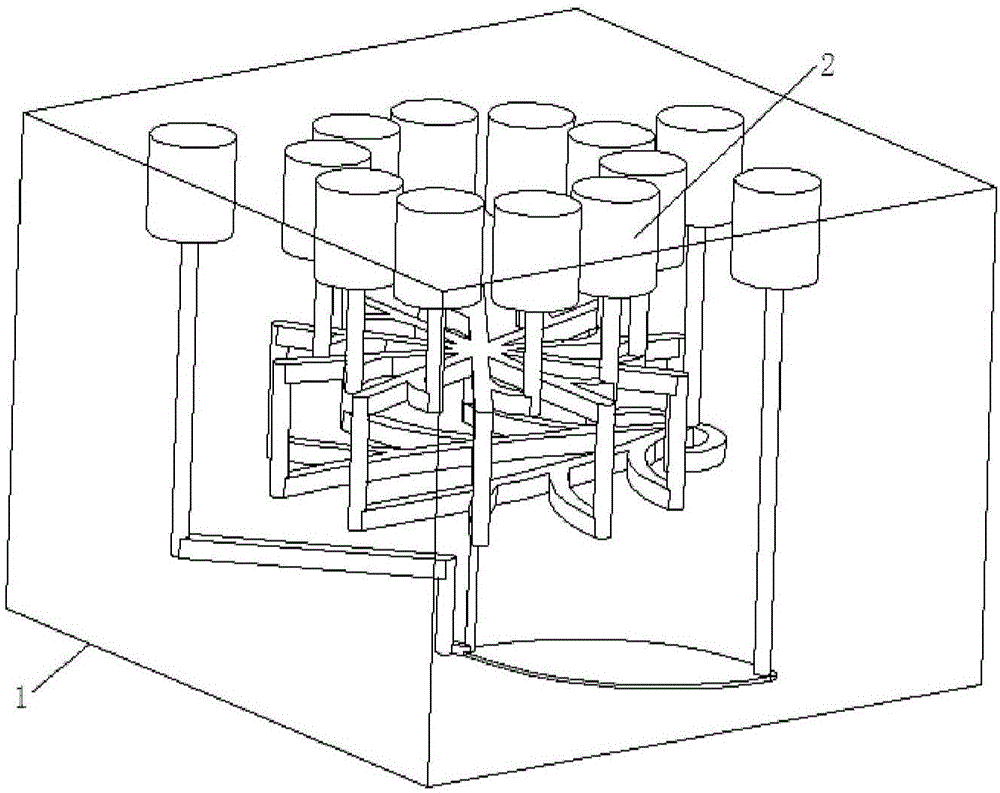

Multi-reagents orderly feeding device for preventing cross contamination

A liquid feeding device and cross-contamination technology, which is applied to feeding devices, laboratory containers, laboratory utensils, etc., can solve the problems of cross-contamination of reagents, inability to effectively eliminate dead volume, inability to rinse clean, etc., to improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

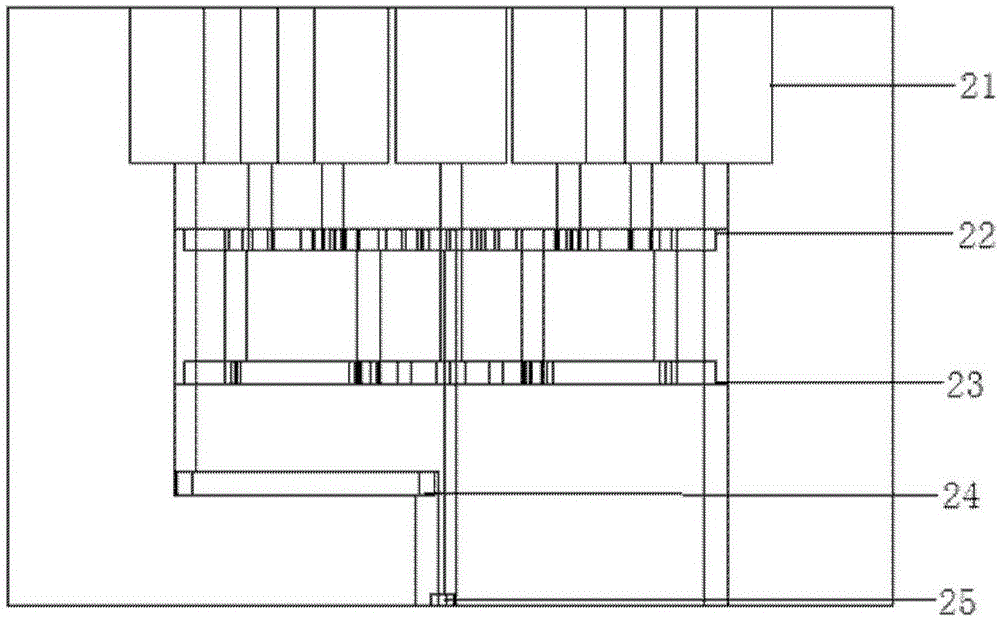

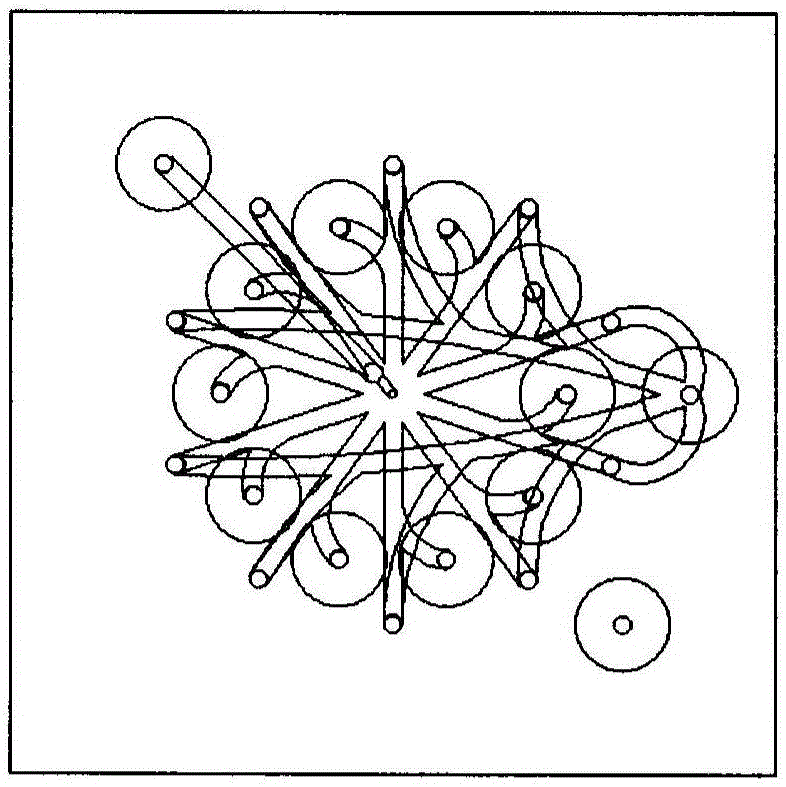

[0065] ginseng image 3 as shown, image 3 It is a structural schematic diagram of the cleaning process using cleaning liquid in the multi-reagent sequential liquid feeding system provided by the present invention. exist image 3 The multi-reagent sequential liquid feeding system shown is a multi-layer structure, that is, it includes a pipe connection layer, a reagent injection diversion layer, a waste liquid diversion layer, a cleaning liquid diversion layer and a reaction pool connection layer, wherein the pipe connection layer The multi-reagent inlets 2101-2110 are respectively connected with the reagent inflow holes 2201-2210 in the reagent injection diversion layer through radial pipes; The hole 2311 and the hole 2411 in the cleaning fluid diversion layer are connected through radial pipes; the waste liquid outlet 2112, the reagent injection hole 2212 in the diversion layer, and the node hole 2312 in the waste liquid diversion layer are connected through radial pipes. ...

Embodiment 2

[0069] ginseng Figure 4 as shown, Figure 4It is a schematic structural diagram of the reagent feeding and cleaning process of the multi-reagent sequential liquid feeding system provided by the present invention. The principle of the reagent feeding and cleaning process is that the reagents start to be fed, but they do not enter the reaction pool immediately, but cooperate with the discharge system through the cleaning process of the cleaning solution to discharge the reagents that may be contaminated at the reagent inlet. In this embodiment, there are 10 reagent inlets. The process will be described by taking 2109 port as an example to start liquid feeding. Other reagent ports 2101-2108 and 2110 stop liquid feeding, and the cleaning reagent continues the cleaning process. The reagent flows into the channel connecting the hole 2220 and the hole 2224 from the hole 2209, and then as the cleaning liquid flows into the 23rd layer of the waste liquid diversion layer, all the reag...

Embodiment 3

[0071] ginseng Figure 5 as shown, Figure 5 It is a structural schematic diagram of the process of injecting reagents into the reaction pool by the multi-reagent sequential liquid feeding system provided by the present invention. The process of injecting the reagent into the reaction pool is after the previous process, that is, the reagent is put into the cleaning process, and the injection of the cleaning solution is stopped. The reagent enters the 22nd floor through the hole 2109 and the hole 2209. On the 22nd floor plane, the reagent flows from the hole 2209 into the connecting hole 2220 and the node. In the channel of the hole 2224, a part flows to the direction of the hole 2220, and the other part flows to the direction of the node hole 2224; the reagent flowing into the direction of the node hole 2224 will be divided into multiple directions, and some of them will leave the 22nd layer and pass through the direction perpendicular to the 22nd layer. Node holes 2224, hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com