United measuring system and its measuring technology for scanning channel microscope and scanning micro electrode

A scanning tunneling and measurement system technology, applied in the field of scanning tunneling microscope and scanning microelectrode combined measurement, can solve the problems of lack of sensitivity to chemical properties of surface microregions, difficulty in interpretation of SPM images, interrelated physical and chemical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below through examples.

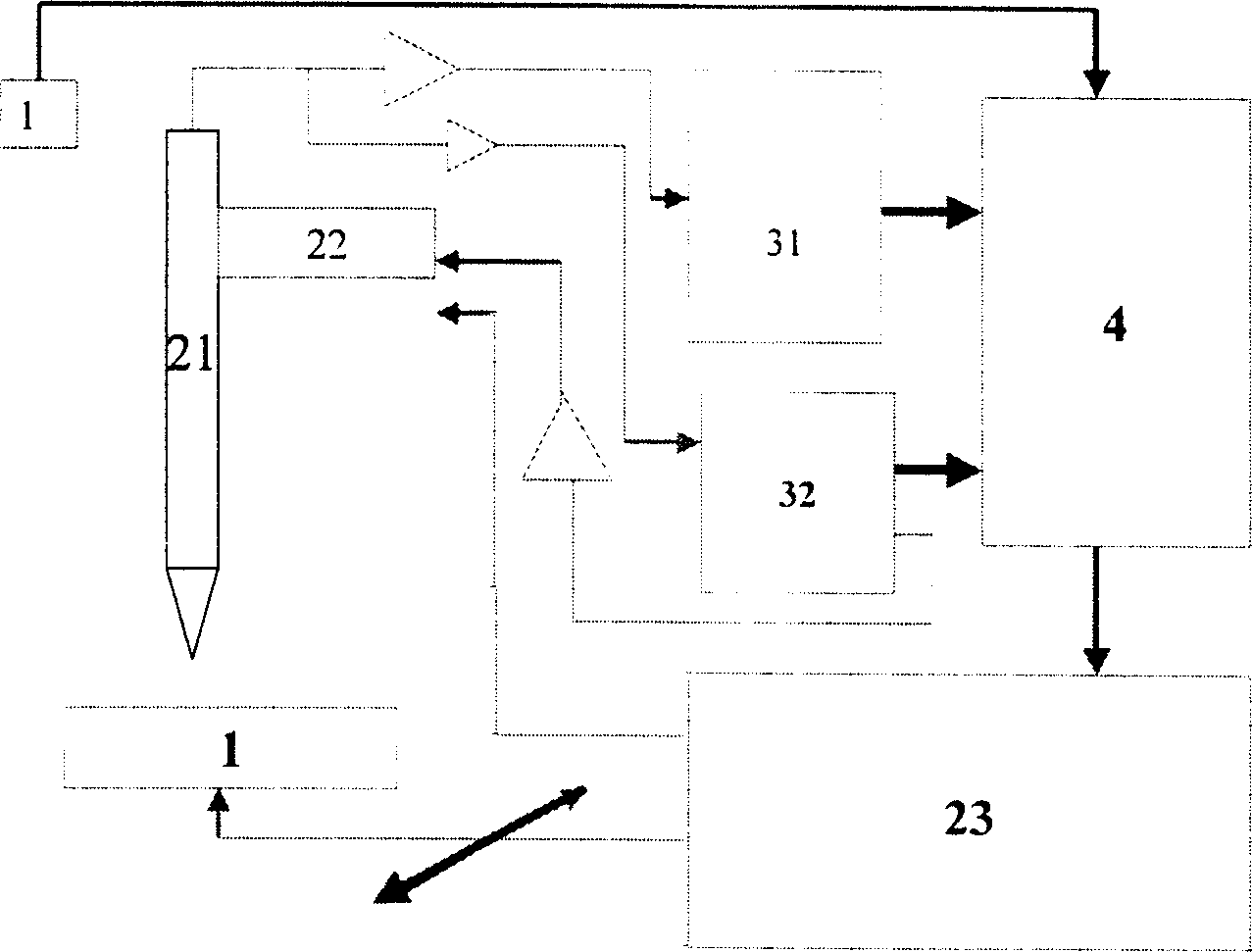

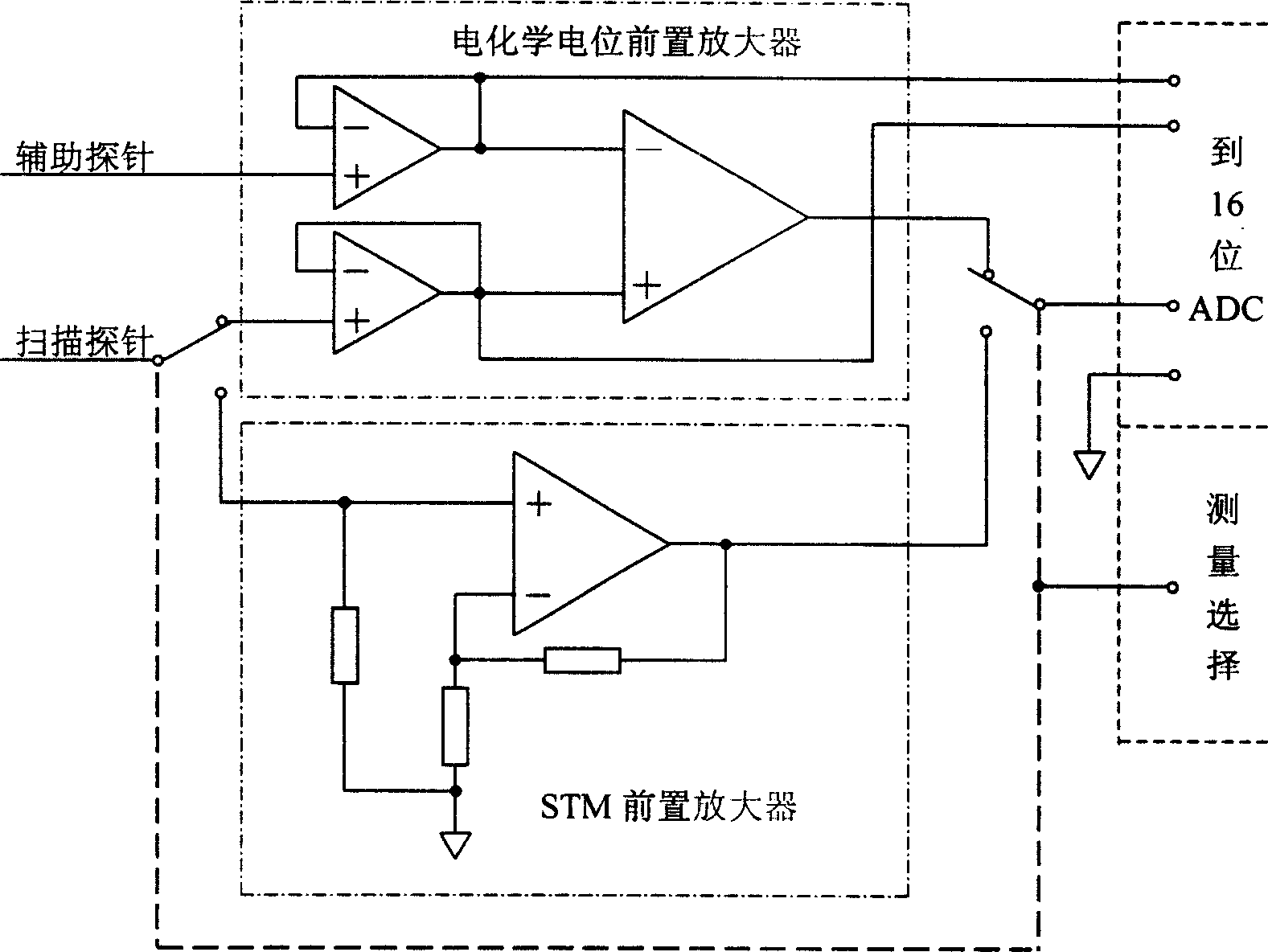

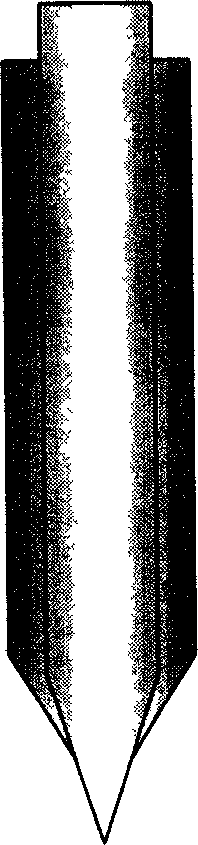

[0015] The scanning tunneling microscope and scanning microelectrode combined measurement system consists of 4 units: scanning tunneling microscope (STM) measurement platform, scanning microprobe and control / drive unit: tunneling current signal and micro-area potential signal measurement unit and measurement signal Control and processing unit. The STM measurement platform is an open commercial STM instrument, see figure 1 , the scanning micro-probe and the control / driving unit include a scanning micro-probe 21, an X-Y-Z three-dimensional piezoelectric micro-scanner 22 and a stepping motor-driven X-Y two-dimensional mechanical scanner 23, wherein the scanning micro-probe is a Pt with a diameter of 0.3mm -Ir alloy wire (see image 3 ), using the mechanical shearing method to prepare the tip of the scanning microprobe, the diameter of which is in the order of nanometers, and encapsulating the tip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com