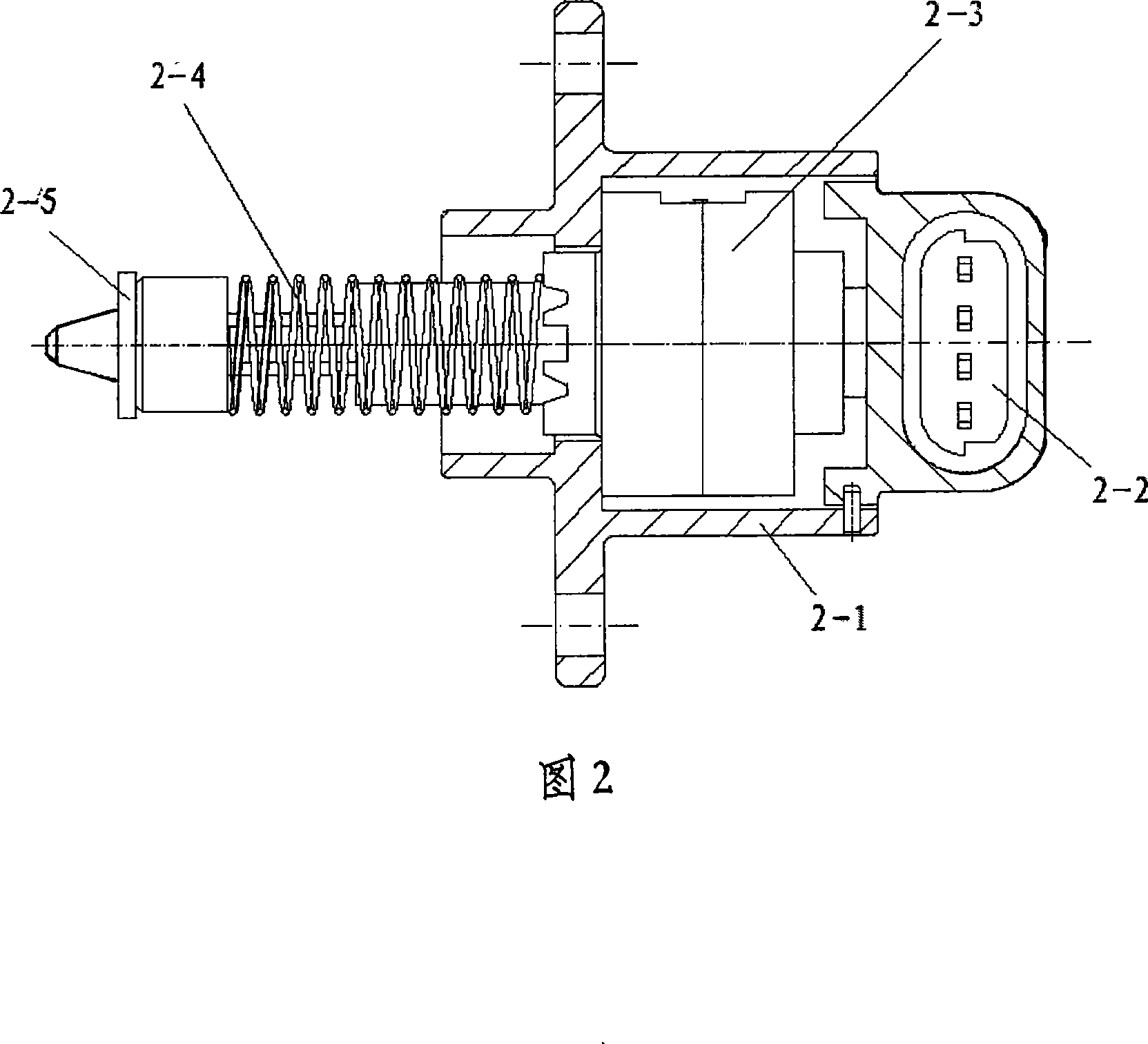

Throttle position sensor

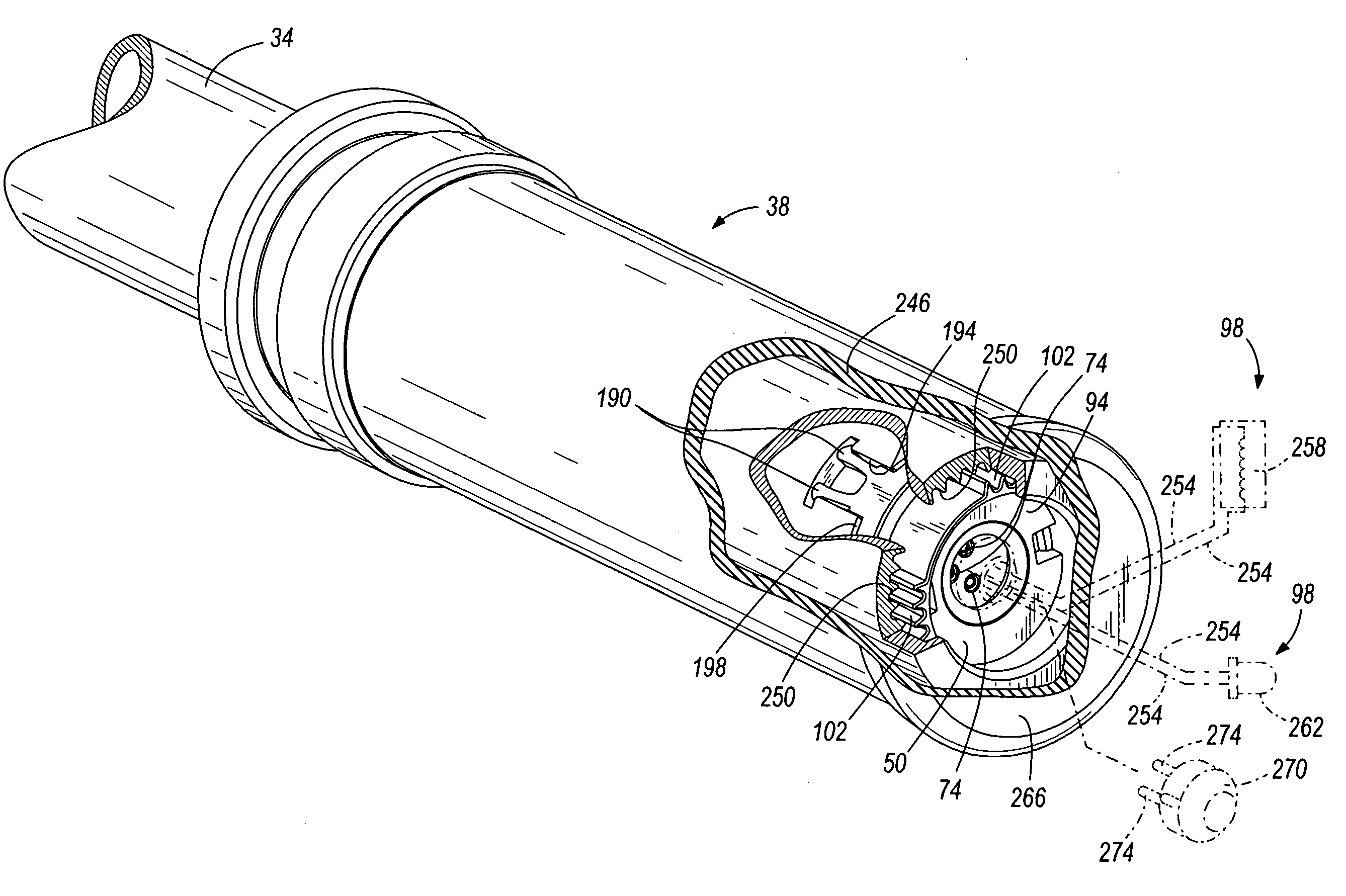

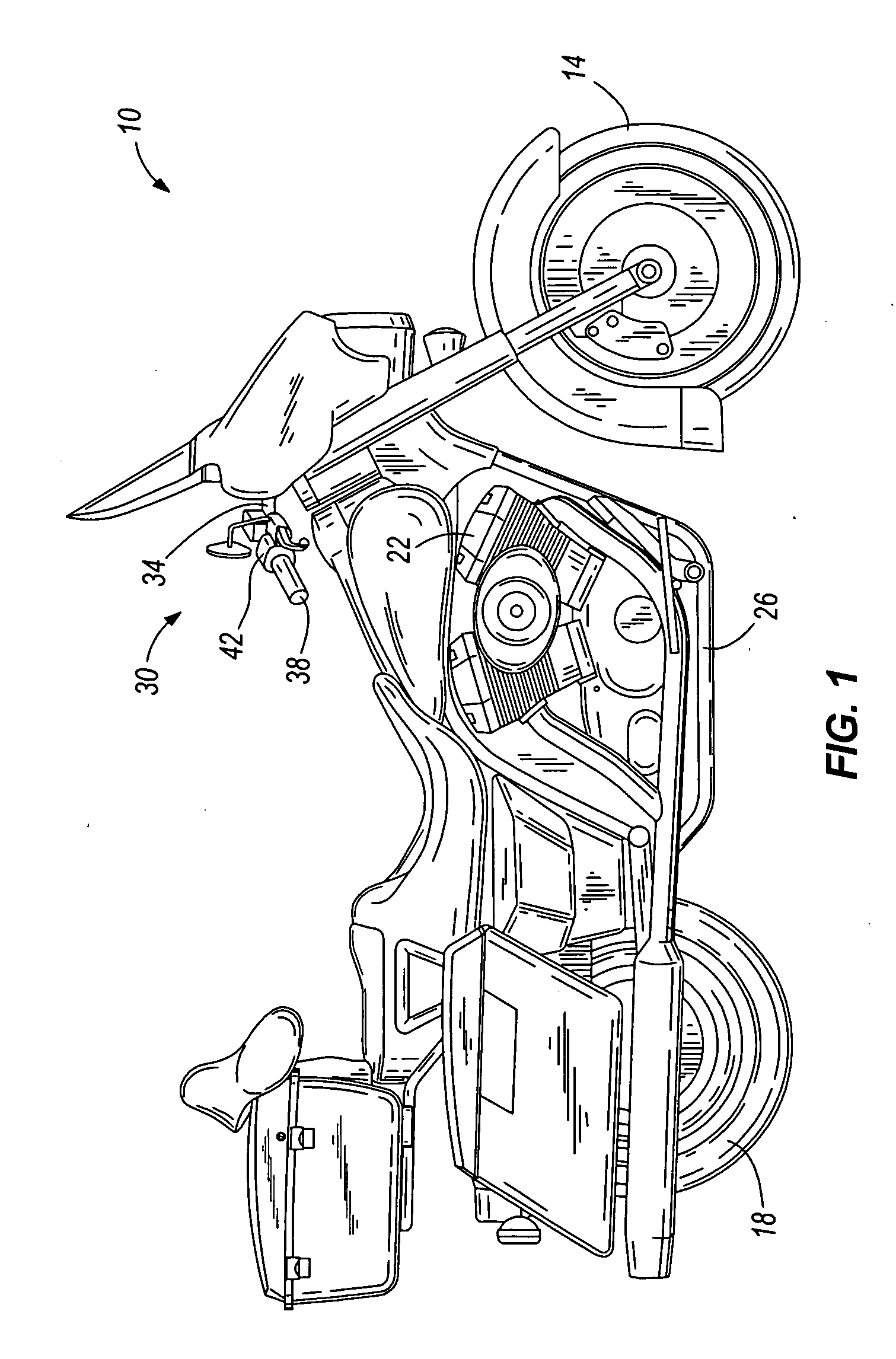

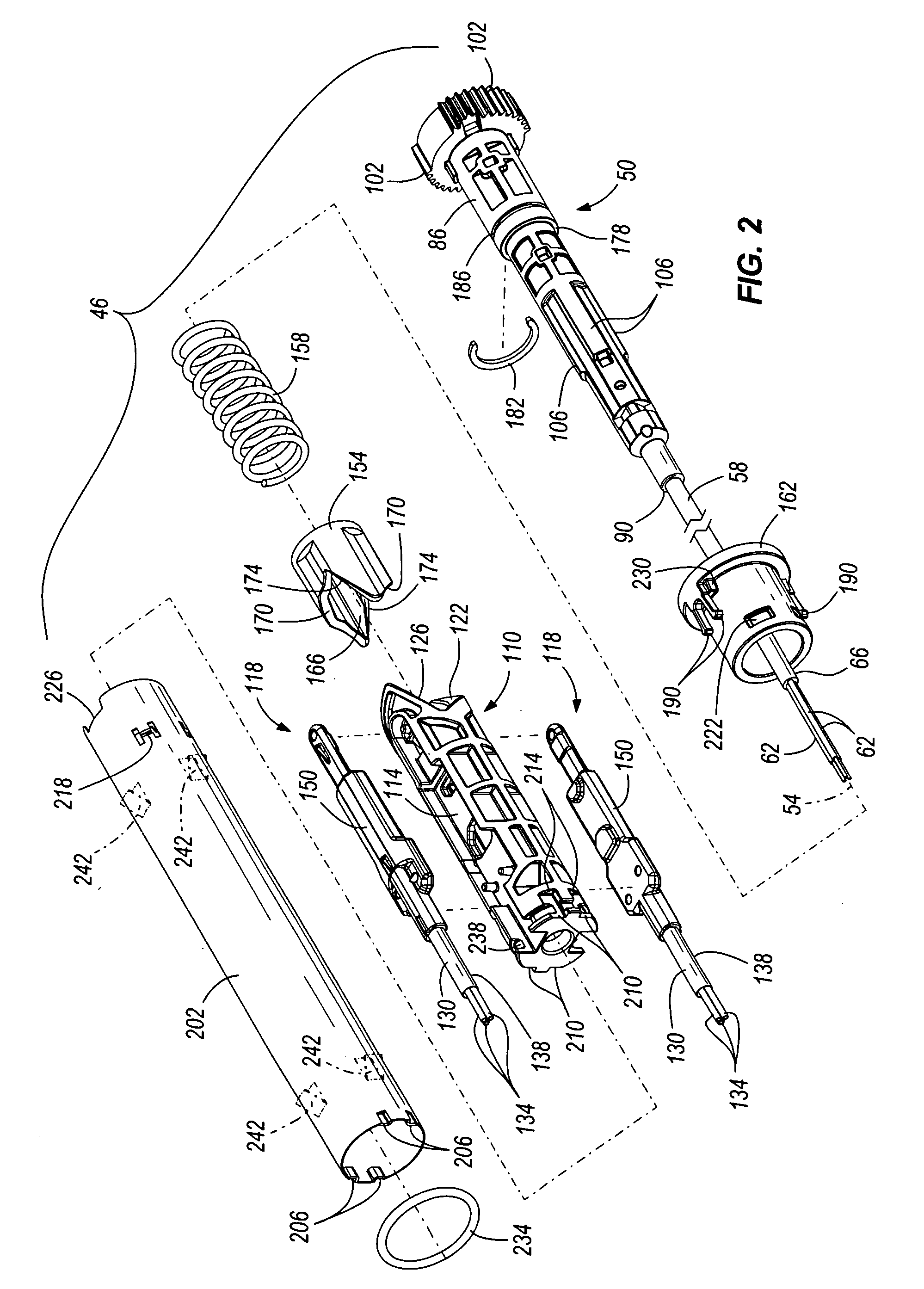

The present invention provides a throttle position sensor for a motorcycle including a handlebar having an end. The throttle position sensor includes a rotor having a first end and a second end. The rotor is positioned within the handlebar and rotated relative to the handlebar. The second end is closer than the first end to the end of the handlebar. The throttle position sensor also includes a sensor operable to detect rotation of the rotor relative to the handlebar and generate a signal corresponding to the rotation of the rotor relative to the handlebar. The throttle position sensor further includes at least one electrical conduit passing into the rotor from the first end. The at least one electrical conduit is routed through the rotor and is accessible from the second end of the rotor.

Owner:HARLEY DAVIDSON MOTOR COMPANY GROUP INC +1

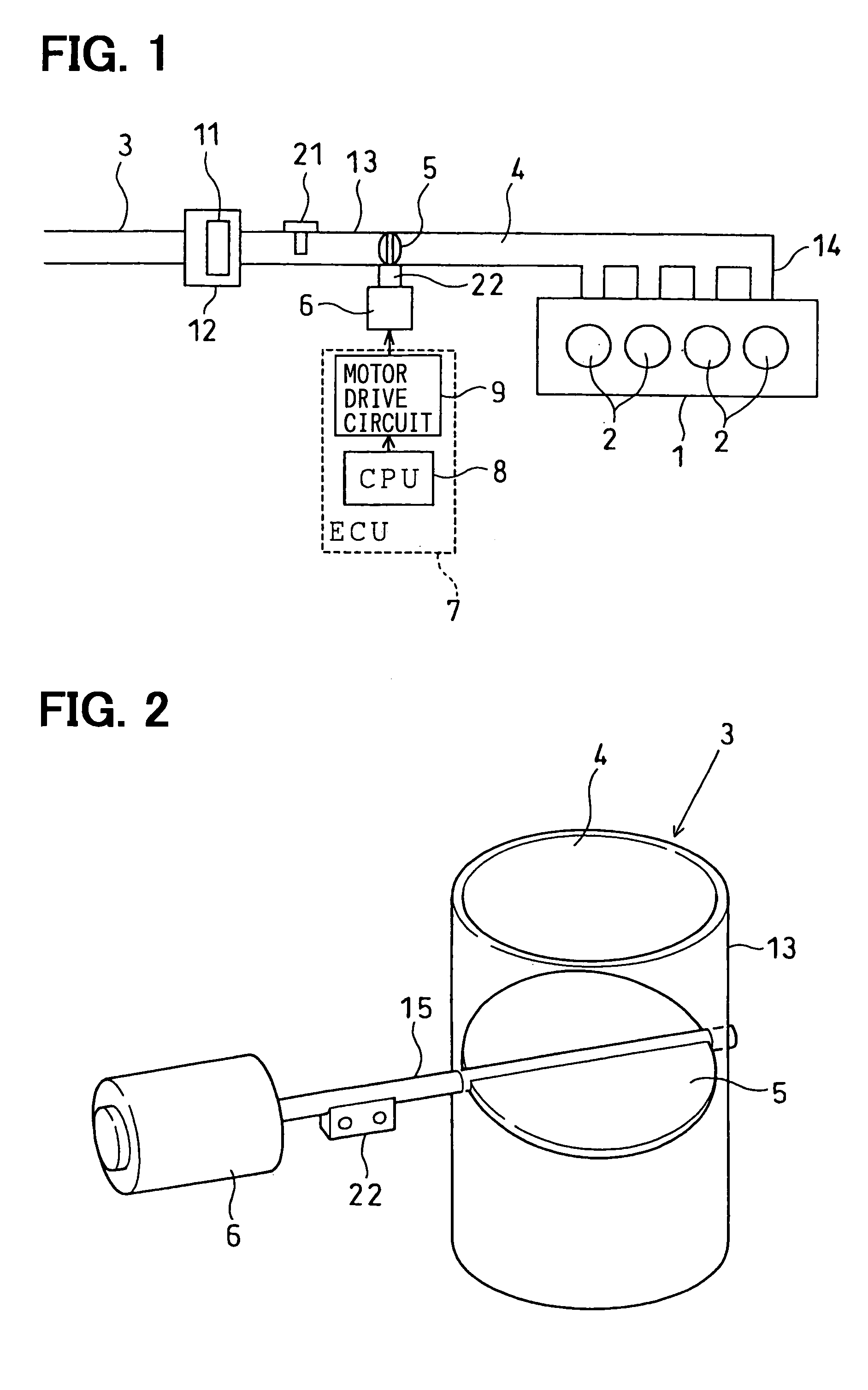

Valve position controller

InactiveUS7143743B2Low costReduce the numberElectrical controlMachines/enginesThrottle position sensorPosition control

The throttle position corresponding to the rotational angle of the throttle valve is calculated based on electric signals output from a rotor position detector constituted by three Hall ICs that detect the rotational position of a magnet rotor of a brushless DC motor. A valve position control quantity of the throttle valve is so calculated as to eliminate the difference between the thus calculated valve position and a target valve position. The motor current control quantity of the brushless DC motor is so determined as to eliminate the difference between the calculated valve position and the target valve position. Though the throttle position sensor is omitted, the electric signals output from the rotor position detector are used for calculating both the valve position control quantity and the motor current control quantity.

Owner:DENSO CORP

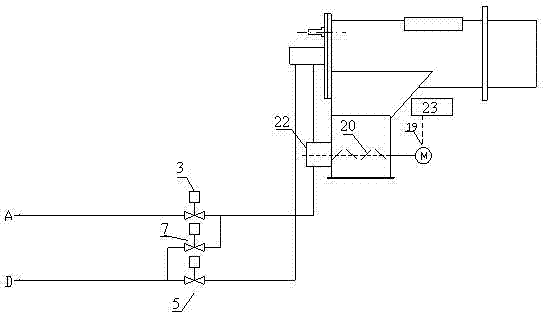

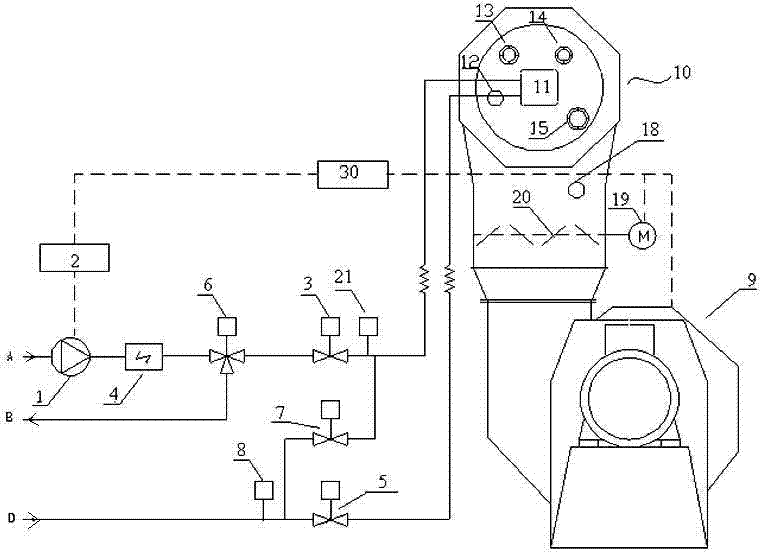

Turbocharged gasoline engine system with pulse width regulating valve and method for controlling supercharging pressure

InactiveCN102278194AAvoid knockingImprove powerInternal combustion piston enginesEngine controllersElectricityWastegate

A turbocharged gasoline engine system with a pulse widening valve and a method for controlling the supercharging pressure, which is to control the supercharging pressure entering the actuator by adding a pulse widening valve to the turbocharged gasoline engine system, The added pulse width control valve has three gas circuit interfaces a, b, c and an electrical signal interface d, the gas circuit interface at the a end is connected with the outlet pipe of the turbocharger compressor, and the air circuit interface at the b end is connected with the air intake of the actuator The port c is connected, the c-end gas circuit port is connected with the intake pipe of the turbocharger compressor, and the electrical signal port d is connected with the engine ECU signal output port. The engine ECU receives the detection signals from the intercooler pressure sensor, intercooler temperature sensor, throttle position sensor, engine speed sensor, engine exhaust temperature sensor, and engine exhaust manifold oxygen content sensor, and then sends the duty ratio signal to the pulse width adjustment The valve controls the boost pressure entering the actuator to achieve the purpose of regulating the waste gas bypass volume.

Owner:HUNAN TYEN MACHINERY

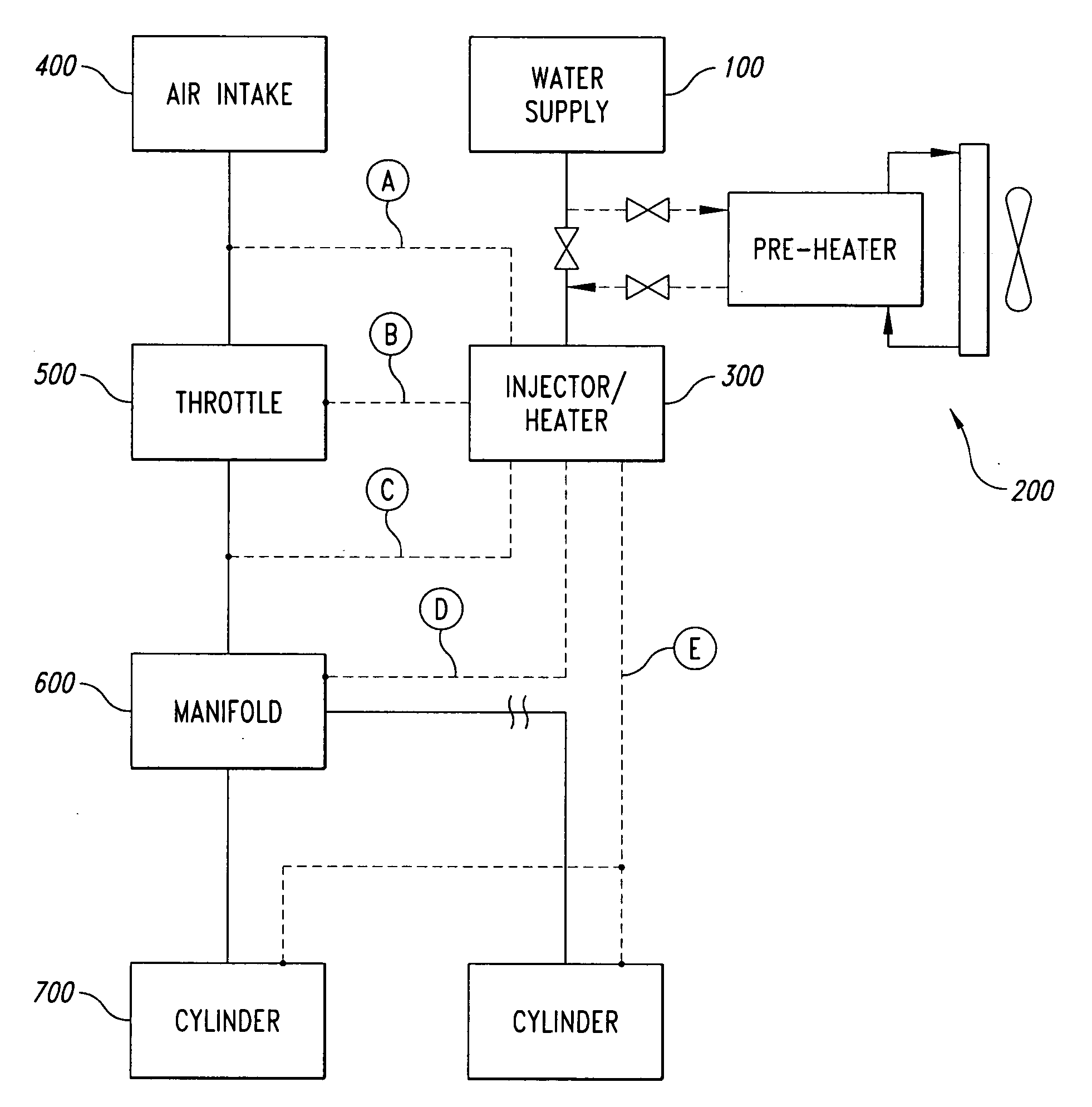

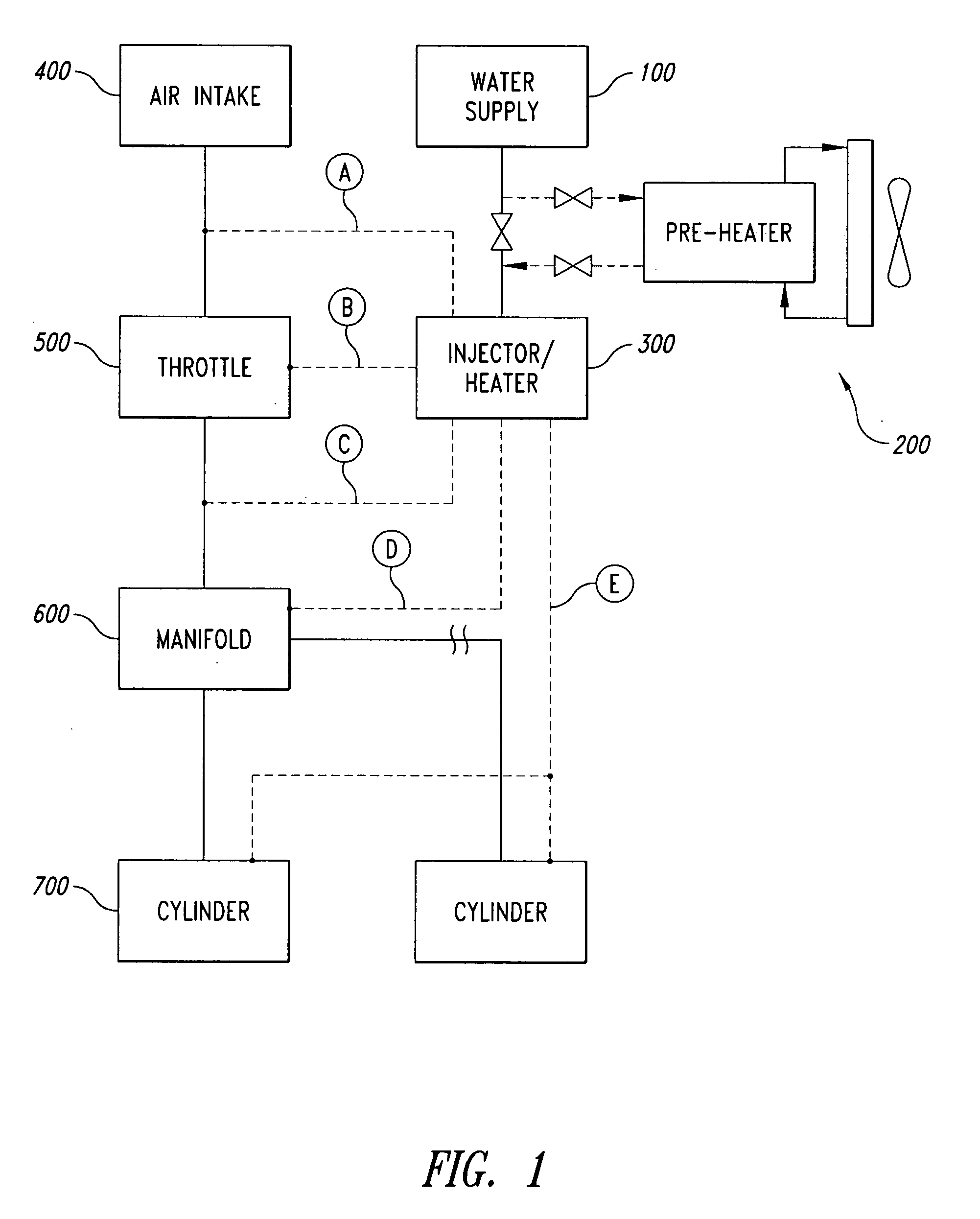

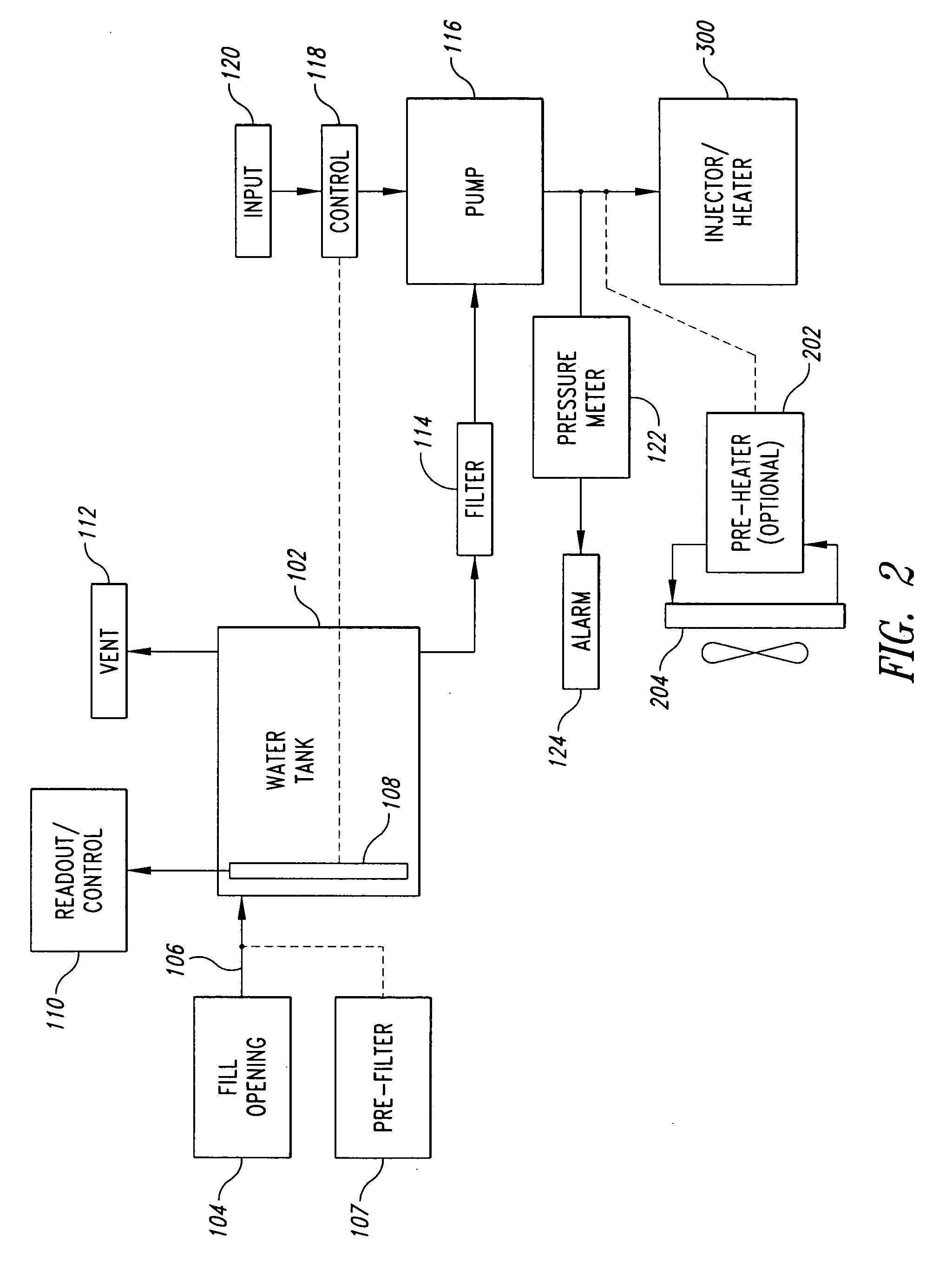

Devices, systems and methods for controlling introduction of additives into an internal combustion engine

InactiveUS20060249102A1Internal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineControl signal

A water injection control system includes a control unit adapted to receive one or more of a plurality of sensor signals from sensors provided as standard equipment in a vehicle, and to provide one or more control signals configured to control the operation of a water injection system associated with an engine of the vehicle. The received sensor signals may include signals from sensors such as an O2 sensor, an engine coolant temperature sensor, a mass air flow sensor, a manifold absolute pressure sensor, a crankshaft position sensor, a vehicle speed sensor, an intake air temperature sensor, and a throttle position sensor. The control signals provided by the controller may include signals for controlling functions such as water injector pulse rate and pulse width, water pump operation, water heater power, dashboard indicators, and PCU O2 sensor input.

Owner:S I S POWER

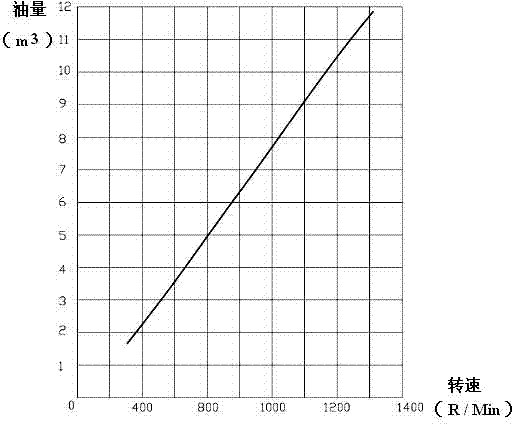

Combustion control system of an oil burner

The invention discloses a combustion control system of a fuel oil burner, which comprises an oil delivery channel, an atomization medium channel, an ignition device, an air volume adjustment device, an oil volume adjustment device and a controller; the oil delivery port of the oil delivery channel is provided with an oil delivery pump , there is an oil pressure sensor in the oil delivery channel, and the oil volume adjustment device is the oil inlet valve; the ignition device includes an igniter and an atomizer; the ignition device is equipped with a flame signal sensor, a wind pressure sensor, and an atomization medium pressure sensor; The adjustment device includes a damper and a damper driver; the damper driver is provided with a damper position sensor; the controller controls the fuel pump, blower device, igniter, atomizer, heater, the start of the damper driver and the opening or closing of the oil inlet valve; The controller receives the output signals of each sensor, and controls the oil intake, the oil pressure in the oil delivery channel, the position of the damper and the air pressure according to the relevant signals. The invention can realize the independent adjustment of oil volume and air volume, has low energy consumption and high system reliability.

Owner:JIANGSU OUBIAO

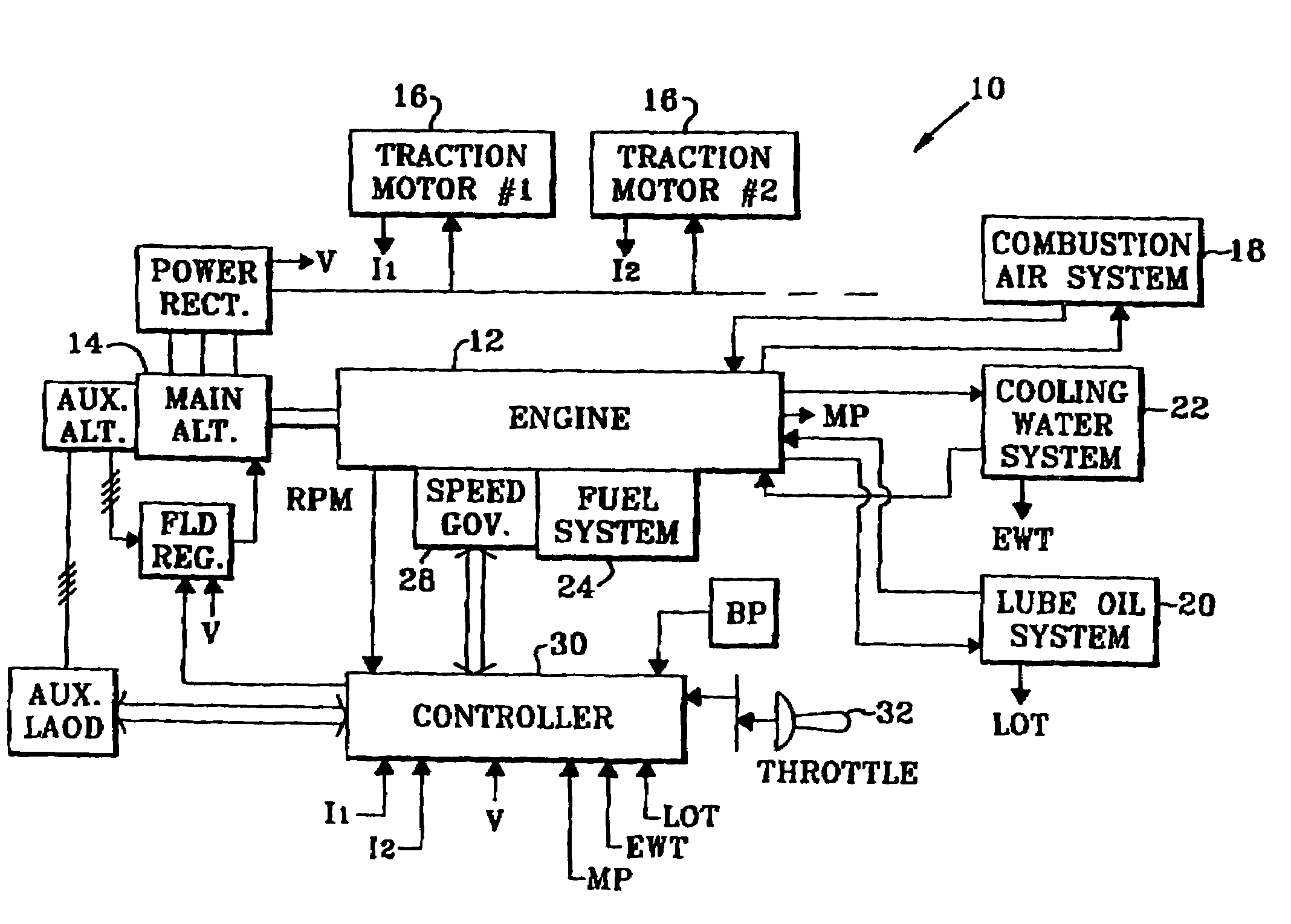

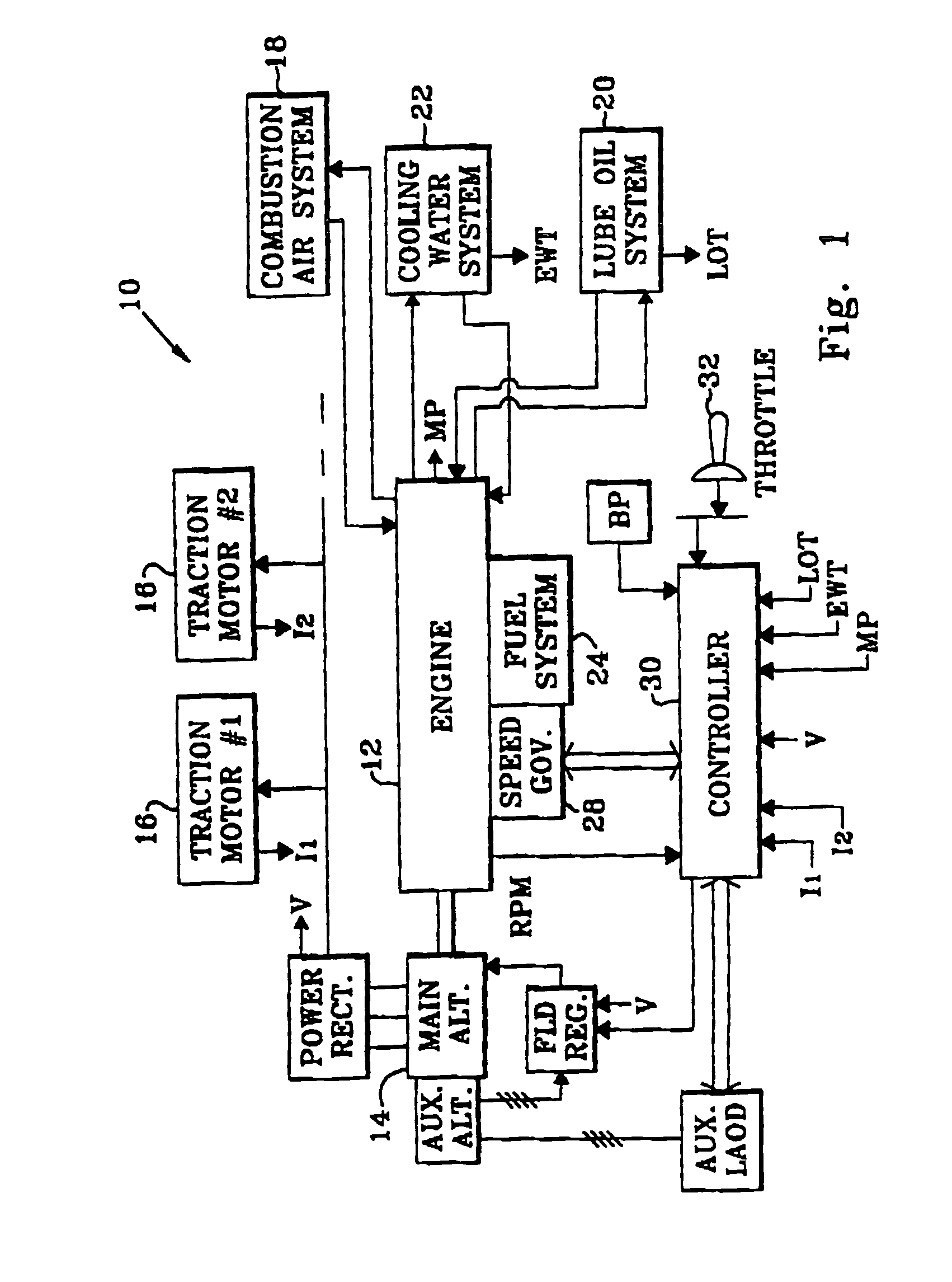

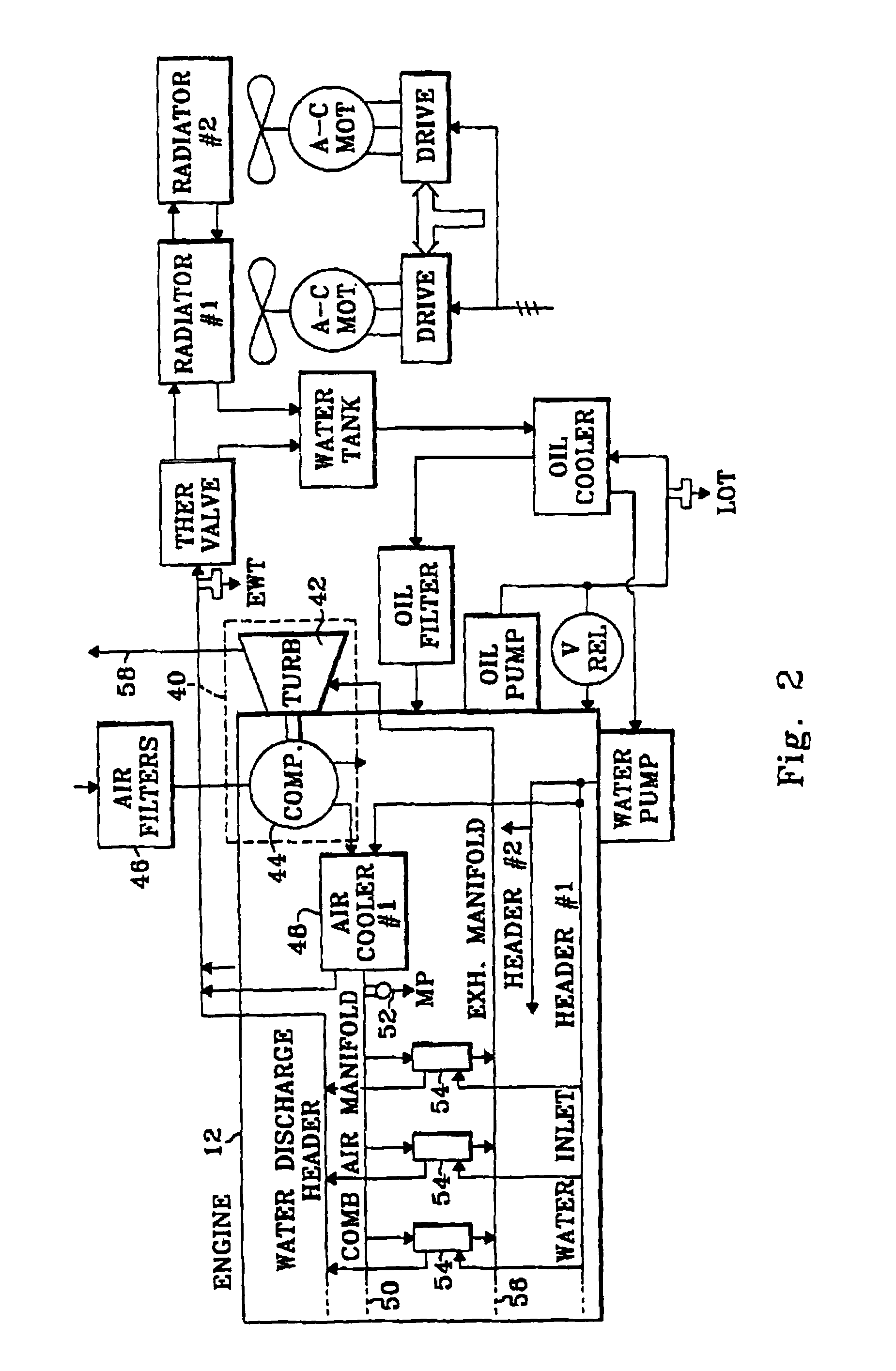

Barometric pressure diesel timing controller

InactiveUS7055504B1Reduce untimely and incomplete combustionEngine efficiencyAnalogue computers for vehiclesElectrical controlEngine efficiencyTurbocharger

A fuel injection timing control system for diesel engines operating at high altitude, including a sensor for a parameter of the engine intake air, such as engine intake air pressure or turbocharger speed. This sensor communicates with a barometric pressure timing controller, and a throttle position sensor communicates with the barometric pressure timing controller. Nominal values of the engine intake air parameter at various throttle notch settings and various engine performance parameters are stored in a table, for a nominal barometric pressure. The barometric pressure timing controller determines the instantaneous barometric pressure by adjusting the nominal barometric pressure based on the difference between the instantaneous value for the engine intake air parameter and the nominal value for the engine intake air parameter, at the known throttle notch setting and the known engine performance parameters. The barometric pressure timing controller then adjusts fuel injection timing in response to the thusly determined barometric pressure and the sensed throttle position, by advancing or retarding the fuel injection timing by predetermined values as the barometric pressure or the throttle position changes. The predetermined values of fuel injection timing are selected to reduce exhaust emissions and increase engine efficiency and performance under various barometric pressure conditions so that the engine may be operated continually and optimally under various barometric pressure conditions.

Owner:GENERAL ELECTRIC CO

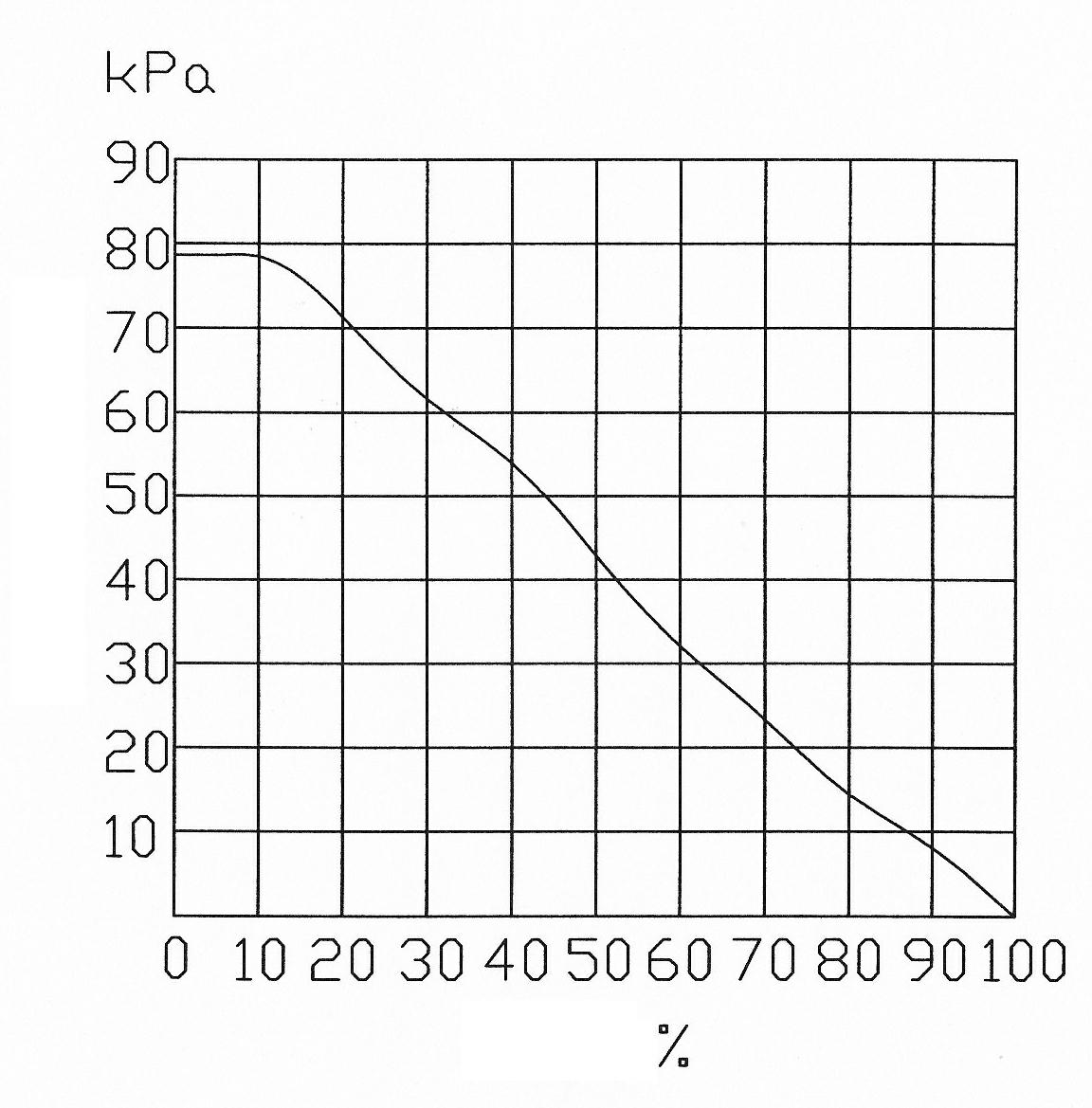

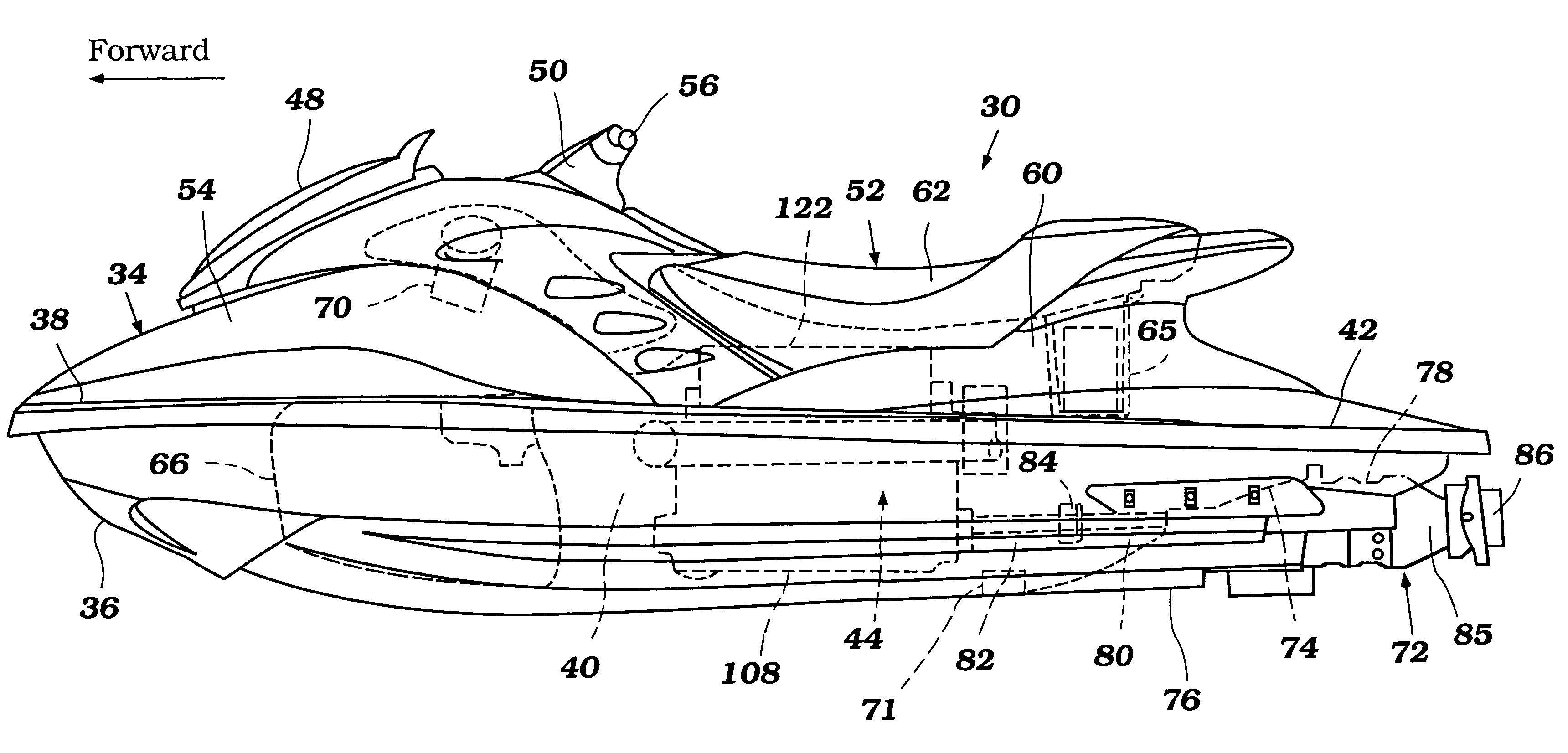

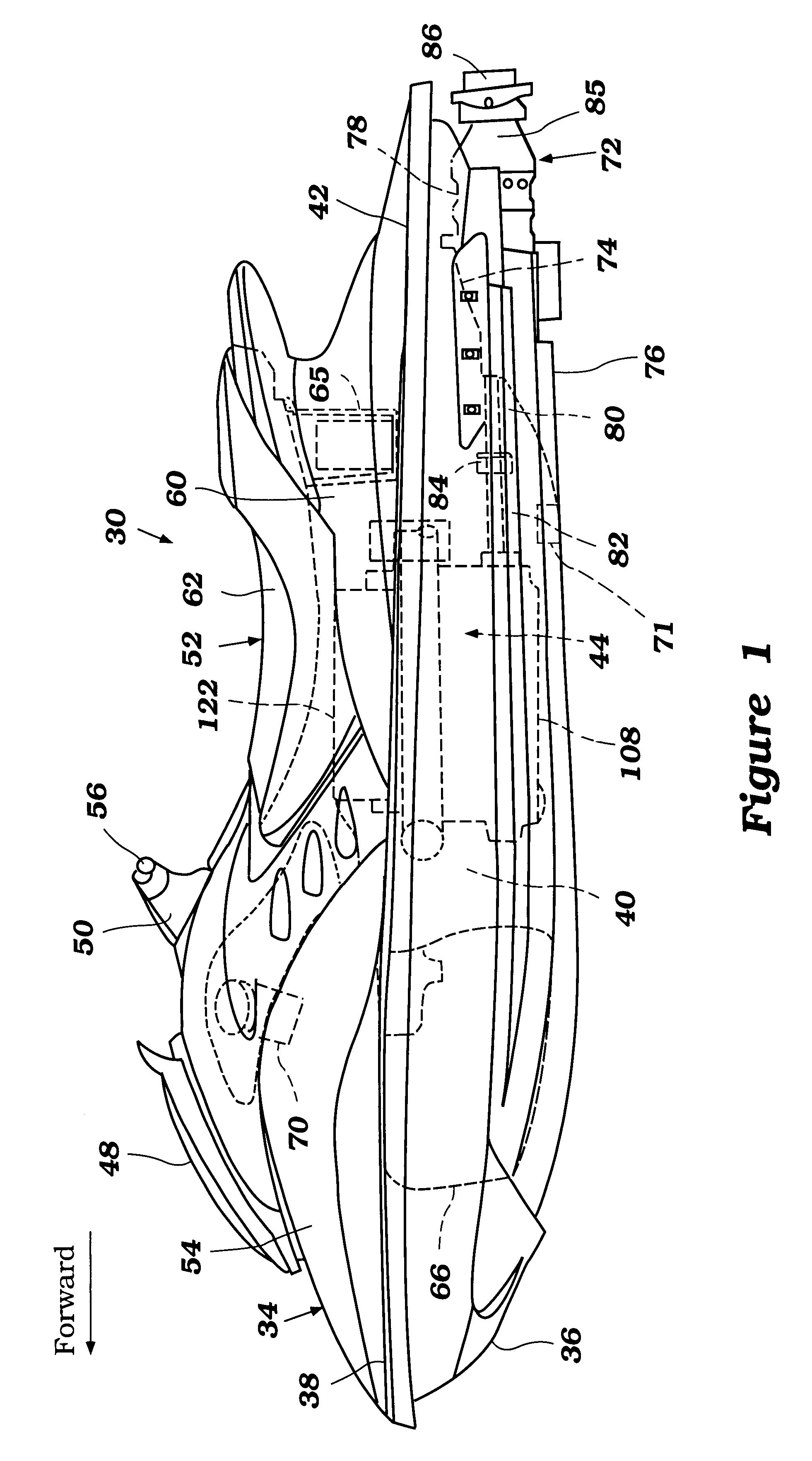

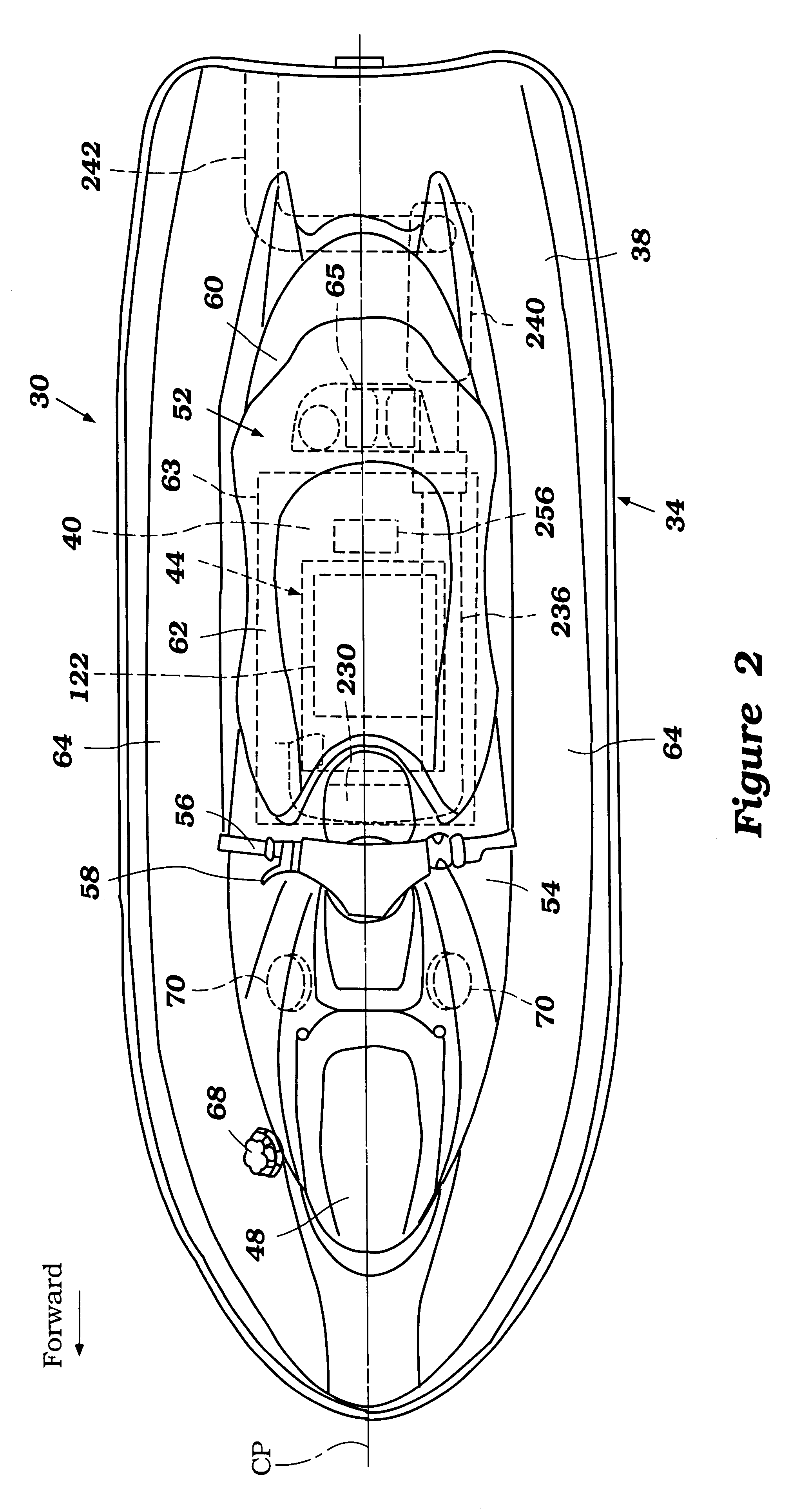

Control system for marine engine

A personal watercraft includes a hull and a jet propulsion unit that propels the hull. An engine powers the jet propulsion unit. The engine includes an air intake system to introduce air to a combustion chamber. The intake system includes a throttle valve to regulate an amount of the air. The throttle valve is moveable generally between a closed position and an open position. A fuel injection system is arranged to spray fuel for combustion in the combustion chamber. The engine also includes an intake pressure sensor, a throttle valve position sensor and an engine speed sensor. A control device is provided to control an amount of the fuel using either a D-j control mode or an alpha-N control mode. The D-j control mode is based upon a signal from the intake pressure sensor and a signal from the engine speed sensor. The alpha-N control mode is based upon a signal from a throttle valve position sensor and the signal from the engine speed sensor. The control device uses the D-j control mode either when the throttle valve is relatively in a low opening degree range or when an engine speed is relatively in a low speed range, and uses the alpha-N control mode either when the throttle valve is relatively in a high opening degree range or when the engine speed is relatively in a high speed range. Additionally, the control device is configured to detect the malfunction of the throttle valve position sensor and the pressure sensor. If the throttle valve position sensor malfunctions, the control device uses only the D-j control mode. If the pressure sensor malfunctions, the control device uses only the alpha-N control mode.

Owner:YAMAHA MARINE KK

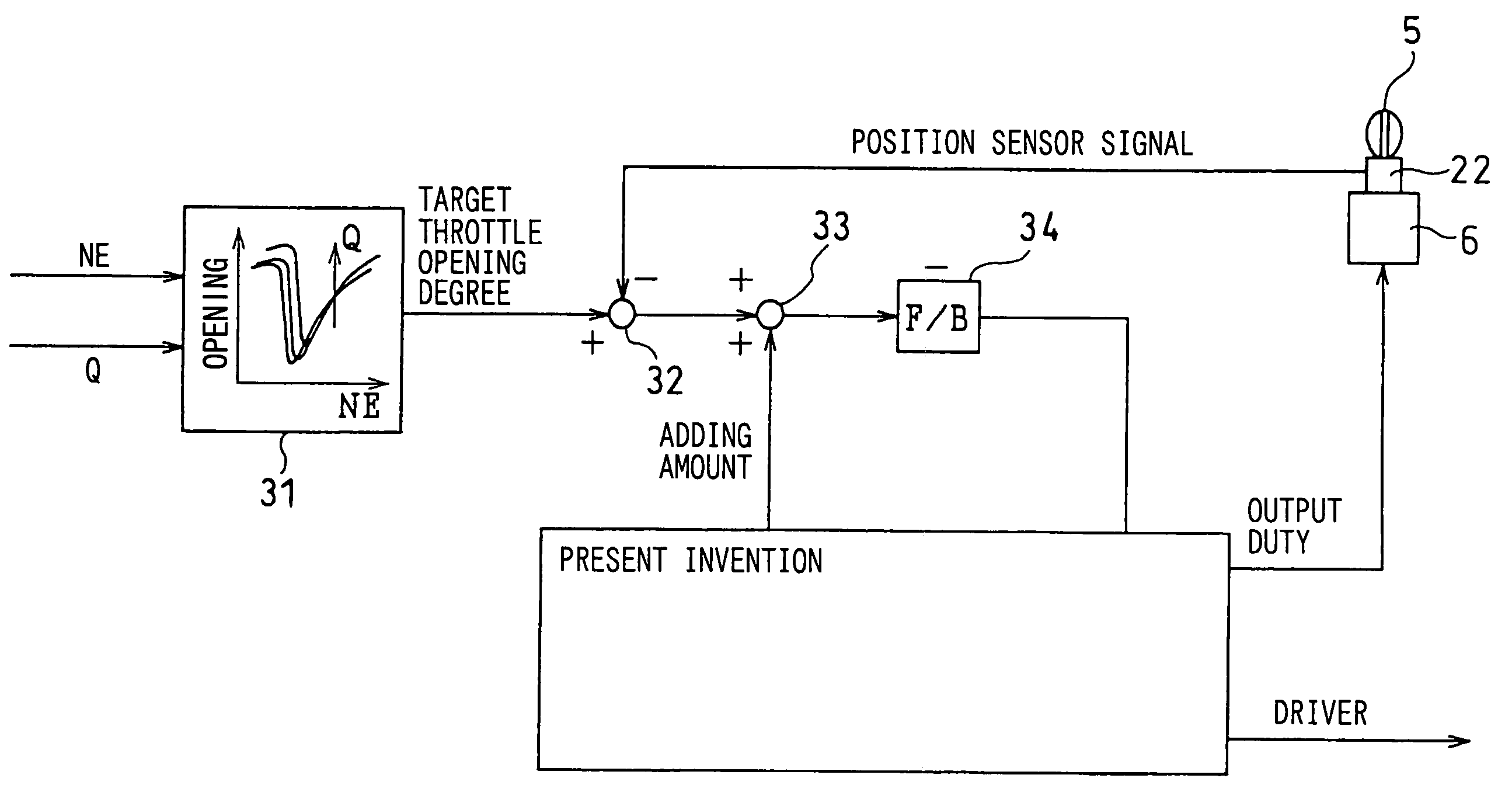

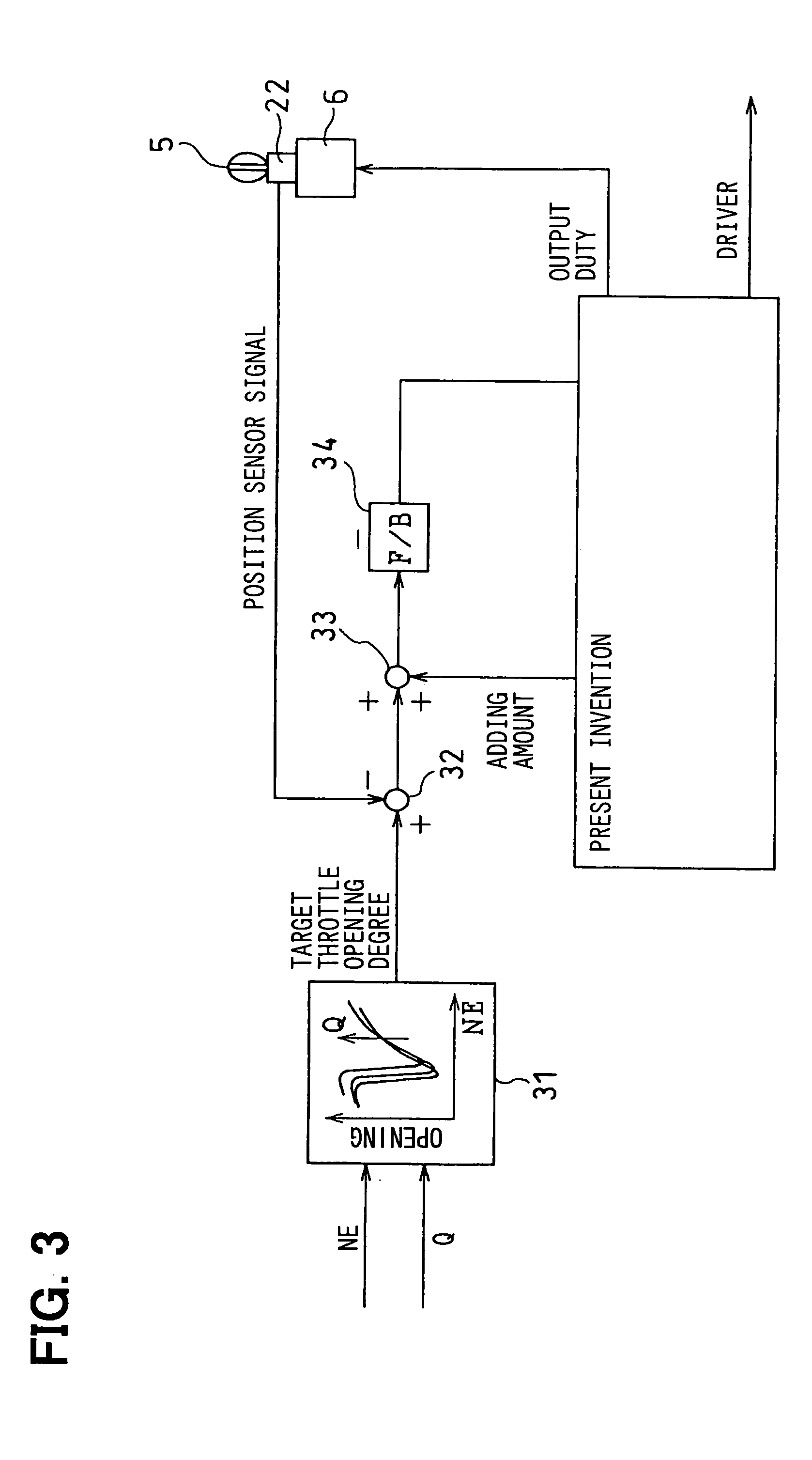

Electronic throttle controller

ActiveUS7017550B2Not deteriorate drivabilityElectrical controlInternal combustion piston enginesElectronic throttleElectronic throttle control

In an electronic throttle controller, when an intake air amount detected by an air flow meter is smaller than a stall prevention judging-purpose each cylinder intake amount, a stall prevention adding amount “large” is added to intake throttle opening degree deviation, a DC motor is driven while neglecting a feedback control operation, and an opening degree of the intake throttle is controlled to be further opened from an actual preceding control position. When an execution number of the engine stop avoiding control is larger than a predetermined number within a predetermined period, an abnormal condition of a throttle position sensor is detected, and thus, energizing operation of the DC motor is stopped. The abnormal condition malfunction of the throttle position sensor can be firmly detected while an engine stall is avoided.

Owner:DENSO CORP

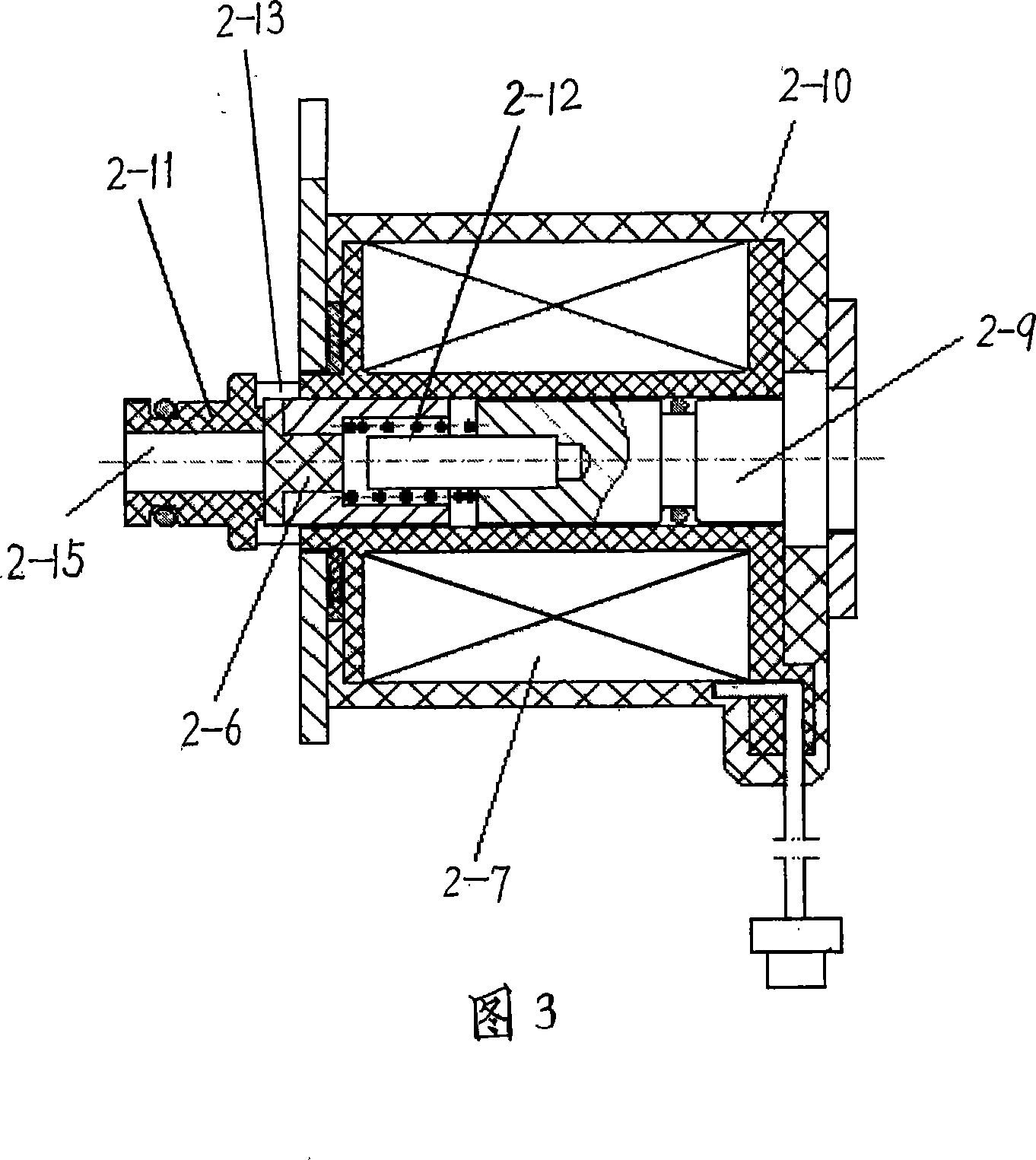

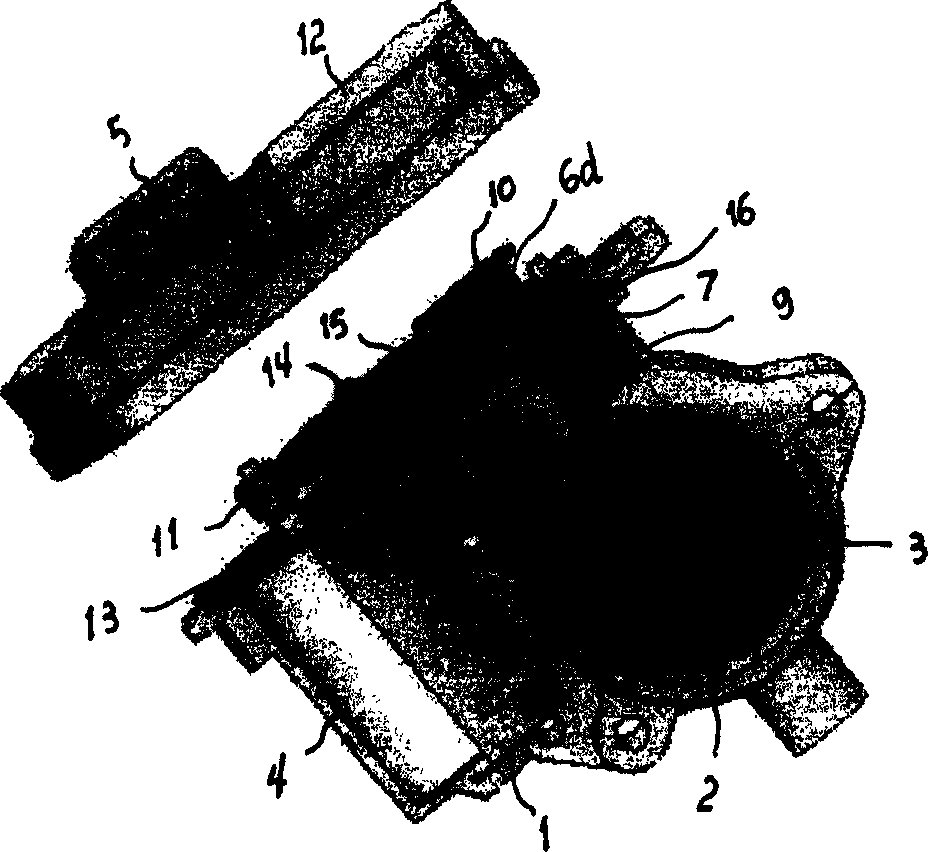

Electronic throttle body

InactiveCN1710267APrecise control of air intakeReduce wearEngine controllersMachines/enginesLow speedElectric machine

This is about a kind of electronic door of saving gas, which belongs to the system of saving air in the engine in the car. It includes the saving gas body, valve chip of saving air, the axis of saving air, DC engine, gear structure for decreasing speed, location sensor and spring, one of whose side is fixed on the body of saving gas, the other side is fixed on the axis of saving gas door. there is also the structure of changing speed. The outside bolt is fixed on the body of saving gas and the inside one on the inside of changing bolt. The spring is fixed between them. In the invention the position is capable to change. The amount of inside gas can be controlled accurately in the low speed, and at the same time it cuts the precision of the production.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

Automotive range extender based on linear ISG(Integrated Starter and Generator) motor/engine

InactiveCN103010037ATake advantage of efficiencyPrice advantagePropulsion using engine-driven generatorsVehicular energy storageSprayerElectric machine

The invention relates to an automotive range extender based on a linear ISG(Integrated Starter and Generator) motor / engine. The range extender comprises cylinders, wherein two piston components are arranged and are respectively located in the two cylinders; the two piston components are connected with the two ends of a connecting rod component; a linear displacement sensor and a Hall sensor are arranged on the connecting rod component; a linear ISG motor rotor is arranged in the middle of the connecting rod component; a linear ISG motor stator is fixed between the two cylinders and outside the linear ISG motor rotor; a scavenging air receiver is arranged on the inner sides of the cylinders; a throttle body is connected with the scavenging air receiver; an oil sprayer, a throttle body position sensor and an air flow sensor are arranged on the throttle body in turn; cylinder covers are arranged on the outer sides of the cylinders; spark plugs are arranged on the cylinder covers; and an electric control unit is respectively in electric connection with the linear displacement sensor, the Hall sensor, the throttle body position sensor and the air flow sensor. Compared with the prior art, the automotive range extender based on the linear ISG motor / engine has the advantages at the aspects of energy use efficiency, cost, mechanical structure, use convenience, and the like.

Owner:TONGJI UNIV

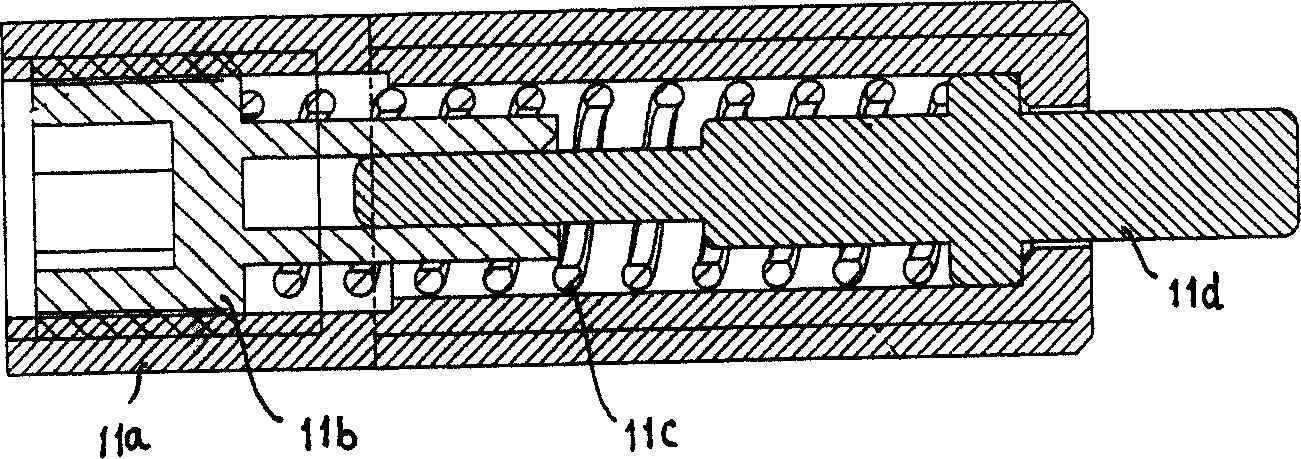

Intake-air control device for internal combustion engine

InactiveUS20070068491A1Reduce displacementDetection output errorEngine testingMagnetic-field-controlled resistorsEngineeringThrottle position sensor

An intake-air control device for an internal combustion engine in which a sensor member can be positioned further accurately is provided. A throttle position sensor includes magnetic field generating means and a magnetic field detecting assembly. The magnetic field detecting assembly includes a plurality of terminal leads, a resin holder secured on the plurality of terminal leads, a sensor member generating a sensor output, and a resin mold body including the plurality of terminal leads, the holder, and the sensor member insert-molded. The resin holder includes a supporting surface which is located on a plane intersecting substantially perpendicularly to an axial line of a throttle shaft, and the sensor member includes a resin mold coat having first and second main surfaces opposing substantially in parallel to each other. The sensor member is held in the resin mold body with the first main surface of the resin mold coat in contact with the supporting surface.

Owner:MITSUBISHI ELECTRIC CORP

Air-fuel ratio controller for internal combustion engine and diagnosis apparatus for intake sensors

InactiveUS7273046B2Improve accuracyLimited robustnessElectrical controlEngine testingLow-pass filterExternal combustion engine

A computer calculates an estimated cylinder-intake-air amount based on outputs from an airflow meter and a throttle position sensor, and then calculates a reference cylinder-intake-air amount based on an air-fuel ratio in an exhaust gas and fuel injection amount. An error of the estimated cylinder-intake-air amount is calculated by comparing the reference cylinder-intake-air amount with an estimated cylinder-intake-air amount base value. The error is low-pass filtered. The estimated cylinder-intake-air amount base value is corrected to obtain the final estimated cylinder-intake-air amount.

Owner:DENSO CORP

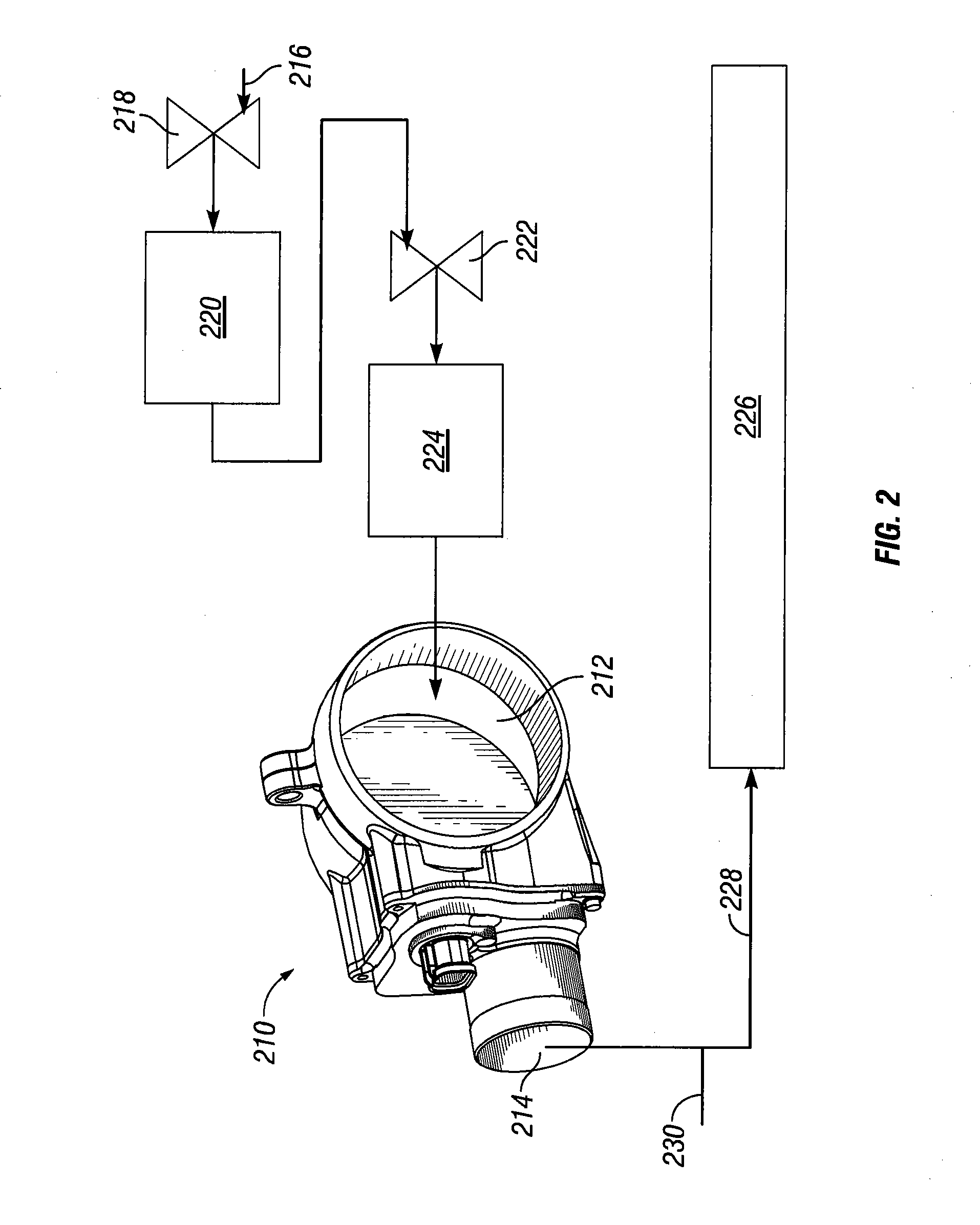

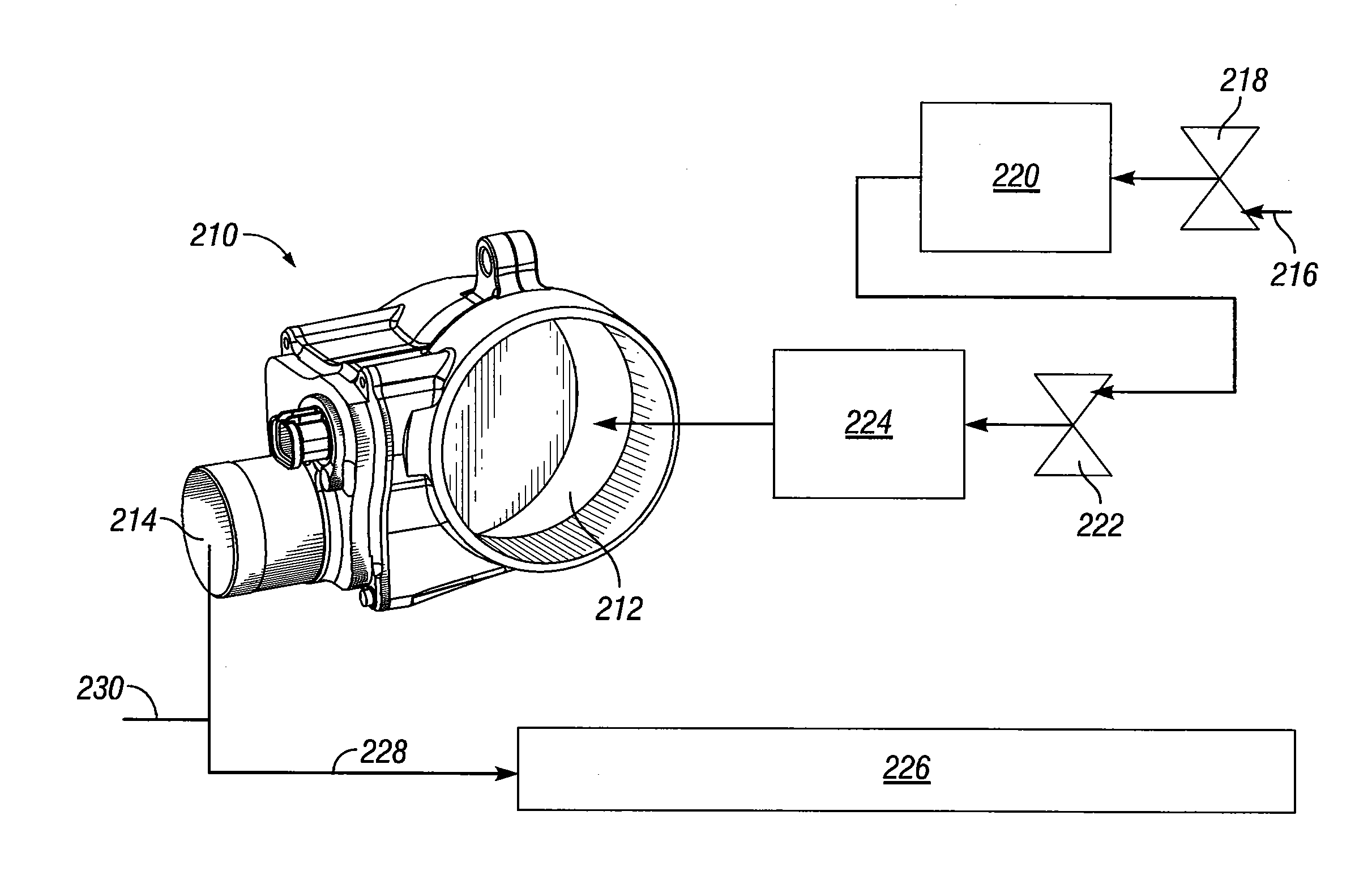

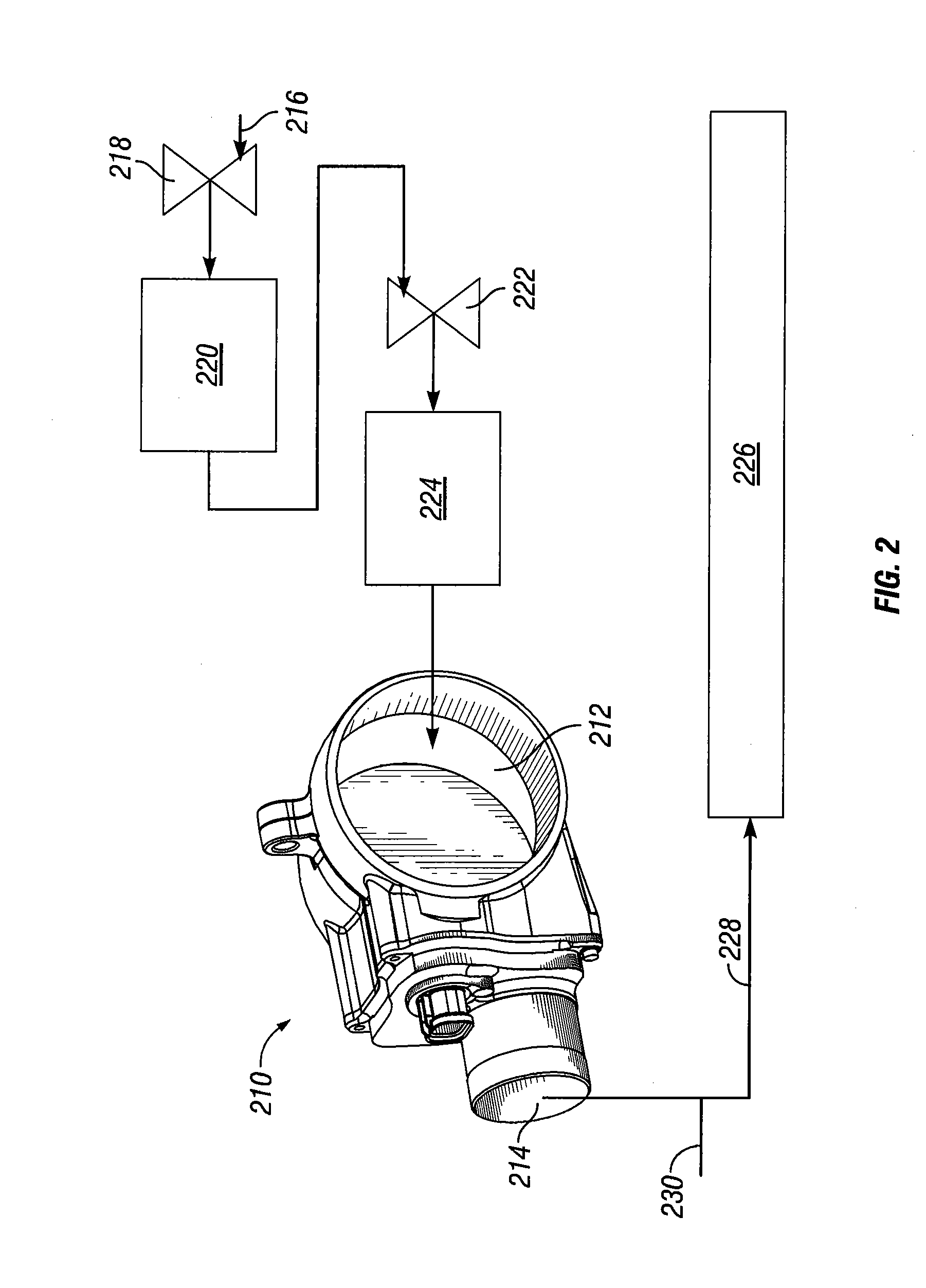

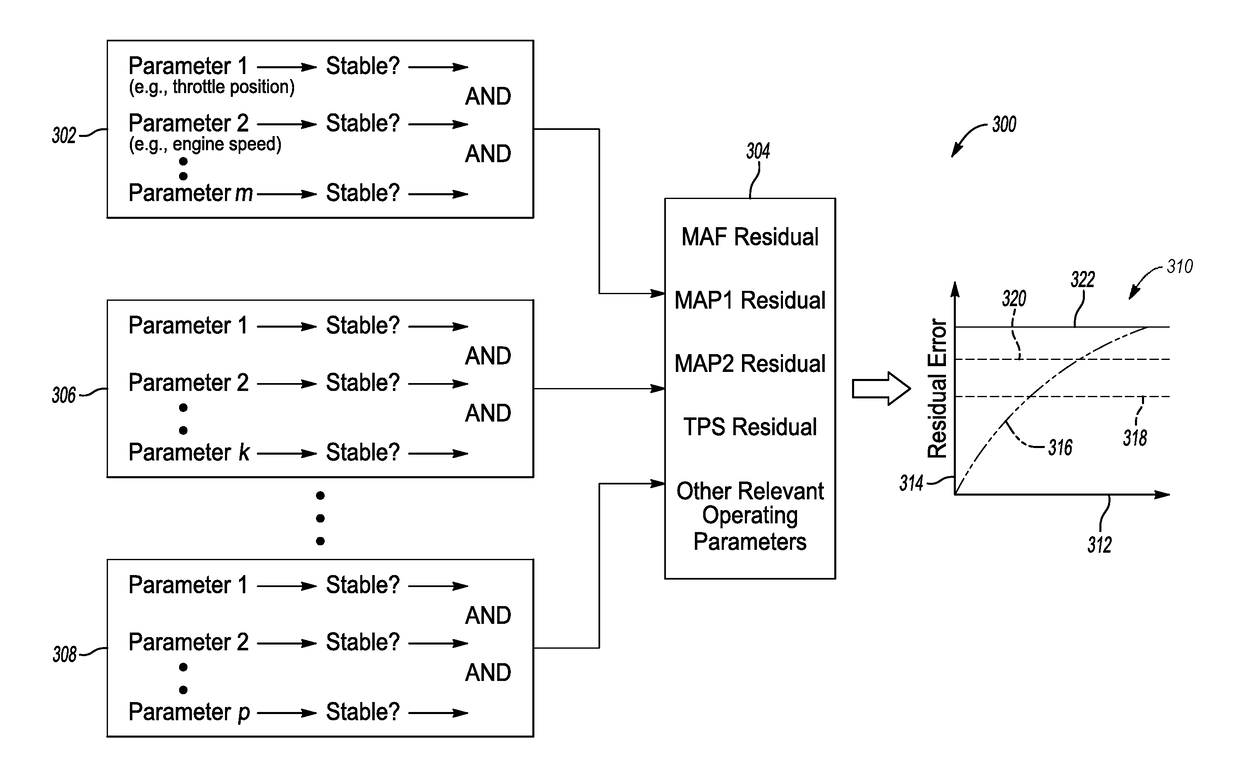

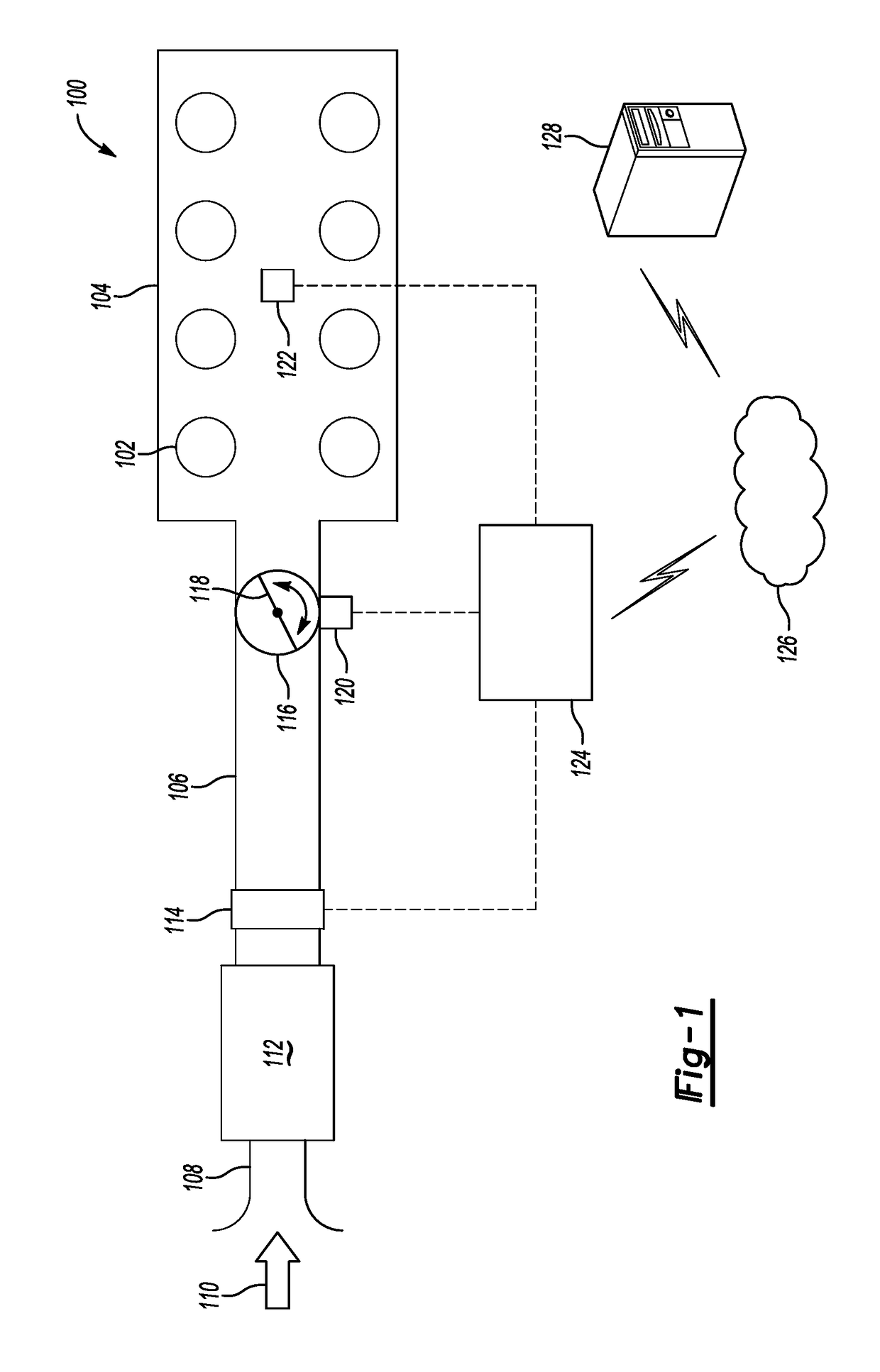

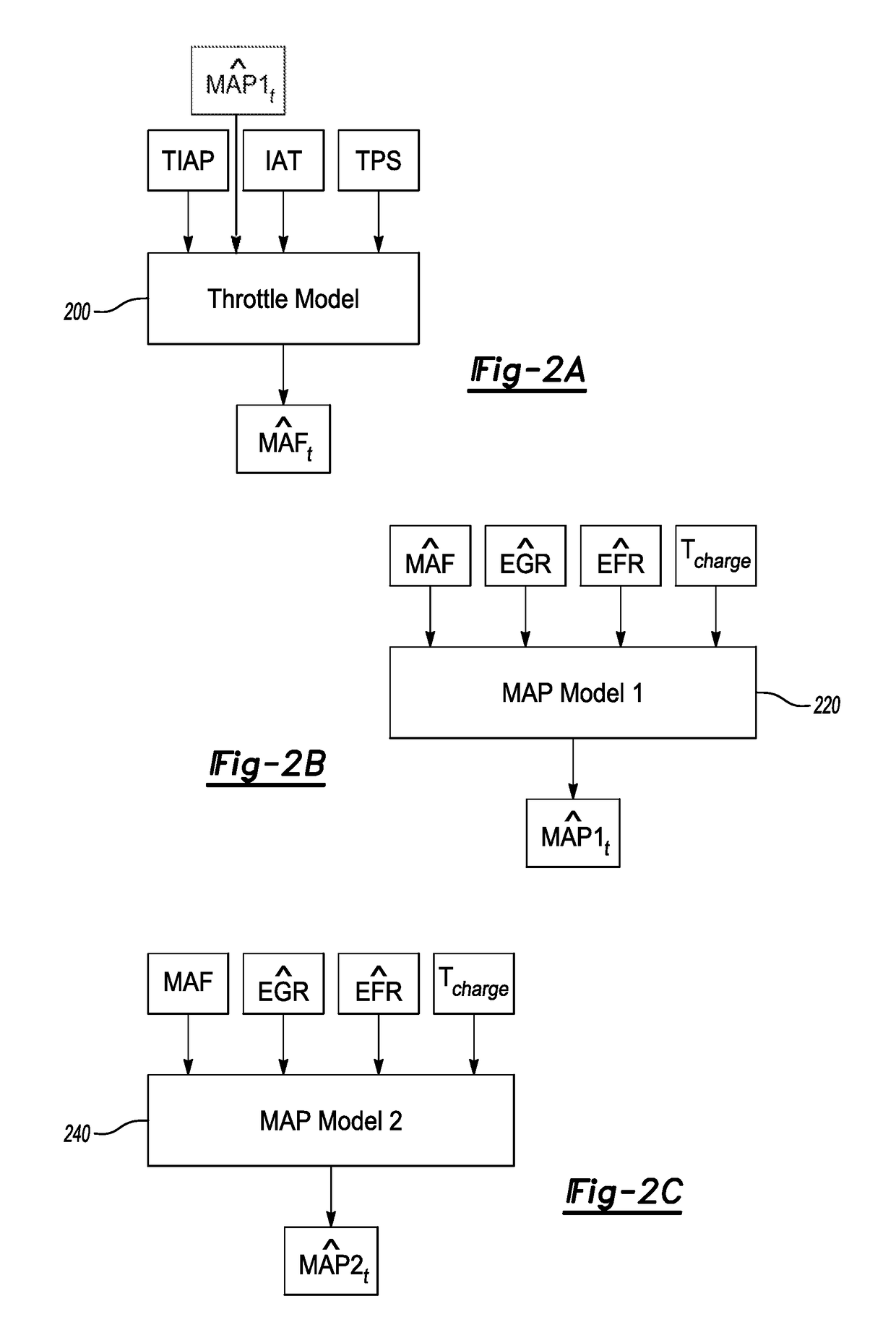

Combustion engine airflow management systems and methods

ActiveUS10026241B1Electrical controlRegistering/indicating working of vehiclesRestricted AirflowCombustion

An engine airflow management system includes an inlet portion to receive ambient air and a mass airflow (MAF) sensor to sense mass flow rate of air passed through the inlet portion. The airflow management system includes a throttle body to selectively restrict airflow and a throttle position sensor (TPS) to sense an opening value of the throttle body. The airflow management system includes an intake manifold in fluid connection with the throttle body configured to direct airflow to a number of combustion cylinders. A manifold air pressure (MAP) sensor detects air pressure at the intake manifold. A controller is programmed to monitor signals from each of the MAF sensor, TPS, and the MAP sensor and generate a residual error value based on a difference between a model-based value and a corresponding monitored signal. A response action is based on a trend of at least two residual error values.

Owner:GM GLOBAL TECH OPERATIONS LLC

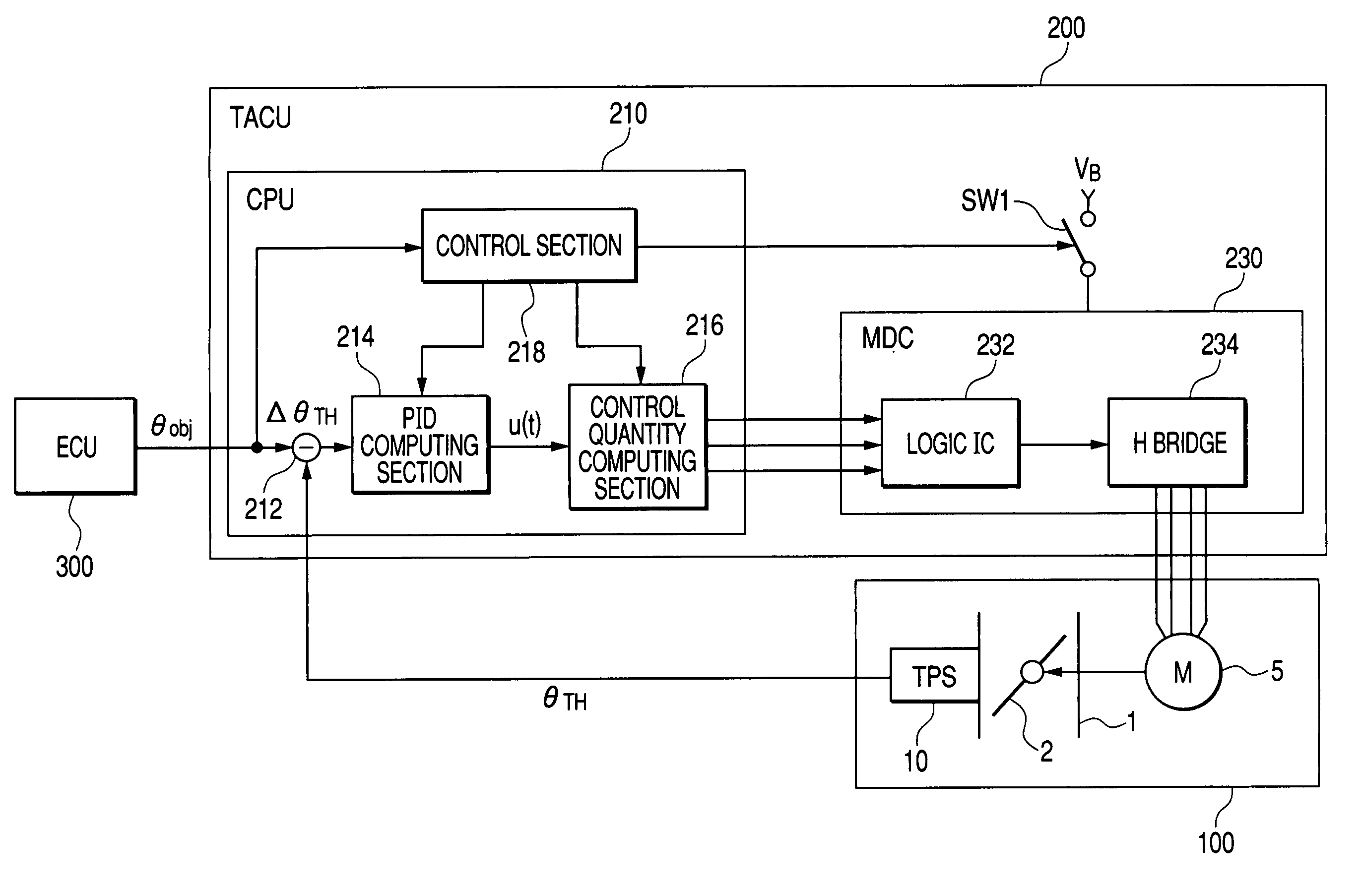

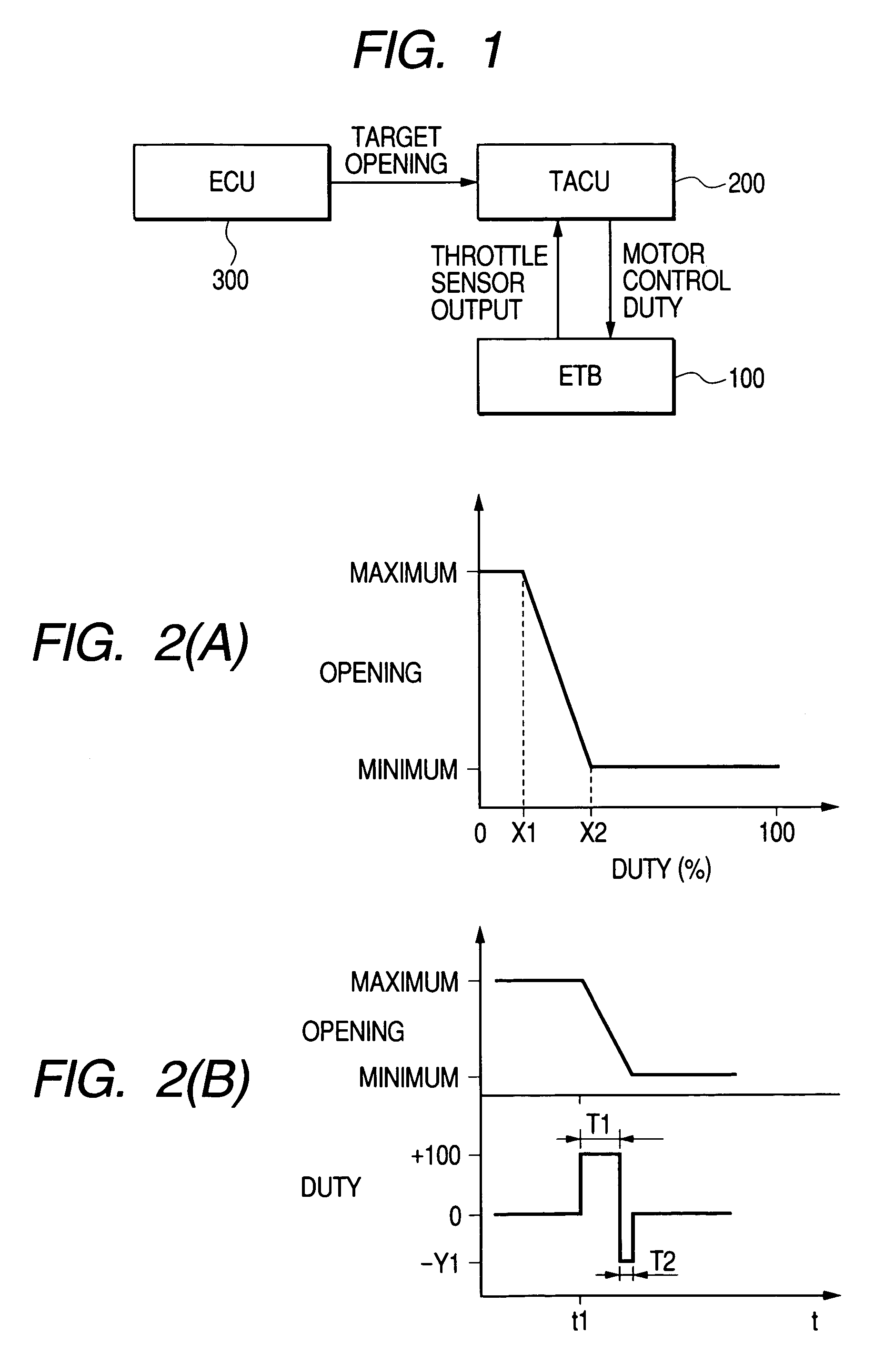

Electronically controlled throttle apparatus

InactiveUS7036486B2Improve reliabilityReduce impactElectrical controlNon-fuel substance addition to fuelEngineeringThrottle position sensor

That is an electronically controlled throttle device comprising a throttle valve held rotatably in a throttle body; an actuator for driving the throttle valve; a return spring which gives a force to return the throttle valve in the full open direction; a throttle position sensor for detecting the opening of the throttle valve; and a throttle actuator control unit for driving the actuator based on the opening of the throttle valve detected by the throttle position sensor and a target opening. Wherein the throttle actuator control unit is provided with a control means which controls the actuator, when EGR control or DPF control has ended, so that the throttle valve turns toward the full open position in a longer period of time than the length of time in which the throttle valve is turned toward the full open position by the return spring only.

Owner:HITACHI LTD

Sensor abnormality detecting method and electronic throttle control apparatus

InactiveUS7603980B2Secure traveling safetyAnalogue computers for vehiclesSafety arrangmentsThrottle controlElectronic throttle control

An electronic throttle control apparatus includes first and second throttle position sensors that detect an opening of a throttle valve for adjusting an amount of supply air to an internal combustion engine, a throttle control unit that controls to drive the throttle valve, first and second accelerator position sensors that detect an operation amount of an accelerator pedal, and an ECU that calculates control parameters for the internal combustion engine on the basis of internal combustion engine operation information including an accelerator opening and a throttle opening and controls a throttle actuator such that a throttle opening position coincides with a target throttle opening position included in the control parameters. The ECU surely detects an abnormality in a sensor output due to contact failure or the like of the throttle position sensors and the accelerator position sensors. As a result, it is possible to provide an electronic throttle control apparatus that can prevent an unintended increase in the number of revolutions of the internal combustion engine, an engine trouble, and the like.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com