Turbocharged gasoline engine system with pulse width regulating valve and method for controlling supercharging pressure

A gasoline engine, pulse width adjustment technology, applied in engine control, combustion engine, machine/engine, etc., can solve the problems of reducing engine power, economic indicators, high boost pressure, affecting the promotion of turbocharging technology, etc. Achieve the effect of avoiding engine knocking, improving dynamic performance and economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

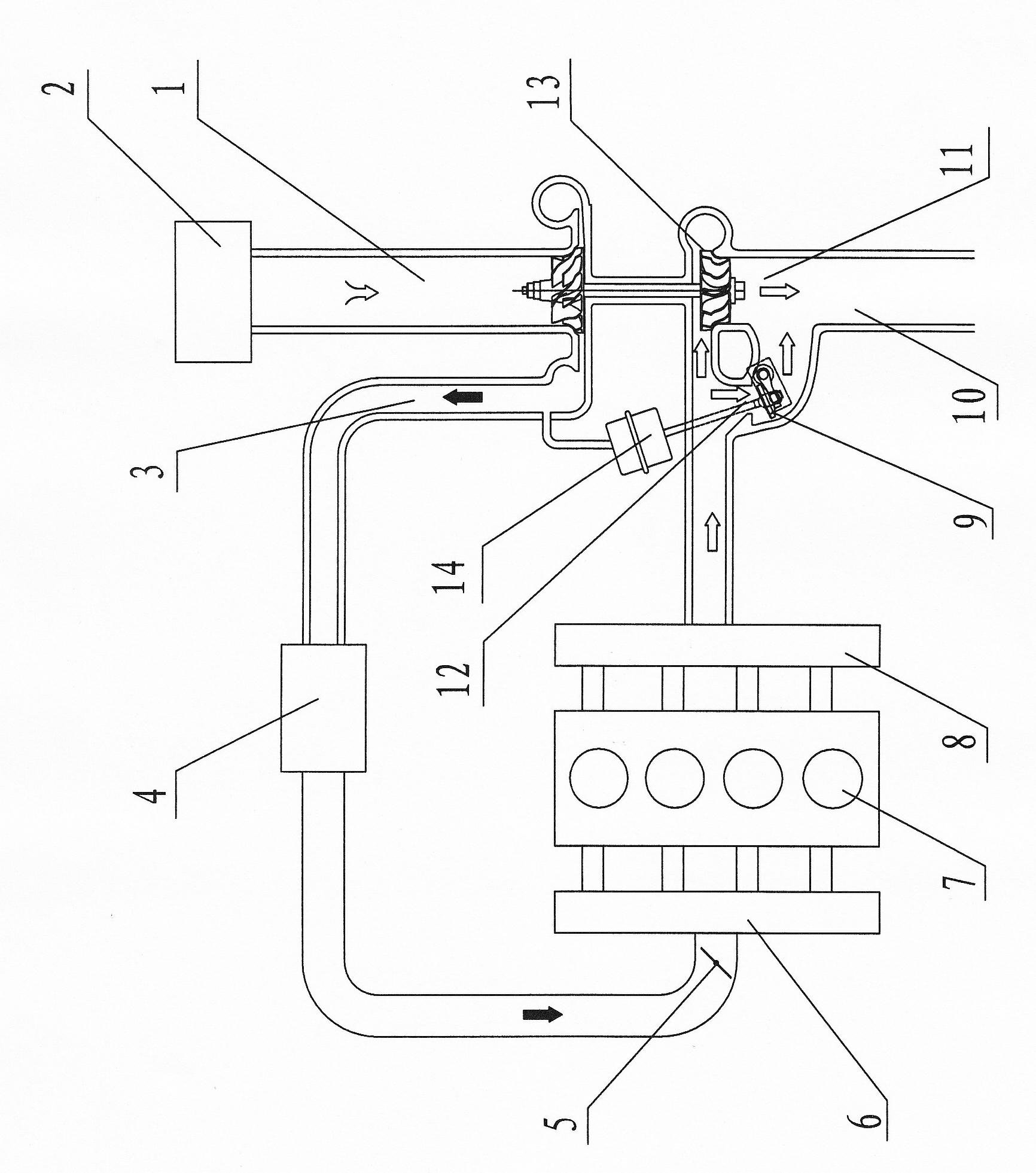

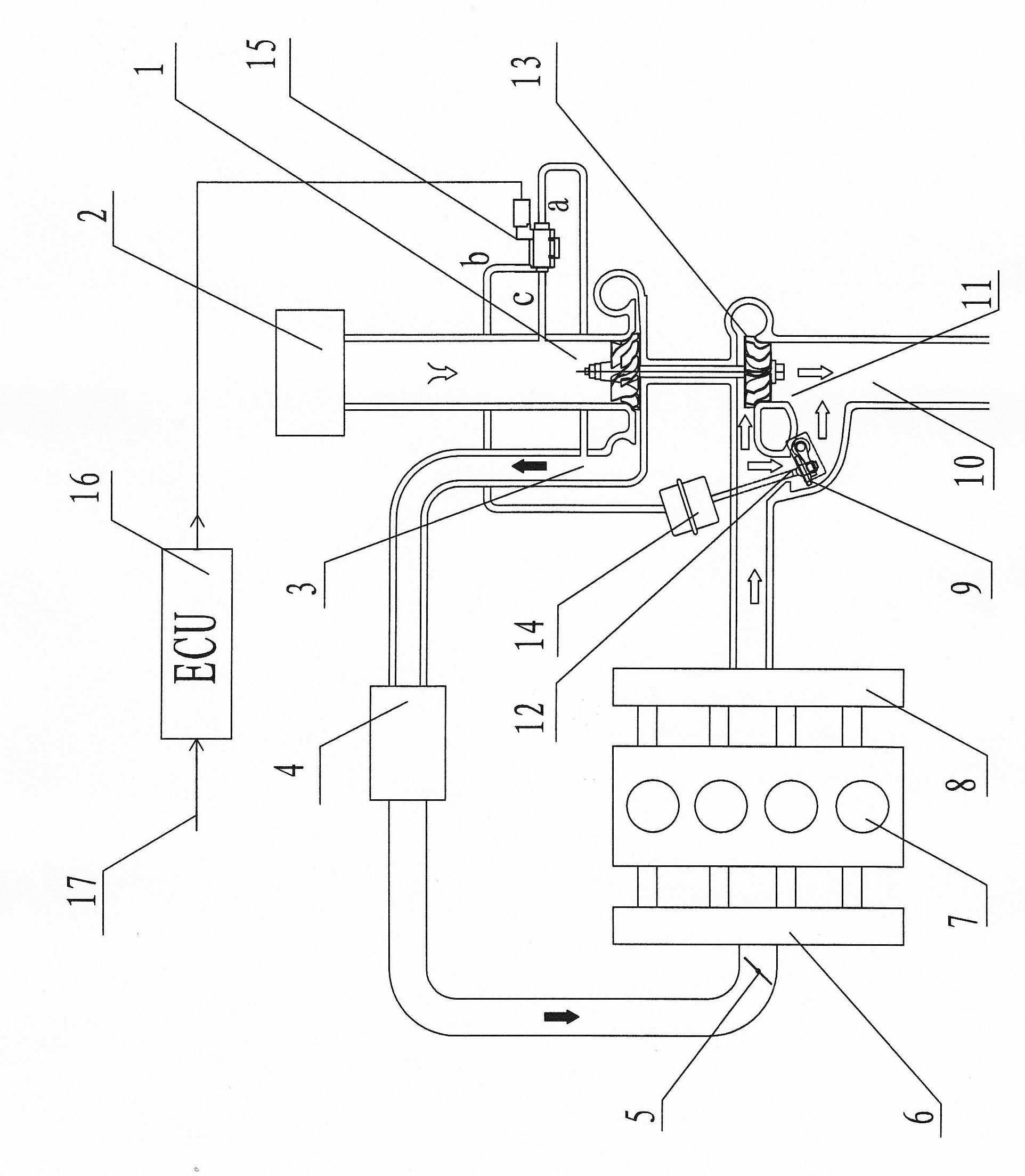

[0033] A turbocharged gasoline engine system with pulse width adjustment valve, which includes turbocharger compressor intake pipe 1, air filter 2, turbocharger compressor outlet pipe 3, intercooler 4, section Valve 5, engine intake manifold 6, engine combustion chamber 7, engine exhaust manifold 8, bleed valve 9, engine exhaust manifold 10, turbocharger turbine box 11, turbine rotor 13, actuator 14, and engine ECU 16 . A waste gas bypass hole 12 is provided at the exhaust gas inlet of the turbine, and a gas release valve 9 is installed at the waste gas bypass hole 12 to control the exhaust gas flow of the waste gas bypass hole 12. The air inlet of the actuator 14 is connected with the outlet pipe 3 of the turbocharger compressor, and the opening and closing of the air release valve 9 is controlled by the actuator 14.

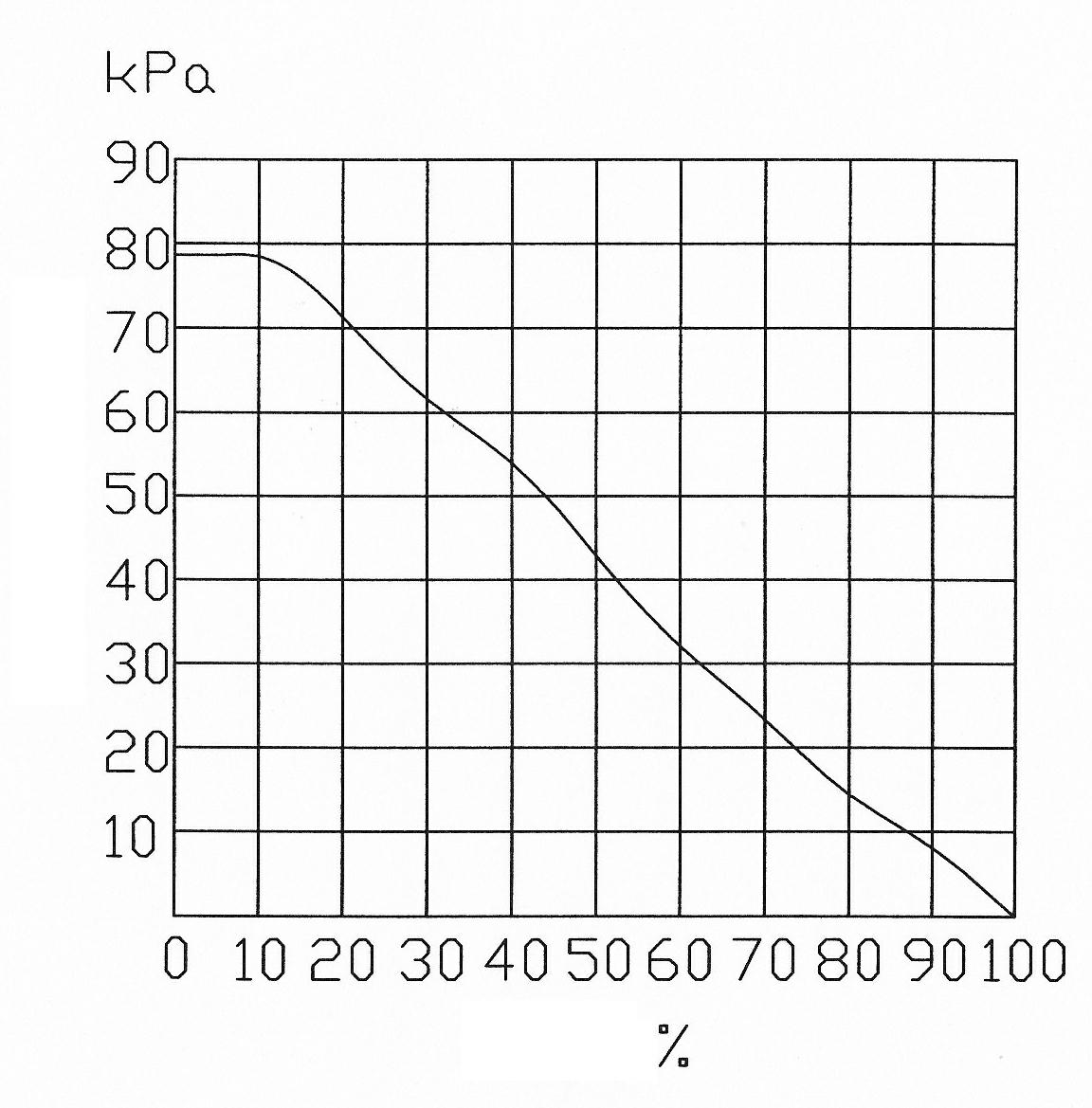

[0034] A two-position three-way pulse width control valve 15 is added to the turbocharged gasoline engine system. The added two-position three-way pulse width co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com