Efficient graphene paint mixing and stirring device

A technology of mixing and stirring, graphene, applied in the direction of mixers with rotating stirring devices, mixers, mixer accessories, etc., can solve the problems of raw material agglomeration, achieve dynamic balance, avoid clogging, and avoid insufficient mixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

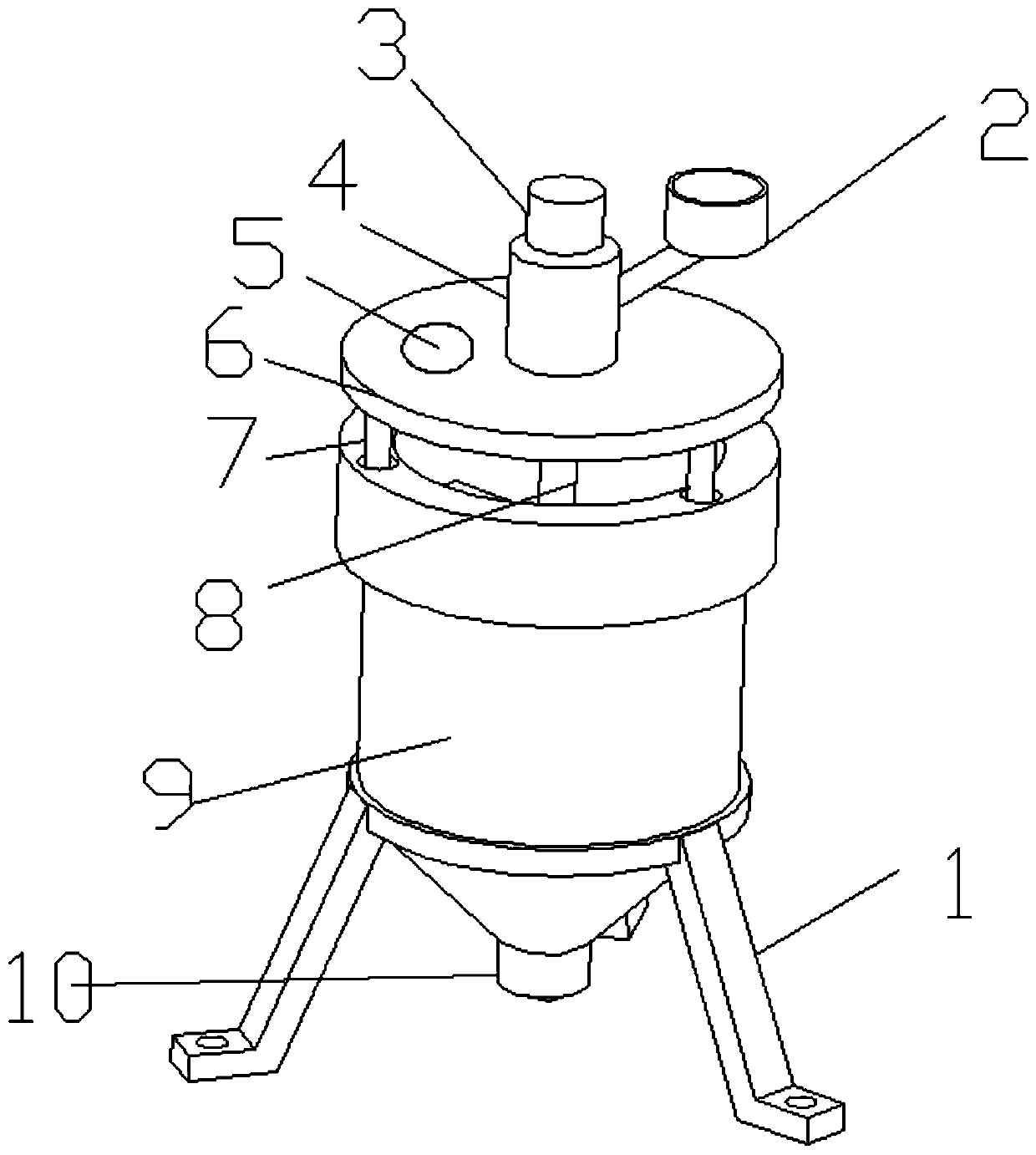

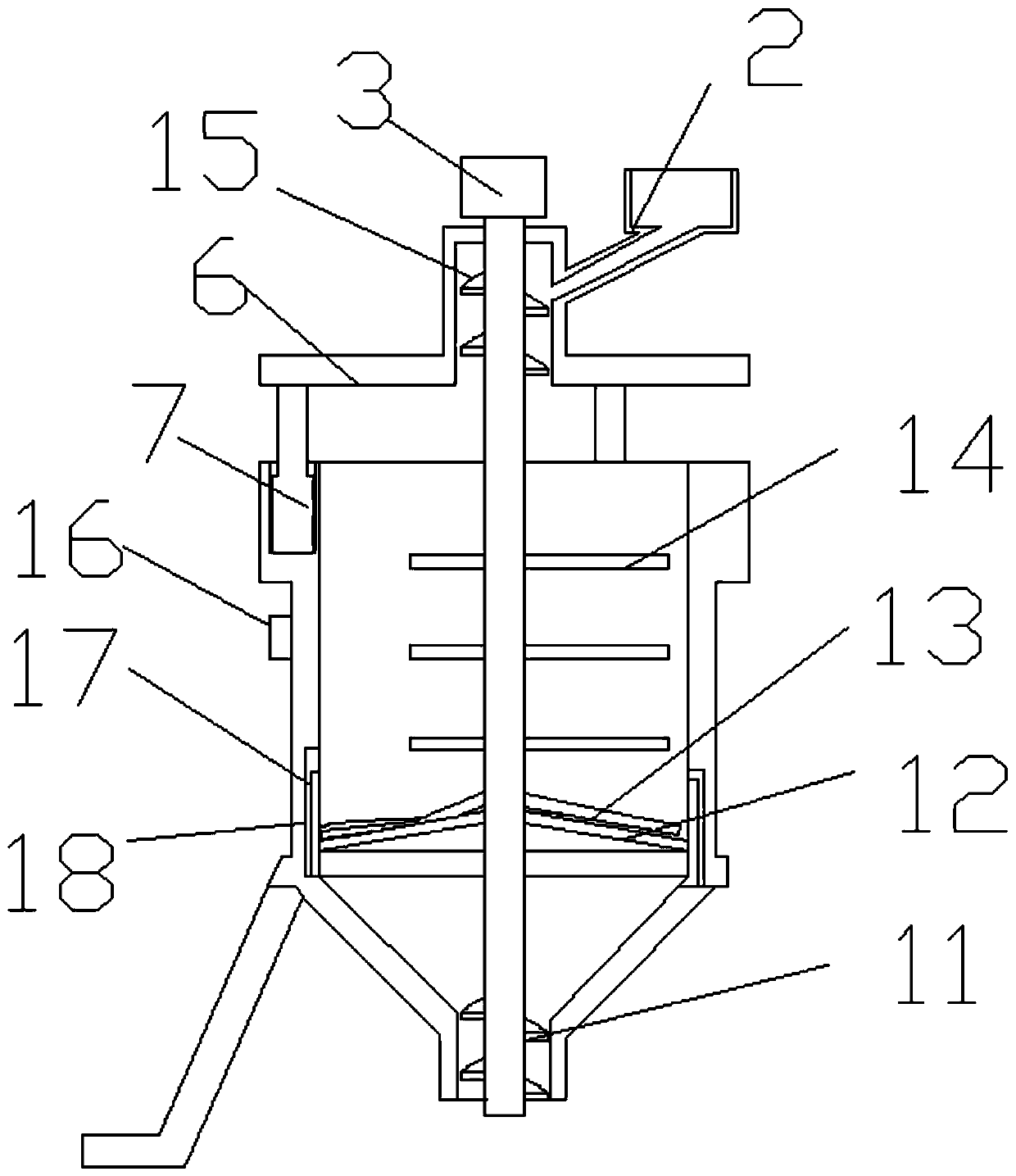

[0024] Please refer to Figure 1-2 , a graphene paint efficient mixing and stirring device, including a mixing cylinder 9 and a top cover 6, the bottom of the mixing cylinder 9 is provided with a supporting leg 1, the supporting leg 1 has a supporting effect on the mixing cylinder 9, the bottom of the supporting leg 1 A perforation is provided, and the fixing bolt can pass through the perforation to fix the support leg 1 on the ground, thereby completing the fixing of the device. The top of the mixing cylinder 9 is provided with a top cover 6 , and the top cover 6 covers the top of the mixing cylinder 9 . The top of the mixing cylinder 9 is uniformly fixed with a number of hydraulic rods 7, and the top of the hydraulic rods 7 is fixedly connected to the lower surface edge of the top cover 6, and the extension of the hydraulic rods 7 can lift the top cover 6, thereby moving the mixing cylinder. 9 open, which facilitates the maintenance and cleaning of the device.

[0025] The...

Embodiment 2

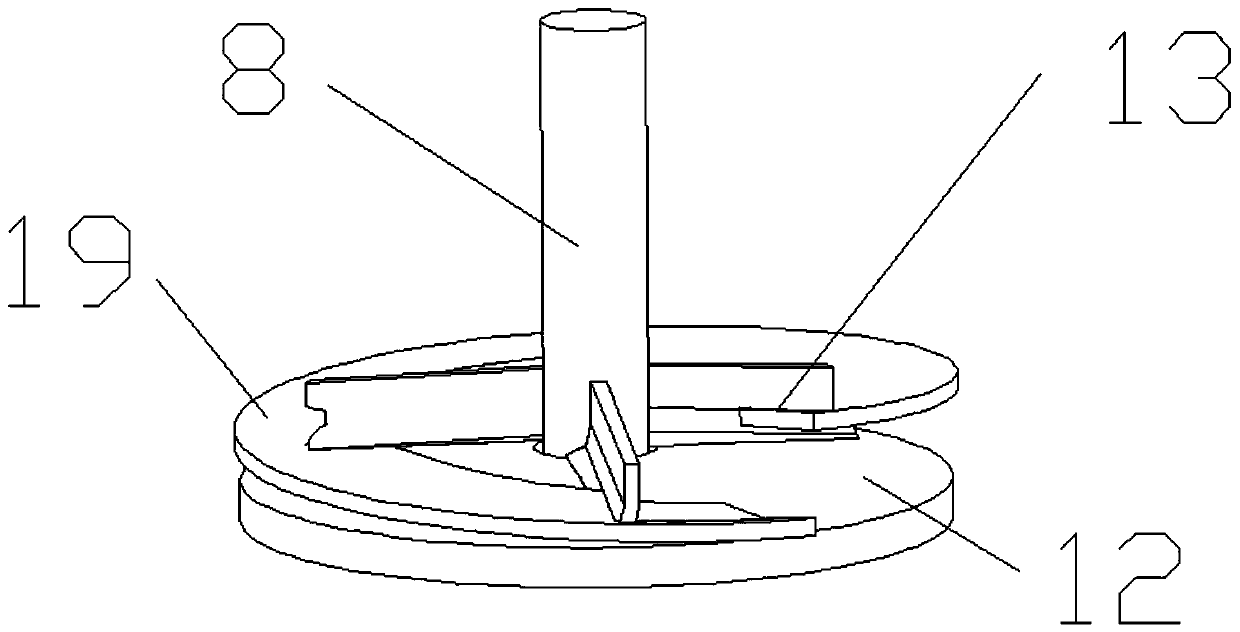

[0030] see image 3 , on the basis of Example 1, the stirring shaft 8 is fixedly provided with a helical blade 19, the helical blade 19 is in contact with the side wall of the mixing cylinder 9, and the helical blade 19 can be deposited on the mesh as the rotation of the agitating shaft 8 The graphene coating material on the plate 12 is stirred, which improves the uniformity of stirring. The outer end of the spiral blade 19 is high and the inner end is low, so that the graphene raw material can be rolled inside and out, and the stirring efficiency is improved. With the expansion and contraction of the hydraulic rod 7, the spiral blade 19 can clean the inner wall of the mixing cylinder 9 in all directions, making cleaning convenient and fast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com