Determination method for cupping value of metal material and die

A metal material and measuring method technology, applied in the measuring method of cupping value of metal materials and the field of molds, can solve the problems of stability level difference, cupping value result dispersion, result dispersion and the like, and achieve sufficient lubrication effect, reliable stability , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

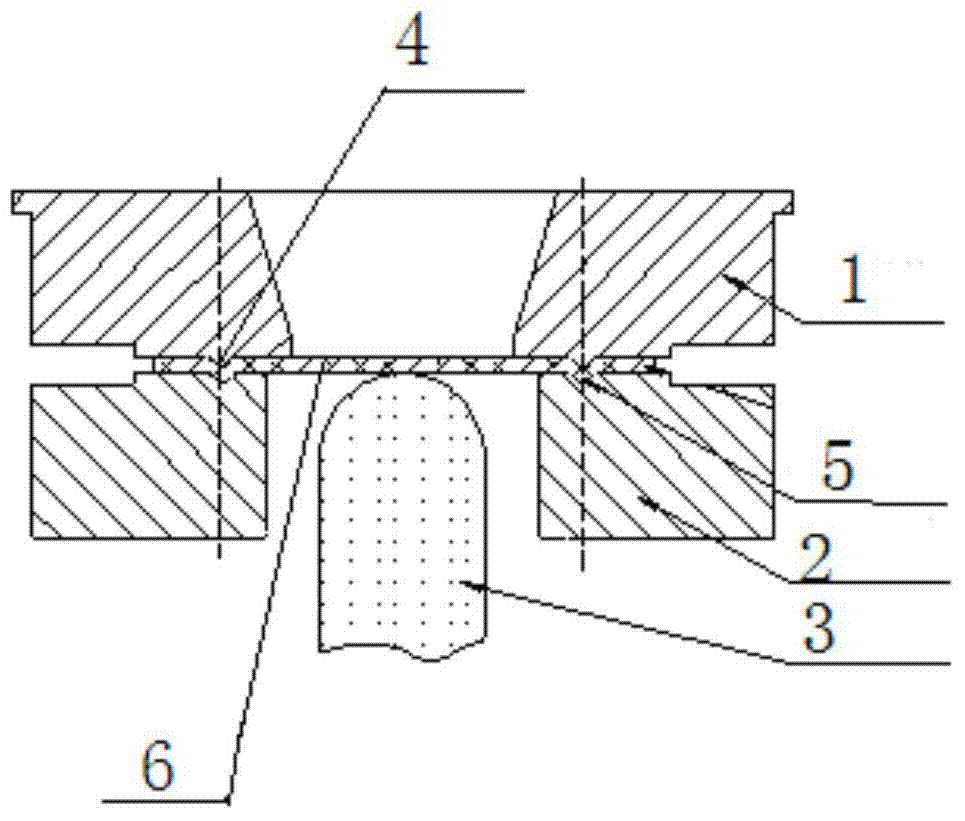

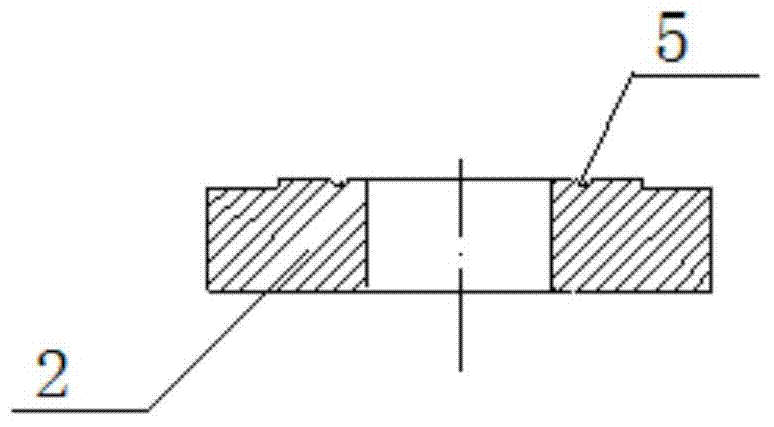

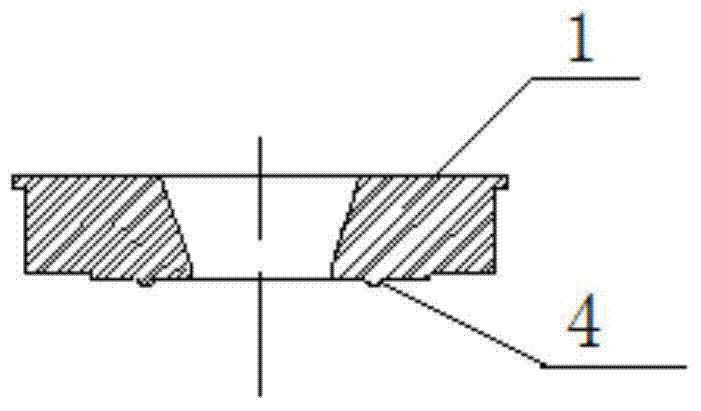

Image

Examples

Embodiment 1

[0034] Select a 1.5mm thick dual-phase steel 600DP sample, the tensile strength of the dual-phase steel is 630MPa, and the elongation is 23.1%. The periphery of the sample is pressed tightly to prevent the flow of material at the edge of the sample; at the same time, a polyethylene film is pasted with grease on the center of the sample for lubrication, and then the center is stamped with a punch at a stamping speed of 1.0mm / s; during the stamping process, the stamping testing machine records the punching force-displacement curve, such as Figure 4 As shown, when the punching force drops by 5kN, stop punching. At this time, read the punch displacement corresponding to the maximum punching force recorded on the punching force-displacement curve, which is the cupping value, and the cupping value of the steel plate is 10.30mm. Among them, the parameters of blank holder force, stamping speed, and punching force for crack judgment are all set before starting the testing machine.

Embodiment 2

[0036] Select 1.5mm thick high-strength IF steel HC260Y, the high-strength IF steel has a tensile strength of 400MPa and an elongation of 36.2%. Place the sample between the die and the backing die, and press the sample with a blank holder force of 150kN. Compress the periphery of the sample to prevent the flow of material at the edge of the sample; at the same time, paste polyethylene film on the center of the sample with grease for lubrication, and then punch the center with a punch at a speed of 2.0mm / s ; During the stamping process, the stamping testing machine records the punching force-displacement curve, such as Figure 5 As shown, when the punching force drops by 6kN, stop punching. At this time, read the punch displacement corresponding to the maximum punching force recorded on the punching force-displacement curve, which is the cupping value, and the cupping value of the steel plate is 10.05mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com