Efficient screening crushing device used for rare earth carbonate

A crushing device and rare earth carbonate technology, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems that rare earth carbonate cannot be screened and crushed, and achieve the effects of high screening and crushing efficiency, easy maintenance and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

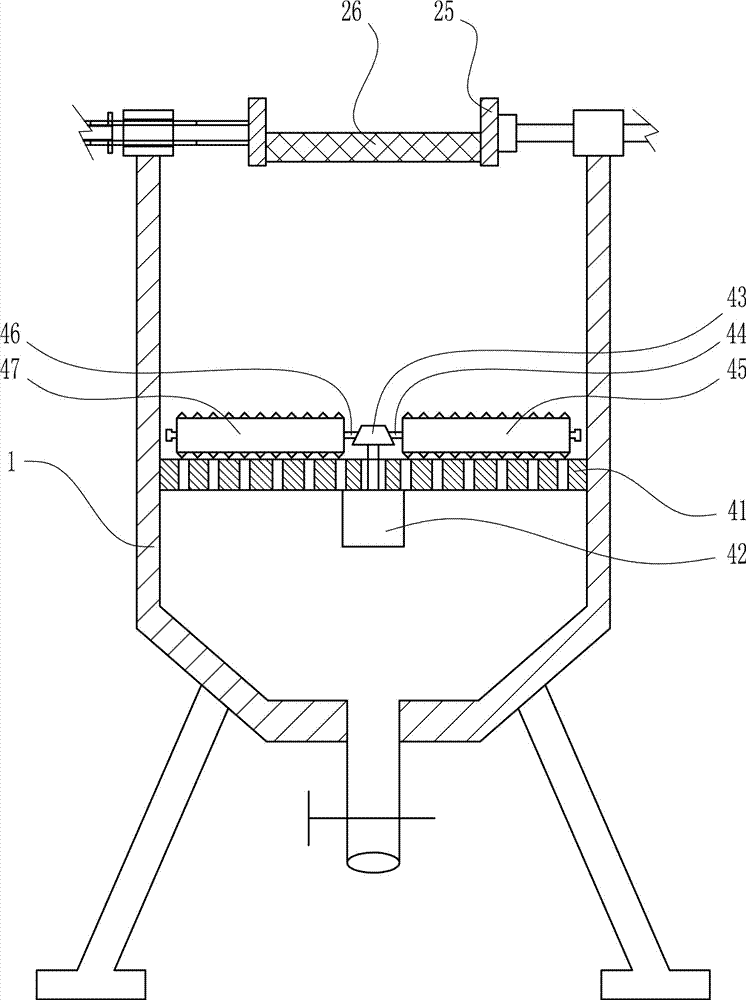

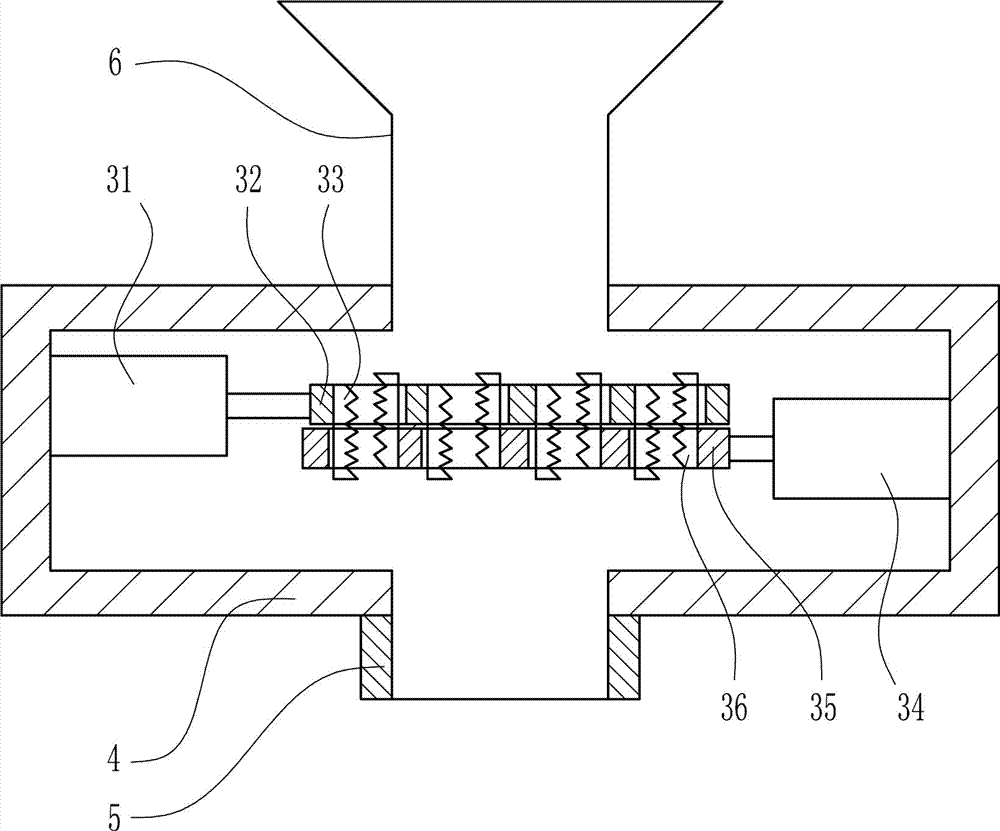

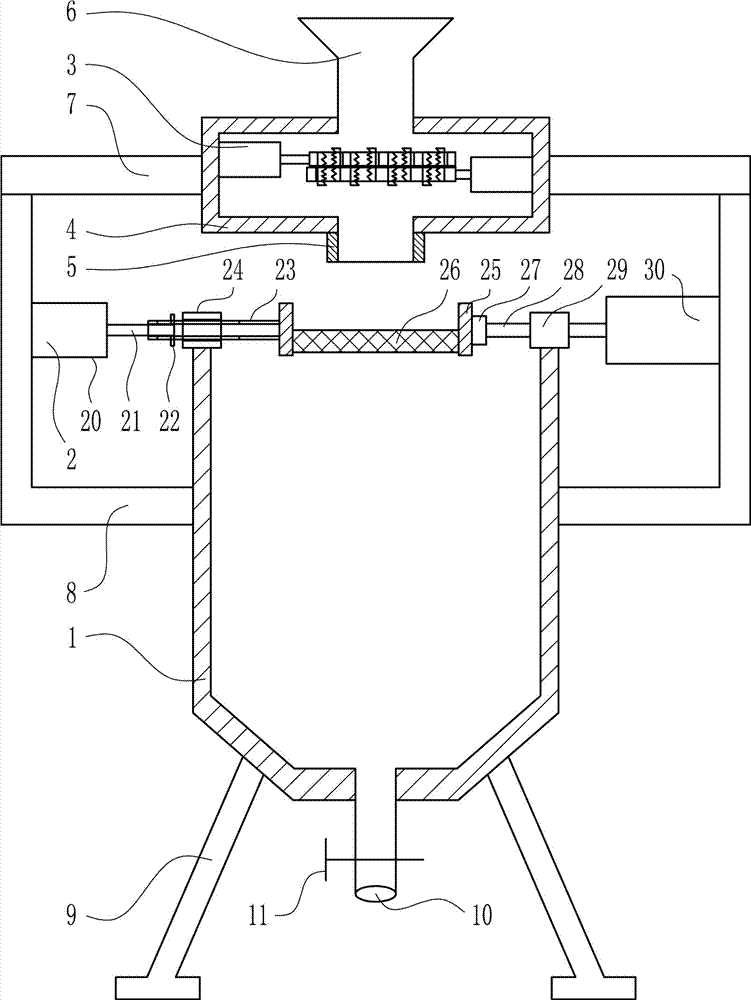

[0029] A high-efficiency screening and crushing device for rare earth carbonate, such as Figure 1-5 As shown, it includes a cylinder 1, a screening device 2, a crushing device 3, a crushing bin 4, a discharge pipe 5, a hopper 6, a connecting plate 7, an L-shaped fixing plate 8, a leg 9, a discharge pipe 10 and The valve 11; the top of the cylinder 1 is open, and the sieving device 2 is arranged above the cylinder 1, and the crushing device 3 is arranged above the sieving device 2, and the crushing device 3 is arranged in the crushing bin 4, The bottom of the crushing bin 4 is welded with a discharge pipe 5, the discharge pipe 5 is connected with the crushing bin 4, and the top of the crushing bin 4 is welded with a feeding hopper 6, and the feeding hopper 6 is connected with the crushing bin 4. A connecting plate 7 is arranged symmetrically on both sides, and the connecting plate 7 is connected to the side wall of the crushing bin 4 by welding, and an L-shaped fixing plate 8 ...

Embodiment 2

[0031] A high-efficiency screening and crushing device for rare earth carbonate, such as Figure 1-5 As shown, it includes a cylinder 1, a screening device 2, a crushing device 3, a crushing bin 4, a discharge pipe 5, a hopper 6, a connecting plate 7, an L-shaped fixing plate 8, a leg 9, a discharge pipe 10 and The valve 11; the top of the cylinder 1 is open, and the sieving device 2 is arranged above the cylinder 1, and the crushing device 3 is arranged above the sieving device 2, and the crushing device 3 is arranged in the crushing bin 4, The bottom of the crushing bin 4 is welded with a discharge pipe 5, the discharge pipe 5 is connected with the crushing bin 4, and the top of the crushing bin 4 is welded with a feeding hopper 6, and the feeding hopper 6 is connected with the crushing bin 4. A connecting plate 7 is arranged symmetrically on both sides, and the connecting plate 7 is connected to the side wall of the crushing bin 4 by welding, and an L-shaped fixing plate 8 ...

Embodiment 3

[0034] A high-efficiency screening and crushing device for rare earth carbonate, such as Figure 1-5 As shown, it includes a cylinder 1, a screening device 2, a crushing device 3, a crushing bin 4, a discharge pipe 5, a hopper 6, a connecting plate 7, an L-shaped fixing plate 8, a leg 9, a discharge pipe 10 and The valve 11; the top of the cylinder 1 is open, and the sieving device 2 is arranged above the cylinder 1, and the crushing device 3 is arranged above the sieving device 2, and the crushing device 3 is arranged in the crushing bin 4, The bottom of the crushing bin 4 is welded with a discharge pipe 5, the discharge pipe 5 is connected with the crushing bin 4, and the top of the crushing bin 4 is welded with a feeding hopper 6, and the feeding hopper 6 is connected with the crushing bin 4. A connecting plate 7 is arranged symmetrically on both sides, and the connecting plate 7 is connected to the side wall of the crushing bin 4 by welding, and an L-shaped fixing plate 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com