Gunning refractory for heating furnace

A heating furnace and gunning material technology, applied in the field of non-metallic refractory materials, can solve the problems of poor adhesion performance and poor bonding strength, and achieve the effect of high adhesion performance, improved bonding strength and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

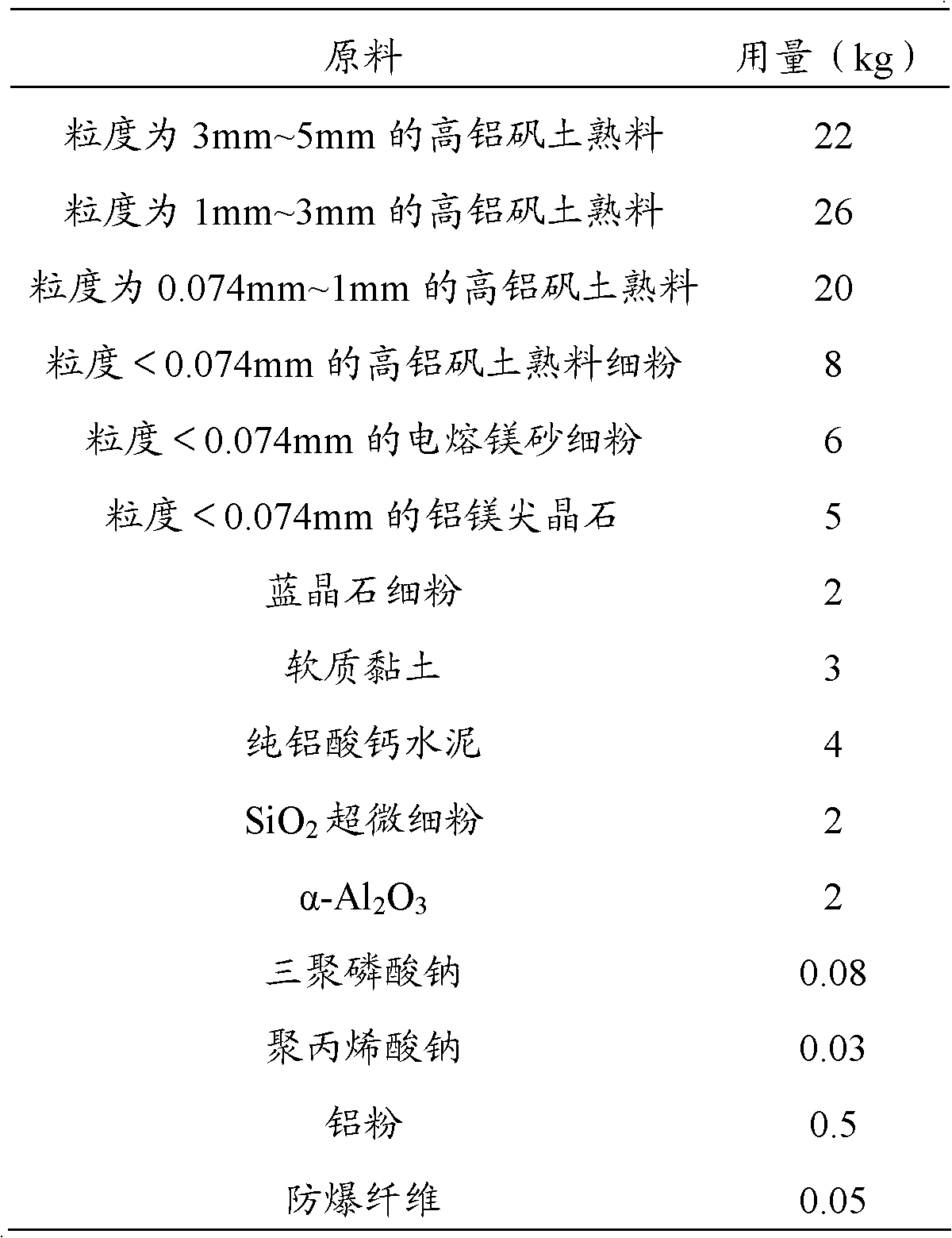

[0074] According to the formula shown in Table 1, the various raw materials were mixed to obtain the gunning material for the heating furnace.

[0075] Table 1 Example 1 provides the gunning material formula for heating furnace

[0076]

[0077] Use the above-mentioned gunning material to repair the damaged parts of the feed port, the discharge port, the end of the fixed beam and the end of the movable beam of the medium-sized steel heating furnace. The specific operation is as follows: add the gunning material into the high-pressure spray tank, Connect the air source and water source, and spray under the condition that the air pressure is greater than 0.5MPa. The amount of water is 7wt% of the amount of gunning material. After spraying, it is sintered for 2 hours. The gunning material is firmly attached to the repaired working surface to form a gunning surface. The average thickness of the gunning surface is up to 50mm, and the repaired heating furnace is used for steel ro...

Embodiment 2

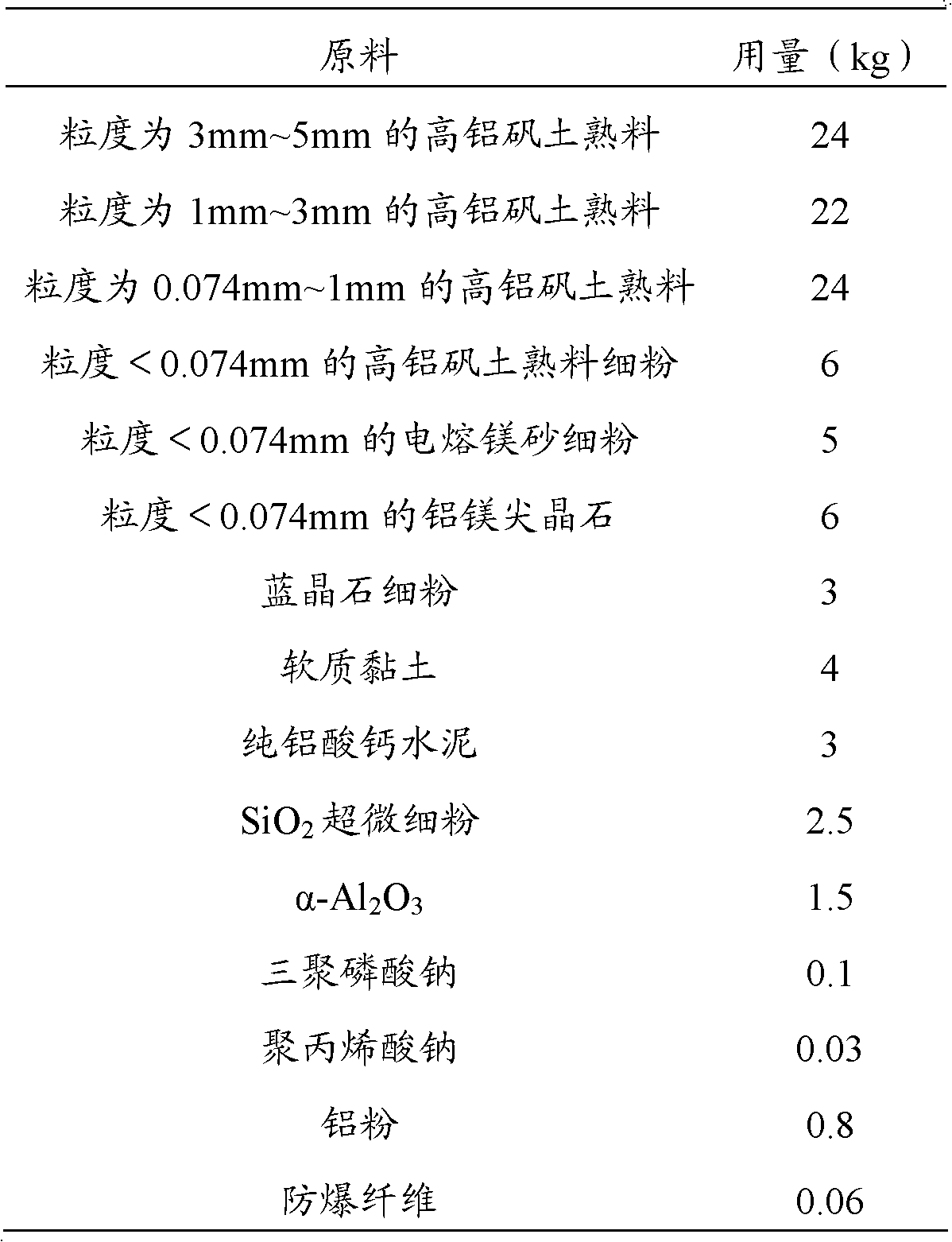

[0080] According to the formula shown in Table 2, the various raw materials were mixed to obtain the gunning material for the heating furnace.

[0081] The gunning material formula for heating furnace provided in Table 2 Example 2

[0082]

[0083] Use the gunning material to repair the roof collapse of the heating furnace. The landslide is 5m long, 0.5m wide, and 20cm thick. The specific operation is as follows: add the gunning material into the high-pressure spray tank, connect the air source and the water source , spraying under the condition of air pressure greater than 0.5MPa, the amount of water used is 7wt% of the amount of gunning material, and sintered for 2 hours after spraying, the gunning material is firmly attached to the collapsed part to form the gunning surface. After 8 months of normal use of the heating furnace, the top of the furnace did not appear to be ignited or damaged or peeled off.

[0084] It can be seen from Example 2 that when the gunning materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com