Equipment for manufacturing easy-tear type thin plastic film

A technology of plastic film and manufacturing equipment, applied in the field of manufacturing equipment of easy-tear plastic film, can solve the problems of poor tearing effect, expensive equipment, and high manufacturing cost, and achieve good bonding strength, good surface tension and adhesion performance, and occupation. small space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

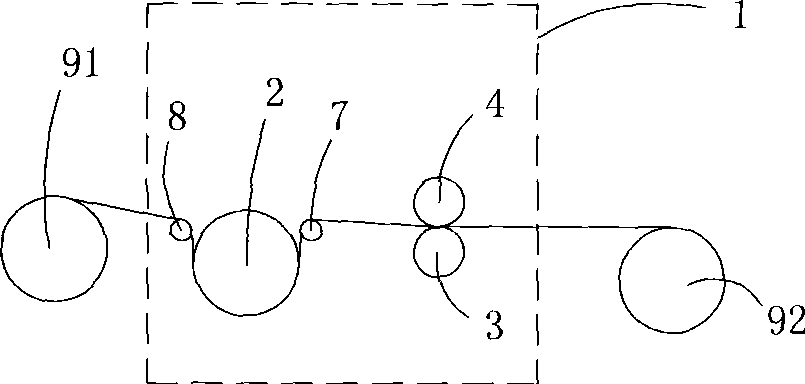

[0030] figure 1 It is a structural schematic diagram of the first structure of the product of the present invention, showing the first specific embodiment of the present invention.

[0031] See figure 1 , the present embodiment is a kind of manufacturing equipment of easy-tear type plastic film, comprises a stretching and regularizing device 1, a discharge reel 91 and a rewinding reel 92; On the direction along film 5 advances, described The unwinding reel 91 is arranged before the stretching and regularizing device 1, and the rewinding reel 92 is arranged after the stretching and regularizing device 1; the unwinding reel 91 releases the plastic film 5, and the rewinding reel 92 rolls Stretch the regular plastic film 5.

[0032] Described each stretch regularizing device 1 comprises the heating roller 2 that is used for heating film 5, is used for the cooling roller 3 that film 5 is cooled, is used to press film 5 on the pressure roller 4 on cooling roller 3, is used for Th...

Embodiment 2

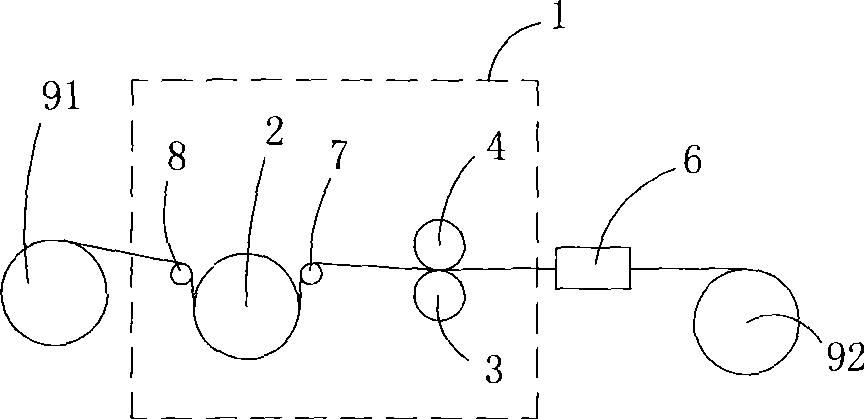

[0035] figure 2 It is a structural schematic diagram of the second structure of the product of the present invention, showing the second specific embodiment of the present invention.

[0036] See figure 2 , the present embodiment is basically the same as Embodiment 1, the difference is that: the equipment also includes a corona treatment device 6; in the direction along the film 5 travel, the corona treatment device 6 is arranged on the stretching regularization device 1 and between the rewinding reel 92. The linear velocity of the cooling roller 3 is 1.1 times of the linear velocity of the heating roller 2 .

[0037] In this embodiment, the corona treatment device can ensure that the finally obtained finished film has better surface tension and adhesion performance, and has better bonding strength when the external additional layer is compounded. The cooling roll is a driving roll, the press roll and the cooling roll are arranged in pairs, and the film passes between the...

Embodiment 3

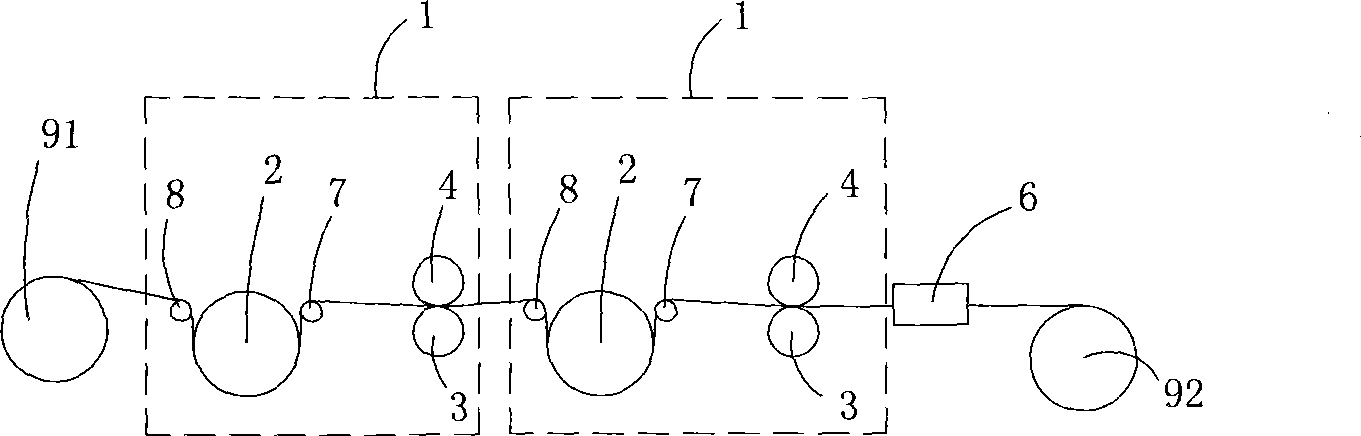

[0039] image 3 It is a structural schematic diagram of the third structure of the product of the present invention, showing the third specific embodiment of the present invention.

[0040] See image 3 , the present embodiment is basically the same as Embodiment 2, the difference is that: the number of the stretching regularization device 1 is two, and the two stretching regularization devices 1 are successively arranged in series repeatedly, and the film 5 is carried out according to the same direction. Stretch regularization. The linear velocity of the cooling roller 3 is 5 times of the linear velocity of the heating roller 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com