Mine trackless transport engine

A technology for trackless transportation and locomotives, applied in locomotives, motor vehicles, electric locomotives, etc., can solve the problems of heavy motor weight, inconvenient maintenance, and large size, and achieve the effect of small motor weight, convenient maintenance, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

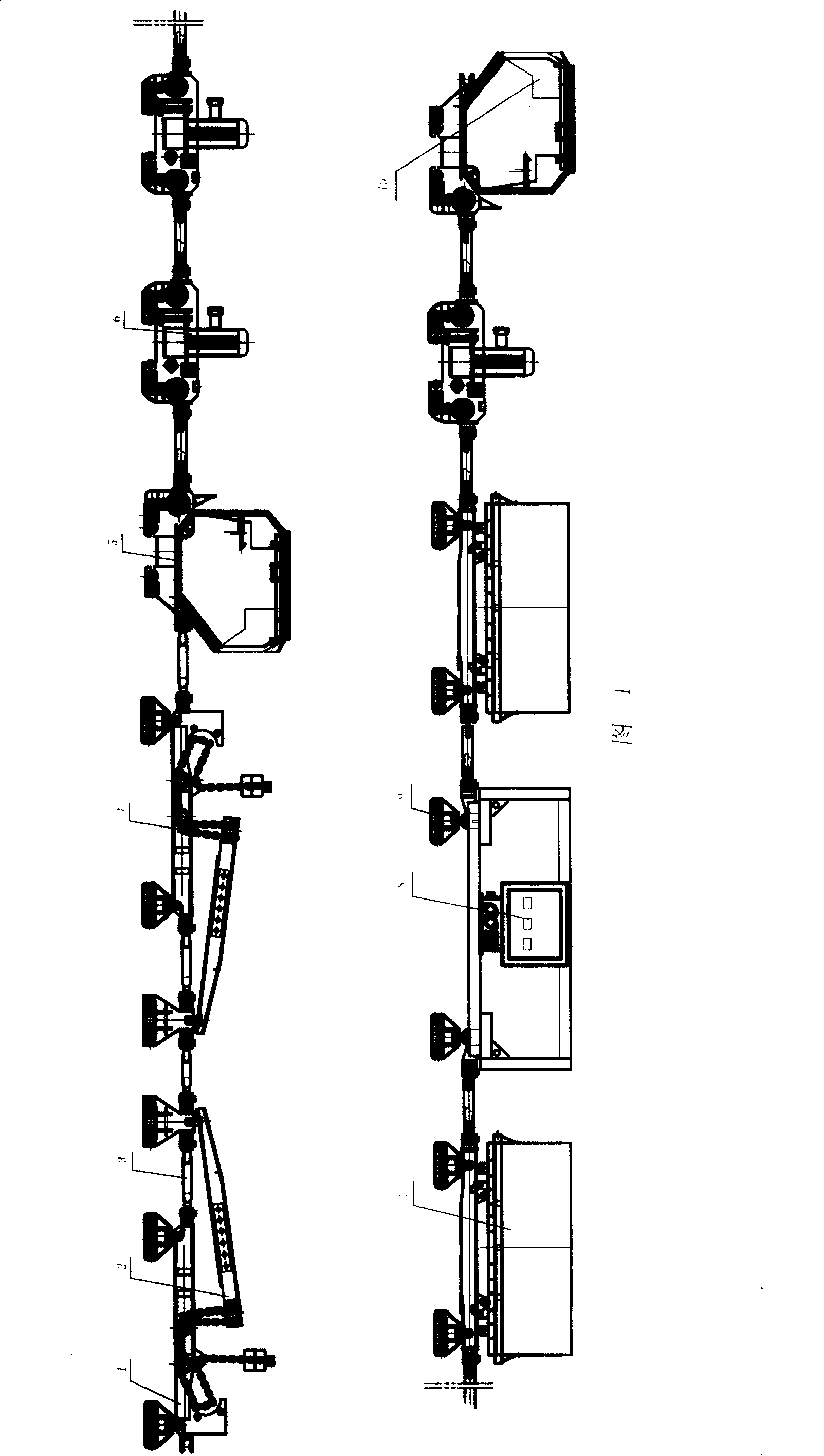

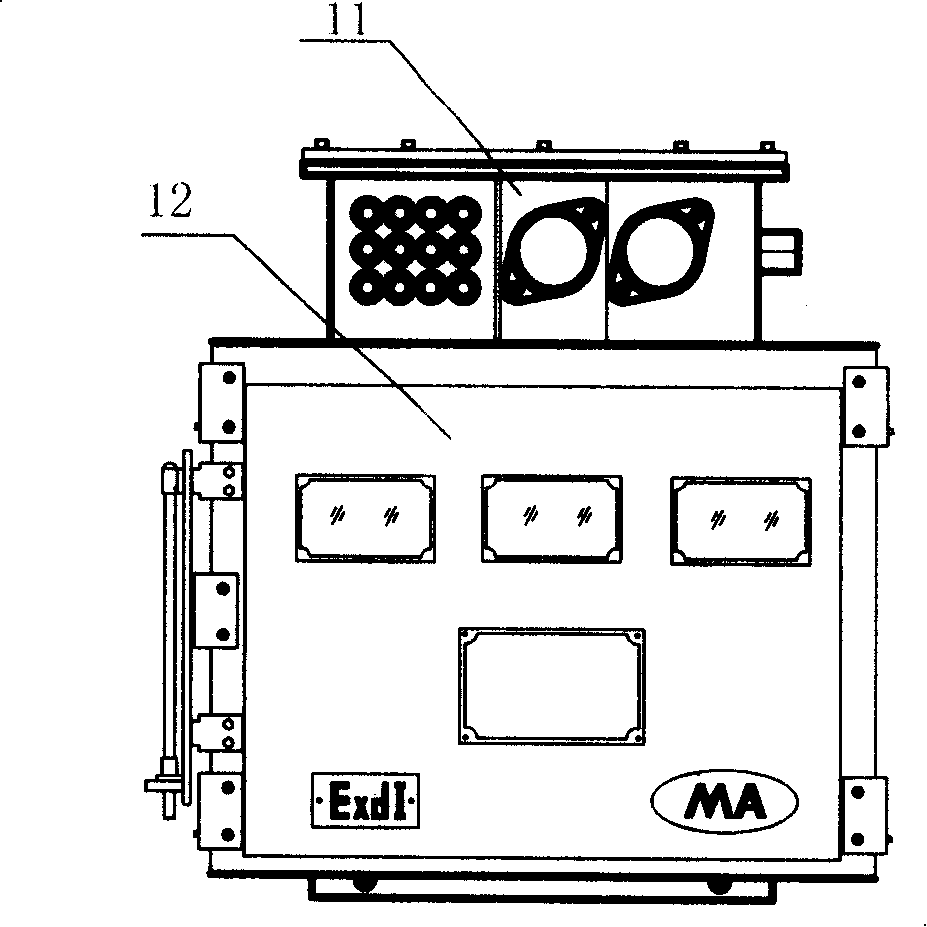

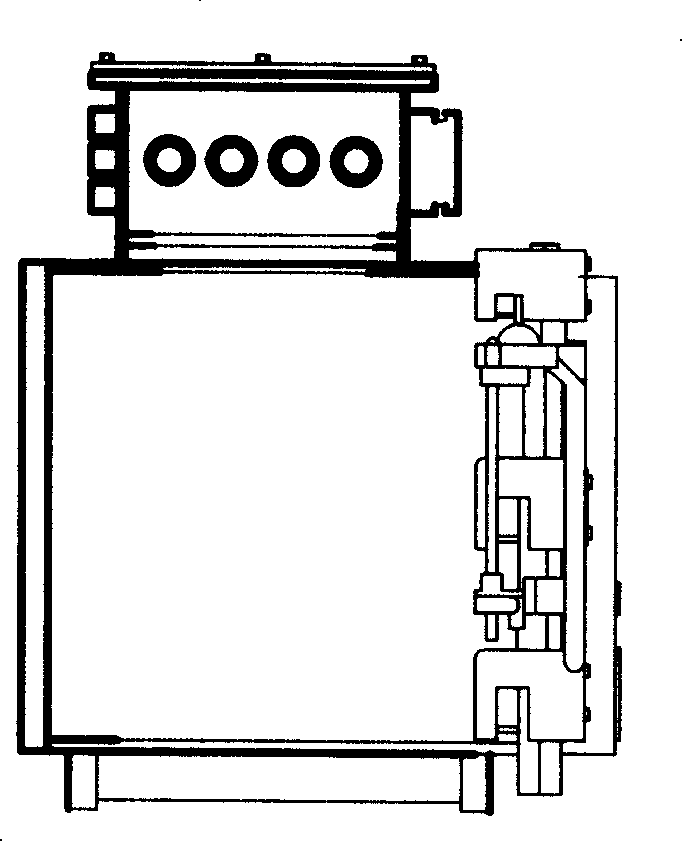

[0042] The composition of the mine trackless transport locomotive according to the invention is shown in FIG. 1 . It is mainly composed of driver's cab 5, driving device 6, battery box 7, electric control box 8, carrying trolley 9, lifting device, connecting rod 3, hydraulic system, and electric control system. The trackless transport locomotive relies on the carrying trolley 9 to hang and run under the guide rail.

[0043] 1. Driver's cab 5: There are two front and rear cabs, which are respectively installed at the two ends of the trackless transport locomotive. In the driver's cab 5, there is a control display stand 10, and a control panel and a display panel are housed on the control display stand 10 for the driver to operate. There is no distinction between the two cabs, and the operating rights are equal. Whichever operates first will ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com