Patents

Literature

186results about How to "Achieving Quantitative Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D printing method for adding reinforcement-ratio based directional fibers into binding materials

ActiveCN106313272AAchieving Quantitative ControlReduce distractionsAdditive manufacturing apparatusCeramic shaping apparatusFiberEngineering

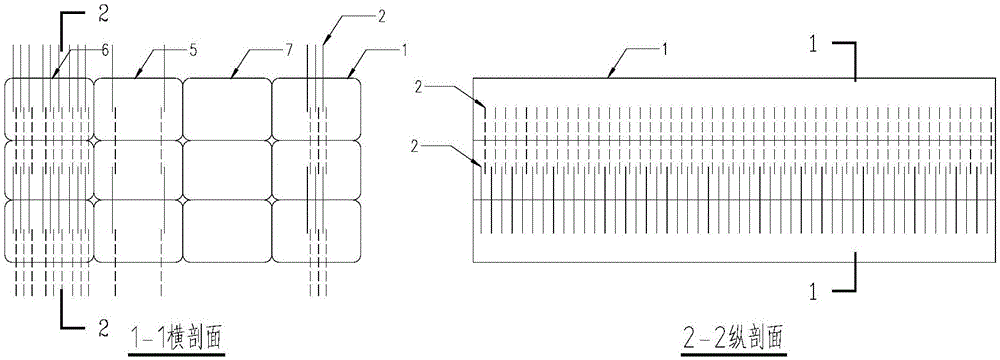

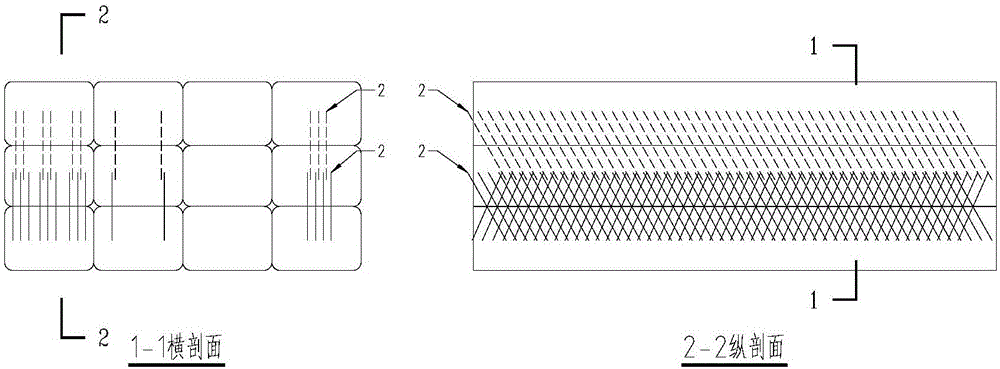

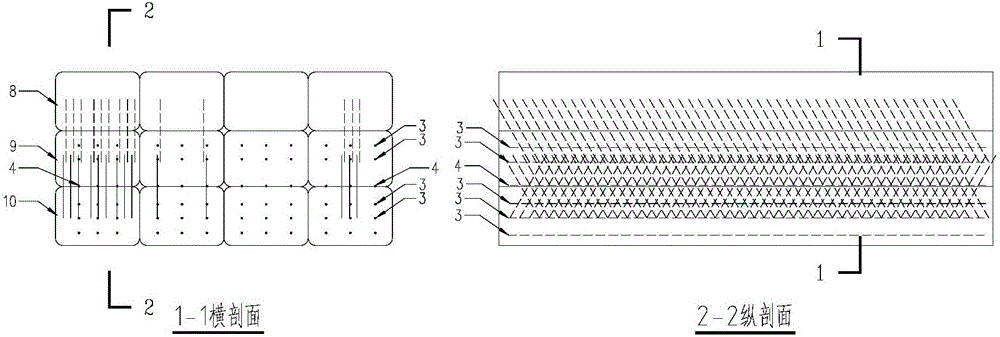

The invention discloses a 3D printing method for adding reinforcement-ratio based directional fibers into binding materials. The technical idea of the invention is to convert the amount of the corresponding cross-section steel bars into the corresponding amount of the drawn fibers, and according to the direction and position of the reinforcing bar arrangement, and to arrange the reinforcing bars in the fixed direction, fixed quantity and position. The 3D printing method comprises, step 1, using the 3D printer technology with two printing heads, one of which is to print normal concrete layer by layer; step 2, when in the reinforcing bar position to be printed, using the other printing head to print steel fibers by being perpendicular to the concrete according to the needed fiber amount; step 3, inserting the steel fibers into the printed concrete and reserving a part of length outside the layers; step 4, when to print the next layer of concrete, covering the exposed fibers with the reprinted concrete, and having the fibers printed later overlapped in the length direction so as to ensure the transmission of bond anchor force; and others.

Owner:TONGJI UNIV

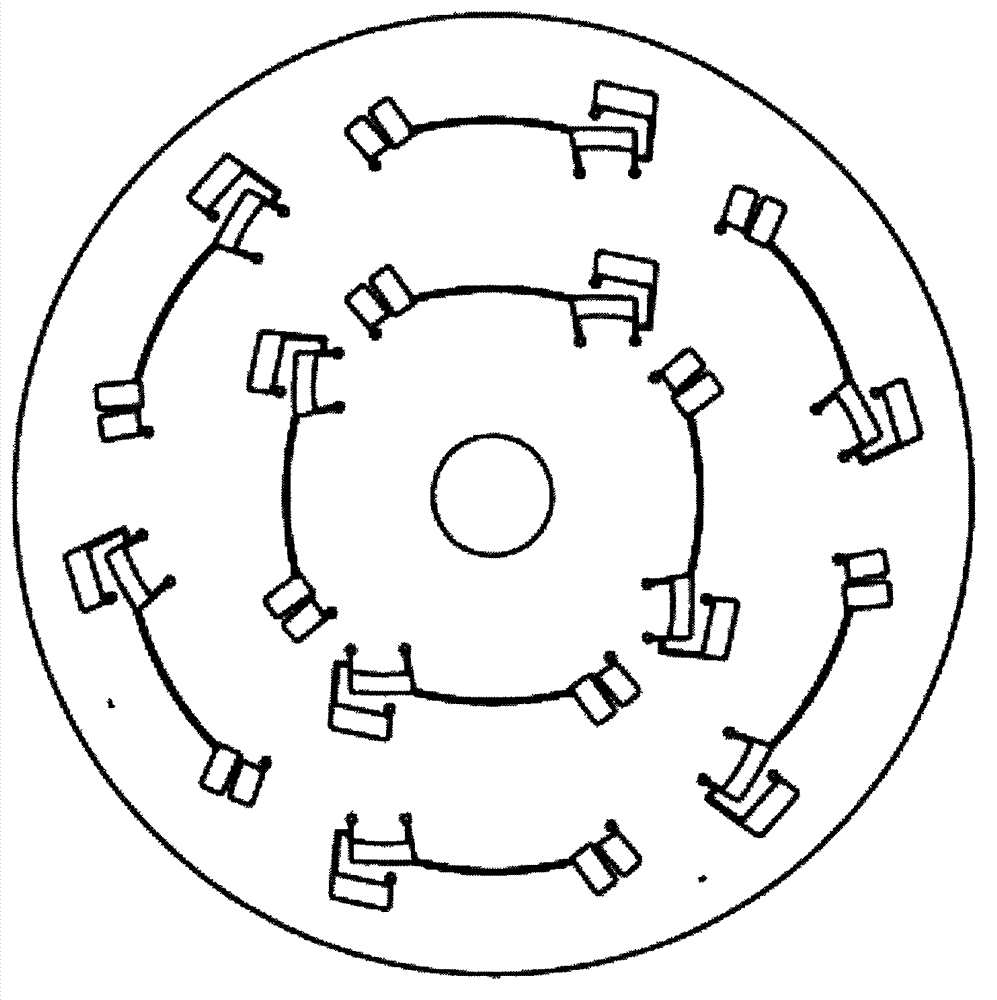

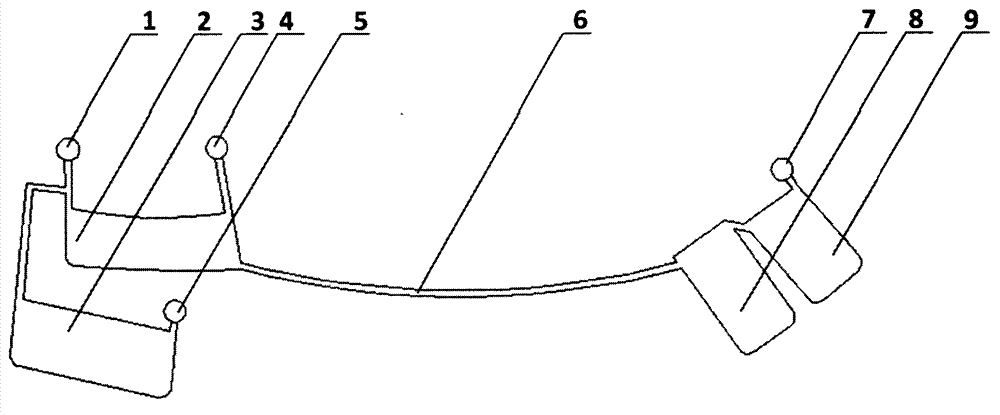

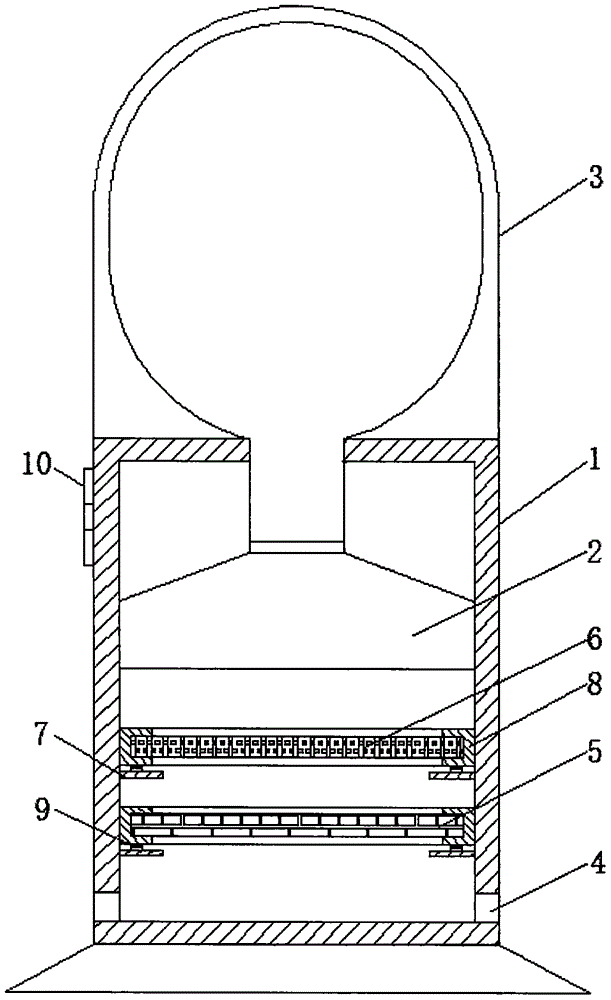

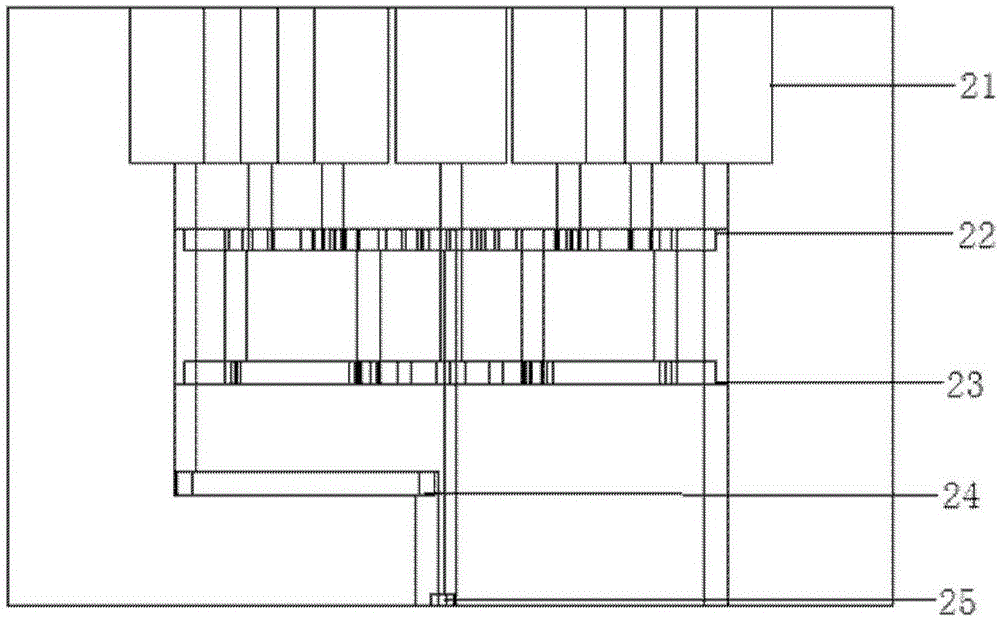

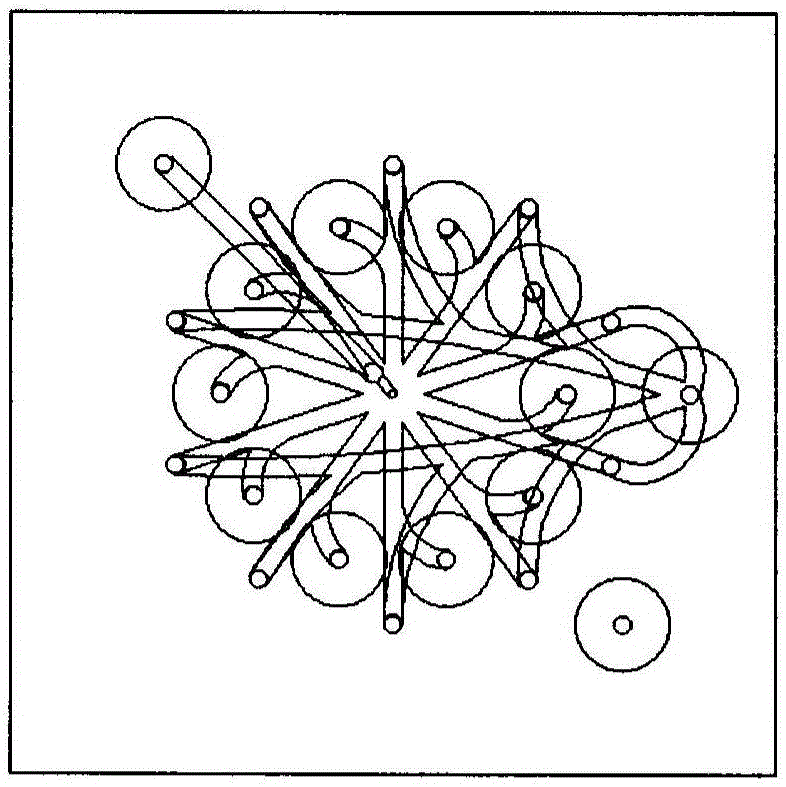

Centrifugal microfluidic serum separation chip and preparation method thereof

InactiveCN102773122ARealize current limitingRealize switchingPreparing sample for investigationLaboratory glasswaresMicro structureRed blood cell

The invention relates to a centrifugal microfluidic serum separation chip and a preparation method thereof. The centrifugal microfluidic serum separation chip is a wafer-shaped microfluidic chip with a micro-structure and a micro-channel, and consists of a chip engraved with a micro-structure and a micro-channel and a blank chip. The centrifugal microfluidic serum separation chip is fixed on a rotation platform of a centrifugal machine, the separation operation of serum and erythrocyte in a micro-upgraded blood sample can be realized by the synergetic process of the micro-structure and the micro-channel on the chip, and the serum for analysis and detection can be acquired. The centrifugal microfluidic serum separation chip is applicable in related application fields, such as biomedicine, clinical diagnosis, health quarantine and the like.

Owner:SUZHOU WENHAO MICROFLUIDIC TECH CO LTD

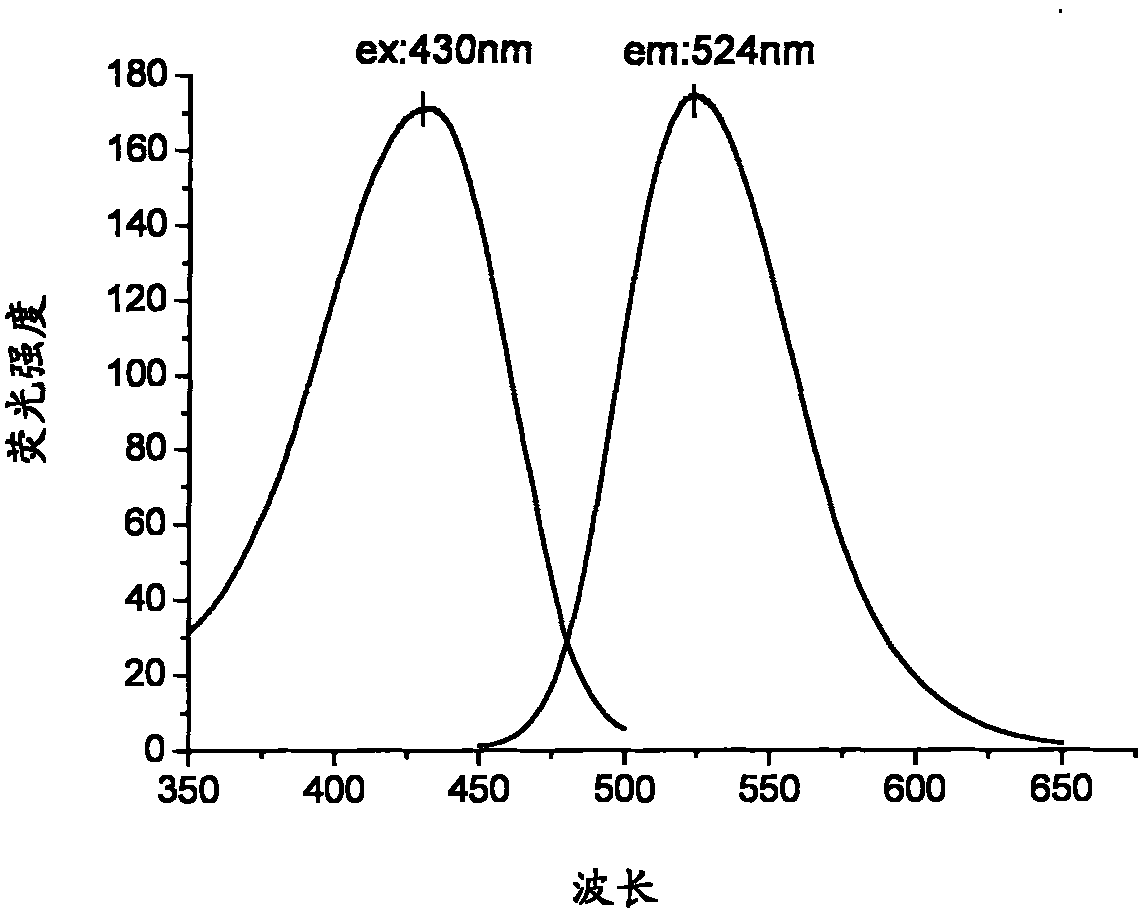

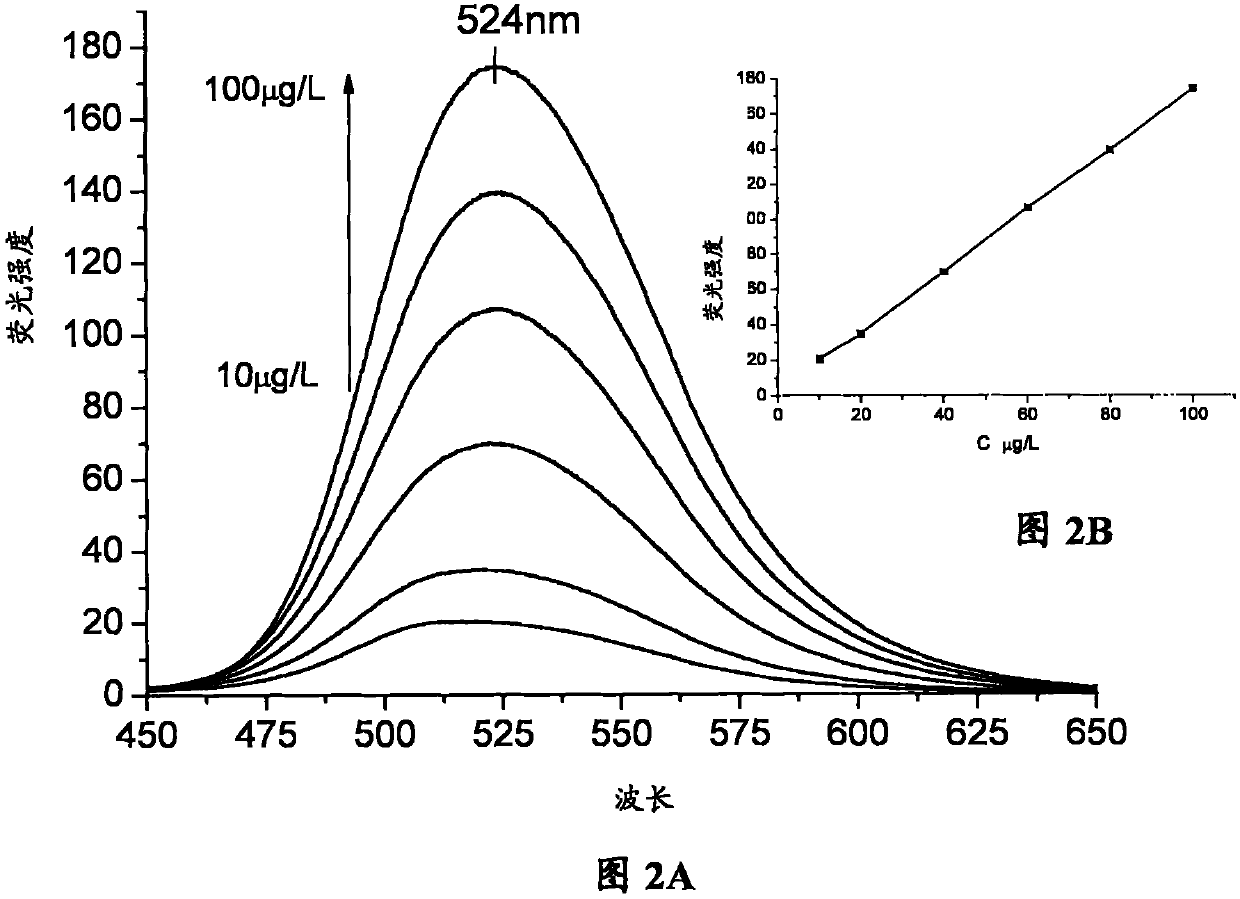

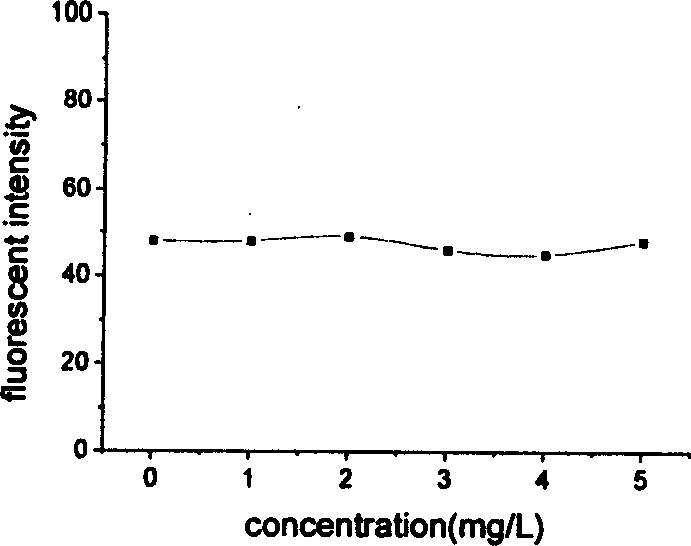

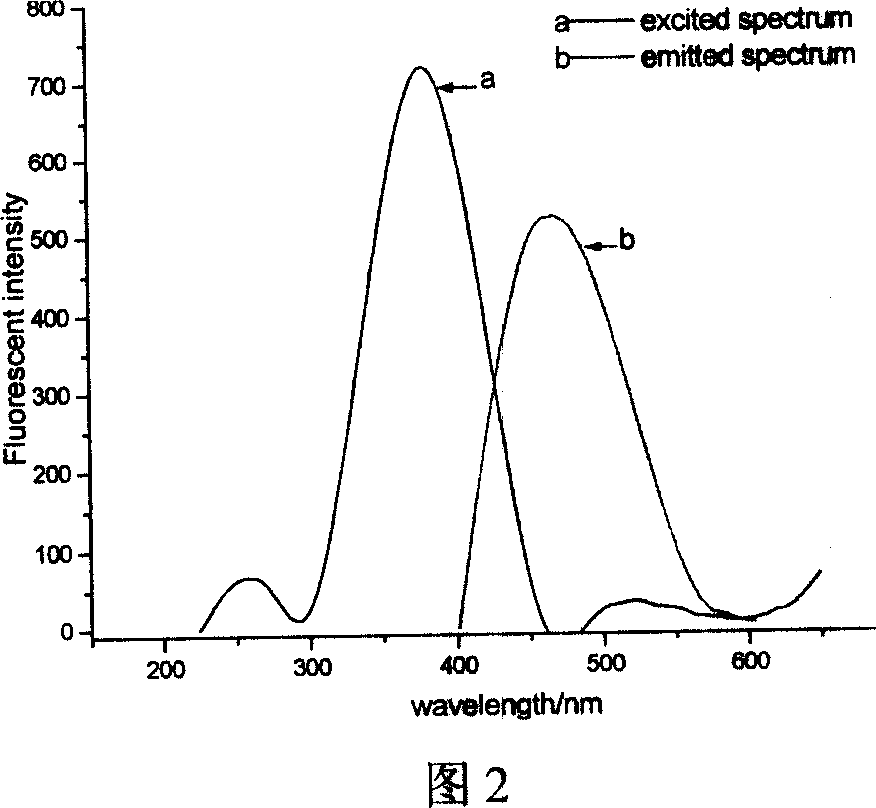

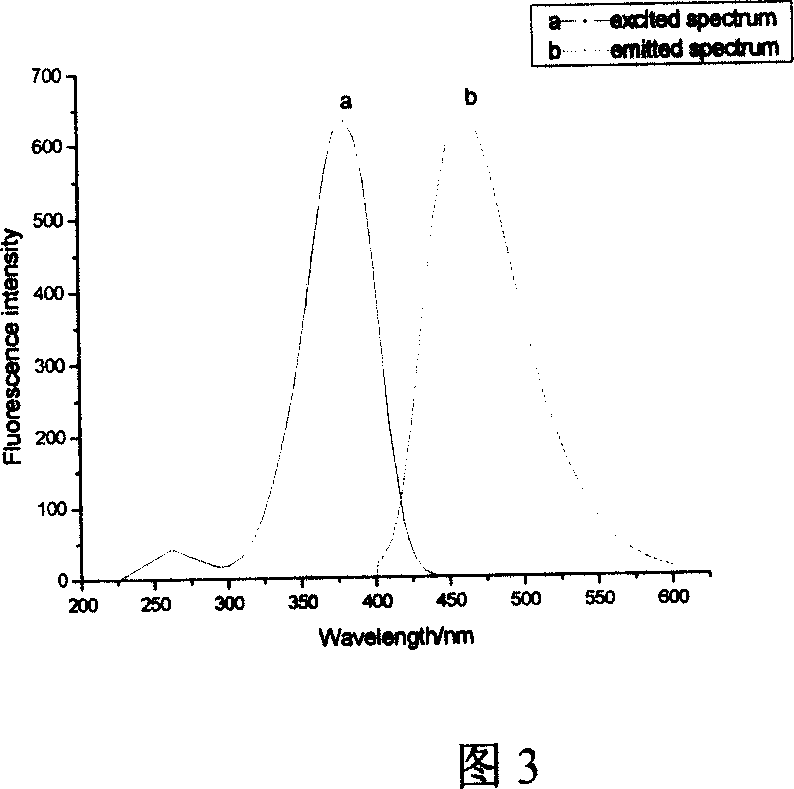

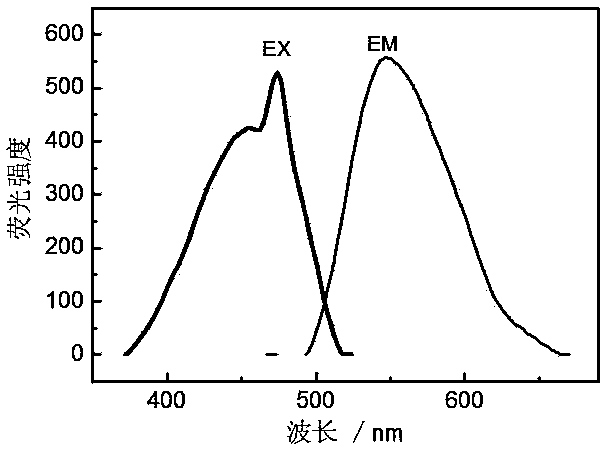

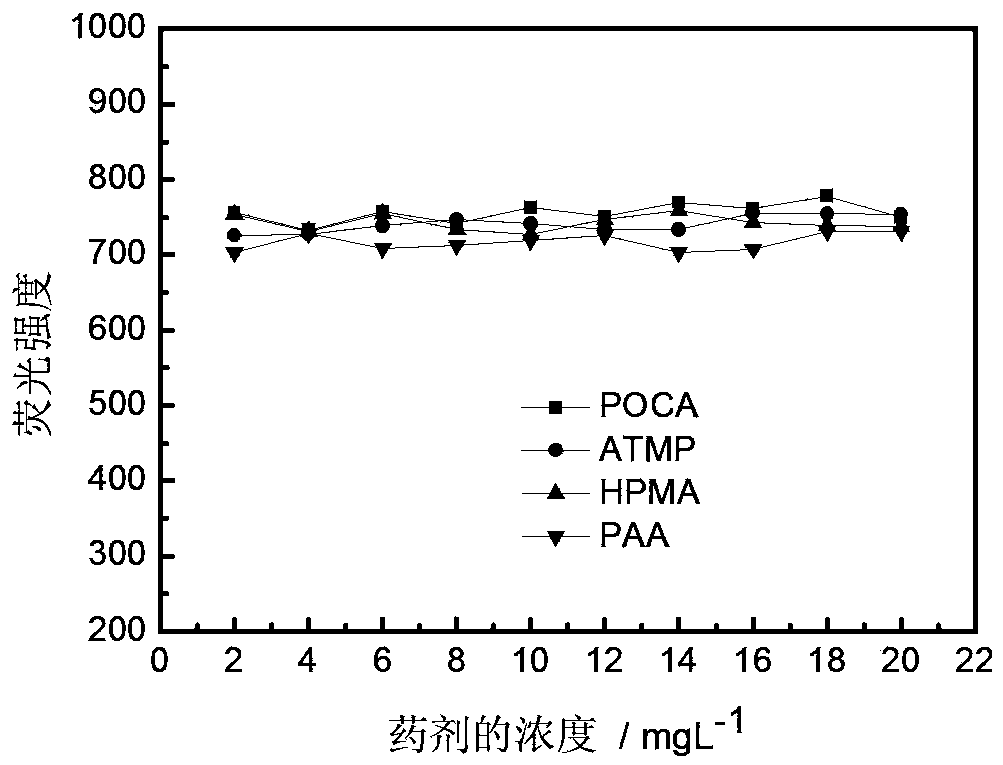

Fluorescent monomer and fluorescent acrylic acid polymer and preparation method of fluorescent monomer and fluorescent acrylic acid polymer

InactiveCN102093290AHas green fluorescent propertiesDispersedOrganic chemistryScale removal and water softeningFluorescent polymerBromine

The invention provides a fluorescent monomer and a fluorescent acrylic acid polymer and a preparation method of the fluorescent monomer and the fluorescent acrylic acid polymer. The monomer and polymer are respectively shown in formulas (I) and (2), wherein m is 1 or 2, n is 10-120, R1 is H or -CH3, R2 is -CH3, -CH2CH3,-CH2CH2CH3 or -CH2CH2(OH)CH3. The preparation method is as follows: reacting 4-bromine-1,8-naphthalic anhydride with n-propylamine so as to obtain N-propyl-4-bromine-1,8-naphthalimide; reacting the N-propyl-4-bromine-1,8-naphthalimide with ethanolamine so as to obtain N-propyl-4-(2-ethoxyamino)-1,8-naphthalimide; reacting the N-propyl-4-(2-ethoxyamino)-1,8-naphthalimide with PBr3 so as to obtain N-propyl-4-(2-bromomethylamino)-1,8-naphthalimide, and dropwise adding unsaturated compound dimethylaminoethyl methacrylate so that the fluorescent monomer is obtained; and condensing the fluorescent monomer with at least one crylic acid monomer. The fluorescent polymer can be used as a special scale inhibitor for a sea water circulating cooling or sea water desalinization system, and has a good scale dispersion property and a good fluorescent trace characteristic.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

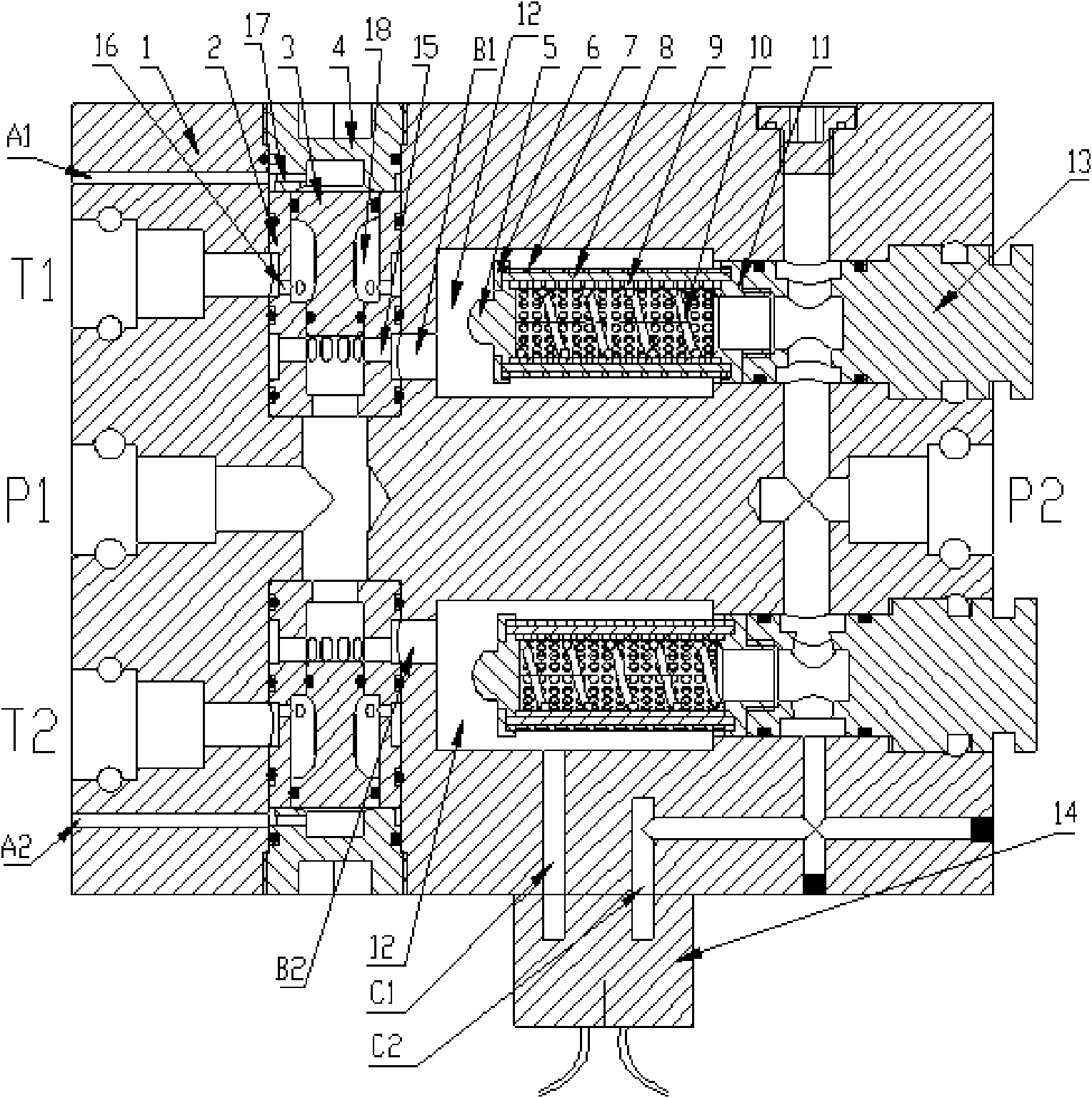

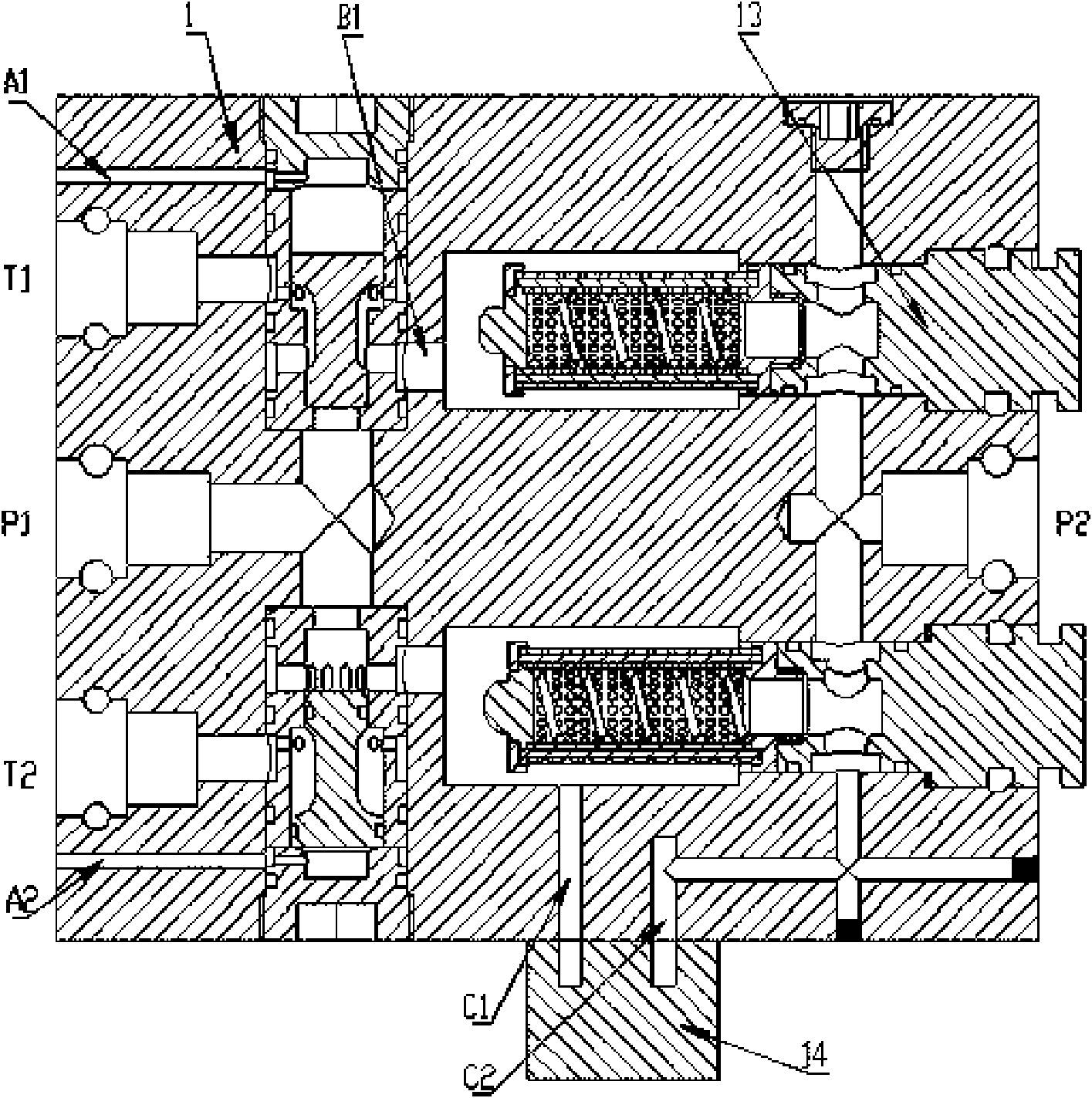

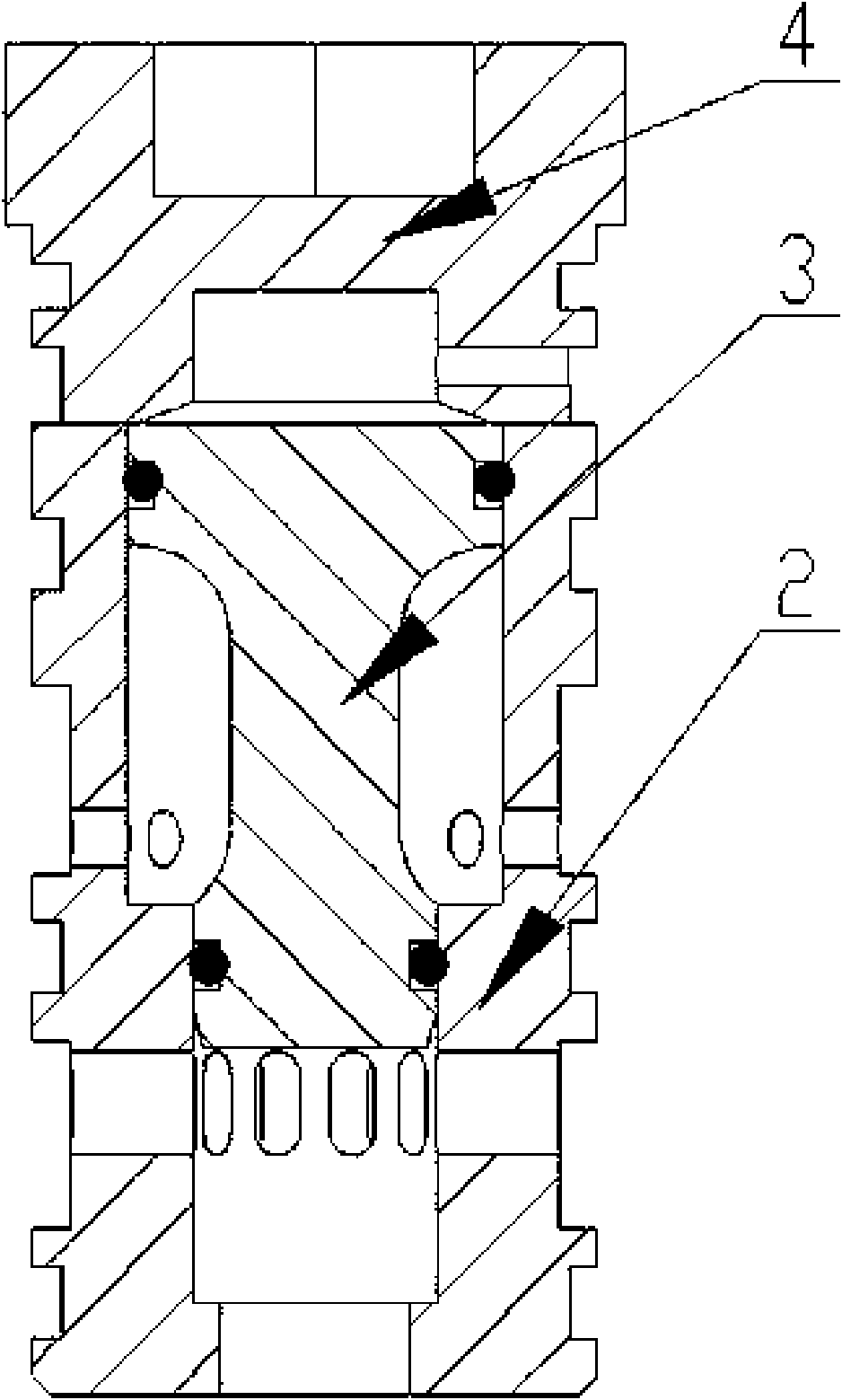

Differential pressure adjustable automatic backwashing filter

InactiveCN101785939AStatus real-time feedbackAchieving Quantitative ControlFluid-pressure actuator componentsStationary filtering element filtersControl engineeringElectrical control

Owner:四川航天神坤科技有限公司

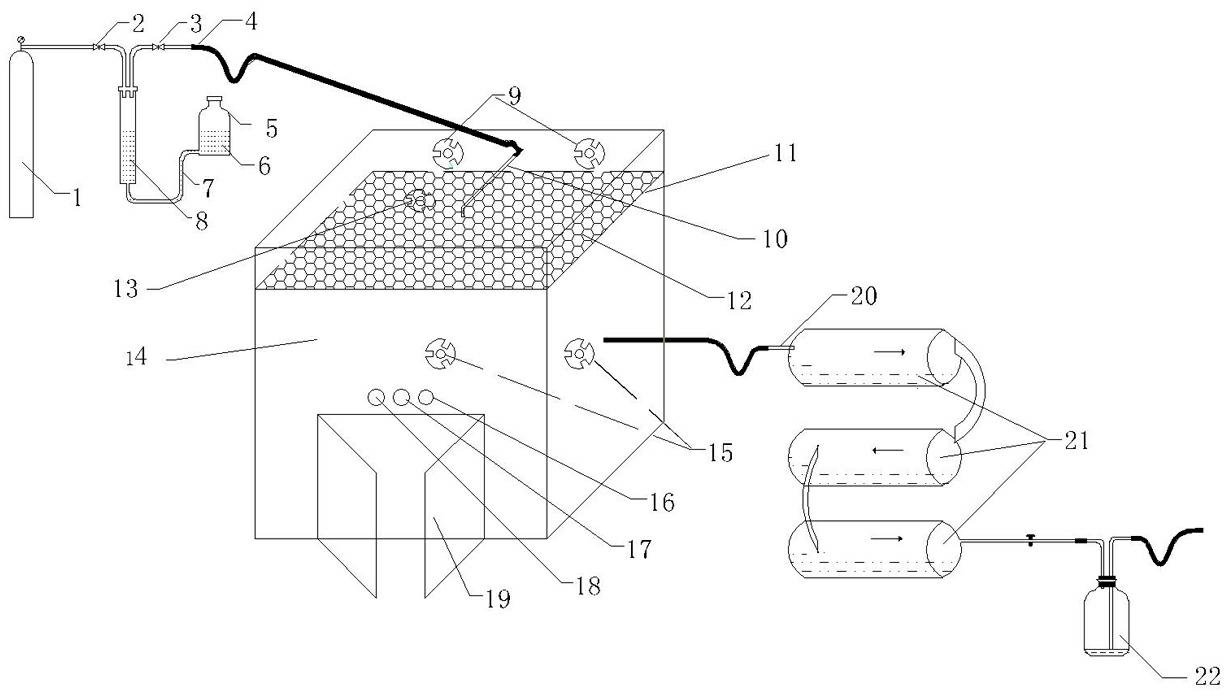

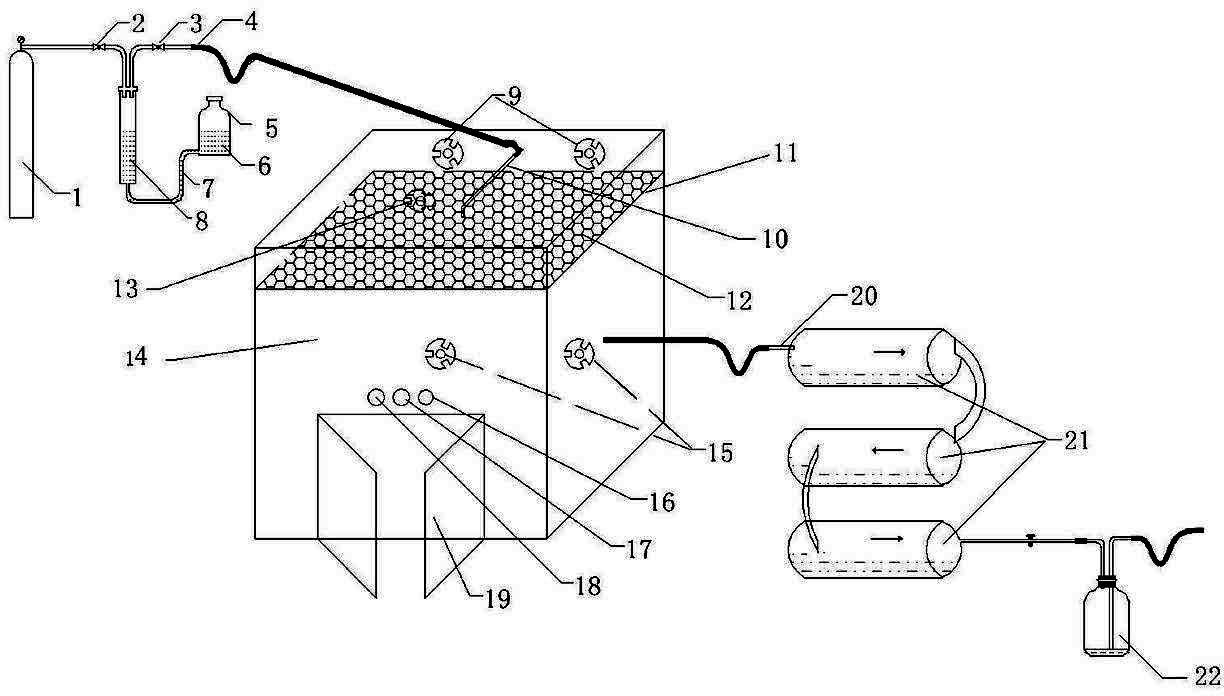

Simple dynamic sulfur dioxide gas toxicant exposure experimental device

InactiveCN102172336AAchieving decompression earlyQuantitative control in advancePreparing sample for investigationBiological testingToxic gasToxicant

The invention provides a simple dynamic sulfur dioxide gas toxicant exposure experimental device. The device consists of a gas decompression dosing device, a dynamic gas toxicant exposure cabinet / chamber and a waste gas absorption and discharge device, wherein the gas decompression dosing device has functions of directly decompressing and quantifying high-purity sulfur dioxide gas, thus omitting assembly of a special decompression gauge and a flow gauge and realizing quantitative control on toxic gas in advance; the dynamic gas exposure cabinet / chamber ensures that a simulated toxicant exposure environment is closer to a natural exposure environment and concentration of the toxic gas is uniform and accurate and can be regulated and controlled in real time; and the discharged gas meets thesafe discharge standard through the waste gas absorption and discharge device. The overall device has the advantages that operation method is simple, the manufacturing expense is low, and the continuous long-time toxicant exposure can be realized, thus solving the difficulty of continuous dynamic toxic gas exposure for a large number of animals, and realizing sulfur dioxide fumigation for variousfood and industrial materials and the like.

Owner:SHANXI AGRI UNIV

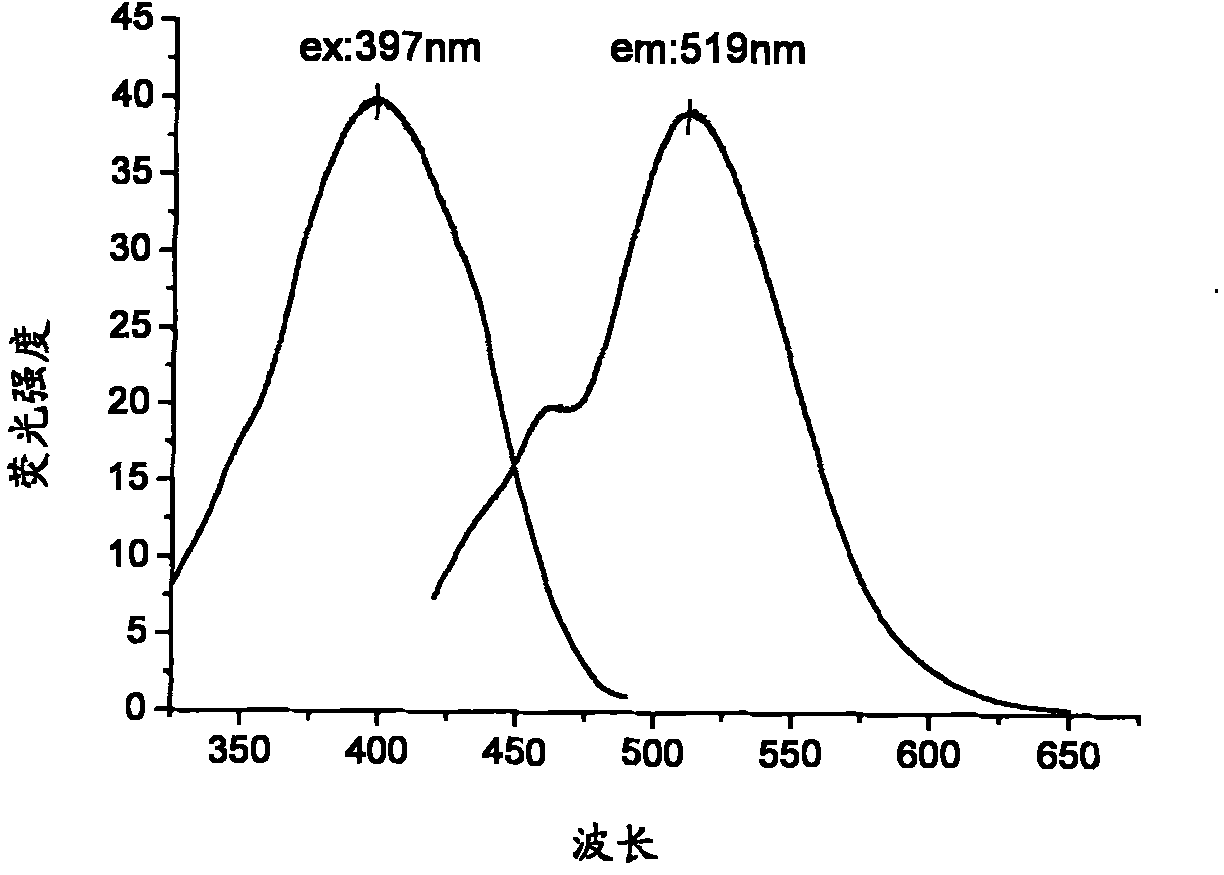

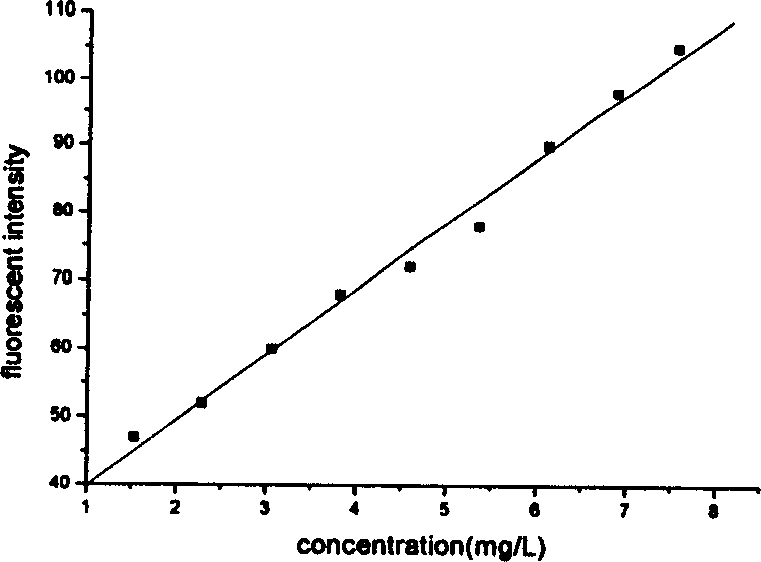

Methoxy group naphthyl fluorescence marked water treating agent and its preparing method

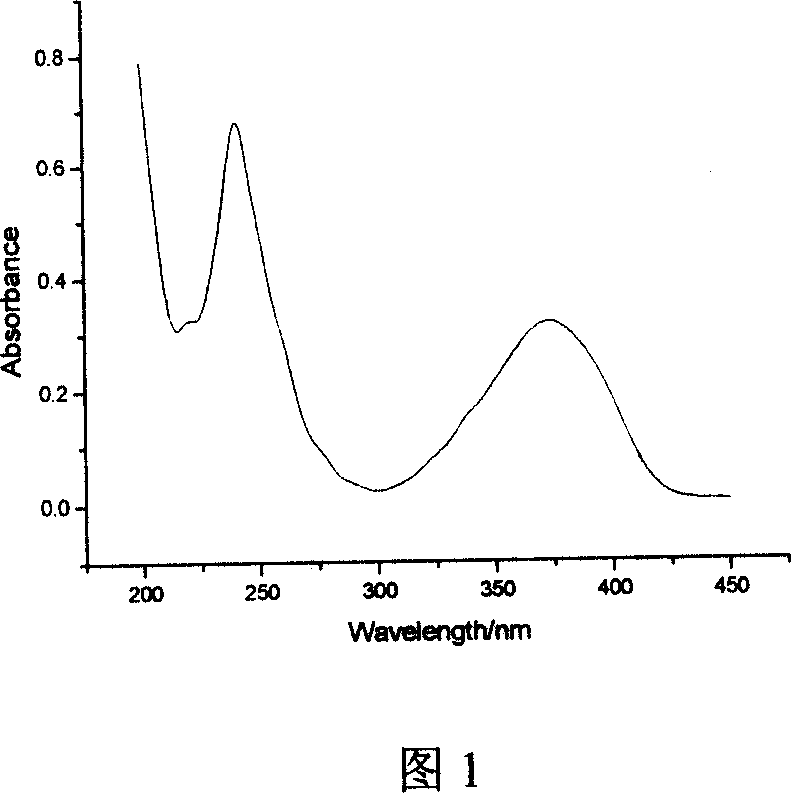

InactiveCN1781857ARaw materials are easy to getMild reaction conditionsScale removal and water softeningSodium methoxideFluorescence

The present invention discloses water treating agent containing methoxy naphthalene as fluorescent marker. The water treating agent is prepared through the first reaction of 4-chloro-1, 8-naphthalic anhydride, glacial acetic acid and 3-dimethylamino propylamine to obtain 4-chloro-N-3-dimethylamino propyl-naphthyl imide; the subsequent reaction with sodium methoxide to introduce methoxy group and obtain 4, 4-methoxyl-N-3-dimethylamino propyl-naphthyl imide, which is reacted with allyl chloride to obtain quaternary ammonium salt of 4-methoxyl-N-3-dimethylamino propyl-naphthyl imide allyl chloride as fluorescent monomer with fluorescent characteristic and double bond; and the final polymerization with phosphorus containing compound, acrylic acid and other monomer to obtain the multifunctional water treating agent with corrosion retarding, scale inhibiting, dispersing and fluorescent tracing functions.

Owner:NANJING UNIV OF SCI & TECH

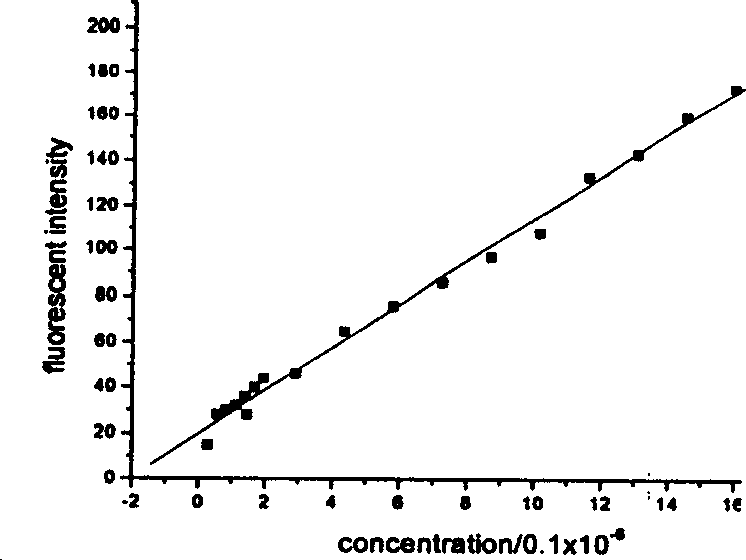

Fluorescence labeling acrylic acid-sodium acrylic sulphonate co-polymer water treatment agent and preparation method thereof

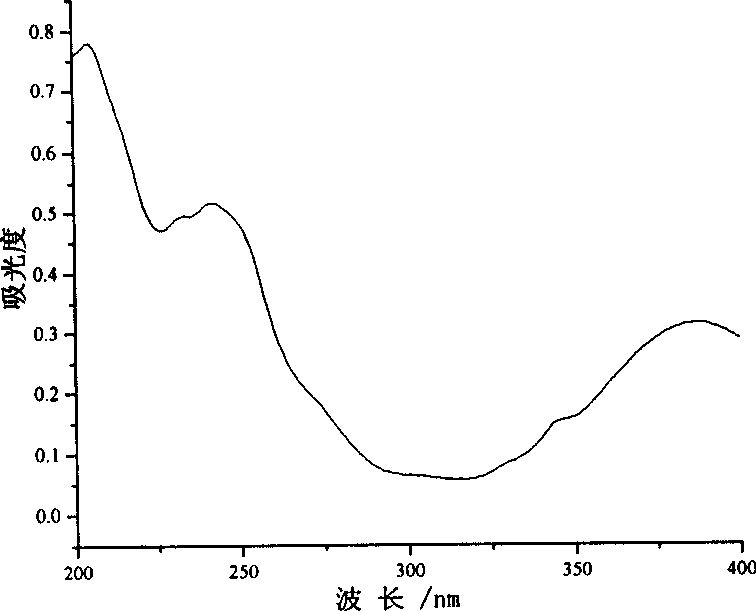

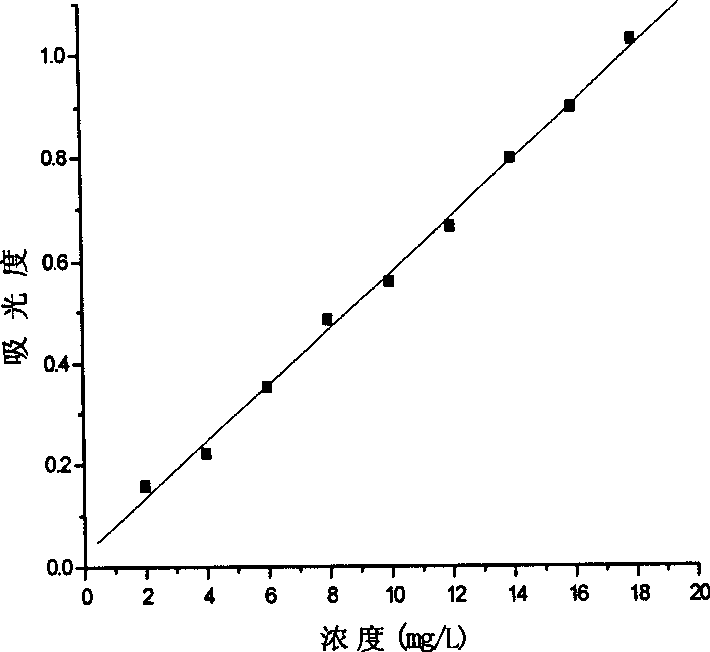

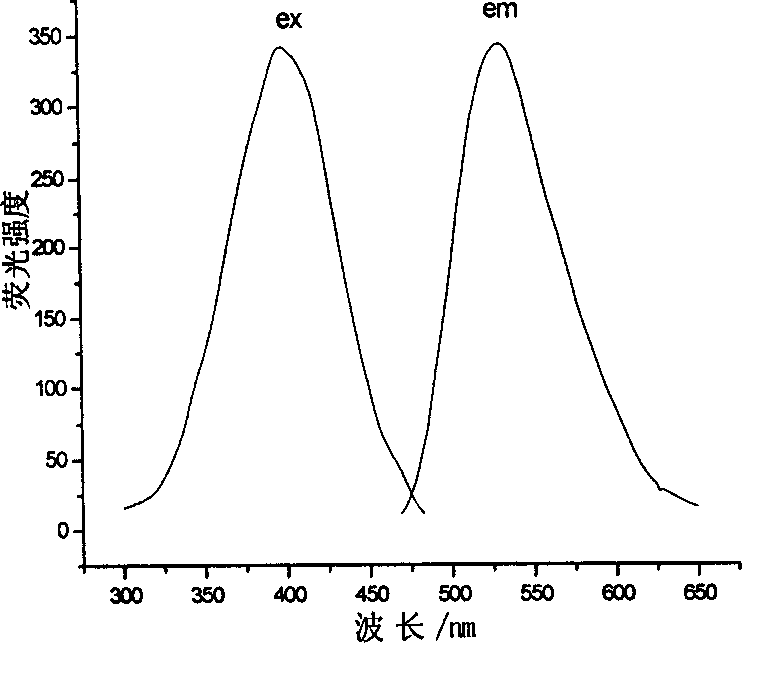

InactiveCN101381168AMild reaction conditionsEasy to operate on siteScale removal and water softeningMaterial analysis by optical meansBromineDiethylenediamine

The present invention discloses a fluorescence labeled acroleic acid-sodium allylsulfonate copolymer and a method for preparing the same. The method comprises the following steps: 4-bromine-1,8-naphthalic anhydride, methylamine, N-methyl diethylenediamine, and the like are used as material and is subject to amidation reaction, amination reaction, and quaternization reaction to be synthesized, and a novel fluorescence monomer 4-(N'-methyl-1-diethylenediamine)-N-methyl-1,8-naphthalimide allyl chloride quaternary ammonium salt is obtained by synthesis; and then the fluorescence monomer is copolymerized with sodium hypophosphite, acroleic acid and sodium allylsulfonate to obtain the FC-AA-SAS product. The raw materials for synthesizing the fluorescence monomer and the polymer are easy to obtain and the reaction conditions are mild. When the product is used in circulating water, the thickness of a medicament in a circulating water system can be accurately, duly and quickly measured through the variation of the fluorescence intensity, and the on-line medicine addition and the quantitative control are realized. Therefore, the on-site operation is largely simplified, and the management level is improved. The functional groups, such as sulfonic group, phosphino group and the like, are introduced into molecules, and thus the polymer has a plurality of functions, such as fluorescent tracing, anti-precipitation, disgregation and the like.

Owner:NANTONG UNIVERSITY

Phosphine-based Marpropy multipolymer containing fluorescent base-group and its production

InactiveCN1939945ARaw materials are easy to getMild reaction conditionsSodium methoxideEthylenediamine

A phosphino-based mapropyl copolymer containing fluorescent group and its production are disclosed. The process is carried out by taking 4-bromine-1,8-naphthalic anhydride, glacial acetic acid and N, N-dimethyl-ethylenediamine as raw materials to obtain 4-bromine-N-(2-N,, N,-dimethylbenzidine-ethyl)naphthalimide, reacting it with sodium methoxide to induce methoxy-group to obtain 4-methoxy-N-(2-N,, N,- dimethylbenzidine-ethyl)naphthalimide, reacting it with allyl chloride to obtain fluorescent monomer 4-methoxy-N-(2-N,, N,- dimethylbenzidine-ethyl)naphthalimide allyl ammonia chloride with fluorescent characteristic and double-bond, polymerizing it with sub-sodium phosphate, maleic anhydride, acroleic acid and propenyl-sodium sulfate to obtain the final product. It has fluorescent tracting, corrosion-inhibting, scale-inhibiting and dispersion functions.

Owner:NANJING UNIV OF SCI & TECH

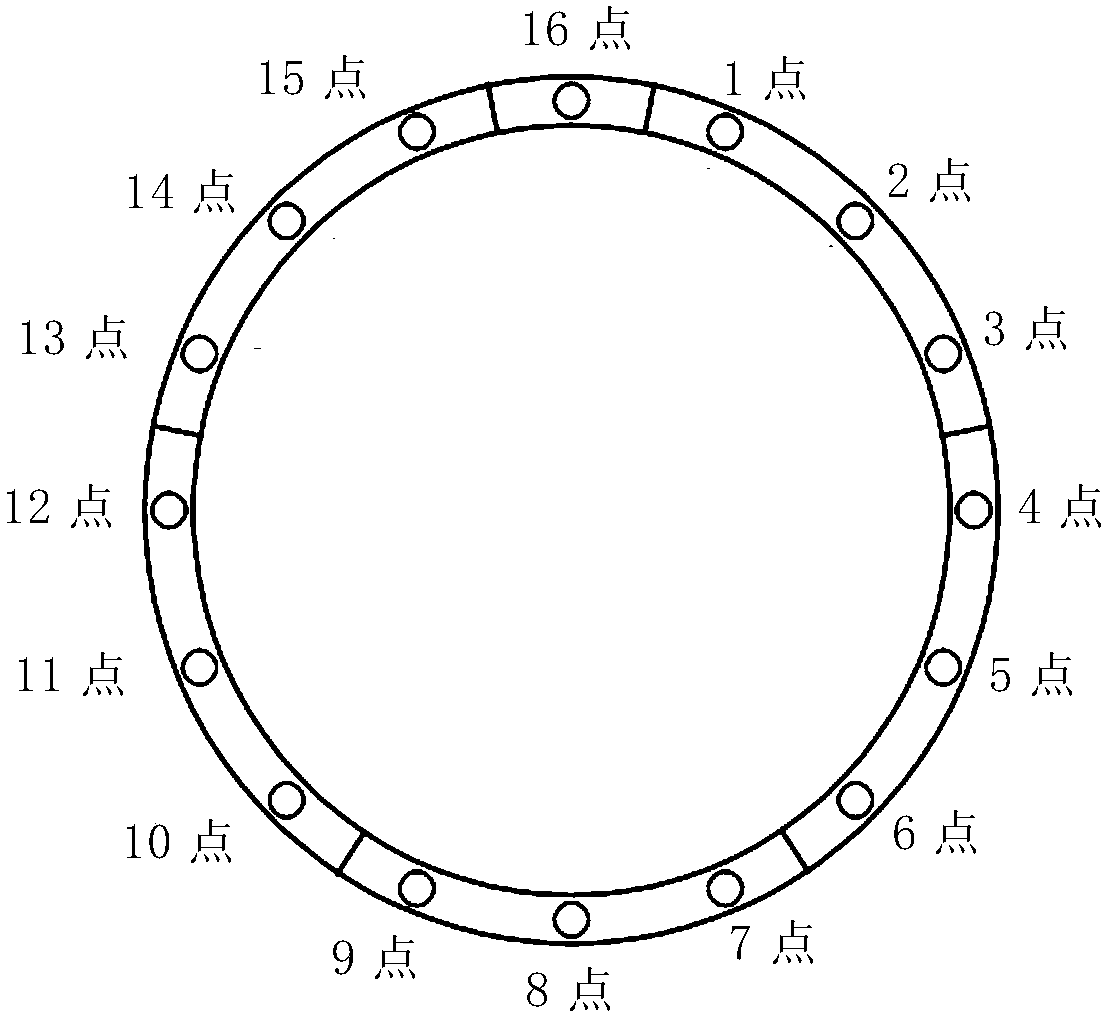

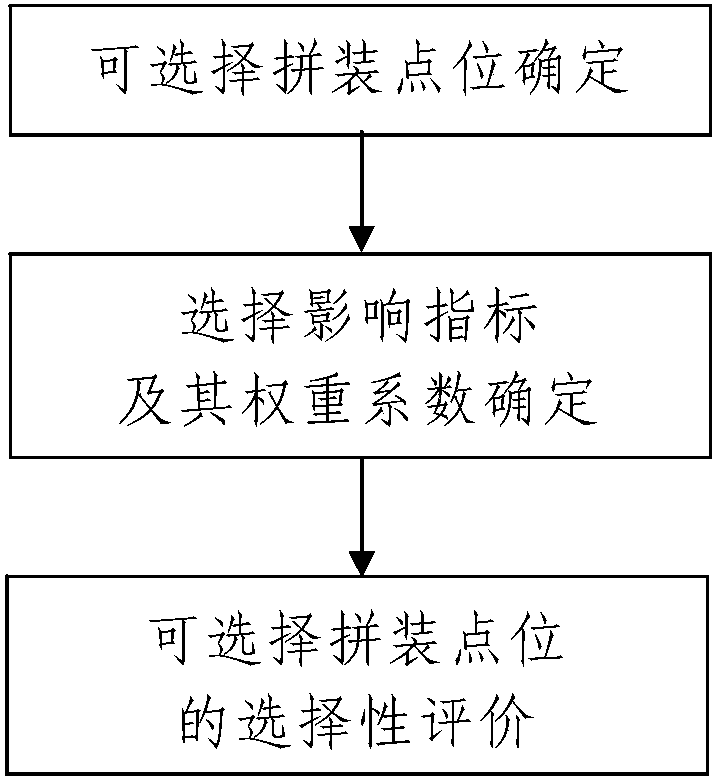

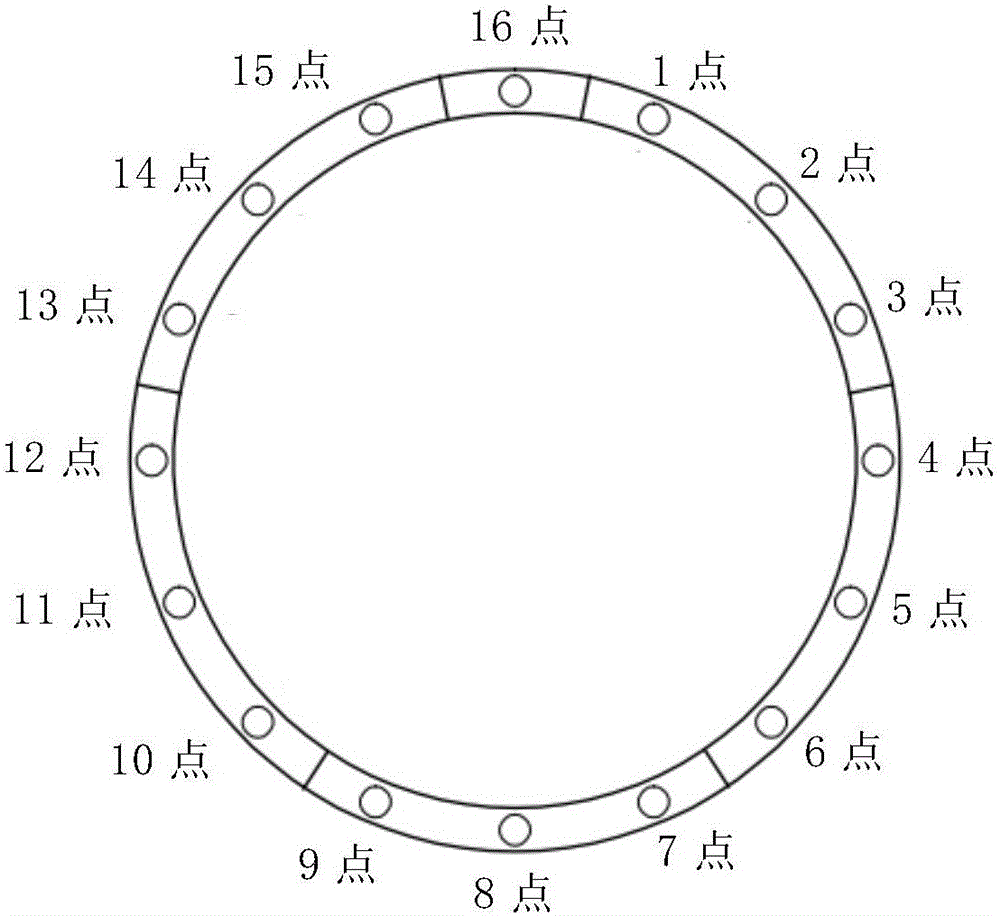

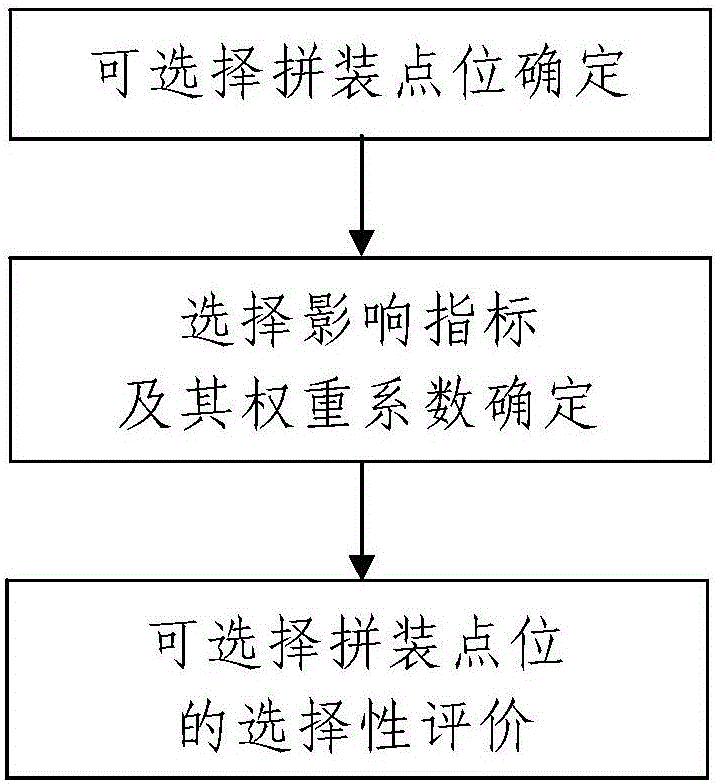

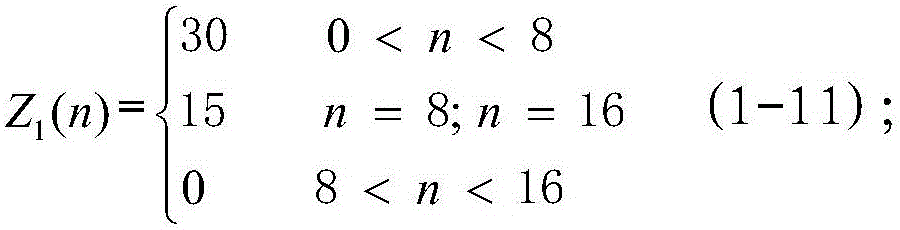

Shield general segment assembling point location determining method

ActiveCN107725067AThe method steps are simpleLow input costUnderground chambersResourcesWeight coefficientEngineering

The invention discloses a metro shield construction general segment assembling point location determining method. A shield tunneling machine is used for conducting shield tunneling construction on a construction tunnel along a tunnel central axis from back to front. After the shield tunneling construction is completed for one link, shield segment assembling construction is carried out. Before anylink of shield segment assembling construction is performed, first of all, segment assembling point locations of current shield segments are determined. Processes include the following steps that firstly, selectable assembling point locations are determined; secondly, selection influence indexes and weight coefficients of the selection influence indexes are determined, and the three selection influence indexes and the weight coefficients of the three selection influence indexes influencing segment assembling point location selection are determined separately; thirdly, the selectable assemblingpoint locations are selectively evaluated, wherein according to a weight coefficient method, the selection of all the selectable assembling point locations is evaluated separately, and the segment assembling point locations of the current shield segments are determined. The shield general segment assembling point location determining method is simple in step reasonable in design, convenient to achieve, good in using effect and capable of conveniently, fast and precisely determining the assembling point locations of the general segments.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

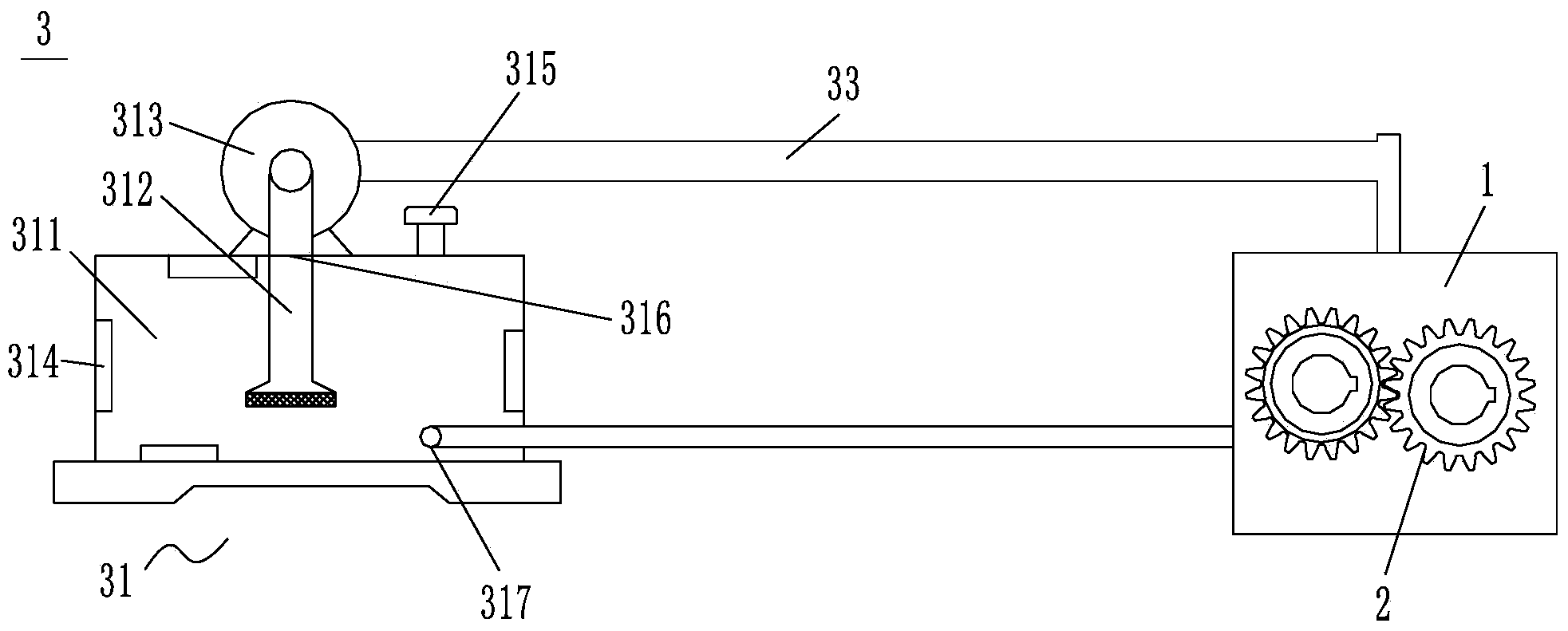

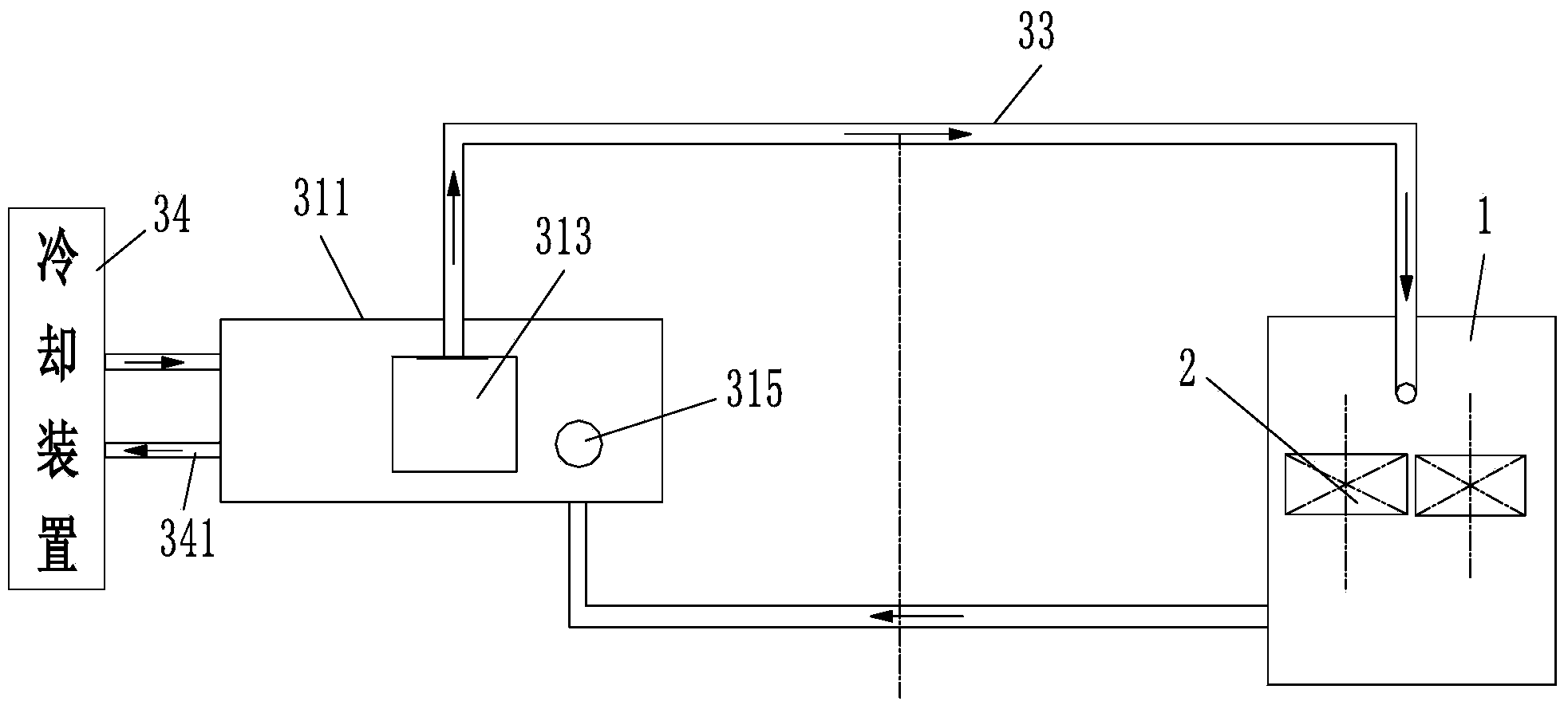

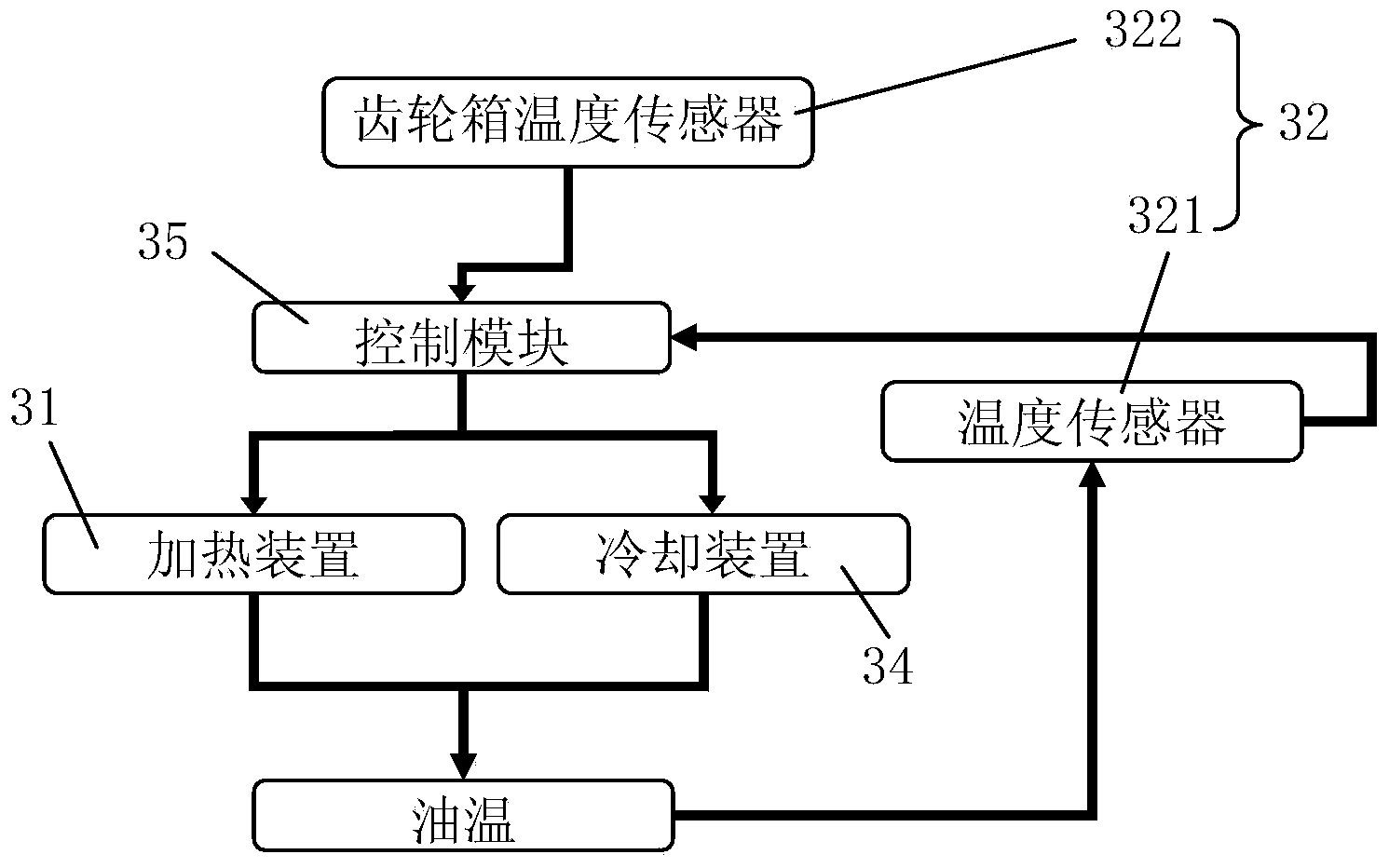

High temperature testing machine for gears

InactiveCN103759938AThermal hasThermal noneMachine gearing/transmission testingAviationReduction drive

A high temperature testing machine for gears comprises a gear transmission case used for testing the fatigue life of the gears, wherein the gears to be tested are installed in the gear transmission case, the gear transmission case is connected with a temperature control system, the temperature control system comprises a heating device and a control module of a temperature monitor device, the heating device is connected with the gear transmission case through a pipeline, the heating device conveys lubricating oil into the gear transmission case through the pipeline to heat and lubricate the gears to be tested in an oil bath mode so that the working condition of gears inside an aviation speed reducer can be simulated, and the lubricating oil is heated to reach the set temperature. The temperature monitor device is installed on the heating device to monitor the temperature of the lubricating oil in real time, temperature information is fed back to the control module, and then the heating temperature can be monitored and controlled. Long-time simulation testing under the high temperature can be carried out on the gears, the testing temperature is high, working time is long, the testing environment is more approximate to the actual working condition of the aviation gears, and testing results are more effective and credible.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

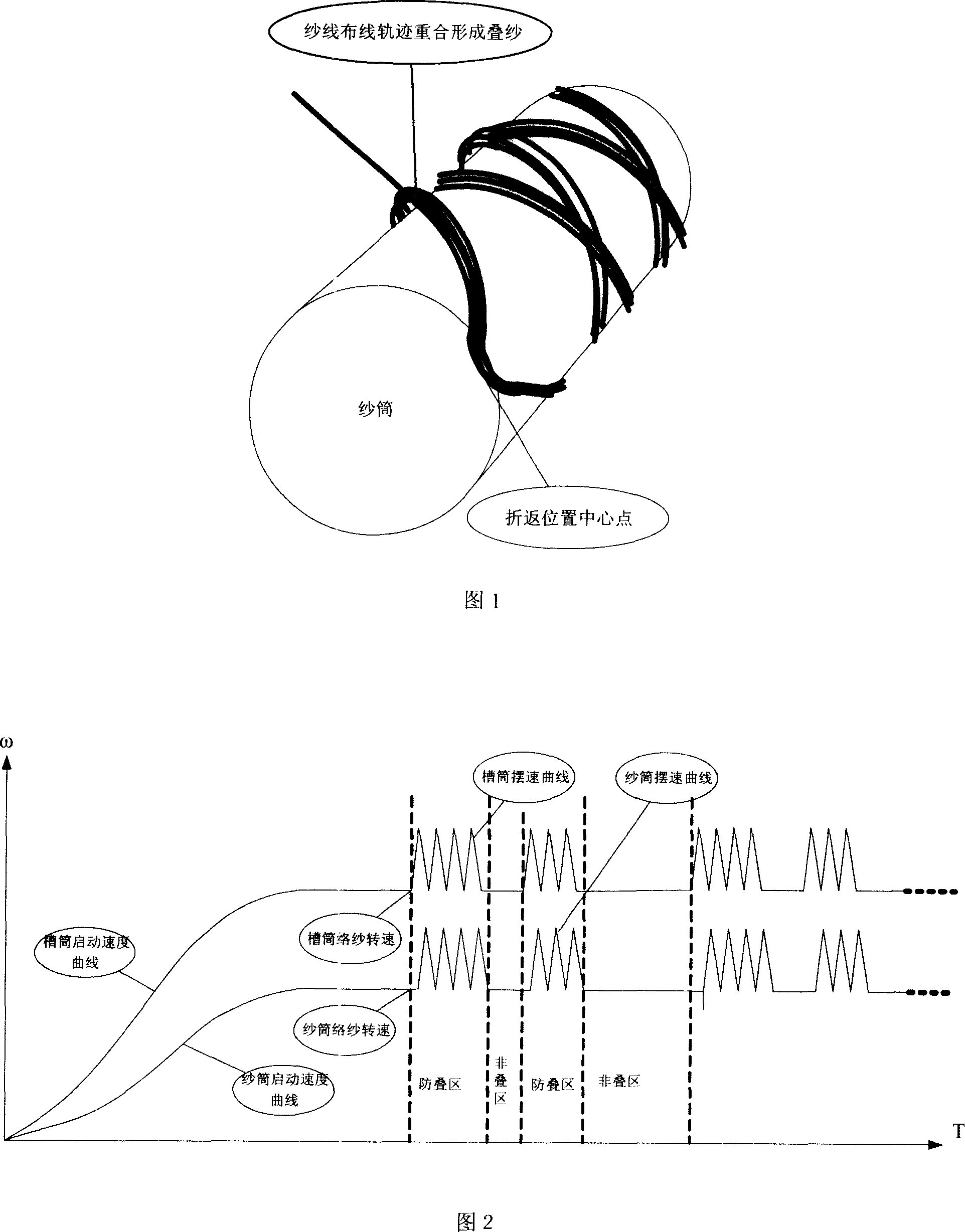

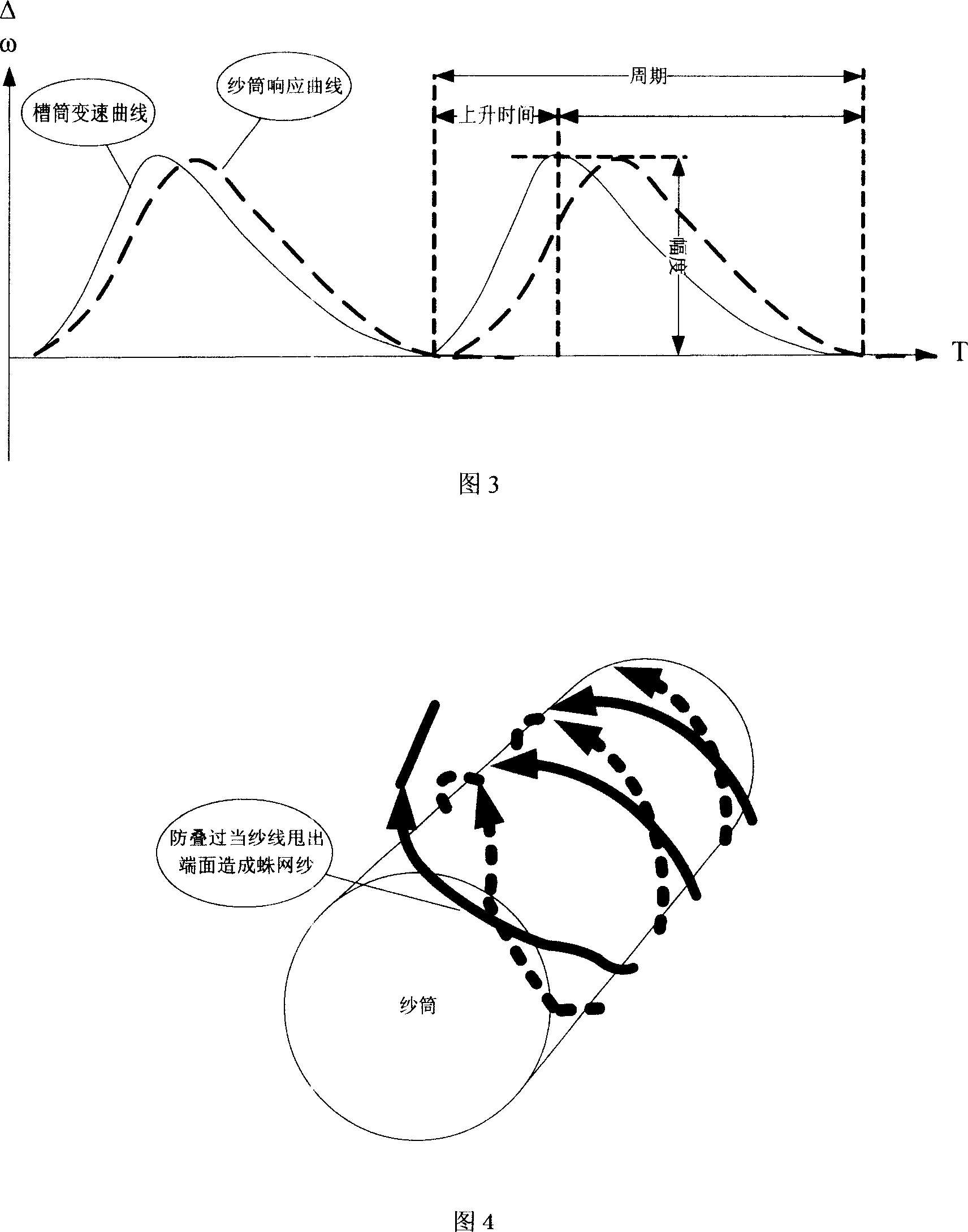

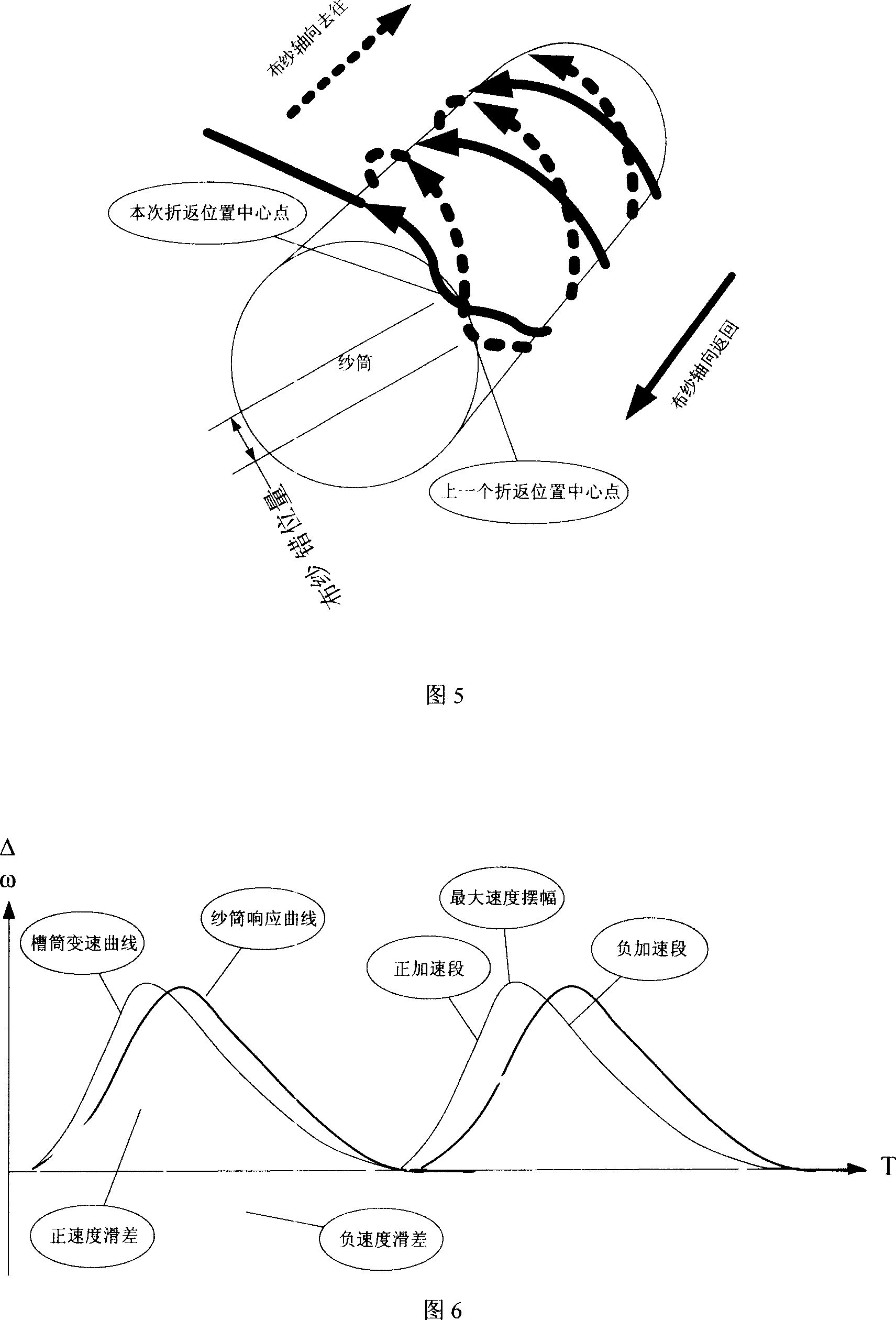

Groove drum guide yarn electric folding-proof device employing self-adapting control and method thereof

ActiveCN101104489AControl misalignment intervalPrecise control of anti-overlap actionFilament handlingTextiles and paperYarnBobbin

The present invention provides a grooved drum yarn guide electronic anti-overlapping self-adaptive control technology, which is a mode to combine the software control in the grooved drum motor control drive. The anti-overlapping swing speed sawtooth wave parameters of the motor control are set through manual intervention, not based on the variety of the yarn and the speed. The invention can measure the speed of the grooved drum and the bobbin at any moment, calculate the rotational speed slip and form a closed-loop control on the rotate speed and the rotate speed acceleration that drive the motor according to the expected yarn setting dislocation amount so as to realize quantitative control on the yarn setting dislocation amount. The invention can automatically adapt to changes of different yarn varieties, yarn winding speed and the weight and the diameter of the bobbins and can markedly increase the quality of bobbin forming, which raises the intelligent level of equipment and simplifies the operation. The invention is applied to various yarn, wire and thread winding equipments which adopts grooved drum yarn guides.

Owner:青岛瑞阳电子有限公司

Direct quantitative control method for indoor air purifier filter screen replacement

InactiveCN105920927AEasy to useAchieving Quantitative ControlDispersed particle filtrationRoom air cleanersParticulates

The invention relates to the field of small household appliances, in particular to a direct quantitative control method for indoor air purifier filter screen replacement. According to the direct quantitative control method for indoor air purifier filter screen replacement, a mass threshold value is set, and then controlling is conducted through the following steps that after a filtering assembly is installed, the initial weight of the filtering assembly is obtained through a weight sensor, when a filter starts working, a controller obtains the current weight of the filtering assembly by reading the weight sensor in real time, the filtrate weight is obtained by subtracting the initial weight from the current weight, and when the filtrate weight exceeds the mass threshold value, the controller controls an alarming mechanism to give an alarm. According to the method, the weight of particulate matter attached to a filter screen is obtained by monitoring the weight added value of the filtering assembly in real time, when the weight of the attached particulate matter exceeds the mass threshold value, the filter screen needs to be replaced, therefore, quantitative control over filter screen replacement is achieved, the replacement cycle of the filter screen reaches the maximum value while the filtering efficiency is guaranteed, and the method is more beneficial for being used by an ordinary family.

Owner:薛景森

Method for determining duct piece splicing point position of universal ring for subway shield construction

ActiveCN105673041AThe method steps are simpleLow input costData processing applicationsUnderground chambersWeight coefficientEngineering

The invention discloses a method for determining a duct piece splicing point position of a universal ring for subway shield construction. The method comprises the following steps: performing shield tunneling construction on a constructed tunnel from back to front along the central axis of the tunnel by adopting a shield tunneling machine; after a ring of the shield tunneling construction is completed, performing shield duct piece splicing construction; before any ring of shield duct piece splicing construction, determining the duct piece splicing point position of shield duct pieces of the current ring first, wherein the method for determining the duct piece splicing point position comprises the following processes: firstly, determining selectable splicing point positions; secondly, determining selection influence indexes and weight coefficients thereof: respectively determining the three selection influence indexes which influence the selection of the duct piece splicing position point and the weight coefficients thereof; thirdly, performing selectivity evaluation on the selectable splicing position points: respectively evaluating the selectivity of each selectable splicing position point according to a weight coefficient method, and determining the duct piece splicing point position of the current shield duct piece. The method disclosed by the invention is simple in step, reasonable in design, convenient to implement and good in using effect, and can determine the splicing point position of the duct pieces of the universal ring easily, conveniently and accurately.

Owner:CHINA RAILWAY FIRST GRP CO LTD

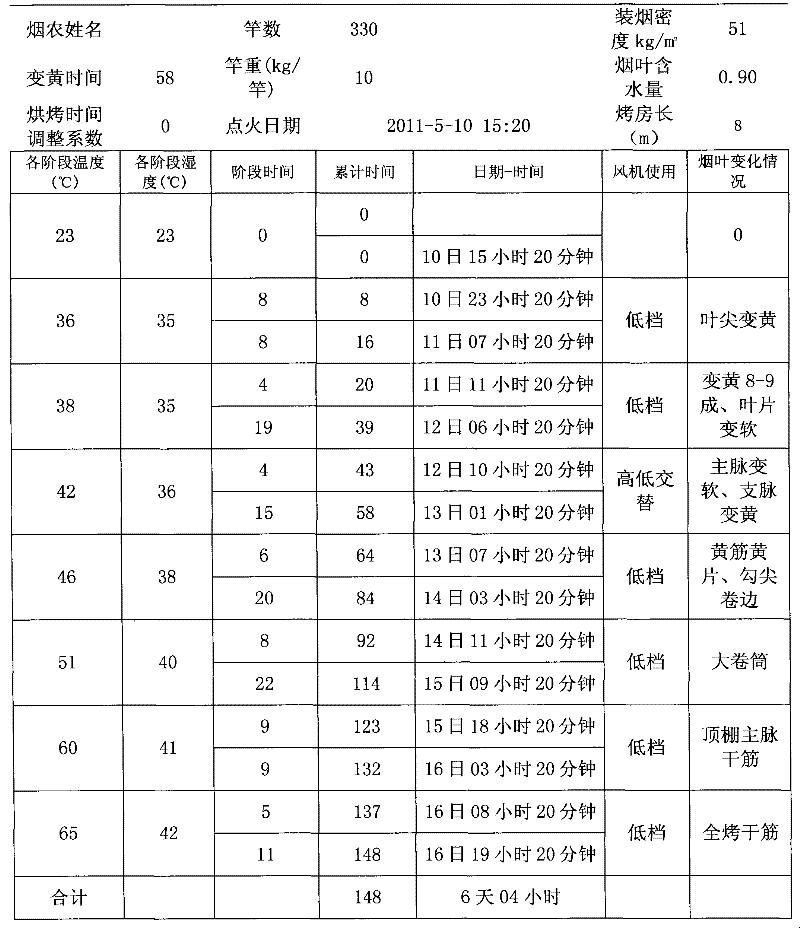

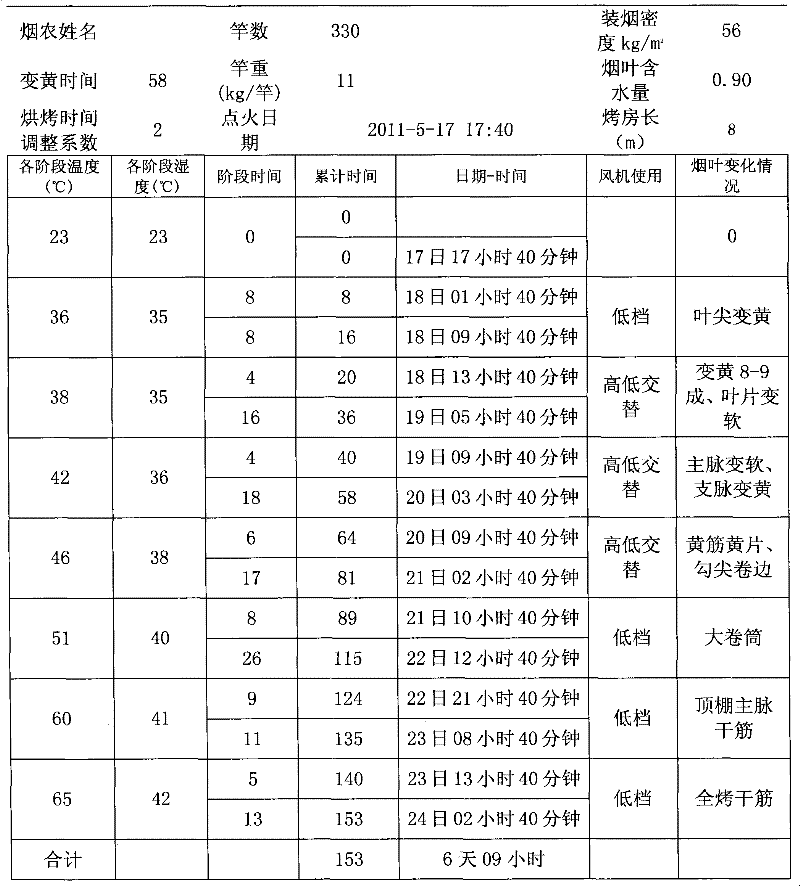

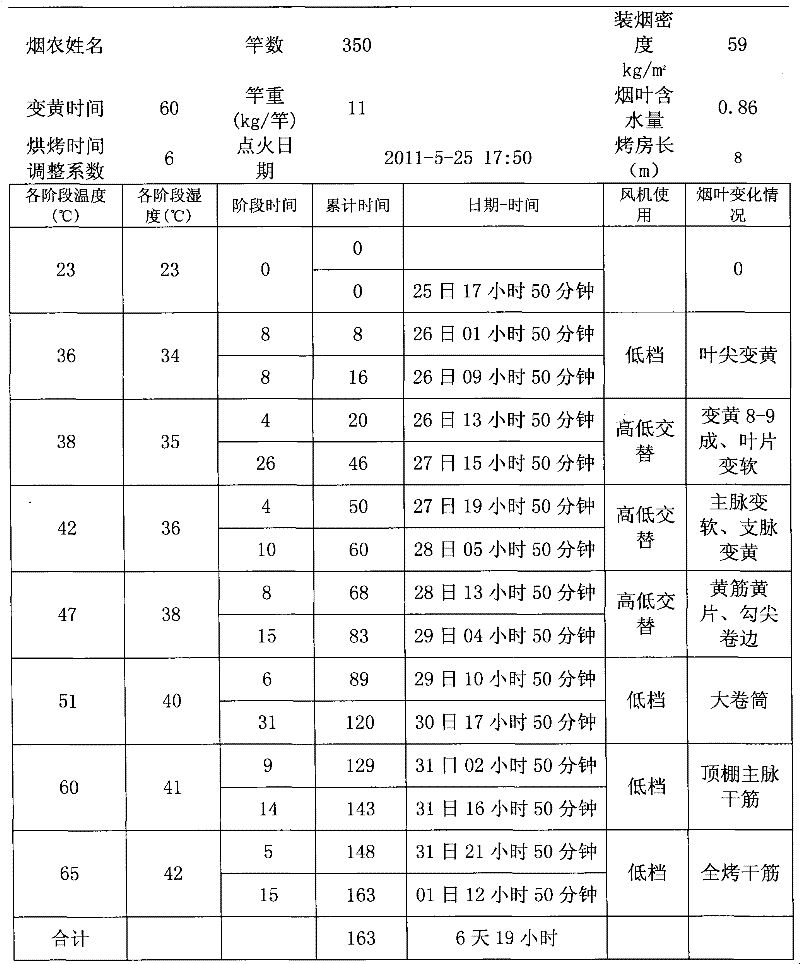

A Method for Accurately Controlling the Curing Time of Tobacco Leaves in Intensive Barns

InactiveCN102283432AAchieving Quantitative ControlPowerful computingTobacco preparationSimultaneous control of multiple variablesEngineeringTobacco processor

The invention discloses a method for accurately controlling the flue-curing time of tobacco leaves in a bulk curing barn. In the method, a tobacco leaf drying function model which relates to factors such as water content of tobacco leaves, loading density and loading amount, temperature and humidity as well as psychrometric difference, fan delivery, flue-curing time and the like is established according to the conventional material drying principle and tobacco leaf drying characteristics; according to different species, the drying model is multiplied by water loss regulation coefficients of tobacco parts and various flue-curing stages respectively, so that water loss rates of the tobacco leaves of different parts, different species and different stages can be calculated; and the flue-curing implementation scheme of the tobacco leaves of the bulk curing barn which is designed by the method for accurately controlling the flue-curing time of the tobacco leaves in the bulk curing barn according to the national technical specification for the flue-curing in bulk curing barns provides the accurate information of the temperature, humidity, time and fan startup of various flue-curing stages of the tobacco leaves for broad tobacco growers, and is the innovation and development of the traditional flue-curing method.

Owner:江西省烟草公司赣州市公司

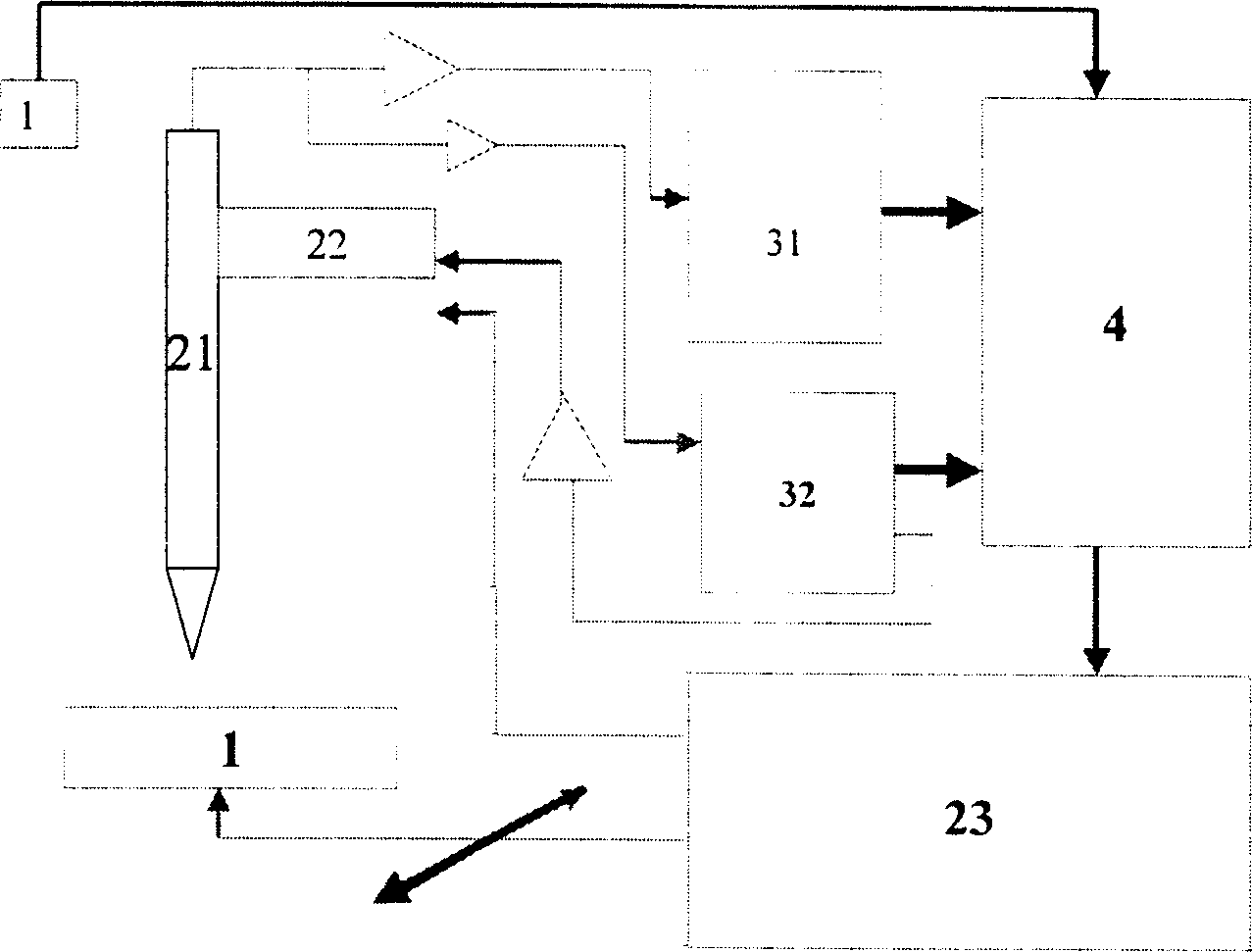

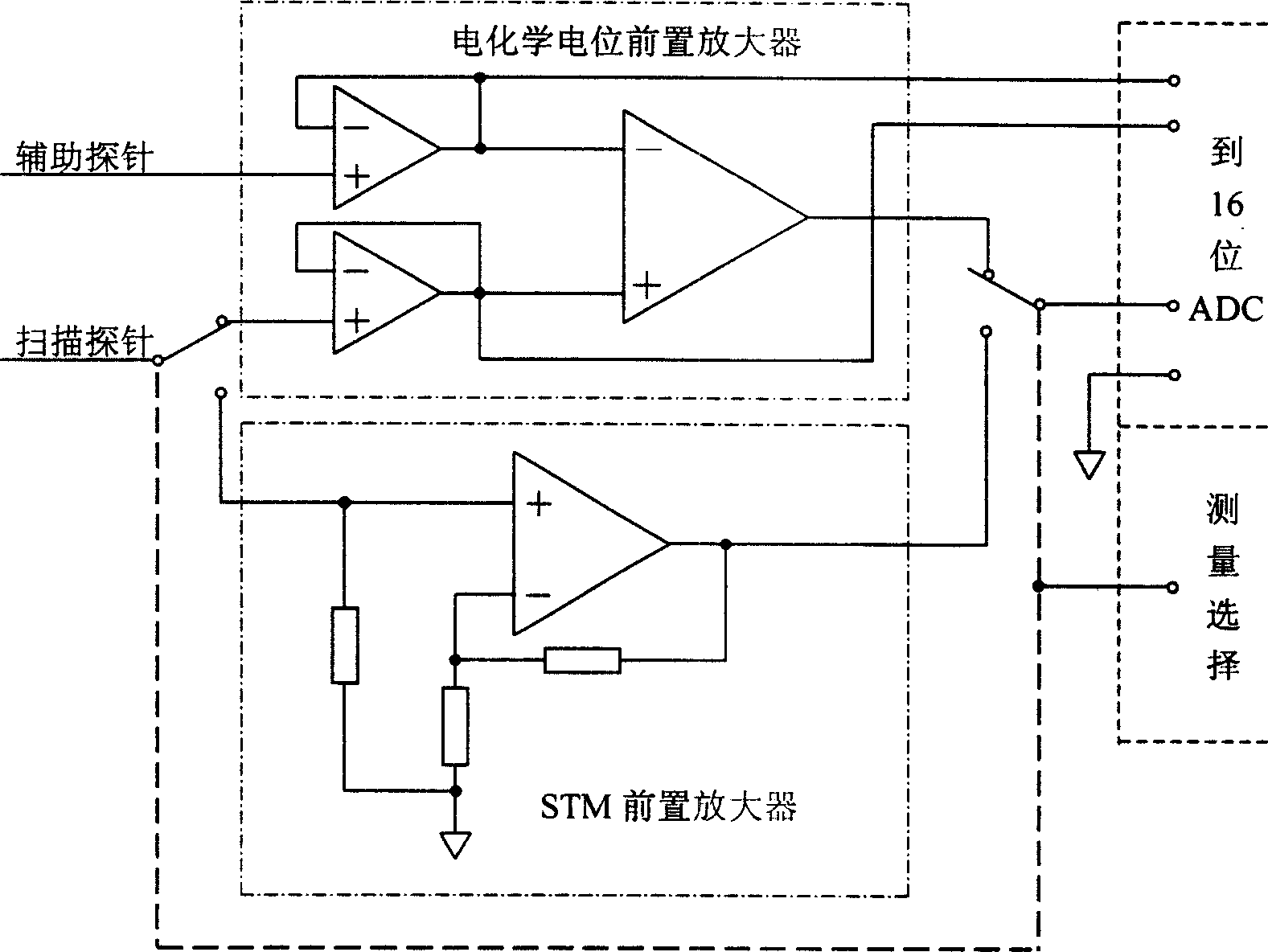

United measuring system and its measuring technology for scanning channel microscope and scanning micro electrode

InactiveCN1683917AImprove spatial resolutionAchieving Quantitative ControlSurface/boundary effectScanning probe microscopyElectricityOpen platform

The present invention relates to measurement system and measurement technology with combined scanning tunnel microscope (STM) and scanning micro electrode. The measurement system consists of STM measuring platform, scanning micro probe and control / driving unit; tunnel current signal and micro area potential signal measuring unit; and measuring signal controlling and processing unit. The present invention utilizes micro scanning probe in simultaneous detection of surface tunnel current and surface potential distribution, adopts scanning mode interchange between micro piezoelectric scanning and mechanical step motor scanning, and uses tunnel current as indication of micro scanning electrode reaching the surface of sample, to realize the quantitative control of the distance between the tip of micro scanning electrode and the sample surface and to raise the spatial resolution in the measurement. The present invention provides opened platform for various surface spatial resolution measuring technology.

Owner:XIAMEN UNIV

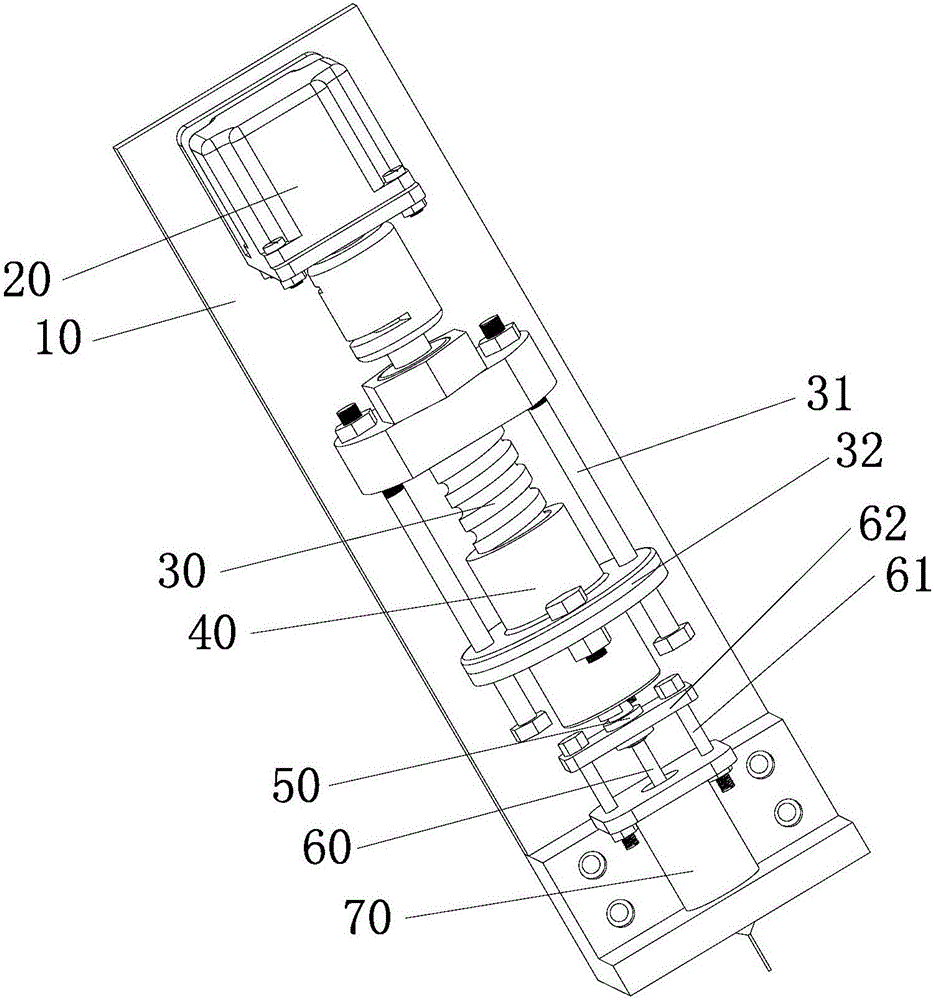

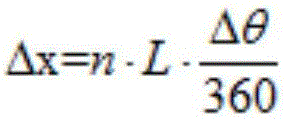

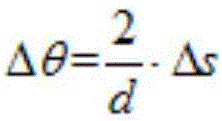

Adhesive dispersing mechanism and adhesive dispersing amount metering control method applying same

ActiveCN106799331AQuality improvementAccurately control the glue outputLiquid surface applicatorsCoatingsVolume variationBall bearing

The invention provides an adhesive dispersing mechanism and an adhesive dispersing amount metering control method applying the same. The adhesive dispersing mechanism comprises a base plate, a stepping motor, a ball bearing lead screw, a lead screw nut, a flexible connecting assembly, a piston rod, a piston and an adhesive barrel, wherein the ball bearing lead screw is in transmission connection with the stepping motor; the lead screw nut is matched with the ball bearing lead screw; one end of the flexible connecting assembly is fixedly connected with the lead screw nut; the piston rod is fixedly connected with the other end of the flexible connecting assembly; the piston is fixed to the piston rod; the adhesive barrel is fixedly connected to the base plate; and the piston is connected into a cylindrical inner cavity of the adhesive barrel in a sliding manner. According to the adhesive dispersing amount metering control method, the actual adhesive dispersing amount is measured accurately, calculated and obtained on the basis of the mass difference principle; the adhesive dispersing amount is compared with the standard adhesive dispersing amount, so that the adhesive dispersing amount of the adhesive dispersing mechanism is adjusted; quantitative control over the adhesive dispersing amount is achieved; adhesive dispersing quality is improved; the adhesive outlet amount is precisely controlled through the rotation angle of the stepping motor and the volume variation of the adhesive barrel; and the adhesive dispersing amount can be controlled precisely, and adhesive dispersing quality can be improved.

Owner:HUAQIAO UNIVERSITY

Method for directly controlling torque of induction motor and control device

InactiveCN102364871ATorque Control ImplementationAchieve torque control compared to omitting the flux linkageElectronic commutation motor controlVector control systemsVoltage vectorVoltage inverter

The invention relates to the field of control of induction motors and discloses a control method and device for directly controlling a torque of the induction motor. In the method, an electrical signal of a given torque angle and a feedback torque angle reaches a space vector modulation generator (SVM) for processing through a difference controller via an expect voltage vector generated by a voltage space vector estimator and then a switch signal of an inverter is transmitted for driving the induction motor. The device is connected with a given torque angle controller through a first input end of a difference controller; a second input end of the difference controller is connected with a first path of output end of a corner magnetic chain observer; and the difference controller is connected with the inverter through the voltage space vector estimator and the space vector modulation generator (SVM). According to the method, the torque control of the induction motor is realized and two adjustors for a magnetic chain and torque control are omitted, so that a control system has a simple structure; in addition, the design difficulty is reduced and the production cost is low.

Owner:LUOYANG INST OF SCI & TECH

Shape memory material with electrical response characteristics and its prepn process

The present invention relates to one kind of shape memory material with electrical response characteristic and its preparation process. The shape memory material is prepared with polyester as mother material and through mixing with conducting stuffing and other assistant. Specifically, the shape memory material consists of aliphatic polyester in 100 portions, conducting stuffing in 10-50 portions, multiple functional radical monomer in 0-10 powder and other assistant 0-30 portions. During the preparation, high energy ray is used to radiate the polymer, and radiation dosage and conducting stuffing content are altered to control the shrinking rate and shrinking force effectively. The material of the present invention has wide responding voltage range, may shrink in different voltages, and has the features of convenient control, easy forming and wide application range.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

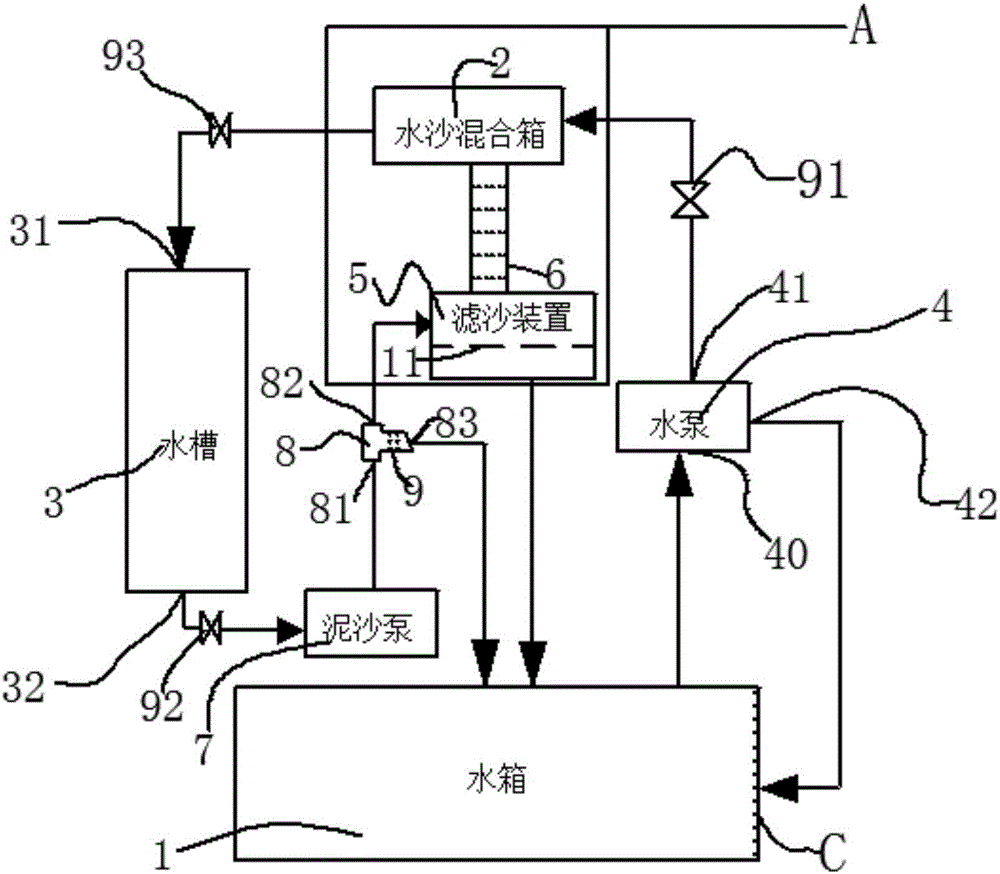

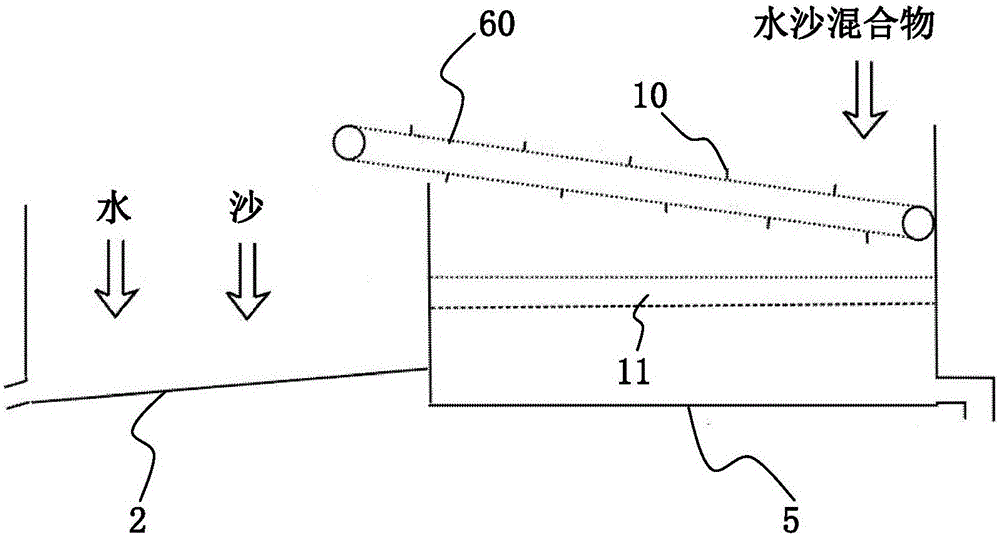

Small-size deposition water channel sand circulation and flow quantitative control system

ActiveCN105136427AAchieving Quantitative ControlLow costHydrodynamic testingPump controlWater dischargeControl system

The invention provides a small-size deposition water channel sand circulation and flow quantitative control system. The system includes: a water tank for storing water, a water and sand mixture box, a water channel, a water pump, a sand filtering apparatus, and a conveyor. The water and sand mixing box is used for receiving water and sand for forming a water and sand mixture. The water channel is used for conducting deposition simulation experiment, and is provided with a water inlet and a water outlet. The water pump is provided with a water pumping opening, a first water discharging opening for providing part of the water pumped by the water pump to the water and sand mixing box, and a second water discharging opening for returning the rest of the water pumped by the water pump to the water tank. The sand filtering apparatus receives the water and sand mixture discharged from the water channel and separates water from sand from the water and sand mixture, and the water separated returns to the water tank. The conveyor conveys the sand separated from the sand filtering apparatus to the water and sand mixing box. According to the invention, the system can simultaneously circulate water and sand, can achieve quantitative control of water flow by adopting cheap large-flow water pump, and can reduce cost.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

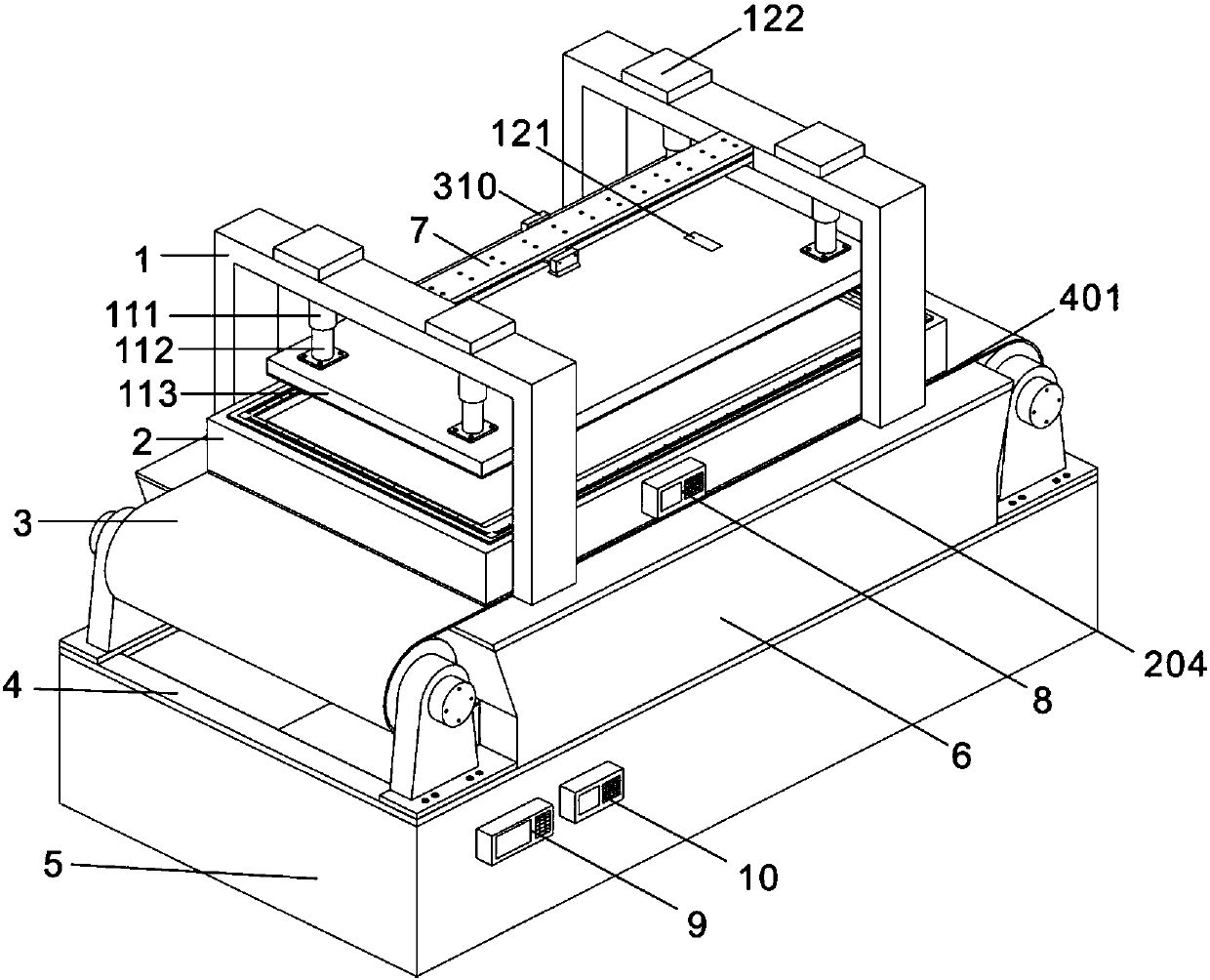

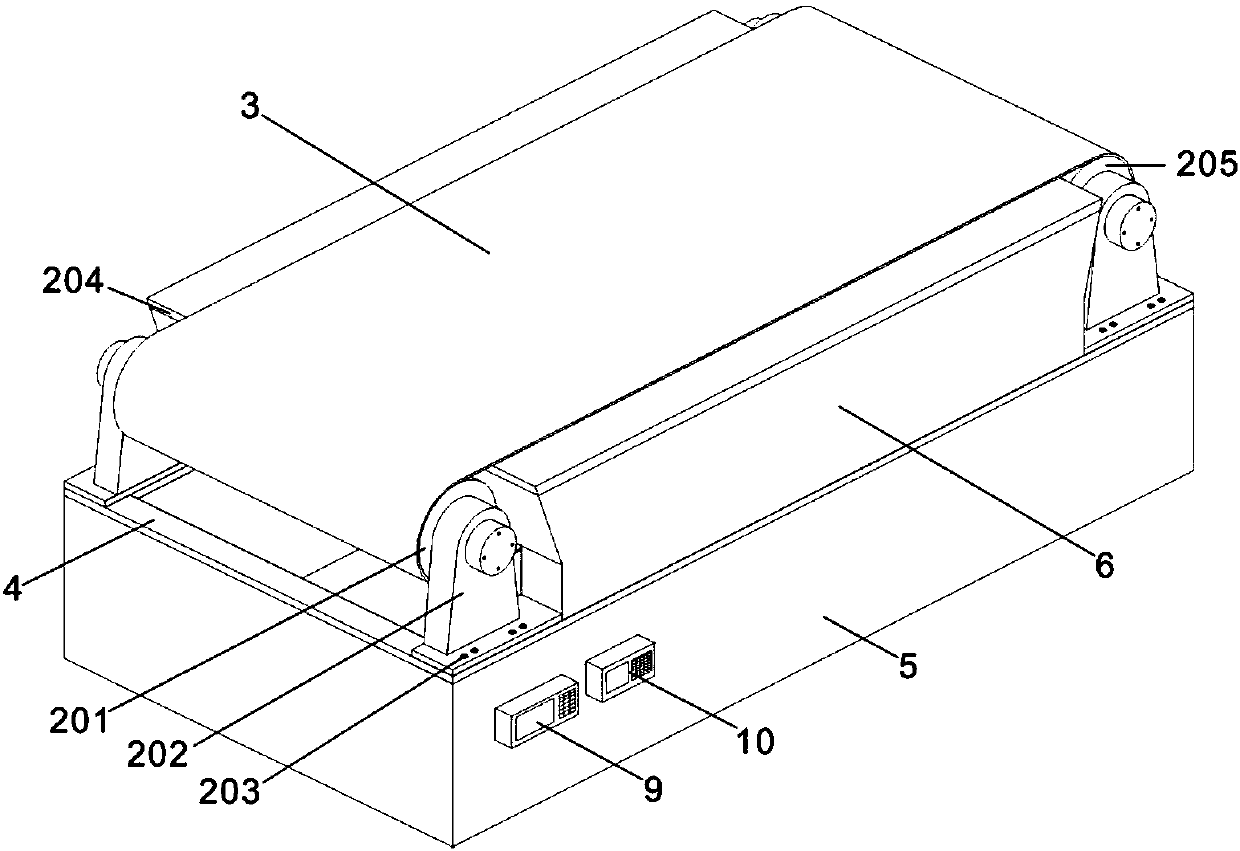

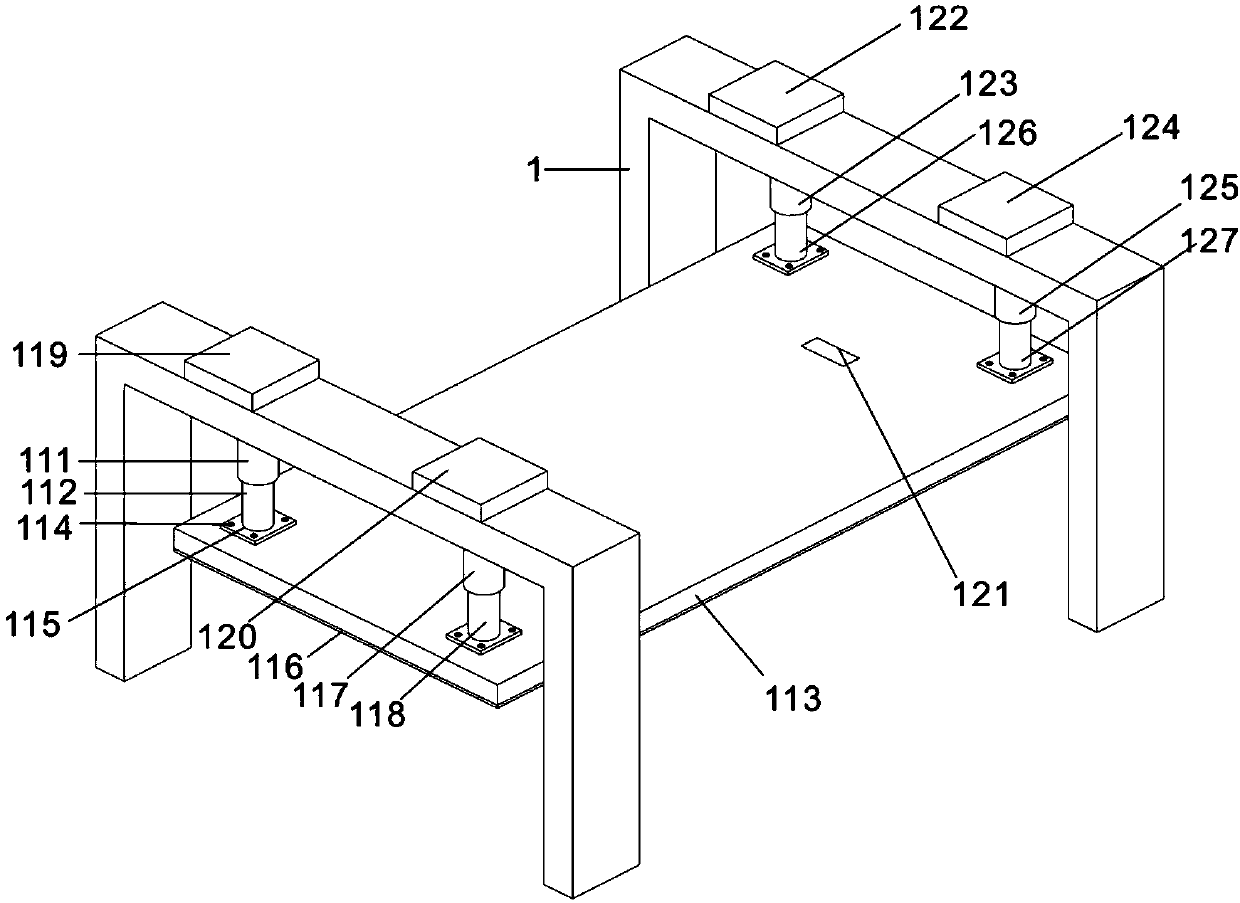

Multi-field real-time monitoring and servo pressurizing bottom friction testing system for large-size rock-soil body

PendingCN107907424AAchieving Quantitative ControlIncrease the simulation rangeMaterial strength using tensile/compressive forcesFrequency changerAlternating current

The invention provides a multi-field real-time monitoring and servo pressurizing bottom friction testing system for a large-size rock-soil body. The multi-field real-time monitoring and servo pressurizing bottom friction testing system comprises a conveyor belt driving system, a model vertical uniform distribution force loading servo system, a friction force determination system and an image acquisition and resolving system. The model vertical uniform distribution force loading servo system comprises a hydraulic column and a pressurizing plate; the pressurizing plate is internally provided with a pressure sensor and is connected with a background controller; the controller is connected with a servo motor connected with a hydraulic oil tank; the conveyor belt driving system comprises an alternating current motor, a frequency converter and a speed monitor; the friction force determination system is composed of a stress sensor and an outer data receiver; the image acquisition and resolving system is composed of a high-speed camera, a sliding rail, an illumination lamp, a scale and a background computer. According to the multi-field real-time monitoring and servo pressurizing bottom friction testing system provided by the invention, a large-size quantitative simulation test of deformation damages of the rock-soil body under the action of gravity and an evolution process of the rock-soil body can be realized; different stress fields are simulated by changing normal stress on a model to be detected and a stress field and a displacement field of the model are monitored in real time.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Manufacturing method with manual welding crack defect test board

The invention discloses a manufacturing method with a manual welding crack defect test board. The test board is mainly used for training of welding quality nondestructive testing personnel. The alloy condition of meeting quenched structure generation should exist in a crack generation area; a gap is precisely prepared in a local area of a multi-layer backing weld or filling bead or cap weld, a restraint condition is formed by carrying out repair welding on the gap, and then a large enough residual stretching stress field is generated; during welding, the large diffusible hydrogen content exists in a welding line, and during later gap repair welding, under formed stretching stress, diffusible hydrogen is diffused and gathered to the area to induce crack generation; and after cracks are pre-manufactured, filling welding and cap welding of a weld bead are carried out through shielded metal arc welding or argon tungsten-arc welding, and the integrity of the front face of the weld bead is guaranteed. According to the method, the positions, length, depth and self height of the cold cracks can be controlled according to design requirements, and therefore the utilization rate of the welding defect test board is increased.

Owner:FUSHUN CHINA PETROLEUM INSPECTION ENG

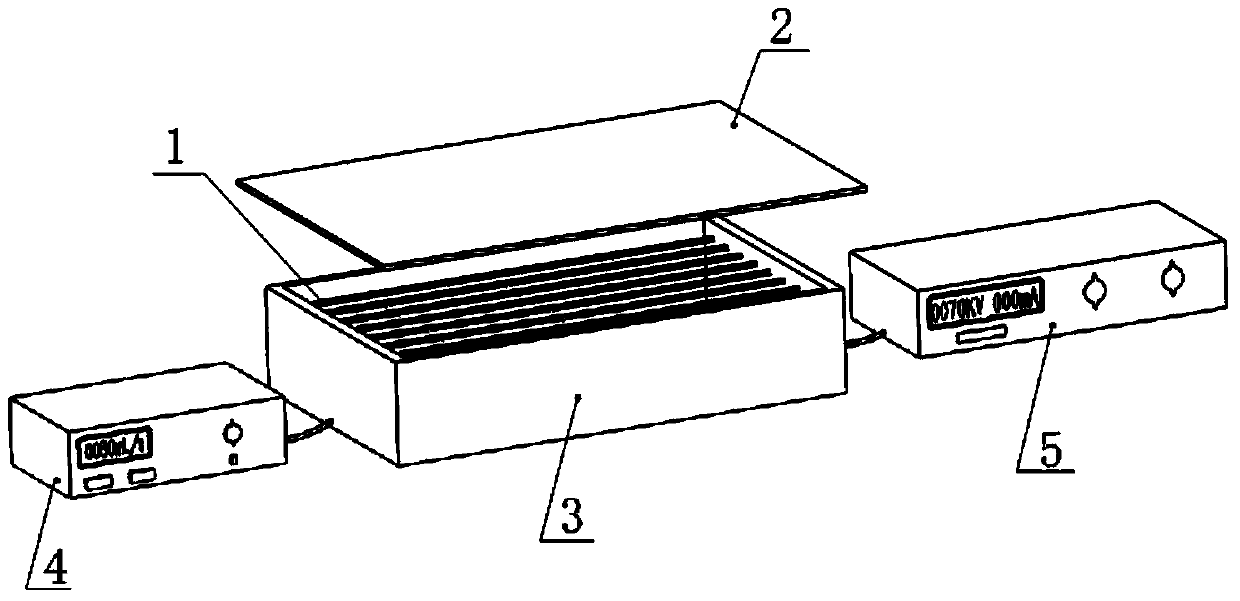

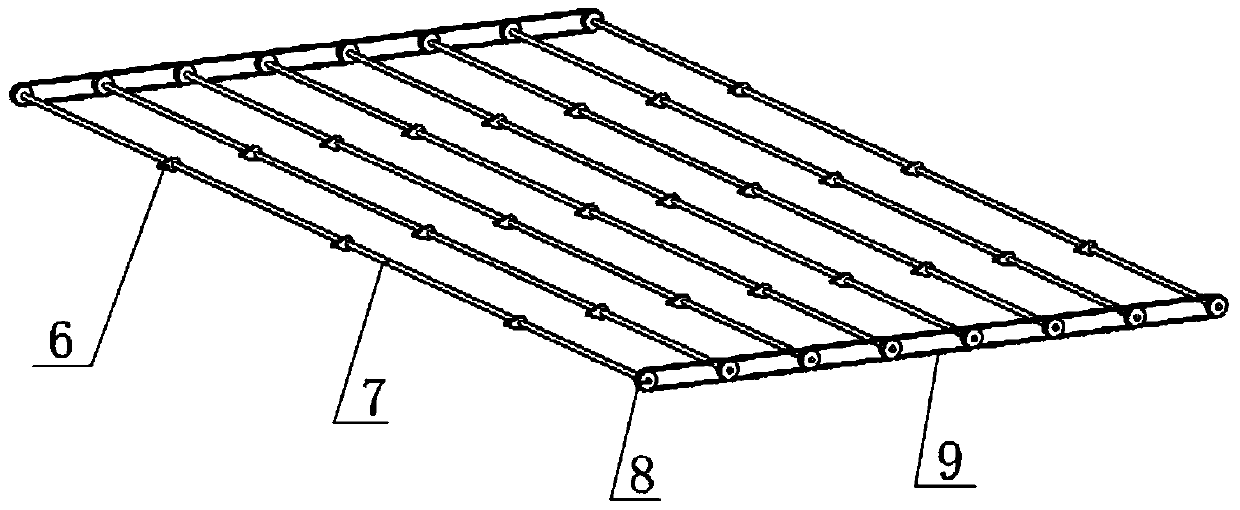

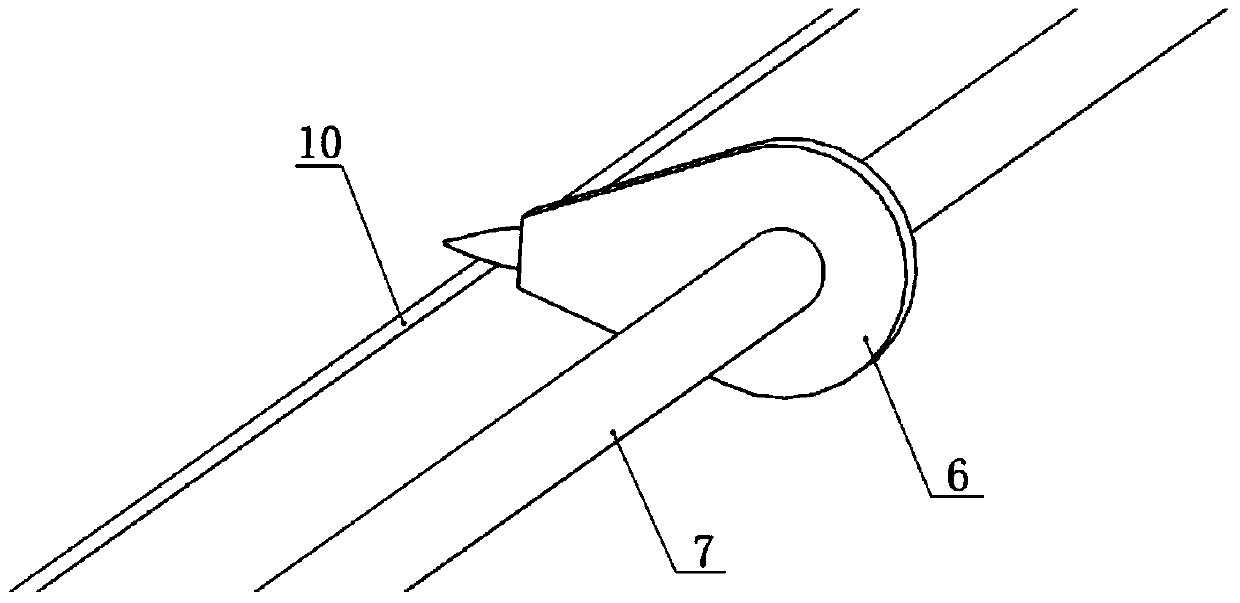

String type electrostatic spinning device and method

ActiveCN103993370AEliminate easy cloggingIncrease productionFilament/thread formingDrive wheelEngineering

The invention discloses a string type electrostatic spinning device and method, and belongs to the field of spinning. The string type electrostatic spinning device mainly comprises spinning strings, an automatic string plucking device, a receiving pole plate, a solution pool, a servo solution supply system and a high-pressure electrostatic generator, wherein the spinning strings are arranged at the top end of the solution pool at equal intervals, and arranged above or below the water level of a solution within a certain range, the automatic string plucking device is composed of plucking heads, a driving wheel and a driving belt, and arranged above the spinning strings, each plucking head is composed of a rubber contact and a cam, the plucking heads are arranged on a guide rail at equal intervals, and the pointed ends of the rubber contacts are arranged on the spinning strings to make the spinning strings to vibrate vertically periodically. On a wave crest, vibrating force and electric field force act together so that a Taylor cone can be promoted to be formed more easily, and the electric field force needed for generating the Taylor cone is reduced. The inherent frequency and the waveform of the spinning strings are changed by having control over the lengths of the parallel spinning strings, the linear density, the tension and the rotating speed, the number and the spacing distance of the plucking heads, and quantitative control over the spinning process is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Determination method for cupping value of metal material and die

InactiveCN103698233AStop the flowImprove accuracyInvestigating material ductilityTest sampleStamping process

The invention discloses a determination method for the cupping value of a metal material and a die. The method comprises the following steps: 1) tightly pressing a test sample, specifically, selecting a proper periphery-pressing force according to the tensile strength of a metal test sample, and tightly pressing the periphery of the test sample by the periphery-pressing force, so as to prevent the flowing of the periphery material of the test sample; 2) stamping the test sample, specifically, lubricating the central part of the test sample by bonding lubricating grease with a polyethylene film, and then stamping the central part by a plunger chip at stamping speed of 0.5-2.0 mm / s; 3) determining the cupping value, specifically, in the stamping process, when a stamping-driving force is reduced by 1-6 kN, stopping stamping, at the moment, a plunger chip displacement corresponding to the maximum stamping-driving force is the cupping value. The die is provided with mutually matched brake beads on a press die and a cushion die. According to the determination method and the die disclosed by the invention, the influence of the periphery-pressing force, the lubricating agent and the stamping speed on the test of the cupping value is adequately considered, quantitative control is performed on crack judgement, and the flowing of the periphery material of the test sample is further prevented by optimizing the structure of the die, thus improving the accuracy of the test result.

Owner:武钢集团有限公司

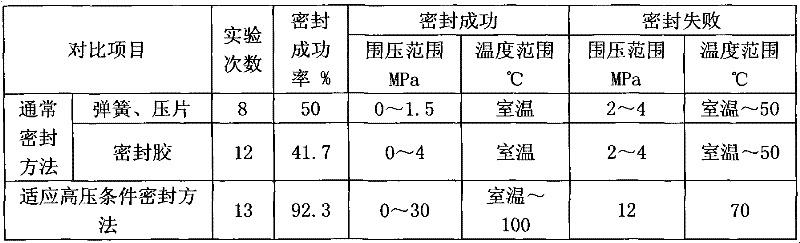

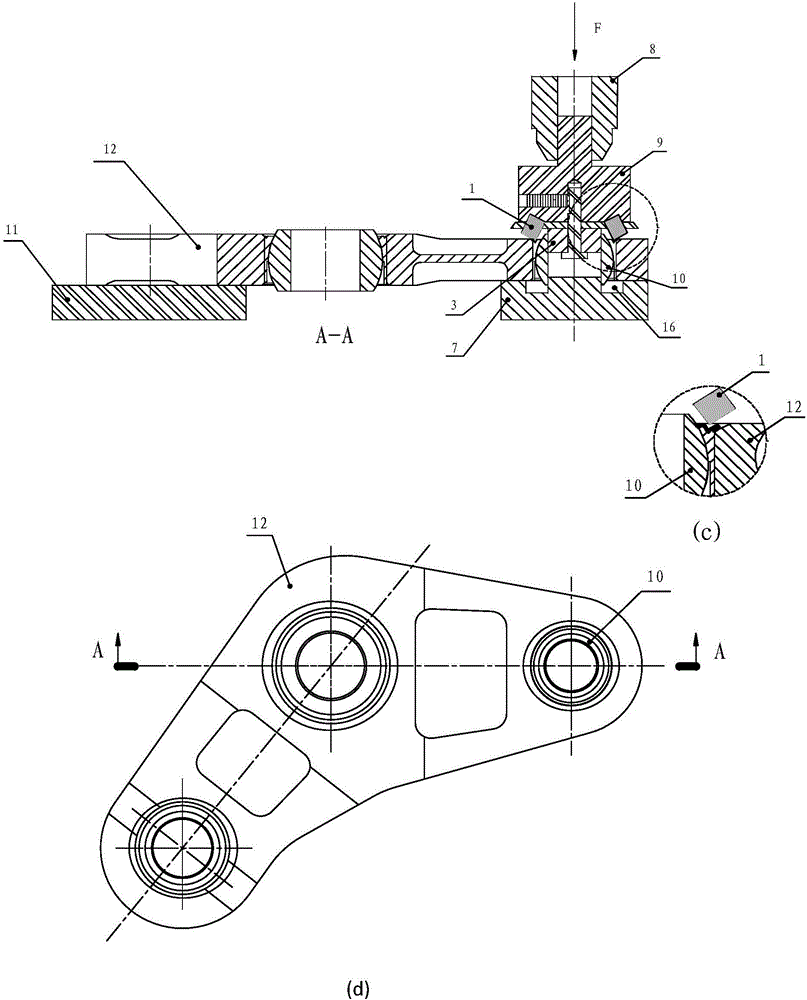

A kind of glass model sealing method

The invention relates to a method for sealing a glass model. The method is realized by a hydraulic sealing clamp, and comprises the following steps of: connecting an inlet of an outer model with an internal thread interface of an upper clamping plate of the hydraulic sealing clamp, and butting an inlet of the glass model with a 2mm back cut; flatly arranging the glass model in the sealing clamp, arranging sealing gaskets on two sides of the inlet of the glass model, slowly injecting machine oil to lift a piston at the lower end of the sealing clamp, clamping the glass model, and closing a needle valve when the pressure is higher than 2MPa; sealing an outlet end of the glass model in the same way; arranging the glass model in the center of an outer model and fixing the glass model; and injecting confining pressure liquid into the outer model for sealing. The problems of leakage and damage of the glass model are effectively solved, and the sealing pressure is quantitatively controlled; and the preparation period of an experiment is shortened, and the efficiency of the experiment is improved.

Owner:PETROCHINA CO LTD

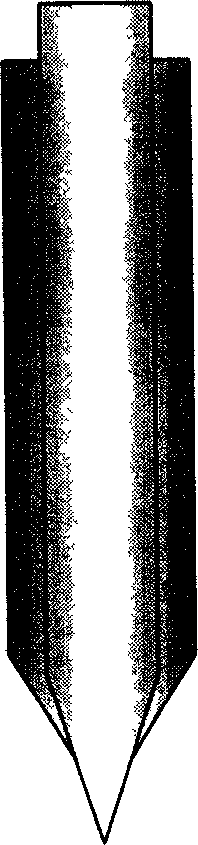

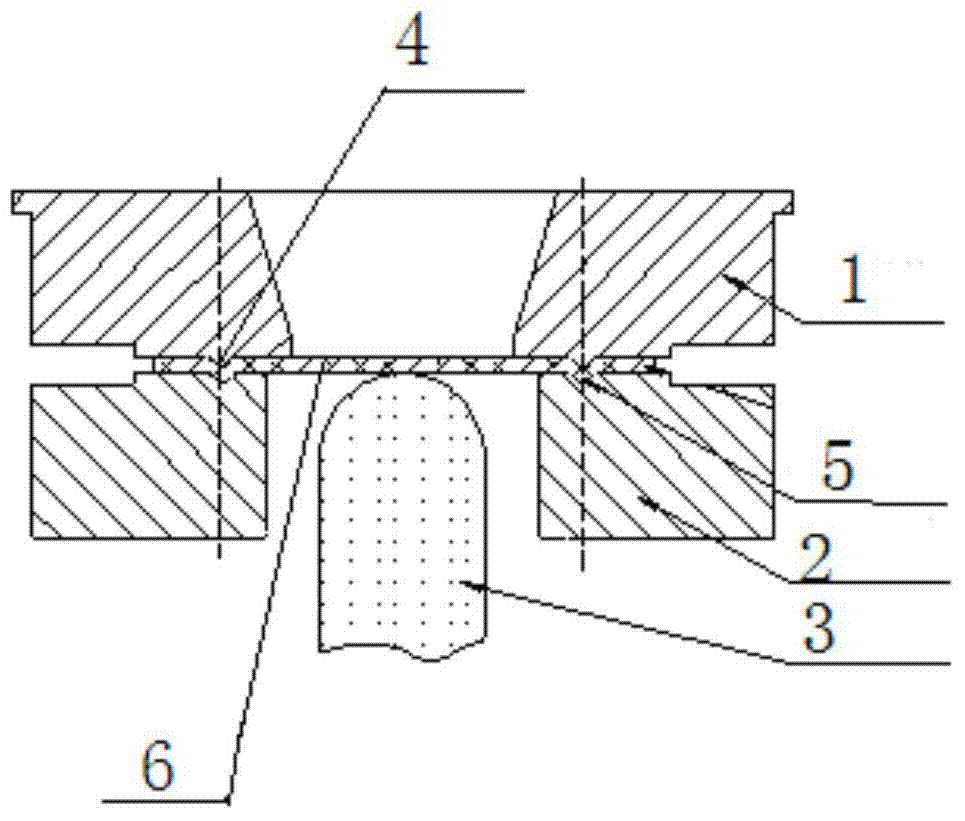

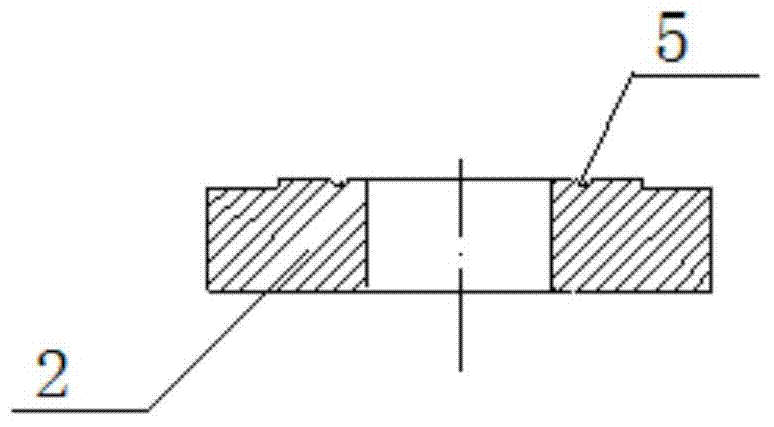

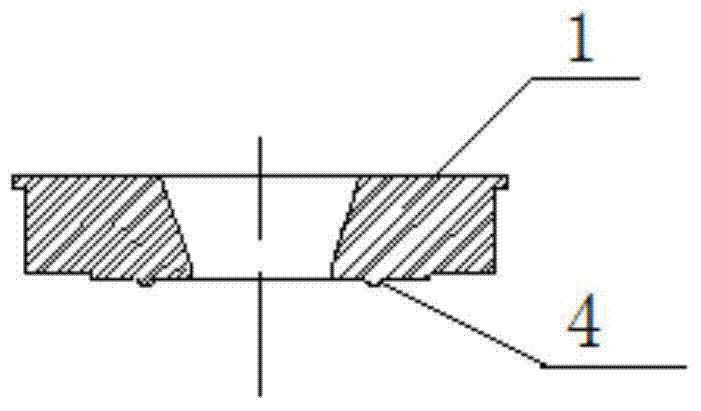

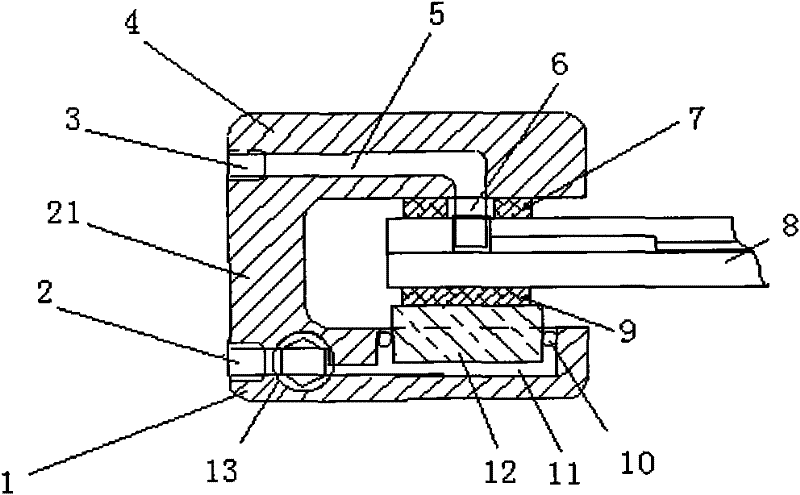

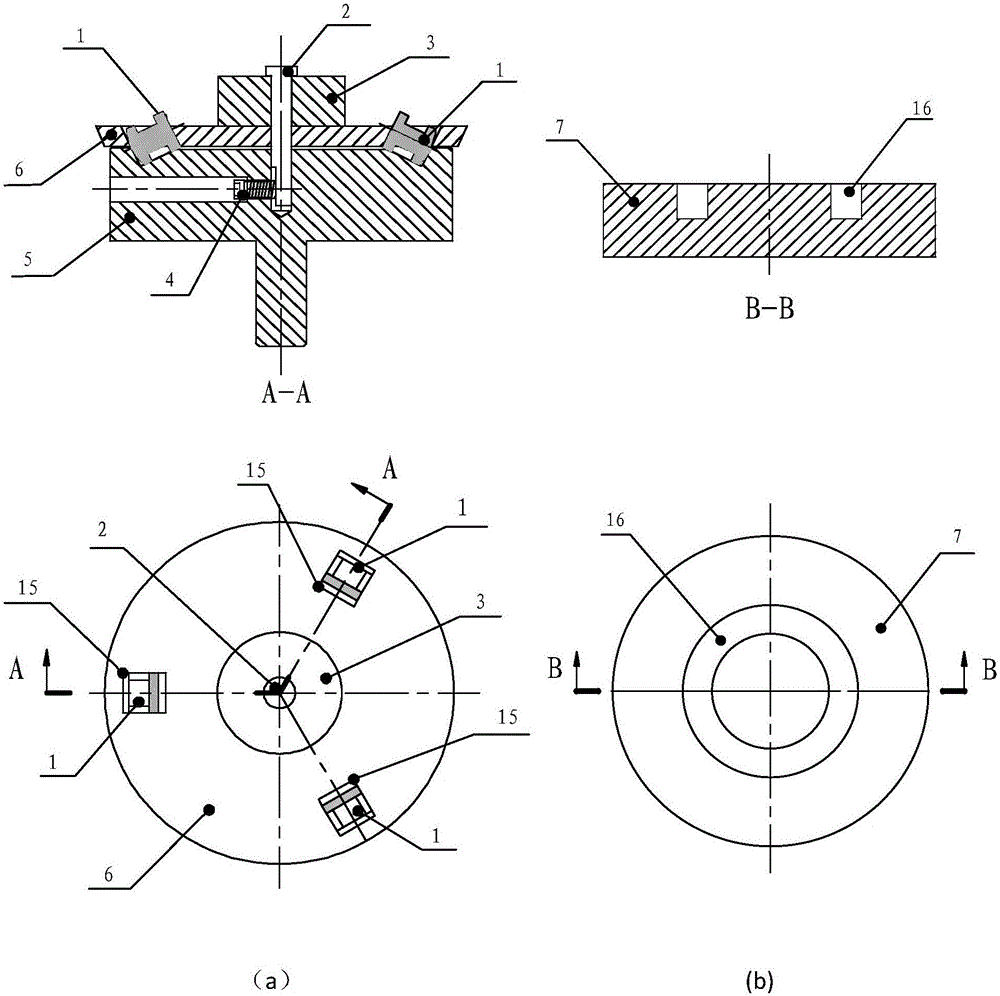

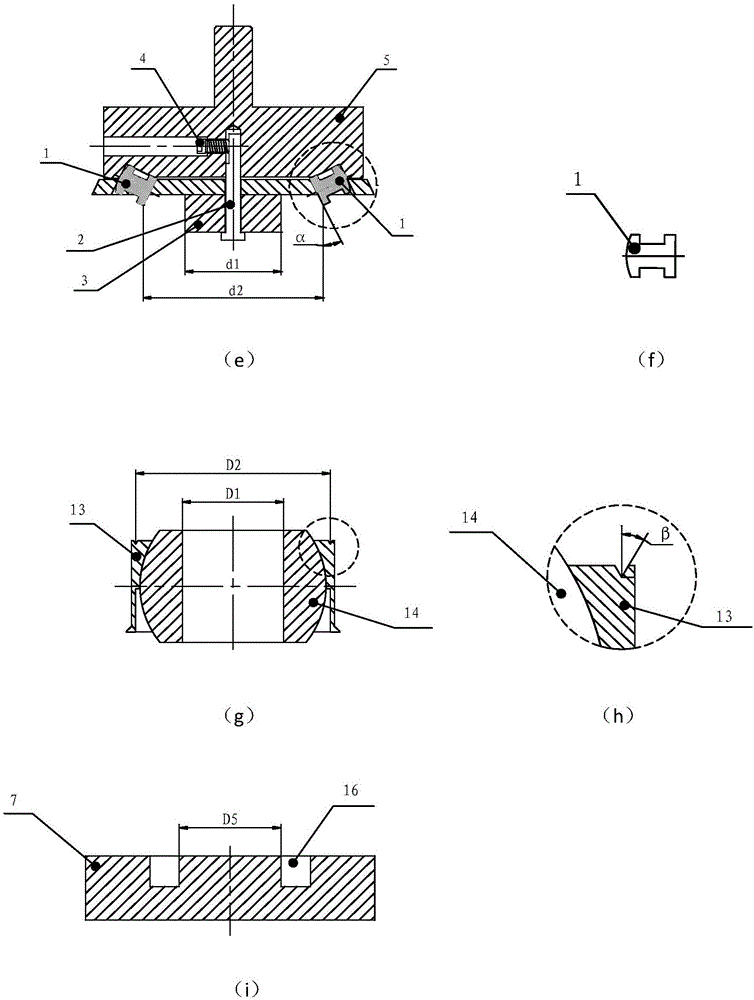

Joint bearing flanging tool and process of using same for joint bearing flanging

The invention relates to a joint bearing flanging tool for aviation hanging parts, and a process of using the same for joint bearing flanging. The joint bearing flanging tool mainly comprises a roll, a retainer, a guide pin, a force-bearing support seat and a location support seat, wherein clearance fit is formed among the components; and the bearing flanging tool needs to be used in a manner of being matched with the flanged joint bearings in the hanging parts in specification and dimension during use. The joint bearing flanging tool is simple in structure, uniform in stress, capable of being automatically centred, stable in performance, reliable in quality, and capable of ensuring stability and smoothness during joint bearing flanging. According to the process of using the joint bearing flanging tool for bearing flanging, which is disclosed by the invention, the joint bearing flanging tool is installed on a spindle of a radial drilling machine, each flanged bearing is rotated and extruded to the required flanging dimensions through enabling the roll to contact with the groove surface of the flanged bearing. The process is stable in machining, simple to operate, short in alignment time, high in efficiency, stable in quality, and convenient for batch production.

Owner:CHENGDU ENGINE GROUP

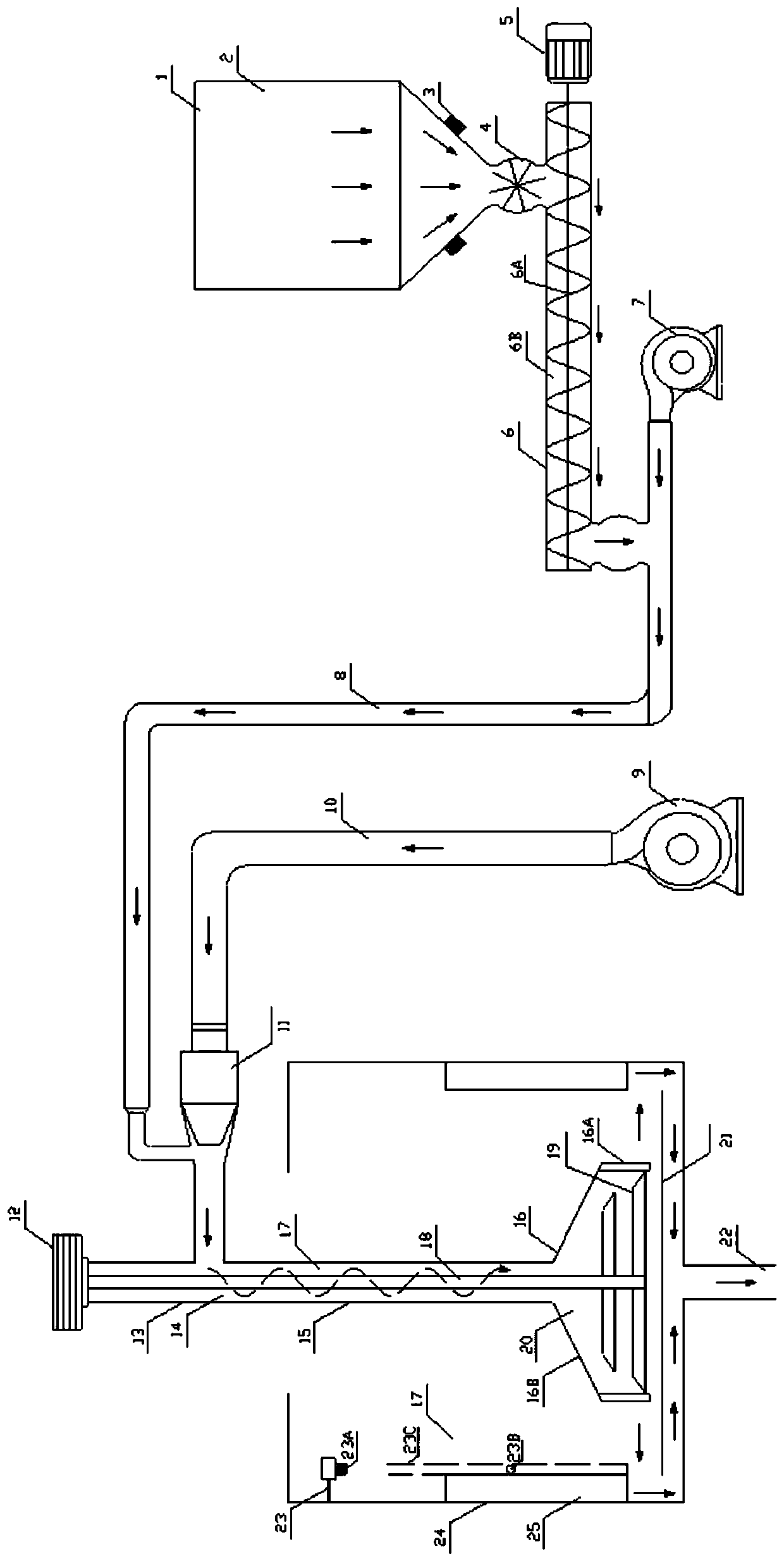

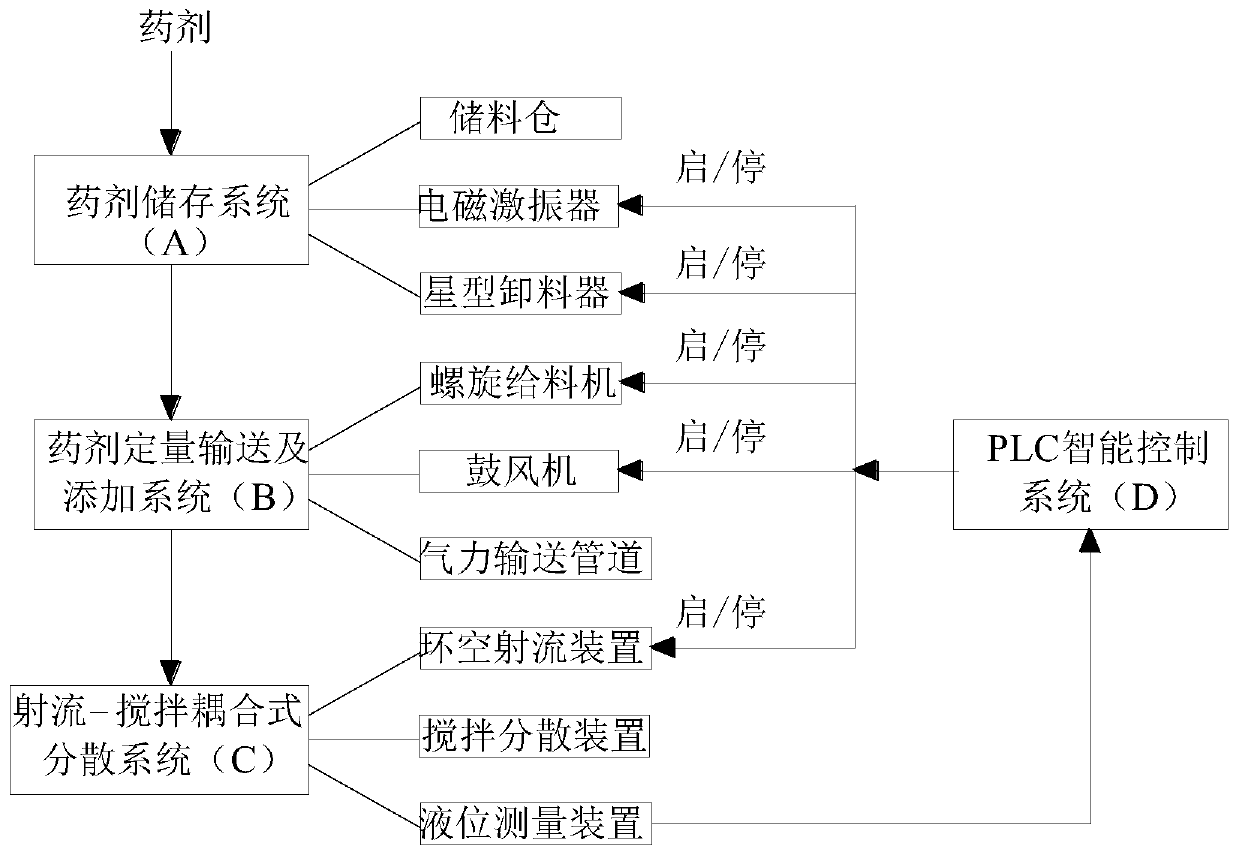

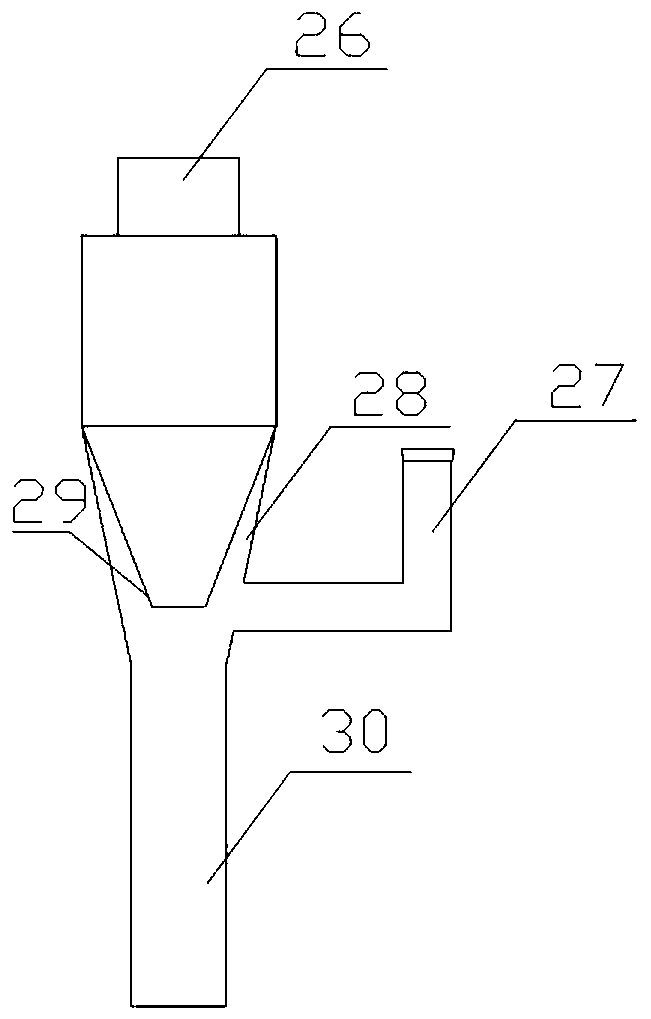

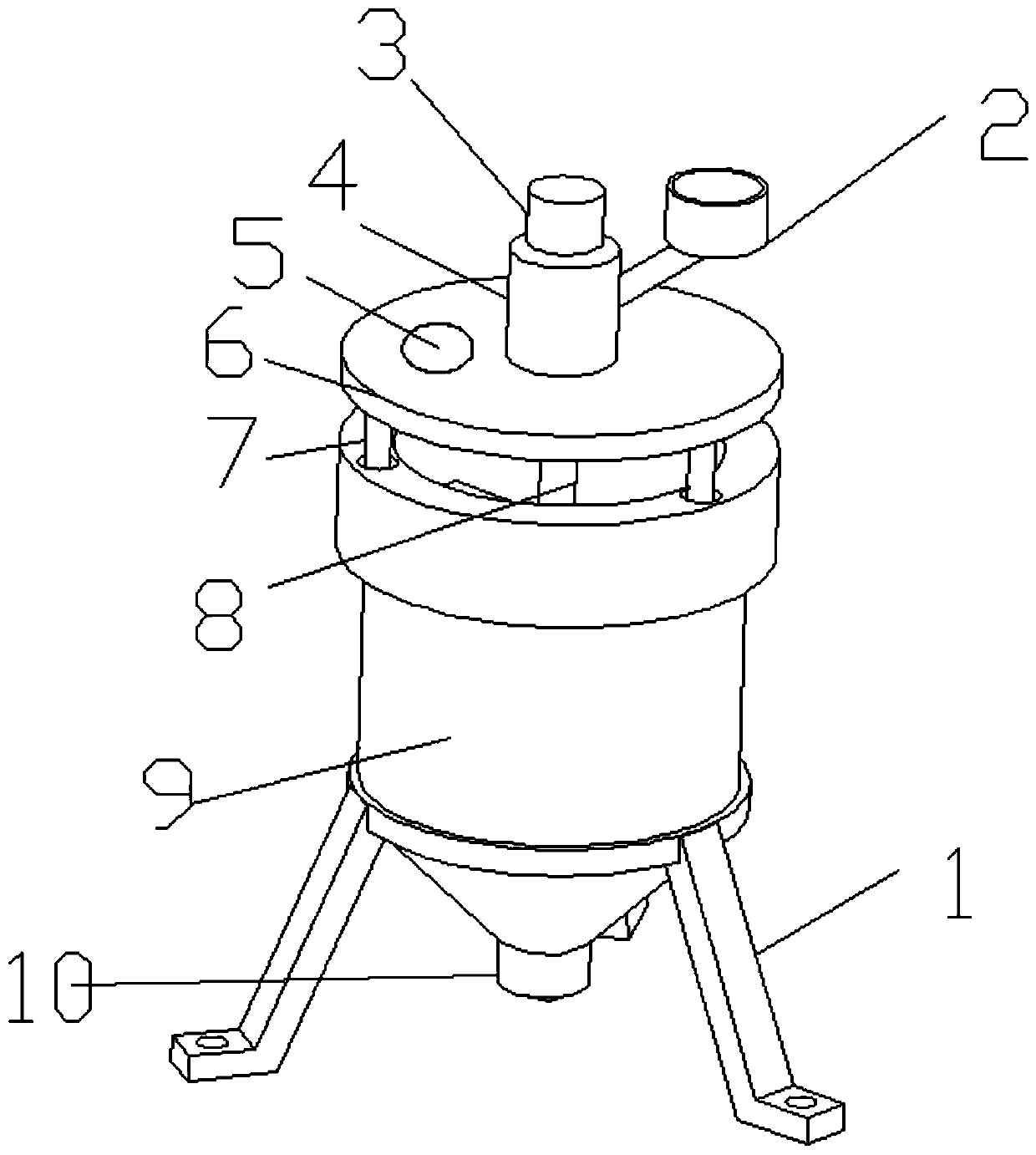

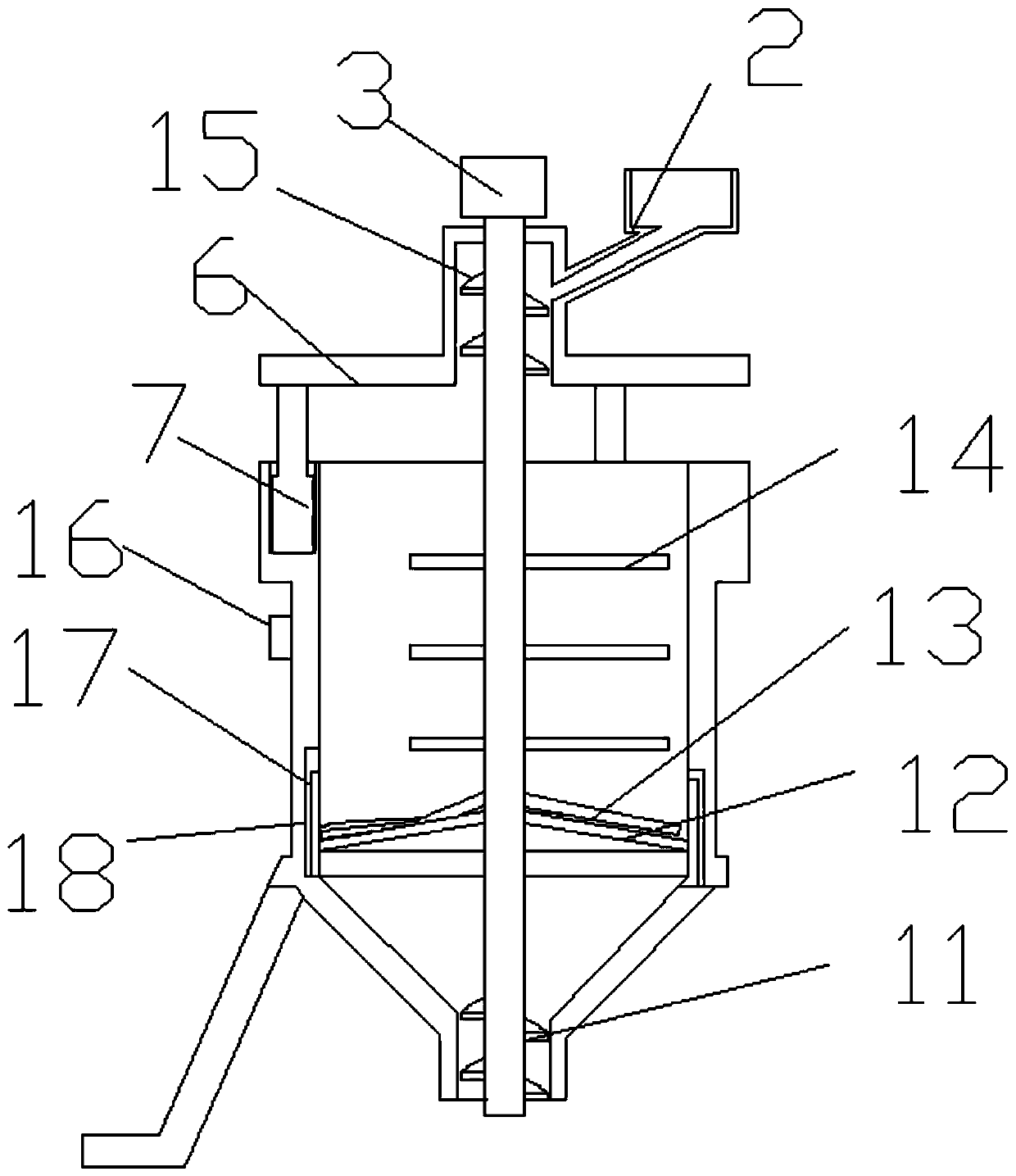

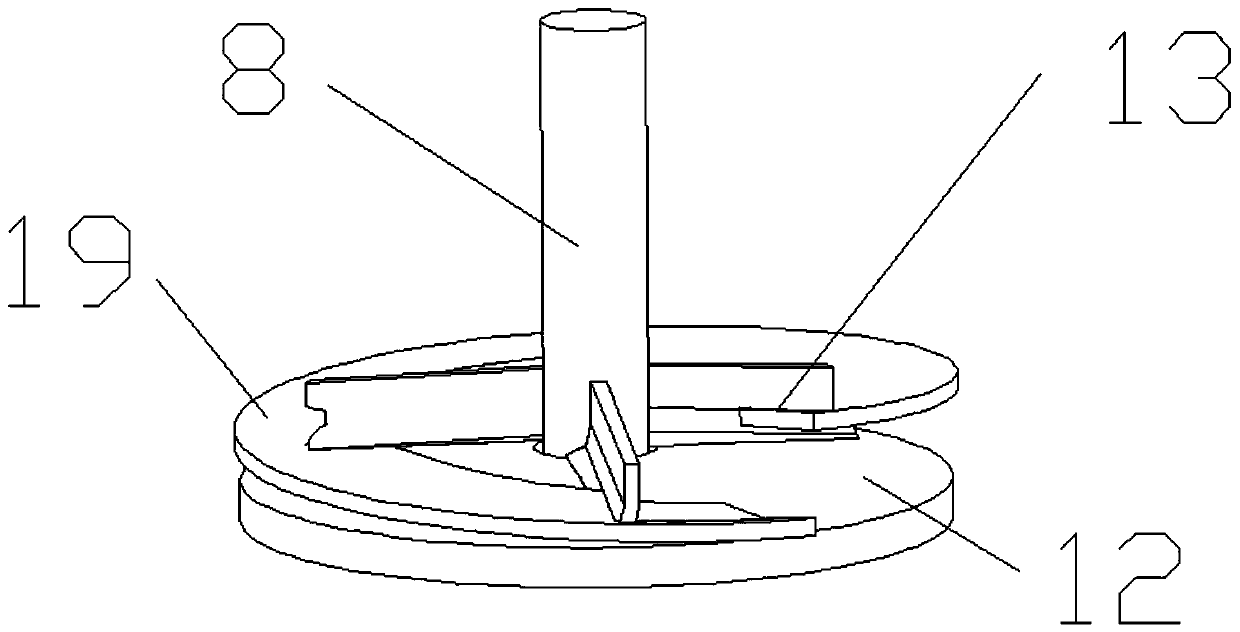

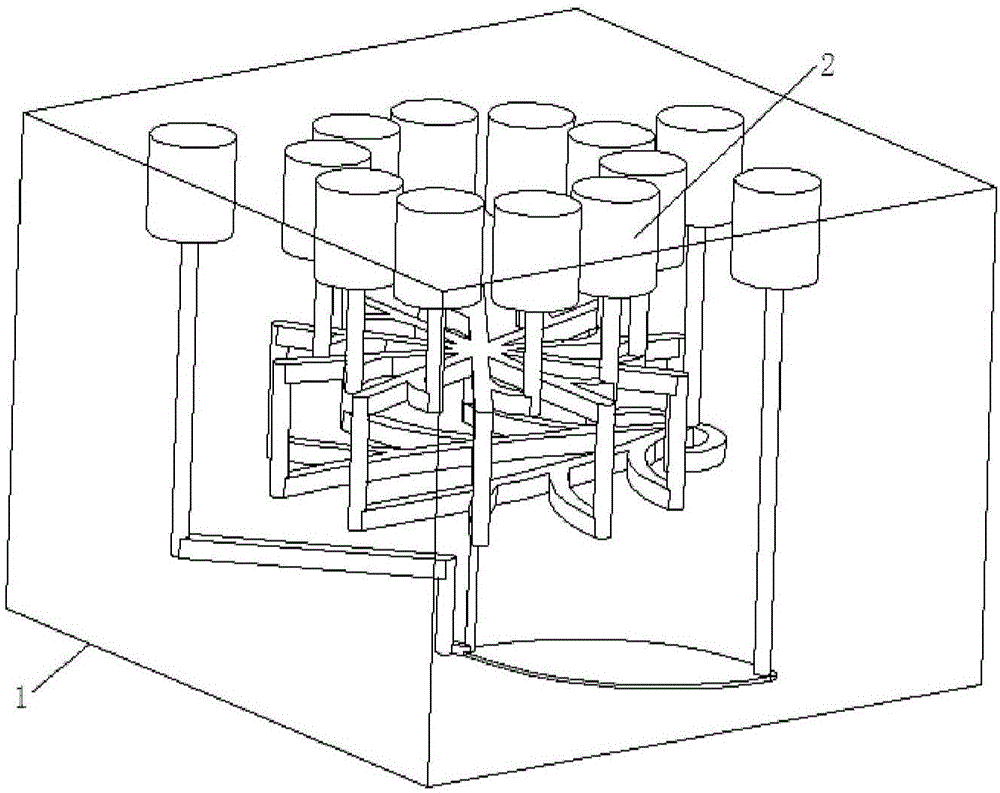

Jetting-stirring coupling type quantitative dispersion and mixing system for powdery flocculation medicament

InactiveCN110038476AEvenly dispersedDisperse completelyTransportation and packagingRotary stirring mixersEngineeringDissolution

The invention relates to the field of addition of flocculation medicament in a slime water treatment technology and specifically relates to a jetting-stirring coupling type quantitative dispersion andmixing system for powdery flocculation medicament. The jetting-stirring coupling type quantitative dispersion and mixing system at least comprises an annular jetting device, and further comprises a medicament storage system, a medicament quantitative conveying and adding system, a jetting-stirring coupling type dispersion system and an PLC (Programmable Logic Controller) intelligent control system. The jetting-stirring coupling type dispersion system is a core subsystem of the jetting-stirring coupling type quantitative dispersion and mixing system and comprises the annular jetting device anda stirring and dispersion device, wherein the annular jetting device is composed of a screw pump, a pressure water pipe, an ejection air pipe, a mixing chamber, a spraying nozzle and a pressure-stabilizing throat pipe; the stirring and dispersion device comprises a stirring mechanism and a mixing and stirring bucket; the stirring mechanism is composed of a stator, a sleeve, a shaft and a double-layer impeller; a false bottom is designed at the bottom of the mixing and stirring bucket; a plurality of baffle plates are arranged on a bucket wall; a liquid level measuring device is distributed above the bucket wall. The system involved in the invention sufficiently considers addition and dissolution characteristics of the flocculation medicament and can be used for accurately and quantitatively adding powdery medicament and solution at the same time.

Owner:ANHUI UNIV OF SCI & TECH

Efficient graphene paint mixing and stirring device

InactiveCN111001343AImprove uniformityAvoid cloggingShaking/oscillating/vibrating mixersTransportation and packagingSpiral bladeElectric machinery

The invention is suitable for the technical field of graphene paint processing, and provides an efficient graphene paint mixing and stirring device. The device comprises a stirring barrel and a top cover. The top cover is arranged at the top of the stirring barrel. The middle position of the top of the top cover is fixedly communicated with a feeding transmission cylinder. A motor is fixedly mounted at the outer top of the feeding transmission cylinder. The output shaft of the motor extends into the feeding transmission cylinder and is coaxially and fixedly connected to the top of a stirring shaft. The feeding transmission cylinder is communicated with a hopper. A feeding spiral blade is arranged on the stirring shaft in the feeding transmission cylinder, and a plurality of stirring rods are fixedly arranged on the stirring shaft in the stirring cylinder. A screen plate is fixedly arranged in the stirring barrel below the stirring rod. A plurality of grinding rods are fixedly arrangedon the stirring shaft. A discharge hole is formed in the middle of the bottom of the stirring barrel; and a discharge spiral blade is arranged on a stirring shaft in the discharge hole. The device hasthe advantages of simple structure, convenient operation, high mixing quality, convenient cleaning, strong controllability and convenience in popularization and implementation.

Owner:张明龙

Multi-reagents orderly feeding device for preventing cross contamination

ActiveCN106824006AHigh precisionNo liquid ingressLaboratory glasswaresFeed devicesLayered structureDead volume

The invention provides a multi-reagents orderly feeding device for preventing cross contamination. The device of the invention comprises a housing and a multi-reagents orderly feeding system, which is arranged inside the housing. The multi-reagents orderly feeding system is a multi-layered structure and at least comprises a pipe connection layer, a reagent injection division layer, a waste liquid diversion layer, a cleaning fluid diversion layer and a reaction tank connection layer. The pipe connection layer, the reagent injection diversion layer, the waste liquid diversion layer, the cleaning fluid diversion layer and the reaction tank connection layer are successively connected through radial pipelines. The multi-reagents orderly feeding device has no dead volume and also effectively avoids reagent residues and cross contamination during feeding of multiple reagents.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

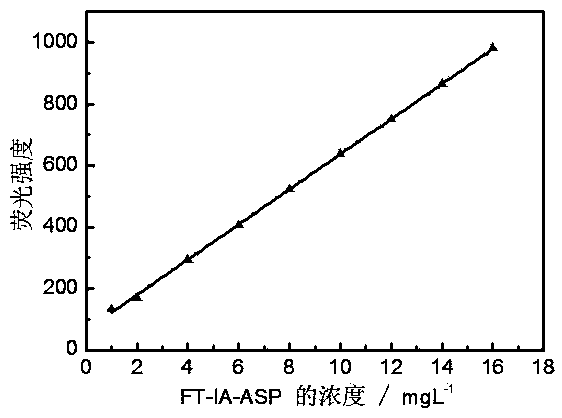

Application of fluorescent tracer type itaconic acid and aspartic acid copolymer in preparation of water treatment agent

ActiveCN109337021ARaw materials are easy to getMild reaction conditionsScale removal and water softeningFluorescence/phosphorescenceSynthesis methodsSolvent

The invention discloses application of a fluorescent tracer type itaconic acid and aspartic acid copolymer in preparation of a water treatment agent. A preparation method of the fluorescent tracer type itaconic acid and aspartic acid copolymer comprises the steps of using 4-bromine-1,8-naphthalic anhydride, ethanol and N, N-dimethyl 1, 3-propane diamine as raw materials to obtain 4-bromine-N-(3-N', N'-dimethyl aminopropyl)-1, 8-naphthalimide first; and then using ethanol and ethylene glycol methyl ether as a mixed solvent to react with n-butylamine so as to obtain a product; enabling the product to react with allyl chloride to obtain 4-butylamino-N-(3-N', N'-dimethyl aminopropyl) naphthalimide diallyl ammonium chloride; and using a water-phase one-step synthesis method to copolymerize a fluorescent monomer FT, itaconic acid and aspartic acid to obtain a product. The application of the fluorescent tracer type itaconic acid and aspartic acid copolymer in the preparation of the water treatment agent, disclosed by the invention, has the advantages that a target has multiple functions such as a fluorescent tracer function and a scale inhibition and dispersion function, the formed scaleis easy to be flushed away by water, and better dispersion performance is shown.

Owner:NANTONG UNIV TECH TRANSFER CENT CO LTD

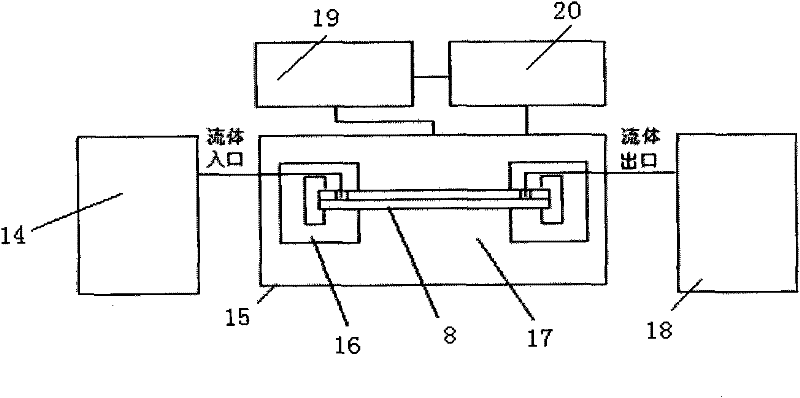

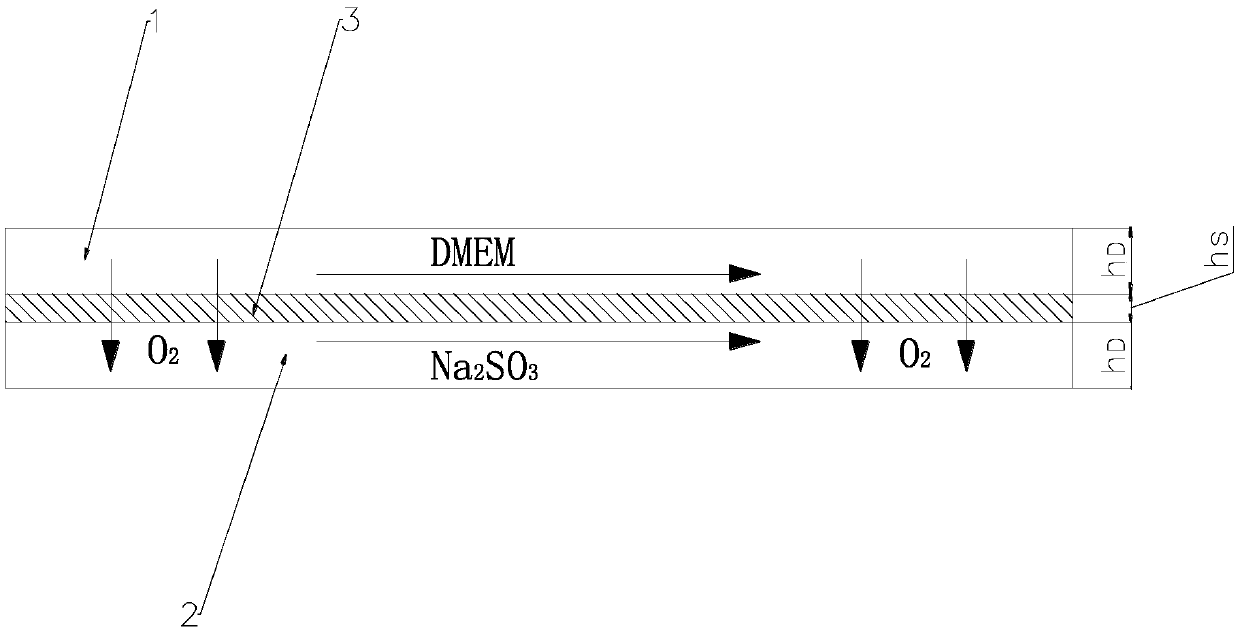

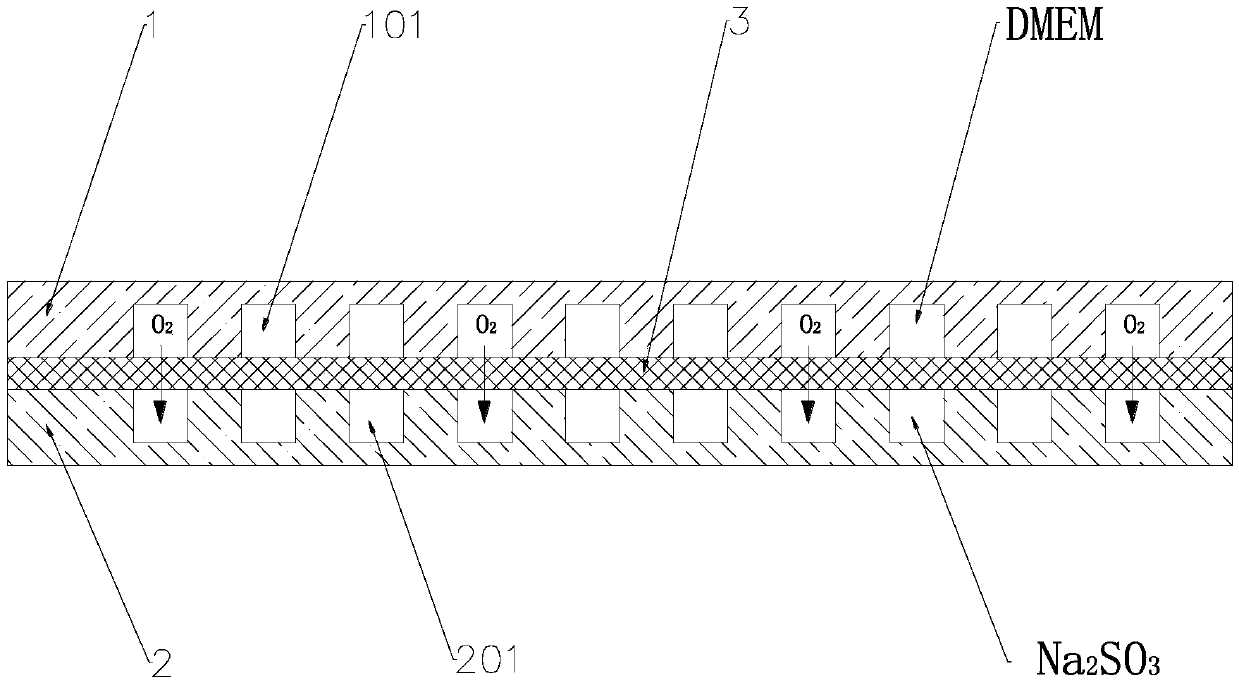

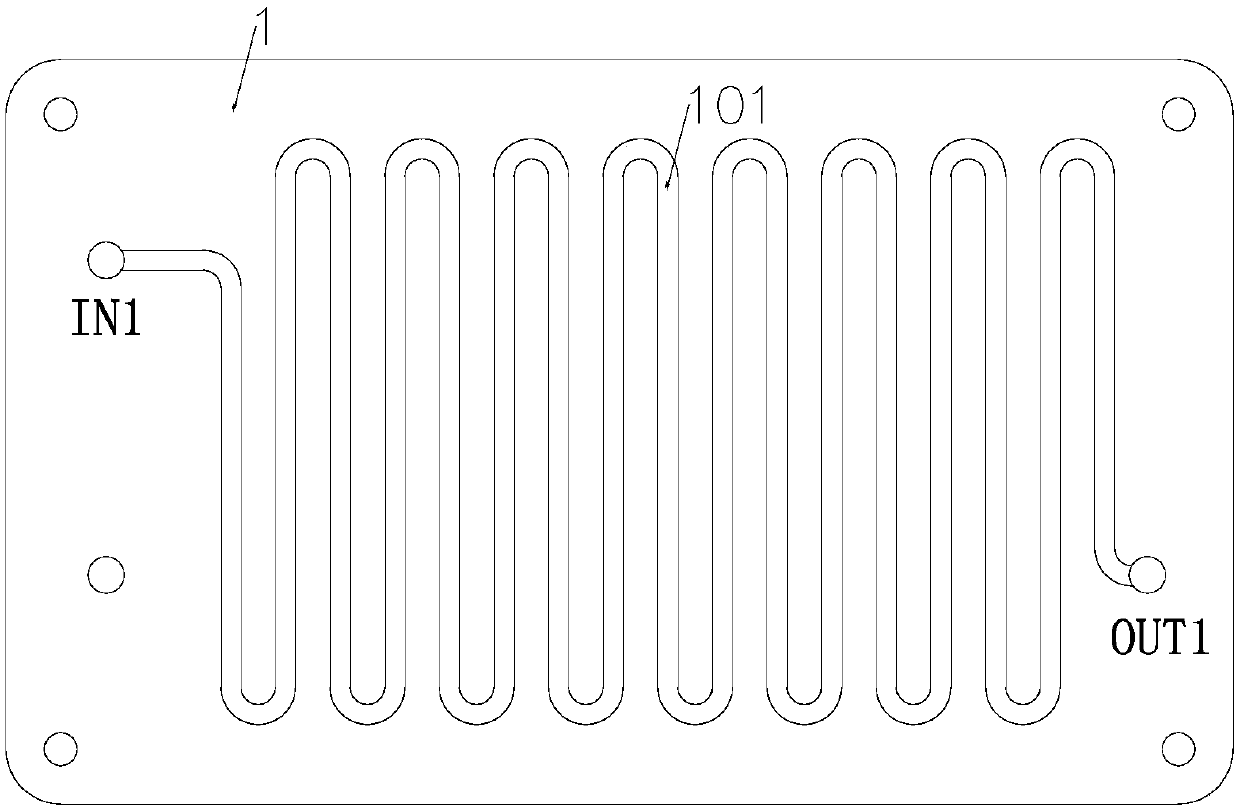

Chip for controlling dissolved oxygen concentration in microfluid

The invention discloses a chip for controlling the dissolved oxygen concentration in a microfluid. The chip comprises a first layer, a silica gel membrane barrier layer and a second layer which are sequentially overlapped, wherein the inner surface of the first layer and the inner surface of the second layer are separately adhered to two side surfaces of the middle silica gel membrane barrier layer in an overlapped mode, a first microchannel is formed by a groove which is formed in the inner surface of the first layer and the side surface, to which the first layer is adhered to, of the silicagel membrane barrier layer, and a second microchannel is formed by a groove which is also formed in the inner surface of the second layer and the other side surface, to which the second layer is adhered to, of the silica gel membrane barrier layer; the first microchannel is isolated from the second microchannel through the silica gel membrane barrier layer, the first microchannel is a unidirectional channel suitable for flowing of a cell culture medium, and the second microchannel is a unidirectional channel suitable for flowing of a Na2SO3 solution; and oxygen in the cell culture medium flowing in the first microchannel can pass through the isolation silica gel membrane and diffuse into the Na2SO3 solution flowing in the second microchannel. Quantitative control of the dissolved oxygen concentration in the microfluid can be achieved through the chip.

Owner:承韶晖

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com