Fluorescent monomer and fluorescent acrylic acid polymer and preparation method of fluorescent monomer and fluorescent acrylic acid polymer

A fluorescent monomer and acrylic technology, which is applied in chemical instruments and methods, luminescent materials, descaling and water softening, etc., can solve problems that do not involve the application of seawater, and achieve the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Green fluorescent monomer N-(2-(methacryloyloxy)ethyl)-N,N-dimethyl-2-((N'-n-propyl-4,5-naphthalimide)amino ) preparation of ethyl ammonium bromide

[0062] Preparation reaction formula (3) is as follows:

[0063]

[0064] Put 13.8g (0.05mol) of 4-bromo-1,8-naphthalene anhydride (A1), 3.0g (0.05mol) of n-propylamine and 65ml of ethanol into a glass reactor with magnetic stirring and reflux condenser, and heat at 78°C Reflux reaction for 3 hours, along with the progress of the reaction, the raw material (A1) undergoes amidation process and dissolves continuously to obtain the product. After the reaction, the solvent was spin-dried to obtain 14.4 g of white solid N-n-propyl-4-bromo-1,8-naphthalimide (A2), with a yield of 90.5%. Then 9.5g (0.03mol) of compound A2 and another reactant ethanolamine 2.4g (0.04mol) and 50ml of reaction solvent ethylene glycol monomethyl ether were heated to reflux under magnetic stirring and 125°C reflux condensation conditions, and after...

Embodiment 2

[0068] The ratio between N-n-propyl-4-(2-bromoethylamino)-1,8-naphthalimide (A4) and dimethylaminoethyl methacrylate (DM) on the yield of fluorescent monomer The influence experiment

[0069] Except that the ratio of the amounts of substances between N-n-propyl-4-(2-bromoethylamino)-1,8-naphthalimide (A4) and dimethylaminoethyl methacrylate (DM) was changed to Except for the ratio shown in Table 1, other operations were the same as in Example 1 to investigate the effect of the ratio of the amount of substances A4 and DM on the yield of fluorescent monomers. The experimental results are shown in Table 1.

[0070] Table 1

[0071] A4: DM

[0072] As can be seen from the above experimental results: the mass ratio of N-n-propyl-4-(2-bromoethylamino)-1,8-naphthalimide and dimethylaminoethyl methacrylate is 1:10 The yield in the range of ~1:1 is greater than 50%, and increases with the decrease of the ratio between the two, that is, the decrease of the amount of A4.

Embodiment 3

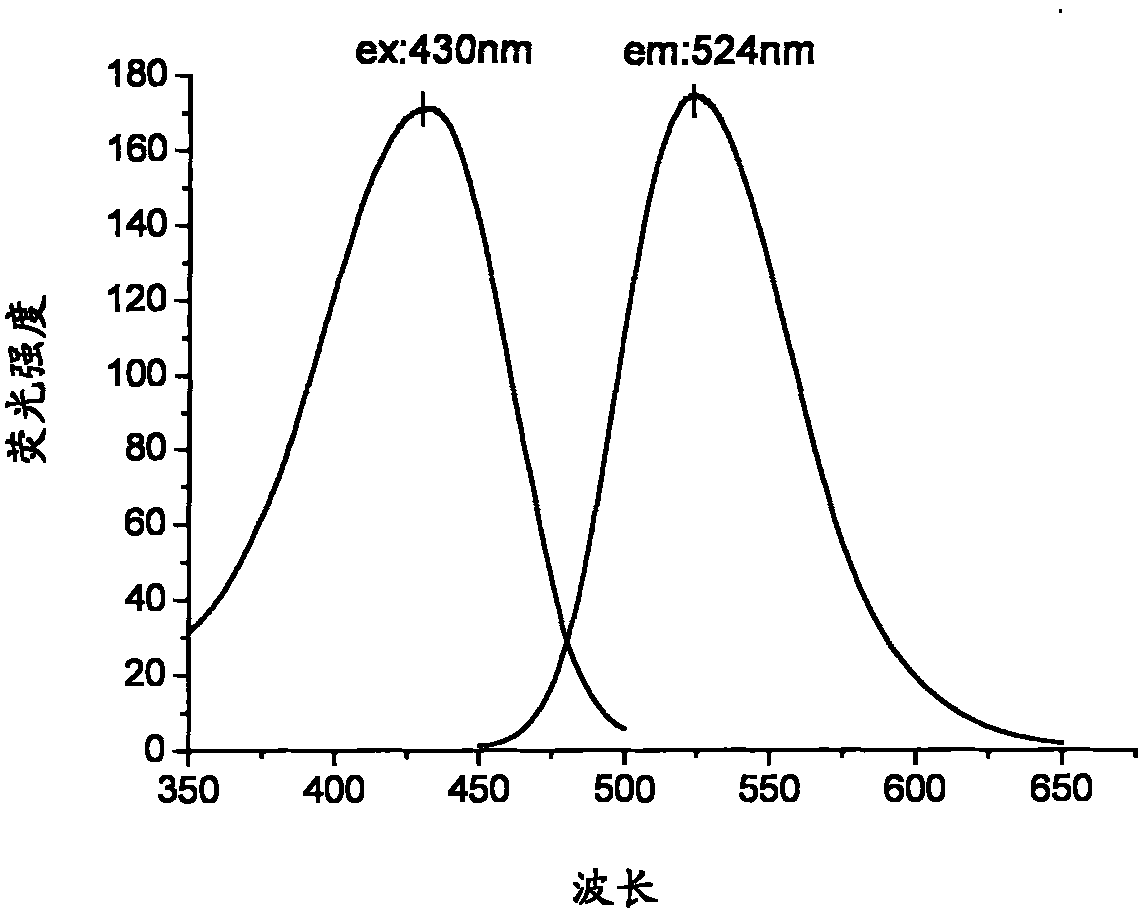

[0074] Fluorescence Spectrum Test of Green Fluorescent Monomer

[0075] Weigh N-(2-(methacryloyloxy)ethyl)-N,N-dimethyl-2-((N'-n-propyl-4,5-naphthalimide)amino)ethyl Hydroxyl ammonium bromide is dissolved in natural seawater with a salinity of 35, and the configuration is 100 μg / L. A fixed Hitachi F7000 fluorescence spectrometer with a slit width of 10 nm was used to scan the excitation and emission spectra respectively. The excitation spectrum and emission spectrum of the fluorescent monomer solution are shown in the attached figure 1 , the obtained maximum excitation wavelength and maximum emission wavelength are 430nm and 524nm respectively, the maximum emission wavelength is in the green range of the visible spectrum (490-580nm), and has a strong fluorescence intensity.

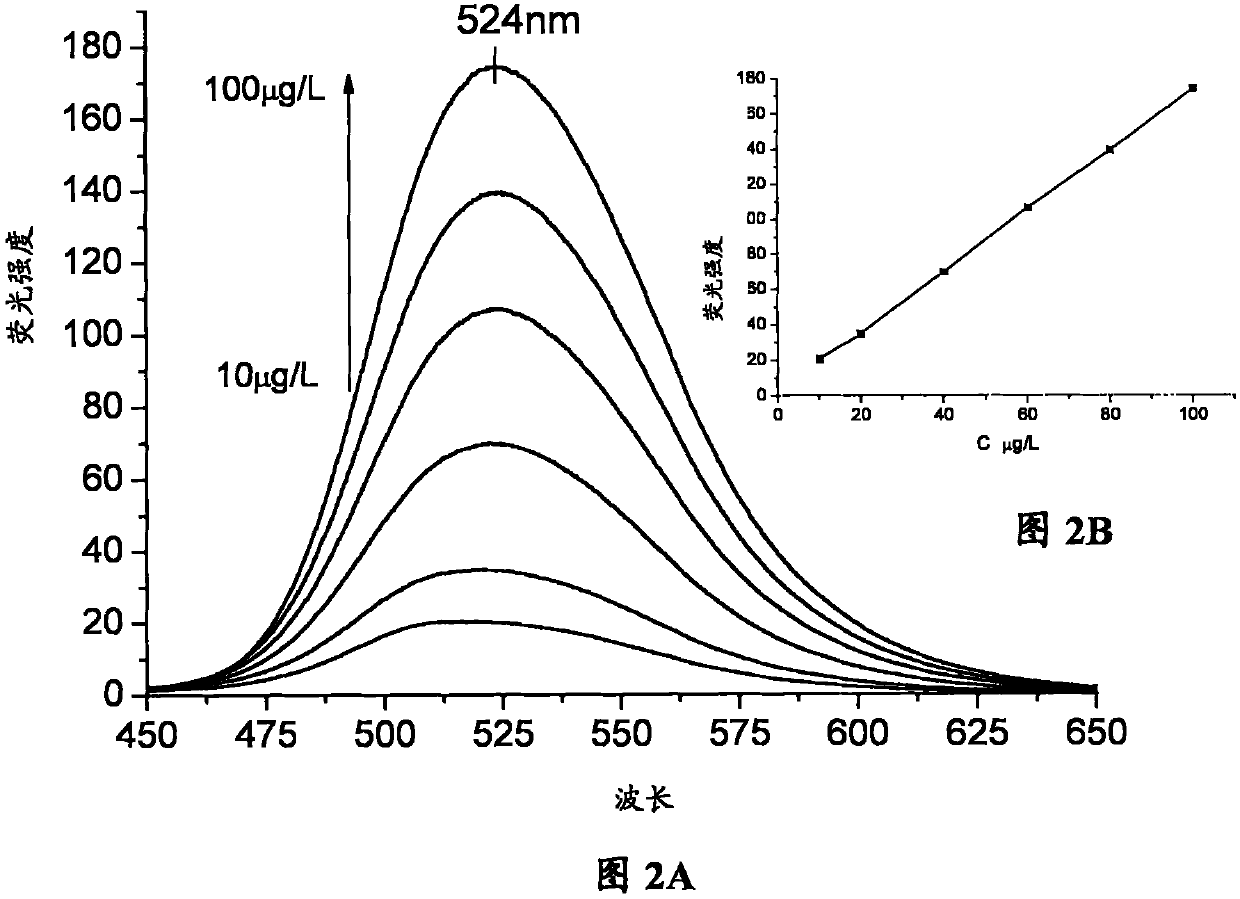

[0076] With a fixed excitation wavelength of 430nm and a slit width of 10nm, the fluorescence intensity of 10, 20, 40, 60, 80, and 100μg / L fluorescent monomer seawater solutions at 524nm was measured, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Linear correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com